Patents

Literature

354 results about "High copper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foods High in Copper. The best copper-rich foods include beef liver, lentils, almonds, sunflower seeds, raw kale, turnip greens, blackstrap molasses, asparagus, dark chocolate, sesame seeds, and goat cheese, among others.

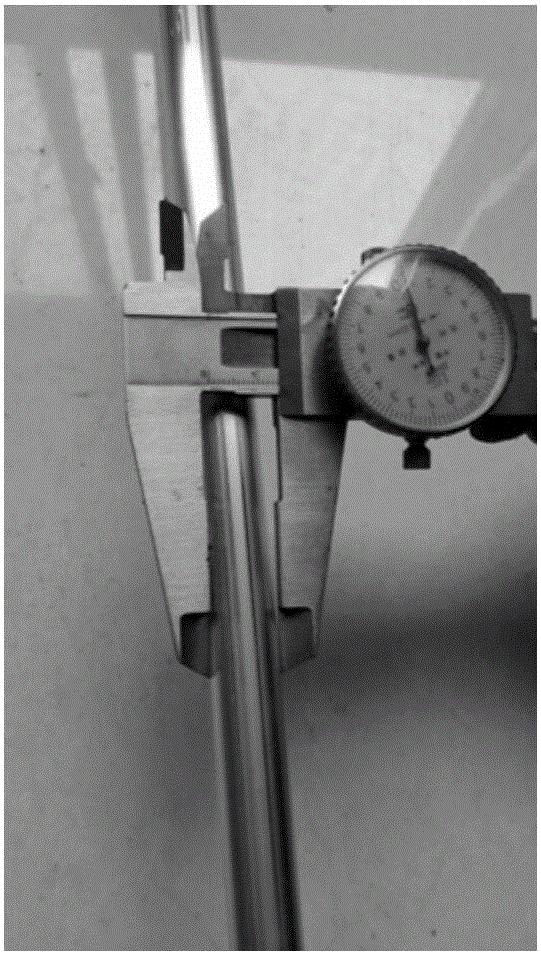

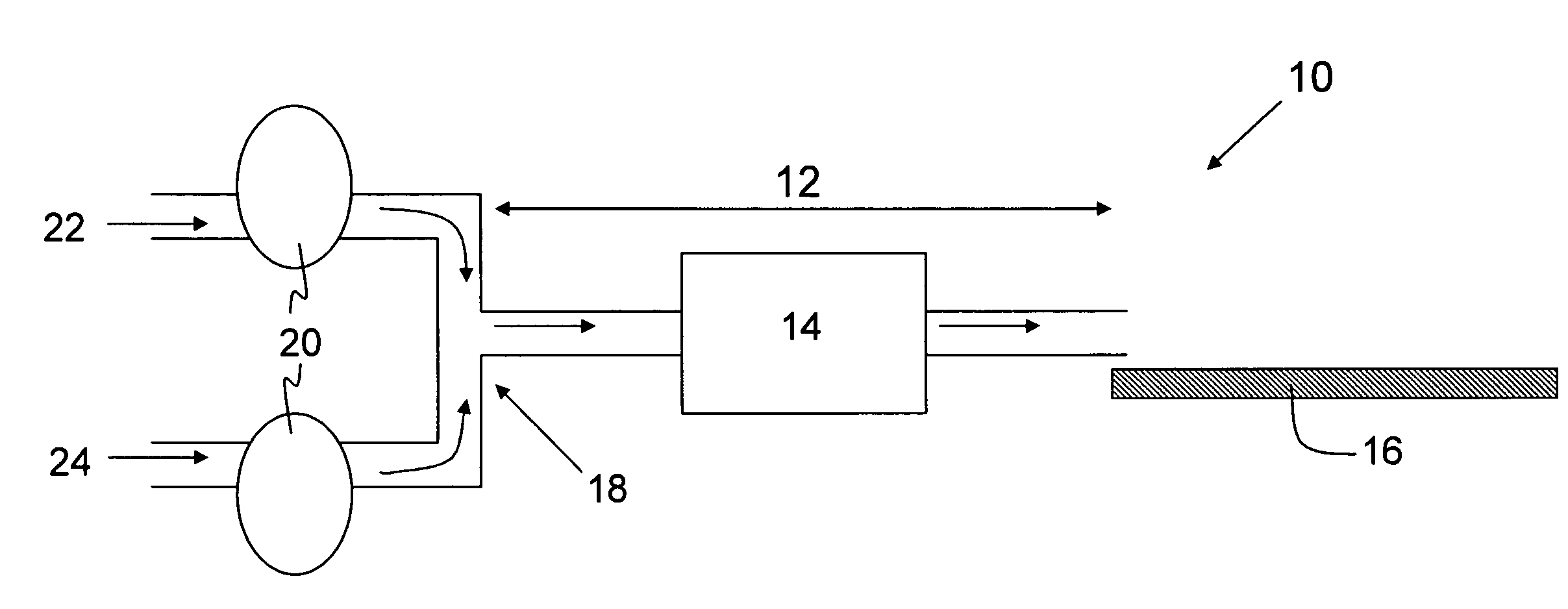

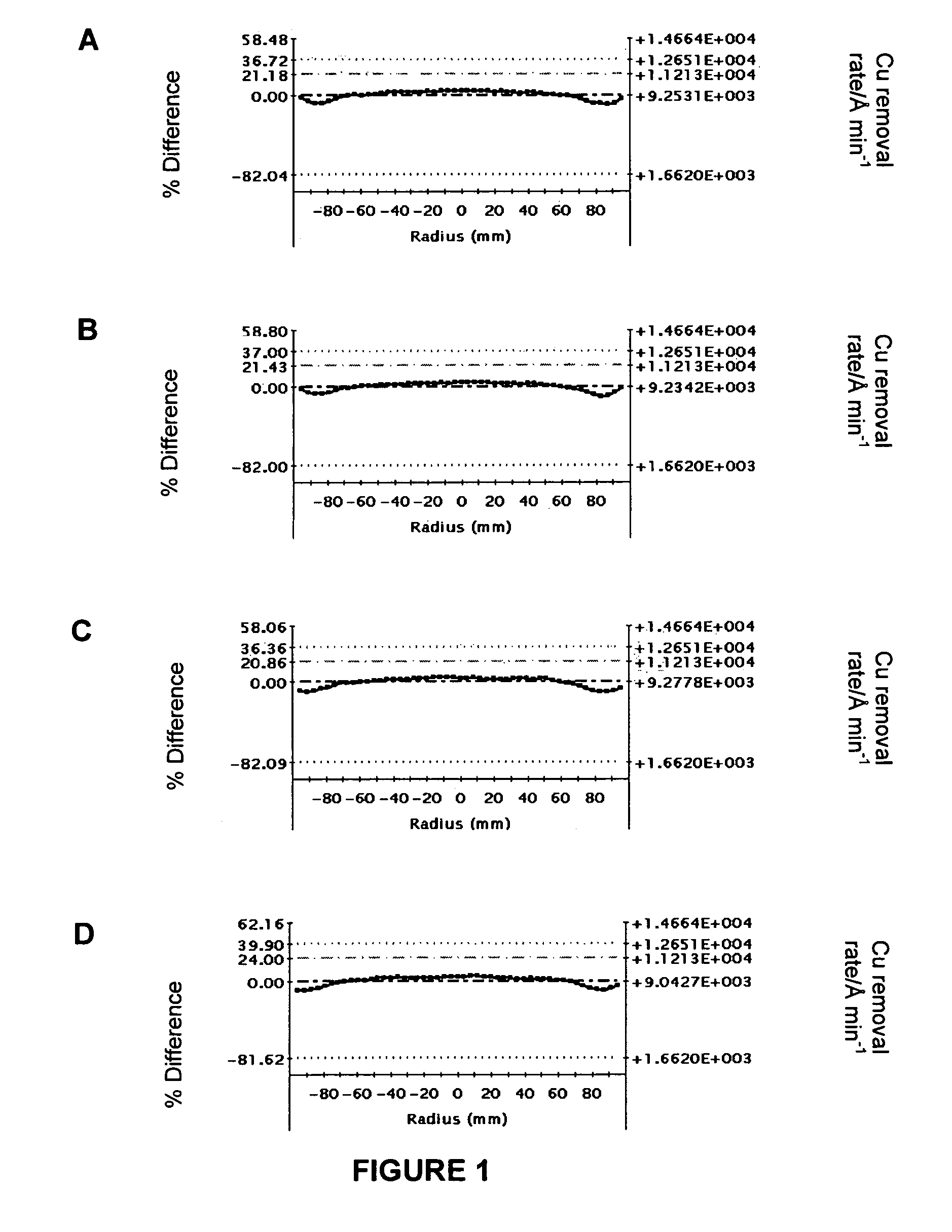

High throughput chemical mechanical polishing composition for metal film planarization

InactiveUS20080254628A1Semiconductor/solid-state device manufacturingLapping machinesMaterial removalHigh flux

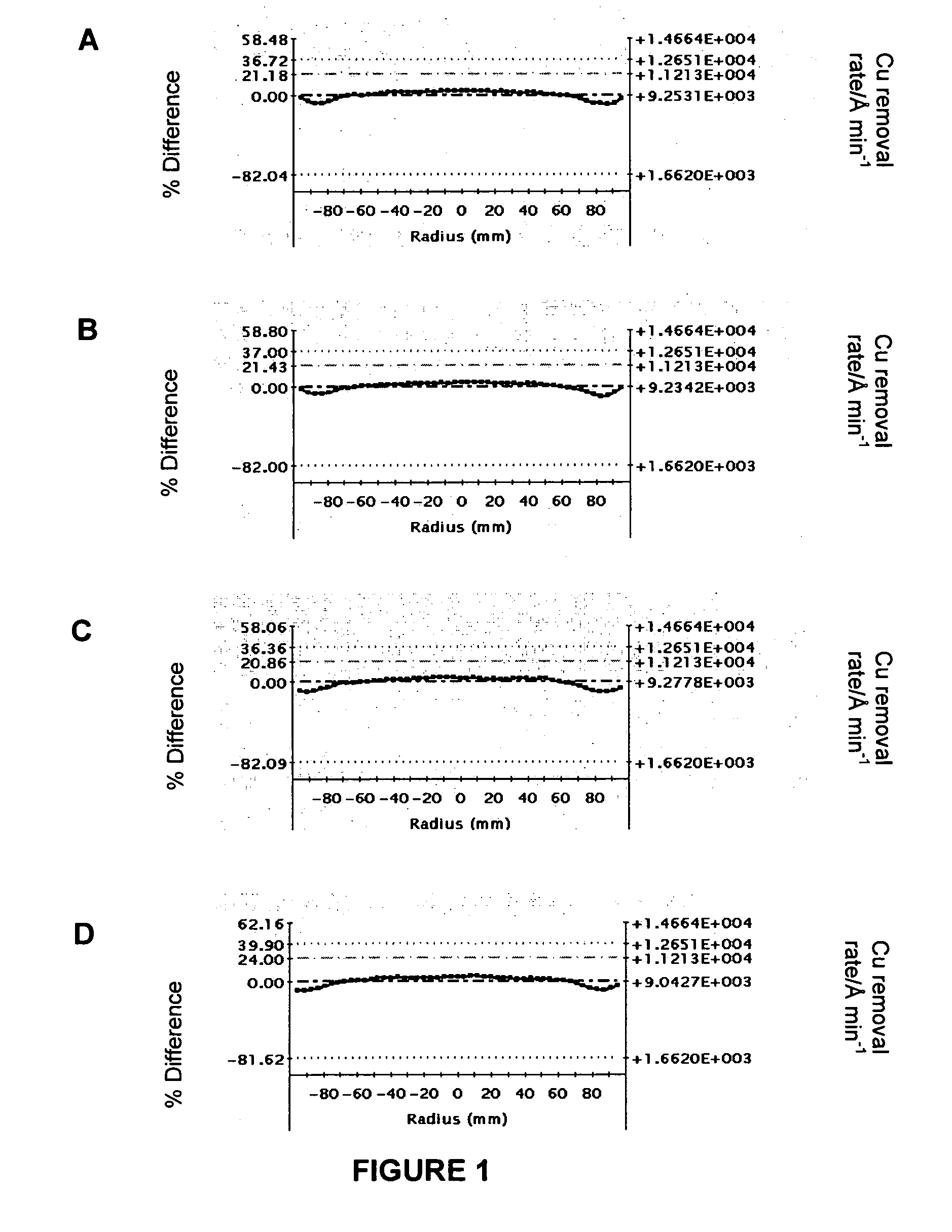

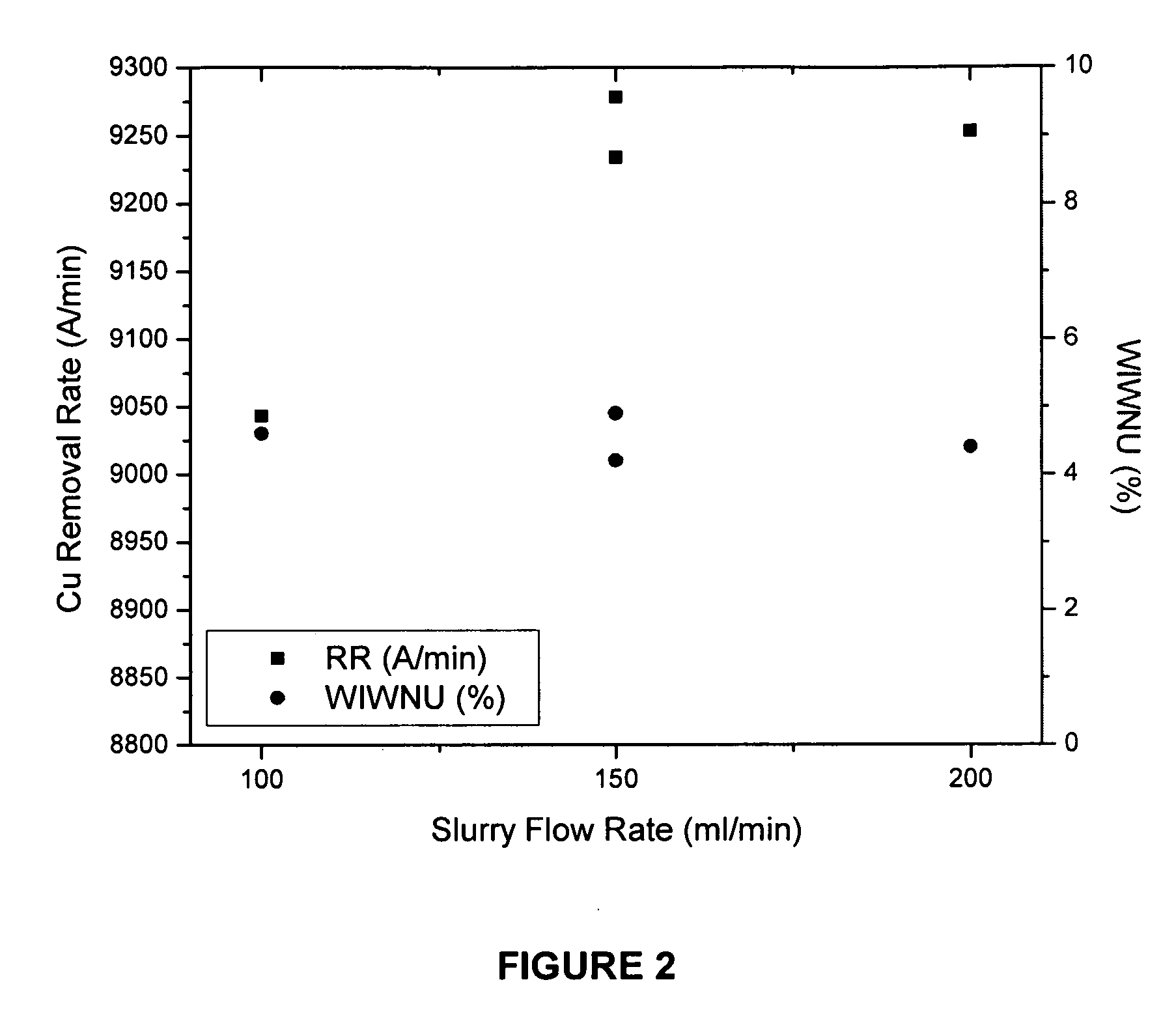

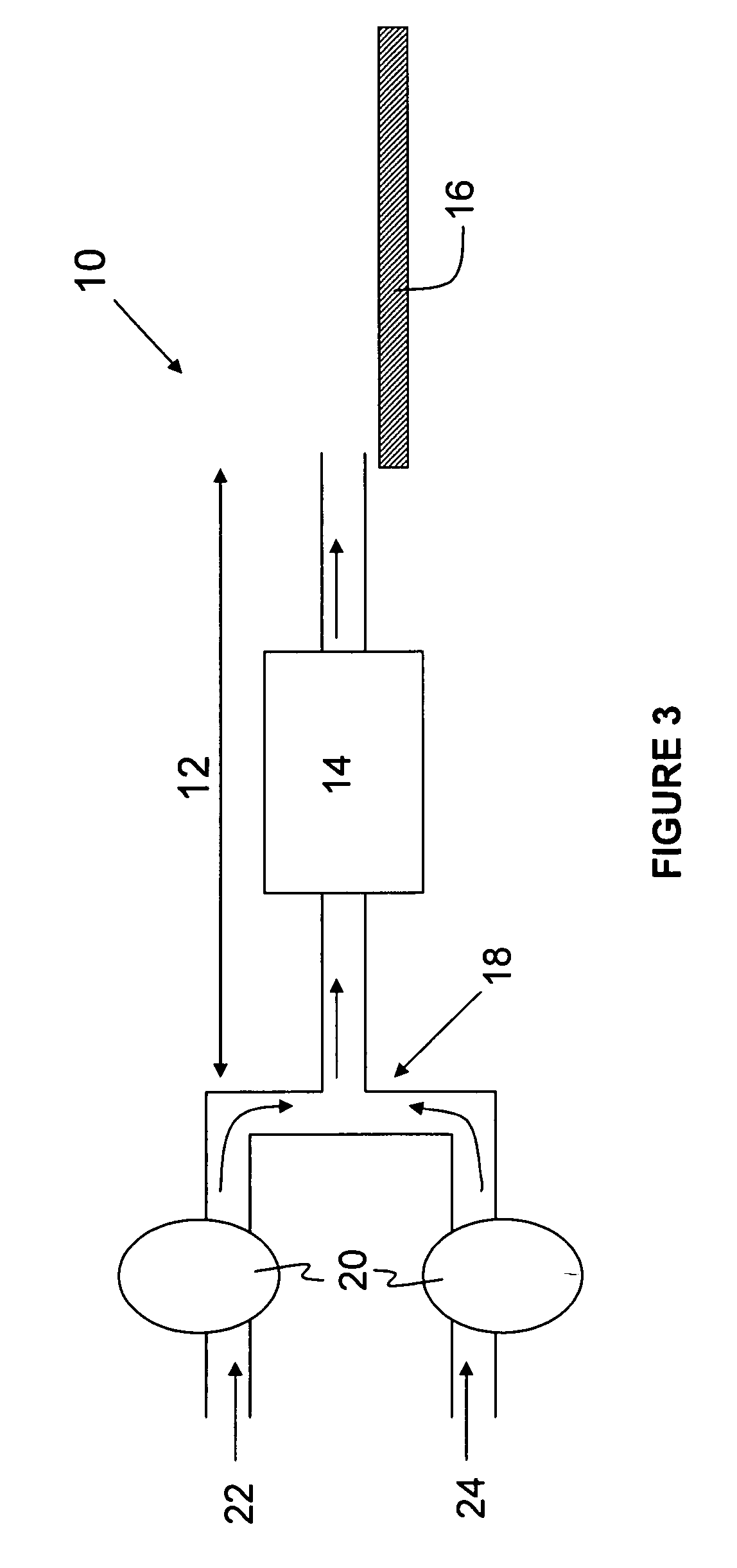

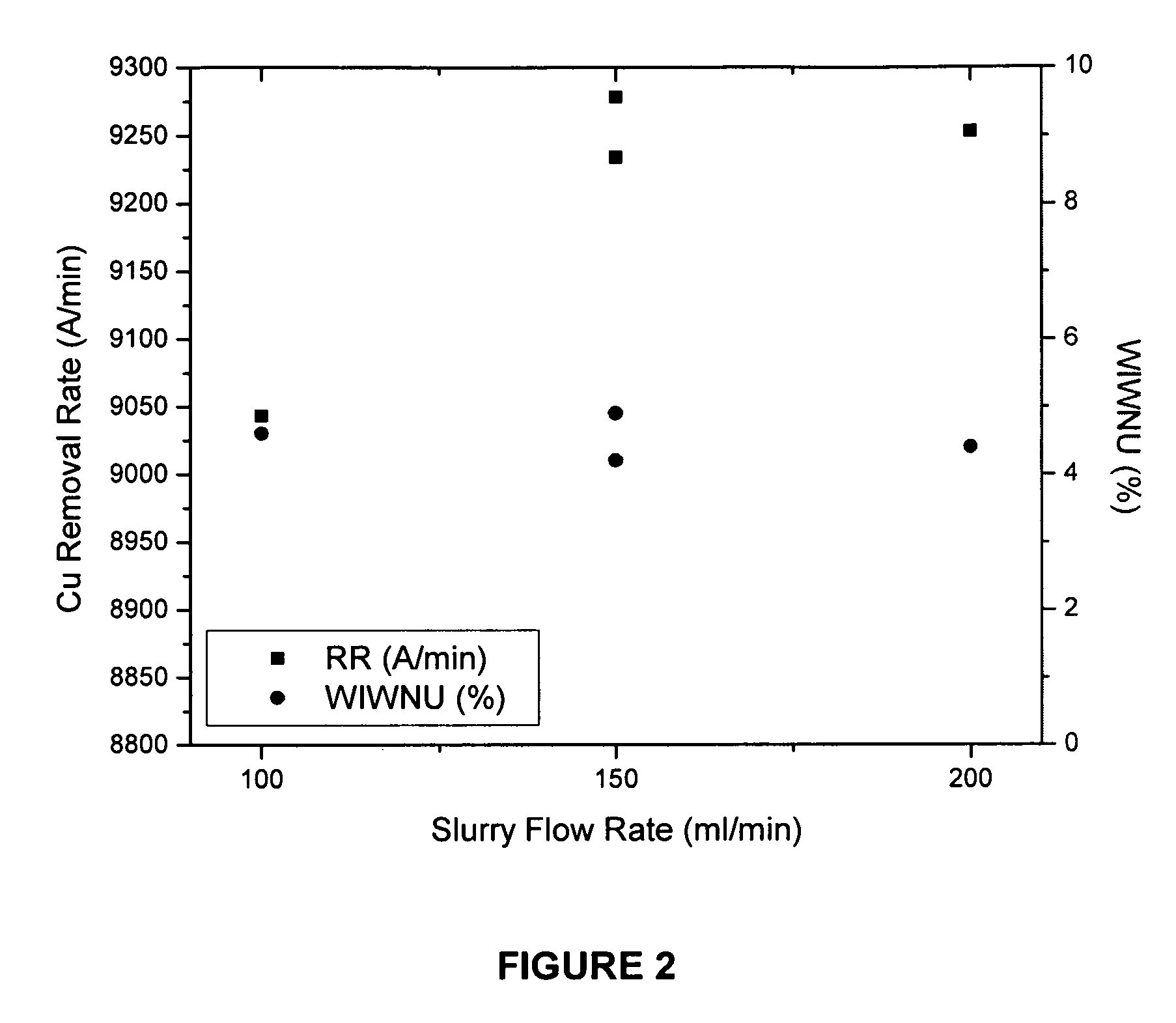

A chemical mechanical polishing process including a single copper removal CMP slurry formulation for planarization of a microelectronic device structure preferably having copper deposited thereon. The process includes the bulk removal of a copper layer using a first CMP slurry formulation having oxidizing agent, passivating agent, abrasive and solvent, and the soft polishing and over-polishing of the microelectronic device structure using a formulation including the first CMP slurry formulation and at least one additional additive. The CMP process described herein provides a high copper removal rate, a comparatively low barrier material removal rate, appropriate material selectivity ranges to minimize copper dishing at the onset of barrier material exposure, and good planarization efficiency.

