Heat pipe cooling device for sliding bearing of melt gear pump

A sliding bearing and cooling device technology, used in pumps, pump components, machines/engines, etc., can solve the problems of small coolant heat capacity, complicated sliding bearing design, poor cooling effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

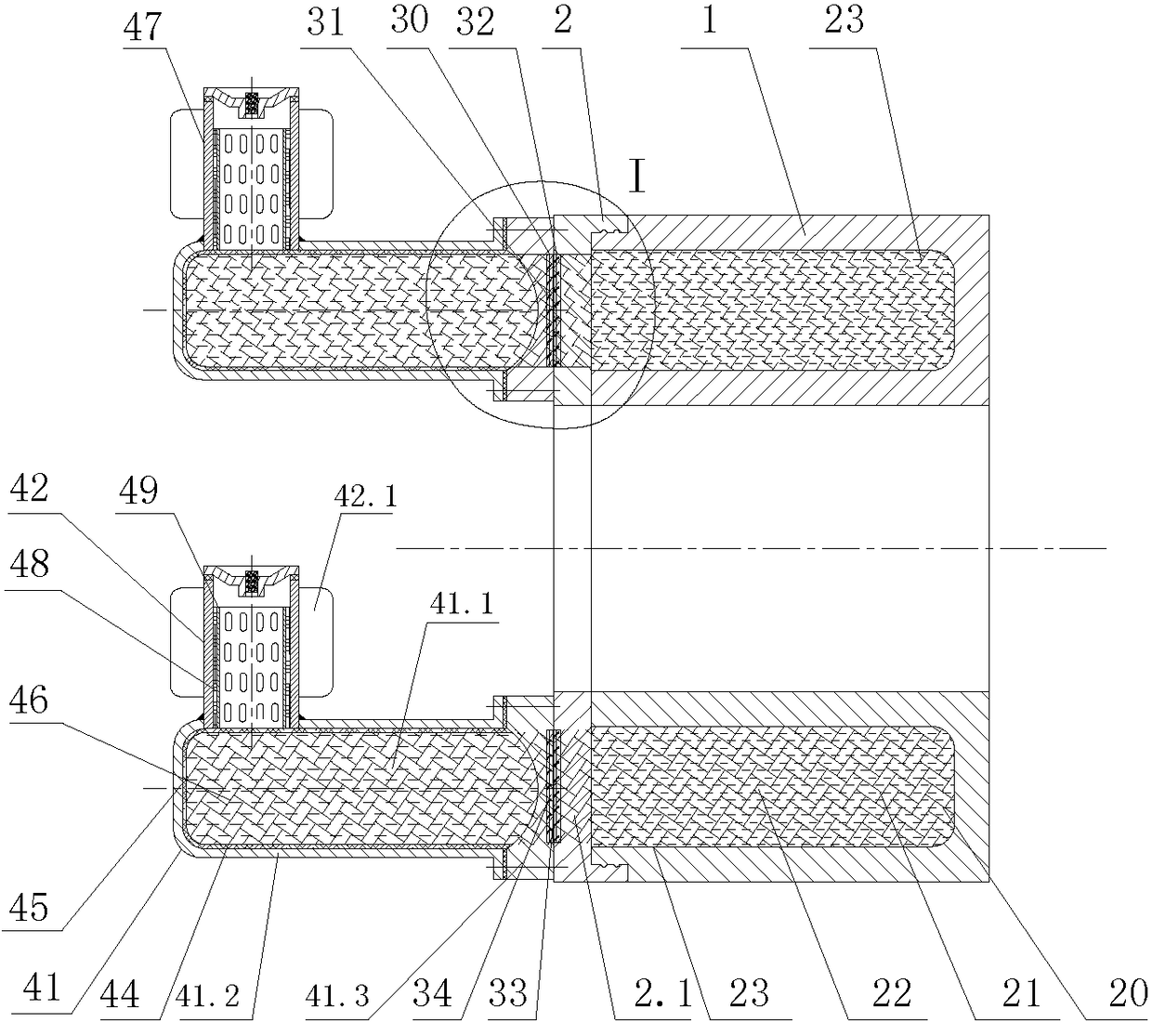

[0049] Such as Figure 1-4 As shown, a heat pipe cooling device for a melt gear pump sliding bearing includes a solid-liquid phase change heat storage structure 20, a thermal coupling structure 30, and a columnar heat pipe heat dissipation structure 40. The solid-liquid phase change heat storage structure 20 includes a heat storage foam metal The ring 21, the heat storage material 22, and the bearing cover 2 are axially sealed and fixed on the side of the sliding bearing body 1 to form an annular heat storage chamber 23, and the solid-liquid phase change heat storage structure 20 is arranged in the annular heat storage chamber 23. A plurality of heat pipe heat dissipation structures 40 are arranged outside the bearing cover 2 , and the solid-liquid phase change heat storage structure 20 is connected to the heat pipe heat dissipation structures 40 through a thermal coupling structure 30 .

