Patents

Literature

126results about How to "Increased footprint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

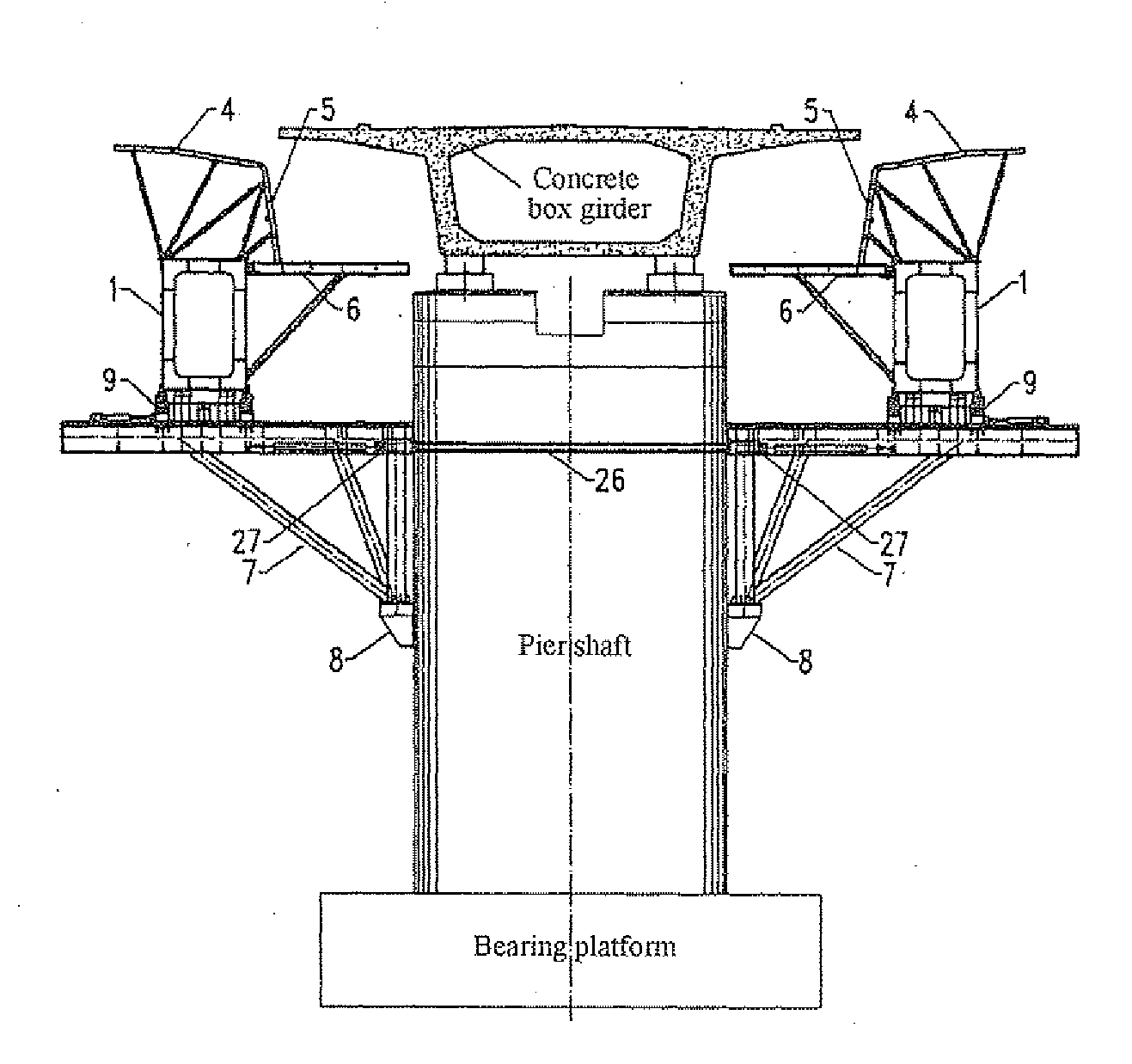

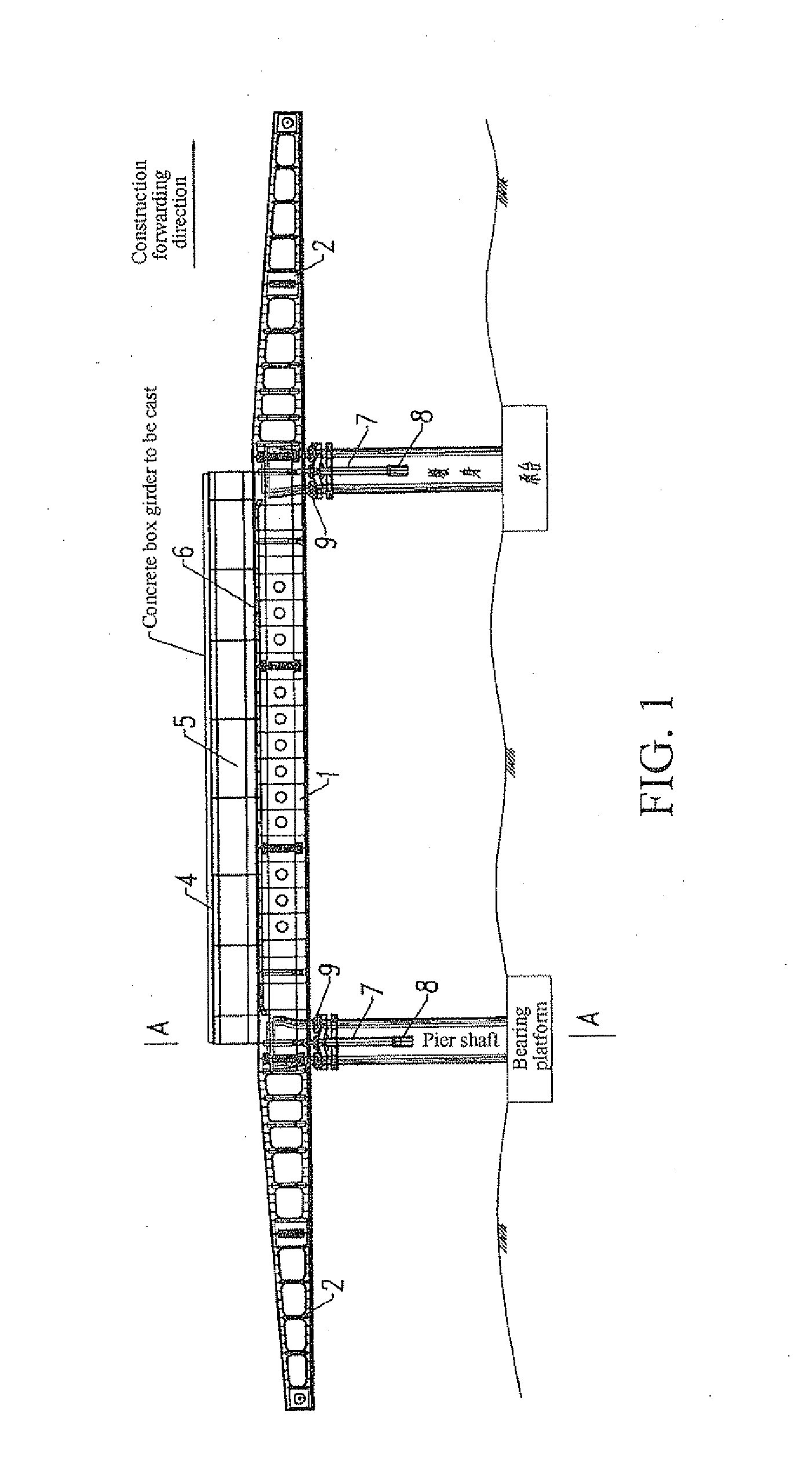

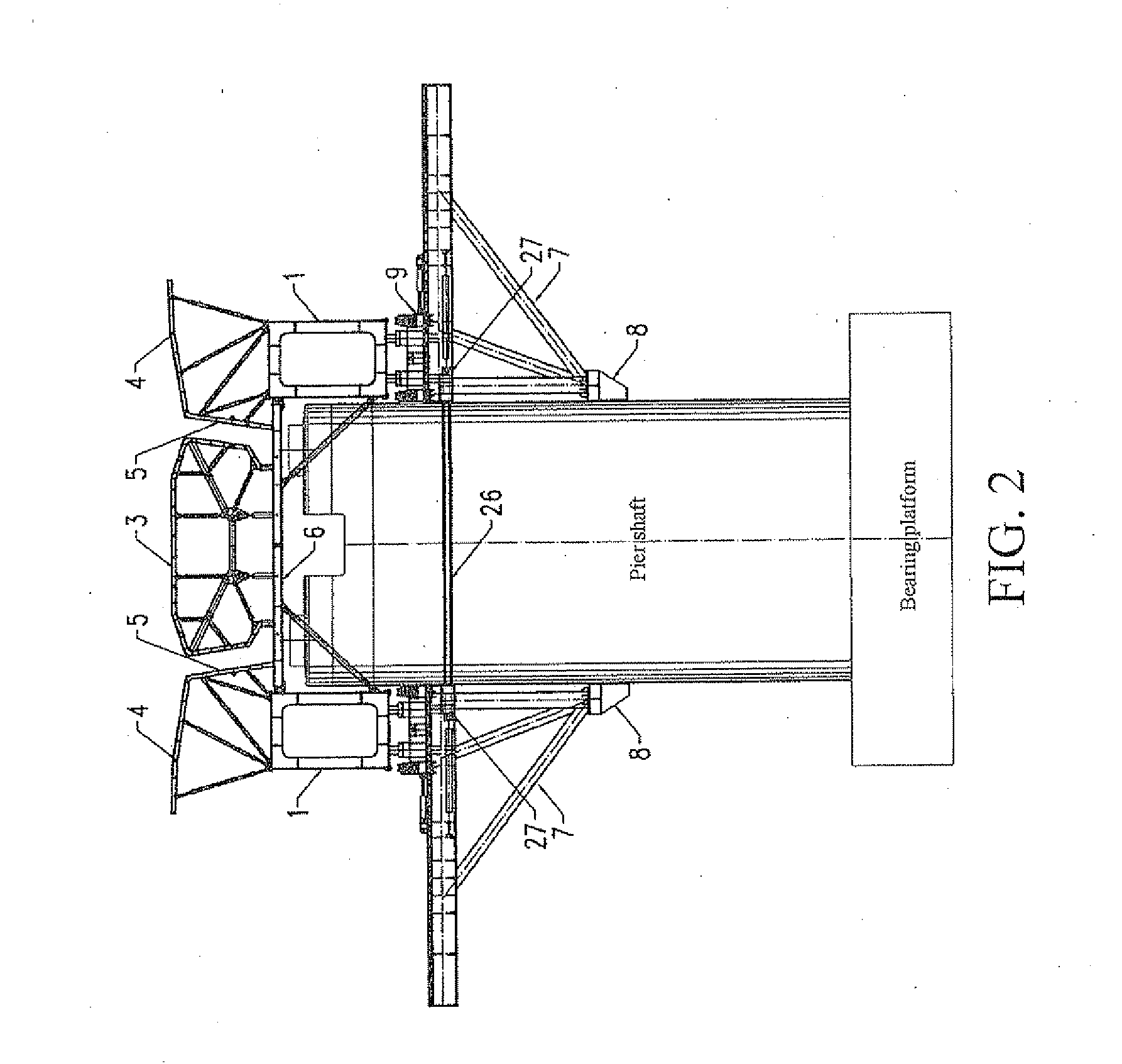

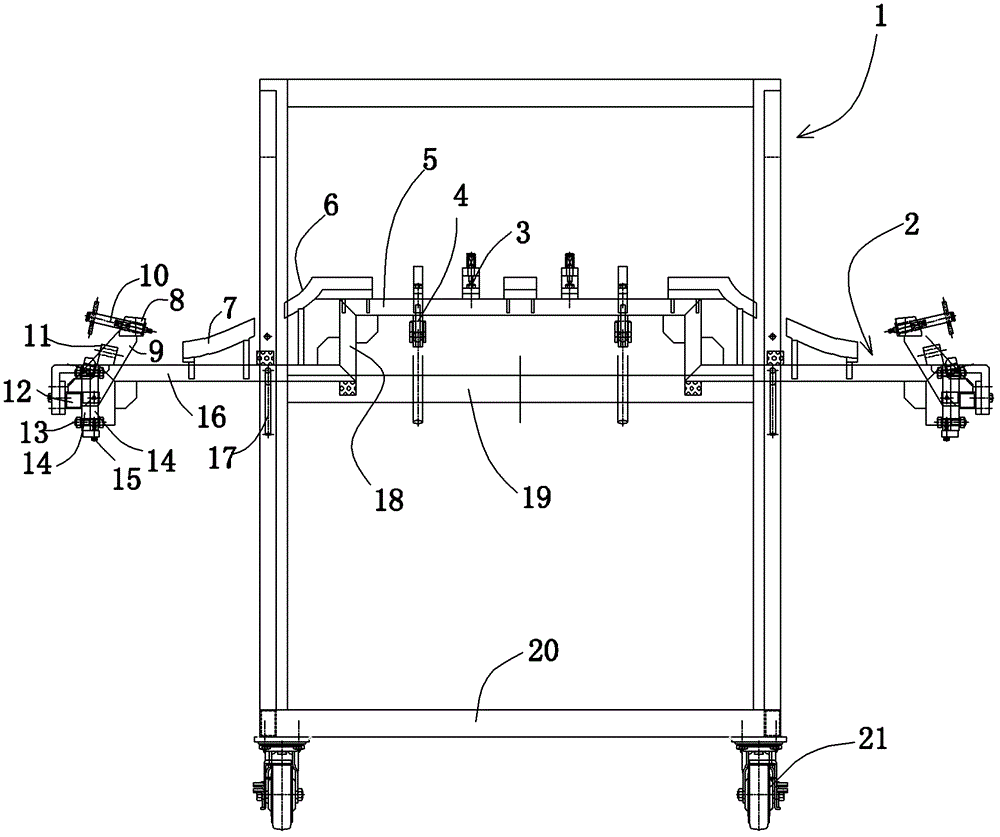

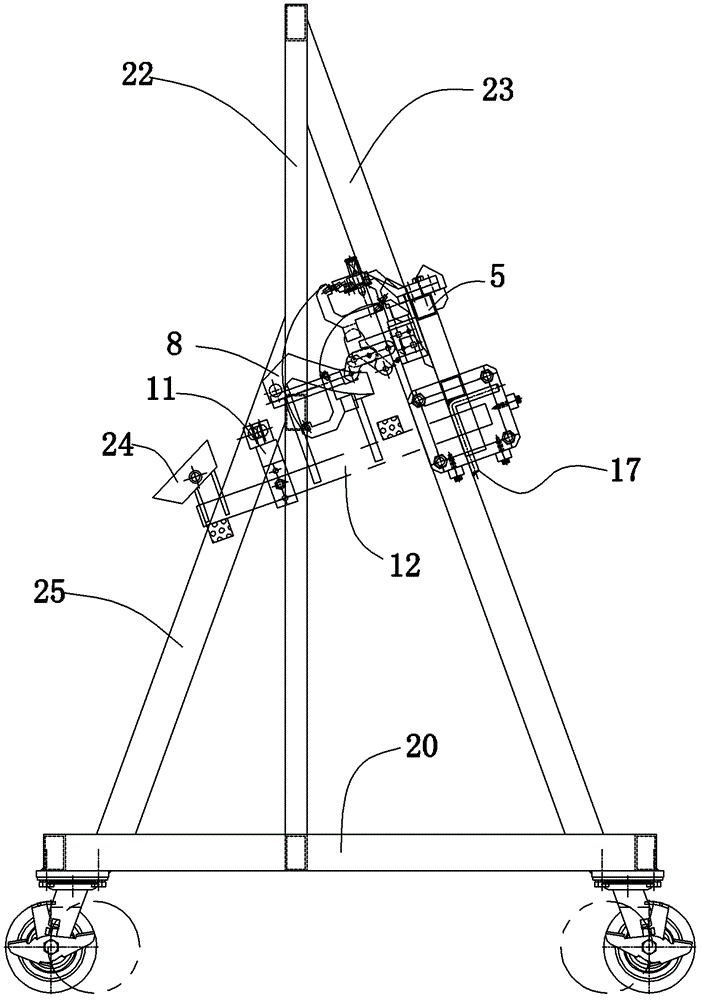

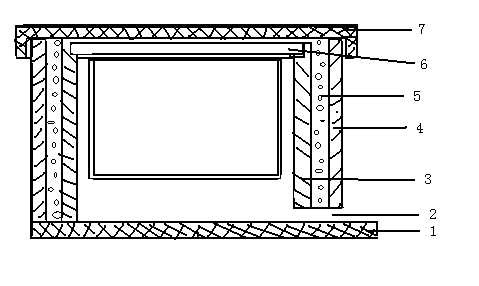

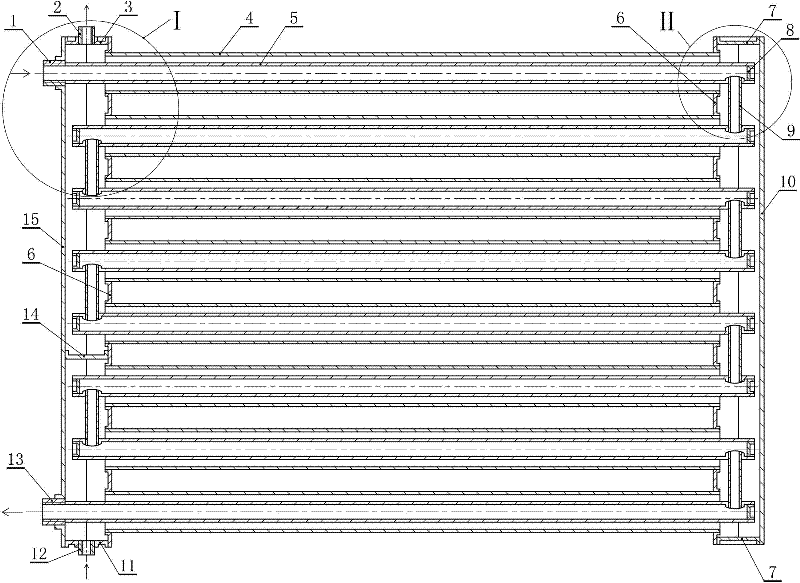

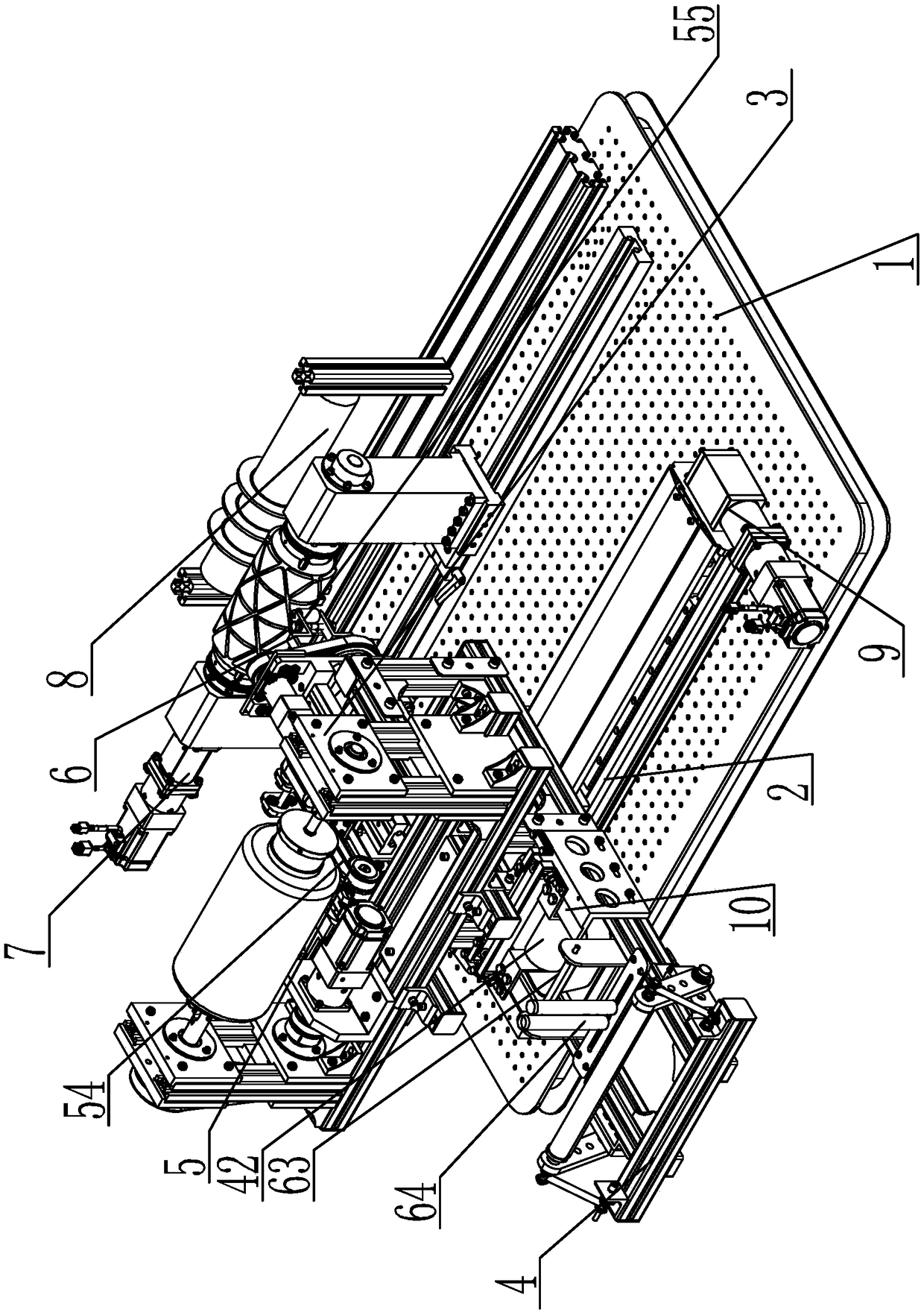

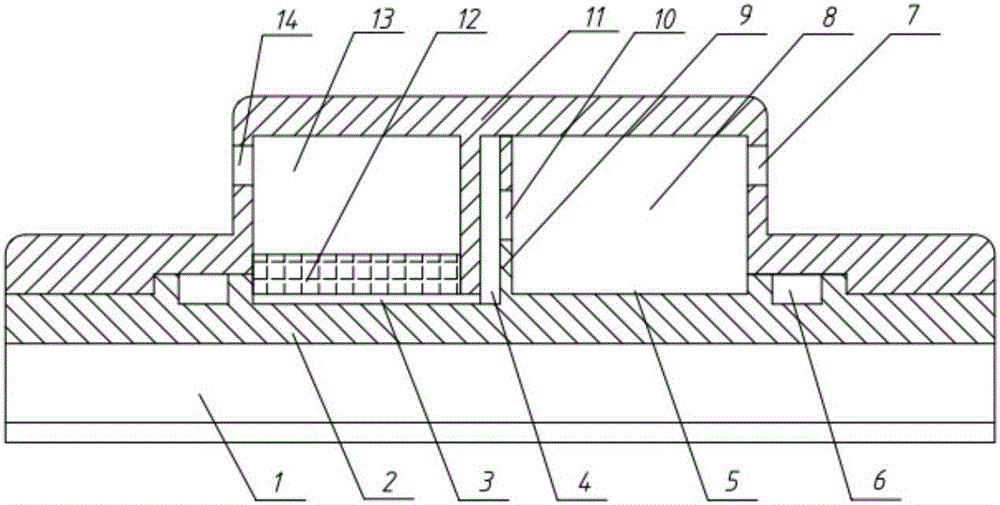

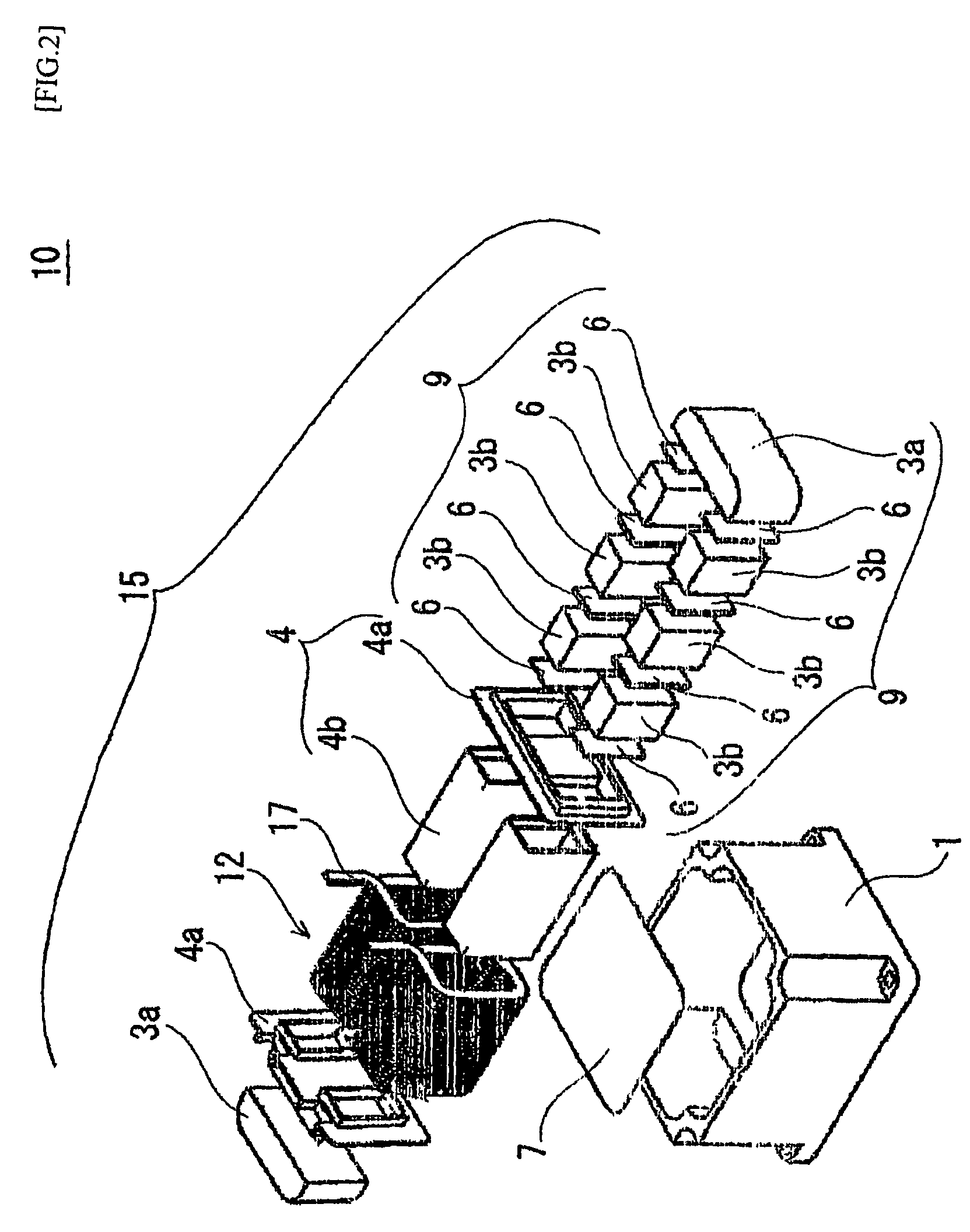

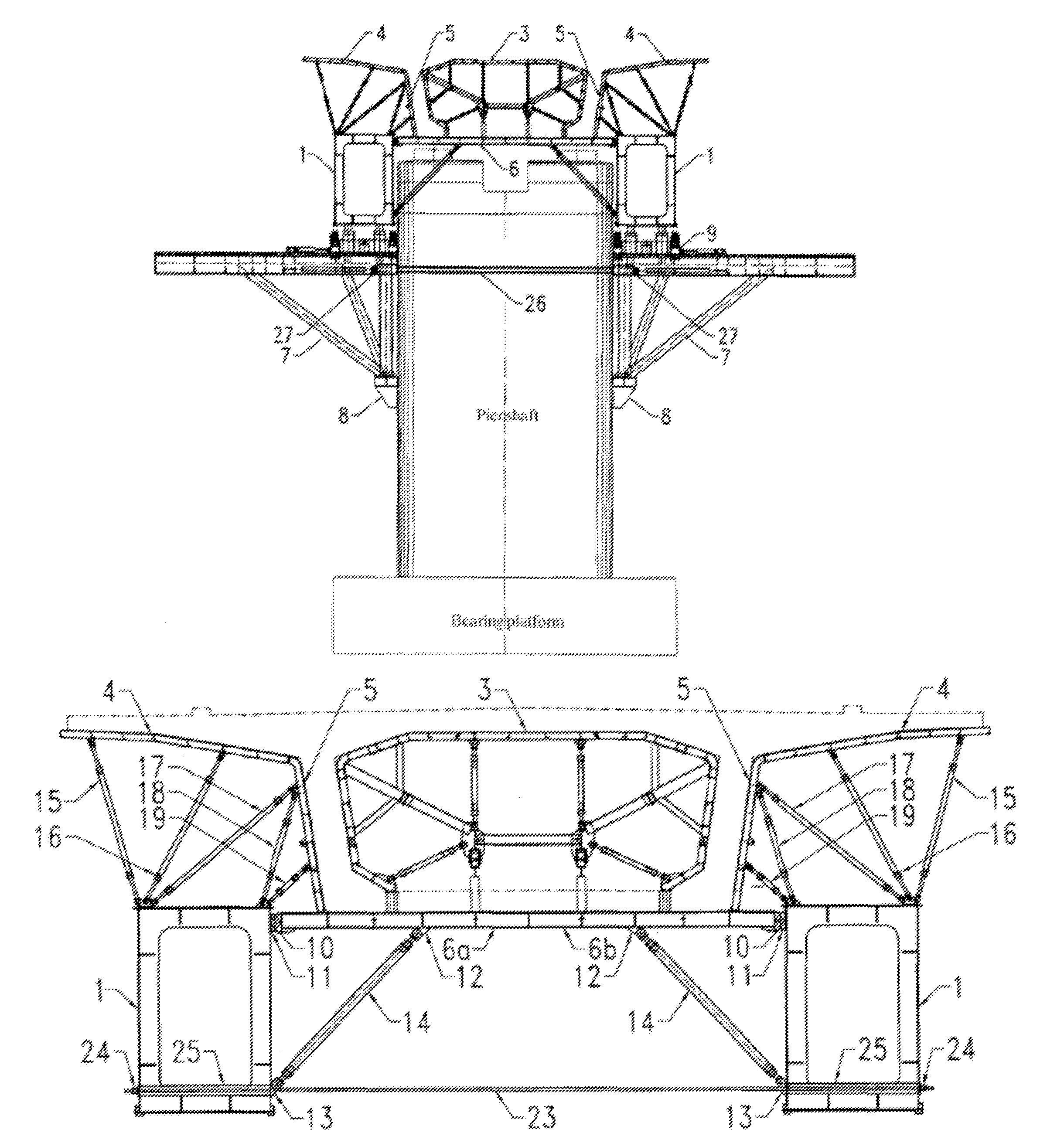

Upper-bearing typed movable formwork

ActiveUS20110133052A1Large dead weightIncreased footprintMouldsForms/shuttering/falseworksEngineeringBridge engineering

