Patents

Literature

177results about "Cobalt sulfates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

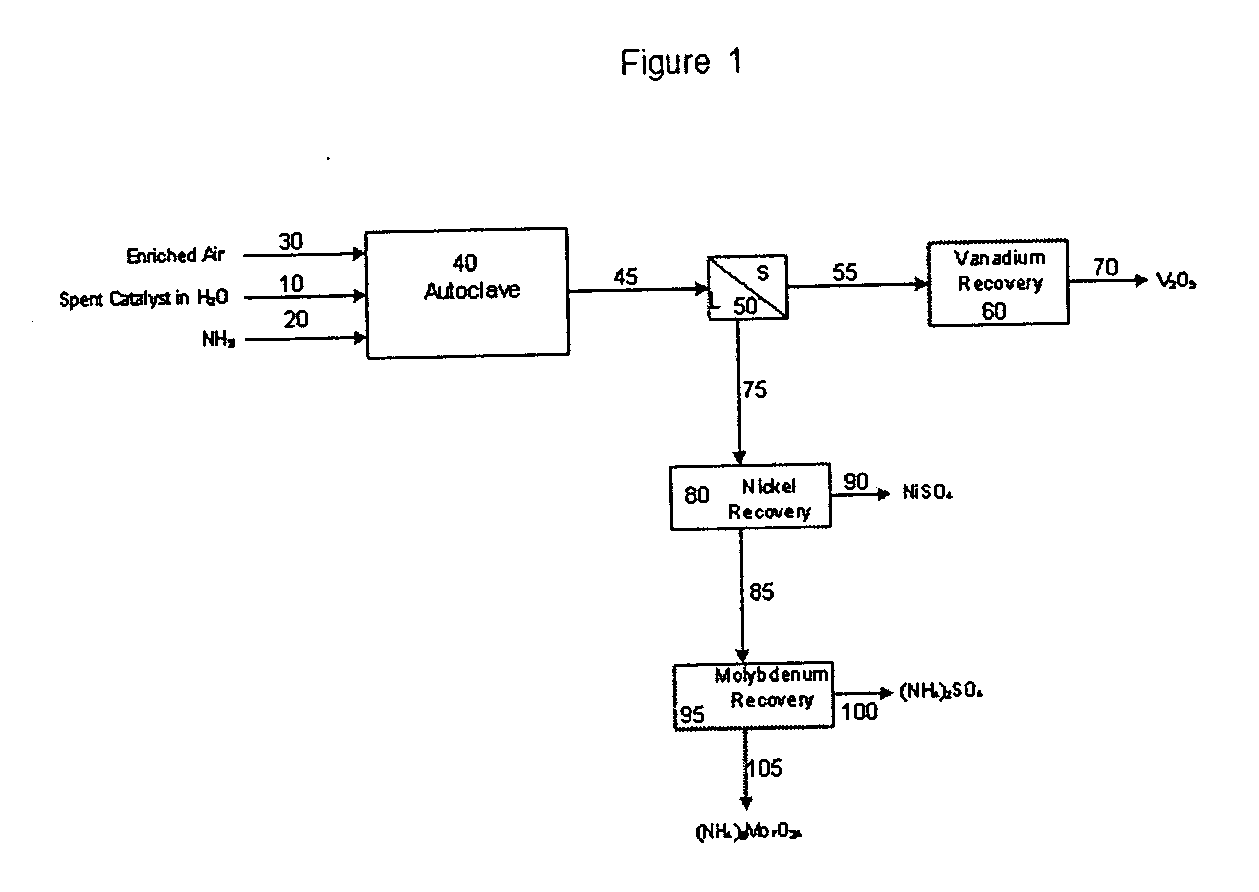

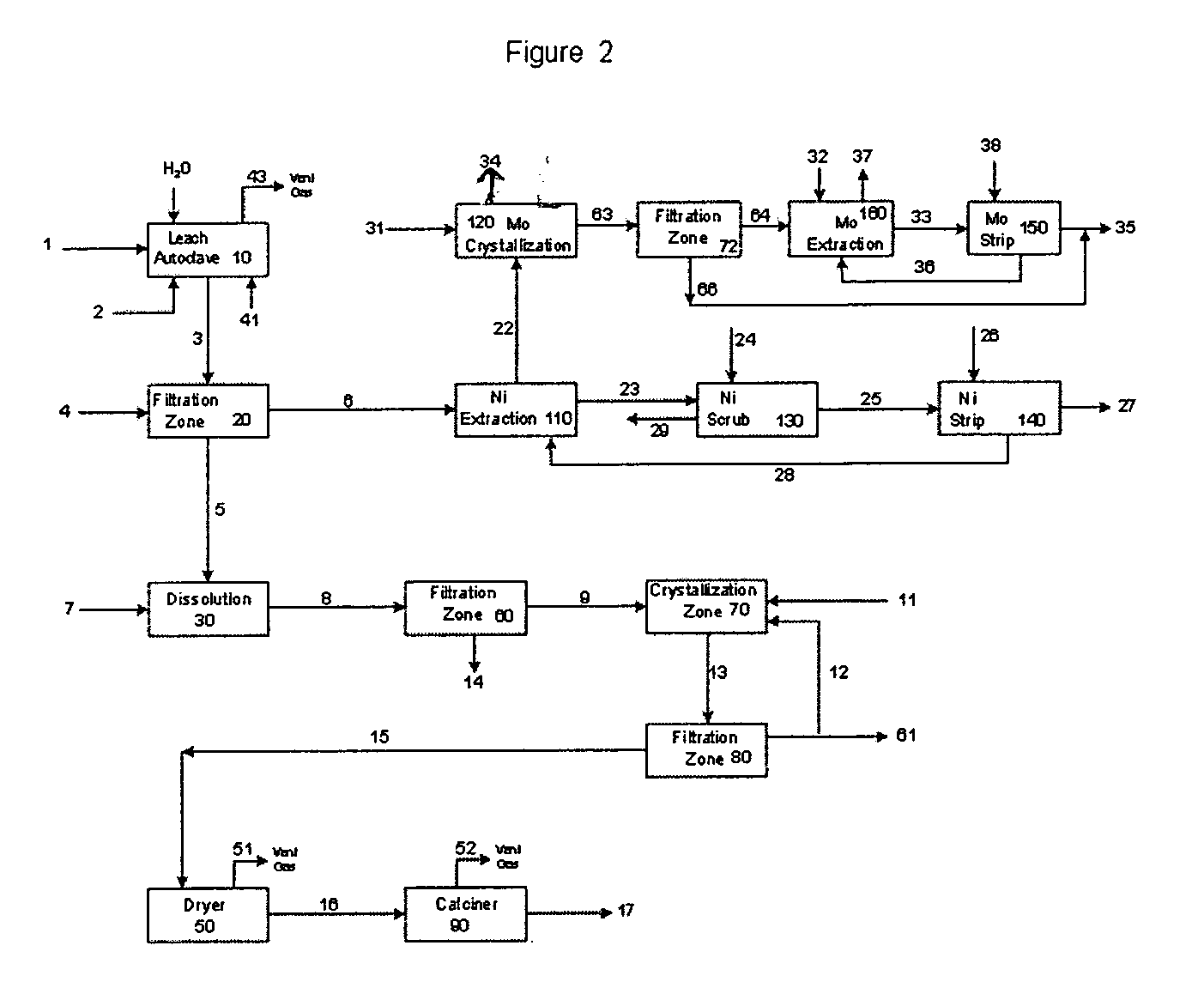

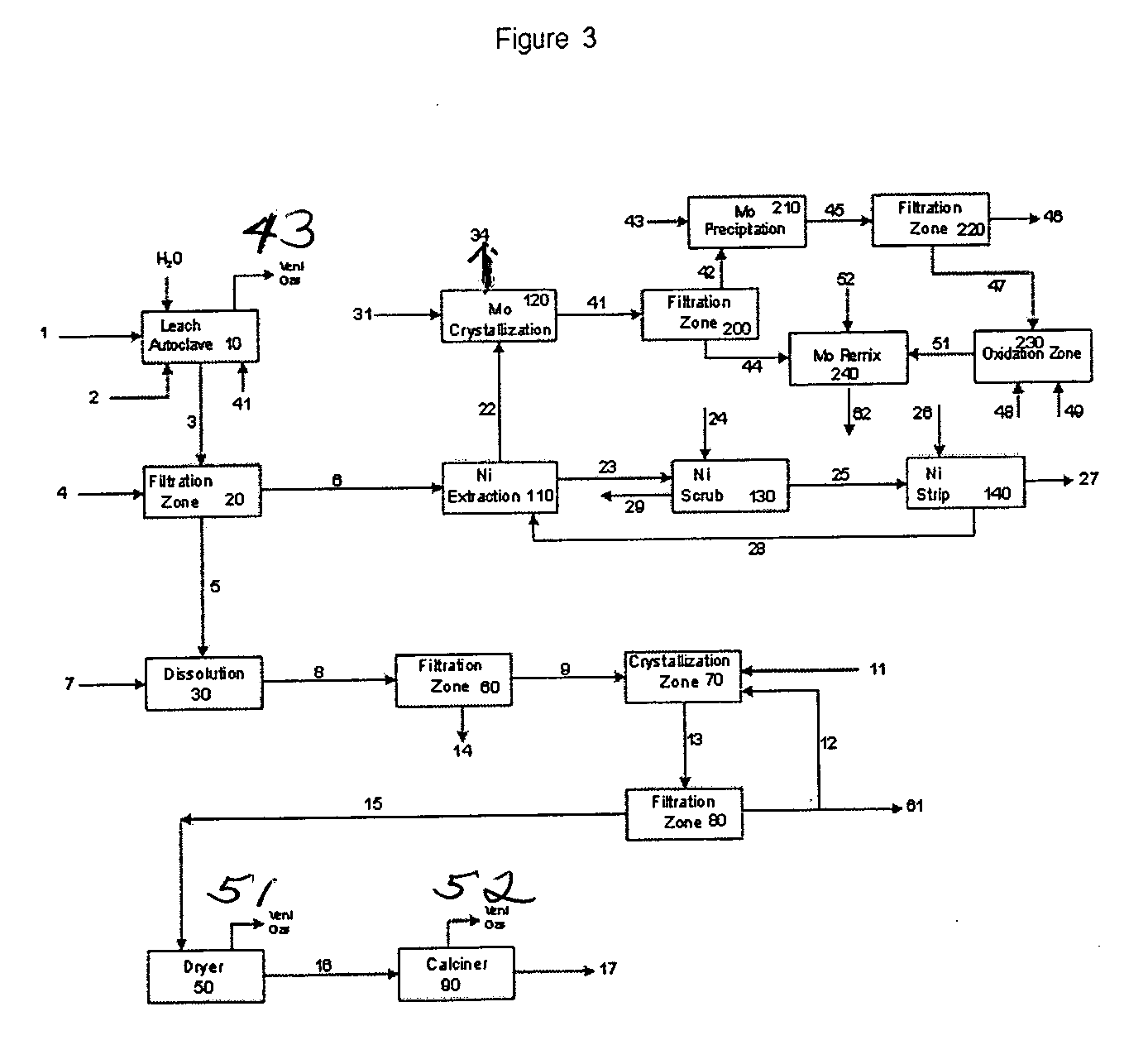

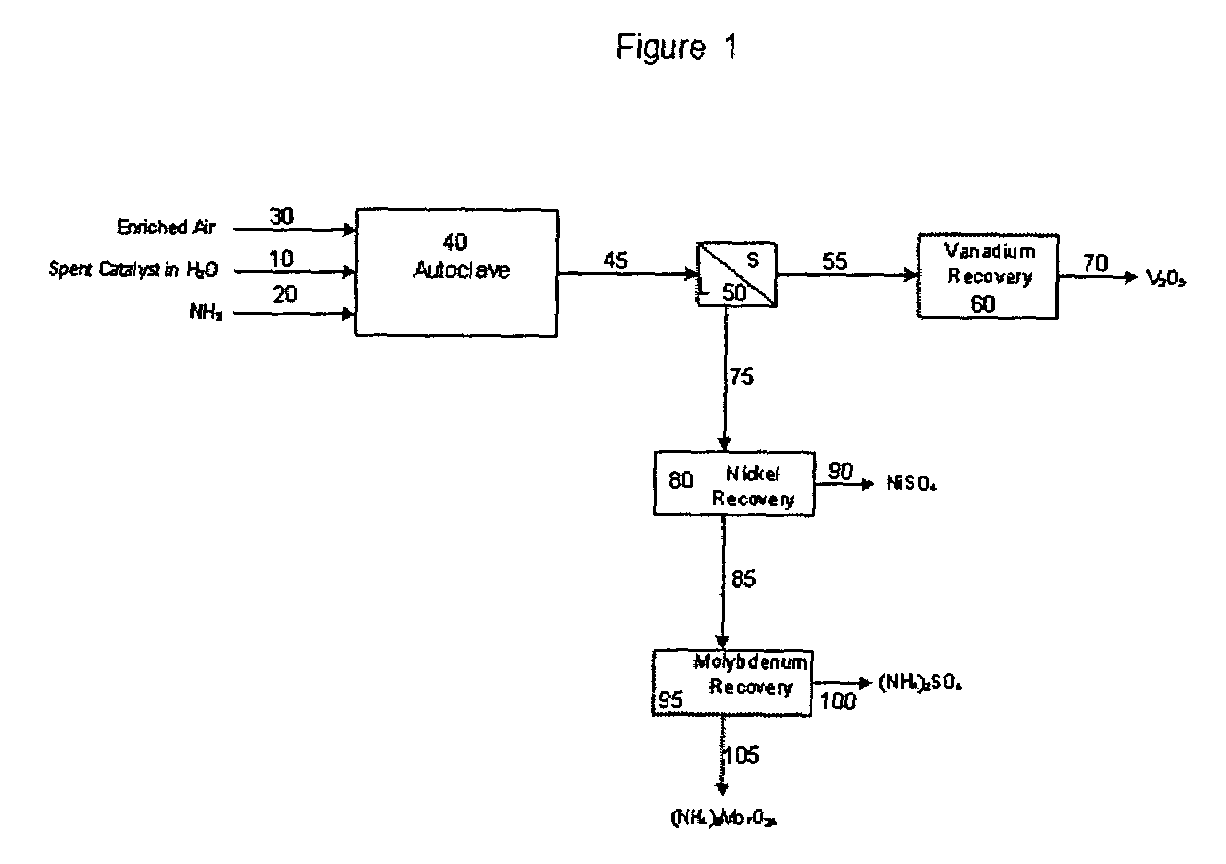

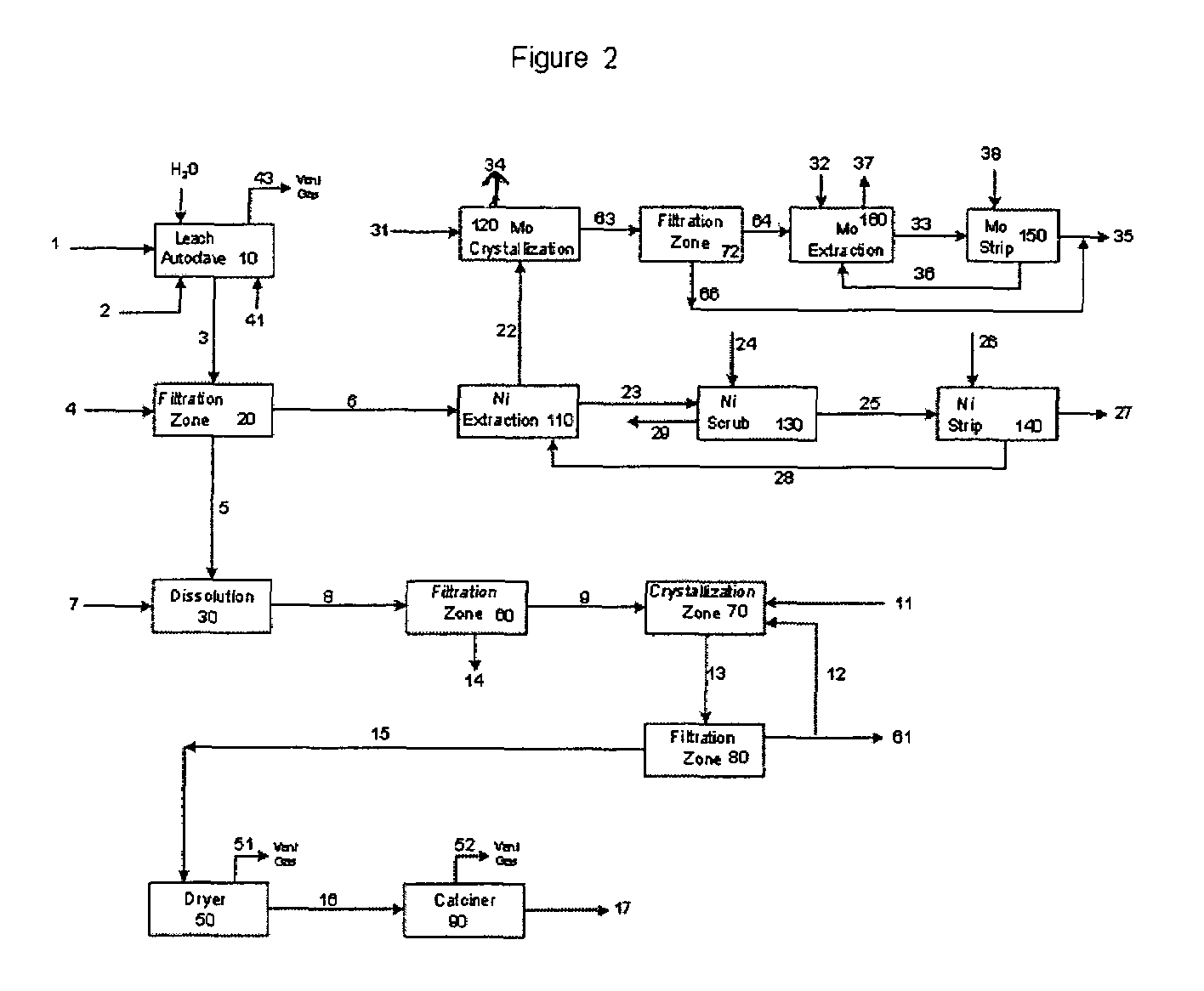

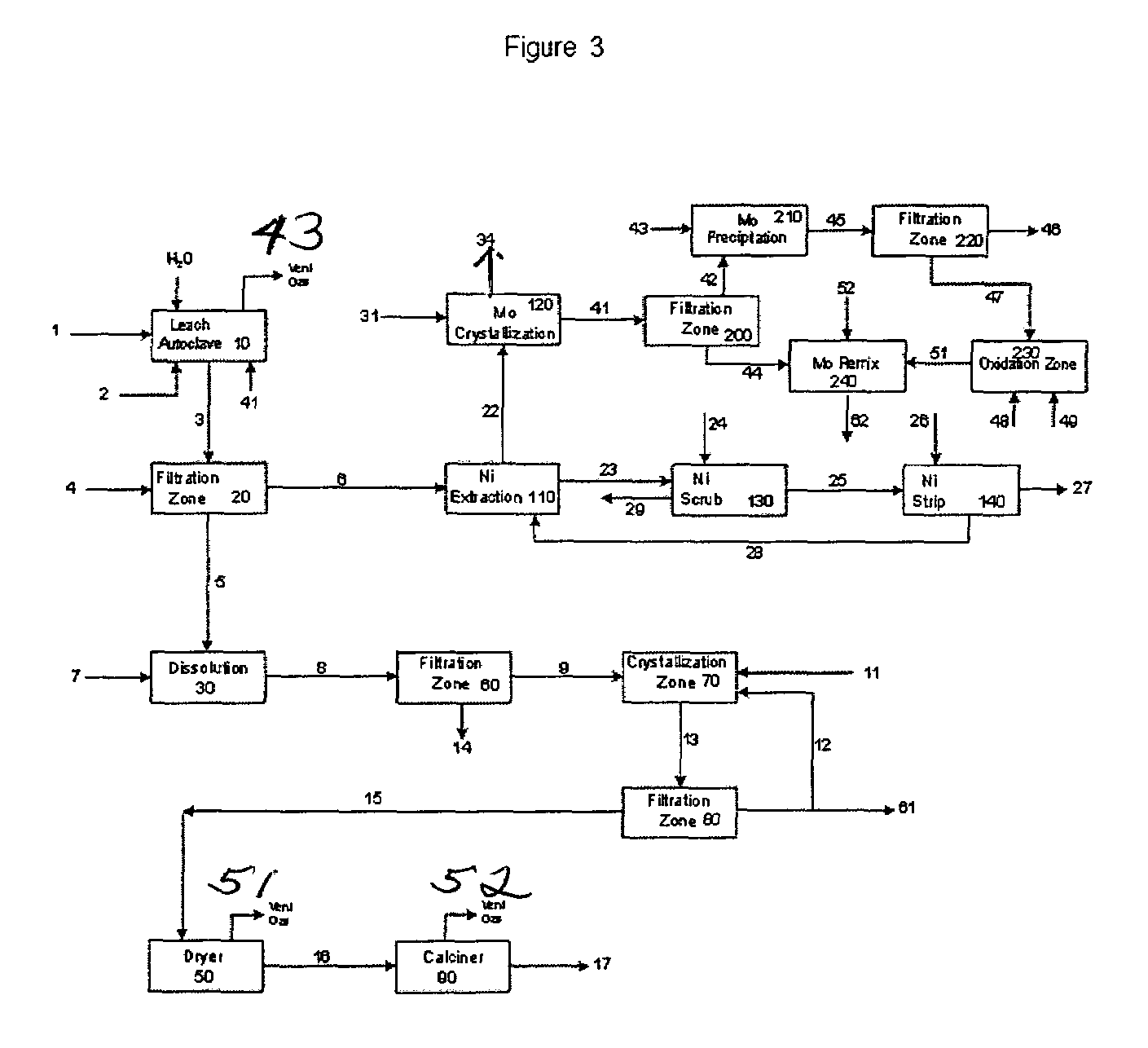

Process for metals recovery from spent catalyst

The process of this invention is directed to the removal of metals from an unsupported spent catalyst. The catalyst is subjected to leaching reactions. Vanadium is