Patents

Literature

419 results about "Nanocrystalline alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ternary and multi-nary iron-based bulk glassy alloys and nanocrystalline alloys

InactiveUS20050263216A1High glass forming abilityIncreased electrical resistivityMagnetic materialsAmorphous phaseAtomic radius

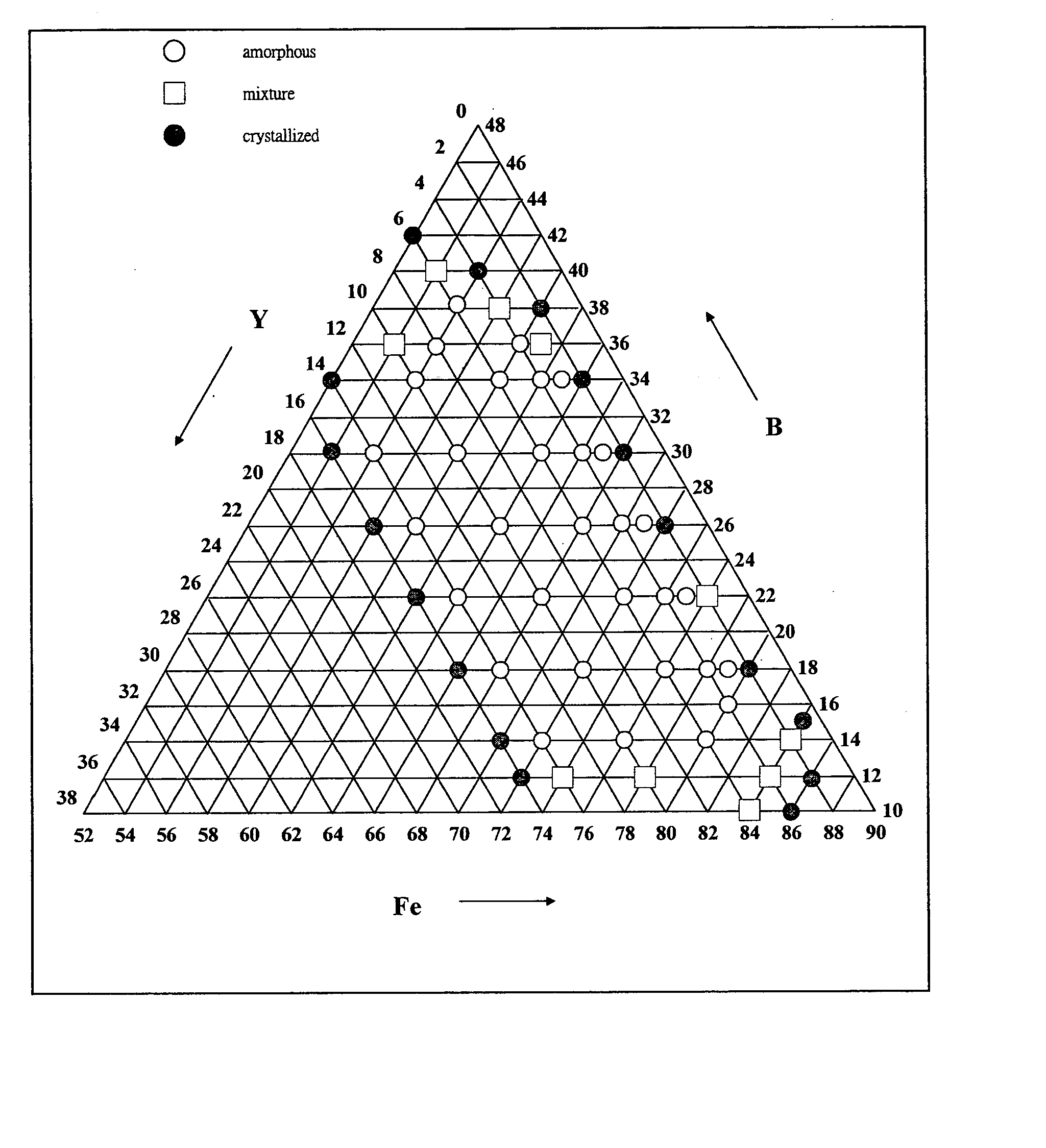

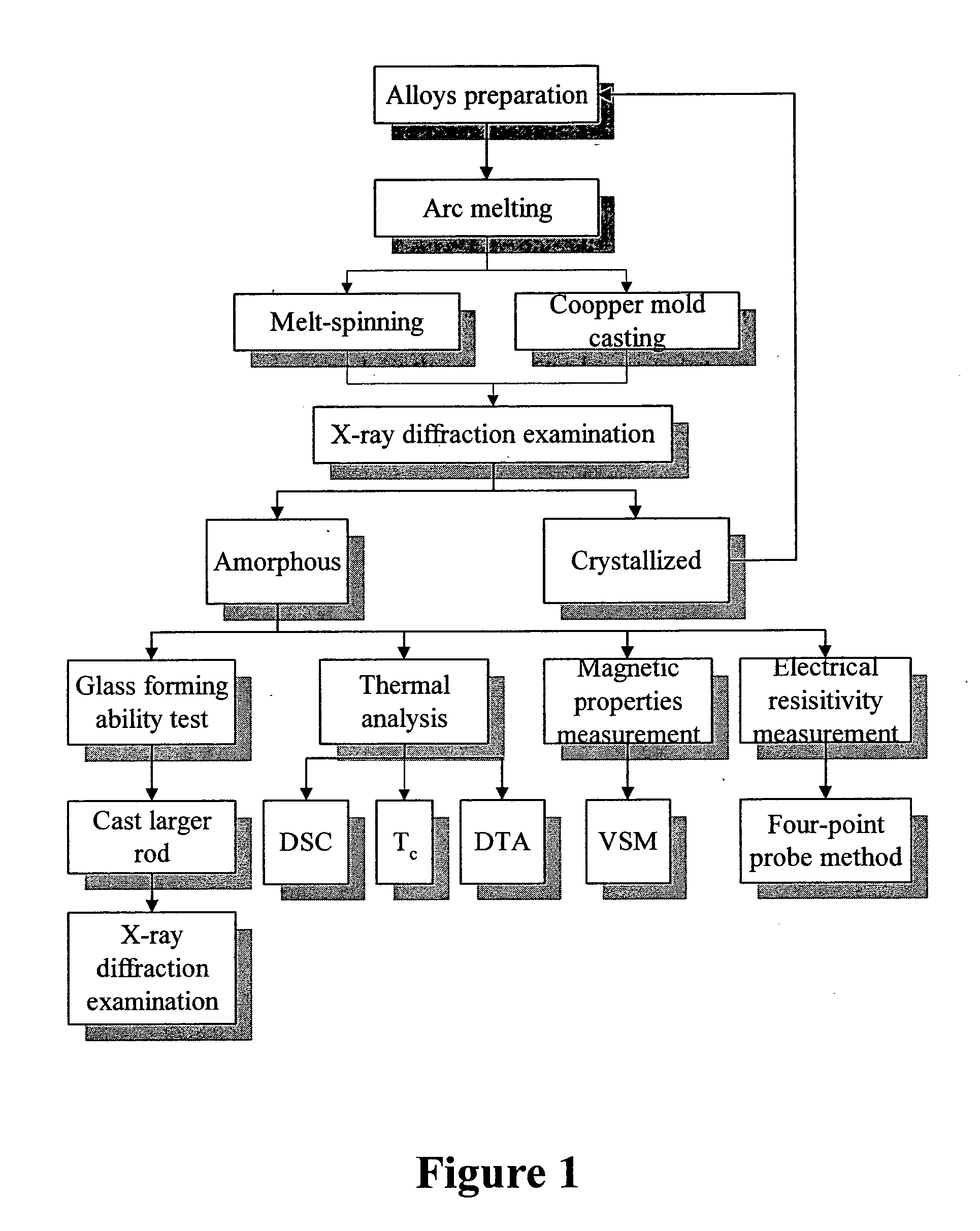

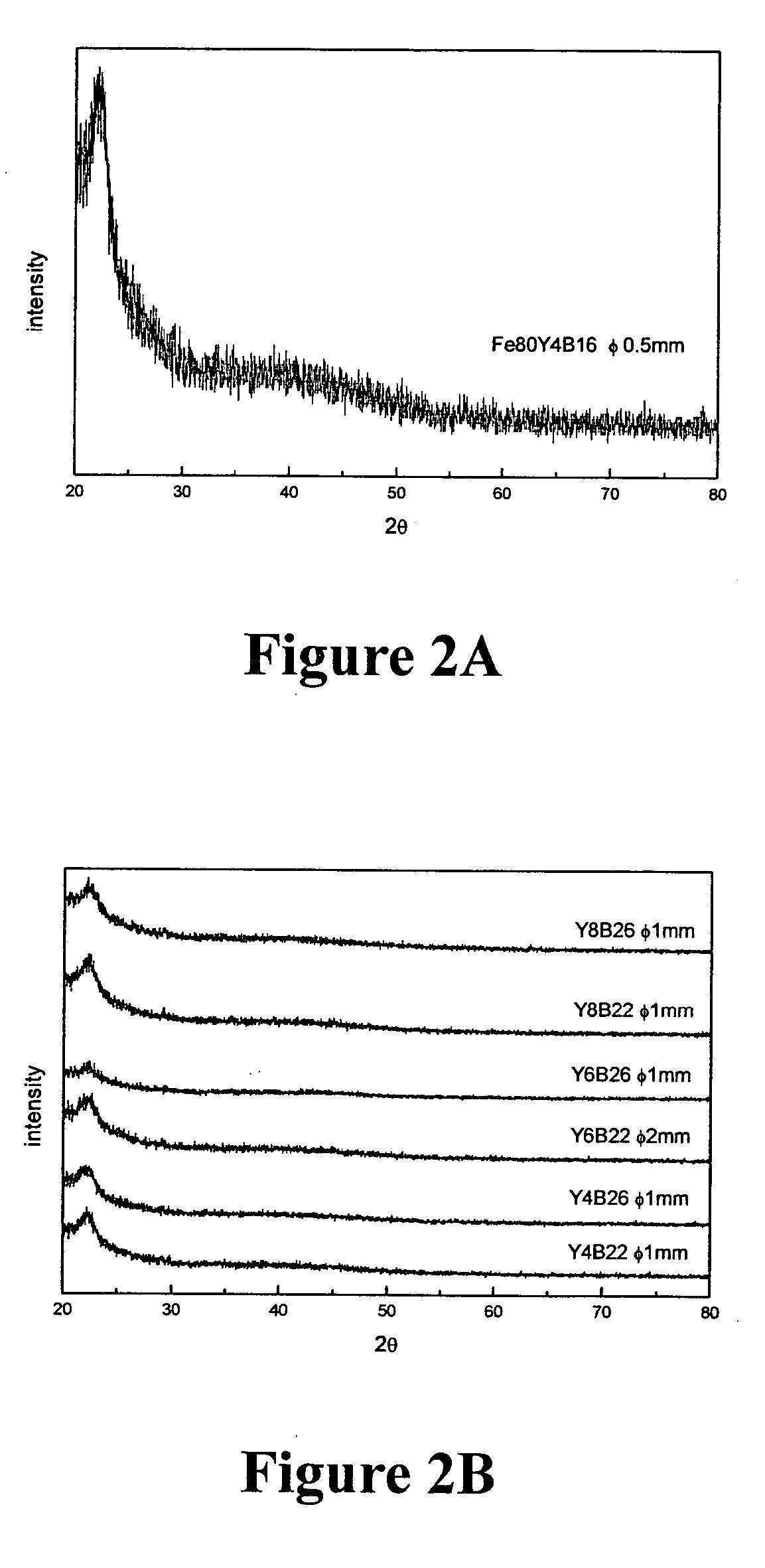

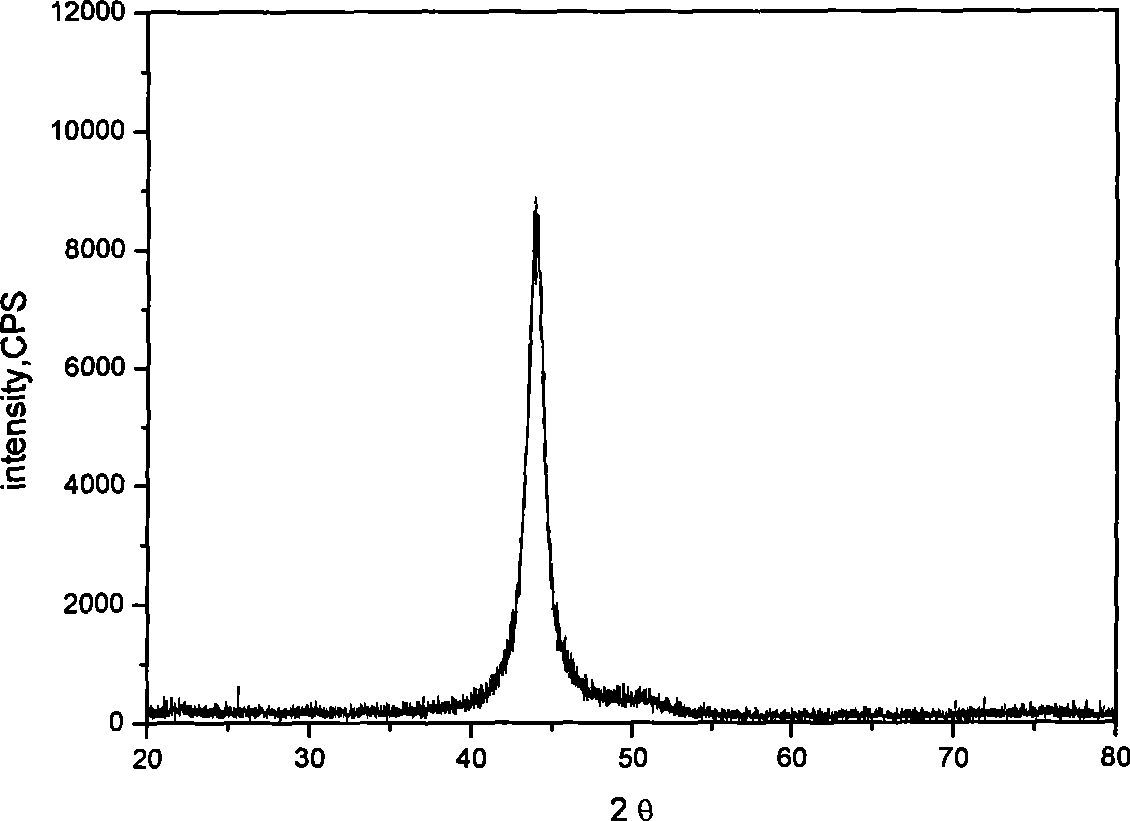

Disclosed in this invention is a family of ternary and multi-nary iron-based new compositions of bulk metallic glasses which possess promising soft magnetic properties, and the composition selection rules that lead to the design of such new compositions. The embodiment alloys are represented by the formula MaXbZc, where M represents at least one of ferromagnetic elements such as iron and may partly be replaced by some other substitute elements; X is an element or combinations of elements selected from those with atomic radius at least 130% that of iron and in the mean time is able to form an M-rich eutectic; and Z is an element or combinations of elements selected from semi-metallic or non-metallic elements with atomic radius smaller than 86% that of iron and in the meantime is able to form an M-Z eutectic; a, b, c are the atomic percentage of M, X, Z, respectively, and a+b+c=100%. When 1%<b<15% and 10%<c<39%, the alloys show a bulk glass forming ability to cast amorphous ribbons / sheets at least 0.1 mm in thickness. When 3%<b<10% and 18%<c<30%, the alloys show a bulk glass forming ability to cast amorphous rods at least 1 mm in diameter. The amorphous phase of these as-cast sheets / rods is at least 95% by volume. This invention also discloses the existence of nano-crystalline phase outside of the outer regime of the bulk glass forming region mentioned above.

Owner:NATIONAL TSING HUA UNIVERSITY

Anticorrosive wearable electrodeposit clad layer of Ni-W-P ternary alloy and manufacturing technique and electroplate liquid thereof

The invention relates to an anticorrosive wearable electrodeposit clad layer of Ni-W-P ternary alloy and manufacturing technique and electroplates liquid thereof, which takes the nickel sulfate, sodium tungstate, phosphate as the main material, electrically depositing the Ni-WP amorphous mixture of amorphous or nanocrystalline alloy coating. The characteristics of the electroplate technique are following: corrosive solution is very small, the entire production of the use of cleaner production, less emissions, in line with the requirements of sustainable production. W of the coating for the content of 1-45wt%, P content of 0.1-5wt%, nickel is the residue. The plating layer is bright and dense; the hardness is 400-1100Hv, which is resistant to acid, alkali, salt and hydrogen sulfide corrosion, wear resistance is better than or equivalent to chrome plating, can not only replace decorative chromium or hard chromium is widely used, and can be used for oil field exploration equipment to deal with wear-resistant anti-corrosion.

Owner:湖南纳菲尔新材料科技股份有限公司

Amorphous alloy powder core and nano-crystal alloy powder core having good high frequency properties and methods of manufacturing the same

InactiveUS6827557B2High molding densityLow dependence on frequencyTransportation and packagingMetal-working apparatusOrganic solventShell molding

A method of manufacturing an amorphous alloy core including the steps of mixing an amorphous alloy powder with a solution made by dissolving a polyimide / phenolic resin binder in an organic solvent, evenly coating the binder in liquid phase on the surface of the alloy powder to make a powder of composite particles, molding the power of composite particles, and performing a heating treatment thereon. This invention also discloses a method of manufacturing a nano-crystal alloy core including the steps of (a) mixing an amorphous alloy powder with a solution made by dissolving a polyimide / phenolic resin binder in an organic solvent, evenly coating the binder in the liquid phase on the surface of the alloy powder to make composite particles, molding the composite particles at room temperature, and performing a heating treatment thereon at a temperature higher than the crystallization starting temperature of the alloy; and (b) performing a heating treatment on an amorphous alloy powder at over a crystallization starting temperature to make a nano-crystal phase, mixing a solution made by solving a polyimide / phenolic resin binder in an organic solvent therewith, evenly coating the binder in liquid phase on the surface of the alloy powder to make composite particles, and molding the power of composite particles at 100 to 300° C.

Owner:KIM KYU JIN +3

Fe-based amorphous or nanocrystalline soft magnetic alloy and preparation method thereof

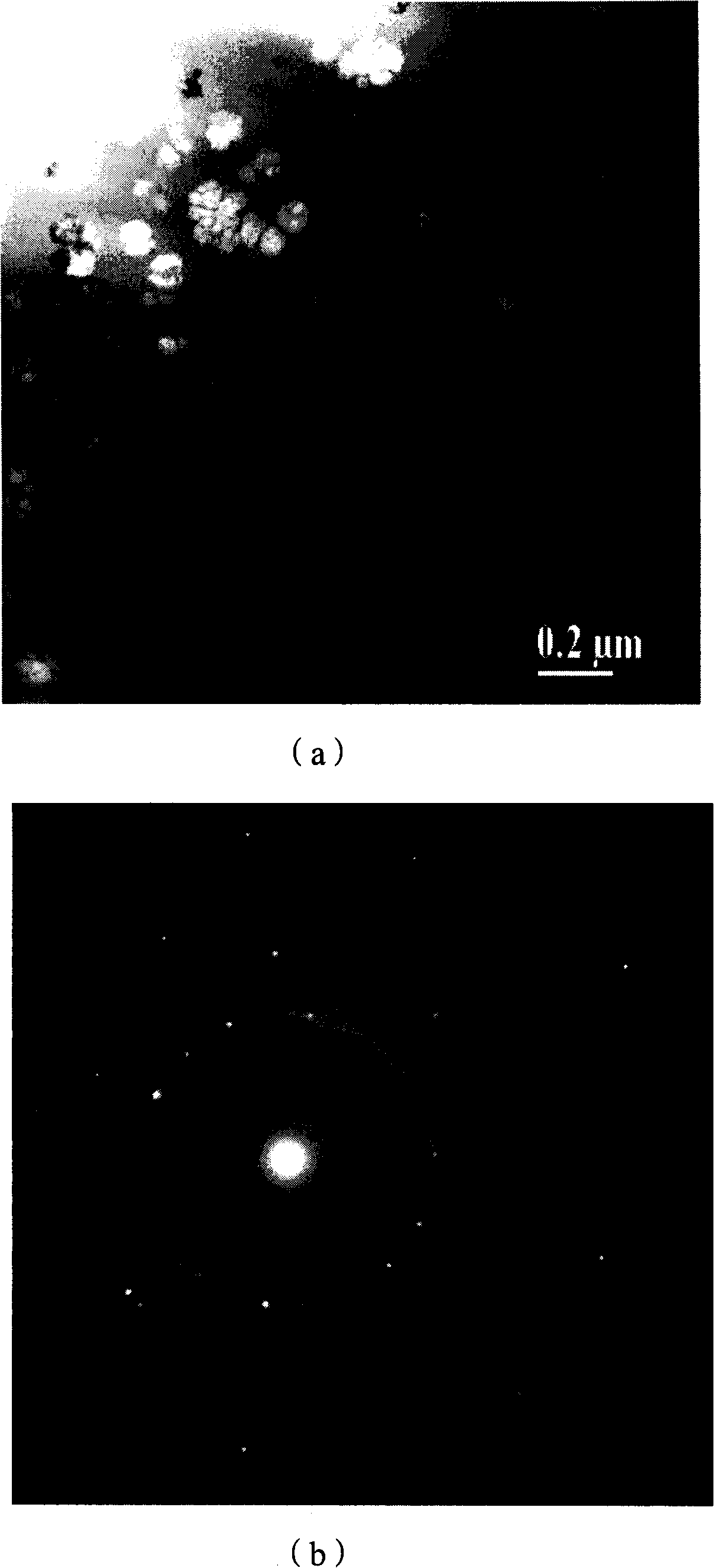

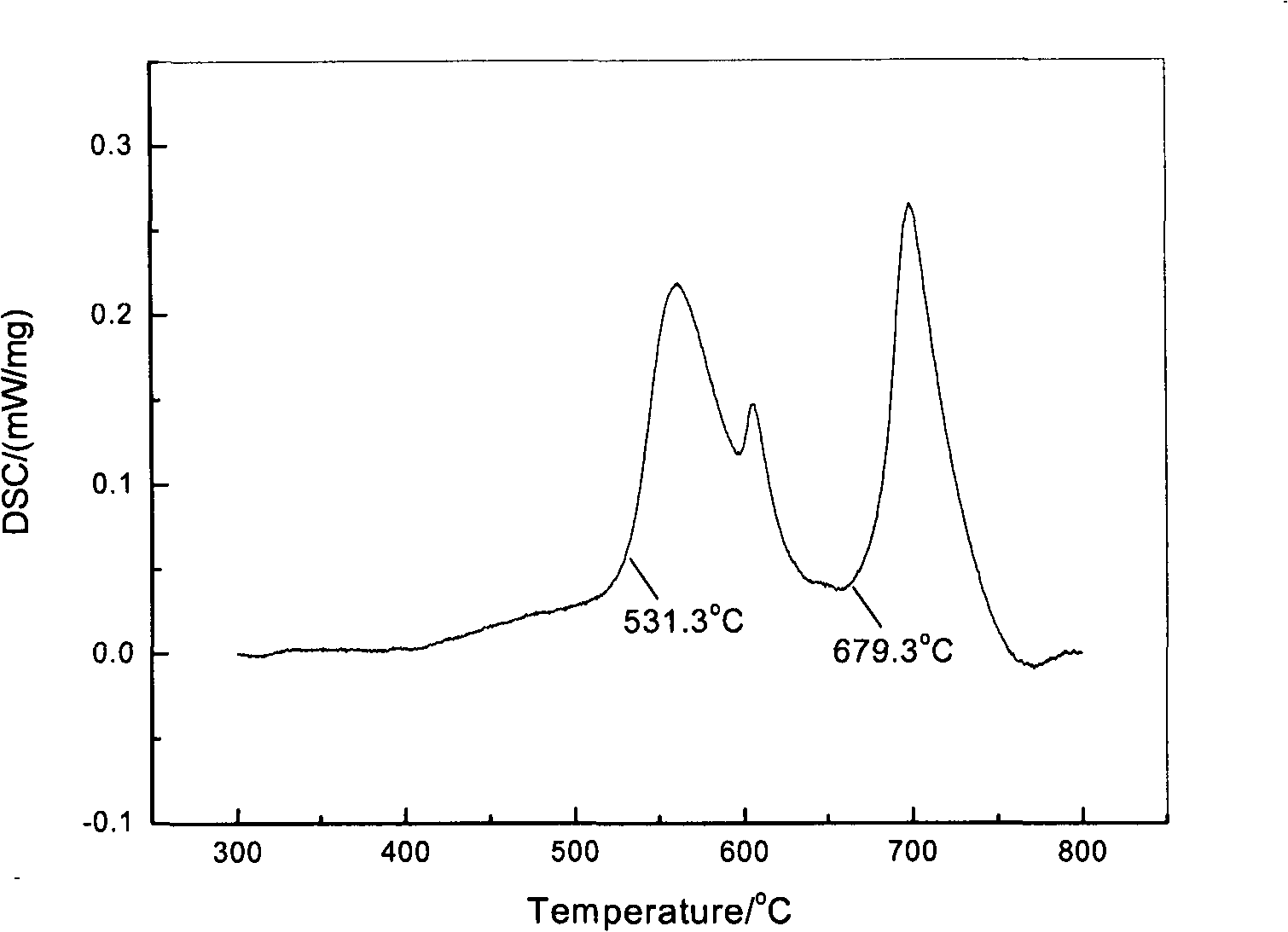

InactiveCN101650999AImprovement and optimization of comprehensive soft magnetic propertiesLow costMagnetic materialsElectric arc furnaceAmorphous matrix

The invention discloses a Fe-based amorphous or nanocrystalline soft magnetic alloy, aiming to favorable performance and low cost. Alloy components can be expressed as FeaSibBcCudNbeMf, wherein M is Al, Ni or P; a, b, c, d, e and f are atom percentages, and the change range is as follows: a is more than or equal to 65 and less than or equal to 85, b is more than or equal to 5 and less than or equal to 20, c is more than or equal to 5 and less than or equal to 25, d is more than or equal to 0 and less than or equal to 5, e is more than or equal to 0 and less than or equal to 5, and f is more than or equal to 0.1 and less than or equal to 10; and a+b+c+d+e+f=100. The preparation method comprises the following steps: placing raw materials of pure ferrum, pure copper, and the like into a vacuum electric arc furnace to smelt to obtain an alloy ingot; crushing, placing into a quartz test tube, and preparing an amorphous alloy ribbon by using a single-rolling ribbon throwing method; placing into a tubular annealing furnace, adjusting the temperature to 510-580 DEG C, isothermally annealing under the protection of Ar gas and getting out of the furnace to cool; and obtaining amorphous alloys with different microstructures or nanocrystalline alloys with nanometer crystal particles evenly arranged on an amorphous matrix through controlling alloy cooling speed and heat treatment temperature as well as time.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing high-performance high-temperature-resisting nanometer composite permanent magnet

ActiveCN102655050AImprove temperature stabilityControl interface responsePermanent magnetsInductances/transformers/magnets manufactureThermal deformationBall mill

The invention discloses a method for preparing a high-performance high-temperature-resisting nanometer composite permanent magnet, relating to preparation techniques of permanent magnetic materials. The method mainly comprises the following steps of: (1) weighing each element raw material according to elements of NdFeB alloy, mixing the element raw materials, melting the mixed raw material in vacuum, and rapidly quenching to prepare thin belts; (2) preparing SmCo ally rapidly quenched belts through the step (1); (3) respectively carrying out high-energy ball milling on the NdFeB and the SmCo alloy rapidly quenched belt to prepare corresponding nanometer crystal alloy powder; (4) mixing the NdFeB and the SmCo nanometer crystal alloy powder according to certain proportion, adding a crystal boundary nanometer modifier to be uniformly distributed on the surfaces of the NdFeB and the SmCo powders to obtain composite powder with the uniformly mixed three; (5) pressing the composite powder to form moulded blanks; (6) carrying out discharge plasma sintering on the moulded blanks to prepare a nanometer composite magnet; and (7) carrying out thermal deformation on the nanometer composite magnet to improve the degree of orientation and obtain the high-performance high-temperature-resisting nanometer composite permanent magnet. The method has the advantages of simple process and easiness in operation, and is suitable for large-scale batch production.