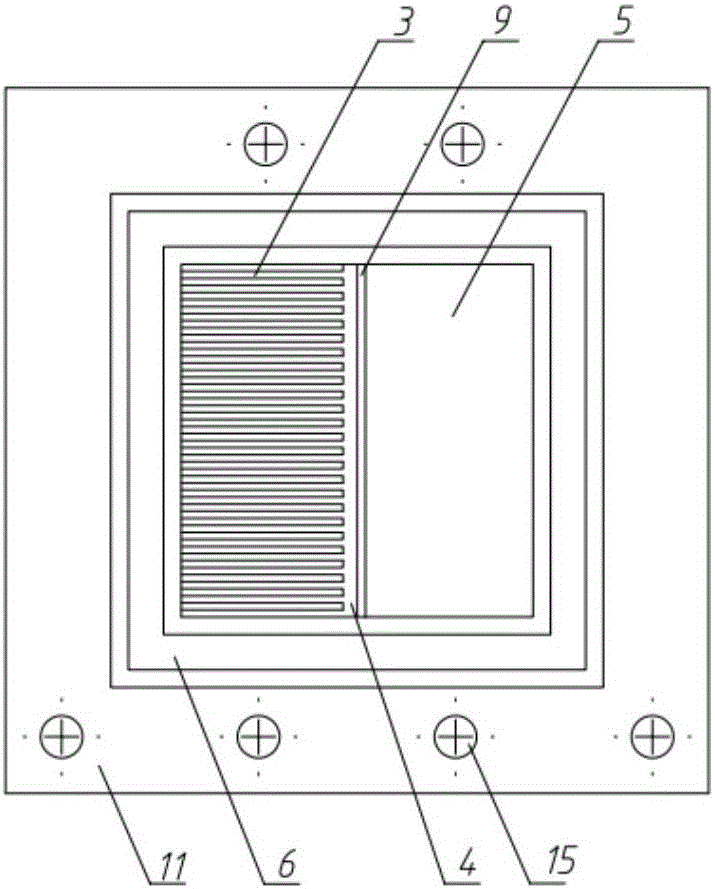

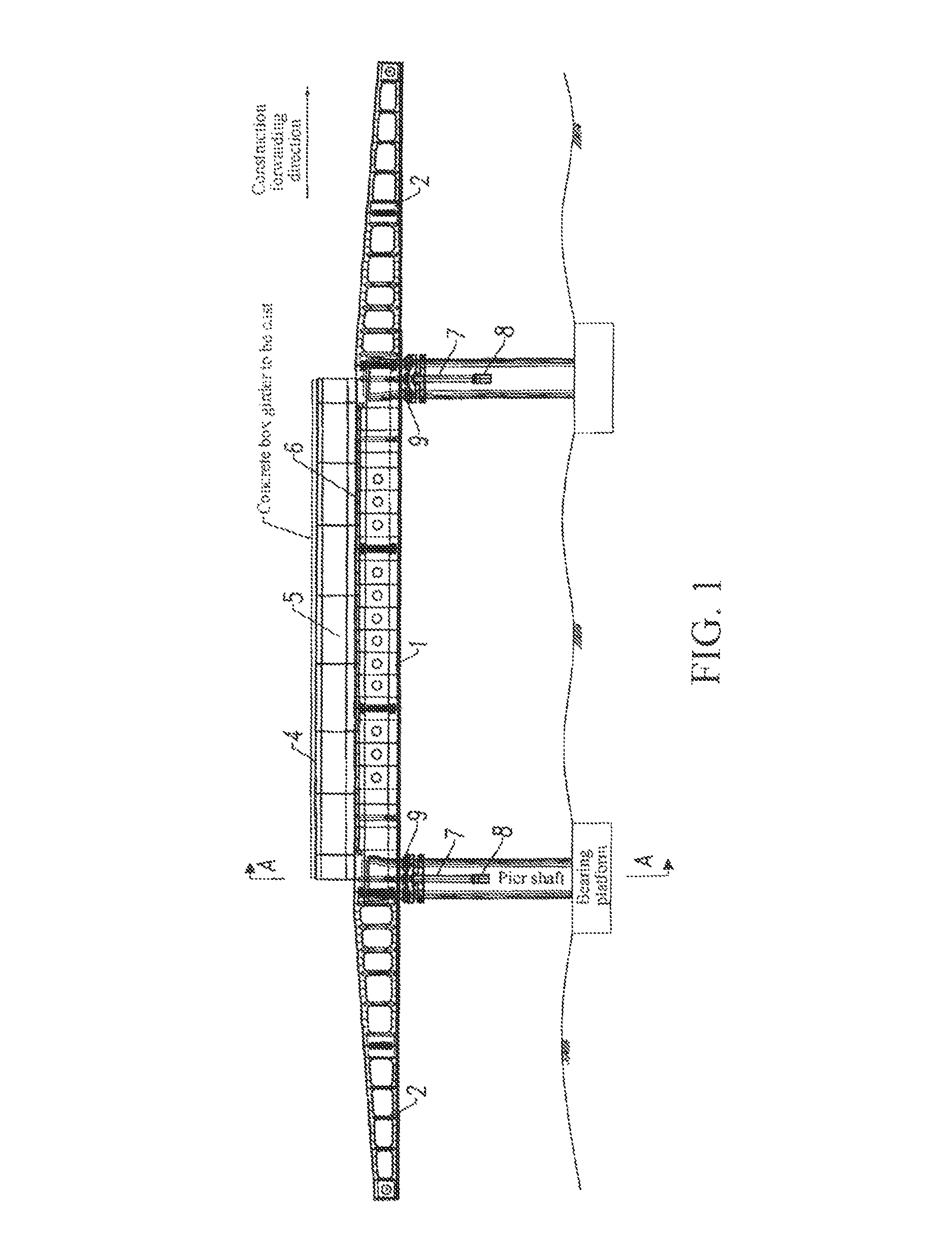

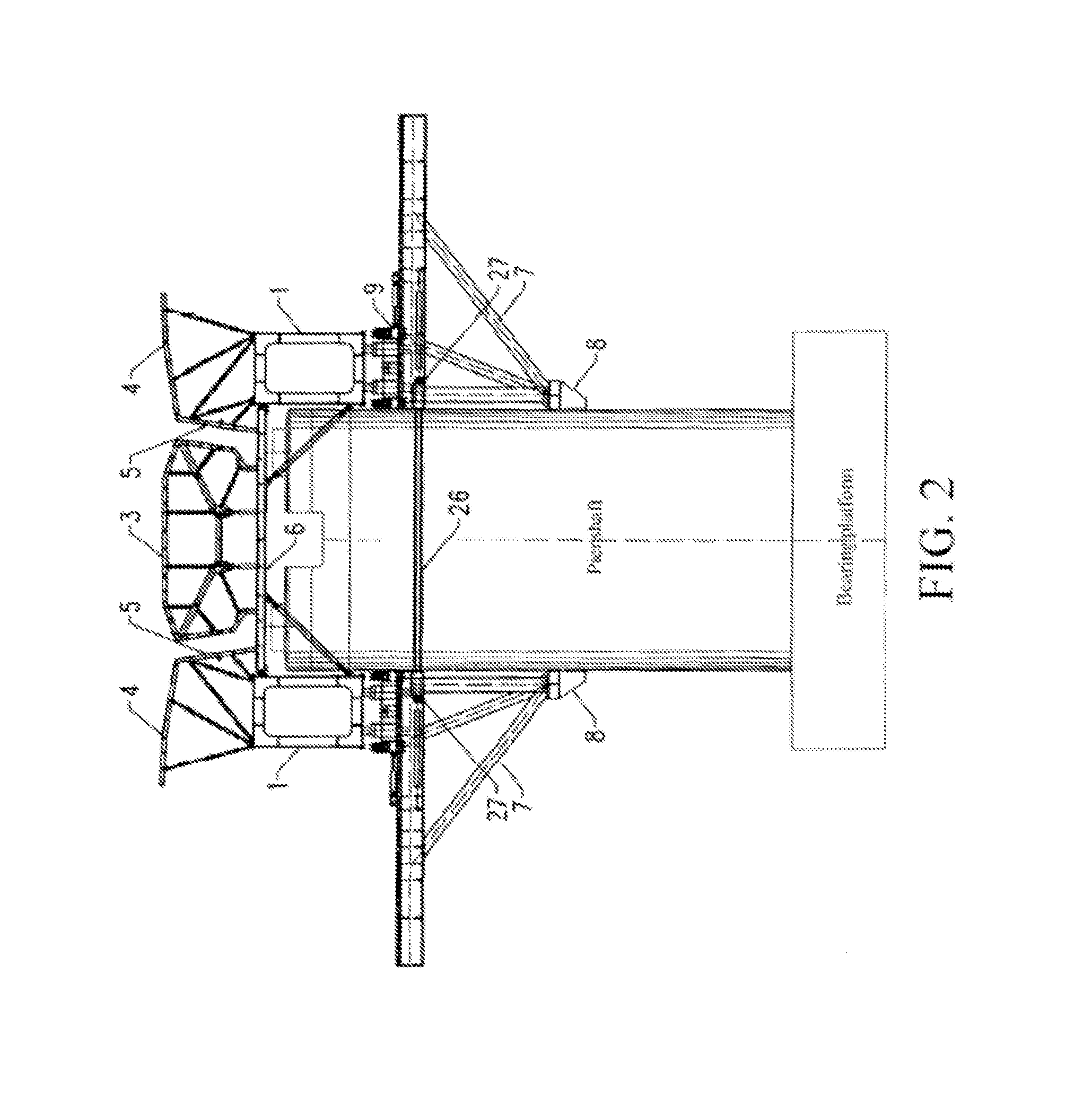

An upper-bearing typed movable formwork used for cast-in-situ of concrete box girder in bridge engineering, comprising left and right legs (7) which are respectively fixed on a pier, left and right longitudinal / transverse sliding mechanisms (9), bearing devices and a template system. The left and right longitudinal / transverse sliding mechanisms (9) are respectively arranged on the left and right legs (7) and can move horizontally along the left and right legs (7), the bearing devices are respectively fixed on the left and right longitudinal / transverse sliding mechanisms (9), the template system comprises a bottom formwork (6), an internal formwork (3), a left formwork and a right formwork, the bottom formwork (6) is formed by screw connection of a left bottom formwork and a right bottom formwork (6a,6b) which are symmetrical about the axis line of the concrete box girder, two ends of the bottom formwork are respectively fixed on two opposite internal side surfaces of the left main beam and the right main beam (1). The movable formwork also comprises a plurality of adjustable supporting rods (14) used for supporting the template system.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