Owner:ADVANCED TECH MATERIALS INC

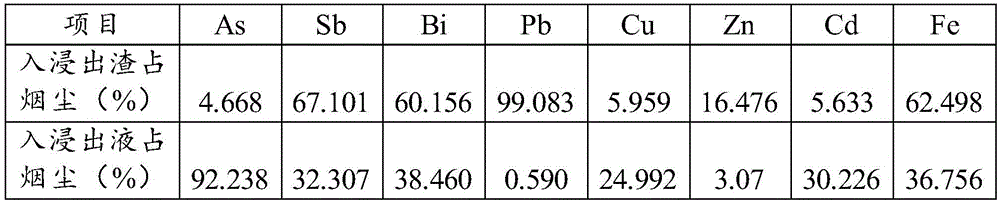

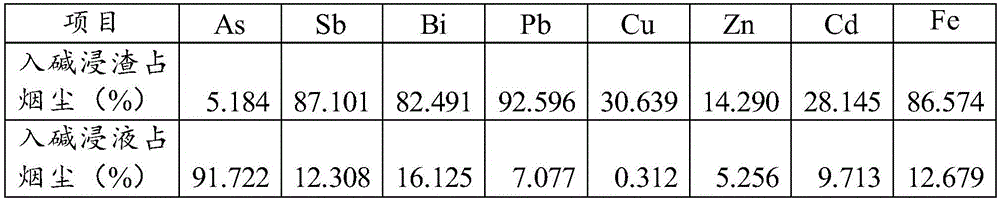

Soot treatment process in copper smelting process

ActiveCN105567983ARealize comprehensive utilizationLow arsenicProcess efficiency improvementArsenateSmelting process

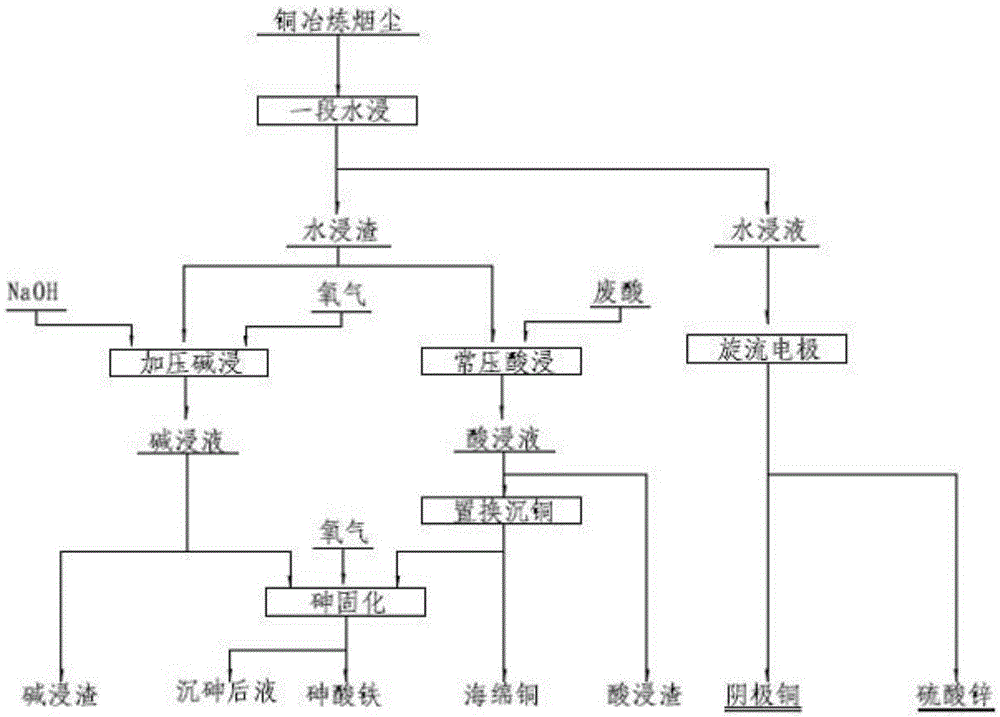

The invention provides a soot treatment process in a copper smelting process. The soot treatment process comprises the following steps: firstly carrying out water leaching on copper smelting soot to obtain a water leaching fluid and water leaching residues; then, carrying out acid leaching on one part of the water leaching residues obtained in the last step to obtain an acid leaching fluid, and carrying out alkali leaching on the other part of the water leaching residues to obtain an alkali leaching fluid; carrying out metal replacement on the acid leaching fluid obtained in the last step to precipitate copper to obtain copper-precipitated filtrate; and finally, neutralizing and oxidizing the copper-precipitated filtrate obtained in the last step and the alkali leaching fluid obtained in the last step to obtain ferric arsenate precipitates and arsenic-precipitated filtrate. The soot treatment process provided by the invention, especially the treatment process for high-arsenic high-copper soot realizes the hazard-free treatment effect of arsenic in the high-arsenic high-copper soot, and comprehensively recycles valuable metal copper, zinc and the like in the high-arsenic high-copper soot, so that gradient recycling and comprehensive utilization of soot impurities are realized.

Owner:YANGGU XIANGGUANG COPPER

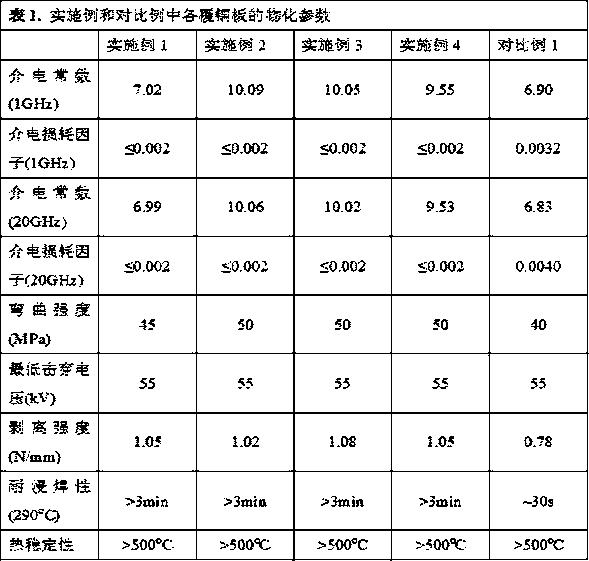

Mixture containing fluororesin and prepreg prepared from same, and copper clad laminate

ActiveCN106854330AEasy to operateMild preparation conditionsSynthetic resin layered productsGlass/slag layered productsPolymer scienceResin matrix

The invention specifically relates to a mixture containing fluororesin and a preparation method thereof, belonging to the field of communication materials. A prepreg prepared by impregnating a glass fabric in dispersion liquid of the mixture containing fluororesin and then carrying out drying and the like has uniform glue content, good impregnation quality, strong resin adhesion, smooth surface and appropriate toughness and viscosity. The invention also relates to a high-frequency copper clad laminate prepared from the prepreg, or a film or copper foil made of the mixture containing fluororesin. The prepared copper clad laminate has good thermal-mechanical properties, excellent dielectric properties and high copper foil strength, and can meet requirements on the comprehensive properties of substrate materials in the field of high-frequency communication. According to the invention, the processing properties of traditional fluororesin are greatly improved by using fluorine-containing resin with a low melting point; and a coupling agent is cooperatively used, so interaction between an inorganic filling material and glass fabric and a resin matrix is improved, dispersibility of the inorganic filling material, processing aids and the like in the fluororesin is enhanced, and the overall performance of the copper clad laminate is made more stable.

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

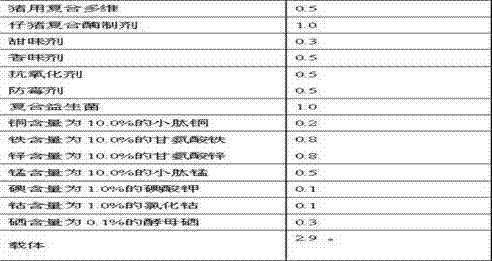

A kind of anti-resistant piglet nursery feed and preparation method thereof

ActiveCN102258156AReduce dependenceDelay drug resistanceAnimal feeding stuffAccessory food factorsBiotechnologyNutritive values

The invention discloses a culture feed for piglets, which mainly comprises corn, rice, full-cream puffed soybean, fermented bean pulp, peeled bean pulp, fish meal and the like. Yeast cell extract is added to enhance the immunity of piglets, and compound enzyme preparations and probiotics are used instead of high copper and high zinc, thereby lowering the environmental pollution, enhancing the digestion and absorption of the feed, and maintaining normal flora of the intestinal tract. Full organic trace elements are used instead of inorganic trace elements, thereby lowering the oxidization of inorganic salts on the feed and organisms. The invention also discloses a preparation method of the culture feed, which effectively reserves beneficial ingredients and discards harmful ingredients through the granulation process, thereby effectively reserving the nutritive value of the feed.

Owner:武汉天龙饲料有限公司

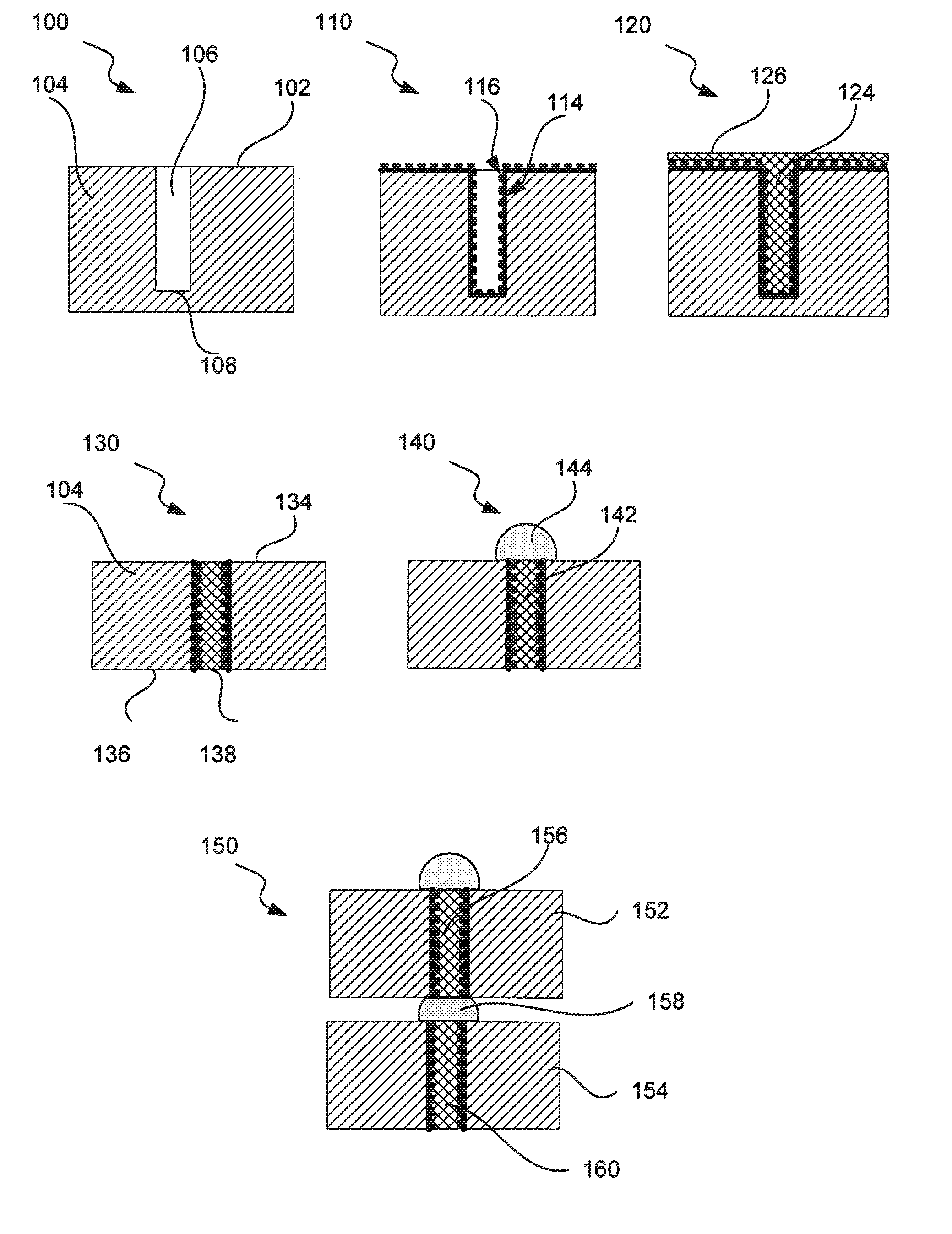

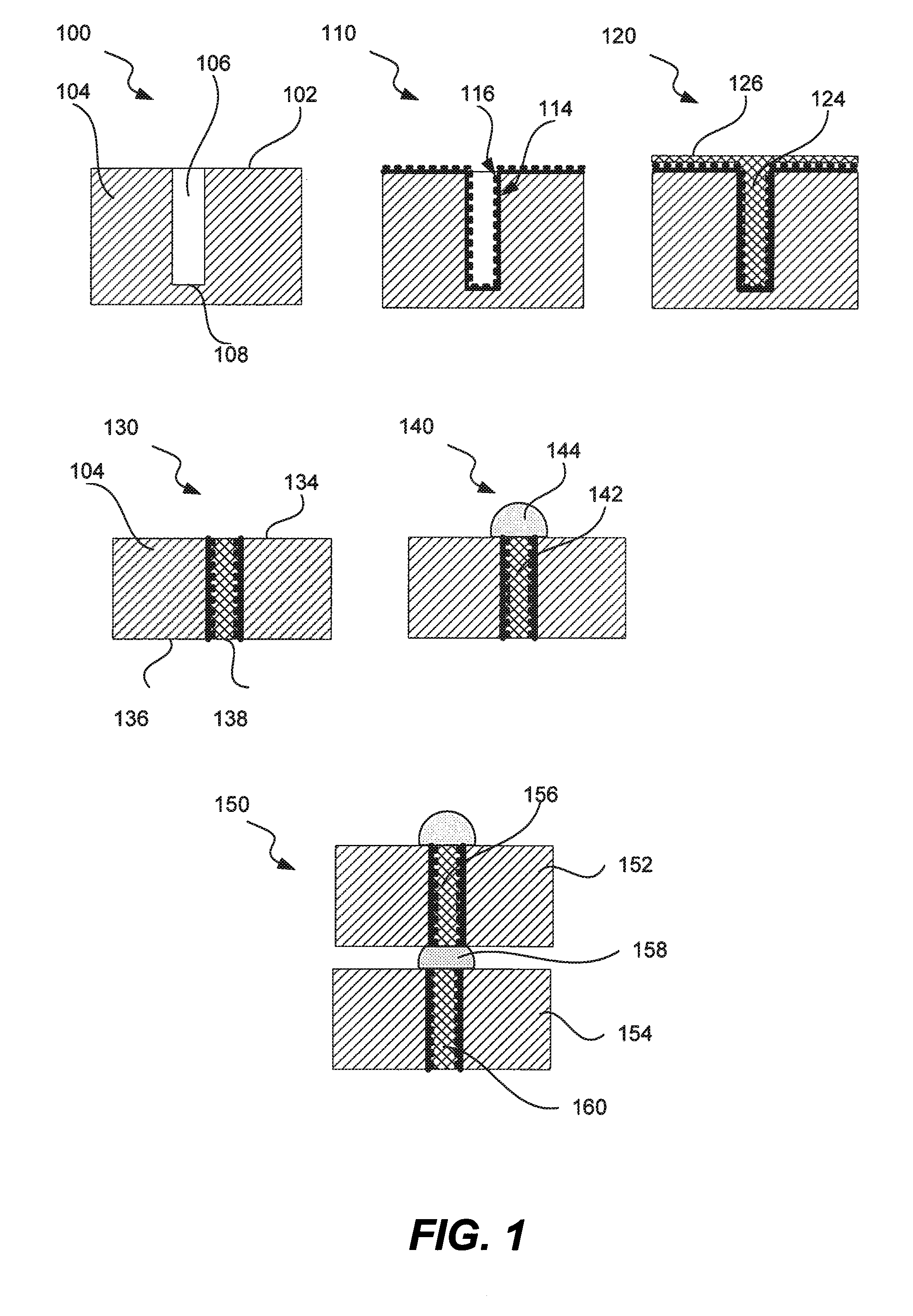

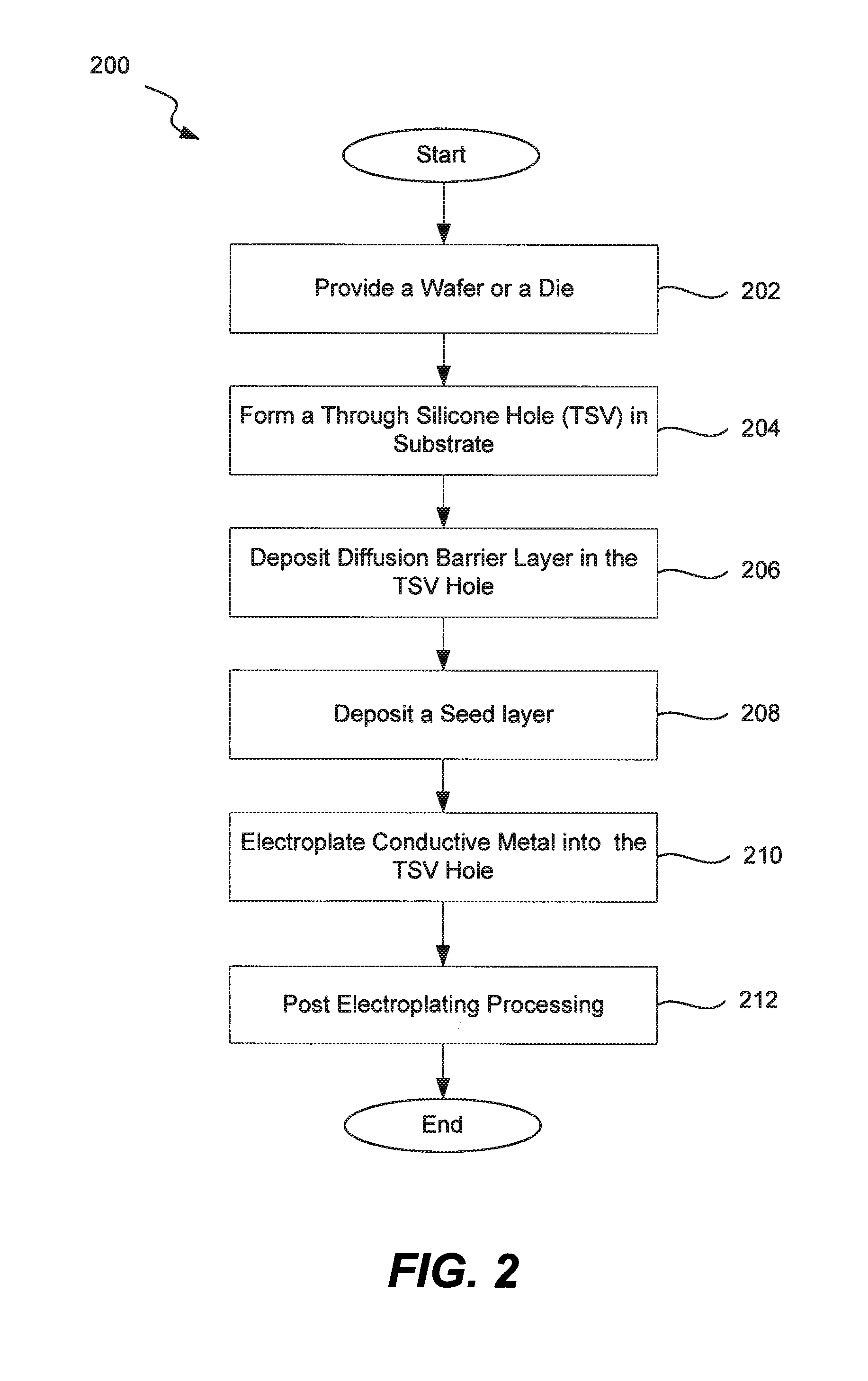

Process For Through Silicon Via Filling

A semiconductor electroplating process deposits copper into the through silicon via hole to completely fill the through silicon via in a substantially void free is disclosed. The through silicon via may be more than about 3 micrometers in diameter and more that about 20 micrometers deep. High copper concentration and low acidity electroplating solution is used for deposition copper into the through silicon vias.

