Patents

Literature

349 results about "Waste generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

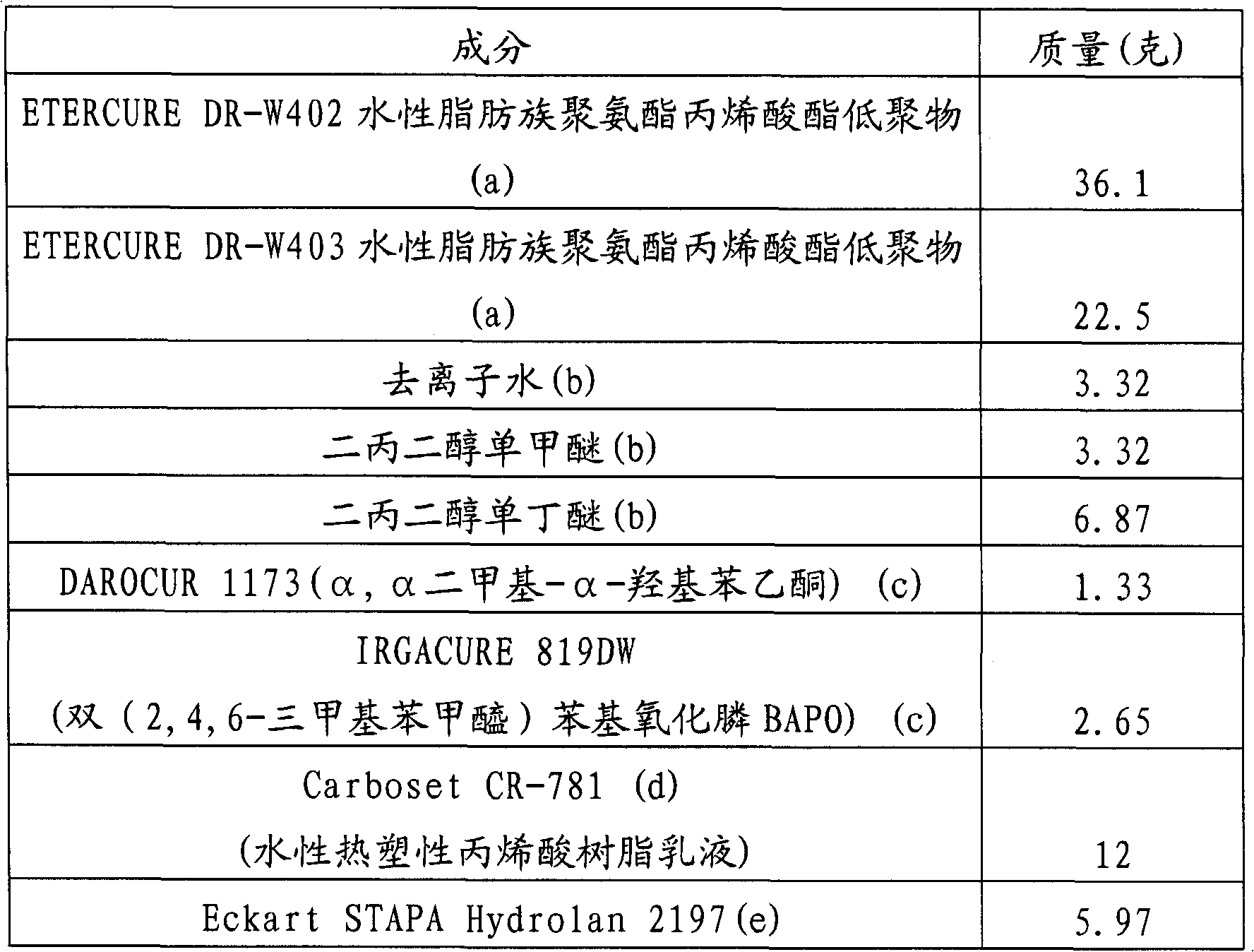

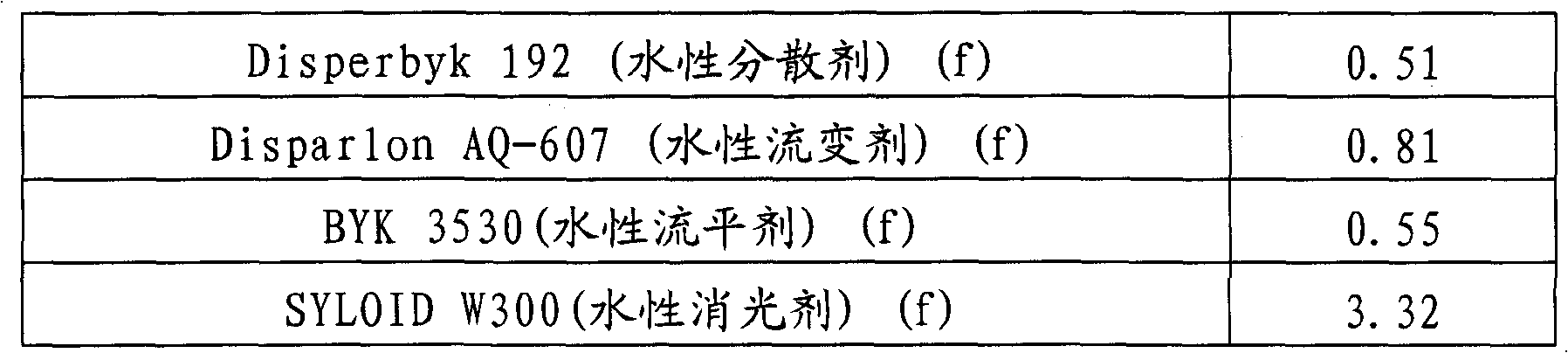

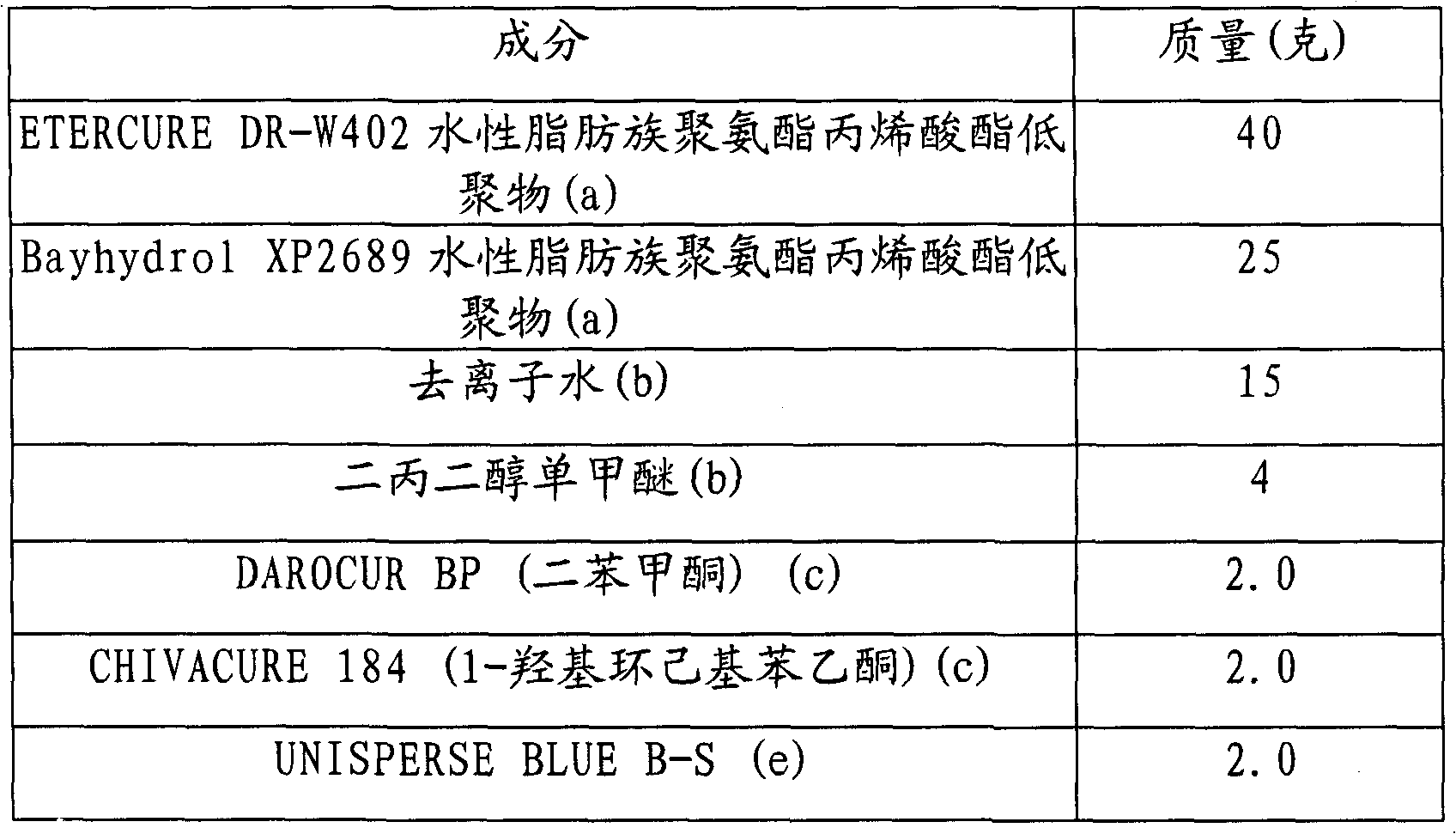

Ultraviolet-curable water-based colored paint composition

Owner:CHUANGXING FINE CHEM SHANGHAI

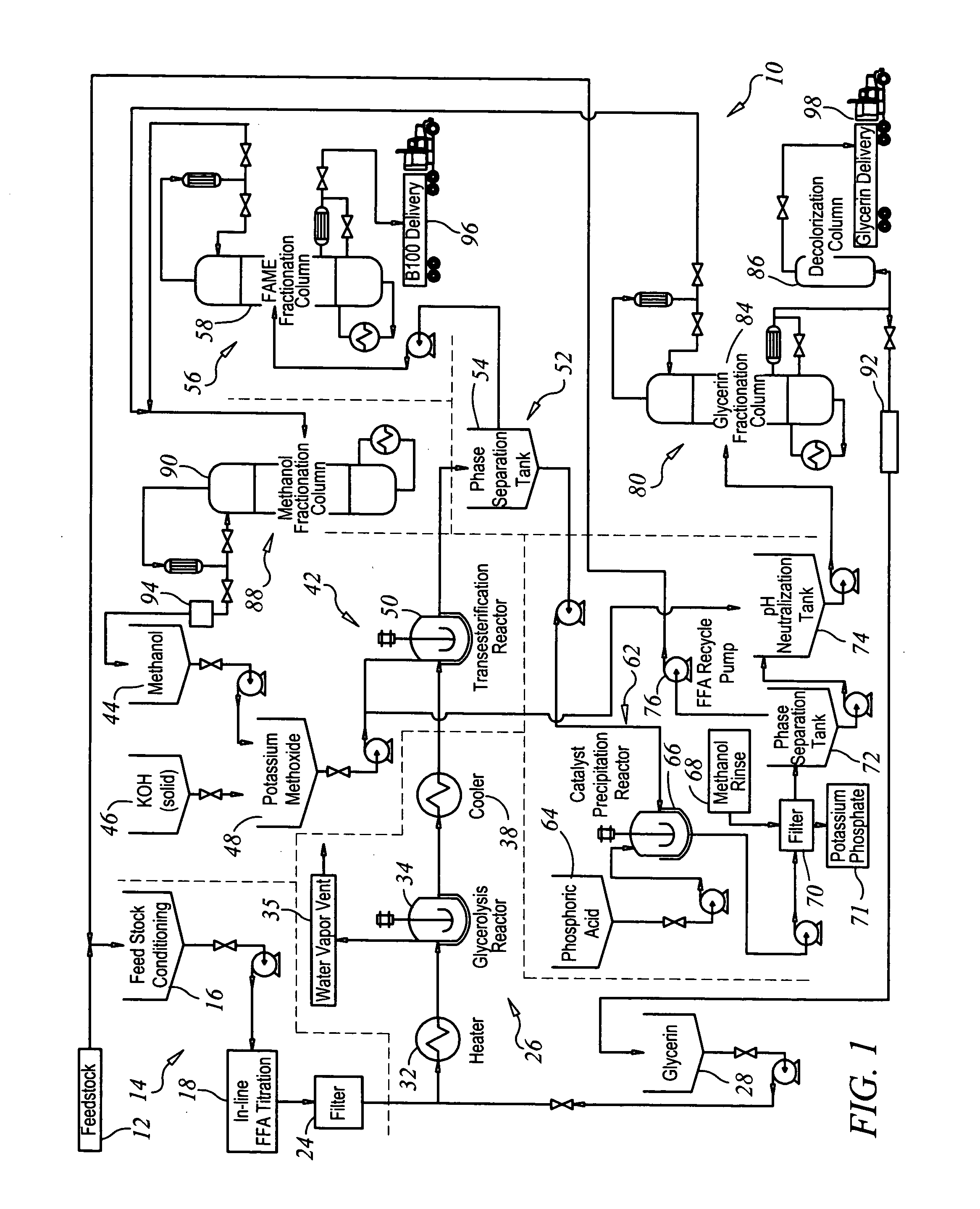

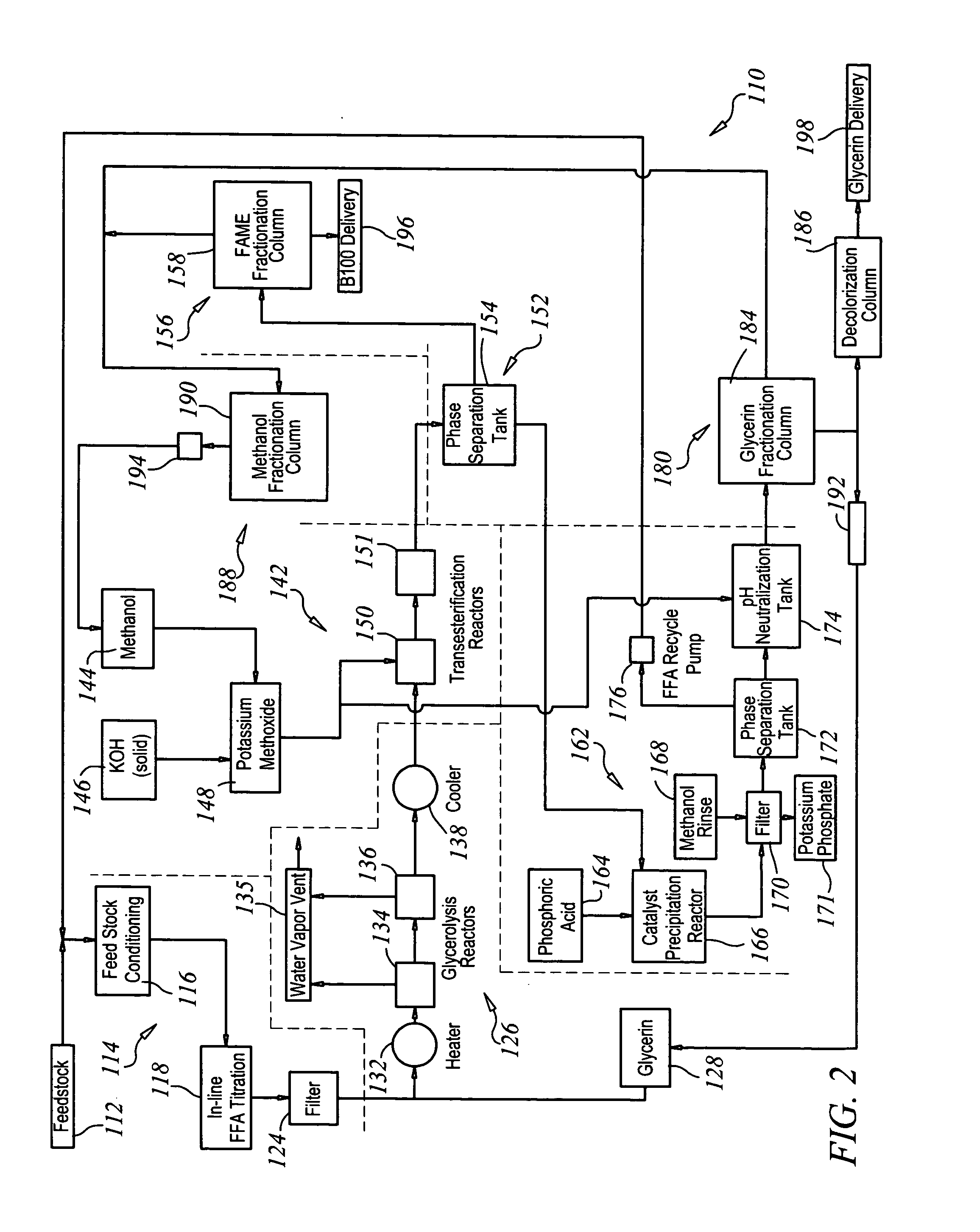

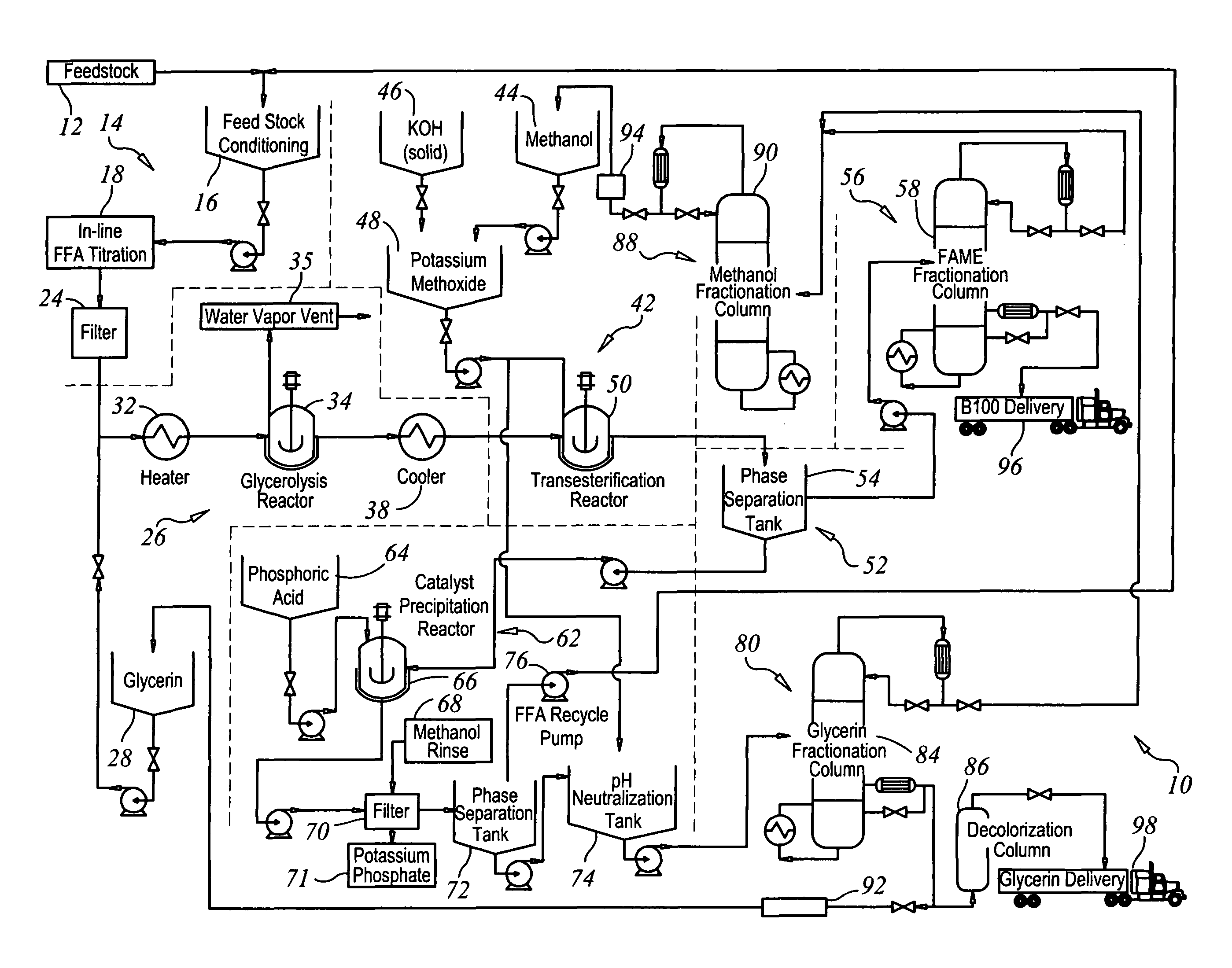

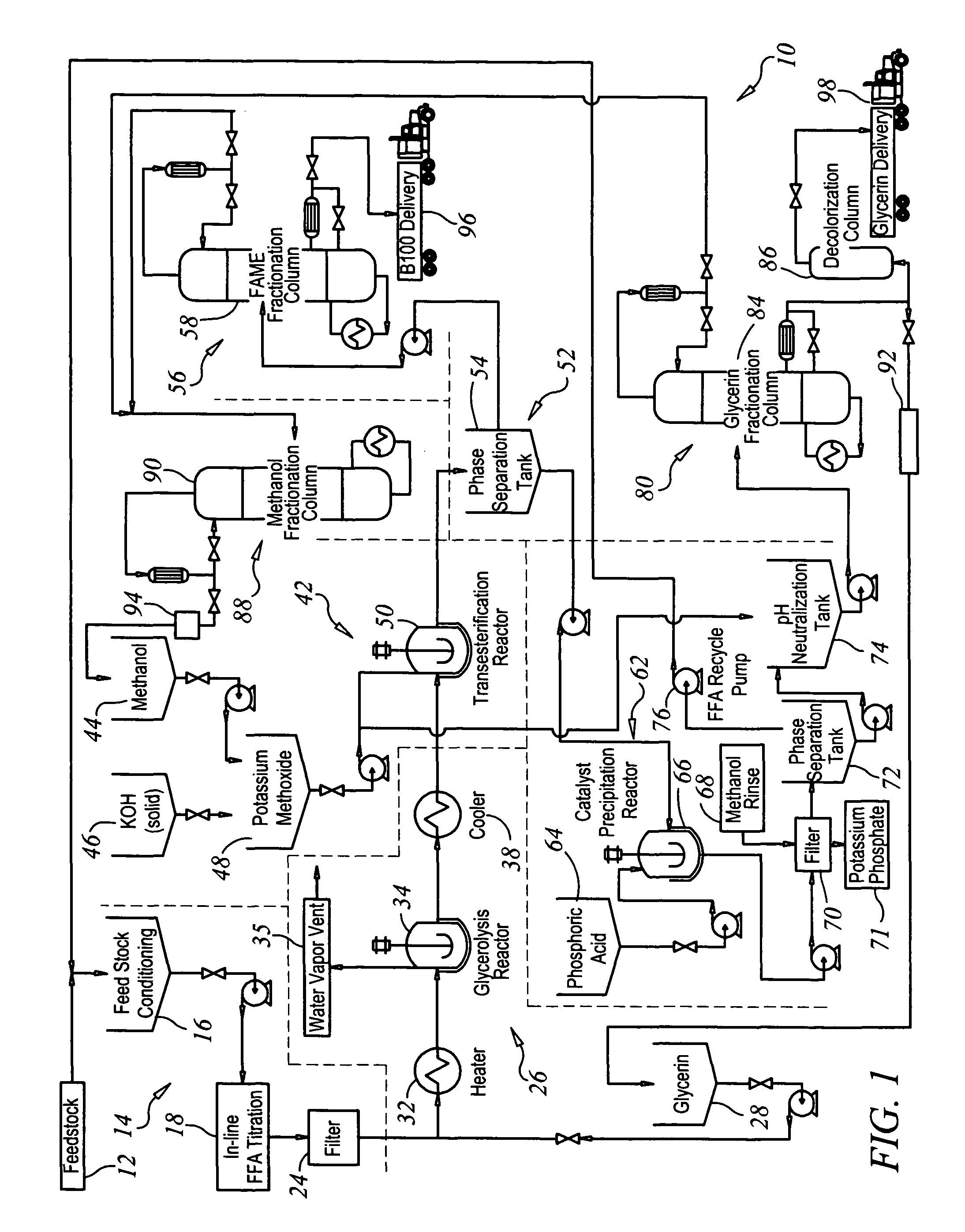

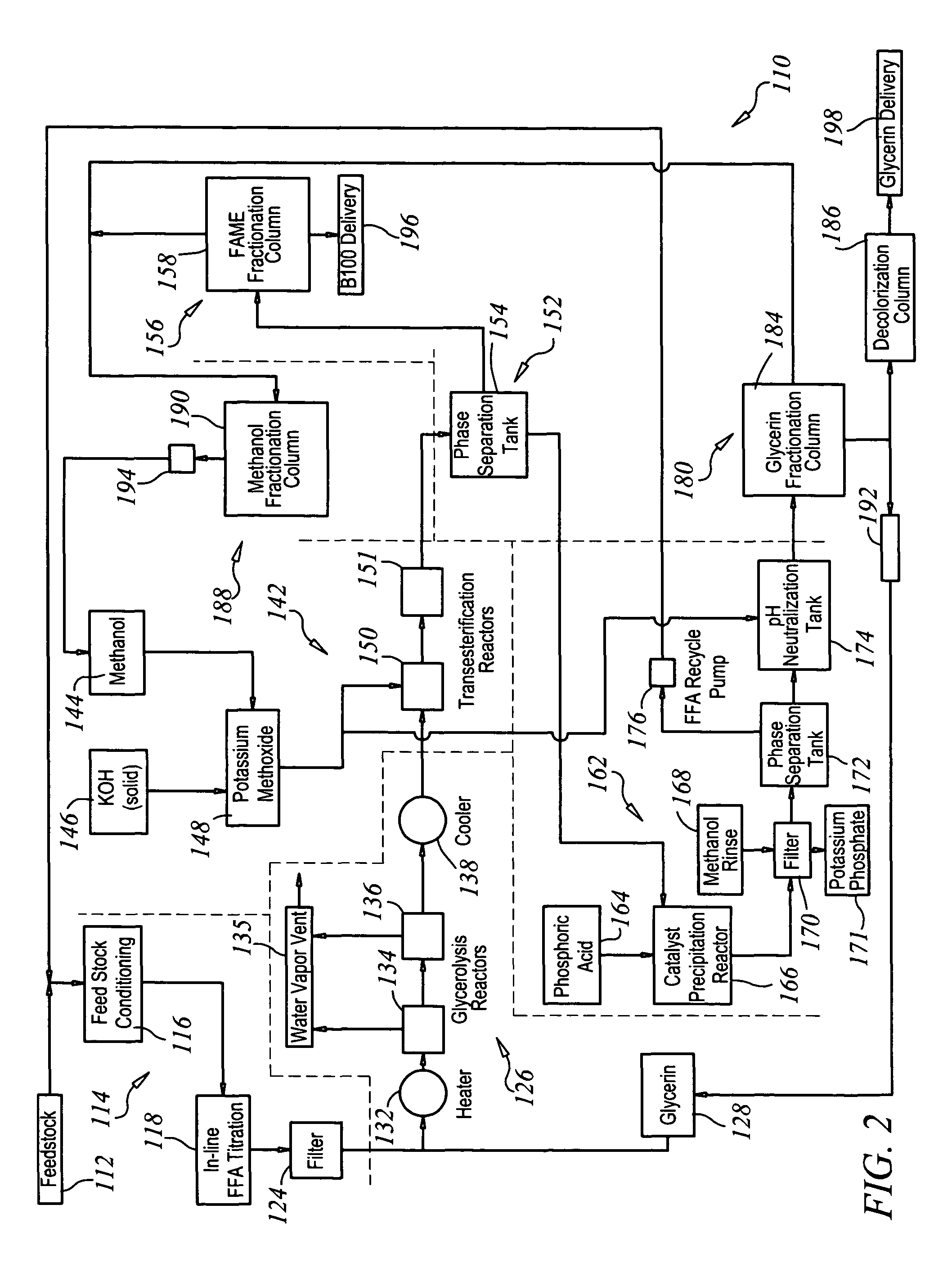

Production of biodiesel and glycerin from high free fatty acid feedstocks

ActiveUS20070277429A1Increase wasteLow costFatty oils/acids recovery from wasteFatty acid esterificationGlycerolGlycerolysis

A system and method for converting a high free fatty acid grease feedstock to biodiesel. The process comprises a glycerolysis reaction to convert free fatty acids to glycerides and a base catalyzed transesterification reaction to produce fatty acid methyl esters and glycerin in the absence of solvents. In preferred embodiments, both glycerin and methanol are recycled. The process can process a feedstock containing up to 100 percent free fatty acid content to produce biodiesel and glycerin with minimal waste generation.

