Aluminum solution stirring device of air-cooled composite magnetic field

A composite magnetic field and stirring device technology, applied in the direction of stirring device, dissolving, mixer, etc., can solve the problems of limited development, large power consumption, complex mechanism, etc., and achieve the effect of increasing the scope of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

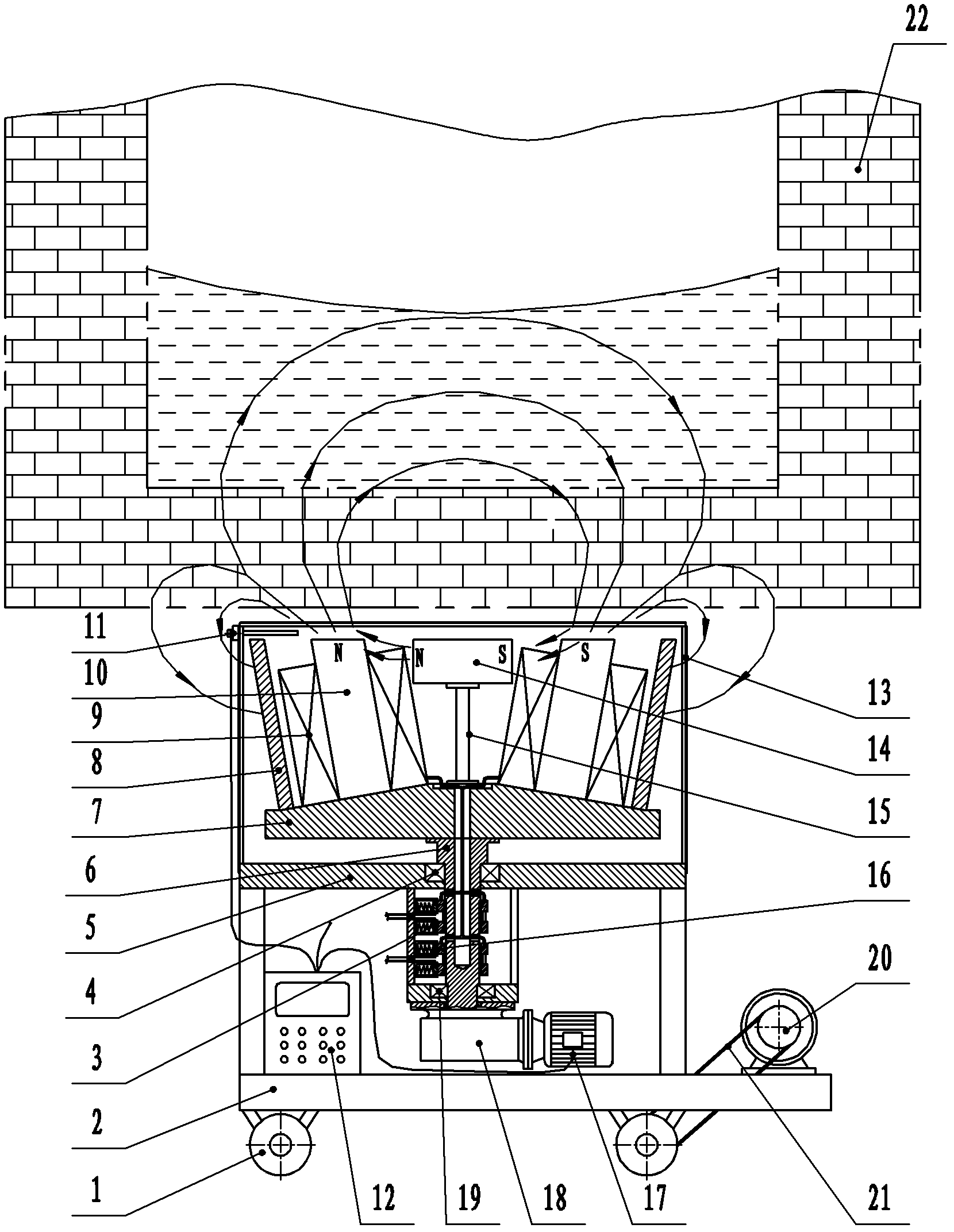

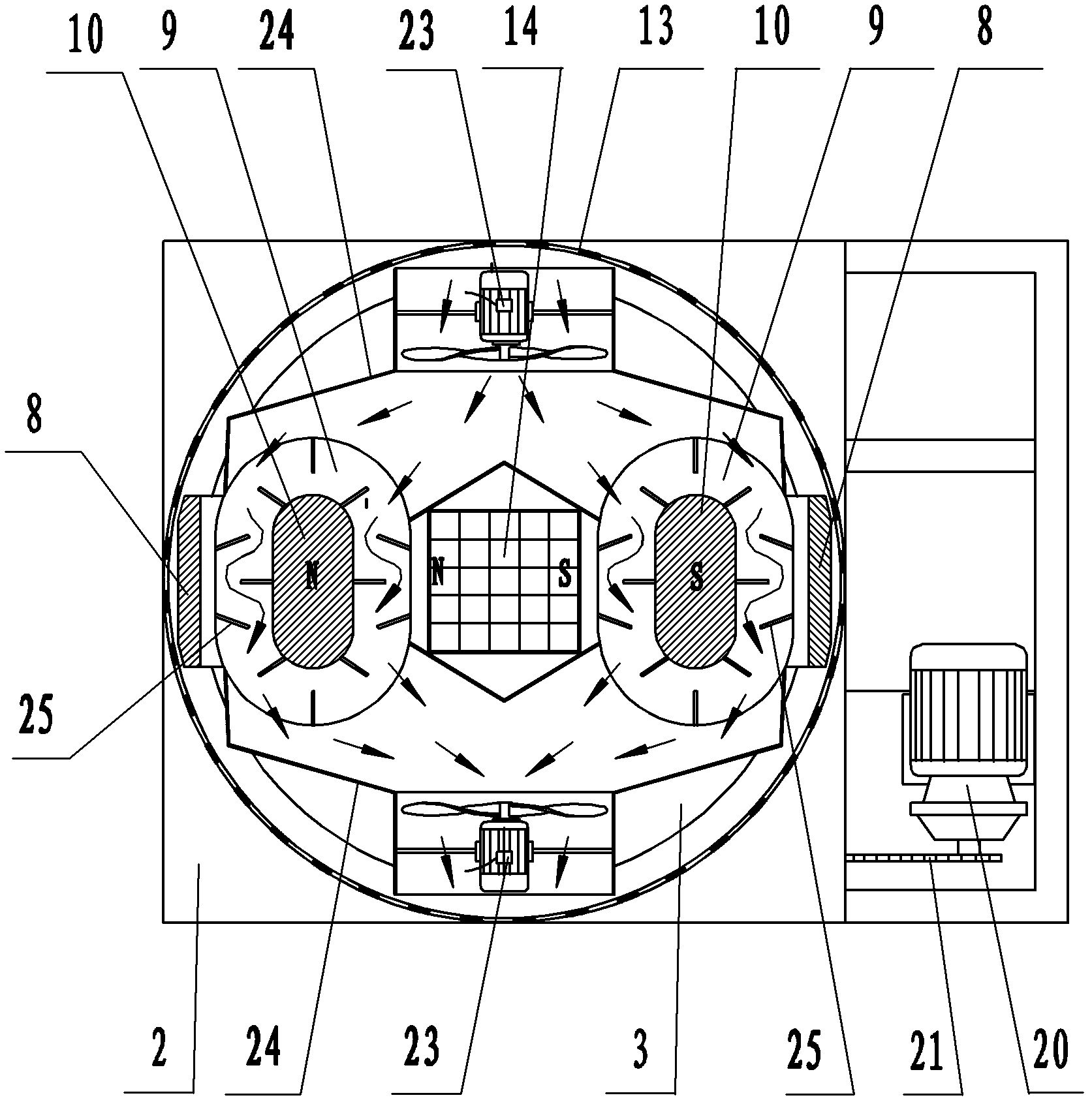

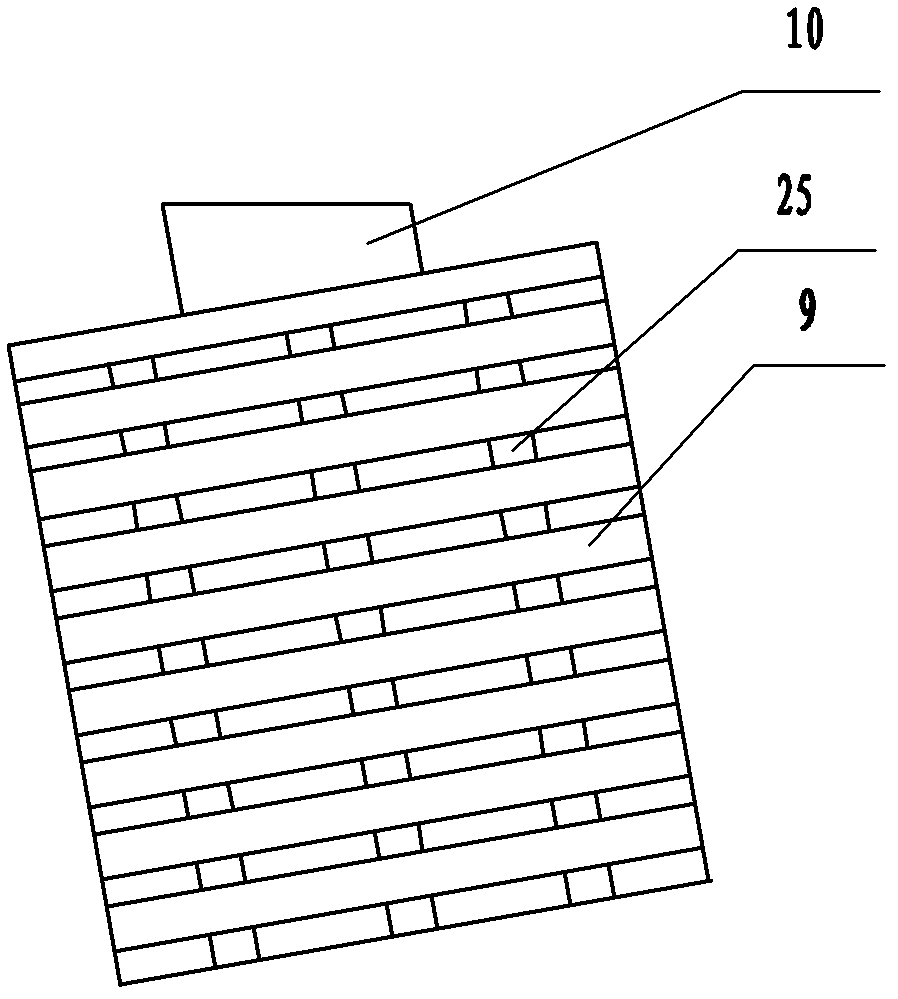

[0026] like figure 1 As shown, an aluminum solution stirring device of an air-cooled compound magnetic field includes a chassis 2, and a frame 5 installed on the chassis 2, and a rotating shaft 6 is vertically installed on the frame 5 through an upper bearing 4 and a lower bearing 19 , the bottom end of the rotating shaft 6 is connected to a power device that drives it to rotate, and the power device is controlled by the control system 12; plane, at least two grid-type DC coils 9 perpendicular to it are installed on the upper plane, and the grid-type DC coils 9 are evenly distributed in a ring shape, and iron cores are installed in each grid-type DC coil 9 10. The polarities of the same-direction ends of two adjacent iron cores 10 are opposite, and a permanent magnet 14 repelling the polarity of the upper end of each iron core 10 is installed between a plurality of the grid-type DC coils 9. The high-temperature permanent magnet 14 is installed and connected with the yoke 7 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com