removed as a precipitate, while a solution comprising molybdenum and nickel is subjected to further extraction steps for the removal of these metals. Molybdenum may alternately be removed through precipitation.

Owner:CHEVROU USA INC

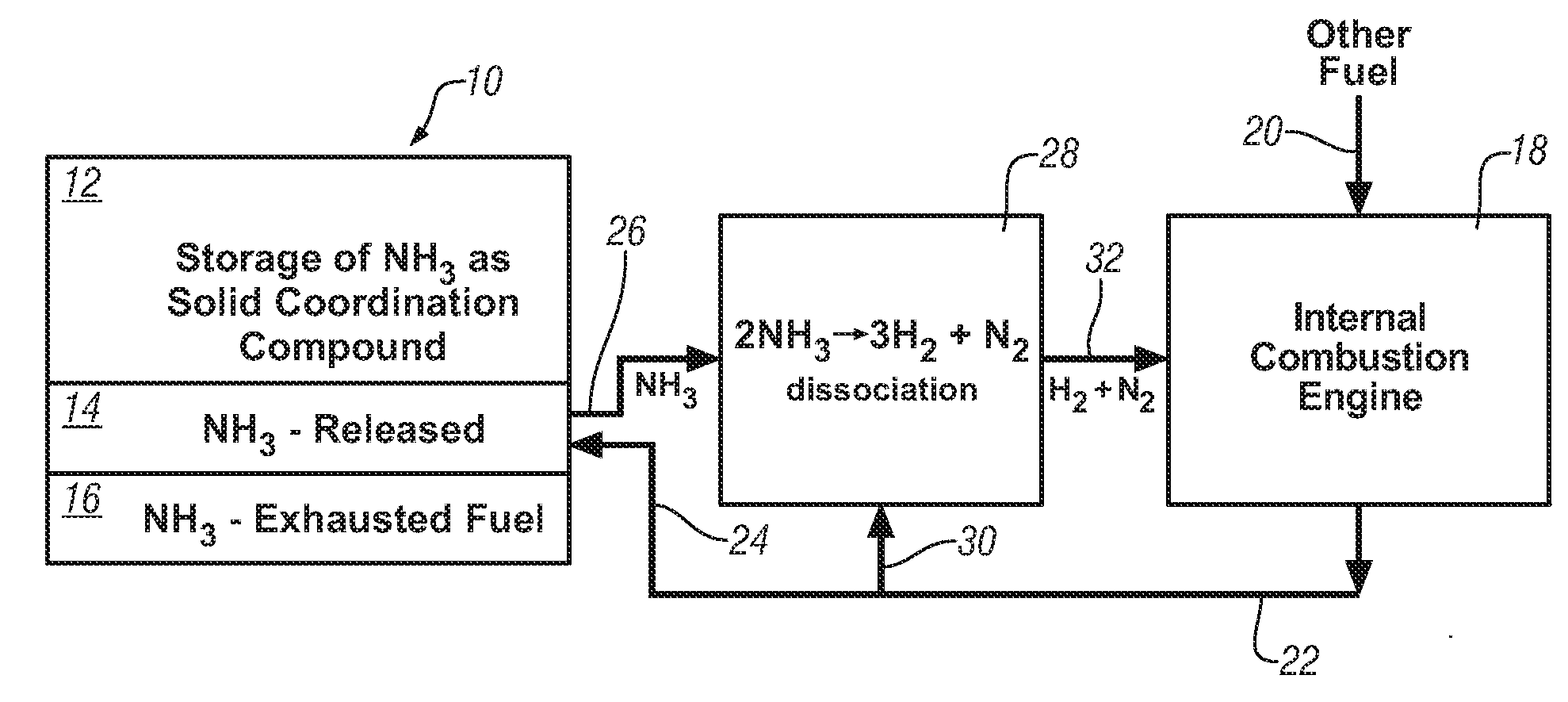

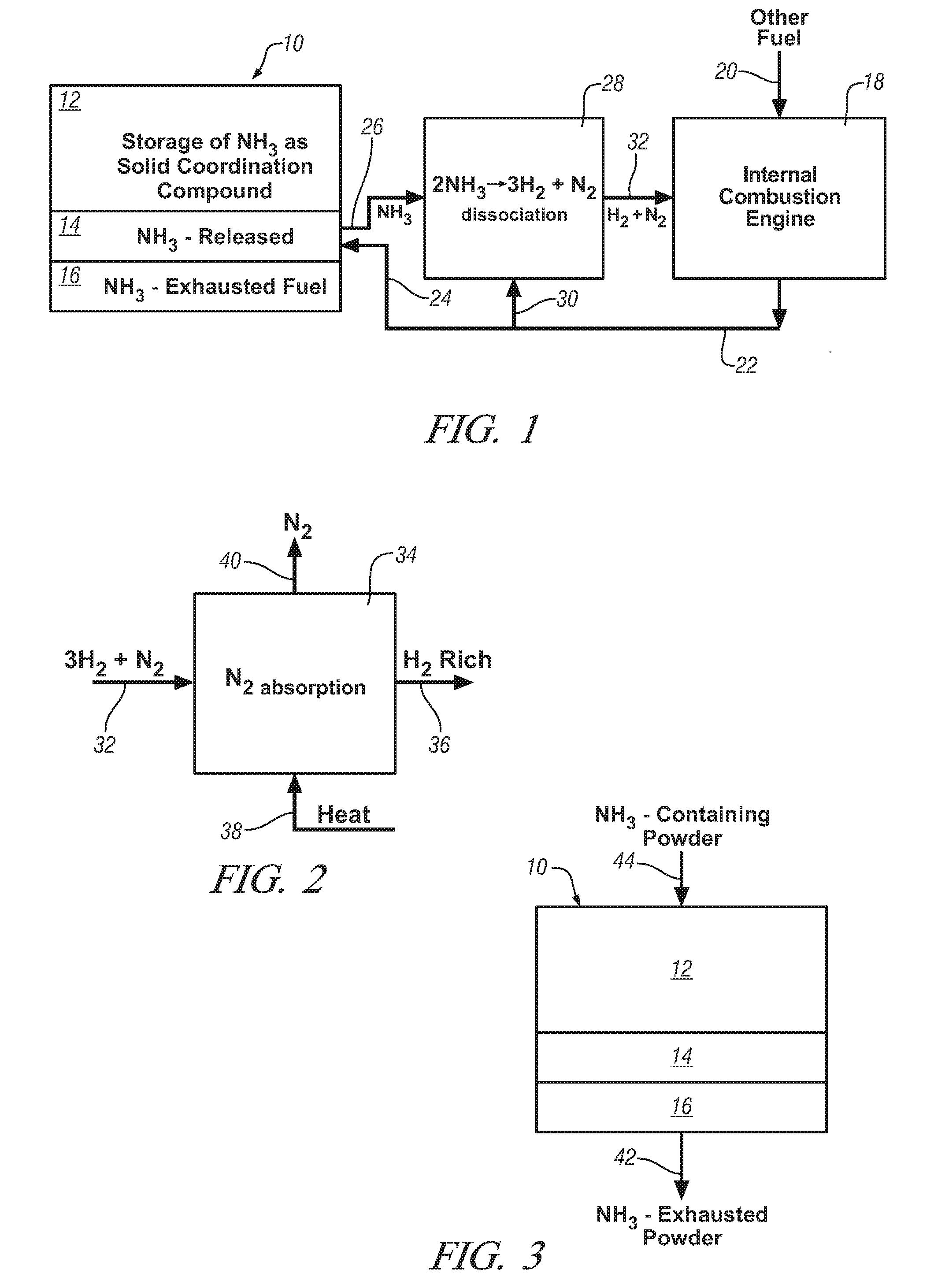

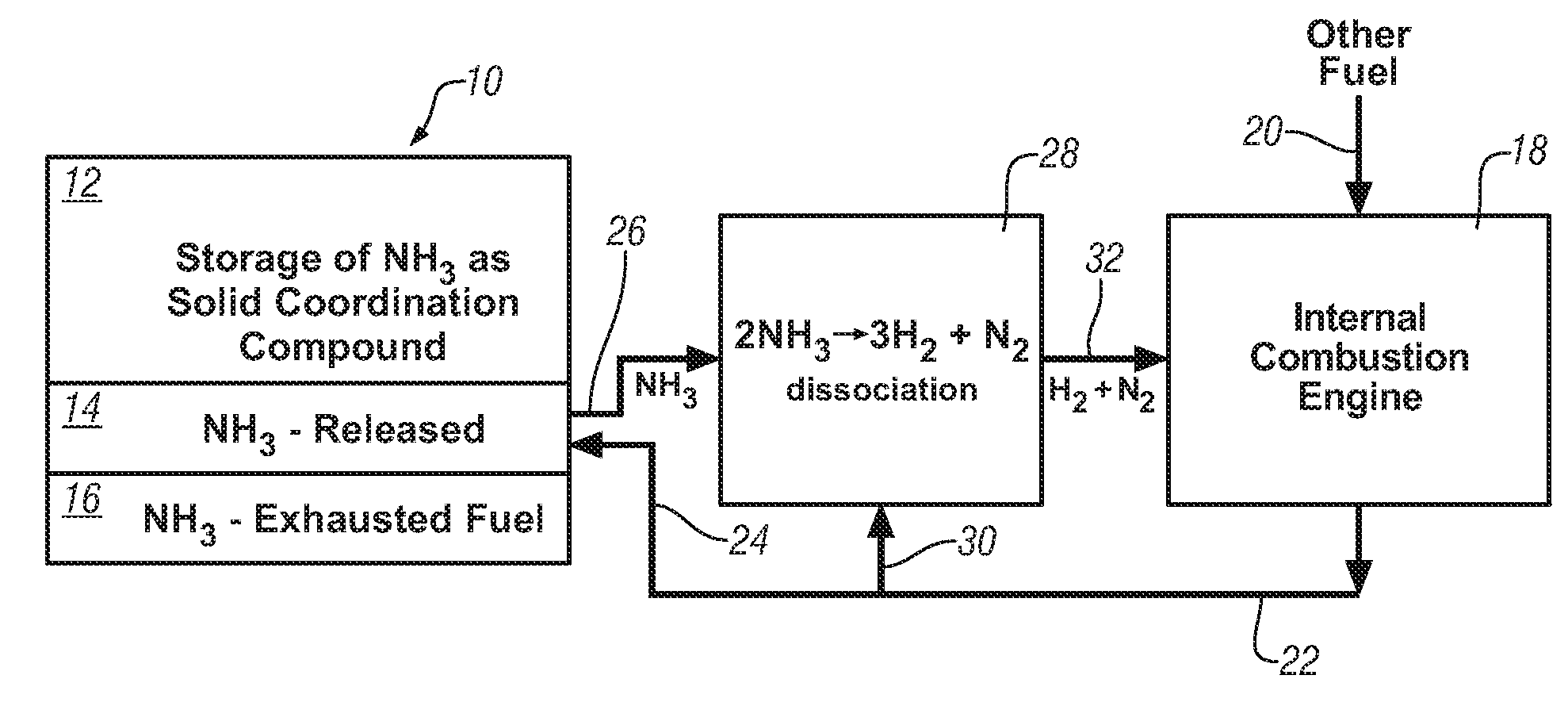

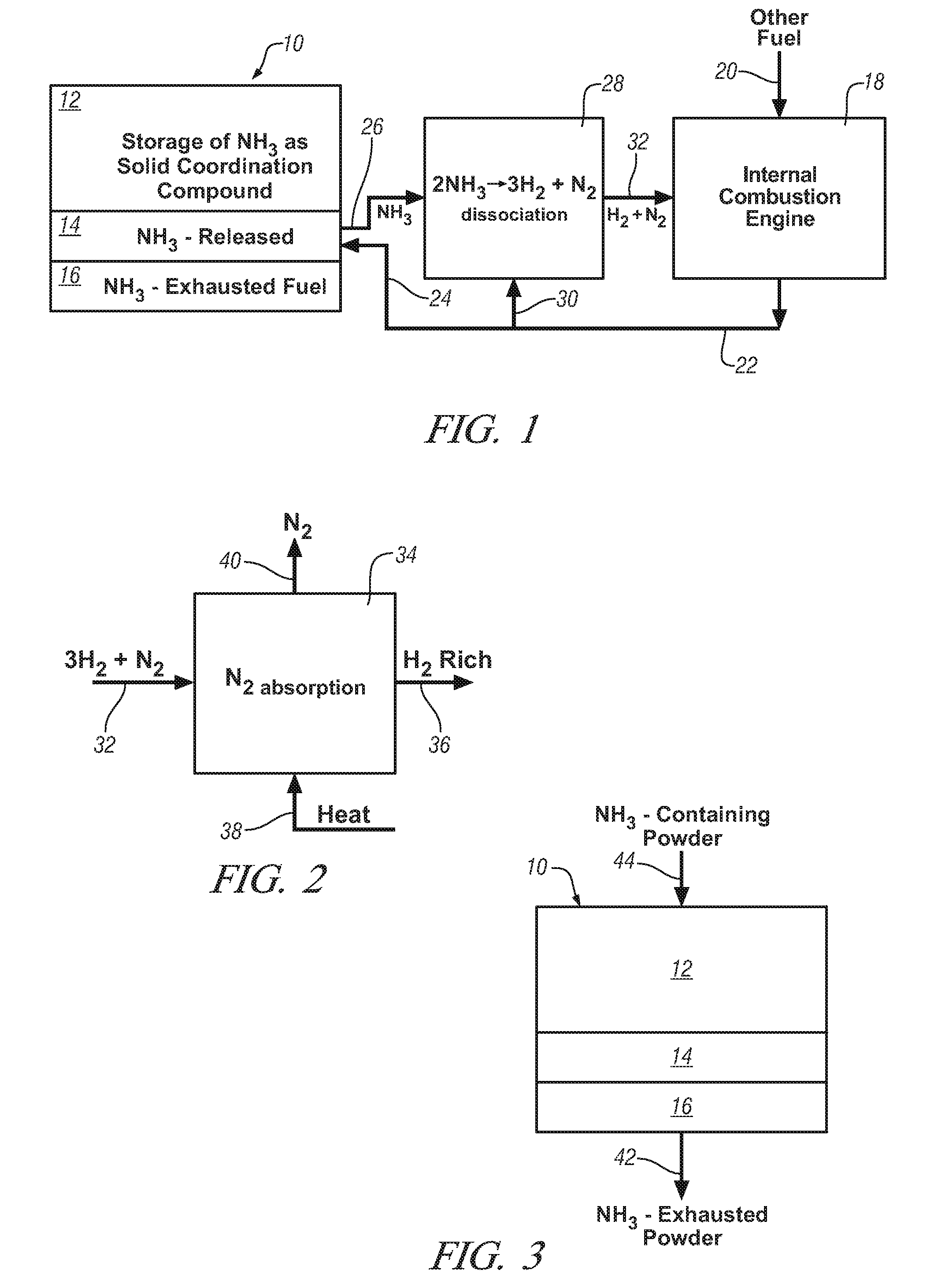

Ammonia storage for on-vehicle engine

InactiveUS20080241033A1Efficient and reversible processCobalt ammonia complexesCyanogen compoundsAmmonia storageExternal combustion engine