Owner:REG SENECA LLC +1

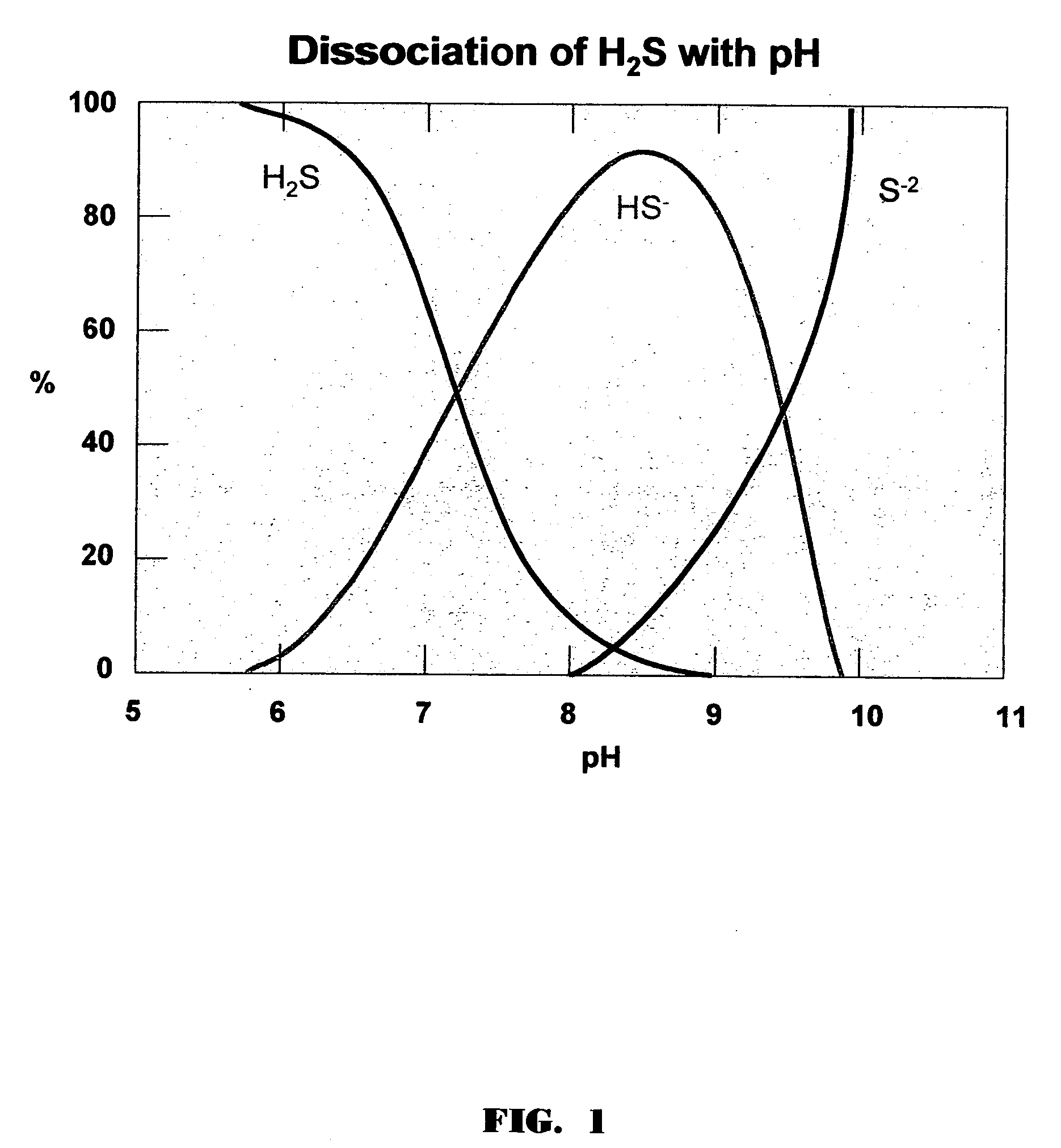

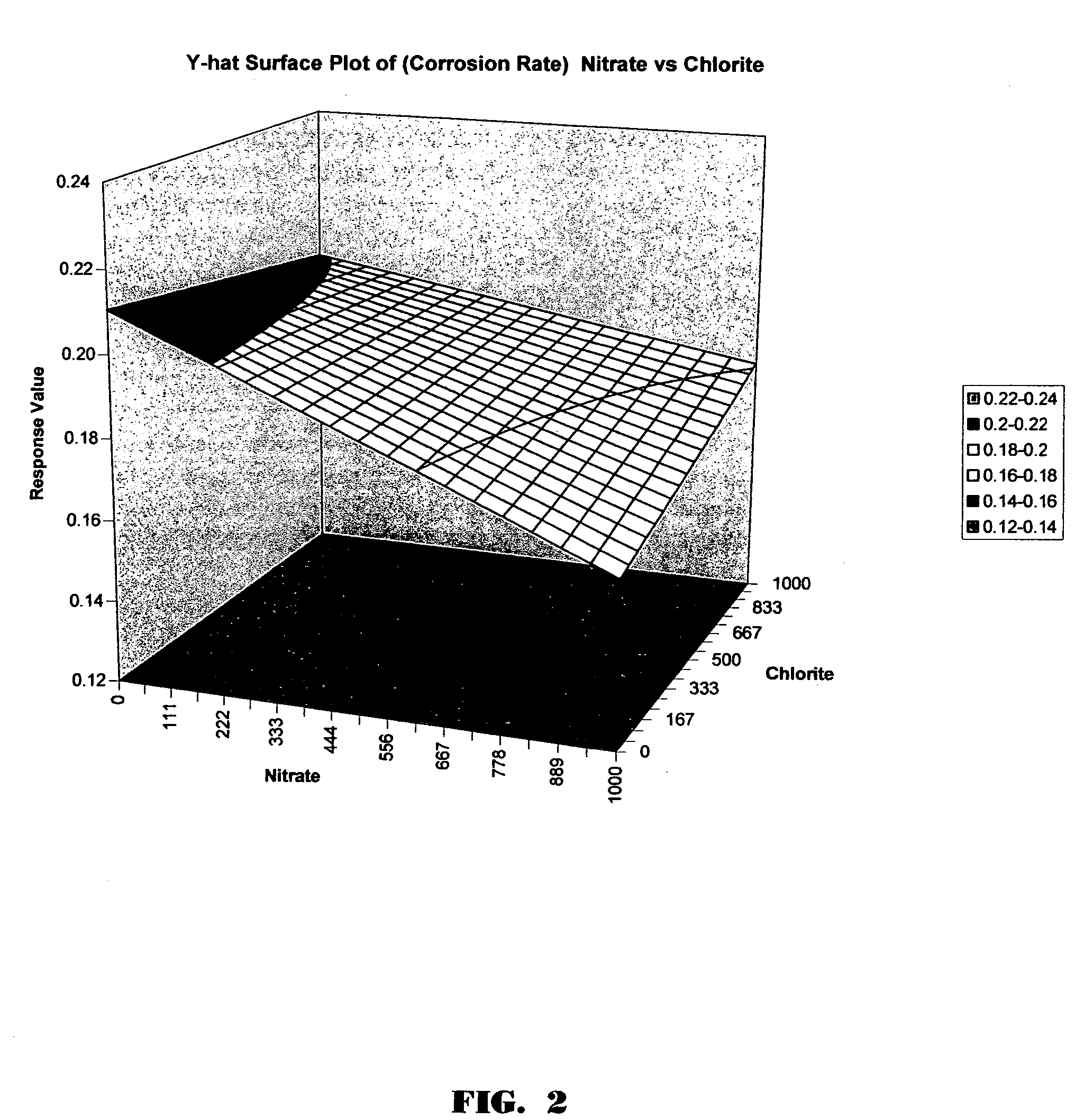

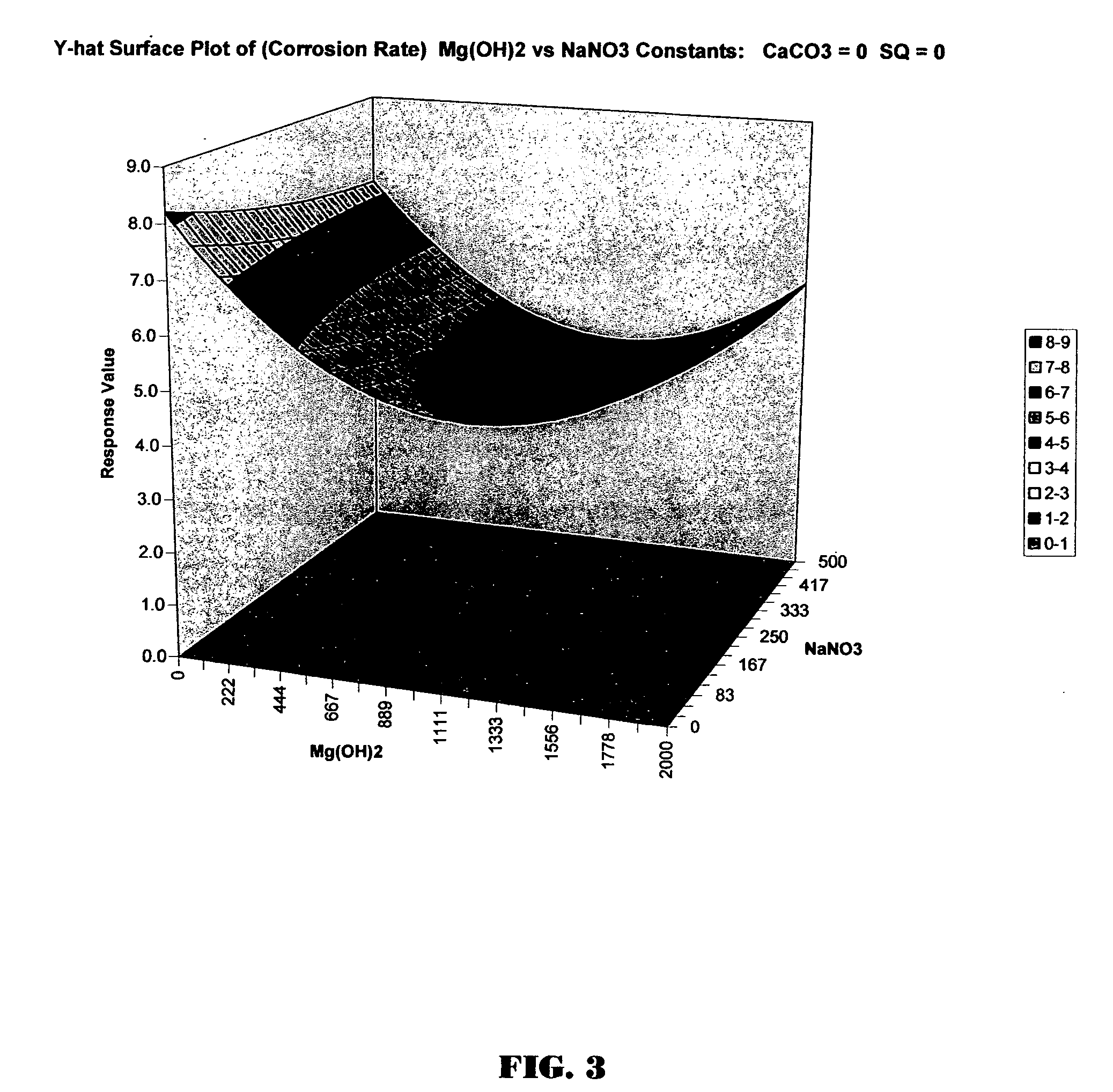

Synergistic composition and method for odor control

InactiveUS20060006121A1Improve dehydration effectEasy to controlSpecific water treatment objectivesWater/sewage treatment by neutralisationWaste streamVolatile fatty acids

A synergistic composition and method is provided for controlling odor from waste products. The composition comprises a combination of magnesium hydroxide and a sulfide-consuming compound. The method includes adding a sufficient amount of the composition to a waste stream to provide sufficient sulfide-consuming compound to effect immediate removal of sulfide. The composition incorporates a pH elevating and buffering compound, which both increases and buffers the pH. The increased pH serves to reduce both the volatile sulfide species and the volatile fatty acid (VFAs) species. The elevated pH also promotes the growth of naturally occurring bacteria which metabolize the sulfide to an innocuous form. Finally, addition of the composition drives the pH into a range where the growth of sulfide producing bacteria is inhibited. The mixture has surprisingly been found to be synergistic with respect to both control of chemical species that produce odors and corrosion of metals commonly found in sludge dewatering equipment.

Owner:SIEMENS WATER TECH CORP

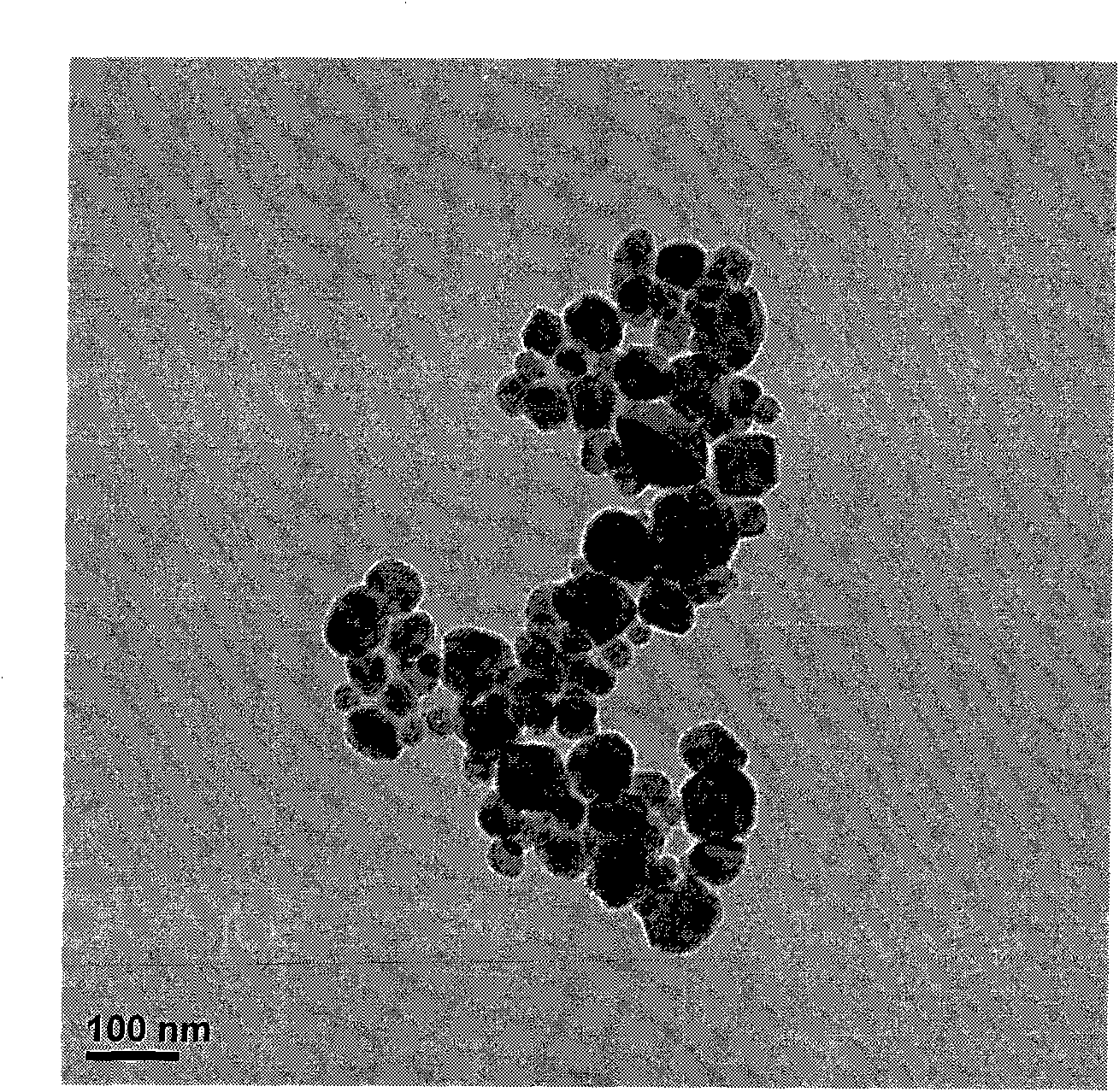

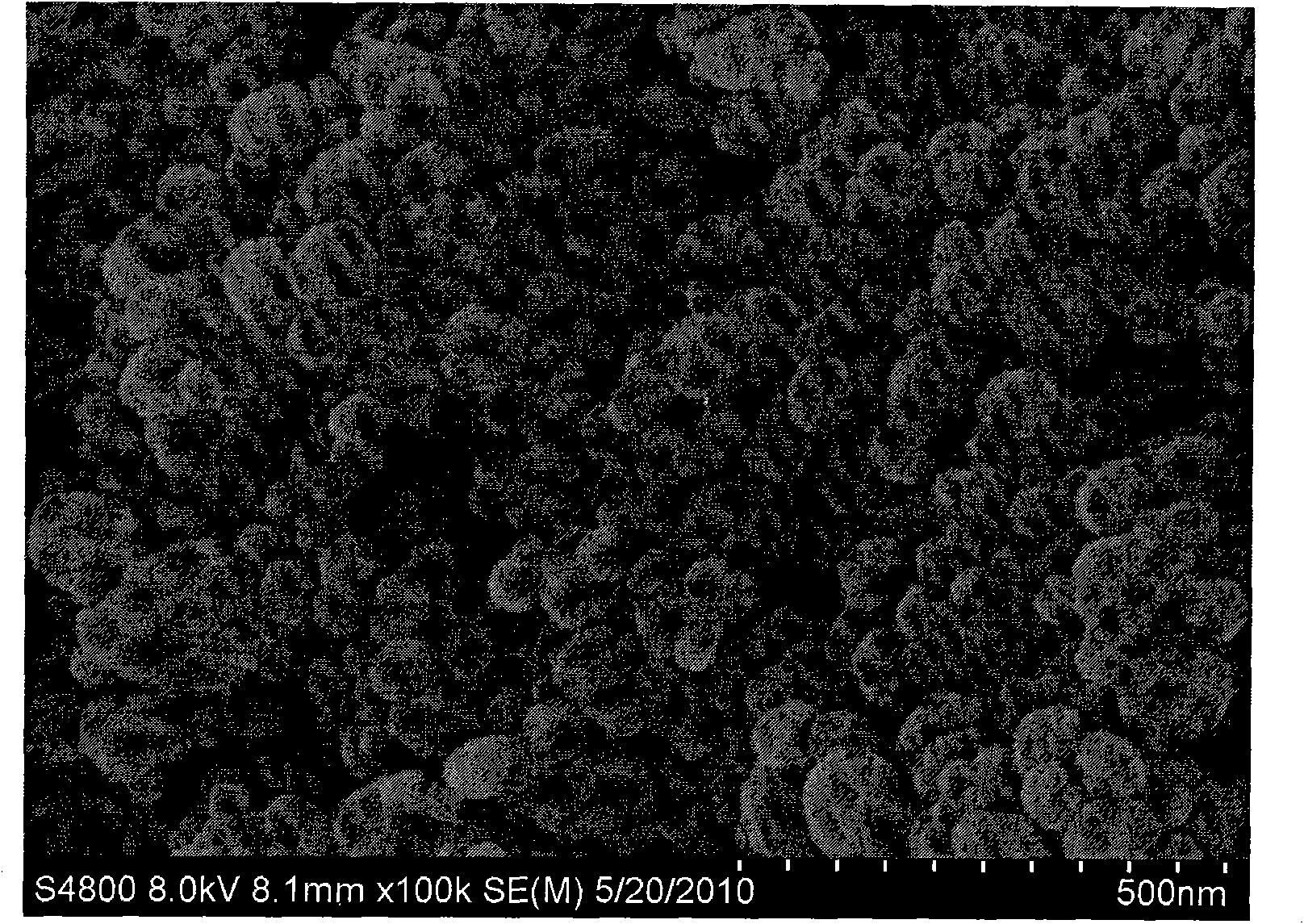

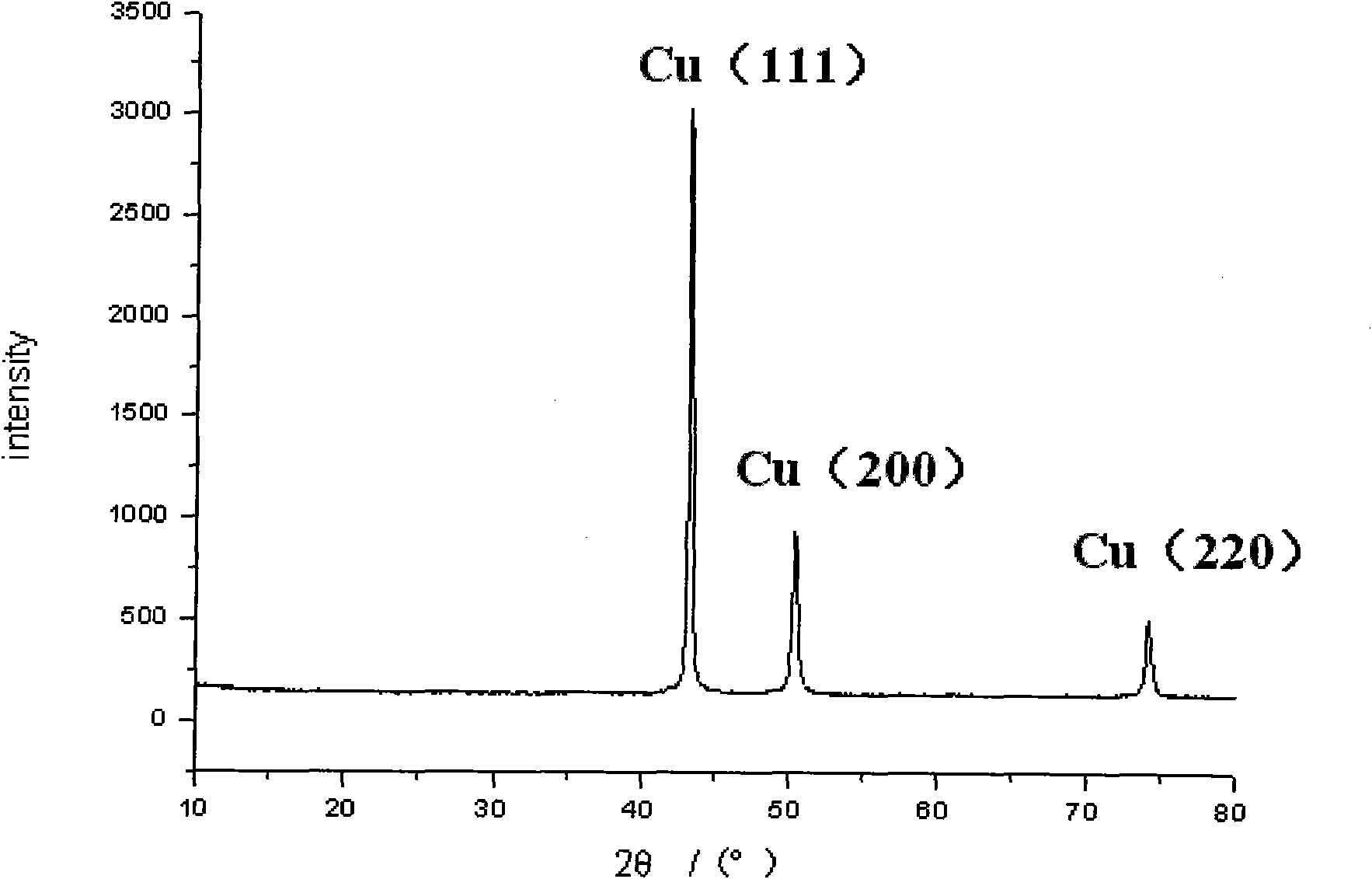

Method for preparing nano copper conductive ink

ActiveCN101880493AGood dispersionCharacteristic peaks are obviousInksNon-conductive material with dispersed conductive materialOrganic solventRoom temperature

The invention discloses a method for preparing nano copper conductive ink, which can be applied in the field of printing electronic technology, in particular ink jet printing technology. The preparation method comprises the following steps of: dissolving copper salt and protective agent into a solvent, heating and stirring the solution, adding a small amount of alkali solution to adjust the pH ofthe solution to between 7 and 10, dripping a reducing agent into the solution, continuously stirring the solution to react for 30 to 60 minutes, and then cooling the reaction solution to room temperature to obtain nano copper dispersion; performing centrifuging, washing and vacuum drying at room temperature on the nano copper dispersion to obtain nano copper granules; and dispersing the nano copper granules into an organic solvent, and ultrasonically treating the solution to obtain the nano copper conductive ink. The method solves the problems of complex preparation process and long preparation period in the prior art, has the advantages of simple and convenient operation, low production cost, short flow and no harmful waste generation, and realizes the goals of environmental protection and economy; and the prepared nano copper conductive ink has good dispersion property and high stability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for stabilizing heavy metal bearing waste in a waste generation stream

InactiveUS6050929AReduce solubilityReduce LeachabilitySolid waste disposalRadioactive decontaminationWaste treatmentHazardous waste

Heavy metal bearing products during production, processing and / or handling, and / or in landfills, storage or retention areas are stabilized prior to the generation or management as a waste by applying heavy metal stabilizing agents into the product stream thus avoiding complex and costly processing and treatment of waste under hazardous waste regulations.

