Mechanical sealing structure with end face being provided with vein-shaped grooves

A mechanical seal and blade vein technology, which is applied to engine seals, mechanical equipment, engine components, etc., can solve problems such as large leakage, seal failure, and poor chip removal ability, so as to improve the hydrodynamic pressure effect, prolong the service life, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the drawings and specific embodiments.

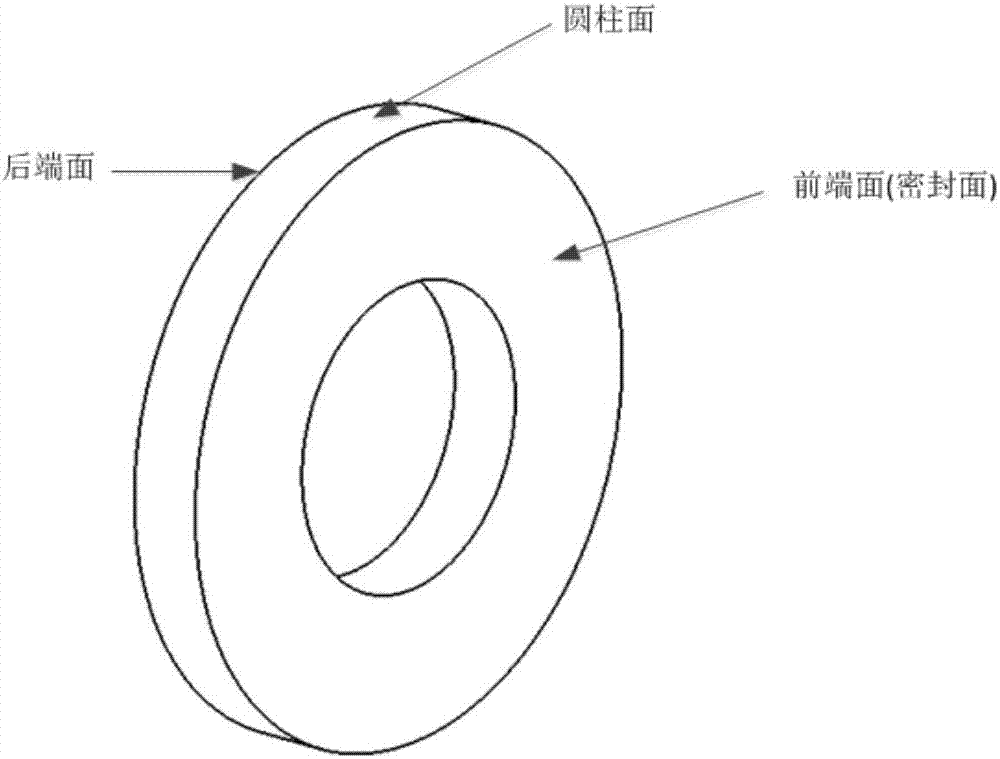

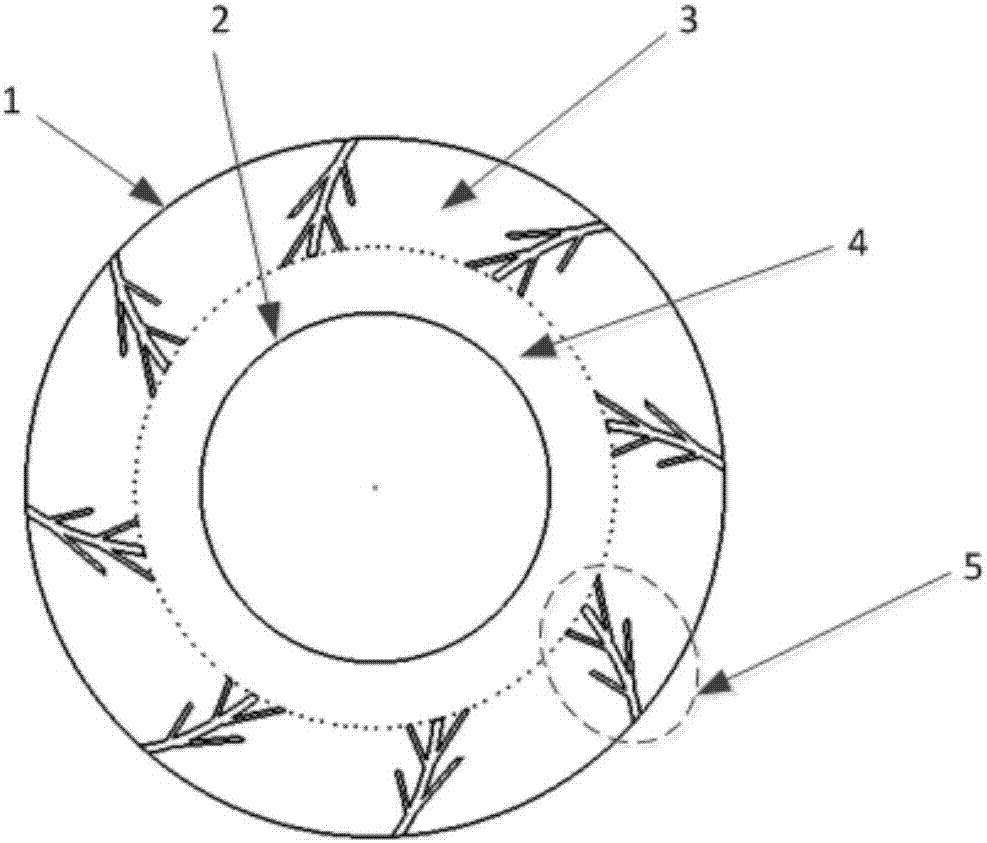

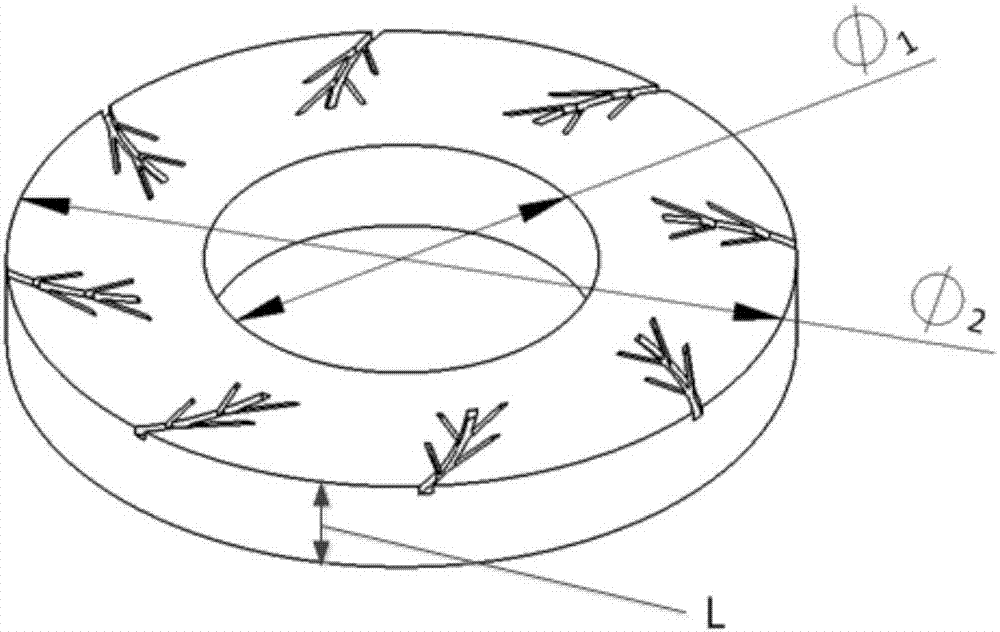

[0036] The structure of the embodiment of the present invention is as Figure 1 ~ Figure 6 Shown. It includes an outer ring (1), an inner ring (2), a sealing weir area (3), a sealing dam area (4), and a vein-shaped groove (5). Such as figure 2 As shown, they are all located at different positions on the front face (seal surface) of the mechanical seal structure. The inner diameter of the entire mechanical seal structure is The outer diameter is The axial thickness of the mechanical seal structure is L. The front end surface (seal surface) of the mechanical seal structure is provided with 8 vein-shaped grooves (5), the number of which varies with the size of the mechanical seal structure, and each vein-shaped groove is symmetrical about the axis of the mechanical seal structure. The vein-shaped groove (5) includes a first branch groove (51), a second bran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com