Patents

Literature

56 results about "Hydrazine nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

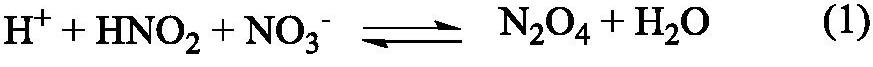

Hydrazine nitrate is an inorganic compound with the chemical formula N₂H₄·HNO₃. It was first synthesized by Germans in 1989. It has usage in liquid explosives as an oxidizer. It exists in two crystalline forms, stable α-type and unstable β-type. The former is usually used in explosives. Its solubility is small in alcohols but large in water and hydrazine. It has strong hygroscopicity, only slightly lower than ammonium nitrate.

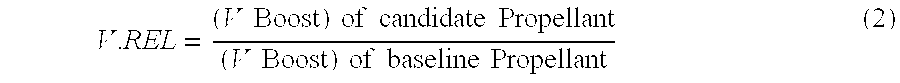

Premixed liquid monopropellant solutions and mixtures

Nondetonable, or low detonation sensitivity, substantially nontoxic liquid monopropellants are provided. The liquid propellants are formed from aqueous solutions of solid oxidizers in liquid oxidizers and water soluble liquid fuels and formulated to have a freezing point less than −10° C. Liquid oxidizers may be inorganic or organic aqueous solutions, with hydrogen peroxide being preferred. Preferred solid oxidizers are water soluble nitrates including ammonium dinitramide, aminoguanidine dinitrate, ammonium nitrate, hydroxylamine nitrate, hydrazine nitrate, guanidine nitrate and aminoguanidine nitrate. Preferred liquid fuels are water soluble alcohols, amines and amine nitrates, hydroxyethyl hydrazine, hydroxyethylhydrazine nitrate, cyanoguanidine, guanidines, aminoguanidines, triaminoguanidines, and their nitrate salts, ethanolamine dinitrate, ethylenediamine dinitrate, polyvinyl nitrate, and aziridine.

Owner:AEROJET GENERAL CORP

Smokeless flameless gunpowder agent

InactiveCN101215211AImprove stabilityImprove moisture resistanceNon-explosive/non-thermic compositionsFirecrackerFireworks

The invention discloses a firework agent with no smoke, which is characterized in that the invention is produced by nickel hydrazine nitrate blending with accessories , wherein, the nicker hydrazine nitrate is generated by mixing and reaction of nickelous nitrate hexahydrate and hydrazine hydrate, The weight ratio of raw materials of the nickel hydrazine nitrate is that nickelous nitrate hexahydrate takes 35-85 portions of weight per percentage, hydrazine hydrate takes 15-65 portions of weight per percentage, the weight ratio of raw materials of the fireworks agent with no smoke is that nickelous nitrate hexahydrate takes 20-62 portions of weight per percentage, excipients takes 40-80 portions of weight per percentage, wherein the excipients are mineral powders with 80-120 orders which are incombustible, such as pearlite powder or sepiolite powder or river sand, two or more of the excipients can be used in manufacture of different firework products. Protocol fireworks with color flowers and firecrackers which are made by the firework agent with no smoke are smokeless and flameless, and are in according with the environment-friendly requirement.

Owner:邹建文

Micro-priming powder for detonator

InactiveCN101440011ASimple structureHigh working reliabilityNitrated pentaerythritol explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsDetonatorAdhesive

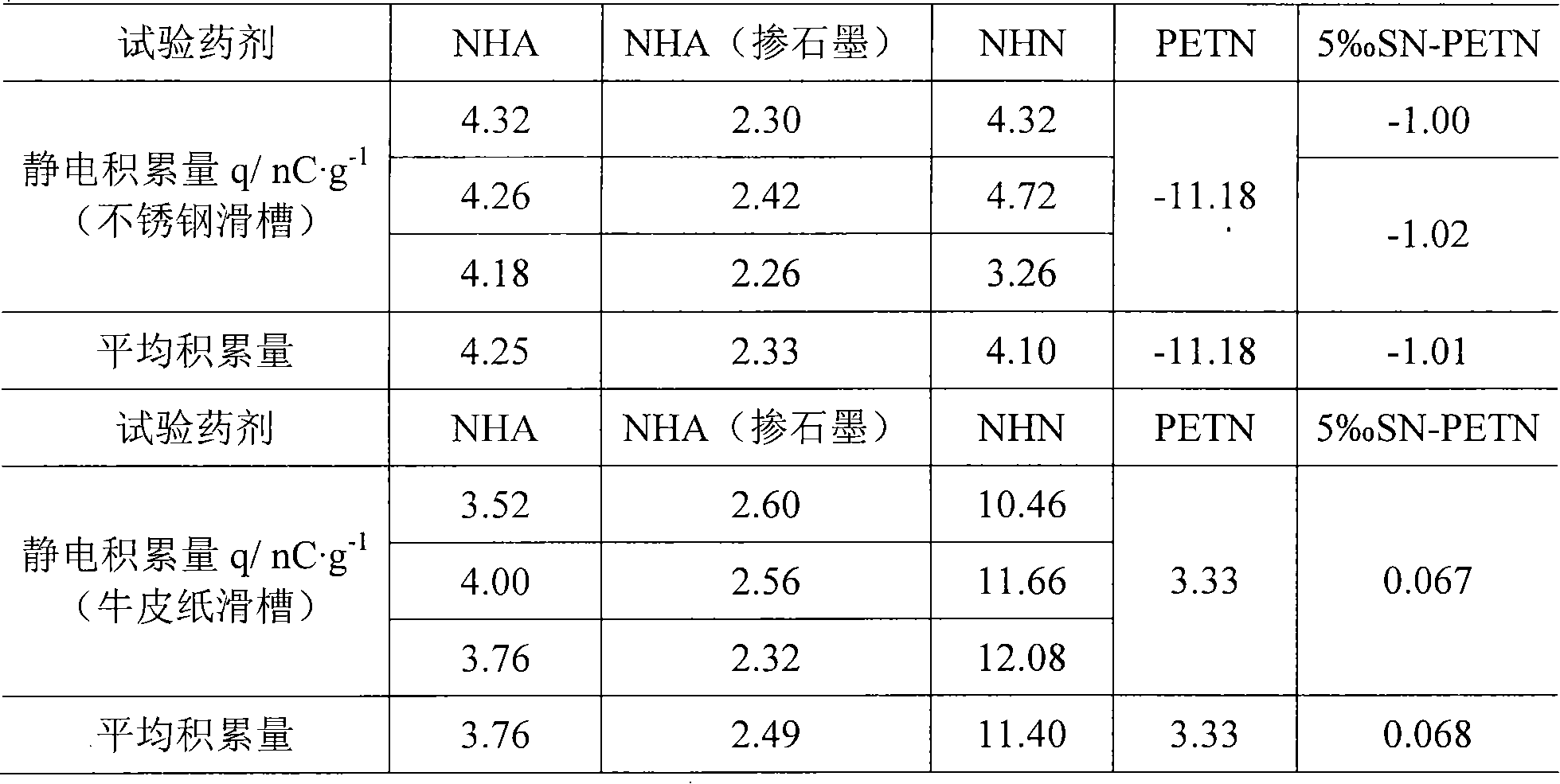

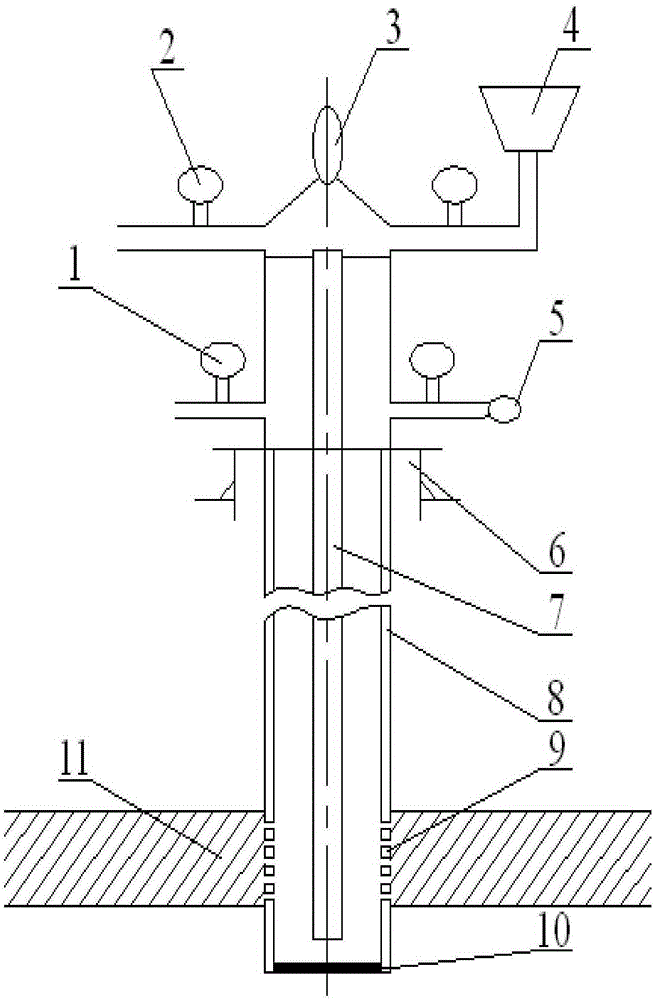

The invention relates to micro initiating explosive for an exploder, and solves the problems of insecurity of the exploder with the initiating explosive and high cost of the exploder without the initiating explosive. The micro initiating explosive comprises more than one high explosive and more than one initiating explosive. The high explosive comprises hexogen and PETN; the initiating explosive comprises dinitrodiazophenol, lead azide, lead trinitroresorcinate, nickel hydrazine nitrate and perchloric acid tricarbohydrazide cadmium complex; and the more than one high explosive and the more than one initiating explosive are mixed to prepare the micro initiating explosive. Adhesive and surfactant can also be used. The micro initiating explosive has the advantages that the micro initiating explosive can reduce the content of the initiating explosive by 30 to 60 percent compared with the conventional exploder filled with the explosive, lower 20 to 30 percent of cost compared with the prior exploder, improve safety during assembly of the exploder, reduce static electricity, friction, impact and light and heat sensitivity while ensuring initiating force and flame sensitivity, improve safety during production, transportation, storage and use of the exploders, can reduce explosive feeding amount of the exploder, and improve free-running property of preparations.

Owner:ANHUI UNIV OF SCI & TECH

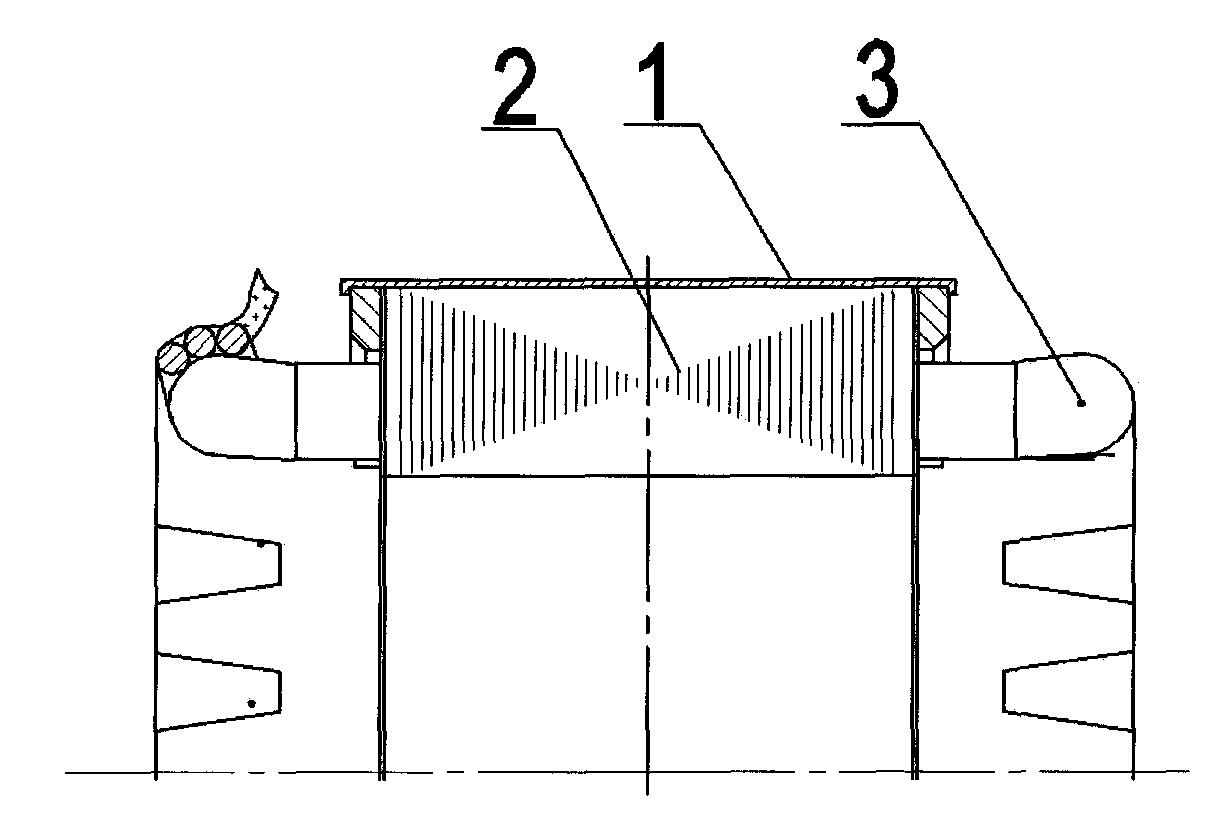

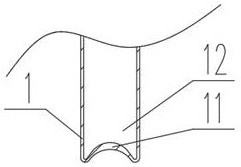

Insulating method and device of oil pump motor stator of electric locomotive transformer powered up by frequency converter