Ammonia is used as precursor source of hydrogen fuel in an on-vehicle internal combustion engine. Ammonia is stored as, for example, a ligand in an on-vehicle transition metal composition. Upon demand for hydrogen by the vehicle's engine control system, ammonia is expelled as a gas from some of the composition and the ammonia gas is dissociated into a mixture of hydrogen and nitrogen and delivered as a fuel-containing mixture to the engine. In a preferred embodiment, the hydrogen is used as a supplement to gasoline as a fuel for engine operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

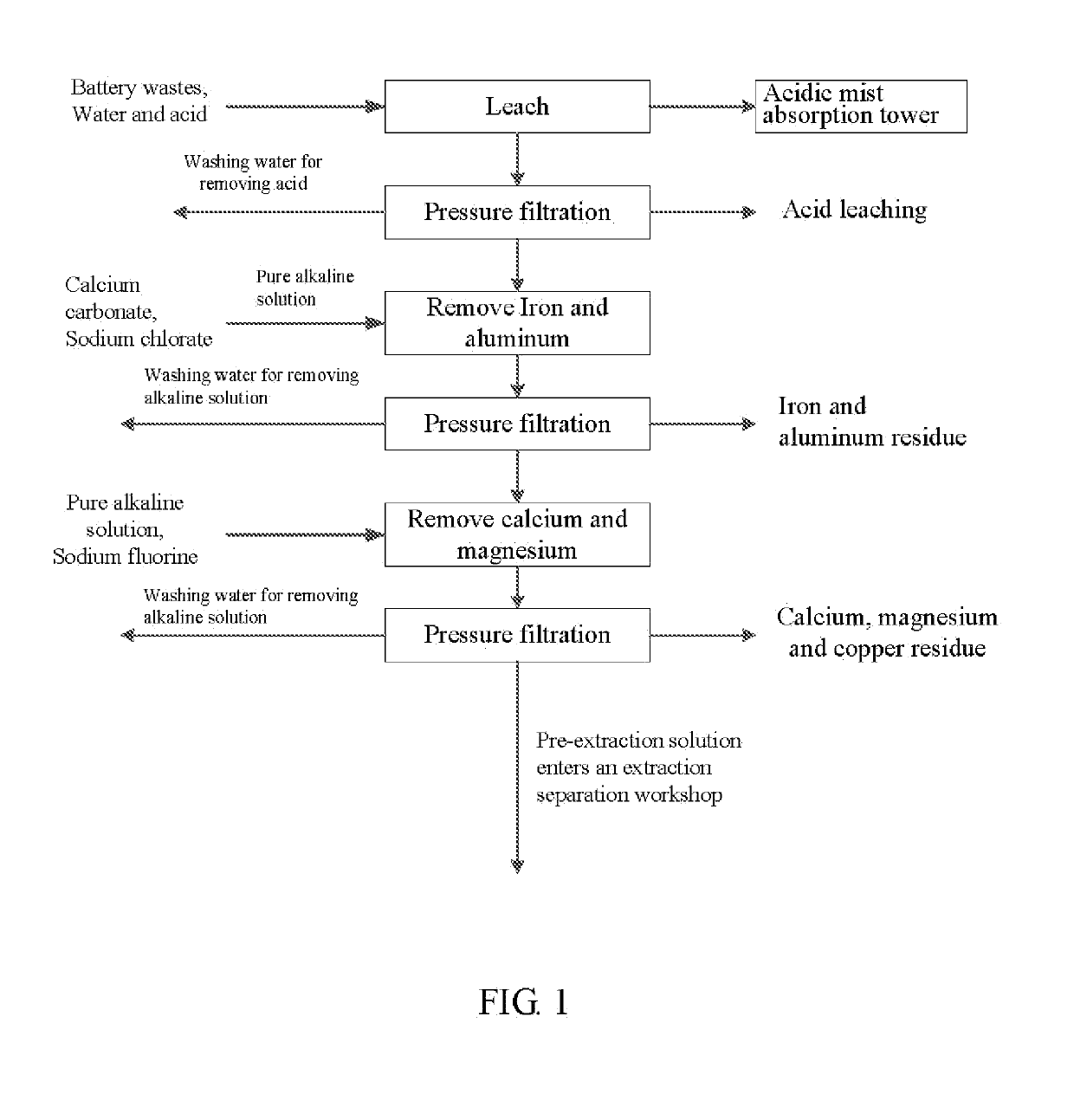

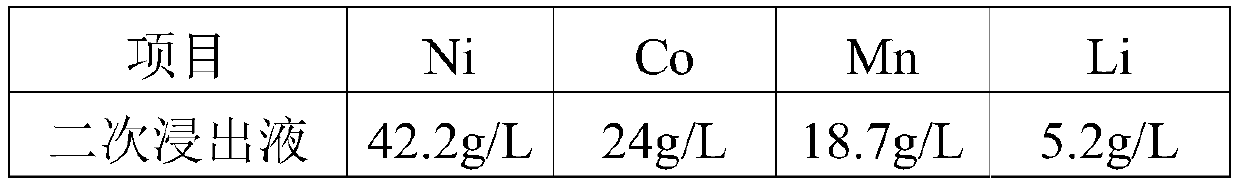

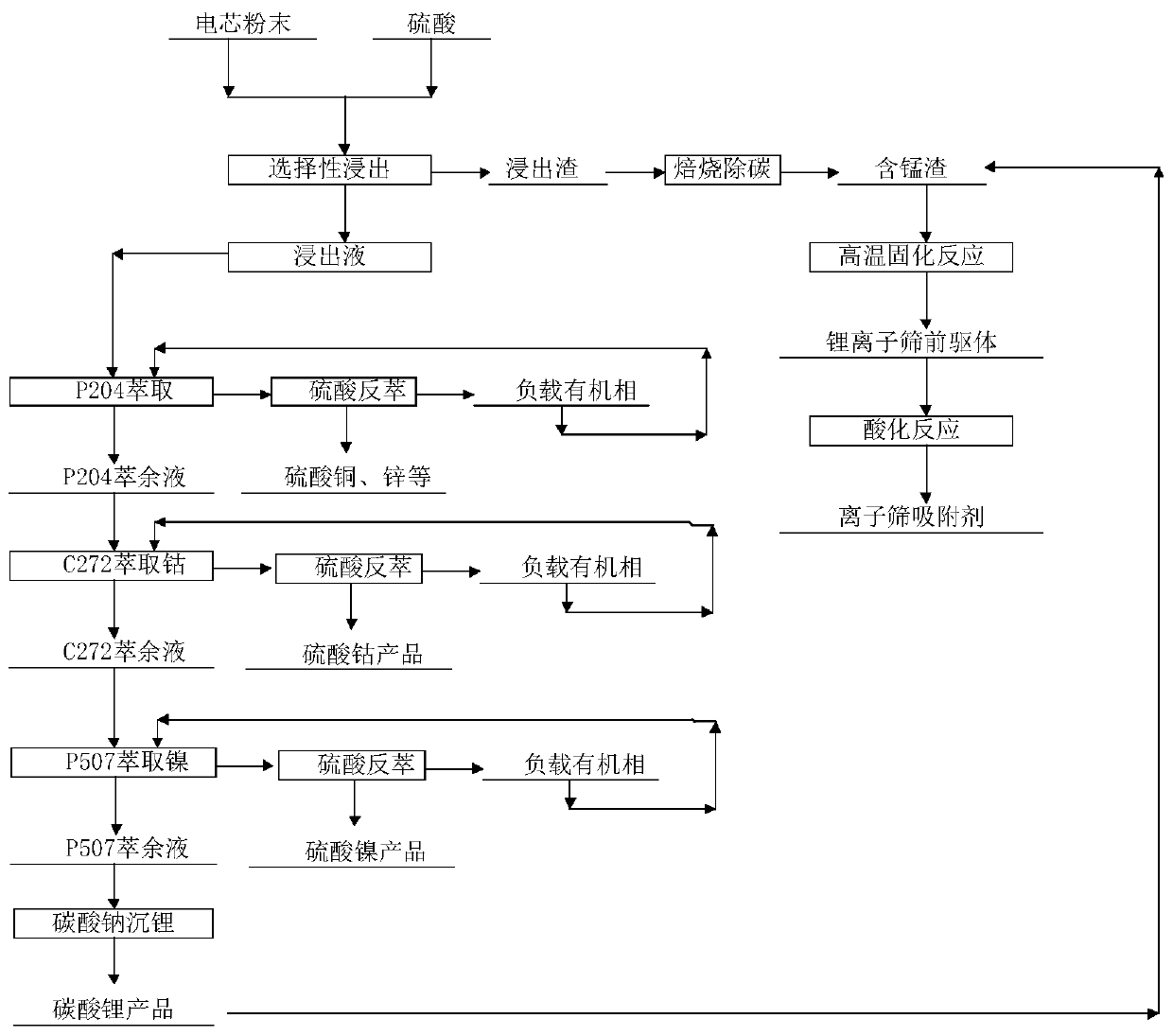

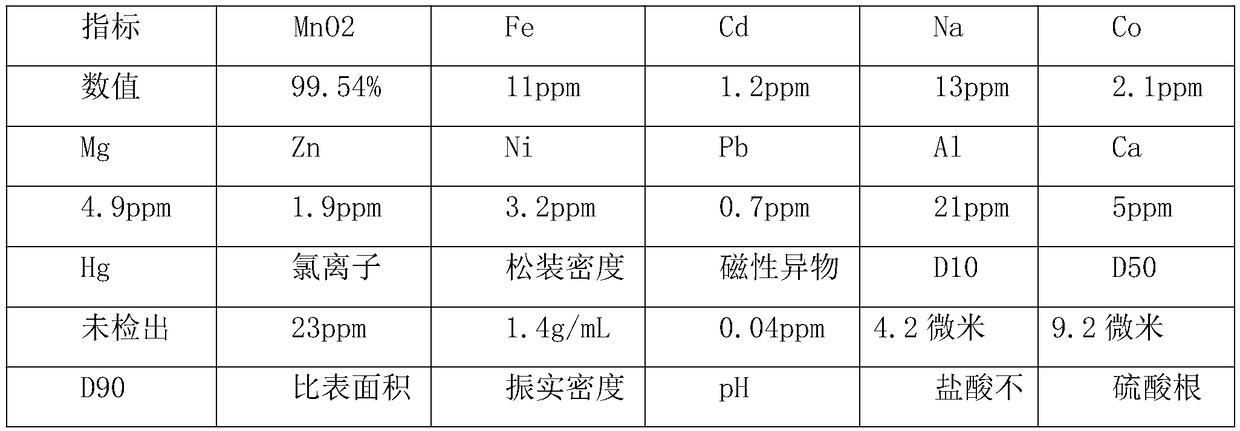

Method for preparing nickel/manganese/lithium/cobalt sulfate and tricobalt tetraoxide from battery wastes

ActiveUS20190152797A1Reduce productionHigh puritySolvent extractionCobalt sulfatesManganeseCobalt Sulfate

A method for preparing nickel / manganese / lithium / cobalt sulfate and tricobalt tetraoxide from battery wastes adopts the following process: dissolving battery wastes with acid, removing iron and aluminum, removing calcium, magnesium and copper, carrying extraction separation, and carrying out evaporative crystallization to prepare nickel sulfate, manganese sulfate, lithium sulfate, cobalt sulfate or / and tricobalt tetraoxide. By using the method, multiple metal elements, such as nickel, manganese, lithium and cobalt, can be simultaneously recovered from the battery wastes, the recovered products are high in purity and can reach battery grade, battery-grade tricobalt tetraoxide can also be directly produced. The method is simple in process, low in, energy consumption and free in exhaust gas pollution, and can realize zero release of wastewater.

Owner:HUNAN JINYUAN NEW MATERIALS CO LTD

Recovery method for valuable metal in waste nickel-cobalt-manganese ternary lithium batteries

The invention discloses a recovery method for valuable metal in waste nickel-cobalt-manganese ternary lithium batteries. According to the recovery method, Fe2+, Al3+, Ca2+ and Mg2+ are subjected to impurity removal before extraction is carried out, so that the purity of valuable metal products recovered in the following process is high. During cobalt extraction, the oil-water ratio is controlled to be (0.8-0.9):1, the saponification rate is controlled to be 55%-60%, compared with the prior art that the saponification rate is reduced and the oil-water ratio is properly reduced, cobalt in a water phase is controlled to be not completely extracted, a small amount of cobalt is still left in the water phase, thus, it is guaranteed that magnesium is not extracted up, and it is guaranteed that magnesium impurities in cobalt sulfate products reach standards. One step of magnesium extraction operation is added after cobalt extraction and before nickel extraction, residual magnesium is removed as much as possible, and the purity of nickel sulfate products obtained after nickel extraction is improved. A C272 extracting agent is used for magnesium extraction, by means of the characteristic that extraction isothermal curves of the C272 extracting agent on cobalt, magnesium and nickel are separated, the situation that only magnesium and cobalt are extracted and nickel is not extracted is controlled, and therefore magnesium and nickel are separated.

