Patents

Literature

419 results about "Process manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process manufacturing is a branch of manufacturing that is associated with formulas and manufacturing recipes, and can be contrasted with discrete manufacturing, which is concerned with discrete units, bills of materials and the assembly of components.

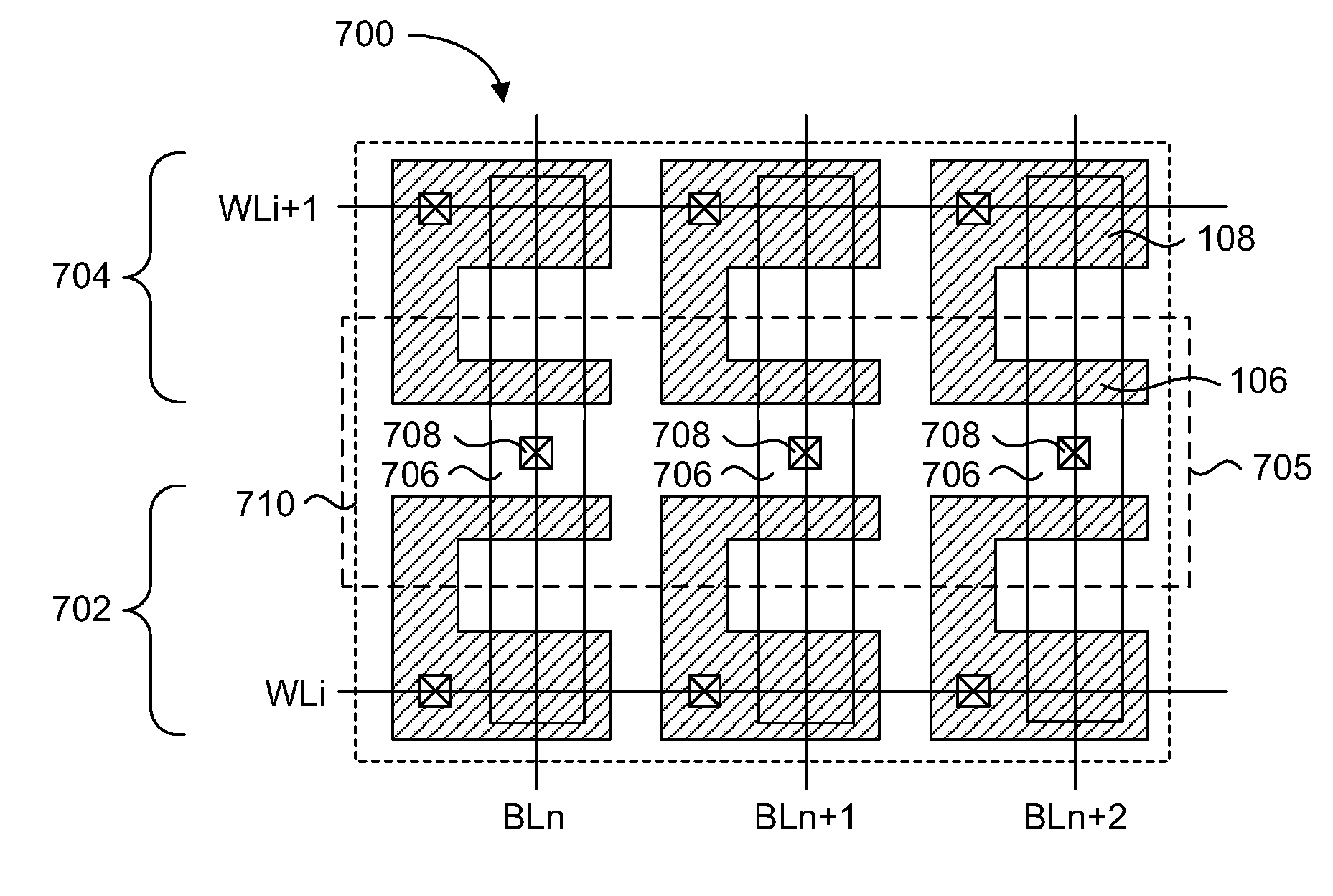

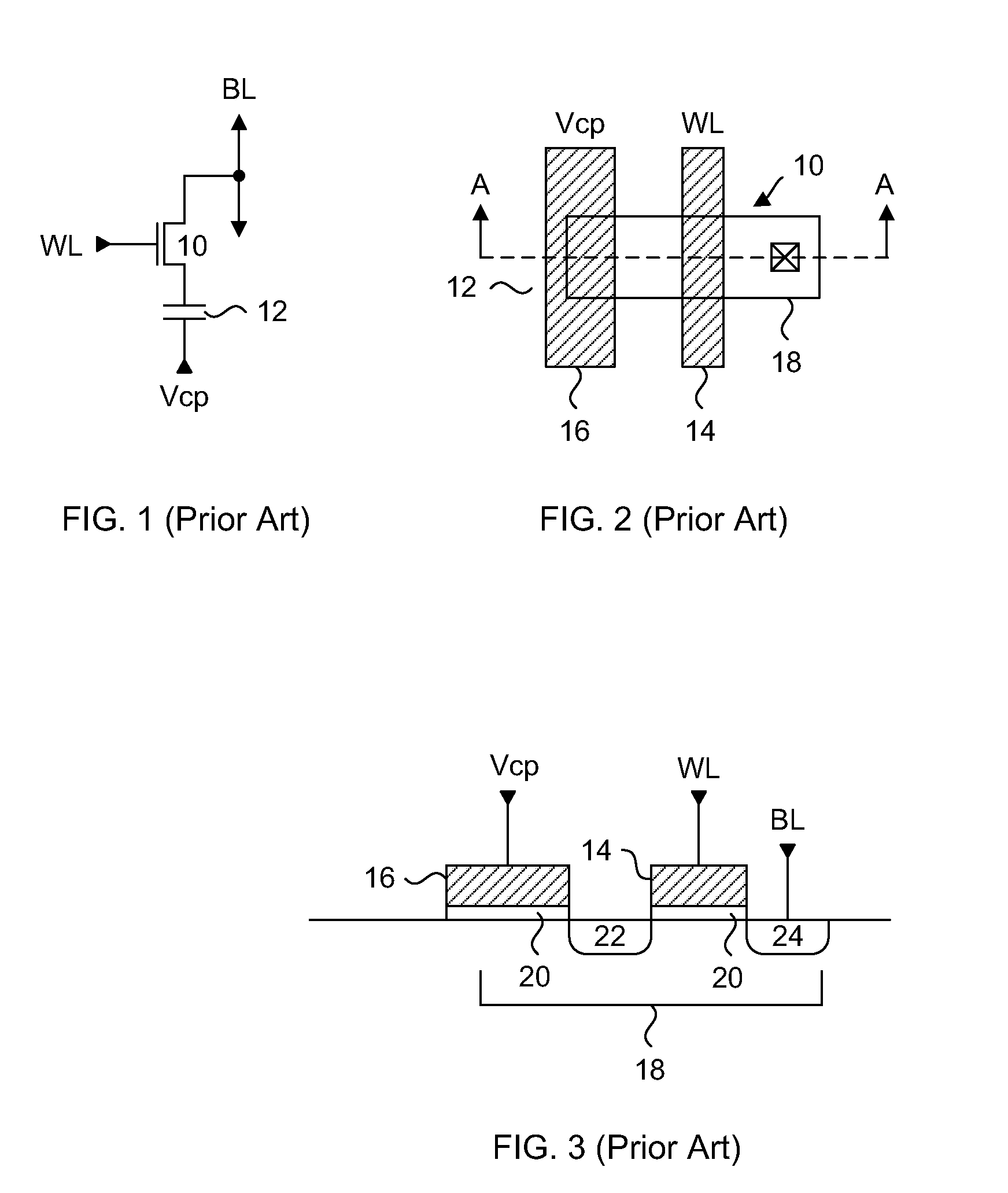

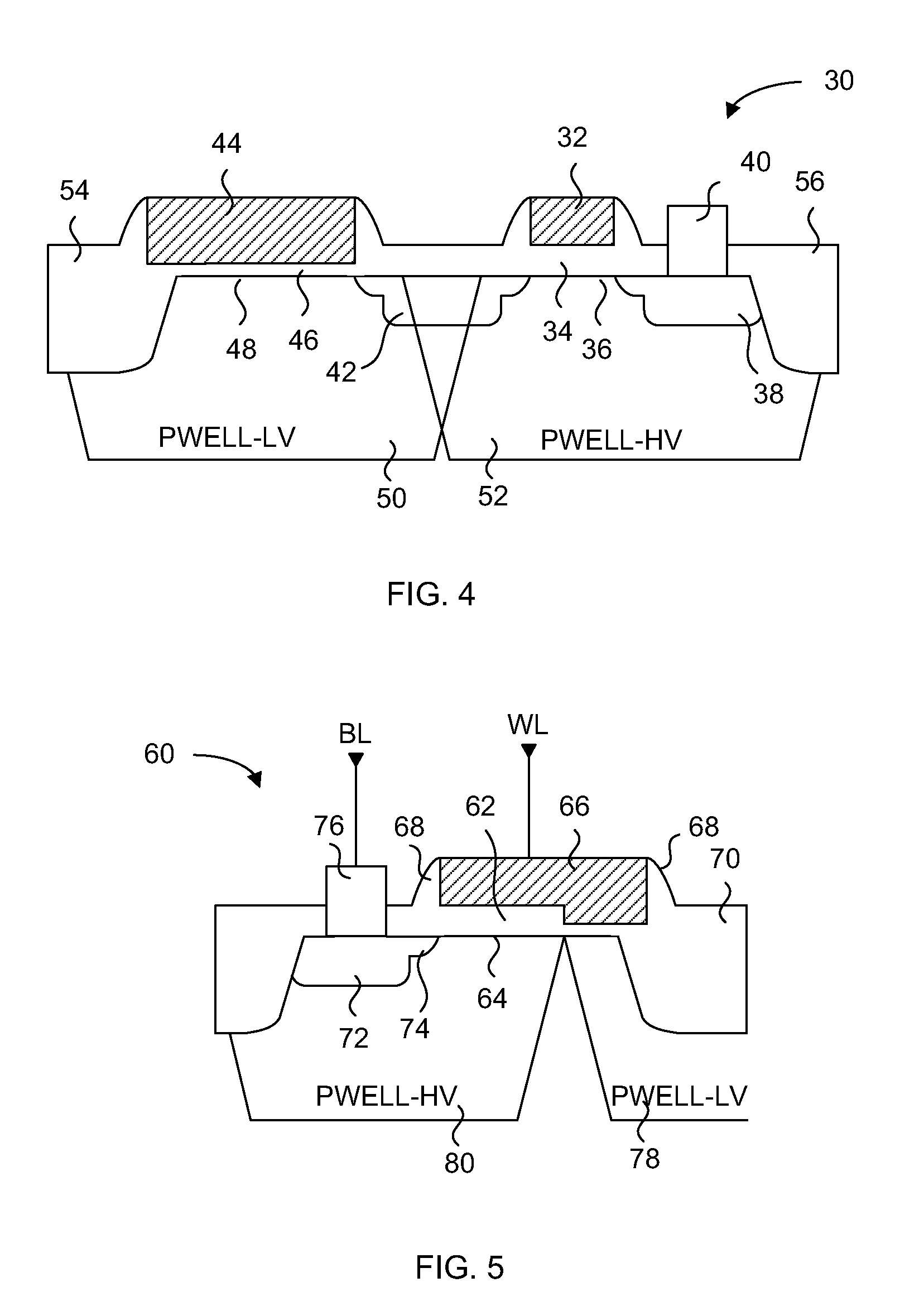

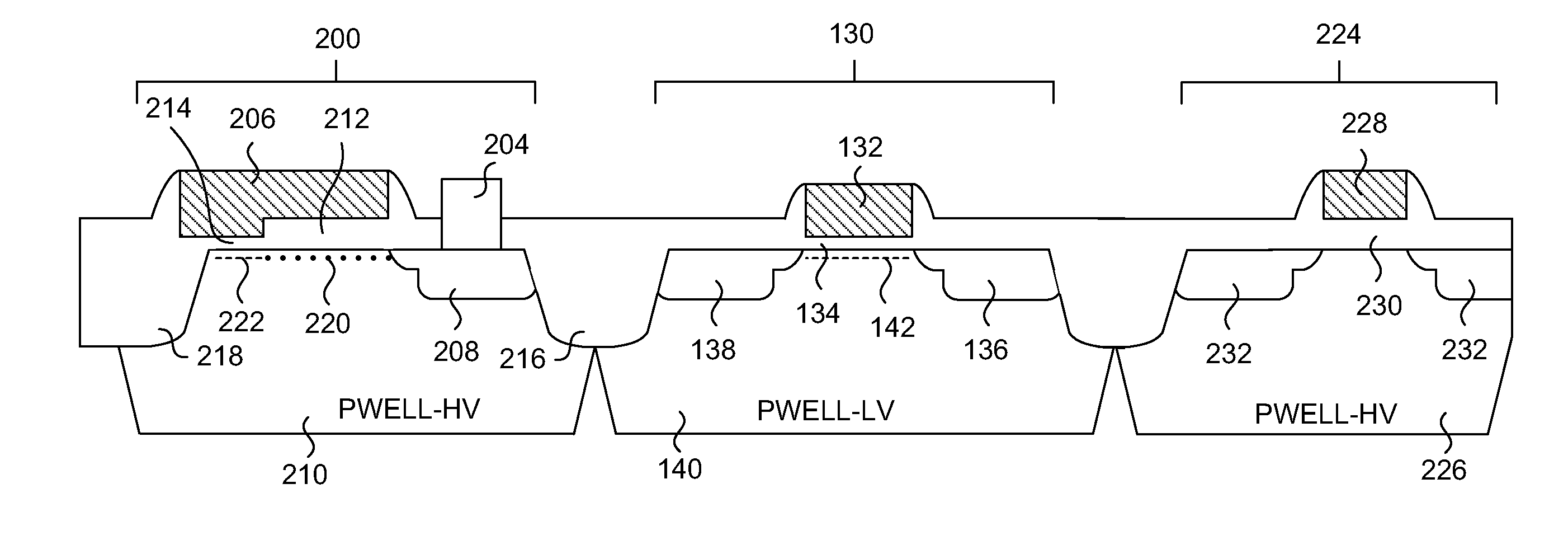

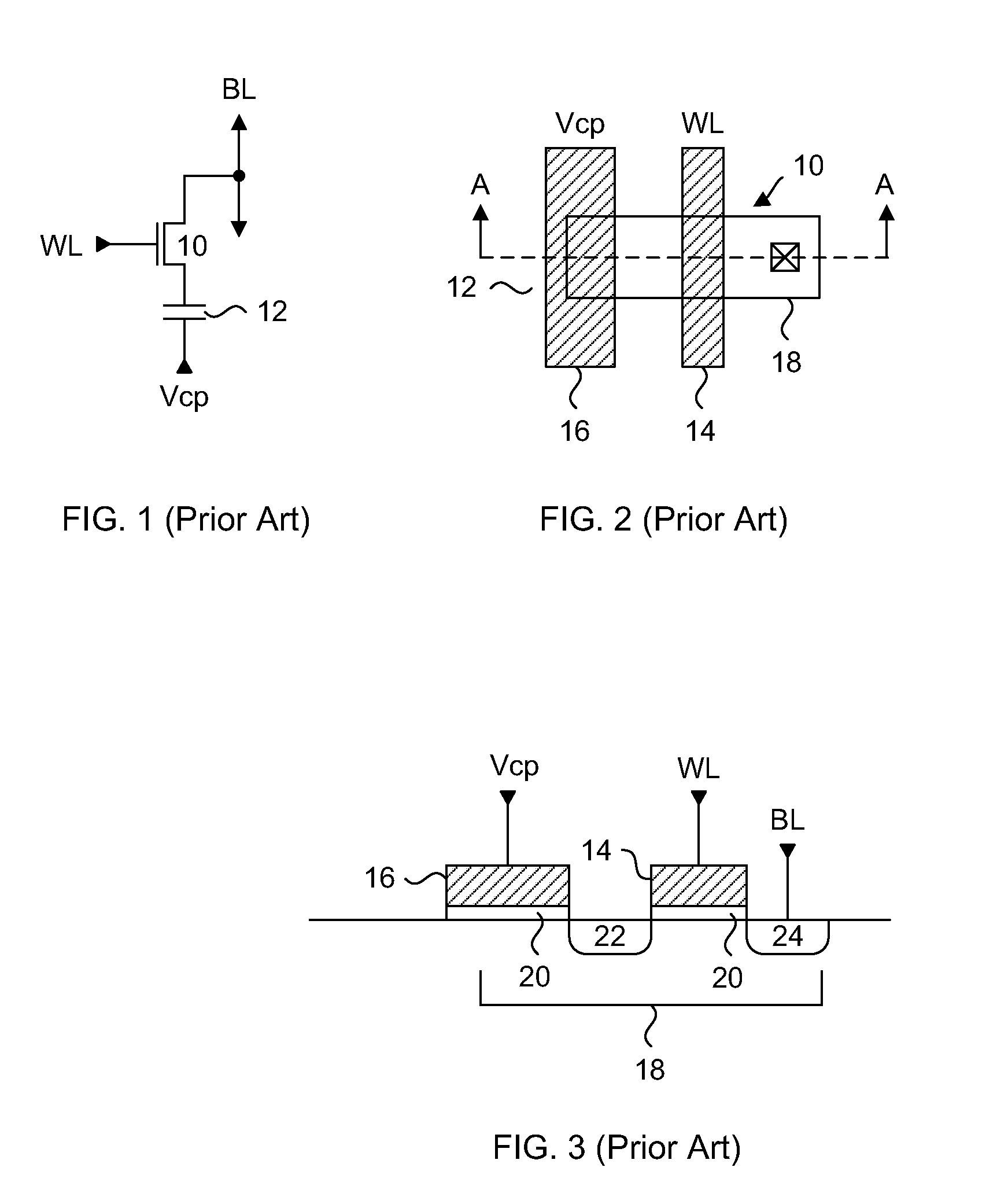

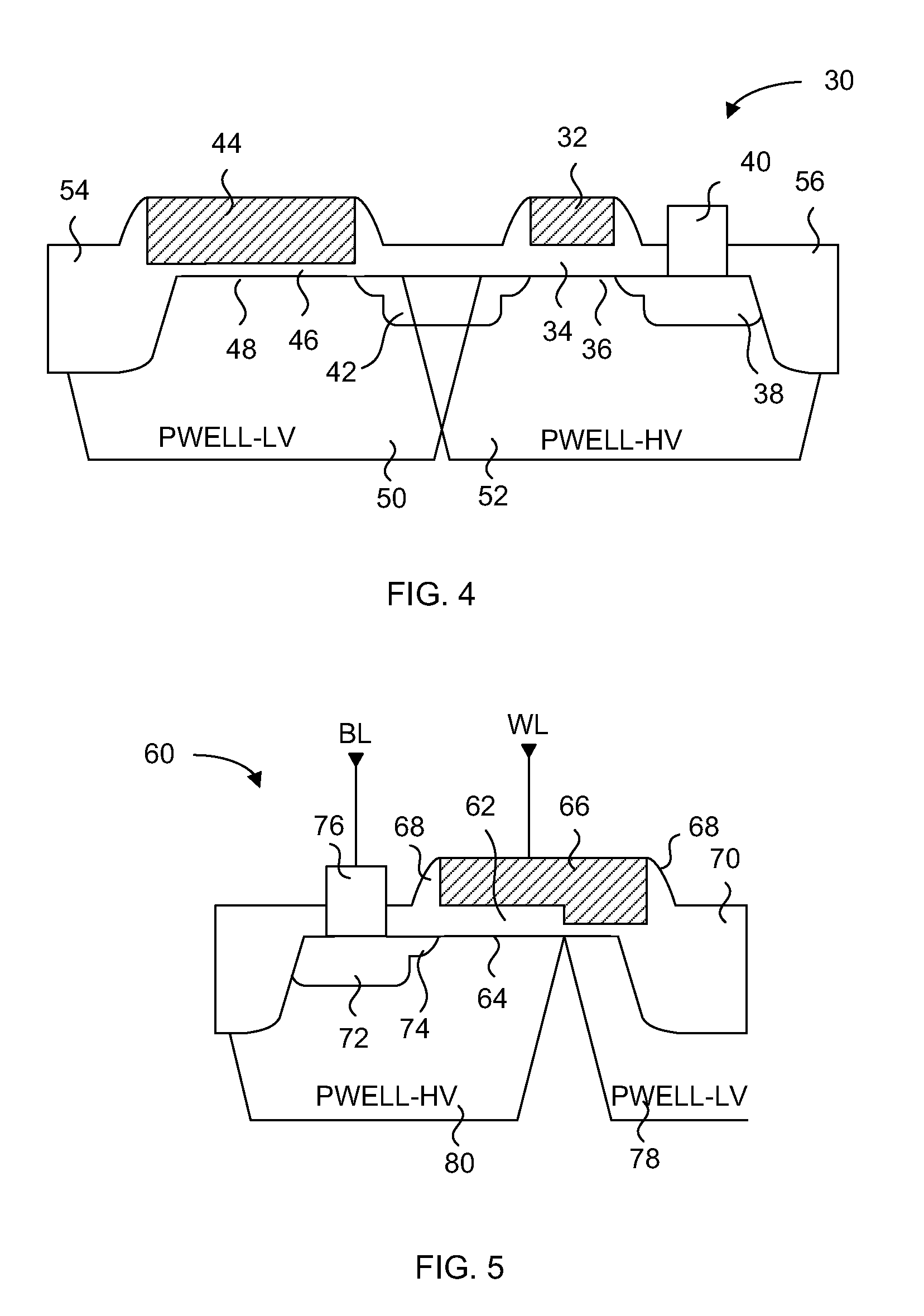

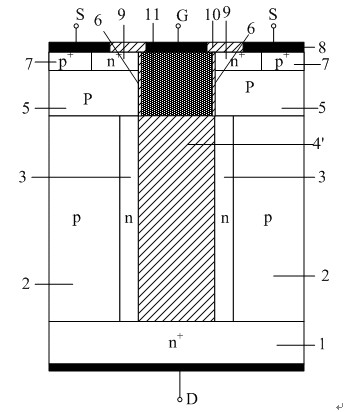

Low vt antifuse device

ActiveUS20090250726A1Semiconductor/solid-state device detailsSolid-state devicesHigh voltage transistorsProcess manufacturing

A one time programmable memory cell having an anti-fuse device with a low threshold voltage independent of core circuit process manufacturing technology is presented. A two transistor memory cell having a pass transistor and an anti-fuse device, or a single transistor memory cell having a dual thickness gate oxide, are formed in a high voltage well that is formed for high voltage transistors. The threshold voltage of the anti-fuse device differs from the threshold voltages of any transistor in the core circuits of the memory device, but has a gate oxide thickness that is the same as a transistor in the core circuits. The pass transistor has a threshold voltage that differs from the threshold voltages of any transistor in the core circuits, and has a gate oxide thickness that differs from any transistor in the core circuits. The threshold voltage of the anti-fuse device is lowered by omitting some or all of the threshold adjustment implants that is used for high voltage transistors fabricated in the I / O circuits.