ActiveCN101789654AHigh resistance to high frequency electrical breakdownHigh strengthApplying solid insulationFrequency changerSolvent free

The invention relates to insulating method and device of an oil pump motor stator of an electric locomotive transformer powered up by a frequency converter. An electromagnetic wire with a polyimide hybridized nano material insulating layer is adopted to manufacture a stator winding, and a stator adopts a random single-layer winding structure; an NHN (nickel hydrazine nitrate) composite foil with the capacity of resisting corona is adopted to carry out isolation and insulation treatment in a stator insulating groove, ground insulation and phase to phase insulation; then a motor stator is placed in a vacuum container containing a TJ1158H level solvent-free immersion paint, and an inorganic nano material (such as an aluminum oxide derivative with a grain size of 50-100 nanometers) accountingfor 3-5 percent of the total quantity of the immersion paint is added to the solvent-free immersion paint; and integral-immersion and drying treatment is carried out by utilizing a vacuum pressure integral-immersion (also known as V.P.I) insulating treatment technology. A hard corona resistant paint film is formed on the surface of the motor after the motor stator is subjected to the integral-immersion treatment, and after the motor is finally assembled, cleaned and arranged on the transformer, high vacuum evacuation treatment is carried out on the transformer, wherein the vacuum degree is the pressure of 1*10-5 to 1*15-6 milli Hg; and after a required vacuum degree is reached, transformer oil is filled.

Owner:株洲博扬轨道电气有限责任公司

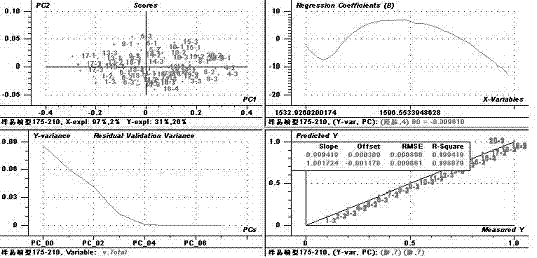

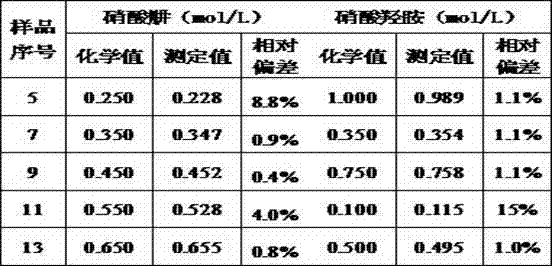

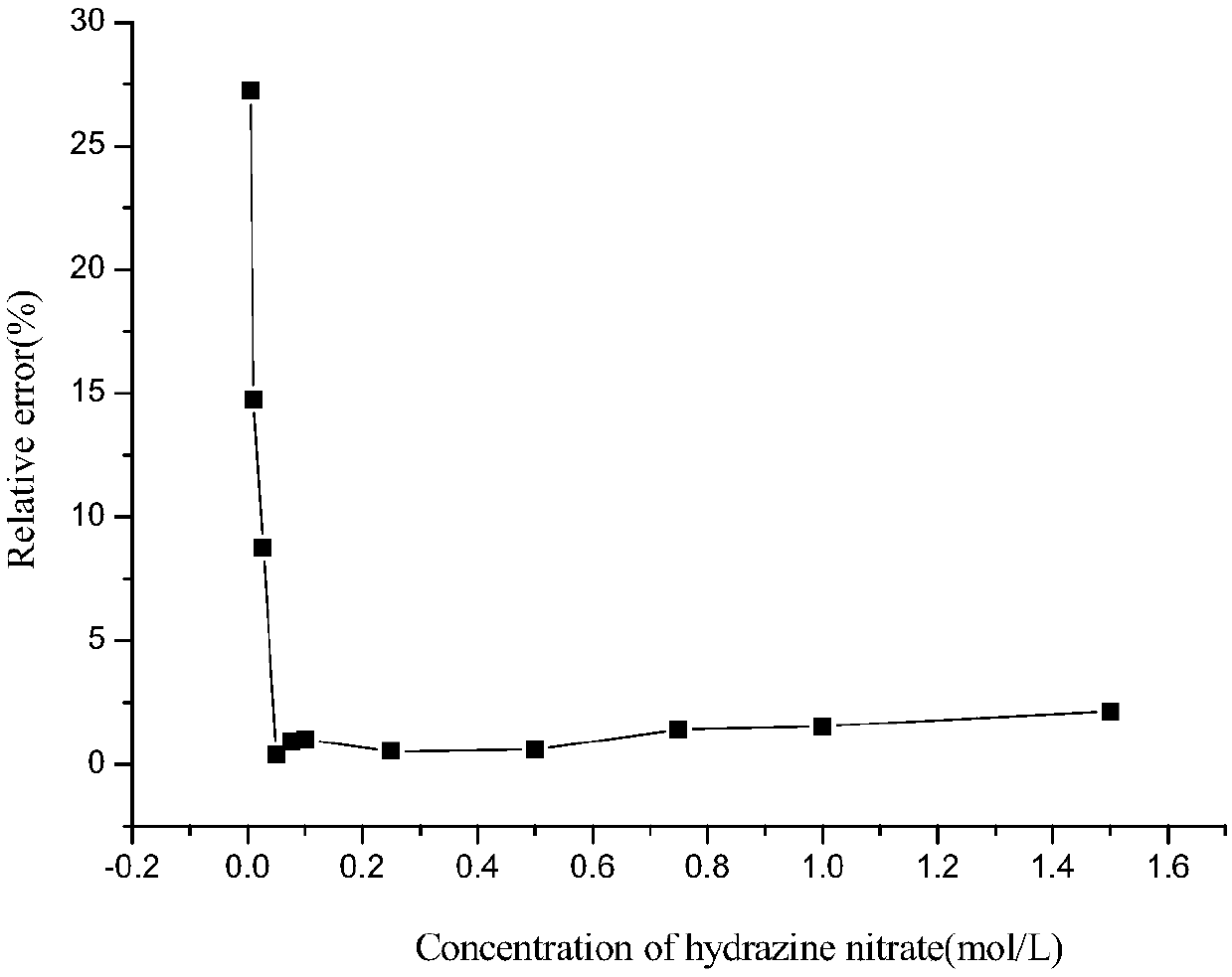

Determination method of hydrazinium mononitrate and hydroxylamine nitrate

InactiveCN102788765ASimplify the analysis processColor/spectral properties measurementsHydroxylamineAfter treatment

The invention belongs to the technical field of after treatment of nuclear fuel, and discloses a determination method of hydrazinium mononitrate and hydroxylamine nitrate. The method utilizes a near infrared spectrum method to determine the hydrazinium mononitrate and the hydroxylamine nitrate. The key points of the determination method are that the wavelength range is 1532nm-1656nm, the sweep integration time is 0.5-0.6ms, the optical path length is 2-3mm, and water or air is used as reference. The determination method disclosed by the invention has the characteristics of simpleness, high efficiency and capability of simultaneously determining the contents of the hydrazinium mononitrate and the hydroxylamine nitrate.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

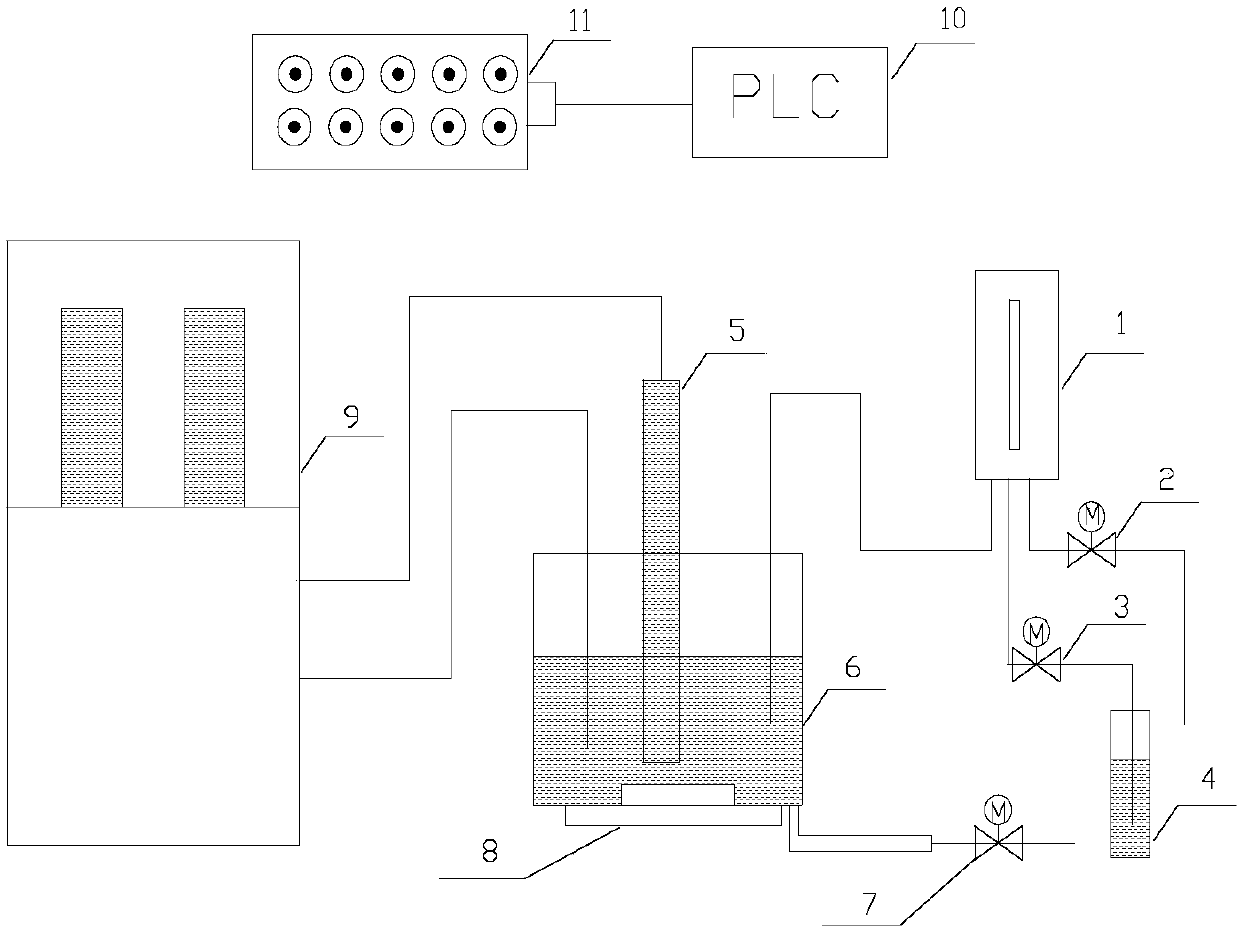

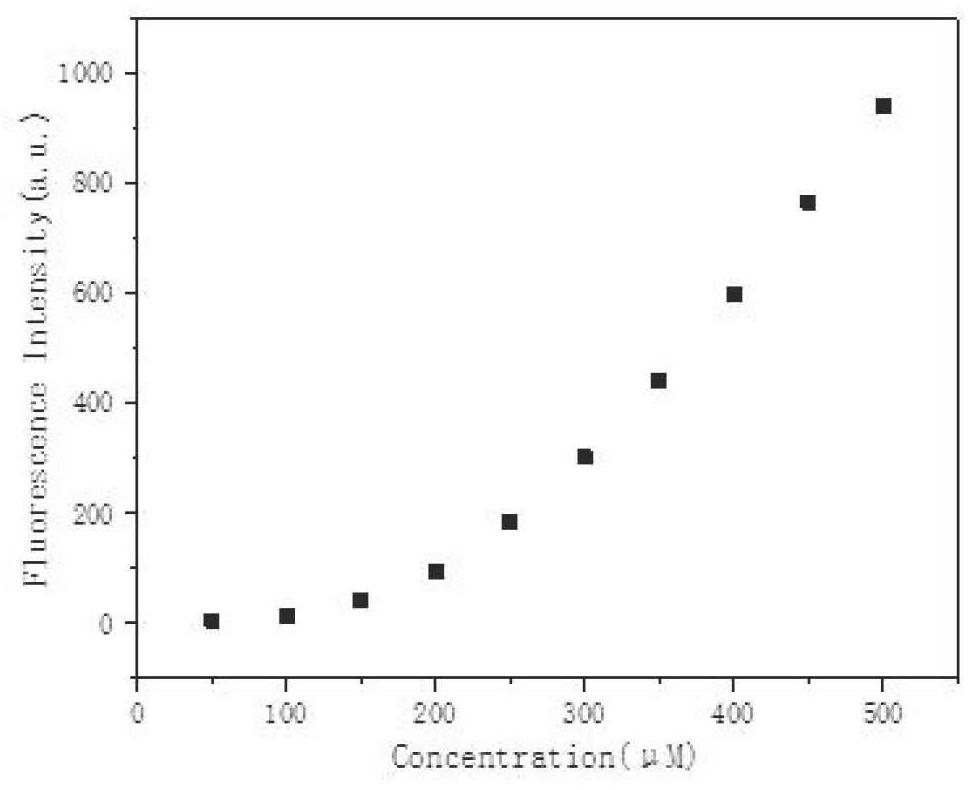

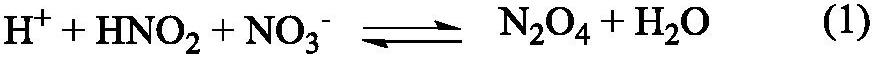

Online monitoring system for detecting hydrazine nitrate and hydroxylamine nitrate simultaneously

