Patents

Literature

69results about How to "Reduce waste generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

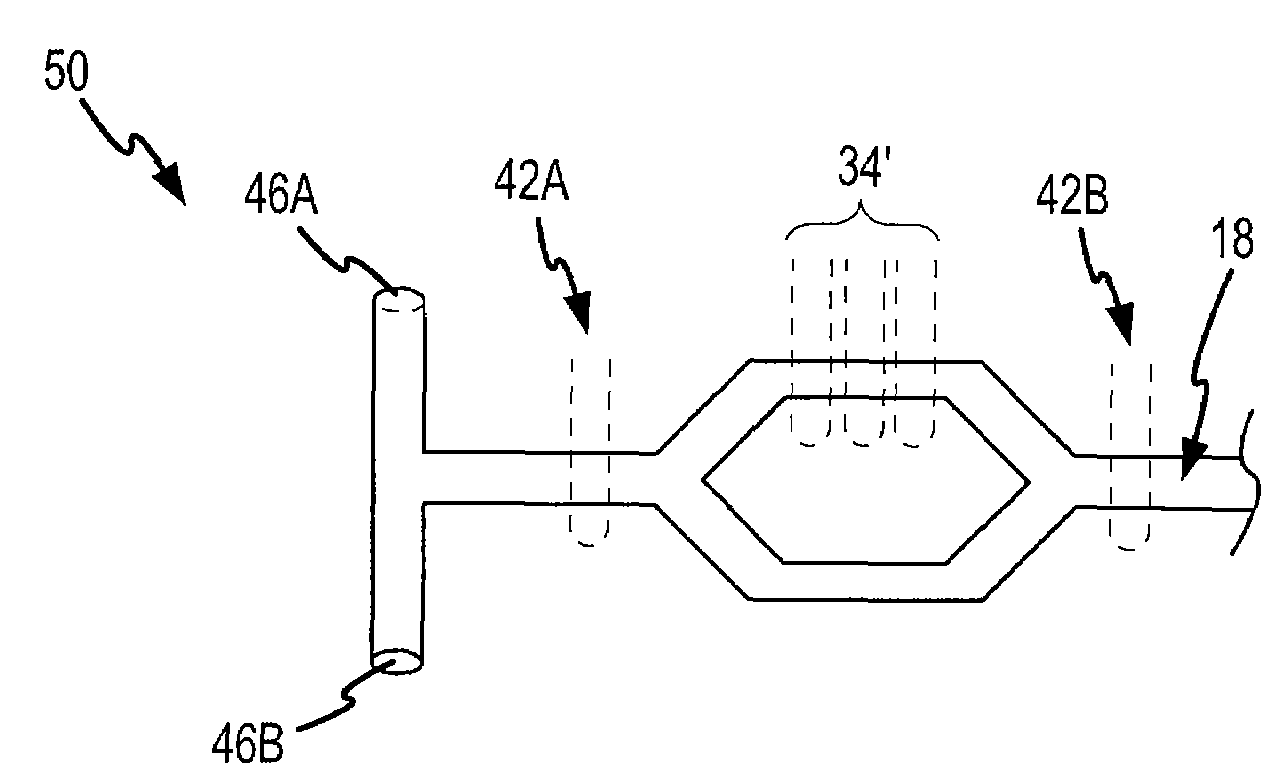

Microfluidic-based electrospray source for analytical devices with a rotary fluid flow channel for sample preparation

InactiveUS7442556B2Low costReduce resource consumptionParticle separator tubesFixed microstructural devicesElectrosprayAnalytical chemistry

Owner:FLUIDIGM CORP

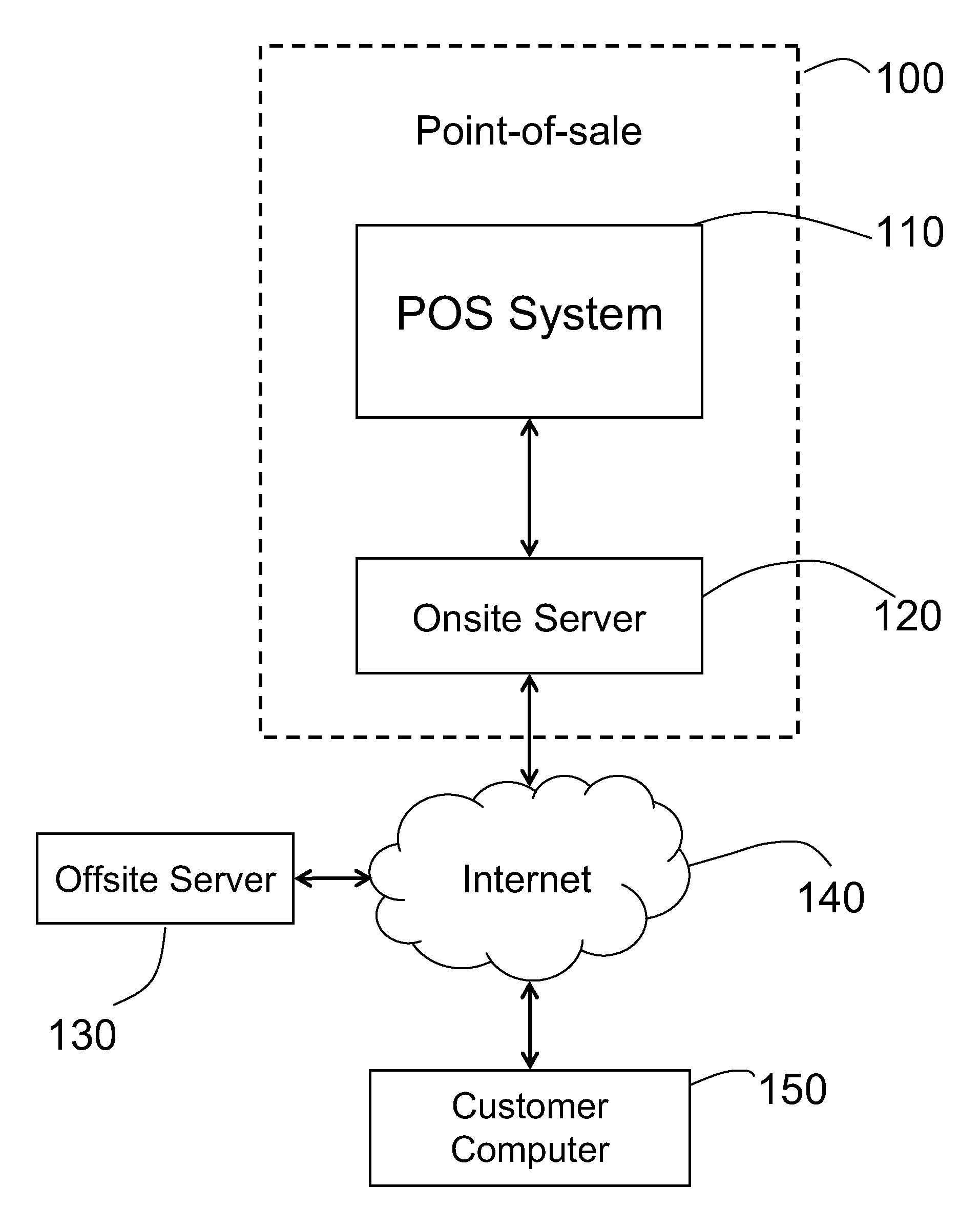

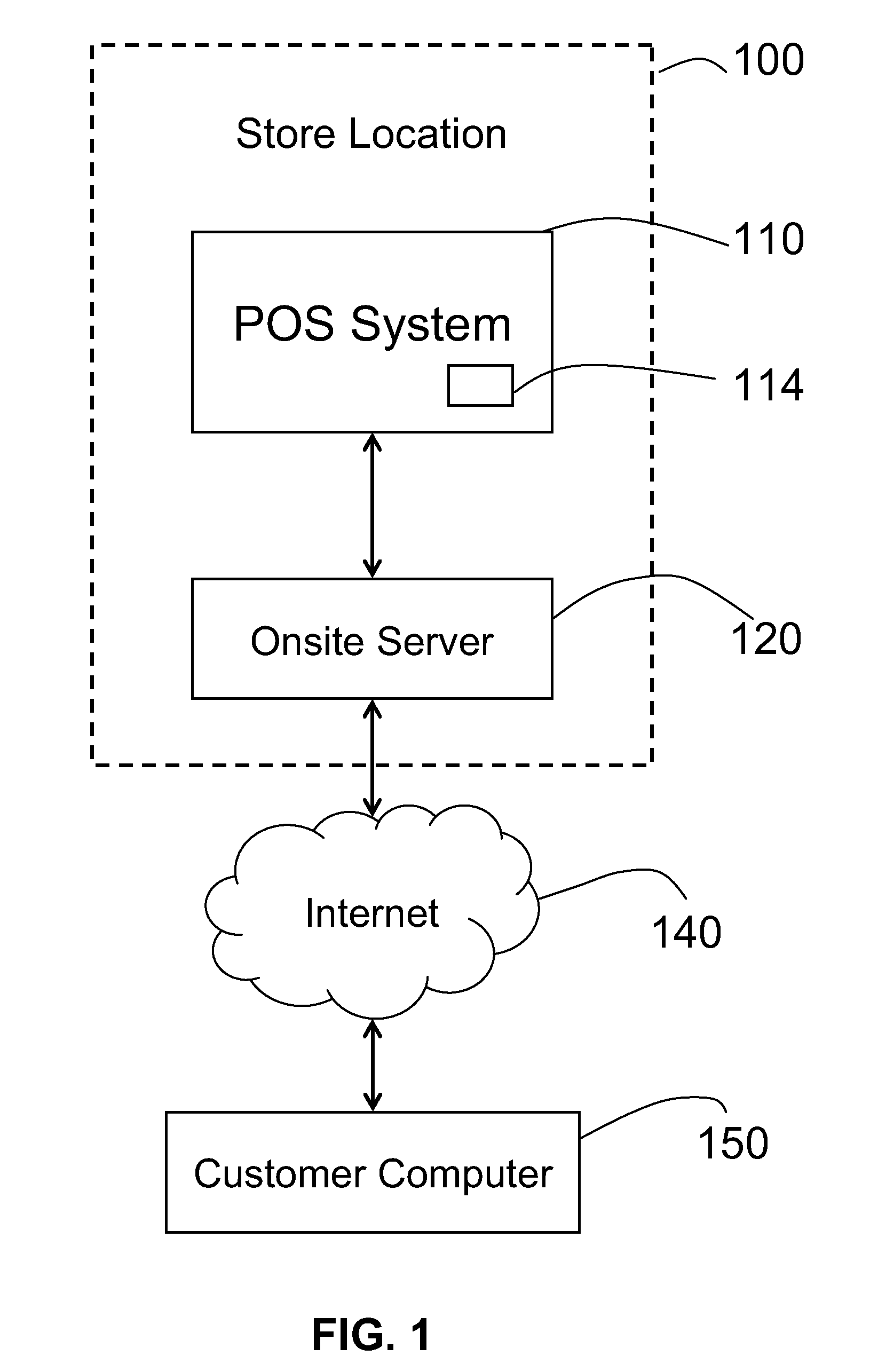

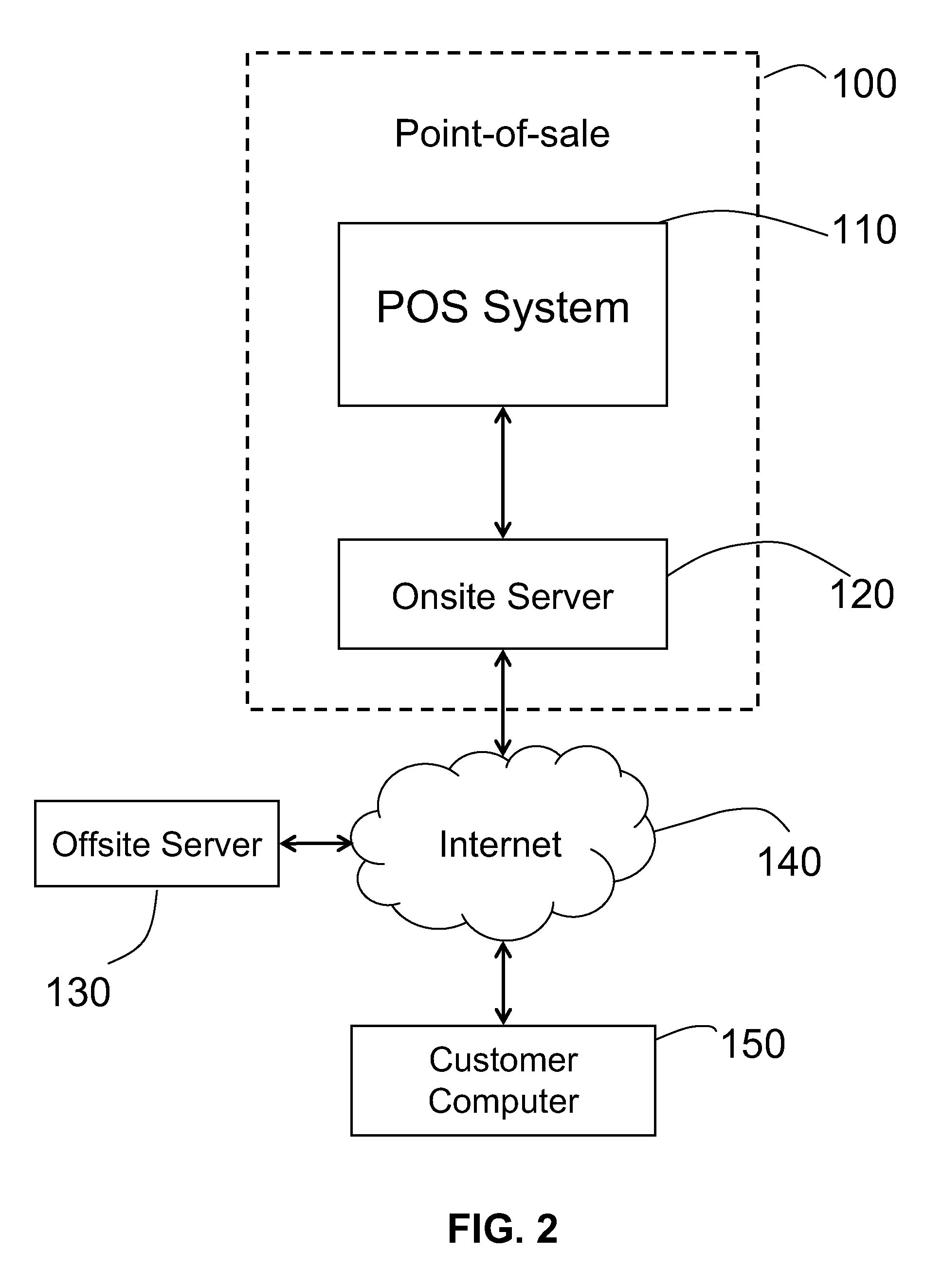

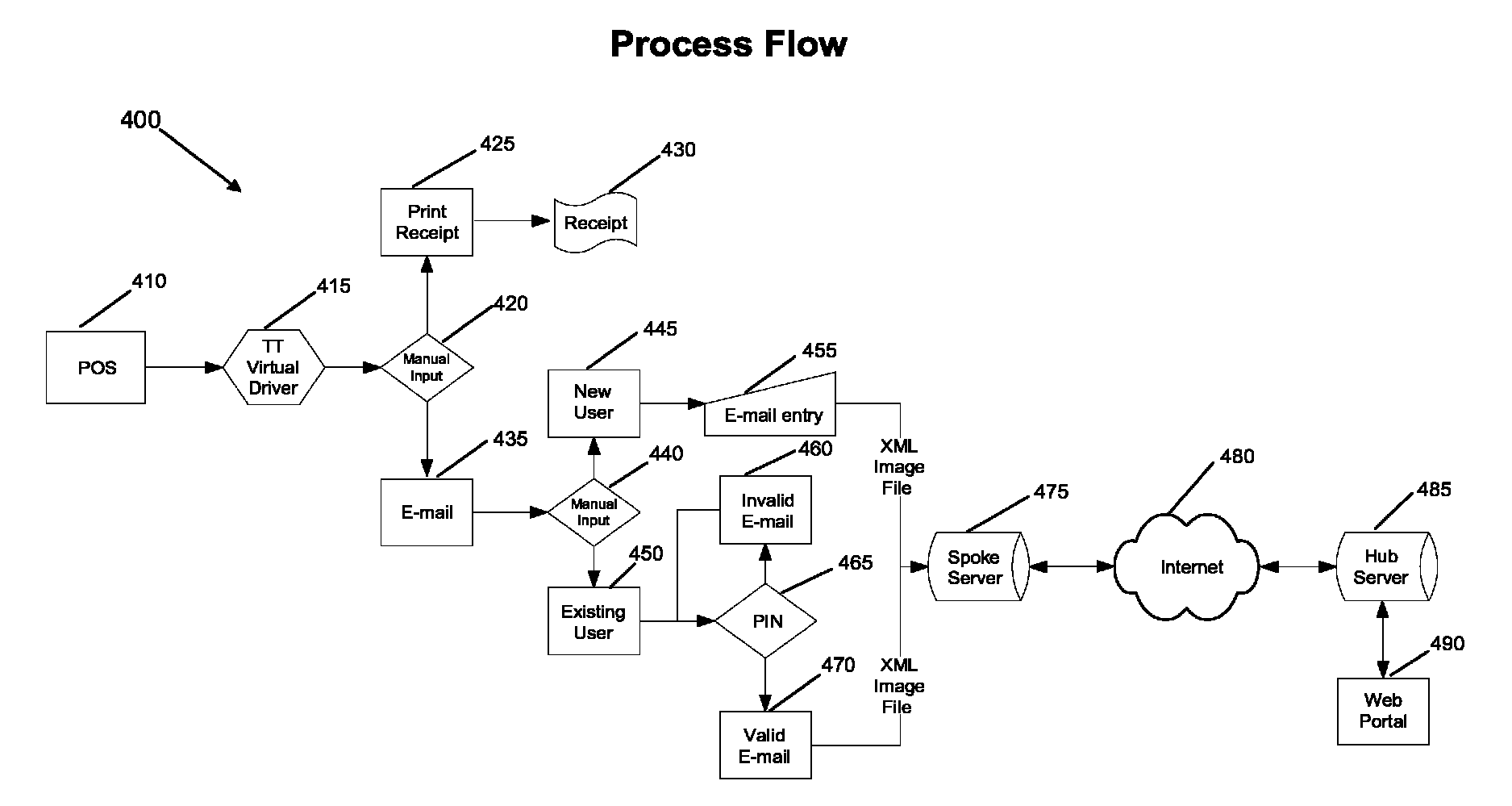

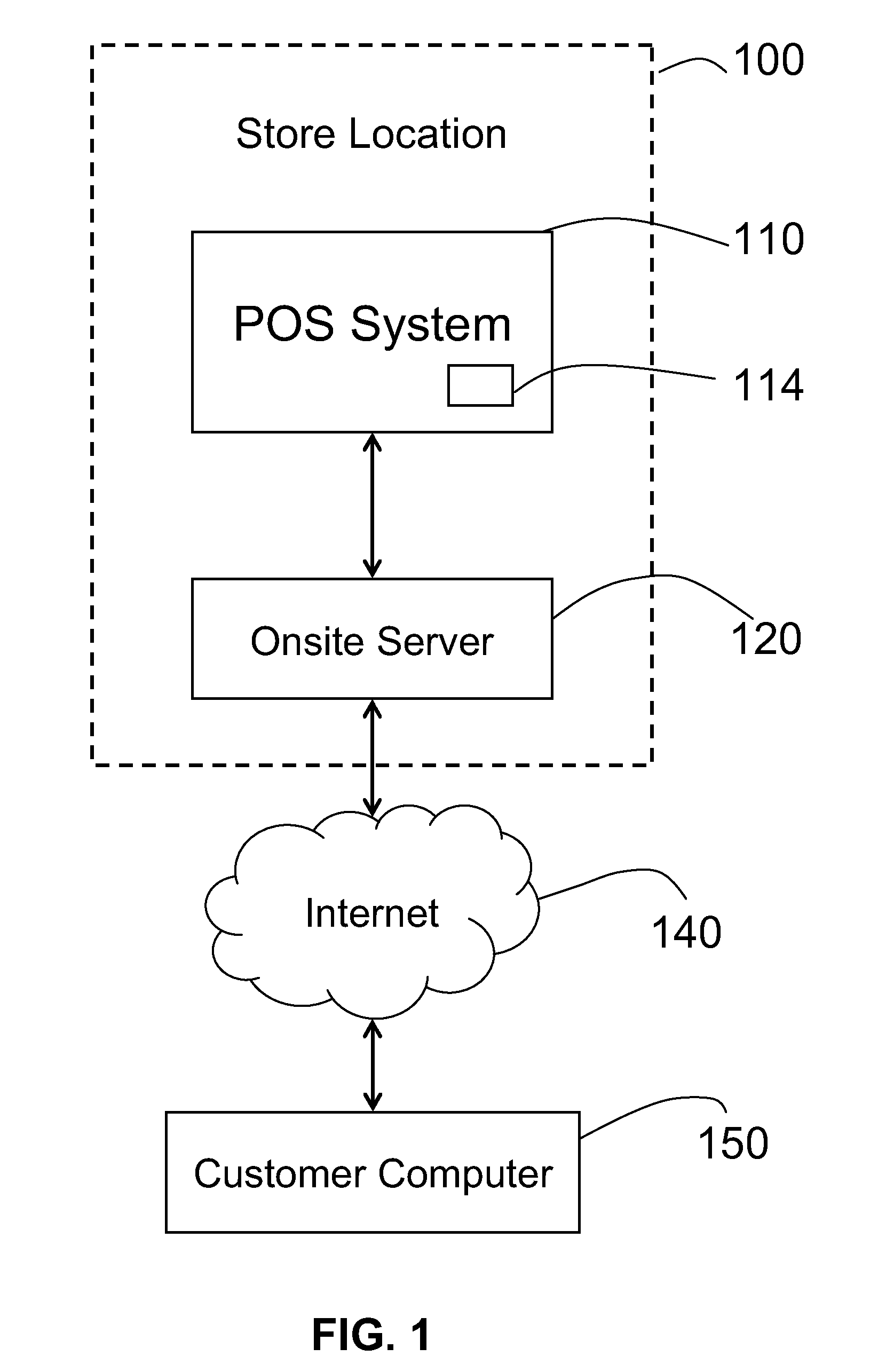

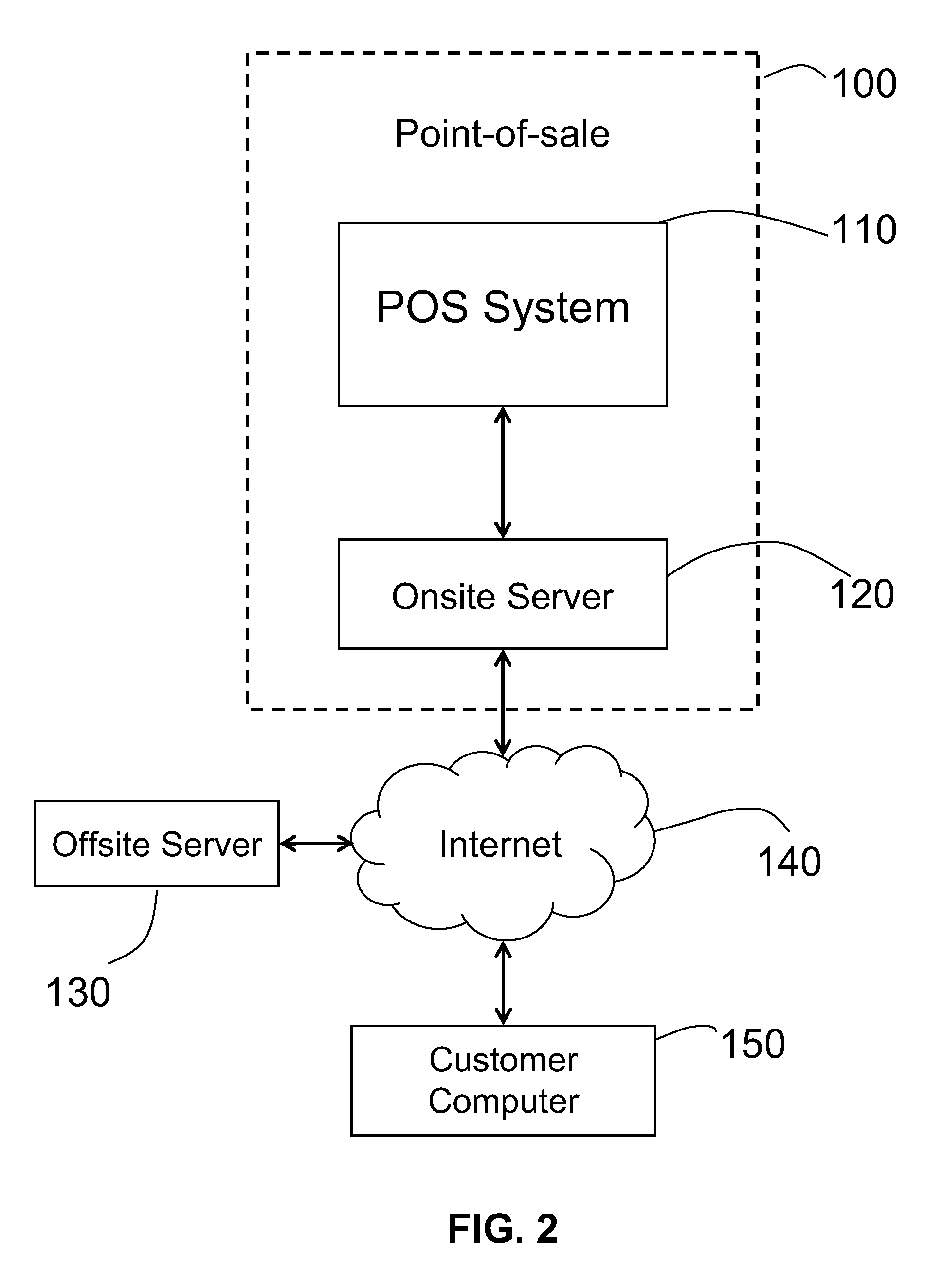

Receipt handling systems, print drivers and methods thereof

ActiveUS20100177343A1Reduce productionReduce waste generationHand manipulated computer devicesDigital data processing detailsEmail addressTransaction data

A method of processing receipts, including: obtaining transaction data including a plurality of categories of information necessary to describe a purchasing transaction of a customer at a store location; obtaining image data representing a receipt corresponding to the purchasing transaction of the customer at the store location; obtaining an e-mail address of the customer; providing an option to print the receipt at the store location and an option to e-mail the receipt to the customer; obtaining a selection of at least one of the provided options; if the option to print is selected, initiating printing of the image at the store location; and if the option to e-mail is selected, sending an e-mail to the e-mail address of the customer, the e-mail including providing at least one of the image data and the transaction data.

