Flexible inspection device for front portion of automobile

A technology of automobiles and inspection tools, which is applied in the direction of measuring devices, instruments, etc., can solve problems such as low inspection stability, low inspection accuracy, and serious wear, and achieve the effects of accurate position, improved accuracy, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

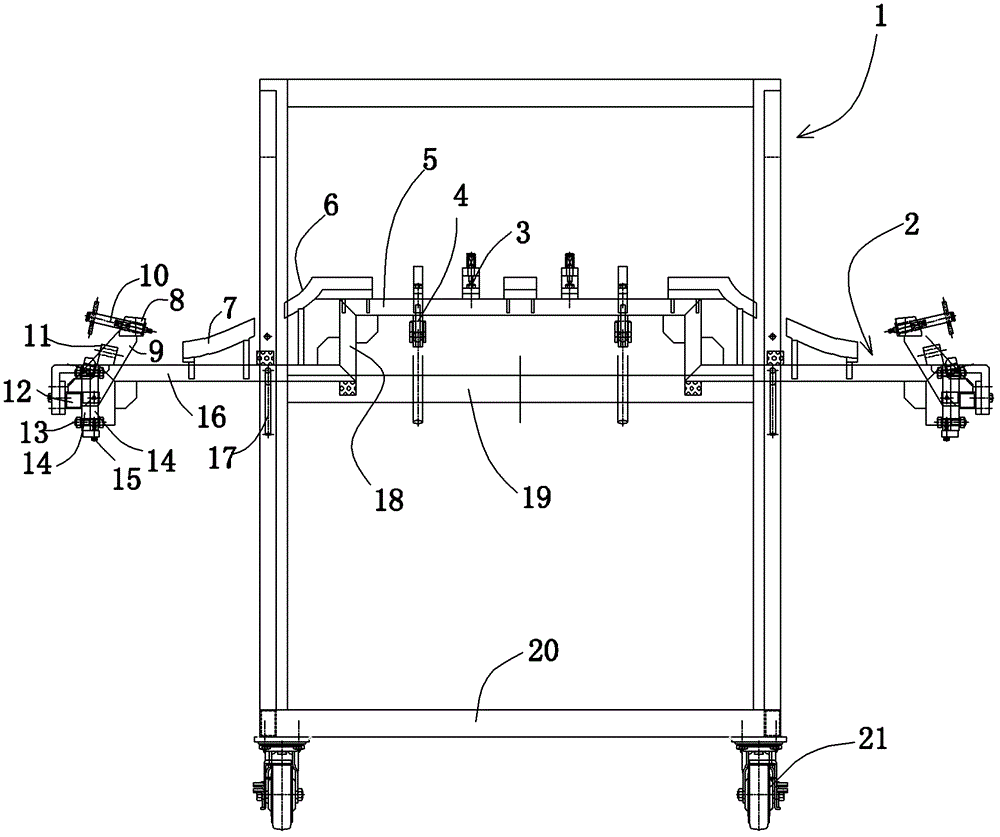

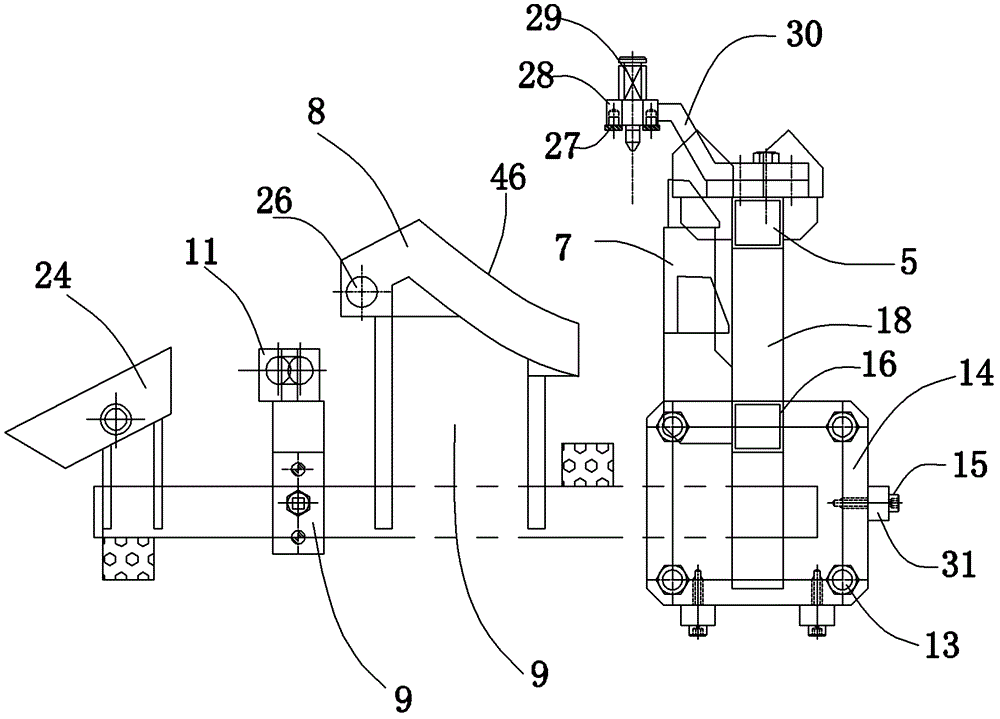

[0029] Embodiment: a kind of automobile front flexible checker (see attached figure 1 attached figure 2 ), including a storage rack 1, a bracket 2 placed on the storage rack, a positioning device 3 symmetrically arranged on the bracket, a locking device 4 and various detection devices.

