Patents

Literature

215results about How to "Great penetration depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

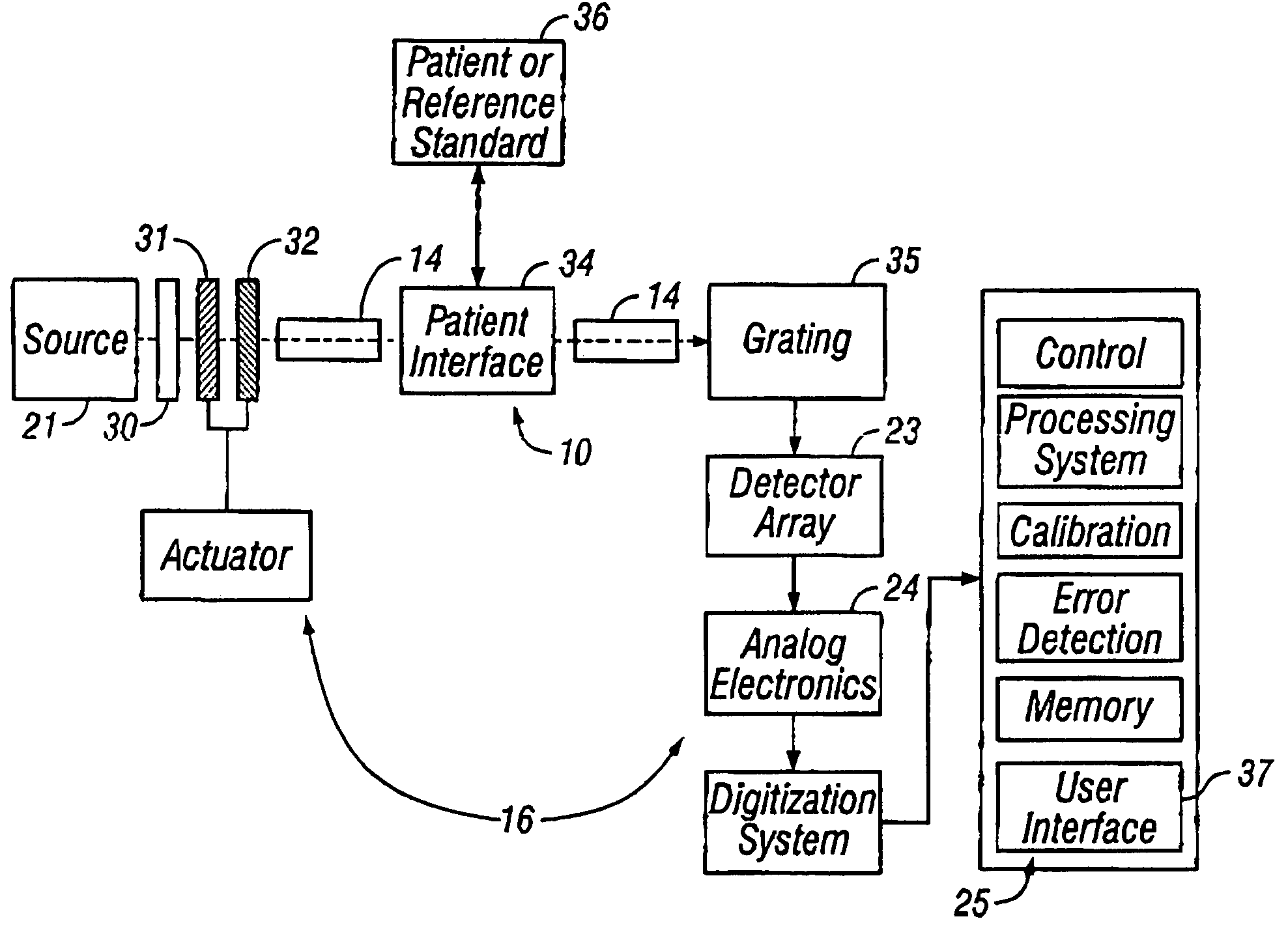

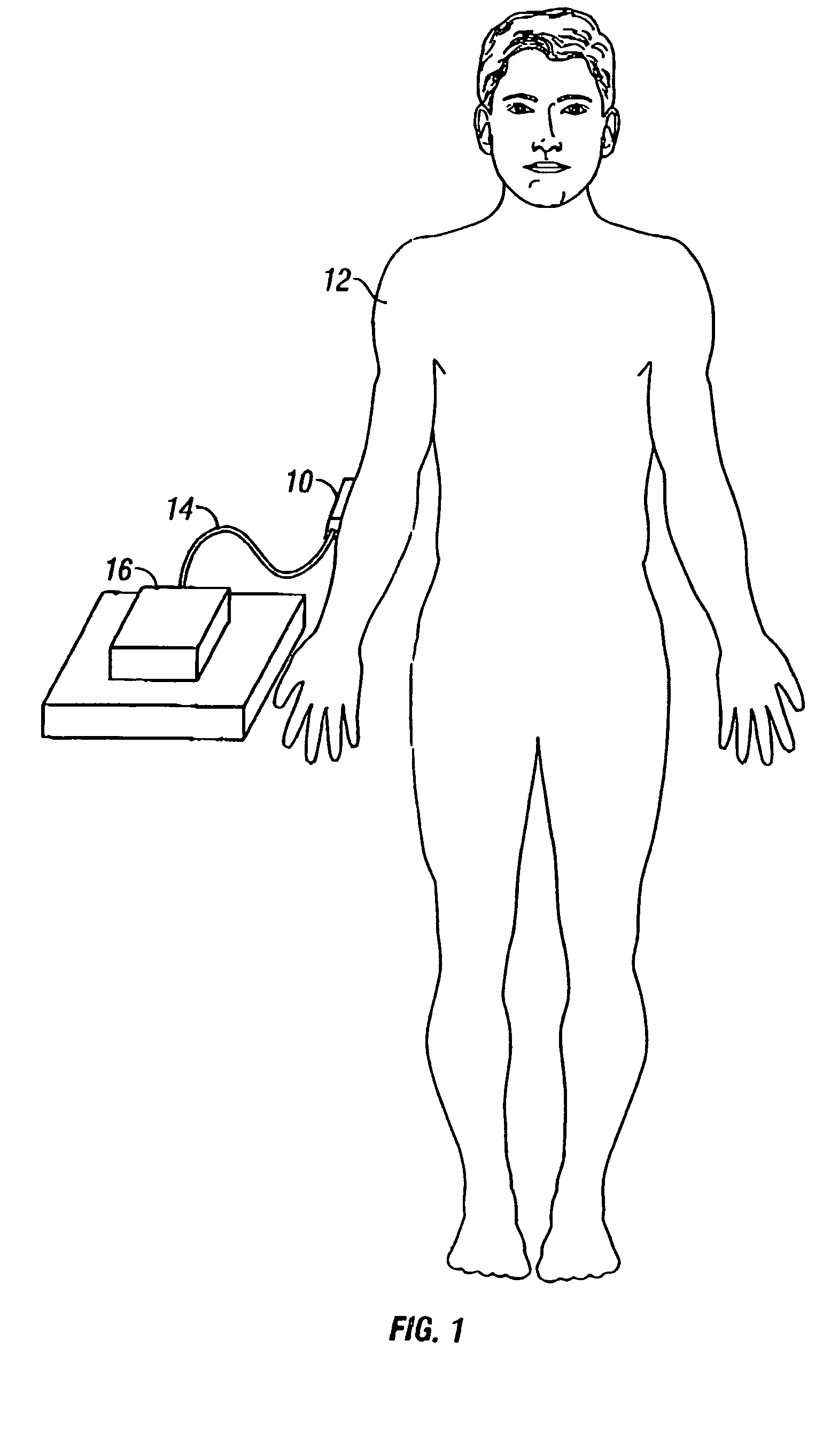

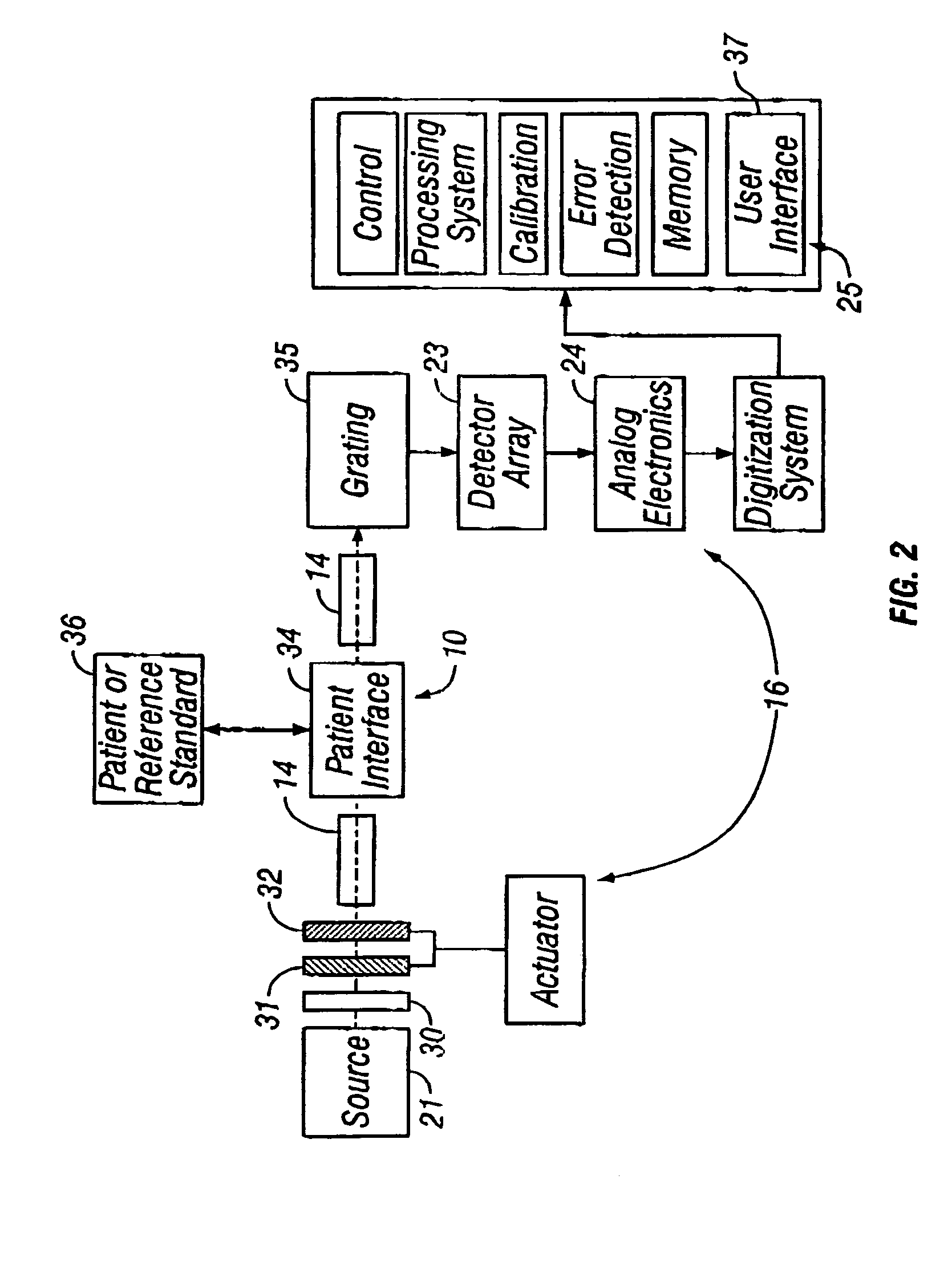

Compact apparatus for noninvasive measurement of glucose through near-infrared spectroscopy

ActiveUS7299080B2Minimize samplingMaximize collection of lightDiagnostics using spectroscopyScattering properties measurementsFiberSignal-to-noise ratio (imaging)

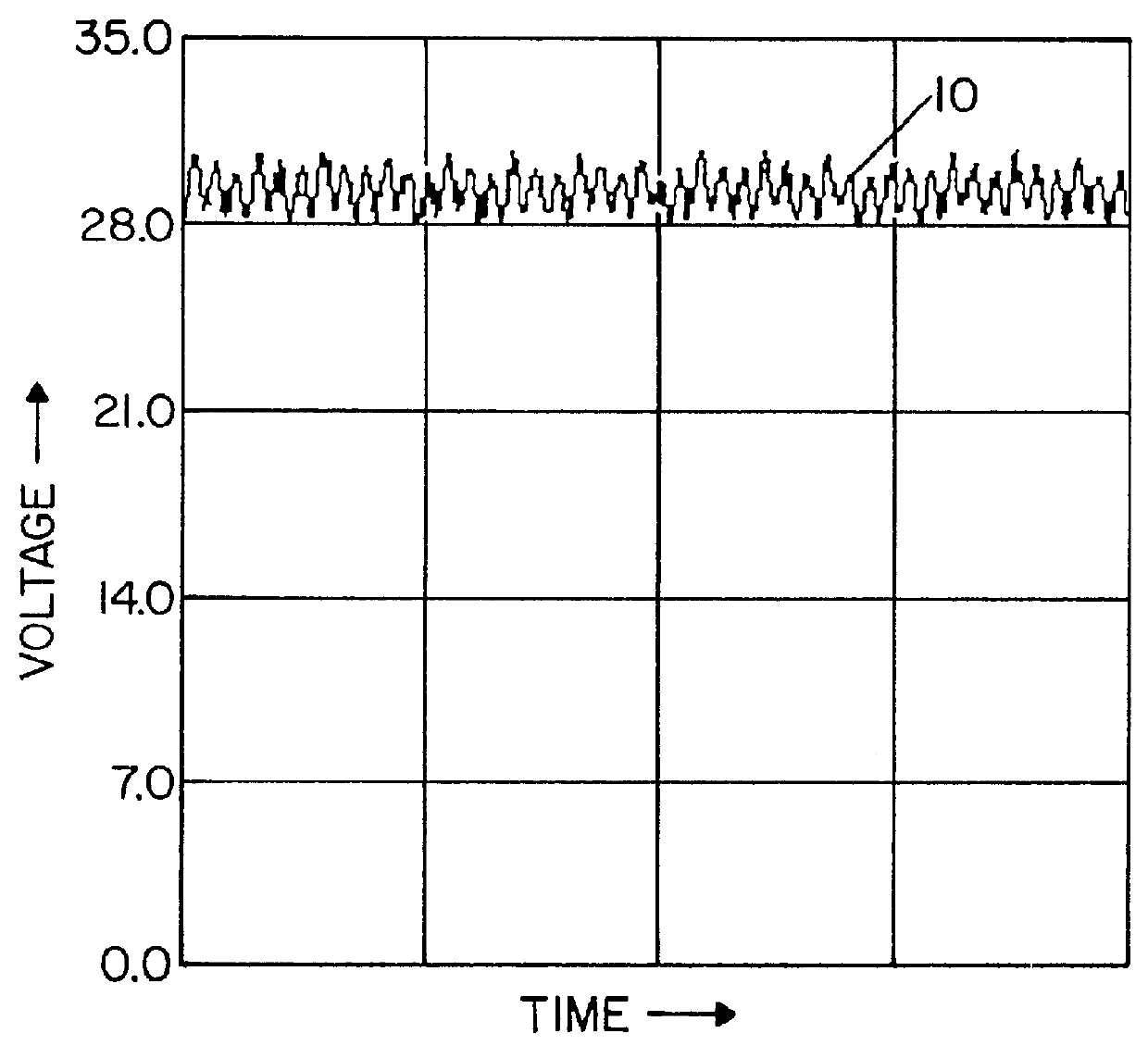

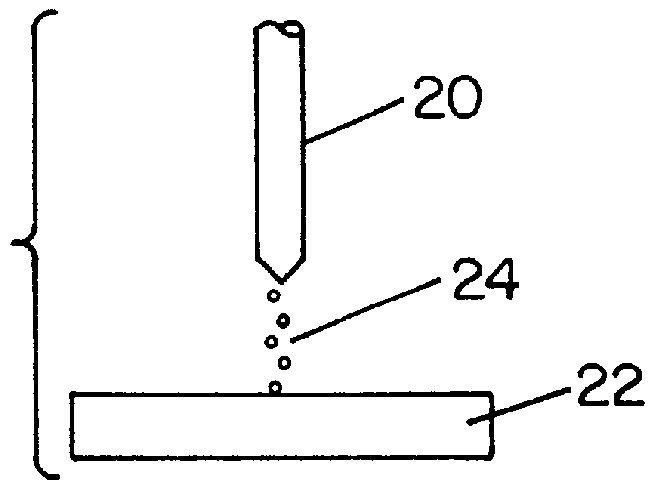

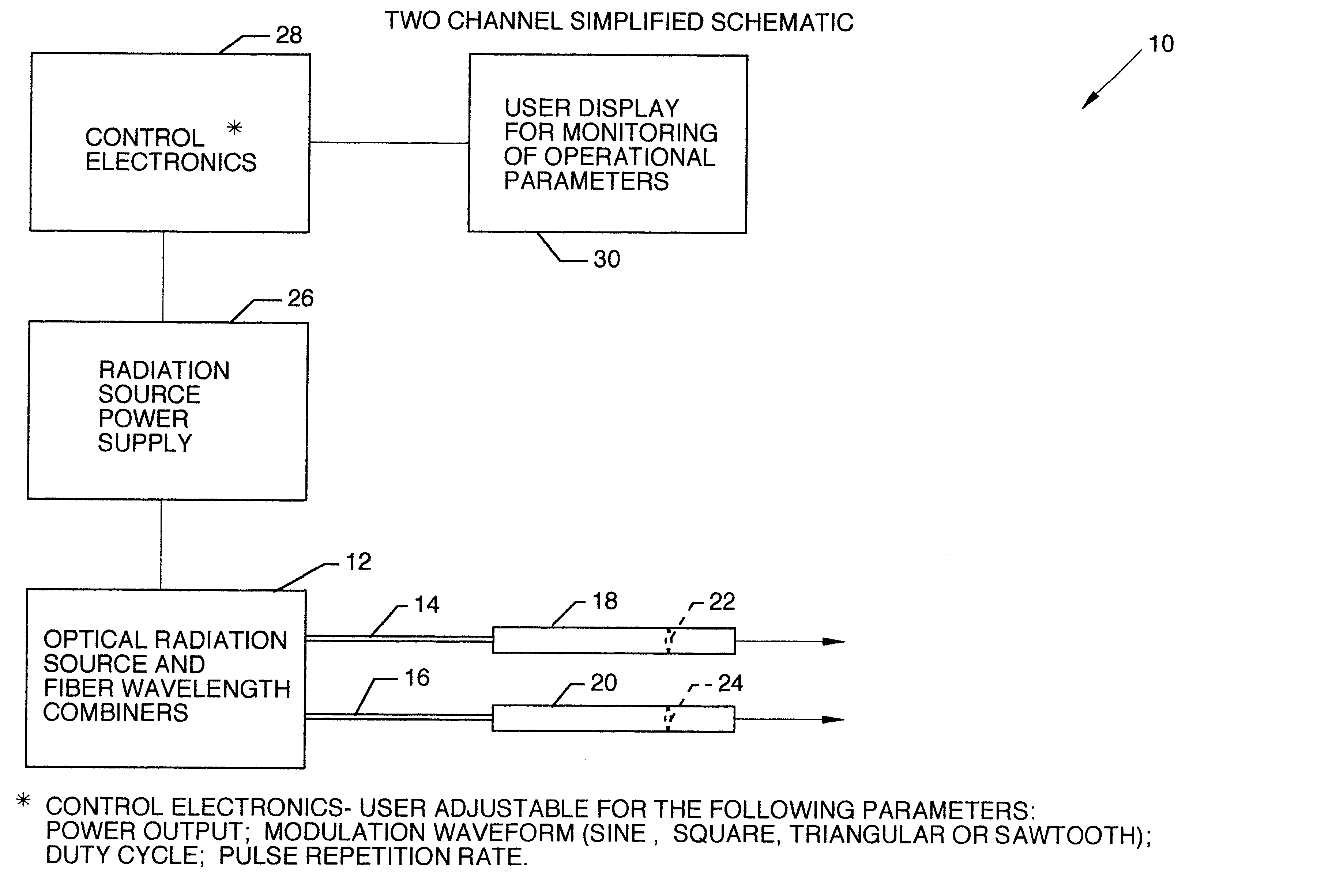

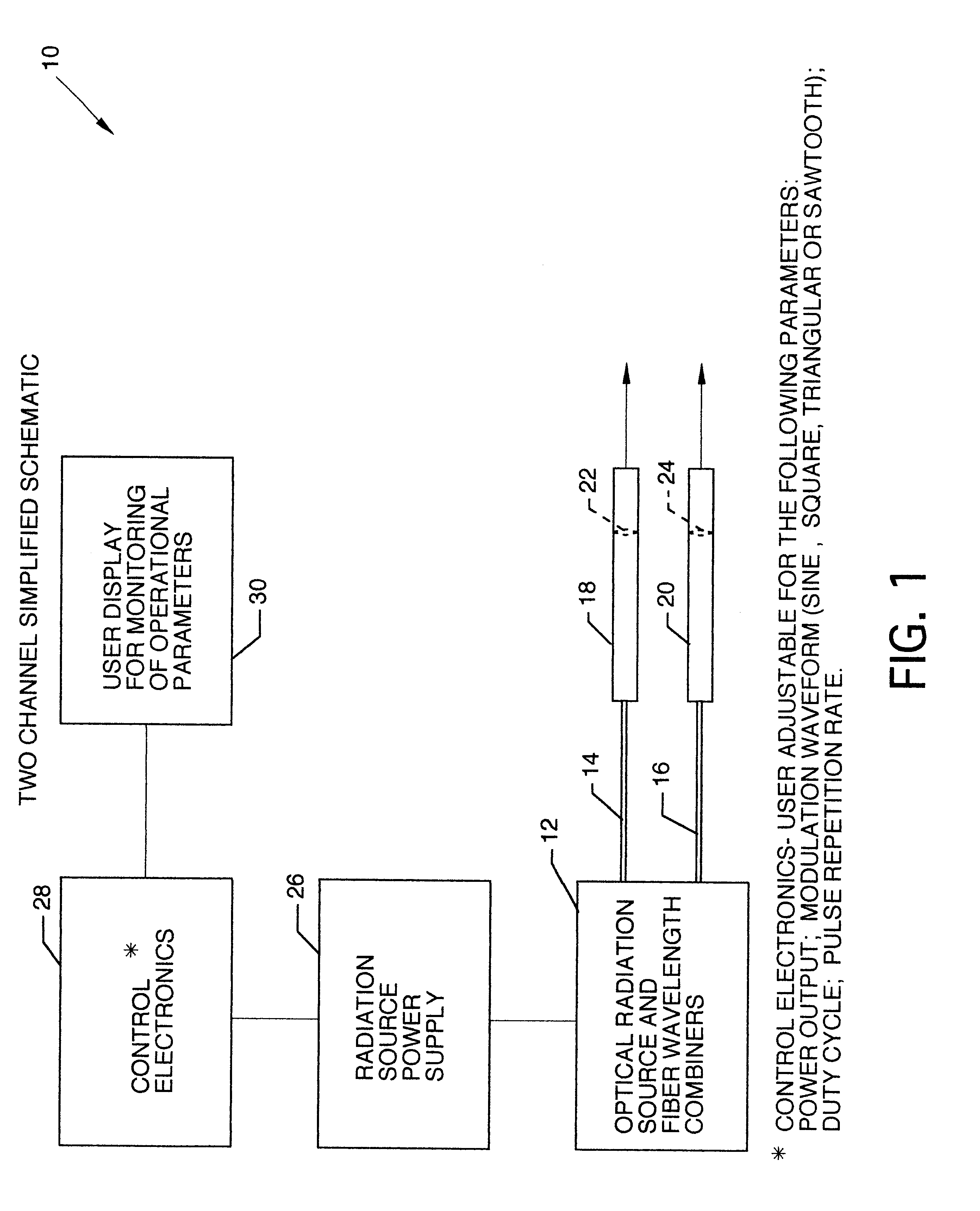

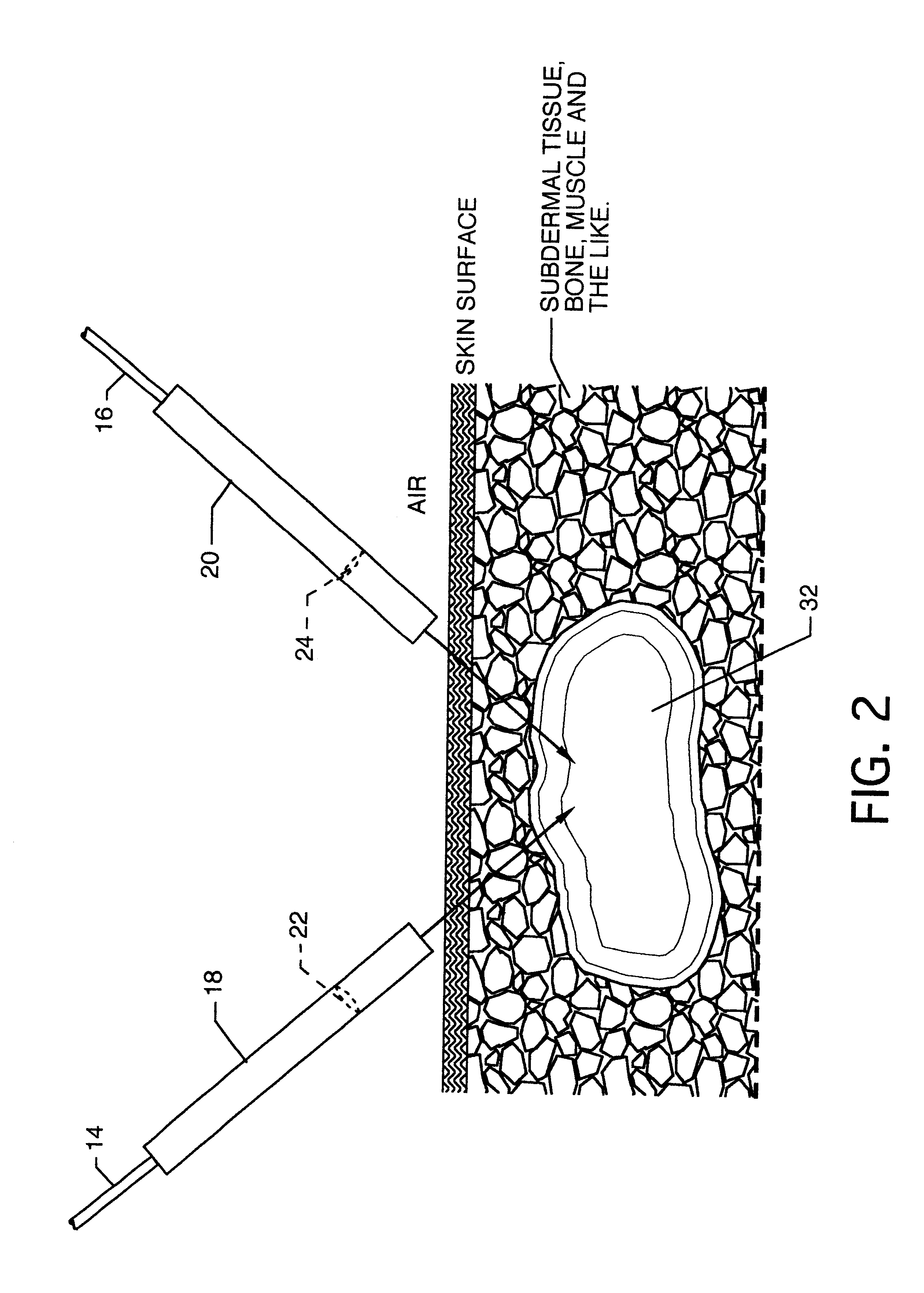

A near IR spectrometer-based analyzer attaches continuously or semi-continuously to a human subject and collects spectral measurements for determining a biological parameter in the sampled tissue, such as glucose concentration. The analyzer includes an optical system optimized to target the cutaneous layer of the sampled tissue so that interference from the adipose layer is minimized. The optical system includes at least one optical probe. Spacing between optical paths and detection fibers of each probe and between probes is optimized to minimize sampling of the adipose subcutaneous layer and to maximize collection of light backscattered from the cutaneous layer. Penetration depth is optimized by limiting range of distances between paths and detection fibers. Minimizing sampling of the adipose layer greatly reduces interference contributed by the fat band in the sample spectrum, increasing signal-to-noise ratio. Providing multiple probes also minimizes interference in the sample spectrum due to placement errors.

Owner:GLT ACQUISITION

Method of controlling a welding process and controller therefor

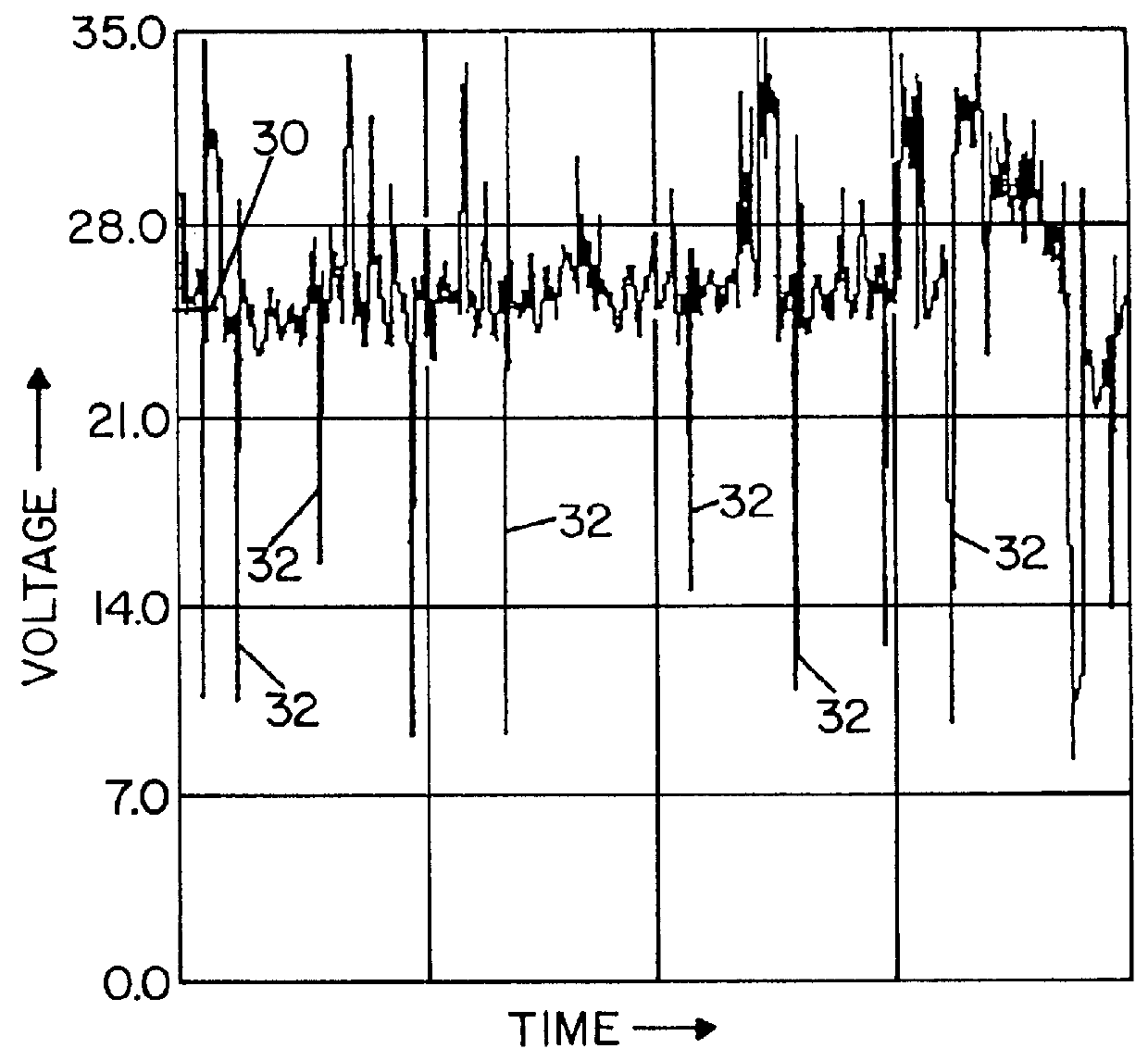

A controller and method for adjusting an output welding parameter of a D.C. electric arc welder for controlling a welding process wherein a welding wire is advanced toward a workpiece while an arc voltage is applied across the advancing wire and the workpiece, the control and method comprise measuring the rate of spatter events and then adjusting the output parameter to maintain the measured rate of spatter events at a selected rate in the range of 10-30 spatter events per second.