Owner:SYNOPSYS INC

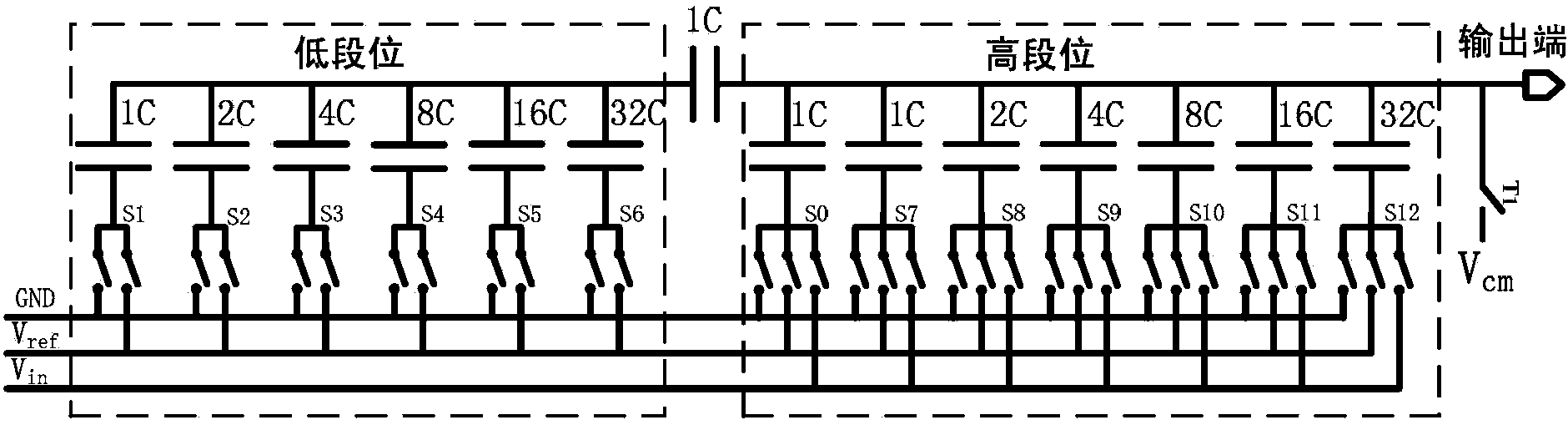

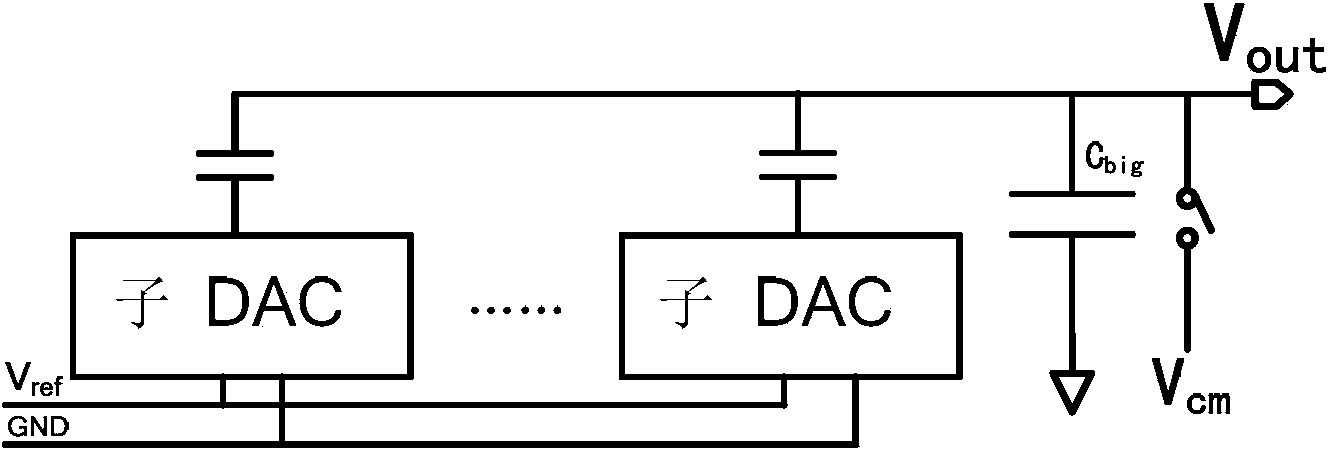

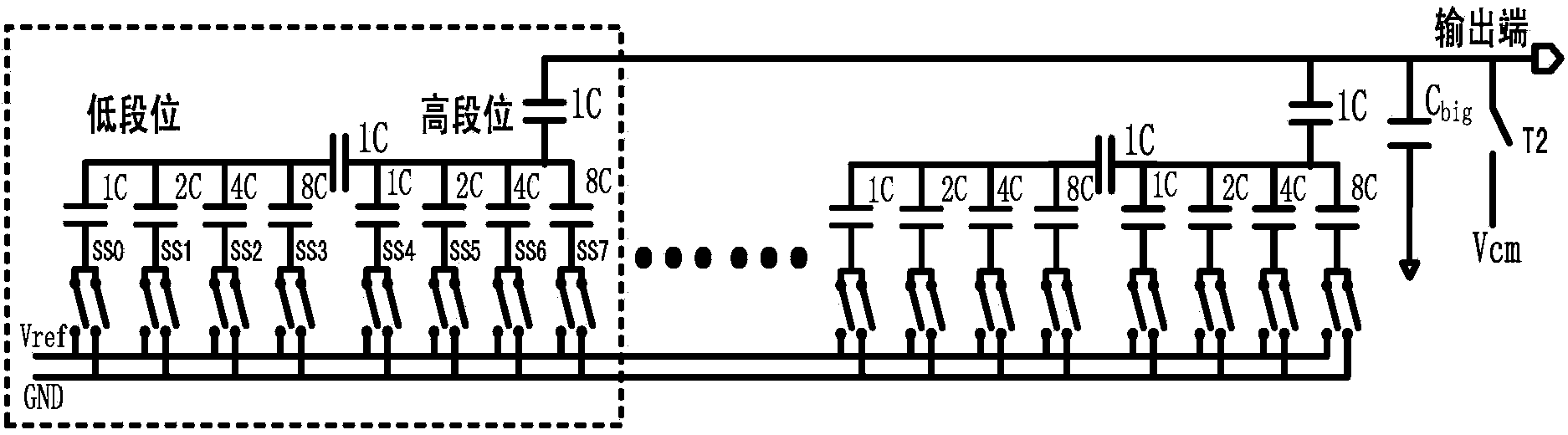

Digital calibration method for high-precision SAR ADC (successive approximation register analog to digital converter)

ActiveCN103873059AHigh precisionReduce areaAnalogue/digital conversion calibration/testingDigital down converterParasitic capacitance

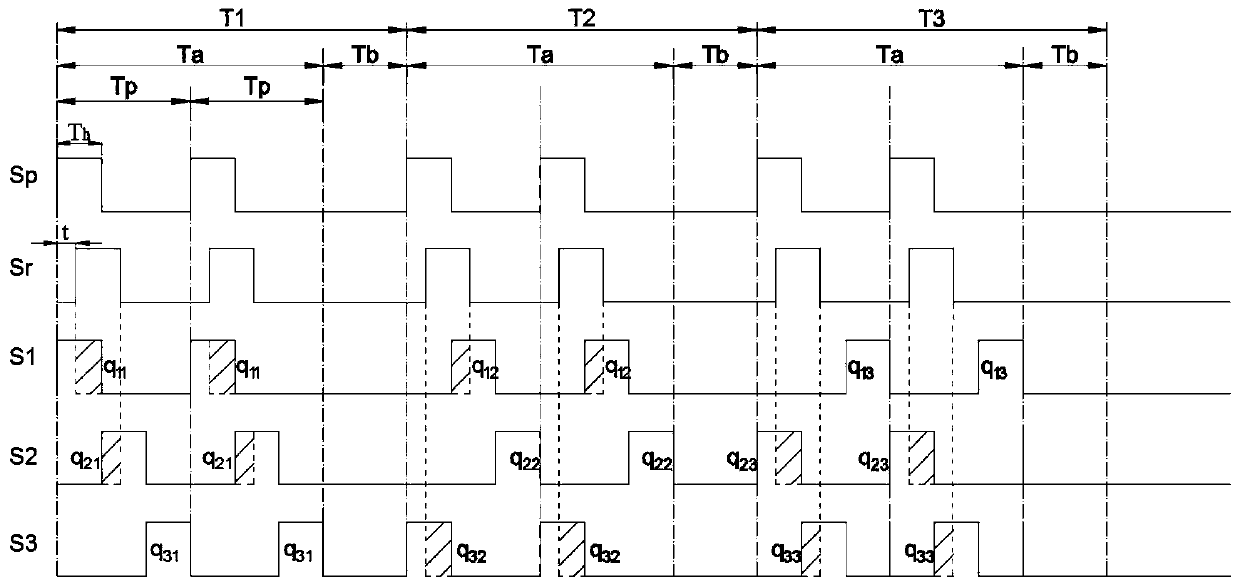

The invention discloses a digital calibration method for a high-precision SAR ADC (successive approximation register analog to digital converter). The method comprises the following steps of (1) designing of a calibration DAC (digital to analog converter), digitalizing the error voltage of each capacitor in the high segment of a main DAC, and carrying out digital to analog conversion on the processed calibration codes; (2) designing of digital calibration time sequence, obtaining the calibration codes, maintaining sampling, and gradually converting. The method is applied to the high-precision SAR ADC, and a capacitor array of the high segment in the sectional main DAC is subjected to digital calibration, so the mismatch of the capacitors caused by parasitic capacitors and the process manufacturing error is reduced, the problem of unable realizing of precise double relationship due to the mismatch of the adjacent capacitors in the high segment is greatly corrected, and the precision of the SAR ADC is effectively improved.

Owner:TIANJIN UNIV

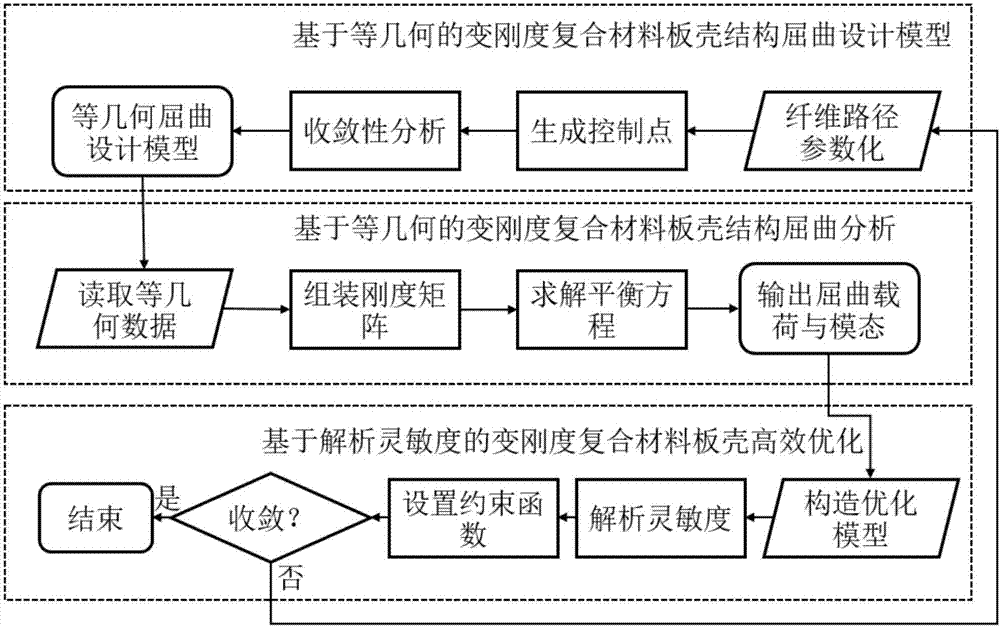

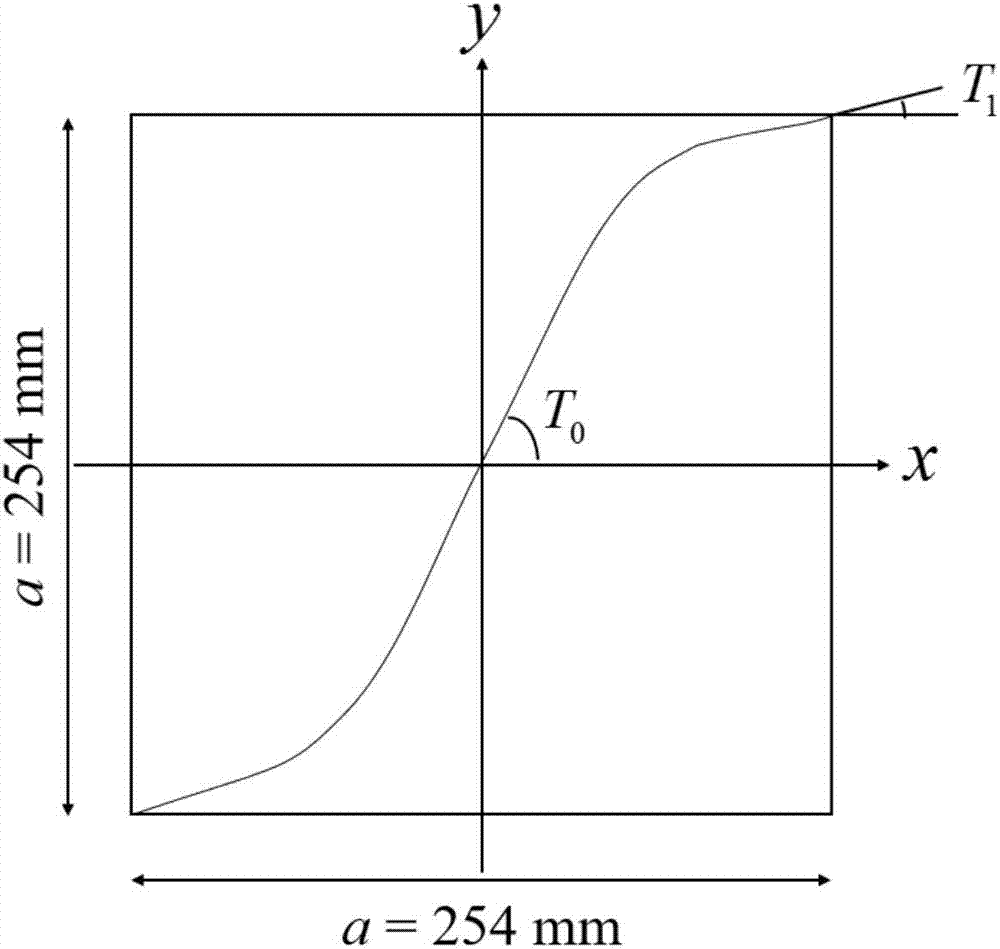

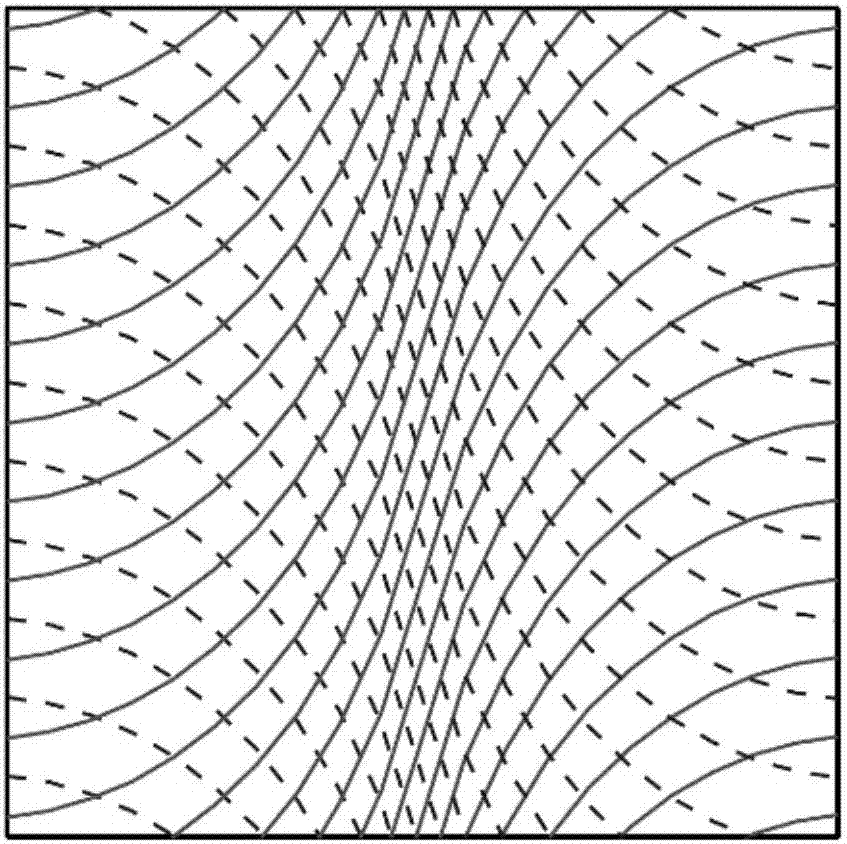

Efficient optimization method for variable stiffness composite material plate shell structure

ActiveCN107220461AImprove the efficiency of laying path optimizationAvoid high time-consuming problemsDesign optimisation/simulationSpecial data processing applicationsVariable stiffnessFiber

The invention relates to composite material structure design in aerospace structures, and provides an efficient optimization method for a variable stiffness composite material plate shell structure. The method includes the steps: performing curve fiber path accurate modeling and buckling analysis on the variable stiffness composite material plate shell structure based on an isogeometric method; building an isogeometric buckling design model of the structure; deriving total analytical sensitivity of buckling response of the variable stiffness composite material plate shell structure; efficiently optimizing fiber paths of the variable stiffness composite material plate shell structure by a gradient-based method to obtain an optimal structure meeting process manufacturing constraints. According to the structure, the carrying efficiency of the variable stiffness composite material plate shell structure can be remarkably improved, and the development period of products is greatly shortened.

Owner:DALIAN UNIV OF TECH

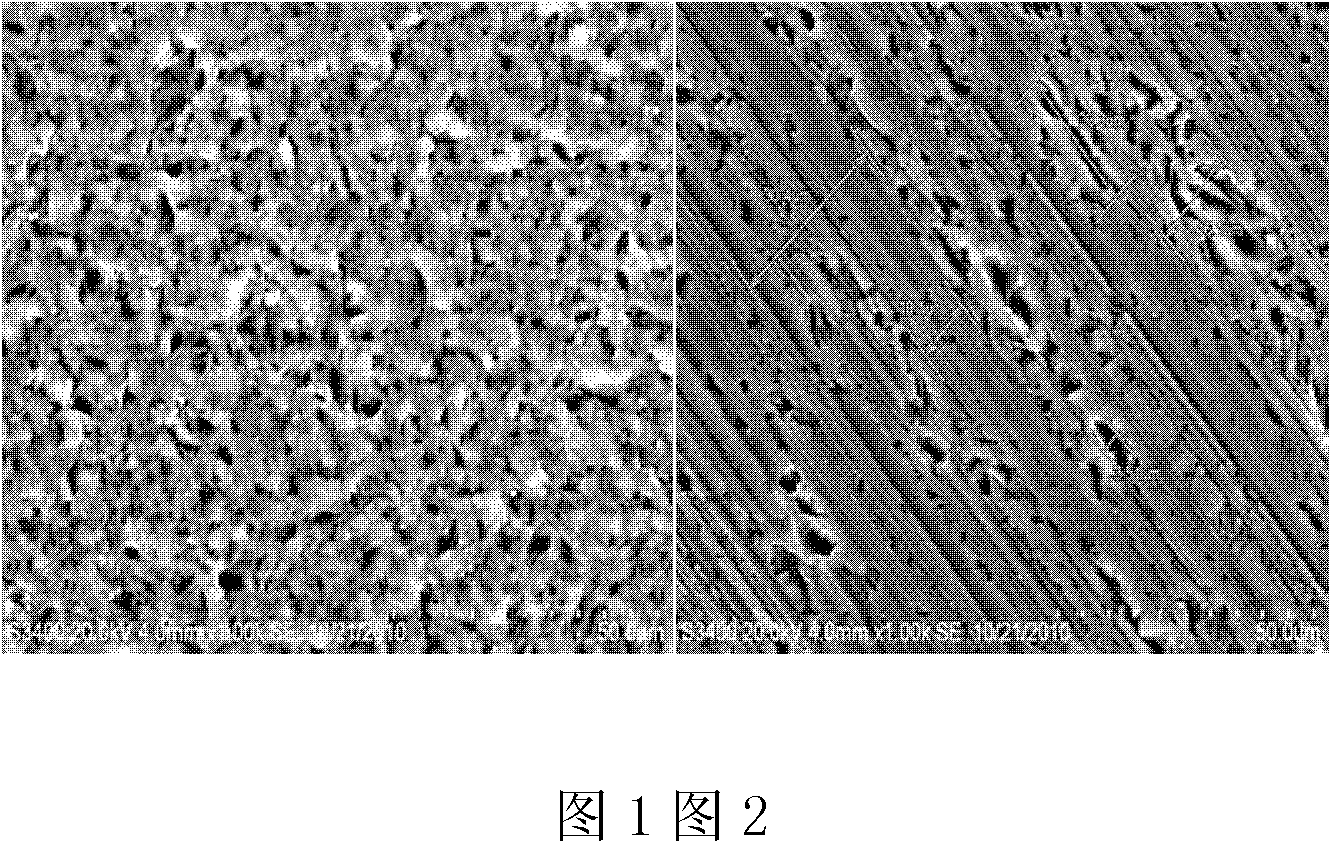

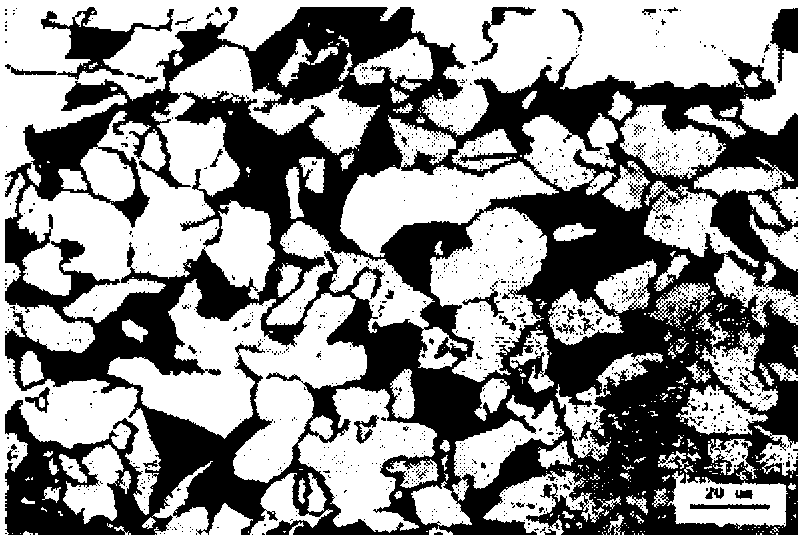

Method for texturing silicon wafer cut by diamond wire

ActiveCN102220645AReduce reflectivityAfter-treatment detailsFinal product manufactureCorrosion reactionProcess manufacturing

The invention belongs to the technical field of the texturing of silicon wafers, and particularly relates to a method for texturing a silicon wafer cut by a diamond wire, which comprises the following steps of: 1, cleaning the silicon wafer cut by the diamond wire; 2, performing acidic corrosion reaction on the cleaned silicon wafer in H2SO4 or H3PO4-HF-HNO3 mixed acidic solution for 30 to 70 seconds, wherein a volume ratio of the H2SO4 or the H3PO4 to the HF to the HNO3 is (2-10):(1-4):(1-4), the concentration of the H2SO4 is 98 percent, the concentration of the HF is 49 percent, the concentration of the HNO3 is 63 percent, and the concentration of the H3PO4 is 85 percent; 3, soaking the silicon wafer which reacts with the acids in alkali texturing liquid, and reacting for 10 to 30 seconds; 4, soaking the silicon wafer which reacts with alkali in HCL-HF solution for 30 to 120 seconds; and 5, drying the reacted silicon wafer, and performing subsequent cell process manufacturing. Compared with the conventional texturing process, the optimized method for texturing the silicon wafer cut by the diamond wire has the advantages that: the reflectivity of the textured silicon wafer is reduced by about 6 percent, and the cell efficiency is improved greatly.