Owner:FORRESTER KEITH EDWARD

Production of biodiesel and glycerin from high free fatty acid feedstocks

ActiveUS7806945B2Increase wasteQuality improvementFatty oils/acids recovery from wasteFatty acid esterificationGlycerolSolvent

A system and method for converting a high free fatty acid grease feedstock to biodiesel. The process comprises a glycerolysis reaction to convert free fatty acids to glycerides and a base catalyzed transesterification reaction to produce fatty acid methyl esters and glycerin in the absence of solvents. In preferred embodiments, both glycerin and methanol are recycled. The process can process a feedstock containing up to 100 percent free fatty acid content to produce biodiesel and glycerin with minimal waste generation.

Owner:REG SENECA LLC +1

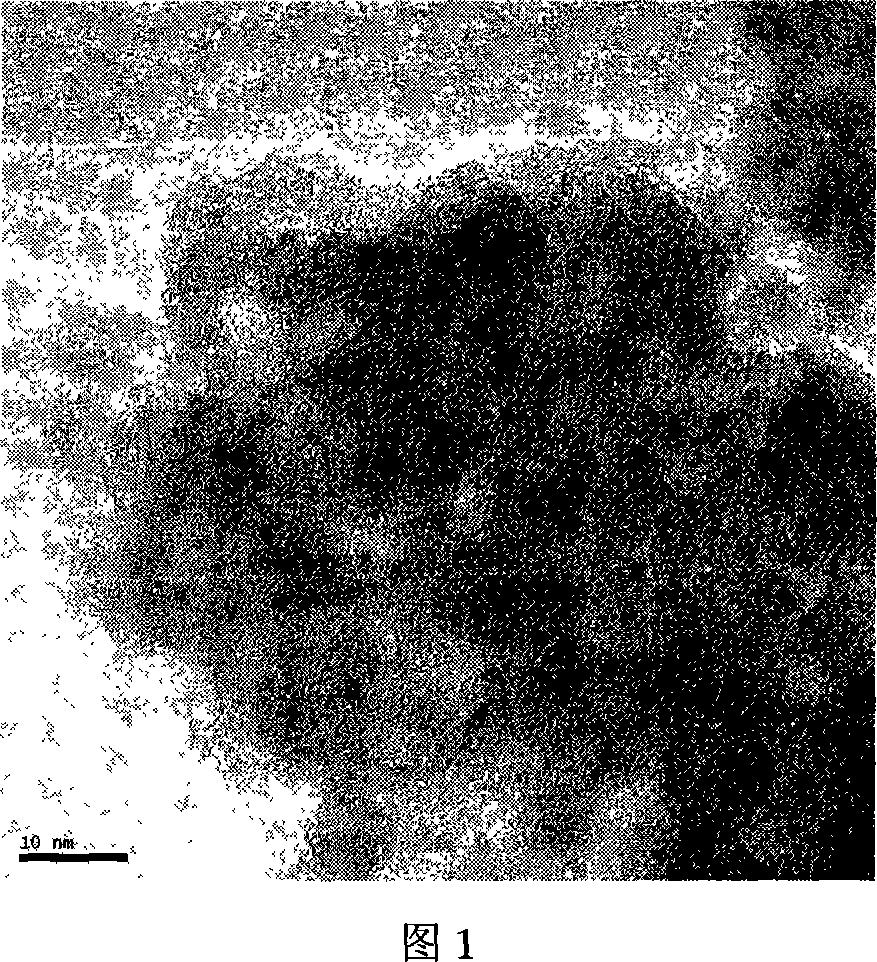

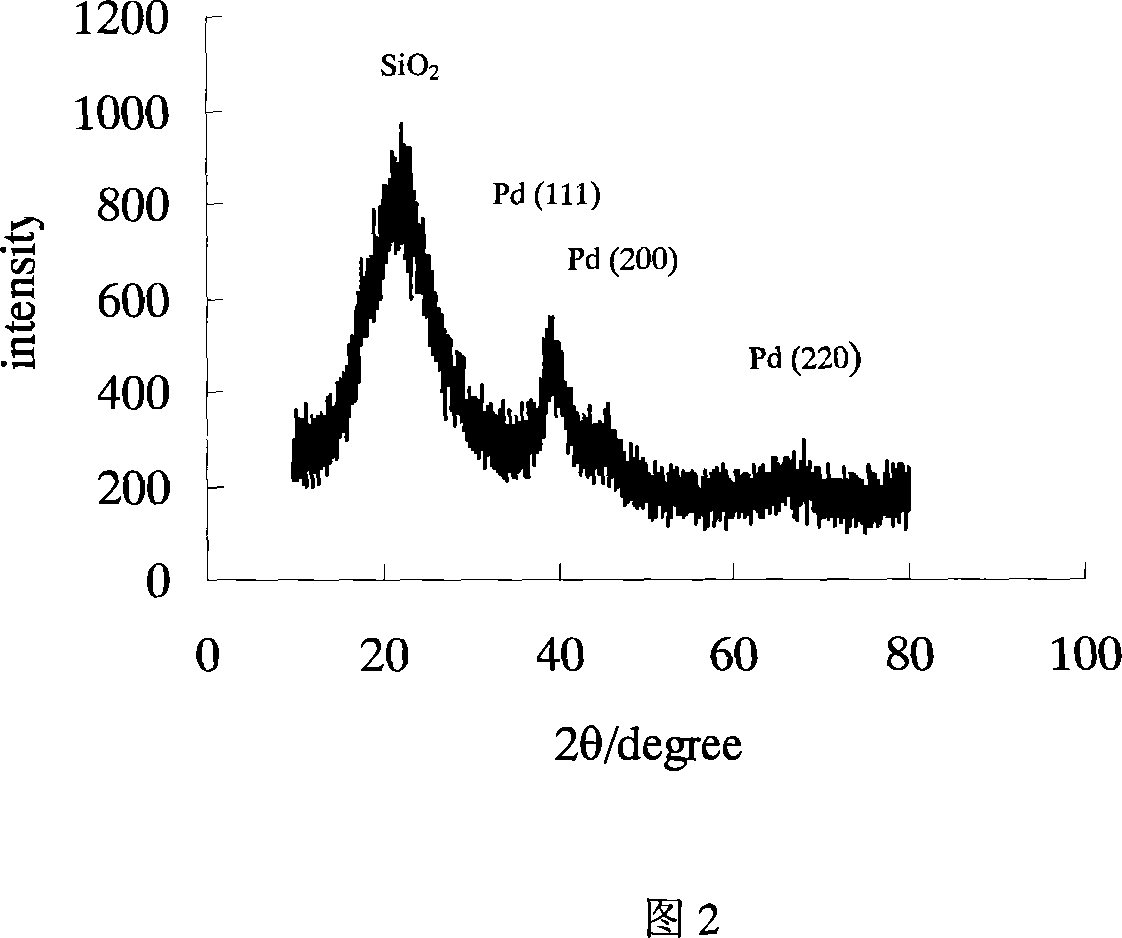

Solid carried ion liquid-nanometer metal particle catalyst, and its preparing method, and application in synthesis of arylamine

InactiveCN101045213AAvoid churnNot easy to eluteOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsNitro compoundMetal particle

A catalyst carrying ionic liquid and metallic nanoparticles for preparing high-quality arylamine by hydrocatalyzing aromatic nitro compound is prepared through preparing immobilized ionic liquid by bonding the ionic liquid onto carrier, binding it with the active component containing transition metal or precursor, and reductive exchange. Its advantages are low reaction temp, long service life and no waste generation.

Owner:SHAANXI NORMAL UNIV

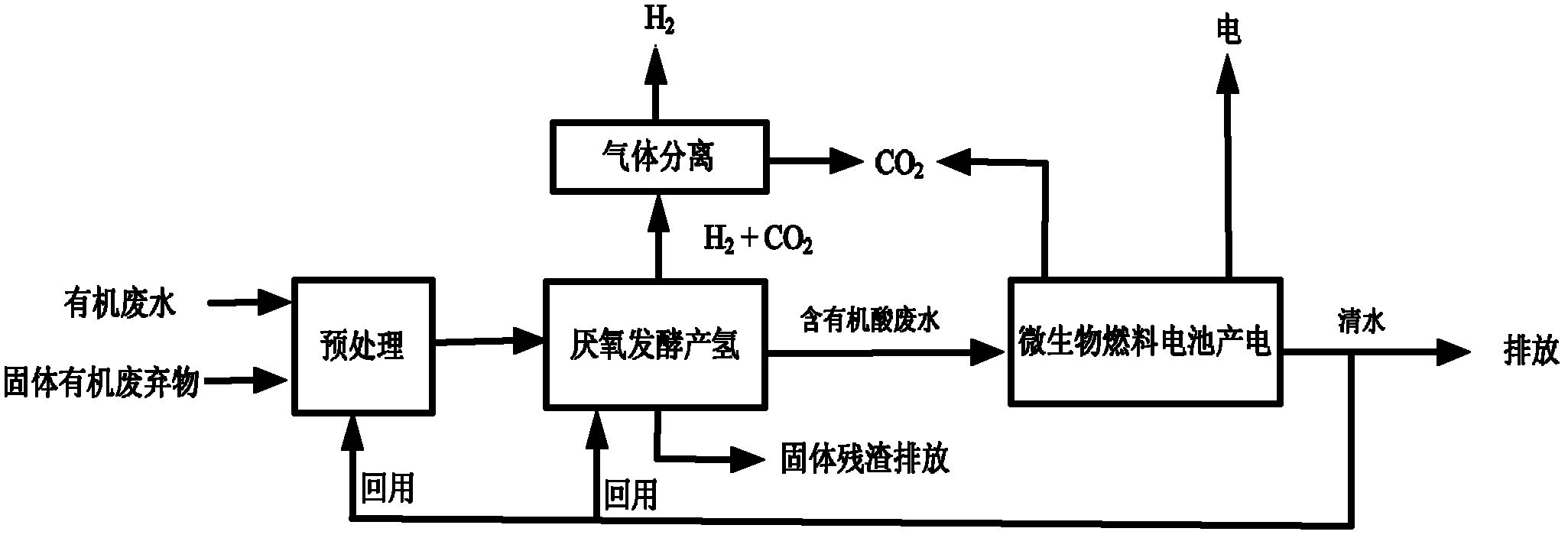

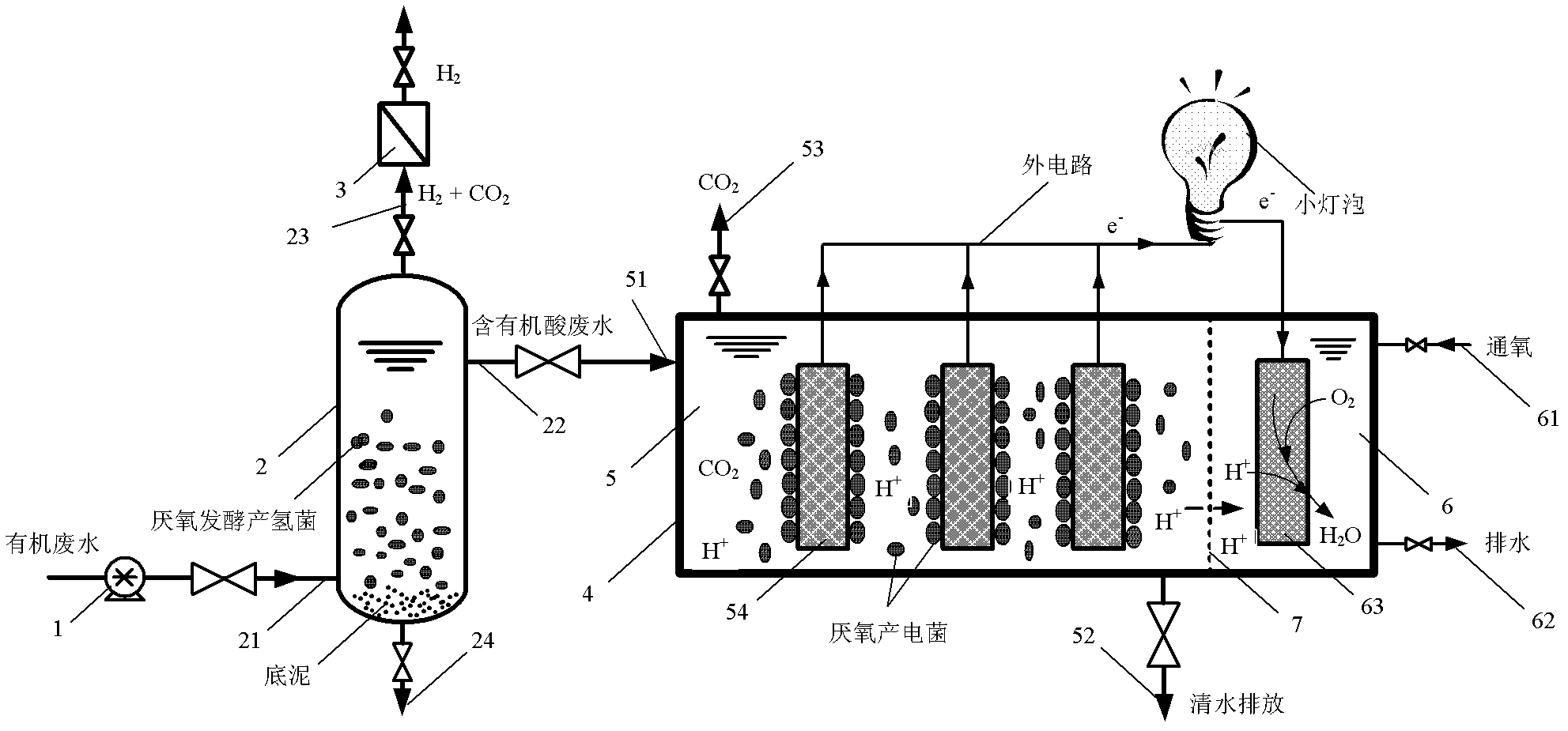

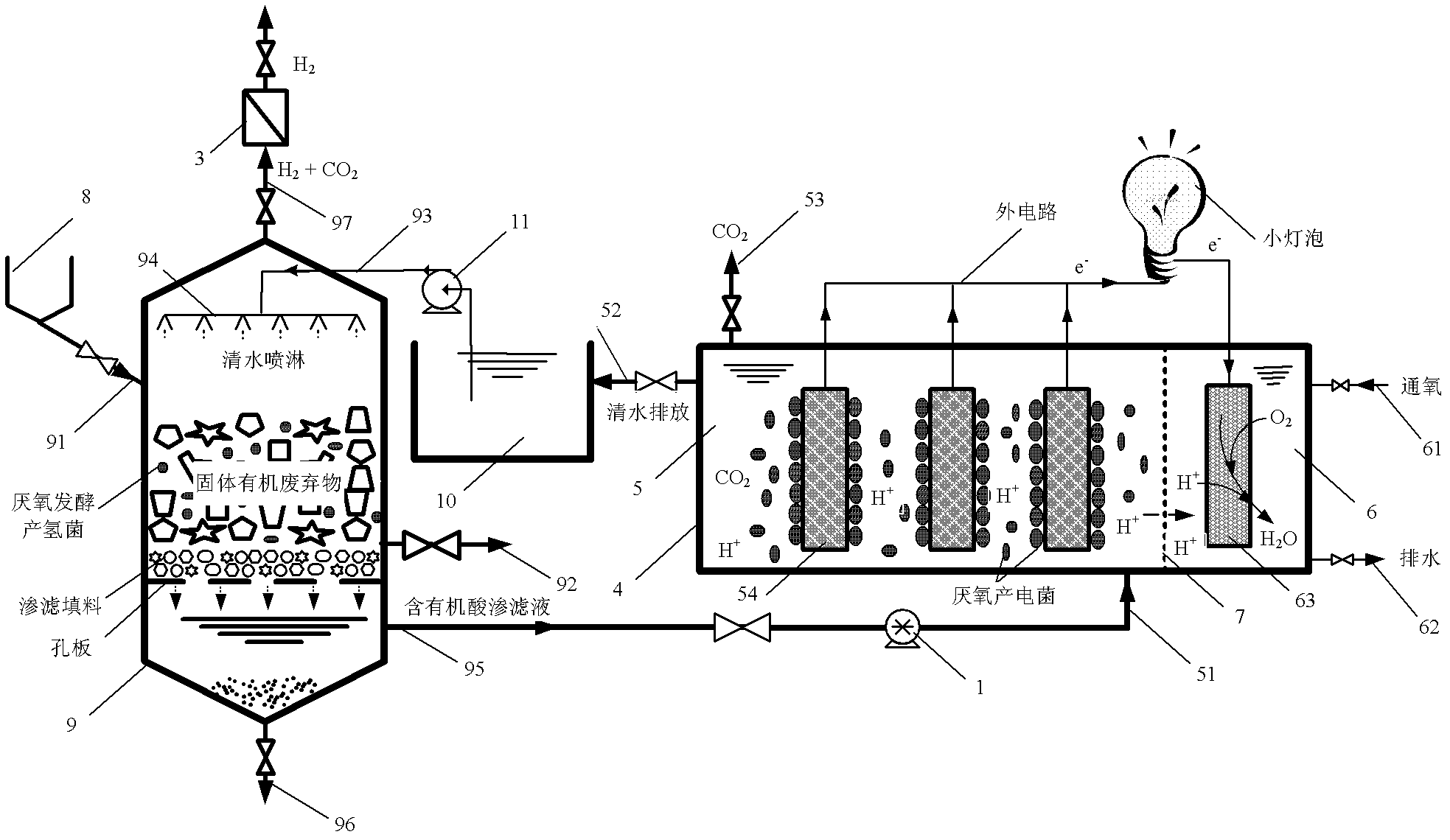

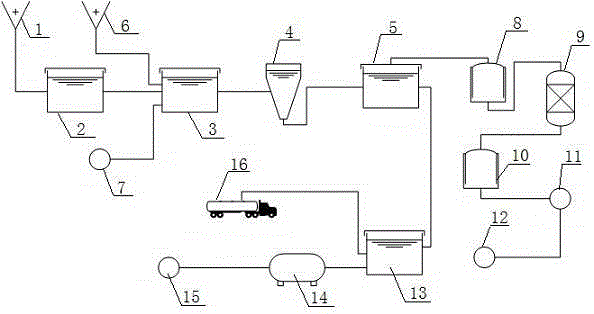

A method and device for co-producing hydrogen and electricity from organic waste

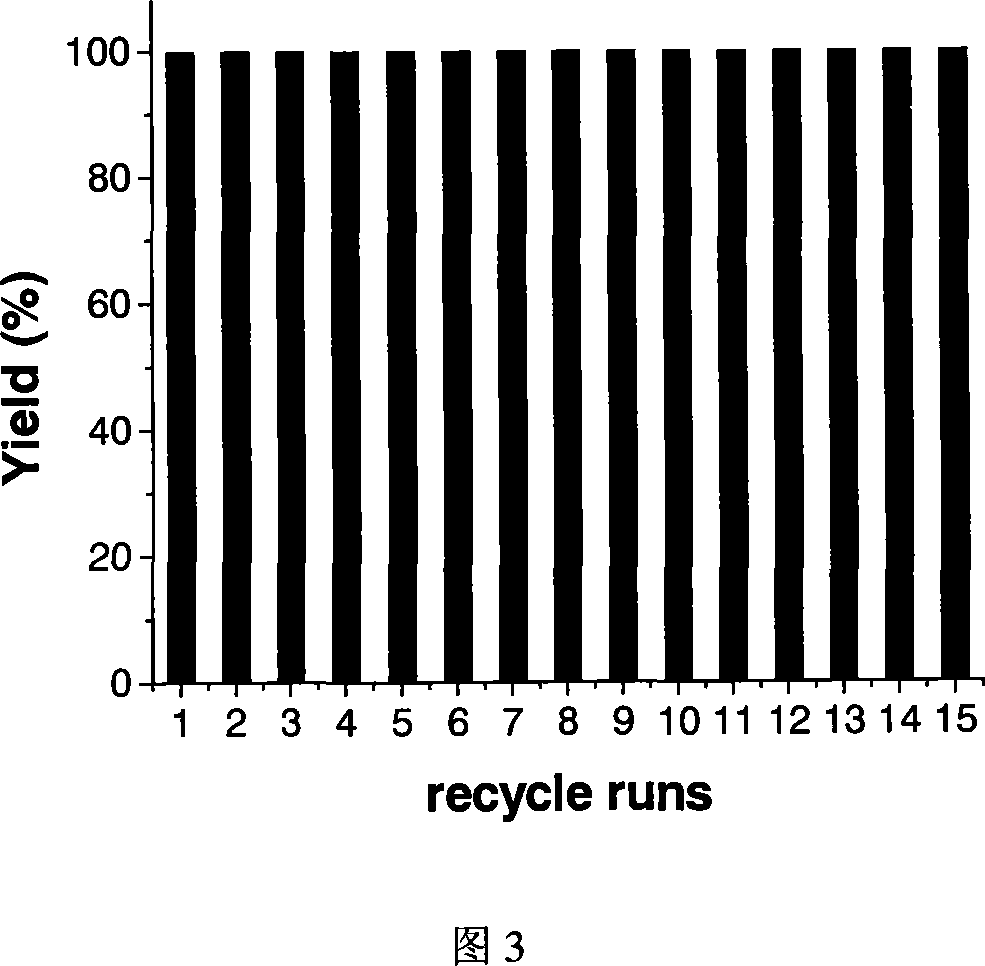

ActiveCN102277388AIncrease profitHigh recovery rateBioreactor/fermenter combinationsGas production bioreactorsEnergy recoveryFood processing

The invention provides a coproduction method and device of hydrogen and electricity by organic wastes. The method comprises the following steps: (1) strain preparation and raw material pretreatment; (2) hydrogen production by anaerobic fermentation; (3) electricity generation by microbial fuel cell; and (4) clear water recycle or discharge. The device comprises a feed device, an anaerobic hydrogen-producing reactor and a microbial fuel cell which are communicated sequentially, wherein the water outlet of the anaerobic hydrogen-producing reactor is communicated with the water inlet of an anode chamber of the microbial fuel cell. According to the method and the device, the energy recovery rate of organic waste can be improved, further treatment of the organic waste can be realized. The method and the device are suitable for treating various organic waste water and solid organic wastes, including but not limited to organic acid waste water, sugar making waste water, starch waste water, wine brewing waste water, food processing waste water and residues, kitchen wastes, fruit and vegetable wastes and crop straws. By the application of the method and device, environmental governance and clean renewable energy source development can be effectively combined.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

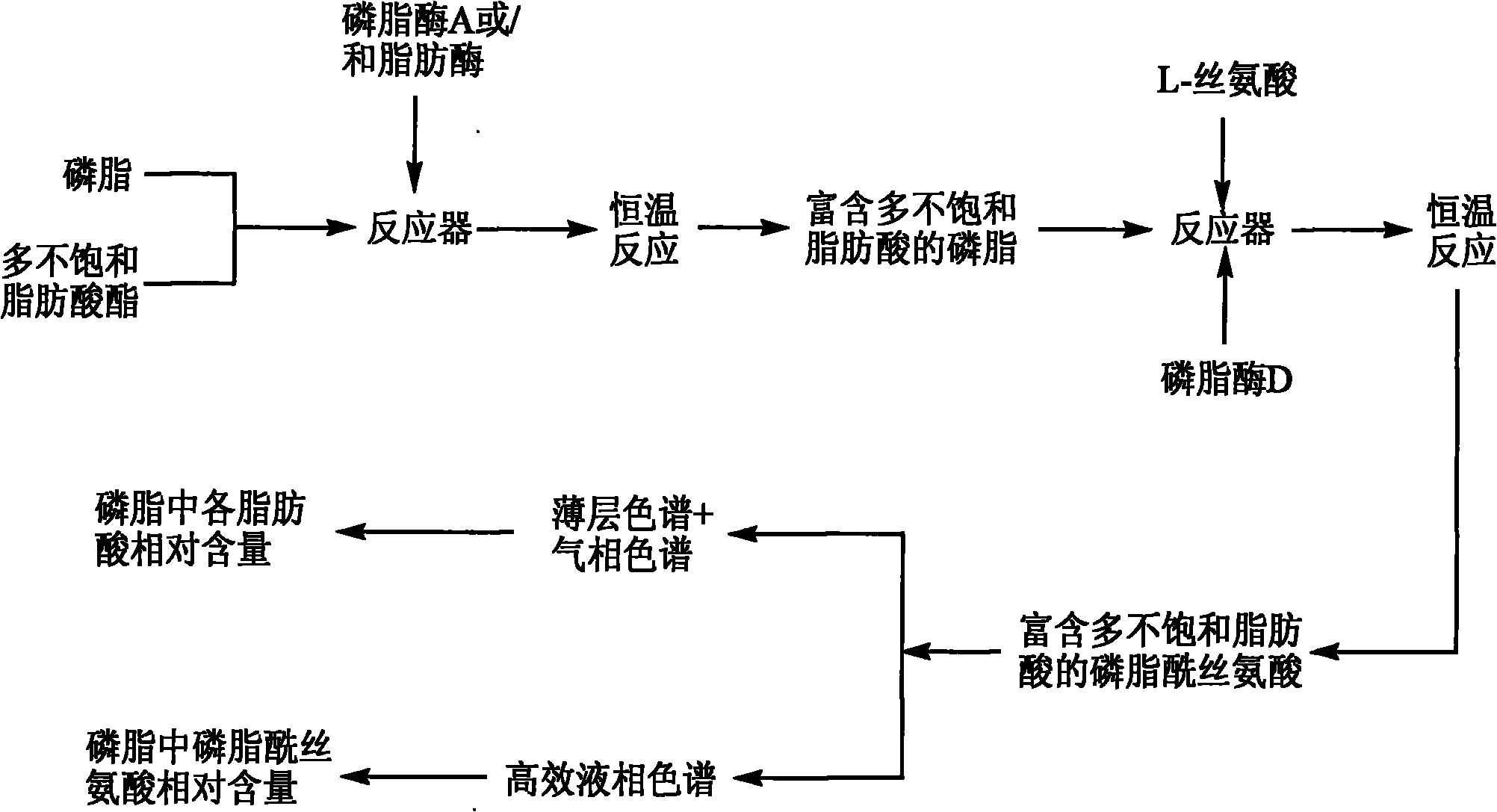

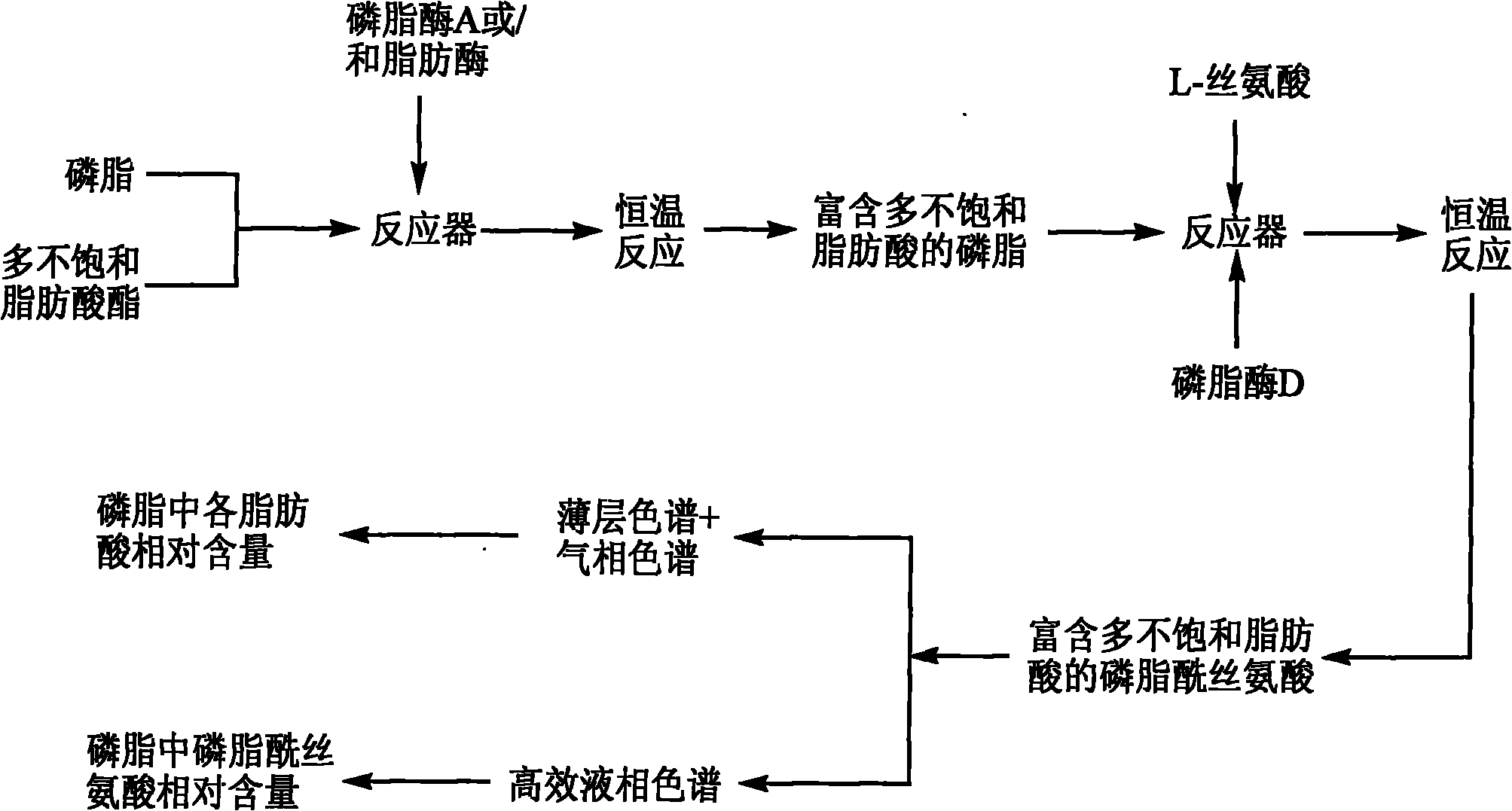

Method for preparing phosphatidylserine abundant in polyunsaturated fatty acid

InactiveCN101818179ANo emissionsImprove product qualityMicroorganism based processesFermentationUnsaturated fatty acid esterPhospholipid