ActiveCN109856221ASimplify the analysis processHigh measurement accuracyMaterial analysis by electric/magnetic meansHydroxylamineMonitoring system

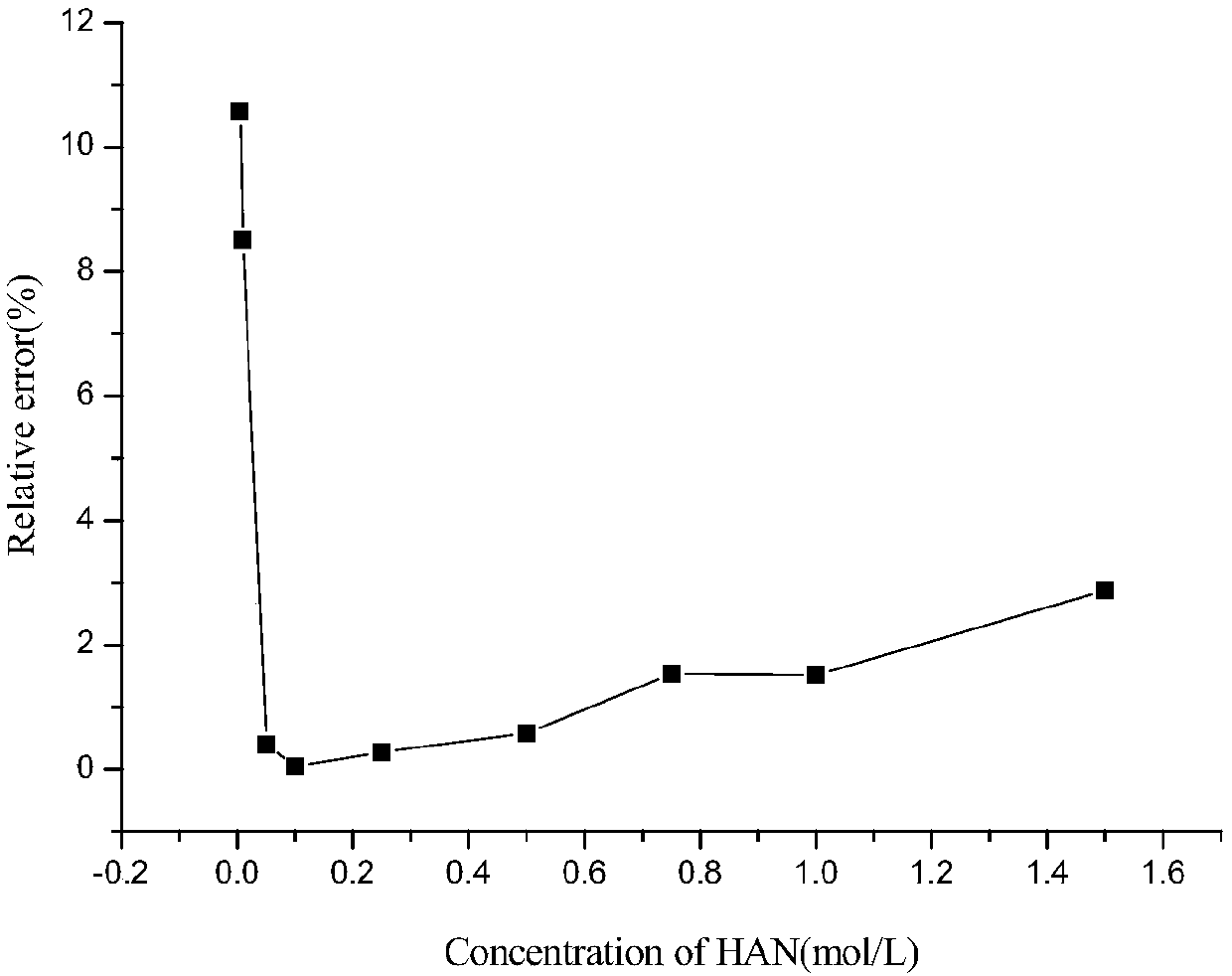

The invention relates to an online monitoring system for detecting hydrazine nitrate and hydroxylamine nitrate simultaneously, and belongs to the technical field of nuclear fuel post-treatment. The online monitoring system comprises a solution extraction system, a potential titration system and a system control center, and uses a standard sodium hydroxide solution to determine the hydrazine nitrate and hydroxylamine nitrate simultaneously, and when a detection result is beyond the detection range of (0.05-0.5)mol / L, the system samples the liquid to be tested in a multiplication or dilution way. Thus, the relative measurement error for concentration determination of hydrazine nitrate and hydroxylamine nitrate is lower than 1%, operation is simple, and the average consumption time of a sample is 60-100s. Compared with a present determination method, the system is characterized by high precision, short time, and simultaneous detection for the contents of hydrazine nitrate and hydroxylamine nitrate.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Manufacturing method of nickel hydrazine nitrate-minium silicon series igniting powder

The invention relates to a manufacturing method of nickel hydrazine nitrate-minium silicon series igniting powder, relating to a manufacturing method of igniting powder contained in an electric firing head of an industrial electric detonator. The nickel hydrazine nitrate-minium silicon series igniting powder comprises minium-silicoferrite. The nickel hydrazine nitrate-minium silicon series igniting powder is characterized in that a base stock of the igniting powder comprises the following components in the terms of the weight of 100 grams: 85-92 grams of nickel hydrazine nitrate and 8-15 grams of minium-silicoferrite, wherein the apparent specific gravity of the nickel hydrazine nitrate is 0.75-1.10 grams / cm<3>, and the water content is less than 0.1%; and the proportion of the minium to the silicoferrite of the minium-silicoferrite is 75%:25%. The manufacturing method comprises the following steps of: uniformly mixing the nickel hydrazine nitrate with the minium-silicoferrite; then taking 15 ml of a water solution with the main component of polyvinyl alcohol and the concentration of 8-10 percent to be uniformly mixed with the base stock, and stirring to generate the viscous igniting powder. The invention has the advantages of high igniting capacity, high firing reliability under the action of currents, lower mechanical sensitivity, no corrosion on a leg wire and an igniter wire of the electric firing head, higher shaping degree and rigidity and waste water recycling and is beneficial to environmental protection.

Owner:FUJIAN HAIXIA TECH

Novel energetic base material prepared from porous material and preparation method thereof

InactiveCN102659491AImprove performanceImprove ballistic performanceAmmonium perchlorate explosive compositionsRamjetDetonation