Owner:TRINA SOLAR CO LTD

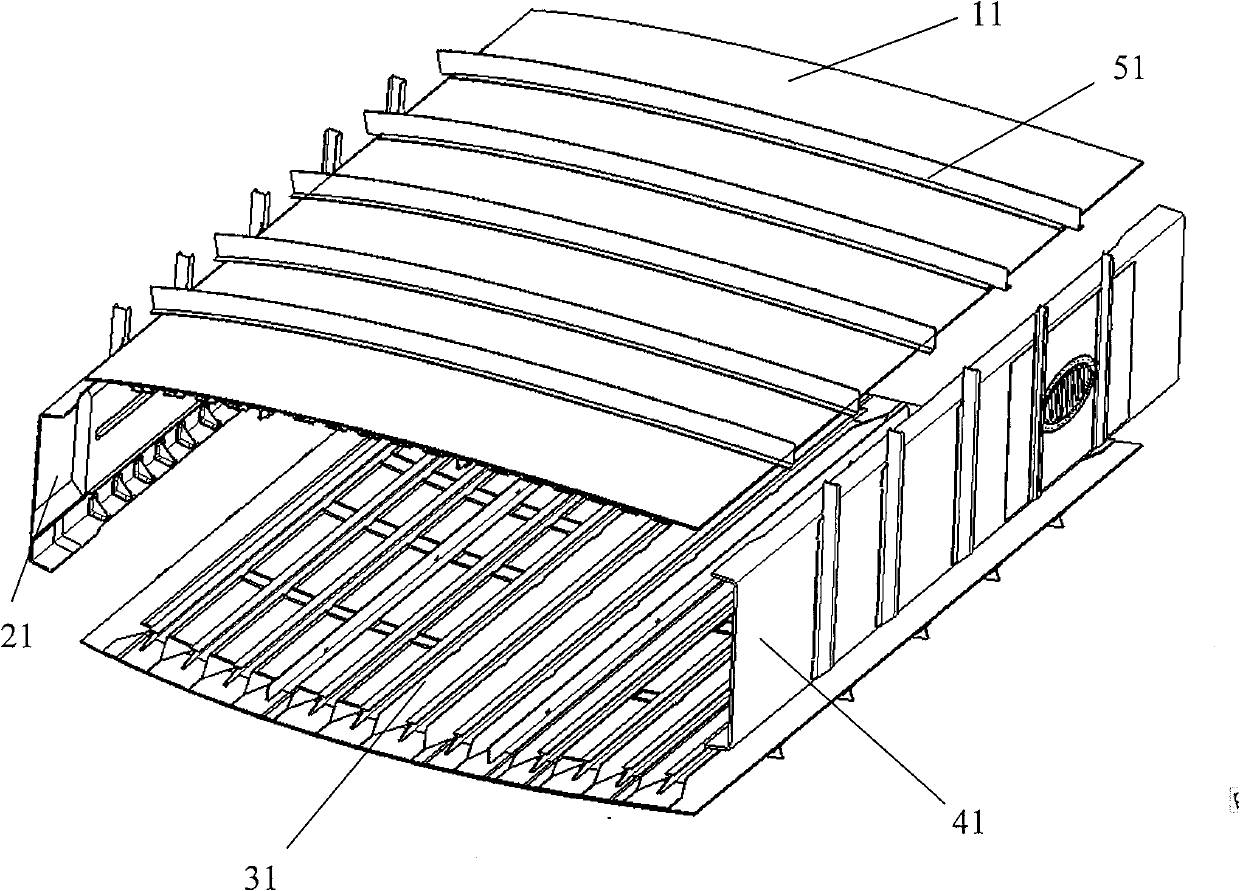

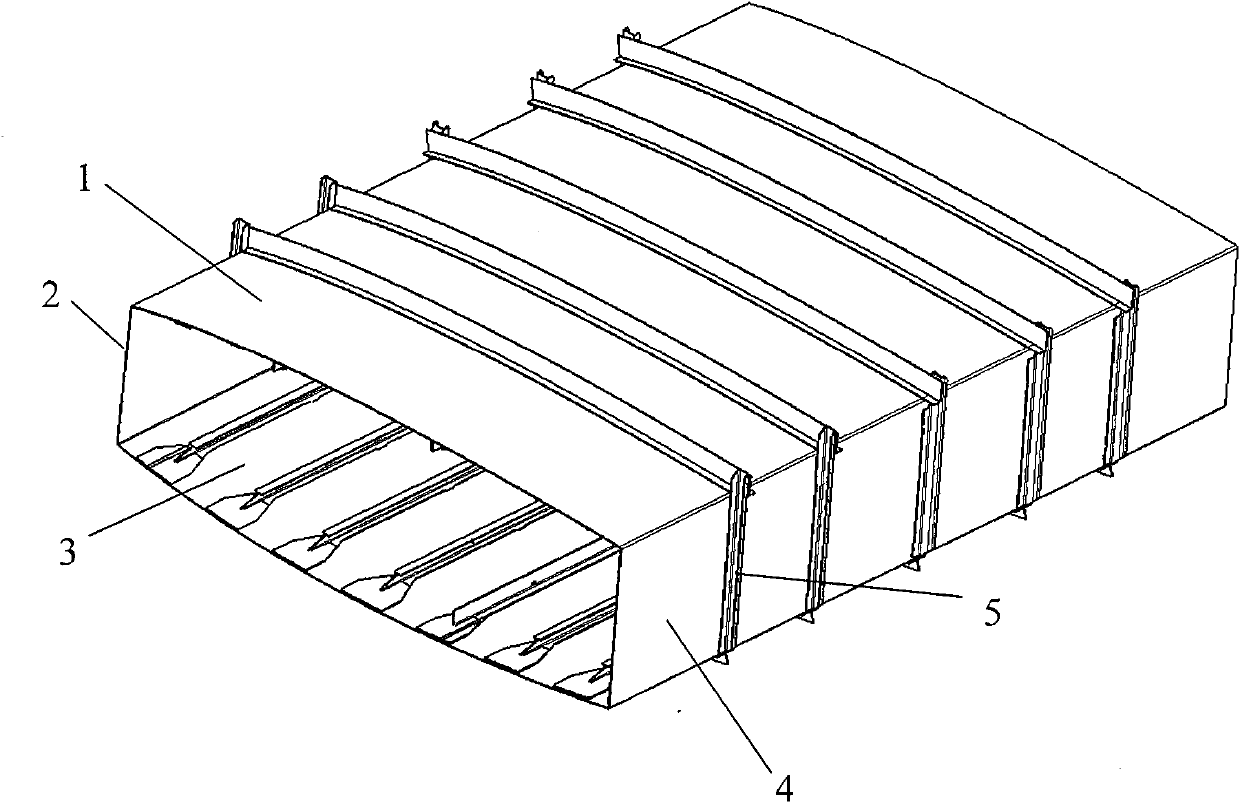

Method for machining aircraft skin part

InactiveCN104972282AImprove manufacturing precisionIncrease profitAircraft componentsProduction rateEngineering

The invention discloses a method for machining an aircraft skin part. The method comprises the following steps that (1) process digital-analog information is extracted; (2) a neutral layer is projected; (3) the neutral layer is unfolded; (4) the unfolding face of the neutral layer is projected; and (5) a chemical milling sample plate and the skin part are machined. The sample plate meeting process requirements is directly produced through three-dimensional unfolding digital-analog calculation. According to the method for machining the aircraft skin part, the manufacturing precision of the part is effectively improved, machining accumulated errors are reduced, and the machining process meets the process manufacturing requirement. Meanwhile, the delivery cycle of the skin part is greatly shortened, and the material utilization rate is improved. An MMS mirror image milling matching edge flexible clamping system is adopted, and the method adapts to skins of various specifications; the space locating and clamping rigidity of workpieces is guaranteed, and productivity and production flexibility are greatly improved.

Owner:JIANGXI HONGDU AVIATION IND GRP

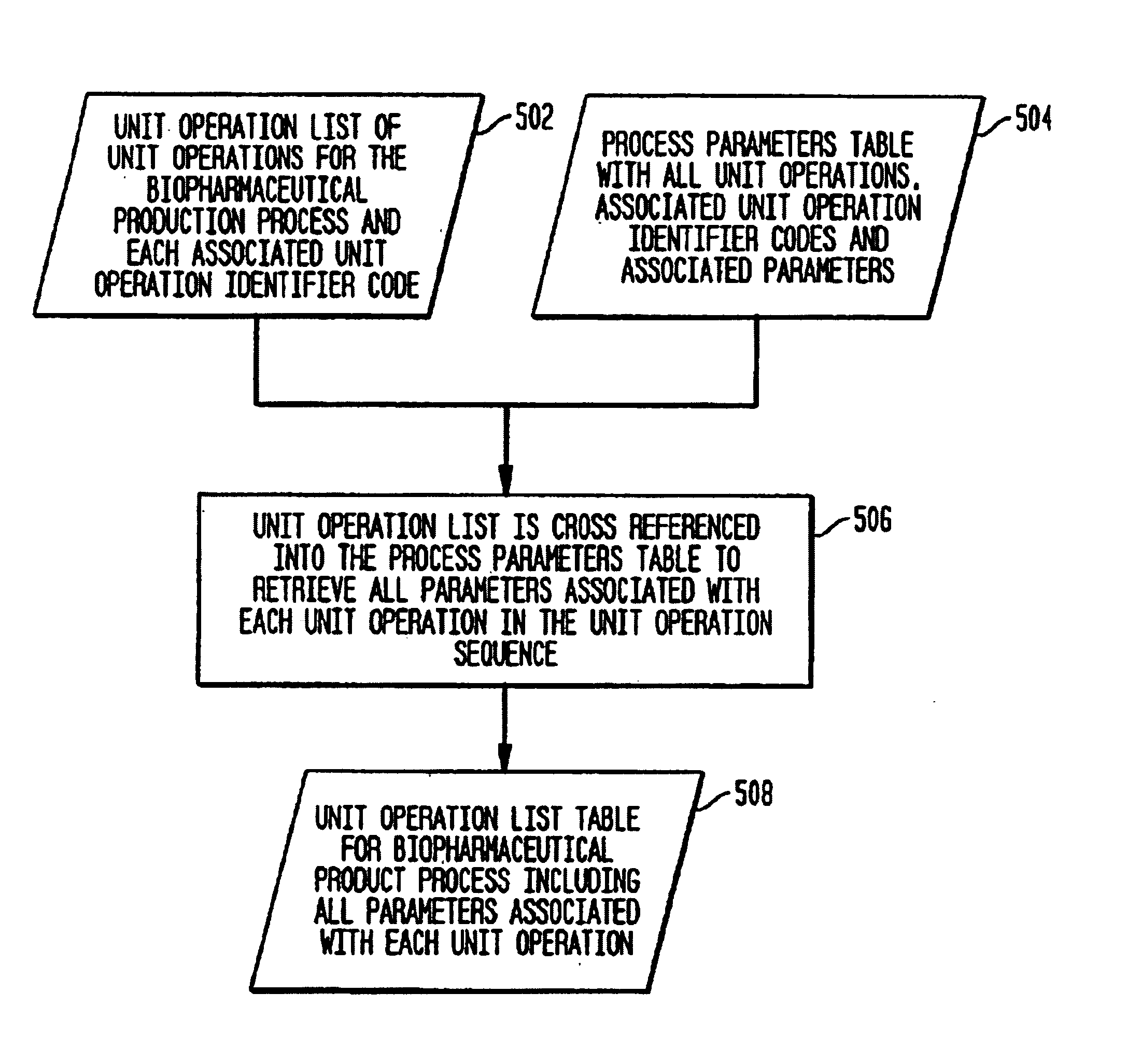

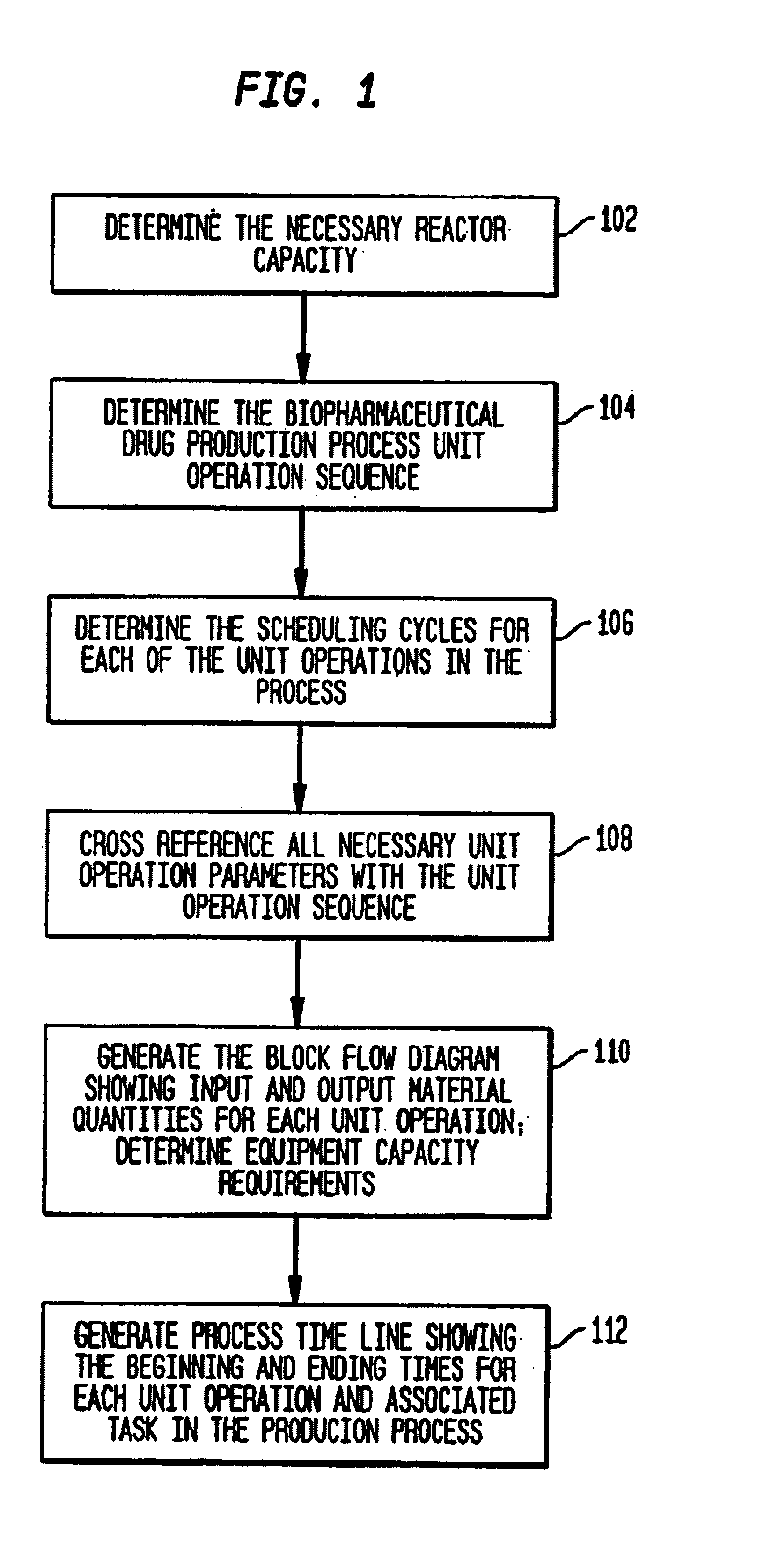

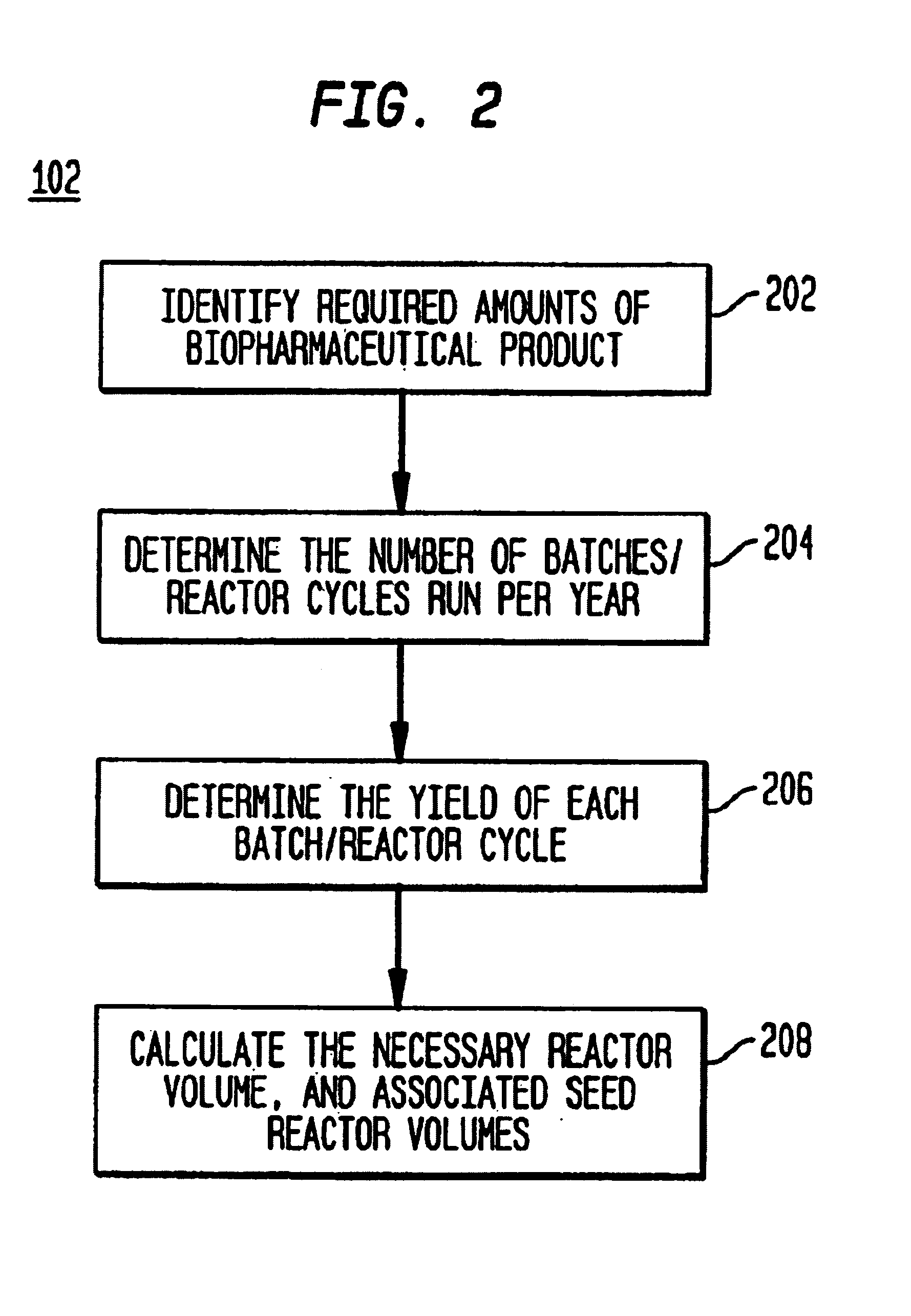

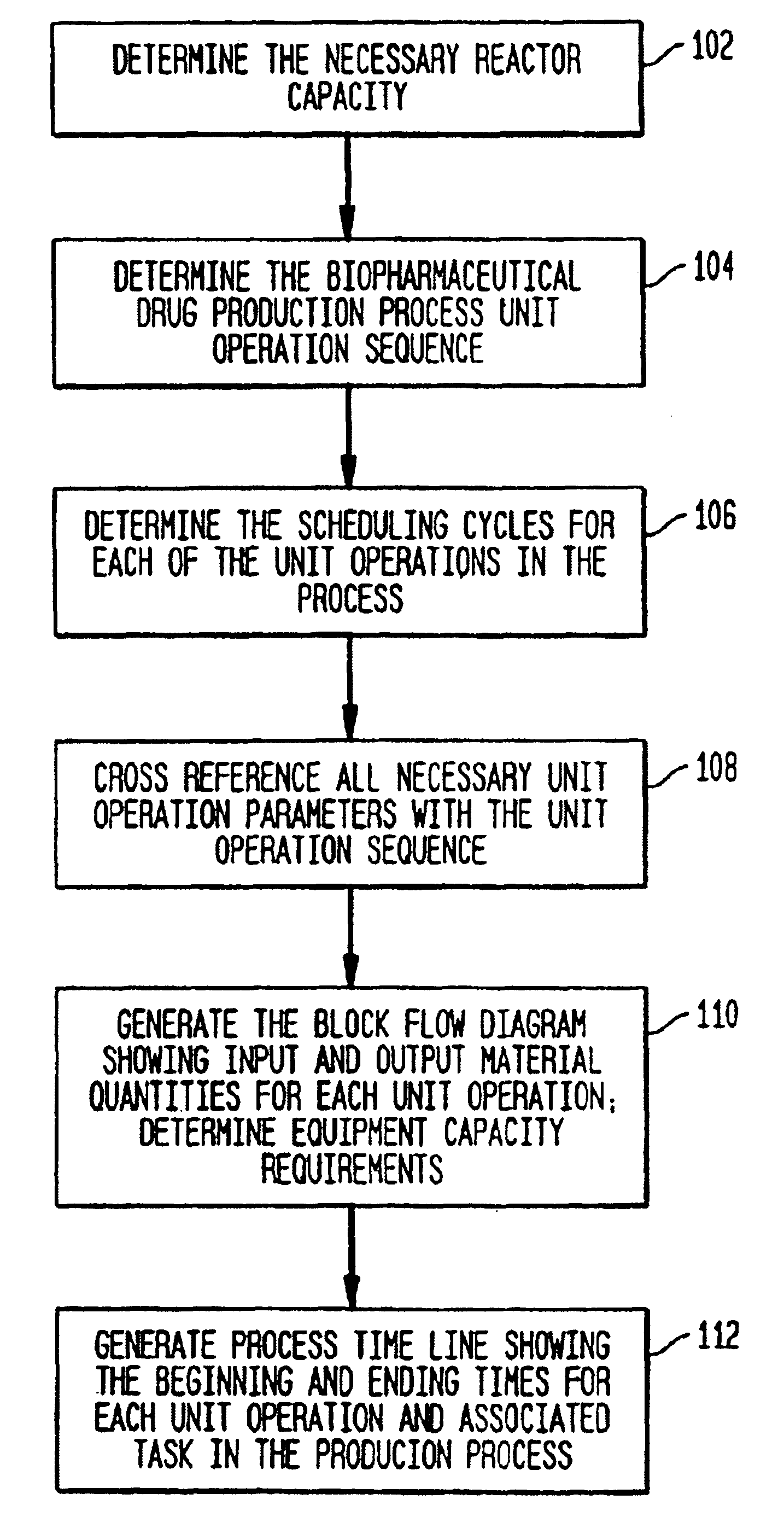

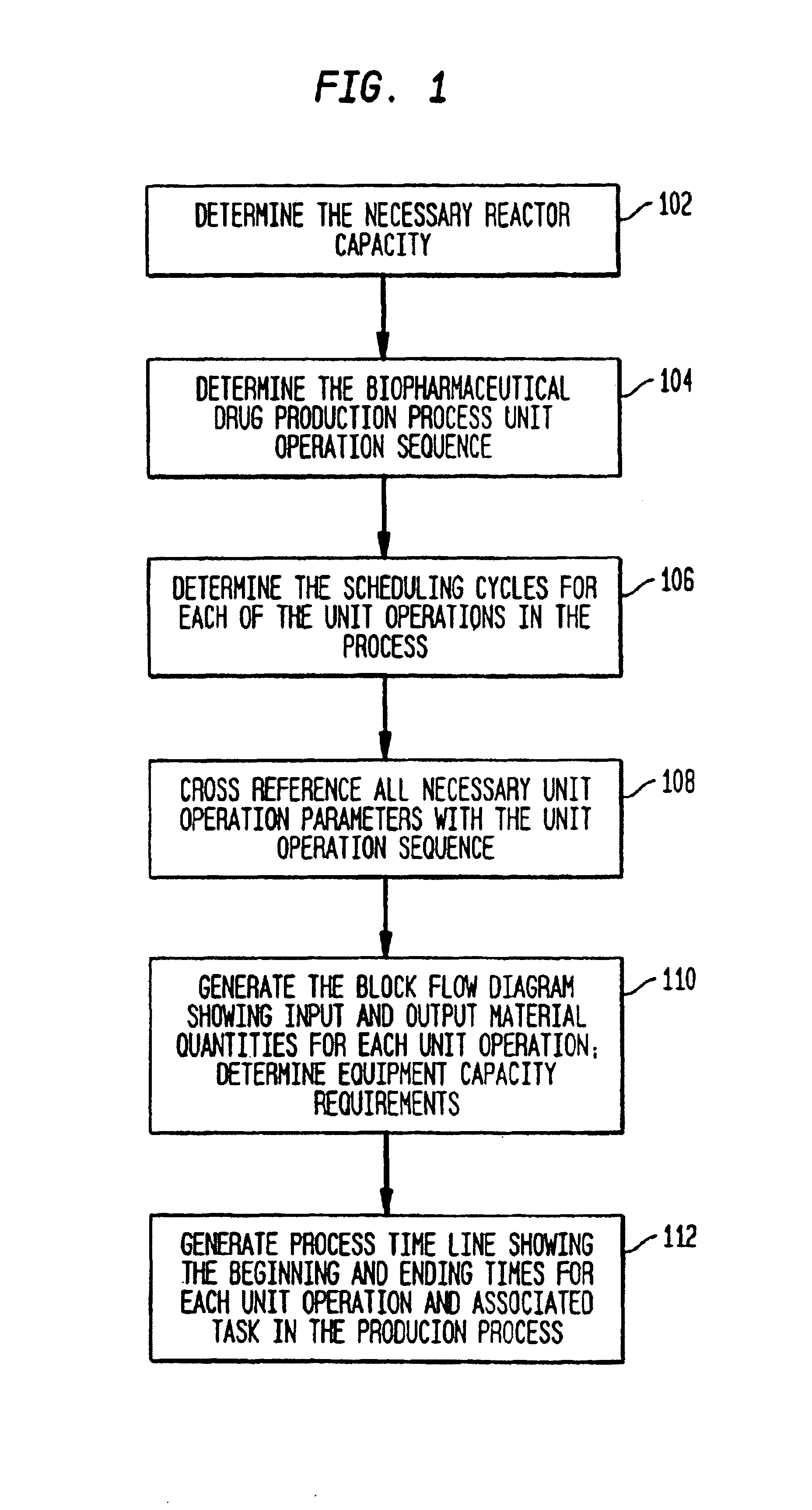

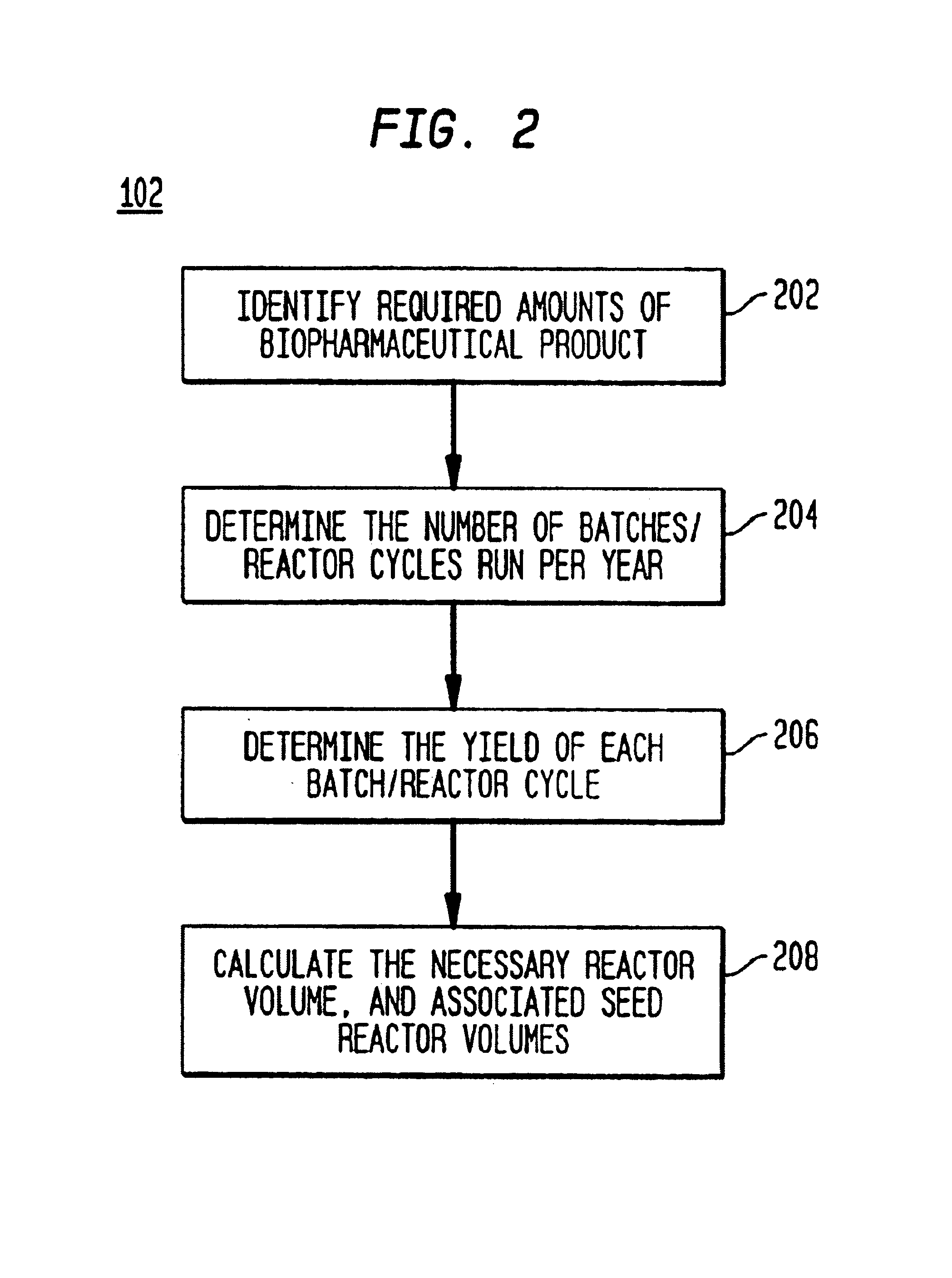

Method for scheduling solution preparation in biopharmaceutical batch process manufacturing

A method and computer program product for simulating, modeling and scheduling solution preparation in the biopharmaceutical production process is described herein. The computer program product and method includes the steps of identifying a solution for preparation and its associated volume. After the solution for preparation is identified, a predetermined start date and one successive start date for solution preparation for the solution are identified. After the solution, start and successive start dates are identified, the solution is assigned to a preparation vessel. After the solution has been assigned to a preparation vessel, the duration of the solution preparation procedure is determined and assigned to the solution preparation vessel.