Owner:LINCOLN GLOBAL INC

Violation of time reversal invariance in living tissue

InactiveUS6592611B1Eliminate needSynergistic effectivenessSurgical instrument detailsLight therapyDiseaseWavenumber

The present invention provides for a device, a method, and a treatment system for chronic disease conditions. The present invention was designed using the theoretical concepts of Quantum Biology. The principles of operation are based on the device's ability to stimulate a Bose-Einstein condensate and excitation of Frolich resonance in living tissue The wavenumbers necessary for this excitation are derived from the solution to the equations for optical phonon scattering in living tissue generated by optical photon excitation. The establishment of this degeneracy condition induces a super conducting state in the tissue. This super conducting state facilitates DNA replication, transcription and translation, thereby allowing the proper formation or regeneration of healthy tissue. This superconducting state provides the conditions necessary for establishing the violation of time reversal invariance in living tissue.

Owner:HOBSON MICHAEL A

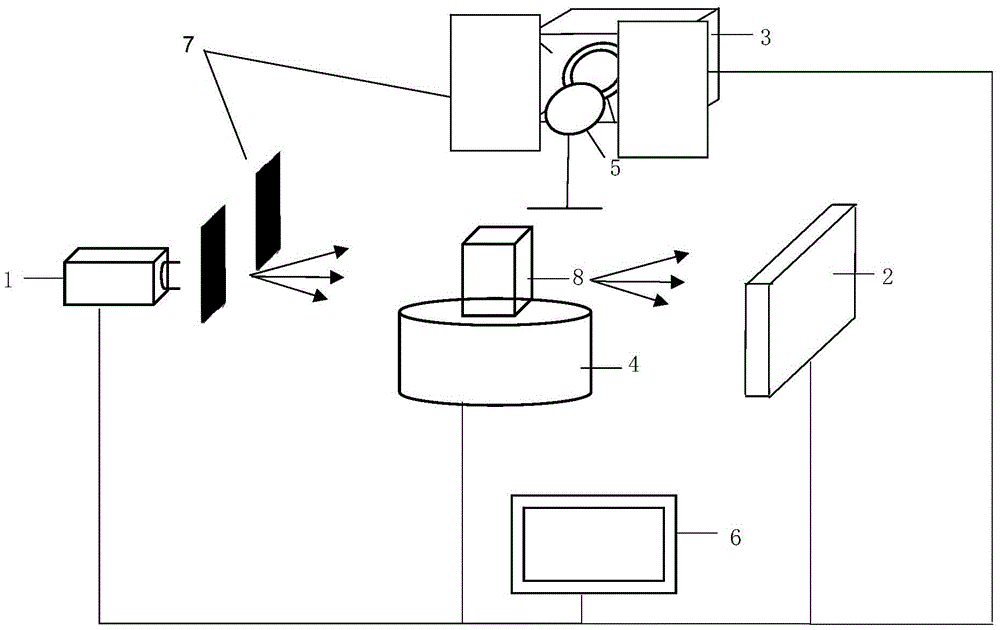

Multifunctional optical micro-control device

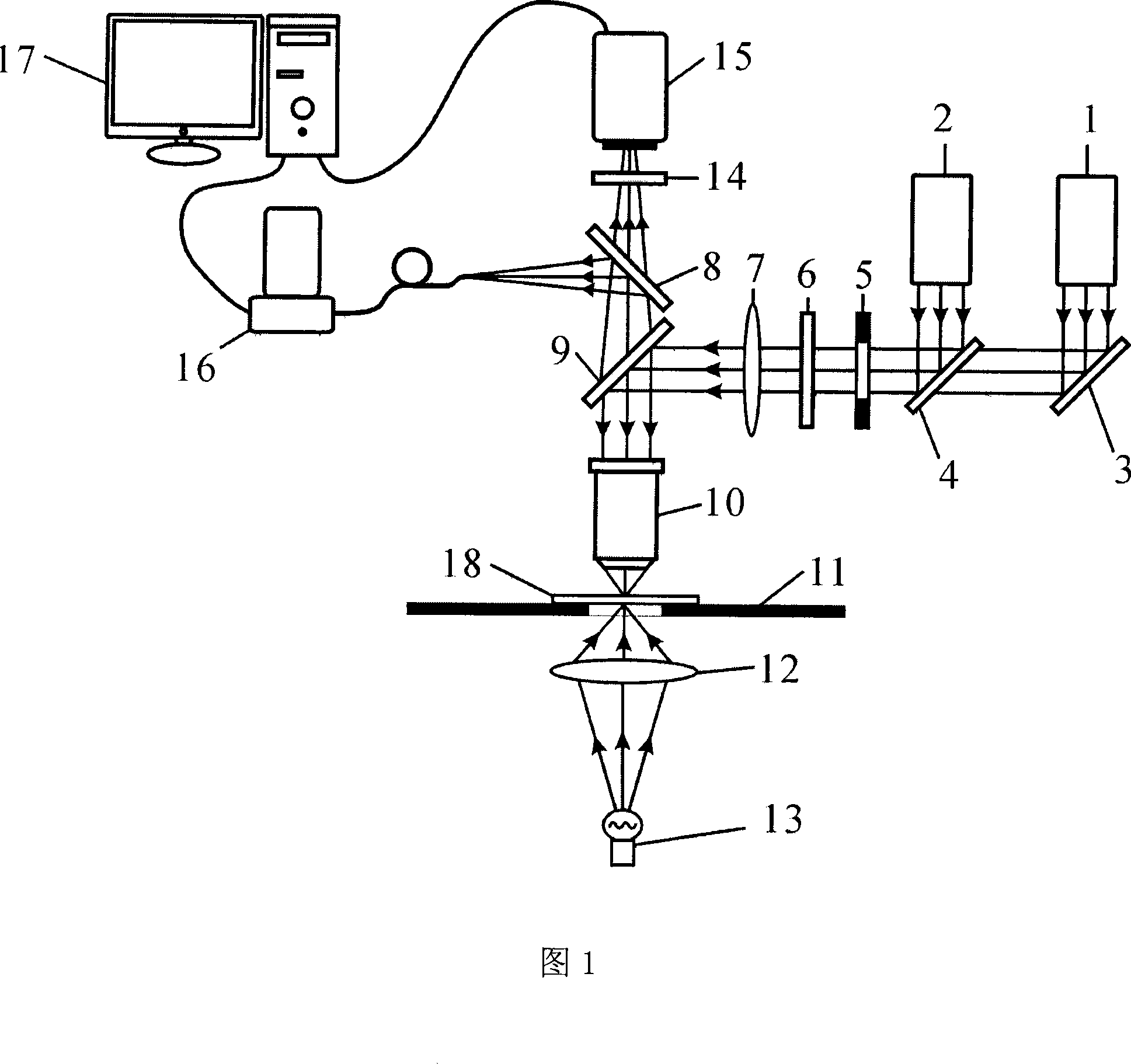

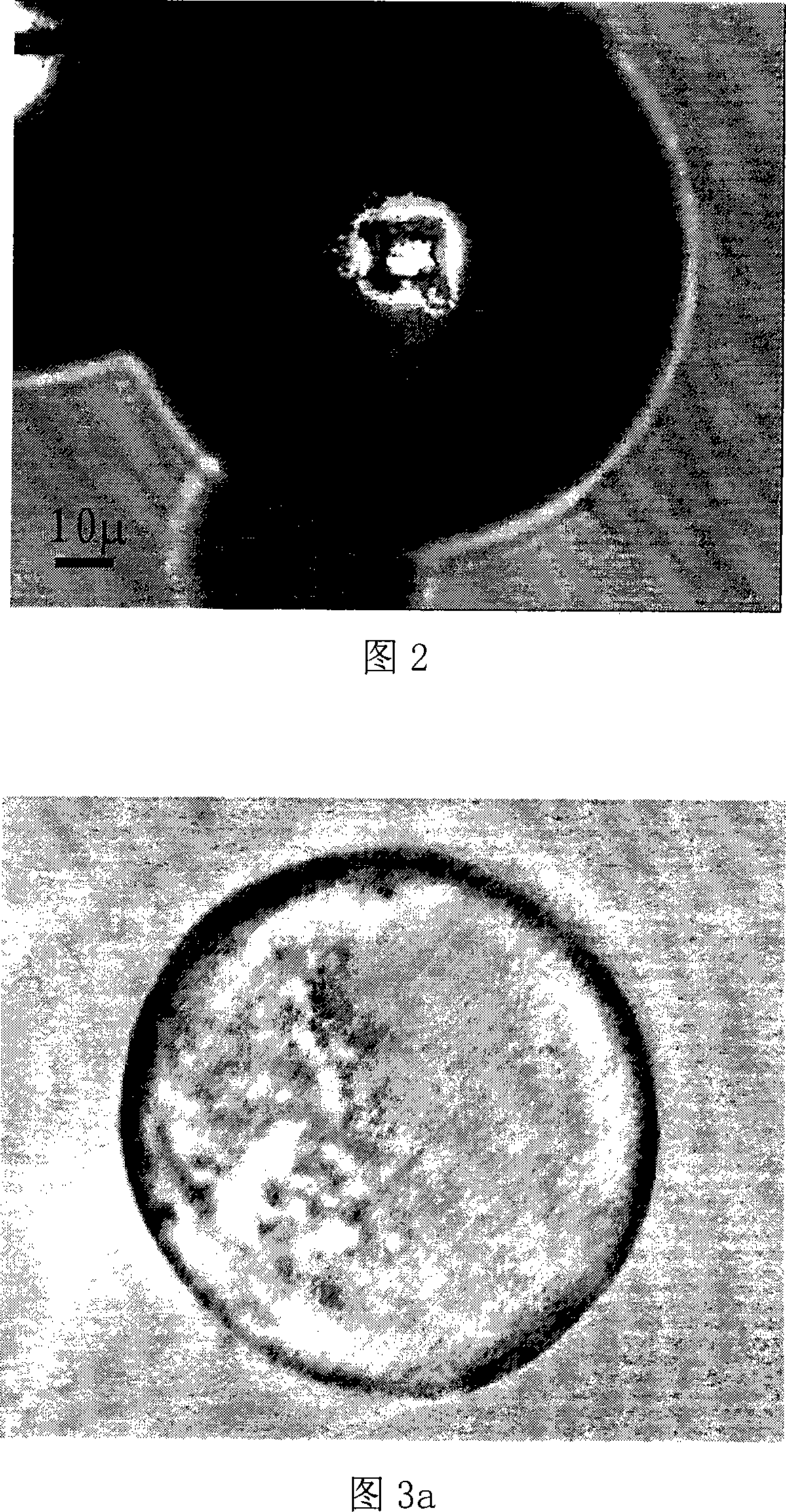

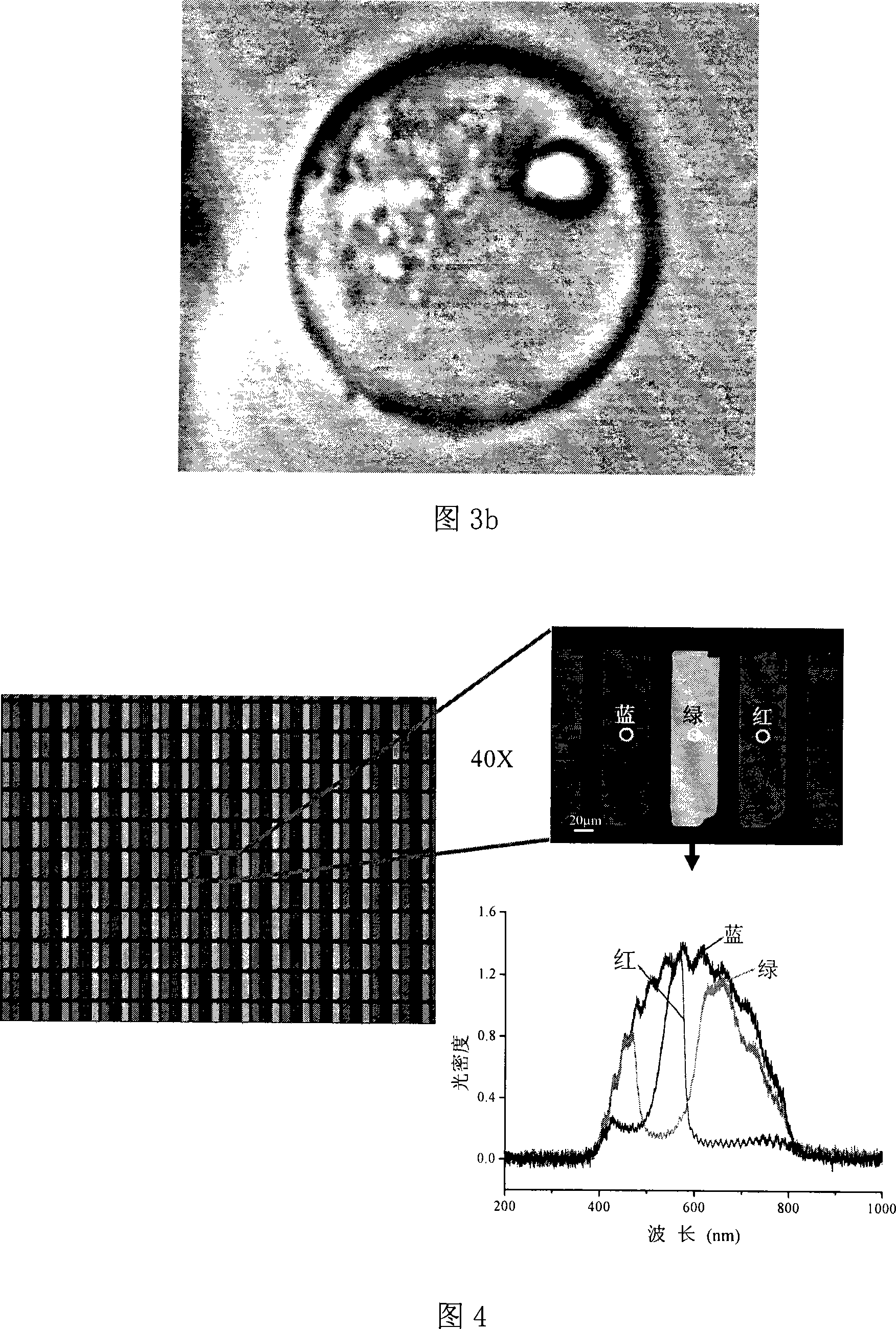

InactiveCN101216414AOvercome singleOvercome deficienciesSurface/boundary effectMaterial analysis by optical meansFemto second laserCcd camera

A multifunctional optical micro-manipulation device comprises a femtosecond laser, an optical tweezers laser, an optical system, a stage, a light source system, an imaging system, a spectral measurement system and a computer, wherein the optical system comprises a shutter, an attenuator, a focusing lens, a near IR reflector and a microscopic objective lens; the light source system comprises an illumination light source and a condenser lens; the microscopic objective lens is arranged on the stage for condensing a laser beam emitted by a laser generator onto a sample; the condenser lens is arranged below the stage for condensing a visible light emitted by the illumination light source onto the sample; and the imaging system includes an IR filter and CCD camera sequentially disposed on the projection light path of the near IR reflector. By integrating three functions of laser tweezers, femtosecond laser scissors and microspectrometer in one system, the invention can overcome the singleness and the disadvantages of the prior laser micro-beam technology and can be widely used for studying in biological, medical, biophysical, material chemistry and nano-technology fields.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

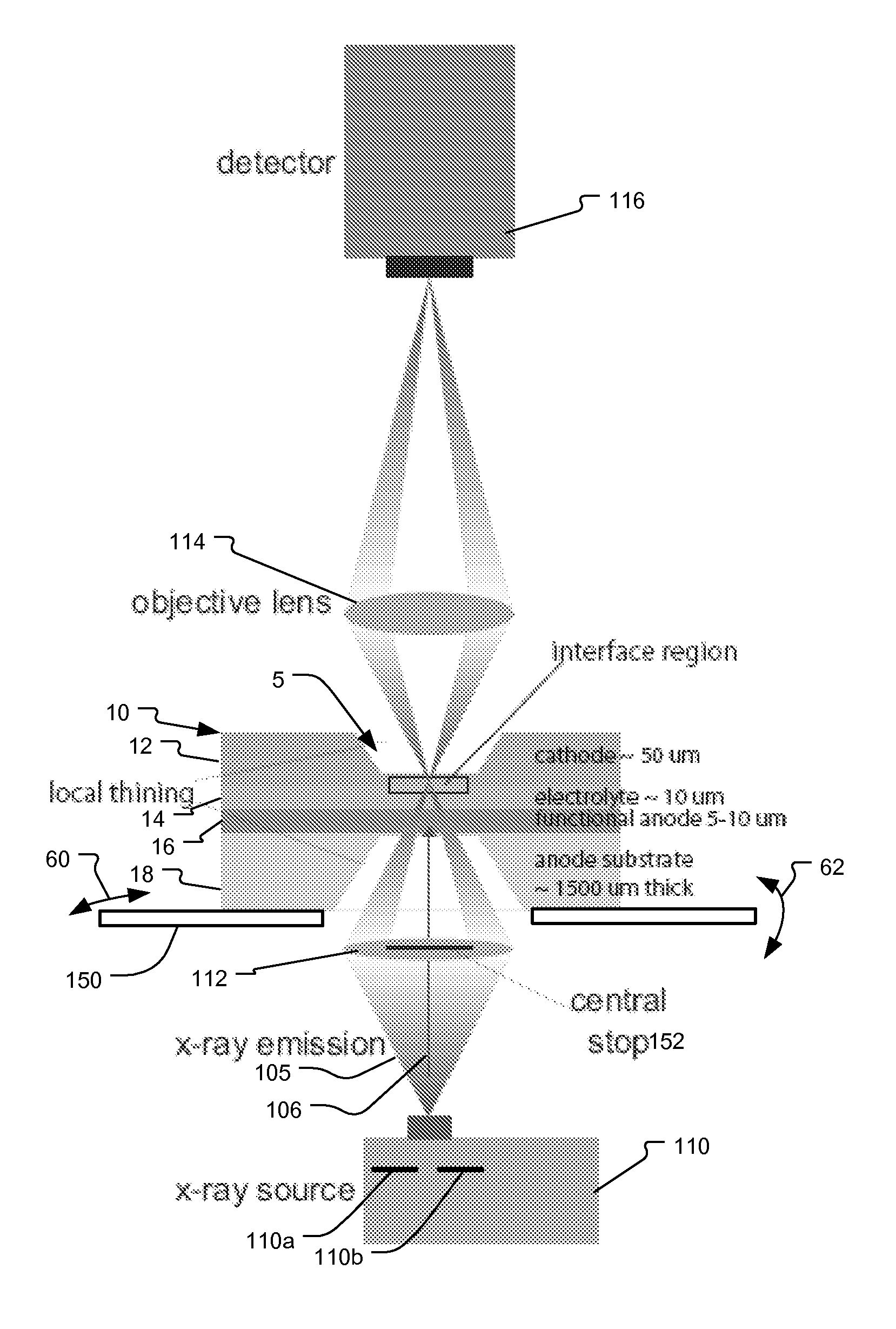

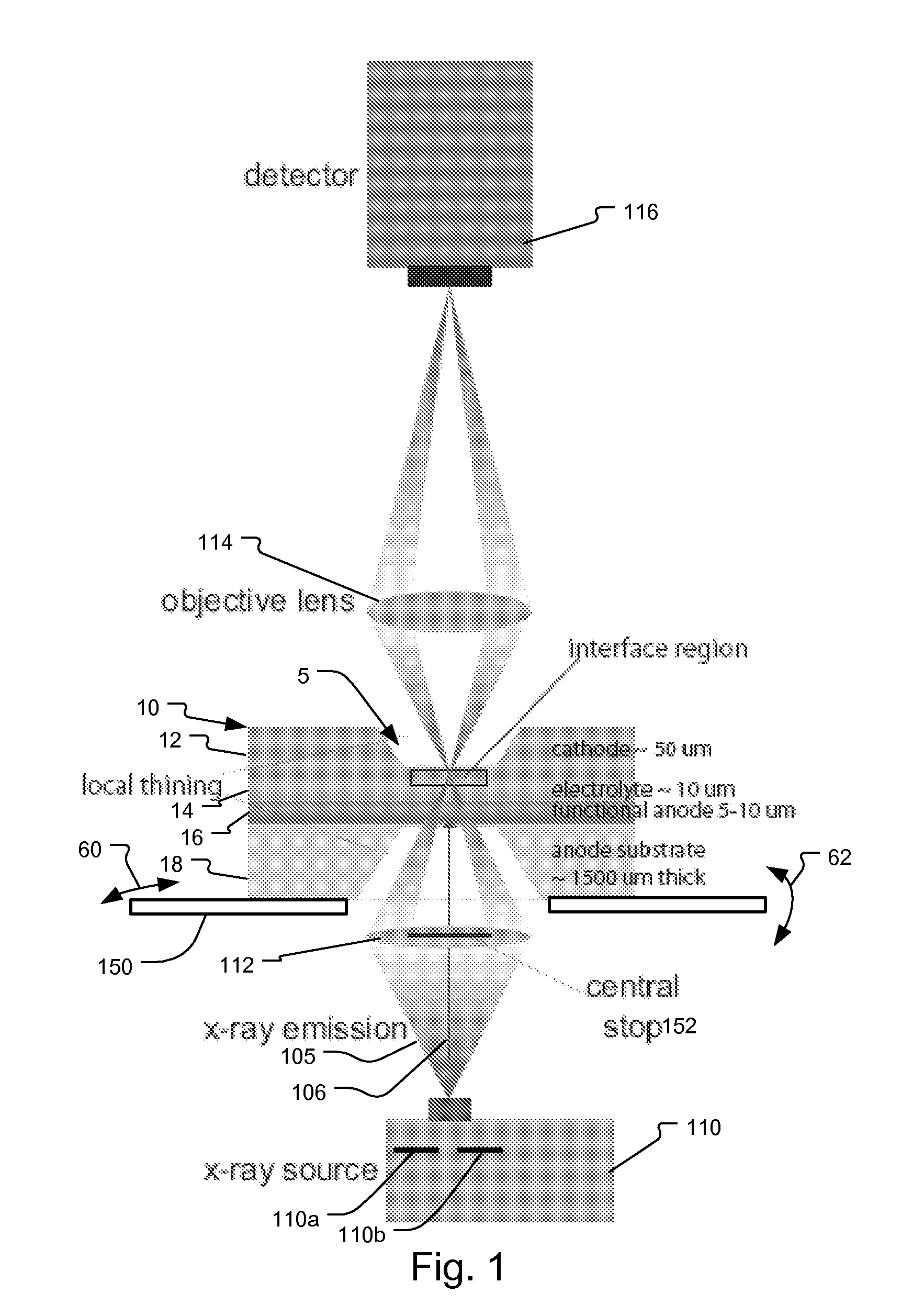

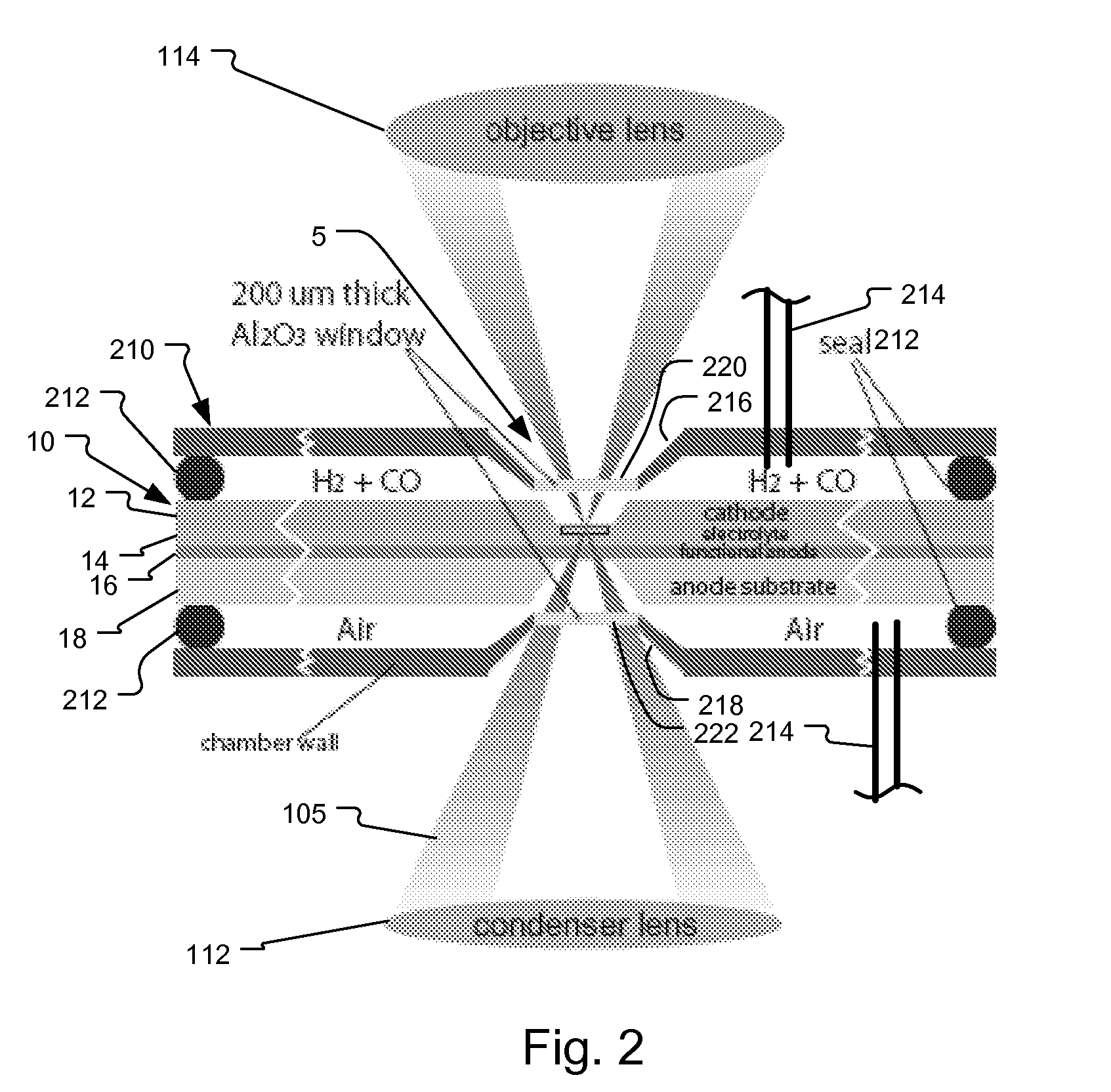

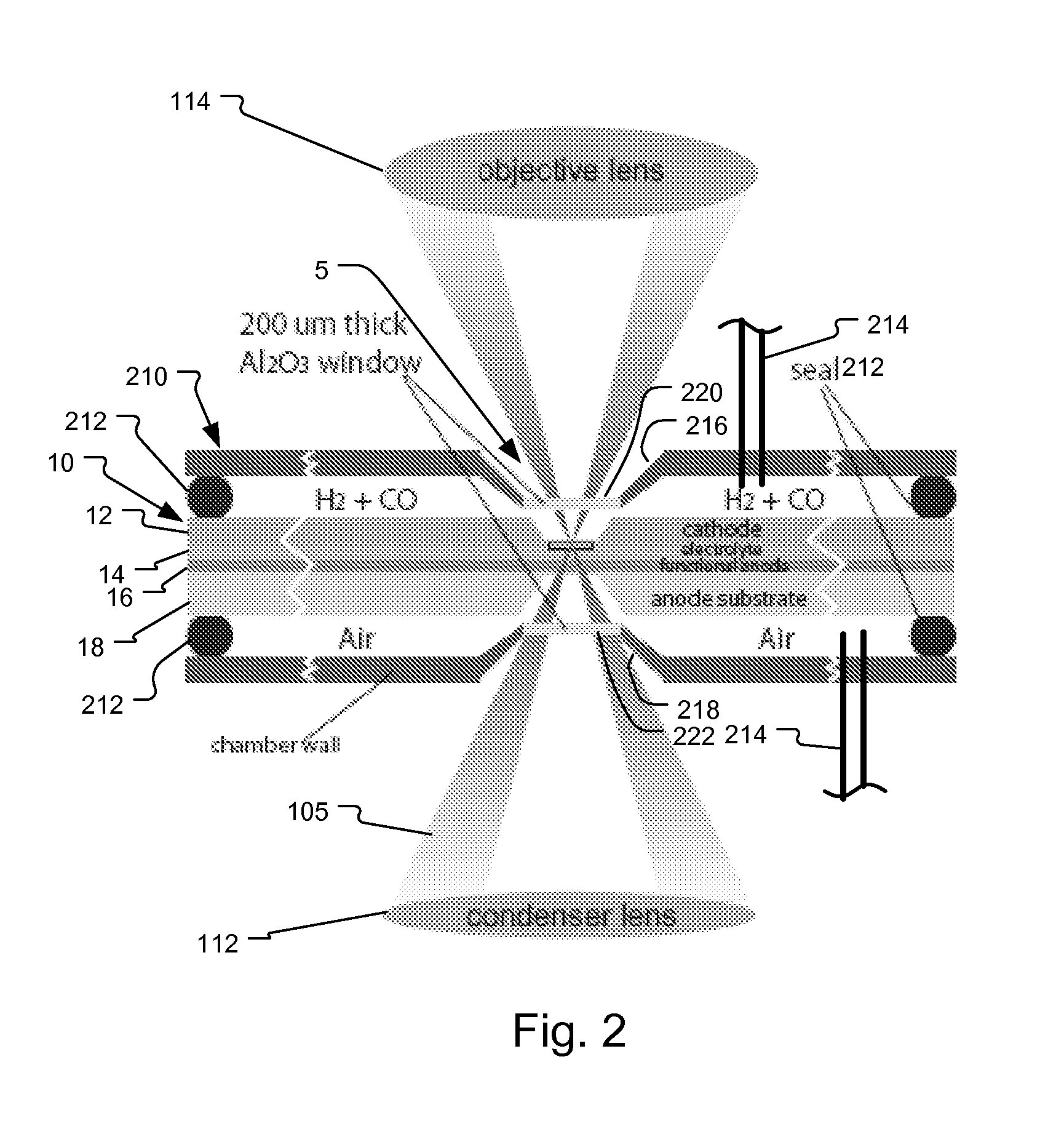

System and method for fuel cell material x-ray analysis

ActiveUS7499521B2Shorten development timeImprove reliabilityRadiation/particle handlingUsing wave/particle radiation meansHard X-raysMetrology

An imaging technology for fuel cells is based on x-ray microscopy. A metrology system images the electro-chemical interaction areas of solid-oxide fuel cells (SOFC) in-situ. This system takes advantage of both the penetrating power and elemental absorption contrast of hard x-ray radiation to image the internal interaction areas in a SOFC. The technology can further take advantage of the strong dependence of the x-ray absorption on material type and energy to distinguish the four major material types: cathode, electrolyte, air, and low-Z contaminants such as sulfur.