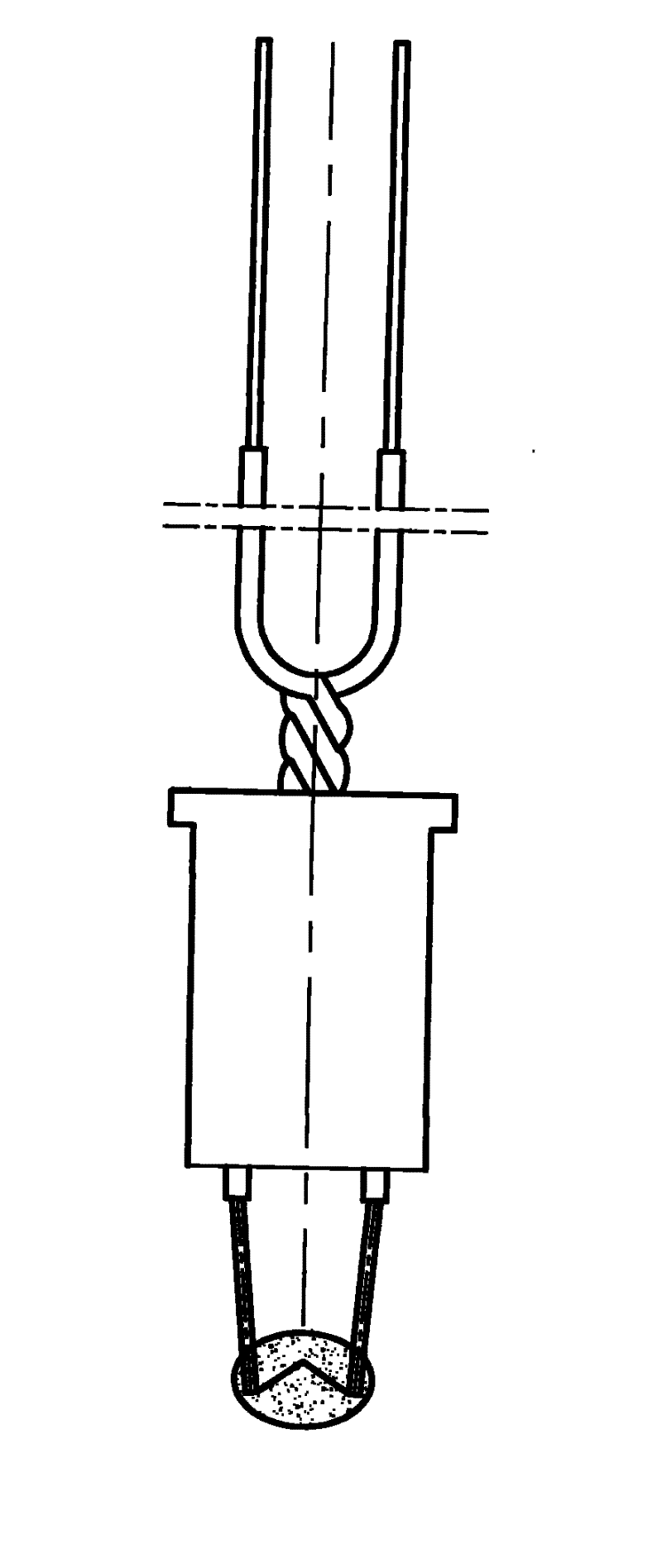

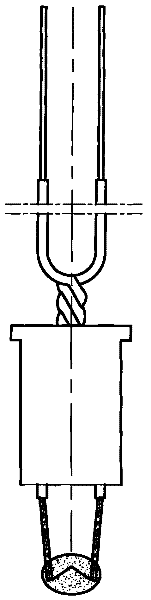

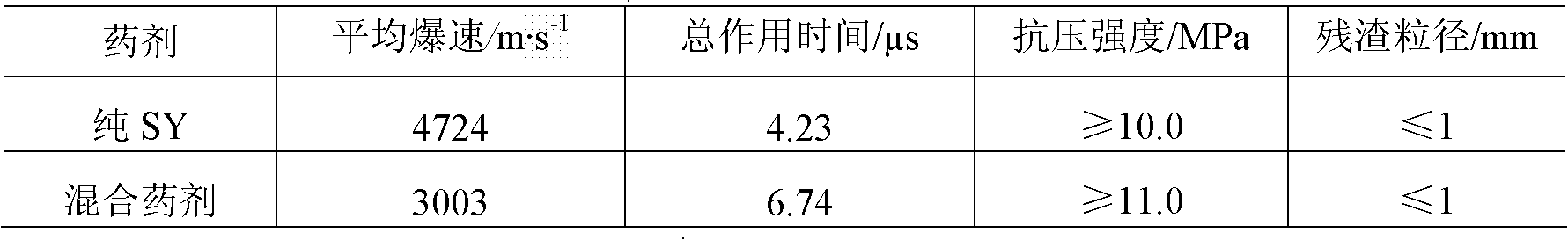

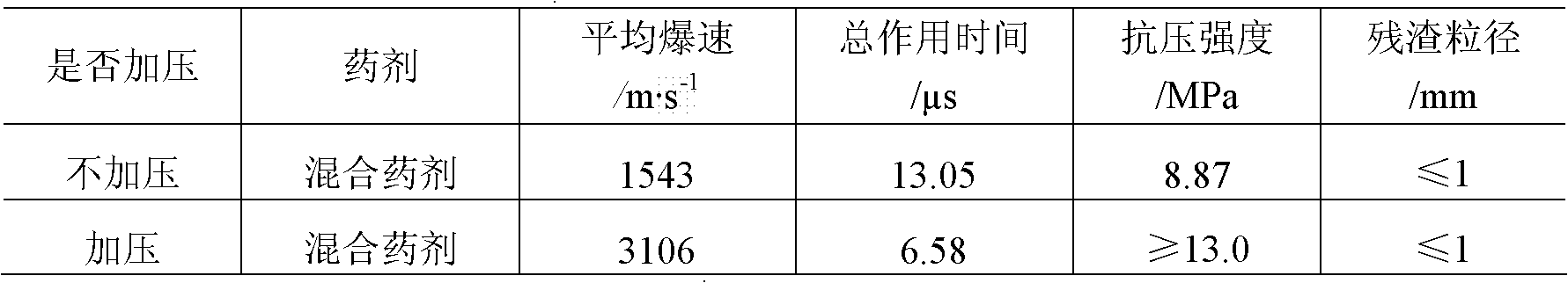

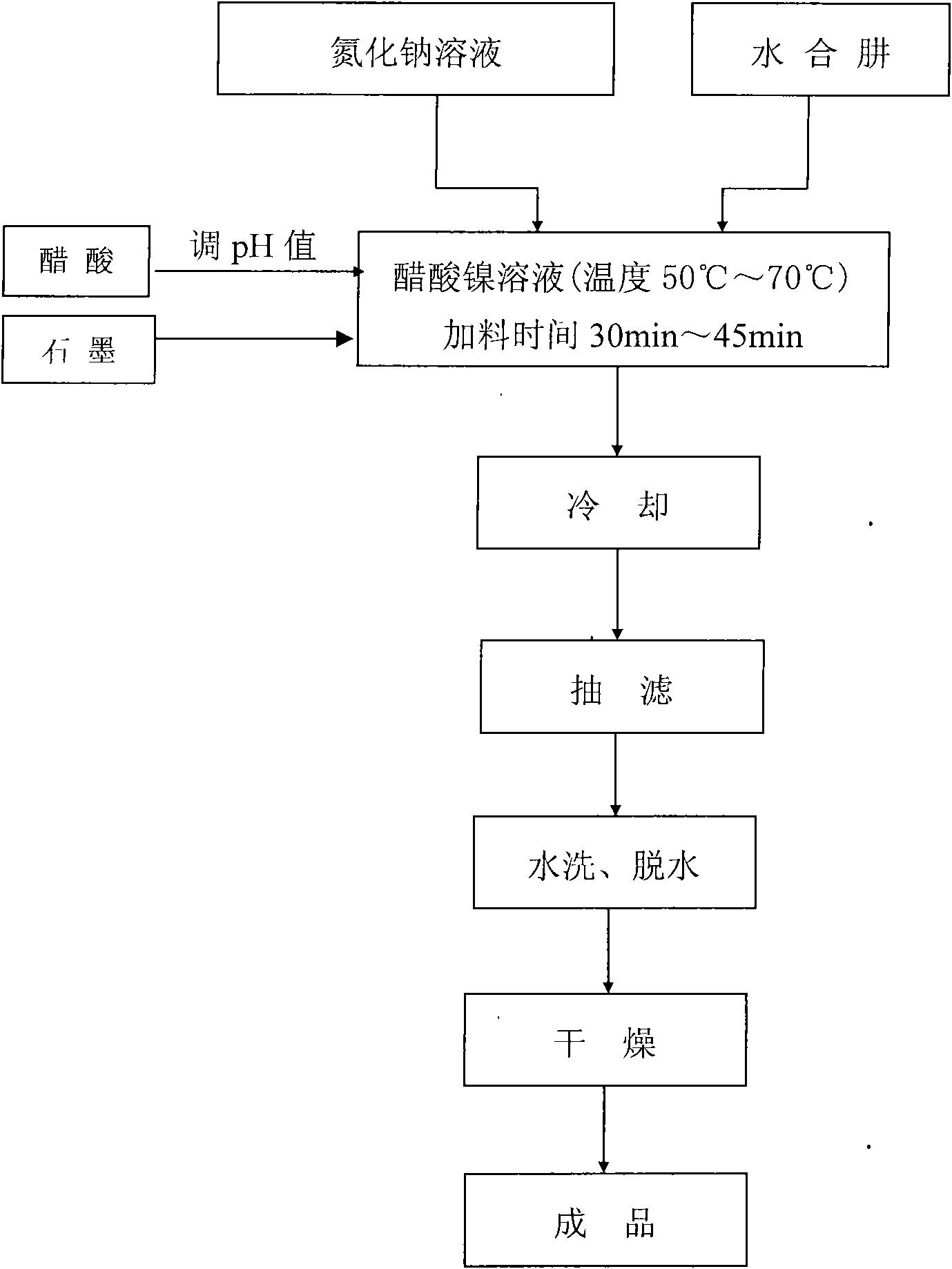

The invention provides a novel energetic base material prepared from a porous material and a preparation method thereof. The novel energetic base material and the preparation method thereof solve the problem that a closure material prepared in China at present has the defects of a large ejecta size, long action time and a complicated structure. The preparation method of the novel energetic base material comprises that an amine perchlorate eutectic compound (SY) or nickel hydrazine nitrate (NHN) as a reagent is added with additives and then the mixture is filled into porous ceramics or porous copper so that the novel energetic base material is obtained. The novel energetic base material obtained by the preparation method has excellent compressive properties, sealing properties and temperature resistance, can explode into fine fragments fast and reliably under the action of output energy from a miniature ignition / detonation device, and can be used as a closure material for a novel solid rocket ramjet air-intake duct.

Owner:NANJING UNIV OF SCI & TECH

Novel safe and environmentally-friendly firecracker lead agent

The invention discloses a novel safe and environmentally-friendly firecracker lead agent. The novel safe and environmentally-friendly firecracker lead agent comprises, by mass, 10-20% of modified high ammonia, 10-20% of China fir carbon powder, 30-40% of nitrocellulose for lacquers, 30-40% of nickel hydrazine nitrate, 5-15% of phenolic resin and 1-2% of rubber powder. Oxidant modified high ammonia is adopted to substitute a potassium chlorate oxidant in the prior art, and the reducing agent China fir carbon powder, nitrocellulose for lacquers phenolic resin and the accelerator nickel hydrazine nitrate are added to greatly reduce the amount of smog generated in the burning and blasting process of the firecracker lead agent, so influences of firecrackers on environment in the use process are effectively improved, and safety and environmental protection are truly realized.

Owner:LILING HENGDA FIREWORKS

Method for preparing nickel hydrazine azide

InactiveCN101618866AGuaranteed singularityImprove detonation abilityHydrazoic-acids/azides/halogen-azidesNickel saltHydrazine compound

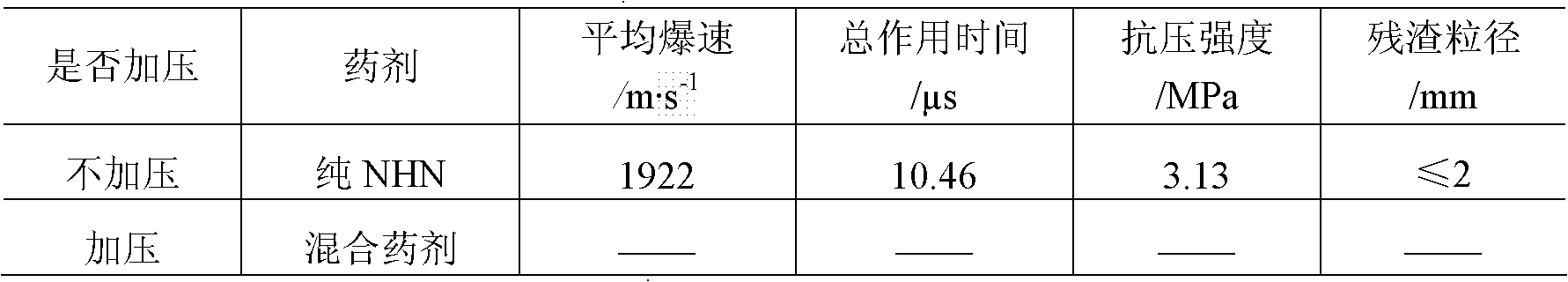

The invention discloses a method for preparing nickel hydrazine azide. The method comprises: taking soluble nickel salts as base solution; using acetic acid to adjust the pH of the formed base solution; using graphite as modified additives of medicaments; adding sodium nitride solution and hydrazine hydrate solution to the base solution dropwise to perform chemical combination; preserving heat, cooling, leaching, washing, dehydrating and drying; and obtaining a finished product of nickel hydrazine azide. The method is simple in pH control, and buffer solution consisting of weak acid and weak-acid salts ensures stable pH, longer effectiveness and the unicity of medicament composition, and significantly improves explosion initiation capacity, so the buffer solution is more suitable to be used as a primary explosive. By adopting nickel acetate as raw material, a small quantity of nickel hydrazine nitrate substances which are formed by use of nitrates and result in worse or unstable pharmaceutical performance can be avoided. Dropping and time difference ensure the complete reaction of sodium nitride and high yield of nickel hydrazine azide.