Owner:ECEIPT

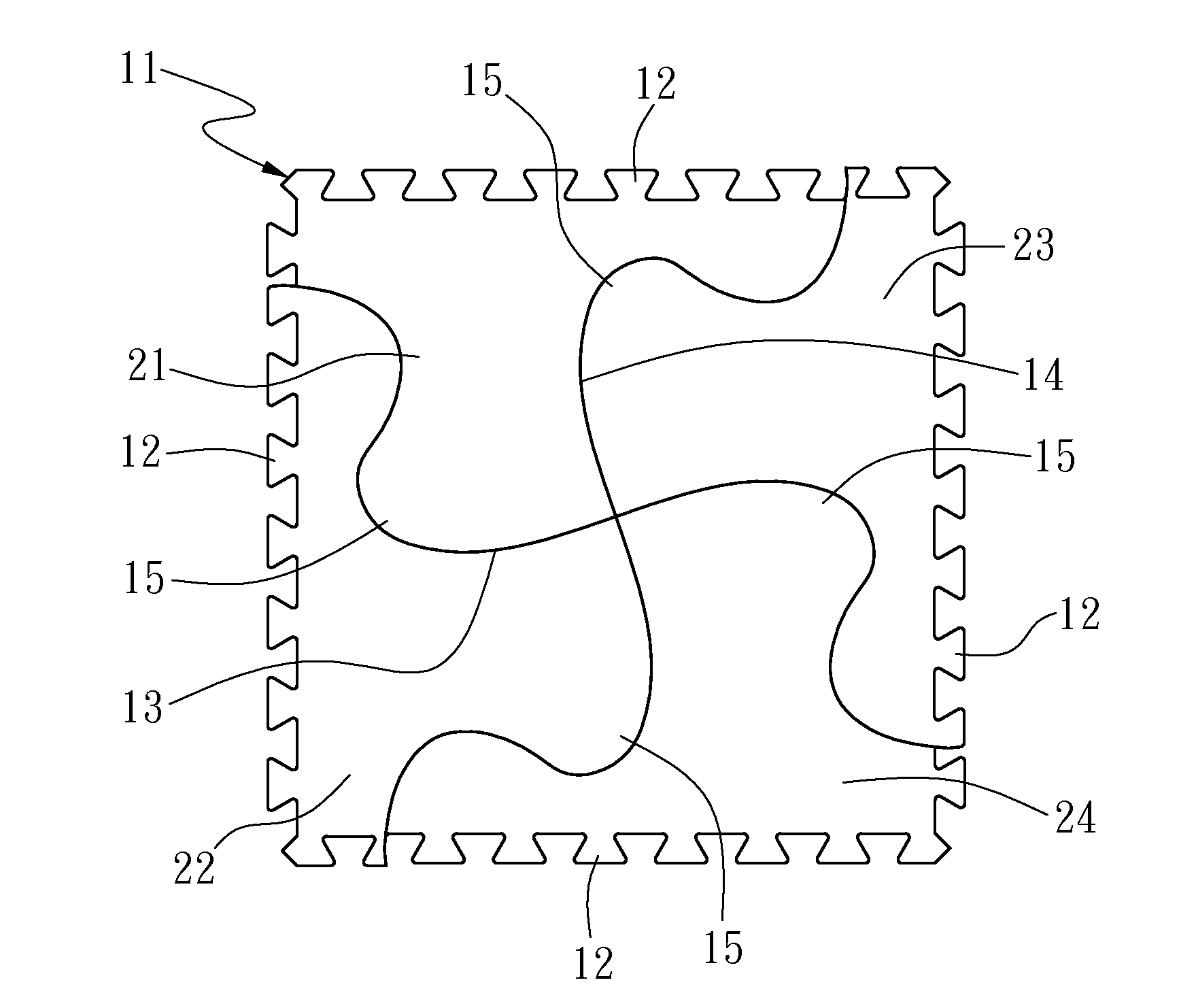

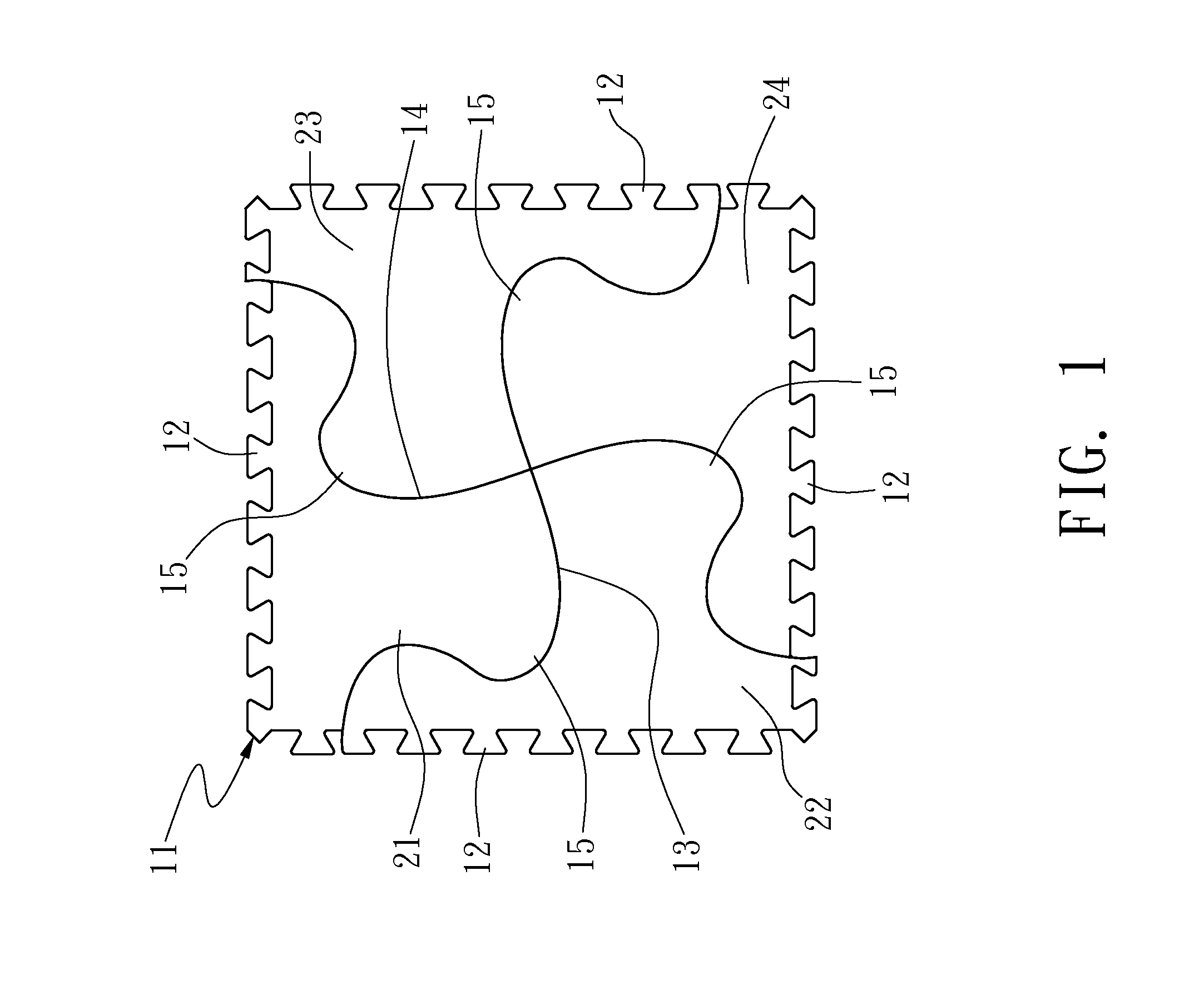

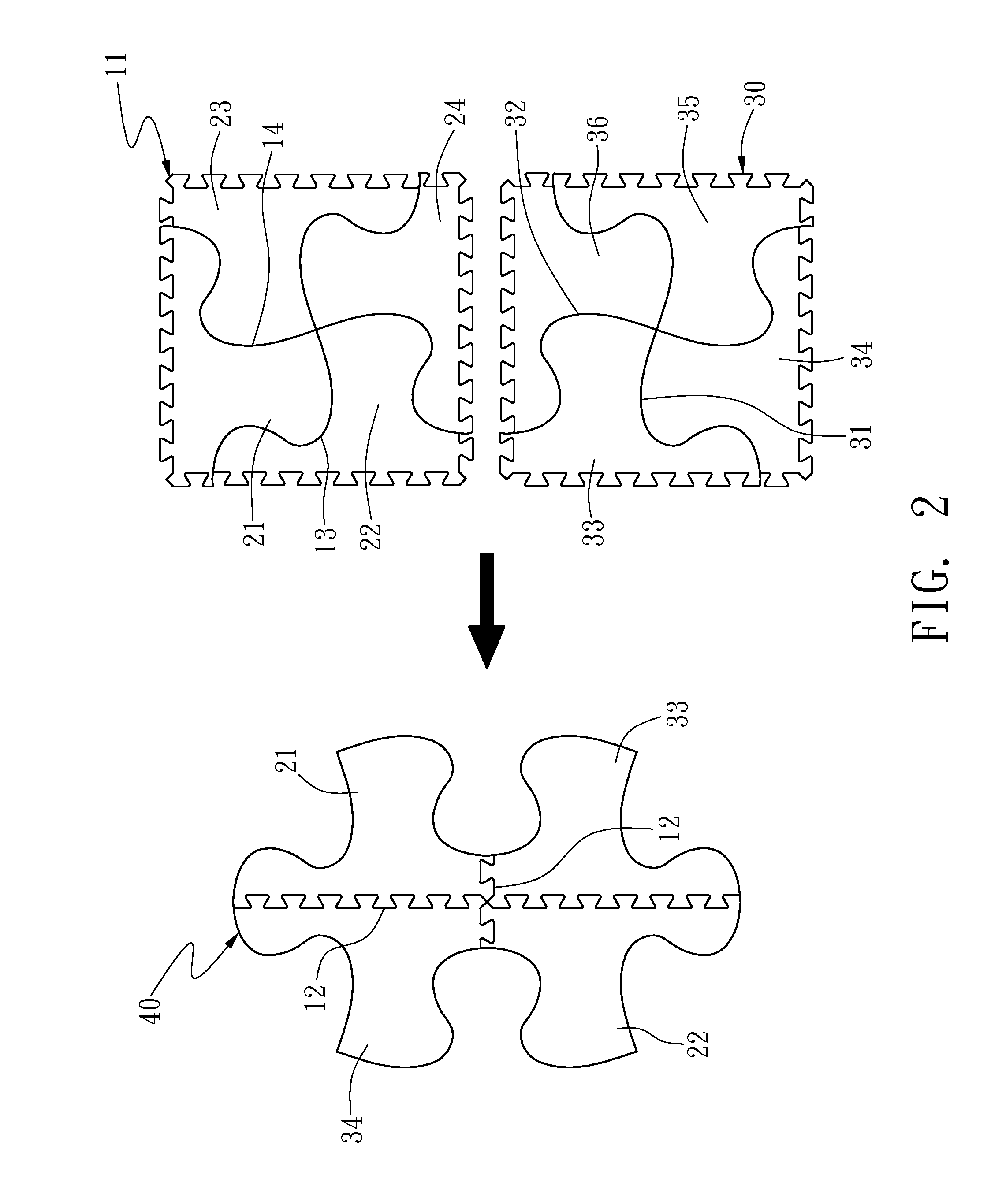

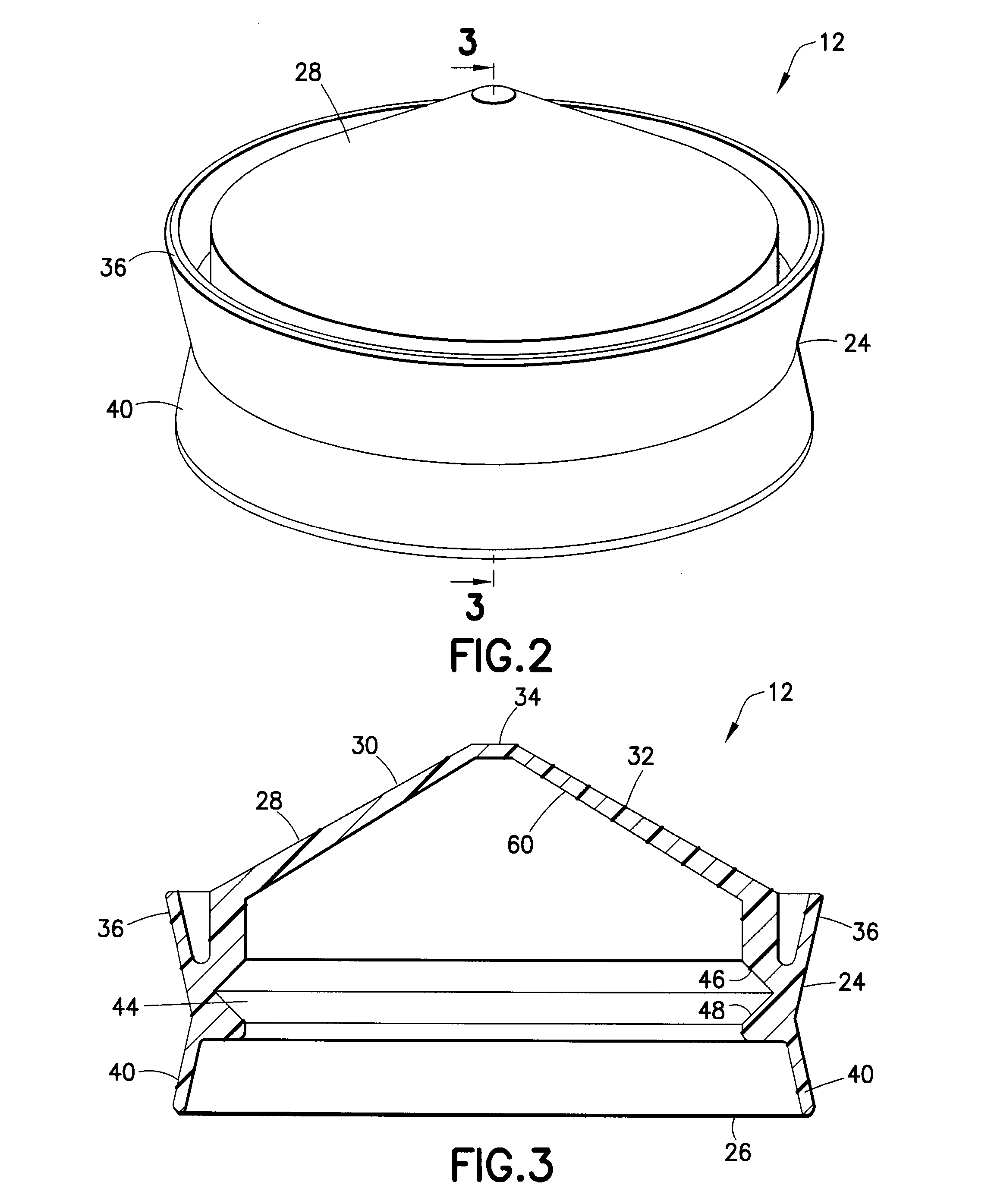

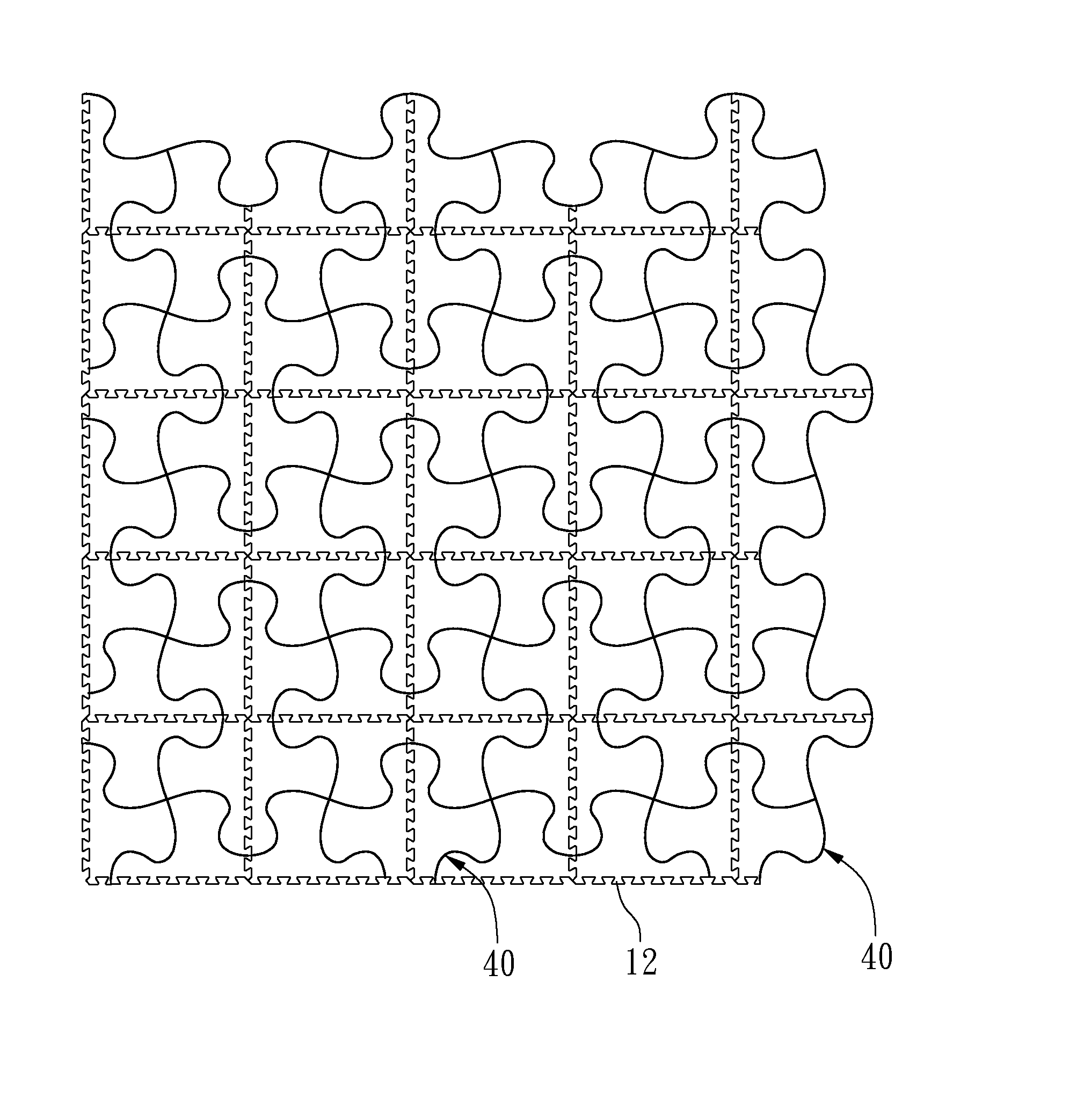

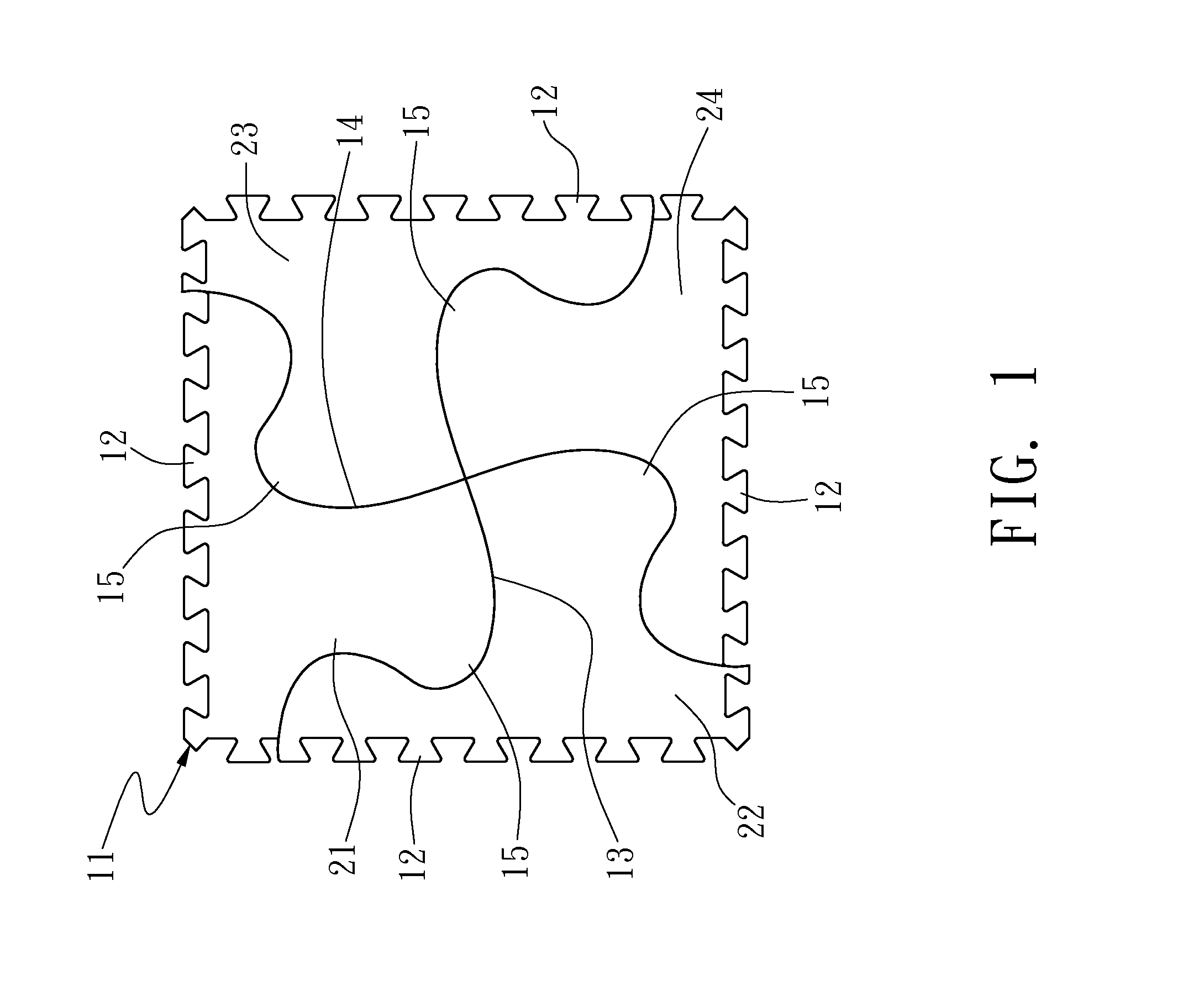

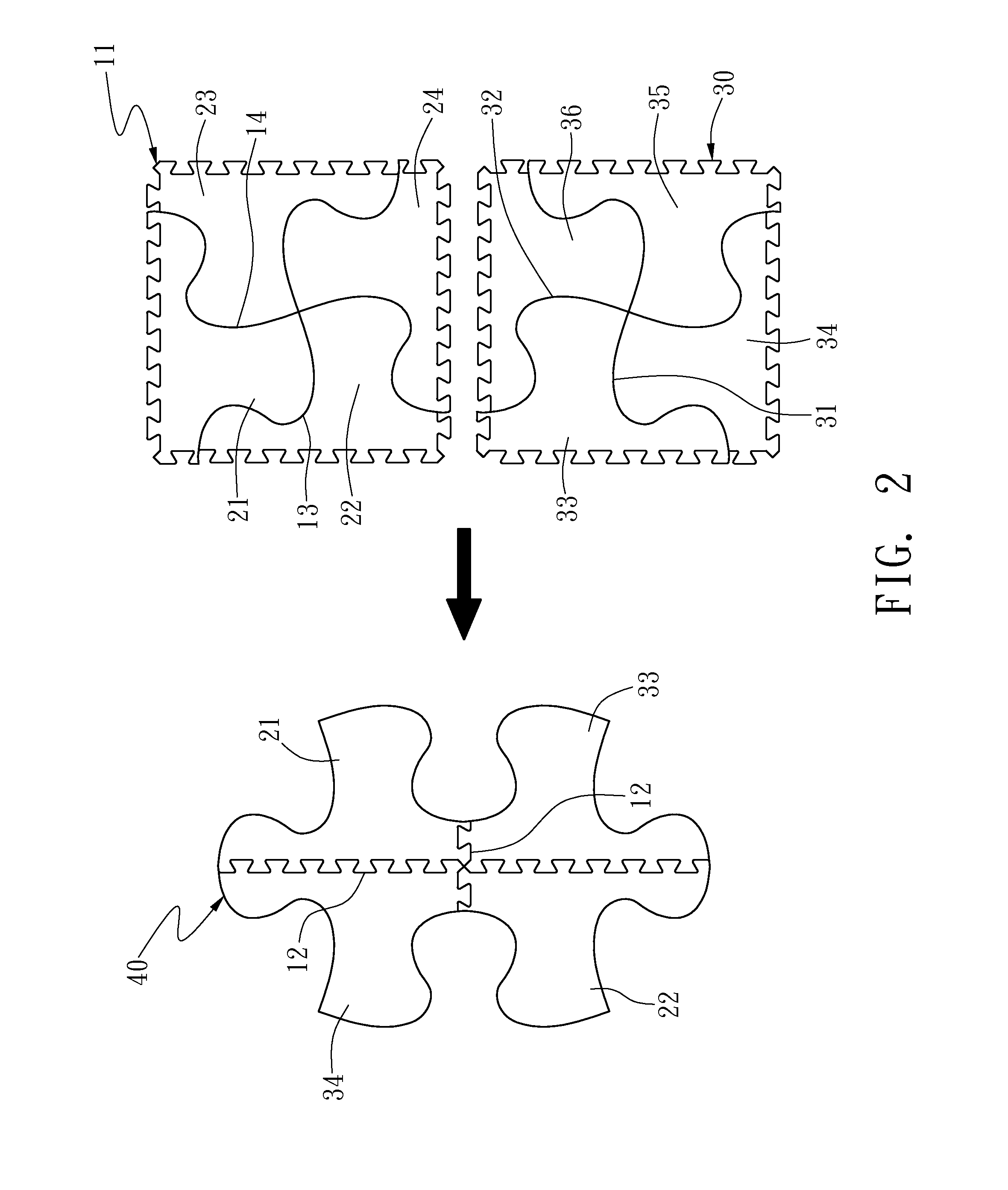

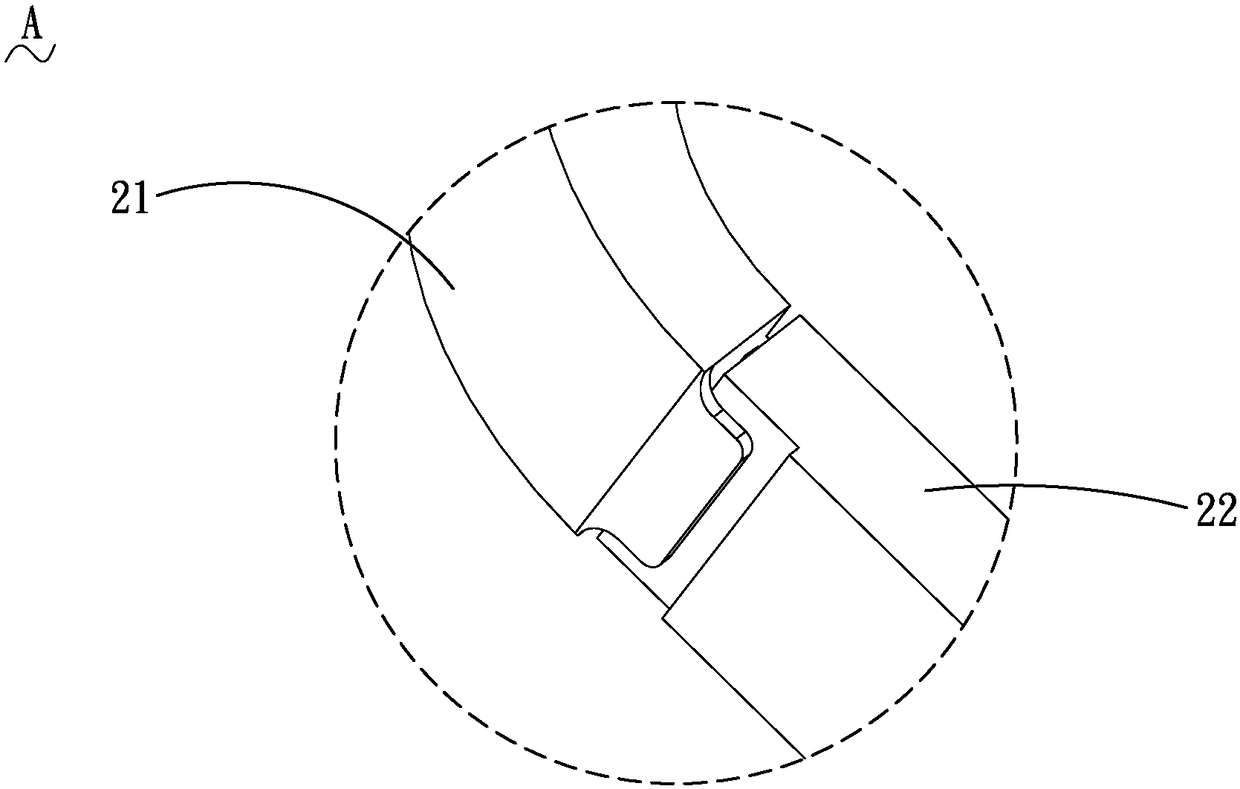

Mat with puzzle function

InactiveUS8806822B1Reduce waste generationLow production costCovering/liningsIndoor gamesEngineeringTooth part

A mat with puzzle function is a four-sided pad. Each side has a tooth part with a succession of teeth. At least two cutting lines divide the mat into four blocks, in such a way that each block has an assembling part with the complementary shape to connect with others. The block of each mat can engage with another block of the mat to form a puzzle mat set.

Owner:WANG WEN PING

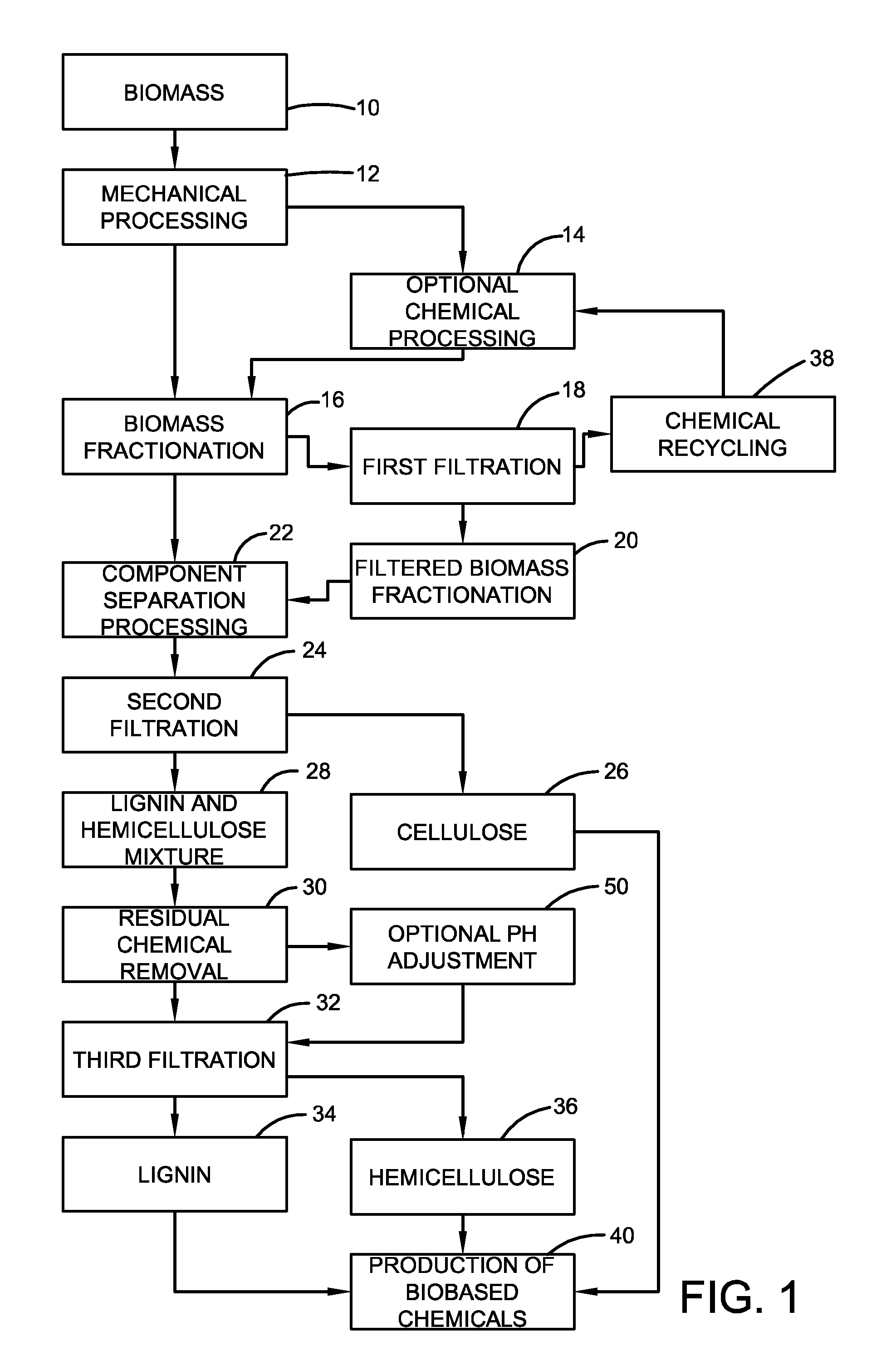

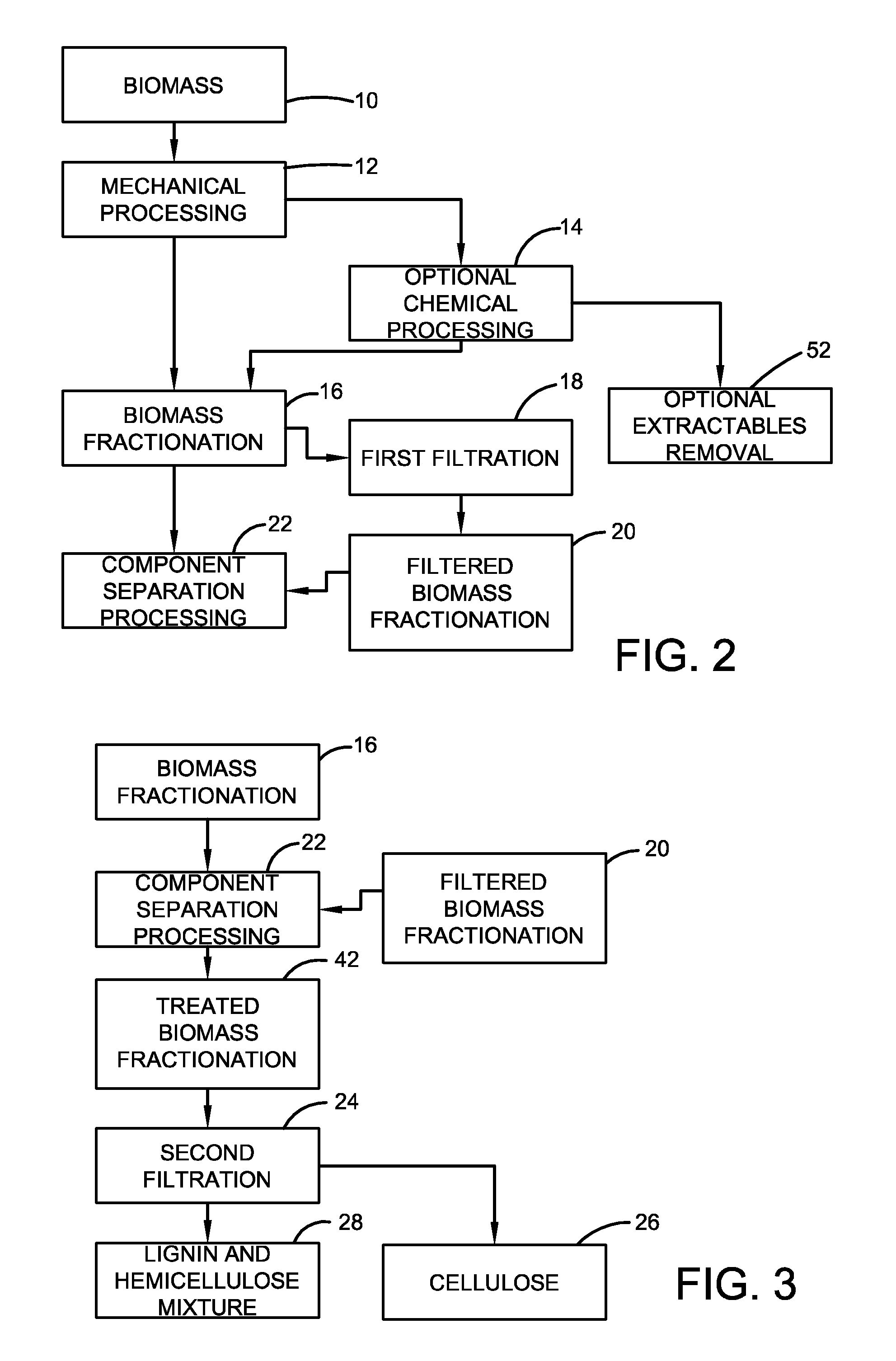

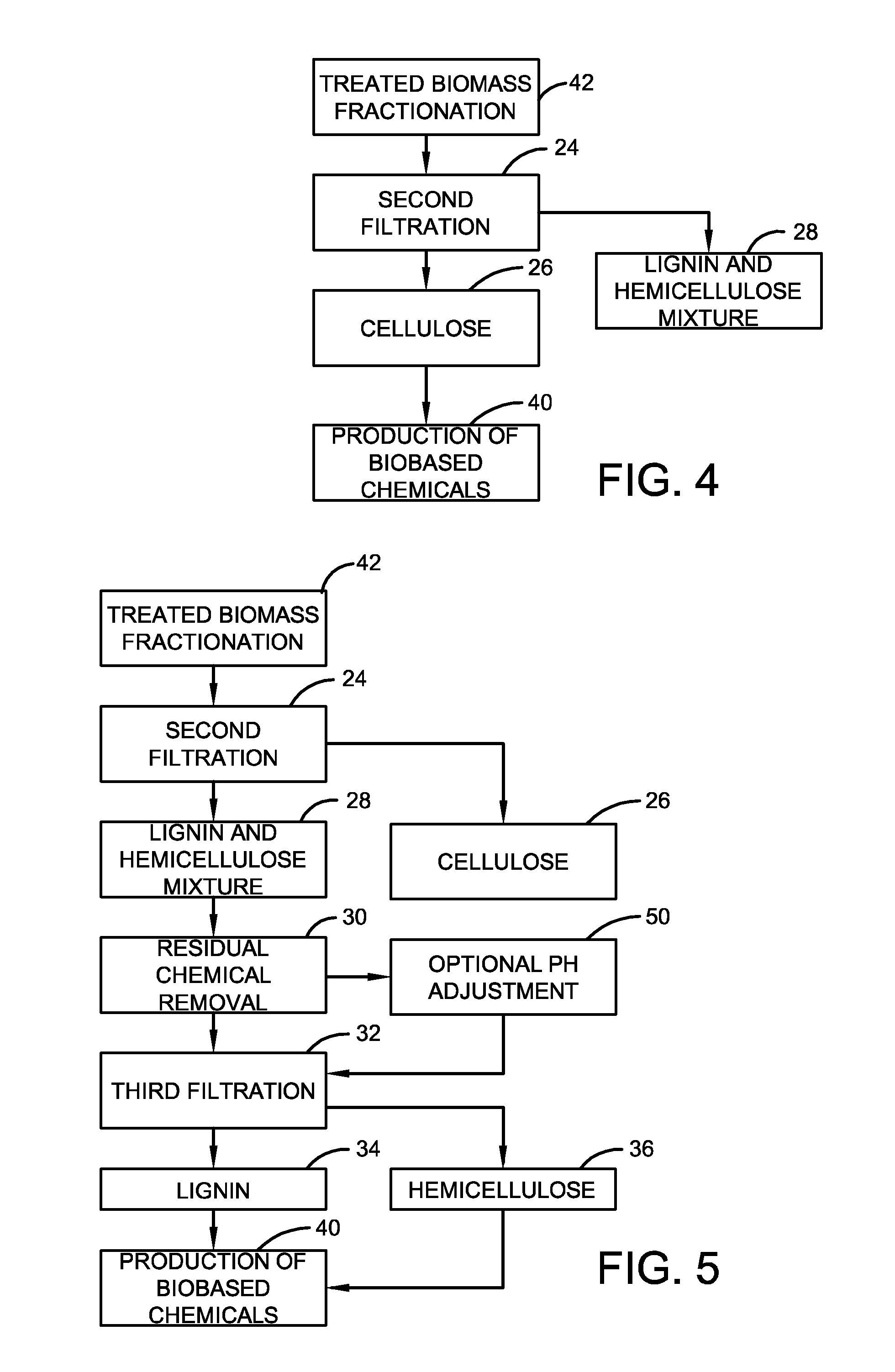

Method for producing biobased chemicals from plant biomass

InactiveUS20130116424A1Reduce waste generationCost-effective methodOrganic compound preparationHydroxy compound preparationPresent methodWaste product

A method for utilizing biomass components, namely cellulose, hemicellose, and lignin, and converting them to value-added biobased chemical products is described herein. The present method provides treatments to obtain a plurality of component streams from biomass for producing derivative products while minimizing waste products.

Owner:VERTICHEM CORP

Method for removing ammonia from a gas comprising hydrogen cyanide, ammonia and water

InactiveUS6872296B2Low cost of treatmentReduce waste generationPolycrystalline material growthLiquid degasificationChemistryCarbon dioxide

A method for removing ammonia from a gas comprising HCN, ammonia and water, by first contacting the gas with aqueous ammonium phosphate to remove ammonia from the gas, and then passing the resulting ammonium phosphate solution through an electrolyzer to convert oxalates and formates into hydrogen and carbon dioxide.

