Patents

Literature

1662results about How to "No safety hazard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exploitation technique for disgorging thick oil by pouring air to assistant steam

The present invention provides a method for production of heavy oil reservoir. It is technically characterized by that in the cyclic steam injection and steam-flooding process it utilizes air injection to raise recovery efficiency and engineering benefits. Said method includes the following steps: after the oil well is drilled, making casing sand control completion of heavy oil reservoir so as to inhibit sand inflow in after-production; constructing artificial bottom hole so as to resist high-pressure produced by injecting steam and high-pressure air; after well completion injecting hot steam (above 200 deg.C), and injecting air into same oil reservoir, reducing heavy oil viscosity, then closing well, making crude oil and oxygen gas produce oxidation reaction; after the wellhead pressure is stabilized, opening well and making production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

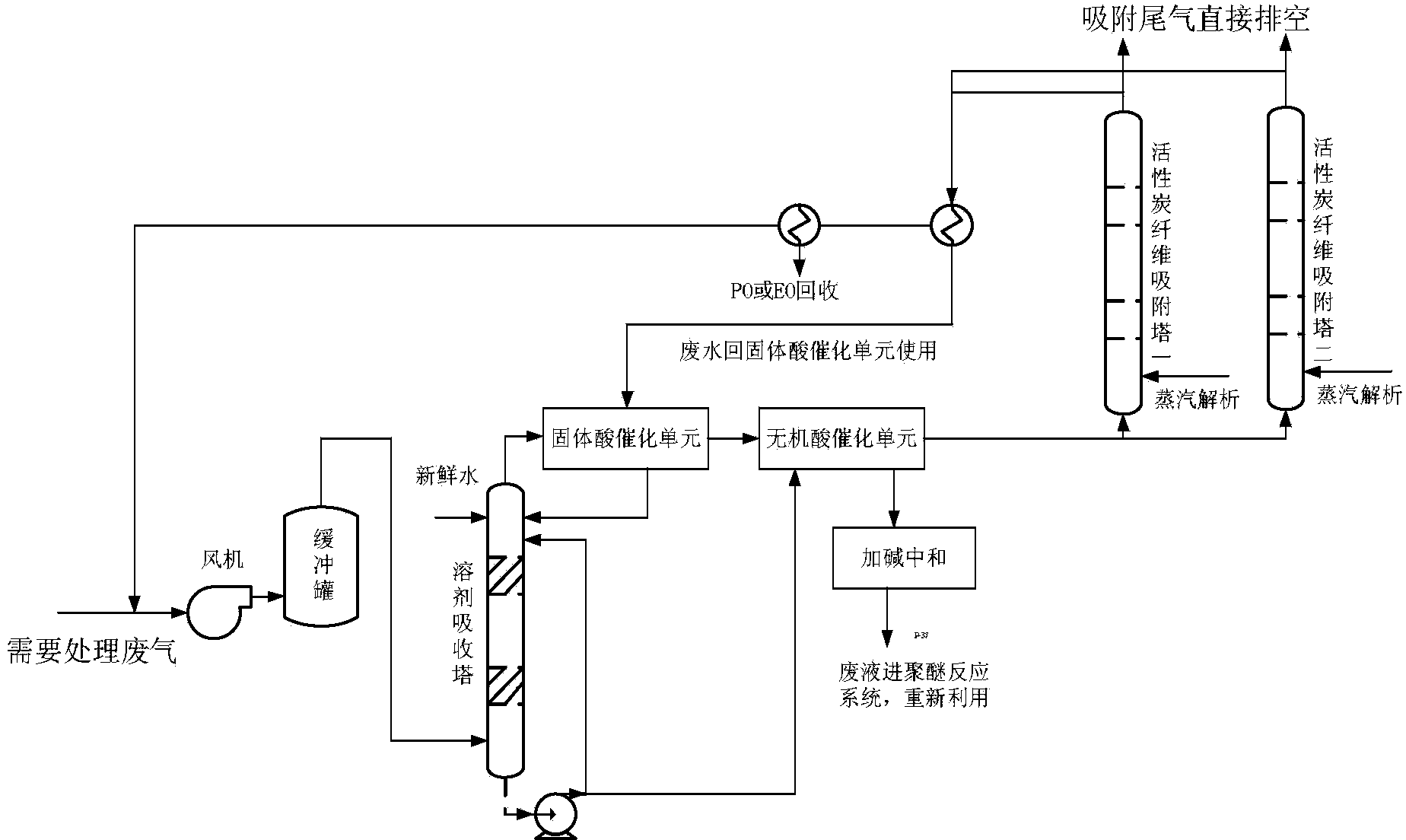

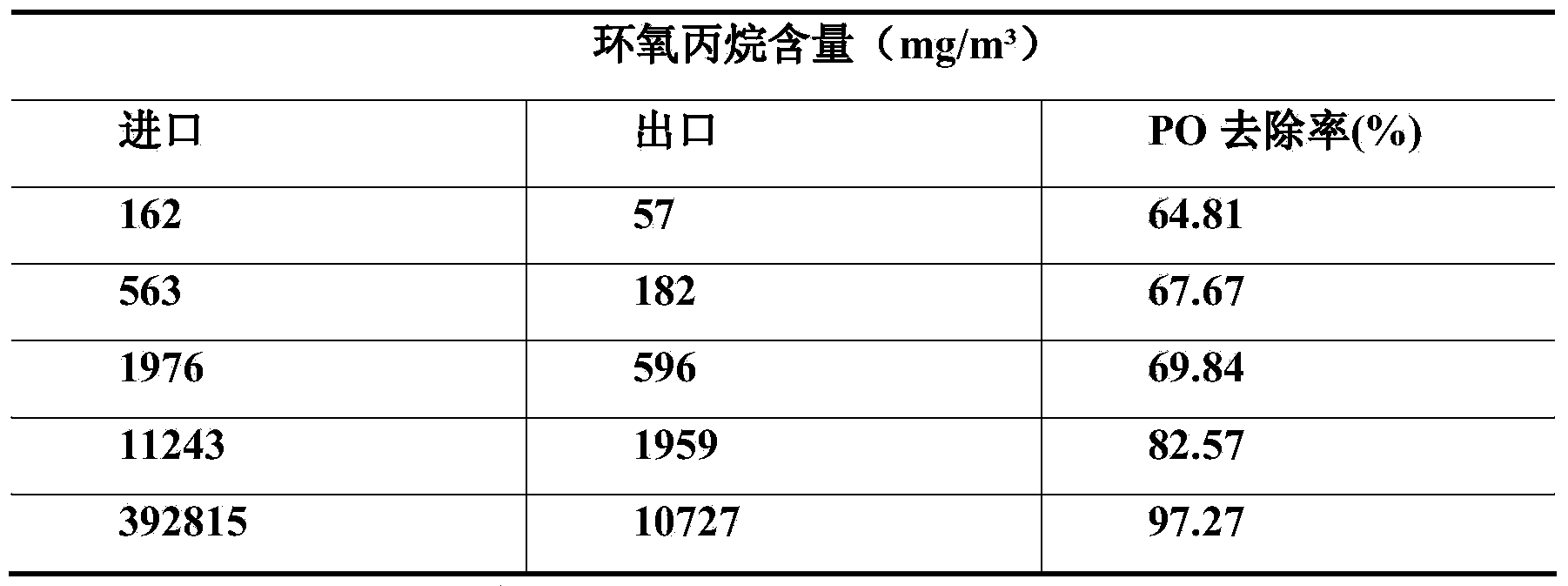

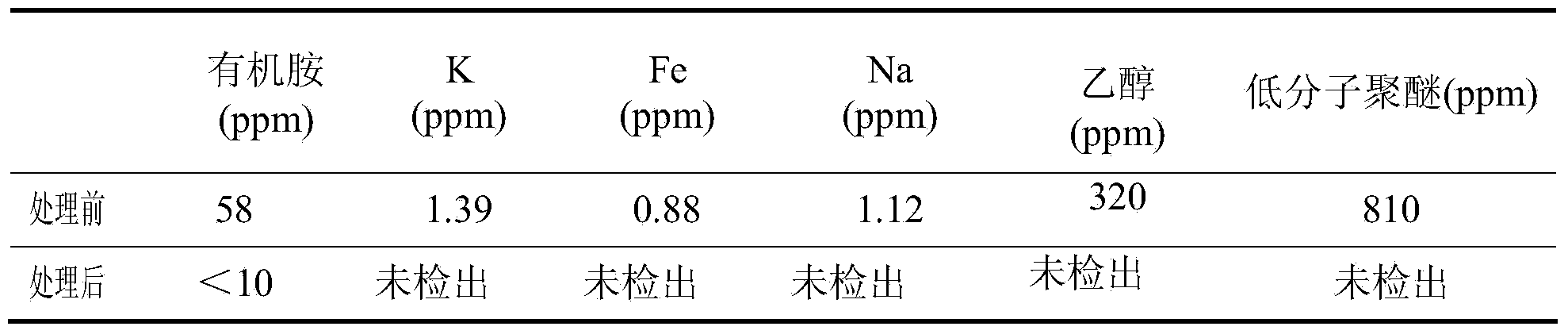

Method for purifying organic waste gas containing epoxypropane or ethylene oxide

ActiveCN104014227AMild reaction conditionsContinuous stabilizationOther chemical processesDispersed particle separationSolventActivated carbon

The invention relates to a method for purifying organic waste gas containing epoxypropane or ethylene oxide. The method comprises the following steps: processing organic waste gas containing epoxypropane or ethylene oxide with concentration of 1v%-40v% sequentially by a solvent absorption tower filled with modified activated carbon filler, a solid acid catalysis unit, an organic acid catalysis unit and an active carbon fiber absorption tower after being homogenized through a buffer tank until the content of epoxypropane or ethylene oxide in the waste gas is less than 2ppm, converting most of epoxypropane or ethylene oxide into propylene glycol or ethylene glycol, and circulating to a polyether production system for recycling. According to the method, the problem that waste gas containing epoxypropane or ethylene oxide, with complicated flow and large concentration fluctuation, influences the stable operation of a waste gas processing device is solved, the outlet concentration of waste gas is continuously qualified, the waste gas emission standard is reached, and no three wastes are emitted outside battery limit in the whole process.

Owner:WANHUA CHEM GRP +1

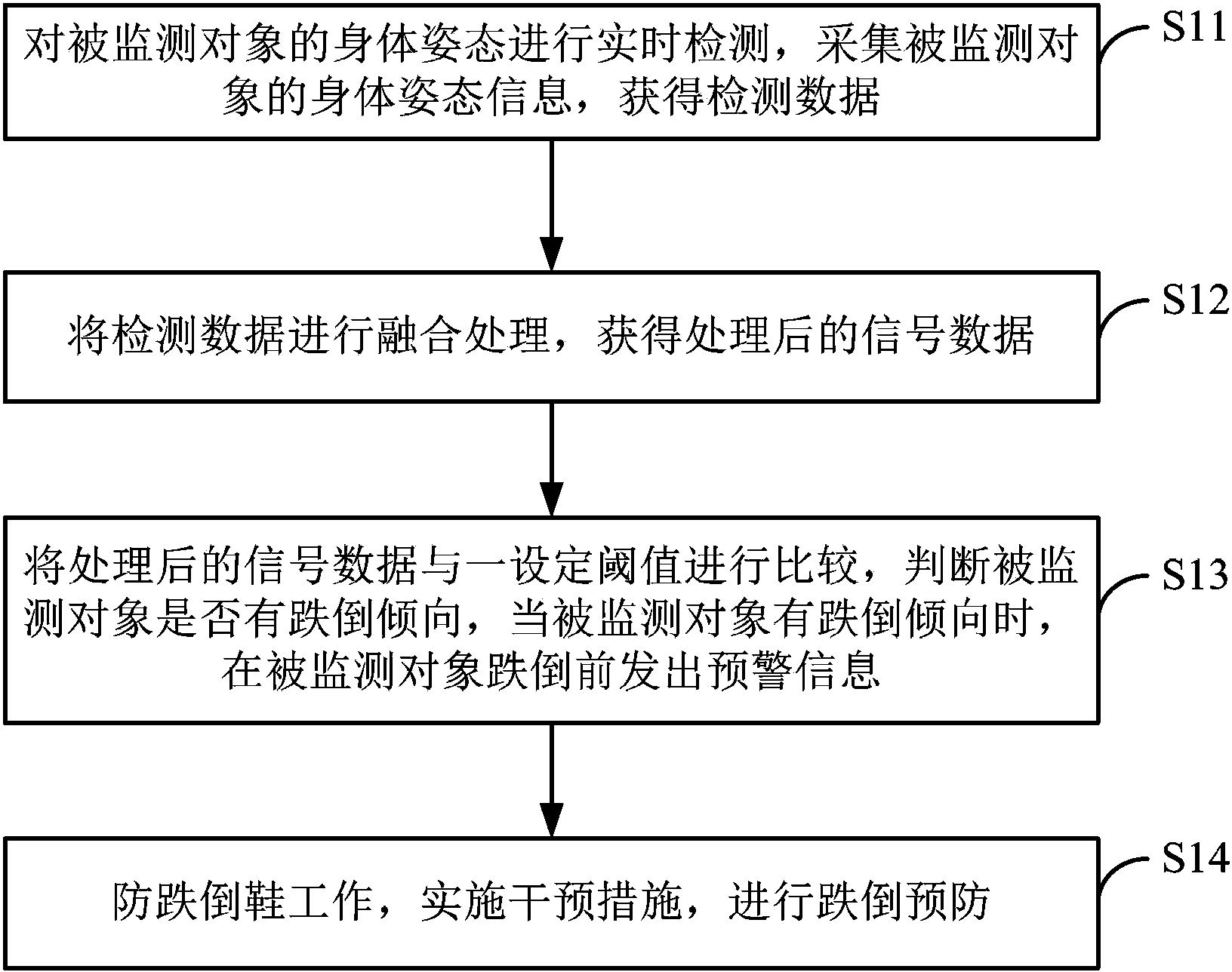

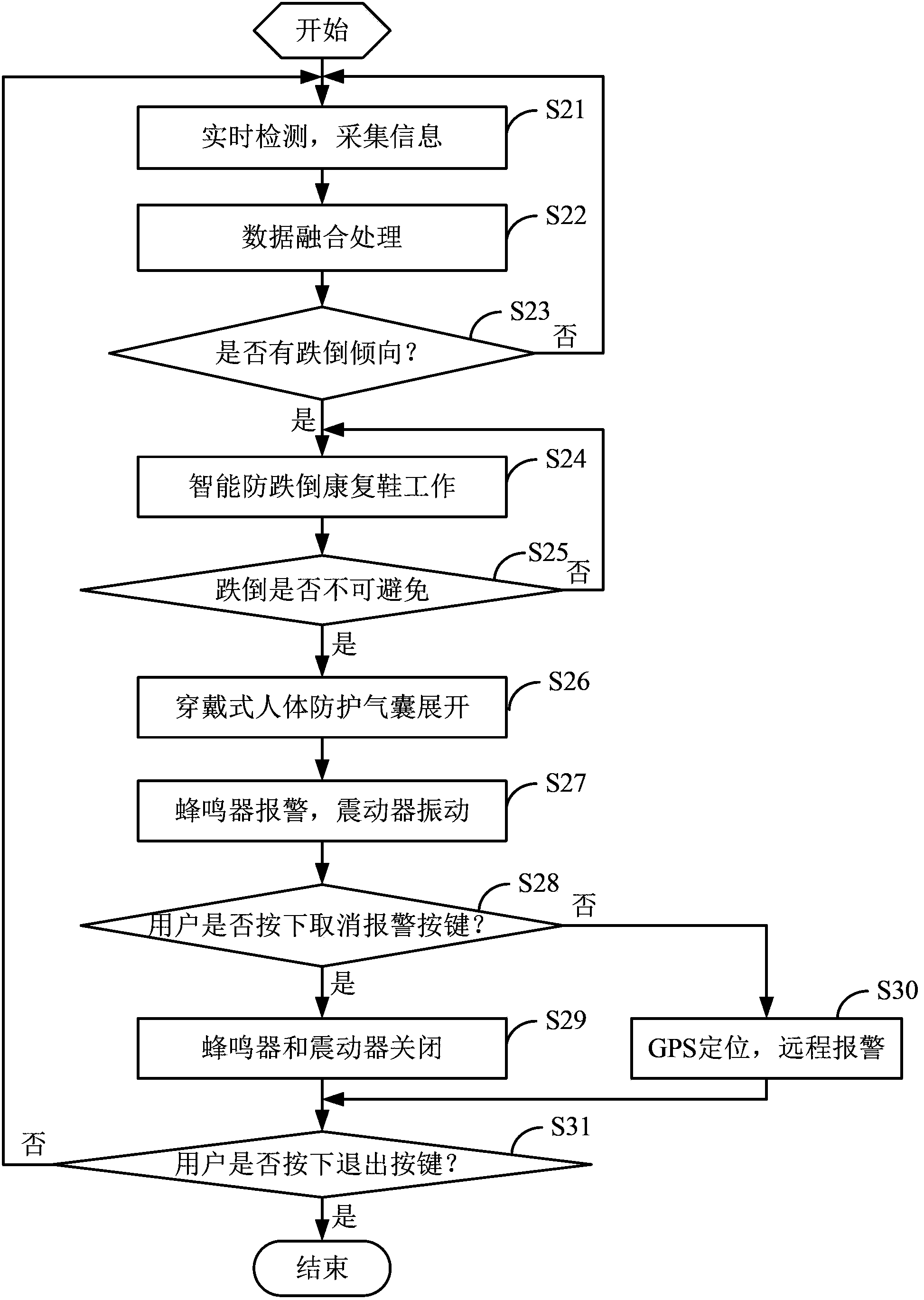

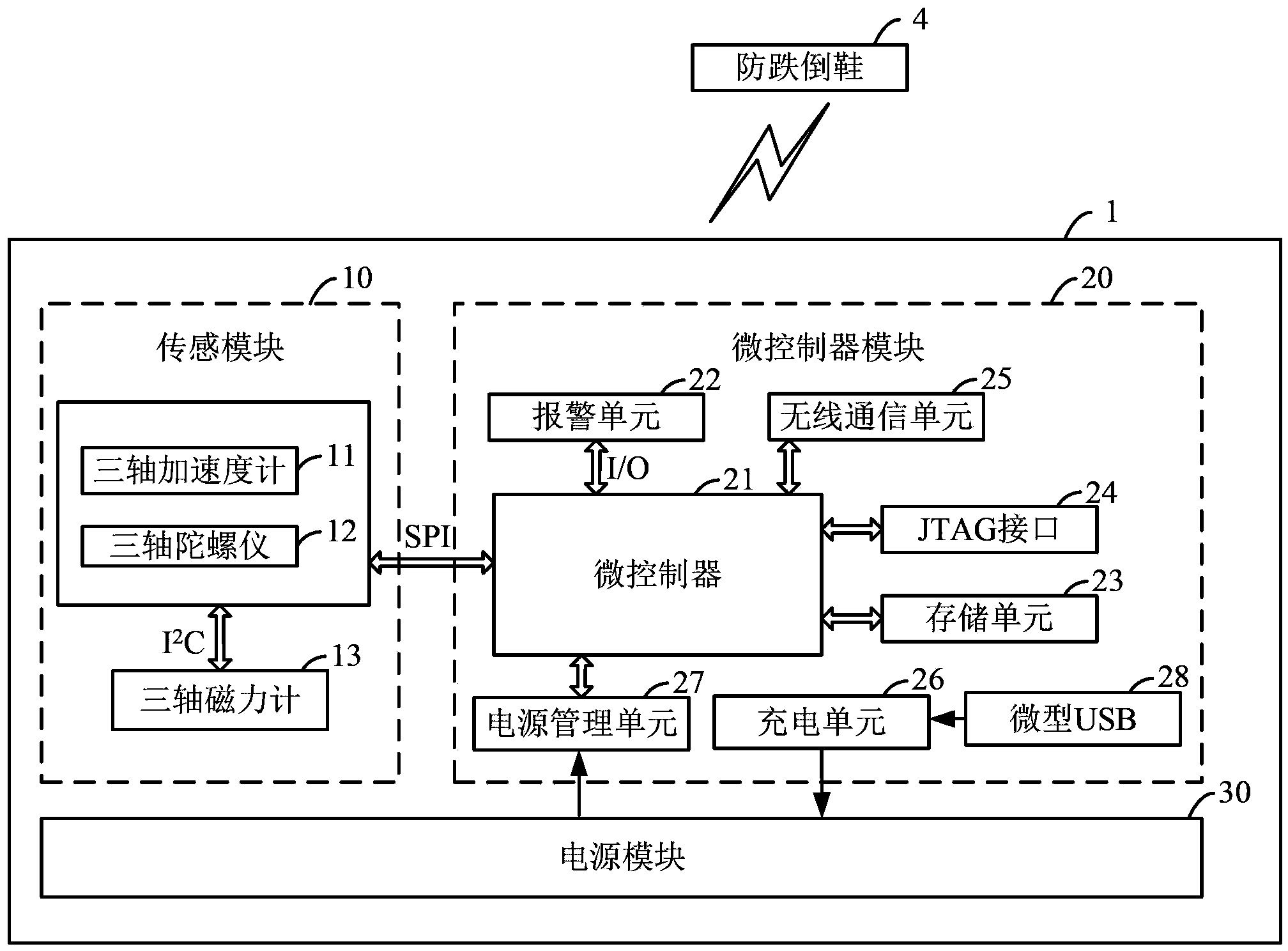

Human body fall-down prevention early warning and intervening method and system

InactiveCN103377541ARealize early warningSolve the problem of the alarm function after fallingAlarmsHuman bodyBody posture

The invention relates to the technical field of human body fall-down detecting and intervening and provides a human body fall-down prevention early warning and intervening method and system. The human body fall-down prevention early warning and intervening method includes the steps that real-time detection is performed on the body posture of a monitored object, body posture information of the monitored object is collected, and detection data are obtained; fusion processing is performed on the detection data so as to obtain the processed signal data; the processed signal data are compared with a set threshold so as to judge whether the monitored object inclines to fall down or not, and when the monitored object inclines to fall down, early warning information is sent out before the monitored object falls down; fall-down prevention shoes work, intervening measures are carried out, and fall-down prevention is performed. The human body fall-down prevention early warning and intervening method and system achieve early warning and intervening before the human body falls down.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

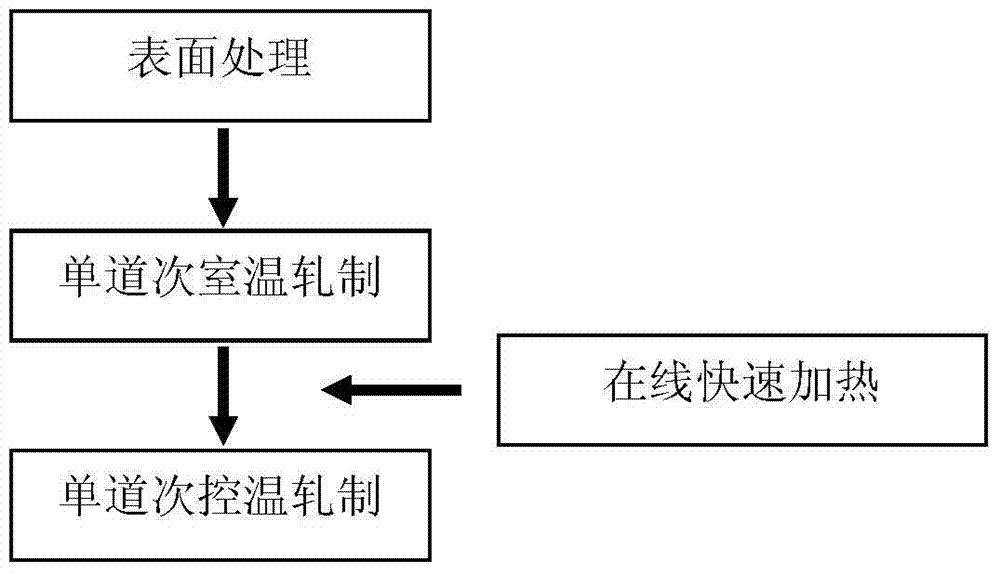

Short-process efficient production method for metal-layered composite board strips

ActiveCN103752611AIncrease profitReduce pollutionMetal rolling arrangementsTemperature controlMetal strips

The invention discloses a short-process efficient production method for metal-layered composite board strips and belongs to the technical field of production of the metal-layered composite board strips. The short-process efficient production method is characterized by including: subjecting to-be-composited double-layered or multilayered metal board strips subjected to surface treatment to single-pass room temperature rolling to obtain pre-composited metal-layered composite board strip plates; rapidly heating the pre-composited metal-layered composite board strip plates to the temperature (lower than recrystallization temperature of metal) required by subsequent rolling; continuing performing single-pass temperature-controlled rolling so as to prepare high-performance metal-layered composite board strips. The short-process efficient production method has the advantages of continuity and high degree of automation, short process, high production efficiency, small environmental pollution, energy conservation, circle-time reduction, freeness of potential safety hazards, high dimensional accuracy of products, flexible specifications, large degree of freedom in raw material combination, high material utilization, low requirements on equipment, low production cost and excellent product quality and performance, and the coiled metal strip plates or long-sized metal plates can be used as raw materials.

Owner:UNIV OF SCI & TECH BEIJING

Intelligent sleep monitoring system for preventing kids from kicking quilts

ActiveCN104900000AEnsure sleep qualityImprove temperature monitoring accuracyAlarmsEngineeringHeat sensitive

The invention provides an intelligent sleep monitoring system for preventing kids from kicking quilts, comprising a control assembly, magnetic sensors, stretching motors, drive pulleys, pull ropes, a humidity-sensitive resistor, a thermal-sensitive resistor, magnets, temperature sensors, and a remote alarm assembly. The humidity-sensitive resistor and the thermal-sensitive resistor are arranged on the obverse side of a bed body. The magnetic sensors and the stretching motors are arranged in the corners of the bed body. The control assembly is connected to the humidity-sensitive resistor, the thermal-sensitive resistor, the magnetic sensors and the stretching motors. A quilt is connected to the stretching motors through the pull ropes. The temperature sensors are arranged on the quilt, and the temperature sensors are connected with the control assembly in a wireless communication mode. The control assembly is connected with the remote alarm assembly in a wireless communication mode. The intelligent sleep monitoring system of the invention has the functions of automatically covering a kid with a quilt, alarming for high fever and enuresis, and the like, and has a high level of intelligence. Long-term test shows that the intelligent sleep monitoring system can prevent kids from kicking quilts in sleep in a fully automatic way and improve the quality of sleep of both kids and parents.