Owner:NANJING UNIV OF SCI & TECH

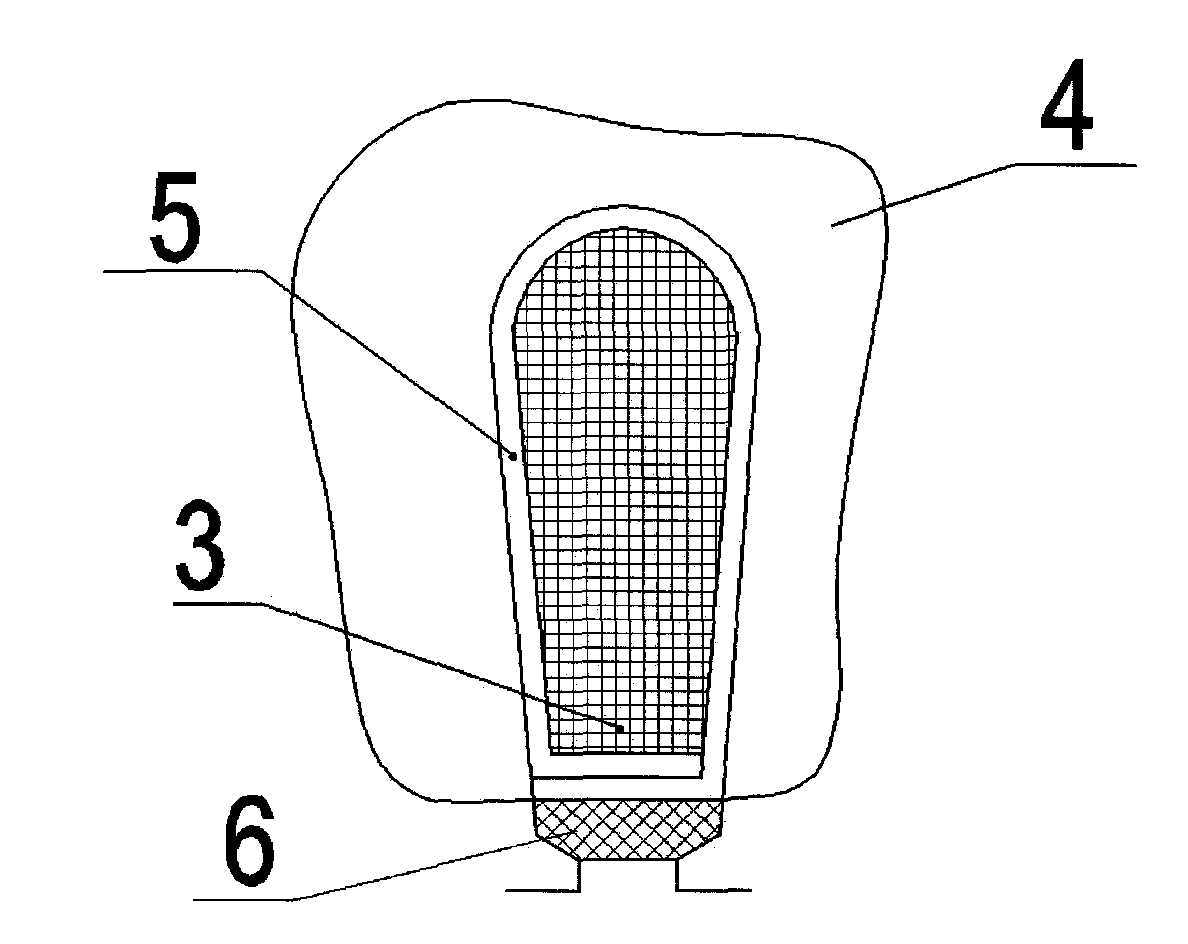

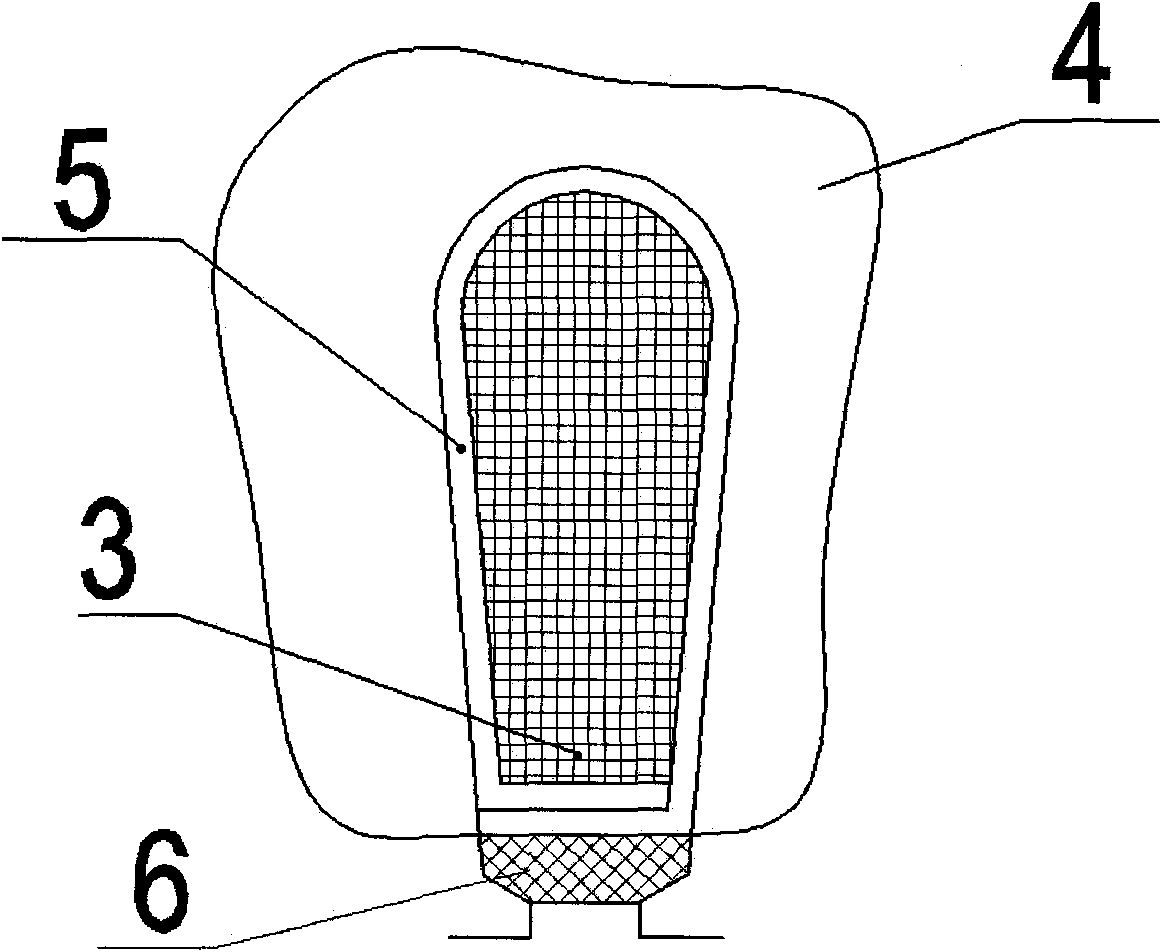

Coal mine permitted industrial electric detonator

InactiveCN104447149ACombustion to detonationMechanical insensitivityDetonatorsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsElectricityDetonator

The invention belongs to the technical field of industrial detonators, and in particular relates to a coal mine permitted industrial electric detonator; the coal mine permitted industrial electric detonator comprises an inner cap, a delay body and a compound primary explosive; the compound primary explosive comprises a primary explosive, a flame inhibitor, a high explosive and an adhesive; the primary explosive is one or more selected from the group including dinitrodiazophenol, lead azide, lead trinitroresorcinate and nickel hydrazine nitrate; the high explosive is one or more selected from the group including cyclonite and pentaerythrite tetranitrate; and the flame inhibitor is one or more selected from the group including a cryolite flame inhibitor, a calcium fluoride flame inhibitor and a sodium fluoride flame inhibitor. According to the invention, aiming at the problem that gas explosion is easily caused by the industrial electric detonator, the novel coal mine permitted industrial electric detonator is provided; the gas safety problem is solved; coal mine blasting safety is ensured; and the coal mine permitted industrial electric detonator has good popularization value and is applied to scale production.

Owner:山东圣世达化工有限责任公司

Method and combined solution for increasing productivity of low-porosity, low-permeability and low-pressure reservoir oil well

InactiveCN105156082AHigh porosityImprove permeabilityFluid removalDrilling compositionPorosityChemical reaction

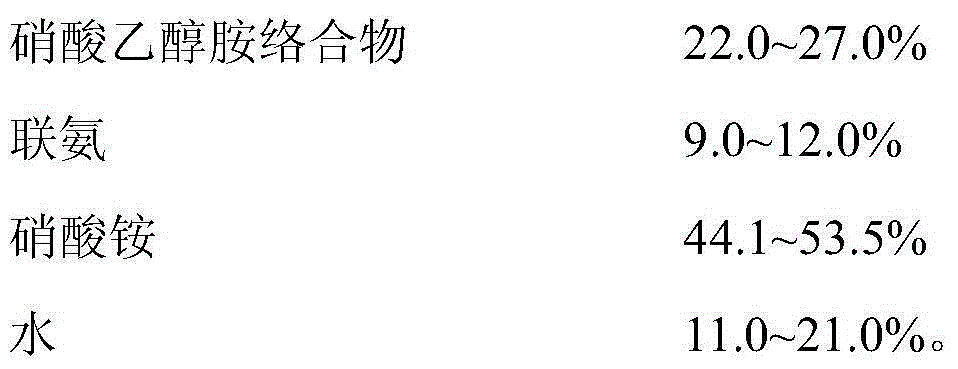

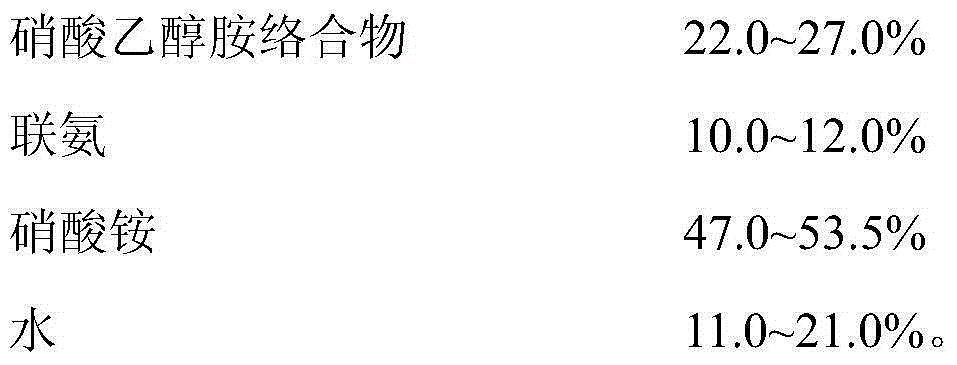

The invention provides a method and a combined solution for increasing productivity of a low-porosity, low-permeability and low-pressure reservoir oil well and relates to oil production technology. The method specifically includes: according to the hole volume of an operating well, calculating using quantity and proportion of a component A solution and a component B solution which are needed, and preparing the component A solution and the component B solution; sequentially adding the component A solution and the component B solution into the oil well for chemical reaction to increase productivity of the oil well, wherein the component A solution comprises nitric acid-alcohol complex, hydrazine, ammonium nitrate and water, and the component B solution comprises hydrazine nitrate, tetrachloroethylene, sodium hydride and sodium aluminum hydride. Physical and chemical effect, on a near-wellbore area of the oil well, of the chemical reaction between working solutions and between the working solutions and rock strata can be utilized to increase porosity, permeability, kinetic energy, heat energy and fluidity of a production layer so as to increase productivity of the oil well. The method integrates comprehensive effect, on oil-gas reservoirs, of physical and chemical processes and is simple in technique, controllable in process, low in cost and high in efficiency.

Owner:YANAN SHUANGFENG PETROLEUM TECH CO LTD

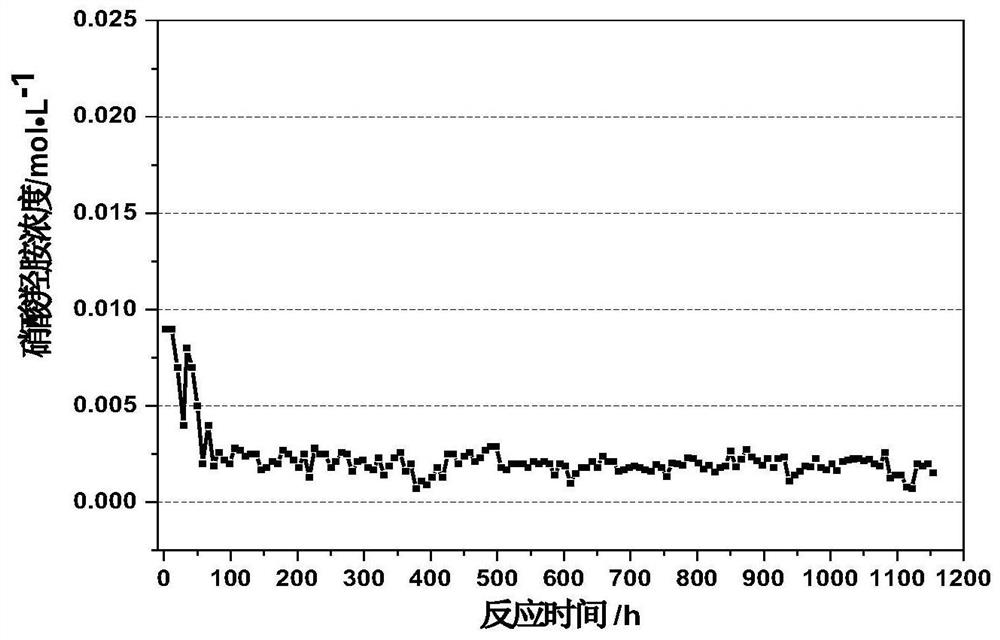

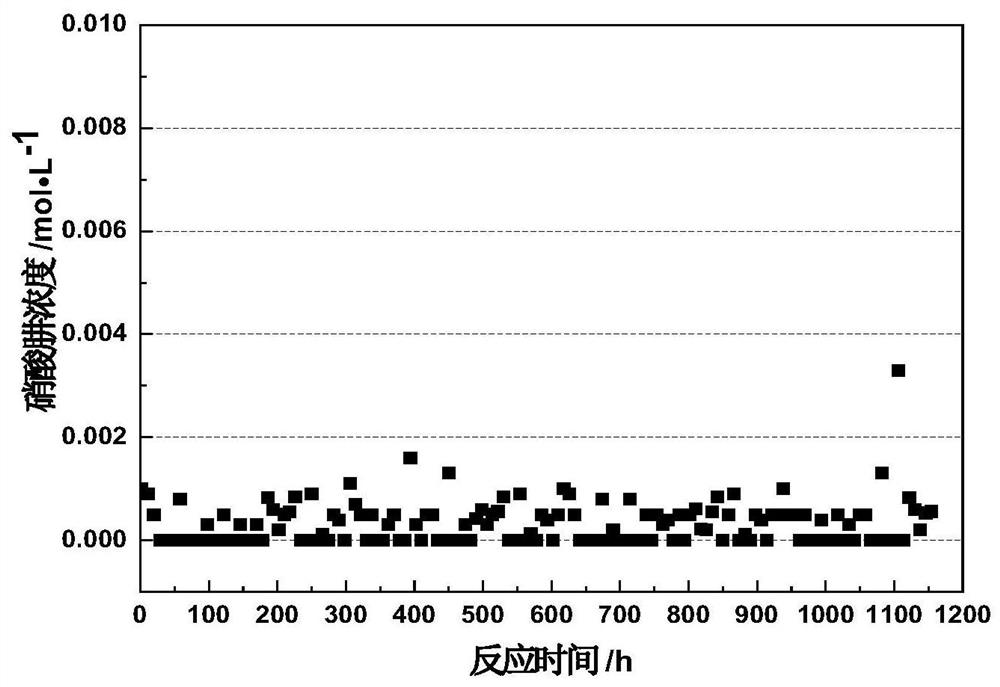

Method for removing hydrazine nitrate and hydroxylamine nitrate in nitric acid

ActiveCN112678939ANo safety hazardImprove economyCatalyst protectionWater contaminantsHydroxylaminePtru catalyst

The invention discloses a method for removing hydrazine nitrate and hydroxylamine nitrate in nitric acid, which comprises the following steps of: contacting feed liquid to be treated with a catalyst under a heating condition to catalyze and decompose hydrazine nitrate and hydroxylamine nitrate into nitrogen, hydrogen, water, trace nitric oxide, ammonium ions and the like, wherein the carrier of the catalyst is coconut shell active carbon-silicon oxide, the active component is ruthenium or a compound of ruthenium and platinum, and the mass fraction of the active component in the catalyst is 1-5%. The invention also discloses a preparation method of the catalyst. The prepared catalyst is high in decomposition activity of hydrazine nitrate and hydroxylamine nitrate, high in nitric acid corrosion resistance and long in service life, and the waste liquid treatment method is efficient, safe, economical and environmentally friendly.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

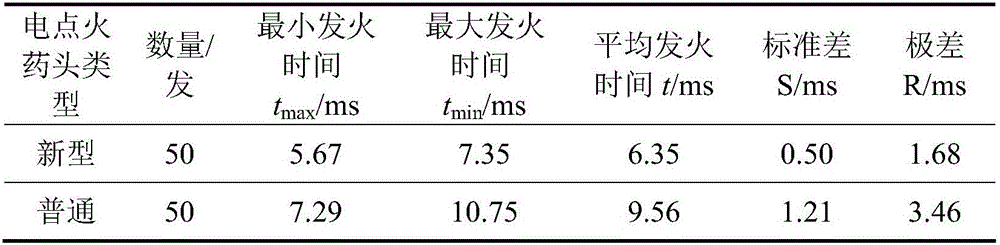

Novel electric ignition fusehead and preparation method thereof

InactiveCN106431795AImprove environmental friendlinessHigh firing time accuracyExplosivesInherent safetyLead dioxide

The invention discloses a novel electric ignition fusehead and a preparation method thereof. The novel electric ignition fusehead comprises the following raw materials in parts by weight: 40-98 parts of nickel hydrazine nitrate, 1-30 parts of lead dioxide, 1-30 parts of zirconium powder and 100-150 parts of an adhesive. According to the invention, nickel hydrazine nitrate is adopted as a basic material for preparing the ignition fusehead, thereby substantially improving the environmental friendliness of the ignition fusehead; in addition, the time accuracy of ignition of the ignition fusehead is high, and nickel hydrazine nitrate used for preparing the ignition fusehead is damp gunpowder, thereby improving the inherent safety of the production process.