Owner:INVISTA NORTH AMERICA R L

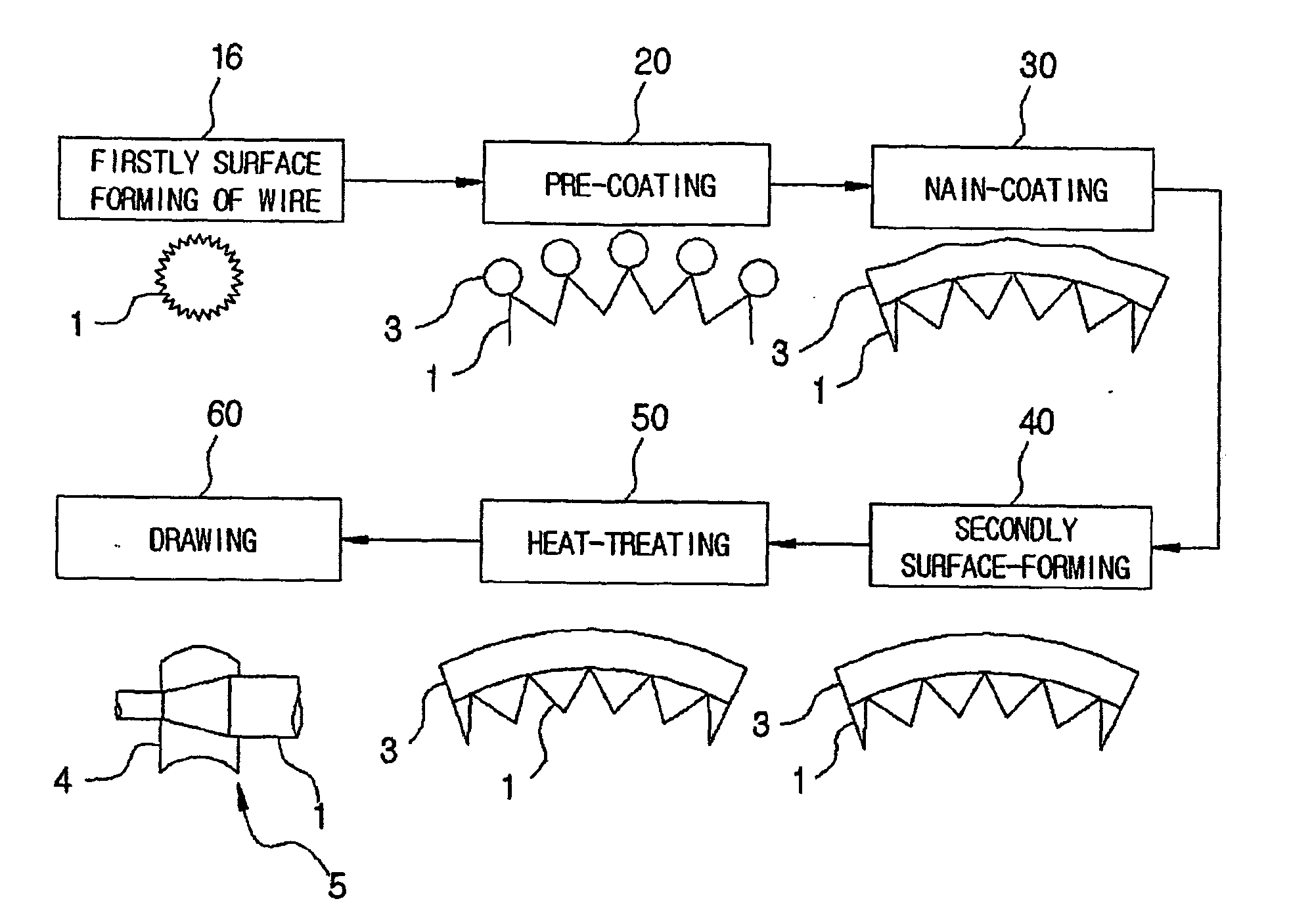

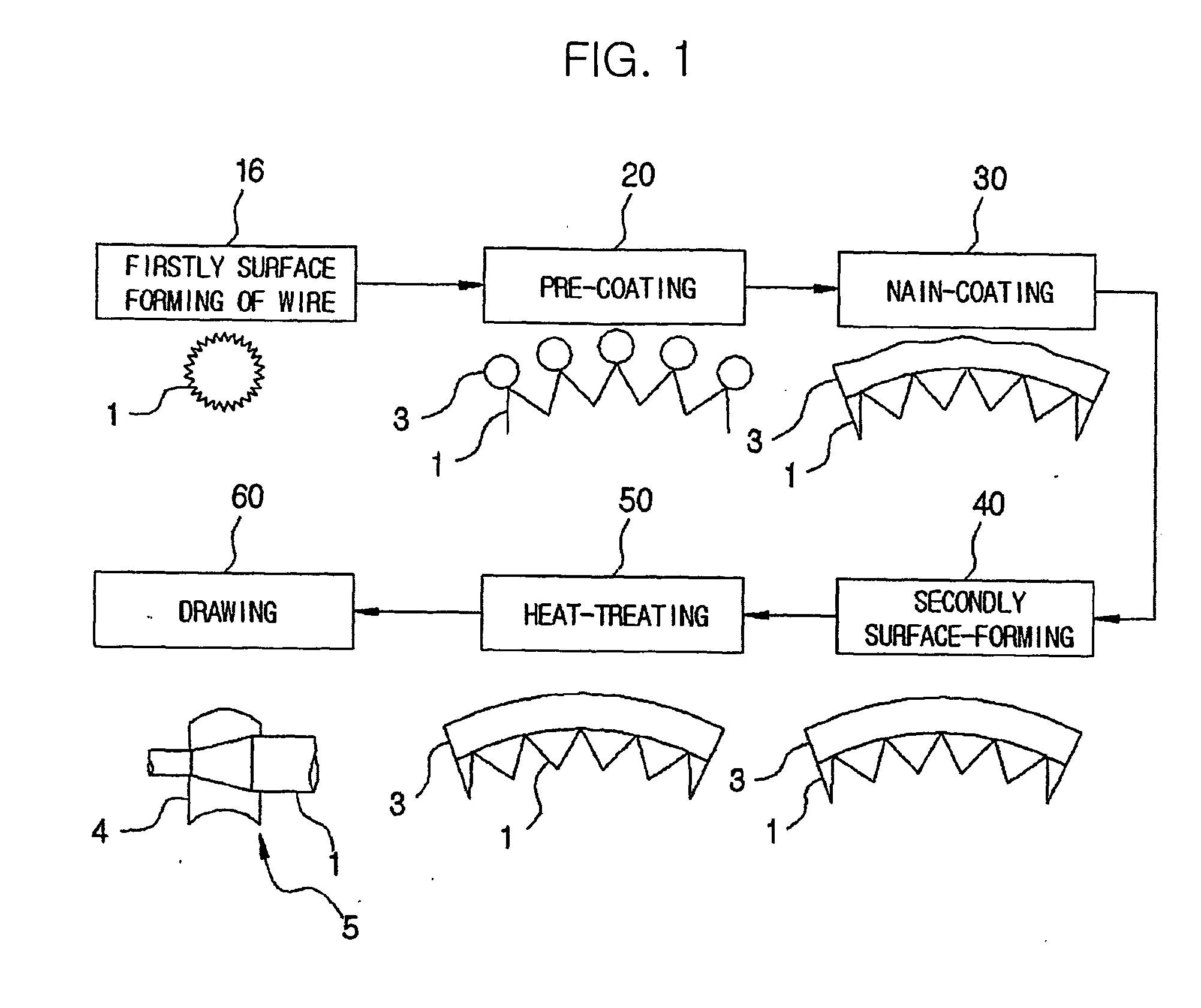

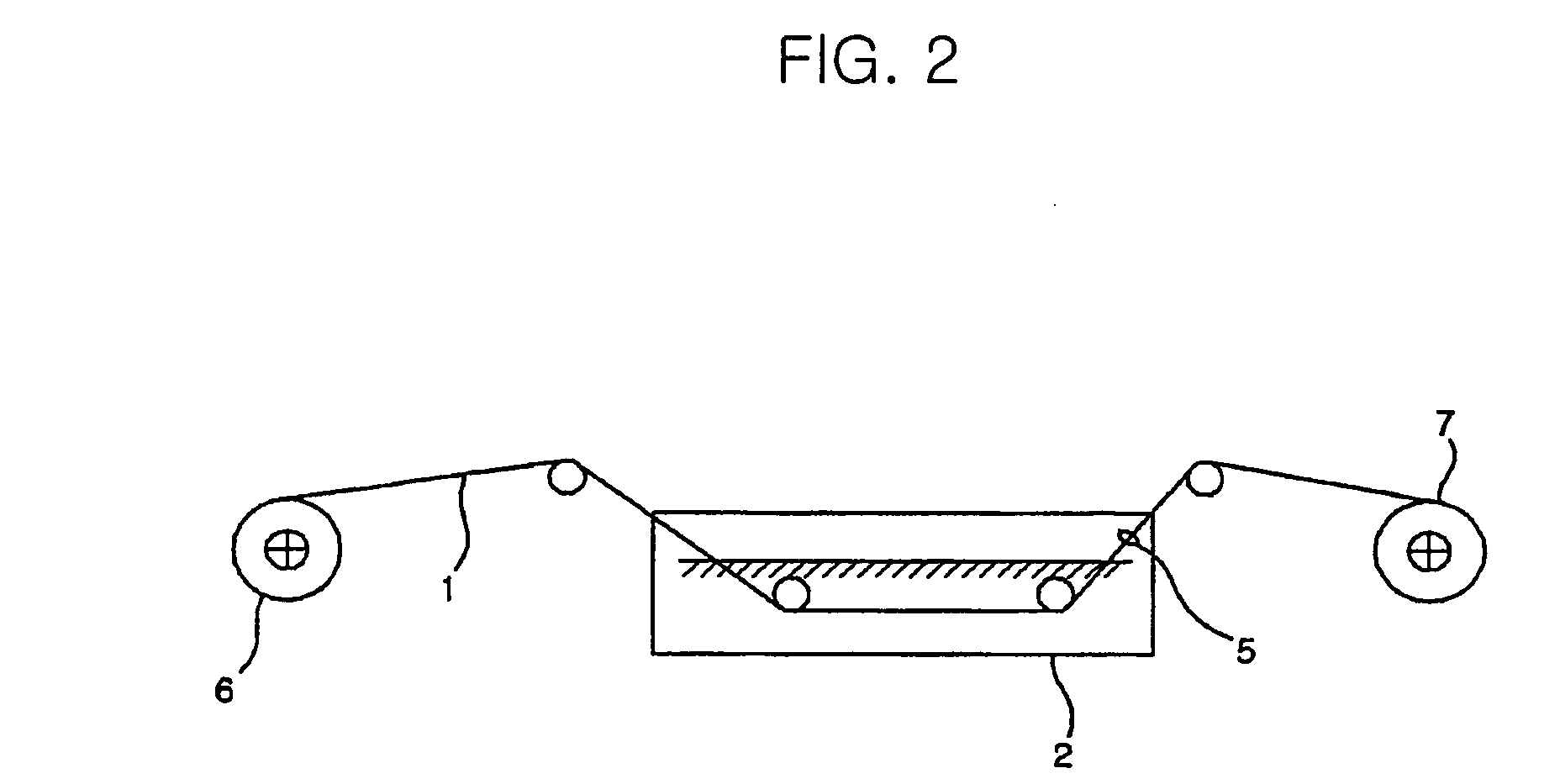

Method of manufacturing zinc-coated electrode wire for electric discharge processors using hot dip galvanizing process

InactiveUS20060138091A1Low manufacturing costDecrease generationHot-dipping/immersion processesElectrical-based machining electrodesHot-dip galvanizationSizing

Disclosed is a method of manufacturing a zinc-coated electrode wire for electro discharge machining using a hot dip galvanizing process. The method includes firstly surface-forming a wire (1) in such a way that its terminal end is tapered while the wire is drawn through a first die at step 10, pre-coating zinc around the firstly processed wire in a molten zinc bath (2) at step 20, main-coating the pre-coated wire with zinc (3) using a sizing die before zinc pre-coated on the wire is hardened at step 30, secondly surface-forming the main-coated wire in such a way that zinc coated around the wire has a uniform thickness using a second die having a smaller diameter than the wire at step 40, heat-treating the secondly surface-processed wire at step 50, and drawing the heat-treated wire using a third die (5) made of natural diamond at step 60.