Owner:BROWN OWEN (I) (US)

Low VT antifuse device

ActiveUS8933492B2TransistorSemiconductor/solid-state device detailsHigh voltage transistorsProcess manufacturing

A one time programmable memory cell having an anti-fuse device with a low threshold voltage independent of core circuit process manufacturing technology is presented. A two transistor memory cell having a pass transistor and an anti-fuse device, or a single transistor memory cell having a dual thickness gate oxide, are formed in a high voltage well that is formed for high voltage transistors. The threshold voltage of the anti-fuse device differs from the threshold voltages of any transistor in the core circuits of the memory device, but has a gate oxide thickness that is the same as a transistor in the core circuits. The pass transistor has a threshold voltage that differs from the threshold voltages of any transistor in the core circuits, and has a gate oxide thickness that differs from any transistor in the core circuits. The threshold voltage of the anti-fuse device is lowered by omitting some or all of the threshold adjustment implants that is used for high voltage transistors fabricated in the I / O circuits.

Owner:SYNOPSYS INC

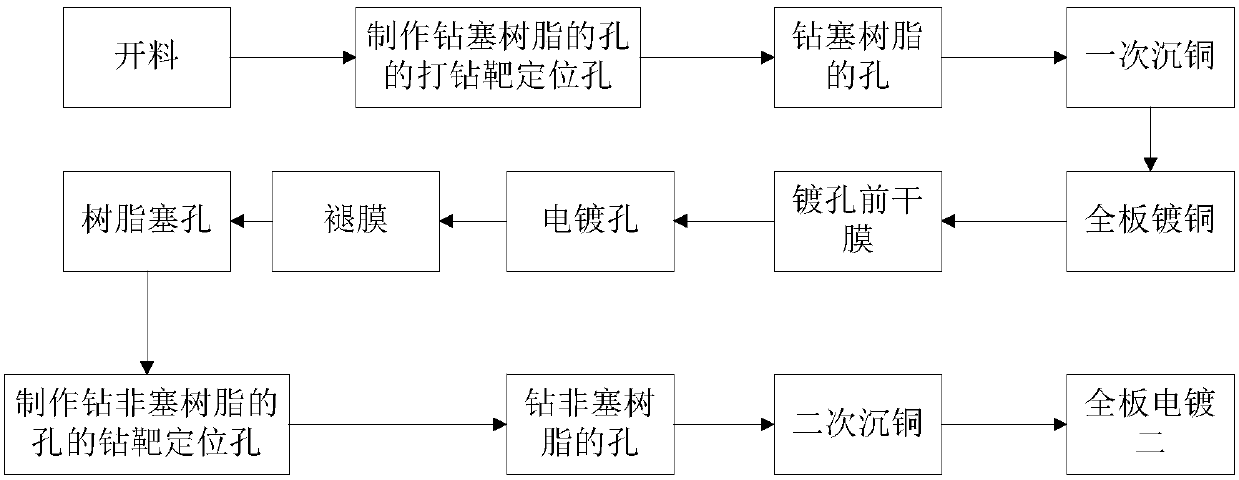

Manufacturing method of circuit board plated hole

InactiveCN107613671ASolve the phenomenon of uneven copper thicknessAvoid Etching AnomaliesPrinted element electric connection formationCopper platingProcess manufacturing

The invention discloses a manufacturing method of a circuit board plated hole. The manufacturing method comprises the following steps of material cutting, internal layer, inspection, pressing, manufacturing the drilling target locating hole for drilling the resin filling hole, drilling the resin filling hole, primary copper plating, whole plate copper plating, film drying before hole plating, holeelectroplating, film stripping, resin hole filling, resin grinding, manufacturing the drilling target locating hole for drilling the non-resin-filling hole, drilling the non-resin-filling hole, secondary copper plating and secondary whole plate electroplating. The method that the resin filling hole is completed and then the non-resin-filling hole and the external line are completed is adopted sothat the phenomenon of non-uniform copper thickness after whole plate copper thickening and chemical copper thinning can be successfully solved, the porthole pit abnormity of the resin filling hole after chemical copper thinning can be avoided, the manufacturing yield rate can be greatly enhanced, the process manufacturing capability can be powerfully enhanced and thus wide application and preference of the circuit board manufacturers can be received. The manufacturing method of the circuit board plated hole is widely suitable for the technical field of circuit board production.

Owner:深圳明阳电路科技股份有限公司

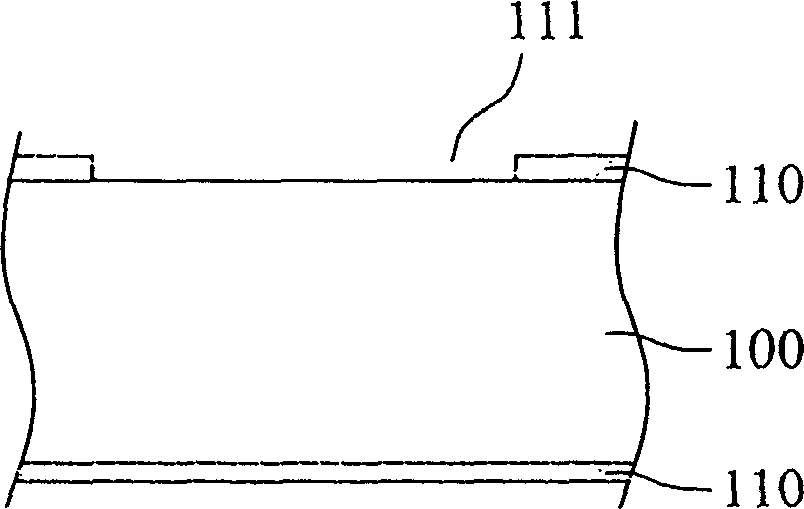

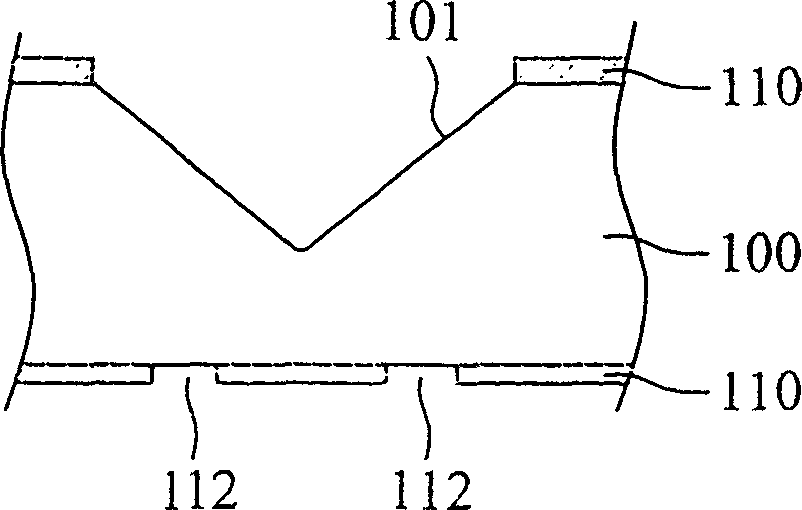

Manufacture of micro syringe array

The present invention relates to the manufacture of micro syringe needle array, and the hollow micro needle array with slant end may be manufactured in low cost and simple manufacture process. The micro needles have sharp tip easy to pierce into biological tissue for medicine injection and micro sampling. The manufacture includes wet etching on silicon wafer to form slant notch area, electroplating metal, exposure to develop, micro machining and other steps.

Owner:IND TECH RES INST

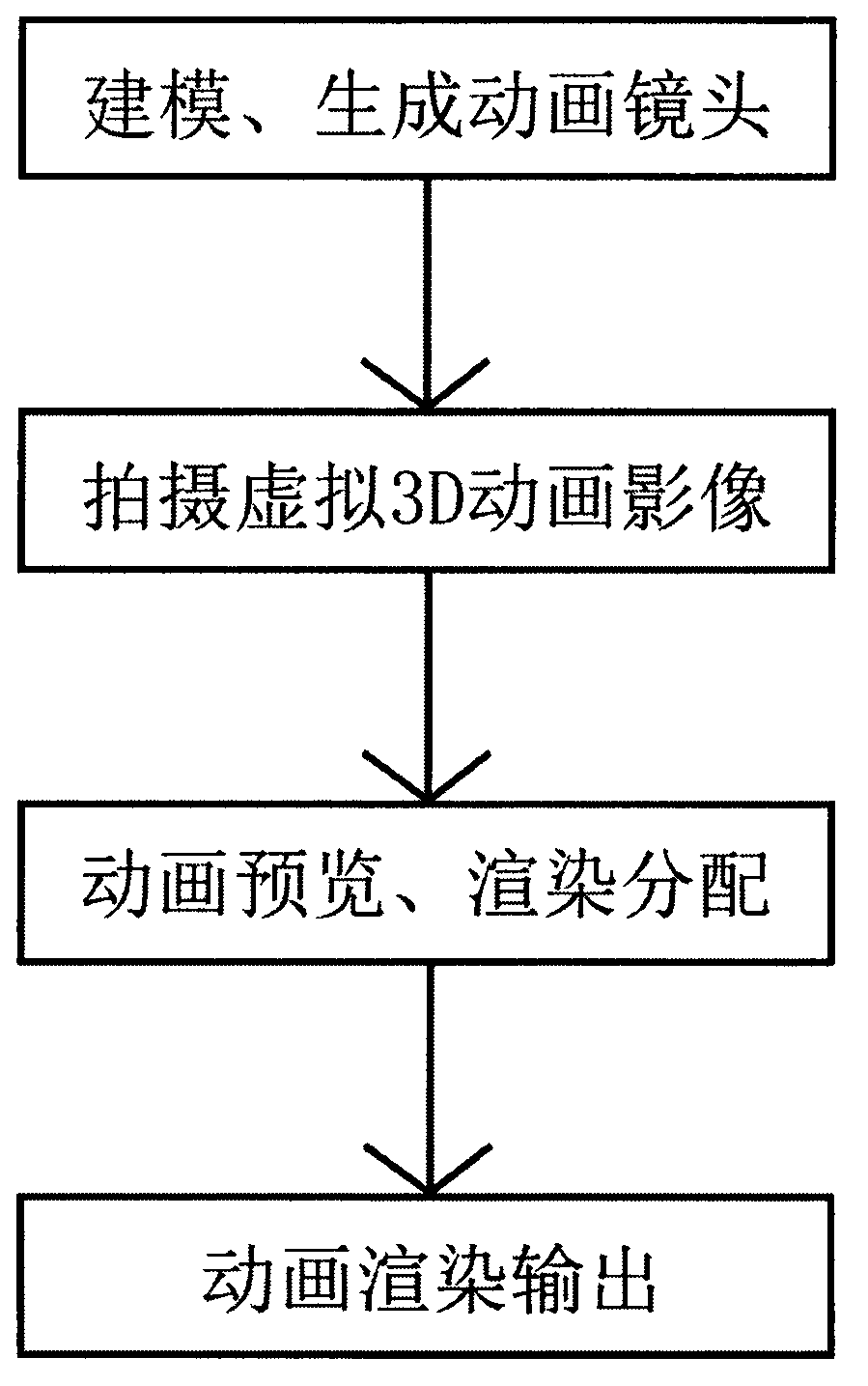

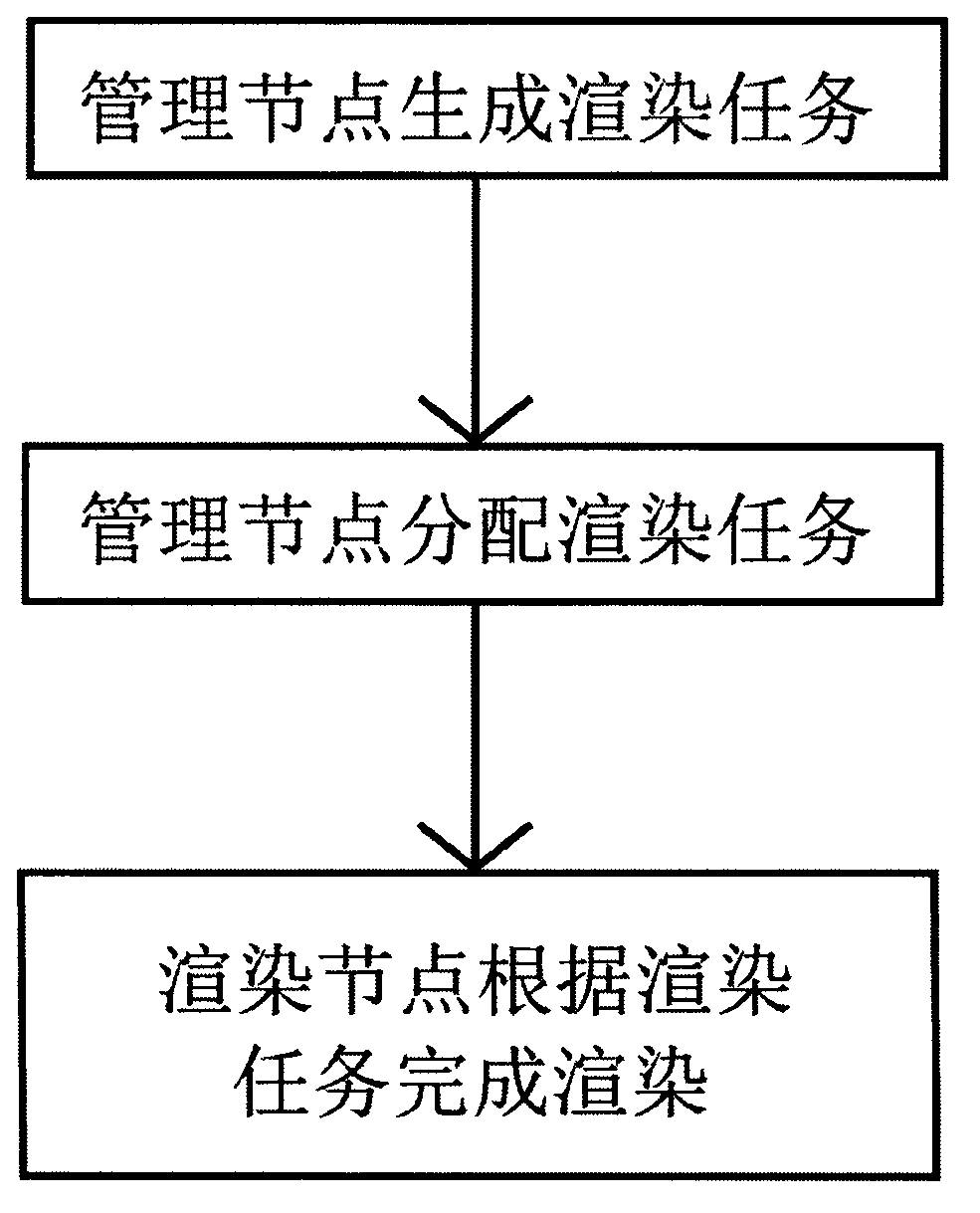

3D animation whole-process manufacturing cloud computing platform

The invention provides a 3D animation whole-process manufacturing cloud computing platform which is characterized by comprising an animation module, a 3D module, a rendering module and a cloud computing module. The animation module is used for modeling and generating an animation camera lens, the 3D module is used for shooting a 3D animation image, the rendering module is used for animation previewing and rendering distribution, and the cloud computing module is used for animation rendering and outputting. The 3D animation whole-process manufacturing cloud computing platform has the advantages that due to the cloud computing mode, the cross-region and cross-time-space brand new communication and cooperation mode can be provided for a user, and the problem of rendering calculation and mobile storage is solved for the user through cloud computing mass storage and the strong parallel computing capability. According to the platform, the modules are applied to the 3D manufacturing whole process from early stage to late stage, and the control capability over the technology can be provided for creatives. The modules further has the cooperation working capability in design, and the modules are easy to integrate, so that manufacturers obtain the whole unified manufacturing process, and a 3D imaging creative tool can be provided for the manufacturers.

Owner:TIANJIN 10 COLOR ANIMATION TECH

Ceramic product with digital process manufacturing mold effect texture and manufacturing method of ceramic product

The invention relates to a ceramic product with a digital process manufacturing mold effect texture. The ceramic product has a three-dimensional concave and convex mold effect texture on the surface,the mold effect texture is made in a digital process mode, and the mold effect texture is formed by forming a texture pattern of a sinking depth of 0.5-3mm in the surface of a glaze layer including apattern layer of a product. According to the ceramic product provided by the invention and the manufacturing method of the ceramic product a conventional physical mold is replaced by the mold effect texture which is made by using a novel digital process and has a controllable sinking depth of 0.5-3mm, digital designing output is directly implemented, the texture can be achieved without changing pressing molds, directions modern environment protection and automatic intelligent manufacturing can be well met, in addition, defects of surface three-dimensional feelings and sharpness of a conventional texture mold can be well solved, the mold effect can be good in three-dimensional feeling, reality and tough feeling, and the digital manufacturing process can be easy to use.

Owner:GUANGDONG SUMMIT CERAMIC CO LTD +2

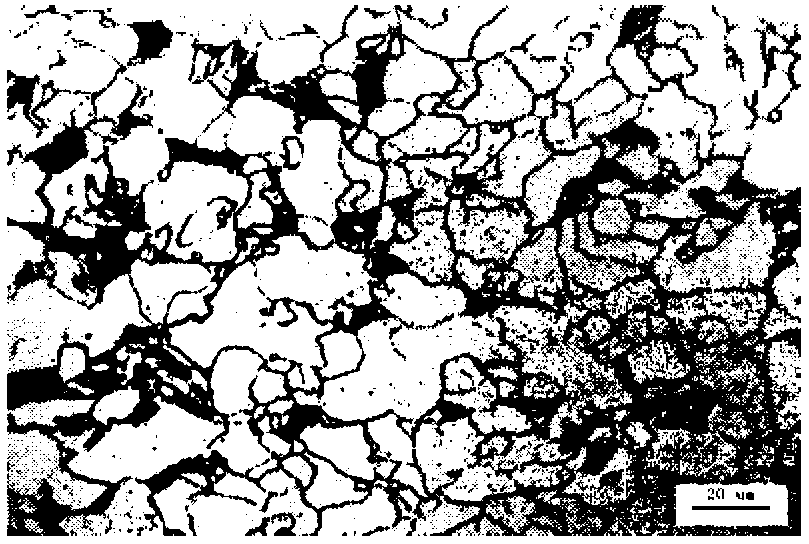

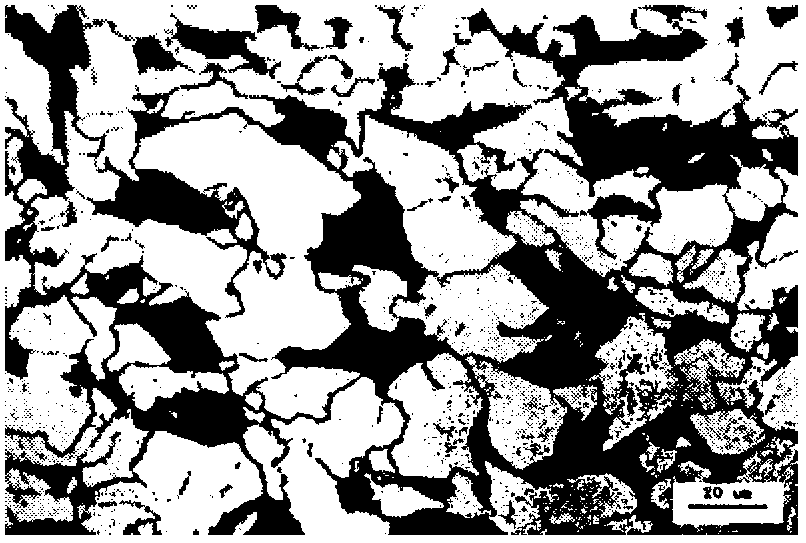

Short-process manufacturing method of cold rolling non-oriented high-silicon steel sheet

The invention belongs to the field of manufacture of an electrical steel sheet, and particularly relates to a short-process manufacturing method of a cold rolling non-oriented high-silicon steel sheet. The short-process manufacturing method comprises the following steps: firstly smelting molten steel which meets the requirements of chemical components of high-silicon steel; then pouring the molten steel into a tundish, carrying out crystallizing roller cast rolling to lead a non-oriented thin high-silicon steel strip out, and carrying out hot rolling on the thin high-silicon steel strip to obtain a hot rolling plate; cooling the hot rolling plate to 150-300 DEG C for warm rolling to obtain a high-silicon steel warm rolling plate; pickling to remove iron oxide scale positioned on a surface, and carrying out cold rolling at 50-100 DEG C to obtain a high-silicon steel cold rolling plate with the thickness of 0.2-0.35 mm; annealing the high-silicon steel cold rolling plate in a hydrogen atmosphere to obtain the cold rolling non-oriented high-silicon steel sheet with 6.5% by weight of Si. According to the technical scheme, a method which combines the cast rolling, the hot rolling, the warm rolling and the cold rolling is adopted; the adopted warm rolling is low in temperature, so that the problem of bad warm rolling plate shape caused by thermal crown is prevented; and especially, the problem of poor surface quality is solved by adopting the cold rolling, so that a thin-specification non-oriented high-silicon steel sheet product with good plate shape and excellent surface quality is easy to manufacture.

