Patents

Literature

4178results about How to "Reduce resource consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

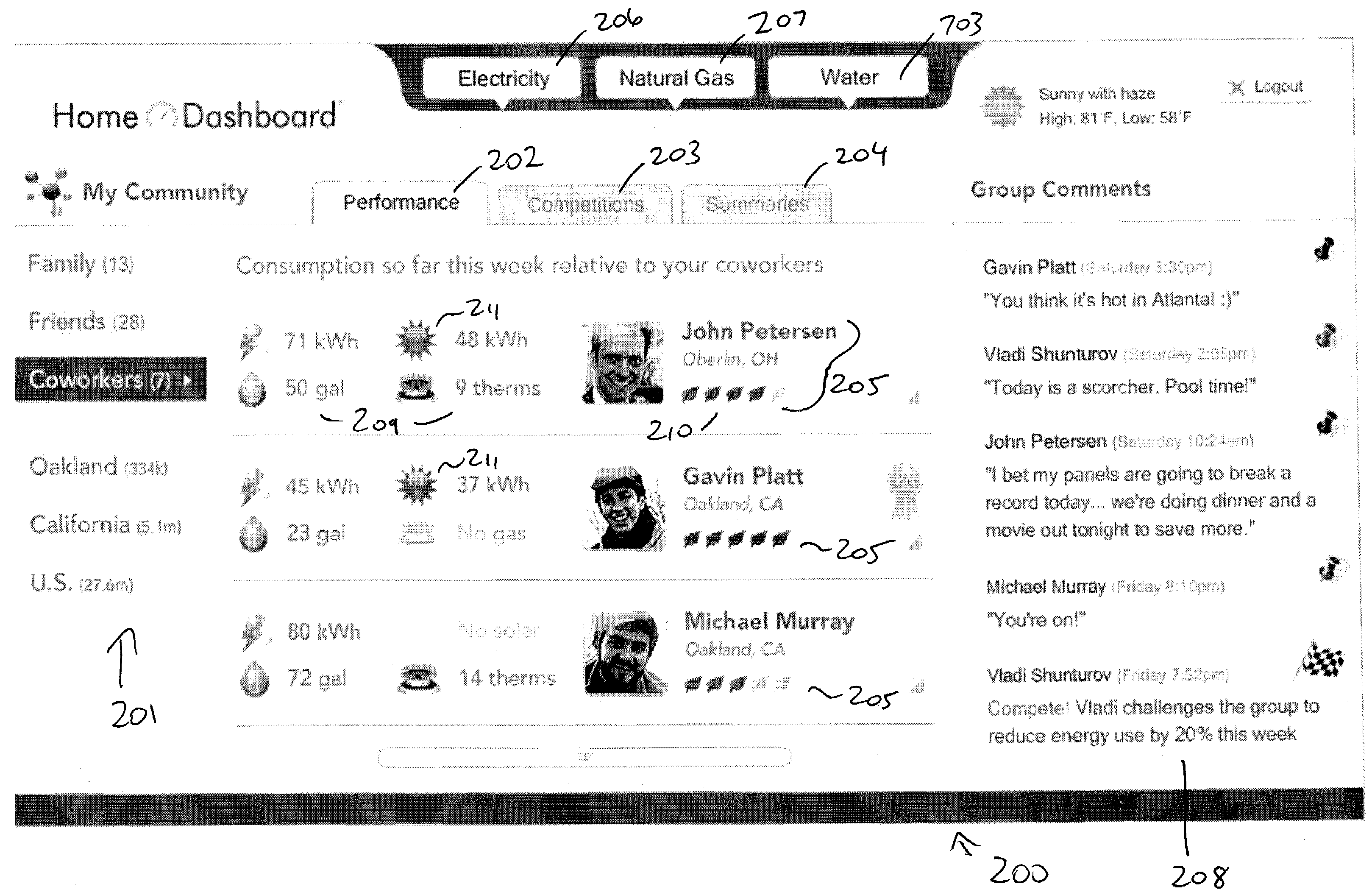

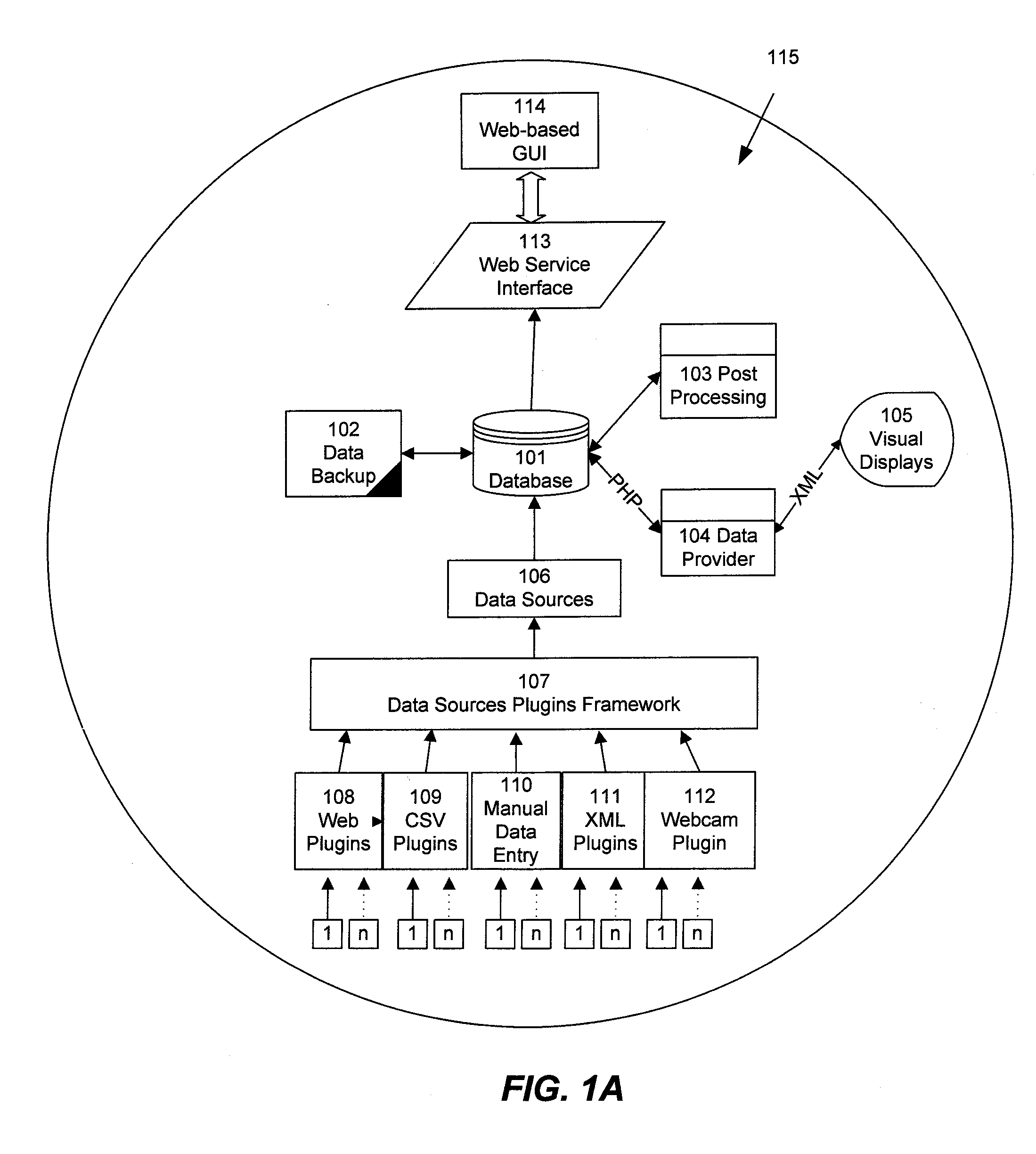

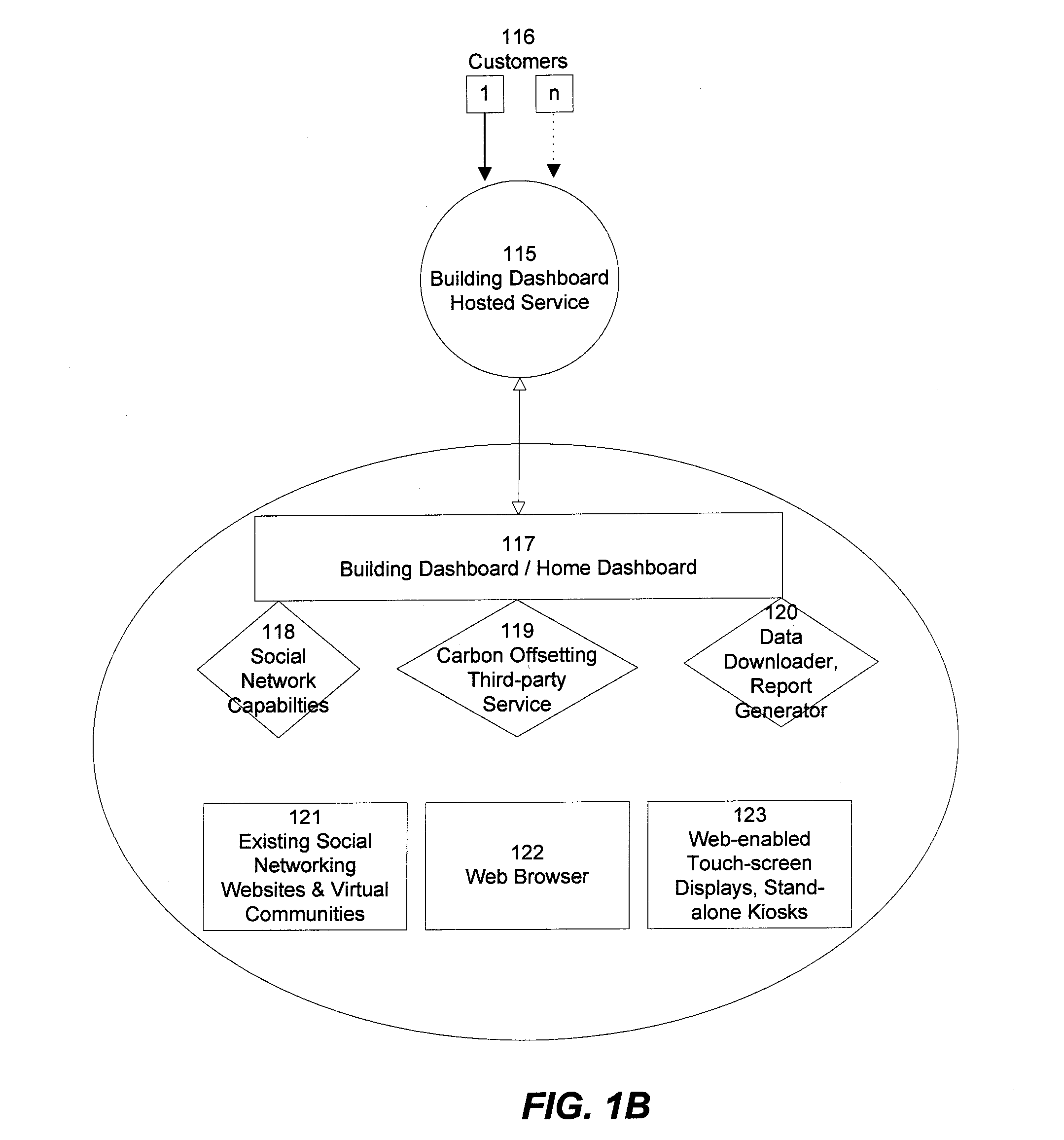

Collecting, sharing, comparing, and displaying resource usage data

ActiveUS20080306985A1Easy to compareThe effect is highlightedOffice automationCommerceGraphicsInteractive displays

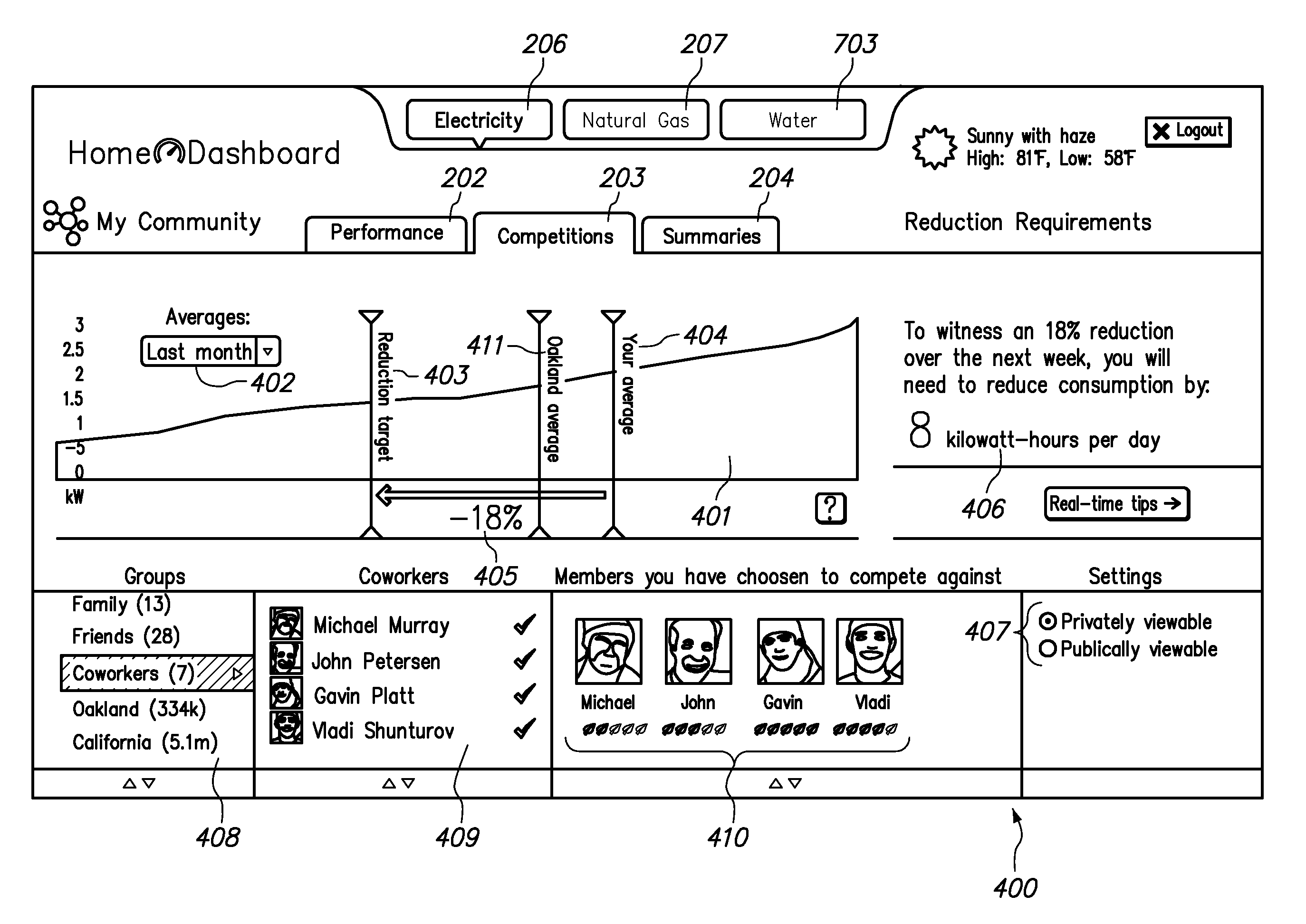

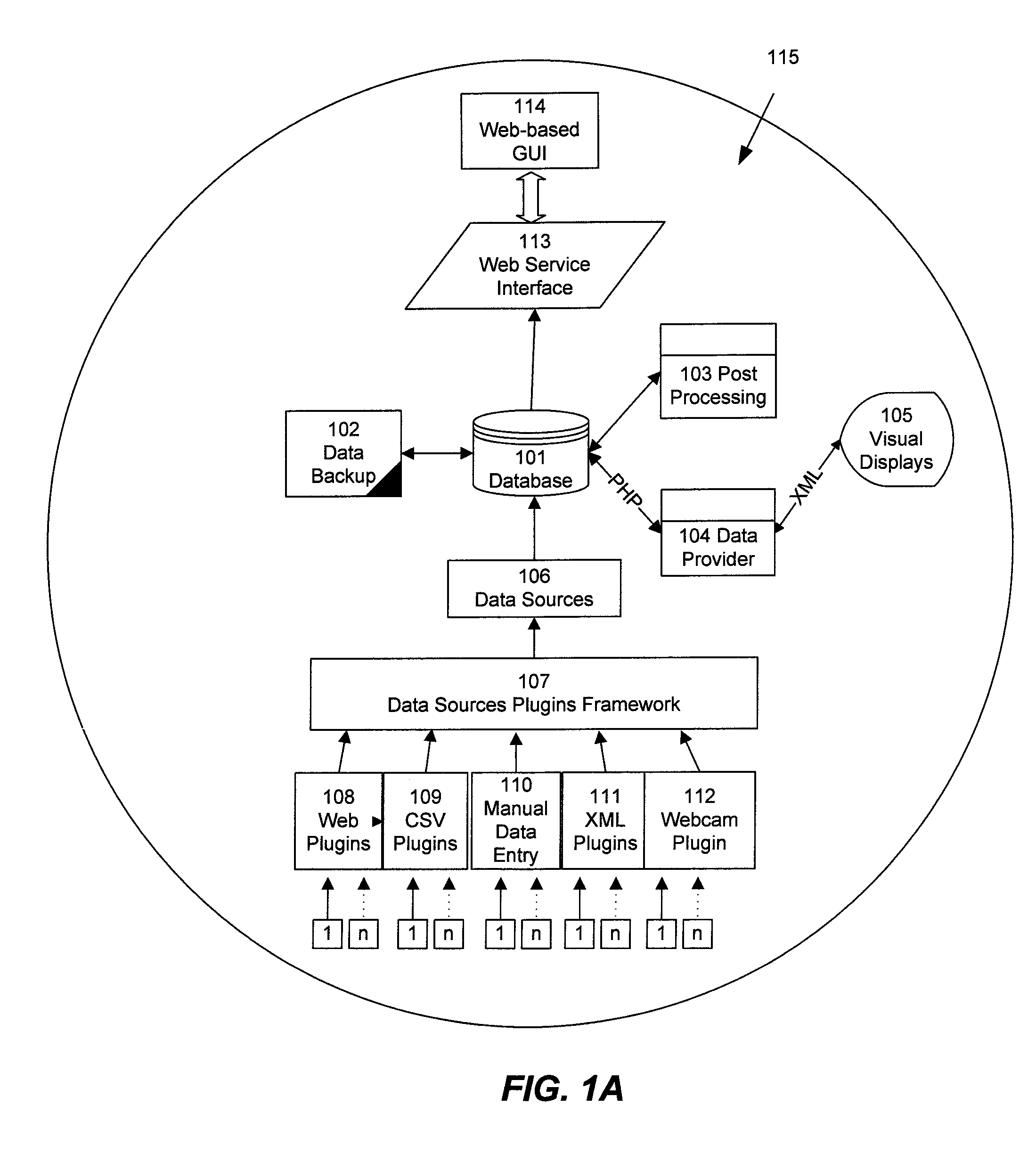

Resource usage data is automatically collected for an individual, house-hold, family, organization, or other entity. The collected data is transmitted to a central repository, where it is stored and compared with real-time and / or historical usage data by that same entity and / or with data from other sources. Graphical, interactive displays and reports of resource usage data are then made available. These displays can include comparisons with data representing any or all of community averages, specific entities, historical use, representative similarly-situated entities, and the like. Resource usage data can be made available within a social networking context, published, and / or selectively shared with other entities.

Owner:ABL IP HLDG

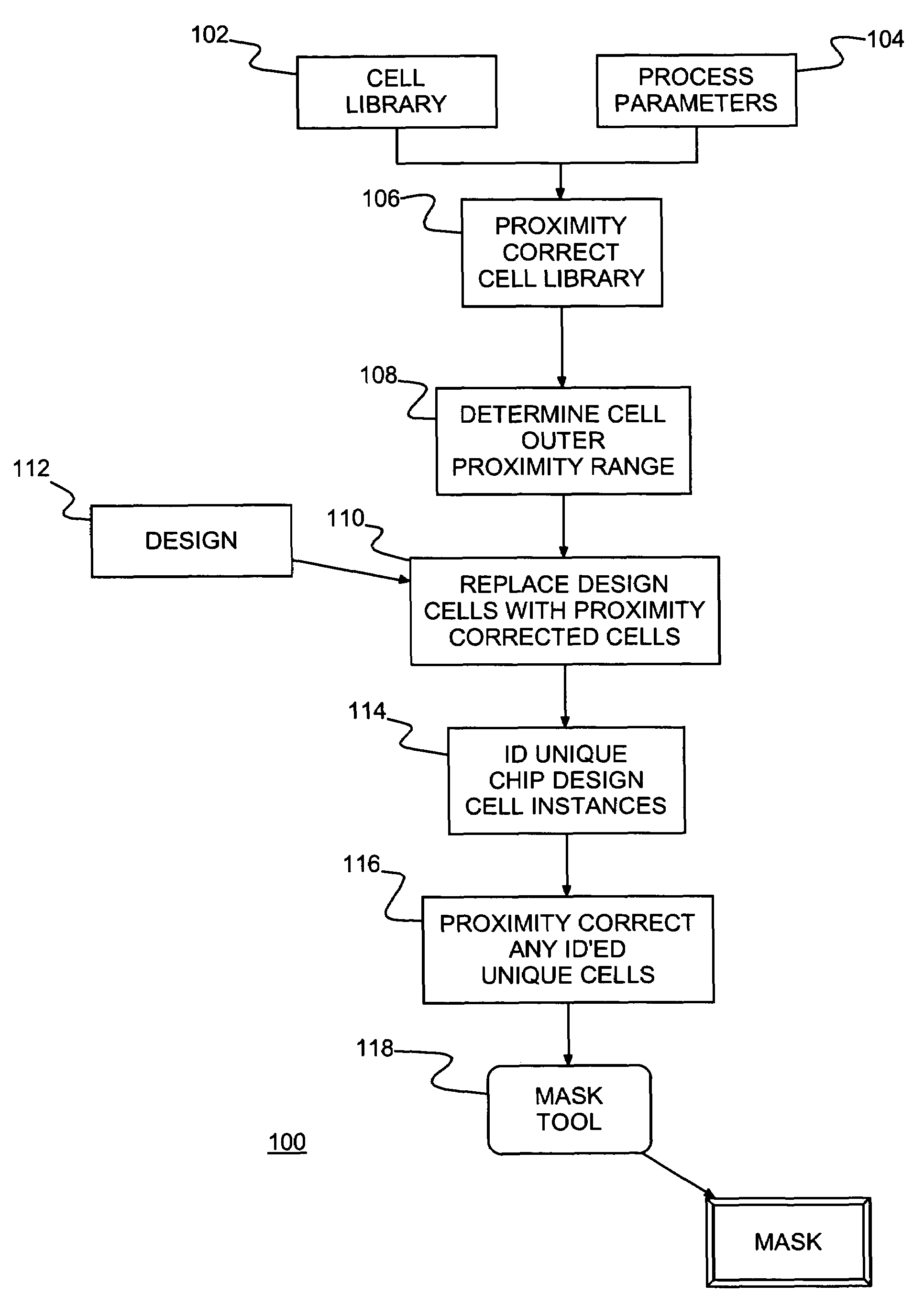

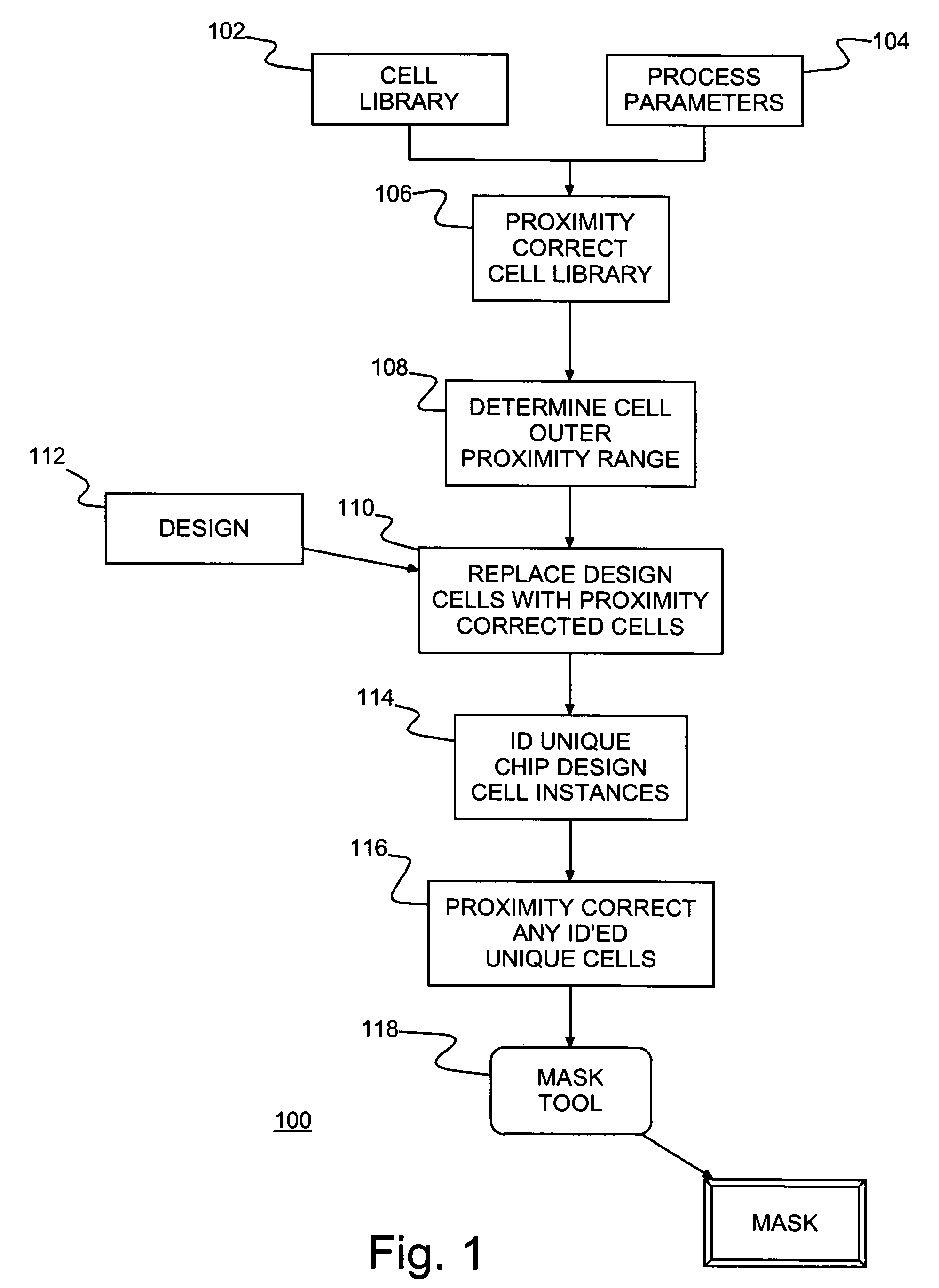

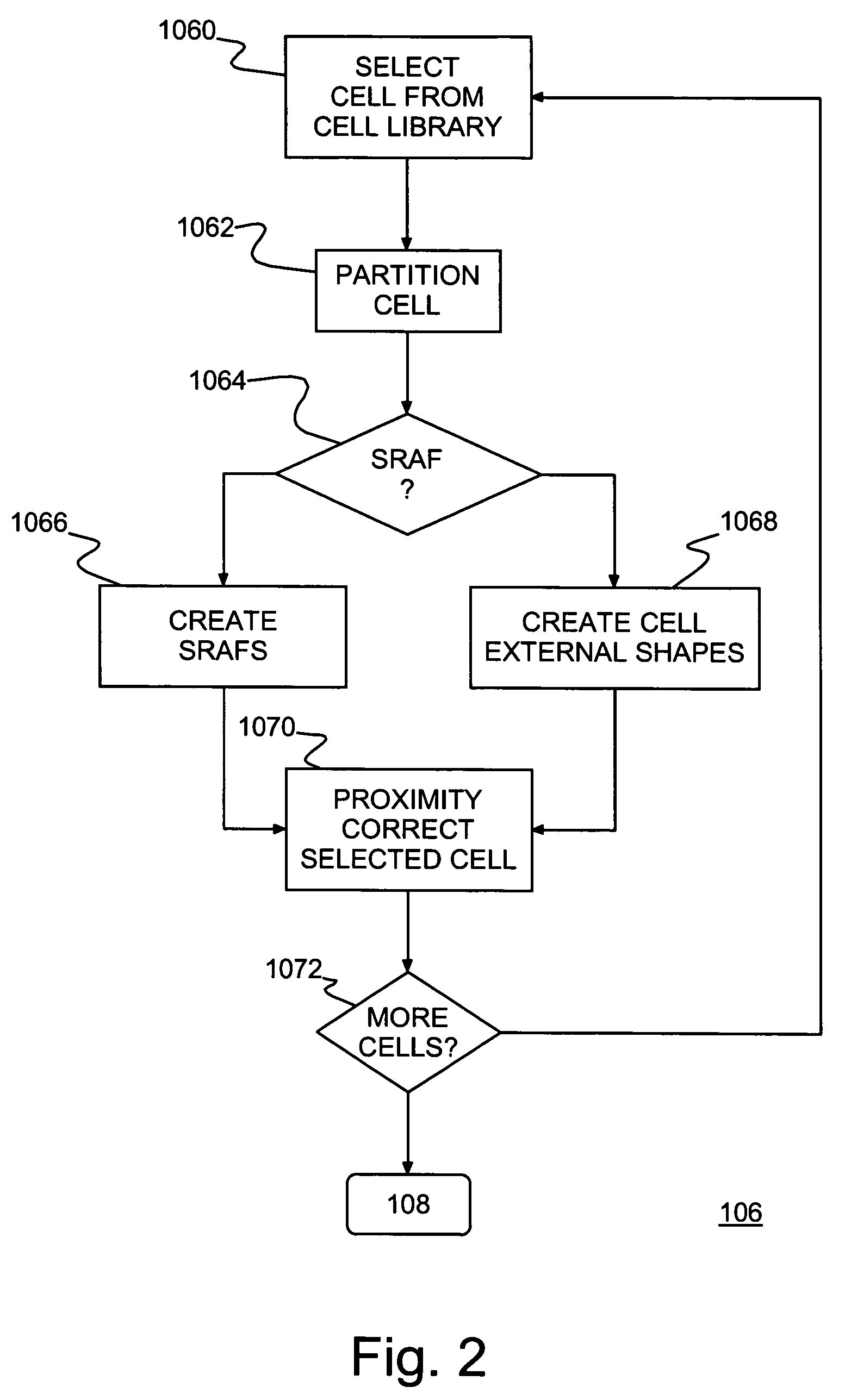

Method of IC fabrication, IC mask fabrication and program product therefor

InactiveUS7353492B2Reduce designReduce resource consumptionPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringBoundary cell

A method of forming integrated circuit (IC) chip shapes and a method and computer program product for converting an IC design to a mask, e.g., for standard cell design. Individual book / macro physical designs (layouts) are proximity corrected before unnesting and an outer proximity range is determined for each proximity corrected physical design. Shapes with a unique design (e.g., in boundary cells and unique instances of books) are tagged and the design is unnested. Only the unique shapes are proximity corrected in the unnested design, which may be used to make a mask for fabricating IC chips / wafers.