Owner:CARL ZEISS X RAY MICROSCOPY

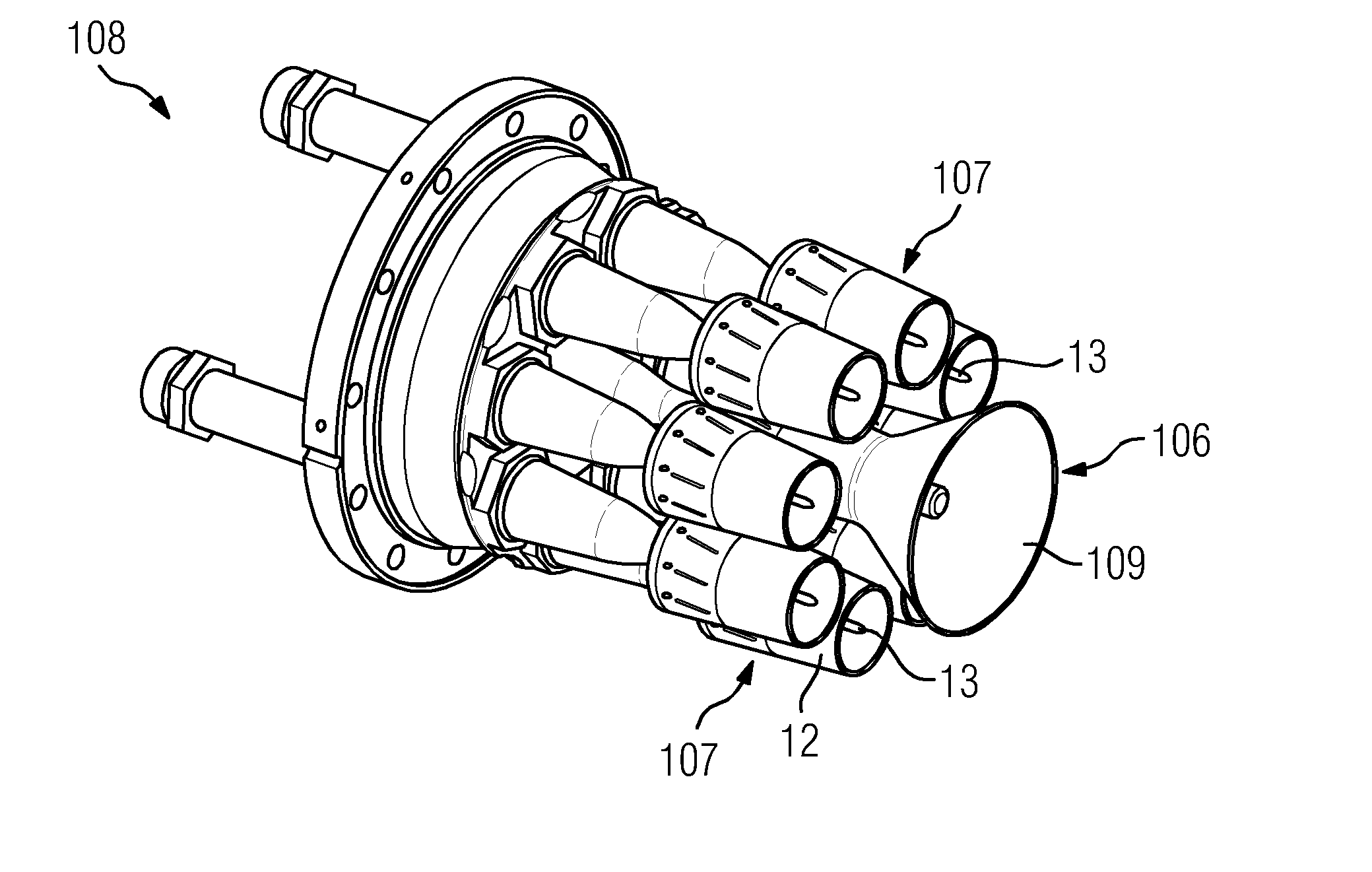

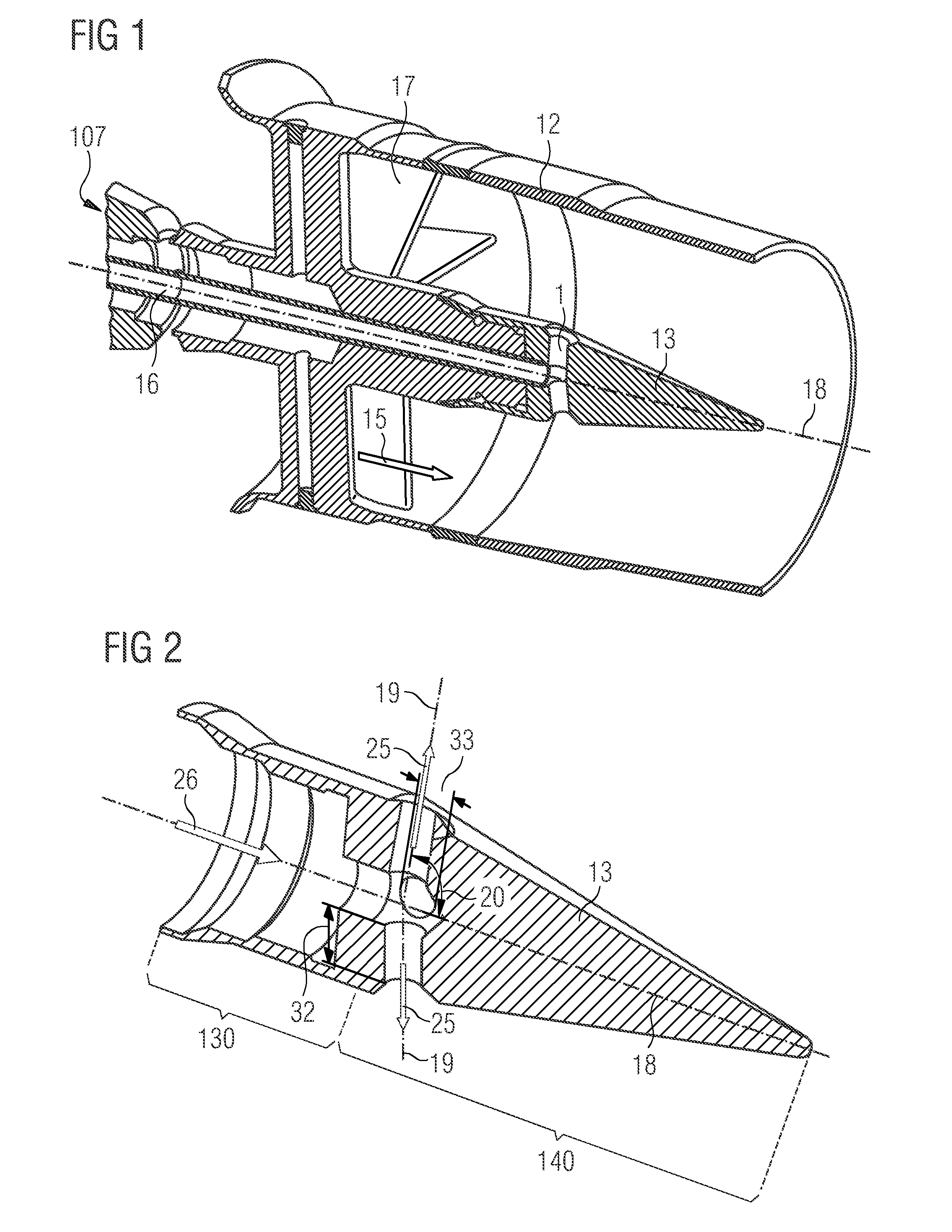

Burner assembly

InactiveUS20130104554A1Increase the diameterNarrow profileBurnersContinuous combustion chamberCombustorLiquid fuel

A burner assembly for a gas turbine is provided. The burner assembly has a combustor, a centrally arranged pilot burner and plurality of main burners surrounding the pilot burner. Each main burner has a cylindrical housing having a lance which is centrally arranged therein and has a fuel channel for liquid fuel. The lance is supported on the housing by swirl blades and an attachment is arranged on the lance in the direction of the combustor. The liquid fuel nozzle is arranged in the attachment downstream of the swirl blades and connected to the fuel channel. For the improved mixing of the fuel with the air, the liquid fuel nozzle is designed as a full jet nozzle and the full jet nozzle has a length and a diameter, the ratio of the length to the diameter is at least 1.5.

Owner:SIEMENS AG

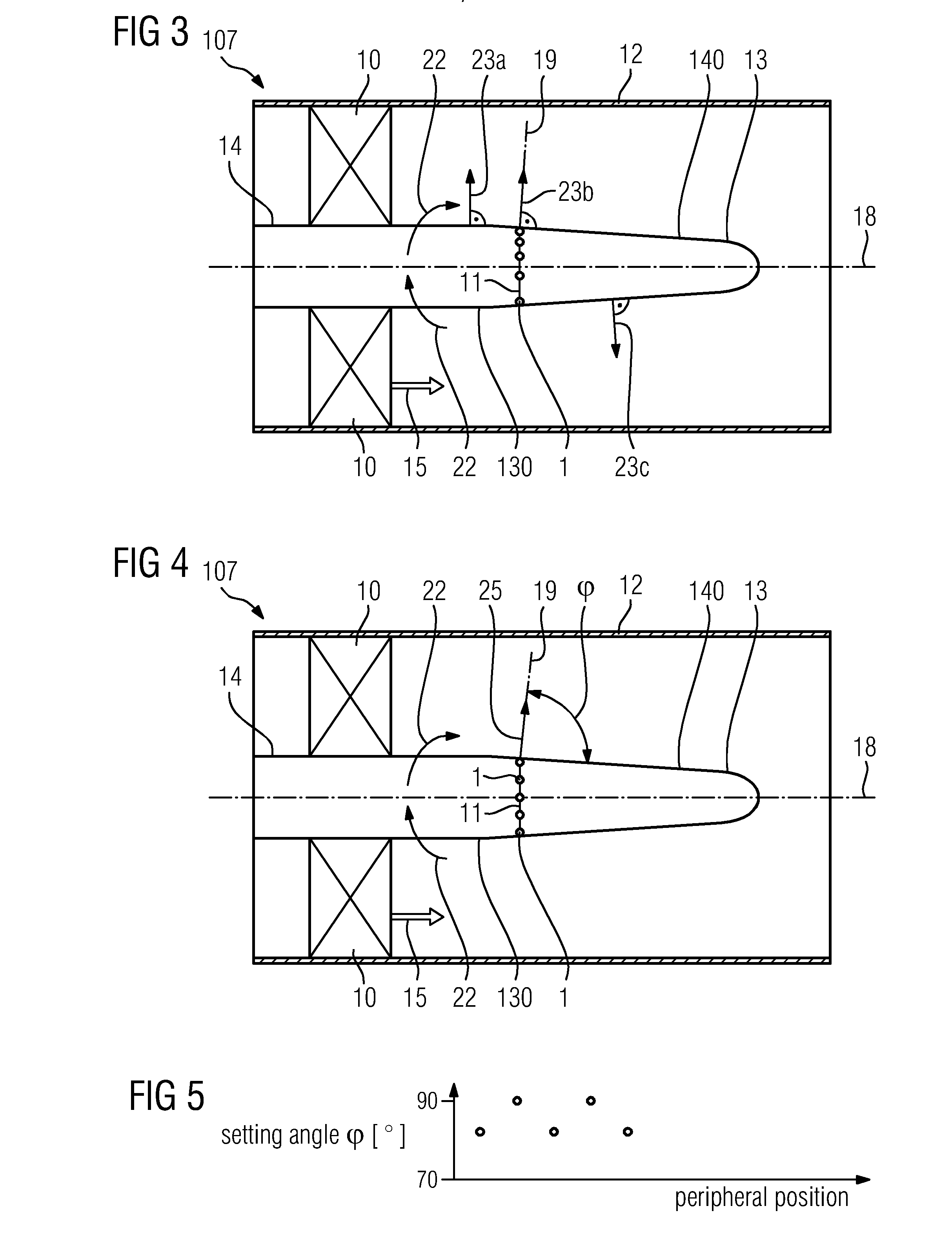

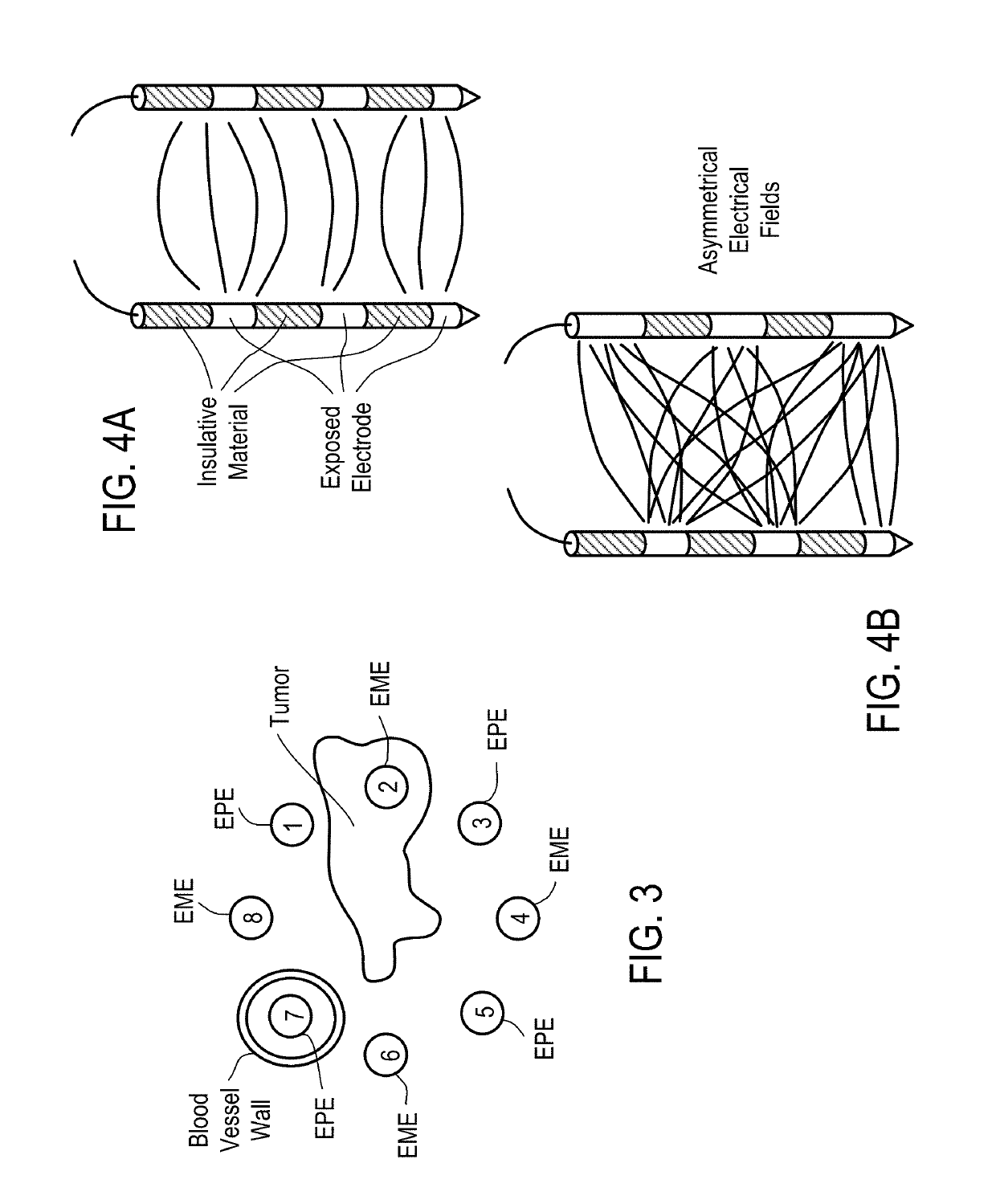

Systems and Methods for Improved Tissue-Sensing Based Electroporation

ActiveUS20190117964A1Improved anchoringFacilitate depth of penetrationExternal electrodesSelf adaptivePulse parameter

An adaptive control method for controlling EP pulse parameters during electroporation (EP) of cells or tissue using an EP system includes providing a system for adaptive control to optimize EP pulse parameters including EP pulse parameters, applying voltage and current excitation signals to the cells, obtaining data from the current and voltage measurements, and processing the data to separate the desirable data from the undesirable data, extracting relevant features from the desirable data, applying at least a portion of the relevant features to a trained diagnostic model, estimating EP pulsing parameters based on an outcome of the applied relevant features, where the initialized EP pulsing parameters are based on the trained model and the relevant features, to optimize the EP pulsing parameters, and applying, by the generator, a first EP pulse based on the first pulsing parameters.

Owner:ONCOSEC MEDICAL

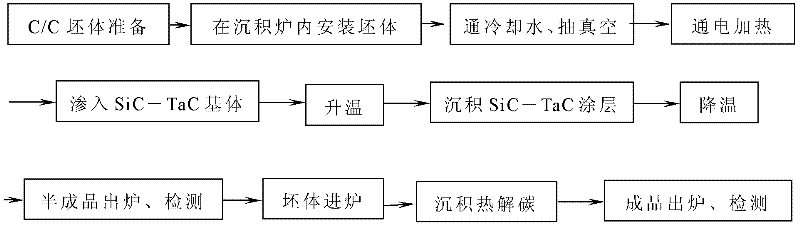

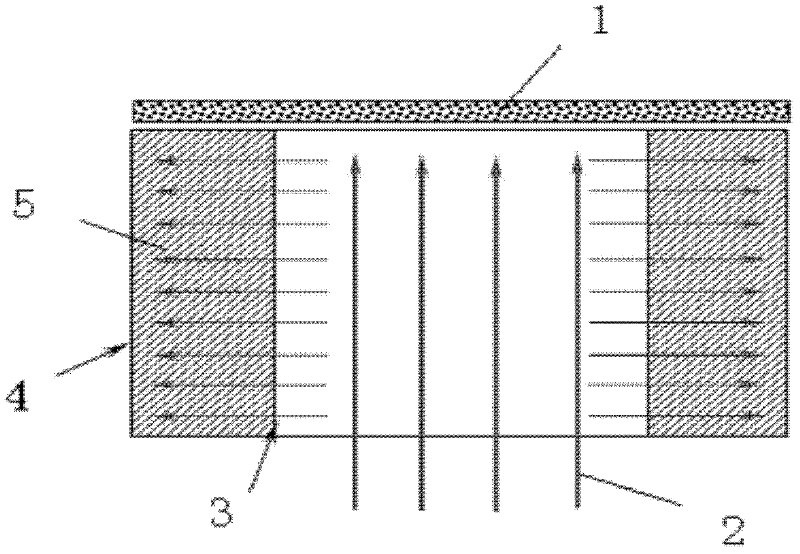

A kind of sic-tac coating/matrix synergistically modified c/c composite material and preparation method thereof

ActiveCN102295474AMitigate Thermal MismatchHigh coefficient of thermal expansionSurface layerHigh density

The invention discloses a SiC-TaC coating / matrix collaborative modified C / C composite material and its preparation method. The composite material provided by the invention comprises two parts. The portion below the surface of the C / C composite material is the matrix modified portion with the thickness being 0.1-10mm. In addition, carbide in the C / C composite material emerges in gradient distribution. The portion which is deposited on the surface of a carbon material is a coating portion with the thickness being 10-300 microns. The preparation method of the composite material comprises the following steps of: cutting a C / C green body at the density of 0.80g / cm<3>-1.60g / cm<3> into an annular shape or a plate shape, followed by ultrasonic cleaning and drying, placing into a multifunctional CVD furnace, depositing carbide on the surface layer and surface of the C / C green body by controlling deposition parameters, further densifying the green body by the use of pyrolytic carbon so as to obtain the high-density coating / matrix collaborative modified C / C composite material. The main advantages of the invention are as follows: by the penetration of carbide through the surface layer of the C / C composite material, the thermal expansion coefficient of the matrix is raised, the interfacial bonding state is improved, a continuous transition of carbide is formed between the coating and the matrix, and the metallurgical bonding is accomplished between the coating and the matrix.

Owner:CENT SOUTH UNIV

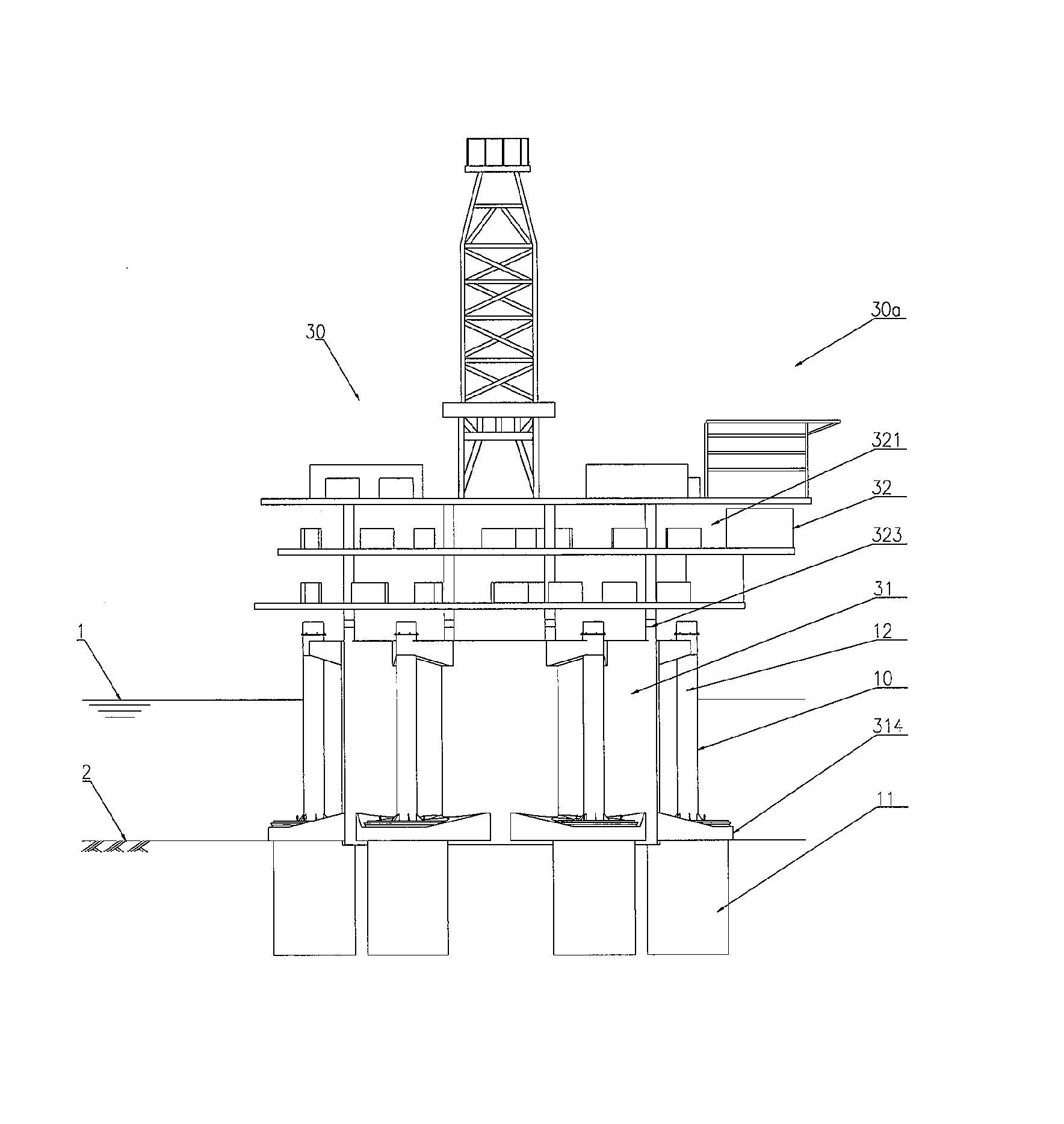

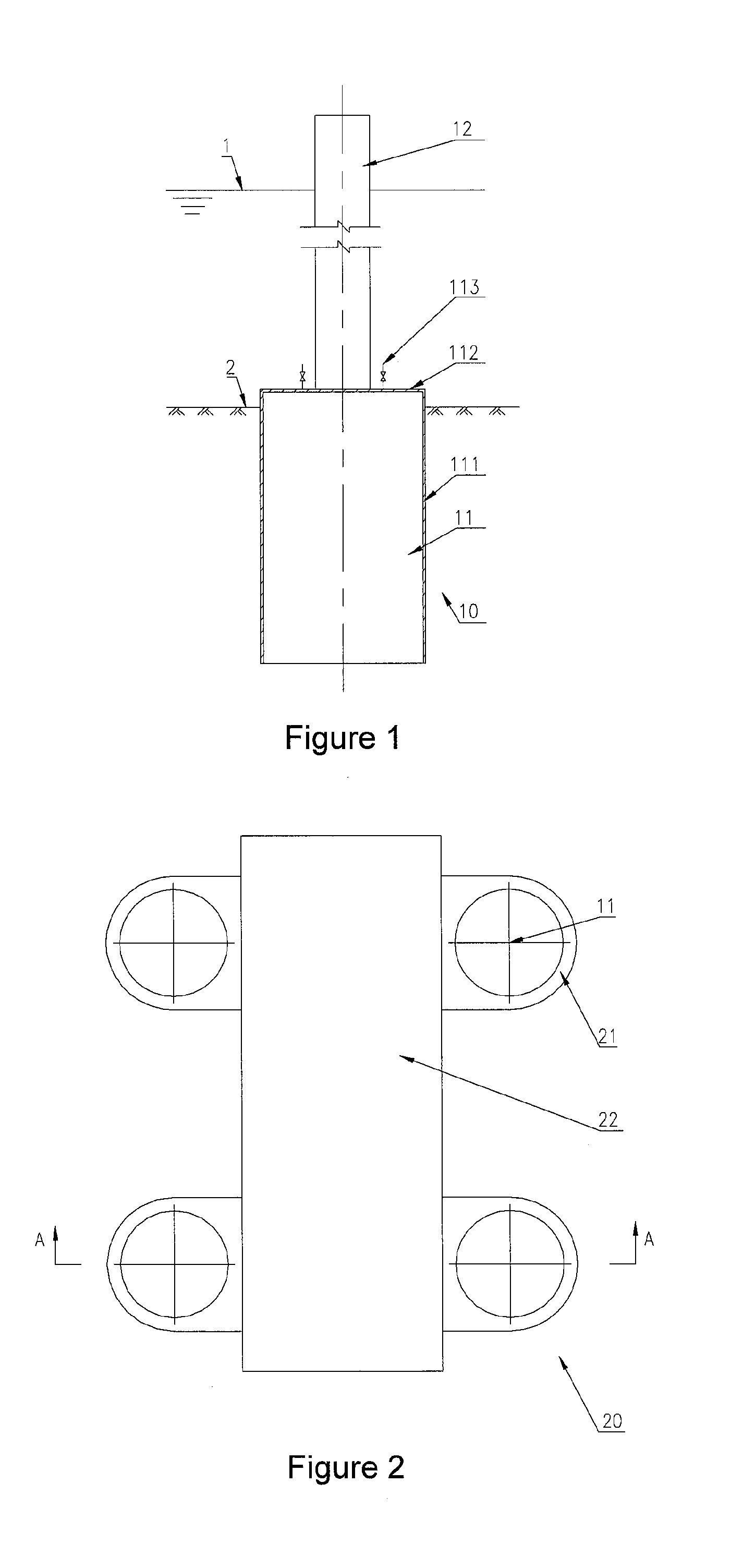

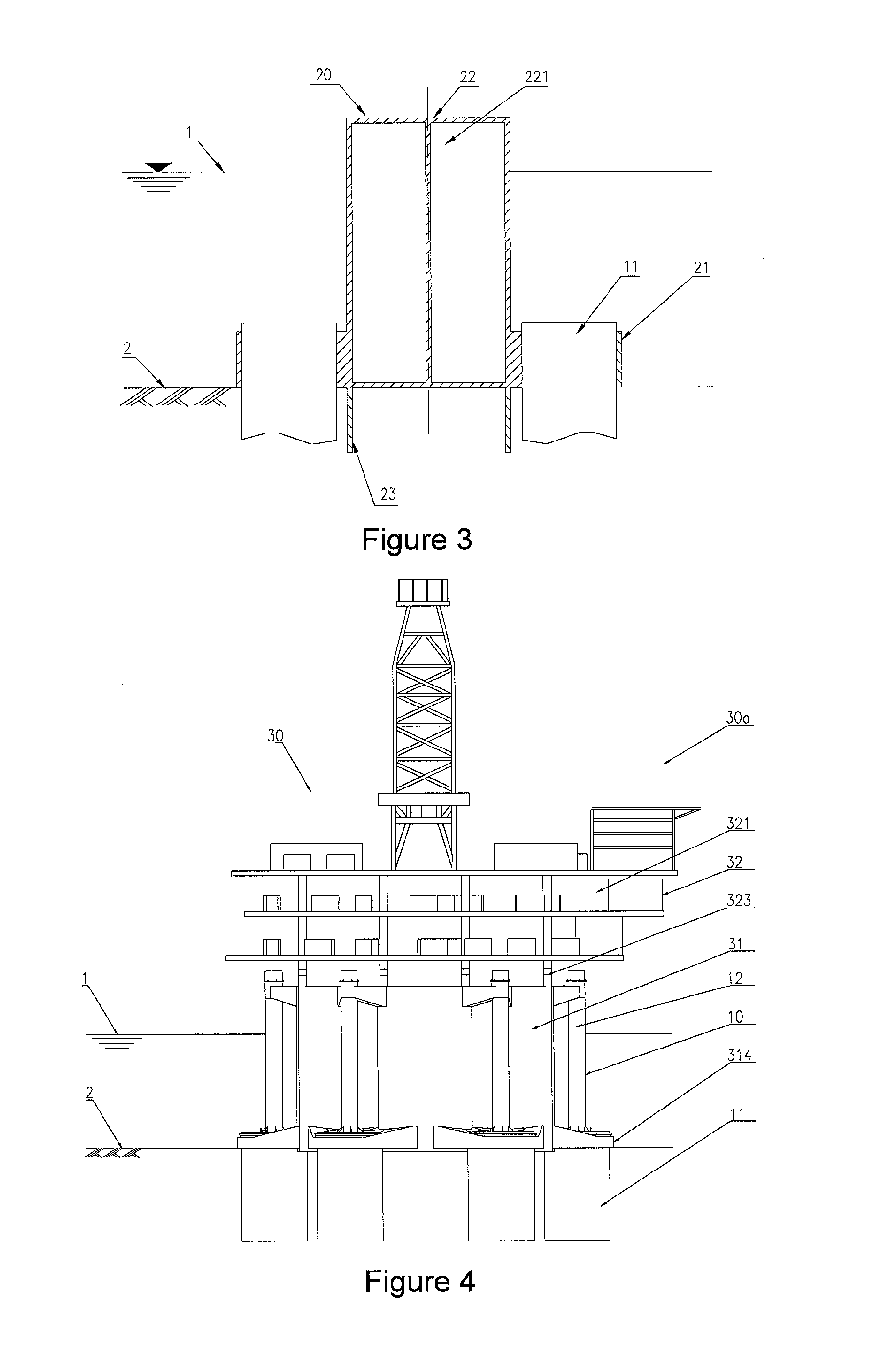

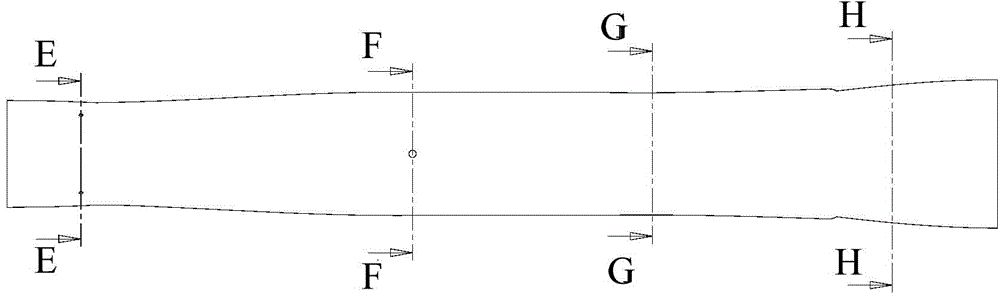

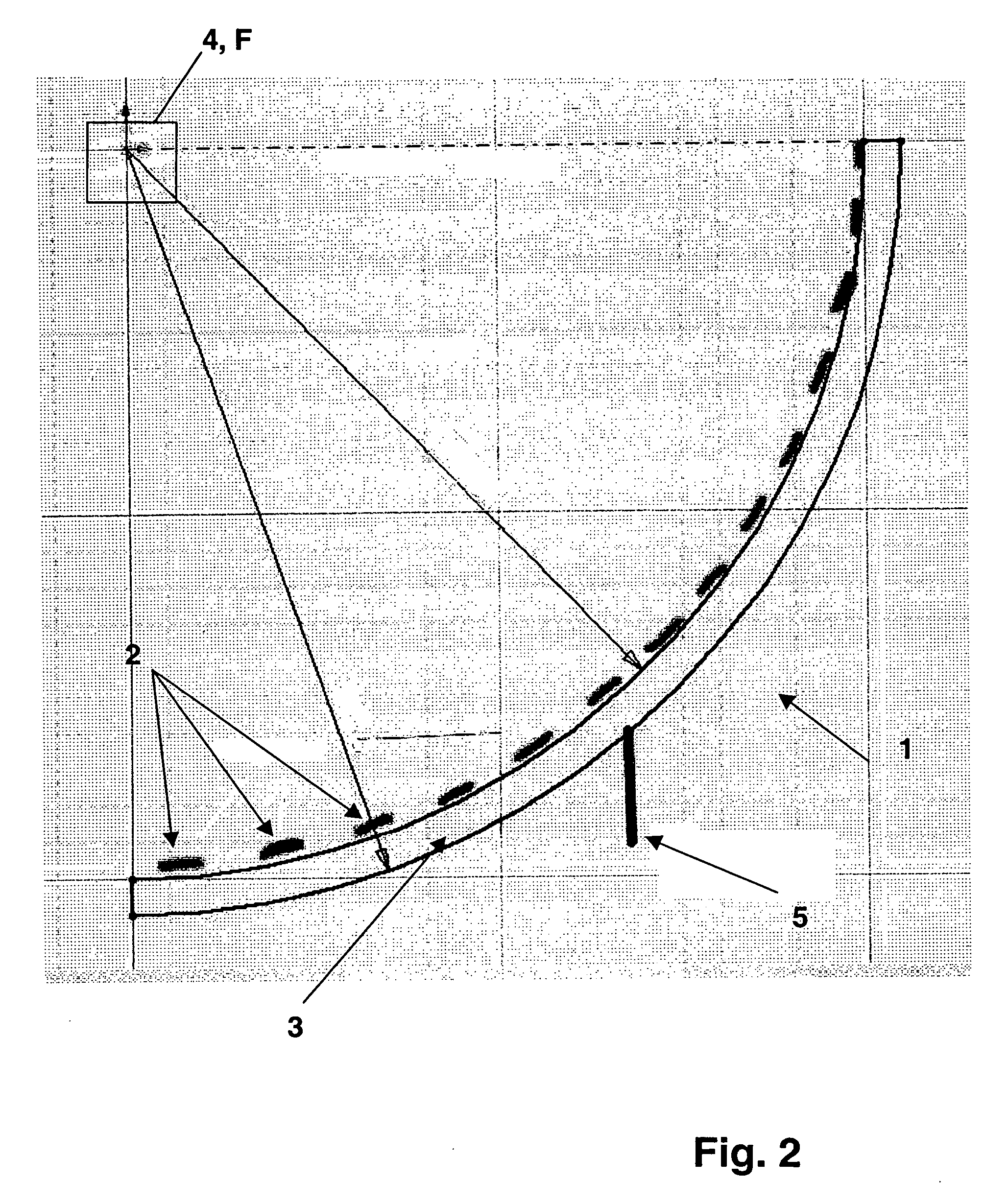

Type of suction leg, an offshore caisson, and a sit-on-bottom offshore platform

InactiveUS20150322642A1Simple structureGreat penetration depthProtective foundationLarge containersEngineeringStructural engineering

This application discloses a new type of suction leg, an offshore caisson, a sit-on-bottom supporting platform. The suction leg includes a sealing long pile, this sealing long pile including a tubular pipe and a top head connected tightly to the tubular pipe to form cylindrical integral structure with sealing top and opening bottom. The top head has at least one opening to be able to open or close. The sealing long pile can be penetrated into the seabed by a gravity penetration method or / and a suction pile penetration method, or pulled out from the seabed by a buoyancy uplift method or / and a suction pile uplift method.

