Patents

Literature

38results about How to "Low detonation velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Explosive welding method for bimetal composite boards with special quality requirements

InactiveCN103056508AReliable weldingMeet welding quality requirementsNon-electric welding apparatusBond interfaceCharged body

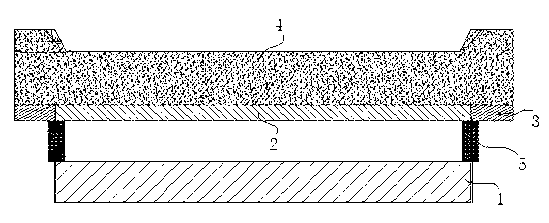

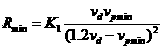

The invention discloses an explosive welding method for bimetal composite boards with special quality requirements. The explosive welding method includes preprocessing blanks; charging powder; and performing explosive welding. In a powder charging procedure, 'basin'-shaped powder charge bodies are arranged on shroud plates and extension plates, upper and lower surfaces of the powder charge bodies are parallel to the shroud plates and the extension plates, and powder charging quantities are acquired by computing according to a formula. The welded rate of the composite boards welded by the explosive welding method reaches 100%, the bonding strength of welded surfaces of the bimetal composite boards meet a bimetal solid-phase metallurgical bonding strength law, bonding interfaces of the bimetal composite boards are finely wavy and are excellent in quality, and accordingly the quality requirements of critical equipment of thermonuclear fusion power generation test reactors on the composite boards are met.

Owner:中国人民解放军理工大学野战工程学院 +2

Emulsified powder-like explosive

InactiveCN101024594ALow detonation velocityLow costExplosive working-up apparatusNon-explosive/non-thermic compositionsEmulsionDiluent

The invention relates to an emulsion powder explosive that has low detonation velocity. The feature is that it has 80-95 portions emulsion powder explosive, 5-20 portions diluents agent, and 0-10 portions density regulator. It could gain emulsion powder explosive that has 2000-2800m / s low detonation velocity, and density at 0.5-1.0g / cm3. The invention could lower the cost to 10-15% and has no adverse effect to explosive.

Owner:宜兴市阳生化工有限公司

High-density low-detonation velocity explosive and preparation method thereof

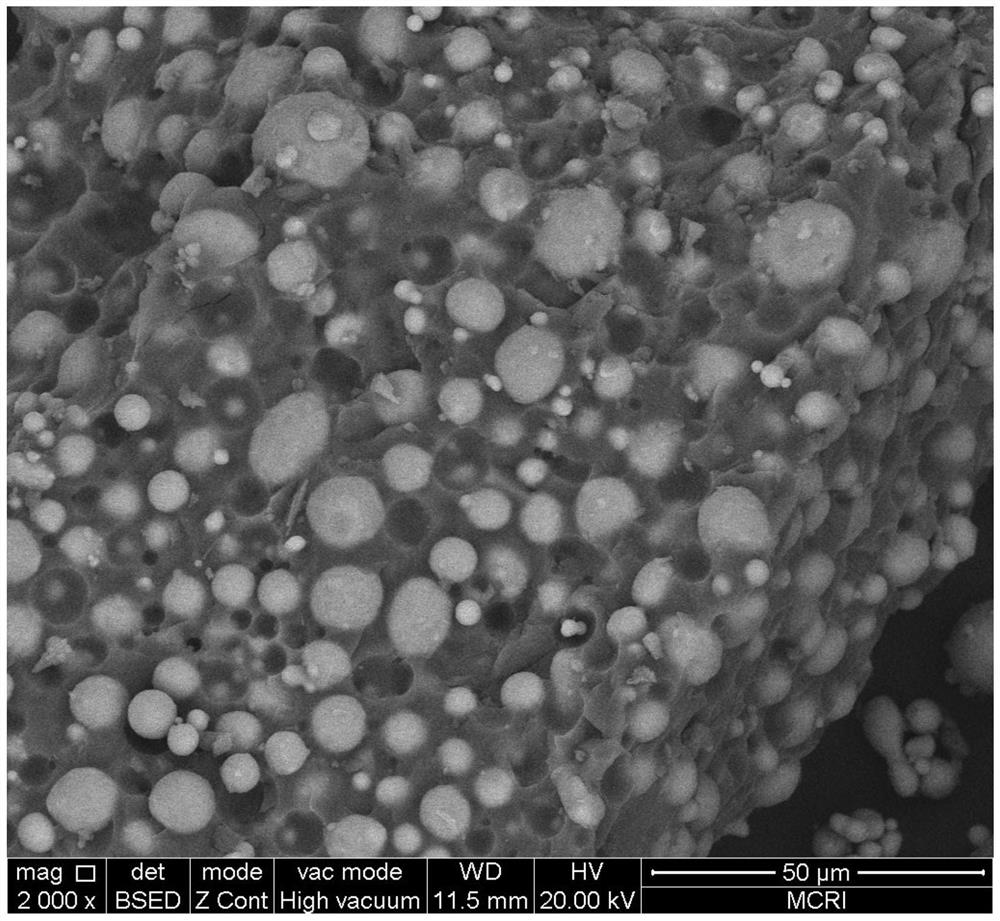

The invention discloses a high-density low-detonation velocity explosive. The explosive consists of the following components in parts by weight: 14-16 parts of cyclonite, 64-66 parts of barium nitrate, 15-16 parts of binder, 4-5 parts of plasticizer and 0.5-0.7 part of curing agent; and grain composition is carried out on the cyclonite, so that density uniformity is improved. The invention further discloses a preparation method for the explosive, wherein the preparation method comprises four steps of preparing materials, mixing, treating in vacuum, casting, heating and curing. The explosive disclosed by the invention has higher density, lower detonation velocity, and has good adaptation to environments such as temperature impact, high temperature, high pressure, and the like.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Explosion welding explosive with low explosion velocity

InactiveCN101602636AImprove mixing uniformitySimple production processExplosivesNon-electric welding apparatusWaxLow speed

The invention discloses an explosion welding explosive with a low explosion velocity for explosion welding between metal sheet materials and preparation method thereof. The explosion welding explosive consists of 66 to 76 portions of ammonium nitrate, 3 to 5 portions of composite oil phase and 21 to 29 portions of doped powder, wherein the composite oil phase consists of 2.6 to 4.8 portions of solid wax and 0.2 to 0.4 portion of stearic amine salt; and the doped powder consists of 15.95 to 23.2 portions of ferric oxide powder and 5.04 to 8.9 portions of diatomite powder. The preparation method comprises the following steps: adding water with 8 to 12 mass percent of the ammonium nitrate into the ammonium nitrate; heating and dissolving the mixture to obtain aqueous solution of ammonium nitrate; under low-speed stirring, dispersing the composite oil phase and the doped powder respectively into the aqueous solution of the ammonium nitrate; mixing and heating the mixed solution till a temperature of between 105 and 125 DEG C to obtain suspended mixed solution; removing moisture in a vacuum tank with vacuum degree of between 0.07 below zero and 0.09 MPa below zero; and cooling, sieving and filling the explosive to obtain the explosion welding explosive with the low explosion velocity of less than 2,400 m / s. Explosive particles have good dispersion and are convenient to distribute; and the explosive has low explosion velocity and stable explosion performance and can meet the requirement of the explosive for the explosion welding of different metal materials.

Owner:黄文尧

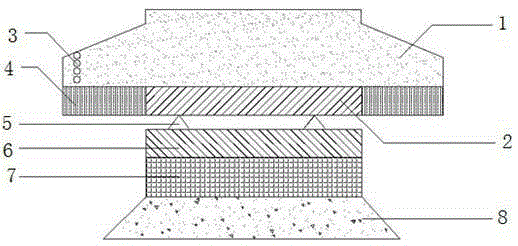

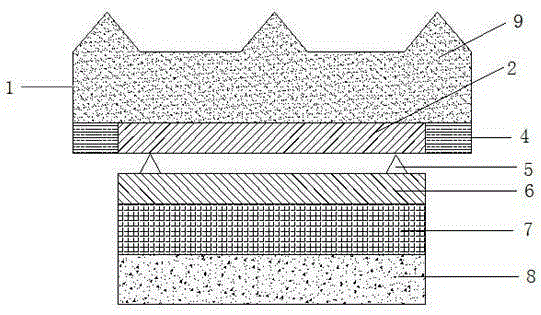

Explosive welding method of metal clad plate of super-thick shroud plate

InactiveCN104096962AGuarantee welding qualityMeet welding quality requirementsMetal working apparatusNon-electric welding apparatusBond interfaceEngineering

The invention discloses an explosive welding method of a metal clad plate of a super-thick shroud plate. The explosive welding method comprises the following steps of 1) pretreating substrate and shroud plate blanks; 2) arranging an extension plate at the periphery of the shroud plate; 3) arranging a substrate and the shroud plate; 4) laying main charge and auxiliary charge; 5) producing and arranging a priming device; 6) carrying out explosive welding. According to the explosive welding method, the welded rate of the clad plate welded through the process reaches 100%, the bonding strength of a welding surface conforms to a strength rule of duplex metal solid phase metallurgical bonding, a bonding interface of the welding surface is in a shape like a micro-wave with excellent quality, the impurity content of the interface is not higher than the corresponding impurity content of raw materials, and the welding quality requirements on the clad plate are completely met.