Owner:GOOGLE LLC

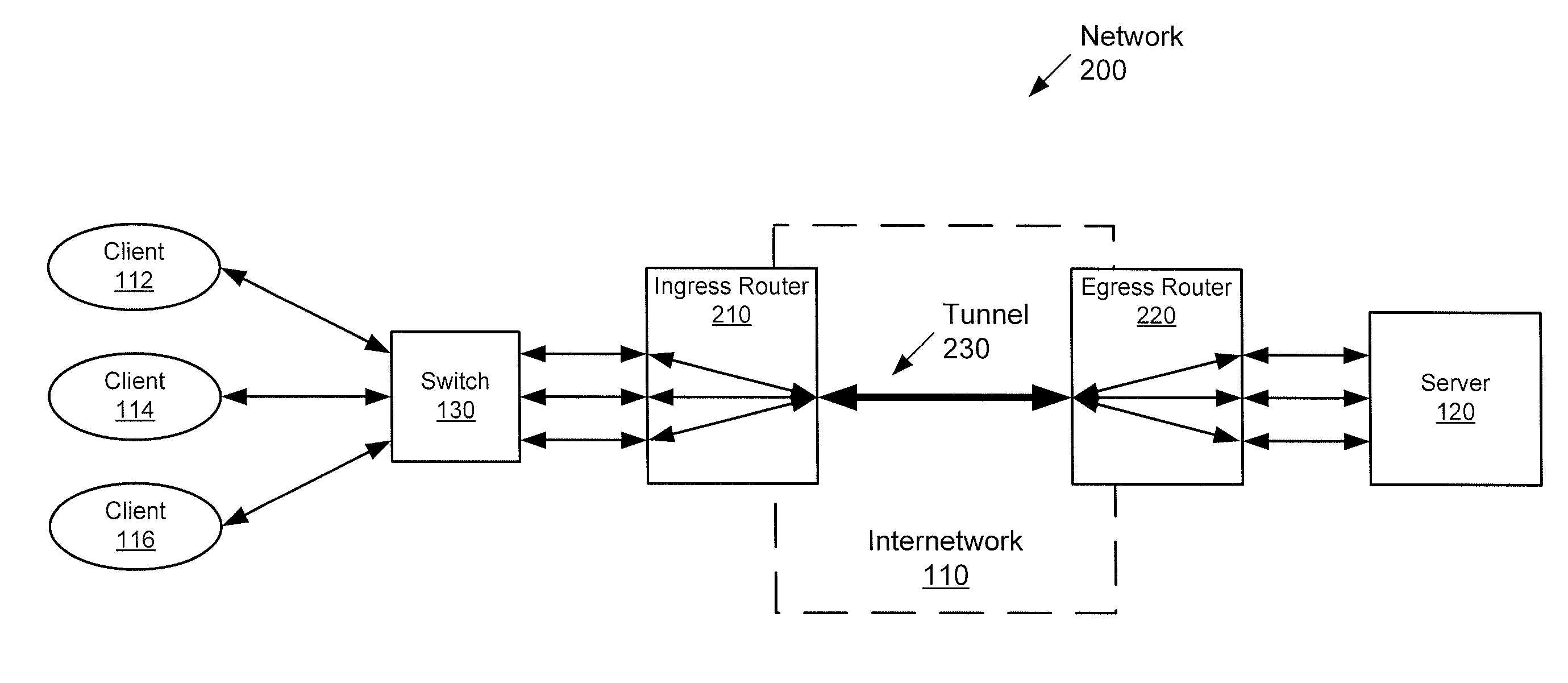

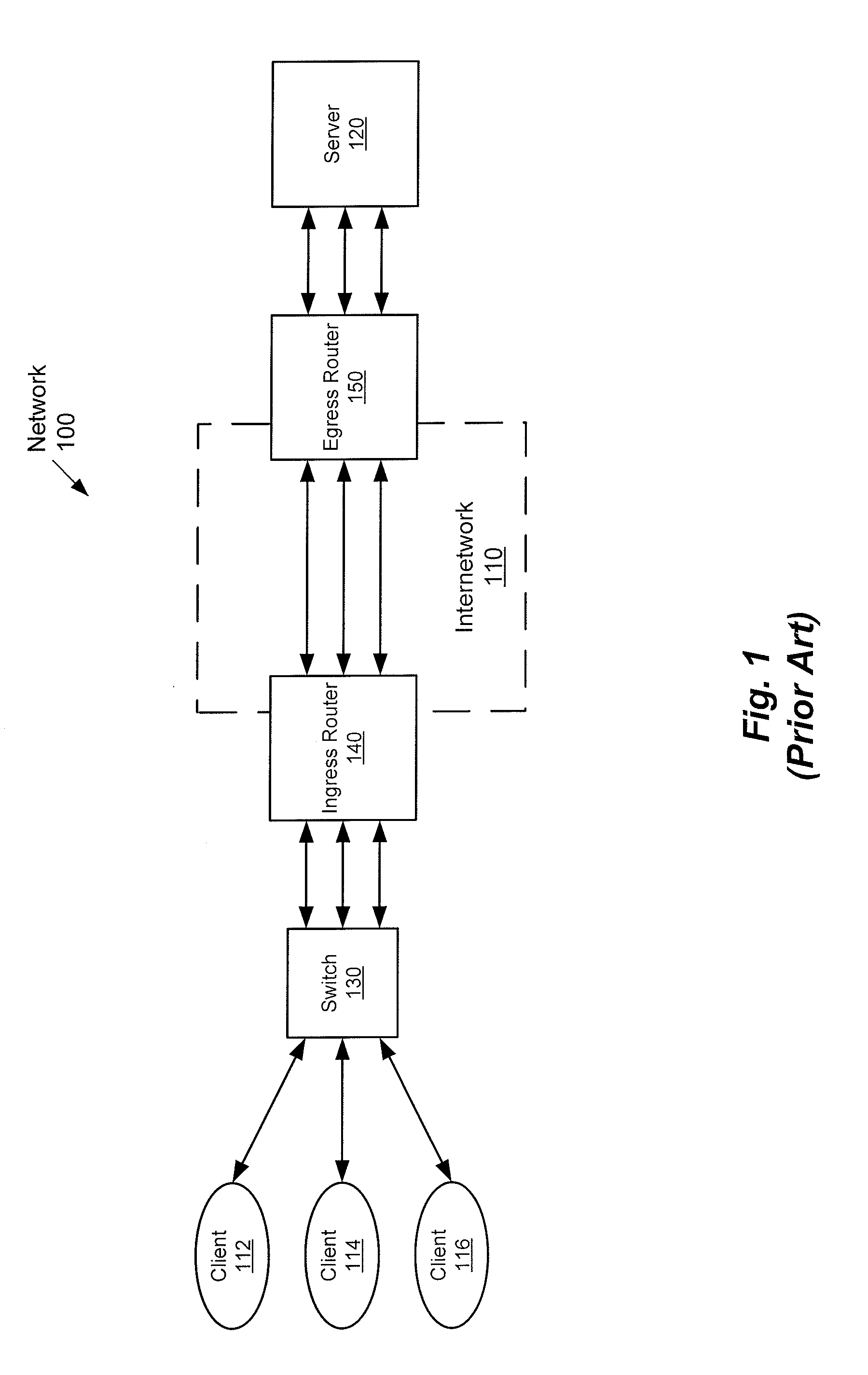

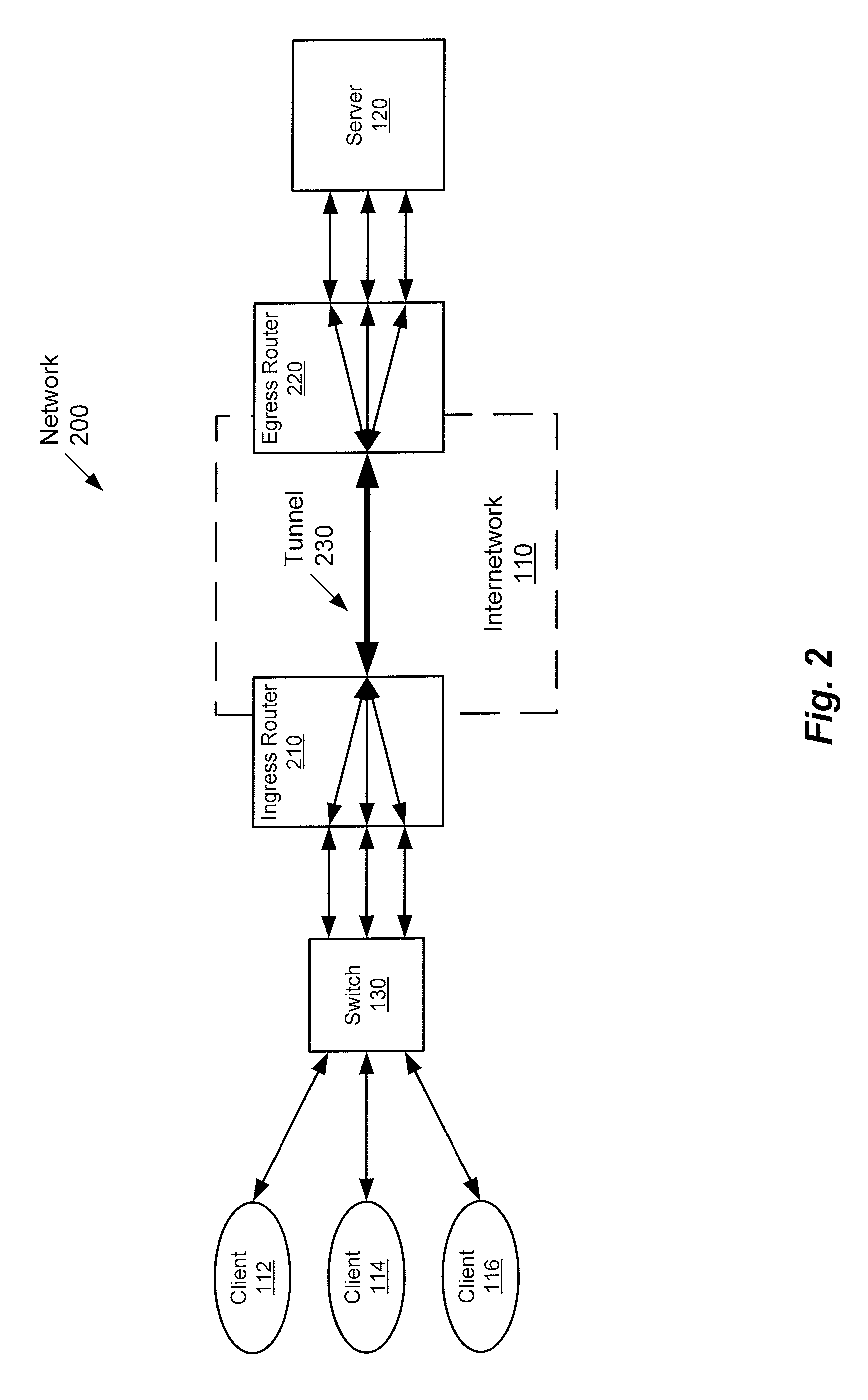

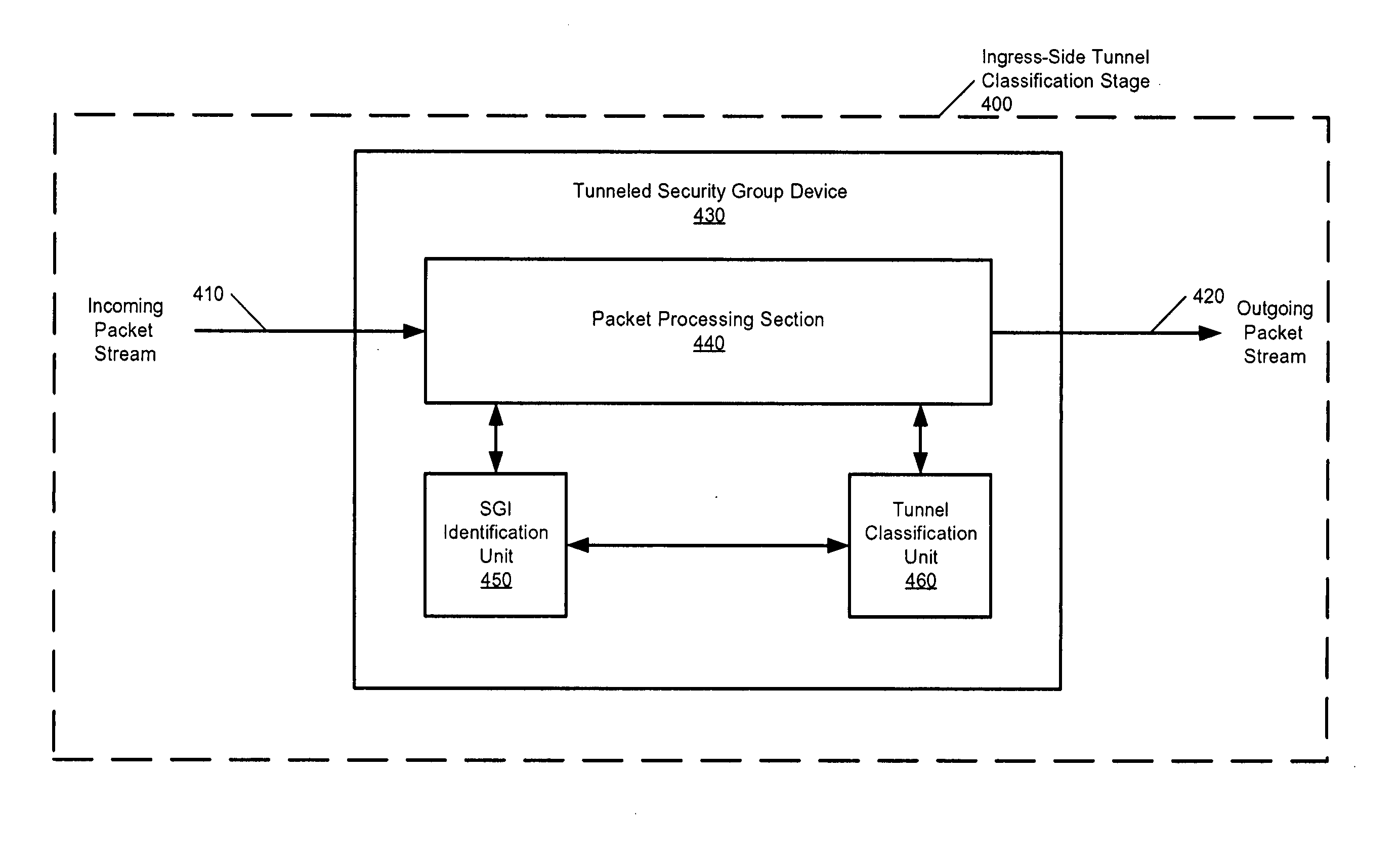

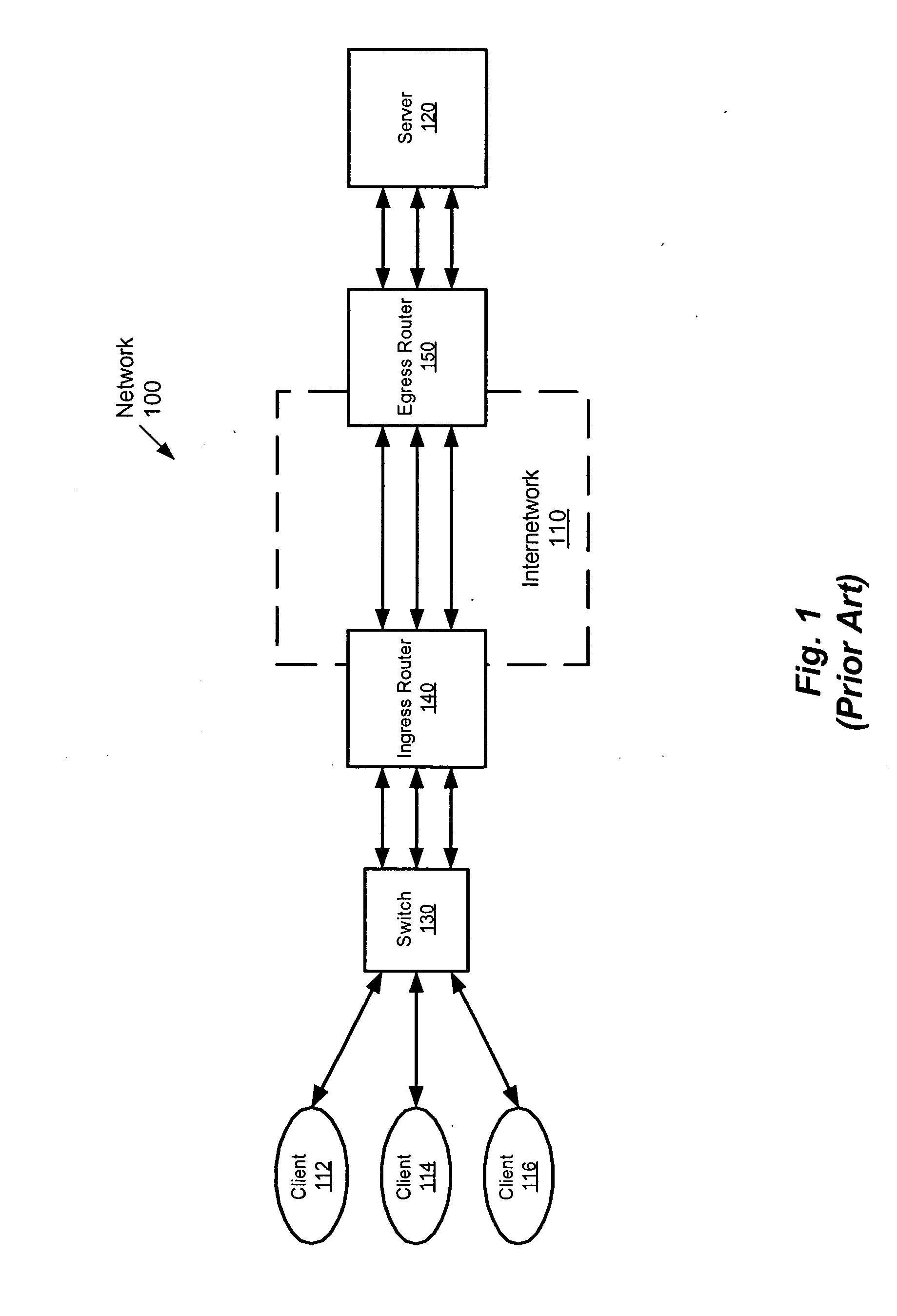

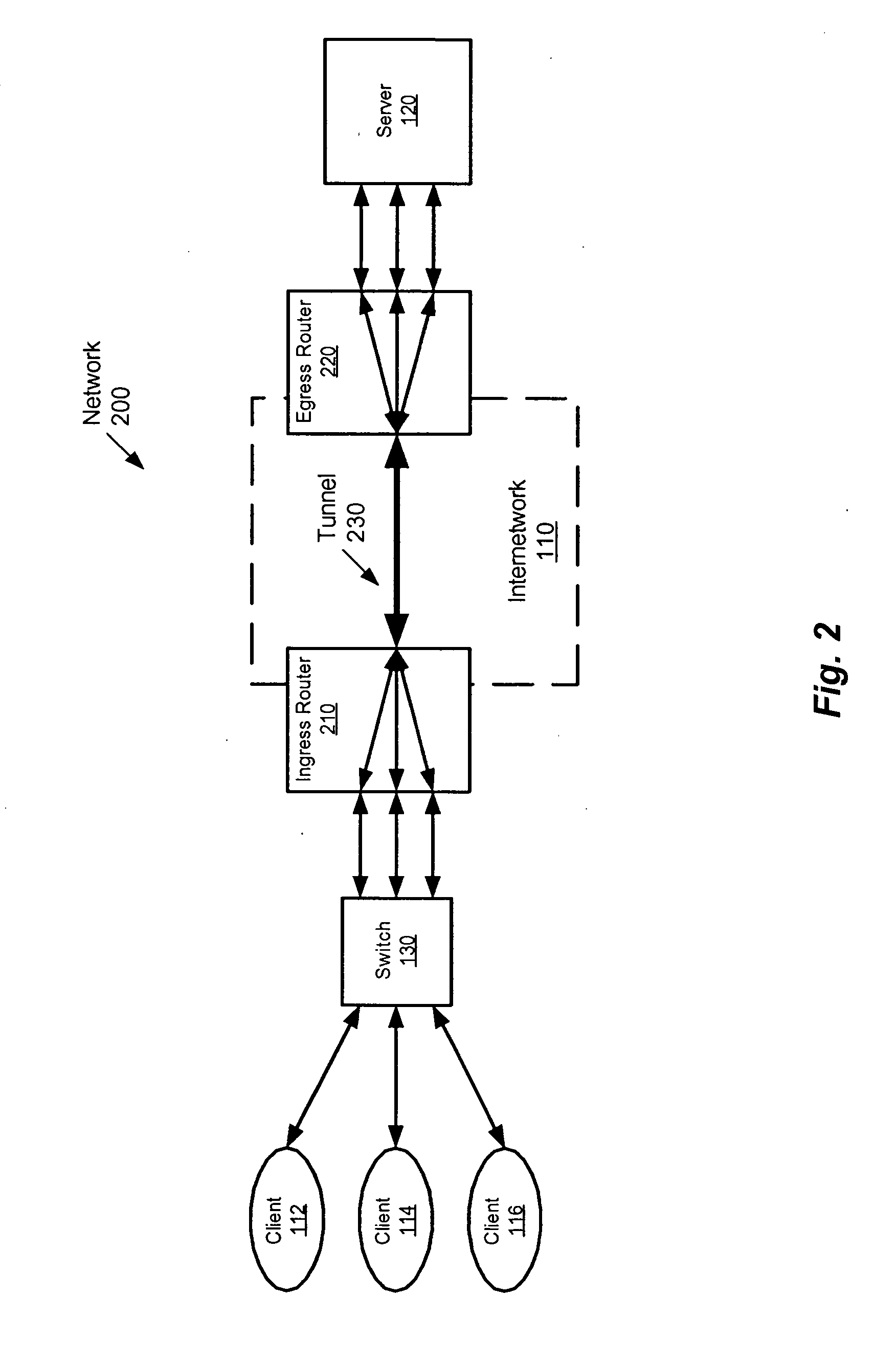

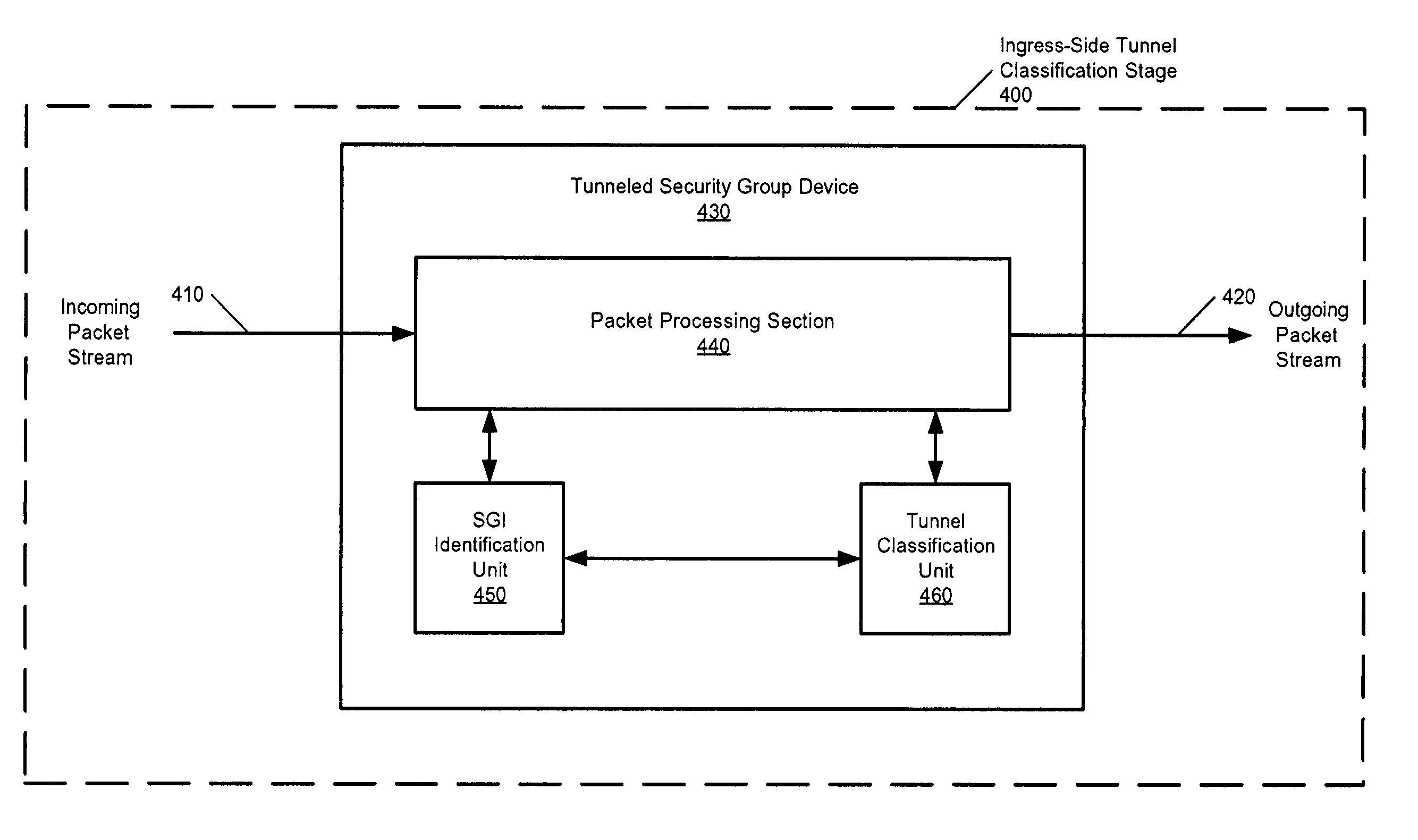

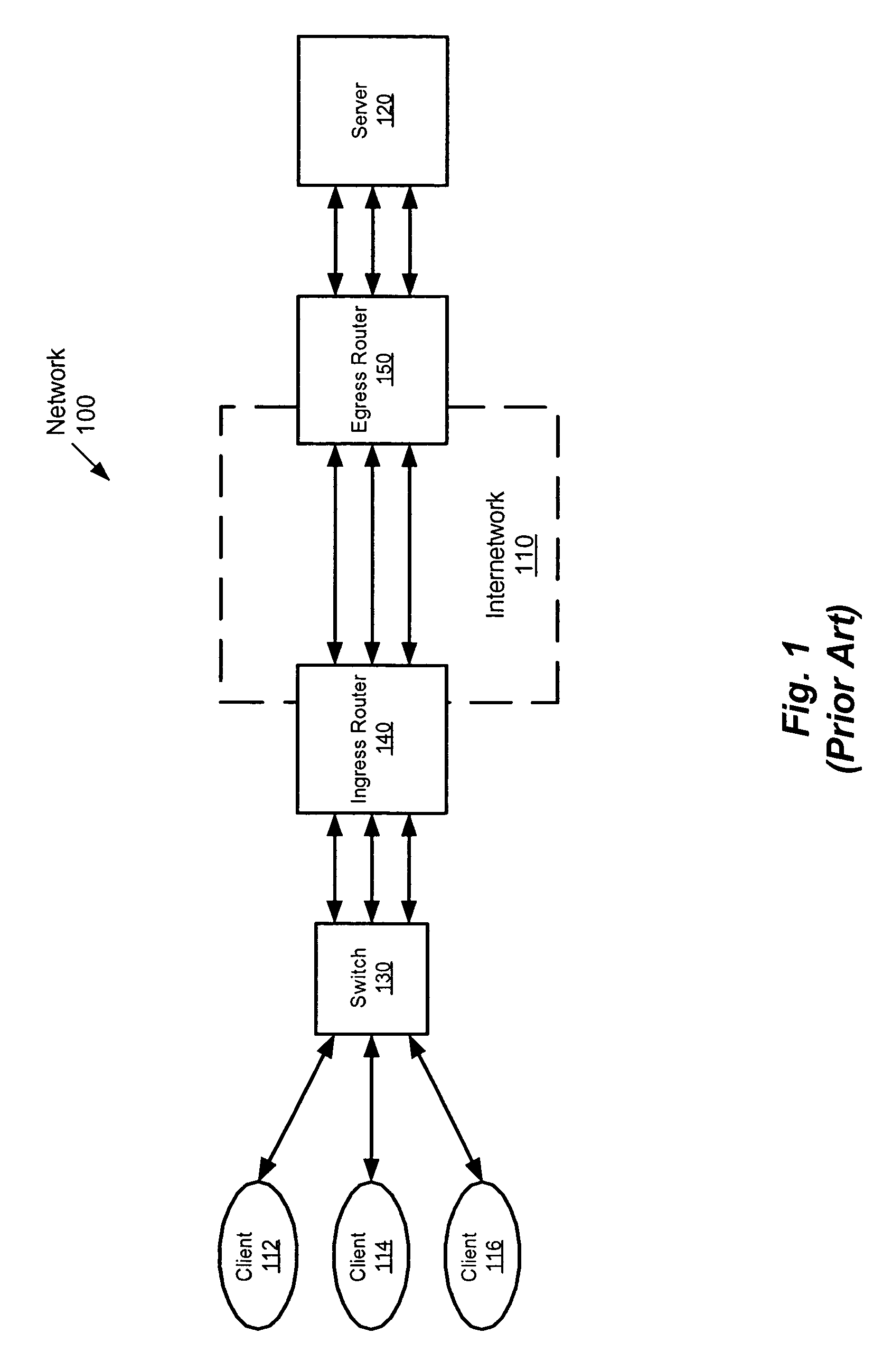

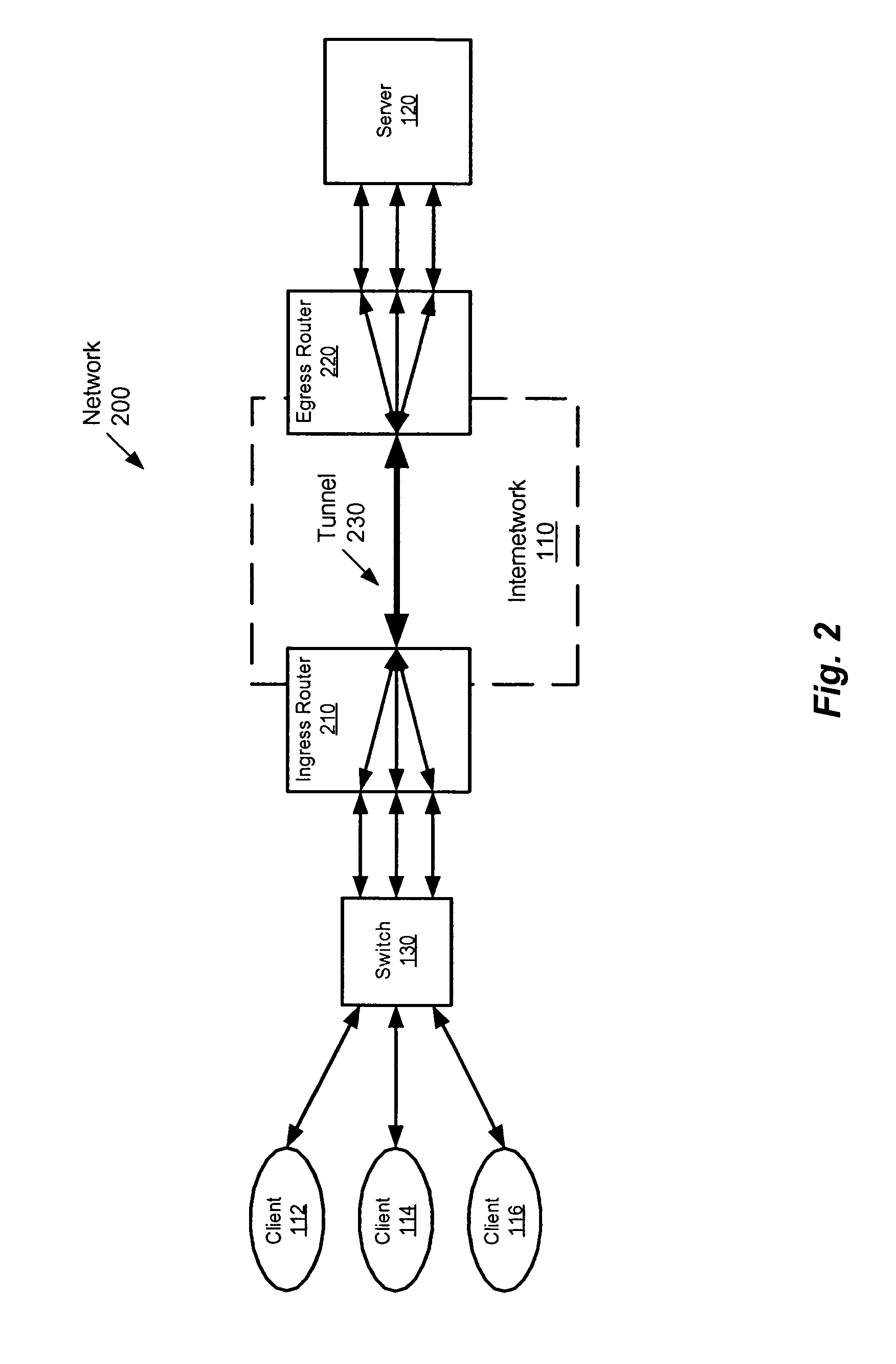

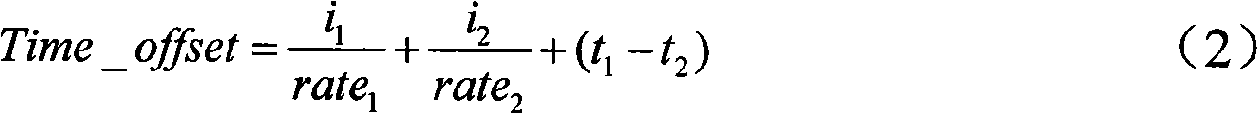

Tunneled Security Groups

InactiveUS20120131643A1Reduce in quantityImprove network efficiencyDigital data processing detailsComputer security arrangementsGroup identifierComputer security

A method for providing security groups based on the use of tunneling is disclosed. The method includes assigning a security group identifier (SGI) to a packet and classifying the packet based on the packet's SGI.

Owner:CISCO TECH INC

Tunneled security groups

ActiveUS20050129019A1Reduce in quantityImprove network efficiencyMultiple digital computer combinationsProgram controlGroup identifierComputer security

A method for providing security groups based on the use of tunneling is disclosed. The method includes assigning a security group identifier (SGI) to a packet and classifying the packet based on the packet's SGI.

