Patents

Literature

104results about How to "Reduce contact wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

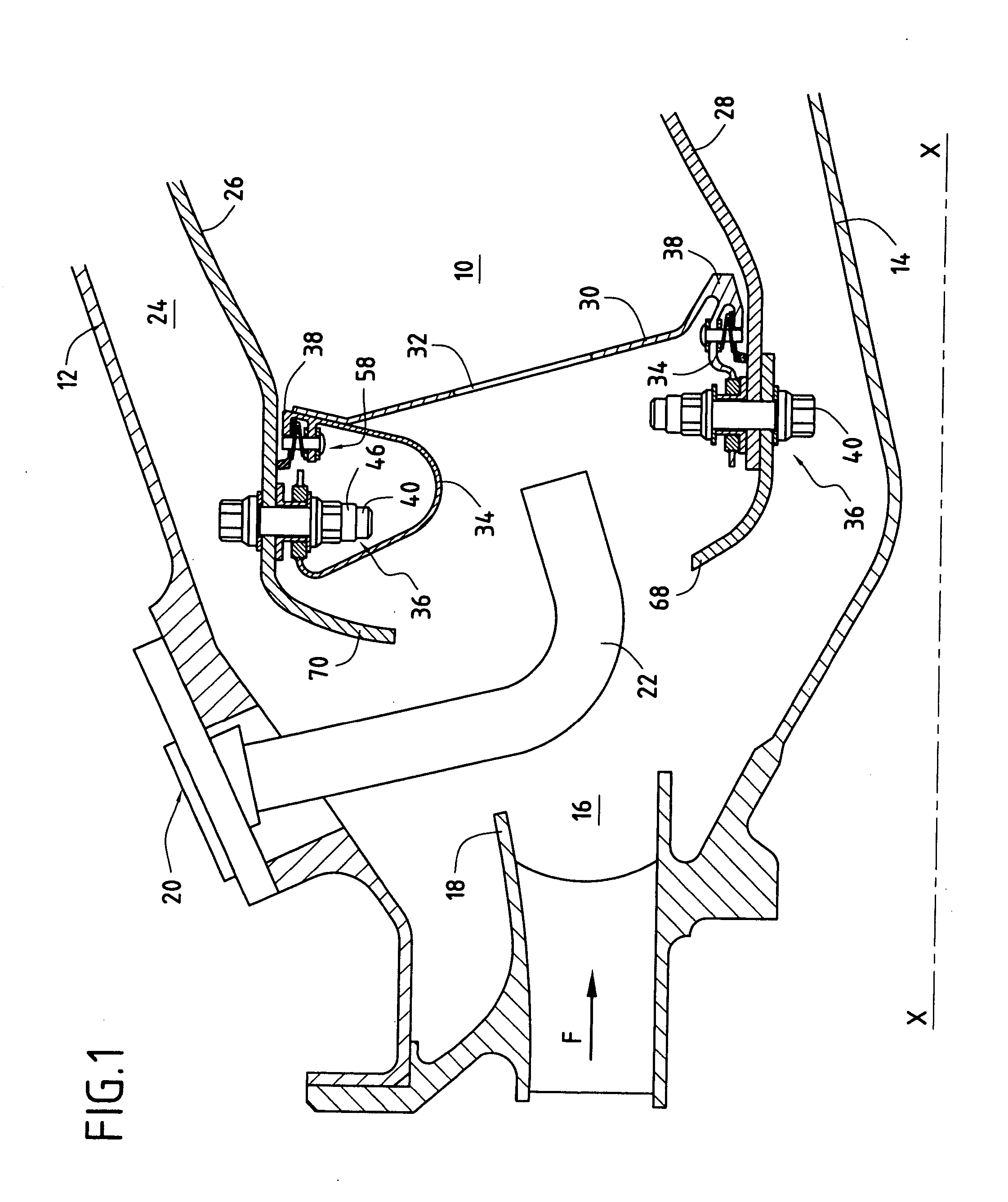

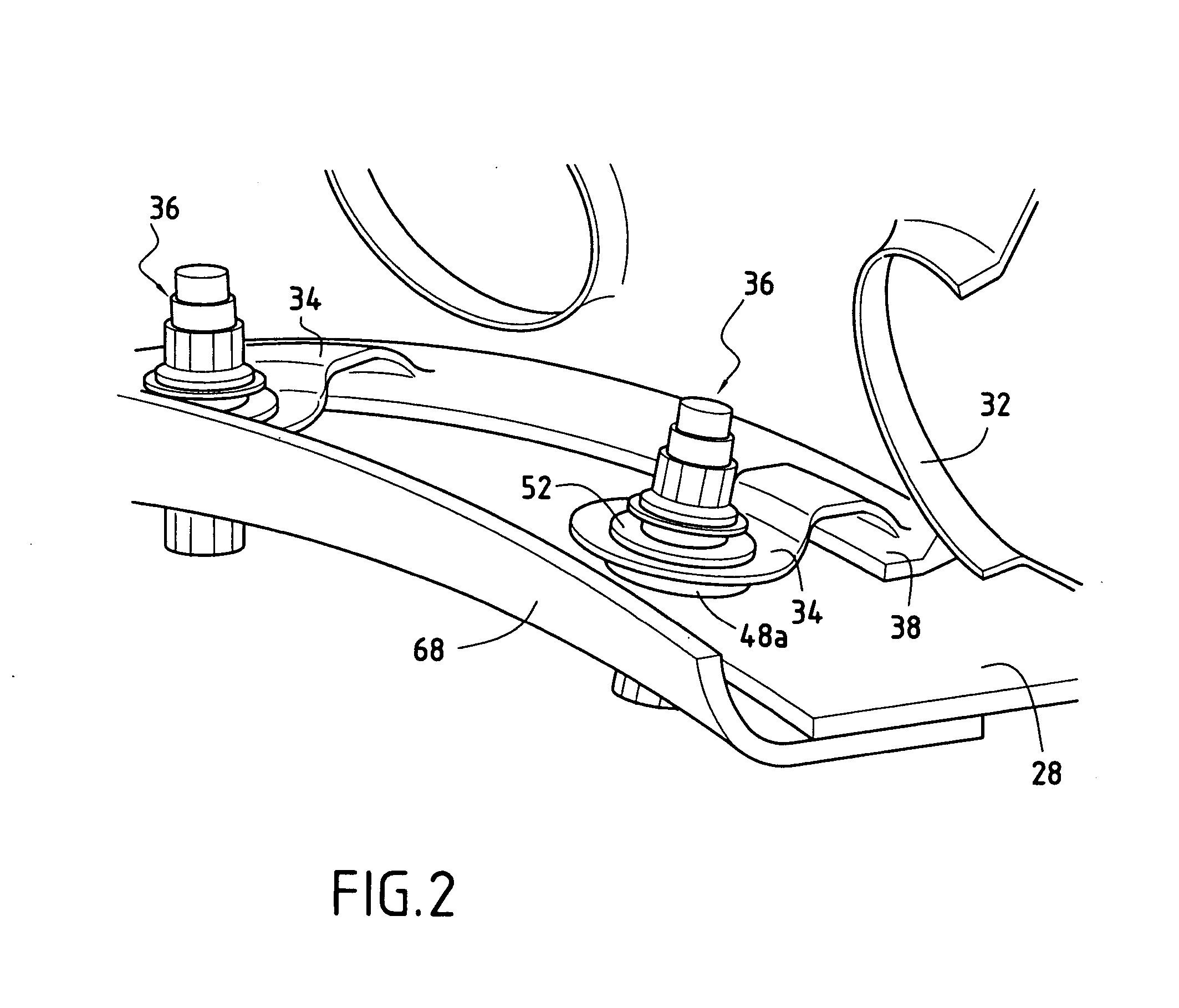

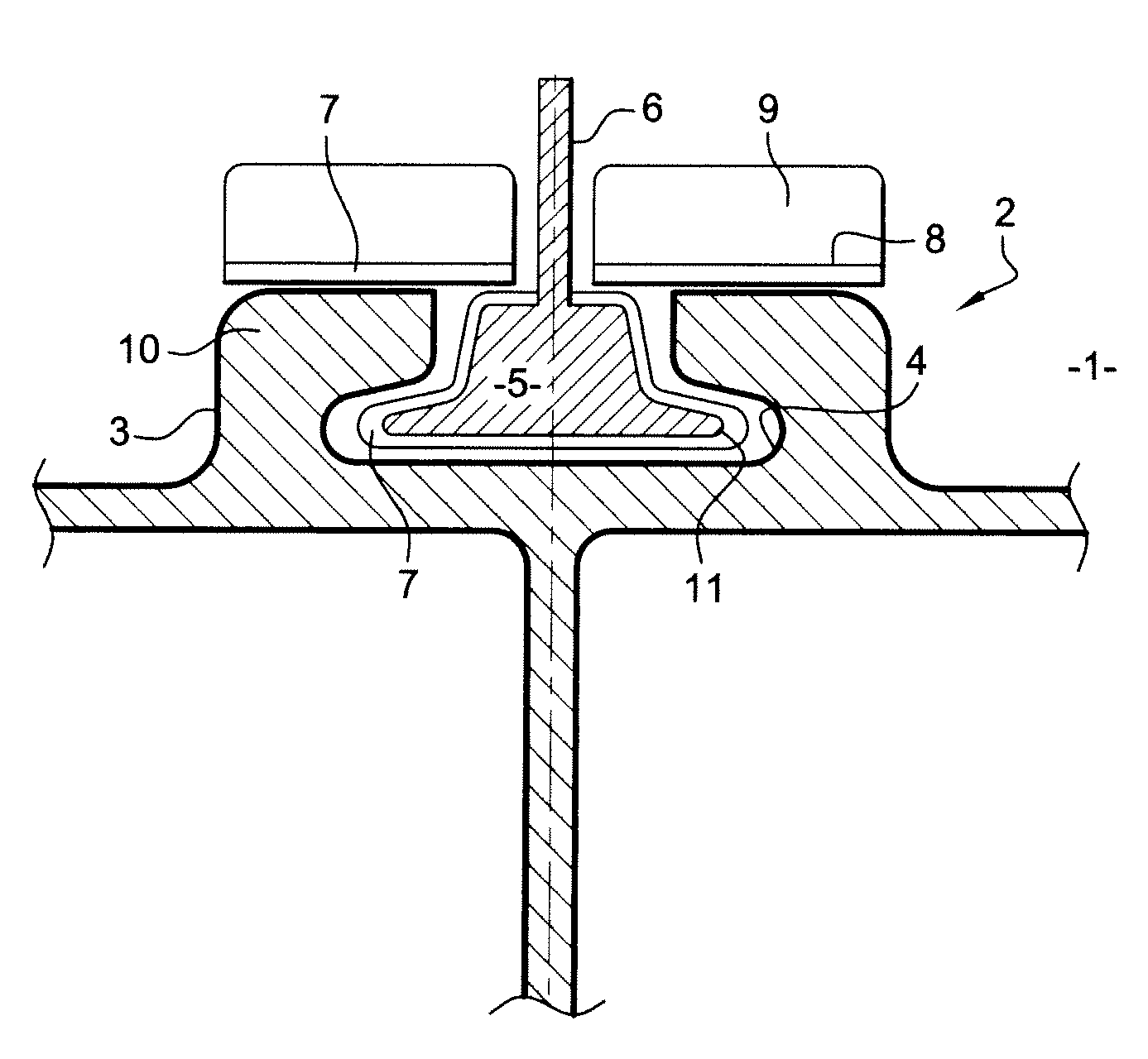

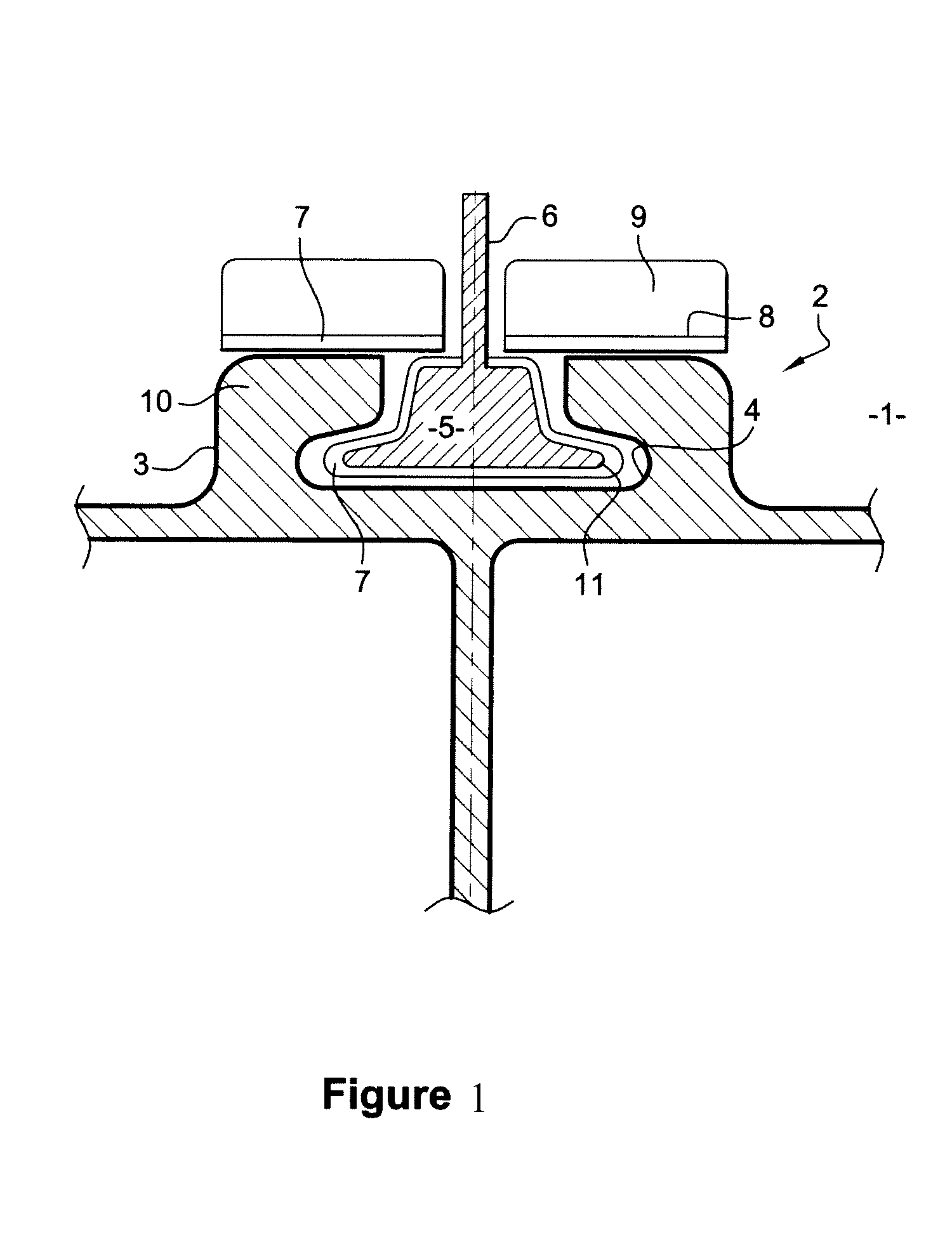

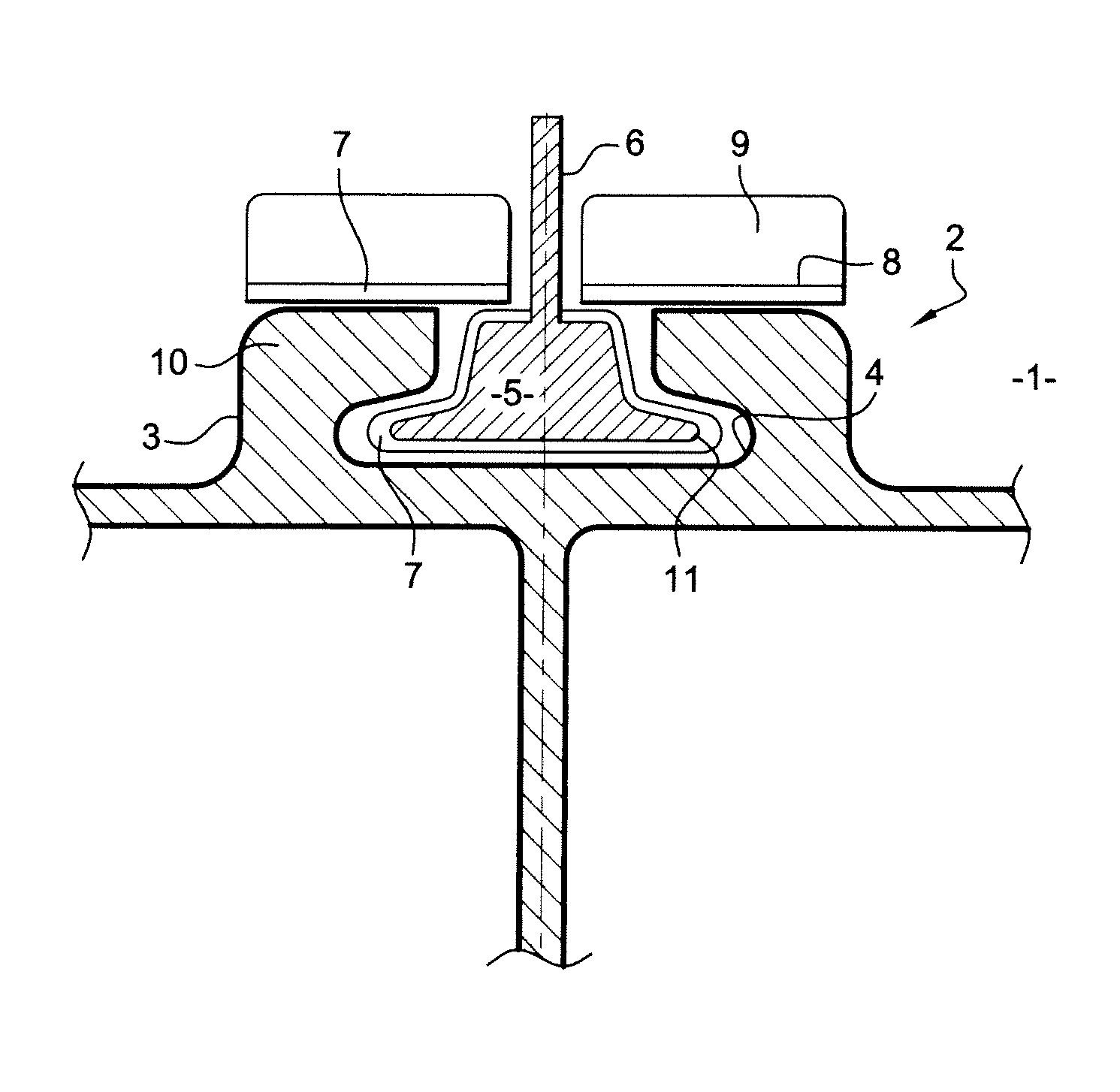

Assembling an annular combustion chamber of a turbomachine

ActiveUS7849696B2Effective dampingMitigate such drawbackContinuous combustion chamberCombustion enginesCombustion chamberThermal expansion