Owner:WU ZHIRONG

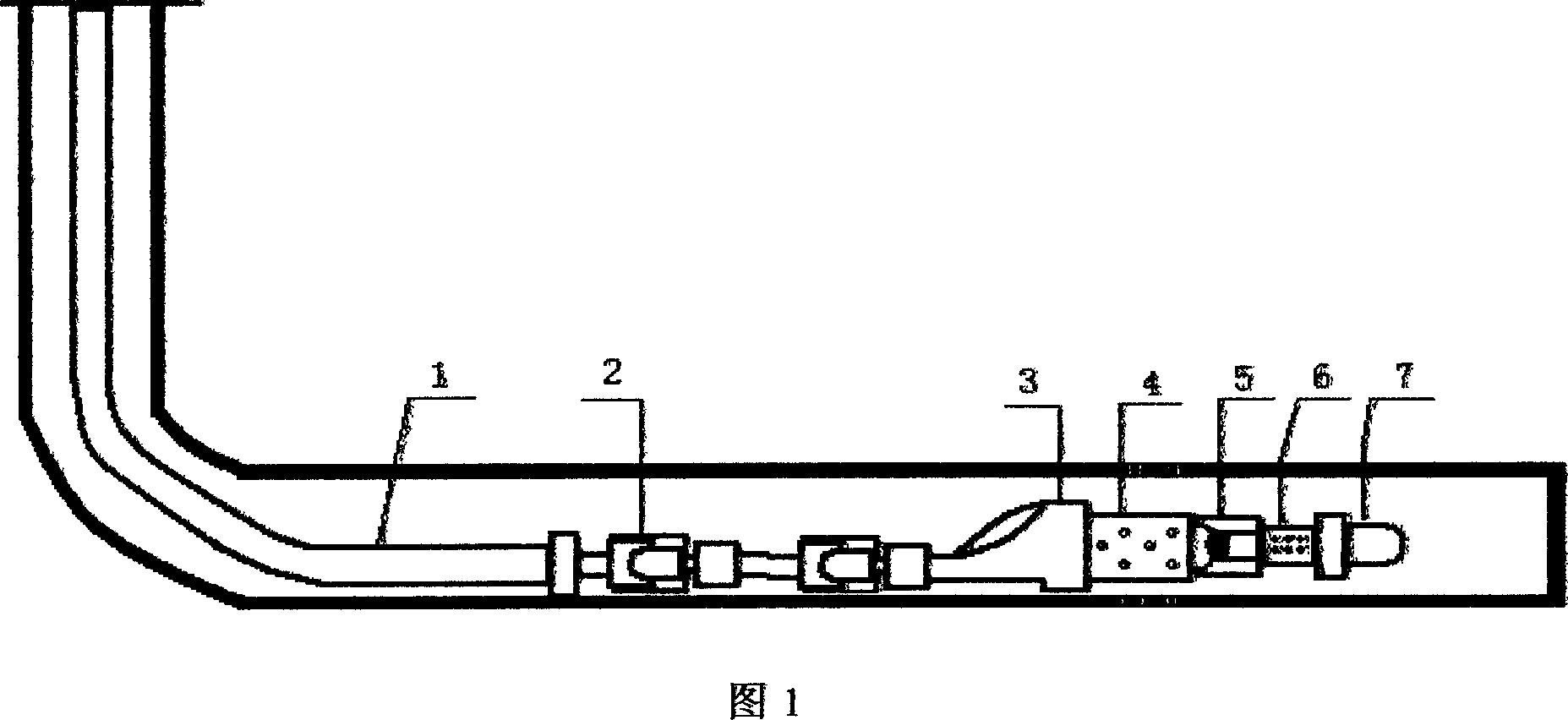

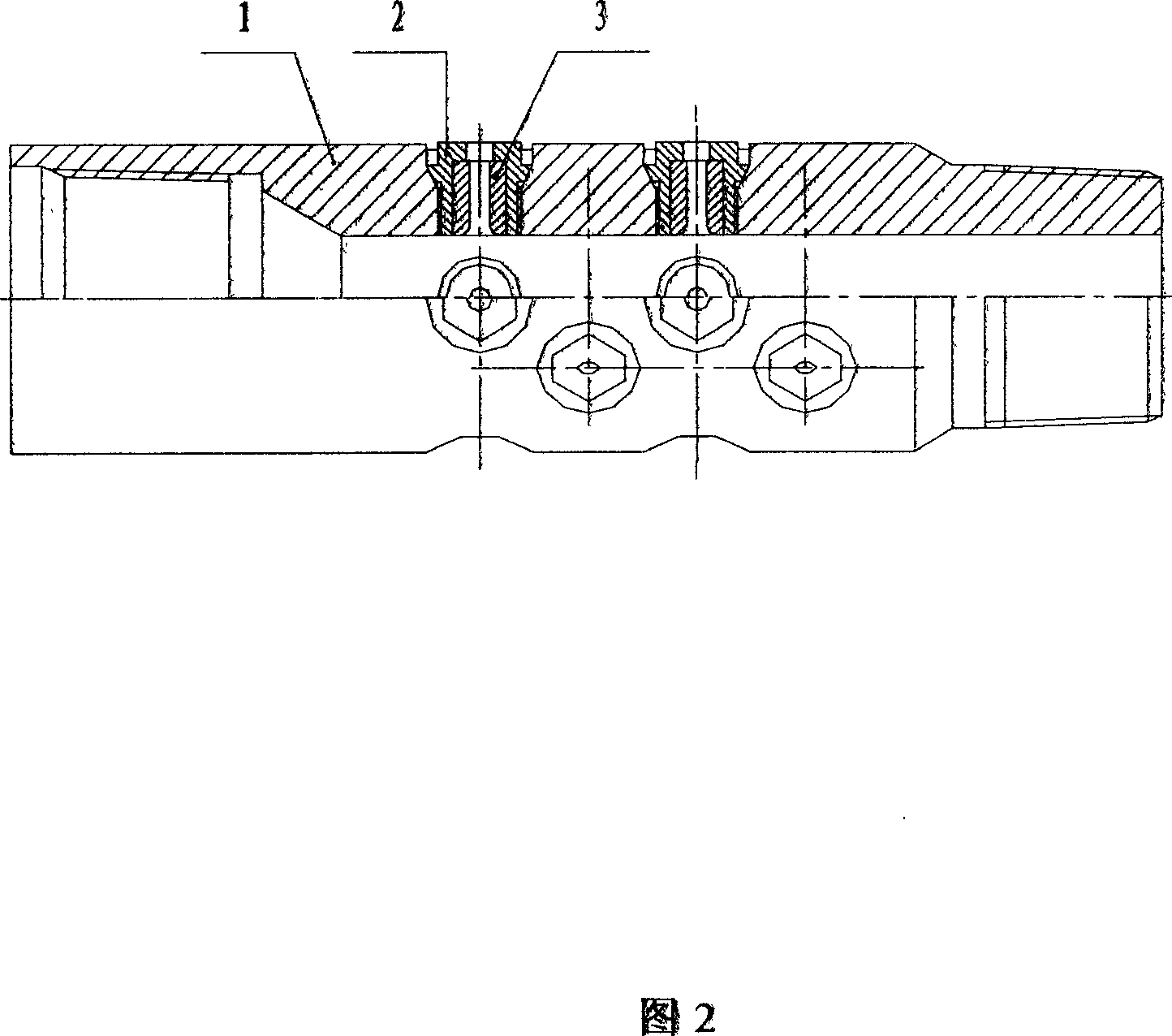

Perforation, fracturing integrated method and its technique pipe

An integral method of perforating hole and fracturing in oil industry and its process pipe column. The first step: aiming the hydraulic ejector 4 at the oil and gas well designed perforating hole section and processing hydraulic projecting, forming a (or more) projecting pore path on the oil and gas layer; the second step: after the pore path is formed, projecting the fracturing fluid into pore path from ejector nipple through oil pipe in very high speed, while projecting certain fluid into the annular according design to improve the well bore pressure, so the ground layer generates cracks and the cracks start extending towards deeper layer. The process pipe column includes hydraulic ejector (4), single-flow valve (5), screen pipe (6) and so on, the oil pipe (1), universal joint (2), eccentric locator (3), hydraulic ejector (4), single-flow valve (5), screen pipe (6) and blind head (7) are connected sequentially, it applies to the multistage layered pressing crack of barefoot horizontal well and composes the perforating hole and fracturing into one unit; it has longer penetrating depth and bigger perforating hole aperture than ordinary polyenergy perforating and avoids the injury of reservoir caused by ordinary perforating.

Owner:PETROCHINA CO LTD

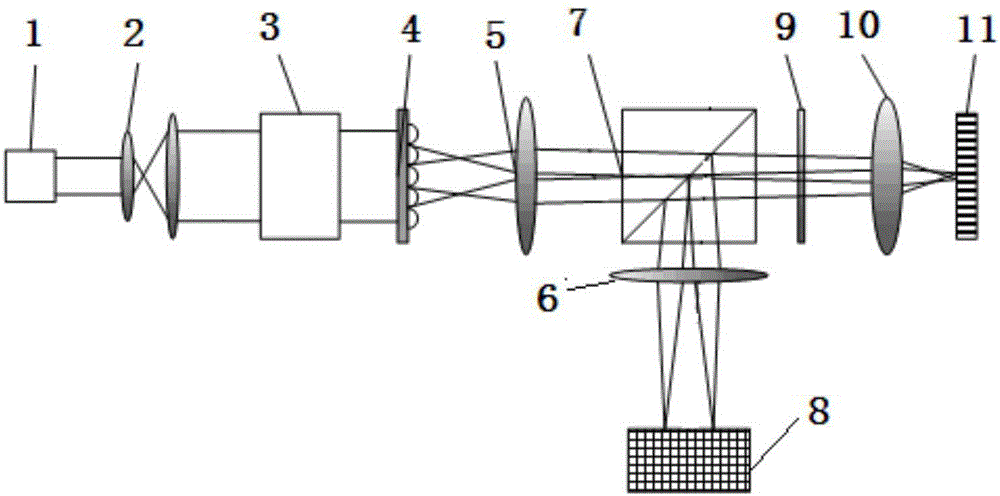

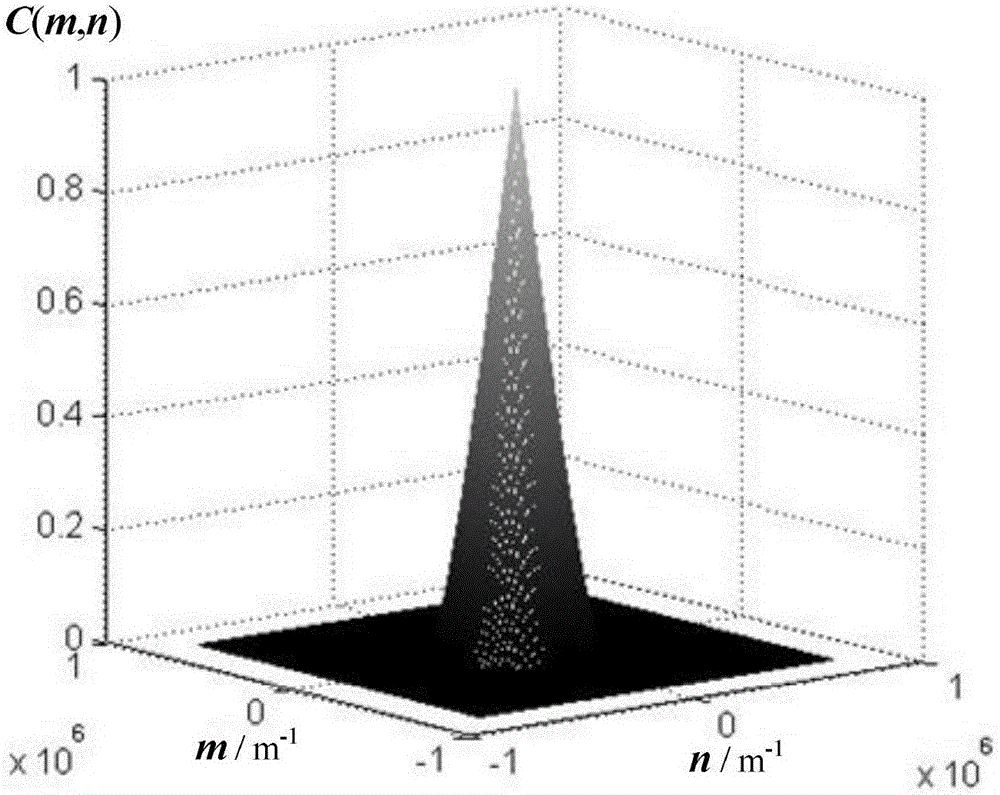

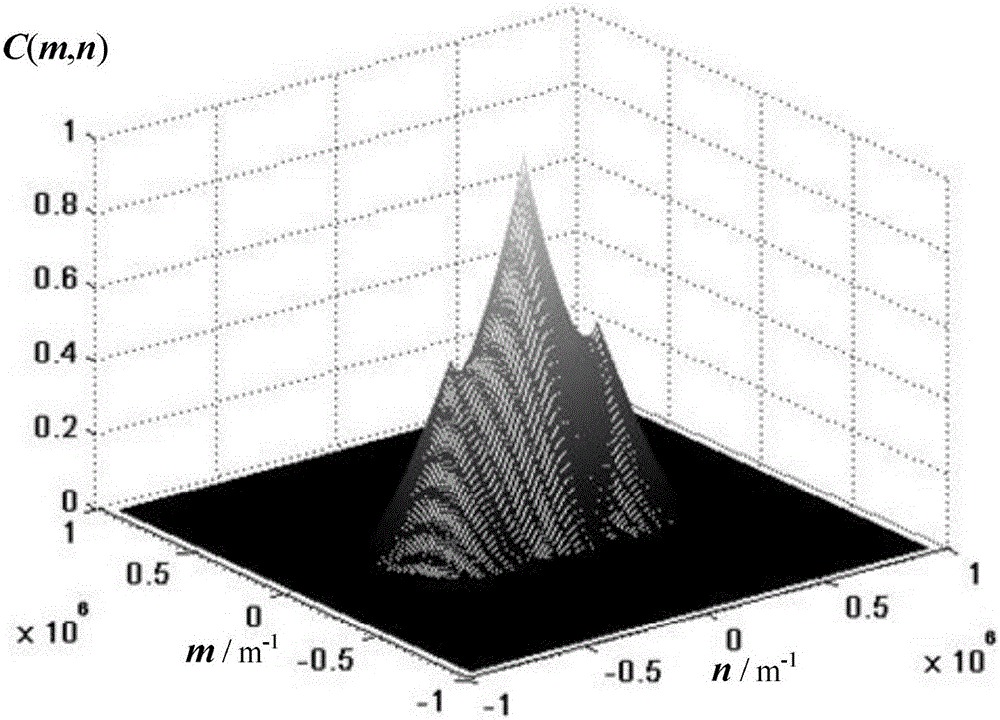

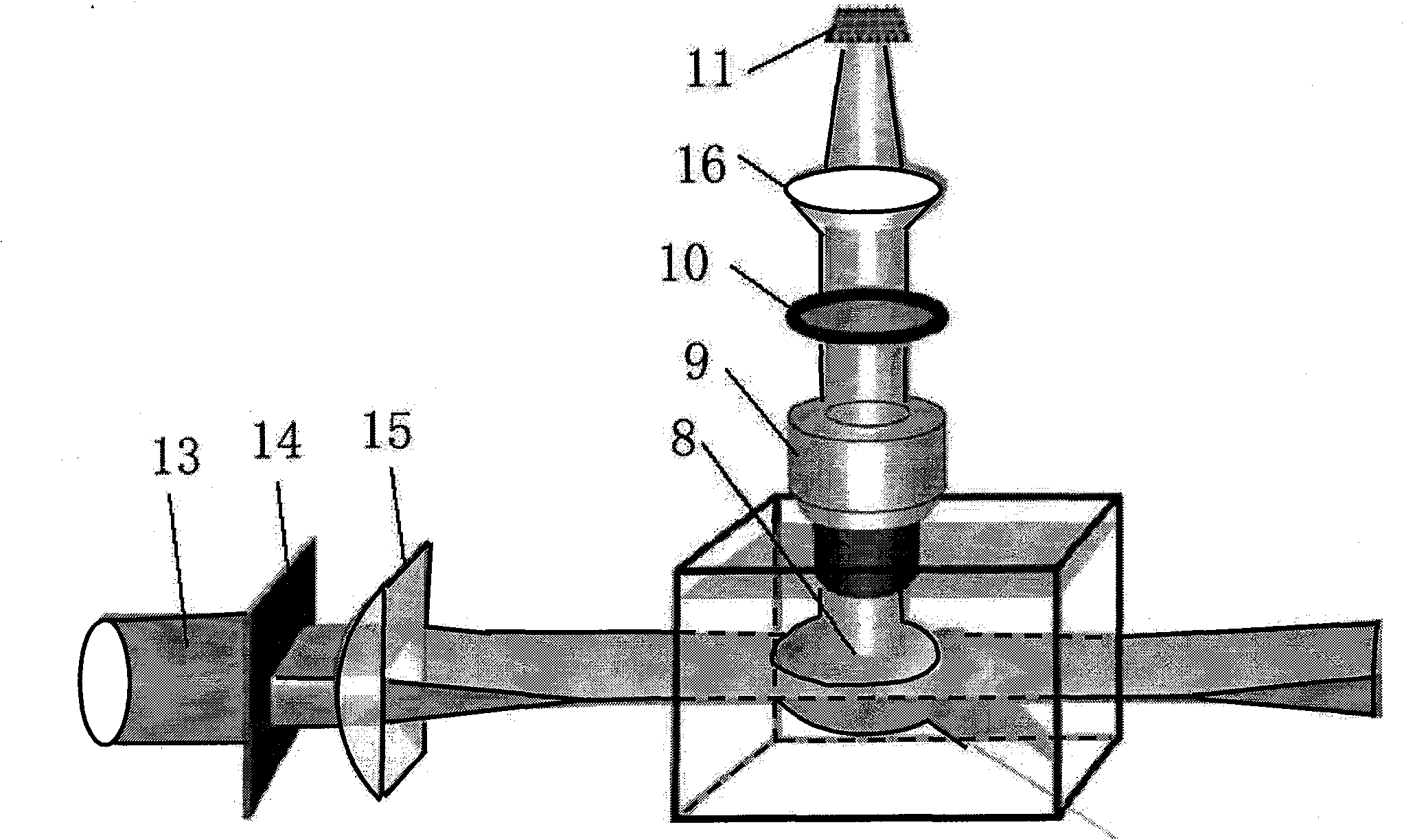

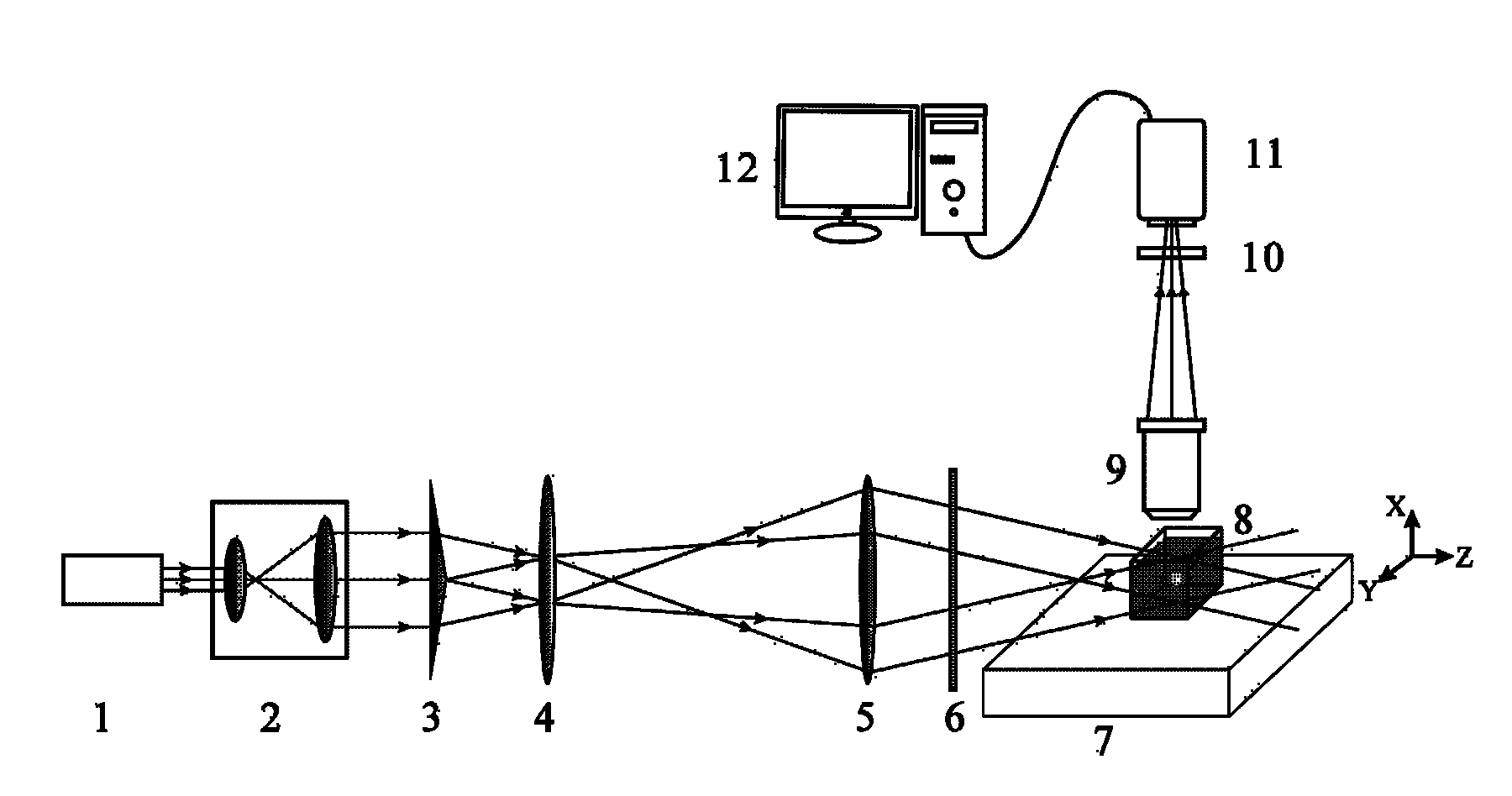

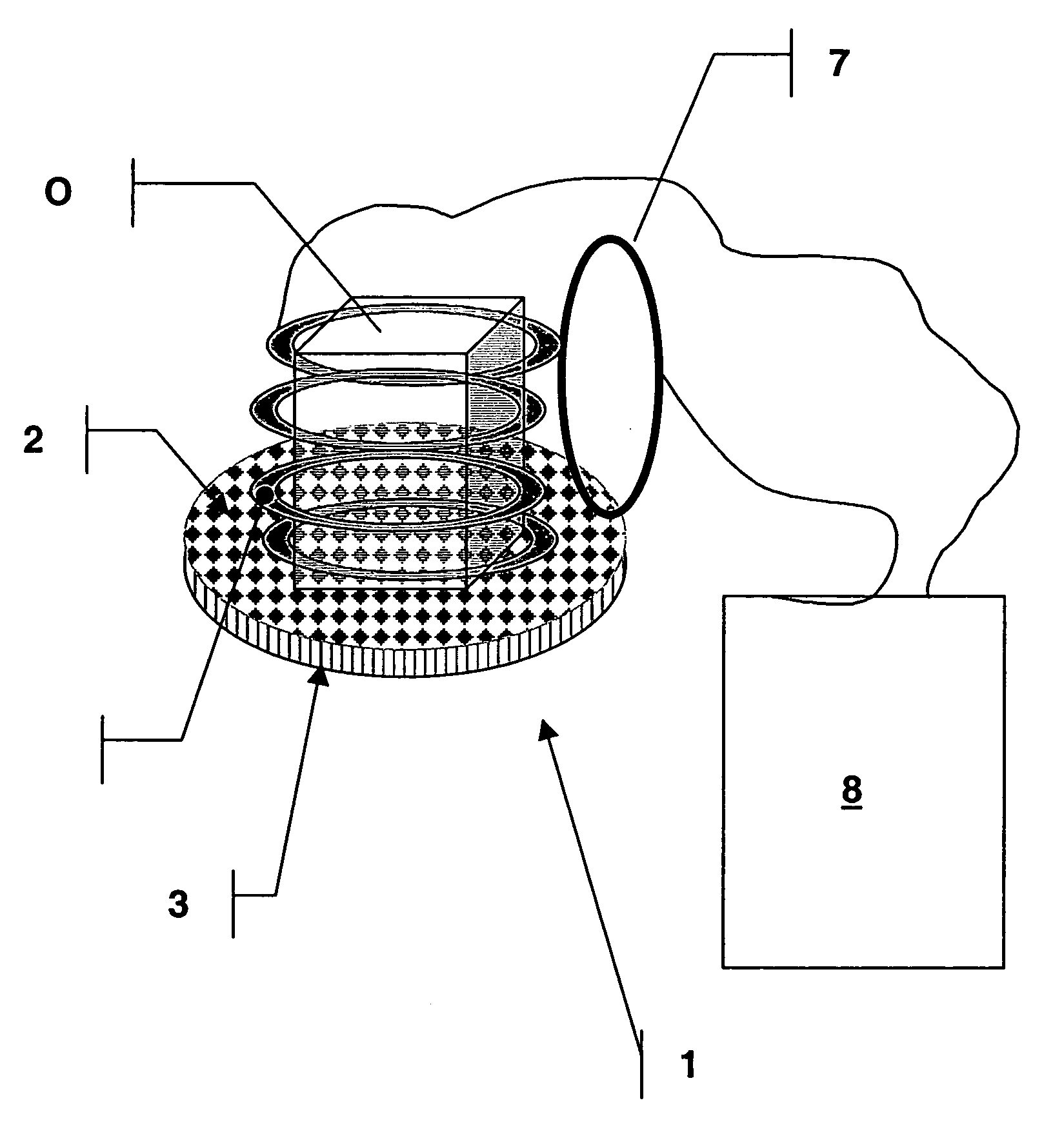

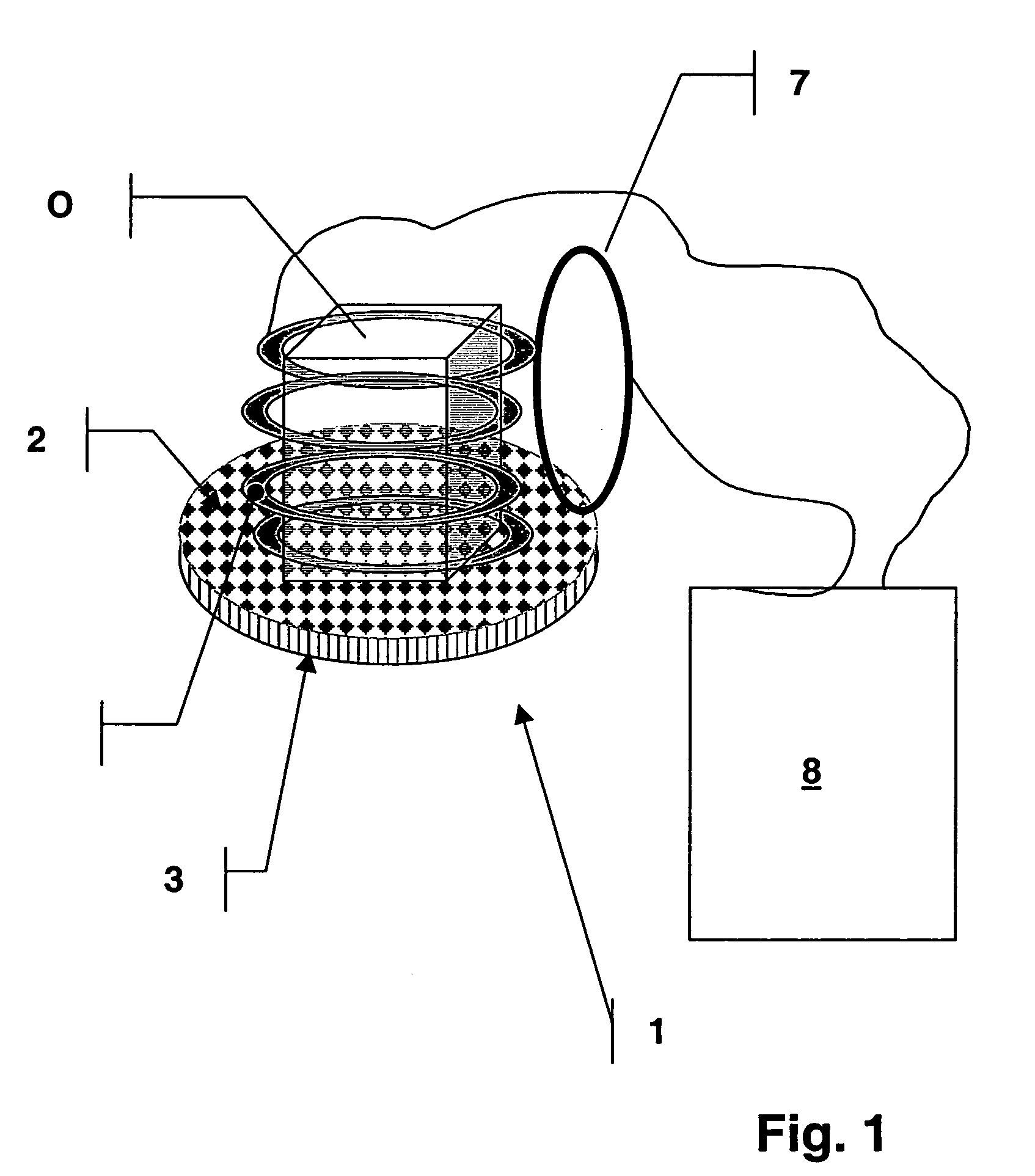

Super-resolution array virtual structure light lighting imaging device and method

ActiveCN105758799ARaise the spatial cutoff frequencyHigh bandwidthMaterial analysis by optical meansBeam expanderLight spot

The invention relates to an imaging device and method, in particular to a super-resolution array virtual structure light lighting imaging device and method, and aims to solve the problem that microscopic imaging technology can only measure thin biological samples, thereby being low in measuring efficiency in the prior art.The device comprises an LED light source 1, a collimating beam expander 2, a scanning system 3, a micro lens array 4, a collimating lens 5, a beam splitting prism 7, a one-fourth wave plate 9, a lighting object lens 10, a sample 11, a collection lens 6 and a CCD (charge coupled device) detector 8.Detection light spots obtained by scanning of each time are directly stacked on the mirror surface to obtain primary detection data, scanning different in phase lighting is performed in each direction, and super-resolution images are obtained through image reconstruction.The super-resolution array virtual structure light lighting imaging device and method expands spatial frequency domain bandwidth and is suitable for the measuring field of industrial shape and thick biological sample imaging.