Owner:NOVELLUS SYSTEMS

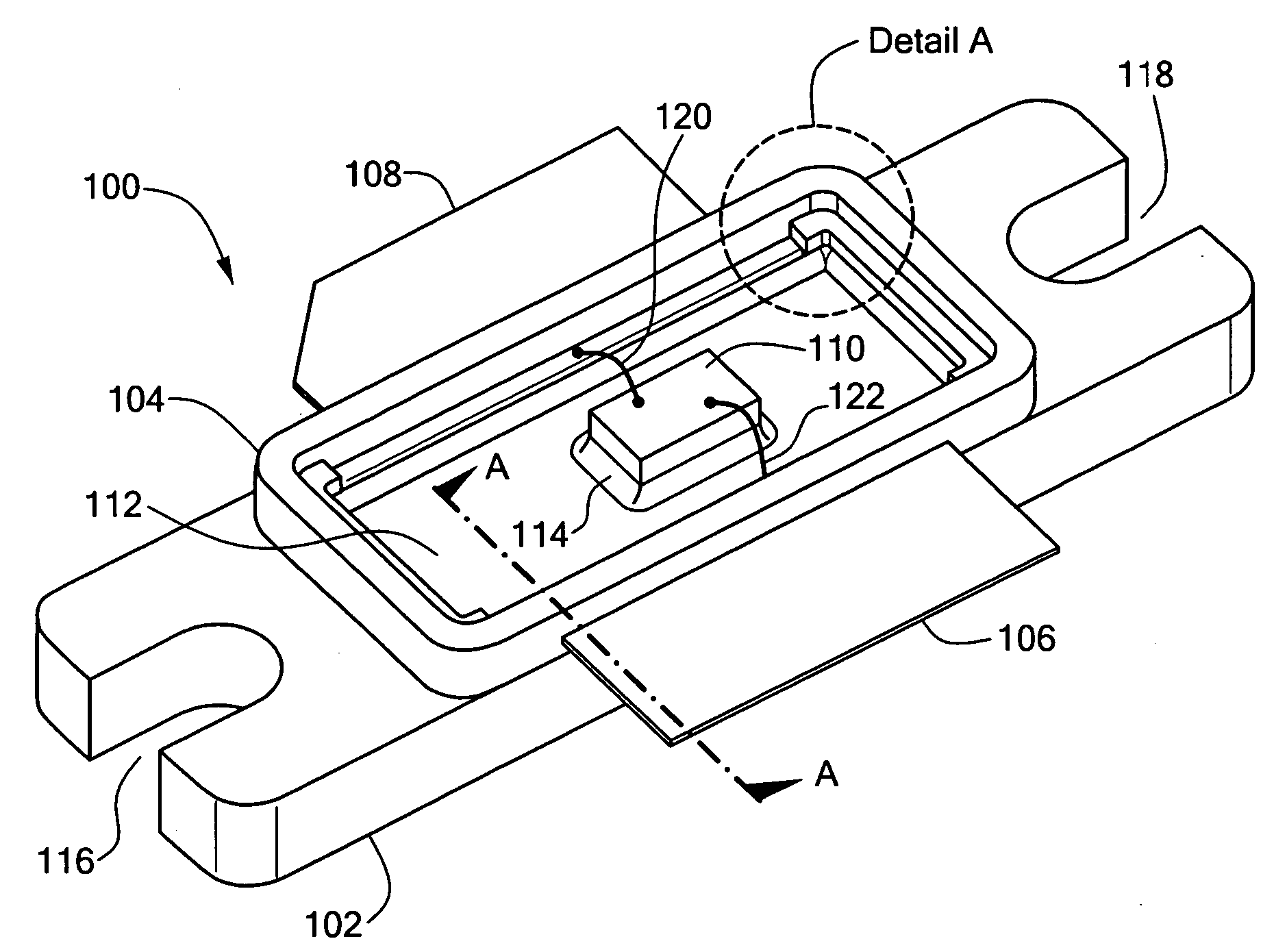

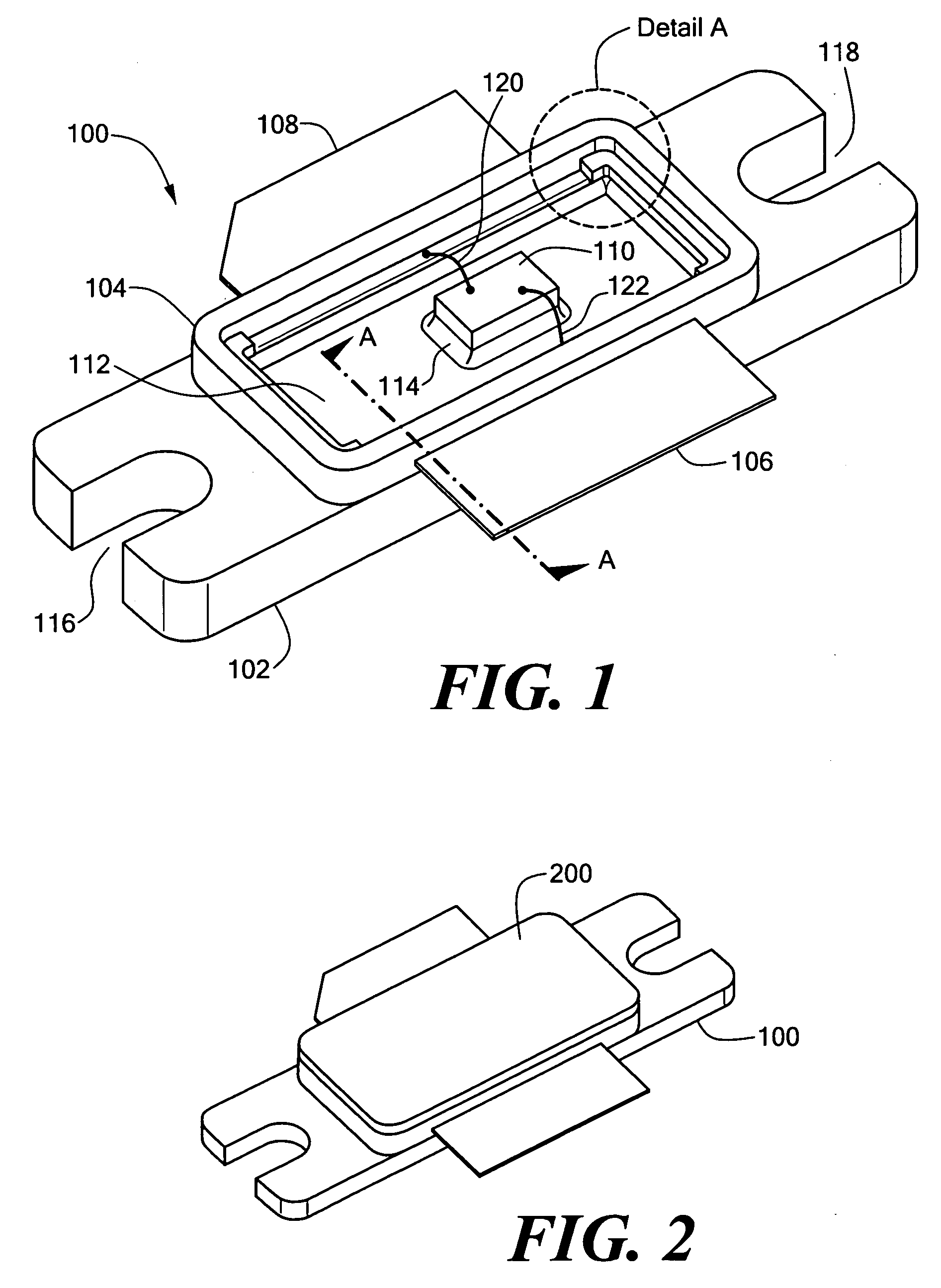

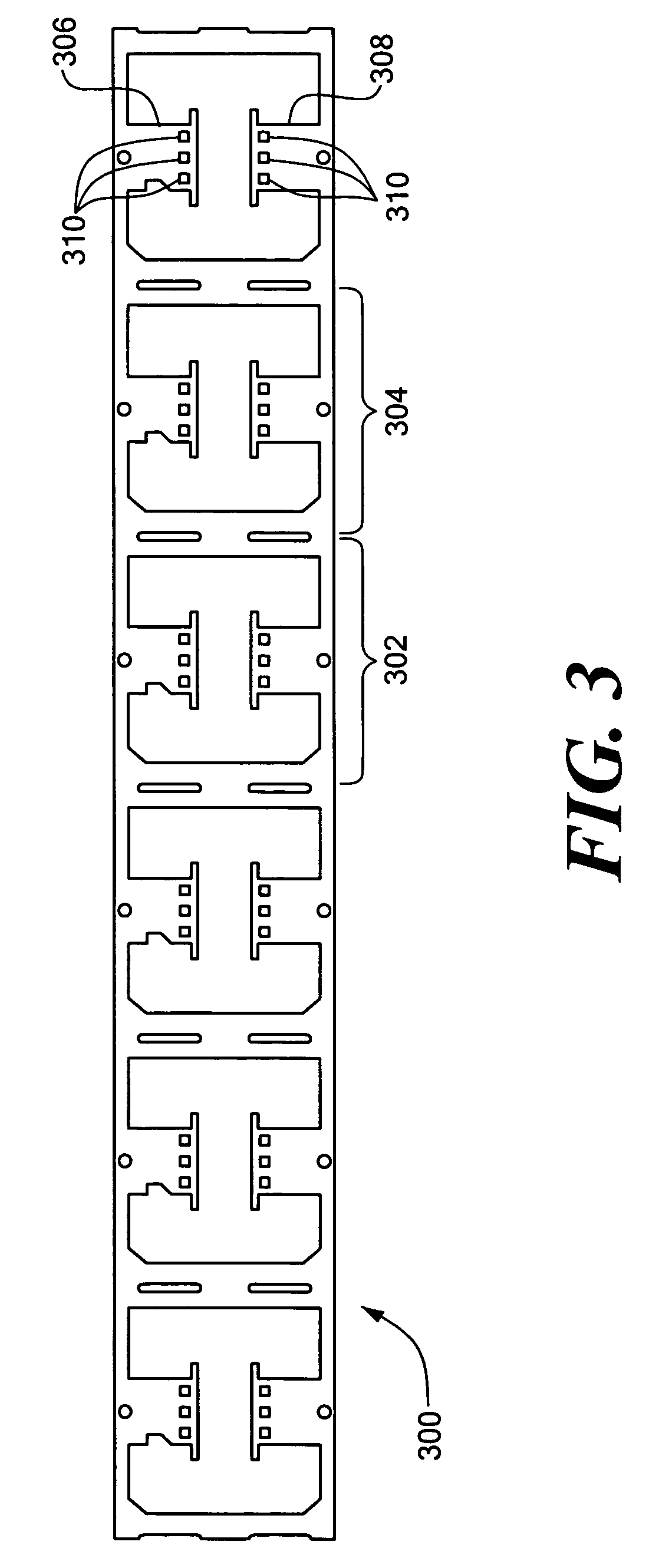

Methods for enclosing a thermoplastic package

InactiveUS20050016750A1Reduce the number of piecesHigh die-attach temperatureSemiconductor/solid-state device detailsCoupling device detailsSemiconductorPolymer

Owner:IQLP

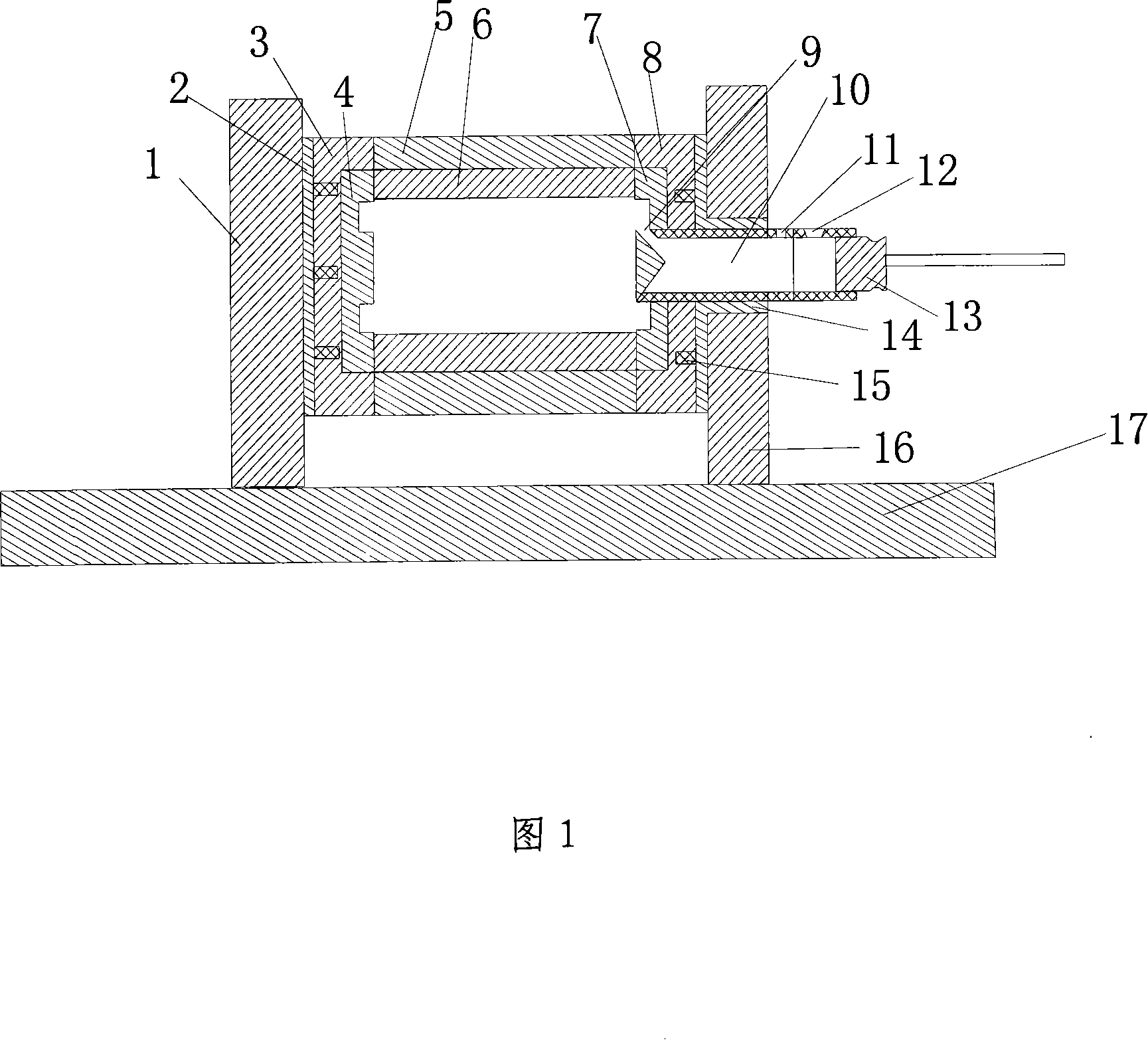

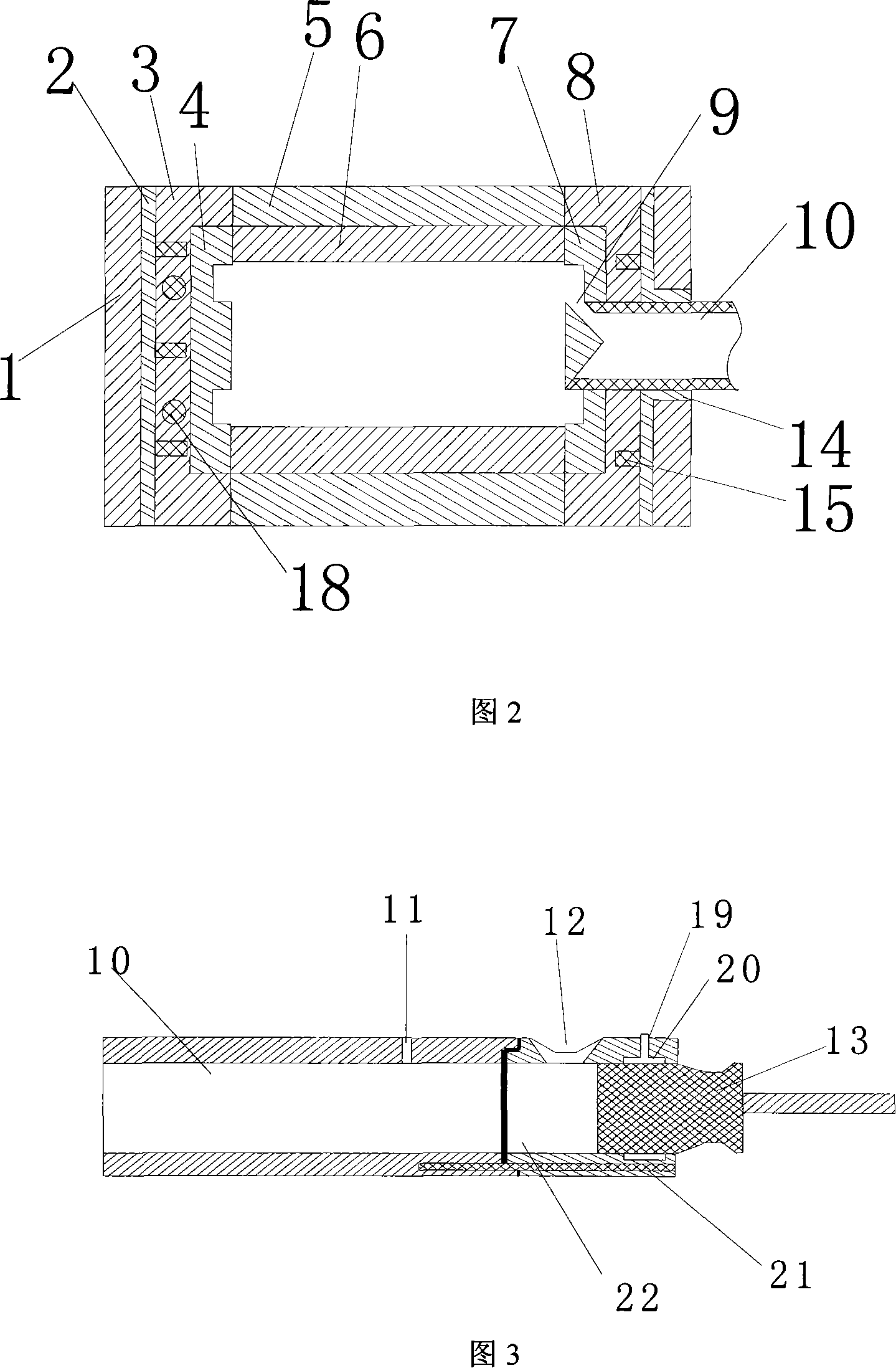

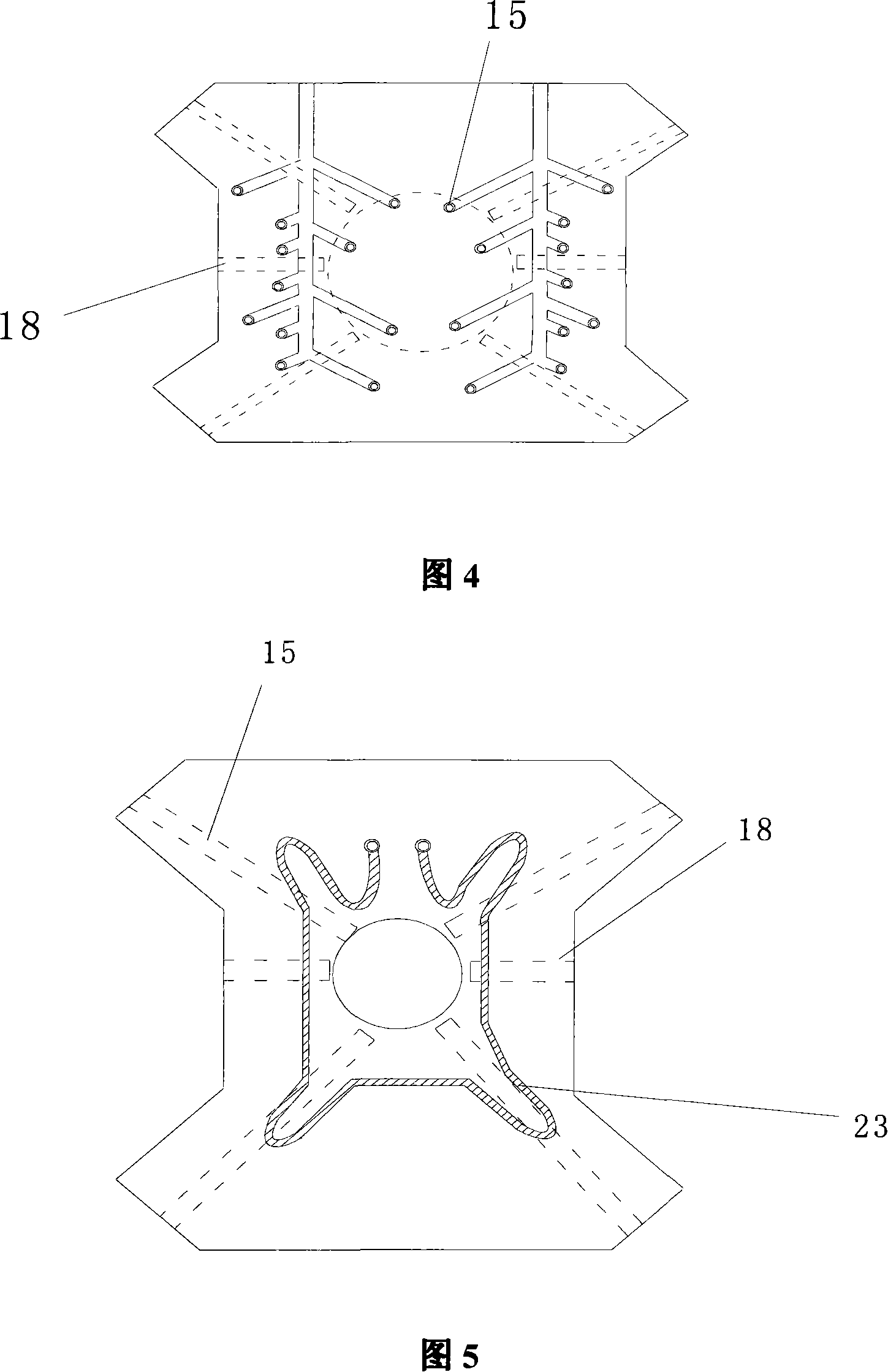

Die-casting method of induction motor copper cage rotor and die casting device thereof

