a polycarbonate-alh 3 Double-shell composite, preparation method and application

A technology of polycarbonate and composites, which is applied in the direction of offensive equipment, explosive processing equipment, non-explosive/non-thermal agent components, etc., can solve problems such as decomposition phenomena, and achieve the effect of improving thermal stability and making the preparation method safe and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

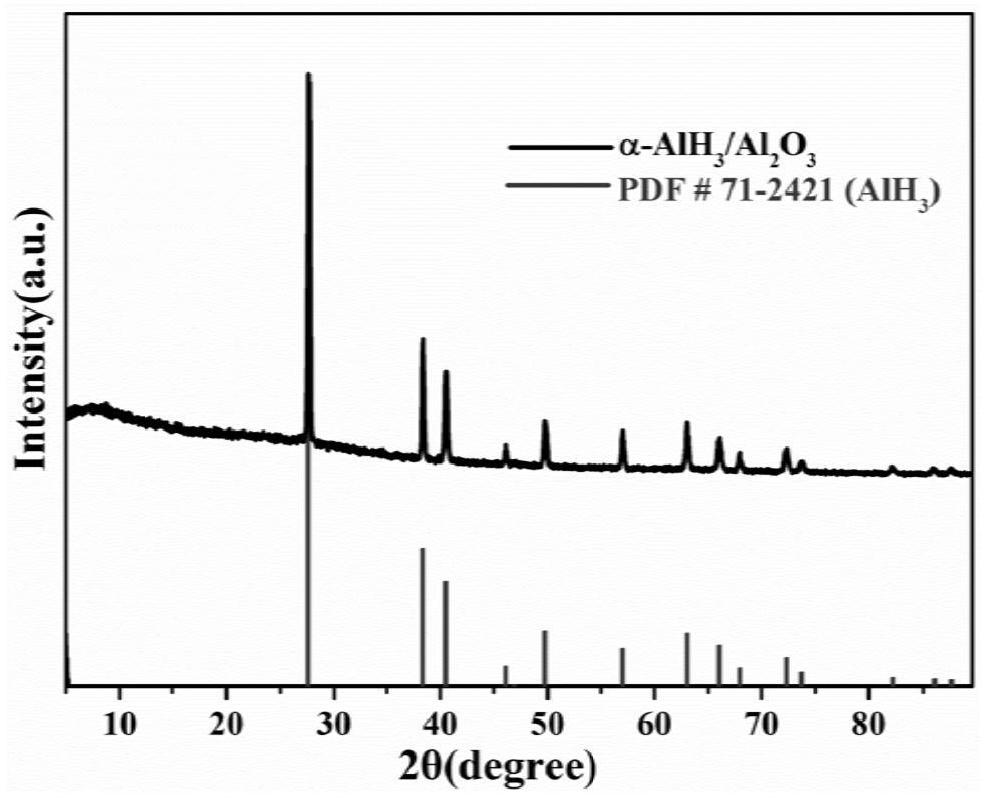

[0031] In order to further improve the high α-AlH on the basis of pickling passivation 3 Thermal stability, the present invention provides a kind of α-AlH 3 / Al 2 o 3 / PC double shell structure complex and its synthesis method.

[0032] In order to achieve the above object, a kind of α-AlH provided by the present invention 3 / Al 2 o 3 The synthetic method of the double-shell structure compound of / PC comprises the following steps:

[0033] (1) Obtain α-AlH by pickling 3 / Al 2 o 3 :

[0034] First, configure a dilute acid solution with a volume fraction of 10%; second, take a certain amount of synthesized α-AlH 3 Add it into dilute acid solution and stir for a certain period of time, filter and wash with volatile organic solvent for 3 times, and finally freeze-dry to obtain off-white powder sample.

[0035] (2)α-AlH 3 / Al 2 o 3 Preparation of / PC double-shell structure composite

[0036] First, take 200mg PC dispersed in chloroform solvent, stir to dissolve; then...