Owner:王晖 +2

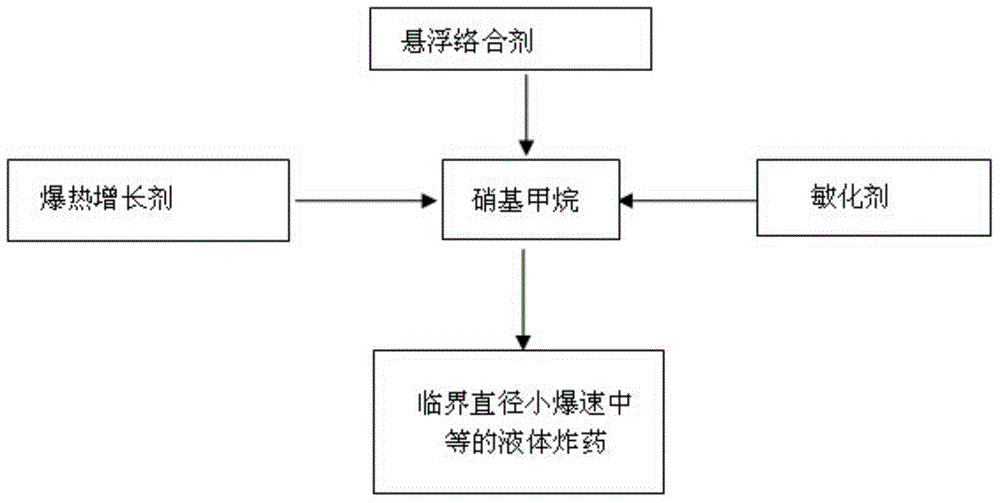

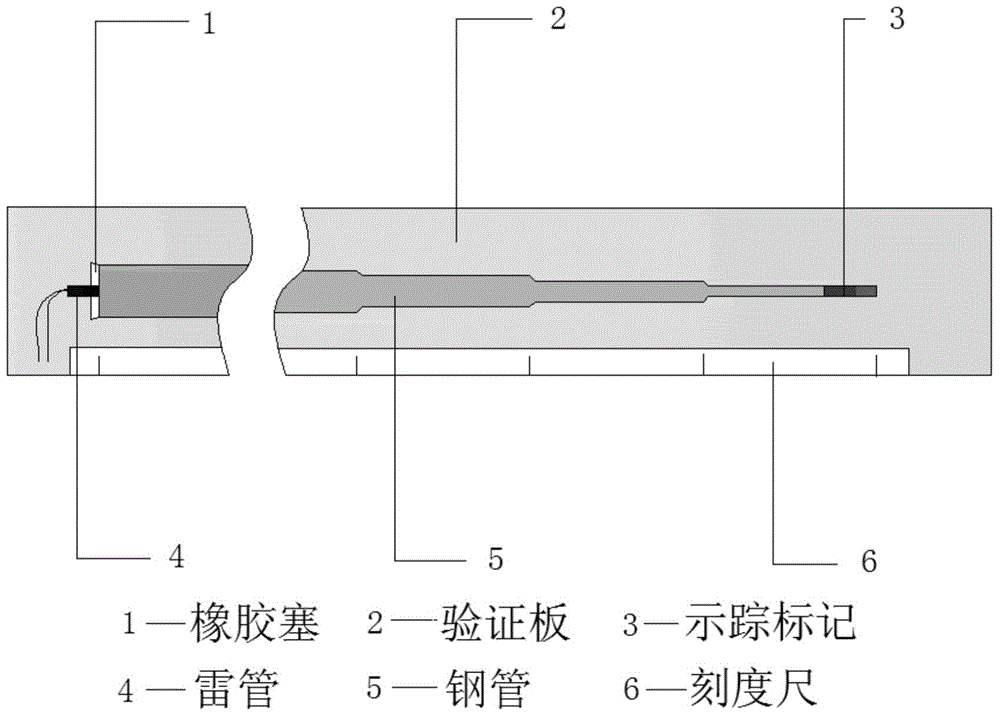

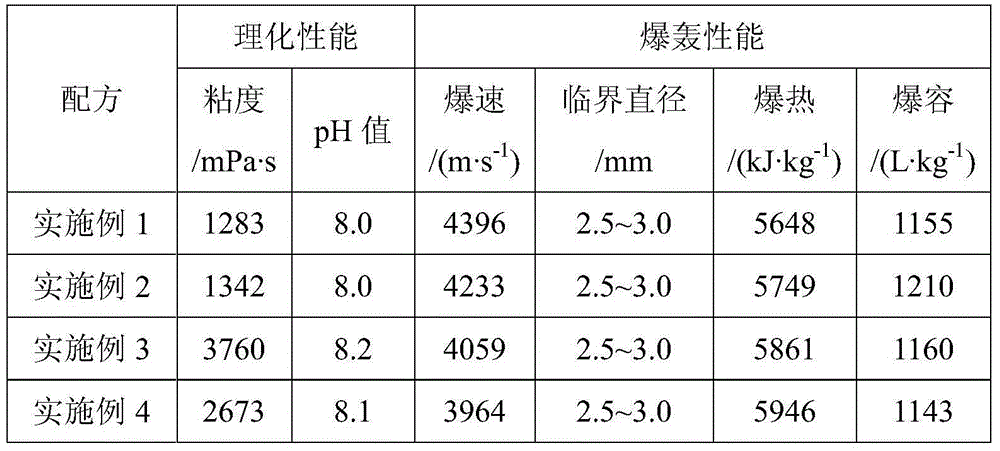

Liquid explosive with small critical diameter and medium detonation velocity and preparation technology thereof

InactiveCN105712808ALow detonation velocityReduce critical diameterNitroparaffin explosive compositionsNitromethaneBuffering agent

The invention discloses a liquid explosive with a small critical diameter and medium detonation velocity and a preparation technology thereof. The liquid explosive is composed of the following components in percentage by weight: 60 to 90% of nitromethane, 3 to 10% of sensitizing agent, 5 to 20% of performance buffering agent, and 2 to 10% of complexing agent. The liquid explosive has the following characteristics: (1) the mechanical sensitiveness is low, and the operation is safe; (2) the detonation is reliable, the critical diameter is small, and the energy is proper; (3) the fluidity is good, and thus the liquid explosive is suitable for long distance pumping; (4) the whole system is in a weak alkali state and is non-corrosive to metals; (5) the preparation method is simple, the price is low, and the liquid explosive can be mixed onsite before using. The liquid explosive is applied to oil and gas exploitation and is especially suitable for oil and gas exploitation in low permeable hard rock areas.

Owner:NANJING UNIV OF SCI & TECH +1

Explosive formulation

InactiveUS20070012387A1Low detonation velocityPromote resultsLoomsExplosivesSolid componentBoiling point

An explosive formulation used in blasting operations such as, but not limited to, mining operations and the like. The formulation is composed of a modified form of Ammonium Nitrate Fuel Oil (ANFO) explosives which have been modified by the incorporation of a solid fuel material. The formulation comprising a dry granular solid component, a liquid high-boiling point component of about 4% by weight, and a solid fuel material. The solid fuel material comprising vitrinite macerals, liptinite macerals, and inert macerals fusinite and semifusinite, and is characterized as (1) having a concentrate of liptinite that is higher than normal coals, and (2) having a concentrate of pseudovitrinite that is significantly lower than normal coals.

Owner:RESPONSIBLE ENERGY OPERATIONS LLC

Explosive welding method for large-size metal composite plate

PendingCN113787249AHigh bonding strengthNo crackNon-electric welding apparatusTEX-explosiveMechanical impact

The invention belongs to the technical field of explosive welding, and provides an explosive welding method for a large-size metal composite plate. The explosive welding method comprises the following steps that a base plate and a composite plate are sequentially subjected to mechanical shock treatment, heating treatment and installation to obtain a composite plate; after a detonating cord is fixed in the length direction of the composite plate, explosive is laid on the composite plate; and the composite plate is subjected to explosive welding with the middle position of the detonating cord as a detonating point, and the large-size metal composite plate is obtained. The bonding rate of the large-size metal composite plate obtained through the method reaches 99.8% or above, cracks and boundary effects do not exist, the bonding strength of a welding face is high, and the layering and desoldering phenomena do not occur; and according to the method, an exhaust path can be reduced, the detonation velocity of the explosive can be reduced, the explosion time is prolonged, the explosion continuity is improved, and the phenomenon of explosion failure is avoided.

Owner:舞钢神州重工金属复合材料有限公司

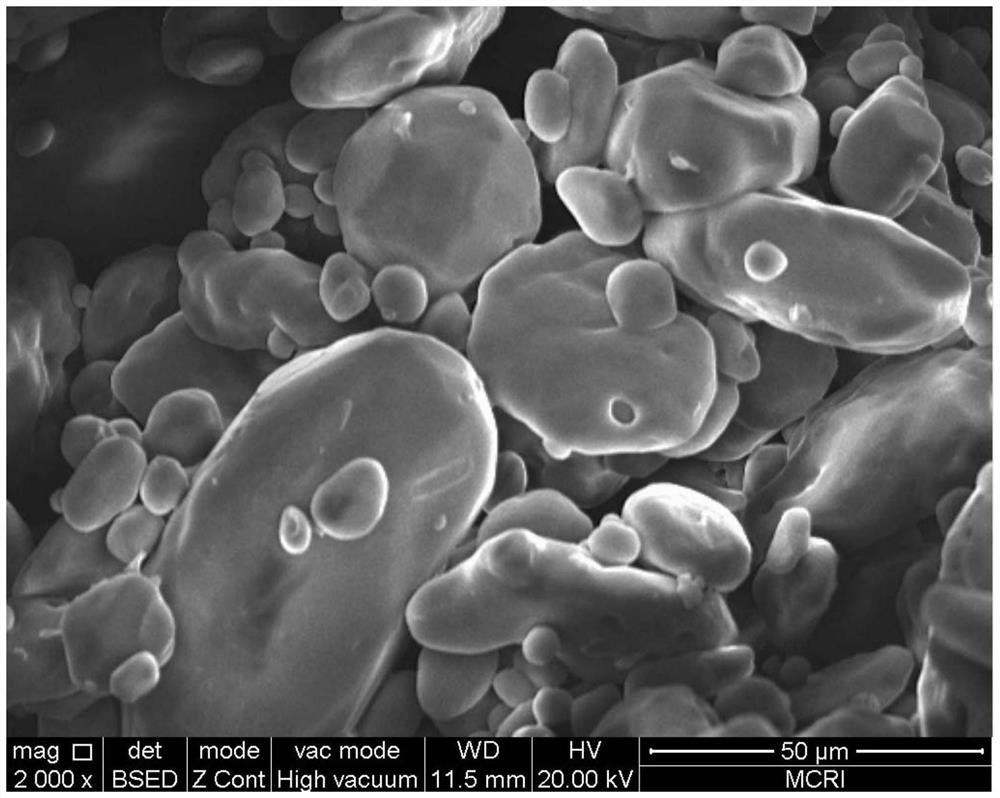

Low explosion speed high-toughness flake explosive and preparation method thereof

InactiveCN109053338AIncrease contact areaImprove density uniformityNon-explosive fillers/gelling/thickening agentsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsPlasticizerAdhesive

