A kind of sic-tac coating/matrix synergistically modified c/c composite material and preparation method thereof

A composite material and synergistic modification technology, which is applied in the field of SiC-TaC coating/matrix synergistically modified C/C composite material and its preparation, can solve problems such as the inability to effectively protect the carbon matrix, achieve improved interface bonding state, and improve Coefficient of thermal expansion, the effect of improving the coefficient of thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

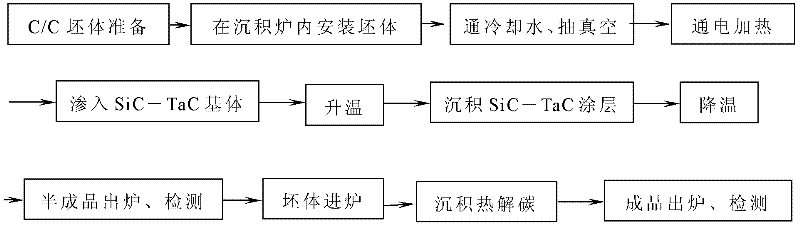

[0038] Embodiment 1: (gradient distribution-co-deposition coating)

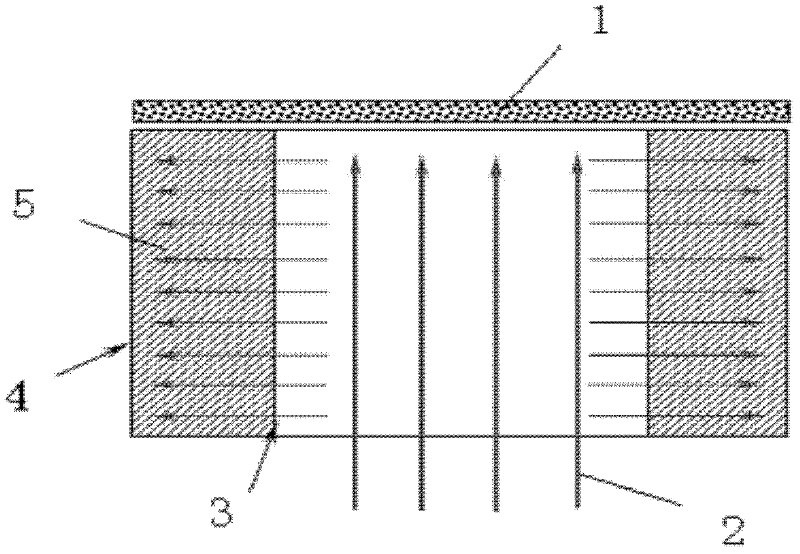

[0039] see figure 1 , the density is 0.80g / cm 3 Cut the C / C blank into 110×110×4mm plate-shaped C / C blank, clean it with ultrasonic waves, dry it in an oven, weigh it, and put it into a chemical vapor deposition furnace to make the reaction gas diffuse from the coating surface Enter the C / C green body and diffuse the reaction by-product gas from the non-coated surface to ensure that SiC-TaC is preferentially deposited on the coated surface of the green body, see figure 2 , 1-cover plate, 2-airflow diffusion path, 3-ablation surface, 4-non-ablation surface, 5-C / C body; vacuumize to below 50Pa, power on and heat up to the set temperature of 900°C After heat preservation, the C / C green body is subjected to matrix modification, densification and coating preparation according to the following steps: (a) pass through trichloromethylsilane (MTS)-H 2 -Ar reaction gas system, the deposition pressure is maintained ...

Embodiment 2

[0040] Embodiment 2: (gradient distribution-co-deposition coating)

[0041] see figure 1 , the density is 1.20g / cm 3 The C / C green body is cut into Φ100 / Φ70×80 ring-shaped C / C green body, cleaned with ultrasonic waves, dried in an oven, weighed, and put into a chemical vapor deposition furnace to ensure that the reaction gas diffuses from the inner surface into the C / C green body, and diffuse the reaction by-product gas from the outer surface, so that SiC-TaC is preferentially deposited on the coating surface of the green body; vacuumize to below 50Pa, send power to heat up, and reach the set temperature of 950°C For heat preservation, carry out matrix modification, densification and coating preparation on the C / C body according to the following steps: (a) MTS-H 2 -Ar reaction gas system, keep the deposition pressure at 1000Pa, infiltrate SiC into the C / C porous body; (b) when the density of the modified C / C body is 1.30g / cm 3 After that, stop feeding MTS-H 2 -Ar reaction ...

Embodiment 3

[0042] Embodiment 3: (gradient distribution-multilayer composite deposition coating)

[0043] see figure 1 , the density is 1.40g / cm 3 The C / C green body is cut into Φ100 / Φ70×80 ring-shaped C / C green body, cleaned with ultrasonic waves, dried in an oven, weighed, and put into a chemical vapor deposition furnace to ensure that the reaction gas diffuses from the inner surface into the C / C green body, and diffuse the reaction by-product gas from the outer surface, so that SiC-TaC is preferentially deposited on the coating surface of the green body, see figure 2 ; Vacuum down to below 50Pa, send power to raise the temperature, and keep warm after reaching the set temperature of 950°C. Carry out matrix modification, densification and coating preparation on the C / C green body according to the following steps: (a) MTS-H 2 -Ar reaction gas system, the furnace pressure is kept at 1000Pa, and SiC is infiltrated into the C / C porous body; (b) when the density of the modified C / C body i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com