Owner:ZHEJIANG TIANNENG NEW MATERIAL CO LTD

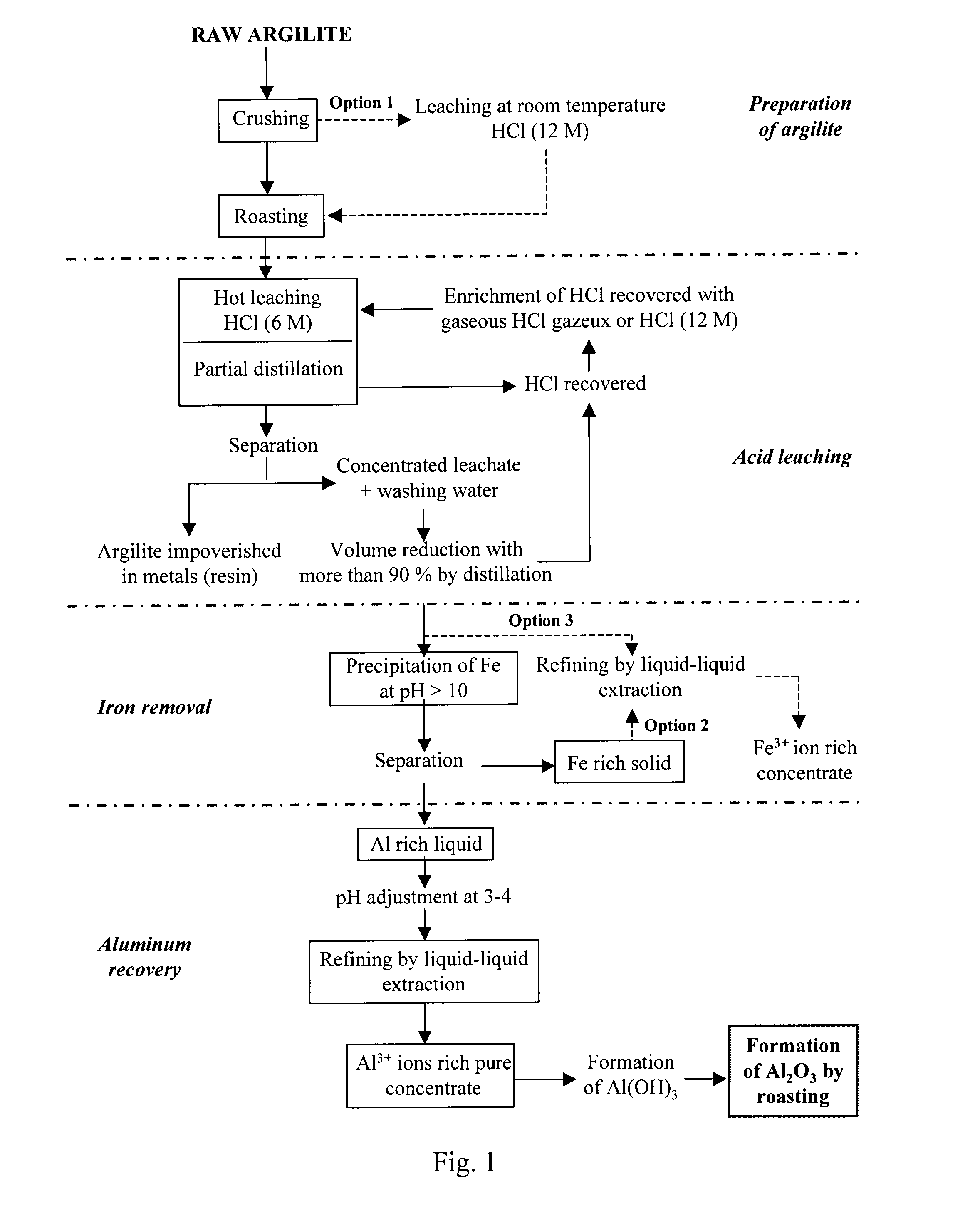

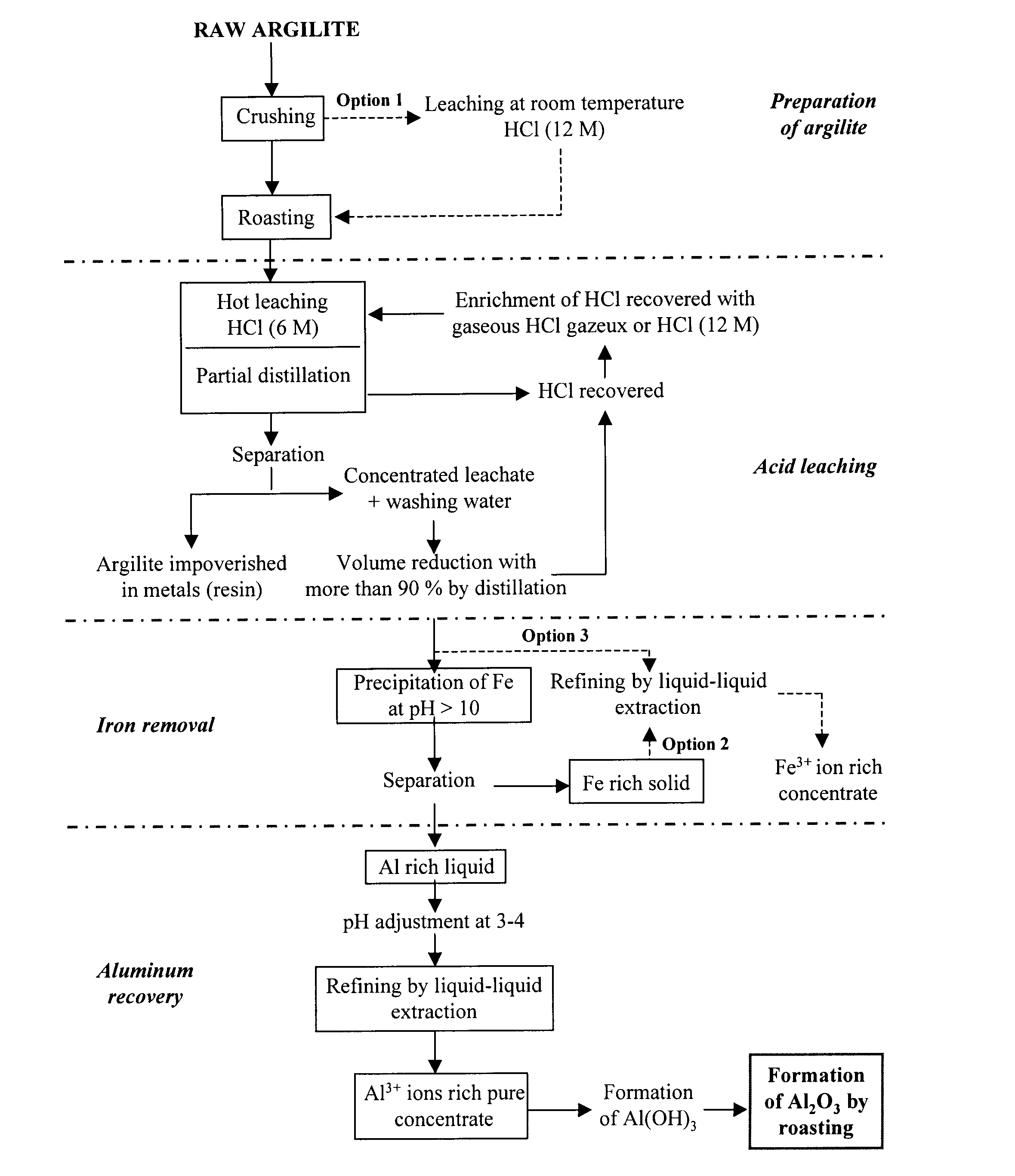

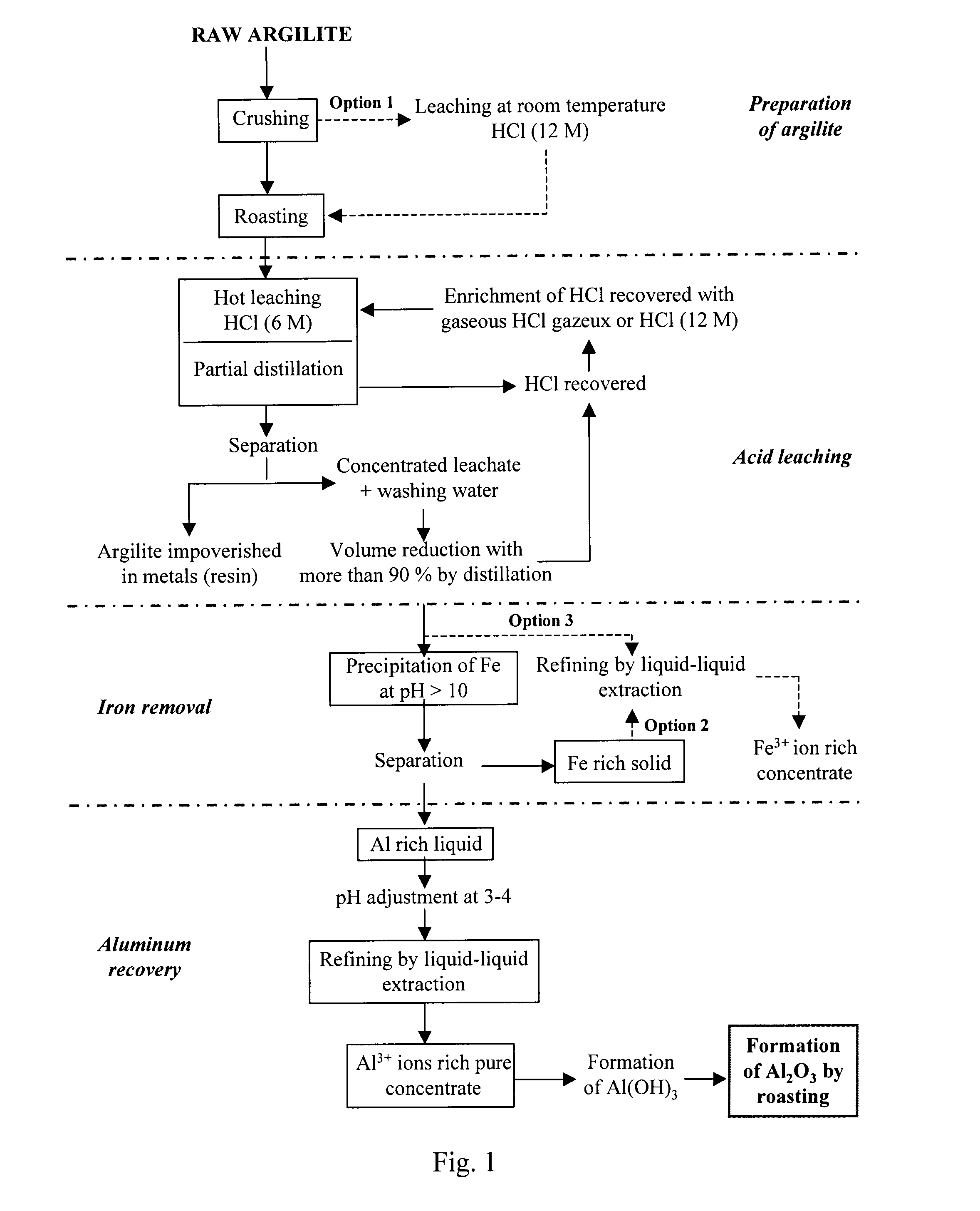

Processes for extracting aluminum and iron from aluminous ores

Owner:ORBITE ALUMINAE INC

Processes for extracting aluminum and iron from aluminous ores

Owner:ORBITE ALUMINAE INC

Process for metals recovery from spent catalyst

The process of this invention is directed to the removal of metals from an unsupported spent catalyst. The catalyst is subjected to leaching reactions. Vanadium is removed as a precipitate, while a solution comprising molybdenum and nickel is subjected to further extraction steps for the removal of these metals. Molybdenum may alternately be removed through precipitation.

Owner:CHEVROU USA INC

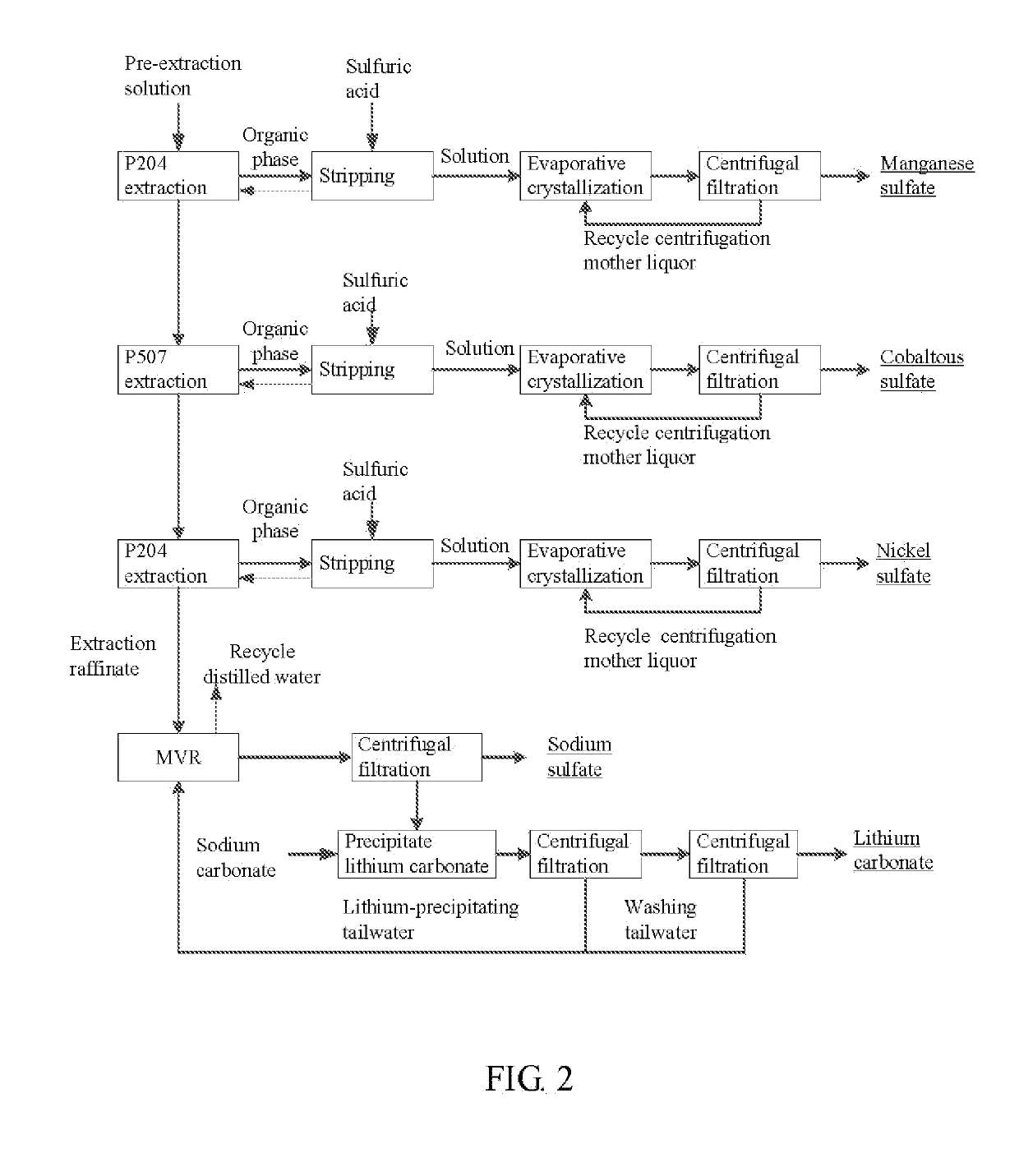

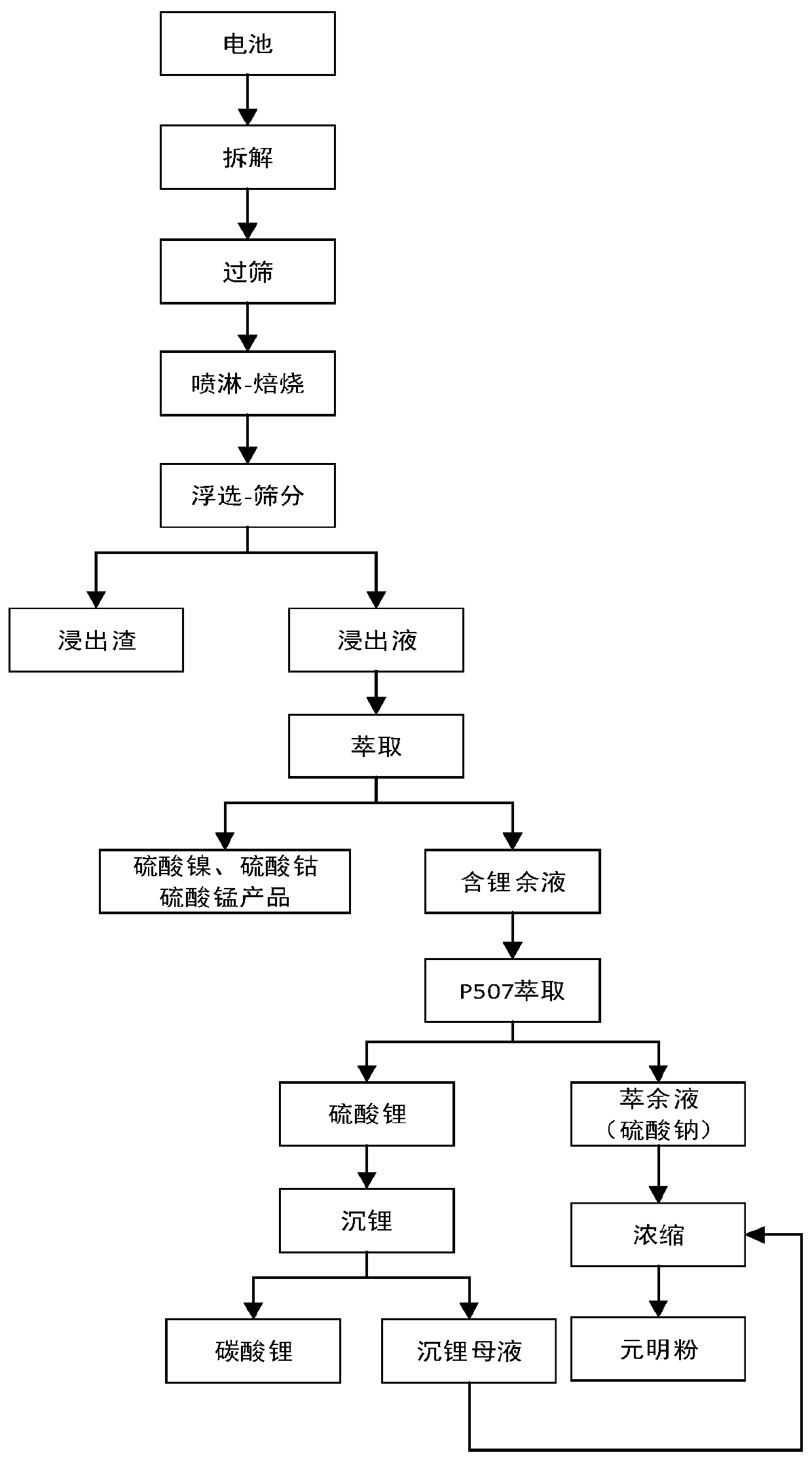

Power lithium ion battery all metal recycling and cyclic utilizing method

ActiveCN110616331AAchieve recyclingShort processCobalt sulfatesWaste accumulators reclaimingElectrical batteryLithium carbonate

The invention discloses a power lithium ion battery all metal recycling and cyclic utilizing method. Waste lithium ion batteries serve as raw materials, the disassembling-screening and roasting procedures are adopted for separating battery pole powder from other parts in the batteries, then, acid leaching is conducted, and leaching liquid containing cobalt, nickel, manganese and lithium is obtained; through extraction, separation and purification of cobalt, nickel, manganese and lithium are achieved, battery-level cobaltous sulfate, nickel sulfate and manganese sulfate are obtained, then, lithium-sodium separation is conducted, and lithium carbonate and sodium sulfate products are obtained through lithium deposition and concentration. The power lithium ion battery all metal recycling and cyclic utilizing method is green and efficient, danger waste generation is avoided, and large-scale production can be achieved. Various valuable metals are systematically recycled from the waste powerlithium batteries, according to the recycling rates, Co is larger than 95%, Ni is larger than 95%, Mn is larger than 98%, Li is larger than or equal to 94%, and the water cyclic utilization rate is larger than 95%. Nickel sulfate liquid, cobaltous sulfate liquid, manganese sulfate liquid and lithium carbonate obtained through the power lithium ion battery all metal recycling and cyclic utilizing method meet the battery level product standard.