Owner:NORTHEASTERN UNIV

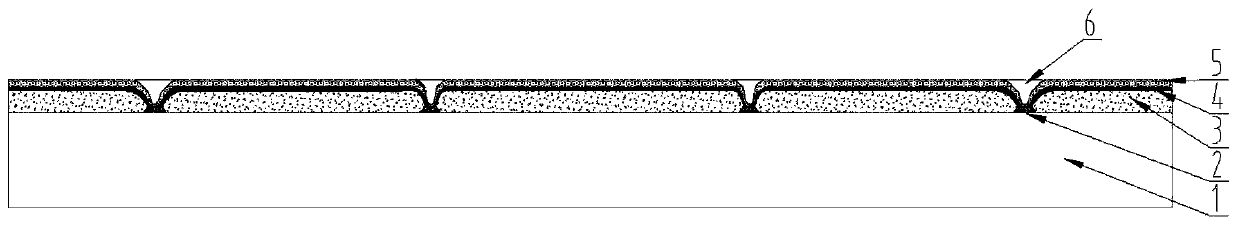

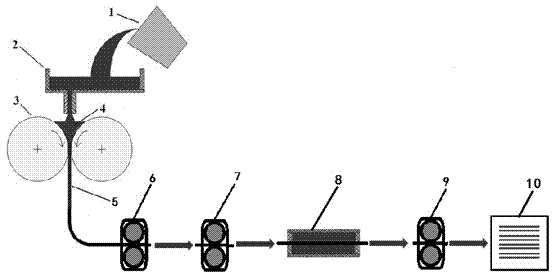

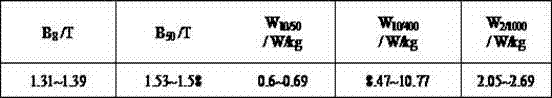

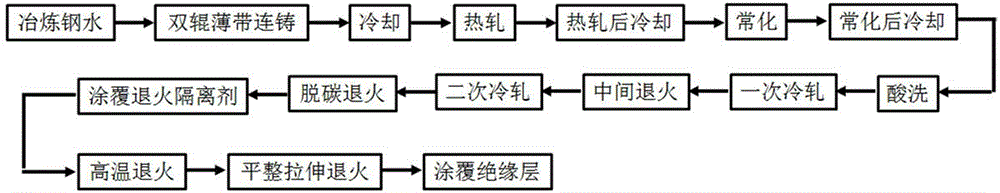

Ultrathin oriented silicon steel sheet and short-process manufacturing method thereof

ActiveCN104962816AQuantity is easy to controlEasy to control distributionProcess manufacturingMolten steel

The invention relates to an ultrathin oriented silicon steel sheet and a short-process manufacturing method thereof. The steel sheet comprises the following components in percentage by mass: 0.002-0.08% of C, 2.8-3.4% of Si, 0.05-0.30% of Mn, 0.015-0.04% of S, 0.005-0.05% of Als, 0.003-0.010% of N, 0-0.6% of Cu, 0-0.2% of Sn, less than 0.004% of O, less than 0.01% of P and the balance of Fe. The thickness of the product is 0.05-0.15mm. The manufacturing method comprises the following steps: (1) smelting molten steel; (2) carrying out continuous casting to obtain a casting band; (3) cooling, carrying out hot rolling and coiling; (4) carrying out normalizing treatment and controlled cooling; (5) pickling, and carrying out primary cold rolling; carrying out interannealing; (6) pickling, and carrying out secondary cold rolling; carrying out decarburizing annealing; (7) coating an annealing separant; and (8) carrying out high-temperature annealing and purification annealing. The method greatly simplifies the ultrathin oriented silicon steel sheet production process, is simple and effective, and has the characteristics of short process, high controllability and low energy consumption.

Owner:NORTHEASTERN UNIV

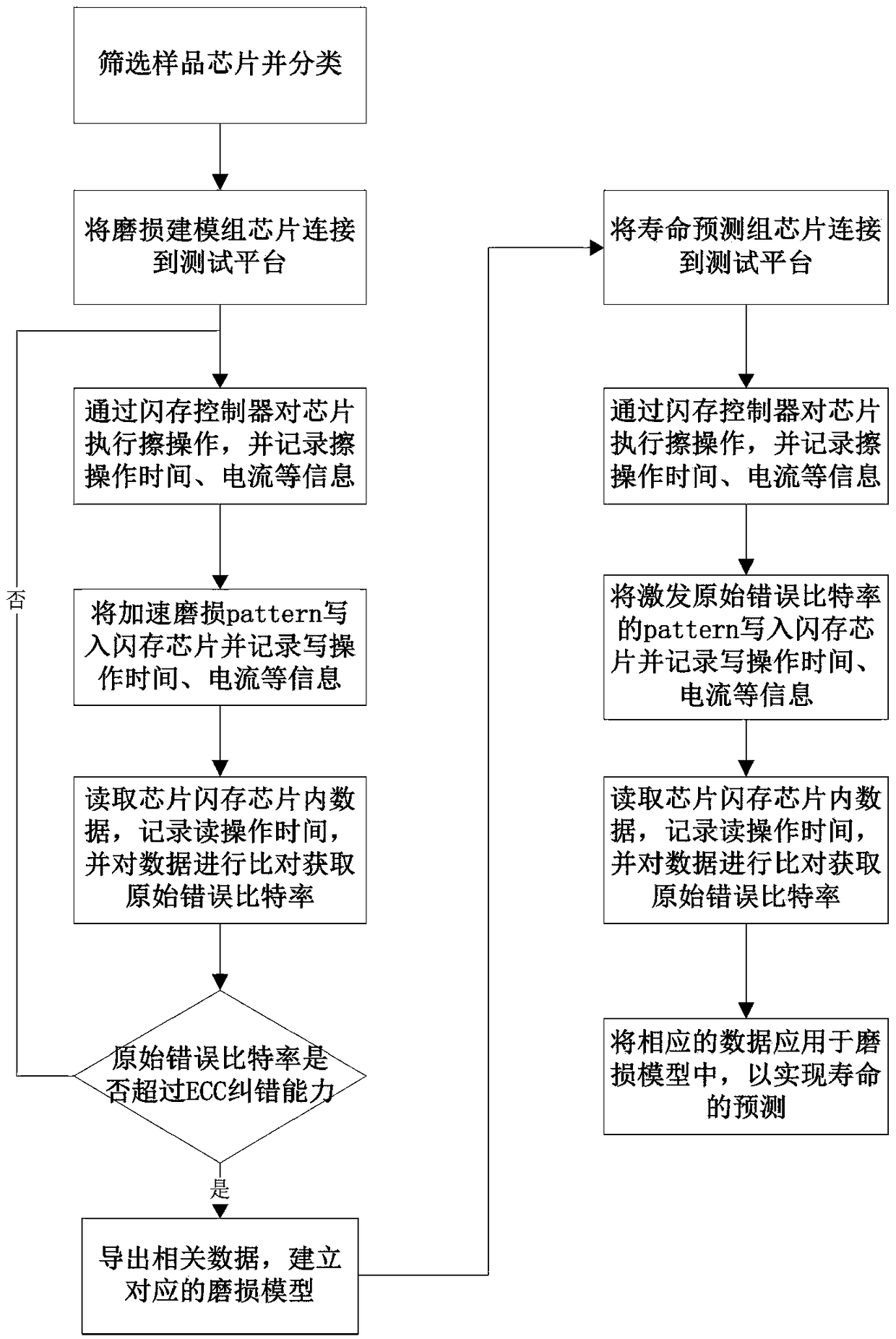

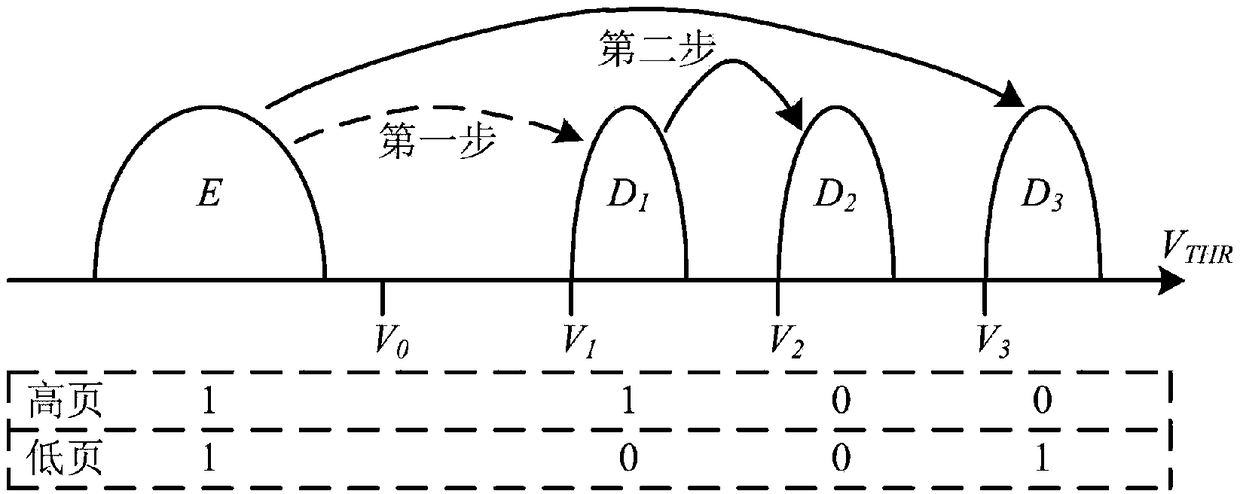

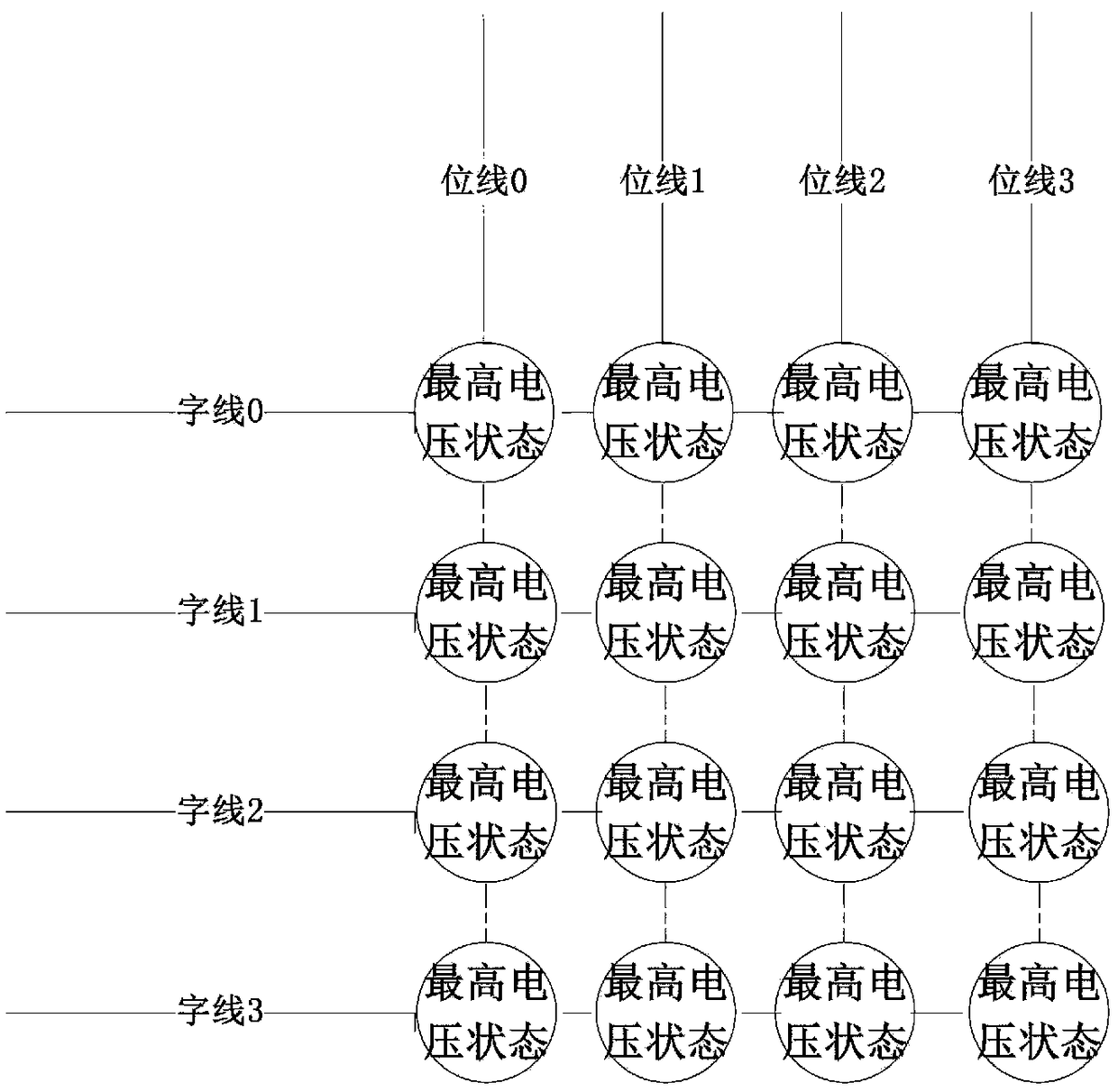

Flash memory life test method based on error mode

The invention relates to a flash memory life test method based on an error mode. The method comprises the following steps: extracting a sample flash memory and connecting a sample flash memory chip with a flash memory test system; writing a test pattern accelerating wearing or a test pattern exciting an error into the flash memory; reading the data in the sample flash memory, recording the original error bit rate and comparing the original error bit rate with the ECC error correction capability of the sample flash memory; and repeating the read and write operation on the sample flash memory chip when the original error bit rate is less than the ECC error correction capability, or the sample flash memory is proved to be damaged and the lifetime of the sample flash memory is the number of erase operation. The characteristics of oxide degradation and present flash memory chip process manufacturing are combined, the specific high-efficiency flash memory test pattern based on the error modeis adopt to accelerate wearing of the flash memory chip and excite the inherent defects of the internal unit of the flash memory chip so as to realize fast flash memory detection.

Owner:FUTUREPATH TECH

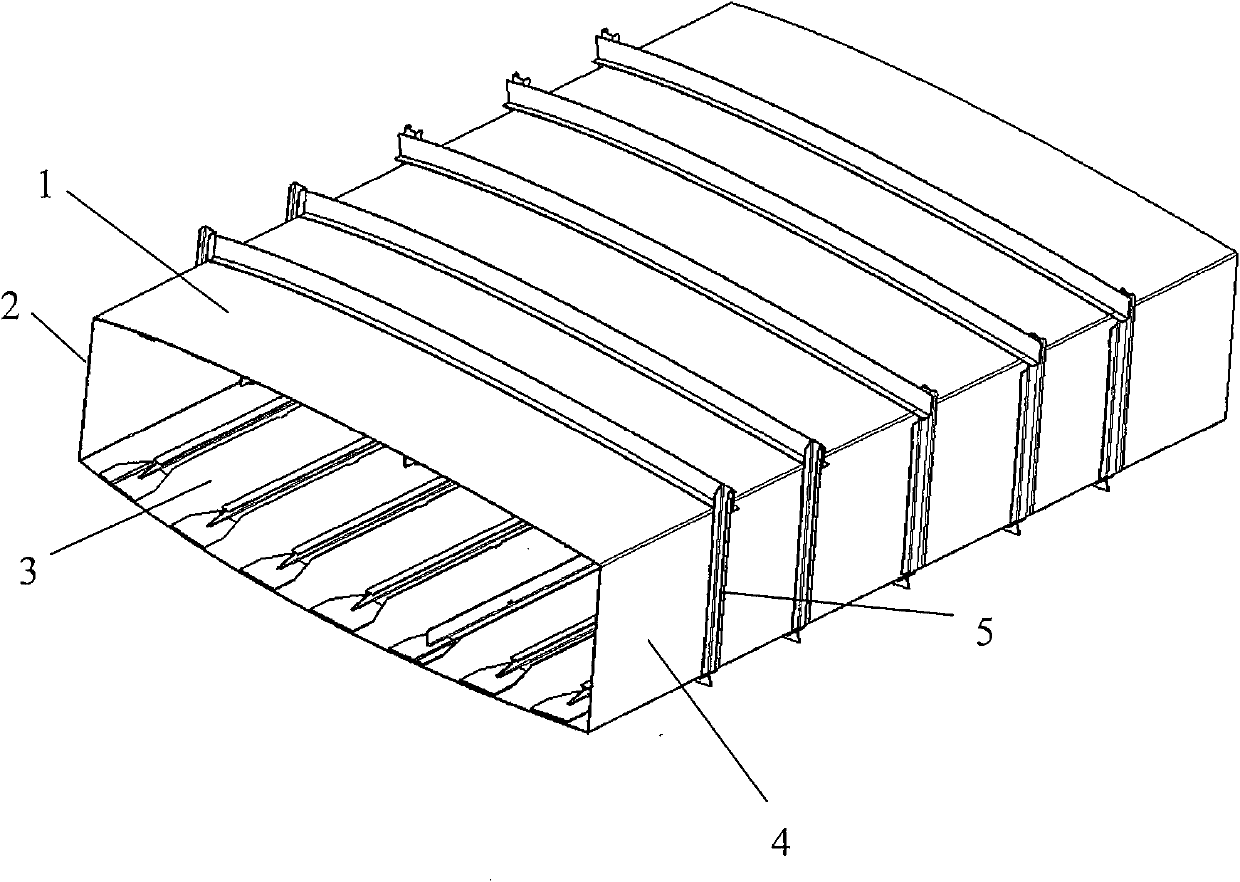

Integral central wing box made of composite materials

ActiveCN102514708AHigh dimensional accuracyImprove heading capacityWingsFuel tankProcess manufacturing

The invention provides an integral central wing box made of composite materials, which comprises a front beam, an upper wall plate, a lower wall plate and a rear beam, wherein the upper wall plate is over against the lower wall plate; the front beam and the rear beam are arranged over against each other on both sides of the central wing box, and both ends of the front beam and the rear beam are respectively connected with the upper wall plate and the lower wall plate; and the central wing box is integrated from the upper wall plate, the lower wall plate, the front beam and the rear beam. According to the integral central wing box, the advanced performance of the structure is improved and the sealing safety of an oil tank is improved, and the process manufacturing and assembly difficulty is reduced, so that the cost is reduced.

Owner:COMAC +1

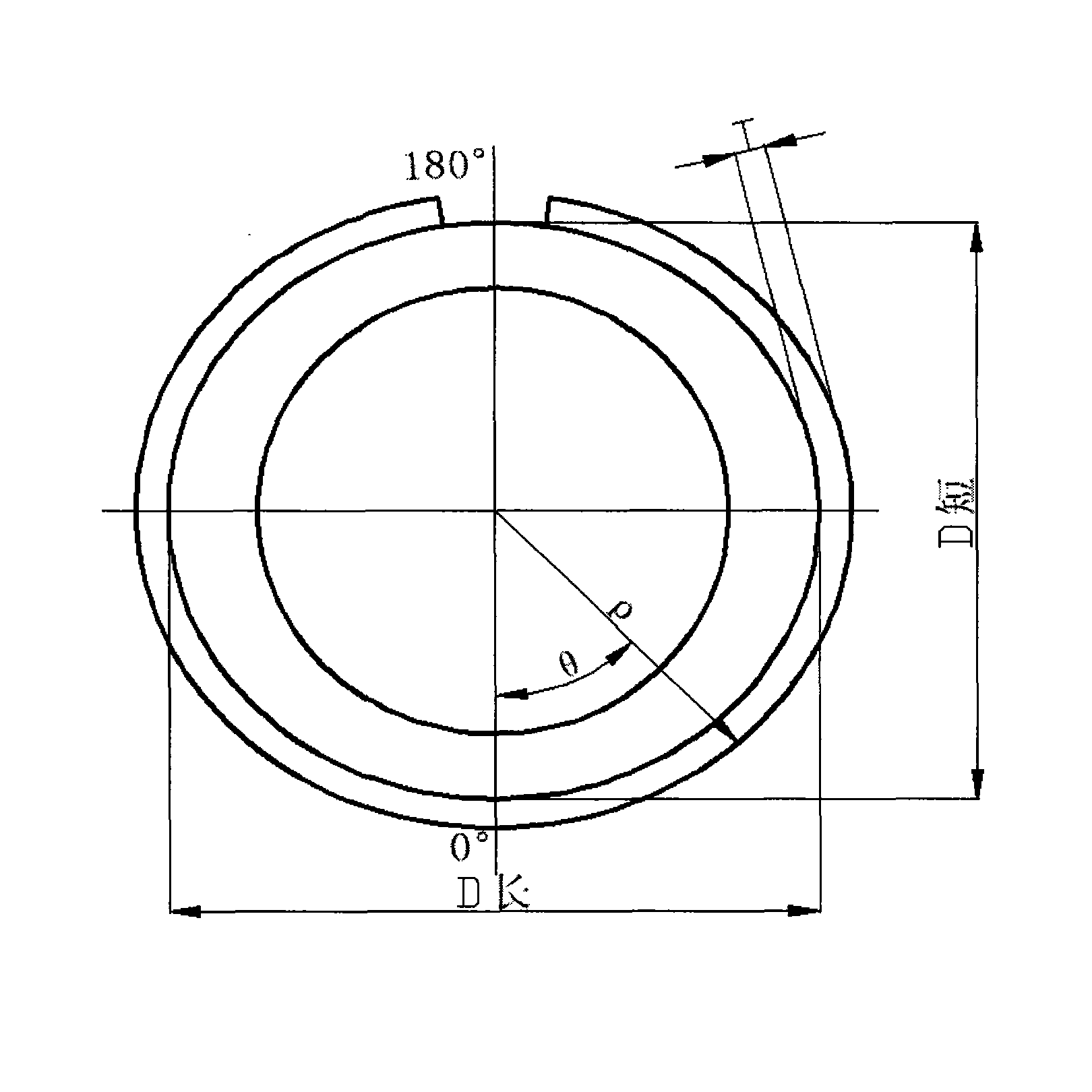

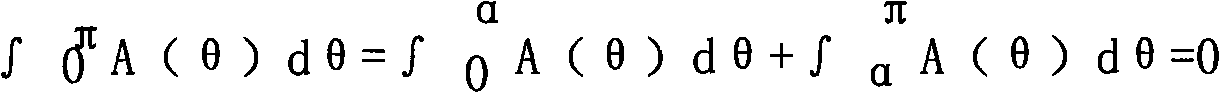

Processing method of steel piston gas ring

ActiveCN101649790ALow yieldSolve the cumbersome machining processPiston ringsMachines/enginesPliabilityProcess manufacturing

The invention discloses a processing method of a steel piston gas ring, which comprises the following steps: winding-destressing-grooving-shaping-top line trimming-flat surface grinding-excircle boning-chroming or nitriding-top line trimming-excircle boning-top line trimming-flat surface grinding; the size of a shaped blank rod is improved by calculating pressure distribution mold lines with different ovality requirements and fully considering the mold line change caused by nitriding shrinkage, thereby the problem of gas ring deformation after procedures, such as nitridation, and the like is greatly reduced, and the finished product ratio of the product is improved. Compared with the defects of long process routes, multi-workshop crossing processing and low comprehensive finished product ratio in the casting iron gas ring, the comprehensive finished product ratio of the steel gas ring processed by using the shaped blank rod can reach up to 95 percent. By utilizing the pliability characteristic of the steel and adopting a shaped steel winding and shaping process, the invention solves the fussy machining process of cast iron material, shortens the manufacturing period, also reduces the procedure waste simultaneously and saves the process manufacturing cost.

