Automatic adjustment multiple-gun welding device

A welding device and automatic adjustment technology, applied in the direction of electrode support device, electrode characteristics, etc., to achieve the effect of reducing strength, convenient positioning, improving welding work ability and weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

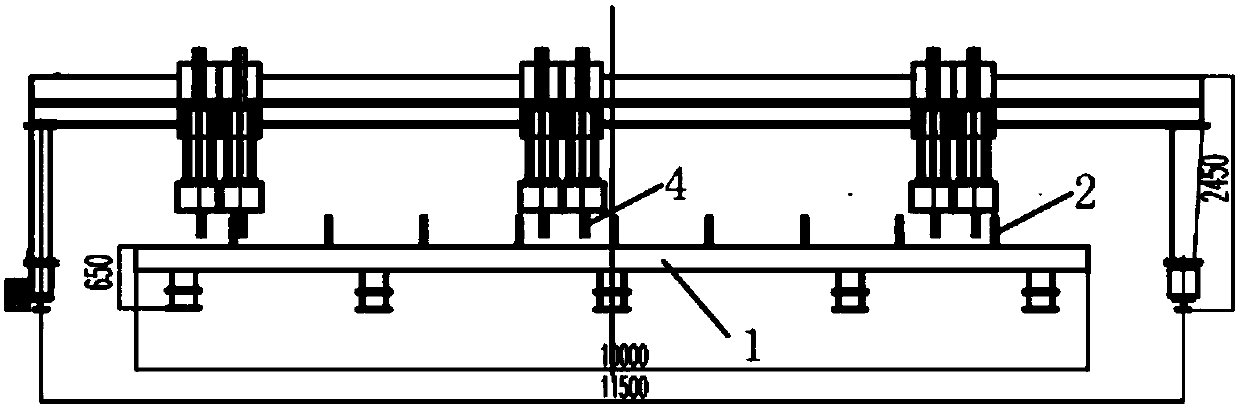

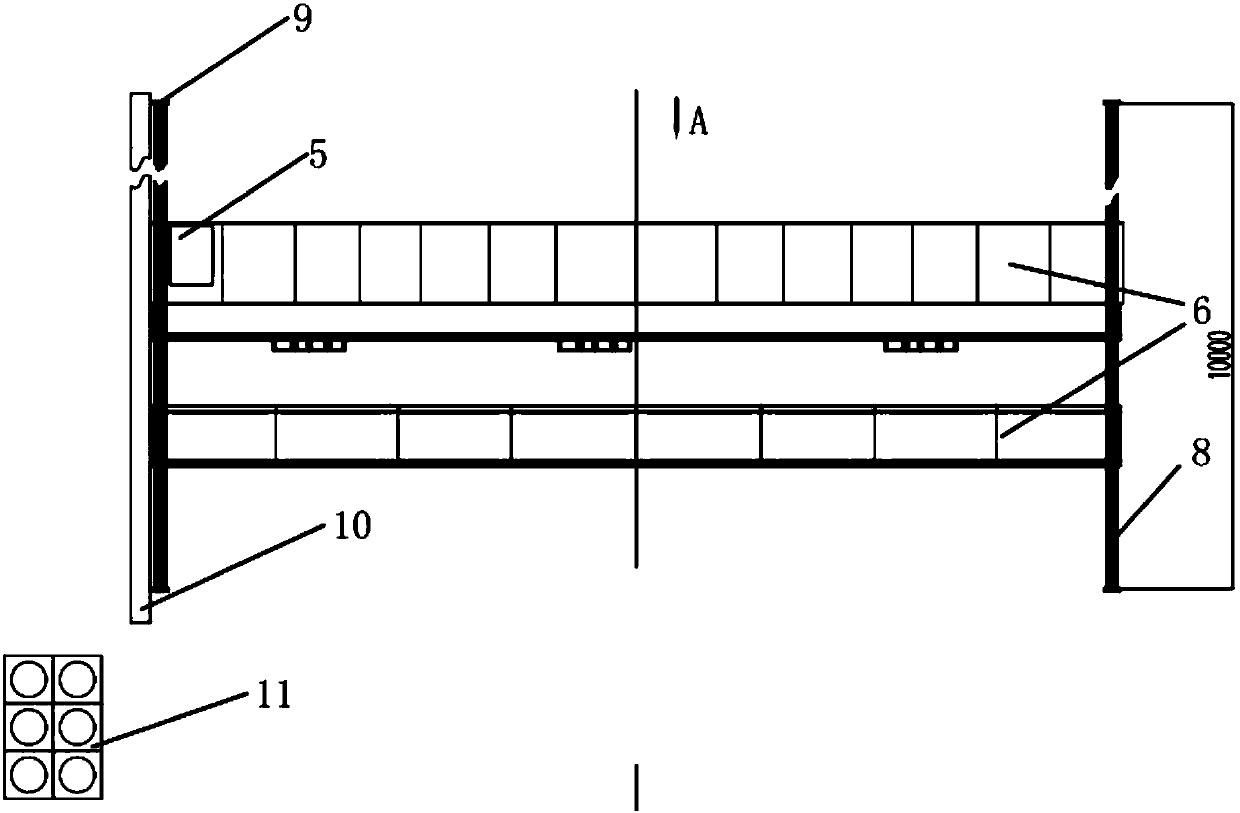

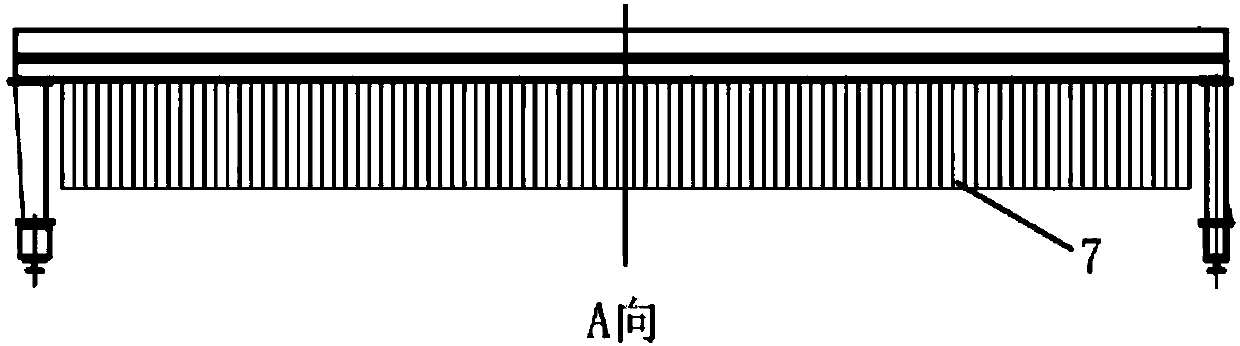

[0035] Such as Figure 1 to Figure 5 As shown, an automatic adjustment multi-gun welding device provided by the present invention includes a welding platform 1, a tooling backer 2, a grounding system 3, a water-cooled welding torch 4, a water-cooled circulation device 5, an equipment platform / operating platform 6, a hanging curtain 7, Precision guide rail 8, safety baffle 9, pipeline protection system 10 and CO 2 Centralized air supply device 11.

[0036] Wherein, the upper surface of the welding platform 1 is not coated with paint to ensure that the box wall is in good contact with it. The foundation of the welding platform 1 and the U-shaped grounding system 3 (flat steel frame) are welded to death by steel plates, and the welding machine grounding wire of the equipment platform / oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com