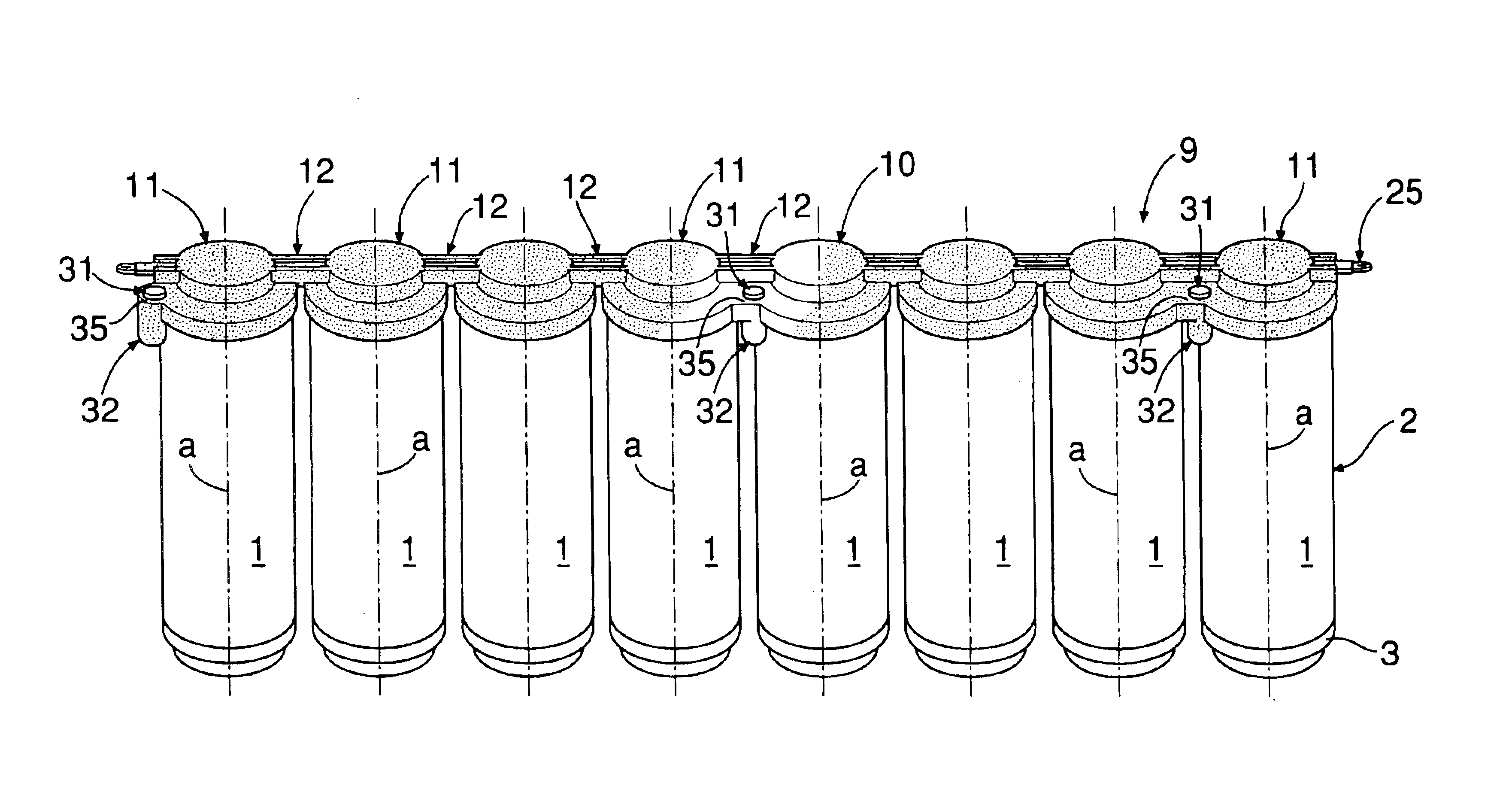

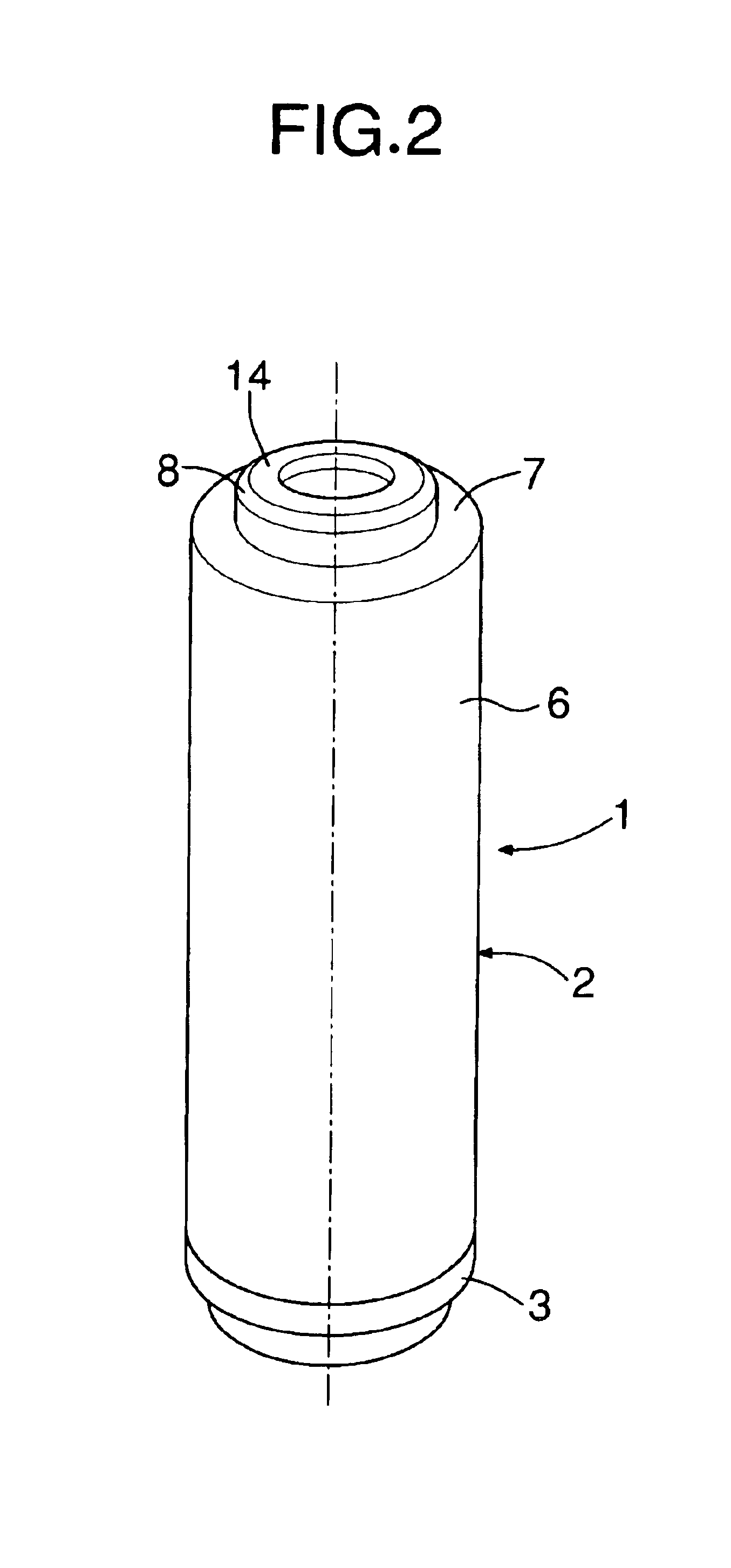

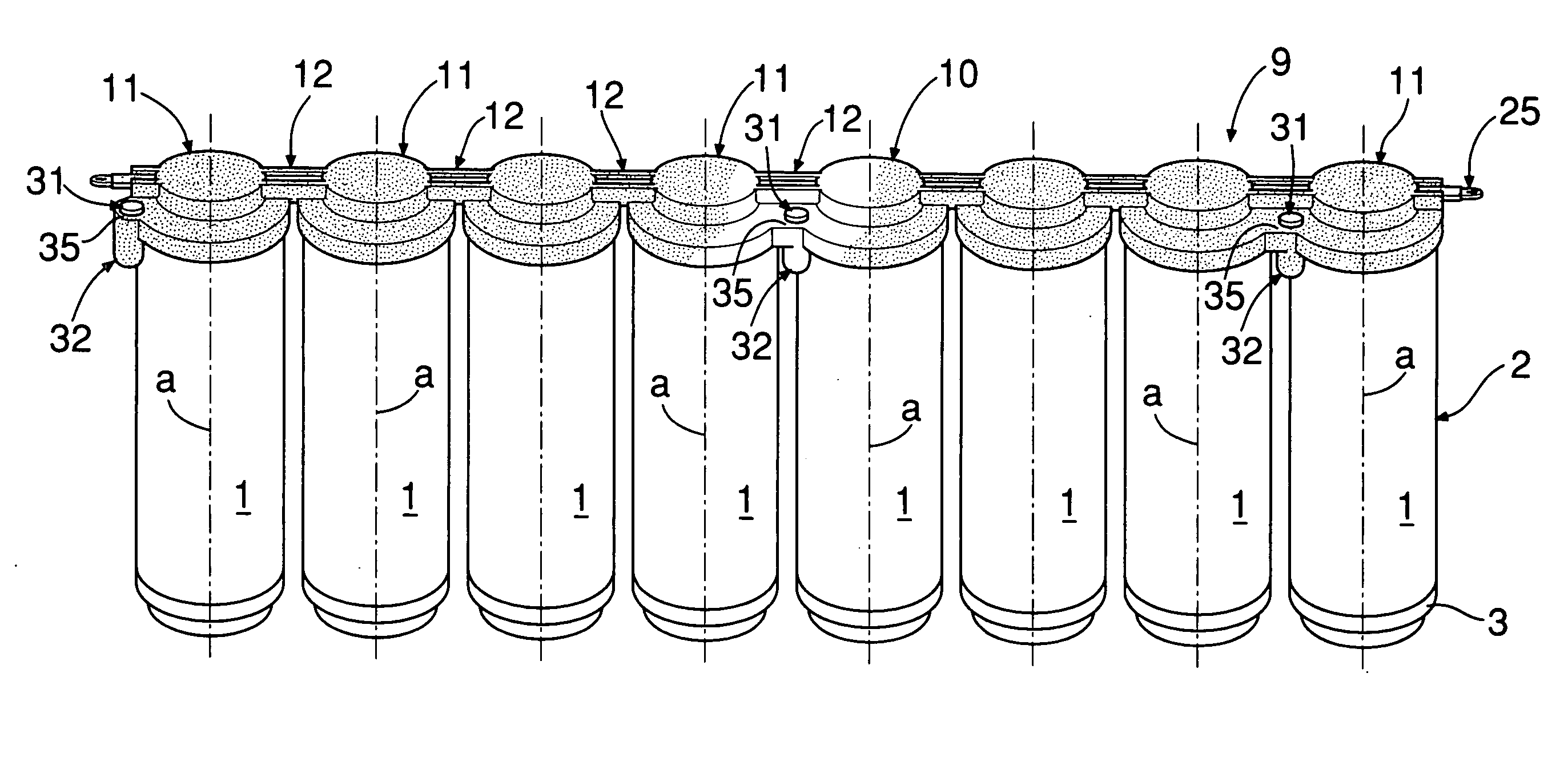

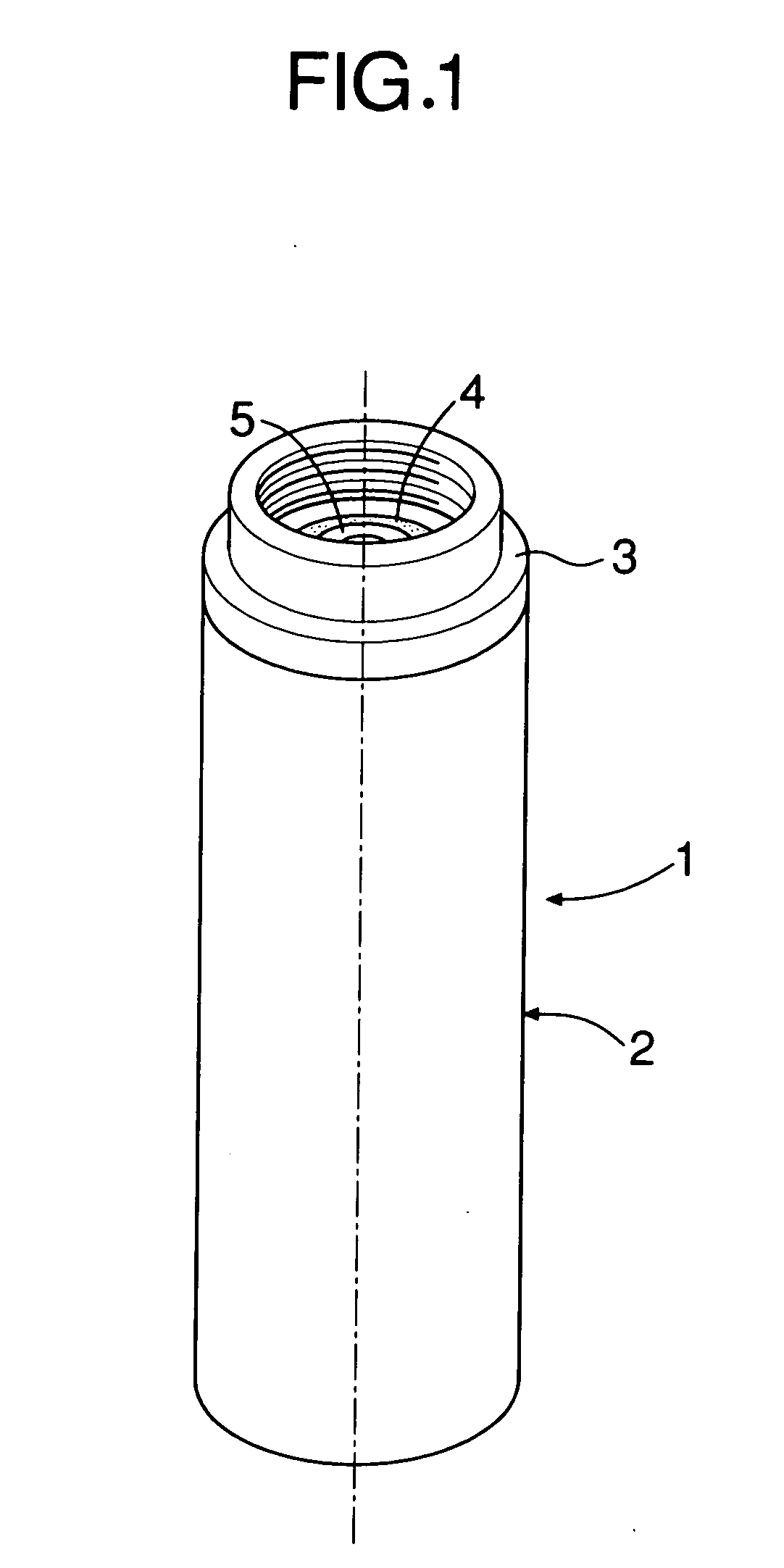

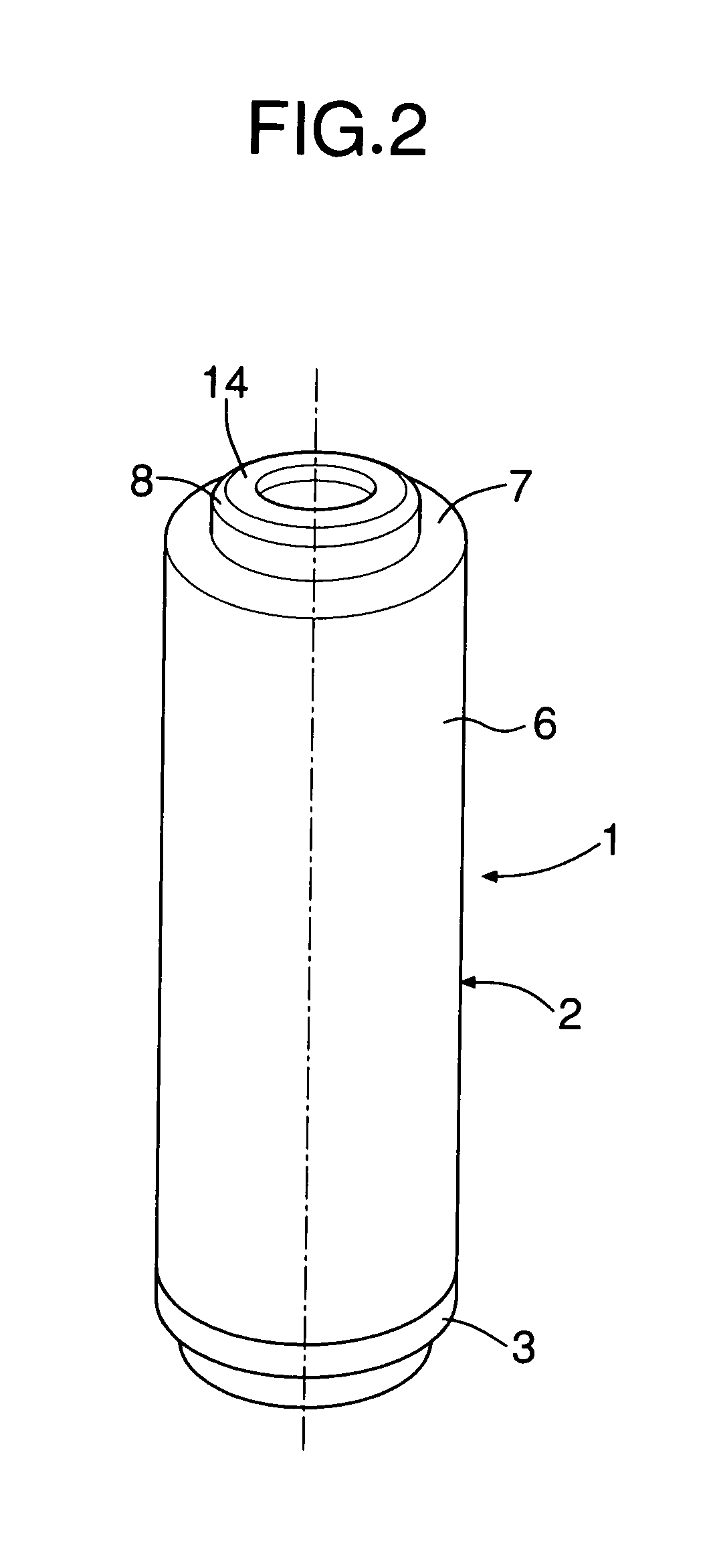

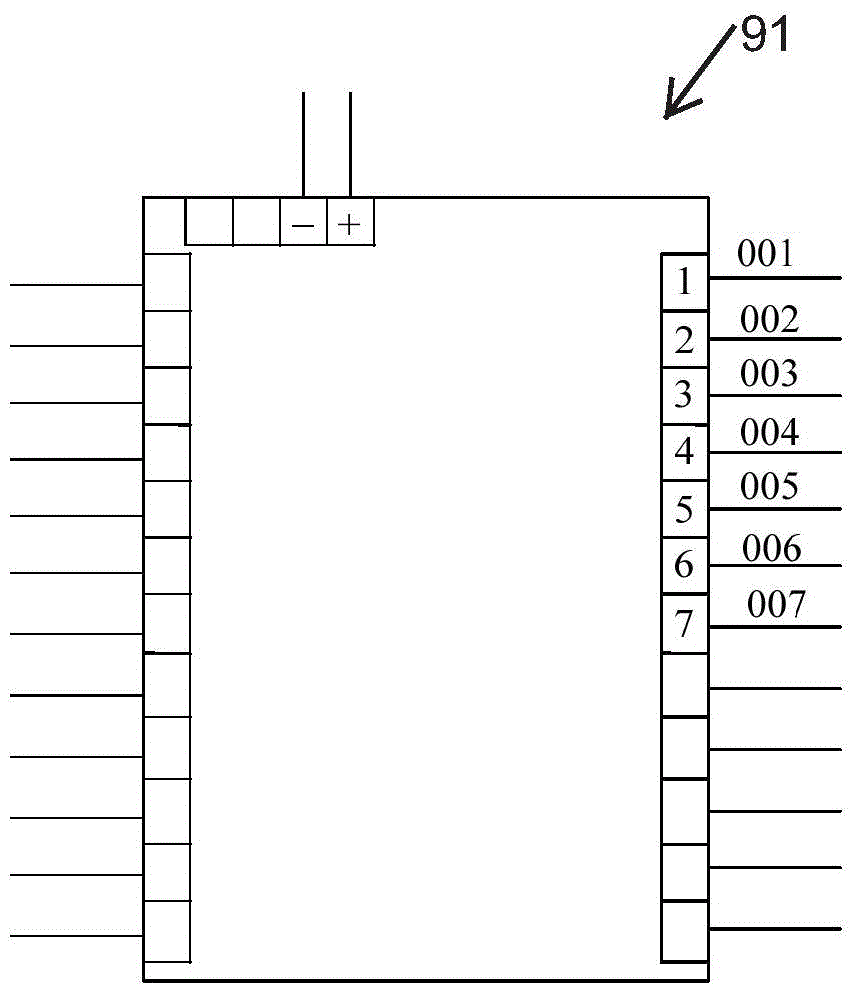

Accumulating element module

InactiveUS6922326B2Improve abilitiesIncreased footprintSeveral cell simultaneous arrangementsMultiple fixed capacitorsBand shapeEngineering

An accumulating element module includes a plurality of accumulating elements, each having a positive pole terminal and a negative pole terminal at one end. The accumulating elements are connected together at their other ends by an insulating connecting member made of a synthetic rubber. The insulating connecting member includes a plurality of caps and connectors. A deformation-resistant, band-shaped, temperature sensing member having a plurality of excessively raised temperature detectors is inserted through the caps.

Owner:HONDA MOTOR CO LTD

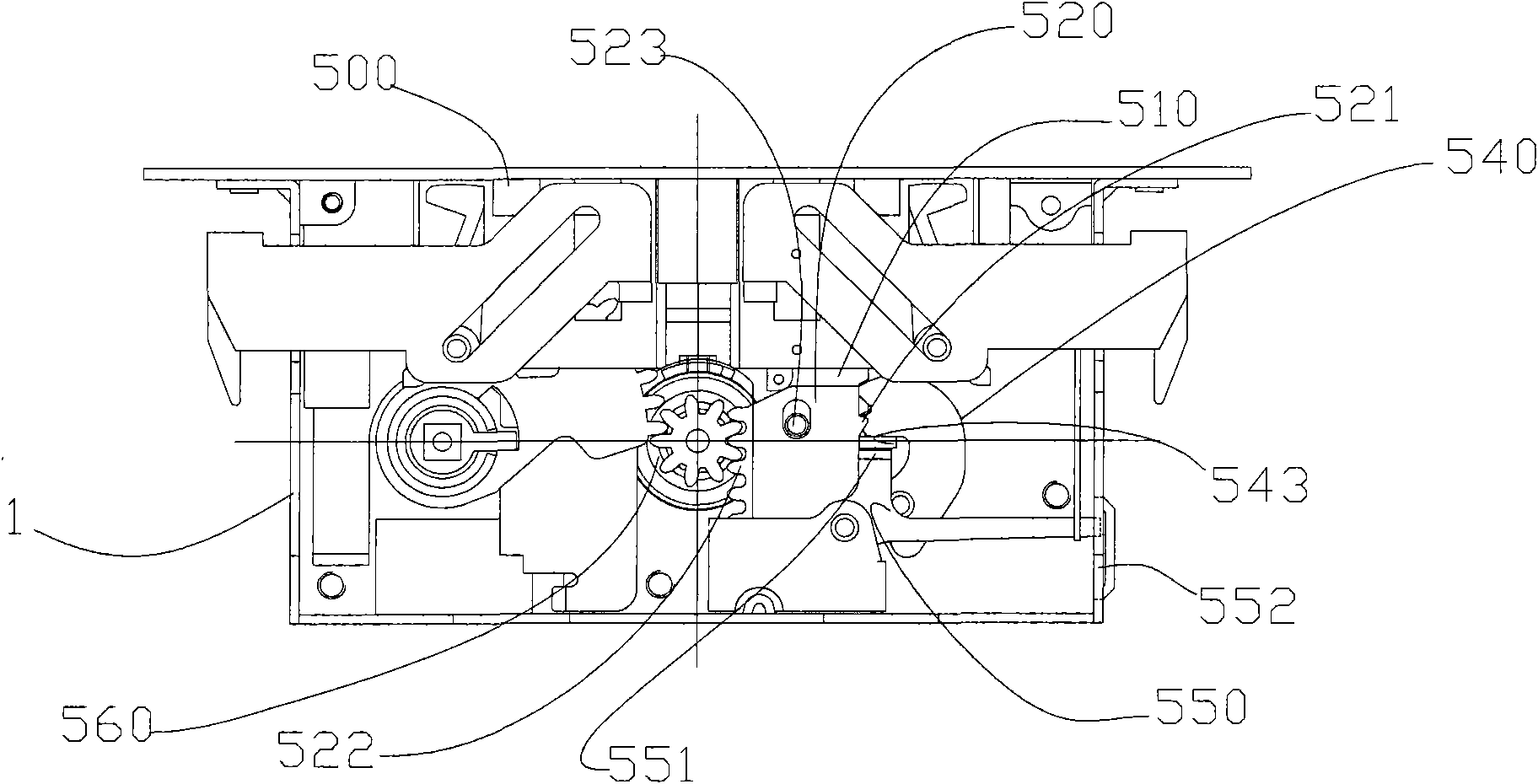

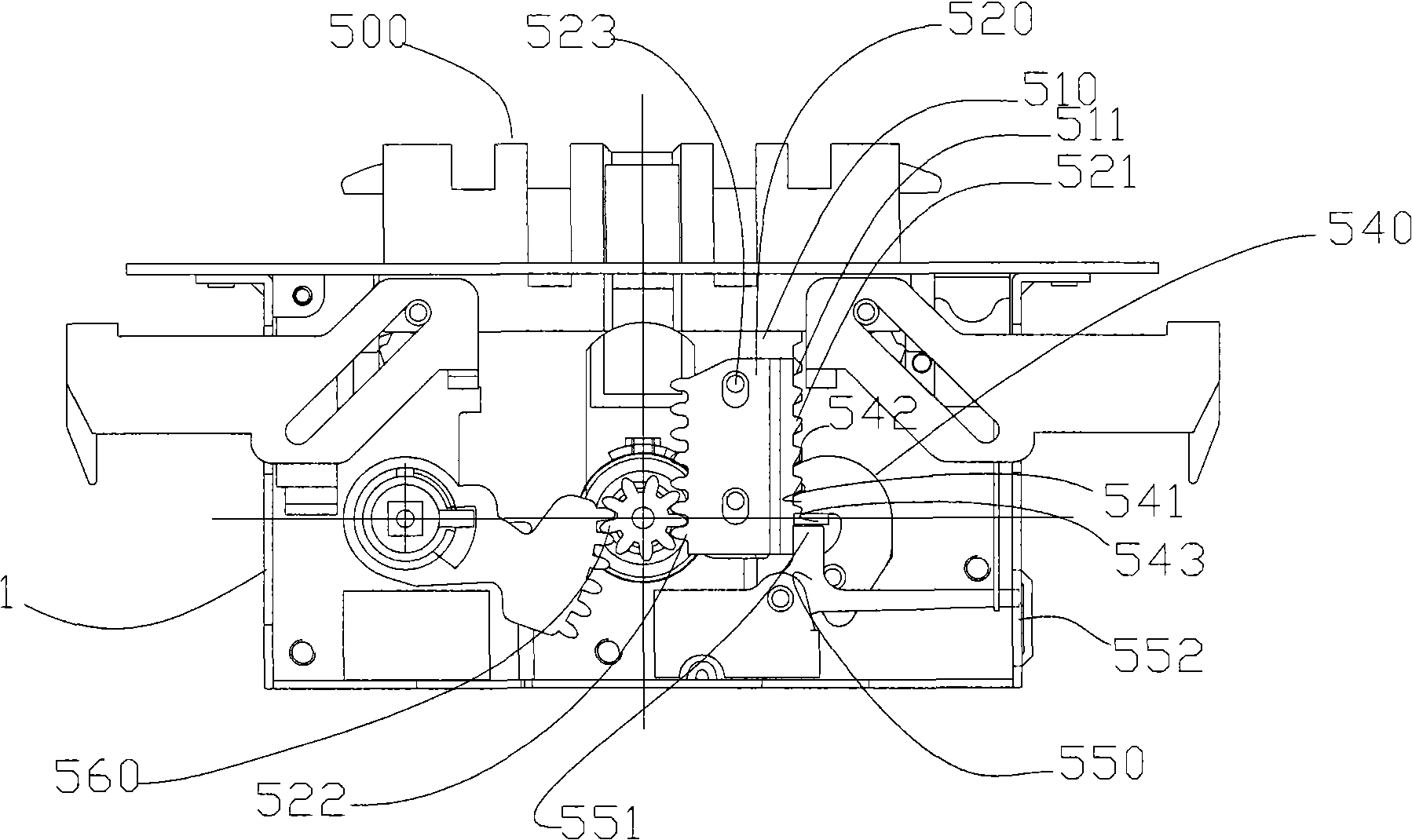

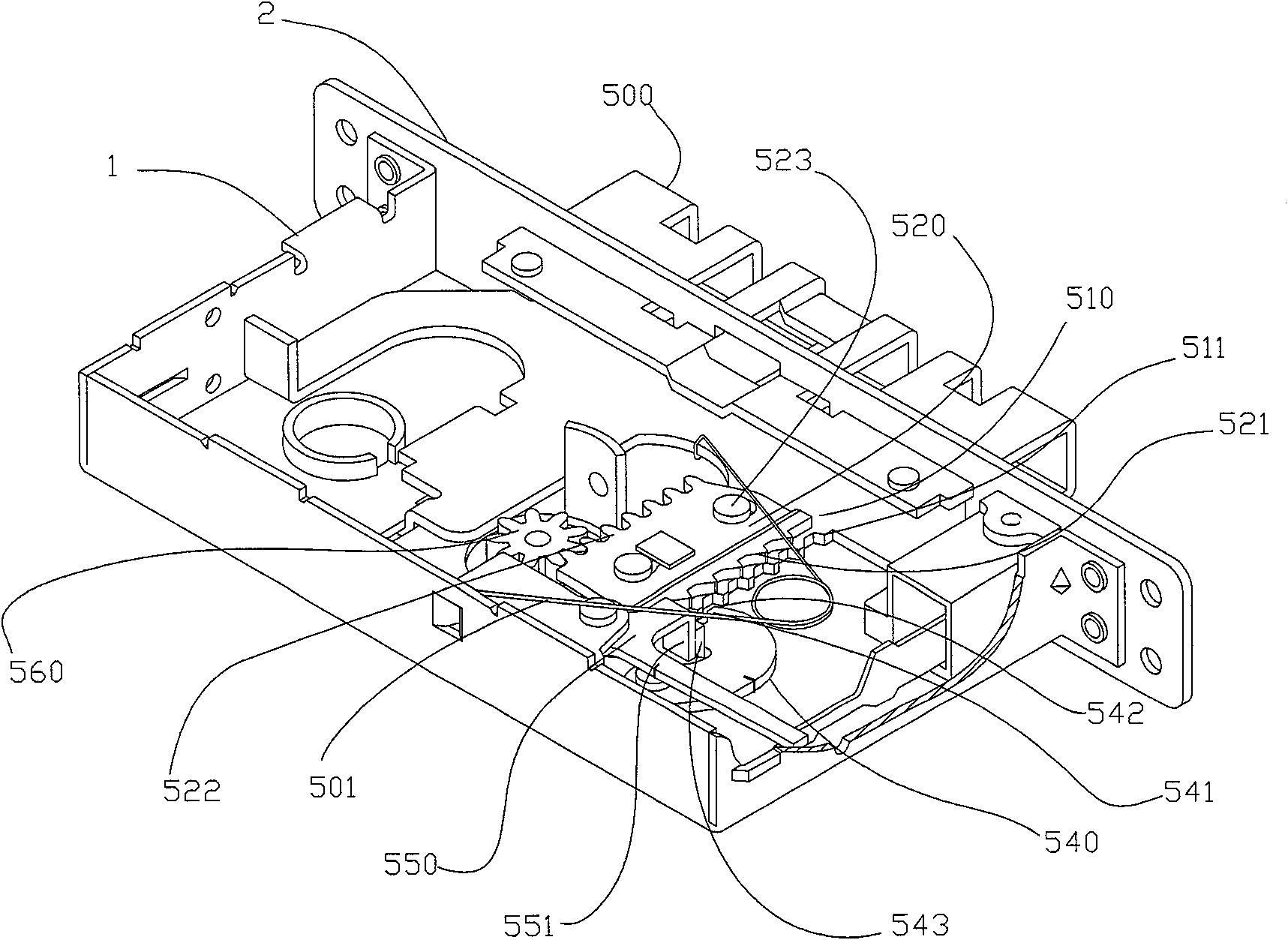

An automatic door lock

ActiveCN101566026ASimple structureCompact structureBuilding locksHandle fastenersLocking mechanismEngineering

The invention provides an automatic door lock, comprising a lock shell having a dead bolt hole molded with dead lock hole; a lock assembly installed on the lock shell panel and the lock shell bottom panel corresponding to a molded lock installation hole; a bolt mechanism installed in the lock shell capable of moving along the direction perpendicular to the lock shell panel; a locking control mechanism for controlling the bolt in the bolt mechanism extruding from and retracting into the panel; and a bolt locking mechanism matched with the door handle operating mechanism. The automatic door lock implements engagement and disengagement of the stop member with a fixed stripe and a movable stripe by coupling of the fixed and the movable stripe, the stop member is capable of engaging with the fixed and the movable stripe at different positions, incomplete unlocking operation due to extrusion of a bolt partially retracted into the shell is prevented.

Owner:WONLY SECURITY & PROTECTION TECH CO LTD

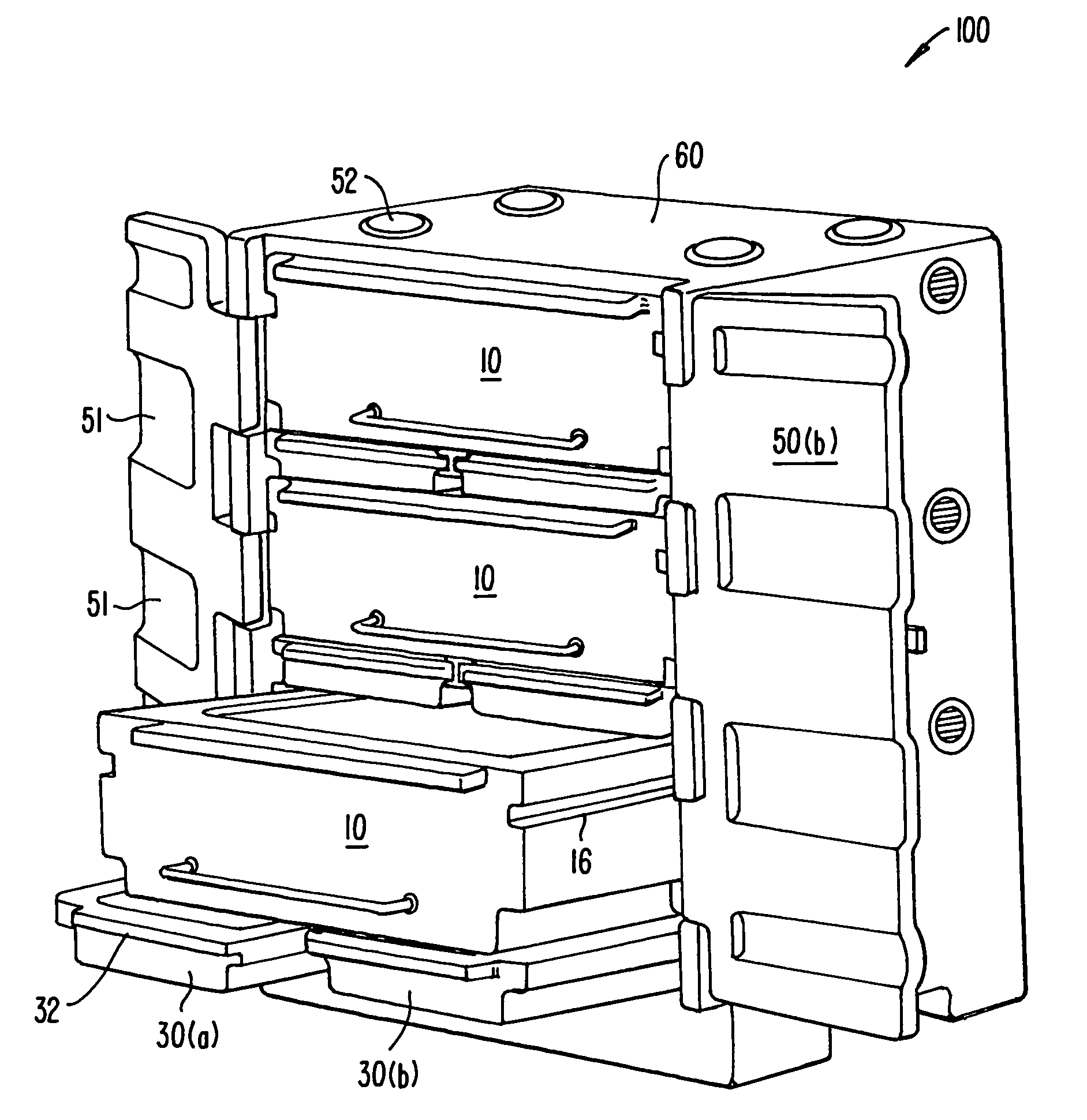

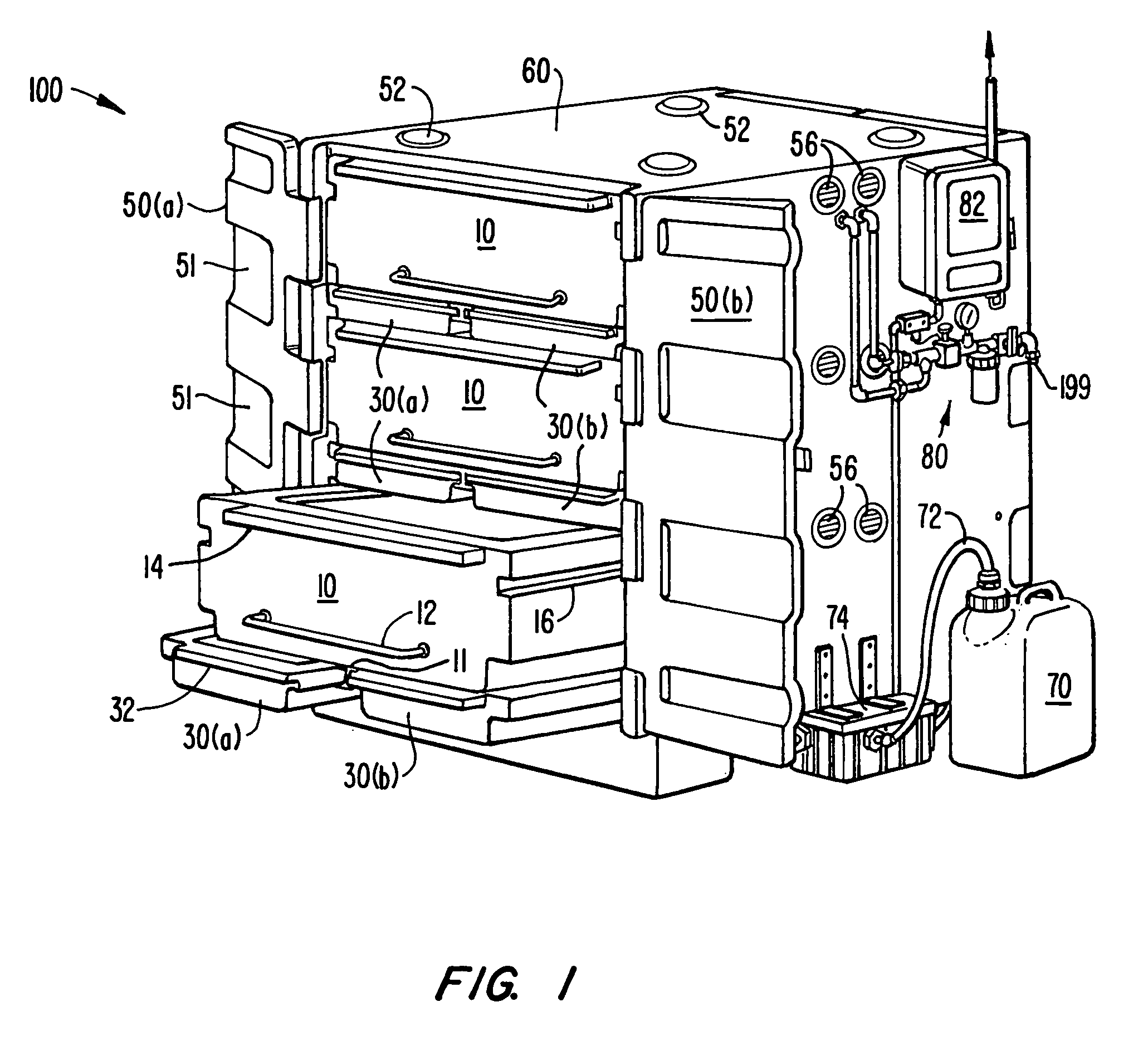

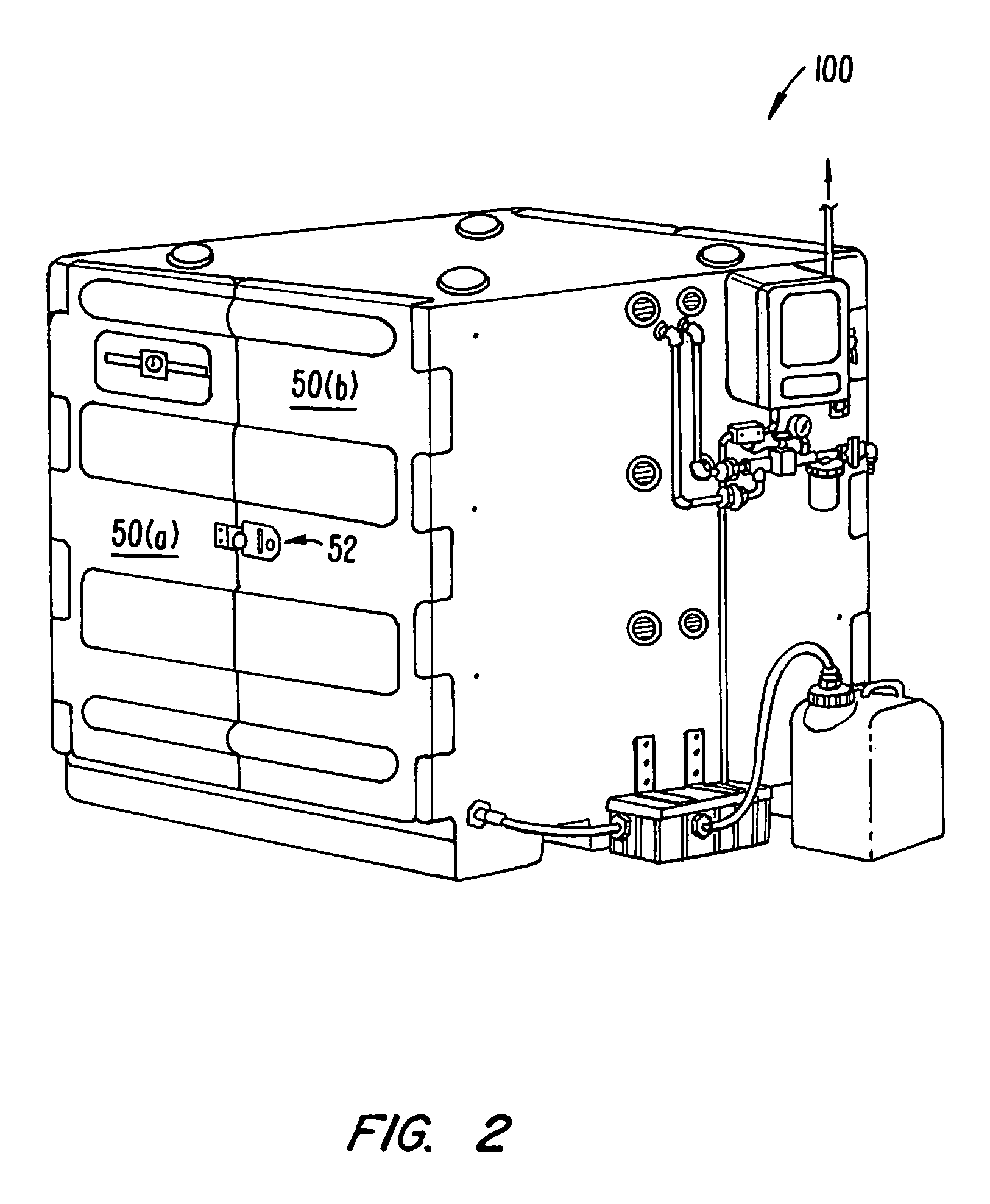

Composting apparatus and method

InactiveUS7018831B2Increased footprintLess laborBioreactor/fermenter combinationsBio-organic fraction processingEngineeringMechanical engineering