Owner:衢州华友资源再生科技有限公司

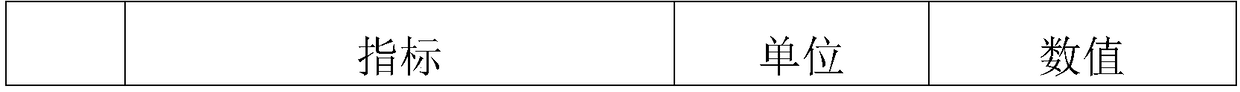

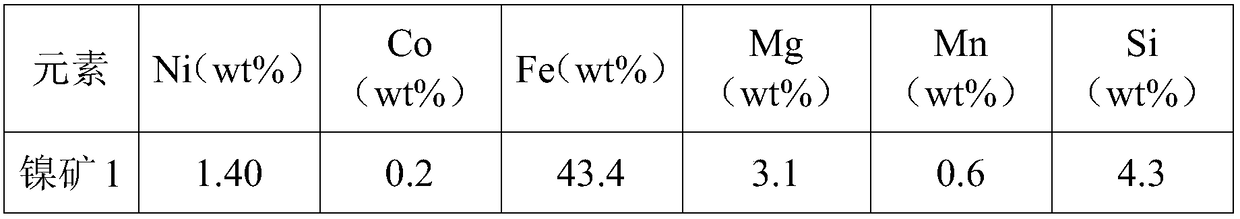

Laterite nickel ore treatment method

ActiveCN109234526AReduce the amount of saline wastewaterReduce foulingCobalt sulfatesNickel sulfatesLateriteEnergy conservation

The invention provides a laterite nickel ore treatment method, which comprises the following steps: sulfuric acid is adopted to carry out pressure leaching treatment on laterite nickel ore pulp, so that laterite nickel ore leachate is obtained; first neutralizer is added into the laterite nickel ore leachate to precipitate iron and aluminum, so that a nickel-and-cobalt-contained solution is obtained; second neutralizer is added into the nickel-and-cobalt-contained solution to precipitate nickel and cobalt, so that a crude product is obtained, and the crude product is gypseous nickel cobalt hydroxide; sulfuric acid is adopted to carry out releaching treatment on the crude product, so that a nickel cobalt sulfate solution and gypsum ore pulp are obtained; after the nickel cobalt sulfate solution is extracted, purified and evaporatively crystallized, nickel sulfate and cobalt sulfate are respectively obtained; the first neutralizer is limestone ore pulp or calcium hydroxide pulp, and thesecond neutralizer is calcium hydroxide pulp. When the treatment method disclosed by the invention is adopted, the amount of wastewater in a production system can be remarkably reduced, energy is saved and energy consumption is reduced, so that the treatment cost is reduced, and moreover, the production efficiency can also be increased.

Owner:CHINA ENFI ENGINEERING CORPORATION

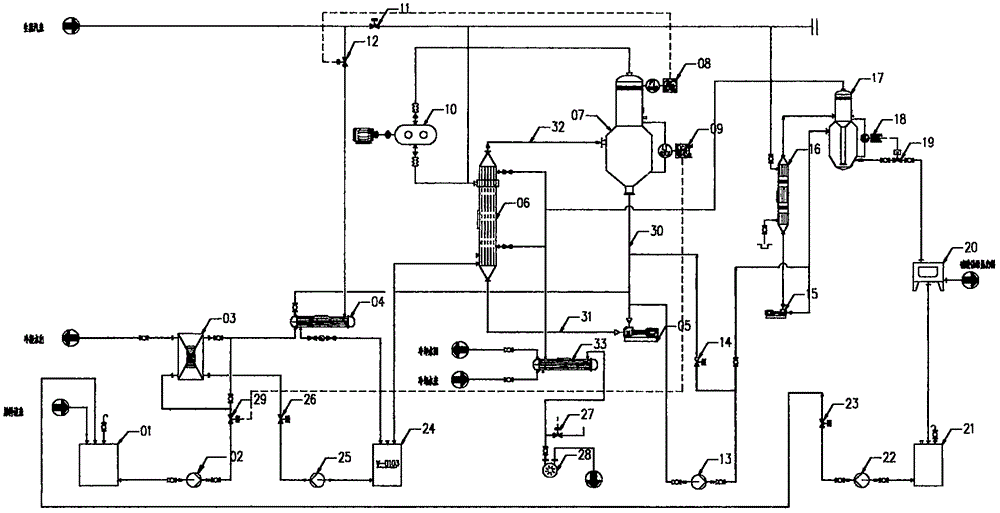

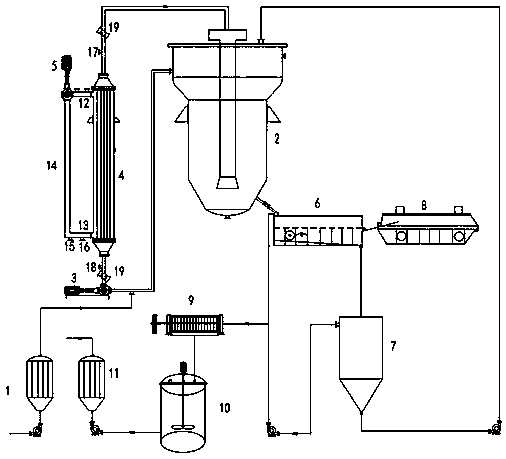

Device system for efficient cobalt sulfate concentration and continuous crystallization

ActiveCN106115804AGuaranteed cooling temperatureReduce dosageVacuum condensationEvaporation with vapour compressionEvaporationStock solution

The invention relates to a device system for efficient cobalt sulfate concentration and continuous crystallization. The device system provided by the invention comprises an evaporation heater (06), an evaporation separator (07), an OSLO vacuum crystallizer (17), a fine grain eliminating heater (16), a steam compressor (10), a condensate water preheater (03), a steam preheater (04), a centrifugal machine (20) and a pump. A stock solution enters the evaporation heater through the preheater, and the heater is connected with the separator and the circulating pump; the separator is connected with the OSLO vacuum crystallizer; a material liquid drop device is arranged in the middle of the OSLO vacuum crystallizer, a flash chamber is arranged at the top of a pipe, a circulating liquid outlet is formed in the side part, a secondary steam outlet is formed in the top of the flash chamber and is connected with a condenser and a fine grain eliminator, the crystallizer is connected with the centrifugal machine, and the centrifugal machine is connected with a mother liquid tank and a stock solution buffer tank to realize overall material liquid circulation. The system has the characteristics of energy conservation, continuity, automation and high efficiency, and obtained products are large in grain size and high in quality.

Owner:湖州惠鹏达节能环保科技有限公司

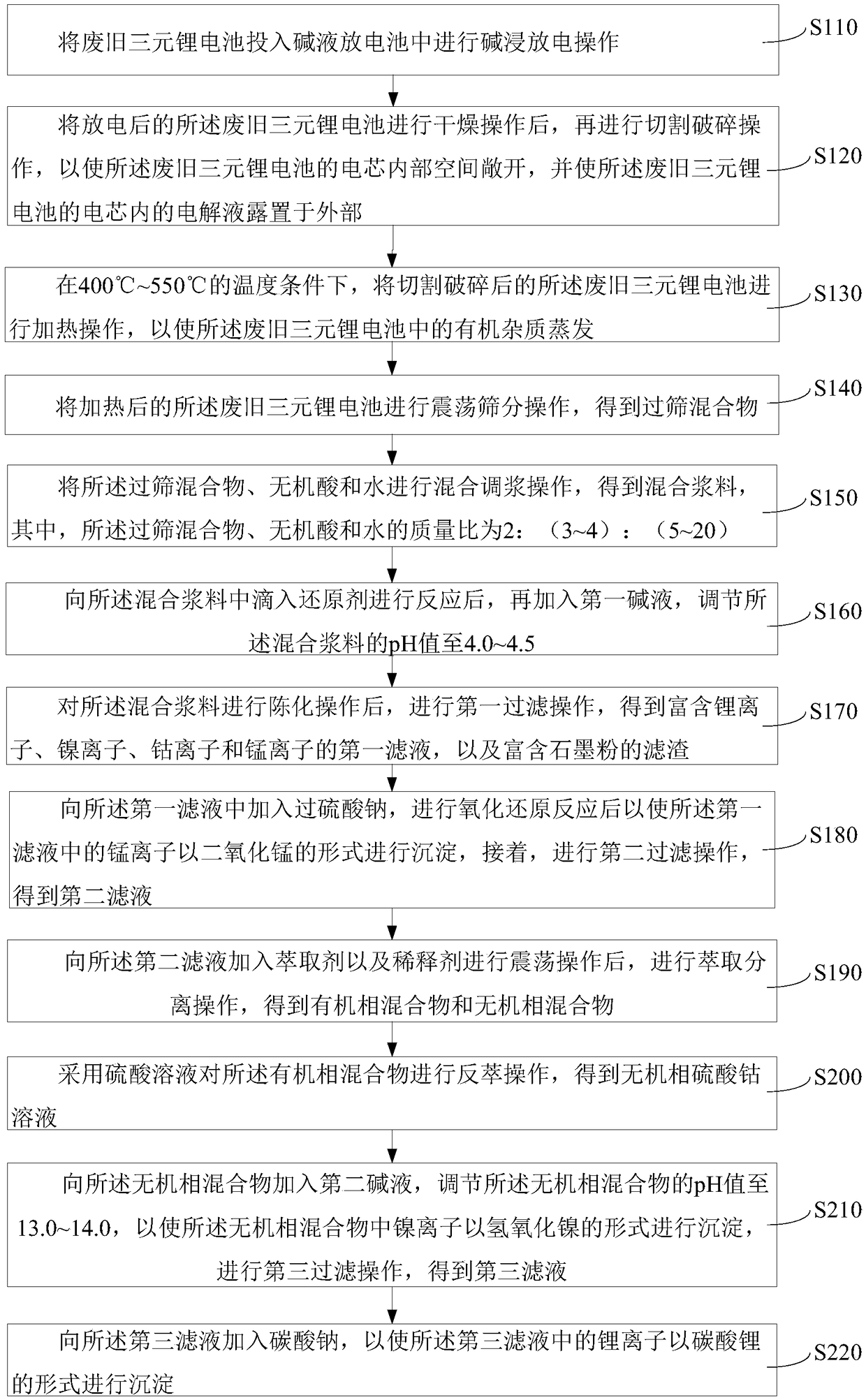

Grading recovery method for waste ternary lithium battery

ActiveCN109182732AReduce consumptionHigh extraction recoveryCobalt sulfatesManganese oxides/hydroxidesRecovery methodManganese

Disclosed is a grading recovery method for a waste ternary lithium battery. After the waste ternary lithium battery is subjected to alkaline leaching discharging, drying and cutting crushing operation, the internal space of a battery cell is opened, and an electrolyte is exposed outside; organic impurities are evaporated through heating, then a sieved mixture is obtained through oscillation sieving, the sieved mixture is mixed with inorganic acid and water, then a reducing agent is added, the pH value is regulated, and after aging, a first filtrate rich in lithium ion, nickel ion, cobalt ion and manganese ion is obtained through filtering; and by adding different materials and chemical agents or controlling the pH value, manganese ions, cobalt ions, nickel ions and lithium ions are subjected to grading extraction, and all valuable metal elements are extracted and recovered. According to the grading recovery method for the waste ternary lithium battery, compared with the mode that all the valuable metal elements are extracted separately, the consumption quantity of the chemical agents is greatly decreased, meanwhile, the extraction and recovery rates of all the valuable metal elements are further greatly increased, and subsequent further recycling is facilitated.