ActiveCN101108416AReduce manufacturing costReasonable workmanshipGearingCylindersMiddle frequencyNon-ferrous extractive metallurgy

The invention relates to a casting method and casting machine of the induction motor cooper squirrel-cage rotor, which is suitable for the casting of pure copper and high copper content alloy. The invention belongs to nonferrous metal smelting and rolling process technology filed. The casting method comprises module pre-process, copper smelting, liquid casting and forming and quench water cooling. The casting method adopts a casting device which is composed of a casting machine and a smelting furnace, wherein, the smelting furnace comprises an integrated pot and middle frequency induction furnace, the heating efficiency of the middle frequency induction furnace is 0 to 100KW; the casting module comprises a group connection which is connected by a plurality of embedded lump. The invention has reasonable technics and equipment, the product has no defects of breakage on casting piece and surface, poor filling and mold sticking, the shaking present value complies with the R degree provision in IEC34-14(1994), which has the advantages of improving by one degree comparing with the N degree stipulated in Y series motor technology condition.

Owner:云南铜业压铸科技有限公司

Treatment method of scrap copper

The invention discloses a treatment method of scrap copper. The treatment method is characterized by comprising the following steps: (1) carrying out detection and analysis on the scrap copper to be melted, and determining the application and smelting production process of the scrap copper according to the alloy components of the scrap copper; (2) according to the analytic result, removing impurity metal elements in the scrap copper on the basis of processes such as loading, melting, oxidizing, degassing, slagging, deslagging, reducing and refining for red impure copper and high-copper alloy;and (3) carrying out degassing, deslagging and deoxidization reduction on liquid copper obtained in the step (2) again. In the invention, a high-quality copper material is produced by directly utilizing the scrap copper, thus the treatment method has the advantages of low investment, low energy consumption, simple production process, low production cost and little environment pollution, valuable metals in the scrap copper can be reasonably utilized, and the competitiveness of a product in market competition can be greatly improved.

Owner:JINCHUAN GROUP LIMITED

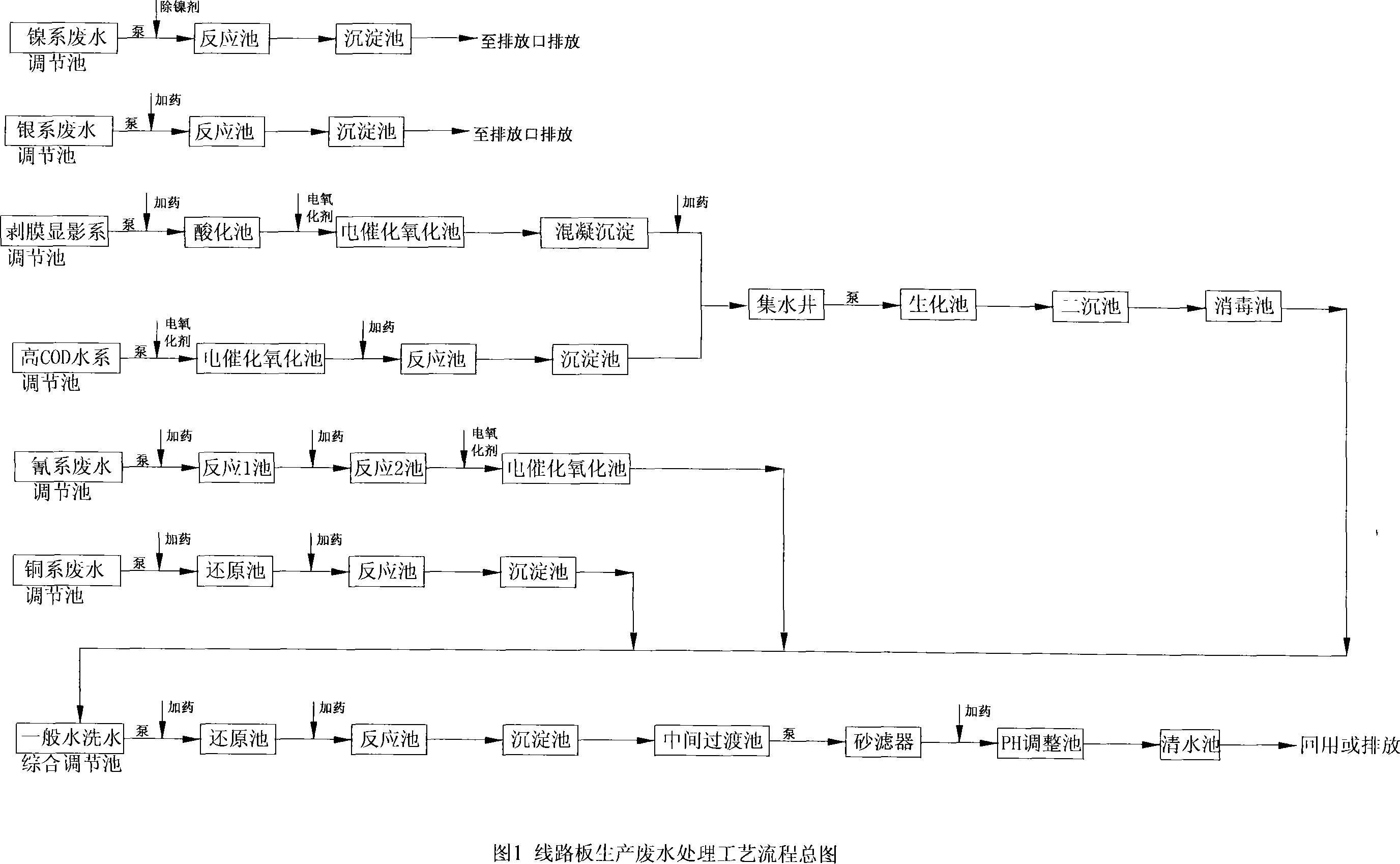

Integrated processing technique for waste water in breadboard production

InactiveCN101054247AThe process principle is clearComplete process principleWater/sewage treatment by electrochemical methodsWaste water treatment from metallurgical processElectricityWater processing

The invention relates to an efficient process technology for processing plenty of waste water generated in circuit board production, in particular to a pretreatment technology of high copper waste water and difficult biochemical degradation waste water with high COD in the process technology and entire waste water processing technology. First, sorting waste water reasonably according to nature thereof, dividing into as gold thread cyanogen waste water, nickel waste water, silver waste water, copper waste water, peel ink development waste water, high COD waste water and general aqueous washing water, collecting and specially processing the seven kinds of waste water independently, which key technology is the pretreatment technology for copper waste water, peel ink development waste water and high COD waste water. For copper, the key of waste water processing lies in to break complex compound and prevent secondary complexation of remnant Cu2+ and EDTA when adjusting pH to alkaline value; the key of peeling ink development waste water and high COD waste water lies in the foundation that carries out electrocatalysis oxidize to remove partial CODs, on with raise BOD / COD ratio thereof to improve biochemicalness radically.

Owner:深圳市宇力科技有限公司

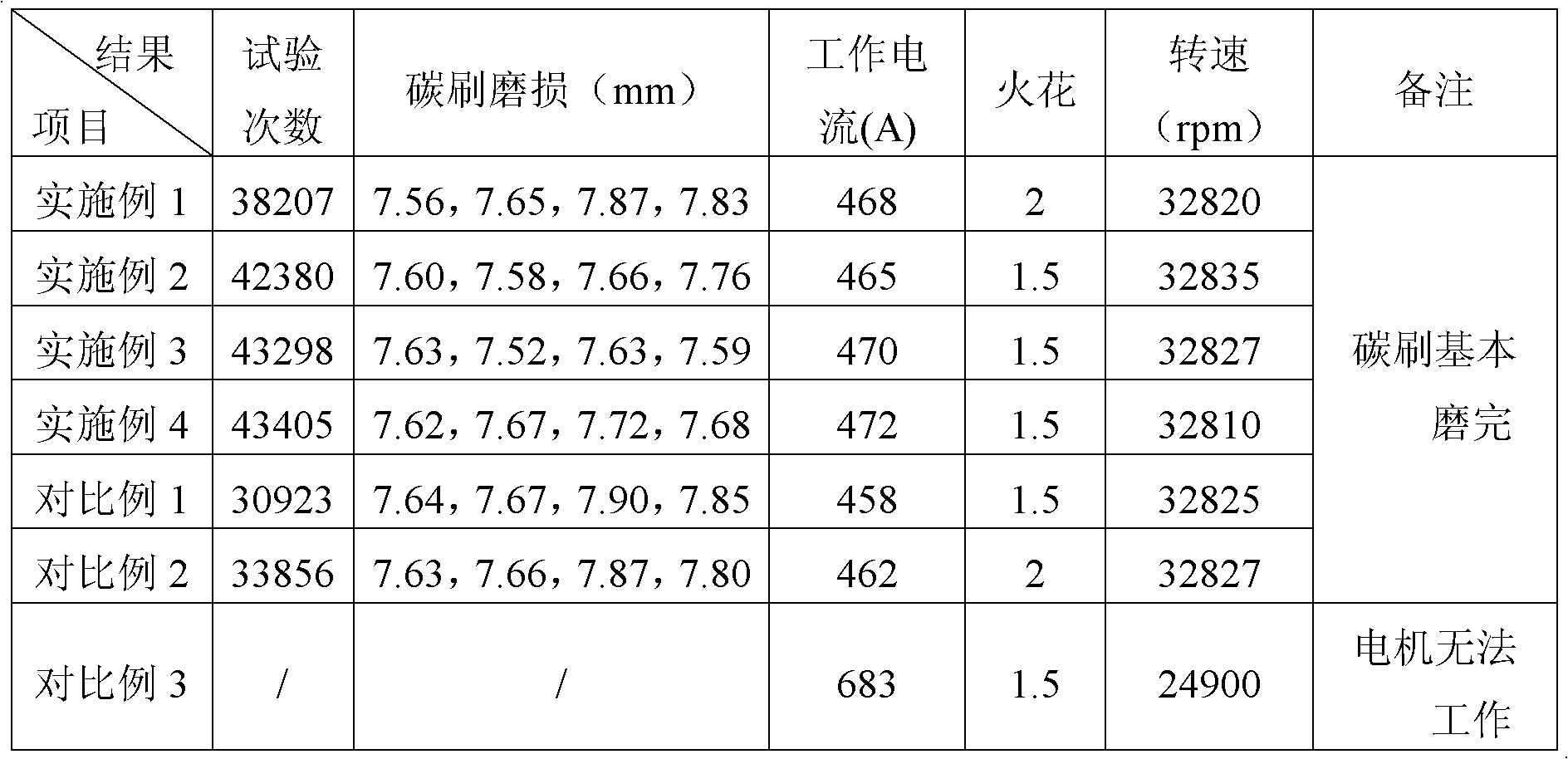

Carbon brush for truck starting motor as well as manufacture method and application thereof

ActiveCN102130407AForm evenlyExtended service lifeRotary current collectorBrushes manufacturePhosphoric acidGraphite

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

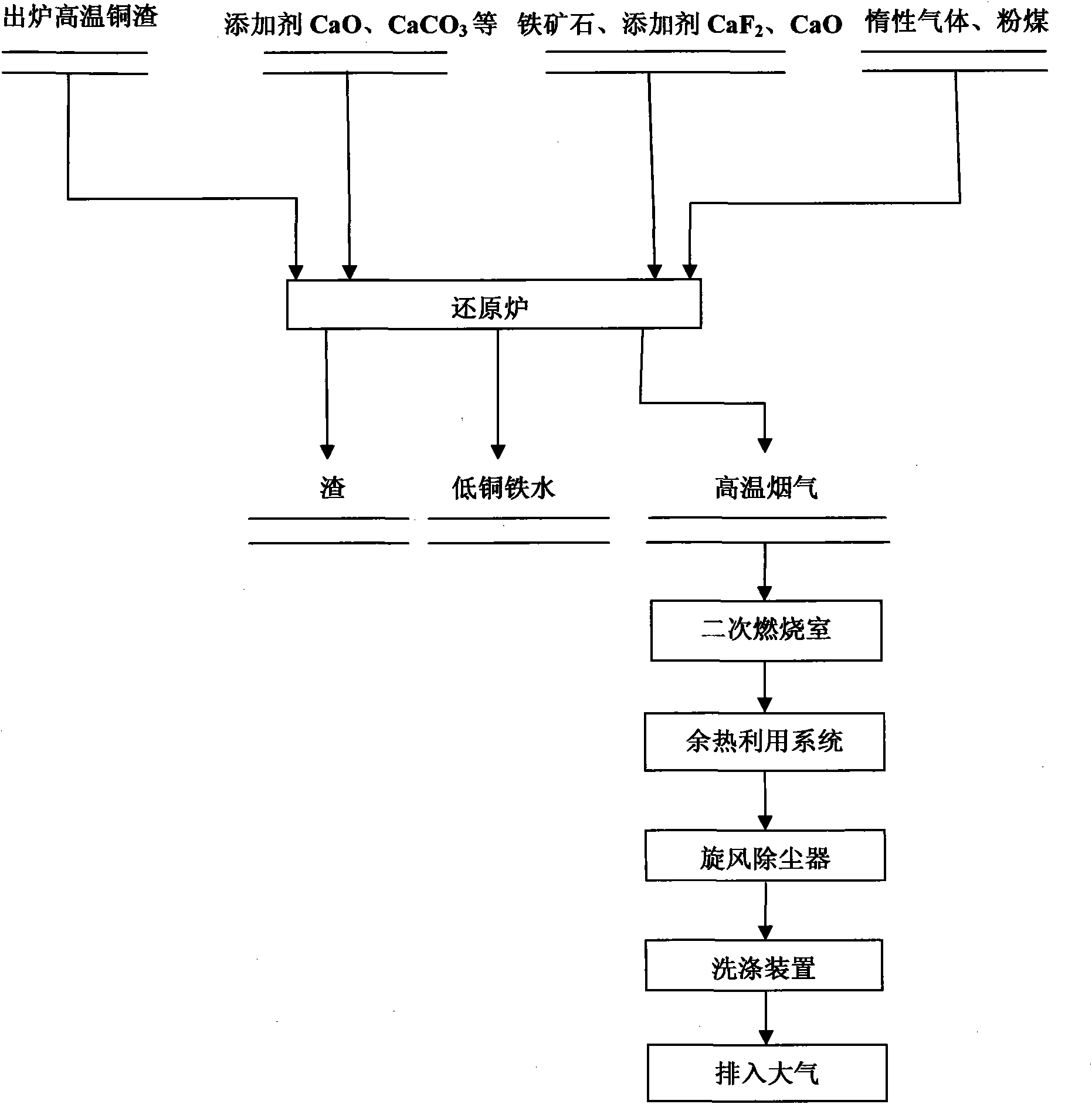

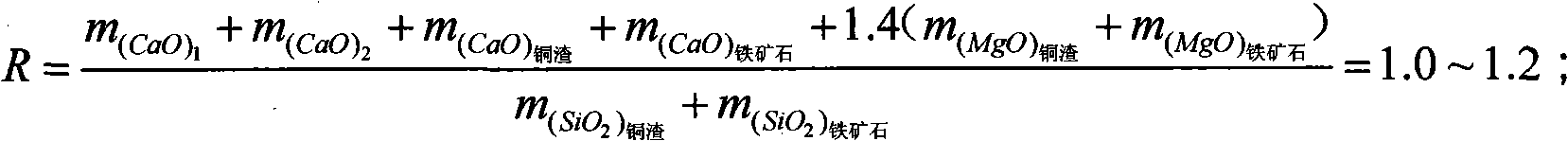

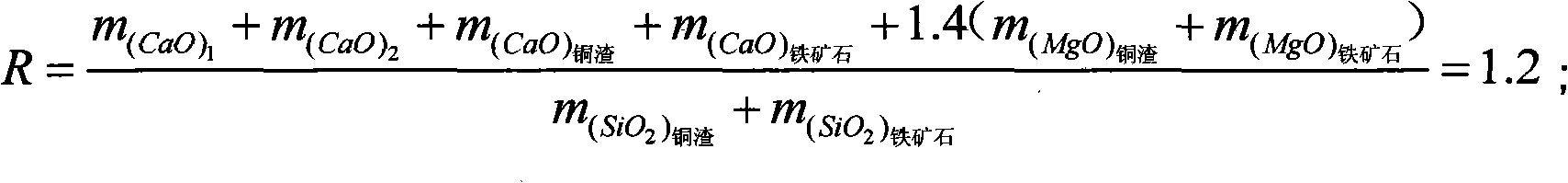

Method for preparing low-copper molten iron by mixed melting reduction of copper slag and iron ore

InactiveCN101886154AHigh copper concentrationOvercome the disadvantage of higher concentrationFluidised-bed furnacesGranularityCoal

The invention discloses a method for preparing low-copper molten iron by mixed melting reduction of copper slag and iron ore. The method comprises the following processes of: putting the high-temperature molten copper slag into a reduction furnace, grinding a certain amount of slag forming agent CaO, CaCO3 and the like into certain granularity, adding the ground slag forming agent into the reduction furnace, fully melting the mixture, and standing the molten pool for 10 minutes; grinding the iron ore, quantitative additive CaF2 and CaO into certain granularity respectively, then uniformly mixing the iron ore, the CaF2 and the CaO, adding the mixture into the reduction furnace, raising the temperature of the furnace to between 1,600 and 1,700 DEG C, fully melting the materials in the furnace, and then standing the molten pool for 20 minutes; and crushing a coal reducing agent to certain granularity, spraying the crushed coal reducing agent to the molten pool by using inert gas as carrier gas through a spray gun, and performing mixed melting reduction reaction of the copper slag and the iron ore. The method greatly reduces the defect of high copper in the molten iron obtained by single copper slag melting reduction by fully using the mutual coupling effect of the components among the copper slag, the iron ore and the additive and the diluting effect of the molten iron obtained by iron ore reduction on high copper content of the molten iron obtained by copper slag reduction, and has wide applicability.