Owner:左冬平

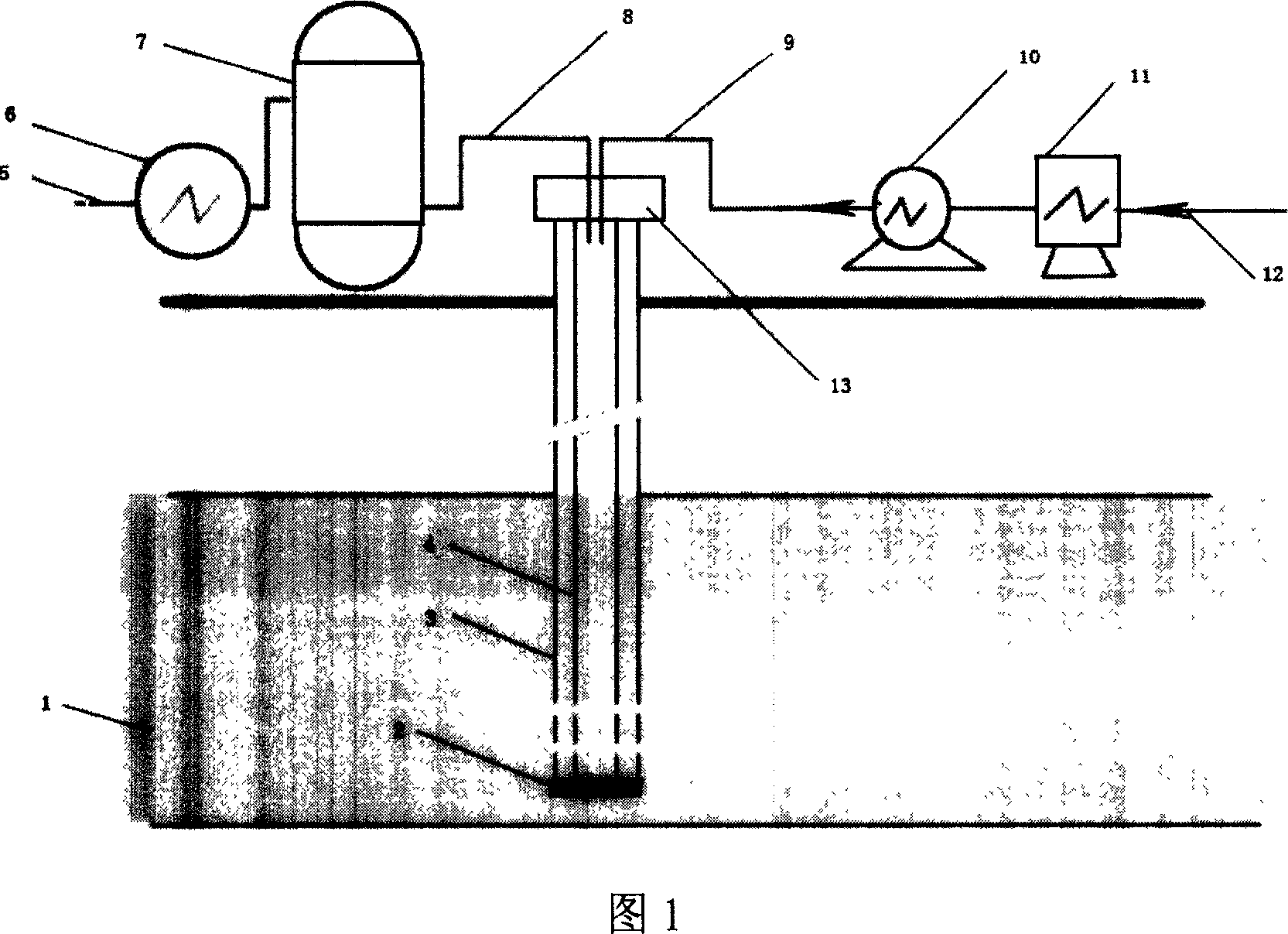

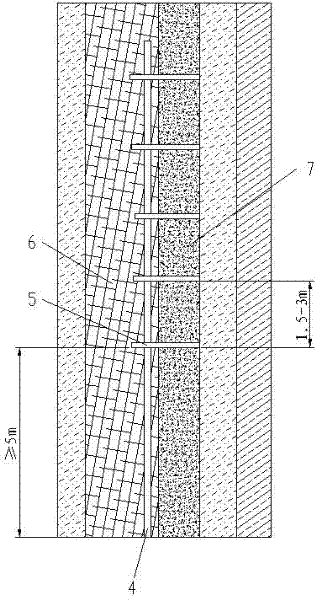

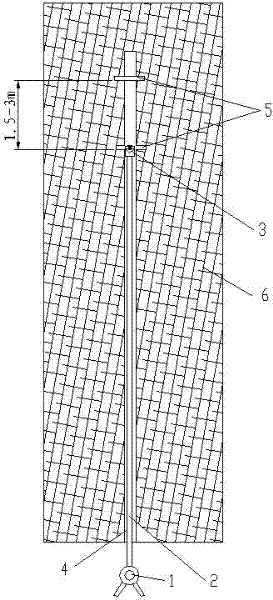

Depressurized extraction method for cutting through roof or floor of coal seam by abrasive water jet

InactiveCN102493833AGood sealing effectReduce gas extraction costsFluid removalGas removalAbrasive water jetCoal

The invention discloses a depressurized extraction method for cutting through a roof or a floor of a coal seam by an abrasive water jet, which comprises the following steps: a. drilling a bedding drill hole to set depth on the roof or the floor of a coal-rock mass or a hard layer by using a drilling machine through a drill stem and a slotting drill bit; b. delivering a high-pressure abrasive water jet of which the pressure is 25-30MPa to the slotting drill bit through the drill stem, wherein the drill stem rotates in situ; forming a radial slit on the hole wall of the bedding drill hole, wherein the slit penetrates the roof or the floor of the coal-rock mass or the hard layer and a soft layer; c. enabling the drill stem to rapidly retreat for 1.5-3m so as to form a new slit; d. repeating the step c until a plurality of radial slits are formed on the bedding drill hole, and moreover, reserving a safety rock pillar of at least 5m at the slit located at the position of the orifice of the bedding drill hole at a certain distance from the orifice; e. retreating the drill stem and the slotting drill bit and sealing the hole; and f. extracting gas by a gas extraction system. The depressurized extraction method for cutting through the roof or the floor of the coal seam by the abrasive water jet has the beneficial effects that the drill hole does not have potential safety hazards and is easy to form; a hole sealing effect is good; the time of reaching the standards of extraction is short; the production efficiency is high; and the extraction is safe.

Owner:重庆市能源投资集团科技有限责任公司

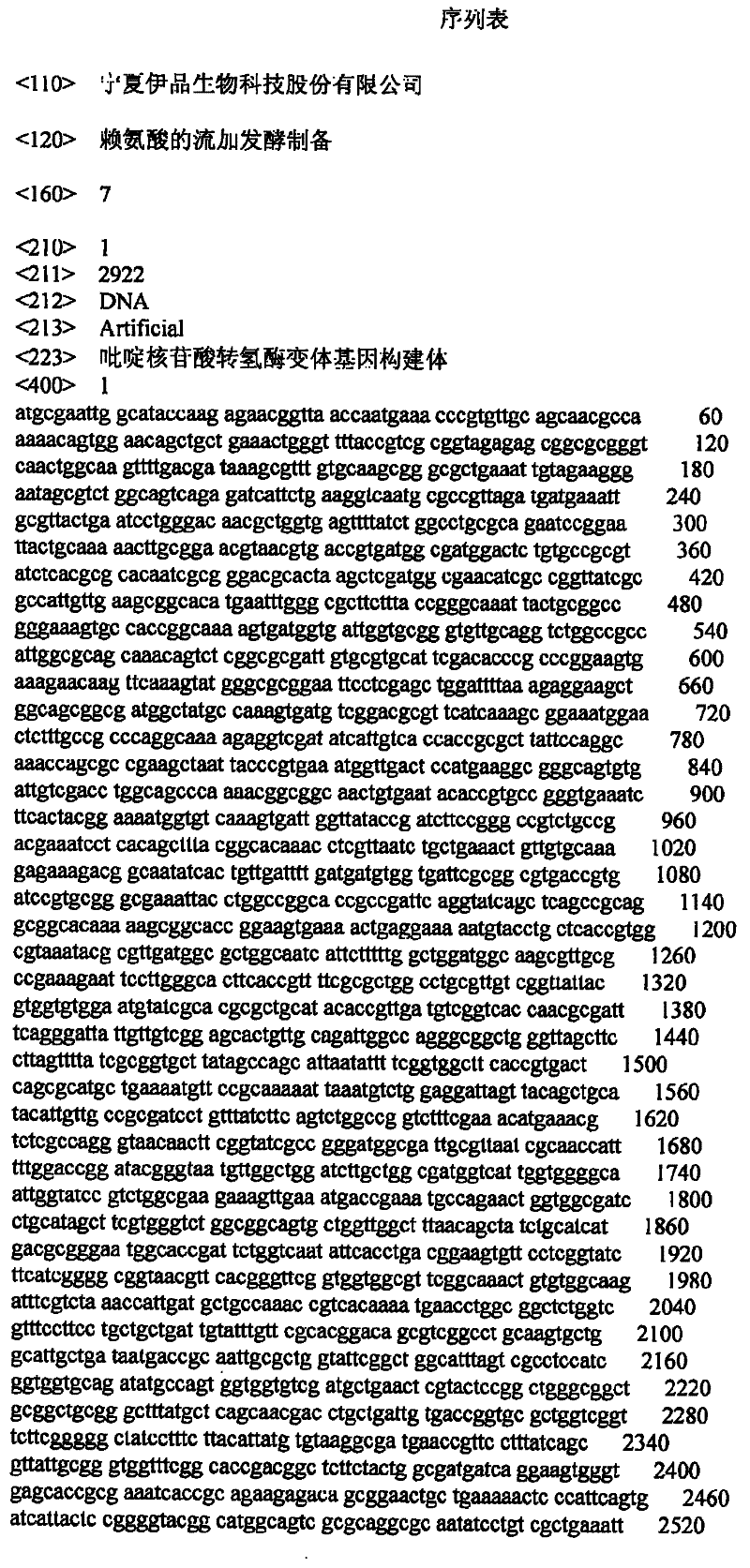

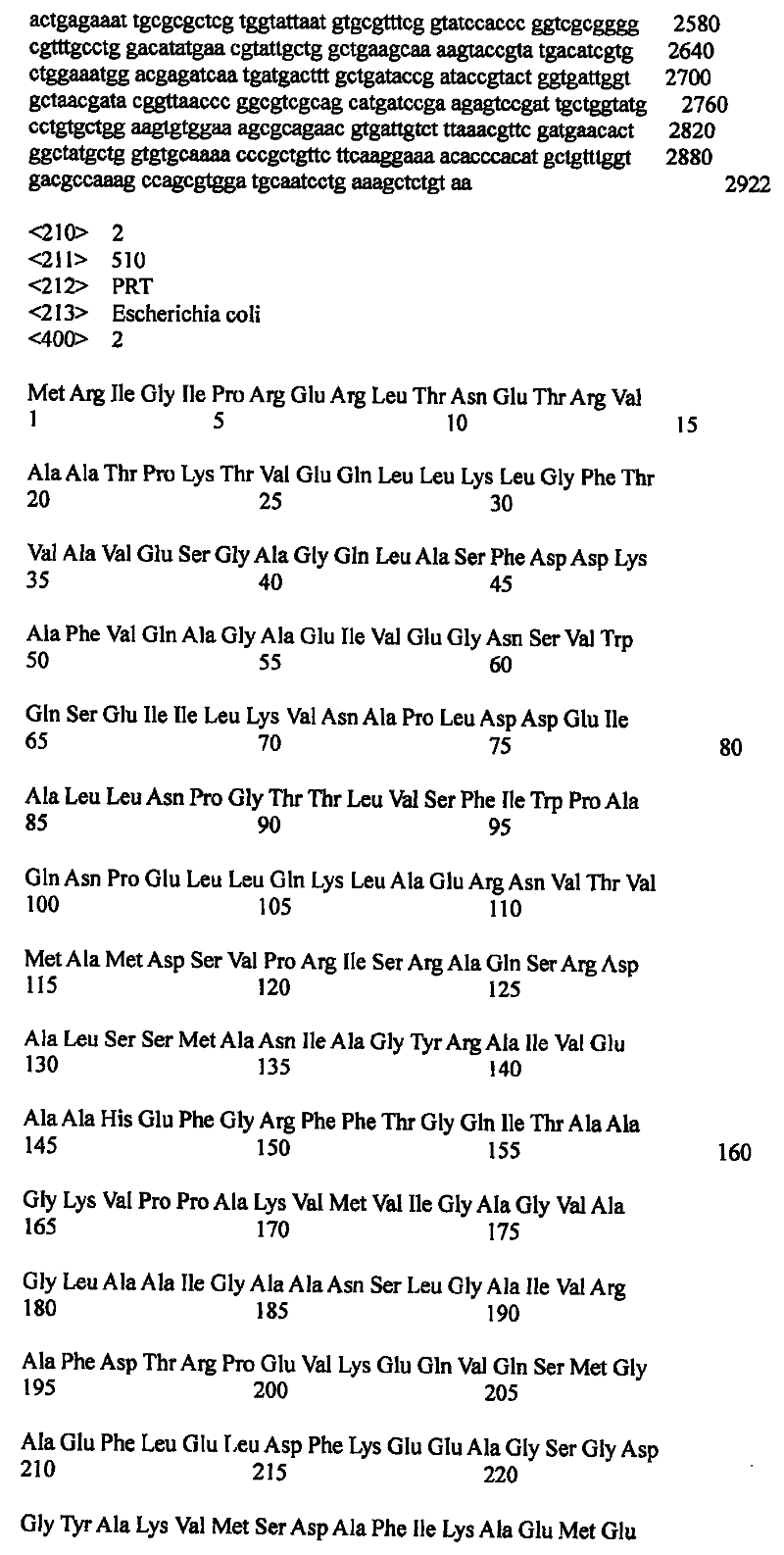

Fed-batch fermentation preparation of lysine

ActiveCN102234666AImprove fermentation yieldIncrease productionMicroorganism based processesFermentationBiotechnologyCulture fluid

The invention provides a method for fed-batch fermentation of L-lysine, which comprises the following steps of: introducing engineering bacteria for expressing pyridine nucleotide transhydrogenase variants into a first fermentation tank for culturing, and inoculating the obtained culture solution to a second fermentation tank for culturing; then, continuously feeding sugar in batches to the second fermentation tank; and then, continuously feeding sugar and nitrogen sources in batches to the second fermentation tank.

Owner:NINGXIA EPPEN BIOTECH +1

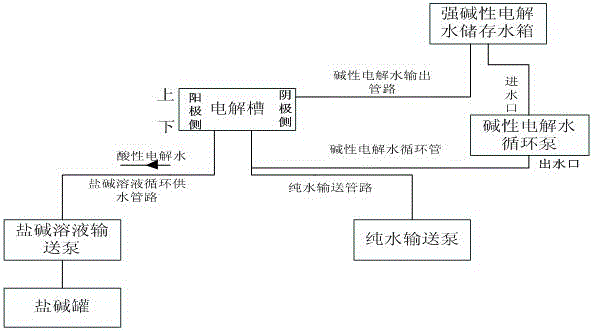

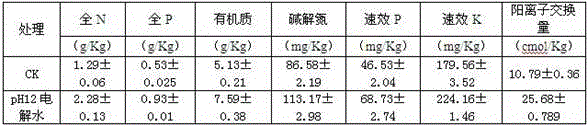

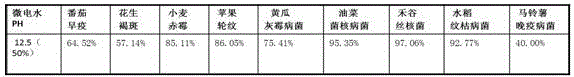

Alkaline electrolyzed water and application thereof to agriculture sterilization

InactiveCN106006852AHigh degree of automationElectrolyzed Water SafetyBiocideDisinfectantsElectrolysed waterPesticide residue

The invention discloses alkaline electrolyzed water, a preparation method of the alkaline electrolyzed water and application of the alkaline electrolyzed water to agriculture. The process comprises the following steps: (1) enabling pure water to enter from the bottom of an electrolytic tank through a pure water conveying pipeline, injecting a saline-alkaline solution from the bottom of the electrolytic tank, and mixing an electrolyte into pure water for electrolysis; (2) sending alkaline electrolyzed water, generated on the cathode side of an ion film, to a strong alkaline electrolyzed water storage tank, and sending acidic electrolyzed water, generated on the anode side of the ion film, to a saline-alkaline tank, wherein solid KOH or K2CO3 is dissolved into a saturate saline-alkaline solution through slightly acid electrolyzed water to be provided for the electrolytic tank, and the alkaline electrolyzed water is circularly electrolyzed in the electrolytic tank; (3) when the pH value of strong alkaline electrolyzed water reaches 13 or above through electrolysis, finally supplying strong alkaline electrolyzed water for equipment and a production line through a strong alkaline electrolyzed water outlet. According to the invention, the extreme alkaline electrolyzed water with the pH value of 13.8 can be produced, and can be used for pesticide preparation processing, farmland sterilization, soil improvement, soil disinfection and sanitation environment disinfection, pesticide residue degradation and fruit preservation.

Owner:潘灿平

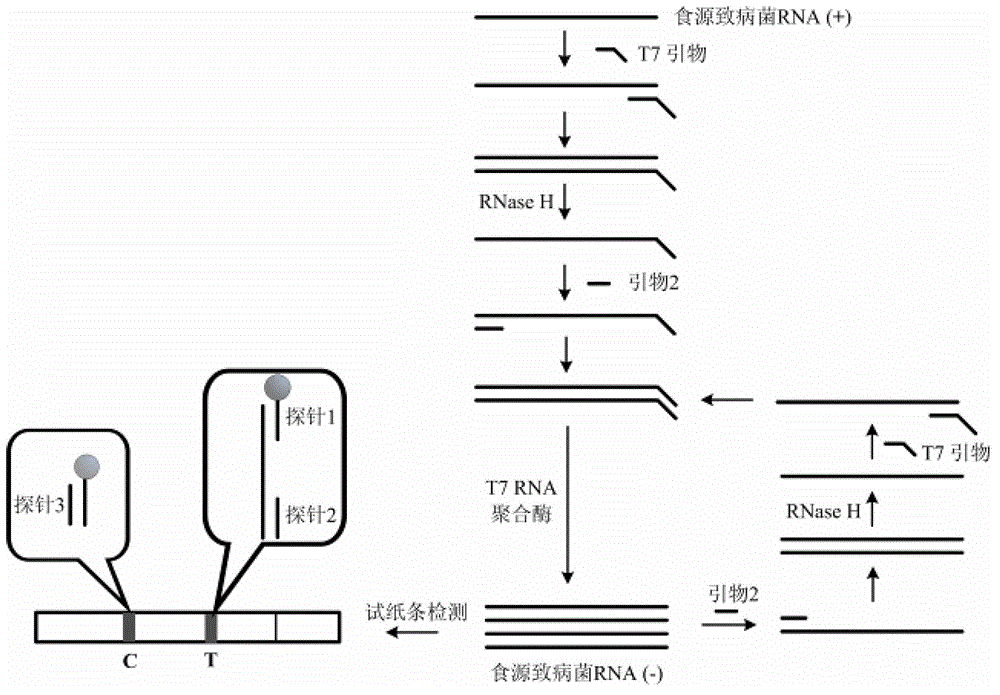

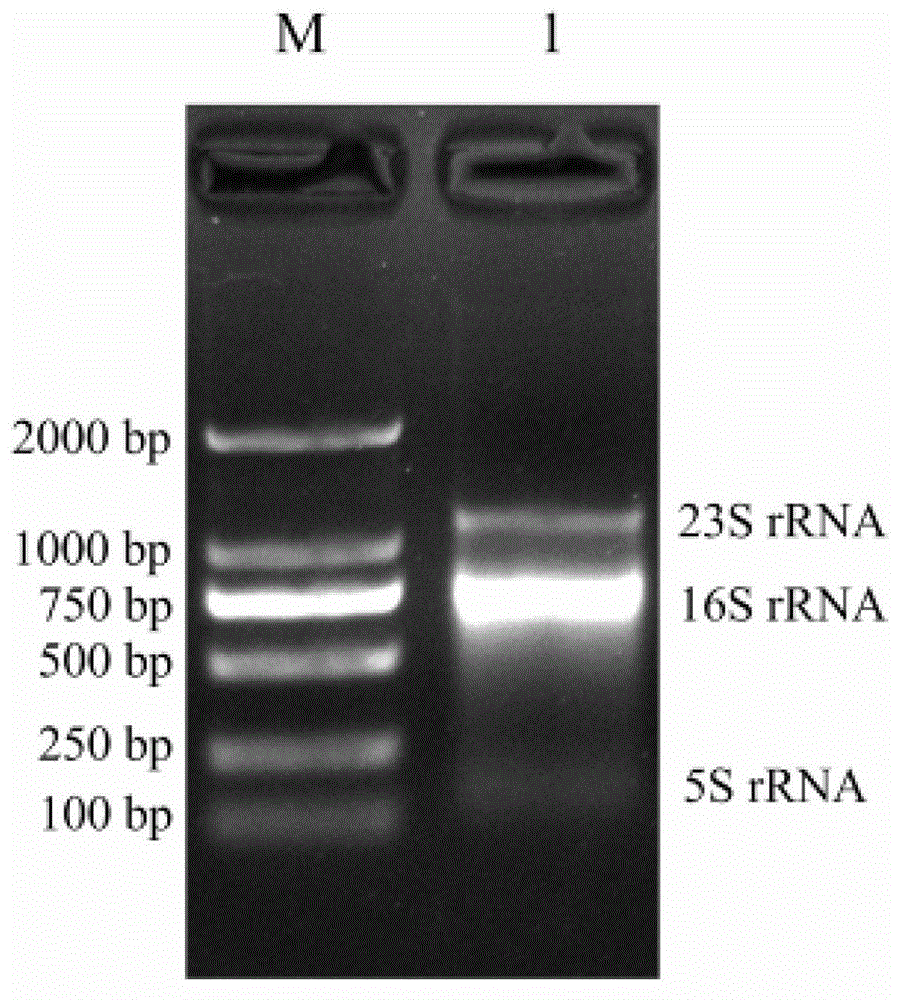

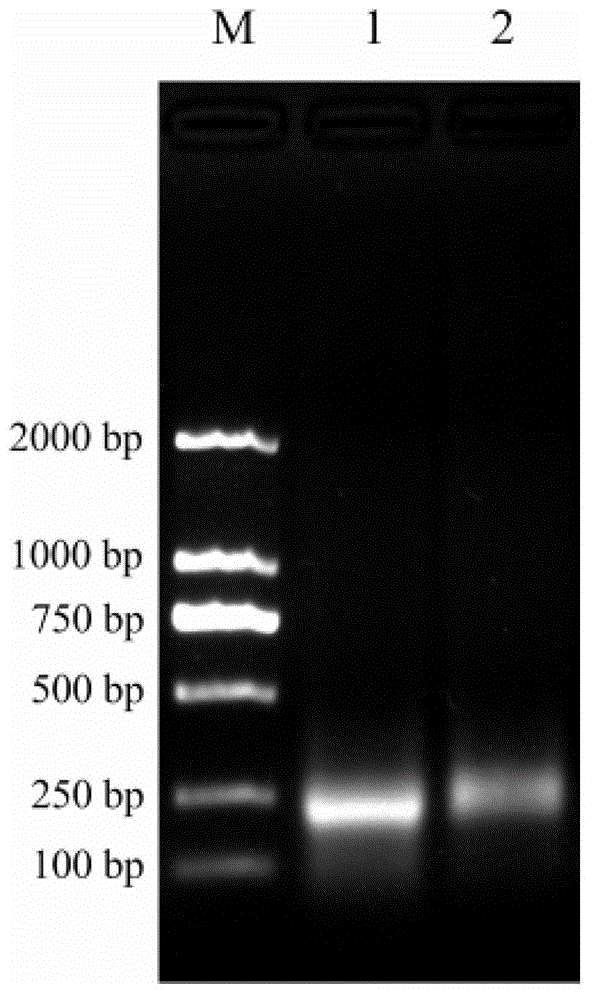

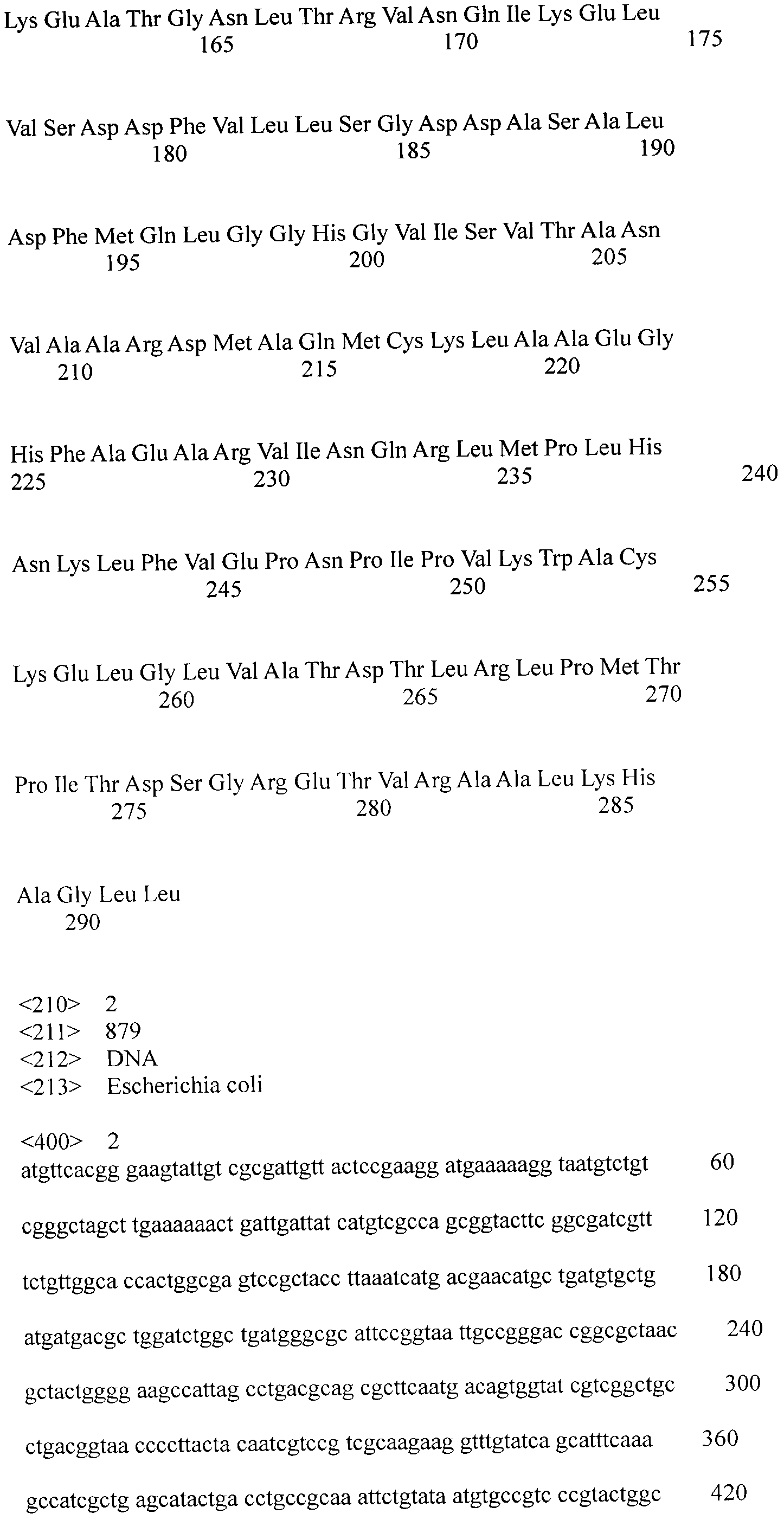

Method and kit for detecting pathogenic bacterium of food source by test strip based on NASBA (Nucleic Acid Sequence Based Amplification)

