Fluorine-containing resin-based copper-clad plate with high dielectric constant and preparation method of plate

A high dielectric constant, fluorine-containing resin technology, applied in the field of communication materials, can solve the problems of weak interaction between alkane chains and fluorine-containing polymer chains, and limited improvement in compatibility, and achieve a good industrial production basis, Easy to batch and large-scale production, simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

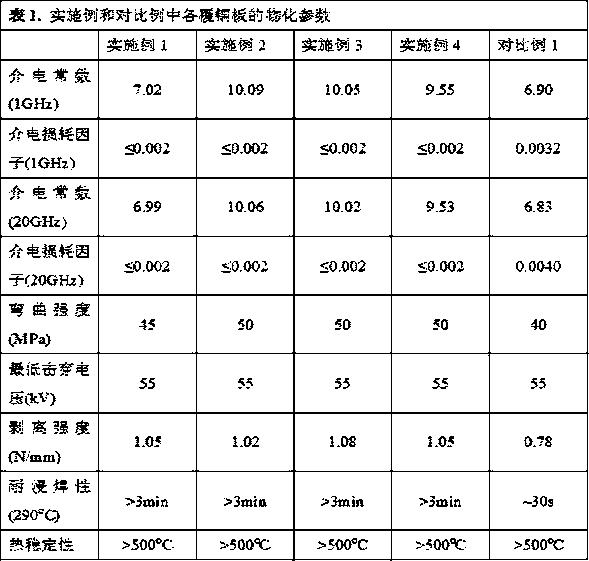

Examples

Embodiment 1

[0026]Add 200 parts of TiO to 1000 parts of water 2 (Tianjin Zhongzheng Huamei Technology), stir well at room temperature; add 2 parts of silane coupling agent KH550 (Nanjing Shuguang Chemical General Factory) and 20 parts of ETFE emulsion (DuPont Teflon® 532-6210), raise the temperature of the system to 60 ° C, continue Stir for 12 hours to obtain TiO whose surface is co-modified by KH550 and ETFE 2 homogeneous aqueous dispersion; then, add 155 parts of polytetrafluoroethylene emulsion (DuPont Teflon® PTFE DISP30, solid content 60%), after stirring evenly, add acetone drop by drop until white sticky precipitate no longer appears, Pour off the solvent to get PTFE and TiO 2 Scrape the compound paste on a clean glass plate into a film with a thickness of about 0.8mm, dry it at 70°C for 1 hour, transfer the glass plate and film to a nitrogen atmosphere, and Set the sintering temperature to 400 o C. The sintering time is 8 hours; after the sintering is completed, wait for it to...

Embodiment 2

[0028] Add 305 parts of TiO to 1000 parts of water 2 (Tianjin Zhongzheng Huamei Technology), stir well at room temperature; add 3.1 parts of silane coupling agent KH550 (Nanjing Shuguang Chemical General Factory) and 27 parts of ETFE emulsion (DuPont Teflon® 532-6210), raise the temperature of the system to 60 ° C, continue Stir for 12 hours to obtain TiO whose surface is co-modified by KH550 and ETFE 2 homogeneous aqueous dispersion; then, add 110 parts of polytetrafluoroethylene emulsion (DuPont Teflon® PTFE DISP30, solid content 60%) and 45 parts of tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer emulsion (DuPont Teflon ® PFAD 335D, solid content 60%), after stirring evenly, add ethyl acetate dropwise until no white sticky precipitate appears, then pour off the solvent to obtain PTFE, PFA and TiO 2 Scrape the compound paste on a clean glass plate into a film with a thickness of about 0.8mm, dry it at 70°C for 1 hour, transfer the glass plate and film to a nitroge...

Embodiment 3

[0030] Add 305 parts of TiO to 1000 parts of water 2 (Tianjin Zhongzheng Huamei Technology), stir well at room temperature; add 3.1 parts of silane coupling agent KH550 (Nanjing Shuguang Chemical General Factory) and 27 parts of ETFE emulsion (DuPont Teflon® 532-6200), raise the temperature of the system to 60 ° C, continue Stir for 12 hours to obtain TiO whose surface is co-modified by KH550 and ETFE 2 A homogeneous aqueous dispersion; then, add 50 parts of polytetrafluoroethylene emulsion (DuPont Teflon® PTFE DISP30, solid content 60%) and 118 parts of polyfluoroethylene propylene emulsion (DuPont Teflon® FEPD121, solid content 54%), After stirring evenly, ethyl acetate was added dropwise until no white sticky precipitate appeared, then the solvent was poured off to obtain PTFE, FEP and TiO 2 Scrape the compound paste on a clean glass plate into a film with a thickness of about 0.8mm, dry it at 70°C for 1 hour, transfer the glass plate and film to a nitrogen atmosphere, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com