The invention relates to a method for preparing phosphatidylserine abundant in polyunsaturated fatty acid and belongs to the technical field of bioengineering. The method is characterized by comprising the following steps of: firstly, catalyzing ester exchange reaction between phosphatide and polyunsaturated fatty acid ester by utilizing one or a mixture of phosphatidase A and lipase to generate phosphatide abundant in polyunsaturated fatty acid; and then catalyzing phosphor-transfer esterification reaction between the phosphatide abundant in the polyunsaturated fatty acid and L-serine by utilizing phosphatidase D to generate the phosphatidylserine abundant in the polyunsaturated fatty acid. The method has the advantages of no discharge of waste water, good product quality, no solvent residue, safe process operation, few reaction byproducts, no waste generation, cost reduction, simple production process and easy realization of scale production because of utilizing two enzymes to perform sub-step catalysis and perform reaction in the same reactor, and completing the reaction process in a non-solvent system. Therefore, the invention provides a good and feasible method for preparing the phosphatidylserine abundant in the polyunsaturated fatty acid.

Owner:DALIAN UNIV OF TECH

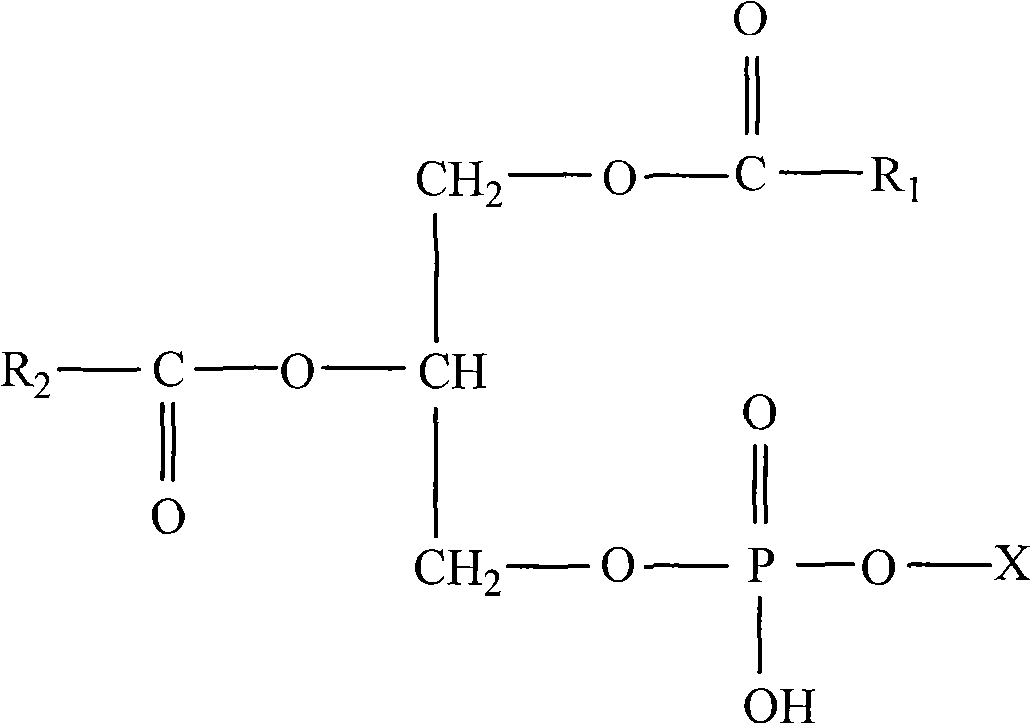

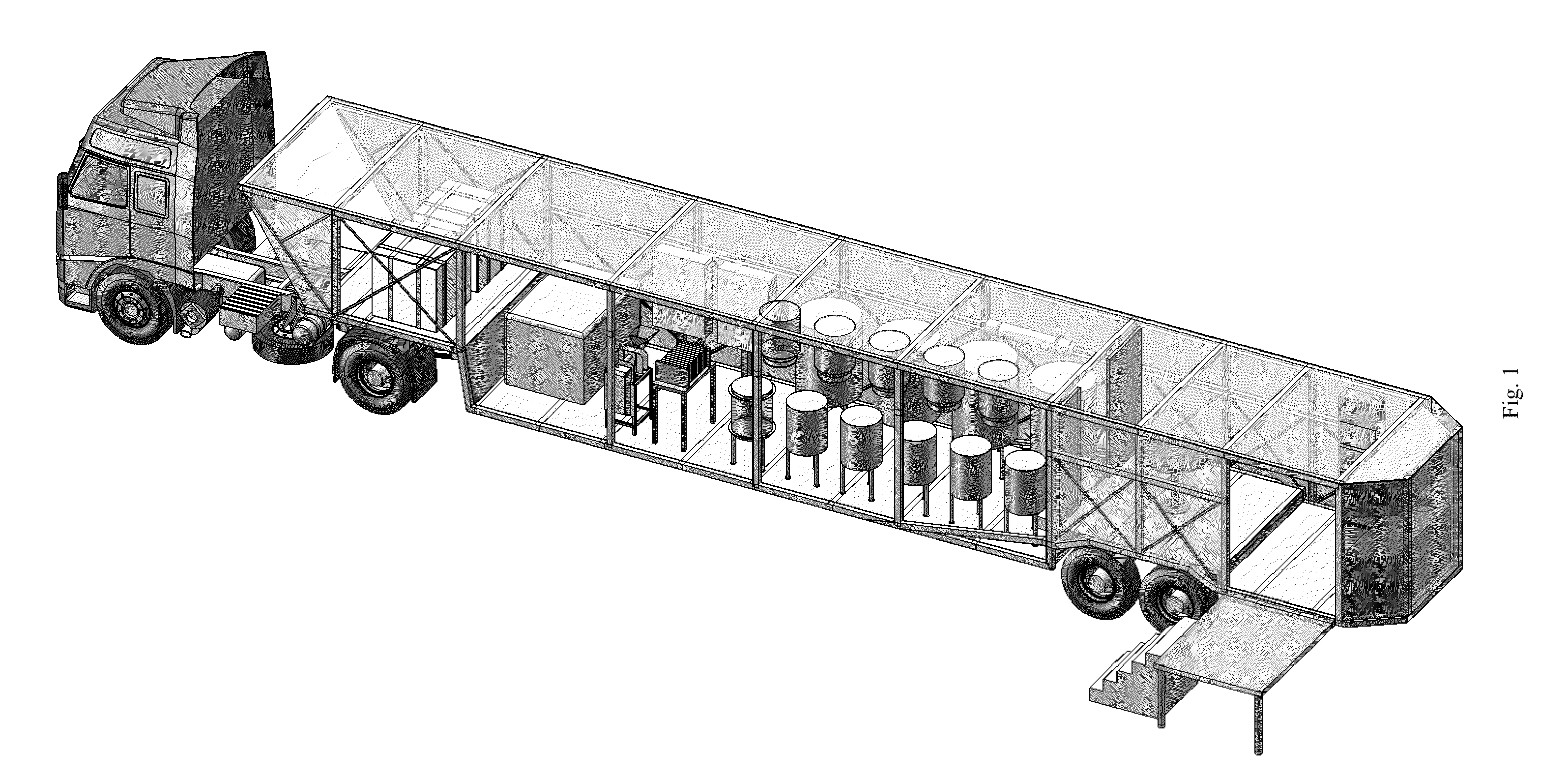

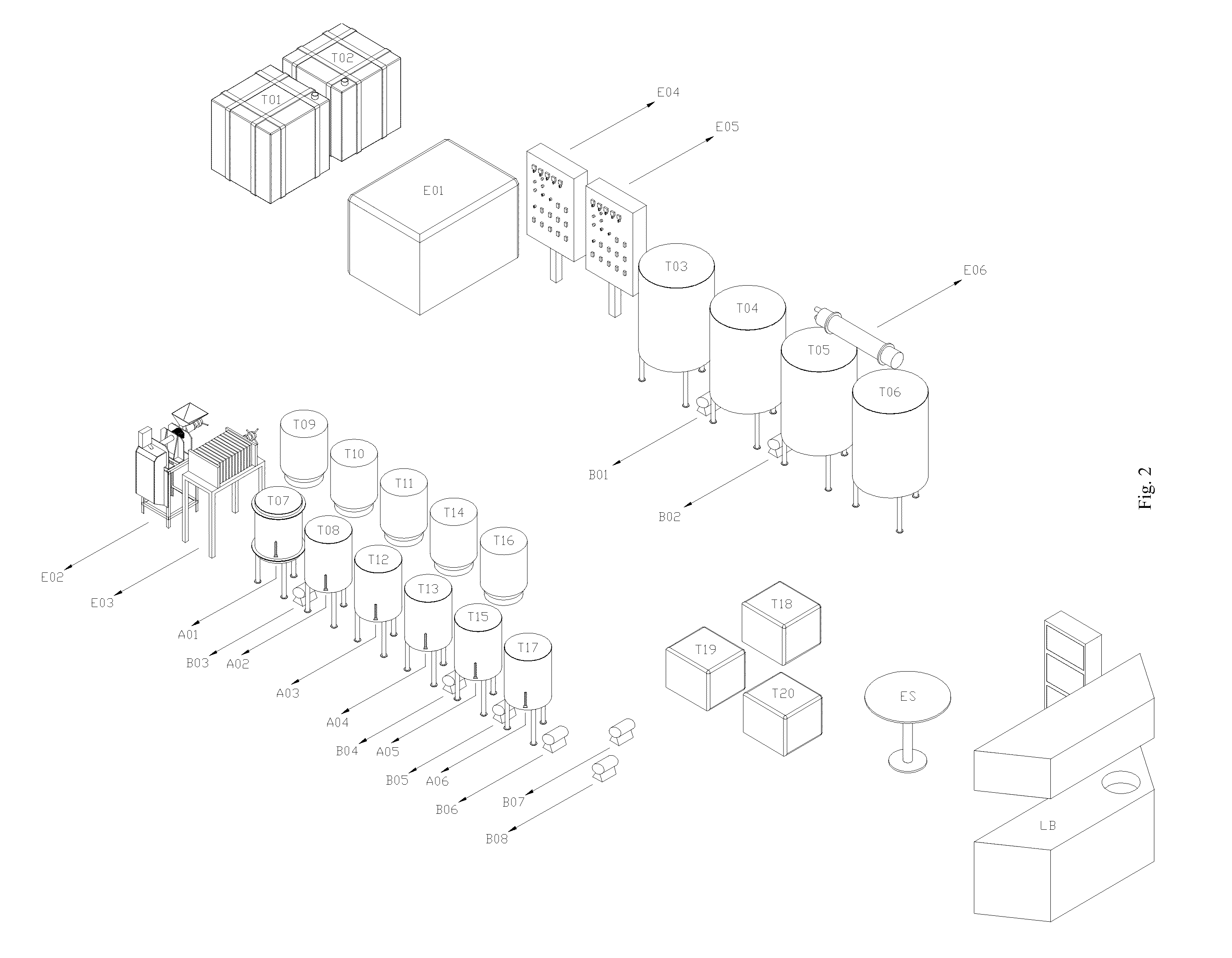

Self-sustainable mobile biodiesel production plant and method

InactiveUS20110167712A1High technicalHigh economic sustainability environmentFatty acid esterificationExhaust apparatusElectricityBiodiesel

The “MOBILE PLANT FOR SELF-SUSTAINABLE BIODIESEL PRODUCTION AND MOBILE PROCESS FOR BIODIESEL PRODUCTION” characterized by a compact equipment arrangement for the biodiesel production in a way intended to reduce waste generation and, additionally, allow reuse / application of some of them; it is organized and arranged over a chassis with axle and wheels that can be attached and taken to various locations, presents a self-sustainable format to use its own fuel to generate electricity to supply the entire plant, if necessary.

Owner:BIOMINAS ENGENHARIA E INDA DE ENERGIA

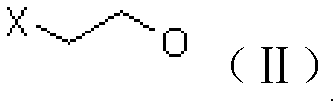

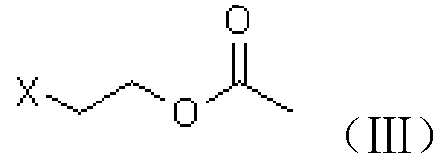

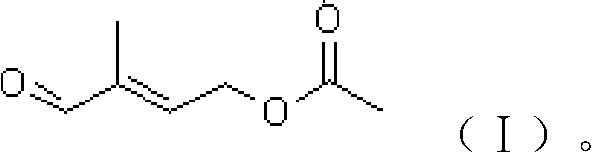

Preparation method of 4-acetoxyl-2-methyl-2-butylenoic aldehyde

ActiveCN101723827AGood reaction selectivityHigh yieldOrganic compound preparationCarboxylic acid esters preparationTriethylphosphiteMethyl group

The invention discloses a preparation method of 4-acetoxyl-2-methyl-2-butylenoic aldehyde. In the traditional method, the yield is lower, the waste water amount is larger, and the requirements on equipment are higher. The preparation method comprises the following steps of: reacting 2-halogenated ethanol as a raw material with an acylating agent to obtain halogenated ester; then preparing phosphonate ester through the Arbuzov reaction between the halogenated ester and triethyl phosphite; preparing glutaraldehyde acetal through the Wittig-Horner reaction between the phosphonate ester and 1,1-dimethoxy acetone under the action of alkaline, and carrying out deprotection on the glutaraldehyde acetal under the acidic condition to obtain glutaraldehyde, namely, the 4-acetoxyl-2-methyl-2-butylenoic aldehyde. The invention has less three waste generation, good reaction selectivity, less by-products and higher yield.

Owner:SHANGYU NHU BIOCHEM IND

Method for treating wastewater generated from fabricating nitrophenol as well as for reclaiming and using resources

InactiveCN1562790AAchieve recyclingCombustible gas purificationWater/sewage treatment by sorptionResource recoveryWastewater

The prodn. process are: pretreatment, adsorpting adsorpting para-nitrophenol in waste water, recovering and utilizing sodium chloride, deadsorpting obsorbed para-nitrophenol. The outstanding characteristic is that recovering ratio for nitrophenol is approach 100 percent, the recovered nitrophenol is reused by being send back to prodn process, large quantity of sodium chloride in waste water is used to produce caustic soda and hydrochloric which can be circulating used.

Owner:NANJING UNIV

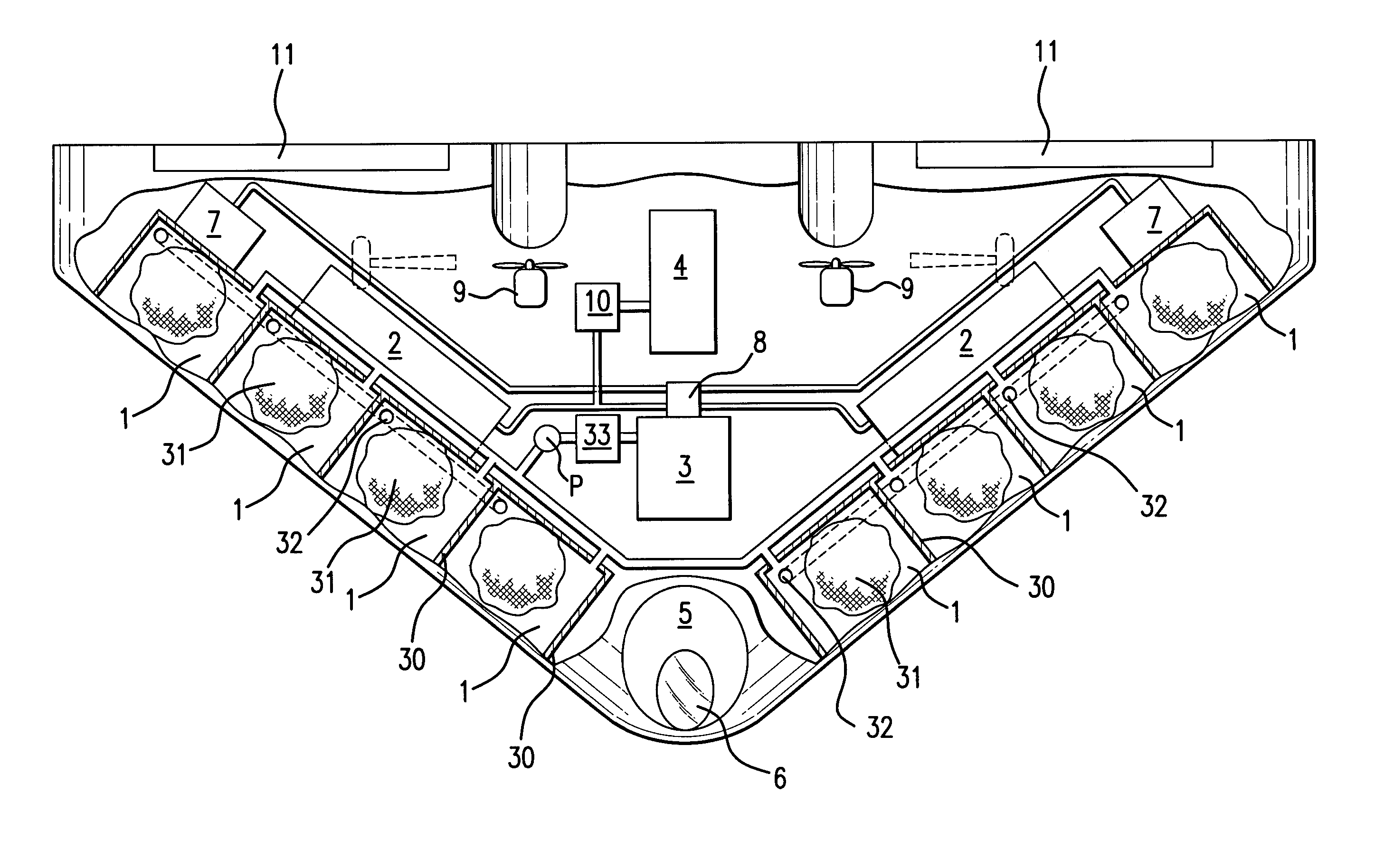

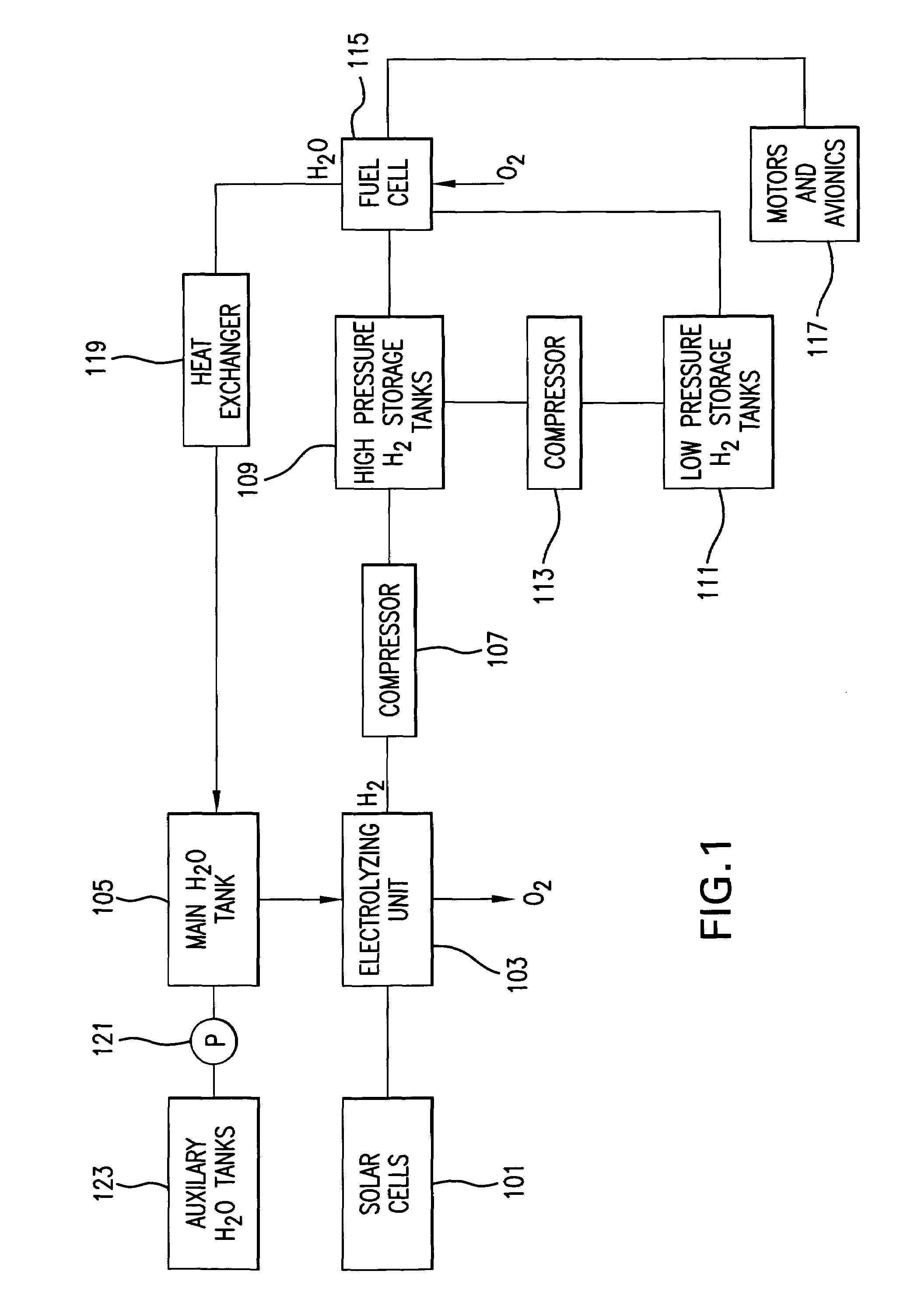

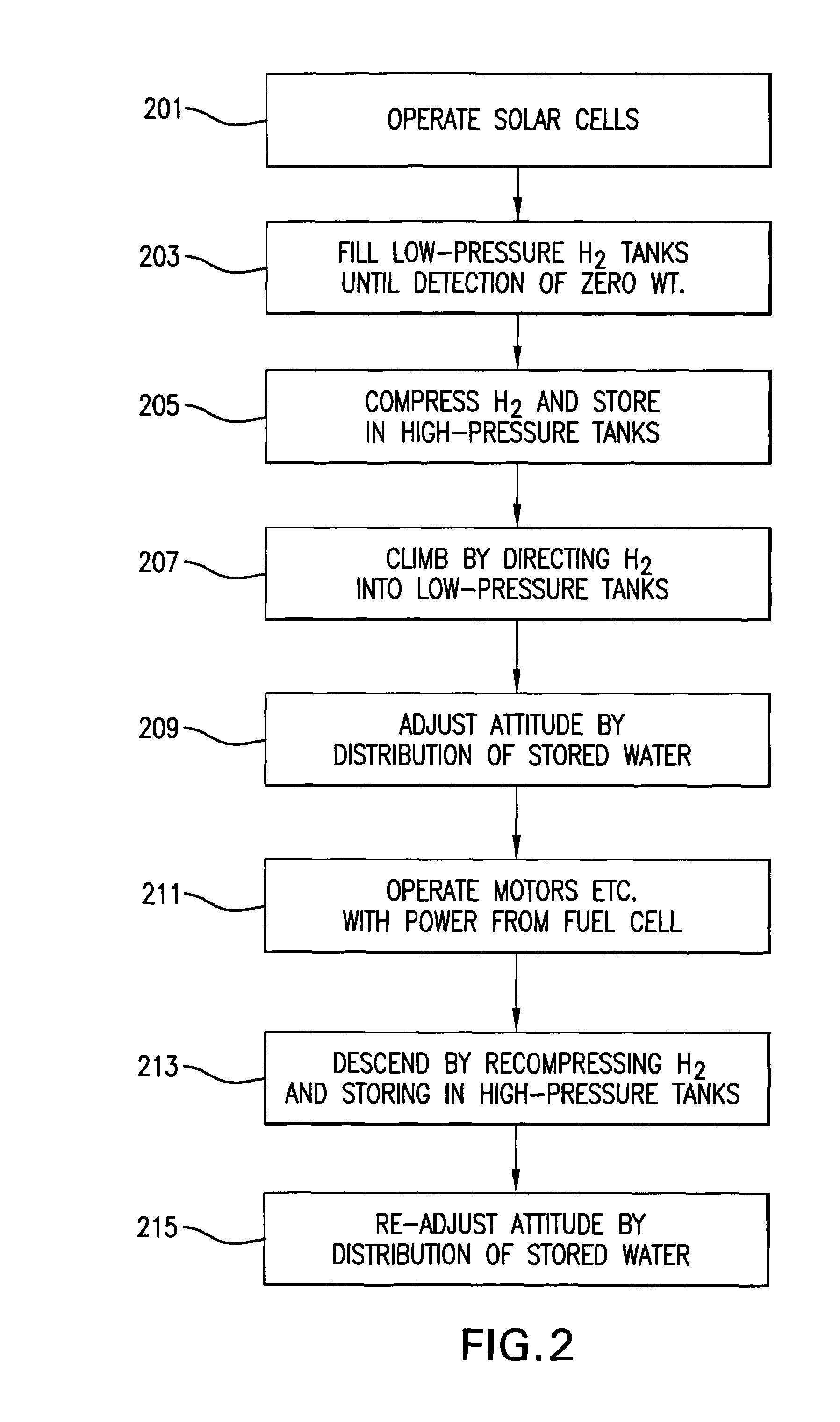

Solar-powered aircraft

InactiveUS7278607B2Weight of to shiftPower installationsEnergy efficient board measuresFuel cellsHydrogen