Owner:KUNMING UNIV OF SCI & TECH

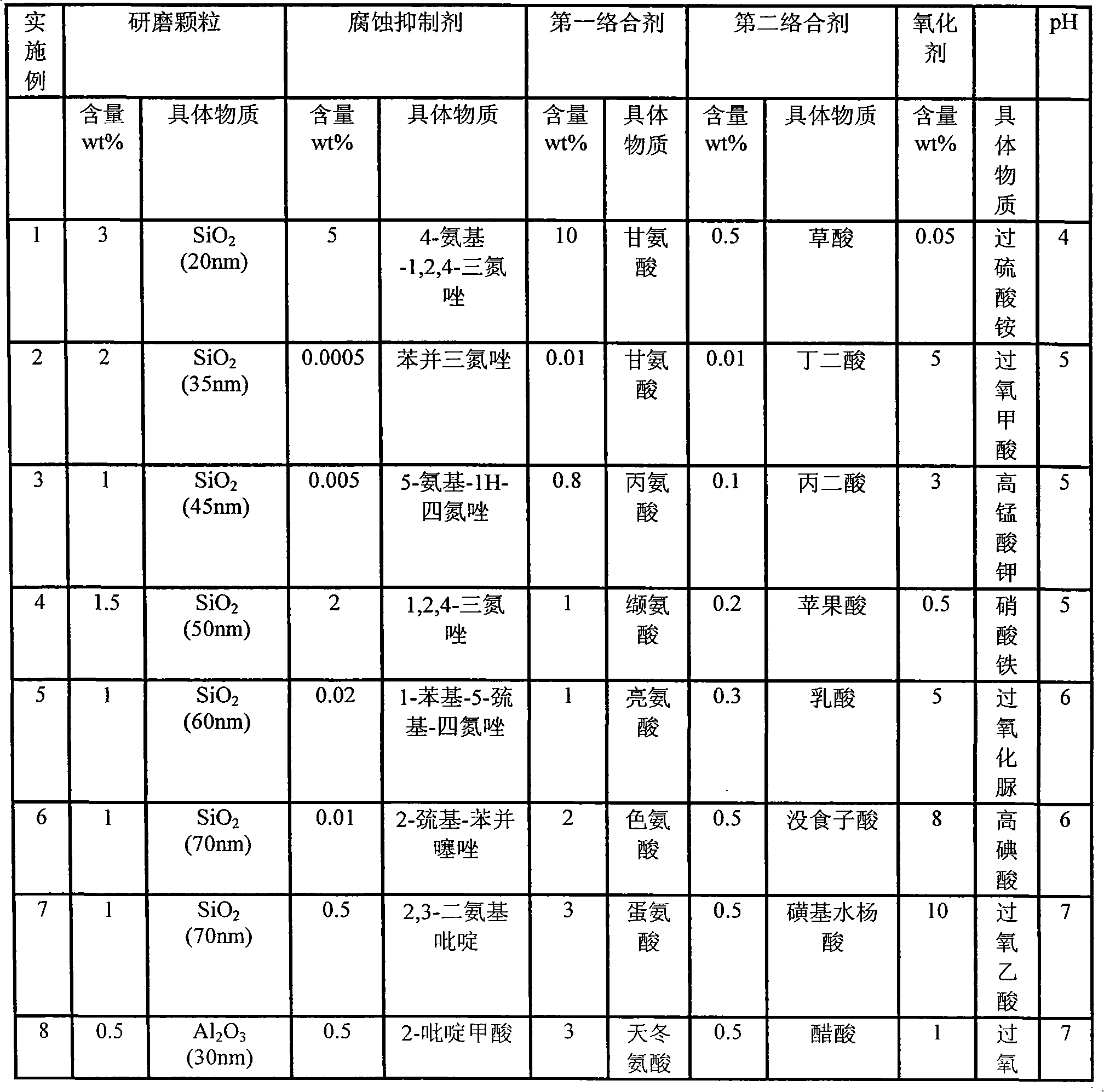

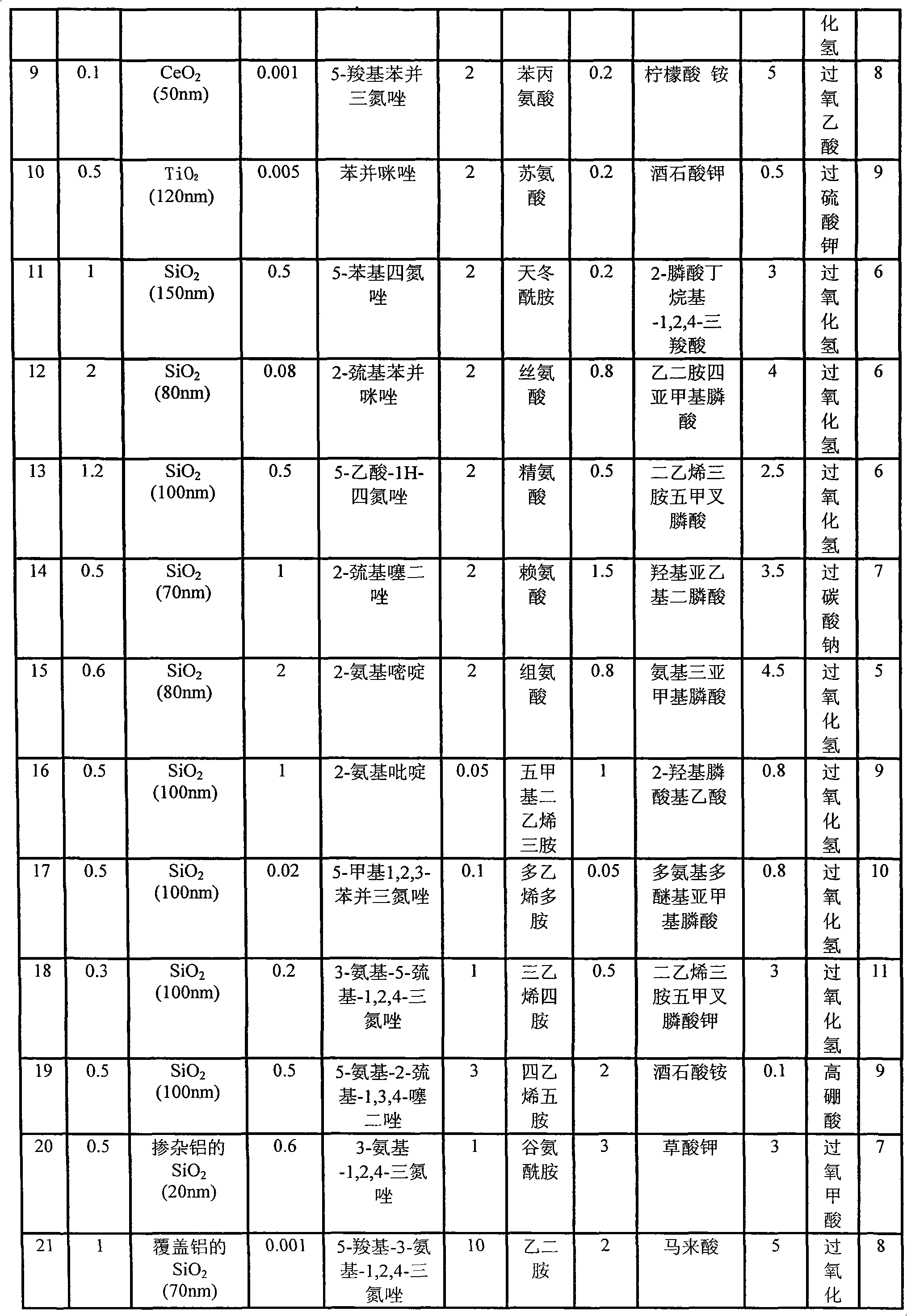

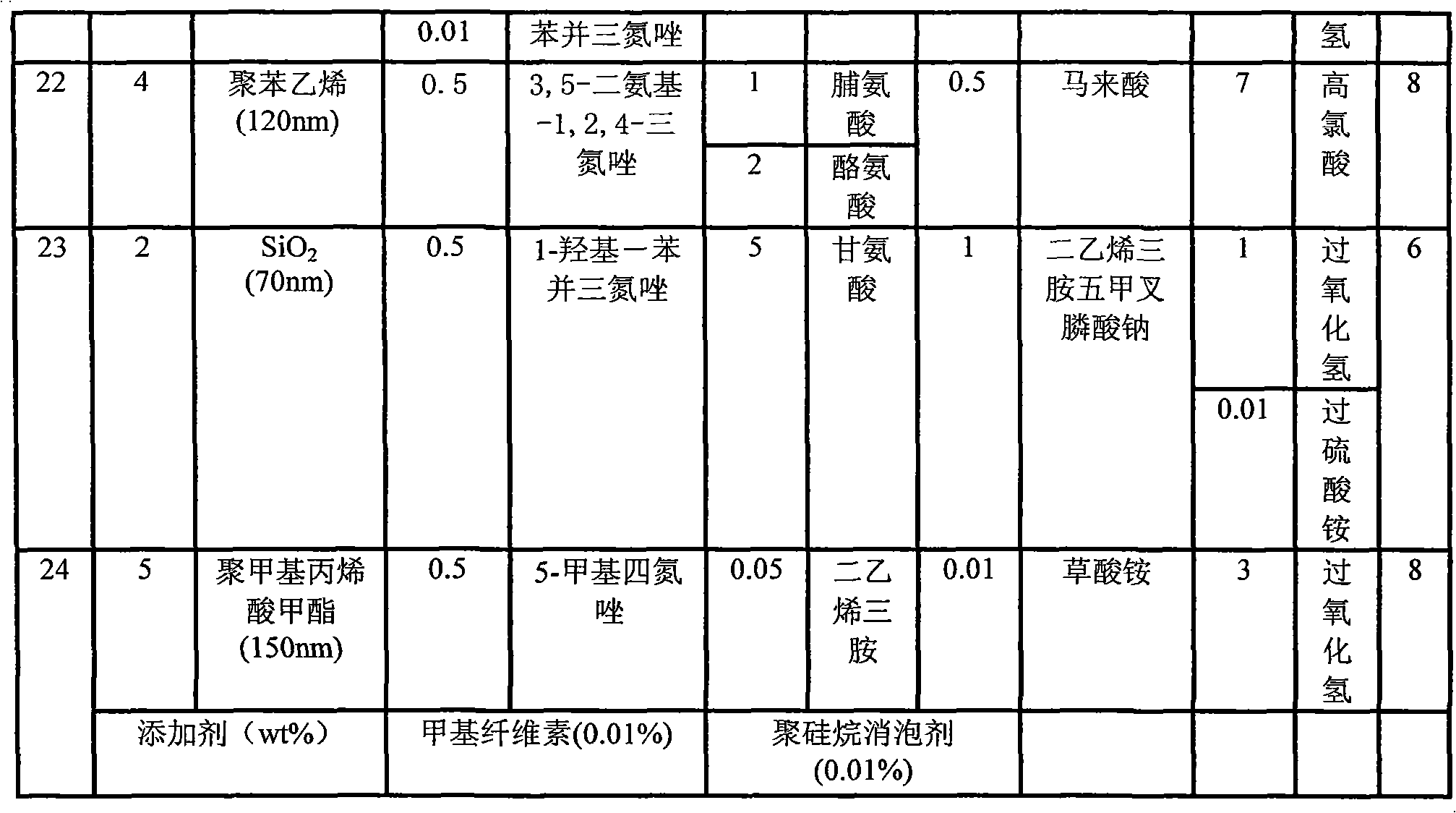

Chemical mechanical polishing solution

InactiveCN102101982AImprove polishing rateSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesCompound (substance)Physical chemistry

The invention discloses chemical mechanical polishing solution, which contains abrasive grains, a corrosion inhibitor, an oxidant, water and at least two complexing agents. The chemical mechanical polishing solution also can keep higher copper removing rate after polishing pad cleaning solution is used.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

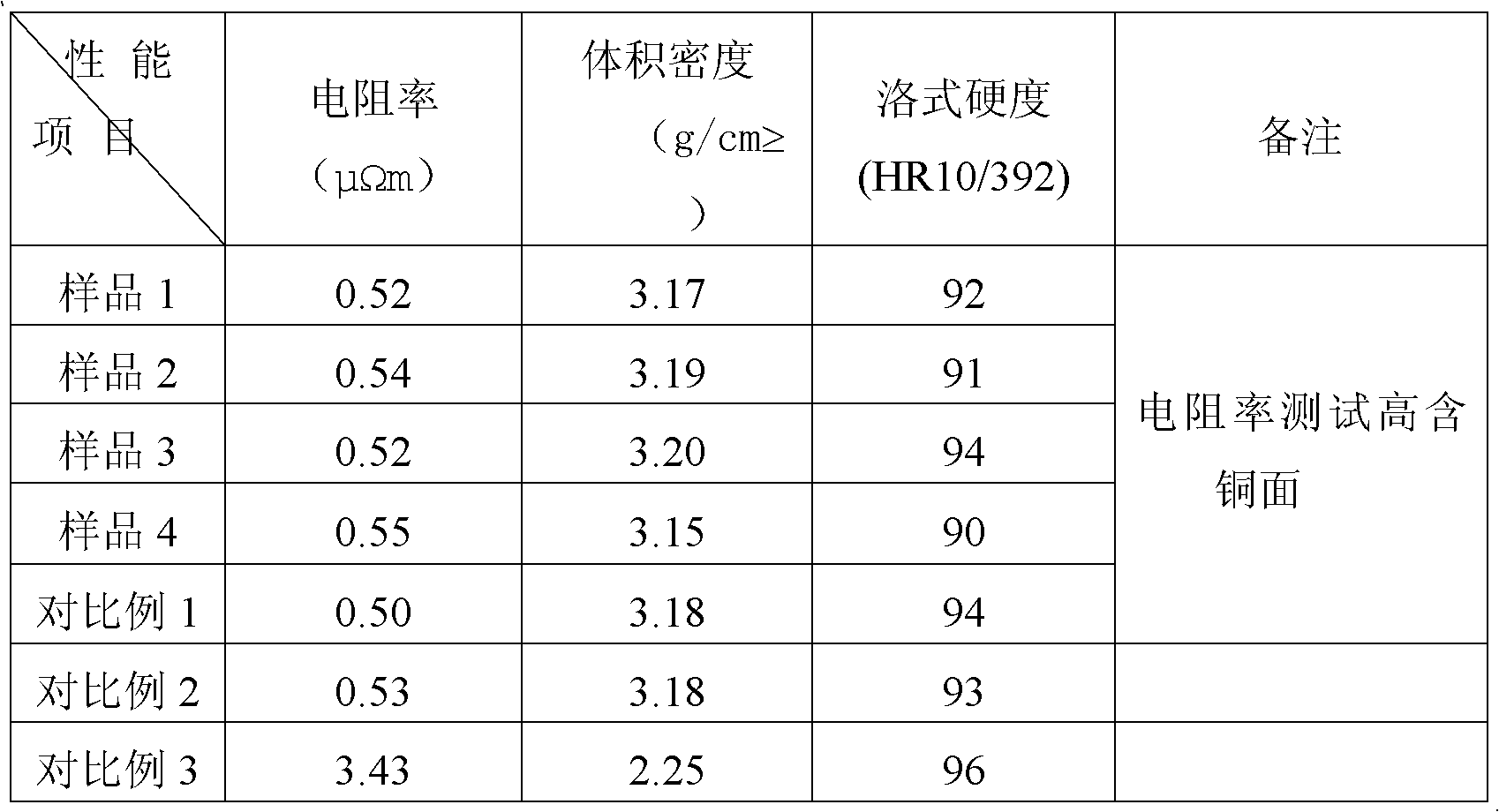

Manufacturing method for high-copper-silicon magnesium powder metallurgy aluminum alloy

The invention relates to a manufacturing method for a high-copper-silicon magnesium powder metallurgy aluminum alloy, and belongs to the field of material forming with a traditional powder metallurgy forming-sintering process combined with aluminum alloy machining. The manufacturing method includes the steps that an aluminum alloy ingot blank is manufactured through indoor temperature pressing-sintering; then, the aluminum alloy ingot blank is subjected to hot extrusion to obtain an aluminum alloy section; the aluminum alloy section is subjected to solid-solution quenching treatment; and finally, the aluminum alloy section obtained after quenching treatment is subjected to aging treatment. The performance of the material is significantly improved through proper low-temperature sintering assisted by heat machining and heat treatment matched with the temperature of low-temperature sintering, and particularly, an unexpected effect on increase of elongation is achieved. The manufacturing process is simple, the obtained product is excellent in performance, and large-scale industrialized application is facilitated.

Owner:CENT SOUTH UNIV

High throughput chemical mechanical polishing composition for metal film planarization

InactiveUS8304344B2Semiconductor/solid-state device manufacturingLapping machinesMaterial removalSlurry

A chemical mechanical polishing process including a single copper removal CMP slurry formulation for planarization of a microelectronic device structure preferably having copper deposited thereon. The process includes the bulk removal of a copper layer using a first CMP slurry formulation having oxidizing agent, passivating agent, abrasive and solvent, and the soft polishing and over-polishing of the microelectronic device structure using a formulation including the first CMP slurry formulation and at least one additional additive. The CMP process described herein provides a high copper removal rate, a comparatively low barrier material removal rate, appropriate material selectivity ranges to minimize copper dishing at the onset of barrier material exposure, and good planarization efficiency.

Owner:ADVANCED TECH MATERIALS INC

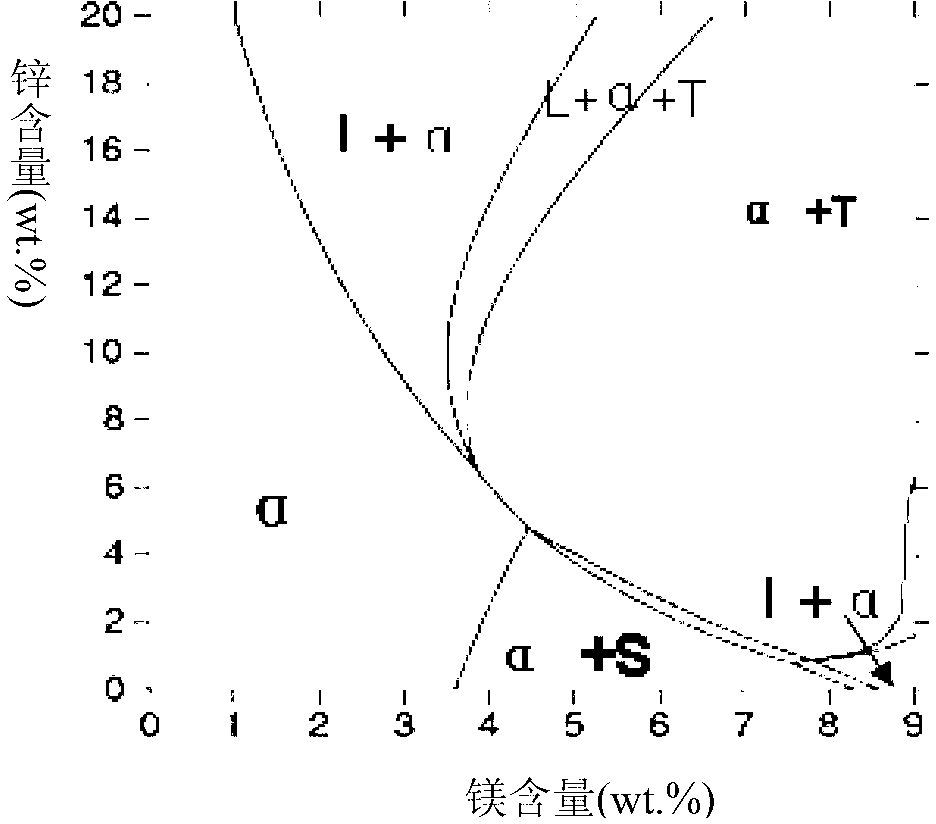

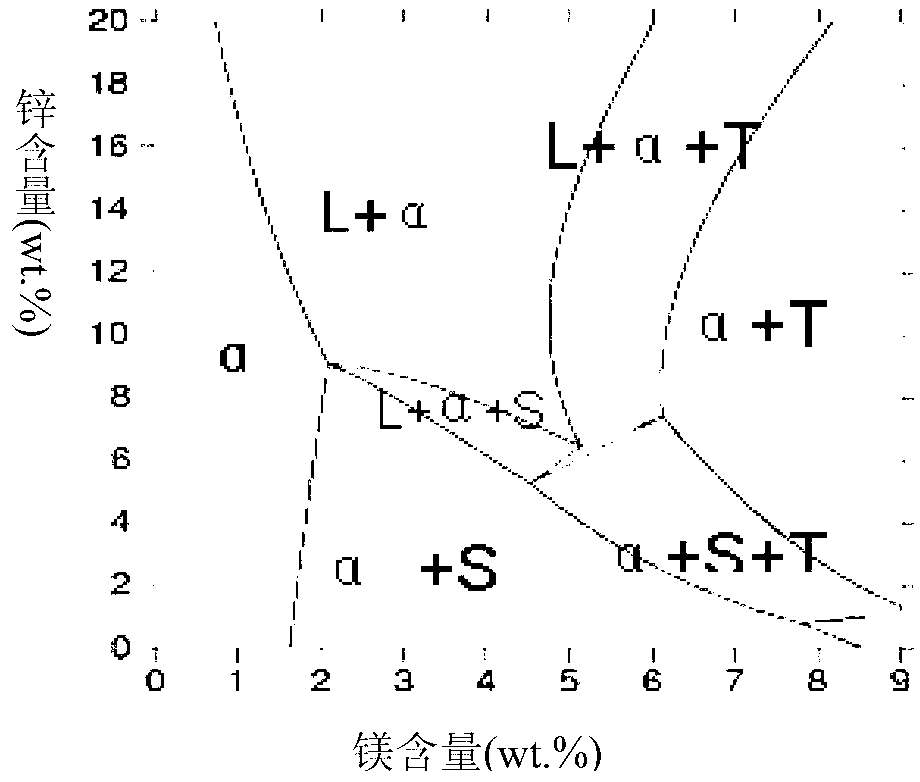

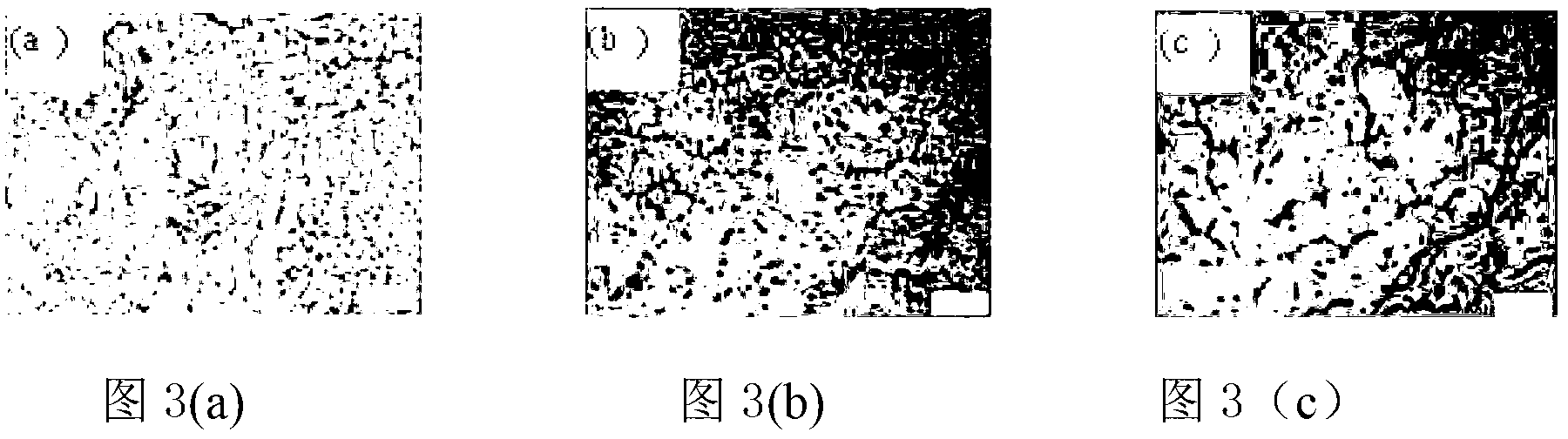

High-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy and heat treatment method

The invention discloses a high-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy and a heat treatment method. The alloy comprises the following components by mass percentage: 6.5-8.3% of Zn, 2.3-3.0% of Mg, 0.8-1.2% of Cu, 0.1-0.2% of Zr, less than 0.15% of Fe, less than 0.1% of Si, and the balance of Al. A preparation method of the alloy comprises the steps of blending, smelting, semi-continuous casting, homogenizing, thermoplastic deformation, short time solid solution, and ageing heat treatment. For the high-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy prepared with the method, the hardness (HV) is 185-209, the tensile strength sigma b is greater than or equal to 650Mpa, the percentage elongation delta is greater than or equal to 7%, the pitting resistance is high, the cast ingot yield is high, and the stress corrosion resistance is further improved while the mechanical property is kept after multiple regression reageing treatment. The alloy and the heat treatment method solve the problems that the cast ingot yield in the existing high-copper Al-Zn-Mg-Cu ultrahigh-strength aluminium alloy is low, and the strength, toughness and corrosion resistance cannot be compromised. The heat treatment method is simple to operate, and the industrial production is facilitated.

