Calcium carbonate powder and preparation method thereof

A technology of calcium carbonate powder and calcium carbonate, which is applied in the field of calcium carbonate powder and its preparation, can solve the problems of poor dispersion and poor rubber compatibility, and achieve the effects of good dispersion, improved mechanical properties, and small agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

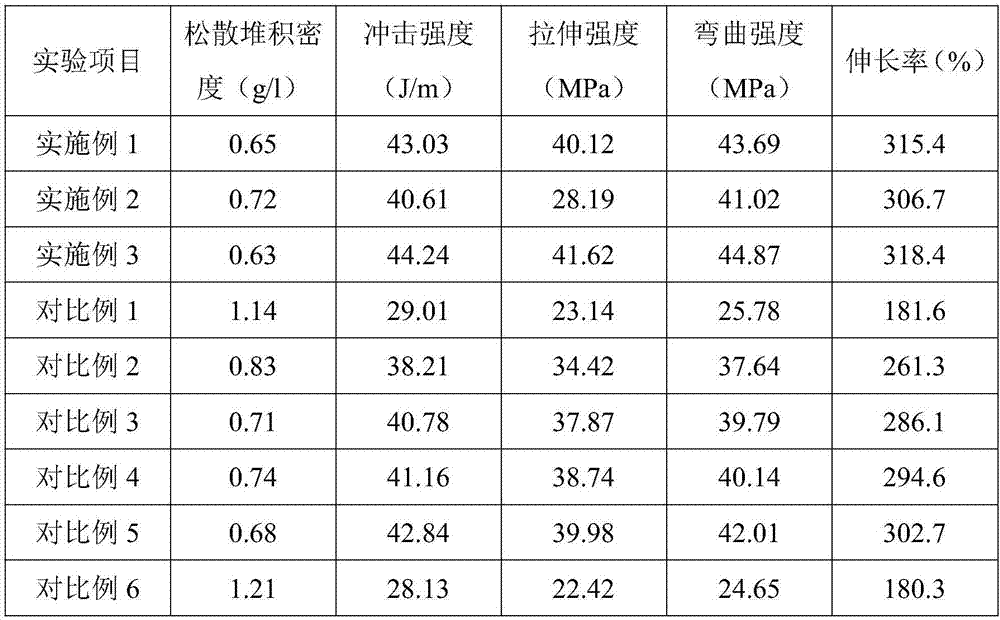

Examples

preparation example Construction

[0025] The preparation method of described calcium carbonate powder, comprises the following steps:

[0026] S1: crush calcium carbonate, pass through a sieve of 800-1200 mesh, and dry at a temperature of 75-82°C until the water content is ≤0.7%, to obtain crushed calcium carbonate;

[0027] S2: Add the calcium carbonate powder obtained in step S1 into a high-speed mixer, then add fatty alcohol polyoxyethylene ether ammonium sulfate, potassium persulfate, N, N-diethylaniline, vanadium pentoxide, and heat up to 95-100°C, stirring at a high speed of 1000-1200r / min for 25-30min to prepare mixture a;

[0028] S3: Add sodium diethylenetriaminepentacarboxylate, acrylic bridging agent, acrylate regulator, silane coupling agent A-151, citric acid ester, maleic anhydride grafting to the mixture a prepared in step S2 compatibilizer, hexenylbisstearamide, control the temperature at 76-85°C, stir at a speed of 800-1000r / min for 35-42min at a high speed, and prepare mixture b;

[0029] S...

Embodiment 1

[0032] A calcium carbonate powder, in parts by weight, comprising the following raw materials: 162 parts of calcium carbonate, 4 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, 0.3 part of potassium persulfate, 0.2 part of N, N-diethylaniline, 0.1 part of vanadium pentoxide, 0.5 part of sodium diethylenetriaminepentacarboxylate, 0.4 part of acrylic bridging agent, 0.1 part of acrylate regulator, 0.4 part of silane coupling agent A-1510.4 part, 1.6 part of citric acid ester, horse 0.3 parts of toric anhydride grafted compatibilizer, 0.4 parts of hexenylbisstearamide, 0.5 parts of 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole , 0.1 part of oxamide, 0.7 part of anti-aging agent BHT, 0.8 part of aluminum stearate;

[0033] The preparation method of described calcium carbonate powder, comprises the following steps:

[0034] S1: crush calcium carbonate, pass through a 1000-mesh sieve, and dry at a temperature of 80°C until the water content is 0.7%,...

Embodiment 2

[0039]A calcium carbonate powder, in parts by weight, comprising the following raw materials: 152 parts of calcium carbonate, 3.2 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, 0.2 part of potassium persulfate, 0.2 part of N, N-diethylaniline, 0.1 part of vanadium pentoxide, 0.4 part of sodium diethylenetriamine pentacarboxylate, 0.3 part of acrylic bridging agent, 0.1 part of acrylate regulator, 0.3 part of silane coupling agent A-1510.3 part, 1.2 part of citric acid ester, horse 0.2 parts of toric anhydride grafted compatibilizer, 0.2 parts of hexenylbisstearamide, 0.3 parts of 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole , 0.1 part of oxamide, 0.5 part of anti-aging agent BHT, 0.7 part of aluminum stearate;

[0040] The preparation method of described calcium carbonate powder is characterized in that, comprises the following steps:

[0041] S1: crush calcium carbonate, pass through a 800-mesh sieve, and dry at a temperature of 76°C until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com