Patents

Literature

82results about "Non-explosive stabilisers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Family of Modifiable High Performance Electrically Controlled Propellants and Explosives

ActiveUS20110067789A1Improve simplicityLow costNon-explosive stabilisersNon-explosive fillers/gelling/thickening agentsElectricityAmbient pressure

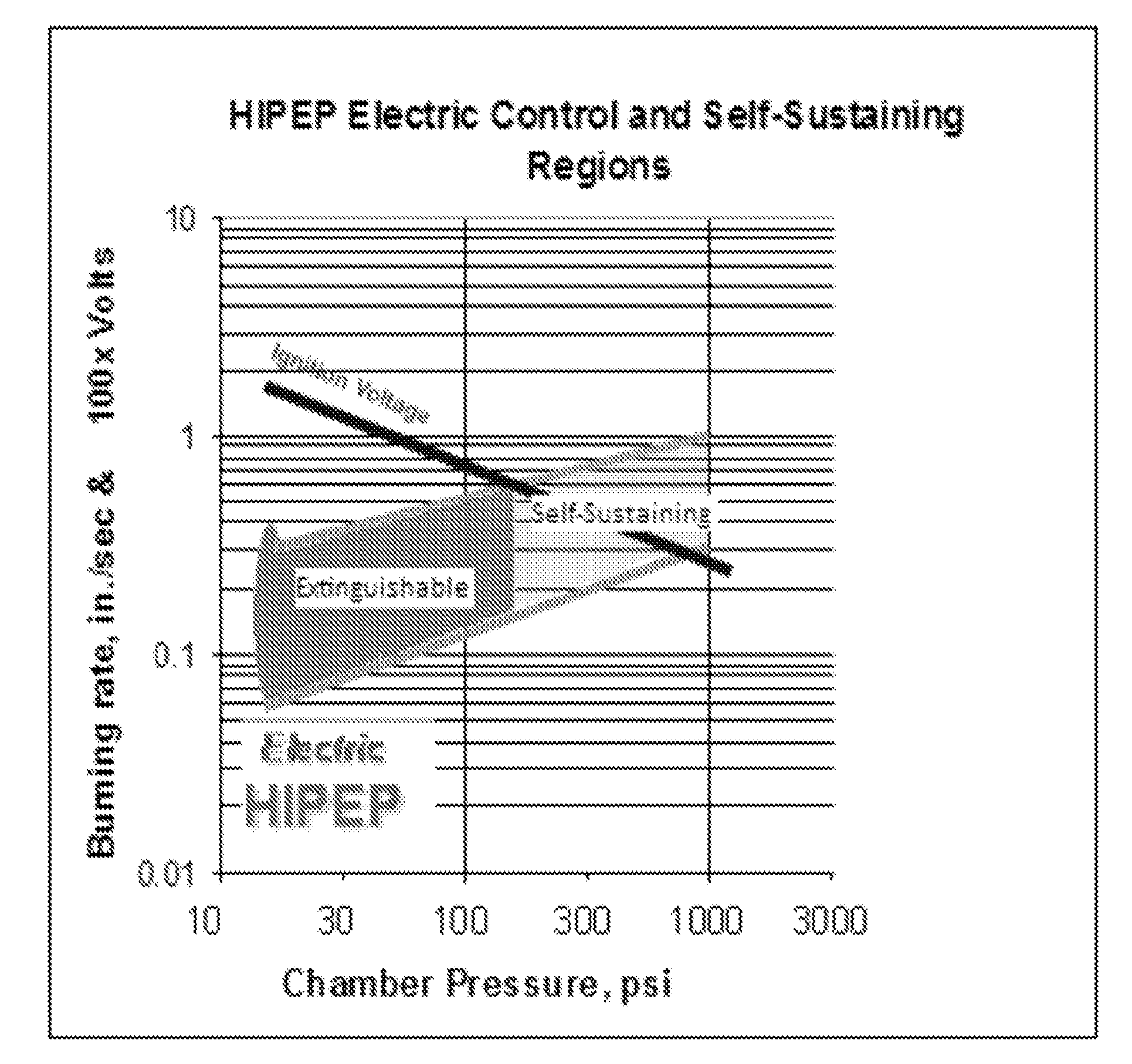

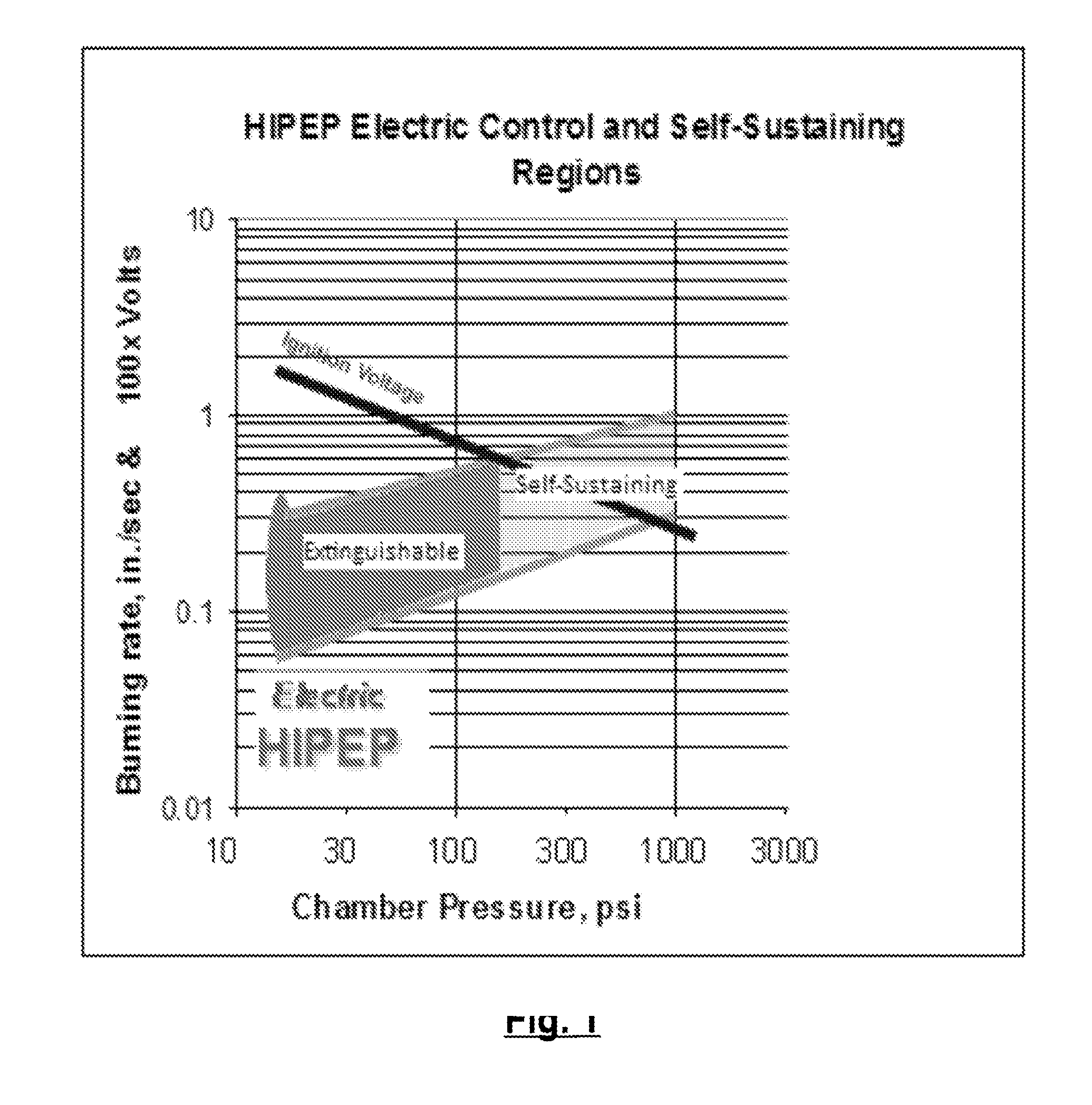

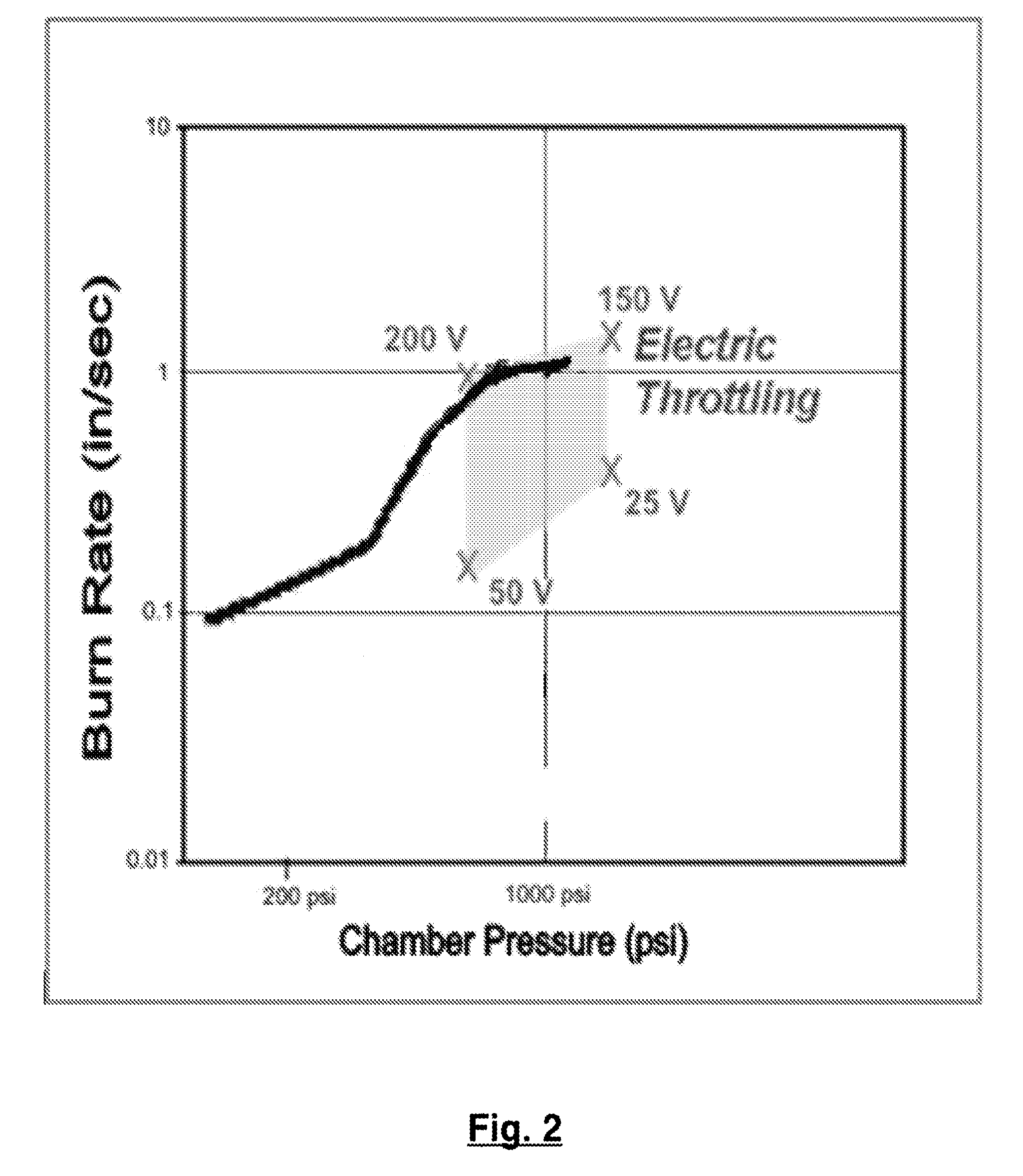

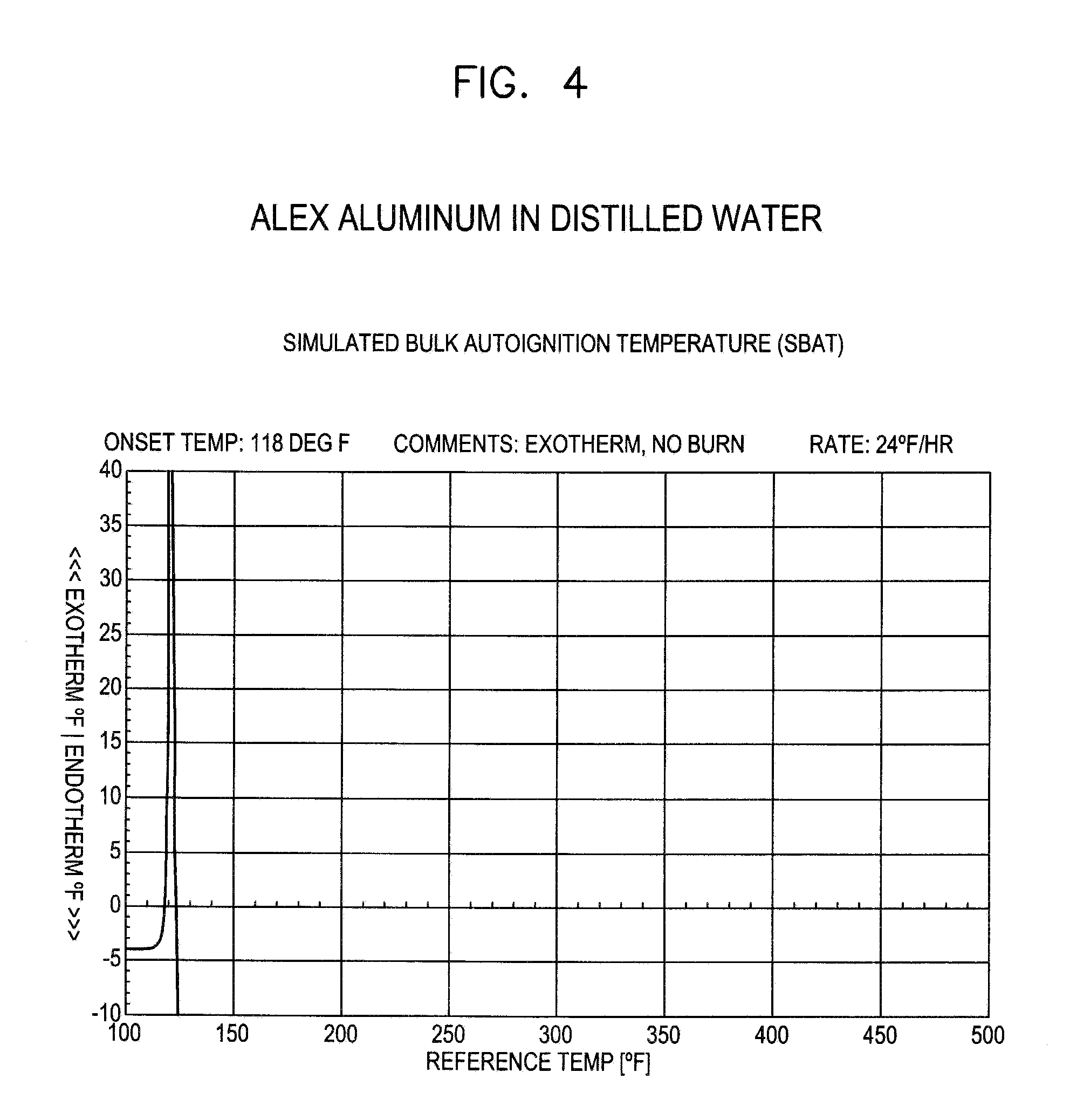

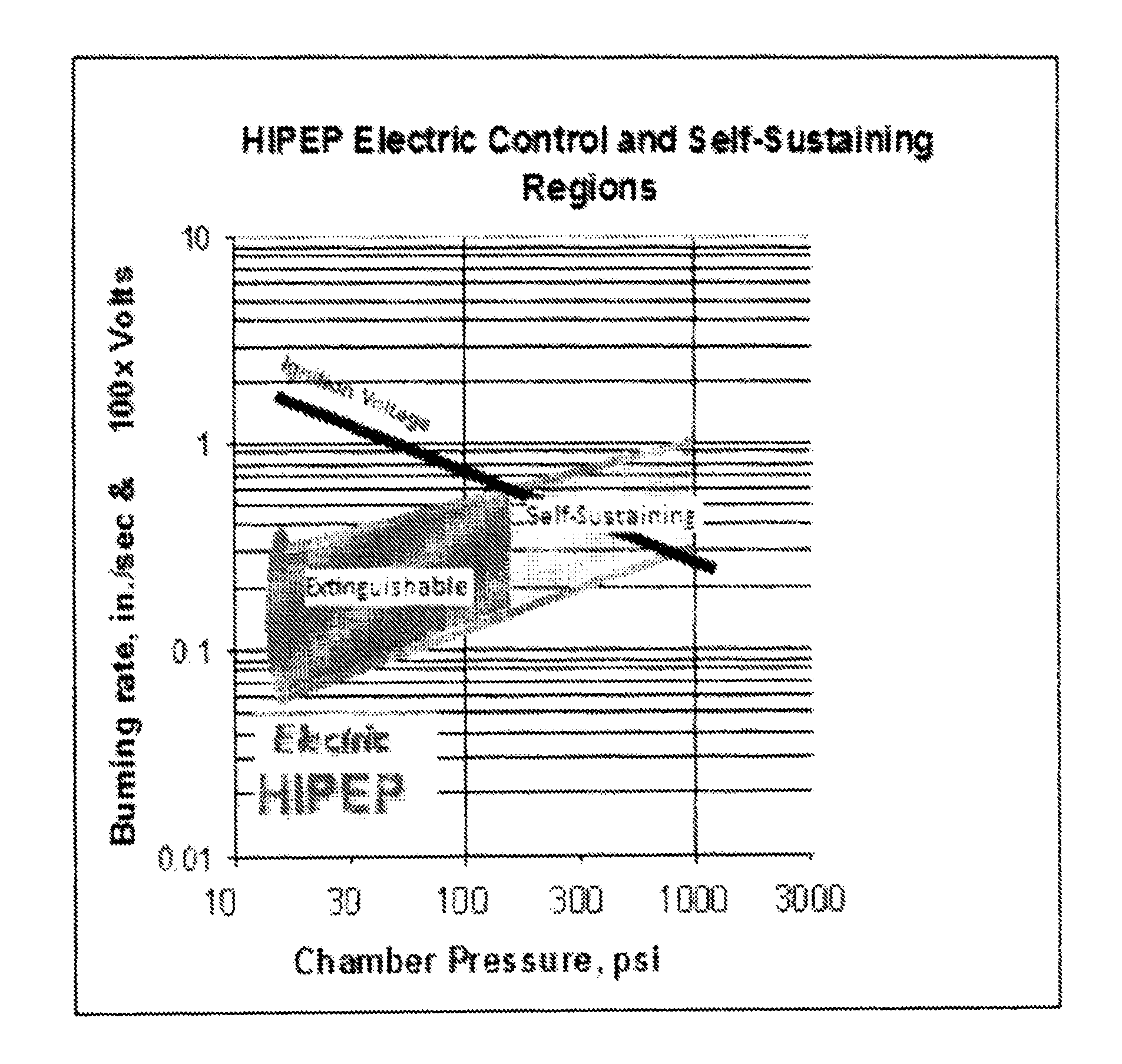

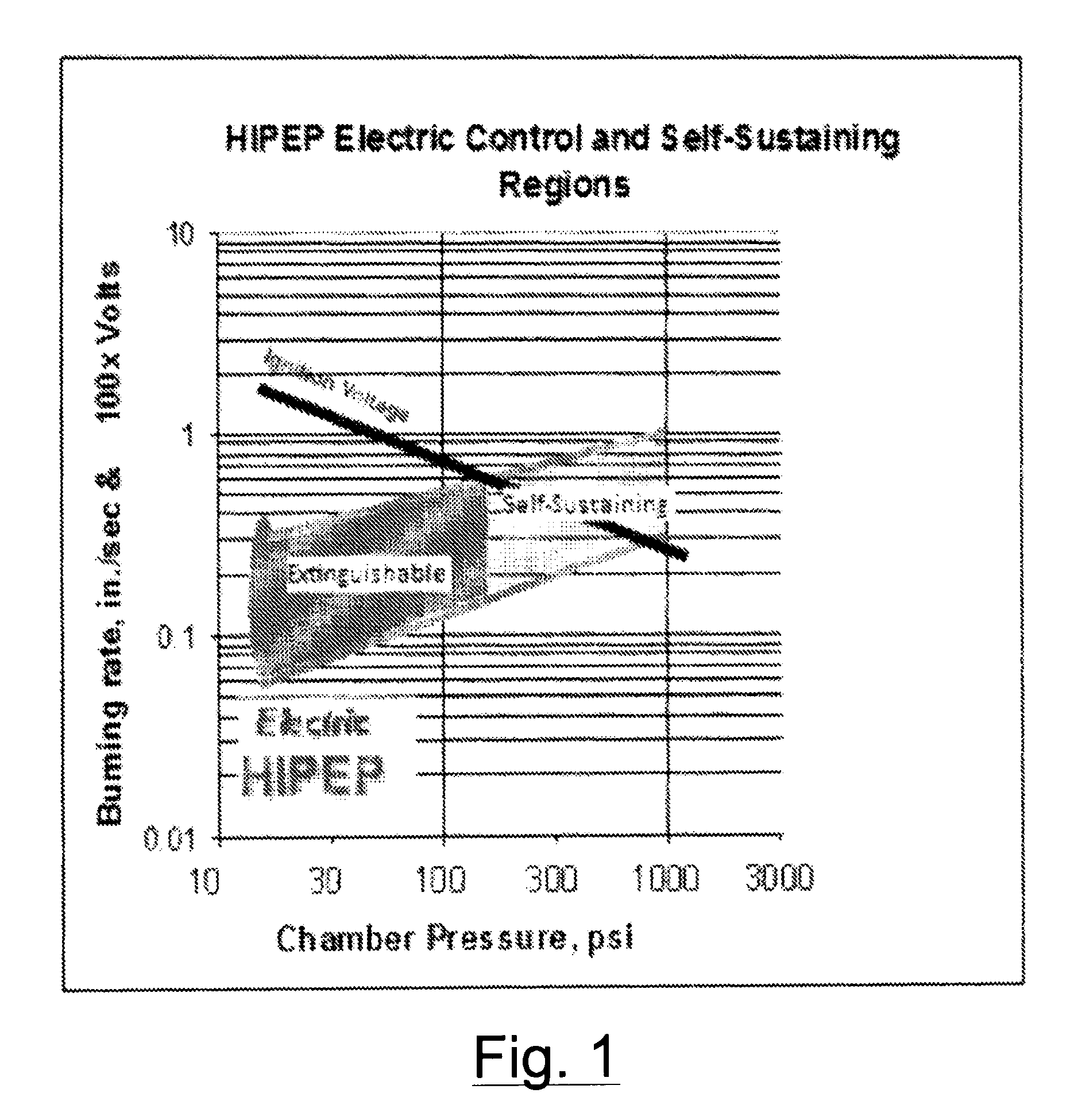

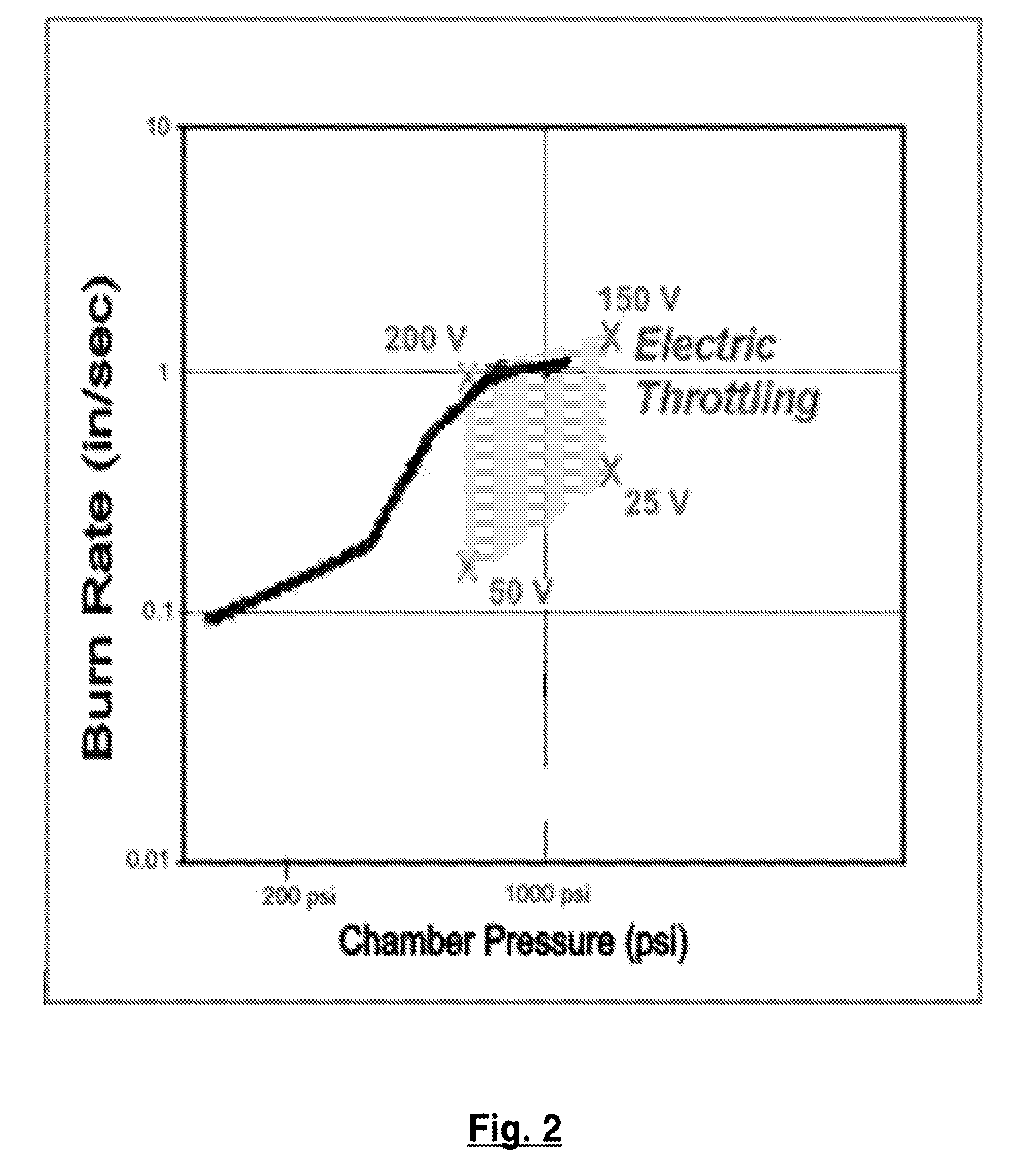

A composition capable of producing either solid propellant grains, liquid or gel monopropellants, all of which are electrically ignitable and capable of sustained controllable combustion at ambient pressure. Additional compositions capable of sustained controllable combustion at elevated pressures are described. Applications for the compositions disclosed herein are provided, and include among other applications use in small micro thrusters, large core-burning solid propellant gains, shaped explosives charges for military application, and pumpable liquids and gel monopropellants or explosives for military, commercial mining or gas and oil recovery. In alternative embodiments the above compositions may also incorporate an energetic nitrate polymer, bum rate modifiers, and / or metal fuel(s). The HIPEP formulation makes it possible to ignite and sustain combustion at ambient and vacuum conditions (a) without continuous electrical power and (b) while providing faster bum rates.