Owner:CISCO TECH INC

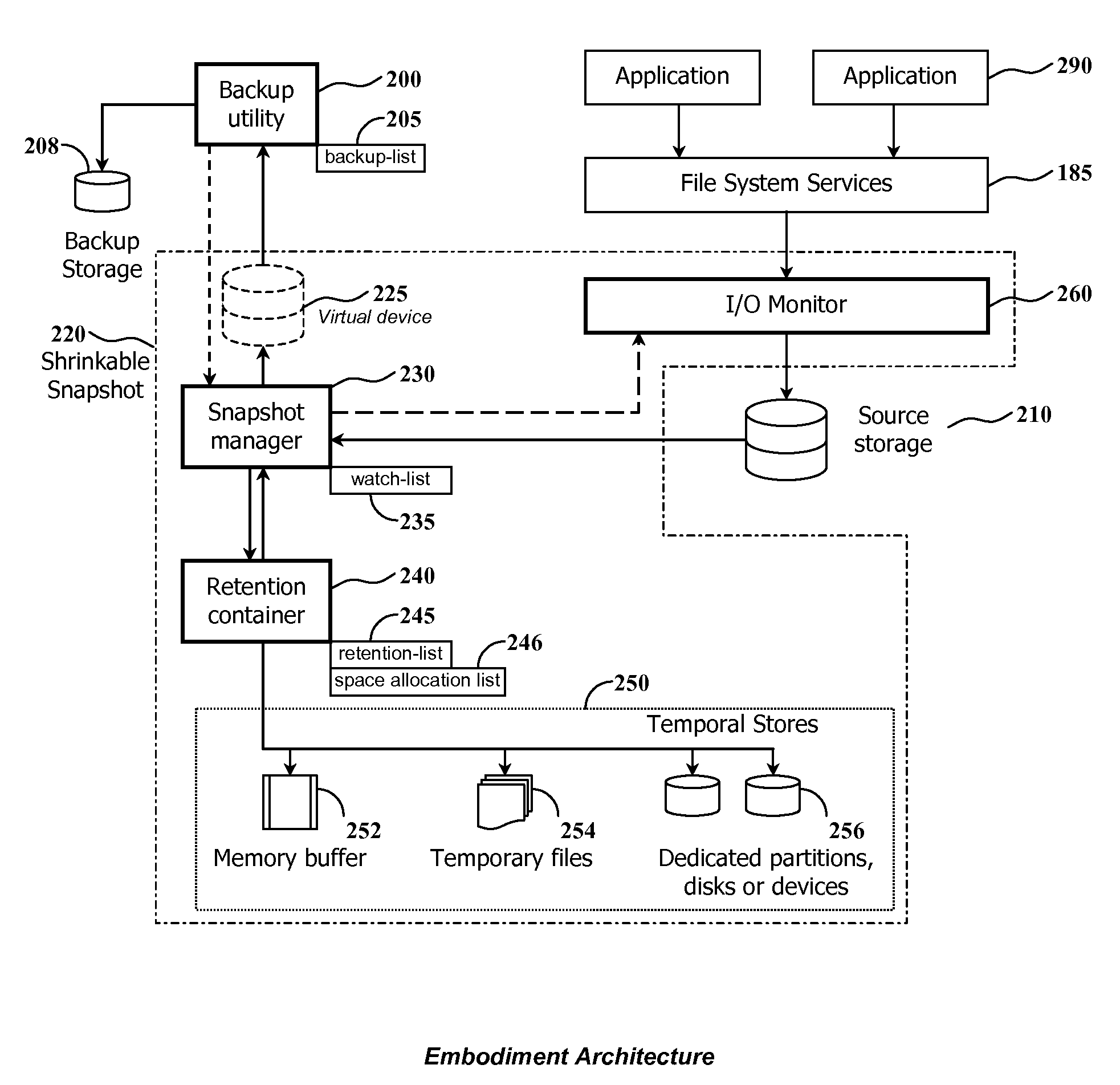

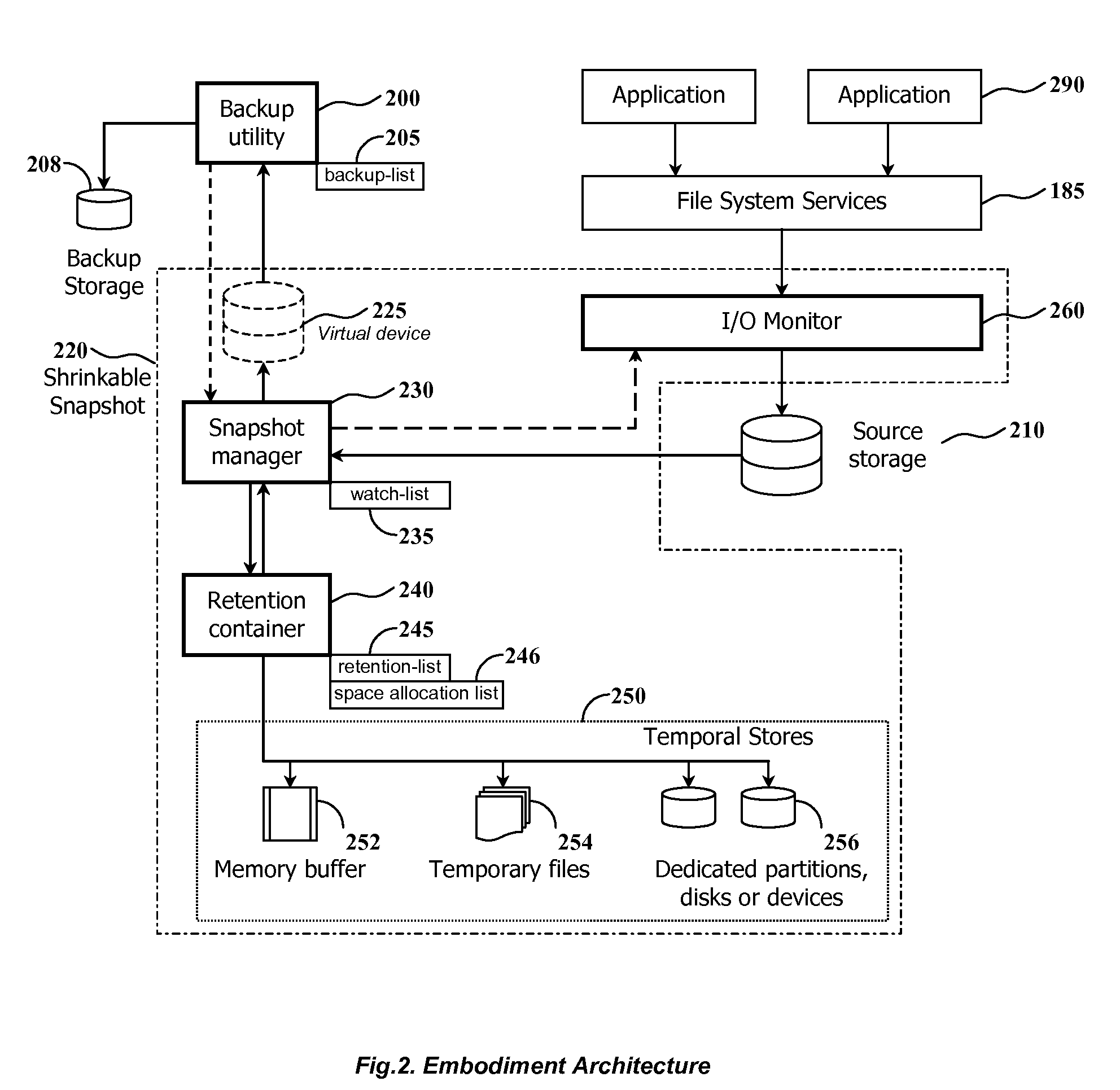

Using shrinkable read-once snapshots for online data backup

InactiveUS20080082593A1Improve performanceEasy to useDigital data information retrievalError detection/correctionRetention timeWatch list

The present invention discloses a method and system for snapshot-based online backup operations permitting reduced requirements to storage capacity and computational overhead for snapshot function.At the beginning of an online backup operation, the backup software system creates a snapshot of source data storage. The snapshot includes a watch-list used for identifying blocks of a source storage which are watched by snapshot management means for update. If a block included into the watch-list was requested for update, the snapshot management means preserve original contents of that block in a retention container for the purpose of temporary store. The retention container includes a set of temporal stores dedicated for transient storing of blocks until they are backed up.The essence of the invention is enabling to exclude blocks from the watch-list and the retention container at any moment within the period of snapshot operation. Therefore it is possible to exclude unnecessary blocks from the scope of blocks managed by the snapshot management means, for the purpose of preserving point-in-time data.Backed up blocks can be operatively excluded from the snapshot so that unchanged blocks are excluded from the watch-list and updated blocks are removed from the retention container. In the latter case temporal stores are shrunk as well. This technique allows to reduce progressively storage expenses and computational overheads required for maintenance of a snapshot being used in the online backup routine.When a volume-level online backup is performed the snapshot is switched to the read-once mode at the beginning of the data copying stage. A backup utility performs sequential read of blocks from the snapshot. The snapshot management means automatically exclude requested blocks from the scope of managed blocks.

Owner:PARAGON SOFTWARE GMBH

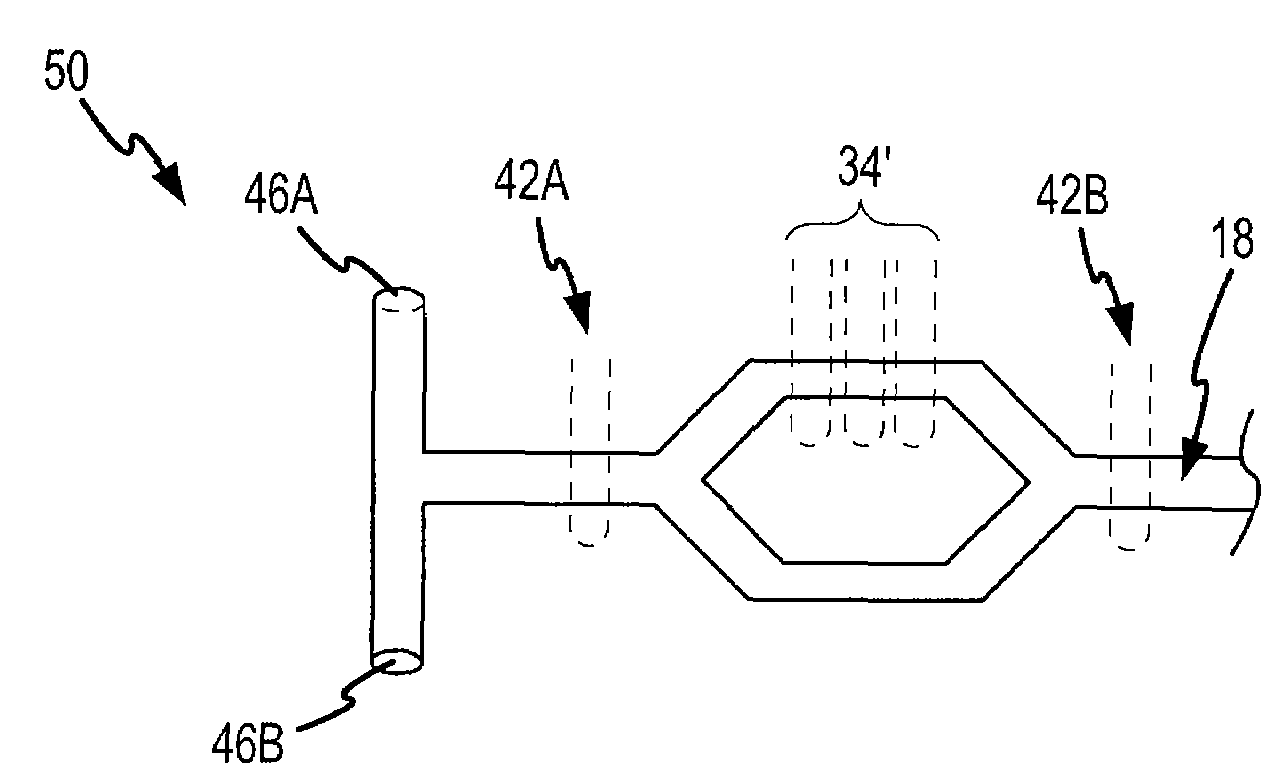

Microfluidic-based electrospray source for analytical devices with a rotary fluid flow channel for sample preparation

InactiveUS7442556B2Low costReduce resource consumptionParticle separator tubesFixed microstructural devicesElectrosprayAnalytical chemistry

Owner:FLUIDIGM CORP

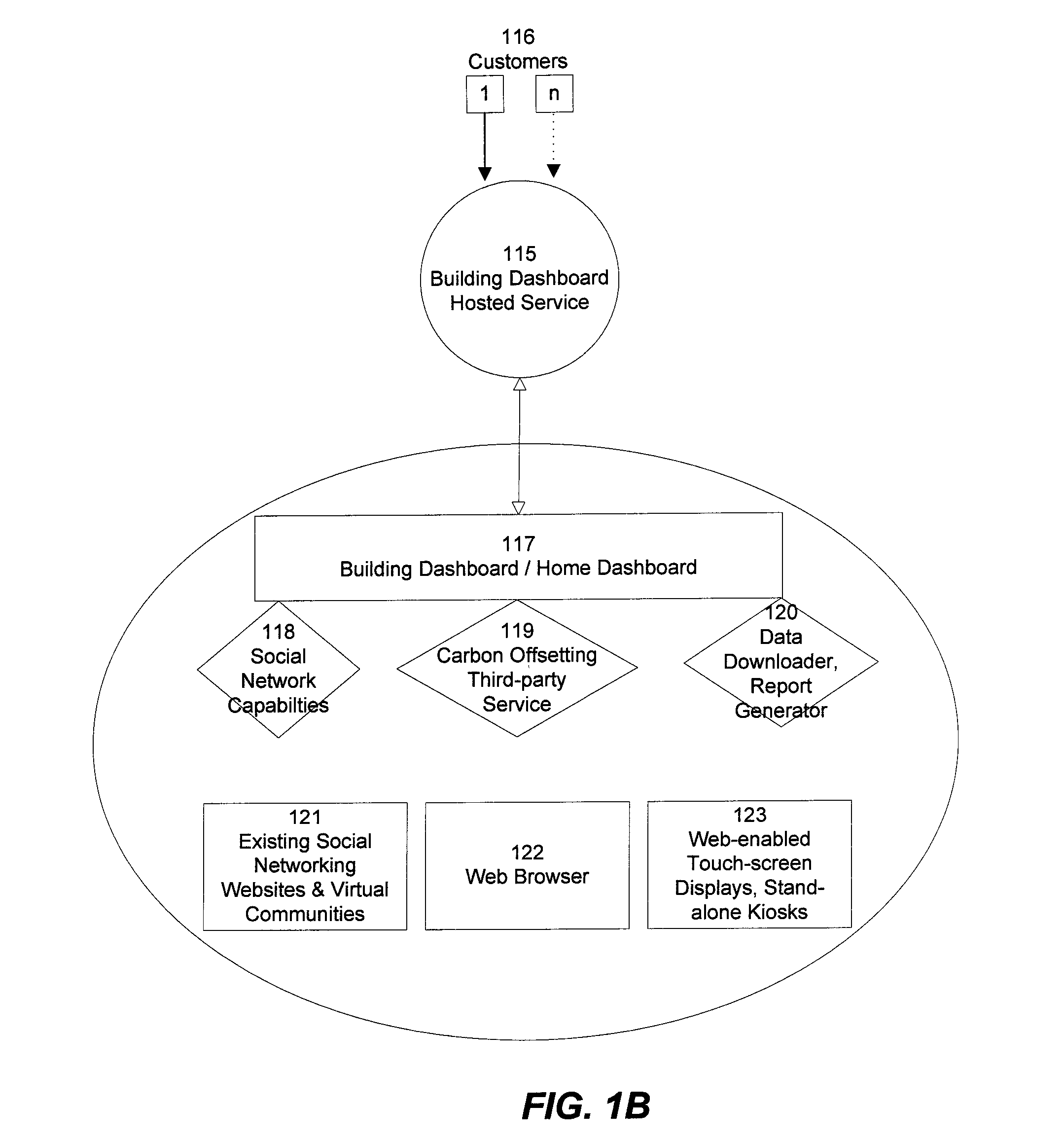

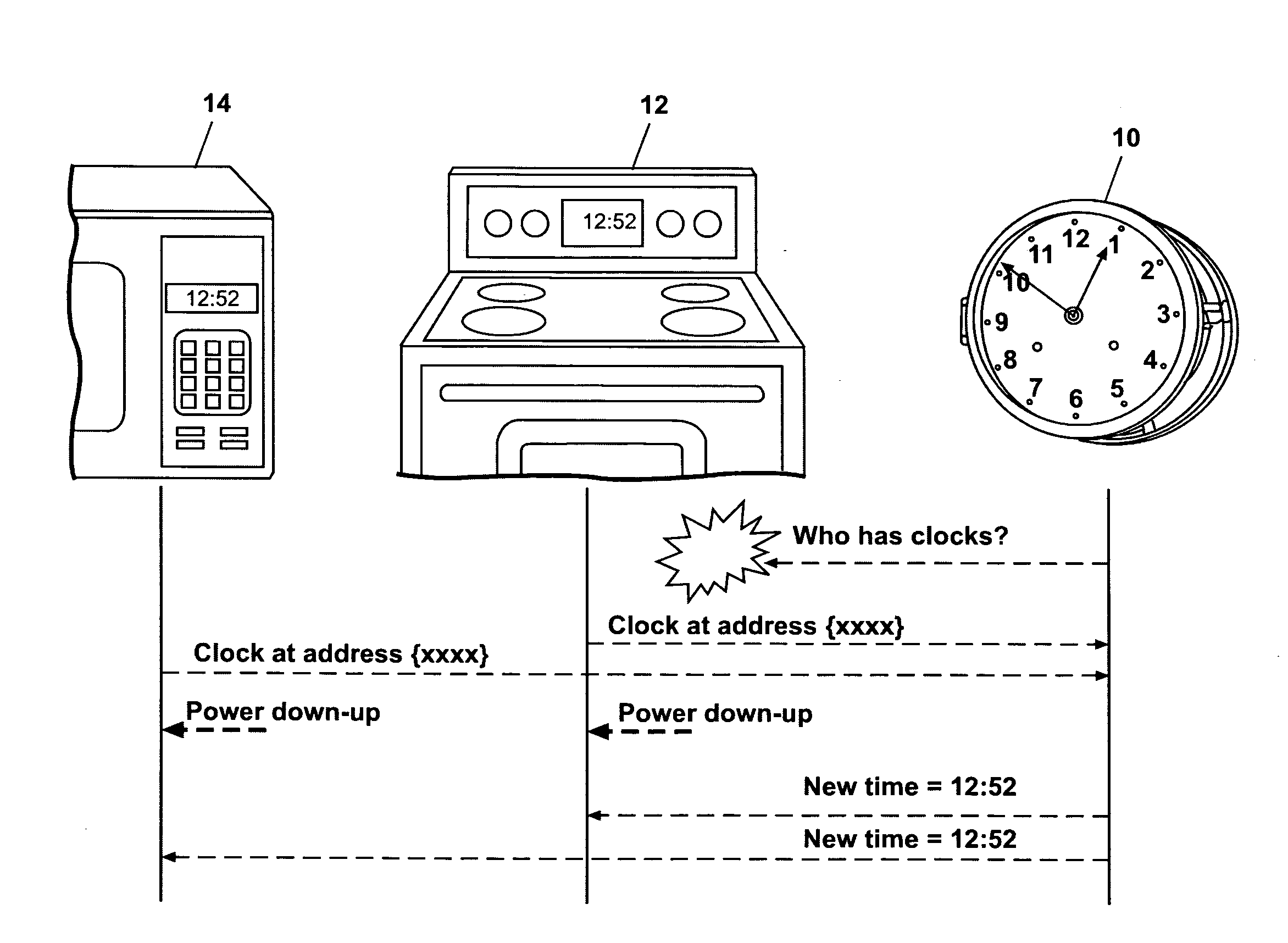

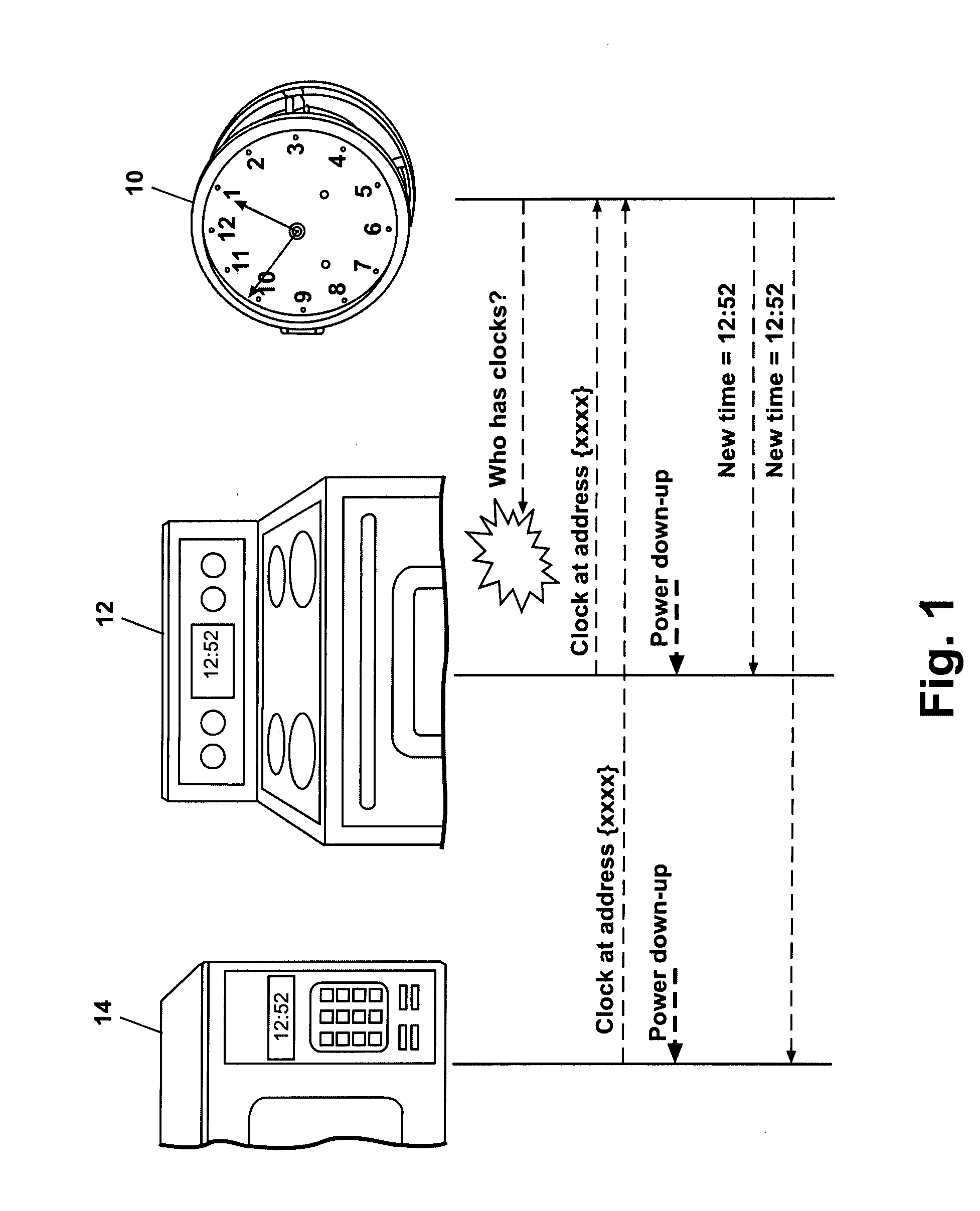

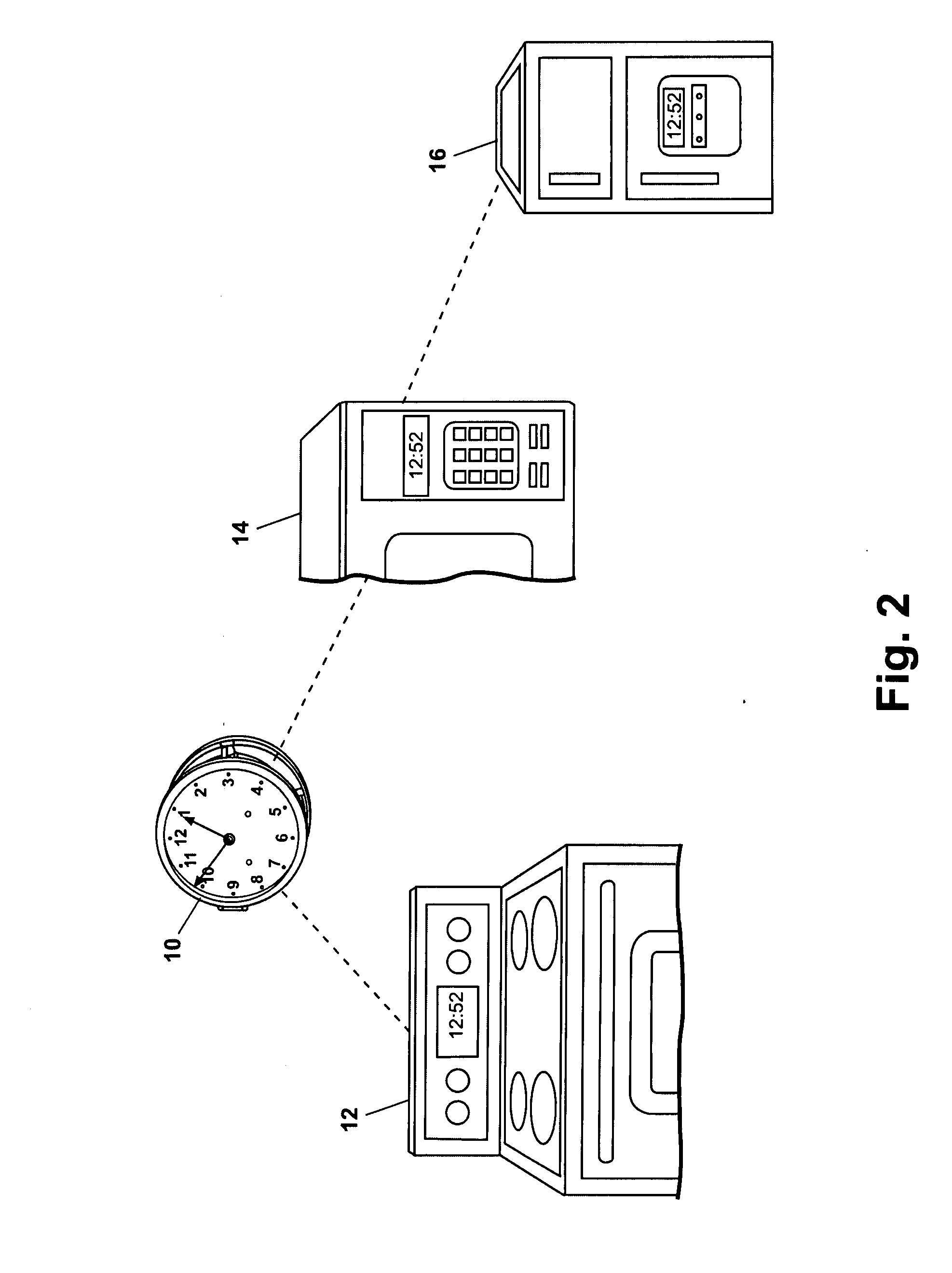

Collecting, sharing, comparing, and displaying resource usage data

ActiveUS8176095B2Save resourcesConservation usageDigital data processing detailsOffice automationGraphicsInteractive displays

Resource usage data is automatically collected for an individual, household, family, organization, or other entity. The collected data is transmitted to a central repository, where it is stored and compared with real-time and / or historical usage data by that same entity and / or with data from other sources. Graphical, interactive displays and reports of resource usage data are then made available. These displays can include comparisons with data representing any or all of community averages, specific entities, historical use, representative similarly-situated entities, and the like. Resource usage data can be made available within a social networking context, published, and / or selectively shared with other entities.

Owner:ABL IP HLDG

Network for changing resource consumption in an appliance

ActiveUS20080122585A1Reduce resource consumptionReduce consumptionMechanical power/torque controlLevel controlResource consumptionSoftware

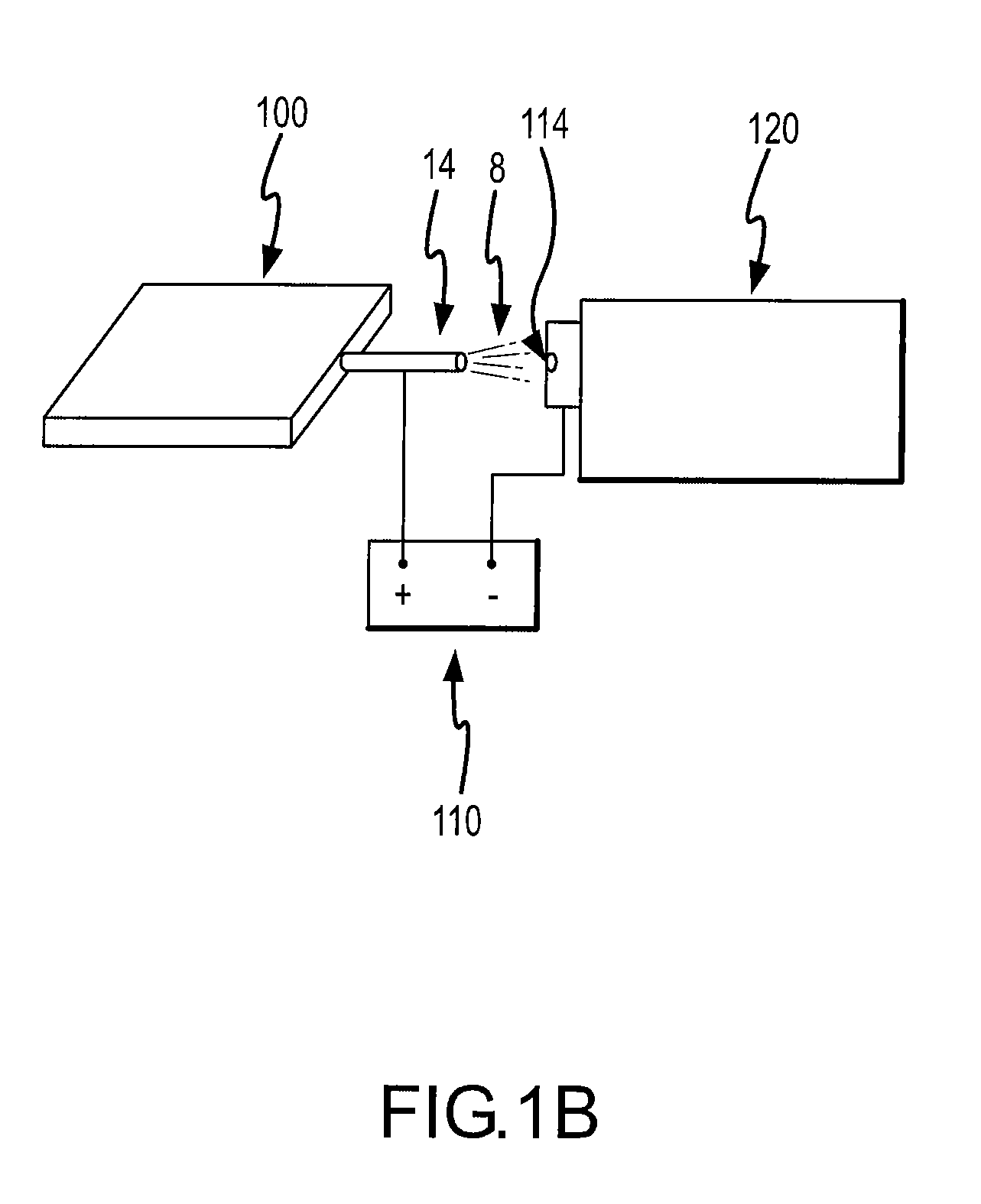

A network includes a smart coupler having a processor, a memory with software, and a power source to energize the processor and the memory, and an appliance configured to perform an operation on a physical article. The appliance is one that consumes at least some of a resource in performing the operation. The network also includes a source of information about the resource. The smart coupler is in communication with the appliance and the source, and the processor and memory operate to request a change to the operation of the appliance in response to a resource parameter or a request communicated by the source.