Owner:HARBIN INST OF TECH

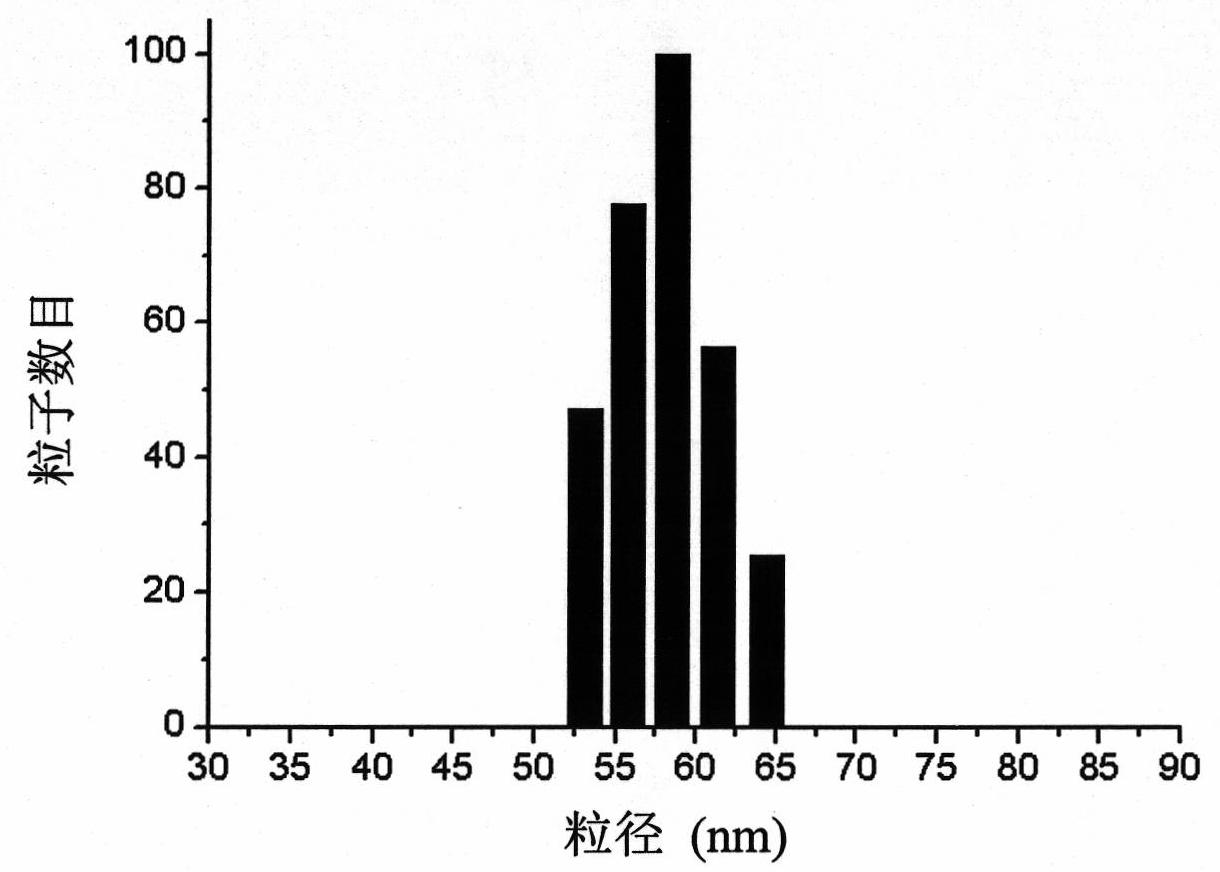

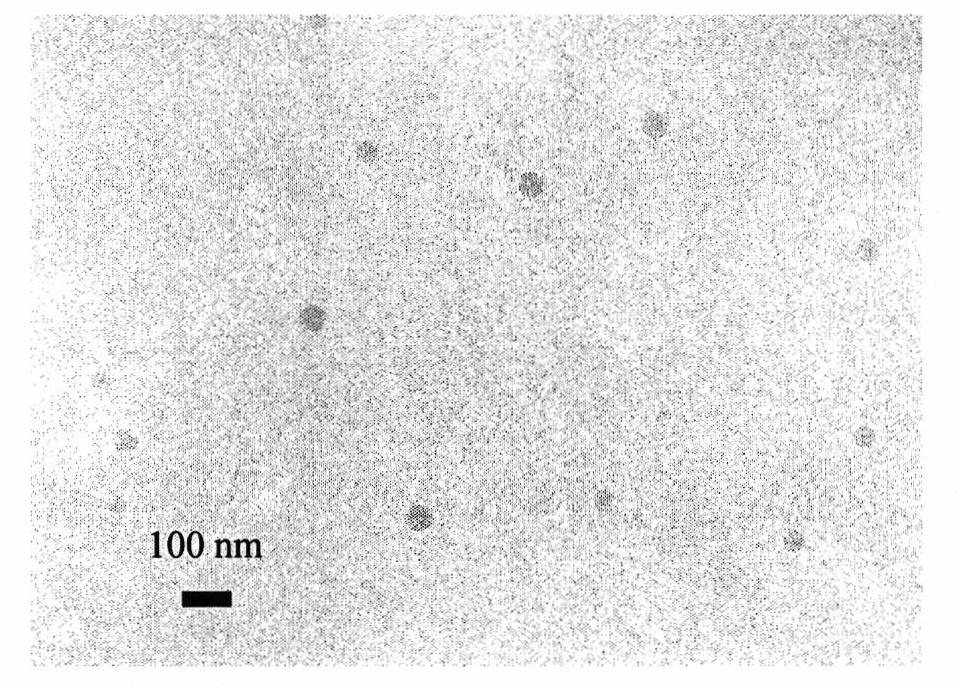

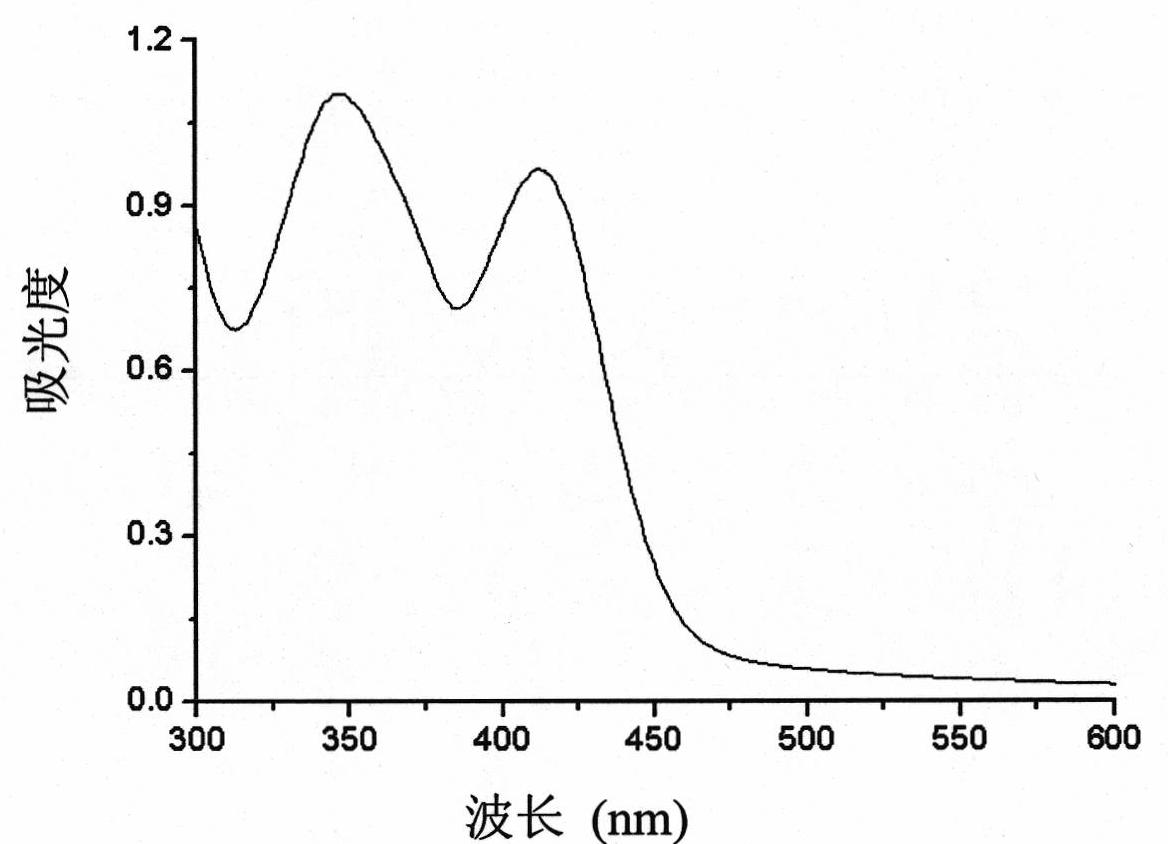

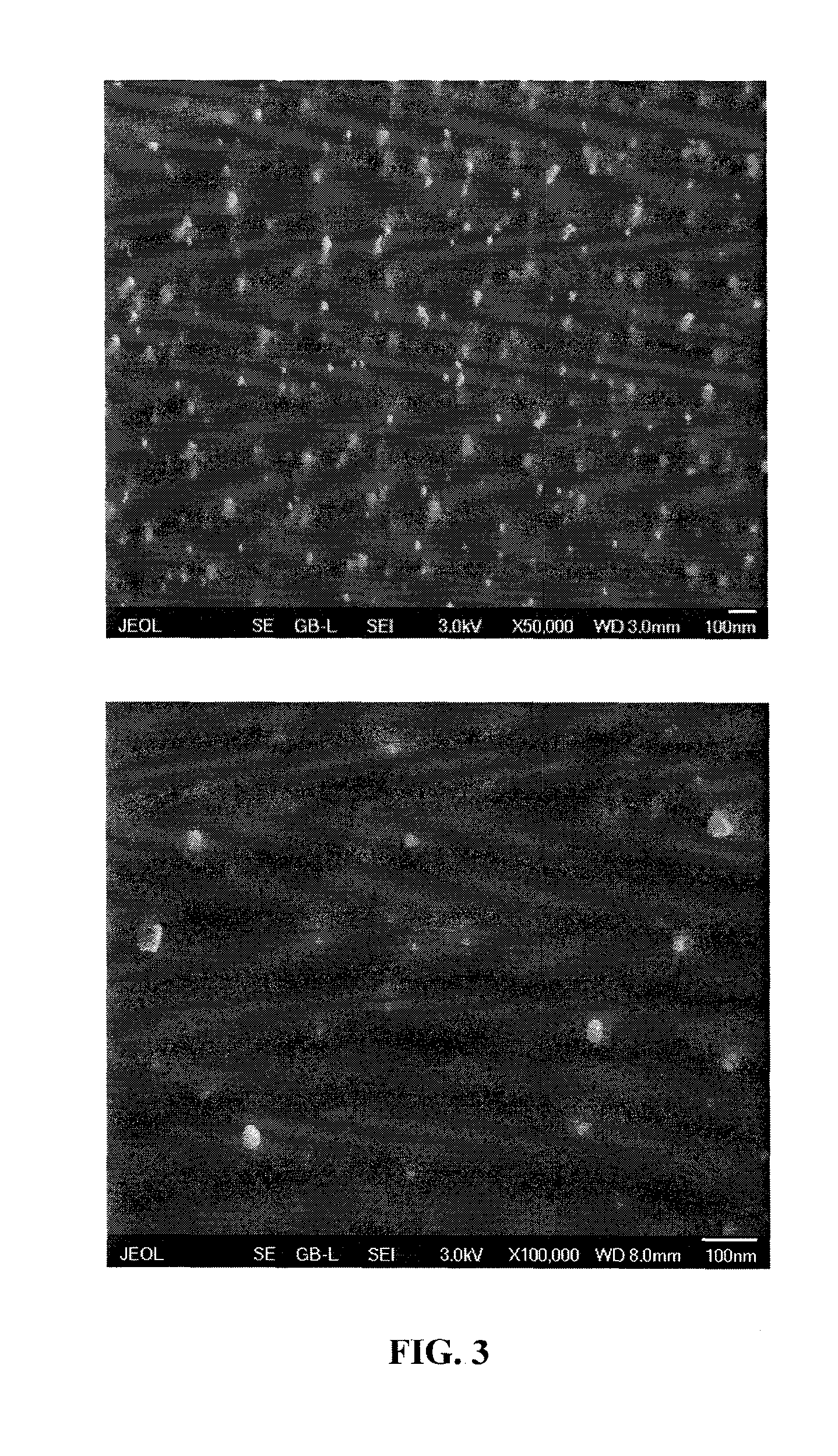

Photoluminescent nano particle as well as preparation method and application thereof

InactiveCN102134253ANarrow emission peakStocks displacement is largeGroup 3/13 organic compounds without C-metal linkagesBiological testingOrganic solventPhotoluminescence

The invention discloses a photoluminescent nano particle as well as a preparation method and an application thereof. The photoluminescent nano particle is composed of a carboxyl-containing copolymer matrix material and a rare earth fluorescent dye dispersed in the matrix material. The preparation method of the fluorescent nano particle comprises the following steps: dissolving the rare earth compound fluorescent dye and the copolymer in an organic solvent which is capable of being miscible with water; and adding the solution in water, so that the fluorescent nano particle is formed by utilizing a coprecipitation-self assembly process. The fluorescent nano particle has the advantages of excellent long wave excitation luminescence property and good stability, and has a surface carboxyl group for coupling biomolecules. A biological probe based on the fluorescent nano particle has a wide application prospect in the aspects of high-sensitivity fluorescent immunoassay, biological imaging and the like.

Owner:PEKING UNIV

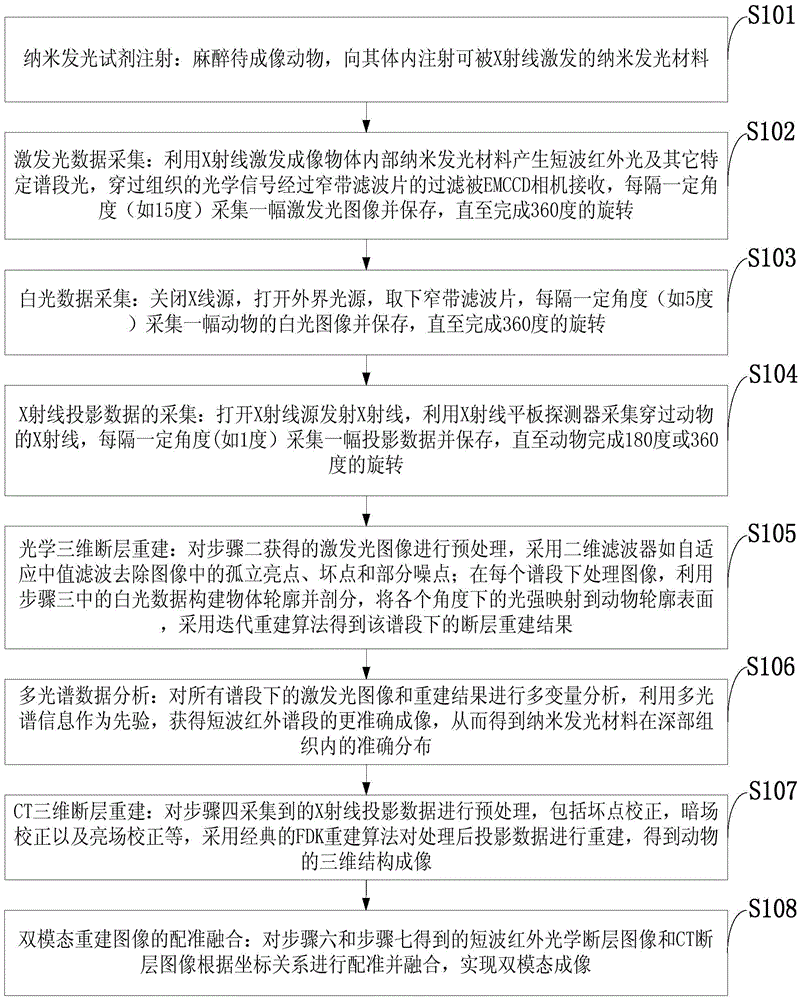

Deep tissue X-ray excitation multispectral tomography system and method

ActiveCN105640582AGreat penetration depthMeet imaging requirementsComputerised tomographsTomographyX-rayWavelength

The invention discloses a deep tissue X-ray excitation multispectral tomography system and method. The system comprises an X-ray source, an X-ray flat panel detector, an EMCCD camera, an electric control rotary table, a narrow-band filter, a lead plate, a computer and an animal to be imaged; nano-luminescence materials are excited through an X ray, short-wave infrared light with the specific spectra sections, particularly high penetration depth is emitted, photons penetrate through tissue to reach the surface of an imaged object, the light of different wave length spectra sections is received by an EMCCD camera by being filtered by the narrow-band filter, and an obtained image and a rebuilt result under each spectra section are obtained; multivariate analysis is adopted for carrying out treatment and analysis on multispectral images and rebuilt results, accurate distribution of the nano-luminescence materials in the object is obtained and combined with CT tomography results, and finally a deep tissue multispectral tomography image is obtained. The imaging depth of X-ray excitation multispectral tomography can be effectively improved, and deep tissue imaging of small living animals is achieved.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

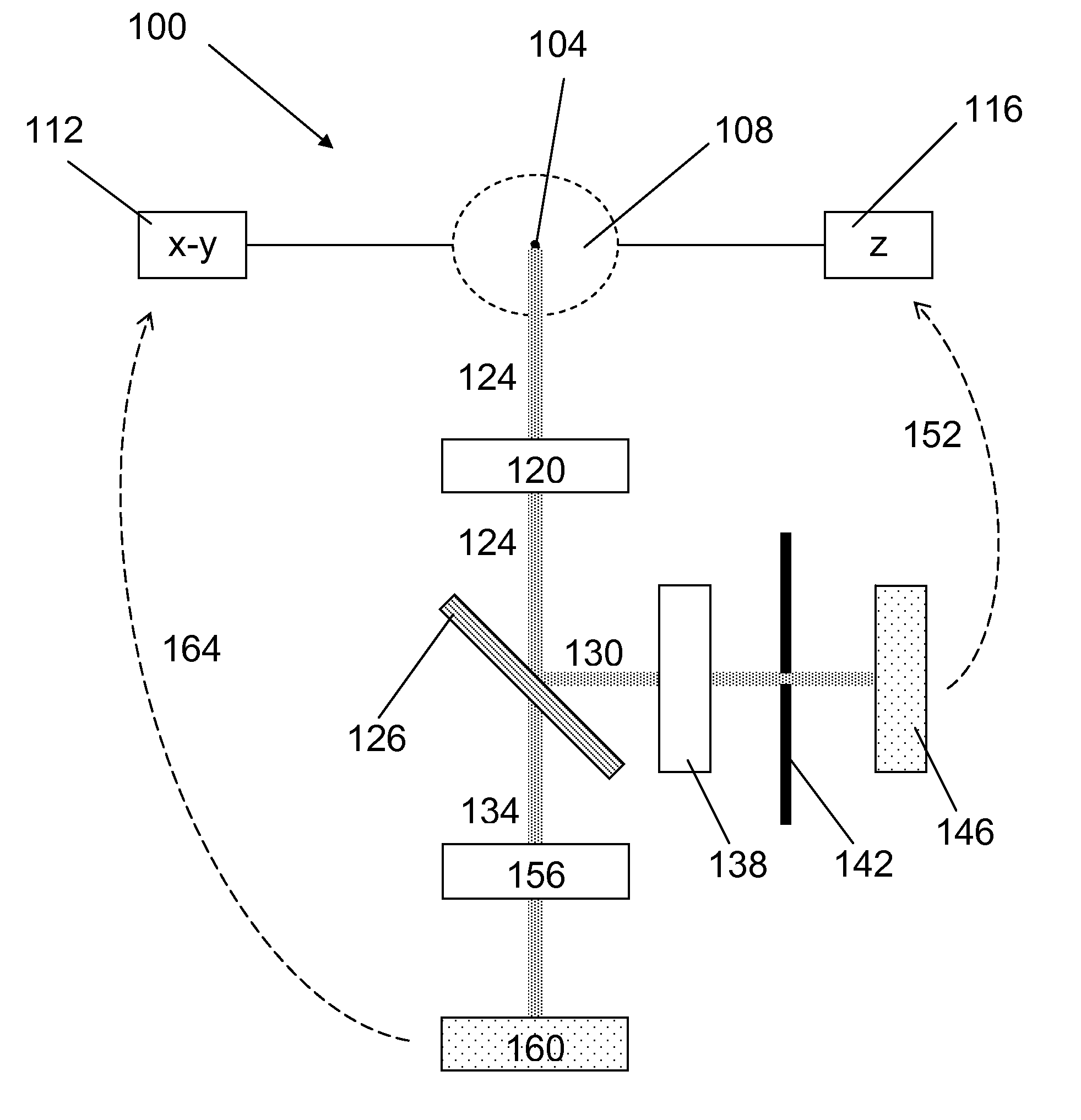

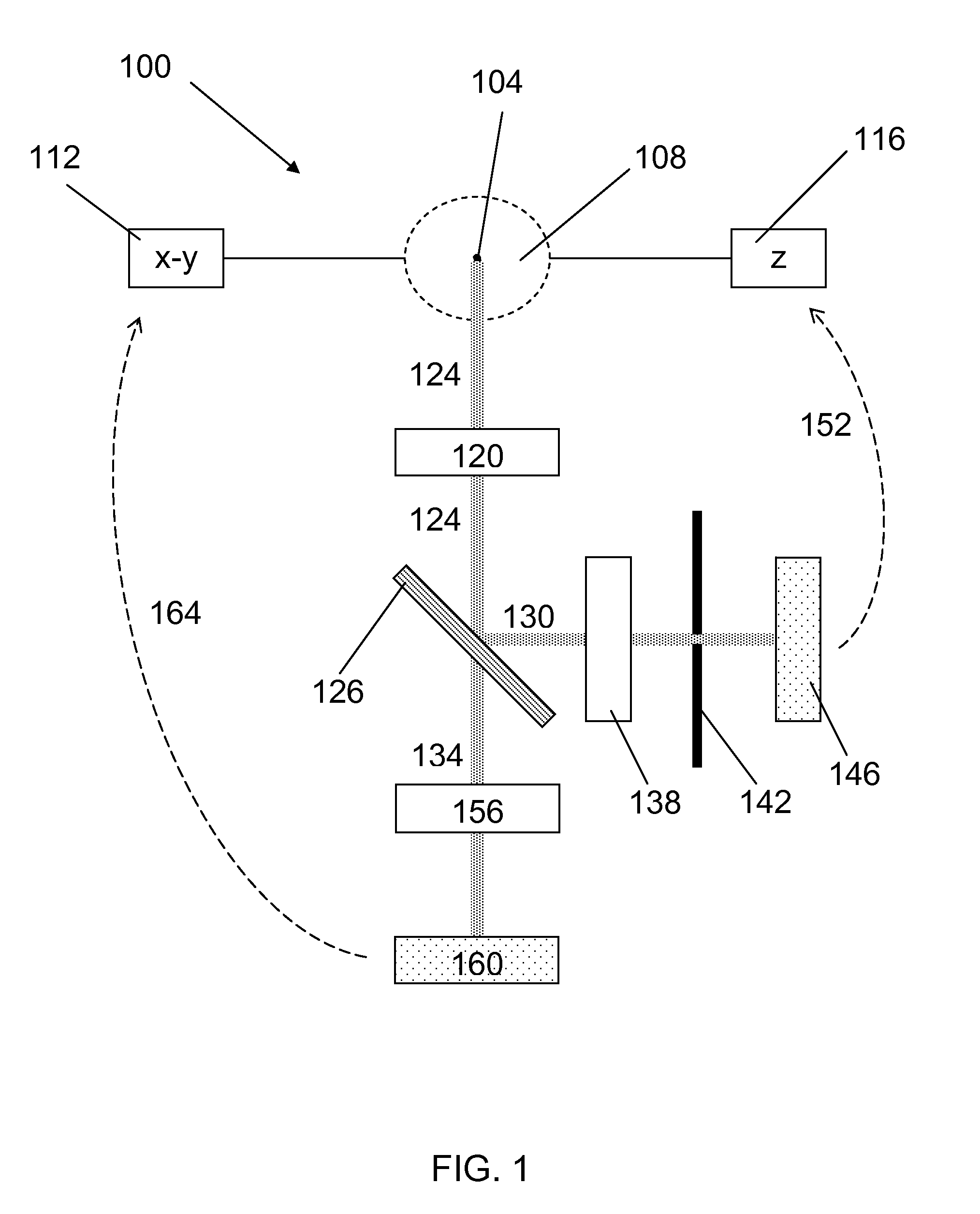

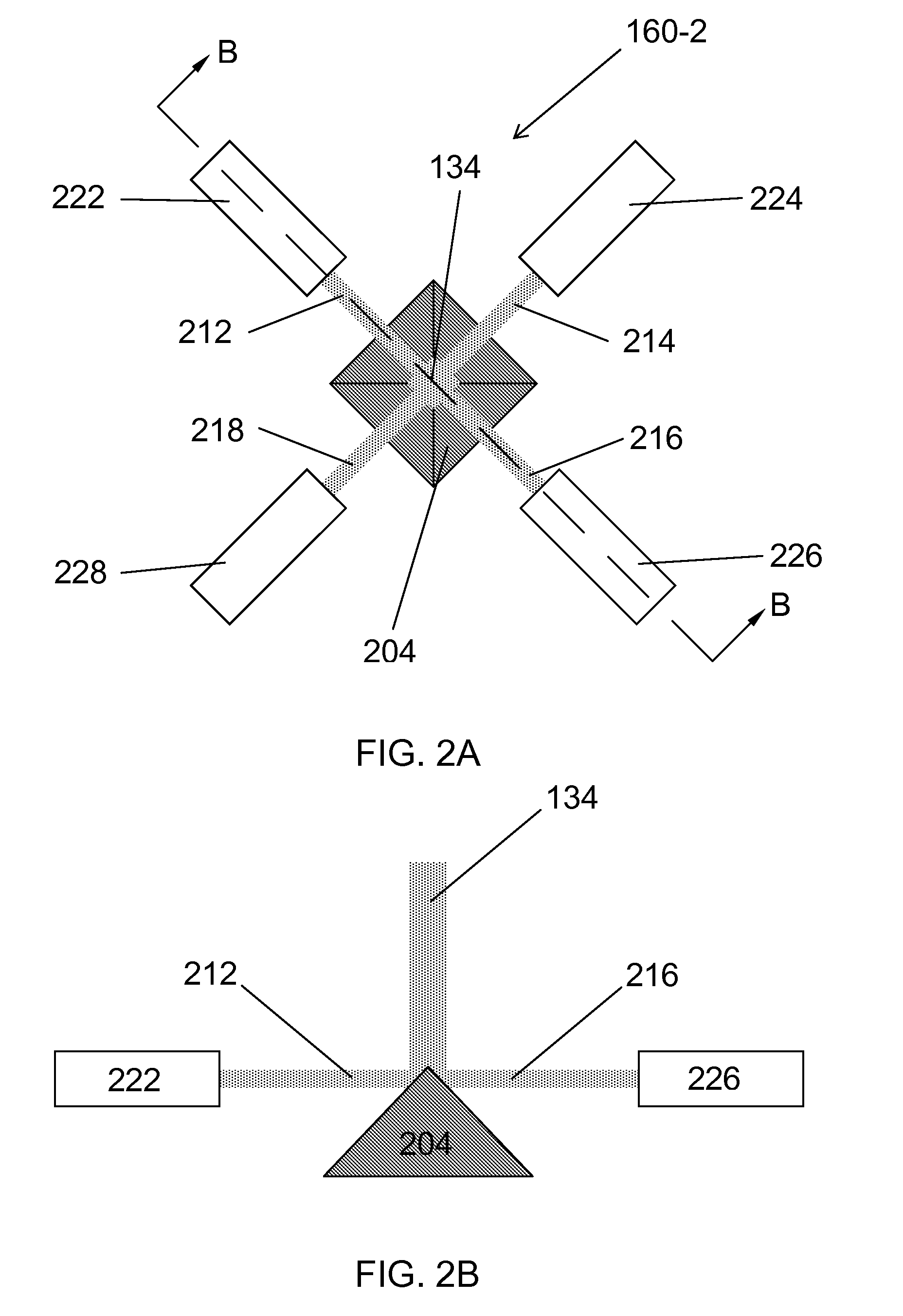

Single nanoparticle tracking spectroscopic microscope

ActiveUS20110057121A1Reduce materialGreat penetration depthThermometer detailsRaman/scattering spectroscopyNanoparticleMicroscope

A system that can maintain and track the position of a single nanoparticle in three dimensions for a prolonged period has been disclosed. The system allows for continuously imaging the particle to observe any interactions it may have. The system also enables the acquisition of real-time sequential spectroscopic information from the particle. The apparatus holds great promise in performing single molecule spectroscopy and imaging on a non-stationary target.