ActiveCN103146835AImprove featuresHigh sensitivityMicrobiological testing/measurementMicroorganism based processesNucleic acid sequence based amplificationMicrobiology

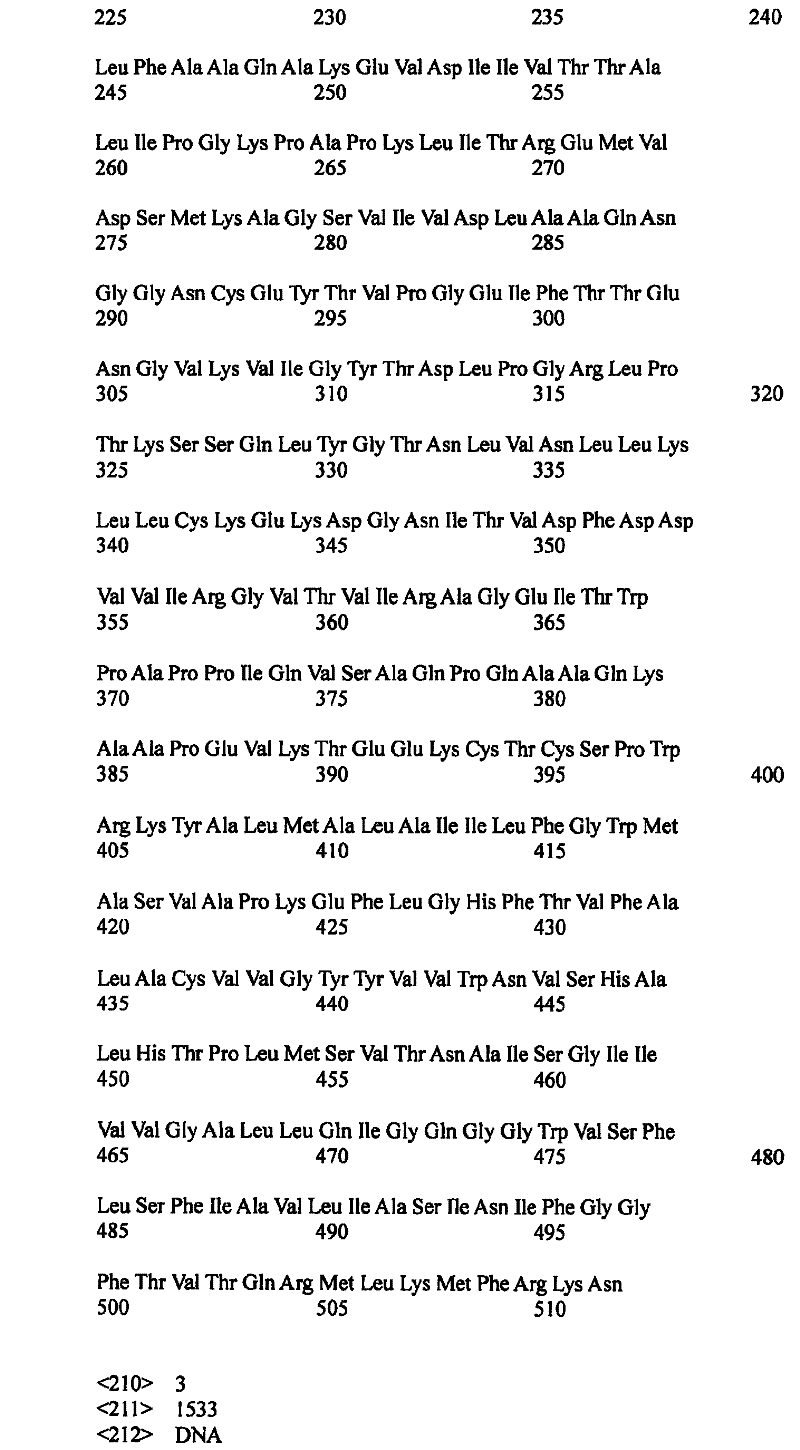

The invention discloses a method and a kit for detecting pathogenic bacterium of a food source by a test strip based on NASBA (Nucleic Acid Sequence Based Amplification) and belongs to the technical field of biological detection. The method comprises the following steps of: (1) extracting RNA of pathogenic bacterium of the food source; (2) designing an amplification primer; (3) performing NASBA reaction; (4) designing a catching probe; (5) preparing a nano-gold probe; (6) preparing a collaurum nucleic acid strip; and (7) detecting the samples. The kit using the method to detect Listeria monocytogenes comprises primers (as shown in SEQ ID NO. 1 and 2), enzyme, buffer solution, RNaseH, RNA enzyme inhibitor, dNTPs, NTPs, probes (as shown in SEQ ID NO. 4, 5 and 6) and collaurum nucleic acid strip, etc. By combining NASBA with detection of the test strip, the method disclosed by the invention can realize qualitative or quantitative detection, and has low cost, high detection speed, good specificity, high sensitivity and safety in use.

Owner:SOUTH CHINA NORMAL UNIVERSITY

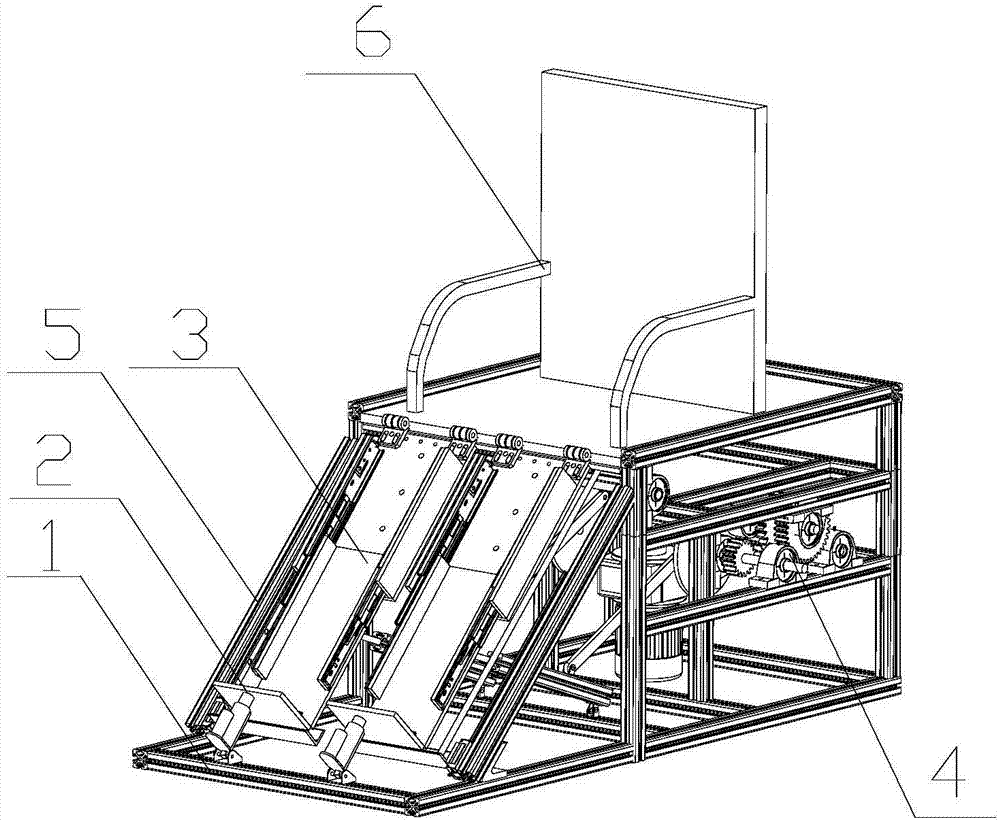

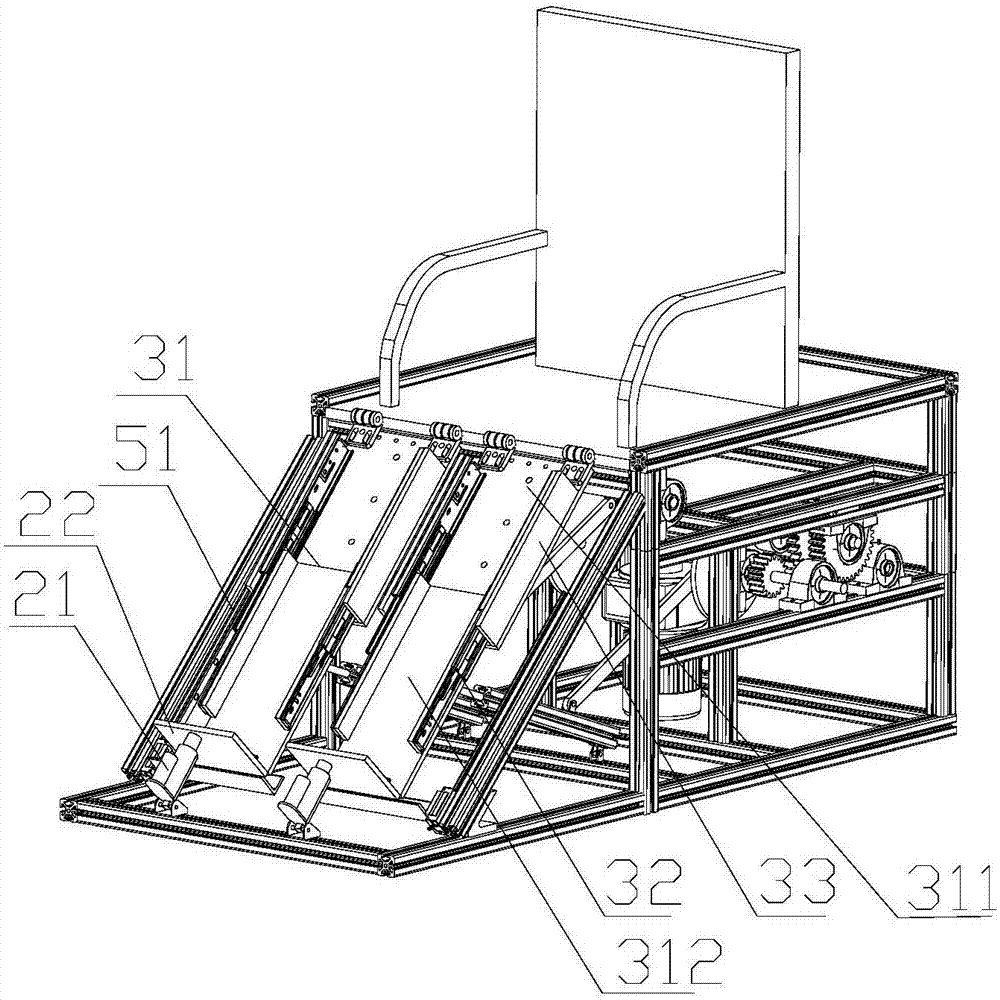

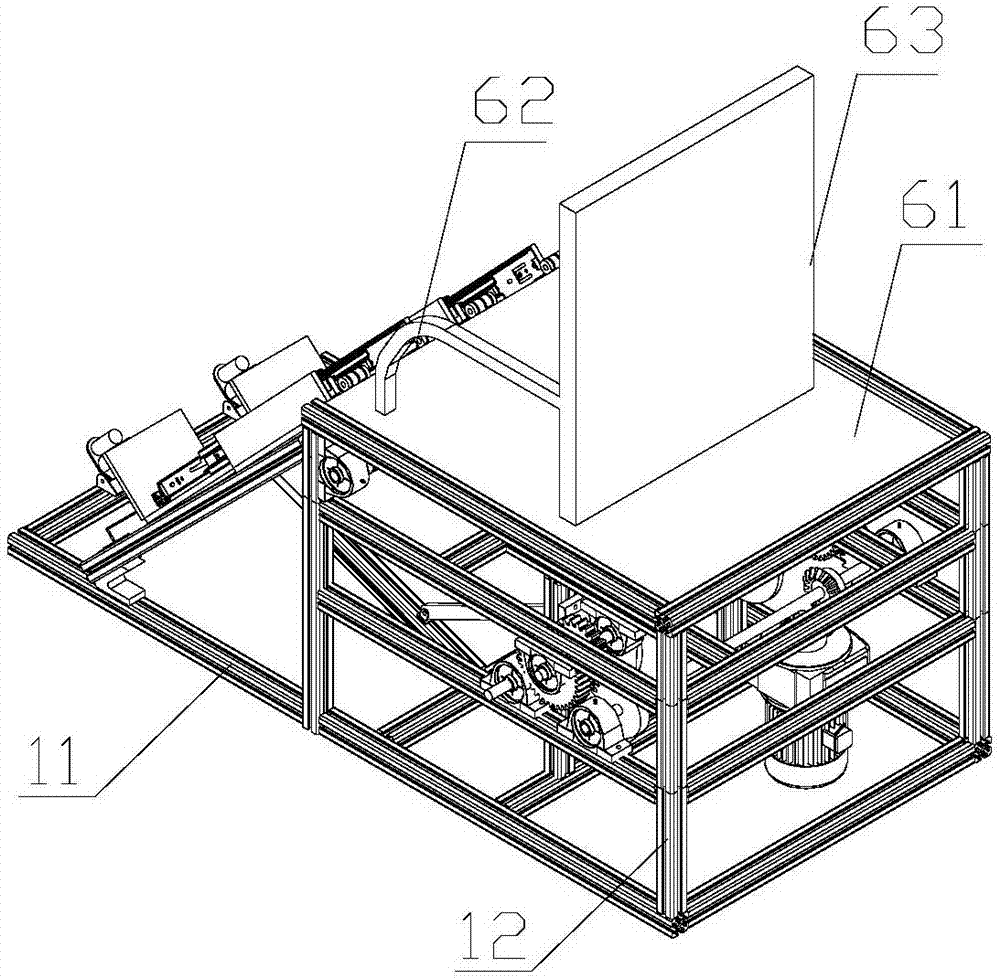

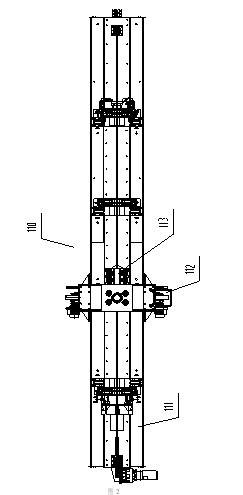

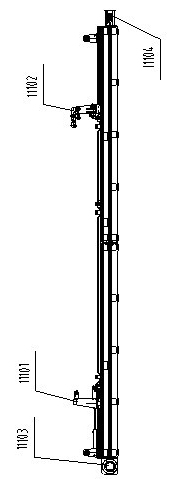

Lower limb rehabilitation training machine

The invention relates to a lower limb rehabilitation training machine. The lower limb rehabilitation training machine comprises an outer frame, two ankle exercising mechanisms, two parallelly arranged leg extension mechanisms, two knee joint exercising mechanisms, two hip joint exercising mechanisms, an adjustable backrest mechanism and a controller, wherein the ankle exercising mechanisms, the leg extension mechanisms, the knee joint exercising mechanisms and the hip joint exercising mechanisms are in one-to-one correspondence; each ankle exercising mechanism is connected with the lower portion of the corresponding leg extension mechanism, and the upper portion of each leg extension mechanism is hinged to the front edge of the seat plate of the adjustable backrest mechanism; the knee joint exercising mechanisms are mounted on the outer frame, and the power output end of each knee joint exercising mechanism is connected with the corresponding leg extension mechanism; the two hip joint exercising mechanisms are mounted on the outer frame; the ankle exercising mechanisms, the knee joint exercising mechanisms and the hip joint exercising mechanisms are electrically connected the corresponding pins of the controller. The lower limb rehabilitation training machine has the advantages that labor input is reduced, and the three joints of legs can be passively and safely exercised at home.

Owner:ZHEJIANG UNIV OF TECH

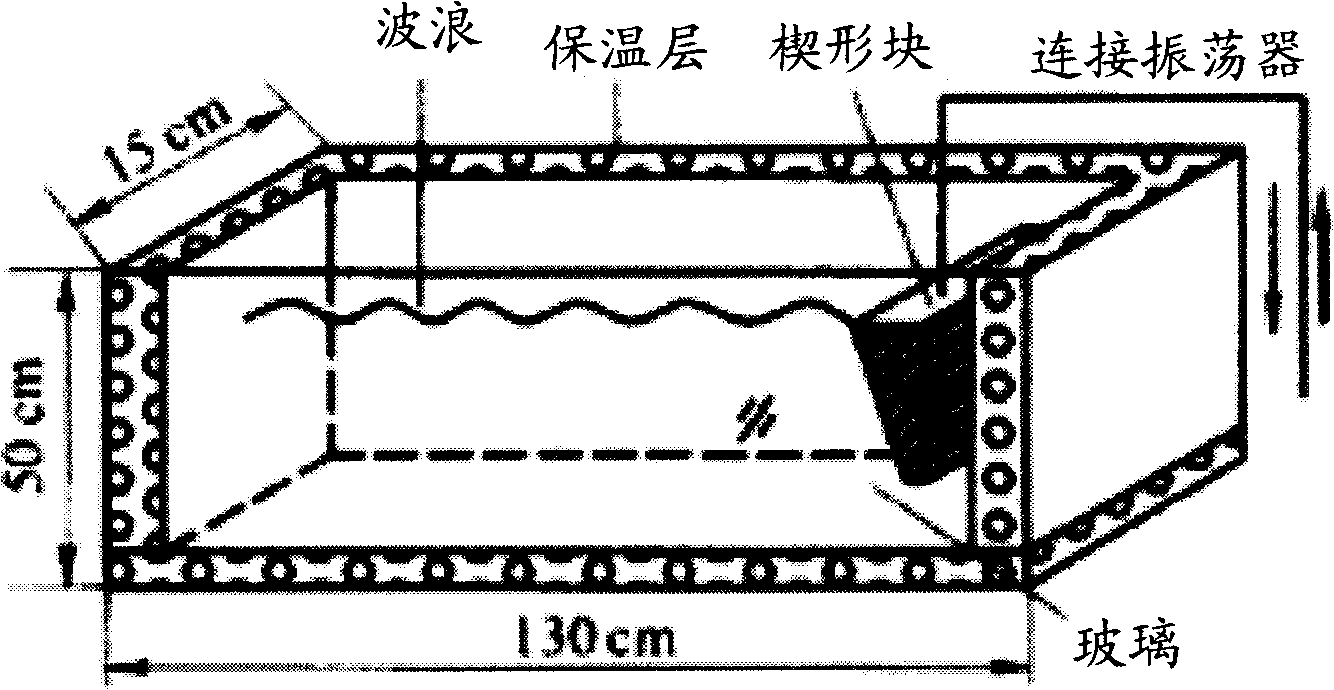

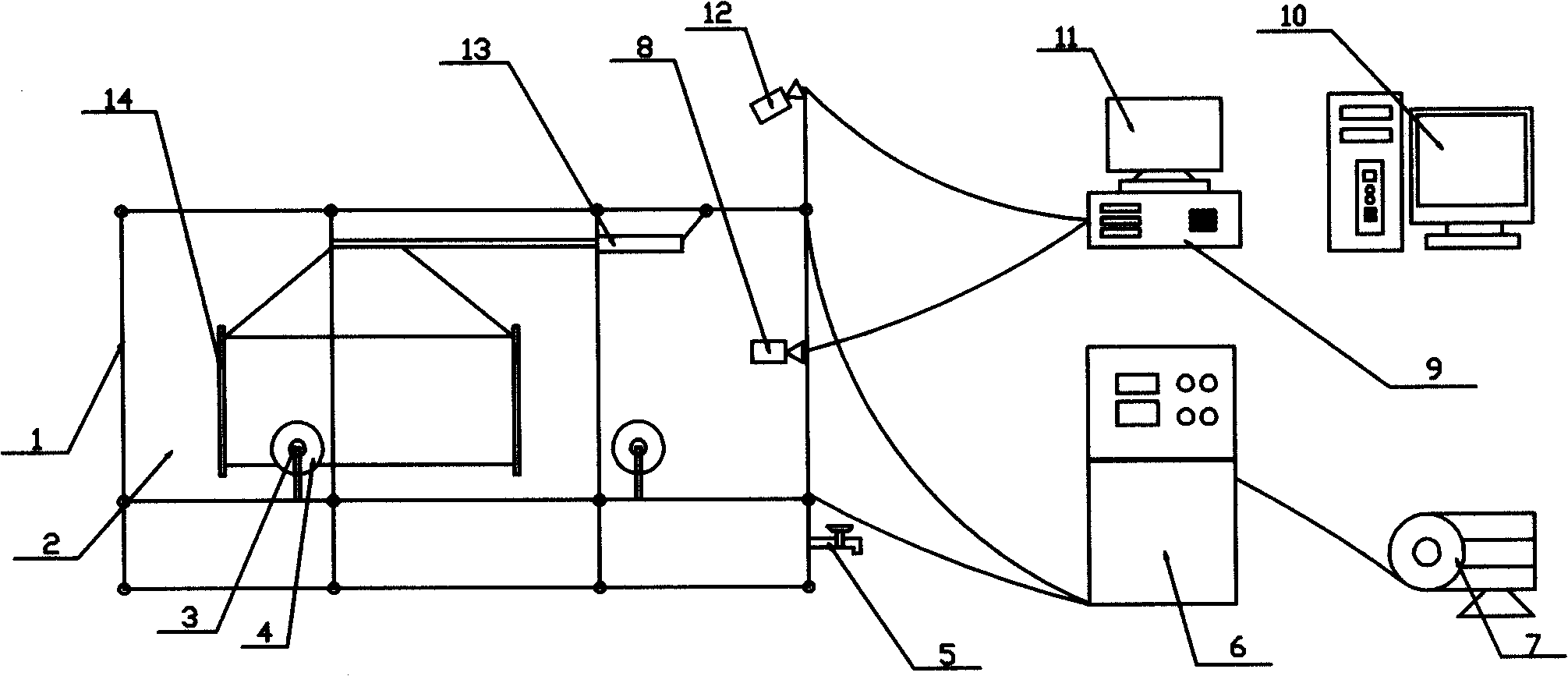

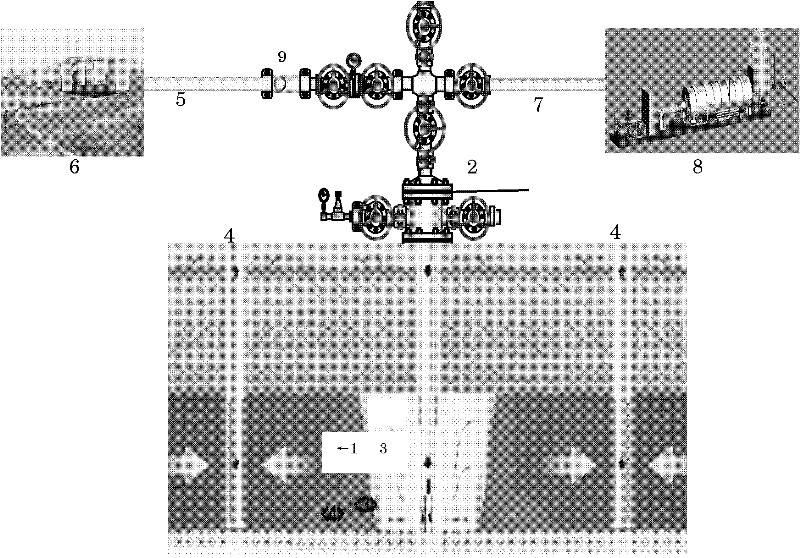

Marine oil overflow air slaking simulation system

InactiveCN101551321AEasy to assemble and disassembleEasy to moveWeather/light/corrosion resistanceSurface oceanPropeller

The present invention provides a marine oil overflow air slaking simulation system, which includes an oil overflow pool and a water flow simulation device, wherein, the water flow simulation device includes a water moving board and a side propeller, wherein, the water moving board is provided in the oil overflow pool, the side propeller is provided on the flank of the oil overflow pool, the movement of the water moving board and the side propeller makes the water stream in the oil overflow pool generate flowing to different directions. The inventive marine oil overflow air slaking simulation system mounts a water moving board, and sets up a side propeller, sea water in the pool is formed into laminar current, local circulation or turbulent current; the water moving board is provided with holes with different positions and bore diameters, so that the flowing intensity degree of the sea water in the overflow oil pool attenuates from top to bottom, the marine flow state in the sea can be more truthfully simulated.