Owner:FULLER HOWARD J

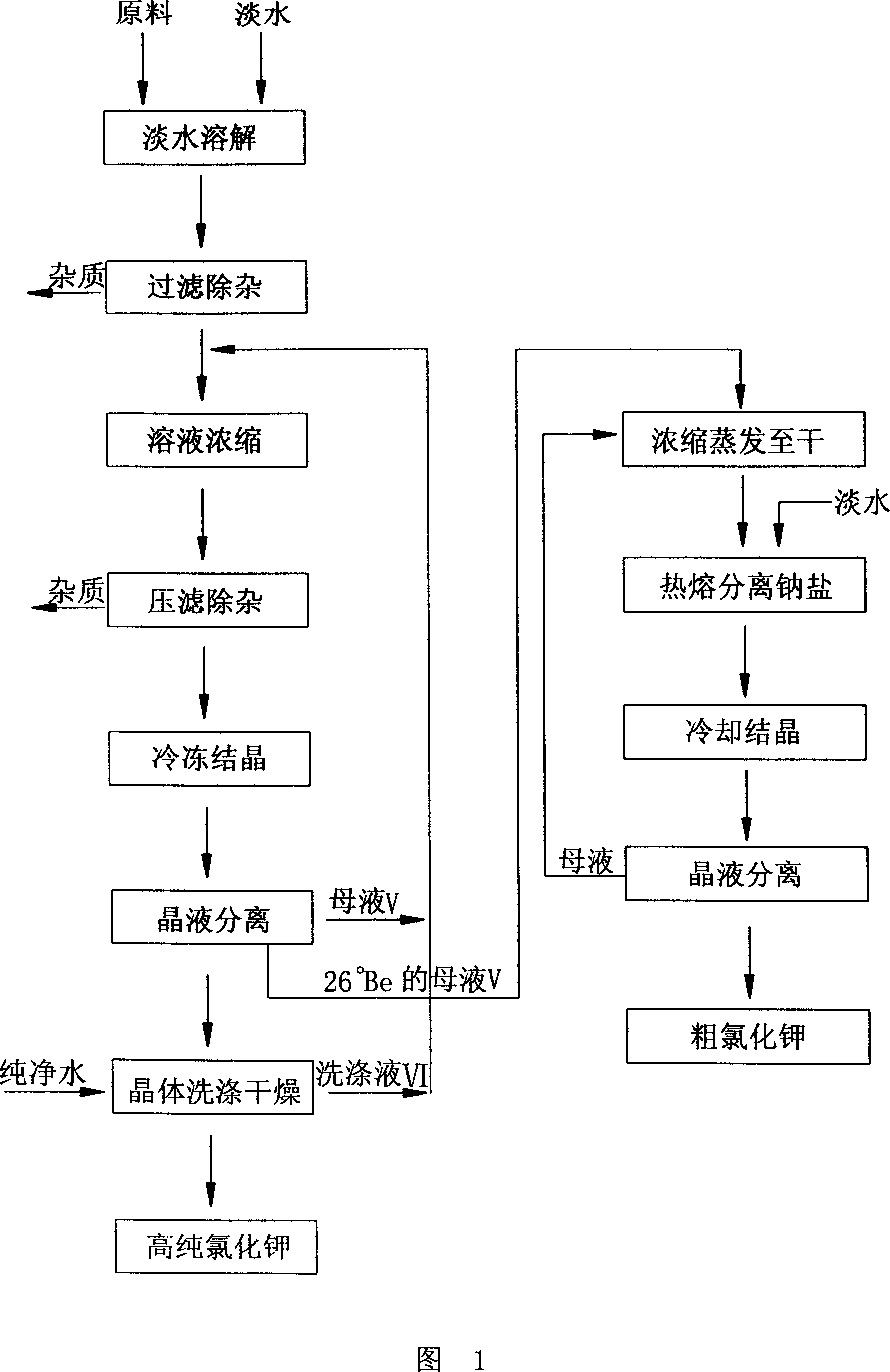

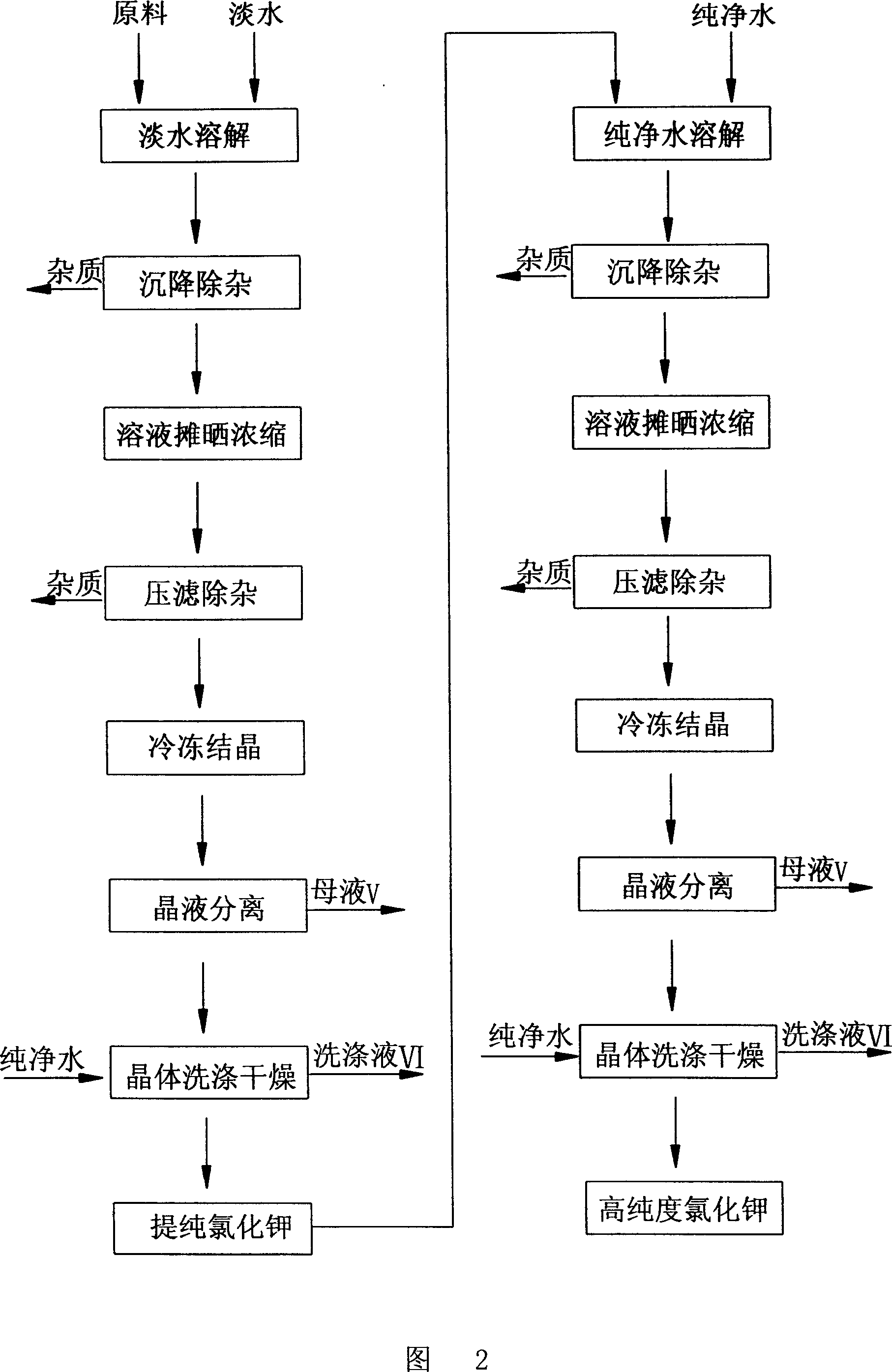

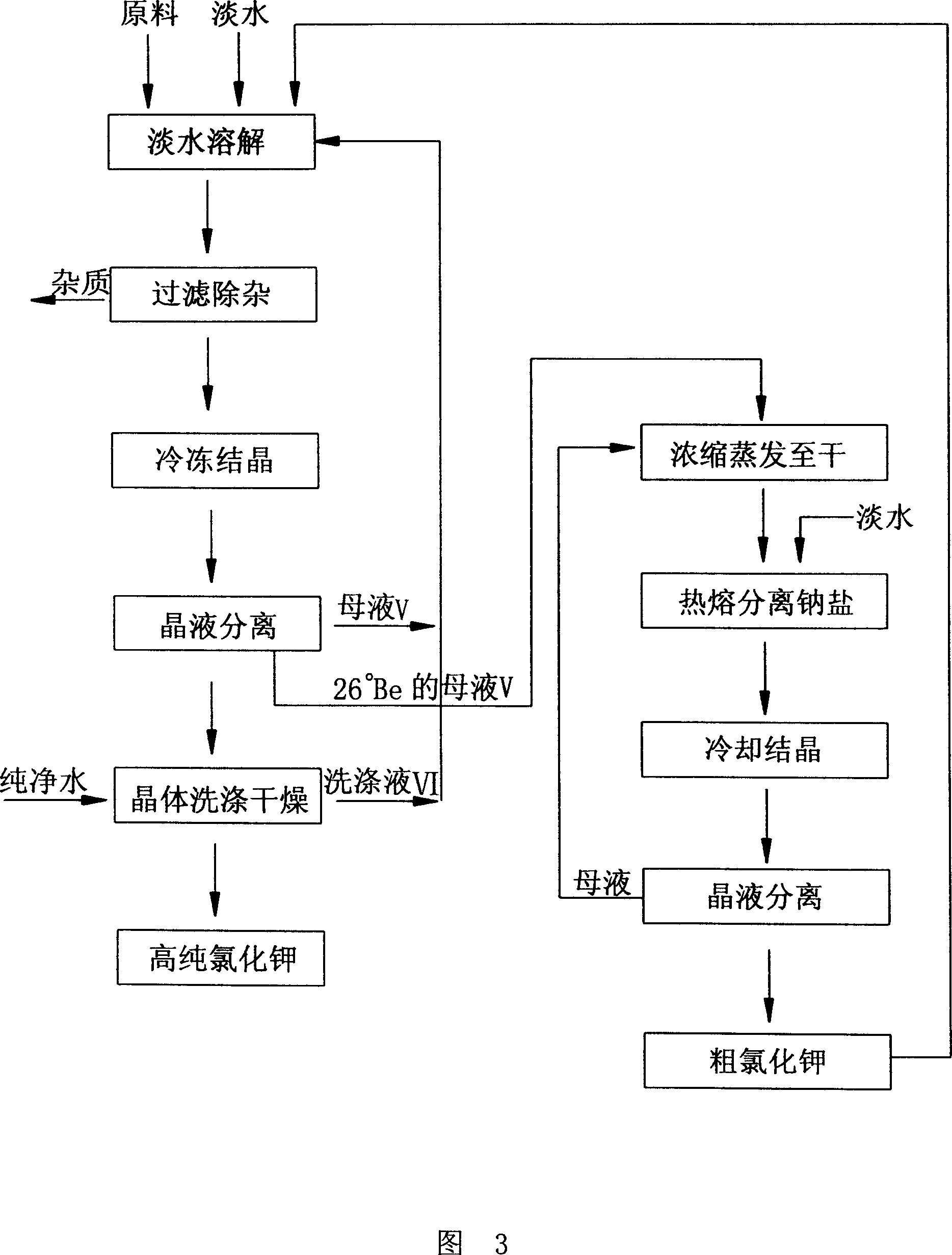

Process for producing high-purity potassium chloride

This invention relates to a producing technology for pure KCl, which takes KCl with the purity below 98% as the raw material characterizing in including steps of dissolving in fresh water, sedmentation and filtration, concentrating and removing trash, reducing the temperature and crystallizing and separation of liquid and crystals to get pure KCl over 99%, another method includes: dissolving in fresh water, sedmentation and filtration, reducing the temperature and crystallizing and separation of liquid and crystals and the whole production applies total blocking out continuous mode.

Owner:高崧耀

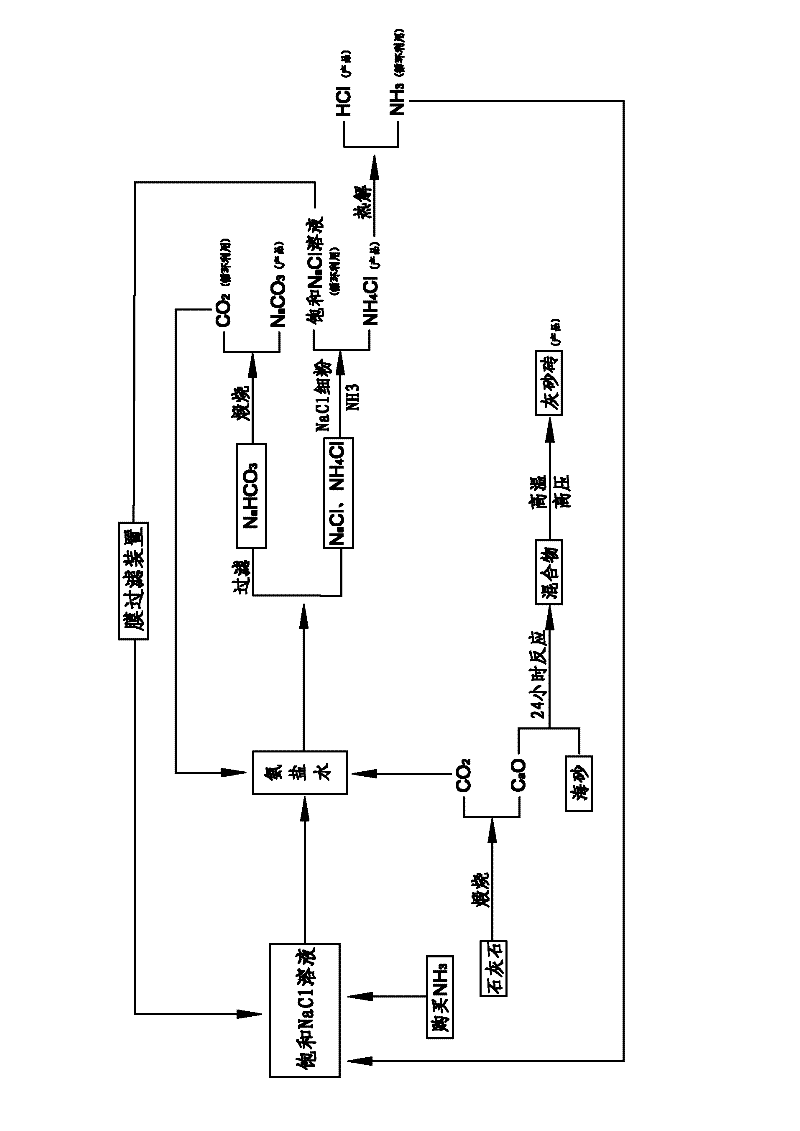

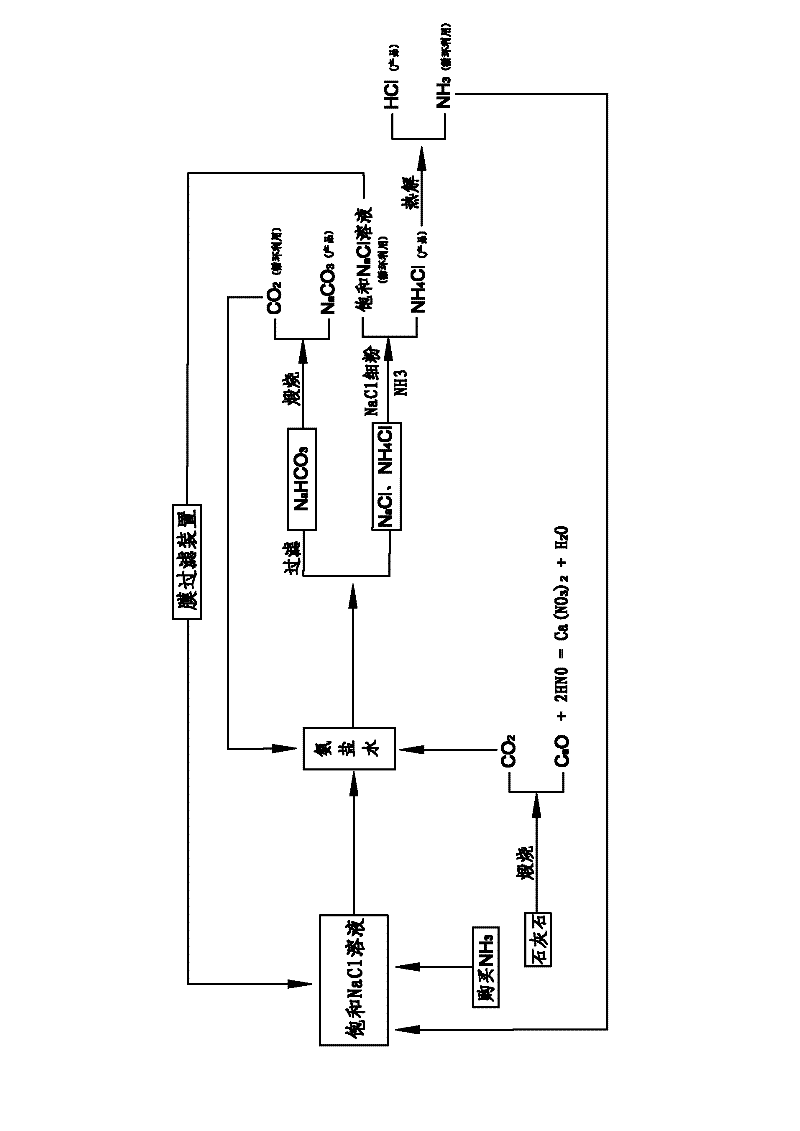

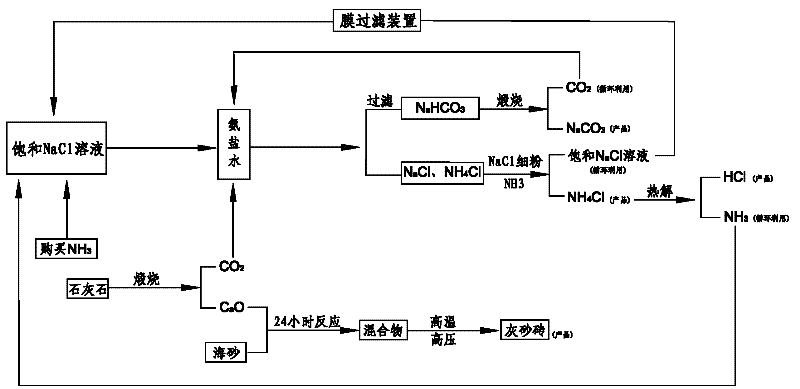

Comprehensive soda ash producing process and product application thereof

ActiveCN102531001AIncrease profitReduce manufacturing costCalcium/strontium/barium nitratesAmmonium halidesSodium bicarbonateProcess engineering

The invention relates to the technical field of soda ash production, and especially relates to a comprehensive soda ash producing process and product applications thereof; the process comprises the following process steps: introducing ammonia gas into a saturated sodium chloride solution to prepare ammoniacal brine; introducing carbon dioxide generated in limestone calcination into the ammoniacal brine to generate a mixture of sodium bicarbonate, sodium chloride and ammonium chloride; filtering the mixture to obtain sodium bicarbonate, sodium chloride and ammonium chloride; calcining the sodium bicarbonate to generate soda ash and carbon dioxide, recycling the carbon dioxide; adding sodium chloride fine powder and ammonia gas into the mixed filtrate of ammonium chloride and sodium chloride to generate ammonium chloride and sodium chloride solutions; separating impurities from the sodium chloride solution by a membrane filter, recycling the sodium chloride solution. The process has the advantages of low production cost, high soda ash whiteness, high sodium chloride utilization rate, no water waste or solid waste generation, environment protection, safety, simple processes, full use of geographic advantages in our country, low raw material purchase cost, waste change into things of value, high economic benefits, and good social benefits.