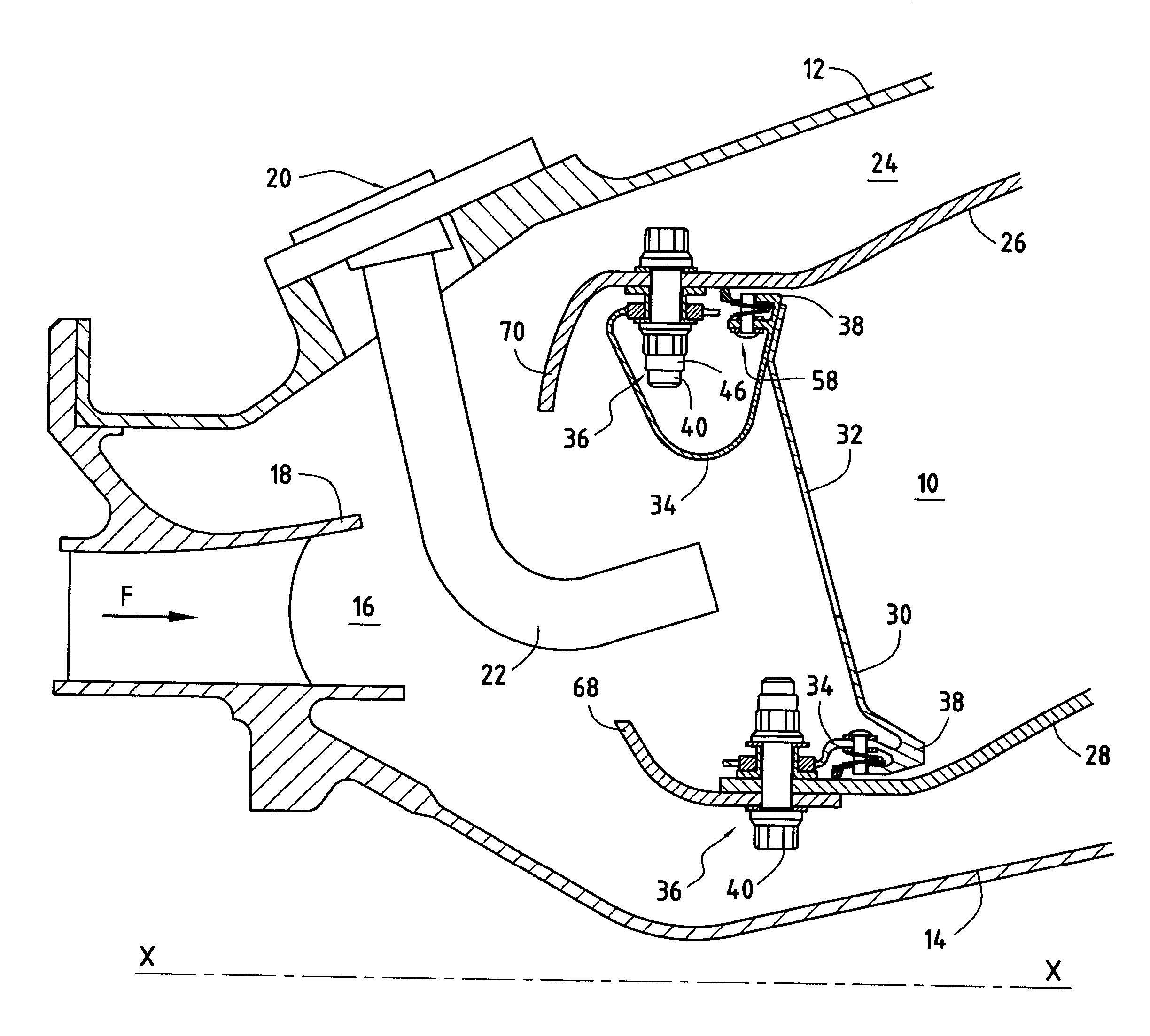

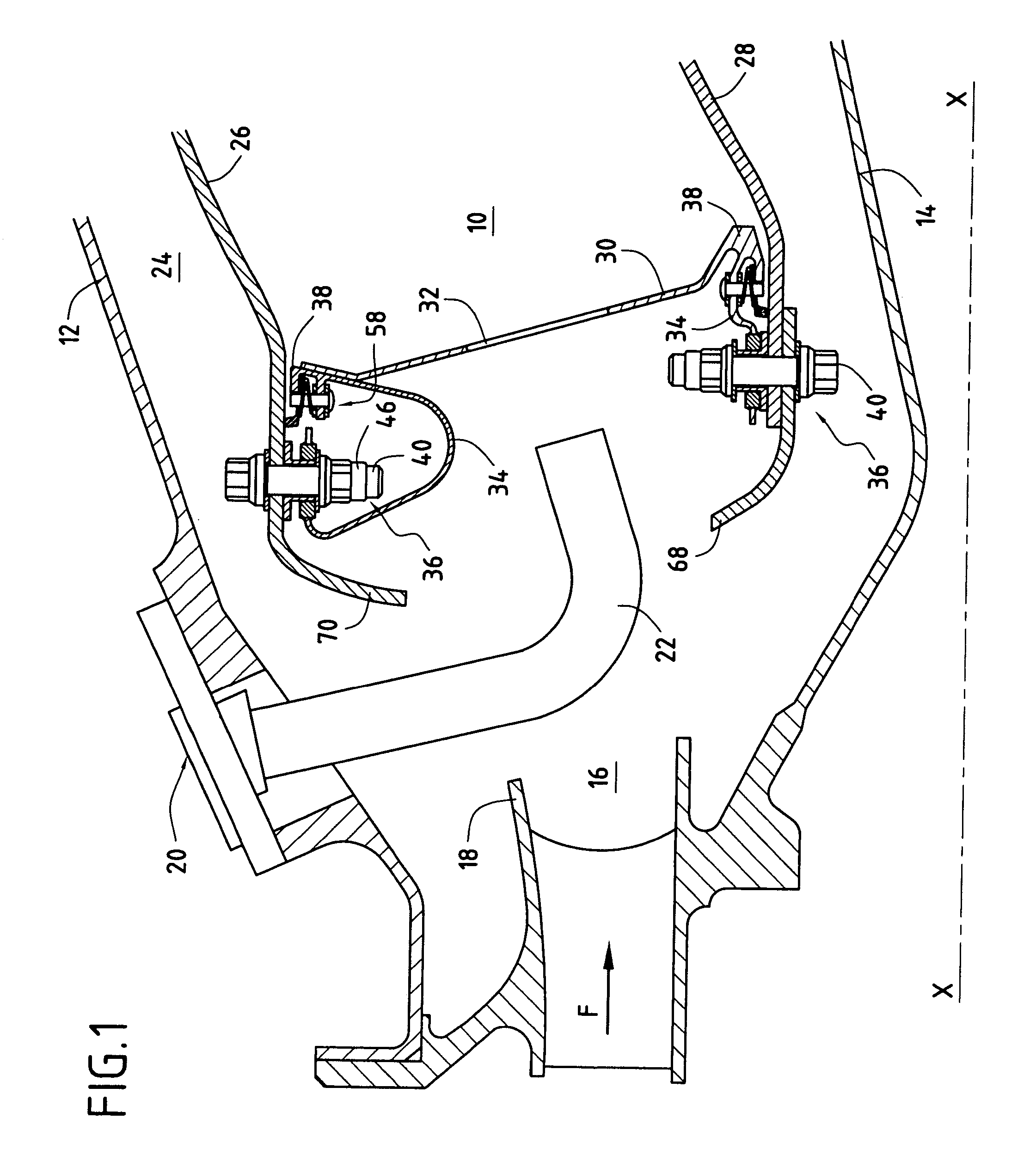

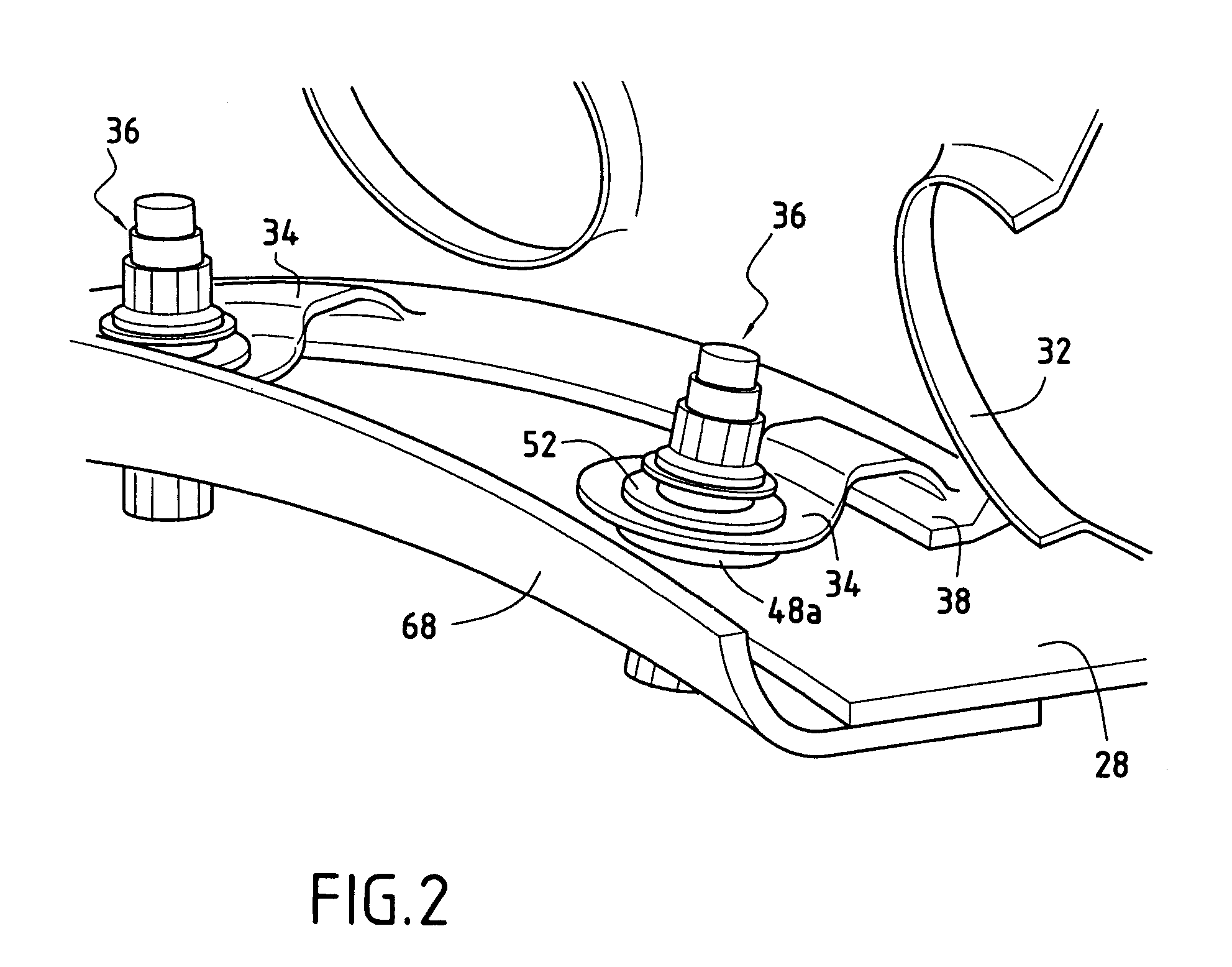

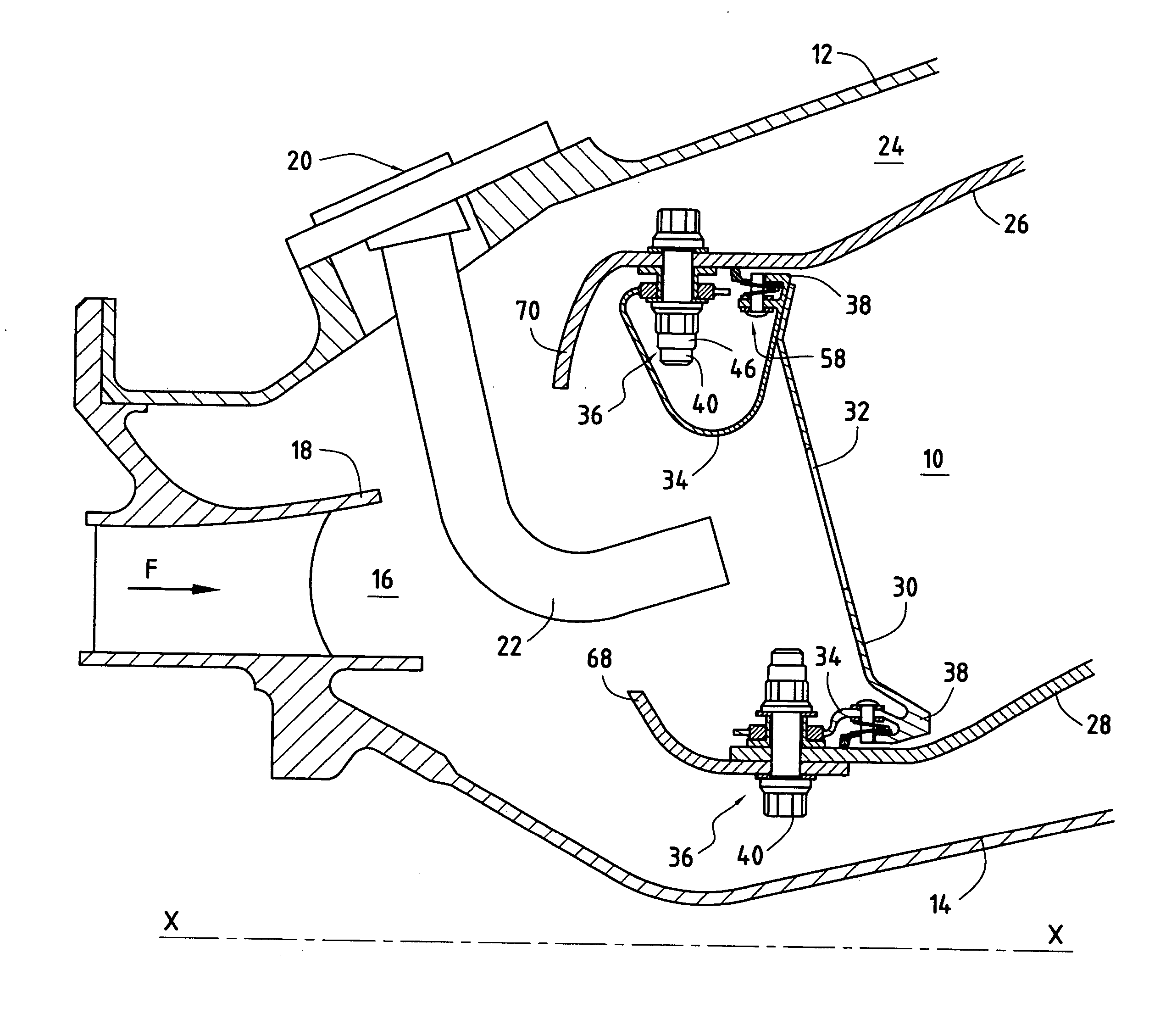

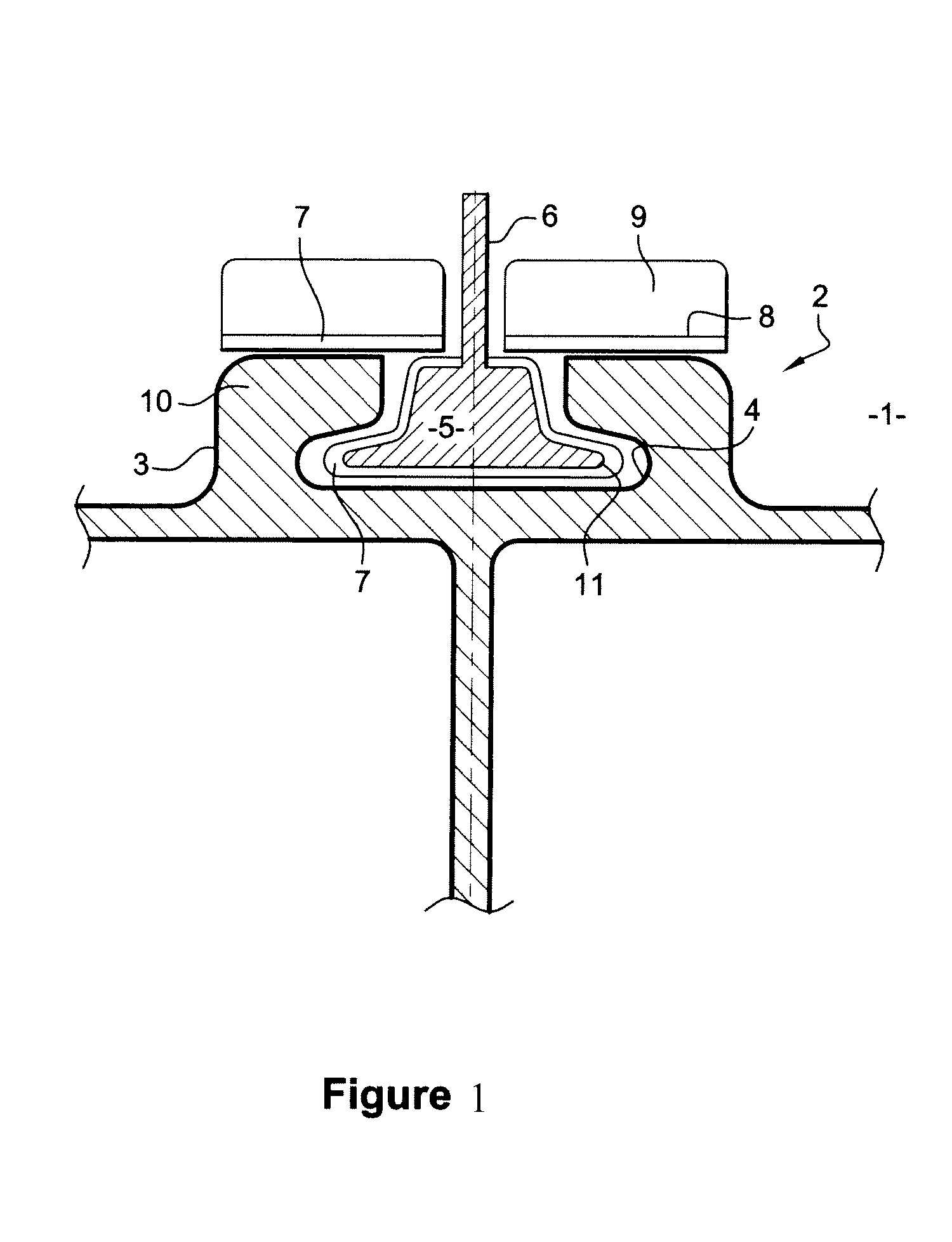

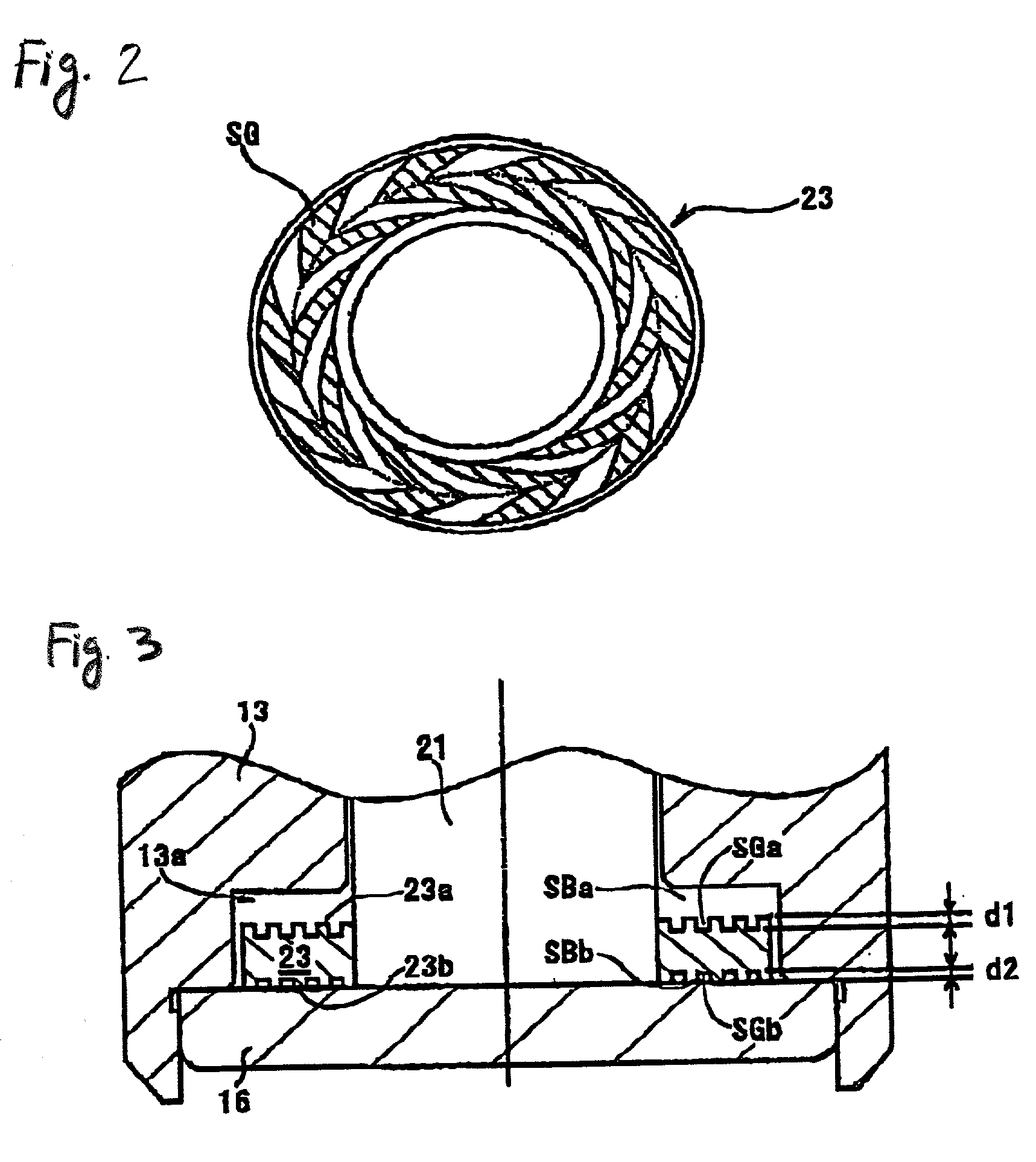

An annular combustion chamber comprising axial walls interconnected by a chamber end wall having a coefficient of thermal expansion that is different from that of the axial walls, the chamber end wall being provided with a plurality of inner and outer fastener tabs secured by fastener systems to the end portions of the axial walls. Each fastener system comprises a bolt, a nut tightened onto one of the ends of the bolt, and a slideway bushing disposed around the bolt between the nut and the end portion of the corresponding axial wall, a determined amount of radial clearance being provided between the nut and the end portion of the axial wall so as to enable the chamber end wall to expand radially freely in operation relative to the axial walls.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Assembling an annular combustion chamber of a turbomachine

ActiveUS20070107710A1Effective dampingMitigate such drawbackContinuous combustion chamberCombustion enginesCombustion chamberEngineering

An annular combustion chamber comprising axial walls interconnected by a chamber end wall having a coefficient of thermal expansion that is different from that of the axial walls, the chamber end wall being provided with a plurality of inner and outer fastener tabs secured by fastener systems to the end portions of the axial walls. Each fastener system comprises a bolt, a nut tightened onto one of the ends of the bolt, and a slideway bushing disposed around the bolt between the nut and the end portion of the corresponding axial wall, a determined amount of radial clearance being provided between the nut and the end portion of the axial wall so as to enable the chamber end wall to expand radially freely in operation relative to the axial walls.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

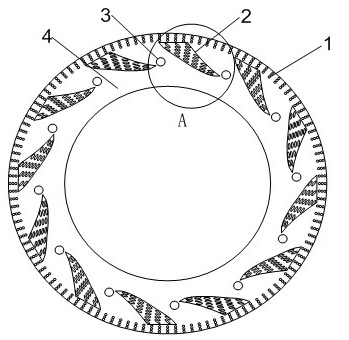

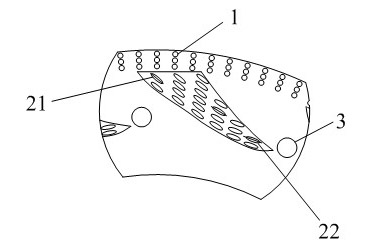

Negative pressure groove end face mechanical seal structure

The invention relates to a negative pressure groove end face mechanical seal structure, comprising a mechanically sealed moving ring and a mechanically sealed static ring, one side of the end faces of the moving ring and the static ring is a high pressure side namely upstream, the other side of the end faces of the moving ring and the static ring is a low pressure side namely downstream, at leastone end face of the moving ring or the static ring is provided with negative pressure groove groups which are symmetrically distributed with the center of rotation, the upstream of each negative pressure groove group is provided with a micropore annular band, each negative pressure groove group is composed of micropore dynamic pressure grooves with spiral deformation and inclination and relief grooves, the micropore dynamic pressure grooves and the relief grooves are distributed at intervals, the relief grooves are close to the terminals of the dynamic pressure grooves, and the downstream of each negative pressure groove group is provided with an annular sealing dam with a smooth plane. The invention has the beneficial effects of enhancing antijamming capability of sealing in operation athigh speed, improving dynamic pressure opening capability of a high speed seal face under the low speed working condition, realizing non-contact stability of the seal face under the high speed working condition, reducing end face contact wear, prolonging service life and improving sealing reliability.

Owner:海宁市黄湾镇资产经营有限公司

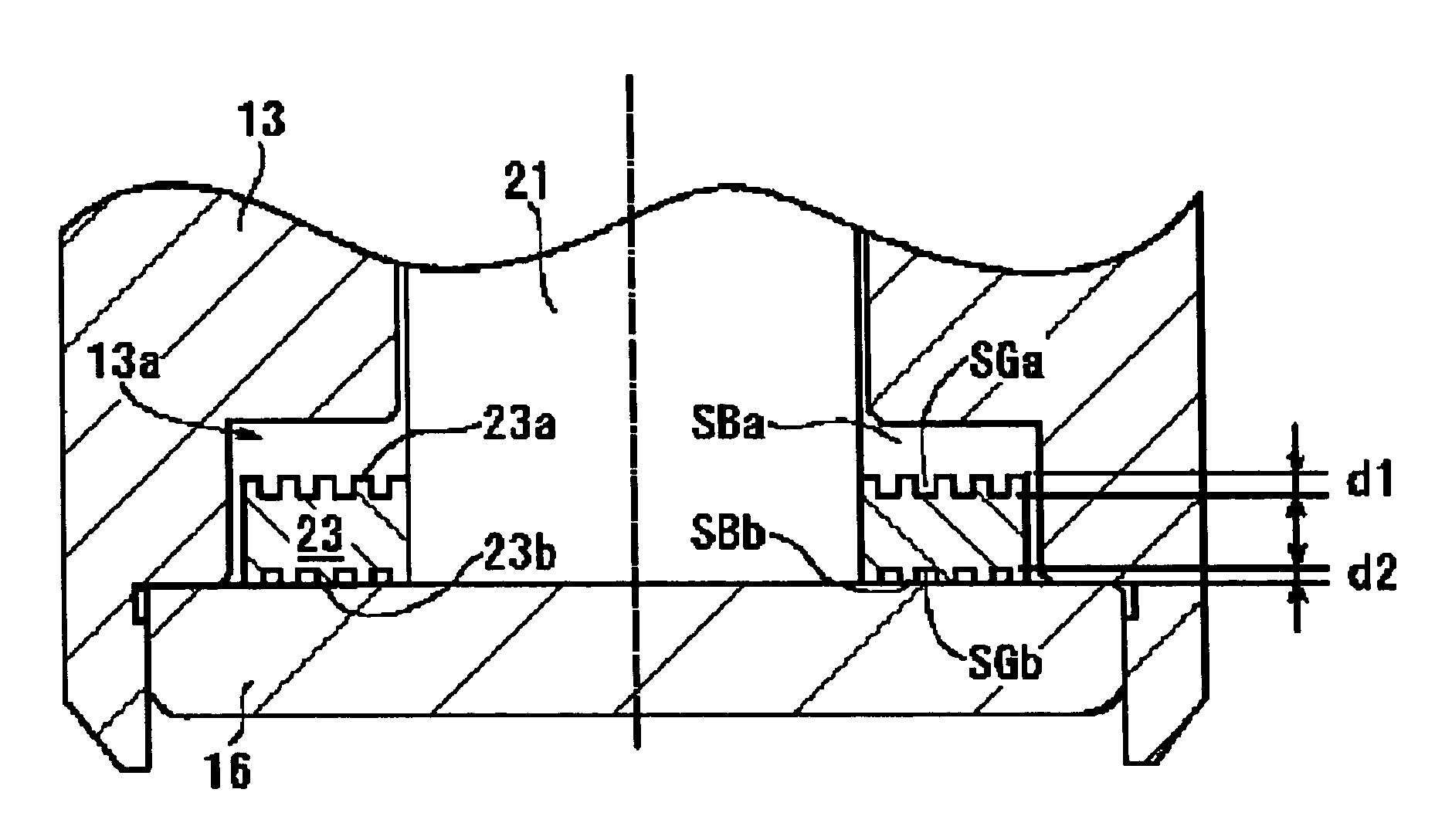

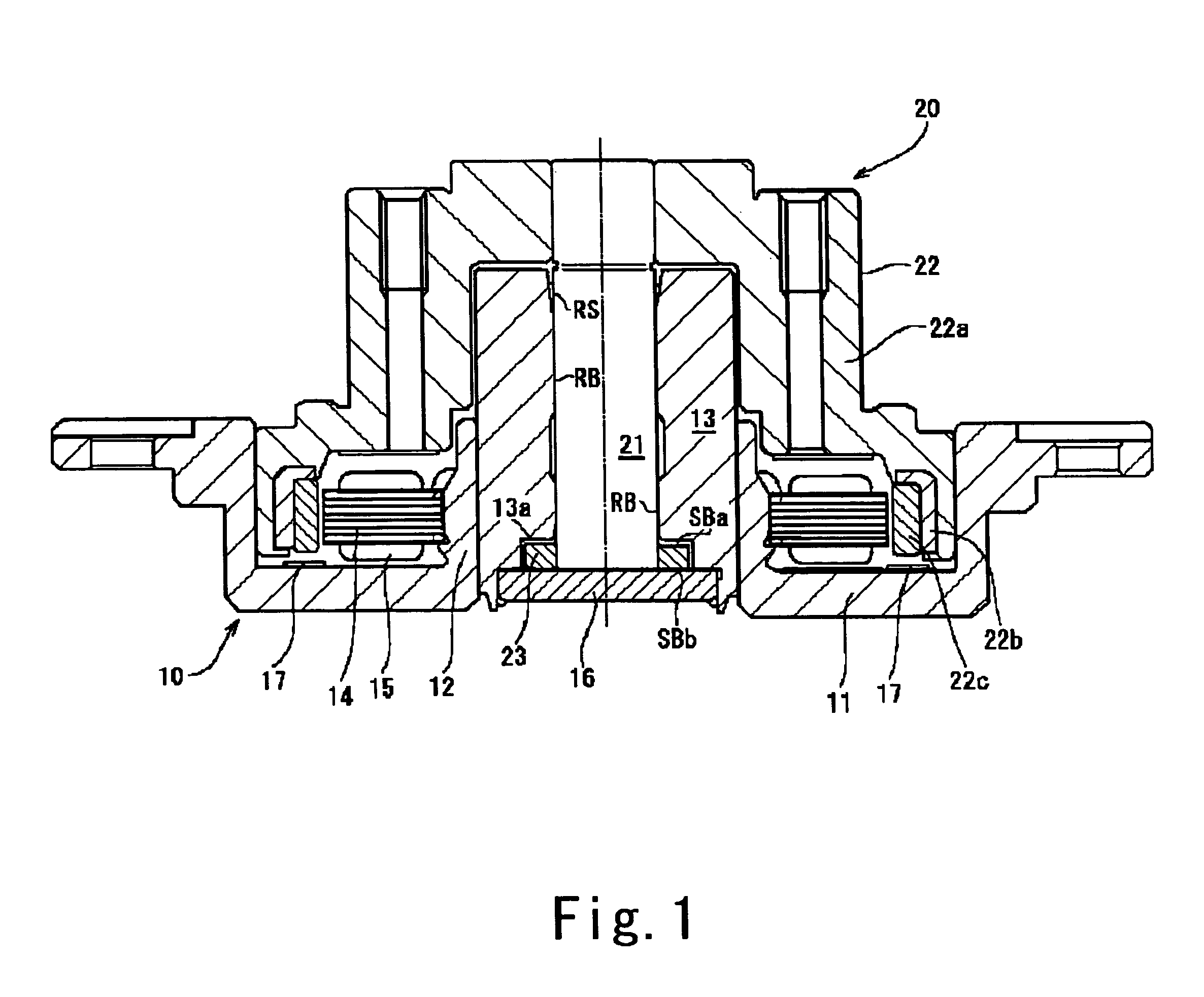

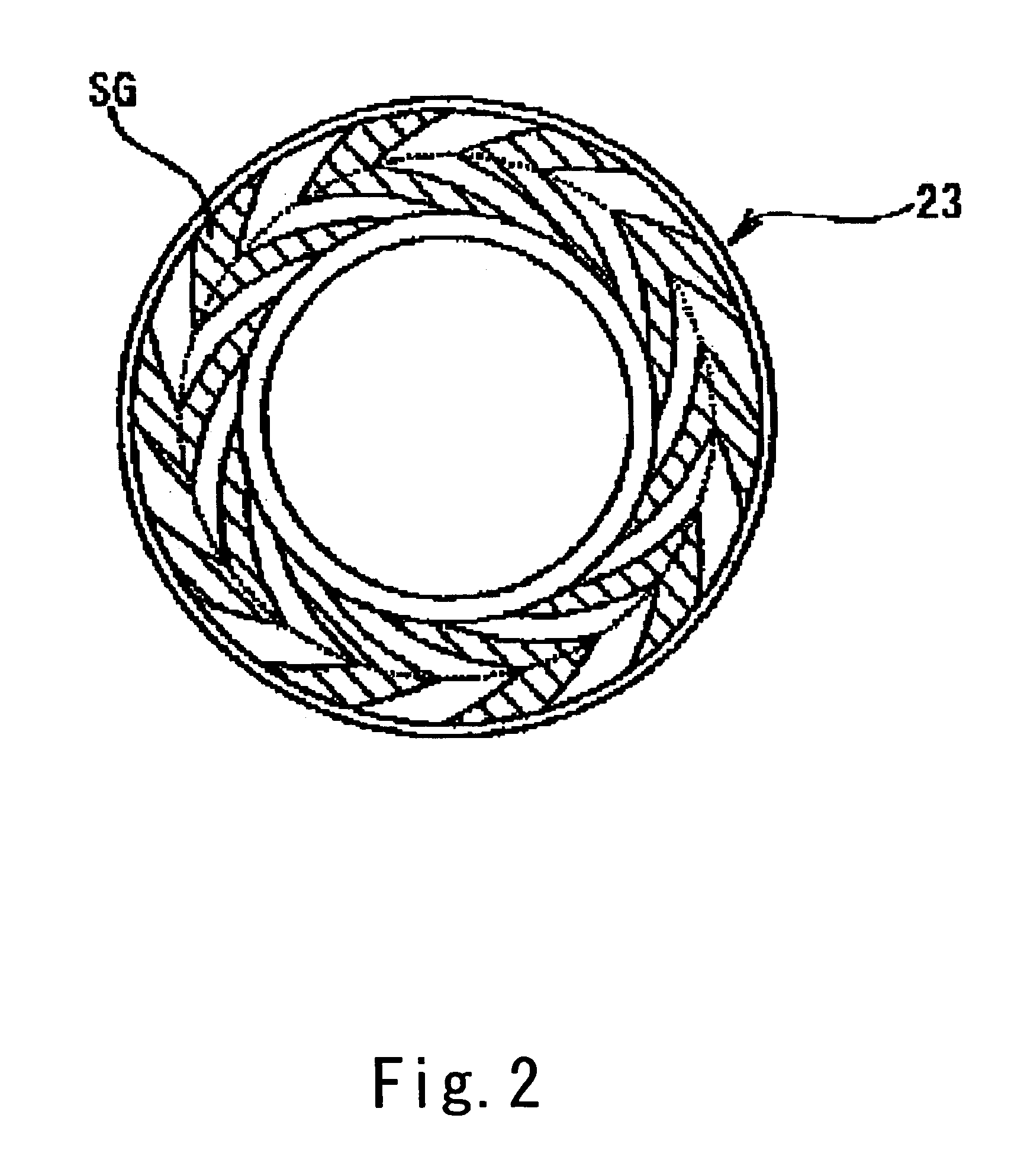

Fluid dynamic pressure bearing apparatus

InactiveUS6962443B2Reduce contact wearIncreased durabilityShaftsRecord information storageThrust bearingEngineering

Owner:NIDEC CORP

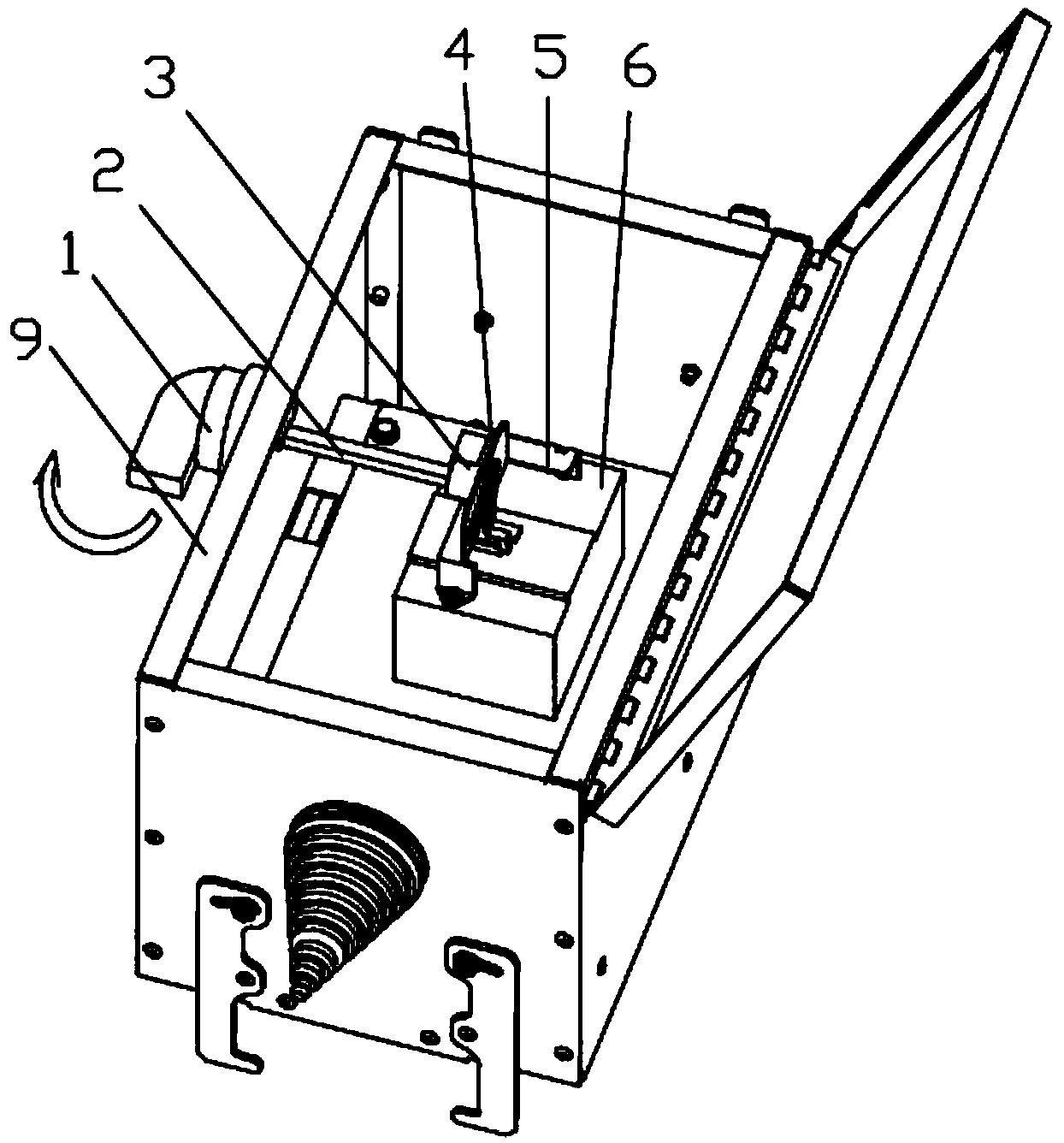

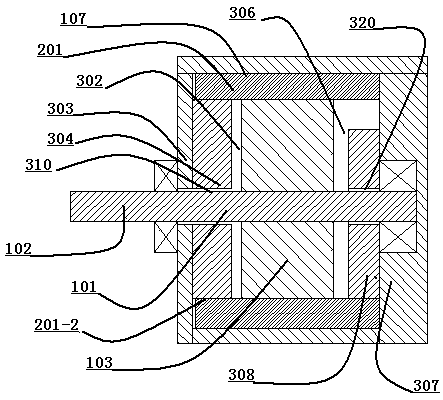

Bus duct plug box

ActiveCN104242196ACompact structureMeet the needs of installation and useBus-bar installationElectrical connectionEngineering

The invention relates to a bus duct plug box and belongs to the technical field of electrical connection facilities. The plug box comprises a breaker arranged in a box body, the breaker is provided with a switching gate handle extending out of the upper surface of the breaker, a main rotary shaft is supported in the box body, one end of the main rotary shaft extends out of one side of the box body, the outer extending end of the main rotary shaft is fixedly connected with a rotary handle, the inner extending end of the main rotary shaft is fixedly connected with guide jaws, and the lower ends of the guide jaws horizontally extend to form poking fingers located on the two sides of the switching gate handle respectively. Due to adoption of the sideward arrangement structure, the upper portion of the breaker does not need to have space for holding rocker supports and other actuation components and the structure is compact. Additionally, points where the poking fingers exert force on the switching gate handle are gradually moved downwards in the poking process, the length of a resistance arm of the switching gate handle is reduced while the lengths of power arms of the guide jaws are kept unchanged, and it is guaranteed that follow-up performance of the switching gate handle is better.

Owner:镇江西门子母线有限公司

Fastener assembly for transport vehicle

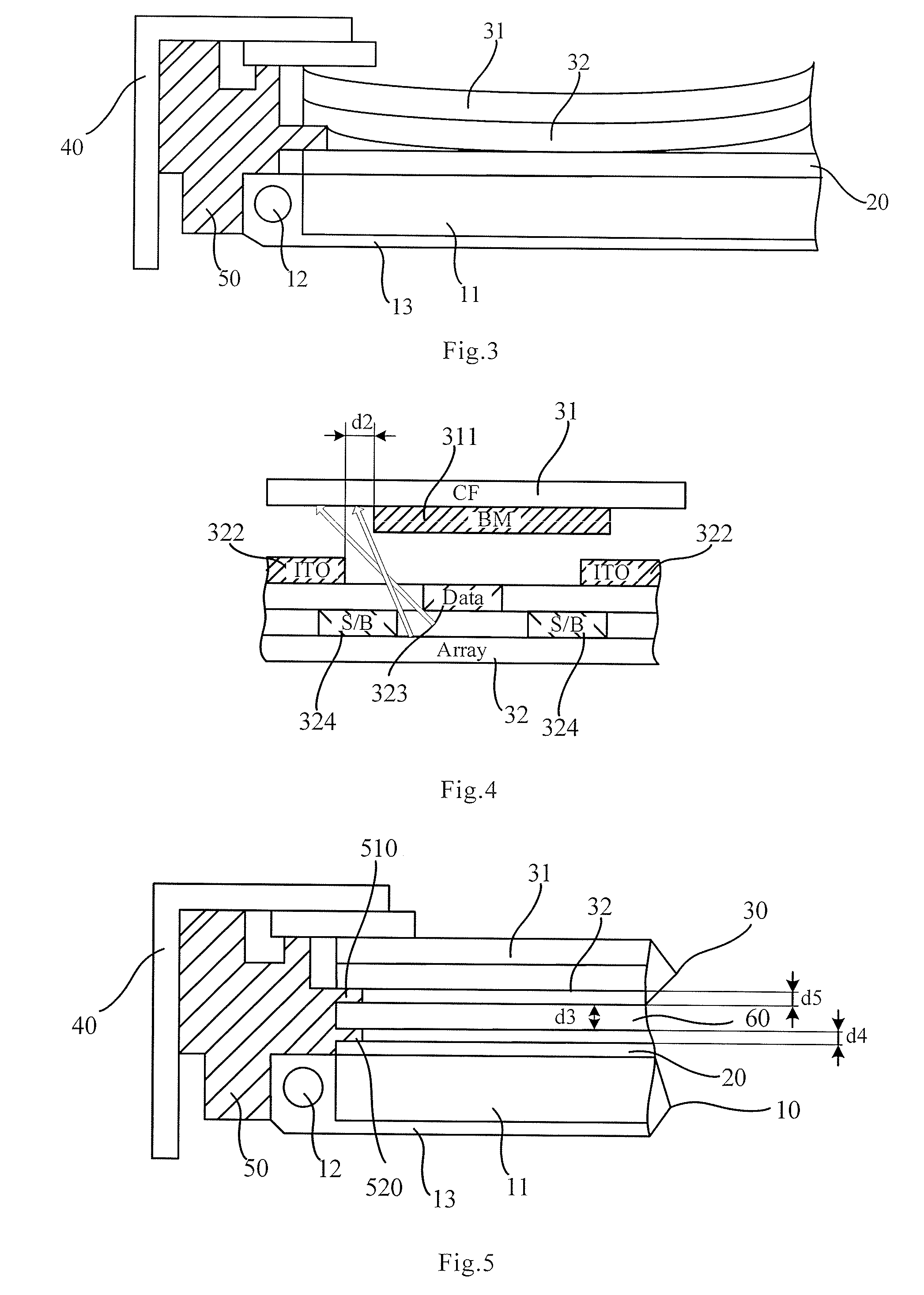

ActiveUS20100067999A1Improve the immunityReduce contact wearFlexible elementsMovable seatsPolymerFastener

This invention relates to a fastener assembly that has a rail (1) and a fastener device (6) that can be installed in a transport vehicle, characterized in that a rail head (2) is coated with a layer (3) of alumina with polytetrafluoroethylene seal and that at least a portion (5) of the fastener device in contact with the rail head is made of metal coated with a layer of polymers (7).

