Automatic plate machining system

A sheet metal processing, one-to-one technology, applied in metal processing equipment, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of increased operator safety hazards, high manual labor intensity, and inconvenient manual transfer, etc., to achieve labor intensity. No potential safety hazards, low labor intensity, and short working cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

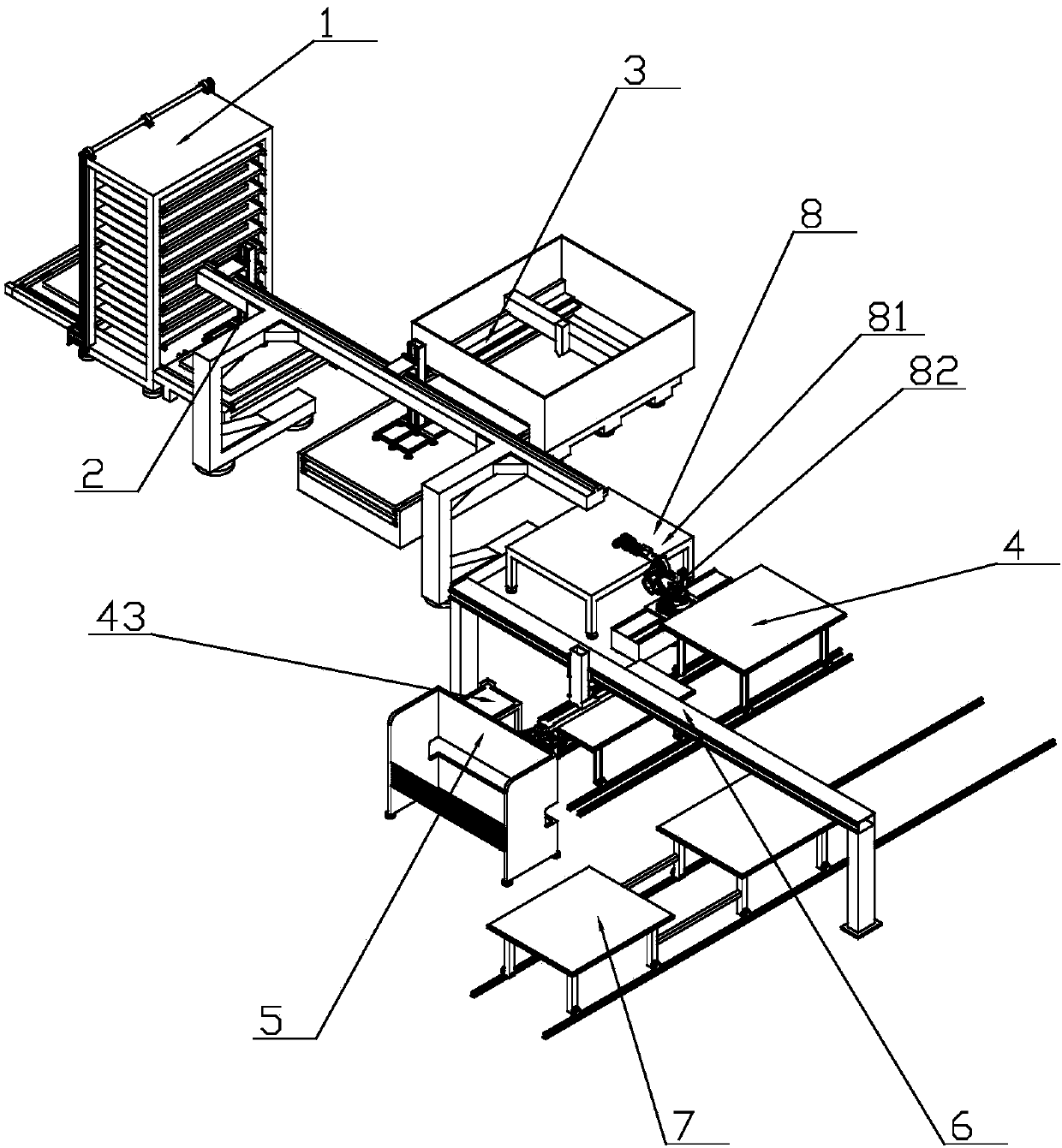

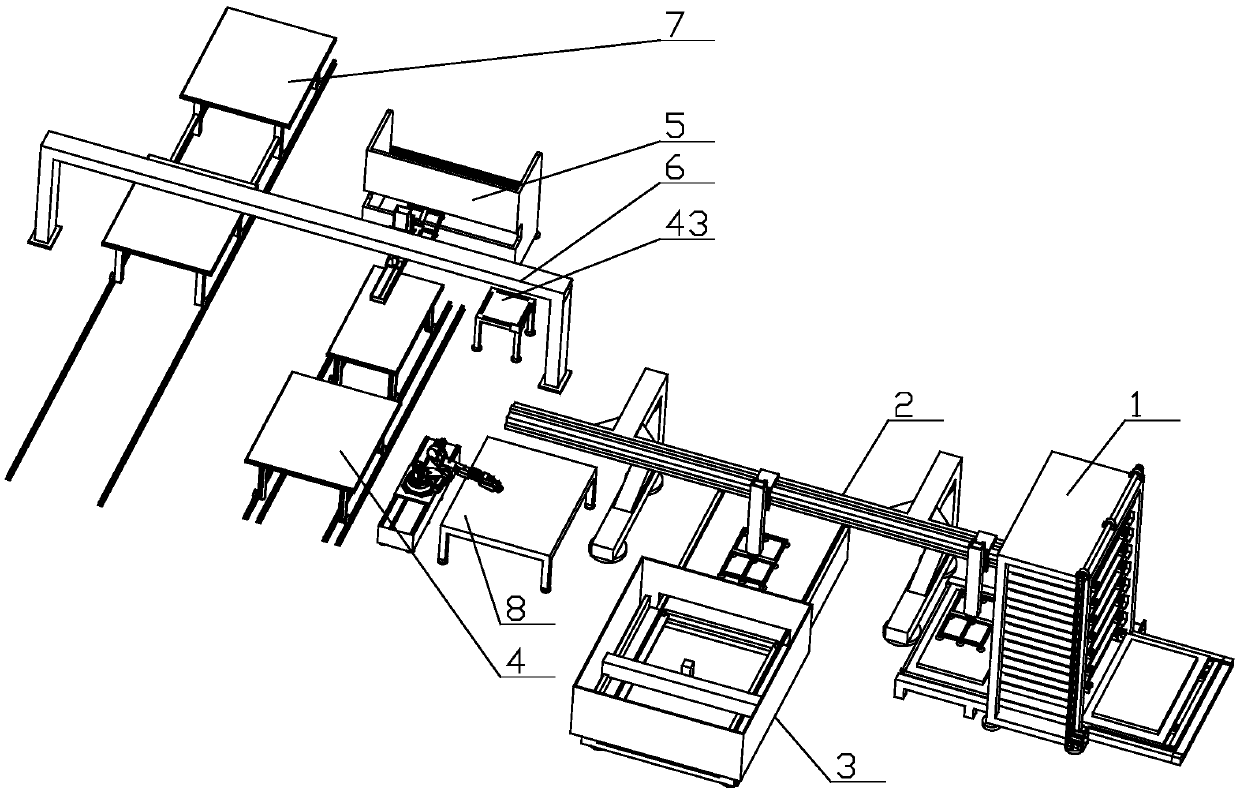

[0067] The present invention as Figure 1-27 As shown, it includes silo 1, translation manipulator assembly 2, laser cutting assembly 3, double-layer movable material table 4, bending machine 5, transfer manipulator assembly 6 and stacking table 7;