Owner:NANJING FAYN PISTON RING

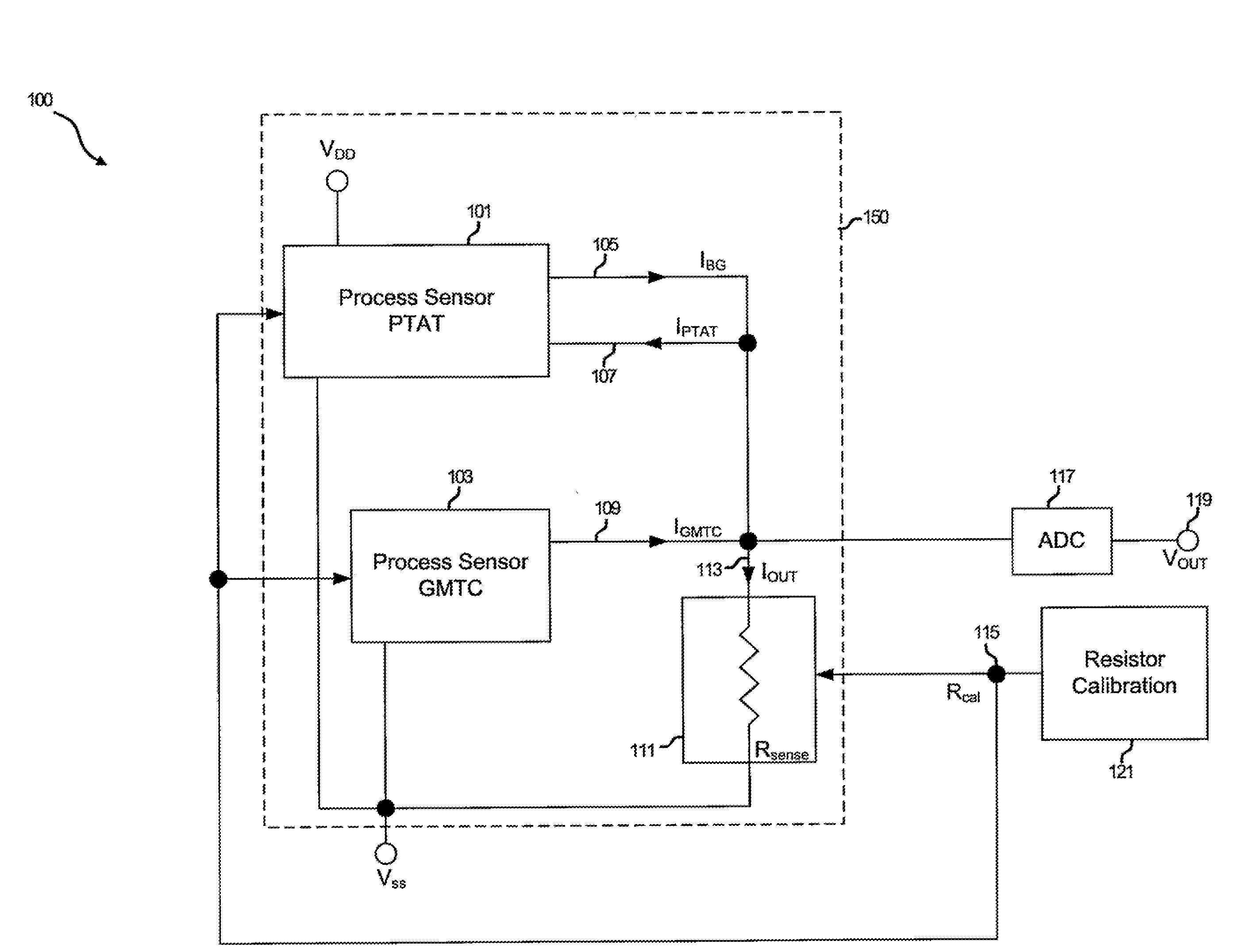

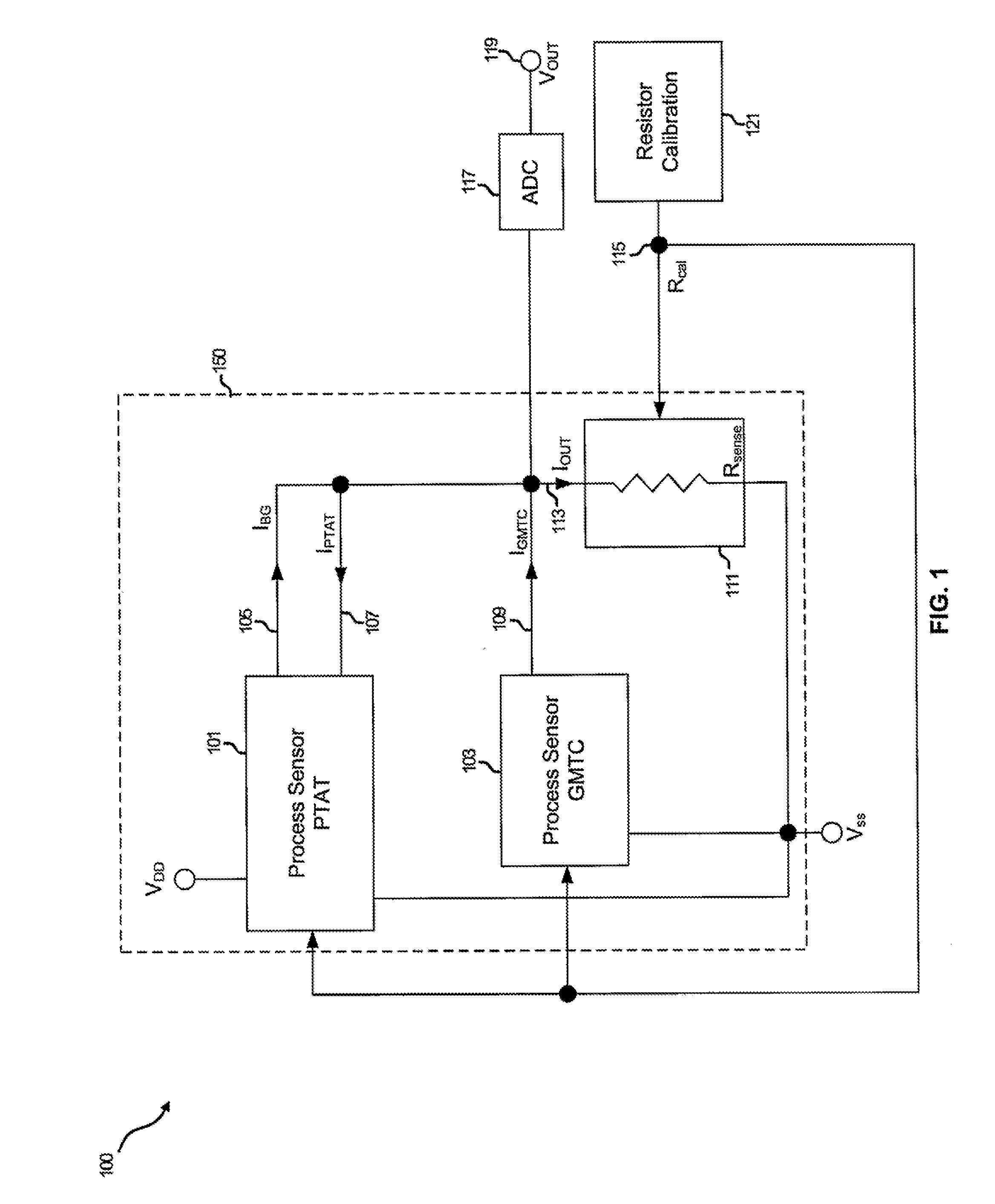

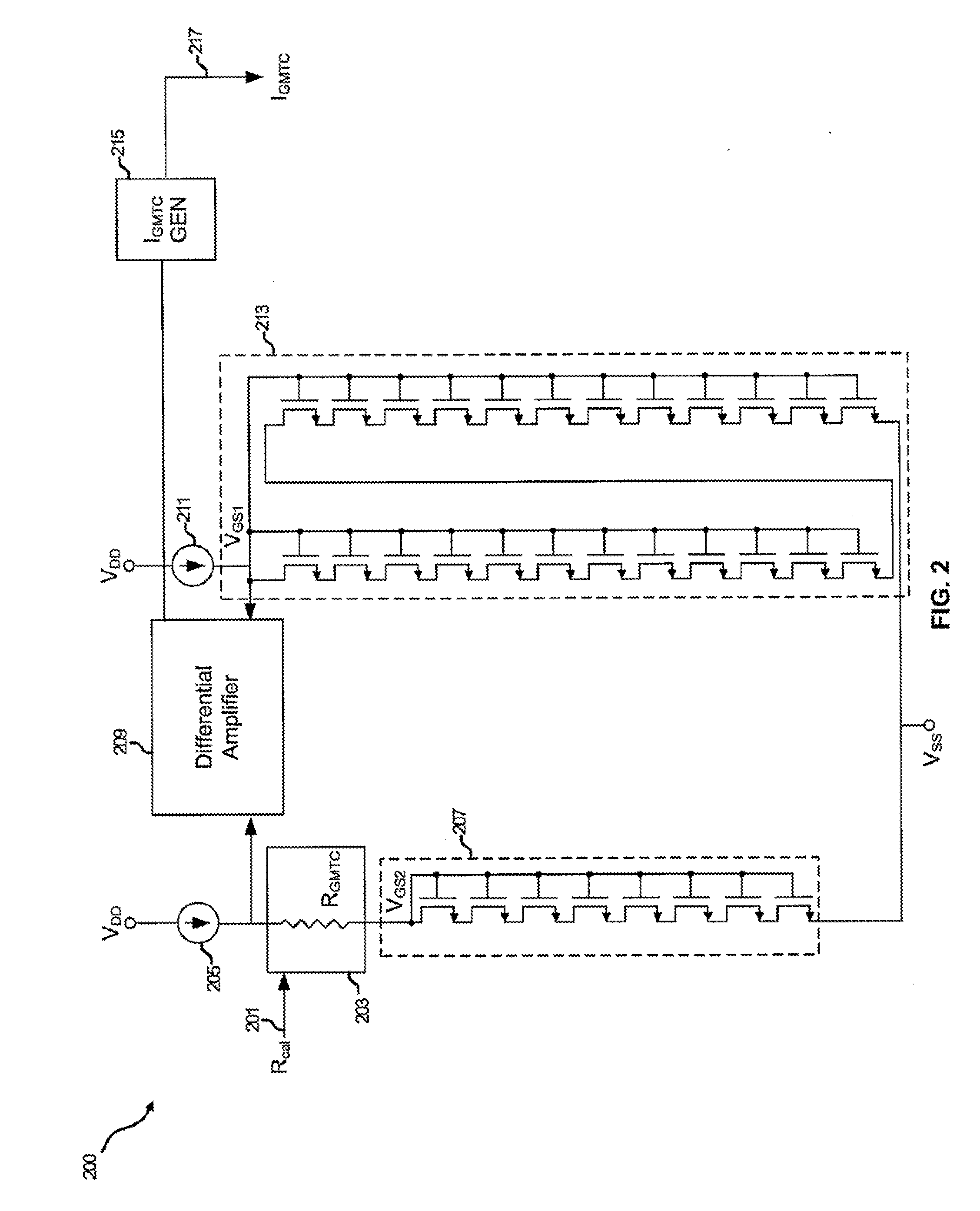

Method and system for a process sensor to compensate soc parameters in the presence of IC process manufacturing variations

InactiveUS20080136503A1Amplifier with semiconductor-devices/discharge-tubesComputing operation arrangementsEngineeringProcess manufacturing

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

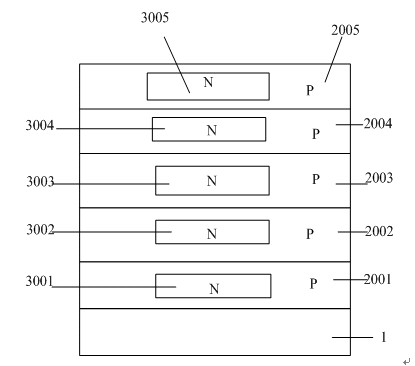

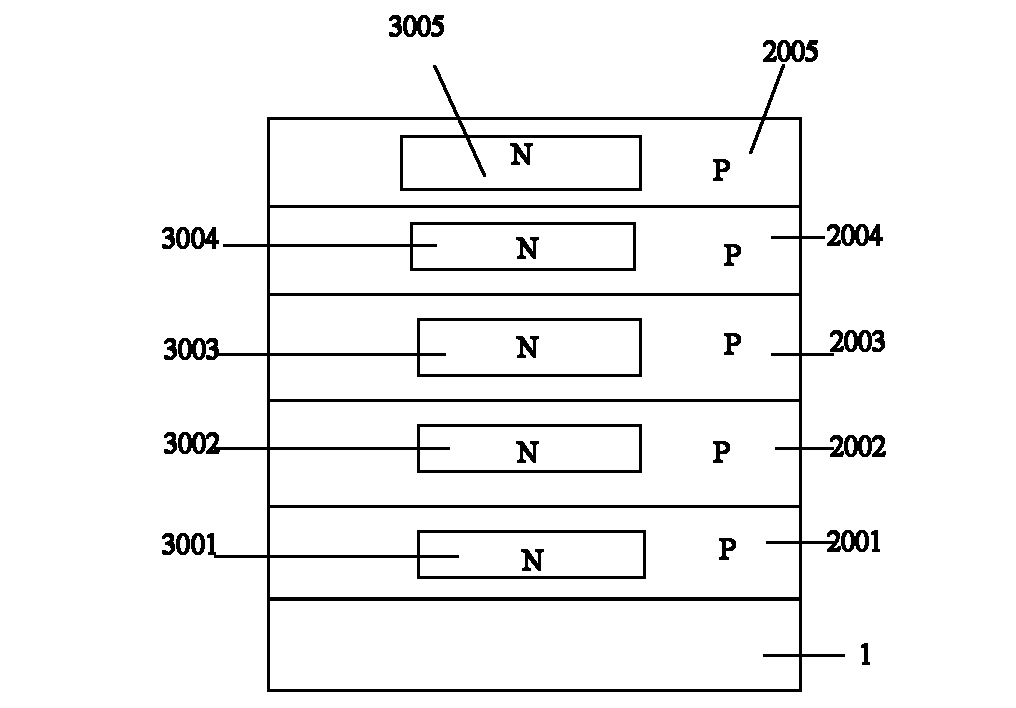

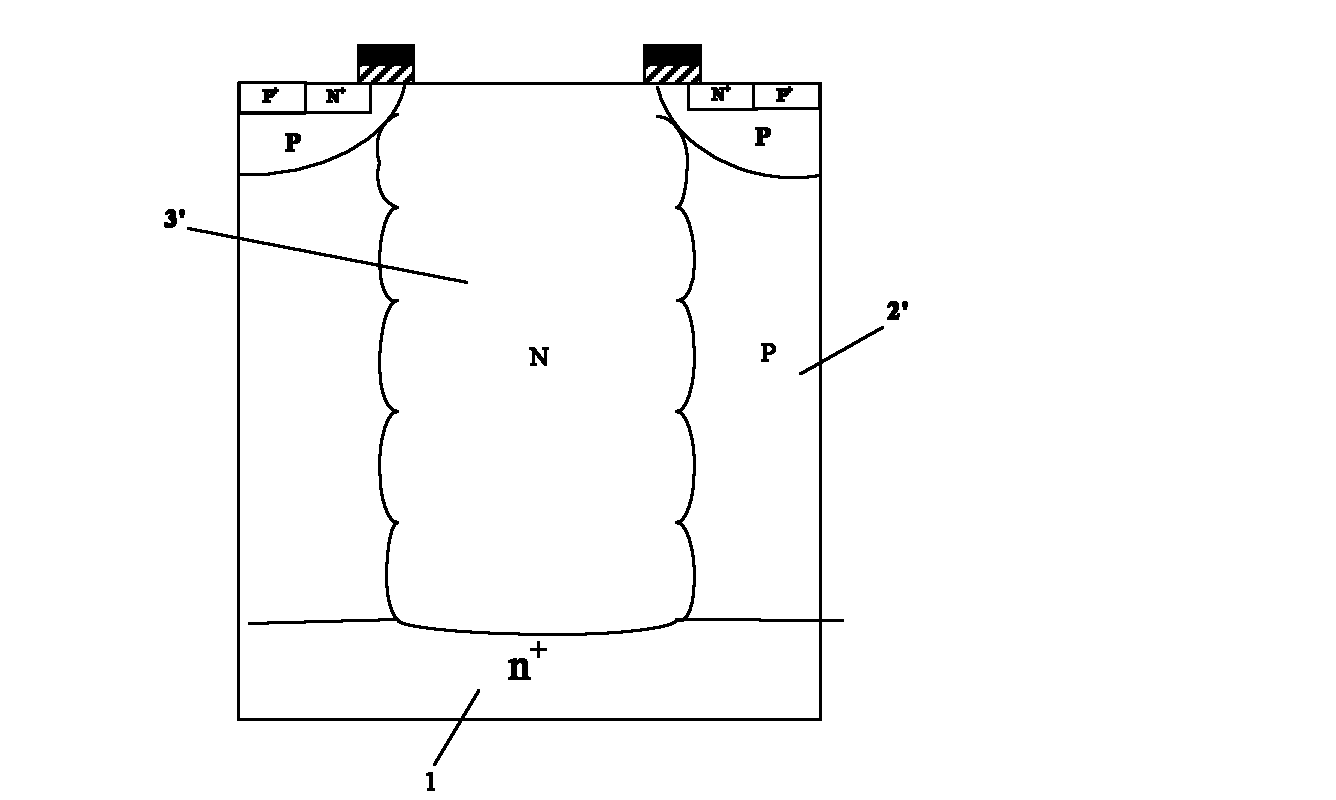

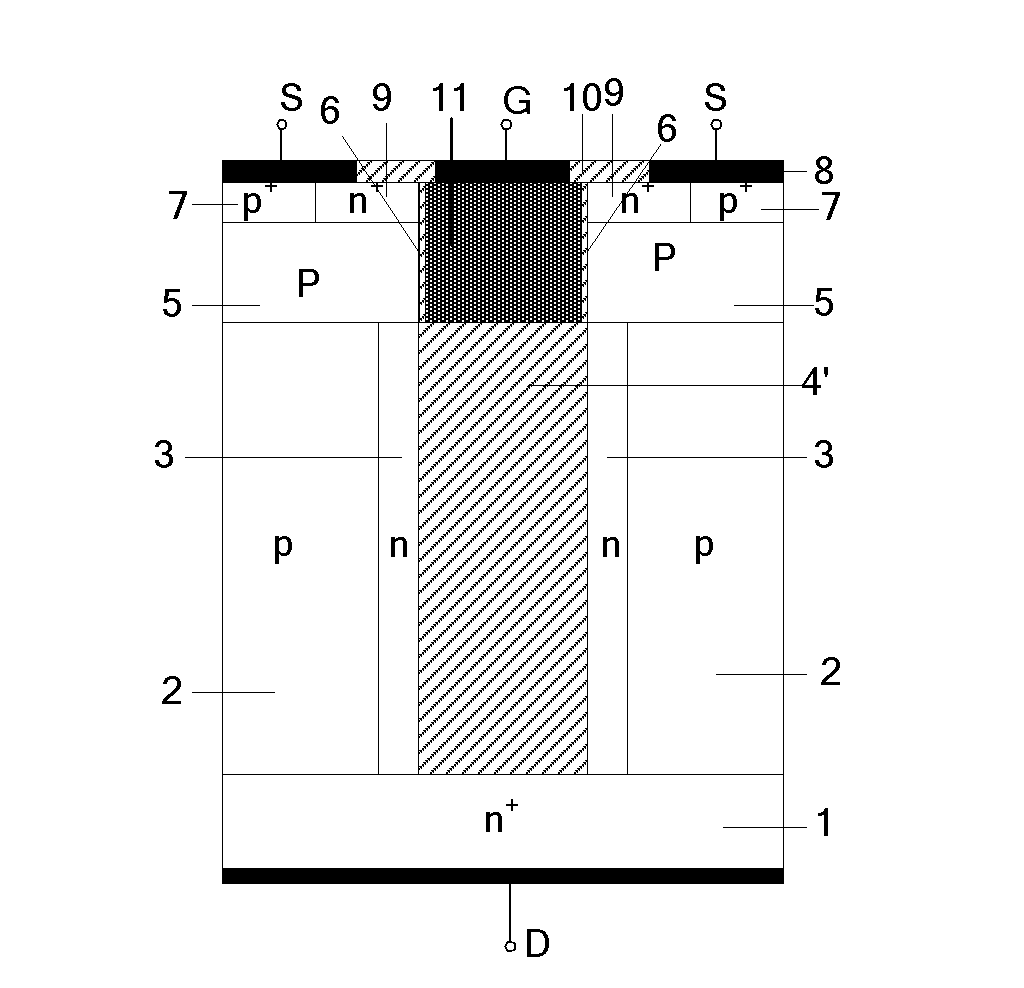

Method for manufacturing super-junction semiconductor device with extended groove

InactiveCN102142378AReduce leakage capacitanceGuaranteed flushSemiconductor/solid-state device manufacturingCapacitanceHigh concentration

The invention discloses a method for manufacturing a novel super-junction semiconductor device with an extended groove. By key process steps of multiple-time extending, multiple-time injecting and etching the extended groove, filling and leveling an insulating medium and then forming an active layer and an electrode and the like, the method realizes the process manufacturing of a novel super-junction structure and super-junction semiconductor device. Compared with the prior art, the method has the following advantages that first, a narrow P column area or N column area with high concentration can be formed to be beneficial to reducing on-resistance; second, the bottom of a groove gate is flush with the lower interface of a body area or is slightly lower than the lower interface of the body area, therefore the withstand voltage performance of the device is increased, and the gate-source and gate-drain capacitance is reduced; third, complicated masking is not needed, and the influence of a small-angle injection technology to a channel region is avoided; and fourth, the negative influences of the extended groove filling and leveling, groove gate manufacturing and leveling to the formed body area, the body contact area and the active area are avoided.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

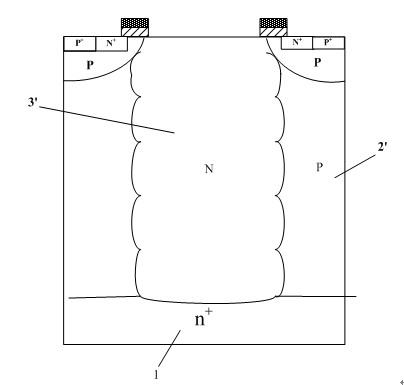

Method for manufacturing groove type longitudinal semiconductor device

InactiveCN102184856AReduce leakage capacitanceImprove pressure resistanceSemiconductor/solid-state device manufacturingCapacitanceHigh concentration

The invention discloses a method for manufacturing a groove type longitudinal semiconductor device, belonging to the technical field of manufacture of semiconductor devices. In the invention, the process manufacturing of the groove type longitudinal semiconductor device can be realized through the process steps such as deep groove etching, high-temperature diffusion, insulating medium padding and planarization, active layer and electrode forming and the like. Compared with the existing process, the process method disclosed by the invention has the following advantages: firstly, a narrow and high-concentration P column region or N column region (namely a second semiconductor drift region) are be formed, thereby being beneficial to reduction of on resistance and decrease of horizontal dimension of the device; secondly, the bottom of a groove grid is ensured to be parallel to the lower interface of a body region or be slightly lower than the lower interface of the body region, further improving the withstand voltage of the device and reducing the low-grid and grid-drain capacitance; and thirdly, complicated masking is not required, and the influence of small-angle injection to the channel region can be avoided; and fourthly, the negative influence on the formed body region, body contact region and source region caused by the padding and planarization of the extended groove as well as manufacturing and planarization of the groove grid can be avoided.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

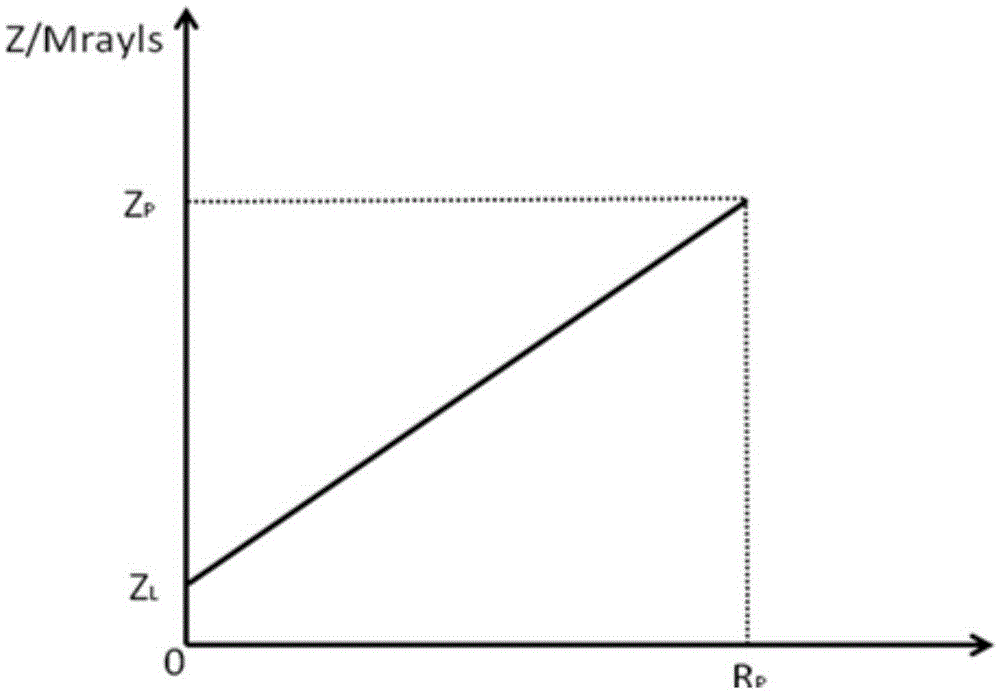

Ultrasonic transducer, gradual-change sound impedance matching layer and manufacturing method of gradual-change sound impedance matching layer

ActiveCN105381943AImproved Time Domain ResponseImprove frequency domain responseElectrical transducersAdditive manufacturing apparatusUltrasonic sensorSound energy

The invention relates to the technical field of transducers and provides an ultrasonic transducer, a gradual-change sound impedance matching layer and a manufacturing method of the gradual-change sound impedance matching layer. The gradual-change sound impedance matching layer comprises a body. Sound impedance of the body is gradually changed from one end of the body to the other end of the body continuously, and the body is made from a tackifier and at least one powder base material. By the adoption of the tackifier and the powder base material, the required raw materials of the manufactured gradual-change sound impedance matching layer are small, operation is convenient, the manufacturing cycle is short, production is easy to conduct, and industrialization is achieved; and furthermore, the efficiency for transmitting sound energy to an object to be detected is improved remarkably, meanwhile, the process manufacturing procedure can be optimized, it is avoided that the tackifier is introduced to bond multiple matching layers, the time domain response and frequency domain response of the ultrasonic traducer are further improved, and the sensitivity of the ultrasonic traducer is improved remarkably, and the bandwidth of the ultrasonic traducer is increased remarkably.