Owner:PUNG KUK

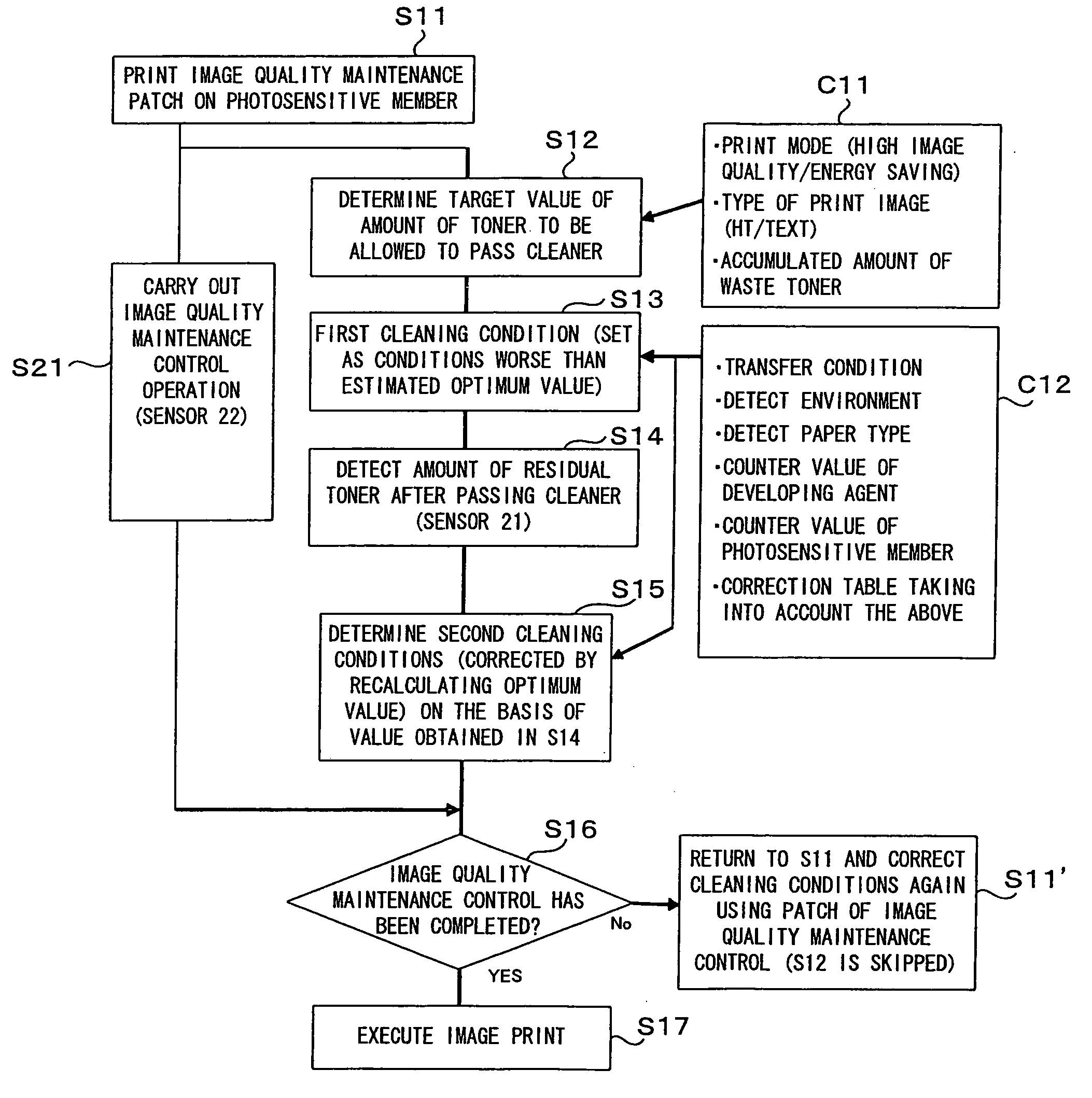

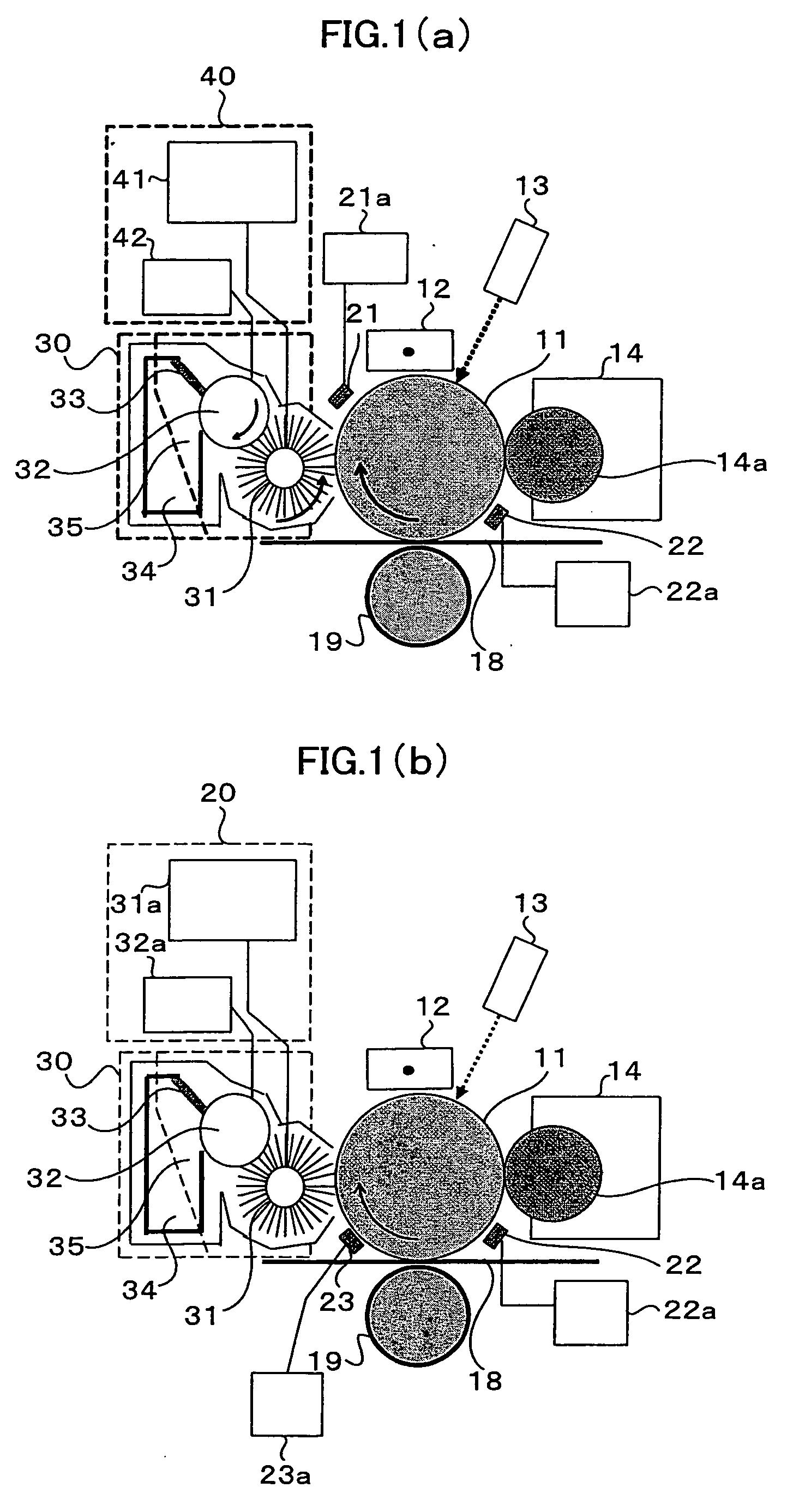

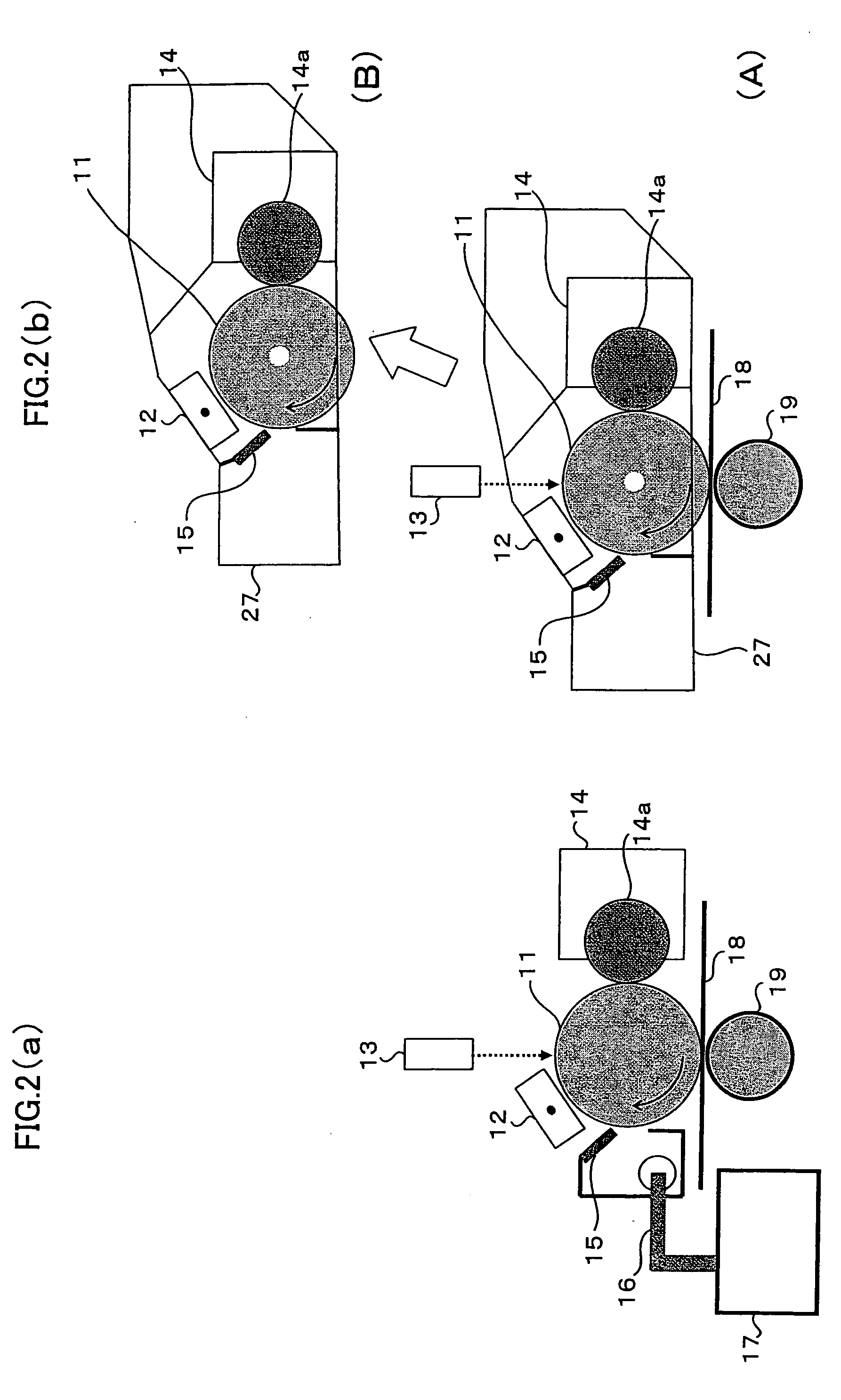

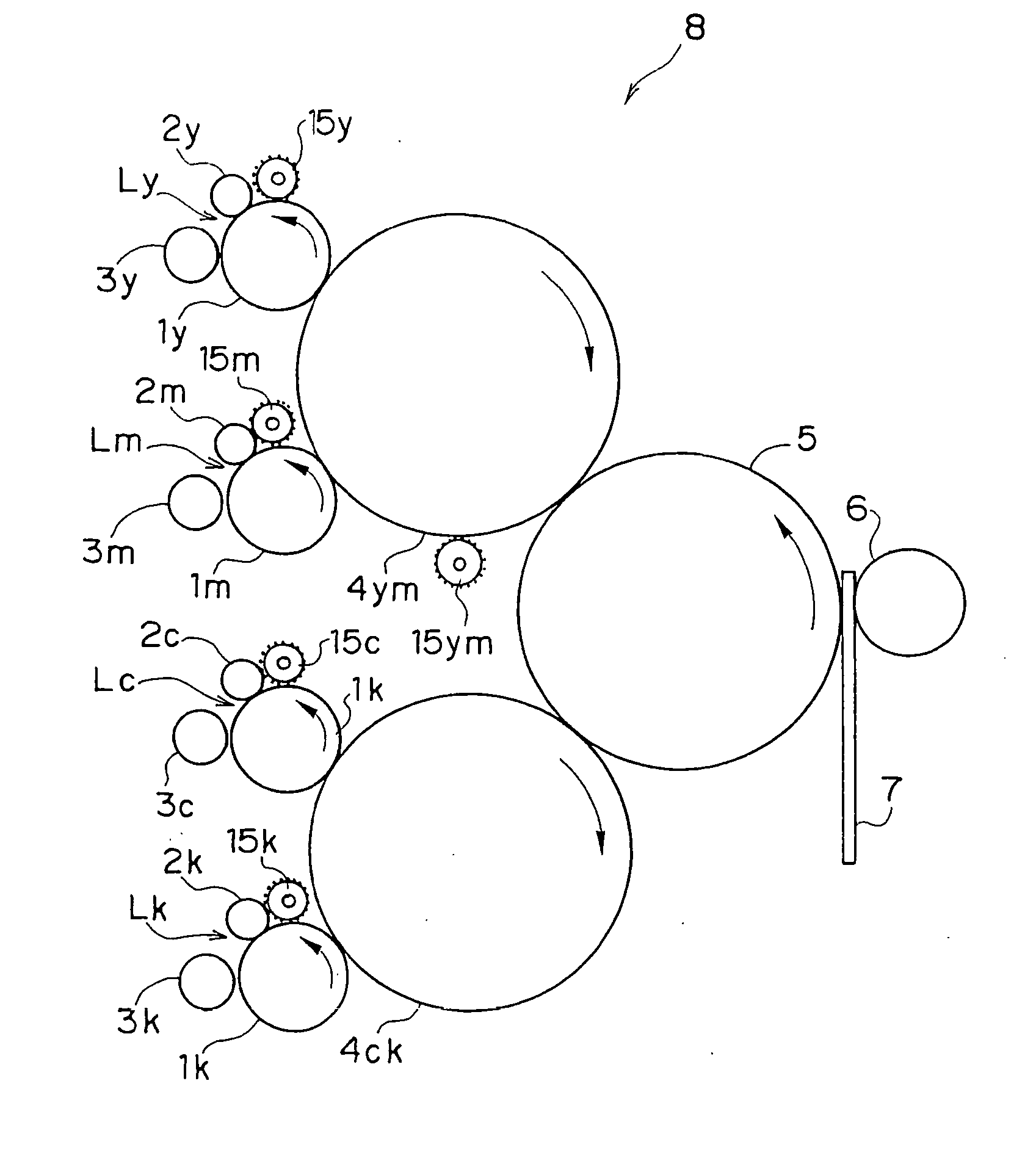

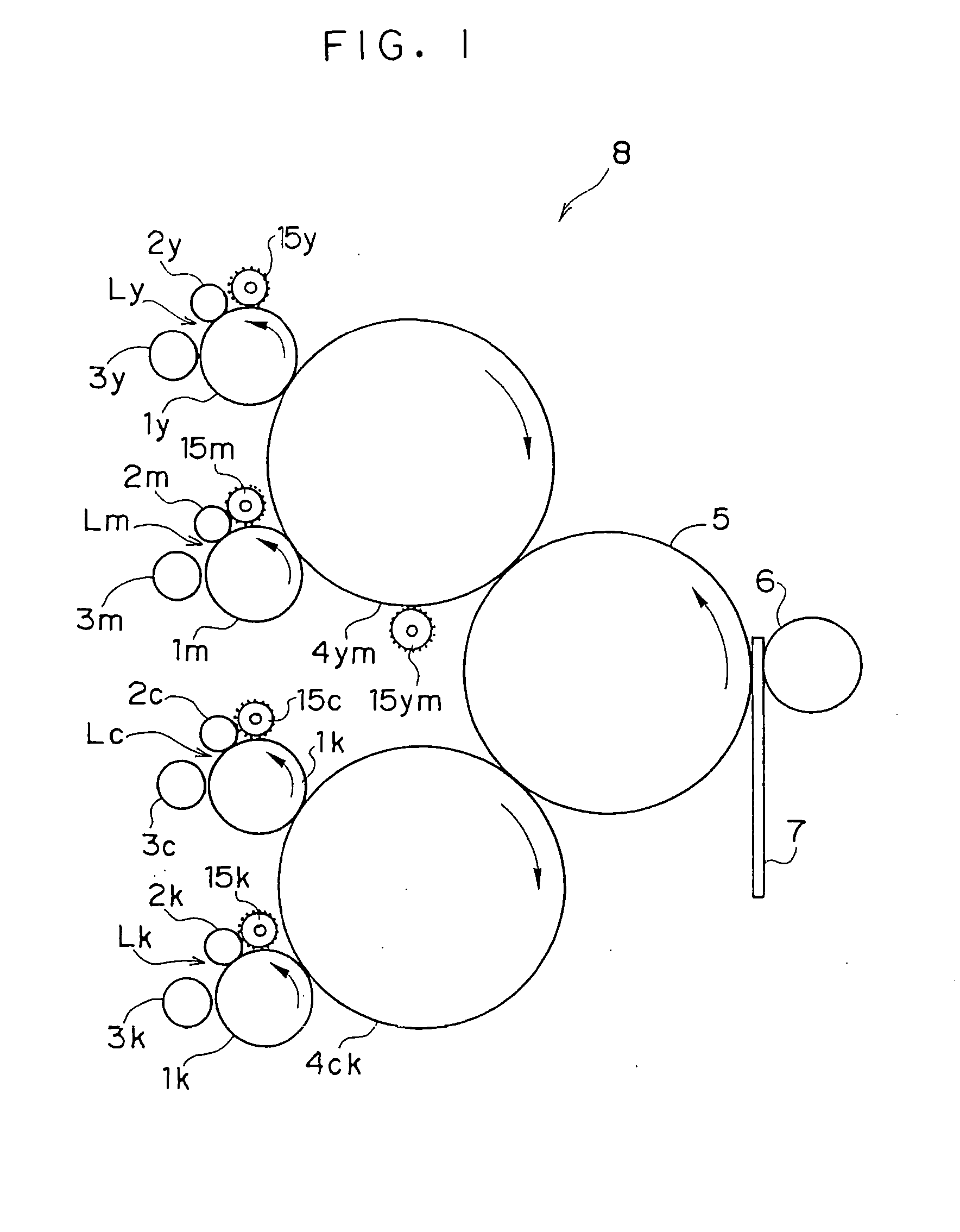

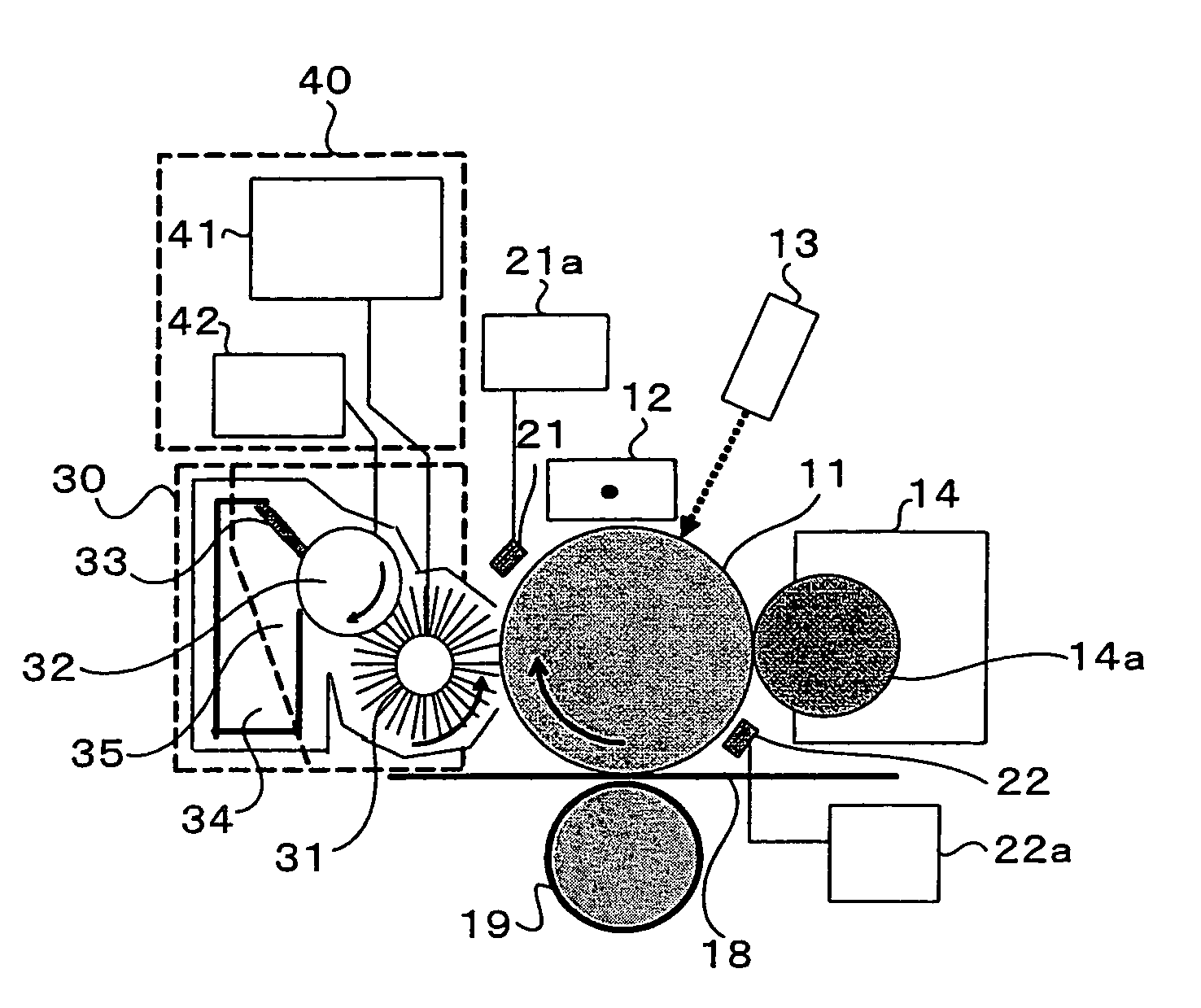

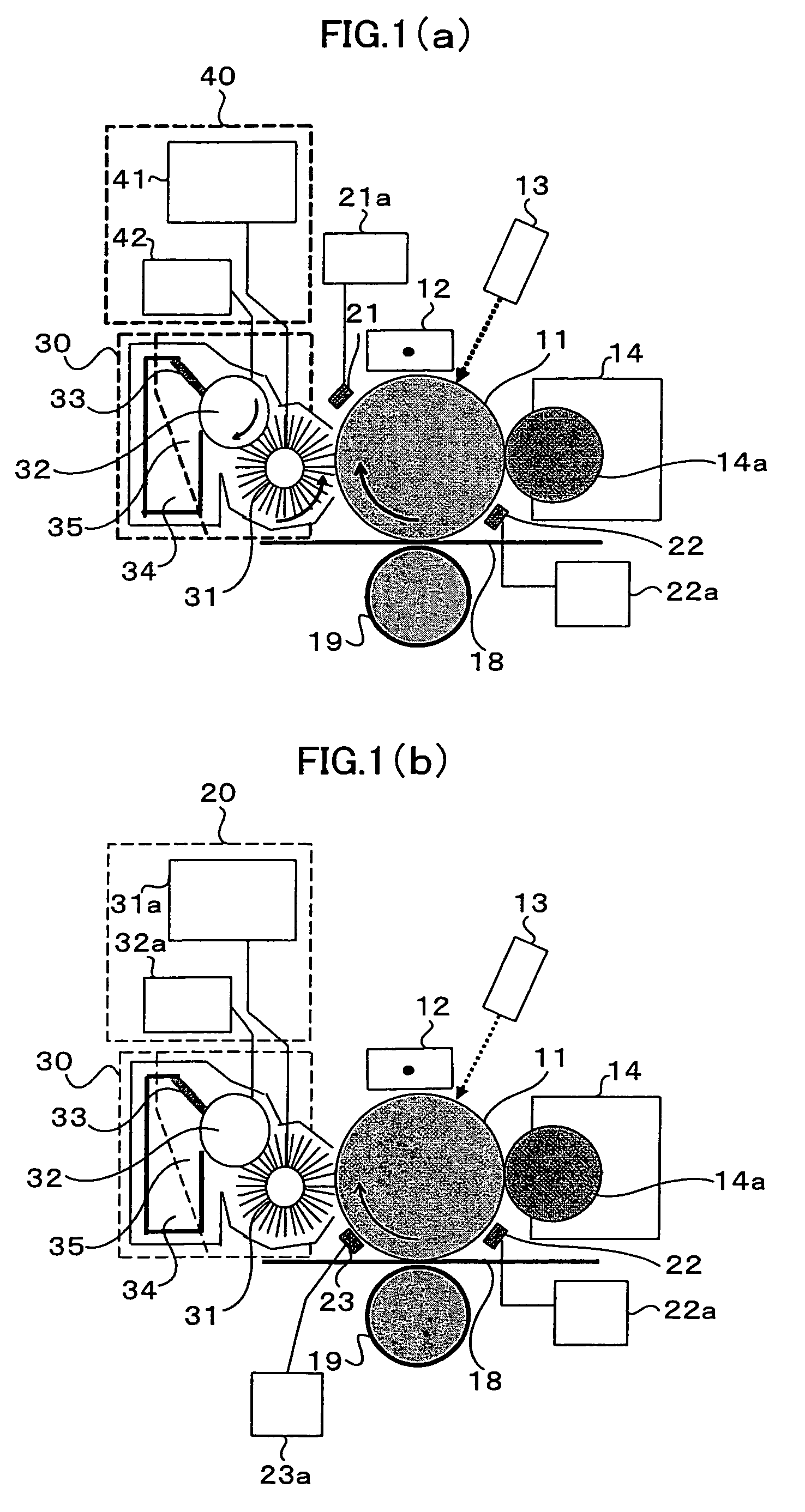

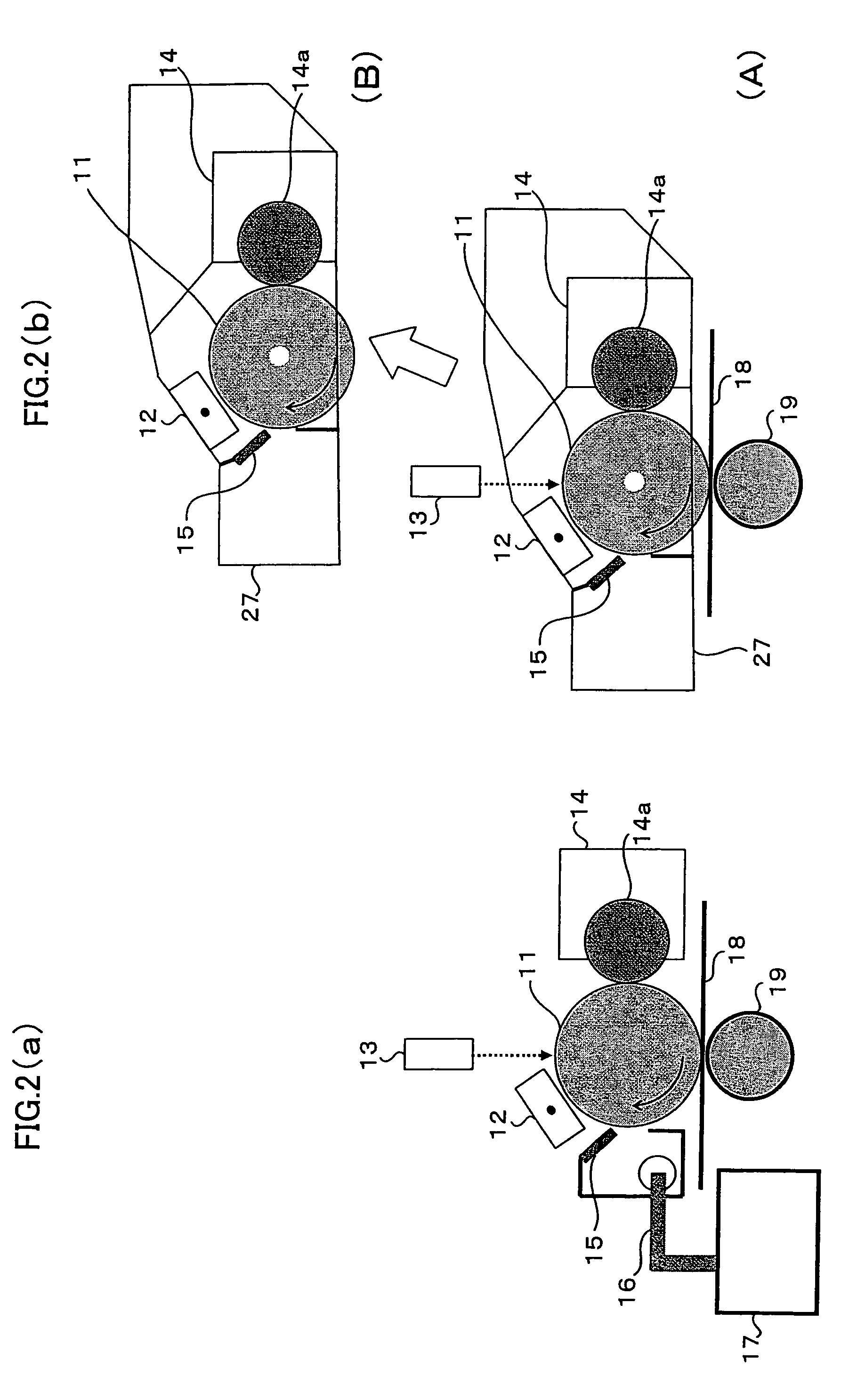

Image forming apparatus and image forming method

InactiveUS20080008489A1Reduce waste generationElectrographic process apparatusImage formationEngineering

It is an object of the invention to provide an image forming apparatus and an image forming method that can reduce generation of a waste toner.An image forming apparatus according to the invention includes an image bearing member on which a toner image is formed, a cleaner that transfers a toner image formed on the surface of the image bearing member and, then, removes a part of a toner remaining on the image bearing member and allows the remainder to pass as a passing toner, a passing toner amount detecting unit for detecting or estimating an amount of passing toner that passes the cleaner, and a cleaner control unit that sets, on the basis of an amount of passing toner detected by the passing toner amount detecting unit, a target value of the amount of passing toner and controls a cleaning operation by the cleaner.

Owner:KK TOSHIBA +1

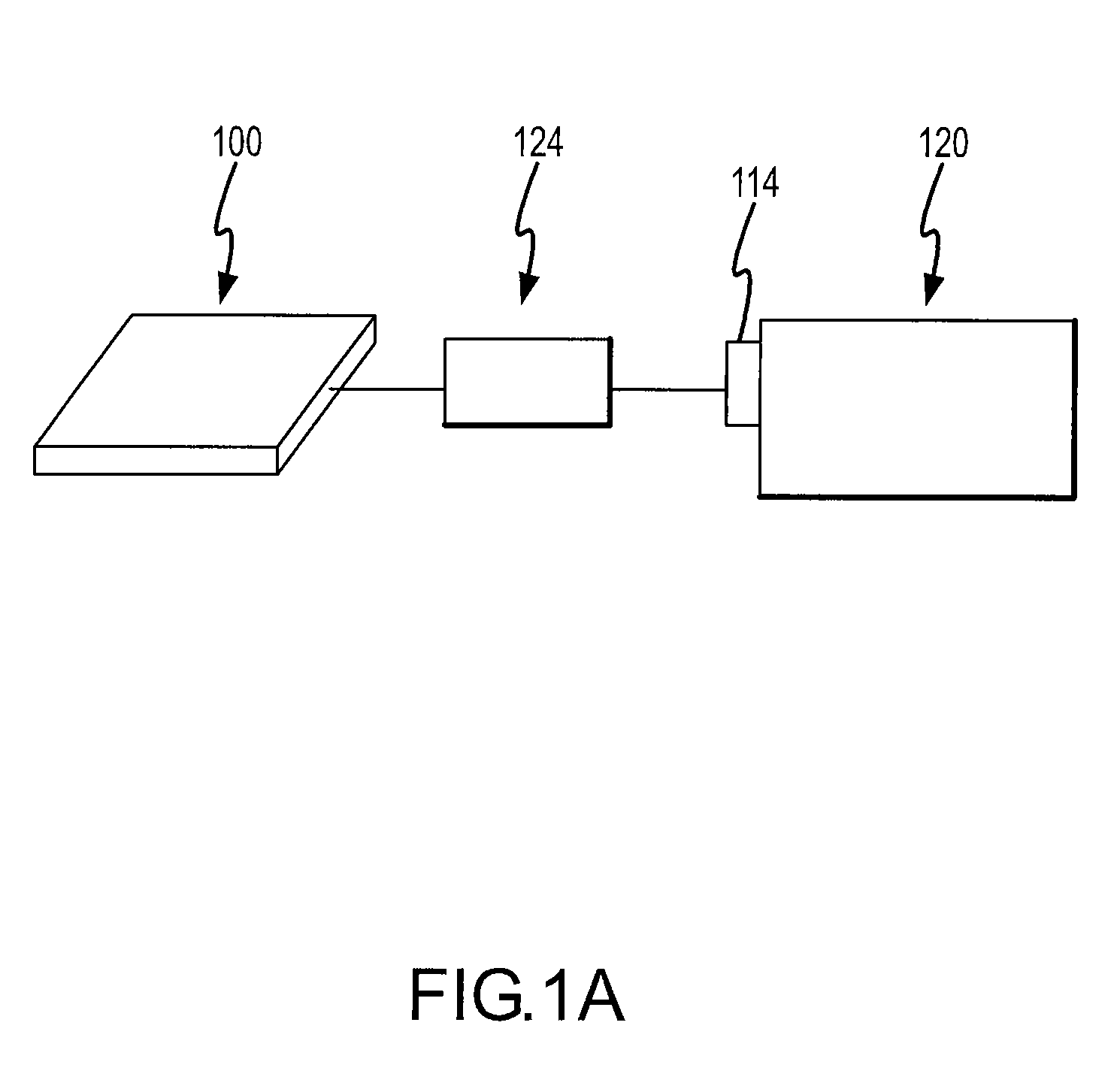

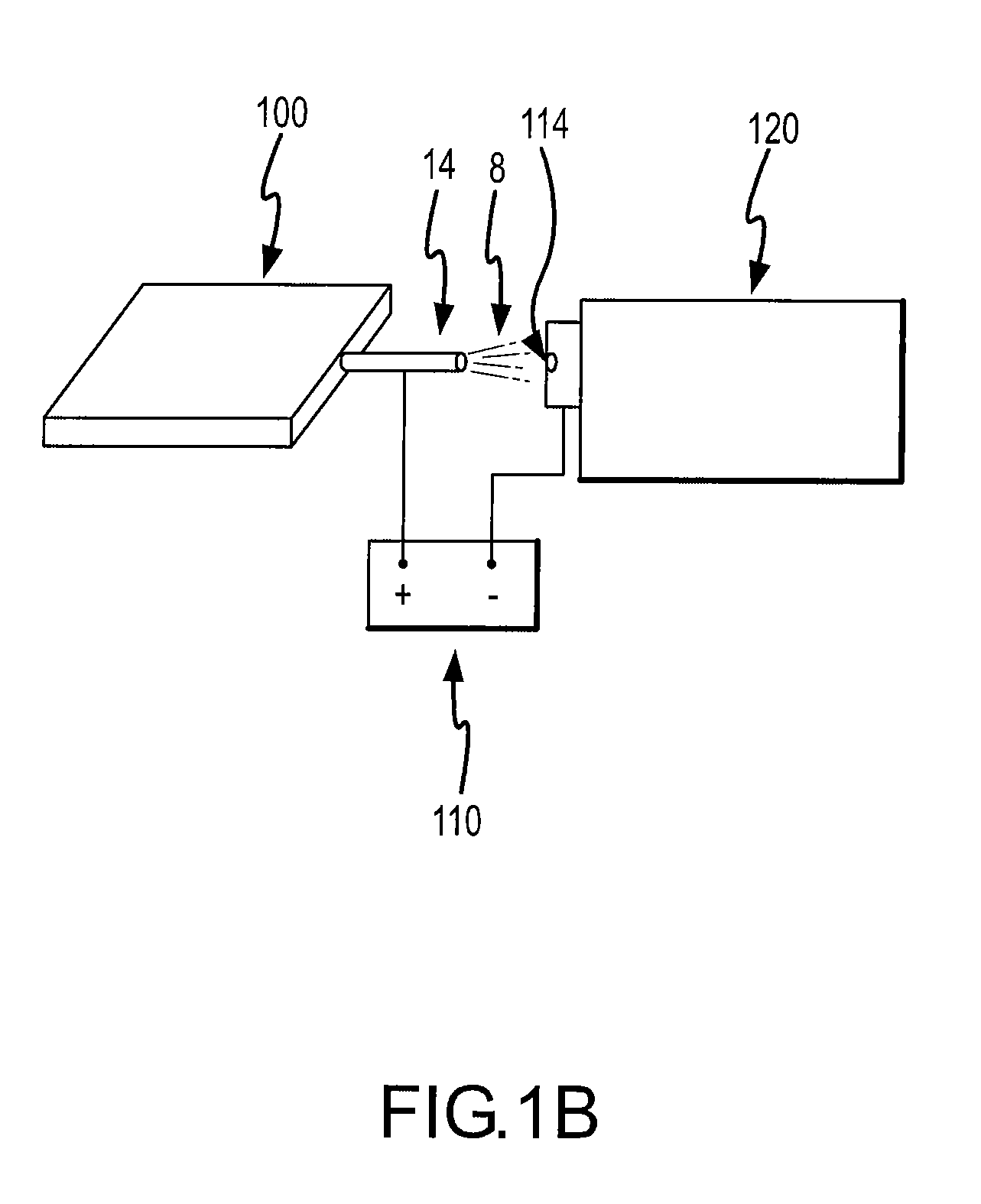

Receipt handling systems, print drivers and methods thereof

ActiveUS8643875B2Reduce waste generationDigitally marking record carriersHand manipulated computer devicesEmail addressTransaction data

A method of processing receipts, including: obtaining transaction data including a plurality of categories of information necessary to describe a purchasing transaction of a customer at a store location; obtaining image data representing a receipt corresponding to the purchasing transaction of the customer at the store location; obtaining an e-mail address of the customer; providing an option to print the receipt at the store location and an option to e-mail the receipt to the customer; obtaining a selection of at least one of the provided options; if the option to print is selected, initiating printing of the image at the store location; and if the option to e-mail is selected, sending an e-mail to the e-mail address of the customer, the e-mail including providing at least one of the image data and the transaction data.

Owner:ECEIPT

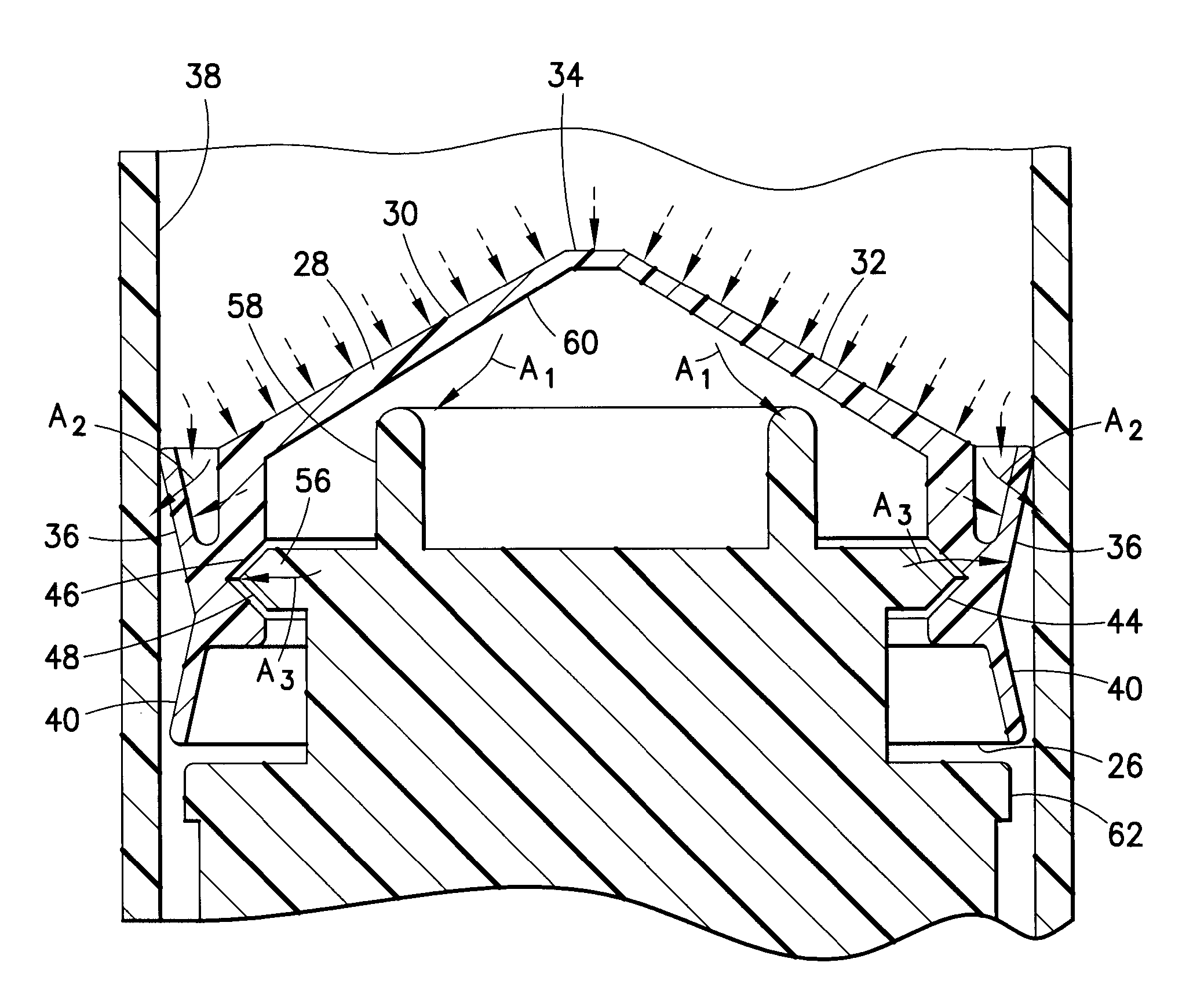

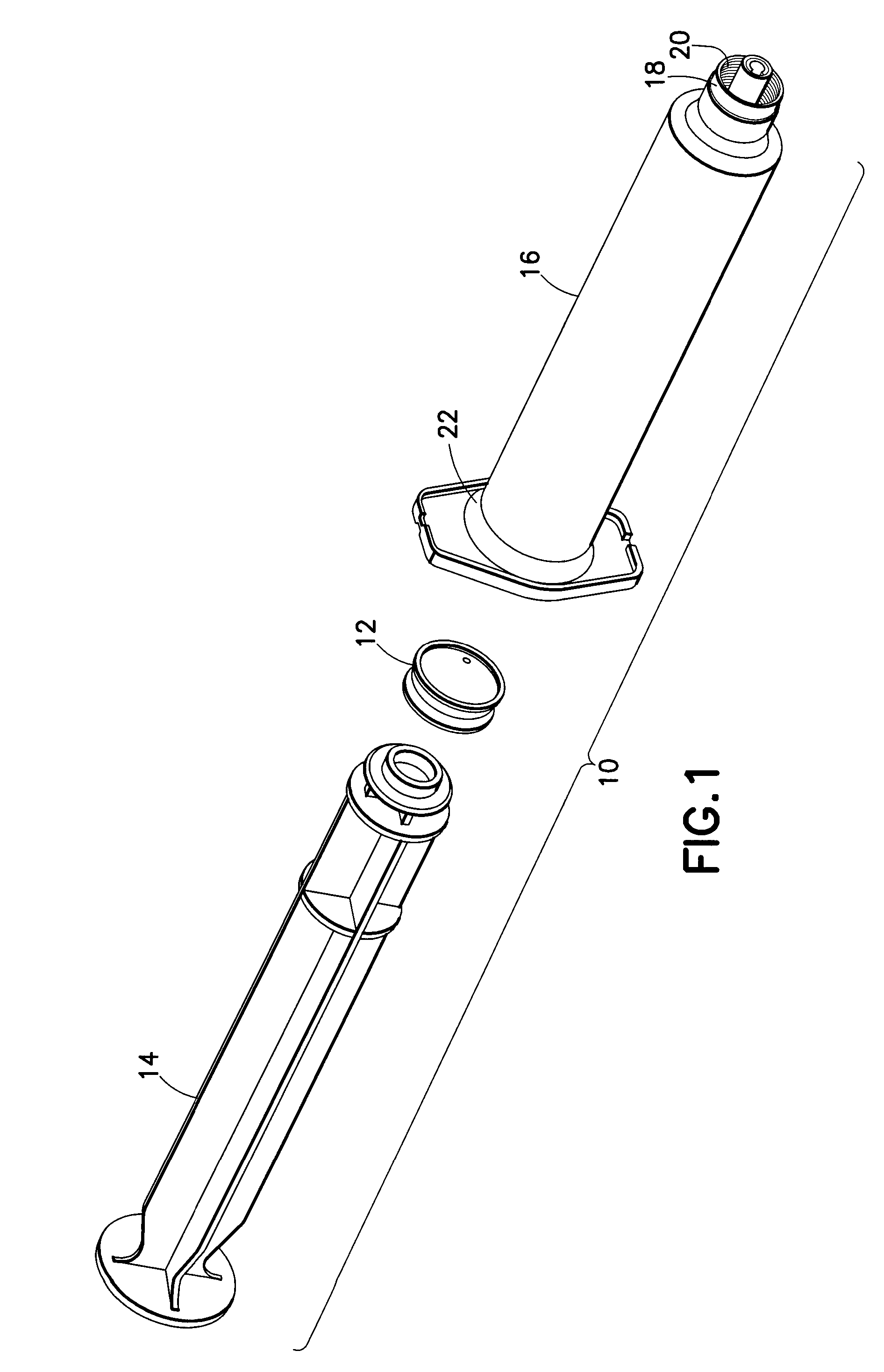

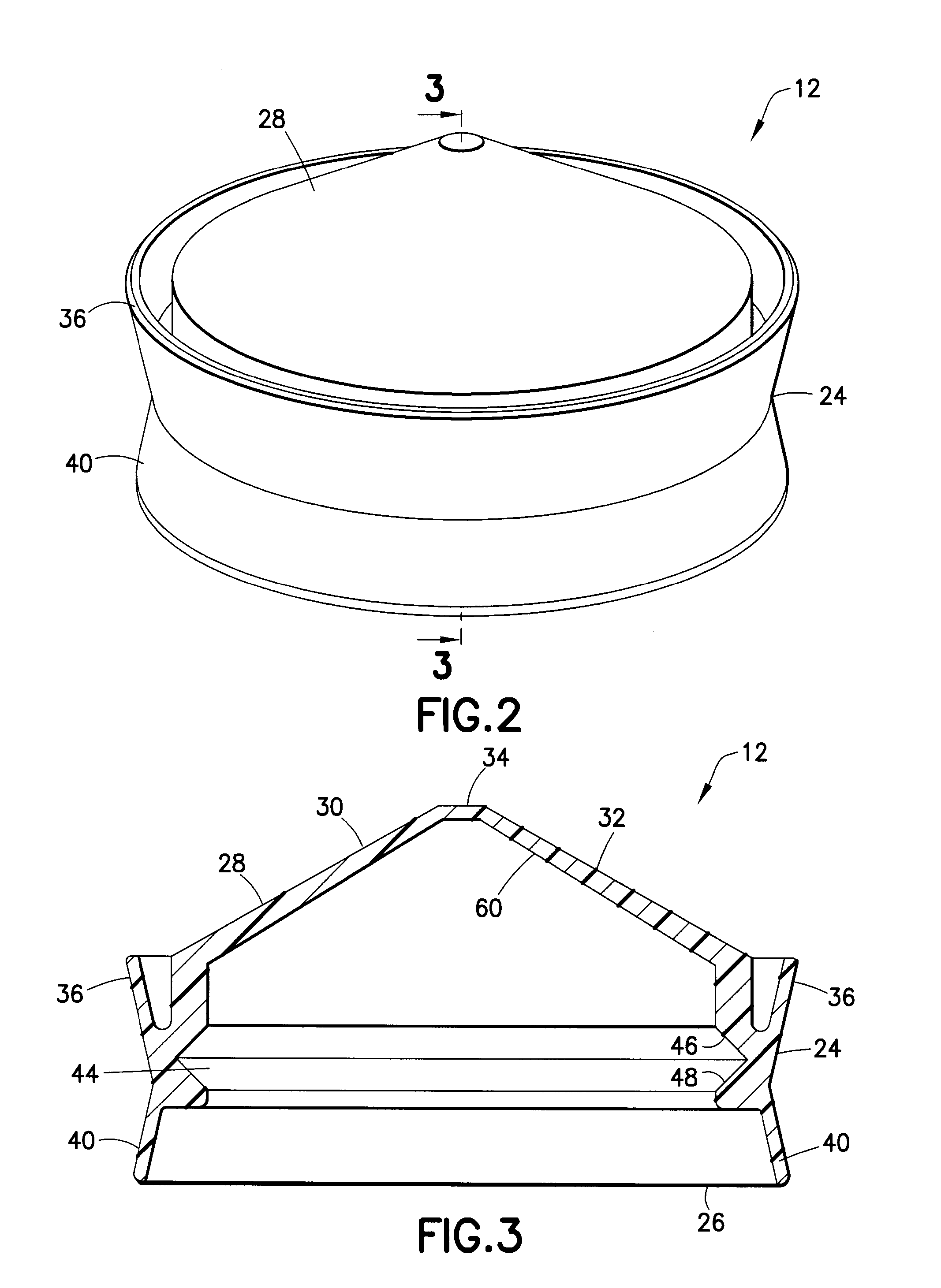

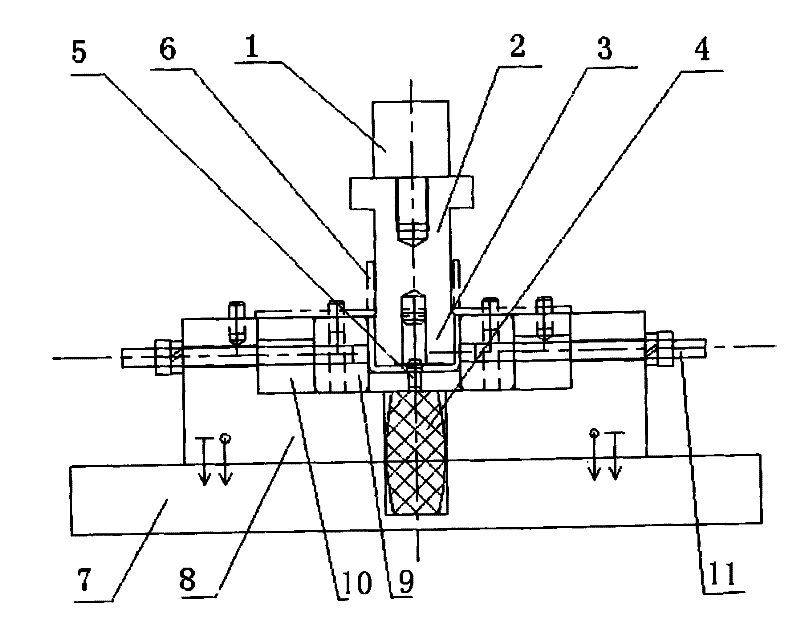

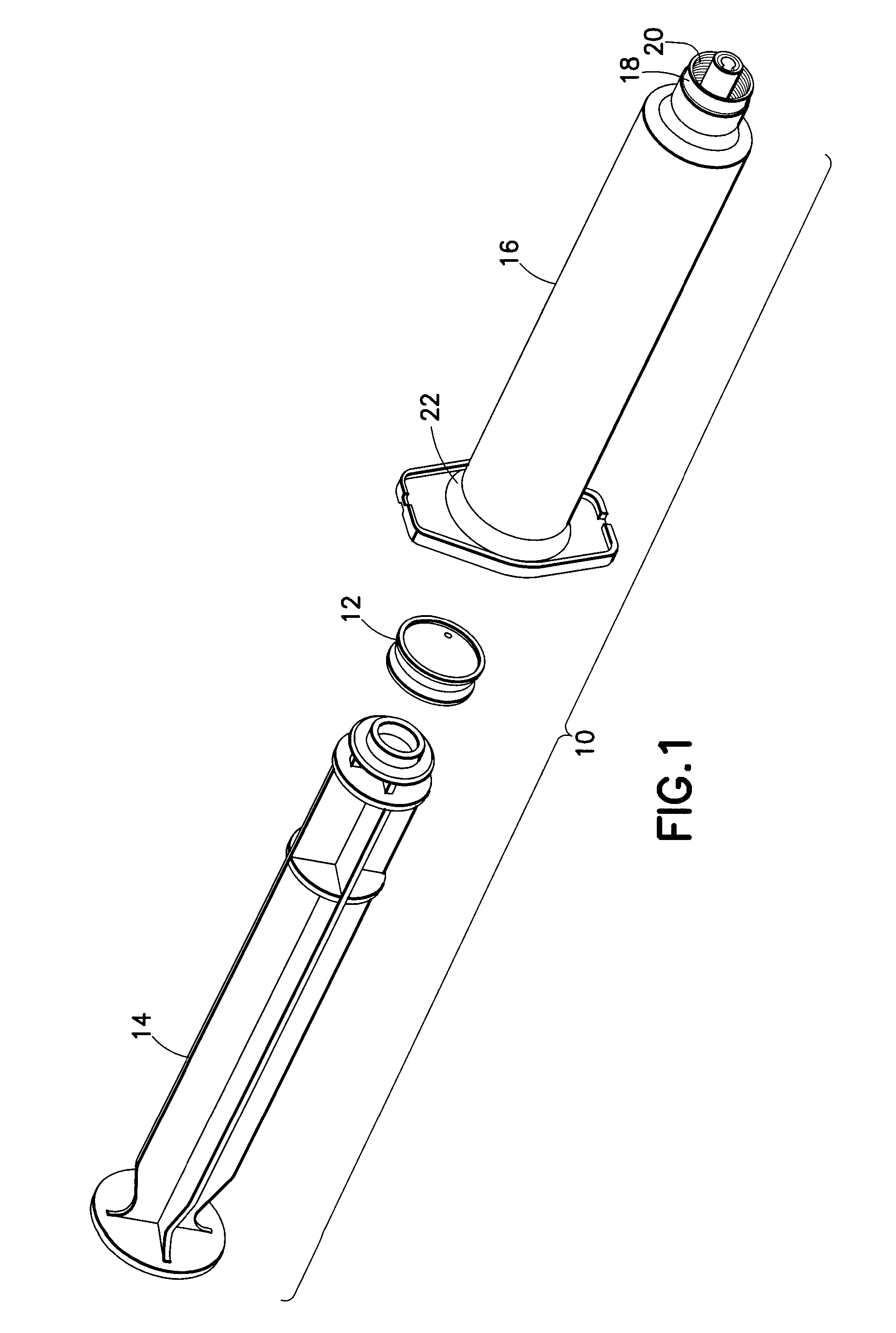

Plastic Stopper

ActiveUS20120253292A1Reduce material usageReduce waste generationInfusion syringesIntravenous devicesEngineeringPlunger

A stopper includes a main body portion defining an open rearward end configured to receive the plunger rod, an engagement portion provided along an inner circumference of the main body portion configured to engage at least a top portion of the plunger rod, a closed front end forming a flexible roof, and a first perimetrical skirt extending around an outer circumference of the main body portion toward the closed front end of the main body portion. When fluid pressure is increased inside the syringe barrel during an injection, the flexible roof expands in a radial direction toward an inner wall of the syringe barrel, the first perimetrical skirt is forced against the inner wall of the syringe barrel, and an engagement between the plunger rod and the engagement portion forces the main body portion to expand in the radial direction toward the inner wall of the syringe barrel.