Embodiment 1

[0044] (1) Obtain α-AlH by pickling 3 / Al 2 o 3

[0045] First, configure a dilute hydrochloric acid solution with a volume fraction of 10%; secondly, take a certain amount of synthesized α-AlH 3 Add dilute hydrochloric acid solution and stir for 5 minutes, filter and wash with ethanol three times, and finally freeze-dry to obtain off-white powder sample.

[0046] (2)α-AlH 3 / Al 2 o 3 Preparation of / PC double-shell structure composite

[0047] First, disperse 80mg of polycarbonate in chloroform solvent, stir and dissolve; then take 300mg of α-AlH 3 / Al 2 o 3 Add it, stir and disperse for 6h, filter and wash 3 times with chloroform, and finally freeze-dry to obtain off-white powder sample.

[0048] The α-AlH that embodiment 1 prepares 3 / Al 2 o 3 Characterization of the structure and thermal stability of / PC double-shell structure composites:

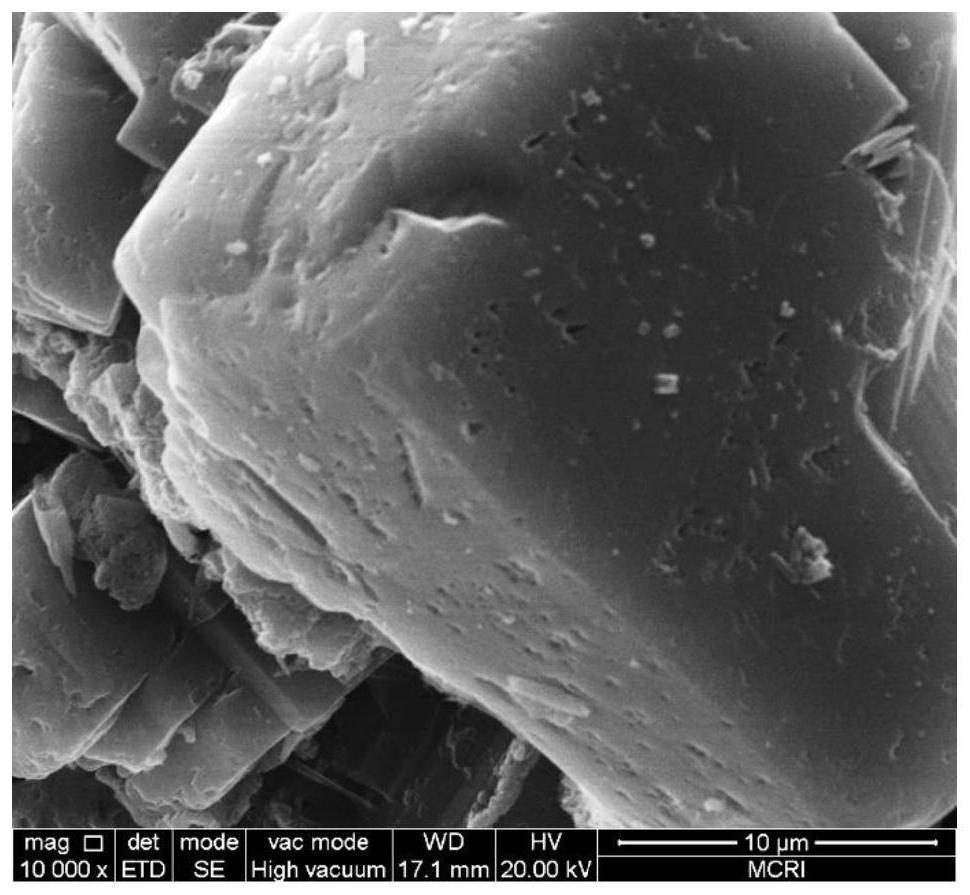