Owner:RGT UNIV OF CALIFORNIA

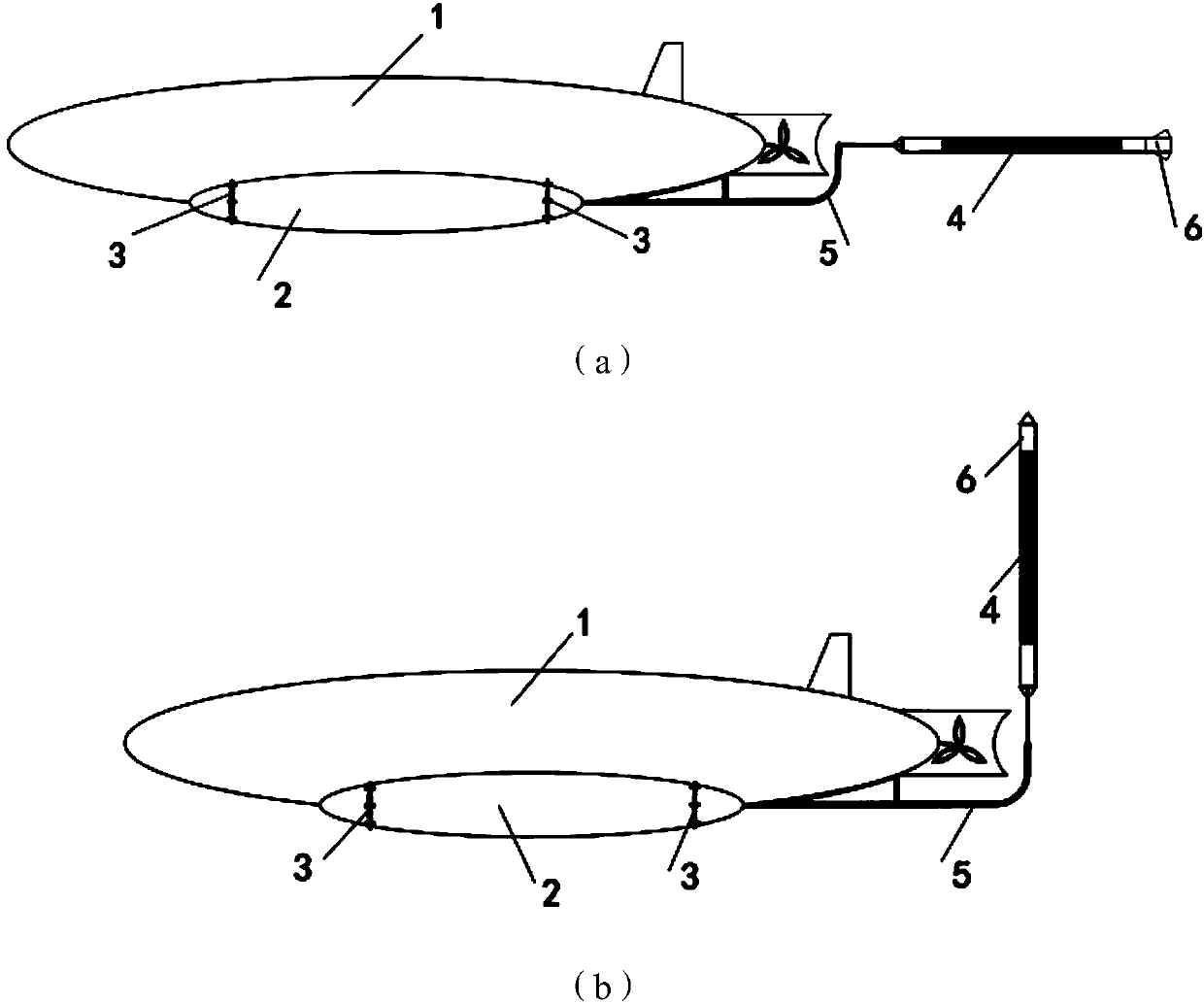

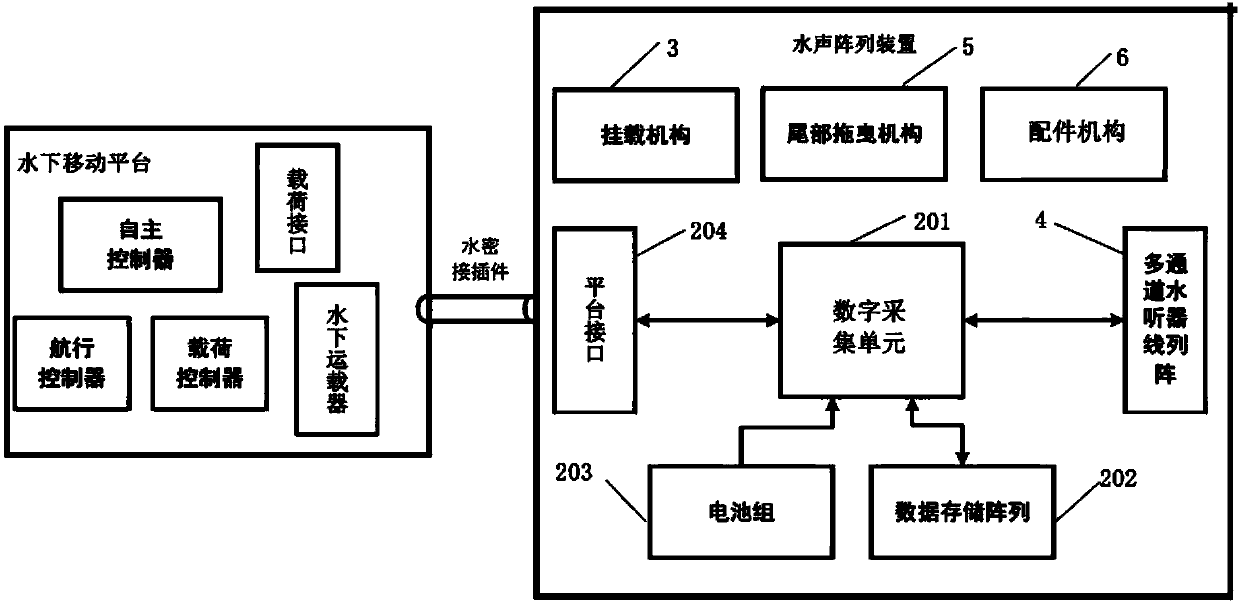

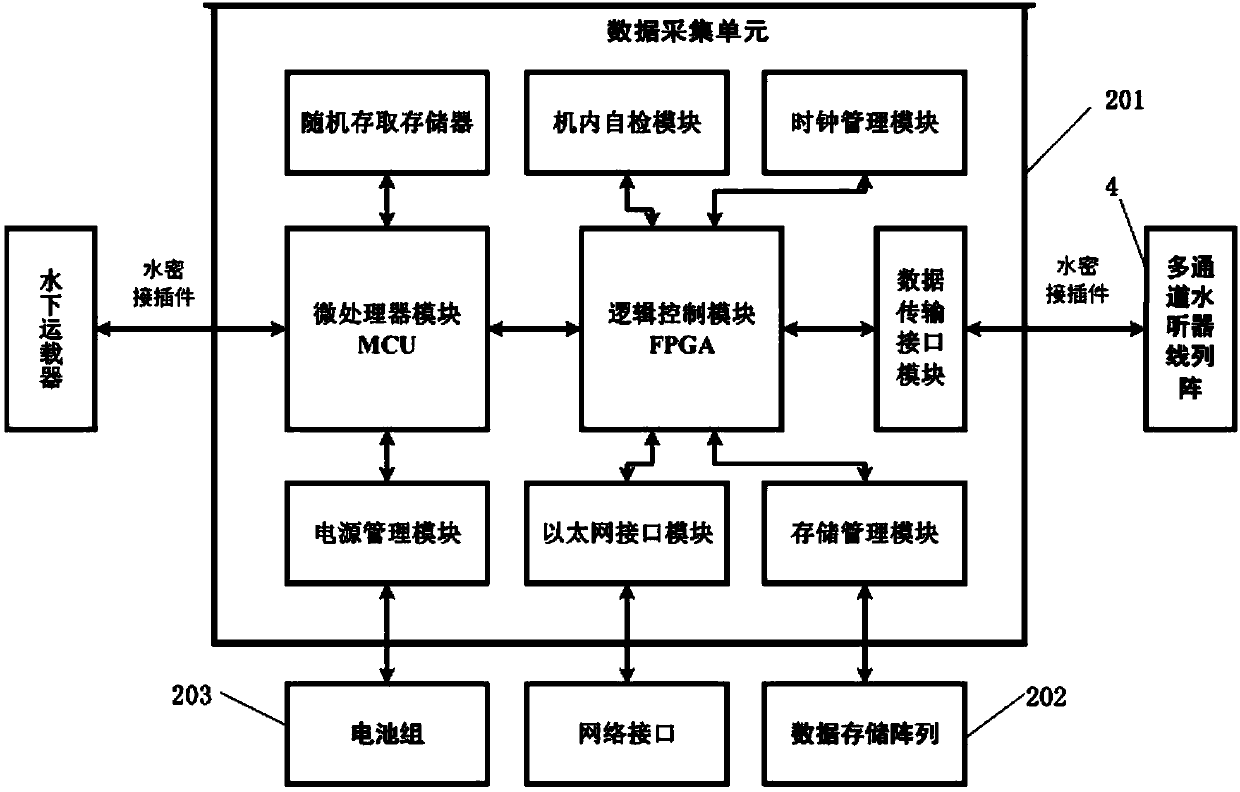

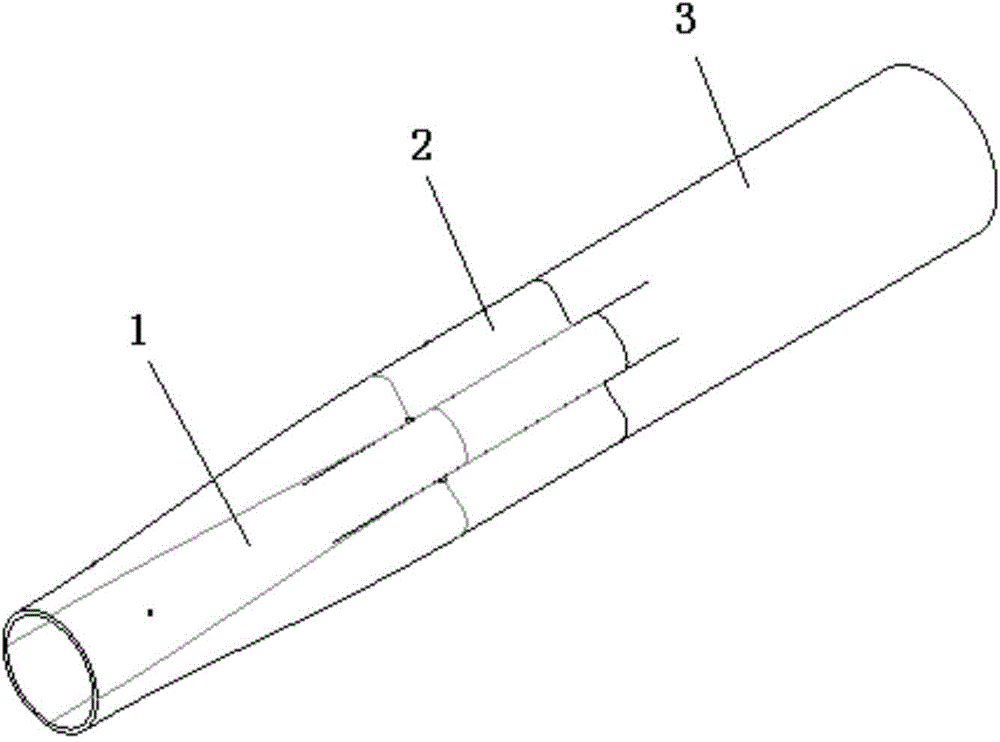

Underwater sound array device based on underwater movement platform

PendingCN108037534AAvoid attenuationGreat penetration depthSeismology for water-covered areasHydrophoneUltrasound attenuation

The invention discloses an underwater sound array device based on an underwater movement platform. The underwater sound array device is connected with the underwater movement platform and comprises anexternally-mounted self-contained collection bin, a multi-channel hydrophone linear array and a mounting mechanism, wherein the externally-mounted self-contained collection bin is externally mountedand fixed on the underwater movement platform through the mounting mechanism; and the externally-mounted self-contained collection bin is connected with the underwater movement platform and is furtherconnected with the multi-channel hydrophone linear array. By utilizing the underwater sound array device, when seismic exploration work is carried out in a deep sea area, the sharp attenuation of sound waves caused by great-depth sea water is avoided, the seismic exploration resolution ratio is increased, and the stratum penetration depth is increased. When the underwater sound array device is applied to hydroacoustic investigation, the underwater movement platform can be conveniently controlled to be sailed and moved to a seabed on the other position and is static again, so that the time forrecycling and rearranging an underwater sound array is saved, and the working efficiency is improved.

Owner:NAT DEEP SEA CENT +1

Method for selectively killing cells utilizing ultraviolet conversion luminous nano particles

InactiveCN1977999AGreat penetration depthNo harmIndividual molecule manipulationRadioactive preparation carriersAntigenUpconversion luminescence

The present invention relates to a method capable of utilizing ultraviolet up-conversion granules to selectively kill cells, and is characterized by that it uses the ultraviolet up-conversion nano granules capable of sending ultraviolet light under the irradiation of infrared light or visible light, makes the antibody capable of implementing specific combination with target cell be connected on said nano granule surface and utilizes the characteristics of that said antibody and cell surface correspondent antigen can make selectively combination so as to implement selective combination of nano granules and target cells, then it adopts infrared light or ultraviolet light to irradiate the ultraviolet up-conversion luminous nano granules so as to kill the cells combined with ultraviolet light sent by said ultraviolet up-conversion granules.

Owner:UNIV OF SCI & TECH OF CHINA

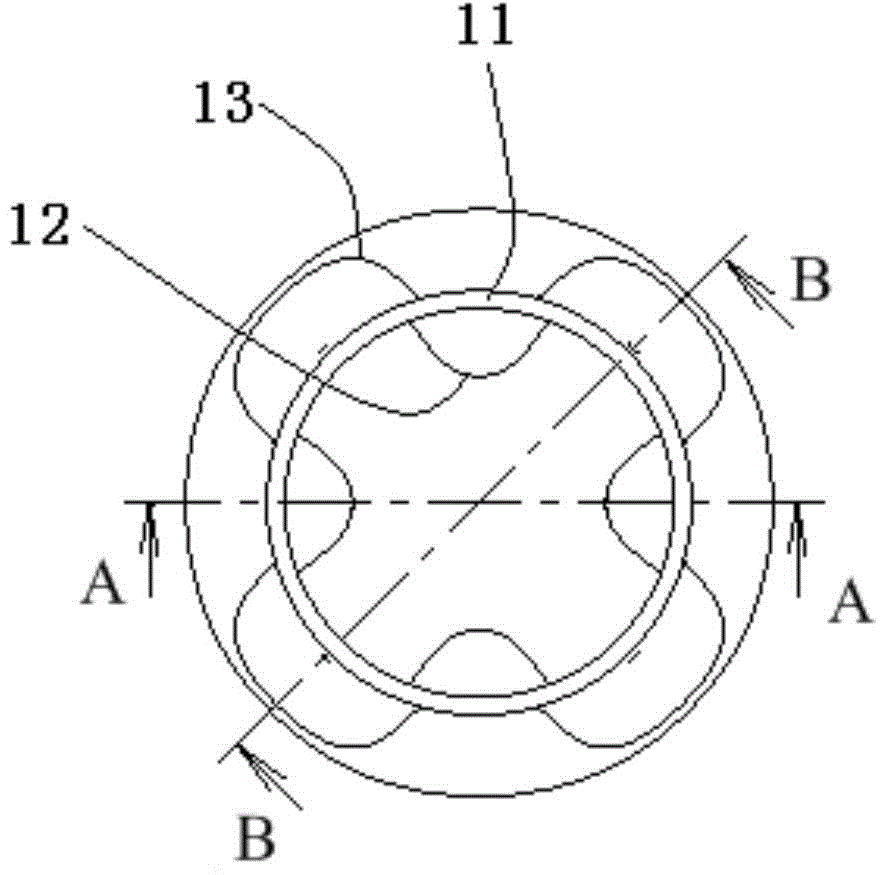

Large-scale hyshot scramjet engine and three-dimensional petal-shaped section combustor

ActiveCN104654362AGreat penetration depthGood for injection mixingContinuous combustion chamberCombustion chamberScramjet engine

The invention provides a large-scale hyshot scramjet engine and a three-dimensional petal-shaped section combustor. The three-dimensional petal-shaped section combustor comprises a fuel injection section, a flame stabilization section and an expansion section, wherein the wall face of the flame stabilization section is in a lobe structure that bumps and recesses are alternatively formed on the circumference direction; the bumps of the lobe structure gradually approach towards a center axis along a flow direction; the lobe structure extends to the tail end of the fuel injection section, so as to form a petal-shaped structure; a second group of orifices are formed in each of the top points of the bumps at the tail end of the fuel injection section; a first group of orifices are formed in each of the top points of the recesses at the upstreams of the second group of the orifices, so as to form combined injection. According to the three-dimensional petal-shaped section combustor, the lobe structure can divide incoming flow air into a plurality of strands of air flows, so that the injection mixing of fuels is beneficial; bump injection and recess injection of a combustor are combined, so that the effect that the fuels are uniformly mixed in a short distance is realized. Furthermore, no support plates exist in the combustor, so that thermal protection limit is easy to realize.

Owner:NAT UNIV OF DEFENSE TECH

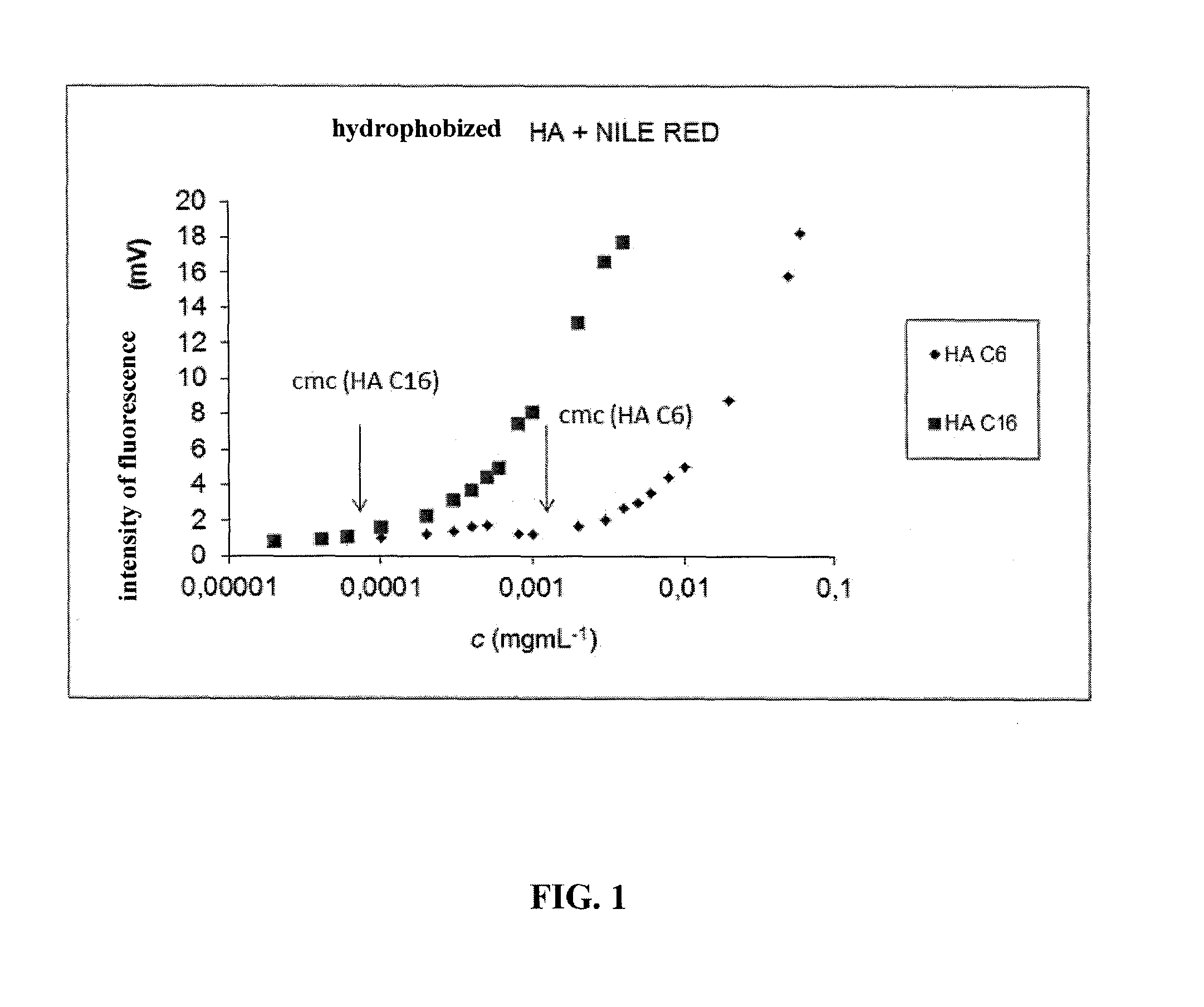

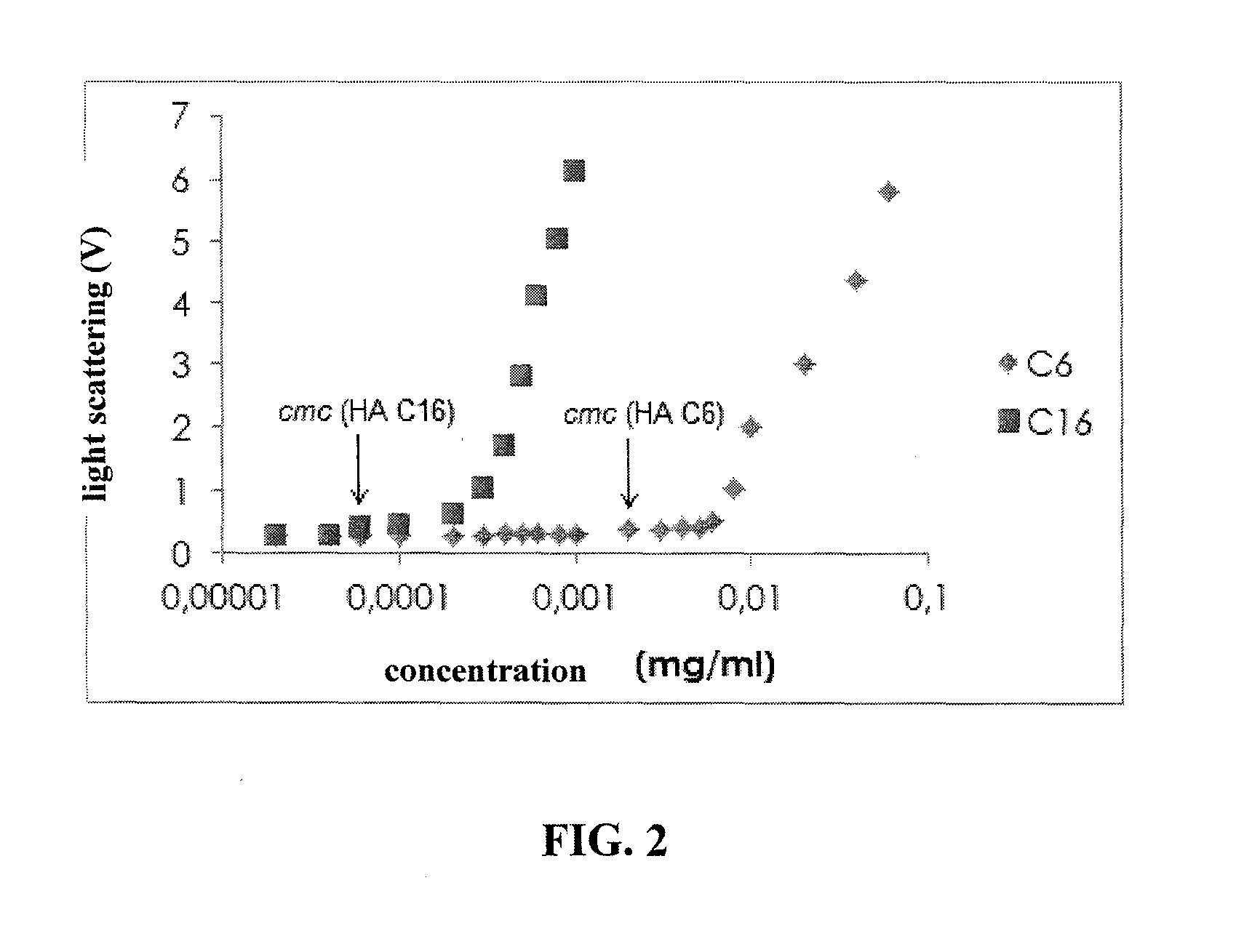

C6-C18-Acylated Derivative of Hyaluronic Acid, Method of Preparation Thereof, Nanomicellar Composition on its Basis, Method of Preparation Thereof and Method of Preparation Stabilized Nanomicellar Composition, and Use Thereof

ActiveUS20150320873A1Improve permeabilityImprove retentionPowder deliveryBiocideBenzoic acidAcyl group

The invention relates to a method of preparation hydrophobized hyaluronic acid (Formula I) and further to a method of encapsulating biologically active substances into the nanomicelles of hydrophobized hyaluronan serving as carriers of biologically active hydrophobic substances. The hydrophobization of hyaluronan is carried out through an esterification reaction of hyaluronan with long-chain carboxylic acids, the latter being activated by a halogenide derivative of 2,4,6-trichlorobenzoic acid or by another organic chloride. In an aqueous environment, water-soluble hydrophobized derivatives can form nanomicelles in which nonpolar substances can be bound by means of non-covalent physical interactions. The core of a nanomicelle is formed by hydrophobic acyl functional groups while the shell of a nanomicelle is formed by hyaluronic acid. The encapsulation of the substances into nanomicelles can be performed by means of the solvent exchange method or by means of sonication. Hyaluronic nanomicelles support the penetration of bound substances in topical applications and enable the bound substances to be transferred into the individual cells. The nanomicelles obtained from hydrophobized hyaluronan derivatives are usable in cosmetic and pharmaceutical applications.

Owner:CONTIPRO AS

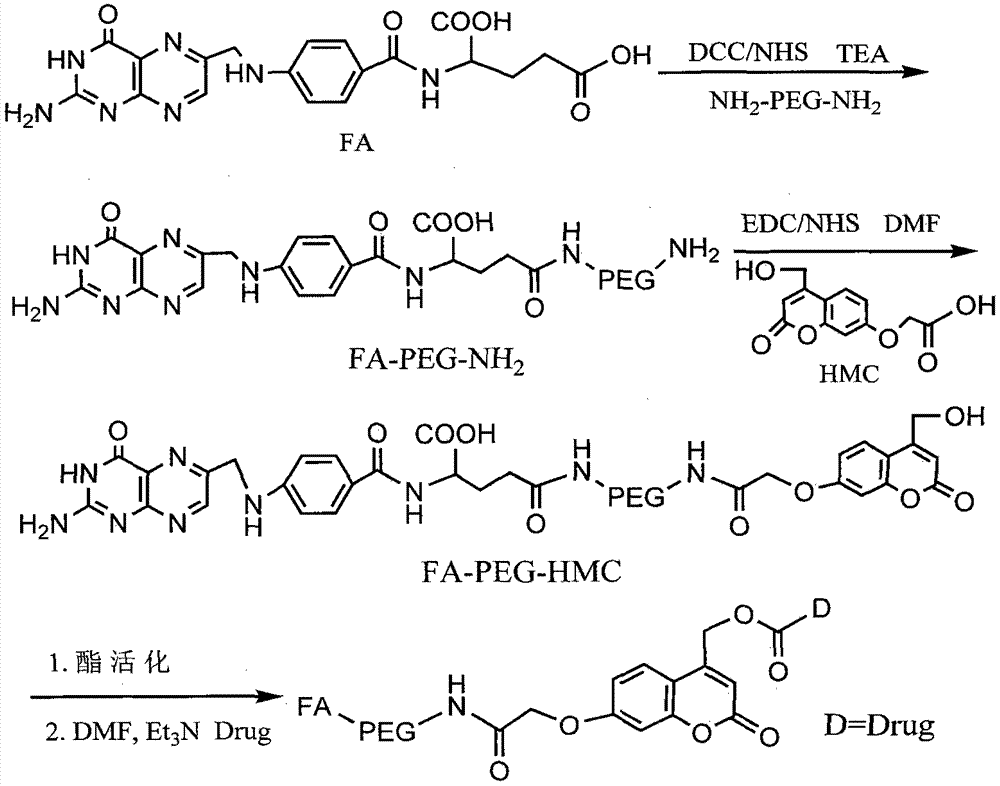

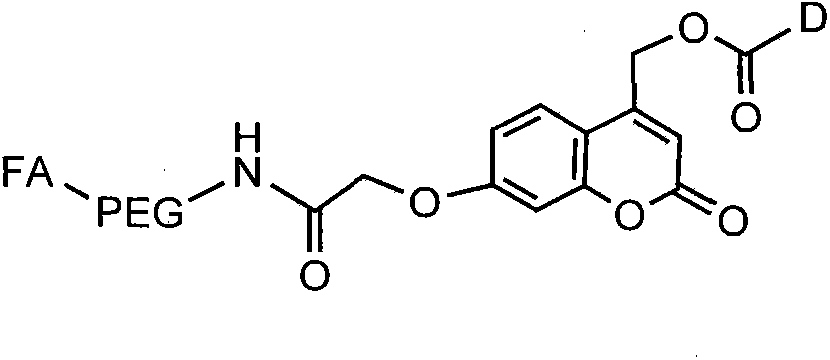

Antitumor medicine conjugate with folic acid receptor-mediated and photoresponsive functions, and preparation method thereof

InactiveCN103768614AHigh affinityAchieve therapeutic effectEnergy modified materialsPharmaceutical non-active ingredientsMedicinal chemistryNear infrared light

The invention belongs to the technical field of high-molecular medicine, and particularly relates to an antitumor medicine conjugate with folic acid receptor-mediated and photoresponsive functions and a preparation method thereof. The preparation method comprises the following steps: firstly, performing amidation reaction on folic acid and amino polyethyleneglycol; then performing amidation reaction on a product obtained in the former step and 7-ethyloic-4-hydroxymethyl coumarin to obtain a polyethyleneglycol flexible chain with a folic acid receptor targeting function and a photoresponse group; finally enabling the polyethyleneglycol flexible chain to be coupled with an antitumor medicine containing amino with an ester activation method to obtain the antitumor medicine conjugate with the folic acid receptor-mediated and photoresponsive functions. The conjugate prepared by the invention can target a tumor cell through a folic acid receptor-mediated function, and enters the cell via the endocytosis to accelerate the accumulation speed of the medicine in the tumor cell; when being irradiated by ultraviolet light with a specific wavelength or near-infrared light, the conjugate is photolyzed to release original medicine, and the medicine quickly reaches the effective concentration, so that controllable 'time / space' treatment is realized; in addition, the method provides a simple and effective manner for preparing target-controllable photoresponsive high-molecular medicine conjugates.

Owner:YANCHENG INST OF TECH

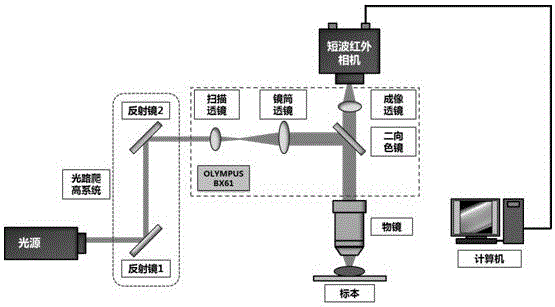

Shortwave infrared fluorescence microimaging method

InactiveCN106596497AGreat penetration depthImprove image signal-to-noise ratioFluorescence/phosphorescenceBeam splitterImage resolution

The invention discloses a shortwave infrared fluorescence microimaging method. A near-infrared light source or a visible light source is used as a light source for exciting a shortwave infrared fluorescence probe, the excitation light source converges on a shortwave infrared fluorescent sample through an objective lens and excites fluorescence, the fluorescence is collected by the objective lens and goes through a beam splitter to separate excitation lights and a fluorescence signal, only the fluorescence signal reaches a shortwave infrared camera, and the shortwave infrared camera transmits a video signal to a computer in order to realize real-time shortwave infrared imaging. Tomographic fluorescence imaging of different depths of the sample can be obtained by adjusting the relative position of the fluorescent sample and the objective lens. Compared with the traditional fluorescence microscopy methods in the visible light band, the method disclosed in the invention has the advantages of large biological tissue penetration depth and small biological damage; and compared with shortwave infrared fluorescence macroimaging methods, the method disclosed in the invention has the advantages of high imaging resolution, high imaging magnification factor, video microimaging realization and tomographic fluorescence imaging realization.

