Noble metal catalyst taking cationic resin as carrier, preparation and application thereof

A precious metal catalyst, cation resin technology, applied in catalyst activation/preparation, physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, etc., can solve problems such as removal of hydrazine nitrate and hydroxylamine nitrate, and achieve Mild reaction conditions, excellent economy, and the effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

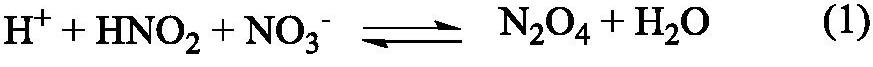

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A kind of cationic resin as described above is the preparation method of the noble metal catalyst of support, comprises the steps:

[0036] 1) Get a cation exchange resin with a quality of M1, add a saturated sodium chloride solution with a volume of L1 and soak it for three days, thereby removing small organic molecules in the resin;

[0037] Filtration, the filtered cationic resin is transferred to deionized water, and repeatedly washed with deionized water until the chloride ion concentration is not greater than 100ppm, so as to avoid its residue and poison the catalyst;

[0038] 2) Soak the resin obtained in step 1) with a nitric acid solution with a volume of L1 and a concentration of 0.1 to 0.3 mol / L for two days, and then rinse it with nitric acid with a volume of 0.5 L1 and a concentration of 1.8 to 2.3 mol / L for three times, Thereby removing the metal ion impurities in the resin;

[0039] Filtration, the filtered cationic resin is transferred to deionized wate...

Embodiment 1

[0067] Take 15g of cation exchange resin carrier, add 100mL saturated sodium chloride solution to soak for three days, filter, transfer the filtered cation resin carrier directly to deionized water, and wash repeatedly until the chloride ion concentration is not greater than 100ppm; use 0.1mol / Soak in 100mL of nitric acid solution of 1 L for two days, then rinse three times with 50mL of 1.8mol / L nitric acid, filter, and transfer the filtered cationic resin carrier directly to deionized water, and wash repeatedly until the pH test paper is neutral; A good cation exchange resin was dispersed in 100mL deionized water, and 30mL containing 1.94g RuCl was added dropwise 3 ·3H 2 O solution, the above solution was impregnated and adsorbed at room temperature for 12h, and then 80mL containing 3.0g NaBH was added dropwise in an ice bath 4 solution and continued to stir for 3 hours, filtered and washed repeatedly until the concentration of chloride ions was not greater than 100ppm, and...

Embodiment 2

[0072] Take 15g of cation exchange resin carrier, add 100mL saturated sodium chloride solution to soak for three days, filter, transfer the filtered cation resin carrier directly to deionized water, and wash repeatedly until the chloride ion concentration is not greater than 100ppm; use 0.3mol / Soak in 100mL of nitric acid solution of 1 L for two days, then rinse three times with 50mL of 2.3mol / L nitric acid, filter, and transfer the filtered cationic resin carrier directly to deionized water, and wash repeatedly until the pH test paper is tested to be neutral; A good cation exchange resin was dispersed in 100mL deionized water, and 30mL containing 1.94g RuCl was added dropwise 3 ·3H 2 O solution, the above solution was impregnated and adsorbed at room temperature for 12h, and then 80mL containing 1.5g NaBH was added dropwise in an ice bath 4 solution and continued to stir for 3 hours, filtered and washed repeatedly until the chloride ion concentration was not greater than 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com