Owner:SHENZHEN ACAD OF METROLOGY & QUALITY INSPECTION +1

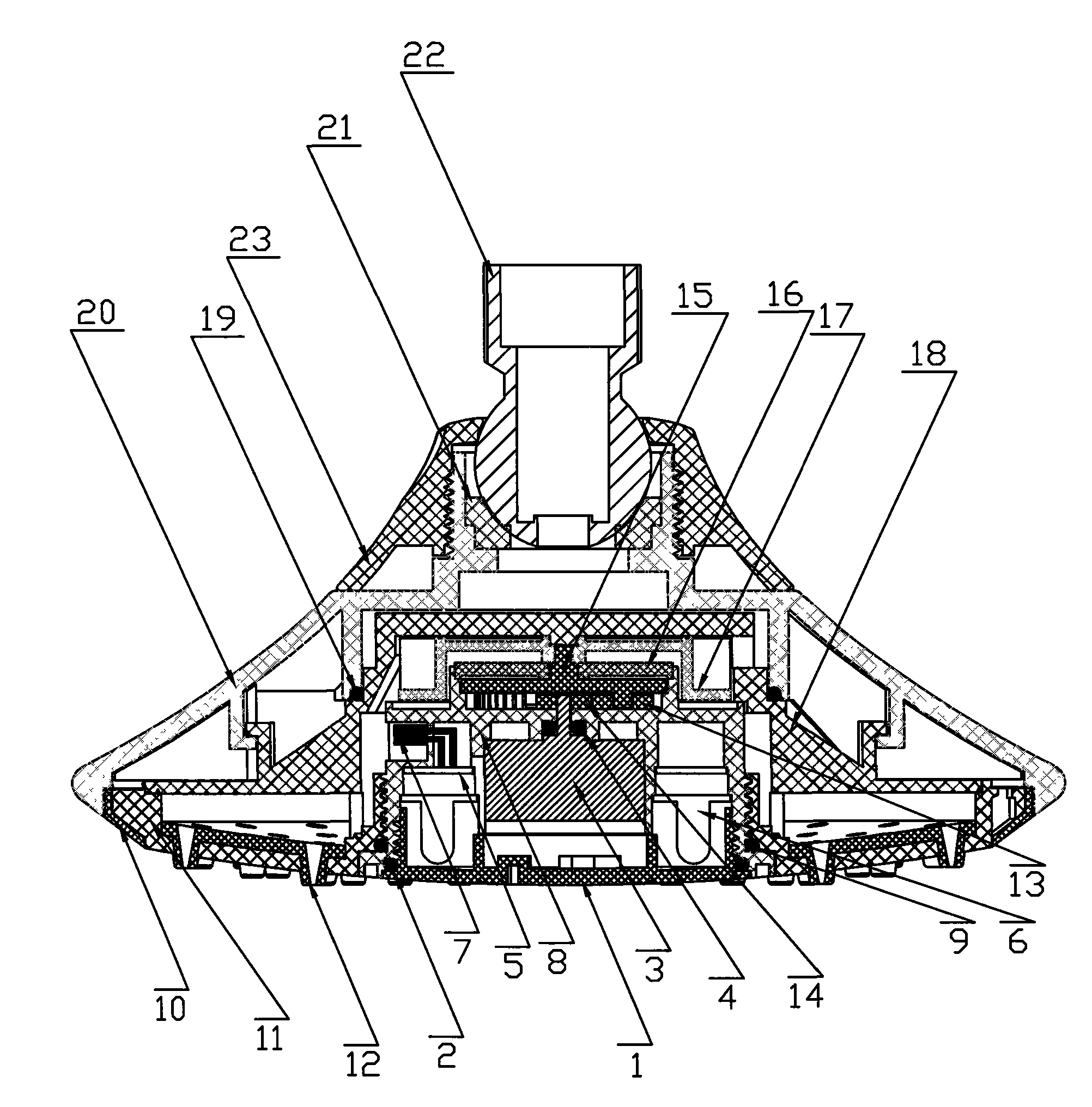

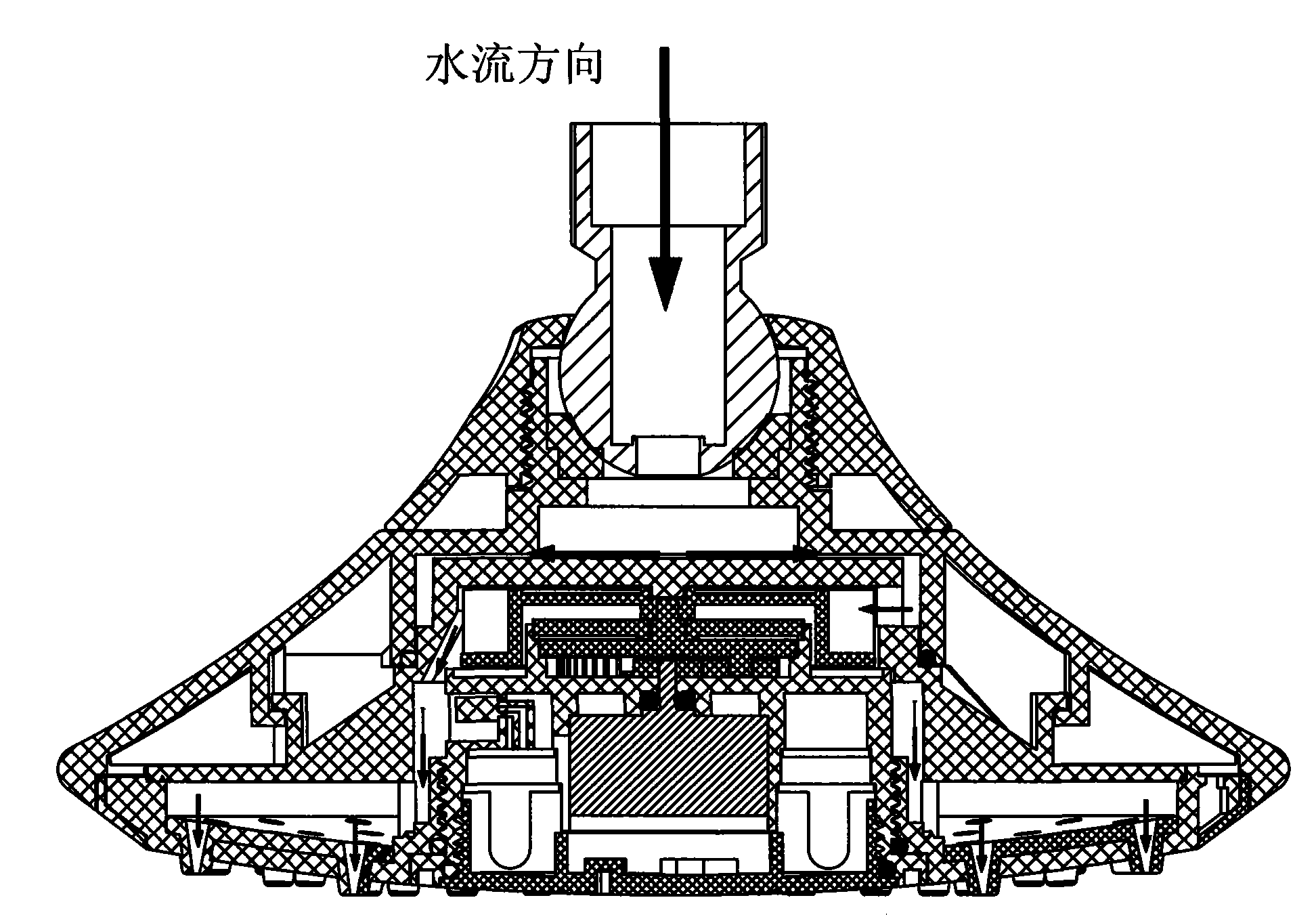

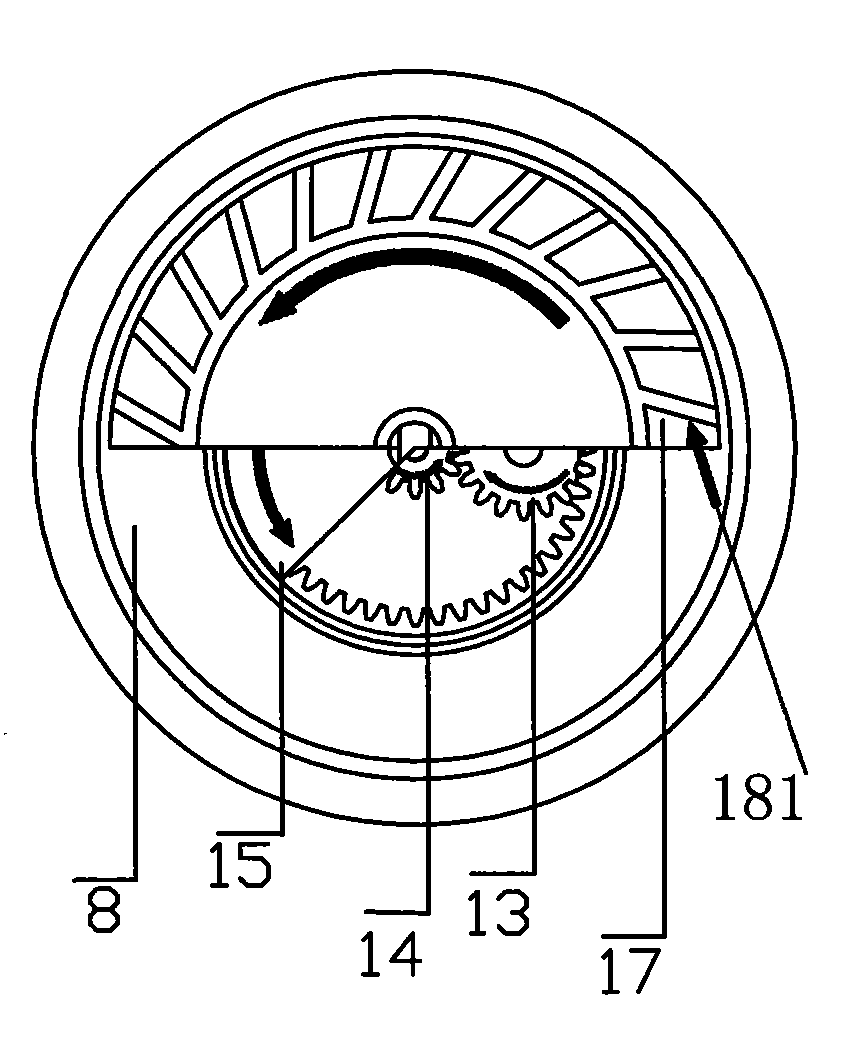

Self-generating shower head for indicating water temperature by light

InactiveCN101590455AStyling is not affectedNo safety hazardThermometer detailsPoint-like light sourceImpellerWater flow

The invention discloses a self-generating shower head for indicating water temperature by light, which comprises a shower head shell, an internal water flow generating mechanism and a color variable LED luminous circuit; the water flow generating mechanism comprises a generator, an impeller and a gearwheel and pinion transmission mechanism; the impeller drives a gearwheel of the gear transmission mechanism, a pinion of the gear transmission mechanism is fixed on a shaft of the generator, and the gearwheel is meshed with the pinion; the color variable LED luminous circuit is provided with a thermo-sensitive element, and the thermo-sensitive element is arranged on a water flow passage which is formed between a water outlet plate at the upper part of the shower head shell and a water outlet level at the lower part; and the impeller is placed at a water inlet hole of the water outlet plate. The self-generating shower head has the advantages that the shape of the shower head is not influenced and has no potential safety hazard, and the shower head is applicable under low water pressure and has wide applicable range, is convenient for a user to adjust the water temperature, and is convenient to adjust the direction of the shower head according to the service condition.

Owner:施才军

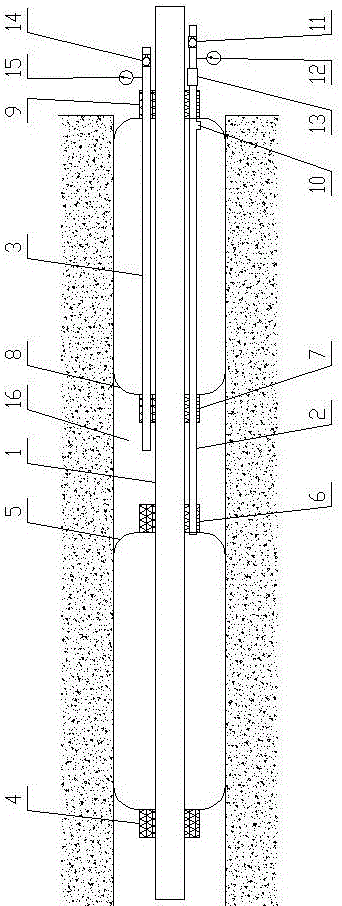

Coal mine two-end gas plug and middle water seal layer penetrating drill hole sealing device and method

InactiveCN105756599ALow costEasy to operateGas removalSealing/packingAir compressionCoal mine methane

A coal mine two-end gas plug and middle water seal layer penetrating drill hole sealing device comprises a gas extraction pipe, a gas injection pipe and a water injection pipe which are arranged in parallel.A first limiting block, a first expansion gas bag, a second limiting block, a third limiting block, a second expansion gas bag and a fourth limiting block are sequentially arranged on the gas extraction pipe from inside to outside, an inner end opening of the gas injection pipe is communicated with the interior of the first expansion gas bag, a gas injection hole communicated with the interior of the second expansion gas bag is formed in the gas injection pipe, and an inner end opening of the water injection pipe is located between the second limiting block and the third limiting block.The invention further discloses a hole sealing method.Cheap water and air are adopted as hole sealing materials in the device and the method and can be supplemented through an underground air compression system and a water supply system as needed to ensure good hole sealing quality, the whole device can be recycled and reused after the extraction work is finished, pollution to a coal body, underground water and underground air can be avoided, the safety level of a mine is improved, and popularization of the novel coal mine gas treatment technology can be easily promoted.

Owner:关红星

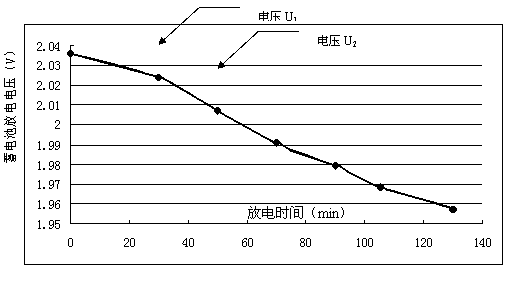

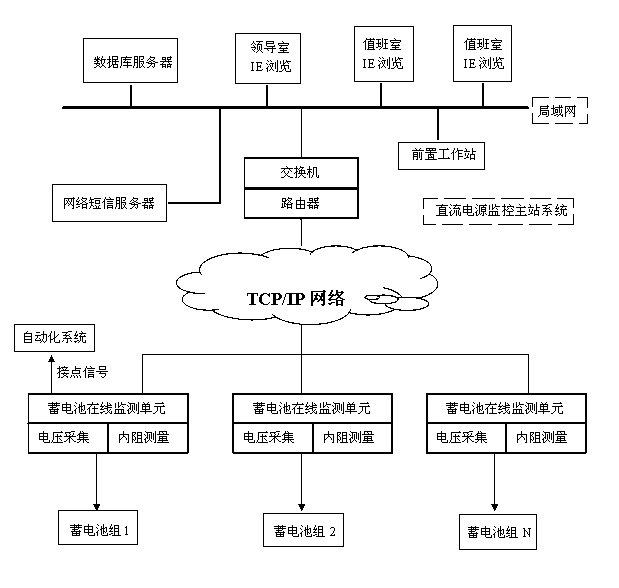

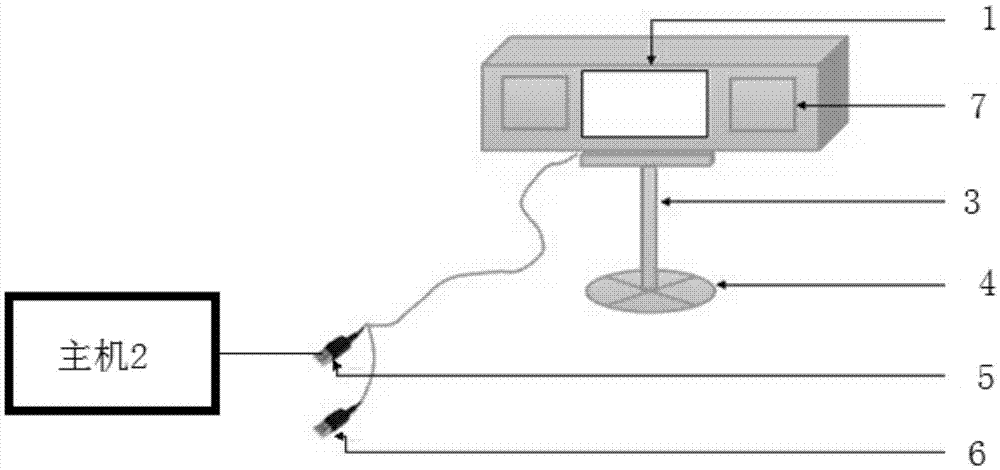

Storage battery performance on-line monitoring system and monitoring method

InactiveCN102707238AGuaranteed test accuracyDoes not affect safe operationElectrical testingWeb publishingServer

The invention discloses a storage battery performance on-line monitoring system and a storage battery performance on-line monitoring method. Each storage battery on-line monitoring unit comprises an acquisition unit, an internal resistance measuring unit and a communication unit; batteries in a storage battery pack are divided into a plurality of units; a load and the batteries in each unit form a closed-loop circuit, and the batteries are discharged; the acquisition unit acquires discharging parameters of each battery; the internal resistance measuring unit calculates the internal resistance of each battery according to acquired information and uploads the internal resistance to the communication unit; the communication unit accesses a local area network and transmits data to a server; after receiving the data, the server analyzes, processes and stores the data; the data are published in a webpage form through a built-in web publishing function; and a computer in the local area network checks the situation of each storage battery pack by accessing a webpage. By adoption of a multi-cycle on-line testing method, safety and reliability are realized, the discharging internal resistance is tested in a grouped mode, and during test, safety operation of a power system is not influenced. The invention has the advantages of stable and accurate test result and convenient testing process.

Owner:STATE GRID CORP OF CHINA +1

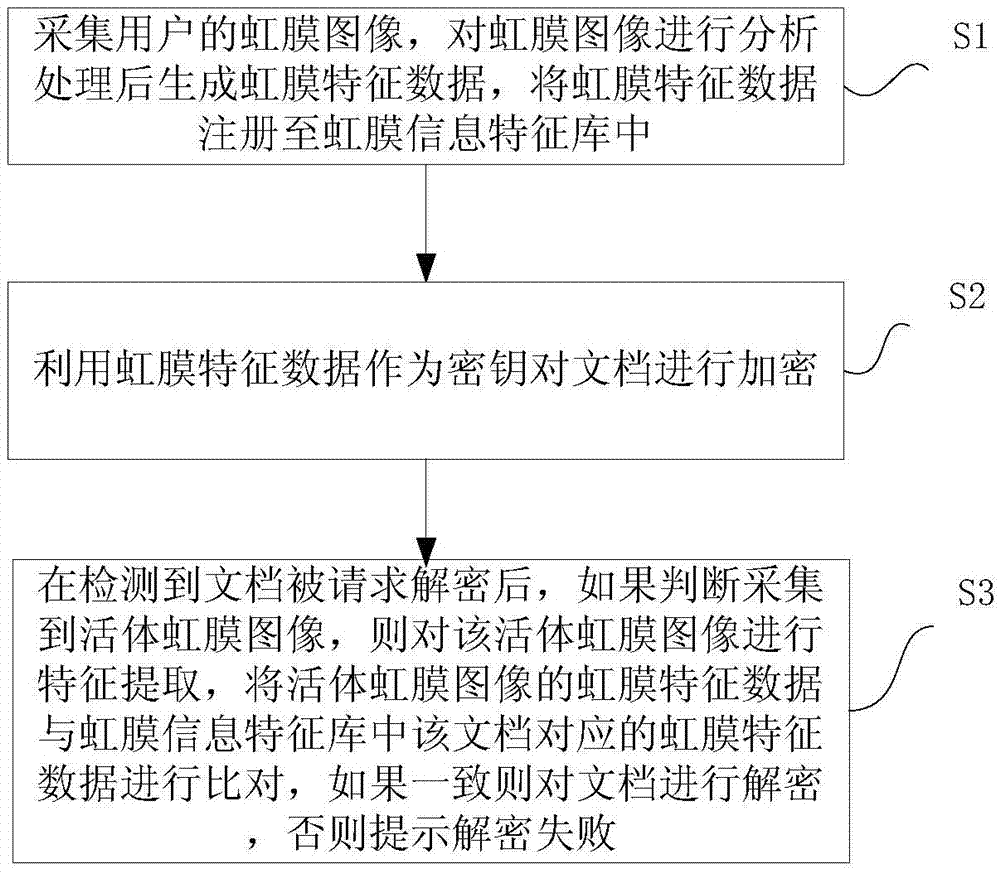

Document encryption/decryption method and apparatus based on iris recognition and authentication

InactiveCN105447405AAvoid interceptionSolve the problem of strong dependenceDigital data protectionDigital data authenticationFeature extractionIdentity recognition

The present invention proposes a document encryption / decryption method and apparatus based on iris recognition and authentication. The method comprises: collecting an iris image of a user, generating iris feature data after analyzing and processing the iris image, and registering the iris feature data into an iris information feature library; encrypting a document by using the iris feature data as a key; and after it is detected that the document is requested to be decrypted, determining whether a living body iris image is collected, if so, carrying out feature extraction on the living body iris image, acquiring iris feature data corresponding to the living body iris image, comparing the iris feature data of the living body iris image with the iris feature data corresponding to the document in the iris information feature library, and if iris feature data of the living body iris image are consistent with the iris feature data corresponding to the document, then decrypting the document, otherwise, prompting that the decryption fails. According to the document encryption / decryption method and apparatus based on iris recognition and authentication, the iris image with uniqueness can be used to carry out identity recognition, thereby triggering an encryption and decryption algorithm to realize security management for the document. The entire encryption / decryption process is simple, convenient and free of potential security hazards.

Owner:南京以太安全技术有限公司

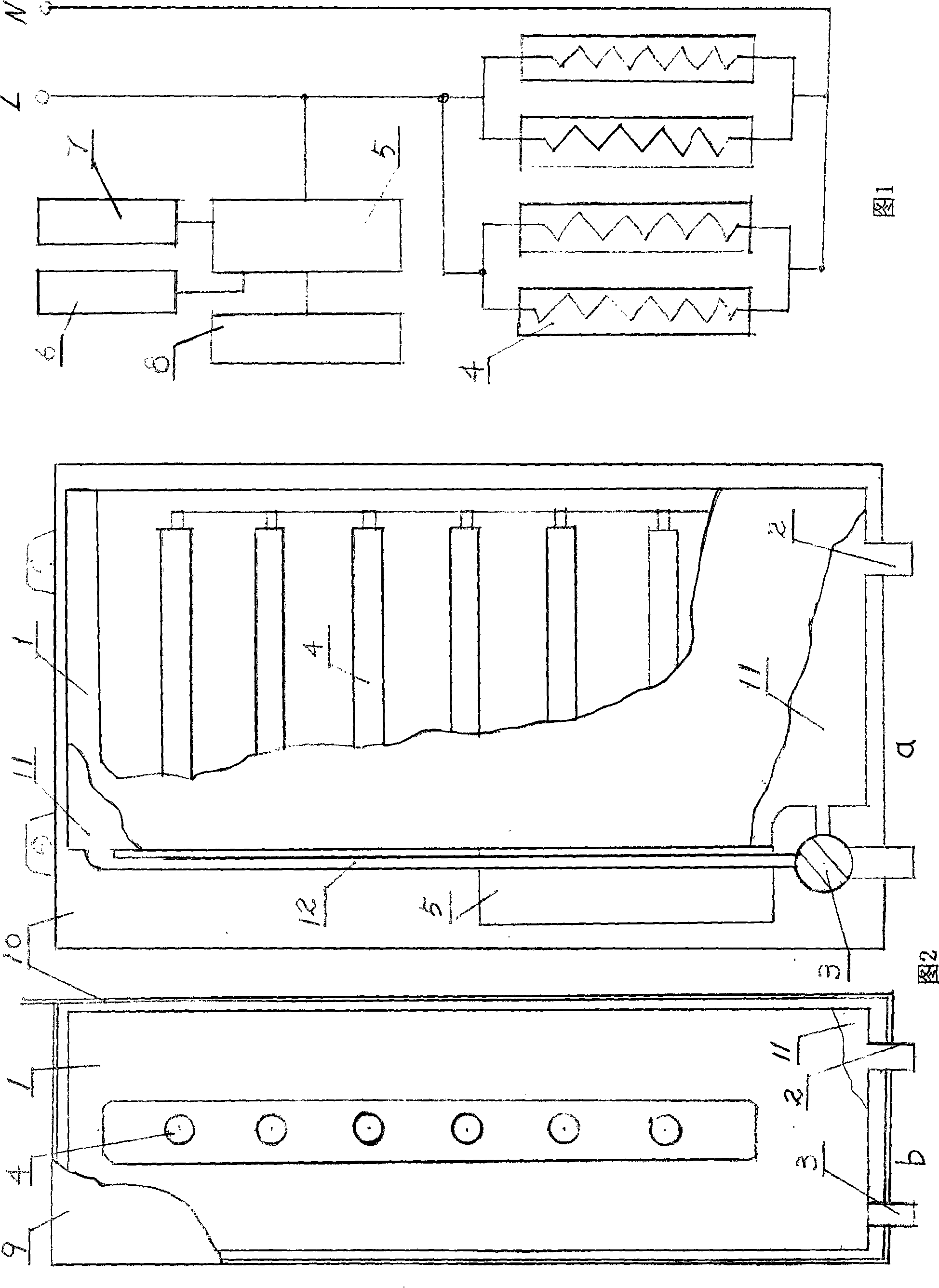

Electric heating tube side heat type water heater

An electric heating tube heater type water heater comprises a casing, a bottom board, a circuit board, an electric heating tube, a water container etc, after the electric power operation is started, the electric heating tube heats and generates heat radiation to heat the water container on both sides, and water in the water container is heated by thermal conduction, the water container has ring packing structure communicating up to down, which has a water inlet on lower part and a water outlet on upper part, the heated water flows out from the upper water inlet, a rectangular splited space on both ends are arranged on medium part of the water container, the electric heating tube is mounted inside the space with a rack without contacting with water.