The invention discloses a low explosion speed high-toughness flake explosive which consists of the following components in parts by weight: 50-55 parts of a single-compound explosive, 20-25 parts of aspeed reduction filler, 9-14 parts of an adhesive, 3-6 parts of a plasticizer, 2-4 parts of a toughening agent, 1-1.5 parts of a curing agent, 3-5 parts of a dispersant and 0.4-0.6 part of a couplingagent. The invention further discloses a method for preparing the low explosion speed high-toughness flake explosive. Due to adoption of silica as the speed reduction filler, the explosion speed of the formula can be reduced; due to adoption of CAB (Cellulose Acetate Butyrate) as the toughening agent, the toughness of the formula can be improved; due to a reasonable ratio of solid phases to liquid phases, the formula can be easily formed as flakes.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Composite dynamite for stainless compound steel plate and its preparation method

InactiveCN1994982AIncreased Explosive Bonding RateLow detonation velocityExplosivesNon-electric welding apparatusPearliteAmmonium nitrate

The invention discloses a composite explosive and making method of stainless steel composite steel board, which comprises the following parts: 95% ammonium nitrate, 4-6% composite oil and 3-10% water-increasing pearlite. The making method of composite explosive comprises the following steps: I, bulking 95% ammonium nitrate; II. adding ammonium nitrate in the 4-6% composite oil; IV. adding 3-10% water-increasing pearlite in the ammonium nitrate; V. stirring evenly; VI. drying.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Low-detonation-velocity explosive for explosive welding and preparation method thereof

InactiveCN104761418AReduced ability to workPerformance lossExplosivesTEX-explosiveEmulsion explosive

The invention relates to a low-detonation-velocity explosive for explosive welding and a preparation technique thereof. The low-detonation-velocity explosive for explosive welding is mainly prepared from 60-83 wt% of third-grade coal mine allowable powder emulsion explosive, 10-25 wt% of talcum powder, 5-10 wt% of silicon aluminum powder and 3-5 wt% of wheat straw powder. The preparation technique comprises the following steps: respectively weighing the following raw materials in percentage by mass: third-grade coal mine allowable powder emulsion explosive, talcum powder, silicon aluminum powder and wheat straw powder; and drying the talcum powder, silicon aluminum powder and wheat straw powder at 80-95 DEG C until the water content is not higher than 0.5 wt%, uniformly mixing, adding the wheat straw powder to obtain the low-detonation-velocity explosive for explosive welding, and packaging for later use. The low-detonation-velocity explosive for explosive welding is easy to produce, and has the advantage of stable performance. The low-detonation-velocity explosive for explosive welding satisfies the requirement that the explosive welding explosive brisance is 9-11mm, the detonation velocity is 2500-2750 m / s, thereby ensuring the explosive welding effect.