Owner:WHIRLPOOL CORP

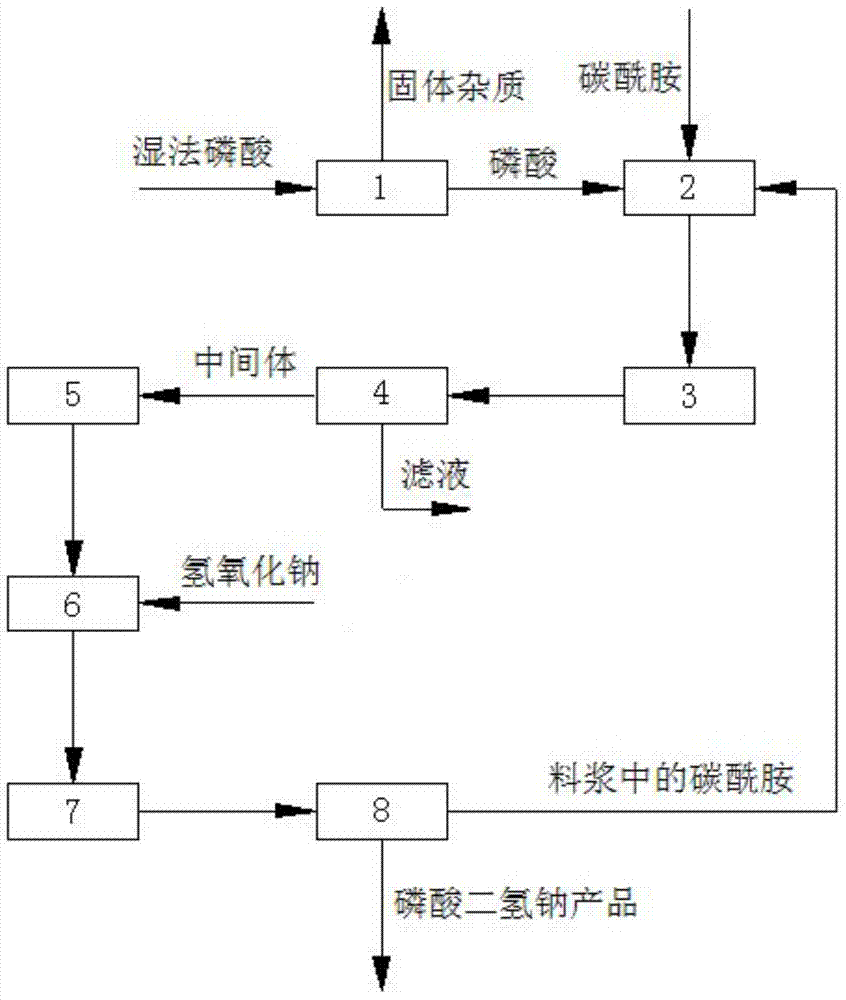

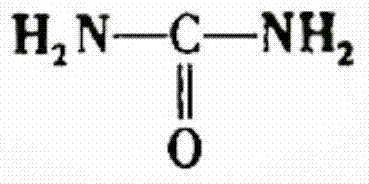

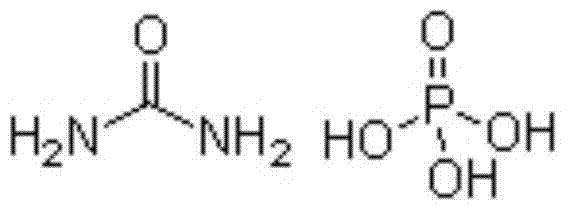

Method for preparing sodium dihydrogen phosphate by utilizing phosphoric acid by wet process

InactiveCN103787293AReduce manufacturing costShort process routePhosphorus compoundsHigh energyPhosphoric acid

The invention discloses a method for preparing sodium dihydrogen phosphate by utilizing phosphoric acid by wet process. The method comprises the steps of carrying out reaction on carbamide and the phosphoric acid by the wet process to obtain intermediate, and then carrying out a reaction on the intermediate and sodium hydroxide to obtain the sodium dihydrogen phosphate product. The method is short in process route, low in energy consumption, stable in product quality, low in production cost, convenient to operate and safe in production; the by-product slurry can be completely recycled; the whole production process is environment-friendly, clean and free from pollution as well as emission of waste gas, waste water and waste residue; therefore, the method responses to the policy of energy conservation and emission reduction as well as clean production, and solves the problems of complicated technology, unstable product quality, high energy consumption, environmental pollution and the like in the prior art; the obtained sodium dihydrogen phosphate product has the purity of more than or equal to 98%.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

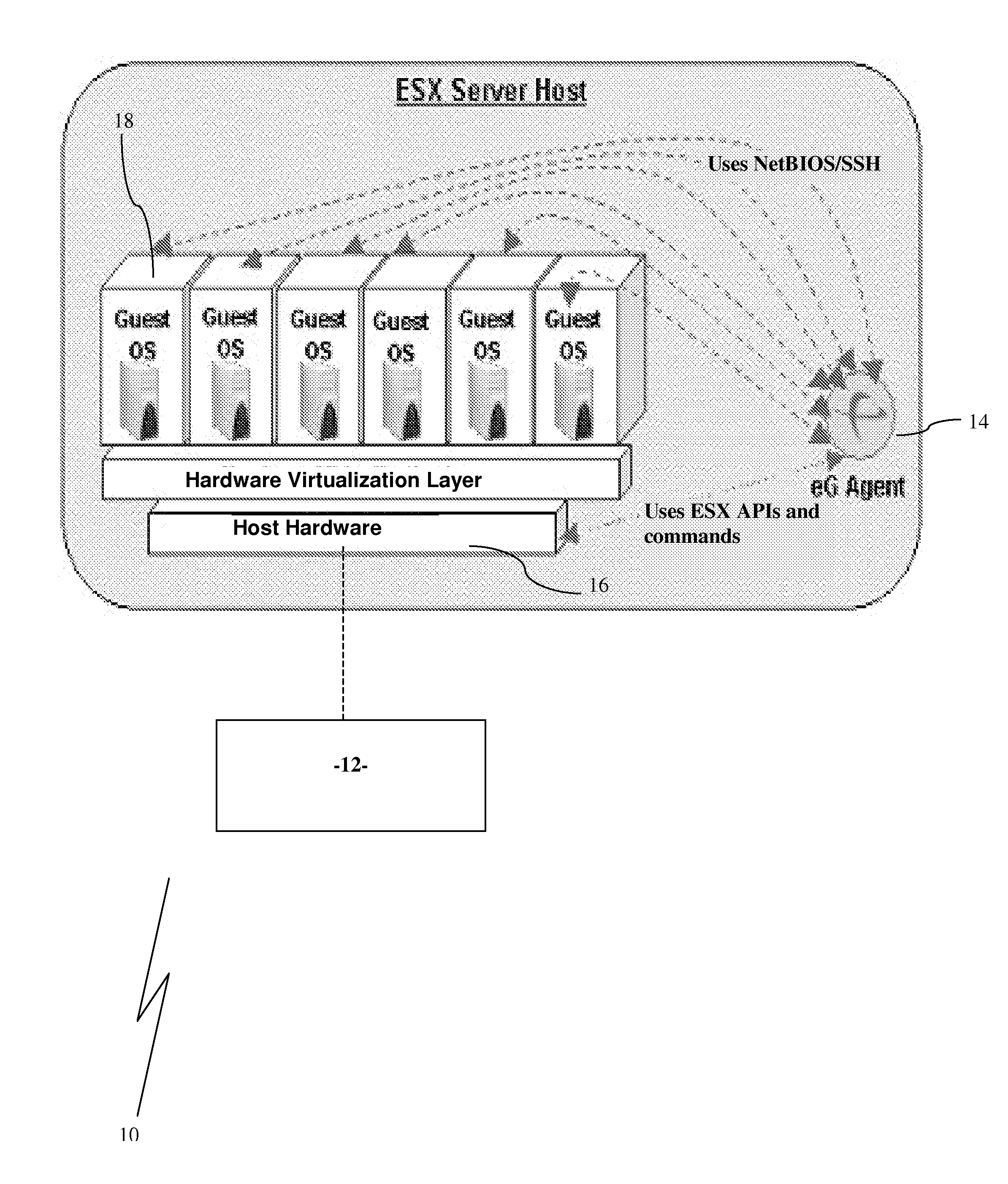

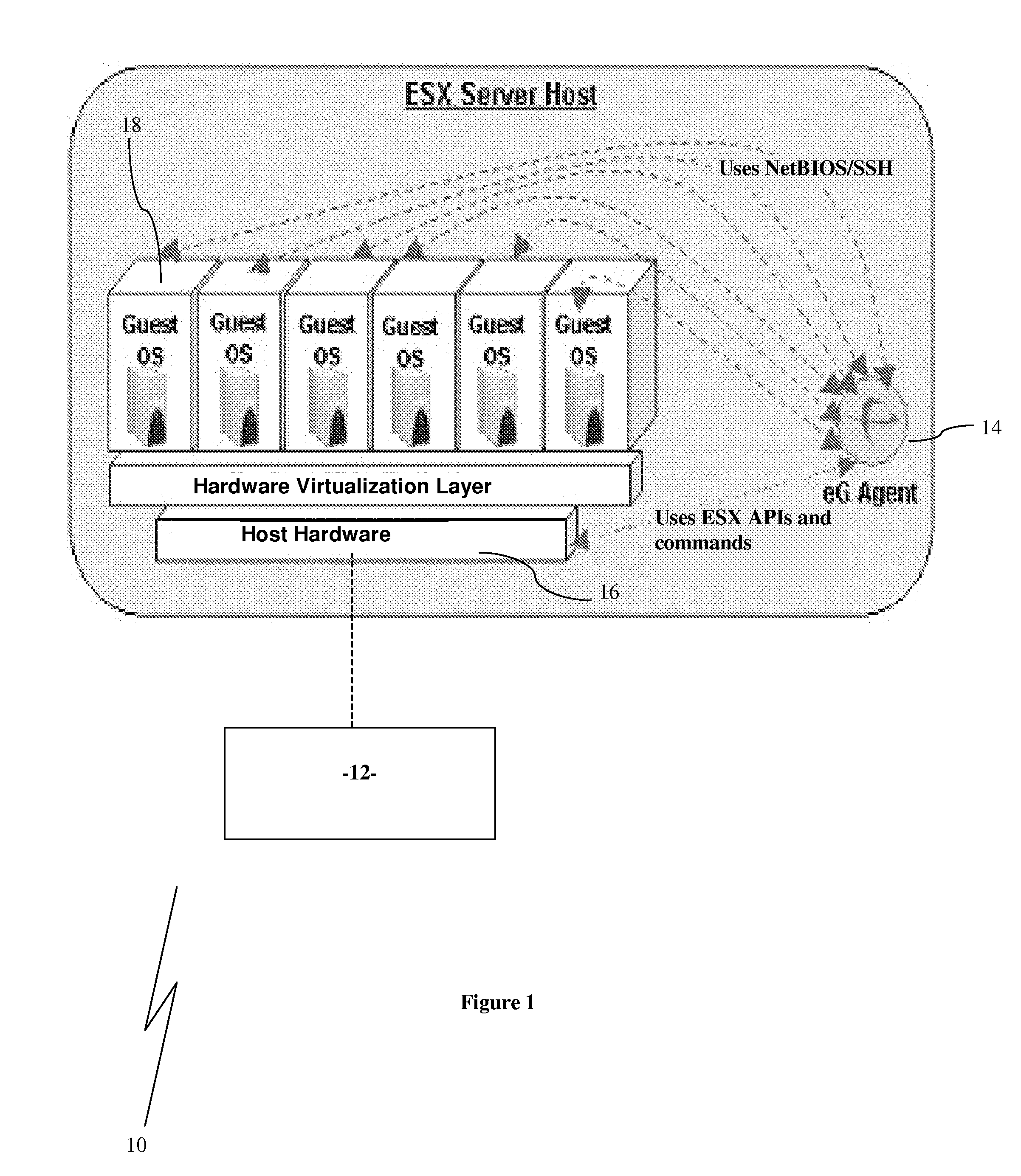

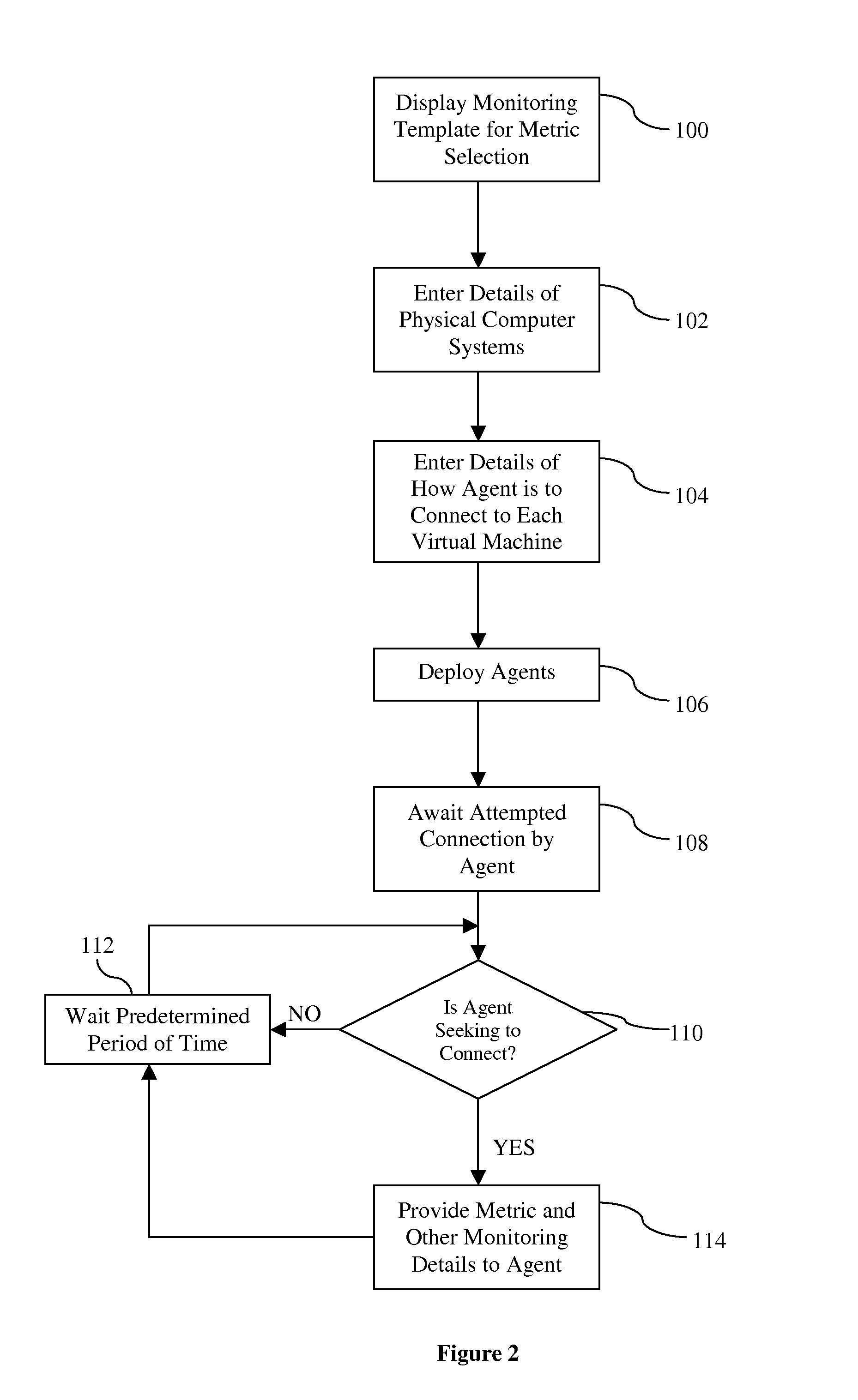

Monitoring System for Virtual Application Environments

ActiveUS20090024994A1Reduce resource consumptionEasy maintenanceError detection/correctionSoftware simulation/interpretation/emulationOperational systemMonitoring system

A monitoring system for virtual application environments comprising: at least one physical machine executing a first operating system; at least one virtual machine operating on at least one of the at least one physical machines, each such virtual machine operating a second operating system; and an agent program operating on each of the at least one physical machines, where, each agent program is operable to obtain a first set of metrics from the first operating system, such first set of metrics including metrics in respect of each virtual machine as viewed by the first operating system, and operable to connect to the second operating system of each virtual machine hosted on the physical machine the agent program operates on and obtain a second set of metrics in respect of the virtual machine from the second operating system, the agent program further operable to communicate the first and second sets of metrics to a manager program.

Owner:EG INNOVATIONS PTE

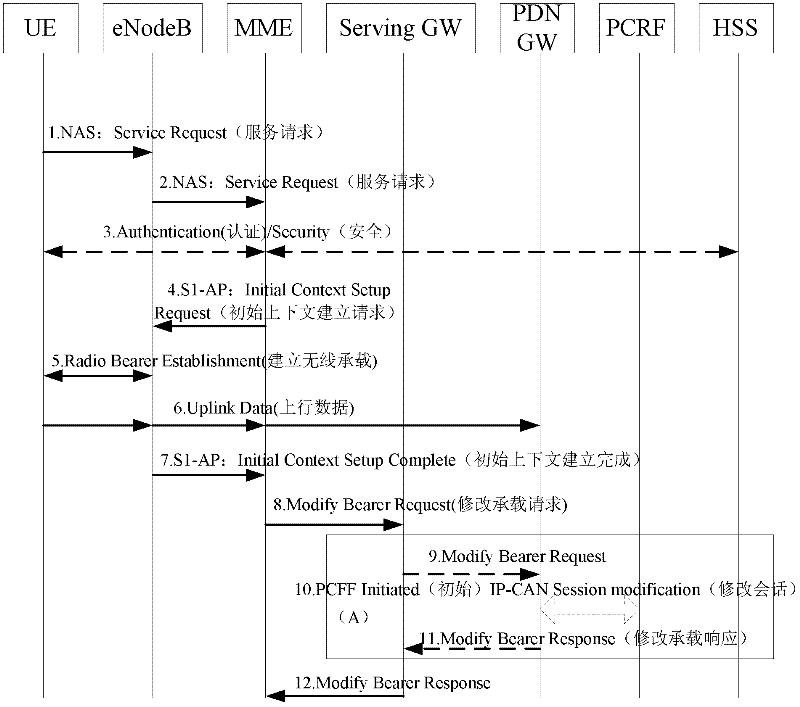

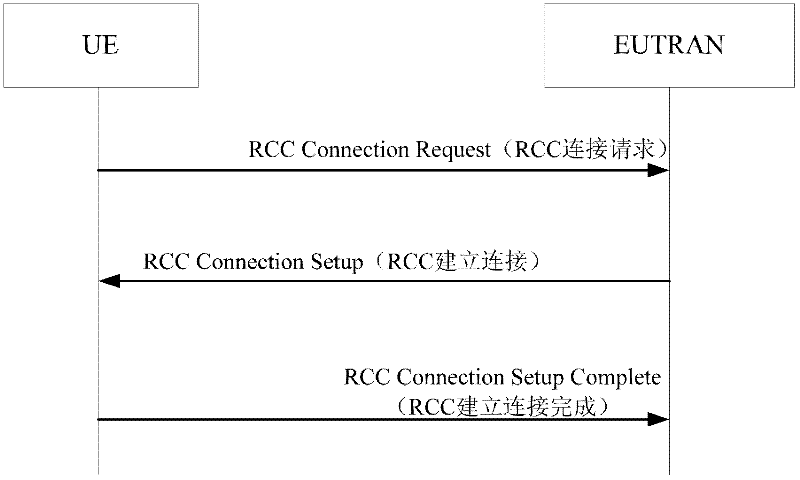

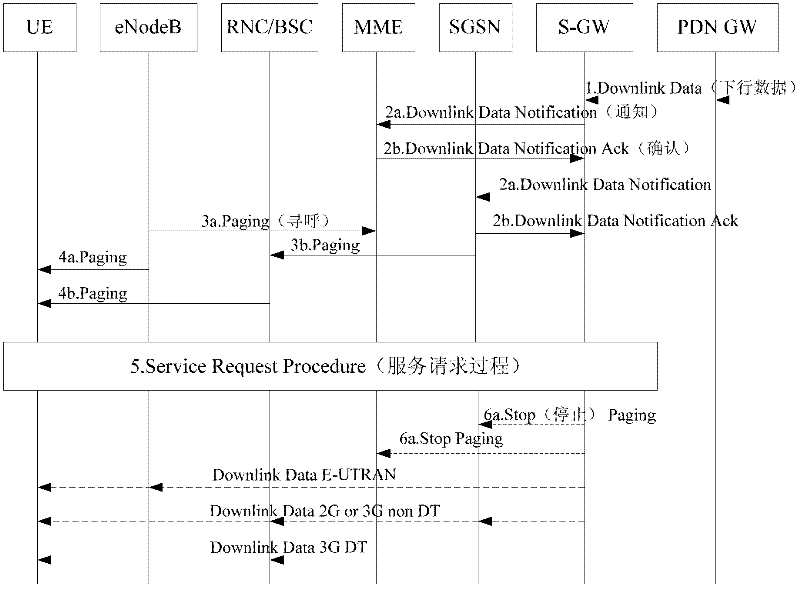

Small data transmission method and equipment

ActiveCN102333293AReduce overheadOptimizing the signaling processNetwork traffic/resource managementServices signallingAccess networkResource consumption

The embodiment of the invention discloses a small data transmission method and equipment. The method comprises the following steps: access network equipment receives a paging message carrying small data from core network equipment; and the access network equipment sends the small data to corresponding UE (user equipment) through an RRC (radio resource control) message. In the embodiment of the invention, the downlink small data is transmitted to the UE in an idle state through RRC signaling, the signaling process of small data transmission is optimized, and the service request process initiated due to the small data transmission is avoided, thereby effectively reducing the signaling overhead in an MTC (machine type communication) scene, reducing the resource consumption of the core network equipment and UE and reducing the possibility of congestion of the core network equipment.

Owner:DATANG MOBILE COMM EQUIP CO LTD

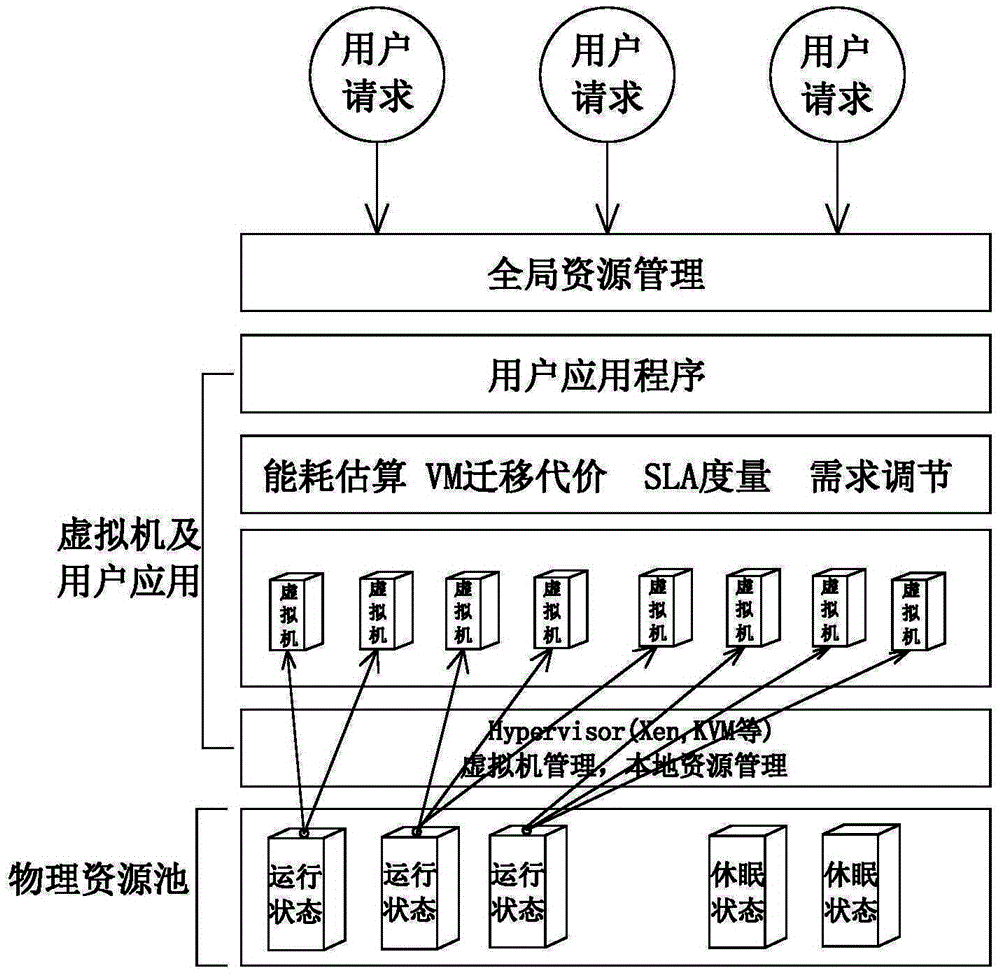

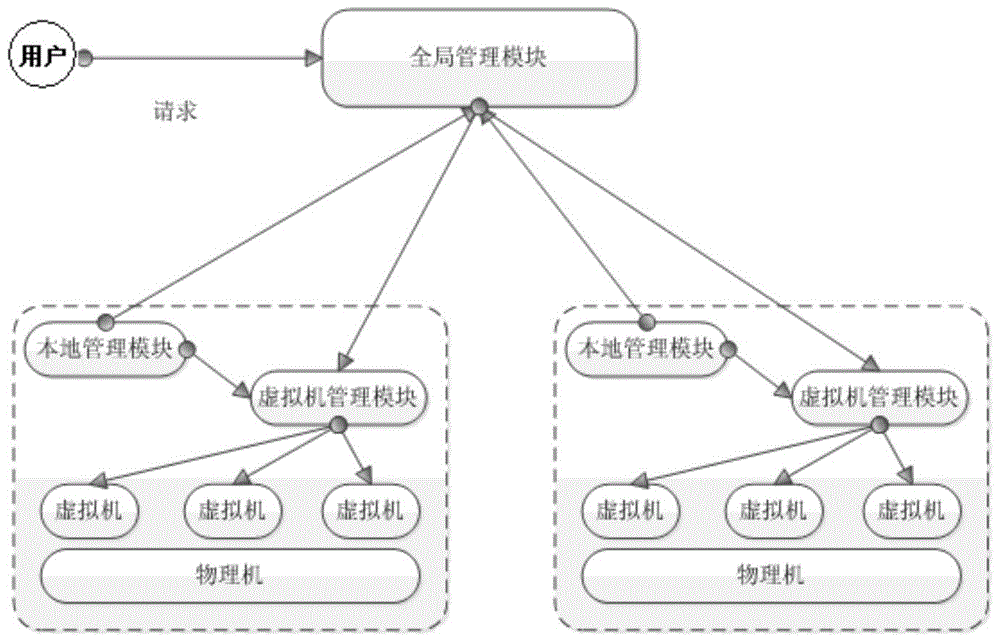

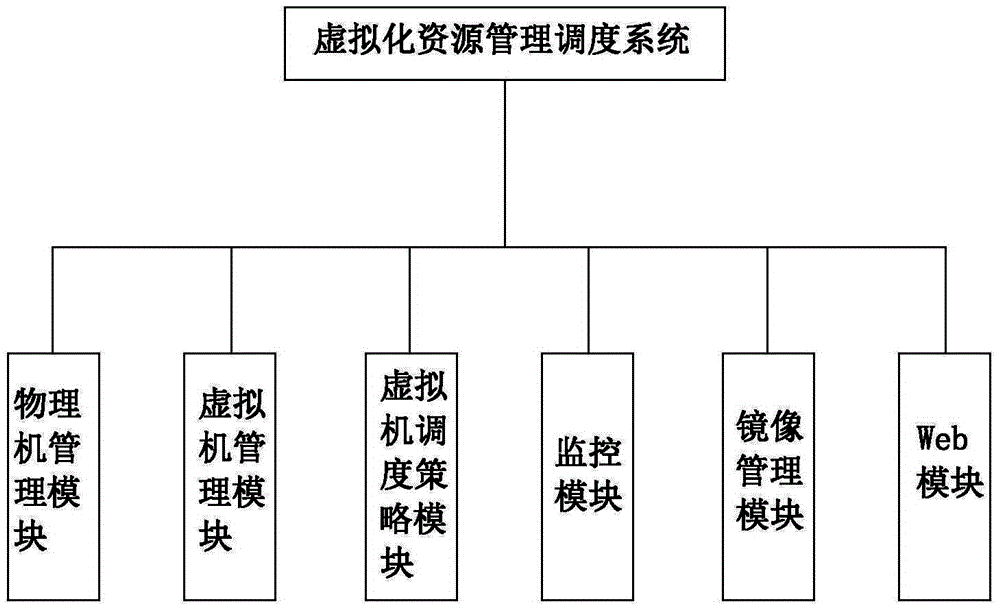

Virtualization energy-saving system in Cloud computing

InactiveCN104657215AReduce resource consumptionReduce consumptionResource allocationEnergy efficient computingService-level agreementMirror image

The invention provides a virtualization energy-saving system in Cloud computing, comprising a Cloud computing resource management prototype system and a backstage data processing system; the backstage data processing system comprises a physical resource pool, a virtual machine layer, a local module, a user's application layer and a global resource manager; the Cloud computing resource management prototype system comprises a physical machine management module, a virtual machine management module, a virtual machine dispatching strategy module, a monitoring module, a mirror image management module and a Web module; the resources are integrated to the least physical machine nodes by transferring the resources of the virtual machine, and the idle resources are closed, so that the consumption of the resources is reduced. The virtualization energy conservation in the Cloud computing is designed and realized in the system by using a VM (Virtual Machine) transfer cost model and an SLA (Service Level Agreement) measurement model as the energy consumption estimation models of a data center.

Owner:NANJING TOPTEAM TECH

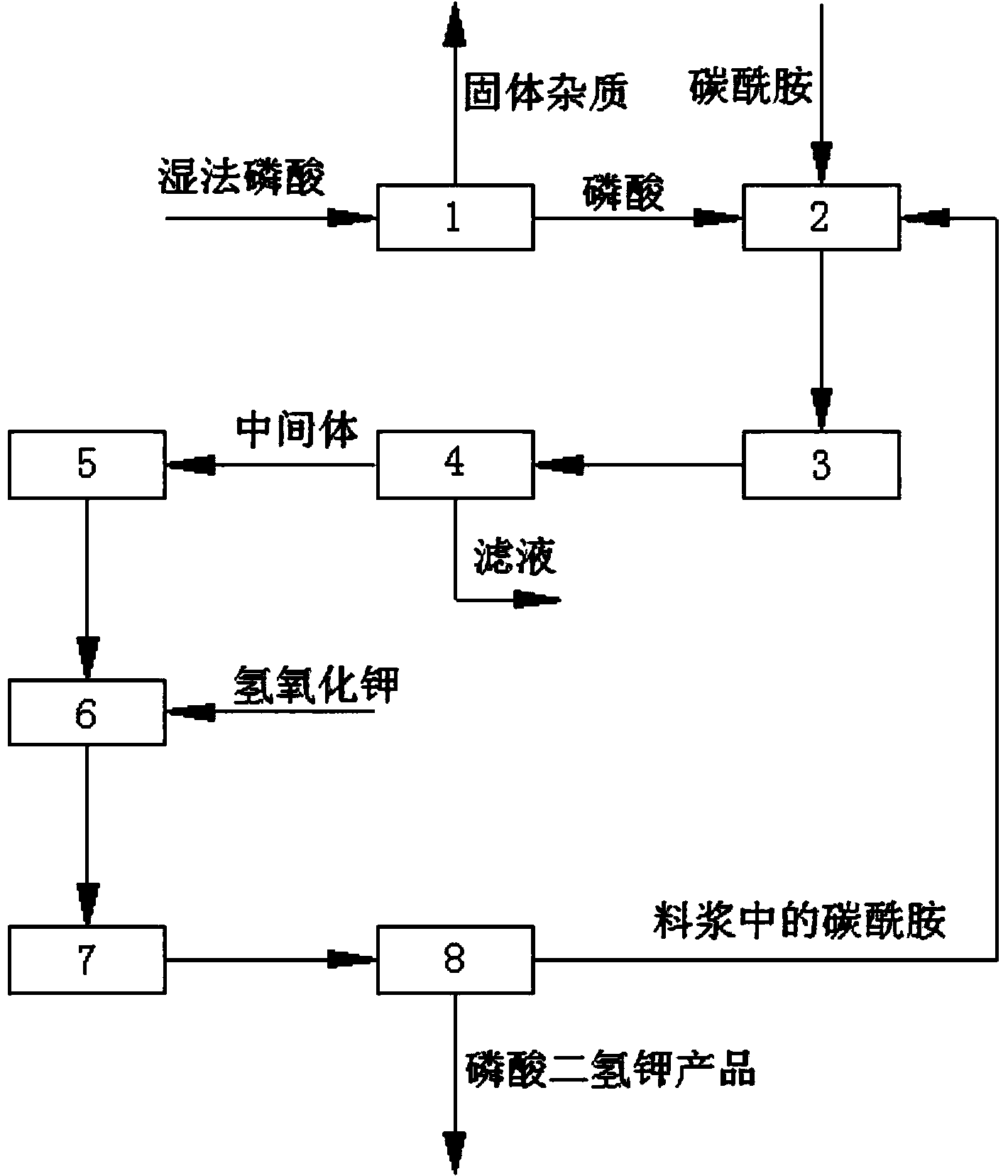

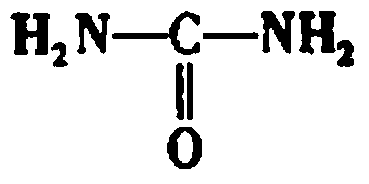

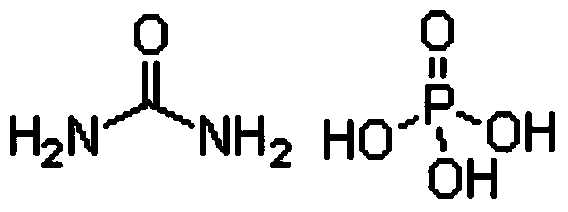

Method for preparing monopotassium phosphate by using wet-process phosphoric acid

InactiveCN103803518AReduce manufacturing costNo pollution in the processPhosphorus compoundsFertilizer mixturesEnvironmental resistanceHigh energy

The invention discloses a method for preparing monopotassium phosphate by using wet-process phosphoric acid. The method comprises the following steps: reacting carbonyl diamide and wet-process phosphoric acid to obtain an intermediate; reacting the intermediate and potassium hydroxide to prepare a monopotassium phosphate product. The method has the advantages of short process route, low energy consumption, stable product quality, low production cost, convenience in operation and safety in production. A side product, namely, slurry can be recycled completely, an entire production process is environment-friendly, clean and free from pollution, and no waste gas, waste water or waste residues are discharged. A response is made to the policy calling of energy saving, emission reduction and clean production, the problems of complex process, instable product quality, high energy consumption and environmental pollution existing in the prior art are solved, and the purity of the obtained monopotassium phosphate product is more than or equal to 98 percent.