Owner:GUANGDONG SHUNDE GUANGSHENG ELECTRICAL APPLIANCE

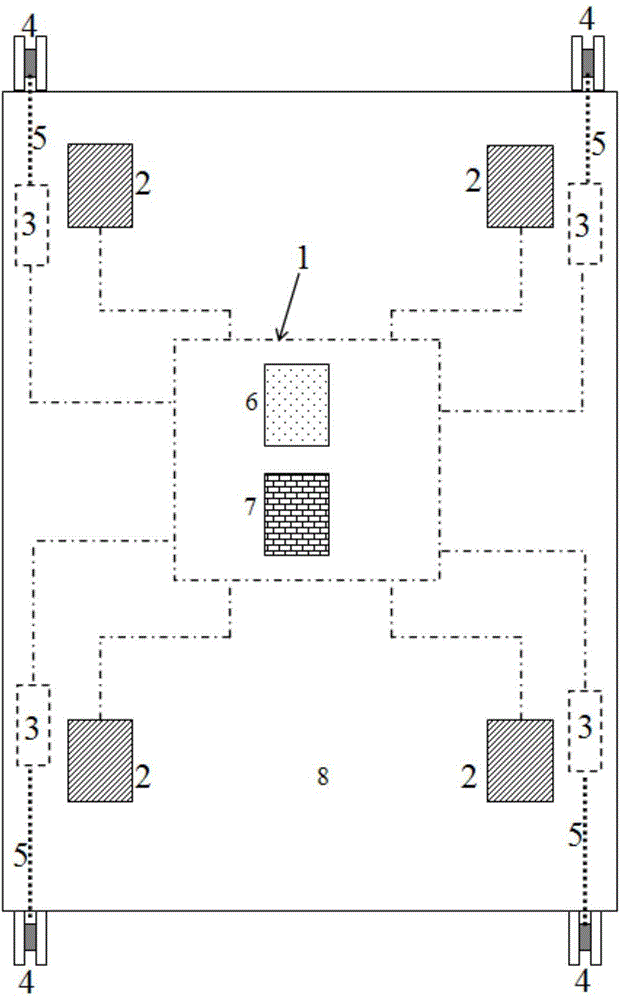

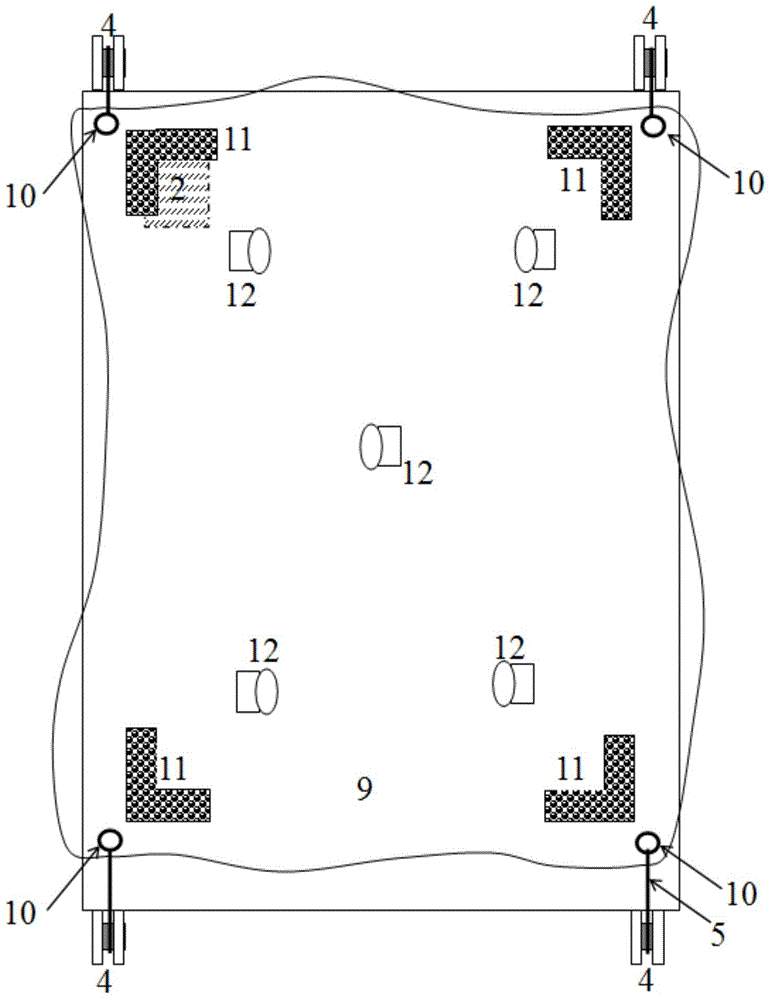

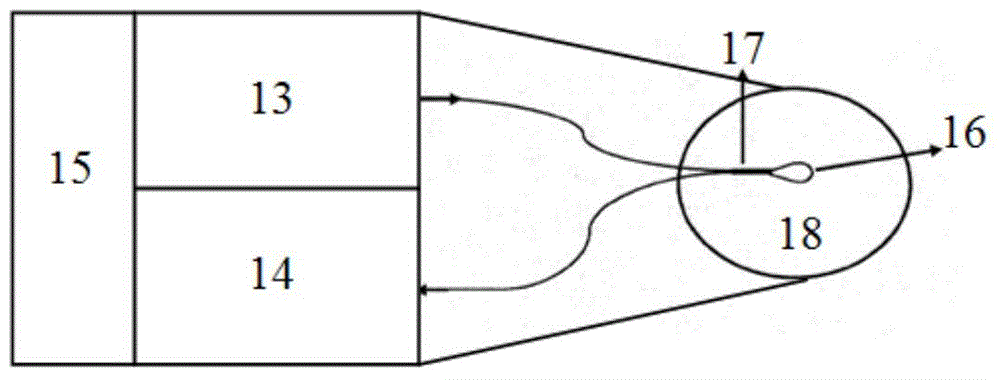

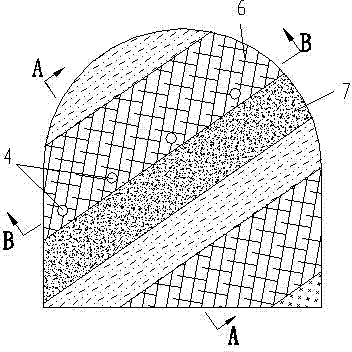

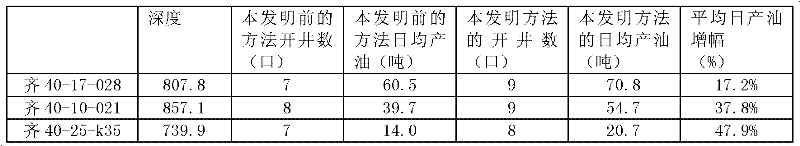

Steam drive exploitation method for heavy oil reservoir

The invention belongs to the field of oil exploitation, and relates to a steam drive exploitation method for a heavy oil reservoir, in particular to a steam drive exploitation method of intermediate-deep layer heavy oil aided by injecting air. The method comprises the following steps of synchronously and continuously injecting steam and air in a steam injection well according to a certain mass ratio in the process of intermediate-deep layer heavy oil steam drive production, and performing a low-temperature oxidation reaction between crude oil and oxygen. According to the method disclosed by the invention, heat utilization and recovery ratio of intermediate-deep layer heavy oil steam drive can be improved; a problem of steam channeling among injection and exploitation wells can be eased, and development effect of steam drive can be improved.

Owner:PETROCHINA CO LTD

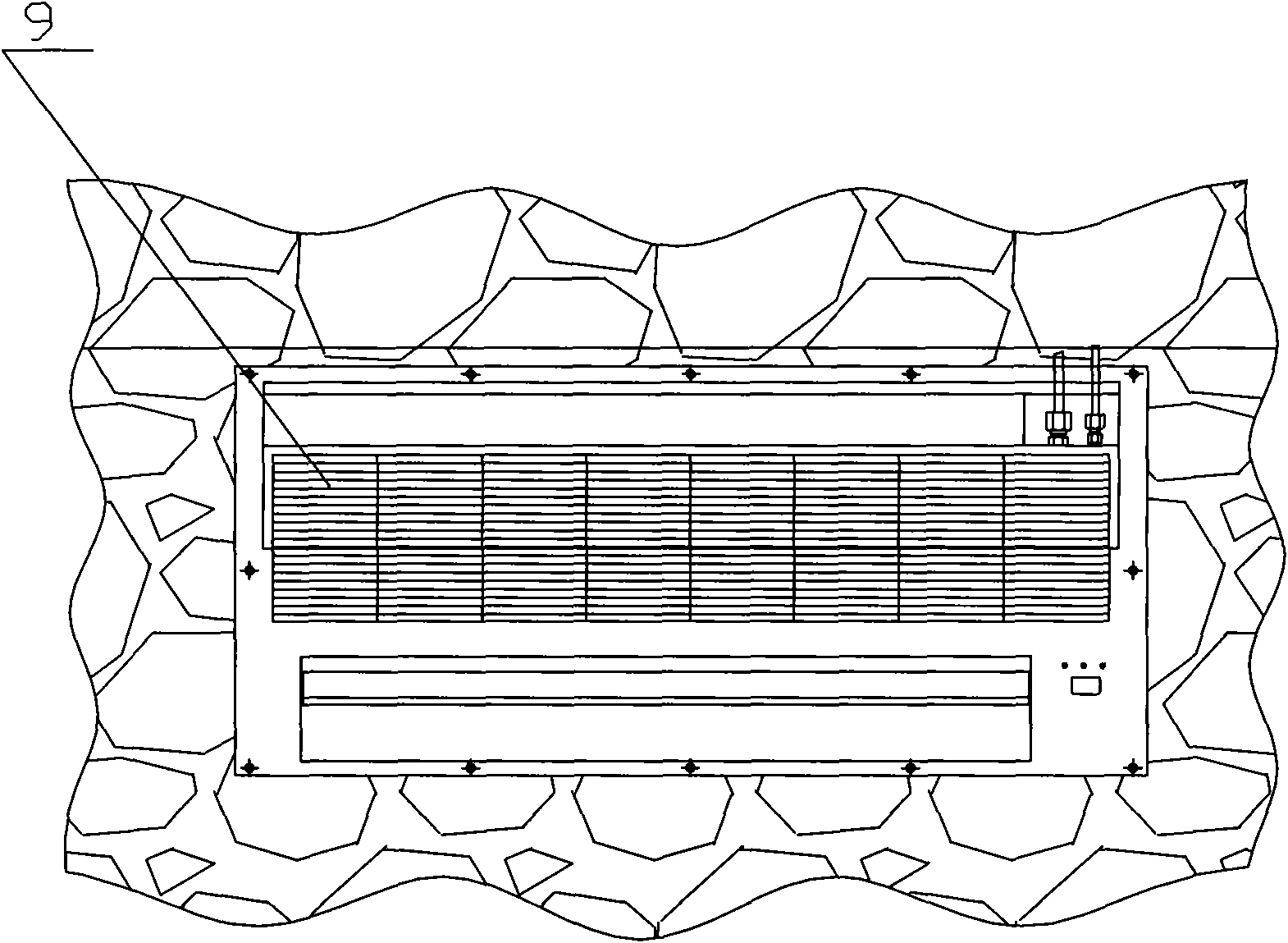

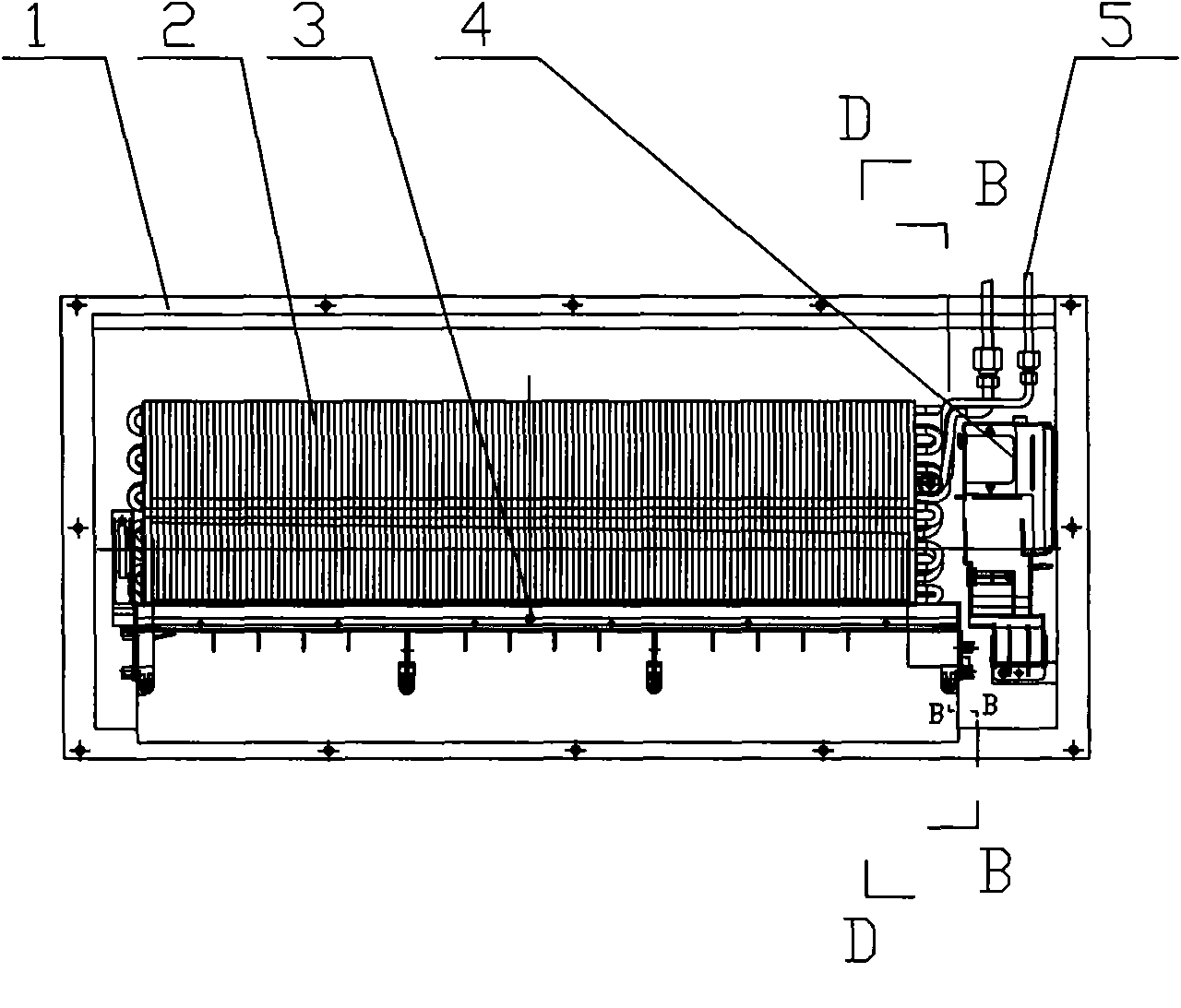

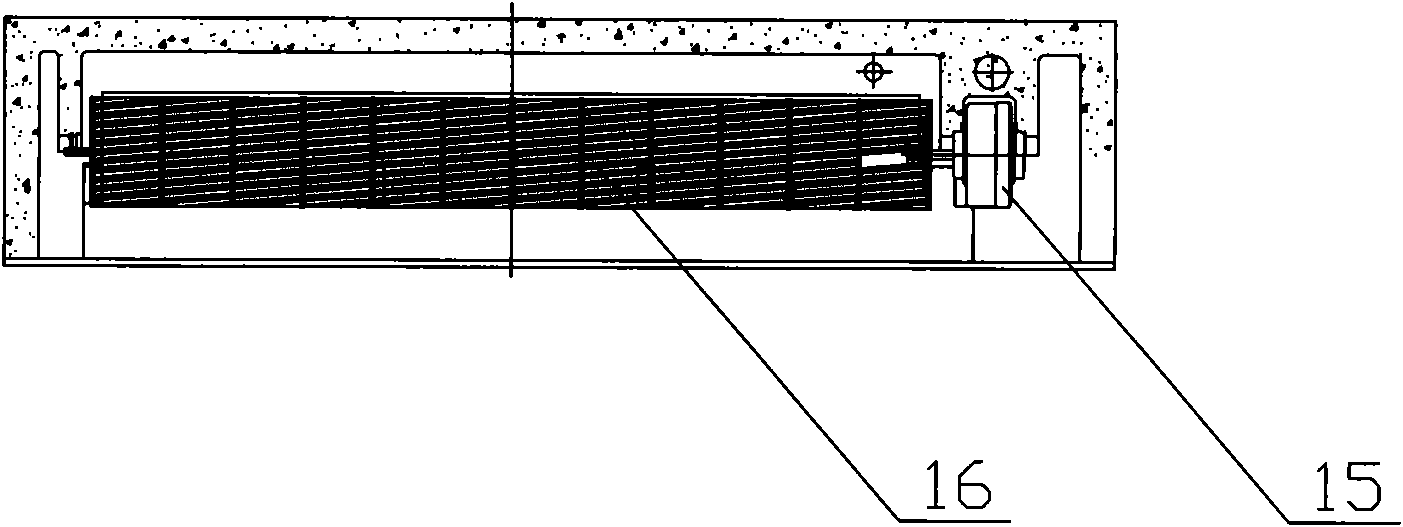

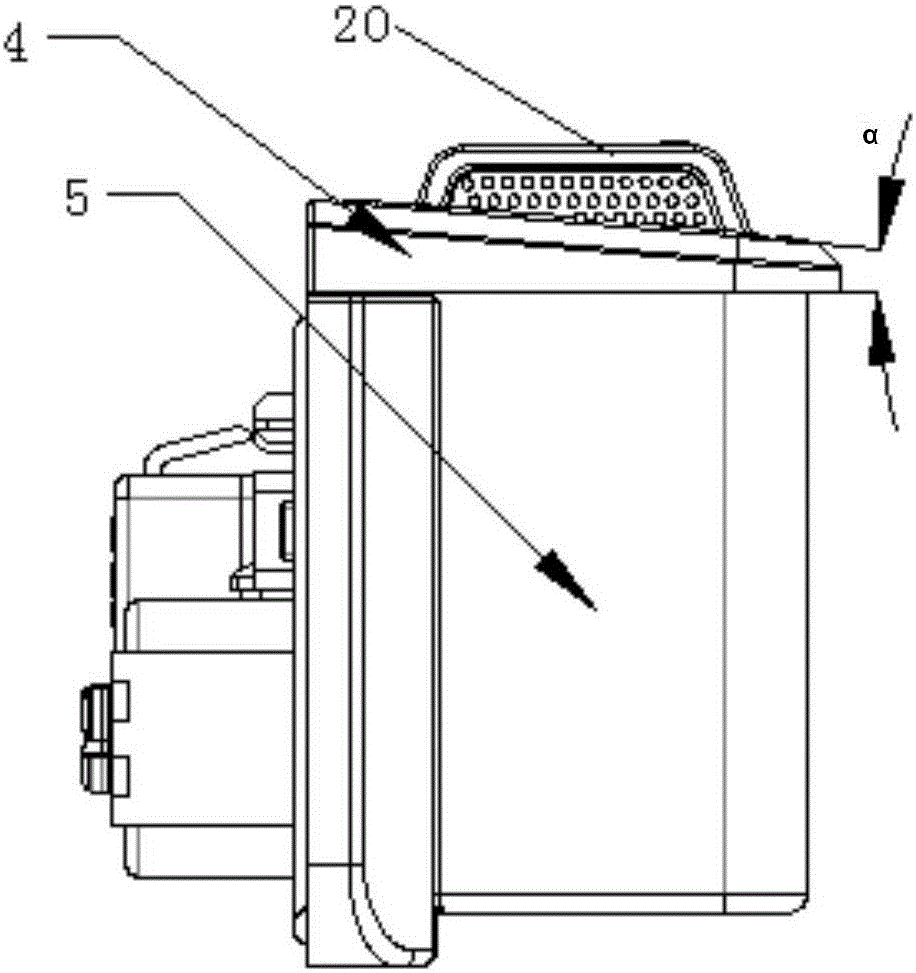

Air conditioning system of project machine

InactiveCN101592370AReduce eddy currentReduce noiseLighting and heating apparatusAir conditioning systemsOperating energyAir conditioning

The invention relates to the field of air conditioners, in particular to an air conditioning system of a project machine, which is installed in a building in a complete hiding way. A common splitting type air conditioner has the defects of wall damage, poor machine working condition and troublesome and unsafe installation during installation. The invention provides the air conditioning system of the project machine, which is installed in the building in the complete hiding way for overcoming the defects of the prior common splitting type air conditioning system. The air conditioning system of the project machine comprises an indoor machine, an outdoor machine and a pipeline connecting the indoor machine and the outdoor machine, wherein the outdoor machine is installed in the building in the hiding way and uses a cavity of the building as a shell; the pipeline comprising a refrigerant pipe, a power supply line, a communication line and a drain pipe is also embedded into the building in advance; the refrigerant pipe is a composite pipe capable of being bent, the power supply line and the communication line penetrate into the same wire pipe, and the drain pipe is communicated with a self-contained rain water pipe of the building. The air conditioning system of the project machine has the advantages of no wall damage, simple and convenient installation, no potential safety hazard and good machine working condition during installation.

Owner:何岳峰

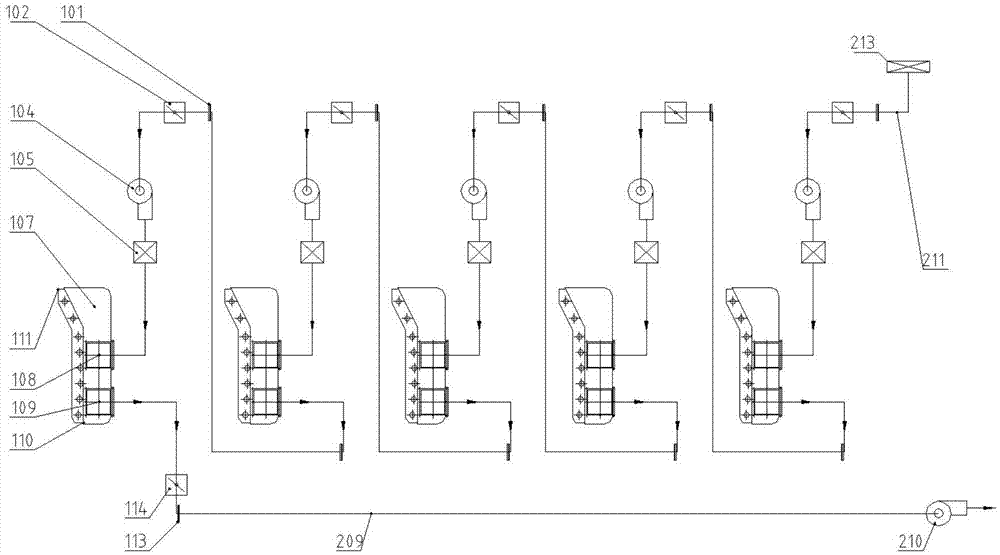

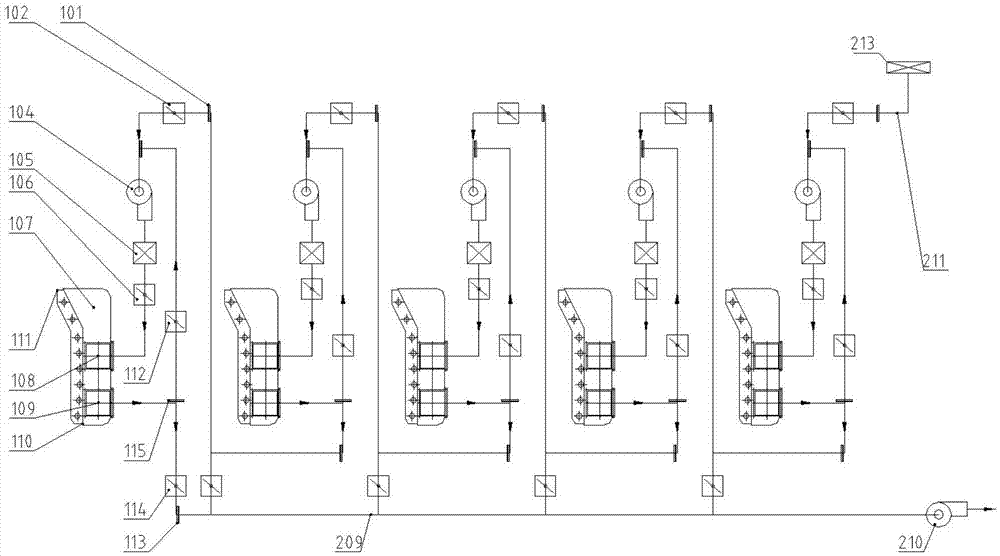

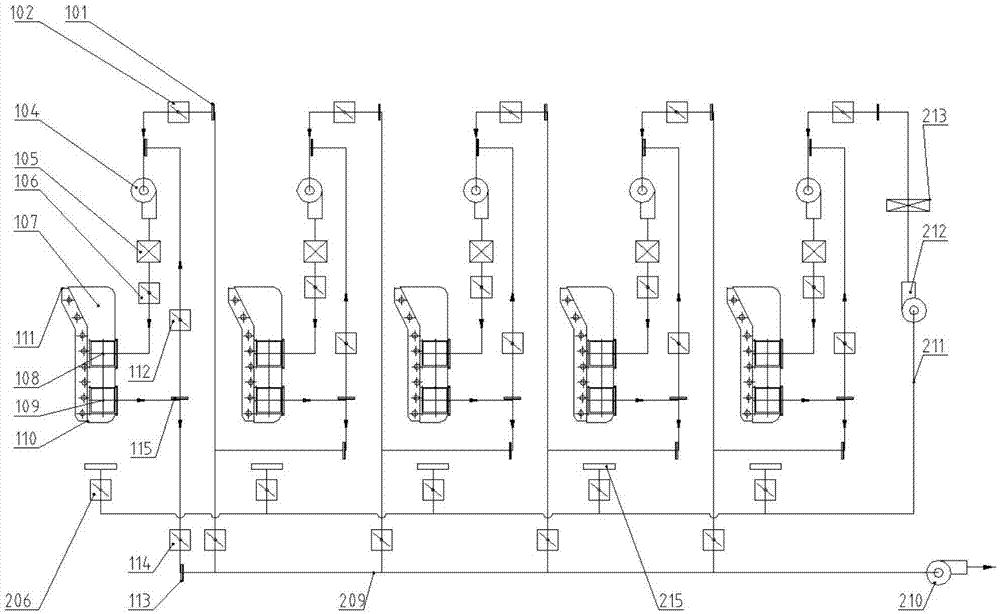

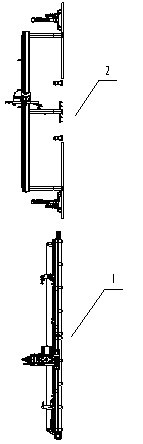

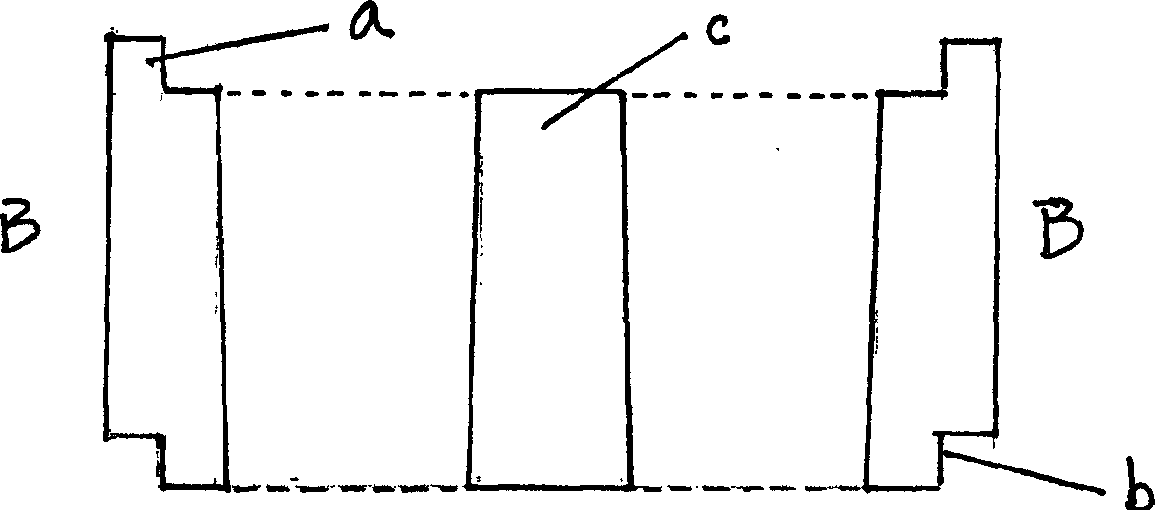

Tandem drying system

ActiveCN105444536AEasy to set upReduce exhaust air volumeDrying gas arrangementsPretreated surfacesWaste management