Owner:HONGDA MINING IND +2

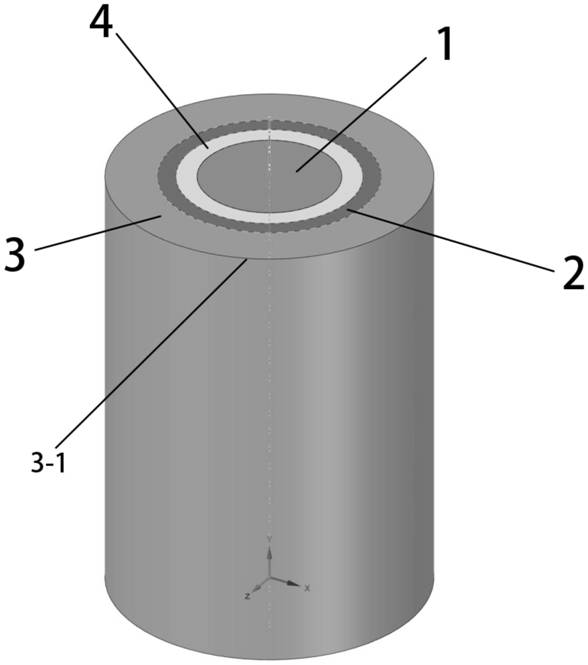

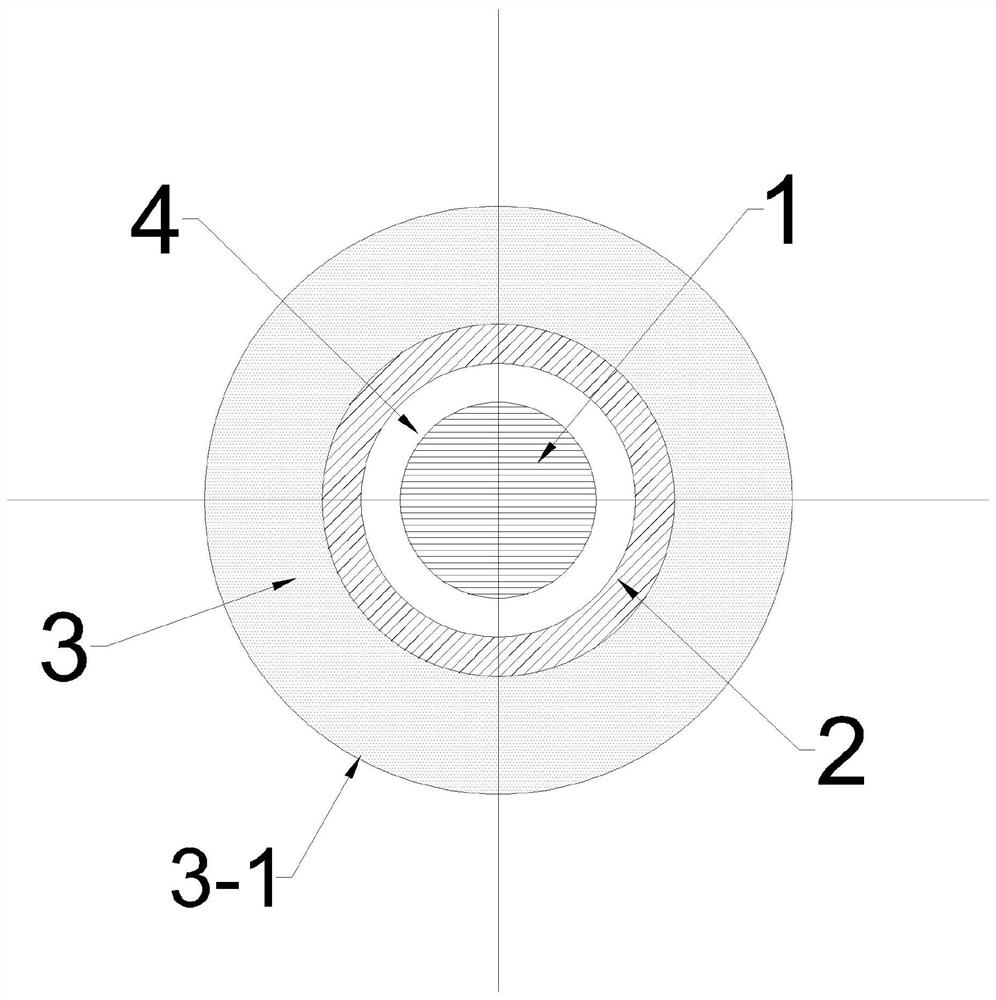

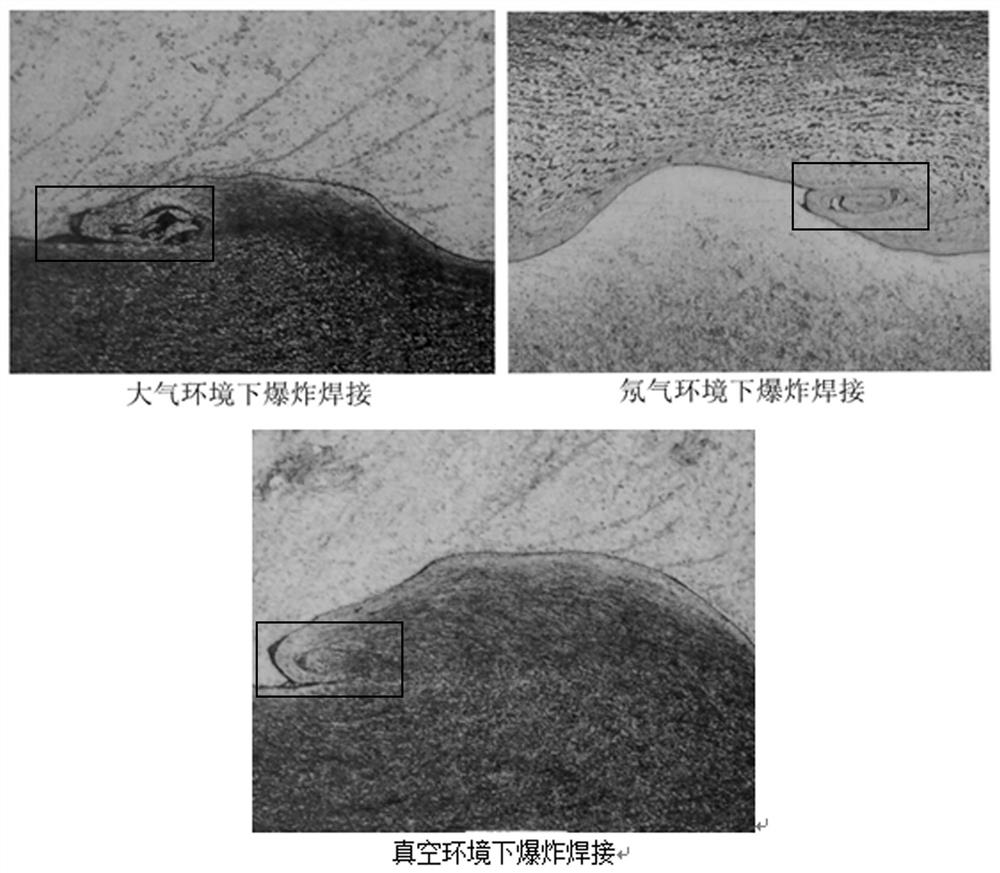

Method for preparing explosive composite rod in local vacuum environment

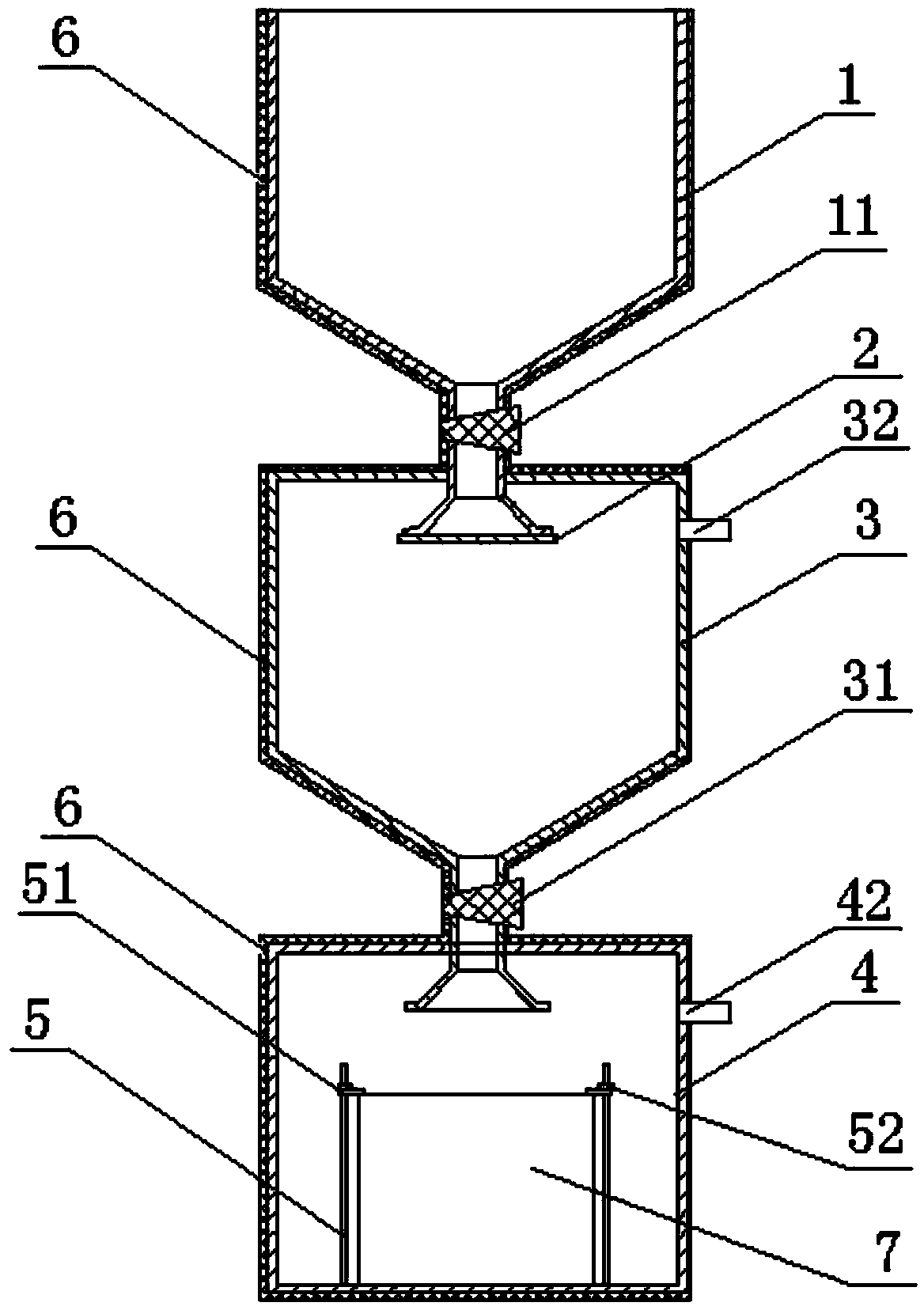

InactiveCN113560709AAvoid local defect problemsLow detonation velocityNon-electric welding apparatusDetonatorExplosive Agents

The invention provides a method for preparing an explosive composite rod in a local vacuum environment. The method comprises the following steps that a to-be-composited rod, a to-be-composited pipe and a pvc (polyvinyl chloride) pipe are coaxially arranged from inside to outside, and the space between the pvc pipe and the to-be-composited pipe is filled with explosive and a detonator to form an explosive device of a to-be-welded material; the two ends of the gap between the to-be-composited bar and the to-be-composited pipe are sealed and vacuumized by reasonably utilizing sealing strips, so that a vacuum gap environment is formed; and the explosive device is detonated, the to-be-composited pipe and the to-be-composited bar are welded and combined through high pressure generated by explosive explosion, and the high-quality explosive composite bar is obtained. Compared with a traditional explosive composite rod preparation method, the method for preparing the explosive composite rod in the local vacuum environment has the advantages that the explosive velocity selection is more free, and the operability is higher; and the bonding strength of the explosive composite rod is remarkably improved, and meanwhile the unavoidable phenomenon that in a traditional preparation method, large-area melting occurs on a composite rod bonding interface due to the fact that gap air is not exhausted in time is effectively eradicated.

Owner:ANHUI UNIV OF SCI & TECH

Water gel explosive with low detonation velocity for mining and method for producing same

InactiveCN100413819CNo pollutionPromote safe productionExplosive working-up apparatusNon-explosive/non-thermic compositionsPolystyreneMethylamine nitrate

The invention discloses a low-exploding slurry explosive and preparing method, which comprises the following parts: 15-30% ammonium nitrate solution, 22-32% methylamine nitrate solution, 8-15% sodium nitrate, 0.8-0.9% sesban powder, 12-15% calcium carbonate, 0.7-3.4% hydrophobic pearlite, 0.3-0.6% polystyrene plastic ball, 0.2-0.4% cross linker and 18-30% composite water resistance grain-sized ammonium nitrate. The preparing method comprises the following steps: preparing ammonium nitrate solution and composite water resistance grain-sized ammonium nitrate (the grain size is 3-5 mm); adding ammonium nitrate solution, methylamine nitrate solution, sodium nitrate, sesban powder, calcium carbonate, hydrophobic pearlite, polystyrene plastic ball, cross linker and composite water resistance grain-sized ammonium nitrate in the mixing tank; blending evenly; loading.

Owner:ANHUI UNIV OF SCI & TECH

Novel low-detonation velocity explosive suitable for titanium material compounding, and preparation method thereof

InactiveCN105384588AMeet the needs of the development of domestic chemical industry and other industriesDensity adjustmentNon-explosive/non-thermic compositionsEffective densityEmulsion explosive

The invention discloses a novel low-detonation velocity explosive suitable for titanium material compounding, and a preparation method thereof. The method comprises the following steps: taking 40 parts by weight of a rock powdery emulsion explosive with the bulk density of 0.58-0.62g.cm<-3>, the detonation velocity of 3500-3700m / s, the brisance of 15-17mm, the gap distance of 9-11cm and the work capacity of 360 / ml, taking 45 parts of sands with the bulk density of 1.40g.cm<-3> and the particle size of 300 meshes, putting above taken materials in a medicine mixer, stirring the materials for 3-5min, taking 7 parts of bran with the bulk density of 0.50g.cm<-3> and the particle size of 300 meshes, putting the taken bran in the medicine mixer, stirring the obtained mixture for 20min until fullness and uniformity, and detecting the density and the detonation velocity of the above obtained product. The sands are used to reduce the detonation velocity, and the bran is used as a density adjusting agent to adjust the density of the obtained mixed explosive; and the effective density of the rock powdery emulsion explosive is reduced through synergism of the sands and the bran, and the novel low-detonation velocity explosive prepared through mixing above materials in proportion can improve the production efficiency, and solves the problem of lack-of-fit of large-area titanium-steel composite plates.

Owner:安徽宝泰特种材料有限公司

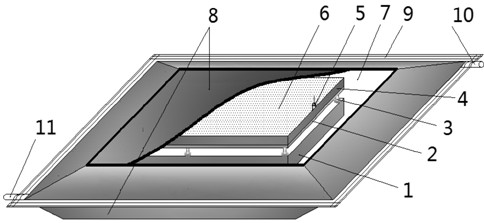

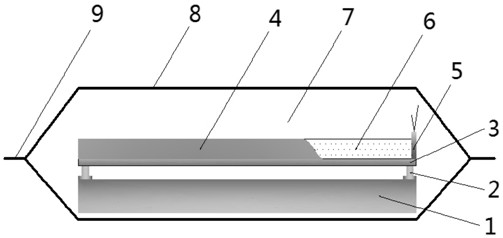

Novel neon gas protection explosive welding method and explosive welding structure

PendingCN113084324AImprove bonding qualityReduced risk of crackingNon-electric welding apparatusDetonatorEngineering

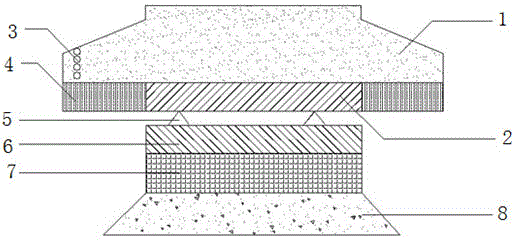

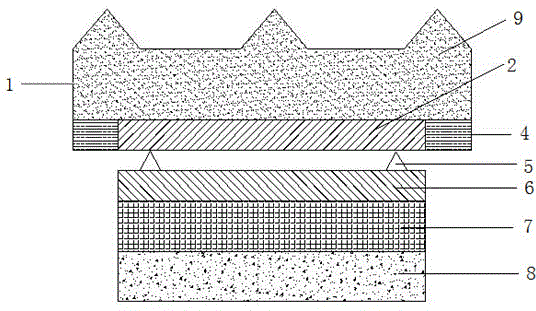

The invention discloses a novel neon gas protection explosive welding method. The novel neon gas protection explosive welding method comprises the following steps that S1, cleaning is conducted, specifically, the to-be-combined surfaces of a base plate and a compound plate are cleaned up; S2, assembling is conducted, specifically, the base plate and the compound plate which are cleaned up in the step S1 are assembled according to the principle that the base plate is located on the lower portion, the compound plate is located on the upper portion, and the to-be-welded surfaces are opposite, and a gap support is placed between the base plate and the compound plate; S3, explosive and detonator distribution is conducted, specifically, an explosive and a detonator are distributed on the upper surface of the compound plate; S4, a welding closed space is prepared, specifically, the base plate and the compound plate which are assembled in the step S3 are sealed through an aluminum-plastic hot melt film, and an air exhaust / inflation port and a gas component / pressure detection port are reserved in the diagonal positions; S5, neon gas is inflated, specifically, air in the closed space in the step S4 is exhausted, and the neon gas is inflated; and S6, explosive welding is conducted, specifically, the explosive is detonated through the detonator, and explosive welding is conducted. The situation that metal jet flow reacts with atmospheric components, and consequently brittle products are generated can be effectively avoided and weakened, the interface bonding quality is improved, and the welding strength is improved.