Owner:GUANGDONG DAZHONG AGRI SCI CO LTD

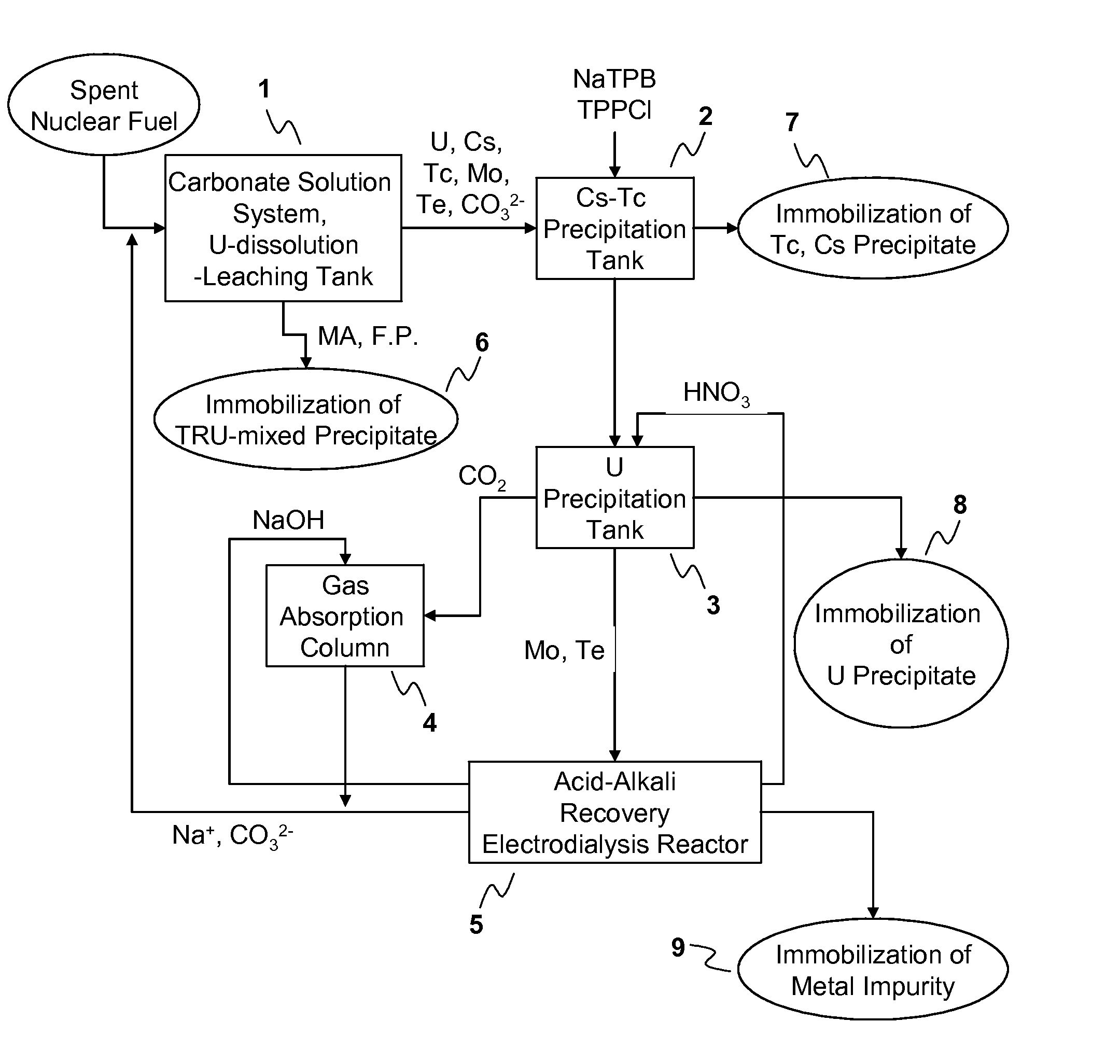

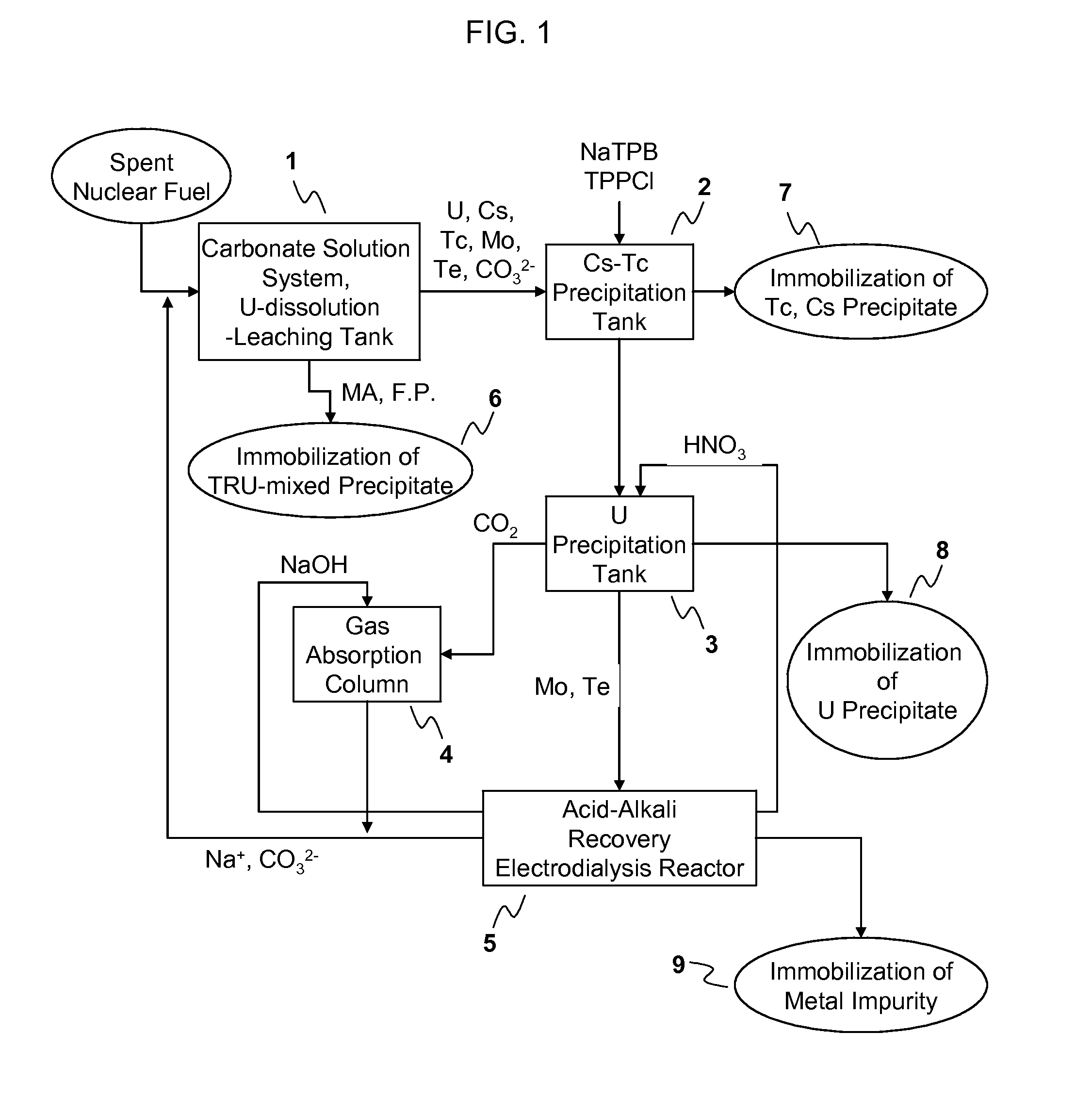

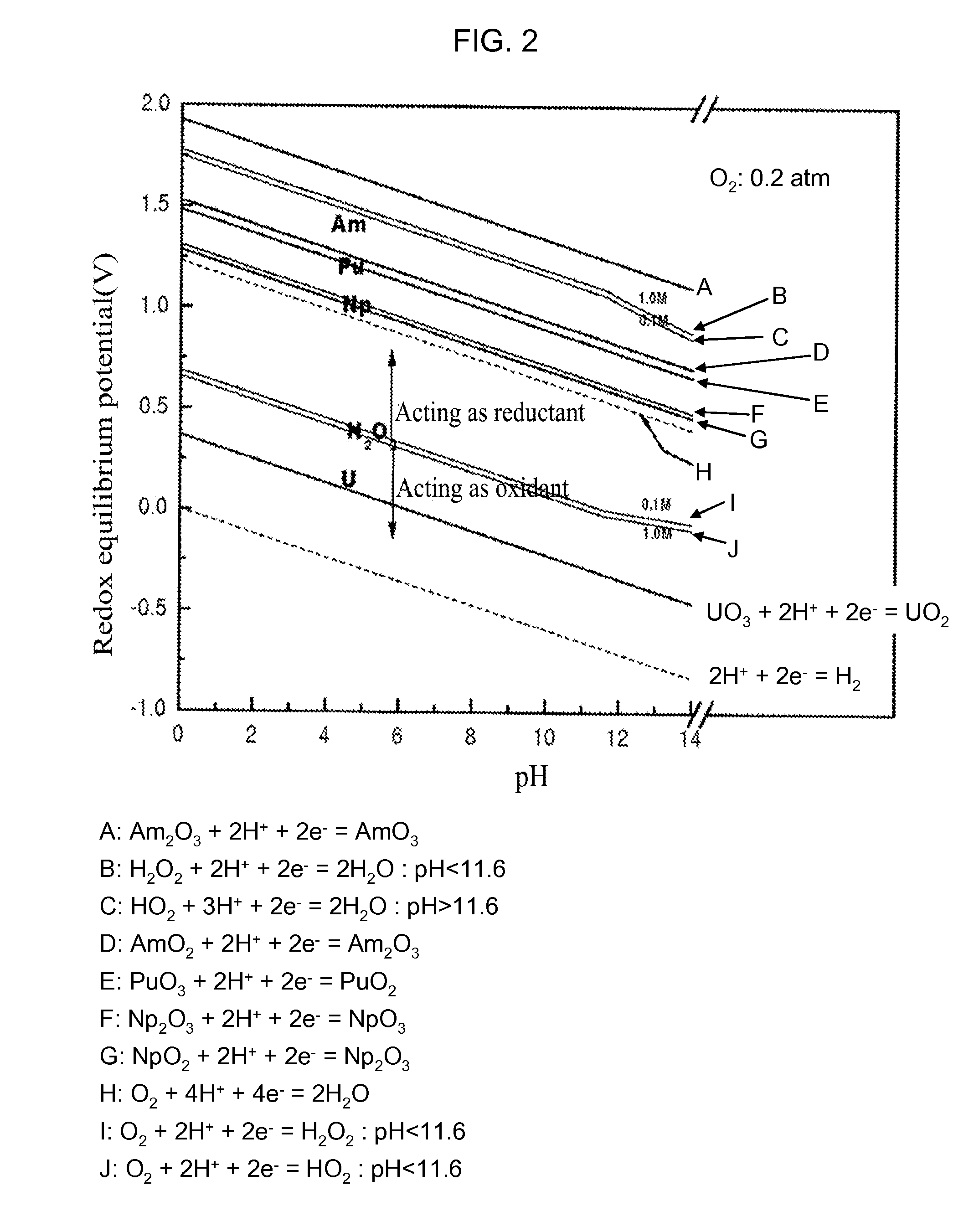

Process for Recovering Isolated Uranium From Spent Nuclear Fuel Using a Highly Alkaline Carbonate Solution

InactiveUS20090269261A1Easy to separateEnhance proliferation resistanceElectrolysis componentsPhotography auxillary processesTransuranium elementCarbonate

Disclosed is a process for recovery of uranium from a spent nuclear fuel using a carbonate solution, characterized by excellent proliferation resistance of preventing leaching of transuranium element (TRU) nuclides such as Pu, Np, Am, Cm, etc. from the spent nuclear fuel as well as environmental friendliness of minimizing waste generation, wherein a highly alkaline carbonate solution is used to separate uranium alone from the spent nuclear fuel.

Owner:KOREA ATOMIC ENERGY RES INST

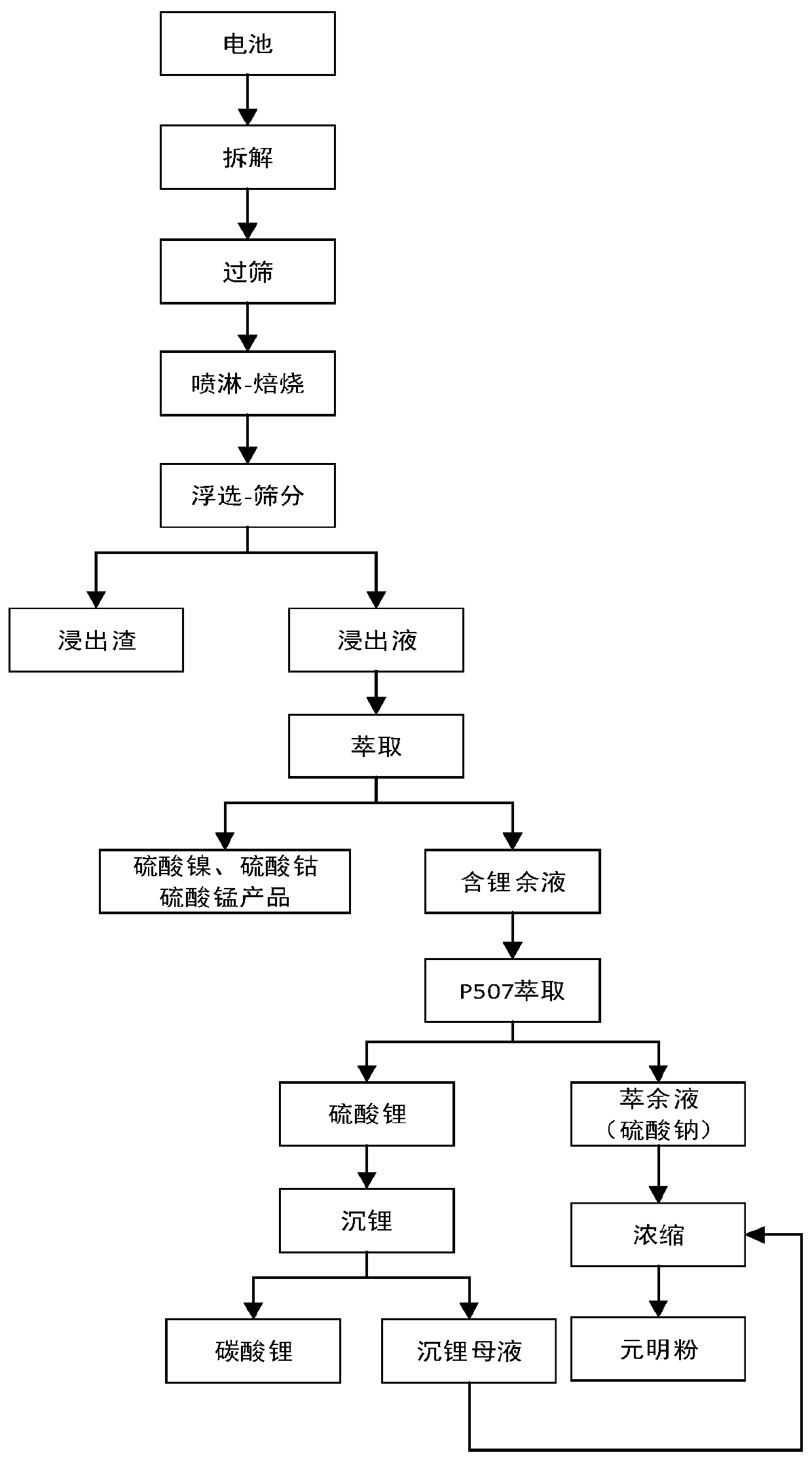

Power lithium ion battery all metal recycling and cyclic utilizing method

ActiveCN110616331AAchieve recyclingShort processCobalt sulfatesWaste accumulators reclaimingElectrical batteryLithium carbonate

The invention discloses a power lithium ion battery all metal recycling and cyclic utilizing method. Waste lithium ion batteries serve as raw materials, the disassembling-screening and roasting procedures are adopted for separating battery pole powder from other parts in the batteries, then, acid leaching is conducted, and leaching liquid containing cobalt, nickel, manganese and lithium is obtained; through extraction, separation and purification of cobalt, nickel, manganese and lithium are achieved, battery-level cobaltous sulfate, nickel sulfate and manganese sulfate are obtained, then, lithium-sodium separation is conducted, and lithium carbonate and sodium sulfate products are obtained through lithium deposition and concentration. The power lithium ion battery all metal recycling and cyclic utilizing method is green and efficient, danger waste generation is avoided, and large-scale production can be achieved. Various valuable metals are systematically recycled from the waste powerlithium batteries, according to the recycling rates, Co is larger than 95%, Ni is larger than 95%, Mn is larger than 98%, Li is larger than or equal to 94%, and the water cyclic utilization rate is larger than 95%. Nickel sulfate liquid, cobaltous sulfate liquid, manganese sulfate liquid and lithium carbonate obtained through the power lithium ion battery all metal recycling and cyclic utilizing method meet the battery level product standard.

Owner:衢州华友资源再生科技有限公司

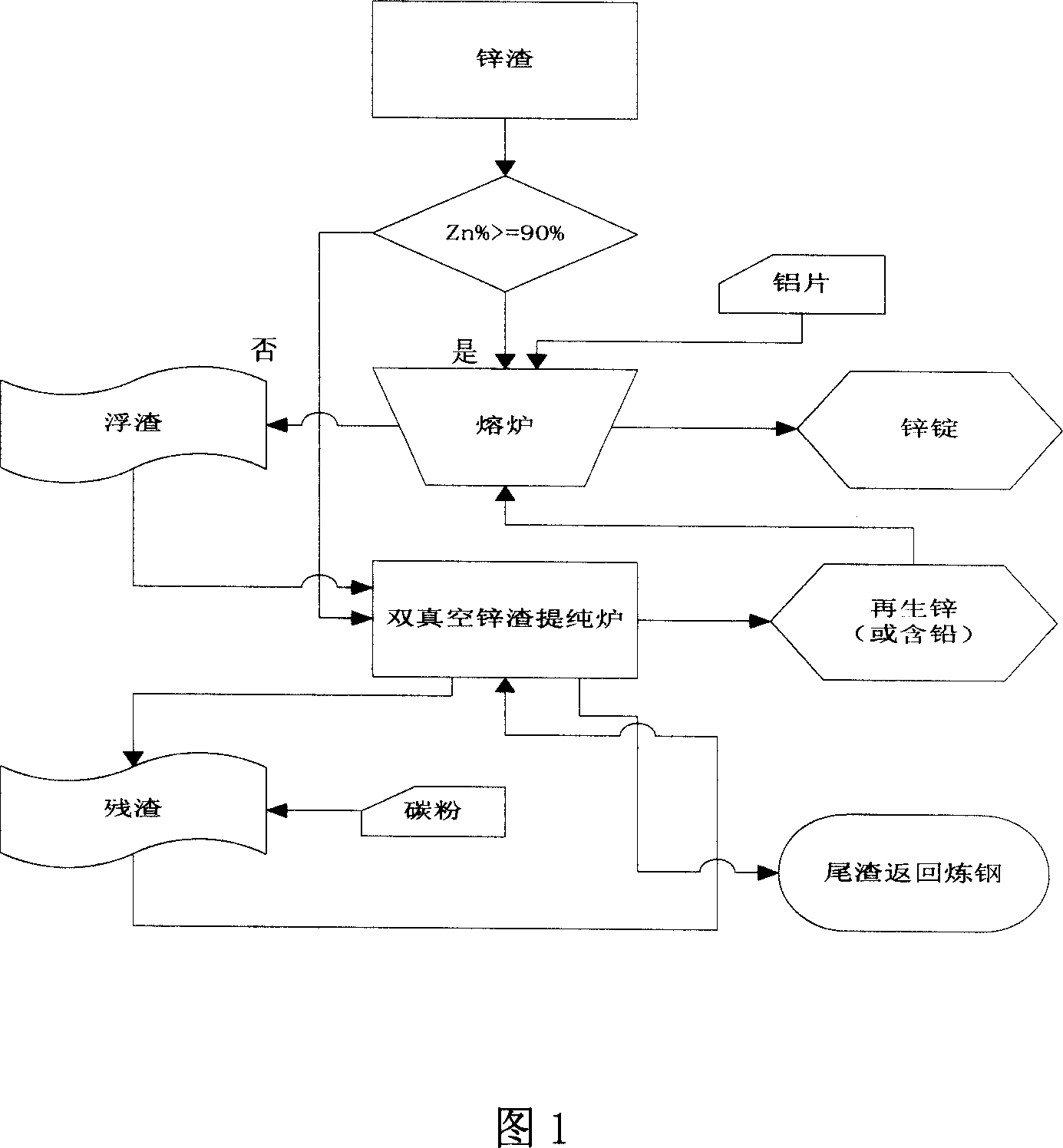

Method for producing zinc alloy from zinc dross

This invention relates to a method for producing zinc alloy from zinc slag. The method comprises: heating zinc slag and aluminum to 500-600 deg.C in a smelter to completely melt, cooling to a certain temperature to adequately separate zinc-aluminum melt from floating residues, cooling the zinc-aluminum melt, processing into zinc-aluminum ingots, treating the floating residues in a double-vacuum purification furnace to obtain regenerated zinc in a crystallizer and residues kept in a material basket, mechanically separating regenerated zinc from the crystallizer, directly conveying into the smelter, melting, ingotting, collecting the residues, adding an appropriate amount of carbon powder, treating above 600 deg.C in the double-vacuum purification furnace to completely reduce volatile components (zinc and tin) in the residues, separating, recovering, and separating the final product from tailings in the crystallizer. By combining melt ingoting and vacuum distillation, the method has such advantages as low energy / material loss, little waste generation, little pollution and recycleable byproducts.

Owner:BAOSHAN IRON & STEEL CO LTD

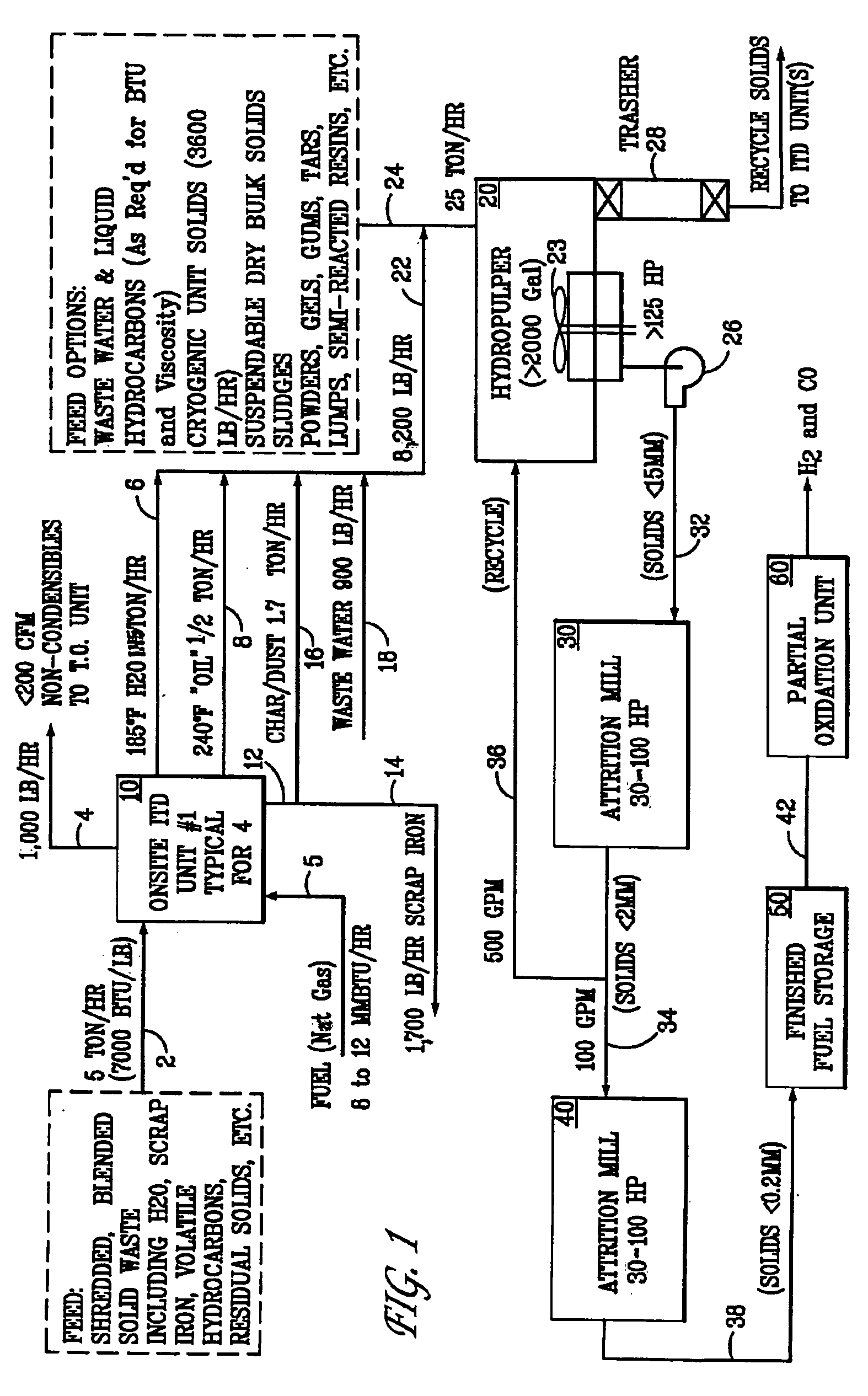

Process for producing a liquid fuel composition

A process to produce a flowable fuel or fuel supplement from solid and / or liquid waste, such as industrial waste. A system to carry out the process includes producing from the solid and / or liquid industrial waste a solid char and vaporize liquids, recombining the char and the liquids, recovered from the wastes feed, to form a feed slurry containing solids, combining the feed slurry with additional combustible waste liquids which are added at a rate and amount to obtain a fuel slurry of specified properties, particularly specified viscosity and BTU content, subjecting the feed slurry and additional wastes to conditions of attrition in at least one attrition zone to produce a product slurry containing solids of fuel size, recovering the fuel slurry which be used as fuel in partial oxidation processes. The liquid waste may be collected as a product, particularly if they are high in organic compounds.

Owner:RINECO CHEM INDS

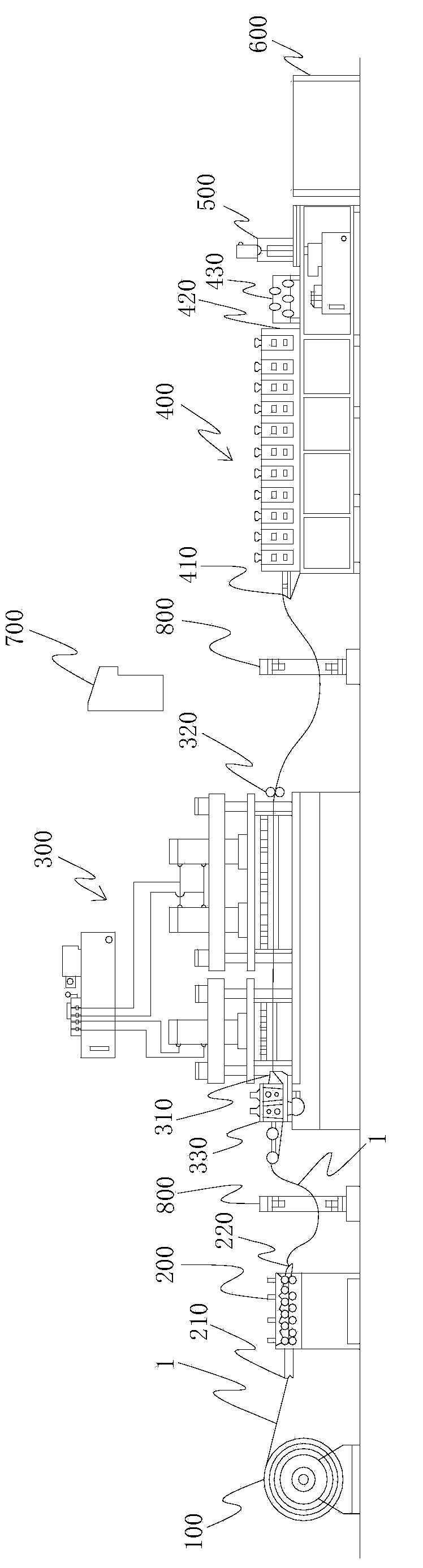

Elevator door frame profile punching and roll bending production line

InactiveCN103861939AReduce generationHigh degree of automatic integrationMetal-working apparatusProduction linePunching

The invention discloses an elevator door frame profile punching and roll bending production line. The elevator door frame profile punching and roll bending production line comprises an emptying uncoiler, a punching machine tool, a roll bending molding machine, a chopping device, and an electronic control system device which are distributed in sequence in a production line direction, wherein the emptying uncoiler is positioned at the starting end of the production line and used for supporting and unfolding a steel plate strip; the punching machine tool is used for carrying out punching treatment on the steel plate strip sent by the emptying uncoiler; the roll bending molding machine is used for performing bending treatment on the steel plate strip treated through punching of the punching machine tool; the chopping device is arranged at the discharging port of the rolling bending molding machine and used for cutting the steel plate strip subjected to bending treatment of the roll bending molding machine; the electronic control system device is respectively connected with the emptying uncoiler, the punching machine tool, the roll bending molding machine and the chopping device. The elevator door frame profile punching and roll bending production line provided by the invention has the beneficial effects as follows: the electronic control system device is adopted for uniform control of the entire production line, all production devices are connected together organically, the automatic integration degree is high, the production efficiency is improved, the labor cost is reduced, and waste generation is reduced.

