Patents

Literature

98 results about "Oxamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxamide is the organic compound with the formula (CONH₂)₂. This white crystalline solid is soluble in ethanol, slightly soluble in water and insoluble in diethyl ether. Oxamide is the diamide derived from oxalic acid.

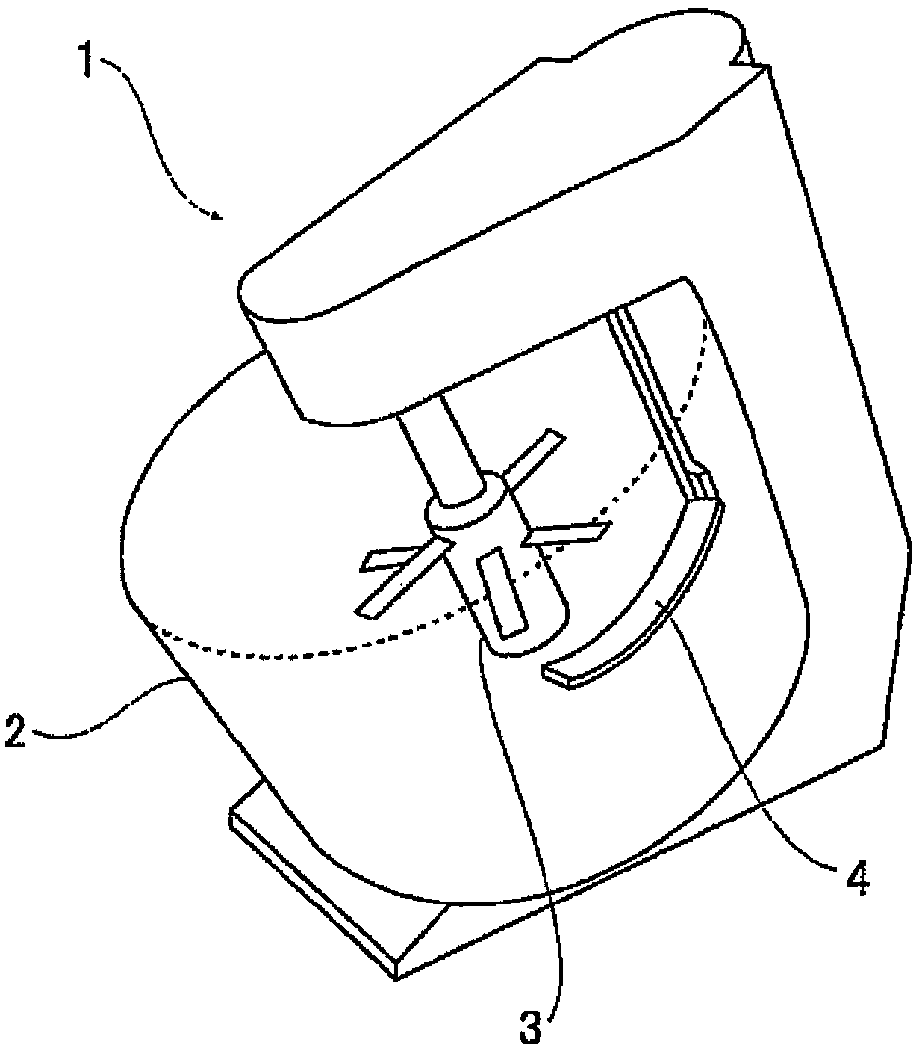

Method and device for directly synthesizing oxamide granules

InactiveCN103242188ASimple processEasy to operateOrganic compound preparationCarboxylic acid amides preparationTemperature controlProcess engineering

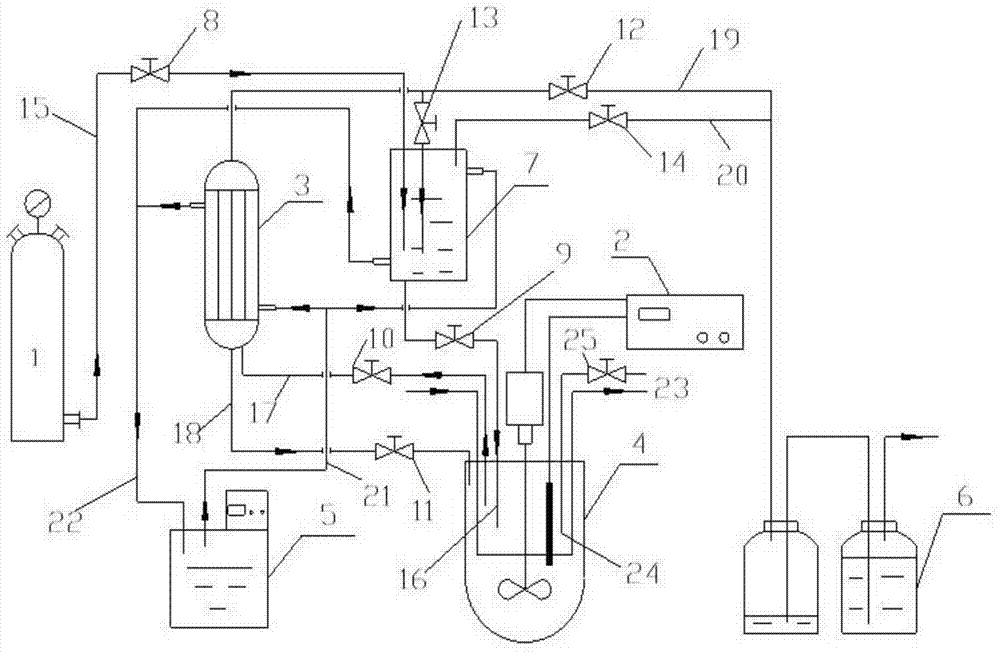

The invention relates to a method and a device for directly synthesizing oxamide granules. Dimethyl oxalate and ammonia serving as reaction raw materials and methanol serving as a reaction solvent are subjected to an ammonolysis reaction under normal pressure, a stirring system and a cooling system are arranged in the reactor, a jacket temperature control device is arranged at the outer side of the reactor, and a condenser is connected to the upper part of the reactor for regulation. A front ammonia absorption tank is arranged at the front end of the reactor, the front end of the reactor is provided with a cooling system, the outlet of the condenser is respectively connected with the front ammonia absorption tank and the tail gas absorption tank. The reaction process and the granule forming process can be performed in the same reactor, the methanol recycling and tail absorption device are equipped, and the ammonia gas is not discharged into atmosphere. The reaction investment and consumption can be greatly saved, the environmental pollution is reduced, and the product can be produced in a large scale until the product is industrially applied, so that the urea and ammonium bicarbonate are replaced, and the occupancy of oxamide in the nitrogenous fertilizer market is increased.

Owner:TIANJIN UNIV

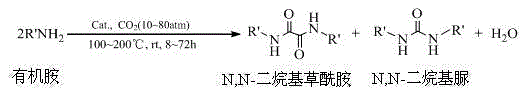

Method for synthesizing N,N-dialkyl oxamide by using CO2

ActiveCN104610088AHigh yieldOptimize spaceOrganic compound preparationCarboxylic acid amides preparationPtru catalystMetal catalyst

The invention provides a method for synthesizing N,N-dialkyl oxamide by using CO2. According to the method, in an organic or inorganic solvent, one-step synthetic reaction is performed on the CO2 and organic amine to synthesize the N,N-dialkyl oxamide, with N,N-dialkyl urea and water as byproducts, in the presence of a certain catalyst and under a certain reaction condition that the reaction pressure is 10-80atm and the reaction temperature is 100-200 DEG C. The invention discloses the method for synthesizing the N,N-dialkyl oxamide by using the CO2. According to the method, a valuable and toxic metal catalyst and a toxic and explosive gas in the prior art are not used, and reactants, products, and added components in a system are safe and environment-friendly; the yield is considerable; technically, an improvement room exists; a safe and environment-friendly new method is provided for preparing the N,N-dialkyl oxamide.

Owner:GUANGDONG UNIV OF TECH

Stabilized photoactive composition and use thereof

ActiveCN103080203AAvoid encapsulationSolid-state devicesSemiconductor/solid-state device manufacturingBenzopyroneUltraviolet

Stabilized photoactive composition comprising: - at least one photoactive organic polymer; - at least one light stabilizer selected from hindered amines; - at least one UV absorber selected from triazines, benzoxazinones, benzotriazoles, benzophenones, benzoates, formamidines, cinnamates or propenoates, aromatic propanediones, benzoimidazoles, cycloaliphatic ketones, formanilides including oxamides, cyanoacrylates, benzopyranones, salicylates, or mixtures thereof. Said photoactive composition can be advantageously used in the construction of photovoltaic devices such as, for example, photovoltaic cells, photovoltaic modules, solar cells, solar modules, on both rigid and flexible supports.

Owner:ENI SPA

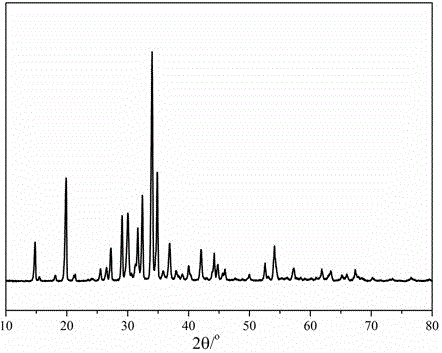

Efficient preparation method of high-purity lithium oxalyldifluoroborate (LiODFB)

InactiveCN106749361AReduce generationAvoid the disadvantages of low yield, high cost and long cycleGroup 3/13 element organic compoundsCrystallinitySolvent

The invention discloses an efficient preparation method of high-purity lithium oxalyldifluoroborate (LiODFB). The method comprises the steps of firstly, synthesizing a high-crystallinity and high-activity needle-shaped mixed crystal A by taking Li2CO3 and H2C2O4.2H2O as raw materials, wherein the needle-shaped mixed crystal A is formed by co-crystallizing lithium oxalate and lithium hydrogenoxalate which are taken as main phases; adding the mixed crystal A into a closed container filled with an organic solvent, then adding a BF3.X complex, at least one of oxamide, oxamic acid, anhydrous oxalic acid and ammonium oxalate as well as a certain amount of initiator, continuously stirring for 30min to obtain an emulsion solution B, and filtering to obtain a clear and transparent solution C; removing the solvent of the solution C under the conditions of certain temperature and pressure to obtain a LiODFB product with the purity of 99% or above. A high-purity LiODFB product with the purity of 99.9% or above is obtained by carrying out recrystallization on the organic solvent for removing impurities at a time. After the preparation method is adopted, the LiODFB product with the purity of 99% or above can be directly obtained by means of a synthetic reaction. The defects of low yield, high cost and long period which are caused by repeated recrystallization are avoided. Furthermore, the preparation method is simple, easy to operate, short in period and easy in realization of industrial production, thus having very good application prospect.