Owner:郑州宇光复合材料有限公司

Low explosion velocity explosive for explosive welding

The invention relates to a low explosion velocity explosive for explosive welding, which comprises the following components by weight percentage: 70-85 percent of No. 2 rock ammonium nitrate explosive, 10-25 percent of NaCl and 5-15 percent of water, and the components are uniformly mixed and prepared on the site. According to the low explosion velocity explosive, the explosion velocity of a common explosive is decreased, the use amount and the cost of a composite explosive for explosion are lowered; the low explosion velocity explosive overcomes the defects of over high explosion velocity and high probability of damaging the composite material low in the fusing point when the No. 2 rock ammonium nitrate explosive is directly used; explosives at different explosion velocities can be prepared according to different requirements of different materials on the explosion velocities on the site, and the technique is simple.

Owner:HUNAN FORHOME COMPOSITE MATERIALS CO LTD

Composite 3Cr13-Cu (Al)-1Cr18Ni9Ti for energy-saving lampblack free boiler

InactiveCN101536867ALow detonation velocitySlow downChemical industryCooking vesselsEngineeringUltimate tensile strength

The invention realizes the welding of composite 3Cr13-Cu (Al)-1Cr18Ni9Ti for a lampblack free boiler through three key technologies of wadding formulation optimization, welding base design and double cladding surface protection by adopting a once-explosion welding method, thereby greatly lowering the cost, improving the bonding strength of the interface of the composite, and being capable of replacing the material imported from foreign countries.