Owner:GUIZHOU JIULIAN IND EXPLOSIVE MATERIALS DEV

Method for converting hydrazine hydrate in waste water

InactiveCN105712463AOvercome volumeOvercome high power consumptionWater contaminantsWater/sewage treatment by oxidationHydrazine compoundWater quality

The invention discloses a method for converting hydrazine hydrate in waste water. The method comprises the steps that a transition metal compound and an alcohol solvent are added to the waste water containing hydrazine hydrate, the pH is adjusted to be 9-14 with NaOH or ammonia water, and a reaction is conducted at the stirring speed of 50-200 rpm and the temperature of 10-40 DEG C for 18-24 h, wherein the transition metal compound is chloride of Fe or Co or Ni or Ru or Pd or Pt or a nitric acid compound, the molar ratio of the transition metal compound to hydrazine hydrate is 1:(400-500), and the mass ratio of the alcohol solvent to a protective agent is (20-40):1. According to the method for converting hydrazine hydrate in the waste water, a series of problems that in the traditional ammonia-nitrogen waste water treatment technology, the equipment size is huge, power consumption is large, the energy consumption cost is high, the occupied area is large, and the water quality requirement is strict are solved.

Owner:XIAMEN UNIV

Platinum-carbon catalyst and preparation and application thereof

ActiveCN112934218AEasy to prepareEasy to controlNuclear energy generationCatalyst activation/preparationActivated carbonPlatinum

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Passivation method for nickel hydrazine nitrate

ActiveCN109293462AEasy to filterImprove securityExplosive working-up apparatusSolventHydrazine nitrate

The invention discloses a passivation method for nickel hydrazine nitrate. The method includes: placing a coating agent in a solvent and conducting stirring to obtain a coating agent solution or dispersion liquid; weighing nickel hydrazine nitrate powder and adding the weighed powder into the coating agent solution or dispersion liquid slowly to obtain a mixed solution; putting the mixed solutionin a single-mouth flask, carrying out vacuum rotary distillation at certain temperature to remove the solvent until no fraction is distilled out, thus obtaining coated nickel hydrazine nitrate. The passivation way adopted by the invention has a wide application range and good coating effect, broadens the application scope of the coating agent, is convenient for screening of the coating agent, andis simple in operation and low in cost, thus being suitable for large-scale production.

Owner:DANCING FIREWORKS GROUP CO LTD

High-safety environment-friendly nitrate fireworks and manufacturing method thereof

ActiveCN112923804ALow hygroscopicitySolve the problem of deliquescent deteriorationChemical industryFireworksCelluloseNitrocellulose

The invention discloses a high-safety environment-friendly nitrate fireworks which comprise the following components: potassium perchlorate, ammonium nitrate, hydrazine nitrate, guanidine nitrate, nitrocellulose, magnesium oxide, barium oxide, copper chloride and an additive, and a preparation method of the additive comprises the following steps: weighing multi-walled carbon nanotubes, adding the multi-walled carbon nanotubes into triethylene glycol, stirring a solution, carrying out ultrasonic treatment for 5-10 minutes, then adding ruthenium acetylacetonate into the solution in a stirring state to form a mixture, heating the mixture to 250-270 DEG C, keeping the temperature for 20-30 minutes, air-cooling the mixture to normal temperature after keeping the temperature, putting the mixture into a vacuum furnace, vacuumizing, heating and evaporating to remove triethylene glycol, cooling the remainder to normal temperature along with the furnace in a vacuum environment, and taking out to obtain the additive. Nitrate compounds in the fireworks are modified, the hygroscopicity of the fireworks is greatly reduced, and the problem that pyrotechnic compositions are prone to deliquescence and deterioration is solved.

Owner:上栗县金信出口烟花制造有限公司

Insulating production process method of large alternating current machine stator core stretching screw

ActiveCN101984543AProtective Dielectric StrengthGuaranteed insulation performanceManufacturing stator/rotor bodiesGlass fiberAlternating current

The invention relates to an insulating production process method of a large alternating current machine stator core stretching screw. Insulation treatment is carried out between the stretching screw and an end plate of a stamped steel so as to guarantee the reliability of insulation. The insulating strength among the stretching screw, the end plate and the stamped steel can be effectively protected by using an insulating structure. The insulating process method of a stator core stretching screw comprises the steps of strengthening the mechanical strength of an insulating material; wrapping nickel hydrazine nitrate (NHN) composite foil with a high mechanical strength on both ends of the screw, wherein the diameter of the polish rod part in the middle of the screw is less than the major diameter of threads on both ends; sheathing a glass fiber sleeve with a low mechanical strength, with the threaded area on both ends bearing extrusion force; and tightly wrapping both ends of the sleeve in a condition that the sleeve is stretched. In order to avoid reduction of insulating resistance in the production process, a bakelite shim is arranged after being dipped by paint.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