Owner:朗峰新材料启东有限公司

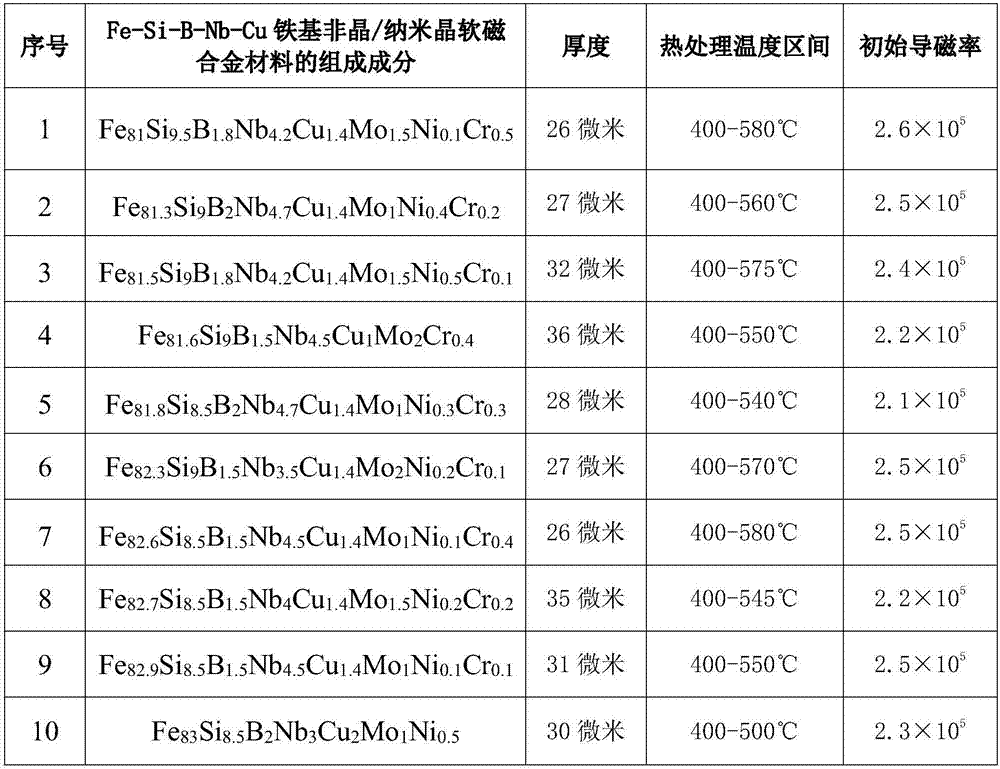

Fe-Si-B-Nb-Cu iron-based amorphous/nanocrystalline soft magnetic alloy material and preparing and heat treatment process

ActiveCN107365950AImprove antioxidant capacityImprove consistencyFurnace typesMagnetic materialsOxidation resistantToughness

The invention discloses an Fe-Si-B-Nb-Cu iron-based amorphous / nanocrystalline soft magnetic alloy material and a preparing and heat treatment process. The Fe-Si-B-Nb-Cu iron-based amorphous / nanocrystalline soft magnetic alloy material comprises following composition elements including, by mass percent, 81 to 83% of Fe, 8.5 to 9.5% of Si, 1.5 to 2% of B, 3 to 4.5% of Nb, 1 to 2% of Cu, 1 to 2% of Mo, 0 to 0.5% of Ni and 0 to 0.5% of Cr. A small amount of metal elements of Mo, Ni and Cr is introduced into the Fe-Si-B-Nb-Cu system, the better amorphous forming capacity of the Fe-Si-B-Nb-Cu iron-based amorphous / nanocrystalline soft magnetic alloy material is ensured, through the heat treatment process, an alloy strip of an amorphous structure is obtained, in the strip spraying and heat treatment process, the oxidation resistance capacity is better, in the heat treatment process, atmosphere protection is facilitated, temperature consistency is improved, product performance discreteness is reduced, and the beneficial effects of being high in heat treatment efficiency and good in toughness are achieved.

Owner:广东咏旺新材料科技有限公司

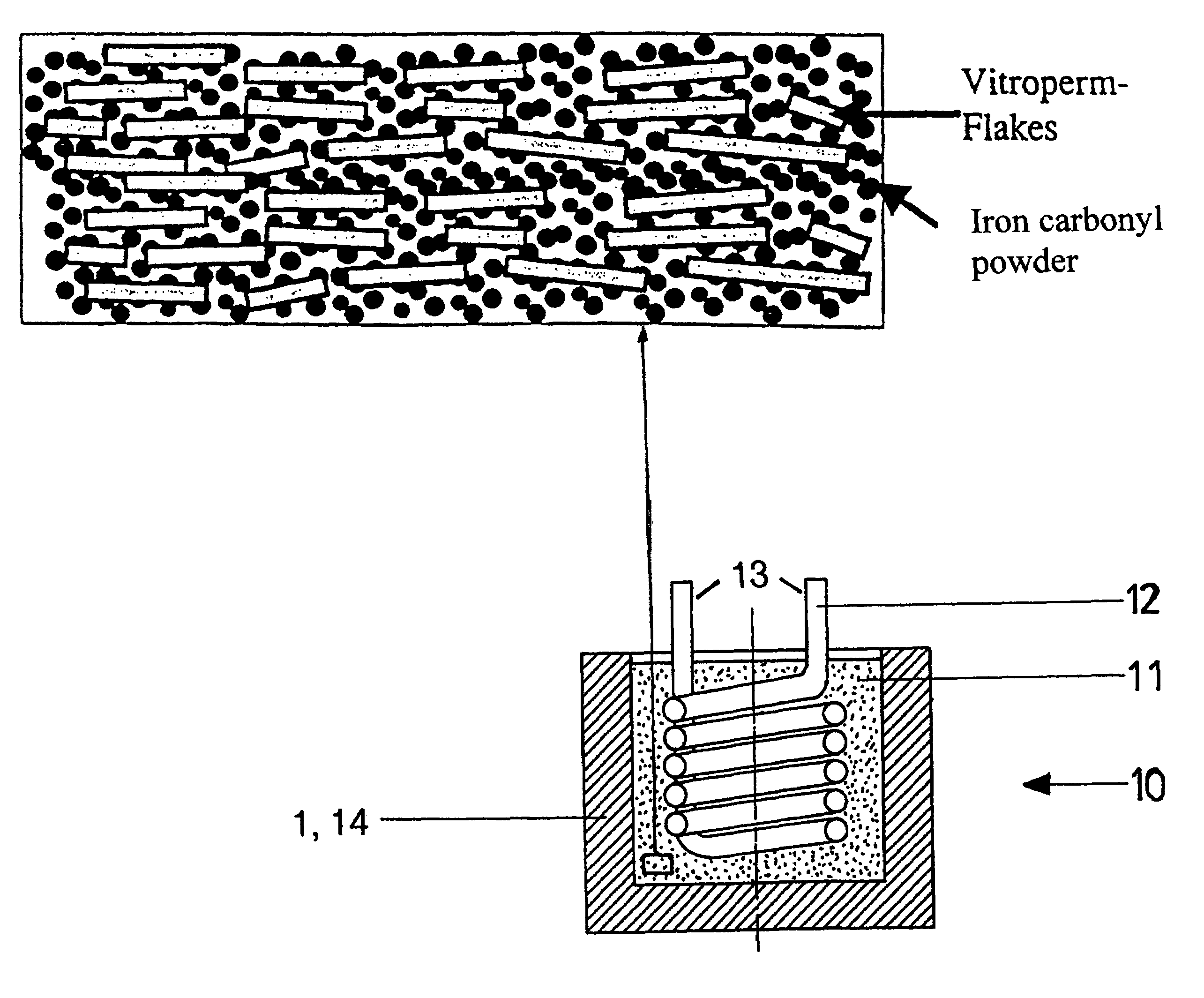

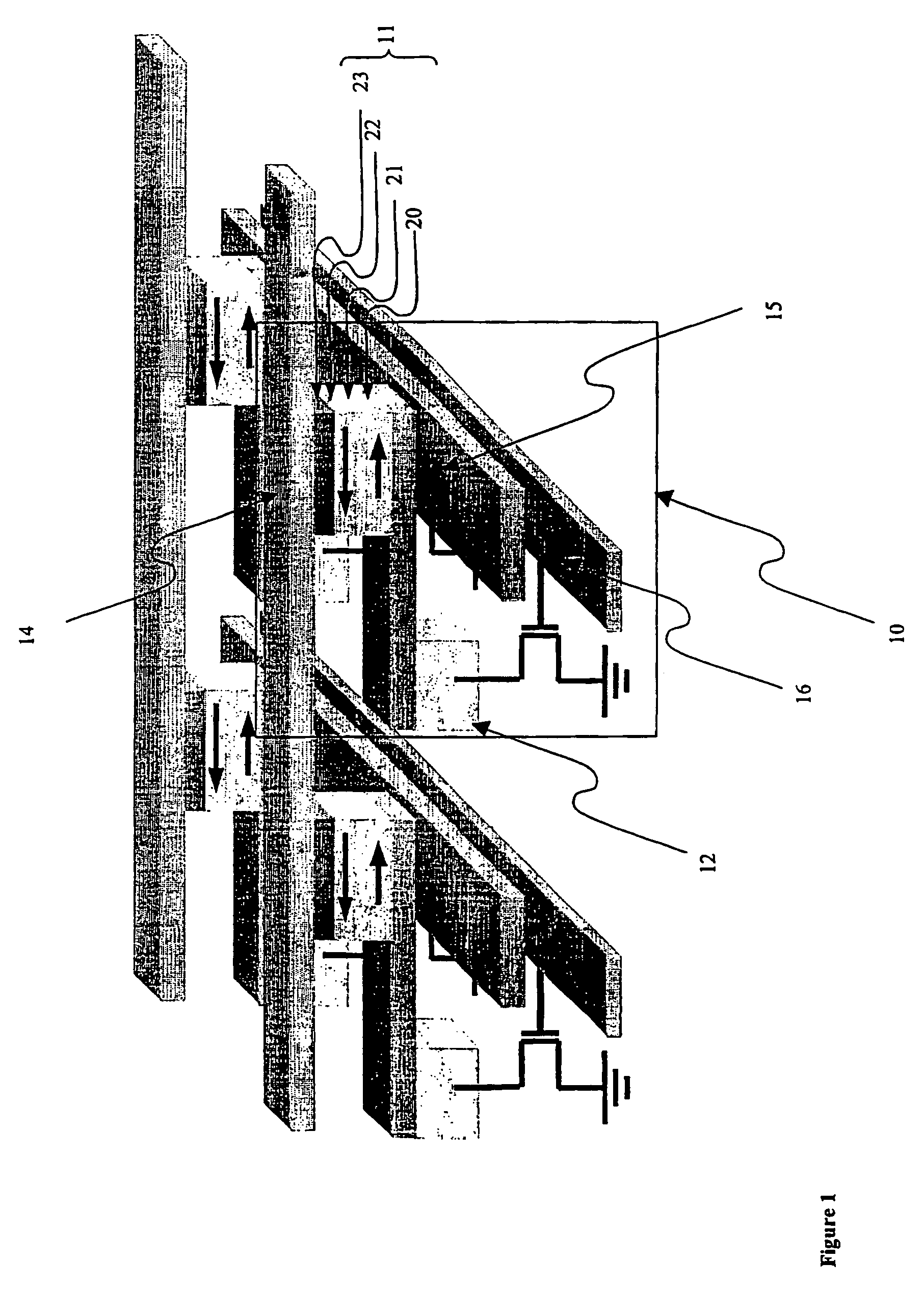

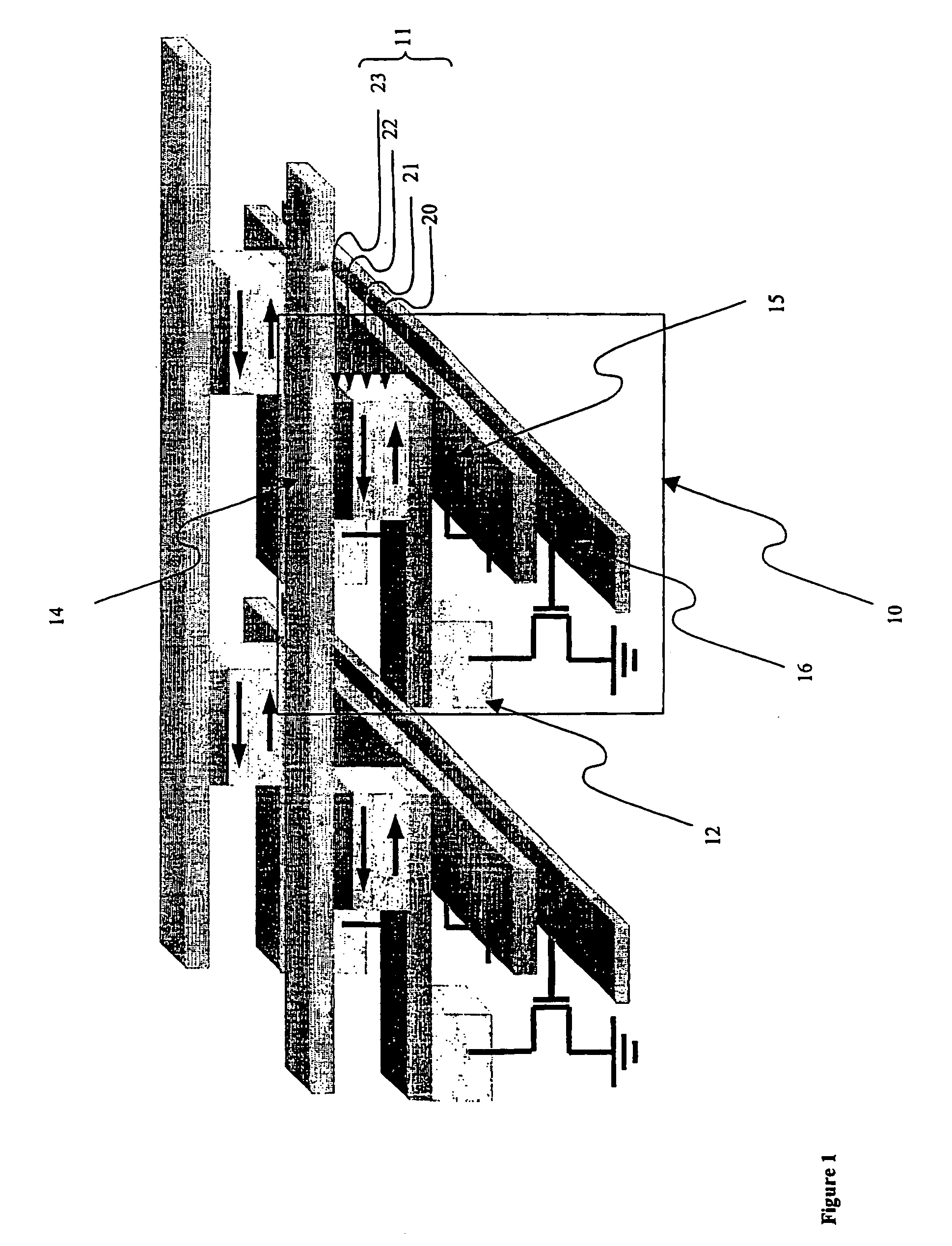

Inductive component and method for producing the same

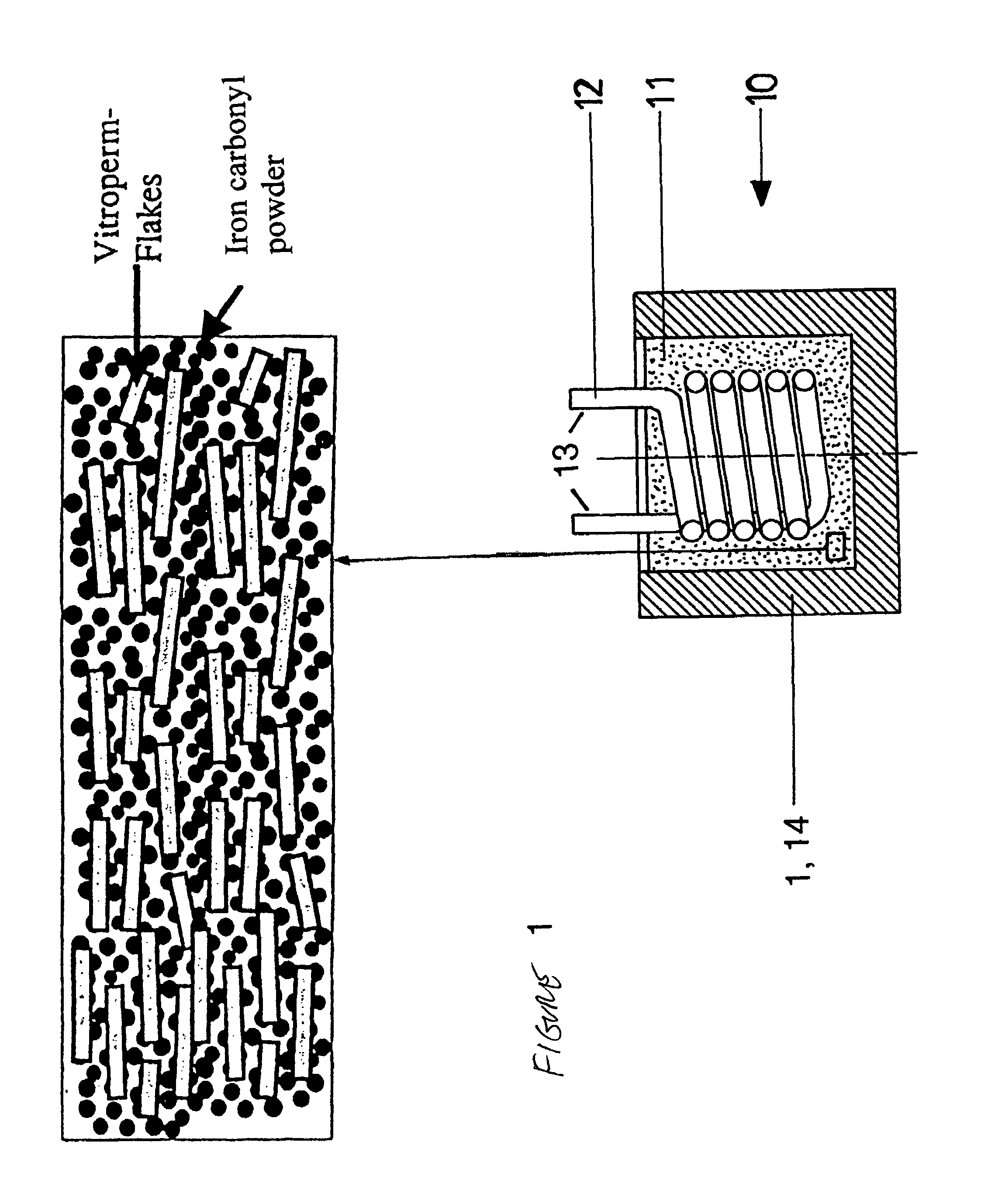

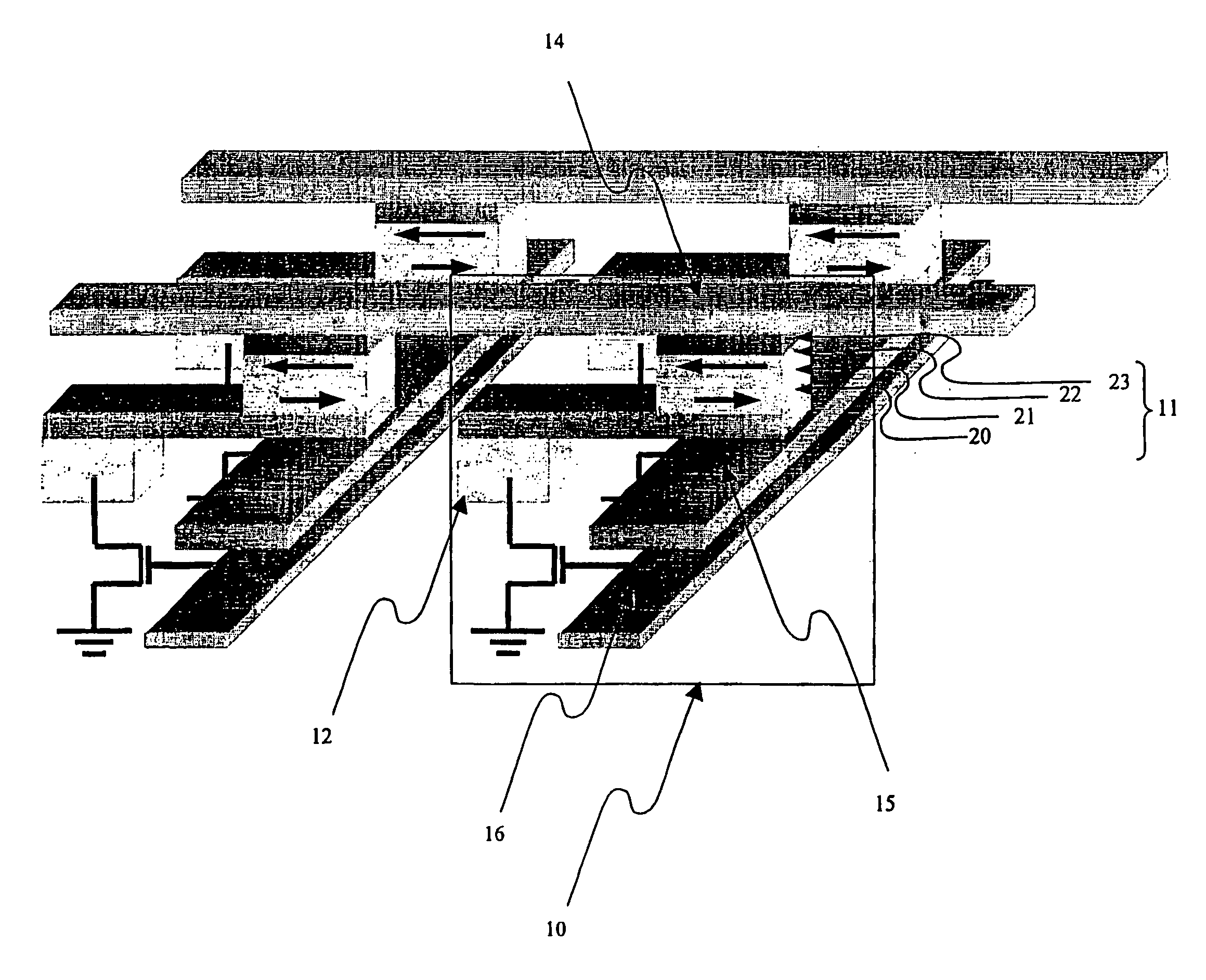

InactiveUS7532099B2Higher ferromagnetic packing densityIncrease field strengthTransformers/inductances casingsInorganic material magnetismInductorInductance

The invention relates to an inductive component (10) whose soft-magnetic core (11) consists of a powder composite. Said powder composite is produced by mixing a ferromagnetic amorphous or nanocrystalline alloy powder with a ferromagnetic dielectric powder and a thermoplastic or duroplastic polymer. Unlike conventional injection-molded or cast soft-magnetic cores, cores from a composite comprising a dielectric ferromagnetic powder allow for packing densities of substantially more than 55% by volume.