Owner:ENG COLLEGE OF ENG CORPS PLA UNIV OF SCI & TECH

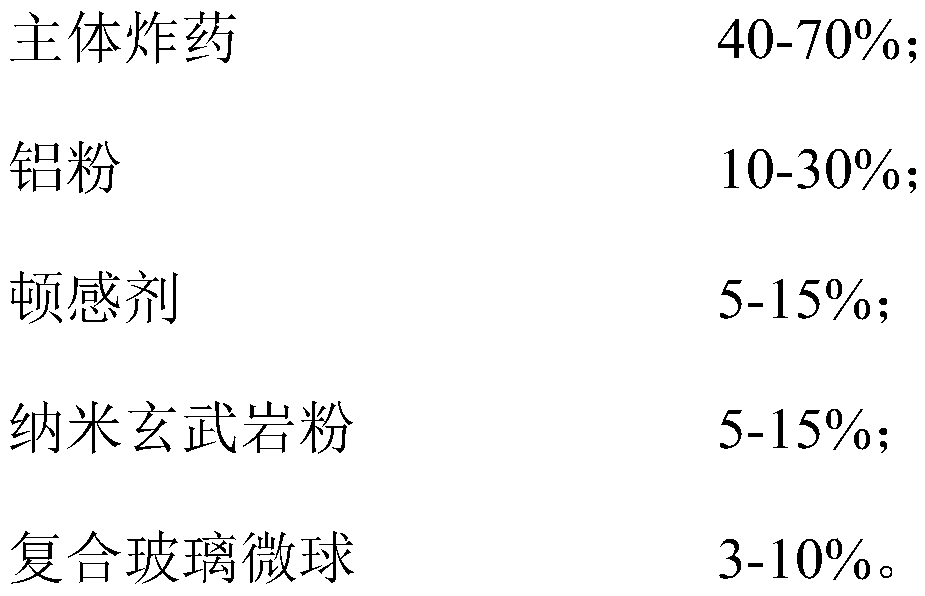

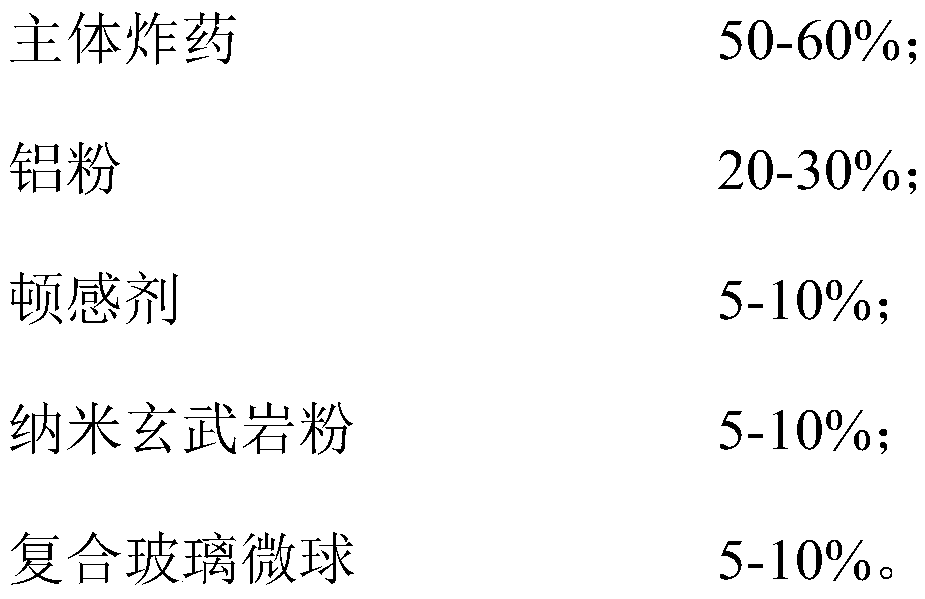

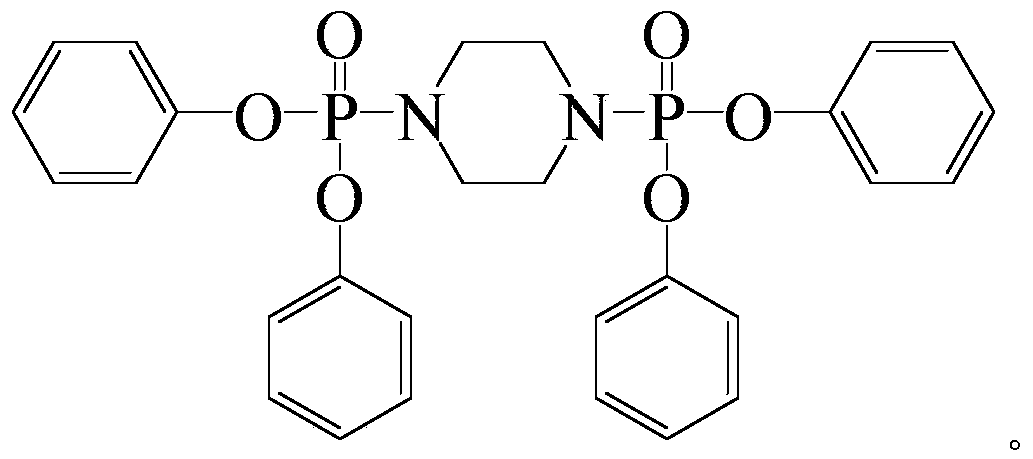

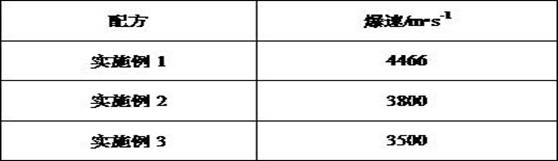

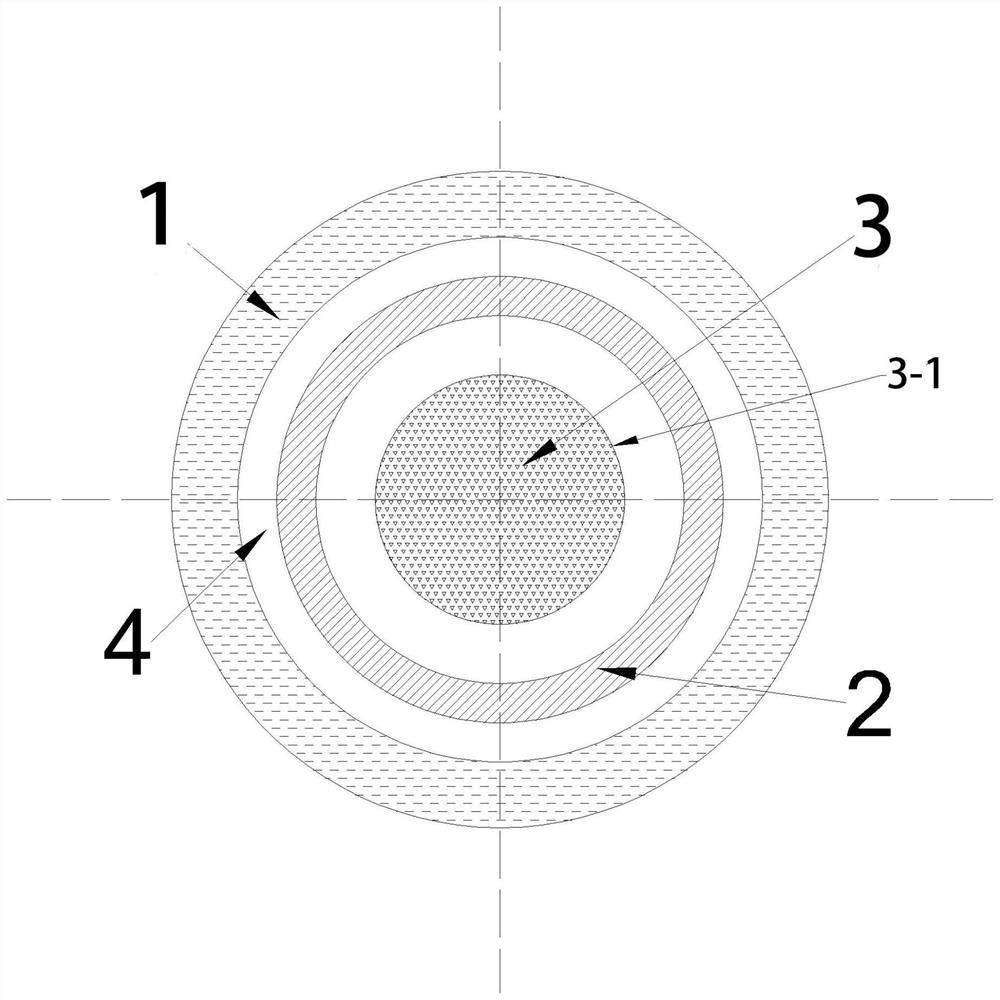

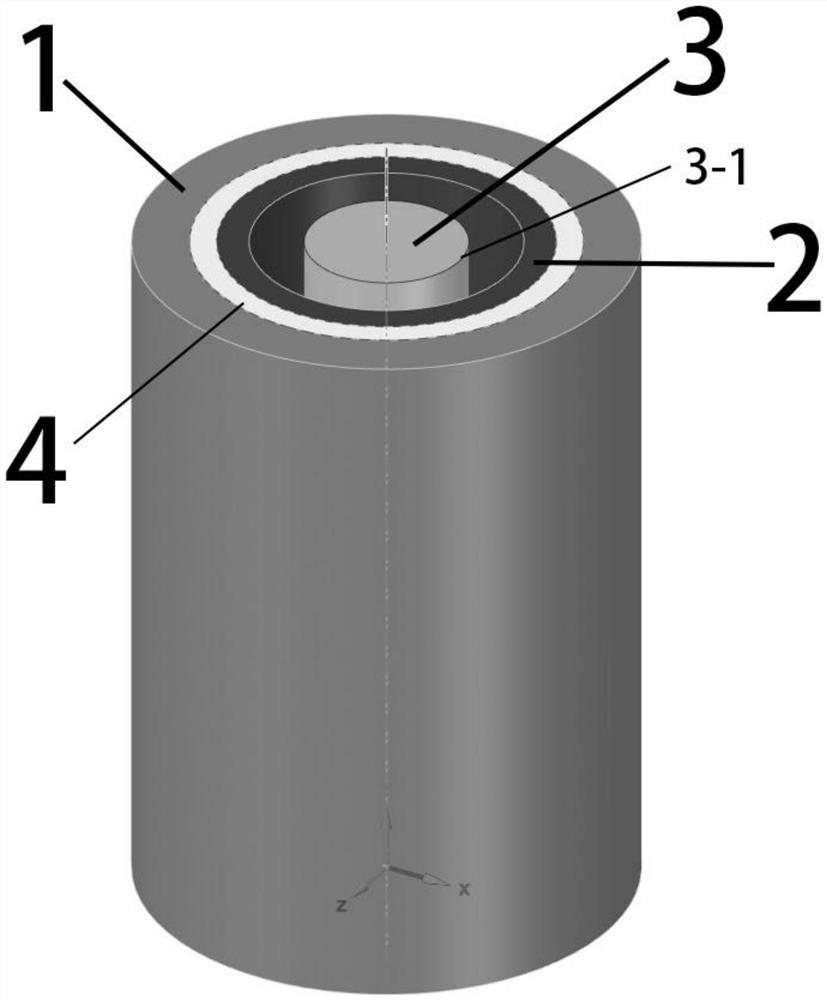

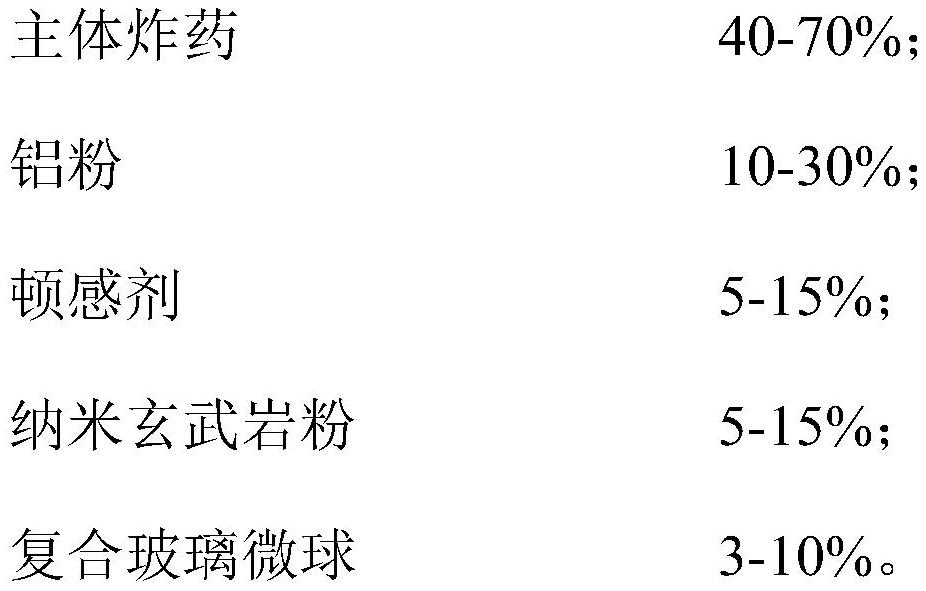

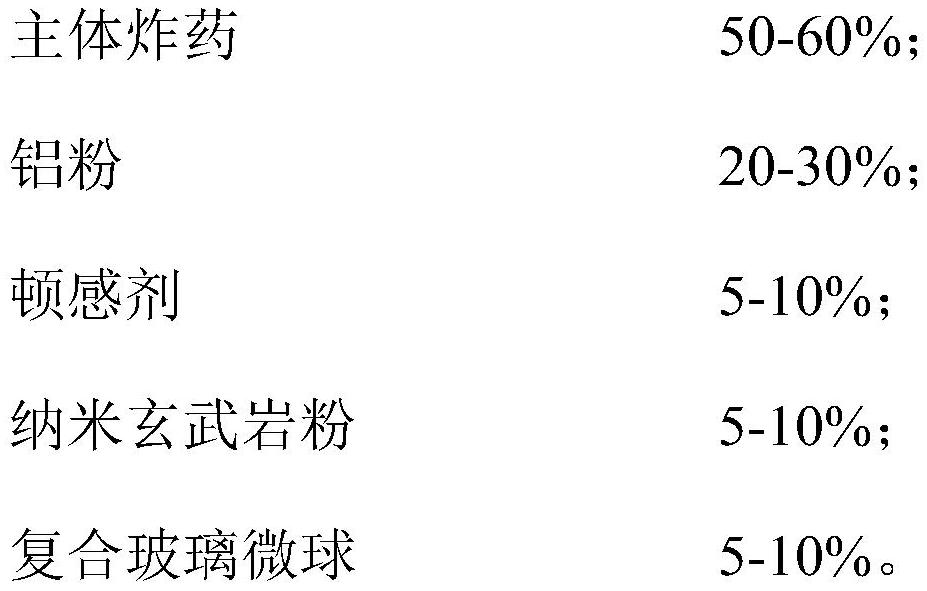

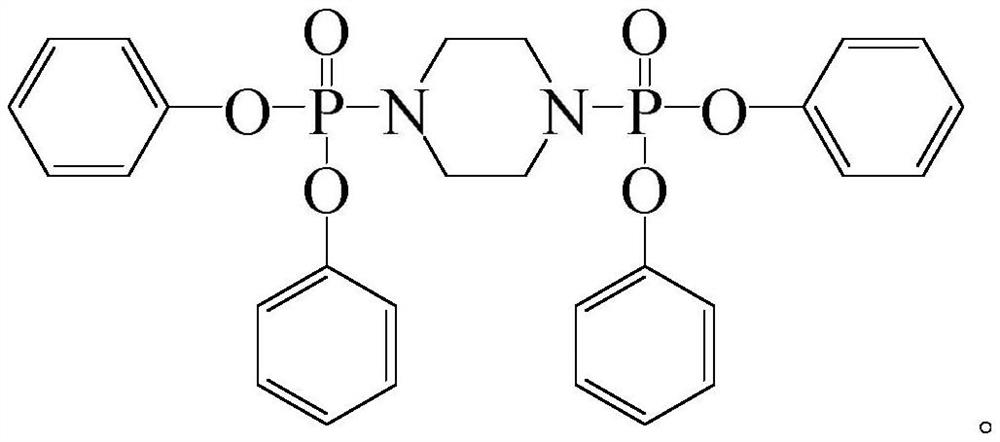

Explosive, and preparation method and application thereof

ActiveCN110218133AReduced explosion rateLow detonation velocityNon-explosive desensitisers/phlegmatisersPressure gas generationFiberExternal energy

The invention discloses an explosive, and a preparation method and an application thereof. The explosive comprises the following components in percentages by weight: 40 to 70% of a main explosive, 10to 30% of aluminum powder, 5 to 15% of a desensitizing agent, 5 to 15% of nanometer basalt powder and 3 to 10% of a composite glass microsphere. According to the invention, through addition of the composite glass microsphere, the explosion rate of the explosive can be reduced through the combined action of silicon dioxide on the surface of the composite glass microsphere and the nanometer basalt powder; meanwhile, under the action of external energy or explosive energy, the silicon dioxide on the surface of the composite microsphere is broken, and a flame retardant located in hollow aluminum fiber can be gradually released; thus, by combination of substances and through combined action, an obtained explosive has low explosion rate and high insensitiveness and flame-retardant performance, can achieve high safety performance and is applicable to the fields of stone mining, etc. The preparation method for the explosive has the advantages of simplicity, easily-available and cheap raw materials, convenient implementation, and applicability to industrial large-scale production application.

Owner:US DIAMOND OIL DRILLING SYST ENG (SHANGHAI) CO LTD

Density moderating agent for powdery explosives for explosive cladding and preparation method

InactiveCN107721780AImprove explosive fluidityImproving the moisture resistance of explosivesNon-explosive/non-thermic compositionsPerliteExplosive cladding

The invention discloses a density moderating agent for powdery explosives for explosive cladding. The density moderating agent is prepared from one or more mutual compounds in parts by weight: 500 to950 parts of perlite, 10 to 400 parts of carbon powder, 50 to 300 parts of aluminum powder and 30 to 200 parts of talcum powder. Raw materials selected by the density moderating agent are hydrophobicsubstances, so that free-flowing property of the explosives can be effectively improved and humidity resistance performance of the explosives is greatly improved. The invention also discloses a preparation method of the density moderating agent for the powdery explosives for explosive cladding. The method comprises the following steps: putting one or more of the perlite, the carbon powder, the aluminum powder and the talcum powder into a mixing machine; turning on the mixing machine and performing mixing for 30 to 60 minutes to obtain a mixture, and then packaging the mixture into a bag. A technological method of the density moderating agent is simple; the density conditioning agent prepared by adopting the method is stable in quality, and can be used for modifying density and detonation velocity of ammonium nitrate fuel oil explosives and multi-pore-particle ammonium nitrate fuel oil explosives and regulating free-flowing property.