Owner:GUIYANG KAILIN FERTILIZER CO LTD +1

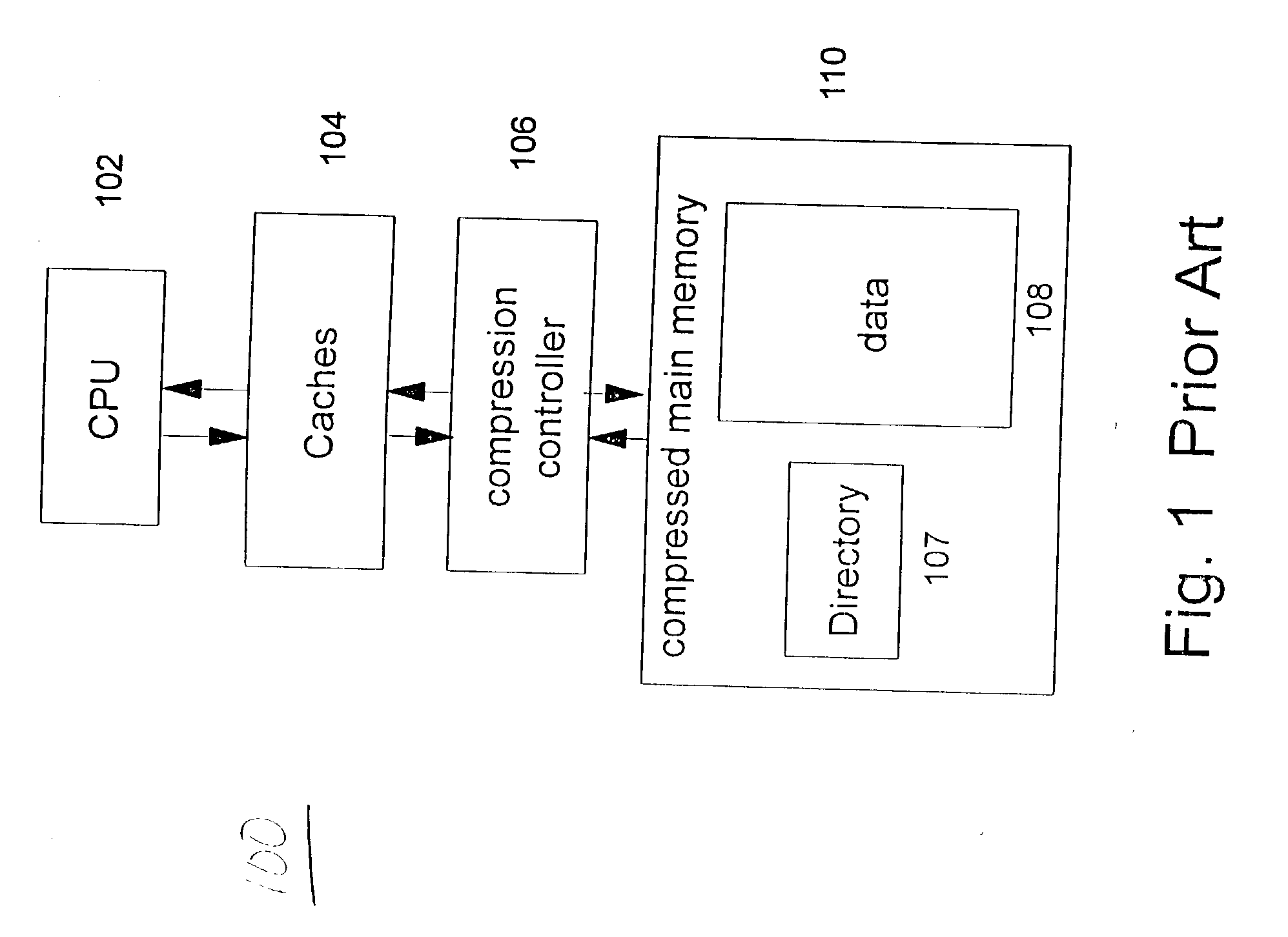

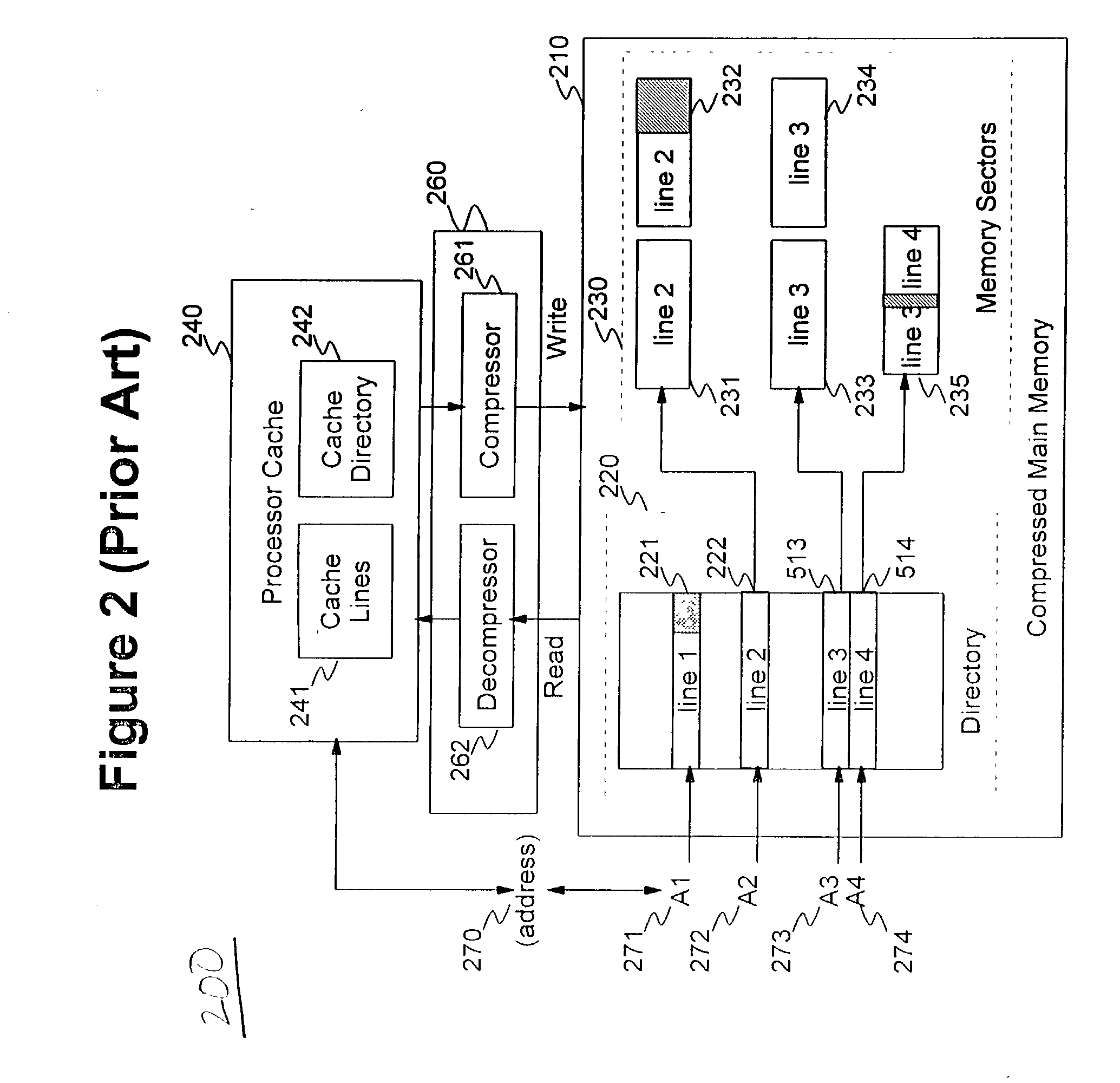

Method and system for storing memory compressed data onto memory compressed disks

ActiveUS20040030813A1Lower latencyReduce resource consumptionMemory architecture accessing/allocationInput/output to record carriersParallel computingCompressed disk

A method (and system) of storing information, includes storing main memory compressed information onto a memory compressed disk, where pages are stored and retrieved individually, without decompressing the main memory compressed information.

Owner:IBM CORP

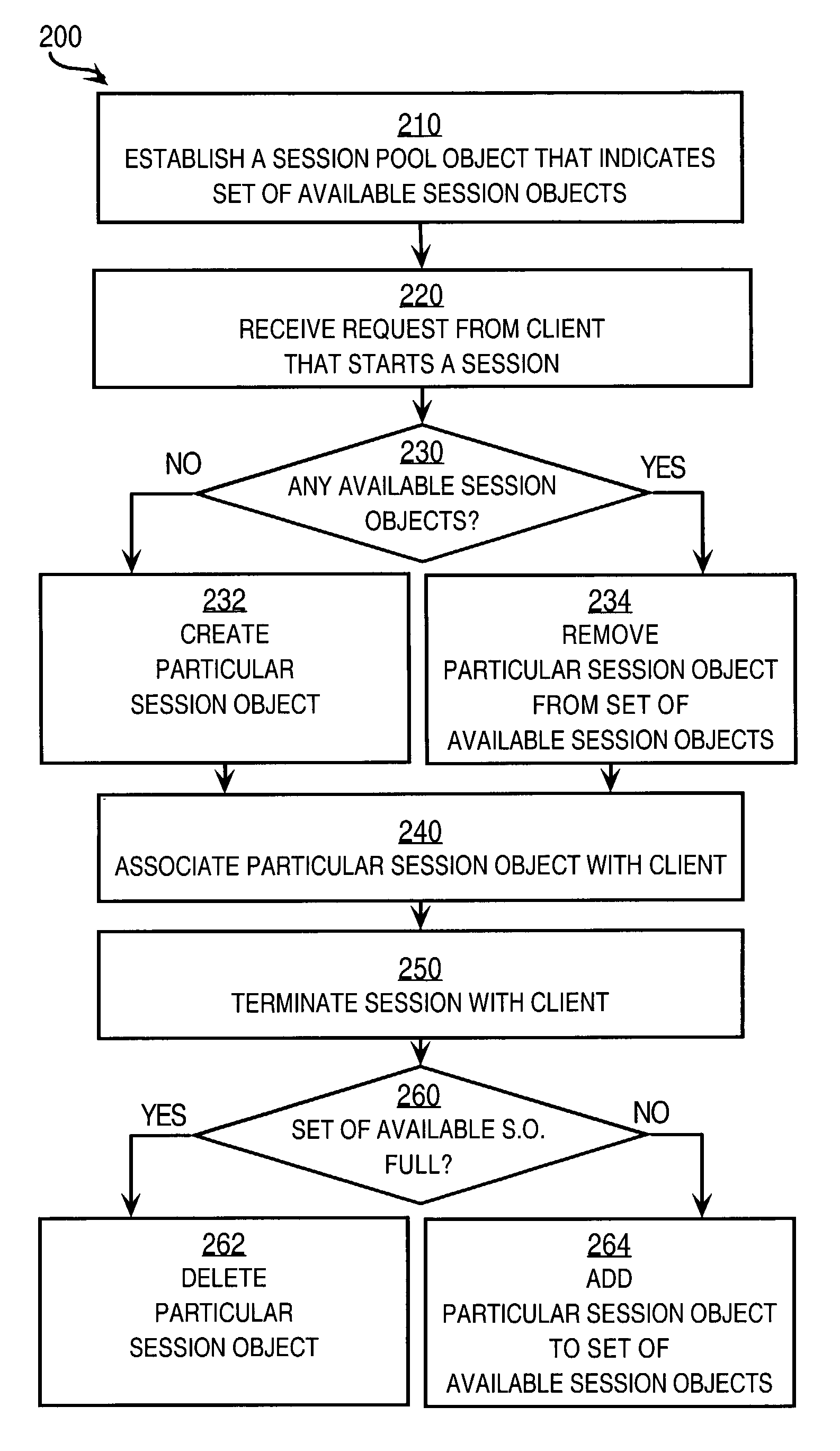

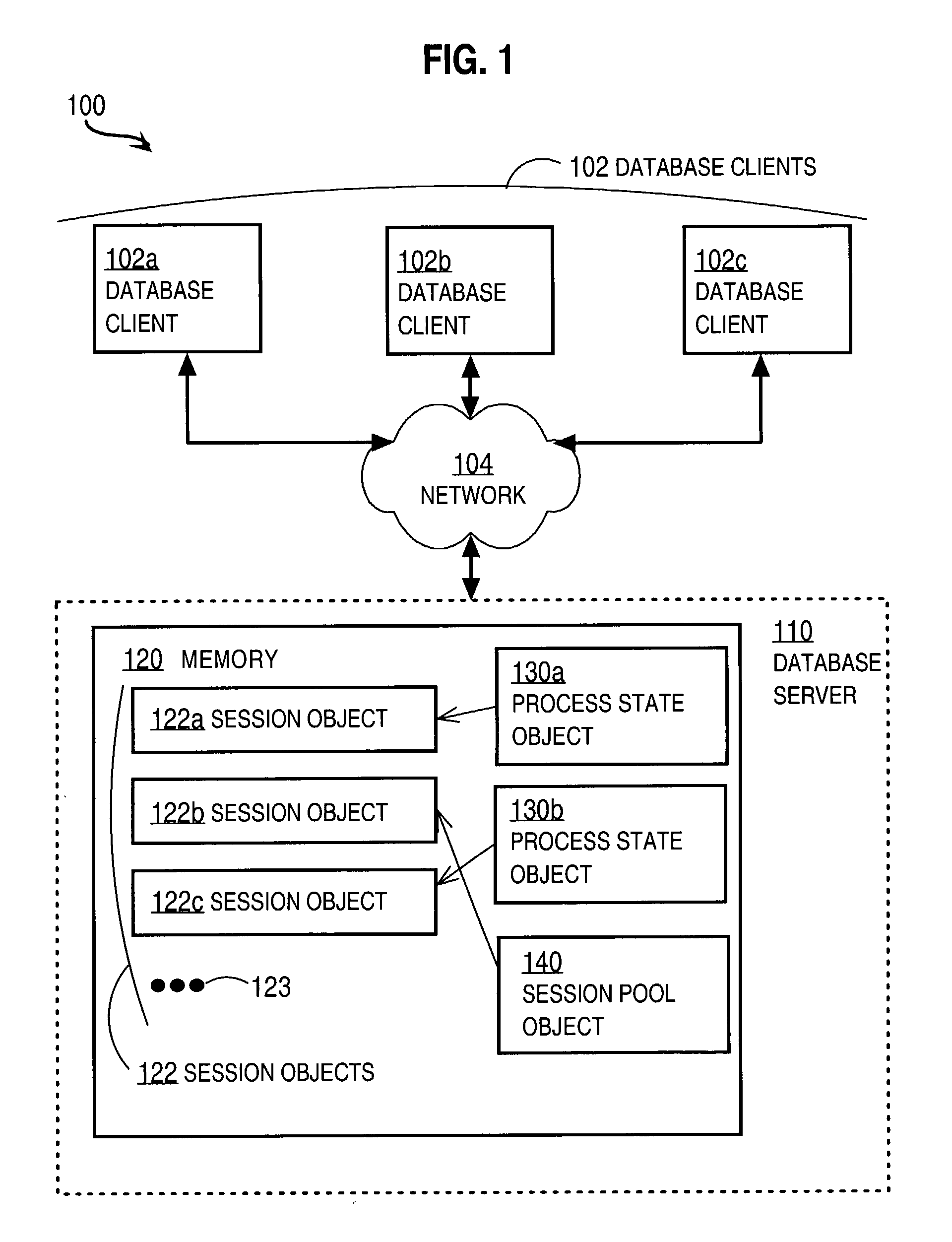

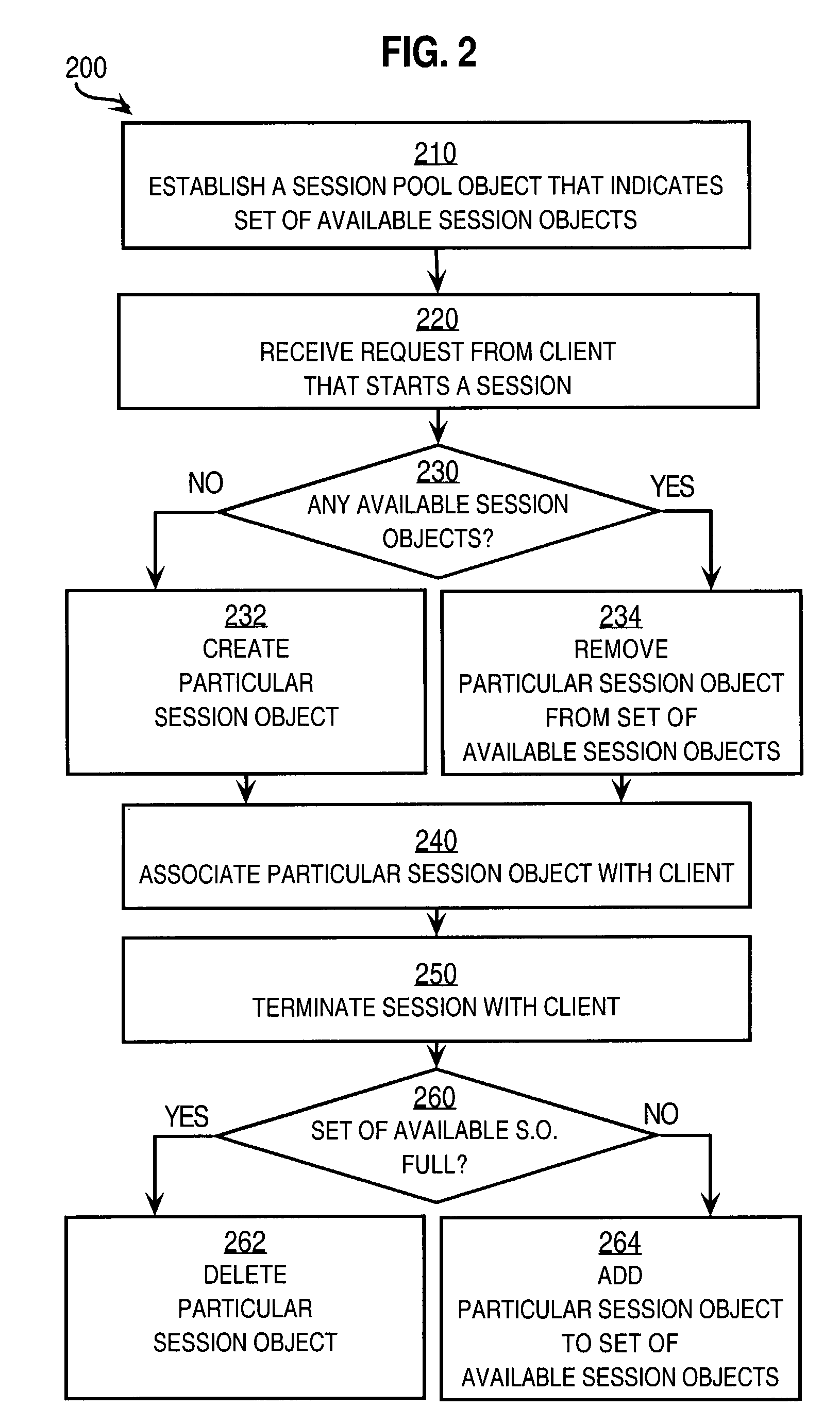

Techniques for increasing efficiency while servicing requests for database services

ActiveUS6950822B1Reduce resource consumptionMultiple digital computer combinationsTransmissionStateless protocolDatabase server

Techniques for servicing requests for database services include maintaining at a database server an available set of one or more database session data structures. Each database session data structure holds information to support one session of one or more requests for database services over a communication connection that persists for one or more communications from one client. A database session data structure in the available set is not associated with any client currently connected to the database server. These techniques allow a database server to more efficiently service more numerous requests for database services, such as generated by communications using a stateless protocol like HTTP.

Owner:ORACLE INT CORP

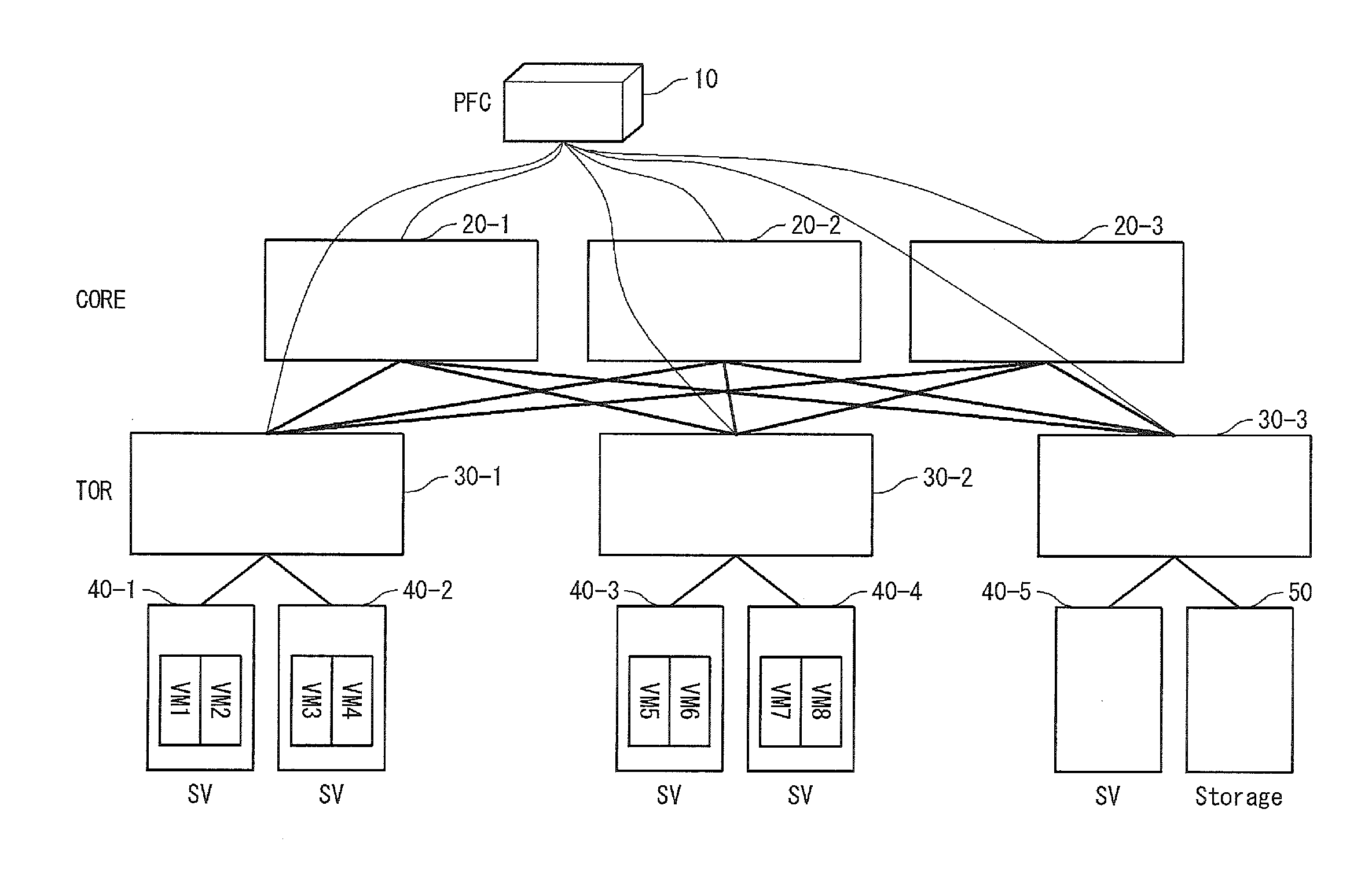

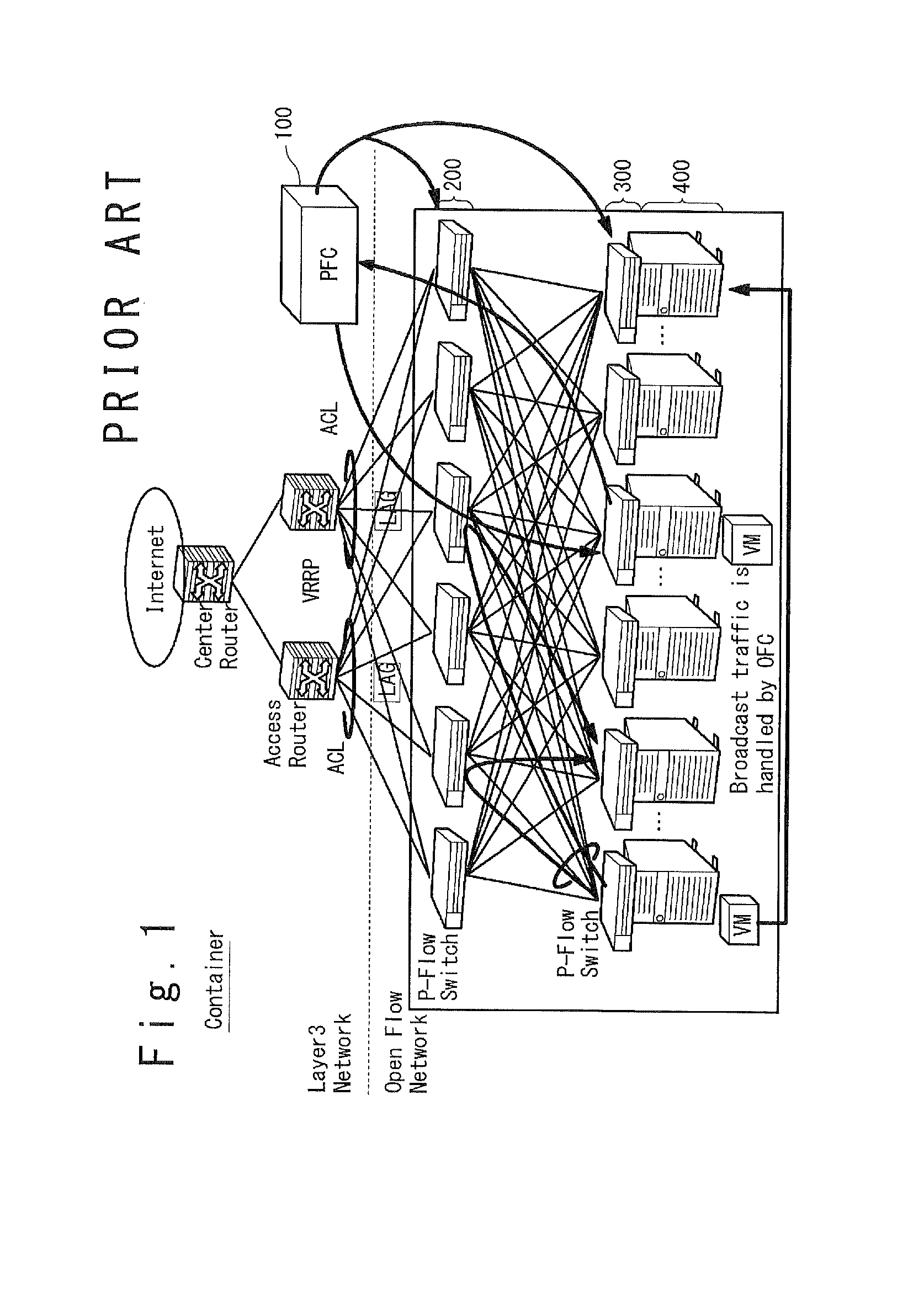

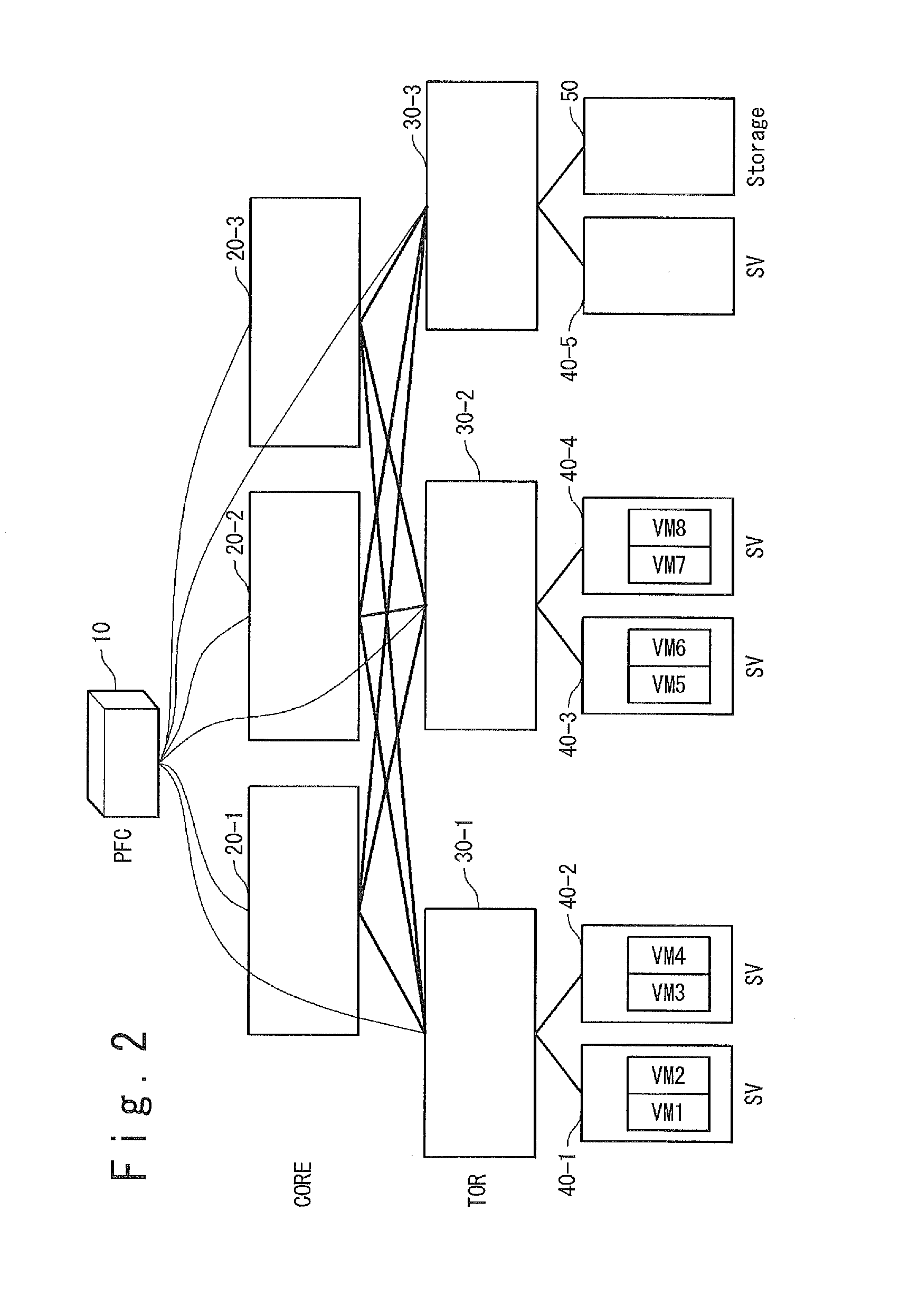

Computer system and communication method in computer system

ActiveUS20130170354A1Reduce resource consumptionReduce consumptionError preventionTransmission systemsComputerized systemDistributed computing

A computer system of the present invention includes a controller which sets a flow entry to each of a plurality of switches before a packet is forwarded from a plurality of nodes, and each of switches which transfers a reception packet which contains a destination address defined in the flow entry, to a destination node defined in the flow entry regardless of a transmission source address of the reception packet.

Owner:NEC CORP

Construction method of anti-plastering putty for concrete structure wall

InactiveCN101363269AThin thickness and small weightLight weightCovering/liningsResource consumptionPutty

The invention discloses a construction method of a wall putty of a plaster-free concrete structure. The construction method comprises the following steps: construction preparation, base course treatment, concave-convex line construction, a first full application of wall putty, flattening, a second full application of wall putty and flattening. The construction method has the advantages of less workload, short construction time, little resource consumption, no hollow drum and crack of the floated coat, no crack at the joint of the primary structure and the secondary structure.

Owner:中建五局第三建设有限公司 +1

Tunneled security groups

ActiveUS8146148B2Reduce in quantityImprove network efficiencyMultiple digital computer combinationsProgram controlGroup identifierComputer security

A method for providing security groups based on the use of tunneling is disclosed. The method includes assigning a security group identifier (SGI) to a packet and classifying the packet based on the packet's SGI.

Owner:CISCO TECH INC

Method for processing multimedia video object

ActiveCN101409831ASimple and seamless splicing schemeAvoid false detectionImage enhancementImage analysisTime domainComputer graphics (images)

The invention discloses a multimedia video object processing method which comprises the steps as follows: (1) carrying out scene dividing on an MPEG video based on macro block information; (2) pre-reading a video needed to be jointed, obtaining various information and searching a proper joint scene; (3) searching the inlet point and the outlet point of the joint and carrying out regulation on various information of the accessed video; (4) selecting a proper audio joint point to realize audio-video seamless joint; (5) setting a video buffer area and unifying the code rate of the video to be jointed; (6) carrying out coarse extraction on a moving object in the video in a time domain; (7) carrying out watershed processing on the coarse extraction result, carrying out space region merging and leading to a accurate segmentation object. The .invention is characterized by simple and high-efficiency algorithm, low system resource consumption and fast speed and high accuracy of processing.