Owner:DIGITAL SOLID STATE PROPULSION

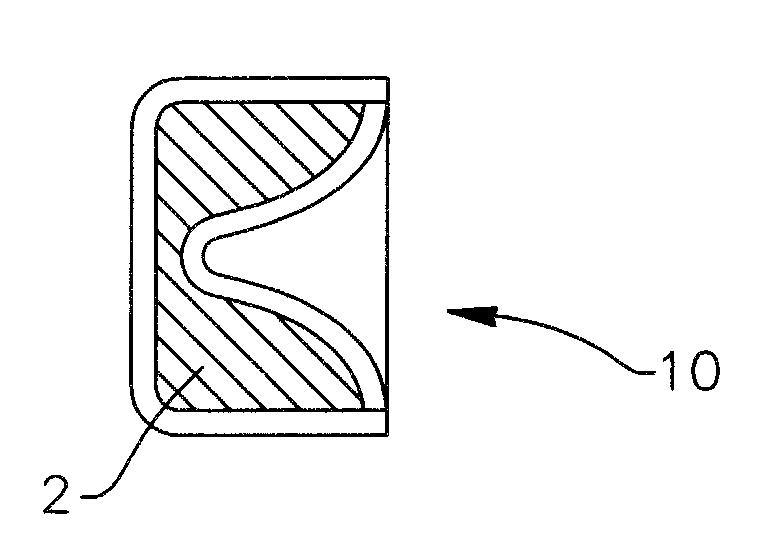

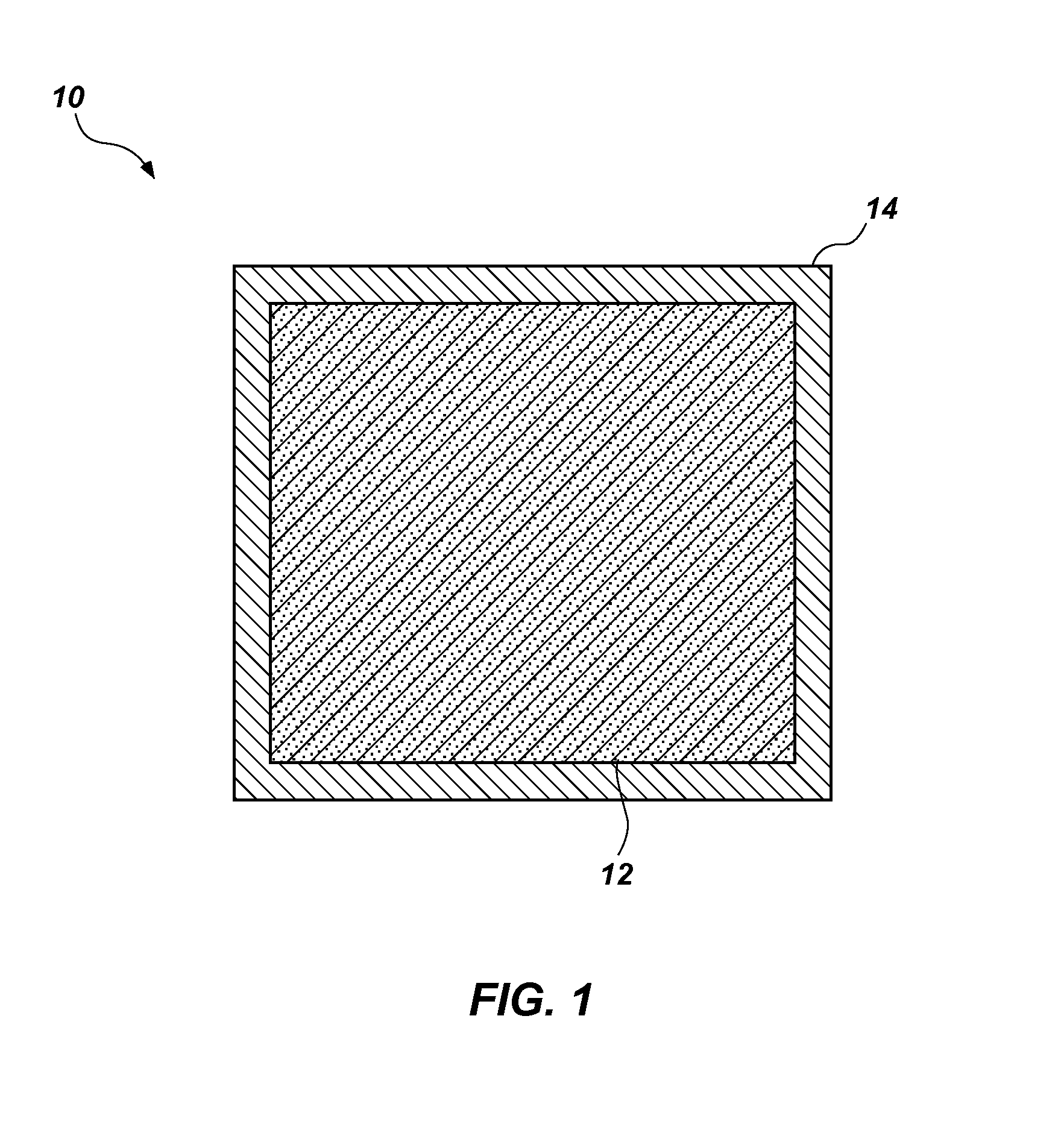

Gas generant

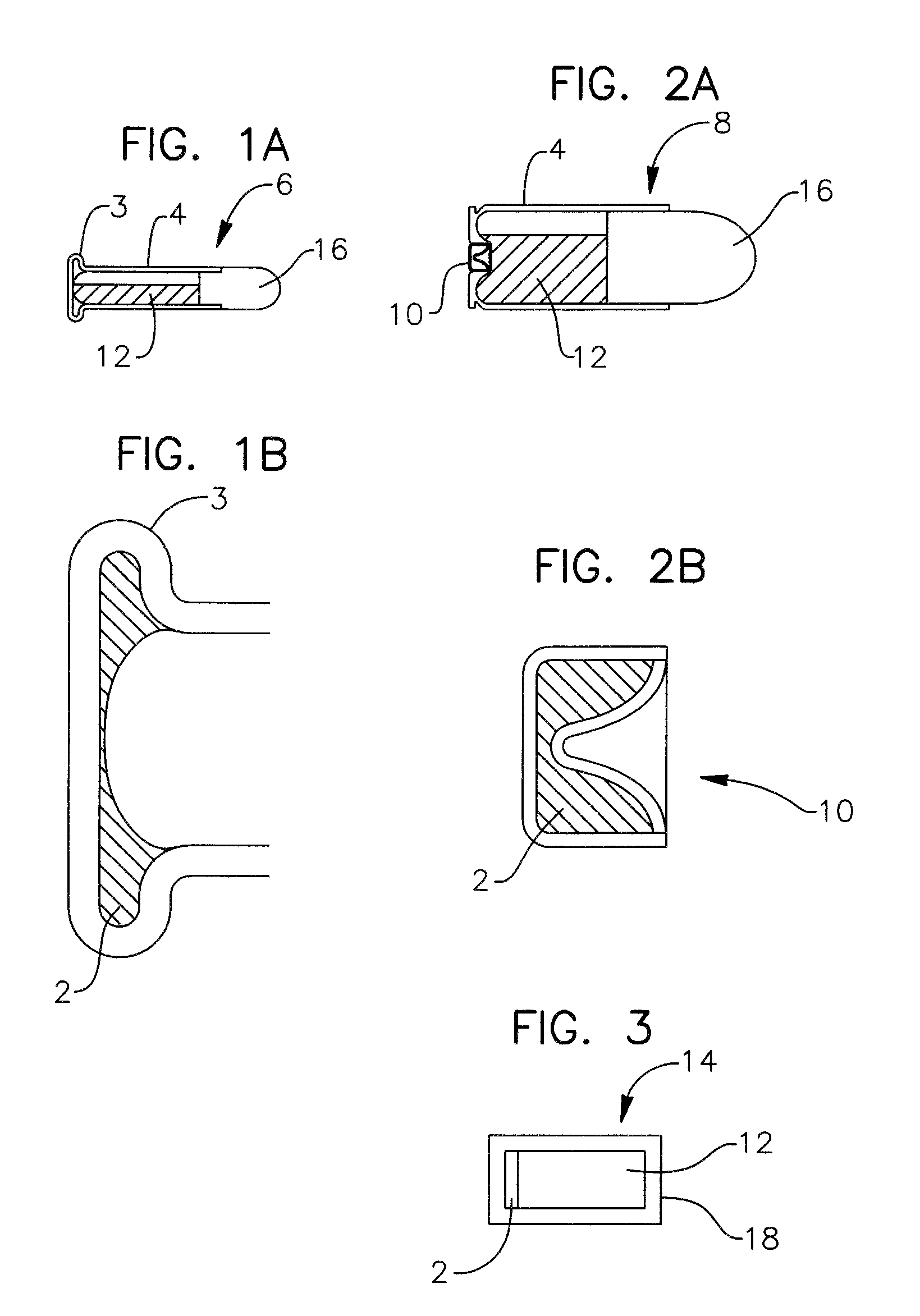

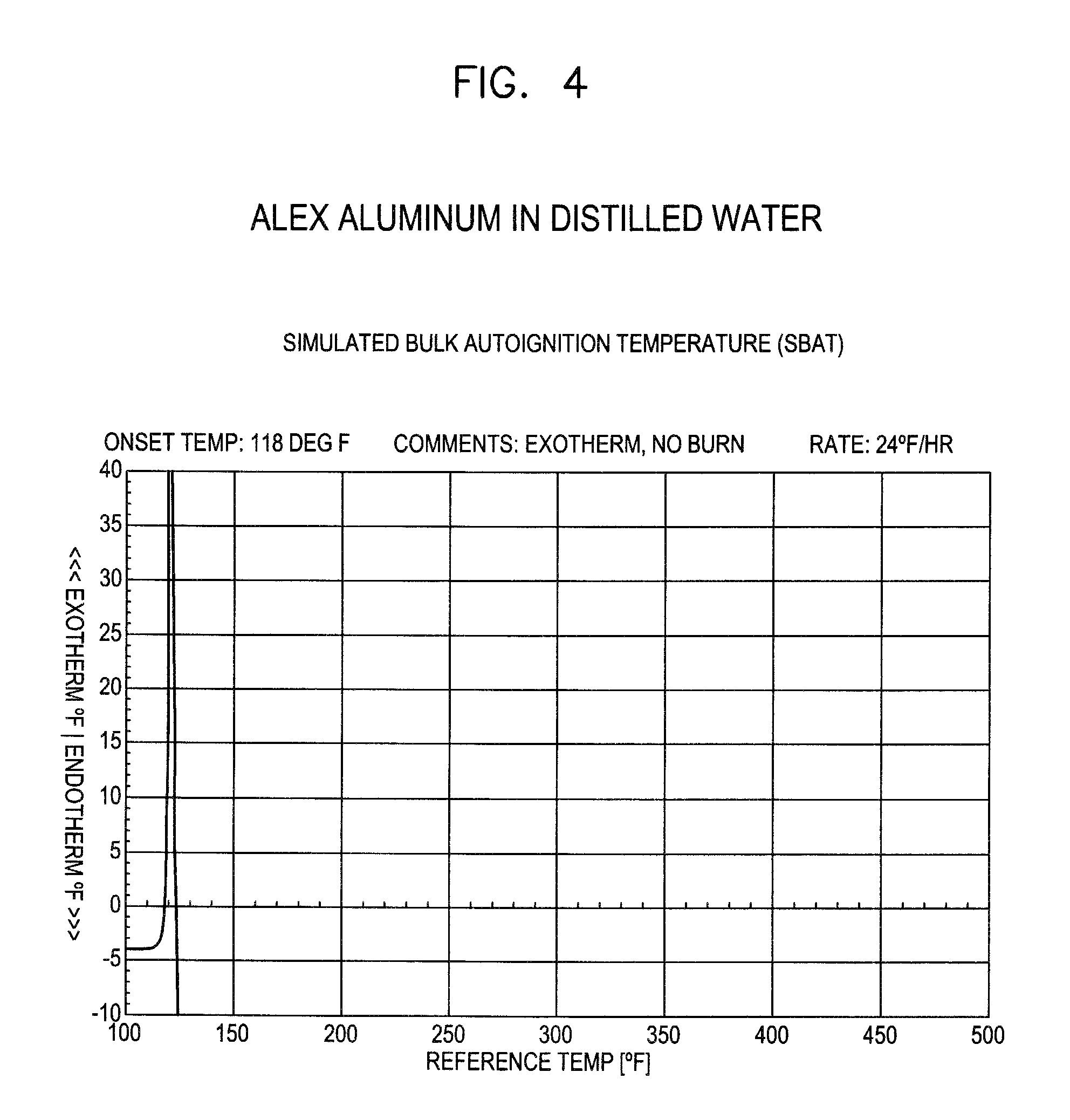

InactiveUS20070084532A1Predictive performanceFacilitating consistent performance predictabilityNon-explosive stabilisersNitrated metallo-organic explosive compositionsMoistureGas generator