Owner:BIOSYSTEM SOLUTIONS INC

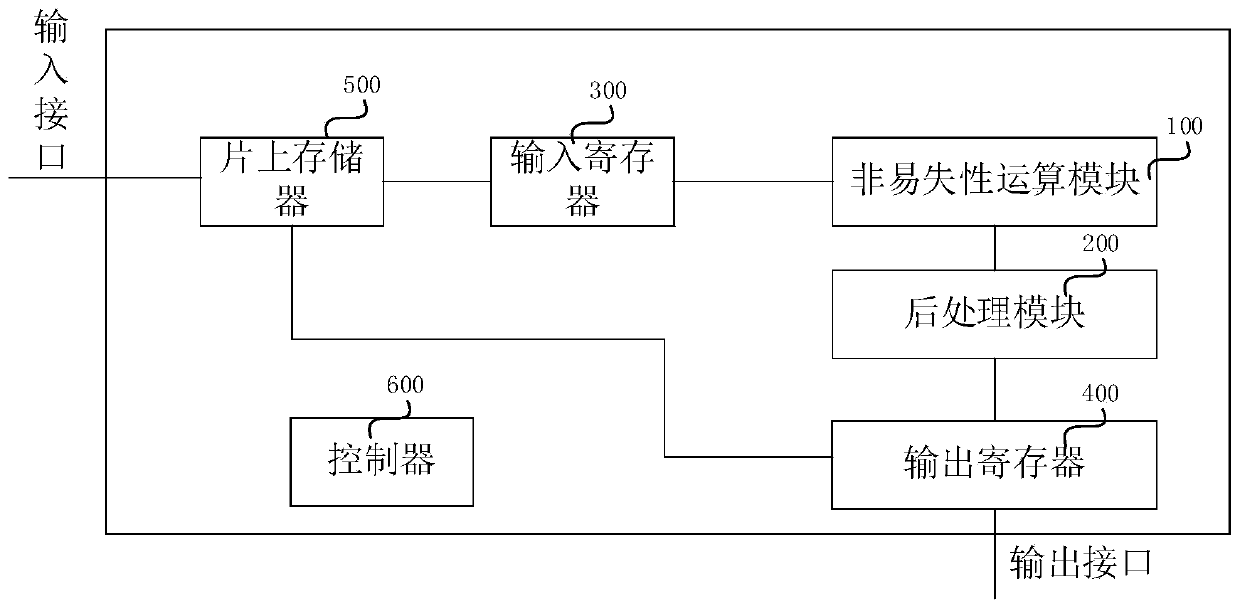

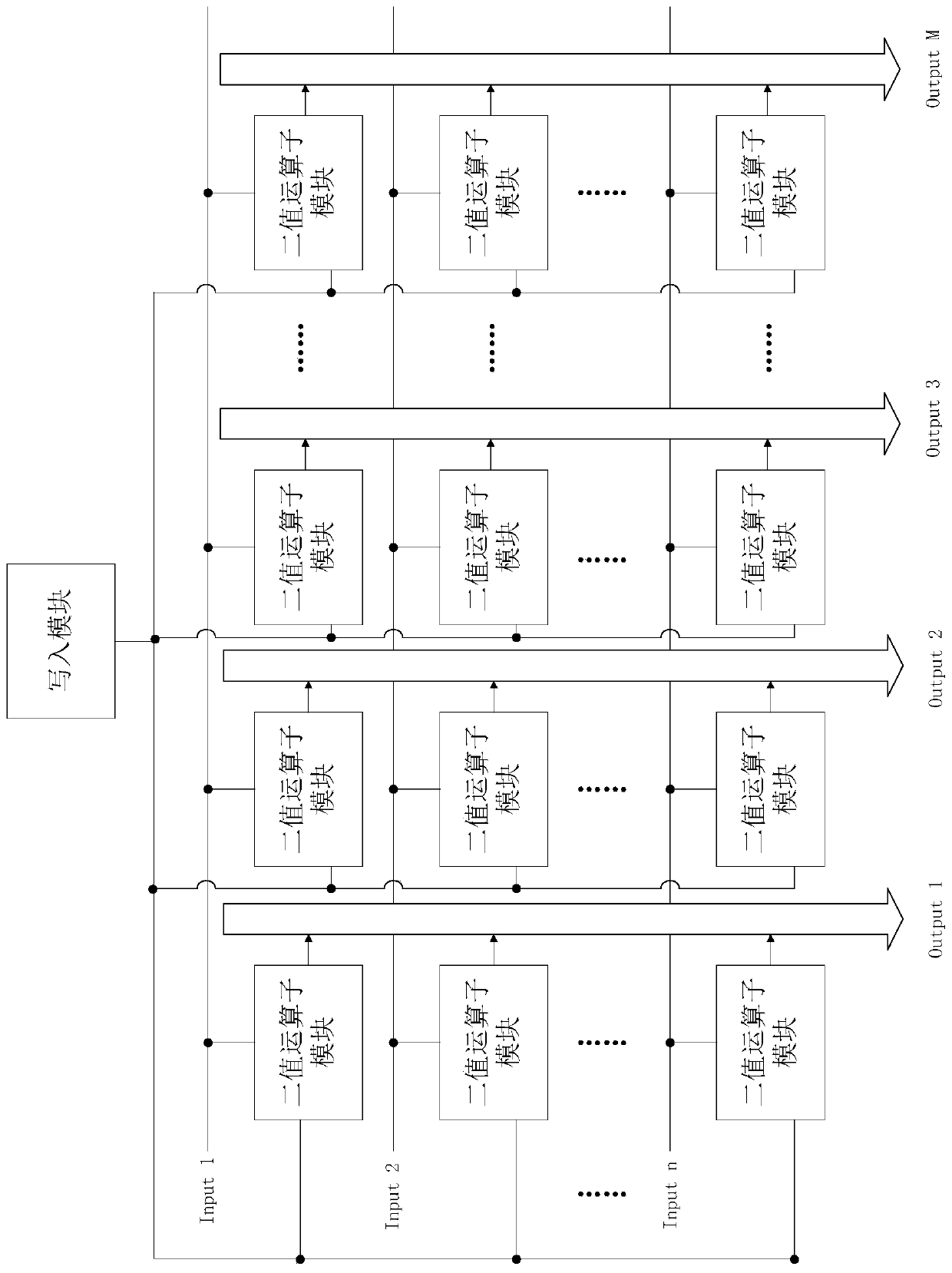

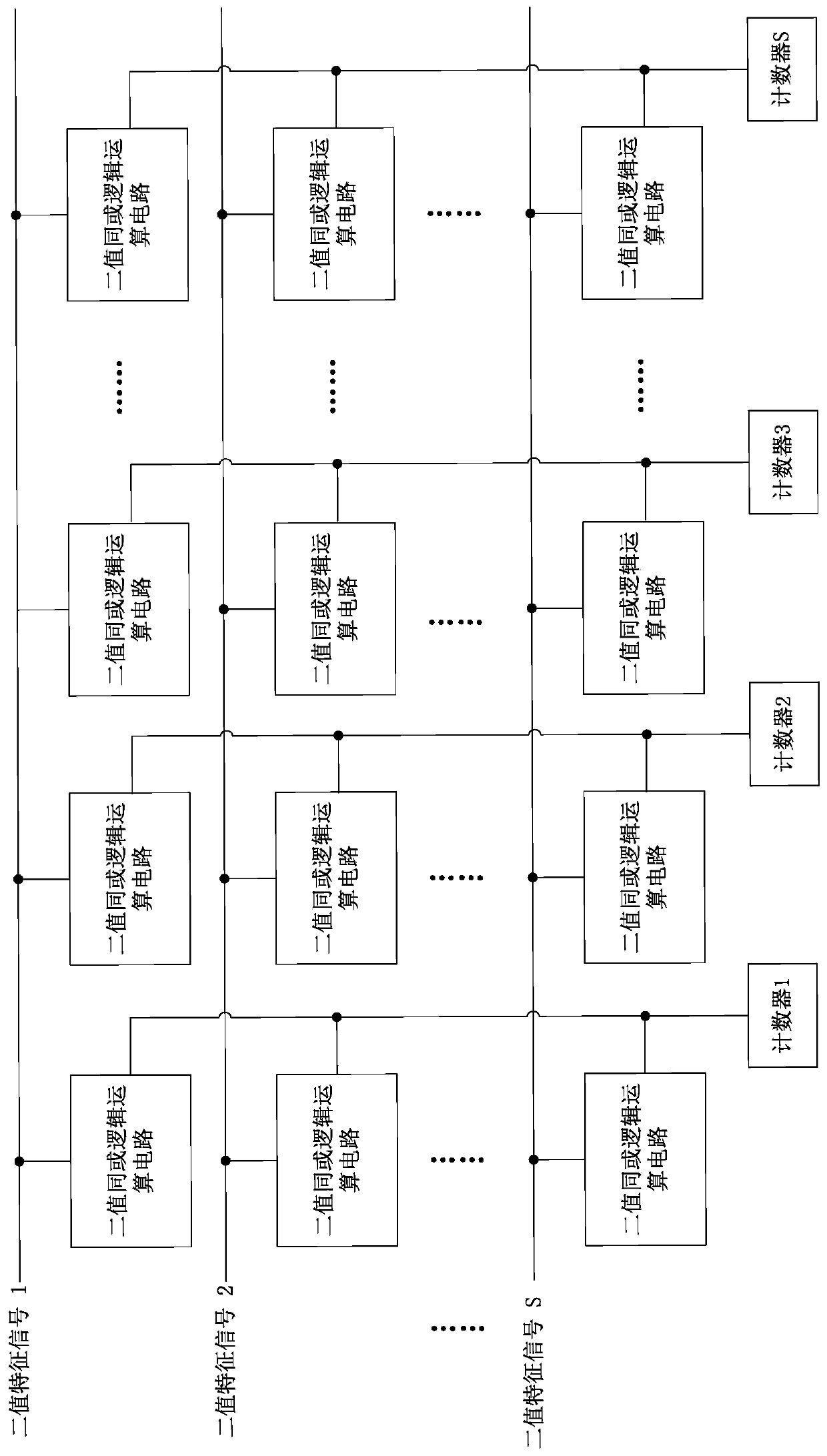

Chip for realizing binary neural network based on nonvolatile in-memory calculation and method

The invention provides a chip for realizing a binary neural network based on nonvolatile in-memory calculation and a method, and the chip comprises a nonvolatile operation module which is used for carrying out the matrix multiply-add operation on a first binary data packet received by the nonvolatile operation module and a second binary data packet pre-stored in the nonvolatile operation module, wherein the weight of the binary neural network is generally fixed during the reasoning process, and the input characteristics corresponding to each layer of neural network are generally changed alongwith the application. The weight of the binary neural network is used as the second binary data packet to be pre-stored in the nonvolatile operation module, and the input characteristics of the binaryneural network are loaded to the nonvolatile operation module, so that the matrix multiplication and addition operation can be realized in the nonvolatile operation module, and the problems of powerconsumption and time delay caused by data migration can be solved.

Owner:BEIHANG UNIV

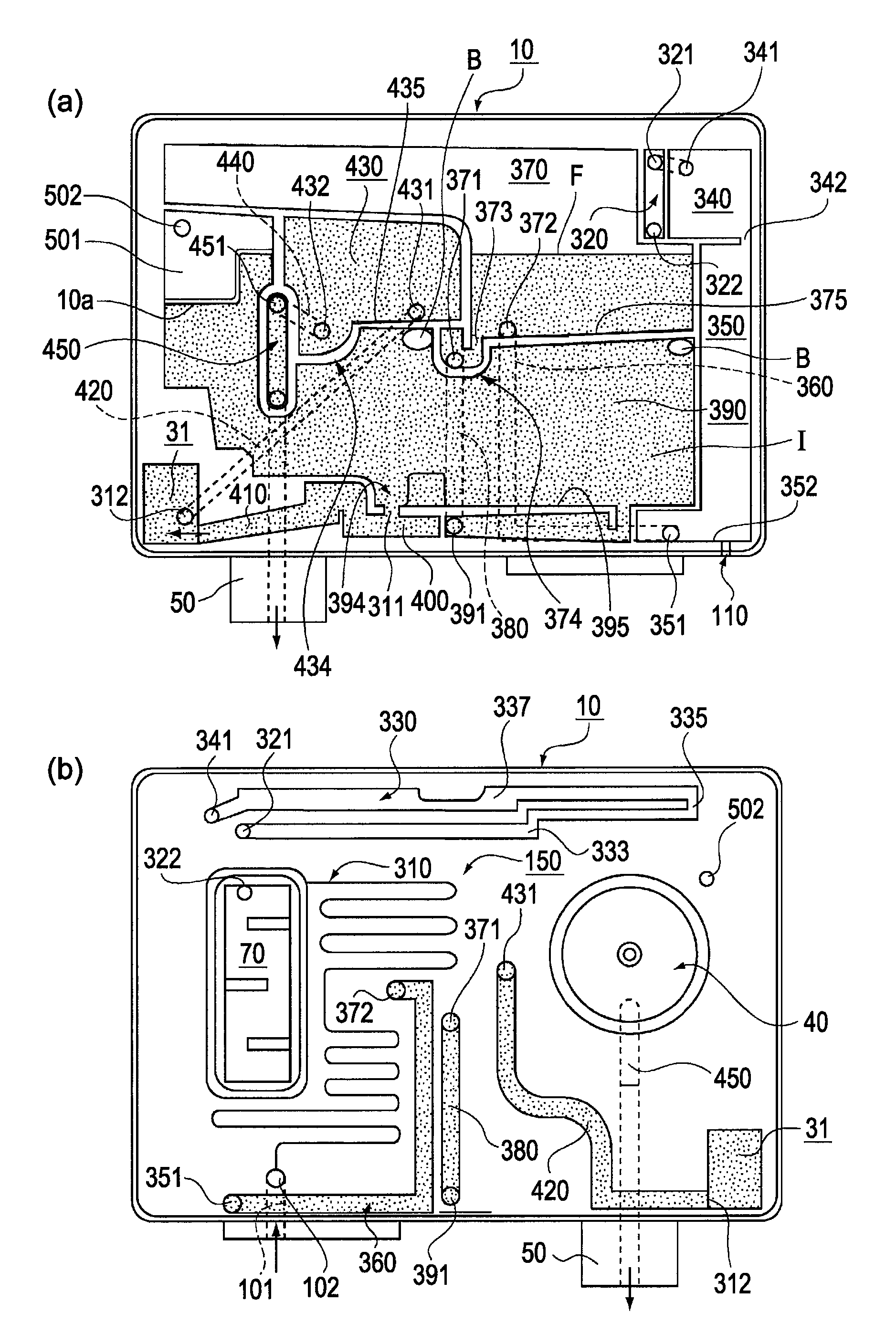

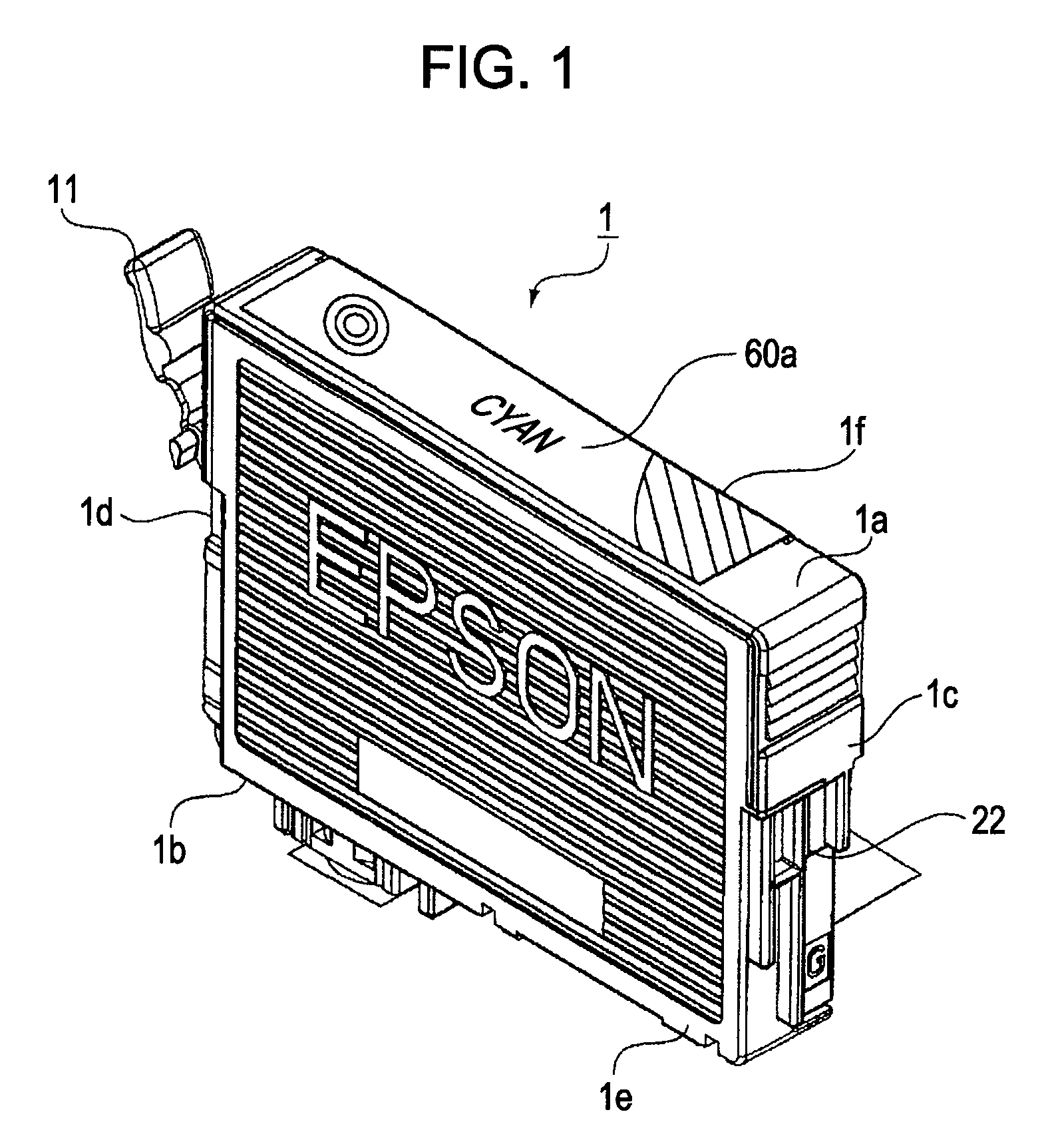

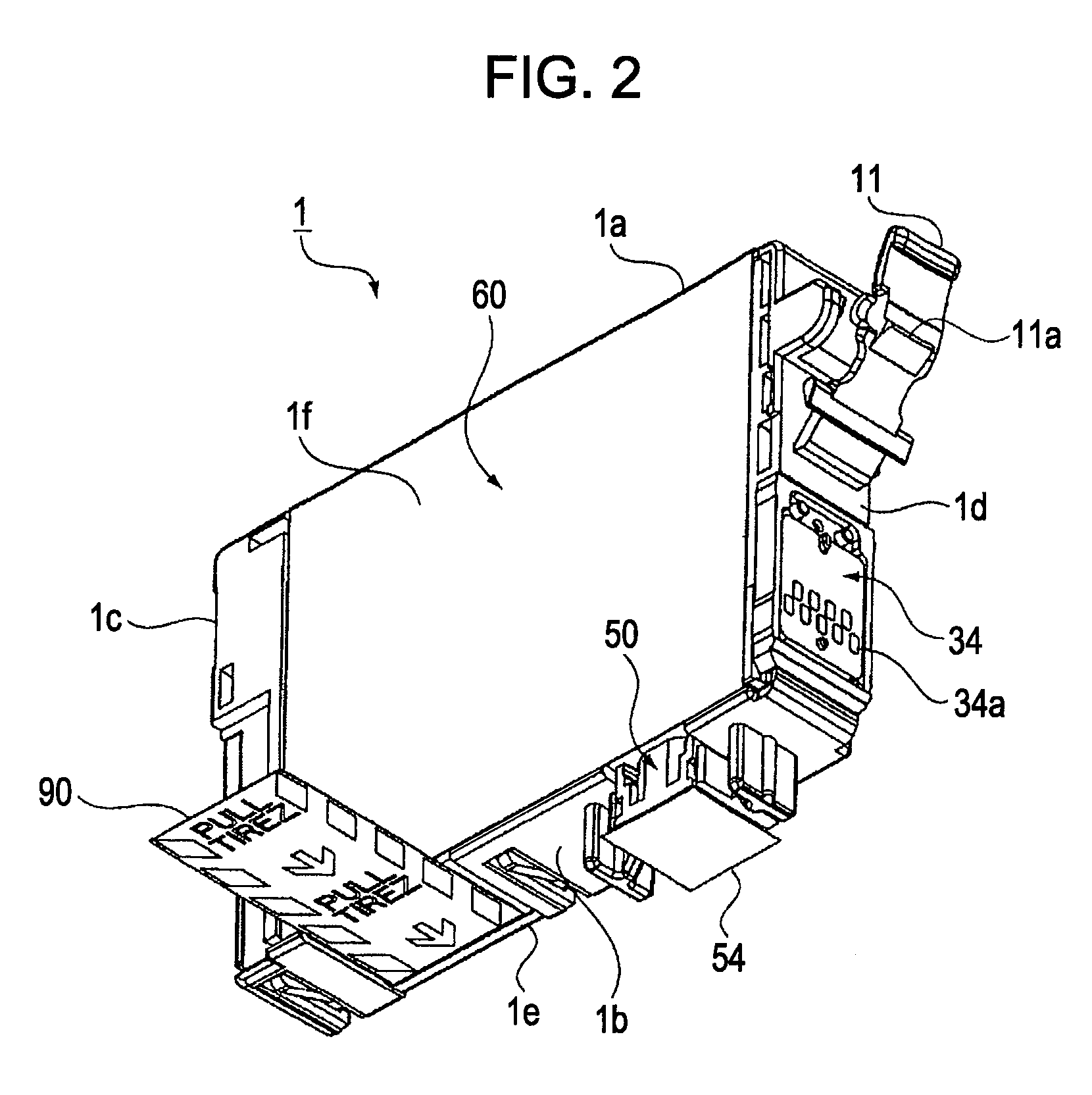

Liquid storage container

InactiveUS7699453B2Reduce remaining amountIncreased footprintOther printing apparatusEngineeringFalse detection

To provide a liquid storage container that can prevent false detection of a liquid remaining-amount sensor by preventing air bubbles from reaching a detection position of the liquid remaining-amount sensor as long as a usable amount of liquid remains in liquid storage chambers even when the air bubbles enter liquid guide paths from the liquid storage chambers. The liquid storage container has a cartridge main body 10 that includes an upper ink storage chamber 370, a lower ink storage chamber 390, and a buffer chamber 430. The upper ink storage chamber 370 and the lower ink storage chamber 390 are connected to each other with an ink guide path 380 which provides a descending connection so that ink I descends downward therethrough. The lower ink storage chamber 390 and the buffer chamber 430 are connected to each other with an ink guide path 420 which provides an ascending connection so that the ink I ascends upward therethrough. Thus, the descending connection and the ascending connection are alternately provided so as to connect the ink storage chambers in series.

Owner:SEIKO EPSON CORP

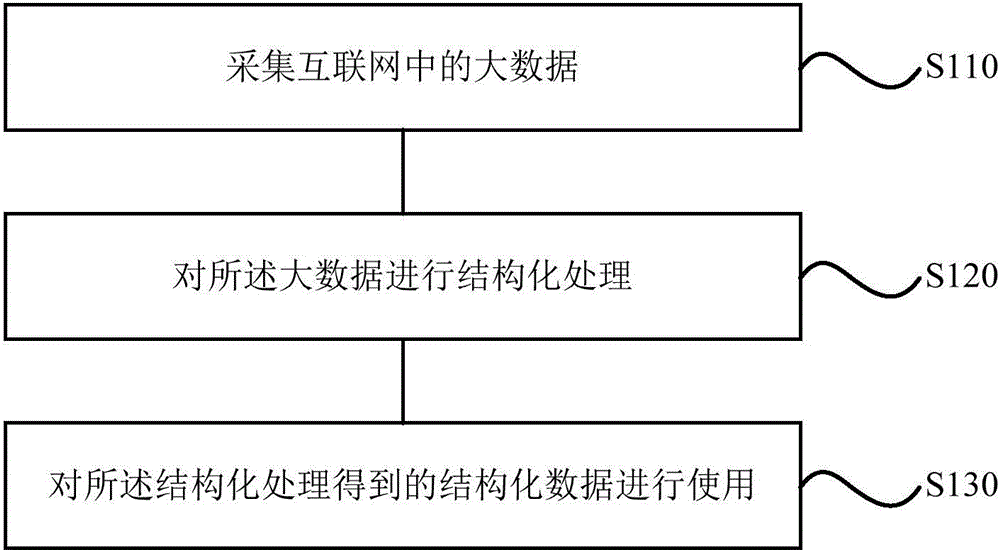

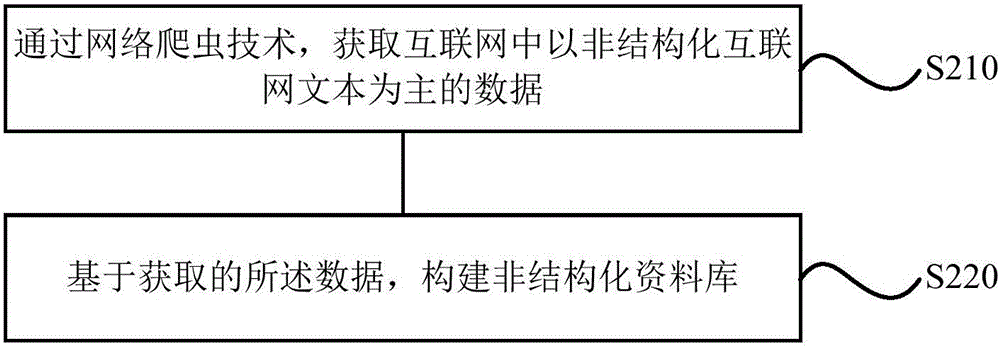

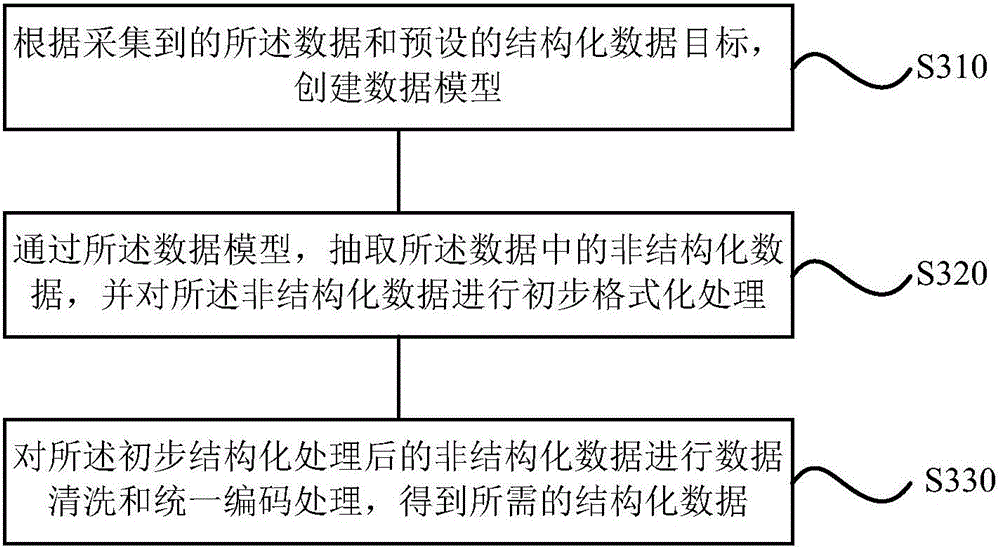

Processing method and processing device for big data and terminal

InactiveCN106227885ARealize processingImprove resource utilizationWeb data indexingSpecial data processing applicationsThe InternetUtilization rate

The invention discloses a processing method and a processing device for big data and a terminal. The method comprises the following steps of collecting the big data in internet; performing structured processing on the big data; using the structured data obtained by the structured processing. According to the scheme provided by the invention, the defects of high processing difficulty, large occupied space, low utilization rate and the like in the prior art can be overcome, and beneficial effects of low processing difficulty, small occupied space and high utilization rate are realized.

