Patents

Literature

217 results about "Hydrodynamic pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The hydrodynamic pressure term will come when fluid is in motion. The head developed by velocity of fluid is called hydrodynamic pressure head. The static pitot tube will give you the measurement of same. So, hydrodynamic pressure will be equal to the 1/2*density of fluid *(v*v).

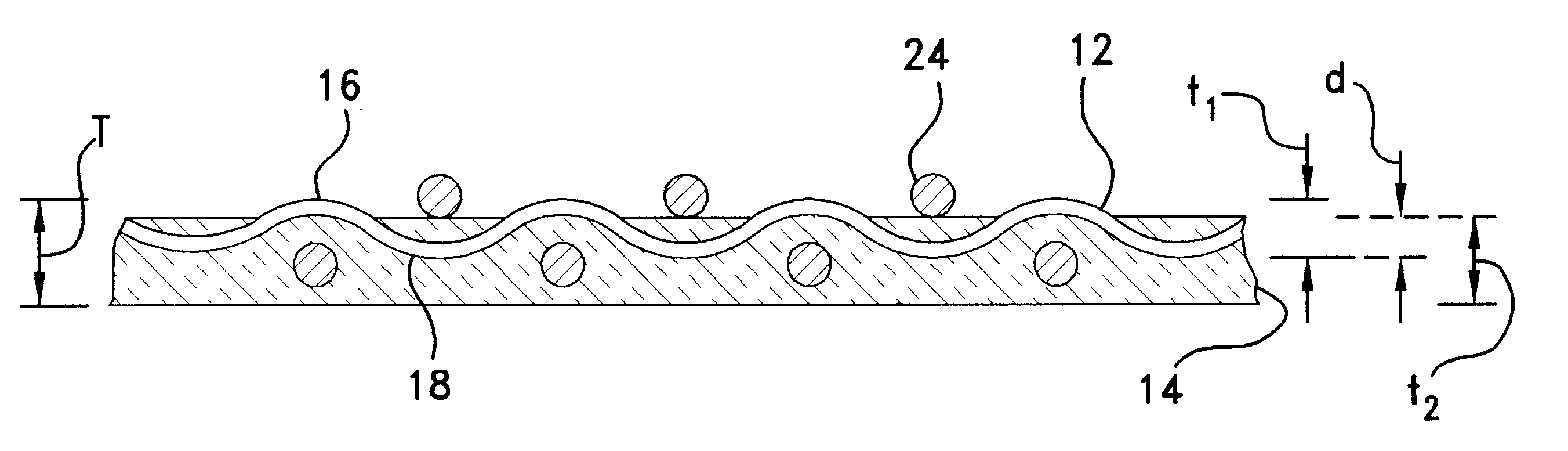

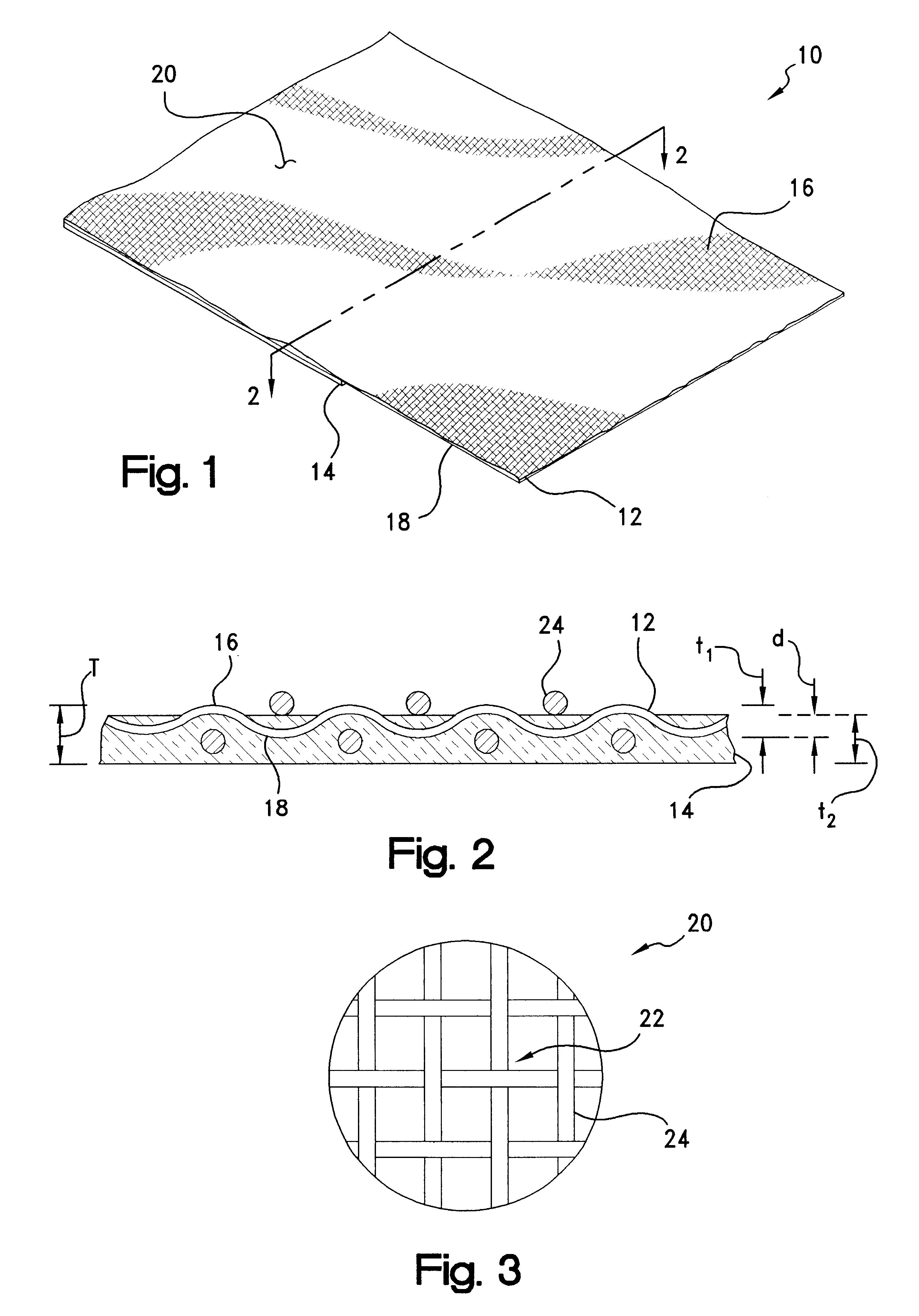

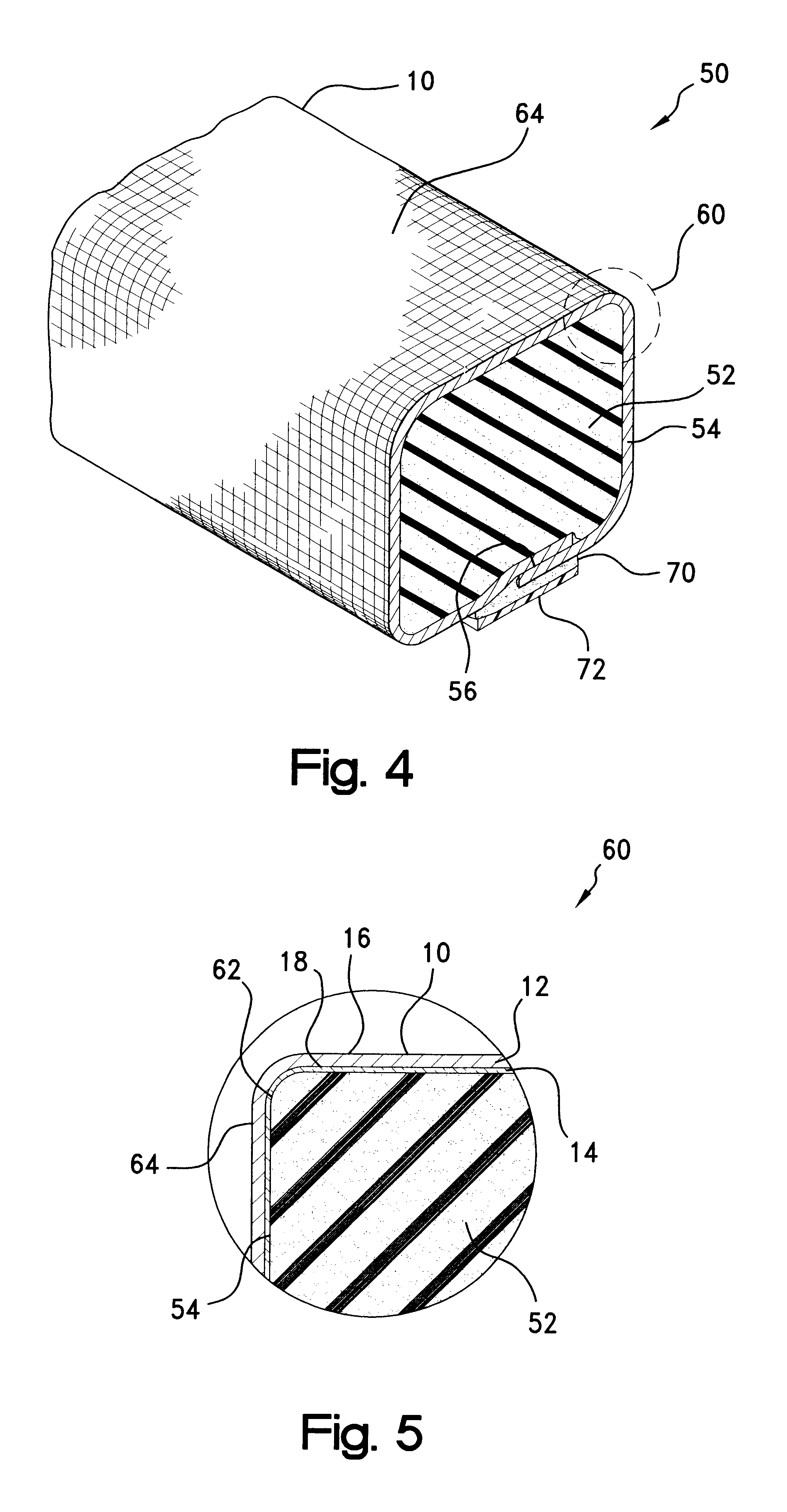

Flame retardant EMI shielding materials and method of manufacture

InactiveUS6248393B1Maintains drapabilityEasy constructionScreening gaskets/sealsPretreated surfacesEngineeringViscosity

An flame retardant, electrically-conductive EMI shielding material and method, the material being particularly adapted for use in fabric-over-foam EMI shielding gasket constructions. In construction, a generally planar, porous fabric member is provided as having at least an electrically-conductive first side and a second side defining a thickness dimension therebetween. A curable layer of a fluent, flame retardant composition is applied under a predetermined hydrodynamic pressure and viscosity to at least a portion of the second side of the fabric member. The hydrodynamic pressure and viscosity of the composition are controlled to delimit the penetration of the layer into the fabric member to a depth which is less than the thickness dimension of said fabric member. The layer then is cured to form a flame retardant surface coating on the second side of the fabric member such that the first side of said fabric member remains electrically-conductive.

Owner:PARKER INTANGIBLES LLC

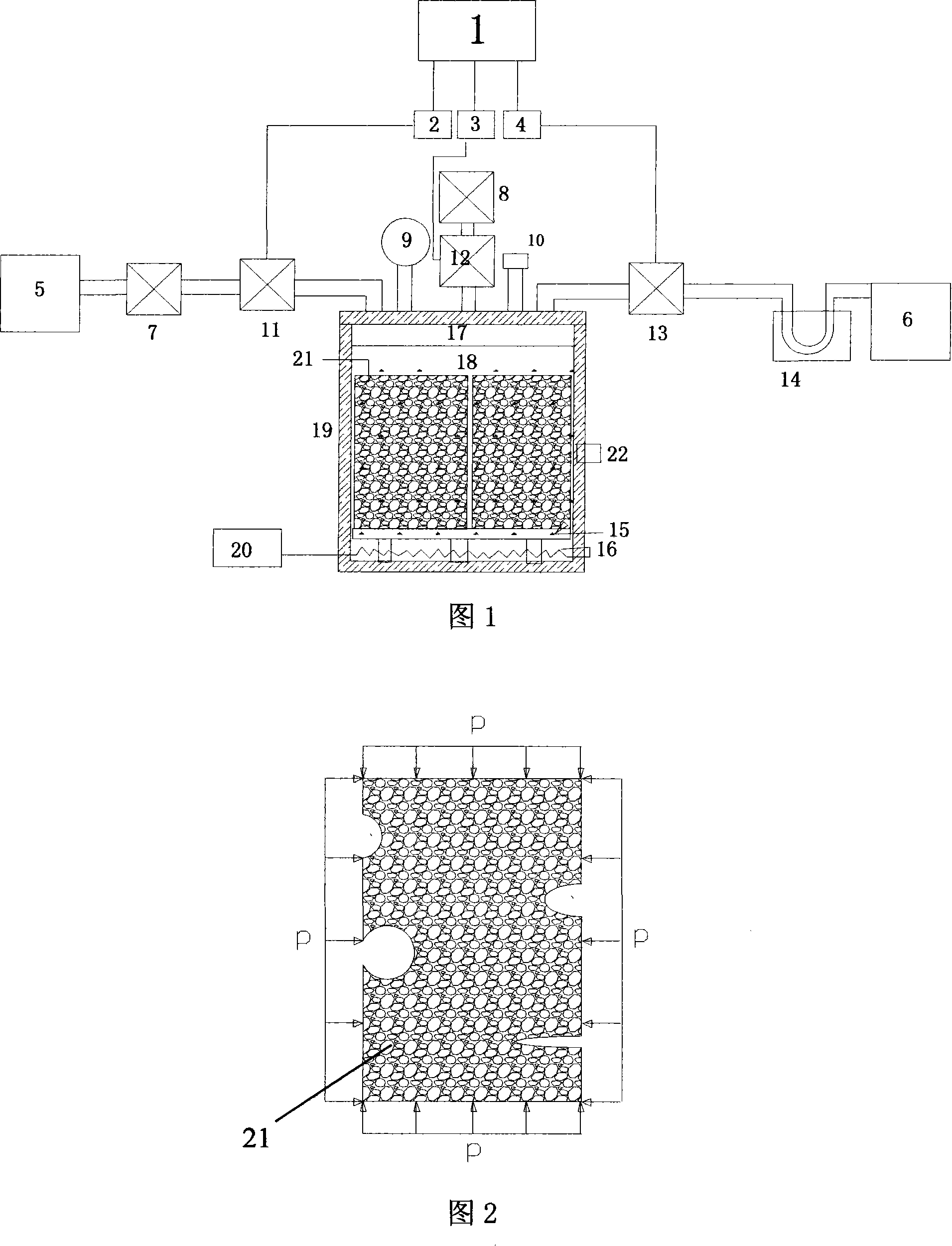

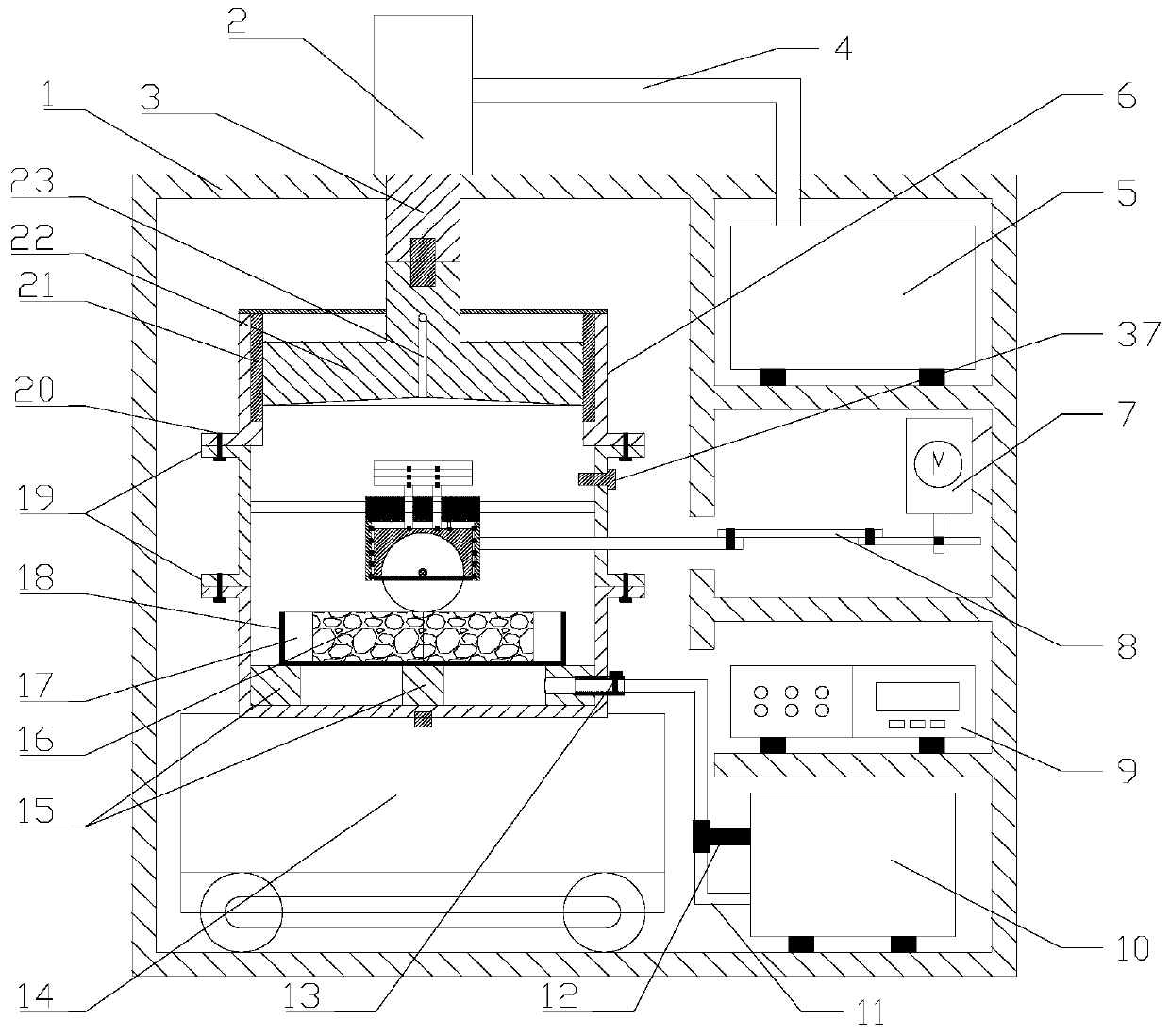

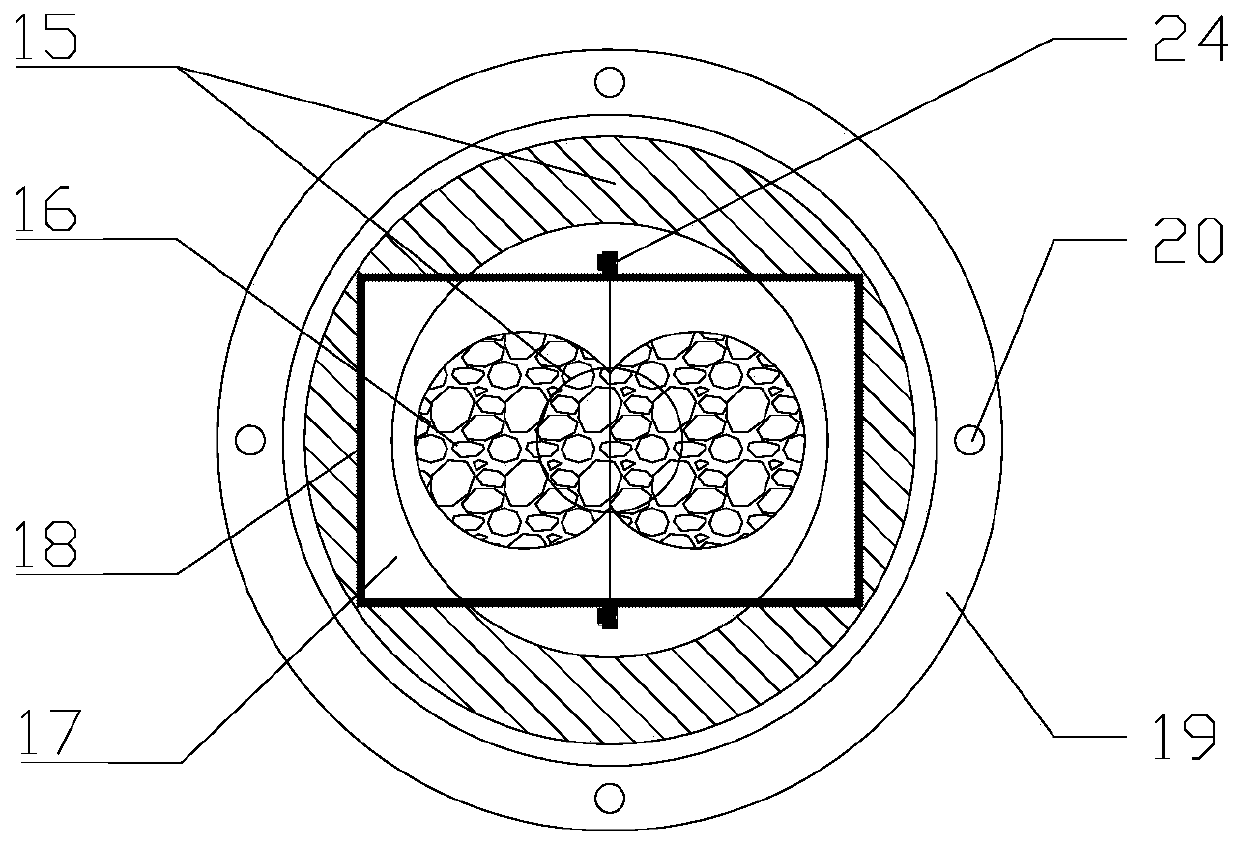

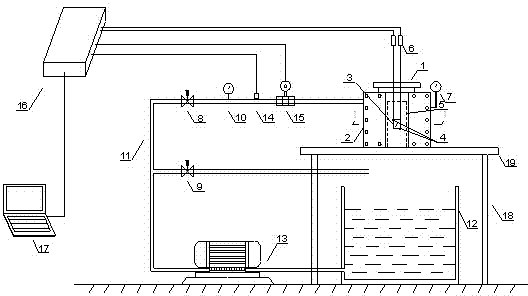

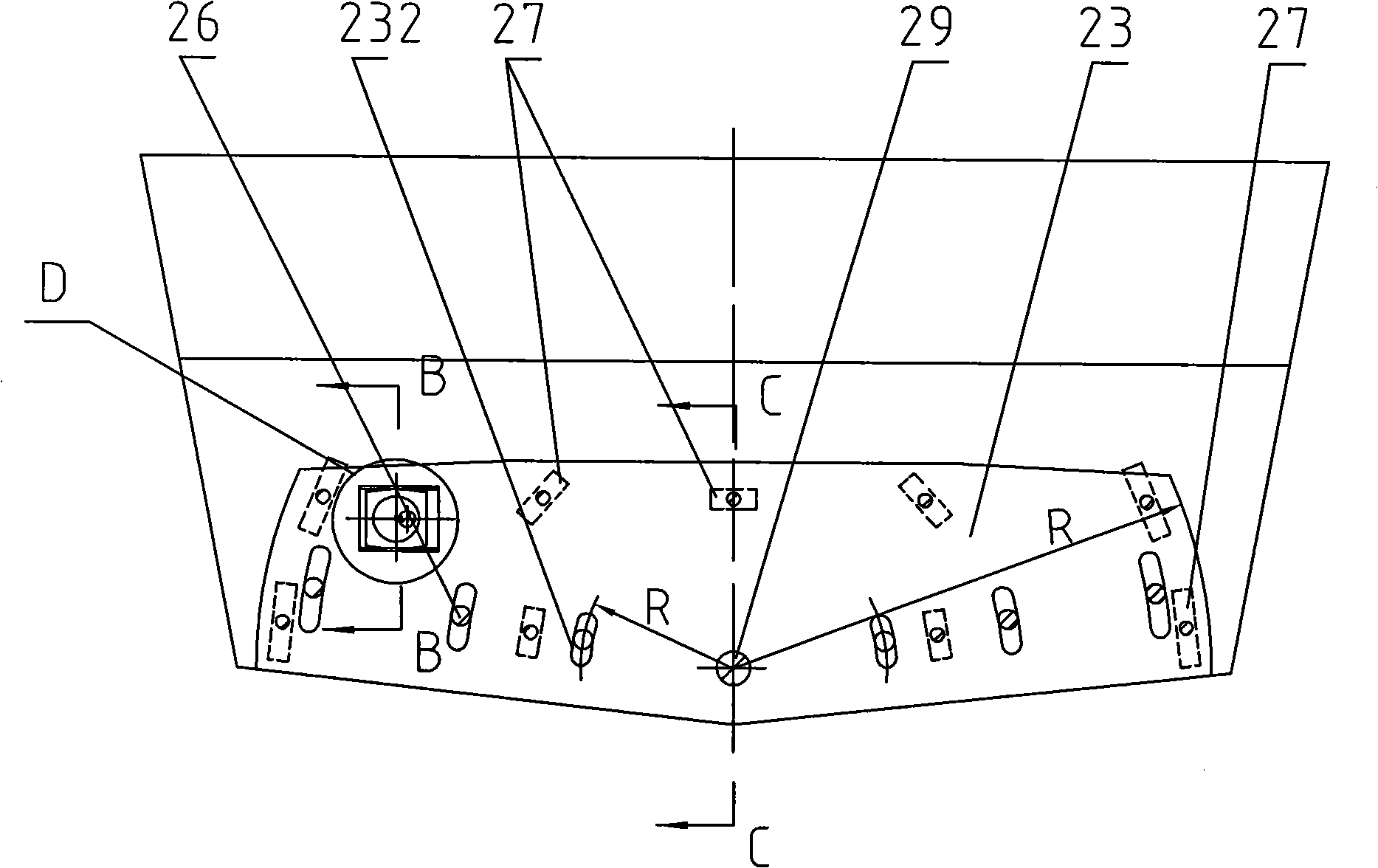

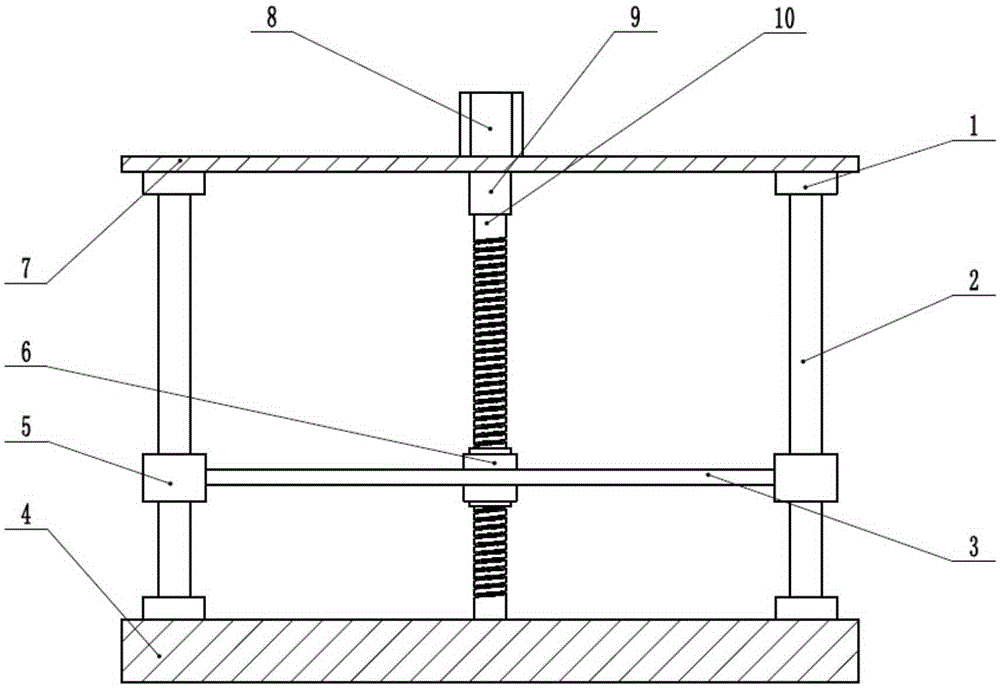

Asphalt mixture hydrodynamic pressure scouring test methods and apparatus

InactiveCN101216401AHigh simulationUsing mechanical meansVehicle tyre testingPositive pressureRoad surface