Owner:VACUUMSCHMELZE GMBH & CO KG

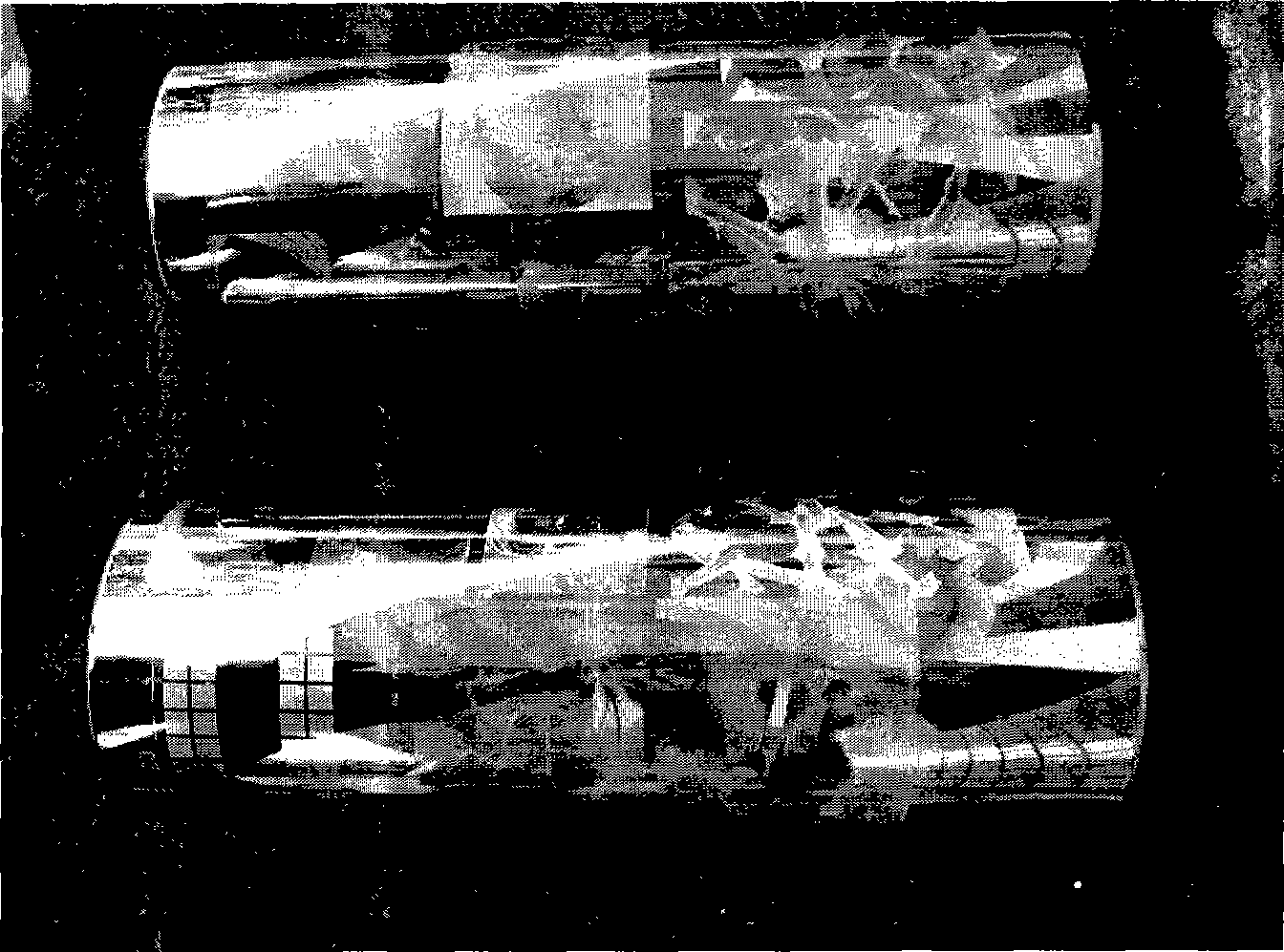

Method for producing amorphous alloy ribbon, and method for producing nano-crystalline alloy ribbon with same

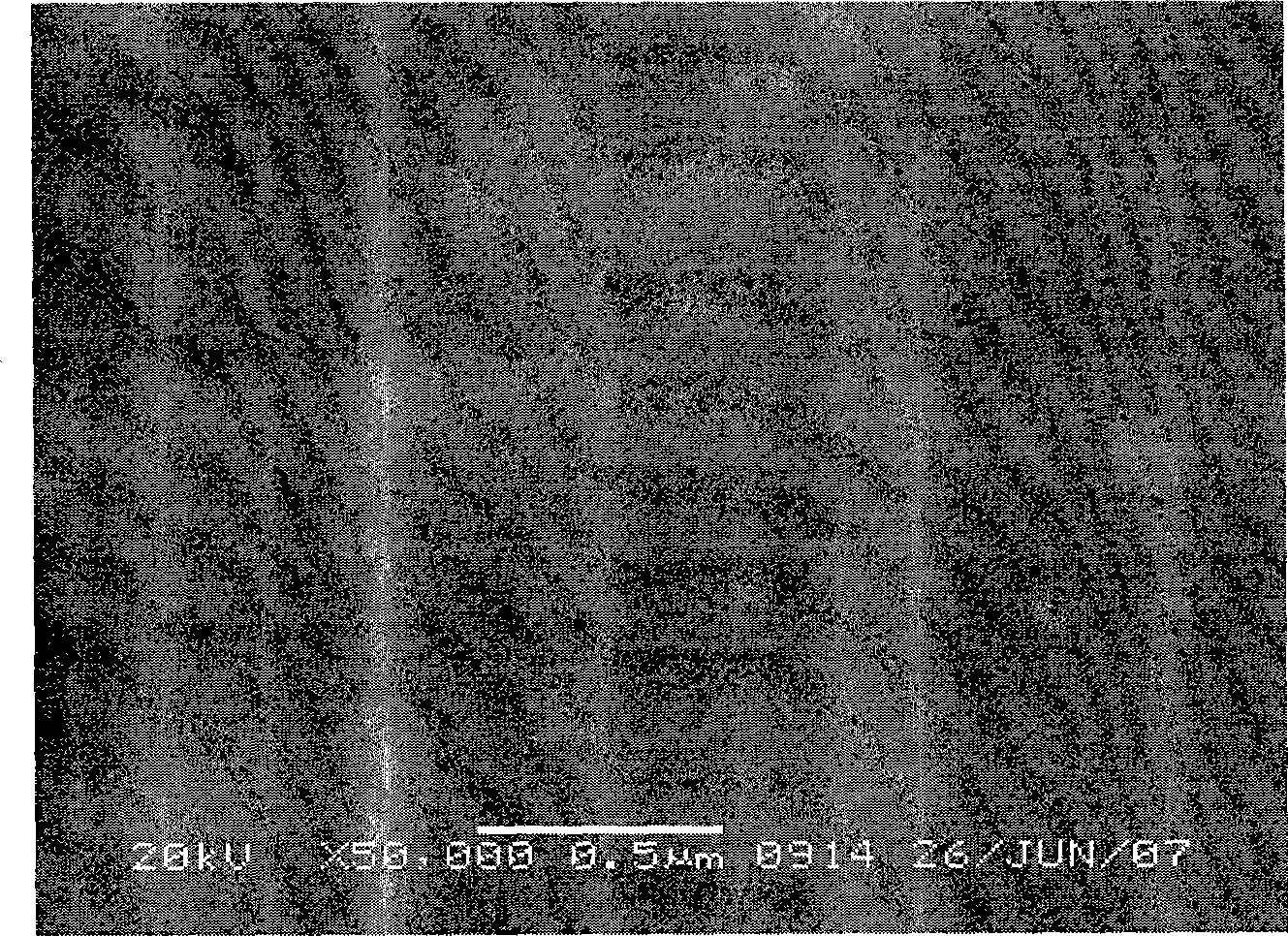

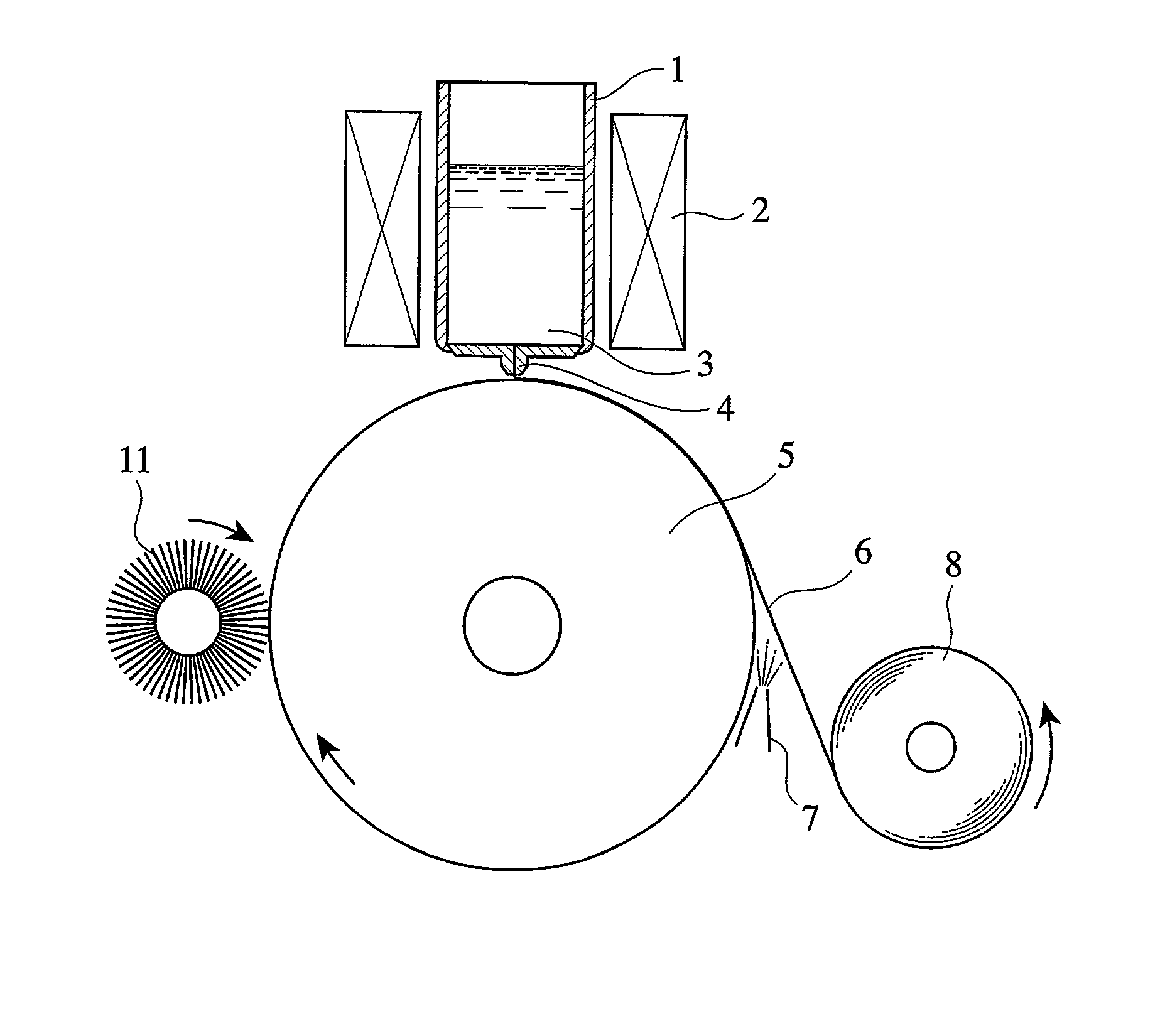

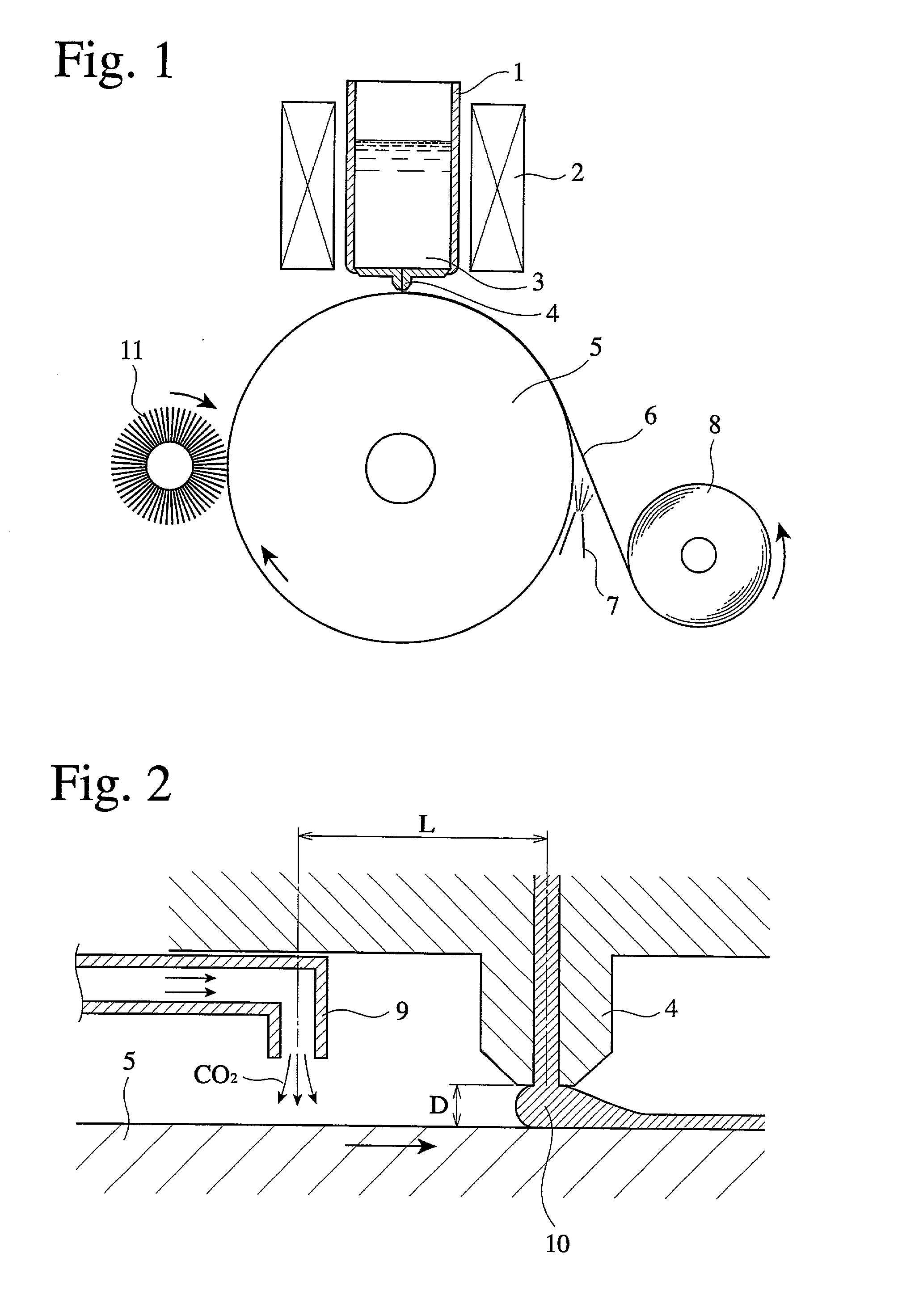

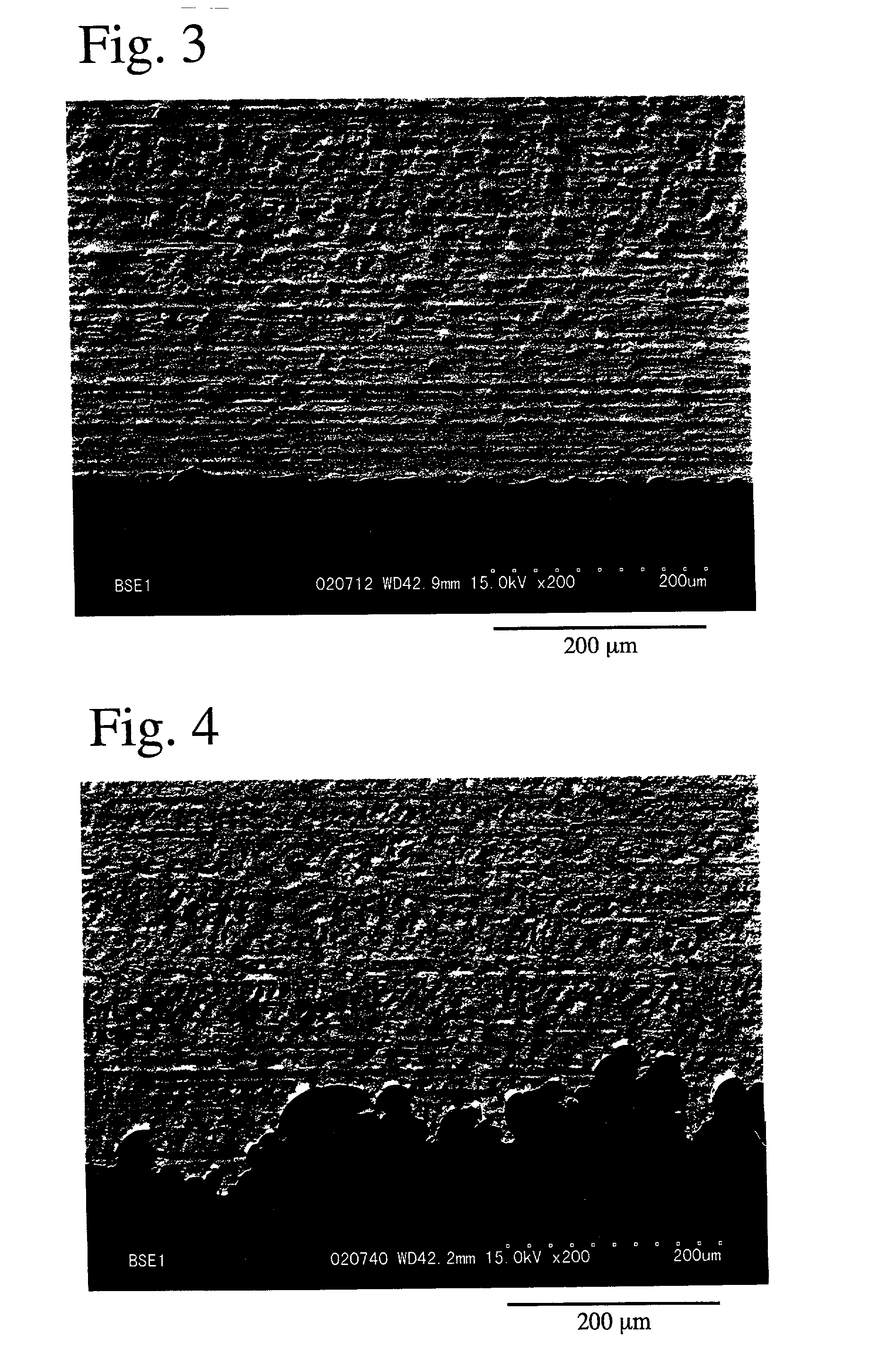

InactiveUS20030041931A1Improve surface conditionGood edge shapeMaterials scienceNanocrystalline alloy

An amorphous alloy ribbon free from embrittlement and crystallization and having excellent surface conditions and shape in edge portions is produced by (a) preparing an alloy melt having a composition comprising 13 atomic % or less of B and 15 atomic % or less of at least one selected from the group consisting of transition elements of Groups 4A, 5A and 6A, the balance being substantially Fe; (b) ejecting the alloy melt at a temperature from the melting point of the alloy +50° C. to the melting point of the alloy +250° C. through a nozzle onto the cooling roll rotating at a peripheral speed of 35 m / second or less, a distance between a tip end of the nozzle and the cooling roll being 200 mum or less; (c) starting to supply a gas based on CO2 to the alloy melt after the surface temperature of the cooling roll has become substantially constant; and (d) grinding the cooling roll while supplying the gas based on CO2.