Owner:陕西红旗民爆集团股份有限公司

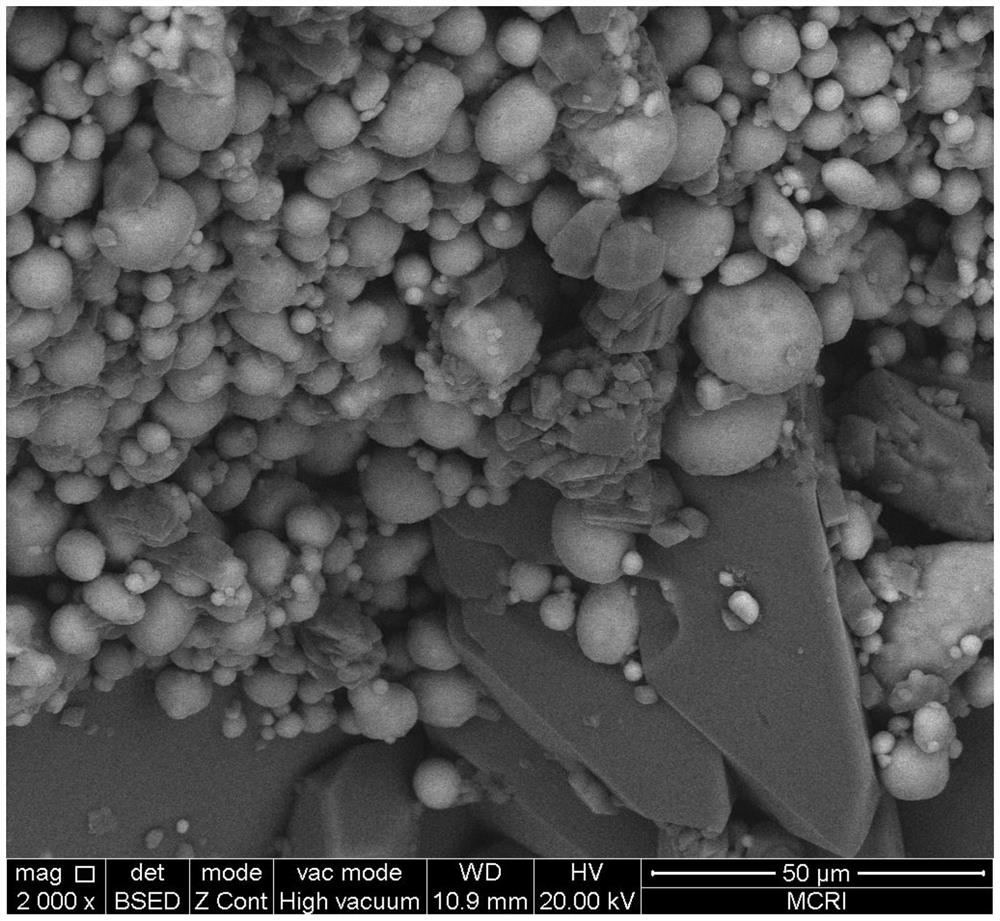

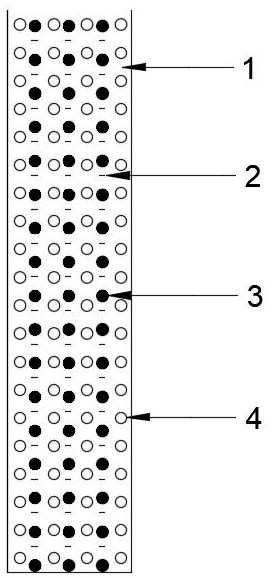

Preparation method of low-detonation-velocity and low-density explosive applicable to nickel-steel compounding

InactiveCN106518581AMeet the needs of the development of domestic chemical industry and other industriesTo meet the needs of the development of domestic chemical industry and other industriesNon-explosive/non-thermic compositionsDetonatorVolumetric Mass Density

The invention relates to a preparation method of a low-detonation-velocity and low-density explosive applicable to nickel-steel compounding. The preparation method comprises the following steps: detecting detonation parameters of an emulsified explosive; if the detonation parameters accord with pre-set parameters, carrying out the following steps: adding the emulsified explosive and pearlite into an explosive mixing machine at the same time and uniformly stirring, wherein the weight ratio of the emulsified explosive to the pearlite is 58 to 38; adding bran into the explosive mixing machine and sufficiently and uniformly mixing, wherein the weight ratio of the emulsified explosive to the pearlite to the bran is 58 to 38 to 15; detecting the density and detonation velocity of a product in the explosive mixing machine; and considering the product with the density of 0.84g / cm<3> and the detonation velocity of 2000m / s-2200m / s as a qualified product. A nickel-steel compound plate obtained by detonation compounding of the explosive has the minimum shearing strength tau b which is more than or equal to 210Mpa; except a detonator shadow region, the fitting rate reaches 100%; and adverse effects on the detonator shadow region are eliminated through avoiding a useless part of a detonating point in the compound plate.

Owner:安徽宝泰特种材料有限公司

Explosive welding method for bimetal composite boards with special quality requirements

InactiveCN103056508BReliable weldingMeet welding quality requirementsNon-electric welding apparatusBond interfaceCharged body

The invention discloses an explosive welding method for bimetal composite boards with special quality requirements. The explosive welding method includes preprocessing blanks; charging powder; and performing explosive welding. In a powder charging procedure, 'basin'-shaped powder charge bodies are arranged on shroud plates and extension plates, upper and lower surfaces of the powder charge bodies are parallel to the shroud plates and the extension plates, and powder charging quantities are acquired by computing according to a formula. The welded rate of the composite boards welded by the explosive welding method reaches 100%, the bonding strength of welded surfaces of the bimetal composite boards meet a bimetal solid-phase metallurgical bonding strength law, bonding interfaces of the bimetal composite boards are finely wavy and are excellent in quality, and accordingly the quality requirements of critical equipment of thermonuclear fusion power generation test reactors on the composite boards are met.

Owner:中国人民解放军理工大学野战工程学院 +2

Composite explosive particle and preparation method thereof

ActiveCN114262249AEasy to wrapGood coating effectNitroparaffin explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsExplosive AgentsActive agent

The invention provides a composite explosive particle and a preparation method thereof. The composite explosive particle is prepared from the following raw materials: CL-20, ADN, a composite surfactant, DOA and EVA, the composite surfactant is prepared from sodium taurodeoxycholate and nonylphenol polyoxyethylene ether. The composite explosive particle has the advantage of high energy, compared with CL-20, the detonation velocity of the insensitive composite particle is reduced by less than 5%, and the explosion heat and oxygen balance are remarkably improved. The composite explosive particle provided by the invention has the advantage of low sensitivity, and the mechanical sensitivity of the composite particle is obviously superior to that of the original CL-20 explosive and ADN explosive. The composite explosive particle is remarkable in heat effect, and the decomposition temperature is higher than that of the simple substance component ADN. According to the composite explosive particle, two sensitive high-energy explosives are adopted as matrixes to prepare the composite particle, and the safety of a composite material is guaranteed through a physical matching technology.

Owner:XIAN MODERN CHEM RES INST

Special explosive for copper-A3 steel explosion welding and preparation method thereof

InactiveCN105481620ADetonation speed adjustableLow detonation velocityEnergy inputExplosive ingredient compoundingMetallic materialsAmmonium nitrate

A special explosive for copper-A3 steel explosion welding and a preparation method thereof belong to special explosives and preparation methods thereof. A 2# rock ammonium nitrate explosive is taken as the main raw material and physically levigated together with sodium salt and expanded perlite to serve as the raw material for preparing the special explosive for copper-A3 steel explosion welding. In the preparation process of the special explosive, according to the weight ratio of the 2# rock ammonium nitrate explosive to sodium salt to expanded perlite of (95-60%): (2.5-20%): (2.5-20%), the 2# rock ammonium nitrate explosive, sodium salt and expanded perlite are mixed and fully stirred to obtain special explosives for copper-A3 steel explosion welding, which are of different explosion velocities. The prepared special explosive has the characteristics of being relatively low in explosion velocity, stable in detonation performance, moderate in energy, wide in material source, low in processing cost and the like. When the prepared special explosive is used for explosive welding of a copper-A3 steel plate, the wavy joint surfaces of the two materials are small in waveform change, compact in combination and stable in welding quality, the quality problems of corrosion, cavity and the like, caused when a high explosive is utilized for metal-material explosive welding are better solved, and the economic benefits are remarkably improved.

