A high-strength hole saw and its manufacturing method

A high-strength, hole-sawing technology, which is applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problem of reduced mechanical strength of hole saws, decreased bonding performance of alloy materials and ceramic-based coatings, and hole Saw damage and other problems to achieve the effect of improving bonding performance, alleviating thermal mismatch, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

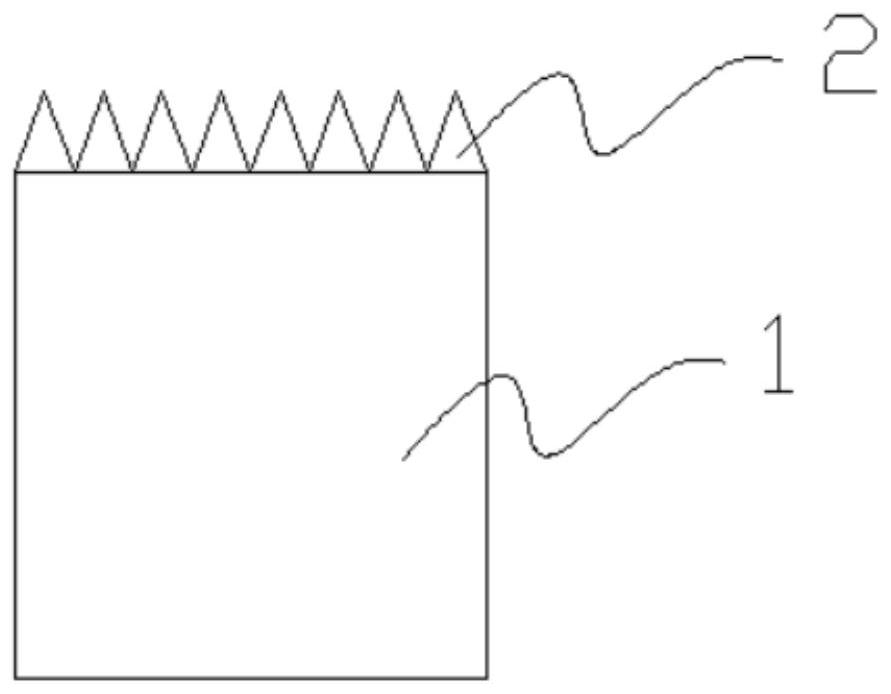

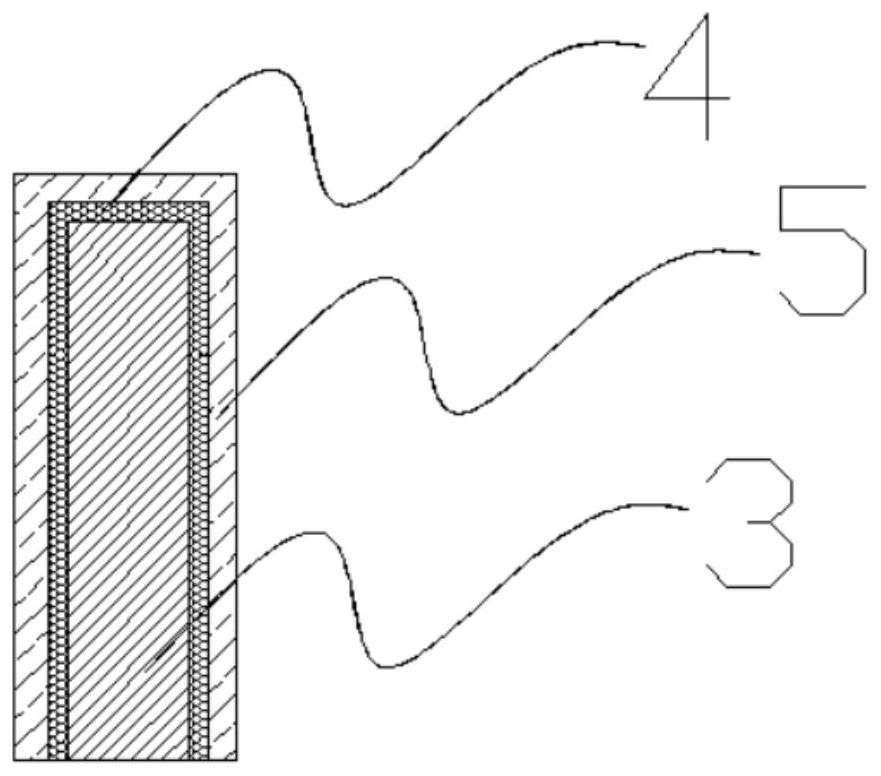

[0034] A high-strength hole saw, consisting of a barrel-shaped base (1) and teeth (2), the saw teeth (2) consisting of a saw-tooth base (3), a bonding layer (4) with a thickness of 0.7 μm and a reinforcement with a thickness of 1.6 μm Layer (5) consists of;

[0035] Both the cylindrical base (1) and the serrated base (3) are made of high-performance high-speed steel;

[0036] The bonding layer (4) is an MCrAlNbY alloy material, wherein M is a combination of Co and Ni, and is composed of the following elements by mass percentage:

[0037] Co: 30%, Ni: 10%, Al: 10.5%, Nb: 2.2%, Y: 0.75%, and the rest is Cr;

[0038] The reinforcement layer (5) is made of TiC 0.4 N 0.6 and CoO 2 Composition by mass ratio 10:1.

[0039] The preparation method of the above-mentioned high-strength hole saw is as follows:

[0040] According to the ratio of elemental composition, block pure metals Co, Ni, Al, Nb, Y, Cr are put into the smelting furnace, and the smelting furnace is evacuated to 1...

Embodiment 2

[0042] A high-strength hole saw, consisting of a cylindrical base (1) and teeth (2), the saw teeth (2) consisting of a saw-tooth base (3), a bonding layer (4) with a thickness of 0.75 μm and a reinforcement with a thickness of 1.8 μm Layer (5) consists of;