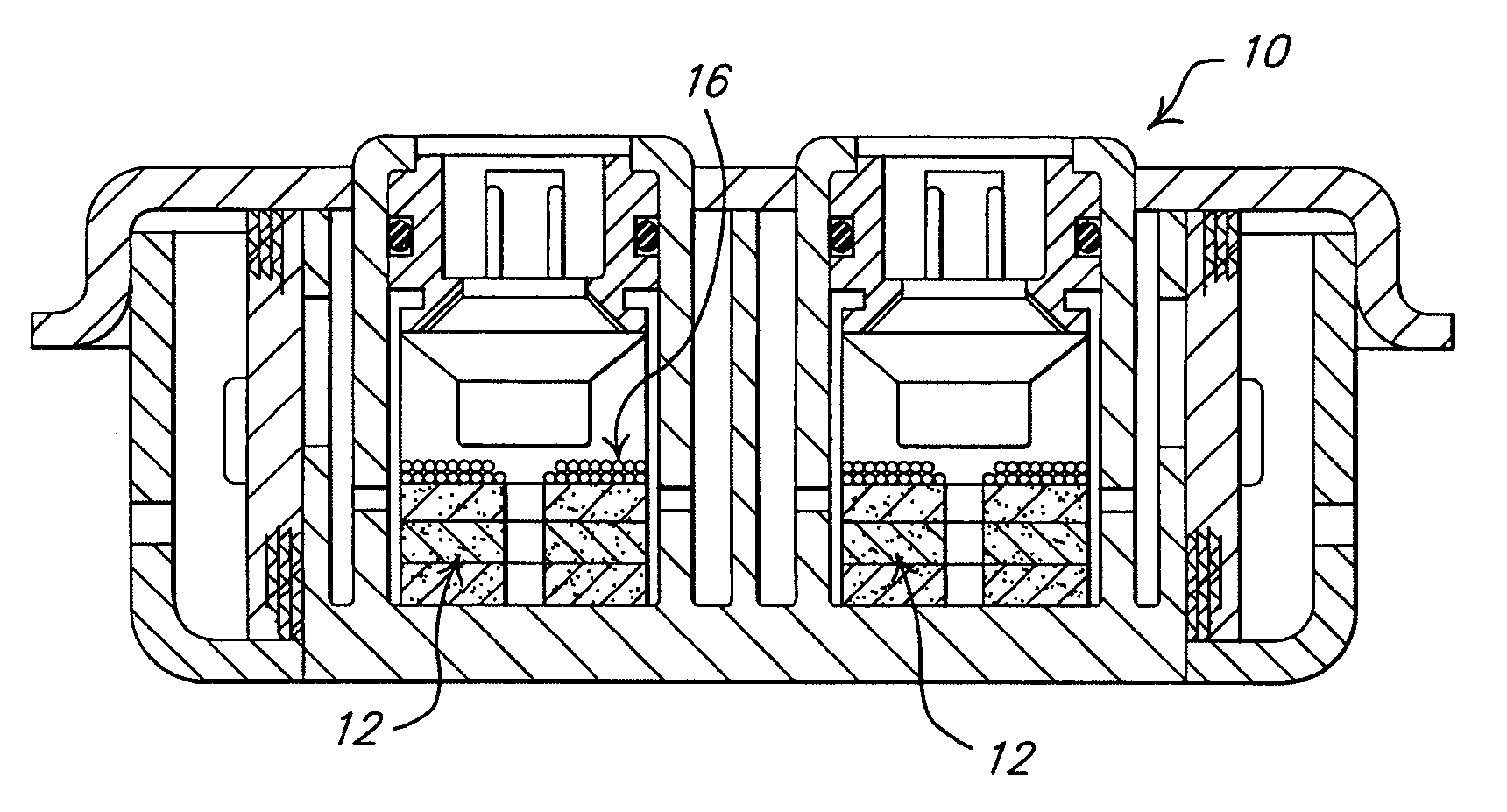

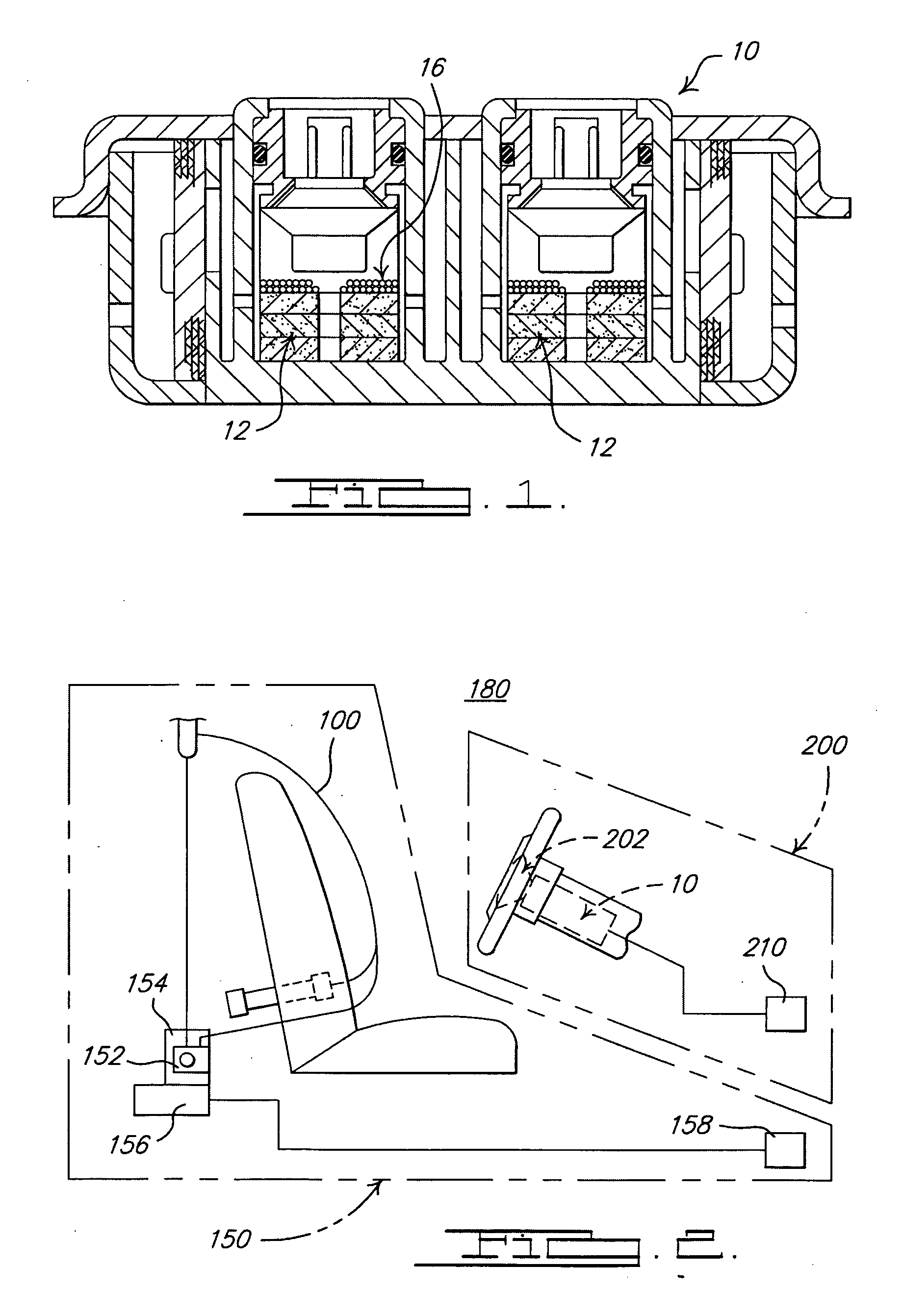

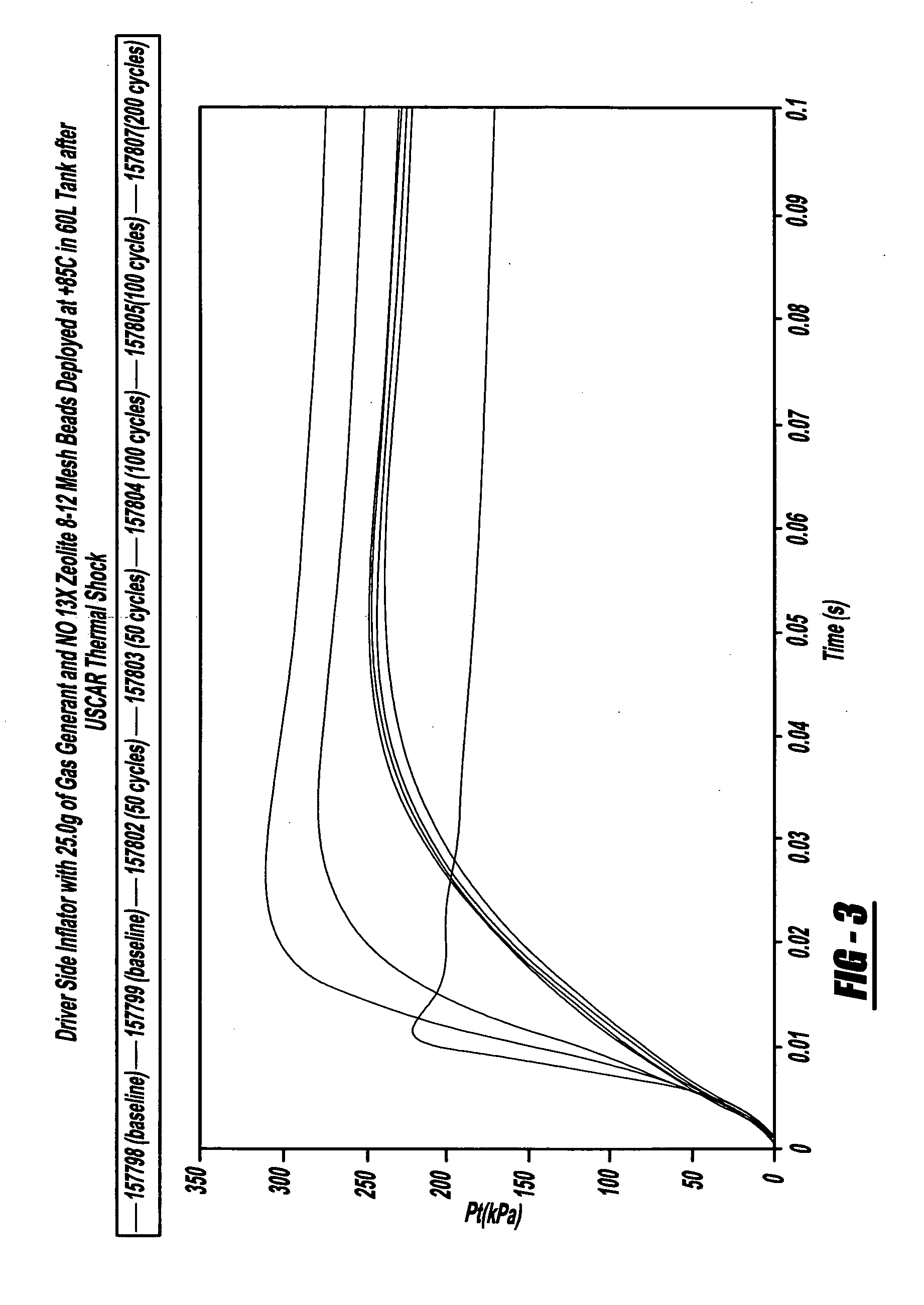

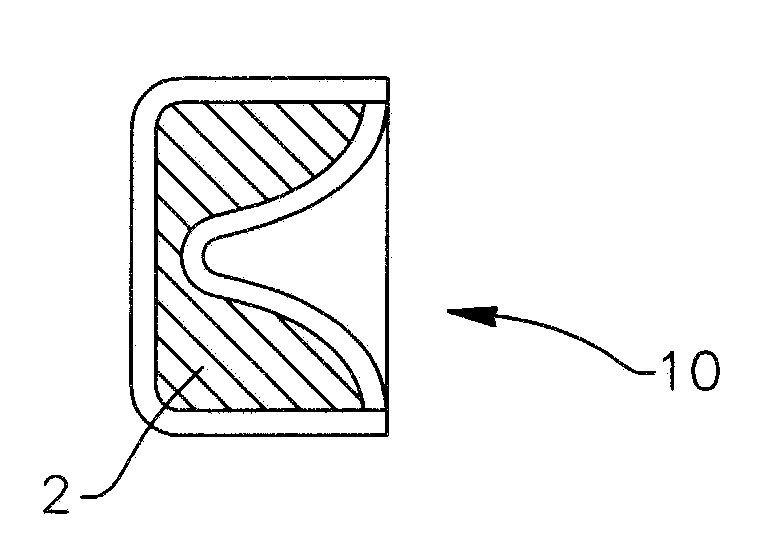

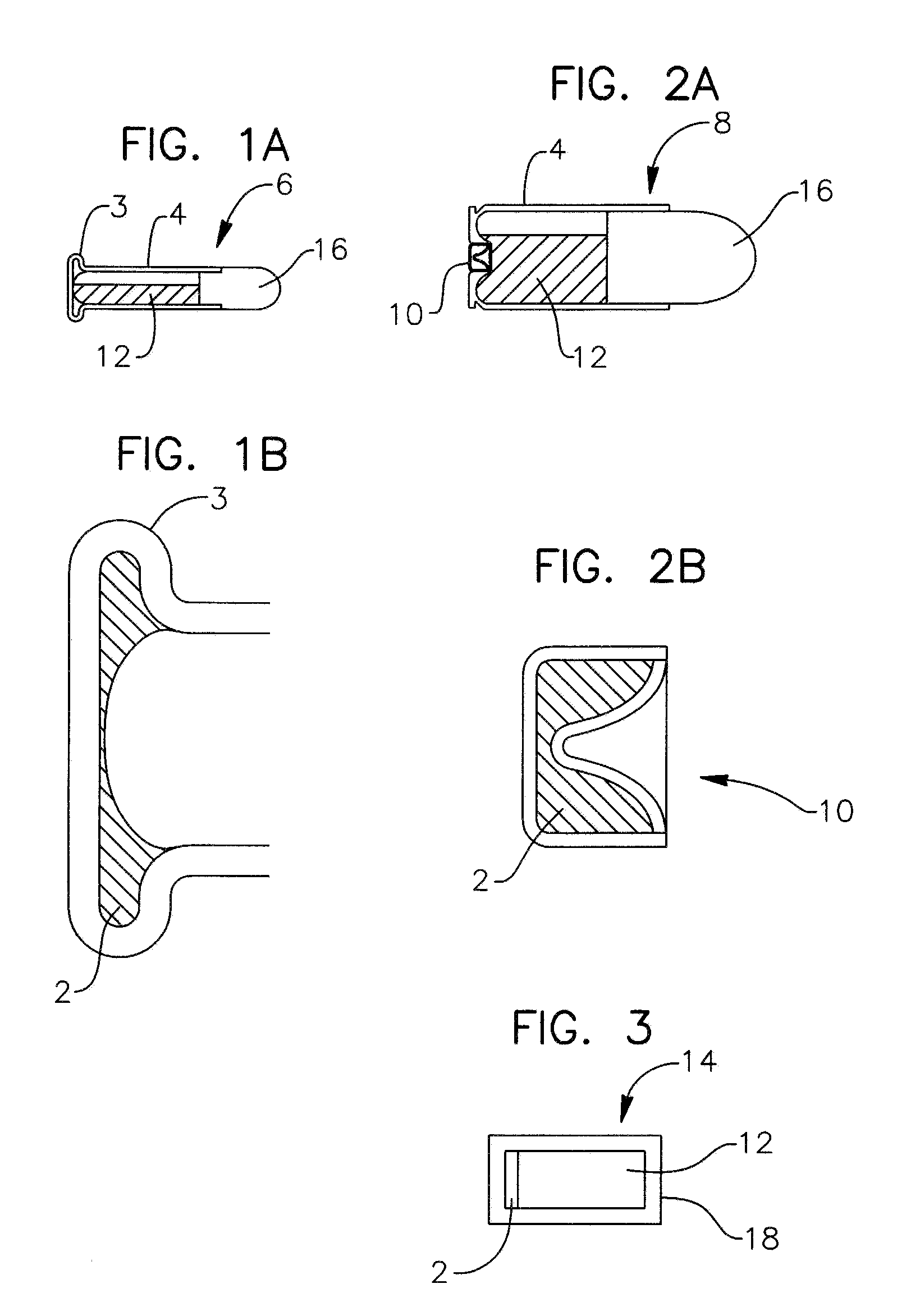

The present invention includes a gas generator 10 that incorporates a gas generating composition 12 and a scavenging additive 16 in heterogeneous but vapor / gaseous communication with the gas generating composition 12. The scavenging additive retains moisture / contaminants typically evolving over time at relatively higher temperatures. The present invention further includes a gas generating system 180 incorporating the gas generator 10.

Owner:AUTOMOTIVE SYST LAB

Non-toxic percussion primers and methods of preparing the same

Owner:FEDERAL CARTRIDGE

Family of modifiable high performance electrically controlled propellants and explosives

ActiveUS8888935B2Improve simplicityLow costNon-explosive stabilisersNon-explosive fillers/gelling/thickening agentsElectricityAmbient pressure

A composition capable of producing either solid propellant grains, liquid or gel monopropellants, all of which are electrically ignitable and capable of sustained controllable combustion at ambient pressure. Additional compositions capable of sustained controllable combustion at elevated pressures are described. Applications for the compositions disclosed herein are provided, and include among other applications use in small micro thrusters, large core-burning solid propellant gains, shaped explosives charges for military application, and pumpable liquids and gel monopropellants or explosives for military, commercial mining or gas and oil recovery. In alternative embodiments the above compositions may also incorporate an energetic nitrate polymer, bum rate modifiers, and / or metal fuel(s). The HIPEP formulation makes it possible to ignite and sustain combustion at ambient and vacuum conditions (a) without continuous electrical power and (b) while providing faster bum rates.

Owner:DIGITAL SOLID STATE PROPULSION

Gas generating composition for air bag

InactiveUS6468369B1Increase productionReduce sensitivityNon-explosive stabilisersPedestrian/occupant safety arrangementGuanidine derivativesCombustion

There is provided a gas generating composition for an air bag which improves combustion behavior and enhances handling safety, generates a large amount of generating gas on combustion, reduces amount generated of mist, and can downsize and reduce weight of a gas generator itself. The gas generating composition for an air bag comprises (a) a guanidine derivative compound, (b) a phase stabilized ammonium nitrate and (c) a silicon compound acting as a pressure exponent controller or a detonation suppressing agent.

Owner:DAICEL CHEM IND LTD

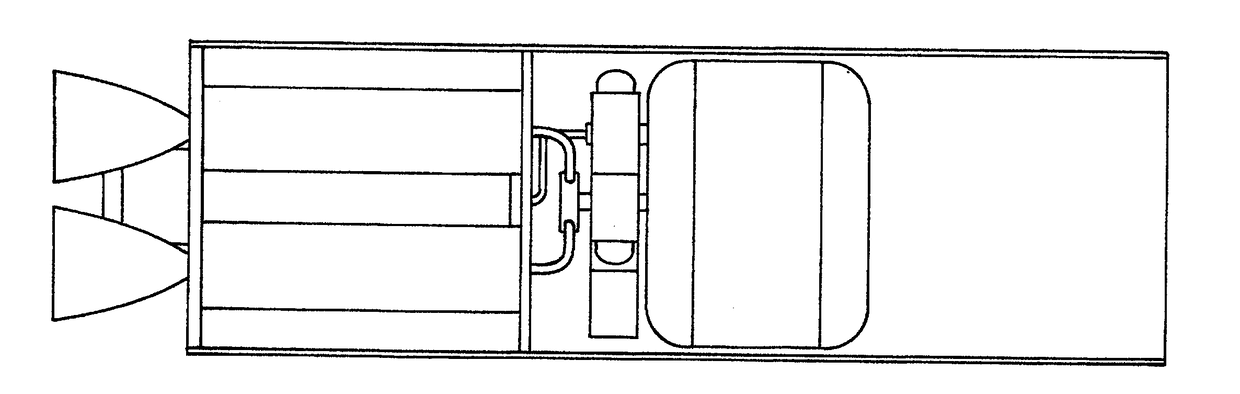

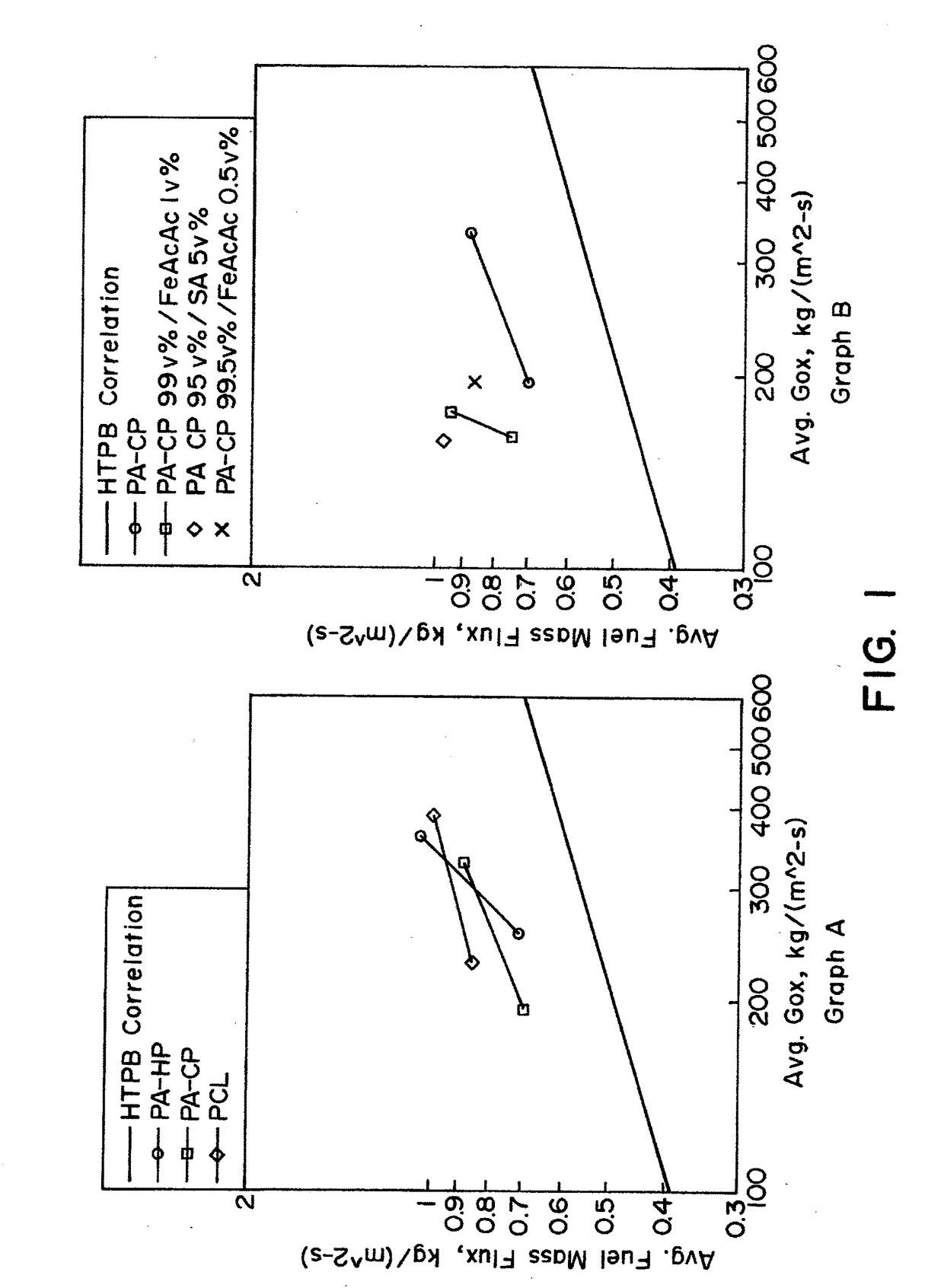

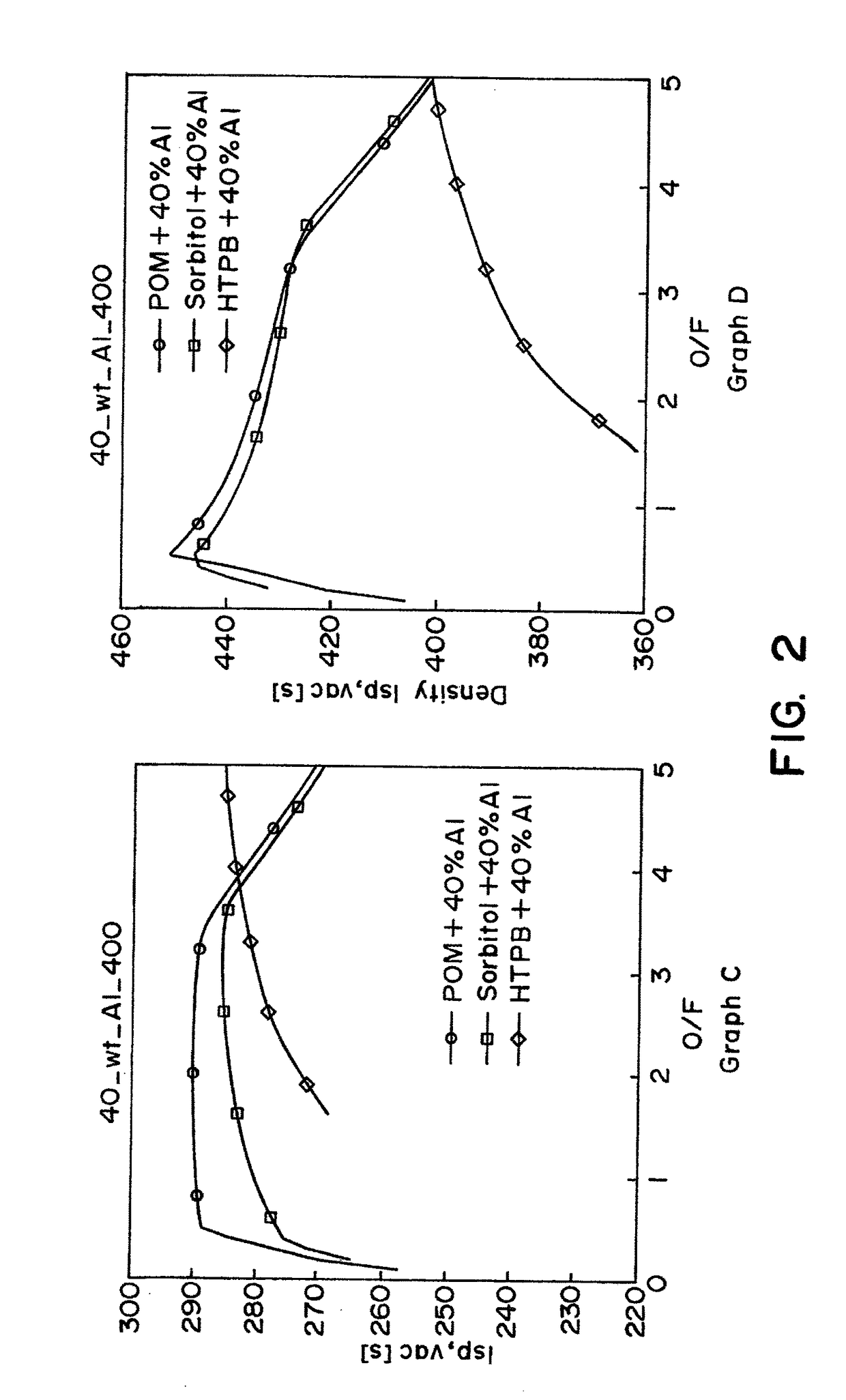

High Density Hybrid Rocket Motor

ActiveUS20180118634A1Increasing performance of volumeHigh regression rateNon-explosive stabilisersNon-explosive fillers/gelling/thickening agentsHigh densityVolumetric Mass Density

A high density, generally recognized as safe hybrid rocket motor is described which has a density-specific impulse similar to a solid rocket motor, with good performance approaching or equal to a liquid rocket motor. These high density hybrid motors resolve the packaging efficiency / effectiveness problems limiting the application of safe, low cost hybrid motor technology.