Owner:AIRBUS OPERATIONS (SAS)

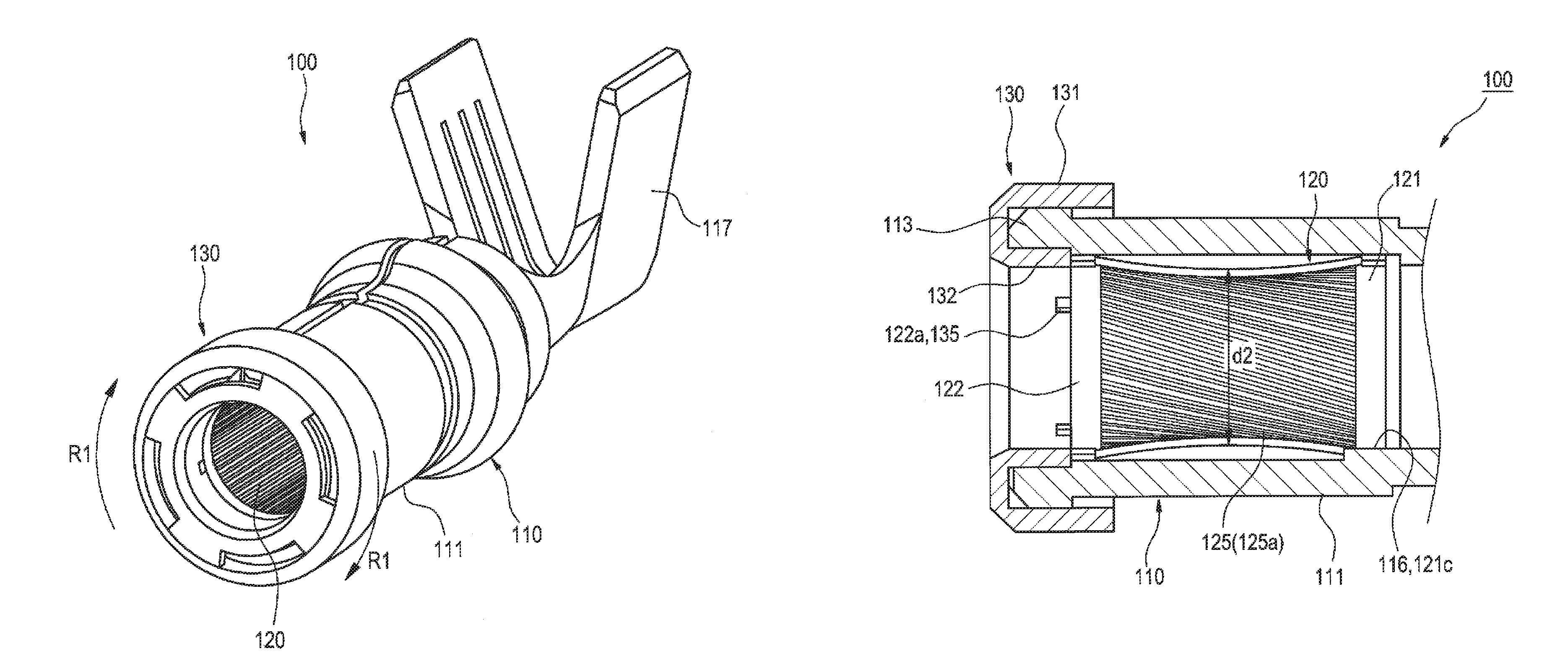

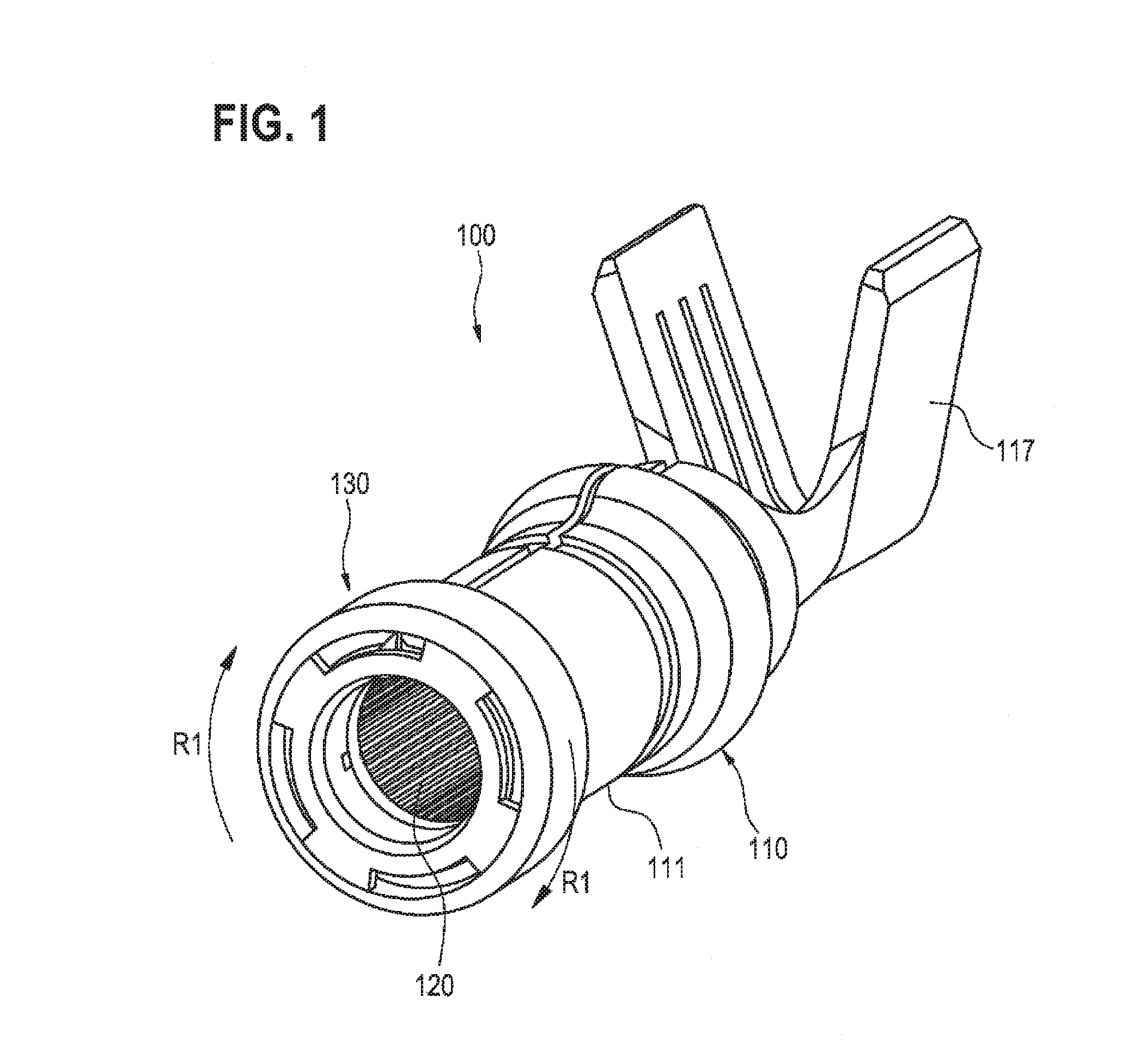

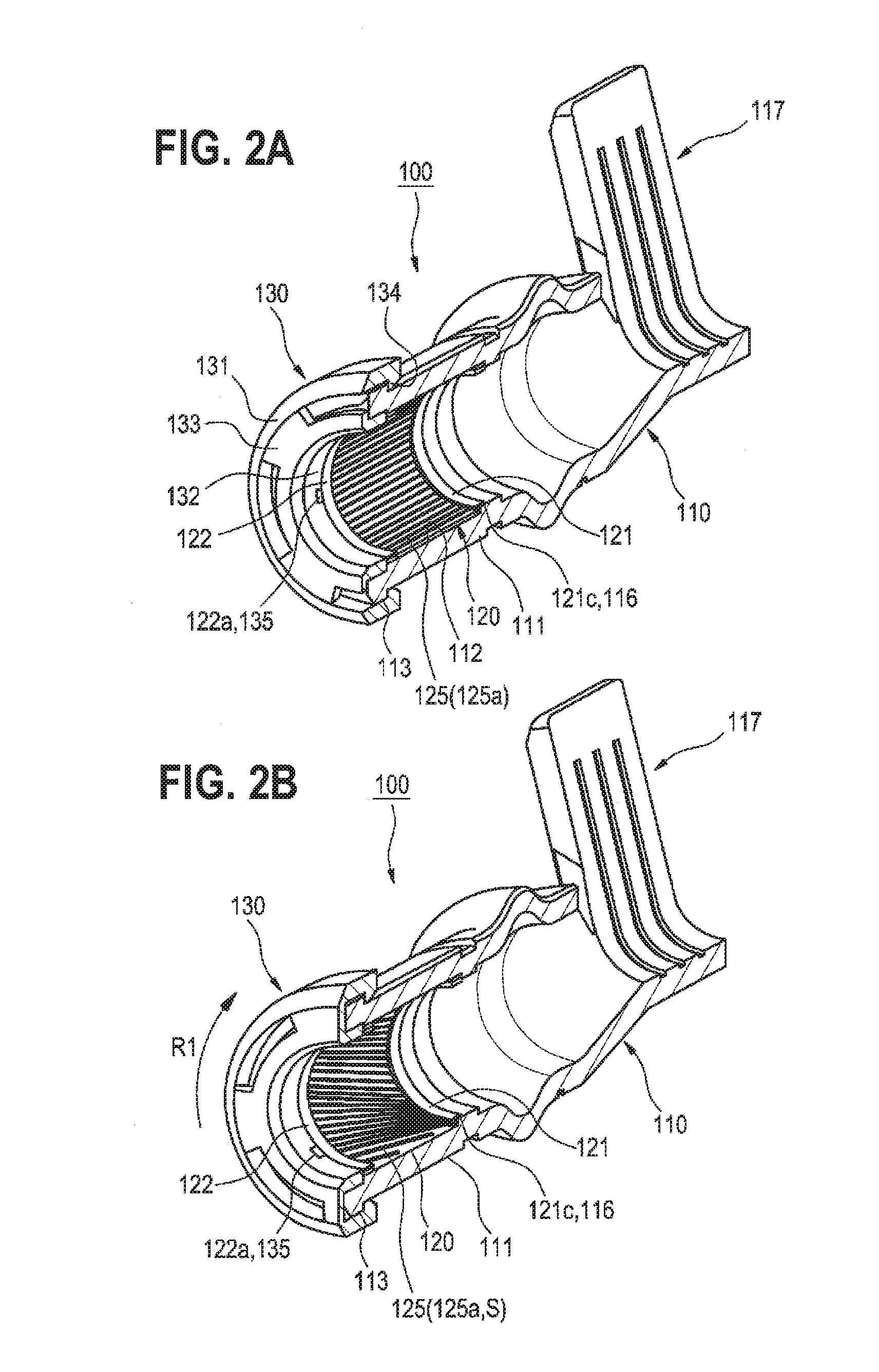

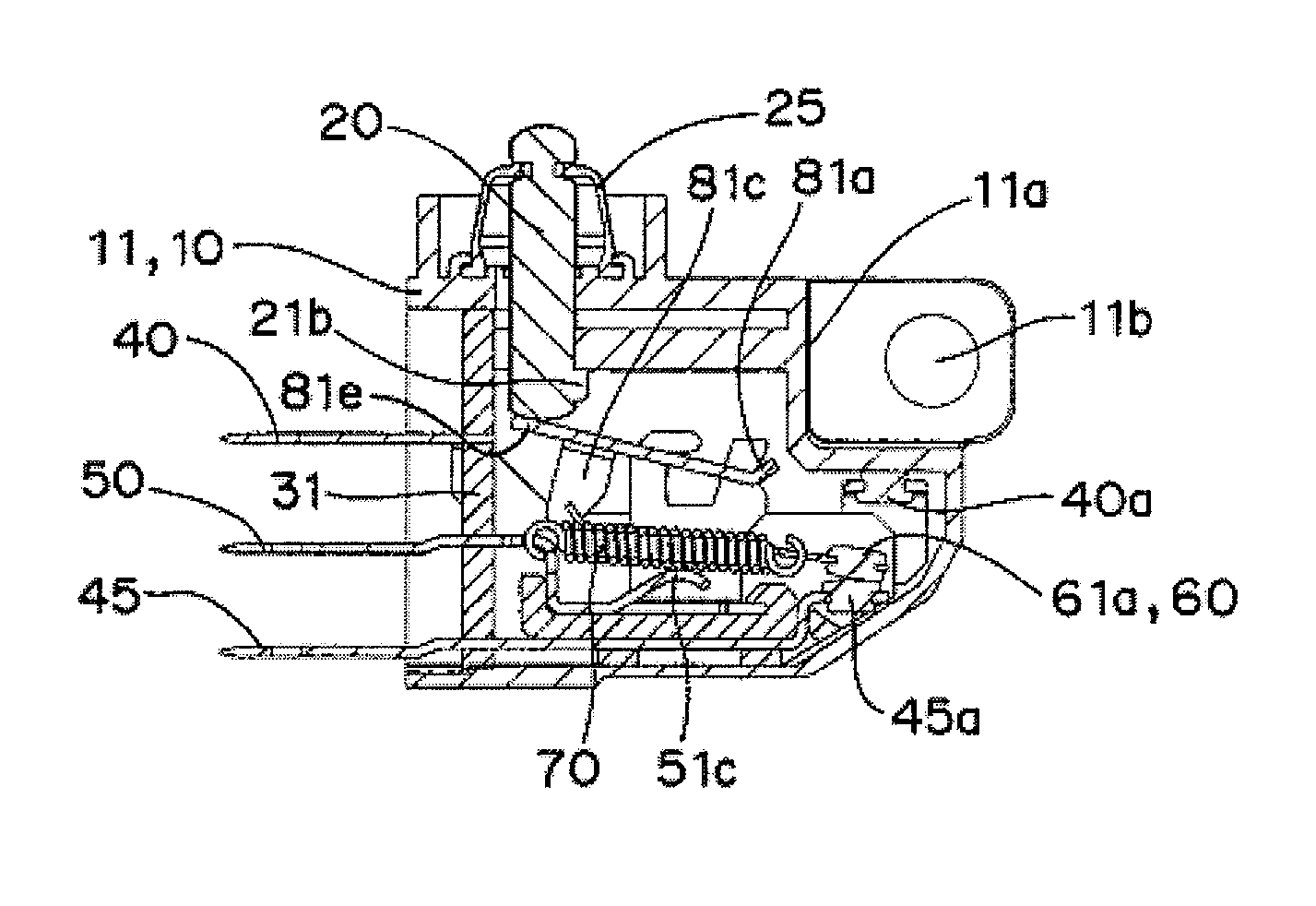

Female terminal

ActiveUS9484641B2Reduce resistanceDiameter variable part of can reduced in diameterOne pole connectionsEngagement/disengagement of coupling partsEngineeringMechanical engineering

A female terminal includes a terminal body having a contact holder in a tubular shape at a front side of the terminal body, a contact member in a tubular shape which is contained inside the contact holder and into which a male terminal is inserted from a front side, and a rotary ring which is mounted to the contact holder. The contact member has a pair of holding rings provided at both ends thereof, and a diameter variable part held by a pair of the holding rings at both ends thereof, an inner diameter of the diameter variable part being set to be larger than an outer diameter of the male terminal in an initial state, and contracted to be smaller than the outer diameter of the male terminal, by twisting a pair of the holding rings.

Owner:YAZAKI CORP

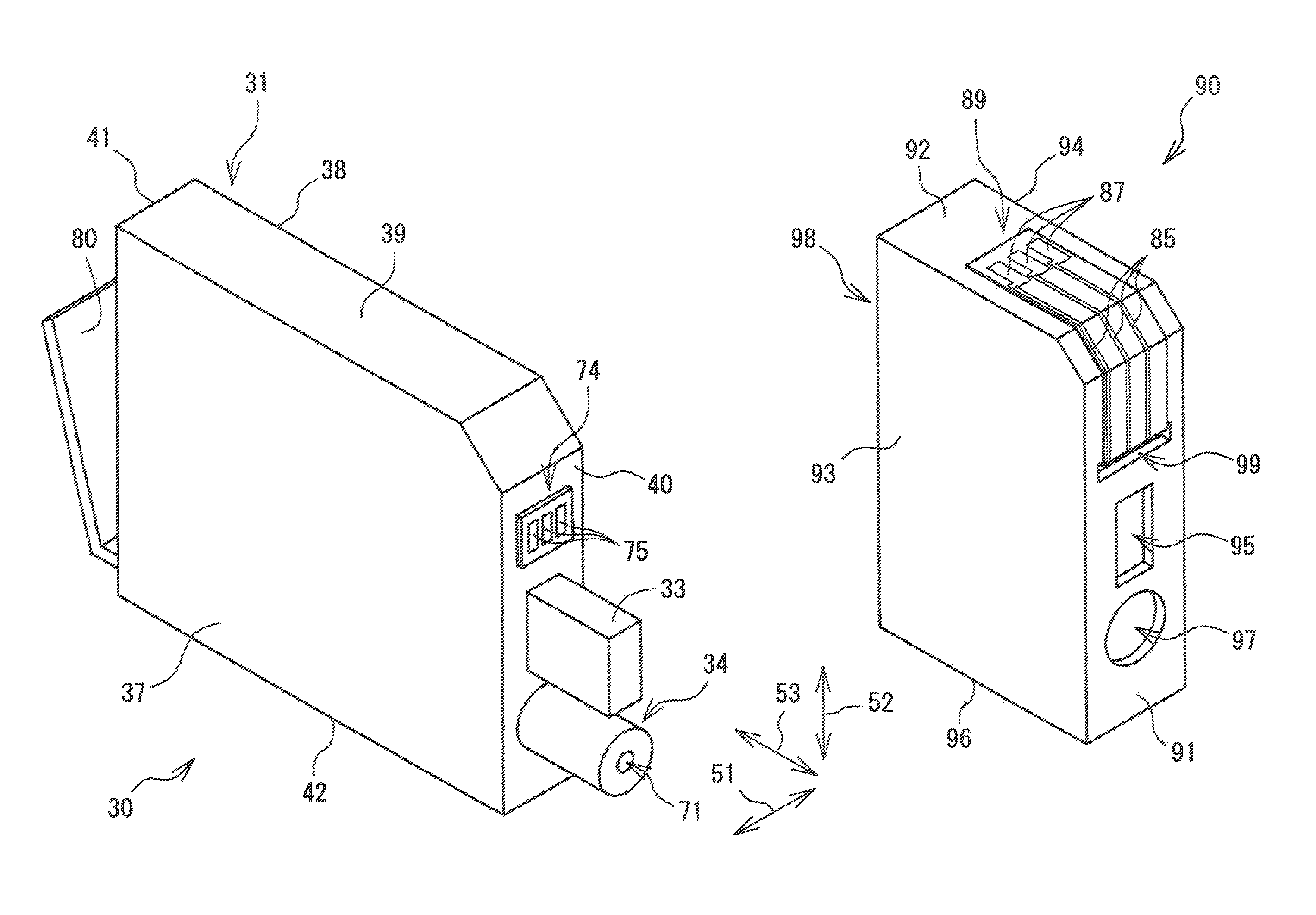

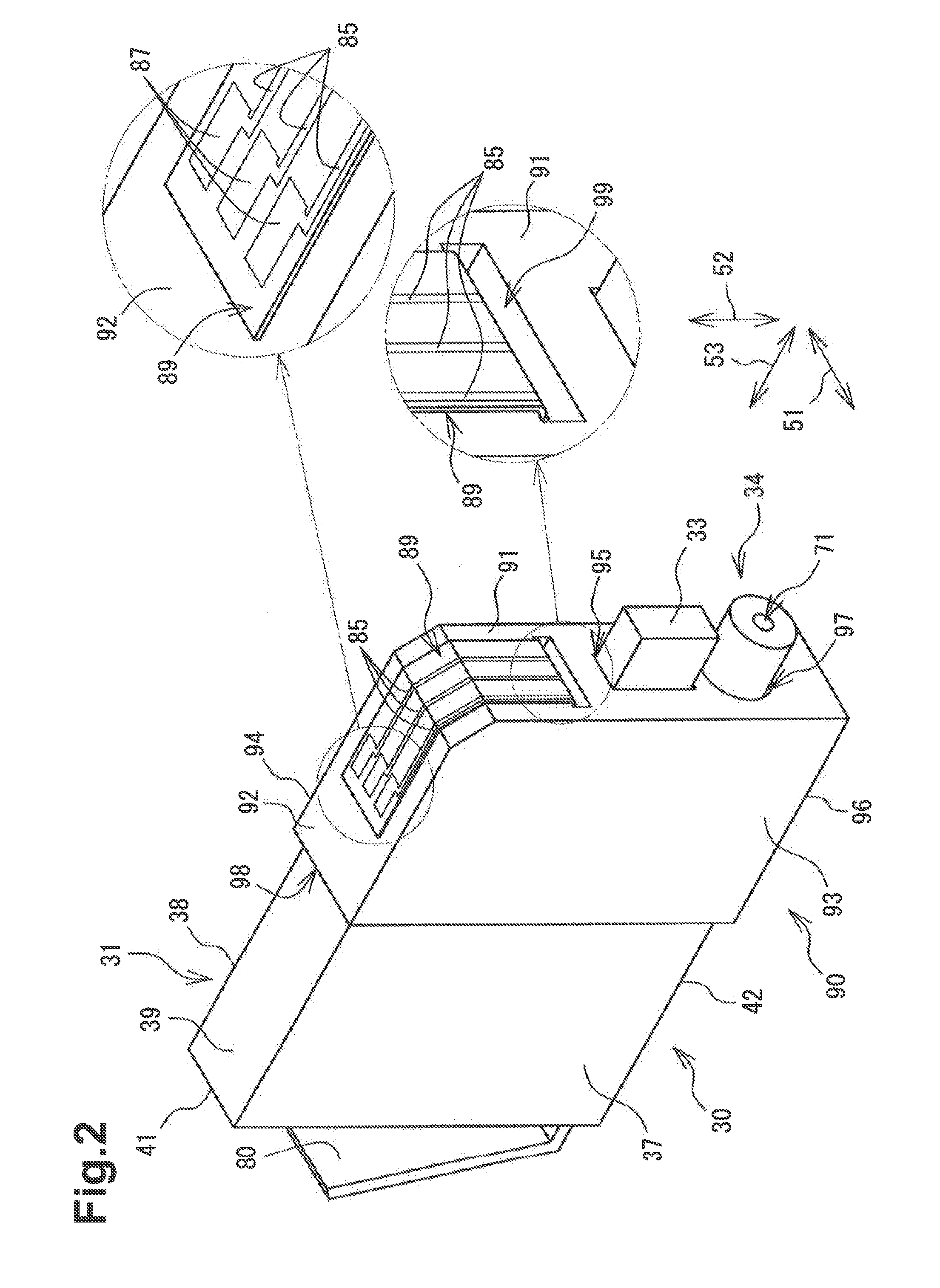

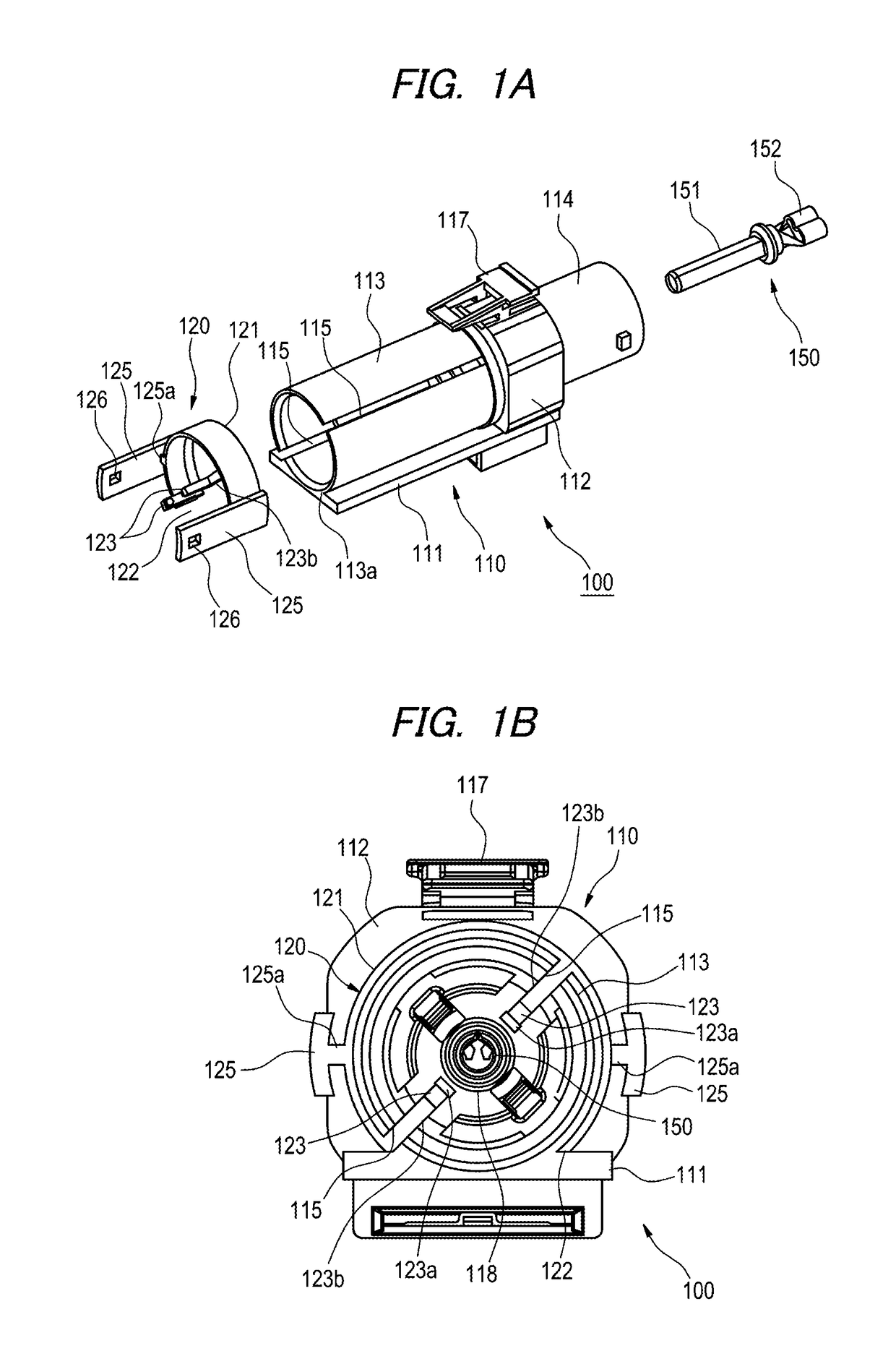

Ink containing device

An ink containing device comprises an ink cartridge and an adaptor. The ink cartridge comprises a first main body comprising a chamber configured to store ink, an ink outlet portion disposed on a first surface of the first main body configured to direct the ink from the chamber to an exterior of the first main body wherein the first surface faces a first direction, and an electrical interface disposed on the first main body. The adaptor is configured to be in an attached state with the ink cartridge. The adaptor comprises a second main body comprising a first contact disposed on a particular surface facing a particular direction, and a second contact disposed on a further surface and electrically connected to the first contact, wherein the second contact is electrically connected to the electrical interface in the attached state.

Owner:BROTHER KOGYO KK

Fastener assembly for transport vehicle

ActiveUS7988393B2Improve the immunityReduce contact wearFlexible elementsMovable seatsPolytetrafluoroethylenePolymer

This invention relates to a fastener assembly that has a rail (1) and a fastener device (6) that can be installed in a transport vehicle, characterized in that a rail head (2) is coated with a layer (3) of alumina with polytetrafluoroethylene seal and that at least a portion (5) of the fastener device in contact with the rail head is made of metal coated with a layer of polymers (7).

Owner:AIRBUS OPERATIONS (SAS)

Liquid crystal display

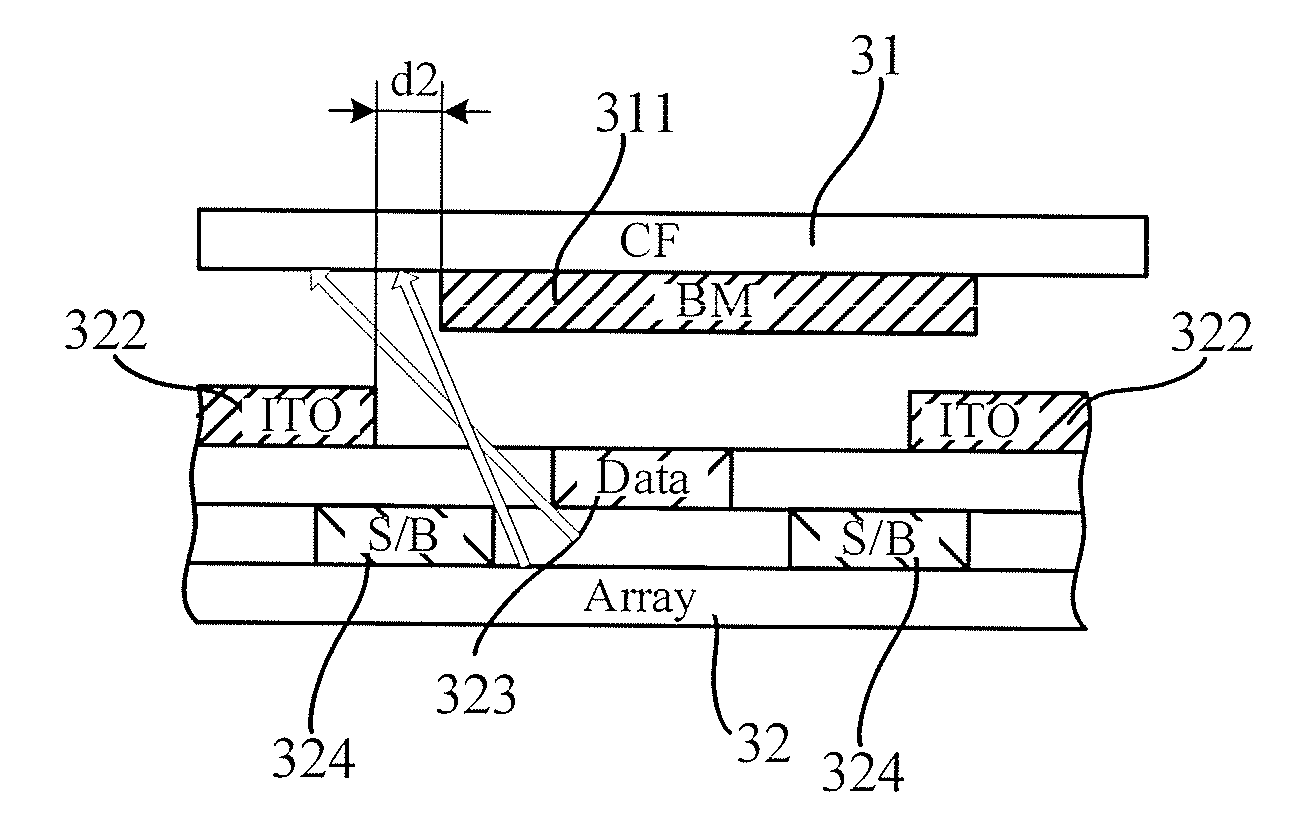

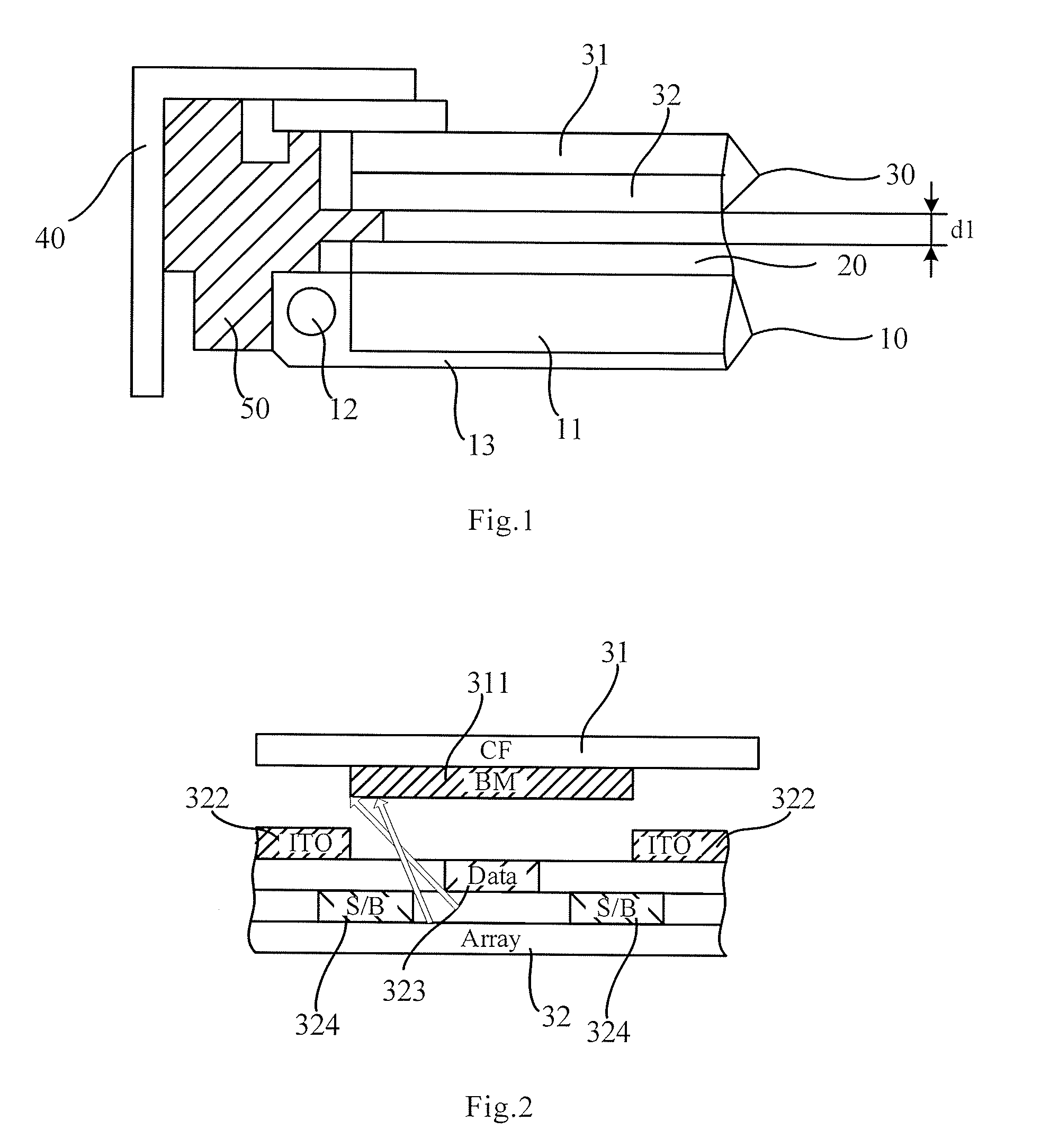

ActiveUS20090213291A1Reduce spacingReduce curvatureOptical light guidesNon-linear opticsLiquid-crystal displayEngineering

The present invention relates to a liquid crystal display (LCD), comprising: a backlight unit; a plurality of optical films disposed above the backlight unit; and a liquid crystal panel disposed above the optical films, wherein a protection layer is disposed between the liquid crystal panel and the optical films in order to support the liquid crystal panel when the liquid crystal panel is bended.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Conductive grease and preparation method thereof

InactiveCN102768873AImprove conductivityAccelerated corrosionNon-conductive material with dispersed conductive materialCable/conductor manufactureLithium soapHeat resistance

The invention relates to the technical field of conductive materials and preparation methods thereof, in particular to conductive grease and a preparation method thereof. The conductive grease comprises the following components in part by weight: 5 to 15 percent of lithium soap, 60 to 70 percent of synthetic basic oil, 23 to 33 percent of pure copper powder, 1 to 2 percent of tin powder and 1 to 2 percent of silver powder. The preparation method comprises the following steps of: weighing the synthetic basic oil, the pure copper powder, the tin powder and the silver powder, adding the synthetic basic oil, the pure copper powder, the tin powder and the silver powder into a reactor, and uniformly mixing to obtain a pasty mixture for backup use; weighing the lithium soap, and smashing the lithium soap into powder; adding the lithium soap powder into the pasty mixture, uniformly mixing, and stirring and grinding to obtain the conductive grease; and putting the conductive grease into a package bottle to obtain a finished product. The conductive grease is relatively high in electrical conductivity, high in electrochemical corrosion resistance and heat resistance and high in conductive connection reliability; the preparation method for the conductive grease is scientific and rational; and the process is simple and convenient.