Owner:EVE ENERGY CO LTD

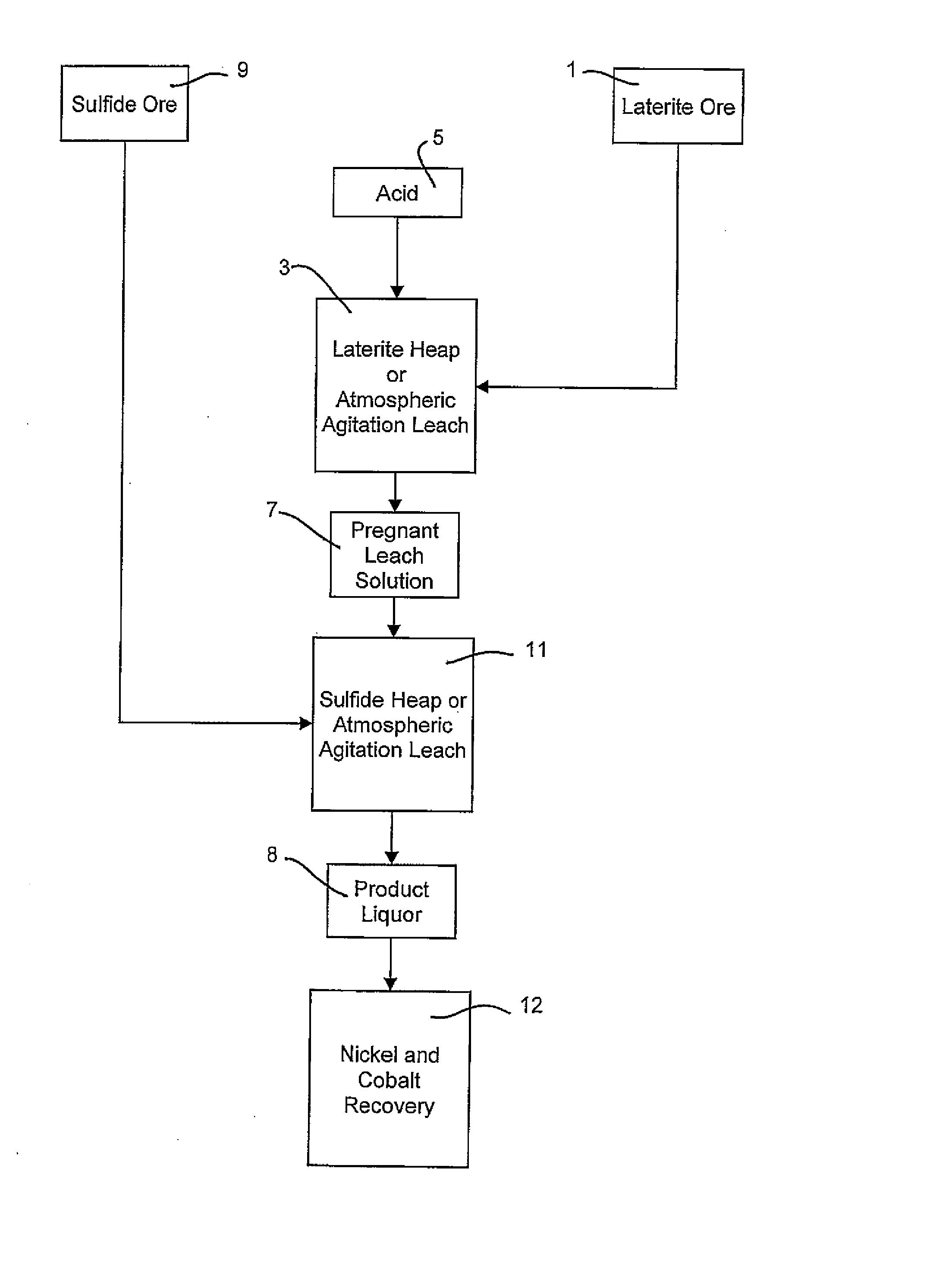

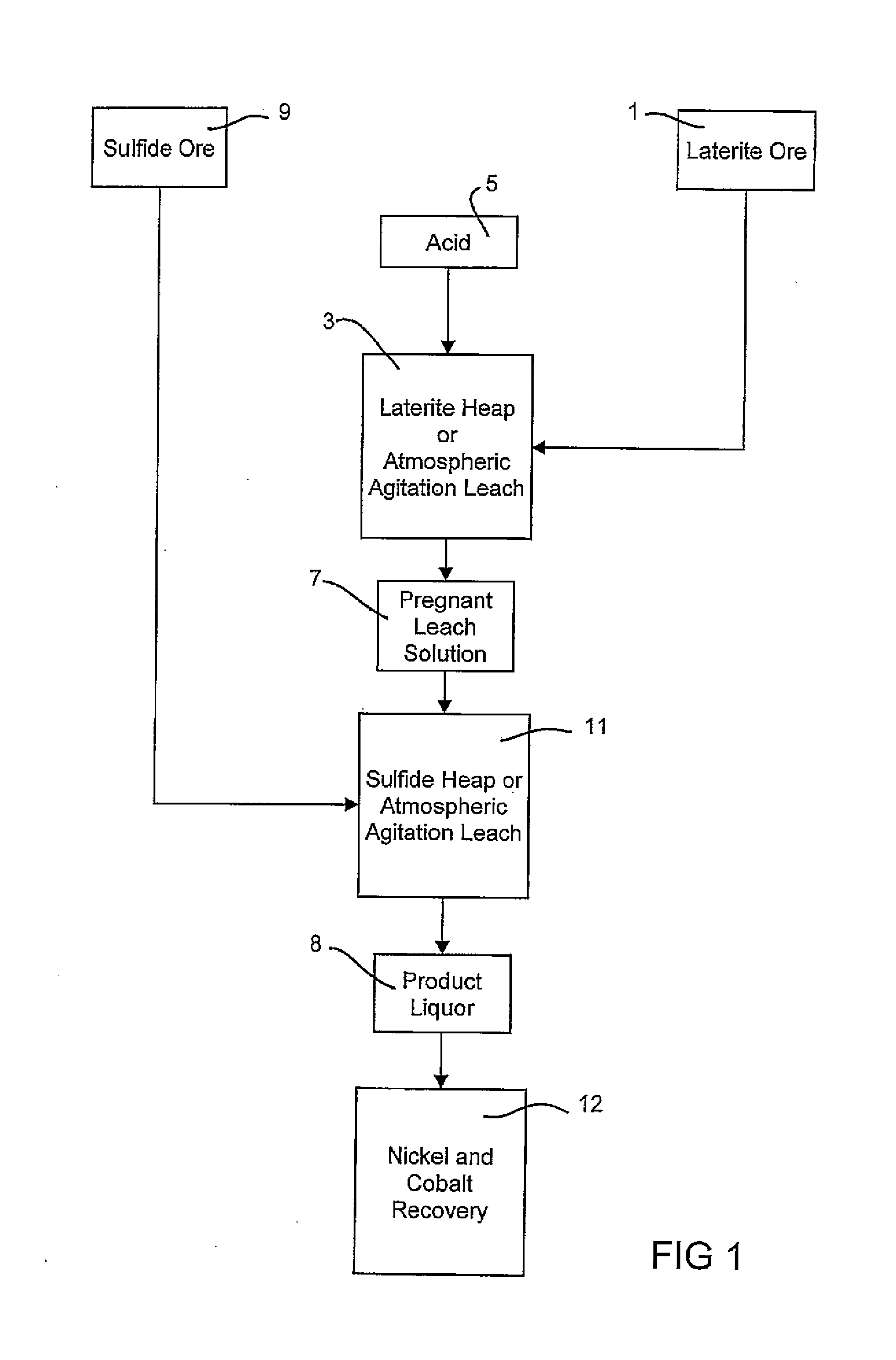

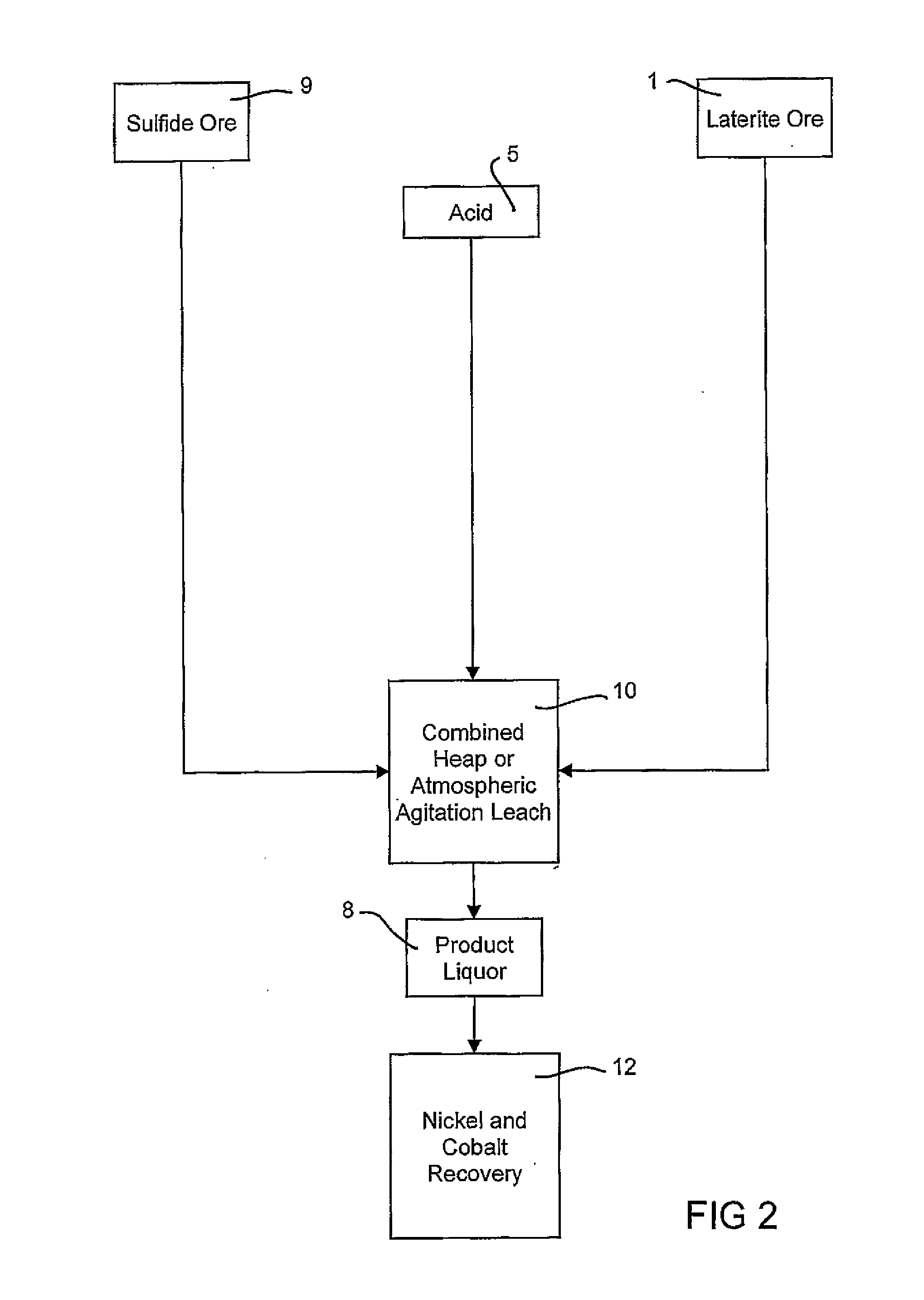

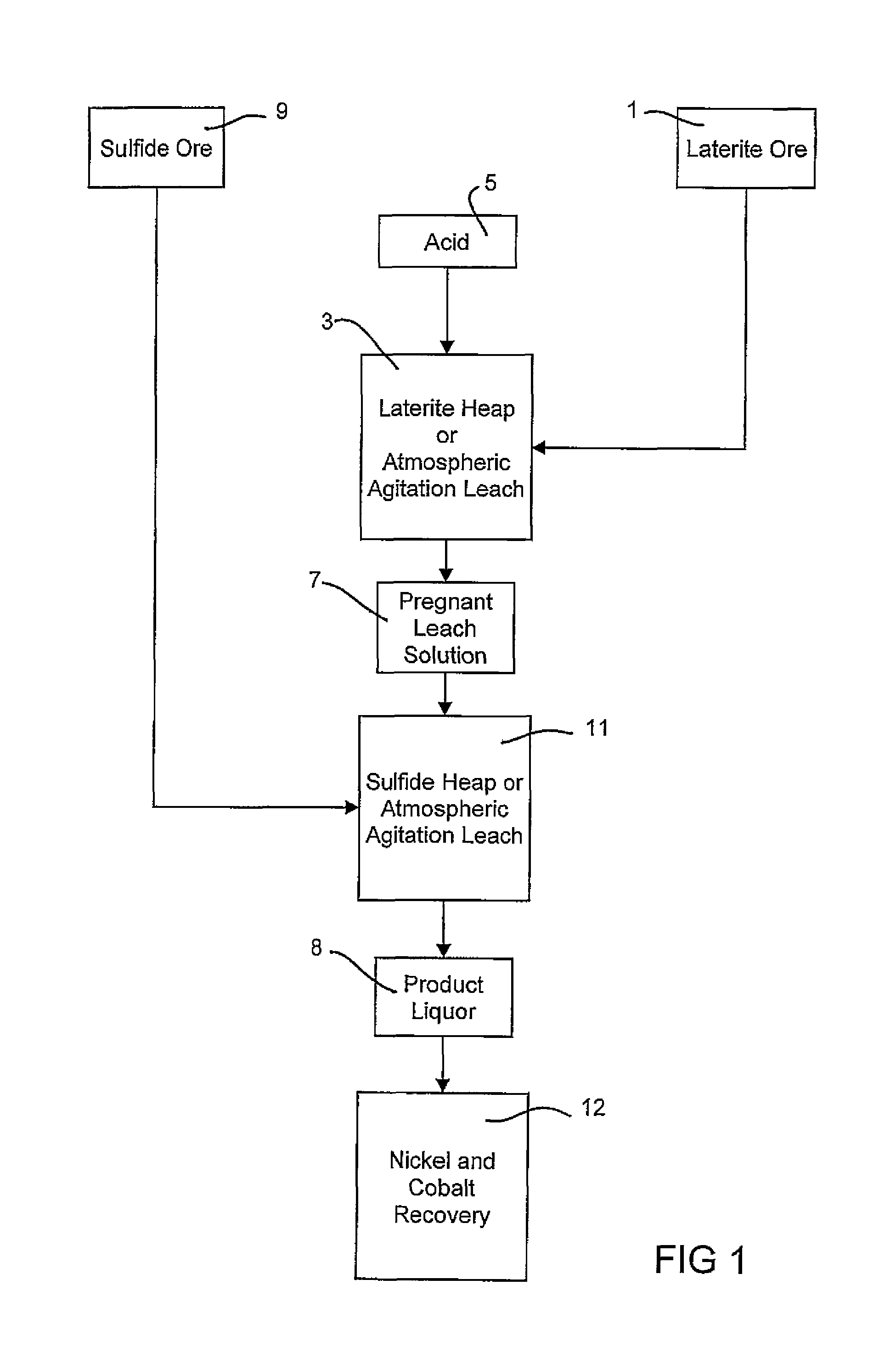

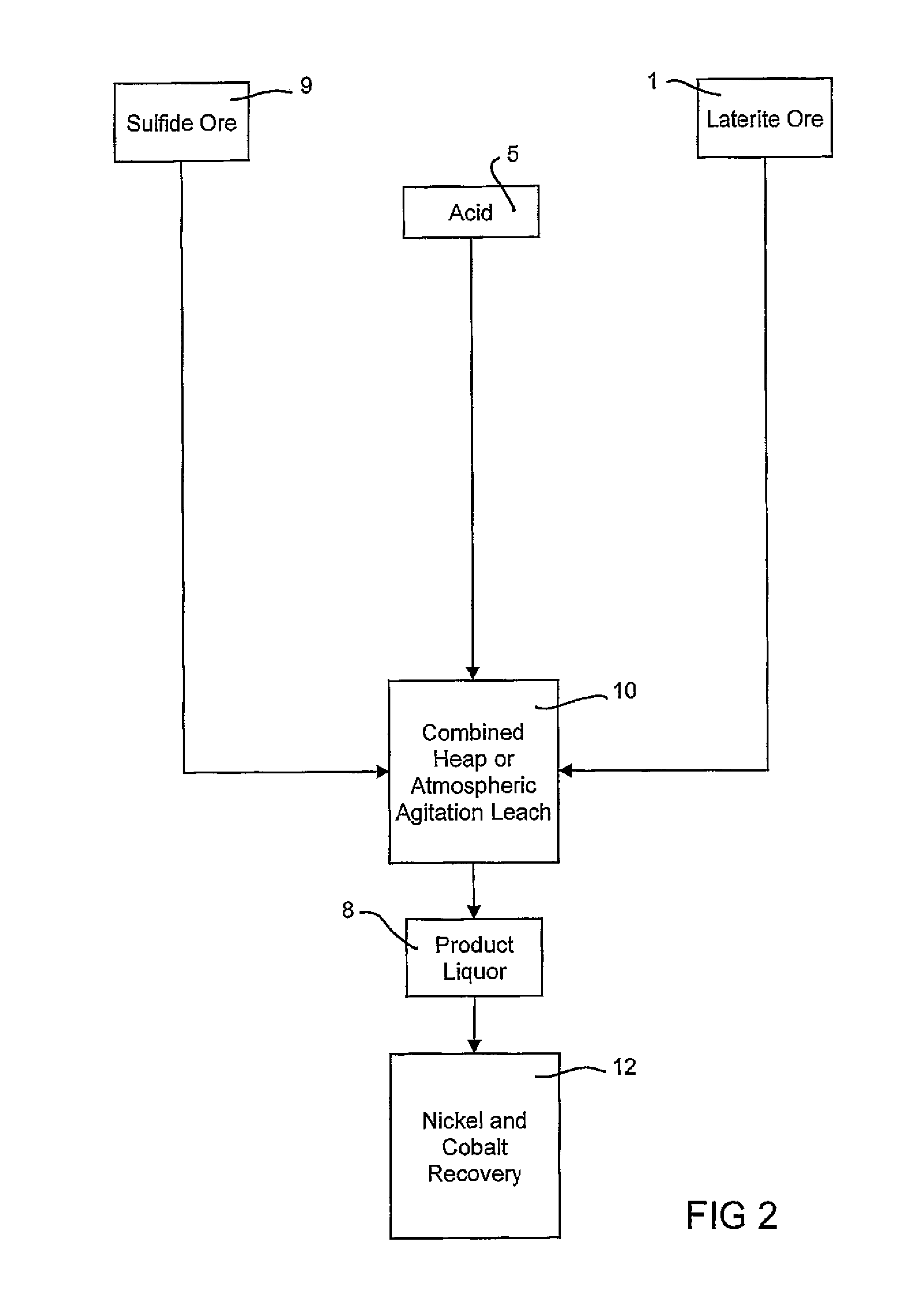

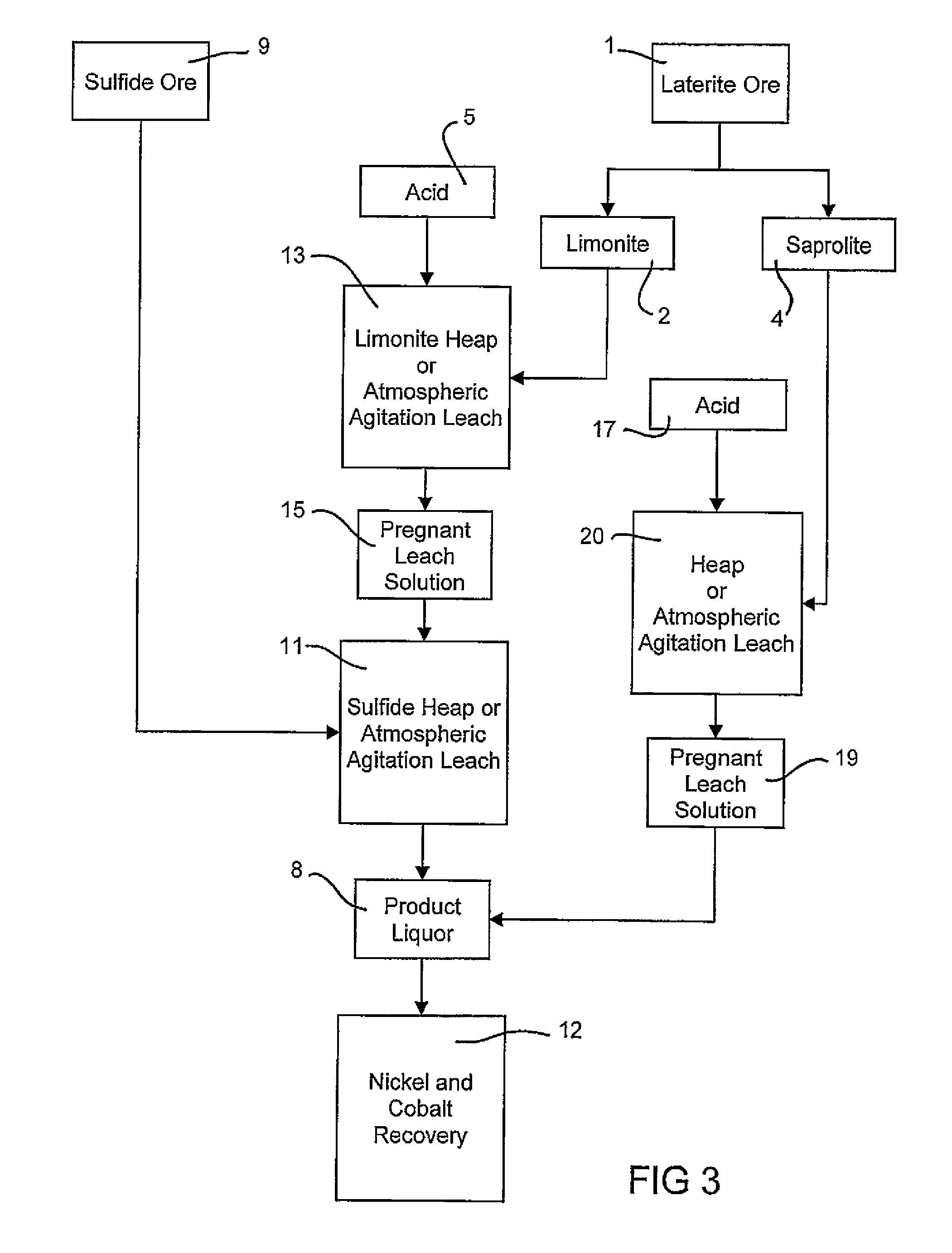

Consecutive or Simultaneous Leaching of Nickel and Cobalt Containing Ores

InactiveUS20080050294A1Minimize equipment sizeIncrease consumptionCobalt ammonia complexesIron oxides/hydroxidesPregnant leach solutionSulfide

A process for the recovery of nickel and cobalt from nickel and cobalt containing ores, including the steps of first leaching a laterite ore and / or a partially oxidised sulfide ore with an acid solution to produce a pregnant leach solution containing at least dissolved nickel, cobalt and ferric ions, and subsequently leaching a sulfide ore or concentrate with the pregnant leach solution to produce a product liquor. Alternatively, the laterite ore and / or partially oxidised sulfide ore can be leached in a combined leach with the sulfide ore or concentrate. The ferric ion content in the pregnant leach solution or in the combined leach is sufficient to maintain the oxidation and reduction potential in the sulfide leach high enough to assist in leaching nickel from the sulfide ore or concentrate.