Owner:HUNAN ZHENGYUAN ENERGY STORAGE MATERIALS & DEVICE INST

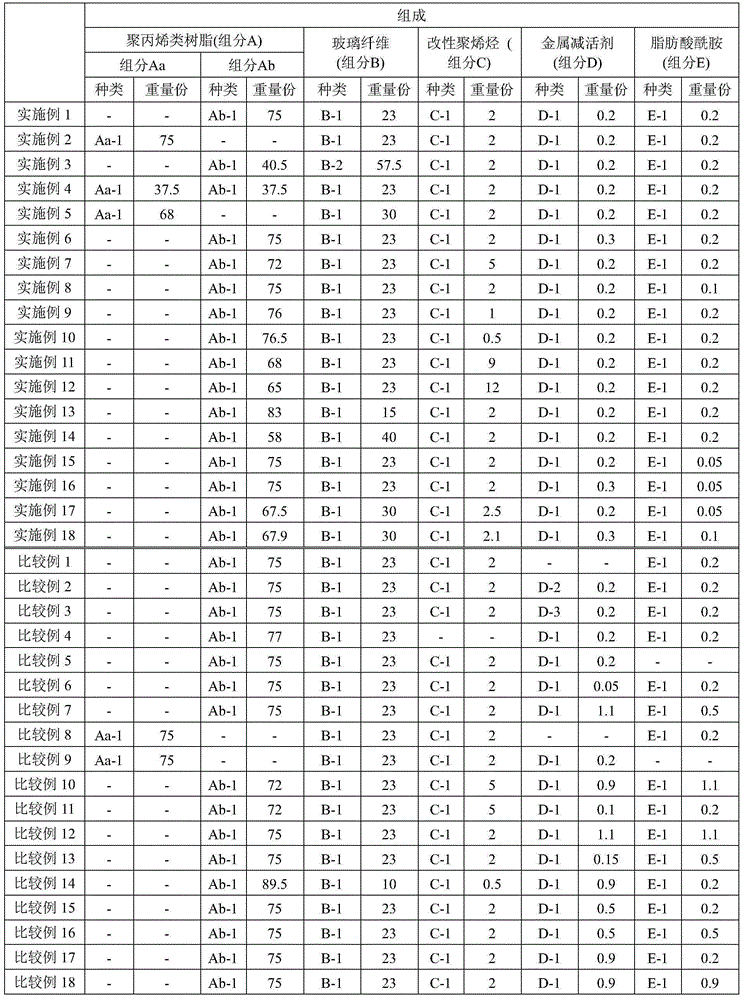

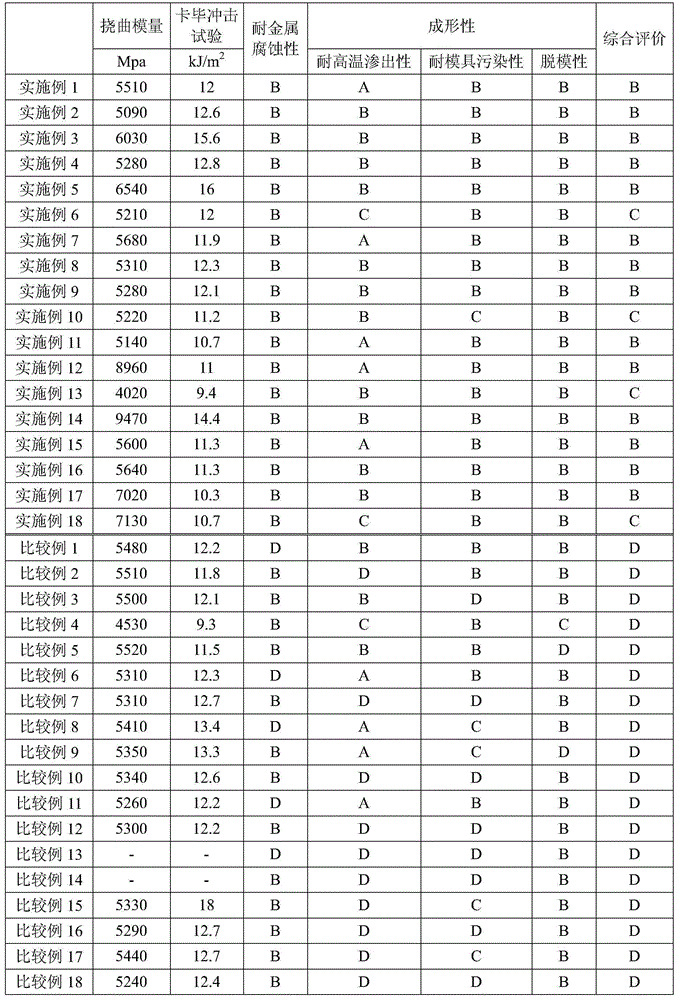

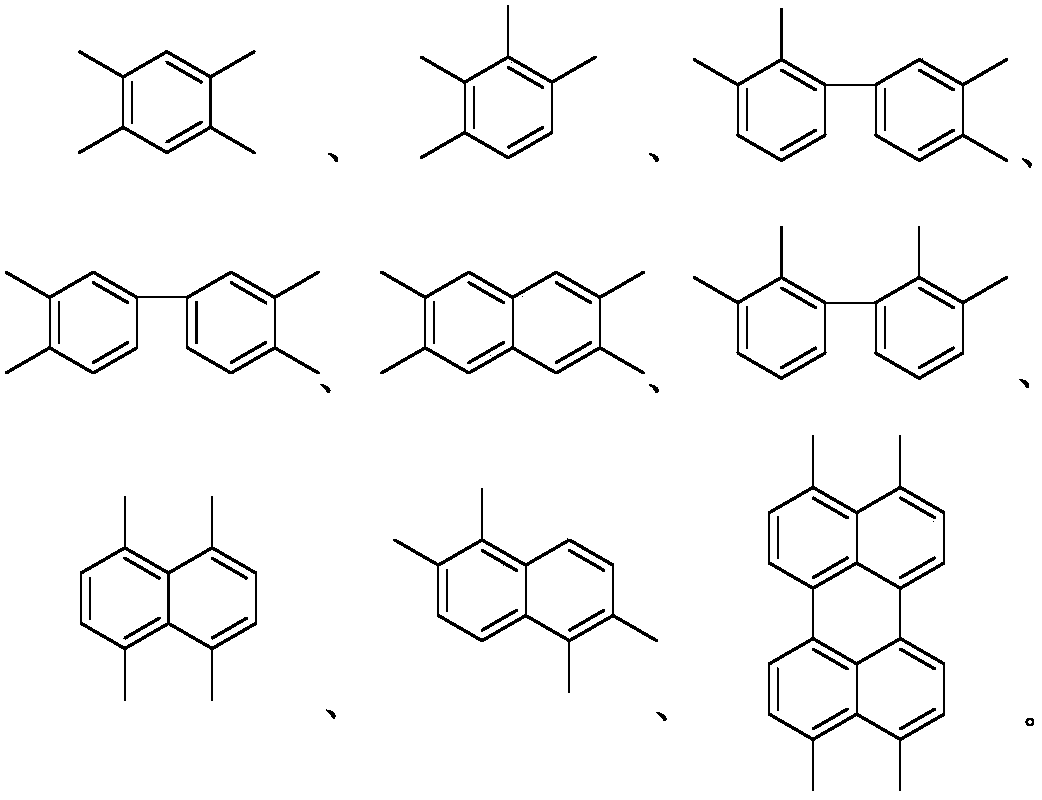

Glass fiber-reinforced polypropylene resin composition and molded body of same

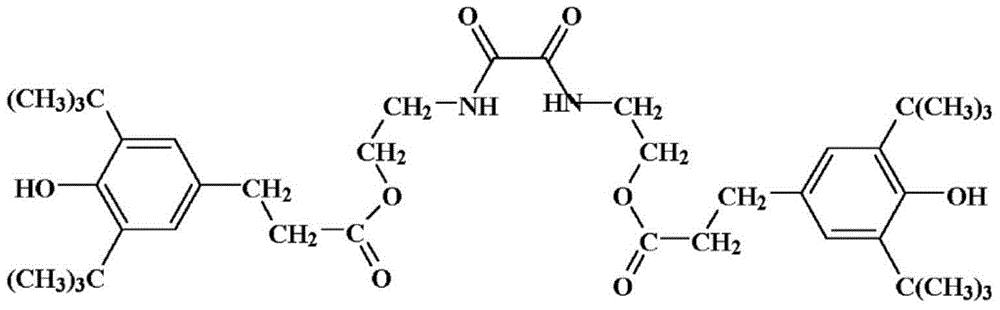

The present invention provides: a glass fiber-reinforced polypropylene resin composition which exhibits high rigidity and high impact strength, while having excellent mold contamination resistance and mold releasability during molding, and which provides a molded body having excellent appearance, metal corrosion resistance and high-temperature bleeding resistance; and a molded body of the glass fiber-reinforced polypropylene resin composition. The present invention relates to: a glass fiber-reinforced polypropylene resin composition which is characterized by containing 35-98.99 parts by weight of a component (A), 1-50 parts by weight of a component (B) and 0.01-15 parts by weight of a component (C) (with the total of the component (A), component (B) and component (C) being 100 parts by weight), and also containing 0.15-0.4 part by weight of a component (D) and 0.01-0.4 part by weight of a component (E) per 100 parts by weight of the total of the component (A), component (B) and component (C); and a molded body and the like of the glass fiber-reinforced polypropylene resin composition. Component A: a polypropylene resin Component B: a glass fiber Component C: a modified polyolefin Component D: an oxamide-based metal deactivation agent having an ester bond Component E: a fatty acid amide

Owner:JAPAN POLYPROPYLENE CORP

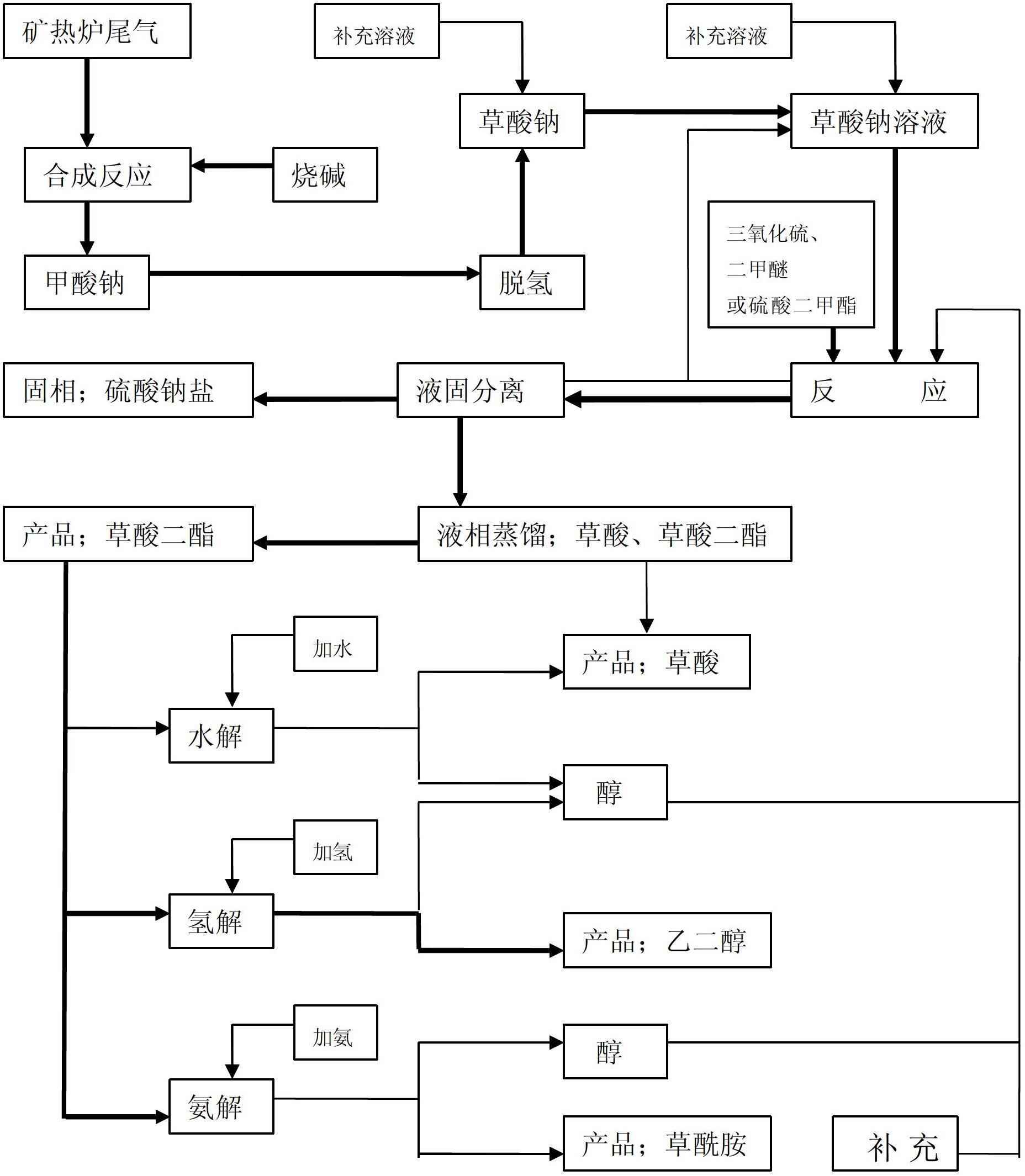

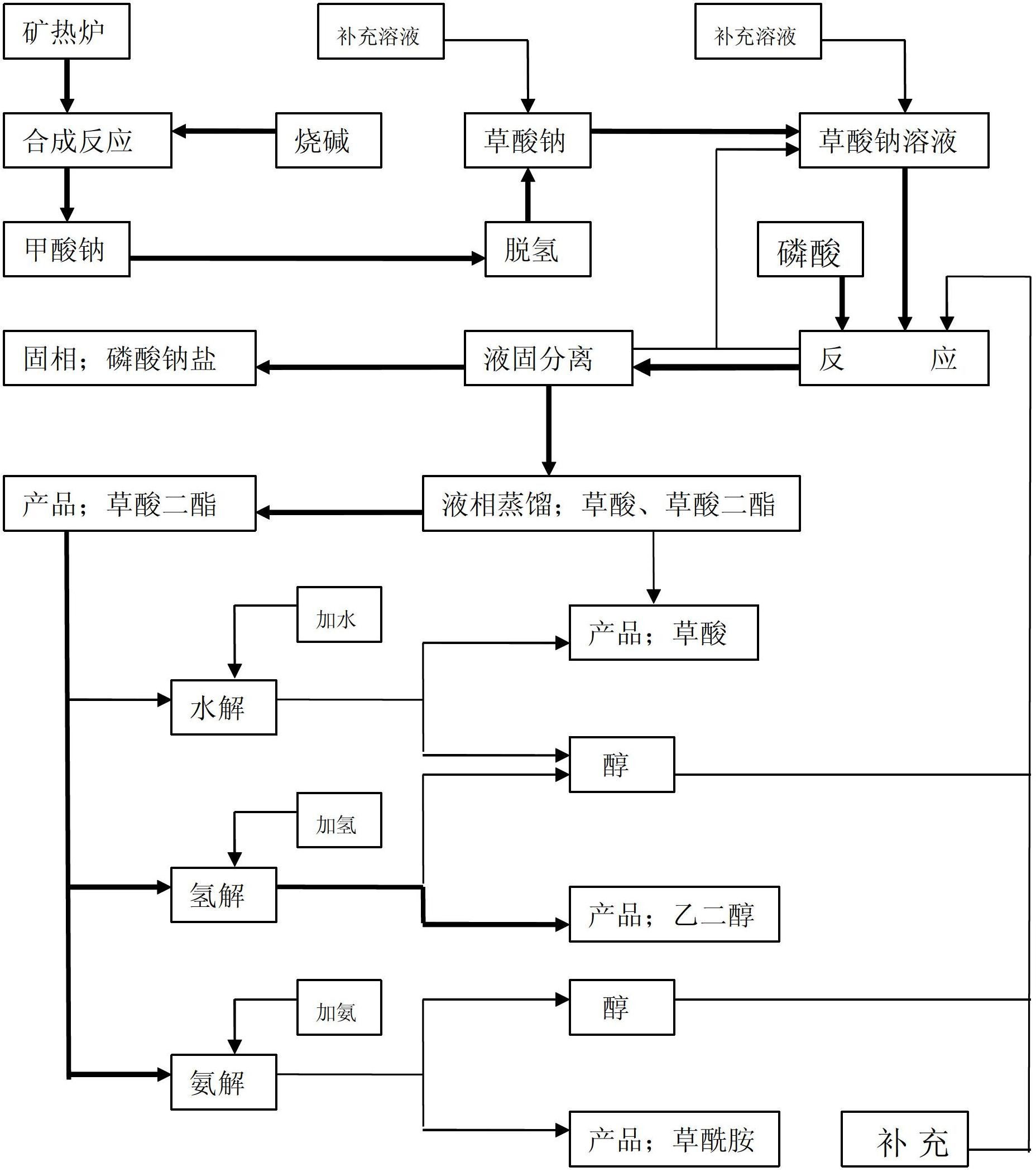

Chemical reaction system for producing oxalic acid diester as main products by using sodium formate as raw materials

InactiveCN102659584AReduced compression energy consumptionNo pollution to the environmentOrganic compound preparationCarboxylic acid esters preparationChemical reactionDistillation

The invention discloses a chemical reaction system for producing oxalic acid diester as main products by using sodium formate as raw materials. The chemical reaction system comprises a first reaction unit, a second reaction unit and a third reaction unit, wherein sodium formate is subjected to dehydrogenation reaction to generate sodium oxalate in the first reaction unit; in the second reaction unit, the sodium oxalate is mixed with solvents, then, the sulfuric acid is added, and the liquid and solid separation is carried out after the reaction, wherein the solid phase is sulfate, and the liquid phase contains rich oxalic acid diester; and in the third reaction unit, the liquid phase containing rich oxalic acid diester is subjected to distillation separation, then, the oxalic acid diester is respectively subjected to hydrolysis, hydrogenolysis and ammonolysis, and oxalic acid, alcohol, glycol and oxamide are obtained. The chemical reaction system has the advantages that the influence on environment is avoided, the environment problems of lead-containing sewage and other waste discharge do not exist, phosphates with higher additional value s re generated by sodium ions, the process separation becomes simple, the implementation is easy, and the production process reaches the requirements of clean production and energy saving environment-friendly type production process.