The invention provides a tandem drying system. The tandem drying system comprises at least two drying units, wherein each drying unit comprises a unit air supply fan and a drying box; a unit air inlet and a unit air outlet are formed in each drying unit; a drying box air inlet and a drying box air outlet are formed in each drying box; each unit air inlet is connected with the corresponding drying box air inlet; each unit air outlet is connected with the corresponding drying box air outlet; an exhaust air inlet which is connected with the unit air outlet of the last drying unit is formed in an exhaust air header pipe; a supply air outlet which is connected with the unit air inlet of the first drying unit is formed in a supply air header pipe; in every two adjacent drying units, the unit air outlet of the former drying unit is connected with the unit air inlet of the latter drying unit; each unit air supply fan is arranged between the corresponding unit air inlet and the corresponding drying box air inlet; and an exhaust air fan is arranged on the exhaust air outlet of the exhaust air header pipe. The tandem drying system has the advantages of simplicity and stability, easiness in adjustment, small exhaust air amount, low energy consumption, no potential safety hazards, low environment protection cost and the like.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

Box girder production line of front suspension arm frame

InactiveCN102615383ABest soldering positionImprove the forceWelding/cutting auxillary devicesAuxillary welding devicesBox girderManufacturing line

The invention discloses a box girder production line of a front suspension arm frame, which comprises an assembly tool. A group of chain tippers and a group of support benches are symmetrically arranged on the lateral side of the assembly tool, and a movable automatic welding joint machine is arranged above the chain tippers and the support benches. The box girder production line has the advantages that inside welds are welded and overturned, outside welds are welded and overturned, the inside welds and the outside welds are merged to be one position, machining positions are simplified, operation is simplified, the chain tippers are adopted to achieve overturn of workpieces, automatic overturn is accurate, time and labor are saved, safety hidden dangers are avoided, the automatic welding joint machine can weld two welds one time, and production efficiency is improved.

Owner:成都佳士科技有限公司 +1

Z-shaped small-sized cement concrete hollow filled non-clod bridge thermal insulation building block and its making method

InactiveCN1702253AHigh compressive strengthStrong collision resistanceWallsThermal insulationAcoustic energy

This invention relates to a Z-shape small cement concrete hollow filled insulating building block, which belongs to the acoustic and heat-insulating material of the architecture field. The technical project is: designing the building outline to Z-shape hollow, filling the straw, chaff or the crushed wheat strew, corn stalk, waste aerated plastics particles which are packed and sealed with the aluminized plastic film. The insulating block obstructs the end wall interlaced through double layer insulating material, and eliminates the self-cold bridge, which increases the insulating property of the wall greatly; in addition, the loose insulating material can absorb acoustic energy and has good deafening effect. The Z-shape block is mainly used in laying the exterior wall and the separated production wall.

Owner:周荣标

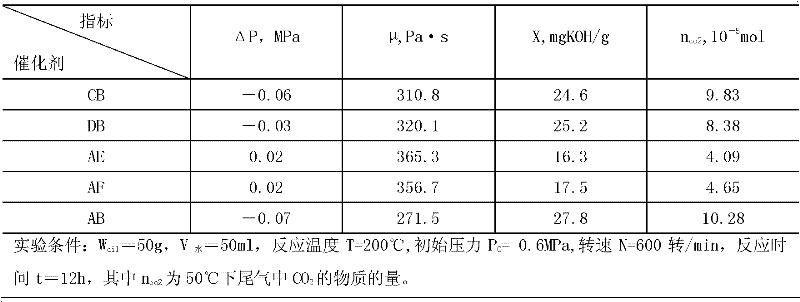

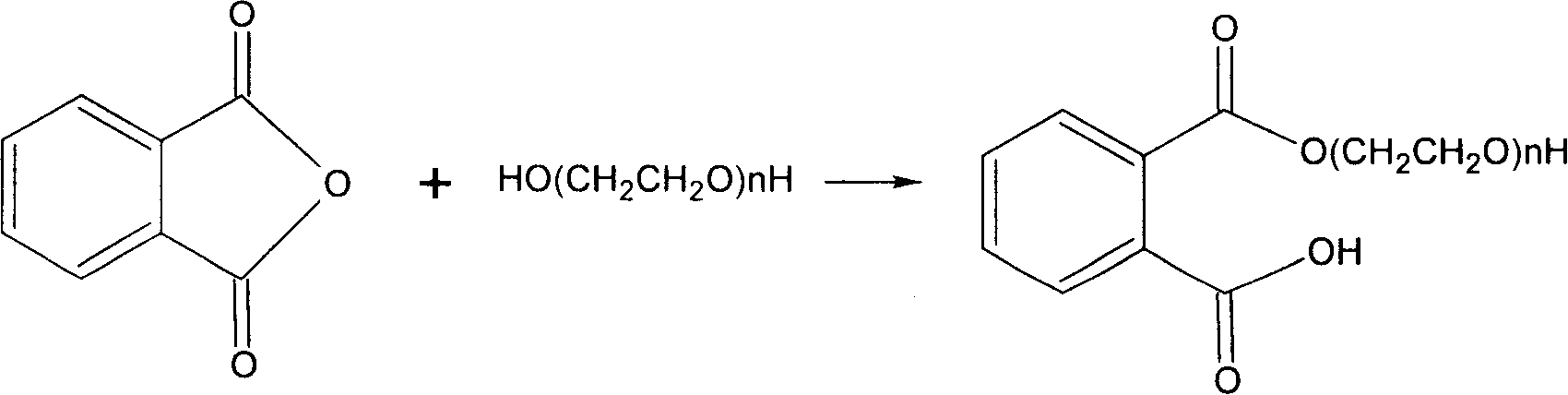

Method of preparing nonionic surfactant o-benzenedicarboxylic acid polyethylene glycol ester

InactiveCN101085420AHigh activityWide range of usesTransportation and packagingMixingSolubilityPolyethylene glycol

The invention relates to a non-ion surface active agent diethyl phthalate, featuring in the material of ortho-phthalic anhydride and carbowax, storing in 75-85deg.C for 3-5 hours, neutralizing PH to 1.5-3.5, and the mole percent of ortho-phthalic anhydride and carbowax being 1: 0.9-1.1. It not only has wide extensive application, and significant in effect in improving solubility of water-soluble dye. It protects environment without generation of wastes, being able to produce with normal equipment and mild in reaction condition. It can keep the solution in normal temperature for 72 hours with even status.

Owner:杨关雨

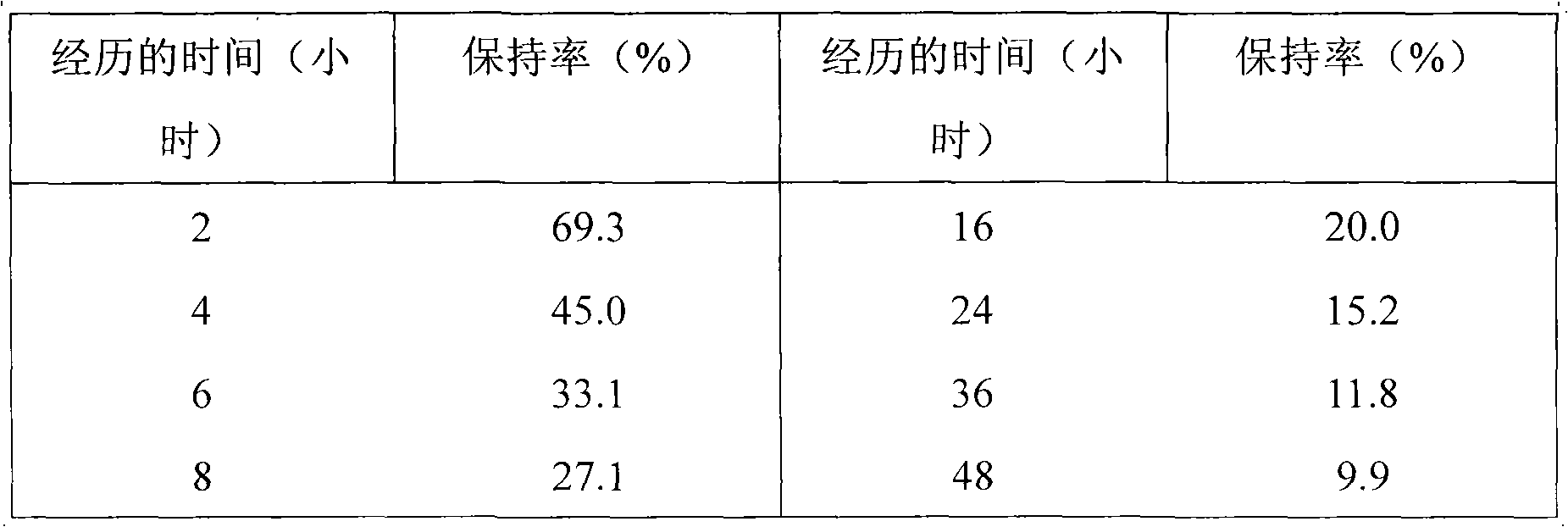

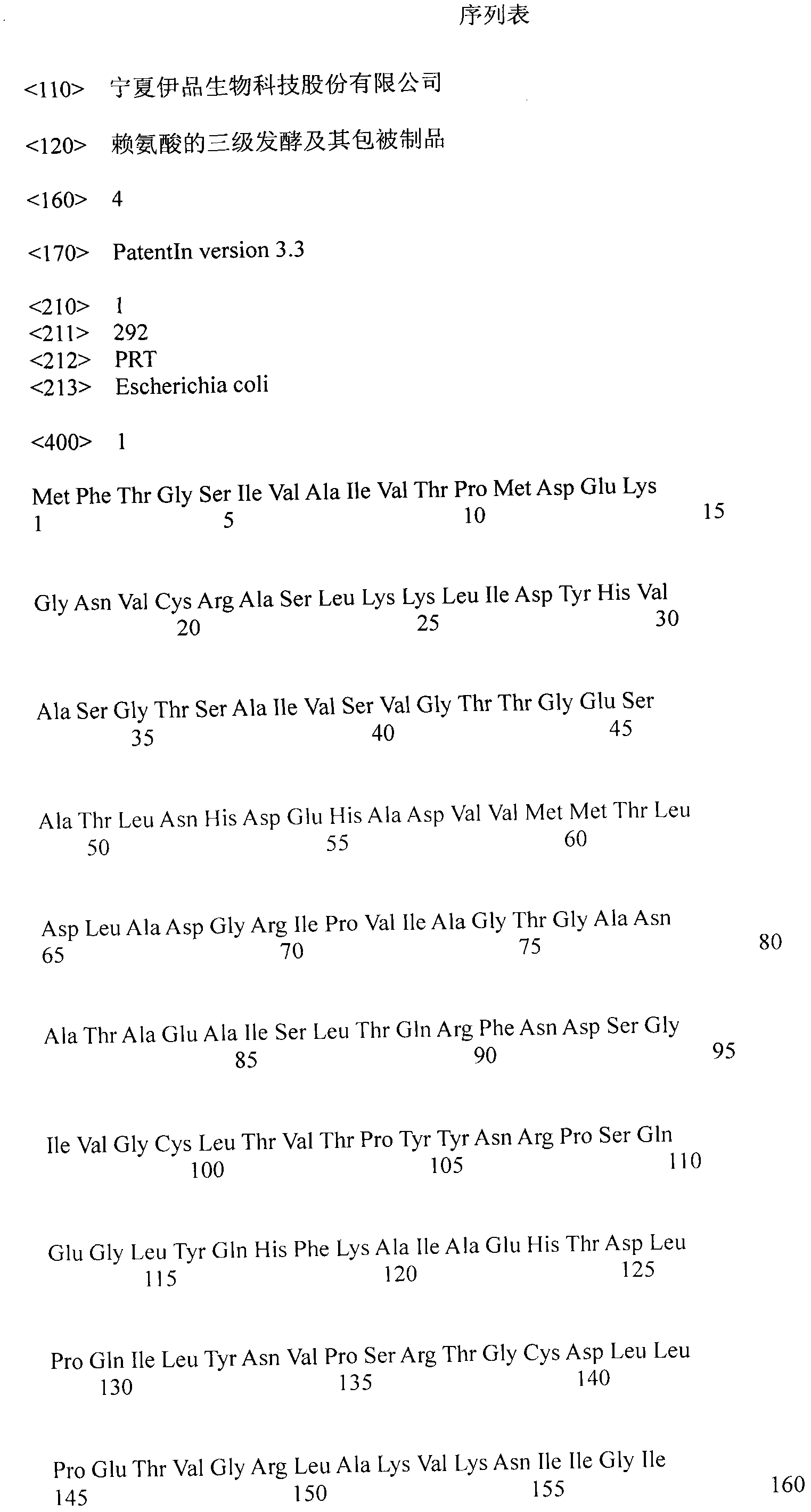

Three-level fermentation of lysine and coating products thereof

ActiveCN102318739ASlow release rateIncrease productionAnimal feeding stuffMicroorganism based processesThree levelFermentation

The invention provides a fermentation method for preparing L-lysine products, which comprises the steps: an L-lysine culture solution is produced through three-level culture fermentation, and fine particles are coated by using fractional palm fat after spray drying. In addition, the invention also provides products prepared by the method, and the retention rate of L-lysine is larger than 15% within 24 hours.

Owner:NINGXIA EPPEN BIOTECH +1

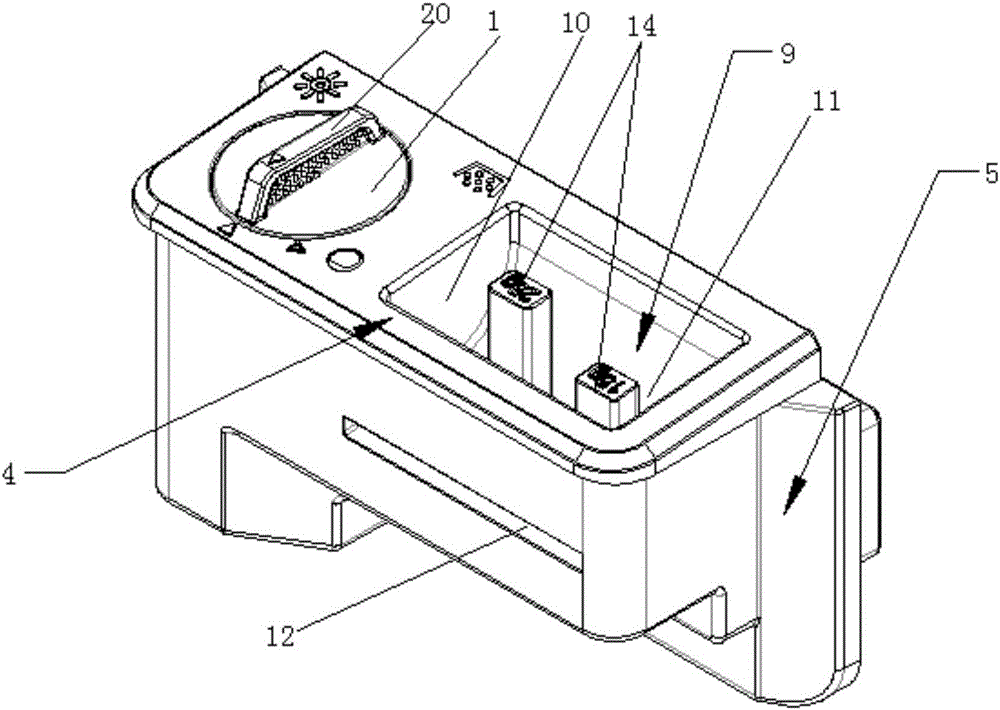

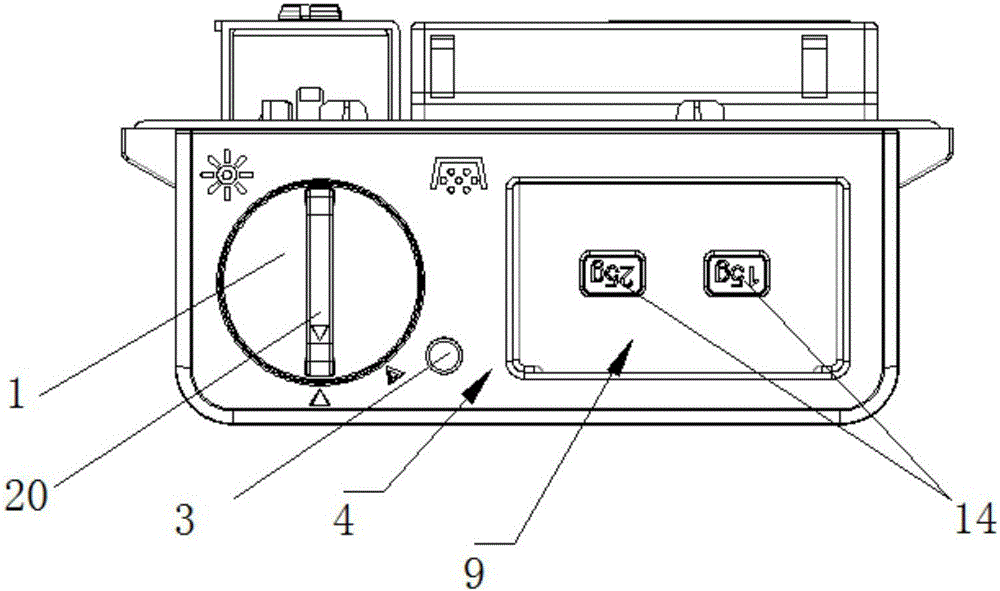

Distributor for dish-washing machine and dish-washing machine

PendingCN106466169ASave spaceImprove space utilizationTableware washing/rinsing machine detailsEngineeringDistributor

The invention provides a distributor for a dish-washing machine. The distributor is fixed to the side wall of an inner container and comprises a cavity and an upper shell fixed to the cavity. The upper shell is provided with an open-type dishwasher powder containing chamber, a user can directly put dishwasher powder into the top of the containing chamber, and a dishwasher powder outlet is formed in the bottom of the dishwasher powder containing chamber. According to the open-type dishwasher powder containing chamber, when the cavity is fixed to the side wall of the inner container, the use of the space inside the dish-washing machine is optimized; the bottom of the dishwasher powder containing chamber is an oblique plane, and by means of the characteristics of the structure, the dishwasher powder can automatically flow into the inner container without other auxiliary structures and control devices. The structure is simple, cost is low and the safety performance is high.

Owner:QINGDAO HAIER DISHWASHER

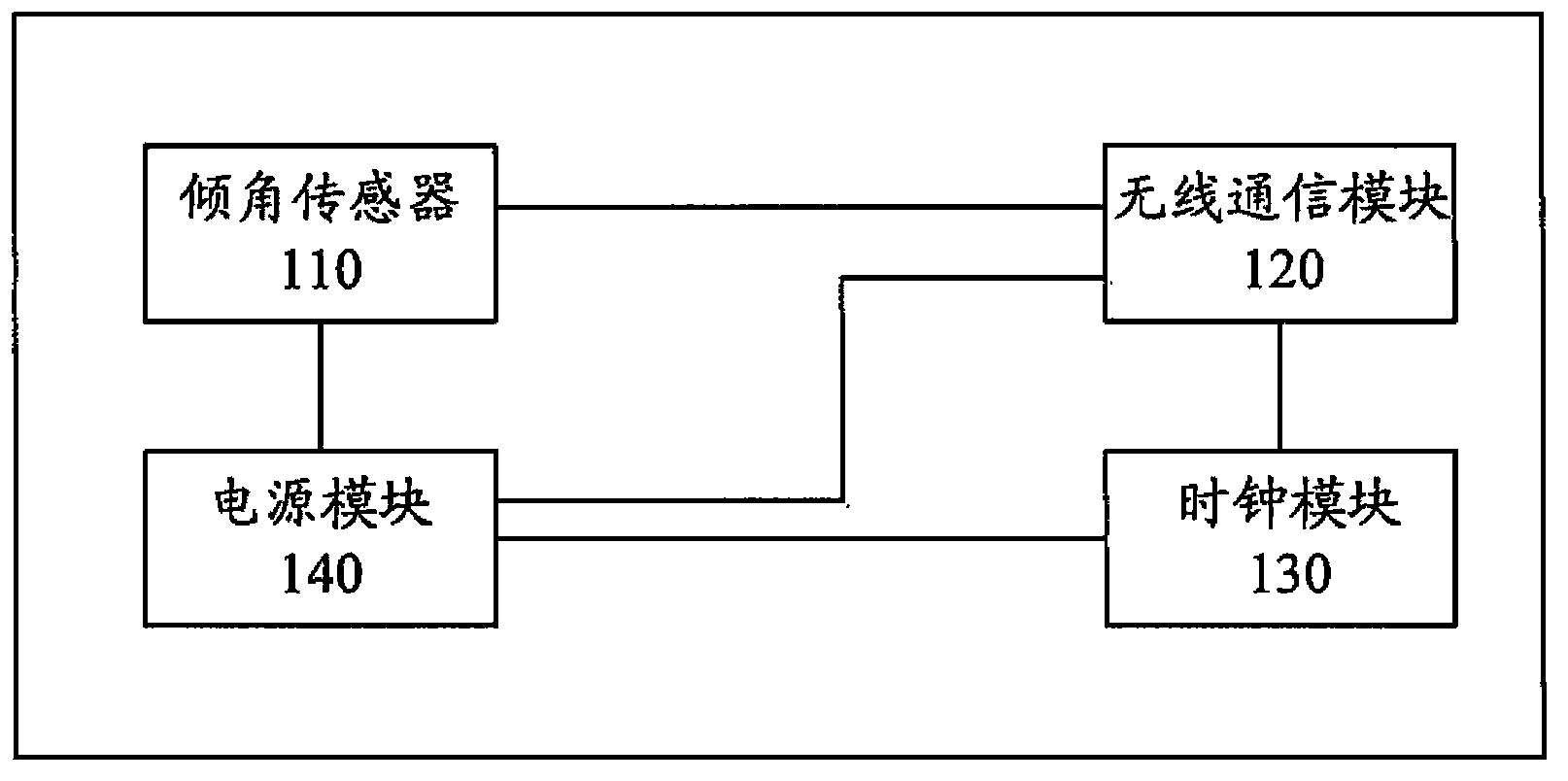

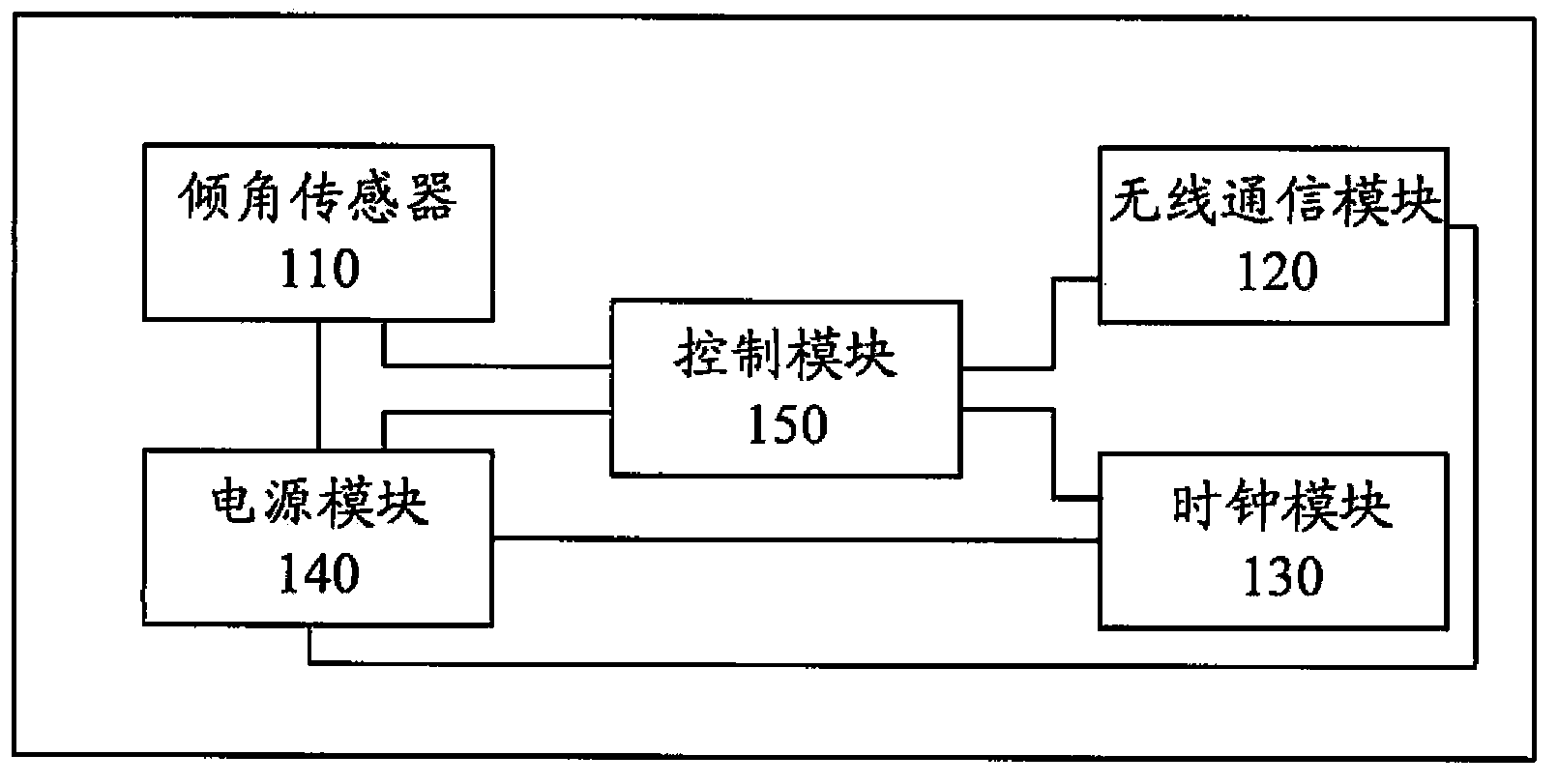

Inclination alarm device for outdoor advertising board

InactiveCN103791888AEasy to manage centrallyReduce consumptionIncline measurementEngineeringAlarm device

The invention relates to an inclination alarm device for outdoor advertising boards, which is fixed on an advertising board, and comprises: an inclination angle sensor configured to measure the inclination angle of the advertising board; a wireless communication module configured to receive the measurement results of the inclination angle sensor, and also configured to send the measurement results of the inclination angle sensor, in a wireless way, to a remote device for monitoring the inclination state of the outdoor advertising board; a clock module configured to enable the wireless communication module to periodically send the measurement results of the inclination angle sensor, in a wireless way, to the remote device for monitoring the inclination state of the outdoor advertising board; and a power supply module configured to supply power for the inclination angle sensor, the wireless communication module and the clock module. The scheme of the invention can realize periodical and automatic report of the inclination angle state of the advertising board, and improve the reliability of the inclination alarm device. Furthermore, the inclination alarm device of the invention facilitates unified management of outdoor advertising boards, and thus reduces potential safety hazard of outdoor advertising boards.