Owner:CENT SOUTH UNIV

Organic-inorganic composite trace element premix

The invention discloses premix of organic-inorganic complex trace element. The premix of the complex trace element is added with the organic trace element and the inorganic trace element, wherein the organic trace element is hydroxyl copper methionine, ferrous fumarate, hydroxyl iron methionine, hydroxyl zinc methionine, hydroxyl manganese methionine, selenomethionine and chromium picolinate. The inorganic trace element is anhydrous cupric sulfate, anhydrous ferrous sulfate, anhydrous zinc sulfate, anhydrous manganese sulfate and chromium nicotinate. The invention has the beneficial effects of greatly reducing the cost under no influence on the use effects, higher absorption and utilization and replacement of high copper, significant reduction on the discharge of the trace element, alleviating the adverse environmental impact from the culture production, effective protecting vitamin from being damaged, extending the product warranty period, increasing the myoglobin level, improving the carcass quality, enabling the animal fur to be ruddy and shiny, promoting the animal growth, improving the return of feed, promoting the body immunity and the anti-stress ability and promoting the reproductive performance of breeding stock and breeding bird.

Owner:广东省农业科学院畜牧研究所 +1

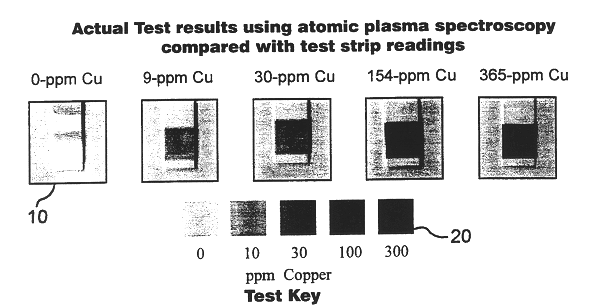

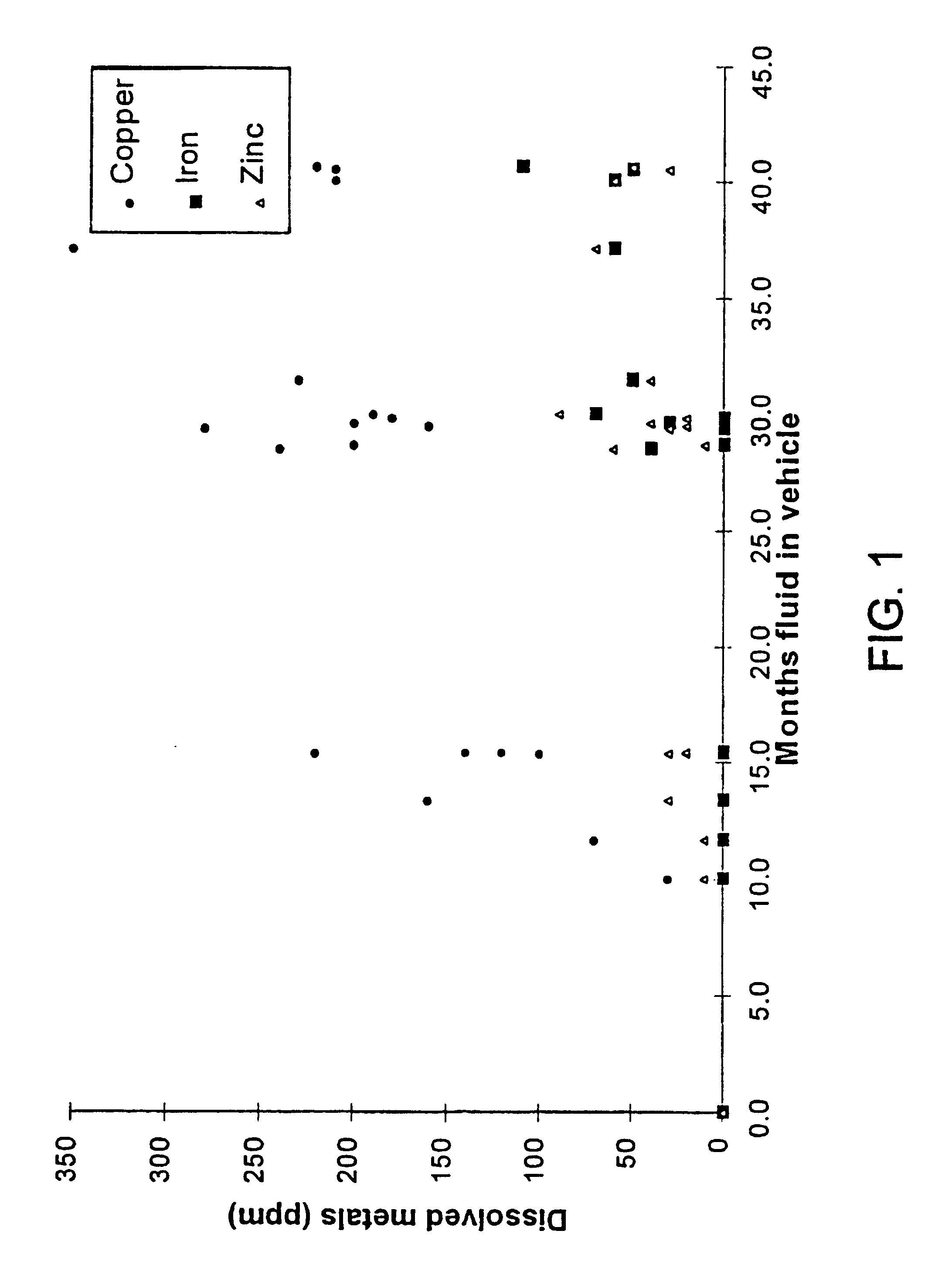

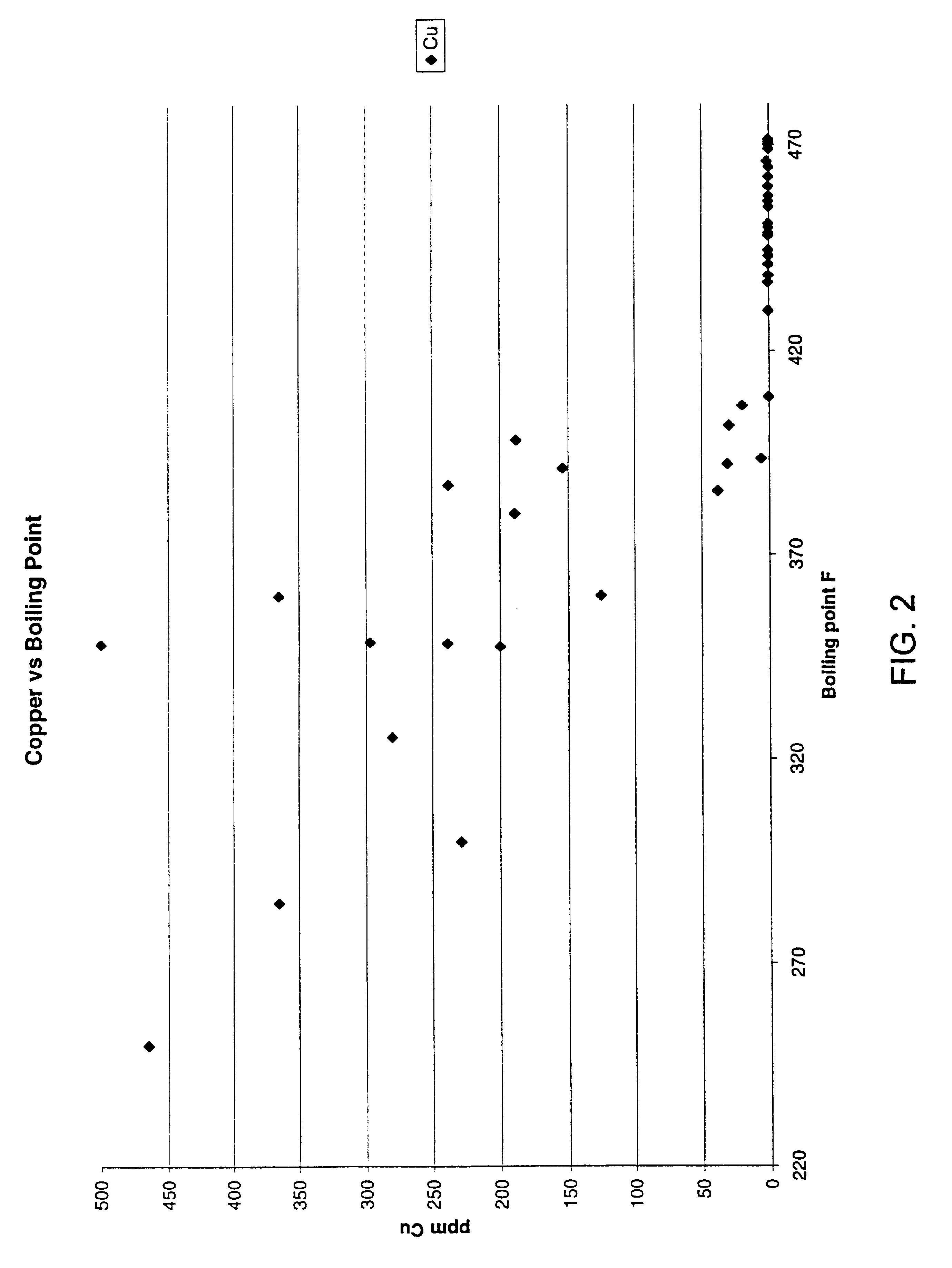

Test for brake fluid age and condition

InactiveUS6651487B1Carry-out quicklyImplemented easily and economicallyAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorEngineeringColor changes

A reactive test strip having a pre-exposure color is used to measure and indicate the concentration of copper ions in brake fluid in terms of a readily visible color change. The strip is immersed in the fluid within a brake fluid container and any resulting color change is compared to a color chart and a known test standard representative of the maximum metal concentration determined empirically to correspond to a boiling point considered safe for normal operation. If the color change indicates a higher copper concentration than the known test standard, then the fluid is considered inadequate for safe operation and thus recommended for replacement without any further tests. Similar copper or metal strips can also be used in a similar test to determine iron or zinc concentration within the brake fluid so as to also determine suitability of the brake fluid for ensuring safe operation. An automated version of the reactive test strip for performing brake fluid testing includes an optical instrument to compare the color obtained during the test against a predetermined test standard and determine whether or not a brake fluid change is recommended.

Owner:PHOENIX SYST

Fluorine-containing resin-based copper-clad plate with high dielectric constant and preparation method of plate

ActiveCN108656683AEasy to operateMild preparation conditionsSynthetic resin layered productsLaminationPolymerInteraction forces

The invention belongs to the field of communication materials, and particularly relates to a fluorine-containing resin-based copper-clad plate with a high dielectric constant and a preparation methodof the plate. According to the plate, surfaces of inorganic fillers are collectively modified by coupling agents and parts of fluorine-containing polymers, so that interaction force among the inorganic fillers and fluorine-containing resin substrates are higher, the loading amount of the inorganic fillers in the fluorine-containing resin substrates is high (>=50wt%), the compatibility among the inorganic fillers and the substrates is good, the bonding power among the inorganic fillers and the substrates is high, dispersion performances among the inorganic fillers and the substrates are better,so that a prepared fluorine-containing resin-based dielectric slice is uniform and good in dielectric property, the dielectric constant is larger than or equal to 5.0, and dielectric loss is only smaller than or equal to 0.002. The fluorine-containing resin-based copper-clad plate has a certain mechanical strength, excellent heat stability and high copper foil peel strength and can meet various performance requirements for diversified and complicated functions of the copper-clad plates and high-density and multilayer circuit arrangement and the like in the field of high-frequency and high-speed communication.

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

Method for removing impurities from nickel electrolysis anolyte

InactiveCN103320811AQuick responseReduce copper to iron ratioElectrolysis componentsPhotography auxillary processesElectrolysisSlag

The invention provides a method for removing impurities from nickel electrolysis anolyte. The method comprises the steps that: (1) a pH value of a solution to be treated is regulated to 3.0-5.0; nascent-state FeS is added, and a reaction is allowed, such that copper is removed; liquid-solid separation is carried out, such that copper-removed liquid is obtained; (2) chlorine and / or air is delivered into the copper-removed liquid, such that Fe<2+> and Co<2+> are oxidized, and Fe(OH)3 and Co(OH)3 precipitates are formed; and solid-liquid separation is carried out, such that a nickel sulfate solution is obtained. According to the method provided by the invention, FeS is used for removing copper, and a copper removing reaction speed is fast, such that copper in the solution can be deeply removed within minutes. Copper removing depth can be ensured, and high copper-nickel ratio can be obtained in the copper-removing slag. With the rapid reaction copper-removing characteristic, FeS is suitable for large-scale industrialized production copper removing. According to the invention, the copper-removing process is changed to before the iron-removing process, such that adverse reaction by a high-potential solution to the copper-removing process is eliminated. Copper-removing reaction speed is fast, such that the method is suitable for industrialized large-scale production copper removing.

Owner:CENT SOUTH UNIV

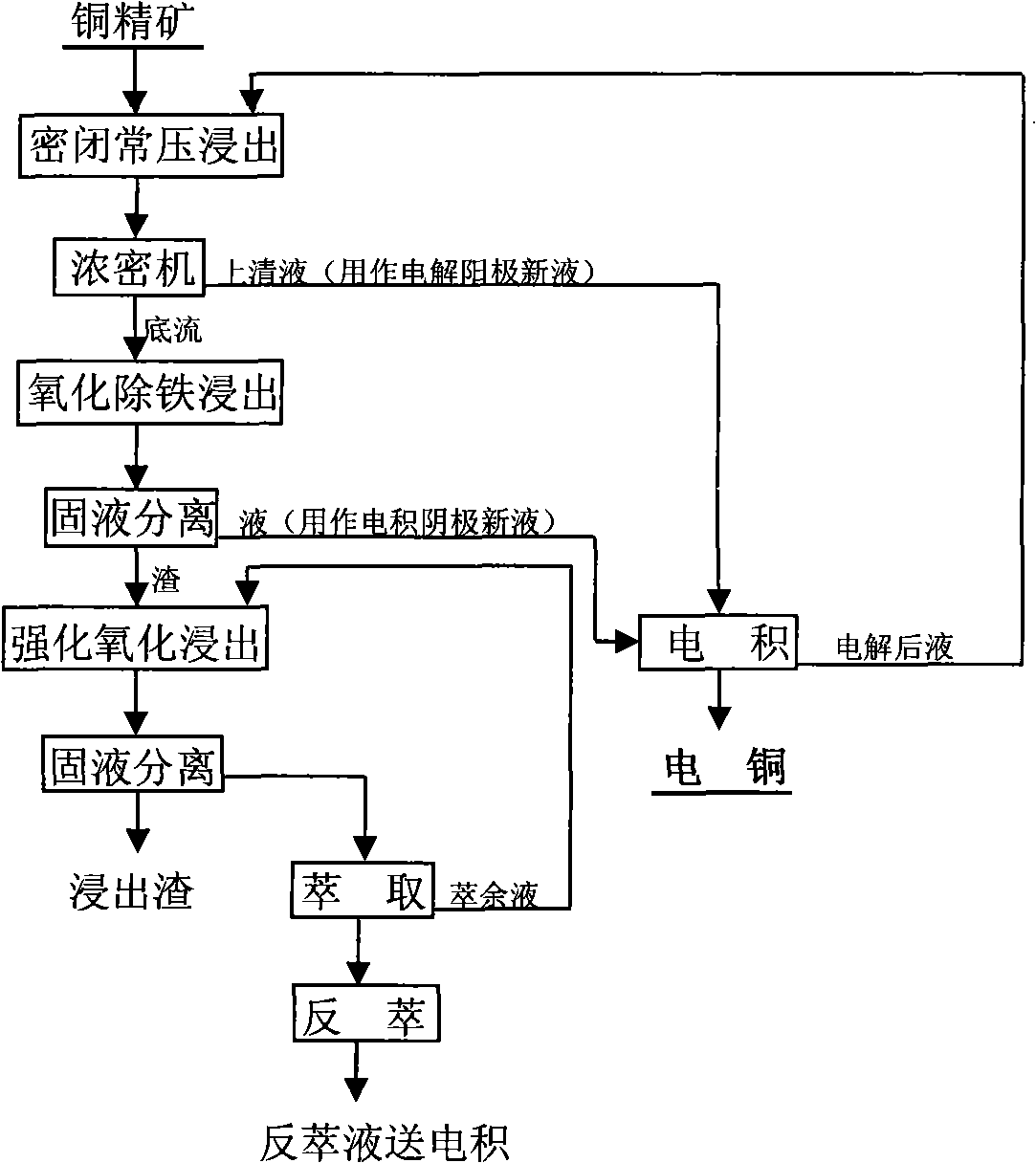

Process for extracting copper by wet method from copper-containing sulfidization ore

ActiveCN101307387AHigh recovery rateShort processPhotography auxillary processesProcess efficiency improvementRaw materialElectrolytic cell

The invention relates to a method for extracting copper by a copper-containing sulphide ore wet method, which is characterized in that: (1) under the catalytic action of chloride ions, acid water solution containing ferric ions is used to leach a copper-containing sulphide ore, ore pulp is precipitated and then is divided into two parts of upper clear liquid and bottom current; (2) the upper clear liquid is sent into an anode chamber of a diaphragm electrolytic cell to perform the anode oxidation reaction to ferrous ions in the upper clear liquid to generate the ferric ions which are returned to step (1) to be served as leachate; the bottom current is leached out through oxidation iron removal and is subject to the solid-liquid separation; (3) solution obtained after the bottom current is leached out through the oxidation iron removal and is subject to the solid-liquid separation in the step (2) is sent into a cathode chamber of the diaphragm electrolytic cell to be electrowon to produce electrocopper, cathode waste liquid is returned to the step (1) to be leached; leaching residue, under the catalytic action of the chloride ions, oxidizes and leaches the copper in the leaching residue, and the leached copper is reclaimed through extraction-electrowinning. The method has short flow, small investment, low power consumption of electrowinning, wide applicable range of raw materials, easy process operation, and high copper recovery rate, and is environment-friendly and so on.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

