Automatic welding equipment for magnesium alloy material machining

A material processing and automatic welding technology, applied in metal processing equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low processing efficiency, labor consumption, and low welding quality of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

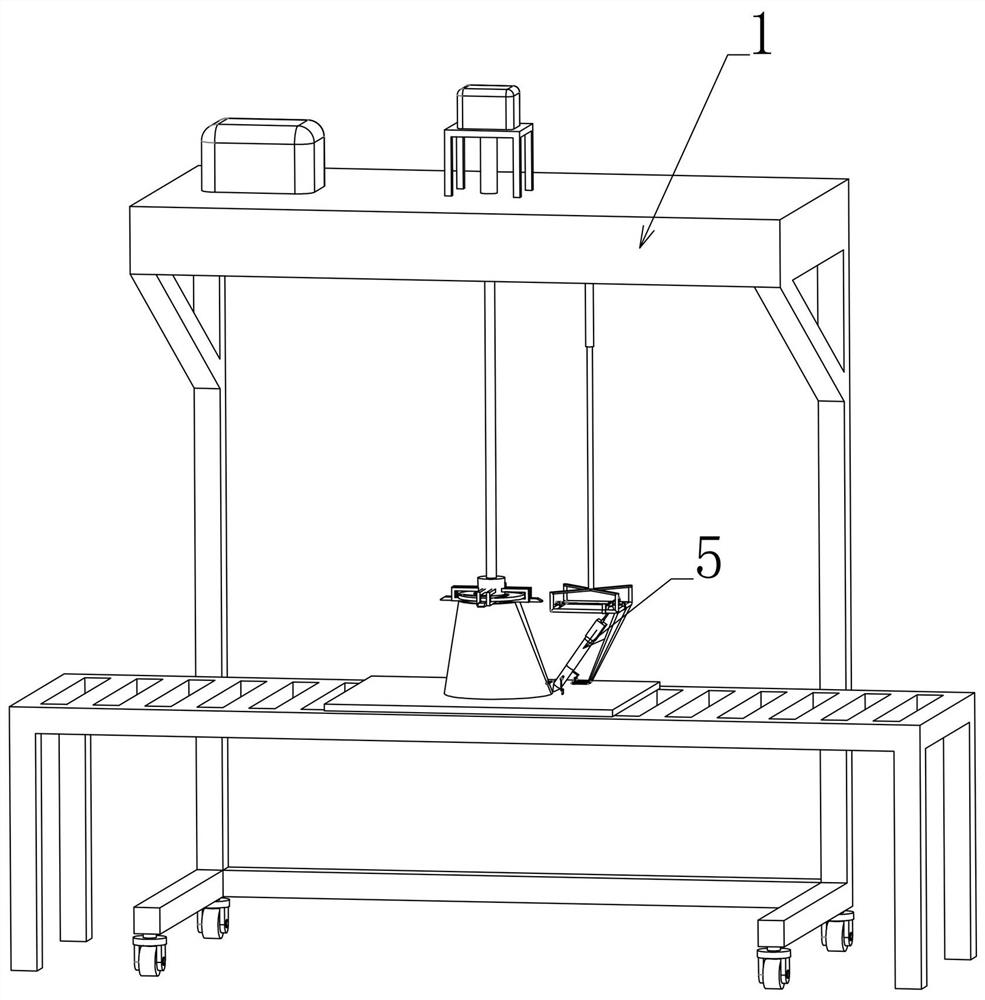

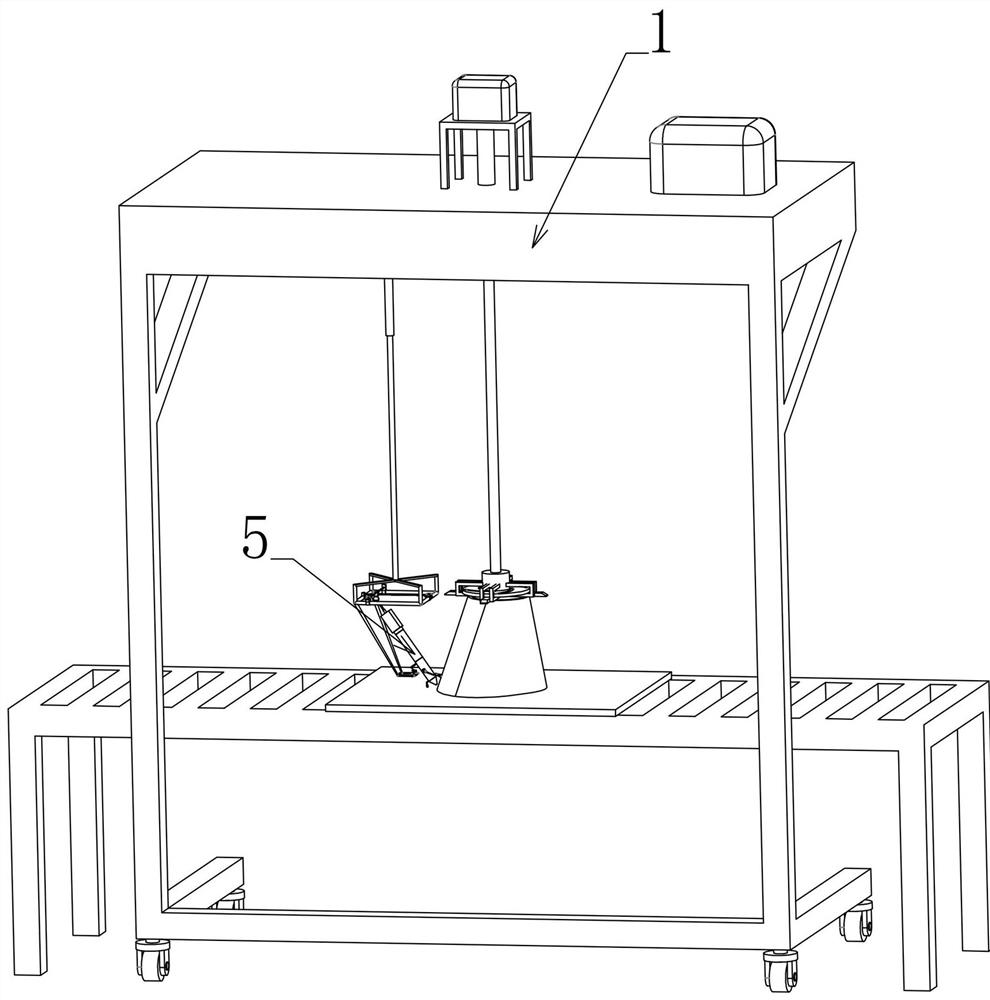

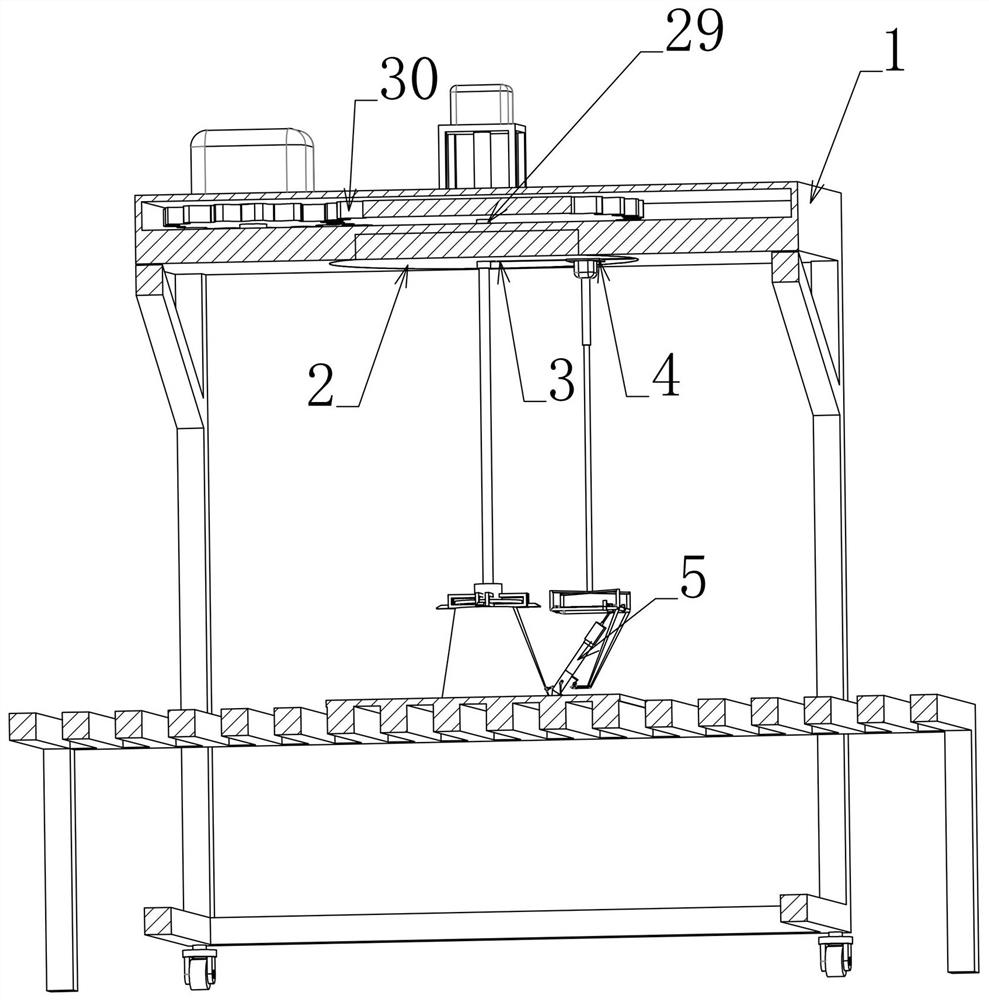

[0030] The following is attached Figure 1-12 The specific implementation manners of the present invention are further described in detail.

[0031]When the present invention is in use, the welding trolley 1 is moved to the position of the welding workbench, and the lowermost end of the welding trolley 1 is rotatably connected with a plurality of universal wheels so that the welding trolley 1 can move in various directions, and the position of the welding trolley 1 is adjusted so that the upper end of the welding trolley 1 The pressing device protruding downward is located directly above the workpiece to be welded, and then starts the pressing motor fixedly connected in the rotating cavity 31, and the pressing motor rotates to drive the coaxially fixedly connected pressure plate 32 to rotate, and the pressure plate 32 is provided with multiple The notch 33 evenly arranged along the circumference, the notch 33 is an arc-shaped groove extending outward from the center position c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com