Owner:ZHEJIANG BOXSAM ELECTRONICS

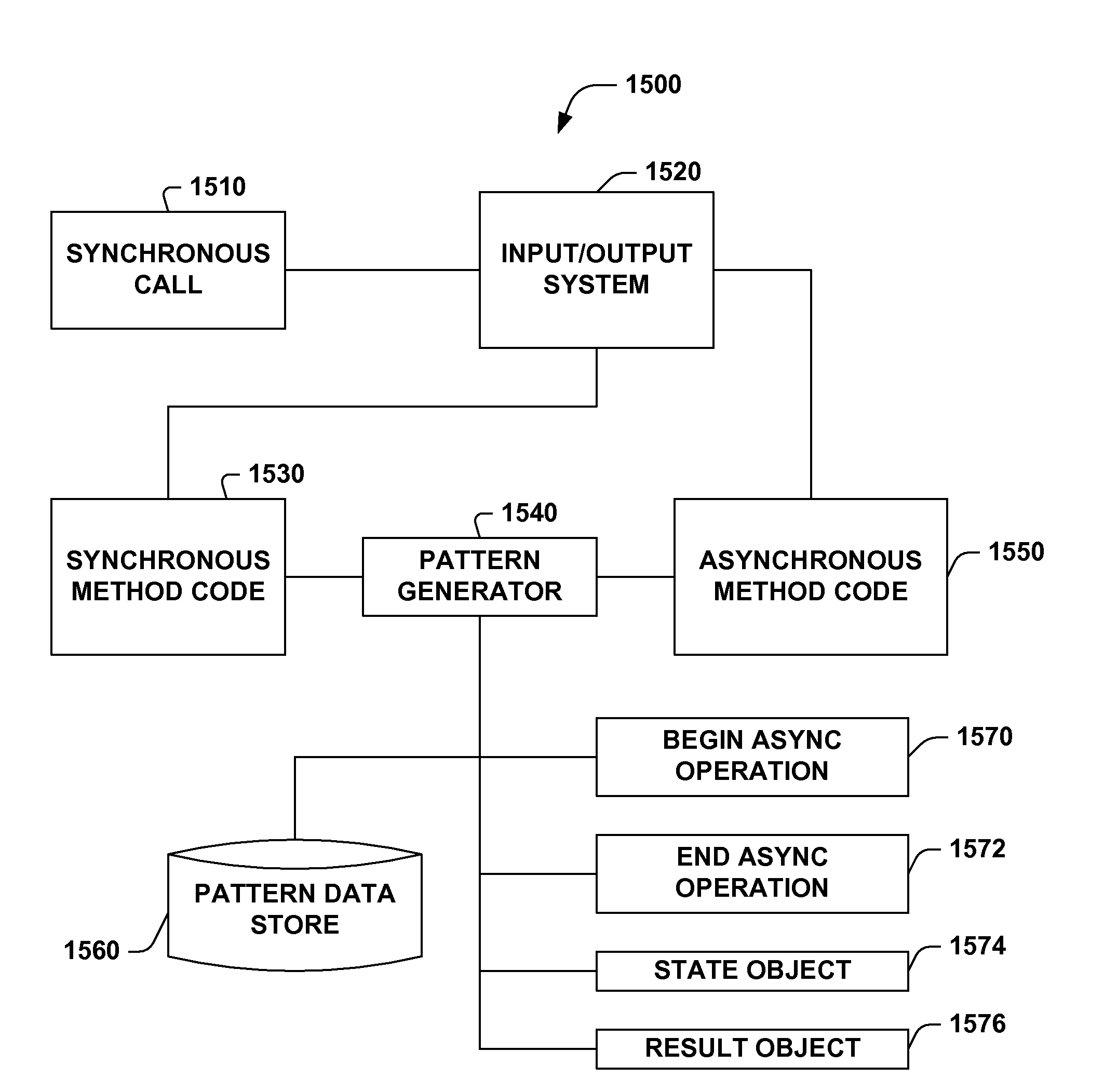

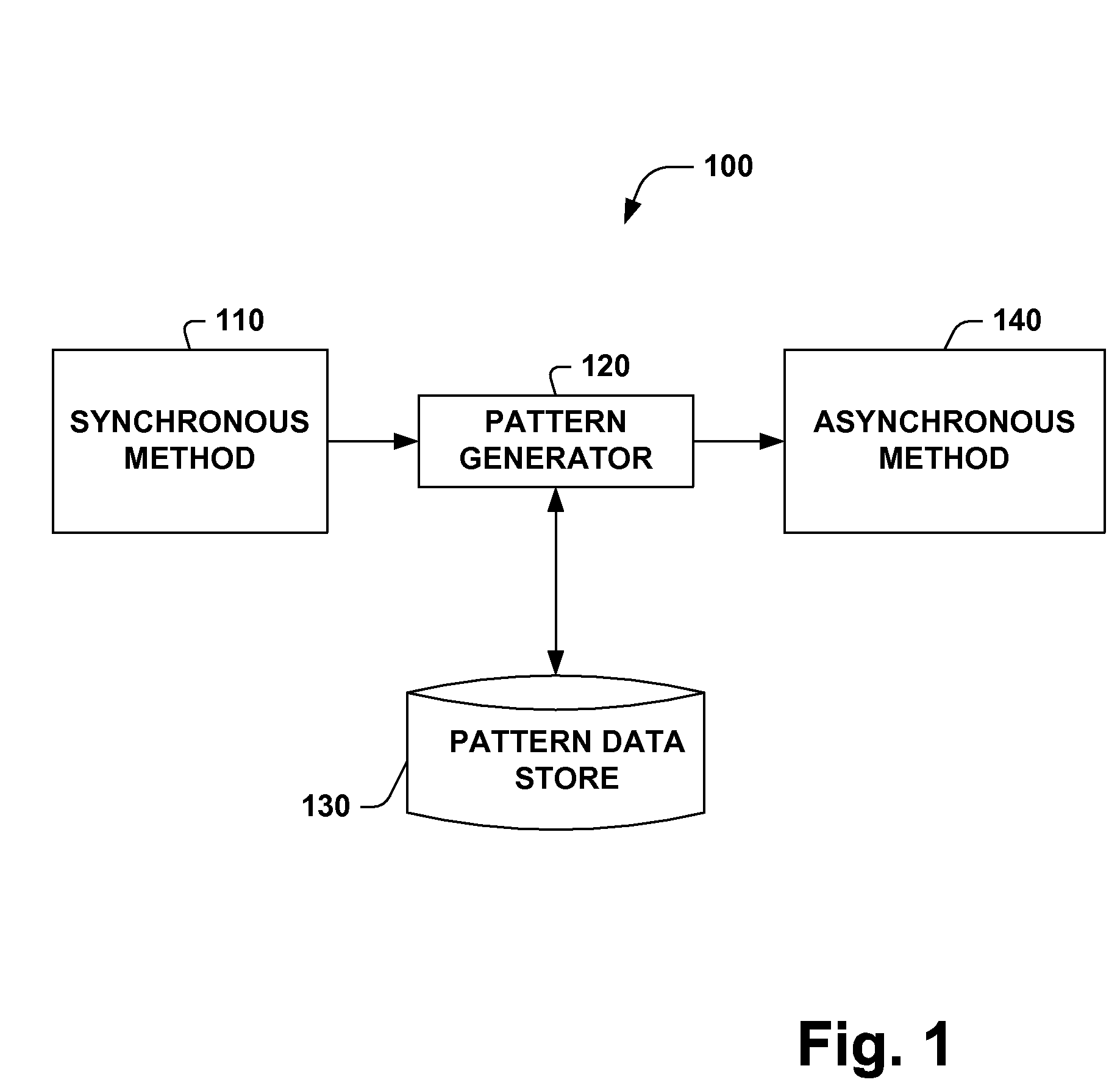

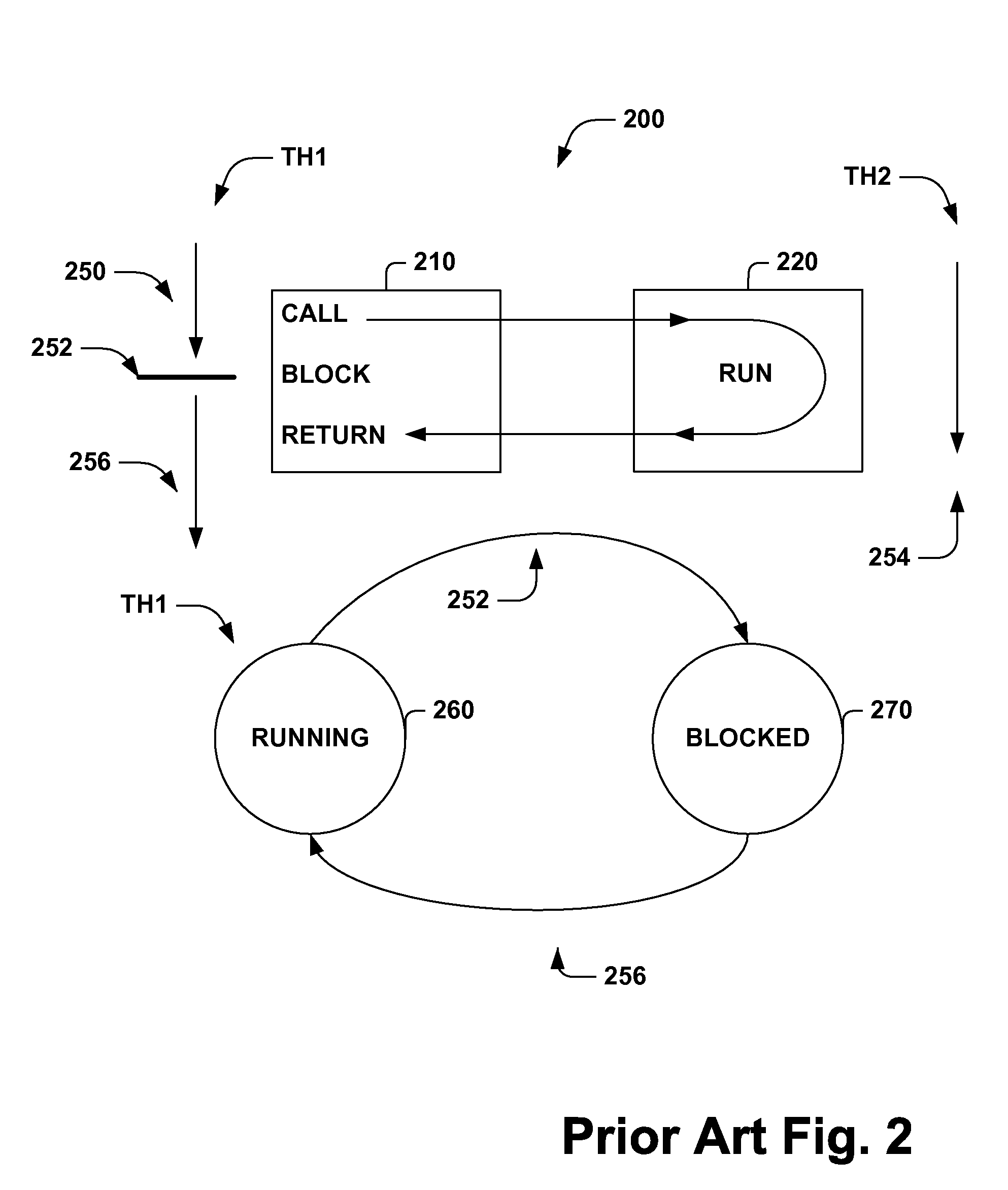

Asynchronous pattern

InactiveUS7248603B1Reduce the possibilityImprove processing efficiencyData processing applicationsTime-division multiplexAsynchronous method invocationMessage queue

A system and method for converting code associated with synchronous method calls to code that can be employed to perform asynchronous method calls and for supporting such asynchronous method calls is provided. The system includes a pattern generator that can break code for a synchronous method call into one or more constituent parts including a begin asynchronous operation method, an end asynchronous operation method, an asynchronous call state object and an asynchronous call result object. The system includes a pattern data store that holds data associated with converting a synchronous method call to an asynchronous method call, which facilitates employing the system consistently across environments like file input / output, stream input / output, socket input / output, networking, remoting channels, proxies, web forms, web services and messaging message queues.

Owner:MICROSOFT TECH LICENSING LLC

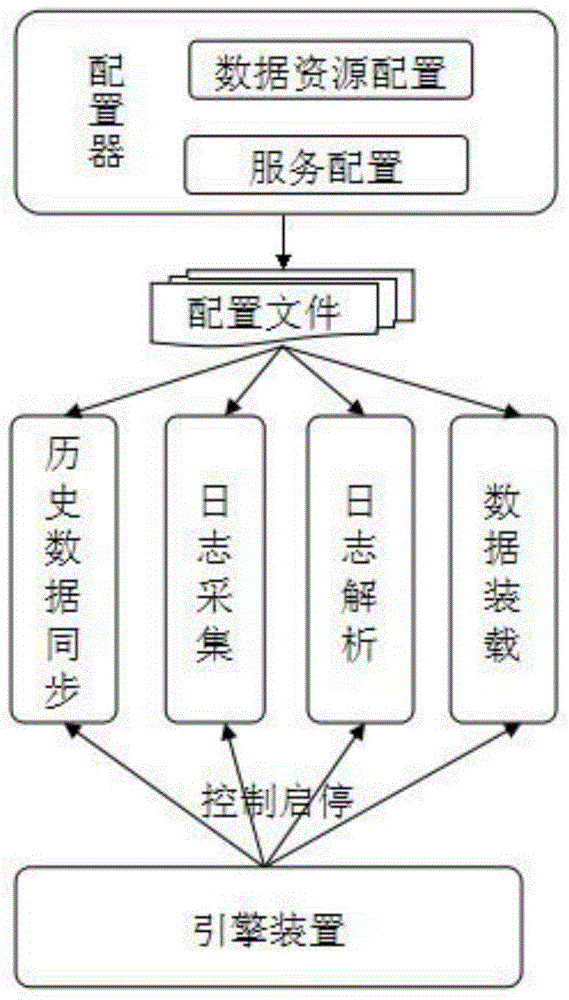

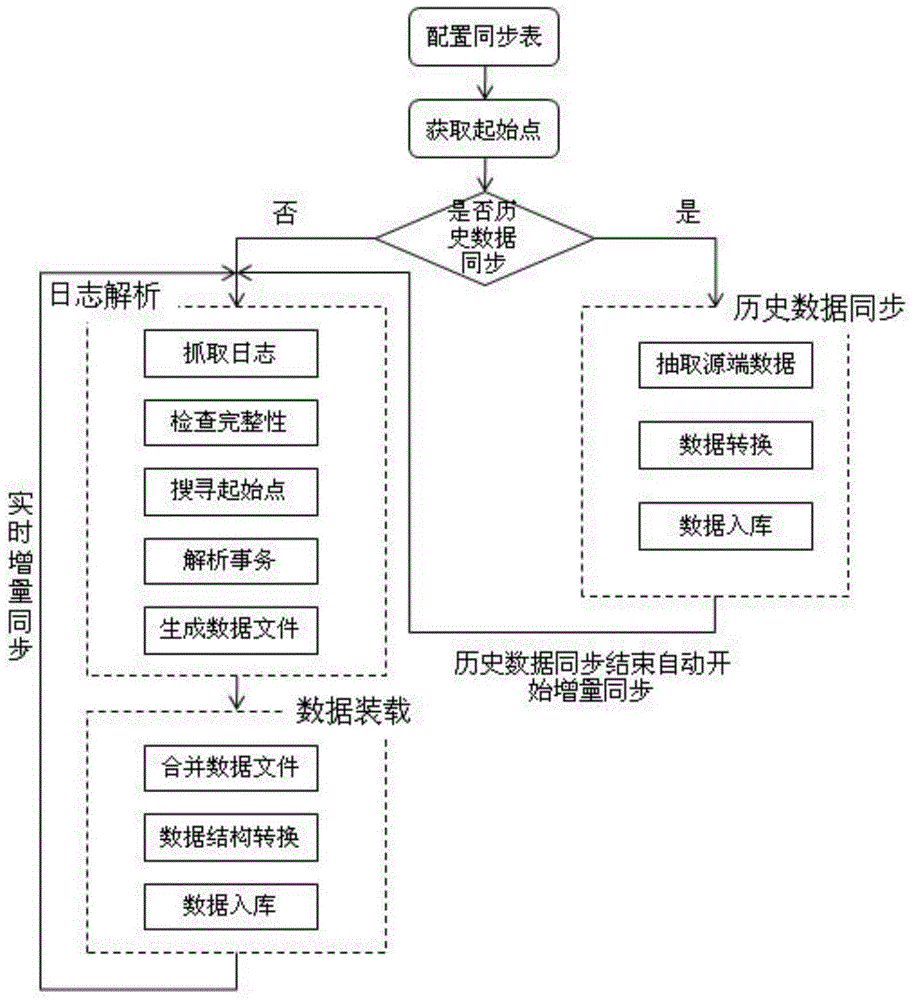

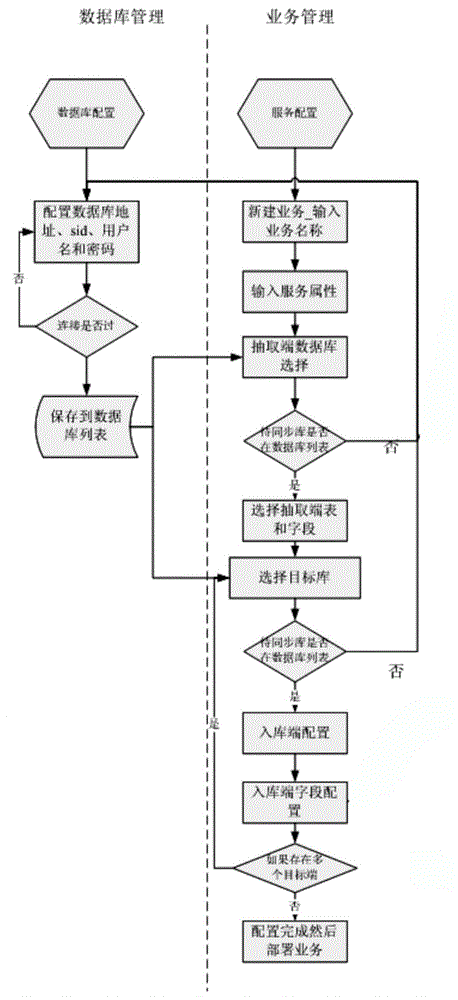

Data synchronization method and system among heterogeneous databases

InactiveCN105005618AReduce the impactReduce dependenceDatabase distribution/replicationSpecial data processing applicationsData synchronizationComplete data

The invention relates to a data synchronization method and system among heterogeneous databases, by which the two purposes of historical data synchronization and incremental data synchronization are achieved. According to the method, heterogeneous synchronization among various types of main databases is supported, other tools and scripts are not needed, the historical data synchronization and the incremental data synchronization can be easily configured and are automatically linked, and the complexity is reduced. The system is simple and easy to understand, backstage scrip writing and database command input are not needed, and a whole data synchronization service can be configured even by a person who has no experience in database application. The method and the system are applicable for a synchronization scenario of various types of data.

Owner:HANGZHOU HEZHONG DATA TECH CO LTD

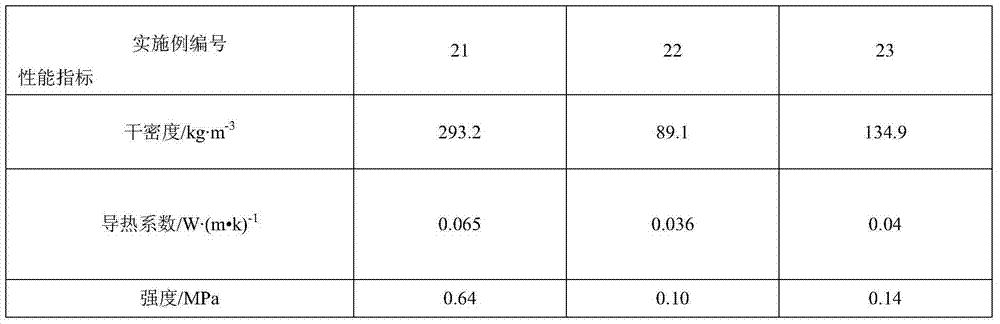

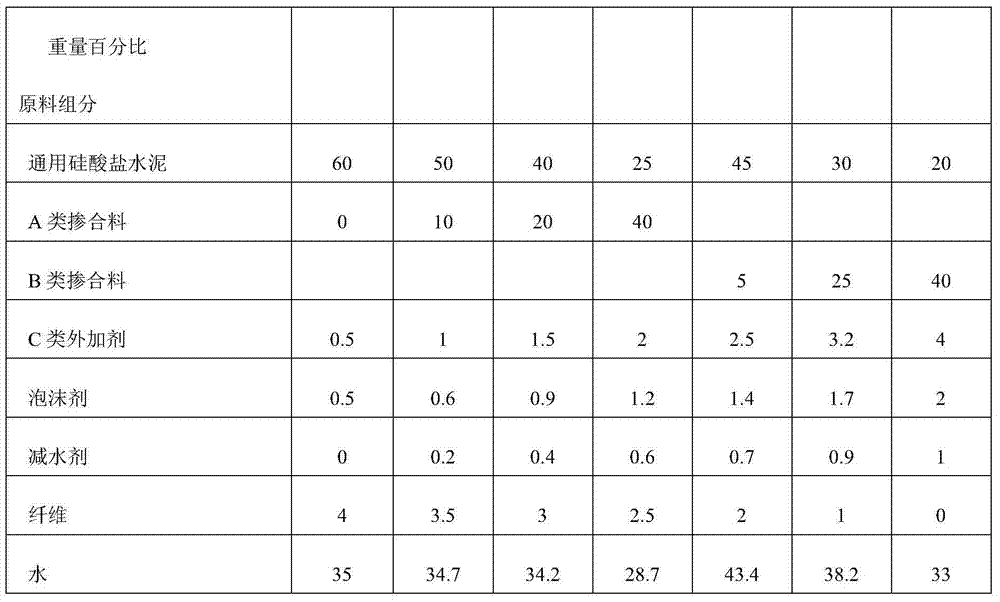

General purpose Portland cement based ultra-light physical foamed concrete

ActiveCN104774033AReduce raw material usageReduce resource consumptionCeramicwareCushionPortland cement

The invention discloses general purpose Portland cement based ultra-light physical foamed concrete which is characterized by being prepared by mixing, forming and maintaining the following components in percentage by weight: 20-70% of general purpose Portland cement, 0-40% of a type A admixture or / and 0-40% of a type B admixture, 0.5-4% of a type C additive, 0.3-2% of a foaming agent, 0-1% of a water reducing agent, 0-4% of fibers and 25-60% of water. The general purpose Portland cement based ultra-light physical foamed concrete disclosed by the invention has the characteristics of ultra-low dry density, low thermal conductivity, relatively high strength, wide raw material source, low cost, simple preparation process, easy maintenance process selection and the like, is suitable to serve as an earthquake-proof and energy-absorbing material, a lightweight cushion course and a catalyst carrier material in a thermal insulation project, a floor heating project and a back filling project, and is particularly suitable for a building exterior wall external thermal insulation system, a roof thermal insulation system, a composite thermal insulation wall body and a buffer energy absorbing system.

Owner:SOUTHWEAT UNIV OF SCI & TECH

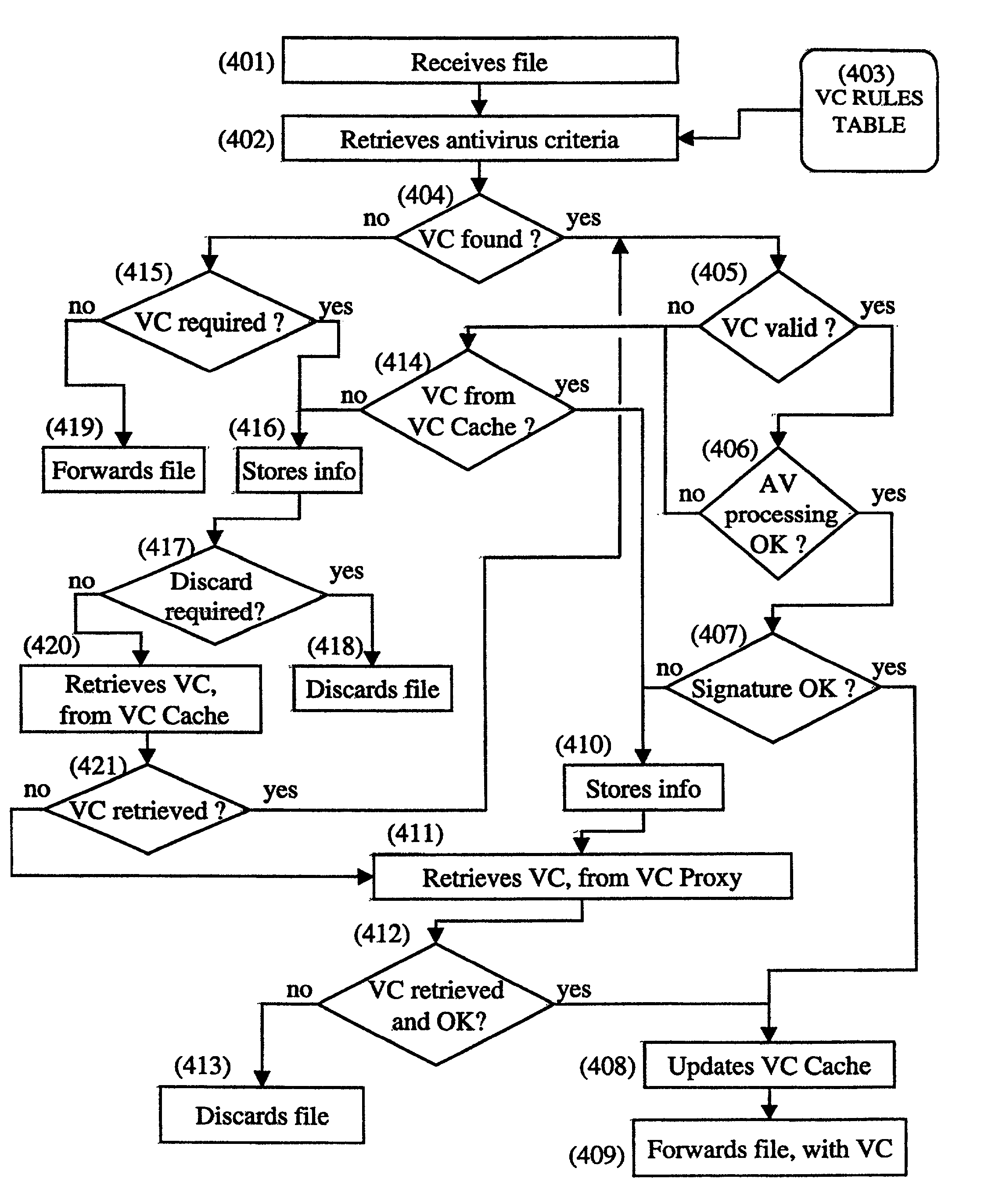

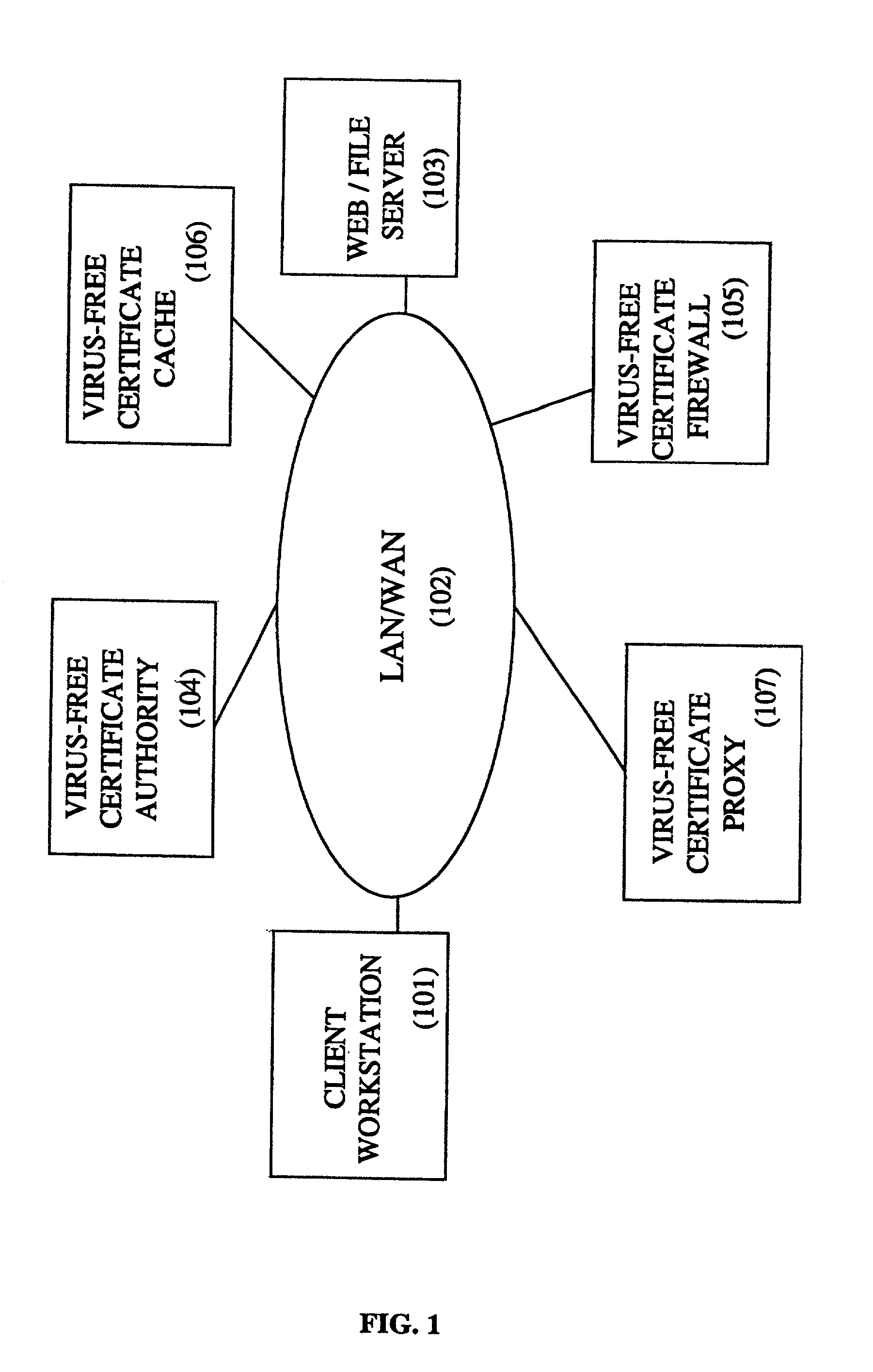

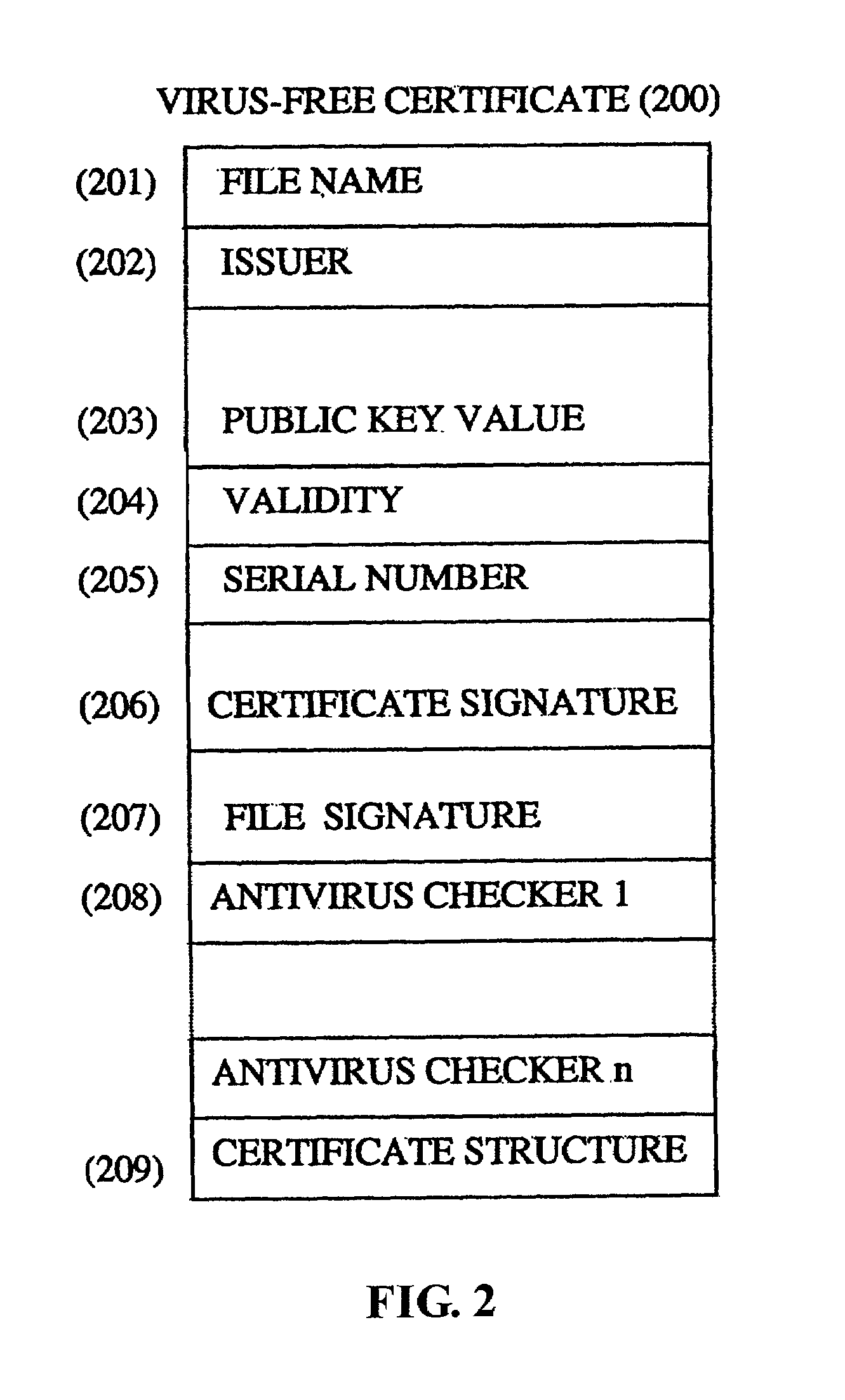

Method and system for controlling and filtering files using a virus-free certificate

InactiveUS6986051B2Simple methodEasy to detectMemory loss protectionDigital data processing detailsVirusAuthentication

The present invention is directed to computer viruses and more particularly to a method and system for use in a virus-free certificate firewall, of controlling and filtering files using a virus-free certificate. An example embodiment of the method comprises the steps of: receiving a file; if a virus-free certificate (200) is required for the file: determining whether the a virus-free certificate is already associated with the file; if a virus-free certificate is already associated with the file: authenticating the associated virus-free certificate, said virus-free certificate comprising a certificate signature; if the virus-free certificate is authenticated, determining whether the file is virus-free or not; if the file is virus-free, forwarding the file with the associated virus-free certificate; if the virus-free certificate is not authenticated or if no virus-free, certificate is associated with the file; determining whether the file is virus-free or not, if the file is virus-free, associating with the file a new virus-free certificate; and forwarding the file with the new virus-free certificate.