Owner:SOUTH CHINA UNIV OF TECH

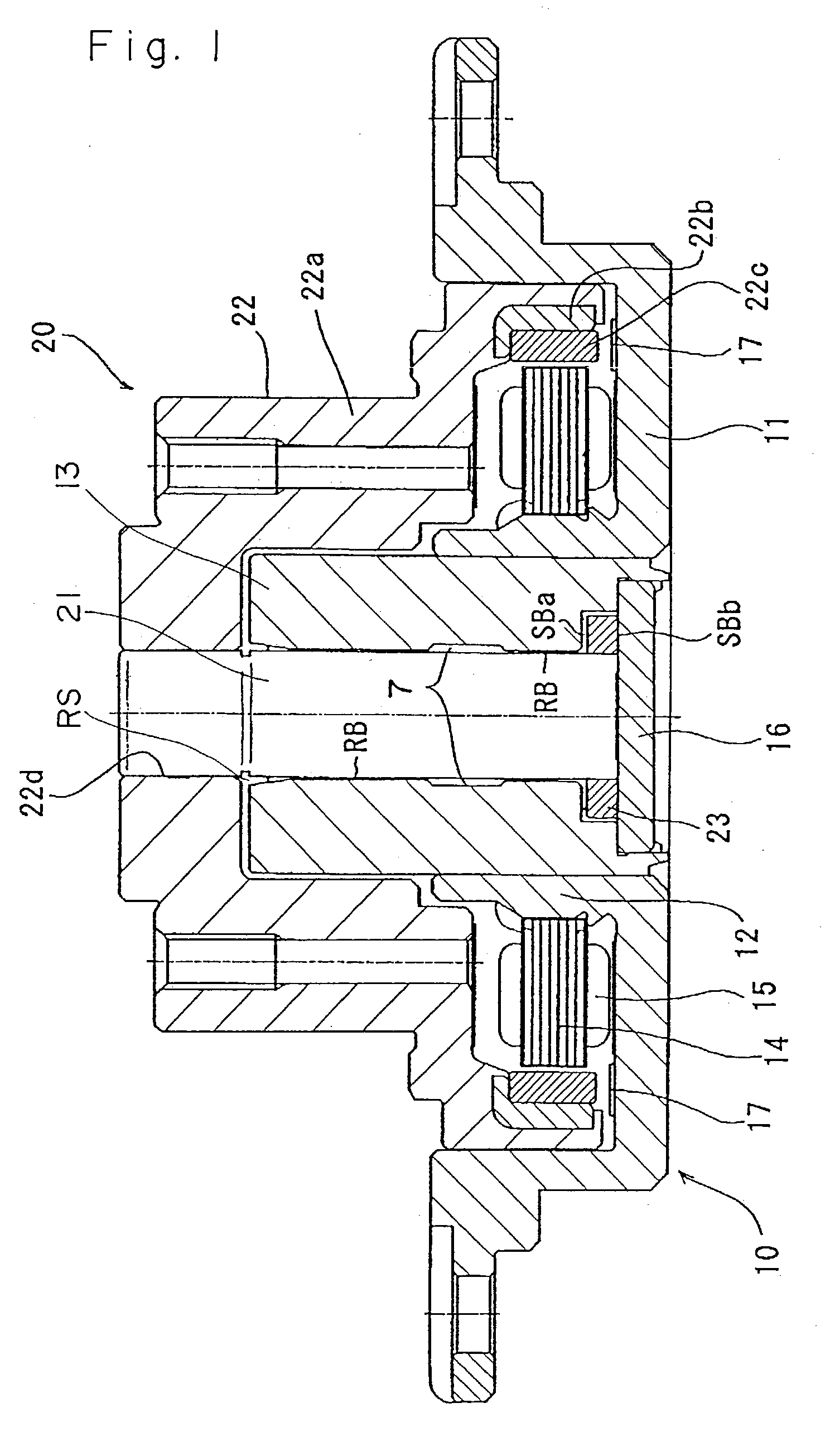

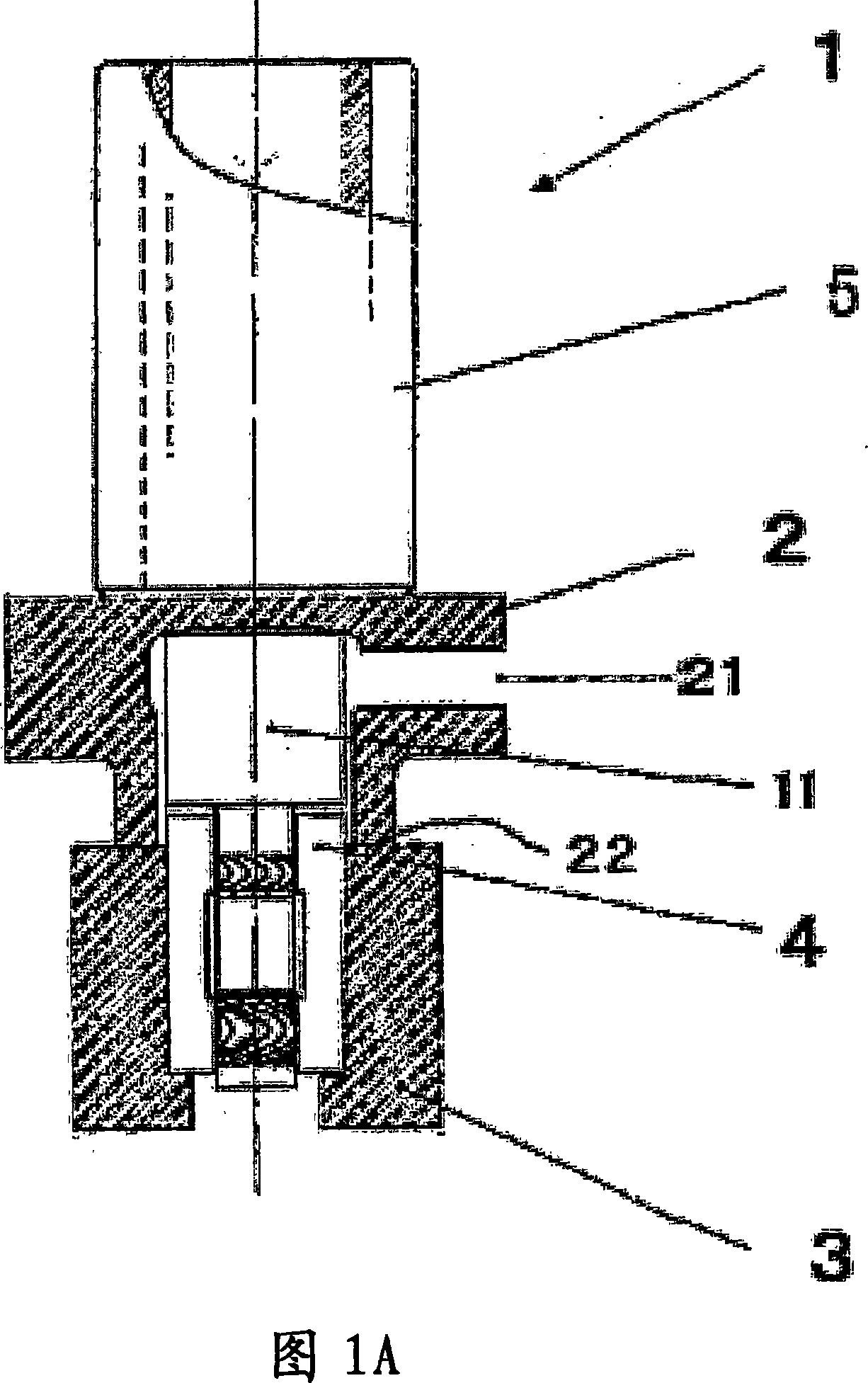

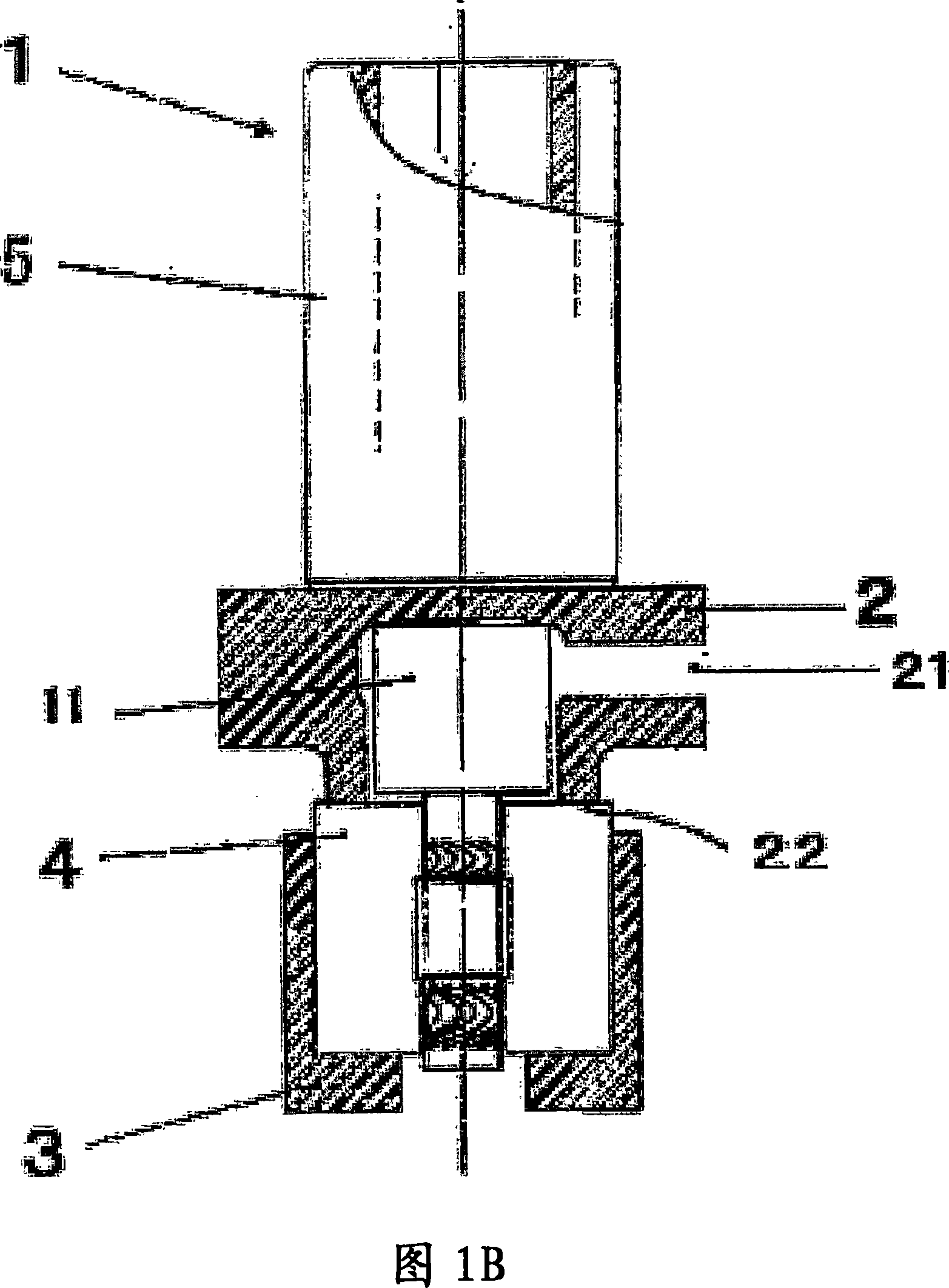

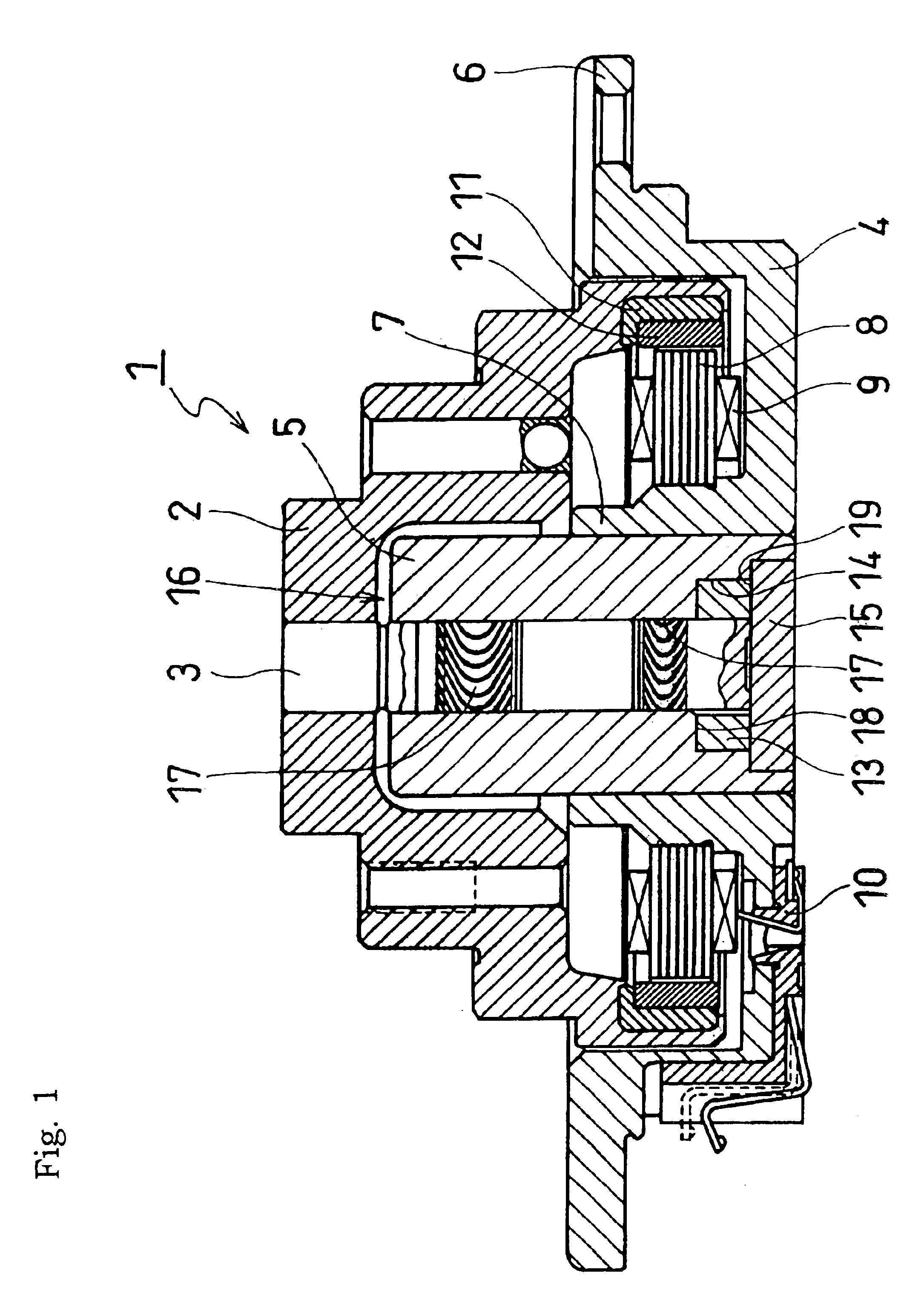

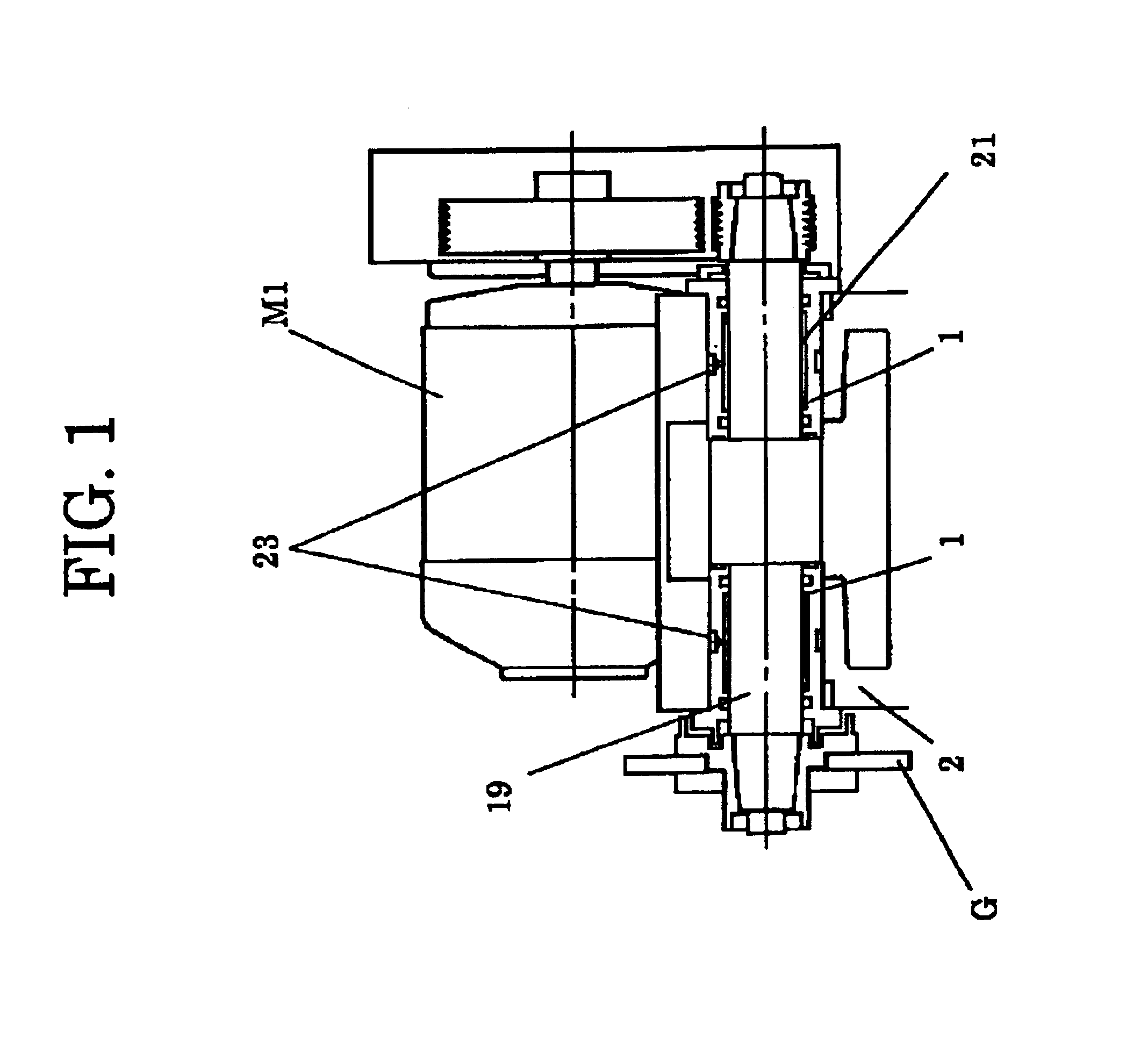

Spindle motor and disk drive utilizing the spindle motor

InactiveUS6888278B2Simplify and slim down structureMaintain relatively stableApparatus for flat record carriersShaftsThrust bearingEngineering

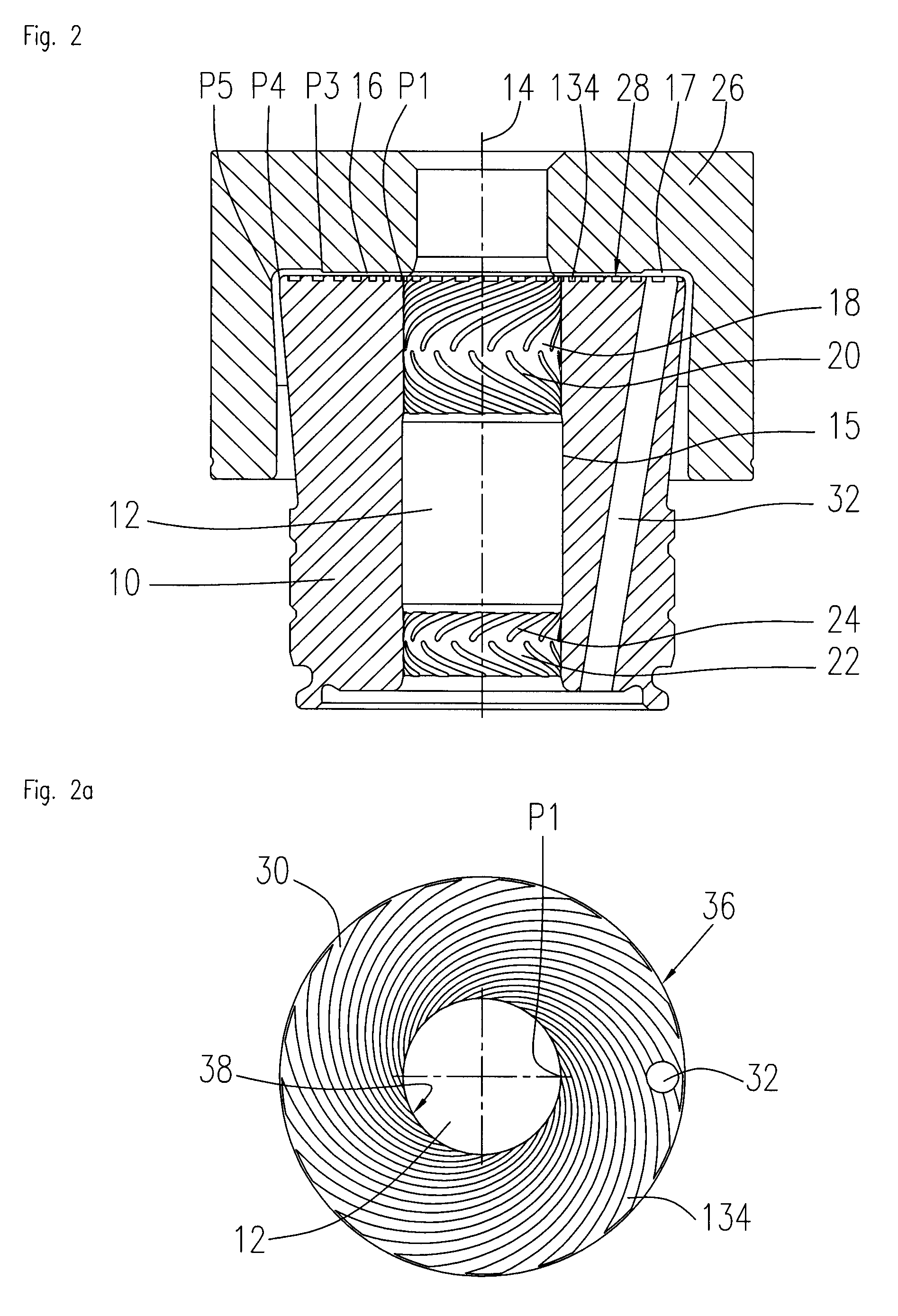

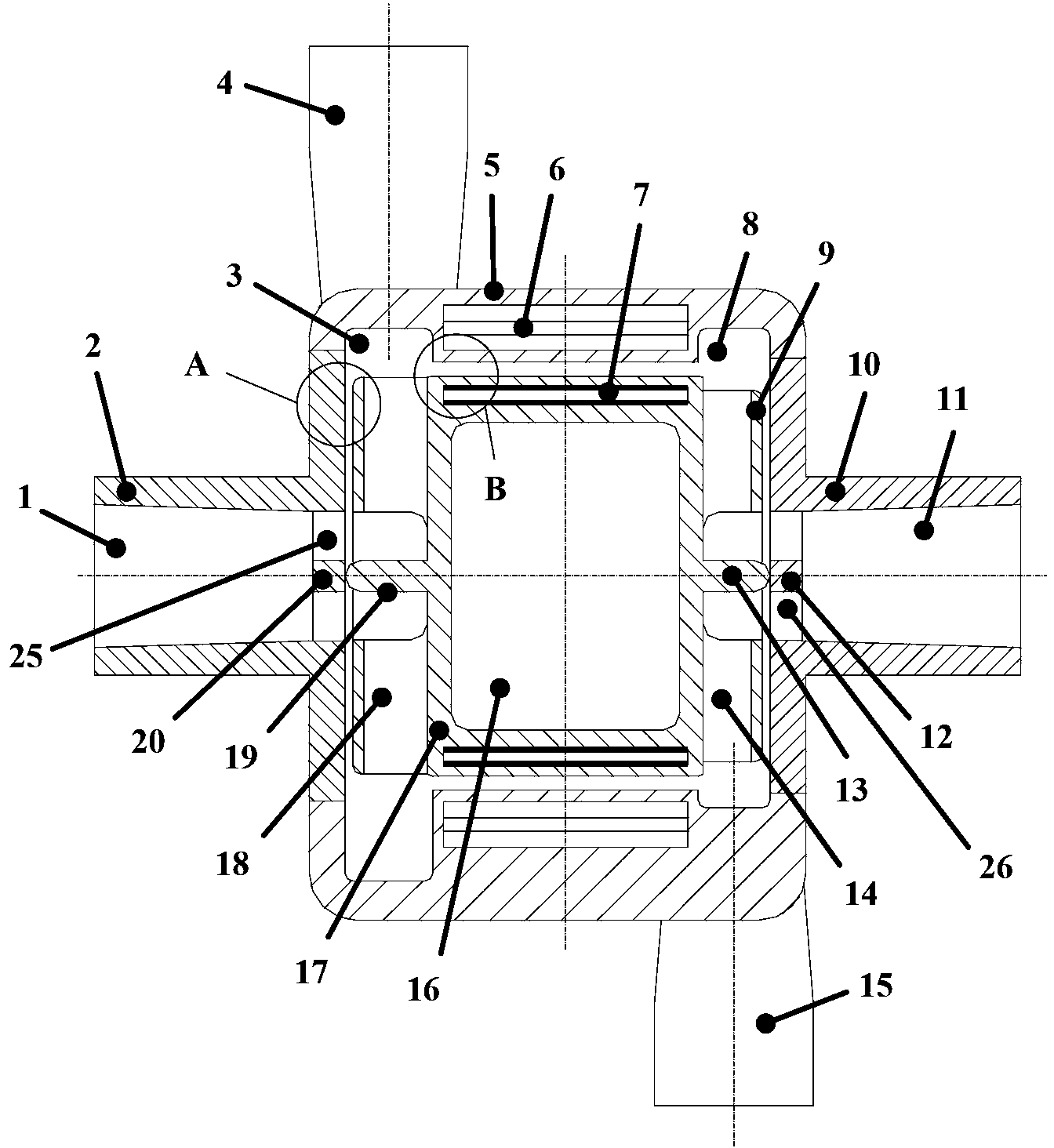

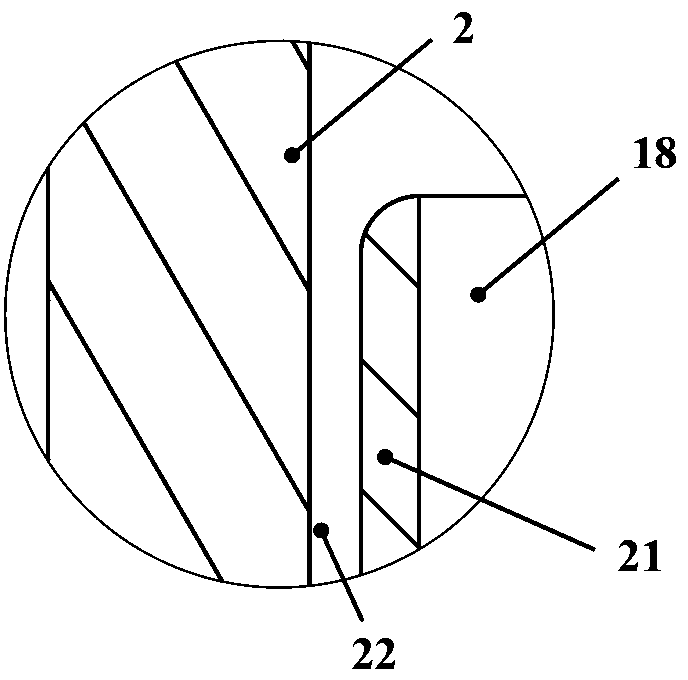

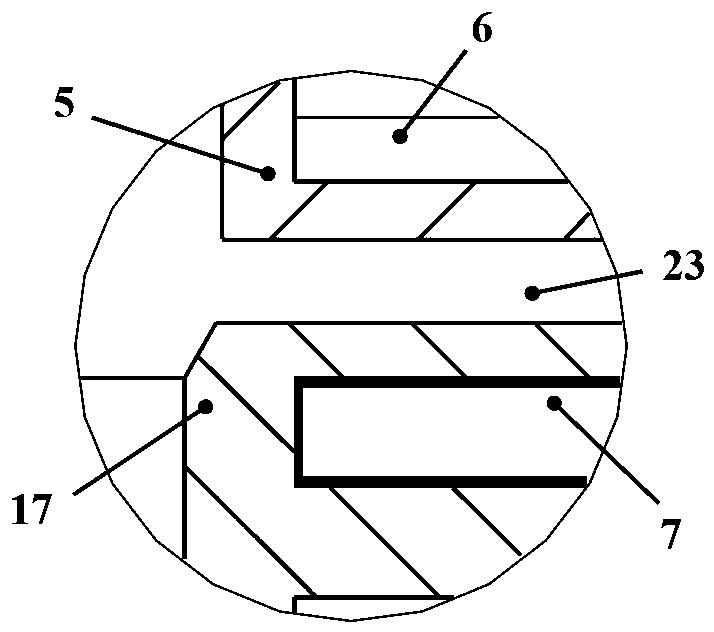

Low-profile spindle motor whose entire shaft length is utilized to configure, along an encompassing sleeve, a radial dynamic-pressure bearing section. One end of the shaft is unitary with the rotor, and a cover member closes the other end. Between the sleeve upper-end face and the rotor undersurface a thrust bearing section is configured. Micro-gaps are formed continuing between the sleeve upper-end face and the rotor undersurface; the sleeve inner-circumferential surface and the shaft outer-circumferential surface; and the cover member inner face and the shaft end face, where an axial support section is established. Oil continuously fills the micro-gaps, configuring a full-fill hydrodynamic bearing structure. Hydrodynamic pressure-generating grooves in the radial bearing section are configured either so that no axial flow, or so that a unidirectional flow that recirculates from one to the other axial end of the radial bearing section through a communicating pathway is induced in the oil.

Owner:NIDEC CORP

Hydraulic bearing device

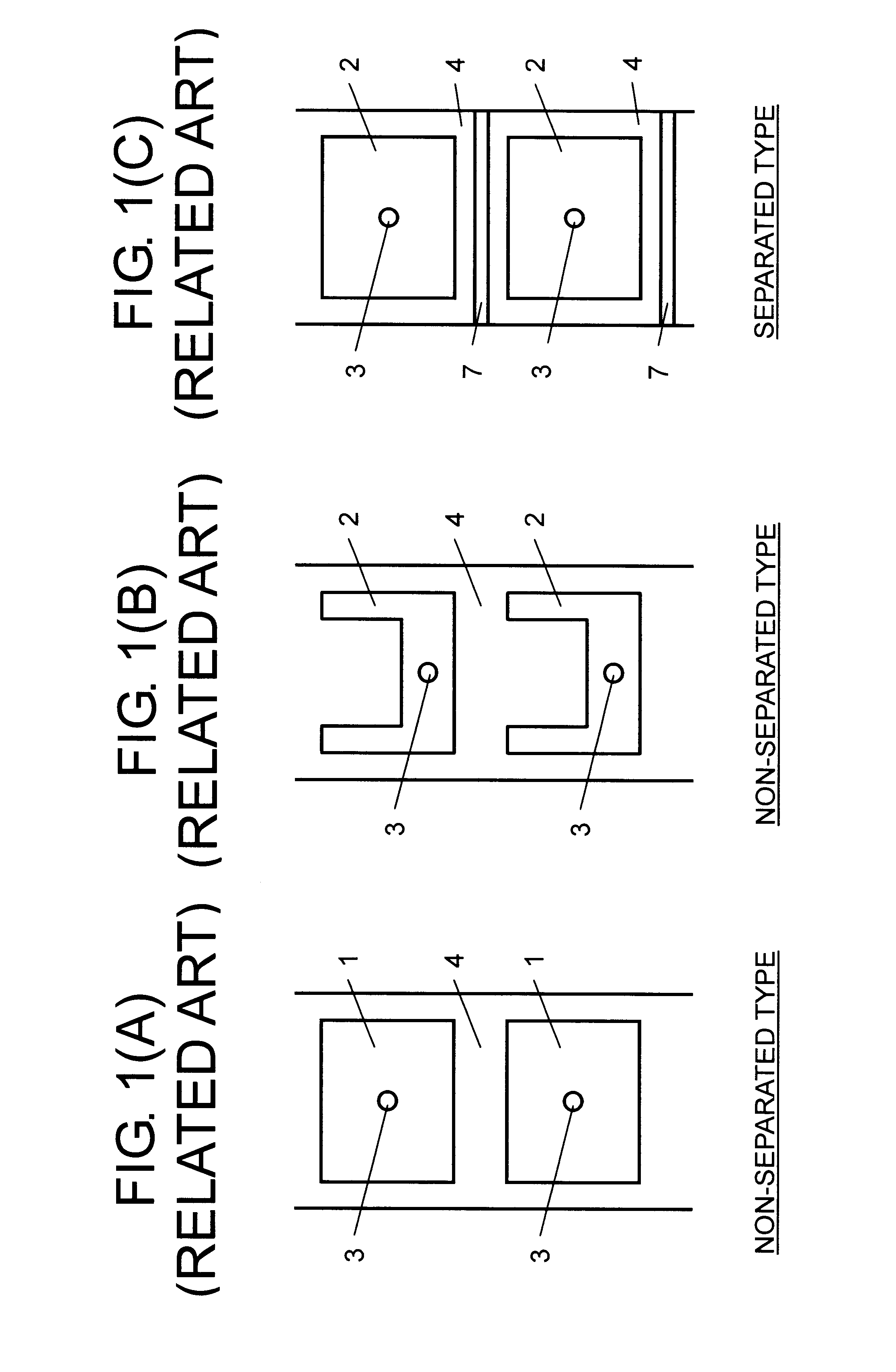

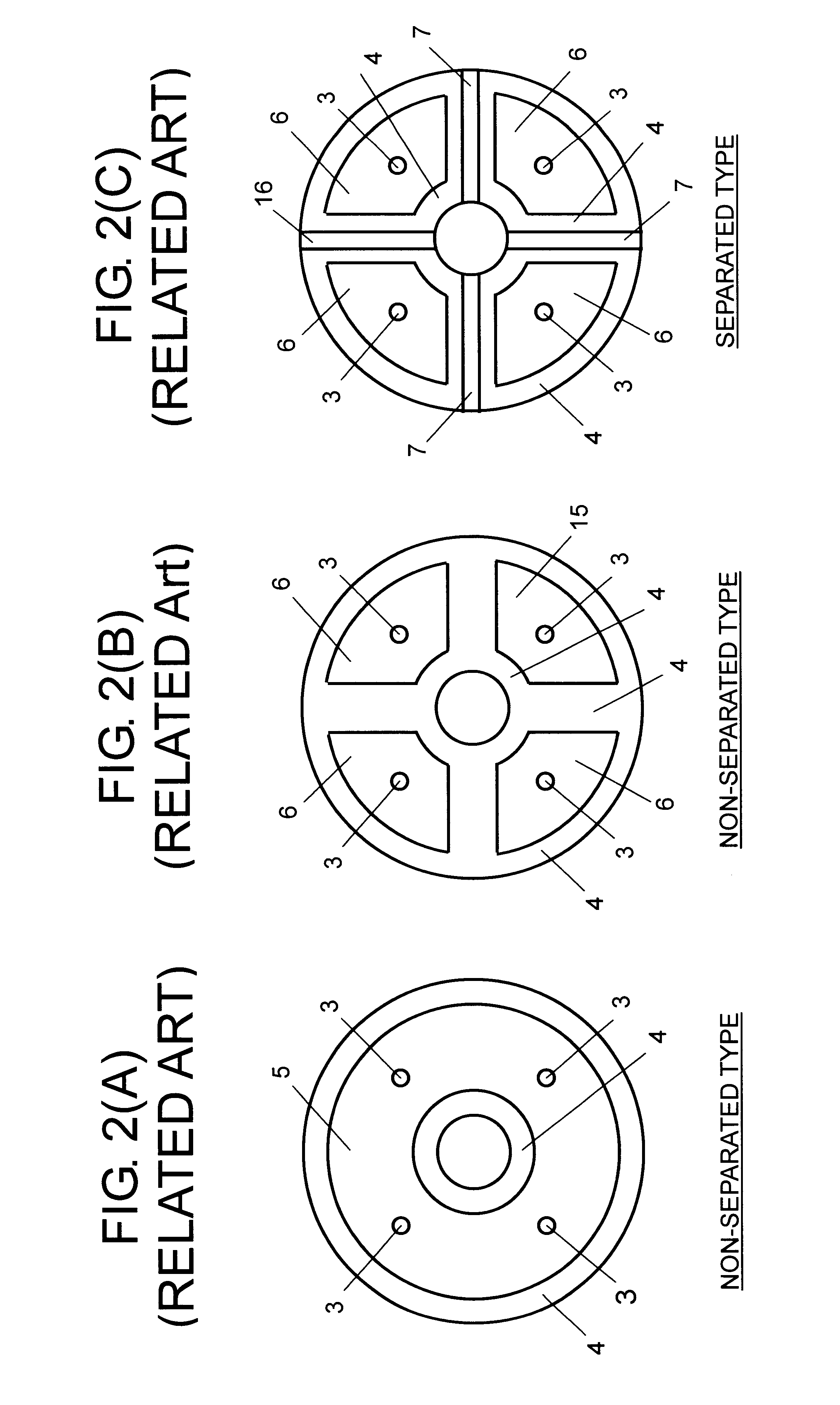

A hydraulic bearing device that supports a rotating shaft comprises a bearing metal. On a surface of the bearing metal, a hydrostatic pocket and a land portion are formed. The land portion is defined by the hydrostatic pocket and generates hydrodynamic pressure. The hydraulic bearing device further comprises a pressure fluid supplying source and an oil-supplying hole. The oil-supplying hole is opened in the hydrostatic pocket and provides pressure fluid from the pressure fluid supplying source to the hydrostatic pocket. On the land portion, a drain hole that drains the fluid is formed. Since the fluid is drained through the drain hole, thermal expansion of the bearing metal due to heat generation of the fluid is restrained. Moreover, since the drain hole does not separate the land portion, deterioration of bearing rigidity is restrained.

Owner:TOYODA MASCH WORKS LTD

Fluid dynamic bearing system

ActiveUS20060210205A1Supports effectivenessPressure equalization can be enhancedShaftsBearing componentsEngineeringBearing surface