Owner:上海库革电气设备制造有限公司

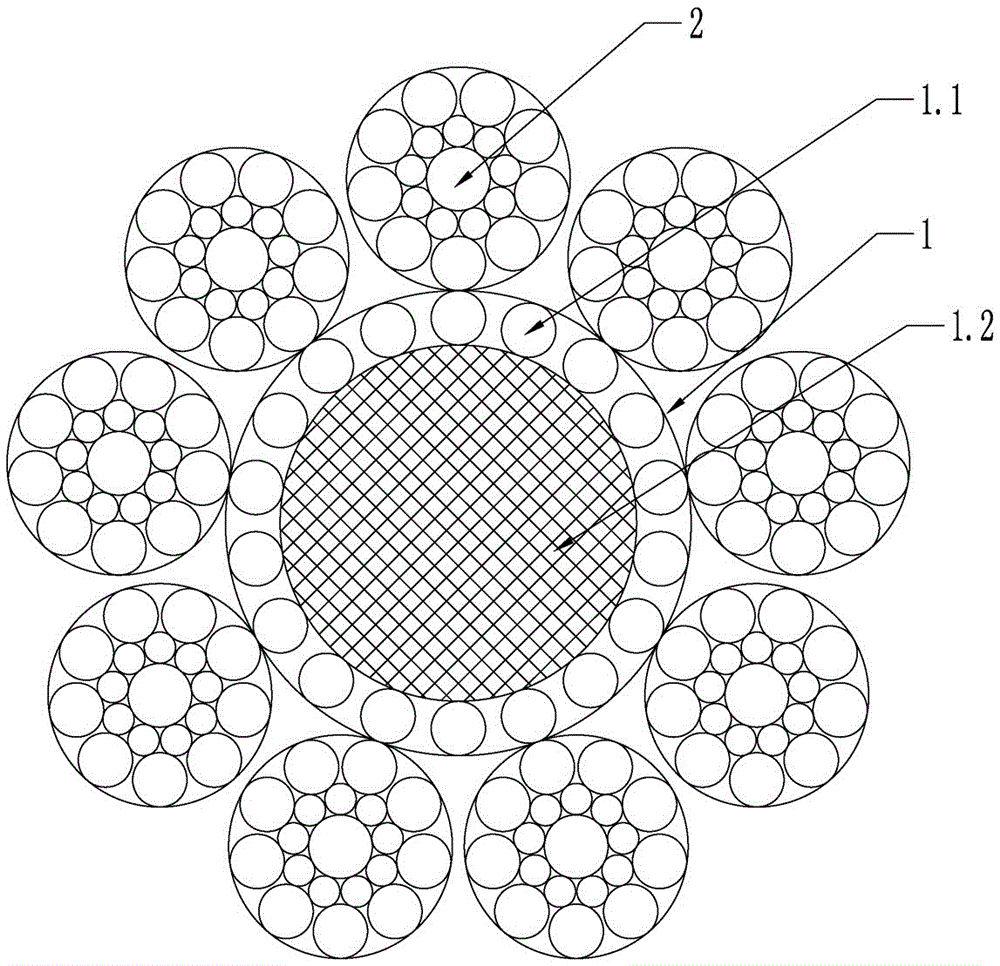

Steel wire rope with single-stranded compound core for elevator

InactiveCN105064105ALittle change in elongationImprove fatigue lifeElevatorsTextile cablesSingle strandZinc

The invention relates to a steel wire rope with a single-stranded compound core for an elevator. The steel wire rope with the single-stranded compound core for the elevator is characterized by comprising the single-stranded compound rope core and outer strands, and the outer side of the single-stranded compound rope core is wrapped with six to nine outer strands; the single-stranded compound rope core comprises ten to thirty-six outer wound steel wires and a fiber core, and the surface of each outer wound steel wire is plated with a layer of pure zinc or zinc-aluminum alloy. The steel wire rope with the single-stranded compound core for the elevator has the advantages that the corrosion resistance and the abrasion resistance are better, and the use requirements of medium and high speed elevators can be met.

Owner:FASTEN HONGSHENG GRP CO LTD

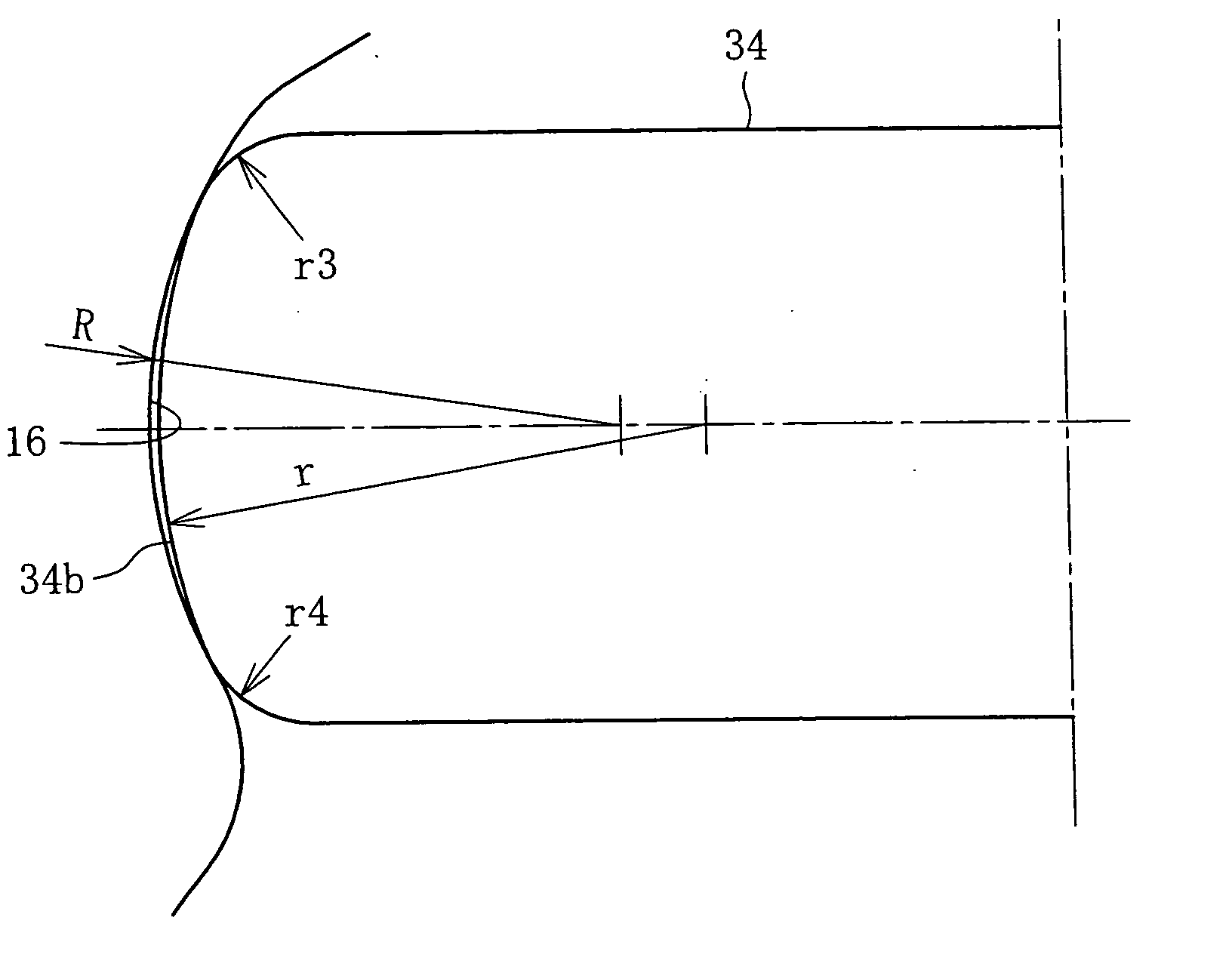

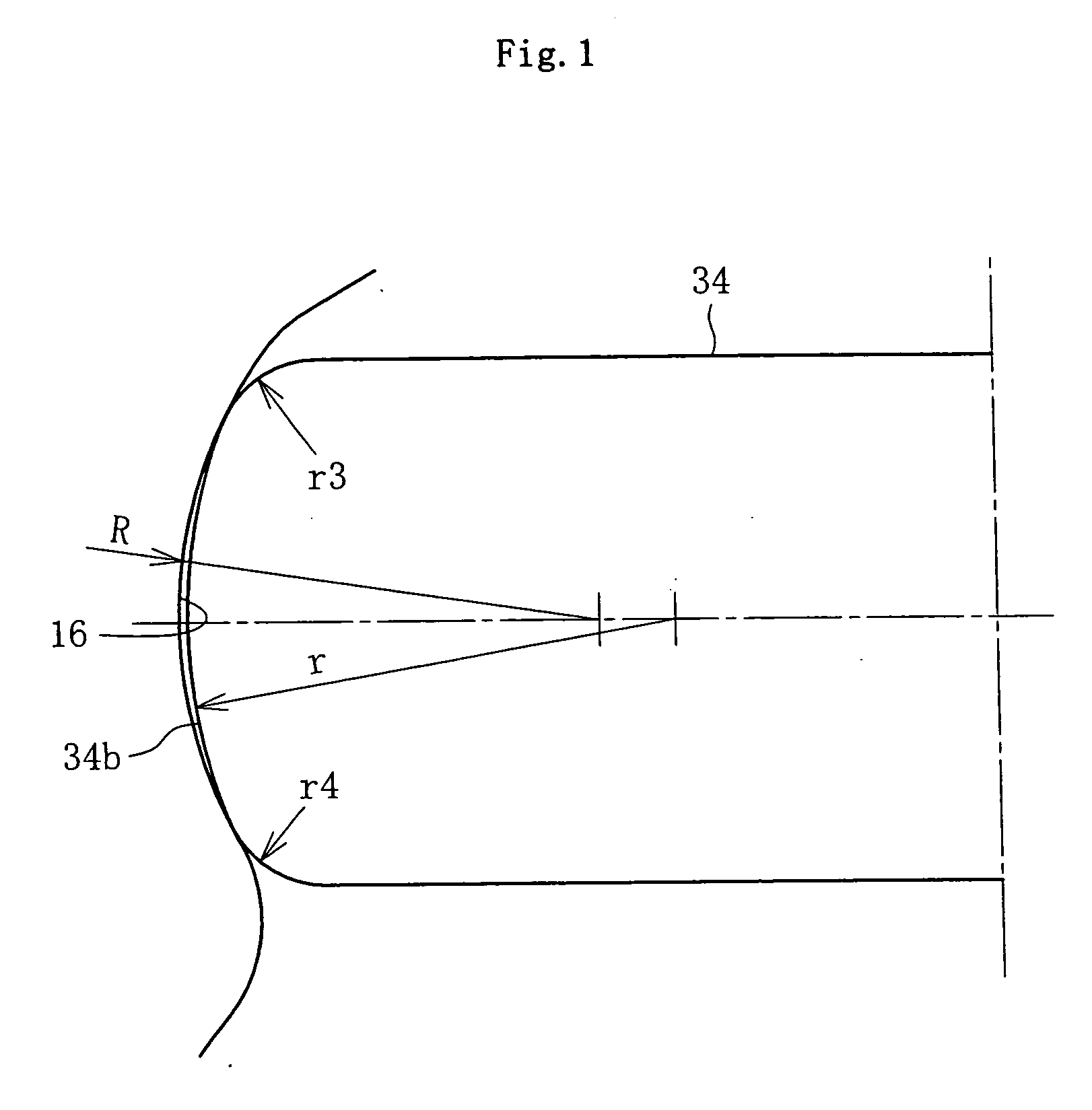

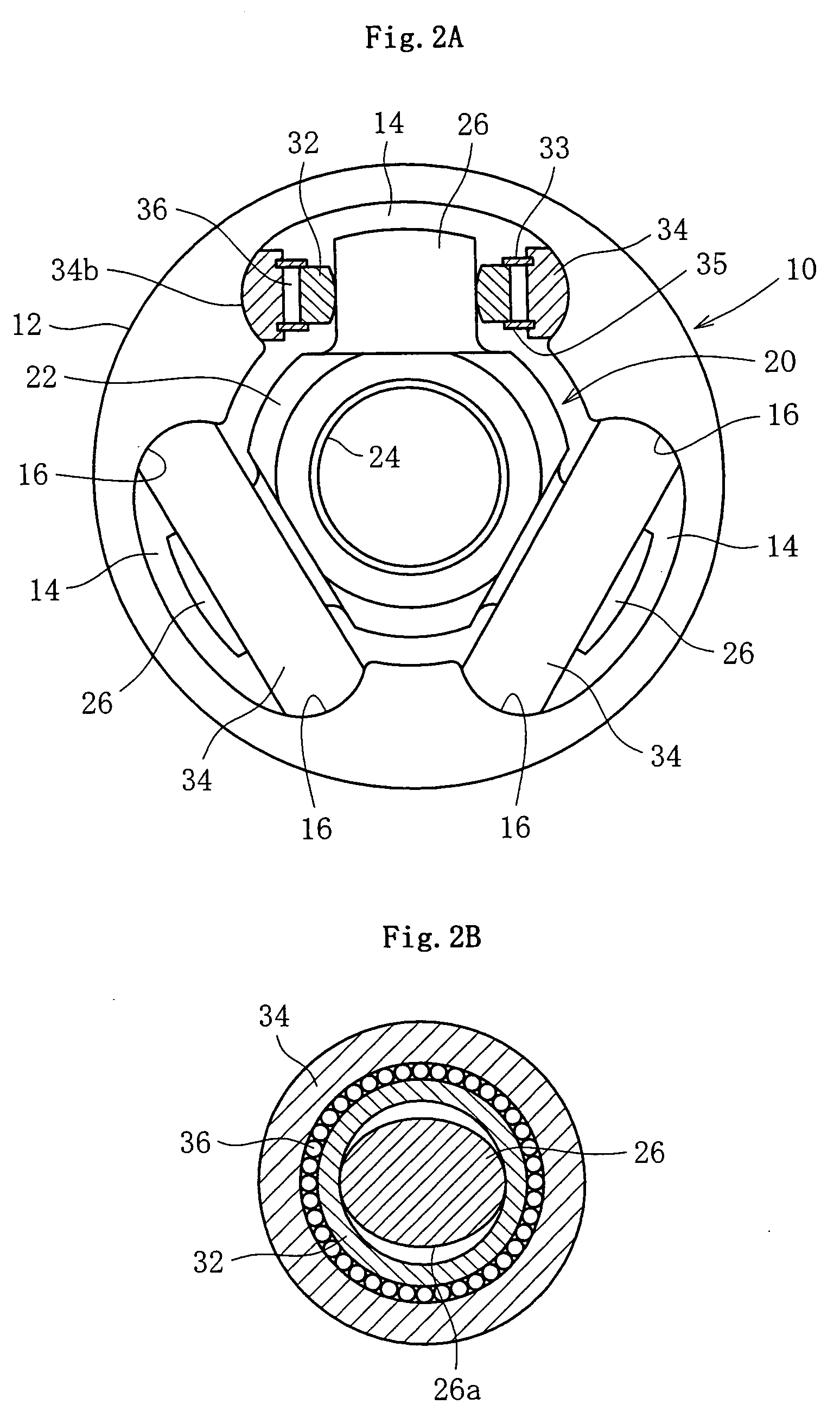

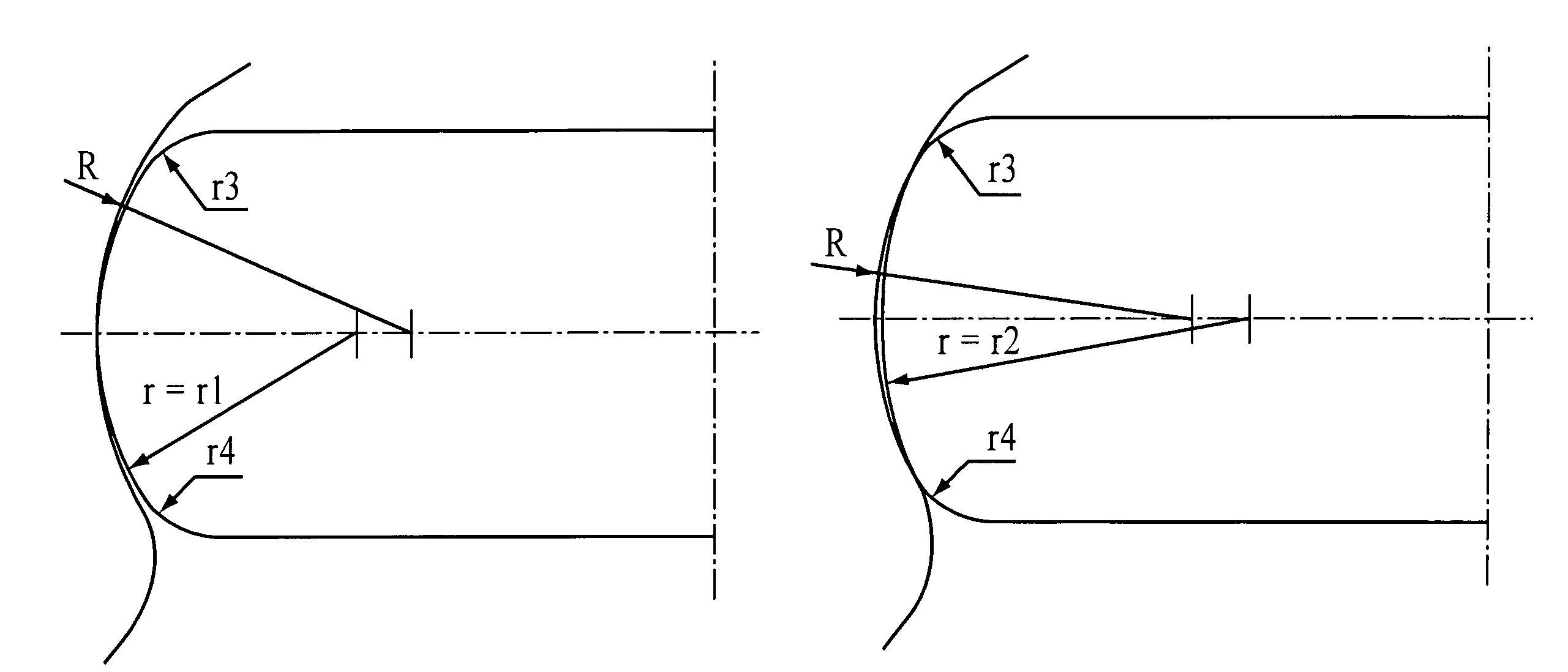

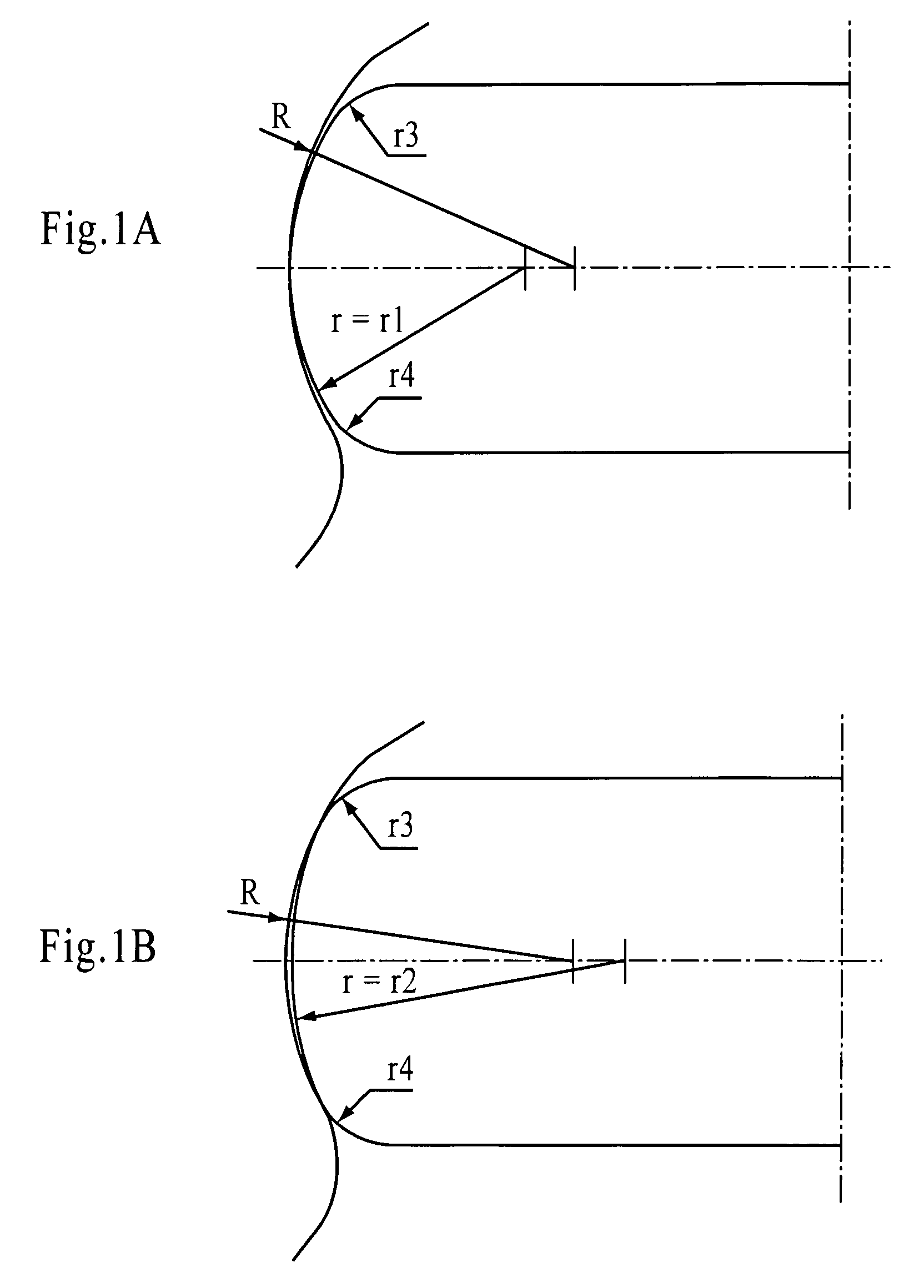

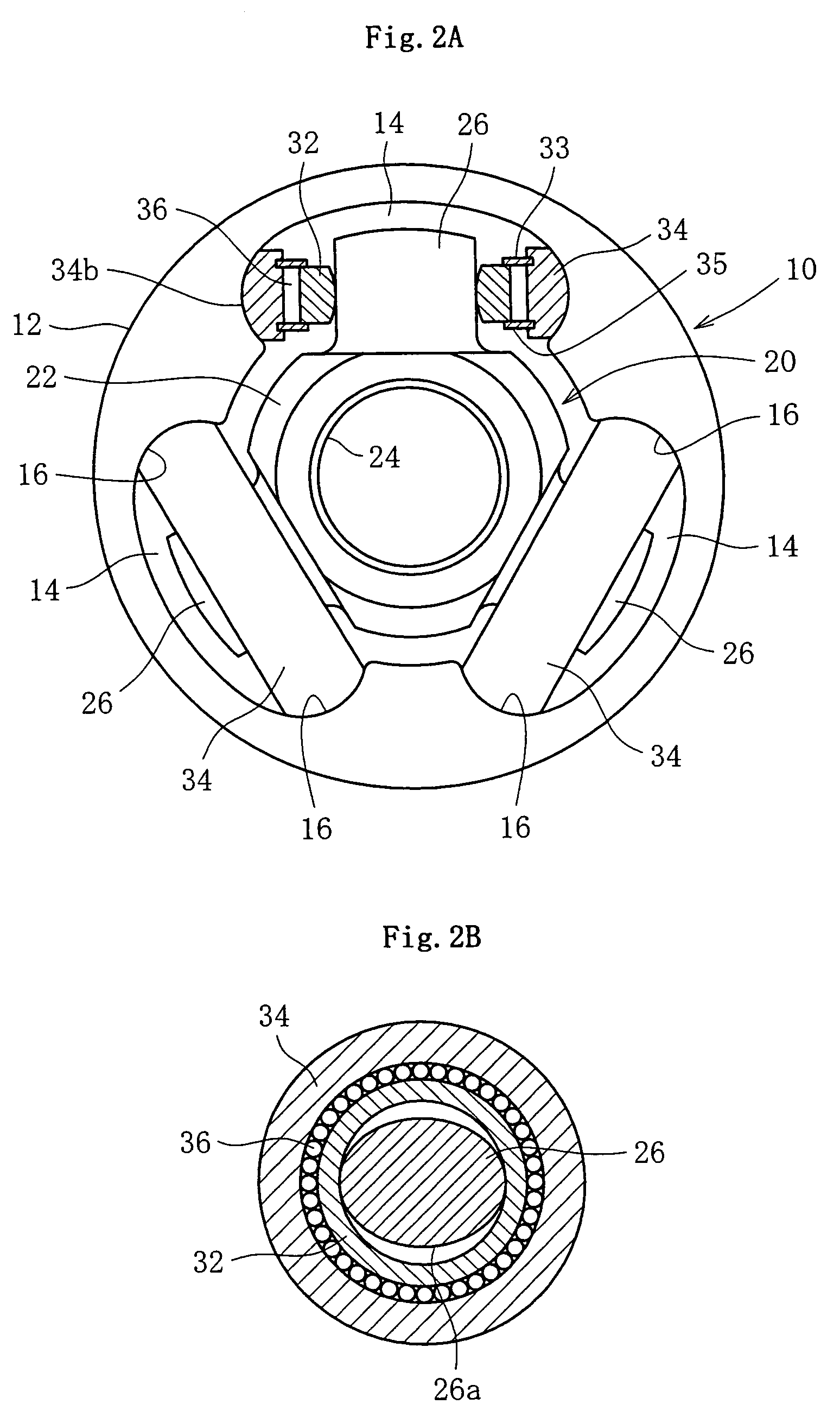

Tripod type constant velocity joint

ActiveUS20050037849A1Reduce wearMaintenance characteristicYielding couplingRotary machine partsEngineeringSurface pressure

In a tripod type constant velocity joint, in order to produce a recovery couple to correct the inclination of the rolling direction of a roller and to reduce surface pressure without using angular contact provided by a Gothic arch-shaped roller guide surface, it is arranged that where r1 and r2 are the minimum and maximum values, respectively, of the radius of curvature of the generatrix for the outer peripheral surface of the roller within the range where solid contact is effected by elastic deformation of the contact section between the roller and the roller guide surface under a predetermined torque load with respect to the radius of curvature of the roller guide surface, the radius of curvature (r) of the generatrix be set in the range r1≦r≦r2.