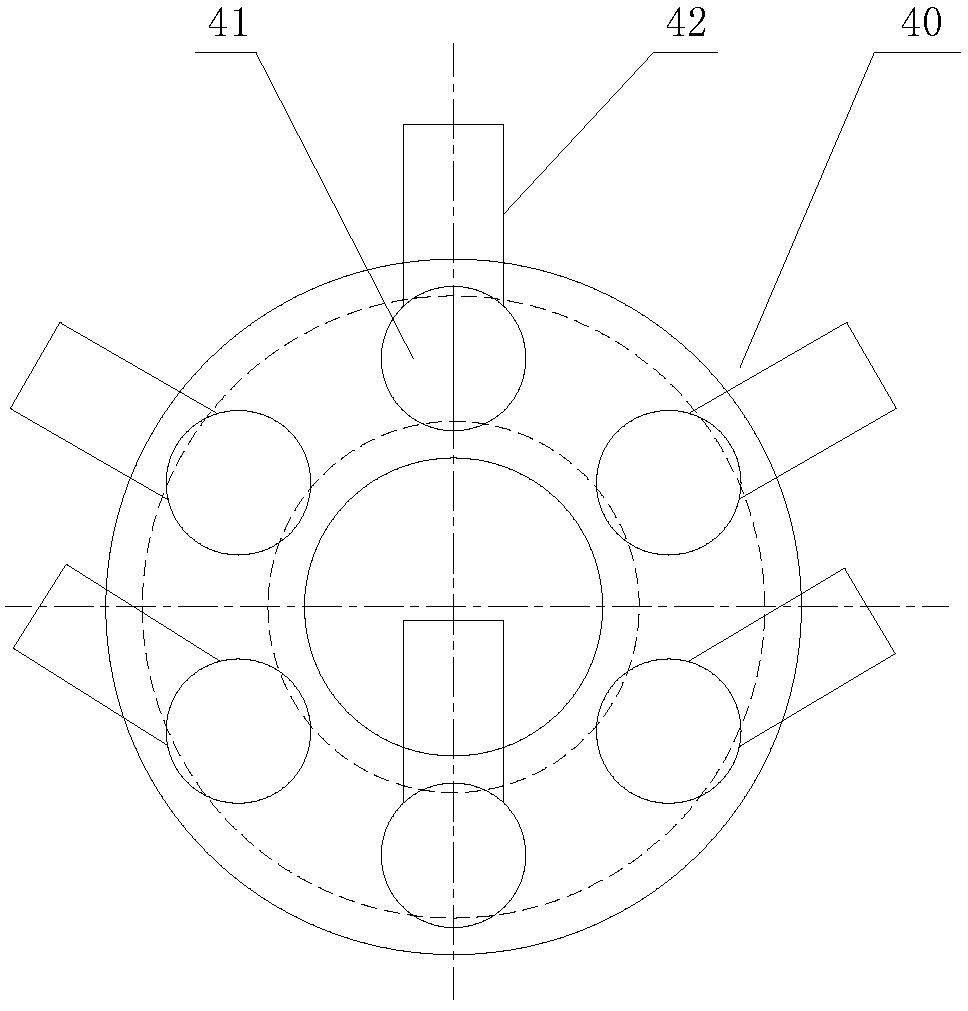

[0050] The heat pipe heat dissipation structure 40 includes an evaporation part 41 and a...

Embodiment 2

[0056] In order to increase the heat dissipation capability of the heat pipe heat dissipation structure 40, the thermal coupling structure 30 is improved.