Owner:TERVES

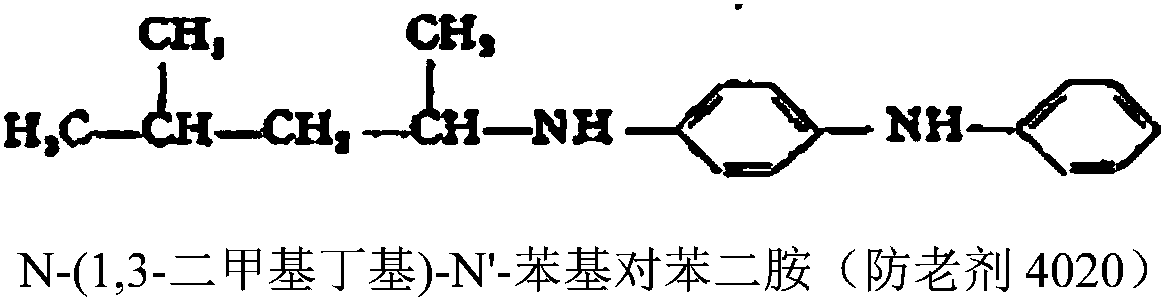

Azido composite solid propellant containing combined stabilizer

ActiveCN107721784AImproved change rate of mechanical propertiesSlow down the change rate of mechanical properties during storageNon-explosive stabilisersTO-18Adhesive

The invention relates to an azido composite solid propellant containing a combined stabilizer. The azido composite solid propellant is prepared from the following components in parts by weight: 7% to12.5% of adhesive, 11% to 18% of plasticizer, 10% to 73% of oxidant, 0% to 60% of energy-containing explosive, 5% to 19% of metal fuel, 0.5% to 1.0% of curing agent, 0.05% of curing catalyst, 0.3% to0.6% of stabilizer, 0.2% of bonding agent, and 0.05% to 0.1% of crosslinking agent. The azido composite solid propellant containing the combined stabilizer has the advantages that the storage propertyis good, and the change rate of mechanical property in the storage process is smaller than 20%.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

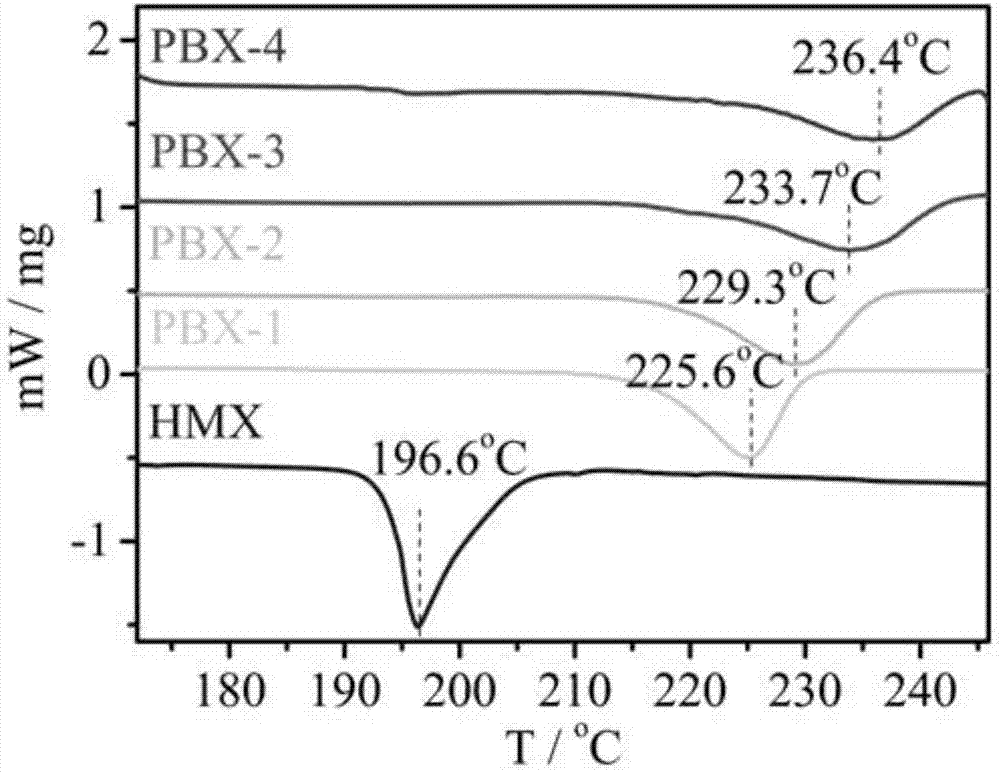

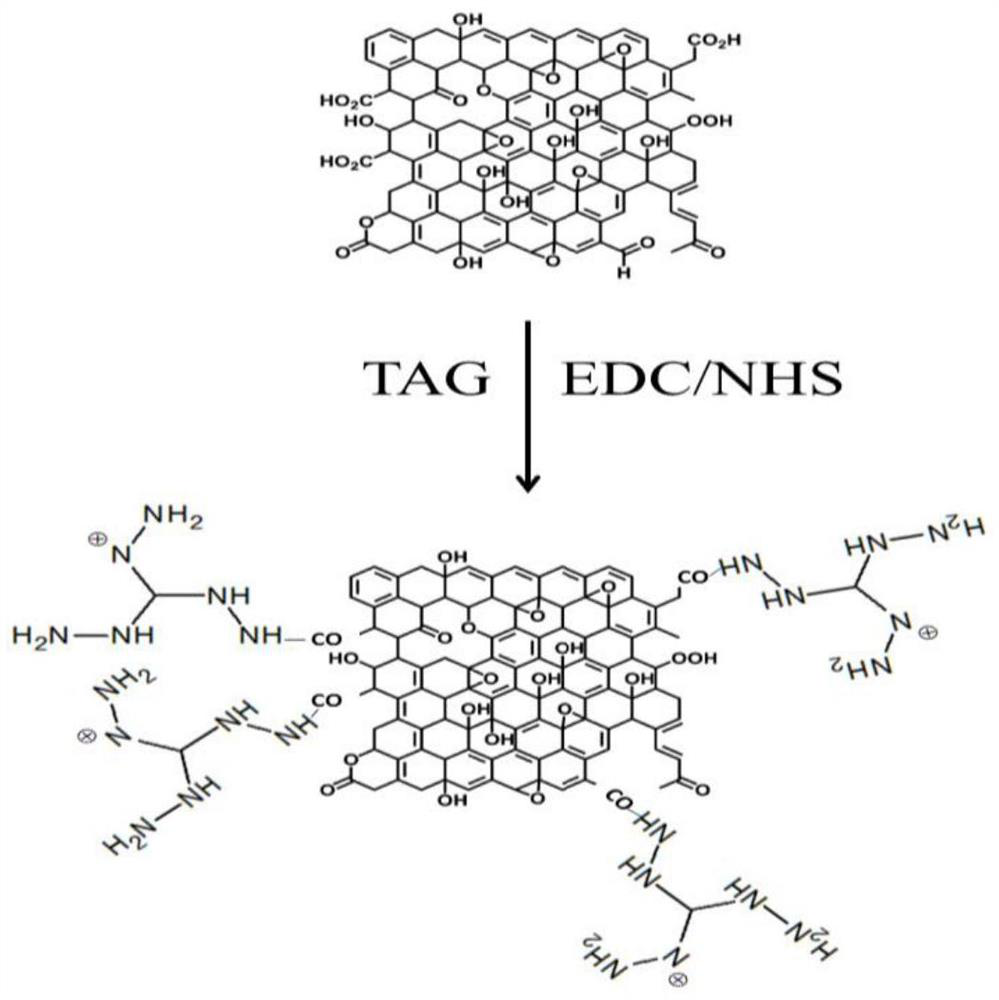

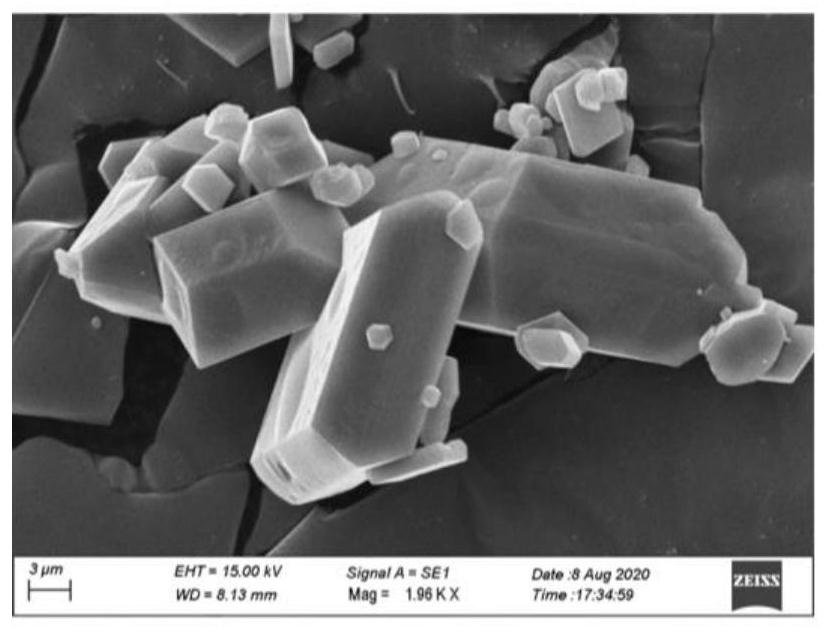

High-density heatproof octogen-based compound and preparation method thereof

InactiveCN106905090AHigh densityNon-explosive stabilisersNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsHigh energyTransition temperature

The invention discloses a high-density heatproof octogen-based compound and a preparation method thereof. According to the invention, polydopamine produced after oxidation and self-polymerization of dopamine forms a strongly-adhesive interfacial action layer on the surface of octogen in advance, and then a high-density heatproof fluorine-containing polymer binder is used for coating, so crystal transfer of octogen under high temperature is inhibited and the density of an explosive compound is improved. The high-density heatproof octogen-based compound comprises, by weight, 88.0 to 96.5 wt% of octogen, 1.0 to 6.0 wt% of polydopamine and 2.0 to 6.0 wt% of the fluorine-containing polymer binder. The octogen-based compound has the characteristics of a high beta-to-delta crystal transfer temperature, higher than about 40 DEG C compared with a raw octogen material, and high density, and is expected to be applied to high-energy heatproof explosives.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Blasting agent

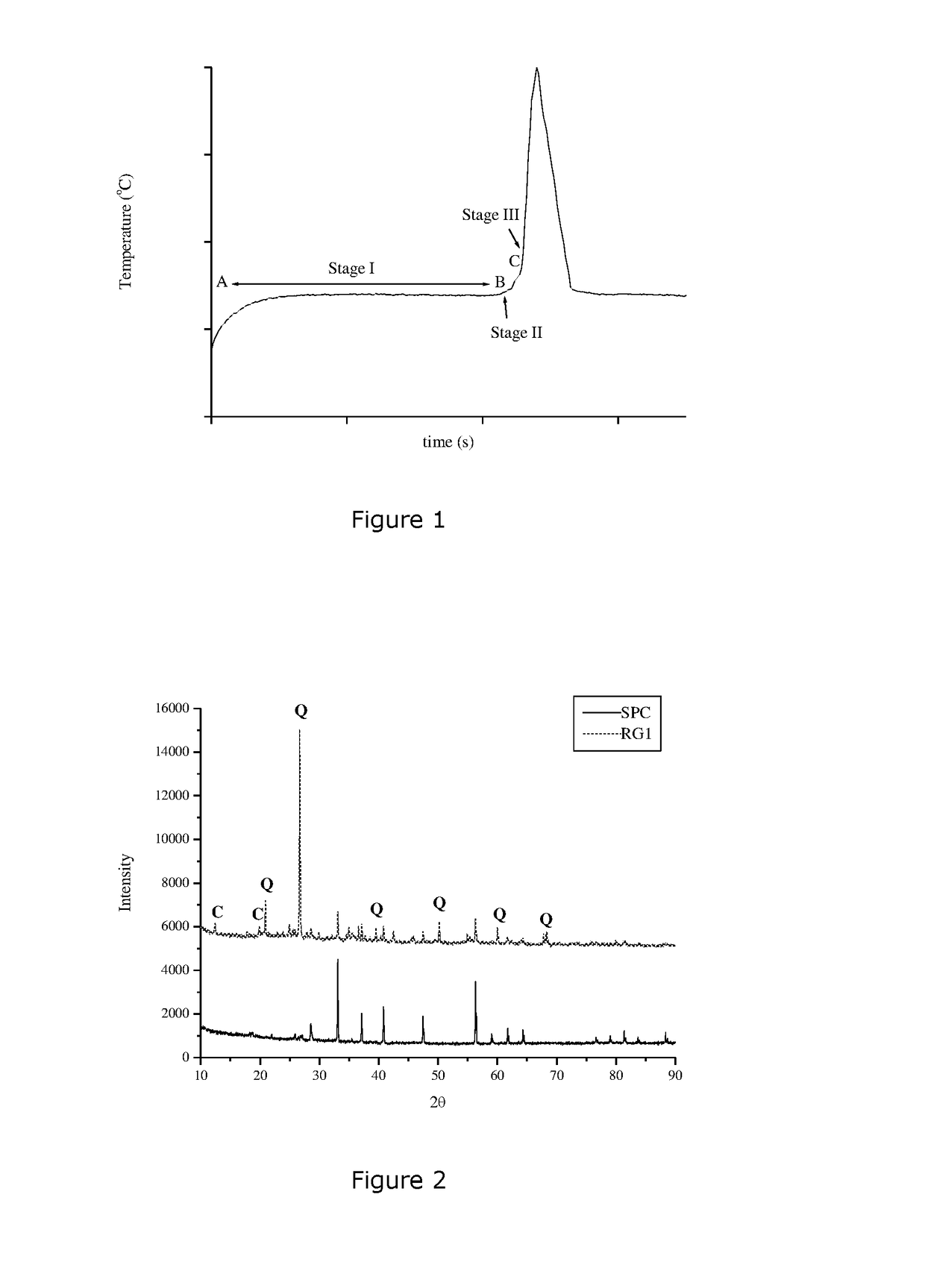

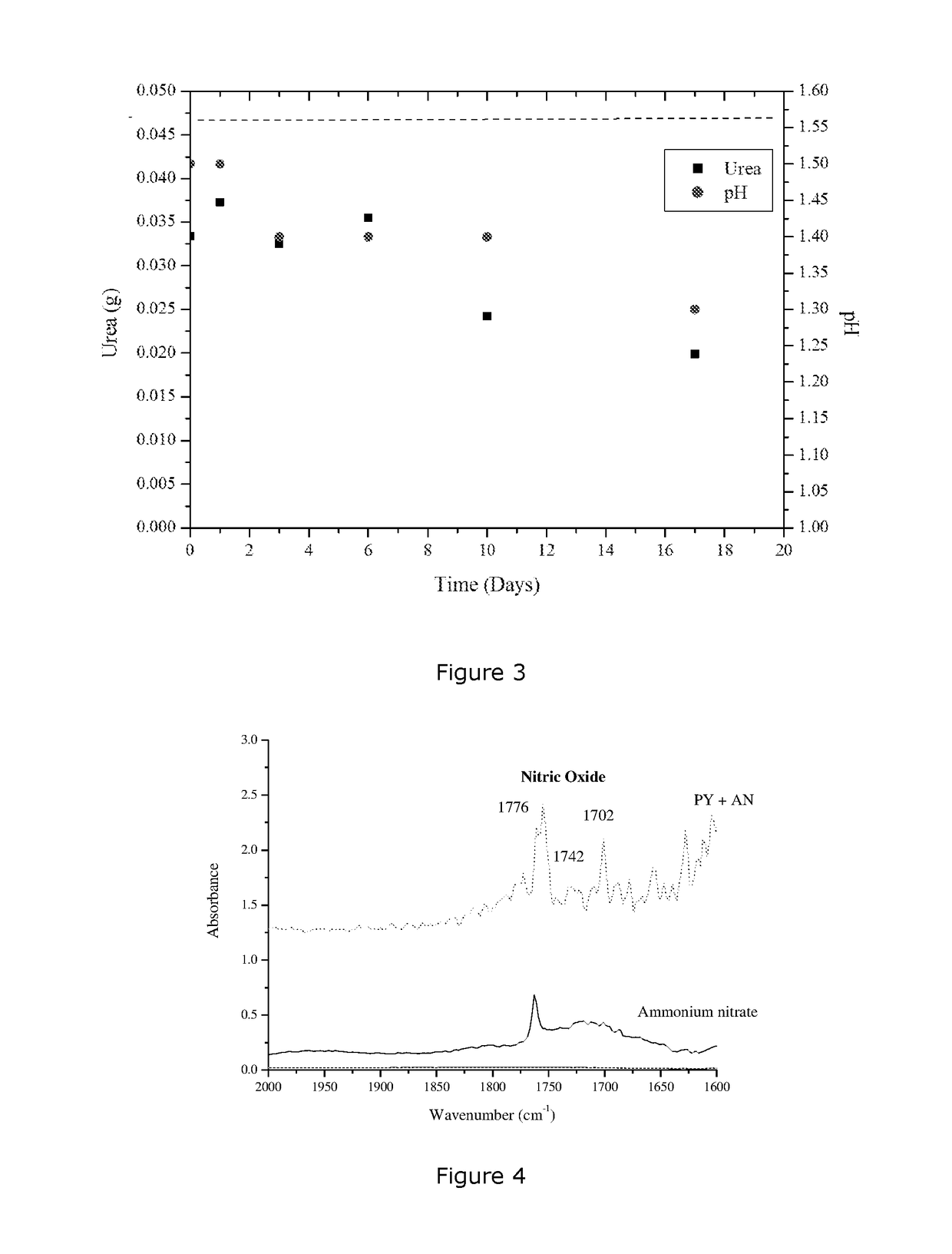

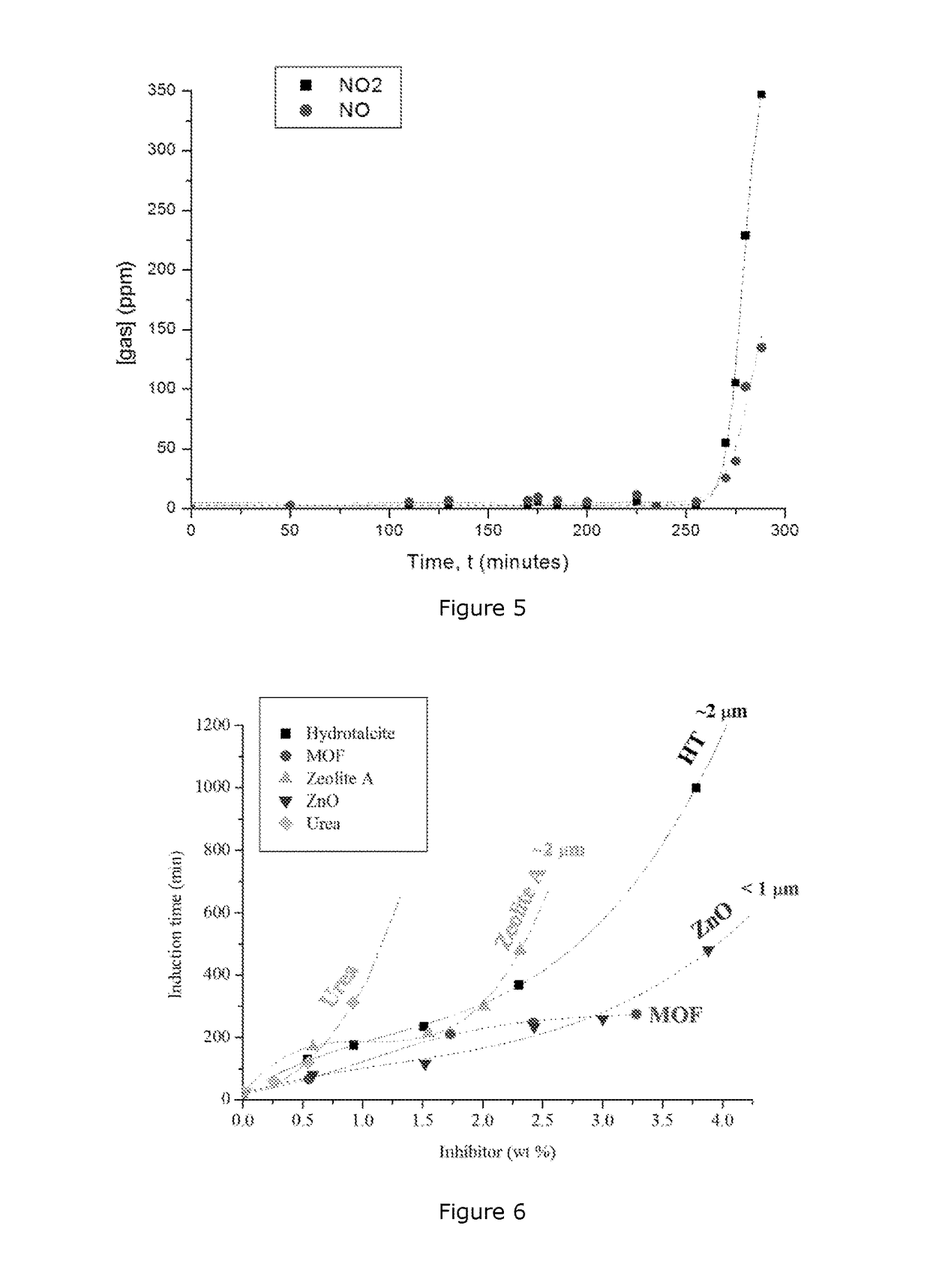

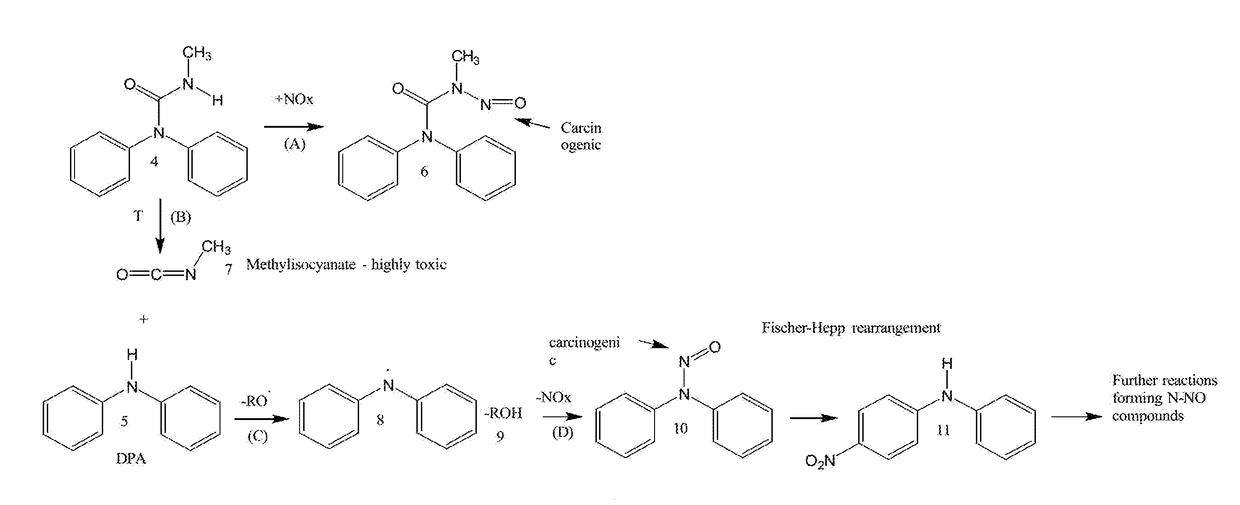

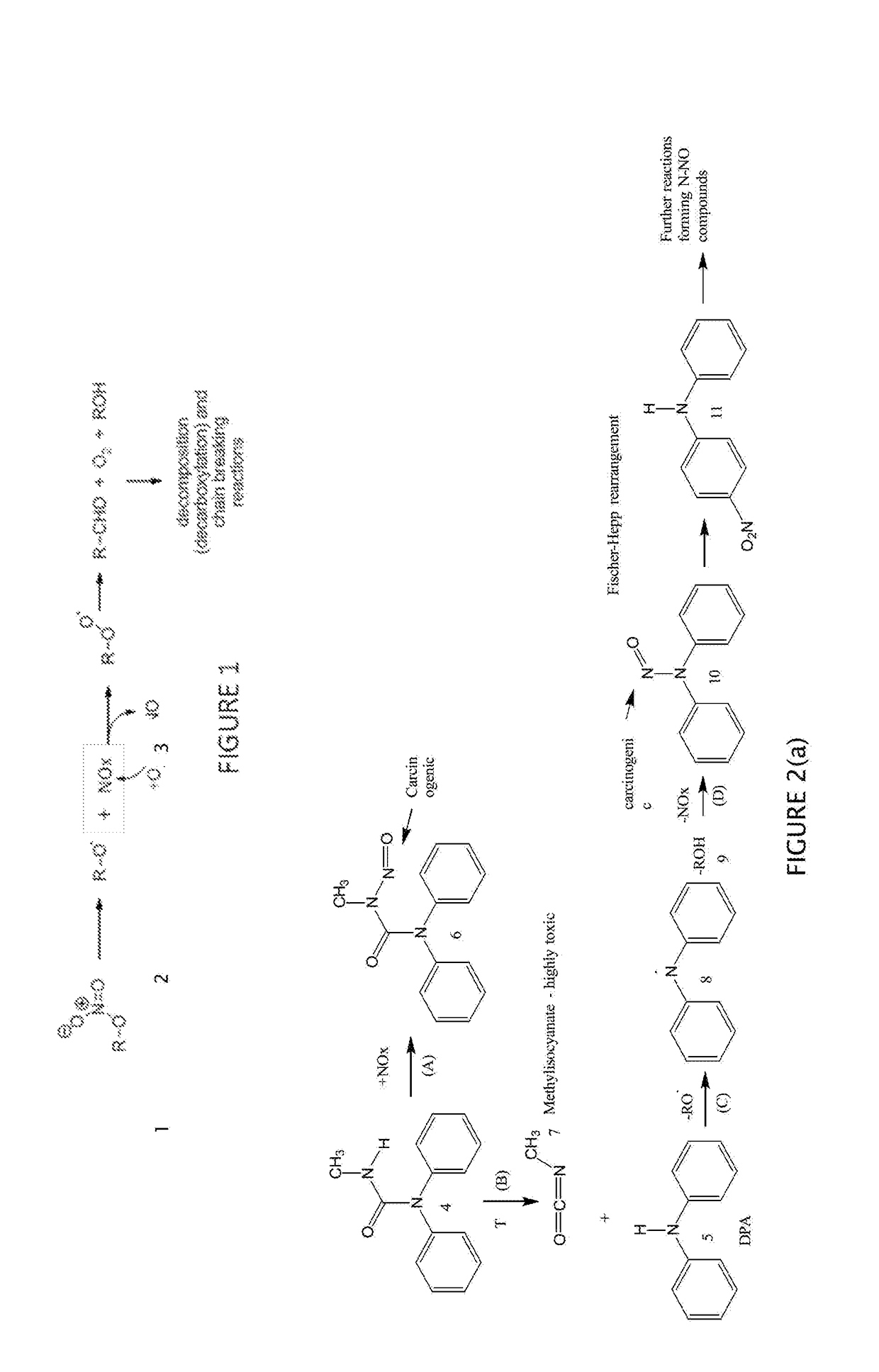

ActiveUS20180244590A1Increase initiativeIncrease in exothermic reactionNon-explosive stabilisersBlastingScavengerAmmonium nitrate

The present invention provides a method of stabilizing a nitrate-based explosive through the use of a NOx scavenger. The present invention further provides a blasting agent including ammonium nitrate and a NOx scavenger. The present invention further provides for a method of blasting adapted for use in reactive and / or elevated temperature ground.