Owner:NTN CORP

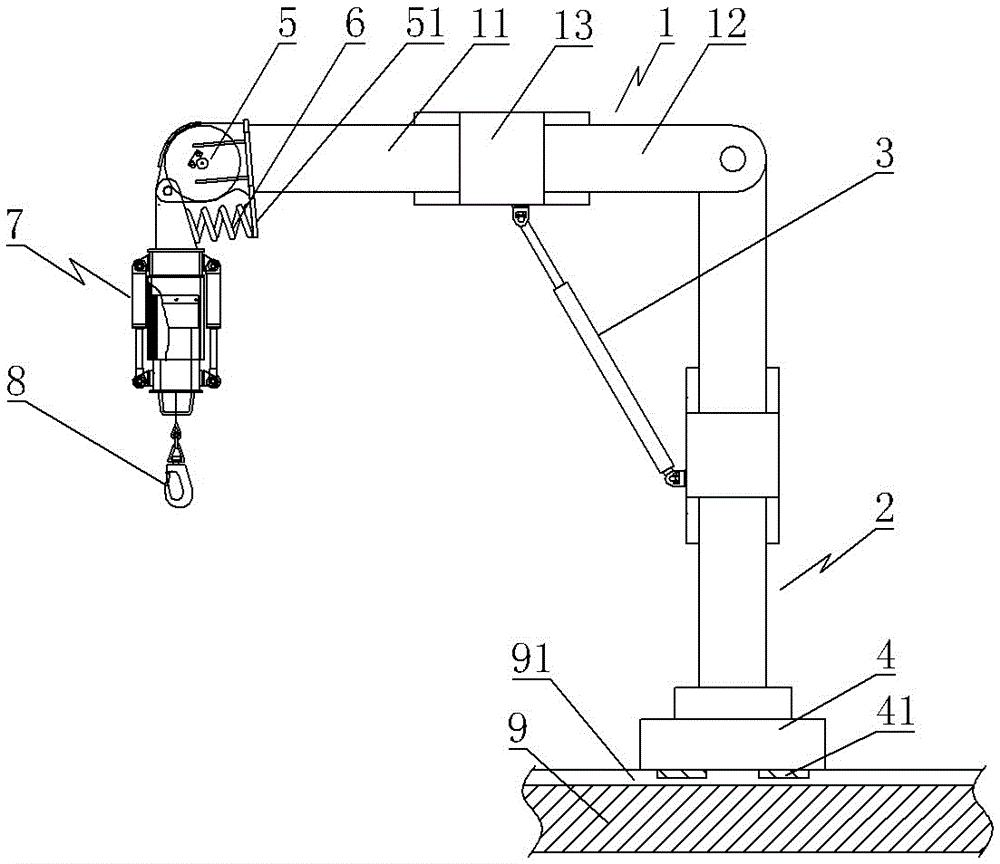

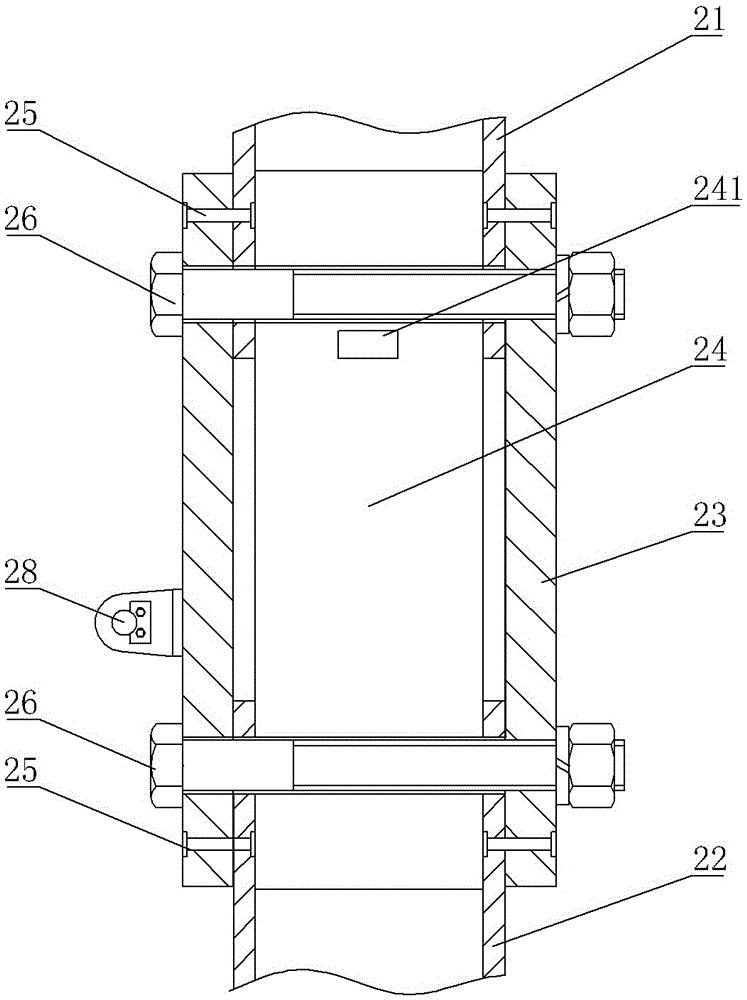

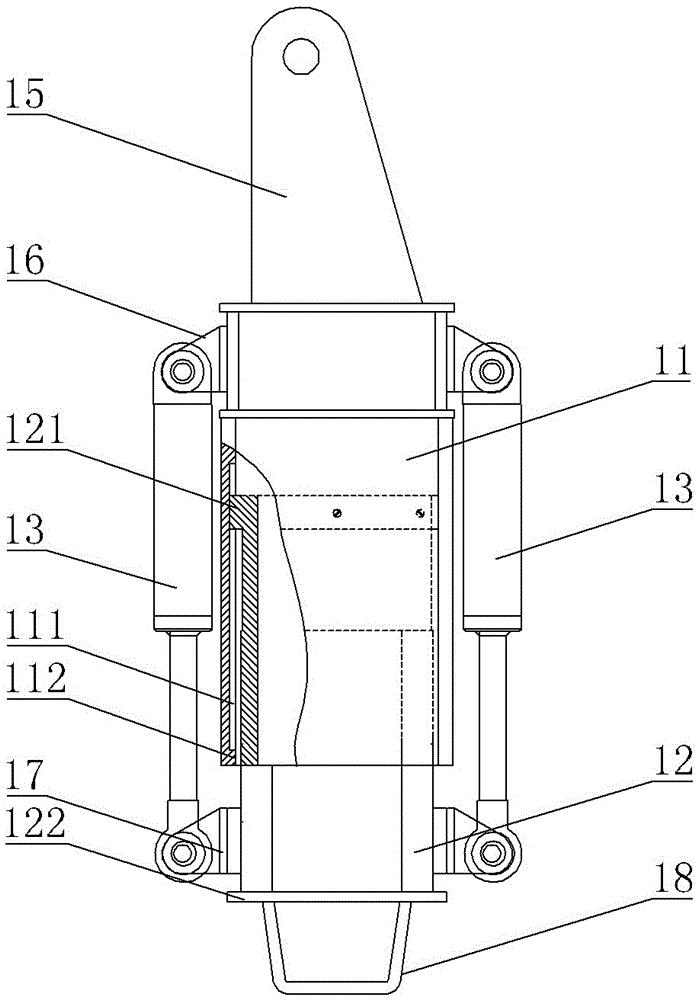

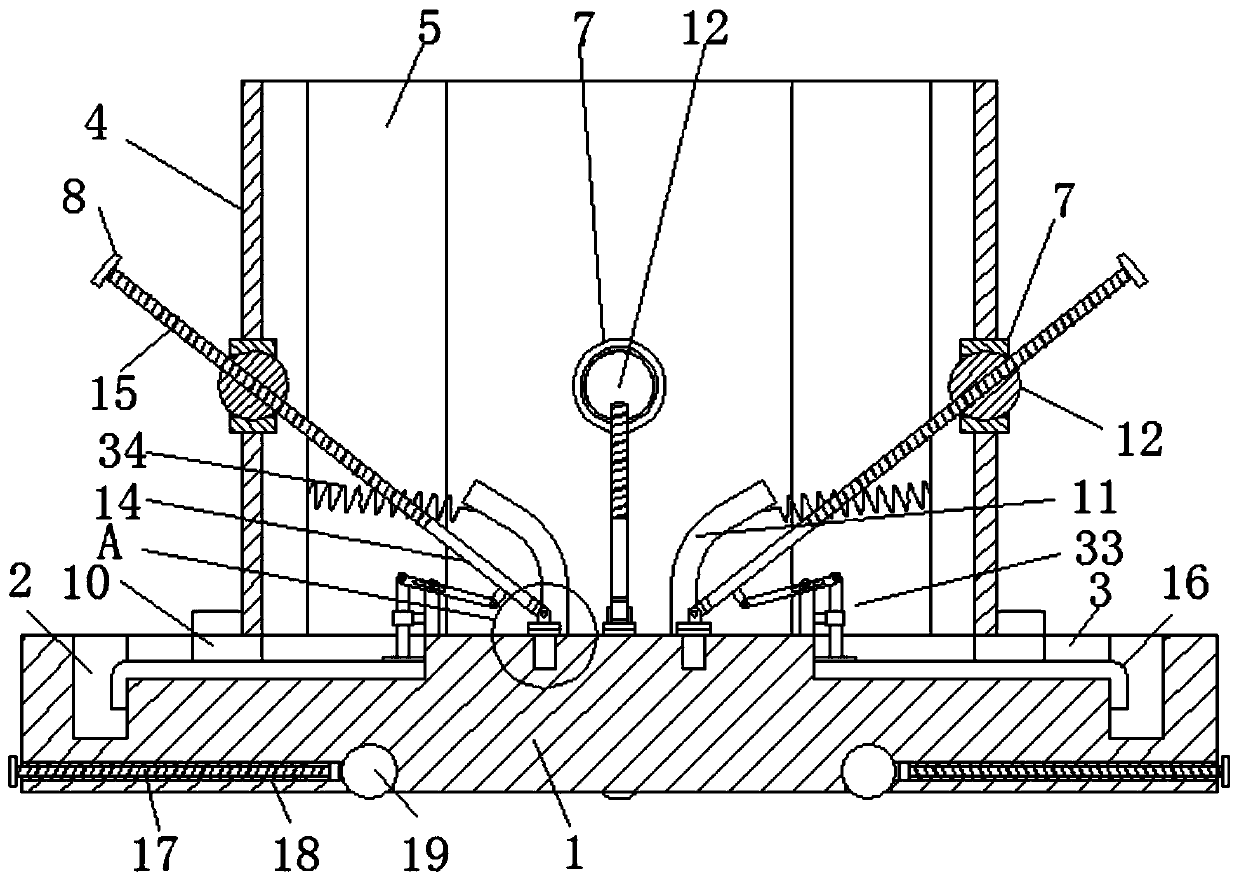

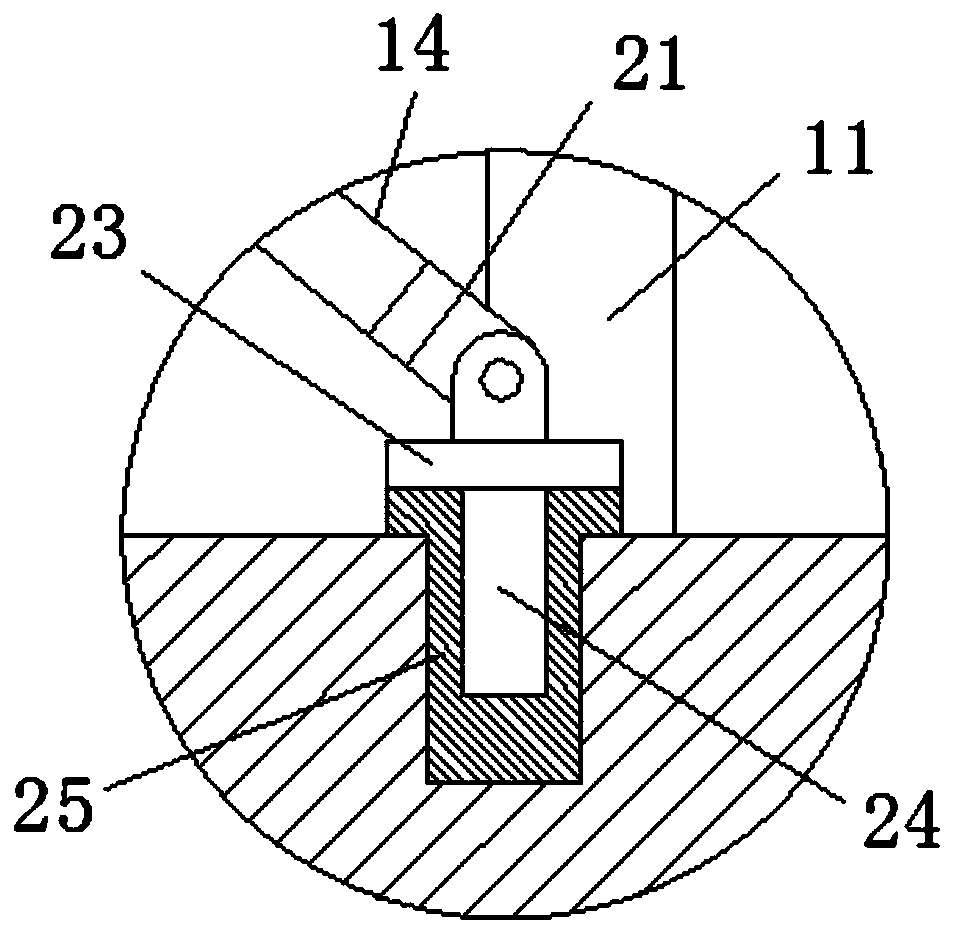

Petroleum pipe lifting device for ship

The invention provides a petroleum pipe lifting device for a ship, which can solve the technical problems that the existing petroleum pipe lifting device is large in size and large in occupied space. The petroleum pipe lifting device for the ship comprises a transverse lifting arm, a longitudinal lifting arm, a winch, a steel wire rope and a hanging hook; the transverse lifting arm is supported on the longitudinal lifting arm through a lifting arm hydraulic rod and is hinged to the longitudinal lifting arm; the petroleum pipe lifting device for the ship is characterized in that each of the transverse lifting arm and the longitudinal lifting arm comprises a plurality of lifting arm monomers, connecting sleeves and fixing assemblies; each lifting arm monomer is of a pipe body structure; the outer sides of the opposite connecting ends of the adjacent lifting arm monomers are connected with each other through the corresponding connecting sleeve which is arranged in a sleeving manner; the inner sides of the opposite connecting ends of the adjacent lifting arm monomers are connected with each other through the corresponding connecting rod which is arranged in an inserting manner; the connecting sleeves are hinged to the lifting arm monomers, and are provided with sleeve body grooves which are matched with the lifting arm monomers; the connecting sleeves, the lifting arm monomers and the connecting rods are fixedly connected through the fixing assemblies; a piston rod end part and a cylinder end part of the lifting arm hydraulic rod are respectively hinged to the connecting sleeves corresponding to the transverse lifting arm and the longitudinal lifting arm.

Owner:WUXI SHENGOU MARINE EQUIP

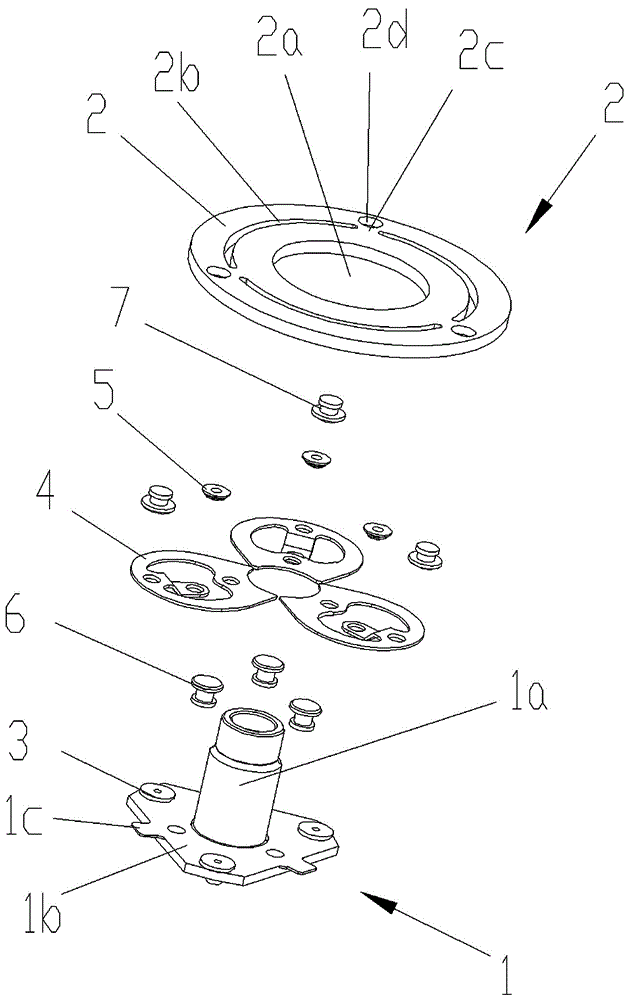

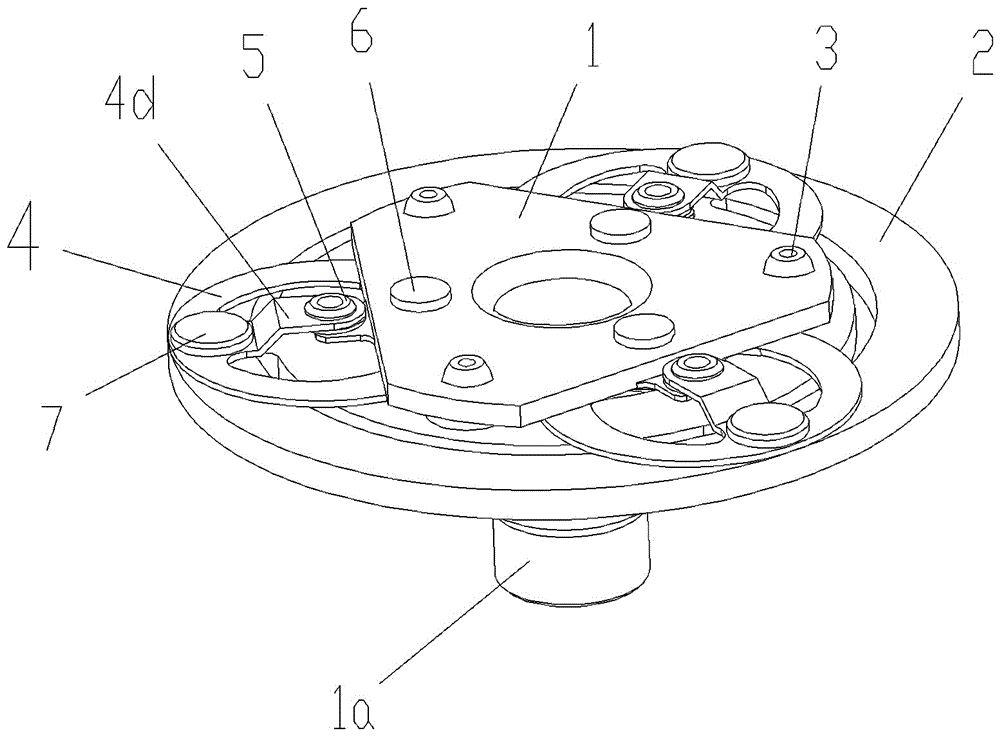

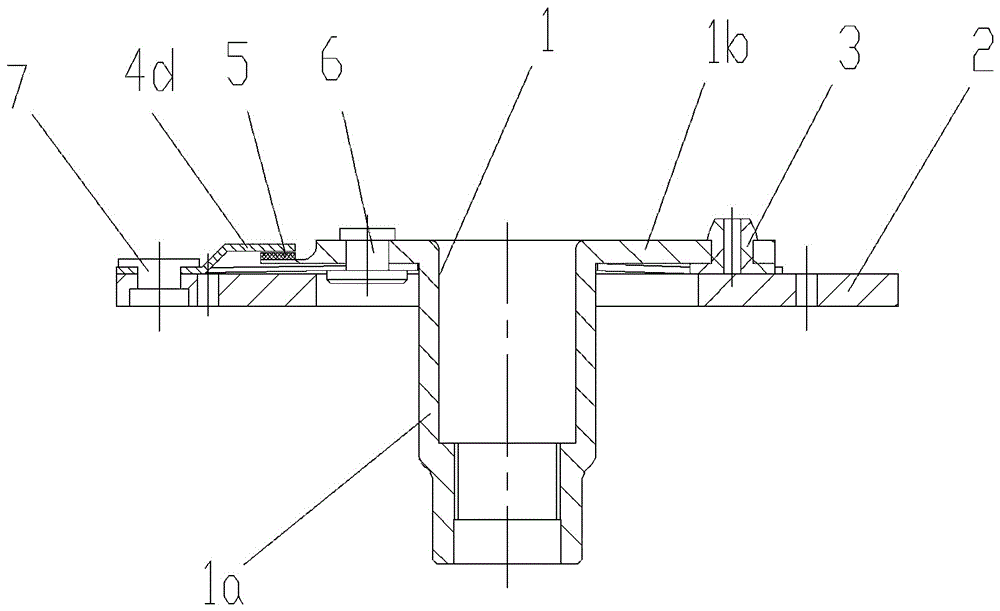

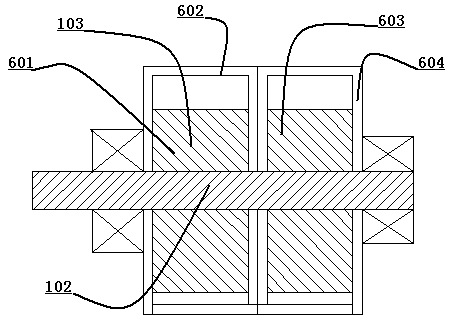

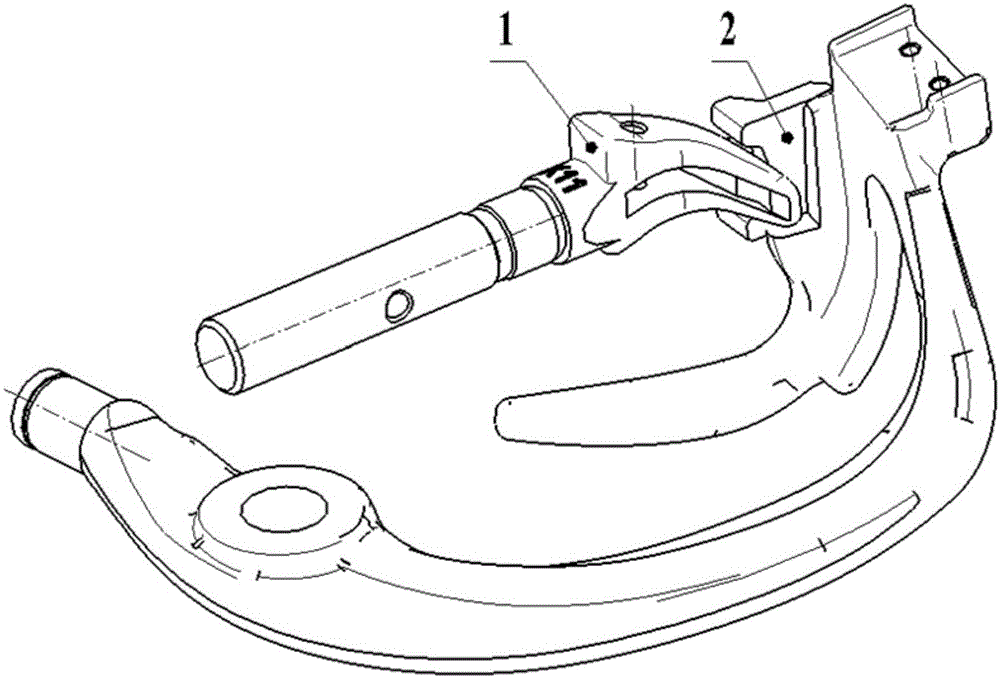

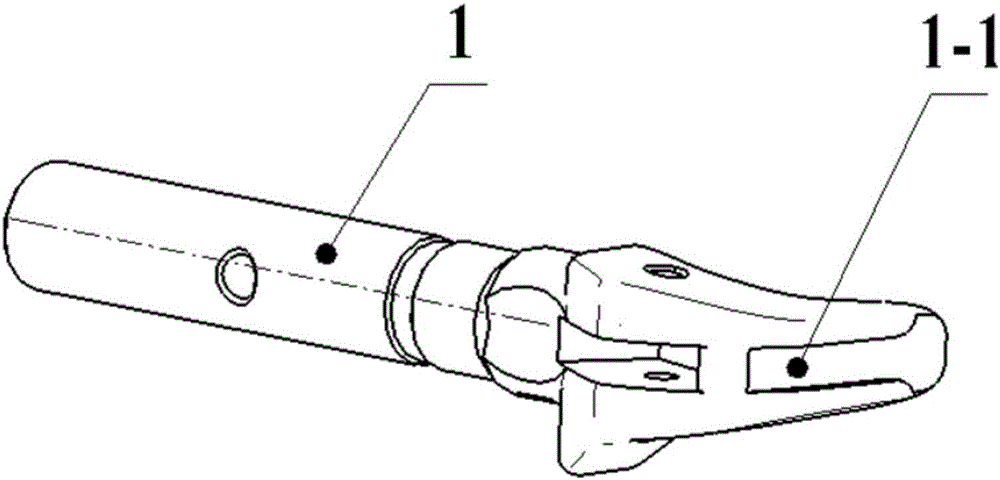

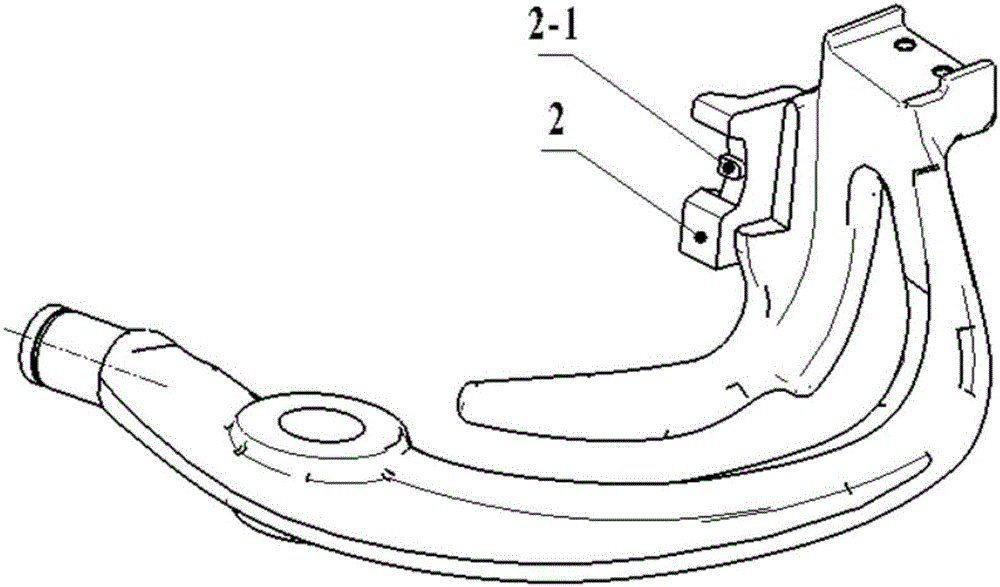

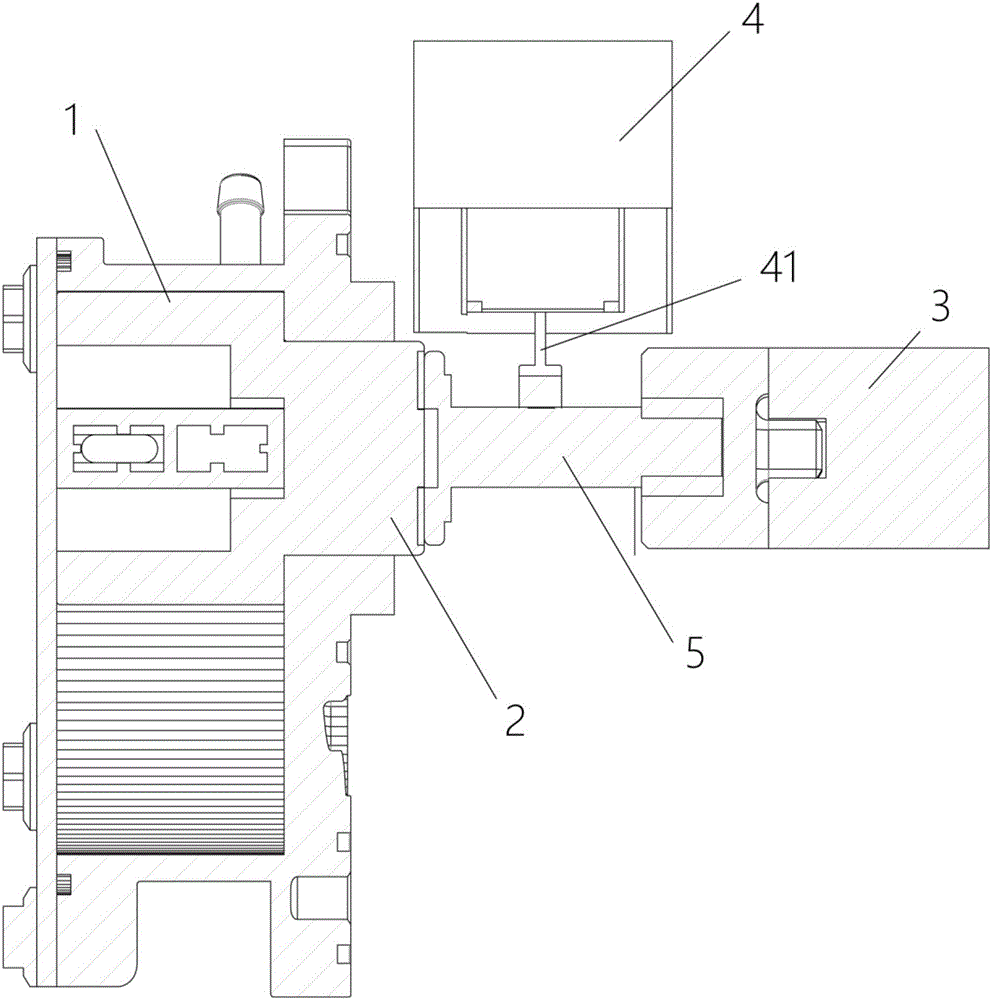

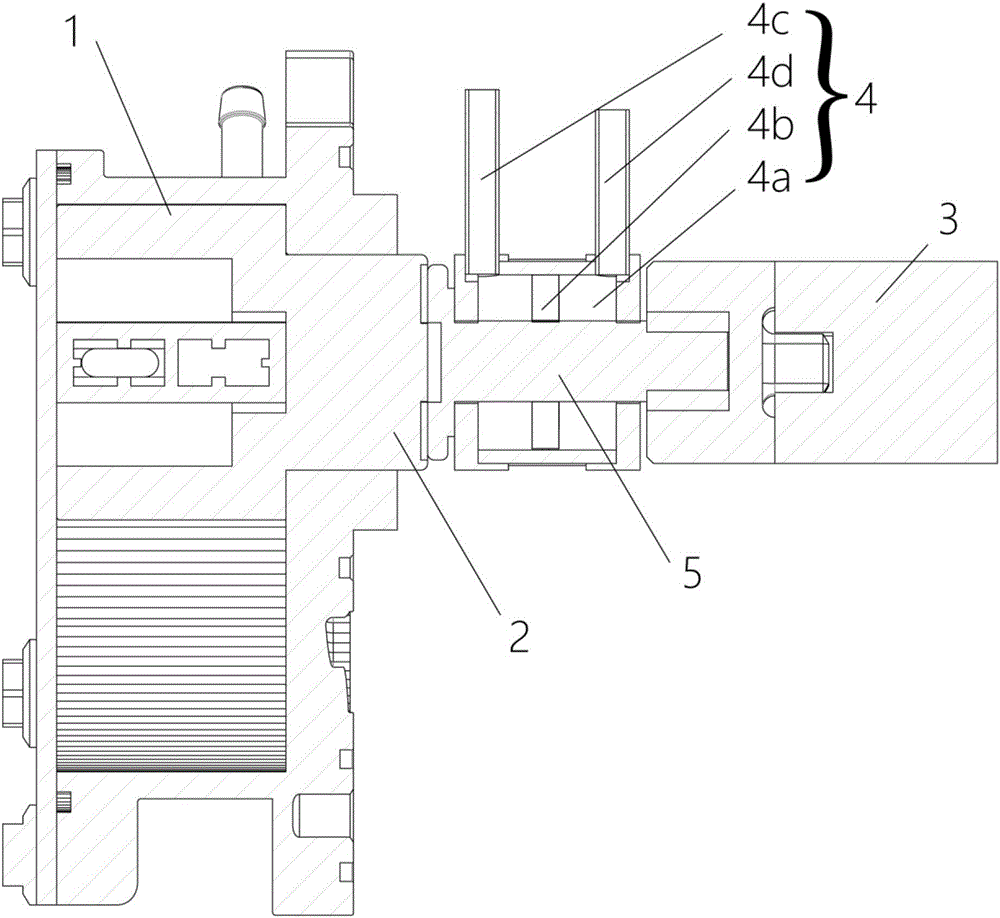

Damping and noise-reduction drive plate assembly for electromagnetic clutch

ActiveCN105697580ASlow down the suction speedReduce rigid impactNon-rotating vibration suppressionMagnetically actuated clutchesElectromagnetic clutchEngineering

The invention relates to a damping and noise-reduction drive plate assembly for an electromagnetic clutch. The damping and noise-reduction drive plate assembly for the electromagnetic clutch comprises a spline plate (1) consisting of a sleeve (1a) and a flange (1b), wherein the spline plate is connected with a suction cup (2) through a group of springs; the flange is connected with a group of first noise-reduction plugs (3); the first noise-reduction plugs are in noise-reduction matching with the suction cup correspondingly; a noise-reduction plate (4d) is arranged on each spring; each noise-reduction plate is connected with a second noise-reduction plug (5); and the second noise-reduction plugs are in noise-reduction matching with the flange correspondingly. The damping and noise-reduction drive plate assembly for the electromagnetic clutch has the advantages that by the damping and noise-reduction drive plate assembly, the suction speed of the suction cup can be reduced effectively, then rigid impact, suction sound and contact abrasion are reduced when the suction cup sucks a belt pulley, so that the effect of reducing vibration and noises is achieved, the service life of the electromagnetic clutch can be prolonged, meanwhile, the structure of a drive plate is improved on the premise of meeting performance, and shortcomings of large resistance to axial deformation of complete-cycle rubber drive plates and three-eye rubber drive plates are avoided effectively.