Owner:天津市碳一有机合成工程设计有限公司

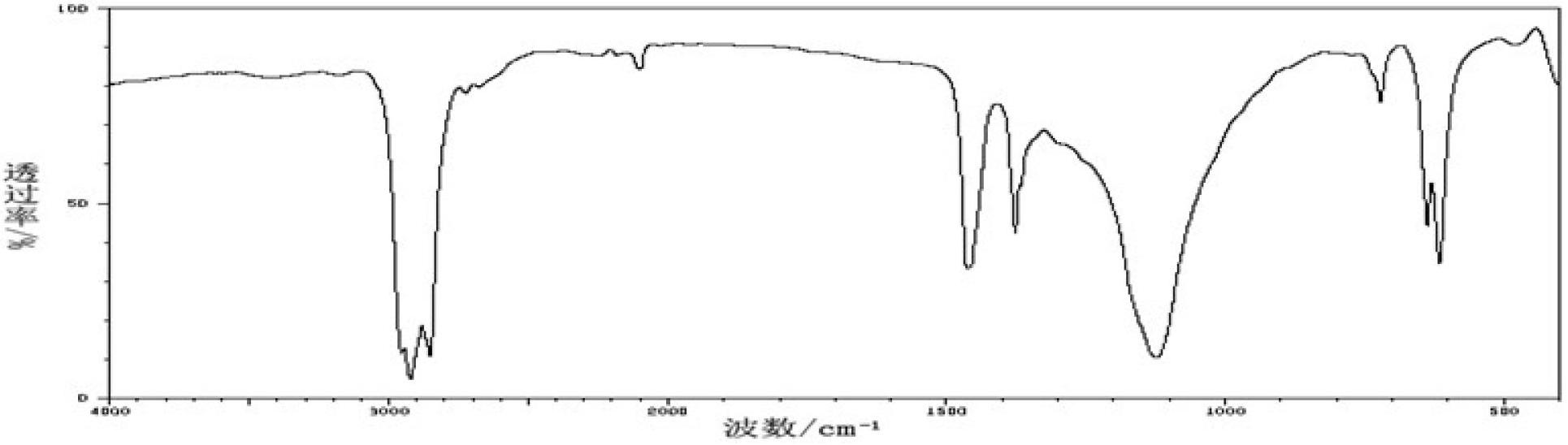

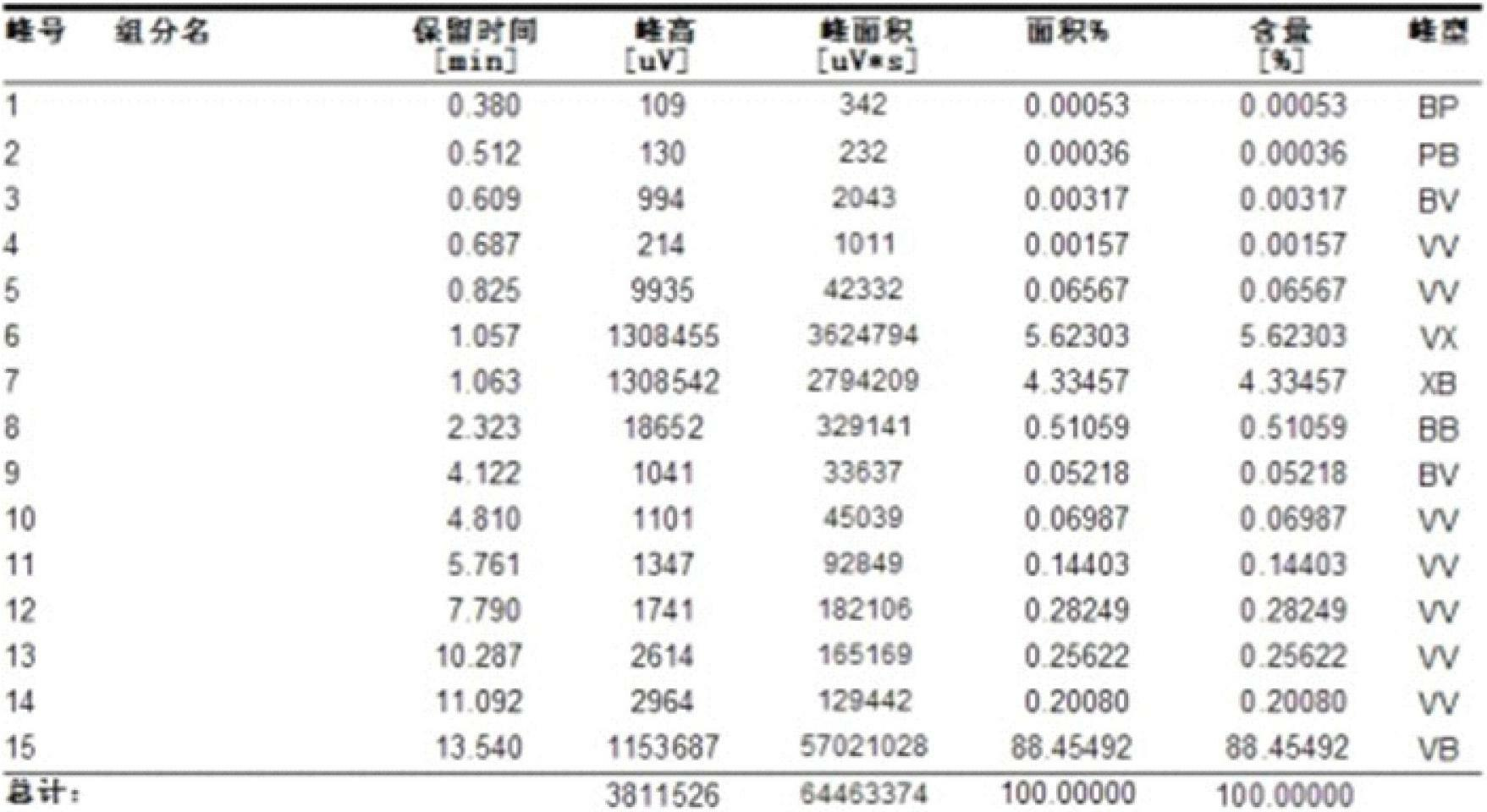

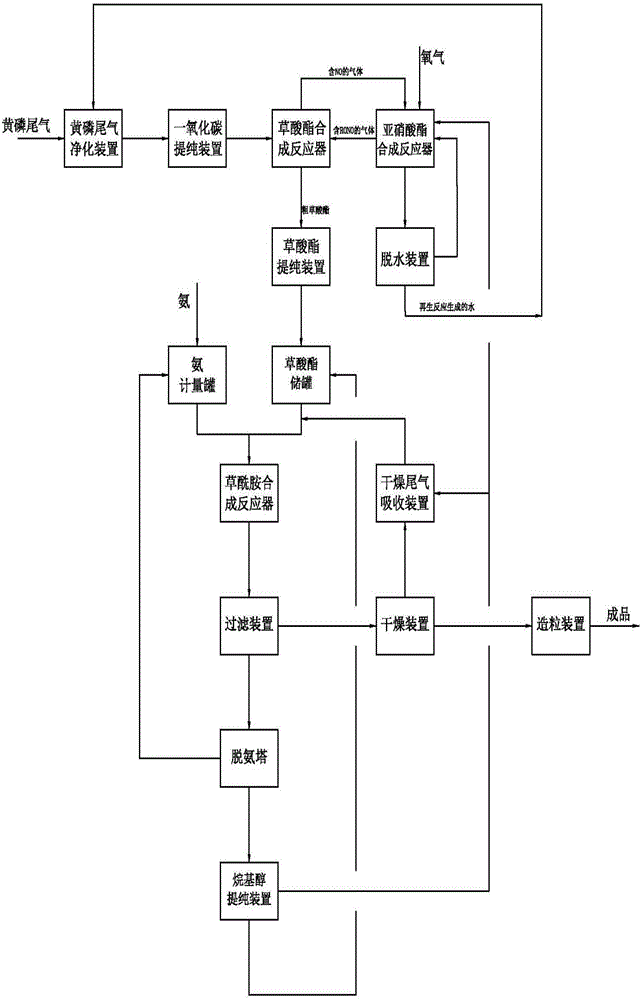

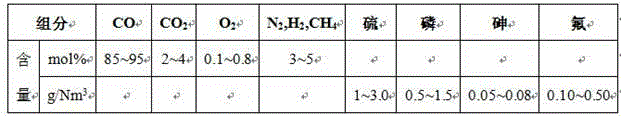

Device and method for purifying yellow phosphorus tail gas and continuously synthesizing oxamide

ActiveCN104610087ASuitable for industrial mass productionOrganic compound preparationCarboxylic acid amide separation/purificationEngineeringOxamide

The invention relates to a device and a method for synthesizing oxamide, and specifically relates to a device and a method for purifying yellow phosphorus tail gas and continuously synthesizing oxamide. The invention relates to the technical fields of chemical engineering, catalysis, chemical fertilizer and environment protection. The device provided by the invention comprises the sequentially connected components which are a yellow phosphorus tail gas purification device, a carbon monoxide purification device, an oxalate synthesis device and an oxamide synthesis device. The method comprises the steps of purifying yellow phosphorus tail gas, purifying CO from purified tail gas, synthesizing oxalate from CO, and synthesizing oxamide through oxalate ammonolysis. According to the invention, a complete set of process rout for continuously producing and synthesizing high-purity oxamide with the yellow phosphorus tail gas as a raw material is established. The device and the method are economical and environment-friendly.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

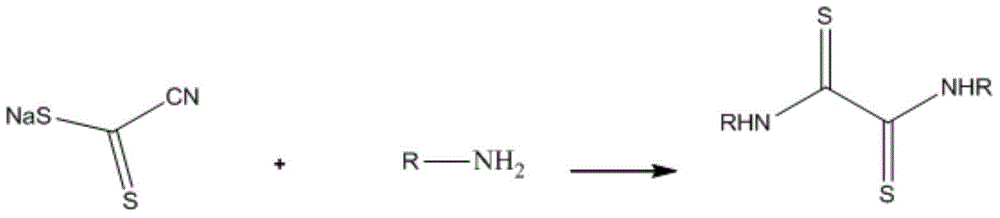

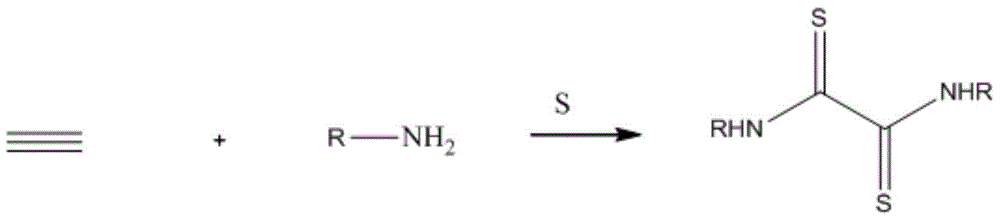

N,N'-dialkyl dithiooxamide as well as preparation method and application thereof

ActiveCN104151220ARaw materials are easy to getLow raw material costOrganic chemistryVulcanizationAntioxidant

The invention discloses N,N'-dialkyl dithiooxamide as well as a preparation method and application thereof. The preparation method comprises the following steps: reacting diester oxalate or oxalyl chloride with amine to generate N,N'-disubstituted oxamide; and generating the N,N'-dialkyl dithiooxamide under the action of a vulcanization reagent. According to the preparation method of the N,N'-dialkyl dithiooxamide, the N,N'-disubstituted oxamide is generated by reacting the diester oxalate or the oxalyl chloride with the amine, and the N,N'-dialkyl dithiooxamide is generated under the action of the vulcanization reagent. The N,N'-dialkyl dithiooxamide is taken as an antioxidant, a herbicide, a sterilizing agent, an analgesic, an anti-tuberculosis, a precious metal platinum-palladium analysis reagent and the like. The preparation method has the advantages of adoption of readily-available raw materials, low price of a finished product, easiness and convenience in operation under the normal pressure, realization of production without special equipment, high reaction yield, low raw material and manufacturing costs, freeness from chromatographic column separation, and purity of up to 99 percent through simple recrystallization.

Owner:HUNAN CHEMAPI BIOLOGICAL TECH

Pyrotechnic composition generating clean gases with low levels of nitrogen oxides, and pellets of such a composition

InactiveUS6024811ARaise the ratioReduce the ratioAmmonium perchlorate explosive compositionsPressure gas generationEpoxyAmmonium nitrate

The present invention relates to gas-generating pyrotechnic compositions. The compositions according to the invention contain a small amount of epoxy binder, stabilized ammonium nitrate, optionally potassium perchlorate or an organic oxidant containing nitrogen and, characteristically, a reactive organic nitrogen compound selected from nitroguanidine, guanidinium nitrate and oxamide. This reactive nitrogen compound may advantageously be combined with cupric oxide. The compositions according to the invention produce nitrogen-rich gases with very low levels of nitrogen oxides, and find their preferred application in the form of pellets as pyrotechnic charges in gas generators for pyrotechnic extinguishers, for devices designed to inflate external structures or for devices designed to protect the occupants of a motor vehicle.

Owner:SNPE MATERIAUX ENERGETIQUES

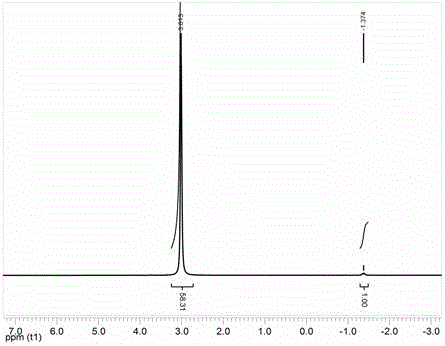

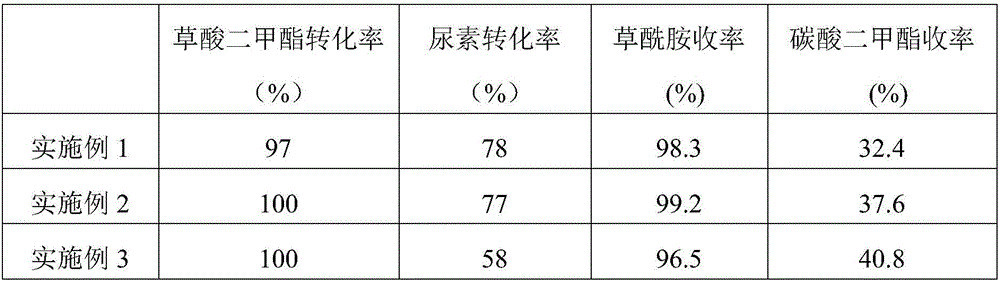

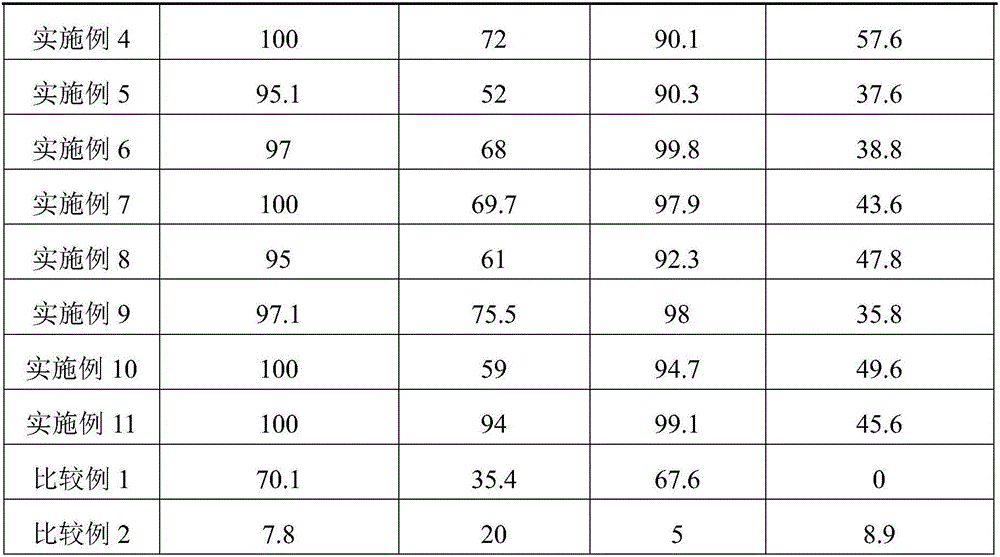

Solid catalyst for dimethyl carbonate and oxamide co-production process and preparation method of solid catalyst

ActiveCN106669684AImprove stabilityRaise the pHOrganic compound preparationHeterogenous catalyst chemical elementsAdjuvantMethyl carbonate

The invention discloses a solid catalyst for a process for co-producing dimethyl carbonate and oxamide by taking urea and dimethyl oxalate as raw materials. The catalyst is represented as CuO / MO, wherein CuO accounts for 50 to 95 percent of the total mass of the catalyst, and MO represents a doped oxide adjuvant and accounts for 5 to 50 percent of the total mass of the catalyst. The catalyst is prepared by using technologies such as a precipitation method and a hydrothermal method; and various oxide adjuvants are doped into a CuO bulk phase, and reasonable distribution of all the components in the catalyst is realized. The introduction of the oxide adjuvants is favorable for improving the stability of the catalyst, adjusting the surface acid-base property of the catalyst and improving the adsorption capacity of an active site for reactants. The catalyst has a good activation effect on the reaction raw materials, namely the urea and dimethyl oxalate; and during a reaction, by the application of the catalyst, the yield of oxamide can be up to 90 to 99.8 percent, and the yield of dimethyl carbonate can be up to 30 to 57.6 percent.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Matrix for cultivating Sparassis crispa

ActiveCN106365800AReduce churnHigh yieldCalcareous fertilisersAlkali orthophosphate fertiliserGlucono delta-lactonePhosphate

The invention discloses a matrix for cultivating Sparassis crispa. The matrix is prepared from the following components (in parts by weight) including a vector, a nutrient and water; the vector is prepared from the following components (in parts by weight) including an acrylic monomer, oxamide, p-ethoxy benzamide, 4-hydroperoxyl cyclophosphamide, tris (butoxyethyl) phosphate, a crosslinking agent, an initiator, a reinforcing agent, maleamic acid and phosphoenolpyruvate; and the nutrient is prepared from the following components (in parts by weight) including starch, dextran, vitamin B1, ammonium phosphate, peptone, D-glucose-6-phosphate, glucono-delta-lactone, glucosamine sulfate sodium, EDTA calcium disodium, sodium propionate and sodium dihydroxyethylglycinate. The prepared matrix can have better preservation action on the nutrient, thus enabling the Sparassis crispa to better grow and have higher yield.

Owner:福建容益菌业科技研发有限公司

Chemical reaction system for producing oxalic acid diester and oxalic acid as main products by using sodium formate as raw materials

InactiveCN102659556ANo pollution to the environmentReduced compression energy consumptionPreparation from carboxylic acid saltsOrganic compound preparationChemical reactionDistillation

The invention discloses a chemical reaction system for producing oxalic acid diester and oxalic acid as main products by using sodium formate as raw materials. The chemical reaction system comprises a first reaction unit, a second reaction unit and a third reaction unit, wherein the sodium formate is subjected to dehydrogenation reaction to generate sodium oxalate in the first reaction unit; in the second reaction unit, the sodium oxalate is mixed with solvents, then, the oxalic acid is added, the reaction is carried out, and then, the solid and liquid separation is carried out, wherein the solid phase is phosphate, and the oxalic acid diester is rich in the liquid phase; and in the third reaction unit, the oxalic acid diester-rich liquid phase is subjected to distillation separation, then, the oxalic acid diester is respectively subjected to hydrolysis, hydrogenolysis and ammonolysis, and oxalic acid, alcohol, glycol and oxamide are obtained. The chemical reaction system disclosed by the invention has the advantages that the influence on environment is avoided, the environment problems of lead-containing sewage and other waste discharge do not exist, phosphates from sodium ions and with higher additional values are generated, the process separation becomes simple, the implementation is easy, and the production process reaches the requirements of clean production and energy saving environment-friendly type production process.

Owner:天津市碳一有机合成工程设计有限公司

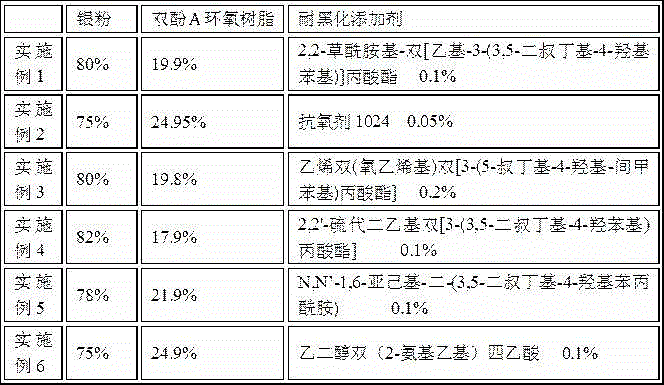

Anti-blackening silver colloid

InactiveCN104388009AHas the property of blackening resistanceAvoid reactionNon-macromolecular adhesive additivesEpoxy resin adhesivesPropionateAcetic acid

The invention relates to conductive silver colloid. The silver colloid comprises silver powder and bisphenol A epoxy resin and also comprises at least one of the following substances which account for 0.05-0.2wt% of the total weight of the silver colloid: 2,2-oxamide-bis[ethyl-3-(3,5-bitertiary butyl-4-hydroxyl phenyl)] propionate, an antioxidant 1024, vinyl bi(oxyvinyl)bis[3(5-tertiary butyl-4-hydroxyl-m-methylphenyl) propionate], 2,2'-sulfo-diethyl bis[3-(3,5-bitertiary butyl-4-hydroxyphenyl) propionate], N, N'-1,6-hexylidene-bis-(3,5-bitertiary butyl-4-hydroxyl fenalamide) and ethylene glycol-bis-(2-aminoethylether)-N,N,N',N'-tetraacetic acid. The substances are added into the silver colloid, element S is preferably fixed when H2S is dispersed on the surface of silver so as to prevent reaction between S and Ag, so that the silver colloid has an anti-blackening property.