Owner:THE UNIV OF SYDNEY

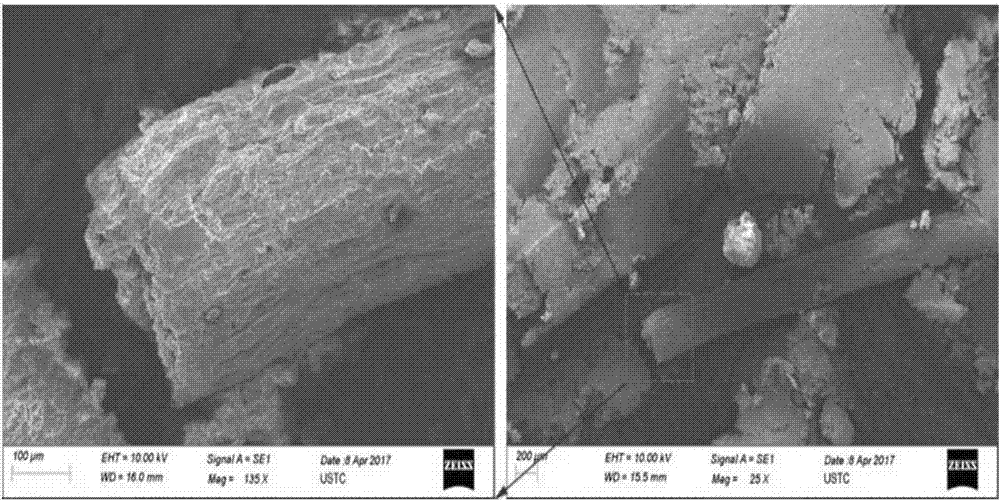

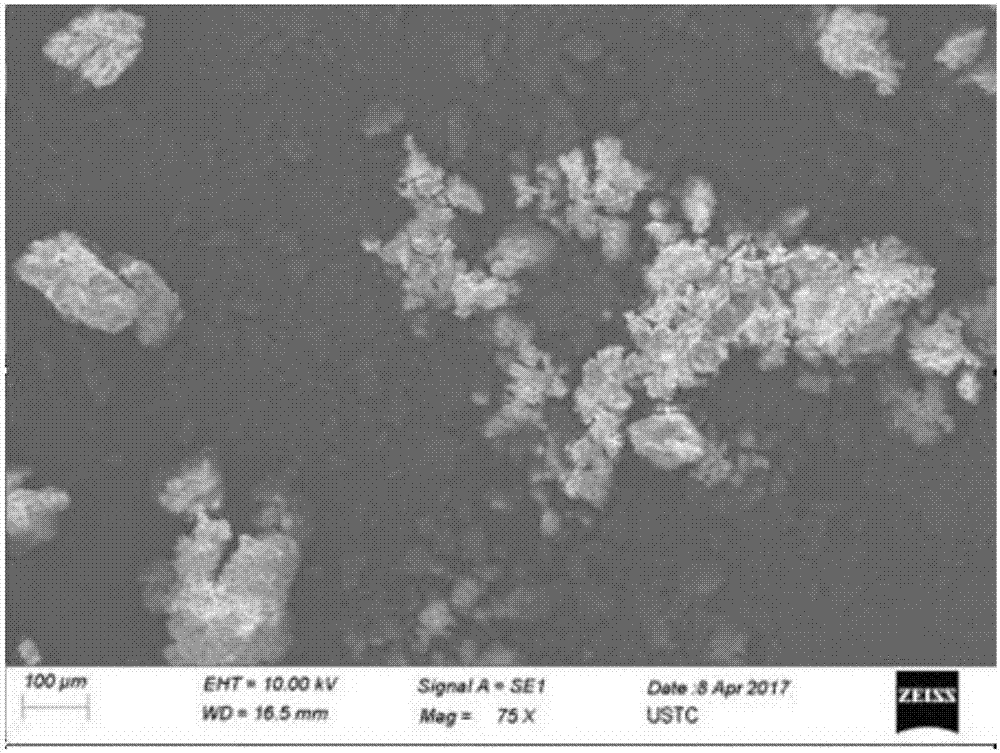

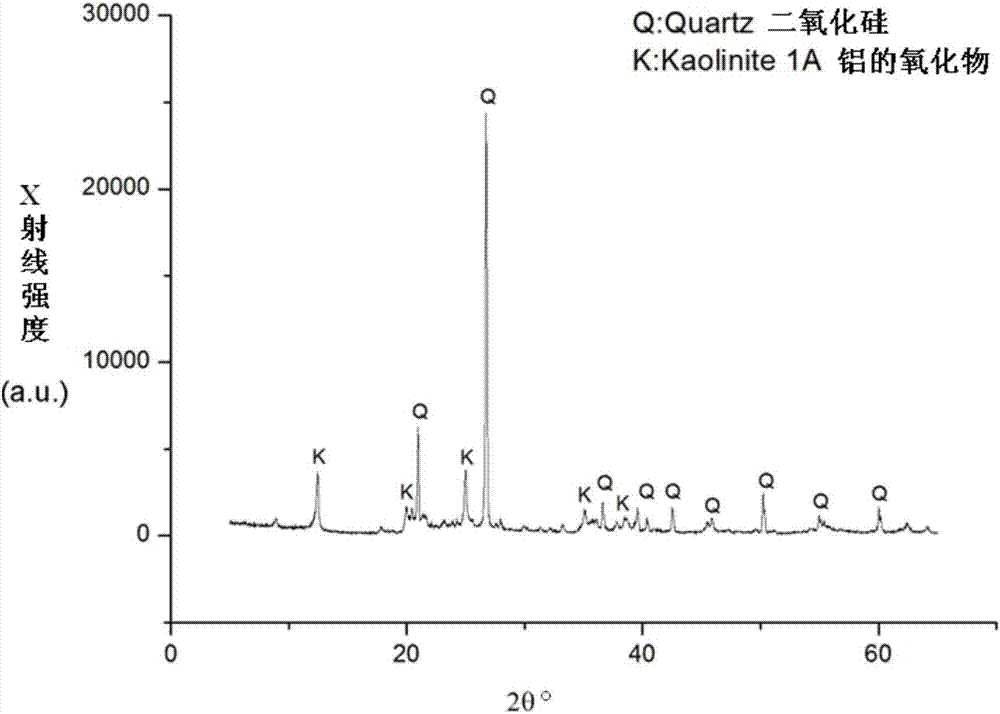

Low-detonation-velocity emulsified explosive and application thereof

ActiveCN107200670AAdjustable detonation speedLow detonation velocityNon-explosive stabilisersNon-electric welding apparatusExplosive AgentsMetallic materials

The invention belongs to the technical field of industrial explosive and provides low-detonation-velocity emulsified explosive. The low-detonation-velocity emulsified explosive is prepared from basic emulsified explosive and clay, wherein the mass percent of the basic emulsified explosive is greater than 70 percent and is less than or equal to 95 percent; the mass percent of the clay is greater than or equal to 5 percent and is less than 30 percent; the basic emulsified explosive is obtained by sensitizing an emulsified matrix through a sensitizing agent; the clay is mainly prepared from main components including silicon dioxide and oxides of aluminum. Moreover, the invention further provides application of the low-detonation-velocity emulsified explosive to metal explosive welding. The low-detonation-velocity emulsified explosive provided by the invention has the advantages of low price and can be used for carrying out explosive welding on different metal materials, so that the detonation velocity and explosive grading of the emulsified explosive are easily adjusted by enterprises according to own requirements; the price of the compound special explosive for detonation is reduced and pollution to the environment is reduced to the greatest extent.

Owner:UNIV OF SCI & TECH OF CHINA

High-low-temperature-resistant emulsion explosive and preparation method thereof

PendingCN111333473APowerful explosionImprove stabilityNon-explosive stabilisersExplosive AgentsActive agent

The invention relates to a high and low temperature resistant emulsion explosive and a preparation method thereof, and belongs to the technical field of emulsion explosives. The technical problem to be solved by the invention is to provide the high and low temperature resistant emulsion explosive. The explosive is prepared from the following components in parts by weight: 93-94 parts of a water-phase material, 6-7 parts of an oil-phase material, 0.8-1.2 parts of expanded graphite and 0.3-0.6 part of a foaming agent, wherein the water-phase material consists of the following components in partsby weight: 76-85 parts of ammonium nitrate, 2-5 parts of sodium nitrate, 1-4 parts of sodium perchlorate, 1-4 parts of ammonium chloride, 0.8-1.2 parts of ethylene glycol, 0.8-1.2 parts of a surfactant and 9-12 parts of water; and a specific stabilizer is added into the oil phase material. Explosive, the explosive is high in explosive power, good in stability, good in safety and resistant to highand low temperature, can be repeatedly used for 30 times at the temperature of-20 DEG C to 45 DEG C, can reach the explosive speed of 3200 m / s or above within the validity period and reach the standard of No. 2 rock emulsion explosives, and is particularly suitable for high-temperature production and storage in summer and explosion in low-temperature and repeated high and low-temperature storageand use environments in winter.

Owner:PANZHIHUA UNIV

Non-toxic percussion primers and methods of preparing the same

Owner:FEDERAL CARTRIDGE

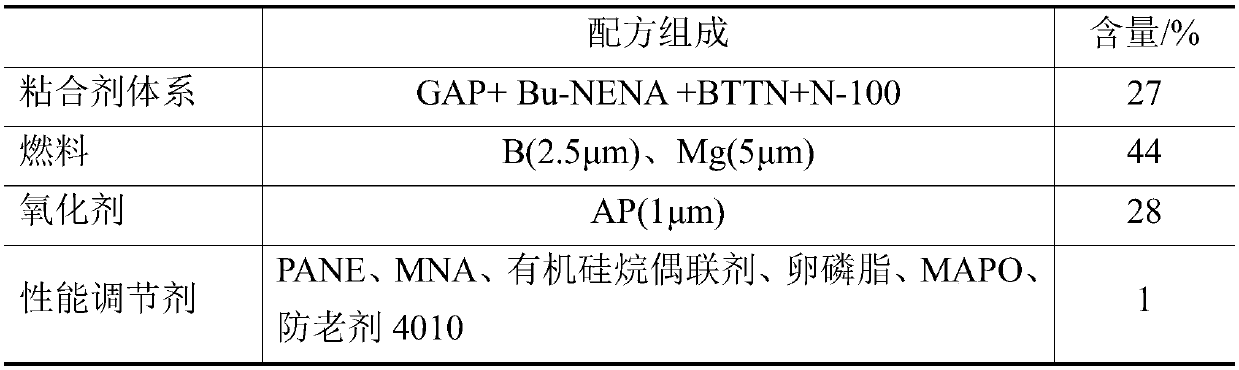

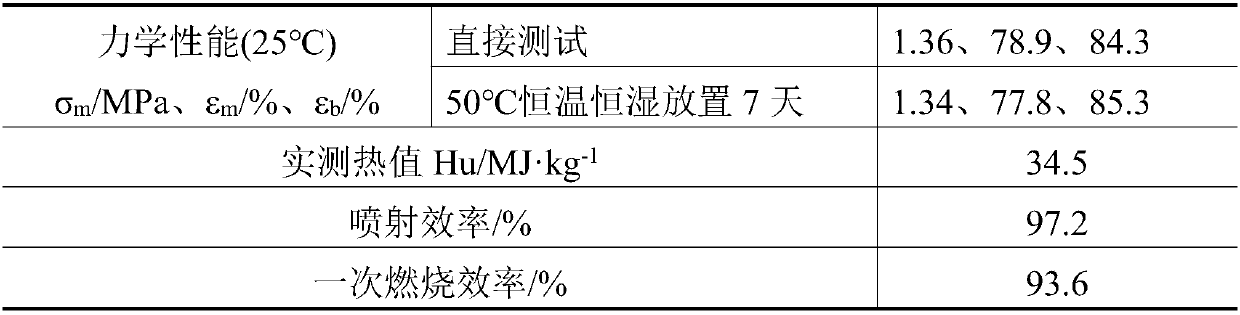

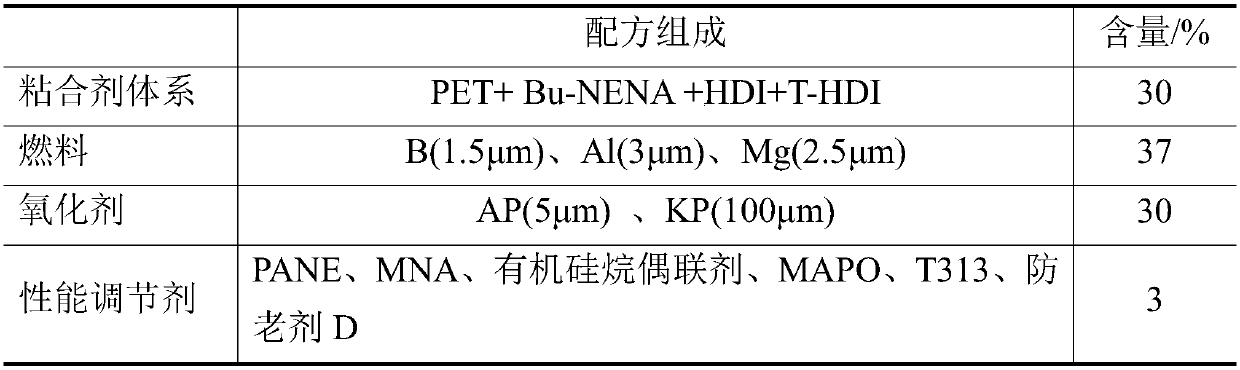

Boron-containing fuel-rich propellant

ActiveCN109574773AImprove injection efficiencyImprove performanceNon-explosive stabilisersNon-explosive fillers/gelling/thickening agentsWeather resistanceCombustion

The invention discloses a boron-containing fuel-rich propellant. The boron-containing fuel-rich propellant comprises the following components by weight percent: 20 to 30 percent of binder system, 22 to 35 percent of oxidant, 35 to 44 percent of fuel, and 0.5 to 4 percent of performance regulator. By virtue of a technical means for adding energizing additive and novel additive into the propellant system, the injection efficiency and primary combustion efficiency of the boron-containing fuel-rich propellant can be significantly improved, the weather resistance of the propellant on the premise ofnot influencing the comprehensive performance of the propellant can be improved, and the comprehensive performance of the boron-rich fuel-rich propellant can be improved.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

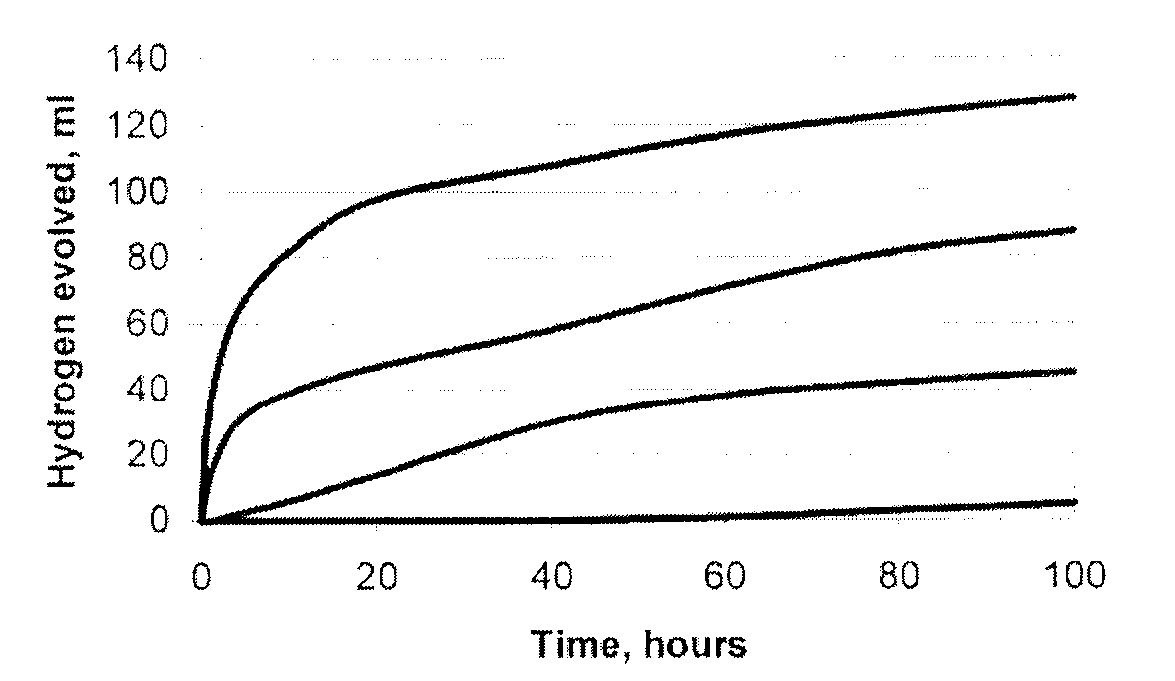

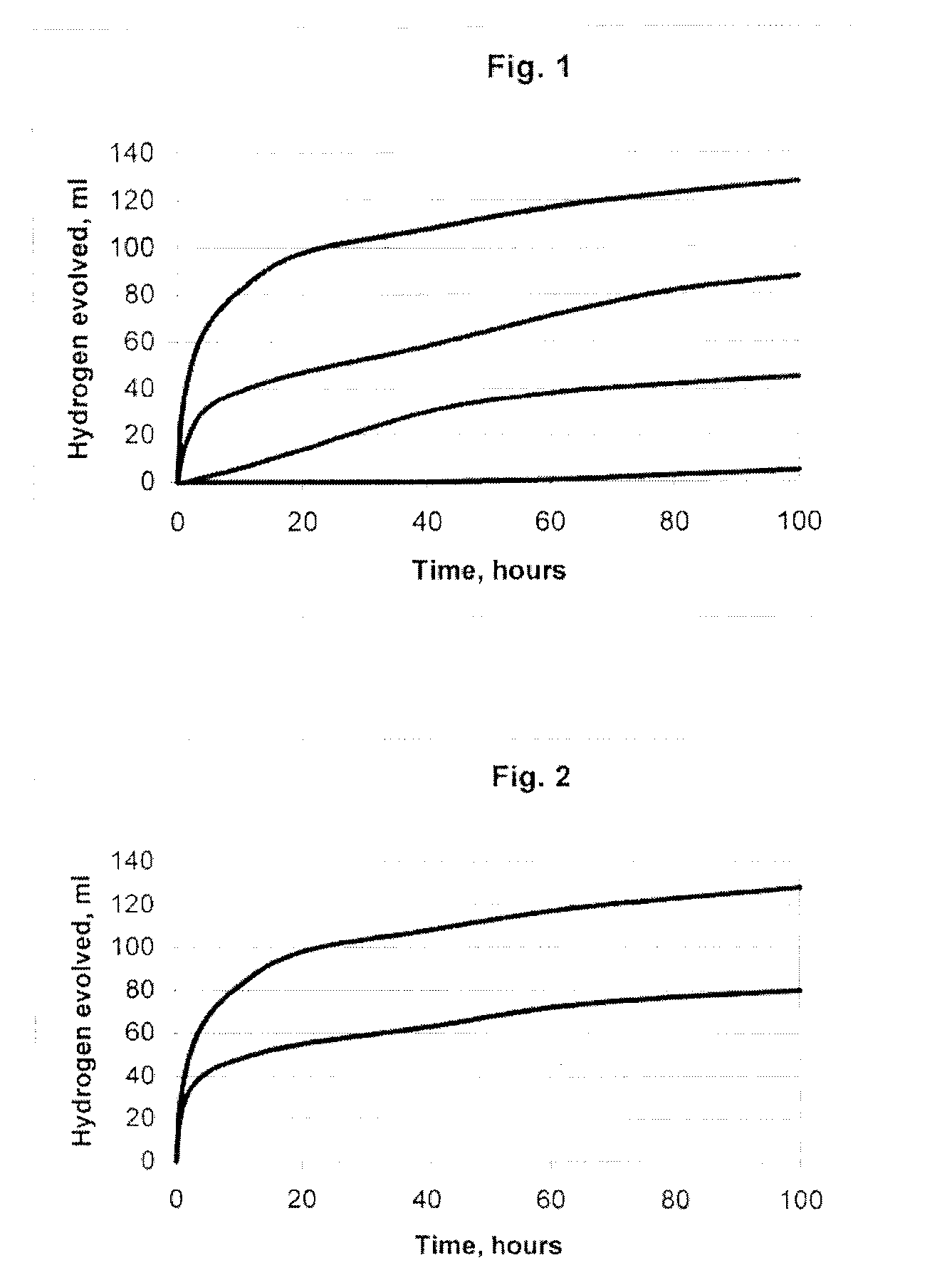

Surface-modified magnesium powders for use in pyrotechnic compositions

InactiveUS20090025841A1Trend downProcess stabilityNon-explosive stabilisersMagnesium halidesMetallurgyPyrotechnic composition

Surface-modified metal fuels, which improve the stability in storage of pyrotechnics and methods for manufacturing such fuels, are provided. Improved storage stability is conferred either by alloying the precursor metal prior to the powder production process, or by forming an enhanced stability coating on the surface of the metal powders during the powder production process.