Owner:ANHUI HAOFANG ELECTROMECHANICS

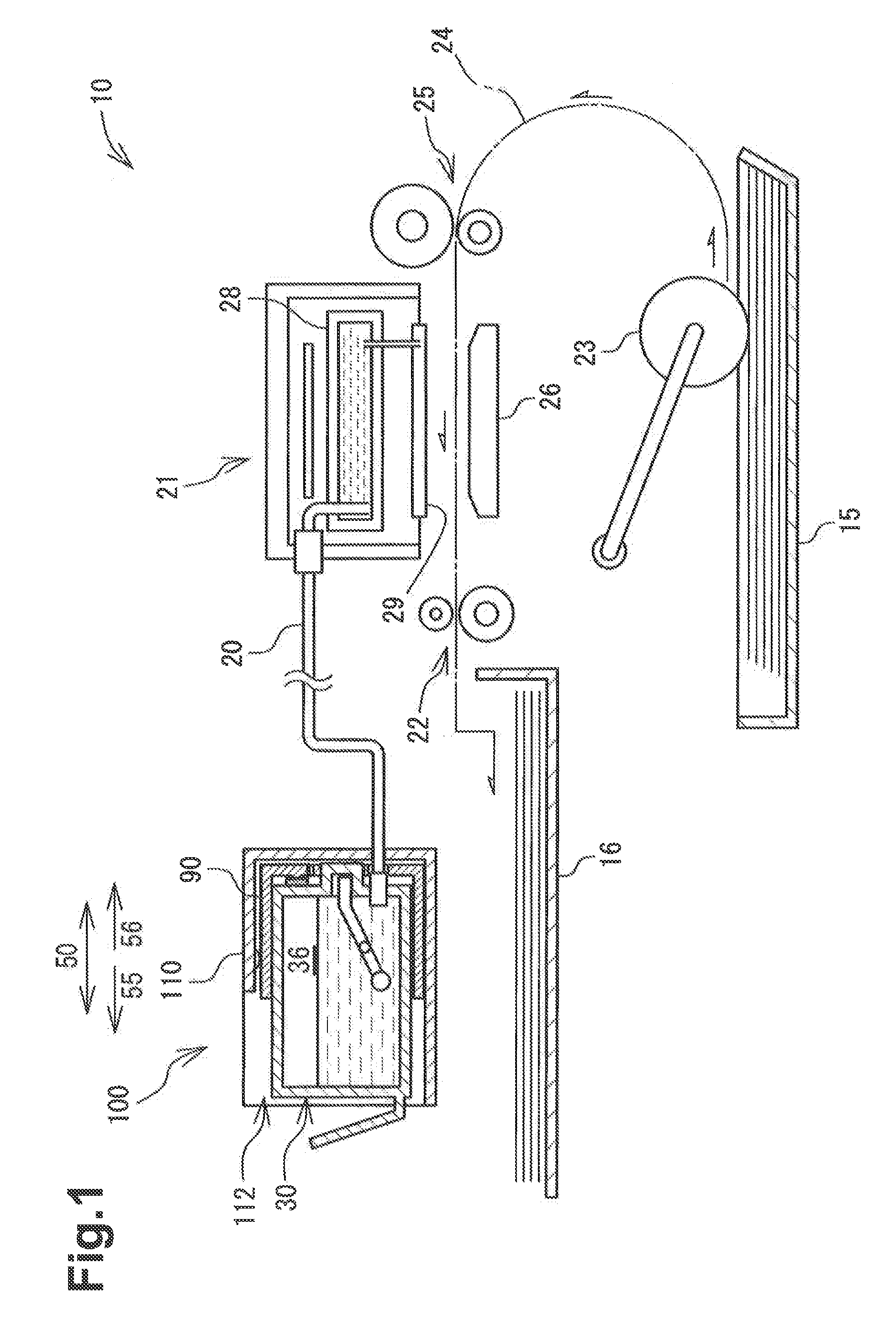

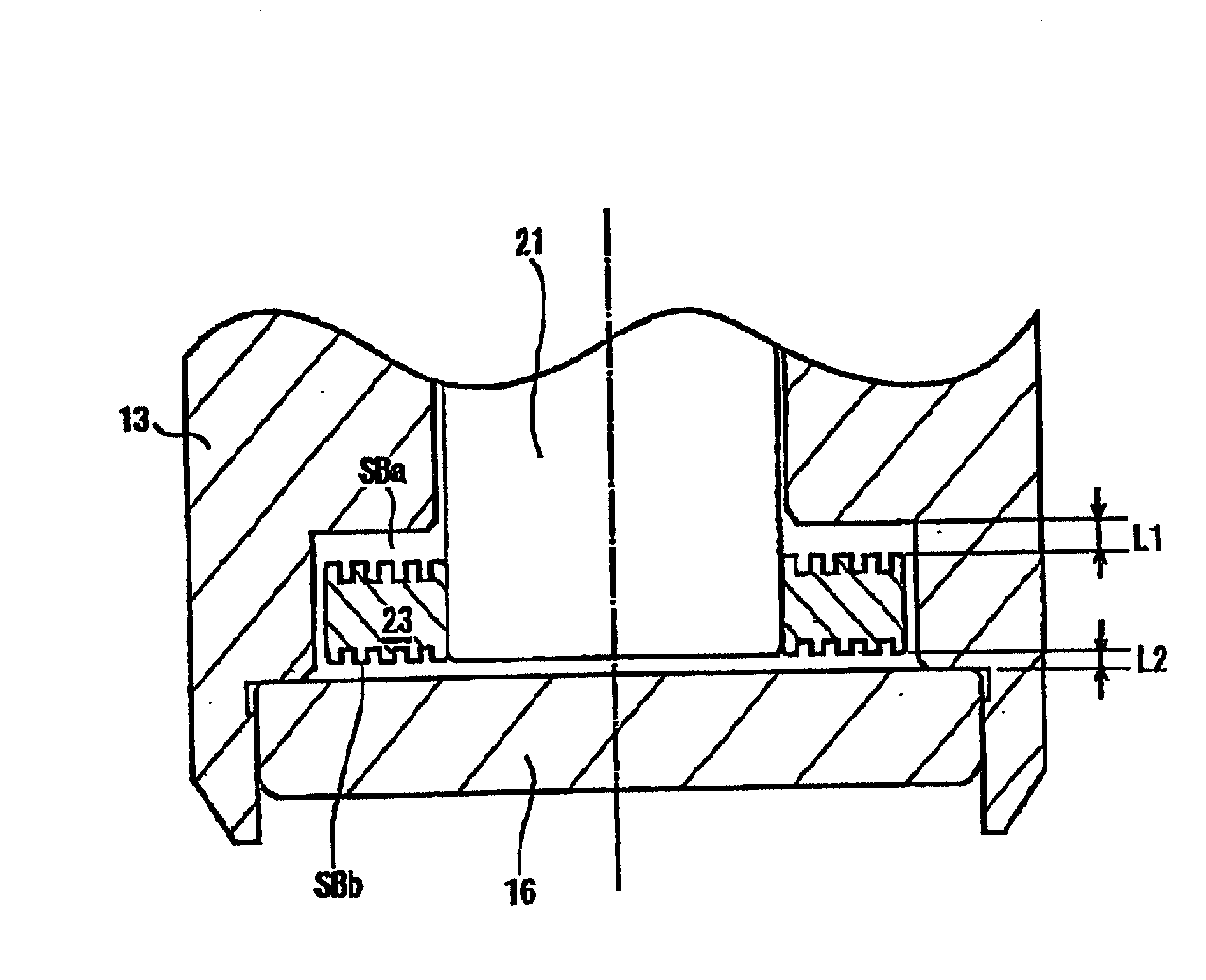

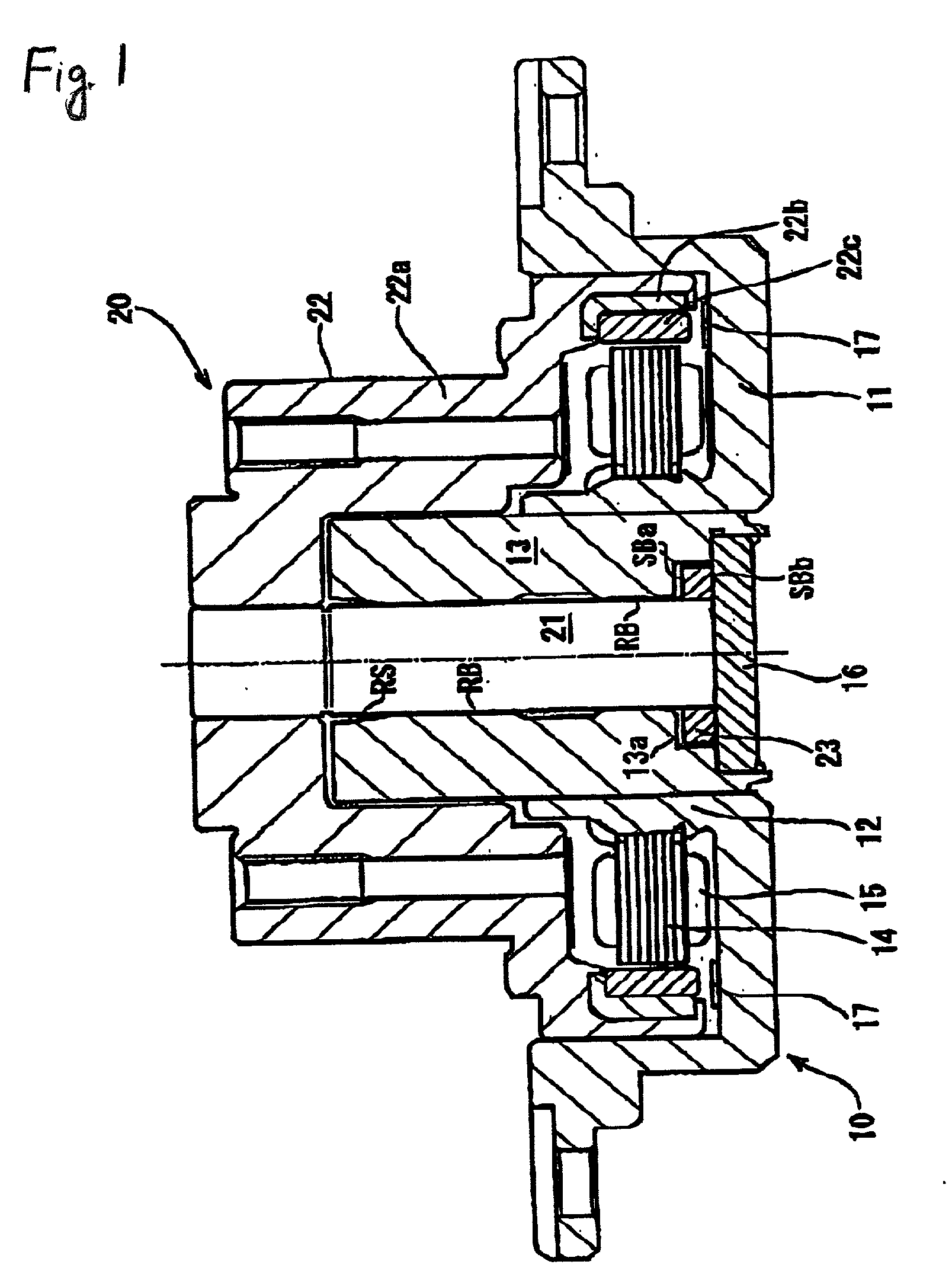

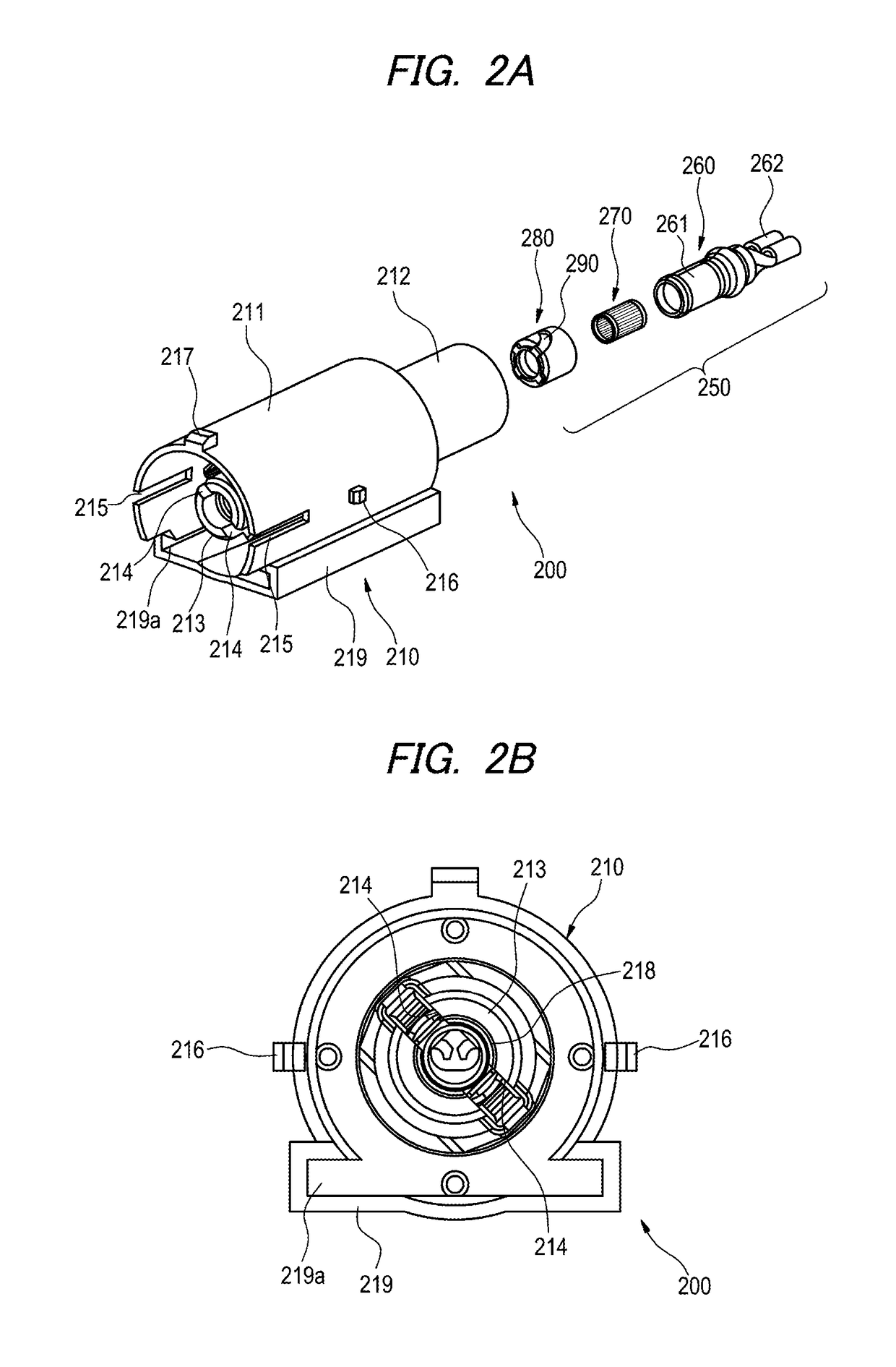

Fluid dynamic pressure bearing apparatus

InactiveUS20020122609A1Reduce contact wearIncreased durabilityShaftsRecord information storageThrust bearingMechanical engineering

A fluid dynamic pressure bearing apparatus includes a radial dynamic pressure bearing formed in a gap portion between a bearing member and a shaft member. The apparatus also includes a thrust dynamic pressure bearing having a first thrust bearing portion formed between a top surface of the thrust plate and a first facing member opposing thereto in the axial direction and a second thrust bearing portion formed between a bottom surface of the thrust plate and a second facing member opposing thereto in an axial direction. Dynamic pressure generating grooves are formed on the radial dynamic pressure bearing and the thrust dynamic pressure bearing. The shaft member and the bearing member are rotated together as a rotation member, such that the rotation member is supported in a position such that a gap space L1 of the first thrust bearing portion is larger than a gap space L2 of the second thrust bearing portion and the depth of the dynamic pressure generating grooves where the gap space is smaller is formed shallower than that where the gap space is larger.

Owner:NIPPON DENSAN CORP

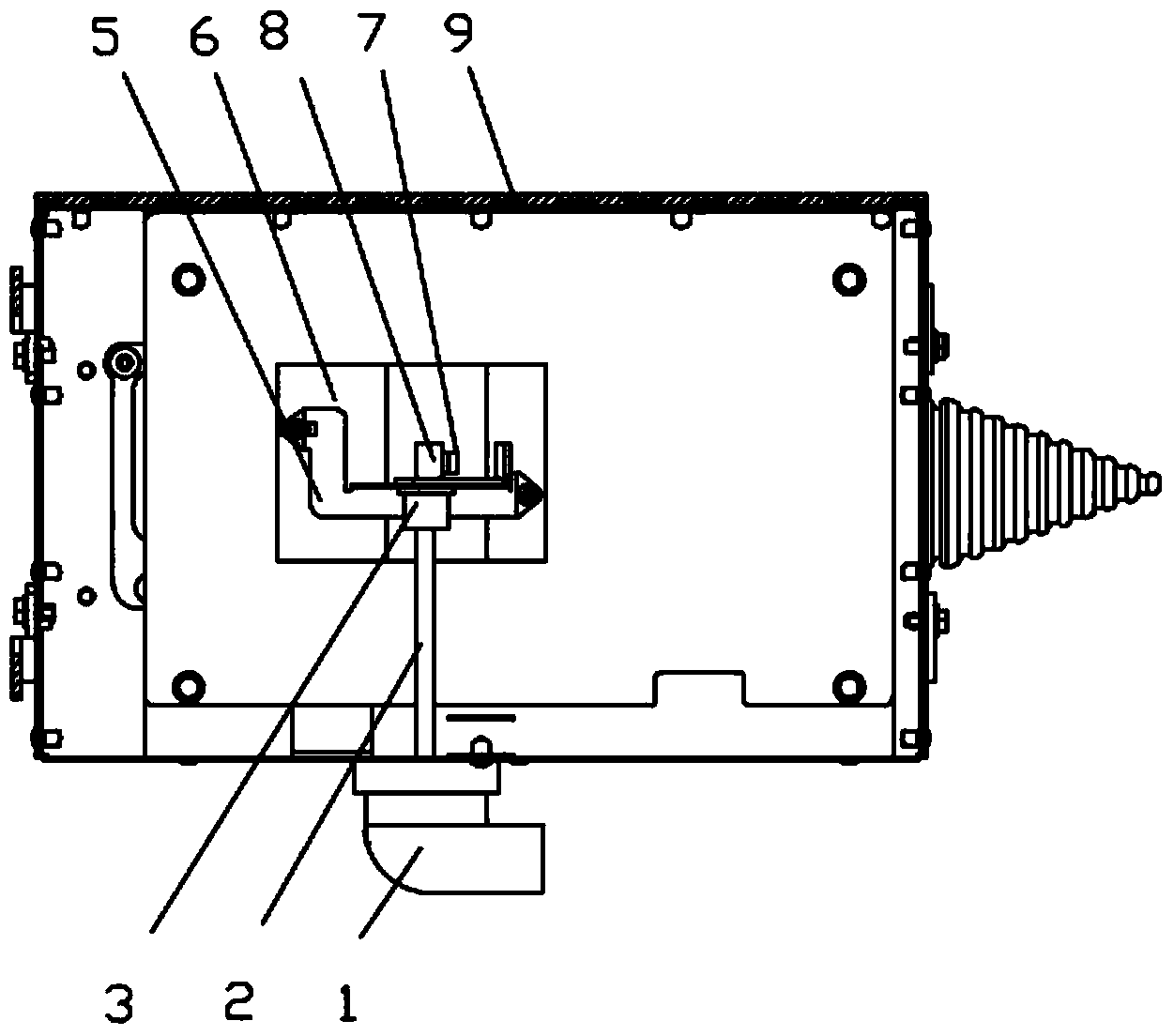

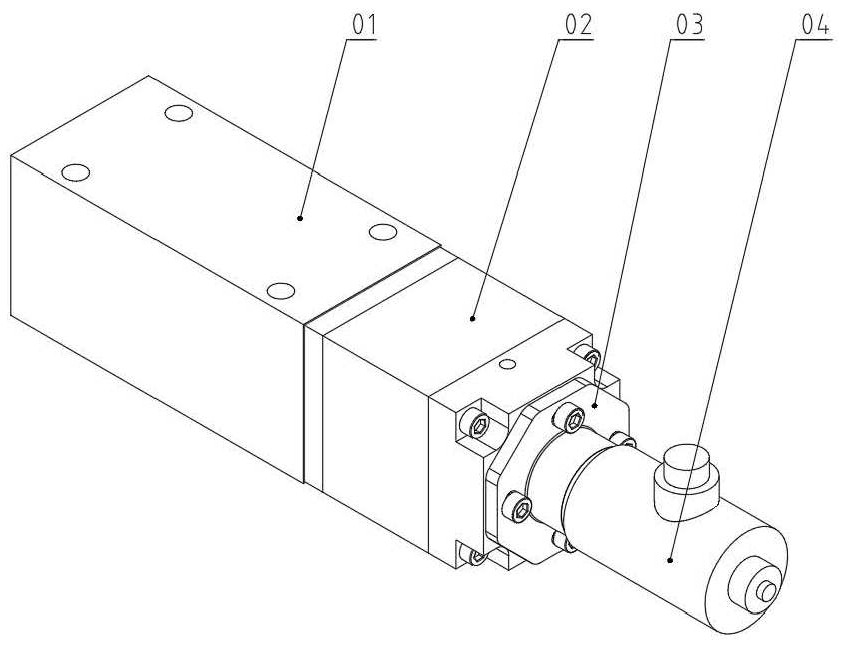

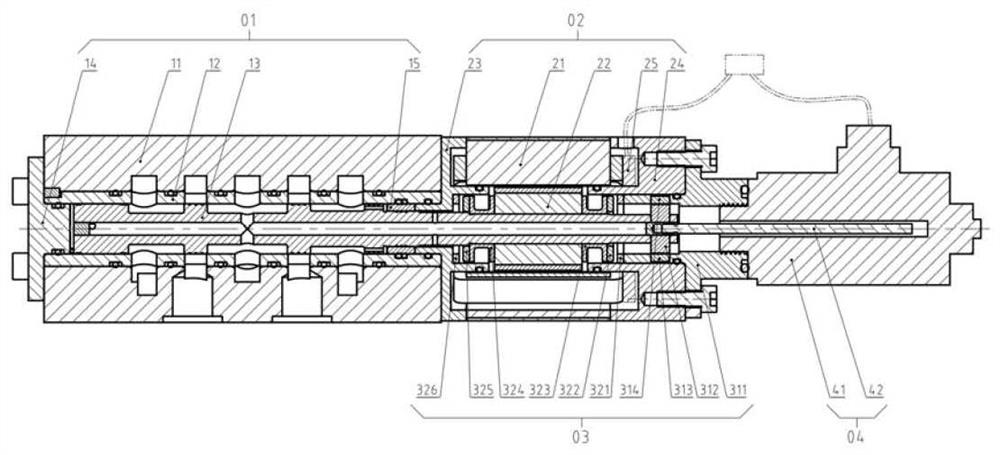

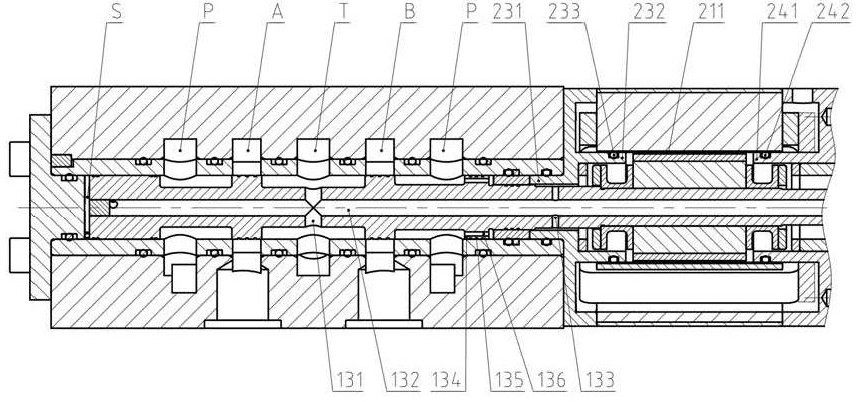

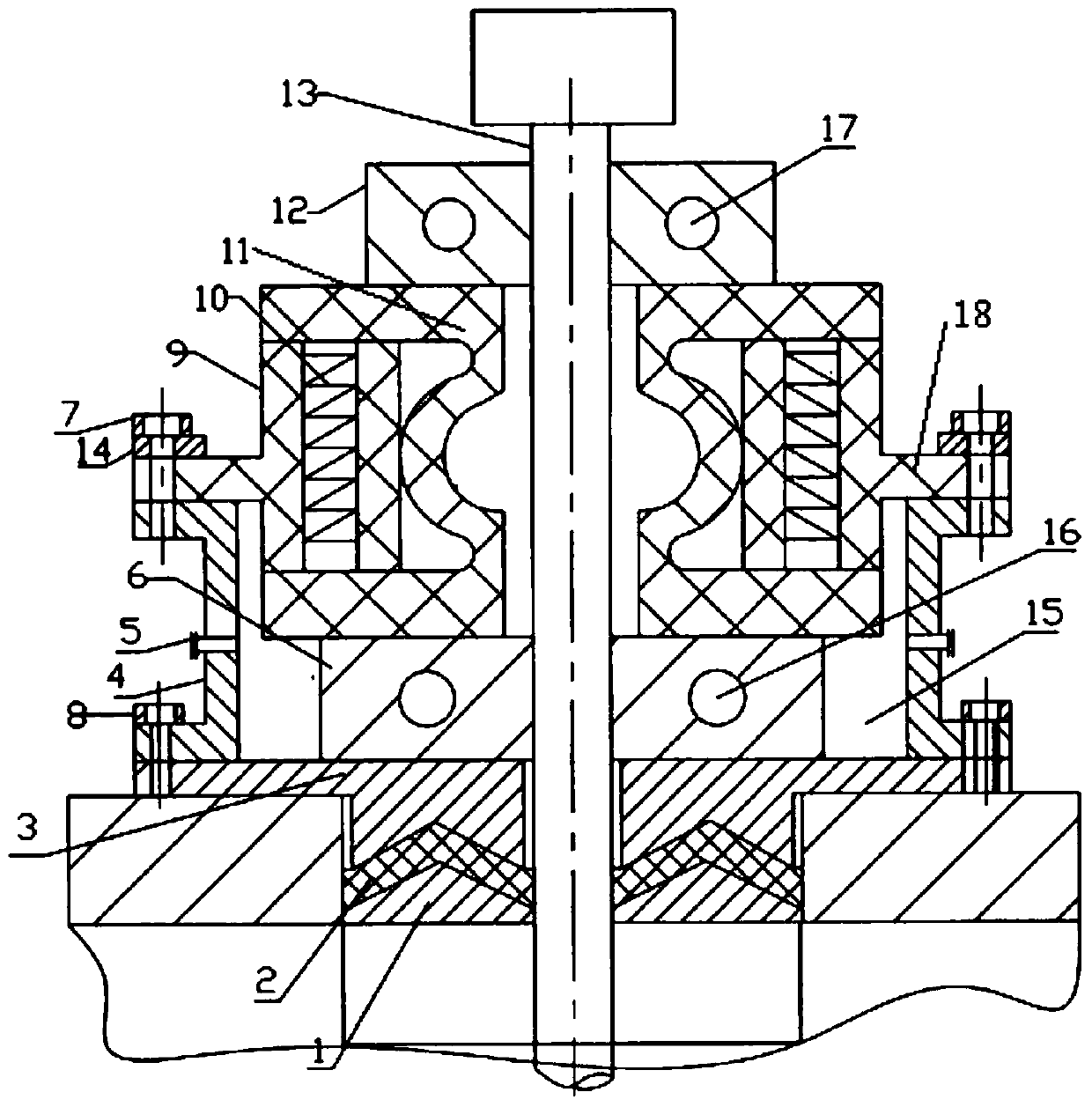

Zero-position-adjustable two-dimensional motor direct-drive electro-hydraulic servo valve

ActiveCN114718933AExtended service lifeSimplify the process of electro-mechanical conversionFluid-pressure actuator testingOperating means/releasing devices for valvesSpool valveLoop control

The invention discloses a zero-position-adjustable two-dimensional motor direct-drive electro-hydraulic servo valve which comprises a sliding valve assembly, a two-dimensional motor, a magnetic steel zero-setting reset mechanism and a displacement sensor which are coaxially arranged. The sliding valve assembly is of a traditional two-dimensional servo valve structure, a two-dimensional motor can directly drive a valve element to rotate so as to control the opening size of a valve port, a magnetic steel zero setting and resetting mechanism is used for zero setting and resetting of the valve, and a displacement sensor can monitor the position of the valve element in real time and feed back signals to achieve closed-loop control. According to the servo valve, the valve element is directly driven through the two-dimensional motor, a transmission mechanism of a traditional two-dimensional valve is omitted, the electro-mechanical conversion process is simplified, non-contact zero adjustment and reset are achieved through the magnetic steel zero adjustment and reset mechanism, contact abrasion is reduced, and the service life of the servo valve can be prolonged. In addition, the two-dimensional motor is of a wet-type rotor structure, heat dissipation can be improved, meanwhile, the problem of high-pressure dynamic sealing is avoided, and the overall reliability is improved.

Owner:ZHEJIANG UNIV CITY COLLEGE +1

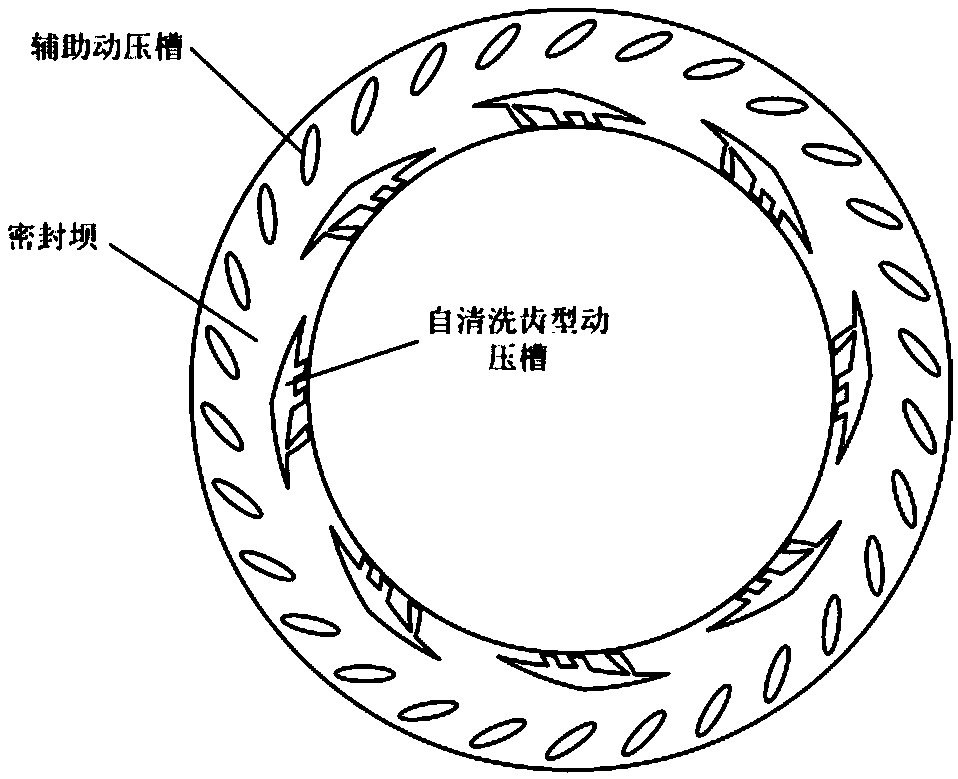

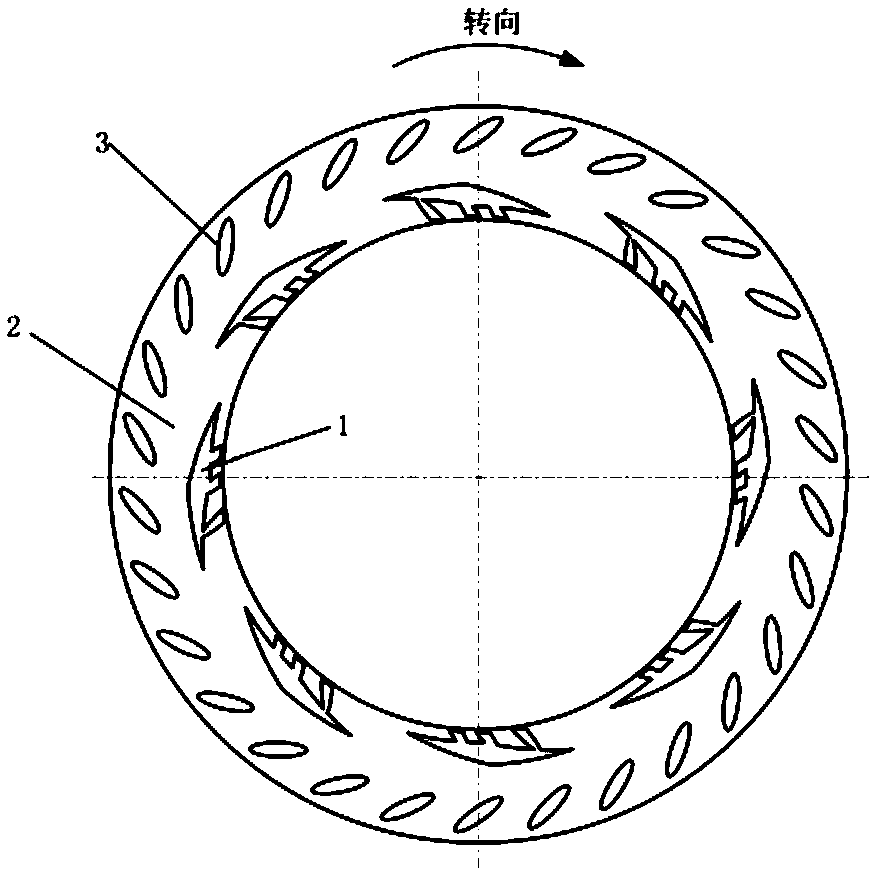

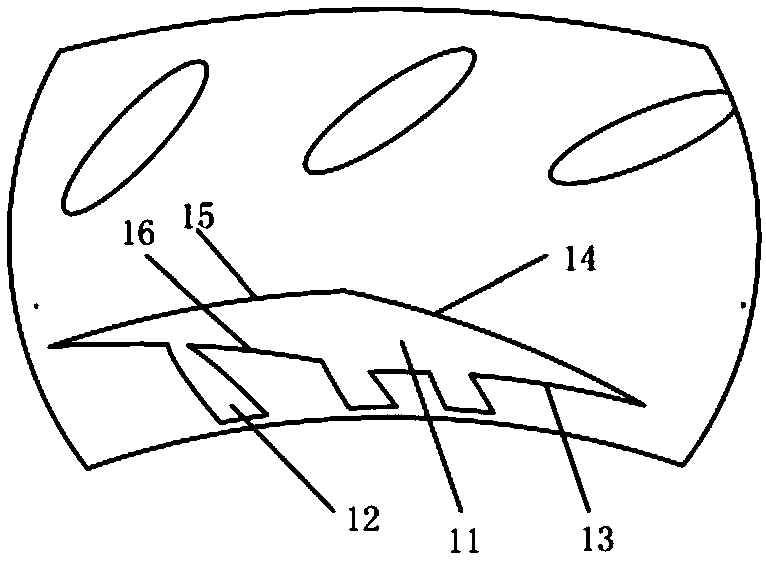

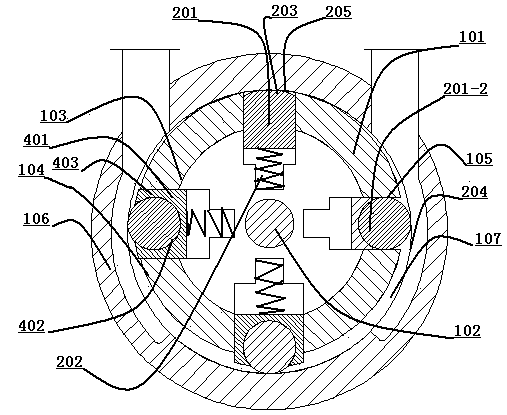

Self-cleaning toothed dynamic-pressure-type groove end face mechanical sealing structure

InactiveCN109237042AAchieve non-contact stabilityReduce contact wearEngine sealsCentre of rotationEngineering

The invention discloses a self-cleaning toothed dynamic-pressure-type groove end face mechanical sealing structure. The structure comprises a dynamic ring and a static ring which are mechanically sealed; one end face of the dynamic ring or the static ring is provided with a self-cleaning toothed dynamic-pressure-type groove ring belt and an auxiliary dynamic-pressure-type groove ring belt which are symmetrically distributed about a rotation center, self-cleaning toothed dynamic-pressure-type grooves are composed of dynamic pressure grooves and cleaning grooves, and the self-cleaning toothed dynamic-pressure-type grooves and auxiliary dynamic-pressure-type grooves are formed in the upstream and downstream portions of the end face respectively and separated by a sealed dam. The non-contact mechanical end face sealing structure prevents deposition blockage of medium particles in end face mold grooves through the cleaning groove structures, solves the blockage problem of the sealed end face mold grooves under high temperature and multi-particle medium conditions, reduces the contact wear of the sealed end face since the dynamic pressure opening force of the sealed end face decreases, and is long in service life.