Owner:惠州市富济电子材料有限公司

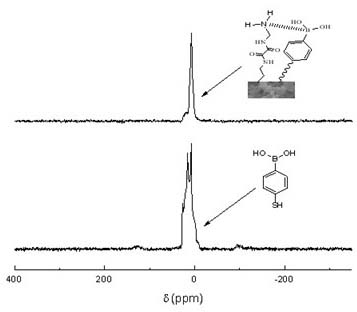

Biomimetic monolithic material with affine selectivity similar to that of protein A and preparation method and application thereof

InactiveCN102675602AEasy to makeSafe preparationPeptide preparation methodsImmunoglobulinsEpoxyPhenylboronic acid

The invention discloses a biomimetic monolithic material with the affine selectivity similar to that of a protein A, and a preparation method thereof, wherein the material is capable of purifying, separating and immobilizing antibodies. N, N'-di-(2-aminoethyl) oxamide and 4-mercapto-phenylboronic acid are used as common functional monomers, tri-(2, 3- epoxy group propyl group) isocyanate is used as a monomer, polyethylene glycol is used as a porogenic agent, and reaction is carried out in a mode of in-situ ring-opening polymerization to prepare the biomimetic monolithic material with the affine selectivity similar to that of the protein A. The material can be combined with antibodies specifically, and can be applied to the fields of antibody purification, separation, immobilization and the like. The material has the advantages of high selectivity, low cost, good stability, easiness in elution, reusability and the like, and the immunity affinity and the selectivity of the antibodies are not affected.

Owner:NANJING UNIV

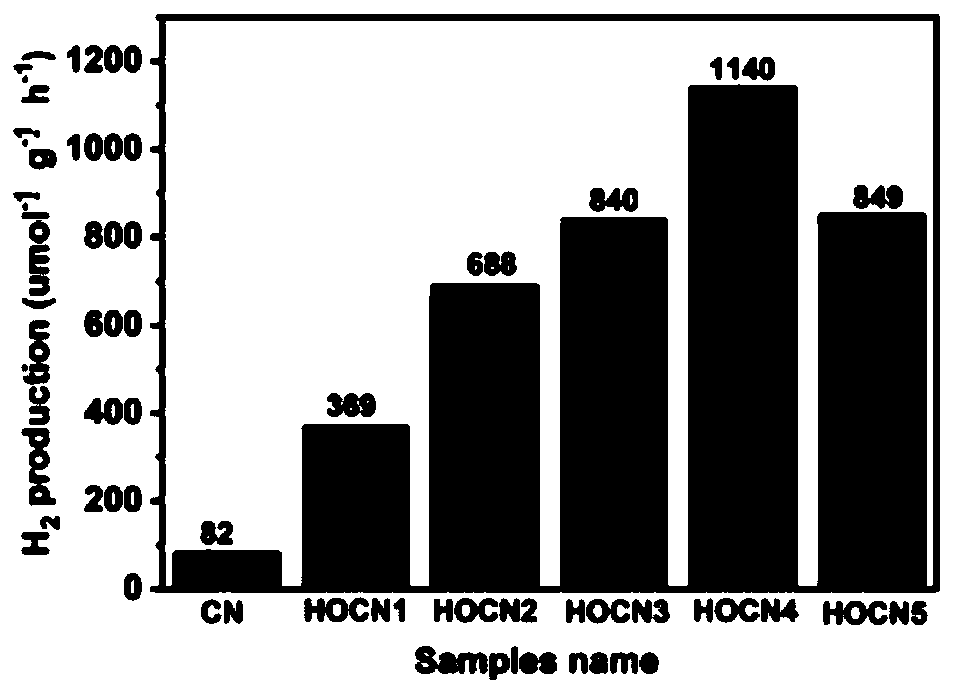

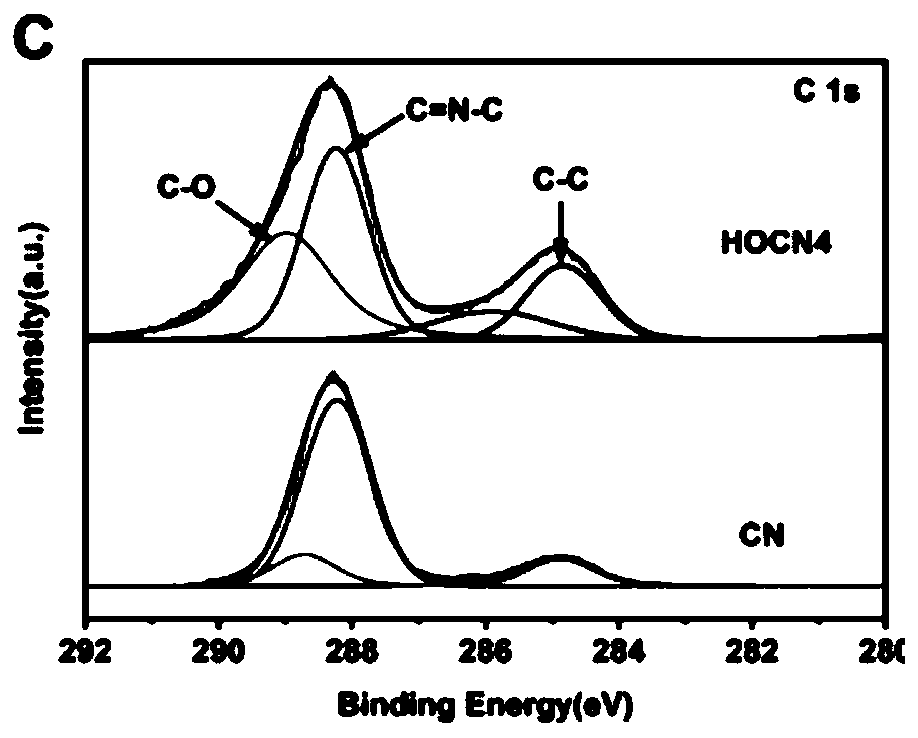

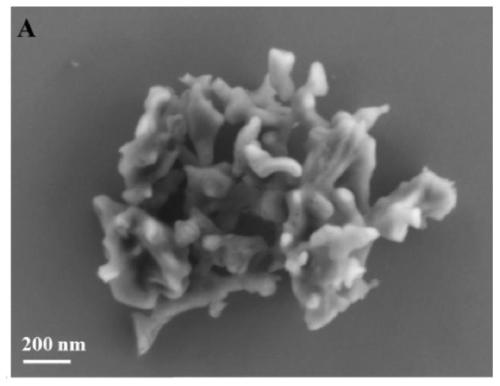

Honeycomb-like oxygen-doped carbon nitride photocatalyst, preparation method and applications thereof

InactiveCN110433851ABroaden the photoresponse rangeImprove photocatalytic performancePhysical/chemical process catalystsHydrogen productionReactive siteCarbon nitride

The invention discloses a honeycomb-like oxygen-doped carbon nitride photocatalyst, a preparation method and applications thereof. The preparation method comprises: S1, uniformly mixing dicyandiamideand oxamide, and completely grinding; and S2, calcining the mixture to obtain the photocatalyst. According to the present invention, dicyandiamide and oxamide are physically mixed, the mixture is graded, and one-step calcining is performed to prepare the honeycomb-like graphite phase carbon nitride with wide sub-band gap, wherein the ratio of dicyandiamide to oxamide is further optimized, and themorphology and the sub-band gap position of the photocatalyst are adjusted, such that the light absorption region is broadened and the specific surface area is increased so as to shorten the migrationdistance from the charge to the surface, provide more active sites for photocatalysis, achieve the efficient charge transfer and separation, and achieve good photocatalytic hydrogen production effect.