Owner:BHP BILLITON SSM TECH PTY LTD

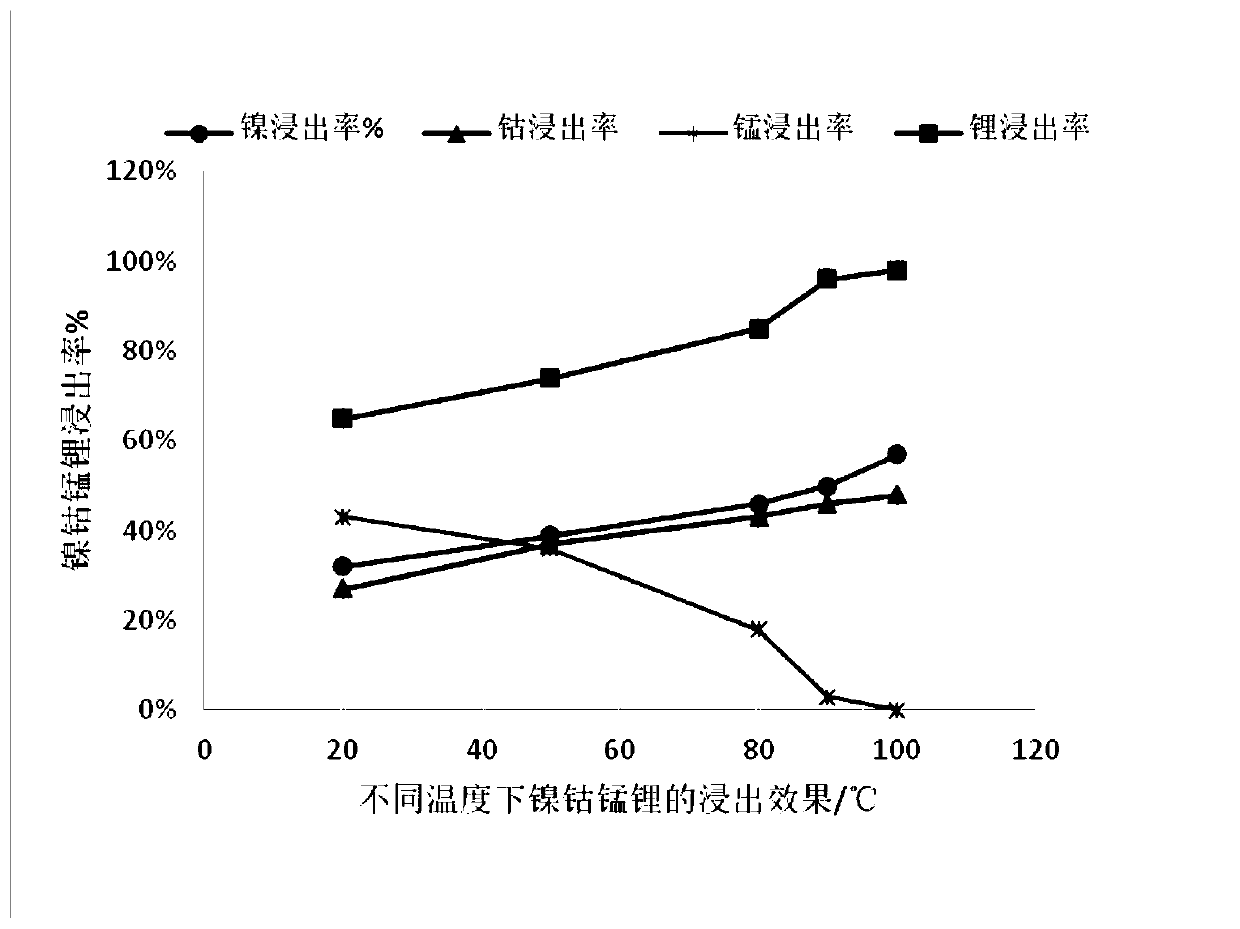

Method for preparing lithium-ion sieve from waste lithium-ion batteries

InactiveCN109761250ASimple processReduce manufacturing costCobalt sulfatesNickel sulfatesSlagManganese

The invention discloses a method for preparing a lithium-ion sieve from waste lithium-ion batteries. The method is characterized by comprising the steps: sulfuric acid and a manganese-containing wastelithium-ion battery cathode material react at 40-100 DEG C to obtain leaching slag and leachate; the pH of the leachate is adjusted, and the leachate is subjected to extraction for impurity removingthrough P204; the pH of P204 raffinate is adjusted, and cobalt is extracted from the P204 raffinate through C272; the C272 after extracting is subjected to reextraction, and evaporative crystallization is conducted to obtain a cobalt sulfate product; the pH of C272 raffinate is adjusted, and nickel is extracted from the C272 raffinate through P507; the P507 after extracting is subjected to reextraction, and evaporative crystallization is conducted to obtain a nickel sulfate product; P507 raffinate is subjected to a sodium carbonate lithium sinking process to obtain a lithium carbonate product;the leaching slag and the lithium carbonate product are mixed to be roasted, and a lithium-ion sieve precursor is obtained; and the lithium-ion sieve precursor is subjected to acidic conversion through hydrochloric acid, and the lithium-ion sieve is obtained. The technological process is simple, and battery-grade cobalt sulfate, nickel sulfate, lithium carbonate and lithium-ion sieve with high added value can be obtained.

Owner:天齐锂业资源循环技术研发(江苏)有限公司

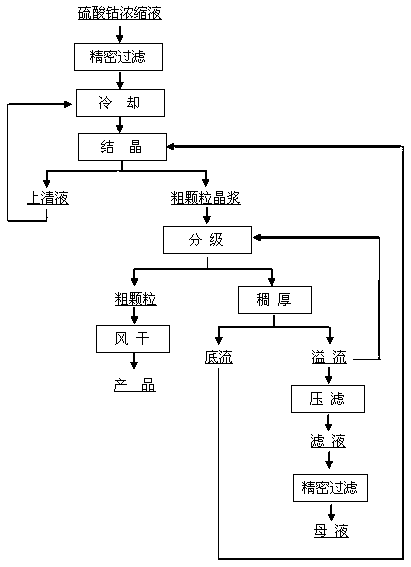

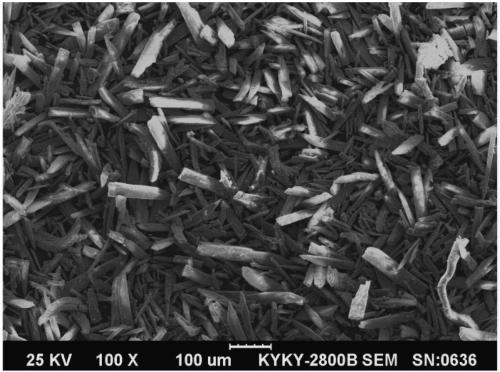

Continuous crystallization system of cobalt sulfate with coarse grain and low water insoluble matters as well as process thereof

ActiveCN107837557ARealize continuous productionHigh degree of automationCobalt sulfatesSolution crystallizationWater insolubleLotion

The invention discloses a continuous crystallization system of cobalt sulfate with coarse grain and low water insoluble matters as well as a process thereof. The continuous crystallization system comprises a filtering machine set, a cooling crystallization set, a discharging set, and connecting pipelines. The continuous crystallization process is as follows: a cooling crystallizer is full of a stock solution or mother liquor, a crystallization circulating pump is opened, cobalt sulphate concentrate which is precisely filtered and a crystallizer supernatant are mixed and enter an external cooler in order to form a supersaturated solution, and the solution enters a crystallizer through a crystallizer guide shell and grows on an original crystal nucleus; cobalt sulfate from an Oslo cooling crystallizer aging zone is discharged and enters a grader, and air drying of cobalt sulfate of coarse grain is directly carried out in order to obtain a qualified cobalt sulfate product; the grader fines enter a thickener, and underflow of the thickener returns the crystallizer and is used as a crystal seed; a part of the thickener overflow returns and is used as a washing lotion for grading, and apart of the thickener overflow is filtered by a filter press and a precision filter and enters an evaporative concentration process. The process has the advantages of good continuity, large proportionof products with coarse grain, low content of water insoluble matters, high crystallization rate, and the like.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

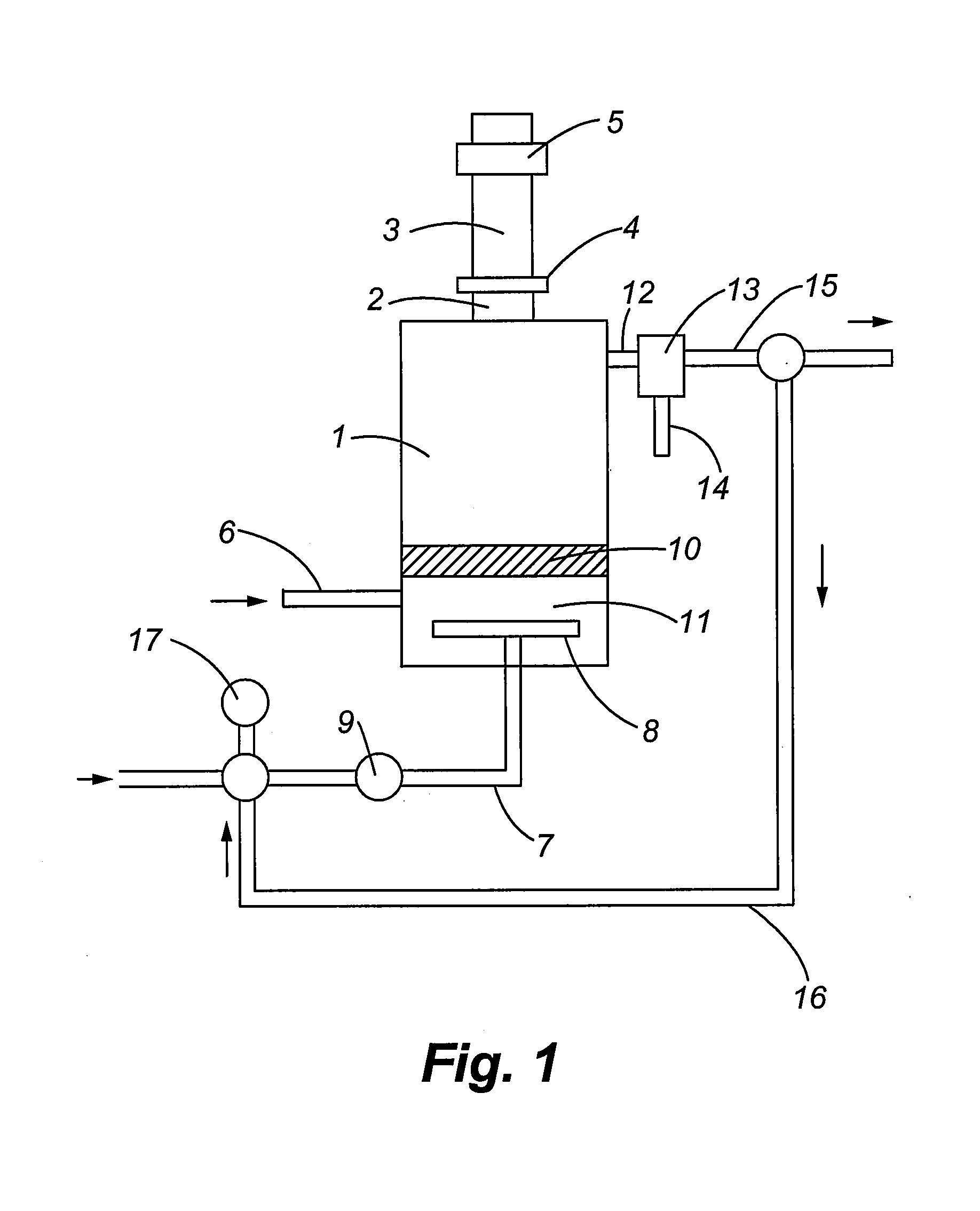

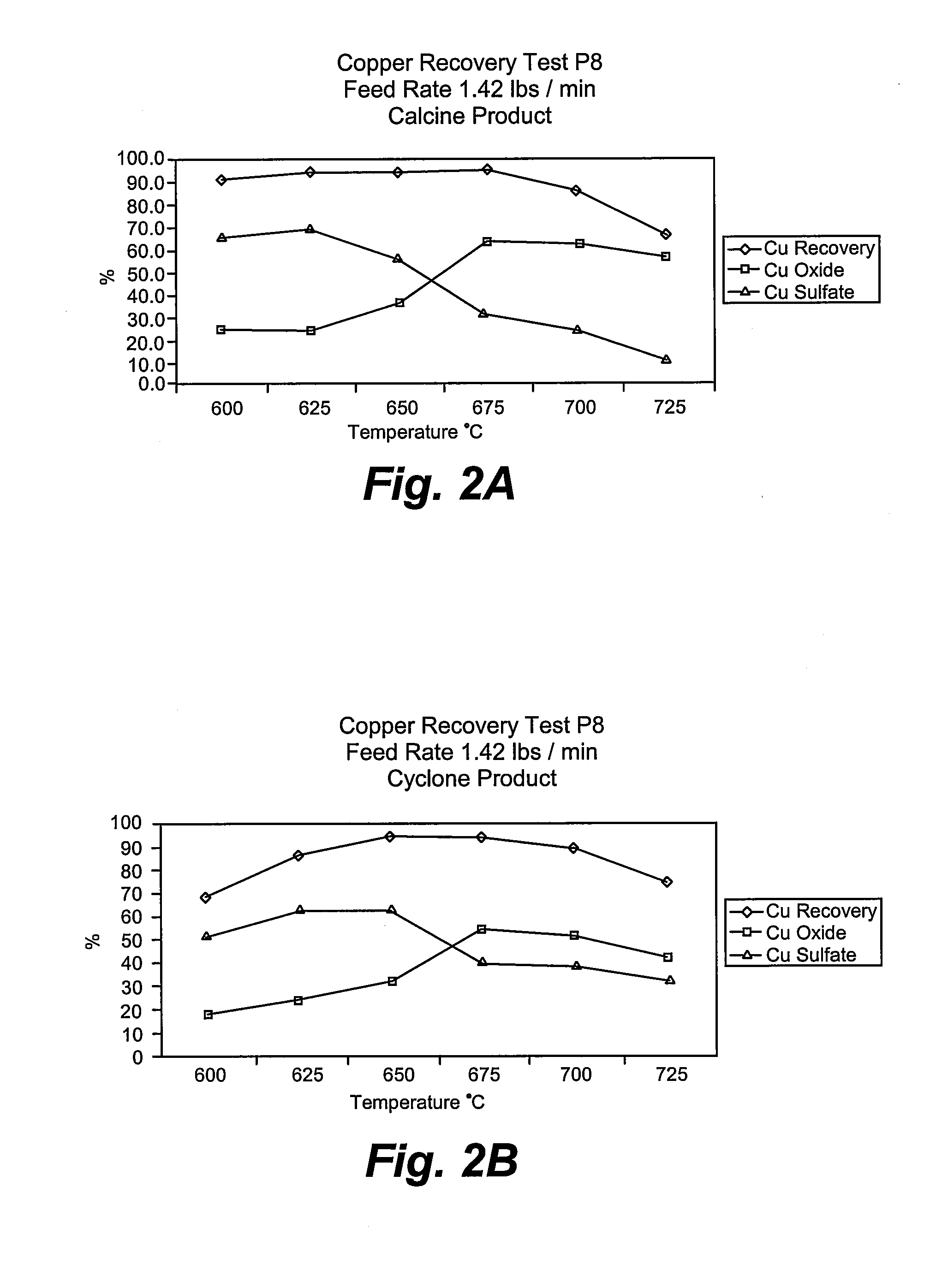

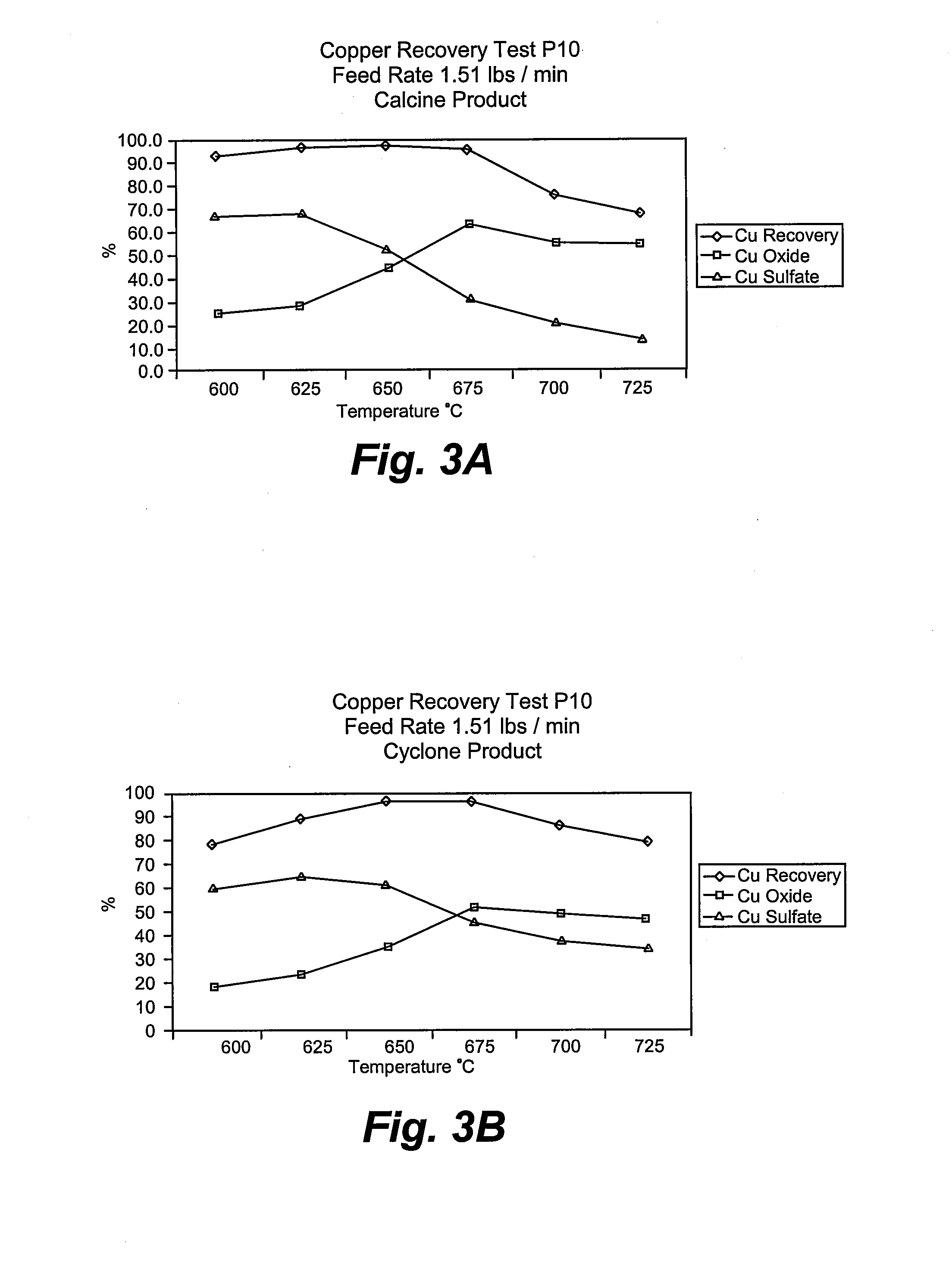

Method and means for using microwave energy to oxidize sulfidic copper ore into a prescribed oxide-sulfate product

InactiveUS20080118421A1Highly solubleLow costOxide/hydroxide preparationCobalt sulfatesMicrowaveChalcopyrite

The present invention is directed to the microwave treatment of a class of selected metal ores and concentrates, particularly those known as chalcopyrite, in a fluidized bed reactor. The end product is commonly a mixture of copper oxide and copper sulfate, both of which are liquid soluble and directly recoverable by known techniques. The ratio of the oxide-sulfate mixture end product may be controlled by suitable control of microwave parameters.