Owner:HITACHI METALS LTD

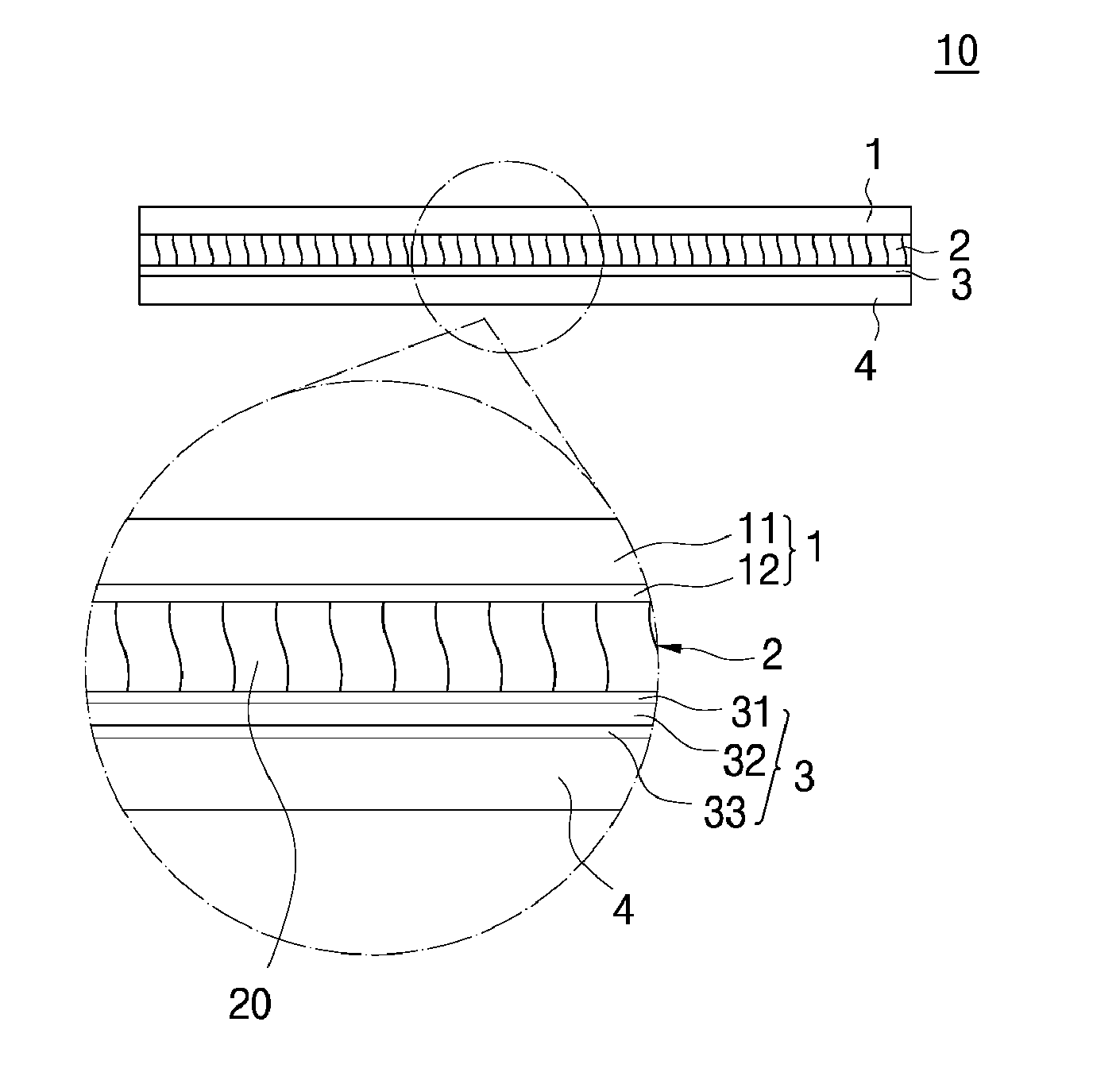

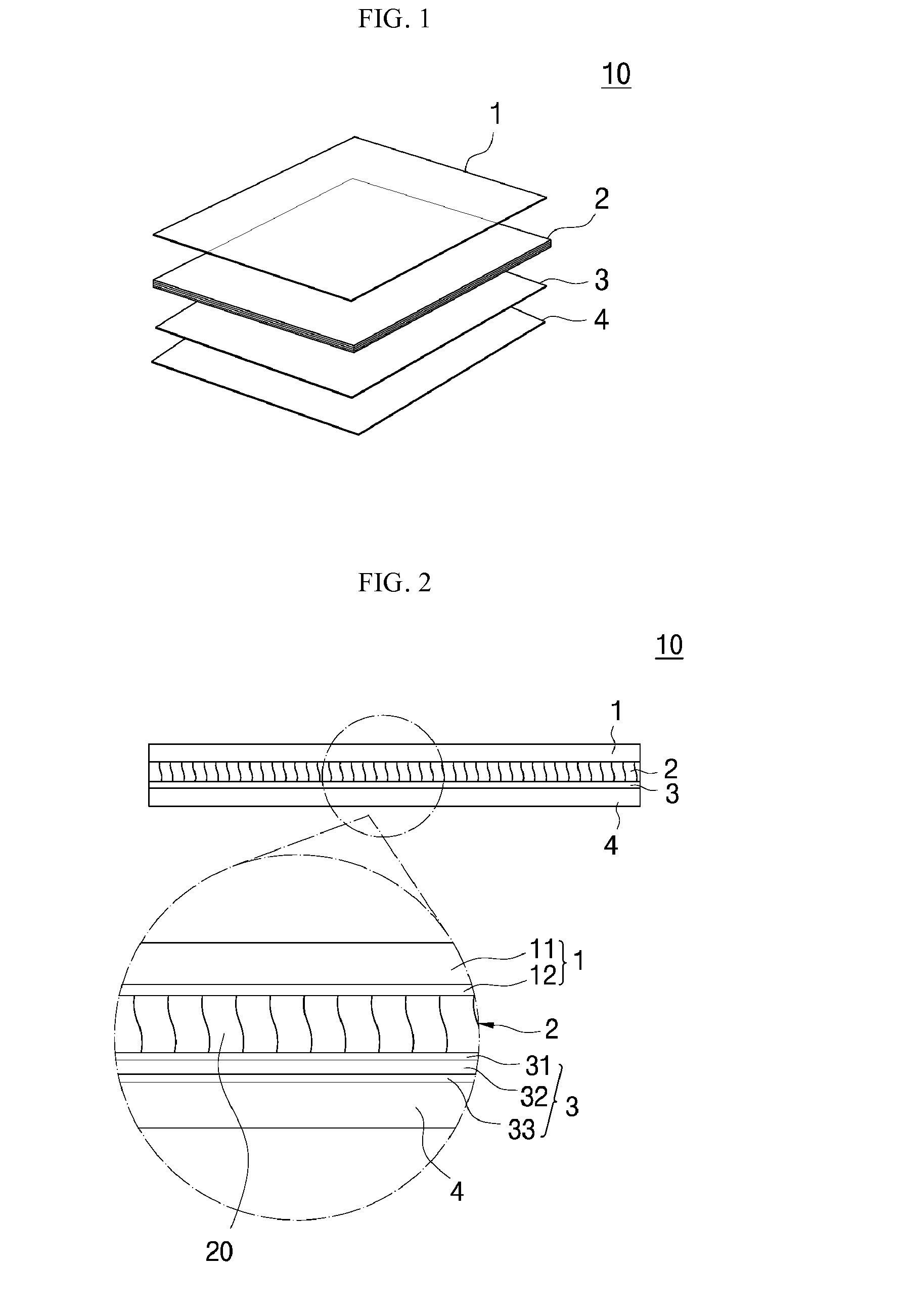

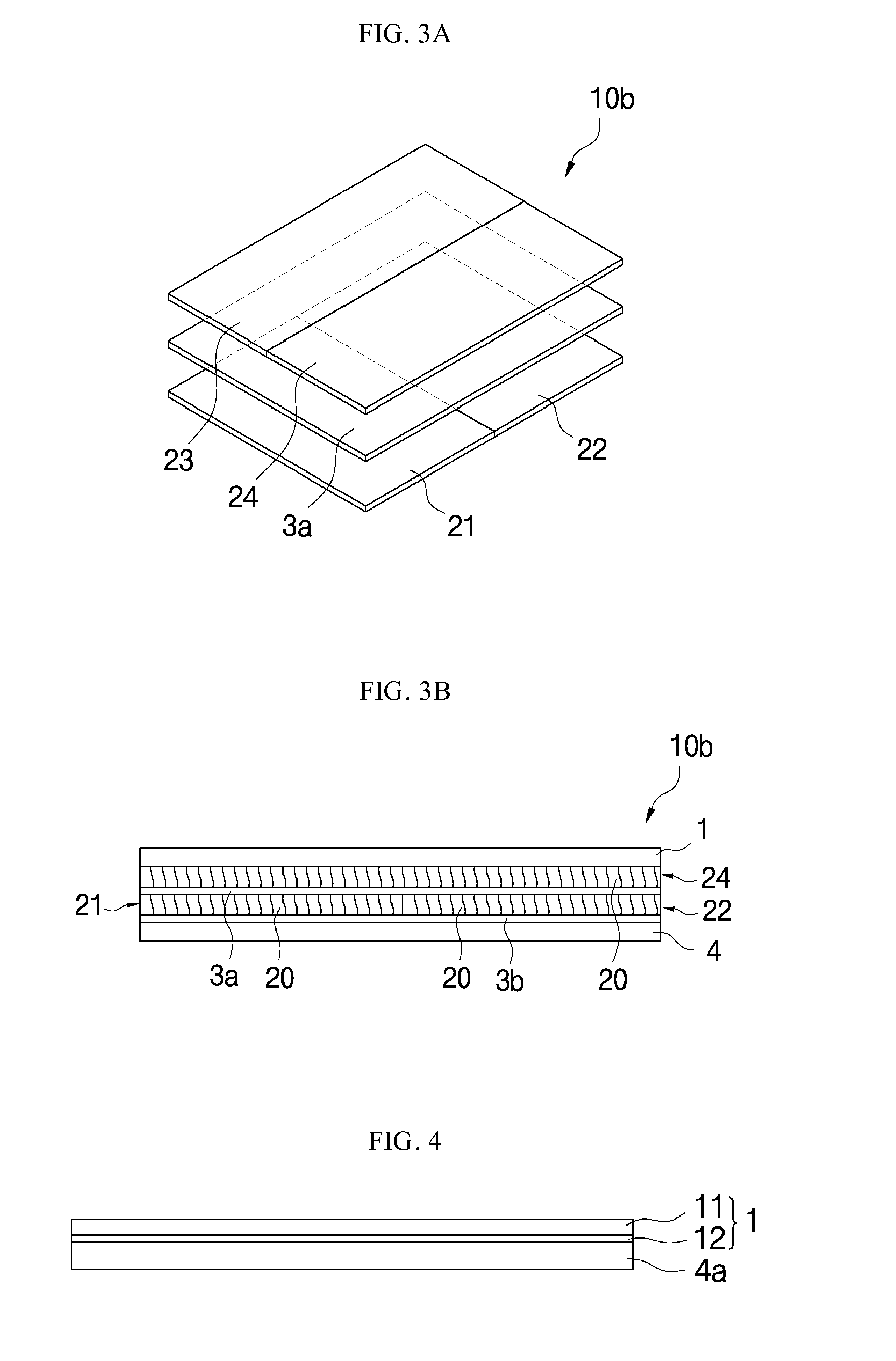

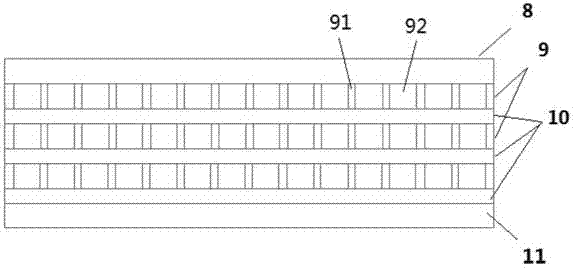

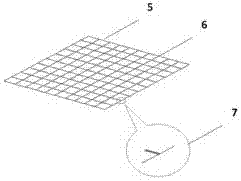

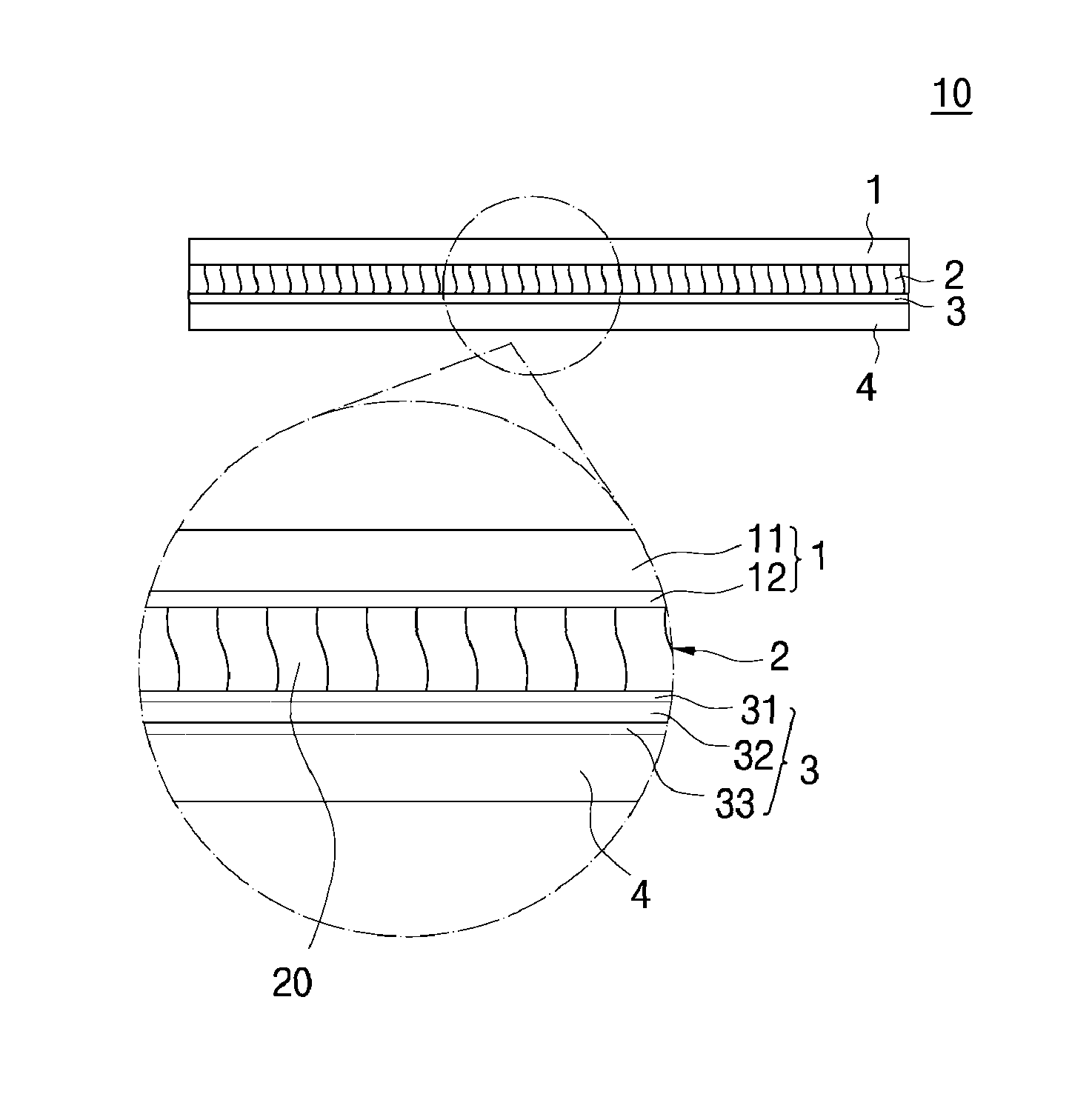

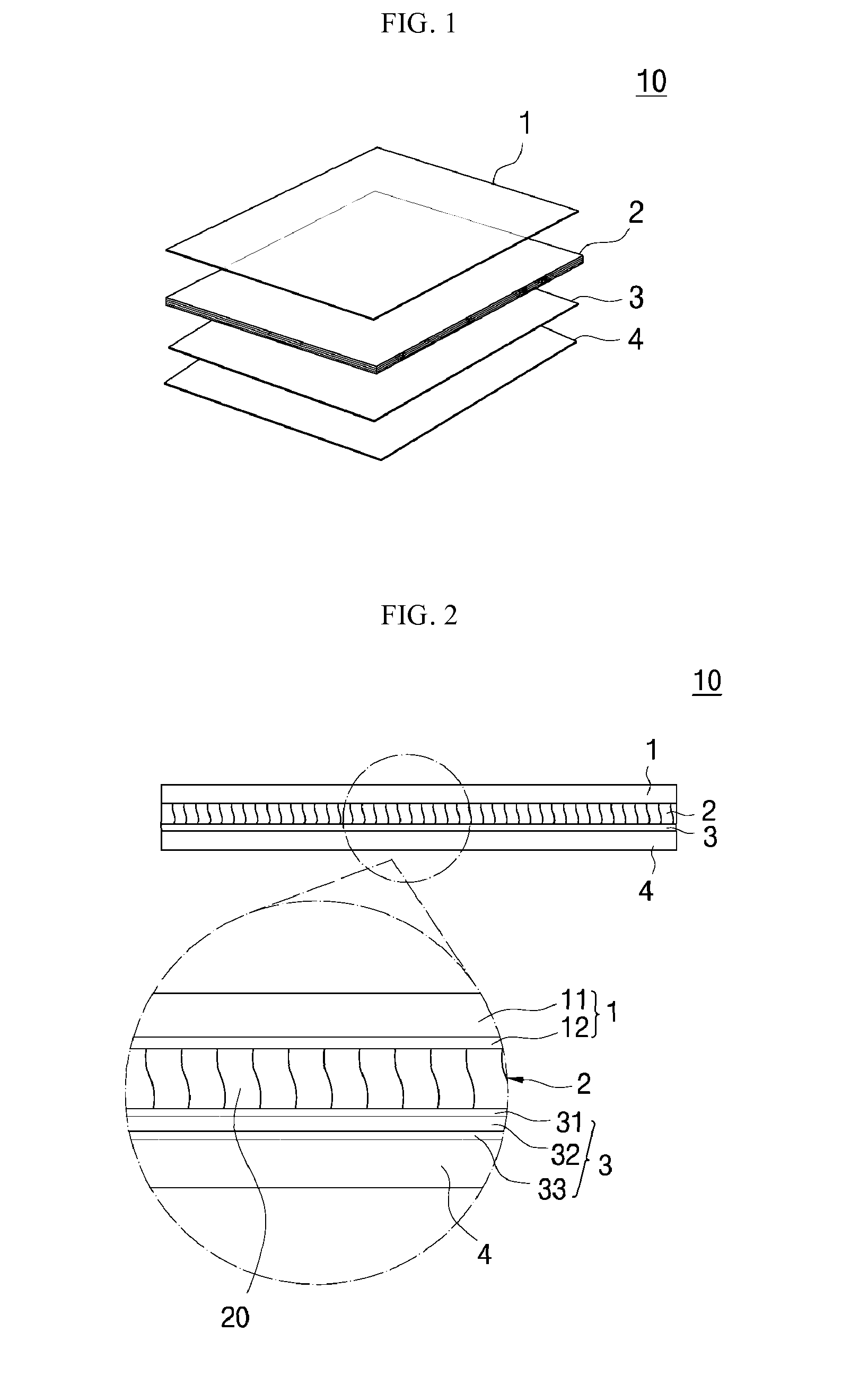

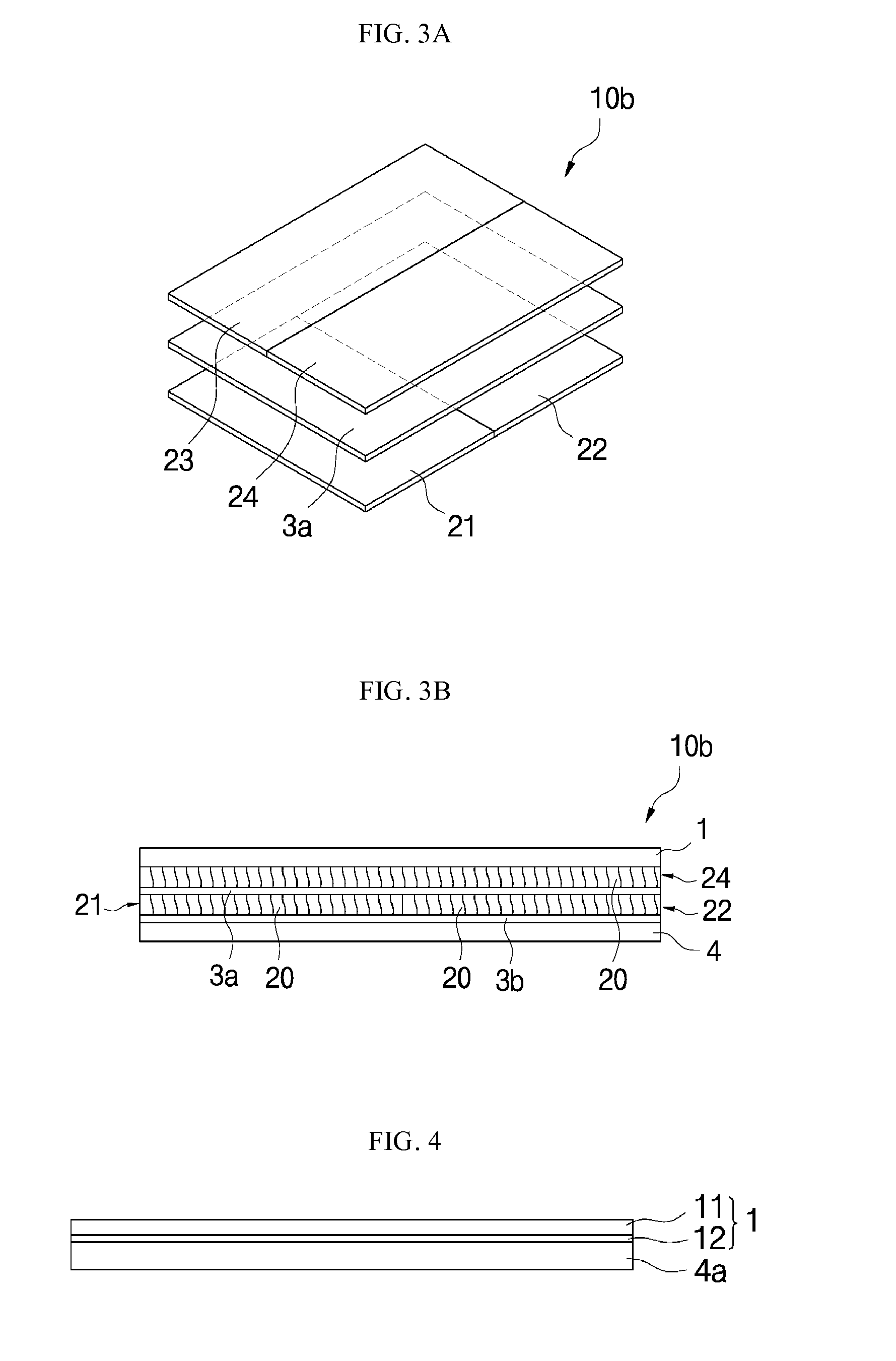

Magnetic field shielding sheet for digitizer, manufacturing method thereof, and portable terminal device using same

ActiveUS20140362505A1Easy to manufactureEasy to controlShielding materialsNanomagnetismTectorial membraneTerminal equipment

Provided is a magnetic field shield sheet for a digitizer, which blocks an effect of a magnetic field generated from various components of a main body of the portable terminal device and at the same time improves the sensitivity of an electronic pen when a digitizer feature is implemented in the portable terminal device, while minimizing an influence upon a geomagnetic sensor. The magnetic field shield sheet includes: at least one layer thin magnetic sheet made of a nanocrystalline alloy and flake-treated so as to be separated into a plurality of fine pieces; a protective film that is adhered on one surface of the thin magnetic sheet via a first adhesive layer provided on one side of the protective film; and a double-sided tape that is adhered on the other surface of the thin magnetic sheet via a second adhesive layer provided on one side of the double-sided adhesive tape.

Owner:AMOSENSE

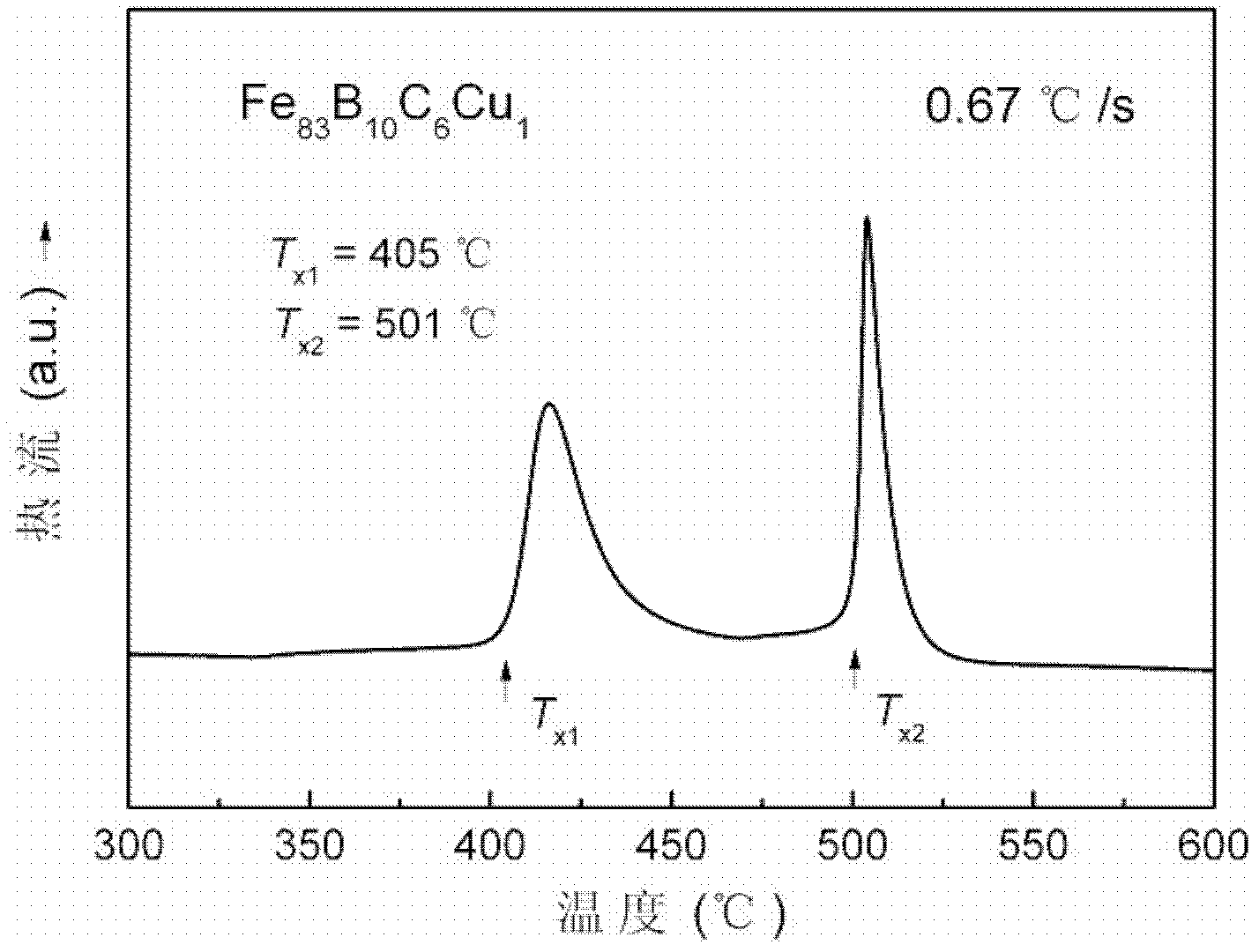

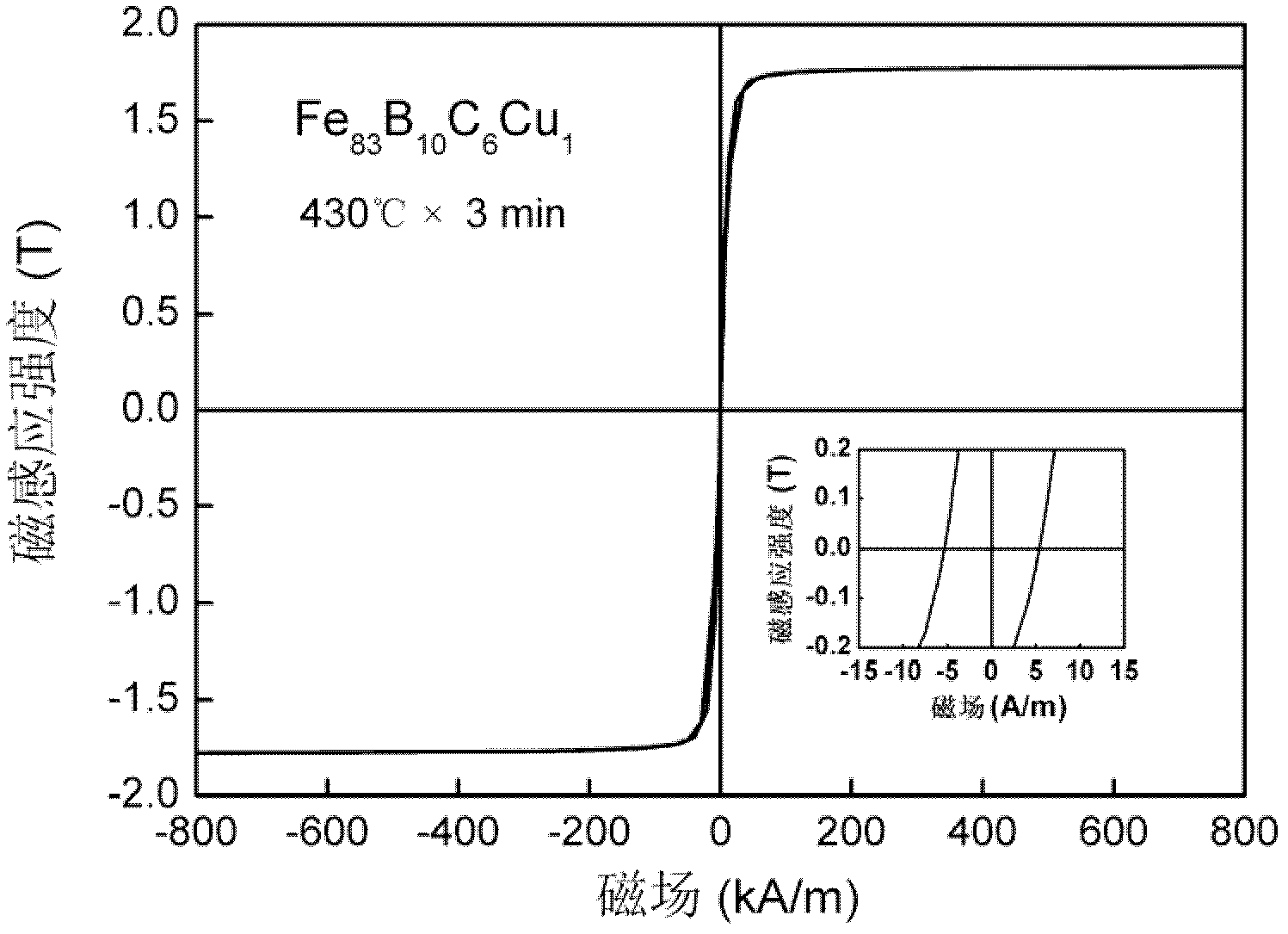

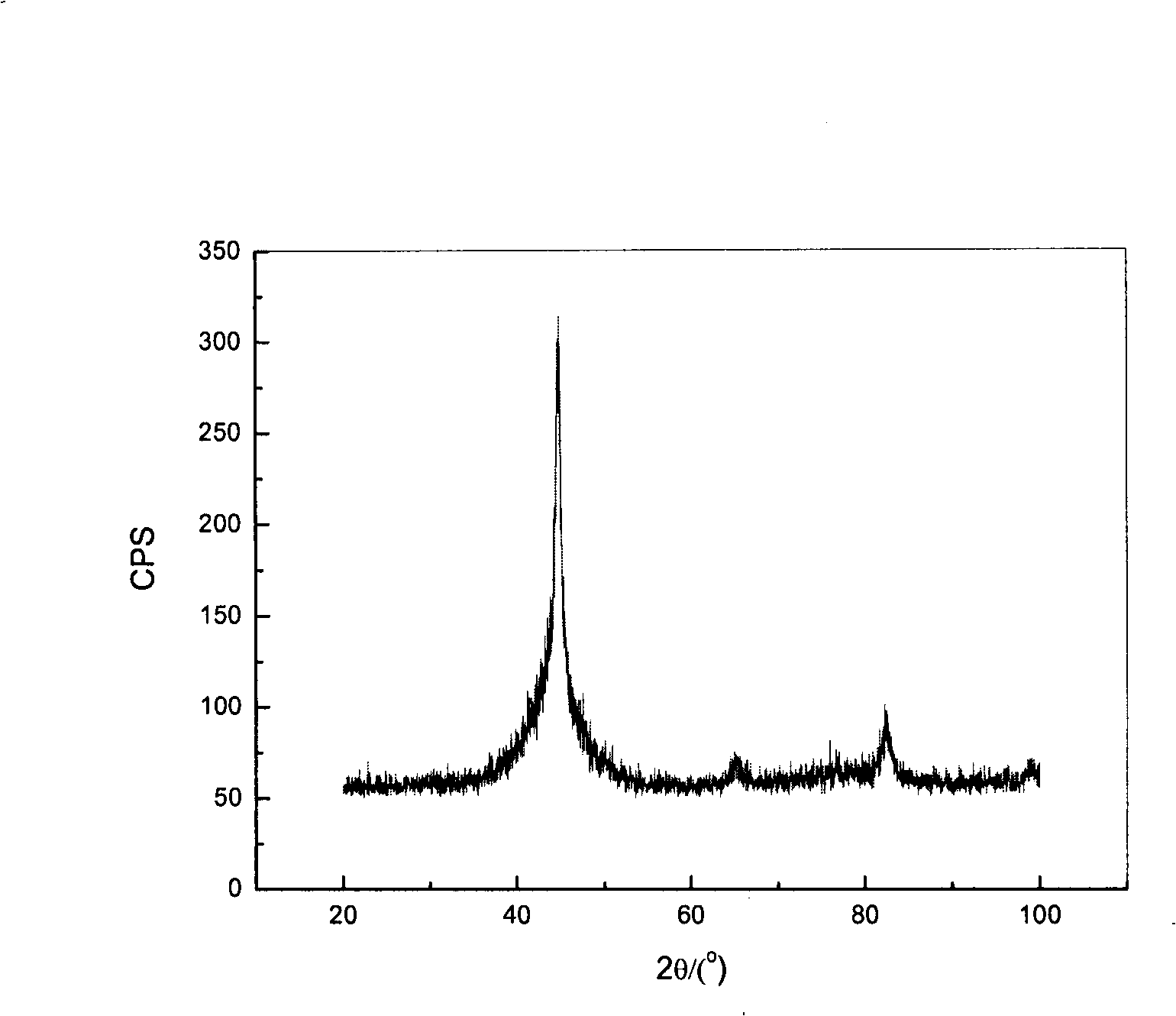

Iron-based nanocrystalline soft magnetic alloy with high saturation magnetic induction and low cost

ActiveCN102304669AHigh saturation magnetic inductionLow coercivityMagnetic materialsProcessing costAmorphous matrix

The invention relates to an iron-based nanocrystalline soft magnetic alloy. The alloy is characterized in that: the alloy meets the following relation in composition: FeaBbCcMdCue, wherein M represents one or more of Si, Al, Cr and Mn, the subscripts a, b, c, d and e represent the atom percents of the corresponding elements of the alloy respectively and meet the following conditions: 78<=a<=88, 4<=b<=16, 3<=c<=10, 0<=d<=8, 0.3<=e<=1.5 and a+b+c+d+e=100. The iron-based nanocrystalline alloy consists of an amorphous matrix phase and a nanocrystalline phase. The alloy is obviously characterized in that: the alloy has excellent soft magnetic performances such as high saturation magnetic induction, low coercivity, low loss and the like; and the alloy does not contain precious metal elements and volatile elements, thereby reducing the processing cost of the raw materials and bringing convenience to popularization and application. The invention also relates to a preparation method of the alloy.