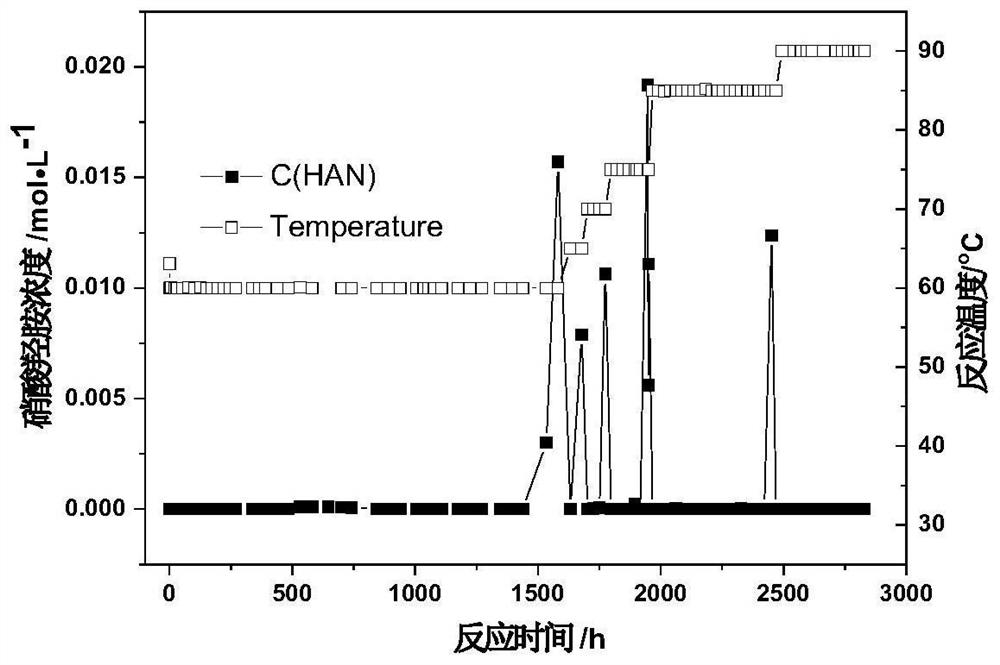

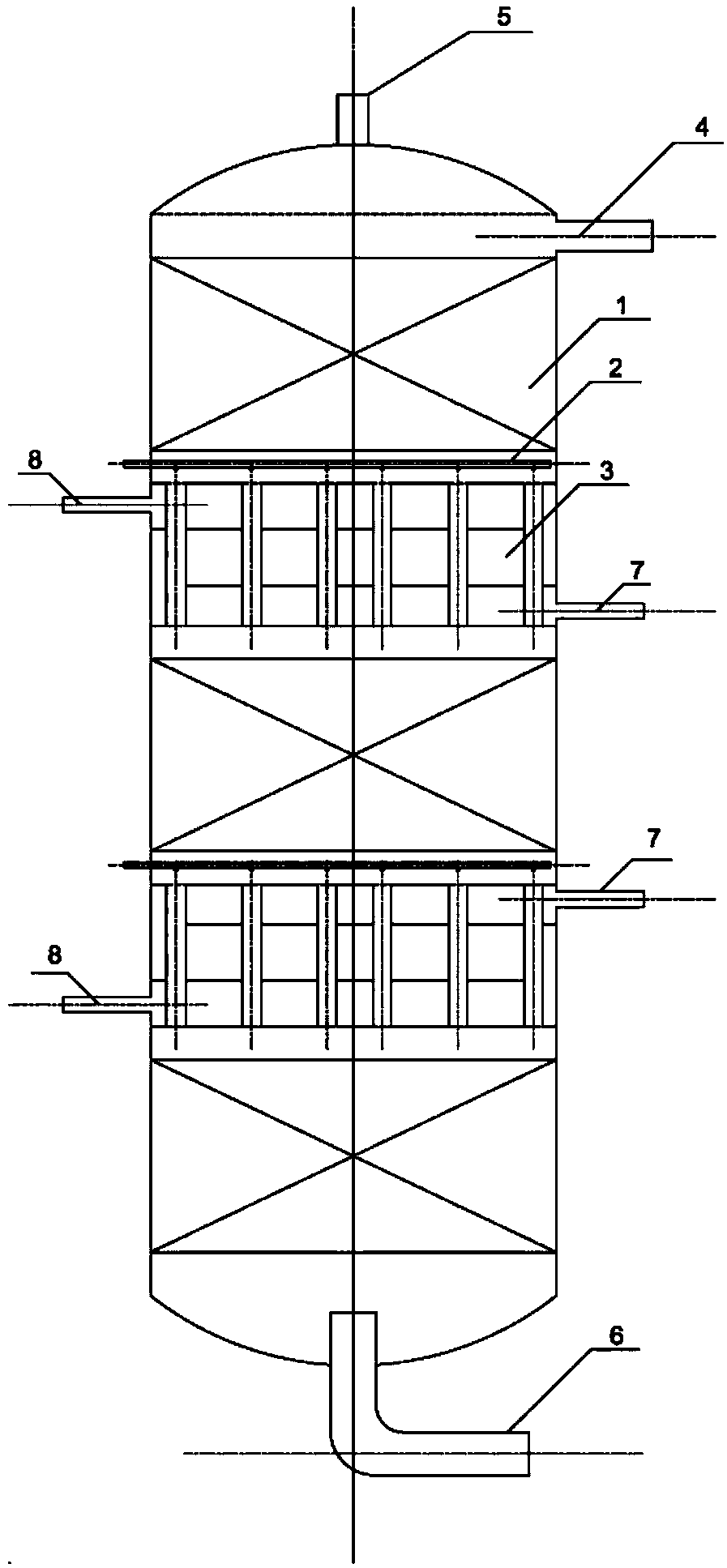

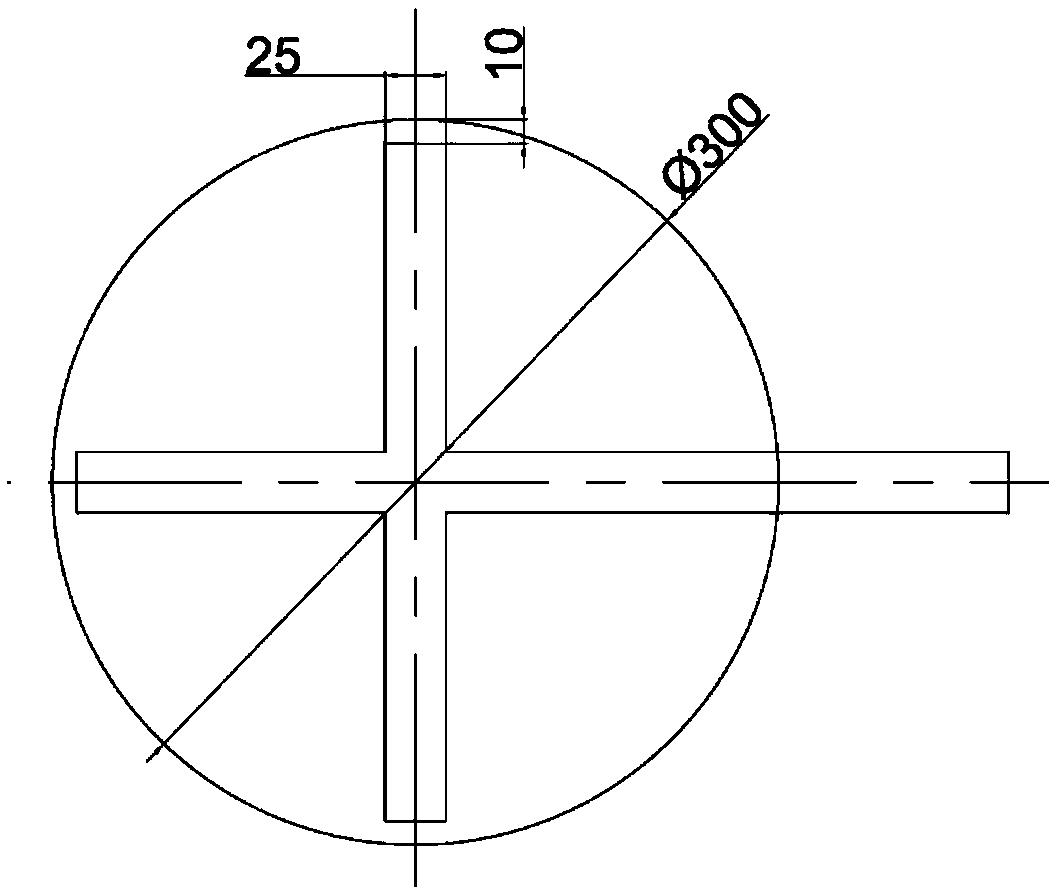

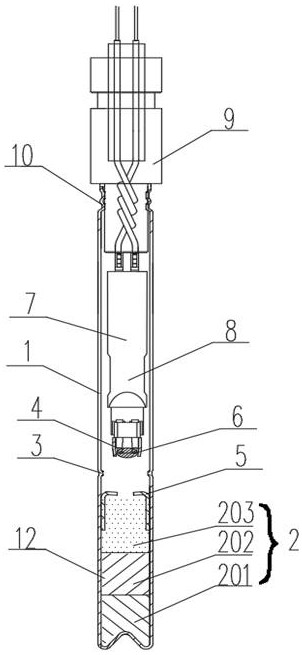

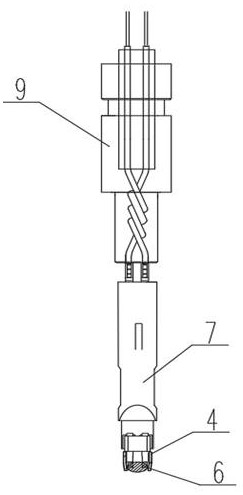

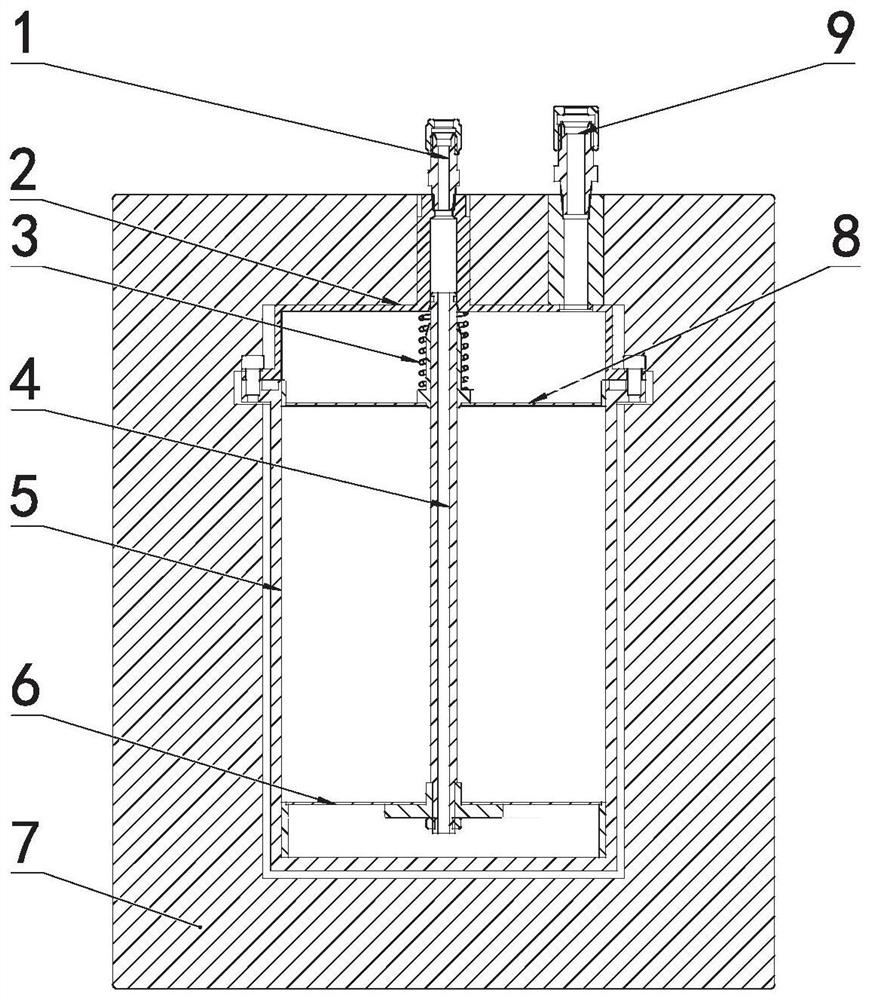

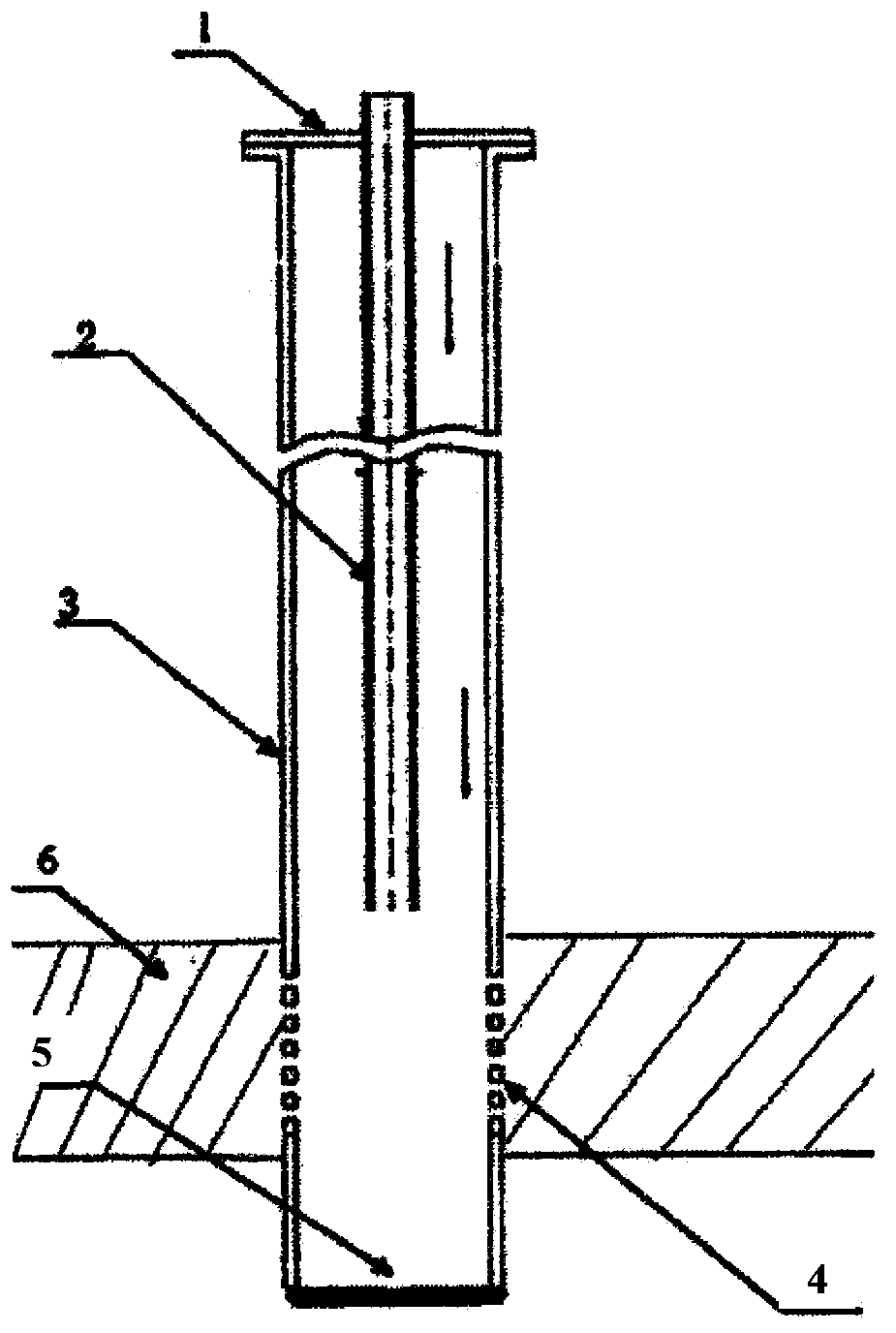

Fixed bed reactor for catalytic reduction of hexavalent uranium by hydrazine nitrate, and application thereof

InactiveCN111249999AAvoid oxidative inactivationChemical/physical processesPtru catalystPhysical chemistry

The invention discloses a novel multi-section adiabatic fixed bed reactor device for producing tetravalent uranium through catalytic reduction of hexavalent uranium by hydrazine nitrate. The main function of the device is to control the reaction liquid residence time distribution, the reaction temperature and the acidity in a reaction process in the form of a multi-section adiabatic fixed bed reactor so as to enable the reaction liquid to be in the optimal operation interval, so that minimization of solid high-level radioactive waste discharge is achieved, and the purposes that the content oftetravalent uranium at an outlet meets the requirement and a catalyst is prevented from being oxidized and inactivated due to excessive consumption of hydrazine nitrate. In the optimal implementationscheme, the conversion rate of hexavalent uranium at the outlet of the reactor is greater than 98%, the conversion rate of hydrazine nitrate is lower than 35%, and the content of tetravalent uranium at the outlet of the reactor is greater than 200 g / L.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

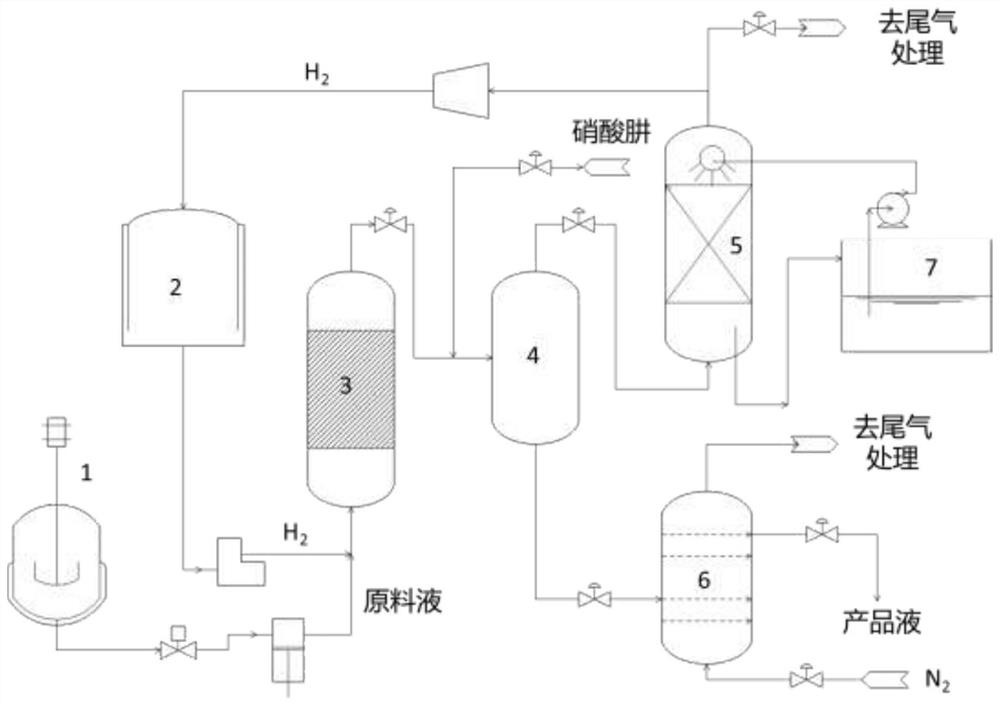

Method for preparing uranium nitrate through catalytic hydrogenation reduction of uranyl nitrate

ActiveCN113526558AImprove conversion rateInhibit side effectsProcess efficiency improvementUranium compoundsPtru catalystLiquid storage tank