Owner:MINEBEAMITSUMI INC

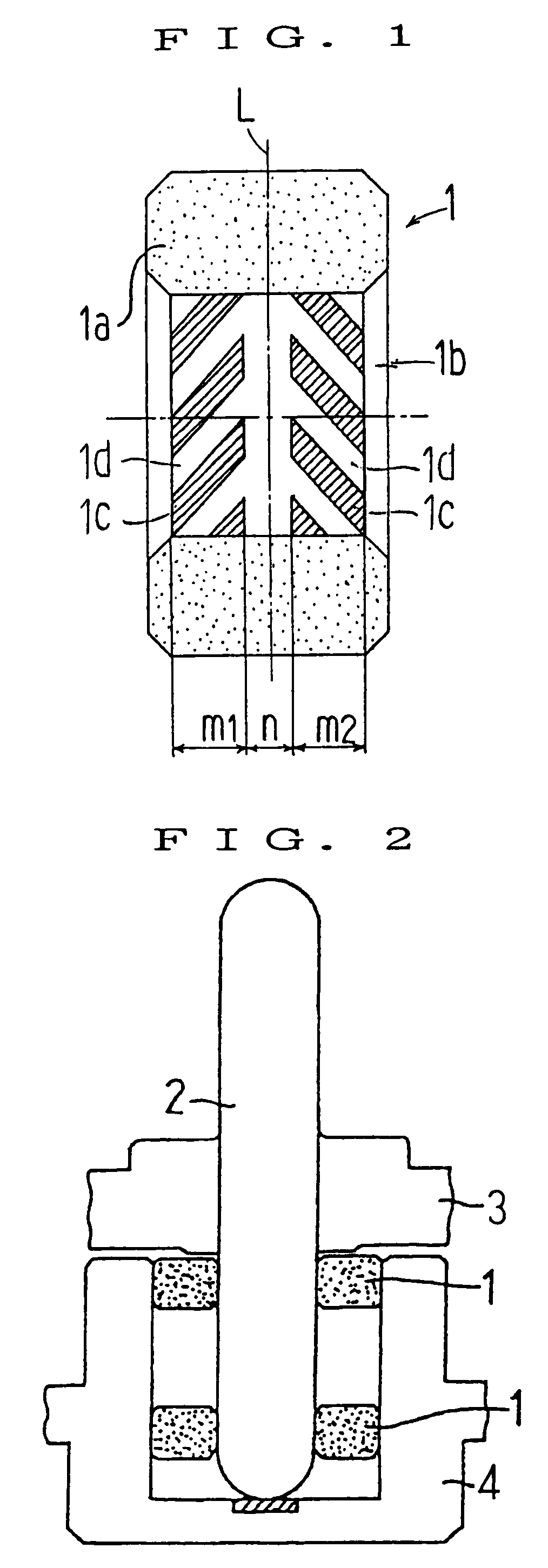

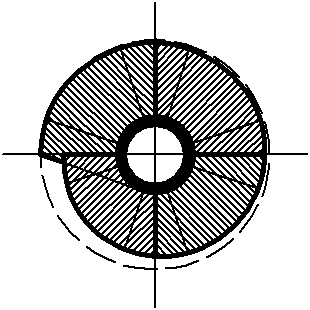

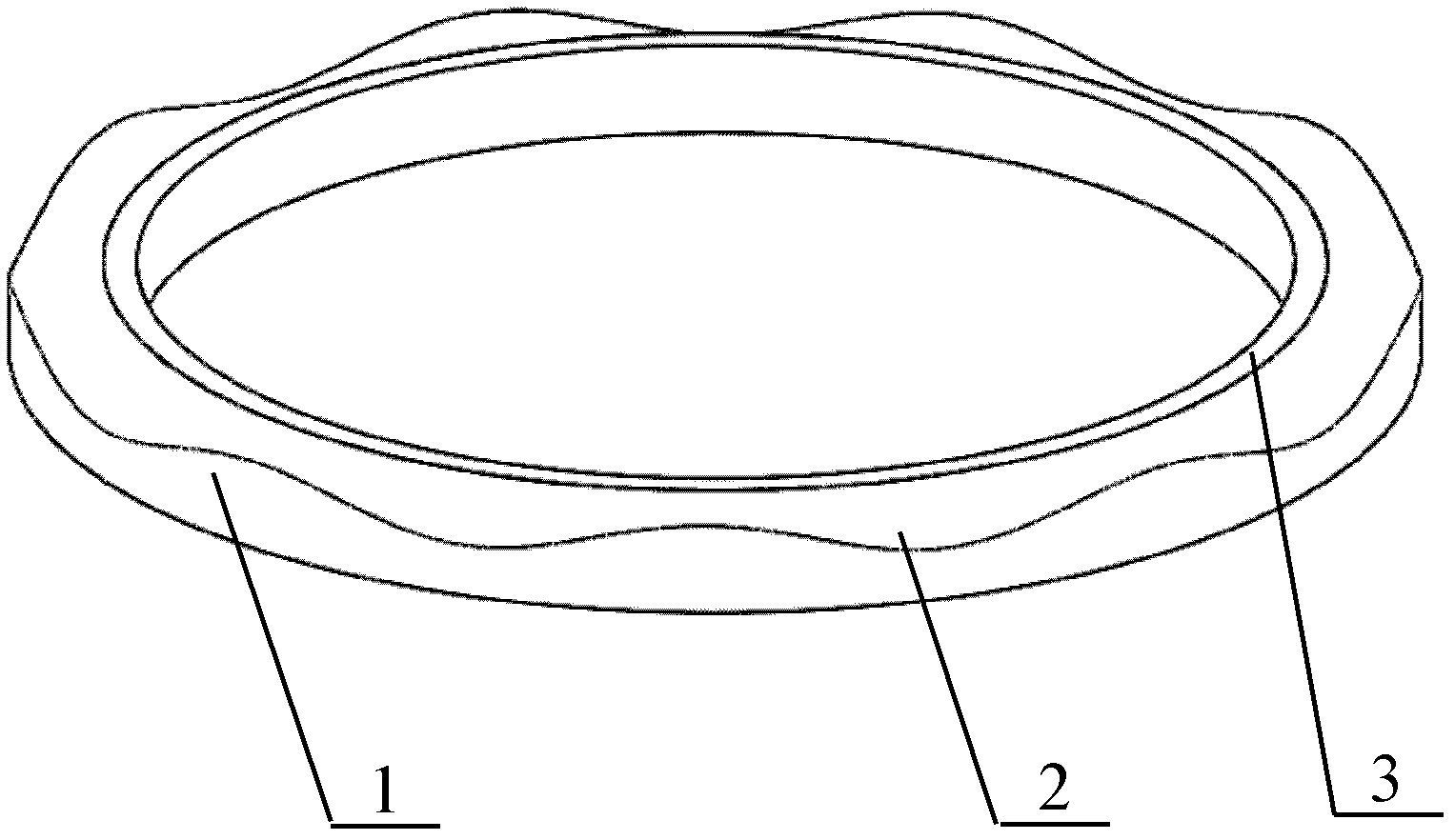

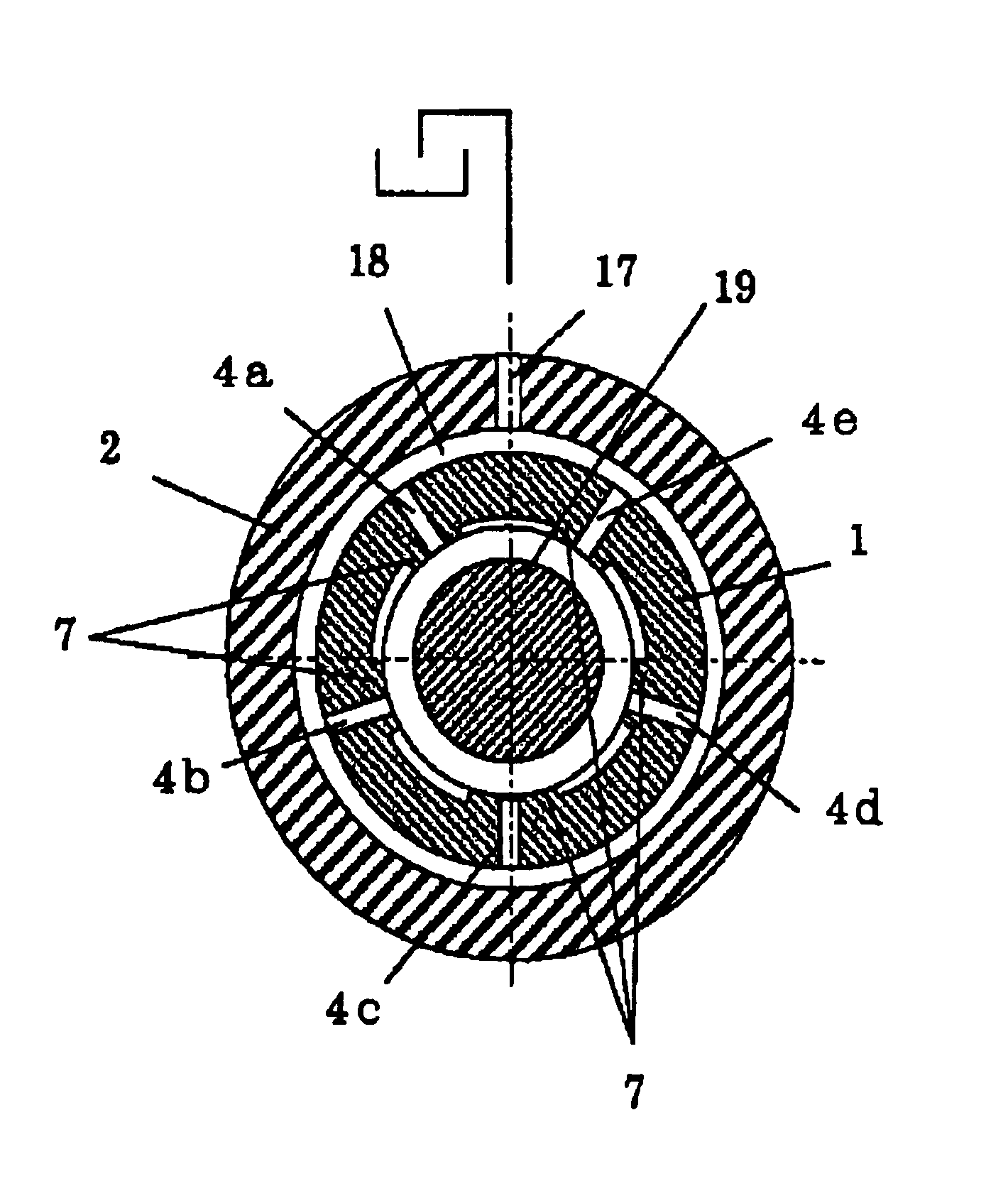

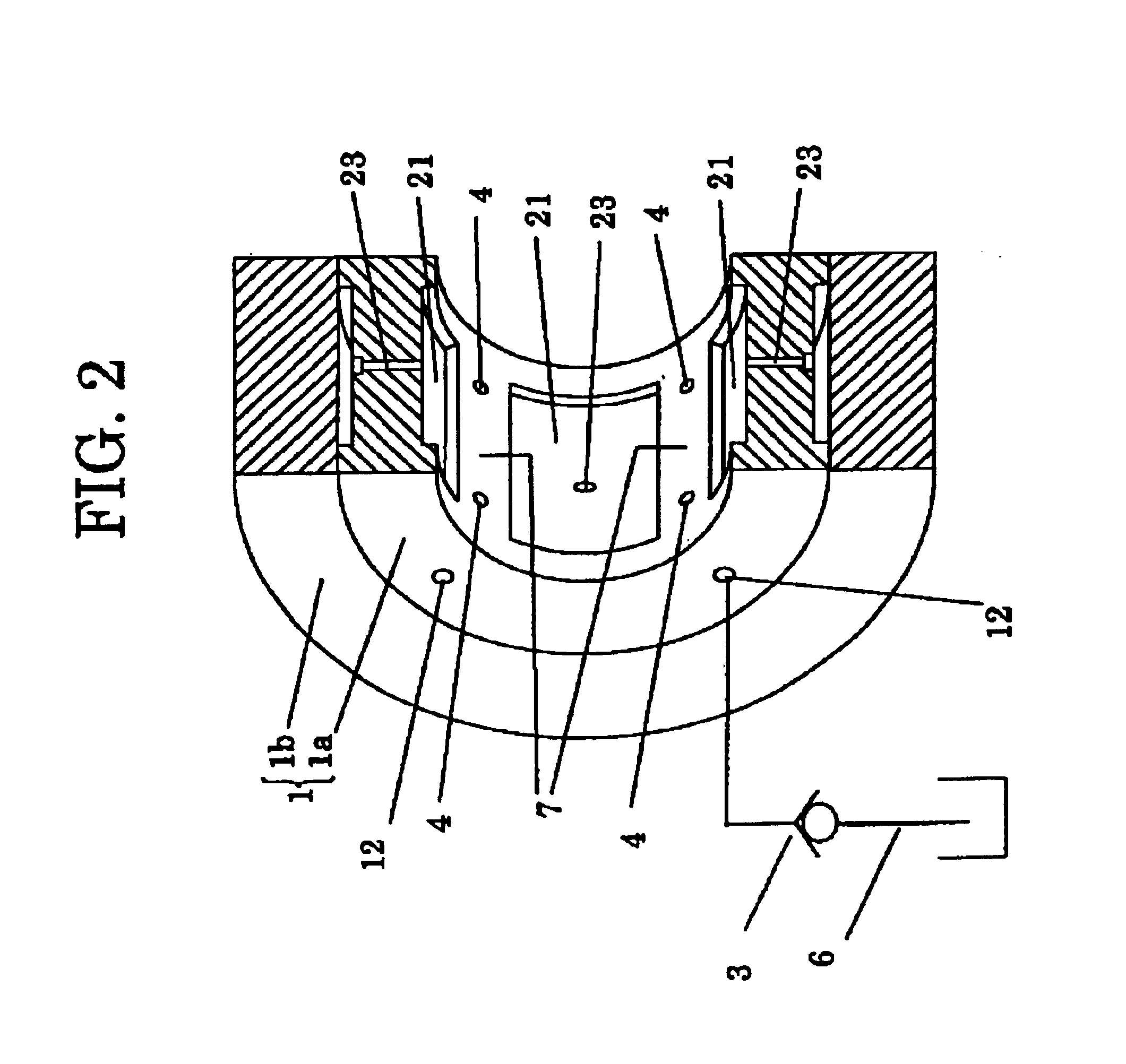

Hydrodynamic type porous oil-impregnated bearing

InactiveUS7059052B2Inhibit deteriorationGood effectMetal-working apparatusBearing componentsEngineeringBearing surface

The porous oil-impregnated bearing 1 comprises a bearing body 1a made of a porous material, and oil retained in the pores of the bearing body 1a by impregnation with lubricating oil or lubricating grease. The inner peripheral surface of the bearing body 1a is formed with a bearing surface 1b opposed to an outer peripheral surface of a shaft to be supported, with a bearing clearance defined therebetween. The bearing surface 1b has a first region m1 in which a plurality of hydrodynamic pressure generating grooves 1c inclined in one direction with respect to the axial direction are circumferentially disposed, a second region m2 which is axially spaced from said first region m1 and in which a plurality of hydrodynamic pressure generating grooves 1c inclined in the other direction with respect to the axial direction are circumferentially disposed, and an annular smooth region n disposed between the first and second regions m1 and m2.

Owner:NTN CORP

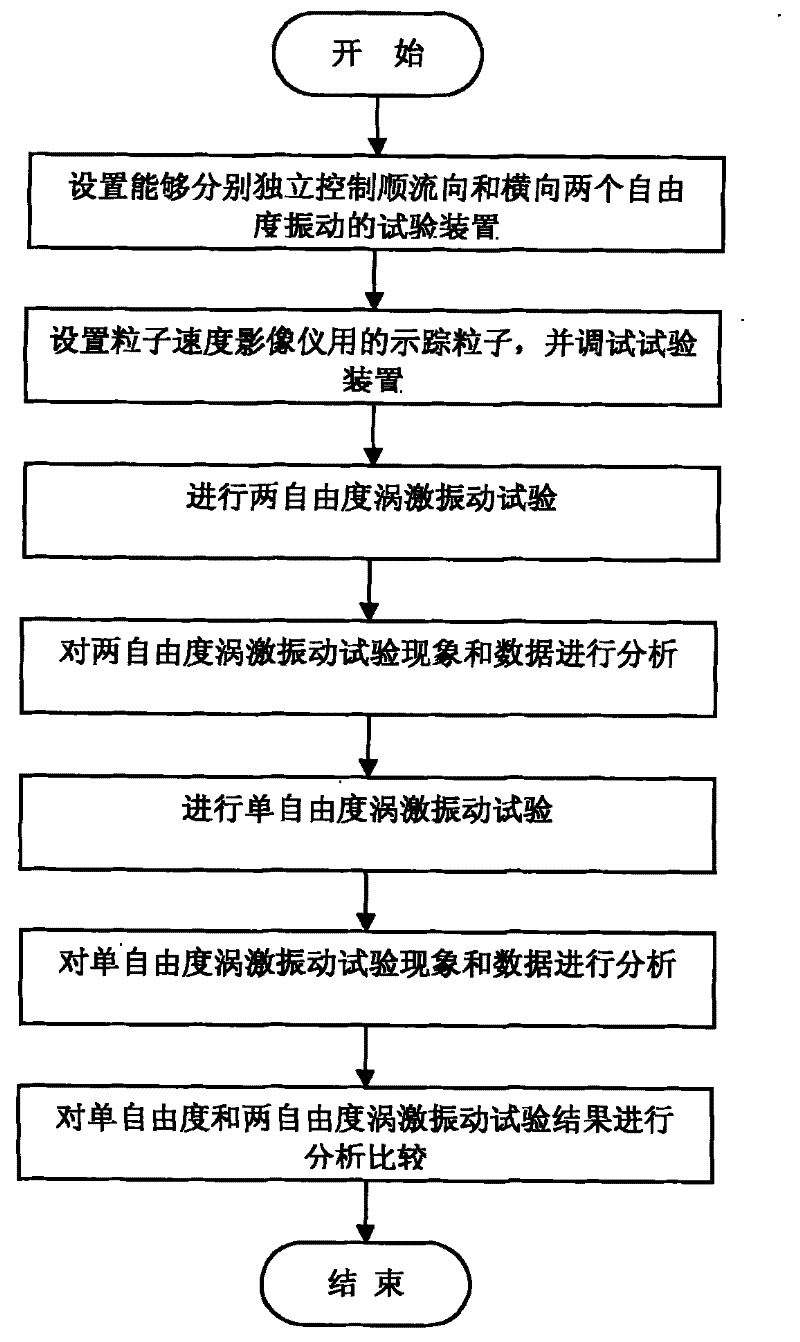

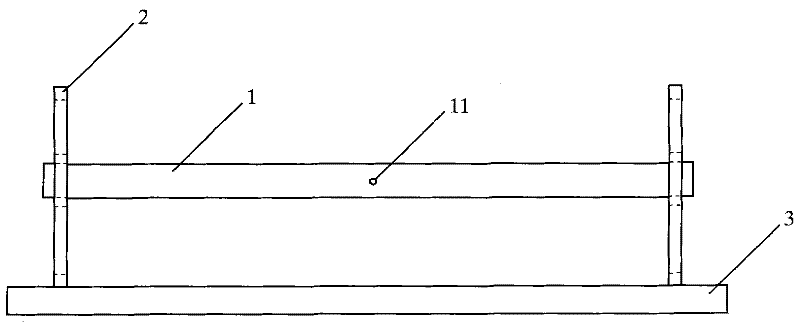

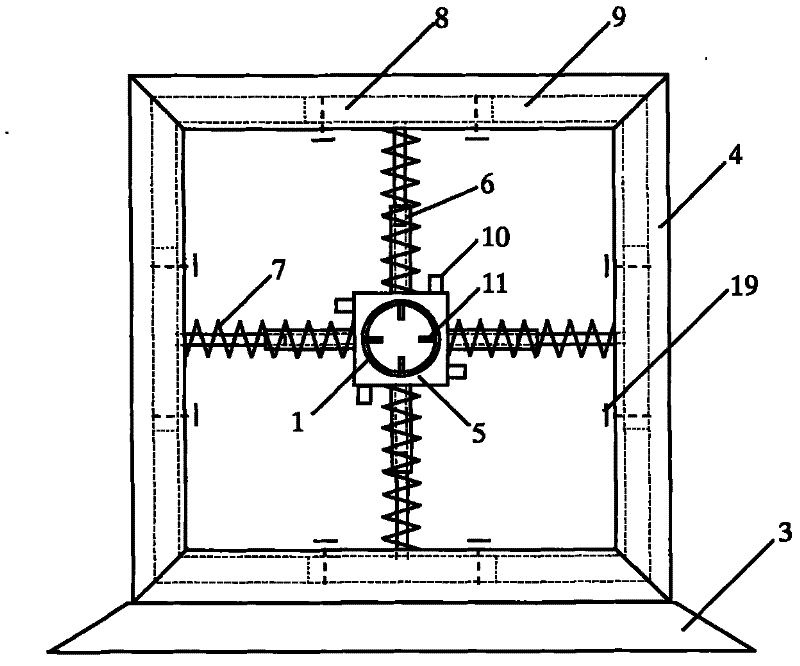

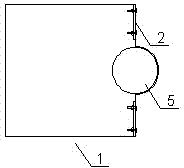

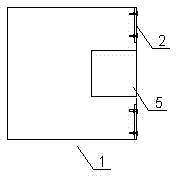

Testing method of vortex-induced vibration of cylinder

InactiveCN102252816ASolve the test technologySolve the vortex induced liftHydrodynamic testingVibration testingSingle degree of freedomMotion parameter

The invention relates to a testing method of vibration of a structure in a flow field, in particular to the testing method of vortex-induced vibration of a cylinder. In the method, a testing device which can independently control the two-degree-of-freedom vibration along the flow direction and the transverse direction respectively is utilized for performing two-degree-of-freedom vortex-induced vibration testing and single-degree-of-freedom vortex-induced vibration testing respectively, analyzing phenomena and data of the two-degree-of-freedom vortex-induced vibration testing and the single-degree-of-freedom vortex-induced vibration testing and comparing analysis results of the single-degree-of-freedom vortex-induced vibration testing and the two-degree-of-freedom vortex-induced vibration testing. Under the same testing conditions, the single-degree-of-freedom vortex-induced vibration testing along the flow direction or the transverse direction and the two-degree-of-freedom vortex-induced vibration testing along the flow direction or the transverse direction can be completed and synchronous measurement of hydrodynamic pressure, motion parameters (displacement, speed and acceleration) of a testing model and vortex discharge can be realized.

Owner:OCEAN UNIV OF CHINA

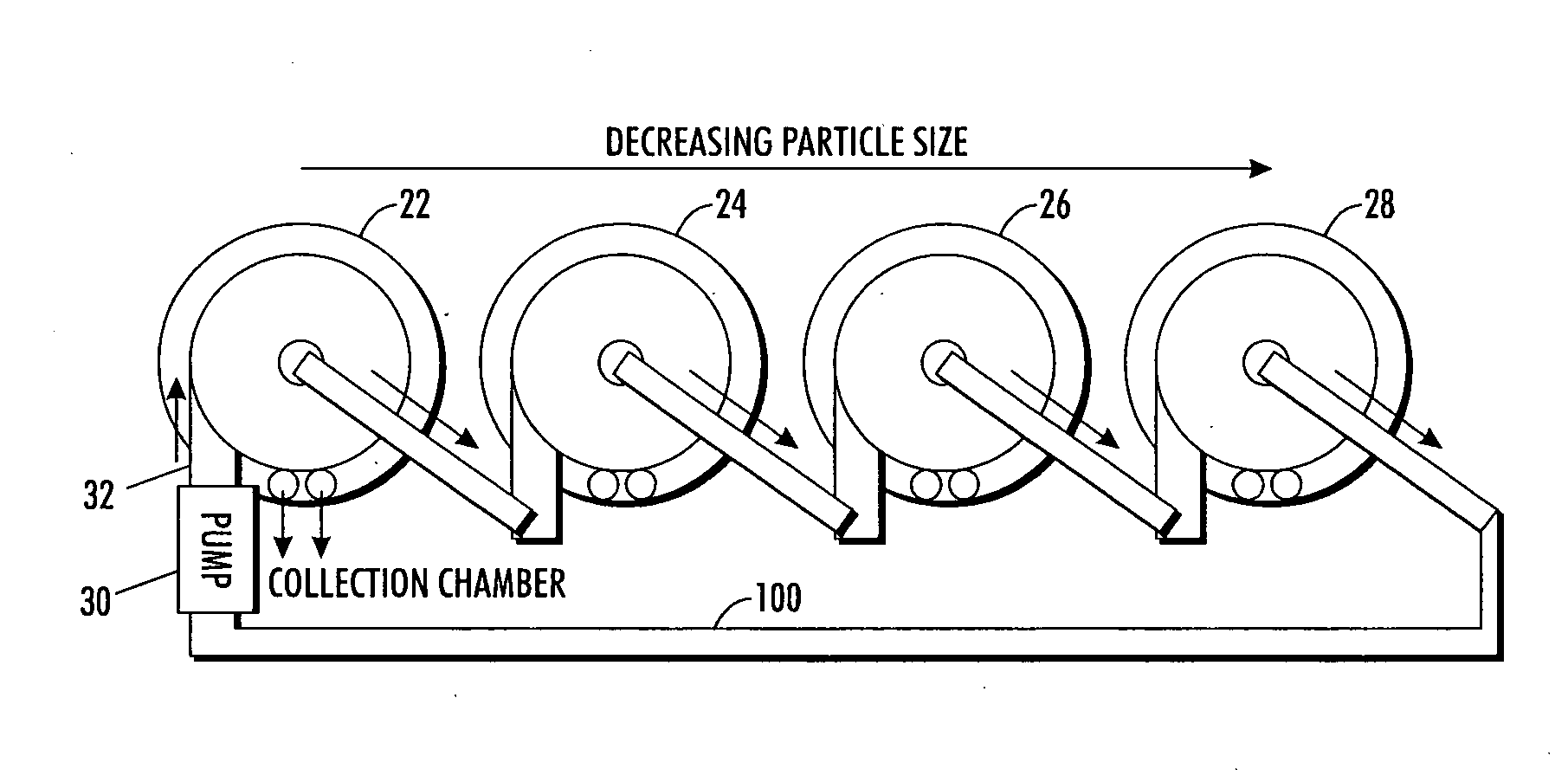

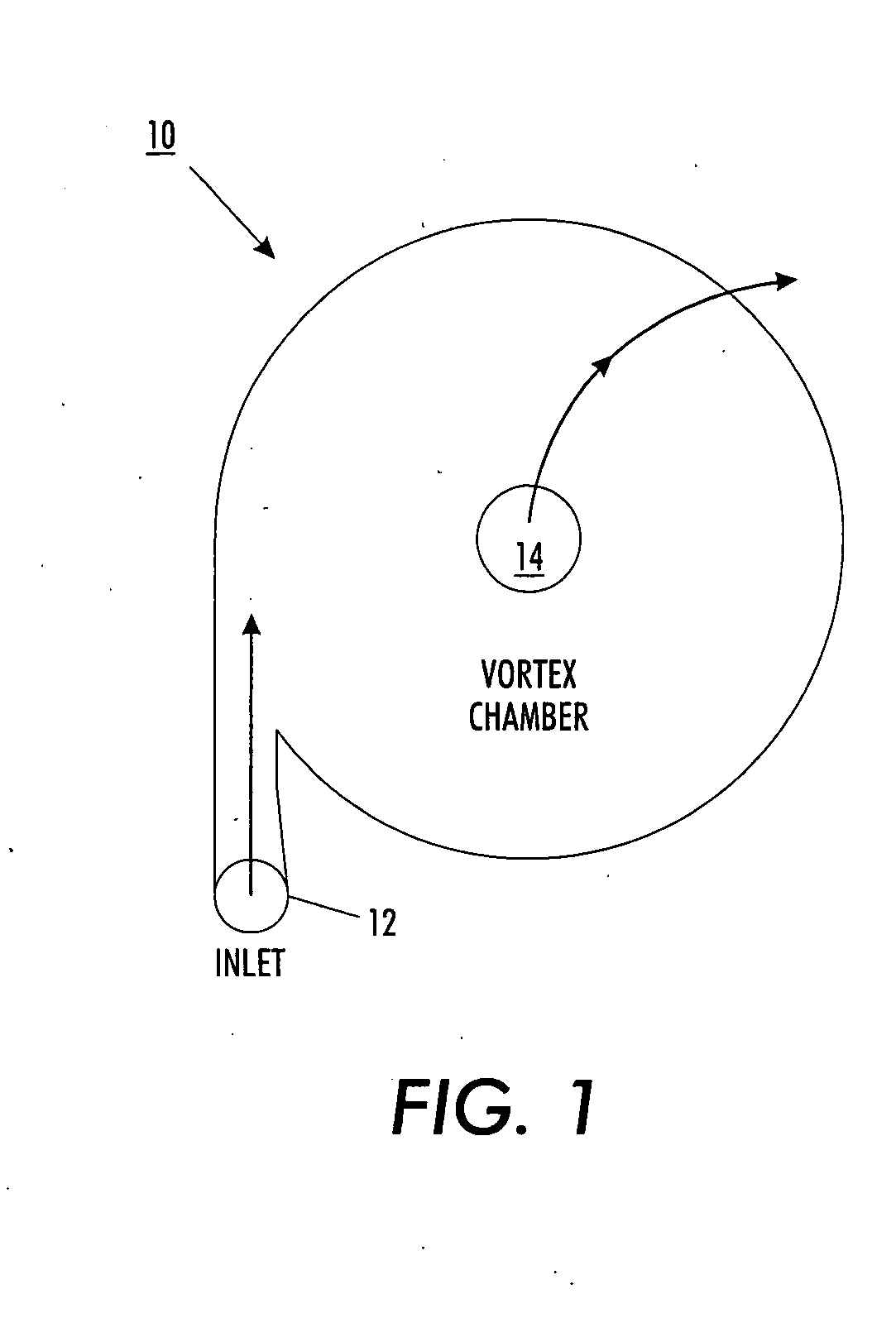

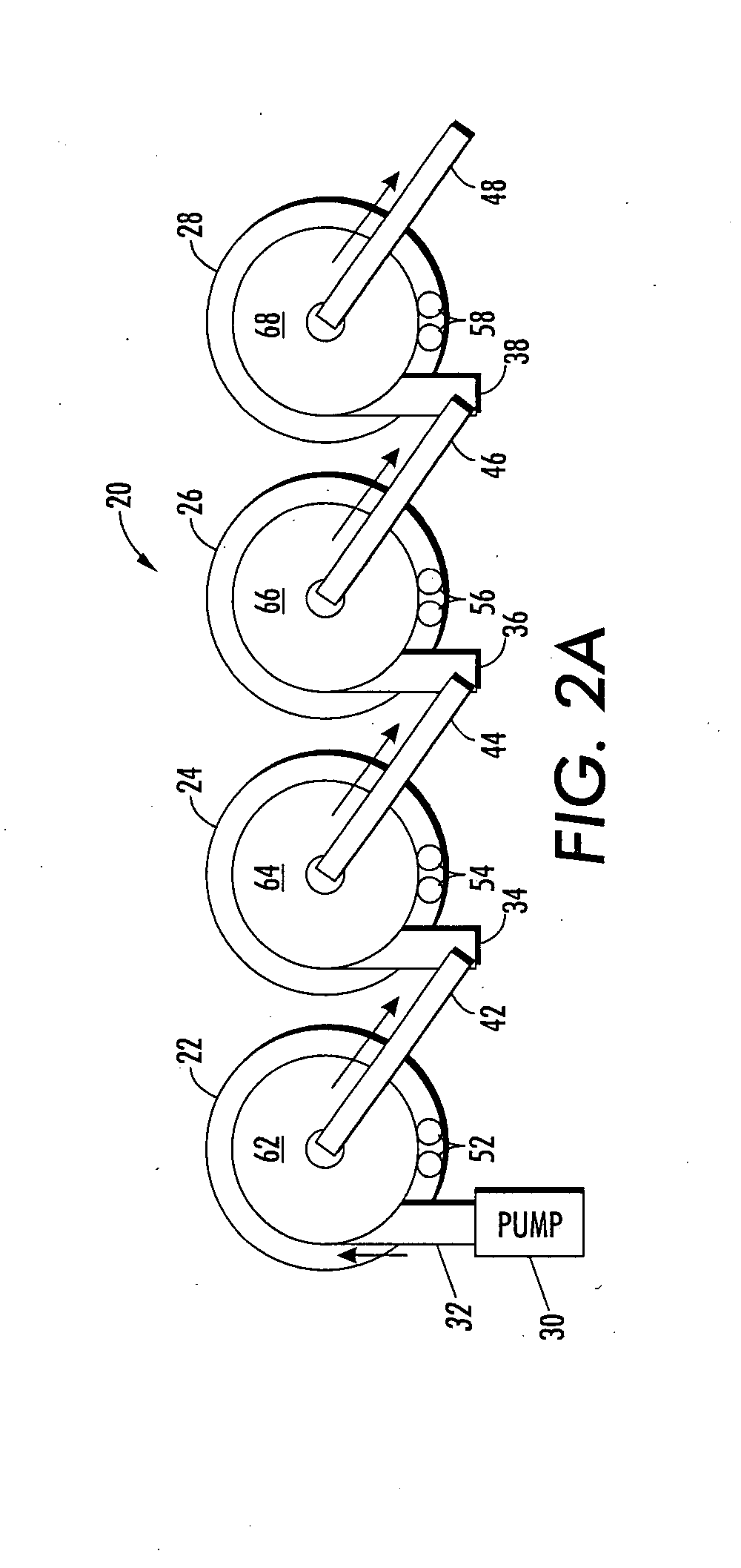

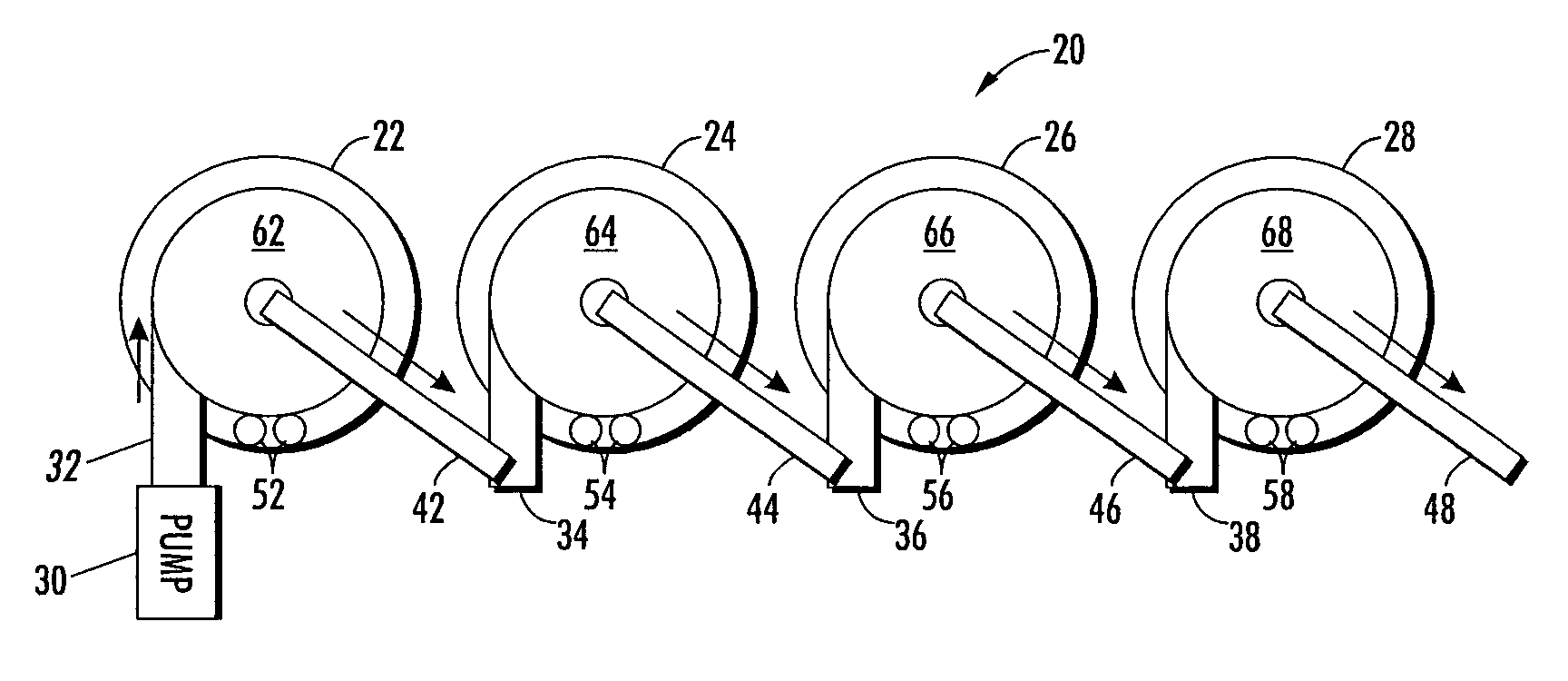

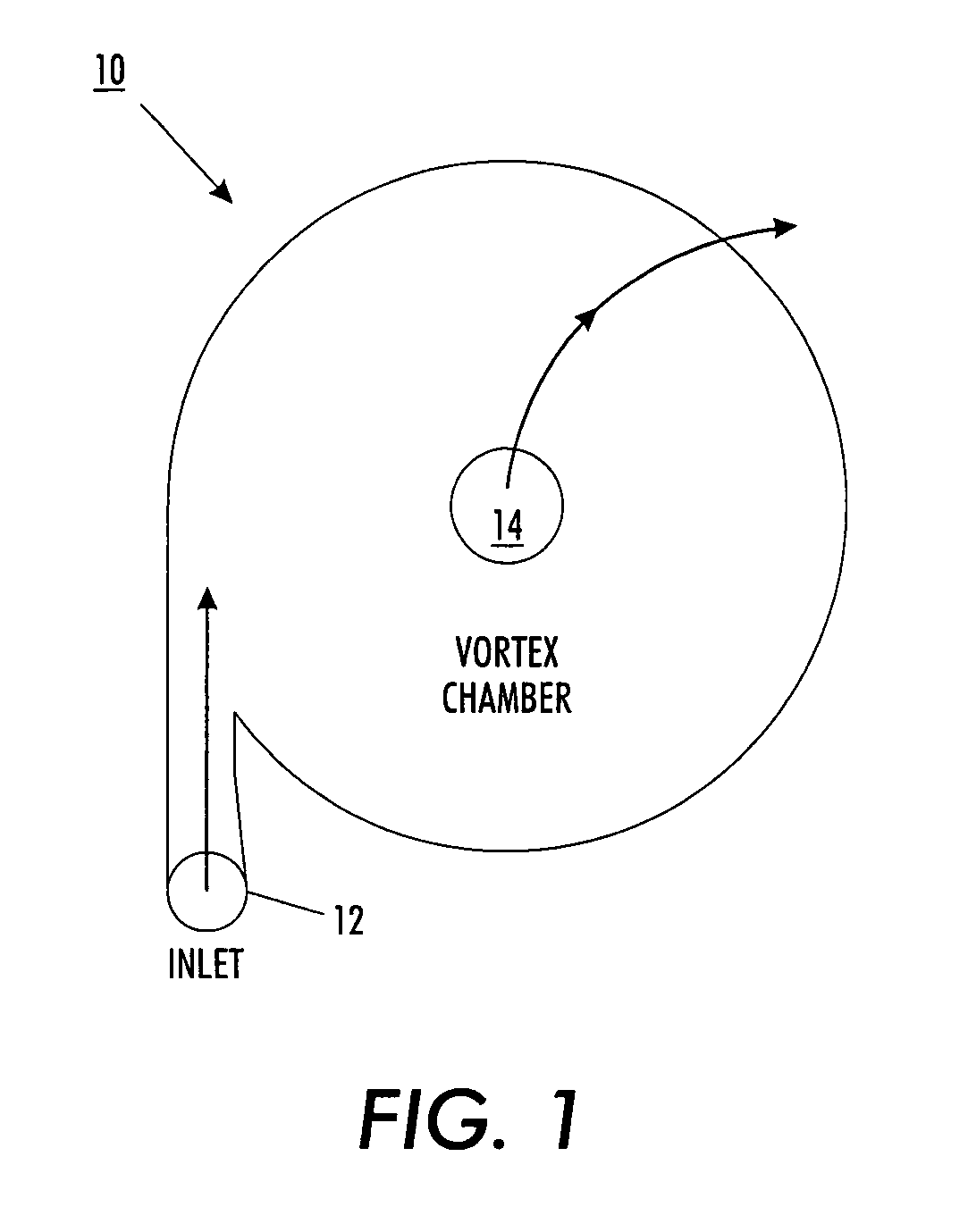

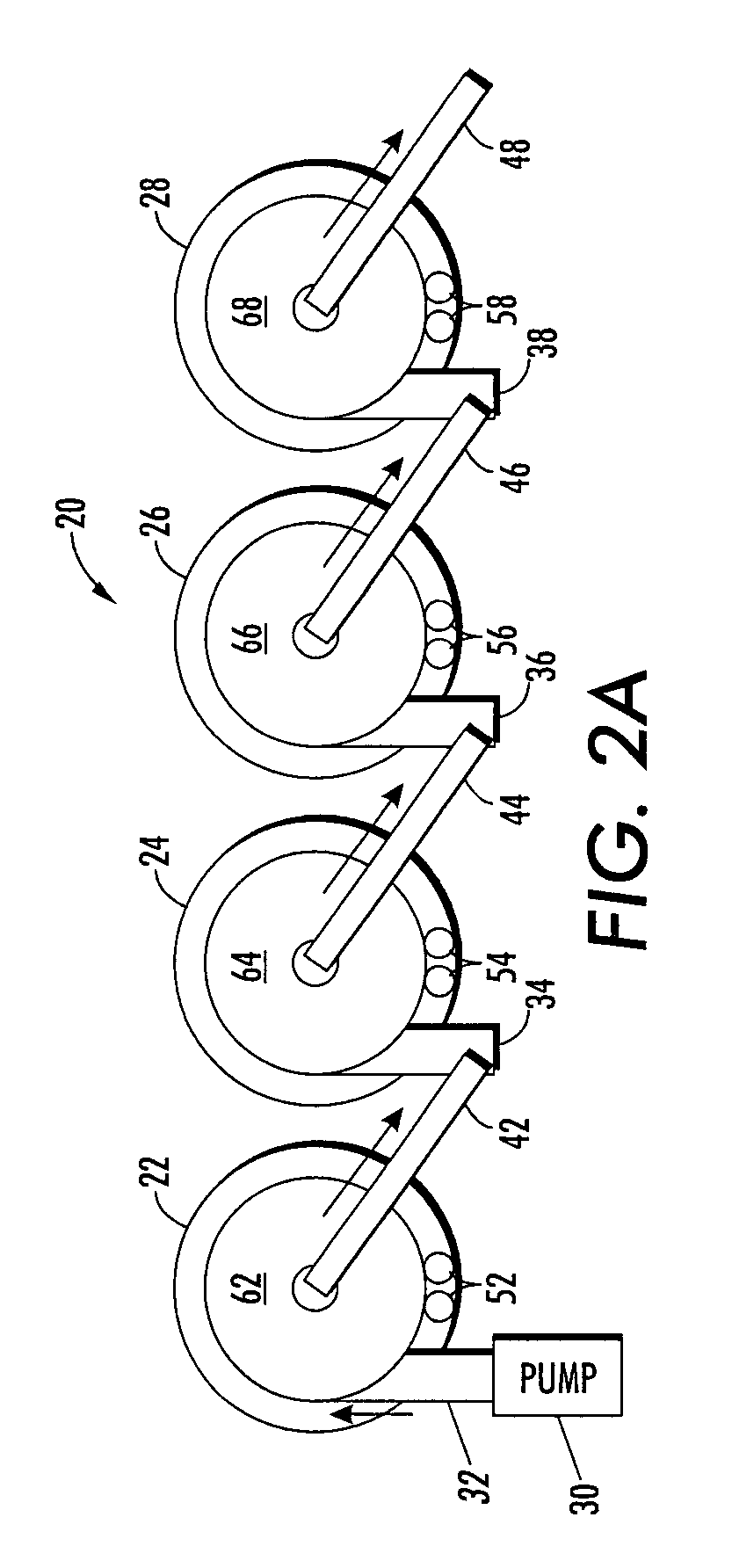

Vortex structure for high throughput continuous flow separation

InactiveUS20080230458A1Improve efficiencyHigh selectivityReversed direction vortexDispersed particle separationSuspended particlesEngineering

A system to facilitate separation and concentration of particles based on centrifugal force on suspended particles, including biological matter, which are made to flow in a vortex structure is provided. The centrifugal force urges larger particles to collect along outer portions of the vortex flow. Conversely, within a vortex structure, a radial hydrodynamic pressure drop is also amplified to urge smaller particles toward inner portions of the vortex flow. This force created by the pressure can reach magnitudes that encourage a sharp cut-off and improved resolution discrimination between particle sizes. Thus, separated streams of particles can be collected with both increased concentration and purification.