[0043] Both the cylindrical base (1) and the serrated base (3) are made of high-performance high-speed steel;

[0044] The bonding layer (4) is an MCrAlNbY alloy material, wherein M is a combination of Co and Ni, and is composed of the following elements by mass percentage:

[0045] Co: 20%, Ni: 20%, Al: 10.5%, Nb: 2.2%, Y: 0.75%, and the rest is Cr;

[0046] The reinforcement layer (5) is made of TiC 0.4 N 0.6 and CoO 2 Composition by mass ratio 10:1.

[0047] The preparation method of the above-mentioned high-strength hole saw is as follows:

[0048] According to the ratio of elemental composition, block pure metals Co, Ni, Al, Nb, Y, Cr are put into the smelting furnace, and the smelting furnace is evacuated to 1×...

Embodiment 3

[0050] A high-strength hole saw, consisting of a barrel-shaped base (1) and teeth (2), the saw teeth (2) consisting of a saw-tooth base (3), a bonding layer (4) with a thickness of 0.65 μm and a reinforcement with a thickness of 1.5 μm Layer (5) consists of;

[0051] Both the cylindrical base (1) and the serrated base (3) are made of high-performance high-speed steel;

[0052] The bonding layer (4) is an MCrAlNbY alloy material, wherein M is a combination of Co and Ni, and is composed of the following elements by mass percentage:

[0053] Co: 30%, Ni: 15%, Al: 10%, Nb: 2%, Y: 0.1%, and the rest is Cr;

[0054] The reinforcement layer (5) is made of TiC 0.4 N 0.6 and CoO 2 Composition by mass ratio 8:1.

[0055] The preparation method of the above-mentioned high-strength hole saw is as follows:

[0056] According to the ratio of elemental composition, block pure metals Co, Ni, Al, Nb, Y, Cr are put into the smelting furnace, and the smelting furnace is evacuated to 1×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com