Owner:TREND MICRO INC

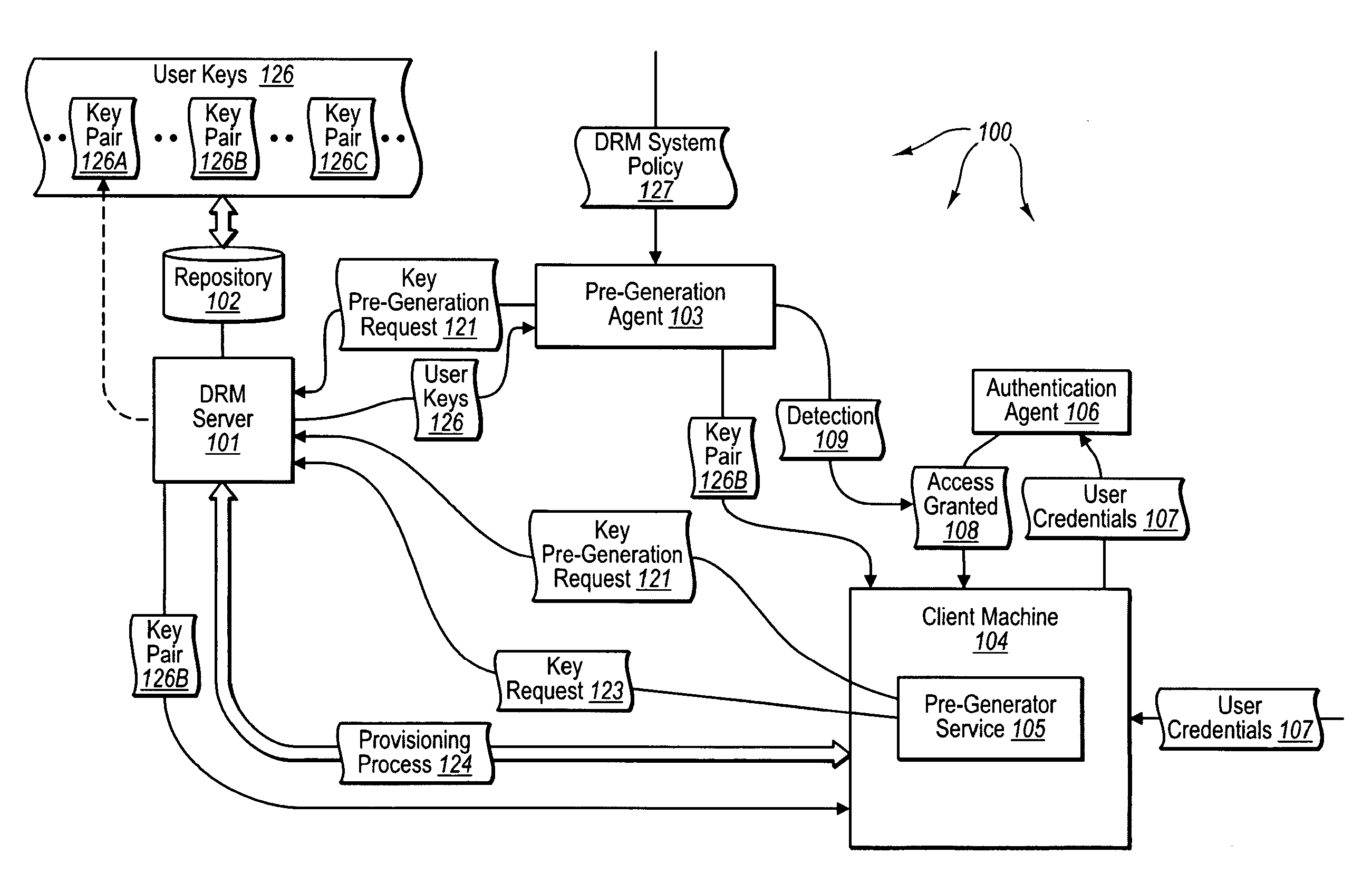

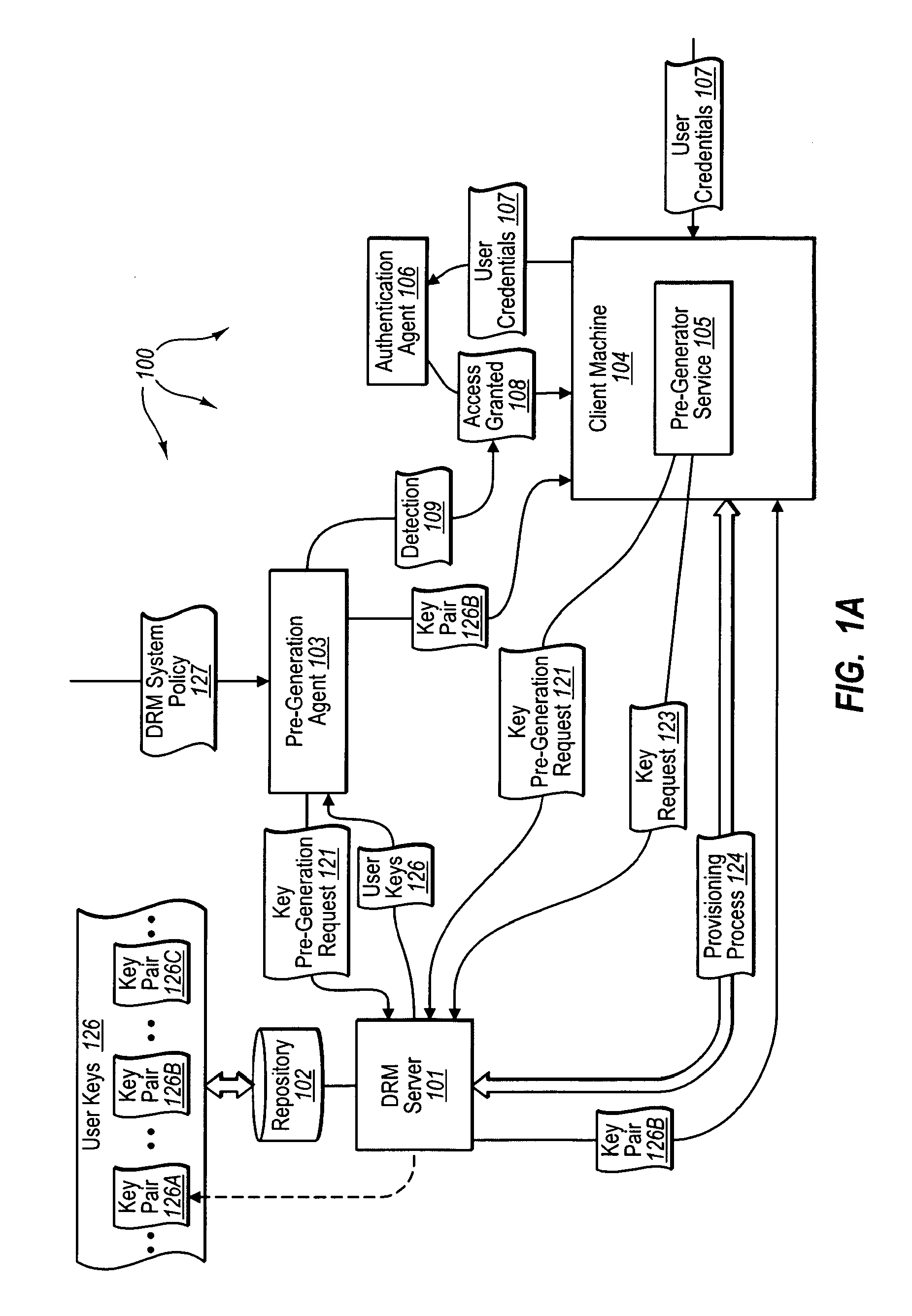

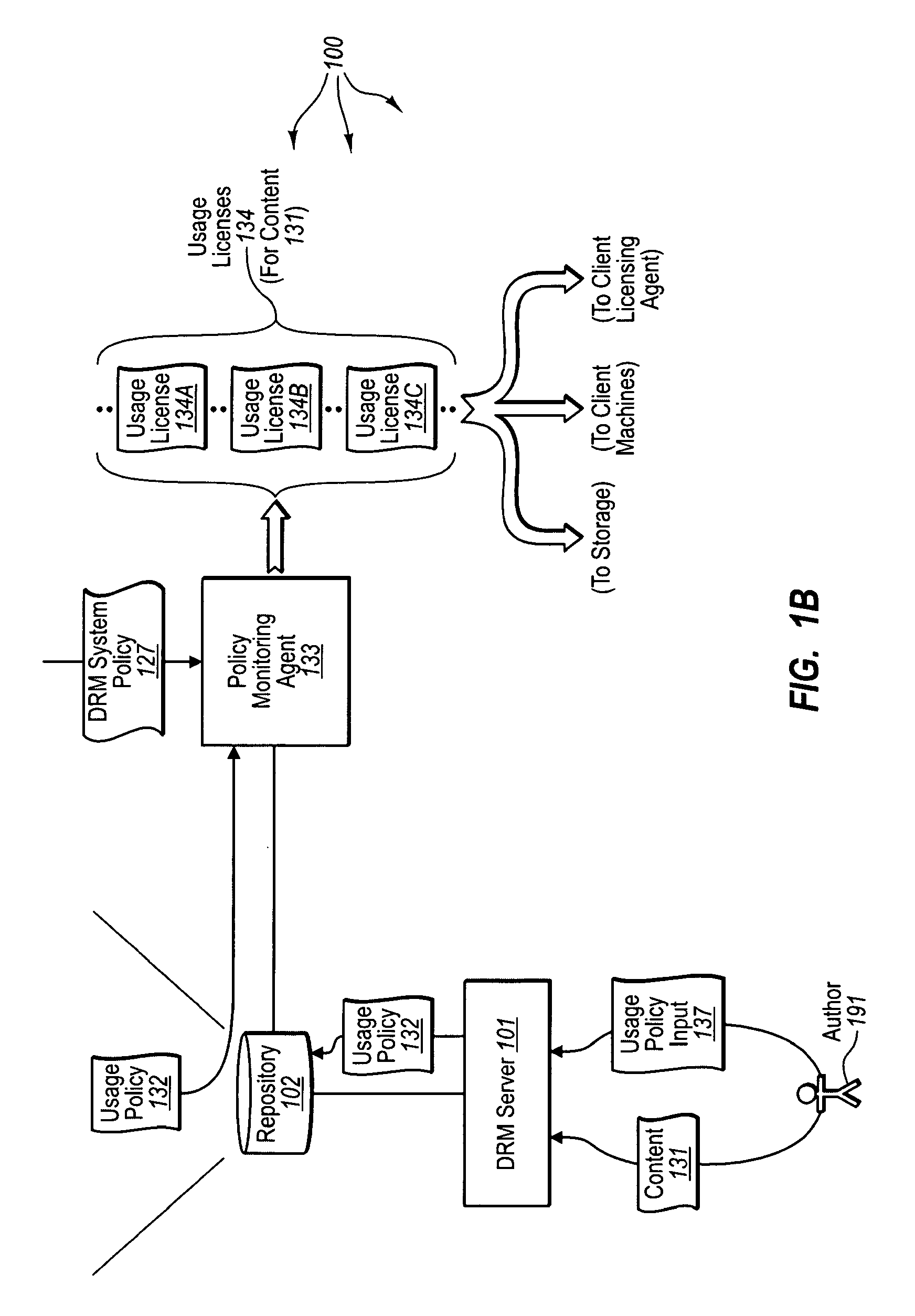

Pre-performing operations for accessing protected content

InactiveUS20090192942A1Reduce resource consumptionKey distribution for secure communicationPublic key for secure communicationDigital rights management systemResource consumption

The present invention extends to methods, systems, and computer program products for pre-performing operations for accessing protected content. Cryptographic user key pairs can be pre-generated and distributed in response to a variety of different events prior to provisioning client machine for accessing protected content. Usage licenses can be pre-generated and allocated prior to requests for usage licenses. Usage licenses can be pre-obtained for client machines prior to client machines access protected content. Pre-performed operations can be performed in response to detected events, such as, for example, reduced resource consumption in a Digital Rights Management system.

Owner:MICROSOFT TECH LICENSING LLC

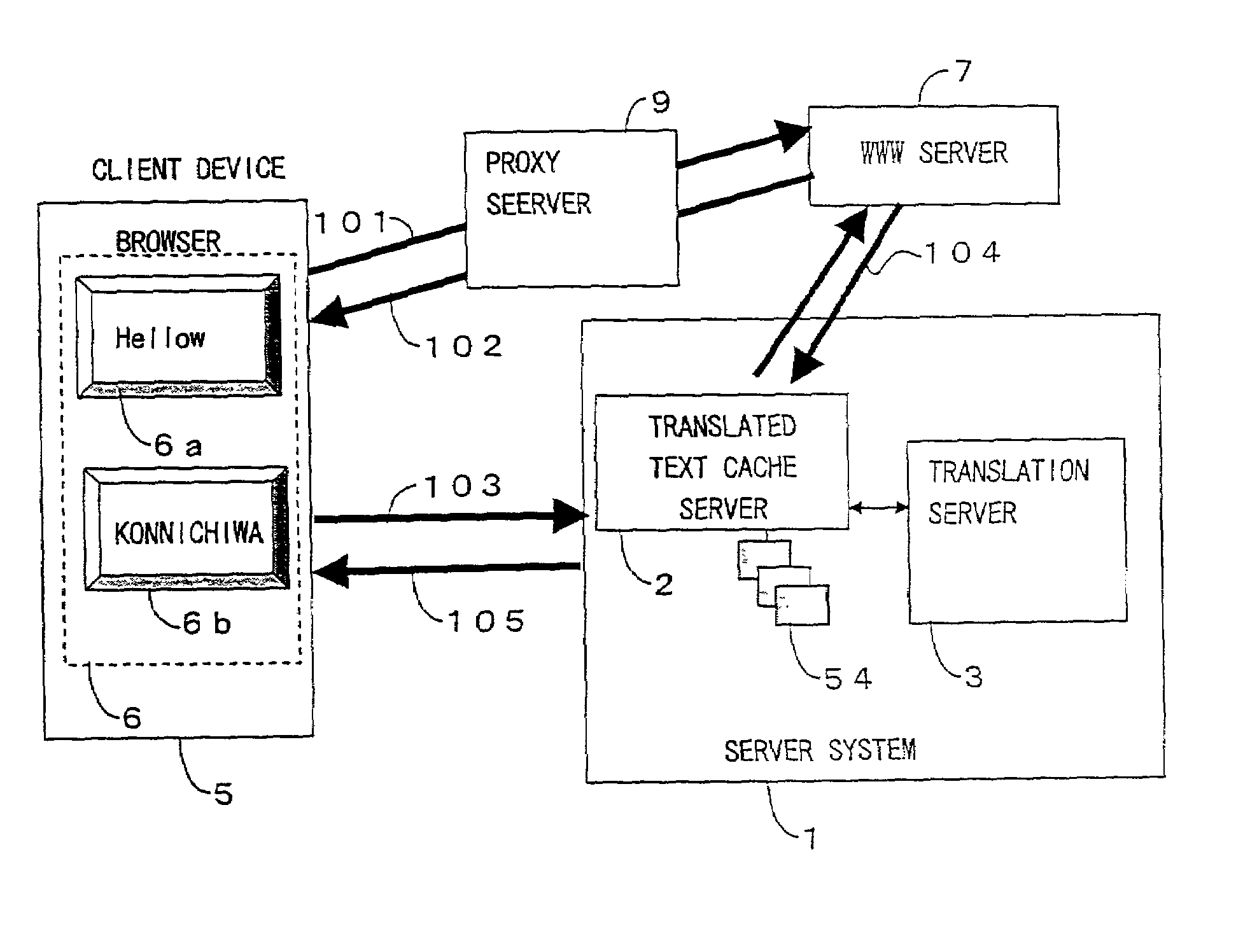

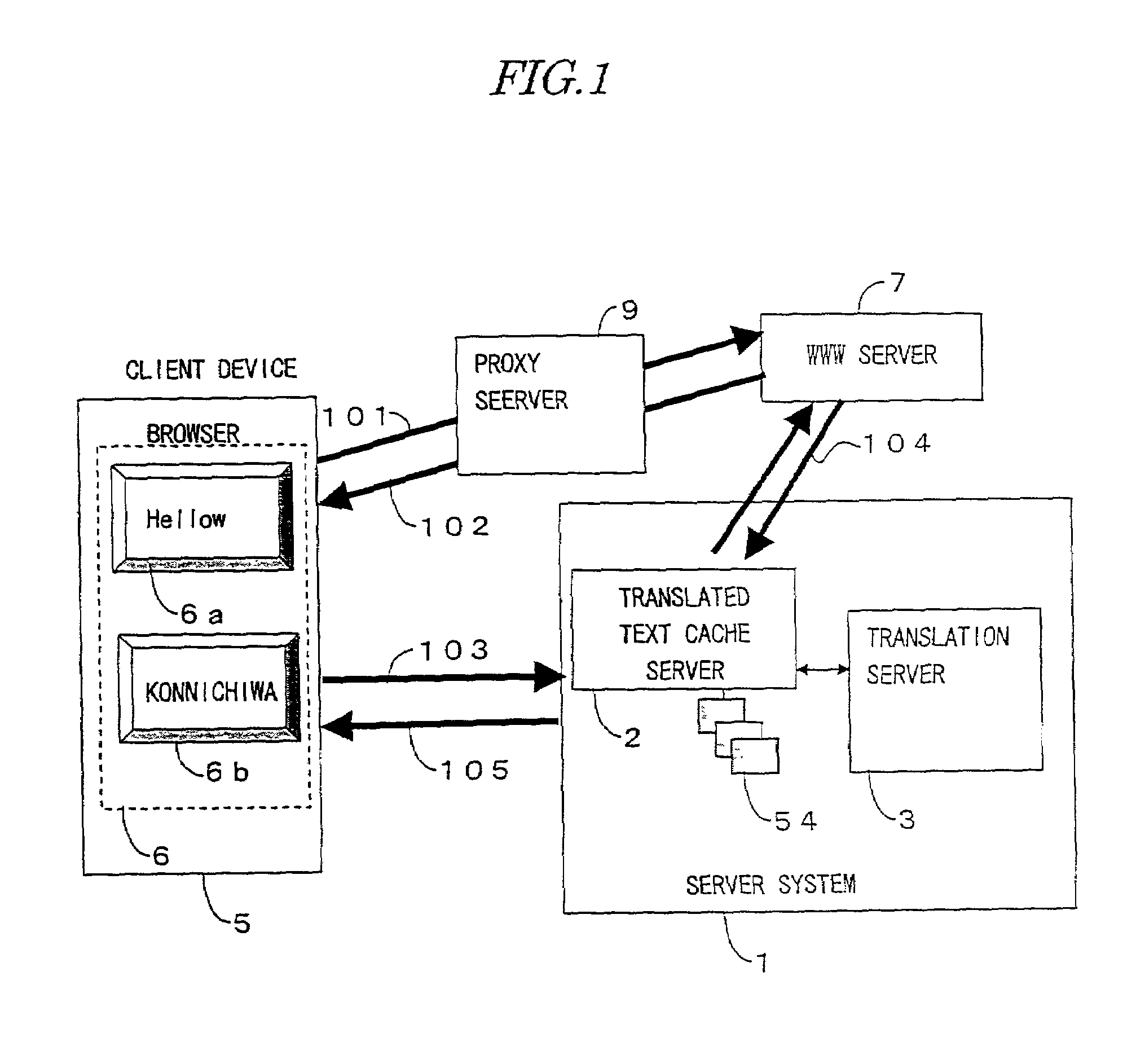

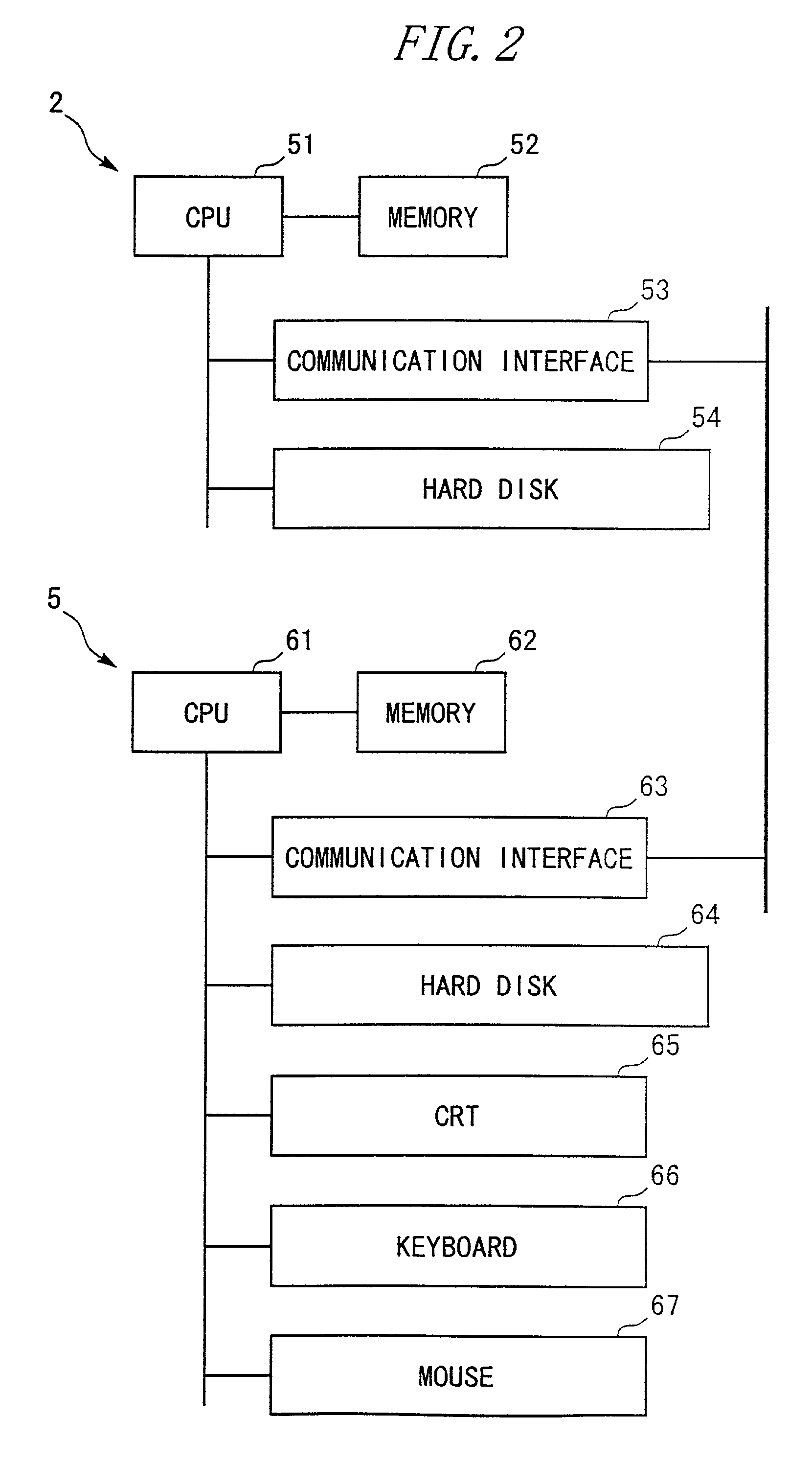

Relay device, server device, terminal device, and translation server system utilizing these devices

InactiveUS7216072B2Without any stressReduce resource consumptionNatural language translationSpeech recognitionTerminal equipmentServer appliance

A translation server system of the present invention provides a function of translating a document without feeling any stress irrespective of a performance of a user's own terminal device. A relay device for relaying request data from a terminal device to a server device and response data from the server device to the terminal device in response to the request data, includes a control unit for performing communications with a translation server for translating text information contained in the response data. The translation server translates the text information contained in the response data received from the server device, and a result of this translation is transmitted as response data to the terminal device.

Owner:FUJITSU LTD

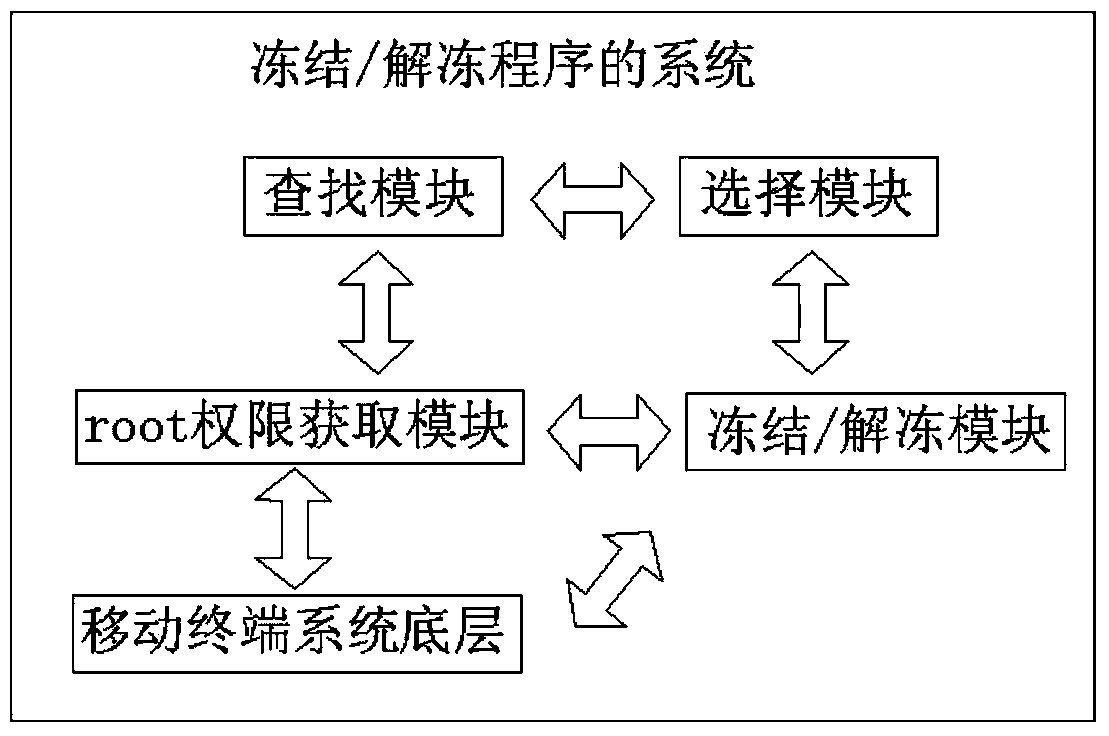

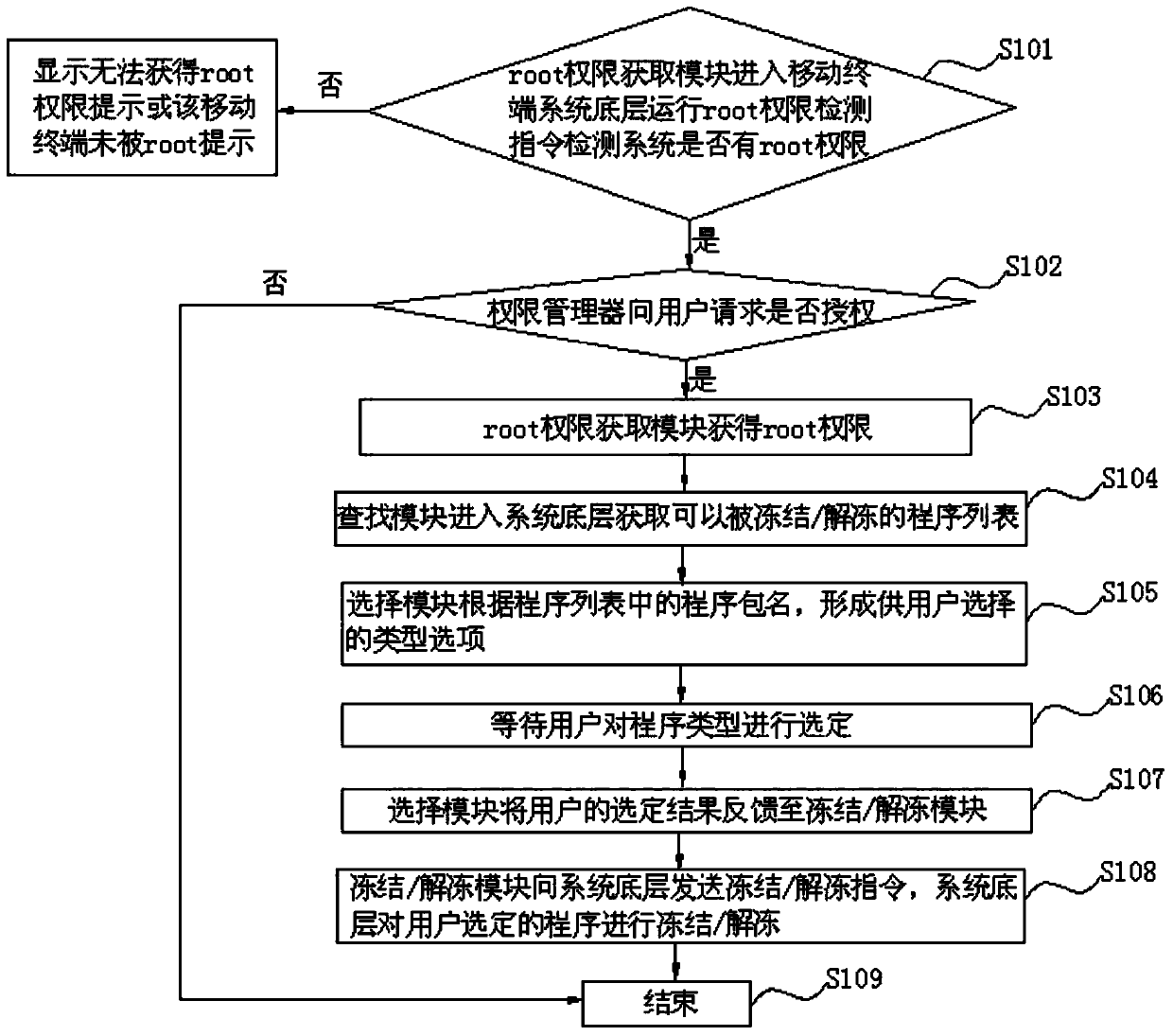

Method and system for freezing/thawing procedures

InactiveCN103744681AReduce resource consumptionPower saving system operating efficiencySpecific program execution arrangementsElectricityPersonalization

The invention provides a method for freezing / thawing procedures. The method comprises the following steps that a root jurisdiction acquiring module acquires root jurisdiction of a mobile terminal; a seeking module enters a bottom layer of a system and acquires a procedure list which can be frozen / thawed; type options selected by a user are formed by a selecting module according to procedure package names in the procedure list; types of procedures are waited to be selected by the user; the selecting module feeds back a selected result of the user to a freezing / thawing module; and the freezing / thawing module transmits a freezing / thawing command to the bottom layer of the system, and the procedures selected by the user are frozen / thawed by the bottom layer of the system. On the one hand, the user can quickly and simply freeze unnecessary procedures, resource consumption during running of the system is reduced, and the purpose of saving electricity and improving the running efficiency of the system is achieved; and on the other hand, required procedures can be thawed by the user according to self needs, and individual needs of the user are met. The invention also provides a system for freezing / thawing procedures.