Owner:NINGBO INNOVATION CENT FOR APPLIED MAGNETICS CO LTD

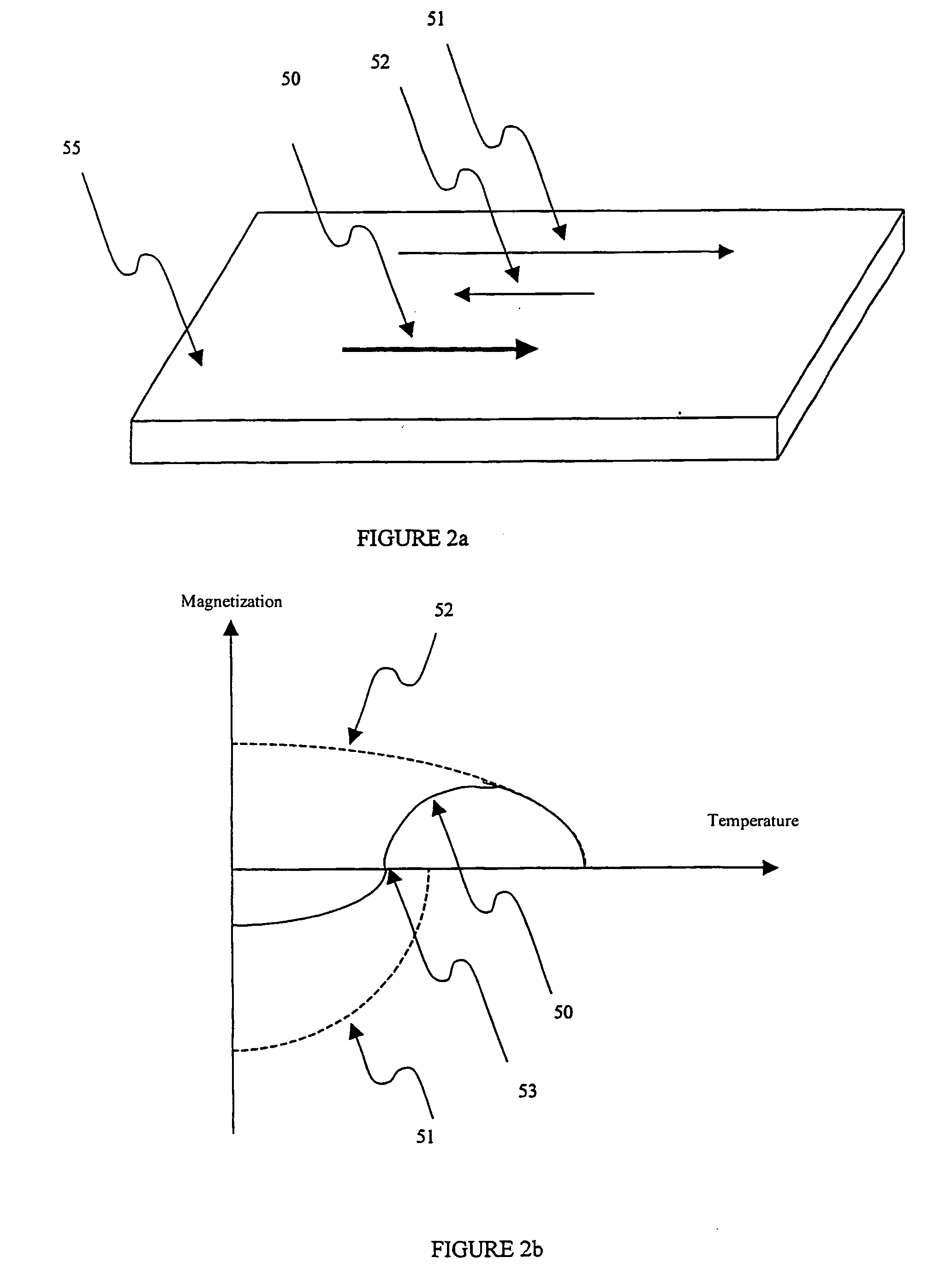

Magnetic memory with write inhibit selection and the writing method for same

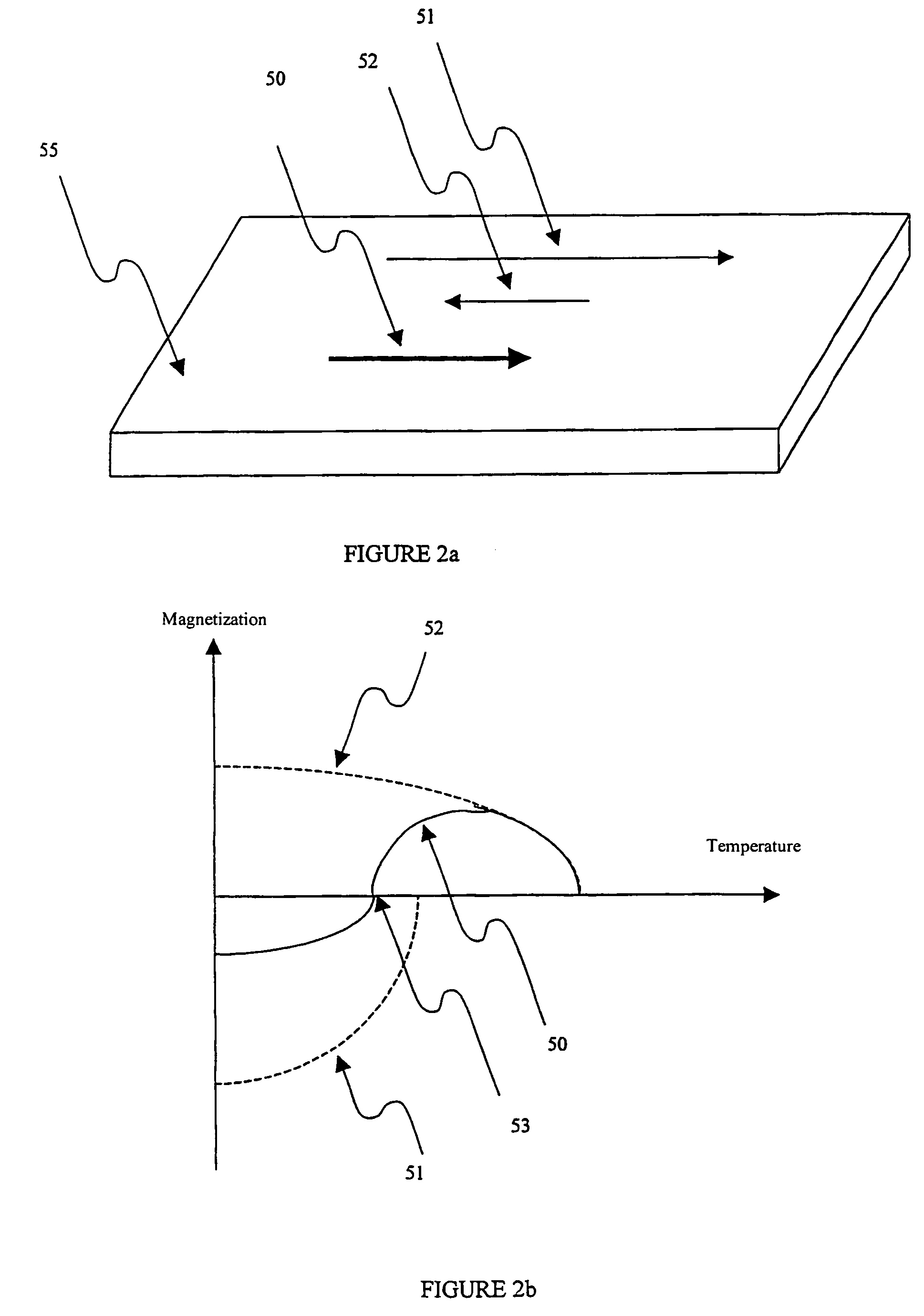

InactiveUS7129555B2Error minimizationNanomagnetismMagnetic-field-controlled resistorsRare earthMagnetization

The invention relates to a magnetic memory with write inhibit selection and the writing method for same. Each memory element of the invention comprises a magnetic tunnel junction (70) consisting of: a magnetic layer, known as the trapped layer (71), having hard magnetisation; a magnetic layer, known as the free layer (73), the magnetisation of which may be reversed; and an insulating layer (72) which is disposed between the free layer (73) and the trapped layer (71) and which is in contact with both of said layers. The free layer (73) is made from an amorphous or nanocrystalline alloy based on rare earth and a transition metal, the magnetic order of said alloy being of the ferrimagnetic type. The selected operating temperature of the inventive memory is close to the compensation temperature of the alloy.

Owner:CENT NAT DE LA RECHERCHE SCI

Nanocrystal alloy, fabrication method of electromagnetic shielding sheet for wireless charging and electromagnetic shielding sheet

ActiveCN106922111AReasonable structureReduce lossMagnetic/electric field screeningRare-earth elementElectromagnetic shielding

The invention provides a nanocrystal alloy material, a fabrication method of an electromagnetic shielding sheet for wireless charging and the electromagnetic shielding sheet. The nanocrystal alloy material conforms to the following formula 1: Fe<100-d-e-f-g-z-m>D<d>E<e>Si<f>B<g>Z<z>M<m>, in the formula 1, D expresses at least one element selected from Cu and Au, E expresses at least one element selected from V, Nb, Ta, Mo, Mn and rare-earth elements, Z expresses at least one element selected from C, N and P, M express at least one element selected from Ni or Co, d, e, f, g, z and m respectively express contents of corresponding constituents and conform to the relation: 0.01<=d<=3at%, 0.01<=e<=5at%, 0<=f<=25at%, 0<=g<=20at%, 0<=z<=10at%, 0<=m<=40at%, 15<=(d+e+f+g+z)<=35at%, and at% expresses atomic percent.

Owner:SHANGHAI LINEPRINTING MATERIALS CO LTD

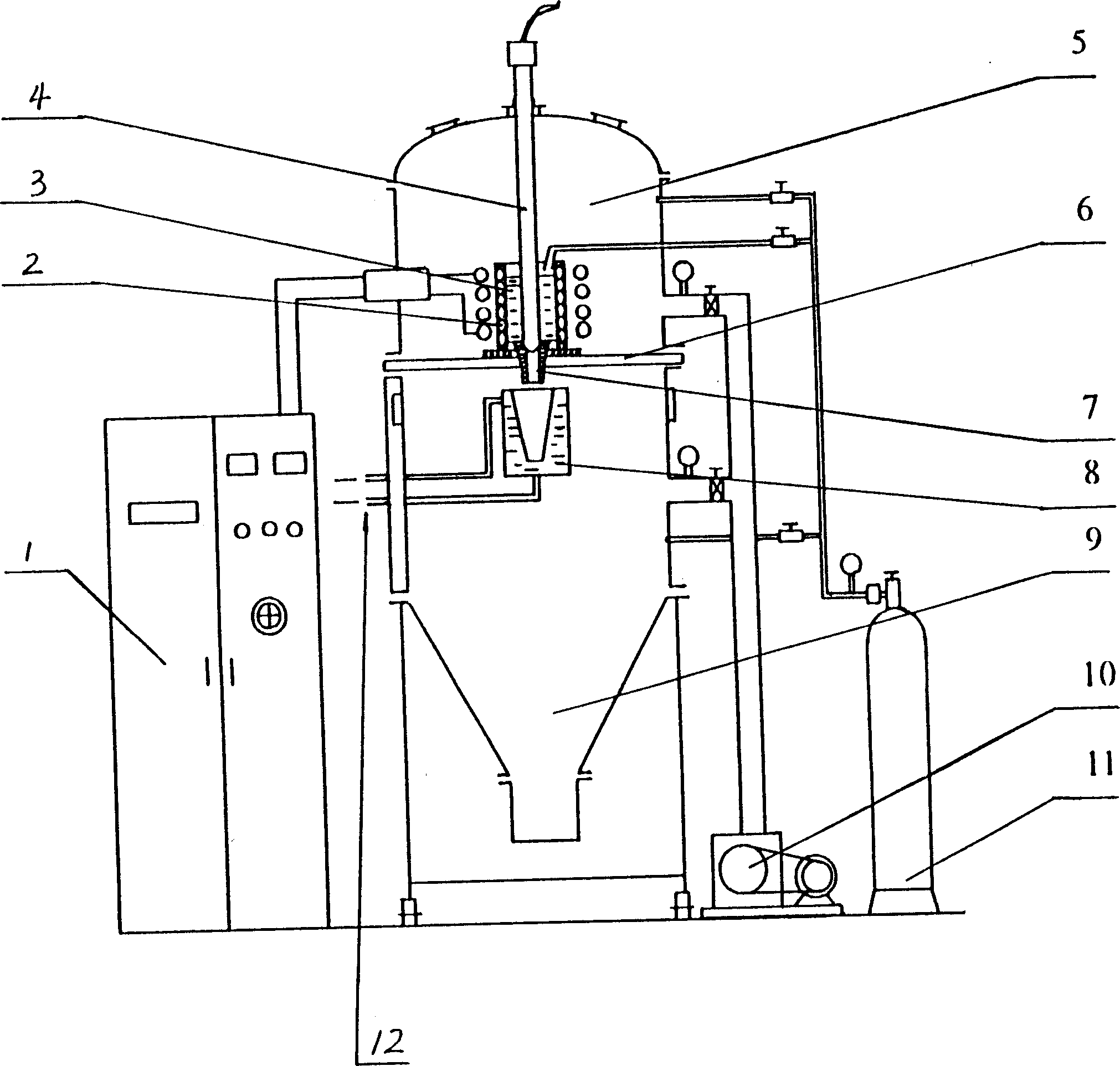

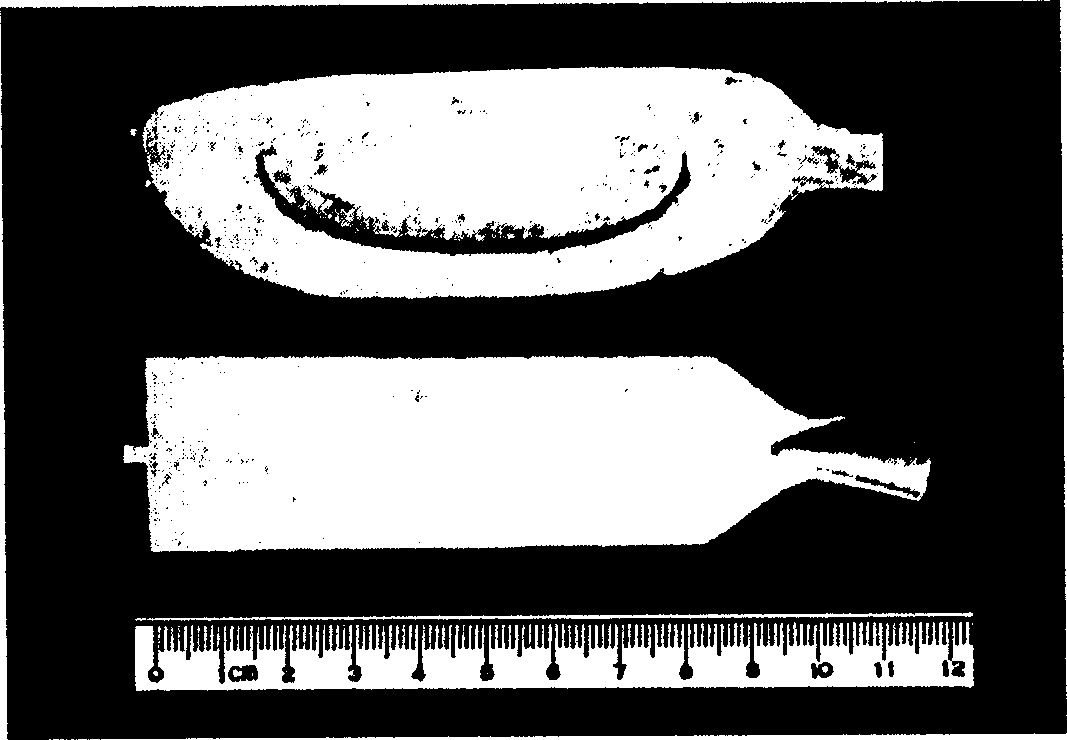

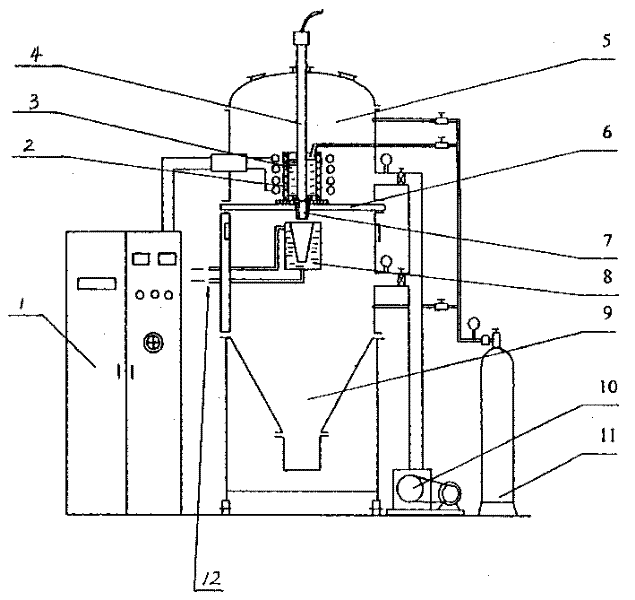

Melt near quick setting method and special apparatus

A near-fast solidifying method and apparatus for molten body are disclosed. Said apparatus is composed of a vacuum chamber consisting of upper and lower vacuum cavities and central sealing unit, heater in the upper vacuum cavity, quartz crucible in the heater, mould in the lower vacuum cavity, and circulating cooler. Its method includes vacuumizing said vacuum chamber repeatedly, filling argon gas, heating mother alloy to a temp which is 50-200 deg.C higher than its melting point, pulling up plunger rod while filling pressure argon gas to pour the molten alloy in mould instantaneously, and quick cooling.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

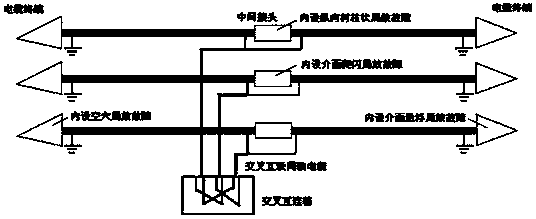

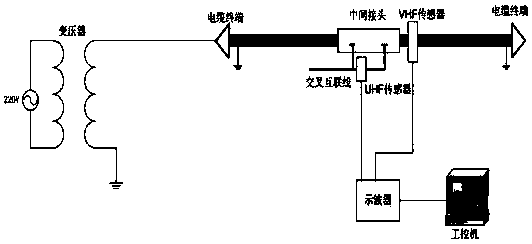

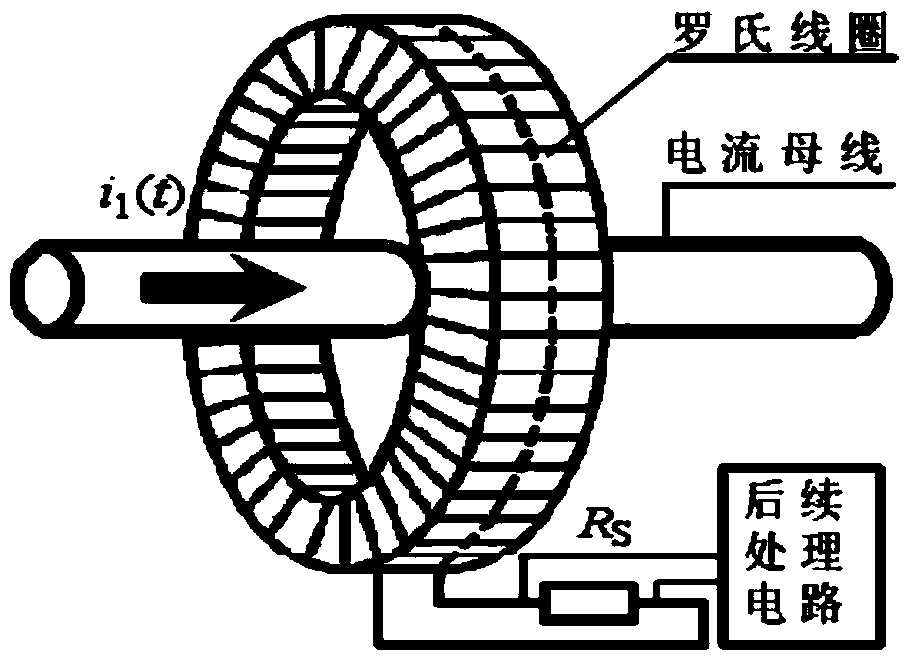

UHF (Ultra High Frequency) broadband current sensor based on Rogowski coil principle and joint monitoring system

ActiveCN103529366AAccurate extractionReduce Interfering SignalsTesting dielectric strengthCurrent sensorConductor Coil

The invention discloses a UHF (Ultra High Frequency) broadband current sensor based on a Rogowski coil principle and a joint monitoring system, and belongs to the technical field of local discharge monitoring of cables. The magnetic core of the UHF broadband current sensor is partitioned into two half rings, and is made of an iron-based nanocrystalline alloy material; a winding is a copper lead which is 0.8 millimeter in diameter; a coil is of 15 turns. The joint monitoring system consists of the UHF broadband current sensor and a VHF (Very High Frequency) sensor, wherein the VHF sensor and the UHF broadband current sensor are used together for monitoring a running cable in real time; data are transmitted to an oscilloscope; the oscilloscope is connected with an industrial control computer. According to the UHF broadband current sensor, a local discharge signal can be calibrated, so that background noise interference can be eliminated effectively, and a local discharge waveform is extracted accurately. A detection test is performed on a middle joint of a real cable with local discharge in an experiment and on field, and a test result indicates that the sensitivity is below 10pV; interference signals can be reduced effectively; a basis is provided for the judgment of field personnel.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