Owner:PALO ALTO RES CENT INC

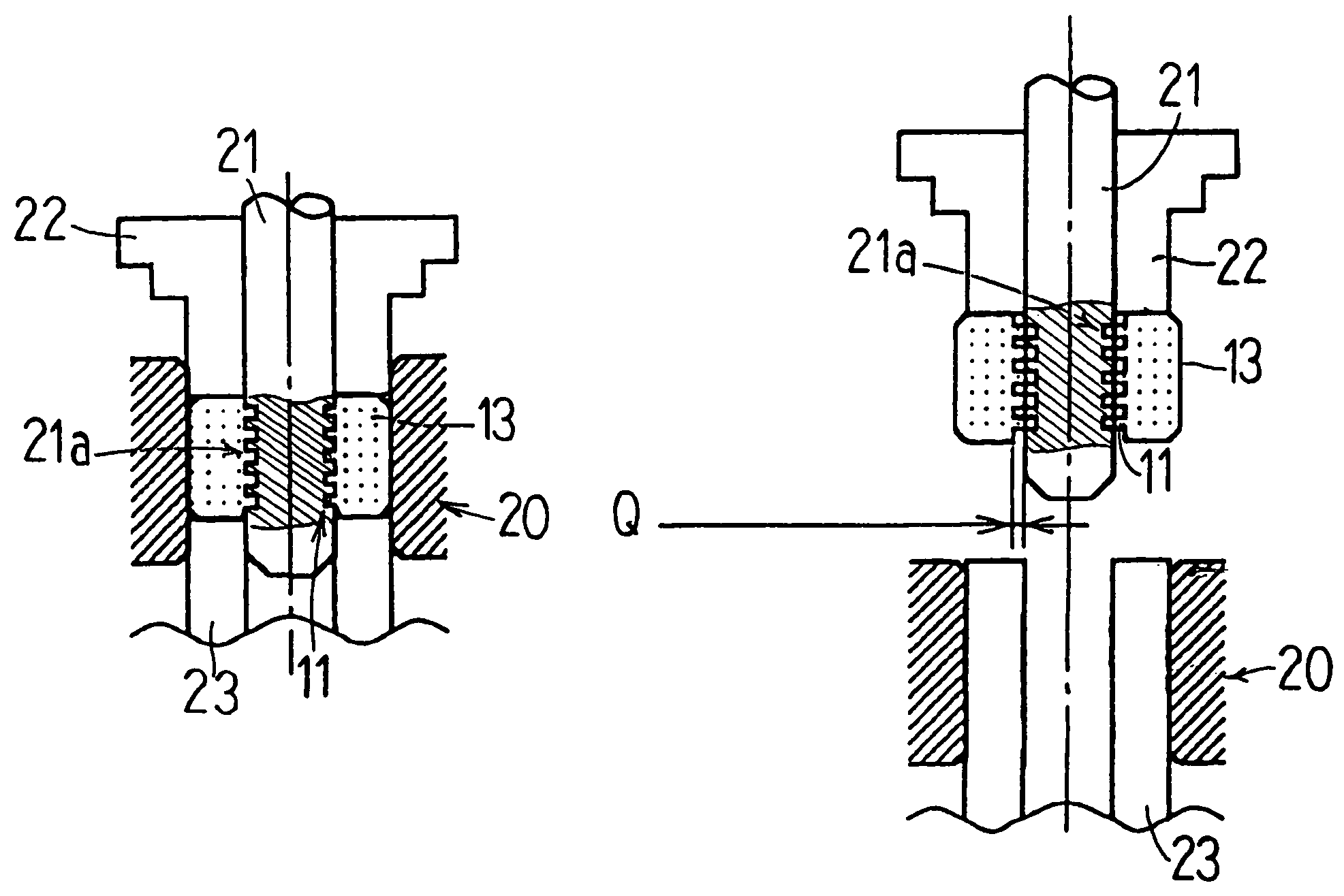

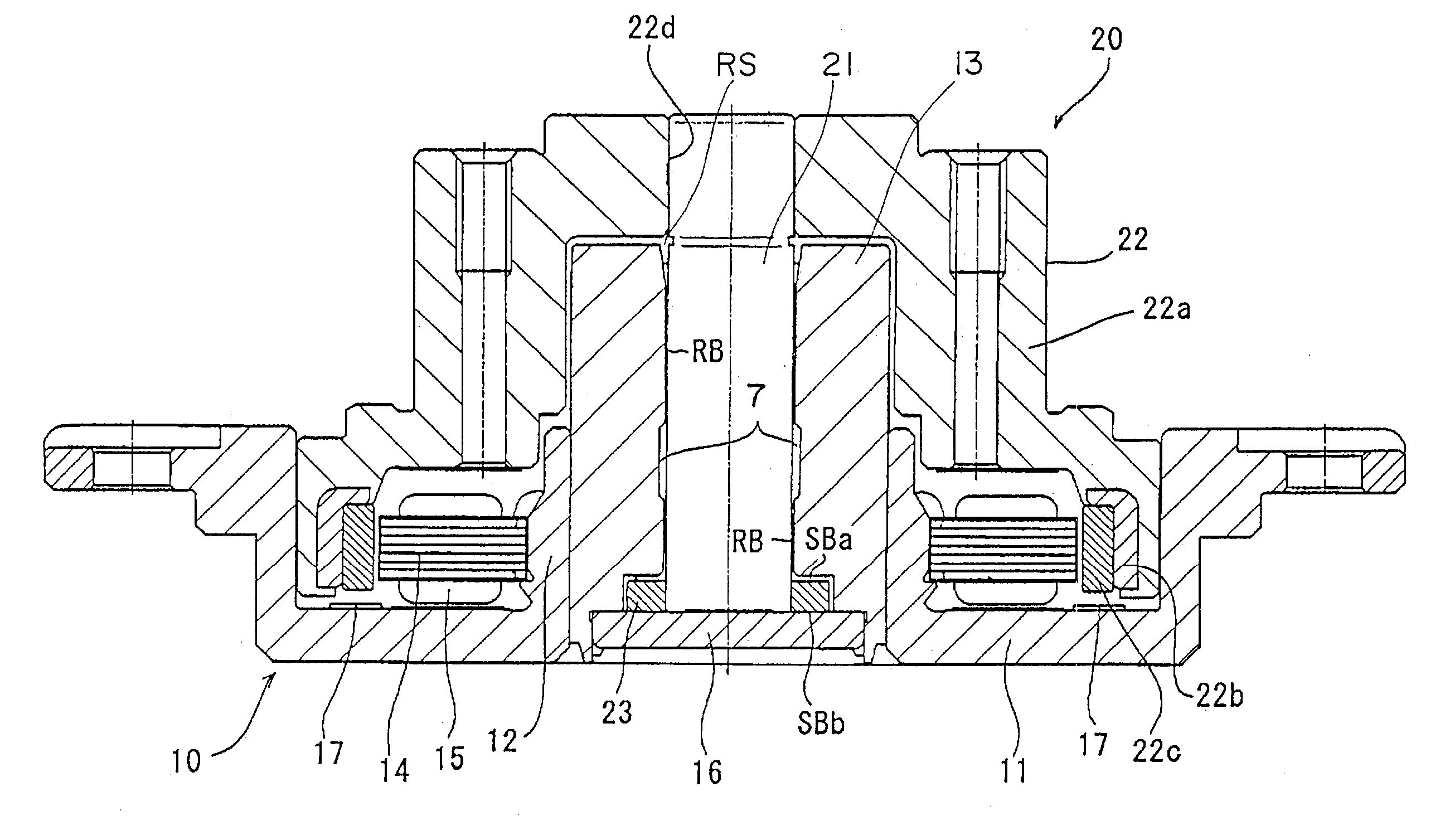

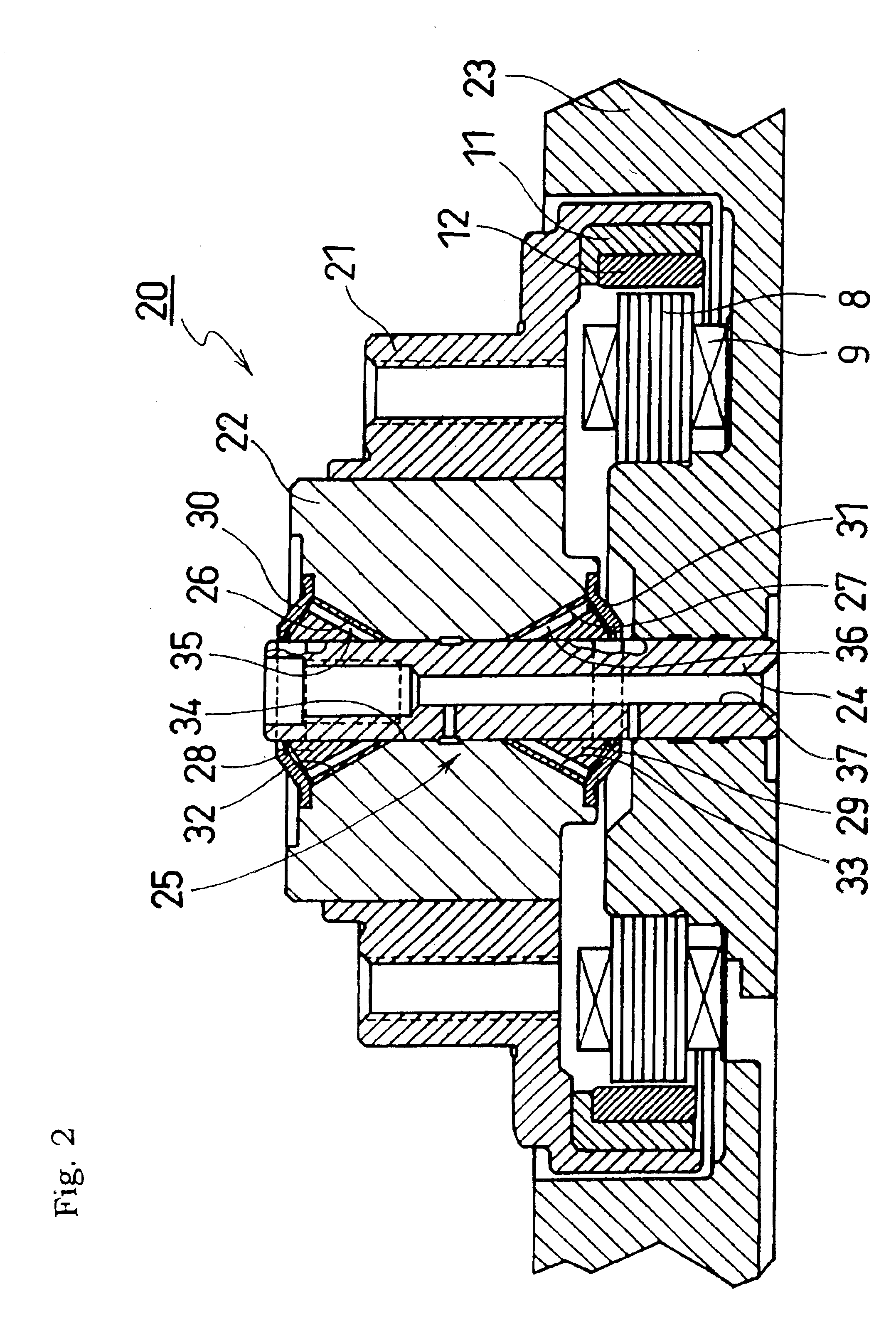

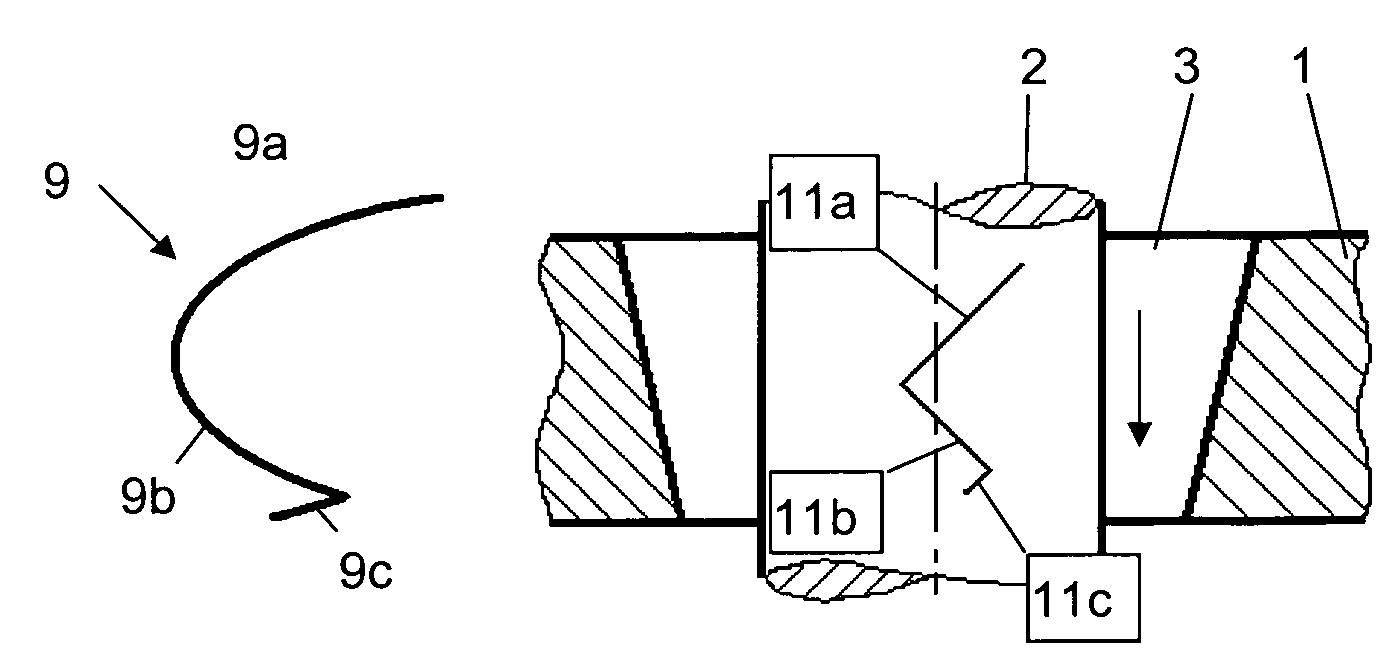

Hydrodynamic bearing device

InactiveUS20030185473A1Excellently preventing the lubricating fluidExtend your lifeShaftsRecord information storageEngineeringMechanical engineering

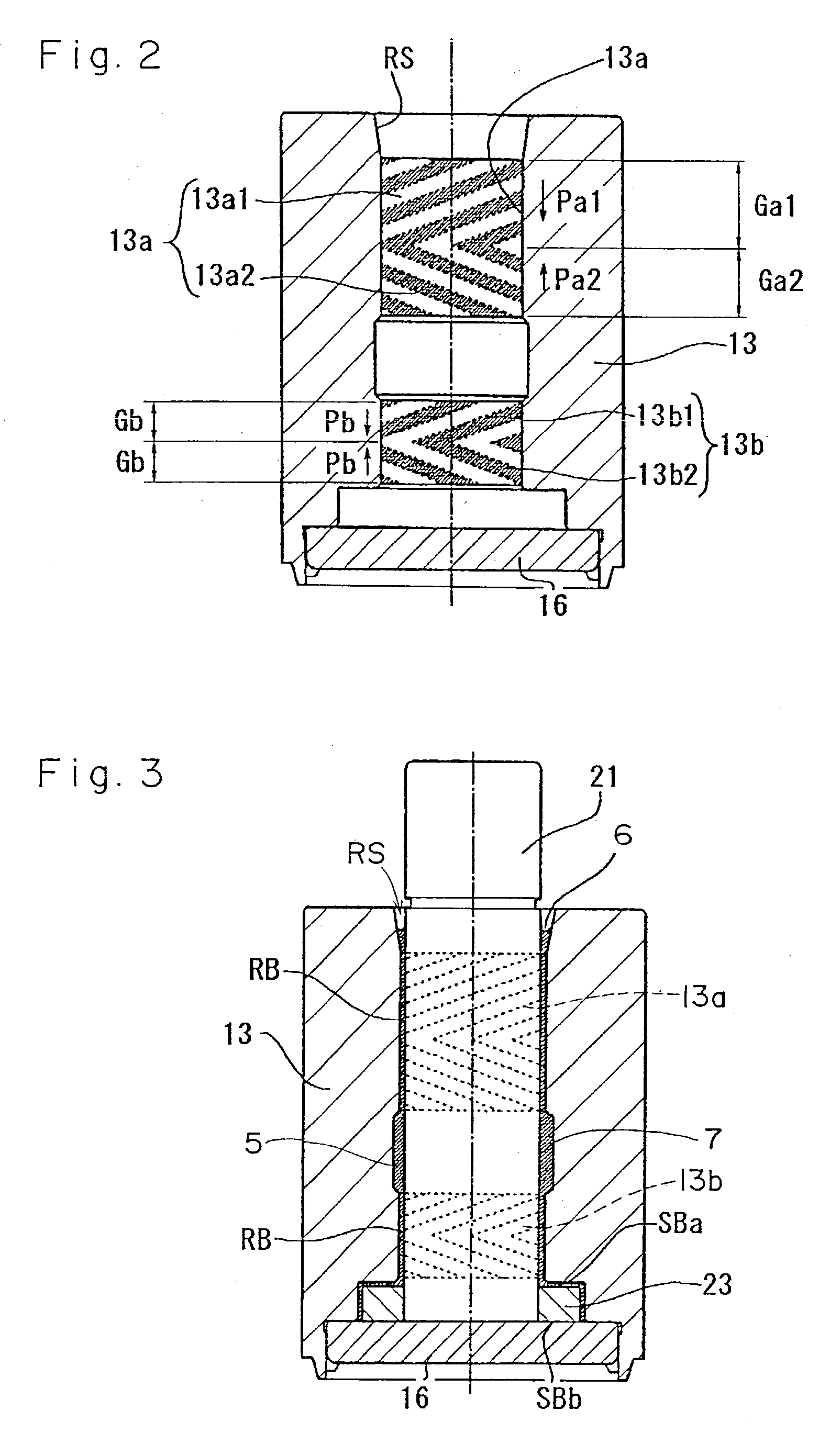

A hydrodynamic bearing device which supports a relative-rotation shaft or bearing by the hydrodynamic pressure of lubricating fluid which develops in a clearance between the bearing and the shaft, wherein leakage of the lubricating fluid to the outside of the bearing is satisfactorily prevented by a simple arrangement. A fluid pressing means applying to the lubricating fluid (5) an inward pressing force directed from the opening side of the bearing clearance toward the closed side, for example, a hydrodynamic pressure producing groove (13a) in which a hydrodynamic pressure (Pa1) having an inward vector component and a hydrodynamic pressure (Pa2) having an outward vector component are simultaneously produced, the hydrodynamic pressures being unbalanced in that the hydrodynamic pressure (Pa1) having an inward vector component is prevailing, has an inward pressing force imparting action which ensures that the lubricating fluid (5) in the bearing clearance is constantly pressed toward the closed side of the bearing clearance to hold that the gas-liquid interface (6) of the lubricating fluid (5) so that it is pushed inward. By setting the filling amount of the lubricating fluid (5) at a value with which the fluid pressing means is filled with the lubricating fluid (5) even upon occurrence of relative movement of the gas-liquid interface (6) toward the bearing clearance, which relative movement takes place upon relative upward movement of a thrust plate (16) or the like in the thrust direction, leakage of the lubricating fluid (5) through a seal portion (RS) is satisfactorily prevented.

Owner:SANKYO SEIKI MFG CO LTD +1

Fluid dynamic bearing having pressure-generating surface patterns

Owner:MINEBEAMITSUMI INC

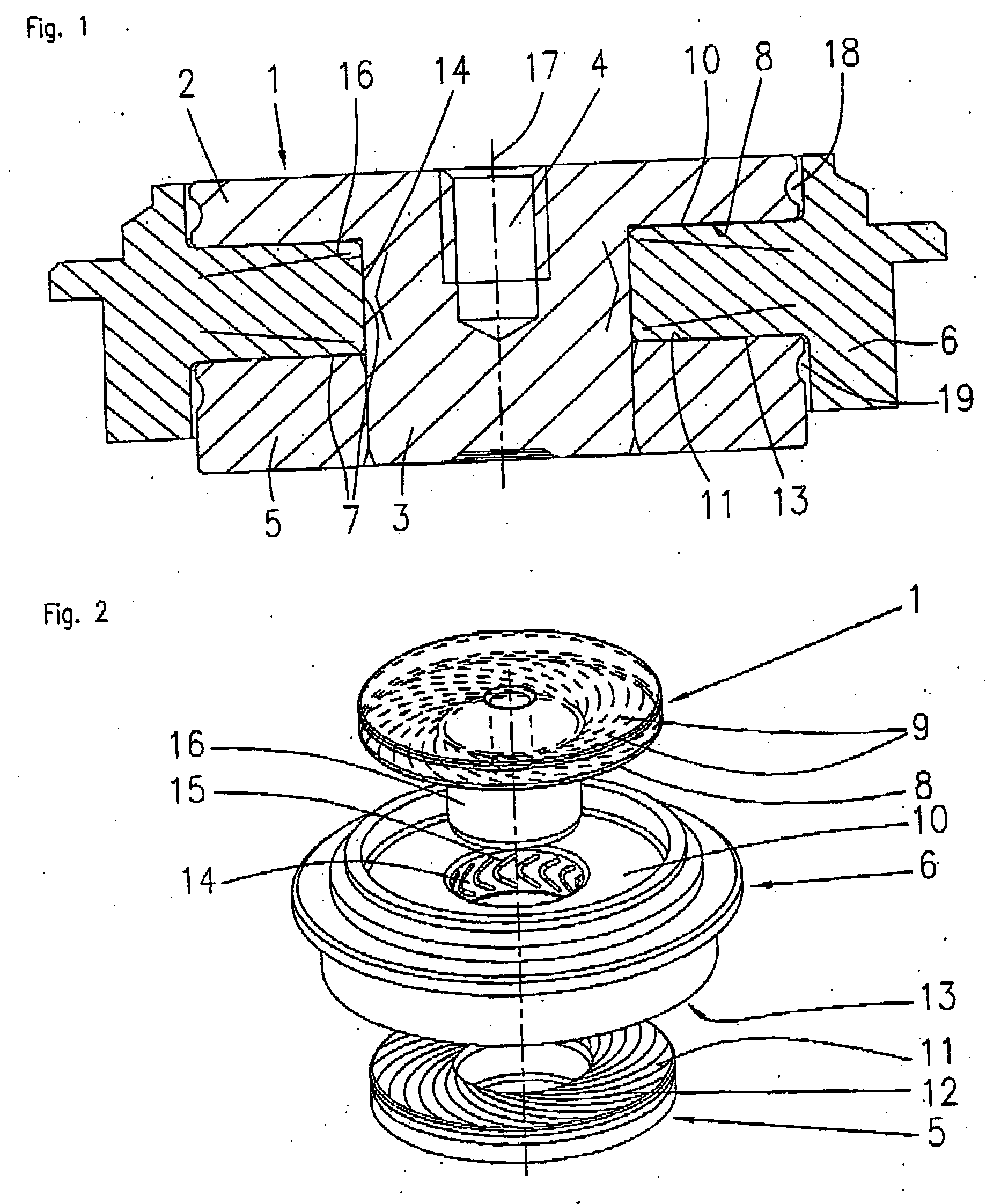

Methods of Manufacturing Fluid-Dynamic-Pressure Bearing and Spindle Motor Incorporating the Bearing, and Spindle Motor and Recording-Disk Drive Incorporating the Bearing

ActiveUS20050274018A1High bonding strengthImprove sealingMetal-working apparatusRecord information storageAdhesiveCapillaria obsignata

In spindle motors journaled on fluid-dynamic-pressure bearings, especially in such spindle motors employed in recording-disk drives in implementations that subject the drives to vibration and shock, sealing performance of a capillary seal formed between motor rotor-side and stator-side bearing surfaces, cohesiveness of oil-repellant on rotor-side / stator-side dry-area surfaces adjoining the capillary seal section, and motor inter-component adhesive strength are improved. The capillary-seal-constituting rotor-side / stator-side surface(s) are exposed to a plasma or to ultraviolet rays under predetermined conditions to improve the wettability of the surface(s) for the bearing fluid. The dry-area surface(s) are similarly irradiated so as to improve their wettability for the oil-repellant. Adhesively bonded component surfaces are likewise irradiated so as to improve their wettability for the adhesive, enhancing adhesive strength. Exposed surfaces may be constituted of a synthetic resin to enhance their wettability further, or may be made of metal, to yield a cleaning efficacy from the plasma / UV exposure.

Owner:NIPPON DENSAN CORP

Vortex structure for high throughput continuous flow separation

InactiveUS8875903B2Improve efficiencyHigh selectivityReversed direction vortexDispersed particle separationSuspended particlesContinuous flow

A system to facilitate separation and concentration of particles based on centrifugal force on suspended particles, including biological matter, which are made to flow in a vortex structure is provided. The centrifugal force urges larger particles to collect along outer portions of the vortex flow. Conversely, within a vortex structure, a radial hydrodynamic pressure drop is also amplified to urge smaller particles toward inner portions of the vortex flow. This force created by the pressure can reach magnitudes that encourage a sharp cut-off and improved resolution discrimination between particle sizes. Thus, separated streams of particles can be collected with both increased concentration and purification.

Owner:PALO ALTO RES CENT INC

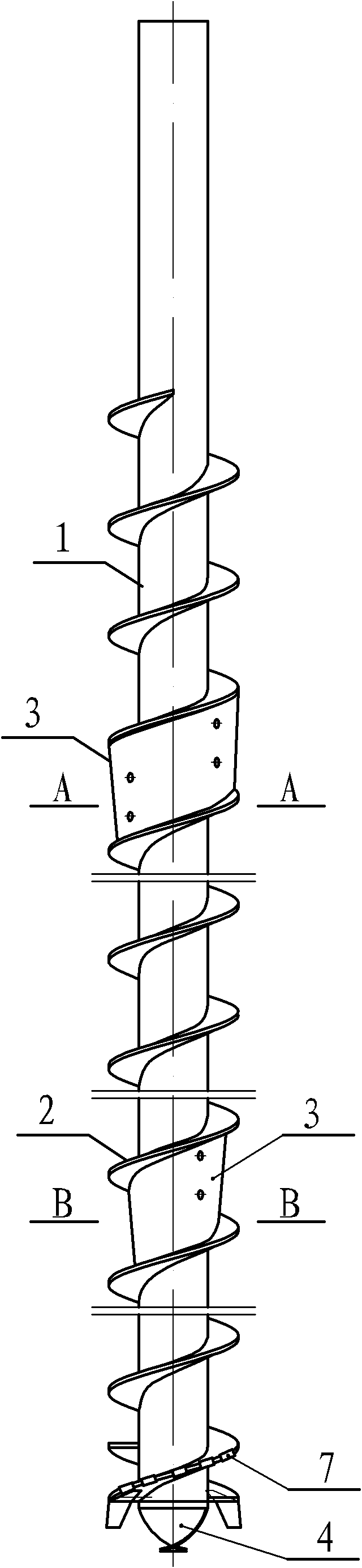

Adjustable multiple coil extruding and expanding drilling tool

ActiveCN101812976AStrong penetrating pore forming abilityWide formation adaptabilityDrilling rodsDrilling casingsHelical lineHelical blade

The invention relates to an adjustable multiple coil extruding and expanding drilling tool, comprising a hollow connecting rod, the lower part of the lateral wall of the connecting rod is provided with a helical blade, the bottom end of the connecting rod is provided with a drill, the connecting rod is coaxially connected with a plurality of helical extruding expanding bodies, the helical extruding expanding body is arranged between the helical blades, the margin of the cross section of each helical extruding expanding body is helical line, maximum outer diameter and minimum outer diameter ofeach helical extruding expanding body are respectively constant or increased from bottom to top, and the maximum outer diameter of each helical extruding expanding body is equal to or less than the outer diameter of the helical blade. The invention aims at providing an adjustable multiple coil extruding and expanding drilling tool which can penetrate thick hard clay or dense sand soil layer, avoid collapse when drilling into finished hole in high ground eater level and high hydrodynamic pressure stratum and can implement complete extruding soil or partial extruding soil type cast-in-place pile through multiple stage extruding and expanding at different depths by freely adjusting the position of multi-stage extruding expanding body according to longitudinal distribution of stratum.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