Owner:CHINA UNIV OF MINING & TECH

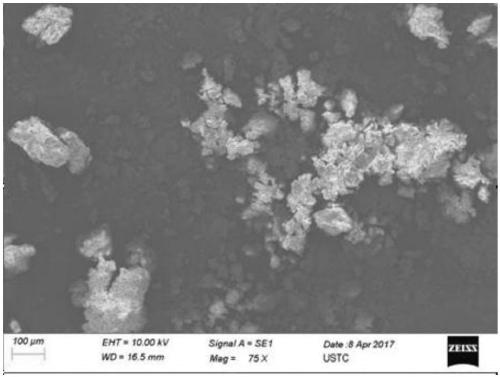

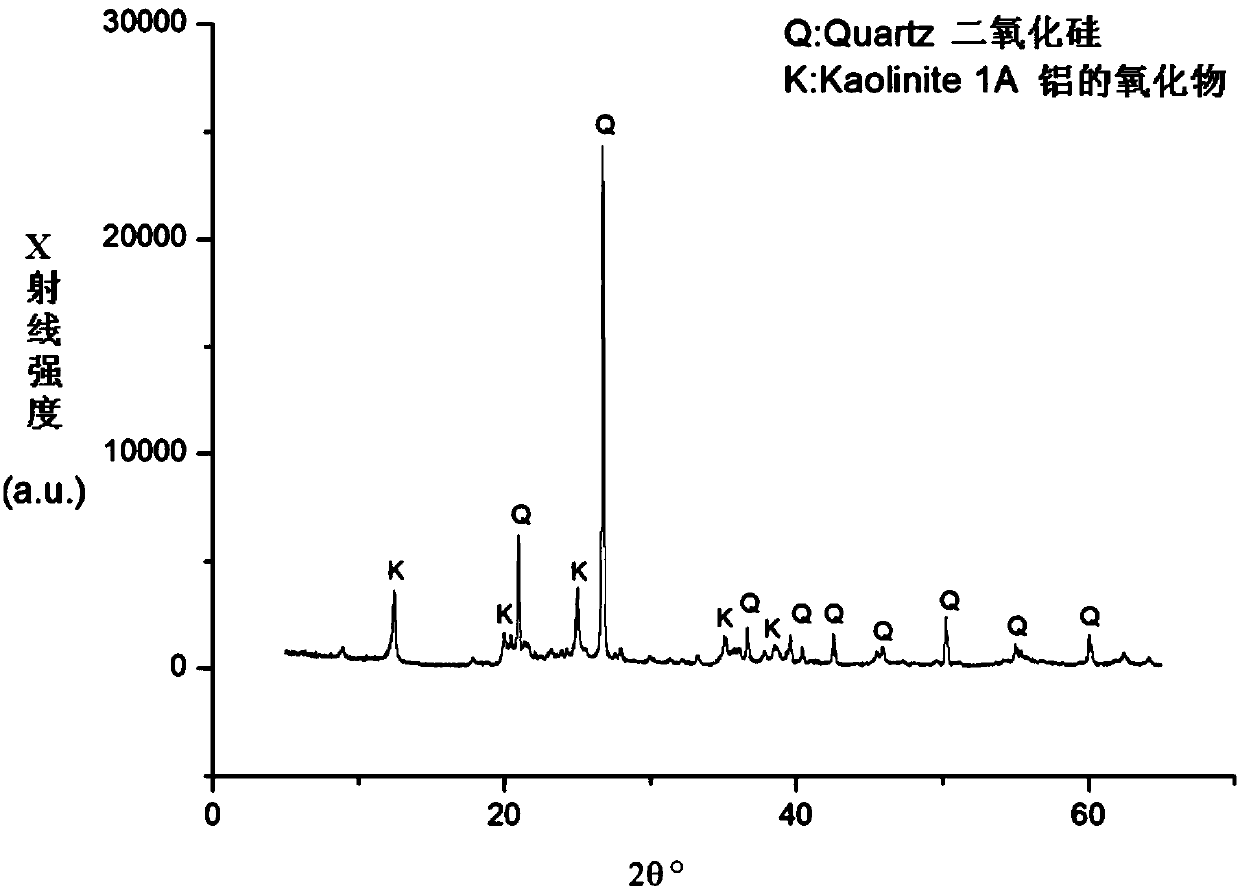

A low detonation velocity emulsion explosive and its application

ActiveCN107200670BAdjustable detonation speedLow detonation velocityNon-explosive stabilisersNon-electric welding apparatusExplosive AgentsThermodynamics

The invention belongs to the technical field of industrial explosive and provides low-detonation-velocity emulsified explosive. The low-detonation-velocity emulsified explosive is prepared from basic emulsified explosive and clay, wherein the mass percent of the basic emulsified explosive is greater than 70 percent and is less than or equal to 95 percent; the mass percent of the clay is greater than or equal to 5 percent and is less than 30 percent; the basic emulsified explosive is obtained by sensitizing an emulsified matrix through a sensitizing agent; the clay is mainly prepared from main components including silicon dioxide and oxides of aluminum. Moreover, the invention further provides application of the low-detonation-velocity emulsified explosive to metal explosive welding. The low-detonation-velocity emulsified explosive provided by the invention has the advantages of low price and can be used for carrying out explosive welding on different metal materials, so that the detonation velocity and explosive grading of the emulsified explosive are easily adjusted by enterprises according to own requirements; the price of the compound special explosive for detonation is reduced and pollution to the environment is reduced to the greatest extent.

Owner:UNIV OF SCI & TECH OF CHINA

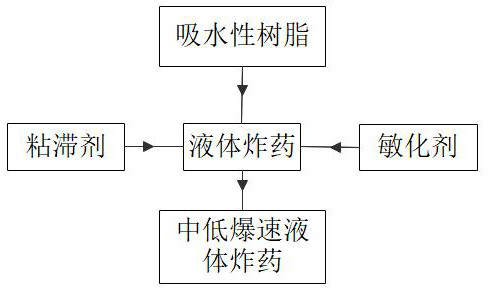

Medium-low detonation velocity liquid explosive and preparation process thereof

PendingCN113087581ADetonation is easyDetonation velocity controlNitroparaffin explosive compositionsExplosive ingredient compoundingChemistryComposite material

The invention relates to a medium-low detonation velocity liquid explosive and a preparation process thereof. The liquid explosive comprises the following components by mass: 45-88% of a liquid explosive, 1-6% of an adhesive, 2-7% of a sensitizer, and 9-42% of water-absorbent resin. The medium-low detonation velocity liquid explosive has the following advantages: (1) the energy density of the liquid explosive is diluted, and the detonation velocity of the liquid explosive is reduced; (2) the detonation velocity is easy to control and convenient to adjust, all components in the system are uniformly distributed, and energy density is uniform; (3) the detonation is reliable, the detonation velocity is easy to control, mechanical sensitivity is low, and the safety is high; (4) a large amount of water is brought into the liquid explosive and mixed uniformly, the explosion temperature generated during explosion is reduced, and water mist generated during explosion absorbs generated harmful gas and dust; and (5) the operation is convenient, the preparation method is simple, and the use cost is reduced.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A kind of explosion welding method of titanium/aluminum/steel multilayer composite board

ActiveCN105215536BReduce intensityLow melting pointWelding/soldering/cutting articlesMetal working apparatusTitaniumUltimate tensile strength

The invention provides an explosive welding method of a titanium-aluminum-steel multilayer explosive composite board. The explosive welding method comprises the following steps of: carrying out explosive welding three times, to be specific, carrying out explosive welding for the first time by taking aluminum as a composite layer and titanium as a base layer to obtain an aluminum-titanium composite board; carrying out explosive welding for the second time by taking aluminum as a composite board and steel as a base board to obtain an aluminum-steel explosive composite board; and carrying out explosive welding for the third time by taking the aluminum-titanium composite board as a composite board, the aluminum-steel composite board as a base board and an aluminum board as an explosive joint surface to obtain a titanium-aluminum-aluminum-steel four-layer composite board which is the titanium-aluminum-steel explosive composite board in fact. When titanium, aluminum, aluminum and steel are composited through the third explosion, the upper and lower of the joint surface are aluminum plates which are low in intensity and melting point, and welding is realized by a low-detonation velocity and low-explosive load explosion method; and an aluminum-steel interface is ensured not to be stratified.

Owner:安徽弘雷金属复合材料科技有限公司

Explosive composite pipe preparation method based on implosion method in local vacuum environment

InactiveCN113927148AAvoid local defect problemsReduce lossNon-electric welding apparatusPumping vacuumEngineering

The invention provides an explosive composite pipe preparation method based on an implosion method in a local vacuum environment. The explosive composite pipe preparation method comprises the following steps: a to-be-composited pipe 1, a to-be-composited pipe 2 and a pvc pipe are coaxially arranged in sequence from outside to inside; the pcv pipe is filled with a grain made of a detonator and explosive, and an explosive device of the to-be-welded pipes is formed; the two ends of a gap between the to-be-composited pipes are sealed by using sealing strips and vacuumized, and a vacuum gap environment is formed; and the explosive device is detonated, and to-be-composited materials are welded by utilizing high pressure generated by explosive explosion to obtain the explosive composite pipe. Compared with a traditional preparation method, the explosive composite pipe preparation method has the following advantages: higher energy utilization rate of the explosive, freer selection for the detonation velocity and higher operability are achieved; the phenomenon of large-area melting of a composite interface caused by insufficient discharge of a gap air layer in the traditional preparation method is completely eradicated; and the energy utilization rate of the explosive is effectively increased, and the production cost is greatly reduced.

Owner:ANHUI UNIV OF SCI & TECH

A kind of explosive and its preparation method and application

ActiveCN110218133BReduced explosion rateLow detonation velocityNon-explosive desensitisers/phlegmatisersPressure gas generationFiberExplosive Agents

The invention discloses an explosive, and a preparation method and an application thereof. The explosive comprises the following components in percentages by weight: 40 to 70% of a main explosive, 10to 30% of aluminum powder, 5 to 15% of a desensitizing agent, 5 to 15% of nanometer basalt powder and 3 to 10% of a composite glass microsphere. According to the invention, through addition of the composite glass microsphere, the explosion rate of the explosive can be reduced through the combined action of silicon dioxide on the surface of the composite glass microsphere and the nanometer basalt powder; meanwhile, under the action of external energy or explosive energy, the silicon dioxide on the surface of the composite microsphere is broken, and a flame retardant located in hollow aluminum fiber can be gradually released; thus, by combination of substances and through combined action, an obtained explosive has low explosion rate and high insensitiveness and flame-retardant performance, can achieve high safety performance and is applicable to the fields of stone mining, etc. The preparation method for the explosive has the advantages of simplicity, easily-available and cheap raw materials, convenient implementation, and applicability to industrial large-scale production application.

Owner:US DIAMOND OIL DRILLING SYST ENG (SHANGHAI) CO LTD

Low-detonation velocity anfo explosive and preparation method thereof

ActiveCN101844956BImprove mixing uniformitySimple production processExplosivesParaffin waxMicrosphere

The invention relates to a low-detonation velocity anfo explosive and a preparation method thereof. The low-detonation velocity anfo explosive comprises 77-88 parts of modified powdery anfo explosive, 10-20 parts of porous granulated ammonium nitrate and 2-3 parts of polystyrene foam plastic microballoon, wherein the modified powdery anfo explosive mainly comprises 74.54-84.66 parts of crystallized ammonium nitrate, 0.15-0.26 part of modifying agent and 2.31-3.08 parts of compound oil phase; and the compound oil phase comprises 1.71-2.12 parts of paraffin, 0.58-0.86 part of rosin and 0.02-0.06 part of Span 80 emulsifying agent. The preparation method comprises the following steps of: mixing the crystallized ammonium nitrate and the modifying agent, crushing and drying; and then mixing with the compound oil phase; finally adding the porous granulated ammonium nitrate and the polystyrene foam plastic microballoon and uniformly mixing to obtain the low-detonation velocity anfo explosive with the density less than 0.55g / cm<3> and the detonation speed less than 2,600m / s. The explosive has the advantages of favorable particle flowability, convenience for filling into a blast hole, low detonation velocity, low density and capability of meeting the requirements for using the explosive on smooth surface blasting and presplitting blasting of mines, highways, railways and open-air deep-hole slopes.

Owner:HUAINAN SHUNTAI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com