Ceramic product with digital process manufacturing mold effect texture and manufacturing method of ceramic product

A technology of ceramic products and production methods, which is applied in the field of architectural ceramic tiles, can solve the problems of weak subsidence depth, unstable production and quality, and decreased yield of pressed products, so as to reduce instability, save resource consumption, reduce The effect of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

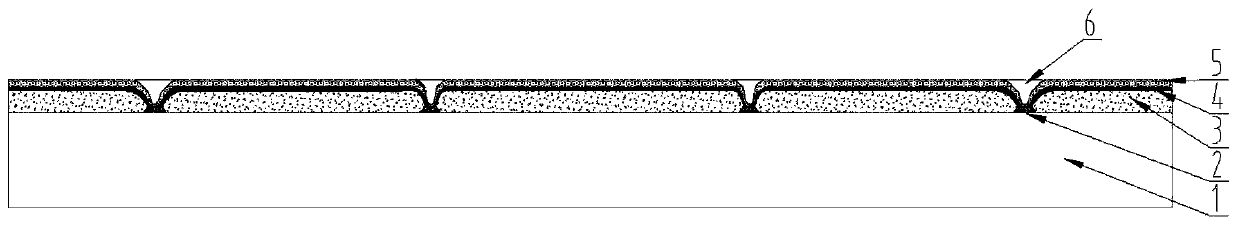

Image

Examples

Embodiment 1

[0060] (1) Select kaolin, feldspar, quartz and other raw sand materials, and prepare ceramic powder for the bottom blank according to the matching brick shape control requirements, and set aside.

[0061] (2) According to the conventional configuration, the production line equipment for inkjet ceramic craft products is equipped as a spare.

[0062] (3) Install a ceramic inkjet machine for printing mold-effect texture ink before the bottom glaze spraying process of the production line, and load the corresponding mold-effect texture ink in its channel, which is composed of silicon dioxide according to the weight percentage of the formula 21.3%, 8.3% aluminum oxide, 1.58% sodium oxide, 6.5% calcium oxide, 0.25% magnesium oxide, 2.4% zinc oxide, the others are burning loss and trace impurities, for future use. The ink formula contains oxides with a fluxing effect, which can be fully fused with the unfired glaze surface to produce relatively large shrinkage to form a concave-convex...

Embodiment 2

[0075] This embodiment is the same or similar to [Example 1]. The only difference between the two is the ink formula and its content in step (3). The specific description is as follows: Similarly, this embodiment 2 needs to be installed before the bottom glaze spraying process of the production line. A ceramic inkjet machine for printing mold-effect texture ink, and the corresponding mold-effect texture ink is loaded in its channel, and the formula is composed of 28.3% silicon dioxide, 2.3% aluminum oxide, 0.13% sodium oxide, and Calcium 7.5%, Magnesium Oxide 0.55%, Potassium Oxide 1.2%, Zinc Oxide 4.4%, others are burnt out and trace impurities, for future use.

[0076] The ink formula described in Example 2 contains oxides with a fluxing effect, which have a low initial melting point and can fully melt with the unfired glaze surface to produce relatively large shrinkage to form a concave-convex texture. The concave-convex texture has the characteristics of roundness and finen...

Embodiment 3

[0078] This embodiment is the same or similar to [Example 1]. The only difference between the two is the ink formula and its content in step (3). The specific description is as follows: Also install the spray-printed mold effect texture before the bottom glaze spraying process of the production line A ceramic inkjet machine for ink, and the corresponding mold effect texture ink is loaded in its channel. The ink described in this embodiment is composed of 0.35% silicon dioxide, 0.61% aluminum oxide, and 0.18% sodium oxide according to the weight percentage of the formula. , phosphorus pentoxide 0.52%, sulfur trioxide 3.0%, bismuth trioxide 20.1%, zinc oxide 0.09%, vanadium pentoxide 7.2%, barium oxide 2.3%, the others are ignition loss and trace impurities, for future use.

[0079] When making ceramic products according to the ink formula described in Example 3, the ink forms a concave-convex texture due to the difference in surface tension between the ink and the bottom glaze w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com