Owner:GUANGZHOU UNIVERSITY

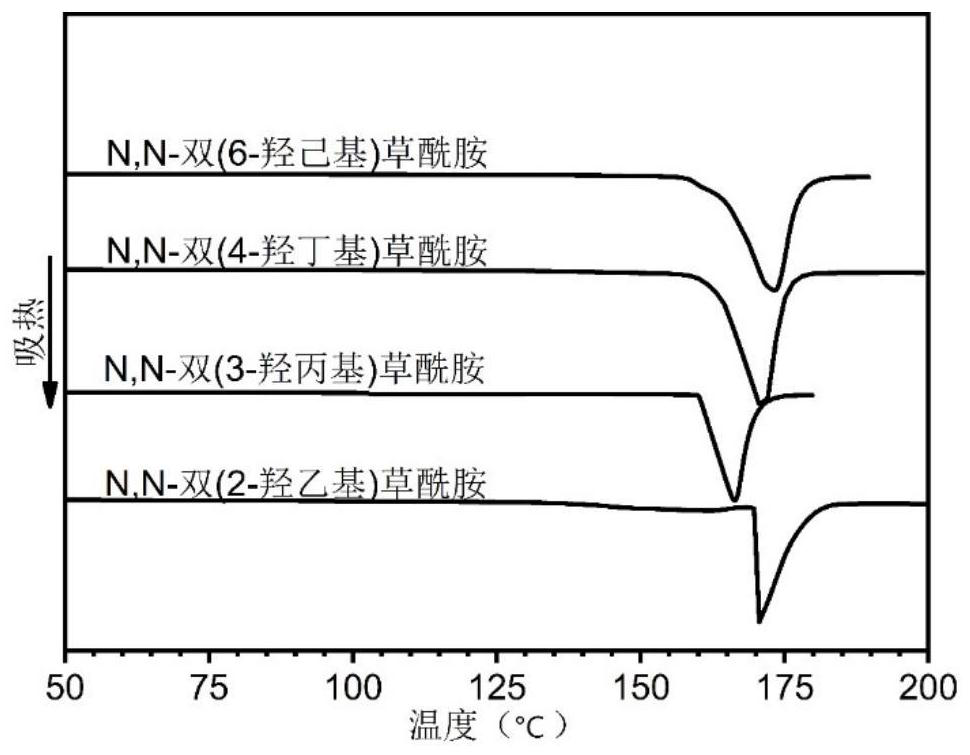

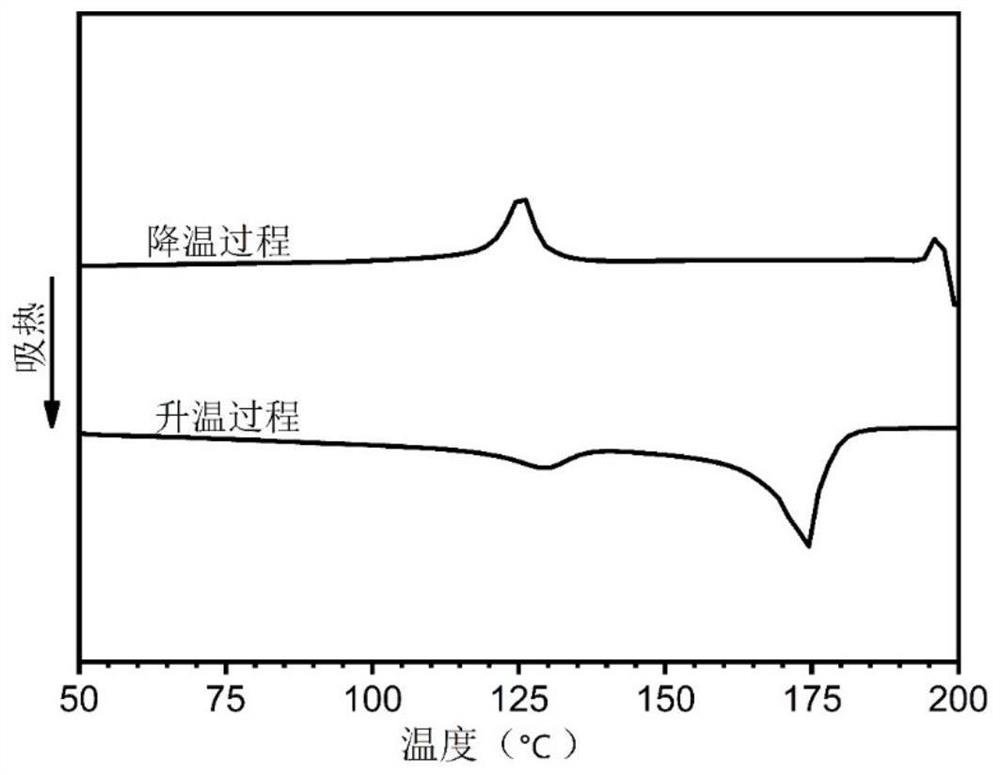

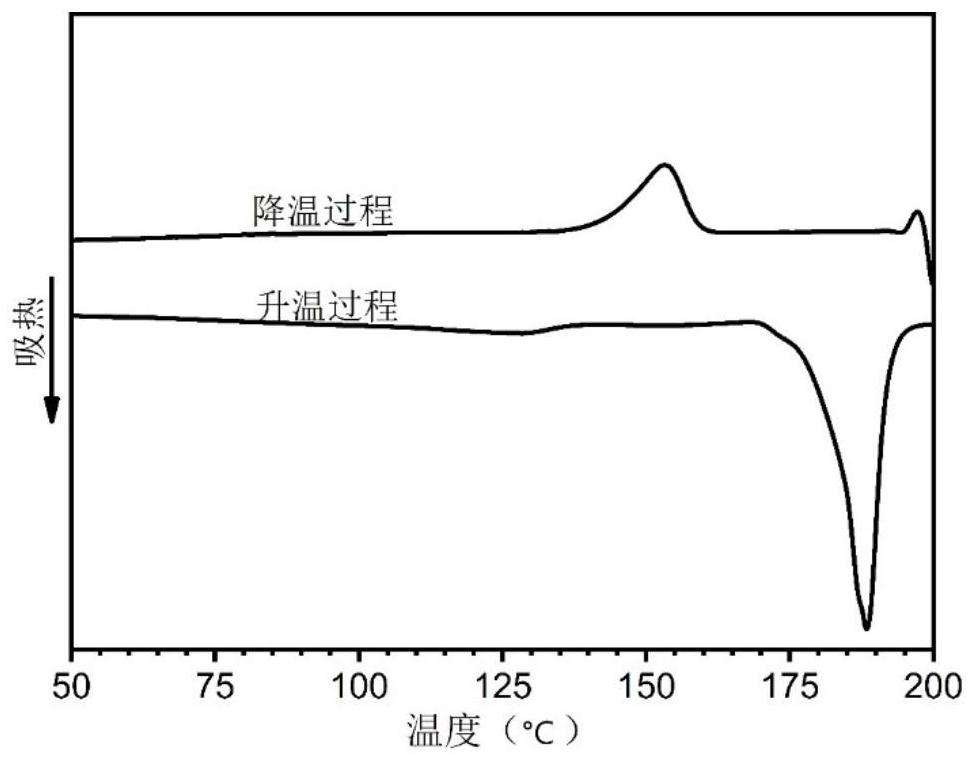

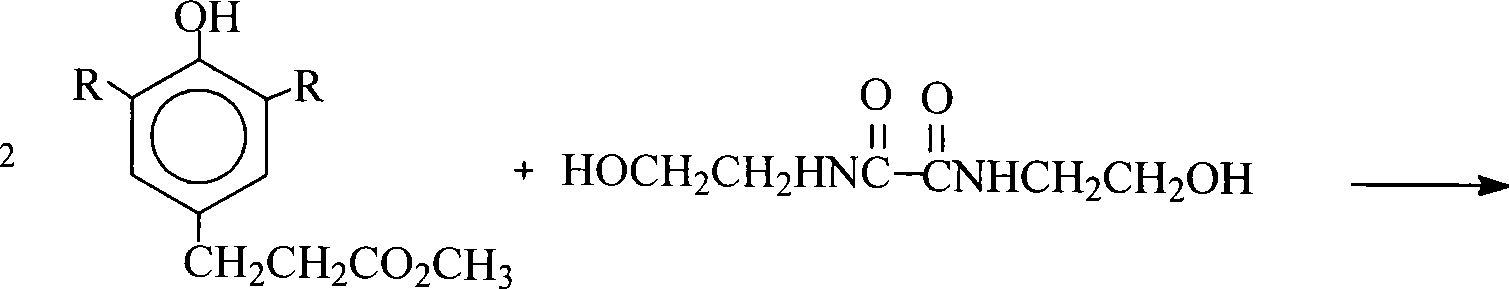

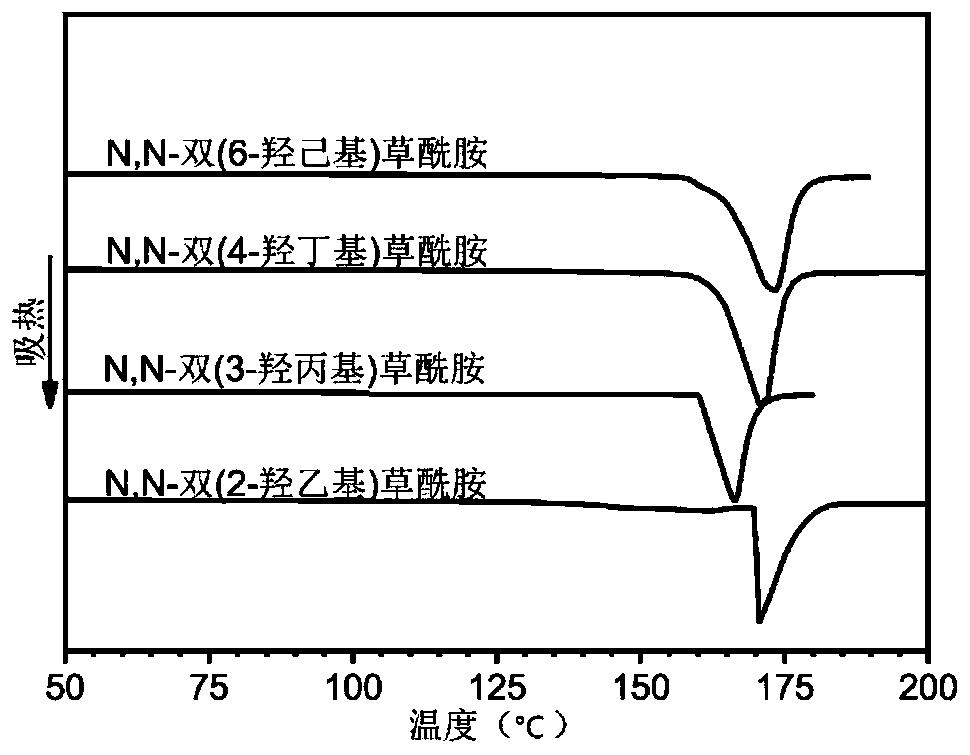

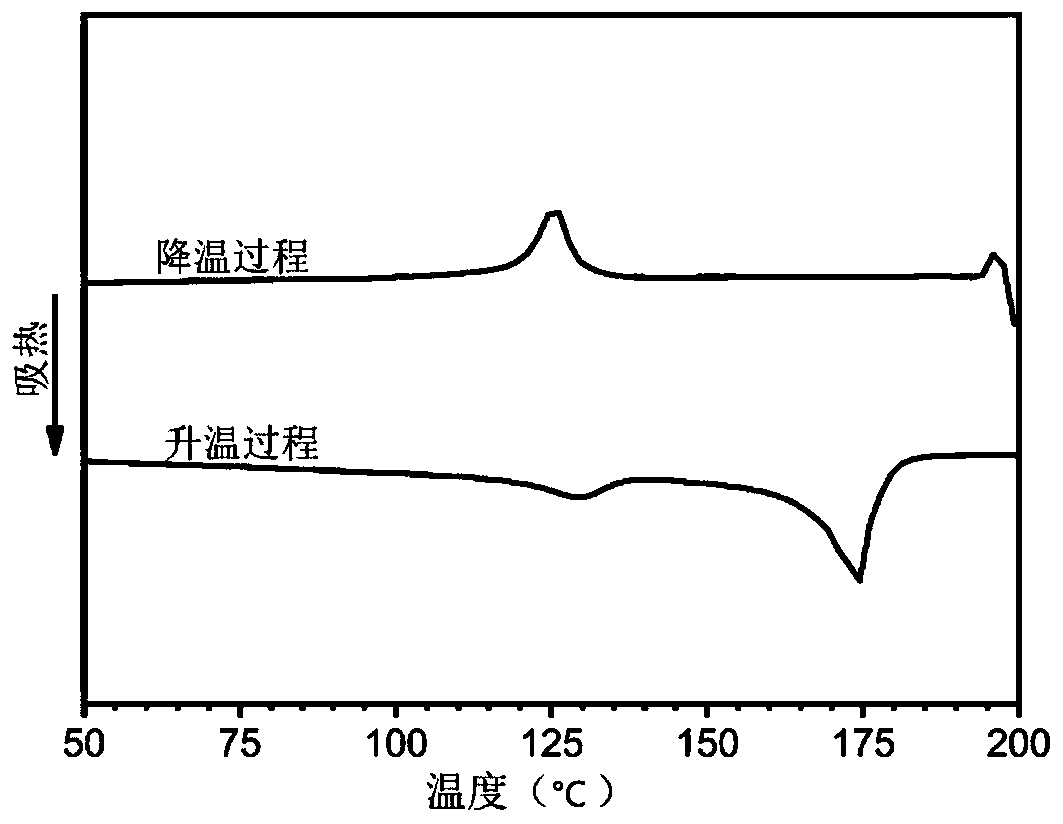

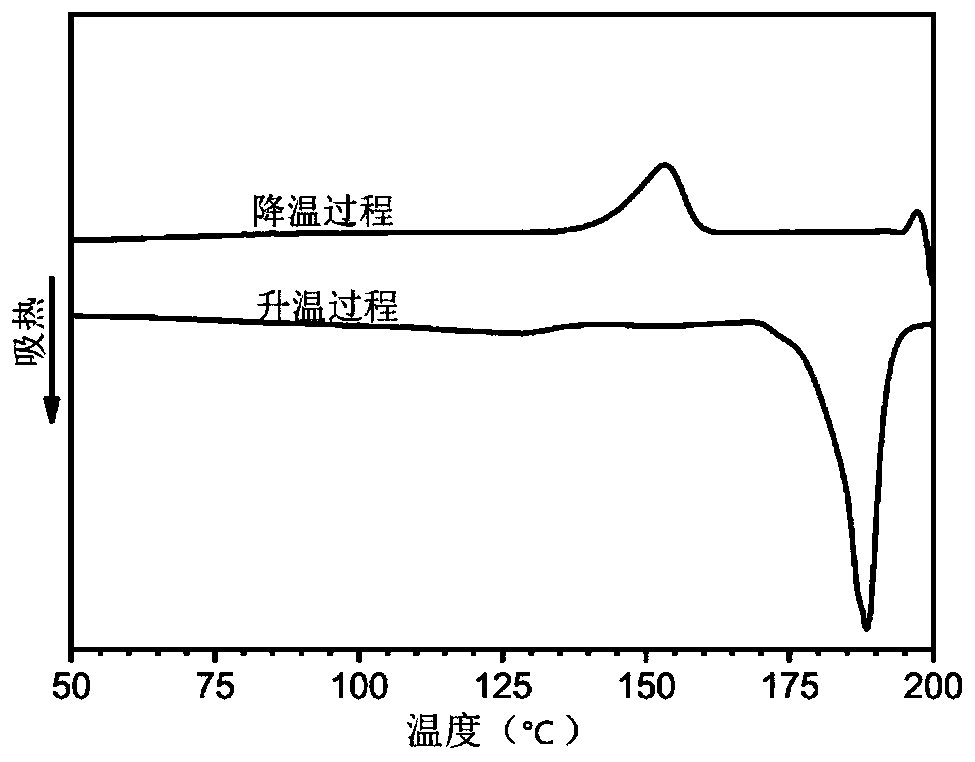

A kind of biodegradable alternating aliphatic polyester amide and its preparation method

The invention relates to a biodegradable alternating aliphatic polyester amide and a preparation method thereof. The preparation method is as follows: under the action of a catalyst and a phosphorus-containing cocatalyst, linear oxamide diol and a linear aliphatic diacid are prepared The polycondensation reaction produces a biodegradable alternating aliphatic polyester amide, wherein the phosphorus-containing cocatalyst is an ammonium salt containing hydrogen phosphate, a calcium salt containing hydrogen phosphate, a sodium salt containing hydrogen phosphate or a magnesium salt containing hydrogen phosphate; The main chain of the finally obtained biodegradable alternating aliphatic polyester amide is formed by alternating bonding of straight-chain oxamide diol units and straight-chain aliphatic diacid units, and the biodegradable alternating aliphatic polyester amide The weight average molecular weight is 50,000 to 1,000,000 g / mol. The preparation method of the present invention is simple to operate, pollution-free, and has few by-products. The finally obtained biodegradable alternating aliphatic polyester amide has good biodegradability, and the alternating structure is regular, the molecular weight is high, and the thermal and mechanical properties are excellent. good.

Owner:DONGHUA UNIV

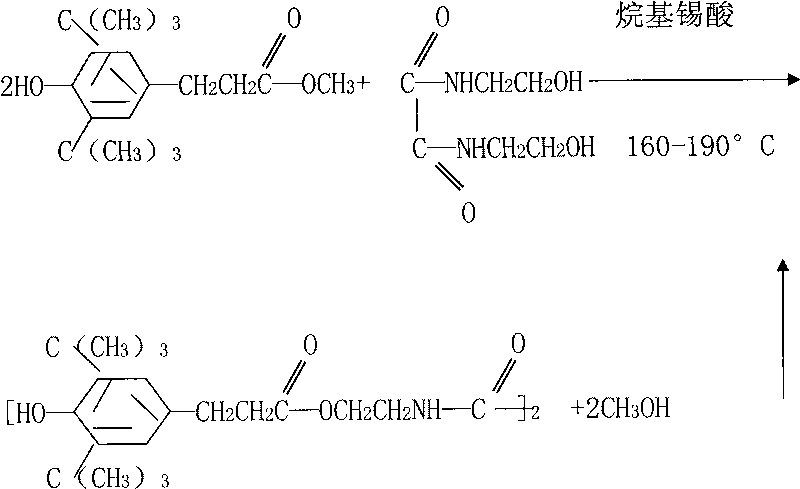

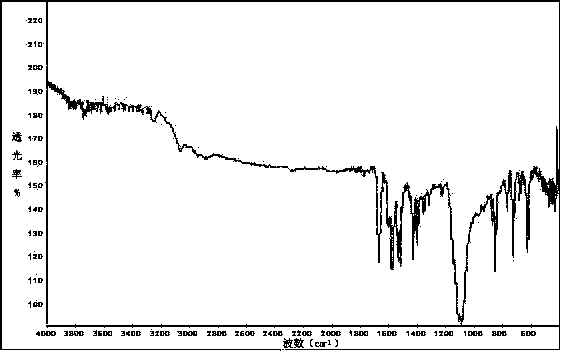

Preparation method of anti-oxidizing agent

InactiveCN101225053AFull recoveryTake advantage ofOrganic compound preparationCarboxylic acid amides preparationPropanoic acidAntioxidant

The invention relates to a preparation method of antioxidant for N, N'-bis (2-hydroxyethyl) oxamide-di [3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate], which is characterized in that: 3-(3, 5-i-tert-butyl-4-hydroxyphenyl-4-hydroxyphenyl) propionic acid and N, N'-bis (2- hydroxyethyl) oxalamide and mono-n-butyltin stannonic acid are added in xylene or toluene for jointly boiling, water removing and esterification reaction; active carbon or active clay is used for decoloring and filtering; the filtrate removes the solvent to get melt liquid comprising antioxidant; crystallization solvent is added into the melt liquid to get antioxidant through crystallizing and filtering; the crystallization solvent is recovered from the filtrate, thereby getting distill residue liquid; sodium hydroxide is added into the residue liquid for hydrosis reaction before sulfate is added for acidization reaction; the reaction liquid is crystallized and filtered, thereby recovering 3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionic acid. The preparation method of antioxidant for N, N'-bis oxamide-di propionate has the advantages of fully recovering and using 3-(3, 5-i-tert-butyl-4-hydroxyphenyl) propionic acid and improving the yield of products.

Owner:RIANLON

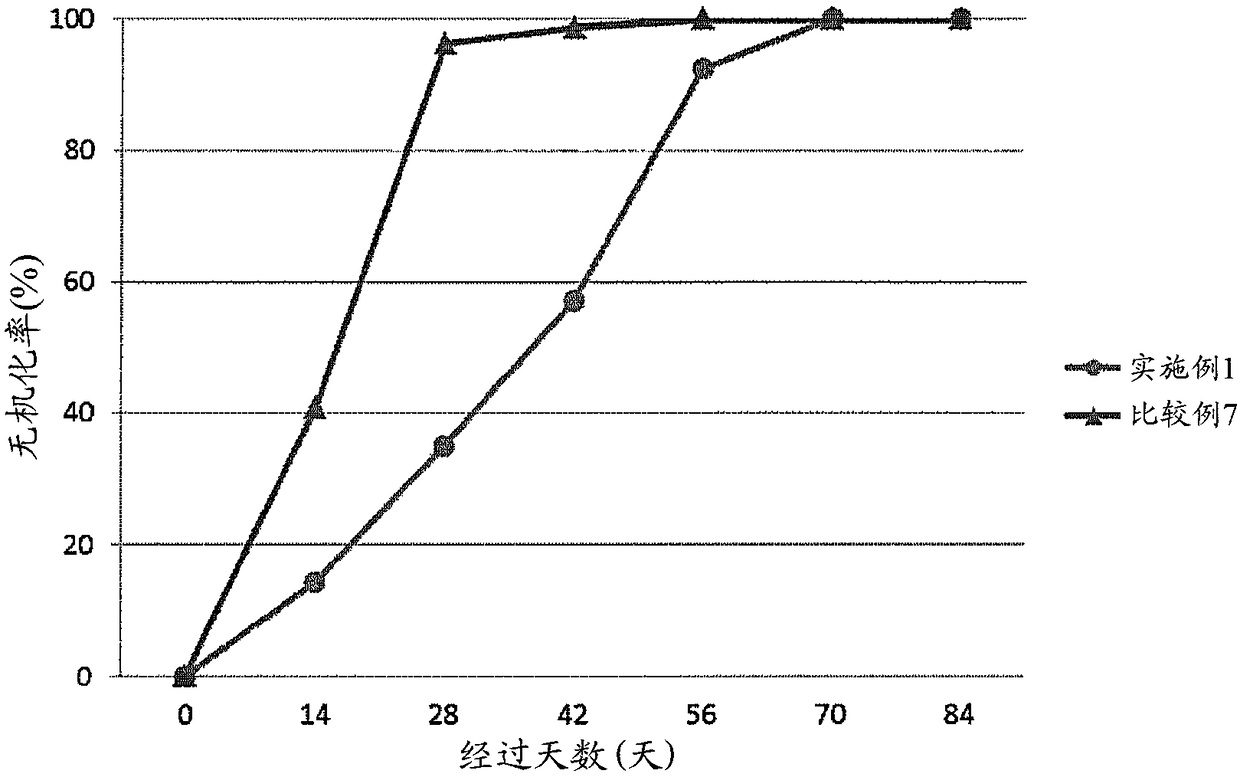

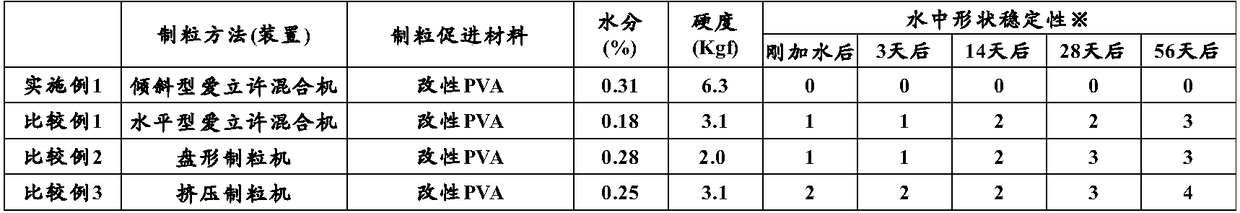

Process for preparing granular oxamide

PendingCN108623333AHigh hardnessHigh disintegration resistanceNitrogenous fertilisersSolid/semi-solid fertilisersPolyvinyl alcoholOxamide

The invention provides granular oxamide which is high in fertilizer particle hardness, and high in shape stability in water and has stable slow-release property. The number of topdressing times and the workload of topdressing can be reduced. A mixture of 0.5 parts by weight or more of polyvinyl alcohol or modified polyvinyl alcohol relative to 100 parts of oxamide powder is subjected to high-speedstirring and granulation in an inclined mixing disc container, and then is dried to prepare the granular oxamide.

Owner:MC FERTICOM

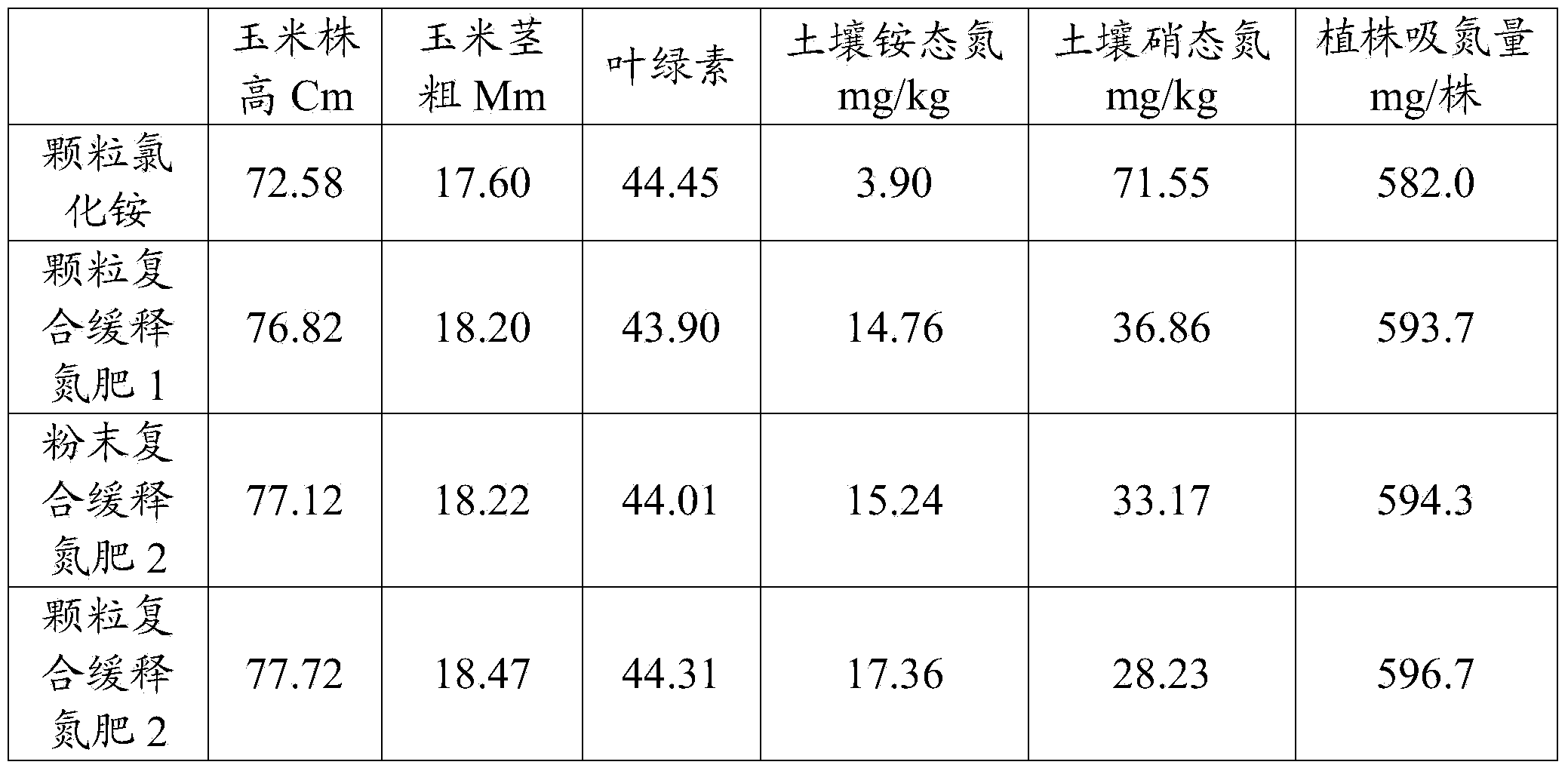

Compound slow-release nitrogen fertilizer

InactiveCN103848681ANot easy to take awayLong validity periodFertilizer mixturesOxamideNitrogen fertilizer

The invention relates to a compound slow-release nitrogen fertilizer, which comprises 0.1-95 percent by mass of oxamide, 0-5 percent by mass of inhibitor and 0-95 percent of nitrogen fertilizer. By adopting the oxamide, inhibitor and nitrogen fertilizer in the compound slow-release nitrogen fertilizer, the applied nitrogen fertilizer is effectively prevented from being brought away by water, nitrogen is kept in soil in the presence of the inhibitor, loss due to excessive conversion is prevented, the own shelf life of the nitrogen fertilizer is prolonged remarkably, and the utilization ratio of the nitrogen fertilizer is increased, thereby ensuring slow release supply of nitrogen needed in the entire growing period.

