Method for manufacturing ceramic tile mortar blank

A technology of ceramic bricks and mud blocks, which is applied in the field of architectural ceramics production, can solve the problems of the printed decorative layer being not wear-resistant, and achieve rich decorative effects, good wear resistance, and long-lasting patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

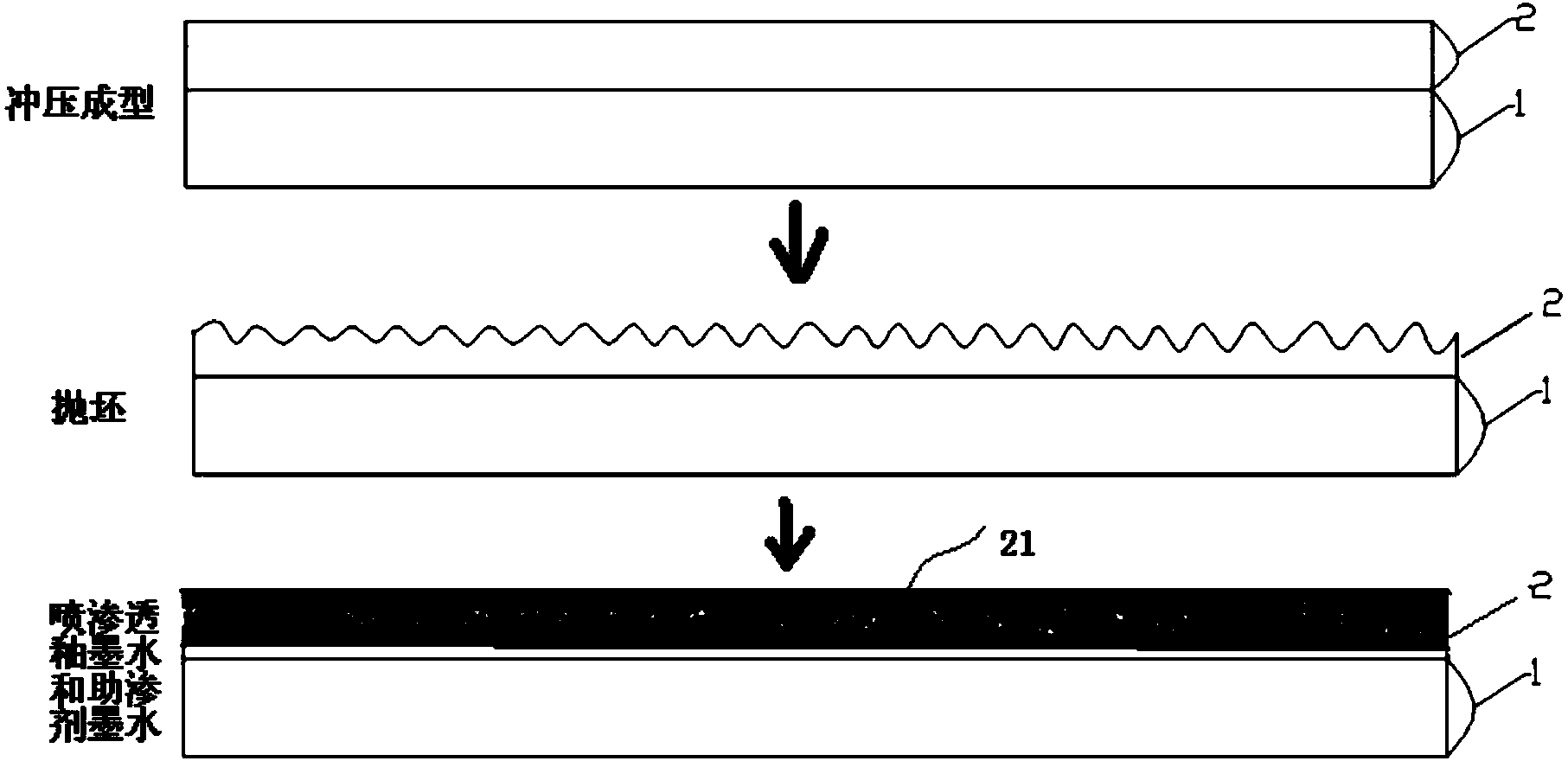

[0031] refer to figure 1 The schematic diagram of the process flow is provided. In this embodiment, a ceramic brick mud and ceramic bricks manufactured by using it are provided. The mud mud includes a bottom material layer 1 with a thickness of 8-10mm from bottom to top, which is processed by polishing and grinding. The surface is frizzy and has a fabric layer 2 with a texture thickness of about 2 mm, and the fabric layer includes a permeable layer 21 with a thickness of 1.5 mm. The ceramic bricks obtained after sintering the ceramic brick mud adobe with the above structure have better wear resistance. Compared with the products in the prior art that place decorative patterns on the brick surface, the decorative effect remains long-lasting, and in the process of product processing , can be polished and chamfered. In addition, the fabric layer is polished to make it rough and textured, which can save the amount of penetrating glaze ink and penetrating agent ink.

[0032] Spec...