Owner:星河互联集团有限公司

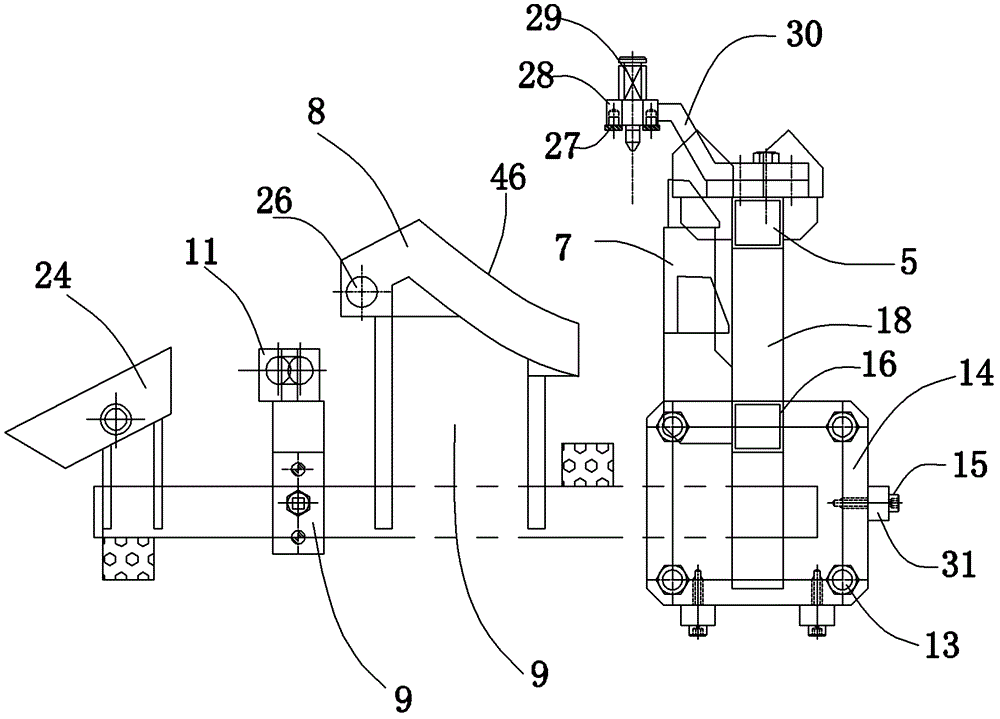

Flexible inspection device for front portion of automobile

InactiveCN102749051APrecise positioningImproved accuracy and stabilityMeasurement devicesEmbedded systemEngineering

Owner:ZHEJIANG HAOQING AUTOMOBILE MFG CO LTD +1

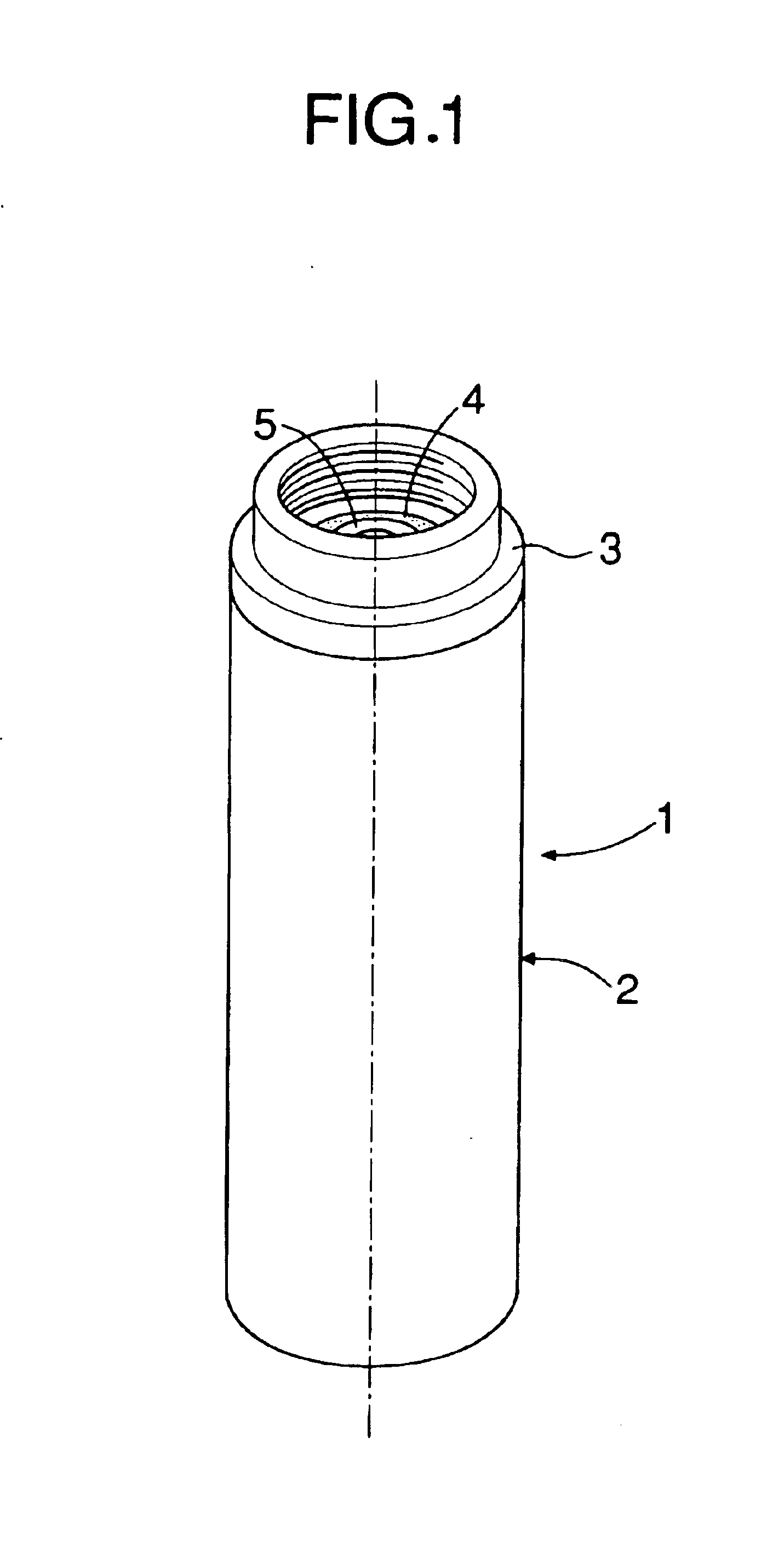

Accumulating element module

InactiveUS20050054240A1Suppress generationPrevent disengagementSeveral cell simultaneous arrangementsMultiple fixed capacitorsBand shapeEngineering

An accumulating element module includes a plurality of accumulating elements, each having a positive pole terminal and a negative pole terminal at one end. The accumulating elements are connected together at their other ends by an insulating connecting member made of a synthetic rubber. The insulating connecting member includes a plurality of caps and connectors. A deformation-resistant, band-shaped, temperature sensing member having a plurality of excessively raised temperature detectors is inserted through the caps.

Owner:HONDA MOTOR CO LTD

Resource utilization method for combined production of biogas and cultivation matrix through utilizing tobacco stalk fermentation

InactiveCN102851318AModerate granularityQuality improvementBio-organic fraction processingInternal combustion piston enginesSocial benefitsResource utilization

The invention provides a resource utilization method for the combined production of a biogas and a cultivation matrix through utilizing tobacco stalk fermentation. The method comprises the following steps: carrying out anaerobic fermentation of a main fermentation raw material which is waste tobacco stalks generated in the tobacco threshing redrying line to produce the biogas; carrying out solid-liquid separation of a biogas slurry and the tobacco stalks to obtain a tobacco stalk biogas residue and a biogas slurry; purifying the biogas to prepare clean fuels or to be used for electricity generation to provide partial energy for a plant area; and decomposing the tobacco stalk biogas residue, and carrying out dry molding to prepare the cultivation matrix, wherein the biogas slurry returns to a fermentation system to be recycled or to be used as a liquid organic fertilizer. The method provided by the invention has the advantages of simple production operation, concentrated and stable raw material, scale production benefiting, low production cost, realization of no pollution, zero discharge and cycle utilization of waste tobacco stalk resources of a threshing redrying plant, and generation of good economic, ecological and social benefits.

Owner:ZHENGZHOU UNIV

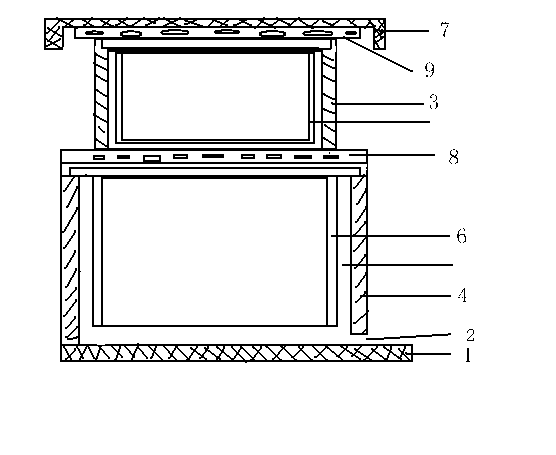

Heat-preservation and heat-insulation hive and application method thereof

The invention relates to the field of bee keeping, in particular to an application method of a heat-preservation and heat-insulation hive which solves the problem of poor heat preservation and heat insulation of existing wooden hives. The heat-preservation and heat-insulation hive comprises nest cases and a case cover. An inner core made of polystyrene foam boards is arranged between an outer nest case and an inner nest case which is so called when placed on a partition board. Since the polystyrene foam board has characteristics of lightweight, heat preservation, heat insulation and low-temperature resistance, the heat-preservation and heat-insulation hive made of the polystyrene foam boards is good in heat-preservation and heat-insulation performances, convenient to transport and carry, time-saving and labor-saving, durable and simple to process, can be mechanically produced in large scale, is suitable for raising all kinds of bees, favorable for rapid development of the bee keeping, and has high promotional value and using value.

Owner:梁永贵

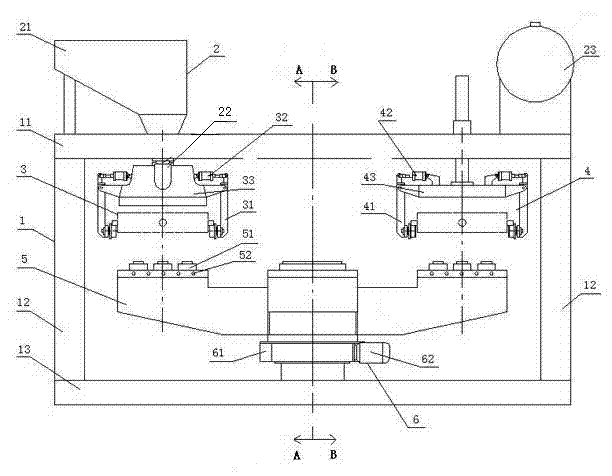

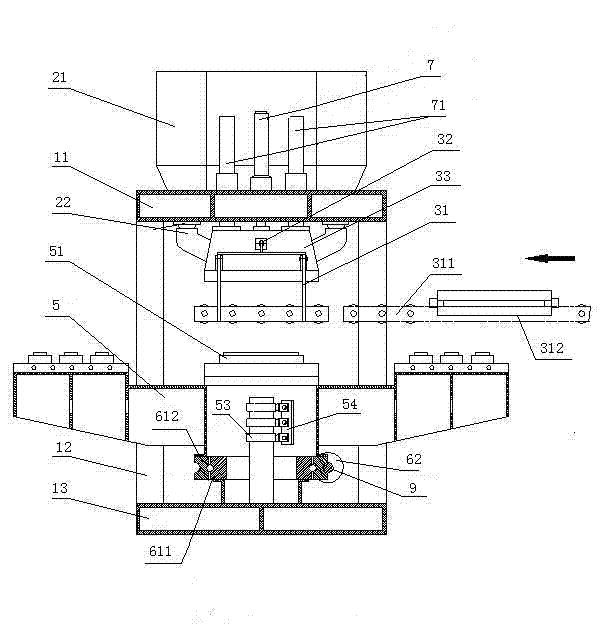

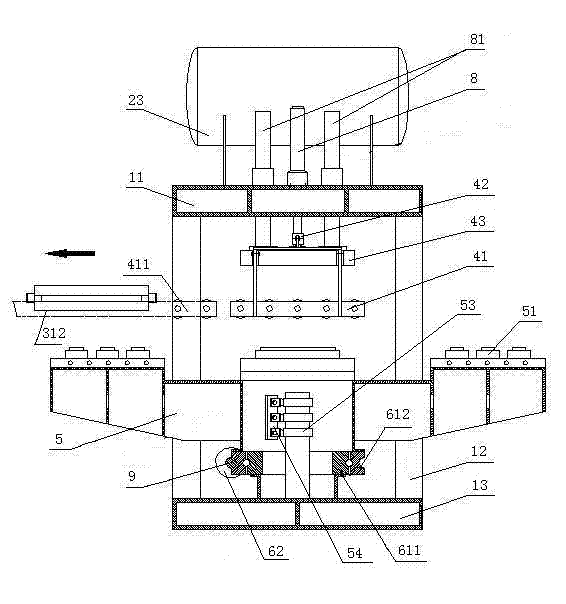

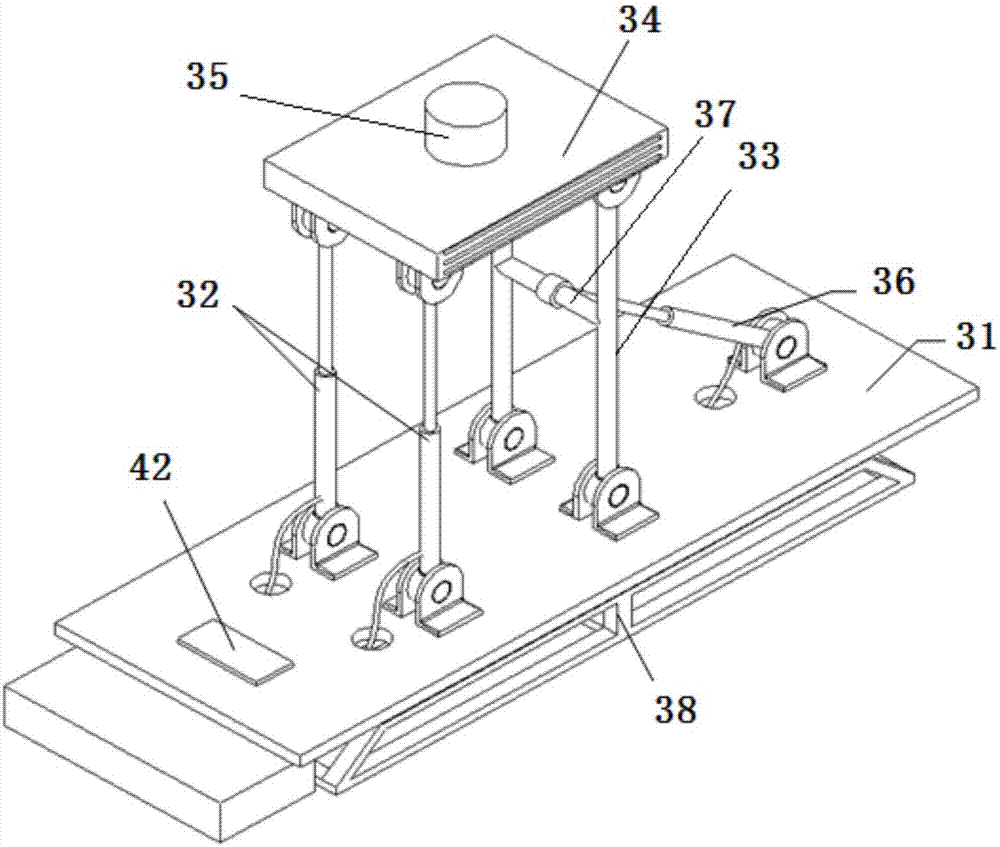

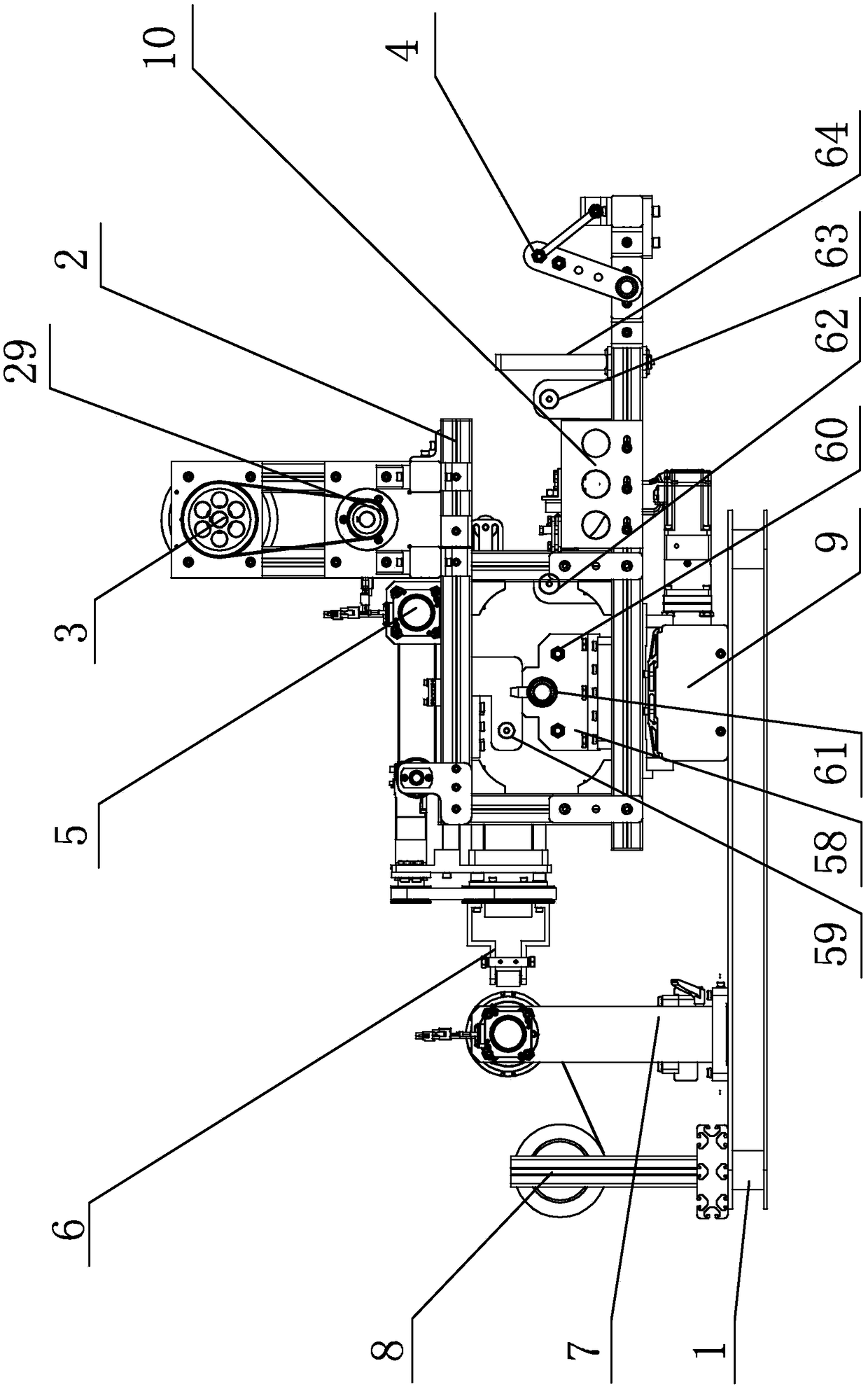

Equipment and method for improving sand lined casting efficiency

ActiveCN103203434AImprove efficiencyReasonable structural designMoulding machinesIndustrial engineeringCasting

The invention relates to equipment and a method for improving sand lined casting efficiency, and belongs to the technical field of iron sand lined casting. The equipment comprises a supporting frame composed of an upper beam, a base and a vertical pillar between the upper beam and the base, a sand adding and jetting device, and a rotating mechanism arranged on the base. The equipment is characterized by further comprising a four-station working platform, a lifting type sand jetting head and a lifting type roller bed opening and closing mechanism, wherein the four-station working platform is fixed on the rotating mechanism; the lifting type sand jetting head is connected at one side of the upper beam, and the lifting type roller bed opening and closing mechanism is connected at the other side; the lifting type sand jetting head and the lifting type roller bed opening and closing mechanism are respectively arranged on left and right sides; and the four-station working platform is arranged below the lifting type sand jetting head and the lifting type roller bed opening and closing mechanism. The equipment disclosed by the invention is reasonable in structure and design, convenient to clean mold, high in sand lined casting efficiency and convenient for users to operate.

Owner:浙江省机电设计研究院有限公司

Light-emitting element, method for producing the same and illuminating device

InactiveUS20100207514A1Well formedSimple processDischarge tube luminescnet screensElectroluminescent light sourcesEngineering

Owner:SUMITOMO CHEM CO LTD

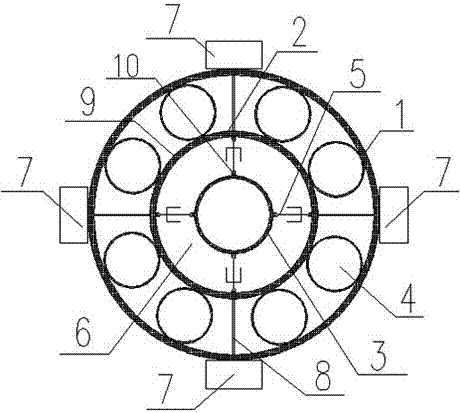

Spherical multidirectional compound type TMD damper

InactiveCN106930592AVibration reduction frequency bandwidthExpand the scope of actionProtective buildings/sheltersShock proofingViscous dampingBall type

The invention provides a spherical multidirectional compound type TMD damper. Two layers of big and small concentric spherical shells are used as a main frame of the spherical multidirectional compound type TMD damper, the two layers of the concentric spherical shells are connected with a support seat through an upper column rod, a lower column rod, a left column rod, a right column rod, a front column rod and a rear column rod, and are fixed to the main structure through the support seat. A large mass ball is located on the innermost portion, the large mass ball are fixed to the inner spherical shell in the upper, lower, left, right, front and back directions through damping springs, and the large mass ball is filled with viscous damping liquid. A certain number of small mass balls are arranged between the outer spherical shell and the inner spherical shell, and the small mass balls are tangent to the spherical shells on both sides. Through the homogeneity of a sphere in all directions, the damper can achieve the multifunctional damping control effect by almost 360 degrees; and in response to the vibration caused by external loads of different intensities, the spherical damper has different damping combinations correspondingly.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