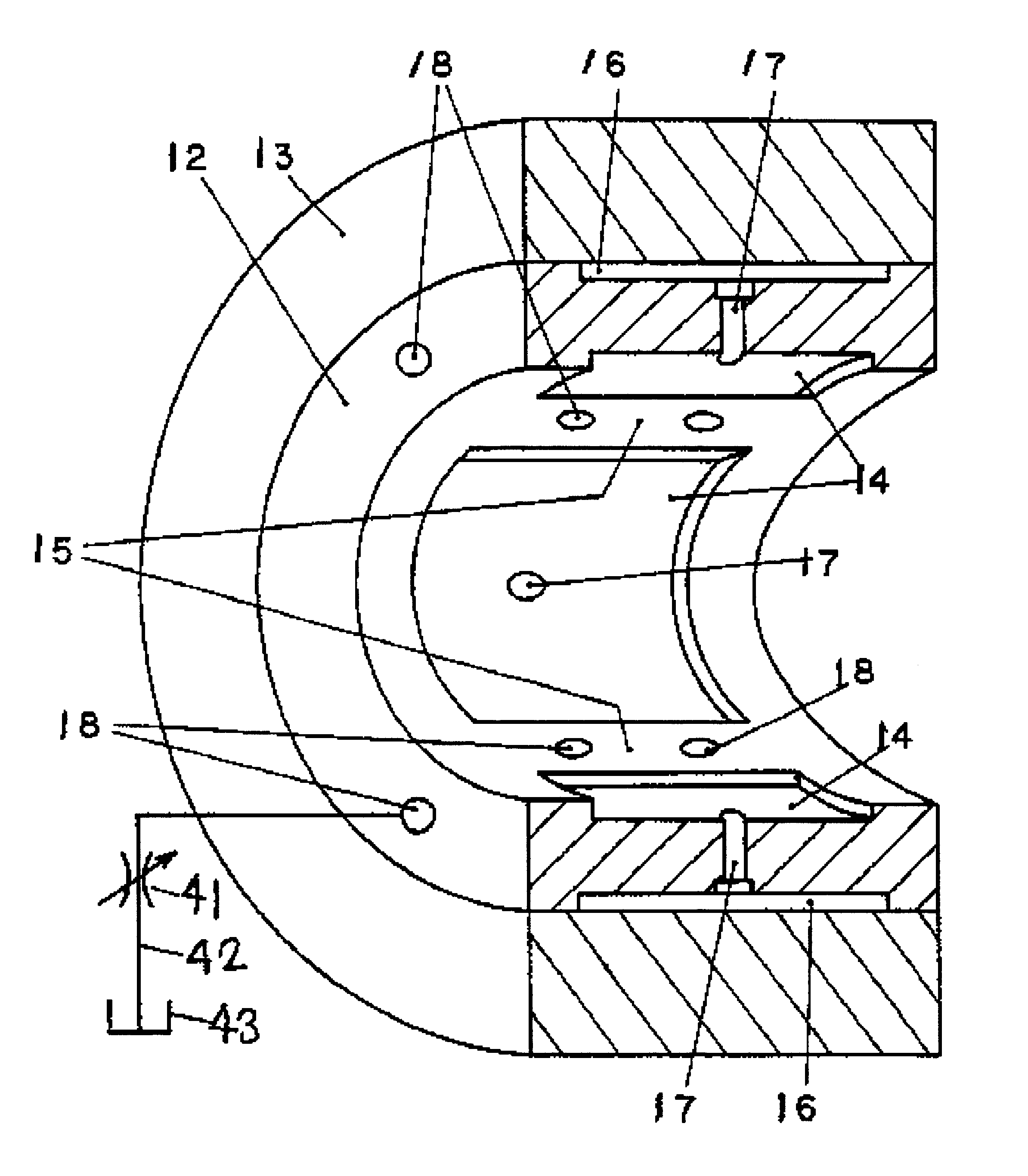

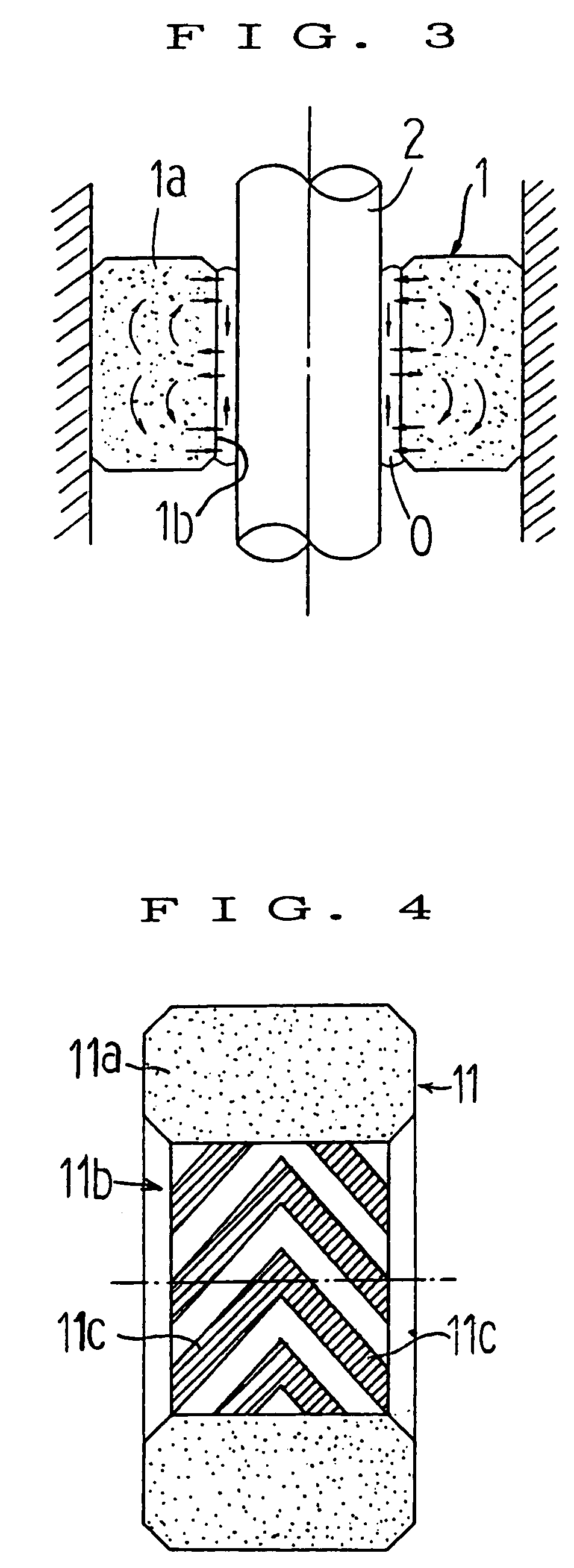

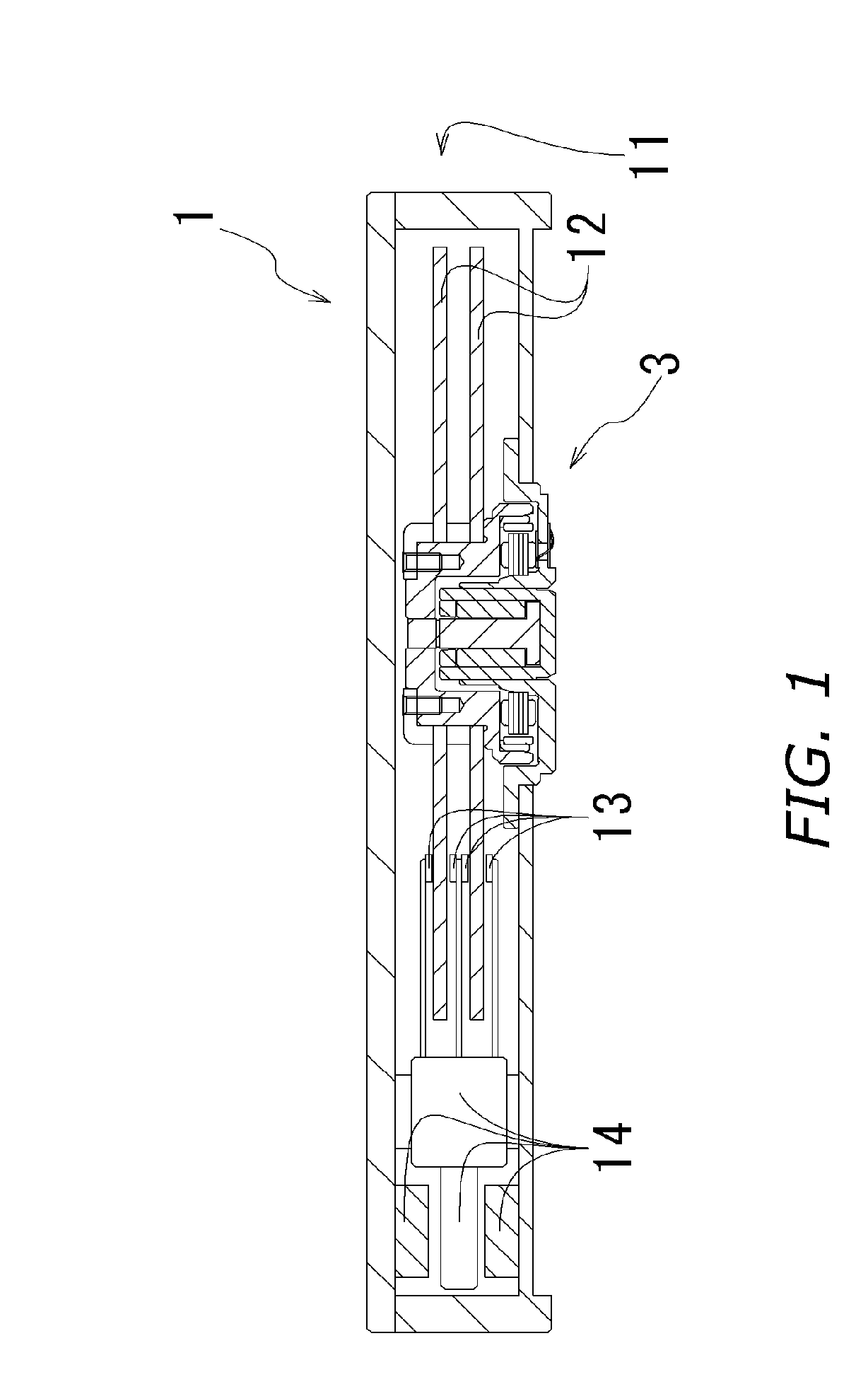

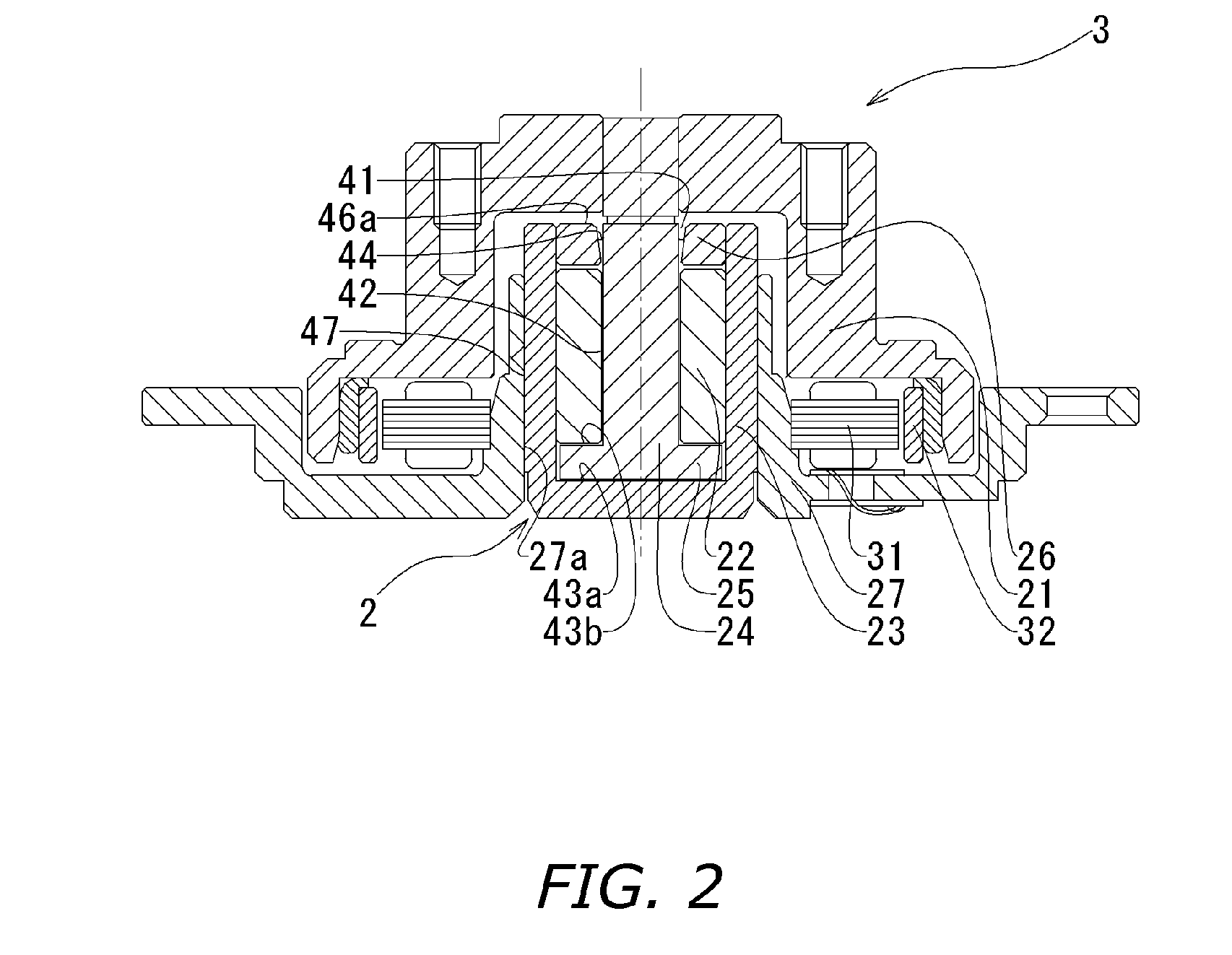

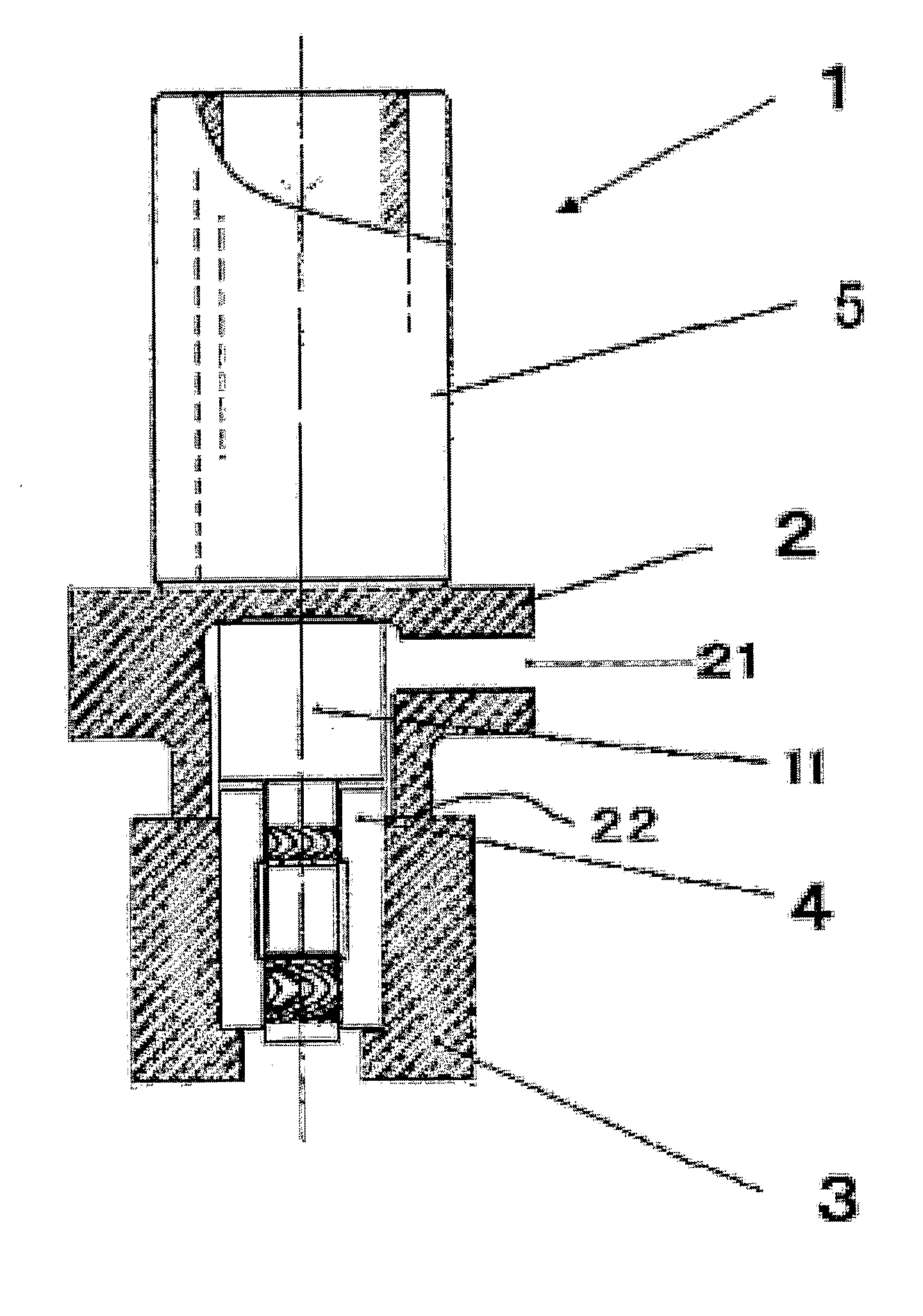

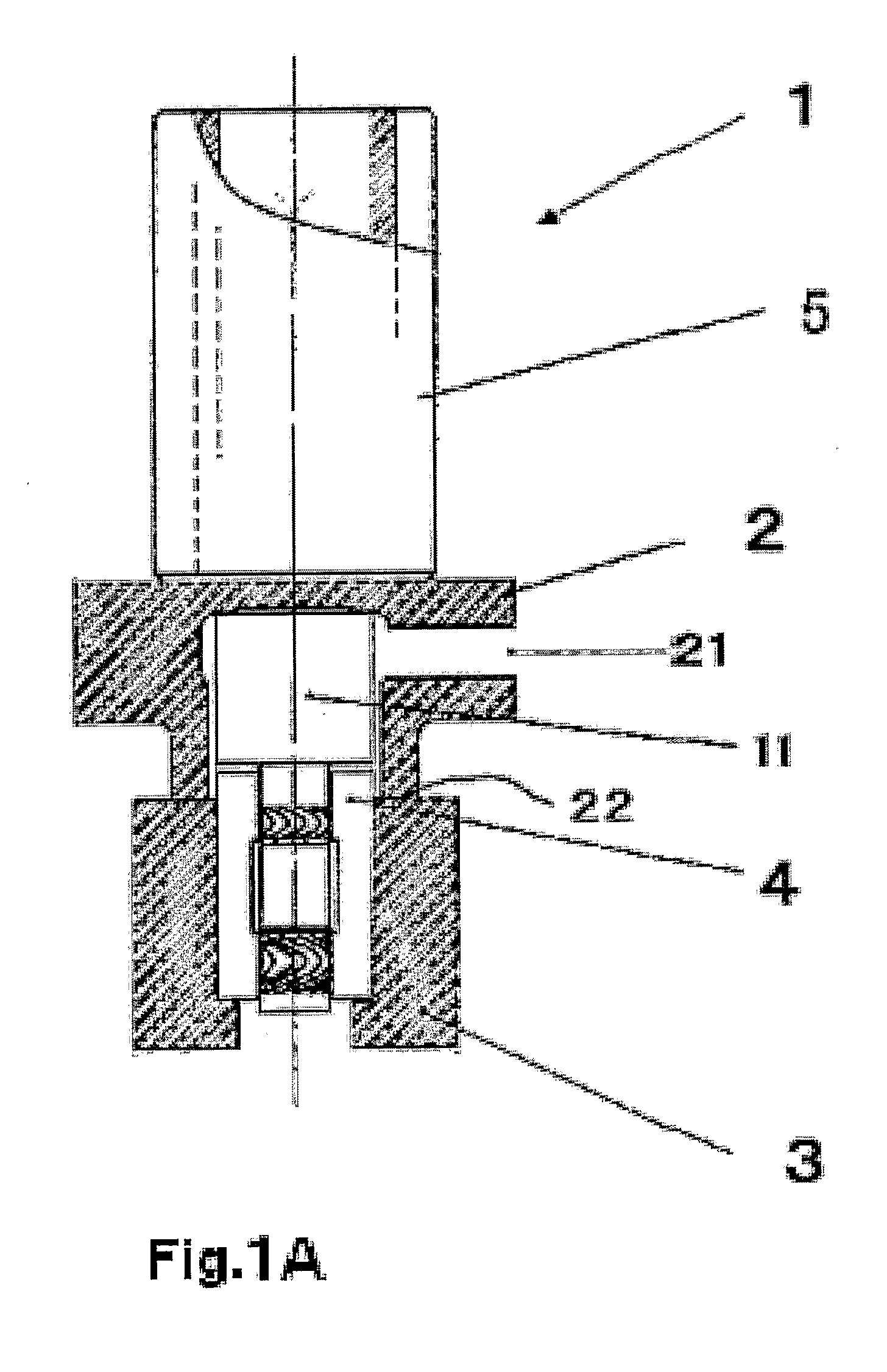

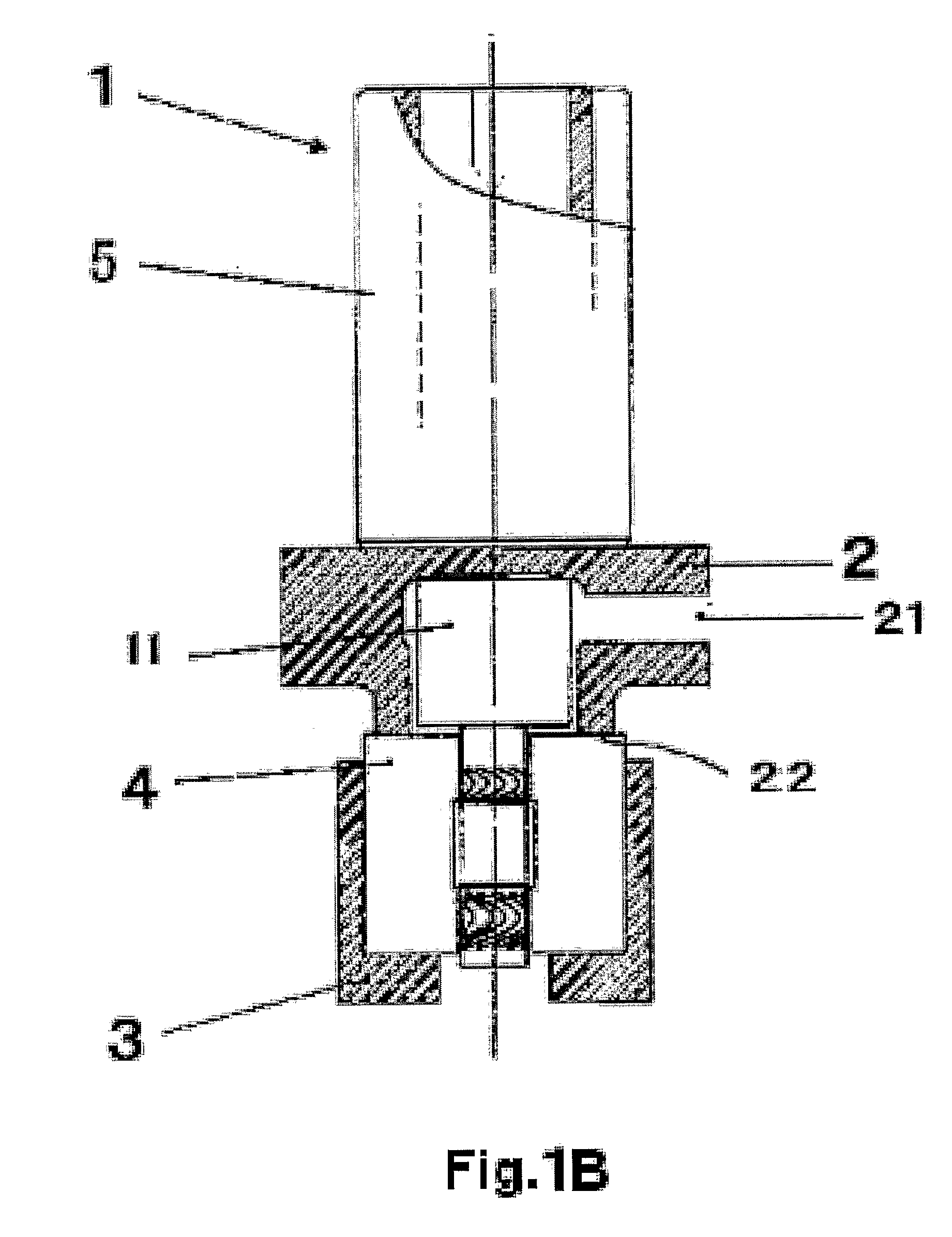

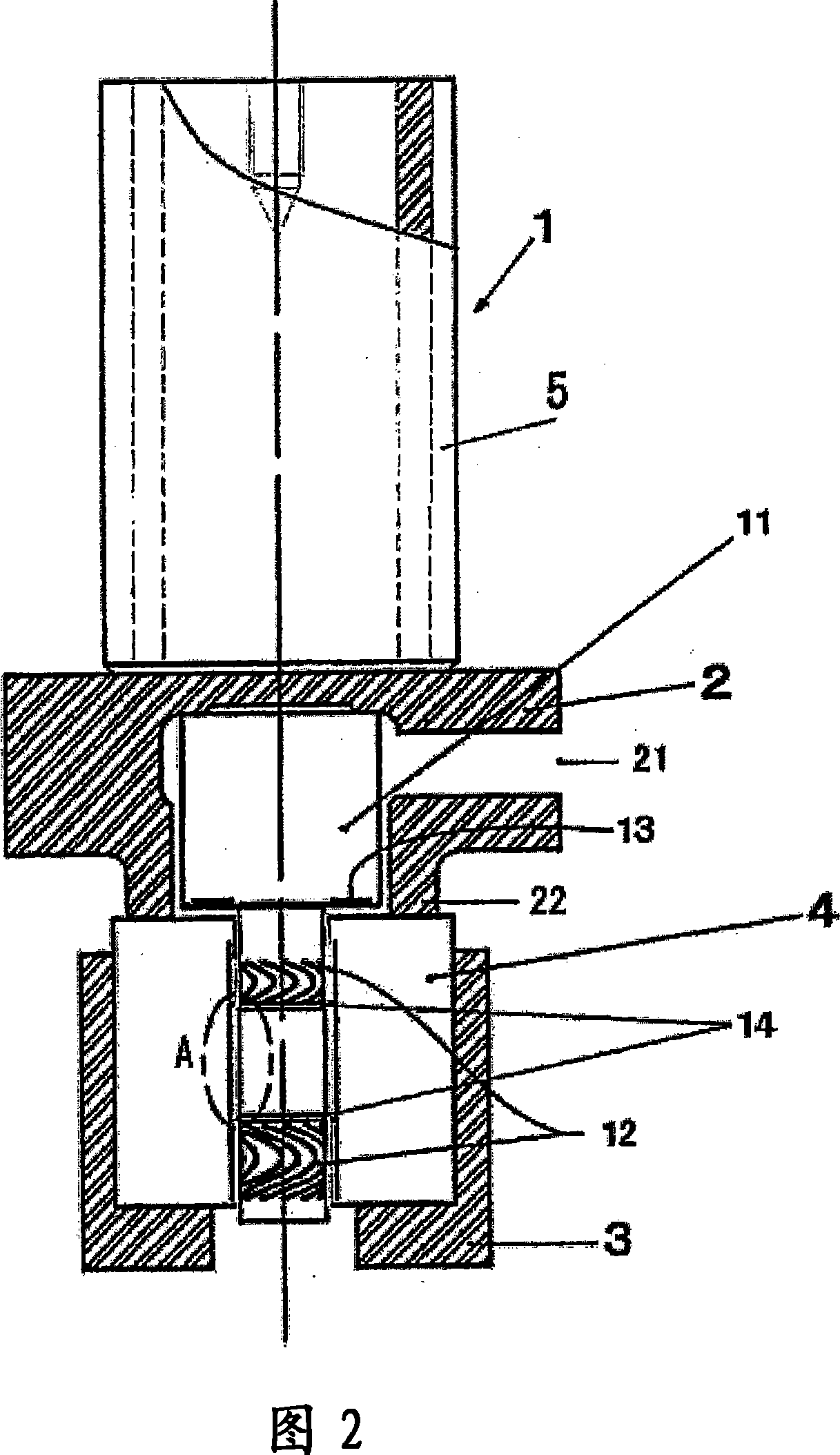

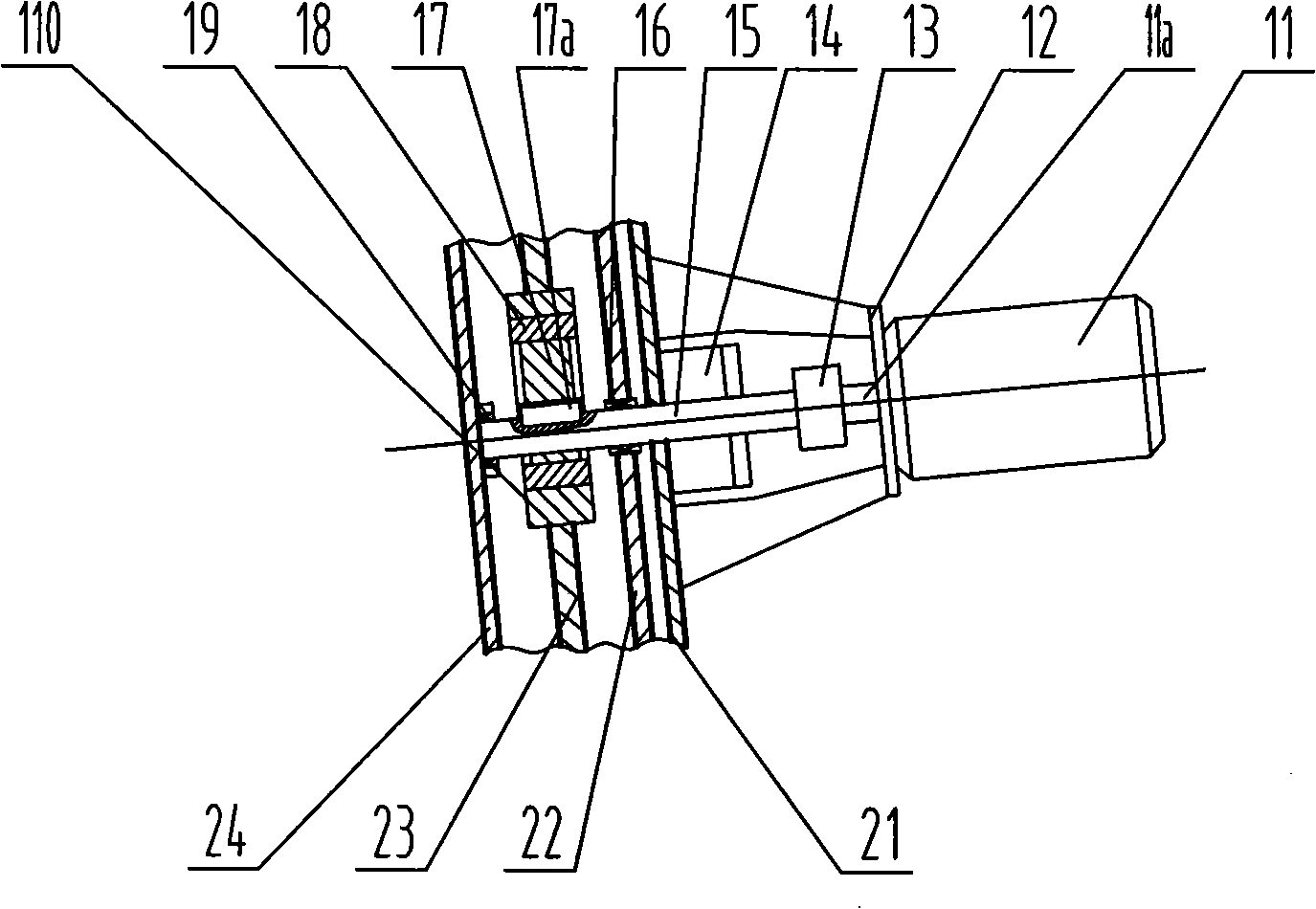

Electrochemical Machining Tool and Method for Machining a Product Using the Same

InactiveUS20070246372A1Low costMaintaining and improving precisionMachining electrodesElectrolysis componentsHard disc driveElectric machinery

An electrochemical machining tool (1) for electrochemical machining includes an electrode body (11). The electrochemical machining tool (1) and associated method can conduct simultaneous electrochemical machining of at least two of a radial dynamic pressure generating groove (43), an axial dynamic pressure generating groove (44), and a removal of a burr (42) associated with an oil pool (41). Electrochemical machining is performed with groove machining electrodes (12, 13) and deburring electrodes (14). A sleeve (4) machined using the electrochemical machining tool (1) and associated method has the radial dynamic pressure generating groove (43), the axial dynamic pressure generating groove (44), and the deburred oil pool (41). The sleeve (4) can be used in a hydrodynamic pressure bearing for use in a spindle motor of a hard disk drive.

Owner:MINEBEA CO LTD

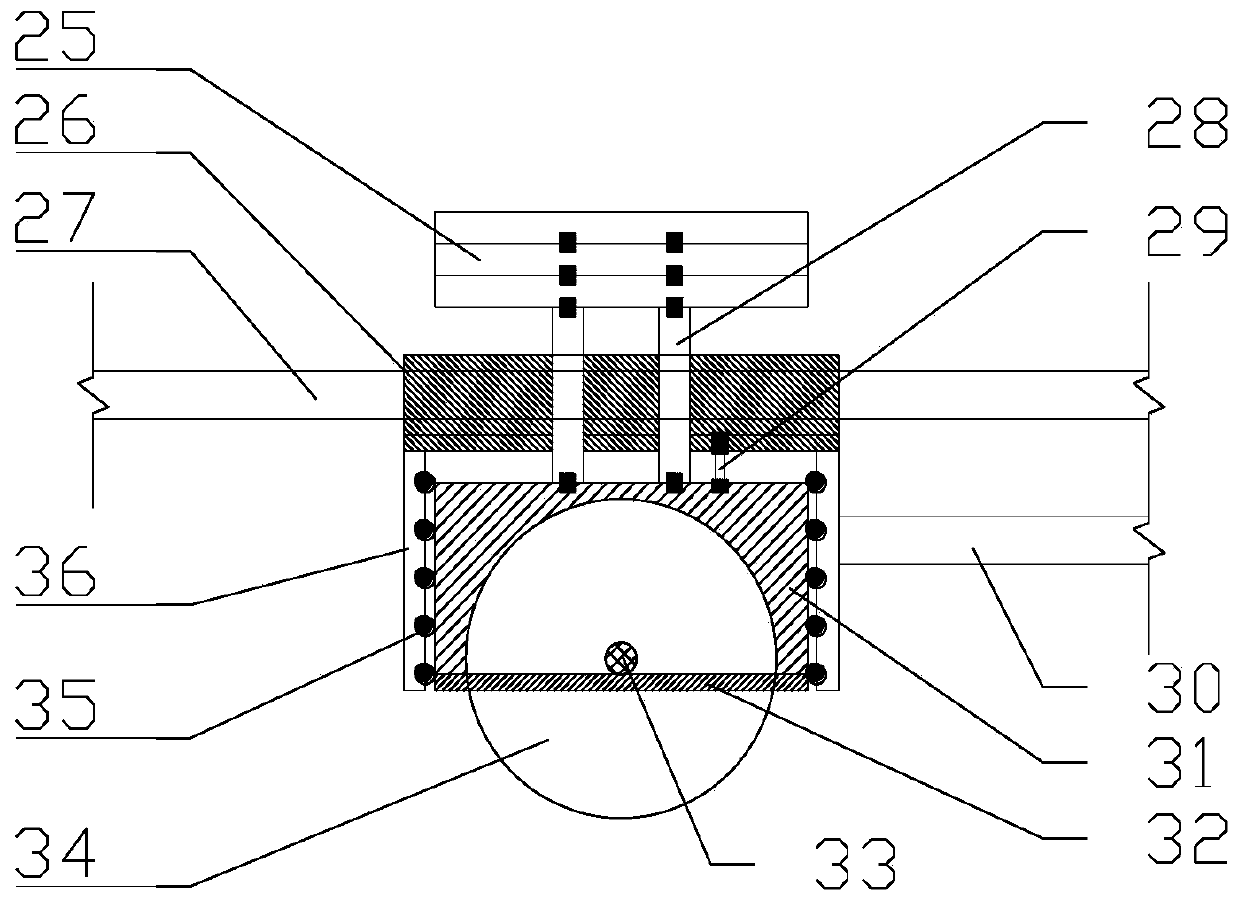

Rut test system for asphalt mixture in hydrodynamic pressure environment and test method

PendingCN109932260AEffective simulationThe test result is accurateMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesWater bathsTemperature control

The invention provides a rut test system for an asphalt mixture in a hydrodynamic pressure environment and a test method, which belong to the technical field of road engineering material performance test. The system comprises a hydrodynamic pressure generating device, a wheel system loading device, an asphalt mixture sample fixing device and a temperature control water bath device. An external servo hydraulic system drives a piston to perform reciprocating movement along a vertical direction according to a preset frequency and an amplitude, a hydrodynamic pressure environment is formed, and the process of generating instantaneous hydrodynamic pressure when a vehicle tire quickly drives on an actual asphalt pavement can be effectively simulated. Constant wheel contact pressure is realized through setting of a linear bearing sliding sleeve, the rut depth is monitored in real time by adopting a form of fixing two ends of a displacement sensor, and the rut test for the asphalt mixture in the hydrodynamic pressure environment can be realized to evaluate the water damage resistance performance. The process of applying the vehicle load to the asphalt mixture in the hydrodynamic pressure environment can be realized, and the specific influences of the hydrodynamic pressure caused by the vehicle tire on the asphalt pavement can be more realistically simulated and quantitatively evaluated.