Owner:ZHEJIANG UNIV

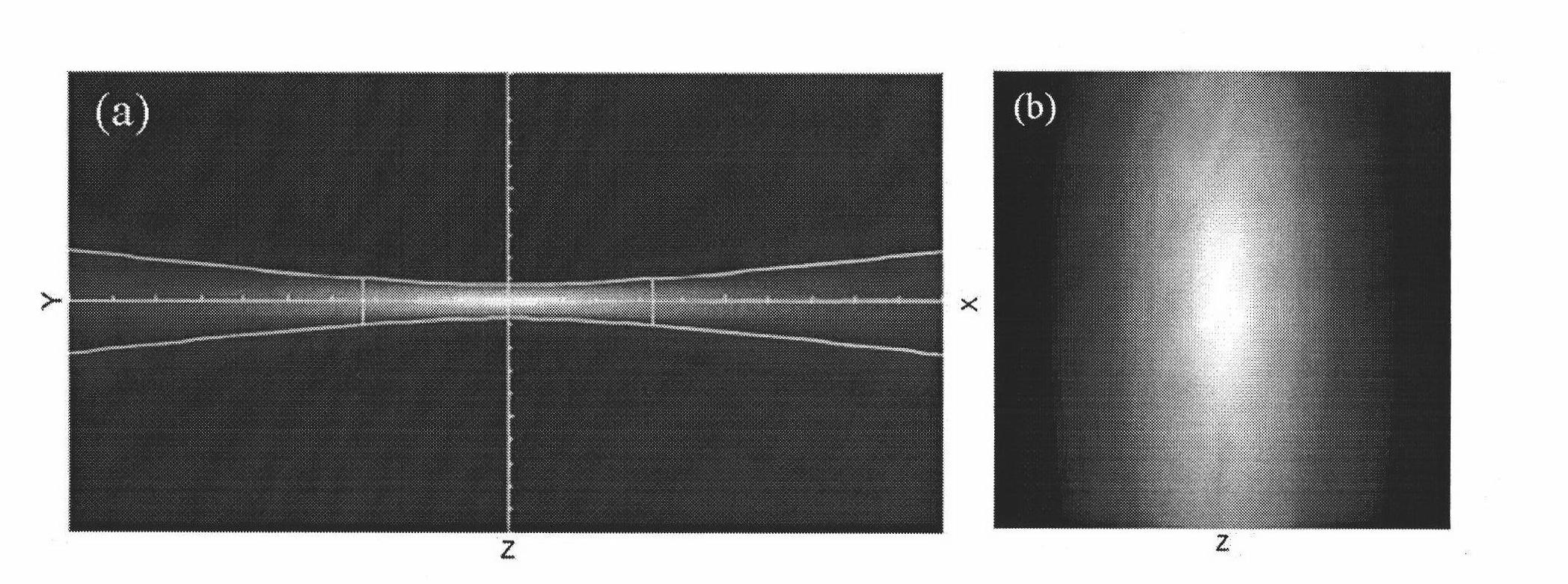

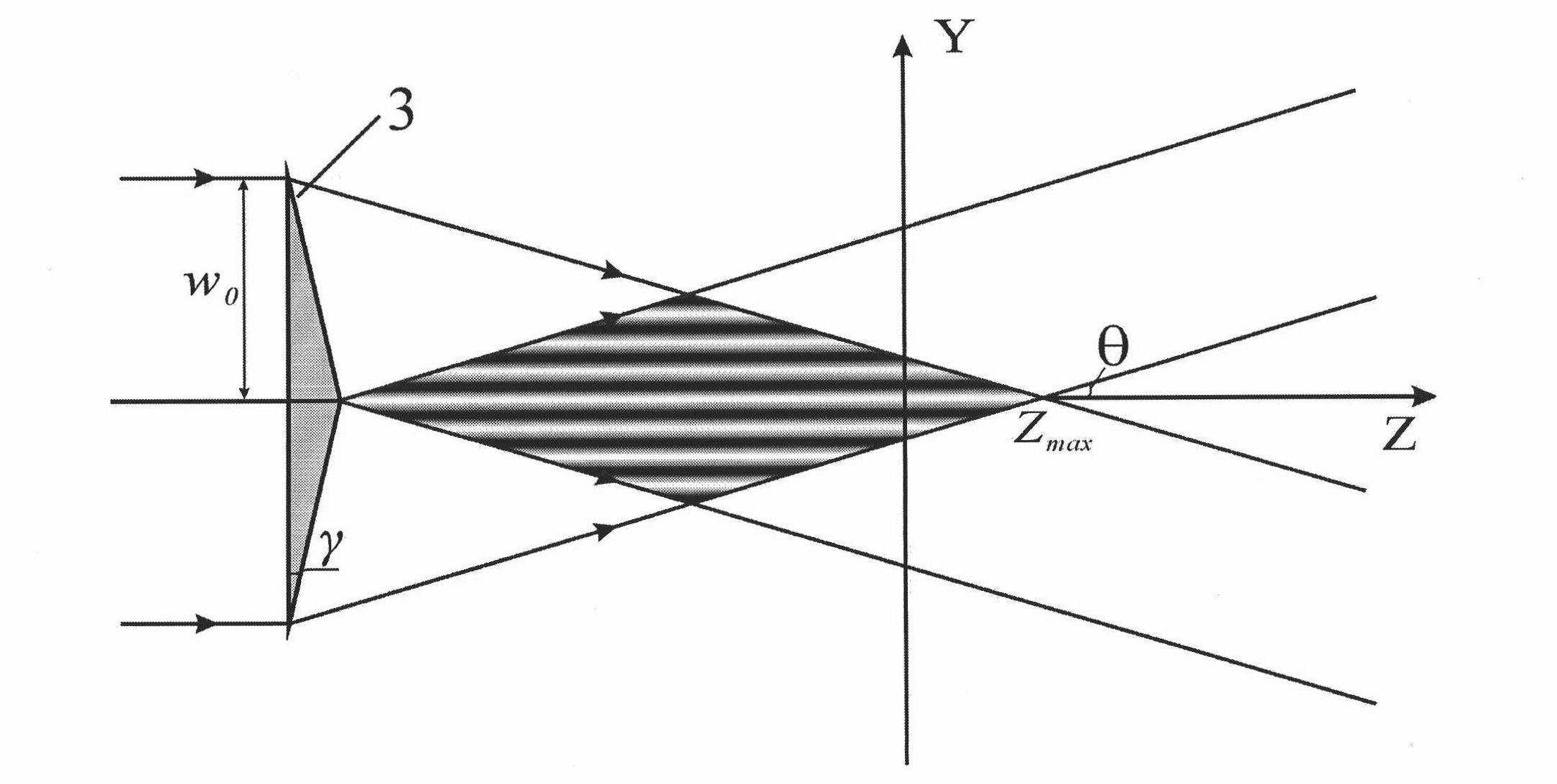

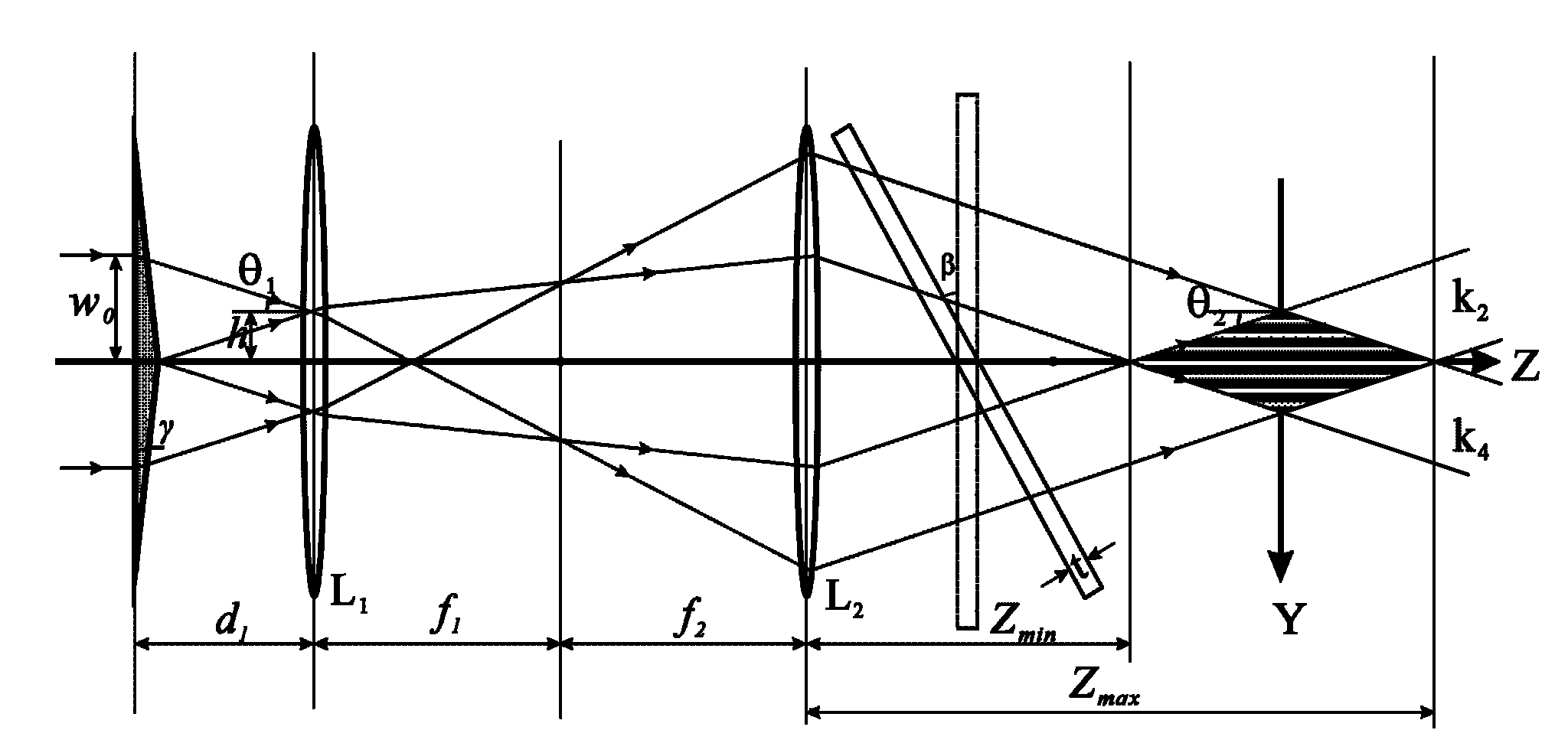

Fluorescence microscopy method to generate multi-layer polished sections by utilizing Fresnel biprism and device

InactiveCN101819319AUniform distribution of light intensityInterference disappearsMicroscopesFluorescencePrism

The invention provides a fluorescence microscopy method to generate multi-layer polished sections by utilizing a Fresnel biprism and a device. The device comprises parallel beams, a generating system of polished sections, a sample cell and an image acquisition system. The generating system of polished sections comprises a Fresnel biprism or a system composed of a Fresnel biprism, a telescope system and a phase shifting glass sheet; the sample cell is arranged at the rear part of the Fresnel biprism or at the rear part of the phase shifting glass sheet. As the parallel beams refract after passing through the Fresnel biprism, an interference field is generated in the beam overlaying region behind the prism, thus the light field of multi-layer polished sections is obtained. The invention solves the technical problems of ununiform luminance, small penetration depth of samples and slow rate of image acquisition in the existing mono-layer microscopy technology; the obtained multi-layer polished sections have great penetration depth, can be applied to fluorescence microscopy imaging of living entity samples; and the image acquisition rate is high.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

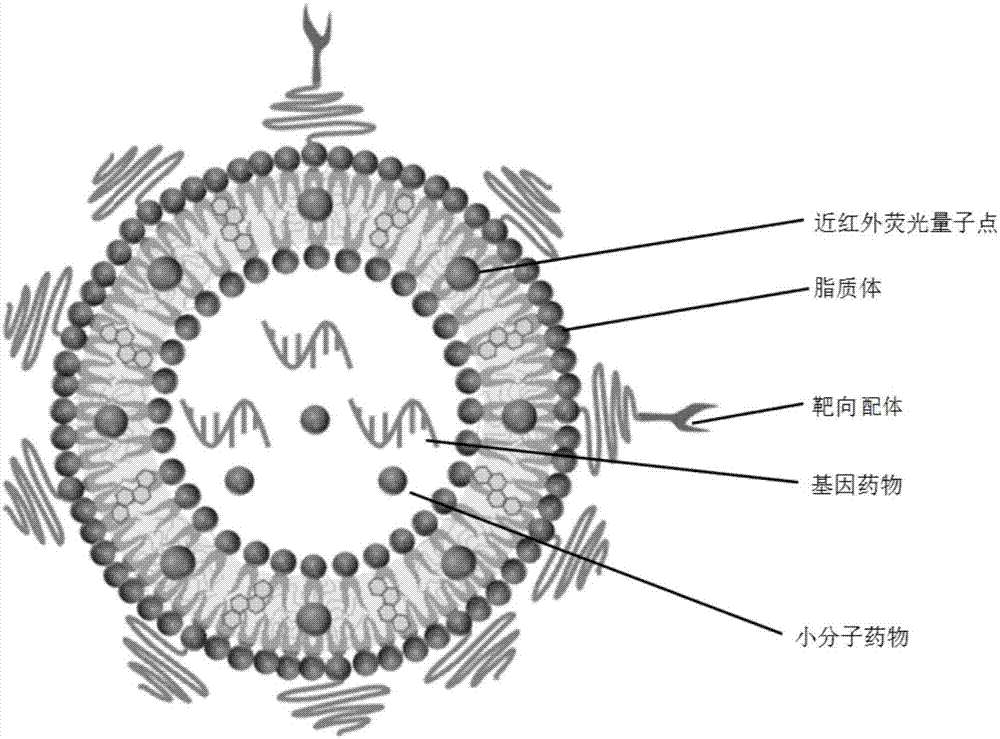

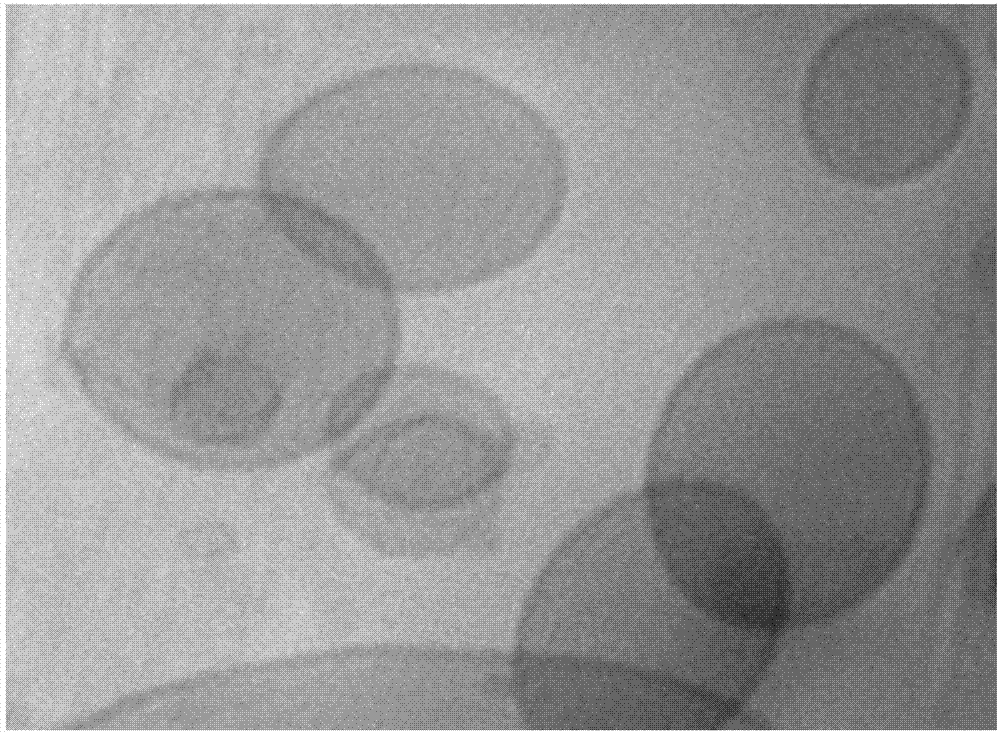

Lipidosome nano medicine delivery system as well as preparation method and application thereof

ActiveCN107982218APromote enrichmentIn vivo targetingPharmaceutical non-active ingredientsIn-vivo testing preparationsTreatment effectMedicine

The invention provides a lipidosome nano medicine delivery system as well as a preparation method and application thereof. The lipidosome nano medicine delivery system comprises a quantum dot and lipidsome, wherein the quantum dot is embedded into a lipid bilayer of the lipidsome; and the lipidsome structurally comprises targeting ligand. The lipidosome nano medicine delivery system prepared by using the preparation method provided by the invention has a double-ligand targeting function, by virtue of targeting titanium of atherosclerotic plaque at different development stages, living targetingof early-stage, middle-stage and late-stage atherosclerotic plaque is achieved, the medicine enrichment of a focus area is improved, and in addition, a near-infrared developing agent can be adopted for in-vivo medicine distribution tracing and treatment effect observation on atherosclerosis.

Owner:苏州影睿光学科技有限公司

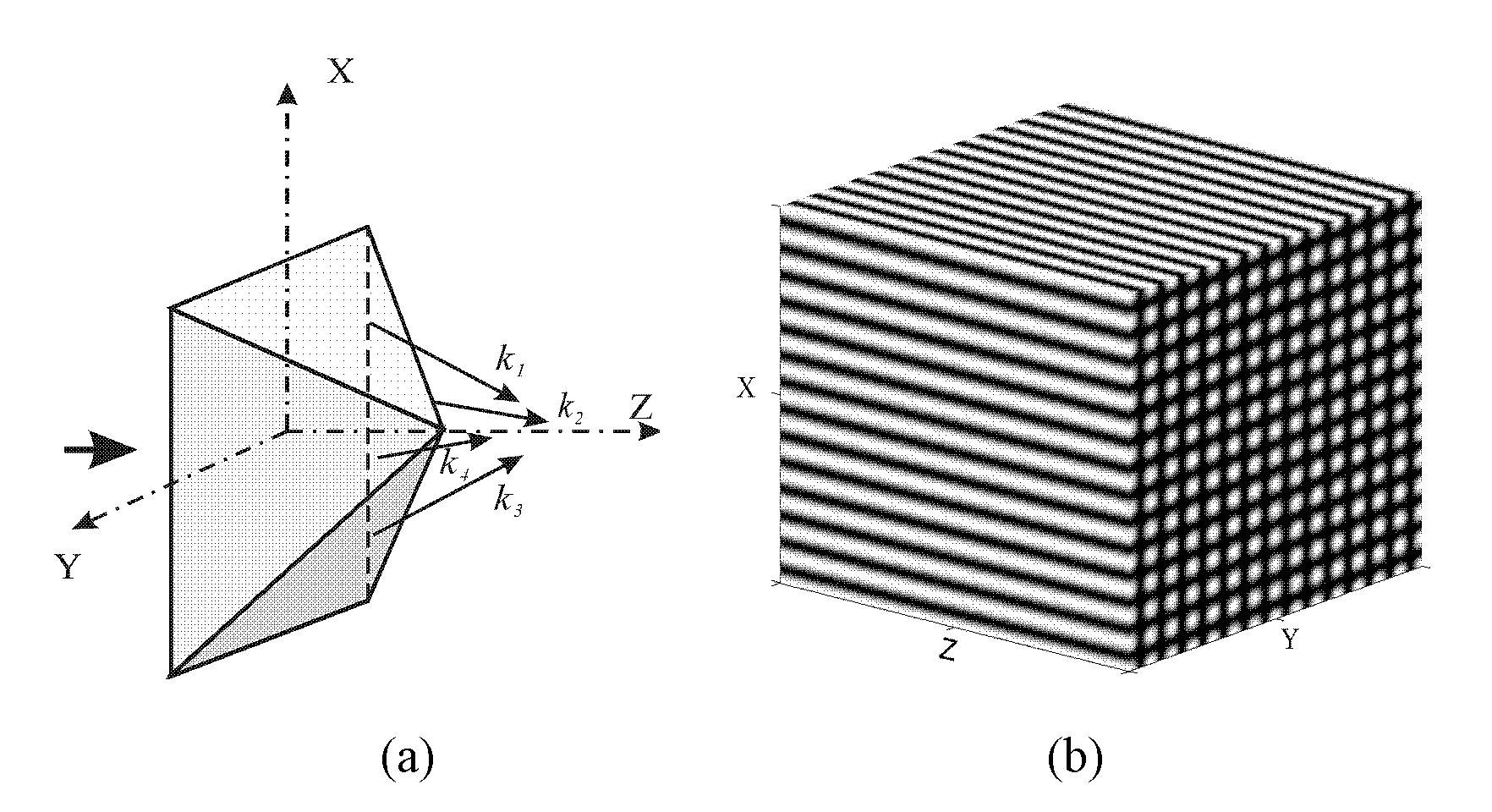

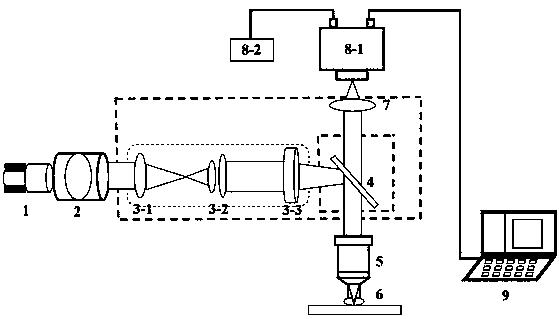

Method and device of fluorescence microscopy by using pyramid lens to generate structured lighting

The invention provides a method and a device of fluorescence microscopy by using a pyramid lens to generate structured lighting. The device comprises parallel beams, a structured lighting system, a sample cell and an image acquisition system, wherein the structured lighting system comprises a pyramid lens, a telescope system and a phase-shifting glass sheet; and the sample cell is arranged at the rear part of the phase-shifting glass sheet. The parallel beams are refracted after passing through the pyramid lens, thus generating a four-beam interference field with two-dimensional space structure distribution and exciting a sample by the four-beam interference field. The three-dimensional tomography can be realized through image processing algorithm by translating the interference optical field acted on the sample Compared with the existing microscopy for structured lighting, the invention can achieve higher axial resolution but lower photo-bleaching effect. Therefore, the invention is suitable for the research on the imaging of living creatures.

Owner:BEIJING LUSTER LIGHTTECH

LED-excited short wavelength infrared fluorescent microscopic imaging system

InactiveCN108982444AGreat penetration depthLittle tissue damageFluorescence/phosphorescenceShortwave radiationTomography

The invention discloses an LED-excited short wavelength infrared fluorescent microscopic imaging system. In the system, laser light emitted by a single-color LED passes through a collimating lens to be collimated firstly and is introduced into a light path of a microscope vertical illumination device, the exciting light is reflected with a dichroic beam combiner and converges onto a back focal plane of a microscopic objective, converging light forms parallel exciting light beams after passing through the objective and illuminates onto a sample, and a fluorescence probe in the sample is excitedto emit fluorescence; and a fluorescence signal passes through the objective, penetrates through the dichroic beam combiner and is finally received by a detection surface of an InGaAs camera to realize photoelectric conversion, and the signal is transmitted to a computer for data processing to obtain an imaged picture or a video. The LED-excited short wavelength infrared fluorescent microscopic imaging system has the remarkable advantages of high signal-to-noise ratio, high magnification, high resolution, capability of real-time imaging, capability of tomography, large penetration depth, small tissue damage and the like.

Owner:ZHEJIANG UNIV

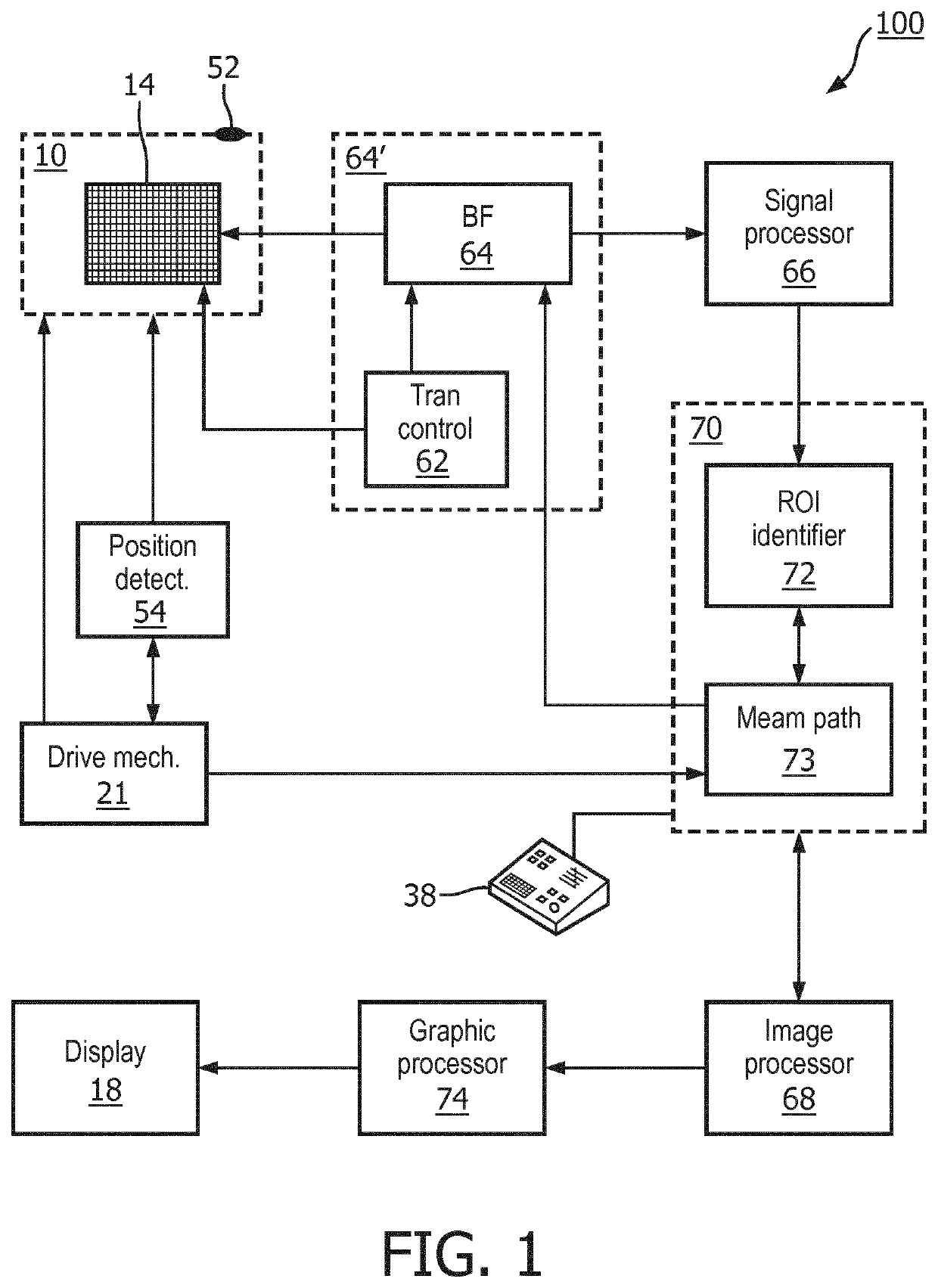

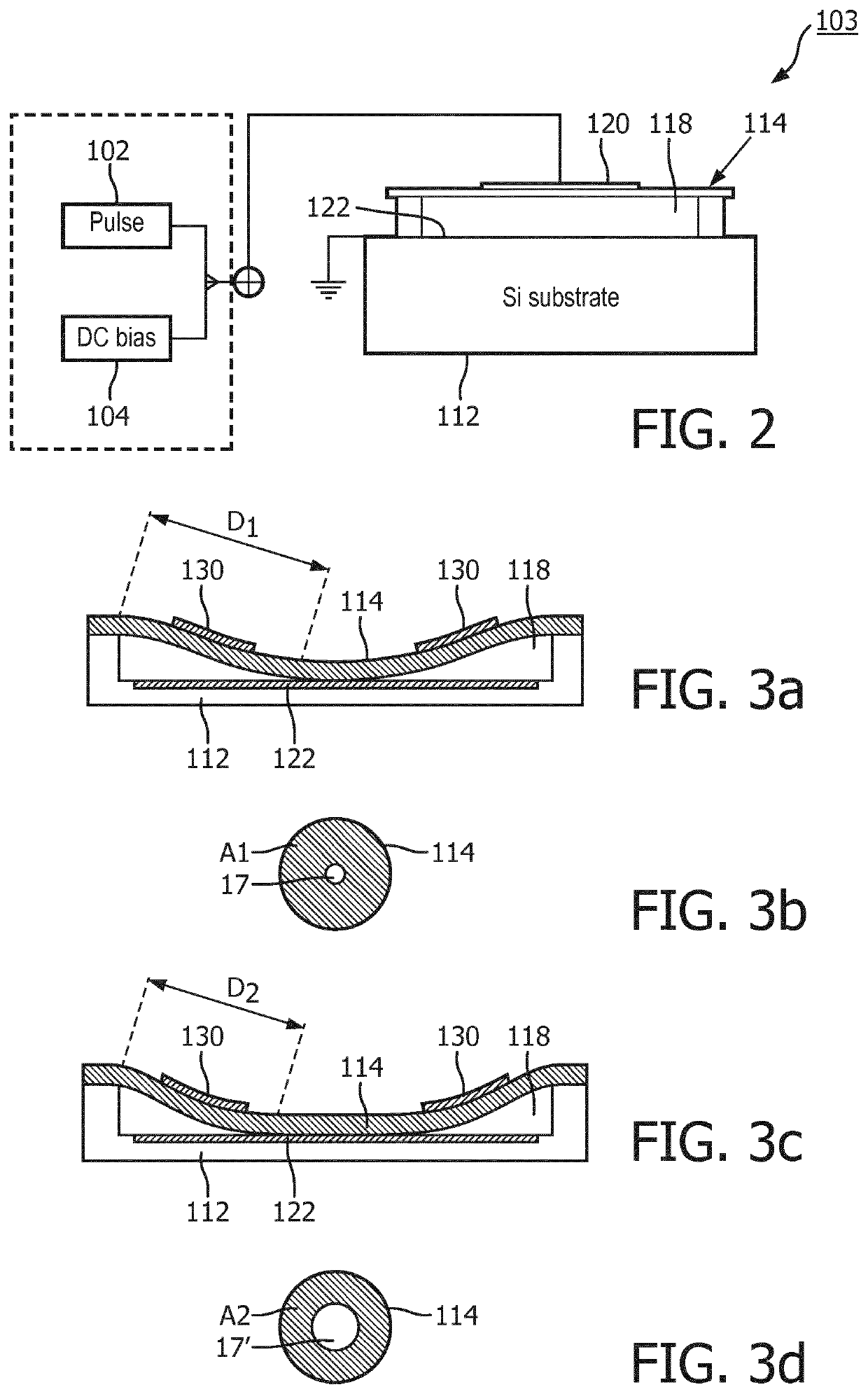

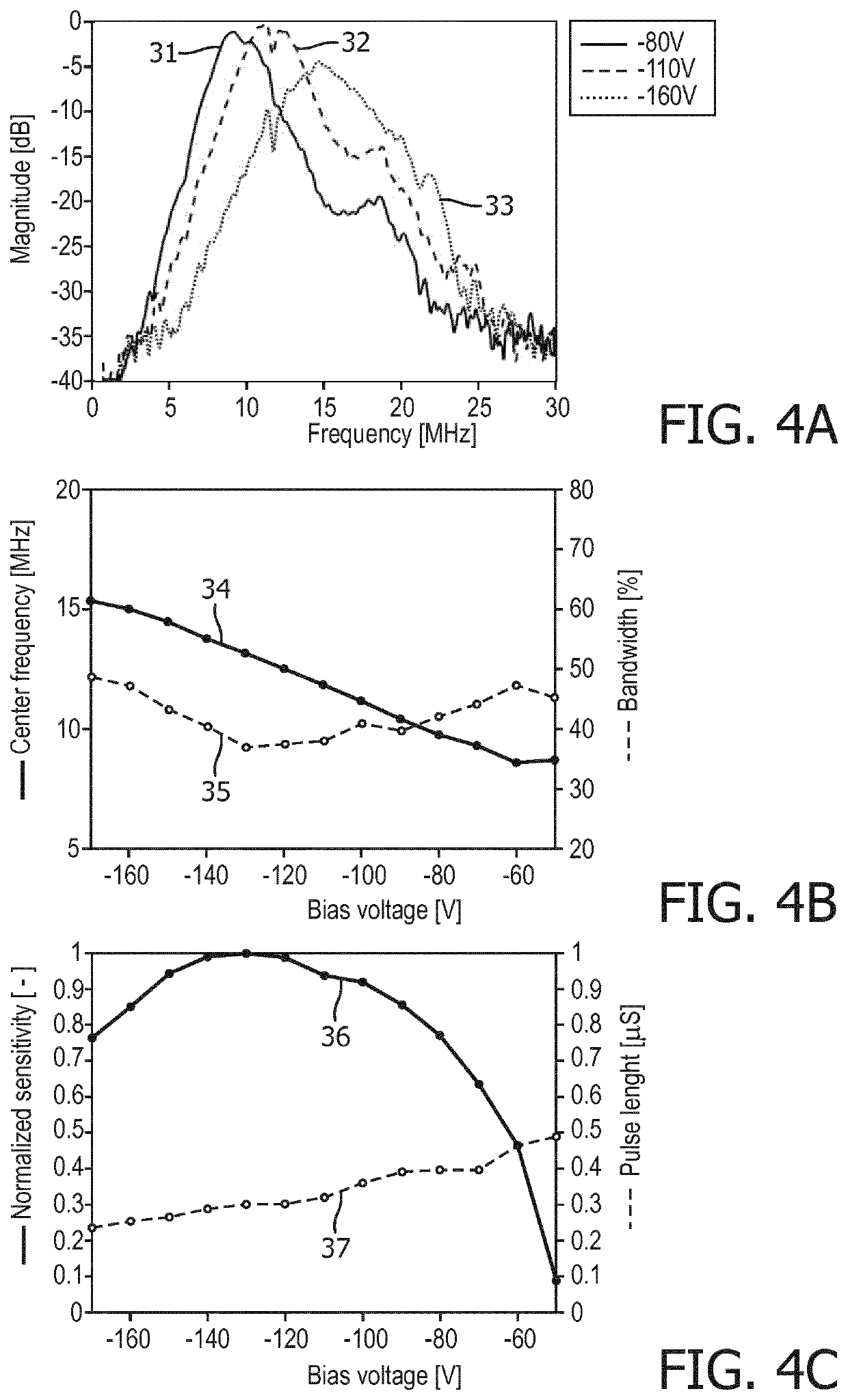

An ultrasound system with a tissue type analyzer

ActiveUS20200049807A1Improve spatial resolutionHigh frequencyMechanical vibrations separationInfrasonic diagnosticsHistology typeControl ultrasound

An ultrasound system (100) for imaging a volumetric region comprising a region of interest (12) comprising: a probe having an array of CMUT transducers (14) adapted to transmit ultrasound beams and receive returning echo signals over the volumetric region; a beamformer (64) coupled to the array and adapted to control ultrasound beam transmission and provide ultrasound image data of the volumetric region; a transducer controller (62) coupled to the beamformer and adapted to vary driving pulse characteristics of the CMUT transducers, a region of interest identifier (72) enabling an identification of a region of interest on the basis of the ultrasound image data; a beam path analyzer (70) responsive to the ROI identification and arranged to detect an attenuating tissue type in between the probe and the ROI based on a depth variation in attenuation of the received signal; wherein the transducer controller is further adapted to change, based on the attenuating tissue type detection, at least one parameter of the driving pulse characteristics.

