Heat treatment method for preparing nanocrystalline alloy

A technology of nanocrystalline alloy and heat treatment method, which is applied in the field of heat treatment of nanocrystalline alloy prepared by amorphous crystallization method, can solve the problems of unfavorable magnetic properties, uneven heating of inner and outer layers of magnetic core, etc., and achieves the promotion of grain refinement, The effect of excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Preparation of Nanocrystalline Alloy Fe by Amorphous Crystallization 83 Si 4 B 12 Cu 1 , including the following steps.

[0050] (1) Select Fe 83 Si 4 B 12 Cu 1 Alloy, the strip is prepared by rapid quenching and solidification at a high copper roll speed of 35m / s;

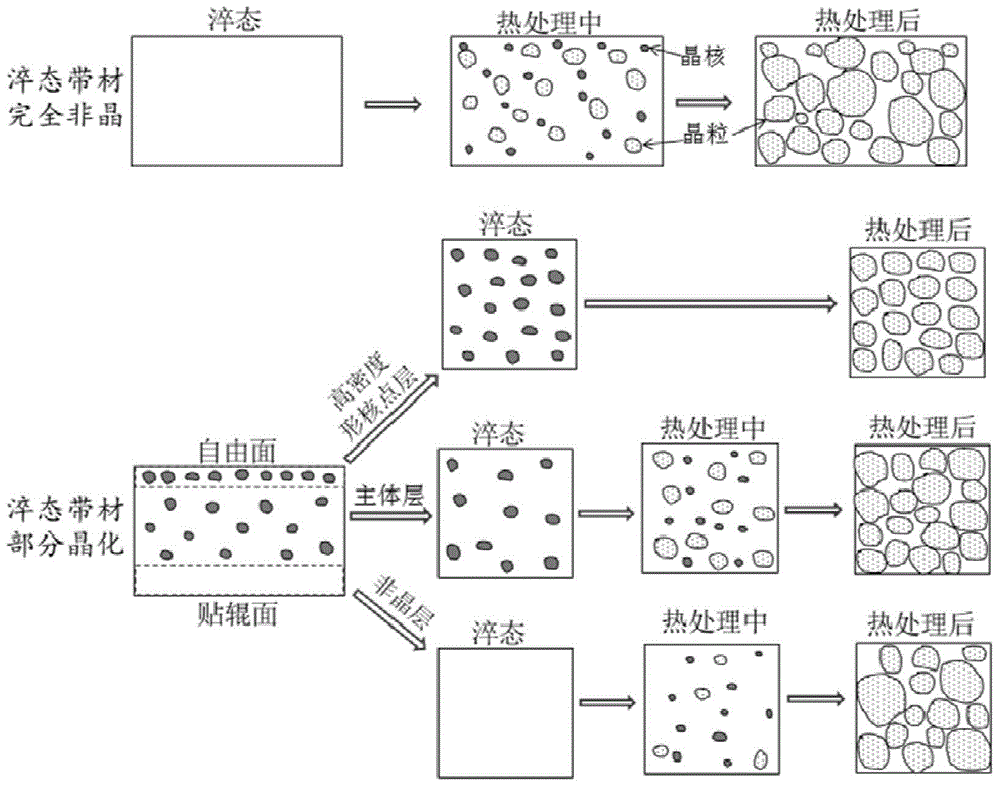

[0051] The microstructure of the strip was detected by XRD, such as Figure 5 As shown, the ribbon is completely amorphous.