Owner:UNIV OF SCI & TECH BEIJING

Electrochemical machining tool and method for machining a product using the same

InactiveCN101052751AOnce installedAllows for flexible handlingMachining electrodesElectrical-based machining electrodesHard disc driveEngineering

Owner:MINEBEA CO LTD

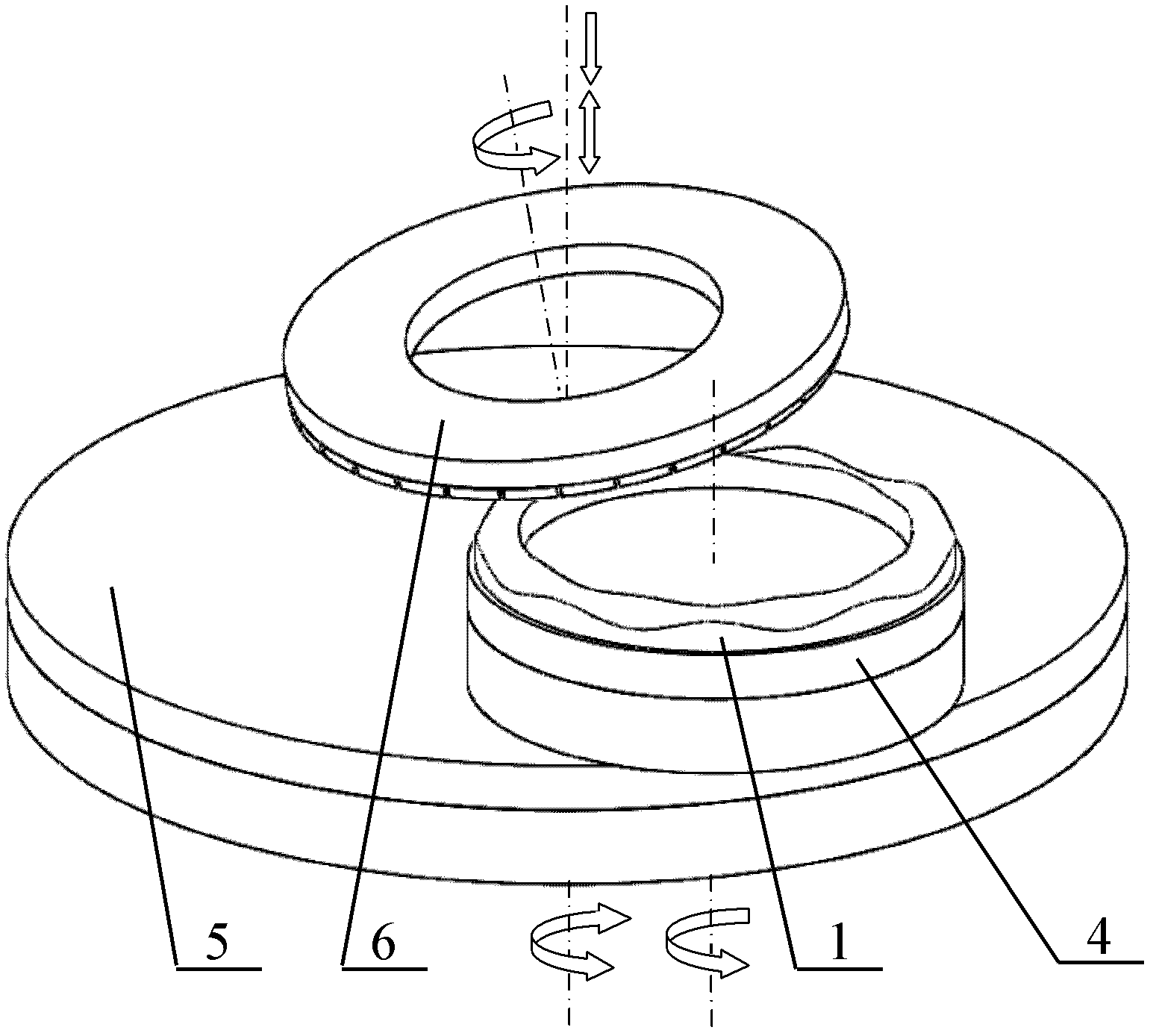

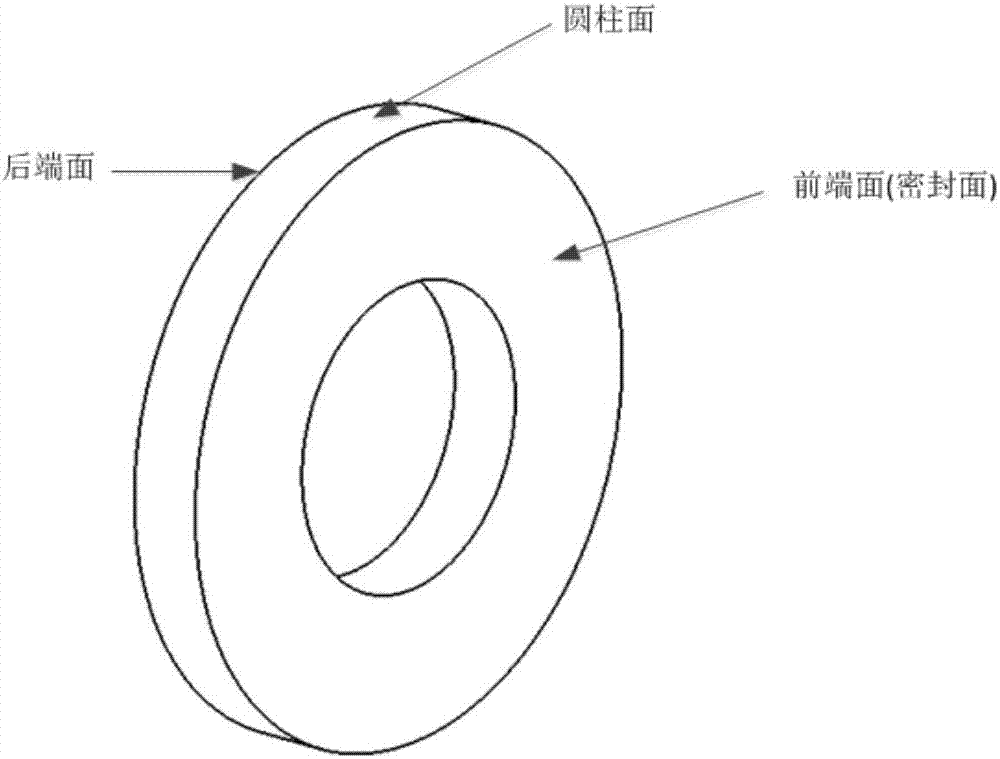

Machining method for complex surfaces of liquid hybrid type mechanical seal rings

ActiveCN102581728AConsistent cutting speedConsistent Depth of CutGrinding machinesHybrid typeRotational axis

A machining method for complex surfaces of liquid hybrid type mechanical seal rings belongs to the technical field of precision machining and is characterized in that a sum of the square of diameter of a cup wheel and the square of medium diameter of a sloped corrugate face is equal to a square of a doubled distance from an intersection of the end face of the wheel and a rotational axis of the wheel to a rotational axis of a rotary worktable, an inclination angle of the wheel is equal to a largest radial outline inclination angle of the sloped corrugate face, rotation of the rotary worktable, reciprocating swing of a swing worktable and periodic following are in linked control when the sloped corrugate face is ground, the end face of the wheel is used for constant micro-feed cut-in grinding in the cutting depth direction of the wheel, the rotary worktable is in constant-speed rotation when a seal dam face is ground, and the end face of the wheel is used for constant micro-speed cut-in grinding in the cutting depth direction of the wheel. The machining method has the advantages that machining high in surface shape precision and low in surface roughness for the complex surface of a hydrodynamic pressure seal ring is achieved, while the hydrodynamic pressure seal ring is composed of a flat circular dam face and a sloped corrugate face which has slight inclined linear radial outline and peripherally and periodically changing inclination.

Owner:DALIAN UNIV OF TECH

Hydrodynamic pressure bearing system and spindle motor using the same

InactiveUS6965493B2Reduce variationImprove finishing accuracyRecord information storageBearing componentsThermal expansionBearing surface

A shaft secured to a hub is inserted and rotatably supported in a sleeve secured to a base. A dynamic pressure groove is formed in the inner peripheral surface of the sleeve, and lubricant is sealed between the shaft and the sleeve. The rotation of the shaft causes dynamic pressure to generate in the lubricant due to the dynamic pressure groove, supporting the shaft floatingly. The crystallized-glass sleeve allows heat generated in a coil to be hardly transferred to the shaft, thereby reducing the variations in the clearance between the shaft and the sleeve due to temperature changes to a minimum in cooperation with the crystallized-glass sleeve with a low thermal expansion coefficient. Finishing accuracy of the bearing surface can be improved by chemical polishing. Consequently, the rotation accuracy can be improved and the leakage of lubricant due to the variations in the clearance can be prevented.

Owner:MINEBEA CO LTD

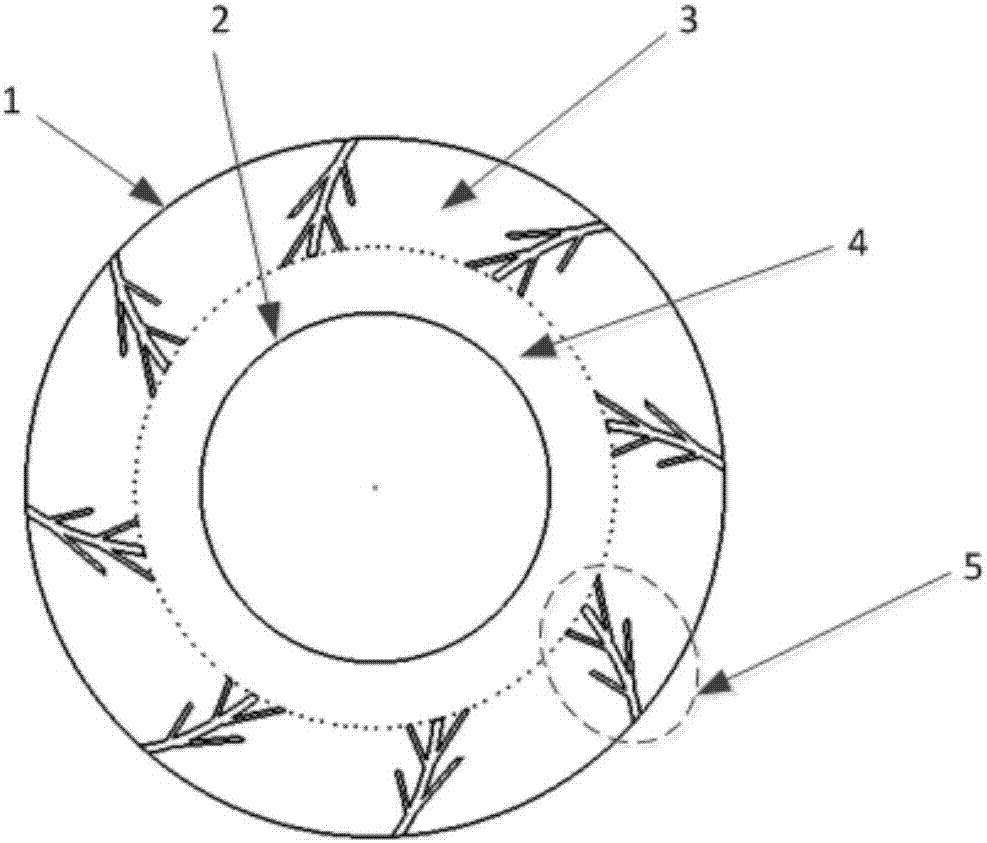

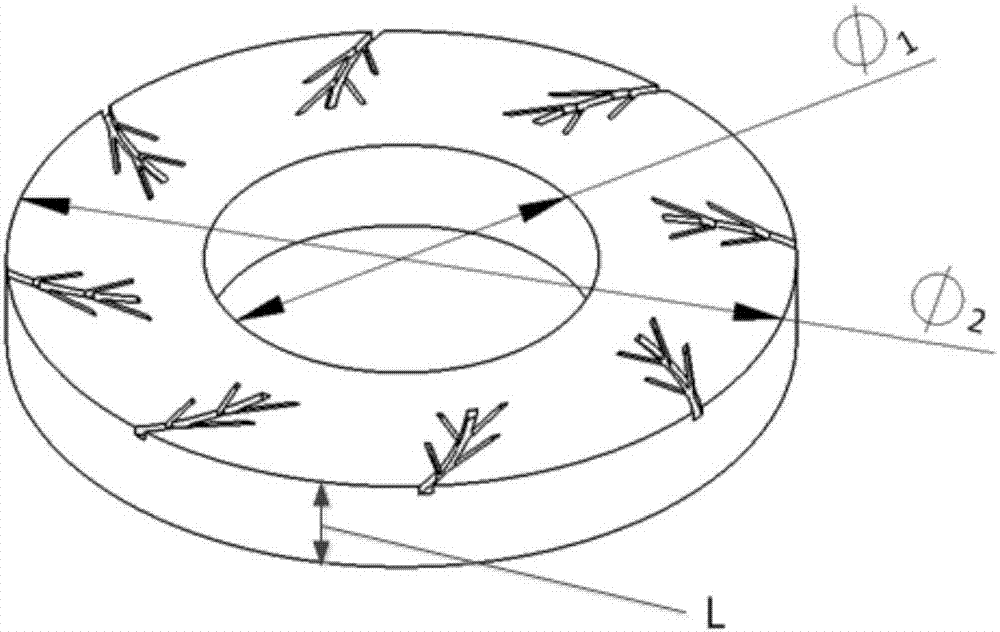

Mechanical sealing structure with end face being provided with vein-shaped grooves

ActiveCN107218396AEnhance the dynamic pressure effectImprove work performanceEngine sealsVeinPressure difference

Owner:BEIHANG UNIV

Hydraulic bearing

InactiveUS6935786B2Improved hydraulic bearingAvoid thermal expansionGrinding machine componentsBearing componentsEngineeringThermal expansion

A hydraulic bearing that supports a rotating shaft comprises a bearing metal. On a surface of the bearing metal, a hydrostatic pocket and a land portion are formed. The land portion is defined by the hydrostatic pocket and generates hydrodynamic pressure in response to a rotation of the rotating shaft. The hydraulic bearing further comprises a pressure fluid supplying source and an oil-supplying hole. The oil-supplying hole is opened in the hydrostatic pocket and provides pressure fluid from the pressure fluid supplying source to the hydrostatic pocket. On the land portion, a drain hole that drains the fluid is formed. On the way of a drain passage, a check valve is disposed. Since the drain hole does not separate the land portion, deterioration of bearing rigidity is restrained. Further, since the fluid is drained through the drain hole, thermal expansion of the bearing metal due to heat generation of the fluid is restrained. Moreover, according to the check valve, it is possible to prevent suctioning air into the hydraulic bearing when negative pressure generates at the land portion.

Owner:TOYODA MASCH WORKS LTD

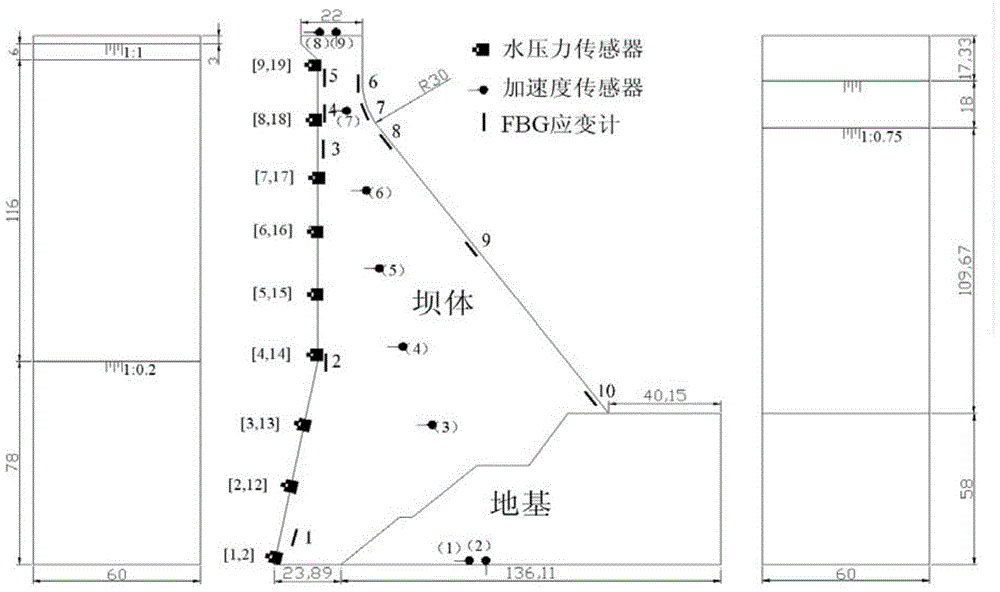

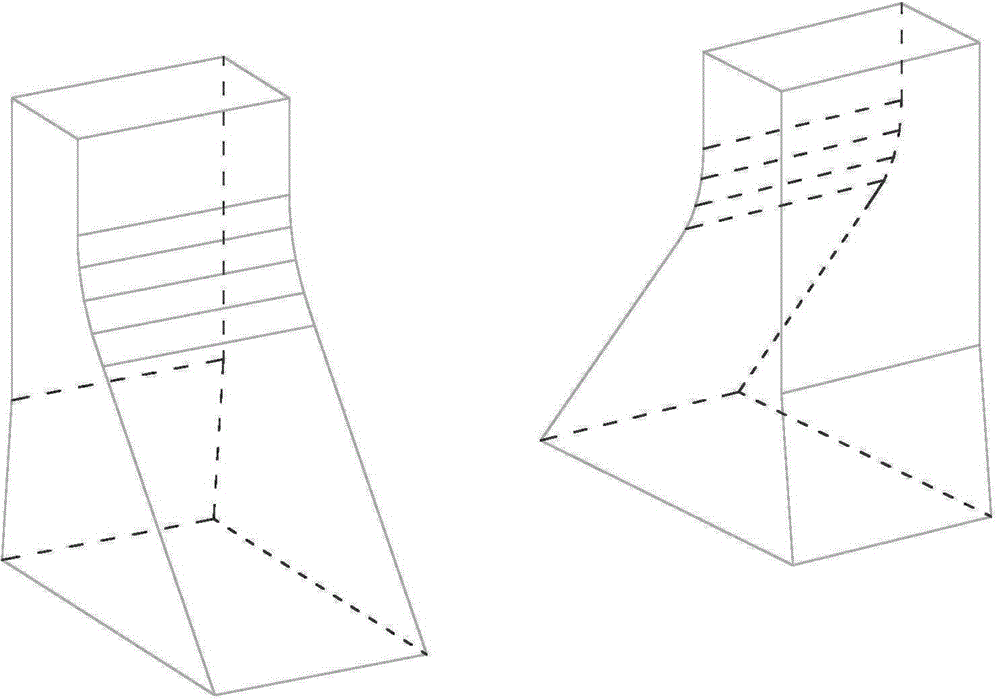

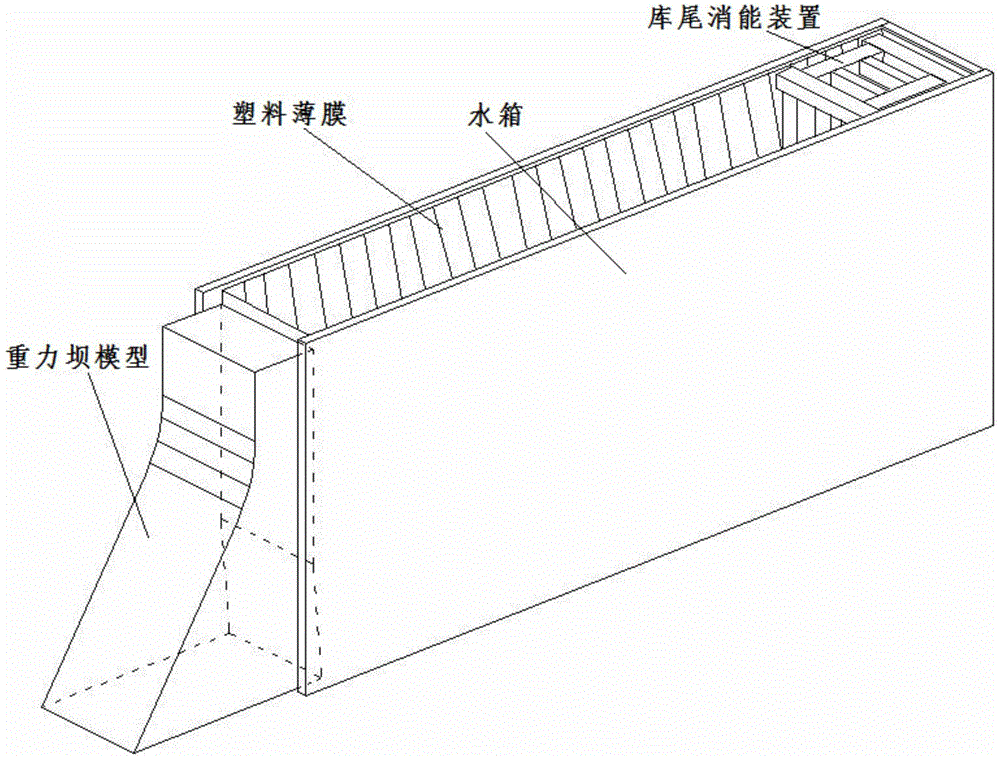

Method of designing dam-reservoir water coupled dynamic model test on vibration table

ActiveCN104977151ASolve the leakSolve the problem of water wave rebound effectHydrodynamic testingDynamic modelsEngineering

The invention relates to a method of designing a dam-reservoir water coupled dynamic model test on a vibration table, which belongs to the field of hydraulic structure engineering and model test study. A geometrical size of each part of a two-dimensional model dam section and a layout scheme for each related monitoring device are firstly designed; main physical and mechanical parameters of the model material are determined; the dam model is cast, and each test instrument is buried in advance according to the well-designed layout scheme; a water tank which simulates the reservoir is lifted to the upstream side of the model dam; a reservoir tail energy dissipation device is placed at one end, far away from the model dam, inside the water tank; and after the model dam and the water tank which simulates the reservoir are assembled and the test instruments are assembled and connected, a model dam seismic dynamic simulation test is begun. According to the method of the invention, the theory is simple and easy to understand, the construction process is simple, and hydrodynamic pressure borne by the upstream dam and influences on a dam dynamic response by the upstream reservoir water in the case of an earthquake can be accurately measured in a lab.

Owner:KUNMING UNIV OF SCI & TECH

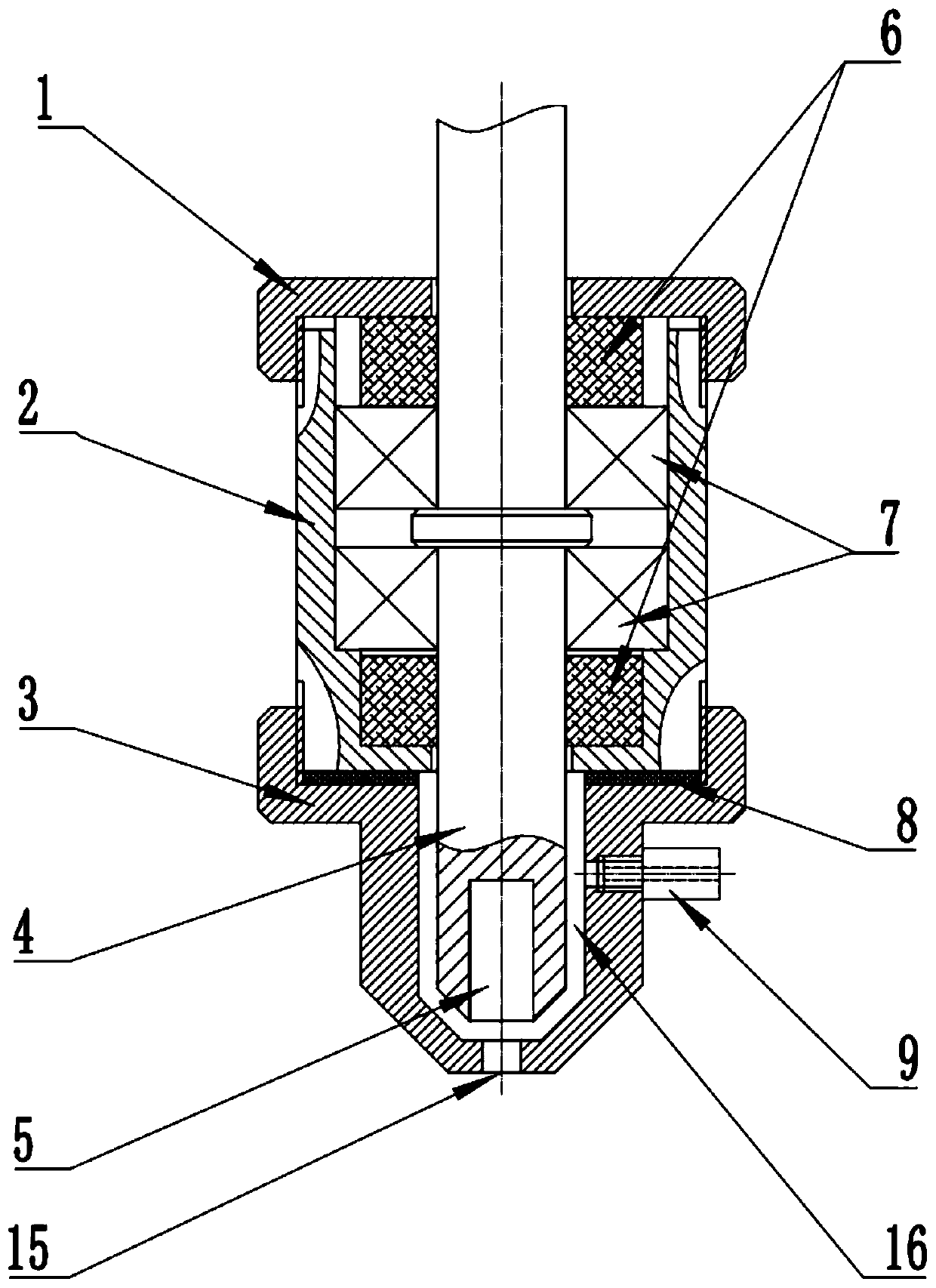

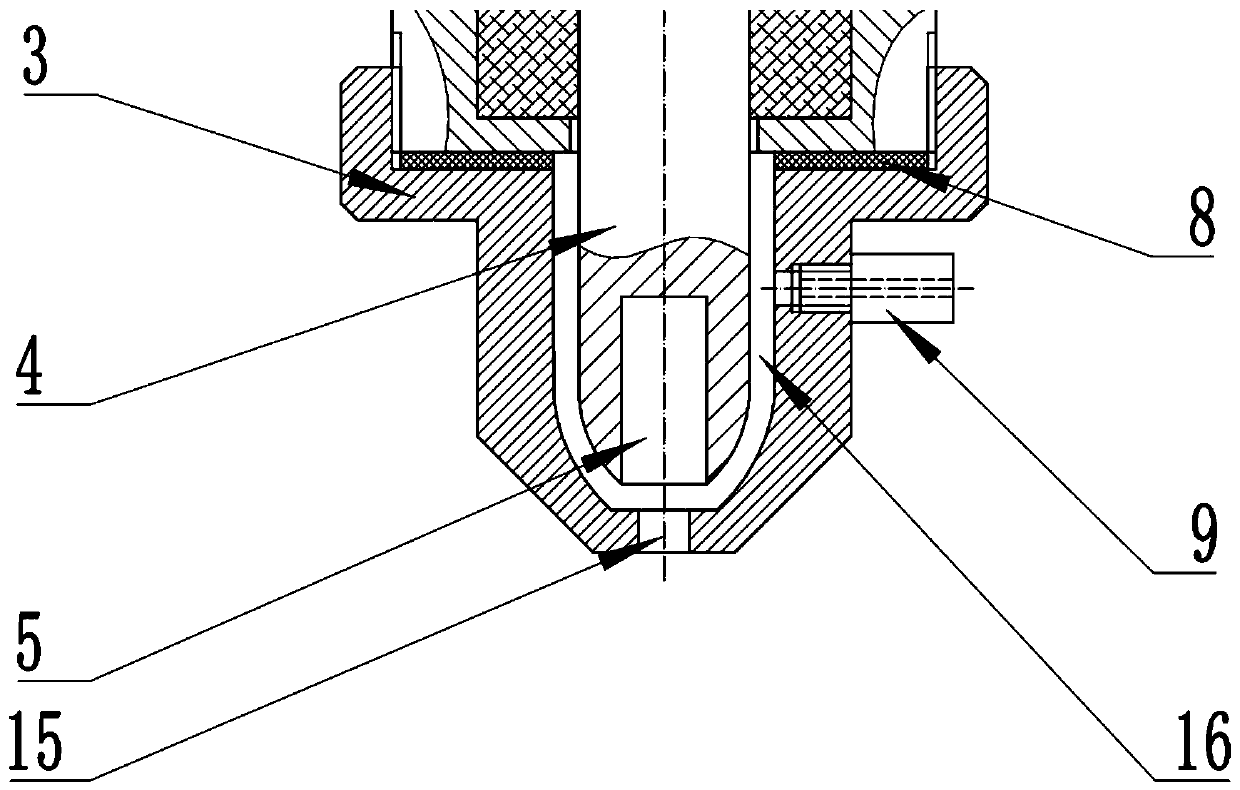

Magneto-rheological polishing device and method based on flow field focusing

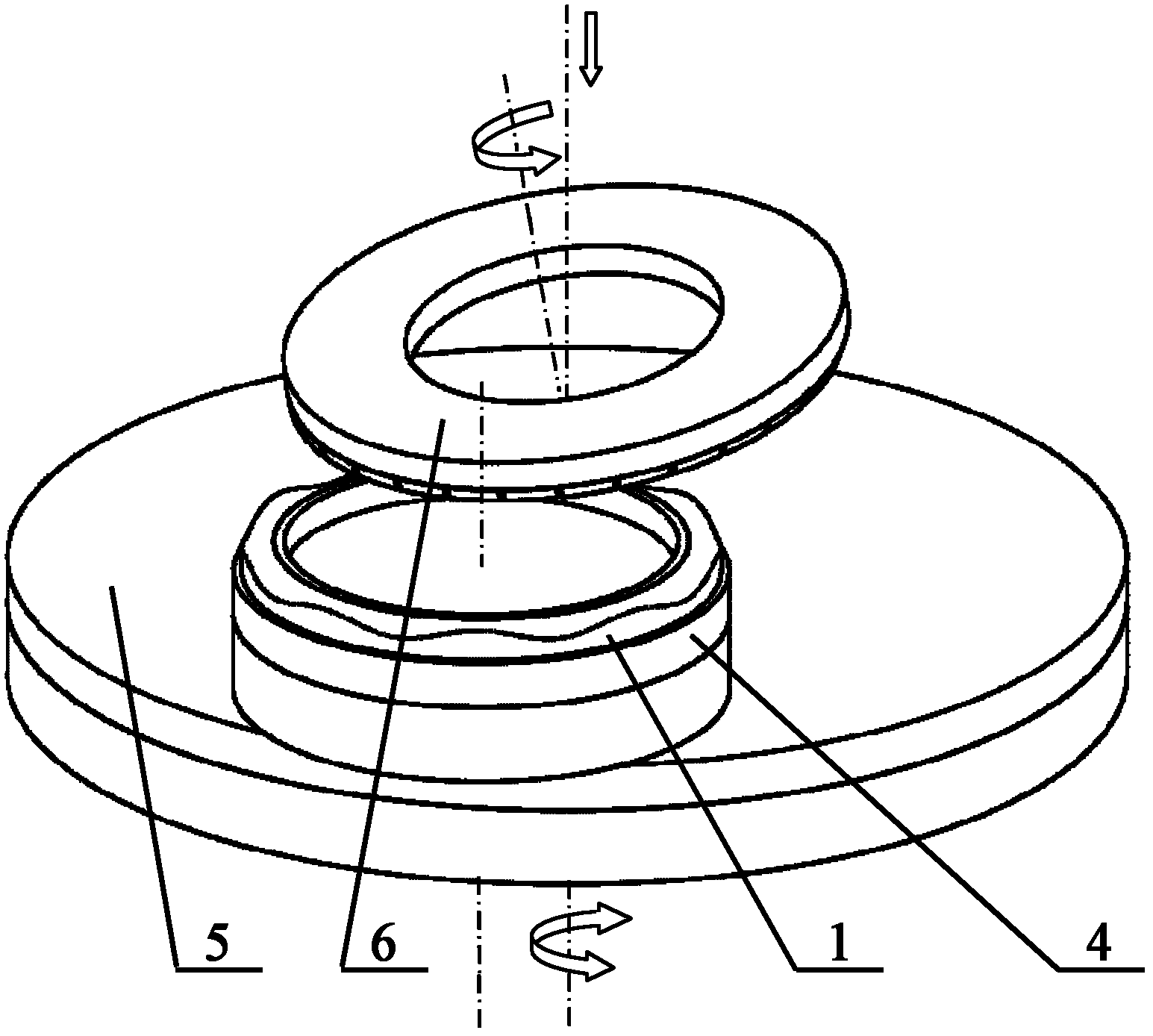

ActiveCN110340736AHigh precisionHigh Efficiency PolishingGrinding machine componentsMagnetic currentExternal rotation

The invention belongs to the field of polishing of ultra-precision optical elements, and in particular discloses a magneto-rheological polishing device and method based on flow field focusing. The magneto-rheological polishing device comprises an end cover, a sleeve, a polishing head shell and a magnetic isolating rotation shaft, wherein the end cover and the polishing head shell are connected with the two ends of the sleeve, and a liquid inlet and a liquid outlet are formed in the polishing head shell; the magnetic isolating rotation shaft is arranged in the sleeve, one end of the magnetic isolating rotation shaft penetrates through the end cover to be connected with an external rotating power source, and the other end of the magnetic isolating rotation shaft is inlaid with a permanent magnet and is inserted into the polishing head shell to form a flow focusing chamber with the inner part of the polishing head shell; and the liquid outlet is positioned directly below the permanent magnet. During polishing, one part of magneto-rheological polishing fluid forms a bingham body under the action of permanent magnet at the end face of the magnetic isolating rotation shaft; and the otherpart of the magneto-rheological polishing fluid flows in the flow focusing chamber and is ejected from the liquid outlet, and the part generates hydrodynamic pressure to extrude the bingham body forshaping during flowing, so that a small bingham body polishing head with the average diameter less than the diameter of the liquid outlet is formed. The magneto-rheological polishing device and methodrealize efficient polishing of workpieces with different surface shapes.