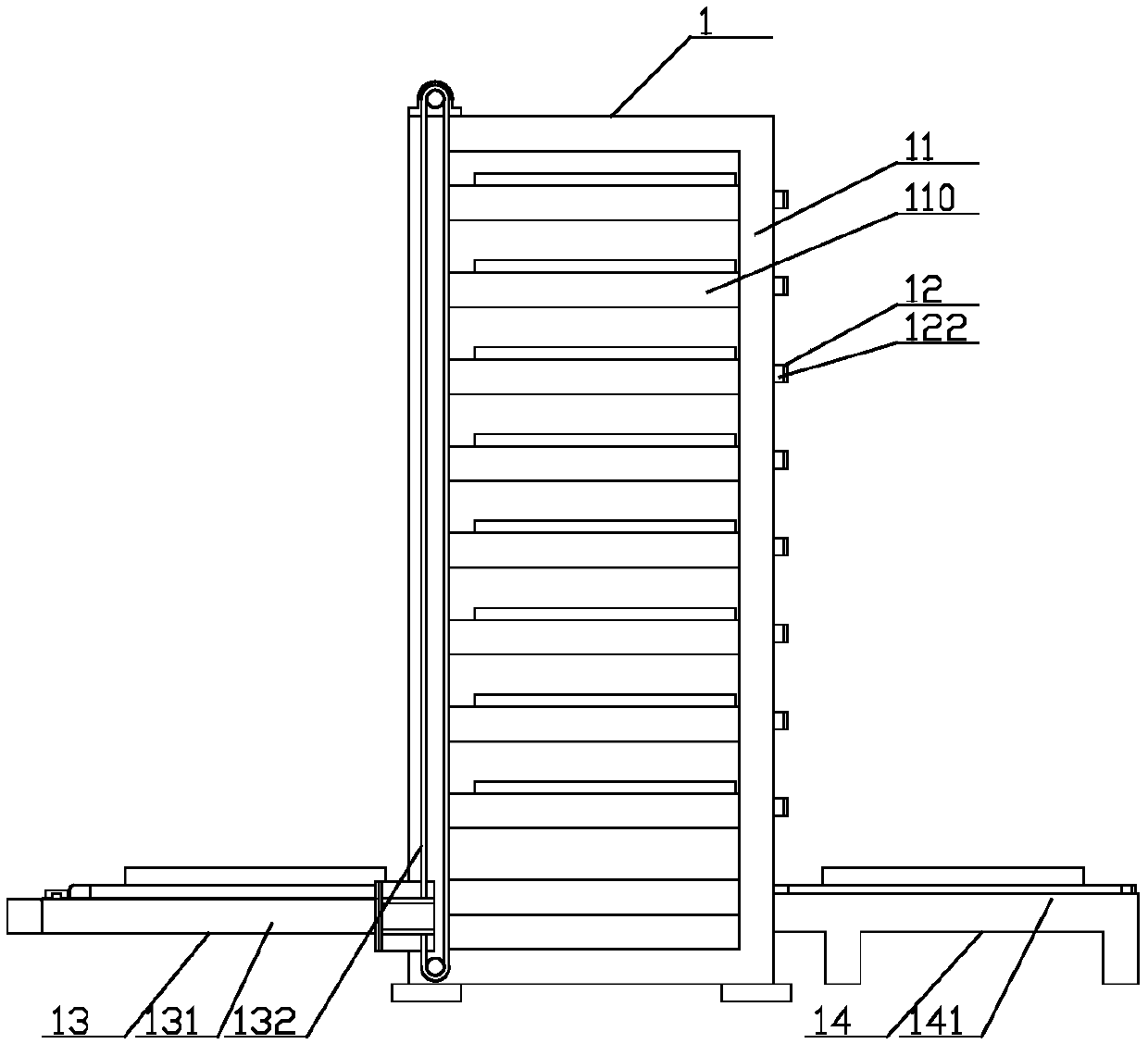

[0068] The silo 1 includes a storage rack 11, a number of support plates 12 (for supporting and storing plates 9), a support plate lifting assembly 13 and a support plate translation assembly 14, and the two sides of the storage rack 11 Several pairs of supporting bars 110 are fixedly connected on the inner wall, and several pairs of supporting bars 110 are evenly distributed from top to bottom, and both sides of the supporting plate 12 are slidingly connected on the same pair of supporting bars 110; (wherein the bottom layer The support strips are only used for the transfer of the pallets, not for the storage of the pallets)

[0069] The supporting plate lifting assembly 13 includes a lifting platform 131, a lifting platform dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com