Owner:BEIJING POWER MACHINERY INST

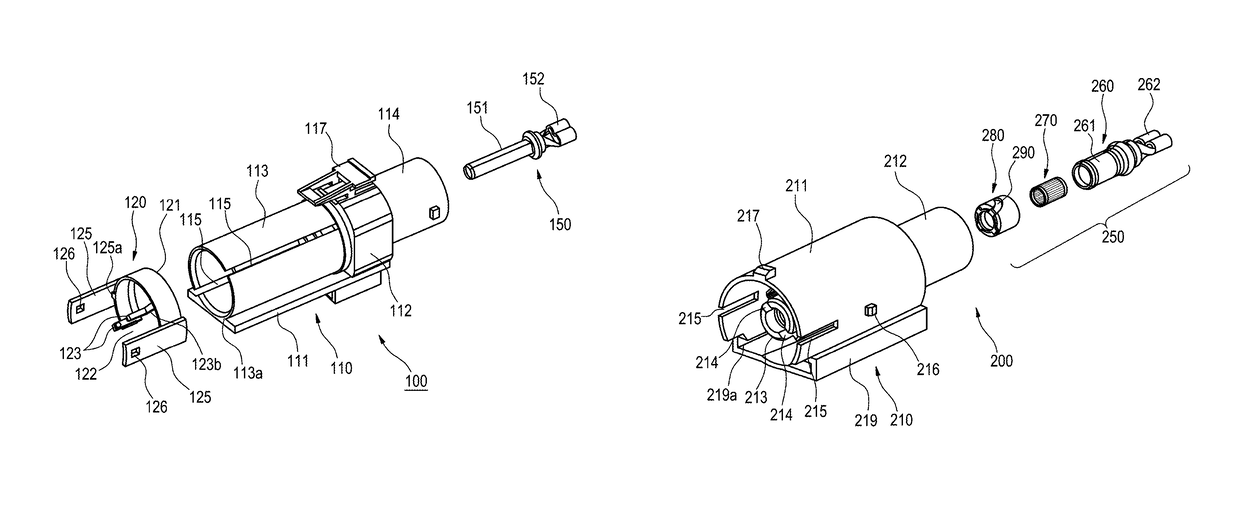

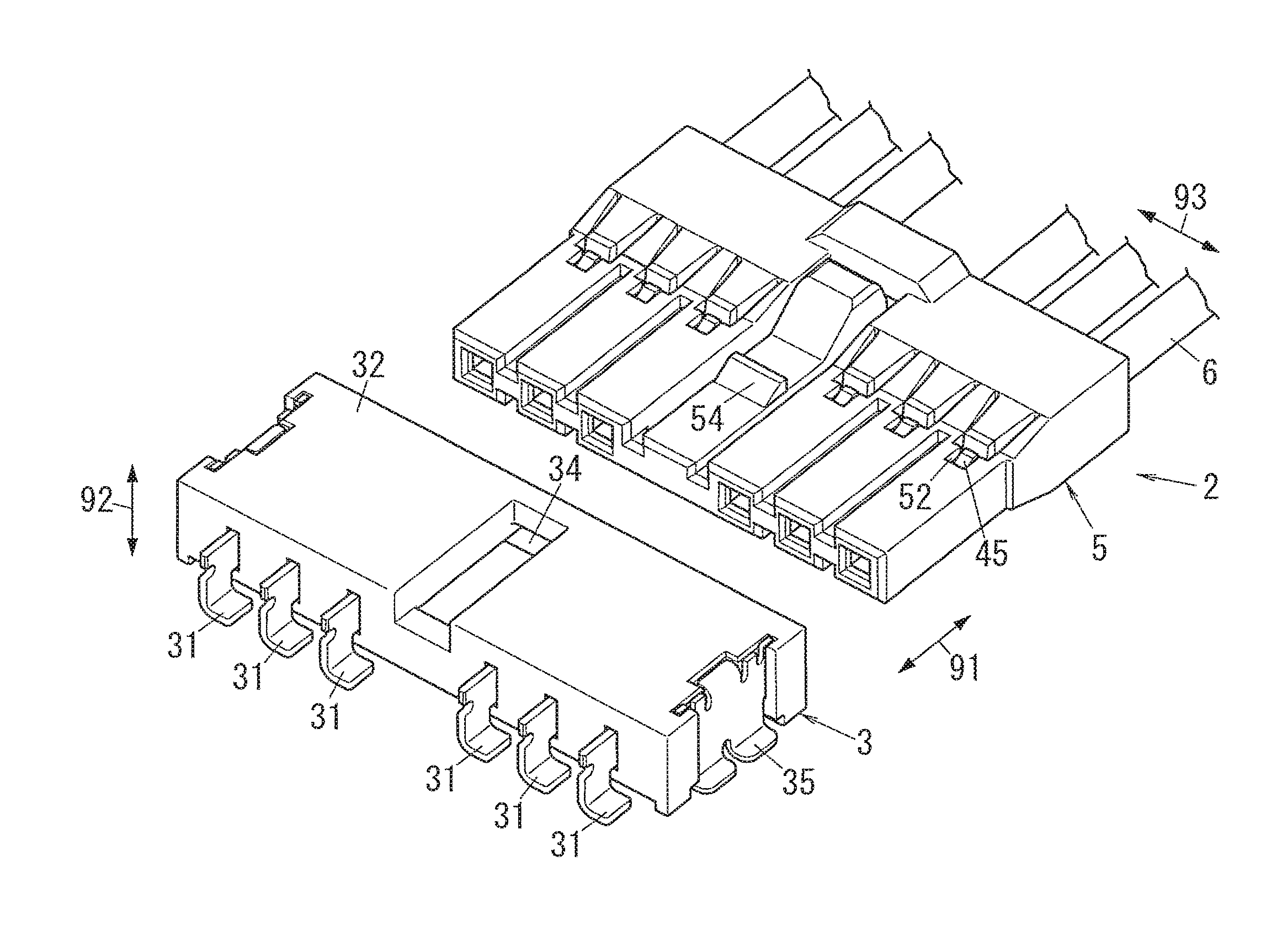

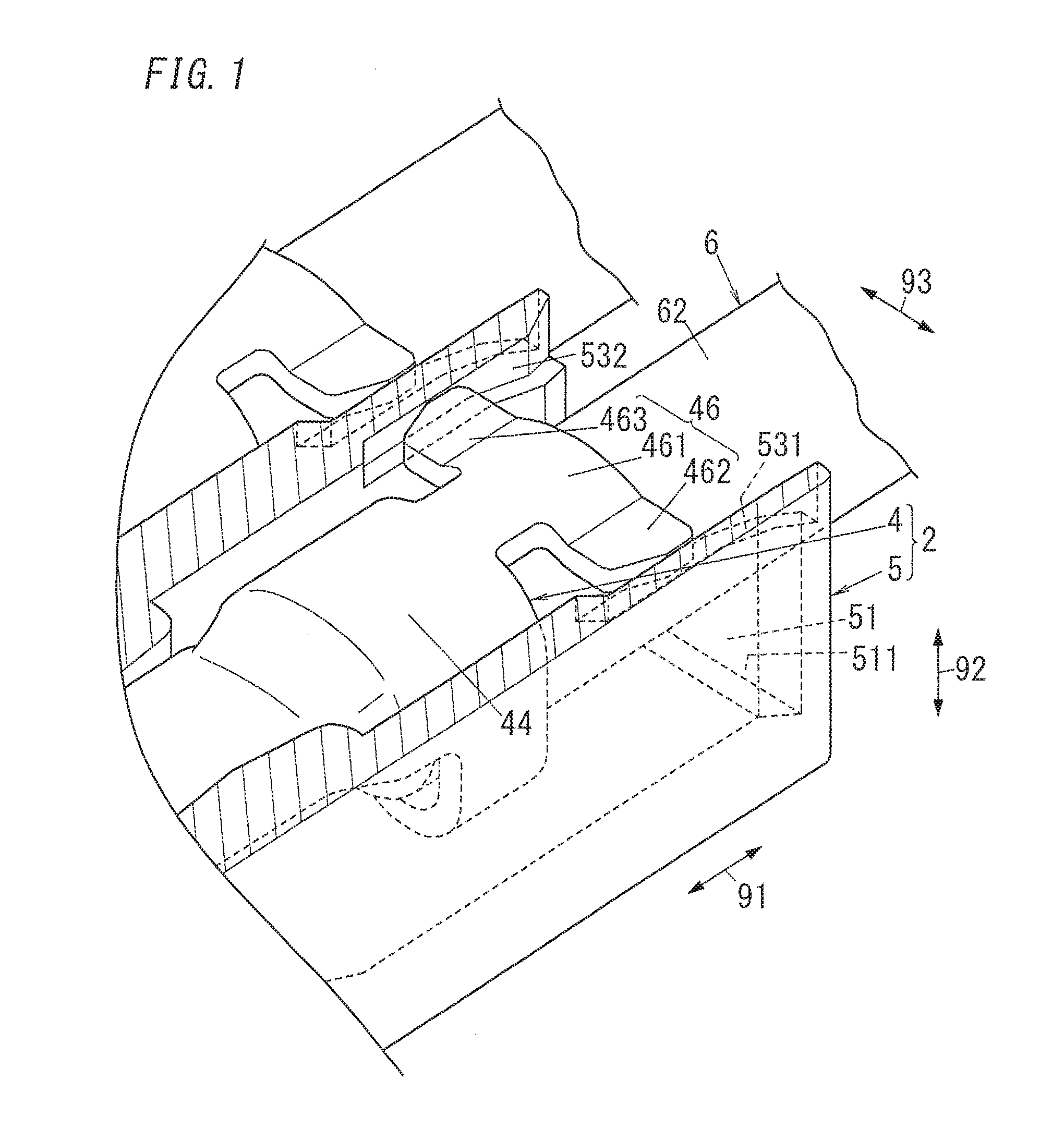

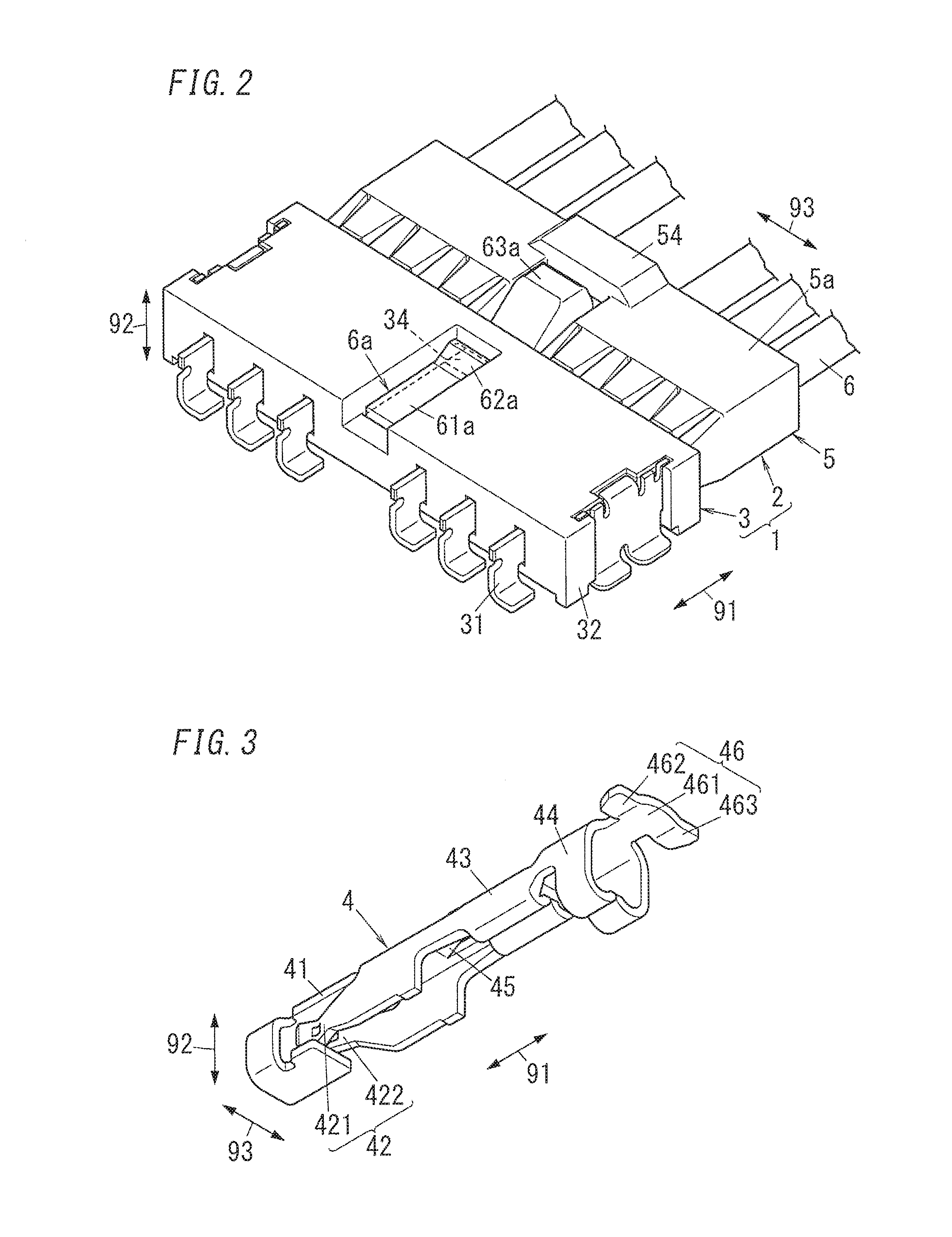

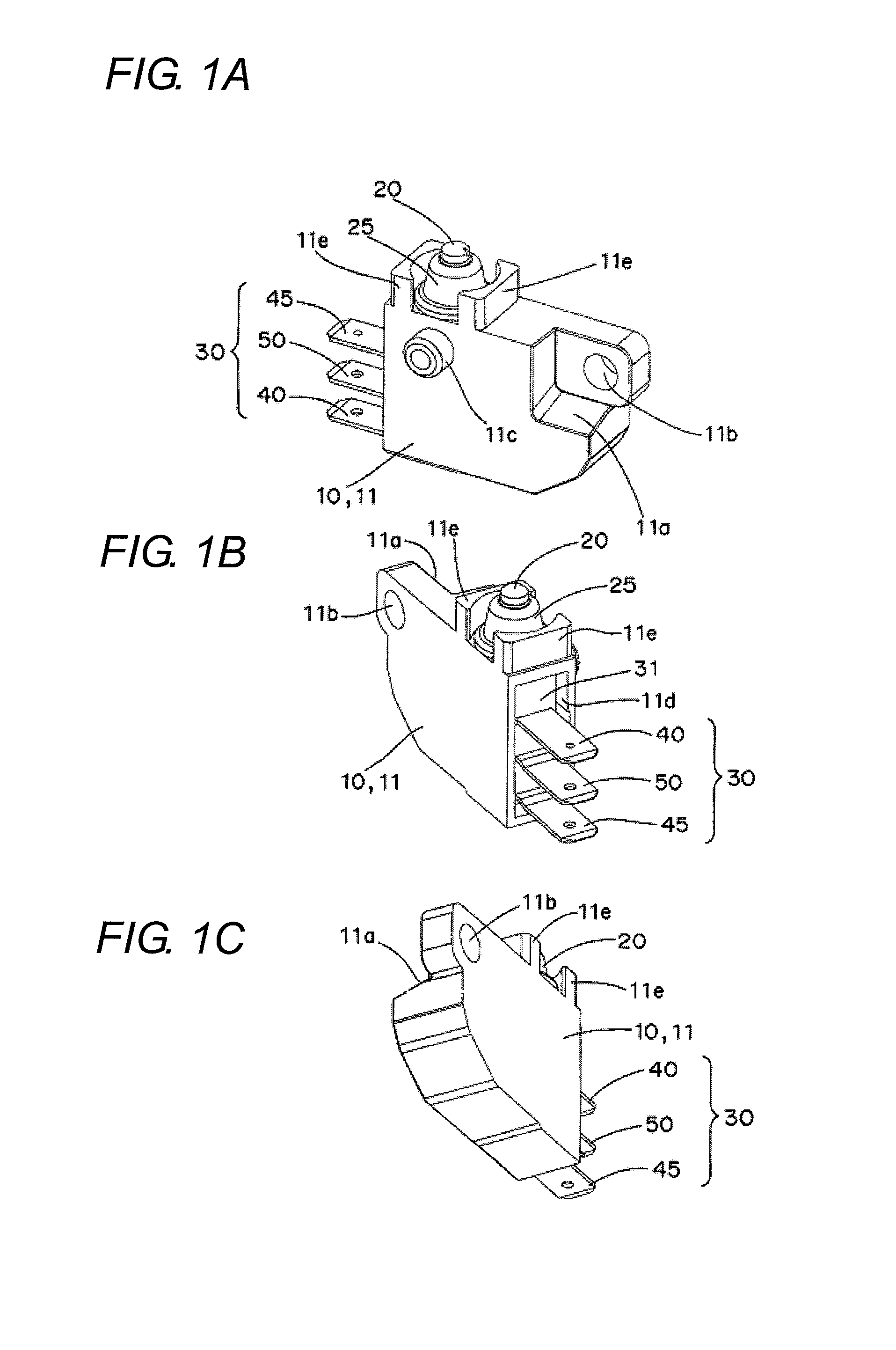

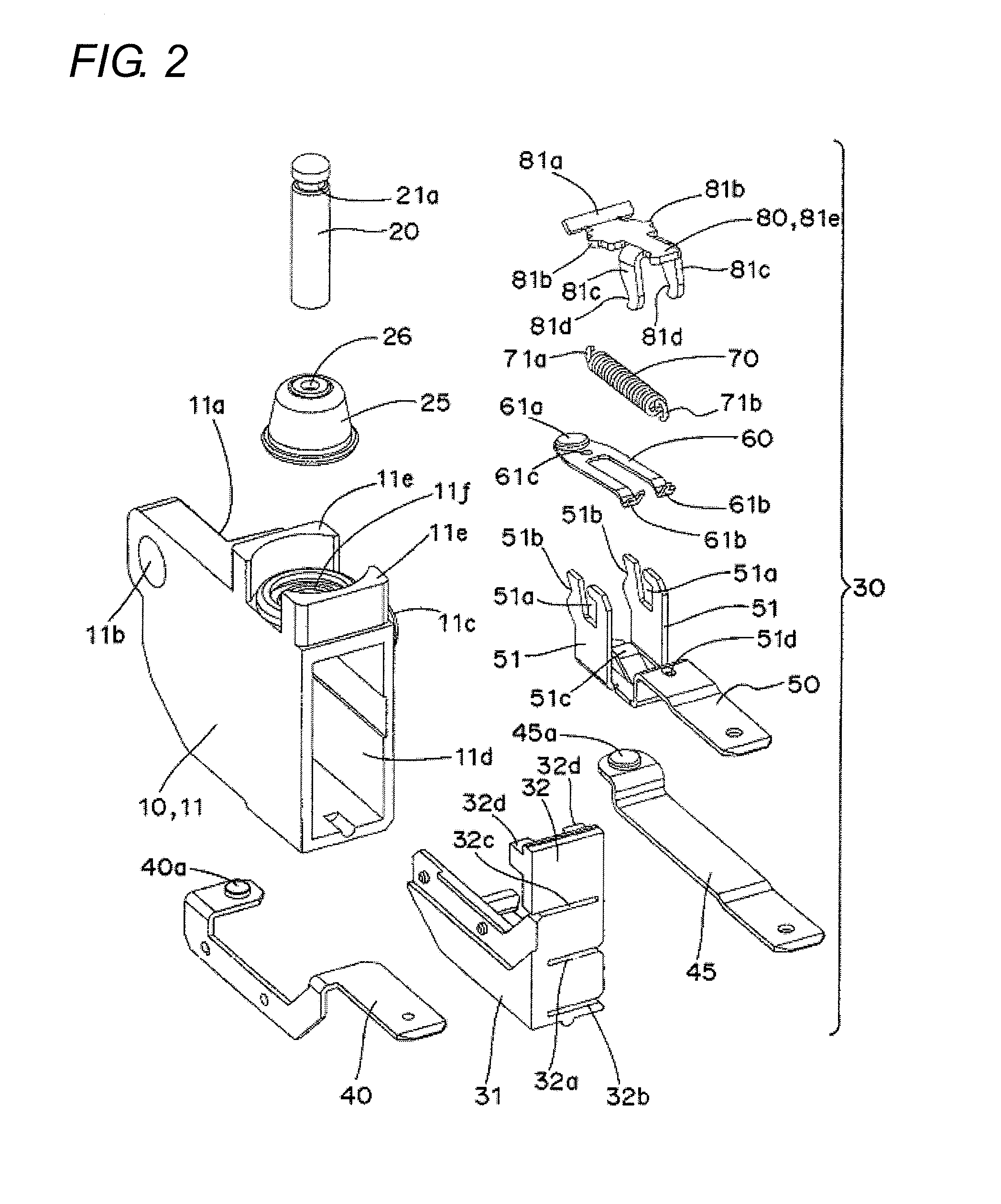

Connector device

ActiveUS9601845B2Reduce insertion loadReduce frictional resistanceCoupling device detailsClamped/spring connectionsLinear motionEngineering

Owner:YAZAKI CORP

Connector and connector device

ActiveUS20170005434A1Reduce contact wearReduce wearVehicle connectorsCoupling device detailsY connectorElectric wire

A connector includes a contact in an elongated shape that is electrically conductive, and a housing that has an internal space is formed. The contact includes a contact portion, a connection portion, a fixing portion, and a protruding portion. The contact portion is to be electrically connected to an electrically conductive member when the contact is housed in the housing. The connection portion is electrically connected to a core wire of an electrical wire. The fixing portion is provided on a side opposite to the contact portion relative to the connection portion, and fixes a covering of the electrical wire. The protruding portion is provided on an end portion side of the fixing portion opposite to the connection portion so as to protrude. The protruding portion reduces the amount of movement of the contact inside the internal space of the housing.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Rotating shaft sealing device

The invention discloses a rotating shaft sealing device comprising a rotating shaft. The bottom end of the rotating shaft is sleeved with a split support ring. V-shaped sealing filler is arranged above the split support ring. A pressure cover with a pressure ring sleeves the outside of the rotating shaft above the V-shaped sealing filler. A first split moving ring sleeves the top of the pressure cover. Split faces of the first split moving ring and a contact face of the rotating shaft are coated with sealant, and the first split moving ring and the rotating shaft are rotatably fixed through first rotating bolts. A split sealing shell is arranged outside the rotating shaft above the pressure cover. Both the upper and lower ends of the split sealing shell are bent out. The lower end of the split sealing shell is fixedly connected with the pressure cover through second bolts. The original filling seal is modified into the V-shaped seal, contact wear of the rotating shaft is reduced, sealing performance is more effective, the sealing effect remains unchanged even when the rotating shaft is eccentric, and the rotating shaft sealing device is capable of operating stably and reliably and is long in service life.

Owner:马鞍山市荣亿密封材料有限责任公司

Runner blade convoluting mechanism

InactiveCN108343474AReduce contact wearExtended service lifeRotary piston pumpsRotary piston liquid enginesEngineeringCentrifugal force

The invention provides a runner blade convoluting mechanism. Blades are installed in sliding vane grooves of a turning wheel. Under the action of rotational centrifugal force of the turning wheel or elastic force of springs installed in the sliding vane grooves, the outer arc surfaces of the top ends of the blades are in line contact with the inner arc wall surface of a cylinder body. The structures of the blades are rolling blades or sliding blades, the rolling blades are in a cylindrical shape, and the rolling blades roll in the sliding vane grooves of the rotating wheel. The sliding bladesslide in the sliding vane grooves of the rotating wheel, and the outer arc surfaces and the lower arc surfaces of the sliding blades are of the same center of a circle. Through the technical improvement, a blade meshing control device changes the contact rotary motion between the blades and the cylinder body into the meshing rotary motion, and the rotational speed is not affected by the speed of acontact line. The performance of pumps, hydraulic power machines, pneumatic machines, compressors, expansion power machines and engines in the technical field of fluid machinery is improved.

Owner:周觉明

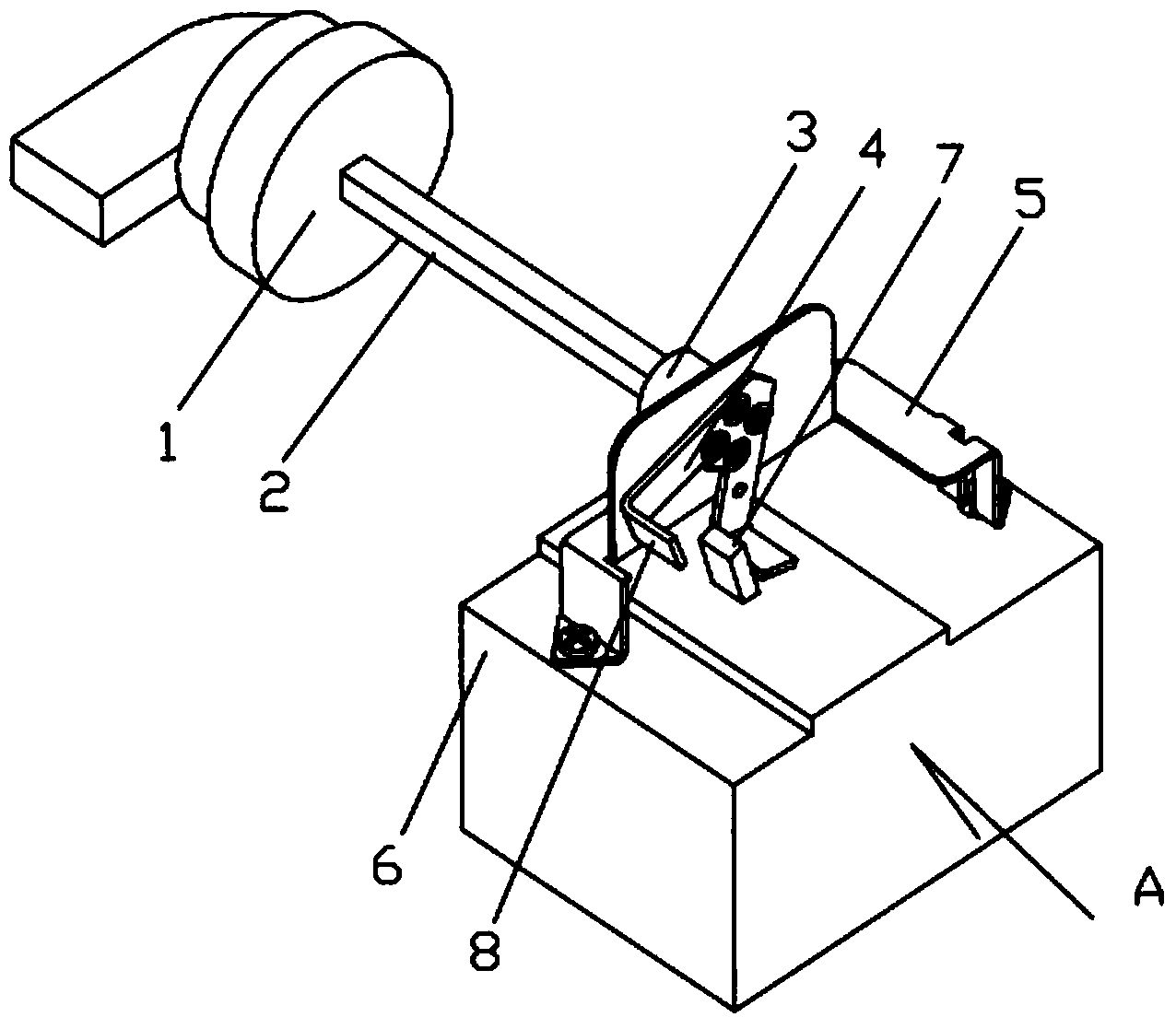

Knot disengaging mechanism and method of knotter

InactiveCN106211949AAvoid wear and tearImprove use reliabilityHarvestersBalingEngineeringContact friction

The invention discloses a knot disengaging mechanism and method of a knotter. The knot disengaging mechanism of the knotter comprises a knotter jaw and a tool rest, a long groove is machined in the circular-arc-shaped ridge of the knotter jaw, the matching surface of the tool rest with the circular-arc-shaped ridge of the knotter jaw is provided with a protrusion, and the protrusion is matched with the groove and can move along the groove. According to the knot disengaging mechanism and method of the knotter, optimization and improvement are conducted on the tool rest and the knotter jaw part, an original knot disengaging mode is changed, mutual contact friction of the tool rest and the knotter jaw is avoided in the knot disengaging process, and the purposes of reducing abrasion of related structures and forcefully disengaging a knot are achieved. The use reliability of the knotter is improved, the assembly difficulty is reduced, the interchangeability of parts is improved, and the knot formation rate of the knotter is guaranteed. The knot disengaging mechanism and method of the knotter are mainly applied to the field of knotter application.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

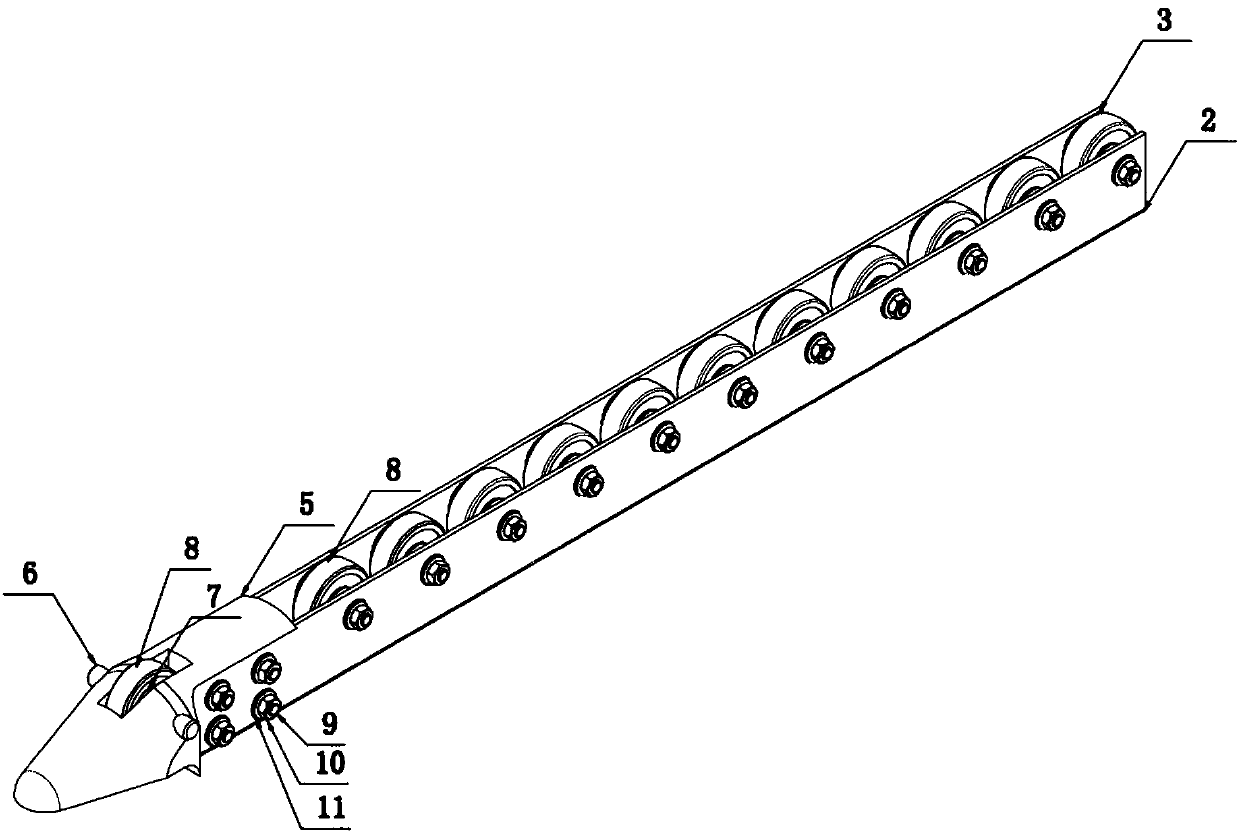

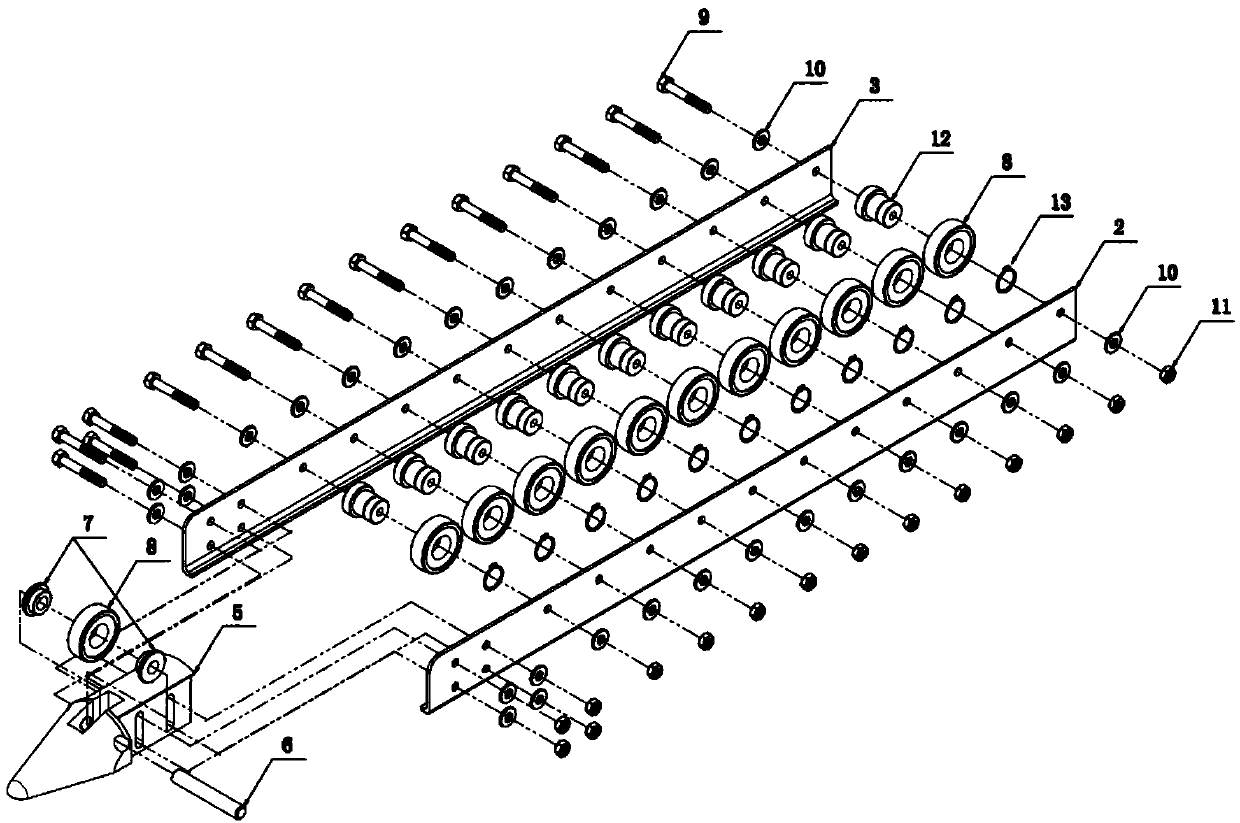

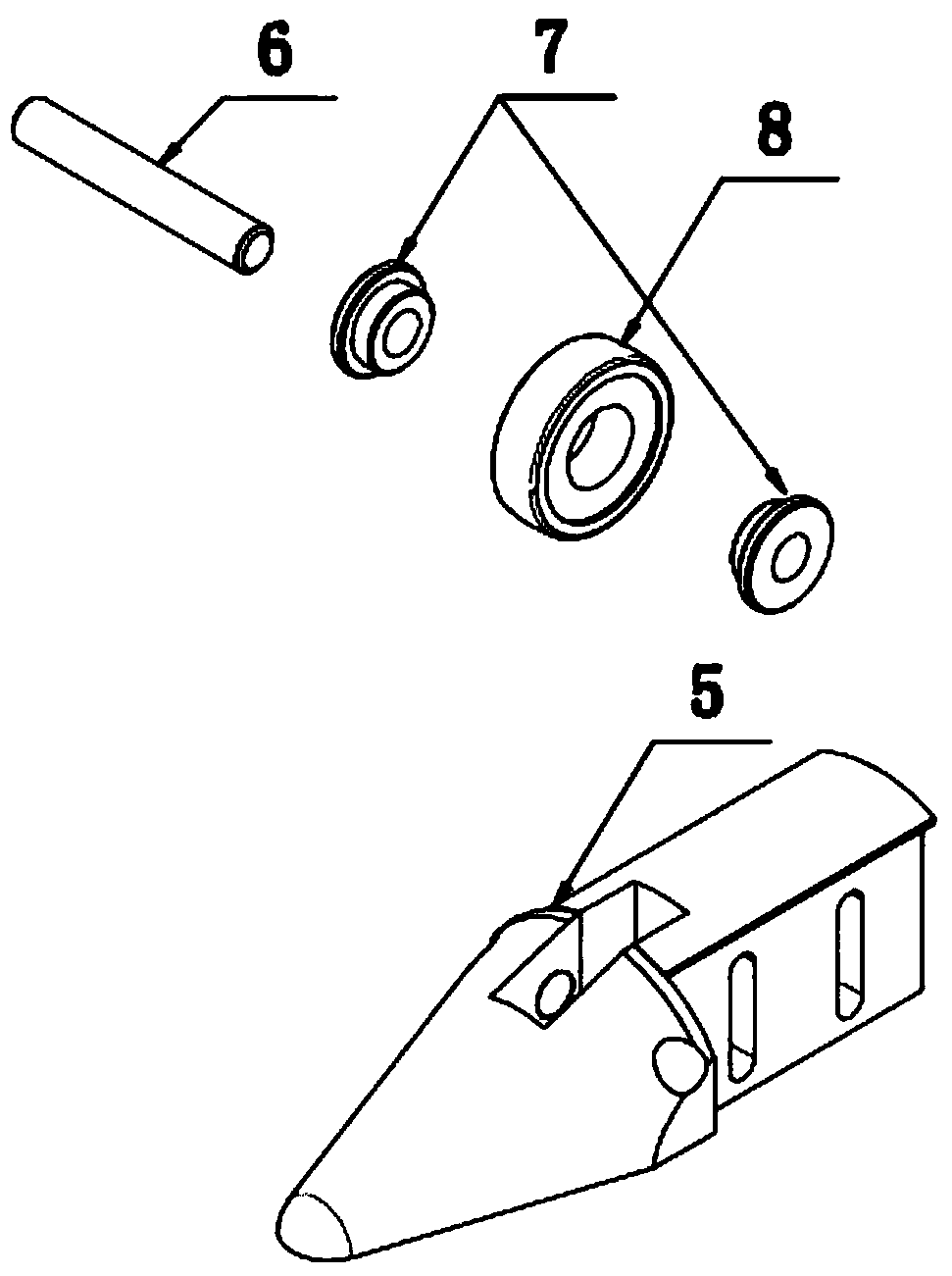

Idler wheel strip with guide

InactiveCN107651354ASolve the process problems that cannot be producedReduce scrapConveyorsRollersEngineeringIdler-wheel

The invention discloses an idler wheel strip with a guide. The idler wheel strip with the guide comprises an idler wheel assembly and idler wheel strip flanges. The idler wheel strip flanges include the left idler wheel flange and the right idler wheel flange. The left idler wheel flange and the right idler wheel are parallel and symmetric. The idler wheel assembly is arranged between the left idler wheel flange and the right idler wheel flange. One end of the left idler wheel flange and one end of the right idler wheel flange are provided with a guide head assembly. By means of the idler wheel strip with the guide, the problems that in the threading process, plates with different specifications, thicknesses and materials droop, and consequently material clamping and surface defects are caused are solved, smooth plate conveying is achieved, and the material clamping shutdown rate and the reject ratio of the plate surface quality are reduced.