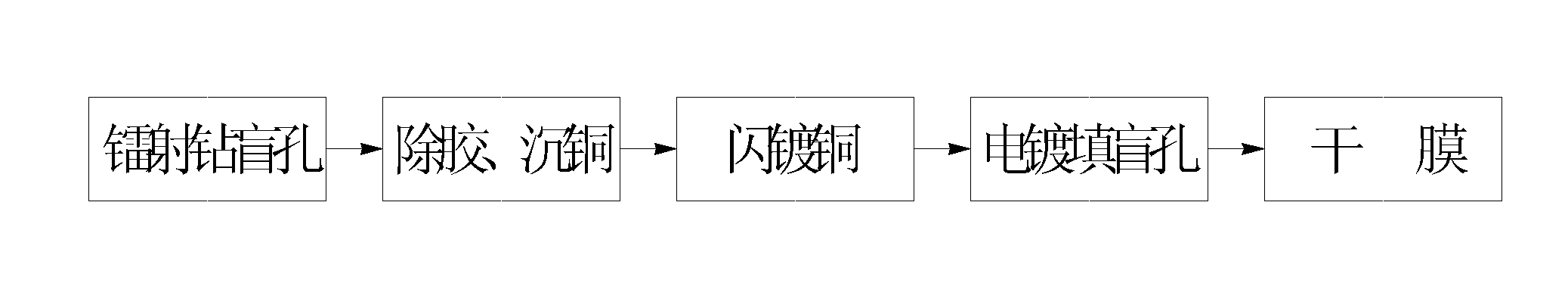

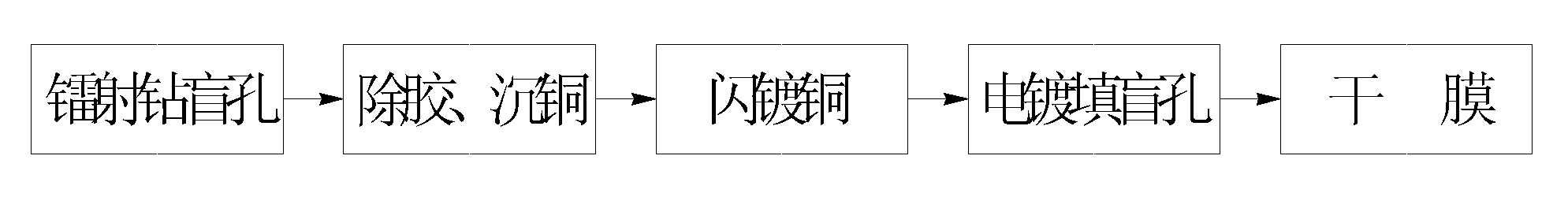

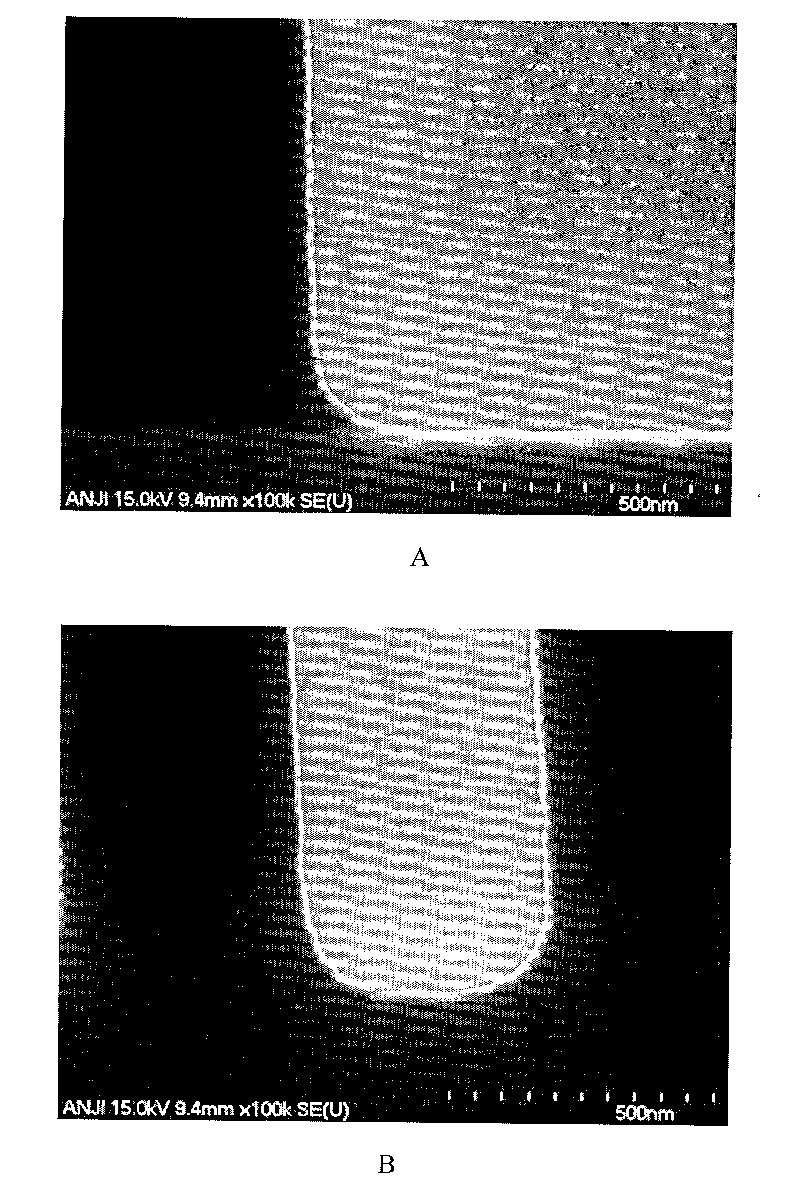

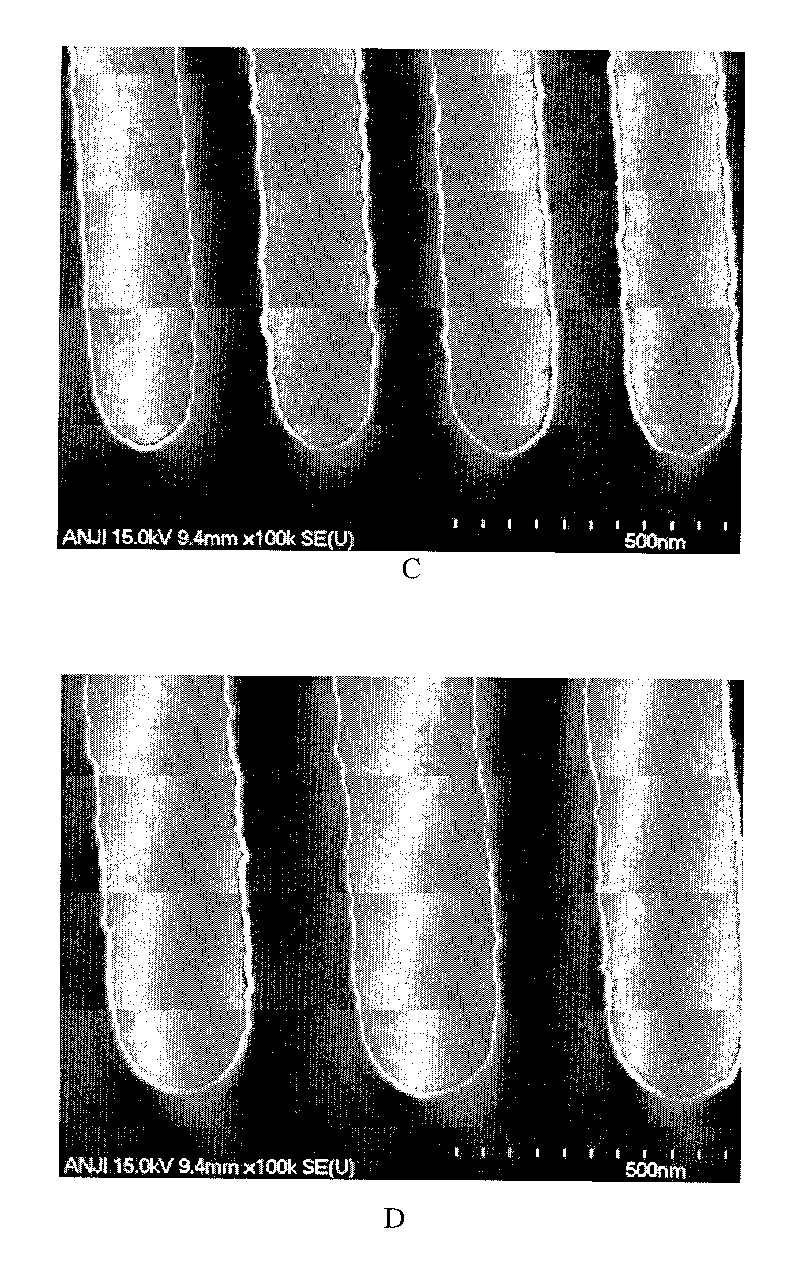

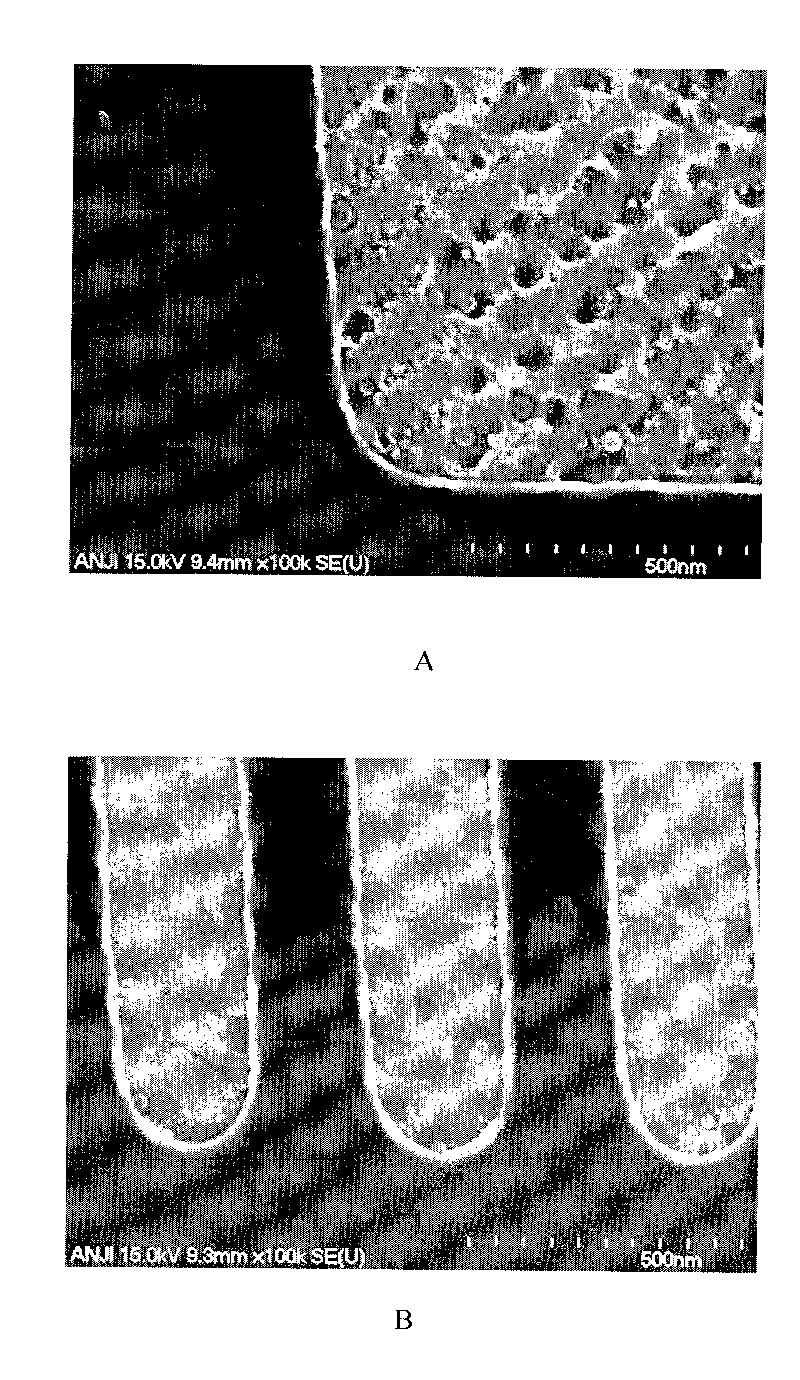

Blind via filling plating method using different current parameter combinations

ActiveCN102647862AShorten the timeIncrease productivityPrinted element electric connection formationAdhesiveSulfate

The invention discloses a blind via filling plating method using different current parameter combinations, which belongs to the field of circuit board plating technology. The blind via filling plating method comprises the steps of (1) removing adhesive, chemically depositing copper and flash-plating copper; (2) filling a blind via and plating; (3) drying film. The step (2) specifically includes regulating a plating solution to a solution containing high copper sulfate and low sulfuric acid content; and conducting plating for three periods of time using different current densities, wherein the plating operation is conducted for 30 minutes at the first period of time using a current density of 1.5 to 2.5 A / dm<2>, for 23 to 35 minutes at the second period of time using a current density of 1.2A / dm<2>, and for 10 to 20 minutes at the third period of time using a current density of 1.5 to 2.5A / dm<2>, respectively. The blind via filling plating method provided by the invention has high processing efficiency, low cost, and high processing quality, and is used for plating and blind via filling of circuit boards.

Owner:BOMIN ELECTRONICS CO LTD +1

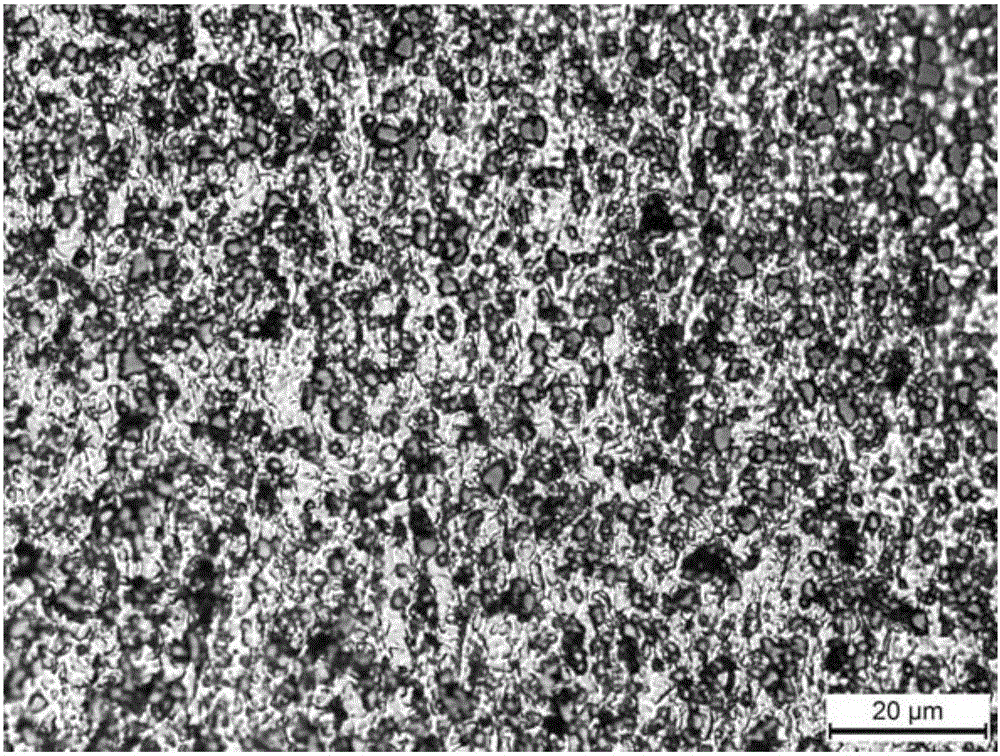

Chemically mechanical polishing solution and application thereof

ActiveCN101747844AImprove sunkennessReduce static corrosion rateSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesPhysical chemistryPigment

The invention discloses a chemically mechanical polishing solution and application thereof. The chemically mechanical polishing solution comprises star polymer containing pigment affinity group, ground granules, complexing agent, oxidant and water. By using the inventive polishing solution, flaws of copper billets can be reduced, partial and entire corrosion of the meal copper can be prevented, and the static corrosion velocity of copper at normal temperature and polishing temperature can be reduced under the condition of maintaining higher copper removal velocity.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Method for comprehensively recycling copper, selenium and uranium from stone coal extraction vanadic acid immersion liquid

InactiveCN102747225APrecipitation completeParticles grow upProcess efficiency improvementElemental selenium/telluriumPotassiumCoal

The invention relates to a method for comprehensively recycling copper, selenium and uranium from a stone coal extraction vanadic acid immersion liquid, which mainly comprises the following steps: crystallizing potassium alum or ammonia alum from stone coal sulfuric acid leach solution to remove aluminum, adding a copper-containing material and a phosphorus-rich material into the solution to regulate the copper concentration and the uranium / phosphorus ratio of the solution, adding an alkali to regulate the pH value, and adding a reducer to reduce and precipitate copper, selenium and uranium in the solution, thereby implementing efficient separation and enrichment of the copper, selenium and uranium in the stone coal vanadium extraction process. The invention has the advantages of simple technique, high copper / selenium / uranium recycling rate, low reagent consumption, low recycling cost, environment friendliness and the like.

Owner:CENT SOUTH UNIV +1

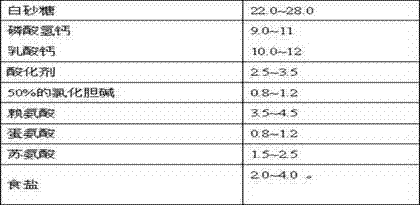

Creep and weaning feed for anthony pigs and preparation method thereof

InactiveCN101999547AAddressing Weaning DiarrheaSolve the problem of fat lossAnimal feeding stuffAccessory food factorsAntigenVegetable oil

The invention relates to a creep and weaning feed for anthony pigs and a preparation method thereof. The invention discloses an early creep and weaning feed for anthony pigs, which comprises corn or puffed corn, flour, shelled bean pulp, low-antigen enzymolysis vegetable protein, fish meal, choline chloride, an acidifier, flavoring, a flavor enhancer, multi-vitamins for anthony pigs, composite organic trace elements for anthony pigs, lysine, methionine, probiotics (lactic acid bacteria, microzyme), calcium hydrogen phosphate, vegetable oil and rock flour. The feed overcomes the weaning stress of piglets, fully displays the growth potential of anthony pigs and enhances the economic benefit. By using low dose of special non-absorbent antibiotics for animals, the feed ensures the food safety. The feed uses organic trace elements with higher bioavailability, does not contain high calcium, high phosphorus, high copper or high zinc, and solves the problem of environmental protection.

Owner:北京资源亚太饲料科技有限公司

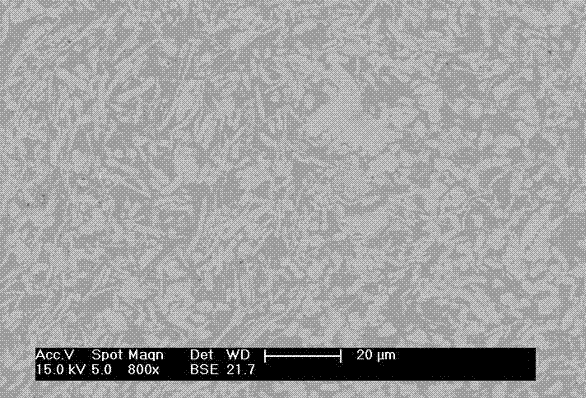

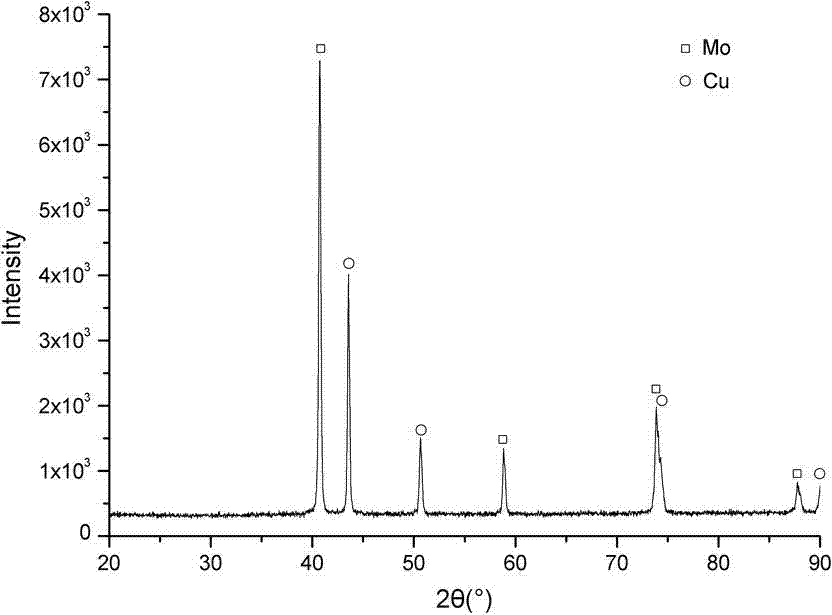

Hot isostatic pressing preparation method of high-density molybdenum-copper alloy

InactiveCN104762498AHigh degree of densificationUniform distribution of two phasesSmall sampleHeat conducting

The invention discloses a hot isostatic pressing preparation method of a high-density molybdenum-copper alloy and the hot isostatic pressing preparation method is used for solving the problems that material heat conductivity and device air tightness are influenced by defects such as relatively low relative density, non-uniform component distribution and relatively small sample sizes existing in a process of preparing a molybdenum-copper alloy by using an existing method. The hot isostatic pressing preparation method comprises the following steps: performing ball milling on weighed raw materials, firstly preparing a cold-pressed billet, and then removing a low-density oxide phase by virtue of hydrogen reduction. By adopting a high-vacuum hot isostatic pressing dense sintering method, the density problem of the molybdenum-copper alloy can be successfully solved, the sintering temperature can also be greatly reduced, interface structures of the materials can be effectively controlled, uniform distribution of components can be achieved, and the heat-conducting properties of the materials can be optimized. By adopting the hot isostatic pressing preparation method disclosed by the invention, the molybdenum-copper alloy with high density, high copper content and large size can be successfully prepared, requirements of electronic packaging and heat sink materials for the properties such as material strength and heat conductivity can be met, relatively good market application prospects can be achieved, and the molybdenum-copper alloy is worthy of being popularized and applied in large scale.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

