Preparation method of CuW (Copper Tungsten) and CuCr (Copper Chromium) integrated material used for high voltage electric contact

A monolithic material and high-voltage technology, applied in circuits, electric switches, electrical components, etc., can solve problems such as insufficient bonding strength and fracture of the bonding surface, and achieve the effects of low preparation cost, improved interface bonding strength, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

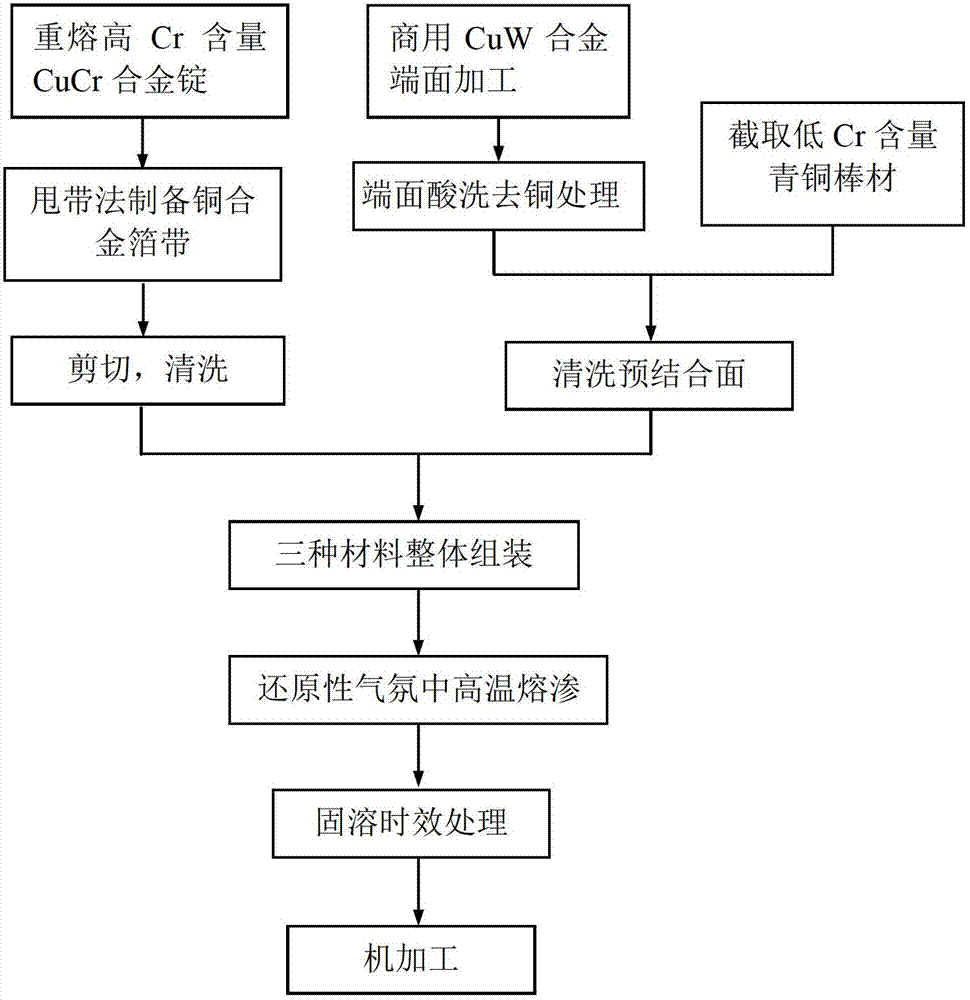

[0031] The invention provides a method for preparing CuW and CuCr monolithic materials used for high-voltage electrical contacts, such as figure 1 The flow shown is implemented in the following steps:

[0032] Step 1, prepare copper alloy foil strip

[0033] The commercial CuCr alloy ingot with a mass percentage of Cr of 10% is machined to remove various defects and cleaned; it is placed in the induction heating furnace of the rapid solidification device, and argon is used as the protective atmosphere, and remelted at 1150~1250 °C After heat preservation for 40min, the copper alloy foil strip was prepared by the rapid solidification single roll stripping method, and its thickness was 40-60 μm;

[0034] Step 2, processing the CuW bonding surface

[0035] According to the product size of the overall electrical contact, a commercial CuW alloy with a suitable length is selected, and the mass percentage of Cu is 10-30%. After machining the pre-bonded end of the machine, put the ...

Embodiment 1

[0047] Firstly, the copper alloy foil strip is prepared, and the commercial CuCr alloy ingot with a Cr content (mass percentage) of 10% is machined to remove various defects, and placed in the induction heating furnace of the rapid solidification device, with argon as the protective atmosphere. After remelting at 1150°C for 40 minutes, the copper alloy foil strip was prepared by the rapid solidification single-roll stripping method, and its thickness was 40 μm.

[0048] Then process the CuW bonding surface. After machining the pre-bonded end of the machine, put the fresh end into the nitric acid solution with a volume concentration of 30%. The fresh end is immersed in the solution to a depth of 1mm, and the soaking time in the solution for 3 hours. Take out the CuW alloy whose end has been corroded into a porous structure, first wash the corroded end with clean water, then put it into an ultrasonic oscillator filled with distilled water for cleaning for 30~40min, and then put ...

Embodiment 2

[0053] Firstly, the copper alloy foil strip is prepared, and the commercial CuCr alloy ingot with a Cr content (mass percentage) of 10% is machined to remove various defects, and placed in the induction heating furnace of the rapid solidification device, with argon as the protective atmosphere. After remelting at 1200°C for 40 minutes, the copper alloy foil strip was prepared by the rapid solidification single-roll stripping method, and its thickness was 45 μm.

[0054] Then process the CuW bonding surface. After machining the pre-bonded end of the lathe, put the fresh end into the nitric acid solution with a volume concentration of 25%. The fresh end is immersed in the solution to a depth of 2mm. for 3.5 hours. Take out the CuW alloy whose end has been corroded into a porous structure, first wash the corroded end with clean water, then put it into an ultrasonic oscillator filled with distilled water for cleaning for 30~40min, and then put it into a container filled with absol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com