Liquid explosive with small critical diameter and medium detonation velocity and preparation technology thereof

A technology of liquid explosives and critical diameter, applied in the direction of nitroalkane composition, etc., can solve the problems of low mechanical sensitivity, scarcity of raw materials, slow loading speed, etc., achieve the effect of reducing compaction, simple preparation method, and slow loading speed

- Summary

- Abstract

- Description

- Claims

- Application Information

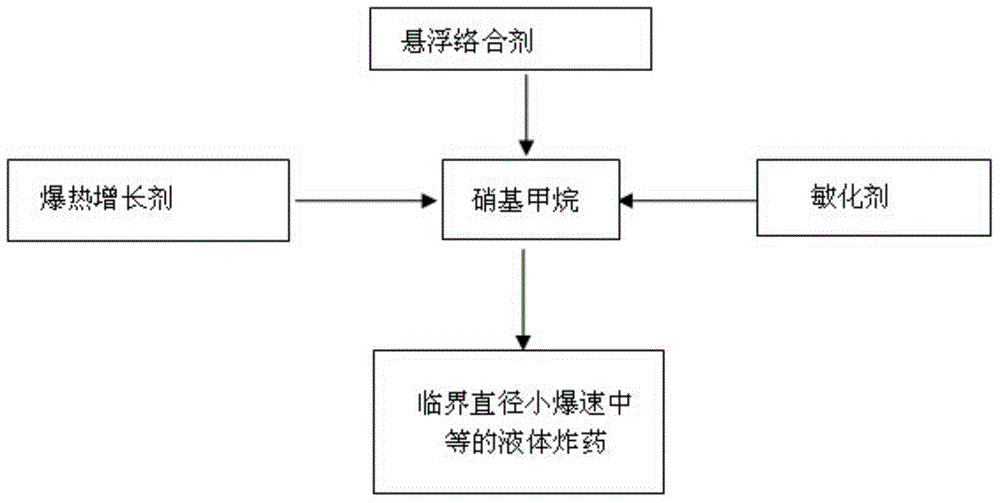

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

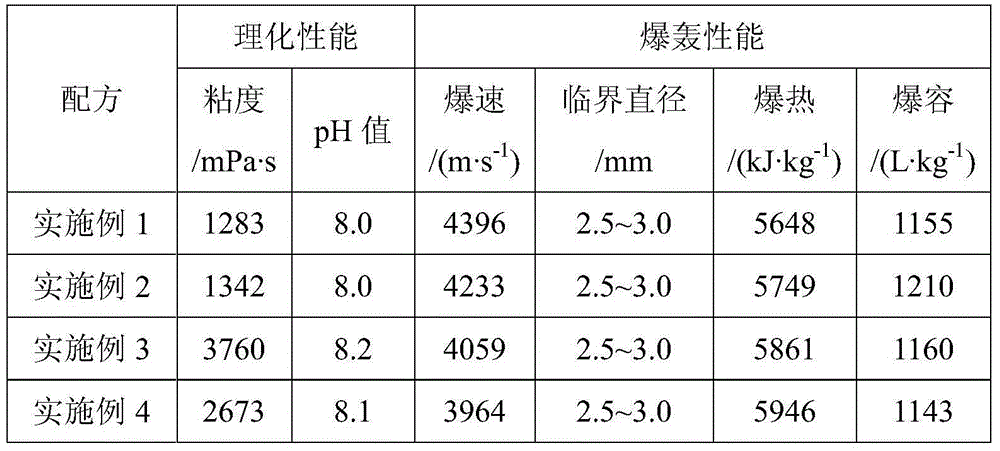

[0037] Example 1: Add 10 g of performance buffer to 76 g of dinitromethane, stir for 10 minutes, then add 6 g of triethanolamine and keep stirring until the liquid explosive is uniform, then add 8 g of ethylenediamine and stir evenly. The measured physical and chemical properties and detonation properties are shown in Table 1.

Embodiment 2

[0038] Example 2: Add 12 g of performance buffer to 78 g of mononitromethane, stir for 10 minutes, then add 5 g of sodium edetate and keep stirring until the liquid explosive is uniform, then add 5 g of ethylenediamine and stir evenly. The measured physical and chemical properties and detonation properties are shown in Table 1.

Embodiment 3

[0039] Example 3: Add 14g of performance buffer to 75.3g of mononitromethane, stir for 10 minutes, add 5g of diethanolamine and keep stirring until the liquid explosive is uniform, add 5.7g of diethylenetriamine and stir evenly. The measured physical and chemical properties and detonation properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com