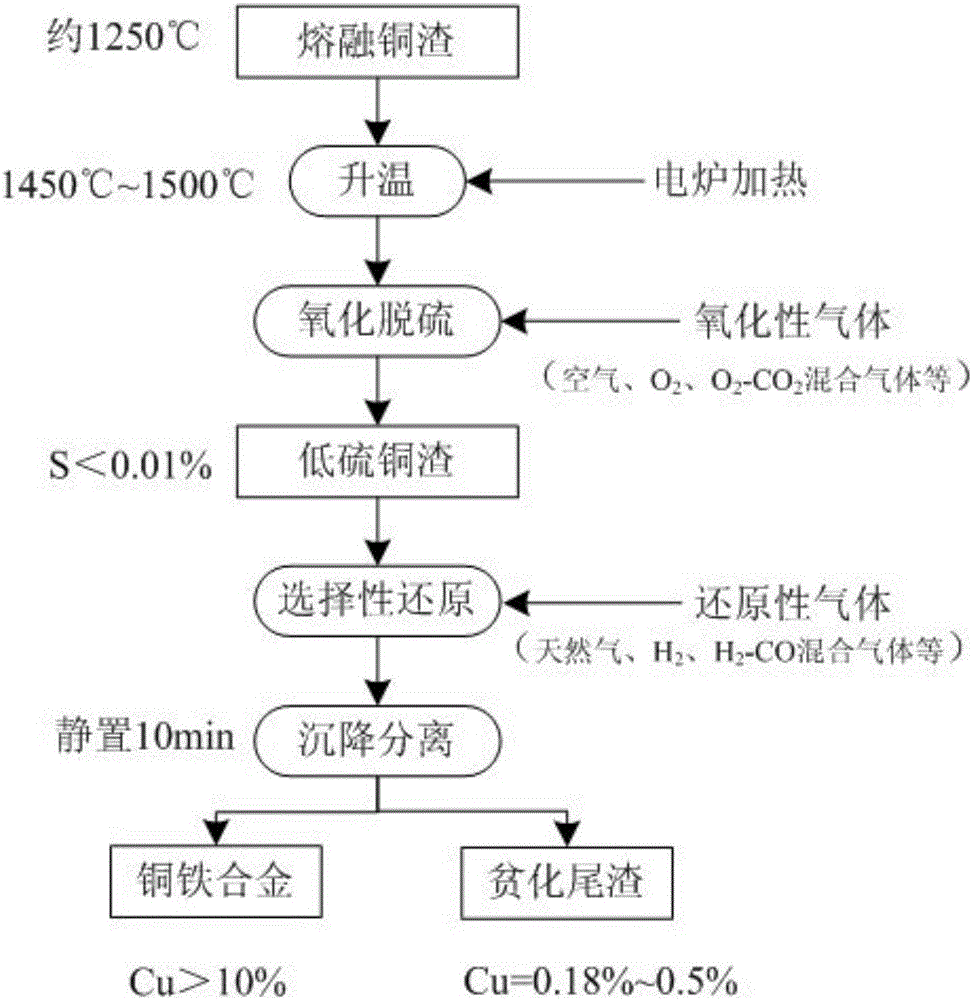

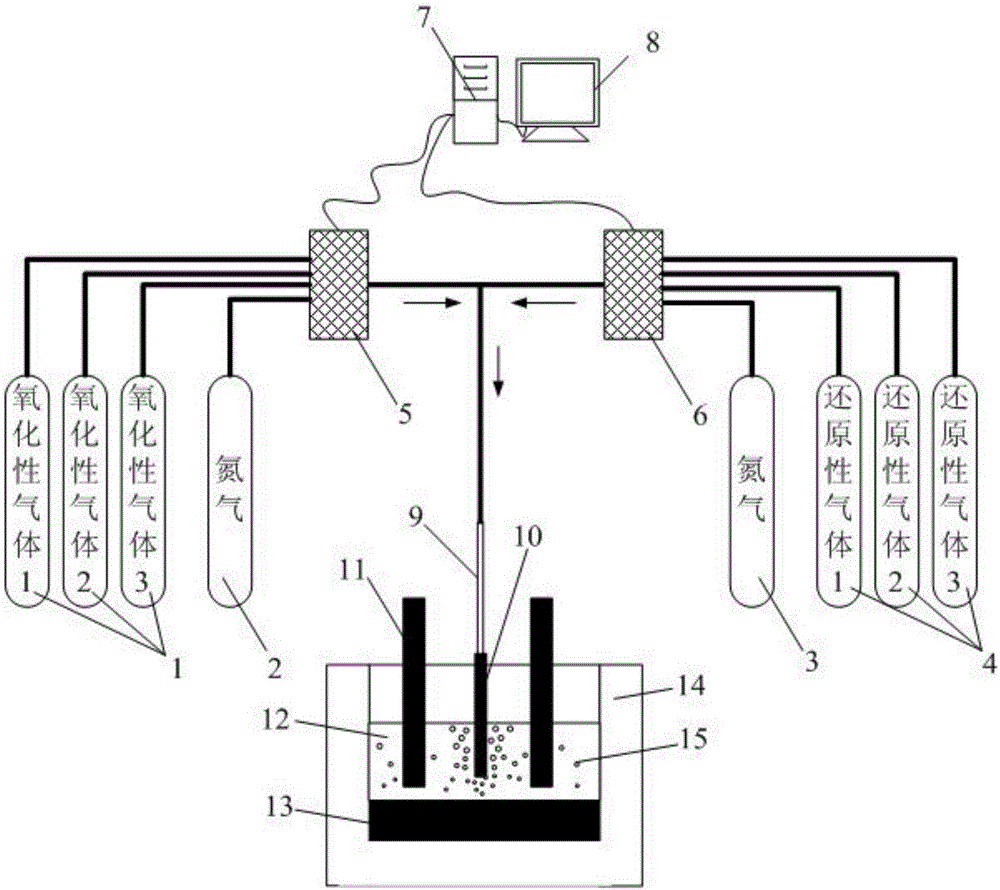

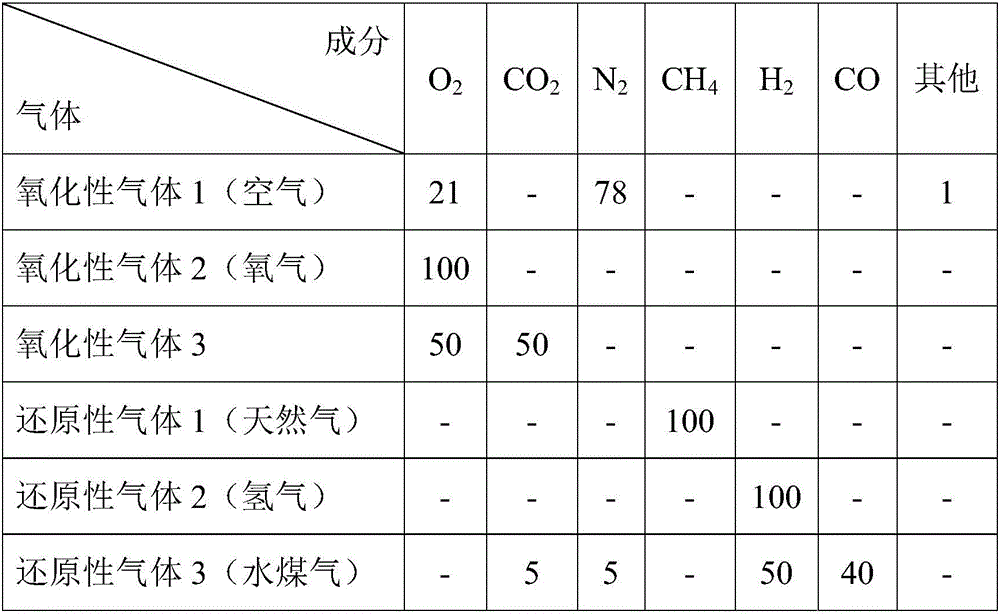

Method for realizing deep depletion on copper slag through multielement gas substep injection

ActiveCN106756062ARealize deep depletionComprehensive depletion results are excellentRotary drum furnacesCrucible furnacesLow copperMaterials science

The invention provides a method for realizing deep depletion on copper slag through multielement gas substep injection. The method fully utilizes waste heat of molten copper slag, copper matte is converted into oxide through gasification desulphurization, then selective reduction is carried out to obtain copper iron alloy with higher copper content, the problem of copper slag depletion in a smelting process is solved, and low-sulfur low-copper depletion slag is produced, so that conditions are created for a follow-up iron extracting process, and the deep depletion on the copper slag is realized; the traditional matte-producing depletion process is abandoned, but a gasification desulphurization process is firstly carried out for converting the copper matte into the oxide, then the oxide is subjected to selective reduction by virtue of a reducing agent, so that a copper-iron alloy phase is obtained. Operation is simple, adaptability is strong, the method can be realized by modifying the original electric furnace, nickel slag similar to the copper slag in properties can be treated, and metal elements such as Cu, Ni, Co and Fe can be comprehensively recycled.

Owner:UNIV OF SCI & TECH BEIJING

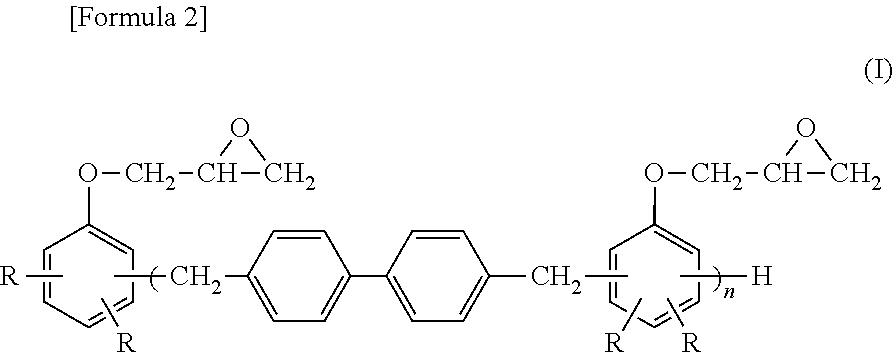

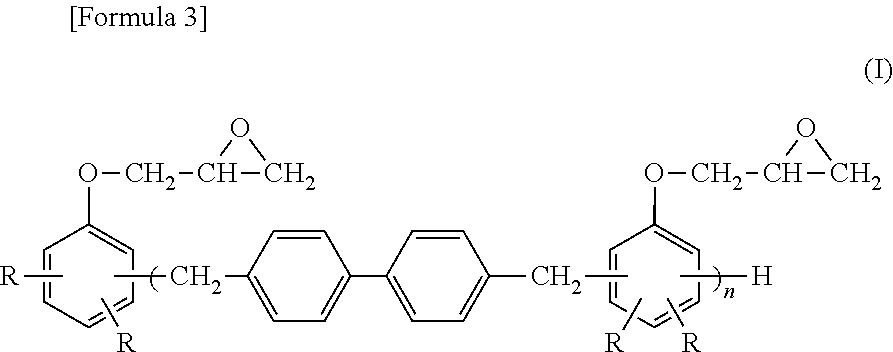

Resin composition, and prepreg as well as laminate using the same

ActiveUS20130337269A1Improve curing effectImprove thermal conductivitySynthetic resin layered productsElectrical equipmentHexagonal boron nitrideMetal foil

A resin composition is provided which can be suitably used in a printed wiring board having high glass transition temperature, high copper foil peel strength, heat resistance in moisture absorption, flame resistance, resistance to soldering heat, low water absorption and high heat dissipation characteristics, and a prepreg using the resin composition, and a laminate as well as a metal foil-clad laminate using the prepreg. There is used a resin composition including an epoxy resin (A), a curing agent (B), a first filler (C), a second filler (D) and a wetting dispersant (E), wherein the first filler (C) is borate particles coated with hexagonal boron nitride.

Owner:MITSUBISHI GAS CHEM CO INC

Chemo-mechanical polishing slurry for metal, and its application

InactiveCN103866326AImprove removal rateCorrosion controlOther chemical processesPolishing compositions with abrasivesPhosphateSlurry

The invention provides a chemo-mechanical polishing slurry for copper, and its application. The slurry comprises abrasive particles, a complexing agent, an oxidant, a corrosion inhibitor, and at least one organic phosphate surfactant. The slurry has the advantages of maintenance of a high copper removal rate, improvement of the saucerization and the over polishing window of polished core wires, few pollutants the surface of polished copper, and no corrosion.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

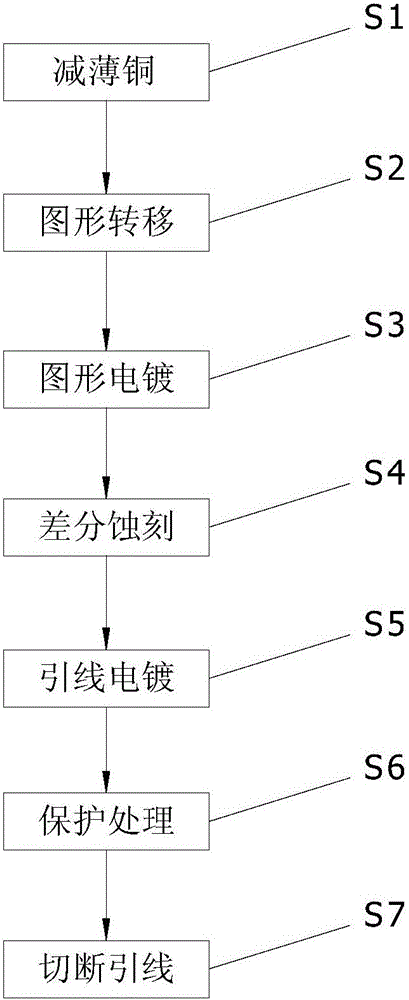

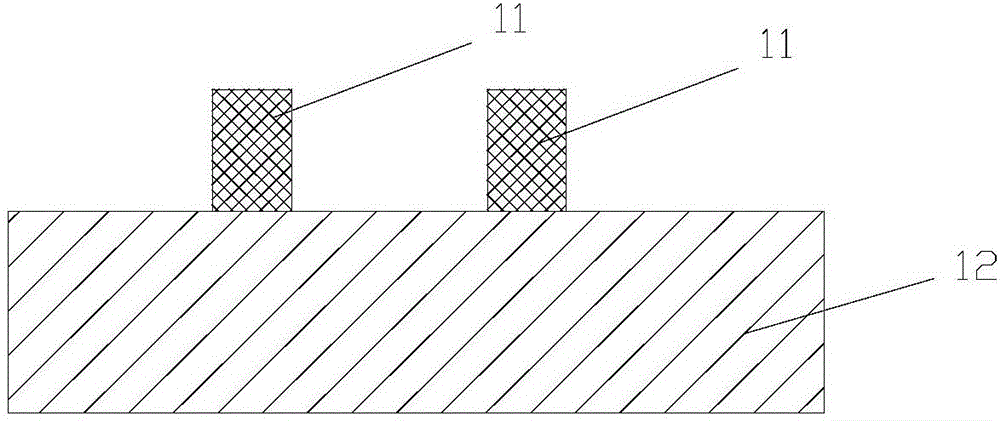

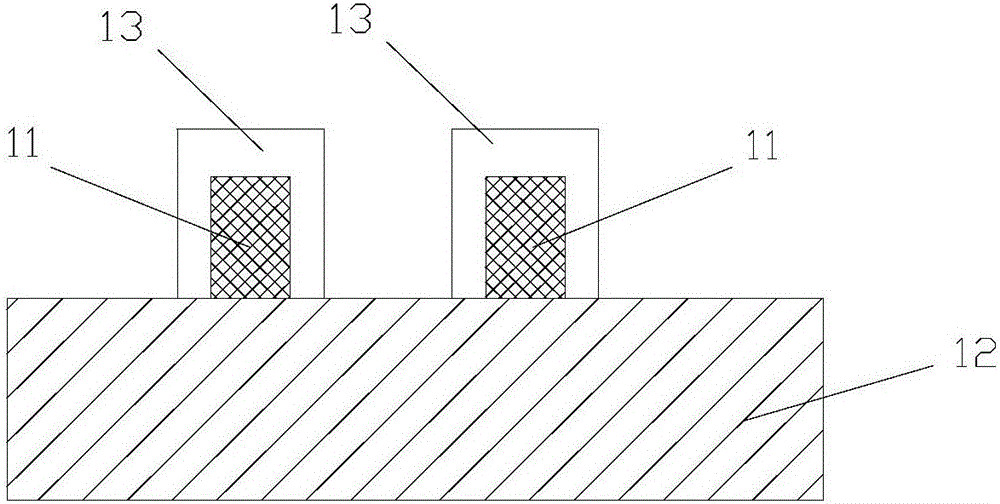

Method for manufacturing printed circuit board through enhancing semi-additive process

The invention discloses a method for manufacturing a printed circuit board through an enhancing semi-additive process. The method comprises the following steps: 1) thinning copper: performing thinning copper treatment on a copper-clad plate, forming a through hole or blind hole, and then manufacturing an electroplating seed layer; 2) transferring pattern: pasting a photosensitive film, forming an electroplating barrier layer on the surface of the copper-clad plate through a pattern transferring method and designing a lead connecting circuit copper layer and a non-circuit copper layer while transferring the pattern; 3) electroplating the pattern: fully plating the blind hole or the through hole while electroplating and forming the circuit pattern; 4) differentially etching: removing the bare bottom copper through a differential etching method and remaining the circuit pattern; 5) electroplating wire: electroplating the circuit pattern through the wire, widening and heightening the circuit; 6) protecting treatment: forming a metal protection layer on the surface of the conductive circuit; 7) cutting off the wire. According to the method provided by the invention, the limitation of the resolution and thickness of the photosensitive film to the cross section of the circuit is broken through and the method is especially fit for manufacturing the fine circuit with high copper thickness.

Owner:广东佛智芯微电子技术研究有限公司

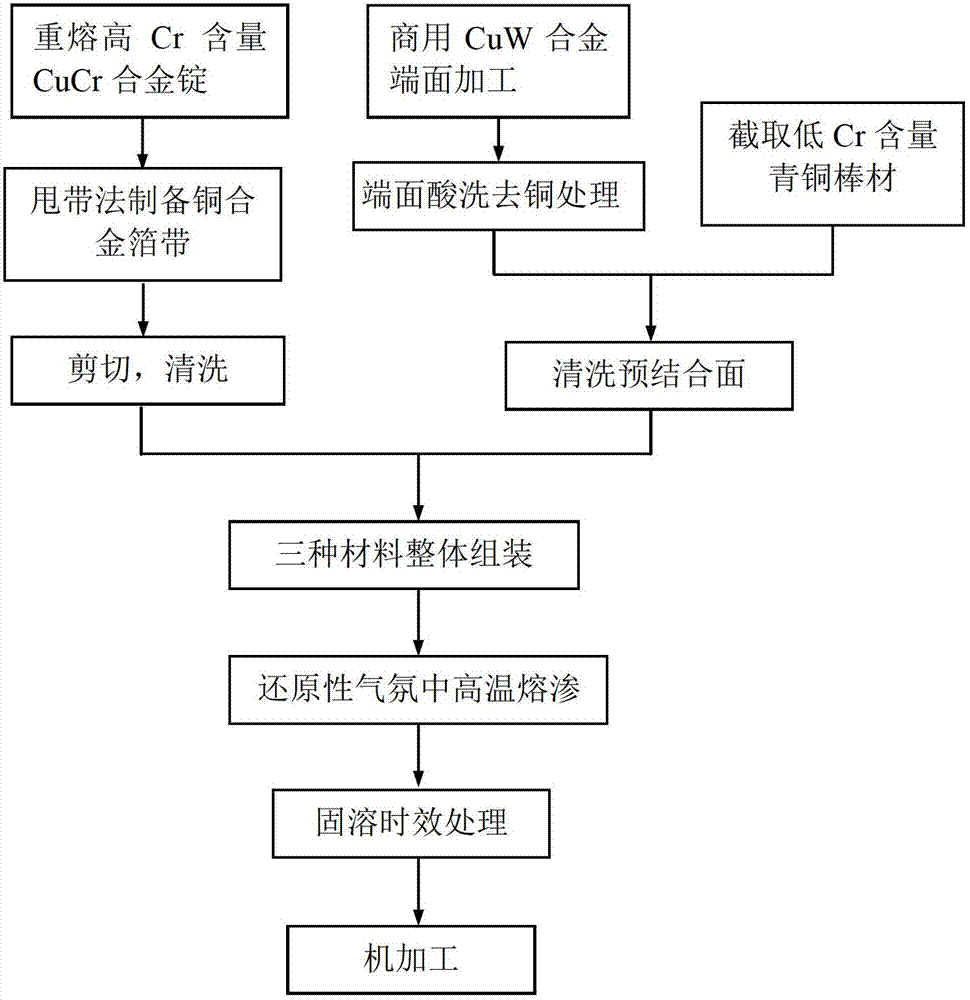

Preparation method of CuW (Copper Tungsten) and CuCr (Copper Chromium) integrated material used for high voltage electric contact

ActiveCN102760597AImprove the bonding strength of the interfaceReduce manufacturing costElectric switchesEmergency protective device manufactureReducing atmosphereSolid solution

The invention discloses a preparation method of a CuW (Copper Tungsten) and CuCr (Copper Chromium) integrated material used for high voltage electric contact. The method comprises the following steps: firstly, a high copper alloy foil strip is prepared by using a rapid solidification melt-spinning method; subsequently the de-coppering treatment is carried out on a CuW pre-combining plane by using an acid dissolving method; a porous W-framework is obtained on the combining plane; the overall sintering infiltration is carried out on the CuW, the alloy foil stripe and the CuCr alloy inside a reducing atmosphere furnace so as to obtain the CuW and CuCr integrated material; and subsequently the solid solution aging treatment is carried out on the material. As the Cr element inside the alloy foil stripe is filled and infiltrated into the porous framework during the infiltration process and is formed into W-Cr solid solution with the W, the metallurgical bonding is realized between the framework and a substrate copper phase; and the boundary bonding strength of the integrated material is improved.

Owner:XIAN UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com