Owner:SMITH PAUL

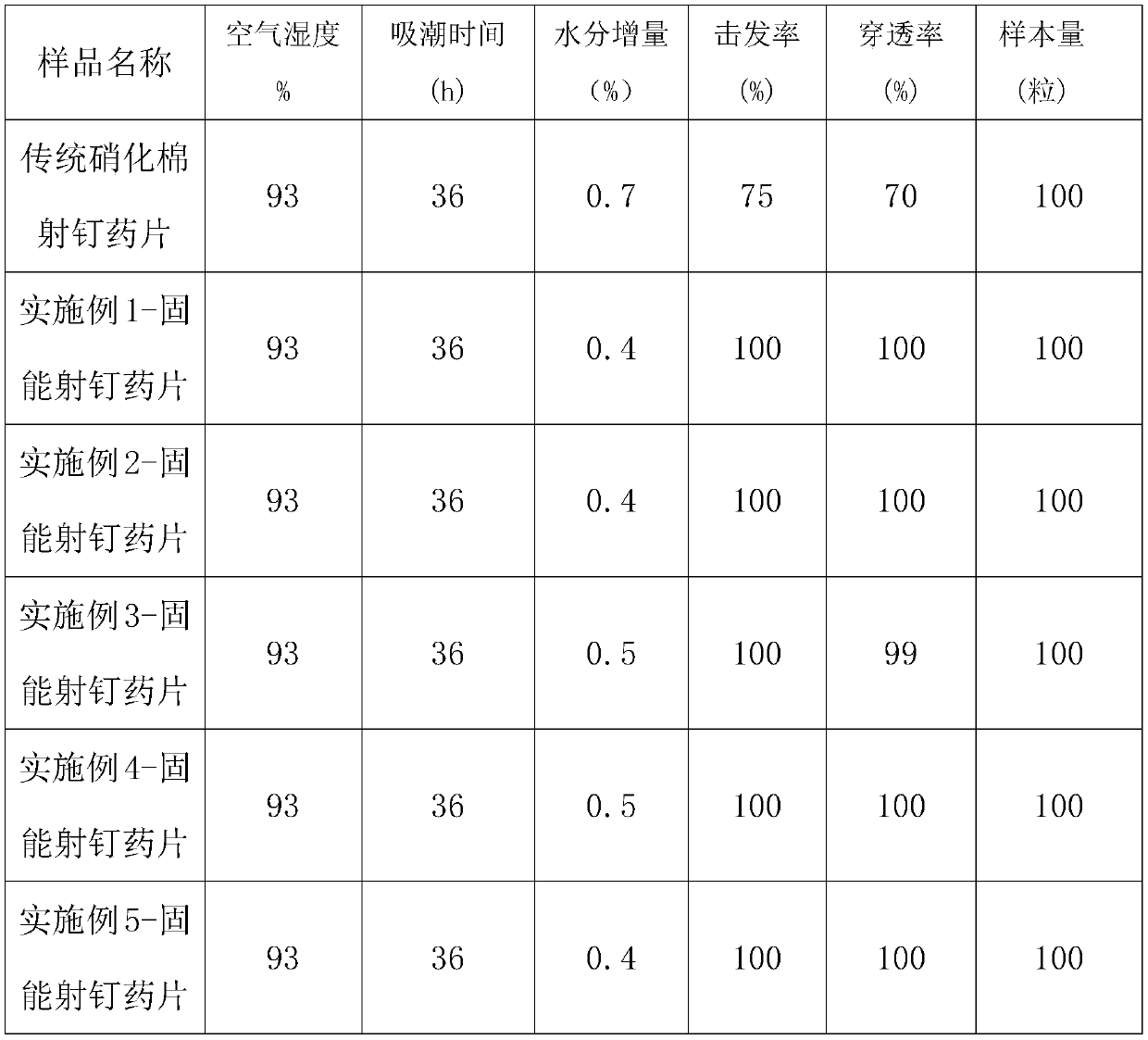

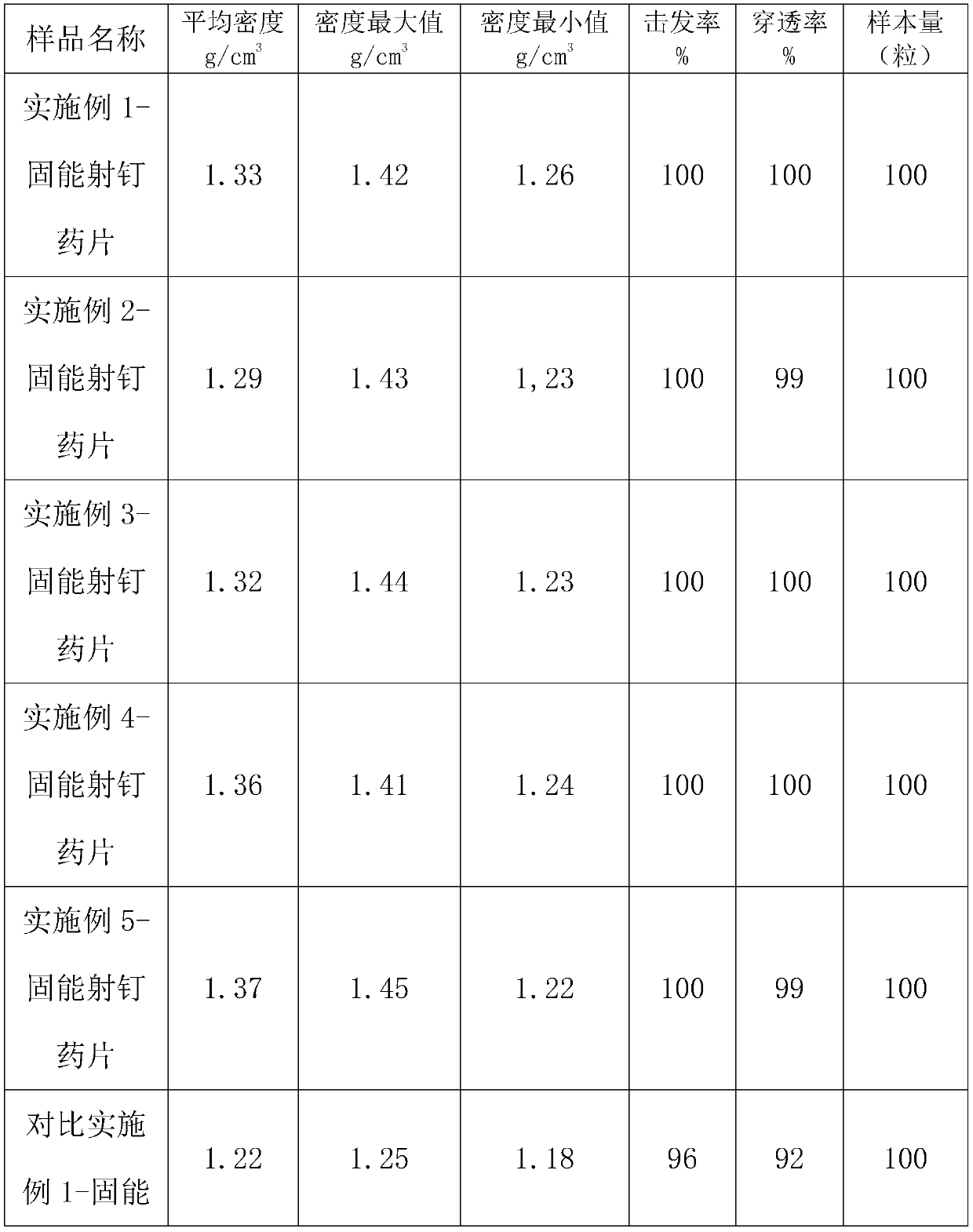

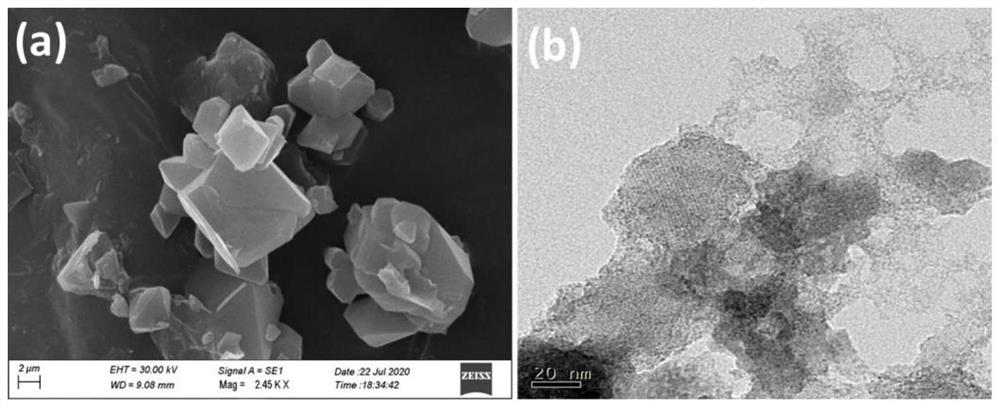

Energy fixation fastener gunpowder flake and preparation process thereof

InactiveCN110117211AGuaranteed weightGuaranteed Dimensional ConsistencyNon-explosive stabilisersExplosive working-up apparatusAcetic acidCombustion

The invention discloses an energy fixation fastener gunpowder flake. The energy fixation fastener gunpowder flake comprises, by weight, 61%-66% of nitrocotton with the nitration degree larger than 201.6 ml / g (N>=12.6%), 0.3%-1.0% of a binder, 0.3%-0.8% of an oxidant, 0.3%-0.8% of a combustion catalyst, 0.7%-1.0% of a stabilizer and the balance ethyl acetate. By selecting the suitable oxidant and catalyst, the effective acting energy and mechanical sensitivity of the energy fixation fastener gunpowder flake are greatly improved, so that the percussion rate reaches 99.9% and the puncture rate reaches 99% or above; meanwhile, by adopting a material prepressing re-granulation and multistage drying process, the particle size of the gunpowder material is selected within the range of 10 mesh-50 mesh, the material preforming moisture is controlled within the range of 6.0%-10.0%, the moisture of the finished energy fixation fastener gunpowder flake is smaller than or equal to 0.7%, the processproduction safety is well guranateed, and the yield of the energy fixation fastener gunpowder flake is increased.

Owner:宜宾鼎天新材料科技有限公司

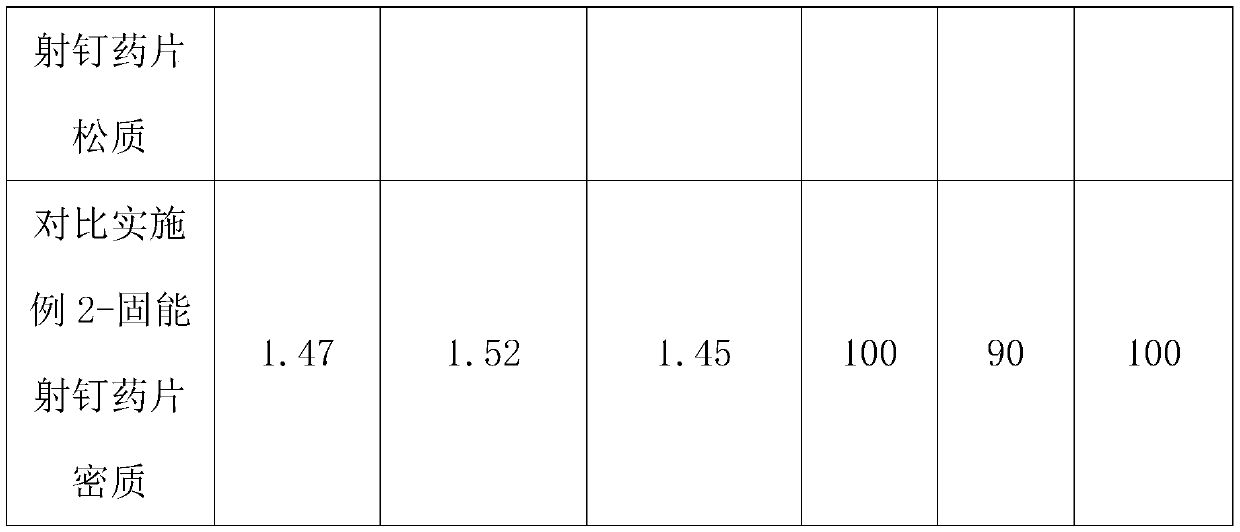

Graphene toughened two-dimensional high-nitrogen material doped nitramine oxidant and preparation method

InactiveCN112266312AHigh densityReduce riskNon-explosive stabilisersExplosive working-up apparatusCrystal transformationComposite material

The invention relates to a graphene toughened two-dimensional high-nitrogen material doped nitramine oxidant and a preparation method. The mass content of the graphene toughened two-dimensional high-nitrogen material is 0.5 wt%-1.5 wt%, and the mass content of the nitramine oxidant is 98.5 wt%-99.5 wt%; the graphene toughened two-dimensional high-nitrogen material is of a two-dimensional structurewhich is formed by graphene oxide, triaminoguanidine nitrate and a 40% glyoxal solution and has a confinement effect on a nitramine oxidant. By introducing the graphene oxide, the risk in the operation process is reduced; the ammonium nitrate energetic material with higher stability and density, namely the GO-TAGP doped ammonium nitrate energetic material, is prepared, the crystal density is improved, and the molecular structure is not changed; the increase of the crystal transformation temperature (or the disappearance of the crystal transformation process) indicates that the thermal stability is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Ammonium nitrate propellants and methods for preparing the same

InactiveUS6913661B2Extended shelf lifeSafe storageNon-explosive stabilisersLoomsMolecular sieveOxamide

The present invention is directed to an age-stabilized and / or strengthened ammonium nitrate propellant composition wherein the strengthening agent is selected from the group consisting of azodicarbonamide, dicyandiamide, oxamide and mixtures thereof and wherein the age-stabilizing agent is a molecular sieve having a pore size of 13 angstroms or less.

Owner:THE BF GOODRICH CO

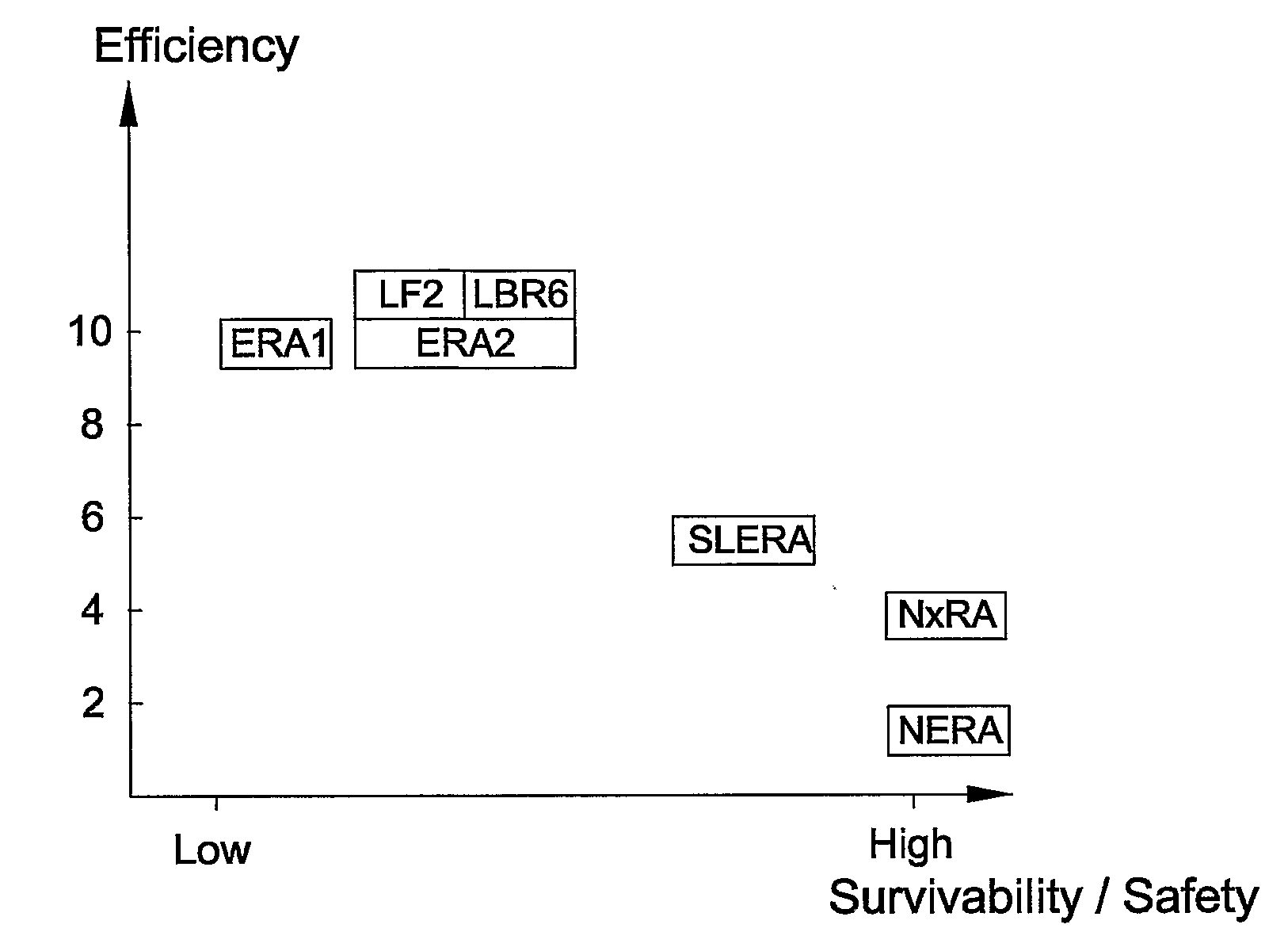

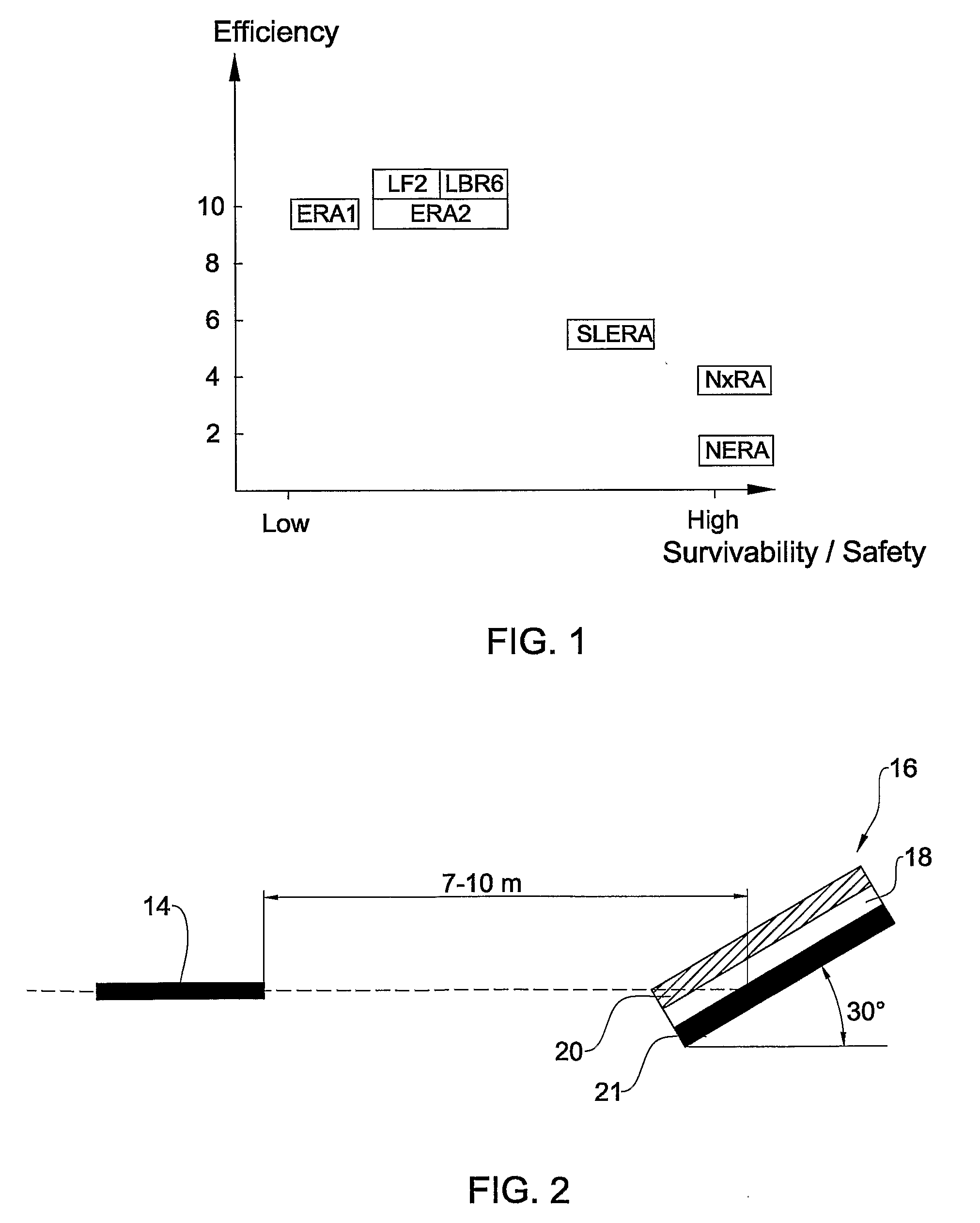

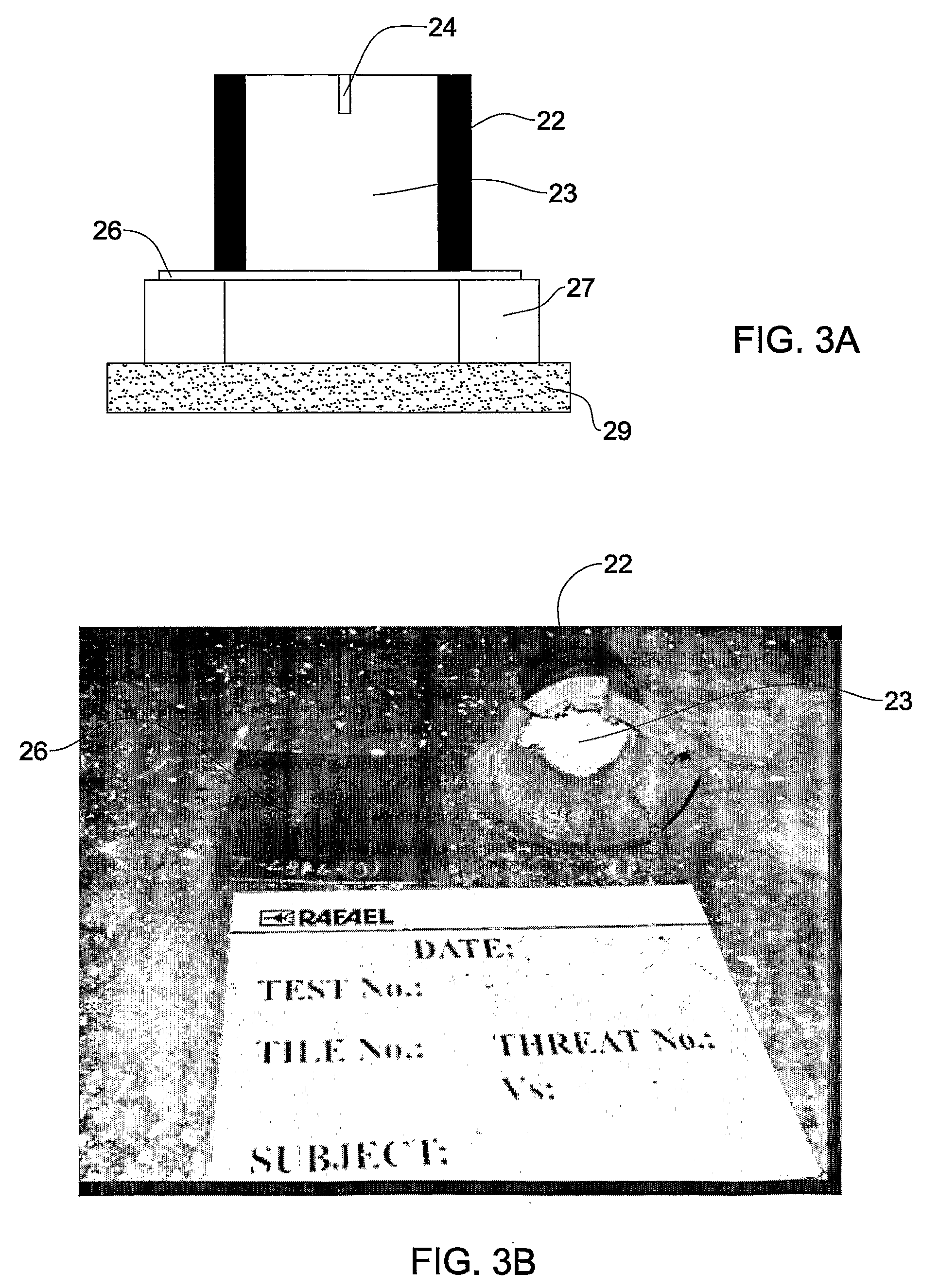

Extremely Insensitive Detonating Substance and Method for Its Manufacture

ActiveUS20090078346A1Reduce sensitivityHigh self-extinguishing rateNon-explosive stabilisersLoomsEngineeringFire retardant

The present invention provides an explosive composition of substantially reduced sensitivity and low flammability, being definable as an extremely insensitive detonating substance (EIDS) according to UN Regulations for the Transport of Dangerous Goods and comprising one or more explosive material 42-58% vol., one or more fire retardant material 15-26% vol. and a binder 20-36% vol.