Owner:GUANGZHOU JIUBANG DIGITAL TECH

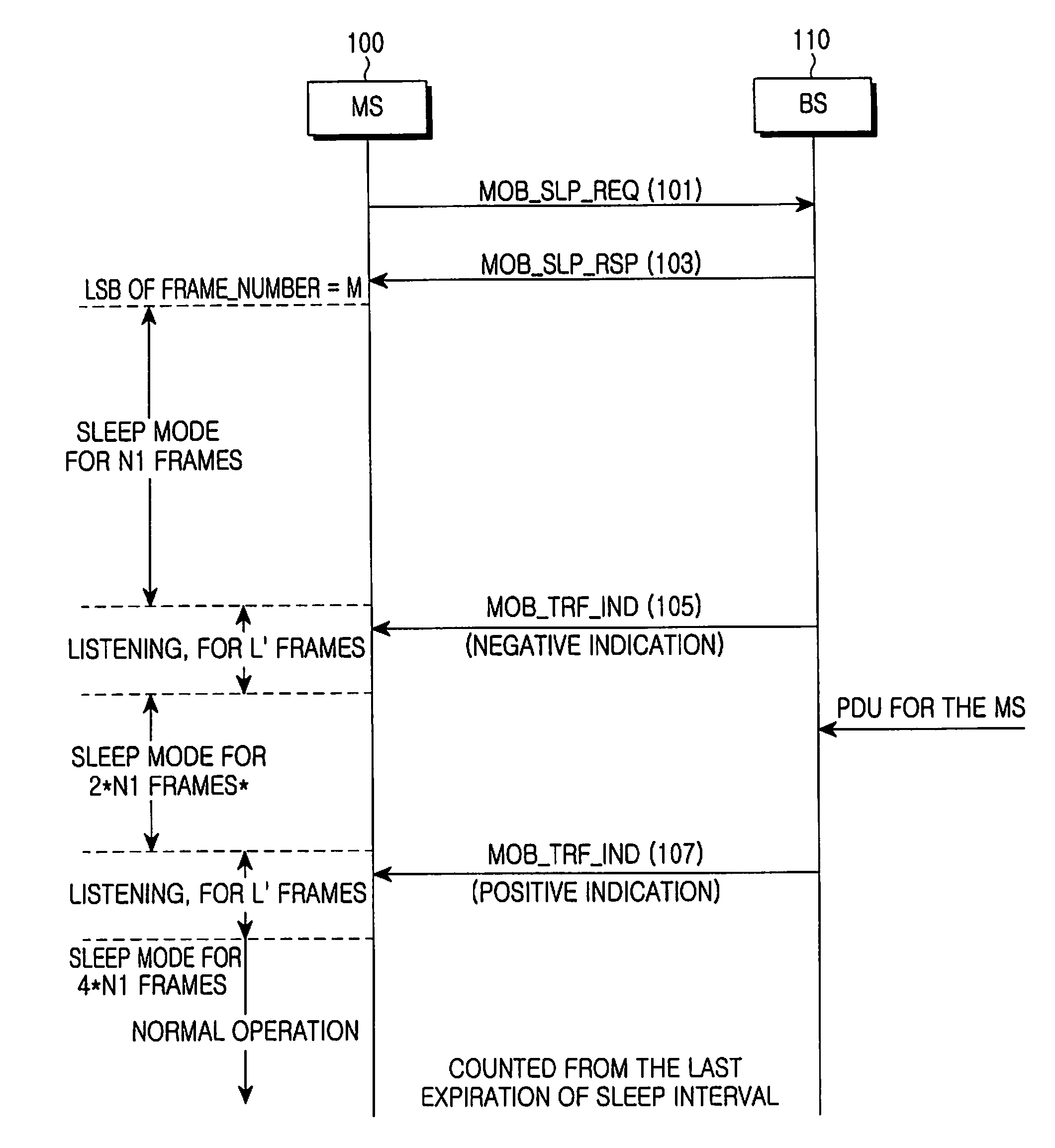

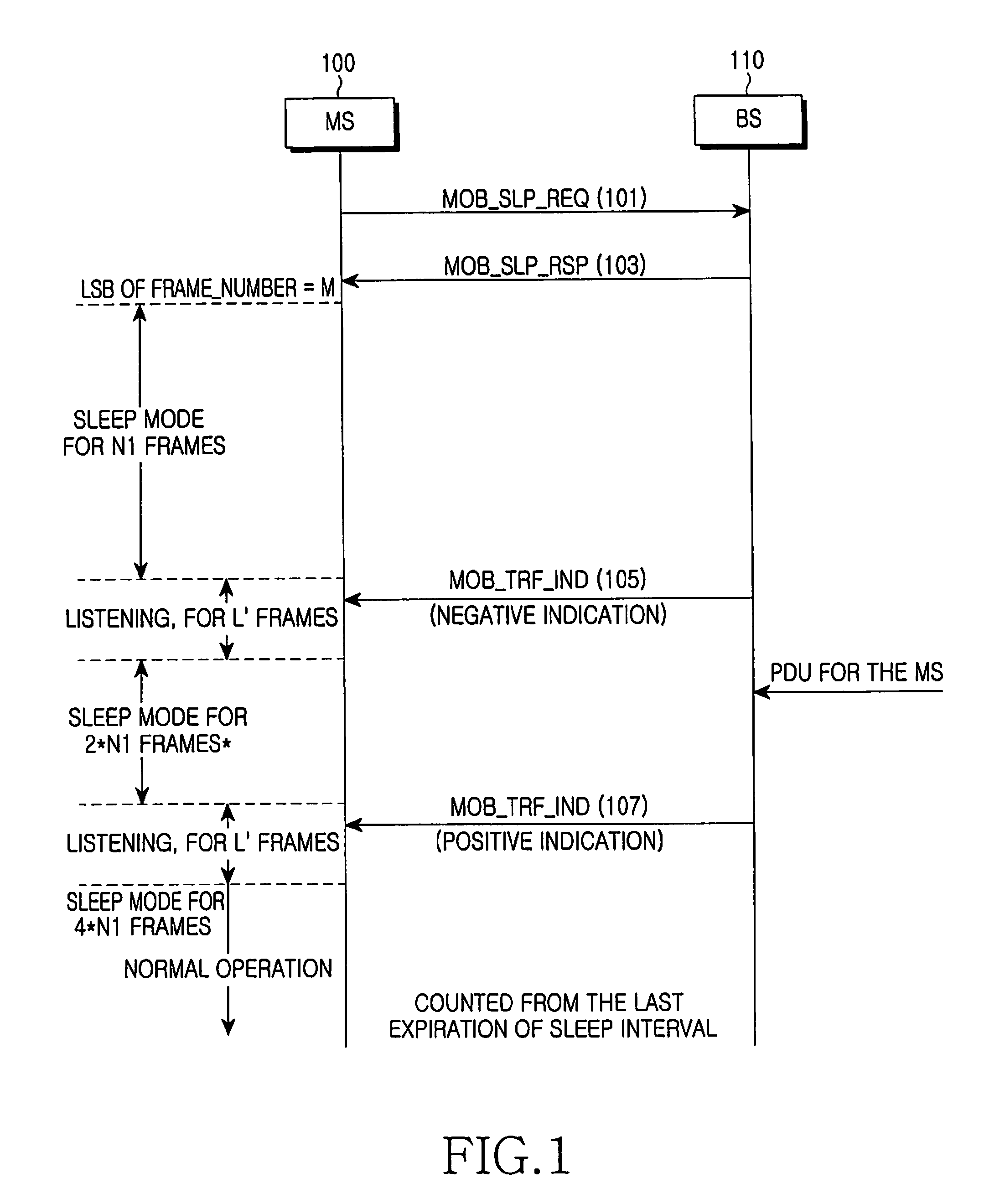

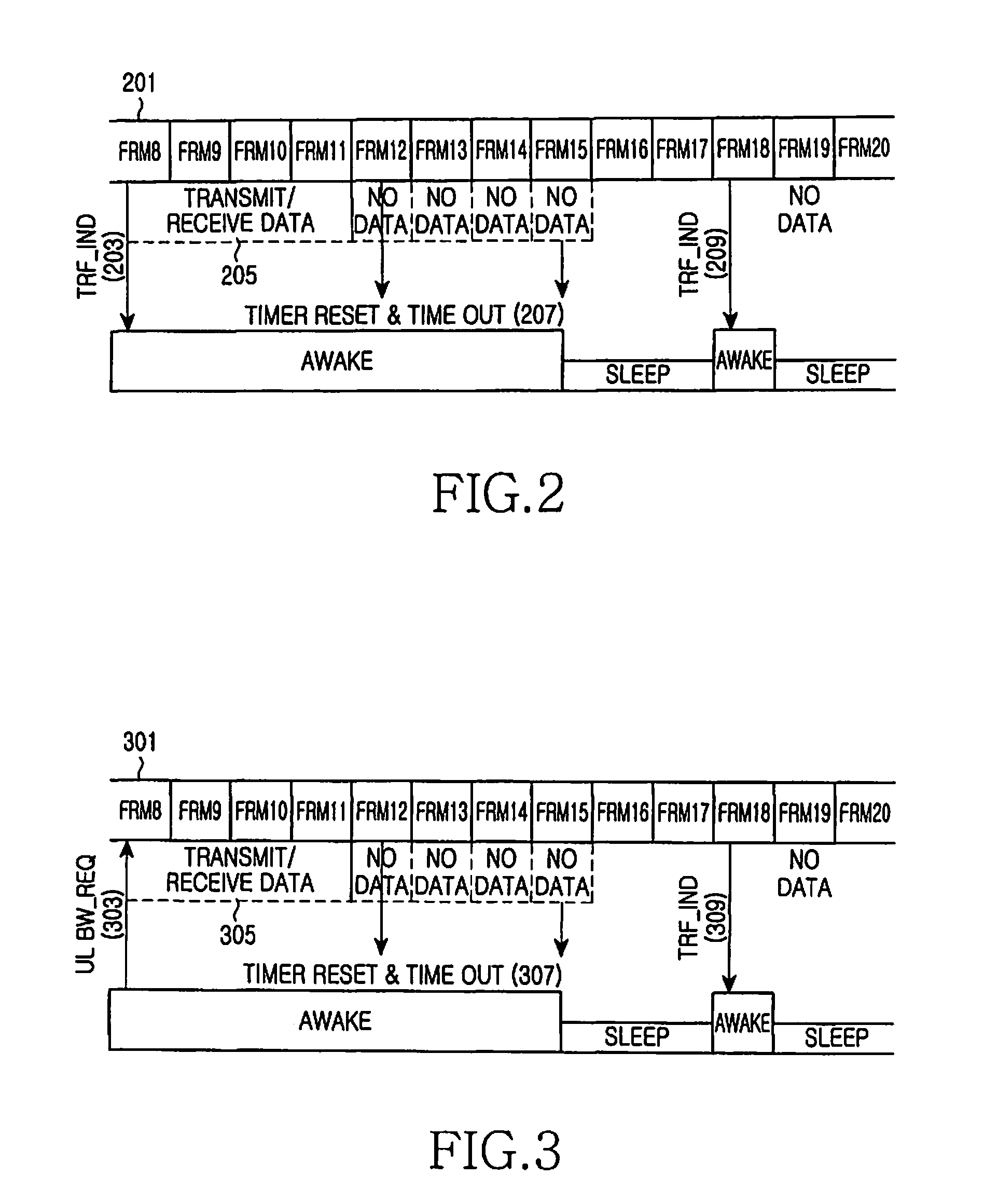

Method for controlling sleep-mode operation in a communication system

ActiveUS20080075026A1Reduce resource consumptionReduce power consumptionPower managementTransmission systemsSleep stateControl communications

A method for controlling a sleep-mode operation in a communication system is provided, in which a Mobile Station (MS) transitions to an awake state in a listening interval of the sleep mode, performs one of a first operation, a second operation, and a third operation in the awake state, and transitions to a sleep state if the MS determines that there is no data to transmit to a BS and no data to receive from the Base Station (BS) after the one operation is performed. The first operation is for receiving data from the BS, the second operation is for transmitting data to the BS, and the third operation is receiving data from the BS and transmitting data to the BS.

Owner:UNWIRED PLANET INT LTD

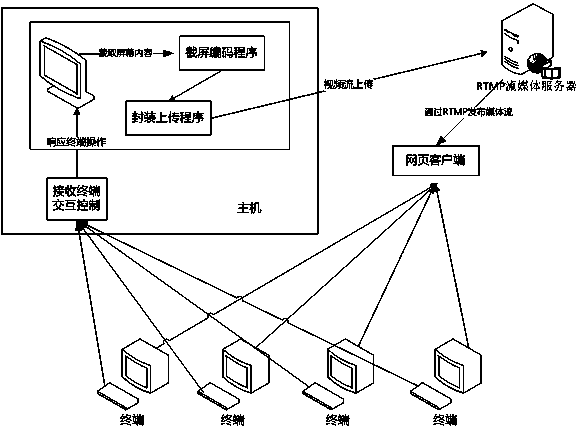

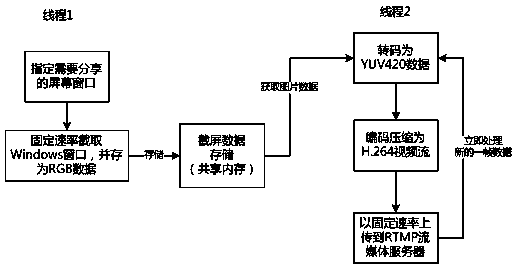

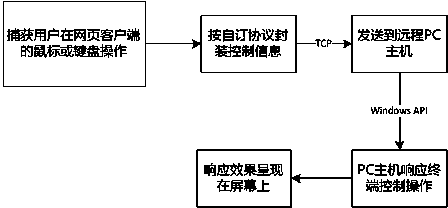

PC screen content sharing/interaction control method

ActiveCN103414751AImprove experienceGuaranteed real-timeTelevision systemsTransmissionResponse effectInteraction control

The invention relates to a PC screen content sharing / interaction control method, specifically, relates to improvement of an existing method of PC screen content sharing. The PC screen content sharing / interaction control method comprises the following steps that: S1, a remote PC host assigns a window of which the content is required to be shared; S2, screen RGB data are obtained in a shared memory data buffer; S3, a software encoder is utilized to perform encoding and compression on data a YUV420 format so as to obtain H.264 video streams; S4, the screen content video streams which have been subjected to encoding and compression are uploaded to a stream media server through an RTMP protocol; S5, a user logs into a Webpage client address which releases media streams of the remote PC host through a browser; S6, control information is transmitted to the remote PC host through a TCP protocol; S7, the remote PC host parses received control information of a user end and displays the received control information on a PC screen; and S8, screen response effect is presented on a Webpage client which the client logs into. With the PC screen content sharing / interaction control method adopted, a user can directly browse the content of the screen through a Webpage browser, and remote interaction control protocols can be customized, and a lightweight system used for PC screen content sharing / interaction can be realized.

Owner:GUANGDONG UNIV OF TECH

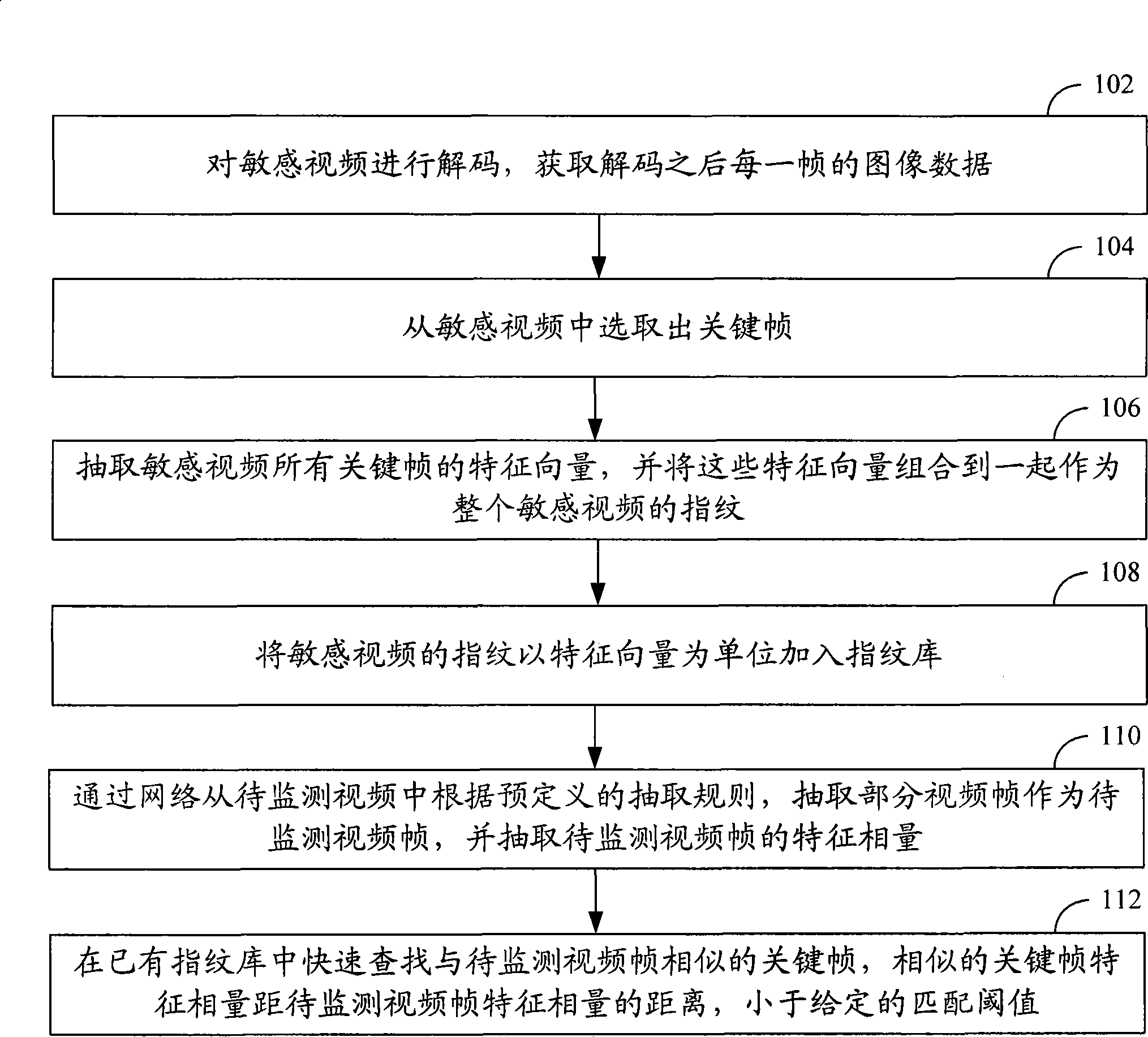

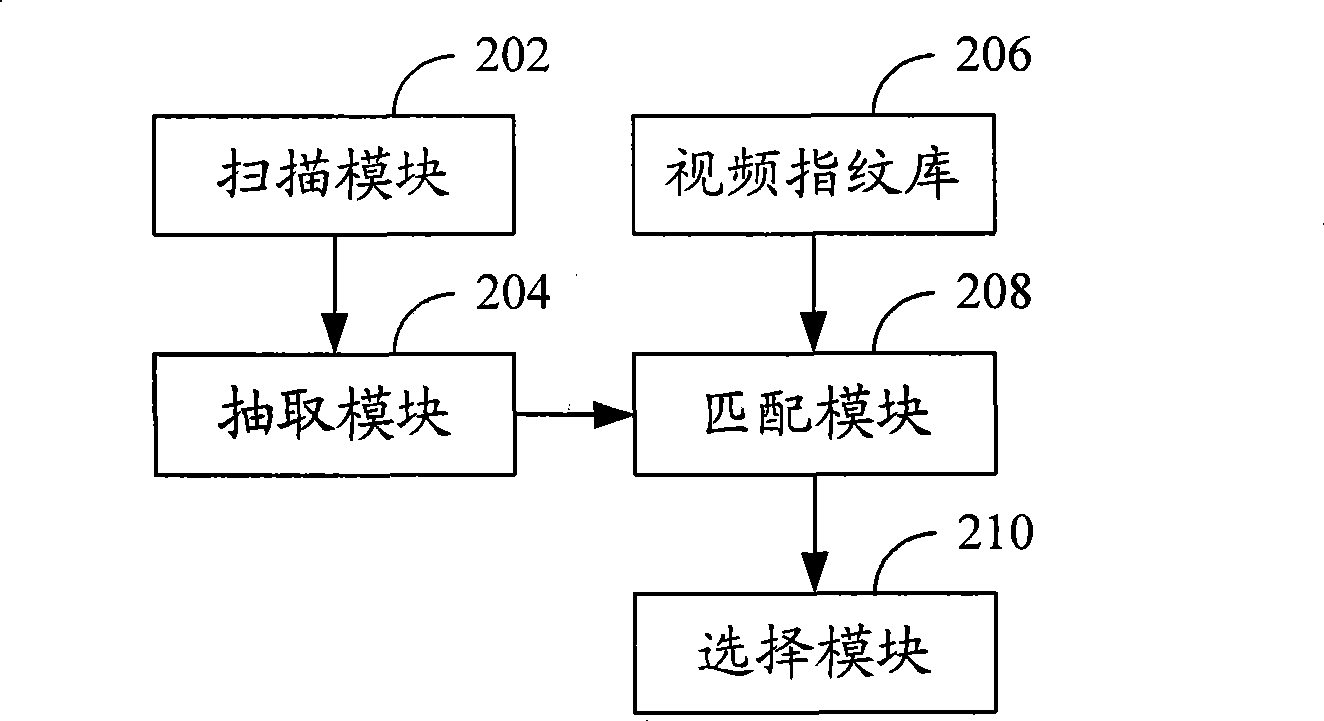

Method and apparatus for monitoring video copy base on content

ActiveCN101374234AReduce contentSave spacePulse modulation television signal transmissionImage data processing detailsResource consumptionKey frame

The invention discloses a content-based video copy monitoring method and a device, and aims to solve the problem of higher consumption for content-based video copy monitoring resources. The method comprises the following steps: extracting a portion of video frames as the video frame to be monitored from videos to be monitored according to the predefined extract rules through the network; extracting the characteristic vector of the video frames to be monitored; and selecting the characteristic vector of a key frame similar to the video frame to be monitored from the key frame characteristic vectors of objectionable videos in a video fingerprint database, wherein the distance between the similar key frame characteristic vector and the characteristic vector of the video frames to be monitored is smaller than a given matching threshold. By selecting a portion of the video frames as the video frame to be monitored, the method can acquire the key frame without a large amount of calculation, and the video acquired through the network has less content and needs less storage space after downloading, thereby reducing the resource consumption during the monitoring.

Owner:TSINGHUA UNIV +1

Asphalt mixture mixing proportion design method based on inert solid fractal distribution characteristic

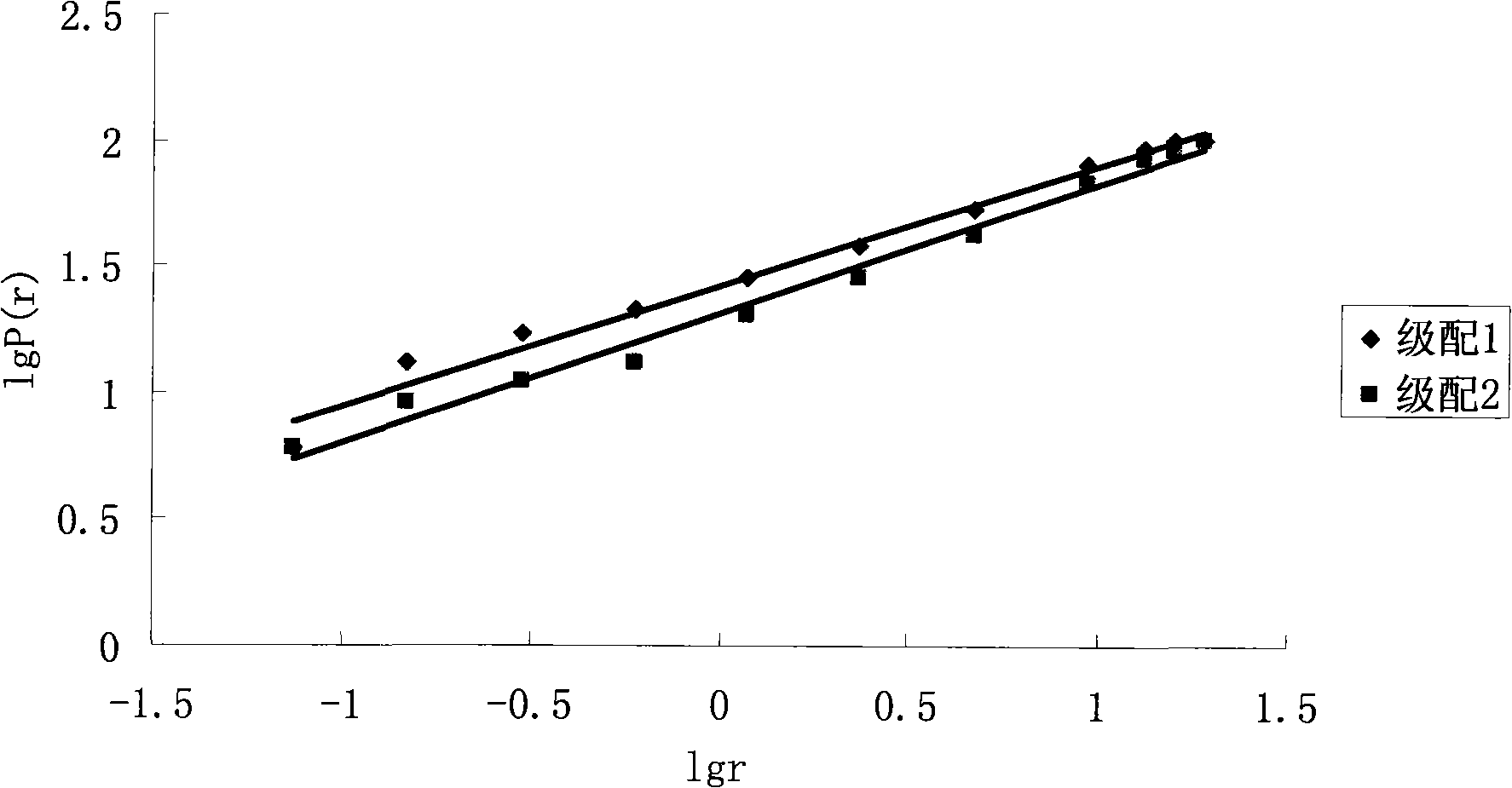

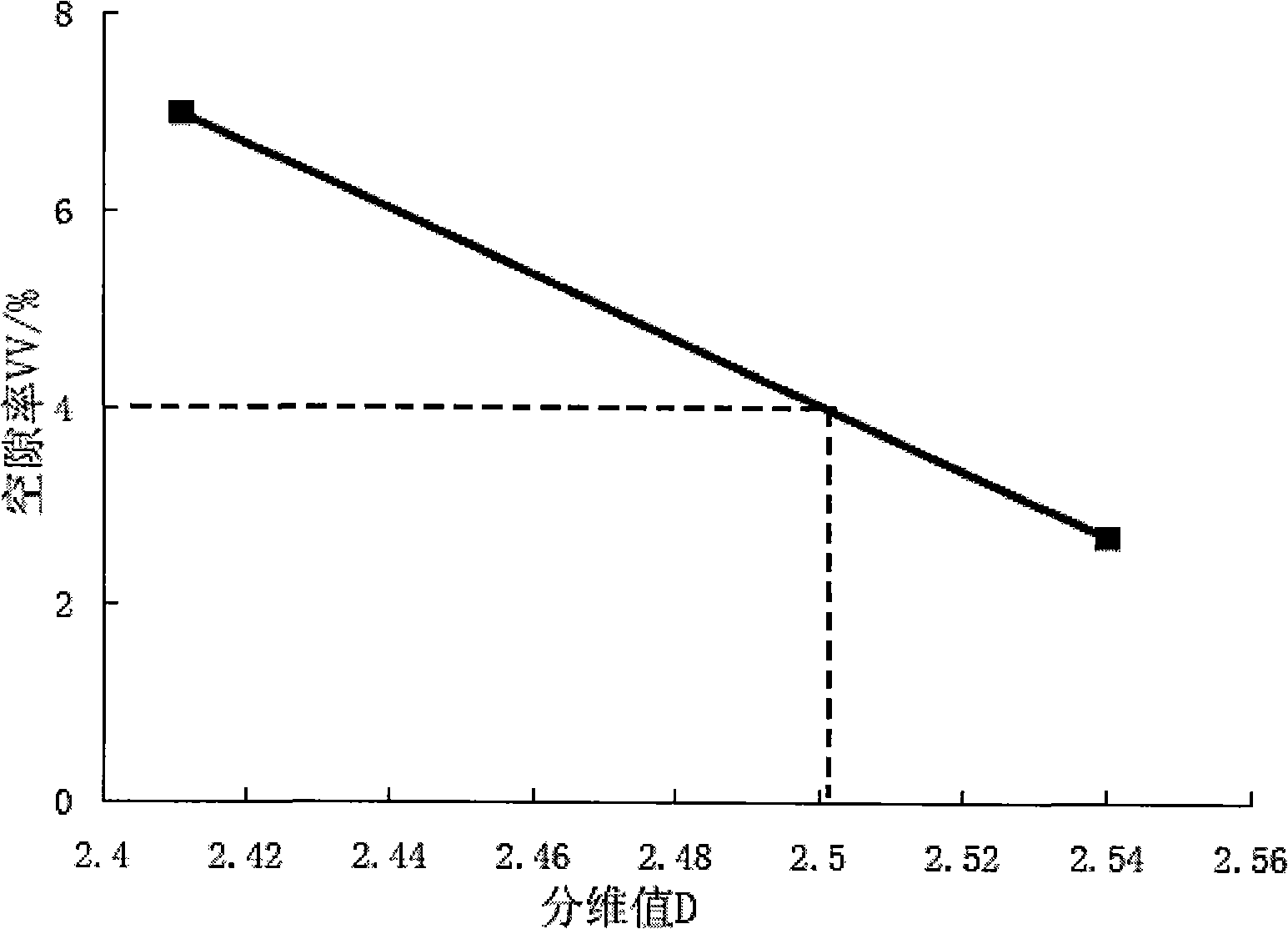

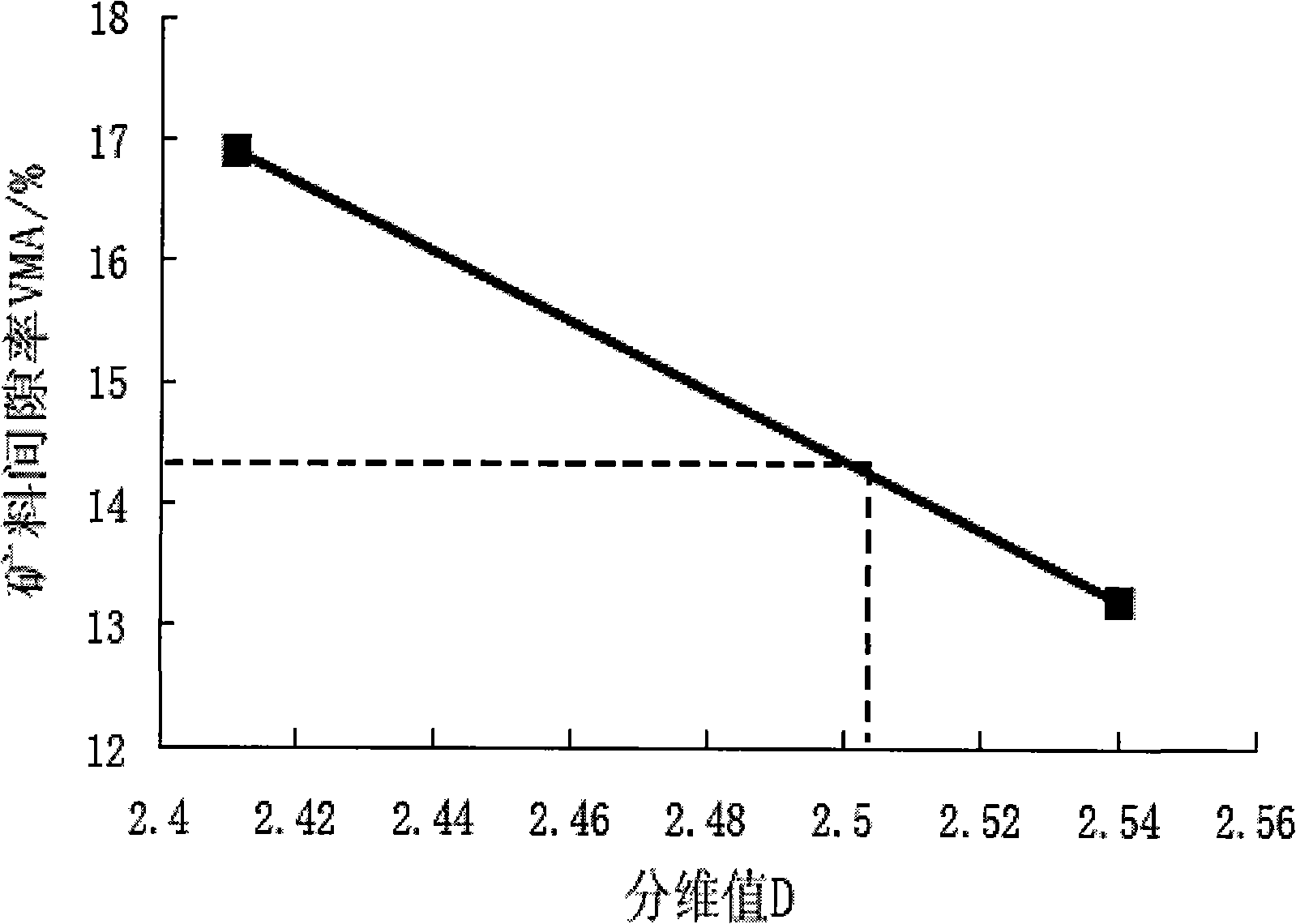

InactiveCN101318794AImprove road performanceSimple internal structureSolid waste managementCeramic shaping apparatusMathematical modelTest sample

The invention relates to a method of designing a mixed ratio for a bitumen mixture based on fractal and distributional features of ore materials. The method comprises the following steps: (1) mathematical models for particle diameter distribution and mass distribution of the ore materials are set up respectively; (2) the type and the grading limit of the bitumen mixture are determined; (3) raw materials are selected and checked; (4) graduations of two arbitrary groups of the ore materials are determined and corresponding fractal dimension values(D) are worked out; (5) the use level of the bitumen is worked out; (6) the bitumen mixture is prepared by stirring; (7) a Marshall test sample is made, the relative density of the bulk volume of the test sample is determined, the theoretical maximum relative density is determined, and the volume index is worked out; (8) relationship curves between the fractal dimension values(D) and the volume indexes are drawn; (9) the graduation of the ore materials and the optimum use level of the bitumen are determined; (10) the road performance of the bitumen mixture is tested; and (11) the construction mixed ratio of the bitumen mixture is determined. The invention utilizes the fractal theory to set up the mathematical models, and in the process of designing the mixed ratio of the bitumen mixture, the optimum bitumen use level and the optimum graduation of the ore materials meeting and regulating all design rules of the bitumen mixture can be quickly determined.

Owner:LANZHOU JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com