Organic waste solid moulding fuel and production method thereof

A technology of solid molding fuel and organic waste, applied in the direction of waste fuel, solid fuel, fuel, etc., can solve the problems of rare production methods, and achieve the effect of low cost, smooth surface and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] (1) First determine the parameters of each process:

[0028] Natural drying moisture content < 12%, crushed particle size 10 mm, one or more than two kinds of mixture, drying moisture content < 8% - 9%, compaction molding 50 - 100 MPa, about 100 ° C - 120 ° C, Finished product volume: 1 / 9-1 / 10 of the original volume, natural cooling temperature: 60°C--15°C, use matching special furnace: patent ZL200620095488.1 Jin'an Vulcan JN-1 energy-saving furnace:

[0029] (2) The production process of the method:

[0030] —Mixed material—drying—compression molding—finished product discharge—natural cooling—packaging—using a special furnace

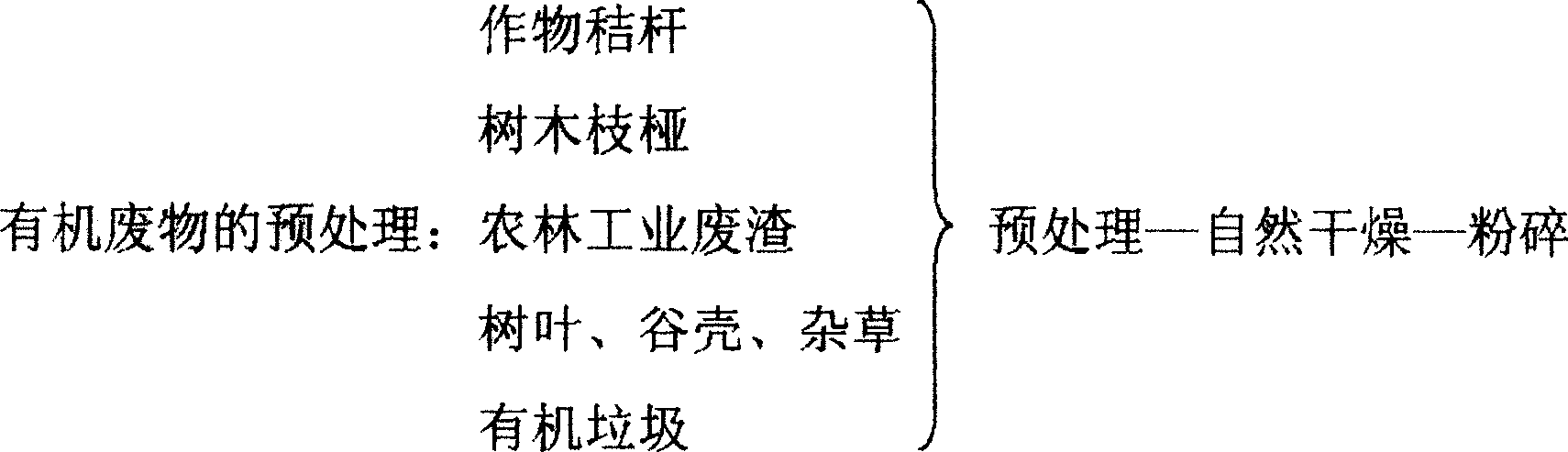

[0031] (3) Pretreatment of organic waste

[0032] ①Crop stalk pretreatment: Harvest crops in good time, remove low-quality, rotten and deteriorated straw, select available straw, and place the freshly harvested straw in the field in a natural drying method to let it dry in the sun. Light exposure dehydration, natural drying, moisture conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com