Owner:BECTON DICKINSON & CO

Image forming apparatus and process cartridge

InactiveUS20040126138A1Prevent surfaceImage stabilizationElectrographic process apparatusDevelopersLatent imageImage formation

An image forming apparatus containing an image holding member, a contact-type charger for charging a surface of the image holding member, an exposure unit for forming an electrostatic latent image by exposing the charged surface of the image holding member, a developing unit for developing the electrostatic latent image with a spherical toner to obtain a toner image, and a transfer member for electrostatically transferring the toner image from the surface of the image holding member onto a transfer material. A number of toner particles remaining on the surface of the image holding member before passing through an abutting portion between the image holding member and the contact-type charger is in a range of 100 to 400 per unit area (mm<2>).

Owner:FUJIFILM BUSINESS INNOVATION CORP

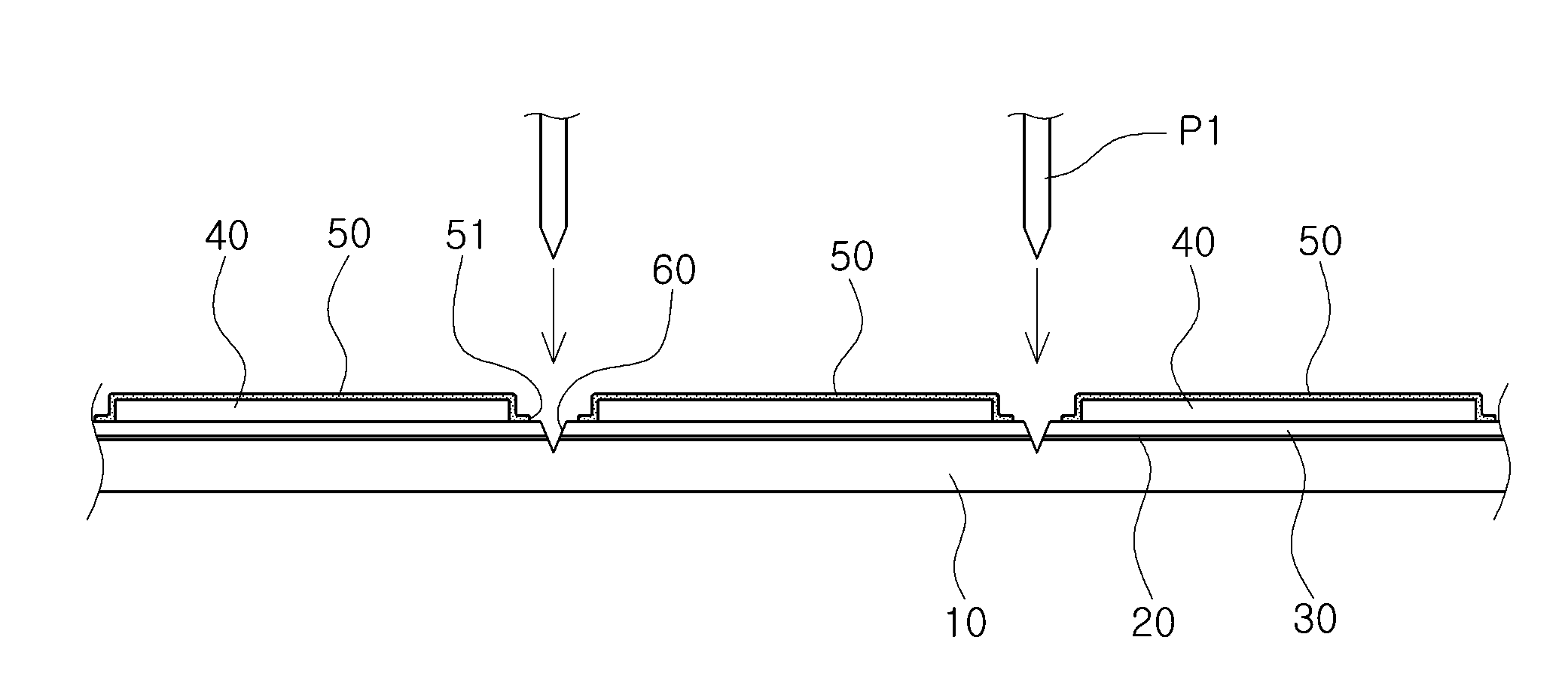

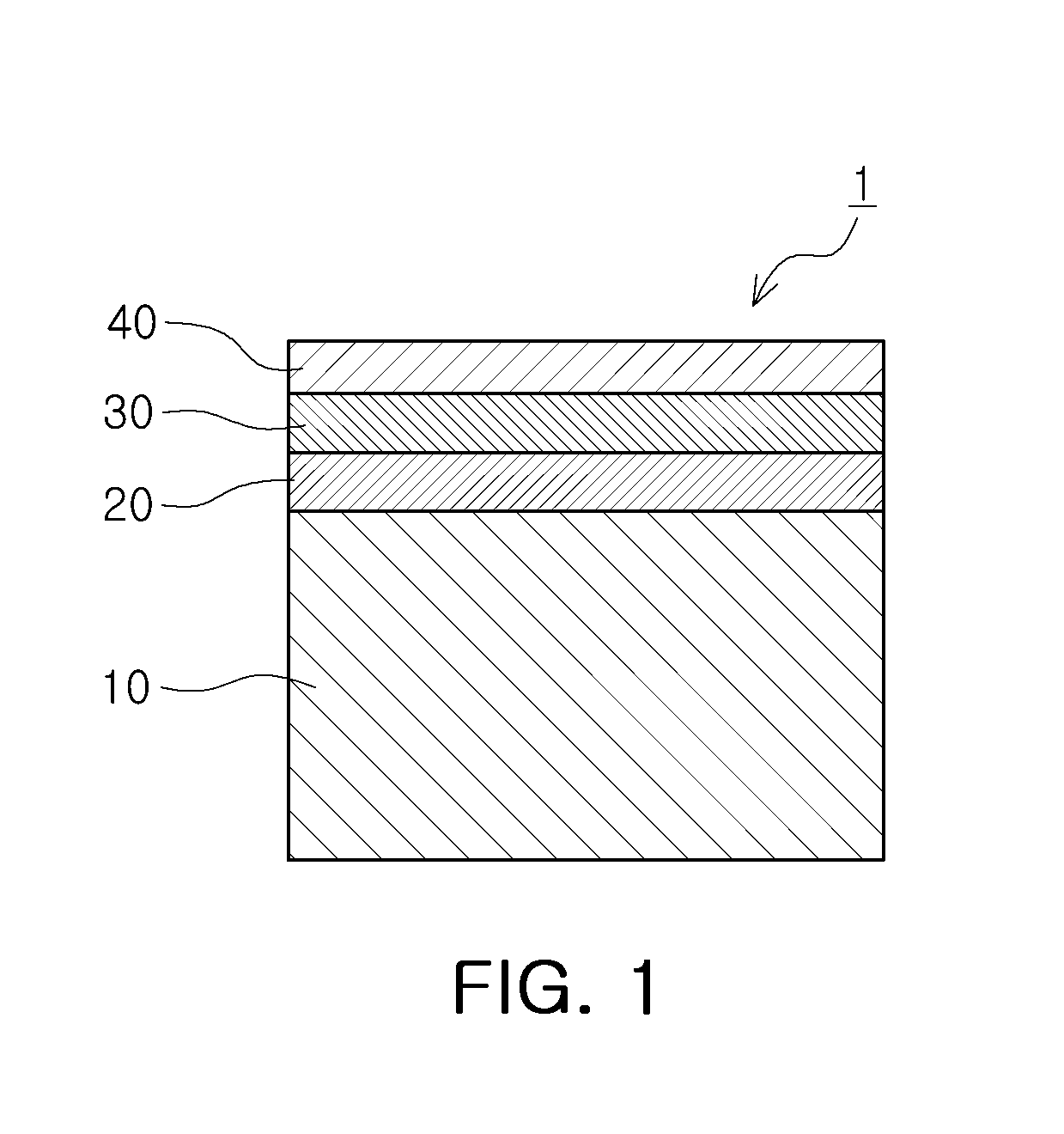

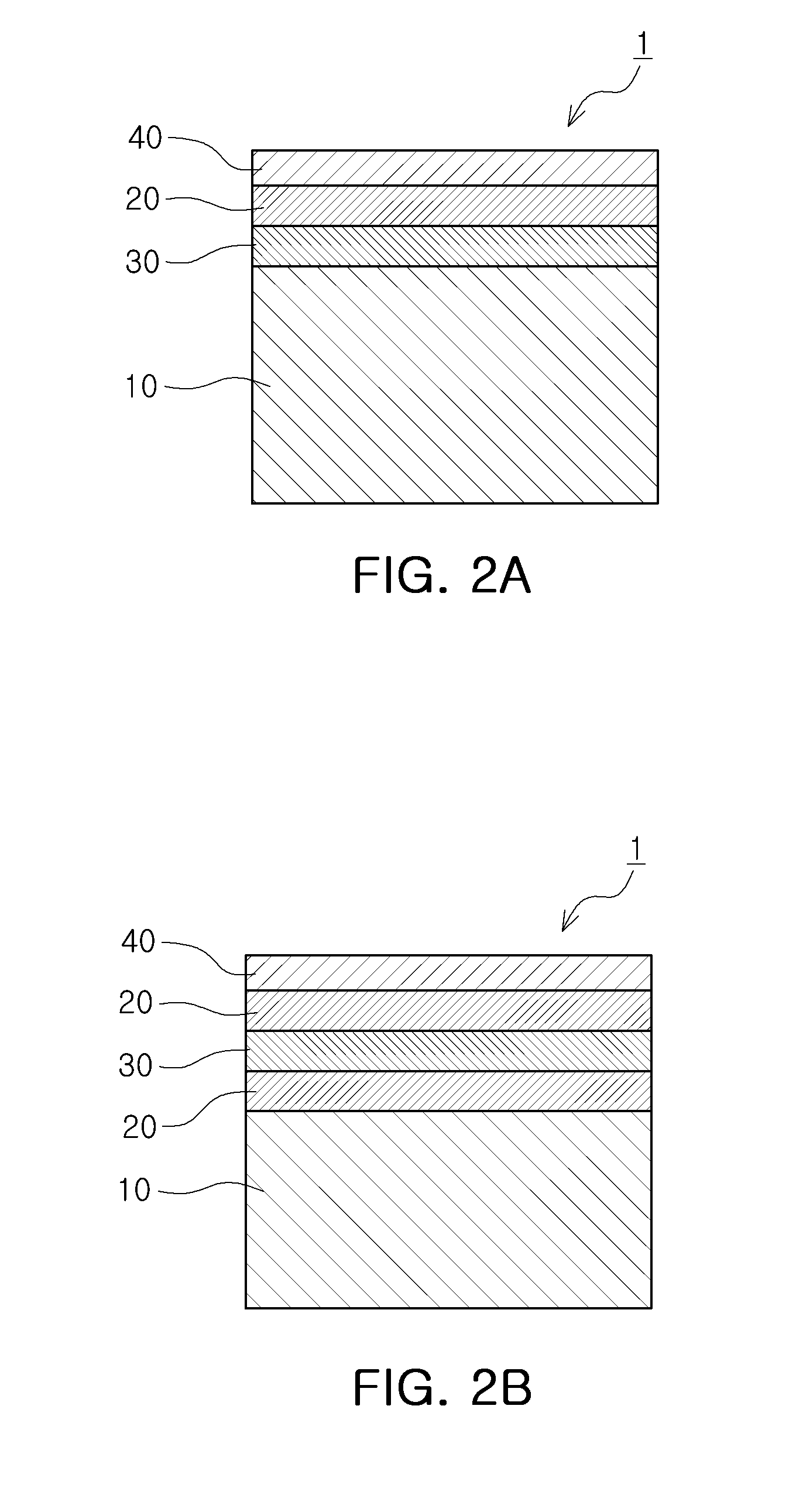

Metal copper clad laminate and method of manufacturing metal core printed circuit board using the same

InactiveUS20130126082A1Maintain thermal conductivityDecrease scrap generationLamination ancillary operationsSynthetic resin layered productsPolyimidePrinted circuit board

Owner:SAMSUNG ELECTRONICS CO LTD

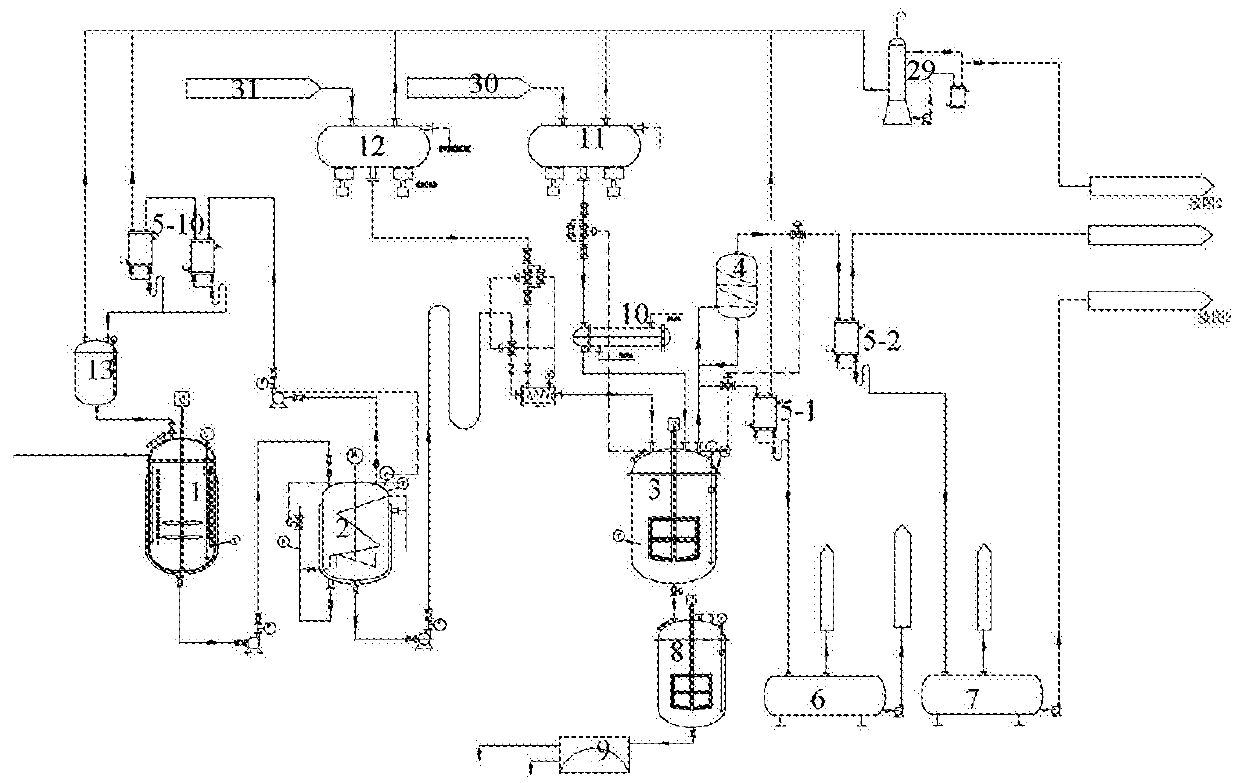

Acidolysis and solvent recycling process and device for producing glyphosate by using glycine method

ActiveCN106699808AGreat energy savingReduce waste generationGroup 5/15 element organic compoundsSolventPre treatment

The invention relates to an acidolysis and solvent recycling process for producing glyphosate by using a glycine method, and belongs to the technical field of glyphosate production processes and methods. The acidolysis and solvent recycling process comprises steps of pretreatment for removing methanol from a synthetic liquid, acid methanol acidolysis, hydrochloric acid acidolysis, solvent recycling and the like. Acid methanol is adopted to replace hydrochloric acid for acidolysis of the synthetic liquid, and a small amount of hydrochloric acid is additionally supplied to stabilize the high-temperature acidolysis process in a later acidolysis period; in the acidolysis process, methylal is separated from a methylal and methanol solution through rectification, a small amount of methanol is replenished into the residual methanol solution which is cooled so as to blend the content of the methanol, the solution can be directly used for absorbing a hydrogen chloride gas, acid methanol can be generated after set contents of hydrogen chloride and methanol are met, and the acid methanol canbe fed back to the acidolysis process for reuse. Compared with a conventional glyphosate acidolysis and solvent recycling technique with a glycine method, the acidolysis and solvent recycling process has the advantages that the methanol recycling wastewater can be reduced by 2.5 t / t or greater, the mother liquid amount can be reduced by 0.3 t / t or greater, the steam consumption can be reduced by 1.5 t / t or greater, the power can be saved by 80 KWh / t or greater, the content of chloromethane can be increased by 0.3 t / t, the yield of glyphosate is increased by 0.3% or greater, and the production cost of the glyphosate can be lowered by 15-20%.

Owner:HUBEI TAISHENG CHEM

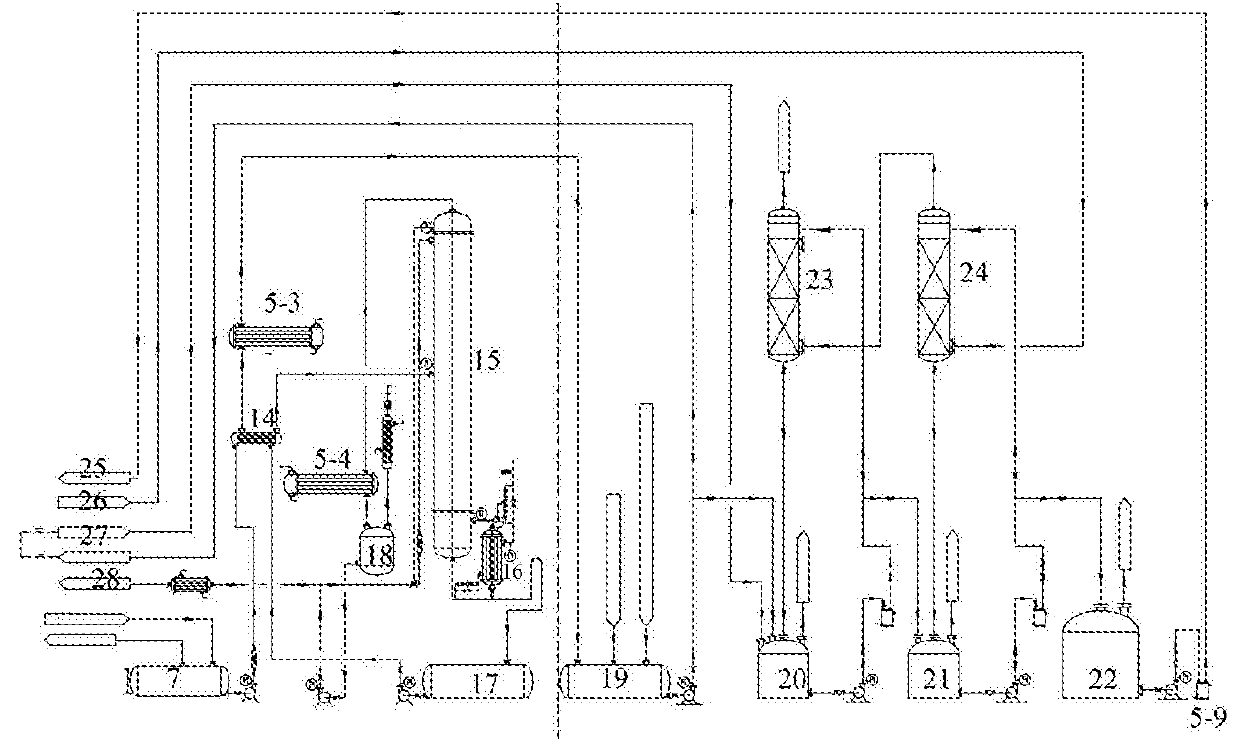

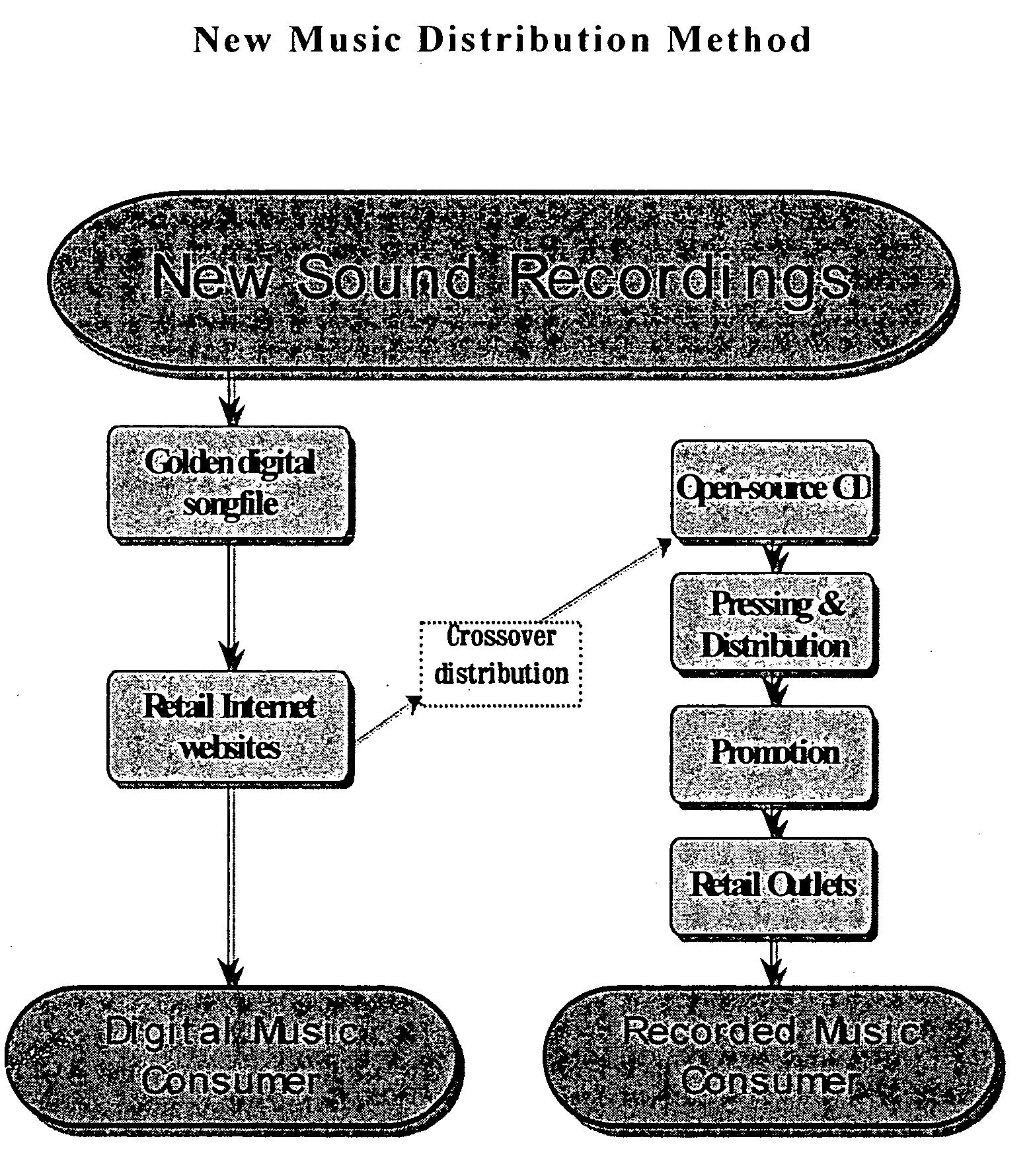

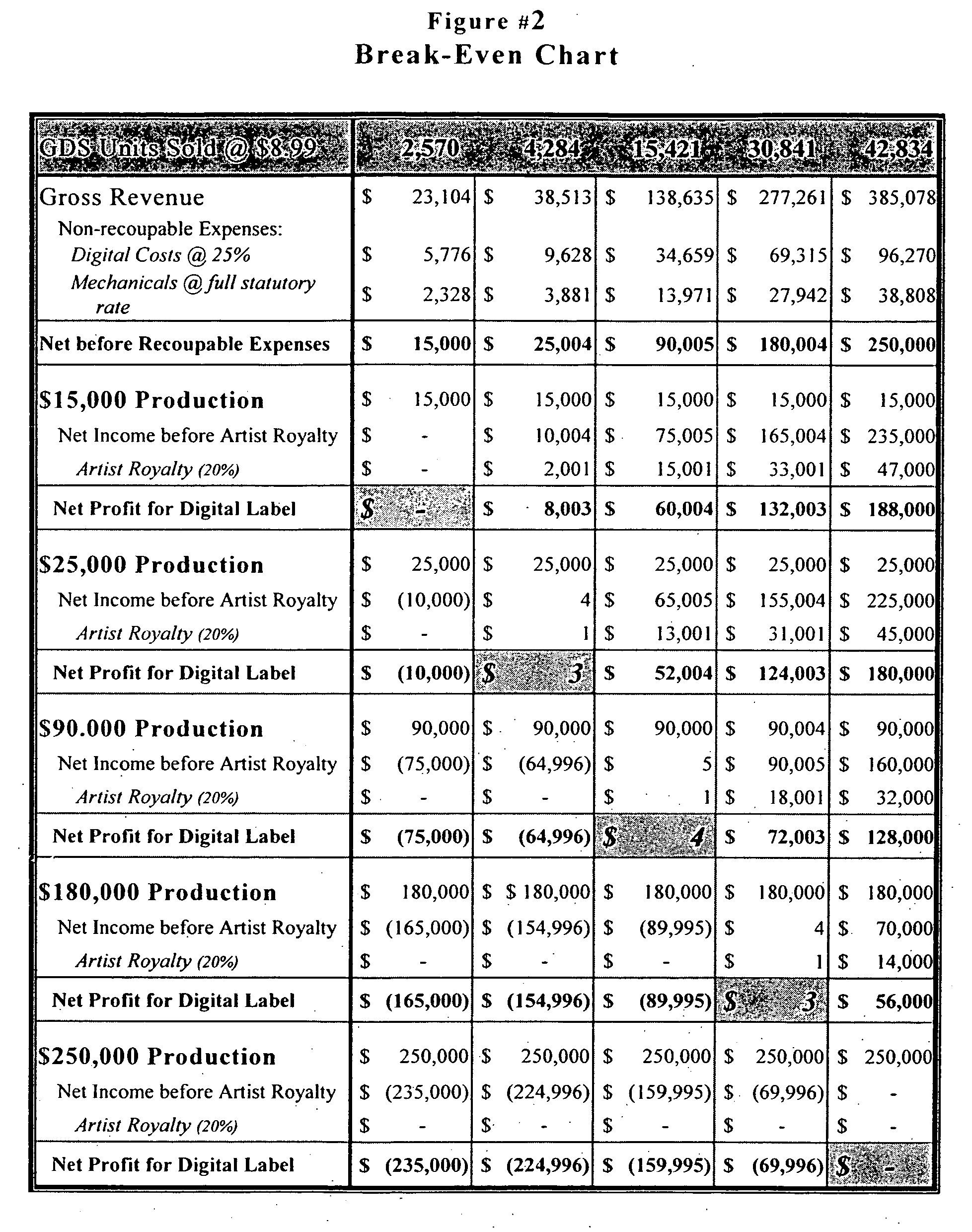

Method of selling new sound recordings

InactiveUS20050182634A1Increase demandReducing extensive manufacturingFilamentary/web record carriersSpeech analysisData compressionMusic industry

An original business method that significantly improves the recorded music industry-standard street release method (a coined term) of selling recorded music in the open-source CD format, by reconfiguring the use of conventional and Internet distribution channels; including first obtaining ownership and / or distribution rights in and to groups of approximately 100 new sound recordings featuring artists generally recognizable to the public within a definable genre of musical style, then creating a Golden digital songfile(a coined term) for each new sound recording acquired, utilizing any one of a number of suitable data compression / decompression technologies, then storing the GDS(s) in an open-portal database, then promoting and marketing the GDS(s) over the Internet through first-click access (a coined term) to genre-specific main music menus on any number of retail website(s), then offering the GDS(s) for electronic purchase to the computer consumer, then selecting certain Golden digital songfiles for crossover distribution (a coined term) through industry-standard street release method, then expanding the above formula to other groups of approximately 100 Golden digital songfiles featuring recognized artists in all definable music genres.

Owner:ZITLER JUSTIN A +1

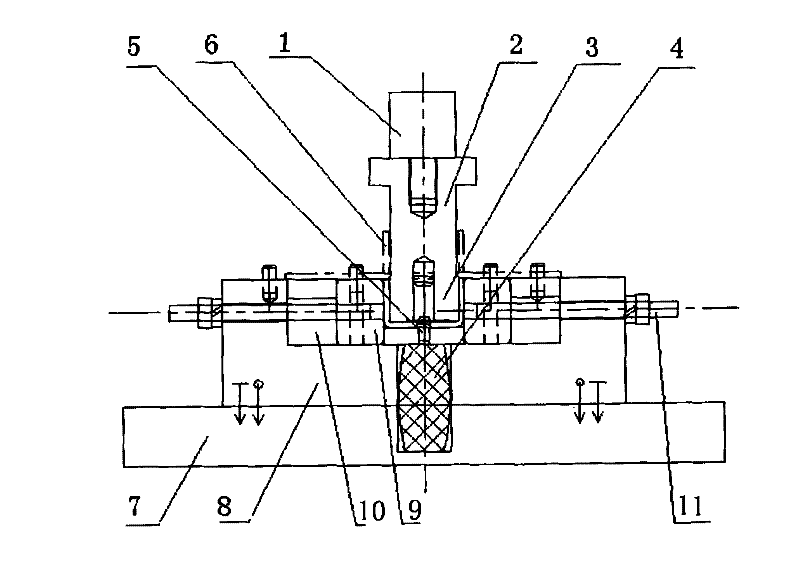

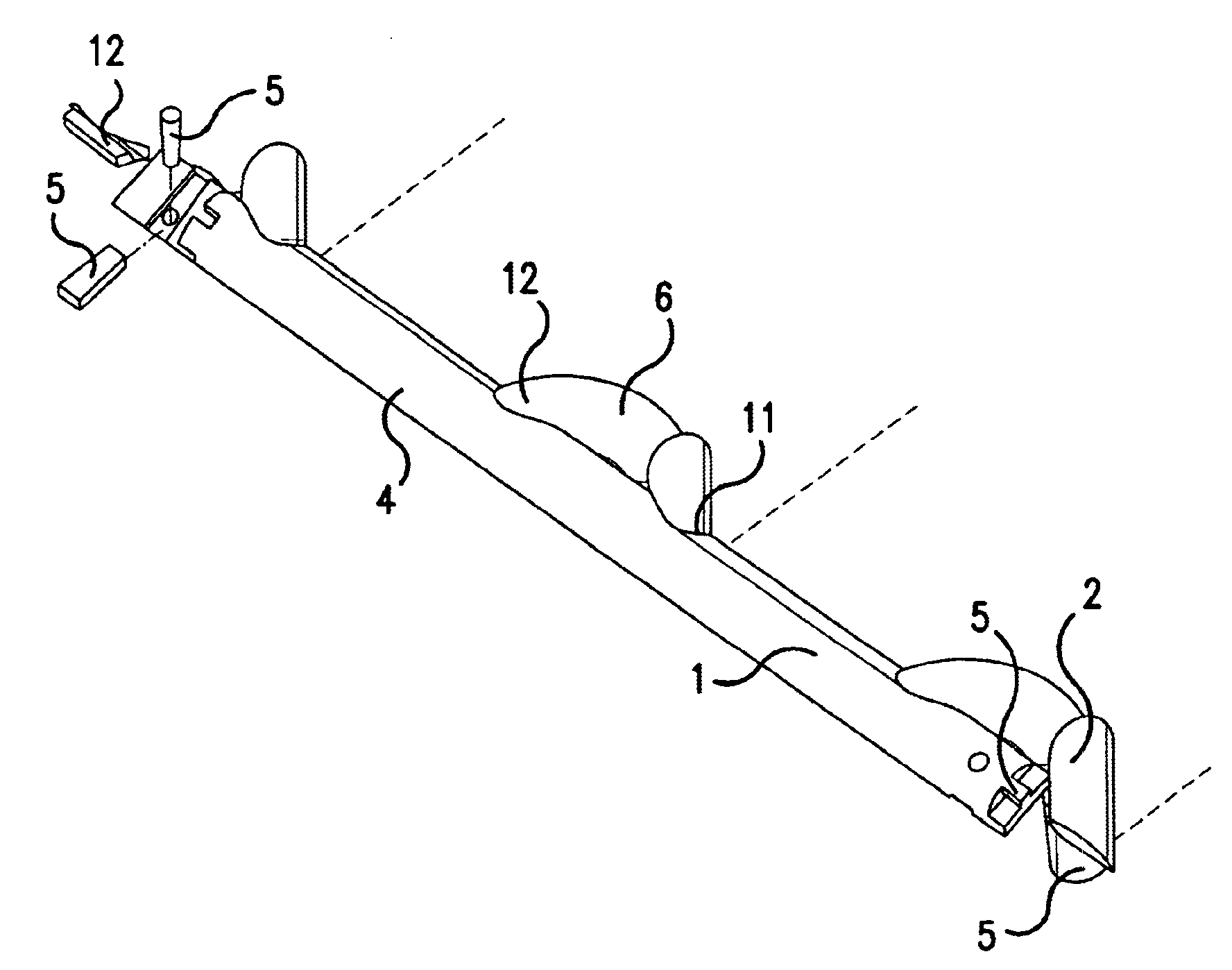

Fixture for forming U-shaped clip of steel plate spring

InactiveCN102327986AHigh forming dimension accuracyReduce waste generationShaping toolsSteel platesEngineering

The invention discloses a fixture for forming a U-shaped clip of a steel plate spring. The fixture is characterized in that: a die shank and an upper module are connected with the upper end and the lower end of an upper die fixing block respectively; a lower die fixing block is arranged on the upper end face of a lower template; two lower modules and a gap regulation base plate are arranged on two sides of the upper end of the lower die fixing block respectively; a gap between the two lower modules corresponds to the upper module; and an elastic material return body with a positioning pin is arranged in the middle of the lower die fixing block. Due to the arrangement, the die shank and the lower template are connected with an upper stamping head and a working table of a pressure machine respectively, so the fixture can form U-shaped clips of steel plate springs of different specifications by bending.