Owner:上海斐菱机电设备制造有限公司

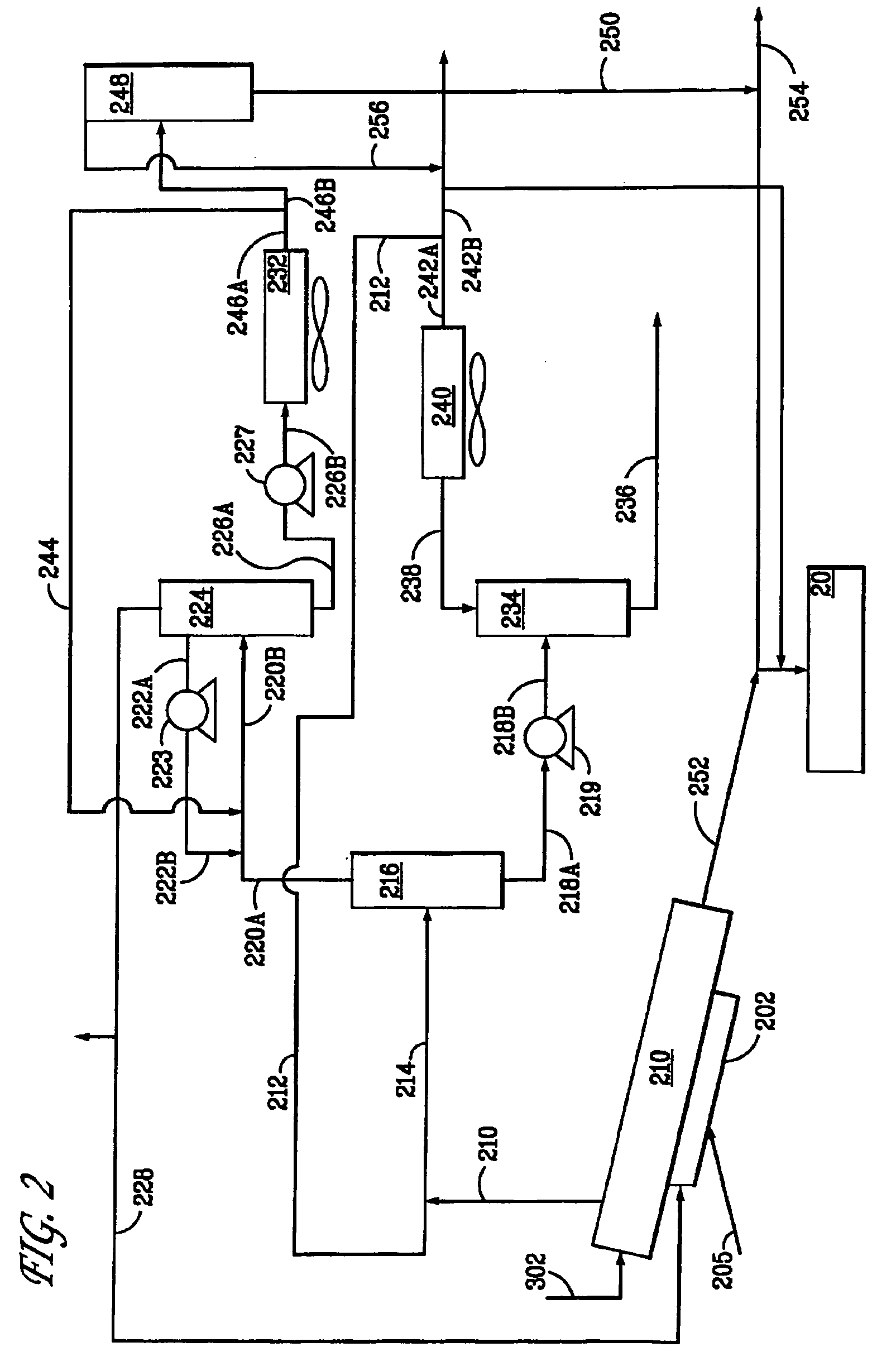

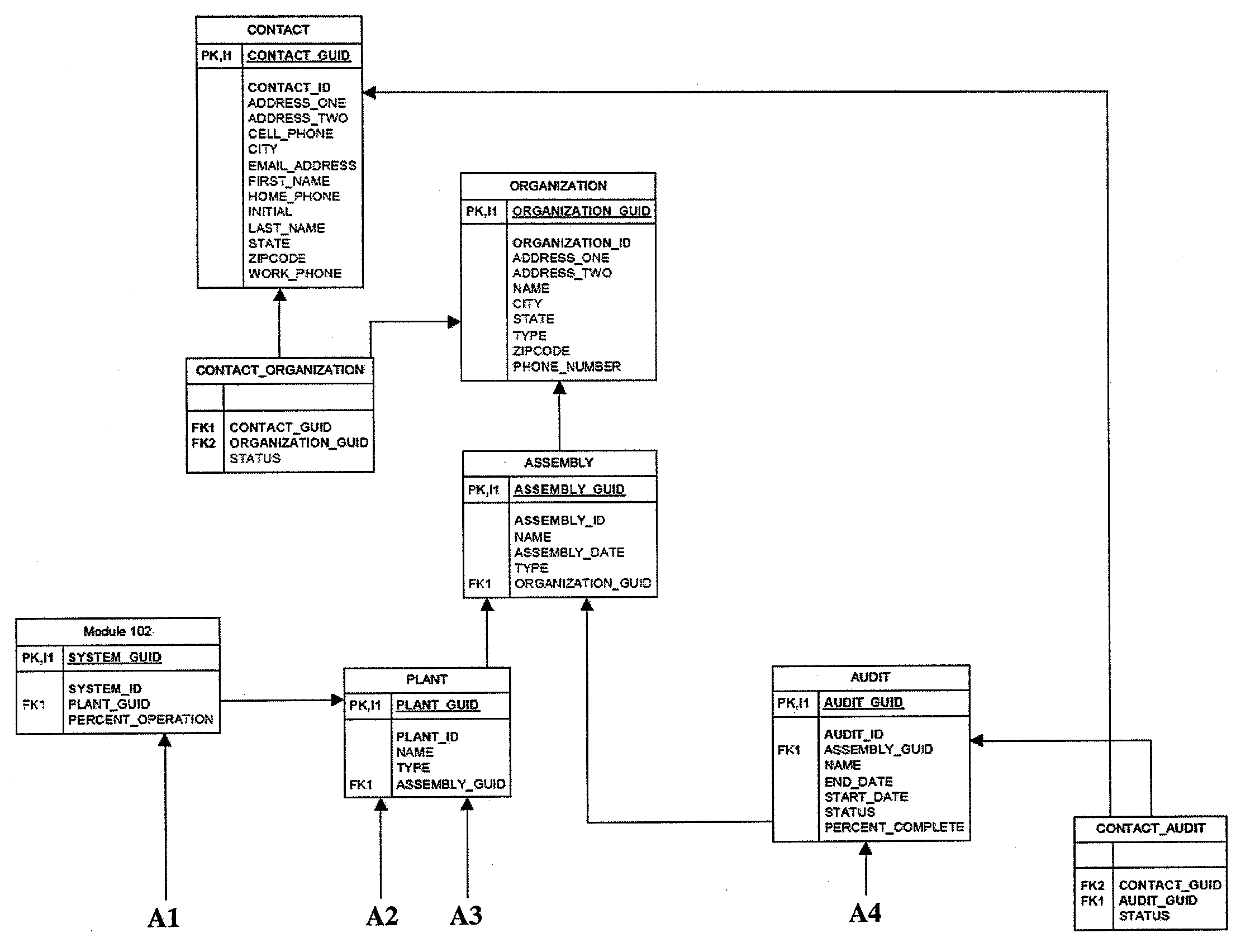

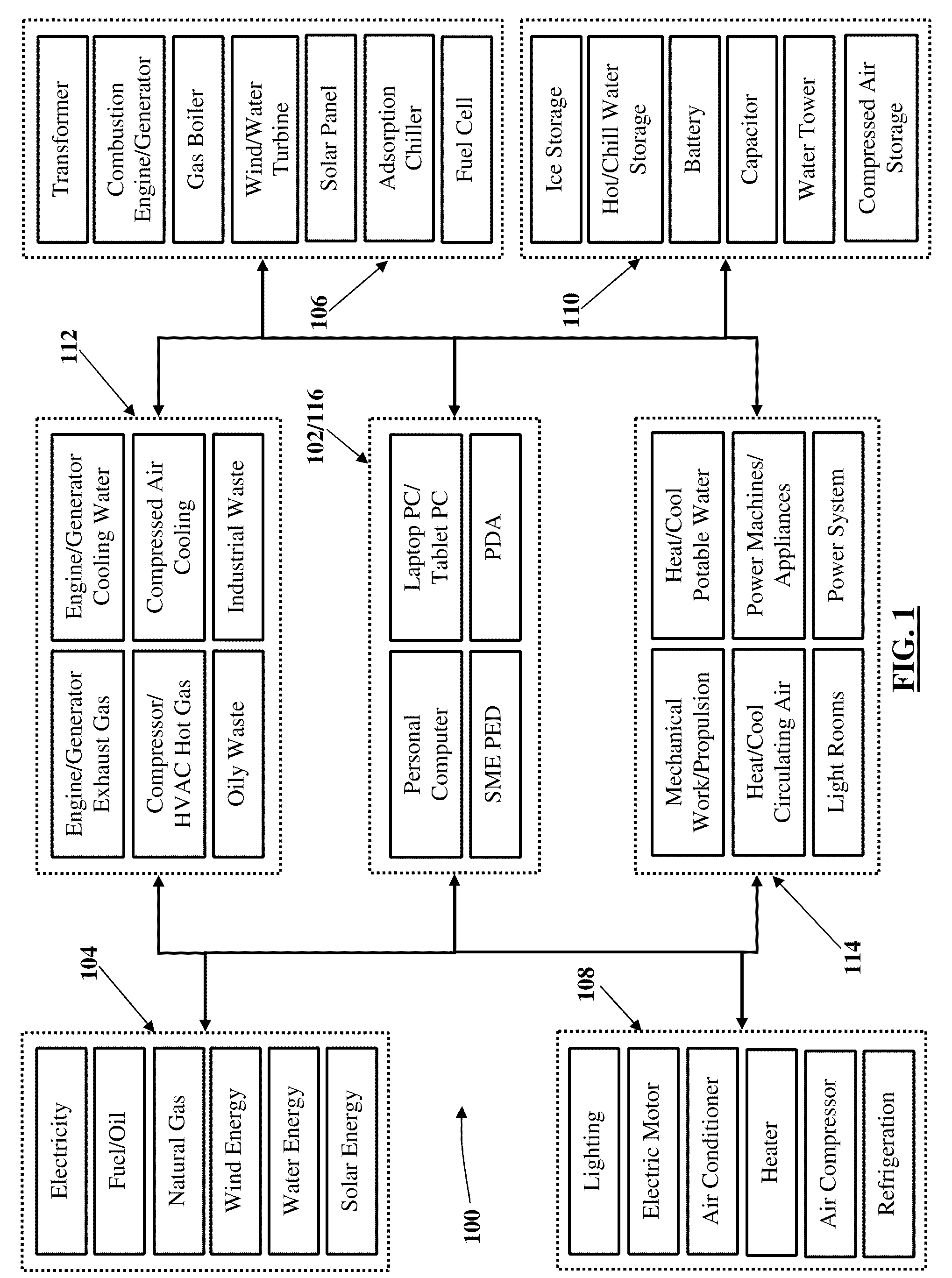

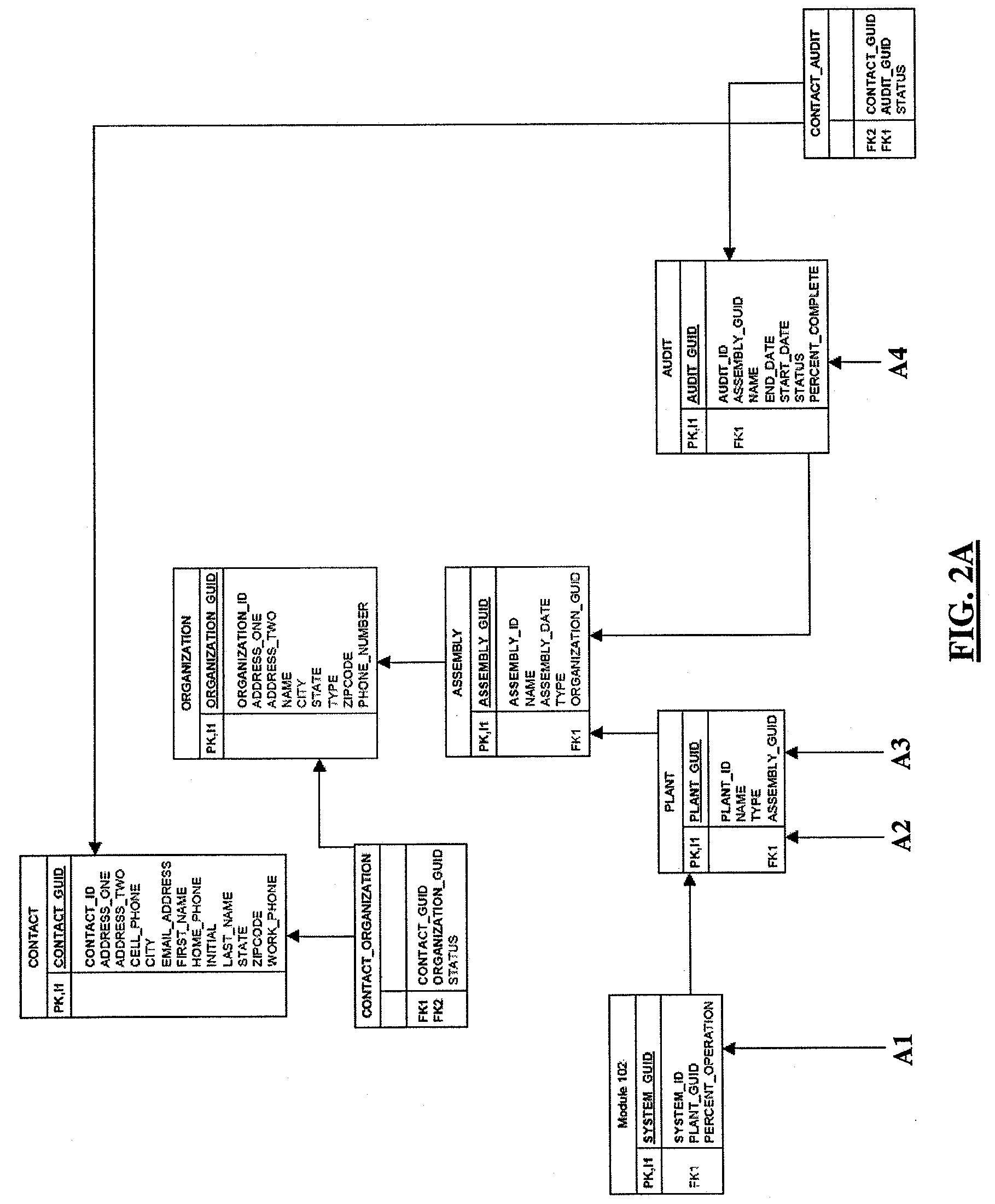

System and method of optimizing resource consumption

A system and method for quantifying and optimizing resource consumption and waste generation of a plurality of resource consumer devices that consume one or more consumable resources to produce useful work. The system and method comprise an input module that receives input data related to each of the plurality of resource consumer devices and each of the one or more consumable resources, a resource consumer module that determines an amount of the one or more consumable resource consumed by each of the plurality of resource consumer devices under a particular load and an amount of waste produced by each of the plurality of resource consumer devices under the particular load based at least in part on the input data, a waste stream module that normalizes and sums the amount of waste produced by each of the plurality of resource consumer devices per amount of useful work produced, and an output module that determines costs associated with operating the plurality of resource consumer devices based at least in part on the amount of the one or more consumable resource consumed by each of the plurality of resource consumer devices and the normalized and summed amount of waste produced by each of the plurality of resource consumer devices.

Owner:ALARIS COMPANY

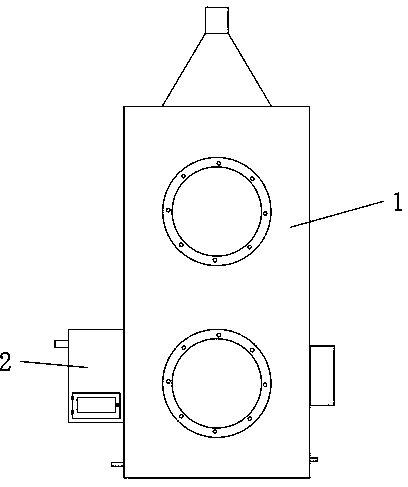

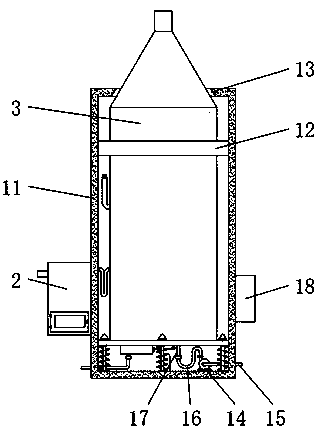

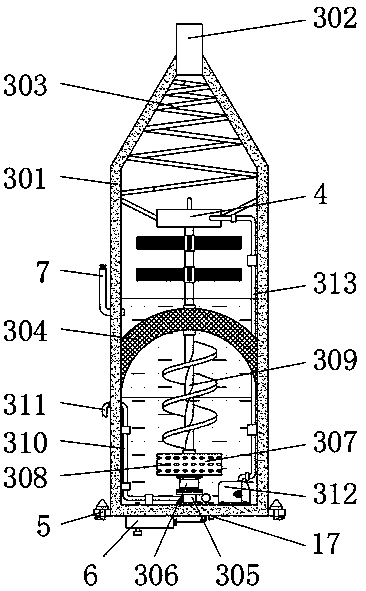

Energy-saving type multiple-effect VOCs purification reactor

ActiveCN110548368AExtended retention timeImprove processing efficiencyGas treatmentDispersed particle filtrationSupersaturationWaste generation

The invention discloses an energy-saving type multiple-effect VOCs purification reactor. The energy-saving type multiple-effect VOCs purification reactor comprise a purification device, and a filter device is arranged on the left side of the purification device; an absorption device operates under pushing of waste gas, absorption liquid is stirred, thus gas-liquid turbulence degree is improved, VOCs can be promoted to enter into the absorption liquid, the rate of the VOCs entering the absorption liquid is increased, the adsorption liquid is sprayed through a spraying mixing device, thus the adsorption liquid is mixed with the waste gas in a fogdrop mode, the waste gas is purified again, the purification effect is further improved, meanwhile the waste gas and fogdrop can be evenly mixed through the spraying mixing device, the purification effect is advantageously improved, through matching of a weighing device, a liquid placing device and a liquid level control device, the using degreeof the adsorption liquid is monitored, the adsorption liquid is replaced automatically, the problems of waste generation due to incompletion using of the adsorption liquid, and waste gas purificationeffect influenced by supersaturation of the adsorption liquid are avoided, and the practicability of the energy-saving type multiple-effect VOCs purification reactor is improved.

Owner:深圳地环生态科技有限公司

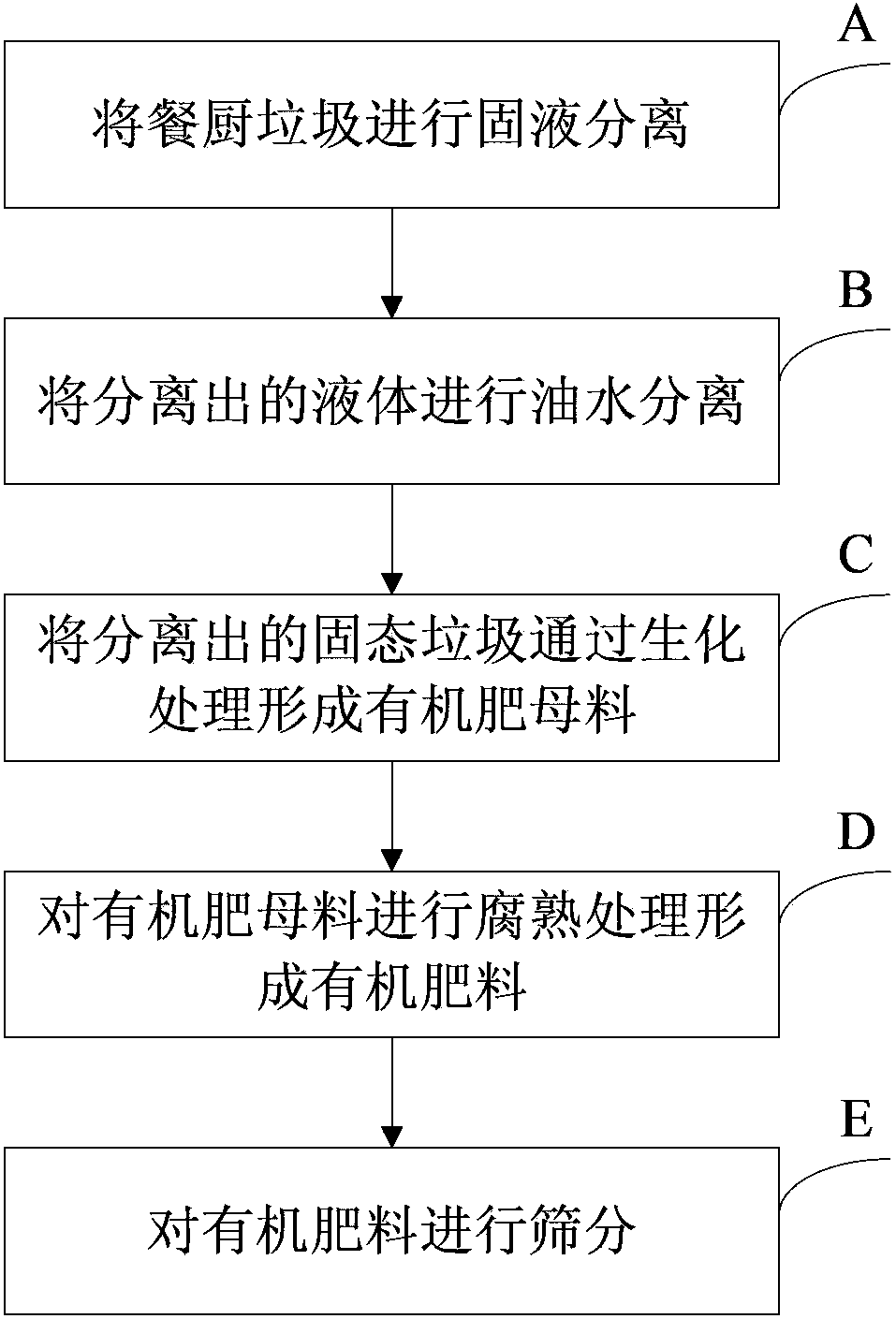

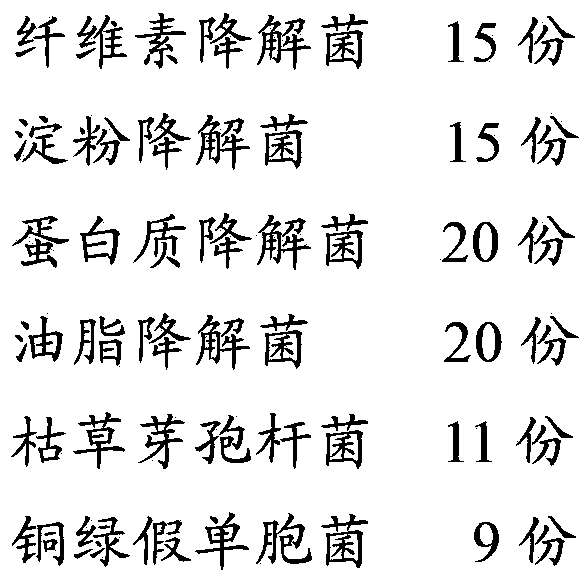

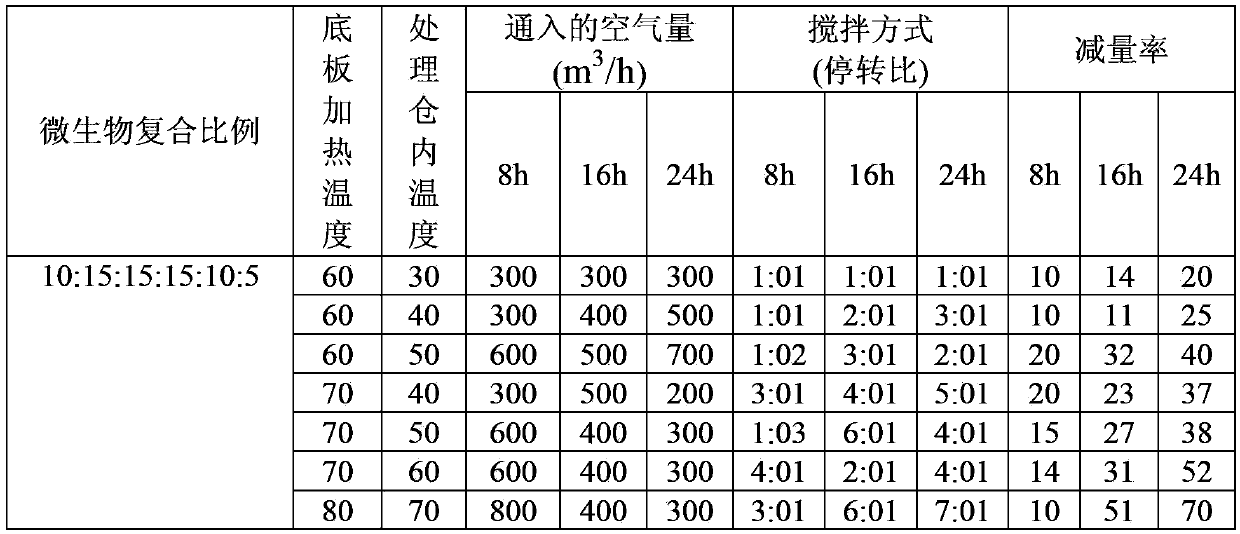

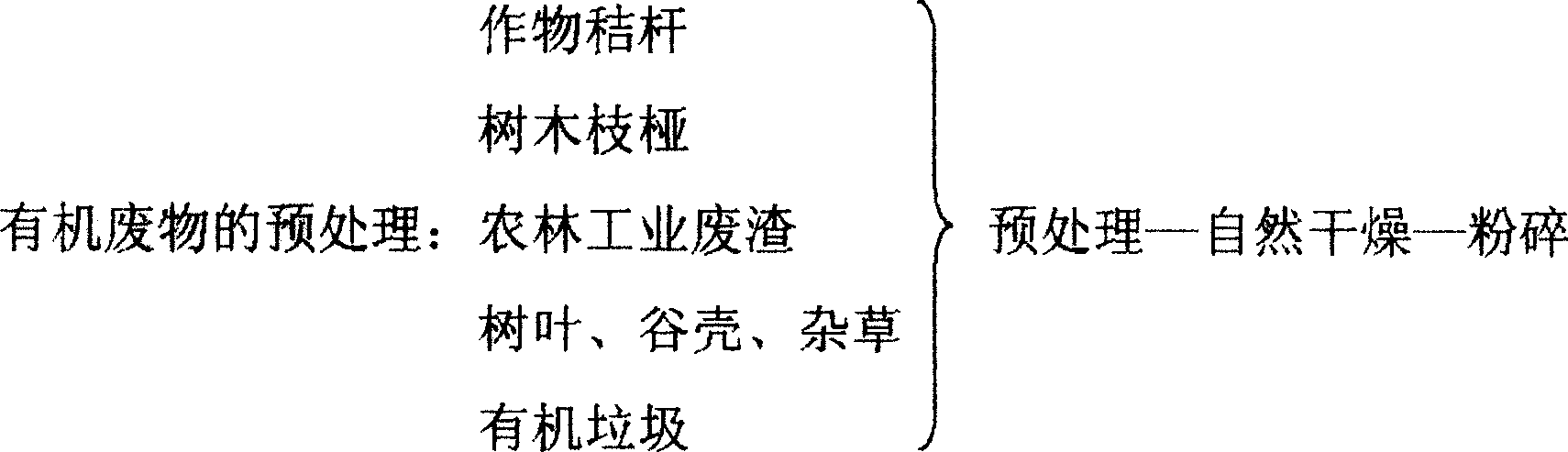

Food waste treatment method

InactiveCN103964902AReduce odorBio-organic fraction processingClimate change adaptationEnvironmental engineeringOrganic fertilizer

The present invention provides a food waste in situ treatment method, which comprises: A, carrying out solid-liquid separation on food waste; B, carrying out a biochemical treatment on the separated solid waste in a treatment bin to form an organic fertilizer master batch; C, carrying out a composting treatment on the organic fertilizer master batch to form an organic fertilizer; and D, screening the organic fertilizer. According to the present invention, the food waste treatment equipment is placed on restaurants, party and government organs, enterprises and institutions, university sites and other waste generation places, the organic domestic food waste is regularly or irregularly treated before rotting so as to reduce the waste transfer link, and the harmless in situ treatment is performed to convert the food waste into the organic fertilizer master batch so as to achieve control of the food waste from the source, such that the waste transportation cost and the landfill burning cost are reduced, and the odor generation during the waste fermentation process is reduced, wherein the whole treatment process is completely sealed.

