Steel wire rope with single-stranded compound core for elevator

A technology of composite core and steel wire rope, which is applied in the field of steel wire rope, can solve the problems of reduced fatigue life, decreased fatigue life, and less contact support points, and achieves the effects of improving fatigue life, increasing fatigue life, and reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

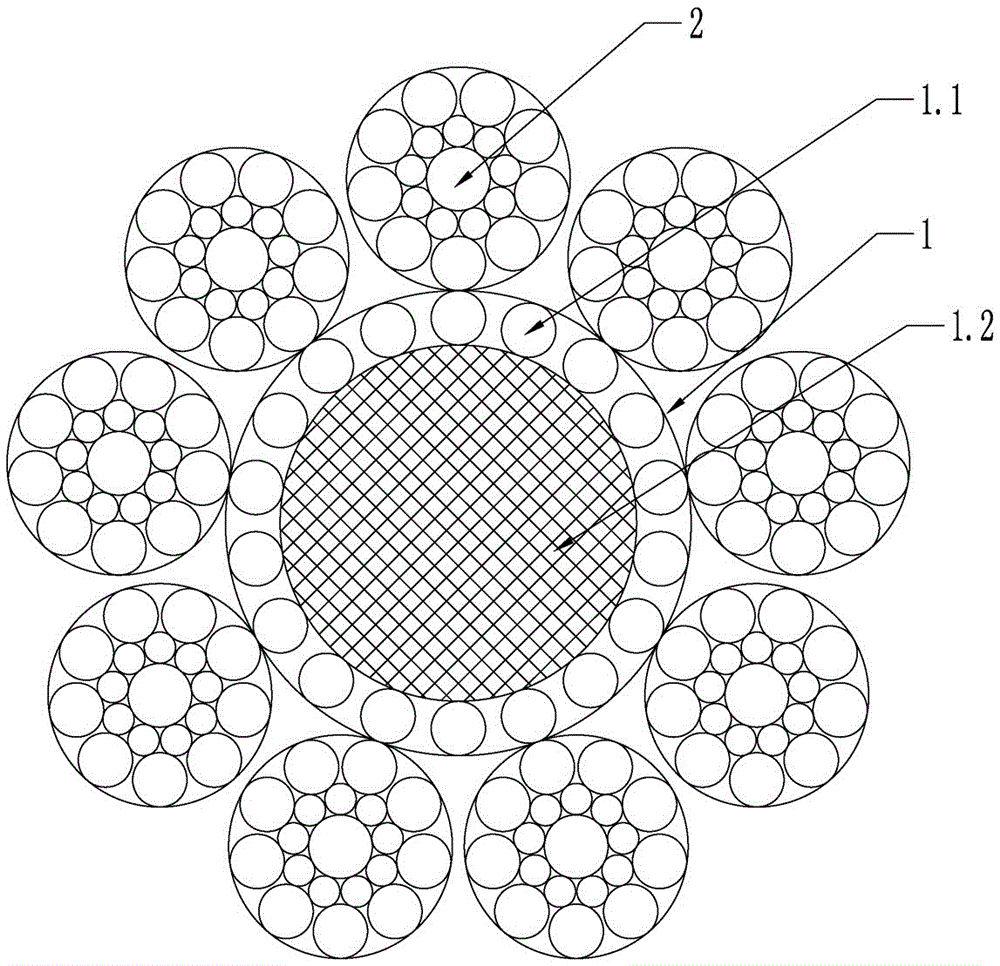

[0020] Example 1, such as figure 1 As shown, a single-strand composite core elevator steel wire rope is characterized in that it includes a single-strand composite rope core 1 and an outer layer strand 2; 9 outer layer strands 2 are wrapped on the outside of the single-strand composite rope core 1; the outer layer strand 2 is 1*19S Xilu type wire contact strand; single-ply composite rope core 1 includes outer winding steel wire 1.1 and fiber core strand 1.2, and a layer of outer winding steel wire 1.1 is coated on the outside of fiber core strand 1.2, and fiber core strand is poly Ester material, the outer winding steel wire of the single-strand composite rope core is coated with a 5μm thick pure zinc layer on the surface, and the strength level of the outer winding steel wire is 1570MPa.

[0021] Example 2, such as figure 1 As shown, a single-strand composite core elevator steel wire rope is characterized in that it includes a single-strand composite rope core 1 and an outer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com