Embodiment 2

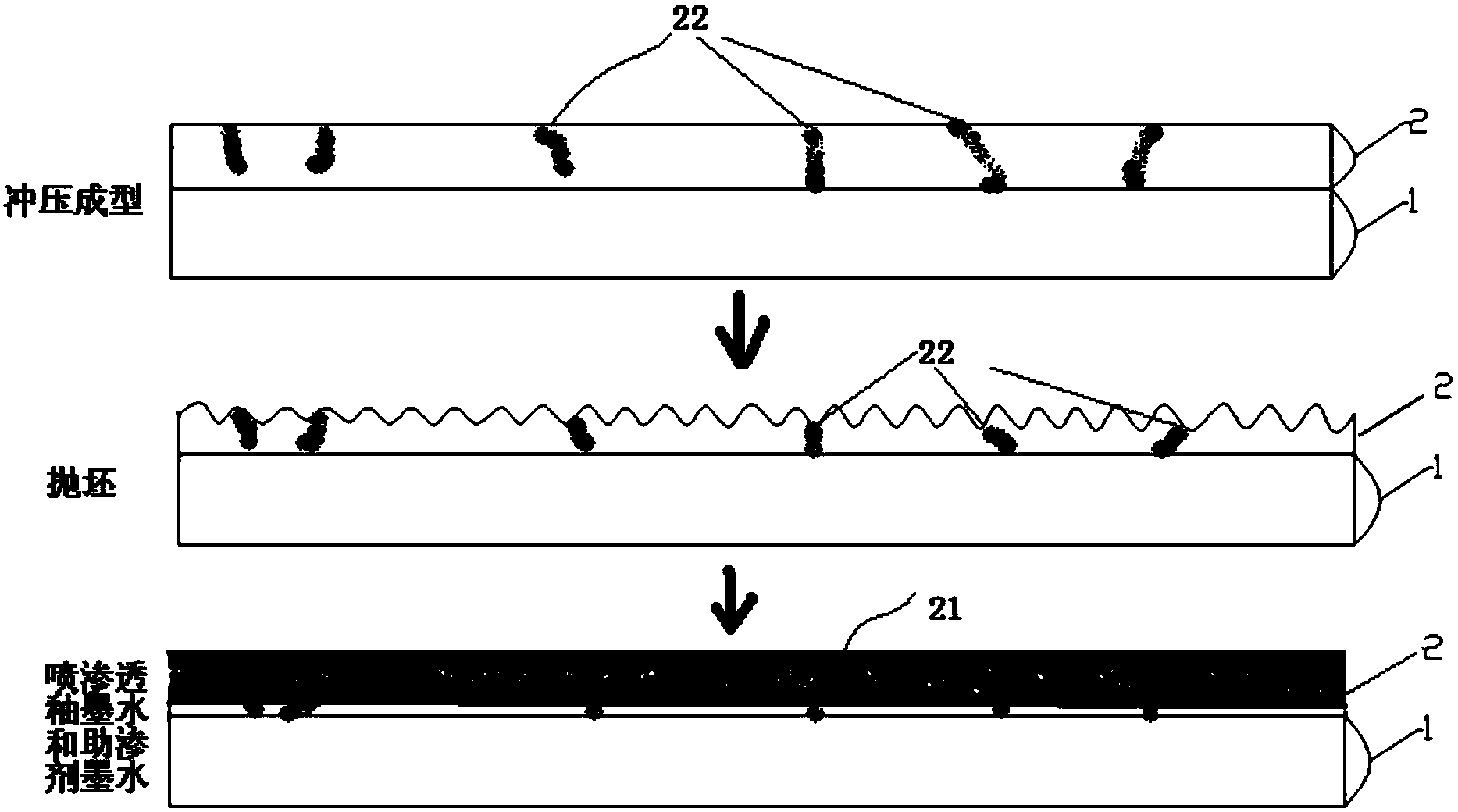

[0042] refer to figure 2 In the schematic flow chart provided, this embodiment is basically the same as Embodiment 1, except that the provided ceramic brick mud has stripes or granular textures 22 embedded in its fabric layer 2 . Through the above settings, the thickness of the permeable layer can also have a corresponding difference (the penetration depth of different raw materials is different). In this embodiment, the thickness of the permeable layer is 1.0-1.5mm, which further reduces the loss caused by polishing. At the same time, it can also Rich decorative effect.

[0043] Specifically, in the manufacturing process, known striped materials or granular materials are added to the fabric, and various textures such as lines, particles, clouds, wood grains, stone grains, etc. are formed by magic cloth.

[0044] Specifically, the manufacturing method of this kind of ceramic tile mud adobe is:

[0045] Using the well-known micro-powder brick anti-beating twice cloth technol...

Embodiment 3

[0053] It has been introduced in the summary of the invention that in order to obtain a better penetration effect, in this implementation, after the inkjet printing of the penetration aid ink, the mass parts of 20-50% sodium citrate, ammonium citrate, EDTA One or more combinations of penetration aids, and then spray water 50-200g / m 2 .

[0054] The thickness of the permeable layer thus obtained is 1.5-2.5 mm.

[0055] In this implementation 3, select the penetration aid that screen printing mass fraction is 20% sodium citrate and EDTA mixed by 1:1 (mass ratio), then by 50g / m 2 Spray clean water in a certain amount to promote the penetration of the penetration aid, and the formed penetration layer is about 1.5mm. It needs to be explained here that in practical applications, the amount of water sprayed should be careful not to affect the strength of the brick, otherwise it may cause high loss. Moreover, it is necessary to control the penetration range of the glaze ink in the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com