Owner:JIANGSU DONGREN NETWORK TECH

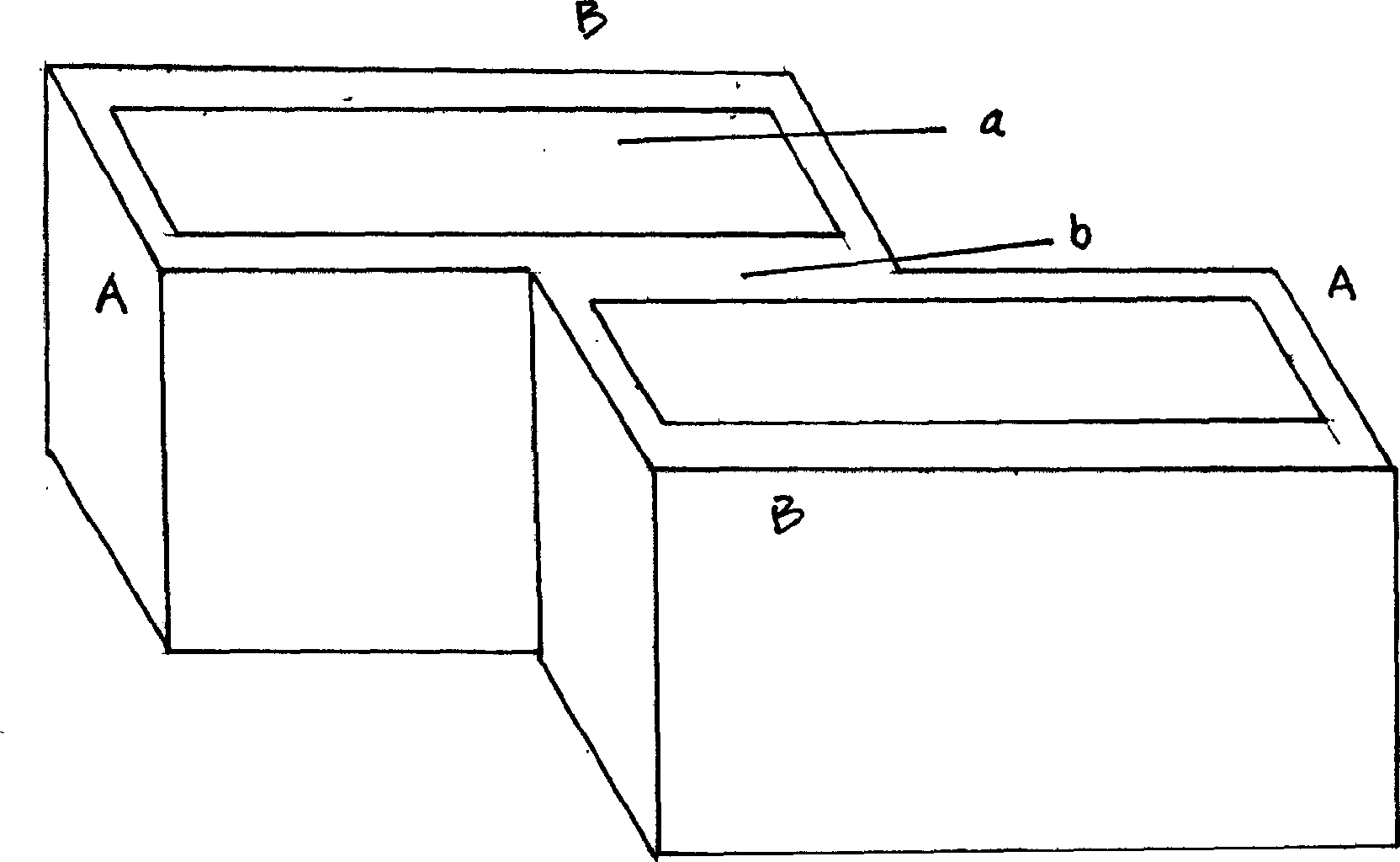

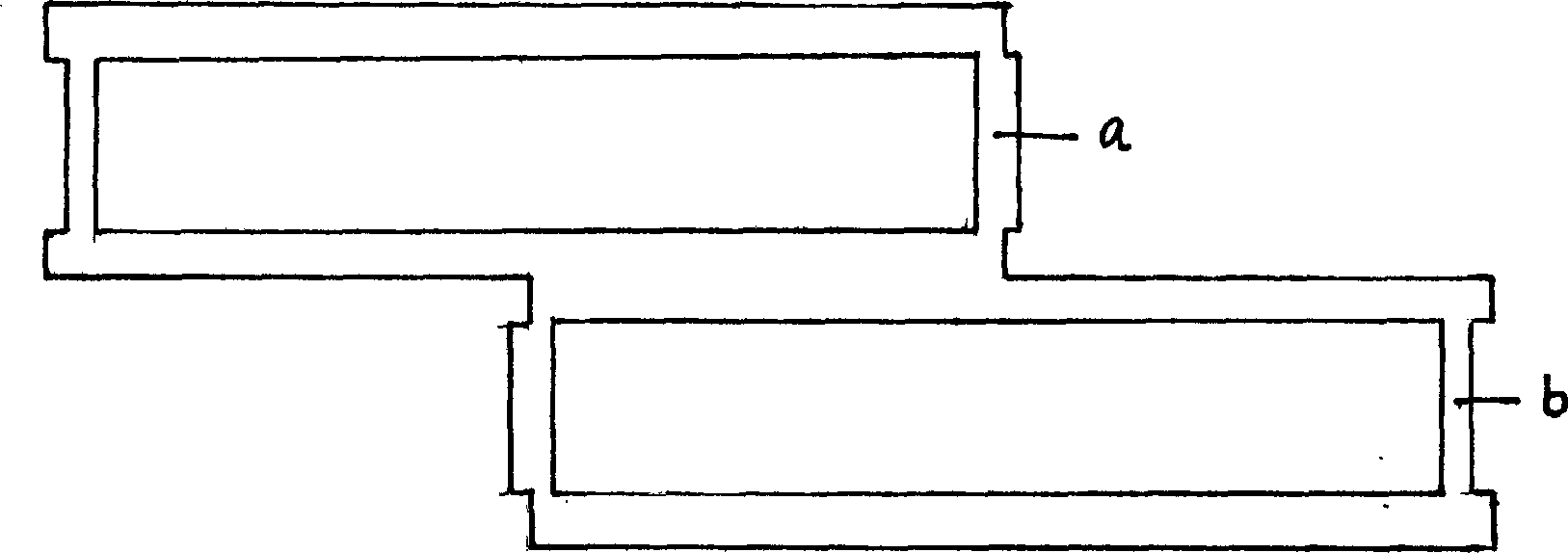

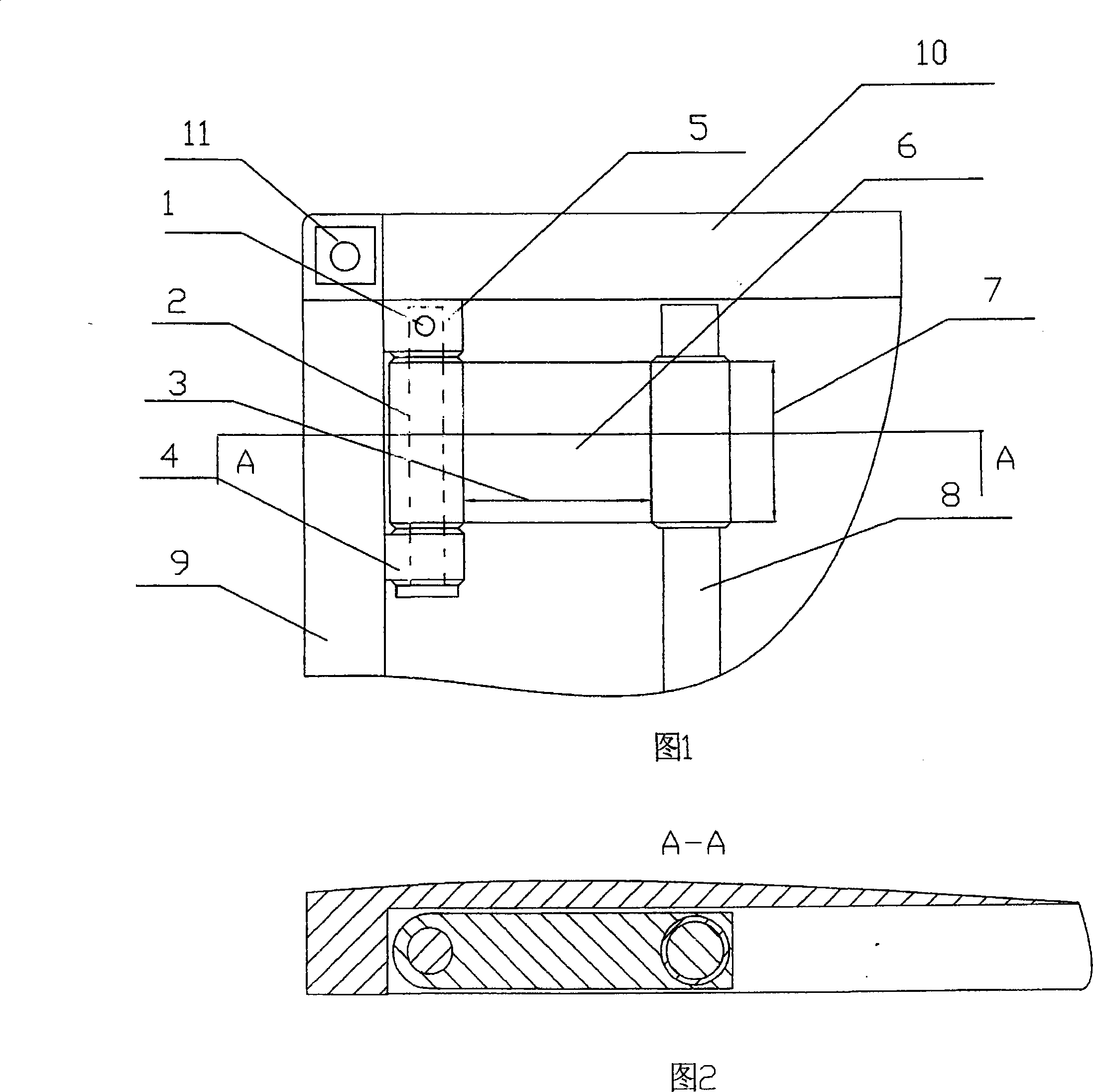

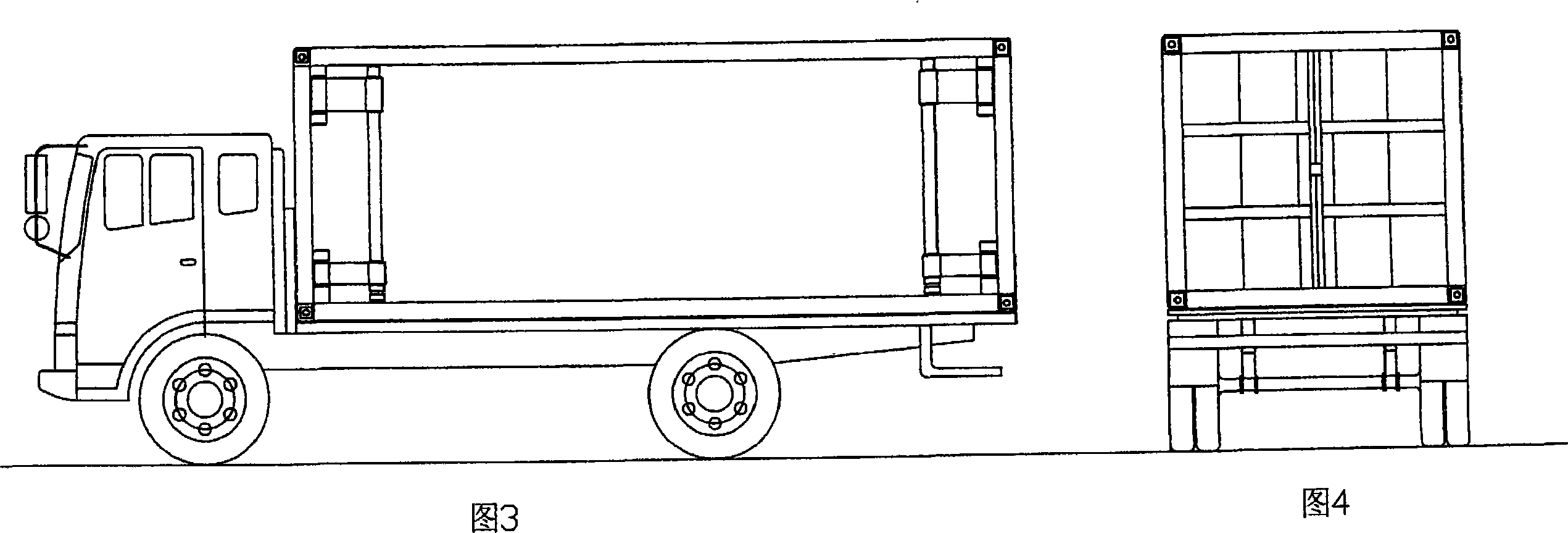

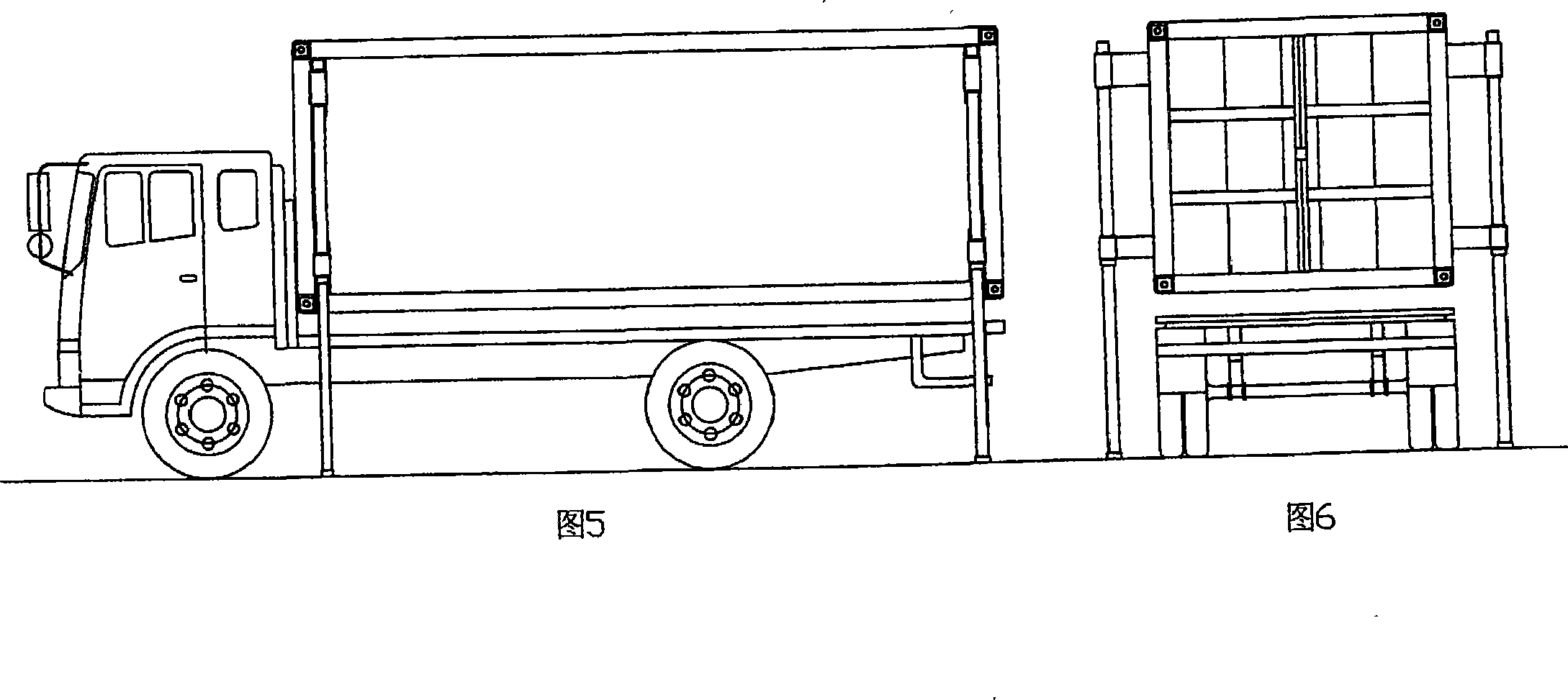

Method for producing up-down container or analogue and device, and application thereof

InactiveCN101195469AFaster turnaroundSolve transportation and loading and unloading problemsLifting devicesHoisting equipmentsEconomic benefitsEngineering

Provided is a lifting container or similar objects (the whole formed by space or large-sized equipment wrapped by a cubic and rigid frame of similar containers), which is characterized in that a lifting device capable of rotating around a bracing column is installed on the side wall of the container, or a bearing column with a lifting device is capable of rotating around the side wall. The invention occupies no space with the weight of about 180 kilograms, and none of standards and any structures of the container are changed, thereby saving costs of lifting containers for most of middle and small clients, being convenient for loading, accelerating goods turnover, extending the transport chain, namely from the containers of port-to-port transport to door-to-port, port-to-door and door-to-door transport, enlarging service range, speeding up turnover of the containers and occupying no driving time in loading and unloading goods. The lifting container has the advantages of no potential safety hazard, easy production, convenient maintenance, simplicity and simple operation. The container is added with lifting function, thereby changing logistics mode and bringing enormous economic benefits.

Owner:沈军

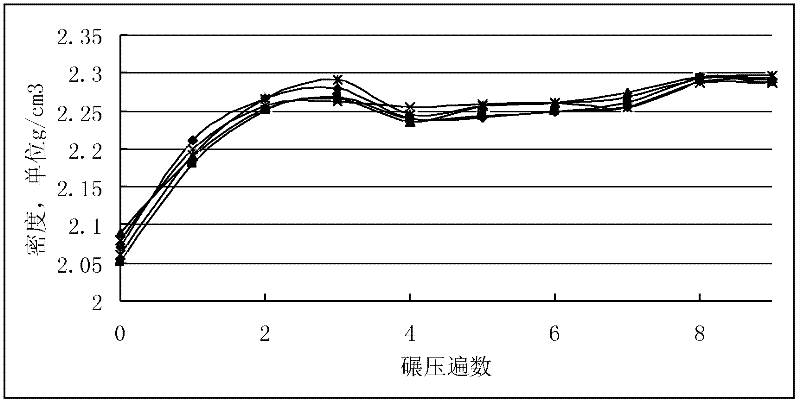

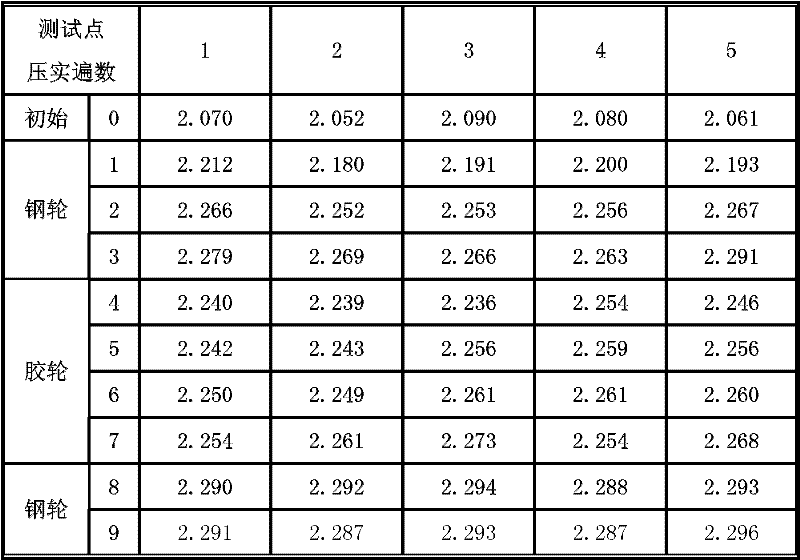

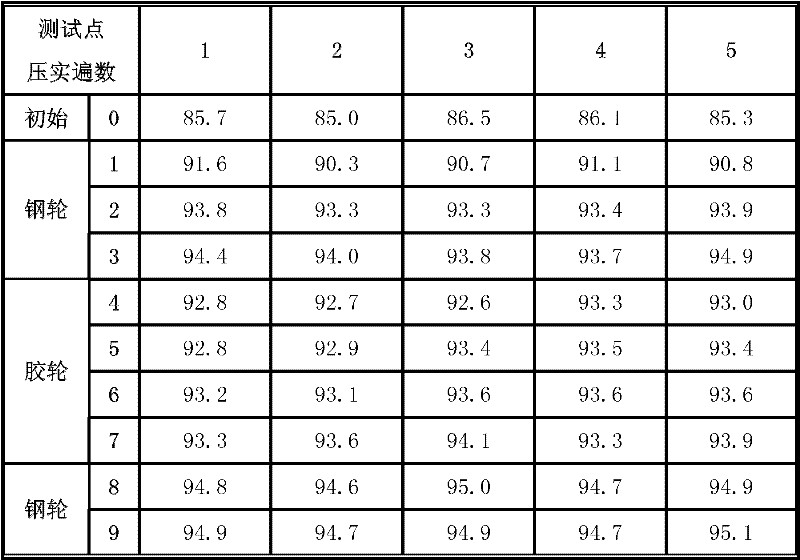

Rubber asphalt compacting technology based on pavement quality indicator

InactiveCN102345269AShort test timeOptimizing the compaction processRoads maintainenceSpecific gravity measurementRubberized asphaltNondestructive testing

The invention belongs to the field of non-destructive testing, and discloses a rubber asphalt compacting technology based on a pavement quality indicator. According to the invention, density data is collected from a rubber asphalt pavement testing path; a relationship figure of the two is drawn; read numbers on the pavement quality indicator are scaled; and real-time monitoring and compaction optimization are carried out upon the compaction degree of the asphalt layer of the rubber asphalt pavement by using the pavement quality indicator. With the technology provided by the invention, the asphalt structural layer of the rubber asphalt pavement is not damaged, the compaction degree of a rubber asphalt surface layer can be simply, rapidly and accurately controlled, and the rolling process of a roller can be optimized. The technology can be simply applied in on-site operations, and provides advantages of no radiation, no damage, and low testing cost.