Owner:诸城市恒信基汽车部件有限公司

Plastic stopper

ActiveUS9289557B2Elimination of barrel creep or localized bulging issuesReduce material usageInfusion syringesIntravenous devicesEngineeringBiomedical engineering

A stopper adapted for attachment with a plunger rod for use within a syringe barrel includes a main body portion defining an open rearward end configured to receive the plunger rod. The main body portion is manufactured from a rigid or semi-rigid polymeric material having an elastic modulus in the range of about 0.01 GPa to about 5 GPa. When fluid pressure is increased inside the syringe barrel during an injection, at least one of the following actions occurs: a) a flexible roof of the main body portion expands in a radial direction toward an inner wall of the syringe barrel; b) a first perimetrical skirt extending around an outer circumference of the main body portion is forced against an inner wall of the syringe barrel; and c) an engagement between the plunger rod and an engagement portion provided along an inner circumference of the main body portion.

Owner:BECTON DICKINSON & CO

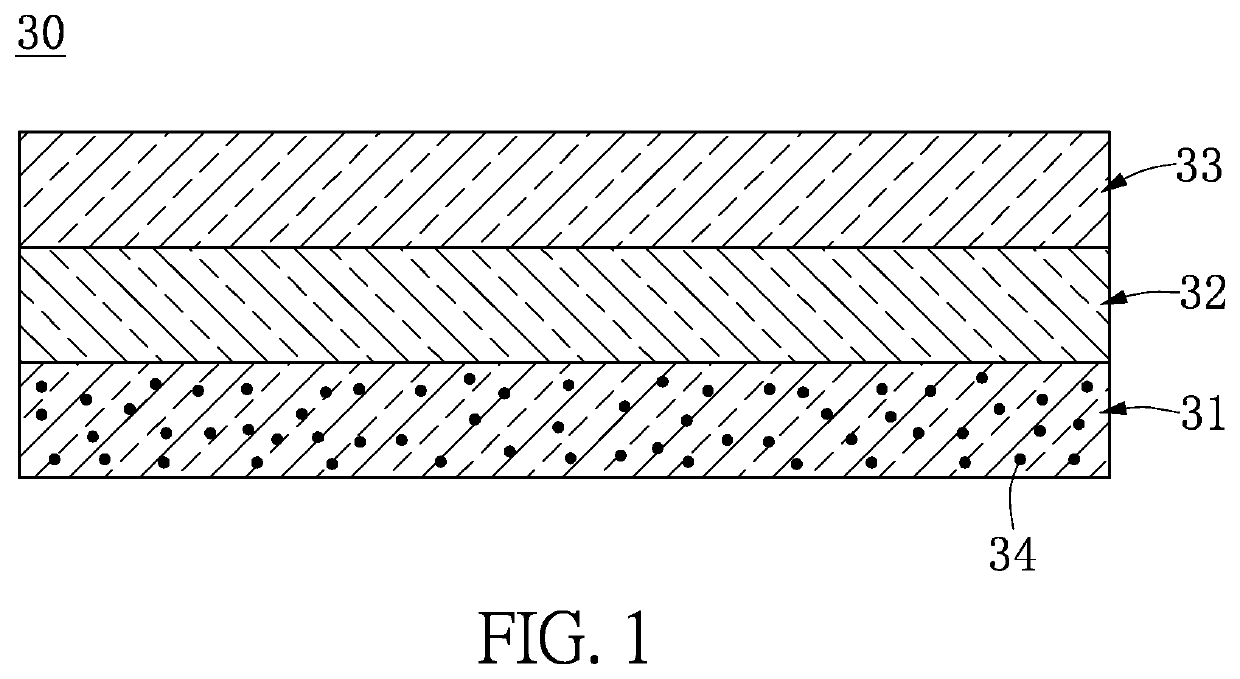

Fruit and vegetable preservation film and preparation method thereof

InactiveUS20200171804A1Reduce air permeabilityImprove freshnessFlexible coversWrappersMaterials scienceFruits and vegetables

A preparation method of a fruit and vegetable preservation film is used for preparing a three-layer co-extrusion film having a thickness ranging from 0.02 mm to 2.0 mm. A preservation master-batch composed of 5-20% of an inorganic nano-powder and 80-95% of a resin material is uniformly distributed in one layer of the co-extrusion film.

Owner:NANYA PLASTICS CORP

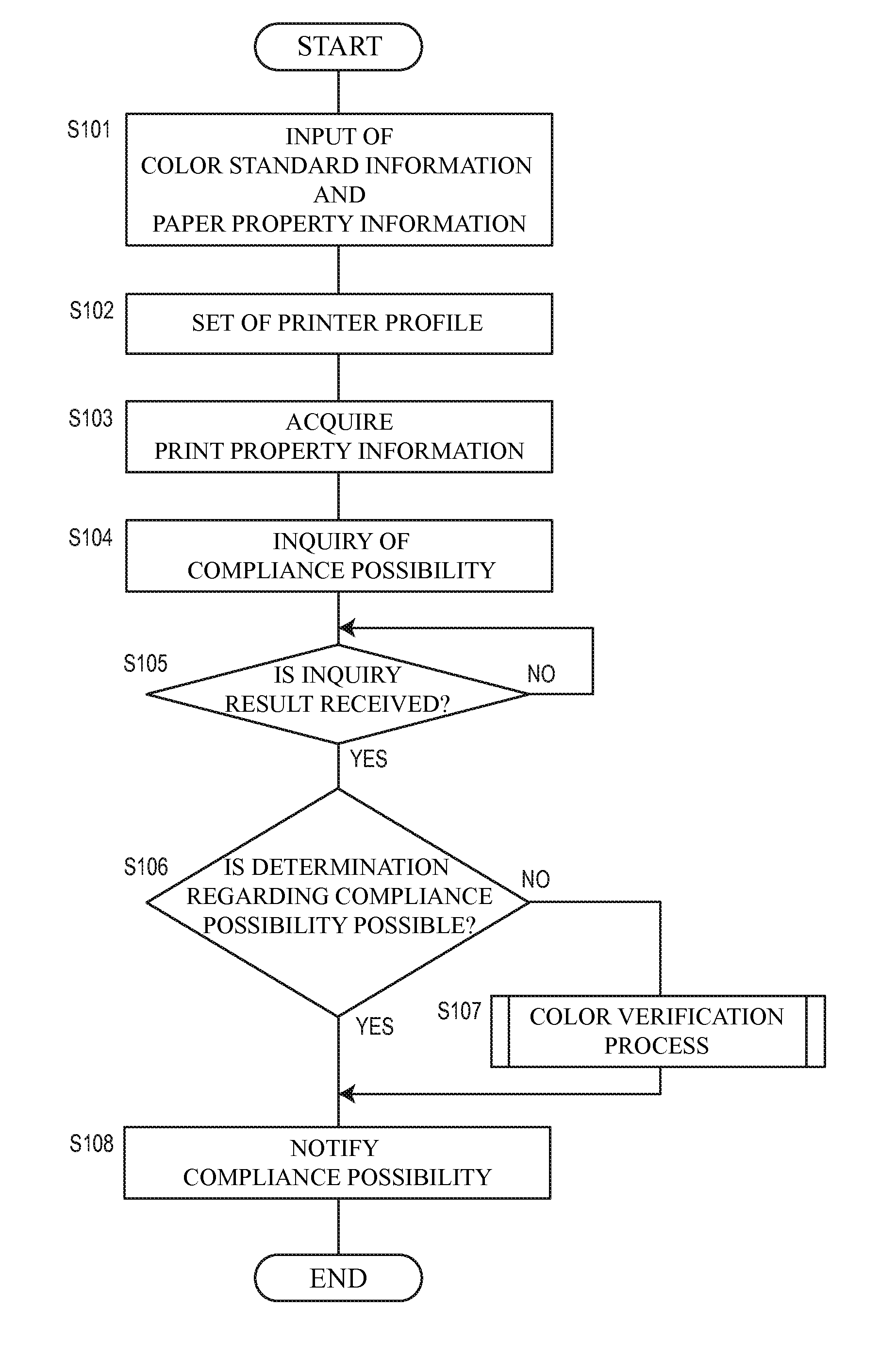

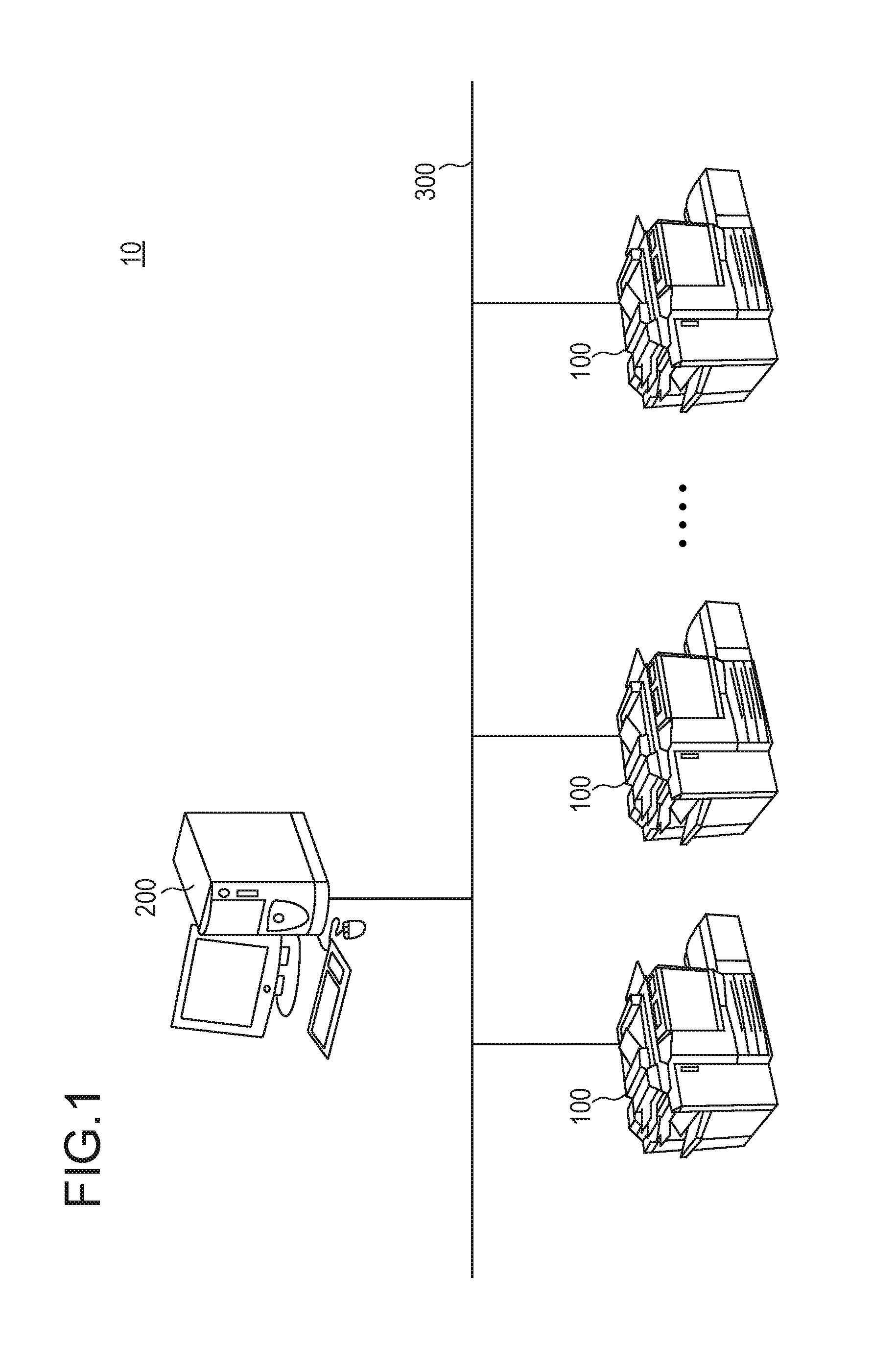

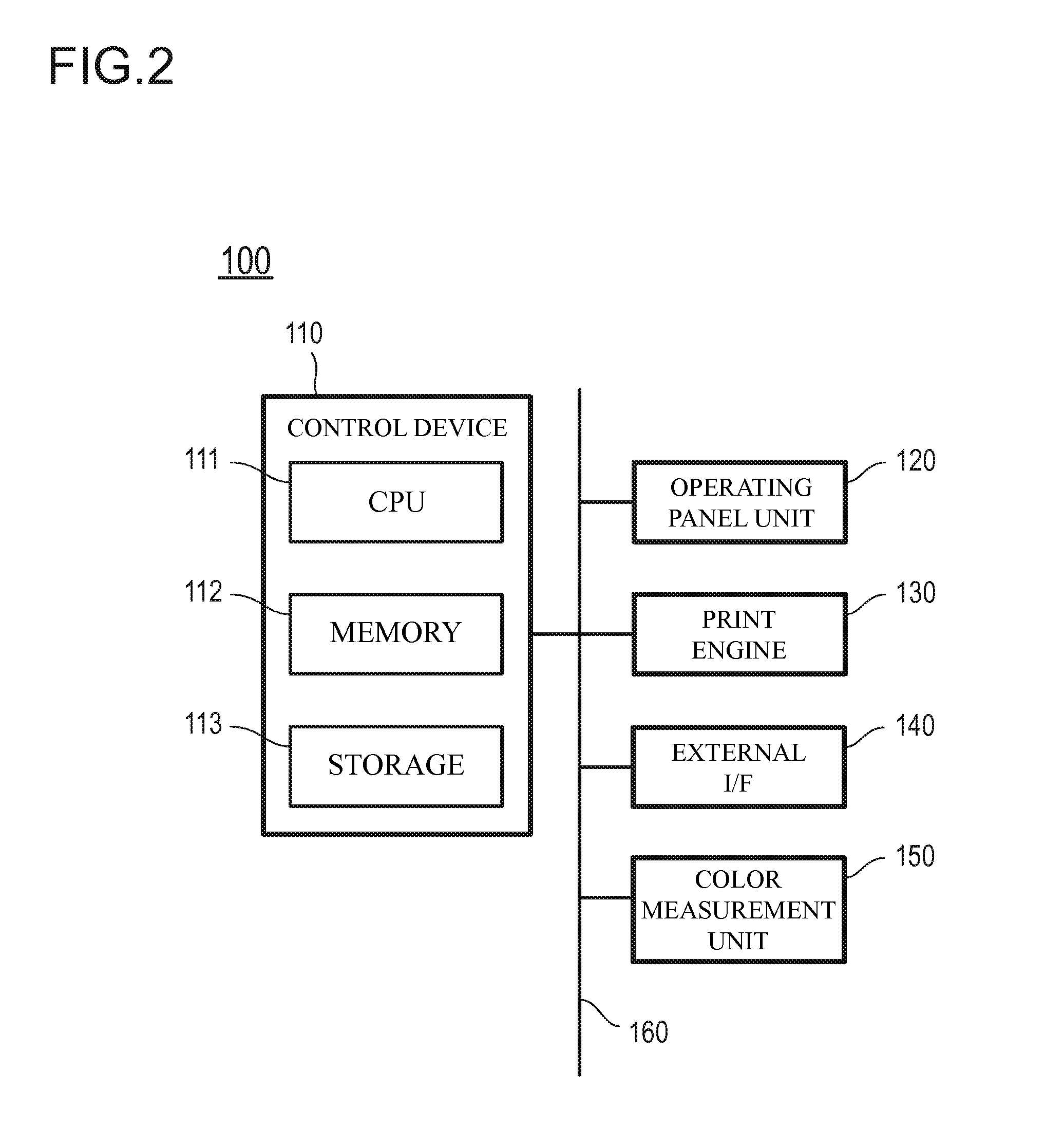

Information processing system, printing apparatus, information processing method, and information processing program

InactiveUS20160080609A1True colorReduce effortDigitally marking record carriersDigital computer detailsInformation processingComputer graphics (images)

The information processing system includes an accumulation unit for accumulating a print result as result data, an input acceptance unit for accepting input of color standard information indicating a standard of a print color and paper property information indicating a property of a print paper, an acquisition unit for acquiring print property information indicating a property of a printing apparatus that performs printing on the print paper, a determination unit for referring the color standard information and the paper property information, which have been input to the input acceptance unit, and the print property information, which has been acquired in the acquisition unit, to the result data of the accumulation unit, and determining whether printing complying with a standard based on the color standard information is possible in the printing apparatus, and a notification unit for notifying a determination result thereof.

Owner:KONICA MINOLTA INC

Mat with puzzle function

InactiveUS20140230353A1Reduce waste generationLow production costIndoor gamesBuilding componentsEngineeringTooth part

A mat with puzzle function is a four-sided pad. Each side has a tooth part with a succession of teeth. At least two cutting lines divide the mat into four blocks, in such a way that each block has an assembling part with the complementary shape to connect with others. The block of each mat can engage with another block of the mat to form a puzzle mat set.

Owner:WANG WEN PING

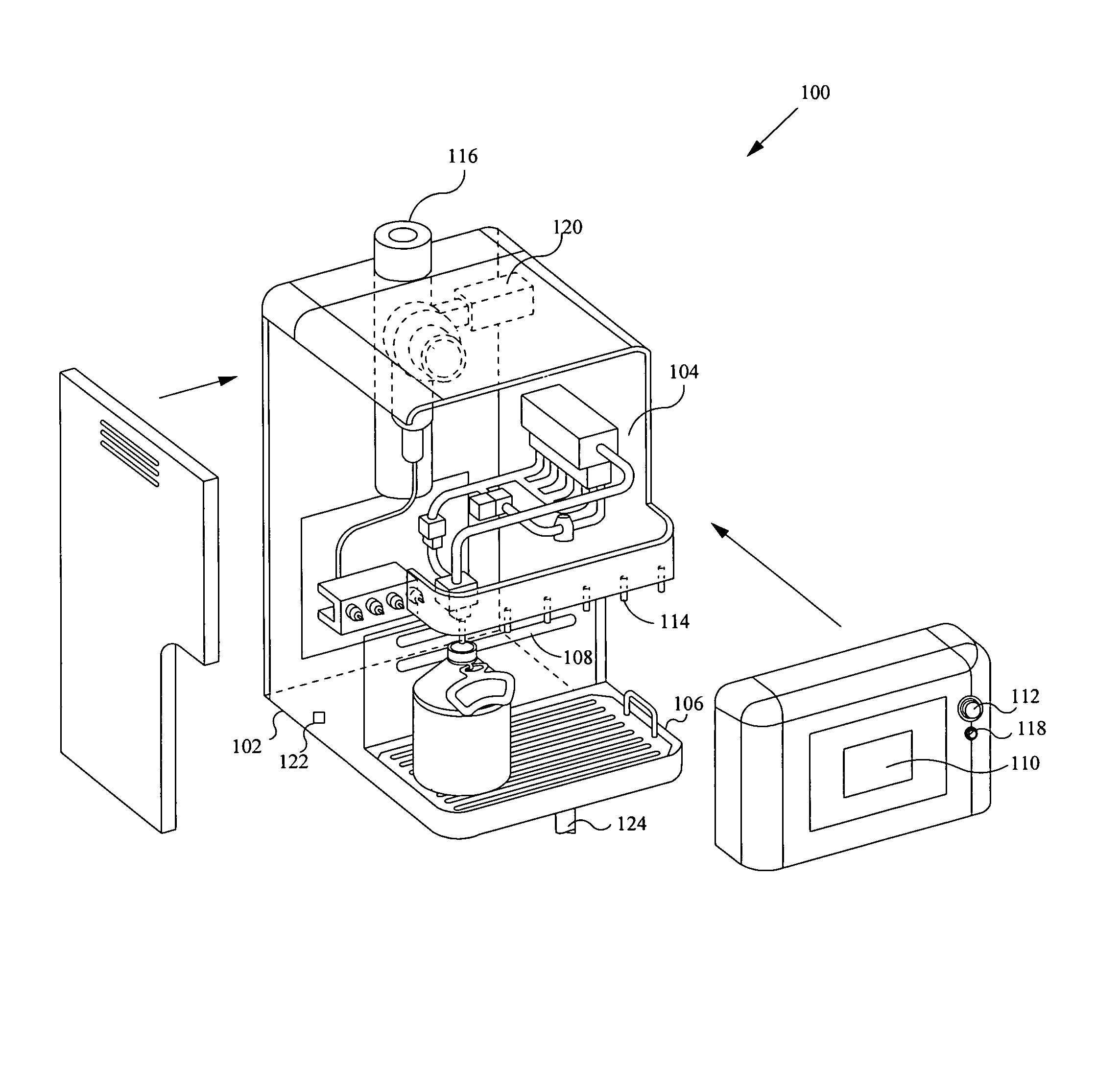

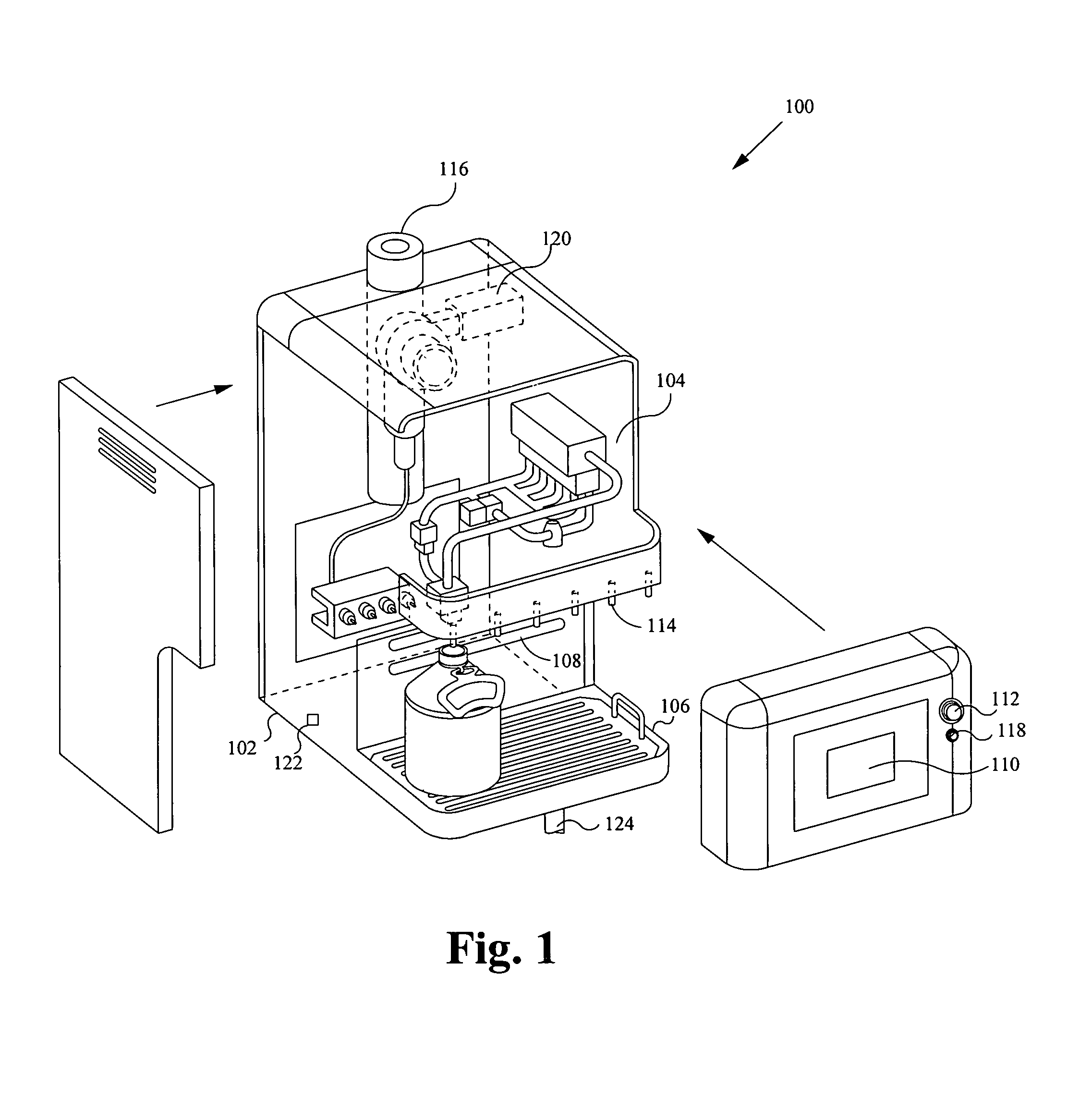

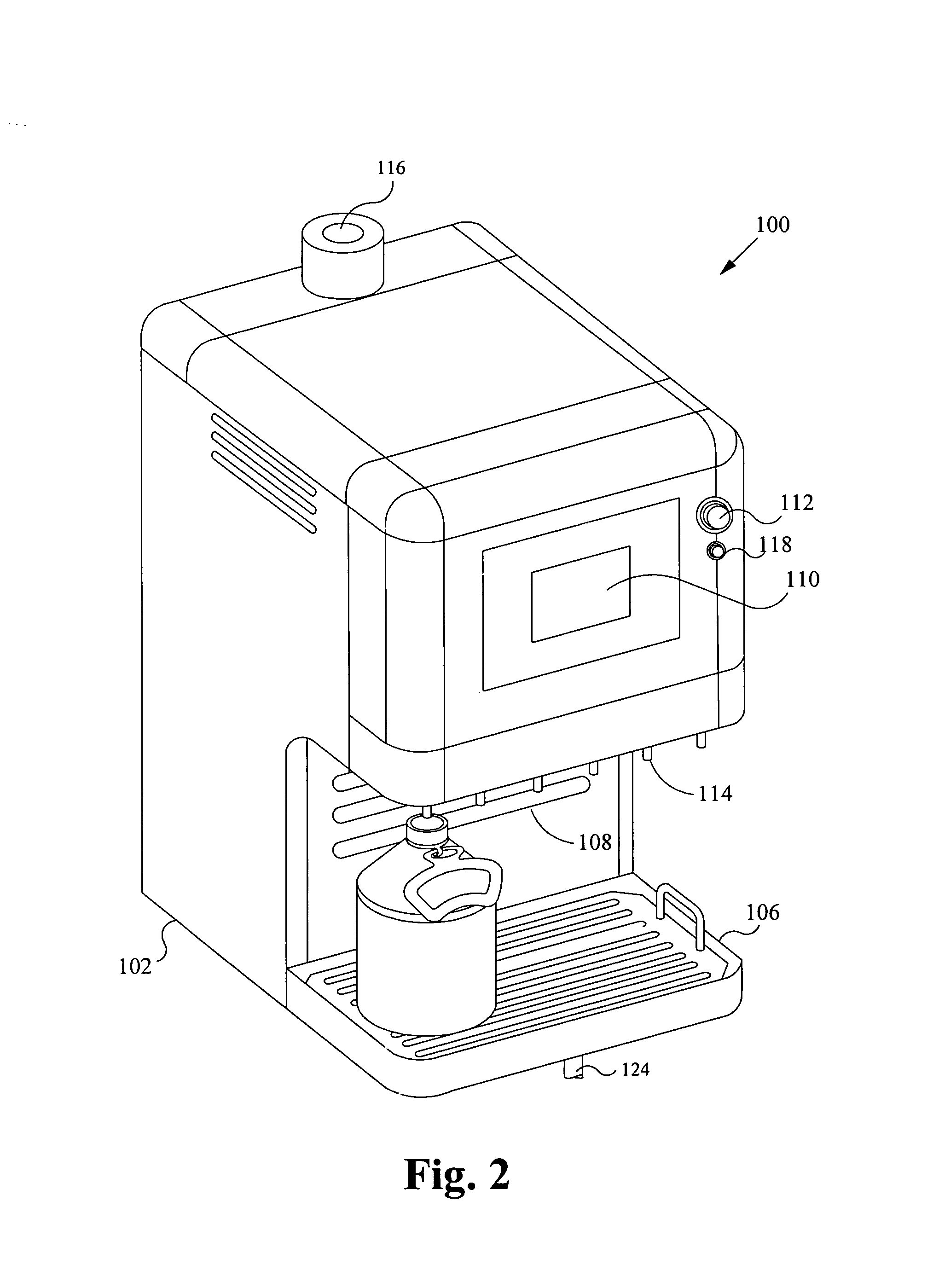

System for dispensing solvents

ActiveUS8485392B1Reduce waste generationEliminate needOpening closed containersBottle/container closureFume hoodSafe handling

A system for dispensing solvents removes the need for storing solvents in multitudes of small containers or containers which are not suitable for storing the solvents for a long duration. The system minimizes laboratory space requirements for the storage and handling of solvents. The system minimizes waste generation. With the system for dispensing solvents, the solvents are stored properly and are able to be dispensed in small quantities for use as needed. The system for dispensing solvents also includes leak detection, a spill tray, a fume hood and other precautionary measures to ensure a safe handling environment.

Owner:TARTER JEFFREY WILSON

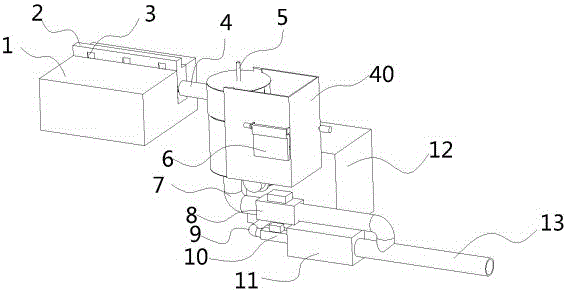

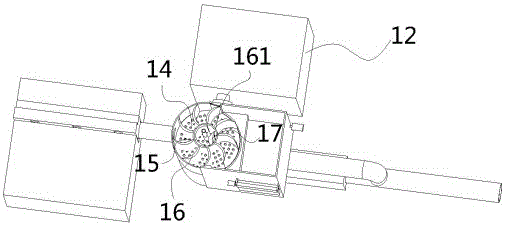

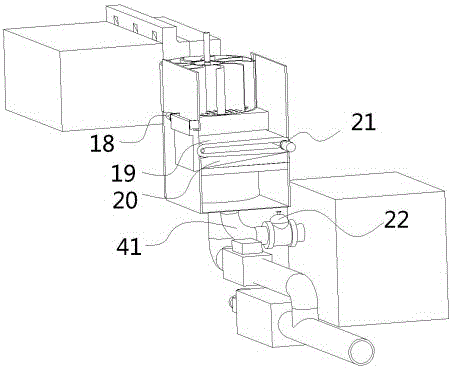

Road drainage apparatus and drainage method thereof

ActiveCN105887618ASave on maintenance and management feesReduce waste generationFatty/oily/floating substances removal devicesSewerage structuresElectric machineryImpeller

The invention discloses a road drainage apparatus, comprising a water collection passage and characterized in that the water collection passage is connected with a separation tank, a water filter plate is disposed in the separation tank, a water collection tank is disposed below the water filter plate, and a spoke impeller driven by a motor are fitted above the water filter plate; a discharge port of the spoke impeller is fitted with a conveying belt driven by a conveying belt motor, and a discharge end of the conveying belt is fitted with a refuse outlet retaining door; the invention has the advantages that a pollution source is directly purified in early rain by using a water purifying filter material, maintenance and management expenditure is saved, both waste and pollution are greatly decreased, the cost is low, and the apparatus is suitable for popularization and use.