Owner:BEIJING GREEN ENERGY ENVIRONMENTAL ENG

Organic waste solid moulding fuel and production method thereof

InactiveCN101497836AHigh densityFlat surfaceSolid fuelsWaste based fuelCompression moldingCombustion

The invention discloses organic waste solid forming fuel and a production method thereof. The production method is as follows: organic waste such as straw, and the like is crushed, is compressed and formed by a machine in an organic waste block pressing device, and is used as the fuel to be directly combusted. The combustion rate of the organic waste solid forming fuel reaches up to 90 percent and is 4 times higher than that of the traditional organic waste solid forming fuel. As a combustion manner, the organic waste solid forming fuel has the heat value close to that of coal. And the organic waste solid forming fuel basically has no pollution emission, can be used as the fuel to be widely applied to the fields of the family life and the warming, the industry boiler, and the straw organic waste generation. Compared with other processes, the organic waste solid forming fuel has the characteristics of simple production process and equipment, easy operation, strong adaptability to various organic raw materials, convenient storage and transportation, easy implementation of industrial production and massive use, and the like. The organic waste solid forming fuel is more convenient for use, and is easy to be accepted by people in towns and countryside villages.

Owner:雷菊花

High-efficiency environment-friendly ketene dimer production technique

ActiveCN104262299AReduce analytic phenomenaReduce aggregationOrganic chemistryPtru catalystEthylic acid

The invention discloses a high-efficiency environment-friendly ketene dimer production technique which comprises the following steps: (1) gasifying an acetic acid water solution into acetic acid gas, mixing with a catalyst phase, and cracking in a cracking furnace at 680-698 DEG C to generate ketene gas, wherein the outlet pressure of the cracking furnace is controlled at the absolute pressure value of 2-20 KP; (2) delivering the purified ketene gas to an absorption unit with a vacuum pump, wherein the pressures before and after the pump are respectively 2-20 KP and 100-120 KP, and the temperature difference change of the absorption liquid is controlled to be less than 10 DEG C; (3) respectively sending the absorption liquid into a high temperature polymerization tank and a low temperature polymerization tank to perform primary and secondary polymerization, thereby obtaining the crude product ketene dimer; (4) carrying out vacuum rectification on the crude product ketene dimer to obtain a ketene dimer finished product; and (5) under the action of a combustion-supporting oxidizing gas medium, delivering the rectification residue to a combustion furnace to perform oxidation treatment while controlling the delivery pressure at 6-10 kgf / cm<2>. The technique has the advantages of fewer side reactions, high product yield and no solid waste generation.

Owner:南通宏信化工有限公司

New process for fixing carbon dioxide

InactiveCN103170226AAchieve full absorptionSolve pollutionCalcium/strontium/barium carbonatesProductsReaction temperatureDissolution

The invention relates to a new process for fixing carbon dioxide and in particular relates to a new method for absorbing carbon dioxide with low concentration by using alkaline wastes. The new process comprises the steps of mixing the alkaline wastes with a certain weight of water, then adding ammonium chloride solution for dissolution to prepare calcium chloride solution and filling CO2 to generate calcium carbonate precipitates. CO2 in the low concentration range can be absorbed by controlling the gas flow rate and the reaction temperature, so that the limitation that CO2 with concentration being more than 30% (volume ratio) can be only absorbed by the traditional methods is overcome, thus achieving complete absorption and near-zero emission of CO2. The process avoids new waste generation when being used for fixing carbon dioxide and meets the requirements of cyclic economy and low-carbon economy.

Owner:杨晓林

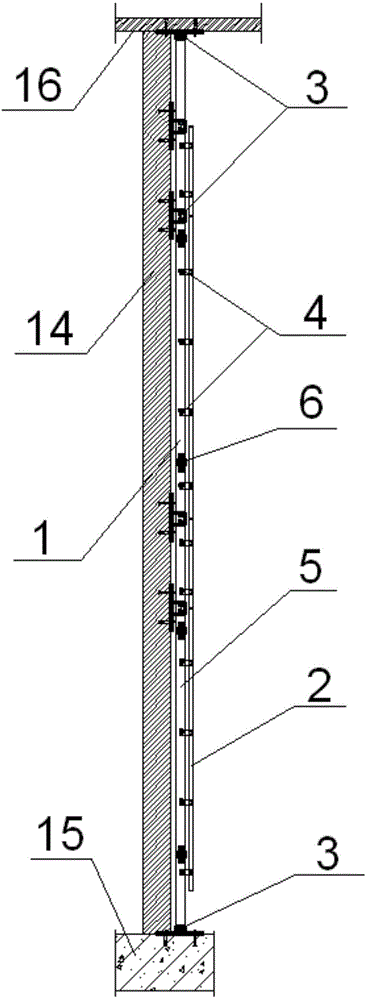

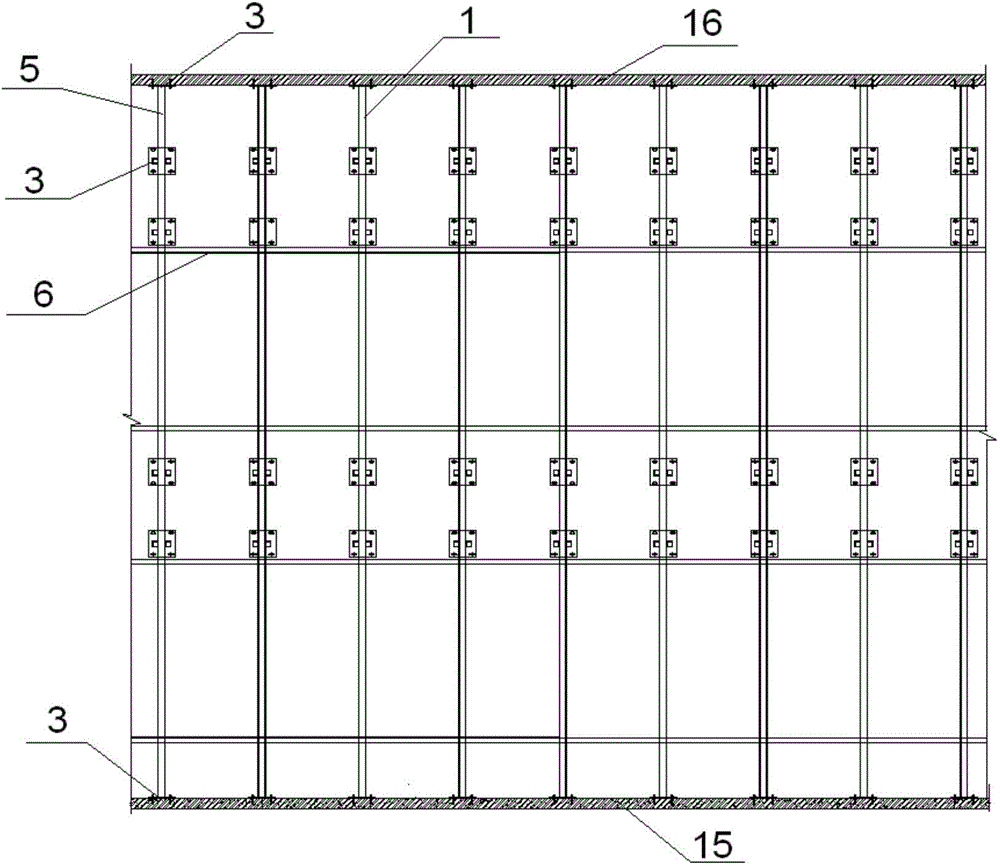

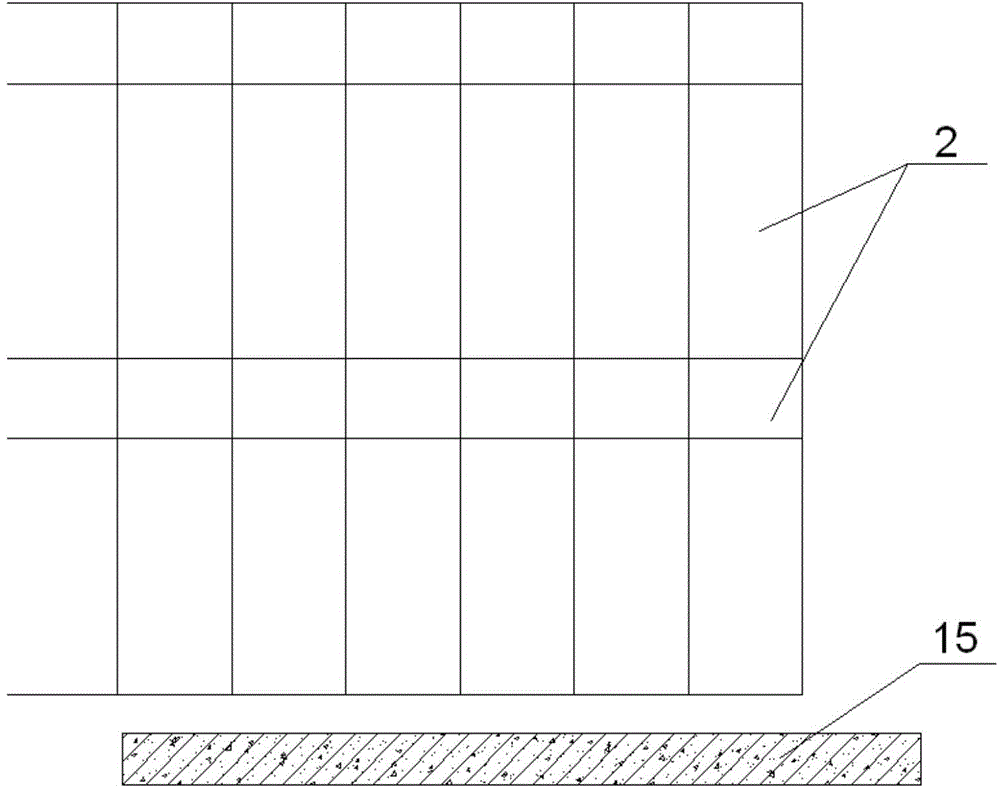

Wall-face dry-hanging system of large metal aluminum sheet

InactiveCN104358374AOvercome precisionOvercoming Fire HazardsCovering/liningsEngineeringFire prevention

The invention discloses a wall-face dry-hanging system of a large metal aluminum sheet. The system comprises a steel support (1), an aluminum sheet (2) and a plurality of support fixing devices (3), wherein the steel support (1) is fixedly arranged on a wall body (14) through the support fixing devices (3); the steel support (1) is also fixedly connected with ground (15) and a ceiling (16) through the support fixing devices (3); the aluminum sheet (2) is in limiting supporting connection with the steel support (1) through steel fasteners (4). The system overcomes the defects of poor accuracy, fire hidden trouble, serious labor consumption, high waste generation rate, low procedure efficiency and the like caused by massive welding in a traditional wall-face installation way of the large metal aluminum sheet, and has the advantages of convenience in construction, reliable quality, seismic resistance, fire prevention, corrosion prevention, unlikely deformation, environmental protection, easy maintenance and the like.

Owner:CHINA CONSTR DONGFANG DECORATION CO LTD

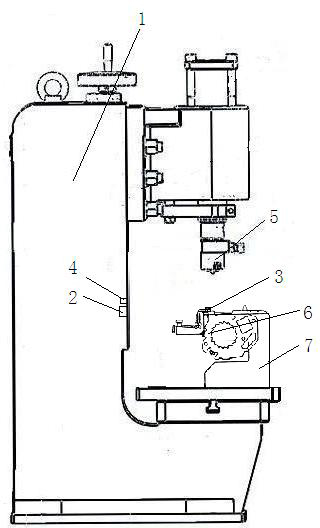

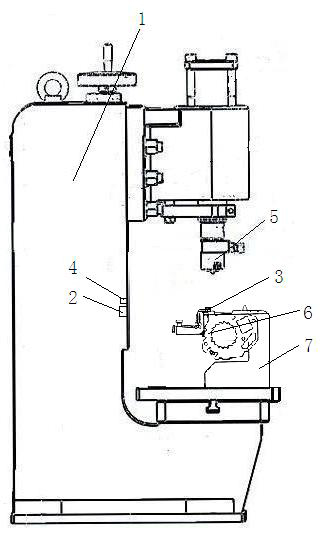

Riveting pressure detection device

InactiveCN102279418AReduce generationSame diameterOptical detectionUsing optical meansEngineeringLaser light

The invention discloses a riveting pressure detection device, which is characterized in that it includes a laser sensor arranged on a fixed frame at the riveting station, the laser light emitted by the laser sensor points to the position of the rivet to be riveted, and the fixed frame There is also a sensor for detecting the height of the riveting point of the rivet after riveting, and the laser sensor and the sensor are both connected to a control unit. The riveting detection device of the present invention uses a laser sensor to detect whether the rivets are complete before riveting, and then starts riveting after they are complete. If there are no rivets, the workpiece will not be riveted, and the workpiece will be automatically transferred to the next step by the control device. Work station, re-enter the riveting process after the rivet is loaded, reducing the generation of waste products. After riveting, the height sensor is used to detect whether the height of the riveting point of the rivet is standard, so as to ensure that the diameter of the riveting point is consistent and the quality of the riveting product is guaranteed.

Owner:SIP GOLDWAY TECH

Community organic matter in-place digestion degradation biogas preparation electrical power generating system, and applications thereof

InactiveCN105296337AShort processReduce processing costsBioreactor/fermenter combinationsInternal combustion piston enginesHigh concentrationNew energy

The invention provides a community organic matter in-place digestion degradation biogas preparation electrical power generating system. According to the community organic matter in-place digestion degradation biogas preparation electrical power generating system, kitchen waste of each household in a community is smashed into small particle organic waste, and is mixed with toilet wastewater of each household and community green garbage, and high concentration waste water is obtained via concentration; the high concentration waste water is subjected to anaerobic digestion so as to obtain biogas and a digestion liquid; biogas is subjected to desulfuration purifying so as to obtain pure biogas, the biogas is used for generating electric energy via combustion in an internal combustion engine, and electric energy is recycled back to users in the community; the digestion liquid is treated so as to obtain a fertilizer and terminal waste water; and terminal waste water is subjected to simple treatment in septic tanks, and then is discharged into municipal sewage pipe networks. The community organic matter in-place digestion degradation biogas preparation electrical power generating system is capable of realizing pretreatment of waste sources, and in-place anaerobic digestion, so that technological process is short, treatment cost is low; kitchen waste is not stacked or transported, environment pollution is not caused, and transportation cost is reduced; and at the same time, electric energy generated by the community organic matter in-place digestion degradation biogas preparation electrical power generating system can be used, new energy policy subsidies from the government can be obtained, and economic efficiency maximization is realized.

Owner:WISDRI ENG & RES INC LTD

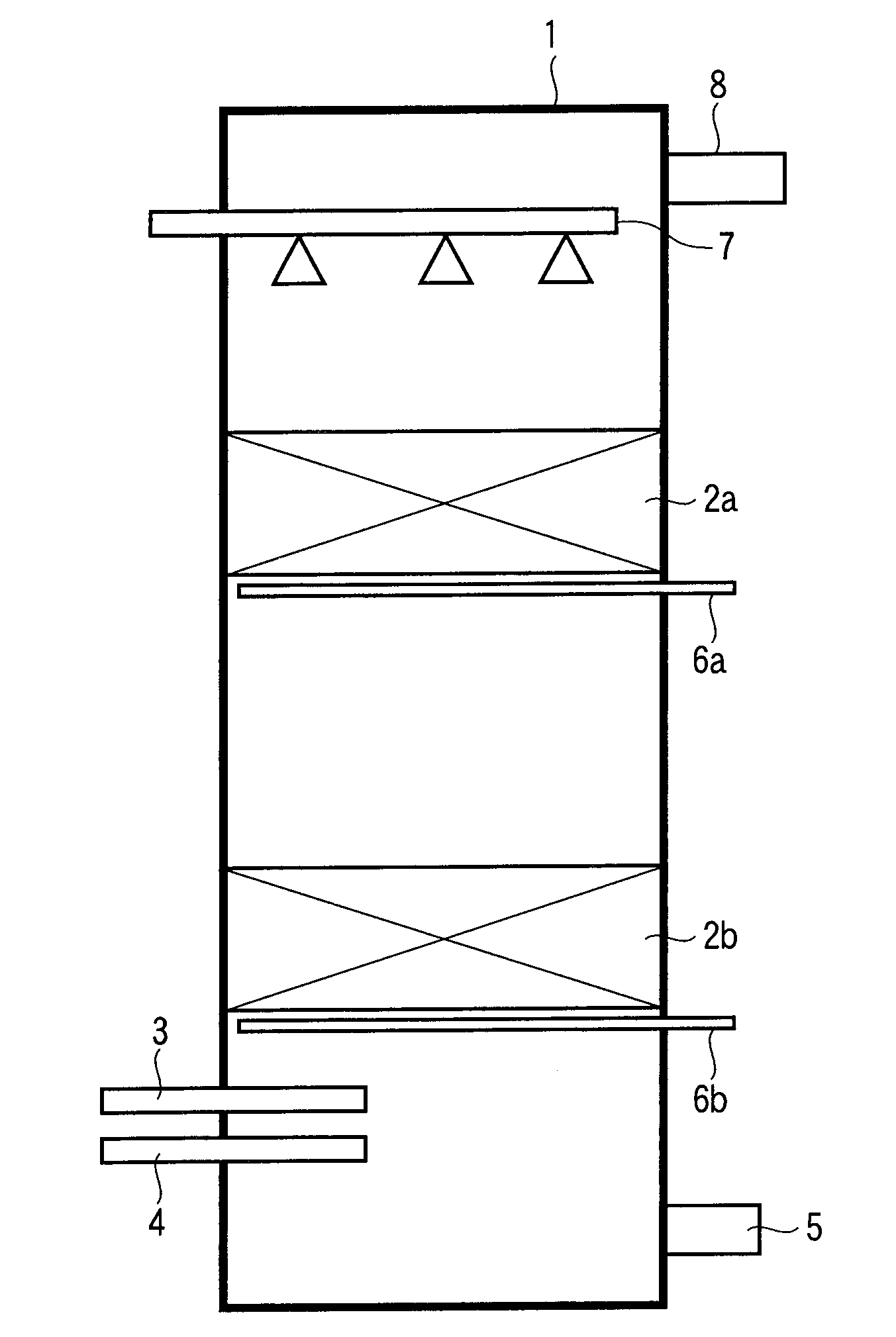

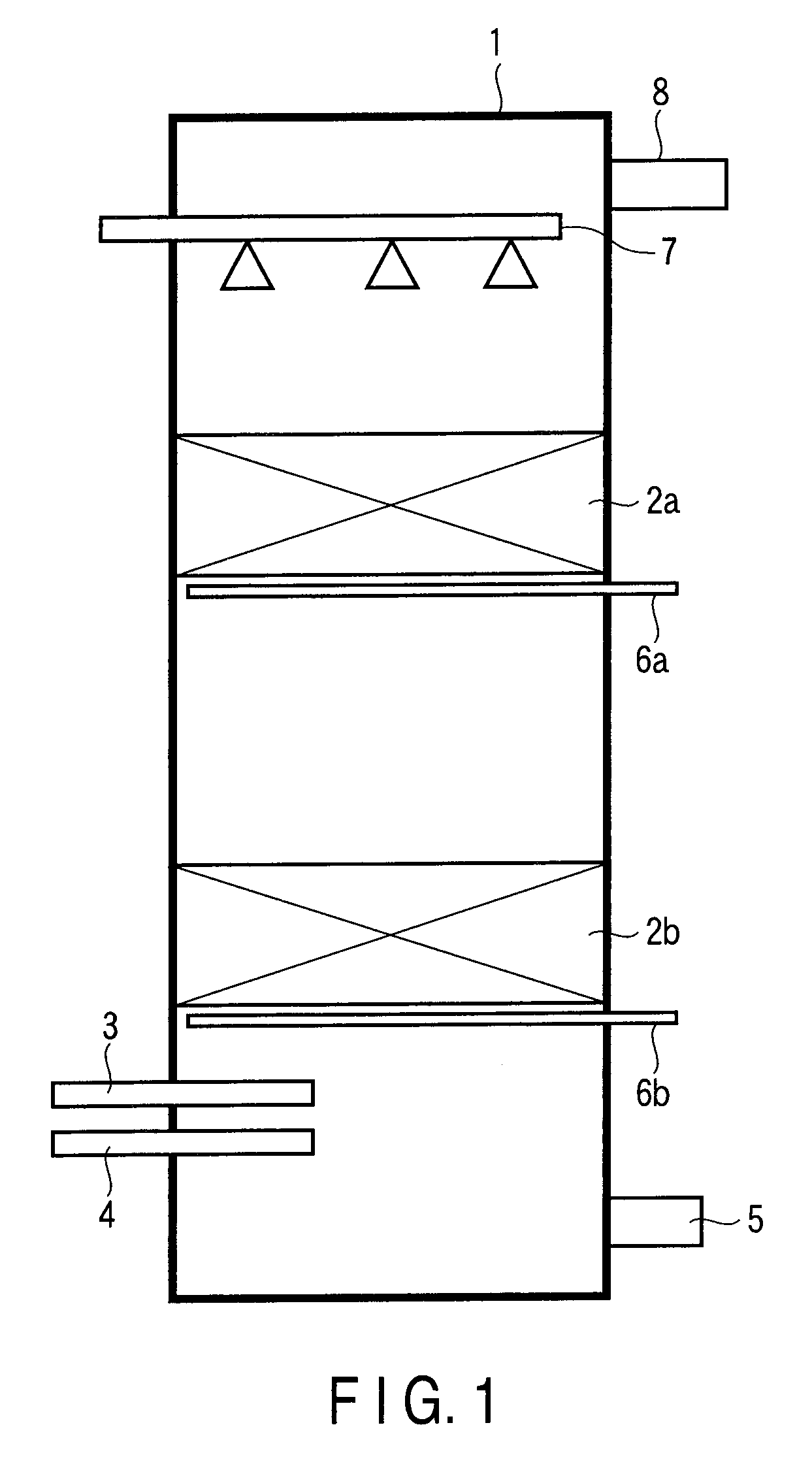

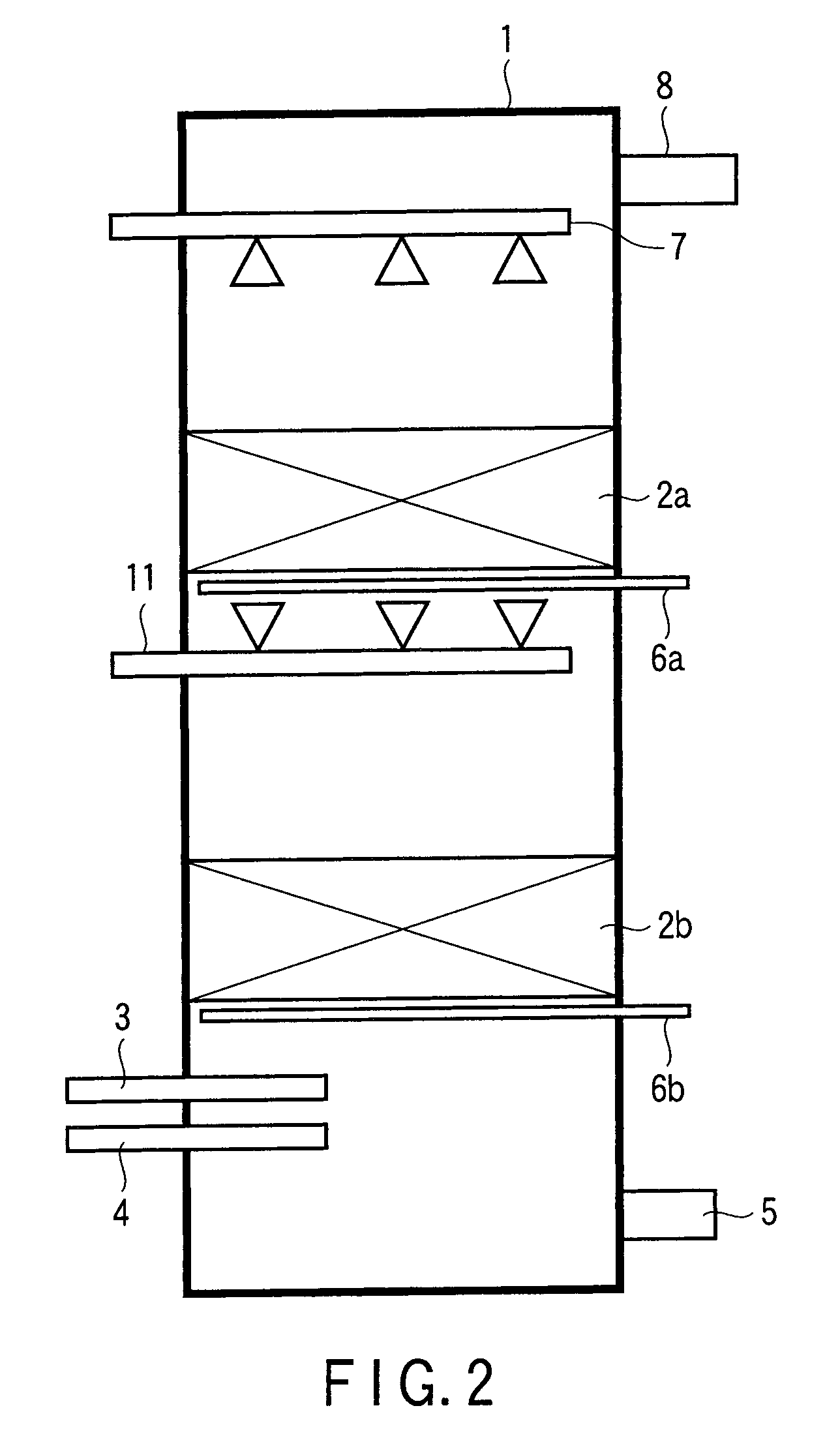

Biological desulfurization apparatus

InactiveUS20100261266A1Treatment stableAvoid cloggingBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemical engineeringTower

Disclosed is a biological desulfurization apparatus including a reaction tower 1 into which biogas generated by anaerobic fermentation of organic waste is to be introduced, a carrier-packed layer 2a, 2b arranged in the reaction tower and provided with a carrier to which microorganisms have adhered, an air feeding pipe 3 that mixes air into a lower part of the reaction tower, and a sprinkling mechanism 7 that sprinkles water on an upper part of the reaction tower, wherein the carrier-packed layer is arranged in two or more stages.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com