Mechanical seal end face structure of imitated grinding disc texture

A mechanical seal and end face technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of limited end face fluid film bearing capacity, poor start-stop effect, short seal life, etc., to extend life, reduce leakage, The effect of reducing end-face contact wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

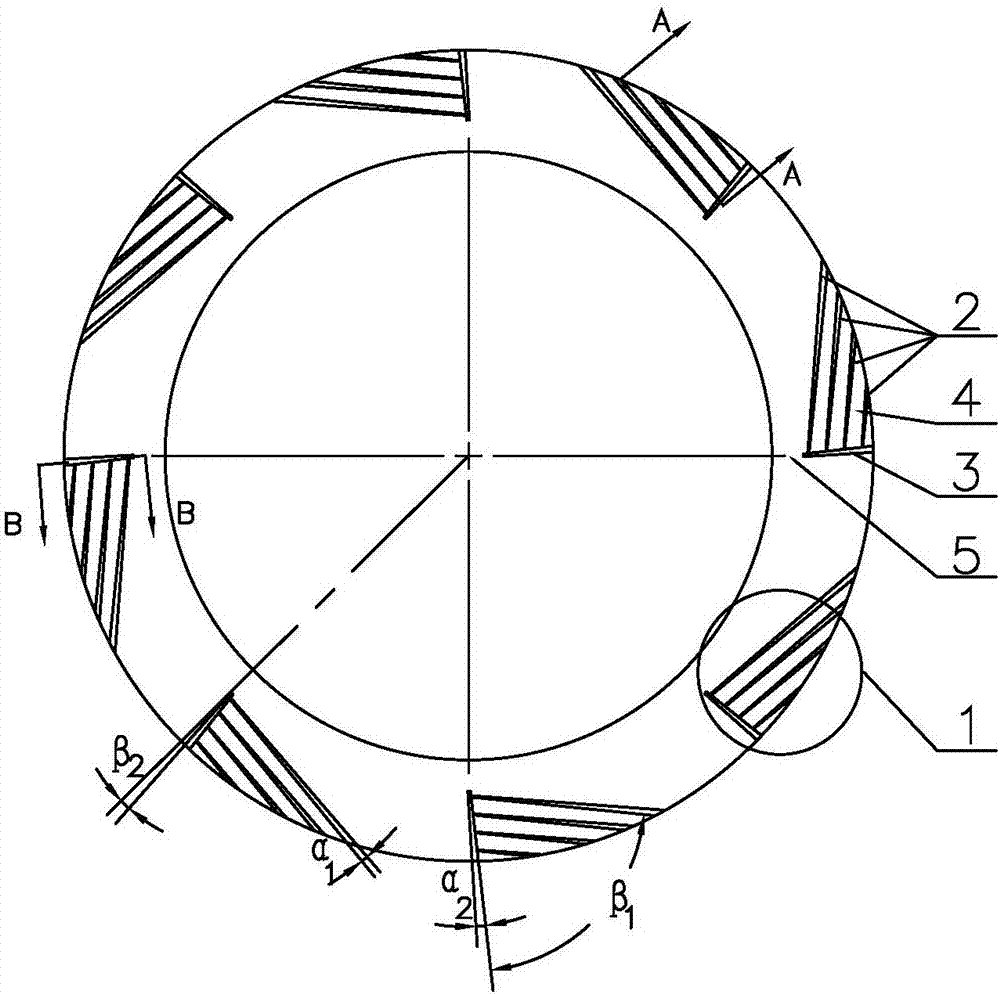

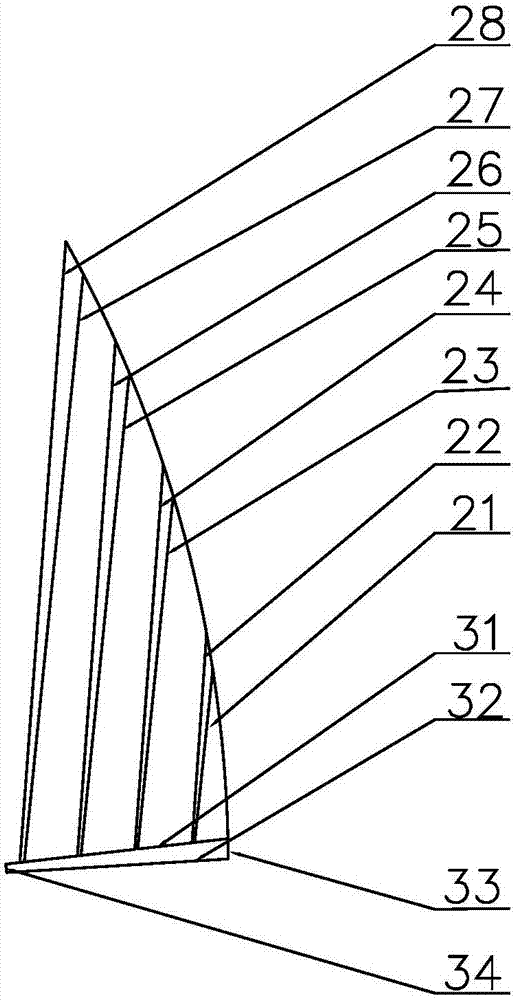

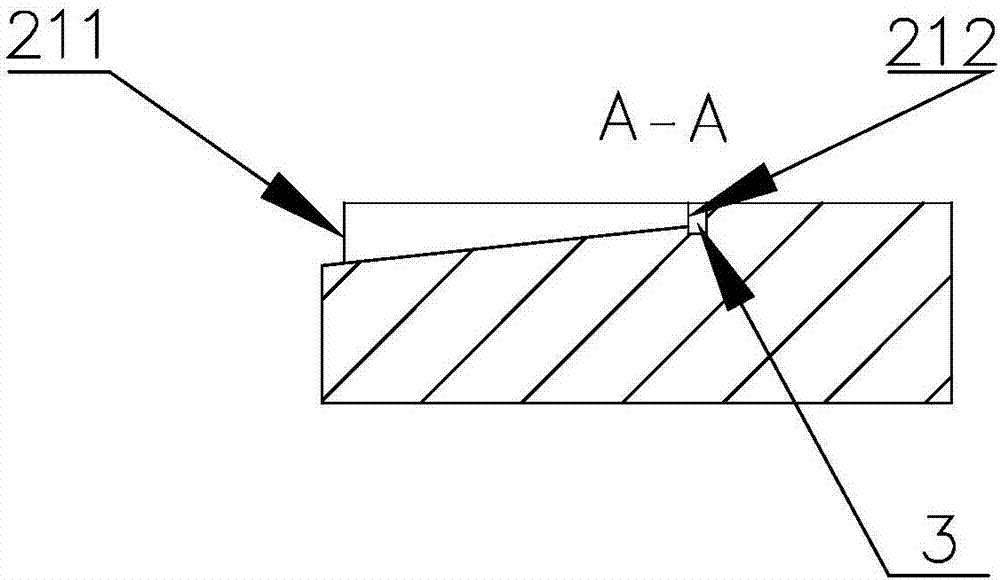

[0021] Reference Figure 1 ~ Figure 4 , A mechanical seal end surface structure that imitates the texture of a grinding disc, comprising a moving ring and a static ring of the mechanical seal. One side of the end surface of the moving ring and the static ring is the high pressure side, that is, upstream. The other side is the low pressure side, that is downstream; the end surface of at least one of the moving ring and the static ring is provided with a plurality of streamlined grooves 1 that are evenly distributed along the circumferential direction, imitating the surface texture of the grinding disc; the streamlined grooves are moved by the base The pressure groove 2 and the diversion groove 3 are composed of gradually narrowing from upstream to downstream, and the depth becomes shallower. The basic dynamic pressure grooves are multi-row parallel, and the grooves are separated by a sealing weir 4 of equal depth; The diversion groove penetrates through each basic dynamic pressur...

Embodiment 2

[0028] Reference Figure 5 The difference between this embodiment and embodiment 1 is that there are multiple sections of diversion grooves 6 in the streamlined groove, the number of diversion grooves is equal to the basic dynamic pressure grooves, and the basic dynamic pressure grooves are connected to each other, and each section of the guide The flow troughs all present a convergent structure with deep upstream and shallow downstream. Refer to Example 1 for the specific depth range. The left and right side walls of the diversion groove are flat, and the included angle range can refer to Example 1. The upstream and downstream width of the diversion groove is equal to the distance between the basic dynamic pressure grooves. This kind of groove type can generate high pressure zone near the diversion groove area. Due to the different positions of diversion grooves, it can enhance the dynamic pressure effect on the overall end surface, improve the fluid film rigidity, thereby redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com