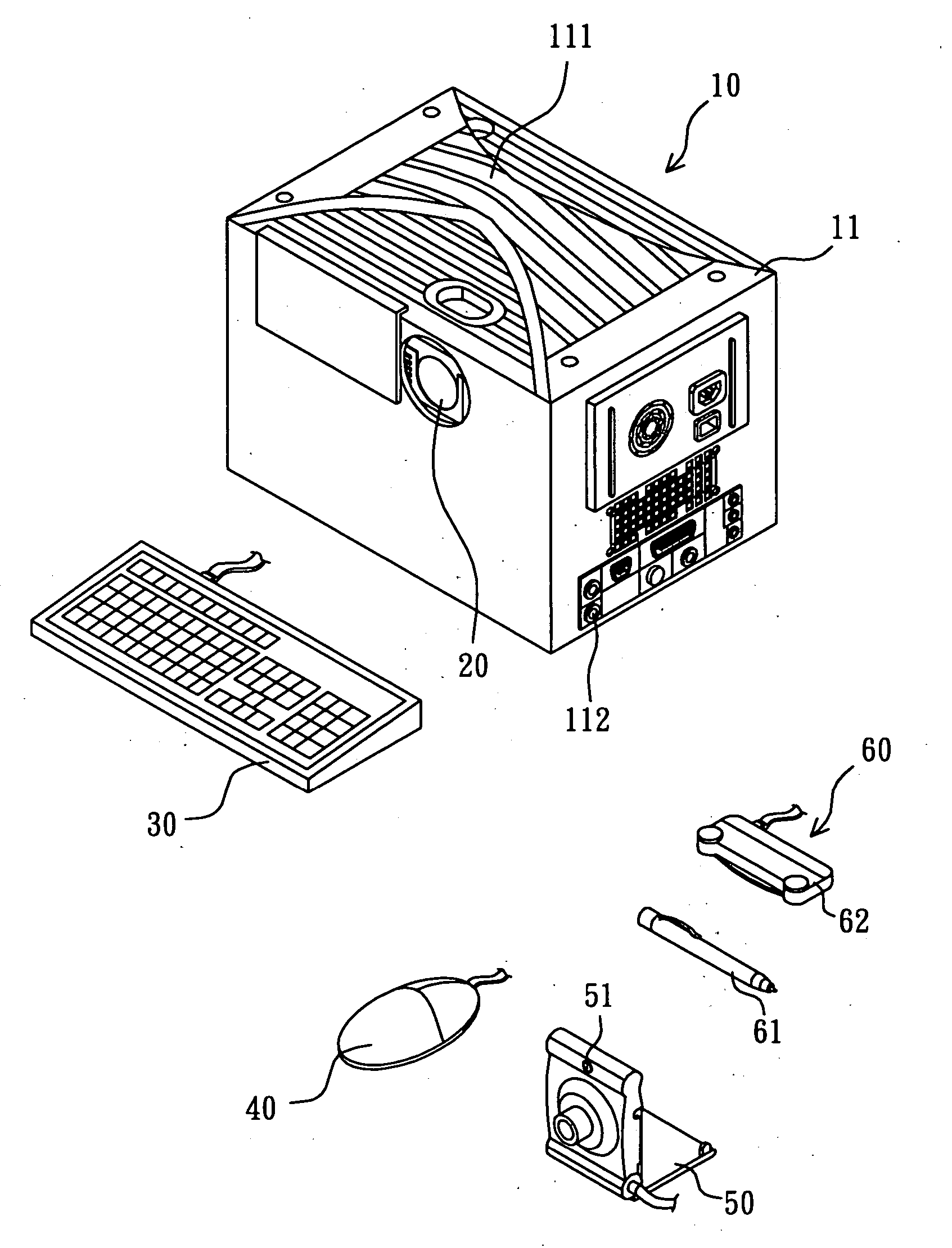

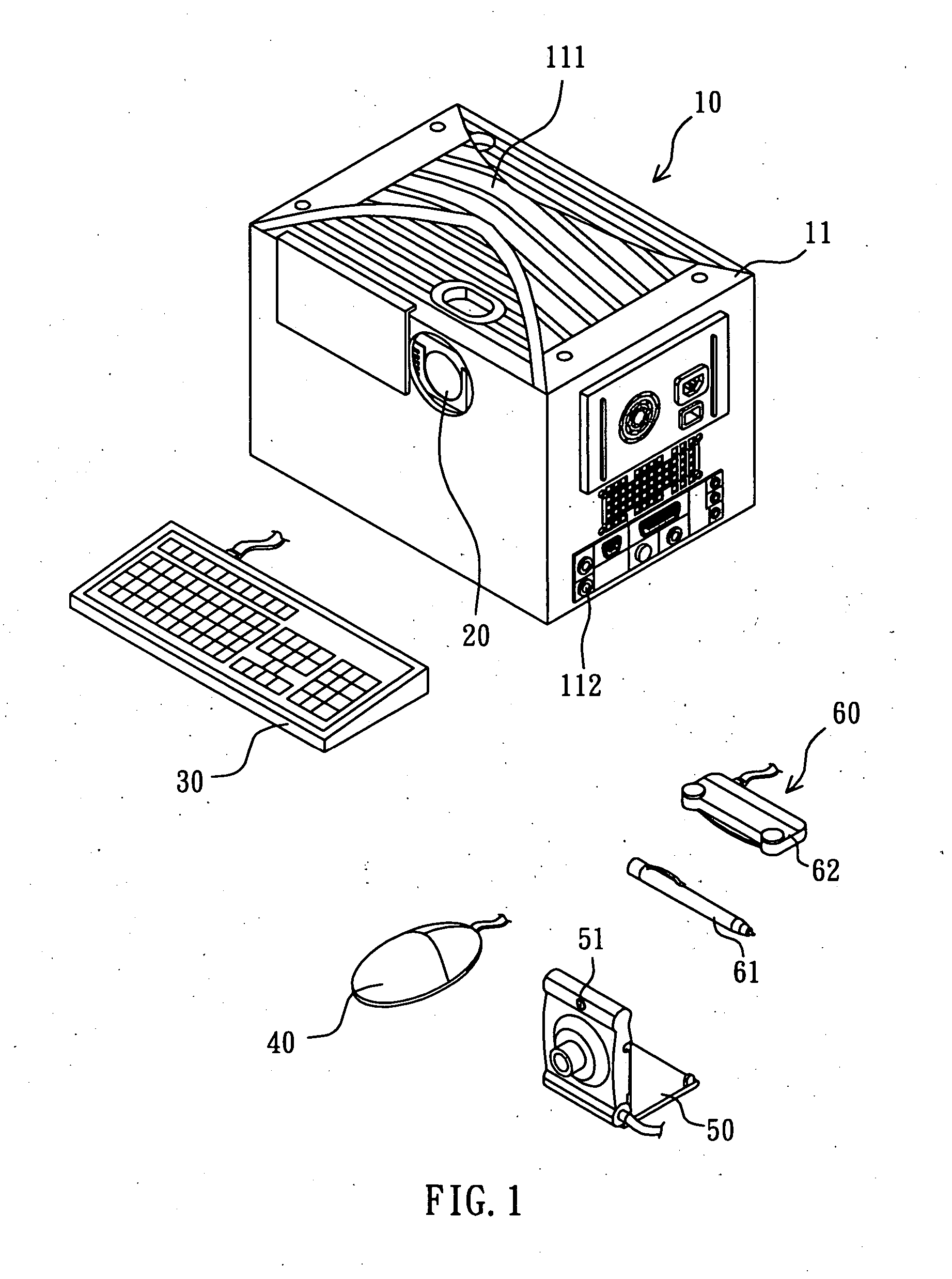

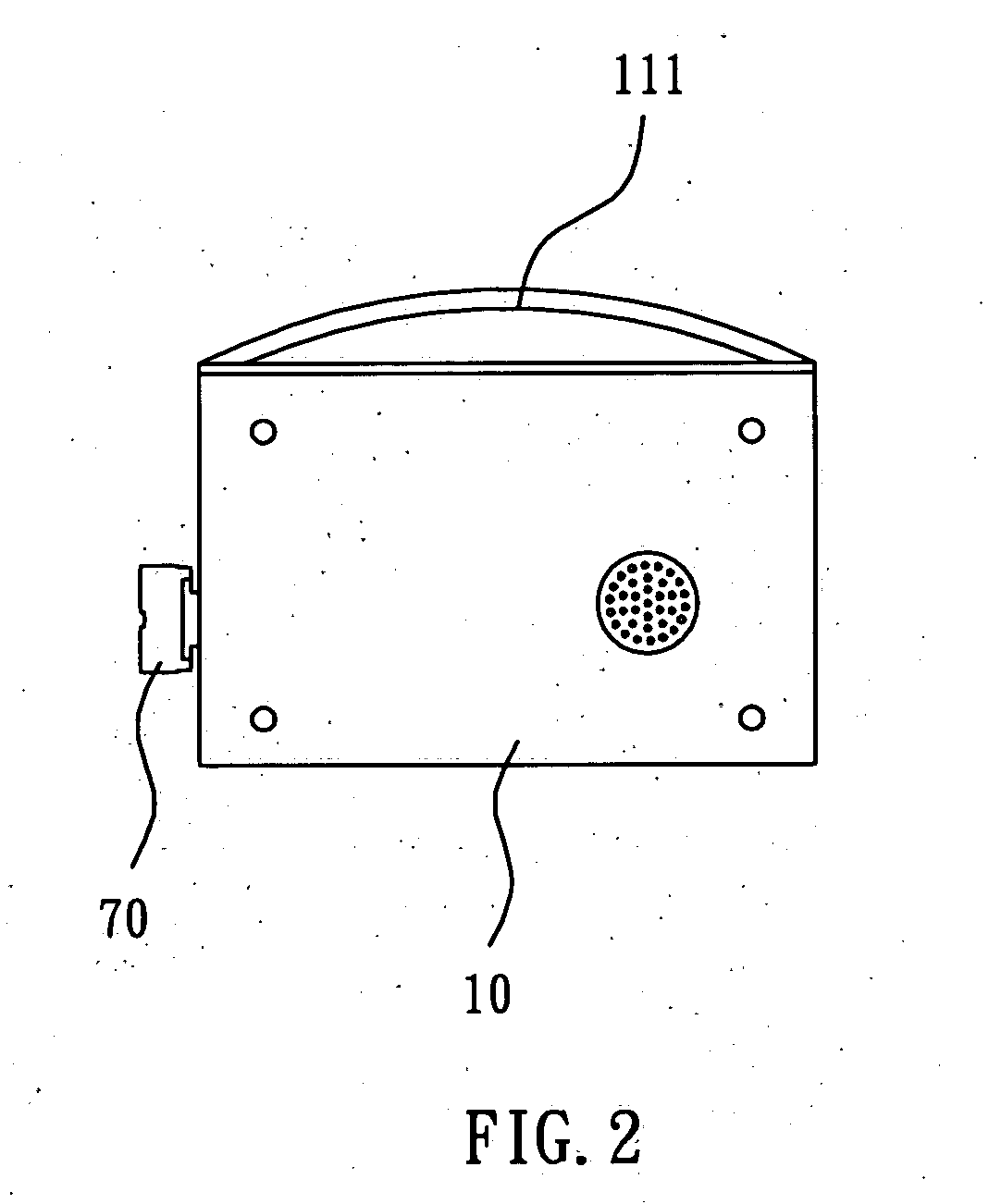

Mobile teaching aid with audiovisual amusement device

InactiveUS20050112537A1Convenient teachingIncreased footprintElectrical appliancesHandwritingDigital camera

A mobile teaching aid with audiovisual amusement device is composed of a computer main unit, a projector, a keyboard, a mouse, a digital camera, a handwriting input device and a wireless net communication device (3G). The projector is mounted in the casing of the main unit to facilitate the user while in use. The digital camera and the handwriting input device are capable of helping the user to offer immediate teaching content and images so as to ease the teaching and have a sound surrounded ambience. The wireless net communication device (3G) is able to keep linking with the internet and receive uninterrupted net information.

Owner:LADDER PUBLISHING

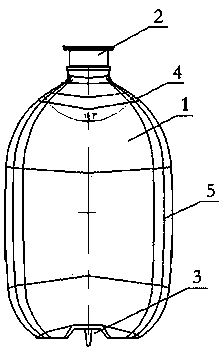

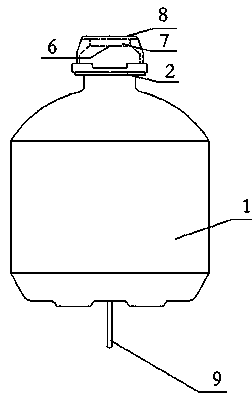

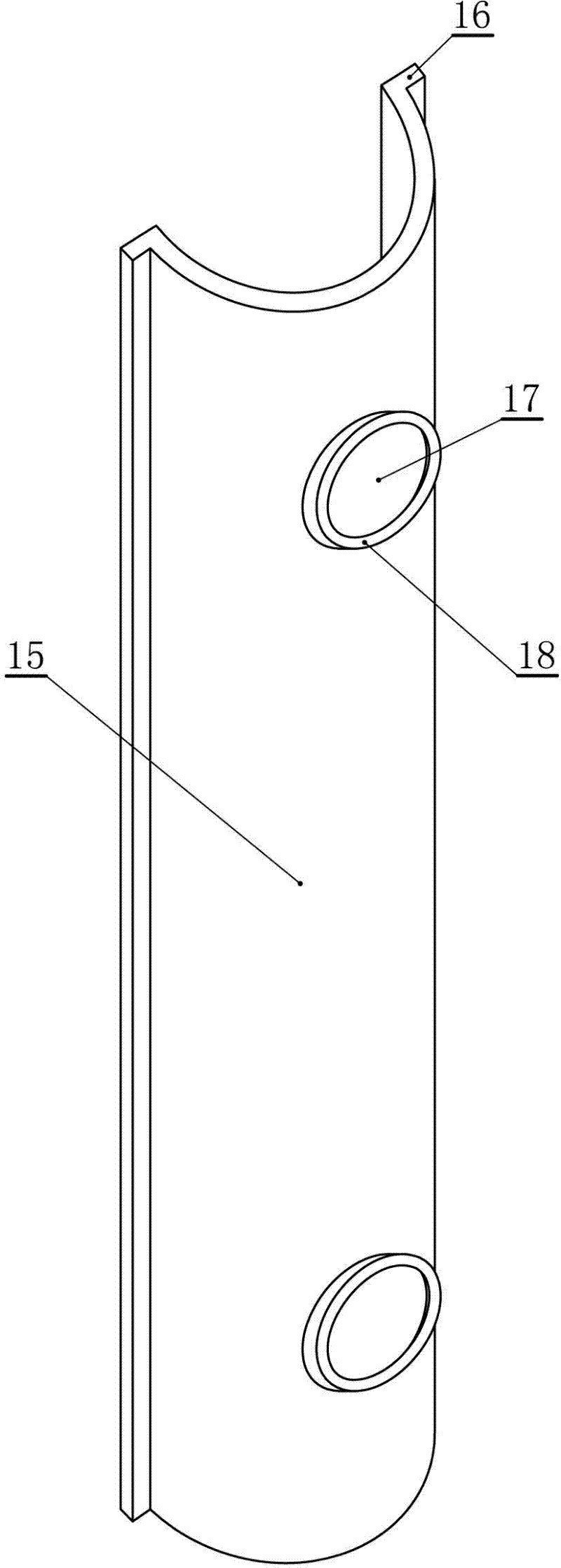

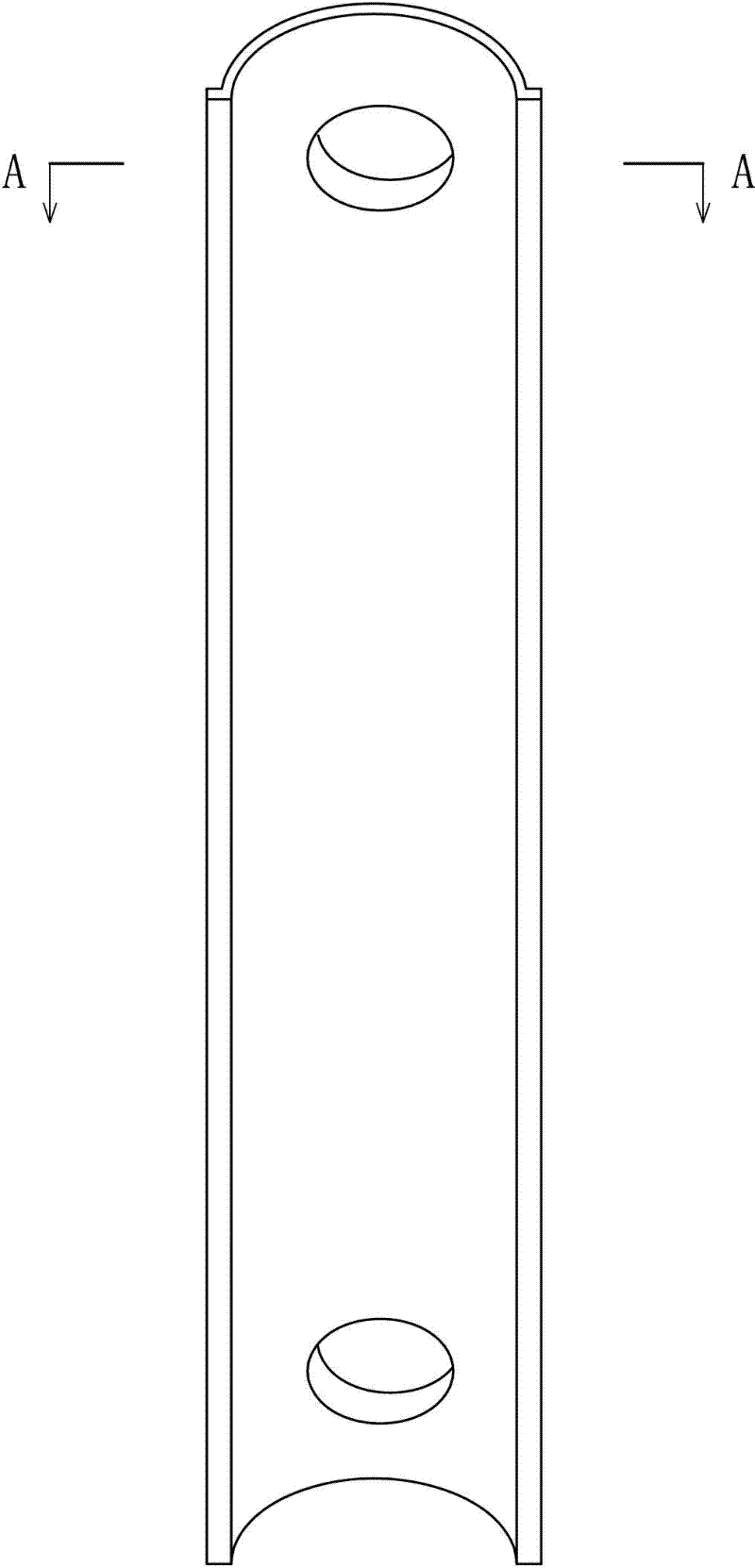

Novel plastic infusion bag and manufacturing method thereof

InactiveCN103519991ASelf-drainingMeet usage habitsPharmaceutical containersMedical packagingBiomedical engineeringDistortion

The invention discloses a novel plastic infusion bag and a manufacturing method of the novel plastic infusion bag. The novel plastic infusion bag comprises a bag body, an infusion bag opening and a hanging structure, wherein the infusion bag opening and the hanging structure are connected with the two ends of the bag body respectively,. The bag body is of a flat shape in the state of being filled with liquid medicine, that is to say, the width of the bag body is larger than the thickness of the bag body when the bag body is on a cross section perpendicular to a connecting line of the infusion bag opening and the hanging structure. Guide ribs are symmetrically arranged on thickness surfaces on the two sides of the bag body. In the infusion process, the bag body can deform along the guide ribs on the two sides of the bag body so that serious deformation and distortion cannot occur, and safety and reliability in use are improved. The manufacturing process of the novel plastic infusion bag comprises the step of blowing the bag body to make the bag body be formed without soldering seal of four edges, so that the microleakage problem is solved; since all process steps are completed in one time period, time for storing the bag body is eliminated, and the possibility of pollution is reduced. The novel plastic infusion bag has the advantages of being capable of being emptied automatically without blood return, free of serious deformation and distortion, and capable of being placed in an upright mode when in use.

Owner:ANHUI DOUBLE CRANE PHARMA

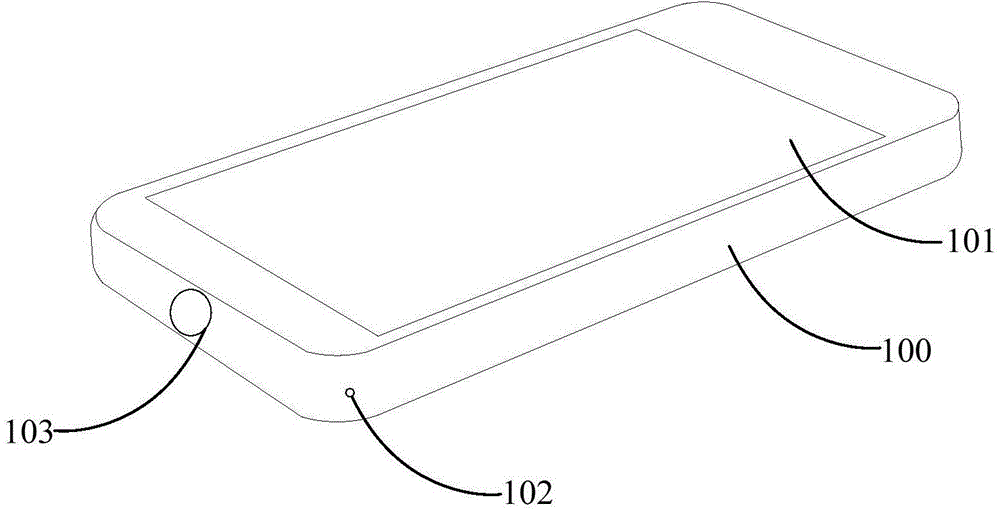

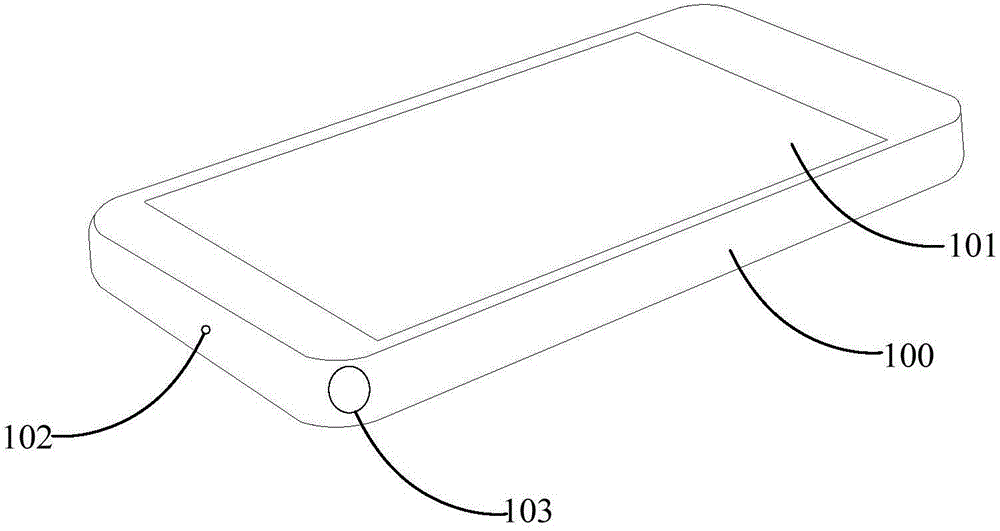

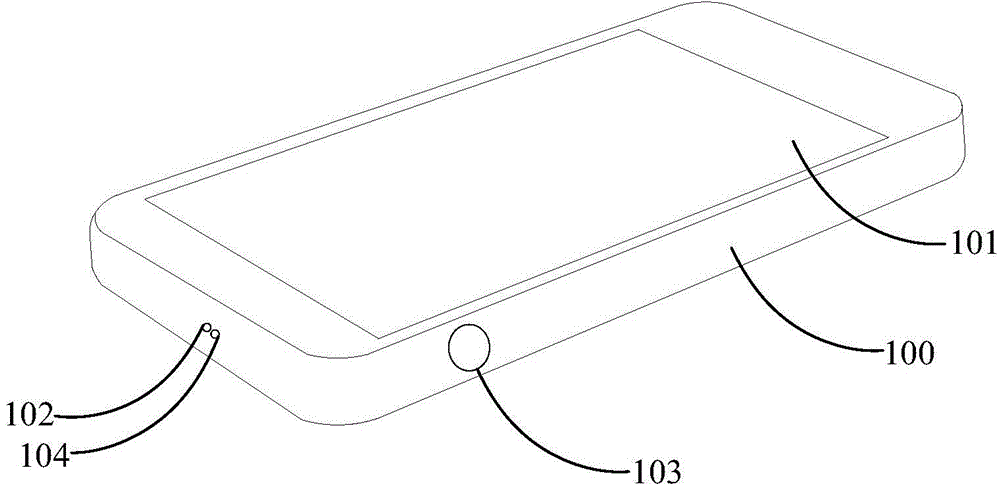

Cellphone

InactiveCN104601763AConvenience guaranteedWon't take up spaceTelephone set constructionsEngineeringHandset

An embodiment of the invention provides a cellphone and effectively solves the problems that since a front camera, a receiver and a home key provided on the same plane in the prior art use certain space, further expansion of a cellphone display is affected, and the actual need of people for larger cellphone displays cannot be met. The cellphone comprises a body provided with a front camera, a receiver and a home key; the front camera, the receiver and the home key are all arranged on the side of the body; such side is a face, with no cellphone display, of the body. The cellphone is simple in structure and ingenious in design, the front camera, the receiver and the home key never use the space of the cellphone display screen, reliable basis for the further improvement in the area of the cellphone display is provided, the actual needs are met, implementing is convenient, and the cellphone is easy to popularize and apply.

Owner:胡伟

Improved sealing composition

InactiveCN101848976AEasy to cleanNo harmful smellOther chemical processesTyresPolymer scienceSuspending Agents

A sealant composition for the sealing of a punctured tyre including a liquid carrier, one or more viscosity and suspending agents, one or more fillers and sealants, and one or more polyacrylates.

Owner:TRYDEL RES PTY LTD

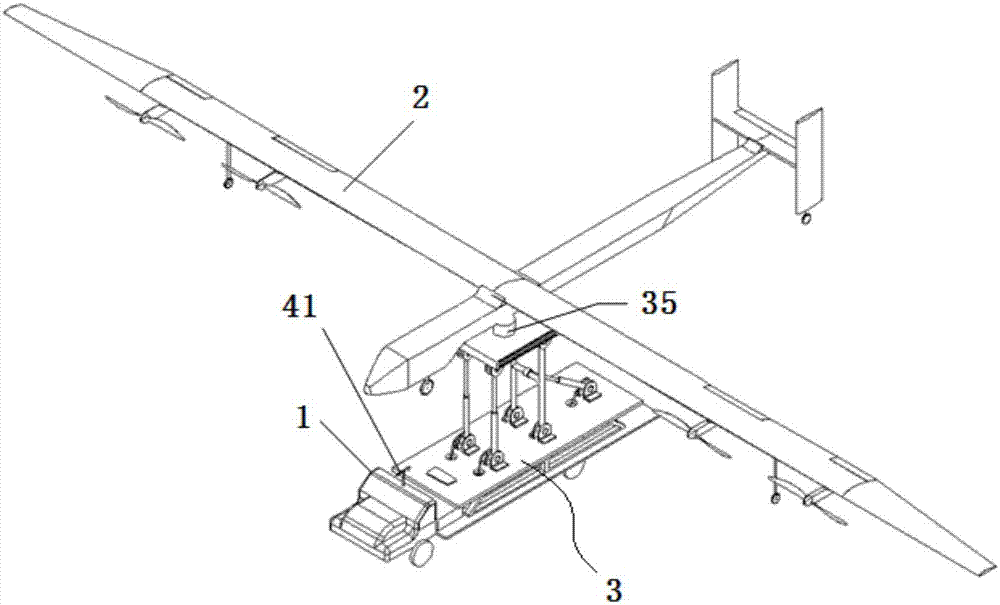

Vehicle-mounted aerodynamic testing system for unmanned aerial vehicle

InactiveCN107472554AImprove test efficiencySmall footprintAircraft components testingVehicle carriersInflow velocityEngineering

The invention relates to aerodynamic testing techniques for aircrafts, in particular to a vehicle-mounted aerodynamic testing system for an unmanned aerial vehicle. The vehicle-mounted aerodynamic testing system for the unmanned aerial vehicle comprises a vehicle bearing device, a supporting device and a data collecting device, wherein the vehicle bearing device is used for bearing the pretested unmanned aerial vehicle and driving the pretested unmanned aerial vehicle to conduct uniform linear motion in a predetermined direction; the supporting device is used for fixedly arranging the pretested unmanned aerial vehicle on the vehicle bearing device, and the supporting device has a folding state and an unfolding state; the supporting device is used for adjusting posture of the pretested unmanned aerial vehicle and testing lift force and resistance of the pretested unmanned aerial vehicle in the unfolding state; and the data collecting device is used for collecting the relative inflow velocity during conducting uniform linear motion and the lift force and the resistance of the pretested unmanned aerial vehicle. According to the vehicle-mounted aerodynamic testing system for the unmanned aerial vehicle, the pretested unmanned aerial vehicle can be conveniently installed by operating personnel, the angle of attack of the unmanned aerial vehicle to be tested can be precisely and continuously controlled, and experimental and testing efficiency is improved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

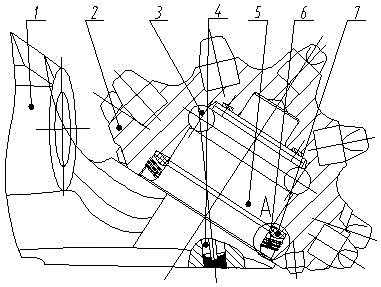

Bearing spiral combined sealing structure of high-speed roller bit

The invention relates to a bearing spiral combined sealing structure of a high-speed roller bit. The bearing spiral combined sealing structure comprises a roller cone, a bearing, a spiral seal ring and an O-shaped rubber ring. The spiral seal ring is installed in a spiral groove of a roller cone inner hole. When the bit rotates at a high speed, through the pumping effect of the spiral groove, a function of automatically draining sand is achieved. The pressure of the outer side of the O-shaped rubber ring is added, the pressure difference of the two sides of the O-shaped rubber ring is reduced, and the sealing effect of the O-shaped rubber ring is improved. The O-shaped rubber ring is located above the spiral seal ring and installed in a bearing groove with a certain interference. When the bit rotates at a high speed, the auxiliary two-stage sealing is achieved, and the bit can also achieve the effective sealing effect when stopping rotating. The bearing spiral combined sealing structure has good sand draining performance, the abrasion to the bearing can be effectively reduced, the sealing requirements under different working conditions can be met, the sealing reliability and stability are greatly improved, the sealing service life is prolonged. Other supporting elements are not needed for the sealing, and precious time is saved for the roller bit.