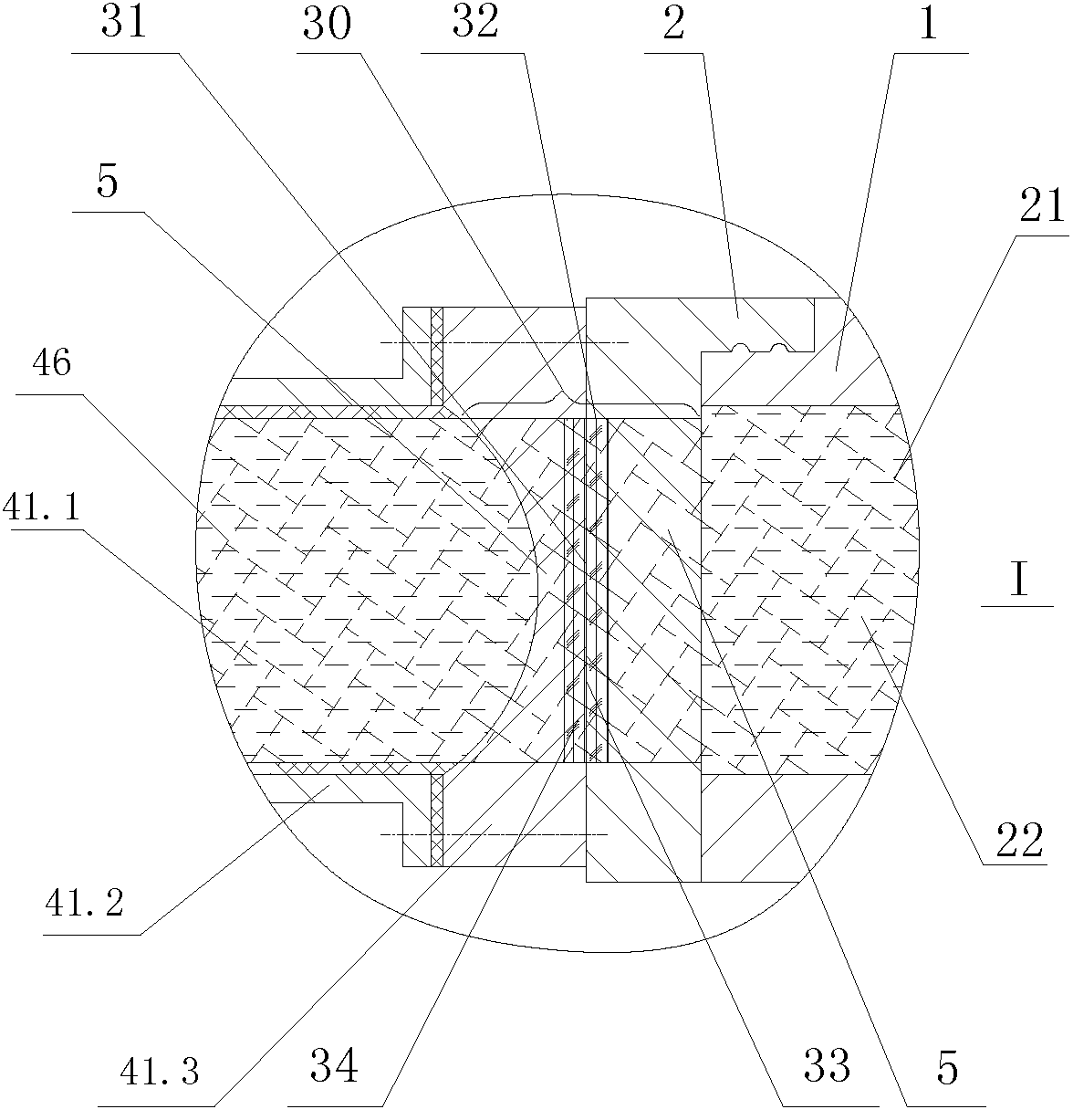

[0057] Such as Figure 5-7 As shown, a heat pipe cooling device for a melt gear pump sliding bearing includes a solid-liquid phase change heat storage structure 20, a thermal coupling structure 30, and a heat pipe cooling structure 400. The sliding bearing includes a sliding bearing body 1, and the sliding bearing body 1 is provided with an annular Cavity 3 , a pair of Hough rings 4 are embedded in the annular cavity 3 to form a closed annular heat storage cavity 23 . The solid-liquid phase change heat storage structure 20 includes a heat storage foam metal ring 21 and a heat storage material 22 , and the solid-liquid phase change heat storage structure 20 is arranged in an annular heat storage cavity 23 . The heat storage metal foam ring 21 is made up of a pair of half-rings of Hough type. The solid-liquid phase change ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average life expectancy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com