Owner:RAFAEL ADVANCED DEFENSE SYSTEMS

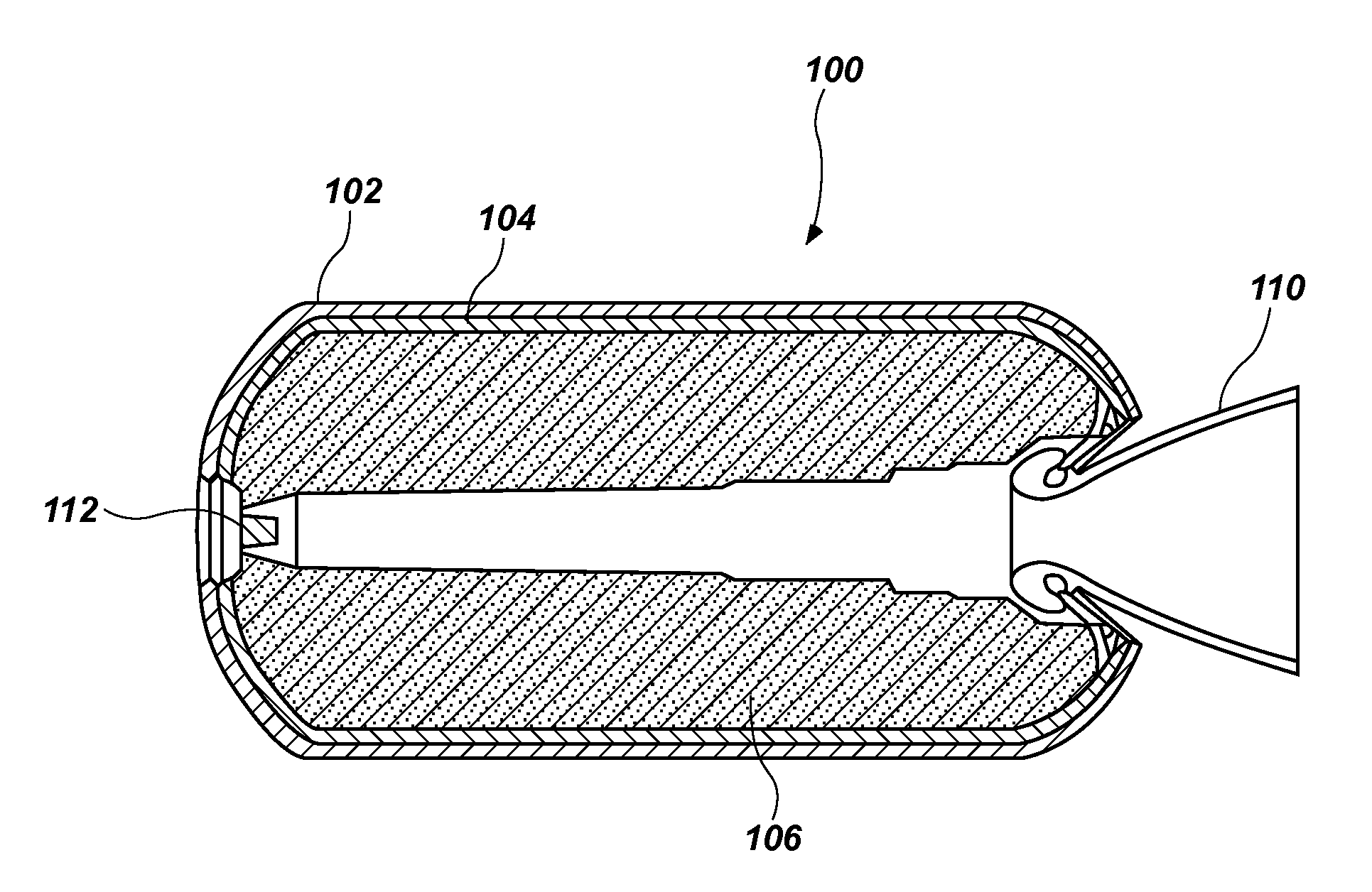

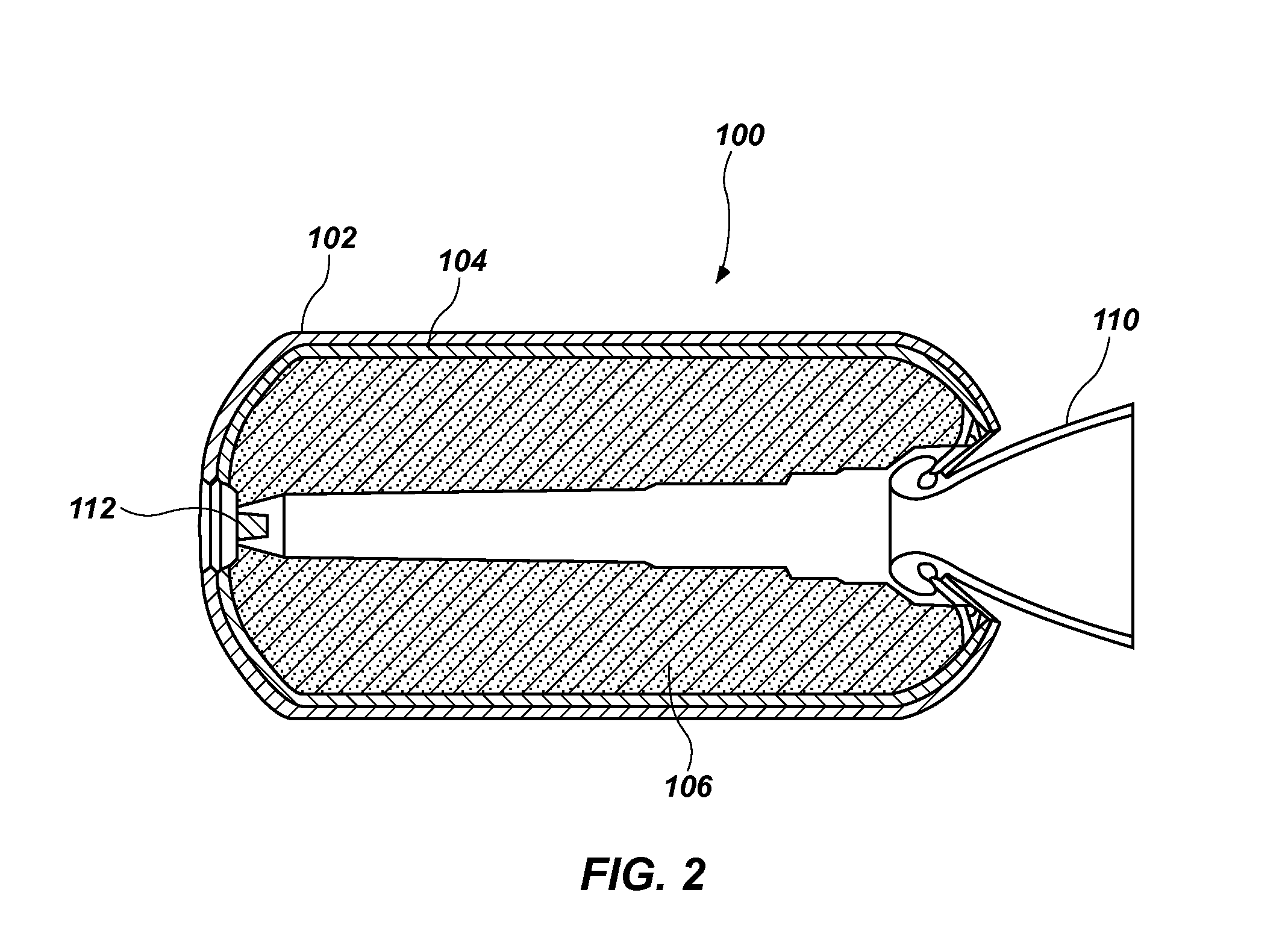

Energetic compositions including nitrate esters, methods of forming such energetic compositions, and articles including such energetic compositions

Methods of forming energetic compositions include forming a premix comprising a nitrate ester, a polymer, and a stabilizer, and combining solids with the premix. Additional stabilizer may be added with the solids and may remain in a crystalline state. Some methods include dissolving a stabilizer in at least one of a plurality of nitrate esters. Energetic compositions include a continuous matrix and a stabilizer. The continuous matrix includes a nitrate ester and surrounds a solid energetic material. Some compositions include a first nitrate ester, a second nitrate ester having a decomposition rate lower than the first nitrate ester, and a stabilizer. An article includes a housing and an energetic composition in the housing.

Owner:NORTHROP GRUMMAN SYST CORP

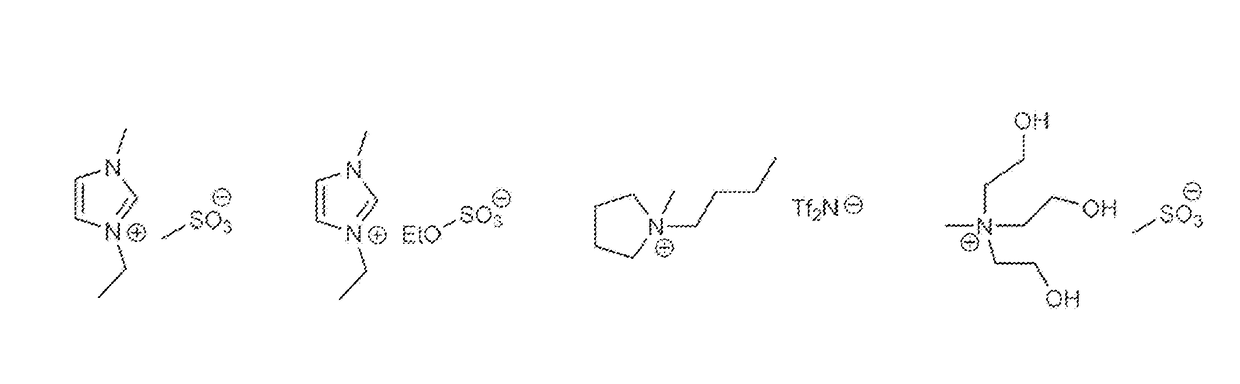

Odor sample for explosives detection dogs, process for producing an odor sample and process for using an odor sample

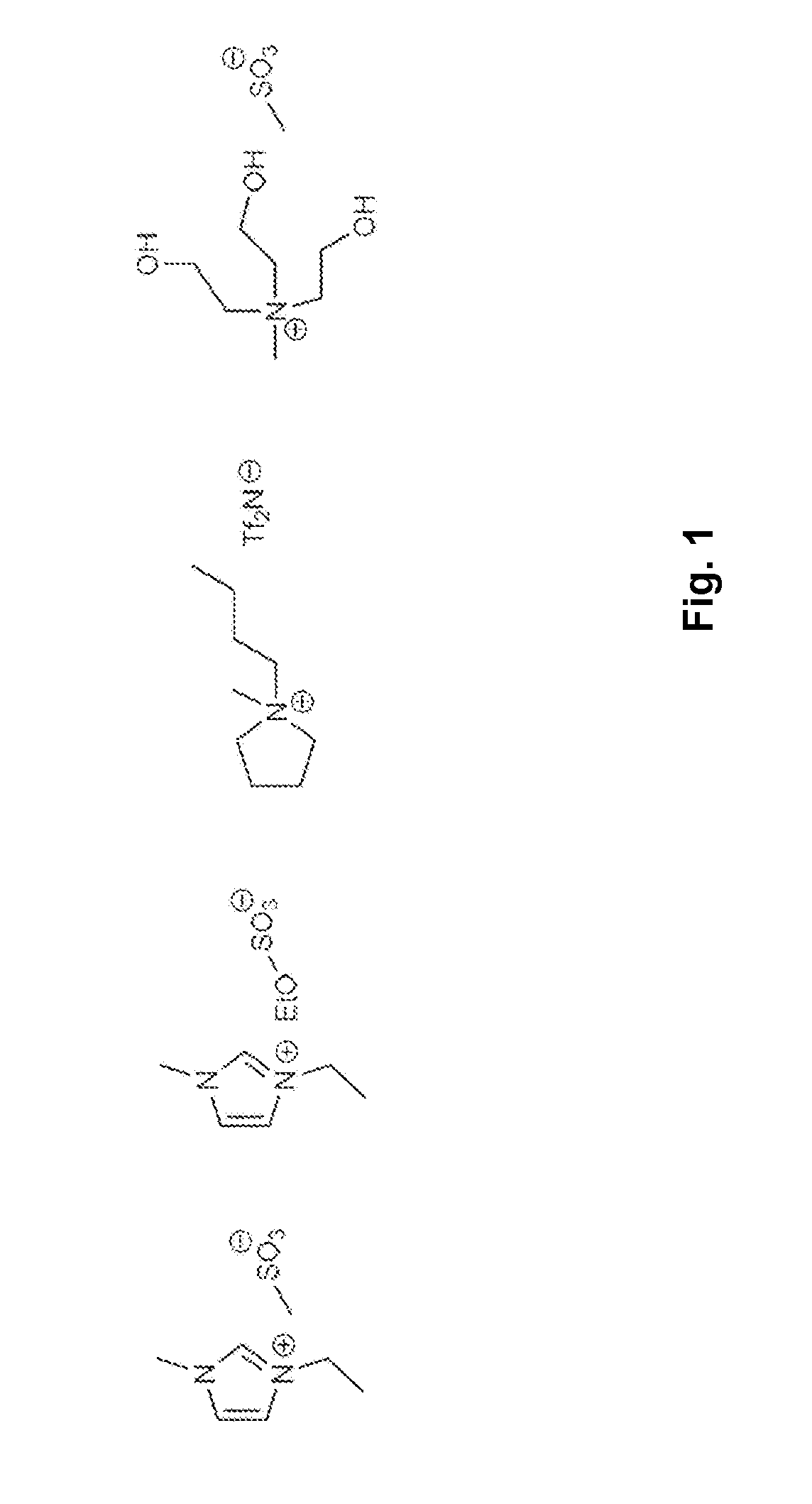

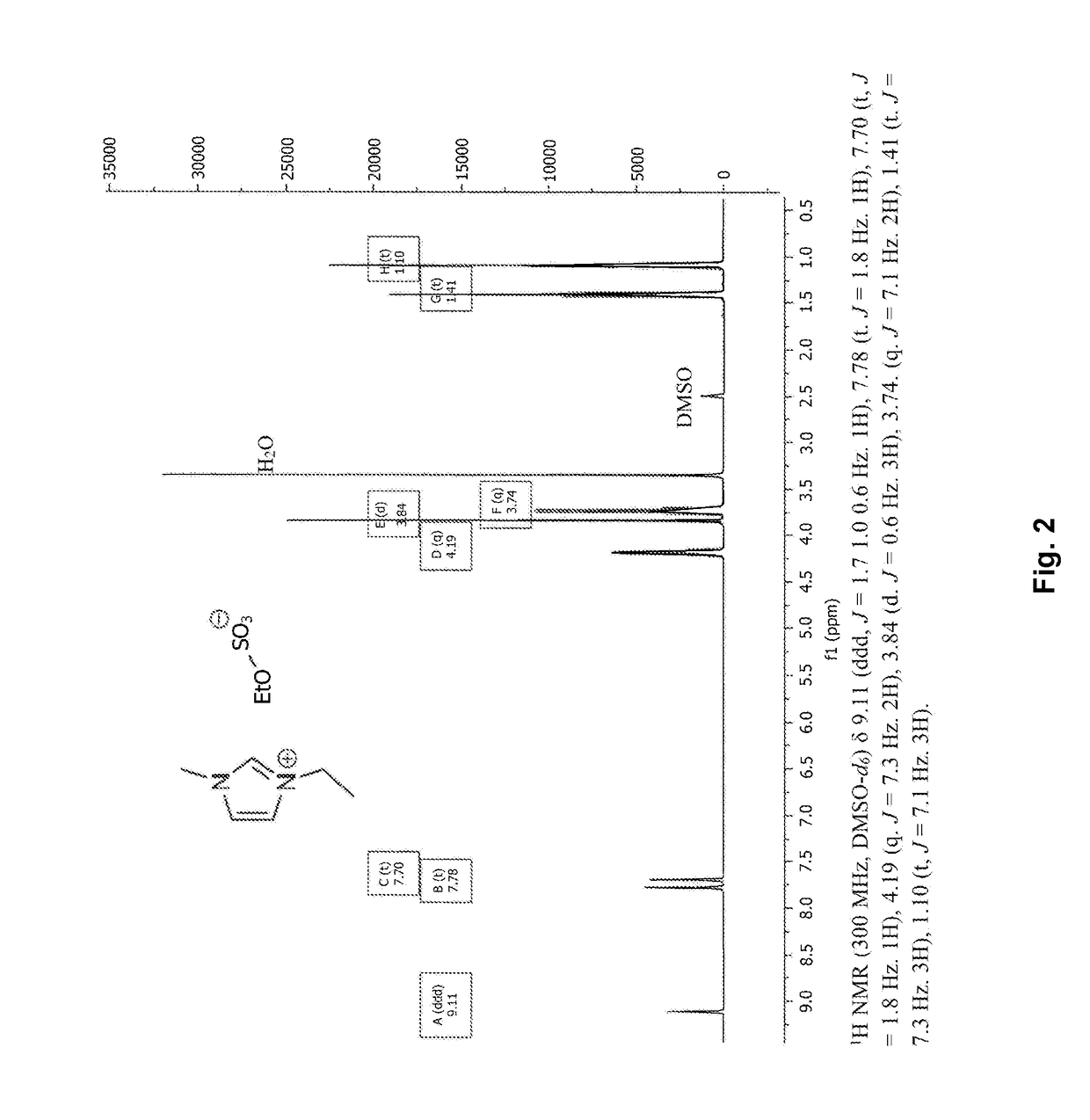

InactiveUS20180044258A1Overcome disadvantagesImprove securityDefence devicesNon-explosive stabilisersCanis lupus familiarisIonic liquid

An odor sample for explosives detection dogs includes a solution of the explosive in an ionic liquid, wherein the explosive is a nonperoxidic explosive. A process for producing an odor sample for explosives detection dogs as well as a process for using an odor sample for explosives detection dogs are also provided.

Owner:CARDIOVASCULAR SYST INC +1

Amorphous energetics

ActiveUS10703687B1Readily detonableImprove responseNon-explosive stabilisersNon-explosive desensitisers/phlegmatisersHigh Blast ExplosiveMaterials science

Stabilized, amorphous high energetic compositions having crystallization inhibiting polymers dispersed throughout the solid composition. The compositions disclosed herein are an improvement over crystalline high energetic compositions in that such disclosed compositions are stable and possess physical properties desirable in propellant and high explosive applications.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Tocopherol stabilisers for nitrocellulose-based propellants

ActiveUS20180029952A1Improve explosive powerGood curative effectNon-explosive stabilisersOrganic chemistryArylNitrocellulose

Owner:PB CLERMONT

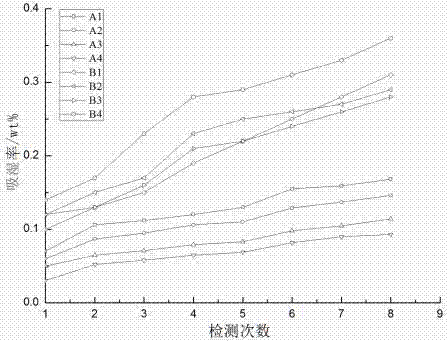

Core of water-resistant detonating cord and method for preparing core

InactiveCN108892596AImprove water resistanceImprove stabilityNon-explosive stabilisersExplosive working-up apparatusWater bathsParaffin oils

The invention discloses a core of a water-resistant detonating cord and a method for preparing the core. The core comprises, by weight, 15-20 parts of paraffin oil and petroleum ether saturated solution, 79.4-84.6 parts of pentaerythrite tetranitrate and 0.4-0.6 part of graphite powder. The method for preparing the core includes adding the paraffin oil and petroleum ether saturated solution and the graphite powder into the pentaerythrite tetranitrate according to raw material ratios; uniformly stirring and mixing the paraffin oil and petroleum ether saturated solution, the graphite powder andthe pentaerythrite tetranitrate with one another to obtain mixtures; granulating the mixtures; drying granules in water-bath drying tanks at the drying temperatures of 45-50 DEG C to obtain the core of the water-resistant detonating cord. The core and the method have the advantages that formulas for the core are improved, accordingly, the water resistance of the core can be integrally improved, the stability of the core can be reinforced, the storage life can be prolonged, and the explosion initiation and propagation performance of the core can be guaranteed; the water resistance and the stability of the core can be improved to the greatest extent by the aid of the method for preparing the core.

Owner:JIANGXI GANZHOU GUOTAI SPECIALTY CHEM

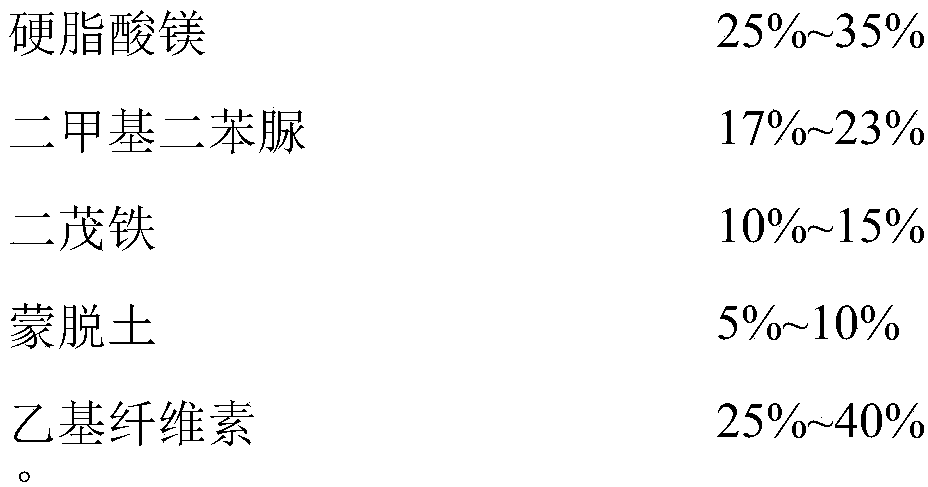

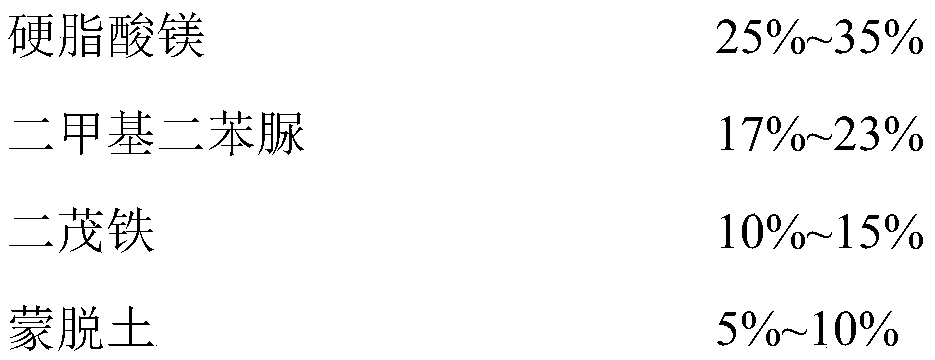

Smokeless sulfur-free firework stabilizing agent and preparation method thereof

ActiveCN110981652ASuitable for assembly line operationSimple processNon-explosive stabilisersCelluloseEthyl group

The invention relates to a smokeless sulfur-free firework stabilizing agent and a preparation method thereof, and belongs to the field of environment-friendly pyrotechnic compositions. The preparationmethod comprises the following steps: weighing magnesium stearate, dimethyl diphenyl urea, ferrocene, montmorillonite and ethyl cellulose; respectively adding magnesium stearate and dimethyl diphenylurea into ethanol in a stirring state to obtain a solution A; adding ferrocene into a dichloromethane / petroleum ether mixed solvent and continuously stirring until ferrocene is dissolved to obtain asolution B; adding the solution A into the solution B in a stirring state, sequentially adding montmorillonite and ethyl cellulose in a heating and stirring state, continuously stirring until the materials form uniform micelles, granulating and drying to obtain a smokeless and sulfur-free firework stabilizing agent crude product; and crushing and sieving the smokeless and sulfur-free firework stabilizing agent crude product to obtain the smokeless and sulfur-free firework stabilizing agent. According to the method, magnesium stearate and ethyl cellulose are used as main components and the decomposition product is gas and does not contain a sulfur element; and the preparation method is simple and no three wastes are discharged in the production process.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Low-smoke pyrotechnic composition

InactiveUS20200325083A1Production is limitedReduce generationNon-explosive stabilisersNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsCelluloseNitrocellulose

A low-smoke, pyrotechnic composition is provided. The composition may include Ceric Ammonium Nitrate as an oxidizer, a fuel source, stabilizer, and a binder. The use of Ceric Ammonium Nitrate as an oxidizing agent within the composition can result in reducing the amount of smoke generated during combustion of the composition, which may be beneficial for certain pyrotechnic applications. In certain constructions, the composition may include Ceric Ammonium Nitrate as an oxidizer, Nitrocellulose and Titanium as fuel sources, Cyanoguanidine as a stabilizer, Cupric Oxide as a burn rate catalyst, and any suitable binder agent. The amount of Ceric Ammonium Nitrate by percent weight of the composition may range between 20-80 percent, 30-40 percent, or 30.0-37.5 percent. In certain configurations, the amount of Ceric Ammonium Nitrate may be about 36.7 percent by weight.

