Spherical multidirectional compound type TMD damper

A damper and composite technology, applied in the direction of building types, building components, earthquake resistance, etc., to achieve the effect of improving energy dissipation and vibration reduction, widening the frequency band of vibration reduction, and increasing the range of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

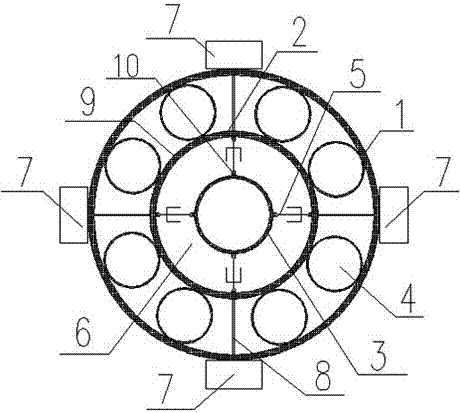

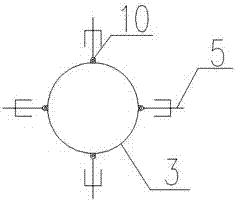

[0012] The invention provides a spherical multi-directional composite TMD damper, the damper is composed of two layers of concentric spherical shells as the main frame (the two layers of spherical shells are connected to the support through six columns up and down, left, right, front and back, and the support and the The main structure is fixed), and there is a large mass ball in the innermost part. The six directions of up, down, left, and right, front and back are fixed by damping springs and the inner spherical shell, which is filled with viscous damping fluid. There are a certain number of small-mass balls between the inner and outer spherical shells, and the small-mass balls are tangent to the spherical shells on both sides.

[0013] Due to the isotropic properties of the sphere, the damper can achieve a nearly 360° multi-directional vibration reduction control effect; and to deal with vibrations caused by external loads of different intensities, the spherical damper has d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com