Owner:GUANGZHOU UNIVERSITY

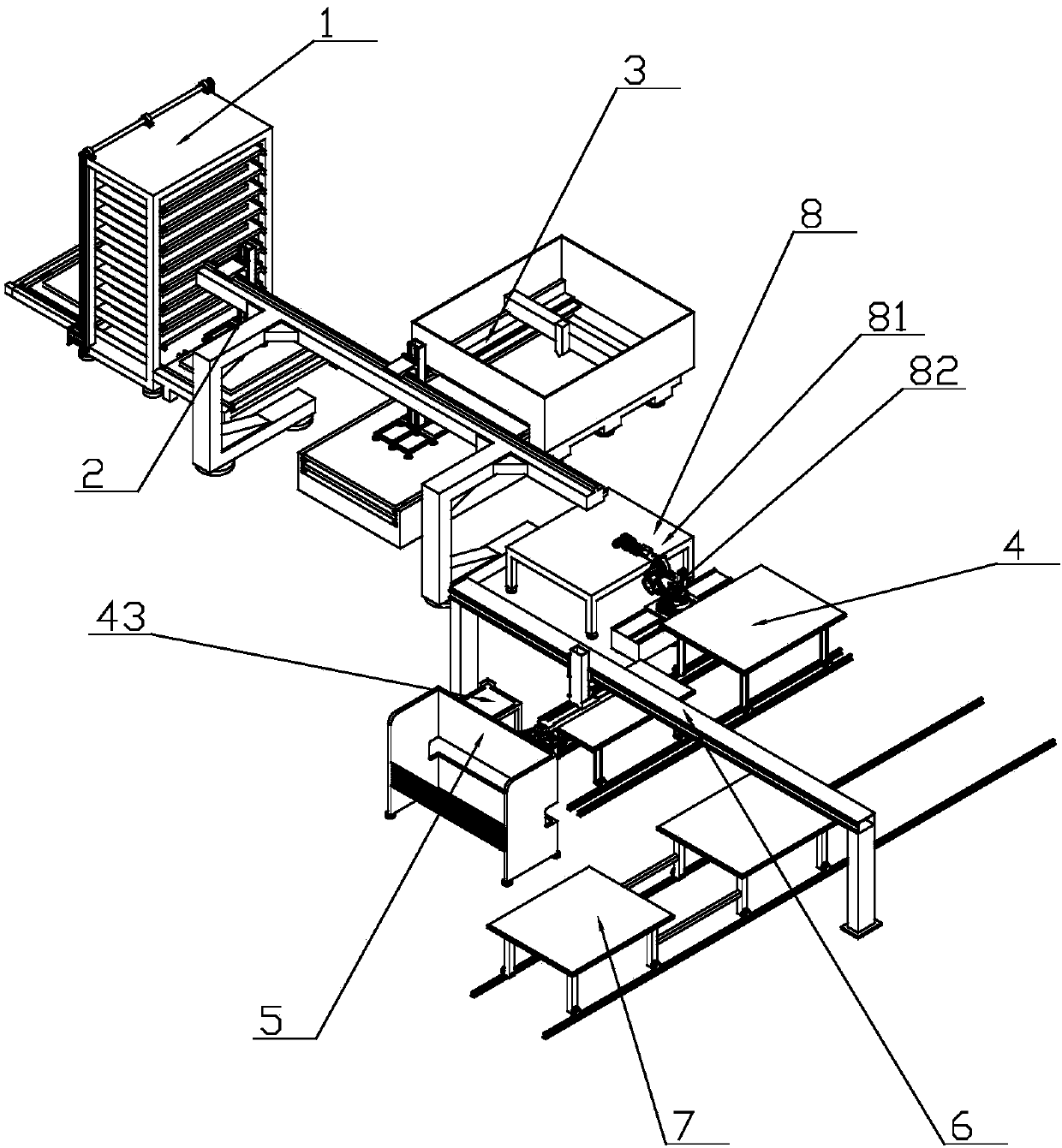

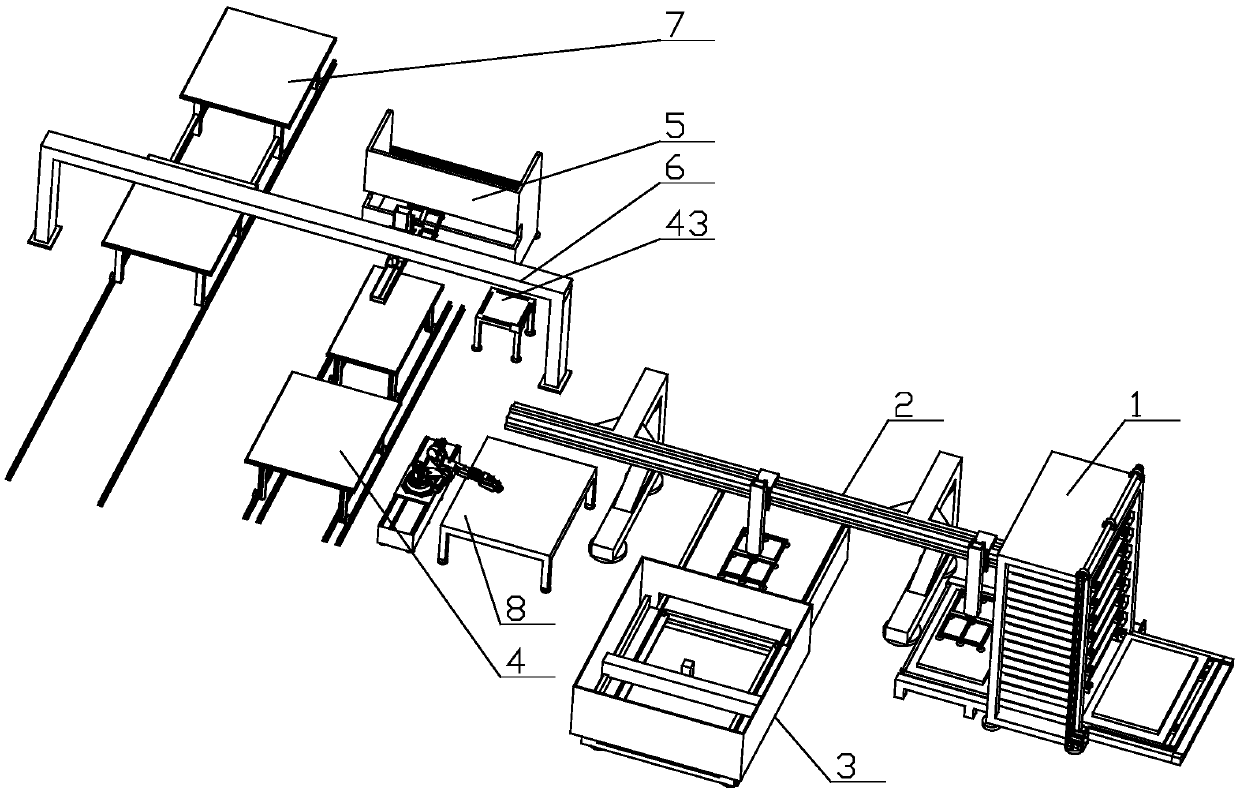

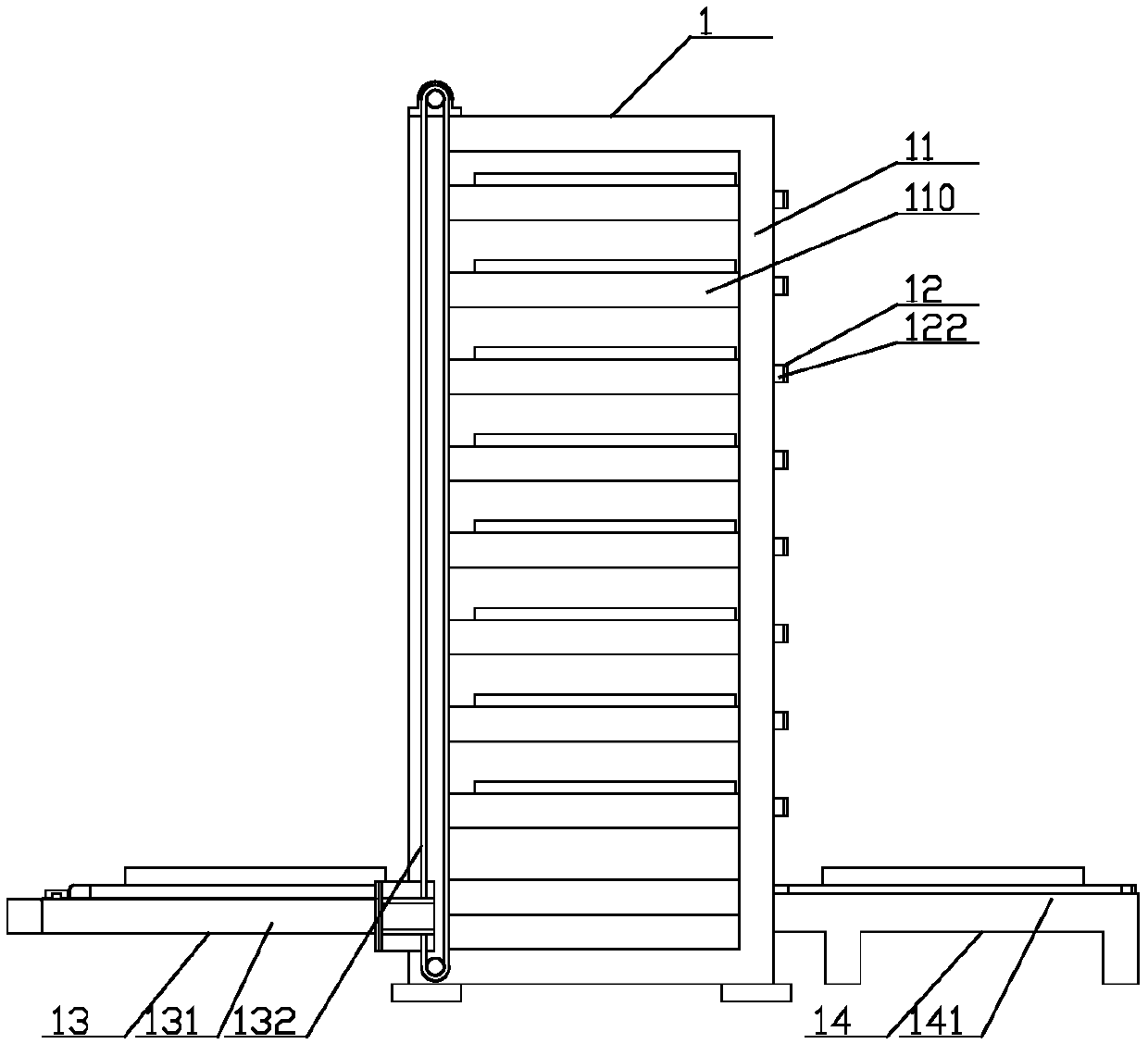

Automatic plate machining system

ActiveCN107598362AReduce labor intensityHigh degree of automationOther manufacturing equipments/toolsLaser beam welding apparatusRemote controlLaser cutting

The invention discloses an automatic plate machining system, relates to the field of plate machining equipment, and particularly relates to an improvement of an assembly line for step-by-step machining of plates. According to the automatic plate machining system, the structure is ingenious, the working efficiency is high, the machining period is short and the stability is good, and continuous andhighly-automatic plate machining can be realized by utilizing manual remote control in the using process. The automatic plate machining system comprises a stock bin, a horizontal moving mechanical armassembly, a laser cutting assembly, a double-layer movable material table, a bending machine, a transferring mechanical arm assembly and stacking workbenches; and the stock bin comprises a material storage frame, a plurality of bearing plates, a bearing plate lifting assembly and a bearing plate horizontal moving assembly, a plurality pairs of bearing strips are fixedly connected to the inner walls of the two sides of the material storage frame, the plurality pairs of bearing strips are uniformly distributed from top to bottom, and the two sides of each bearing plate are connected to the samecorresponding pair of bearing strips in a sliding mode. The automatic plate machining system of the technical scheme on the whole has the advantages of being capable of achieving continuous work, high in working efficiency, short in working period, high in automation degree, low in labor intensity and free of potential safety hazards.

Owner:江苏扬力数控机床有限公司

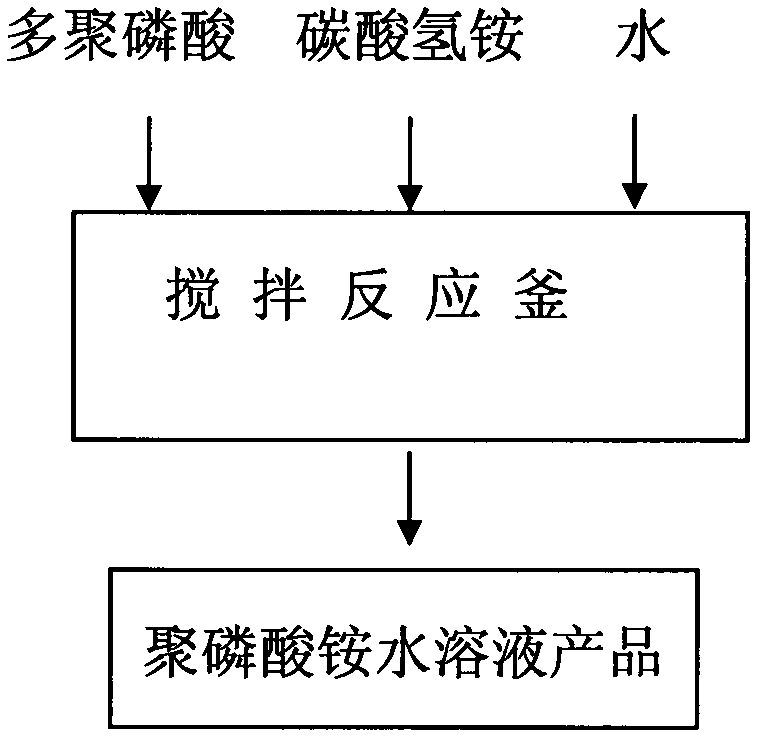

Method for preparing low-polymerization-degree ammonium polyphosphate aqueous solution

ActiveCN103373717AReduce processReduce difficultyPhosphorus compoundsChemical industryEnvironmental resistance

The invention belongs to the technical field of phosphate production in inorganic chemical industry and discloses a novel method for producing a low-polymerization-degree ammonium polyphosphate aqueous solution by using low-temperature methods. Commonly-used ammonium polyphosphate production methods are mainly high-temperature thermal polymerization methods, and methods capable of producing ammonium polyphosphate by using the low-temperature methods do not exist at home and abroad. According to the method, polyphosphoric acid with the concentration of 100% to 120% serves as a main raw material, is adjusted by adding an appropriate amount of water and is mixed with ammonium bicarbonate under a natural, low-temperature and normal-pressure condition, stirring and reacting are carried out, and then, the low-polymerization-degree ammonium polyphosphate aqueous solution with the nitrogen content higher than 11%, the phosphorus pentoxide content higher than 37% and the main content of a dipolymer (ammonium pyrophosphate) is produced in batches, is widely used as a fireproofing flame retardant, a plant nutrient solution (liquid fertilizer) and the like and has high practical values. The method is simple in production operation, high in yield and low in energy consumption, is safe and environmental-friendly and does not need high temperature, the requirements for the performance of equipment and materials are lowered greatly, and the large-scale continuous production is easy to realize.

Owner:BLACK P2 USA INC

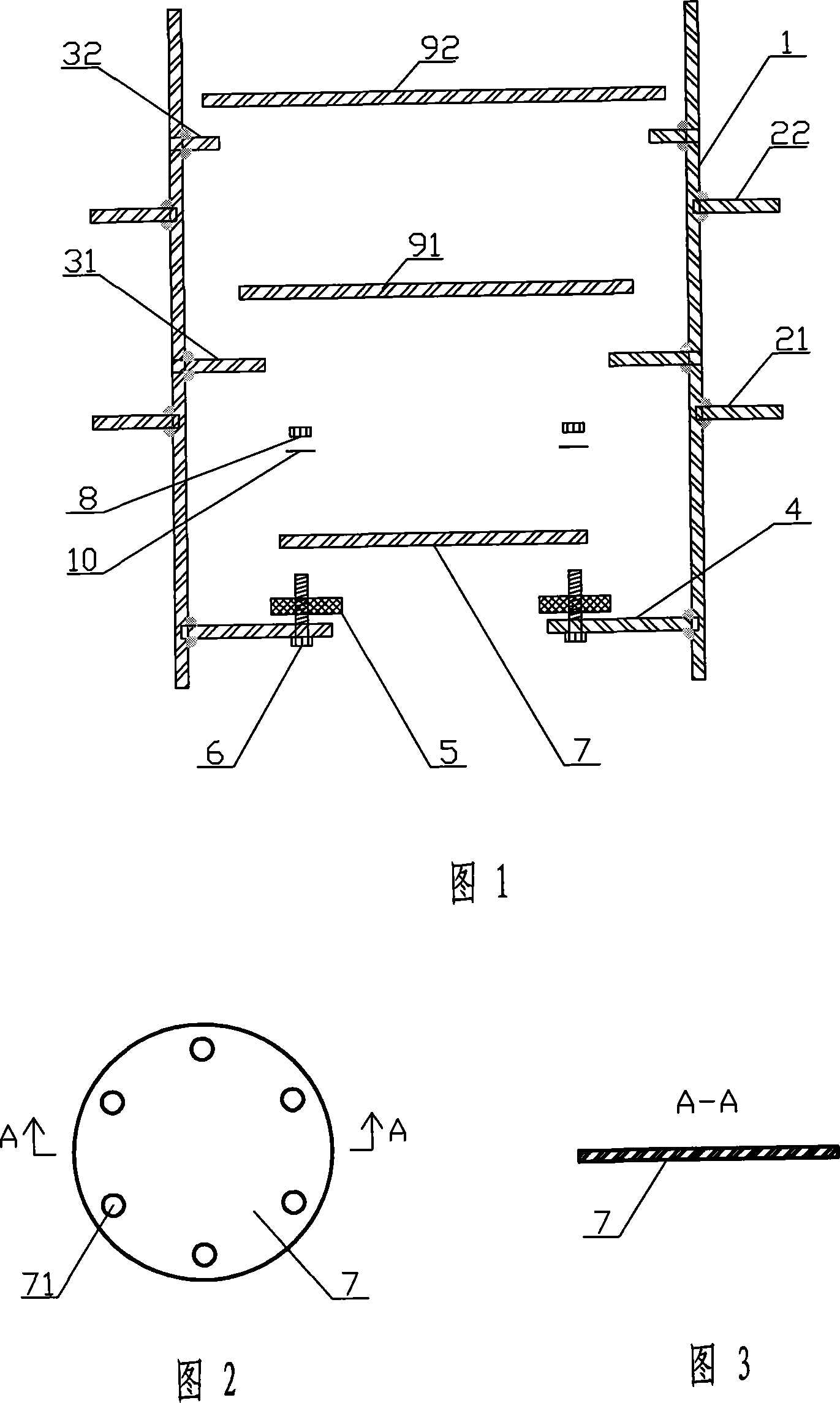

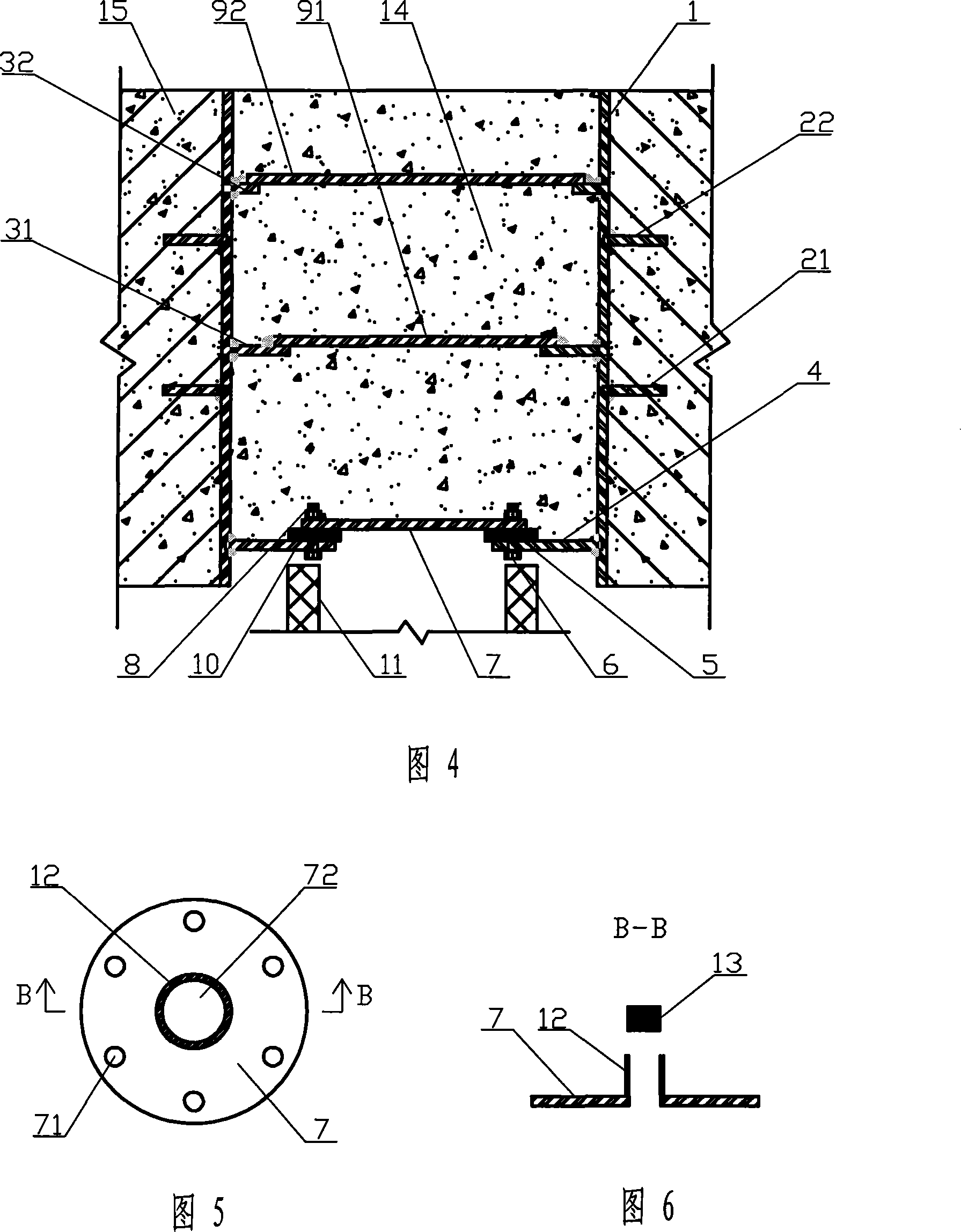

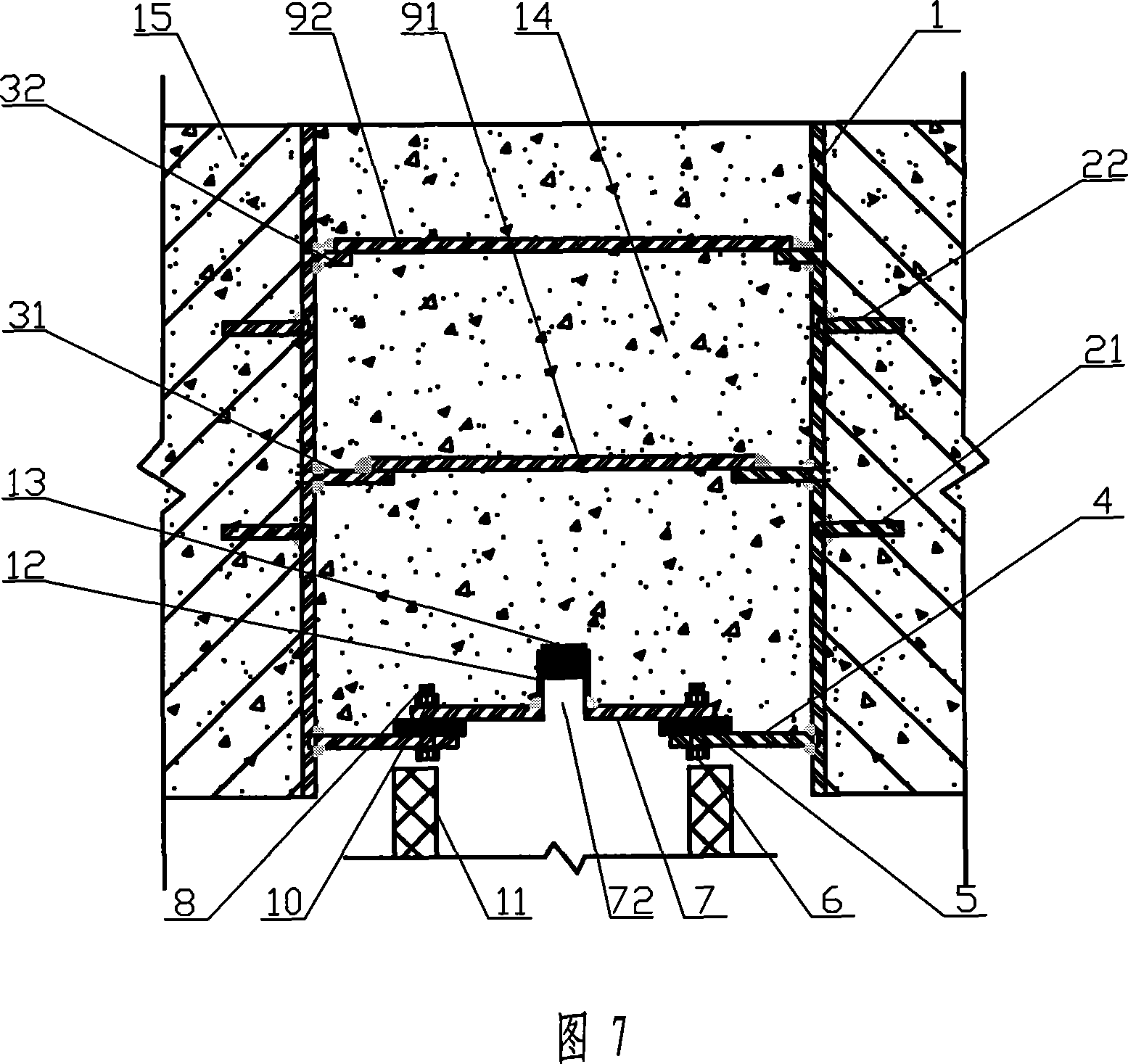

Fast plugging device for deep foundation pit precipitation well

The invention relates to a rapid plugging device of a dewatering well with a deep foundation, which comprises a plugging sleeve, a plugging cover base, a plugging cover, an external water stopping ring, an inner water stopping ring and a water stopping plate, wherein the plugging cover base is a ring base connected and vertically fixed with the lower part of the inner wall of the plugging sleeve, more than three bolts are welded on the circumference in equal parts of plugging cover base, the plugging cover is provided with bolt holes relative to the bolts of the plugging cover base, the inner and external water stopping rings are vertically fixed and connected to the inner and outer walls of the plugging sleeve, the water stopping plate and the inner water stopping ring are connected through welding or flange. The device has simple structure, low process cost, convenient use and wide adaptability, and uses unified construction method to replace each plugging process, has rapid plugging, low cost, no construction risk and dangers, avoids the limitless underground water pumping, and protects the environment.

Owner:JIANGSU NANTONG NO 2 CONSTR ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com