The invention discloses a method for preparing uranium nitrate (tetravalent uranium) by using catalytic hydrogenation reduction of uranyl nitrate (hexavalent uranium).The method comprises the following steps: mixing uranyl nitrate in a raw material liquid storage tank with nitric acid, feeding the mixture and circulating hydrogen into a high-pressure hydrogenation reactor filled with a catalyst through one end of the reactor, and catalytically reducing uranyl nitrate into uranium nitrate by hydrogen; and flowing the excessive hydrogen and product uranium nitrate out of the reactor through the other end of the reactor; dropwise adding a hydrazine nitrate or hydrazine solution on line into the gas-liquid mixture to convert the solution from an oxidation state to a reduction state, then feeding the gas-liquid mixture into a high-pressure gas-liquid separator for separation, absorbing and separating the nitrogen oxides in a gas phase through alkali liquor, pressurizing hydrogen through a compressor, and then feeding the hydrogen into a high-pressure hydrogen storage tank; and discharging a liquid-phase product from the bottom of a separator and enters a normal-pressure liquid-phase product hydrogen replacement tower, and removing the dissolved hydrogen in the liquid phase by using a nitrogen bubbling device in the tower, so that the safety of a subsequent process is ensured, and the obtained gas enters a high-emission tail gas treatment system.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Micro-priming powder for detonator

InactiveCN101440011BSimple structureHigh working reliabilityNitrated pentaerythritol explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsDetonatorMedicine

Owner:ANHUI UNIV OF SCI & TECH

Micro firework shot agent composition

InactiveCN108947750AImprove stabilityImprove moisture resistanceNon-explosive fillers/gelling/thickening agentsFirecrackerHydrazine compound

The invention discloses a micro firework shot agent composition which is characterized by being prepared by the following steps: mixing and reacting nickel nitrate hexahydrate and hydrazine hydrate toproduce nickel hydrazine nitrate, and mixing with auxiliary materials, wherein the nickel hydrazine nitrate comprises the following raw materials in percentage by weight: 25-80% of nickel nitrate hexahydrate and 20-75% of hydrazine hydrate; the smoke-free firework agent comprises the following raw materials in percentage by weight: 15-55% of nickel hydrazine nitrate and 45-85% of auxiliary materials; and the auxiliary materials refer to 120-mesh incombustible mineral powder, such as crushed crude pearlite or sepiolite powder or river sand. During manufacturing of different fireworks and firecrackers, more than two auxiliary materials can be mixed to use. Colorful fireworks and firecrackers made from the smoke-free firework agent have the advantages of being smoke-free and flame-free, andthe environmental protection requirement is met.

Owner:浏阳市恒信烟花制造有限公司

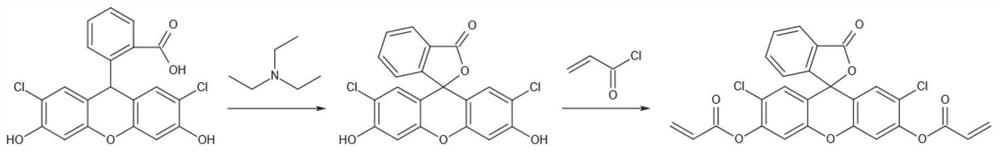

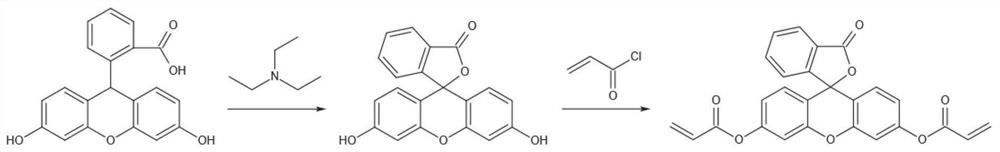

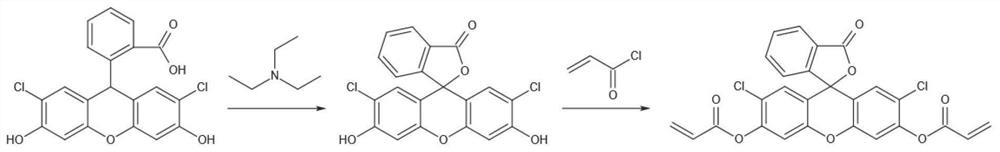

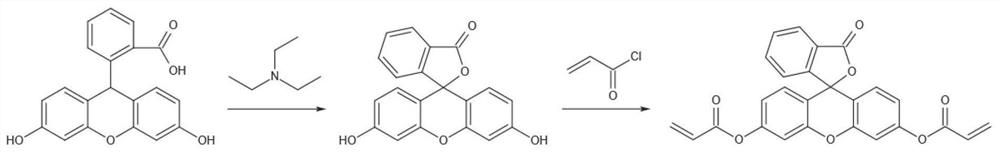

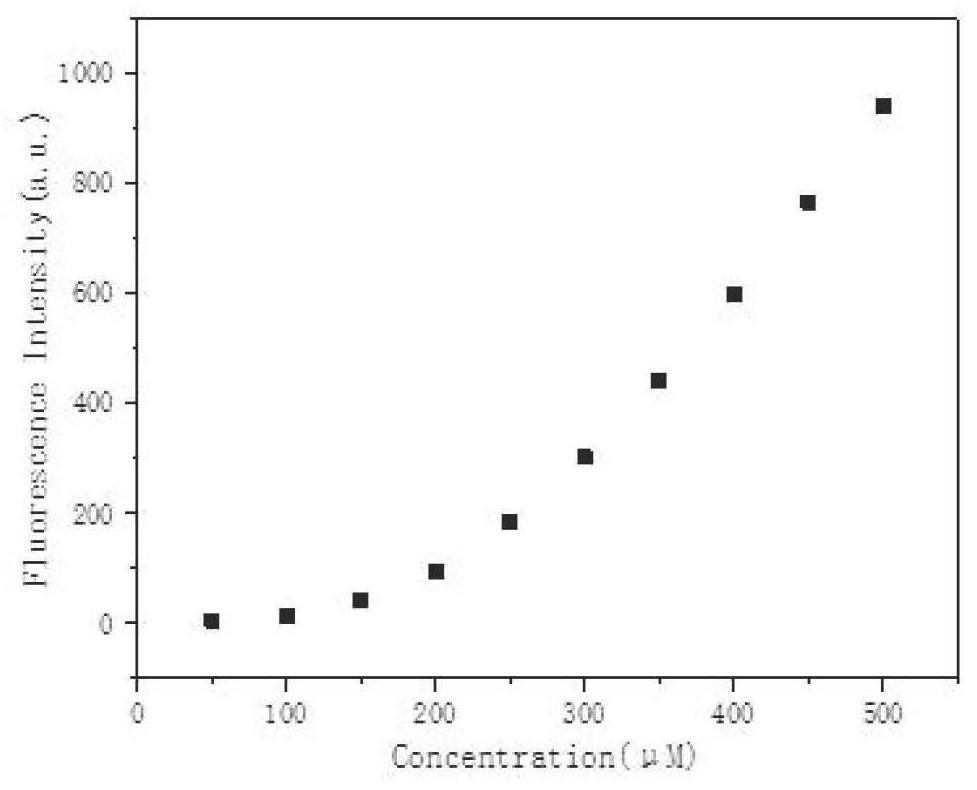

Fluorescent probe for rapidly detecting hydrazine compounds as well as synthesis and application of fluorescent probe

ActiveCN113735872ALow priceLower synthesis costOrganic chemistryFluorescence/phosphorescenceFluoProbesHydrazine compound

The invention relates to the technical field of fluorescent probes, in particular to a fluorescent probe for rapidly detecting hydrazine compounds, the fluorescent probe comprises A-1 and A-2, and the invention discloses a synthesis method of the fluorescent probe for rapidly detecting the hydrazine compounds. The invention further discloses application of the fluorescent probe for rapidly detecting the hydrazine compounds, and the application comprises a detection method. The probe can quickly respond to hydrazine, hydrazine sulfate, hydrazine nitrate and unsymmetrical dimethylhydrazine, fluorescence enhancement is remarkable, the detection limit is low, and meanwhile high anti-interference performance and selectivity are achieved.

Owner:LANZHOU UNIVERSITY +1

Special electronic detonator for tunnel

PendingCN113340162AAvoid damageGuarantee the reliability of detonationAmmunition fuzesDetonatorDust explosion

The invention discloses a special electronic detonator for a tunnel, which comprises a detonator body, a charging part is arranged on the detonator body, a reinforcing cap is arranged in the charging part, a through hole is formed in the reinforcing cap, a main charge is arranged between the charging part and the reinforcing cap, flame inhibitor lac granulation hexogen is arranged at the bottom of the main charge, the middle of the main charge is Taian, nickel hydrazine nitrate is arranged at the upper part of the main charge, and an electronic ignition part is installed in the detonator body. The special electronic detonator has the beneficial effects that a explosive head protection device is arranged to protect a explosive head in the blasting process, damage and early blasting of the explosive head caused by collision between the explosive head and the pipe wall due to blasting high-frequency vibration are avoided, and the detonating reliability of an electronic detonator detonating circuit is guaranteed; and by arranging the flame inhibitor lac granulation hexogen, the Taian, the nickel hydrazine nitrate and the reinforcing cap to be matched, the situation that no open fire is generated in explosion in the explosion environment containing gas and dust, gas and dust explosion accidents caused by tunnel explosion are avoided, and the safety of tunnel explosion is improved.

Owner:QIANJIN IND EXPLOSIVES CO LTD

Application of fixed bed catalytic reactor in removal of hydrazine nitrate and hydroxylamine nitrate

ActiveCN114570289ANo safety hazardImprove economyNuclear energy generationRadioactive decontaminationHydroxylaminePtru catalyst

The invention discloses a fixed bed catalytic reactor and application of the fixed bed catalytic reactor to removal of a small amount of hydrazine nitrate and hydroxylamine nitrate in nitric acid. The fixed bed catalytic reactor comprises a shell, a feed liquid distribution plate and a feed liquid conveying core tube, and a cavity is defined by the shell; a feed liquid inlet and a product outlet are formed in the top of the shell; the feed liquid distribution plate is positioned at the lower part in the cavity; the feed liquid conveying core tube is positioned in the cavity; the upper end of the feed liquid conveying core tube is communicated with the feed liquid inlet; and the lower end of the feed liquid conveying core tube penetrates through the feed liquid distribution plate and is positioned above the bottom of the shell. By utilizing the reactor, the preheated feed liquid is decomposed into nitrogen, hydrogen and water by hydrazine nitrate and hydroxylamine nitrate under the action of the supported ruthenium catalyst, and the nuclear power waste liquid can be safely and efficiently treated.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of cationic resin is the noble metal catalyst of carrier and its preparation and application

ActiveCN113042107BNo safety hazardImprove economyOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsHydroxylaminePtru catalyst

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Hydrogenation heat gas chemical yield increasing solution component for low-permeability sandstone reservoir oil well

ActiveCN102942912BRealization of production increaseHigh porosityFluid removalDrilling compositionMass ratioHigh pressure

The invention belongs to the technical field of oil exploitation, and particularly relates to a hydrogenation heat gas chemical yield increasing solution component capable of being used for increasing productivity of a low-permeability sandstone reservoir oil well. The solution component comprises first solution and second solution, the mass ratio of the first solution to the second solution is 1:1, by the mass sum of 100%, the first solution comprises nitric acid cholamine complex HOCH2CH2NH2*HNO3, ammonium nitrate NH4NO3 and water H2O, and the second solution comprises hydrazine nitrate N2H4*HNO3, sodium hydride NaH, sodium aluminum hydride NaAlH4 and tetrachloroethylene C2Cl4. Gas released in reaction of the first solution and the second solution can carry heat and enter air holes and micro-cracks of near wellbore region rock strata through a well-cased perforating area, the near wellbore region rock strata can generate new cracks under continuous heat shock action of high-temperature high-pressure gas, oil-gas seepage channels are communicated, seepage resistance is decreased, drainage area is increased, and accordingly, permeability of the near wellbore region rock strata is improved.

Owner:吉林贯通能源科技有限责任公司

A fluorescent probe for rapid detection of hydrazine compounds and its synthesis and application

ActiveCN113735872BLow priceLower synthesis costOrganic chemistryFluorescence/phosphorescenceFluoProbesHydrazine compound

Owner:LANZHOU UNIVERSITY +1

Noble metal catalyst taking cationic resin as carrier, preparation and application thereof

ActiveCN113042107ANo safety hazardImprove economyOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsHydroxylaminePtru catalyst

The invention belongs to the technical field of nuclear power waste treatment and environmental protection, particularly relates to a noble metal catalyst taking ZSM-5 as a carrier, a preparation method and application thereof, and aims to provide a noble metal catalyst taking cationic resin as a carrier, preparation and application thereof so as to solve the problem of safe removal of hydrazine nitrate and hydroxylamine nitrate in existing spent fuel post-treatment waste liquid. According to the noble metal catalyst with the cationic resin as the carrier, the carrier of the catalyst is cation exchange resin, the active component of the catalyst is metal ruthenium, and the mass fraction of the active component in the catalyst is 3-10%. According to the invention, dangerous compounds such as hydrazine nitrate, hydroxylamine nitrate and the like in a nitric acid waste liquid are removed in a catalytic decomposition mode, and compared with a traditional oxidizing agent adding mode, the method is cleaner, more environmentally friendly and free of potential safety hazards, and the economical efficiency is better than that of the oxidizing agent adding mode.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com