Box girder production line of front suspension arm frame

A production line and reach stacker technology, applied in welding equipment, auxiliary devices, arc welding equipment, etc., can solve problems such as hidden safety hazards, complicated operation, time-consuming and laborious, and achieve the effect of increasing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The present invention will be further described in detail below in conjunction with specific embodiments.

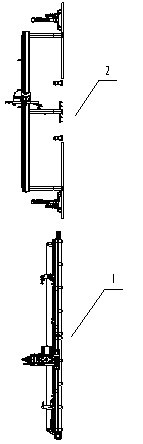

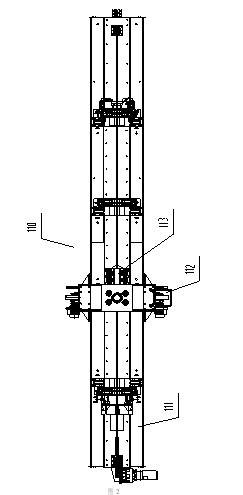

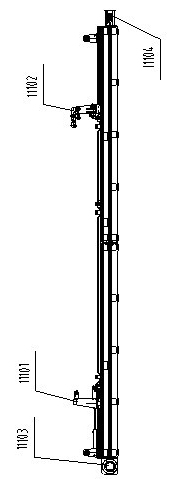

[0093] Such as Figure 1 to Figure 14 As shown, a front boom box girder production line is composed of a pairing station 1 and a welding turning station 2, and the pairing station 1 and welding turning station 2 are arranged side by side. Among them, the pairing station 1 uses the pairing tool 110 to realize the workpiece pairing (extending arm pairing or basic arm pairing), and the welding turning station 2 consists of two chain turning machines 210, two support stools 220, one The movable automatic seam welding machine 230 and an automatic inner seam welding trolley realize inner seam welding and turning over and outer seam welding and turning over. The two chain turning machines 210 are arranged symmetrically on two sets of slide rails, the two supporting stools 220 are correspondingly arranged at the ends of the rails between the two chain turning machines 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com