Owner:SOUTHWEST PETROLEUM UNIV

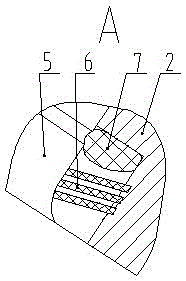

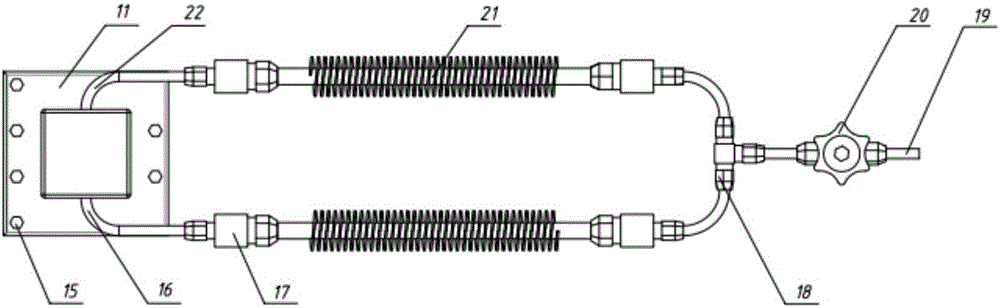

Circular pipe communicated, spliced, edge-pinched, and welded pressure-bearing heat exchanger, and manufacturing process thereof

ActiveCN102418956ASolve the problem of water leakage under pressureReduce difficultySpace heating and ventilation detailsHeat exchanger casingsPlate heat exchangerWater leakage

The invention discloses a circular pipe communicated, spliced, edge-pinched, and welded pressure-bearing heat exchanger, and a manufacturing process thereof. The heat exchanger comprises two headers, wherein a tap water communication pipe is fixedly connected between the two headers; a hot air heat supply pipe passes through the tap water communication pipe; each header is formed by welding two arc plates; the plate edges of the arc plates are flanged outwards; the plate edges of the two arc plates are aligned with each other and are subjected to edge-pinching and self-fluxing welding to form a circular tubular header cylinder body; head blocking plates of the headers are flanged outwards and are embedded at two ports of the circular tubular headers; and the two edges are aligned with a pipe wall surface, are spliced and are subjected to the edge-pinching and the self-fluxing welding to form the headers. An installation hole is punched on each arc plate; the installation hole is stretched inward an arc to form an edge; the aperture and the height of are stretched according to the arc plates; and the end surfaces of the two ends of the tap water communication pipe are subjected to R-angle cutting according to the stretching hole diameter and the stretching height of the arc plates, and then the tap water communication pipe is inserted into the installation holes stretched from the arc plates, are matched with each other, are spliced and are subjected to edge-pinching and self-fluxing welding connection. In the heat exchanger, welding seams are spliced, the edge-pinching welding is easy to realize, and water leakage is avoided; and the heat exchanger is good in pressure-bearing performance, and low in maintenance cost.

Owner:张伟

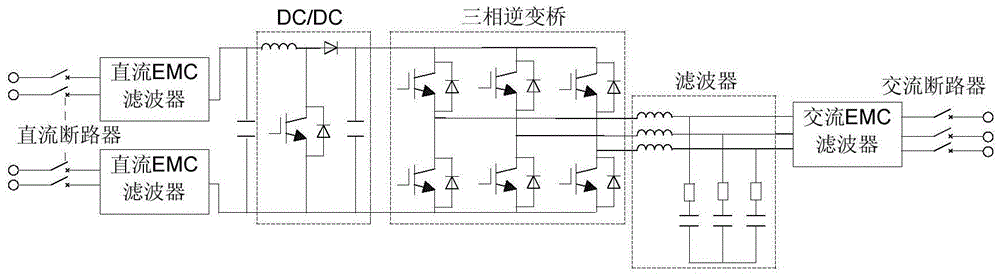

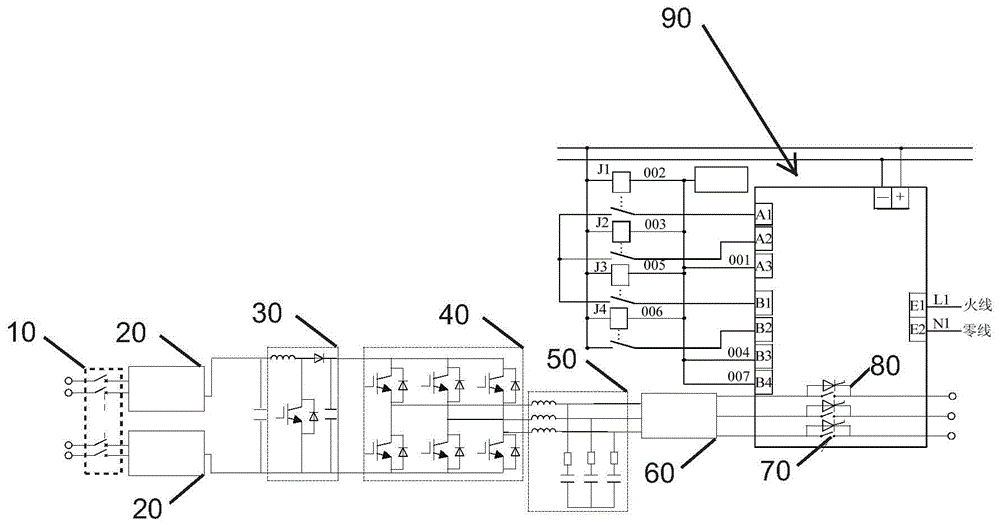

Soft start photovoltaic inverter and photovoltaic power generation system

ActiveCN104993684AReduce shockSmall starting currentAc-dc conversionPhotovoltaicsCapacitanceDc circuit breaker

The invention discloses a soft start photovoltaic inverter and a photovoltaic power generation system. The soft start photovoltaic inverter comprises a direct current breaker, a voltage stabilization capacitor, a three-phase inverter bridge, a filter and a thyristor. The direct current breaker, the voltage stabilization capacitor, the three-phase inverter bridge and the filter are electrically connected in sequence. An input end of the thyristor is electrically connected with an output end of the filter. The thyristor is configured in a way that by controlling a conduction angle of the thyristor, output voltage of the soft start photovoltaic inverter is enabled to be gradually increased from zero, and when the thyristor is fully conducted, the output voltage of the soft start photovoltaic inverter reaches the maximum value. The photovoltaic power generation system comprises a photovoltaic assembly, a combiner box, a box type transformer station, a boost station and the soft start photovoltaic inverter. The soft start photovoltaic inverter can reduce start current, reduce impact of starting of the photovoltaic inverter on a power grid, and improve the equipment integration degree.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

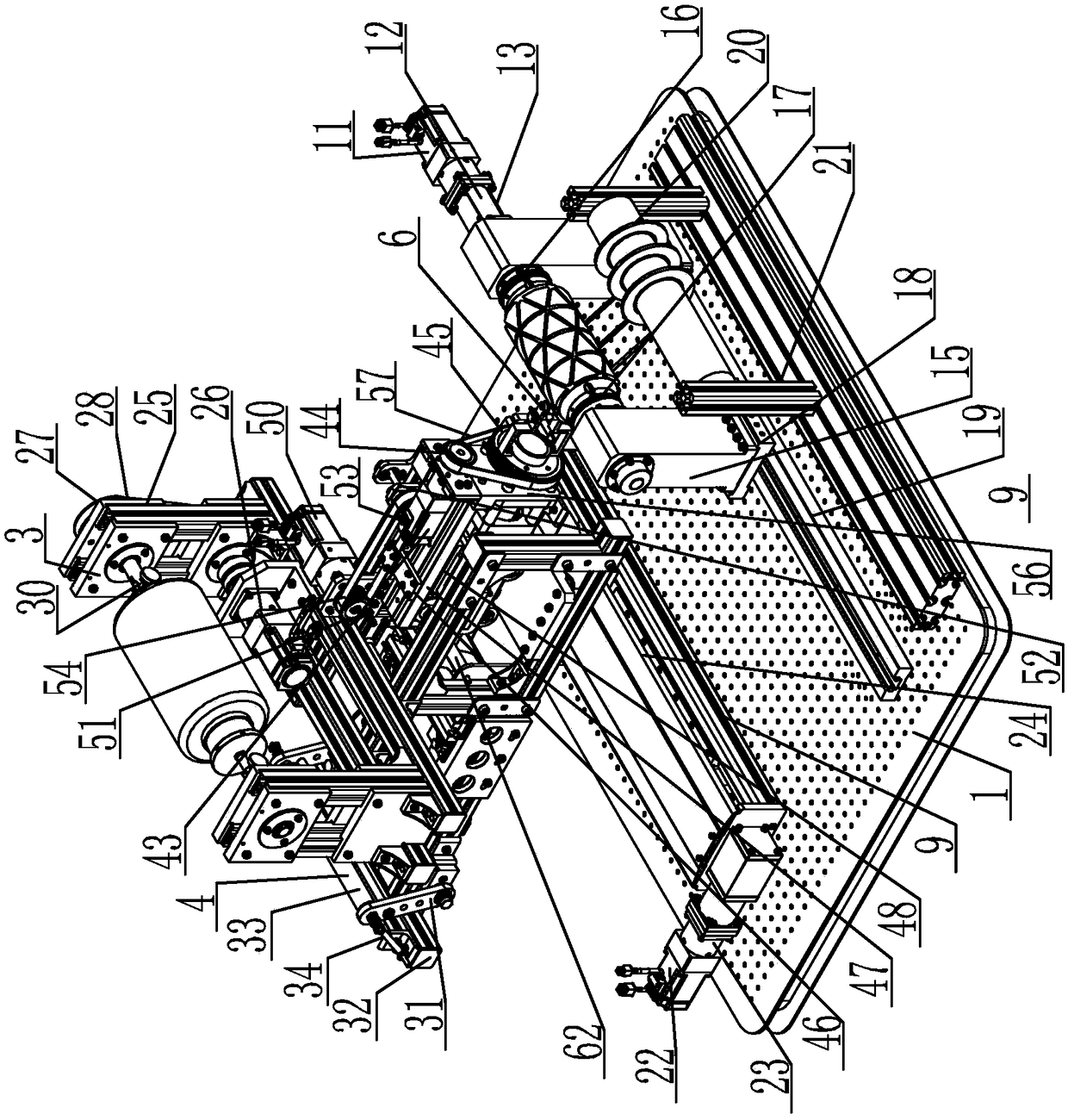

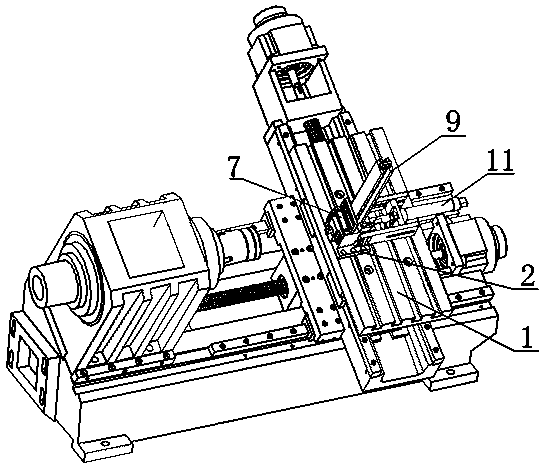

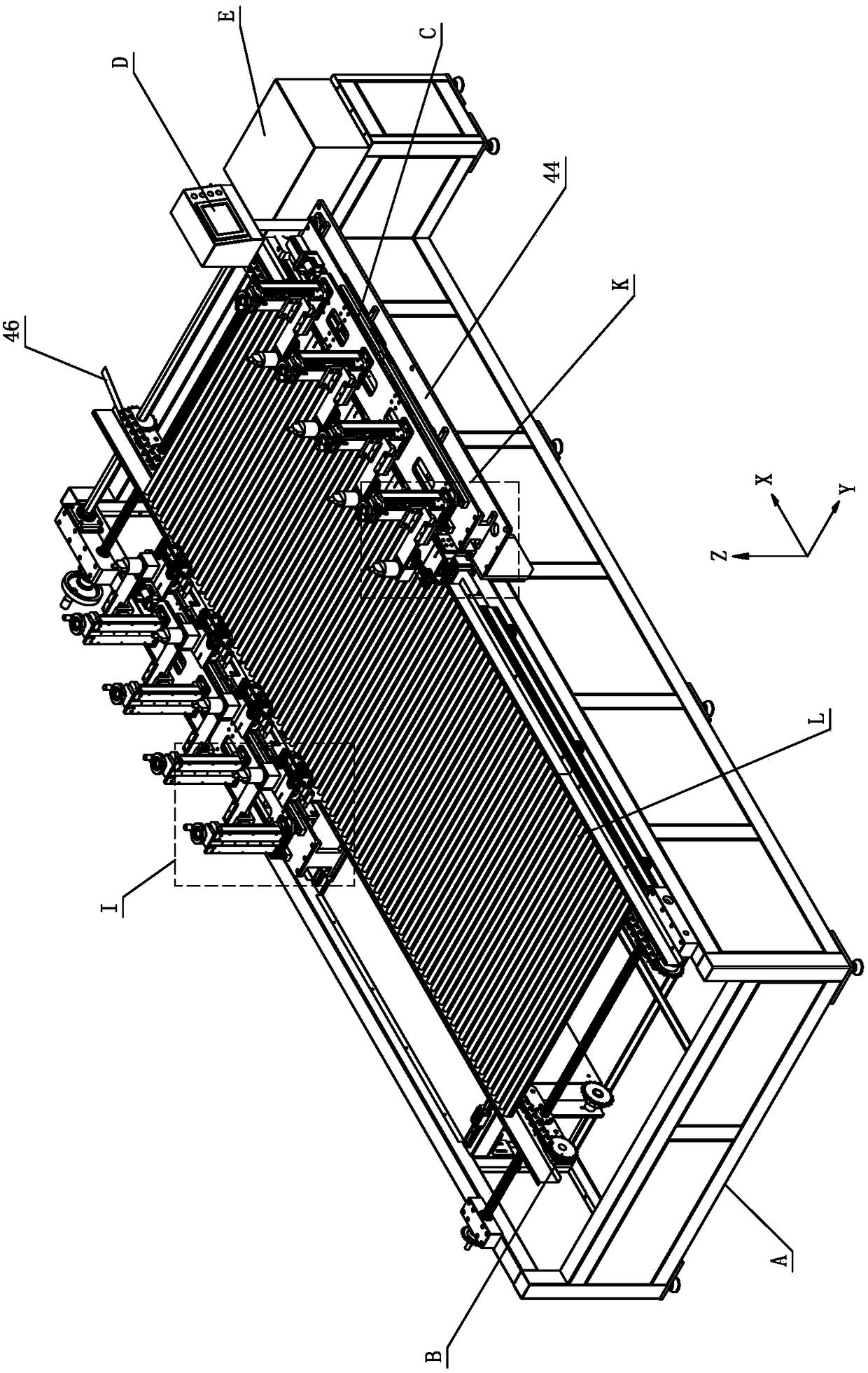

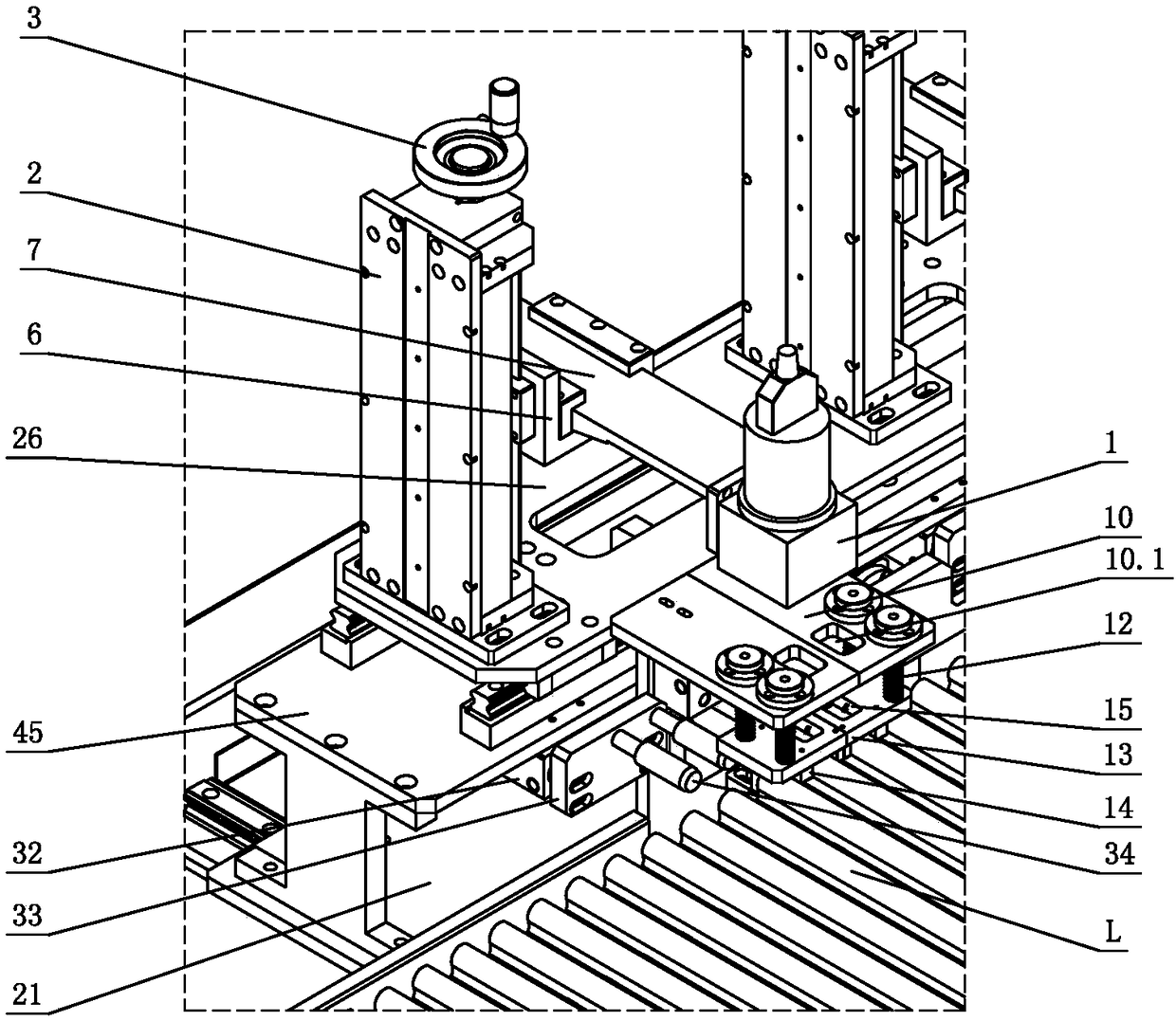

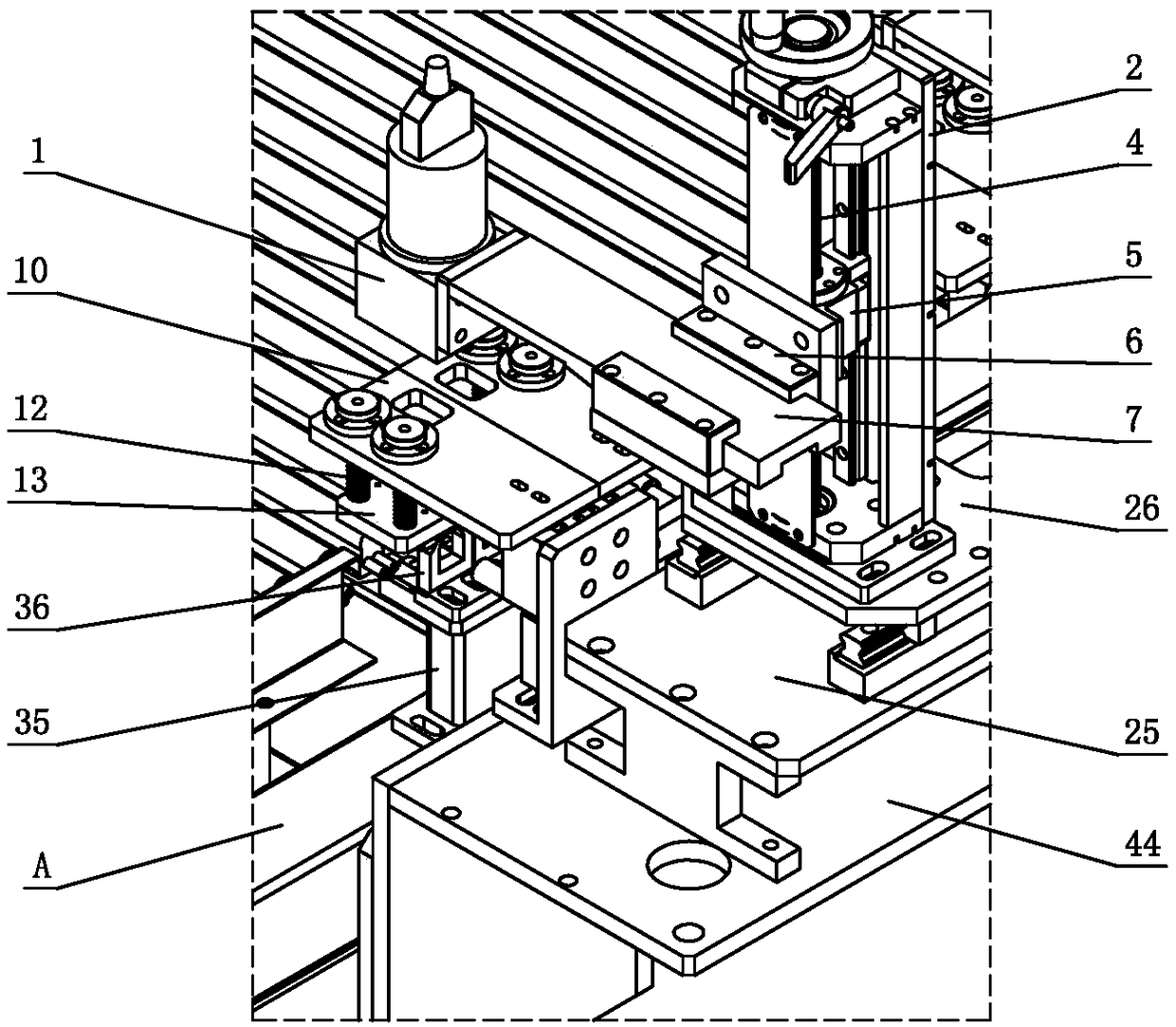

Desktop type four-axis linkage fiber winding machine for molding grid structure

The invention provides a desktop type four-axis linkage fiber winding machine for molding a grid structure and relates to one fiber winding machine, aiming at solving the problems that an existing winding machine cannot meet winding of the grid structure and winding molding of a mini-type spacecraft component. The desktop type four-axis linkage fiber winding machine comprises a machine tool platform, a movable frame body, a frame body movement driving mechanism, a fiber rewinding mechanism, a yarn picking mechanism, a glue immersing mechanism, a retractable arm assembly, a silk nozzle assembly, a main shaft rotary part and an annular rib winding assembly; the frame body movement driving mechanism, the main shaft rotary part and the annular rib winding assembly are mounted on the machine tool platform; the main shaft rotary part is located between the frame body movement driving mechanism and the annular rib winding assembly; the movable frame body is mounted on the frame body movementdriving mechanism; the fiber rewinding mechanism, the yarn picking mechanism, the glue immersing mechanism, the retractable arm assembly and the silk nozzle assembly are mounted on the movable frame body. The desktop type four-axis linkage fiber winding machine belongs to the field of molding of composite materials.