Owner:WENZHOU YONGCHANG CONSTR CO LTD

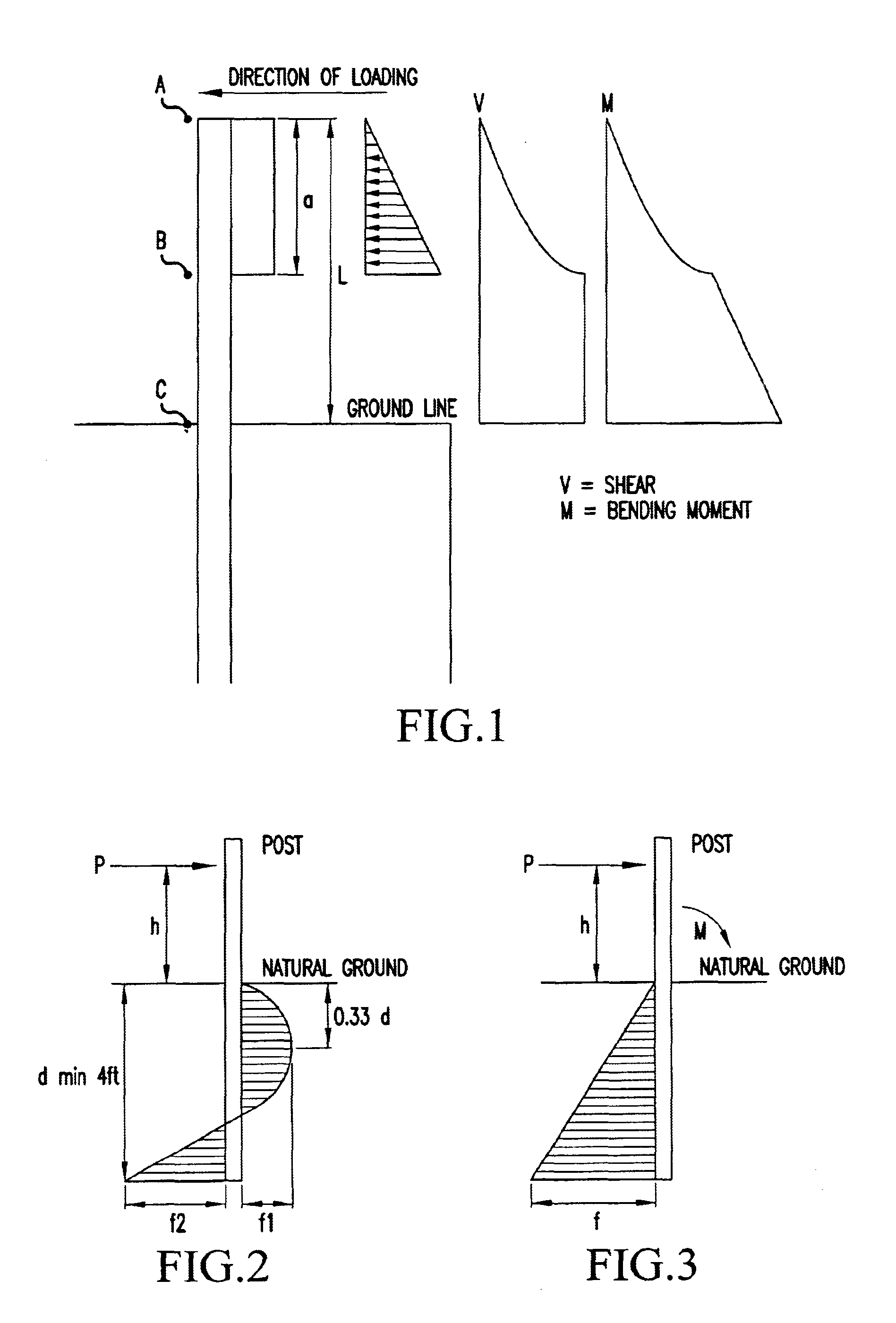

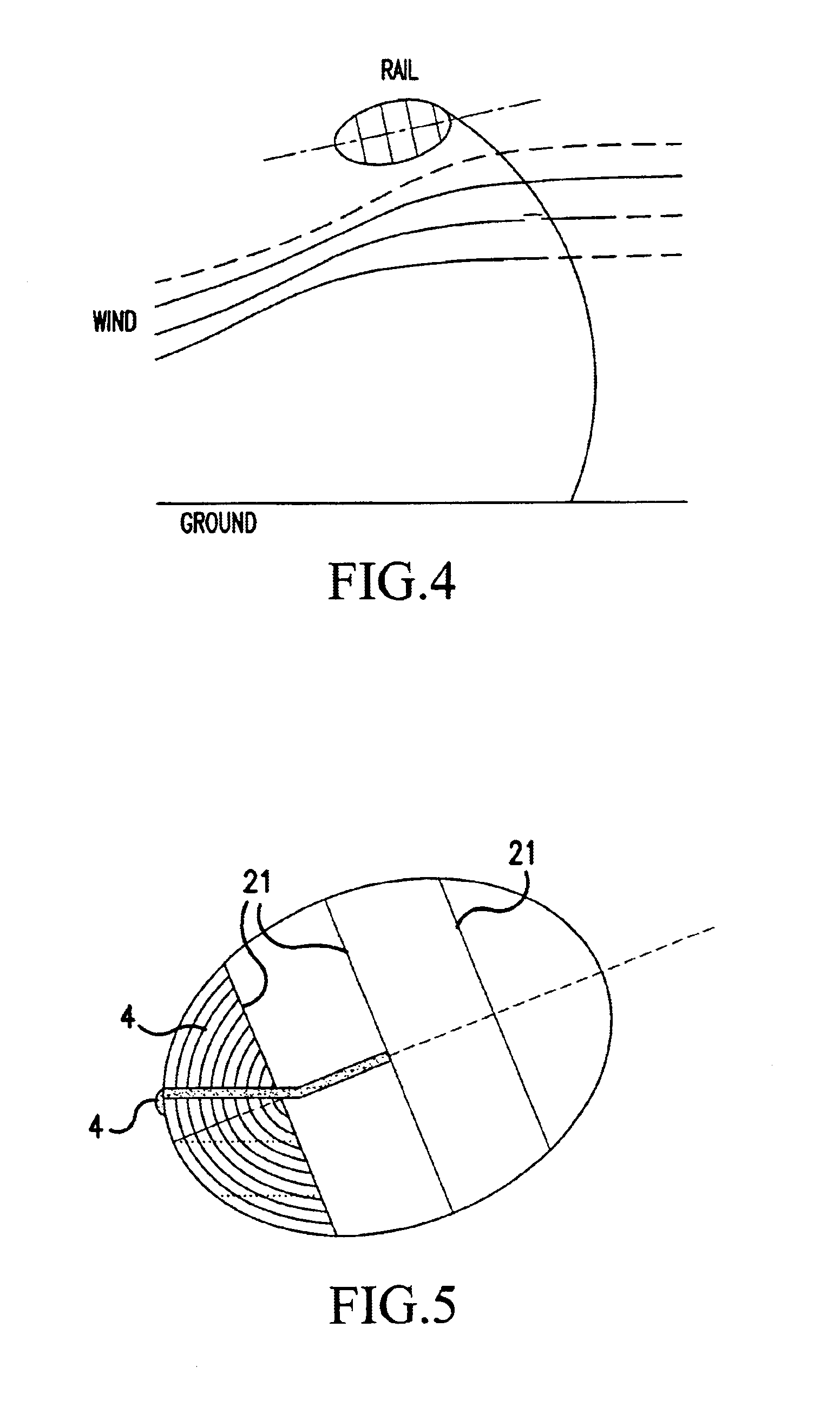

Lateral load bearing structural cantilevered system such as highway guardrail and bridge rail systems

InactiveUS6935622B2Inexpensive to fabricateDesign concernPasturing equipmentTraffic signalsResistance developmentEngineering

The present invention provides cantilevered structural support systems subjected principally to lateral-load conditions, such as guard rail systems, which are made of solid materials and which are designed to remove drifting snow from the road surface. The present invention identifies the design lateral-load plus vertical design loads imposed via installation activities plus design torsional load requirements plus design required soil-matrix resistance development then matches the structural requirements by way of either material mass and / or shape. The post and block section of the rail are combined into one curved object and divided into two or more branches, connecting the post / block object to the rail. The branch' median curve is above the highest point on the rail's surface. The sectional shape of the rail is elliptical and the axes are declined towards the surface of the road. The present invention can be of homogeneous material such as, but not limited to, wood and / or steel and / or aluminium and / or plastic and / or rubber. The present invention can also be of a composite nature of two or more materials.

Owner:JONSSON THORGEIR +1

Uv-curable acrylic copolymers

PendingUS20170096588A1Improve adhesionImprove performancePretreated surfacesEster polymer adhesivesFunctional monomerEthylene Homopolymers

The methods for producing a UV-curable acrylic copolymer is disclosed. The method includes polymerizing a mixture of monomers comprising (i) 40-95 wt % of at a (meth)acrylate monomer, (ii) 5-60 wt % of a copolymerizable monomer, wherein said monomer is selected from those whose homopolymers have a glass transition temperature of higher than −30° C., and (iii) optionally 0.5-20 wt % of a copolymerizable functional monomer having a functional group selected from the group consisting of a hydroxyl group and a carboxyl group to form an acrylic copolymer. The method includes reacting the acrylic copolymer with at least one type of monomer comprising a UV-curable functional group in the presence of a catalyst to form the UV-curable acrylic copolymer. Also encompassed are UV-curable acrylic copolymers thus formed, adhesive composition comprising the UV-curable acrylic copolymers, methods for manufacturing adhesive sheets comprising the UV-curable acrylic copolymers, and use of the UV-curable acrylic copolymers.

Owner:HENKEL KGAA

Anti-aging foods for companion animals

ActiveUS20150313261A1Reduce waste generationImprove the level ofMetabolism disorderDigestive systemProteinCorn gluten meal

The present invention encompasses compositions and methods for the prevention and treatment of age related conditions in animals, particularly in companion animals, in need thereof. The methods for treating or preventing an age-related condition in an animal in need thereof, comprise administering to the animal an effective amount of a composition comprising at least one of a protein source, a carbohydrate source, a vegetable source, a fruit source, or a combination of two or more thereof. In this method, the protein source is selected from the group consisting of chicken, egg protein, corn gluten meal, and combinations thereof; the carbohydrate source is selected from the group consisting of millet, brewers rice, oat groats, and combinations thereof, the vegetable source is selected from the group consisting of carrots, spinach, tomato pomace, and combinations thereof, wherein the fruit source is citrus pulp.

Owner:HILLS PET NUTRITION INC

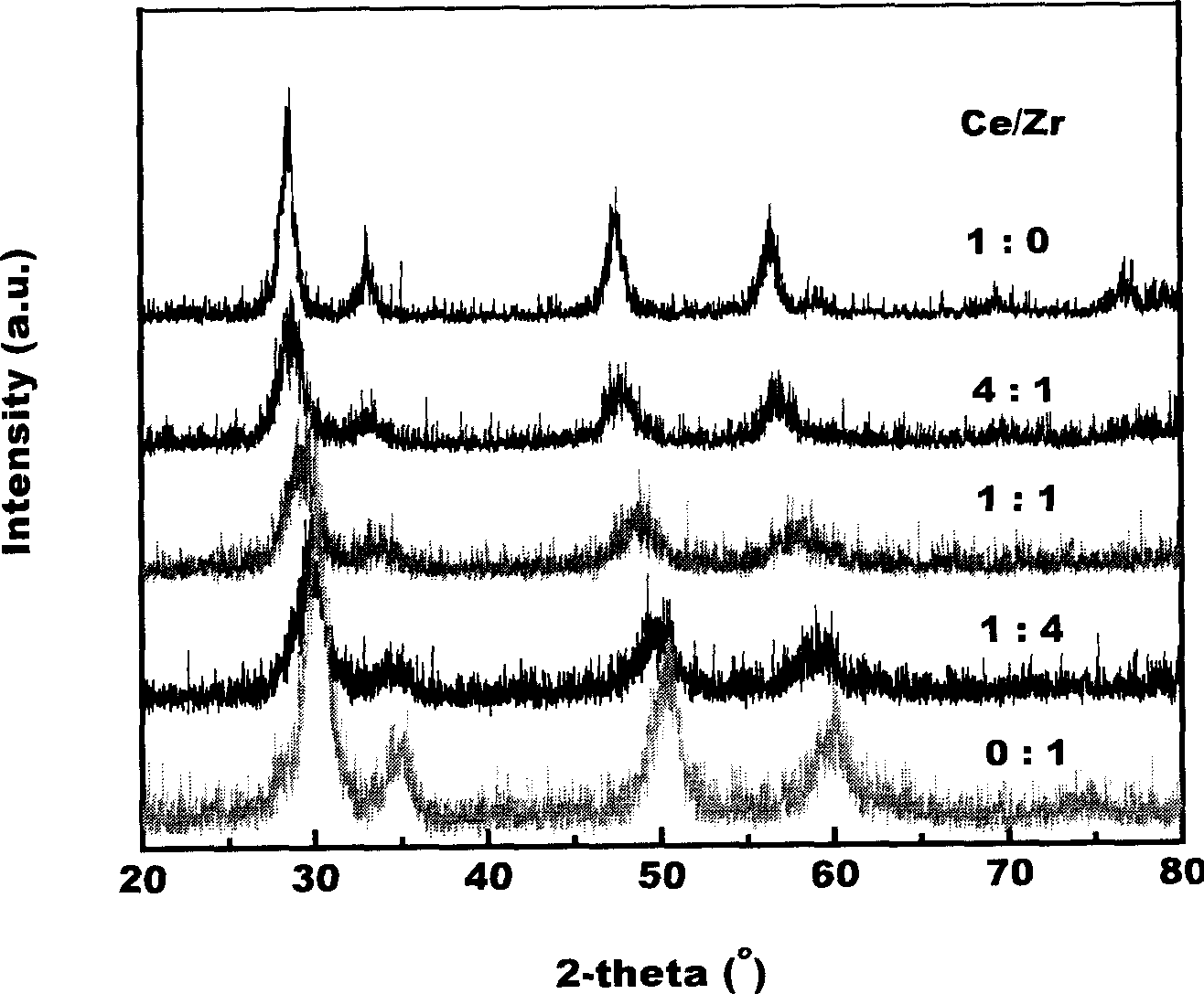

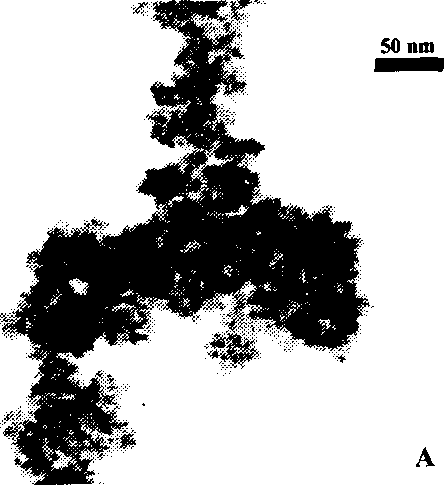

Method for preparing high specific surface metal oxide

The invention relates to a method to prepare high specific surface metal oxides, like the Ce-containing solid solutions of CeO2, ZrO2, CexZr1-xO2, etc. Firstly, it loads metal combination or mixture of the metal combination onto the carbon material by dipping to obtain the fore body, where the carried quantity of the oxide is 1-200% of the weight of the carbon material; then, raises the temperature of the fore body to 450-950 deg.C at the atmosphere of air or 5-20vol.% oxygen at a heating speed of 1-20 deg.C / min, makes constant temperature oxidization for 0.1-10 hours and then lowers the temperature to room temperature, so as to obtain it.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

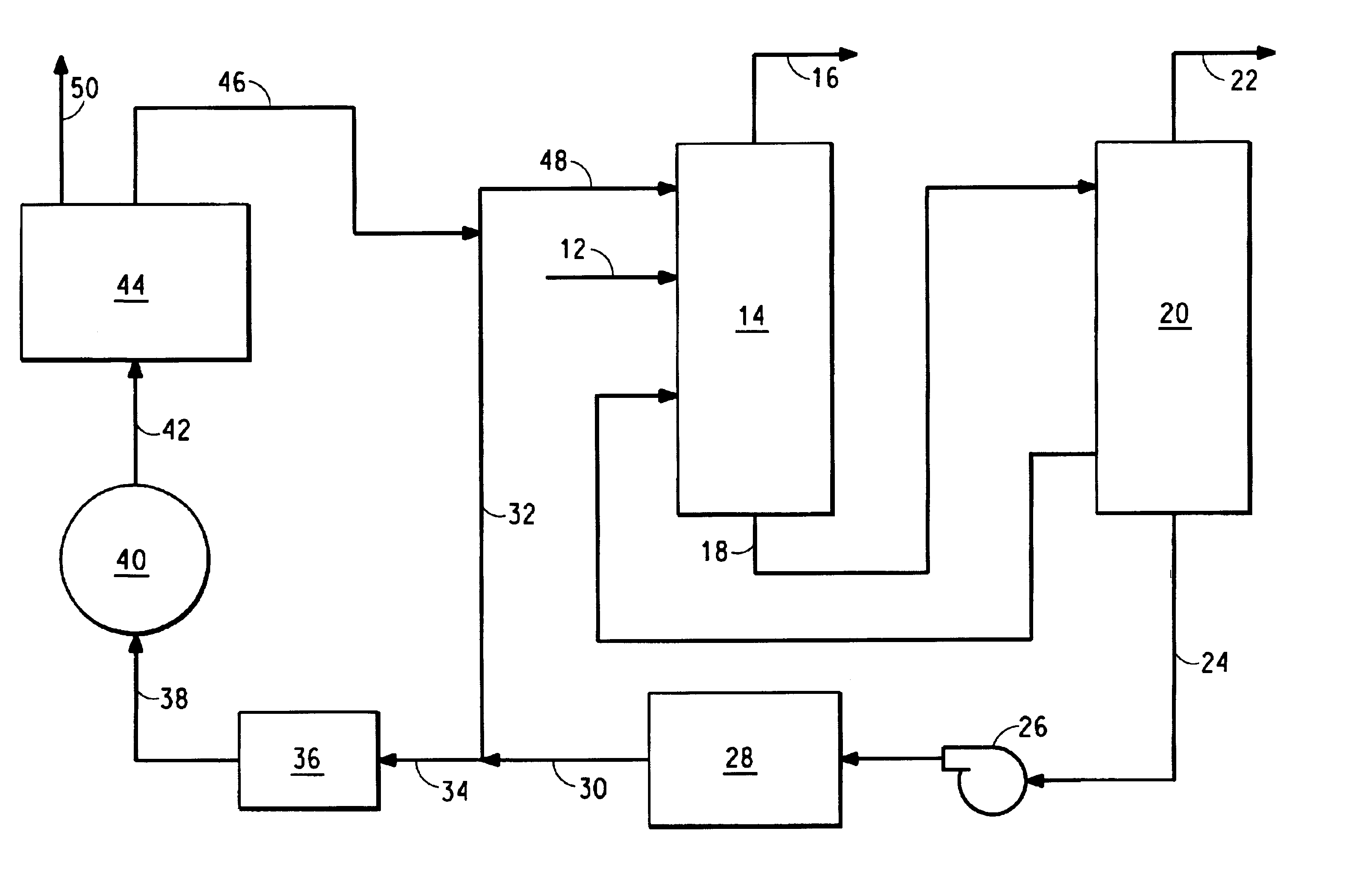

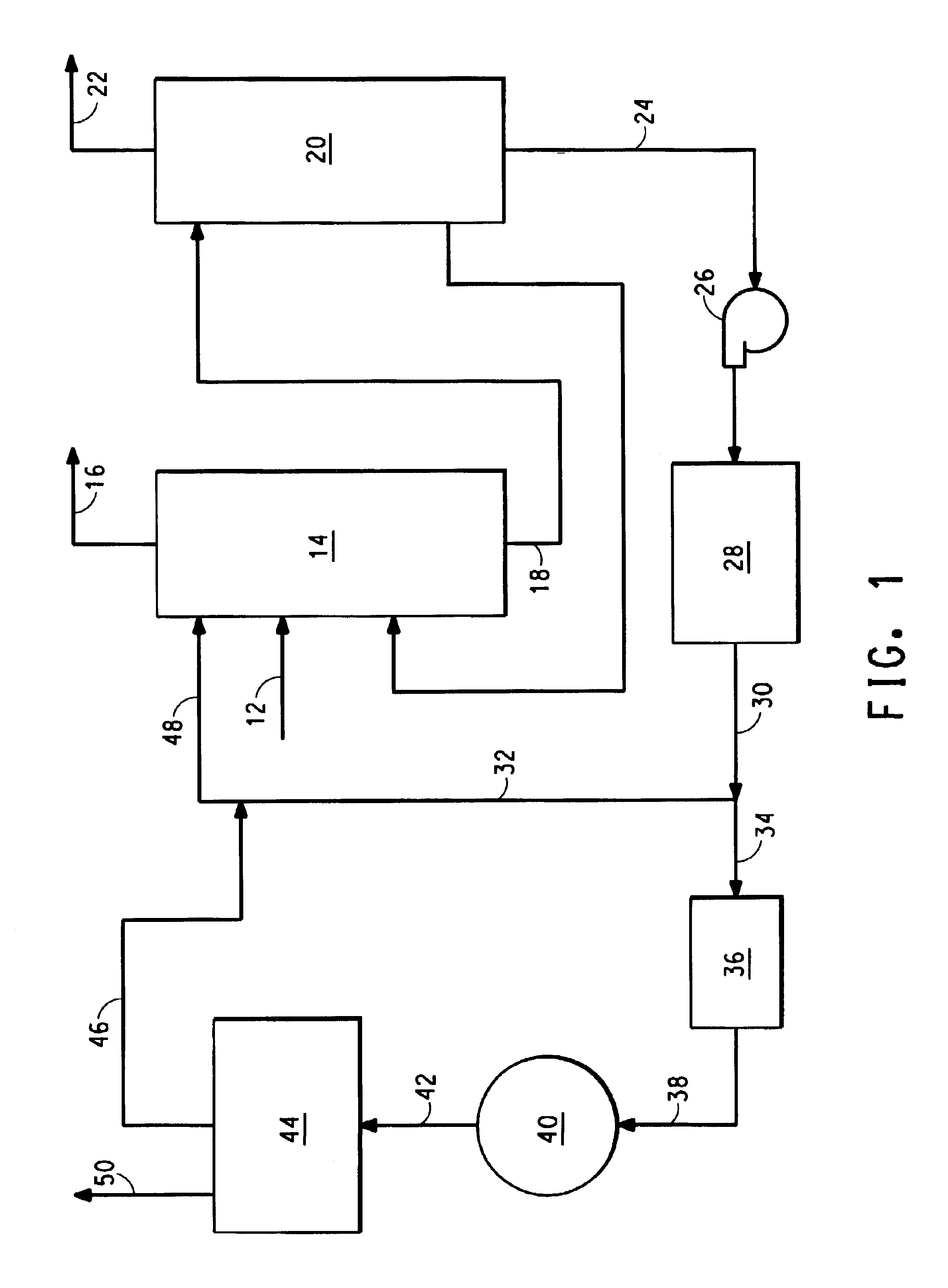

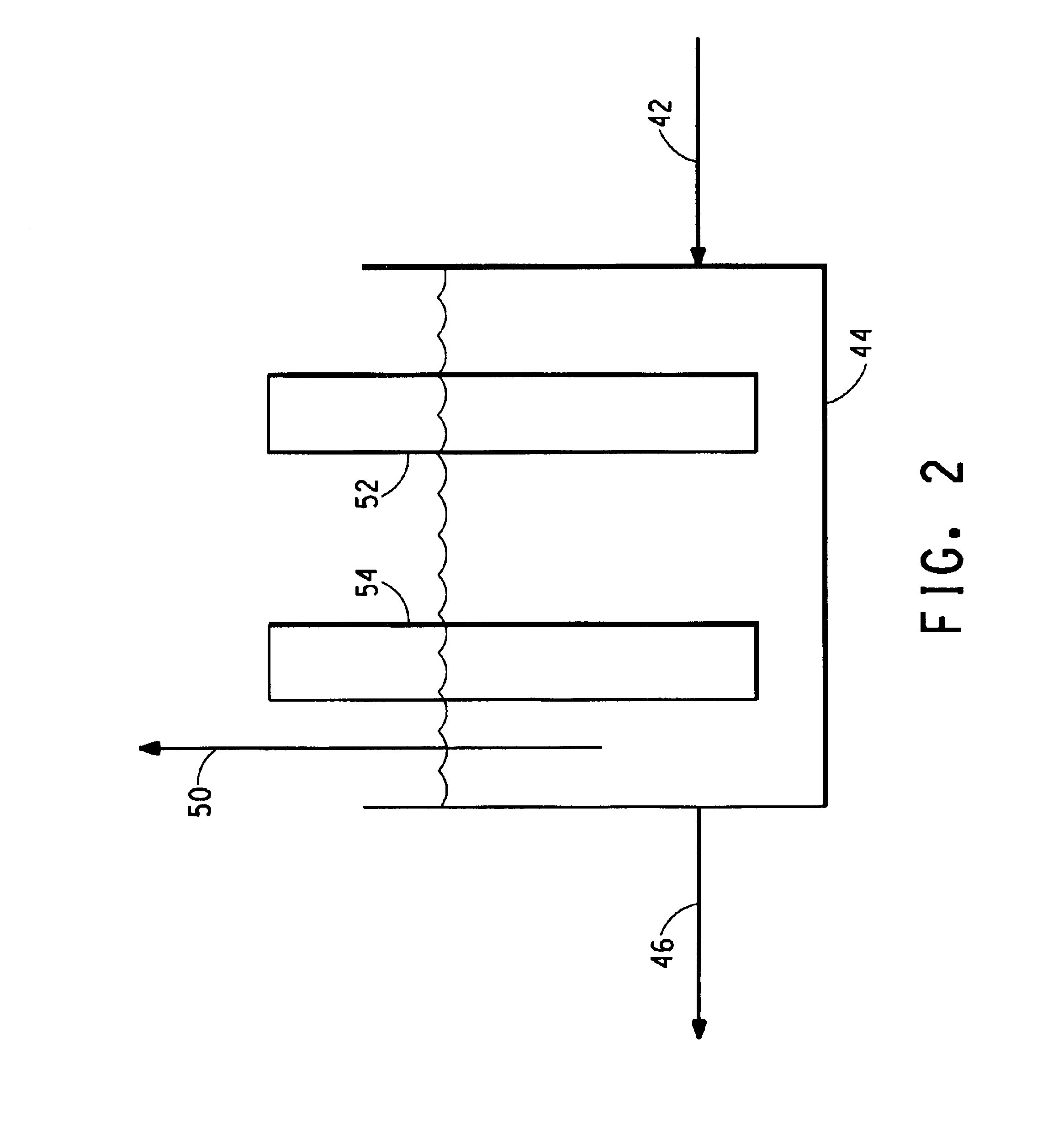

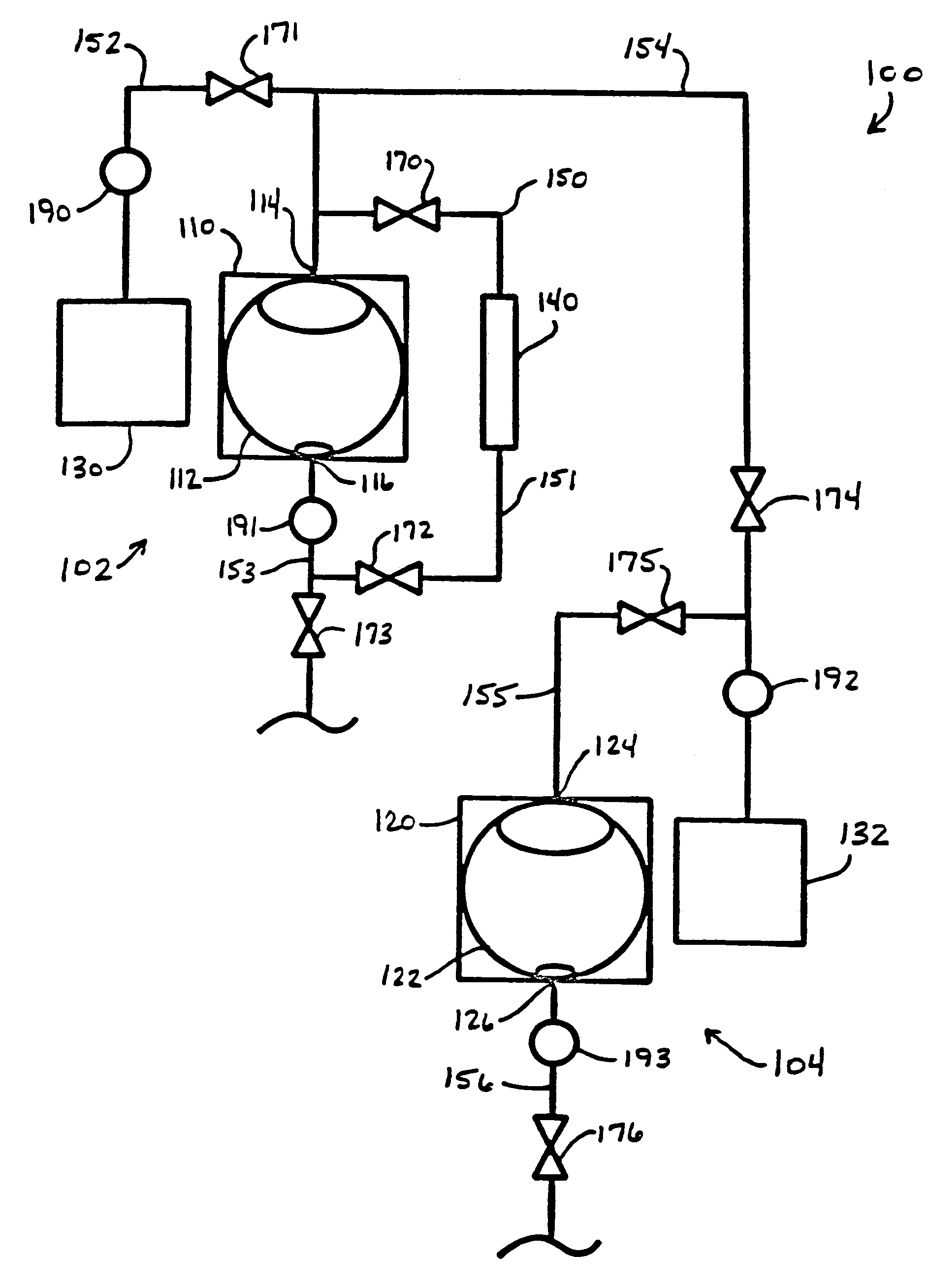

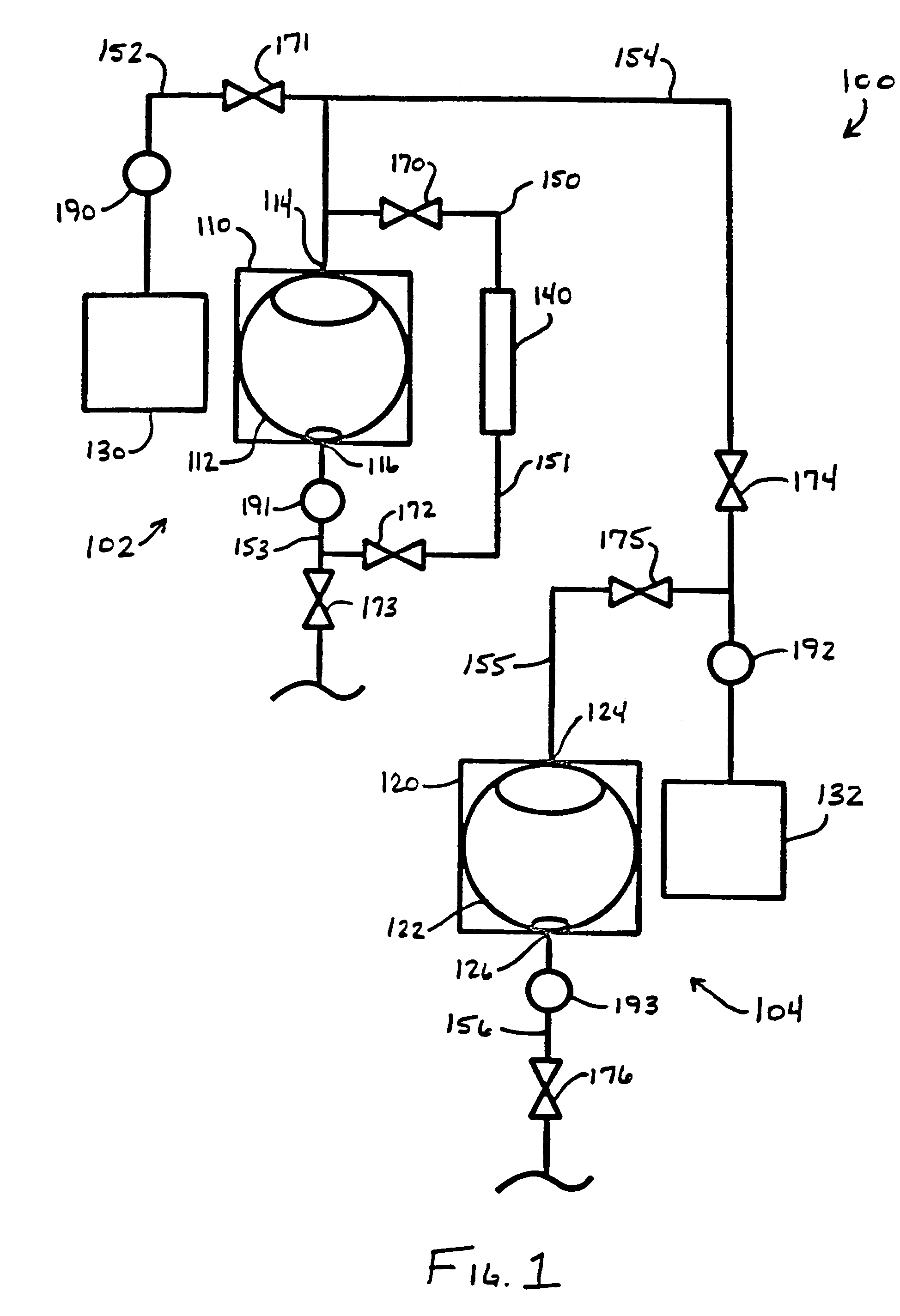

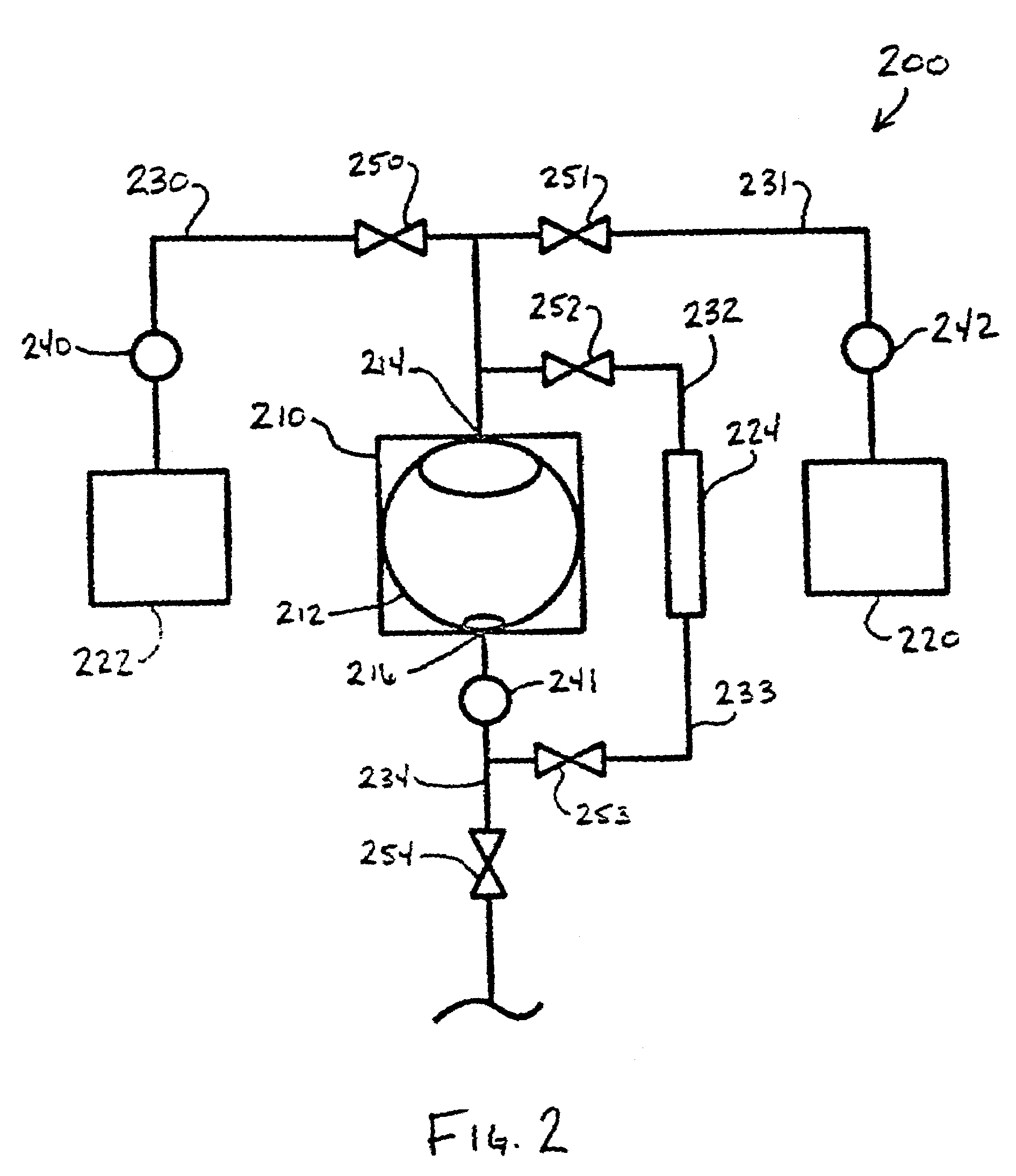

Cleaning system utilizing an organic cleaning solvent and a pressurized fluid solvent

InactiveUS7435265B2Increase vapor pressureLow boiling pointDry-cleaning apparatusDetergent mixture composition preparationSolubilityHalohydrocarbon

A cleaning system that utilizes an organic cleaning solvent and pressurized fluid solvent is disclosed. The system has no conventional evaporative hot air drying cycle. Instead, the system utilizes the solubility of the organic solvent in pressurized fluid solvent as well as the physical properties of pressurized fluid solvent. After an organic solvent cleaning cycle, the solvent is extracted from the textiles at high speed in a rotating drum in the same way conventional solvents are extracted from textiles in conventional evaporative hot air dry cleaning machines. Instead of proceeding to a conventional drying cycle, the extracted textiles are then immersed in pressurized fluid solvent to extract the residual organic solvent from the textiles. This is possible because the organic solvent is soluble in pressurized fluid solvent. After the textiles are immersed in pressurized fluid solvent, pressurized fluid solvent is pumped from the drum. Finally, the drum is de-pressurized to atmospheric pressure to evaporate any remaining pressurized fluid solvent, yielding clean, solvent free textiles. The organic solvent is preferably selected from terpenes, halohydrocarbons, certain glycol ethers, polyols, ethers, esters of glycol ethers, esters of fatty acids and other long chain carboxylic acids, fatty alcohols and other long-chain alcohols, short-chain alcohols, polar aprotic solvents, siloxanes, hydrofluoroethers, dibasic esters, and aliphatic hydrocarbons solvents or similar solvents or mixtures of such solvents and the pressurized fluid solvent is preferably densified carbon dioxide.