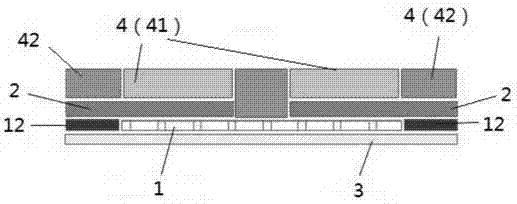

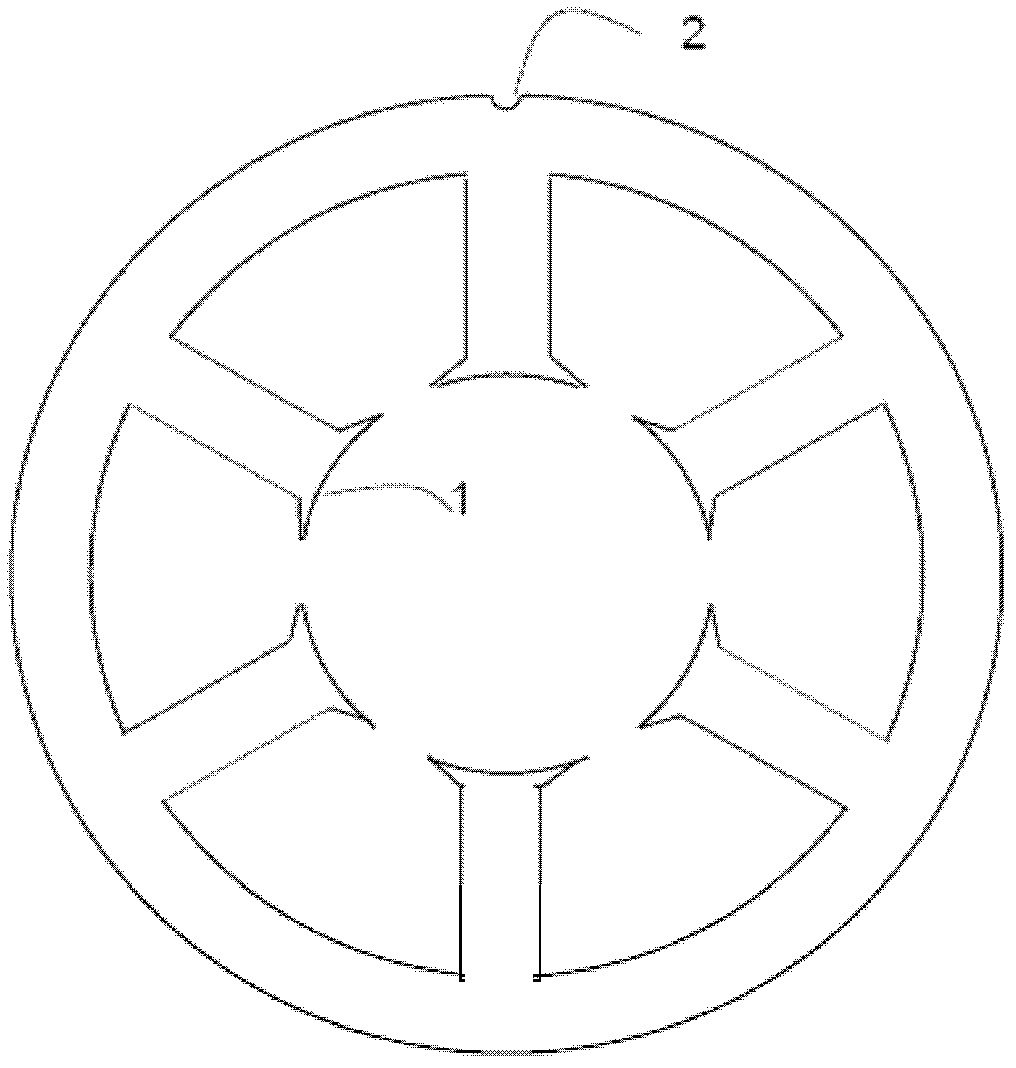

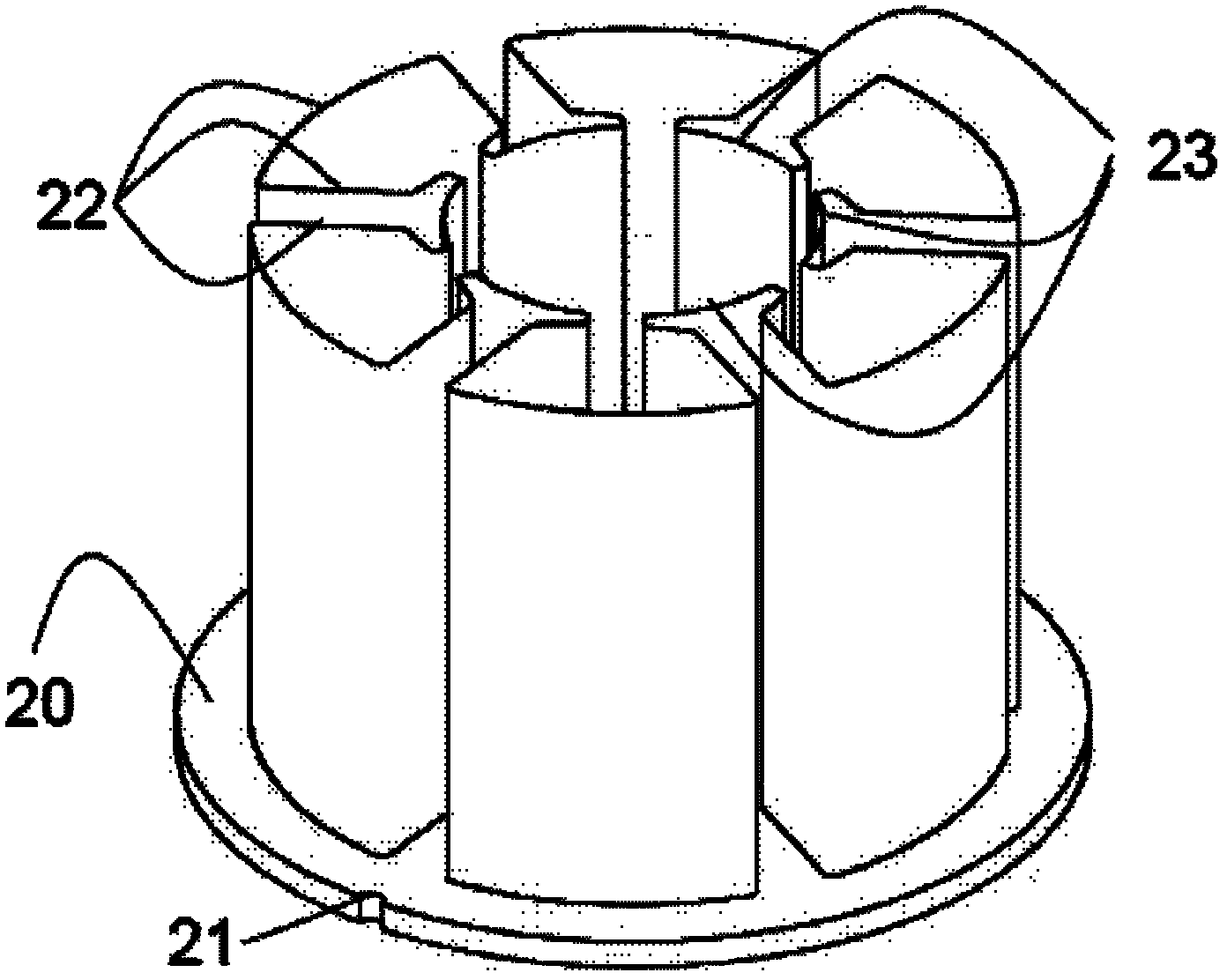

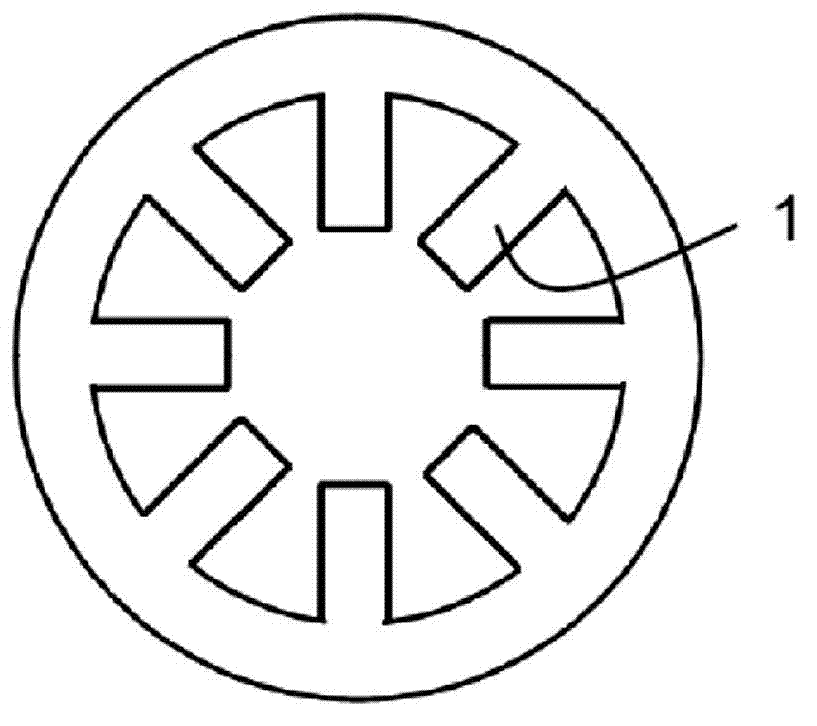

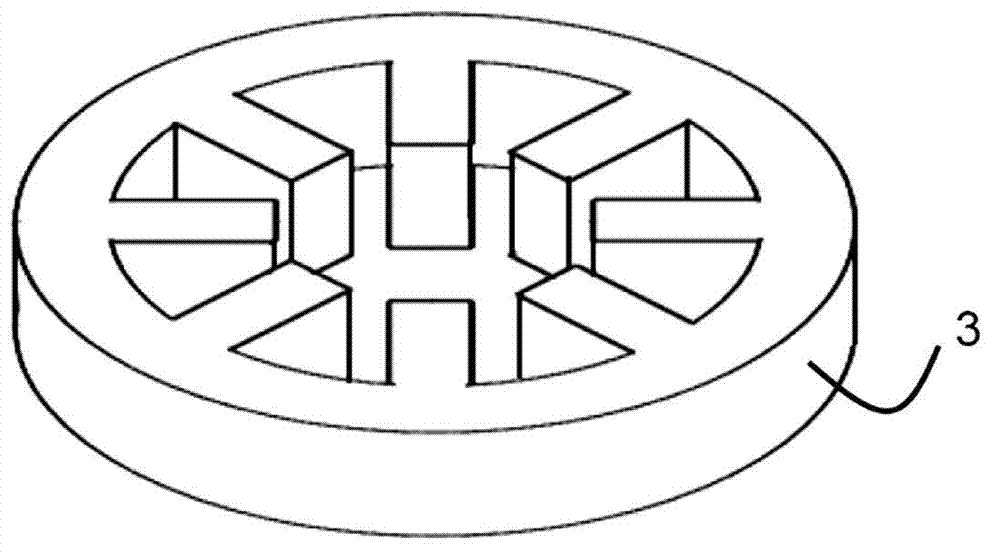

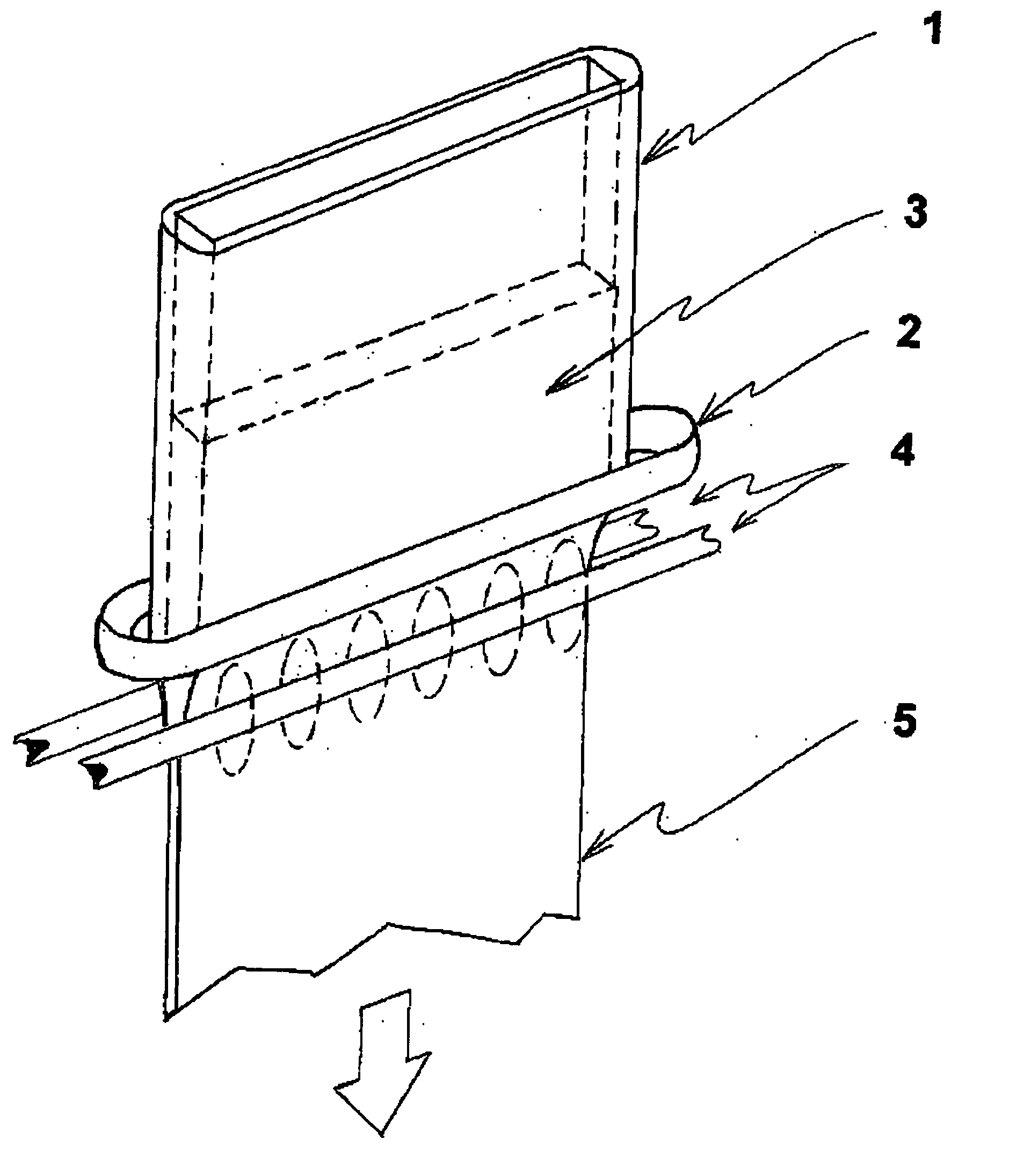

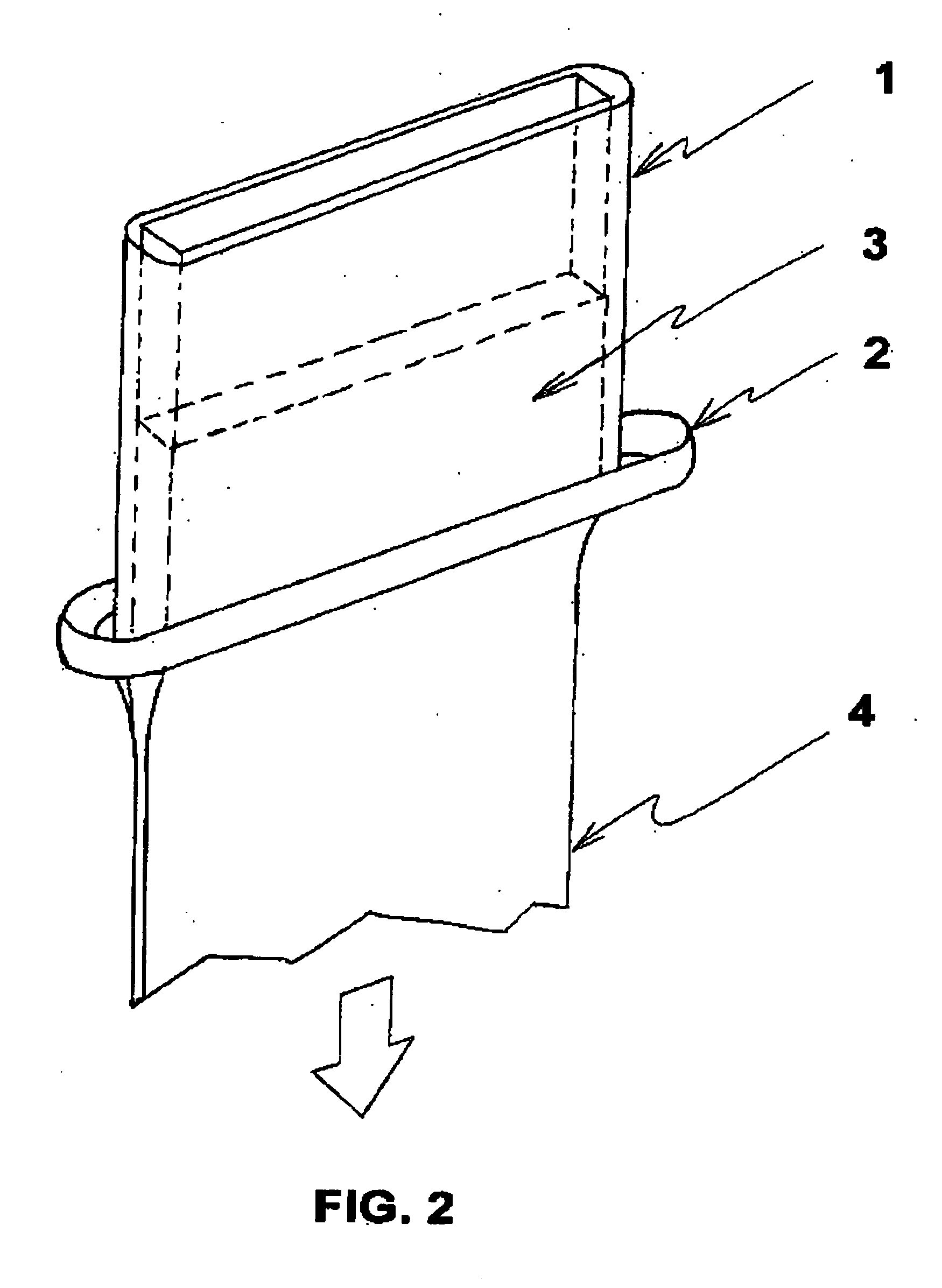

Protective box type amorphous, microcrystal or nano-crystal alloy stator core for motor and preparation method thereof

ActiveCN102361374AShort production processEnergy saving productionManufacturing stator/rotor bodiesDip-coatingNanocrystal

The invention belongs to the field of magnetic circuit parts of motors, and discloses a protective box type amorphous, microcrystal or nano-crystal alloy stator core for a motor and a preparation method thereof. The method comprises the following steps of: stamping a coiled alloy strip (3) to form a plurality of same annular stamped sheets, wherein the tooth ends of inner teeth (1) of the stampedsheets are positioned on the same circumference and the outer side of each stamped sheet is provided with at least one positioning groove (2); stacking the plurality of annular stamped sheets in a protective box with open upper end, putting the stamped sheets and the protective box into insulated coating solution together and performing insulated dip-coating treatment; taking out the stamped sheets and the protective box together, performing compactness treatment on the annular stamped sheets, fixing an upper end panel of the protective box and the inner center surface together, and forming the stator core; and performing integral annealing treatment on the stator core of the sealed protective box. By the method, the process problems that the stator core is easily damaged to drop residue and cracks among layers, the performance declines because the adhesive stress cannot be eliminated and the like are solved, and the performance of the stator core is greatly improved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

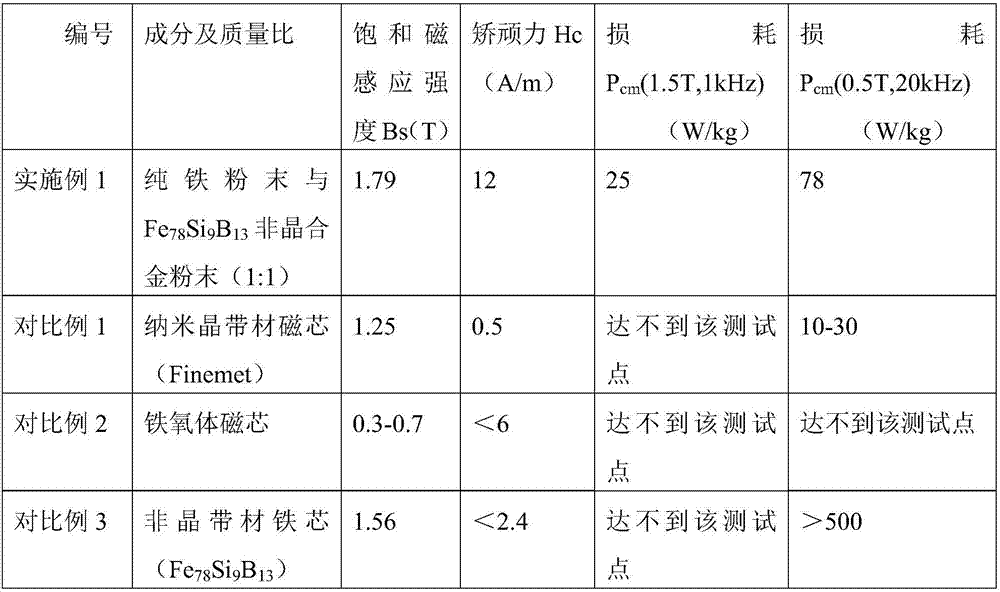

High-saturation flux density composite magnetic powder, magnetic core and preparation methods thereof

ActiveCN107240471AHigh Bs valueReduce loss valueTransportation and packagingMetal-working apparatusIron powderMicrometer

The invention relates to high-saturation flux density composite magnetic powder. The high-saturation flux density composite magnetic powder is prepared from powder A and powder B, wherein the proportion is as follows: 5-95wt% of powder A and 5-95wt% of powder B, the powder A is at least one of iron silicon powder, pure iron powder, iron silicon aluminum power, iron nickel powder, iron nickel molybdenum powder and iron cobalt alloy powder, the powder B is at least one of iron-based amorphous alloy powder, iron-based nanocrystal alloy powder, iron-nickel-based amorphous alloy powder, iron-cobalt-based amorphous alloy powder and iron-cobalt-based nanocrystal alloy powder, and the grain sizes of the powder A and the powder B are 8-200 micrometers. A magnetic core prepared by employing the composite magnetic powder has the characteristics of high Bs, low loss, low cost and the like and is suitable for mass production, the Bs value is 1.71T or above, the loss is not higher than 50W / kg under 1.5T and 1,000Hz, and the magnetic core particularly and suitably works in a medium- and low-frequency range (50Hz-10kHz).

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

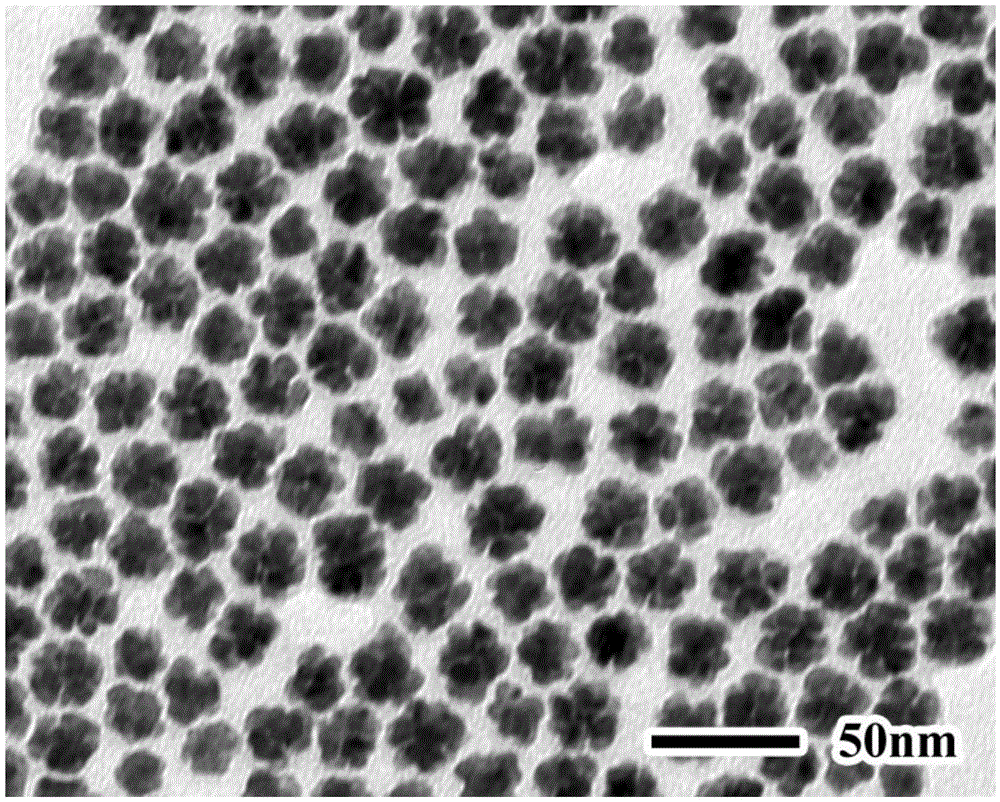

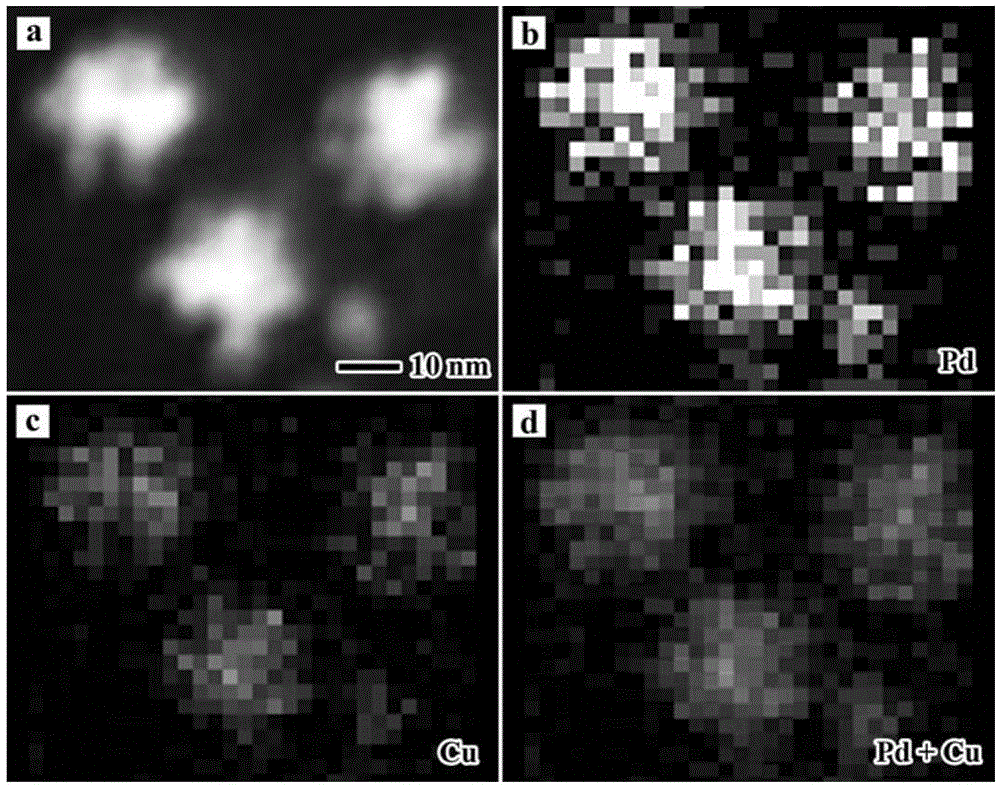

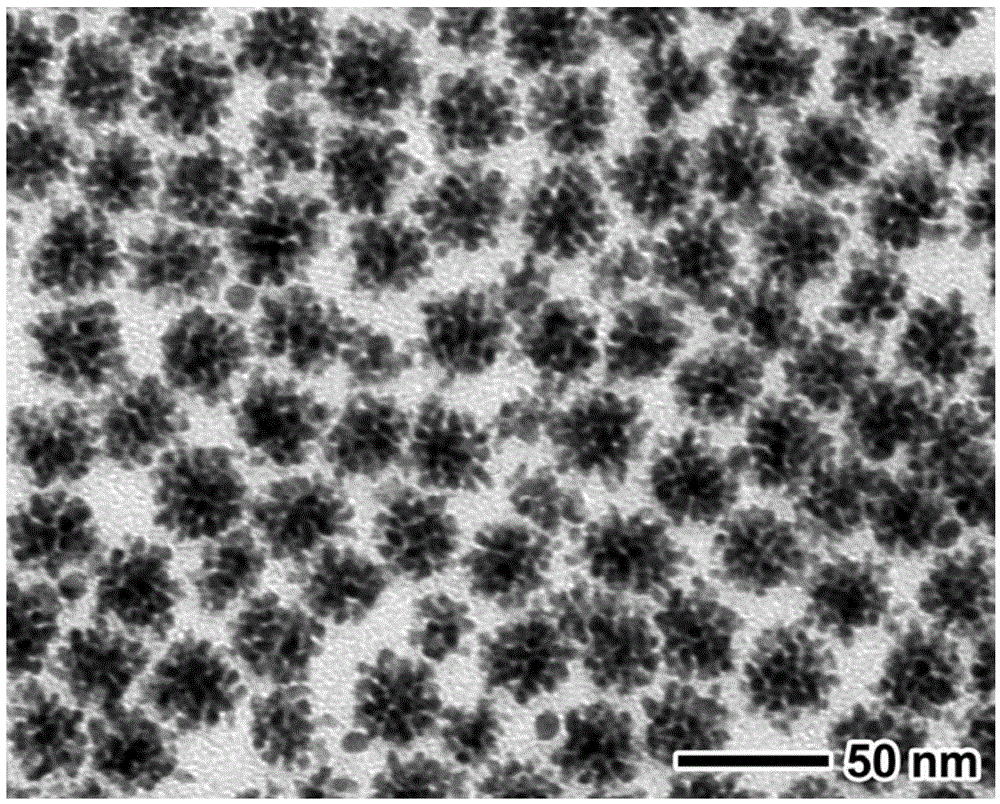

Preparation method for dendritic copper-palladium nanocrystalline alloy and product of preparation method