Owner:AVIC FERTILIZER

Ammonium nitrate propellants and methods for preparing the same

InactiveUS6913661B2Extended shelf lifeSafe storageNon-explosive stabilisersLoomsMolecular sieveOxamide

The present invention is directed to an age-stabilized and / or strengthened ammonium nitrate propellant composition wherein the strengthening agent is selected from the group consisting of azodicarbonamide, dicyandiamide, oxamide and mixtures thereof and wherein the age-stabilizing agent is a molecular sieve having a pore size of 13 angstroms or less.

Owner:THE BF GOODRICH CO

Method for preparing antioxidant

InactiveCN101747225AFully removedHigh yieldOrganic compound preparationCarboxylic acid amides preparationFiltrationNitrogen

A method for preparing N.N'-bis[2-ethyl-3(3.5-di tert butyl-4-hydroxyphenyl) propionic ester group] oxamide is characterized by throwing 3(3.5-di tert butyl-4-hydroxyphenyl) methyl propionate, N.N'-dihydroxyethyl oxamide, dimethylbenzene and alkyl stannate into a reactor in sequence, fully mixing and stirring the materials under the protection of nitrogen, and heating the materials to 160-190 DEG C and reacting for 6h, thus obtaining the N.N'-bis[2-ethyl-3(3.5-di tert butyl-4-hydroxyphenyl) propionic ester group] oxamide through dissolving, decoloring, thermal filtration, cooling, crystallizing and drying. The method has the following advantages and benefits: 1. the method improves the yield by over 10% compared with the traditional methods; 2. the quality of the product is obviously improved, the content is over 99.7% and the light transmittance is over 425nm99%; and 3. the reaction time is shortened.

Owner:天津市北方金恒新材料有限责任公司

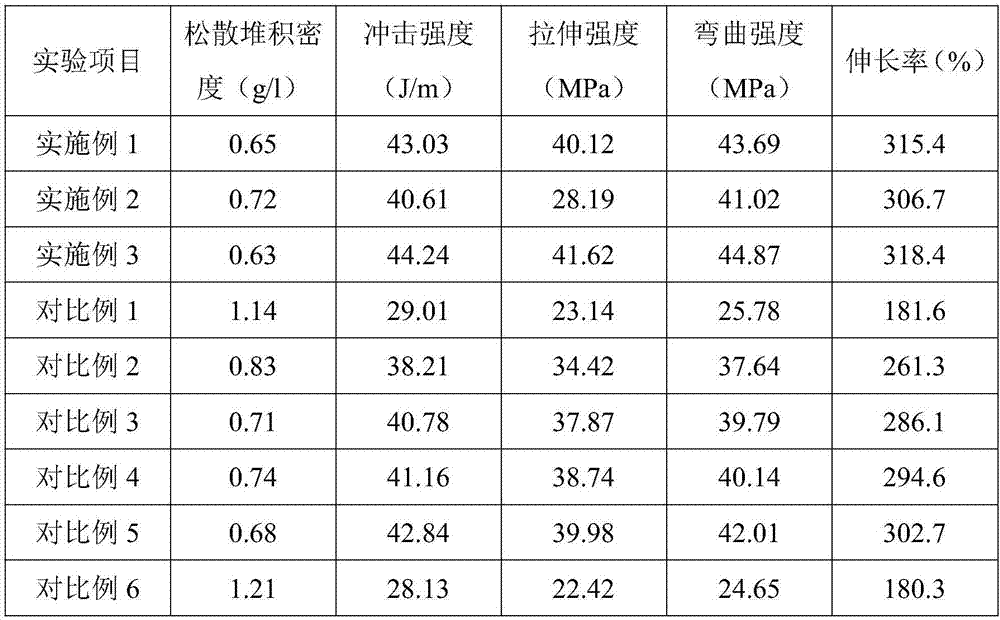

Calcium carbonate powder and preparation method thereof

The invention discloses calcium carbonate powder and a preparation method thereof. The calcium carbonate powder comprises the following raw materials: calcium carbonate, fatty alcohol polyoxyethylene ether ammonium sulfate, diethylene triamine sodium carboxylate, a bridging agent, a modifier, a coupling agent, tributyl citrate, a compatilizer, hexenyl distearamide, 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-benzotriazole chloride, oxamide, an age resister and aluminum stearate; and the calcium carbonate powder is prepared through the steps of surface modification, performance adjustment, crushing, drying and the like. The loose bulk density of modified calcium carbonate is significantly reduced, the calcium carbonate powder is fully dispersed, and is small in agglomeration phenomenon after being applied to plastic and is good in dispersity; and various mechanical properties of the modified calcium carbonate are significantly improved.

Owner:长沙善道新材料科技有限公司

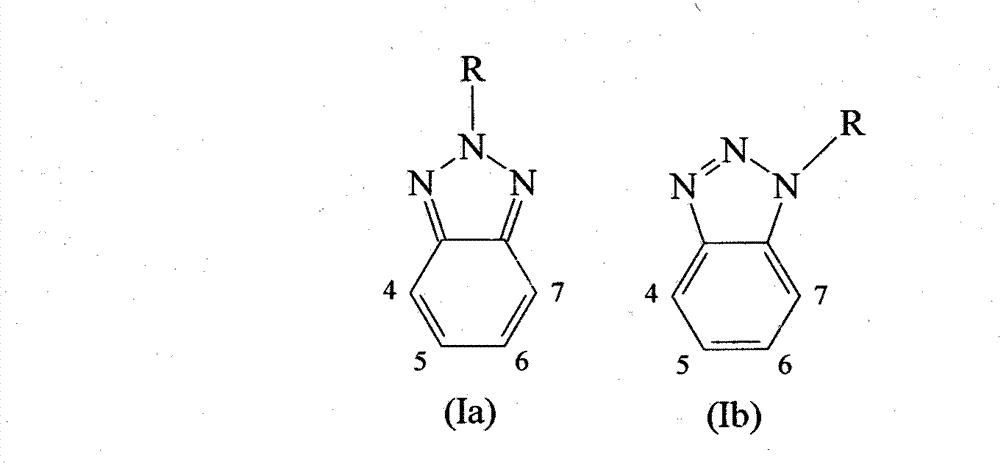

Method for synthesizing 1H,1'H-(2,2'-bis-benzimidazole)-5,5'-diamine

The invention discloses a method for synthesizing 1H, 1'H-(2,2'-bis-benzimidazole)-5,5'-diamine. The method comprises the steps of obtaining N,N'-bis(2,4-dinitrophenyl)oxamide through condensation reaction between oxalyl chloride and 2,4-dinitraniline, obtaining N,N'-bis(2,4-diaminophenyl)oxamide through catalytic hydrogenation of the N,N'-bis(2,4-dinitrophenyl)oxamide and obtaining the 1H,1'H-(2,2'-bis-benzimidazole)-5,5'-diamine through dehydration cyclization of the N,N'-bis(2,4-diaminophenyl)oxamide. The method disclosed by the invention has a shorter synthesizing path, high technological safety, convenience to operate, lower production cost, higher reaction yield and especially smaller environmental pollution, so that the method is suitable for industrial production; in addition, raw materials of the method are cheap and easy to obtain.

Owner:CHANGZHOU SUNLIGHT PHARMA

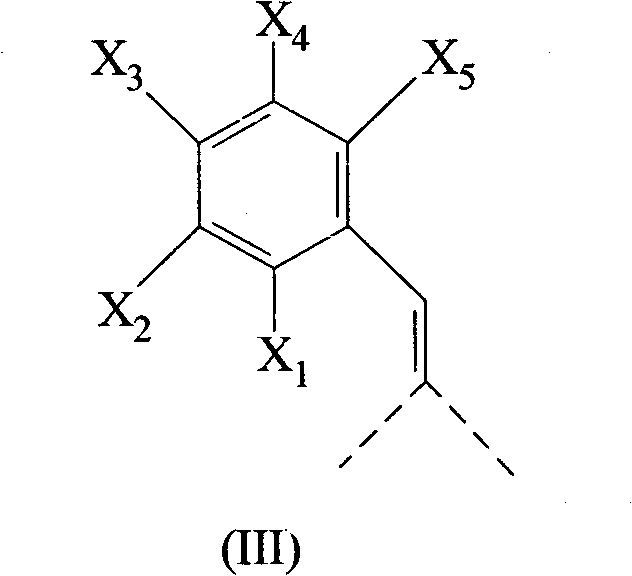

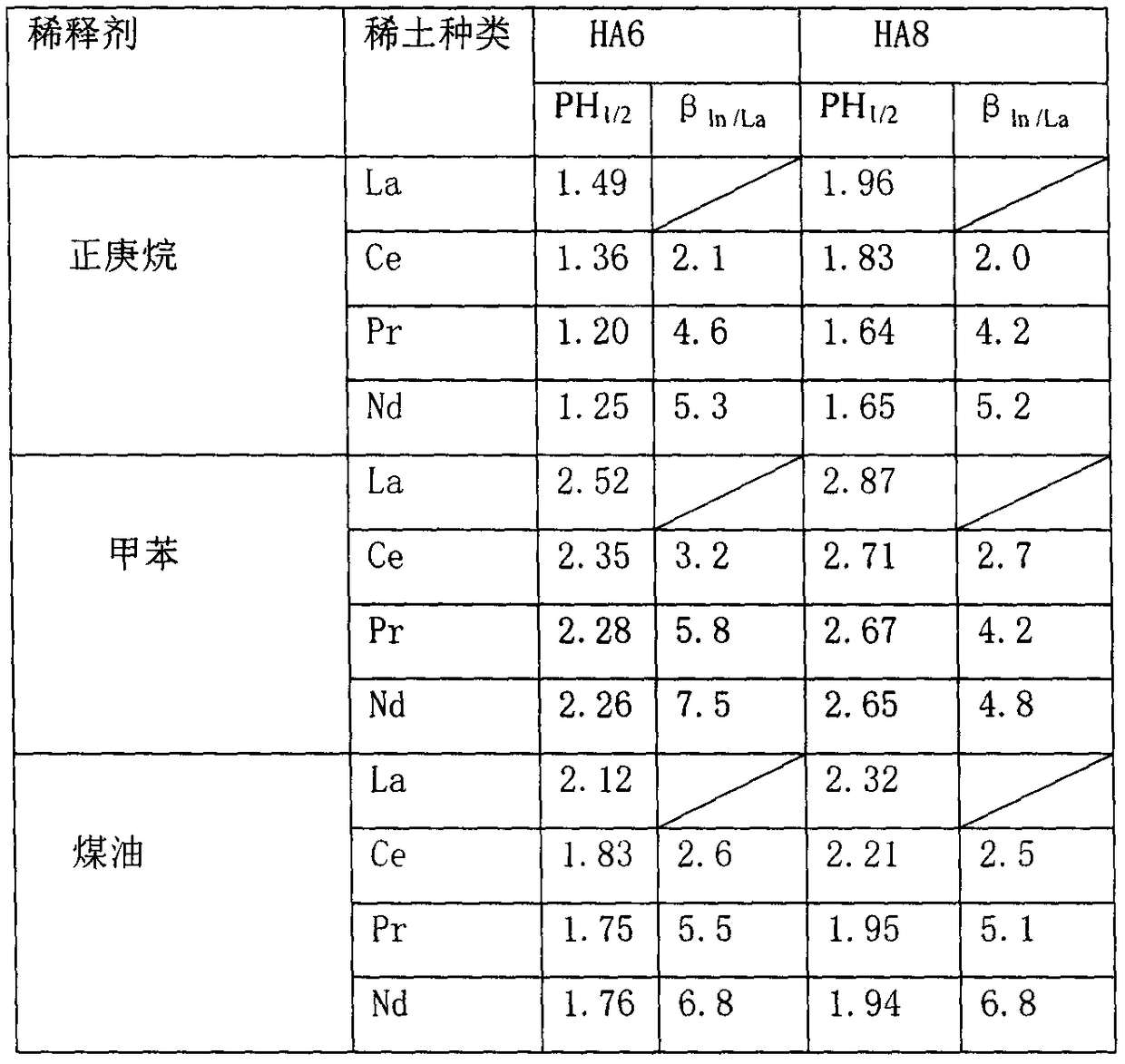

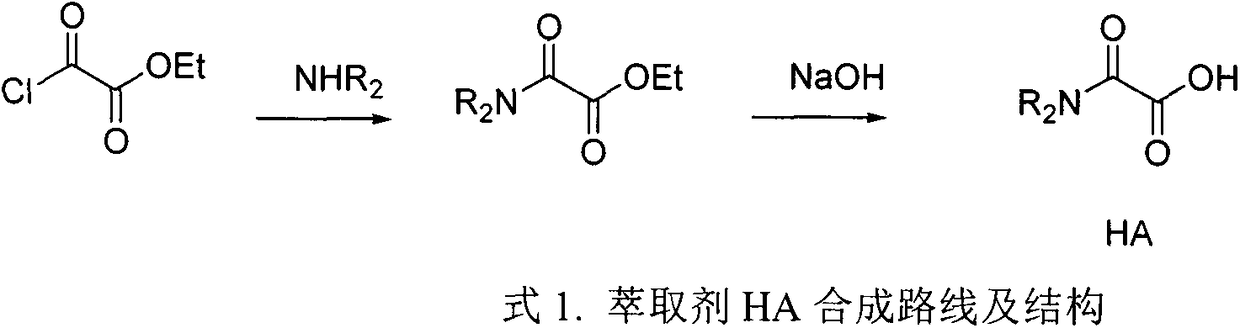

Synthesis of novel efficient extractant oxamide for light rear earth element and extraction separation method

InactiveCN108165744AEasy to synthesizeImprove extraction abilityOrganic compound preparationCarboxylic acid amides preparationRare-earth elementSeparation coefficient

The invention relates to synthesis of a novel efficient extractant oxamide for a light rear earth element and an extraction separation method. The extraction separation method is applied in extractionand separation of light rear earth elements. The extractant has excellent extraction performance on light rear earth elements, the separation coefficient of adjacent rear earth elements in toluene can be up to 3.2, and the half-extraction pH1 / 2 in n-heptane can decrease to 1.2. In addition, the extractant is simple to synthesize and can be obtained through two conventional reaction steps, synthesis conditions are mild and industrial production is convenient, and therefore the extractant is a potential extractant for light rear earth elements.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