Owner:NANJING BAOSTEEL SUMMIT METAL PRODUCTS CO LTD

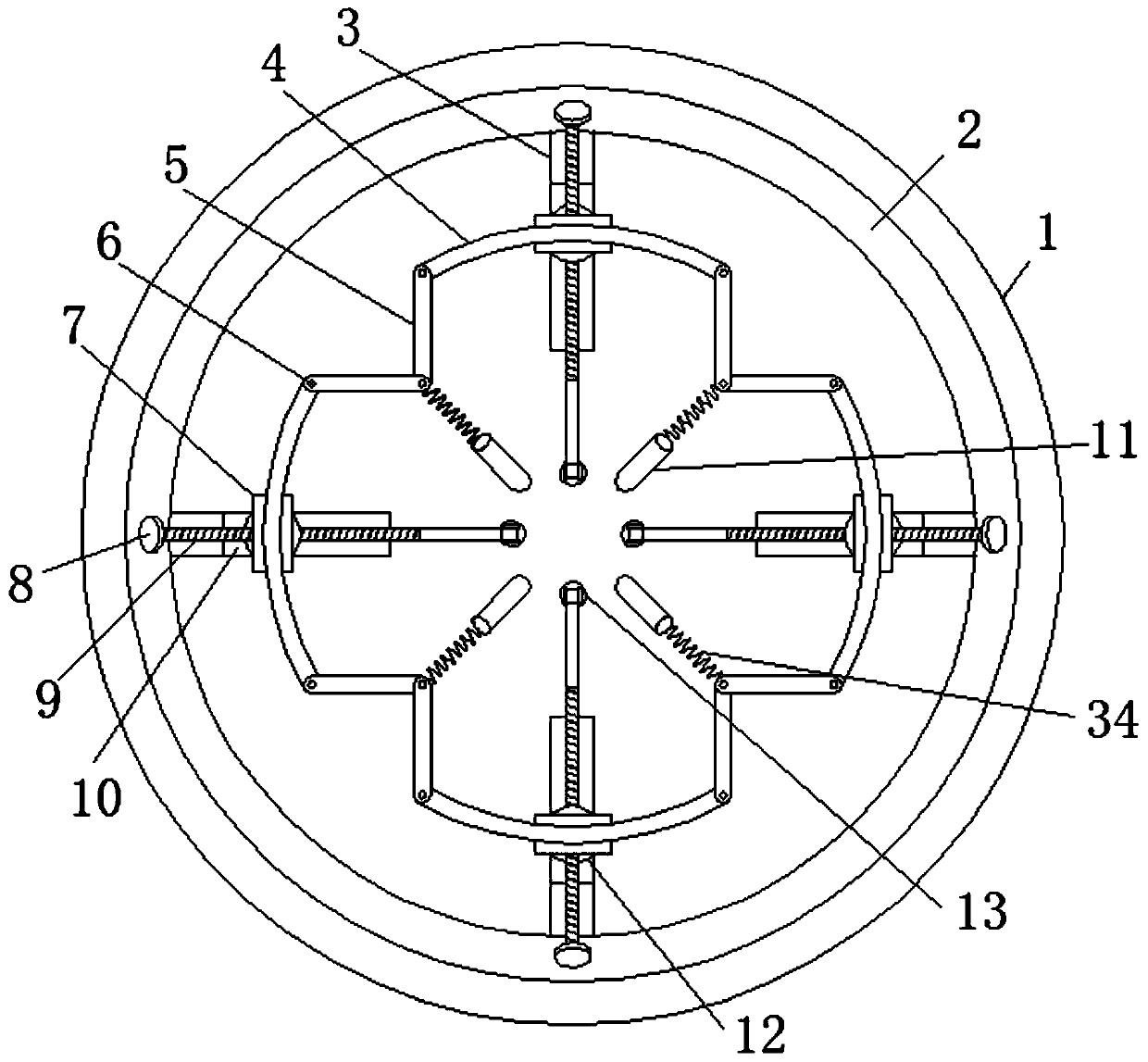

Green plant potting device with variable volume and using method of device

ActiveCN109937750AMeet the needs of planting spaceEasy to operateSelf-acting watering devicesFertiliser distributersEngineeringMotherboard

The invention relates to the field of indoor plant planting, in particular to a green plant potting device with variable volume and a using method of the device. The green plant potting device comprises a base seat and a cylindrical pot body consisting of main boards and auxiliary boards on the base seat, wherein a plurality of sliding grooves I are formed in the upper surface of the base seat atequal intervals along the circumferential direction; a plurality of the sliding grooves I are radially directed to the center of the base seat; the sliding grooves I are connected with sliding blocksI in a sliding manner; the main boards are fixed to the sliding blocks I; two vertical side edges of each the main board are in rotary connection with the auxiliary boards through shaft rods; the auxiliary boards between two adjacent main boards are further in rotary connection through the shaft rods in a shaft fixing manner; the middles of the main boards are connected with adjusting rods throughball hinge mechanisms; the adjusting rods are used for adjusting the size of the pot body to facilitate the cultivation of different green plants; a water supplementing mechanism is arranged on the base seat for supplementing water to the green plants in the pot body; a walking mechanism, which is convenient to move, is arranged at the bottom of the base seat; and supporting mechanisms are arranged on the main boards for improving the stability of the green plants. The green plant potting device with variable volume is convenient to use, convenient to manage, and saves time and labor.

Owner:陈昱成

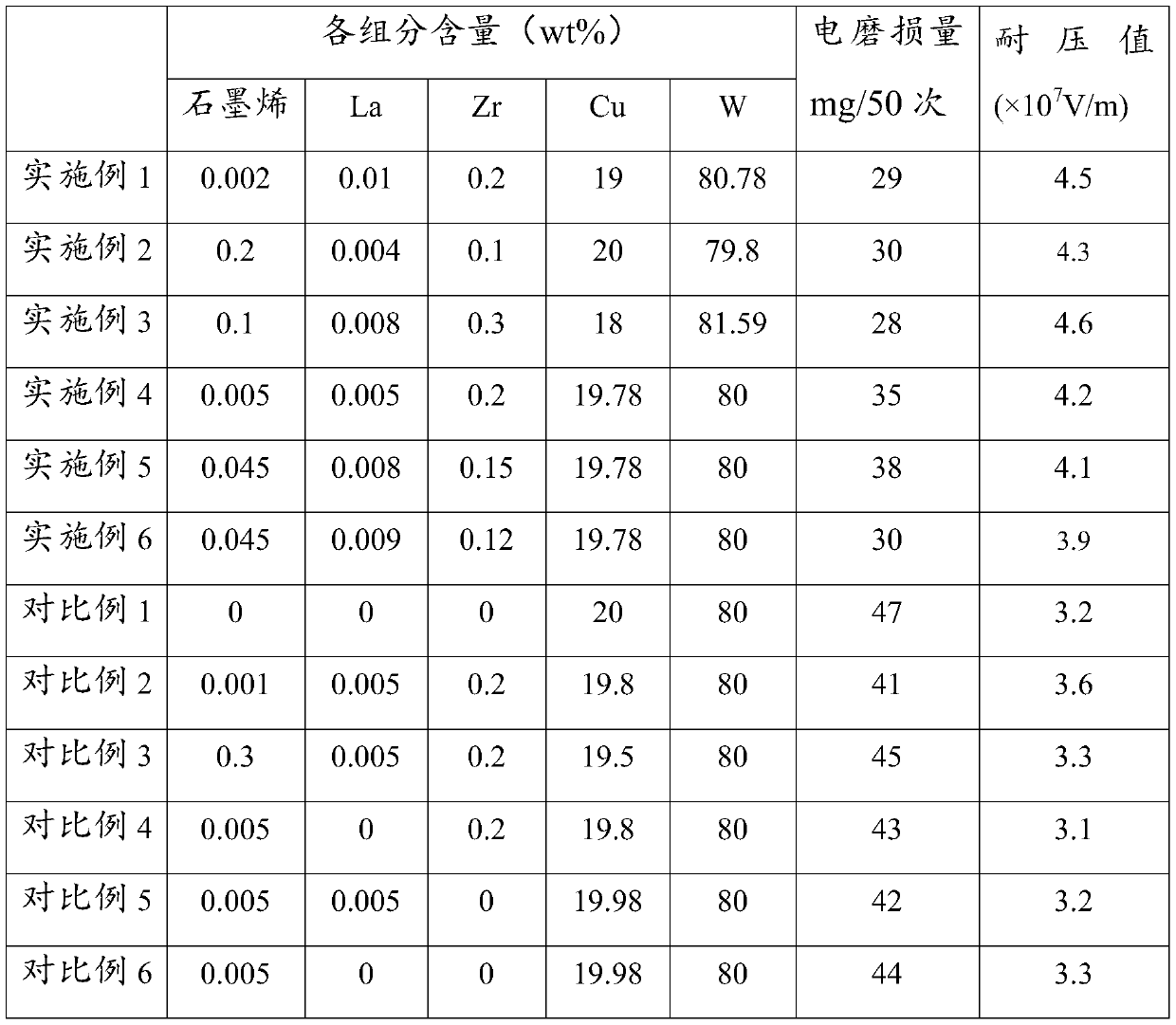

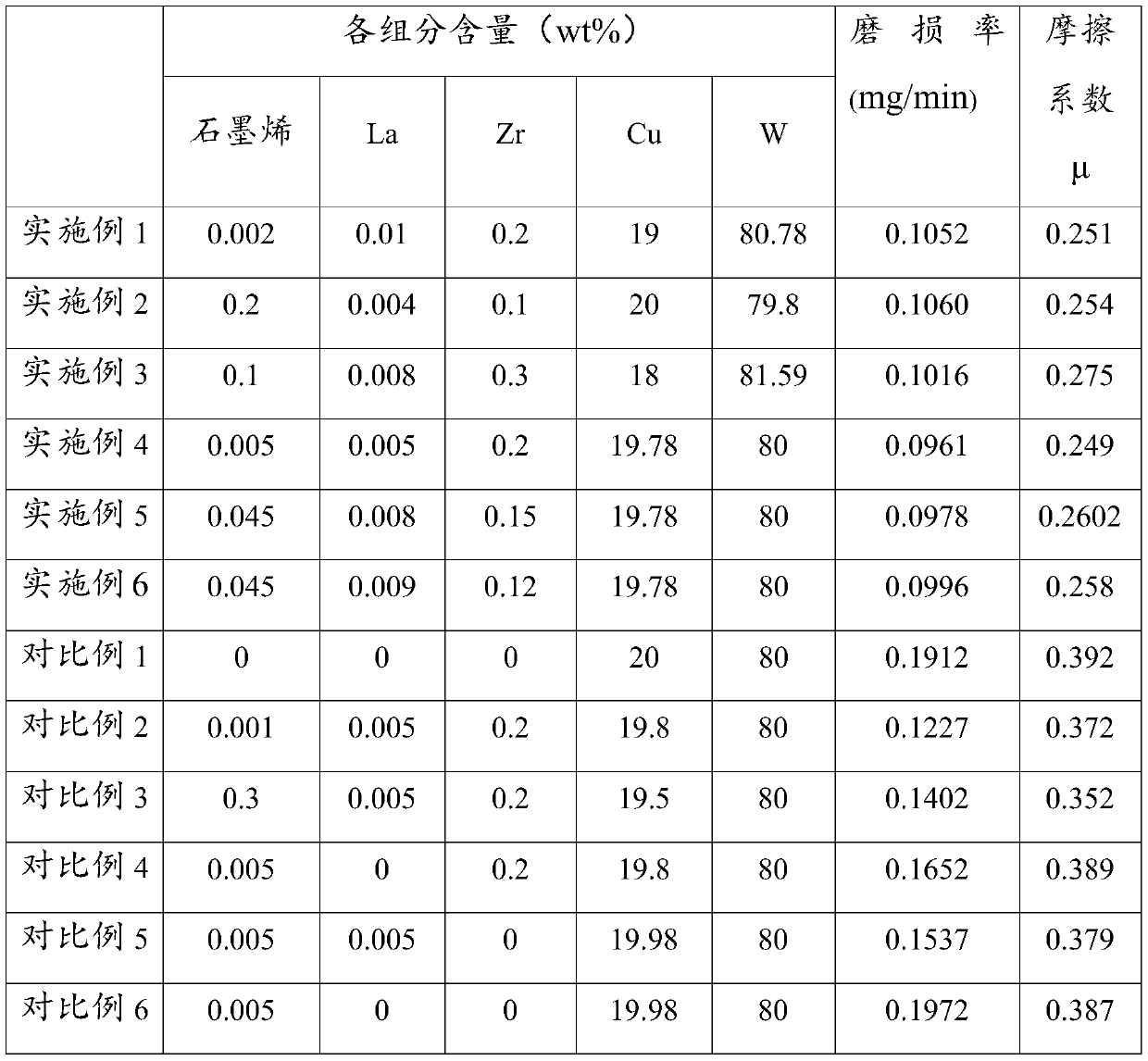

Anti-arc ablation material and preparation method and application thereof

PendingCN110438383AImprove toughnessImprove wear resistanceTransportation and packagingMetal-working apparatusLanthanumContact resistance

The invention provides an anti-arc ablation material and a preparation method and application thereof. The anti-arc ablation material comprises the following components of, in percentage by mass, 0.002%-0.2% of grapheme, 0.004%-0.01% of lanthanum, 0.1%0.3% of zirconium, 18%-20% of copper, and the balance tungsten. According to the method, the graphene, the lanthanum and the zirconium are added andthe contents of the grapheme, the lanthanum and the zirconium are limited, the graphene precursor is prepared in a chemical co-deposition mode, then the graphene precursor is mixed with Cu, W, the lanthanum and the zirconium to obtain mixed powder, and furthermore, the powder forming and a mode of combining sintering and infiltration processes are adopted, the material is enabled to have high electric arc ablation resistance, low contact resistance and low mechanical abrasion loss, and meanwhile good lasting strength under the extra-high-voltage and high-current working conditions.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +3

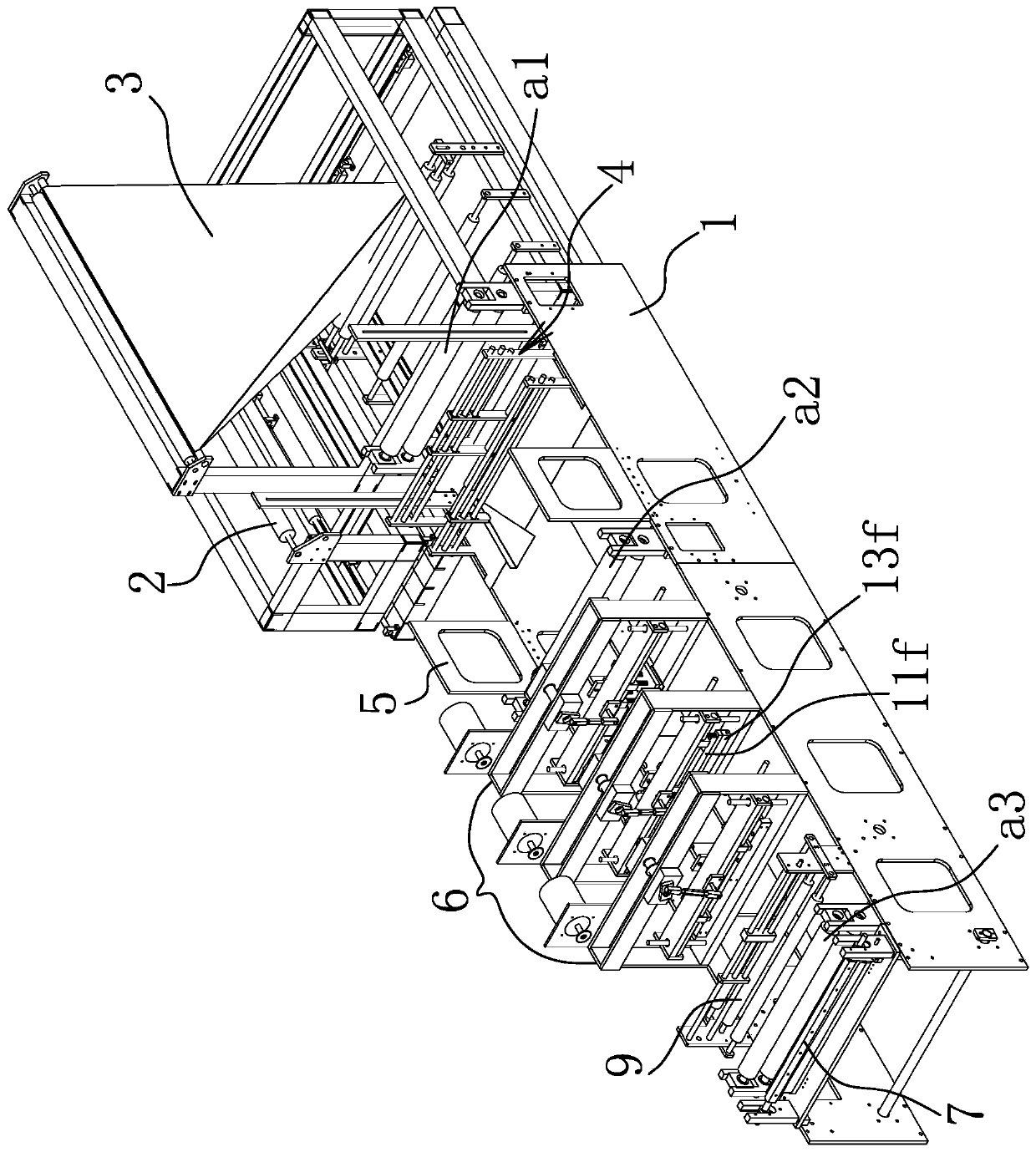

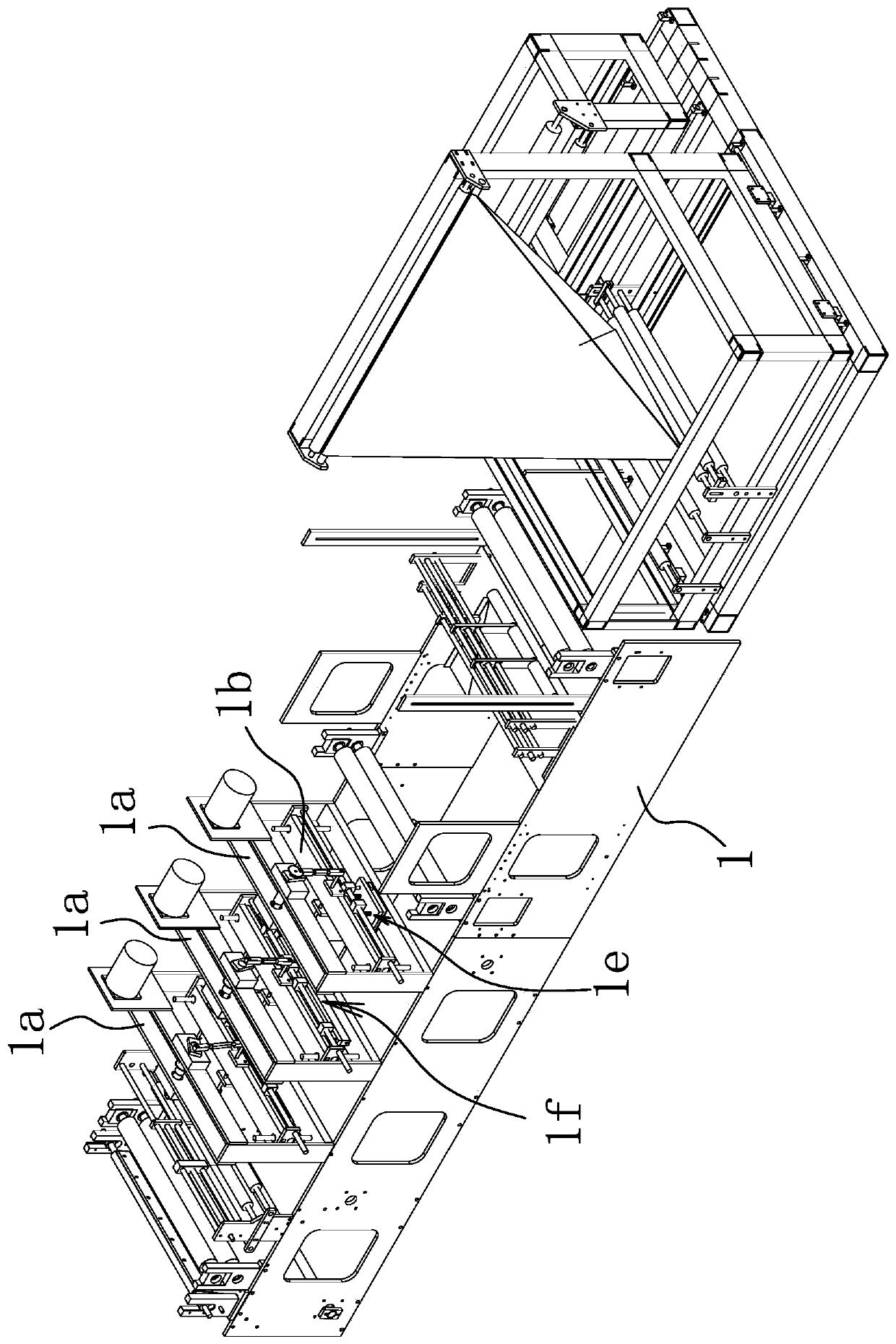

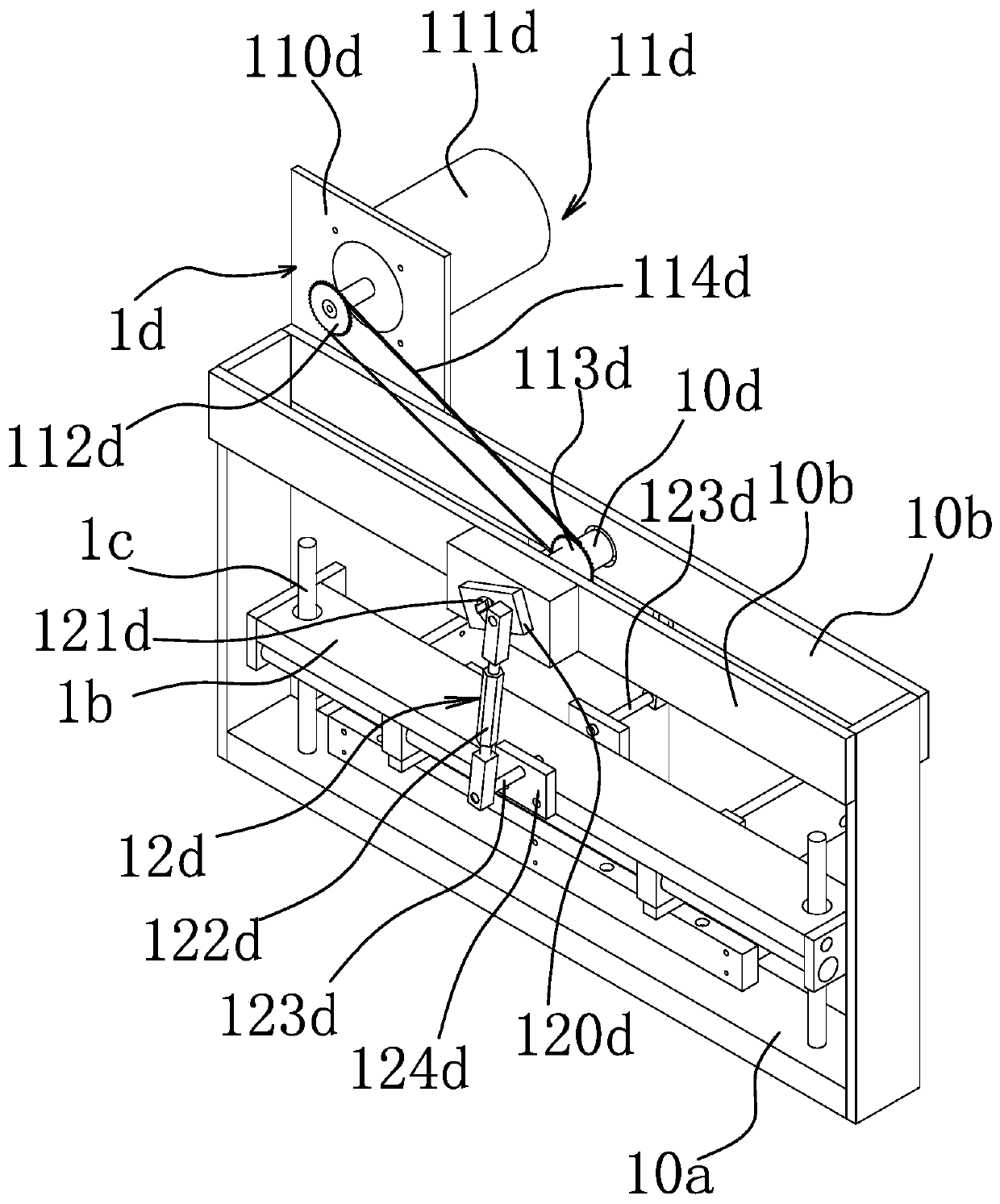

Air column bag equipment driving unit and air column bag machining equipment thereof

ActiveCN110936660AEasy maintenanceReduce the difficulty of processing and manufacturingBag making operationsPaper-makingStructural engineeringMachine

The invention belongs to the technical field of machines, and particularly relates to an air column bag equipment driving unit and air column bag machining equipment thereof. The technical problem that in the prior art, maintenance is not convenient is solved. The air column bag equipment driving unit comprises an outer fixing frame, an executing mechanism installing plate, a vertical guiding mechanism and a lifting driving mechanism, wherein the outer fixing frame is vertically fixed to the rack, the executing mechanism installing plate is horizontally placed inside the outer fixing frame andcan ascend and descend in the vertical direction, the vertical guiding mechanism is connected to the executing mechanism installing plate and the outer fixing frame and used for improving the liftingstability of the executing mechanism installing plate, the lifting driving mechanism is fixed to the top of the outer fixing frame and is connected with the middle of the executing mechanism installing plate, and the lifting driving mechanism drives the executing mechanism installing plate to ascend and descend in a reciprocating mode in the vertical direction. The air column bag equipment driving unit has the advantage of being convenient to maintain.

Owner:浙江华鲲科技有限公司

Switch

ActiveUS8658928B2Avoid misuseAvoid breakingContact vibration/shock dampingSnap-action arrangementsEngineeringContact mechanism

A switch has a housing, a contact mechanism having a movable contact piece disposed in the housing, an operating element that operates the movable contact piece, a spring member of the contact mechanism that operates the movable contact piece to open and close a contact, and a regulating mechanism that suppresses vibration of the spring member arranged at a position contacting the spring member.

Owner:ORMON CORP

Tripod type constant velocity joint

ActiveUS7704148B2Reduce surface pressureAccurate inclinationYielding couplingRotary machine partsEngineeringSurface pressure

In a tripod type constant velocity joint, in order to produce a recovery couple to correct the inclination of the rolling direction of a roller and to reduce surface pressure without using angular contact provided by a Gothic arch-shaped roller guide surface, it is arranged that where r1 and r2 are the minimum and maximum values, respectively, of the radius of curvature of the generatrix for the outer peripheral surface of the roller within the range where solid contact is effected by elastic deformation of the contact section between the roller and the roller guide surface under a predetermined torque load with respect to the radius of curvature of the roller guide surface, the radius of curvature (r) of the generatrix be set in the range r1≦r≦r2.

Owner:NTN CORP

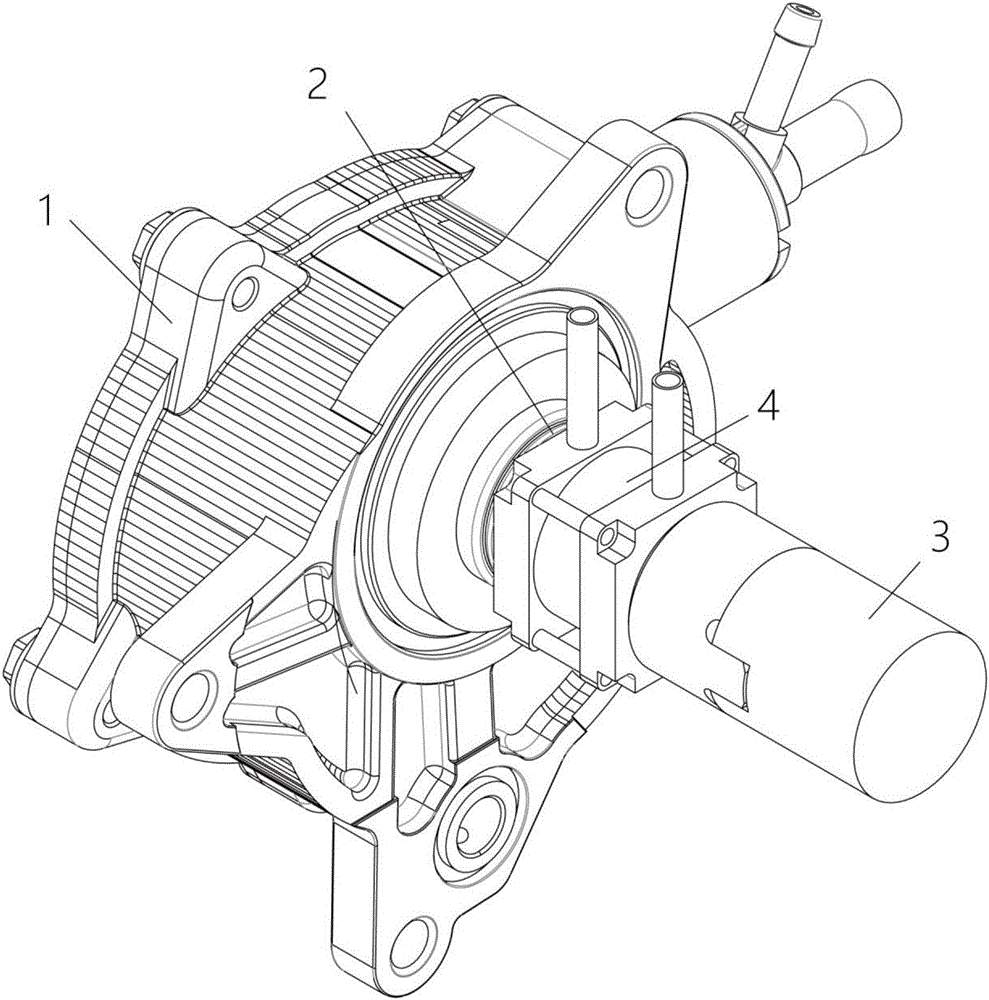

Air cylinder type vacuum pump

ActiveCN106194745AShort working hoursSave time at workFluid actuated clutchesRotary/oscillating piston pump componentsStopped workVacuum pump

The invention relates to the technical field of automobile vacuum, and discloses an air cylinder type vacuum pump. The air cylinder type vacuum pump comprises a pump body and a power input shaft stretching out of the pump body. The power input shaft is opposite to a power transmission shaft extending out of an external power mechanism. The power transmission shaft rotates with the axis of the power transmission shaft as the rotating axis. In addition, the air cylinder type vacuum pump comprises an air cylinder. The air cylinder is used for controlling connection or separation of the power transmission shaft and the power input shaft. When the power transmission shaft and the power input shaft are connected, the power transmission shaft drives the power input shaft to rotate, and the air cylinder type vacuum pump works. When the power transmission shaft and the power input shaft are separated, the air cylinder type vacuum pump stops working. The air cylinder type vacuum pump can be started and stopped according to actual needs, and is fast and accurate in control, lower in energy consumption and longer in service life.

Owner:SHANGHAI ZHAOMIN POWER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com