Testing method of evaluating erosion resistibility of road material under action of hydrodynamic pressure

A technology of road materials and hydrodynamic pressure, applied in the direction of testing wear resistance, can solve the problem of inability to analyze and study the law of road material strength attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

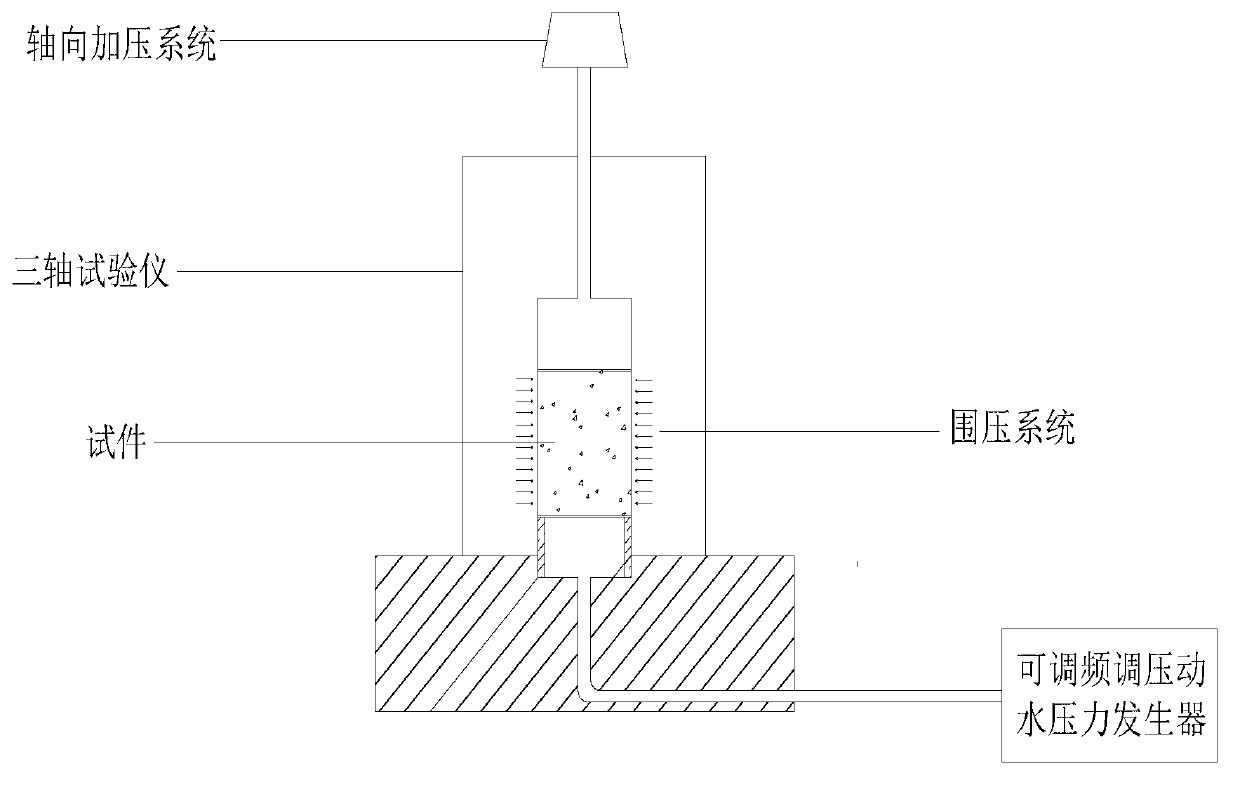

[0018] The following combined technical solutions and attached figure 1 Specific embodiments of the present invention will be described in detail.

[0019] Step 1: Scouring test;

[0020] (1) Prepare a cylindrical specimen with a diameter of 61.8mm and a height of 130mm according to regulations;

[0021] (2) Put the test piece into the pressure chamber of the three-week tester. The internal cavity size of the pressure chamber is 170×170×240. The design pressure is 1Mpa, connect the exhaust pipe, and connect the conduit of the dynamic water pressure generator to the pressure chamber. piece connected;

[0022] (3) Exhaust the air in the pressure chamber and fill it with anaerobic water to fully saturate the specimen;

[0023] (4) Apply axial pressure and axial pressure to the specimen, and the pressure is determined according to the constraint size of the simulated road material;

[0024] (5) Turn on the adjustable frequency and pressure dynamic water pressure generator, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com