Owner:HUAZHONG UNIV OF SCI & TECH

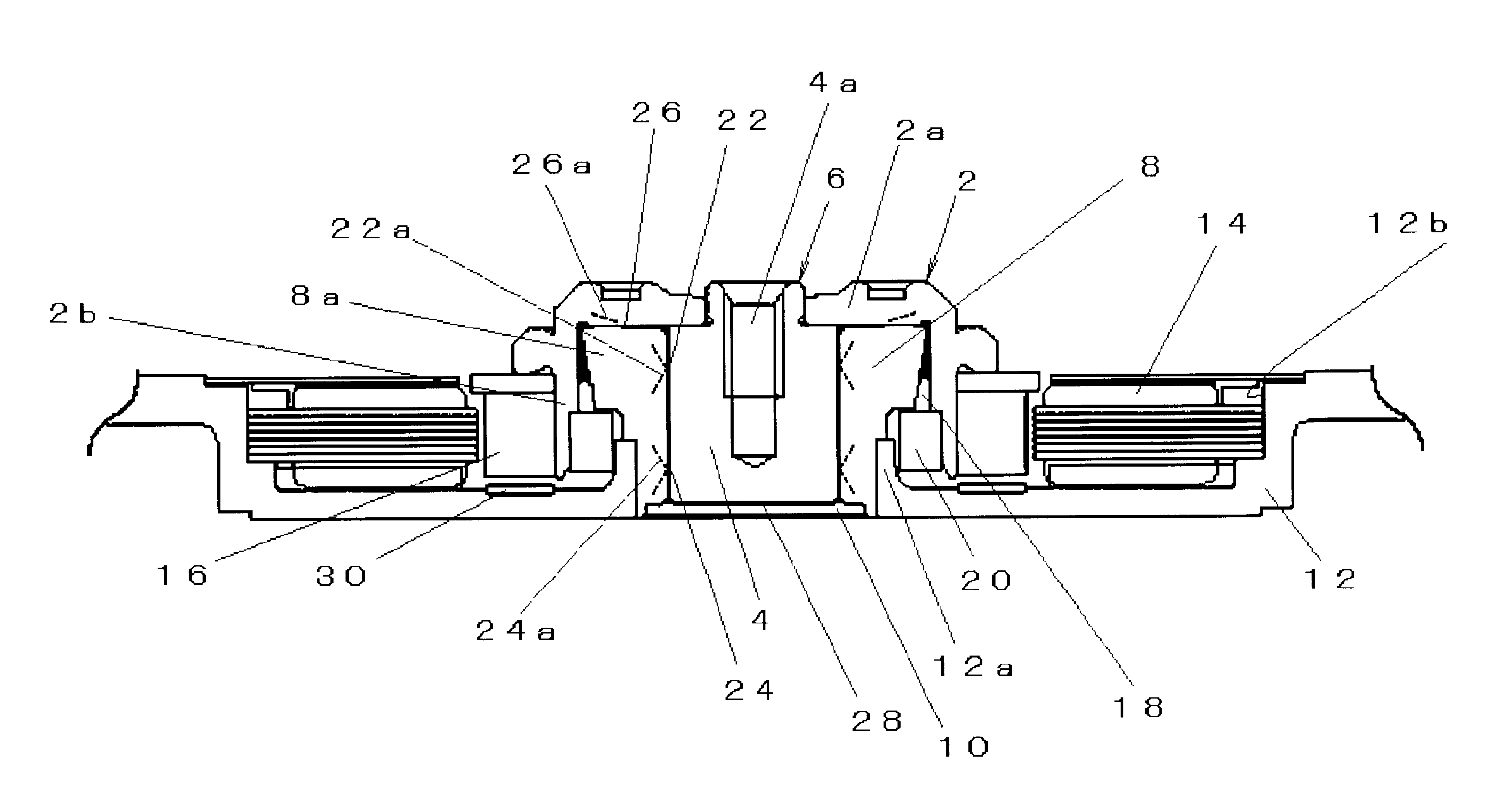

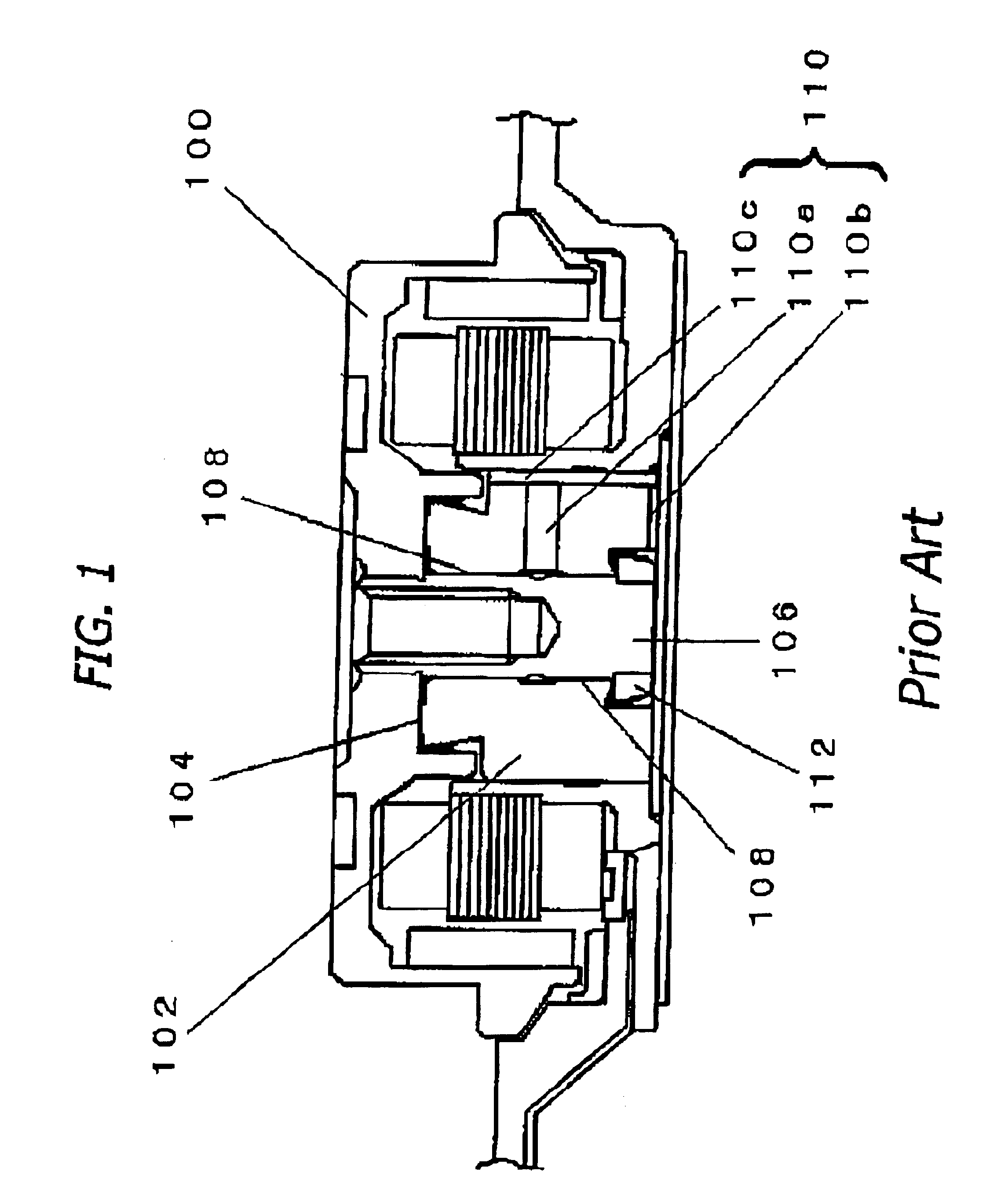

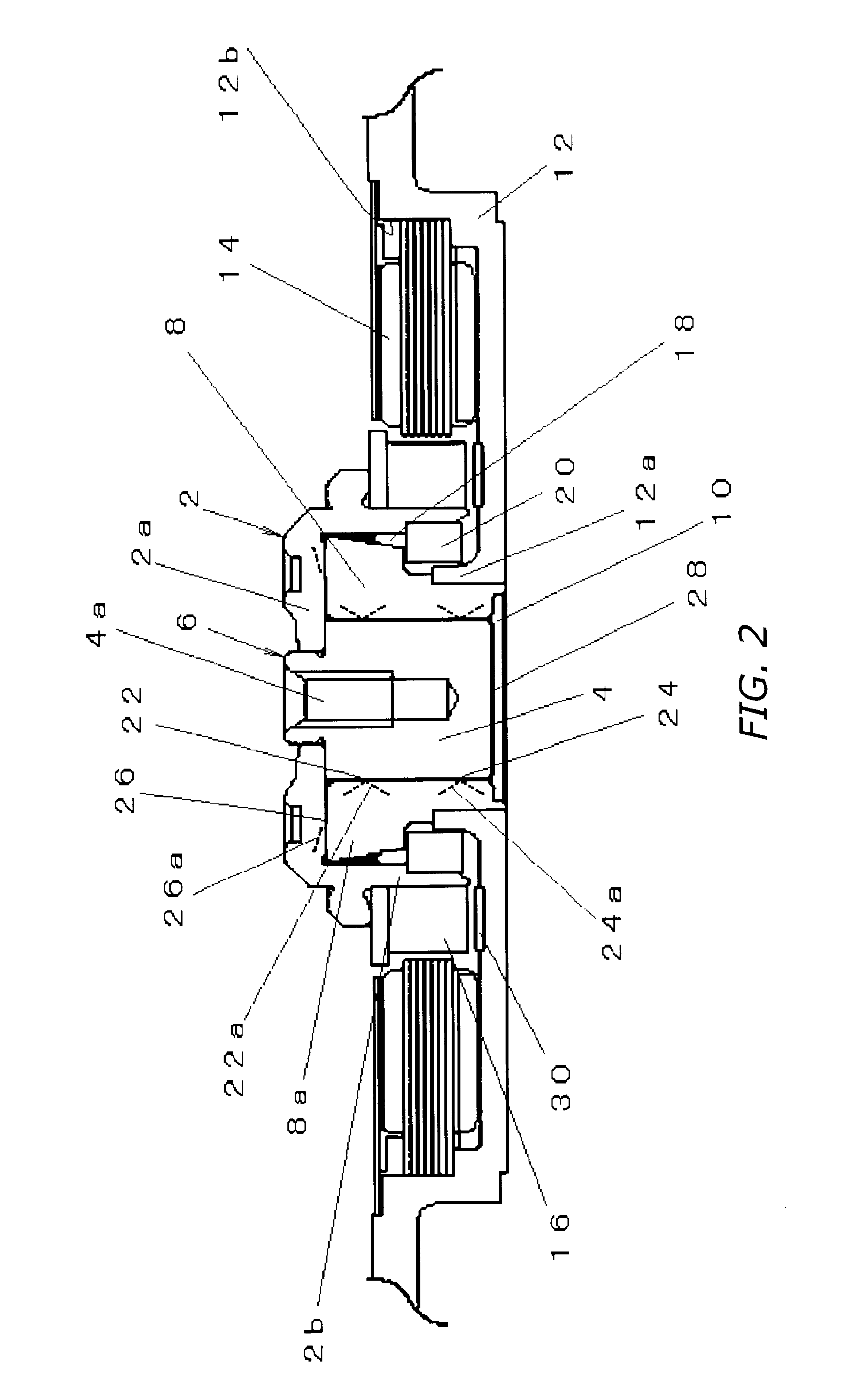

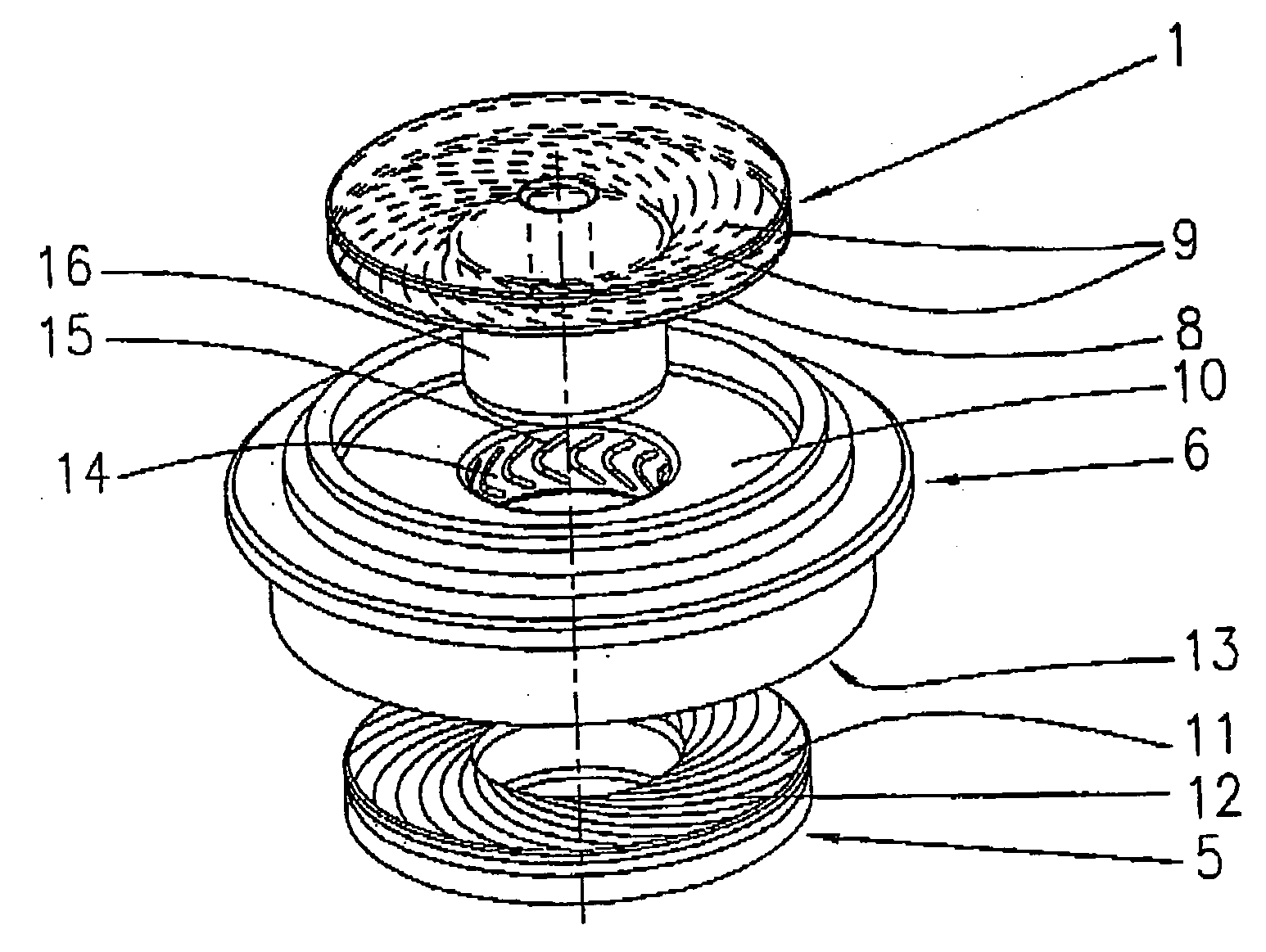

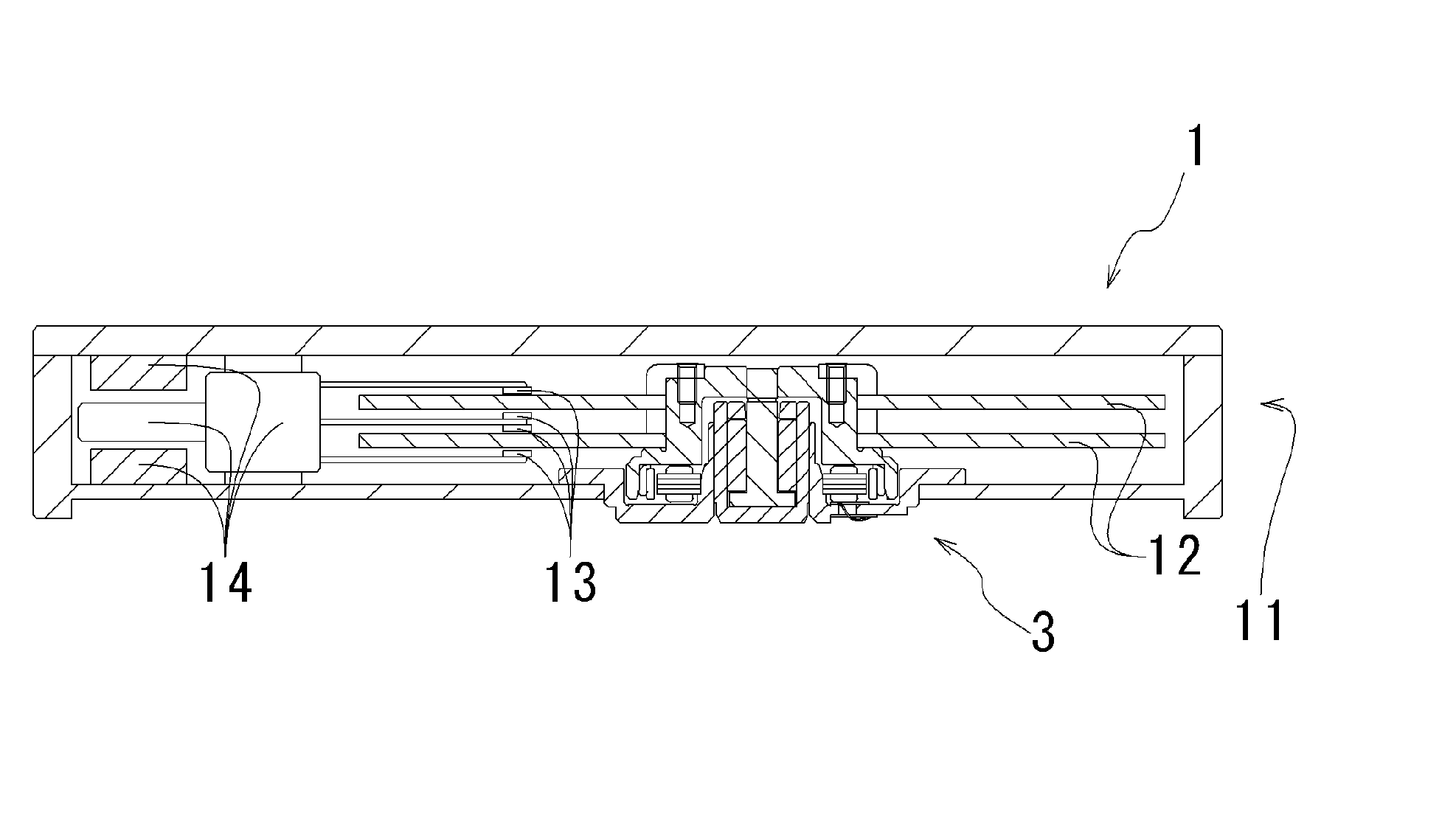

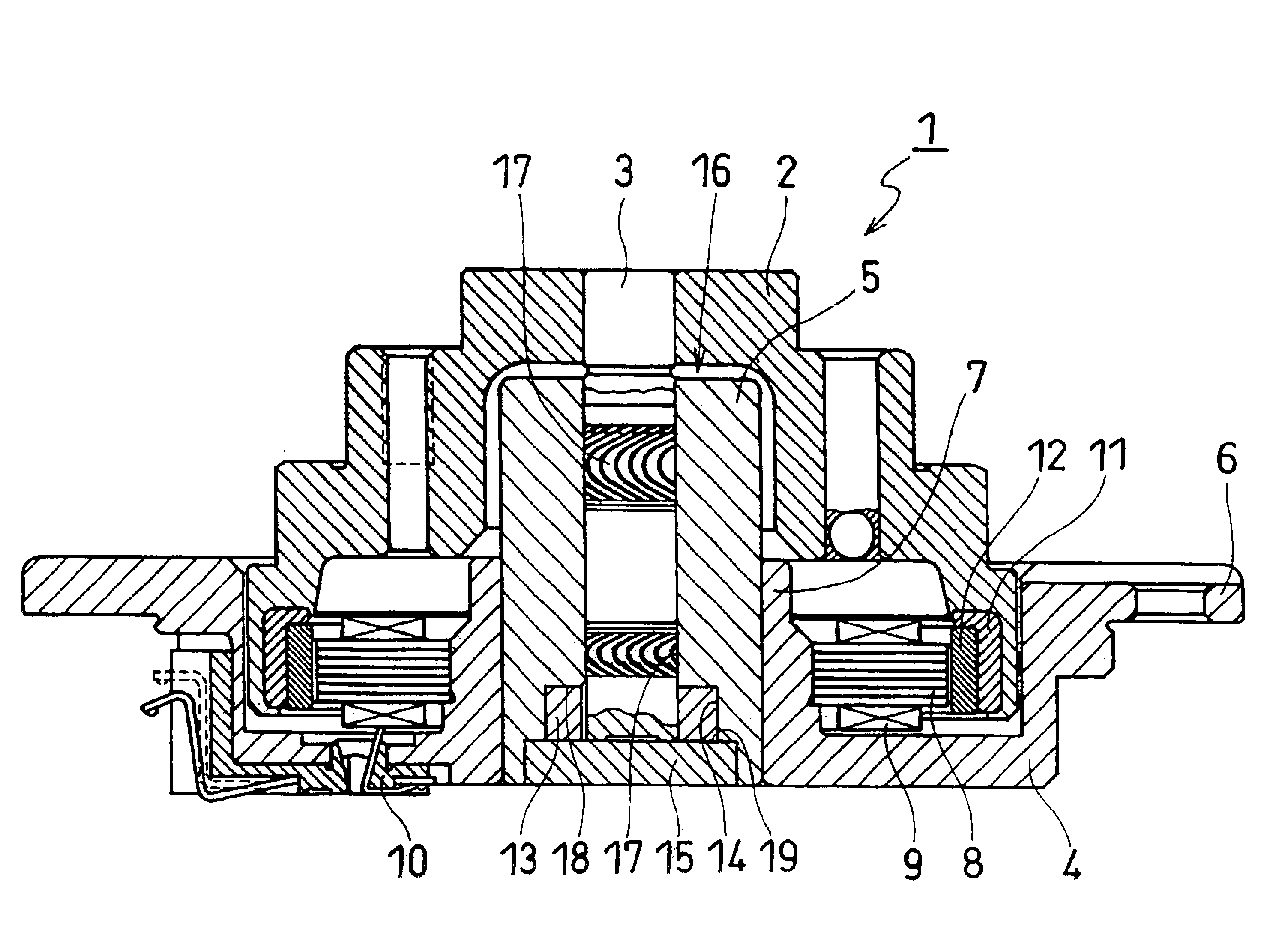

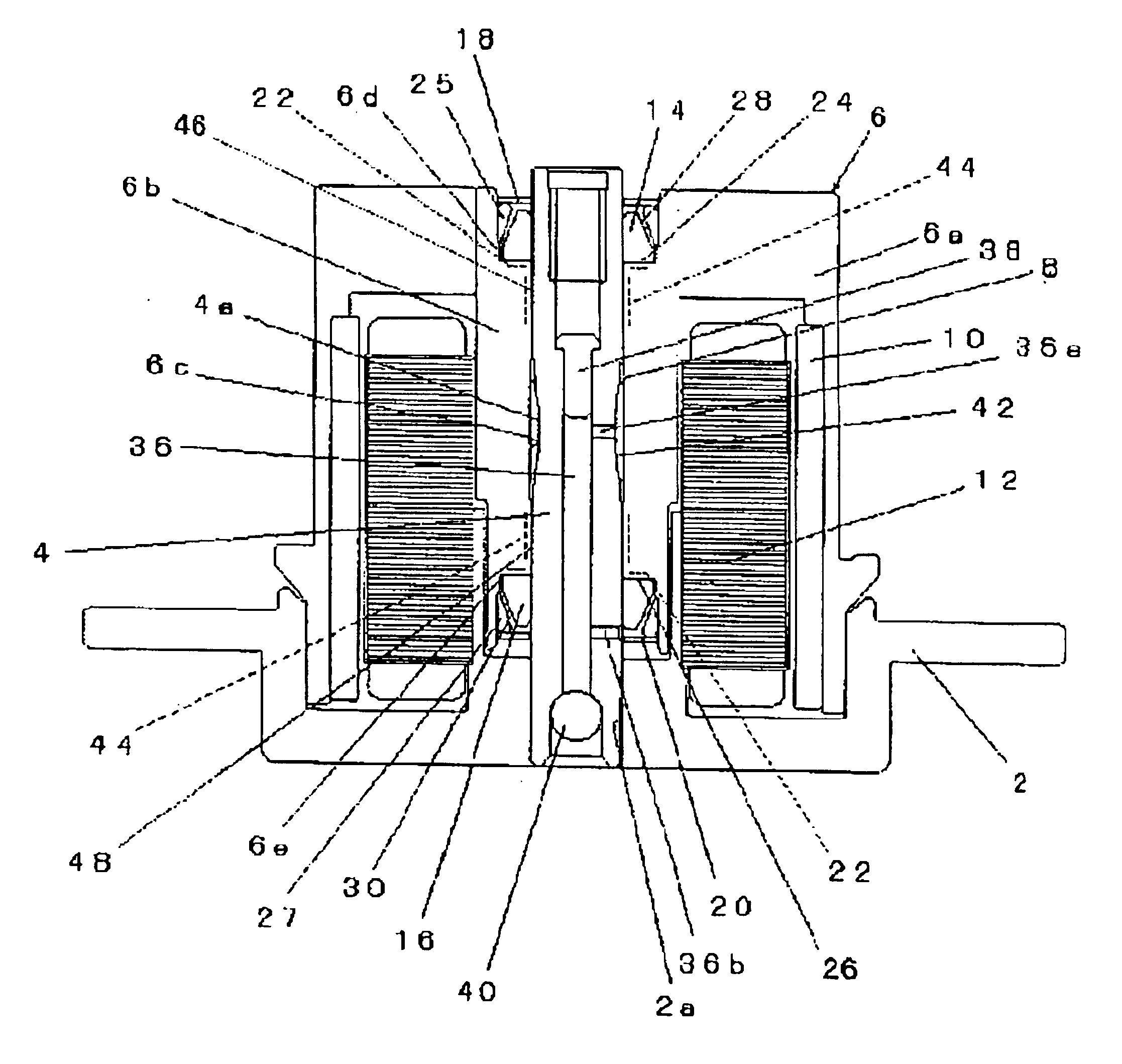

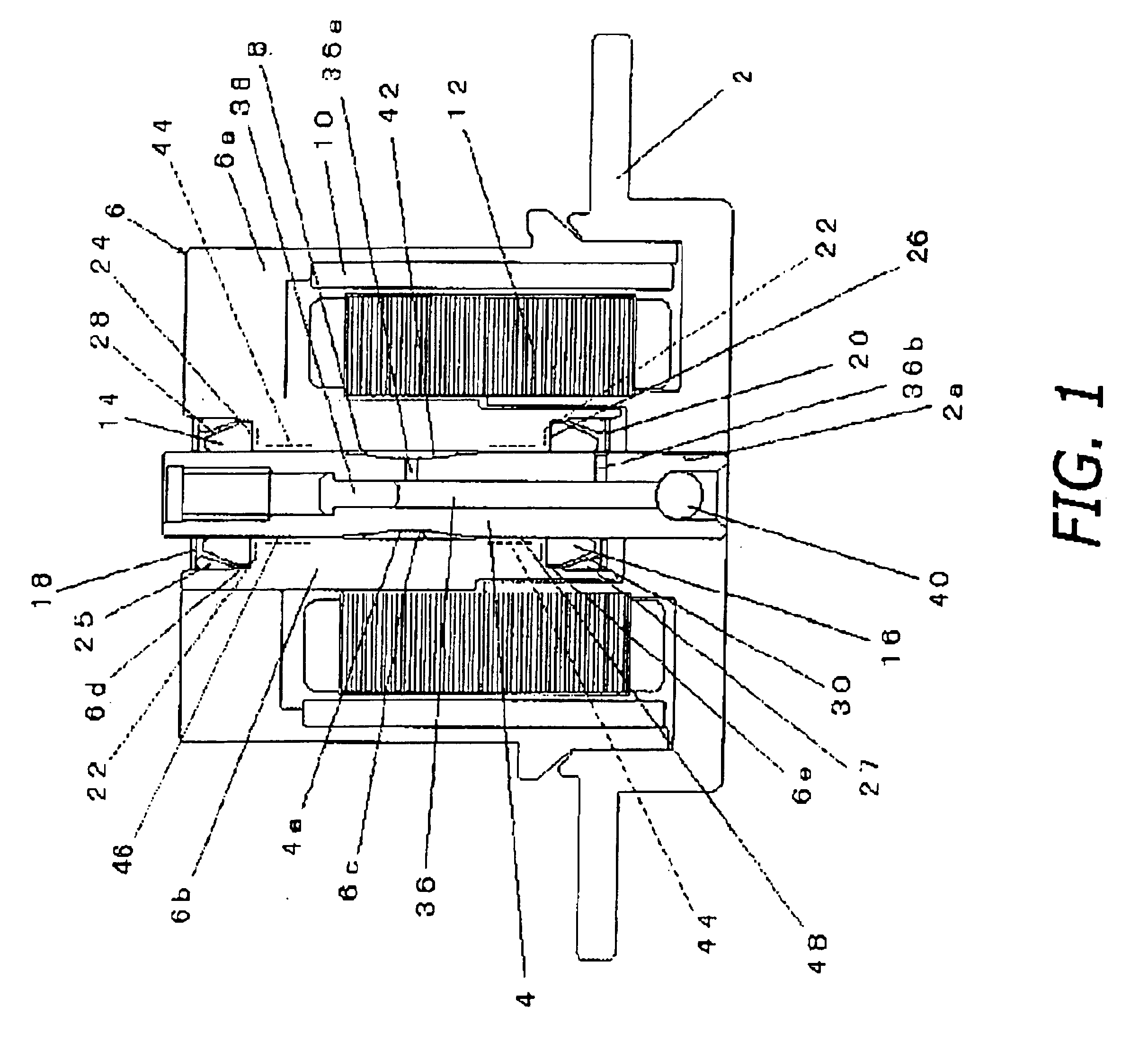

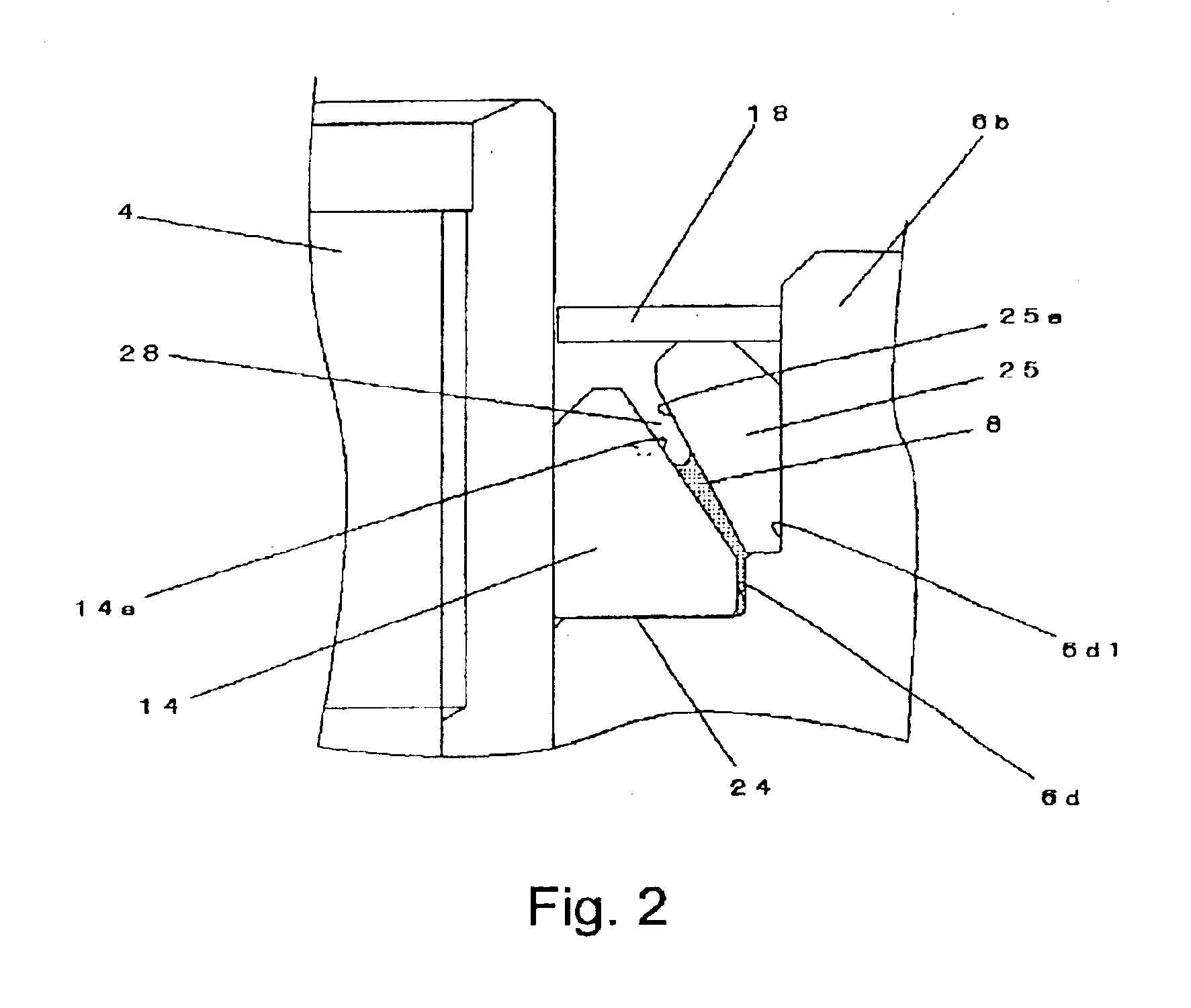

Hydrodynamic pressure bearing, spindle motor in which it is utilized, and disk-drive device furnished with the spindle motor

InactiveUS6854889B2Sealing strengthSufficient amountShaftsBearing componentsThrust bearingEngineering

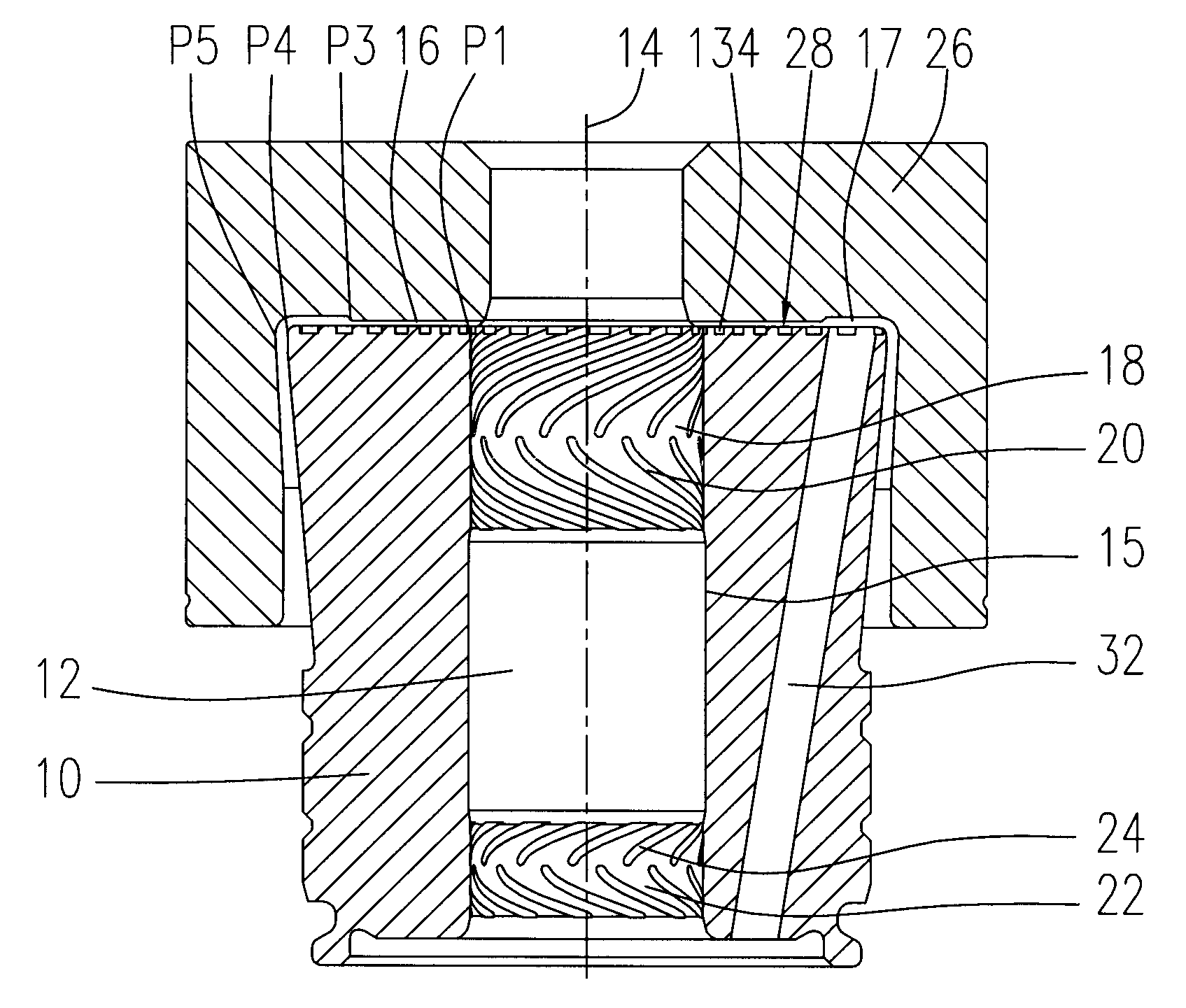

Spindle-motor hydrodynamic bearing configuration having conical taper seals on the thrust-bearing ends. The spindle motor shaft is supported in a bore through the rotor by neighboring radial and thrust hydrodynamic bearings constituted through radial micro-gaps cylindrically between the shaft and rotor, axial micro-gaps between thrust plates on either shaft end and recesses endwise in the rotor bore, dynamic-pressure-generating grooves in the micro-gap forming surfaces, and lubricant retained continuously in the radial and axial micro-gaps. The thrust plates are at least partially conical, tapering axially outward. A ring fitted in each rotor bore recess has a conical inner peripheral surface corresponding to the opposing conical surface of the thrust plate, forming a taper seal sloped with respect to the rotational axial center of the motor. The gap clearance dimension gradually expands heading axially outward, wherein the lubricant forms an axial-end gas-liquid interface to function as a taper seal.