InactiveCN105618784AEasy to operateMild reaction conditionsTransportation and packagingMetal-working apparatusCopper chlorideCopper nitrate

The invention relates to a preparation method for a dendritic copper-palladium nanocrystalline alloy, which comprises the following steps: dissolving a palladium precursor, a copper precursor and a dispersant into a solvent, then adding a reducing agent, performing a reaction at 120-160 DEG C for 1-2 h, and performing centrifugal separation to obtain a dendritic copper-palladium nanocrystalline alloy, wherein the palladium precursor is palladium acetylacetonate, palladium acetate or palladium nitrate; and the copper precursor is copper acetylacetonate, copper chloride, copper nitrate or copper sulfate. The invention further relates to the dendritic copper-palladium nanocrystalline alloy. Dendritic nanocrystals with adjustable sizes and good dispersibility can be prepared according to the preparation method, and the preparation method is simple, has high repeatability and is low in cost.

Owner:ZHEJIANG UNIV

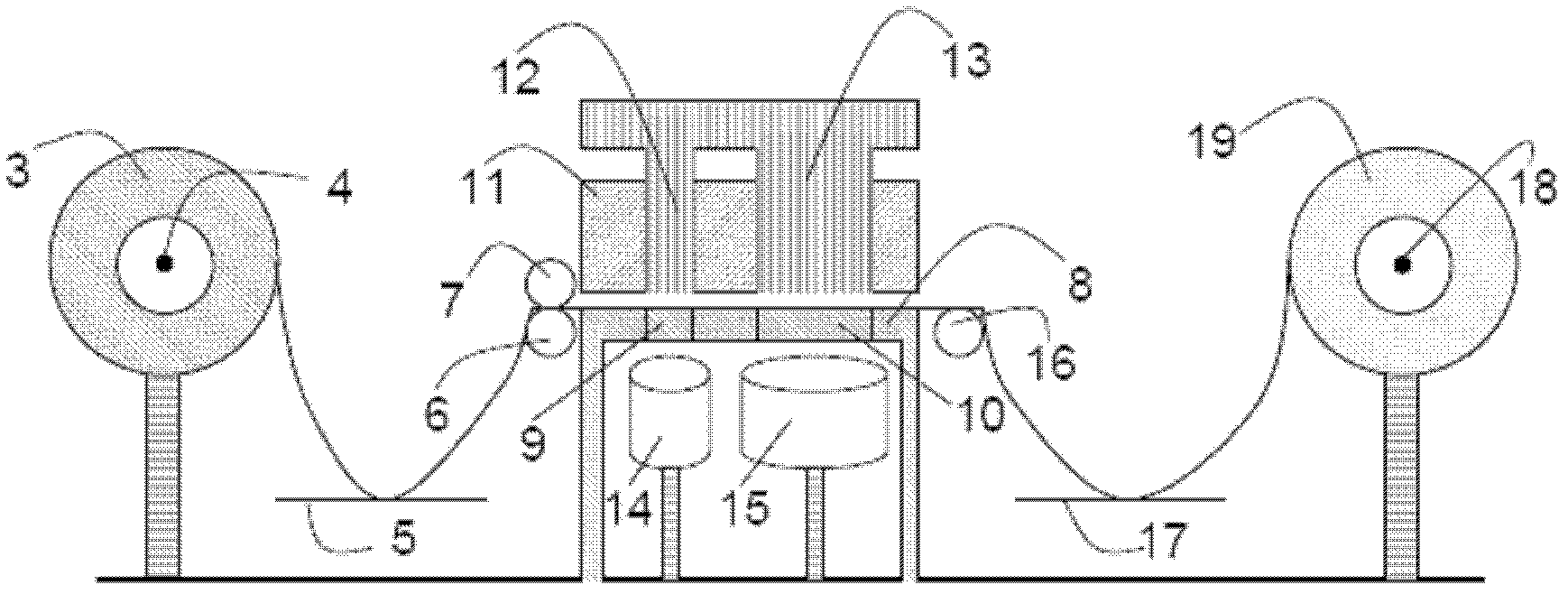

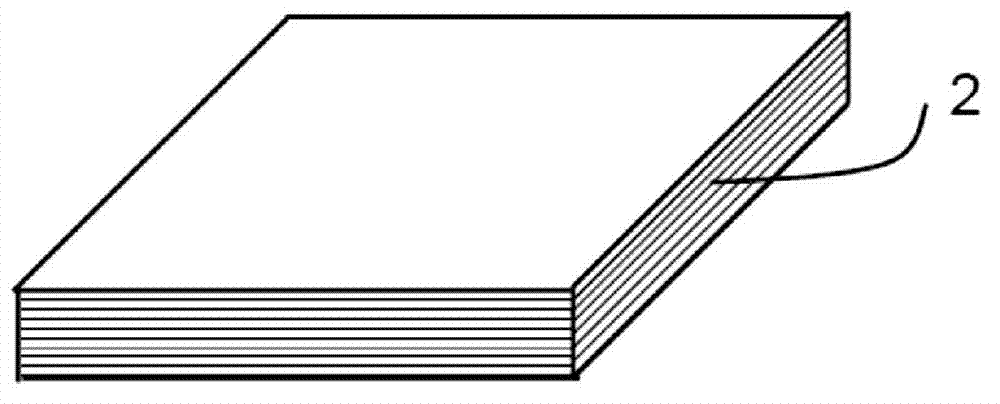

Amorphous, microcrystal or nanocrystalline alloy stator core and method for producing same

ActiveCN102820743AImprove permeabilityReduce lossNanotechnologyManufacturing stator/rotor bodiesEtchingLaser cutting

The invention provides an amorphous, microcrystal or nanocrystalline alloy stator core and a method for producing the same. The method for producing the stator core comprises the following steps that an amorphous, microcrystal or nanocrystalline alloy strip is laterally cut into a plurality of rectangular sheets with the same shape and size; the alloy sheets which are obtained through lateral cutting are subjected to annealing treatment; a plurality of alloy sheets which are obtained through annealing treatment are subjected to resin solidification treatment to obtain amorphous, microcrystal or nanocrystalline alloy sheets with the preset thickness; any one mode of laser cutting, plasma cutting, water cutting, wire cut electrical discharge machining, flame cutting and chemical etching is used to cut the alloy sheets with the preset thickness to obtain annular amorphous, microcrystal or nanocrystalline alloy splicing modules or at least one single-tooth circular arc splicing module; and the annular amorphous, microcrystal or nanocrystalline alloy splicing modules or at least one single-tooth circular arc splicing module are laminated or spliced to form the stator core. According to the method for producing the stator core, the production efficiency can be increased, and the cost can be lowered.

Owner:JIANGSU JICUI ANTAI CHUANGMING ADVANCED ENERGY MATERIALS RES INST CO LTD

Process for preparing amorphous nano-crystalline magnetic powder magnetic-conductive adhesive

InactiveCN1962783AGood magnetic conductivitySimple production processEpoxy resin adhesivesEpoxyAdhesive

The invention discloses a preparing method of non-crystal nanocrystalline magnetic powder magnetic conductive glue, which comprises the following parts: ferric non-crystal / nanocrystalline alloy powder, epoxide resin or silicon rubber, flexibilizer, solvent and filler. The preparing method comprises the following steps: (1) disposing grinded material through vacuum heat disposal or inert gas protective heat disposal at 100-600 Deg C for 0.5-5h; (2) dispersing powder in the solvent through milling, stirring and ultrasonic dispersion; adding base material to stir evenly when the powder disperses to certain grain size; defoaming; packing.

Owner:NANCHANG UNIV

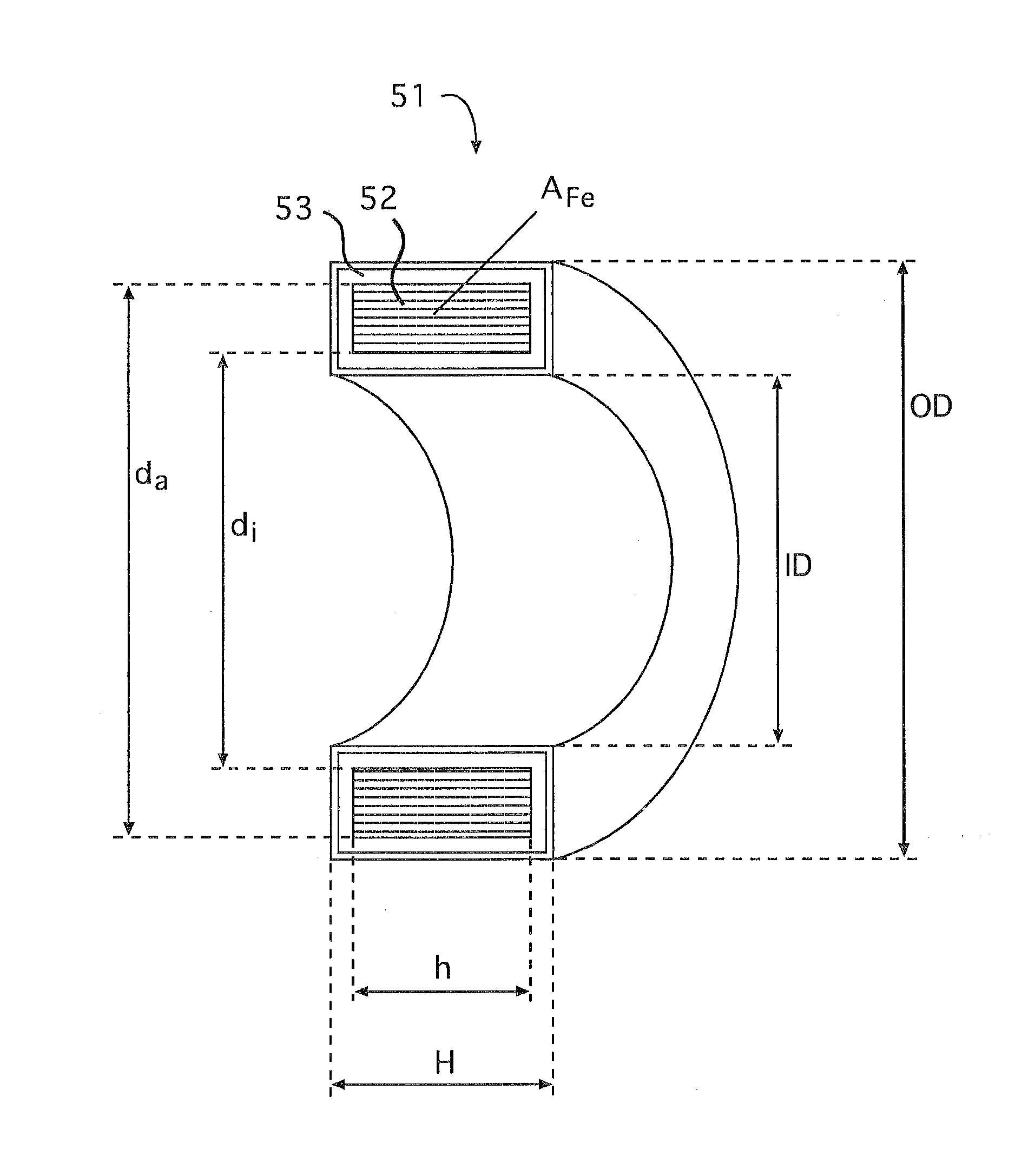

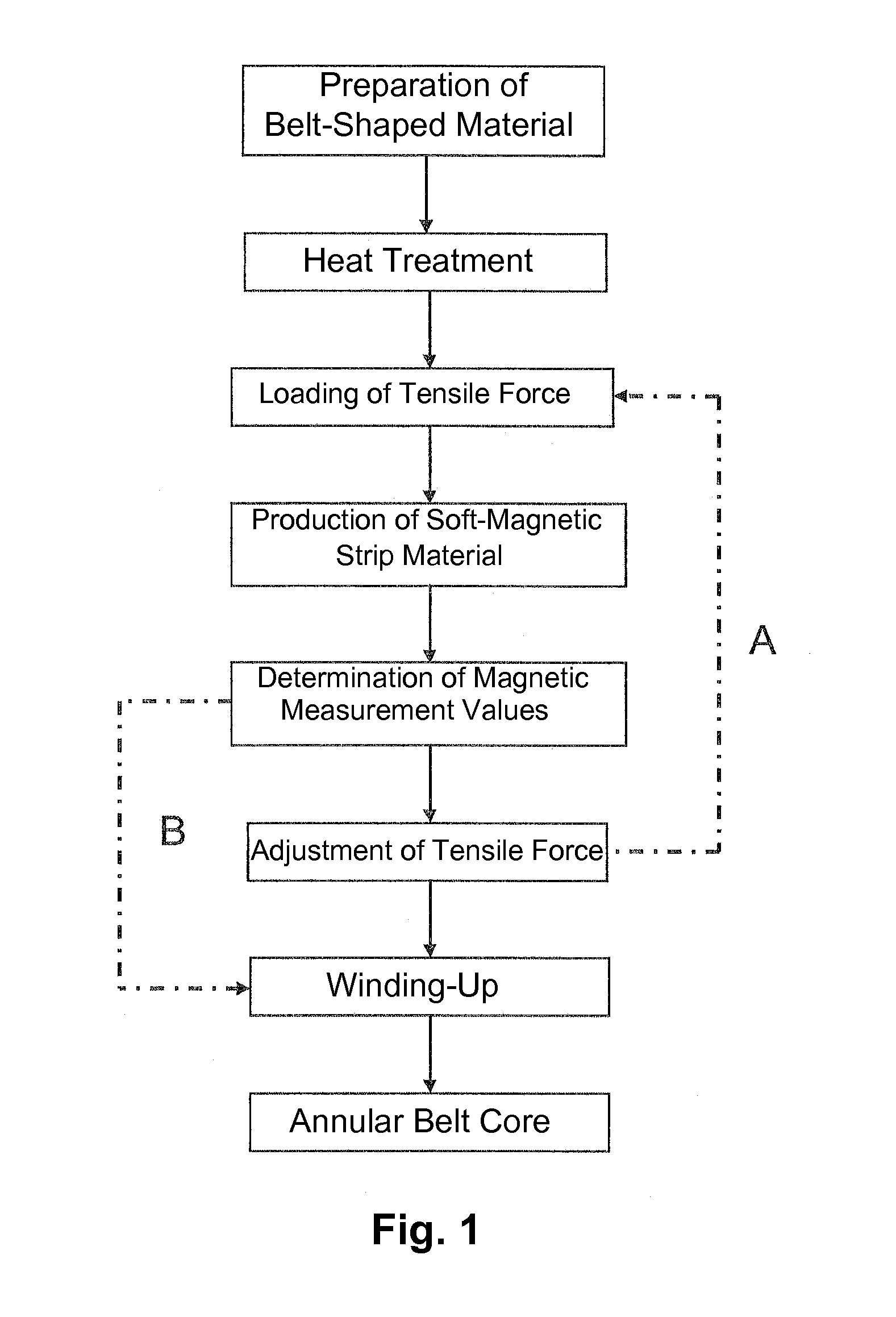

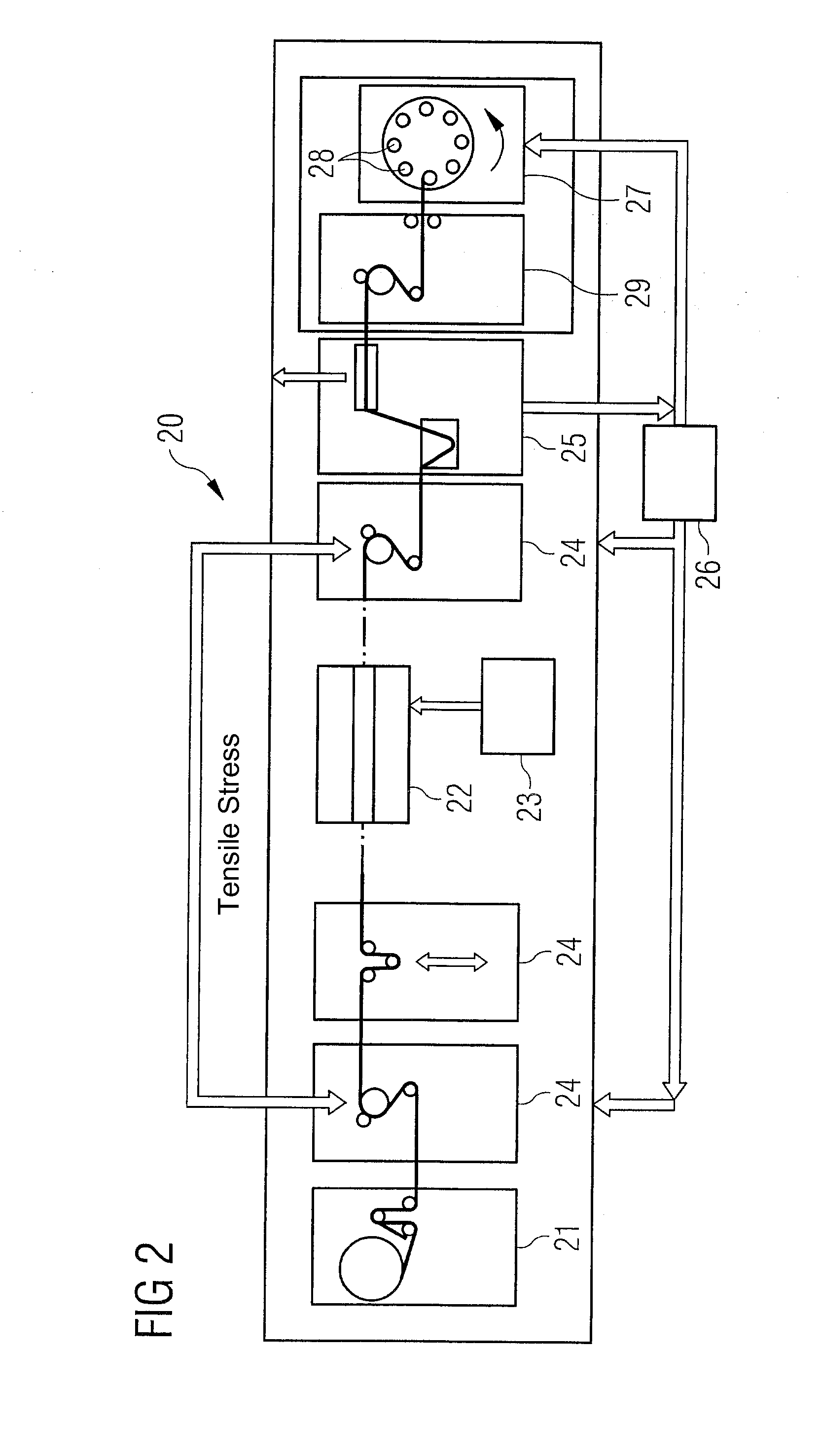

Magnetic core, method and device for its production and use of such a magnetic core

InactiveUS20140152416A1Small lossDrawback can be obviatedInorganic material magnetismTransformers/inductances magnetic coresTransformerImpurity

A magnetic core, such as for an interphase transformer, made of a nanocrystalline alloy, which consists ofFe100-a-b-c-d-x-y-zCuaNbbMcTdSixByZz and up to 1 at. % of impurities, whereby M is one or more of the elements Mo, Ta or Zr; T is one or more of the elements V, Cr, Co or Ni; and Z is one or more of the elements C, P or Ge, and0 at. %≦a<1.5 at. %,0 at. %≦b<4 at. %,0 at. %≦c<4 at. %,0 at. %≦d<5 at. %,12 at. %<x<18 at. %,5 at. %<y<12 at. %, and0 at. %≦z<2 at. %,the core having a saturation magnetostriction of <2 ppm and a permeability between 100 and 1,500, wherein the alloy has been exposed to a heat treatment at a temperature between 450 and 750° C. under a tensile stress between 30 and 500 MPa.