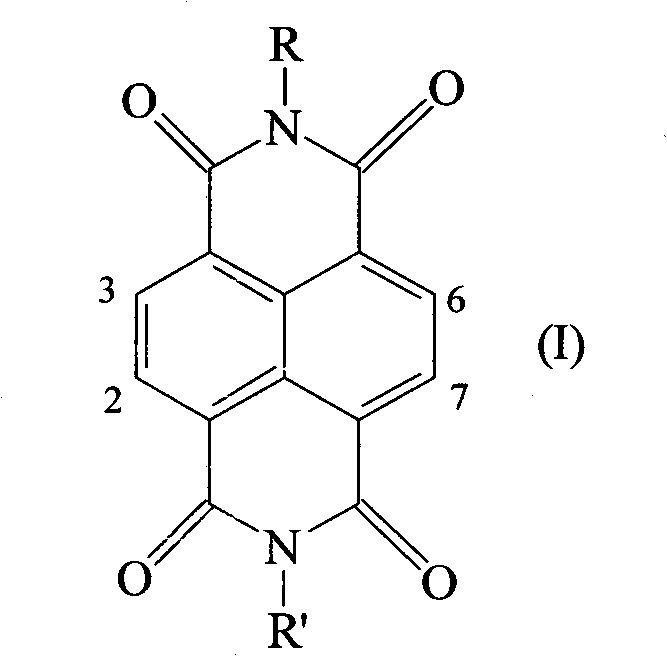

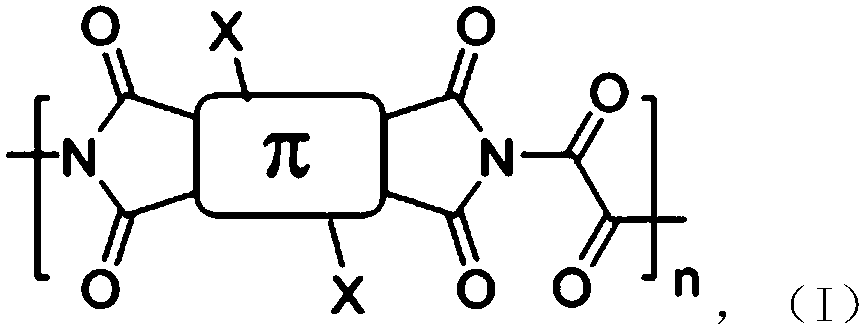

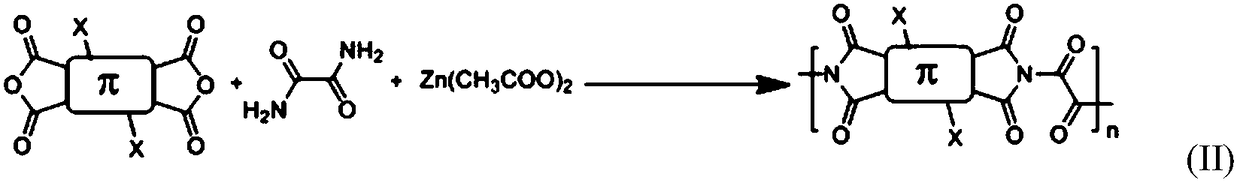

A class of rapid charge and discharge positive electrode active materials, preparation method and applications thereof

ActiveCN109265682AImprove transmission efficiencyImprove cycle performanceCell electrodesSecondary cellsChemical structureSolubility

The invention discloses a class of rapid charge and discharge positive electrode active materials. According to the present invention, the used imide-based small molecules form pi-pi stacking on the plane of a benzene ring, such that the rapid charge and discharge positive electrode active material has good conductivity and insolubility in most common solvents, and is the ionic battery positive electrode material with potential; oxamide and a tetracarboxylic axid dianhydride small molecule are subjected to a reaction to form a polymer, such that the synthesis of the polymer can effectively reduce the solubility in the electrolyte and improve the cycle stability; and by introducing the additional carbonyl between the monomers, the stack of the carbonyl between the molecules form a new ion transport channel to greatly improve the ion transport efficiency, such that the cycle performance and the rate performance of the prepared alkali metal ion battery are substantially improved. The chemical structure general of the imide polymer is defined in the specification.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

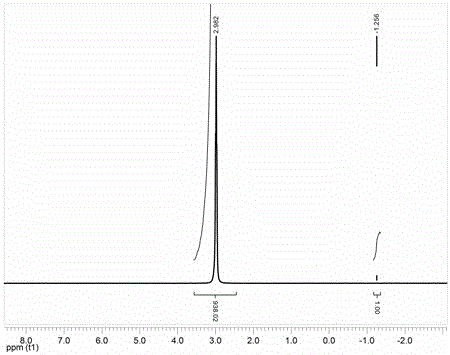

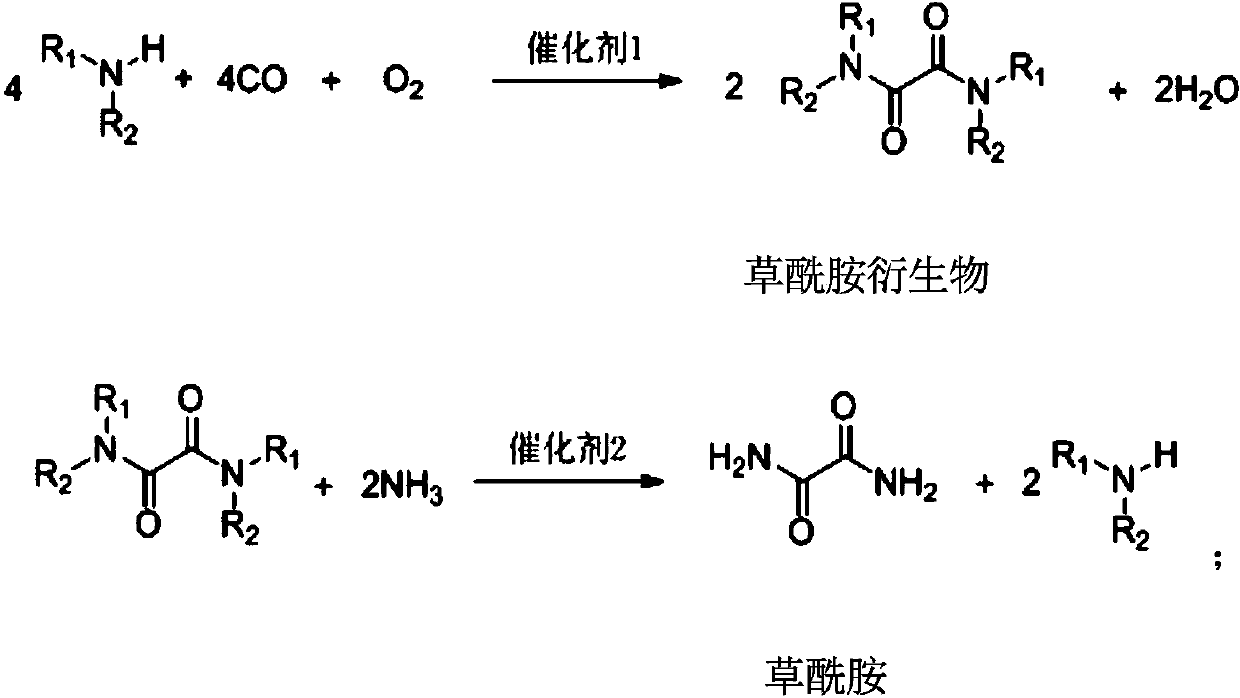

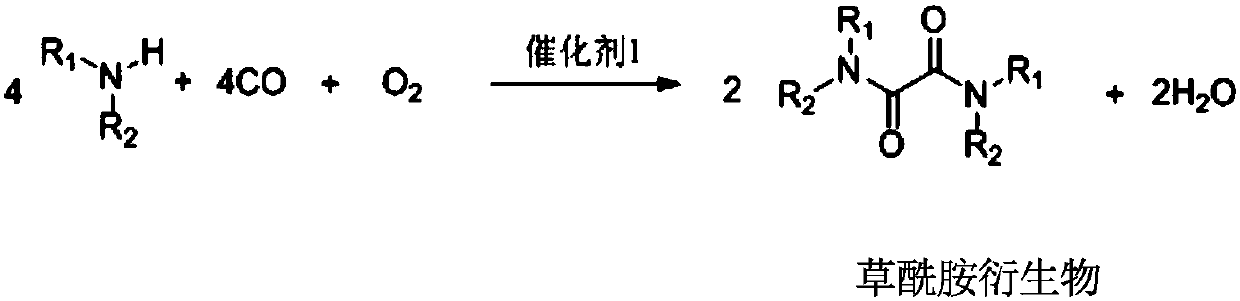

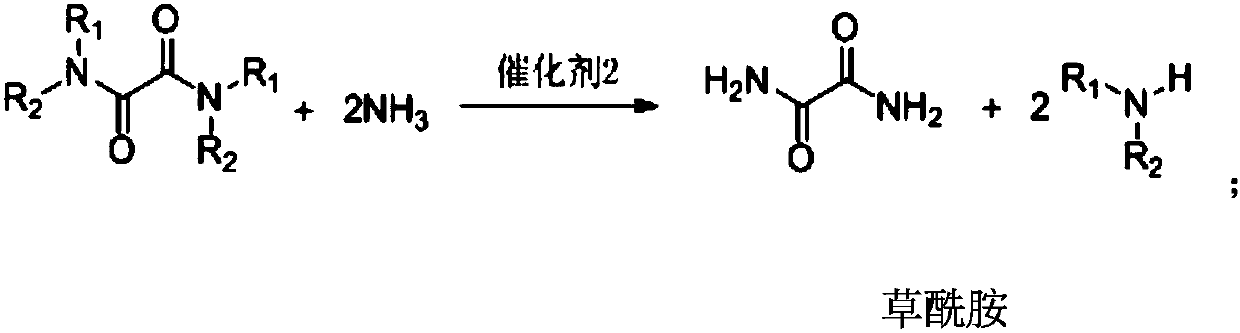

Preparation method of oxamide

ActiveCN110041218ASimple preparation processEasy to recycleOrganic compound preparationCarboxylic acid amides preparationFood additiveAminolysis

The invention provides a preparation method of oxamide. The preparation method comprises the following steps: an intermediate oxamide derivative is prepared from CO, O2 and amine compounds as raw materials by oxidation and carbonylation under the action of a catalyst 1, and then, oxamide is prepared through aminolysis of the oxamide derivative under the action of a catalyst 2. A novel method is used for coproducing oxamide and the oxamide derivative, and the problems that oxalate synthesis materials are poisonous, catalyst efficiency is low and the like in the original technology for synthesizing oxamide through aminolysis of oxalate are solved. Besides, the technologically synthesized oxamide derivative has good substrate applicability and can be applied to fields of medicine, pesticides,synthetic ligands, food additives and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