Owner:EDAN INSTR

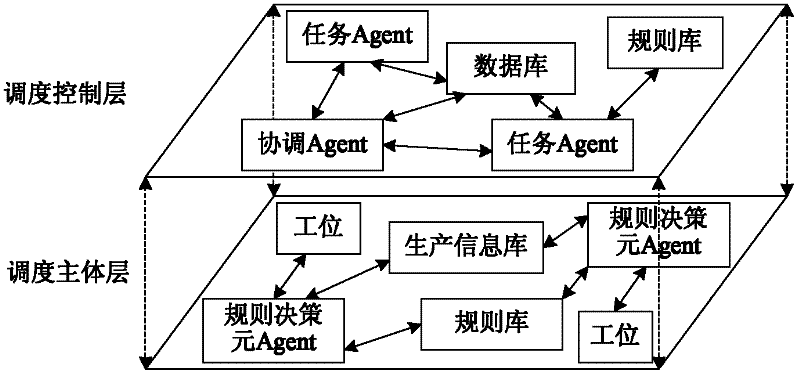

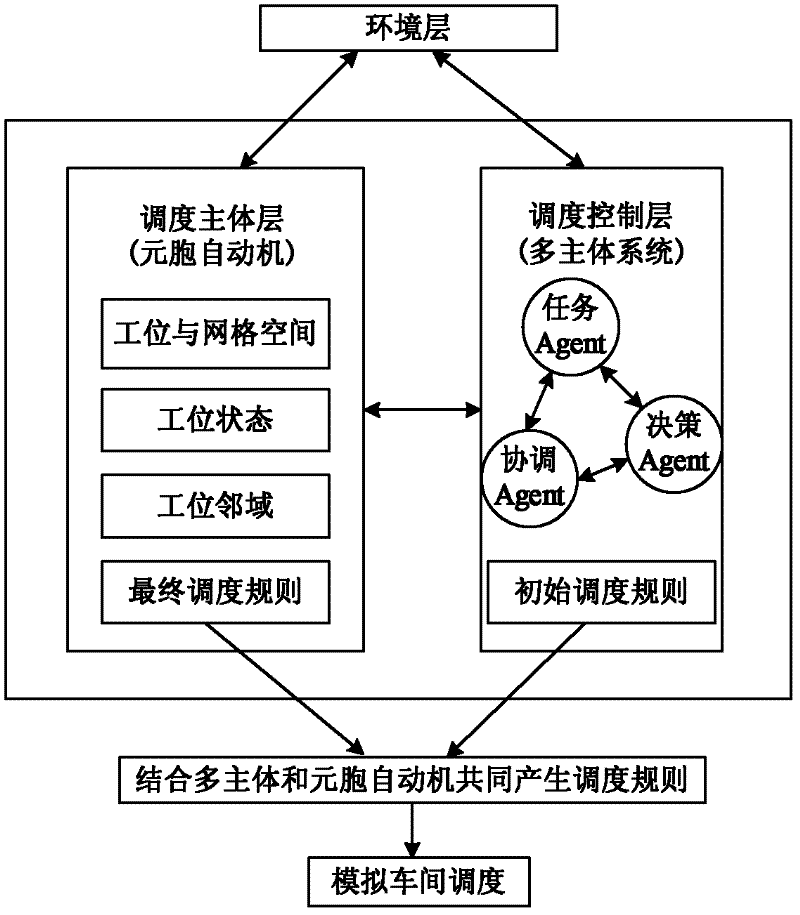

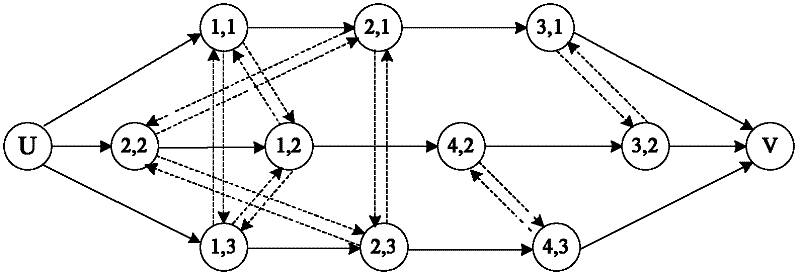

Method for carrying out dispatching control on multi-variety multi-process manufacturing enterprise workshop on basis of ACA (Automatic Circuit Analyzer) model

The invention relates to a method for carrying out dispatching control on a multi-variety multi-process manufacturing enterprise workshop on the basis of an AC (Automatic Circuit Analyzer) model, which comprises the following steps of: 1, setting a target function of the multi-variety multi-process manufacturing enterprise workshop, and when task information of a task Agent is sent to a decision Agent by a coordination Agent, representing the task information with a directed graph G by the decision Agent and using a dispatching rule which is obtained by the decision Agent through a random algorithm as an initial solution of a tabu search algorithm; 2, by a rule decision element Agent, firstly, calculating a target value F, then searching other dispatching methods from the dispatching field by the tabu search algorithm, and using a solution with the minimum target value as the adopted rule; and 3, carrying out state changing on each cell (i.e. a station) in a cell space according to the dispatching rule awarded by the rule decision element. According to the invention, a complex dispatching system can be described, the practical production is well reflected, the computational efficiency of a model is also considered, and the problem of dispatching the dynamic and complex multi-variety multi-process manufacturing enterprise workshop is rapidly and accurately solved.

Owner:ZHEJIANG UNIV OF TECH

Polyester cotton dyeing one-bath process manufacturing process

ActiveCN103132351ABright color and good fastnessBright colorSucessive textile treatmentsHeating/cooling textile fabricsPolyesterCotton fibre

The invention discloses a polyester cotton dyeing one-bath process manufacturing process. The polyester cotton dyeing one-bath process manufacturing process is conducted according to the following steps: gray fabric of polyester cotton intertexture or gray fabric of cotton polyester intertexture is adopted for cloth preparation; and the steps of cold-stacking, cylinder discharging, one-bath dyeing (activity once dyeing of dacron and cotton fiber), soaping, cloth soaping, forming and finish inspection packaging are sequentially conducted. A novel manufacturing process of polyester cotton, a normal manufacturing process of gray fabric (T / C or C / T) scattering and a normal manufacturing process of an activation dyeing one-bath method are adopted in the polyester cotton dyeing one-bath process manufacturing process. After process treatment such as dyeing, production cost is greatly reduced, and environmental pollution is reduced. Shell fabric produced through the process is brighter in colors and luster, softer, smoother and cooler in handle, bright in cloth cover color, and good in cloth cover fastness, and can be widely applied to casual garment shell fabrics.

Owner:JINJIANG LONGXINGLONG DYEING & WEAVING INDALCO

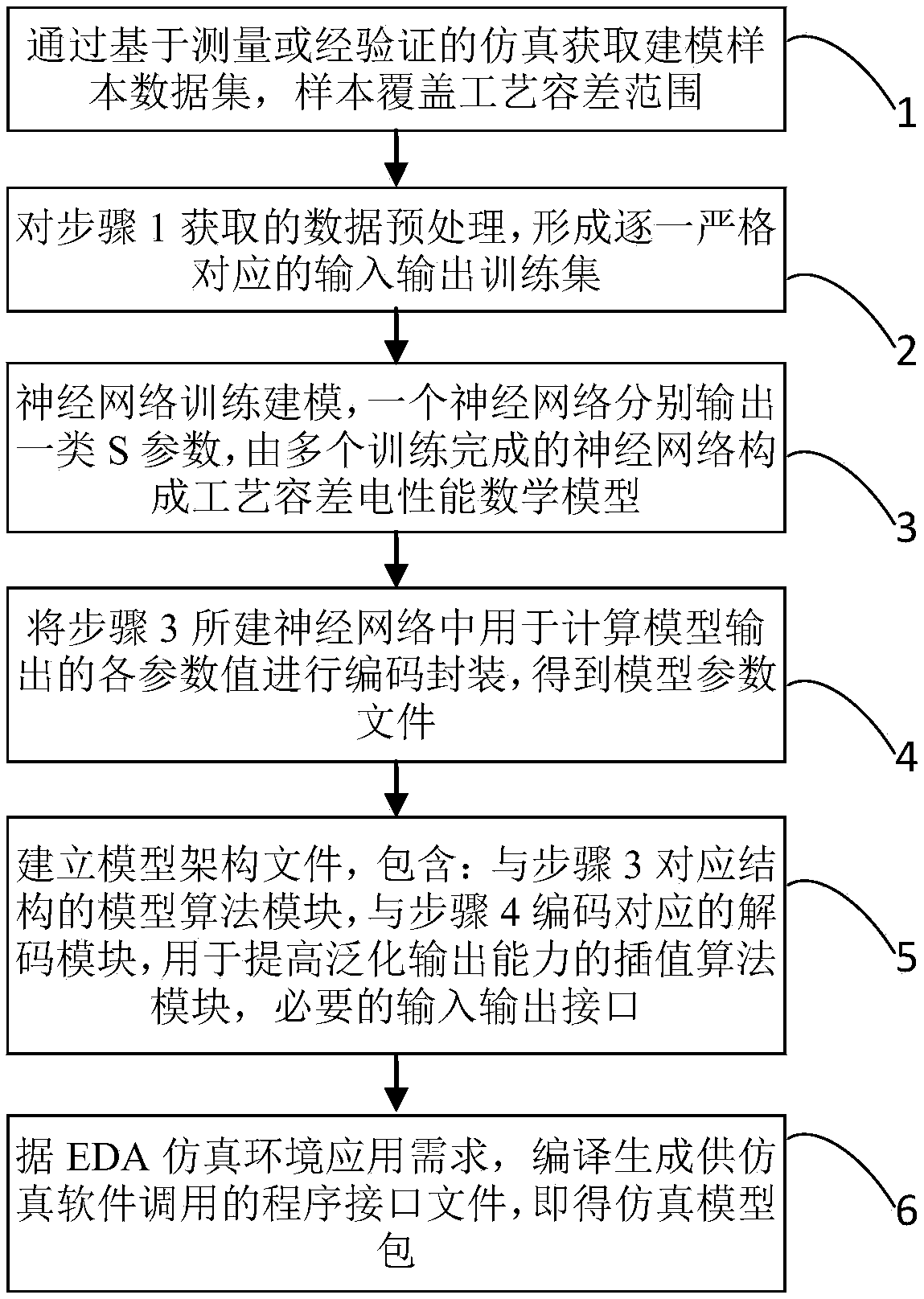

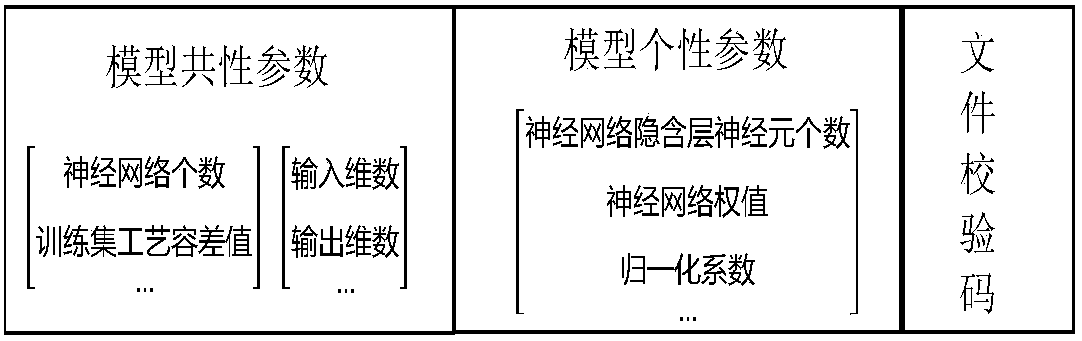

Modeling and packaging method for process tolerance and electric performance coupling characteristics in radio frequency integration

ActiveCN108345749AIncrease opennessCompatibleComputer aided designSpecial data processing applicationsElectricityCombined test

The invention provides a modeling and packaging method for process tolerance and electric performance coupling characteristics in radio frequency integration. The method starts from development and application of process IP models to put forward an integrated scheme which is compatible with existing modeling algorithms and rapidly and correctly realizes model development, integrated packaging andupdating maintenance by utilizing data of electromagnetic simulation combined test, and the integrated scheme is particularly suitable for modeling and simulation of process tolerance and electric performance coupling characteristics in radio frequency microwave integration. According to the method, processing and modeling are carried out on process tolerance data in integrated manufacturing, andmanufacture process levels are truly fed back to designers for calling through a standard IP library form, so that system-level simulation can cover analysis of process tolerance, the simulation is capable of rapidly and effectively verifying influences, on system performance, of the process manufacturing levels, and benefit is brought to shorten the design verification period.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

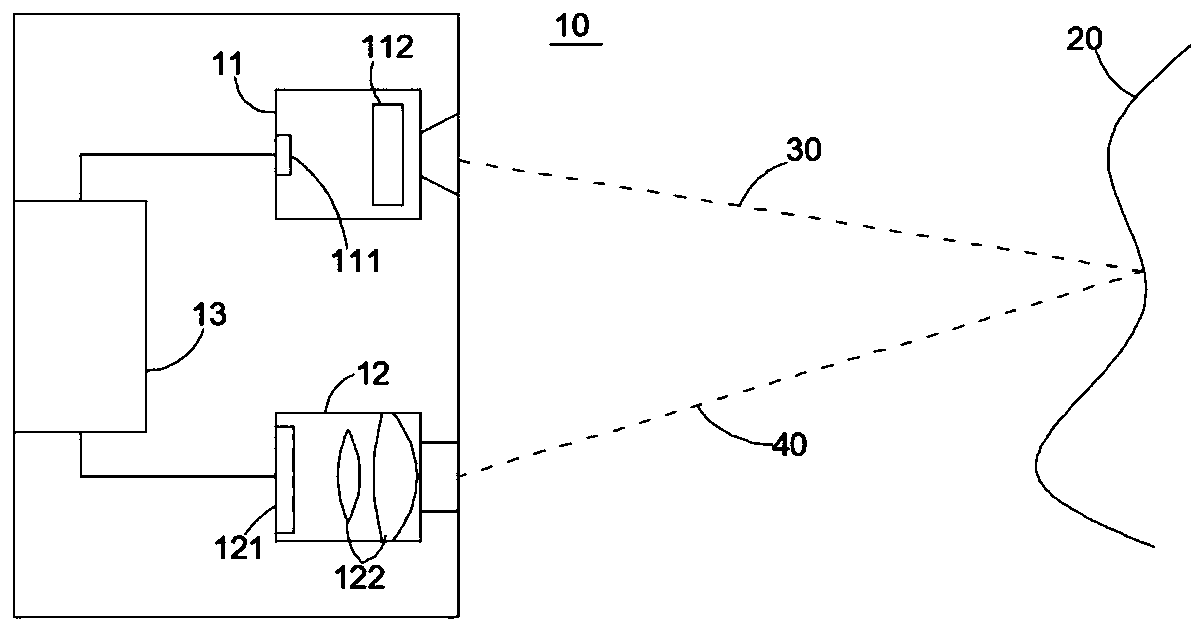

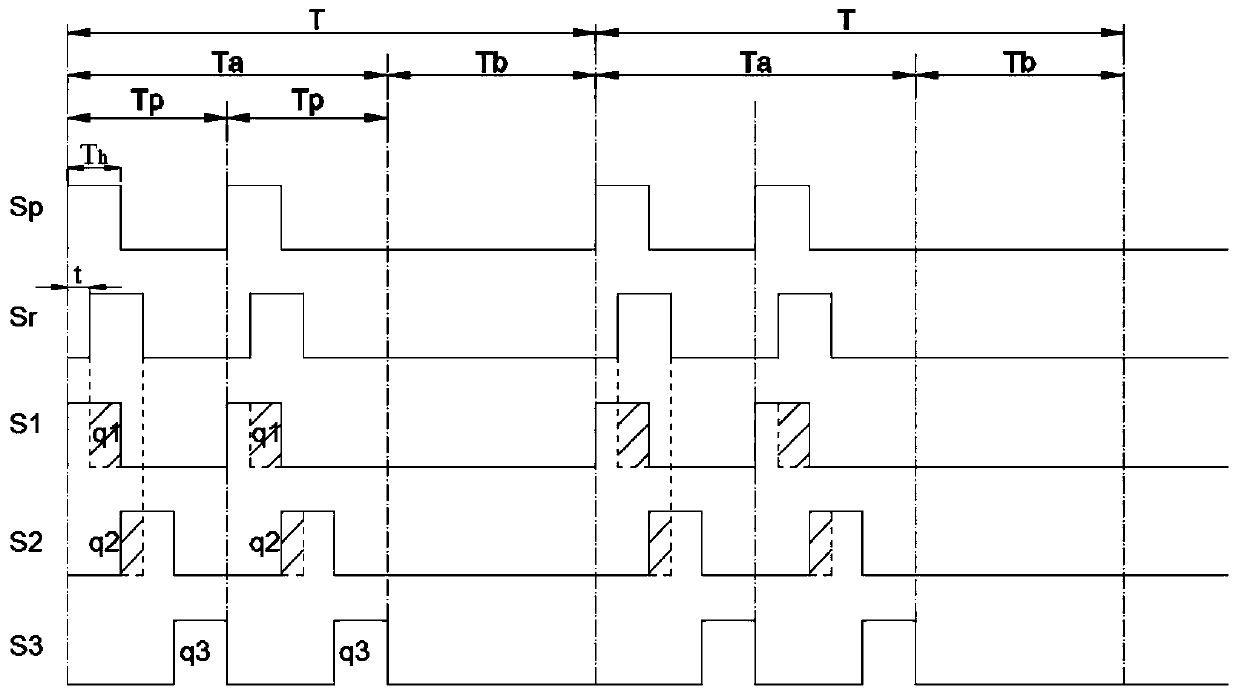

Time-of-flight depth camera and single-frequency modulation-demodulation noise-reducing distance measuring method

ActiveCN110361751AReduce or eliminate stationary noiseShort pulse widthElectromagnetic wave reradiationPulse beamStationary noise

The invention provides a time-of-flight depth camera and a single-frequency modulation-demodulation noise-reducing distance measuring method. The time-of-flight depth camera comprises a transmitting module, an acquisition module and a processing circuit, wherein the transmitting module comprises a light source which is used for transmitting a pulse beam to an object to be measured; the acquisitionmodule comprises an image sensor composed of at least one pixel, each pixel comprises at least three taps, and the taps are sued for acquiring a charge signal generated by a reflected pulse beam which is reflected by means of the object to be measured and / or a charge signal of background light; and the processing circuit is used for controlling the at least three taps to acquire the charge signals alternatively between at least three frame periods of a macro period, and receiving data of the charge signals to calculate a time of flight of the pulse beam and / or a distance of the object to be measured. The expansion of the measurement distance is no longer limited by the pulse width, and the fixed-pattern noise caused by mismatch between the taps or read-out circuits due to process manufacturing errors and the like is reduced or eliminated by adopting a tap alternative acquisition method.