Owner:KONINKLJIJKE PHILIPS NV

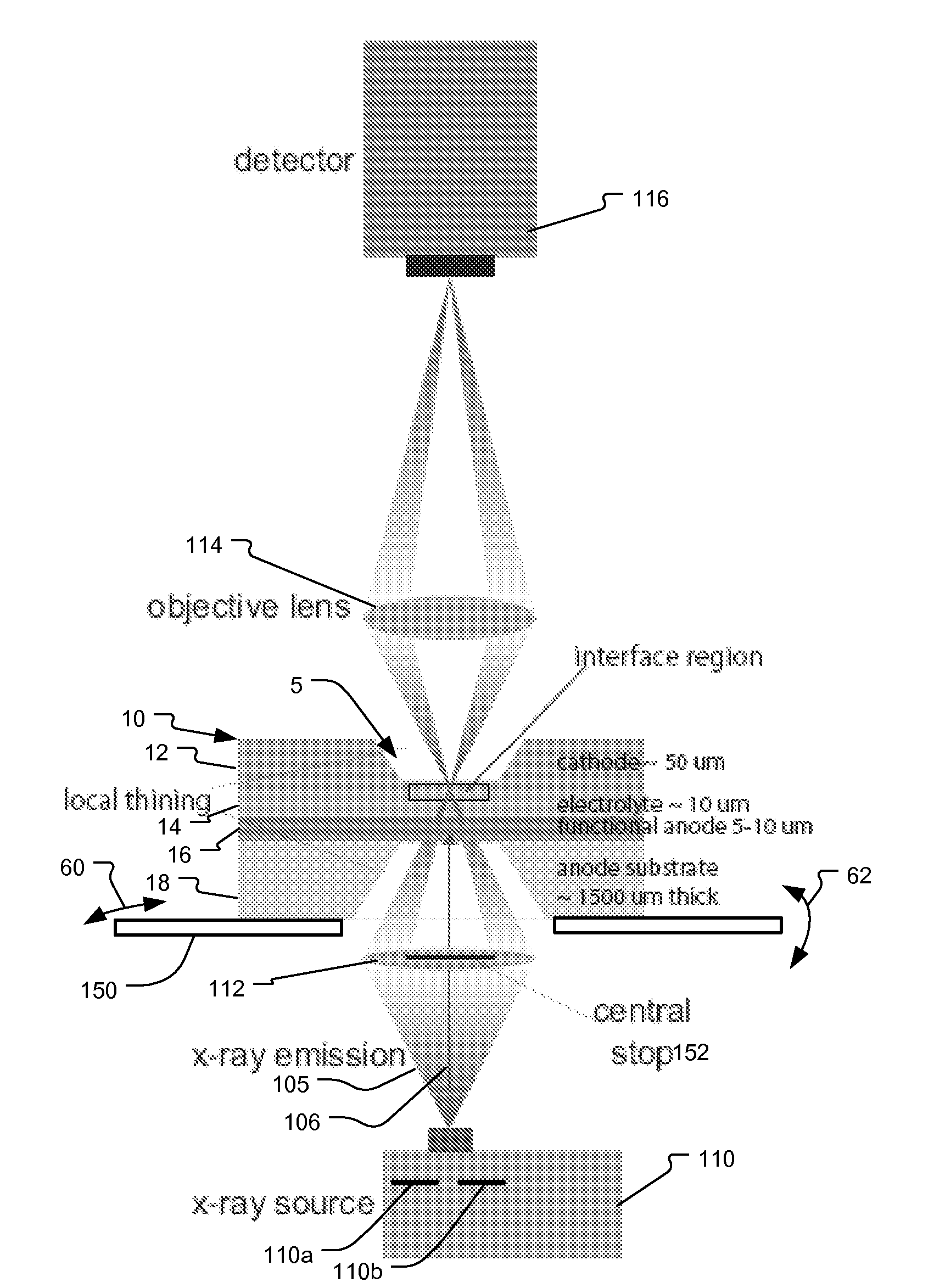

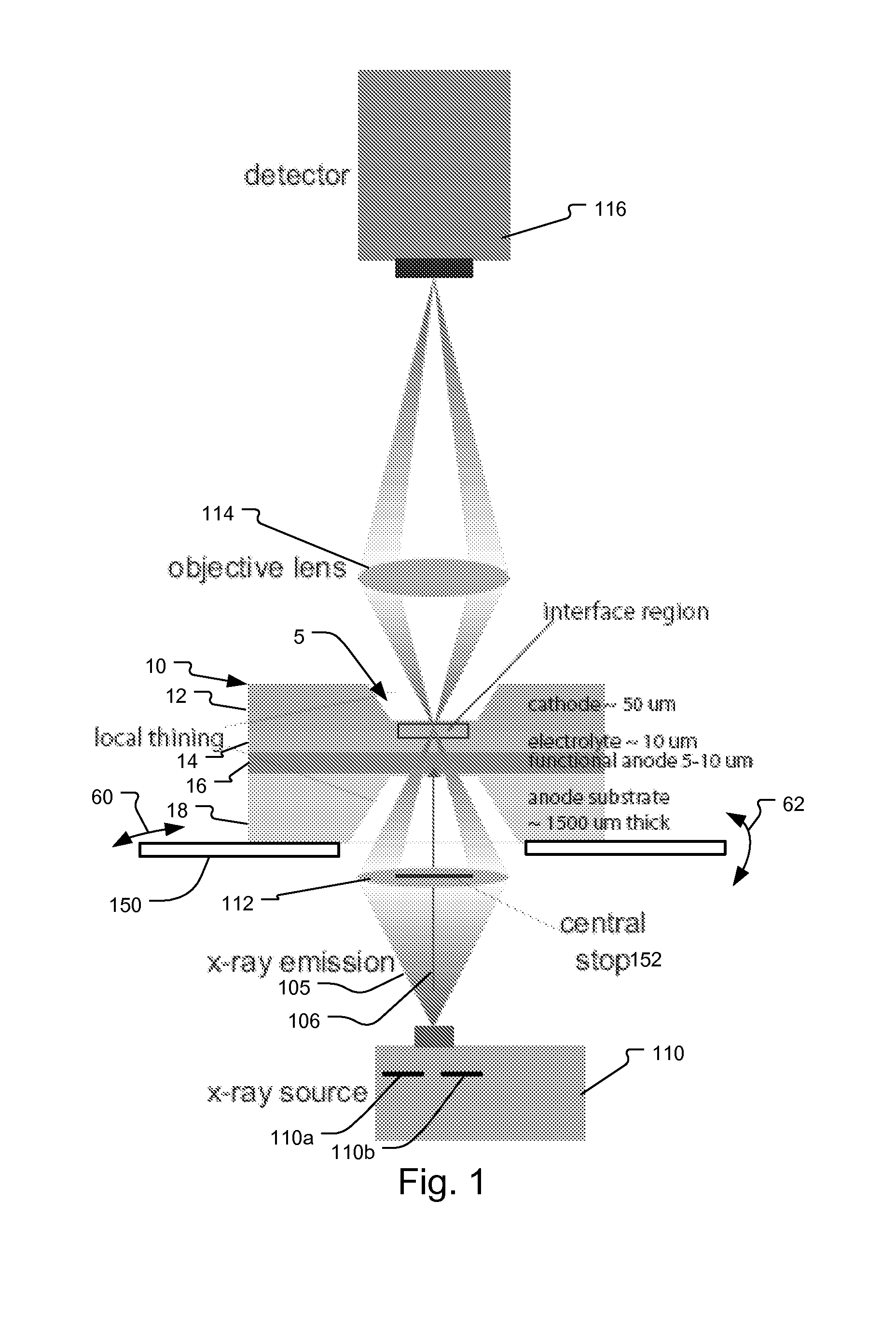

System and Method for Fuel Cell Material X-Ray Analysis

ActiveUS20080165924A1Shorten development timeImprove reliabilityRadiation/particle handlingUsing wave/particle radiation meansMetrologyHard X-rays

An imaging technology for fuel cells is based on x-ray microscopy. A metrology system images the electrochemical interaction areas of solid-oxide fuel cells (SOFC) in-situ. This system takes advantage of both the penetrating power and elemental absorption contrast of hard x-ray radiation to image the internal interaction areas in a SOFC. The technology can further take advantage of the strong dependence of the x-ray absorption on material type and energy to distinguish the four major material types: cathode, electrolyte, air, and low-Z contaminants such as sulfur.

Owner:CARL ZEISS X RAY MICROSCOPY

Imaging nmr method and nmr device

InactiveUS20060055404A1Great detectable measuringGreat penetration depthElectric/magnetic detectionMeasurements using magnetic resonanceControl mannerVolumetric Mass Density

The invention relates to an imaging NMR method as well a NMR device in which a to-be-examined object is exposed to a stationary polarization field B0 and to an electromagnetic alternating field, and nuclear resonant processes which are detected as test signals and are visually represented are induced in said object. The invention is characterized in that said stationary magnetic polarization field is provided with at least one spatially limited volume region inside said object, said spatially limited volume region having a greater magnetic flux density than the remaining region of said object so that said nuclear resonant processes are induced solely in said spatially limited volume region, said test signals from said nuclear resonant processes induced inside said limited volume region are detected, and the spatial position of said limited volume region (4) is changed at least once in a controlled manner and said test signals are detected again from said positionally modified volume region.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Smelting method capable of reducing steel and iron material consumption of electric furnace steelmaking

InactiveCN108570531ASpeed up meltingReduce the amount of ironProcess efficiency improvementElectric furnaceSteelmakingAlkalinity

The invention discloses a smelting method capable of reducing steel and iron material consumption of electric furnace steelmaking. The smelting method comprises the following specific steps: in the furnace burden construction, controlling the ratio of scrap steel to be 15% to 27%, and the ratio of molten iron to be 73% to 85%; transporting the scrap steel by a travelling crane, and adding the scrap steel into a furnace from the top of the furnace once; after the scrap steel is added completely, adding 5kg / t lime into the furnace through an overhead bunker; adding the molten iron into the furnace twice, wherein the molten iron added for the first time accounts for 75% or above of the total amount of the molten iron and is added at the rate of 20-30t / min, and the molten iron added for the second time accounts for 25% or lower of the total amount of the molten iron and is added at the rate of 2-5t / min; and after the first package of molten iron is added completely, starting oxygen blowingoperation, and at the same time, adding the lime into the furnace for slagging, wherein the slag basicity during the entire smelting process is 2.5 + / - 0.5. The smelting method can solve the problemsof splashing in the smelting process and high total iron content of slag under the condition of hot-charging molten iron ratio of 73%-85%, thereby achieving the purpose of reducing the consumption ofsteel and iron materials.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

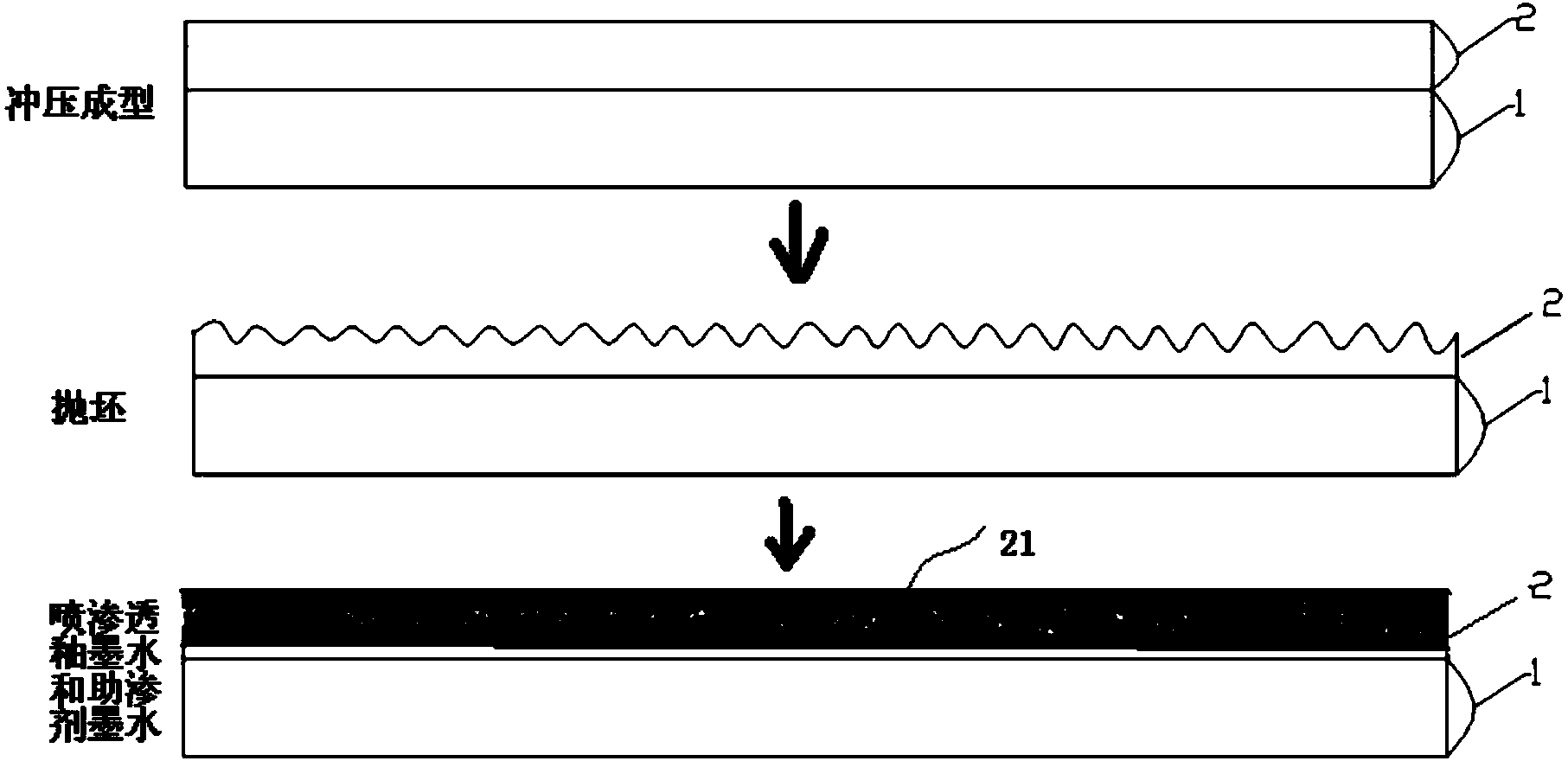

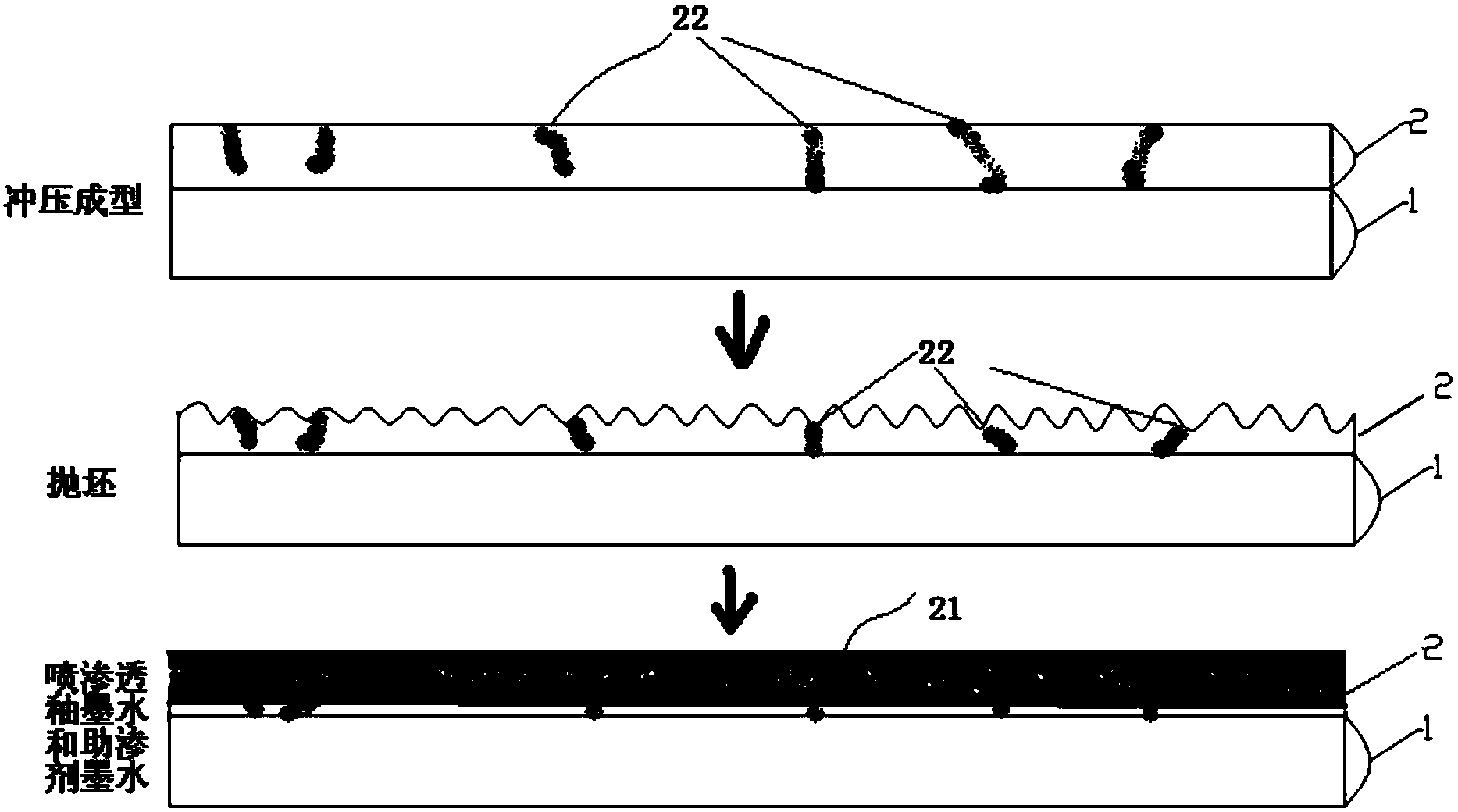

Method for manufacturing ceramic tile mortar blank

The invention provides a method for manufacturing a ceramic tile mortar blank. The method comprises the following steps: A, performing secondary distribution on a surface material and a backing material through a distribution system, pressing to form a green brick, drying, and polishing the surface of the dried green brick, so that the surface of the surface material layer is textured and has polished lines; B, performing ink-jet printing to penetrate glaze ink; C, performing ink-jet printing on penetration-aided agent ink; and D, standing for over 10 minutes, thereby obtaining the ceramic tile mortar blank with a penetrating layer. According to the prepared ceramic tile prepared by the method, the penetrating layer formed by penetrating the glaze ink has a certain thickness and penetrates into the surface material layer, so that decorative patterns are wear-resistant, and the problems that a printed decorative layer formed by the conventional ink-jet printing is not wear-resistant in the prior art and the like are solved.

Owner:FOSHAN DONGPENG CERAMIC +2

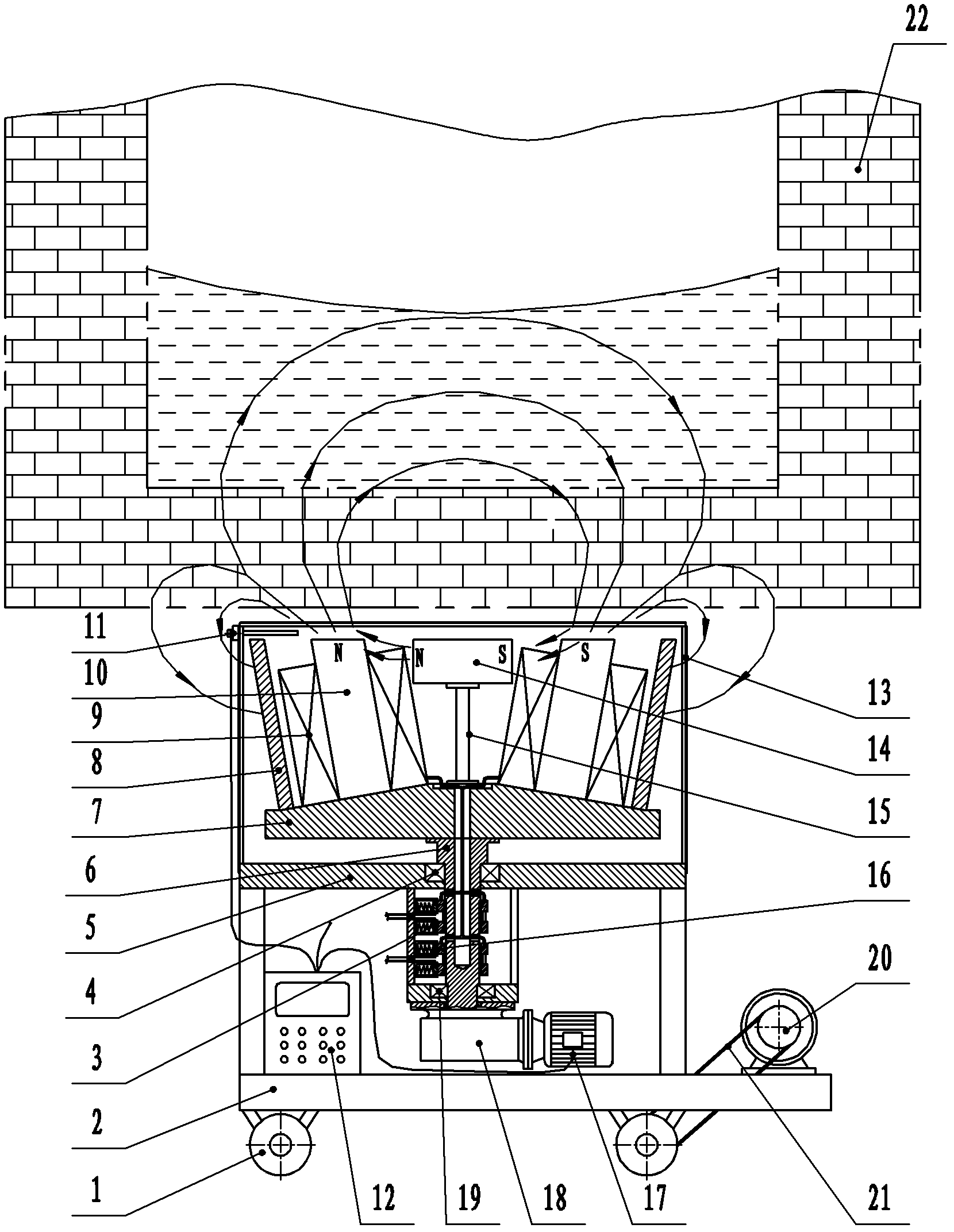

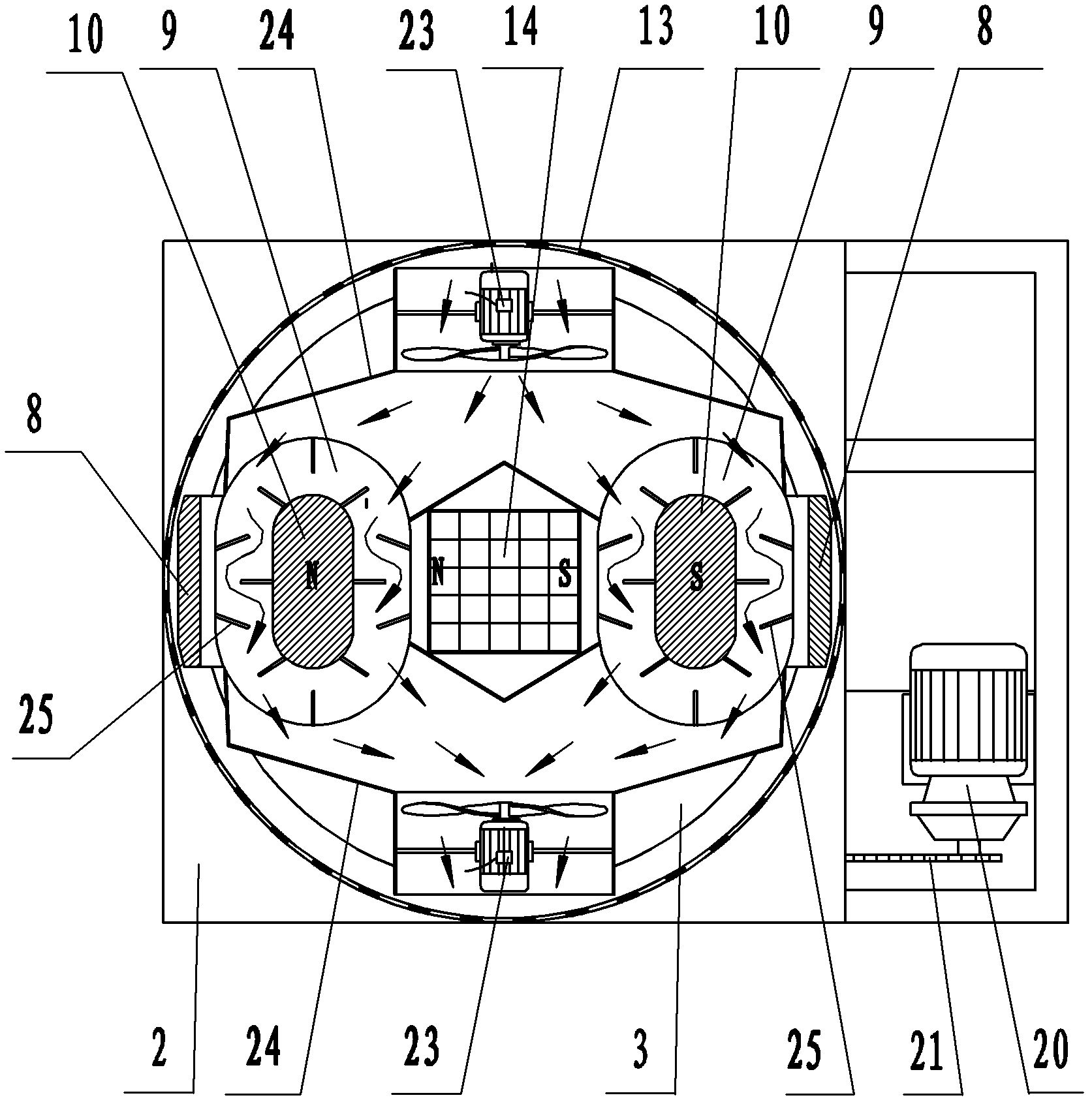

Aluminum solution stirring device of air-cooled composite magnetic field

ActiveCN102230749AExpand the scope of actionIncrease heightStirring devicesMixersElectrical polarityEngineering

The invention discloses an aluminum solution stirring device of an air-cooled composite magnetic field. The aluminum solution stirring device comprises a rotating shaft which is vertically arranged on a frame, wherein the bottom end of the rotating shaft is connected with a power device; a magnetic yoke of which the upper plane inclines outwards is arranged at the upper end of the rotating shaft; at least two grid-type direct-current coils which are annularly distributed uniformly at intervals and are vertical to the upper plane are arranged on the upper plane; an iron core is arranged in each grid-type direct-current coil; the equidirectional ends of every two adjacent iron cores have opposite polarities; a high-temperature-resistant permanent magnet of which the polarity is repellent to that of the upper end of each iron core is arranged between every two grid-type direct-current coils; the outer side of each grid-type direct-current coil is provided with an air cooling device; and a non-magnetic outer cover is arranged above the frame. The stirring device disclosed by the invention has a large acting range on an aluminum solution in an aluminum smelting furnace under the action of a composite magnetic field formed by the coaction between an electromagnetic field and a permanently-magnetic field; the height and the intensity of a magnetic line of force are enhanced; and the aluminum solution stirring device has large permeation depth on the aluminum solution, large magnetic field force, large stirring force, high efficiency for stirring and a wide application range.

Owner:SHANDONG HUATE MAGNET TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com