Integrated loop heat pipe cooling device with boiling pool

A technology of heat dissipation device and loop heat pipe, applied in the field of heat pipe heat dissipation device and integrated loop heat pipe heat dissipation device, can solve the problems of small heat exchange coefficient, complex structure and low operation stability of radiator, and achieve small temperature fluctuation, Large heat transfer coefficient, continuous and efficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

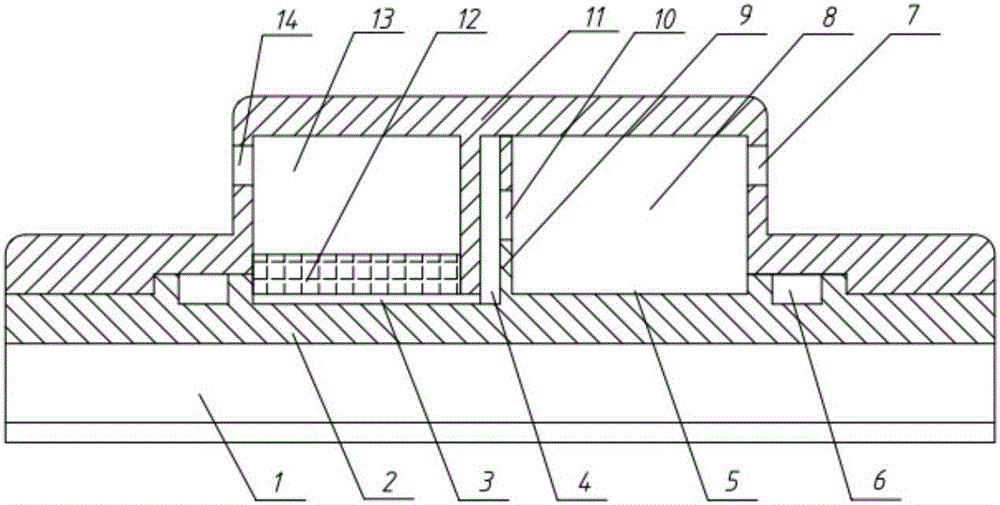

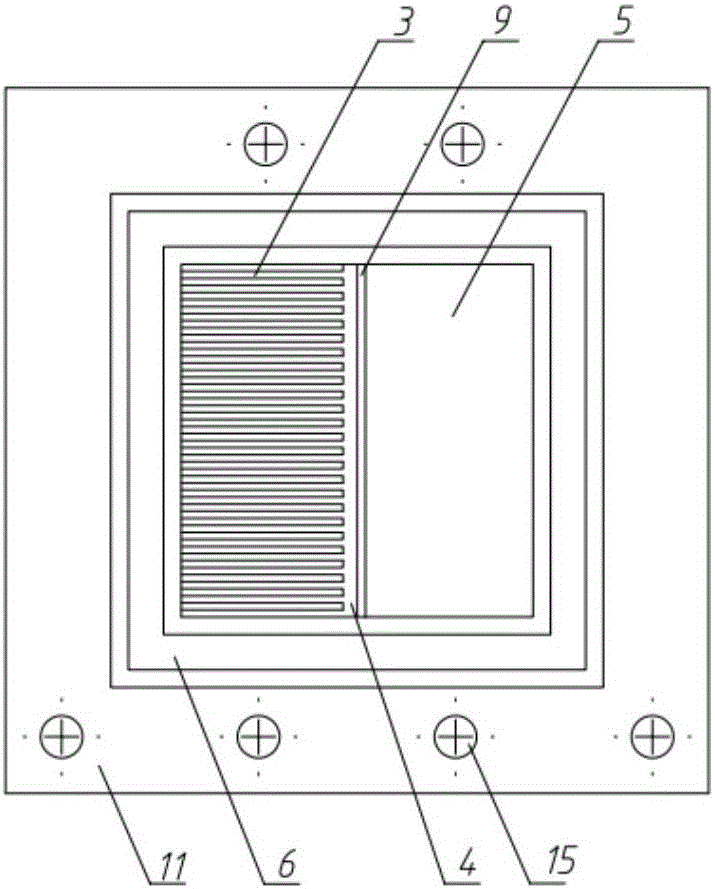

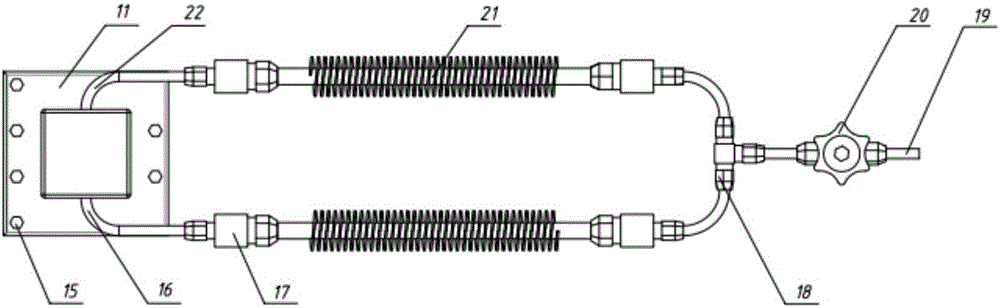

[0033] refer to figure 1 and figure 2 The integrated loop heat pipe cooling device with a boiling pool of the present invention includes an evaporator, a boiling pool 8 and a condenser 21, the evaporator includes a capillary core 12, a steam channel 13 and a compensation chamber 13, and the compensation chamber 13 is provided below for providing The capillary core 12 of the power is provided with a steam channel 3 under the capillary core 12, and the cross section of the compensation chamber 13 is generally rectangular. The channel 3 is arranged horizontally, and the gas collecting groove 4 is arranged vertically. The side wall of the boiling pool 8 is provided with a connecting hole 10 communicating with the gas collecting tank 4, the steam generated at the bottom of the steam channel 3 enters the gas collecting tank 4, and enters the boiling pool 8 through the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com