Method for manufacturing of low-cost super-thick steel plate by short process

A kind of extra-thick steel plate and low-cost technology, which is applied in the field of metallurgy, can solve the problems of reducing production efficiency, reducing rolling rhythm, and consuming large heat energy, and achieves the effects of good product quality, fast rolling rhythm, and low energy consumption

Inactive Publication Date: 2013-06-19

ANGANG STEEL CO LTD

View PDF5 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] "Vacuum Electron Beam Welding Method" patent (publication number CN 101590596A) adopts vacuum seal welding of two continuous casting slabs with a thickness of 300mm to produce a steel plate with a thickness of 150mm, and the compression ratio is 4. It not only consumes a lot of heat energy when heating, but also reduces the rolling rhythm and production efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0022] Example 2

Embodiment 2

[0024] Table 1 Chemical composition (wt, %) of the embodiment of the present invention

[0025] Example C Si mn P S Cr Nb V Ti Ni ALs 1 0.13 0.28 1.05 0.016 0.003 - - - - - - 2 0.14 0.35 1.45 0.017 0.003 0.1 0.035 0.056 0.005 0.12 0.015

[0026] Table 2 mechanical properties of the embodiments of the present invention

[0027]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Login to View More

Abstract

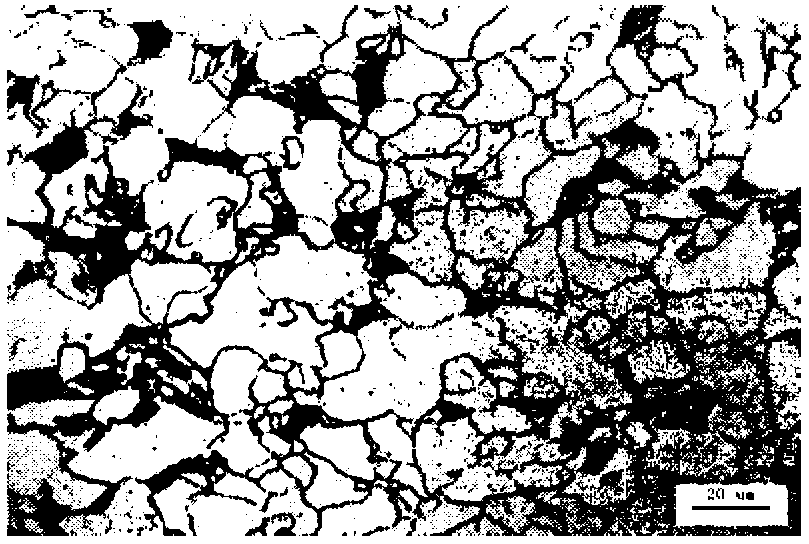

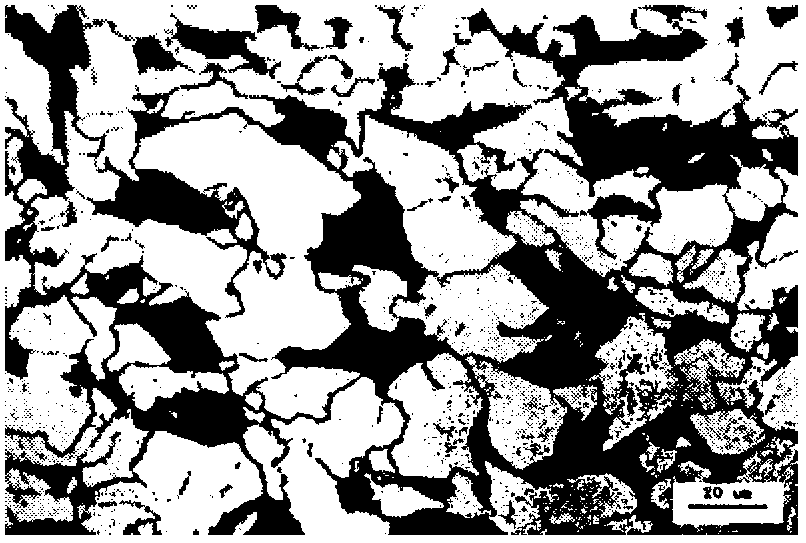

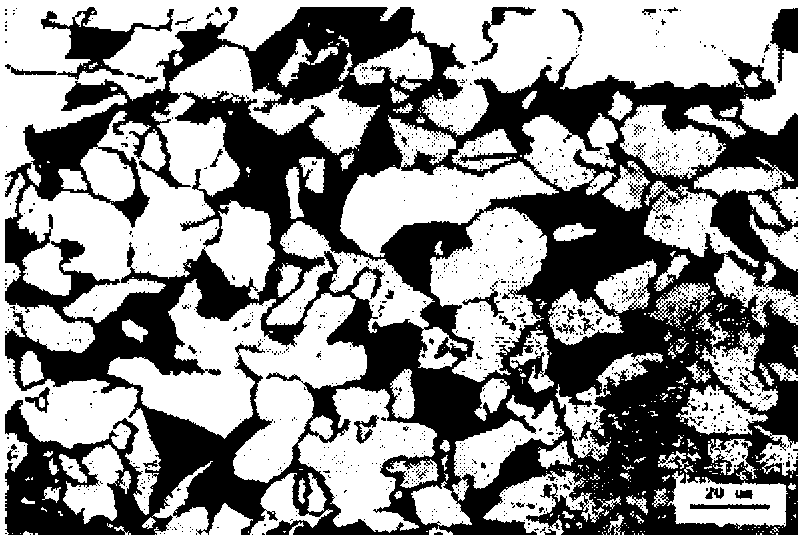

The invention provides a method for manufacturing of a low-cost super-thick steel plate by a short process. The method includes: conducting smelting, continuous casting, and cutting, then performing stacking slow cooling for 20-30h, cleaning the surfaces and lateral sides of blanks, and maintaining the roughness at 6.3 micrometers; subjecting the two blanks to involution, then performing vacuum pumping and welding to maintain the thickness of the combined blank at 200-300mm; sending the combined blank into a walking beam type heating furnace, conducting preheating at a slow heating speed, controlling cold charging at 12-13min / cm, employing a normal speed at a heating