Owner:VACUUMSCHMELZE GMBH & CO KG

Nanocrystalline alloy coating and preparation thereof

The invention relates to a nano-crystalline alloy coating layer and a preparation method thereof. Particularly, the invention relates to a nano-crystalline alloy coating layer, the components of which, expressed by atomic ratio, satisfy the relational expression: (Fe1-aM1a)100-x-y-z-Alpha-Beta-GammaCuxSiyBzM2AlphaM3BetaXGamma, wherein, M1 is one or both of Co and Ni, M2 is at least one of Nb, W, Ta, Zr, Hf, Ti and Mo, M3 is at least one of V, Cr, Mn, Al, Sc, Y, Au, Zn, Sn and Re, X is at least one of C, Ge, P, Ga, Sb, In, Be and As, a is more than or equal to 0 and less than or equal to 0.5, x is more than or equal to 0.1 and less than or equal to 3, y is more than or equal to 0 and less than or equal to 30, z is more than or equal to 0 and less than or equal to 25, and furthermore, y plus z is more than or equal to 5 and less than or equal to 30, Alpha is more than or equal to 0.1 and less than or equal to 30, Beta is more than or equal to 0 and less than or equal to 10 and Gamma is more than or equal to 0 and less than or equal to 10, the volume percent of nano-crystals contained in the nano-crystalline alloy coating layer is above 50 percent and the crystal size of the nano-crystals is below 100nm. The invention also relates to the application and a preparation method of the nano-crystalline alloy coating layer.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

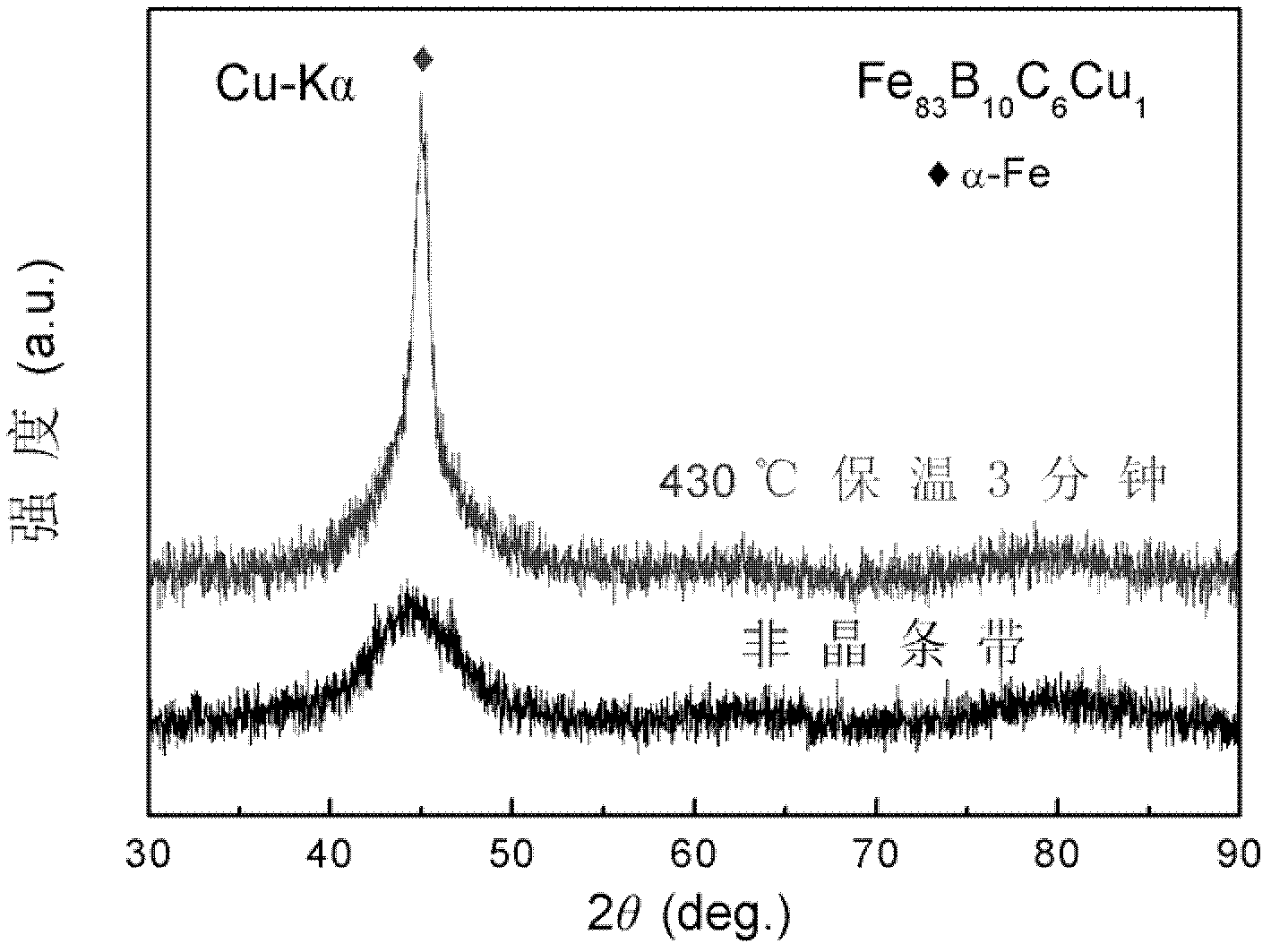

Iron-based nanocrystalline alloy and preparation method thereof

The invention relates to an iron-based nanocrystalline alloy and a preparation method thereof. The alloy comprises the following chemical compositions as well as contents of the compositions: 83.5-85.5wt% of Fe, 7-9wt% of Si, 1.4-2.1wt% of B, 1.2-1.5wt% of Cu, 0.1-0.7wt% of P, 2.5-4wt% of Nb and 1-2wt% of V. Preparation is carried out according to the chemical compositions and contents of the compositions, an induction heating furnace is adopted for smelting, molten alloy is then sprayed on to a copper roller which rotates at a high speed, so that an amorphous alloy strip is produced; and then, the produced amorphous alloy strip is put in a vacuum furnace to be subjected to crystallization annealing, so that the iron-based nanocrystalline alloy is produced. The crystallization annealing technology comprises the following steps of: pre-annealing at 450-480 DEG C for 40-60 minutes, crystallization annealing at 520-570 DEG C for 40-60 minutes, discharging from the furnace, and naturally cooling to be at the room temperature. The iron-based nanocrystalline alloy has the characteristics of low alloy cost, good molten steel liquidity and strong industrial implementation performance, and the produced an iron-based nanocrystalline alloy strip has good glossiness, good amorphous alloy strip tenacity, relatively fine and dispersed nano crystal grains and relatively small effective magnetic permeability variation caused by frequency change.

Owner:WUHAN UNIV OF SCI & TECH

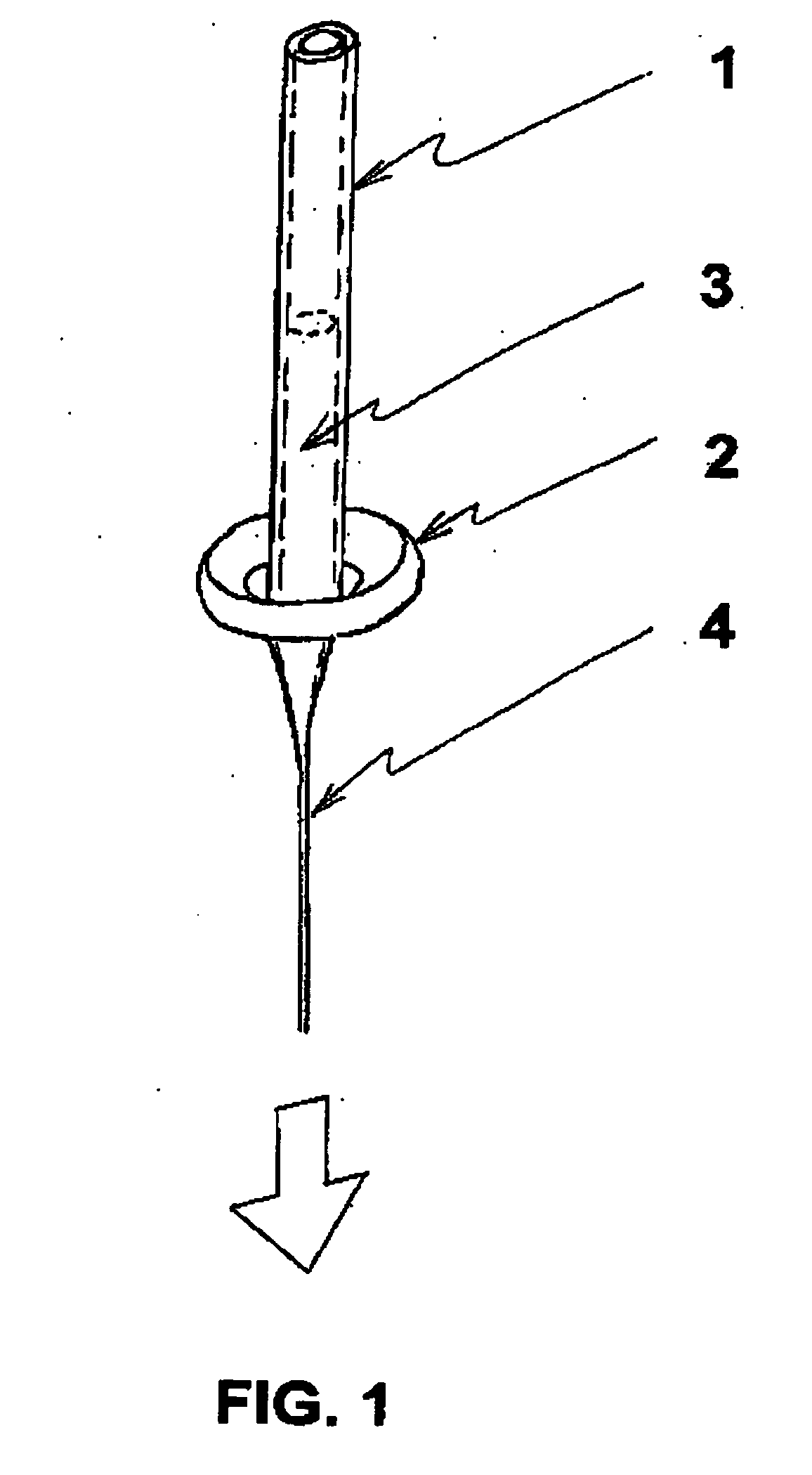

Amorphous and nanocrystalline glass-coated articles

InactiveUS20050000599A1Rapidly solidify molten alloyGlass making apparatusInorganic material magnetismDynamic balanceGlass vessel

A drawn glass-coated metallic member has a thermal contraction coefficient differential such that the thermal contraction coefficient of the glass is less than that of the metallic member. The thermal contraction coefficient differential is maintained within a predetermined range during drawing. The glass is placed under residual compression, interfacial bonding between said glass and said wire is substantially uniform, and surface cracking and bond breaks between metal and glass are substantially prevented. A dynamic balance is maintained between the surface tension of the molten alloy and the resistance to high temperature deformation by the glass vessel in which it is contained, enabling the production of glass-coated amorphous or nanocrystalline alloy members having predefined cross-sectional shapes.

Owner:DEMODULATION

Magnetic field shielding sheet for digitizer, manufacturing method thereof, and portable terminal device using same

ActiveUS9507390B2Easy to manufactureEasy to controlShielding materialsNanomagnetismTectorial membraneTerminal equipment

Provided is a magnetic field shield sheet for a digitizer, which blocks an effect of a magnetic field generated from various components of a main body of the portable terminal device and at the same time improves the sensitivity of an electronic pen when a digitizer feature is implemented in the portable terminal device, while minimizing an influence upon a geomagnetic sensor. The magnetic field shield sheet includes: at least one layer thin magnetic sheet made of a nanocrystalline alloy and flake-treated so as to be separated into a plurality of fine pieces; a protective film that is adhered on one surface of the thin magnetic sheet via a first adhesive layer provided on one side of the protective film; and a double-sided tape that is adhered on the other surface of the thin magnetic sheet via a second adhesive layer provided on one side of the double-sided adhesive tape.

Owner:AMOSENSE

Magnetic amplifier choke (magamp choke) with a magnetic core, use of magnetic amplifiers and method for producing softmagnetic cores for magnetic amplifiers

InactiveUS7442263B2Increased changeover rejectionReduce winding lossesVariable inductancesInorganic material magnetismMagnetizationMagnetic amplifier

The invention relates to a transductor regulator with a magnetic core which is made up of a nanocrystalline alloy which is almost free of magnetorestriction. The core has as low cyclic magnetization losses as possible and as rectangular a hysterisis cycle as possible. Said alloy has the composition: FeaCobCucM′dSixByM″z, M′ representing an element from the group V, Nb, Ta, Ti, Mo, W, Zr, Hf or a combination of these and M″ representing an element from the group C, P, Ge, As, Sb, In, O, N or a combination of these and the following conditions applying: a+b+c+d+x+y+z=100%, with a=100%−b−c−d−x−y−z, 0≦b≦15, 0.5≦c≦2, 0.1≦d≦6, 2≦x≦20, 2≦y≦18, 0≦z≦10 and x+y>18. The inventive transductor regulators are particularly advantageously used in motor vehicle voltage supplies, rail power supplies or in aircraft power supplies.

Owner:VACUUMSCHMELZE GMBH & CO KG

Amorphous alloy powder core and nano-crystal alloy powder core with excellent HF performance and their manufacture method

A method for manufacturing an amorphous alloy core, which is to mix amorphous alloy powder with a solution obtained by dissolving polyimide / phenol resin as a binder in an organic solvent, so that the binder is evenly coated on the alloy On the powder surface, the composite particle powder is prepared, shaped and heat-treated. There is also a method for manufacturing a nanocrystalline alloy core, comprising (a) mixing amorphous alloy powder with a solution obtained by dissolving polyimide / phenol resin as a binder in an organic solvent, so that the binder is uniformly coated coating on the surface of the alloy powder to obtain a composite particle powder, forming at room temperature and heat-treating above the crystallization initiation temperature; and (b) heat-treating the amorphous alloy powder above the crystallization initiation temperature to obtain a nanocrystalline phase, Mix it with the polyimide / phenolic resin as a binder in an organic solvent solution, so that the binder is evenly coated on the surface of the alloy powder, and the composite particle powder is obtained. Shape it.

Owner:未来素材公司

Method for manufacturing super-magnetic conducting nanocrystalline alloy and nanocrystalline alloy

The invention relates to a manufacture method for super magnetic conductive nanocrystal alloy, wherein a master alloy includes 72.5 to 74.5 at% of Fe, 0.5 to 1.5 at% of Cu, 2.5 to 3.5 at% of Nb, 12.5 to 14.5 at% of Si and 8 to 10 at% of B. The method comprises the following steps: the master alloy is prepared by vacuum furnace smelting, the vacuum degree is less than 0.026*10<-6>MPa; when the temperature reaches to 1400 DEG C to 1450 DEG C, C is added to the vacuum furnace for deoxidation and refined, the temperature is lowered to deflate, and an ingot is cast; under argon protection, quenched amorphous nanocrystal alloy is formed by single roller fast cooling through a nozzle packet; the nozzle packet is provided with 25-30PPI Al2O3 ceramic filter to filter steel liquid, making SiO2 less than 0.026% (wt%) and B2O3 less than 0.019% (wt%). The magnetic conductivity mu of the iron core of the super magnetic conductive nanocrystal alloy manufactured by the method satisfies the following conditions: mu50Hz (H=5mOe) >=60*10<4>, and mu1kHz (H=5mOe)>=20*10<4>.

Owner:北京冶科电子器材有限公司

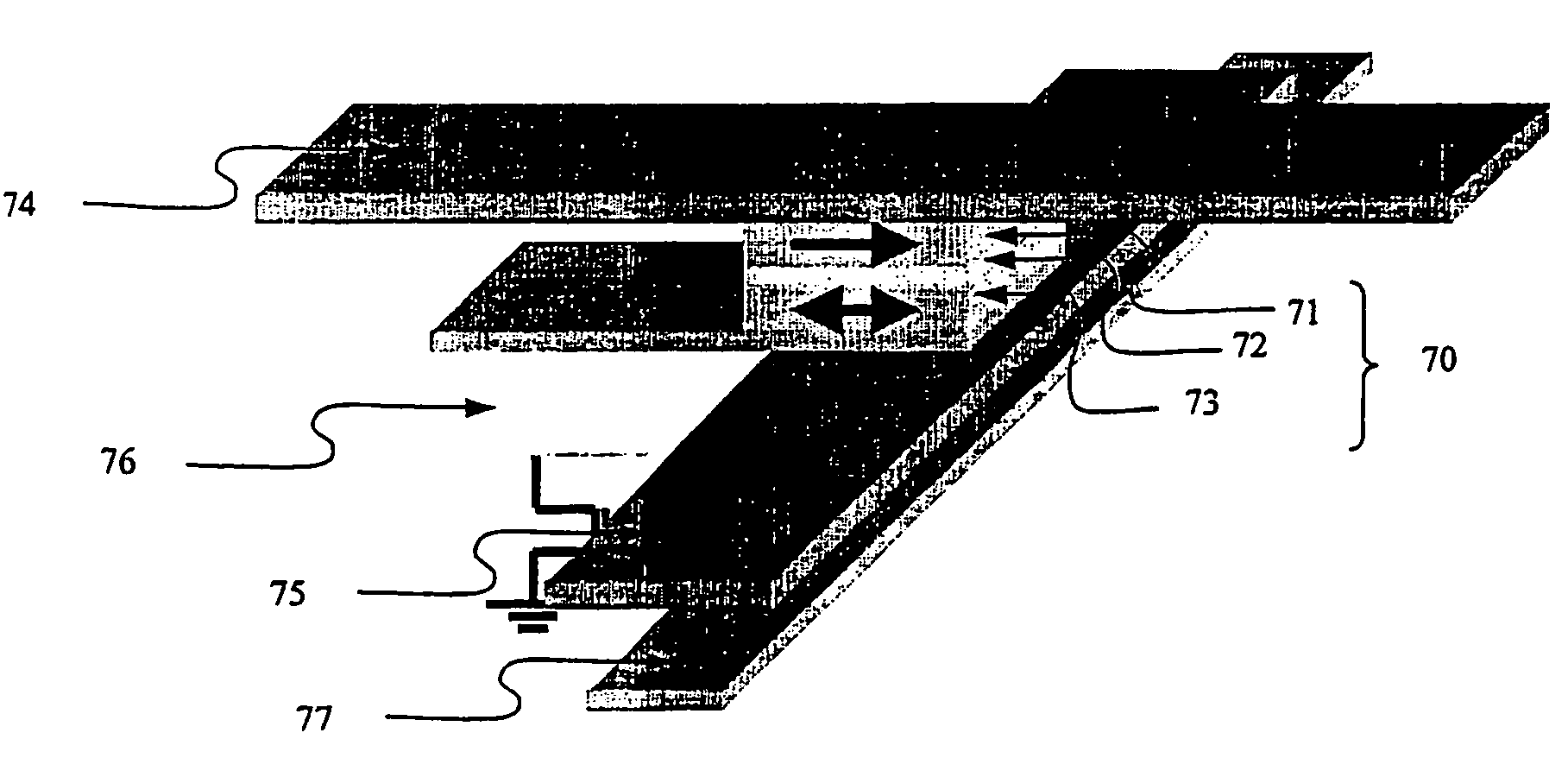

Magnetic memory with write inhibit selection and the writing method for same

InactiveUS20050047206A1Minimizes addressing errorError minimizationNanomagnetismMagnetic-field-controlled resistorsMagnetic memoryRare earth

The invention relates to a magnetic memory with write inhibit selection and the writing method for same. Each memory element of the invention comprises a magnetic tunnel junction (70) consisting of: a magnetic layer, known as the trapped layer (71), having hard magnetisation; a magnetic layer, known as the free layer (73), the magnetisation of which may be reversed; and an insulating layer (72) which is disposed between the free layer (73) and the trapped layer (71) and which is in contact with both of said layers. The free layer (73) is made from an amorphous or nanocrystalline alloy based on rare earth and a transition metal, the magnetic order of said alloy being of the ferrimagnetic type. The selected operating temperature of the inventive memory is close to the compensation temperature of the alloy.

Owner:CENT NAT DE LA RECHERCHE SCI

Amorphous alloy powder core and nano-crystal alloy powder core having good high frequency properties and methods of manufacturing the same

InactiveUS20020124914A1High molding densityLow dependence on frequencyTransportation and packagingMetal-working apparatusOrganic solventRoom temperature

A method of manufacturing an amorphous alloy core including the steps of mixing an amorphous alloy powder with a solution made by dissolving a polyimide / phenolic resin binder in an organic solvent, evenly coating the binder in liquid phase on the surface of the alloy powder to make a powder of composite particles, molding the power of composite particles, and performing a heating treatment thereon. This invention also discloses a method of manufacturing a nano-crystal alloy core including the steps of (a) mixing an amorphous alloy powder with a solution made by dissolving a polyimide / phenolic resin binder in an organic solvent, evenly coating the binder in the liquid phase on the surface of the alloy powder to make composite particles, molding the composite particles at room temperature, and performing a heating treatment thereon at a temperature higher than the crystallization starting temperature of the alloy; and (b) performing a heating treatment on an amorphous alloy powder at over a crystallization starting temperature to make a nano-crystal phase, mixing a solution made by solving a polyimide / phenolic resin binder in an organic solvent therewith, evenly coating the binder in liquid phase on the surface of the alloy powder to make composite particles, and molding the power of composite particles at 100 to 300° C.

Owner:KIM KYU JIN +3

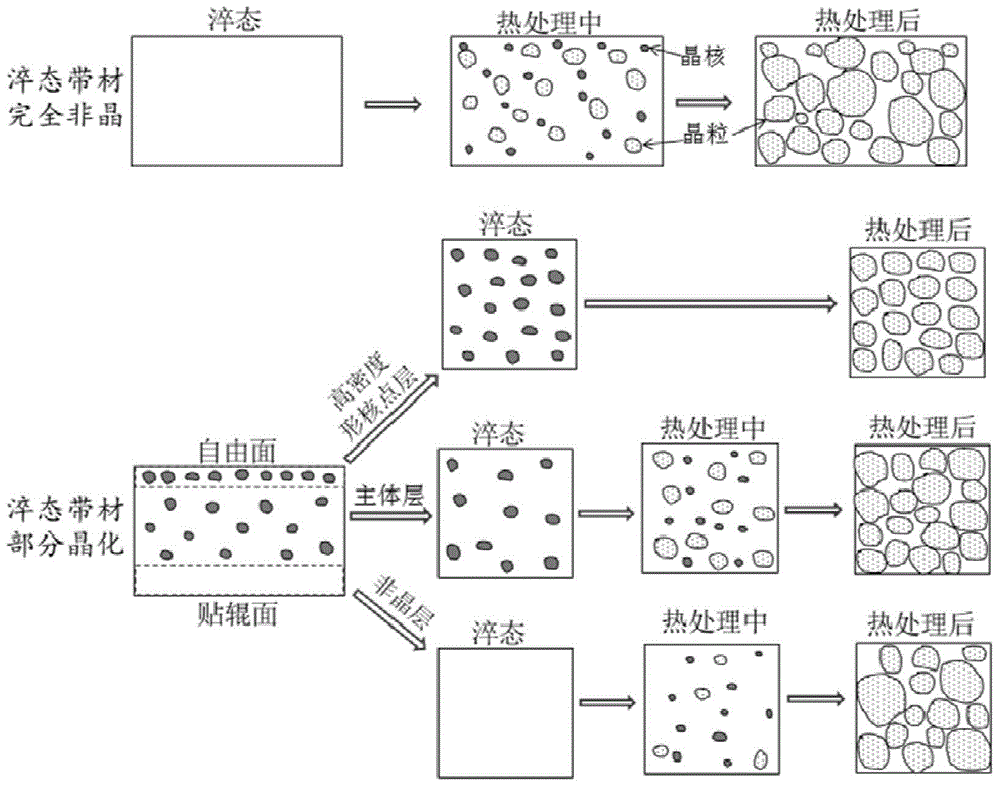

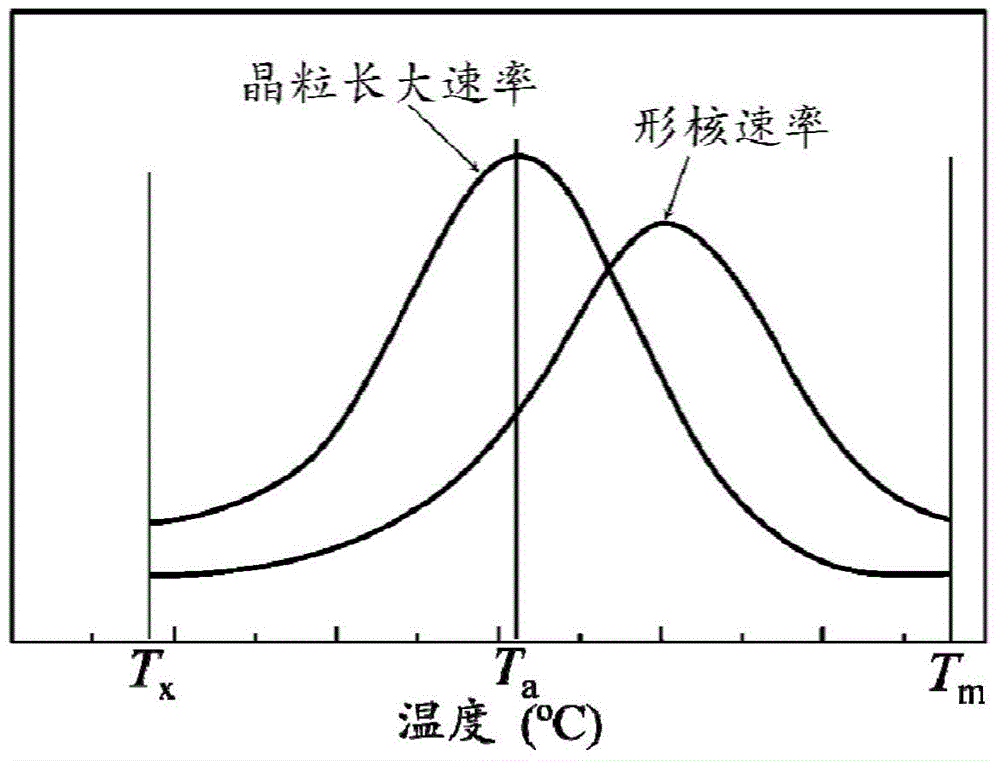

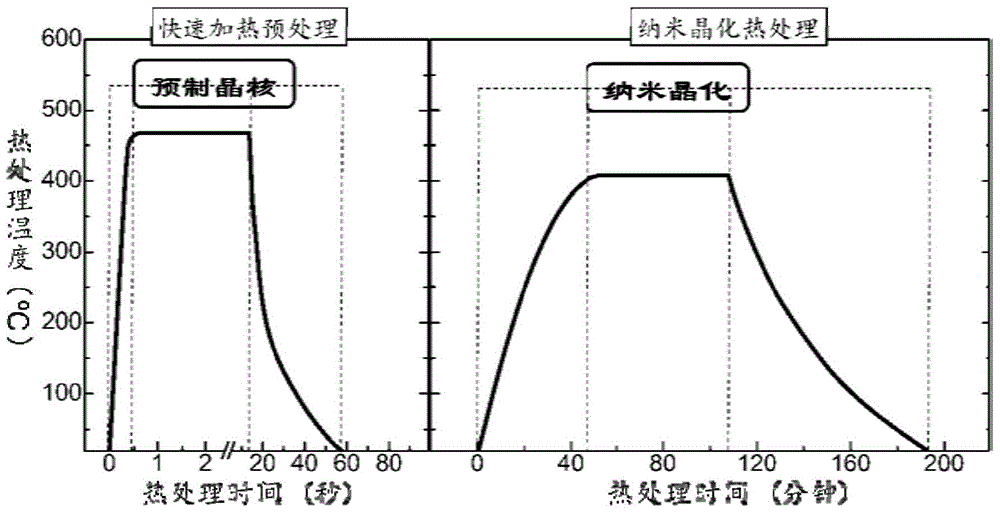

Heat treatment method for preparing nanocrystalline alloy

The invention discloses a heat treatment method for preparing nanocrystalline alloy. According to the method, during the nanocrystalline alloy material preparation by an amorphous crystallization method, a heat treatment process is divided into two steps; in the first step, the characteristics of high heat conductivity and low heat capacity of an amorphous crystallization alloy belt material are used; the fast temperature rise and short-time heat insulation pre-heating treatment is performed; high-density and uniformly-distributed crystal nucleuses are formed in the belt material through excitation; then, in the second step of conventional nano-crystallization heat treatment, high-density crystal particles grow synchronously; the competitive effect between the crystal particles is used for promoting the crystal particle refining. Compared with the existing heat treatment method, the method has the advantages that amorphous crystallization nucleation and crystal particle growth processes are controlled in a separated way; the crystal particle density and the crystallization degree are improved; the crystal particle dimension and the distribution uniformity are improved; in addition, the crystal particles are refined, so that the performance of the alloy is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com