Owner:EMINENT TECHNOLOGY

Process for the synthesis of alpha-olefin polymerization procatalysts

InactiveUS20110015355A1Improve productivityReduce waste generationOrganic-compounds/hydrides/coordination-complexes catalystsSynthetic resin layered productsChlorobenzeneBenzoyl chloride

The invention relates to a process for the synthesis of a Ziegler Natta procatalyst, the process comprising first treating magnesium alkoxide with a twice used mixed solvent of TiCl4 and chloro benzene to form a first stage product, then treating the first stage product with a once used mixed solvent of TiCl4 and chlorobenzene to form a second stage product and finally treating the second stage product with mixed solvent recovered by treatment of effluent from the first treatment with benzoyl chloride so as to convert contaminant of formula TiCl3OR in the effluent to an addition complex which is precipitated, filtered off and hydrolyzed to recover ethyl benzoate and to form Ti(OH)4 as a side product, the product after final treatment being subjected to a plurality of successive washing steps with used as well as recovered hexane.

Owner:RELIANCE INDUSTRIES LIMITED

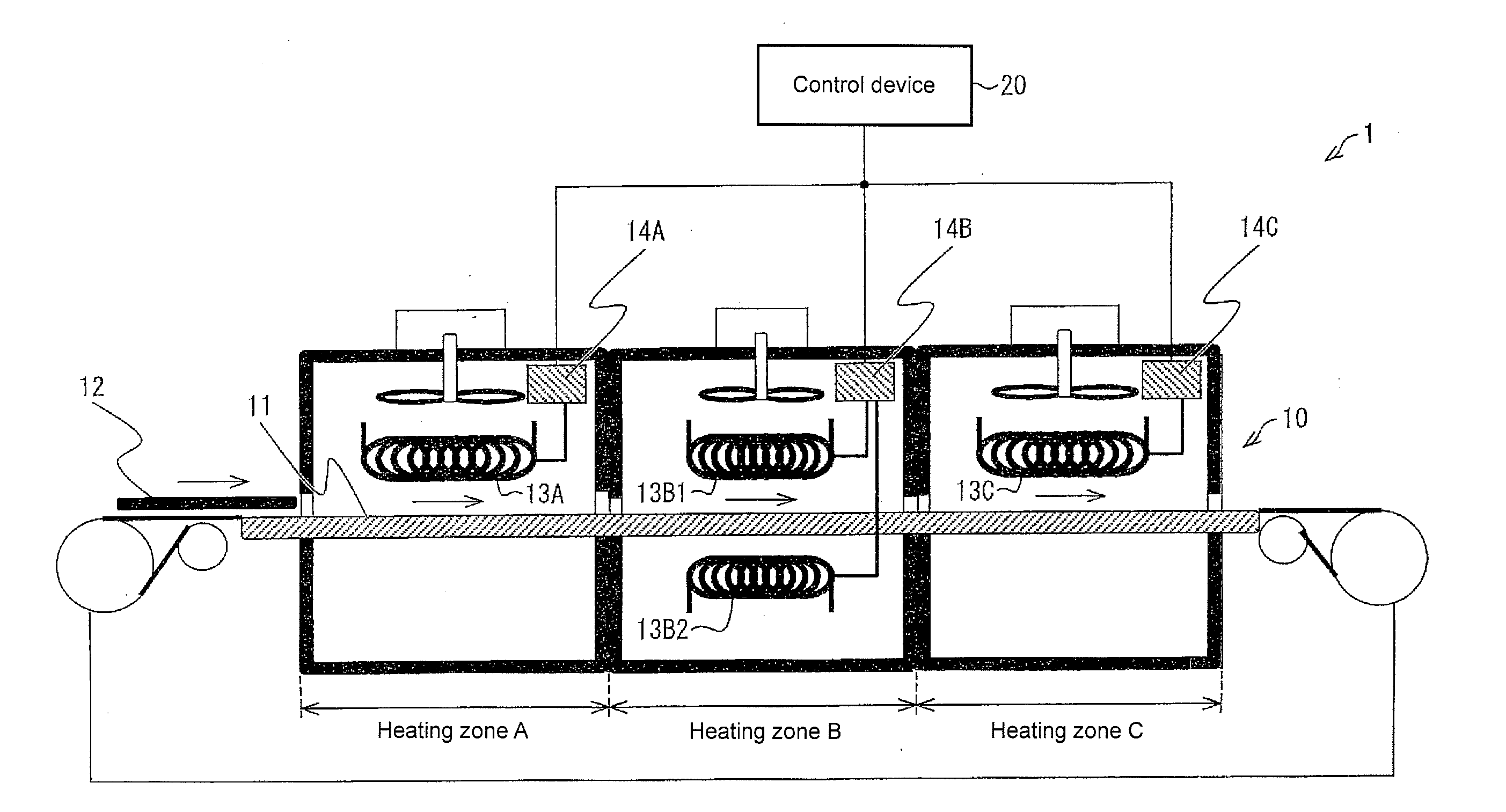

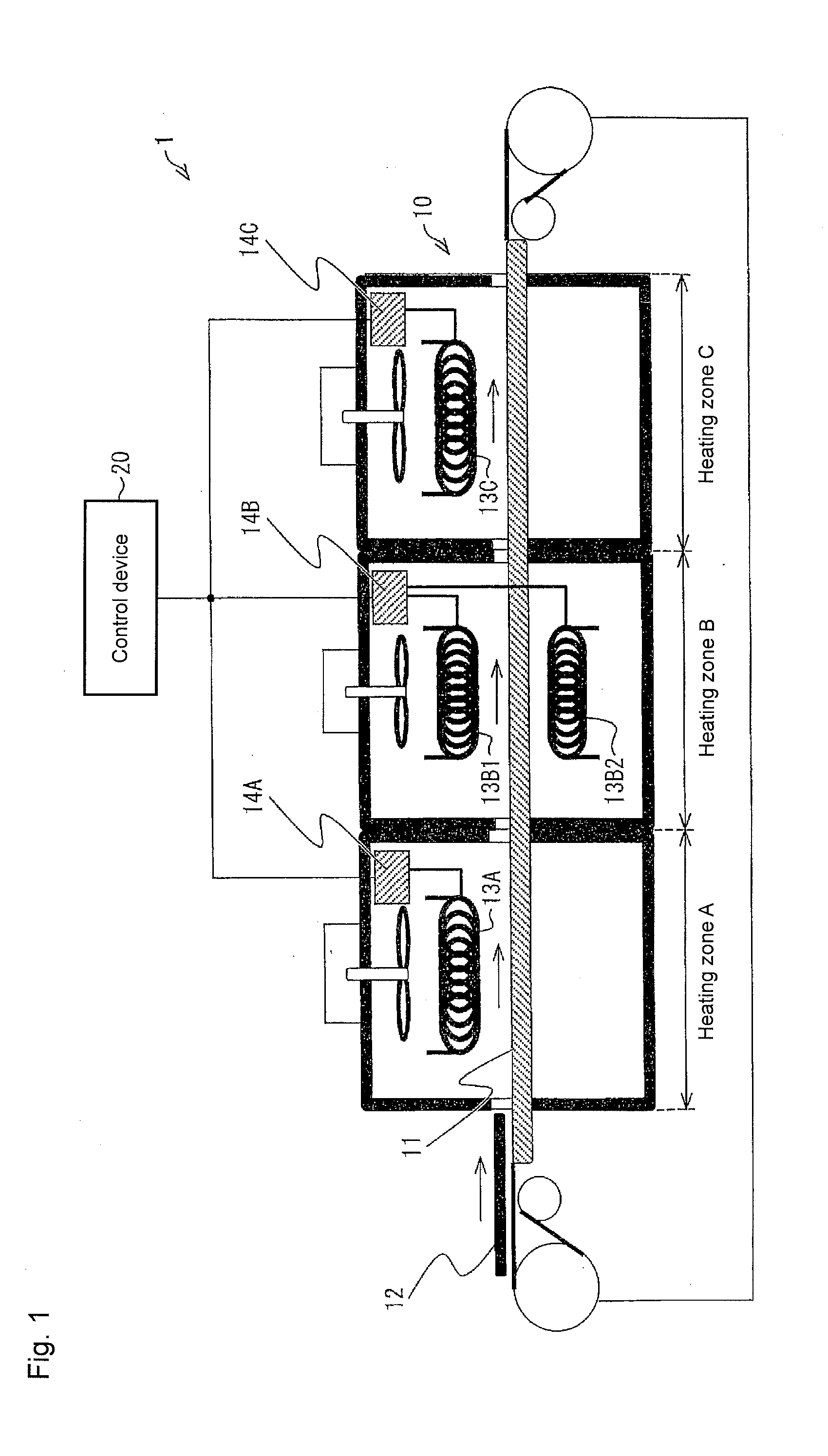

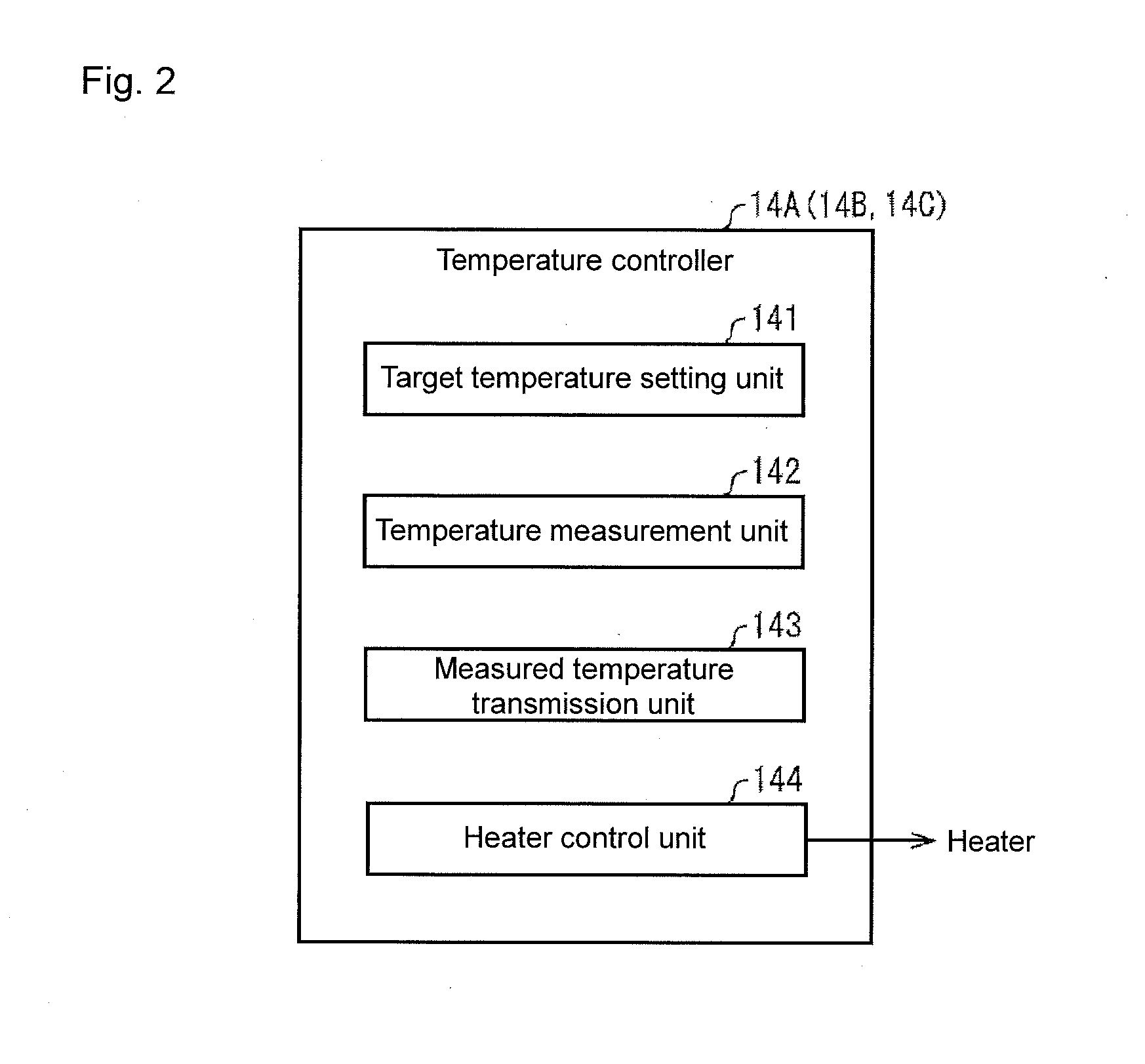

Control device, heating device control system, control method, program, and recording medium

ActiveUS20140129045A1Reduce waste generationReduce generationSoldering apparatusFurnace typesThermodynamicsControl system

A control device that controls a heating device having a plurality of heating zones, has a monitoring unit configured to monitor a temperature of at least a first heating zone in the plurality of heating zones, and a control unit configured to perform heat-up starting control, in which heat-up of at least a second heating zone is started in the plurality of heating zones, based on the temperature of the first heating zone.

Owner:ORMON CORP

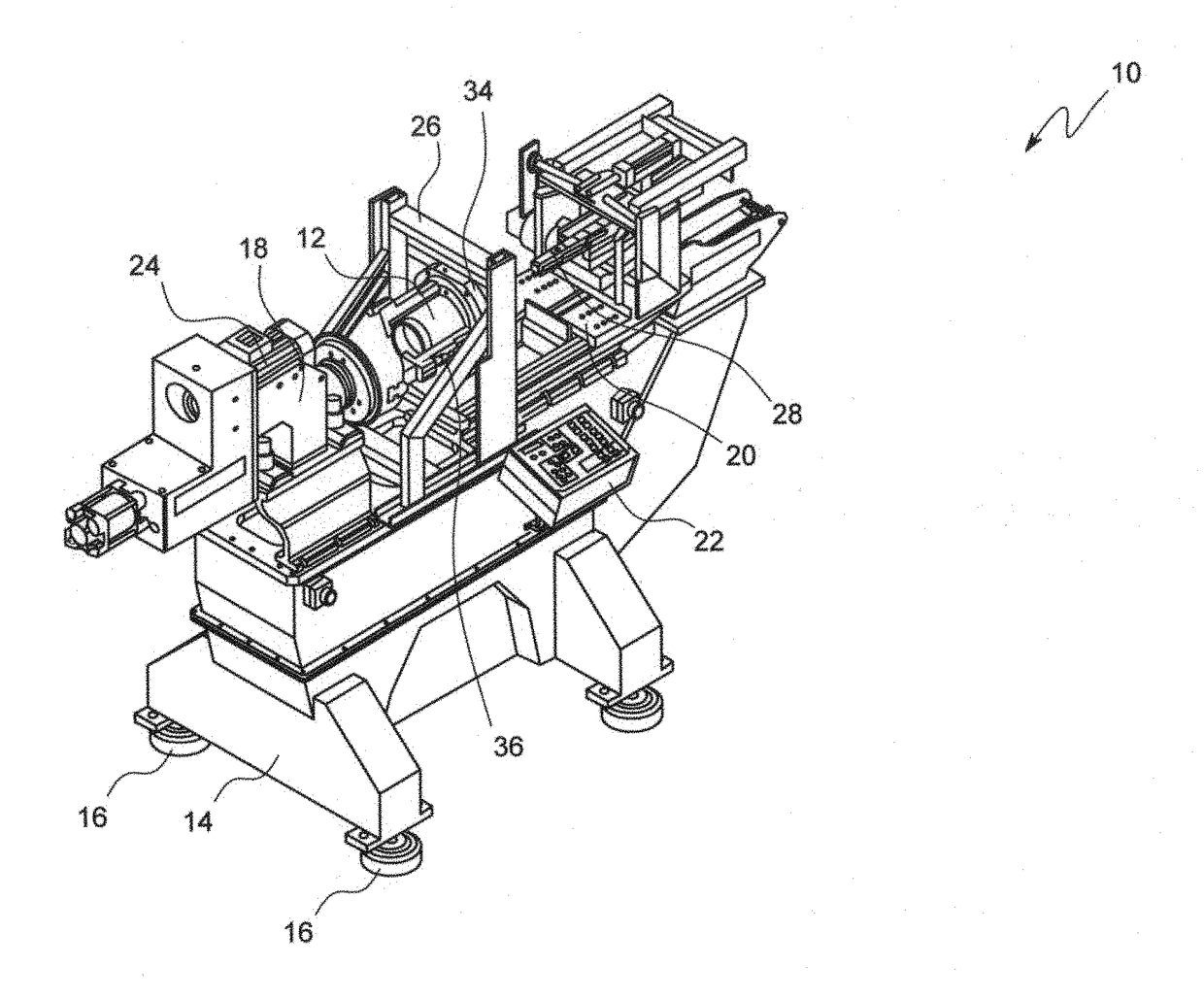

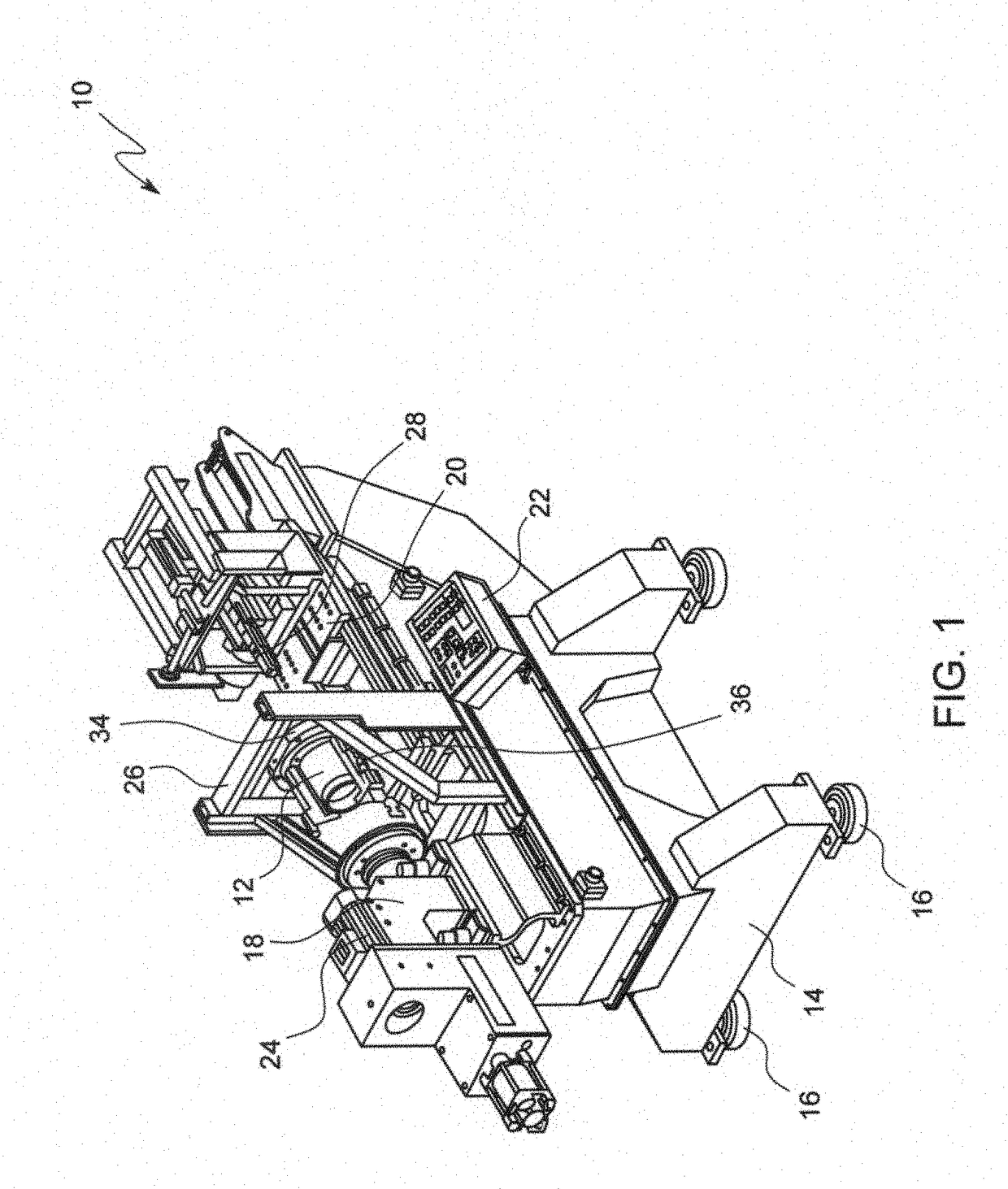

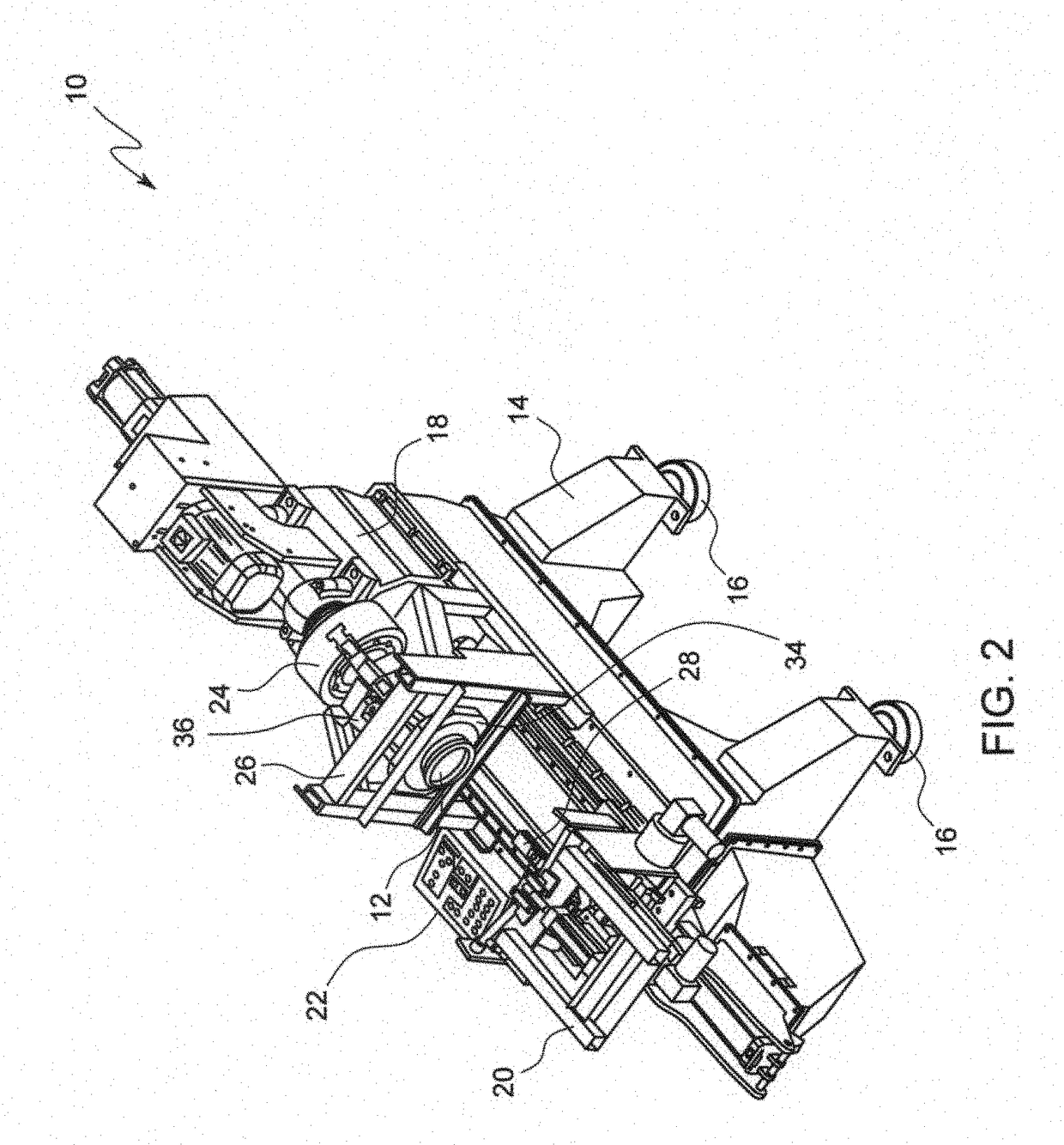

Machining apparatus and methods for performing machining operations

InactiveUS20170341151A1Reduce necessityDevoid of any trace marksAutomatic conveying/guiding stockWorkpiecesKnife bladesMachining

Disclosed is a multiple machining apparatus for, upon receiving a plastic cylindrical work piece therewithin, performing multiple machining operations thereon. The apparatus comprises a rotary fixture capable of rotation; the rotary fixture comprises a proximal means for snugly holding a proximal portion of the work piece, and a distal means for holding substantially the rest of the portion of the work piece. The apparatus further comprises a movable table comprising a blade holder for holding a plurality of blades, each of which corresponding to a machining operation, the movable table and thereby the blade holder capable movement along X, Y and Z axes. The multiple machining operations are executed as the work piece is rotated and with the blades working against the rotating work piece.

Owner:BADALIANS ANDRE HOSEPI +1

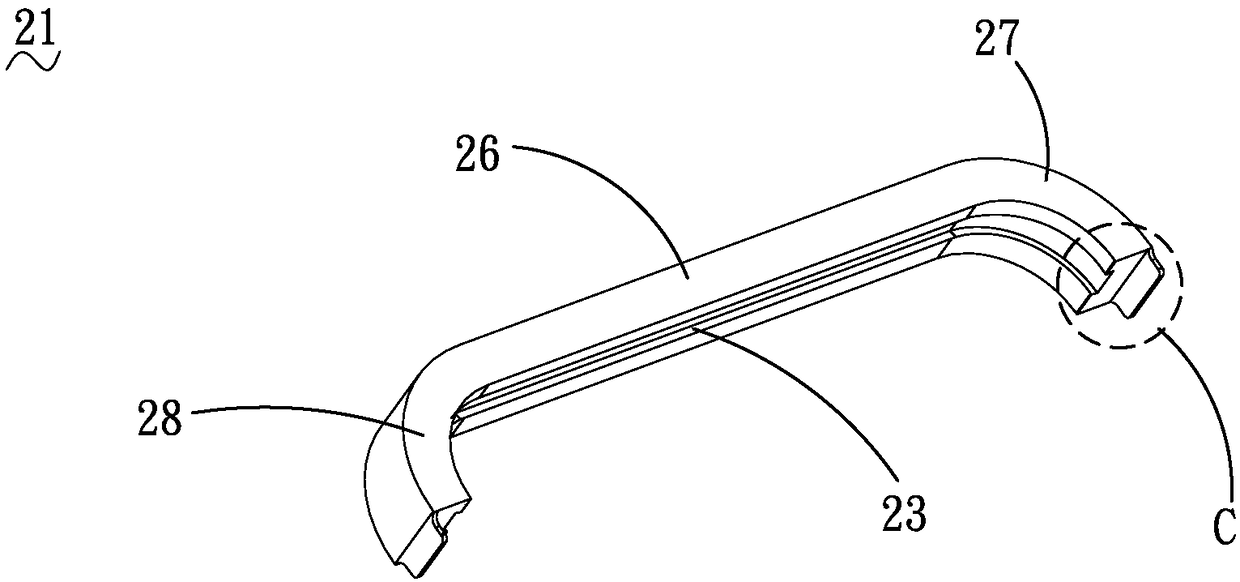

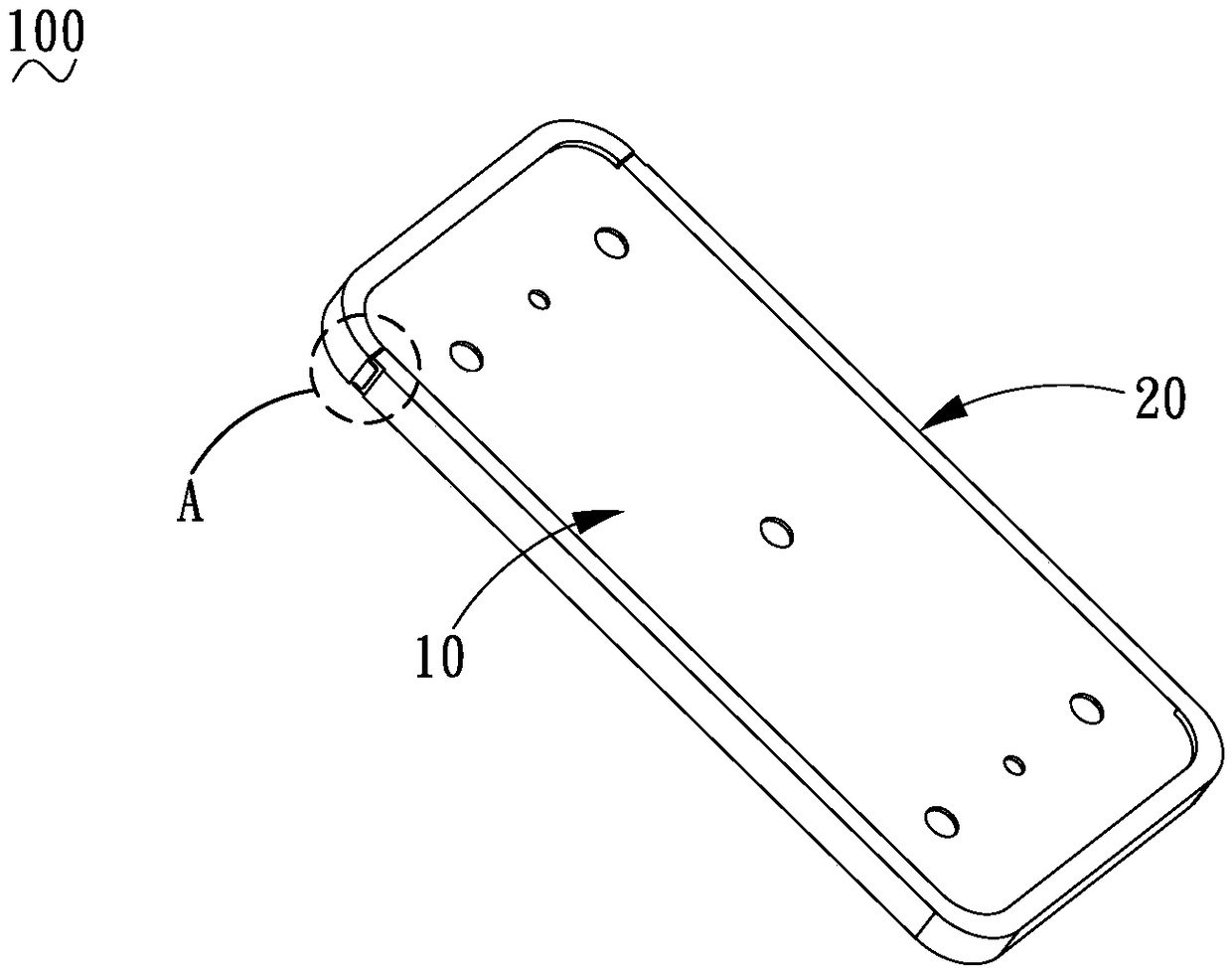

Titanium and aluminum riveted metal intermediate frame and electronic equipment

ActiveCN108289395AIncrease productivityReduce manufacturing costCasings/cabinets/drawers detailsManufacturing cost reductionTitanium

The invention relates to a titanium and aluminum riveted metal intermediate frame. The titanium and aluminum riveted metal intermediate frame comprises an intermediate plate and an edge frame, whereinthe edge frame is riveted on the intermediate plate, the intermediate plate is made of an aluminum alloy material, a convex edge is arranged at circumferential edge of the intermediate plate in a protruding way, the edge frame comprises a plurality of members, the plurality of members are sequentially connected in an end-to-end way, each member is made of a titanium alloy material, the hardness of the member is larger than the hardness of the intermediate plate, the members are all riveted at the circumferential edge of the intermediate plate, a clamping groove is formed in an inner side of each member and is connected with the convex edge, the intermediate plate is deformed by laminating an outer side surface of the edge frame so as to achieve riveting between the convex edge and the clamping grooves. Meanwhile, the invention also provides electronic equipment comprising the titanium and aluminum riveted metal intermediate frame. The titanium and aluminum riveted metal intermediate frame has the beneficial effects that the intermediate plate made of titanium alloy and the edge frame made of titanium alloy are riveted by lamination and deformation, the production efficiency is improved, and the manufacturing cost is favorably reduced.

Owner:GUANGDONG EVERWIN PRECISION TECH

Image forming apparatus and image forming method

InactiveUS7502572B2Reduce waste generationElectrographic process apparatusImage formationEngineering

It is an object of the invention to provide an image forming apparatus and an image forming method that can reduce generation of a waste toner.An image forming apparatus according to the invention includes an image bearing member on which a toner image is formed, a cleaner that transfers a toner image formed on the surface of the image bearing member and, then, removes a part of a toner remaining on the image bearing member and allows the remainder to pass as a passing toner, a passing toner amount detecting unit for detecting or estimating an amount of passing toner that passes the cleaner, and a cleaner control unit that sets, on the basis of an amount of passing toner detected by the passing toner amount detecting unit, a target value of the amount of passing toner and controls a cleaning operation by the cleaner.

Owner:KK TOSHIBA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com