Owner:NIPPON DENSAN CORP

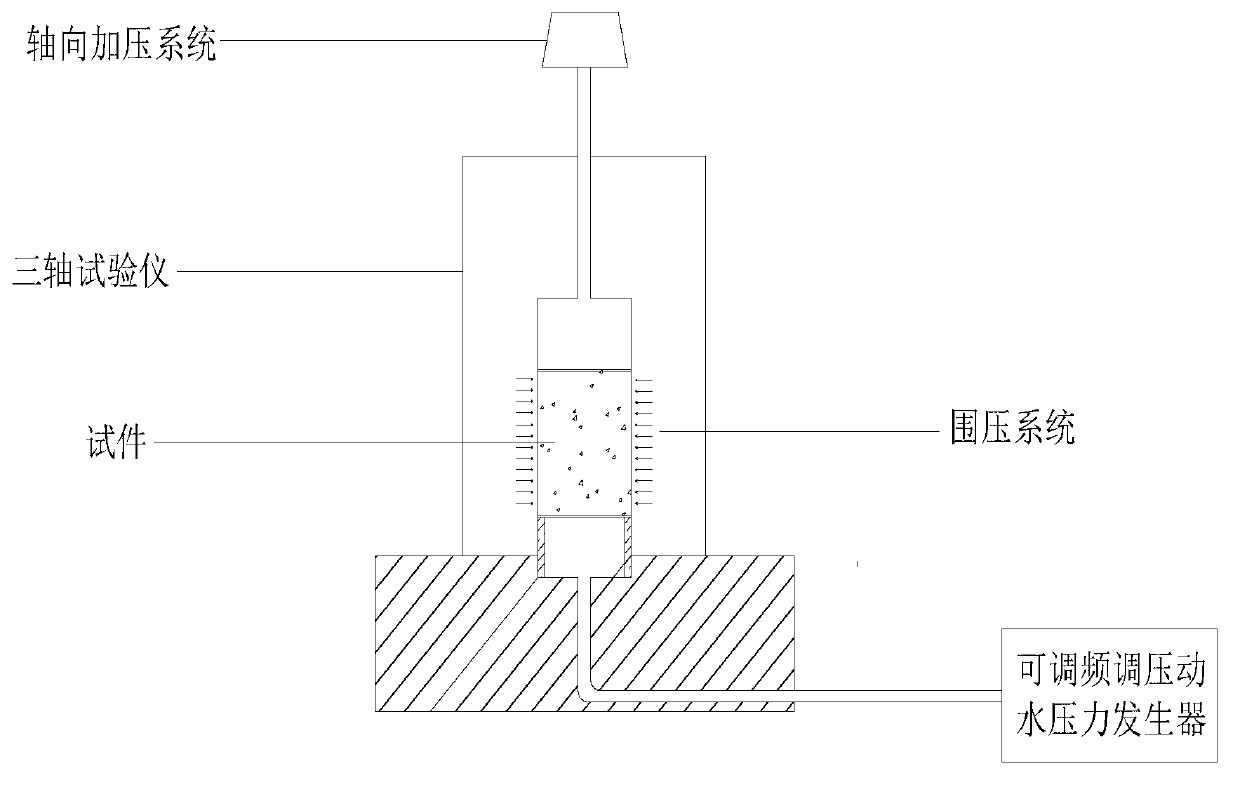

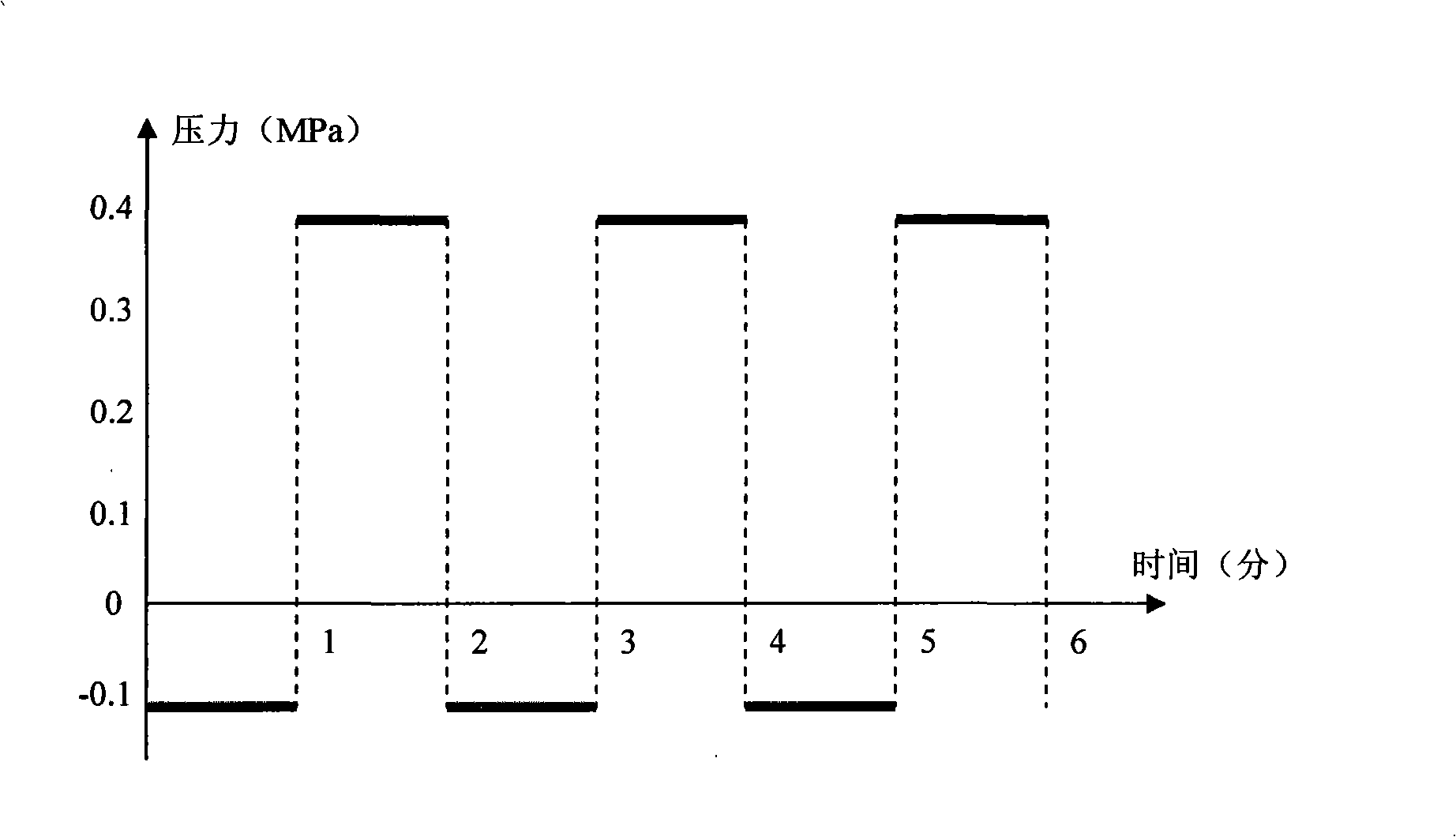

Testing method of evaluating erosion resistibility of road material under action of hydrodynamic pressure

The invention belongs to the technical field of highway engineering asphalt pavement water damage and relates to a testing method of evaluating the erosion resistibility of a road material under the action of the hydrodynamic pressure. The testing method is characterized in that a formed standard specimen is put into a triaxial apparatus pressure chamber and is connected with each ventilation and water passing pipeline, the confining pressure and the axial pressure are applied, a frequency and pressure adjustable hydrodynamic pressure generator is started to carry out an erosion test on the specimen in the pressure chamber, and a triaxial single-axis test is immediately carried out on the eroded specimen after the test; multiple groups of specimen are selected, and the tests are repeatedly carried out on the specimens according to the times without needing erosion; test data is collated, and a rule that the road material strength or modulus continuously attenuates along with the erosion time is analyzed and summarized according to a test result. The testing method has the beneficial effects that according to the testing method disclosed by the invention, the repeated erosion action of different coupling types of water and load to the material can be simulated, the attenuation rule of the mechanical property of the road material under the combined action of the water and repeated load is analyzed and studied, and the theoretical support is provided for pavement structure design with long service life.

Owner:DALIAN UNIV OF TECH

Testing device and testing method for simulating hydrodynamic pressure action in rock fracture

InactiveCN104749023AEasy to manufactureLow costStrength propertiesData acquisitionHigh pressure water

The invention discloses a testing device and a testing method for simulating hydrodynamic pressure action in rock fracture. A rock sample with a crack is placed into a testing water tank, the position of the rock sample is adjusted to enable a crack to directly face a rectangular hole; testing water flows are pumped into the testing water tank to be subjected to hydrodynamic pressure testing through a water injection pipe by a high-pressure water supply pump; a pressure meter, a pressure control valve and a pressure release valve are arranged on the testing water tank for controlling the flow pressure and the flow rate of the inside of the testing water tank; and an anchorage point is arranged on the testing water tank and is connected with a displacement meter and the rock sample, a pressure sensor, a flow sensor and the displacement meter are arranged on the water injection pipe and are used for transmitting the acquired data to a data acquisition instrument and are connected with a computer, and the computer is used for recording the testing data such as pressure, flow rate, the change of the diameter of the rock sample and the like. The structure is simple, the processing operation is easy and the operation is convenient.

Owner:CENT SOUTH UNIV

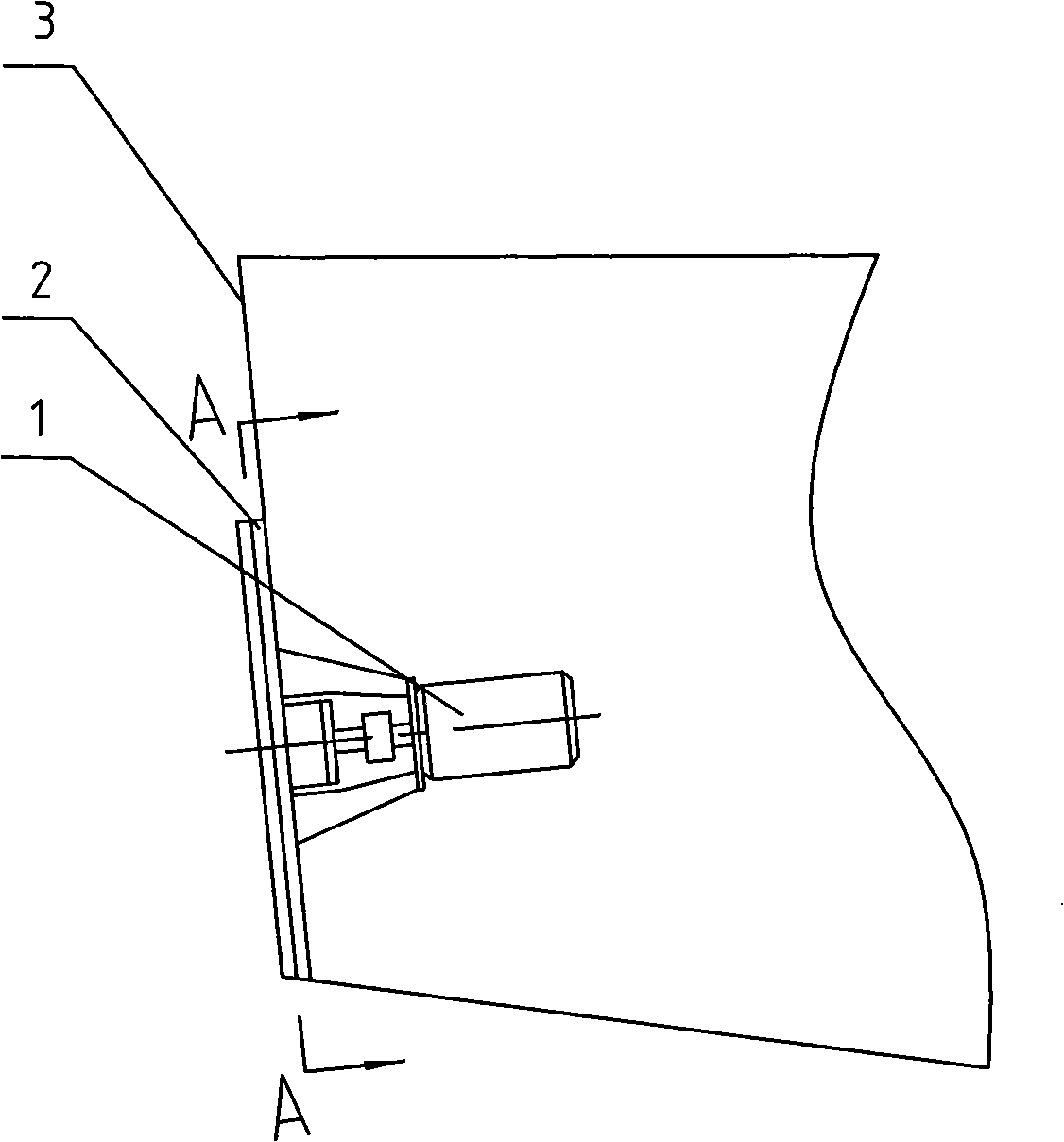

Glider veneer single acting rectifying stabilizer

InactiveCN101327836ASolve the swingCompact structureVessel movement reduction by foilsDrive shaftWater flow

The invention discloses a single-plate single-action rectifying-stabilizing device for planing boats. A stepping motor shaft is connected with a drive shaft; an eccentric wheel is arranged in an oil-bearing drive slider and is fixed with the drive shaft; the oil-bearing drive slider is arranged in a rectangular hole of a top corner of a rectifying plate; a base plate is fixed outside a stern sealing plate; the rectifying plate is arranged between the base plate and a cover plate; a mandrel is supported below the rectifying plate; a plurality of anti-warp pins pass through an arc-shaped groove of the rectifying plate; and a plurality of oil-bearing sliders are respectively fixed on two sides of the rectifying plate, and a plurality of pairs of flat slide rails are correspondingly arranged on the base plate and the cover plate. The device drives the rectifying plate to rotate around the center of the mandrel arranged below the rectifying plate through the eccentric wheel and the oil-bearing drive slider, which ensures that the lower edge of the rectifying plate rotates out from the bottom edge of a planing boat and cuts into water, so as to change the water flow field under the planing boat as well as the hydrodynamic pressure center and then to reduce swing. The device only adds few components to a stern of the planing boat, which solves the problem that a boat body produces great swing when the planing boat slides and sails on water surface.

Owner:JIANGSU UNIV OF SCI & TECH

Appraisement method for asphalt mixture hydrosphere steadiness test

InactiveCN101344517AReasonable test principleReliable test resultsMaterial testing goodsVoid ratioEngineering

The invention discloses a water stability testing and evaluation method of a bituminous mixture, comprising the following steps: (1) a plurality of fashioned cylindrical test pieces of the bituminous mixture are prepared; (2) the test pieces are separated into two uniform groups that have the same average void ratio; (3) diametric compression experiment of a first test piece group is directly implemented, thus measuring the diametric compression intensity and computing the average value TS0; (4) a second test piece group is repeatedly rinsed for 50 times under the action of alternate positive and negative pressure, and then the diametric compression experiment is implemented, thus measuring the diametric compression intensity and computing the average value TS1; and (5) the ratio TSR between the two average diametric compression values is taken as an evaluating indicator. The water stability testing and evaluation method of the bituminous mixture combines the hydrodynamic pressure, and the aerodynamic force and the environmental temperature that are generated under the coupled conditions of driving and the surroundings into the experiments, consequently, the experimental environment conditions is closer to the actual road conditions, the experimental result has better correlation with the actual application effect, and the method is more reliable and effective.

Owner:张宏超

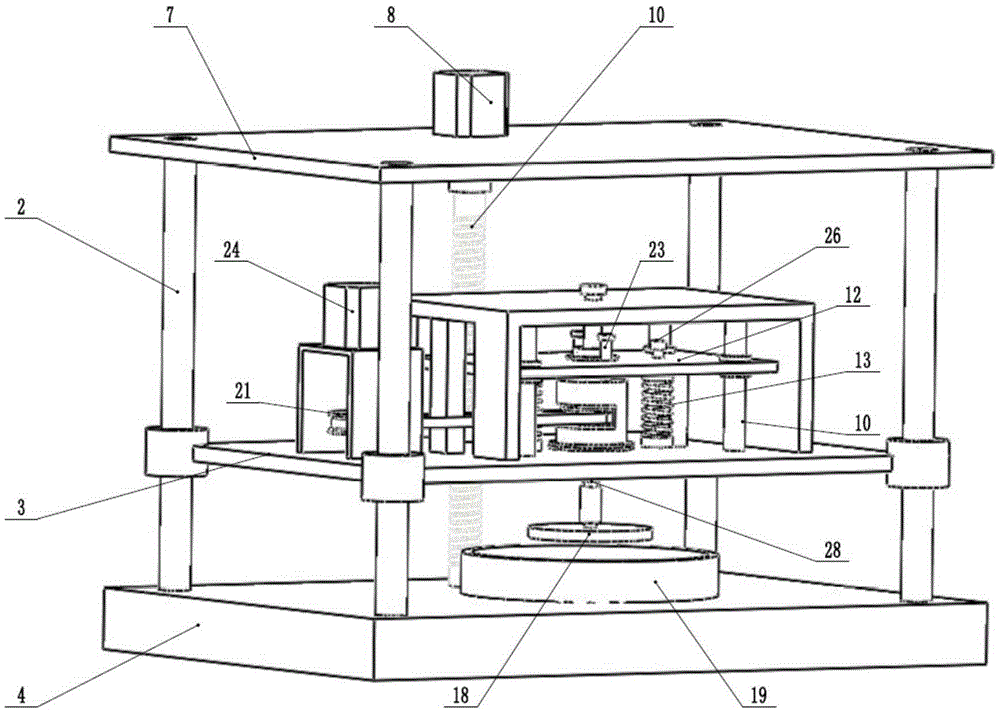

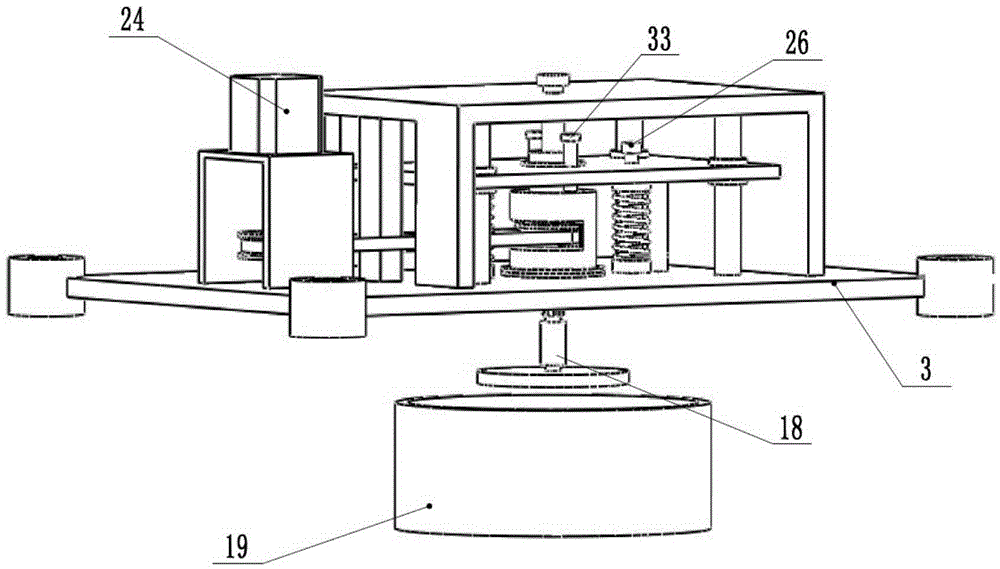

Hydrodynamic pressure suspension polishing device with machining clearance capable of being adjusted

The invention provides a hydrodynamic pressure suspension polishing device with a machining clearance capable of being adjusted. The polishing device comprises a lifting part and a polishing part. The lifting part mainly comprises rolling guide rails, a ball screw, a base, a middle supporting plate, an upper cover plate and a stepper motor. The stepper motor transmits torque through the ball screw to drive the middle supporting plate to go up and down. The polishing part mainly comprises a polishing disk, a ball spline shaft, springs, fine tuning knobs, a movable plate, a middle supporting plate, a guide rail, a servo motor and the like. The servo motor enables the polishing disk to rotate at a high speed through a belt wheel. The weight of the movable plate, the weight of the ball spline shaft and the weight of the polishing disk are overcome by the springs. The distance between the polishing disk and a container is adjusted through the fine tuning knobs. When the hydrodynamic pressure is increased, the polishing disk, the ball spline shaft and the movable plate float upwards overall, and when the hydrodynamic pressure is decreased, the polishing disk, the ball spline shaft and the movable plate descend overall, so that the adaptive suspension of the polishing disk during polishing is achieved. The movement of the movable plate is limited through a limiting threaded rod, and thus the fixed clearance is machined. According to the hydrodynamic pressure suspension polishing device, the machining efficiency is improved, and meanwhile the adjustability of the machining clearance is achieved.

Owner:ZHEJIANG UNIV OF TECH

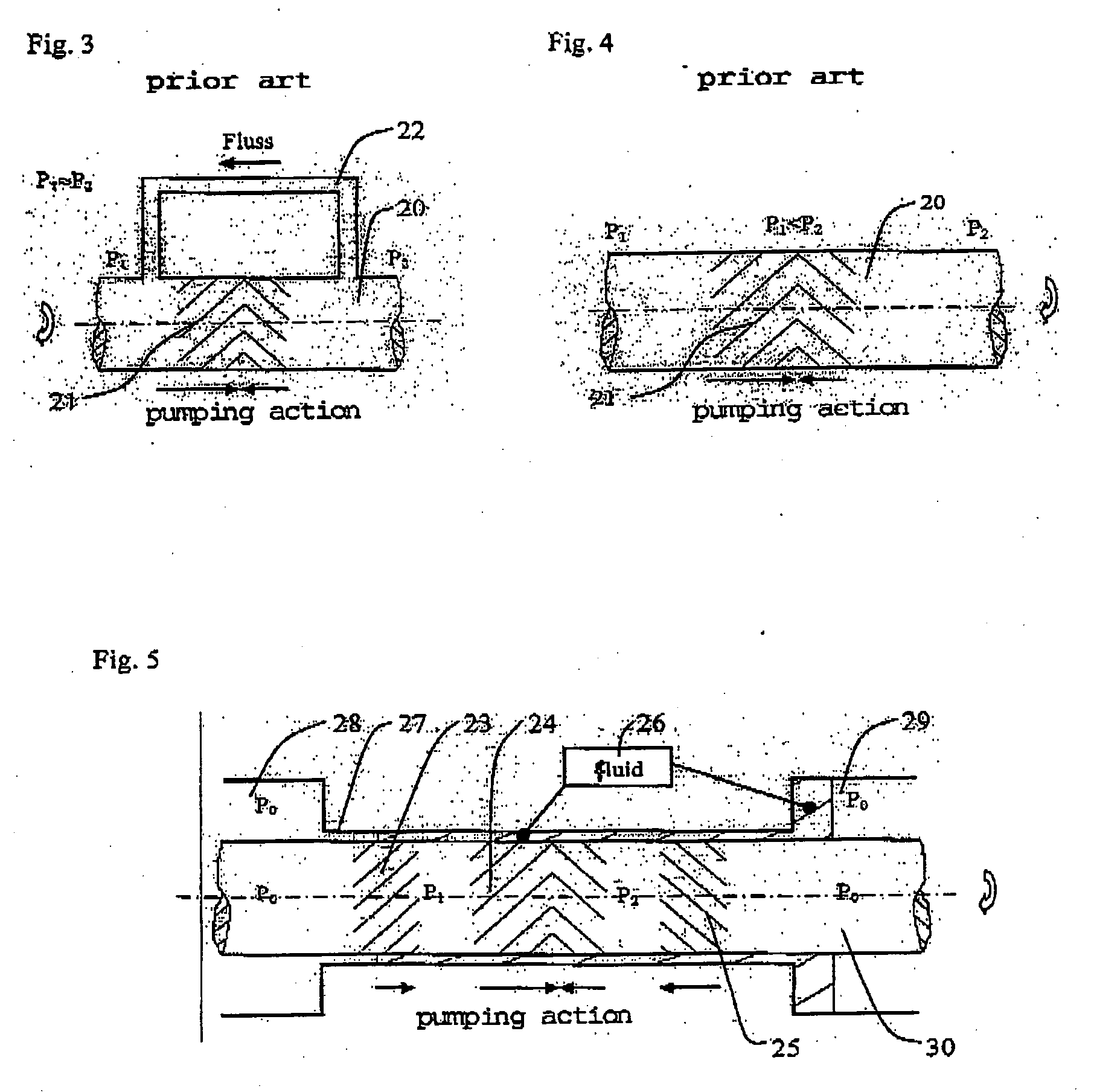

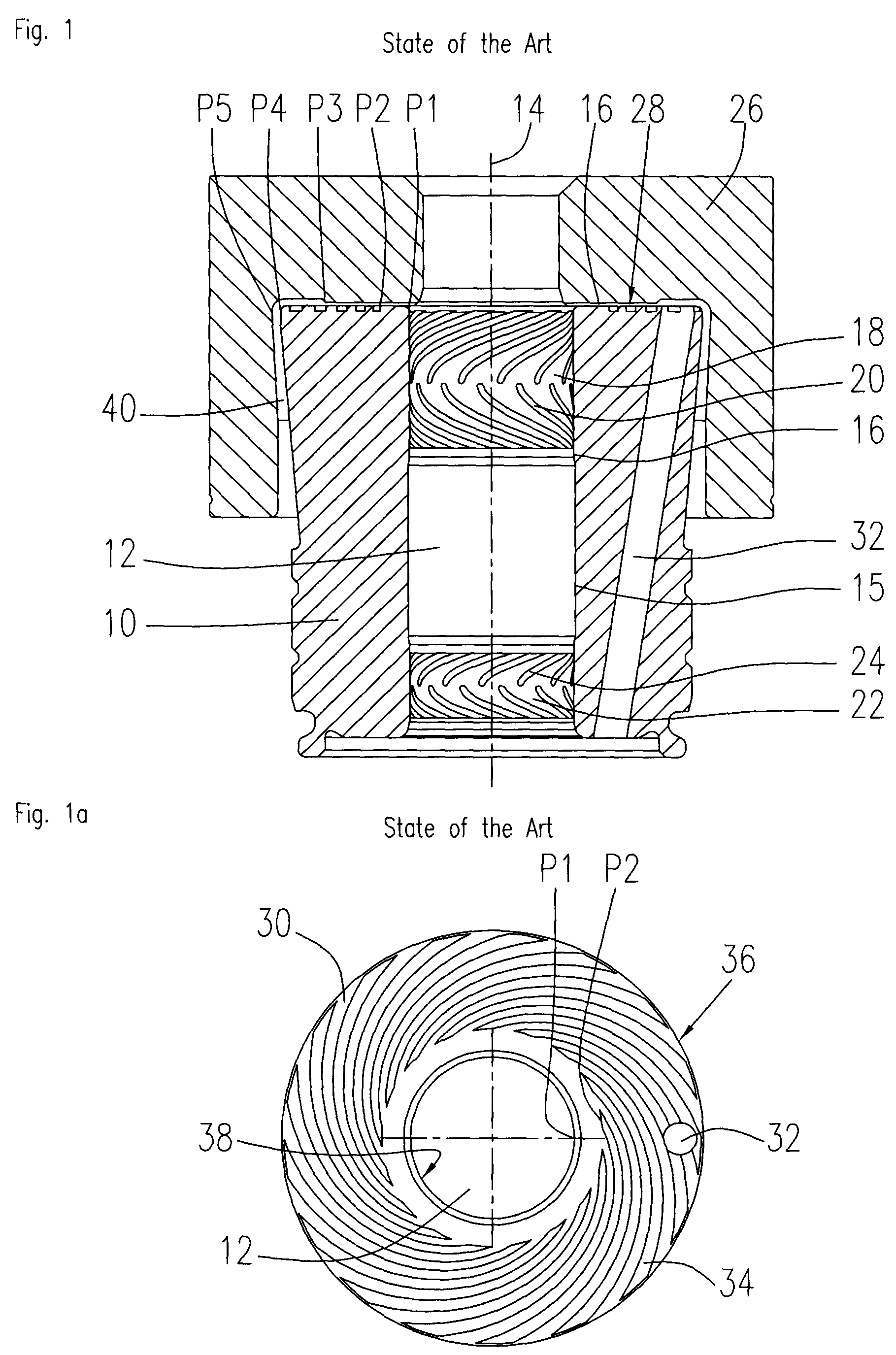

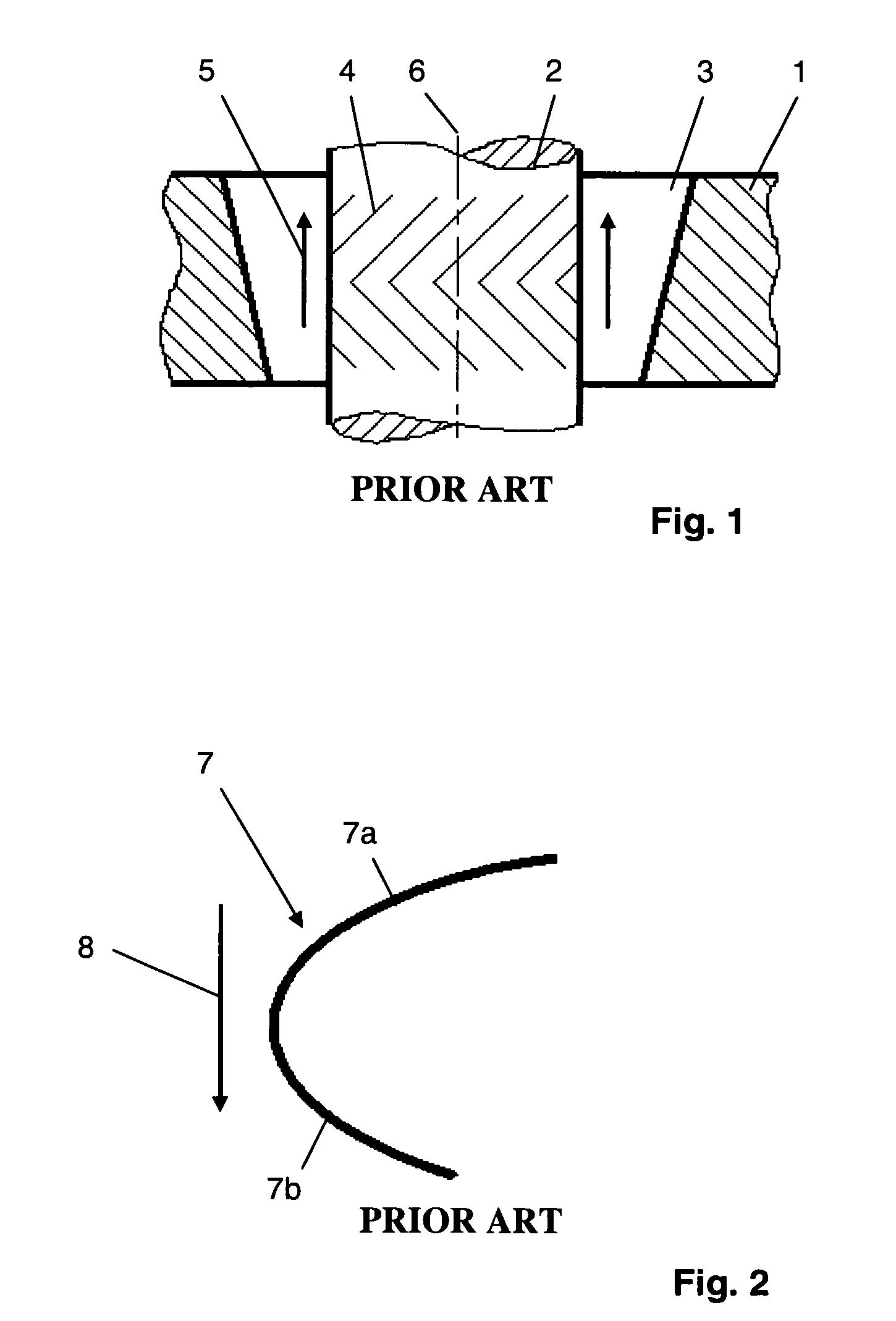

Fluid dynamic bearing having pressure-generating surface patterns

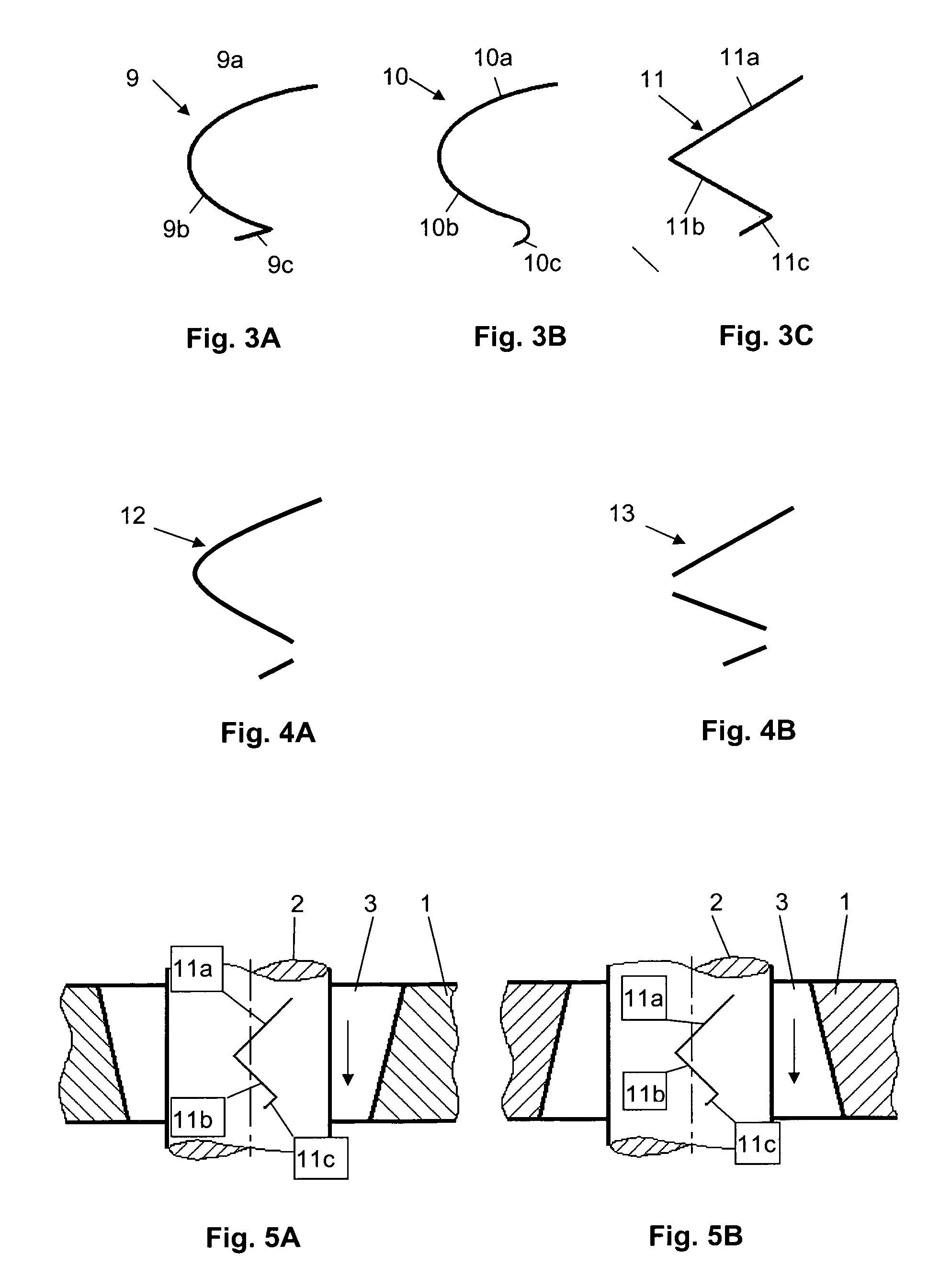

InactiveUS7699529B2Easy to shapeReduce negative impactBearing componentsSliding contact bearingsSurface patternEngineering

A fluid dynamic bearing system having pressure-generating asymmetric surface patterns, having at least two bearing parts that are rotatable with respect to each other and form a bearing gap filled with a bearing fluid between associated bearing surfaces. The surface patterns are disposed on at least one bearing surface so that hydrodynamic pressure is generated within the bearing gap when the bearing parts rotate with respect to each other. Each surface pattern comprises at least three sections, each section generating a pumping action in a defined direction, and the pumping actions of adjacent sections being substantially aligned in opposite directions. Due to the special geometry of the surface patterns, tolerances in the geometry of the bearing gap have a less significant effect on the pre-defined pumping direction.

Owner:MINEBEA CO LTD

Hydrodynamic pressure suspension double-flow pump

InactiveCN103216453APlay the role of heat dissipationAchieve levitationPump componentsBlood pumpsImpellerEngineering

The invention provides a hydrodynamic pressure suspension double-flow pump, relating to an impeller ultra-small pump which has no external mechanism axis and is driven magnetically. The pump comprises two mutually separate flowing channels; each flowing channel consists of an inlet, an impeller, a pressure water chamber and an outlet; and the geometrical parameters of the flowing channels are the same or different; a stator of the pump is embedded in a pump shell, a permanent magnet is embedded in a rotor; and the stator and the permanent magnet are arranged opposite along a radial direction; a radial gap is formed between the internal surface of the pump shell and the external surface of the rotor, so that liquid hydrodynamic support for restricting axial movement is formed during normal operation of the pump; an axial gap is formed between the front cover plate of each impeller and the corresponding pump cover, so that liquid hydrodynamic support for restricting rotor axial movement is formed during the normal operation of the pump. In such a way, the rotor can be suspended in the pump cavity during normal operation. The pump provided by the invention can be used for meeting double-flow use requirement of different flows and pressures, and good flowing condition can be effectively and favorably formed in the internal cavity of the pump shell, and moreover, the operation reliability of the pump can be improved.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com