section, prolonging the heat preservation time of a soaking section by 0-30min, and keeping the tapping temperature higher than or equal to 1100DEG C; after phosphorus removal, employing direct rolling or TMCP rolling, controlling the initial rolling temperature of rough rolling higher than or equal to 1050DEG C, keeping a first pass reduction rate higher than or equal to 10% and a cumulative reduction rate higher than or equal to 30%; and controlling the initial rolling temperature and the final rolling temperature of finish rolling at technological parameter lower limits, controlling a compression ratio at 1.8-2.5, and carrying out air cooling or controlled cooling after rolling as well as a heat treatment. The super-thick steel plate product produced at a small compression ratio has good quality and uniform performance. And the method provided in the invention has low energy consumption and fast rolling pace, is suitable for industrial mass production, and has significant economic and social benefits.

Description

technical field [0001] The invention belongs to the technical field of metallurgy, and relates to a production method of an extra-thick steel plate with a thickness of 80-150 mm, in particular a production method using a short process and low energy consumption. Background technique [0002] As a high-end and high-value-added steel product, extra-thick steel plate has been the focus of research by personnel engaged in the metallurgical industry and the hot pursuit of metallurgical enterprises for many years due to its wide application fields and difficult production technology. In our country, the research on extra-thick plates started relatively late, especially for steel plates with a finished thickness of more than 80mm. Due to the rapid development of various industries in my country, such as large-scale machinery and structure manufacturing, military industry, shipbuilding, boiler containers, deep-sea oil development equipment, nuclear power and other fields, the demand...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21D8/02

Inventor 王储高强王文仲胡昕明梁福鸿

Owner ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com