Owner:HARBIN INST OF TECH

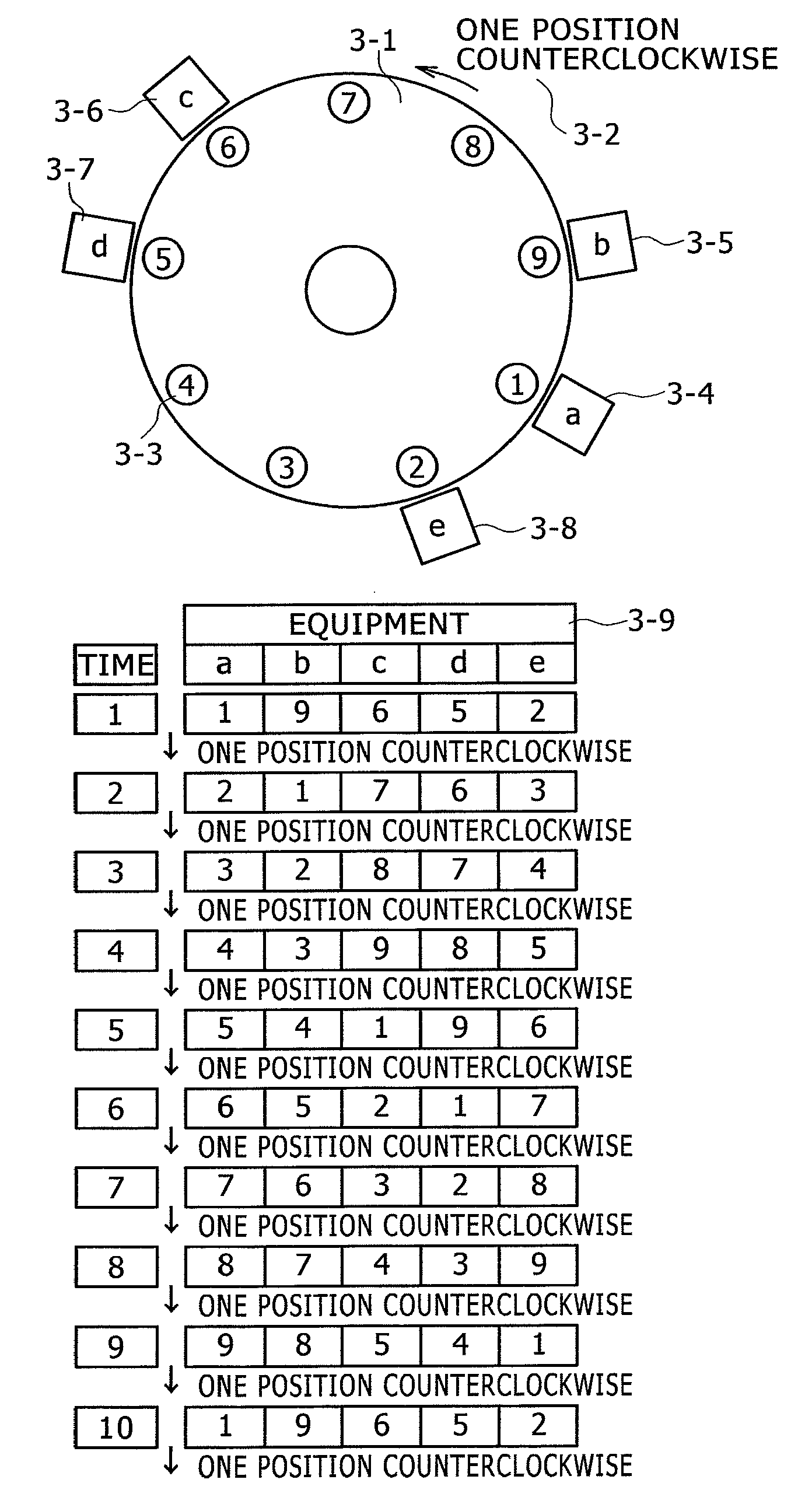

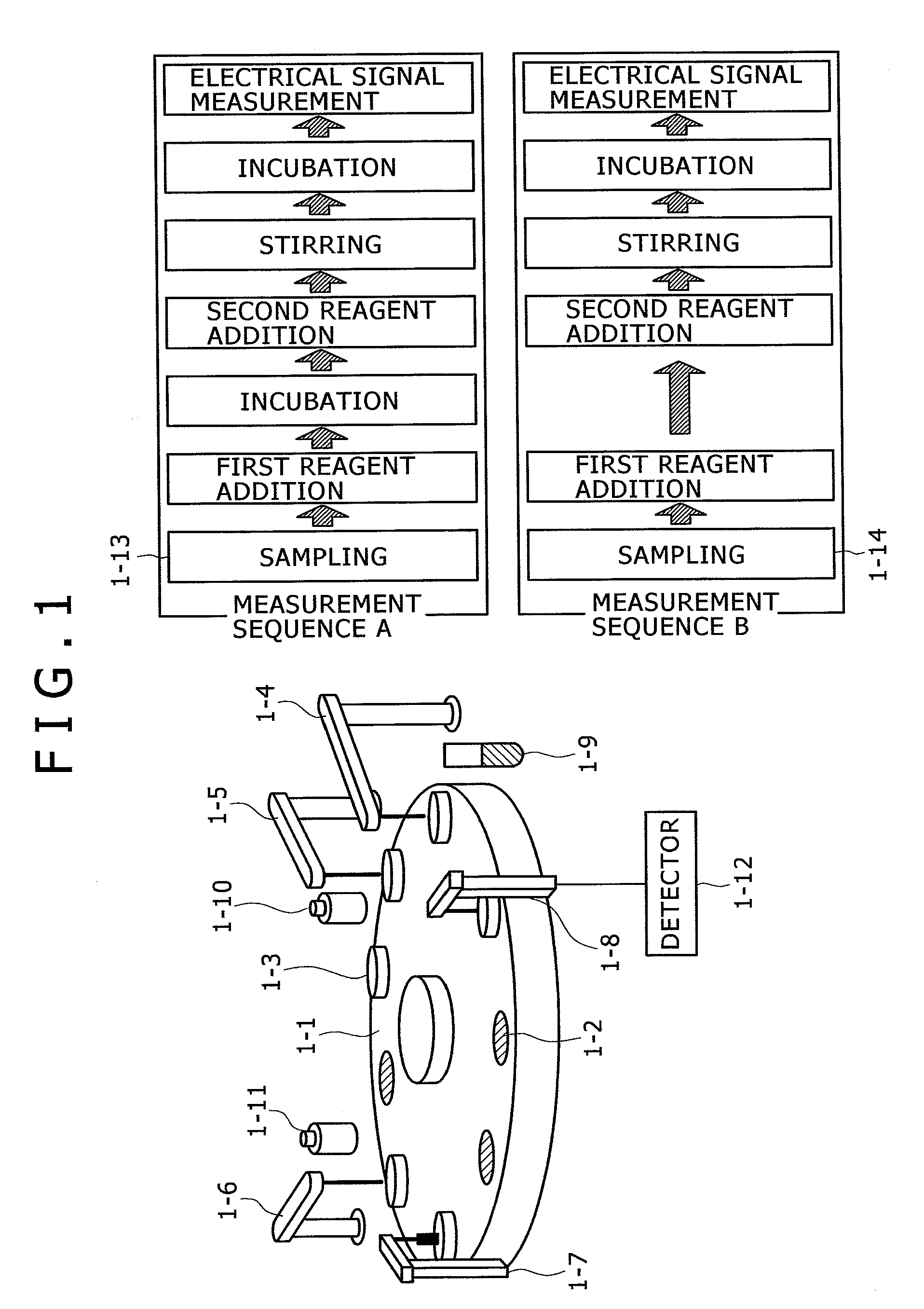

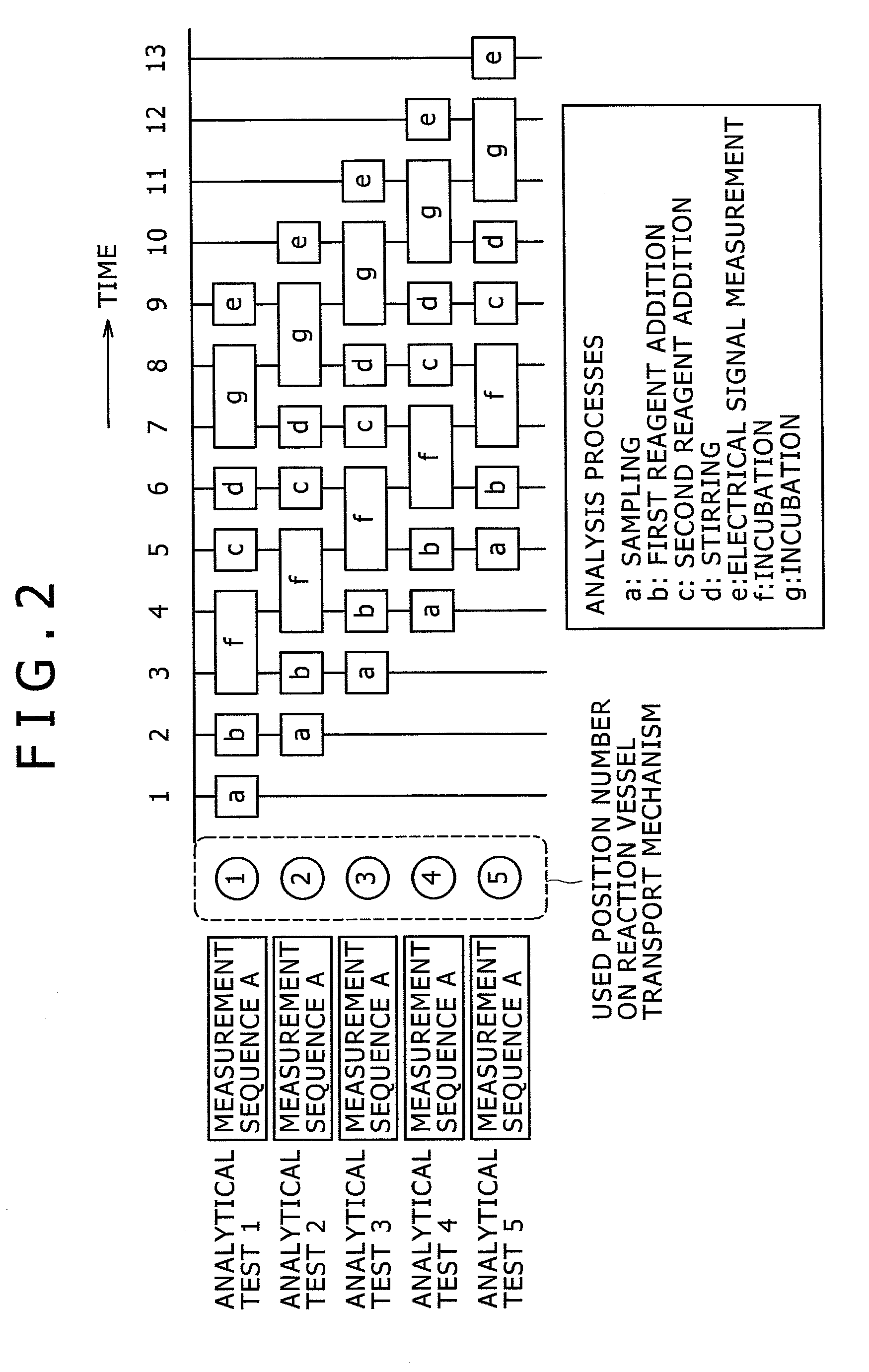

Automatic analyzer

InactiveUS20110293477A1Increased footprintReduce testing costsMaterial analysis by optical meansChemical methods analysisAutoanalysisMechanical equipment

Disclosed is an automatic analyzer that is capable of executing a plurality of different measurement sequences in a sequential, parallel manner, has a check function for avoiding simultaneous mechanical equipment use and interference between the mechanical equipment, incorporates a plurality of different transport mechanism operation schemes for transporting a reaction vessel to the mechanical equipment, and minimizes a decrease in the throughput by choosing an appropriate transport mechanism operation scheme as needed.Before initiating a measurement sequence for a requested analytical test, the automatic analyzer checks for simultaneous use of the mechanical equipment. If it is judged that simultaneous mechanical equipment use would result, the automatic analyzer postpones the start of the requested analytical test. This makes it possible to avoid simultaneous mechanical equipment use and make a proper analysis. Further, the automatic analyzer incorporates a logic that initiates an analytical test irrelevant to simultaneous equipment use prior to the other analytical tests when a plurality of different analytical tests are requested. This makes it possible to make efficient analyses.

Owner:HITACHI HIGH-TECH CORP

Integrated loop heat pipe cooling device with boiling pool

ActiveCN105890415AContinuous and efficient heat dissipationCompact structureIndirect heat exchangersEngineeringLoop heat pipe

An integrated loop heat pipe cooling device with a boiling pool comprises an evaporator, the boiling pool and a condenser, wherein the evaporator comprises a compensating chamber; a capillary core for providing power is arranged below the compensating chamber; a steam channel is formed below the capillary core; an air collecting groove which communicates with the steam channel is formed between the compensating chamber and the boiling pool; a connecting hole which communicates with the air collecting groove is formed in a side wall of the boiling pool; steam generated from the bottom of the compensating chamber enters the air collecting groove and enters the boiling pool through the connecting hole; the compensating chamber communicates with an outlet of the condenser; and the boiling pool communicates with an inlet of the condenser. The evaporator for proving power and the boiling pool as a main cooling component are integrally designed, the integral size is small, the structure is compact, the integrated loop heat pipe cooling device is suitable for cooling electronic devices with small space, by the compact design of the evaporator and the boiling pool, a system only needs a heat source which is a cooled device, an additional heat source or a power device is not required, energy is saved, and the electronic devices can be continuously and efficiently cooled.

Owner:XI AN JIAOTONG UNIV

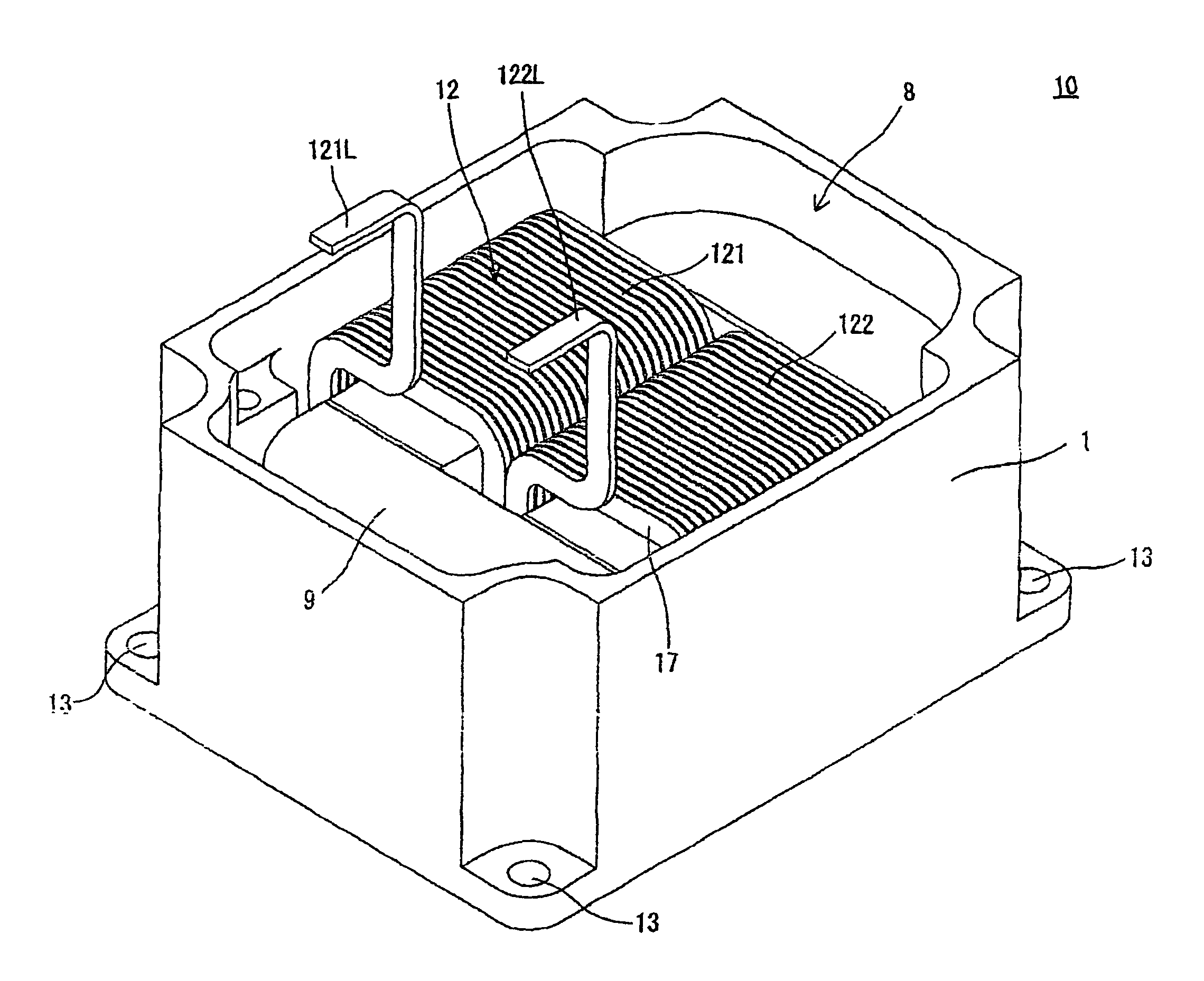

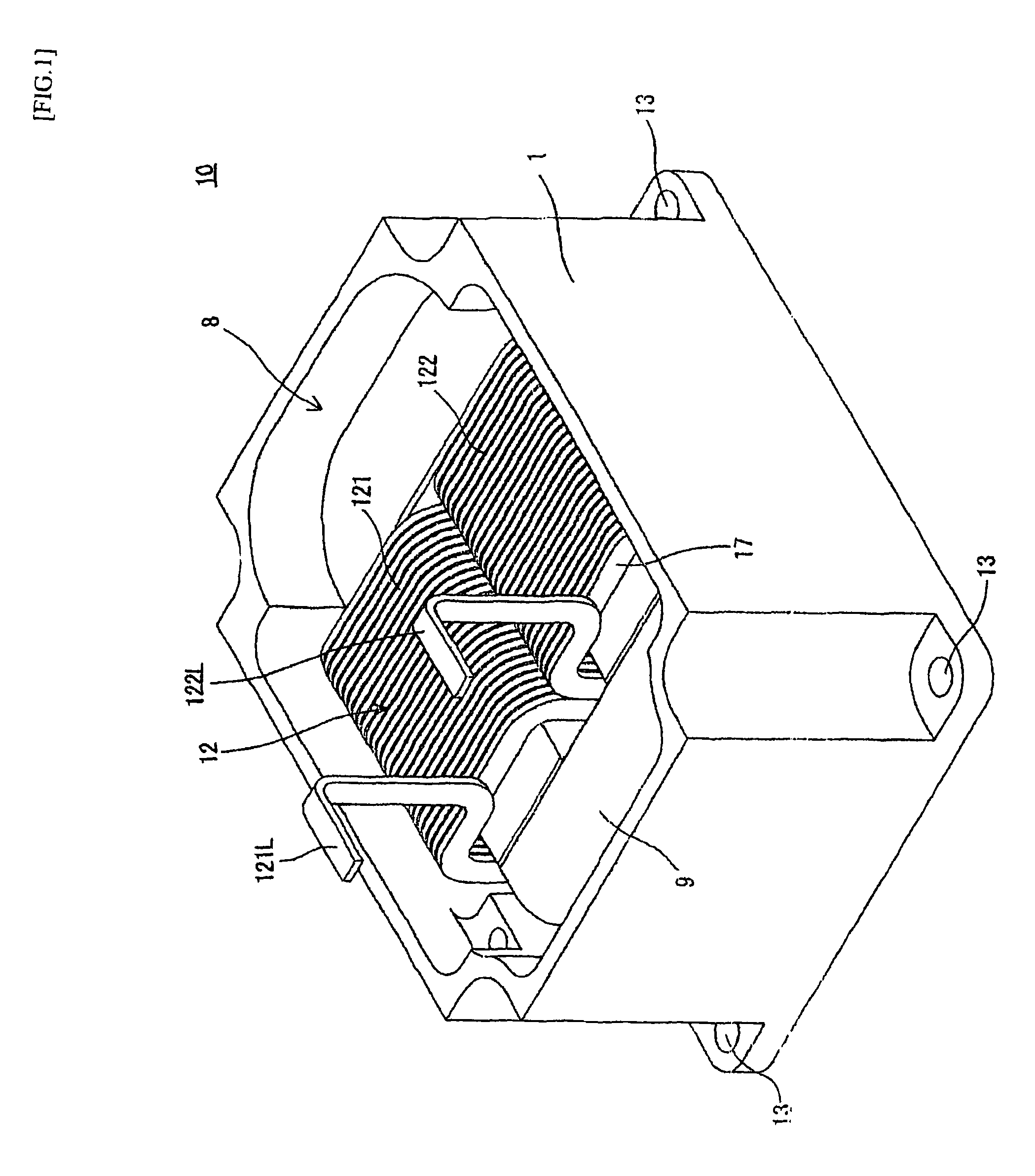

Method for forming coil

ActiveUS8091211B2Simplifying manufacturing workImprove accuracyTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresWire rodEngineering

A reactor coil includes first and second coil elements each formed by edgewise and rectangular winding of one piece of rectangular wire rod in a manner in which the wound rectangular wire rod is stacked rectangularly and cylindrically and, at a winding terminating end point of the first coil element, the rectangular wire rod is bent approximately 90 degrees in a direction opposite to the winding direction of the first coil element so that the rectangular wire rod is stacked in a direction opposite to the stacking direction of the first coil element and is wound edgewisely and rectangularly in a direction opposite to the winding direction of the first coil element to form the second coil element and, as a result, the first coil element and second coil element are aligned in parallel to each other in a continuous state.

Owner:TAMURA KK +1

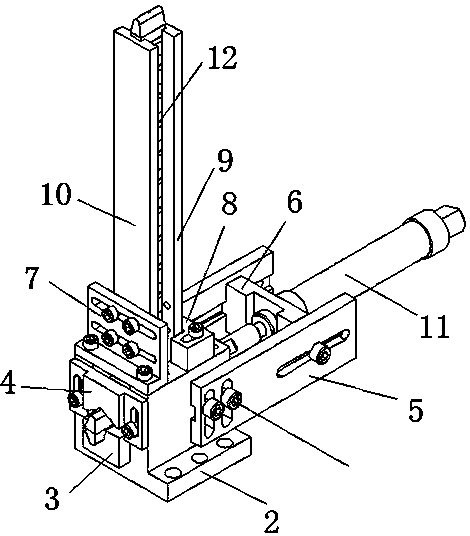

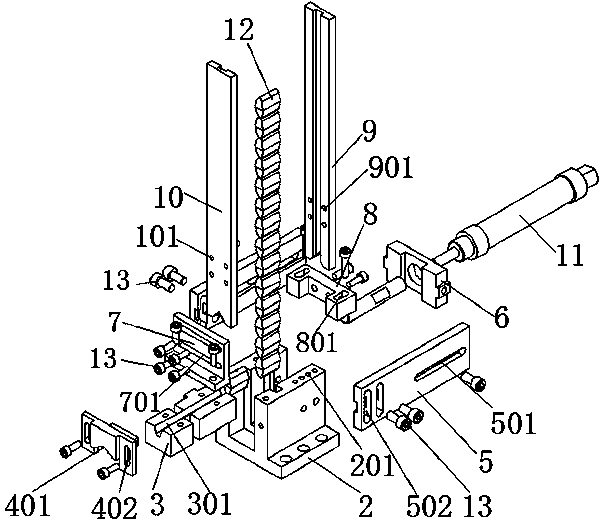

Automatic front feeding device

ActiveCN103611952AImprove processing efficiencySmall footprintMetal working apparatusMachine toolMachining

The invention relates to an automatic front feeding device. The automatic front feeding device comprises a fixed base installed on a moving table of a machine tool, wherein a supporting base is installed in the fixed base, a front leaked-material baffle and a rear leaked-material baffle are arranged on the front side and the rear side of the upper surface of the fixed base respectively, a front blocking strip and a rear blocking strip are installed between the front leaked-material baffle and the rear leaked-material baffle, a workpiece is loaded by the front blocking strip and the rear blocking strip, inverted-V-shaped grooves are formed in the bottom of the front blocking strip and the bottom of the rear blocking strip respectively, a first workpiece position is formed above the supporting base, one workpiece can pass through the first workpiece position, fixing plates are installed on the two sides of the fixed base respectively, an air cylinder base is arranged on the inner sides of the fixing plates, an air cylinder is installed in the middle of the air cylinder base, and a push rod of the air cylinder exactly faces the first workpiece position. According to the automatic front feeding device, full-automatic feeding and clamping of short materials and granular materials are achieved, dozens of workpieces can be loaded on the automatic front feeding device at one time, a plurality of machine tools can be operated by one person at the same time, rapid line connection machining is facilitated, and machining efficiency is greatly improved; meanwhile, the automatic front feeding device is small in occupied space, simple in structure, convenient to control, stable in operation and wide in range of application.

Owner:GUANGZHOU LONGBANG AUTOMATIC CONTROL EQUIP

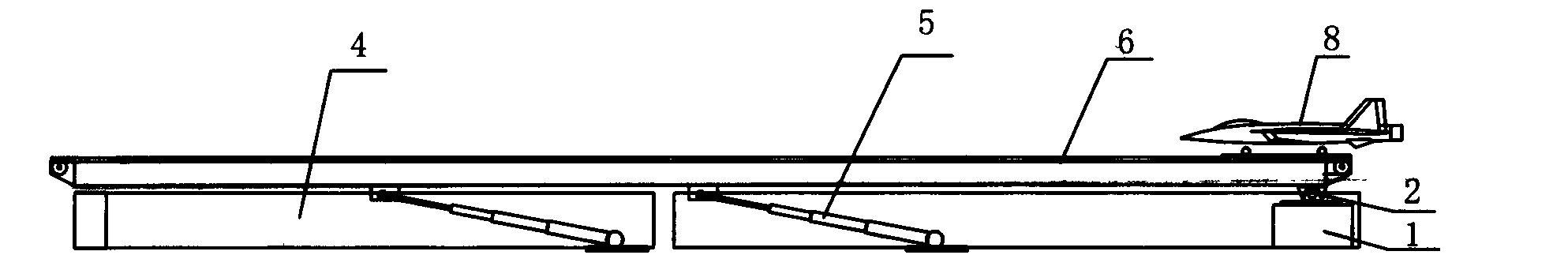

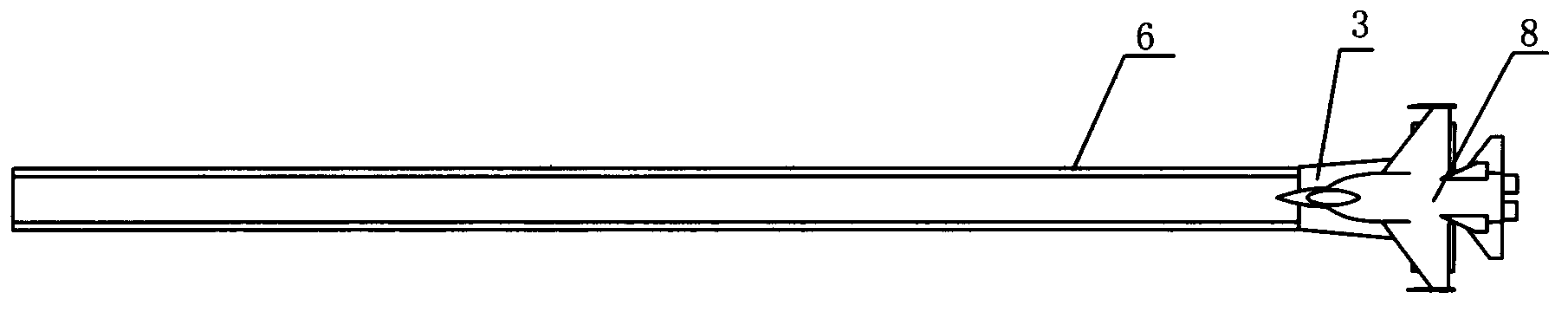

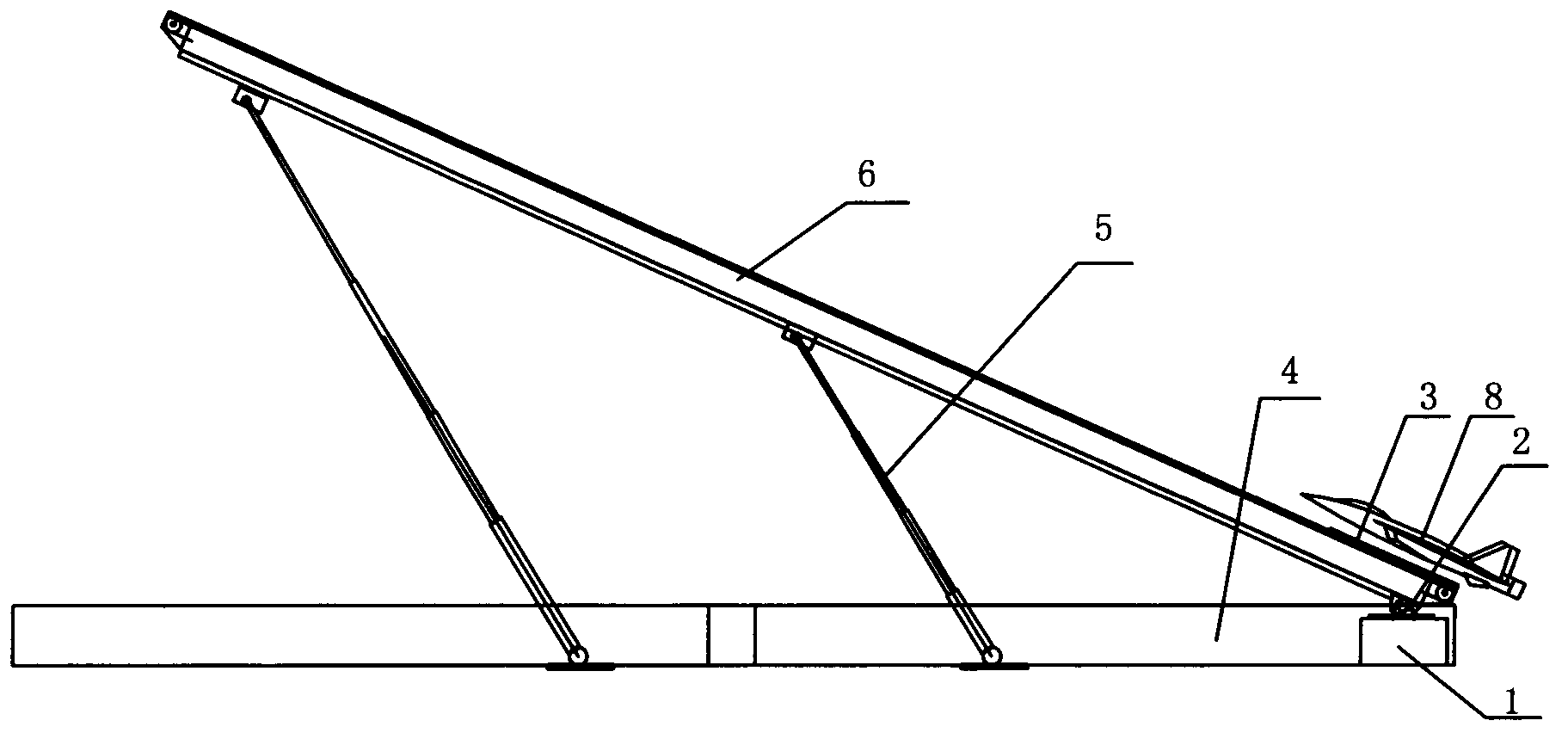

Pneumatic multipurpose land-based catapult launch training device of shipboard aircraft on aircraft carrier

The invention provides a pneumatic multipurpose land-based catapult launch training device of a shipboard aircraft on an aircraft carrier. The device comprises an engine base, hydraulic lifting devices, a cantilever runway, a shipboard aircraft and a catapult, wherein the engine base is arranged in a trough; one end of the cantilever runway is connected with the engine base by a hinge axis; the catapult is arranged in the cantilever runway; landing gears of the shipboard aircraft are connected with the upper surface of a sliding plate; the bottom of the sliding plate is connected with the catapult; and the upper ends of the hydraulic lifting devices are hinged with the bottom of the cantilever runway and the lower ends of the hydraulic lifting devices are connected with the bottom of the trough. The device has the following advantages that 1) the device has a simple structure, high degree of automation and long service life, is convenient to operate and easy to maintain and is safe and reliable; and 2) the land-based take-off runways are unnecessary to be built; the device has strong adaptability; and without occupying the main take-off runways of the existing airports, the device can be installed and used on any airport and has good adaptability and a strong war preparedness function.

Owner:朱惠芬

Upper-bearing movable formwork for constructing continuous box girder for bridge superstructure

ActiveUS8387941B2Large dead weightIncreased footprintMouldsForms/shuttering/falseworksBridge engineeringBox girder

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Automatic welding line for LED tube

PendingCN108581205AImprove connection efficiencyGood connection qualityLaser beam welding apparatusChain conveyorWeld line

An automatic welding line for an LED tube comprises a tube transfer assembly and a laser welding assembly; the tube transfer assembly comprises a chain conveyor mechanism and locating transfer blocksarranged on a conveyor chain in the chain conveyor mechanism, and LED tubes are driven to convey by the conveyor chain through the locating transfer blocks; the laser welding assembly comprises laserwelding mechanisms arranged on one side or the both sides of the chain conveyor mechanism; each laser welding mechanism comprises a laser welding component and a welding locating component; the laserwelding component comprises a laser welding joint; the welding locating component comprises transparent pressing blocks and a pressing locating cylinder, and the LED tubes are located and pressed on the locating transfer blocks by the transparent pressing blocks in the pressed state at least; and in work, laser penetrates the transparent pressing blocks for welding the corresponding LED tubes. Theautomatic welding line has the characteristics of reliable performance, high automation degree, low labor cost, and high welding efficiency and welding quality; and connection of plastic cases of theLED tubes through a laser welding technology is pioneered in the industry.

Owner:广东顺德华焯机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com