Owner:SHENZHEN ORBBEC CO LTD

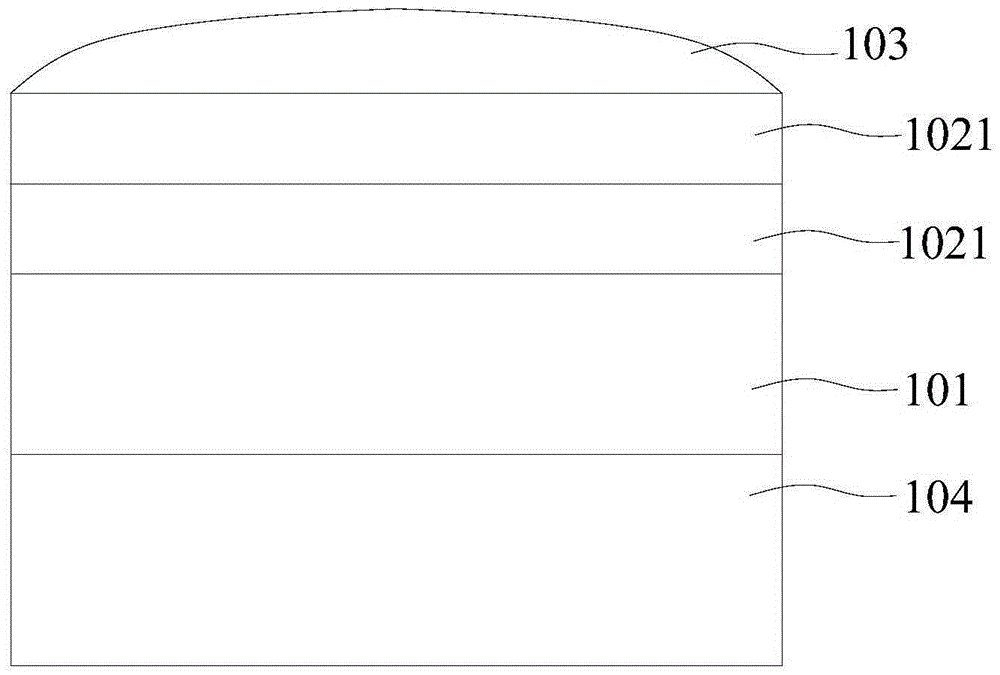

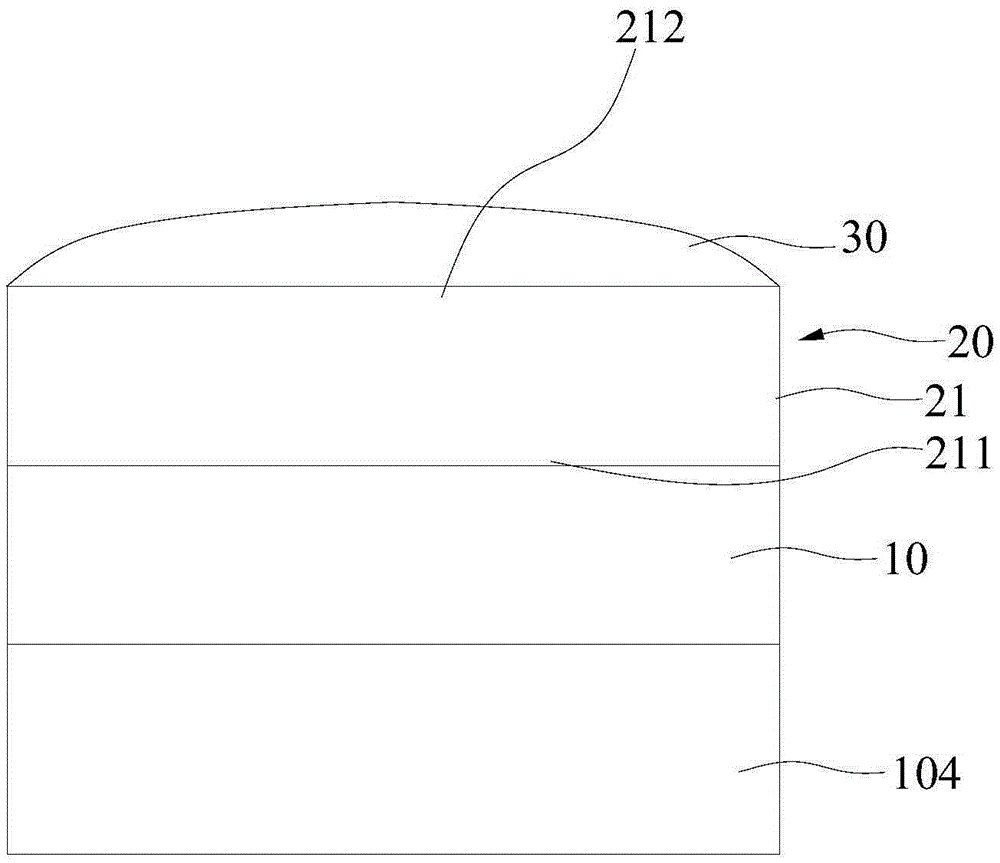

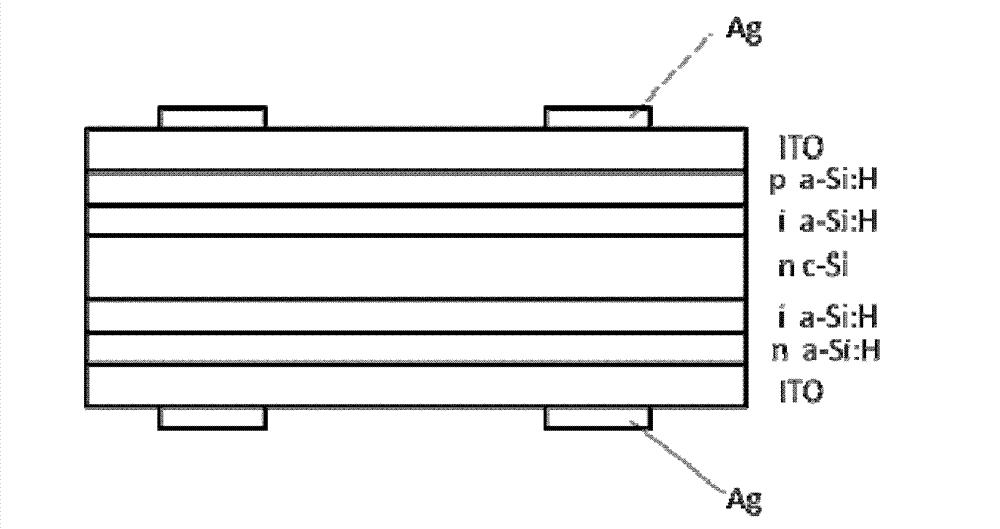

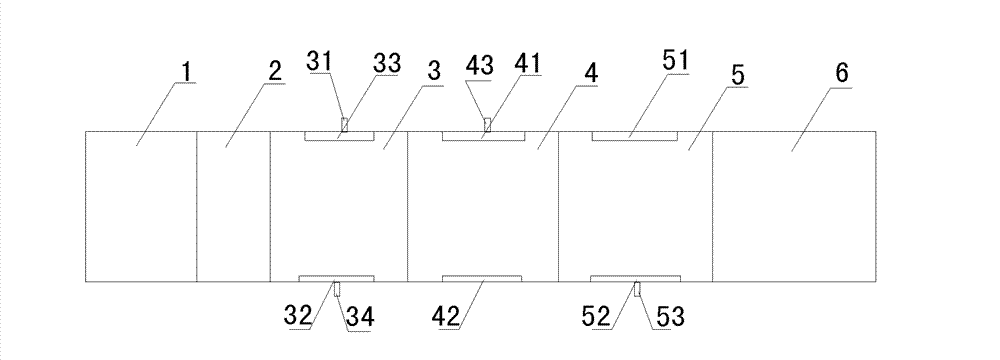

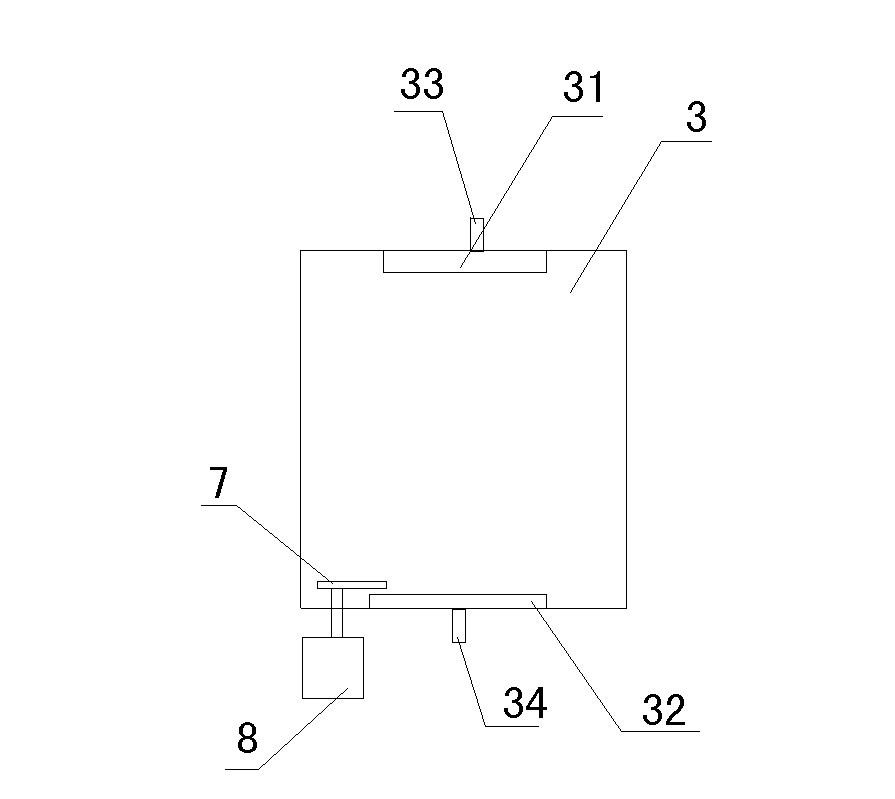

Serial-type equipment for manufacture of double-faced heterojunction solar cell in plasma enhanced chemical vapor deposition (PECVD) method and process

ActiveCN103094403ASimplify the manufacturing processEasy to produceVacuum evaporation coatingSputtering coatingHeterojunctionEngineering

Serial-type equipment for manufacture of a double-faced heterojunction solar cell in a plasma enhanced chemical vapor deposition (PECVD) method comprises a deposit cavity. The deposit cavity comprises a serial-type wafer in-out chamber, a preheating chamber, an intrinsic layer deposit chamber, a p-type deposit chamber, an n-type deposit chamber and a wafer outlet chamber. A process manufacturing the double-faced heterojunction solar cell in the PECVD method is adopted through the serial-type equipment for the manufacture of the double-faced heterojunction solar cell in the PECVD method, and the intrinsic layer deposit for the front and the back of a silicon wafer can be completed in the same chamber. According to the serial-type equipment and the process, the working procedure of turning over the silicon wafer can be eliminated, equipment manufacture cost and production time are saved, and the deposit for the front and the back of the silicon wafer can be well achieved.

Owner:上海太阳能工程技术研究中心有限公司

System and method for simulating, modeling and scheduling of solution preparation in batch process manufacturing facilities

A method and system for simulating, modeling and scheduling equipment preparation procedures in the biopharmaceutical production process is described herein. The use of process vessels in batch process manufacturing is optimized through the use of peak load scheduling frames. The system and method includes the steps of identifying soiled process components and their associated equipment preparation procedures. After the soiled process components are identified, a master list of soiled process components and their associated equipment preparation procedures is generated. After the soiled process components and the equipment preparation procedures are identified, the equipment preparation procedures are scheduled out based on preparation equipment protocols to generate a equipment preparation load summary table. Next, the size and capacity of the preparation equipment is determined based on the information in the load summary table. After the size and capacity of the preparation equipment is determined, an equipment preparation time line is generated.

Owner:BROWN PETER G

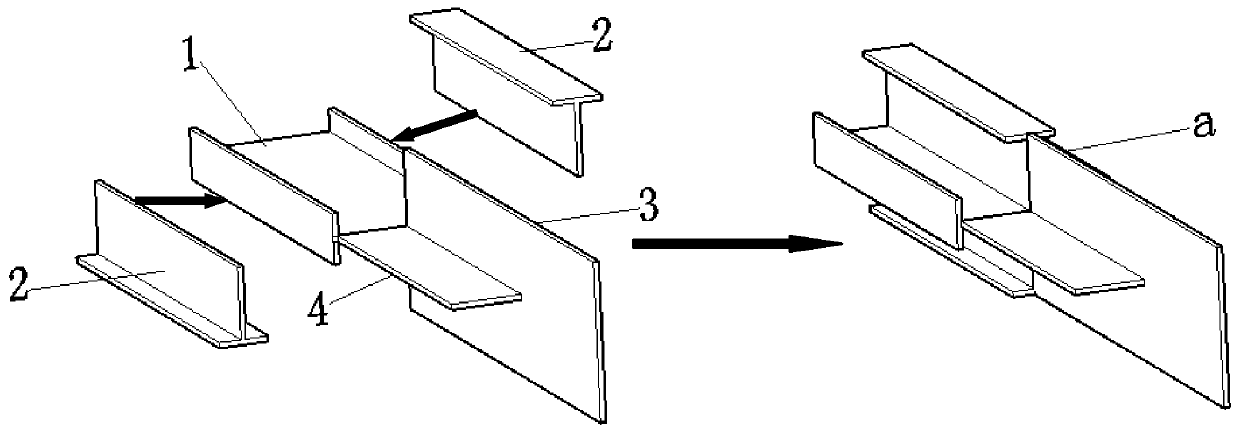

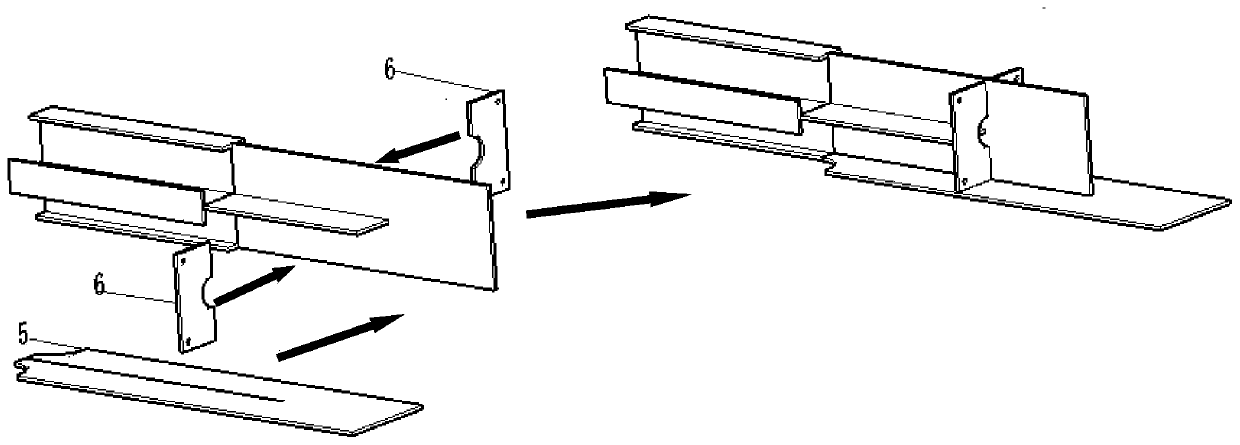

Manufacturing method of cross-shaped box type joint

ActiveCN110711961AOptimize assembly processControl deformationBuilding constructionsWelding apparatusStress concentrationButt welding

The invention discloses a manufacturing method of a cross-shaped box type joint. The method includes assembling and splicing of a cross-shaped column and a box type column. Firstly, the cross-shaped column is assembled and spliced, wherein the cross-shaped column comprises H-shaped steel and two pieces of T-shaped steel; secondly, the box type column is assembled and spliced, wherein a bottom plate and interior of the box type column are assembled, a U-shaped structure of the box type column is assembled, a deformed part is corrected to be qualified according to process manufacturing requirements, and a cover plate of the box type column is assembled; and thirdly, a transition inlaying section is welded. According to the method, a top partition plate welding seam of the box type column iswelded, then the cross-shaped column and the box type column are welded to be connected with the welding seam, and finally, wing plates of the cross-shaped column and the cover plate of the box type column are in butt joint with the welding seam, so that the stress concentration problem is well avoided. The connecting welding seam between the cross-shaped column and the box type column adopts opengroove external plug welding, so that the situation that a welding hole is formed in the end of the cross-shaped column or in the outer side of the box type column and accordingly the appearance of acomponent is affected is avoided, the welding quality of the cross-shaped column and the box type column is controllable, and the cross-shaped box type cross section welding process is optimized.

Owner:YCIH STEEL STRUCTURE CO LTD

Method for manufacturing of low-cost super-thick steel plate by short process

The invention provides a method for manufacturing of a low-cost super-thick steel plate by a short process. The method includes: conducting smelting, continuous casting, and cutting, then performing stacking slow cooling for 20-30h, cleaning the surfaces and lateral sides of blanks, and maintaining the roughness at 6.3 micrometers; subjecting the two blanks to involution, then performing vacuum pumping and welding to maintain the thickness of the combined blank at 200-300mm; sending the combined blank into a walking beam type heating furnace, conducting preheating at a slow heating speed, controlling cold charging at 12-13min / cm, employing a normal speed at a heating section, prolonging the heat preservation time of a soaking section by 0-30min, and keeping the tapping temperature higher than or equal to 1100DEG C; after phosphorus removal, employing direct rolling or TMCP rolling, controlling the initial rolling temperature of rough rolling higher than or equal to 1050DEG C, keeping a first pass reduction rate higher than or equal to 10% and a cumulative reduction rate higher than or equal to 30%; and controlling the initial rolling temperature and the final rolling temperature of finish rolling at technological parameter lower limits, controlling a compression ratio at 1.8-2.5, and carrying out air cooling or controlled cooling after rolling as well as a heat treatment. The super-thick steel plate product produced at a small compression ratio has good quality and uniform performance. And the method provided in the invention has low energy consumption and fast rolling pace, is suitable for industrial mass production, and has significant economic and social benefits.

Owner:ANGANG STEEL CO LTD

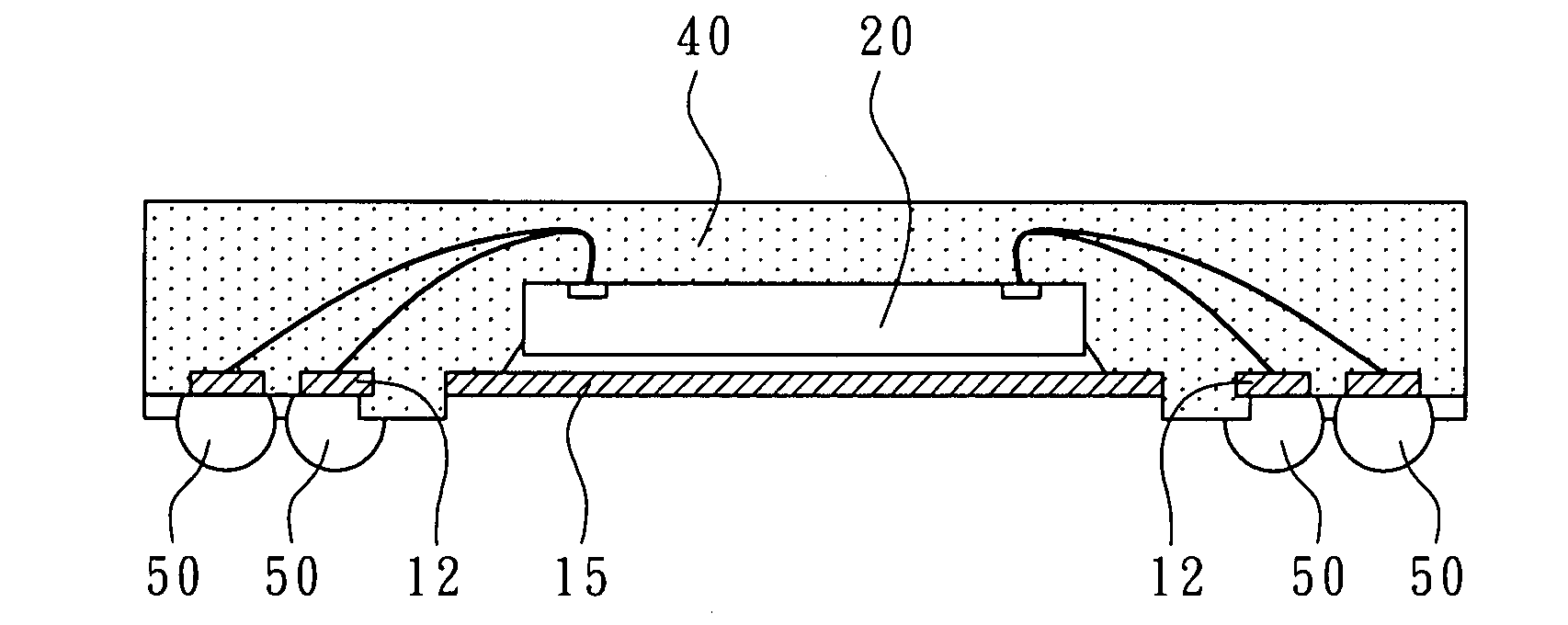

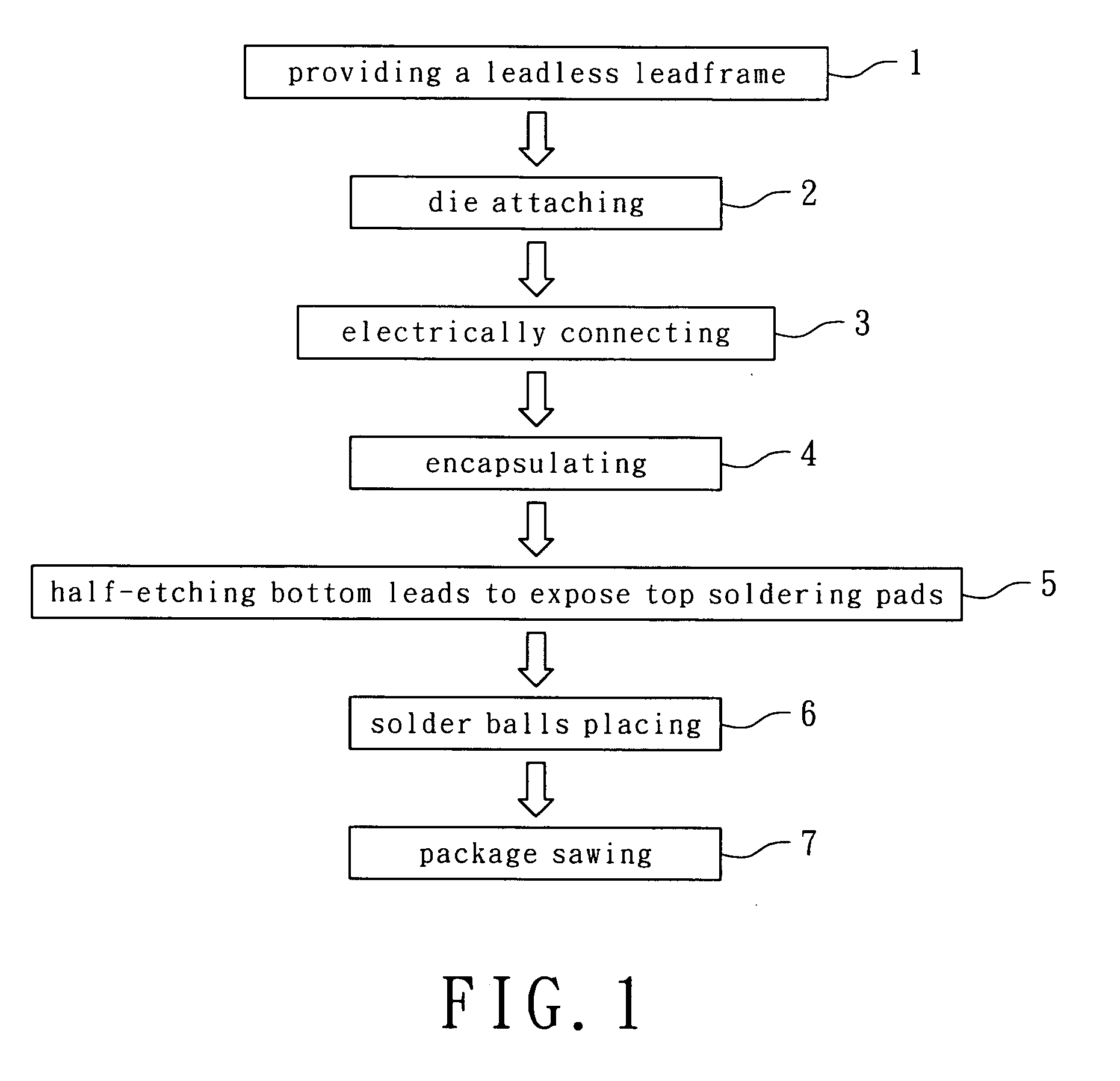

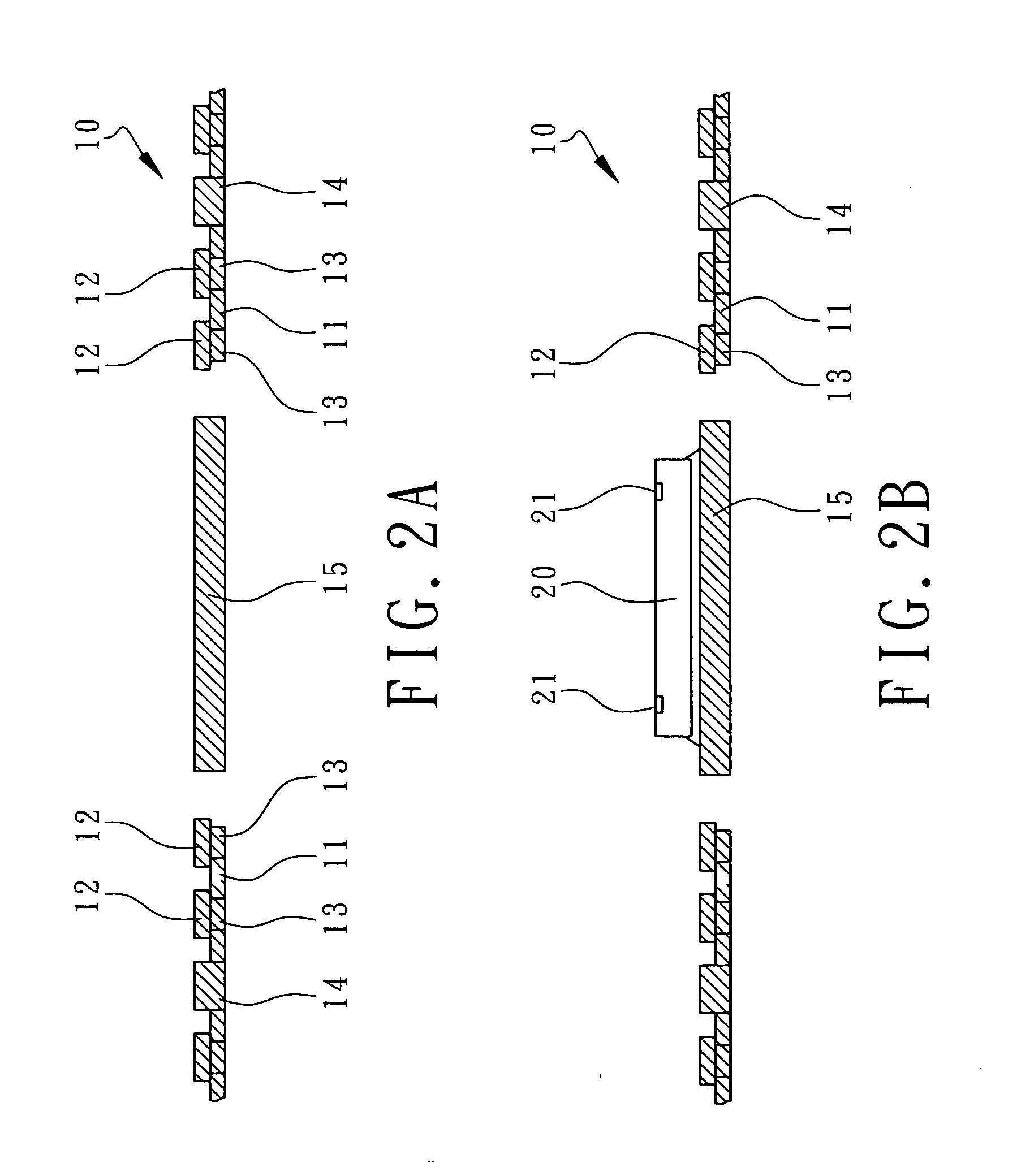

Fabrication processes of leadframe-based BGA packages and leadless leadframe implemented in the processes

InactiveUS20070215995A1Inhibited DiffusionImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesSolder maskSolder ball

Manufacturing processes of a leadframe-based BGA package and a leadless leadframe implemented in the processes are disclosed. The leadless leadframe has a plurality of bottom leads and a plurality of top soldering pads formed in different layers. After encapsulation and before solder ball placement, a half-etching process is performed to remove the bottom leads to make the top soldering pads electrically isolated, exposed and embedded in the encapsulant for solder ball placement where the soldering area of the top soldering pads is defined without the need of solder mask(s) to solve the diffusion of solder balls on the leads during reflow. Moreover, mold flash can easily be detected and removed. The overall package cost can be reduced.

Owner:CHIPMOS TECH INC

Method for expressing relationship of process manufacturing procedures

InactiveCN102364510ATransit time cannot be ignoredSimple methodComputer controlDistribution matrixExtensibility

The invention relates to methods for expressing and operating relationships of process manufacturing procedures, wherein a series of matrix or vector to procedure relationships are designed for modeling in the method for expressing the relationships, specifically, the following matrixes or vectors are comprised, such as a procedure name vector, a procedure equipment quantity vector, a vector of product quantity in one batch, reachability matrixes among procedure equipment, transport time matrixes among procedures, a multi-process route matrix, reachability weight matrixes among the procedure equipment, processing starting time and ending time matrixes of products, and processing device distribution matrixes of the products in all procedures. The method for operating the relationships is used for operating the relationships of the procedures by using a matrix calculating manner. Compared with the prior art, the methods are simpler and general, and have better flexibility and expandability; and the integration degree of the expressing and the operating methods of the relationships of the procedures and an information system as well as a solution scheme is improved.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com