Owner:NEXT F X INC

Explosive modification composition, and preparation method and application thereof

ActiveCN106966842AIncrease packing densityStable surface propertiesNon-explosive stabilisersO-Phosphoric AcidAmmonium nitrate

The invention provides an explosive modification composition, and a preparation method and application thereof, belonging to the technical field of explosives. The explosive modification composition is prepared from the following raw materials by weight: 15 to 25 parts of octadecyl primary amine, 60 to 80 parts of phosphoric acid, 5 to 15 parts of stearate, 0 to 3 parts of a coloring agent and 0 to 3 parts of an accessory material. The explosive modification composition is applicable to rock expanded ammonium nitrate explosives and can improve the free-running property of the rock expanded ammonium nitrate explosives, adjust charging density and enhance the explosive strength, safety performance and storage performance of explosives.

Owner:HENAN JIULIAN IND AUDIO SUPPLIES CO LTD

Special compound wax for emulsion explosives based on heavy deasphalting oil

ActiveCN105384587AIn line with the production processMeet production requirementsNon-explosive stabilisersMicrocrystalline waxEmulsion explosive

The invention discloses special compound wax for emulsion explosives based on heavy deasphalting oil. The special compound wax comprises the following components: heavy deasphalting oil, dewaxing sweat oil, Fischer-tropsch wax and cerate. The preparation method comprises the following steps: melting the heavy deasphalting oil, sequentially adding the residual components under the condition of 85 to 95 DEG C, uniformly mixing, cooling and forming the product. The heavy deasphalting oil and dewaxing sweat oil serve as main raw materials, and the condition that the raw materials are contested during production of microcrystalline wax and petroleum wax; wax-containing raw resources in oil refinery are directly and effectively utilized, and the condition that the production cost is improved due to secondary processing is avoided; the use amount of cerate is as small as possible, so that the cost of the compound wax is reduced to the lowest degree; and the Fischer-tropsch wax at relatively low price is introduced, so that the viscosity, hardness, oil content and the like of the product are adjusted, and the requirements on novel emulsion explosive production process and performance improvement are met.

Owner:CHINA PETROLEUM & CHEM CORP

Emulsion explosive with long-term storage stability and preparation method thereof

ActiveCN111925259AImprove storage effectGood explosive performanceNon-explosive stabilisersPhosphoric Acid EstersDodecane

Owner:HENAN HUATONG CHEMICAL CO LTD

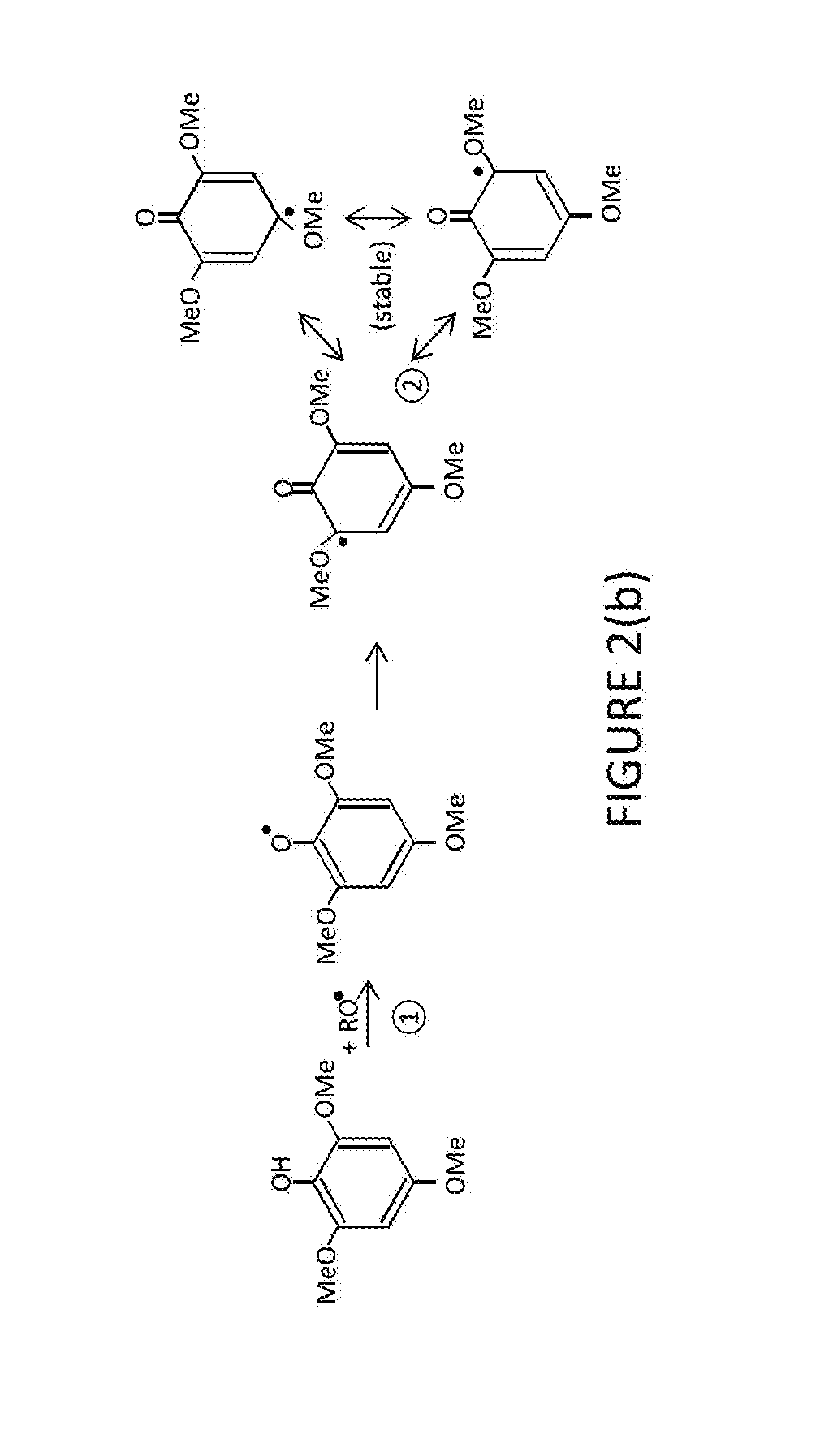

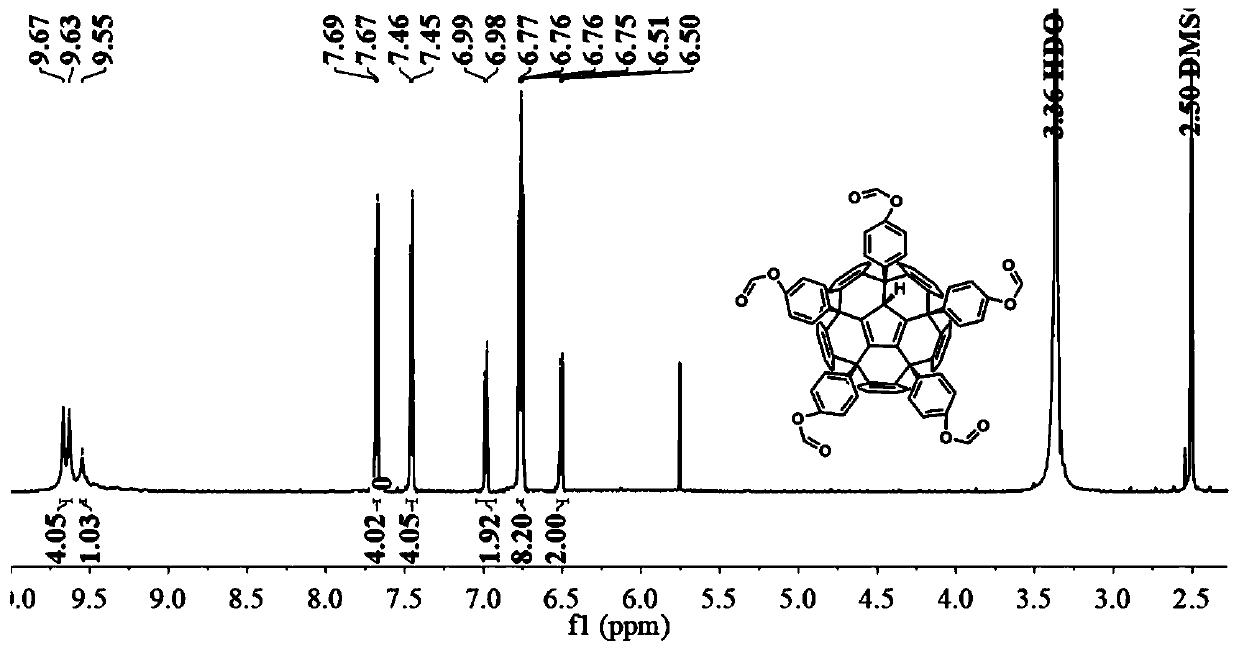

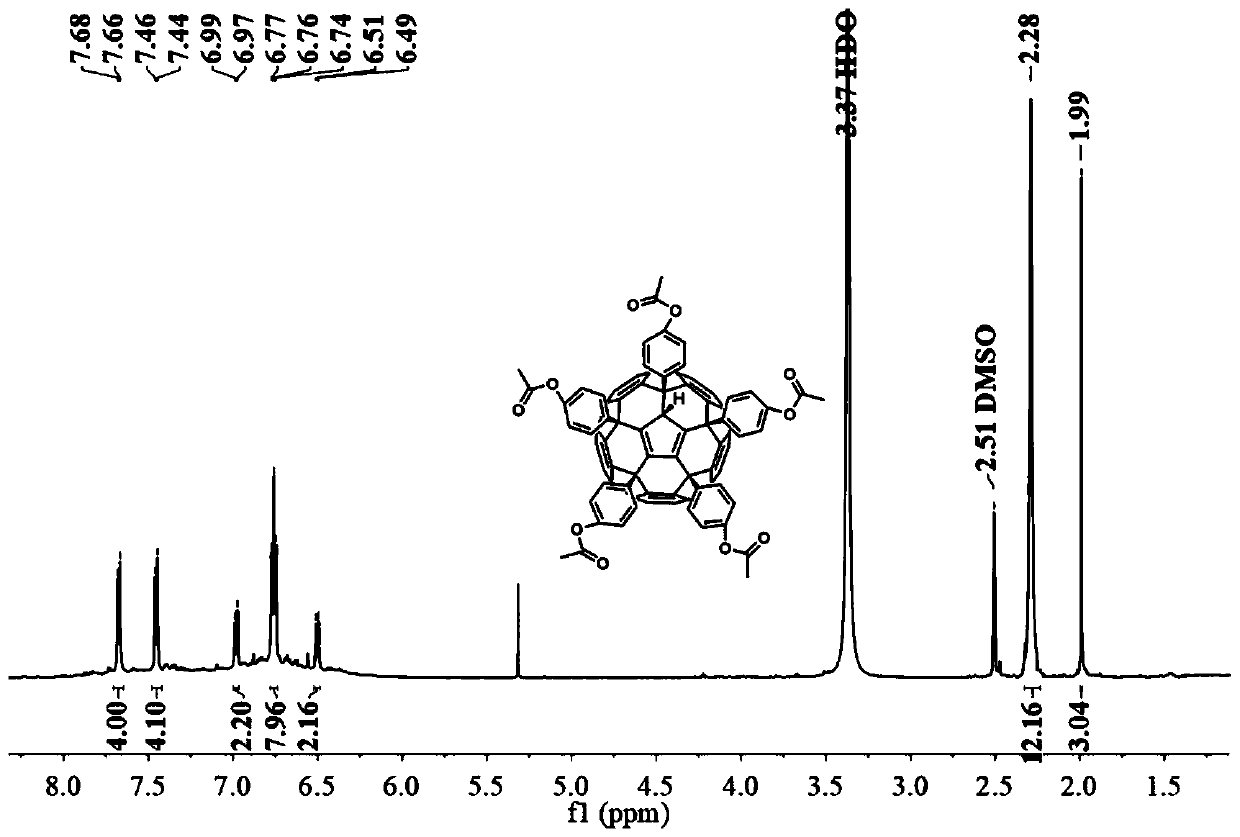

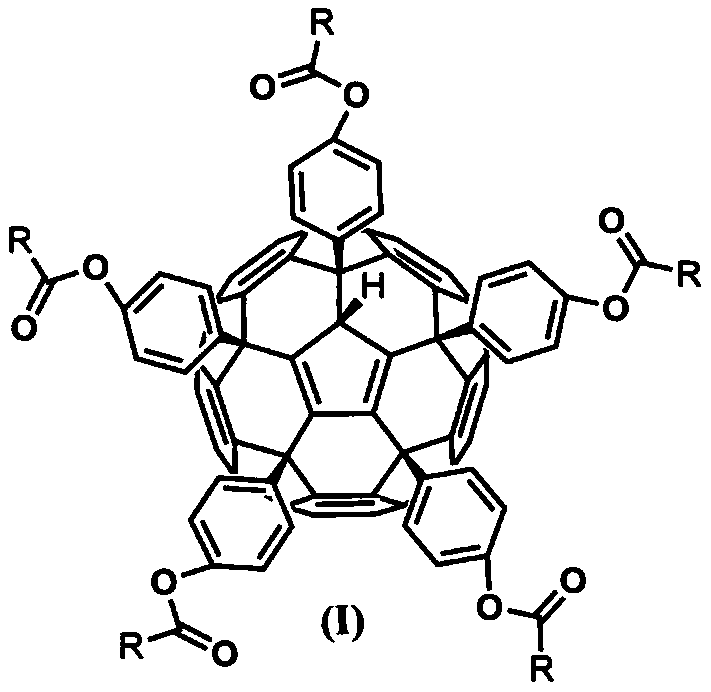

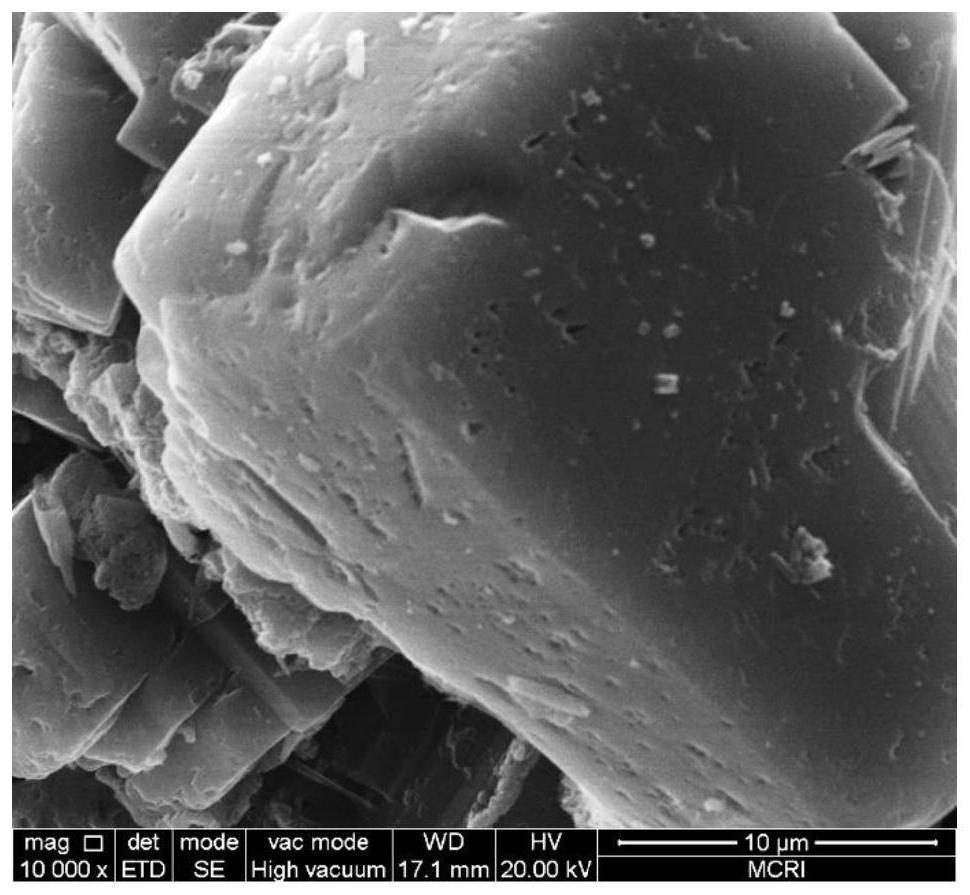

Fullerene phenolic ester derivative as well as preparation method and application thereof

ActiveCN110078616AGood thermal stabilityImprove specific impulseNon-explosive stabilisersOrganic compound preparationAlkyl transferAlkylation

The invention discloses a fullerene phenolic ester derivative shown in a formula (I) and a preparation method thereof. The fullerene phenolic ester derivative is synthesized by utilizing optimized Friedel-Crafts alkylation reaction and by taking hexachlorofullerene and phenolic ester as raw materials. The fullerene derivative can serve as a novel fullerene stabilizing agent applied to a solid rocket propellant. In the formula (shown in the description), R=-H, -CH3, -CH3CH2, -CH(CH3)2, -CH2CH2CH3, -CH2CH2CH2CH3.

Owner:SOUTHWEAT UNIV OF SCI & TECH

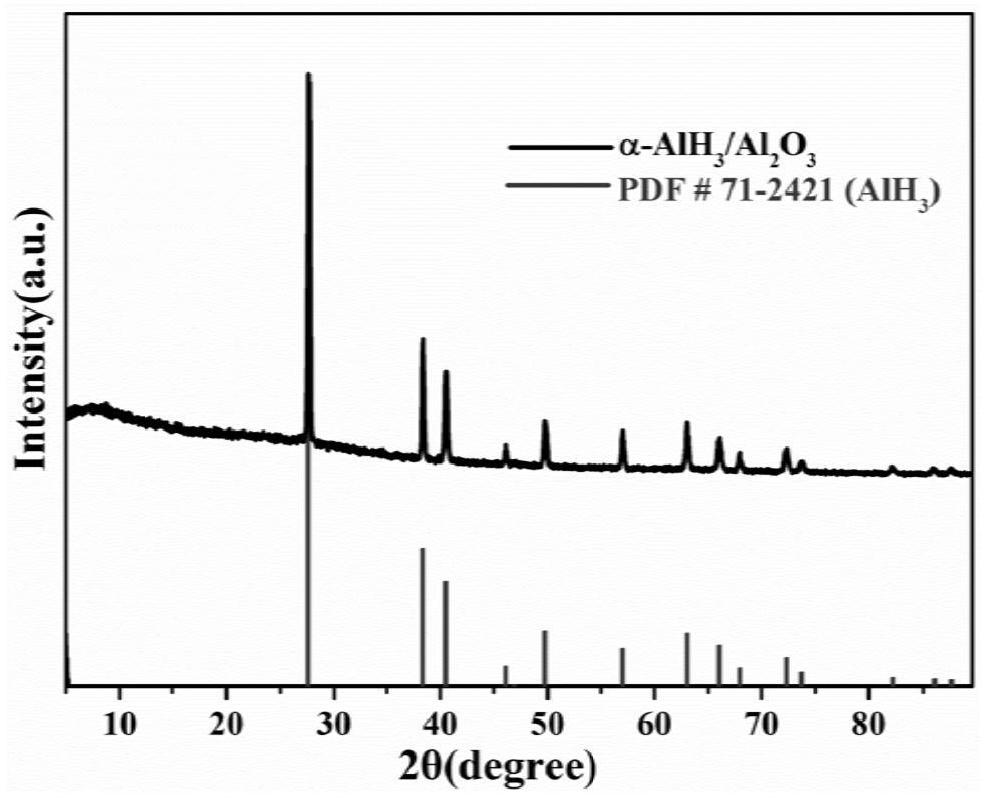

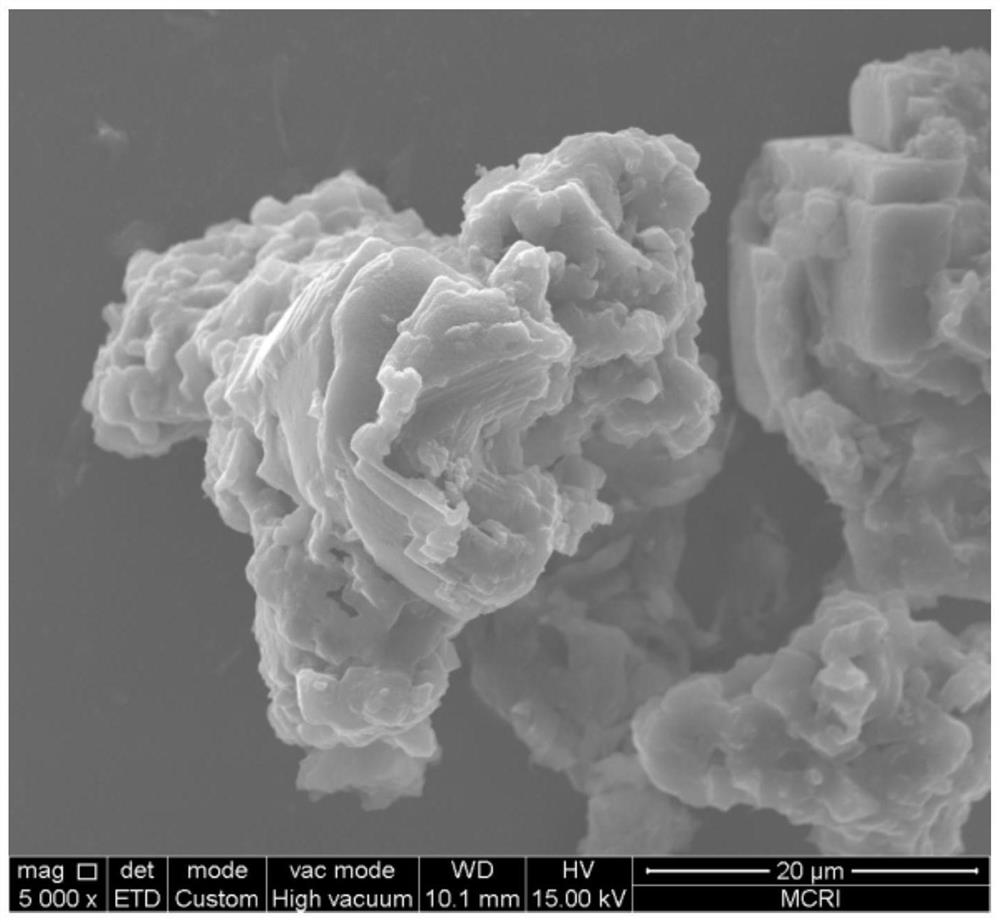

a polycarbonate-alh 3 Double-shell composite, preparation method and application

ActiveCN112125768BImprove thermal stabilityMethod securityNon-explosive stabilisersExplosive working-up apparatusPolymer scienceCarbonate ester

The invention discloses a polycarbonate-AlH 3 Double-shell composites, methods of preparation and applications, polycarbonate‑AlH 3 Double-shell structure composite, from inside to outside, the composite includes an inner core, a first shell wrapping the inner core, and a second shell wrapping the first shell; the inner core is α‑AlH 3 core, the first shell is Al 2 o 3 layer, and the second shell layer is a polycarbonate layer. with α‑AlH obtained by the pickling method 3 / Al 2 o 3 In contrast, the double-shell structure composite α-AlH synthesized by this method 3 / Al 2 o 3 The thermal stability of / PC is significantly improved.

Owner:XIAN MODERN CHEM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com