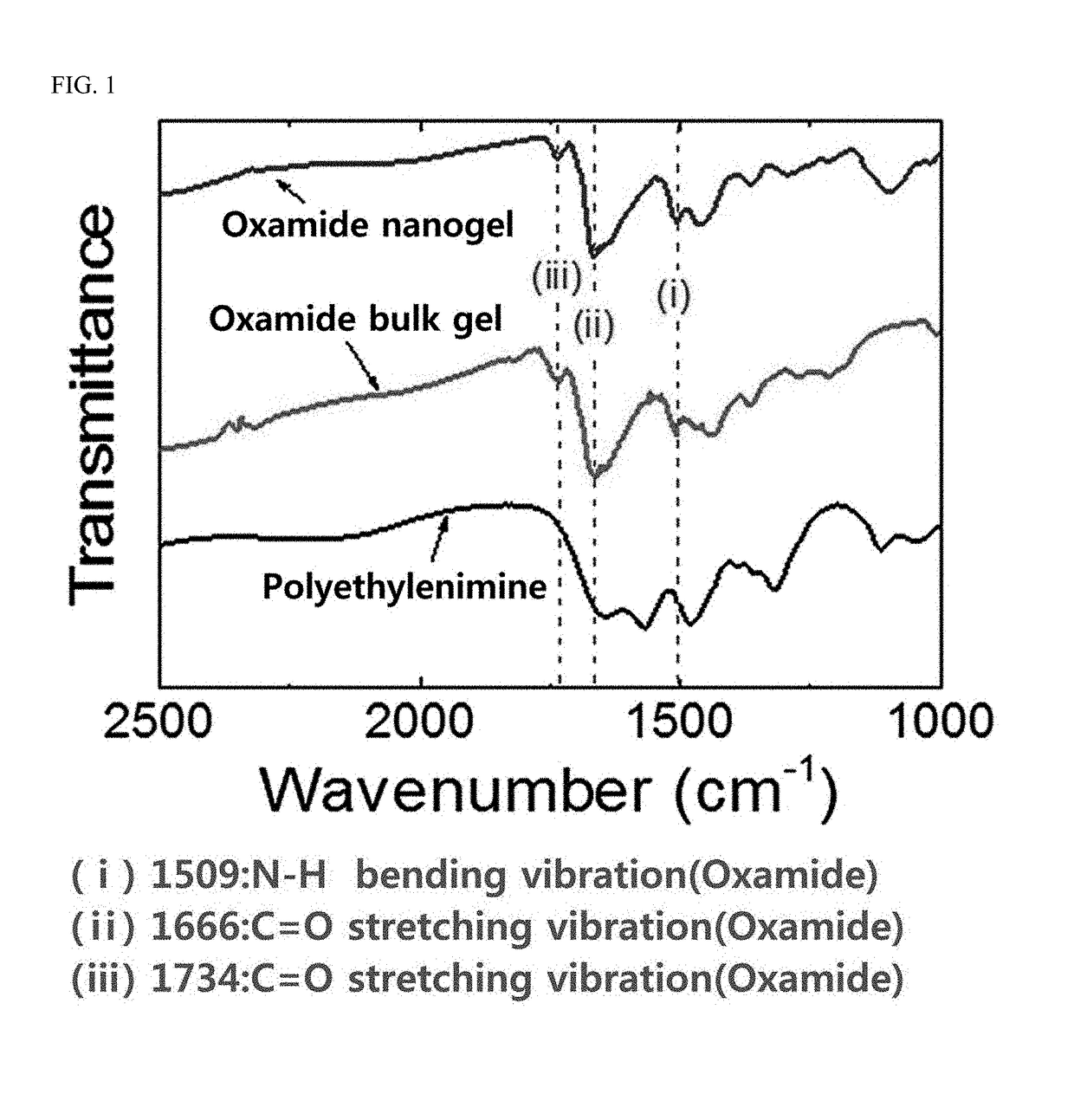

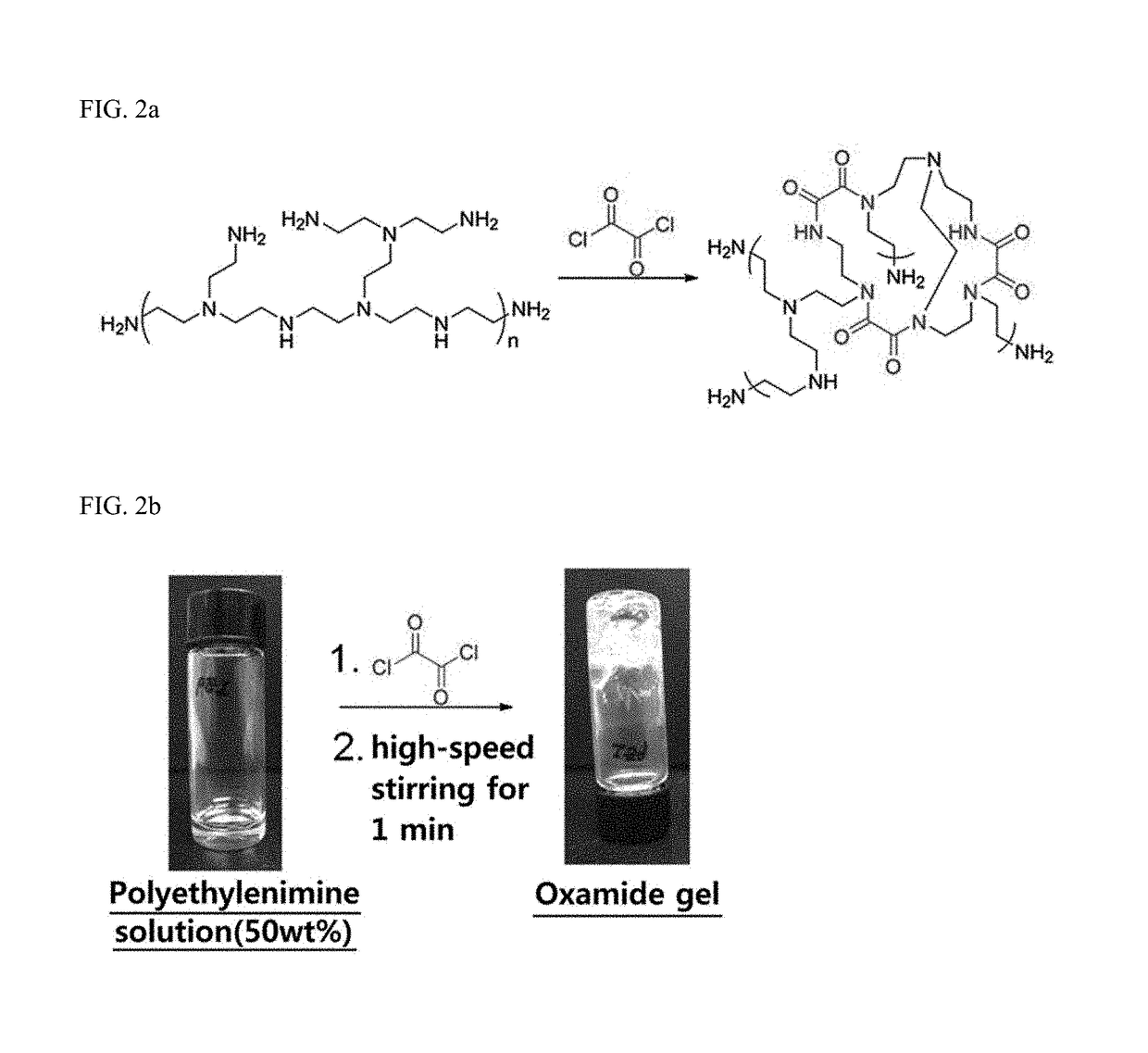

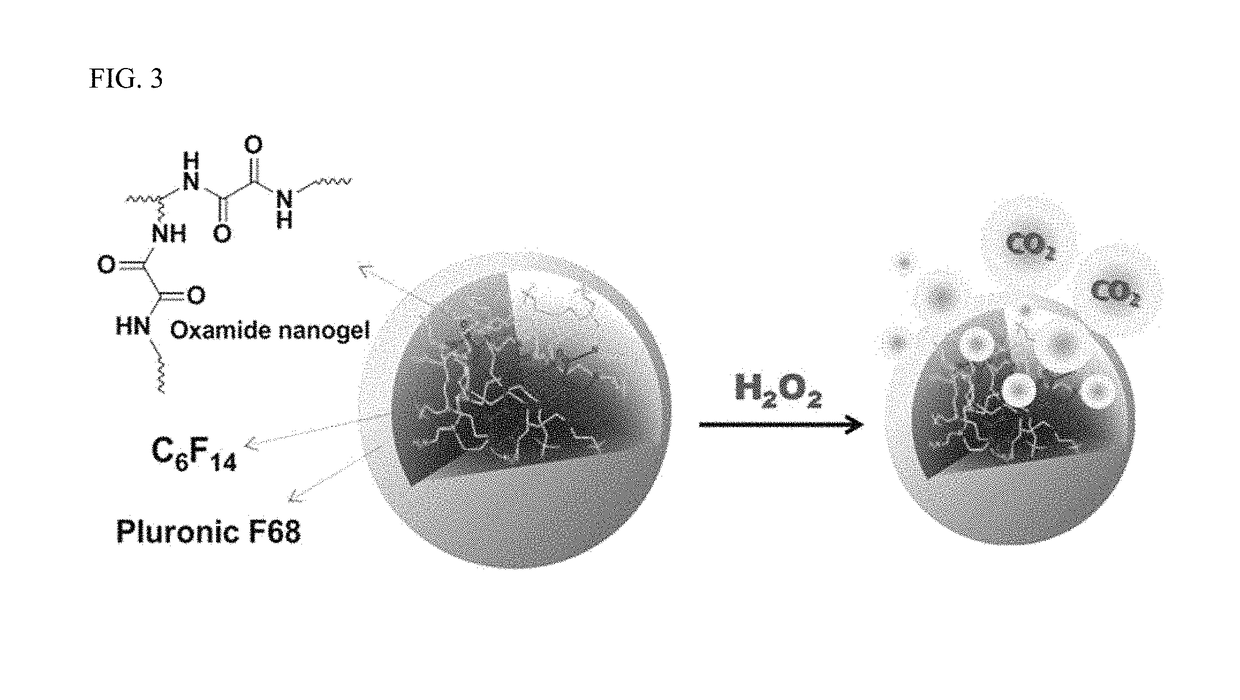

Oxamide nanogel, a preparation method of the same, and use thereof

ActiveUS20180064832A1Excellent gas-capturing abilityPowder deliveryEchographic/ultrasound-imaging preparationsDiseaseUltrasound imaging

The present invention relates to a nanogel comprising a polyamine-based polymer cross-linked by oxamide bonds, a preparation method of the nanogel, a contrast agent for ultrasound imaging comprising the nanogel, a composition for ultrasound diagnosis of inflammatory diseases comprising the contrast agent, a preparation method of the contrast agent, and a method for providing information for diagnosis of inflammatory diseases using the composition for ultrasound diagnosis.

Owner:KOREA INST OF SCI & TECH

Biodegradable alternative aliphatic polyester amide and preparation method thereof

The invention relates to a biodegradable alternative aliphatic polyester amide and a preparation method thereof. The preparation method comprises the following steps: under the action of a catalyst and a phosphorus-containing cocatalyst, straight-chain oxamide diol and straight-chain aliphatic diacid are subjected to condensation polymerization to prepare the biodegradable alternating aliphatic polyester amide, wherein the phosphorus-containing cocatalyst is an ammonium salt containing hydrogen phosphate, a calcium salt containing hydrogen phosphate, a sodium salt containing hydrogen phosphateor a magnesium salt containing hydrogen phosphate; a main chain of the finally prepared biodegradable alternative aliphatic polyester amide is formed by alternate bonding of a straight-chain oxamidediol unit and a straight-chain aliphatic diacid unit, and the weight-average molecular weight of the biodegradable alternative aliphatic polyester amide is 50,000-1,000,000 g / mol. The preparation method disclosed by the invention is simple to operate, pollution-free and few in byproducts, and the finally prepared biodegradable alternate aliphatic polyester amide has good biodegradability, regularalternate structure, higher molecular weight and good thermal performance and mechanical performance.

Owner:DONGHUA UNIV

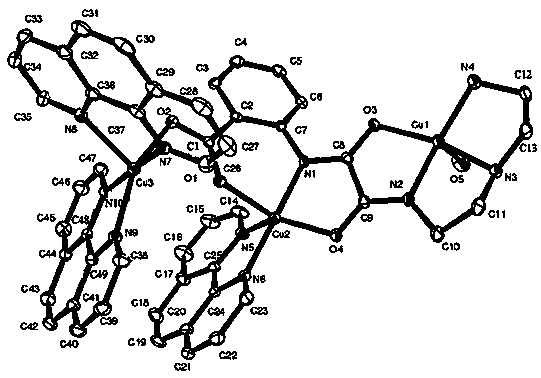

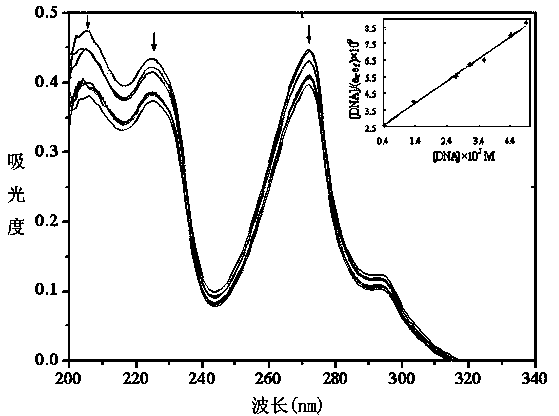

Asymmetry oxamide fiber-bridged three-kernel copper complex as well as preparation method and application thereof

InactiveCN103724364AStrong growth inhibitory effectHigh selectivityOrganic active ingredientsCopper organic compoundsSolubilityFiber

The invention discloses an asymmetry oxamide fiber-bridged three-kernel copper complex as well as a preparation method and application thereof. The complex is generated from Cu<2+> and asymmetry oxamide ligand H3bdeox, perchlorate and 1,10-phenanthroline; the coordination polymer is of a trimetal central structure, and the molecular structure formula of the coordination polymer is [Cu3(bdeox)(phen)3(H2O)](ClO4)3?H2O, wherein Cu is bivalent copper ion, and H3bdeox is N-(2-carboxyl benzene)-N'-[(2-aminoethyl)ethyl] oxamide. The asymmetry oxamide fiber-bridged three-kernel copper complex disclosed by the invention is low in cost, the raw materials for synthesis is readily available, the product is separated out in a crystal mode, is large in purity and high in yield, and moreover, the coordination polymer is stable in a natural state, and is good in water solubility and grease solubility; in addition, the coordination polymer has an excellent inhibition function on various cancer cells of liver cancer, lymphatic leukemia and the like, and is wide in action spectrum and wide in application range.

Owner:QINGDAO MUNICIPAL HOSPITAL

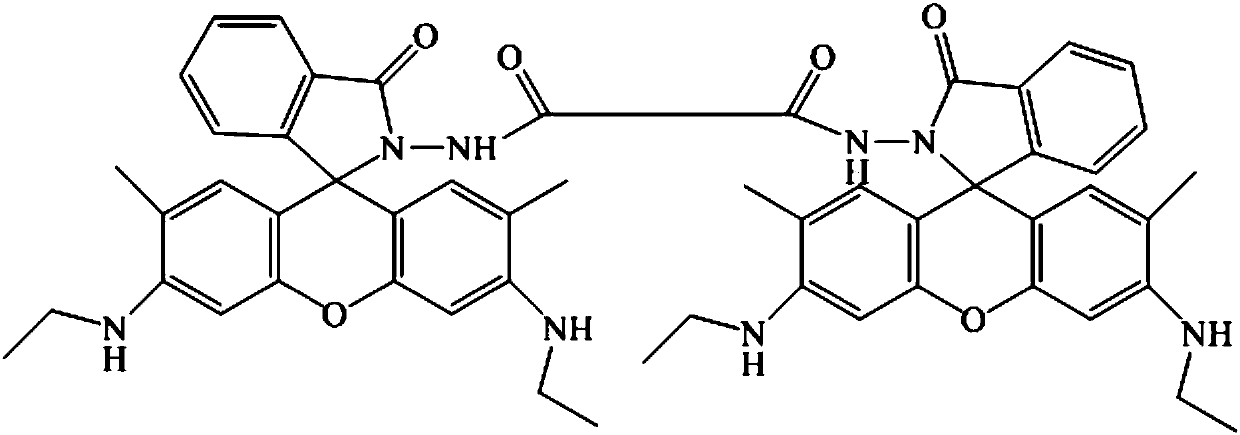

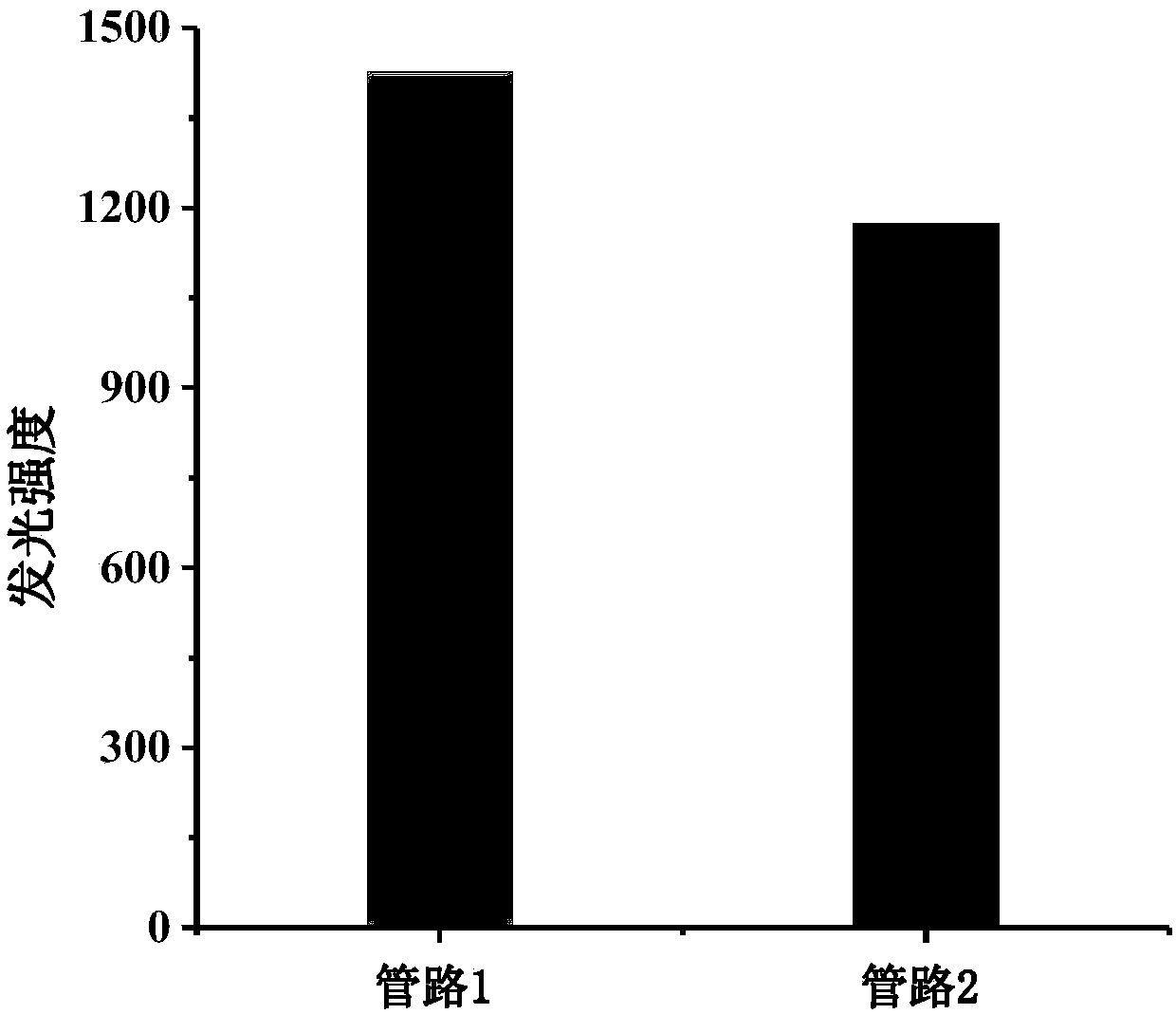

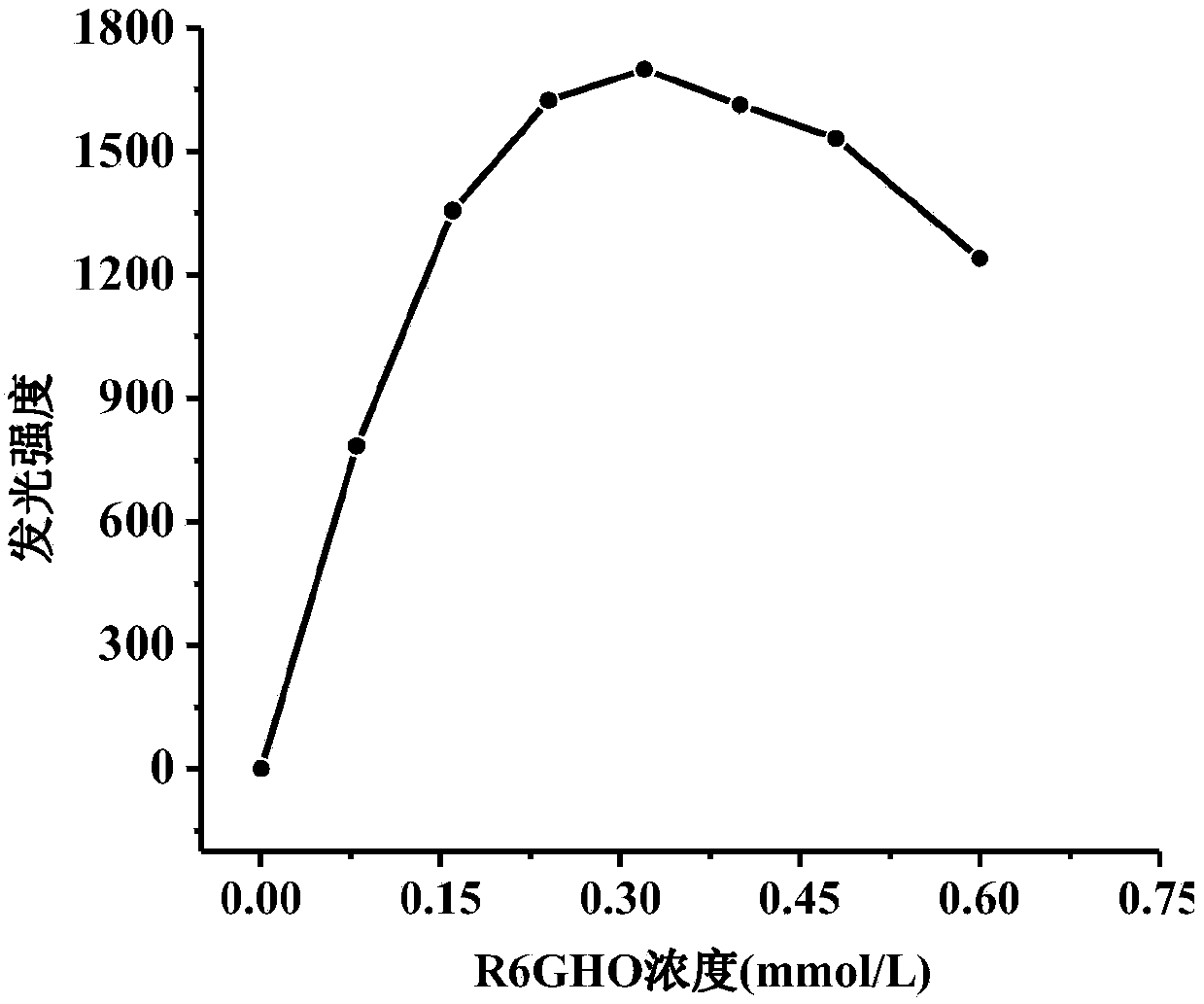

Preparation method and chemiluminescence analysis method of R6GHO

The invention relates to a preparation method and a chemiluminescence analysis method of R6GHO, and discloses a preparation method of rhodamine 6G hydrazide oxamide and a new method for determining the content of nitrites in a water phase by using the synthesized R6GHO. The R6GHO reacts with hydrogen peroxide and nitrite ions under an acidic condition to make a five-membered amide ring be opened and form azide, and the azide is converted into strong-fluorescence rhodamine 6G together with energy change. An R6GHO fluorescence probe makes up for some function defects of a single-molecule probe,and has the advantages of high sensitivity, high selectivity, high reliability, and facilitation of analysis and detection.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com