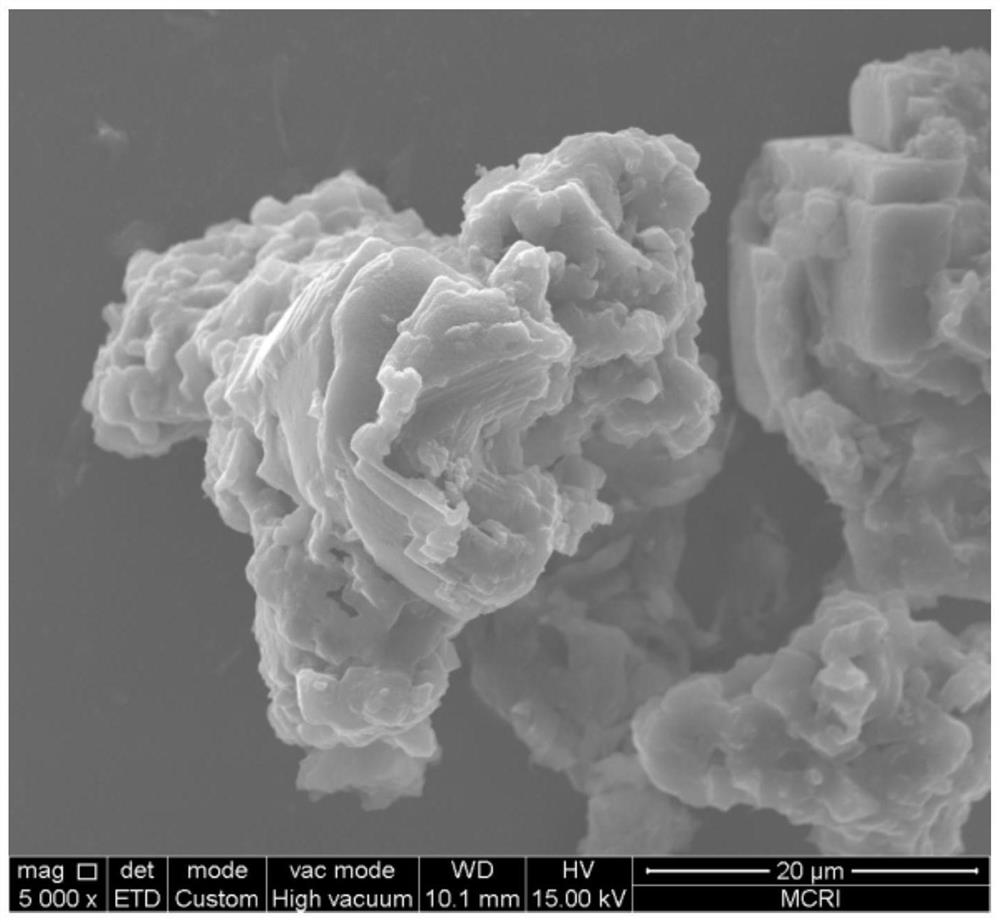

[0049] α-AlH 3 / Al 2 o 3 SEM image of / PC double-shell structure composite image 3 As shown, the morphology of the ...

Embodiment 2

[0054] (1) Obtain α-AlH by pickling 3 / Al 2 o 3

[0055] First, configure a dilute hydrochloric acid solution with a volume fraction of 5%; secondly, take a certain amount of synthesized α-AlH 3 Add dilute hydrochloric acid solution and stir for 5 minutes, filter and wash with ethanol three times, and finally freeze-dry to obtain off-white powder sample.

[0056] (2)α-AlH 3 / Al 2 o 3 Preparation of / PC double-shell structure composite

[0057] First, take 200mg of polycarbonate and disperse it in chloroform solvent, stir and dissolve; then take 300mg of α-AlH 3 / Al 2 o 3 Add it, stir and disperse for 6h, filter and wash 3 times with chloroform, and finally freeze-dry to obtain off-white powder sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com