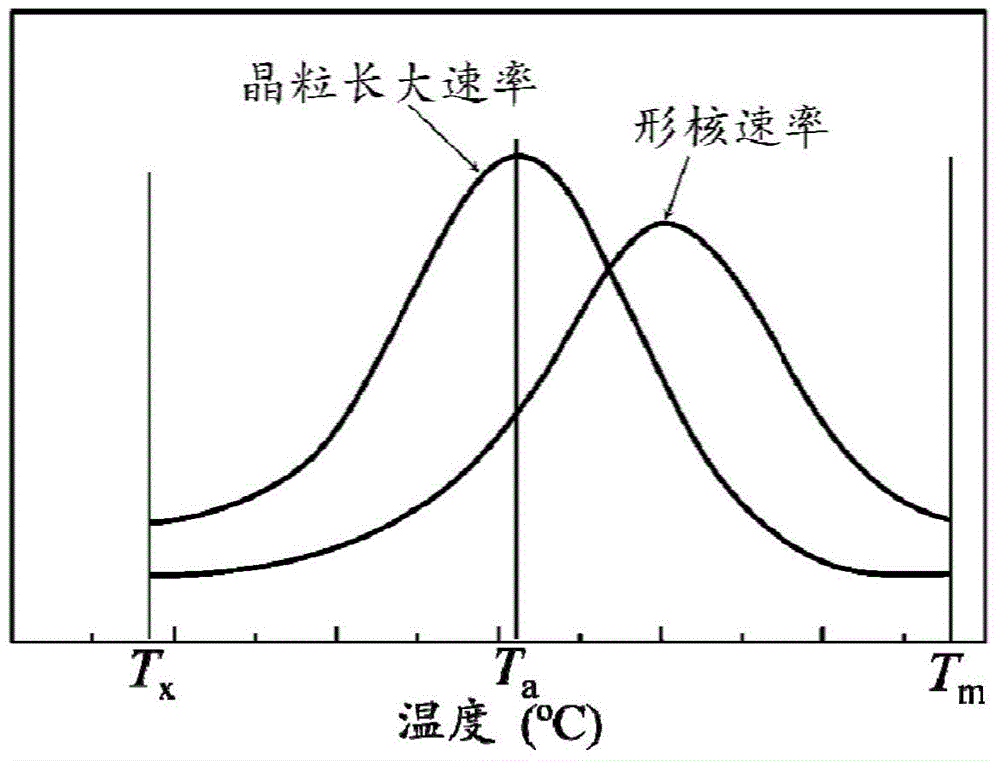

[0052] The crystallization temperature of the strip was detected by DSC at a heating rate of 40°C / min. Such as Figure 6 As shown, the first crystallization start temperature is 393°C, the first crystallization end temperature is 438°C, and the second crystallization start temperature is 522°C. According to the DSC diagram, it is determined that the optimum nucleation temperature range is 450-510°C, and the optimum grain growth temperature range is 400-430°C.

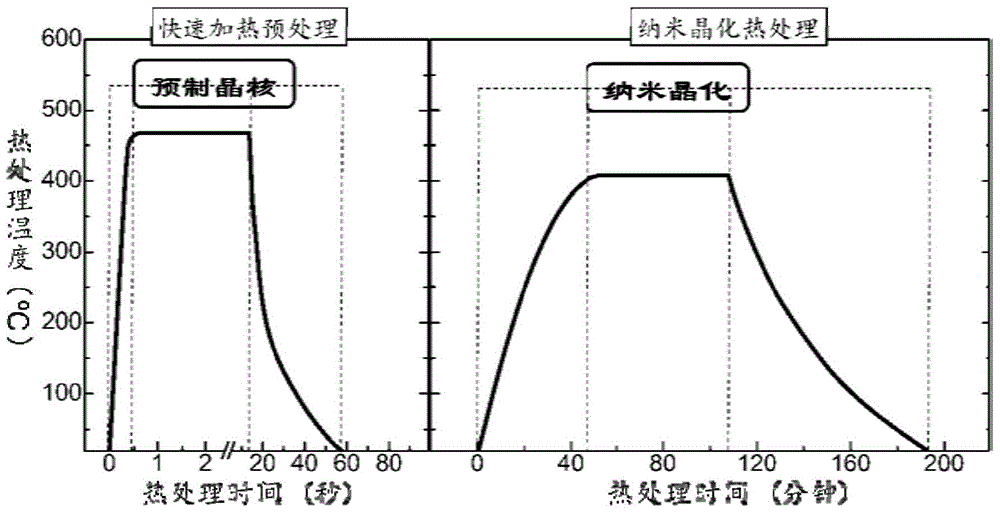

[0053] (2) Preheat the strip with a rapid heating furnace, specifically: heat the strip to 490° C. and then keep...

Embodiment 2

[0063] Preparation of Nanocrystalline Alloy Fe by Amorphous Crystallization 83 Si 4 B 12 Cu 1 , including the following steps.

[0064] (1) Select Fe 83 Si 4 B 12 Cu 1 Alloys were rapidly quenched and solidified at a low copper roll speed of 25m / s to prepare strips.

[0065] The microstructure of the strip was detected by XRD, such as Figure 5 As shown, there has been obvious crystallization of the free surface of the strip.

[0066] Use DSC to detect the crystallization temperature of the strip at a heating rate of 40°C / min, such as Figure 6 As shown, the first crystallization start temperature is 353°C, the first crystallization end temperature is 443°C, and the second crystallization start temperature is 521°C. According to the DSC diagram, it is determined that the optimum nucleation temperature range is 450-510°C, and the optimum grain growth temperature range is 360-440°C.

[0067] (2) Preheating the strip with a rapid heating furnace, specifically: heat the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com