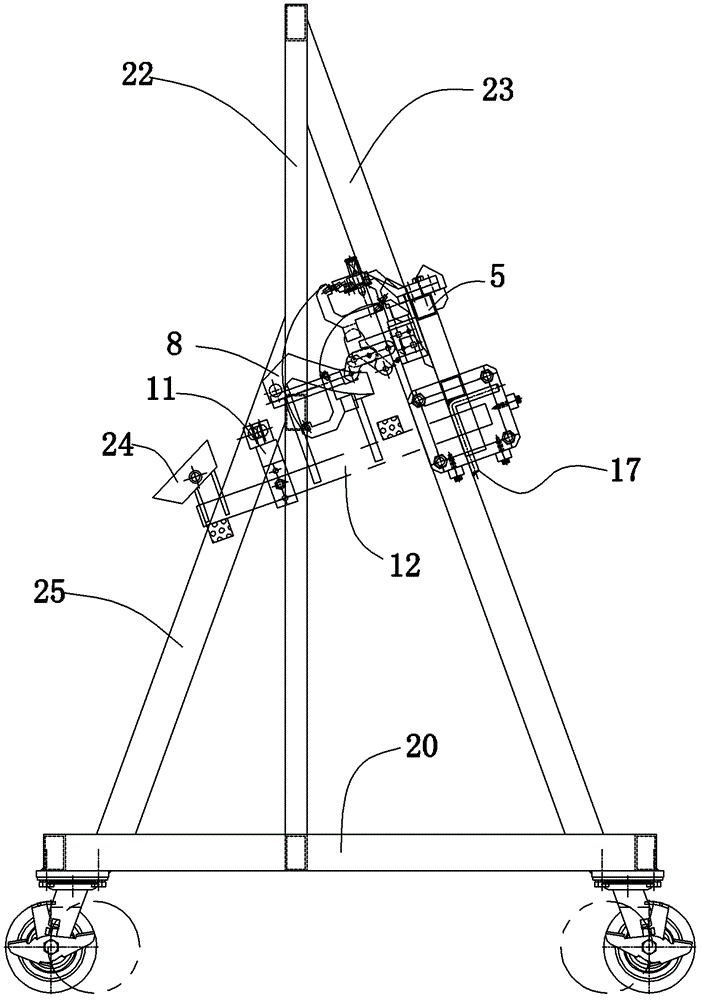

[0030] The storage rack comprises a base base 20 and two columns 22 vertically fixed on the base base, a horizontal tube 19 is connected between the two columns, and a short diagonal brace 25 and a long diagonal brace 23 are respectively fixed on both sides of the column, and the long diagonal brace On the back side opposite to the upright column, an L-shaped hook 17 is fixed, and the long side of the hook is fixed with a long diagonal brace, and the short side of the hook is vertically long with a diagonal brace, and four corners of the foundation base are provided with rollers 21.

[0031] The bracket is in a convex shape as a whole and is connected by square tubes. The middle part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com