Owner:HW PROCESS TECH

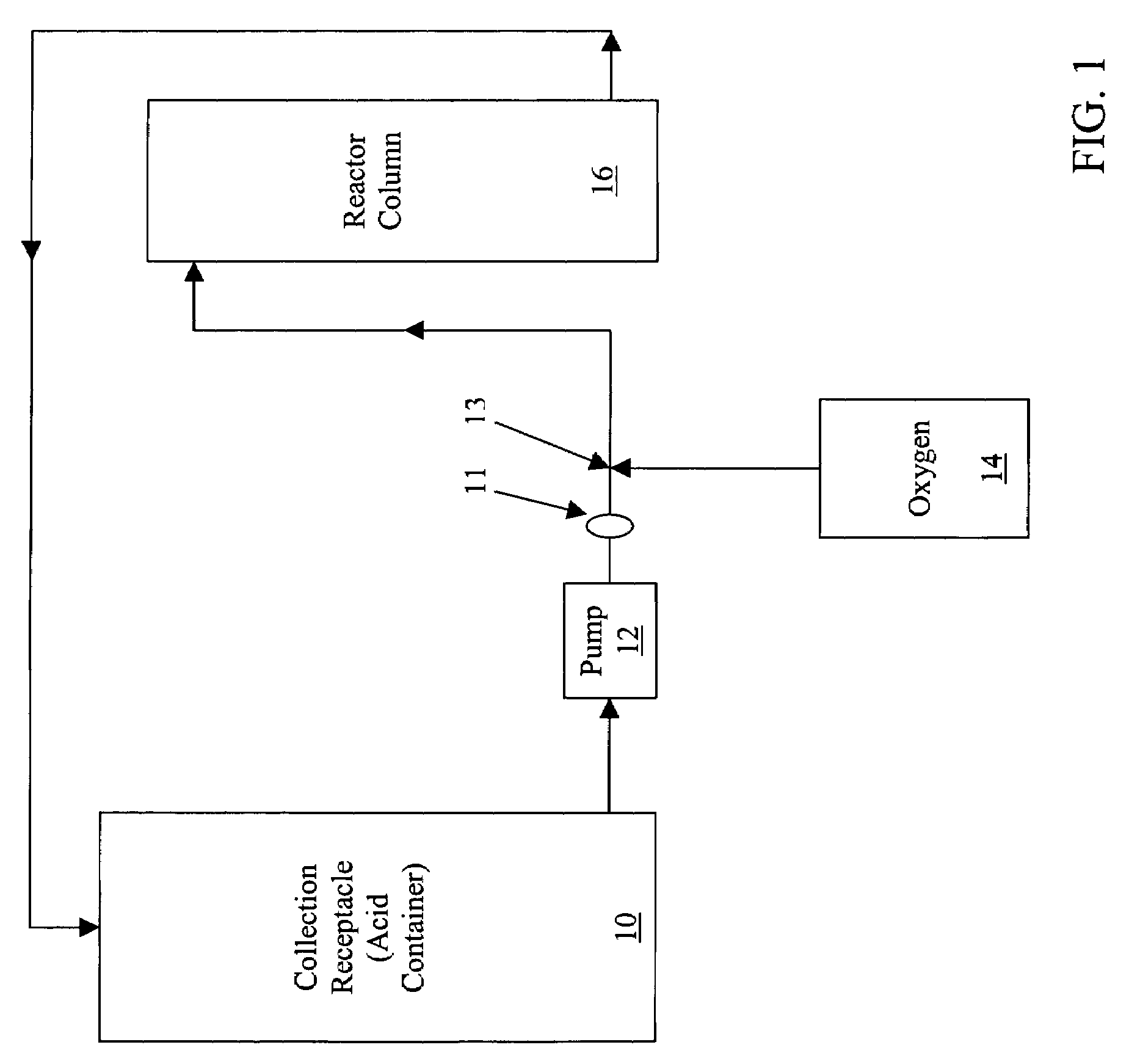

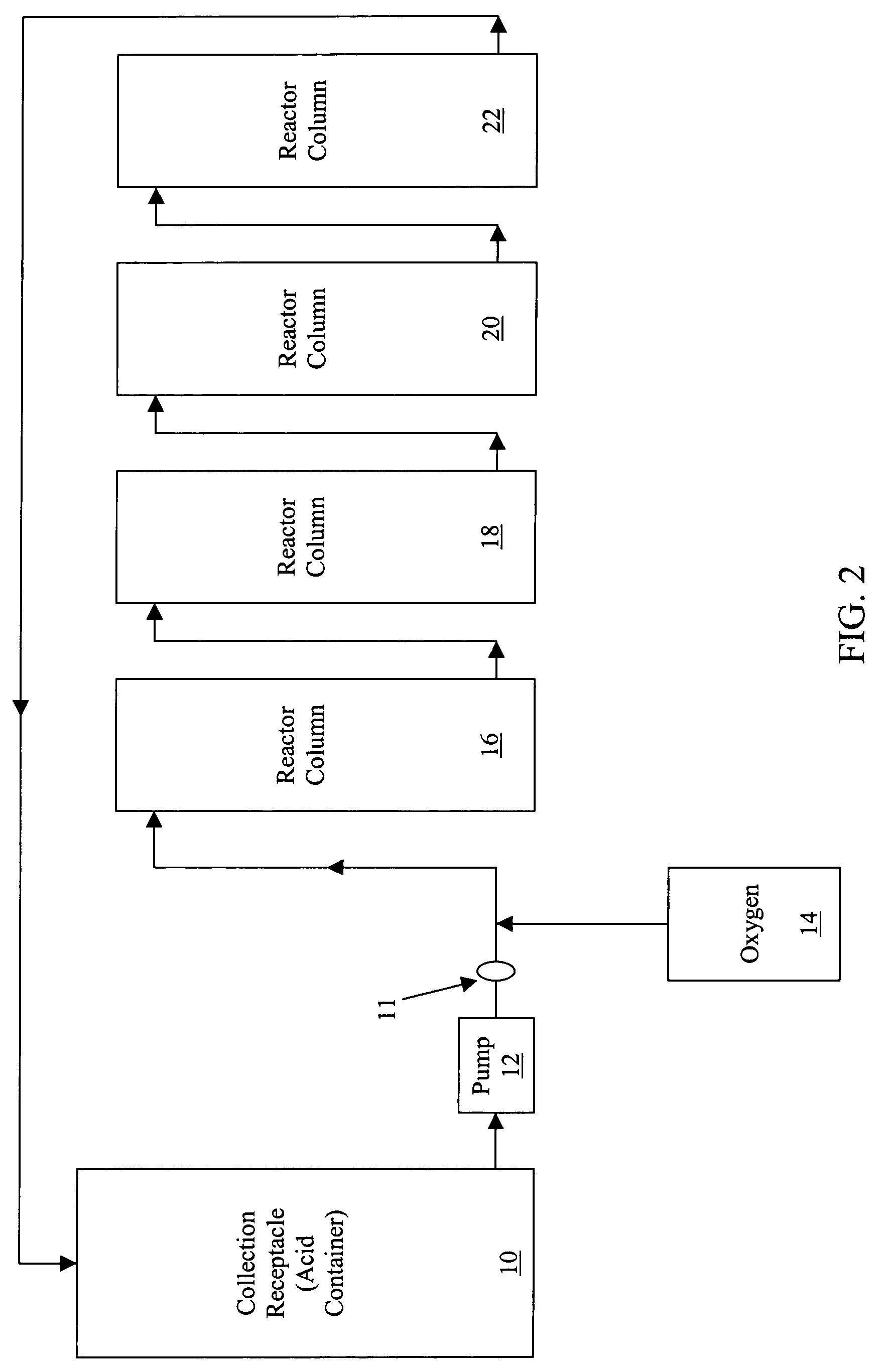

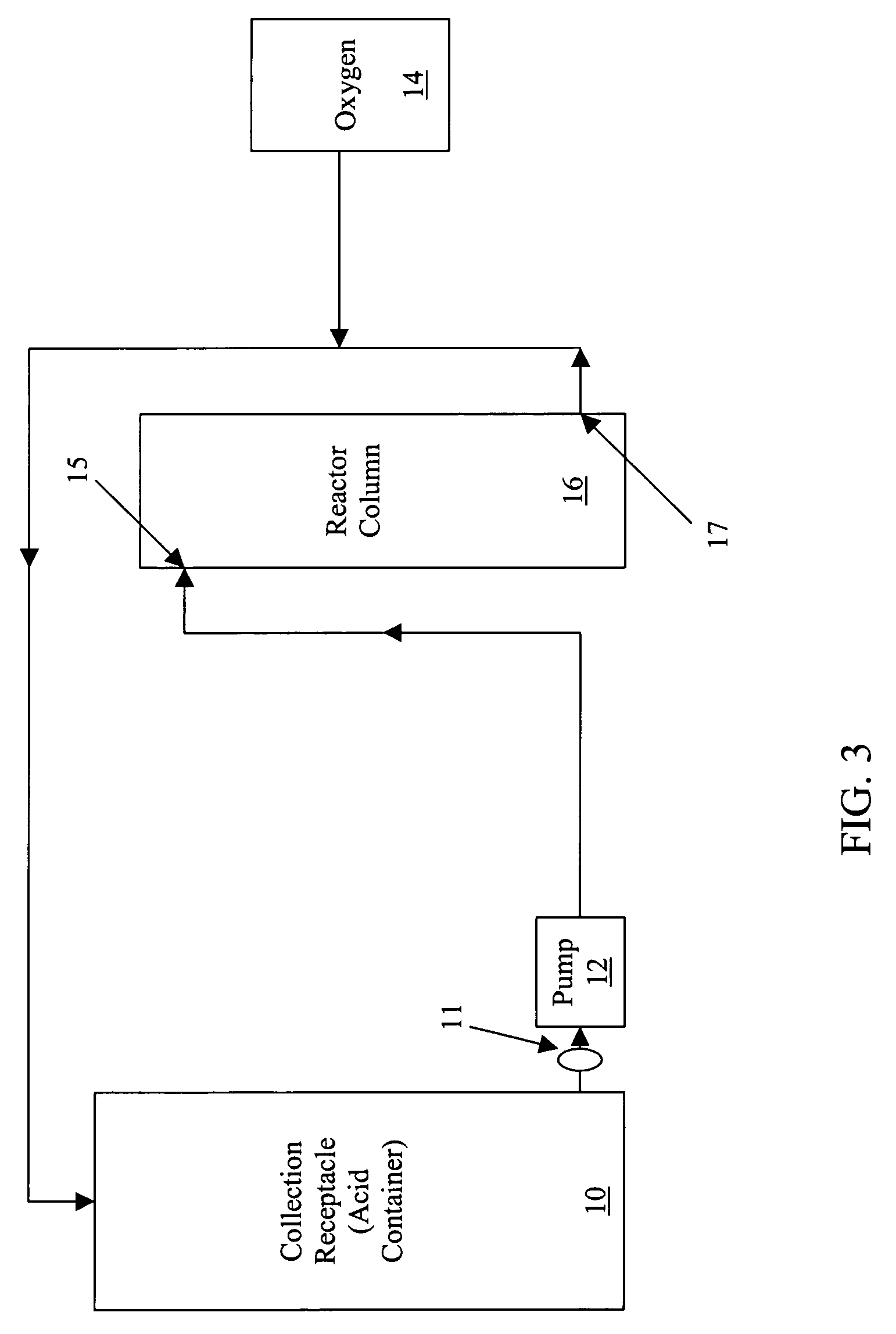

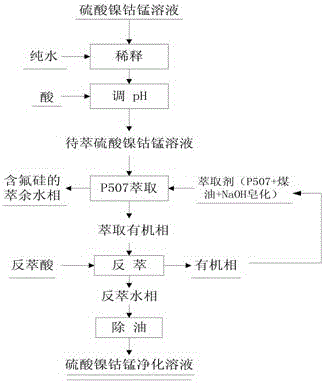

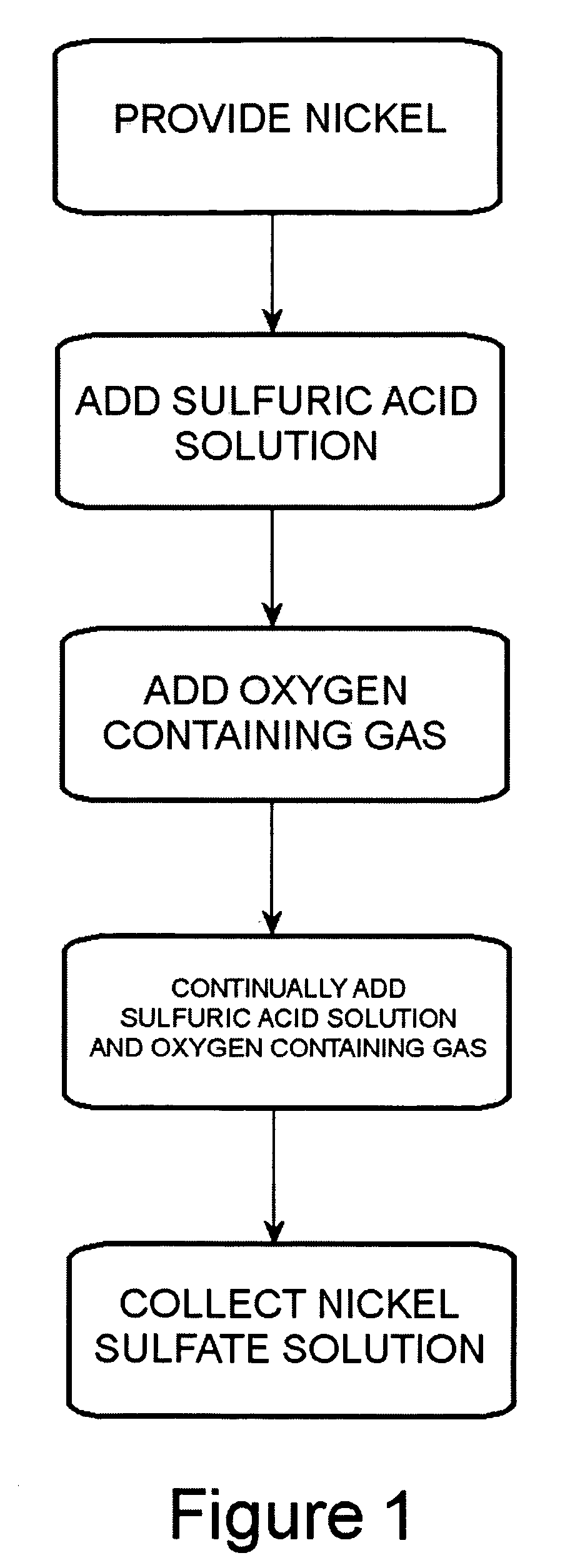

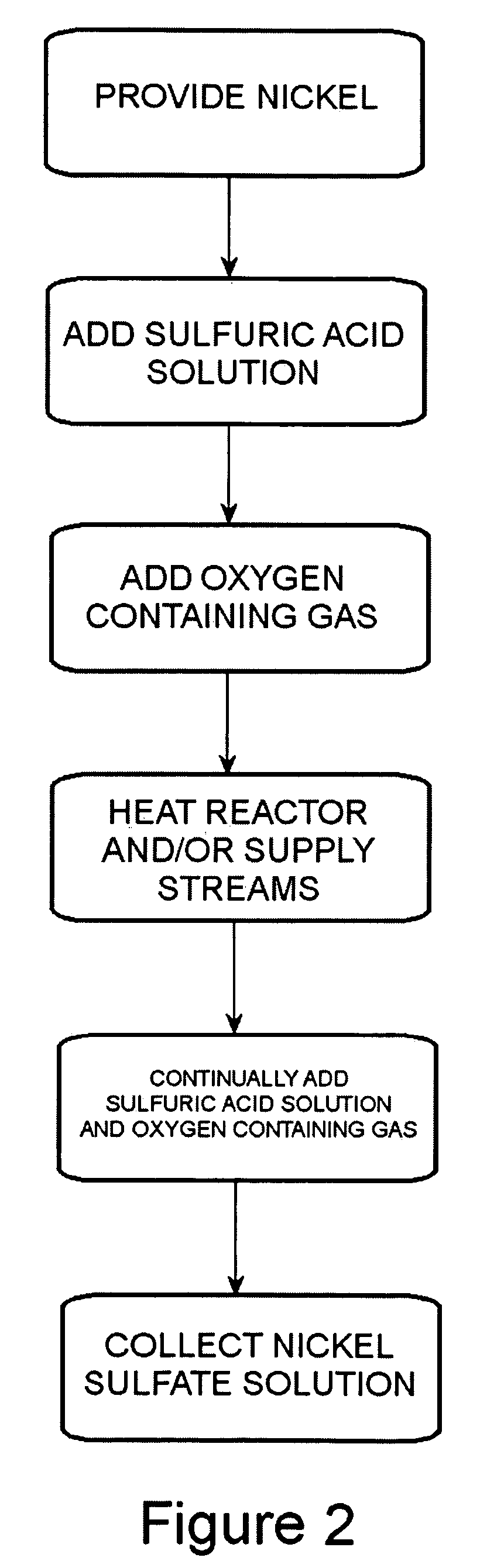

Process for converting nickel to nickel sulfate

A preferred embodiment of the present invention provides a process for making nickel sulfate by converting nickel metal into nickel sulfate, which may be converted to nickel hydroxide. Nickel metal is dissolved in sulfuric acid and oxygen containing gas is introduced to produce a nickel sulfate solution having nickel sulfate and water as illustrated in the following chemical equation.Ni+H2SO4+½O2→NiSO4+H2OThe nickel sulfate is filtered and sulfuric acid is continually added to maintain stoichiometry within a reactor until the nickel metal is dissolved. The sulfuric acid, oxygen containing gas and nickel metal may be heated to facilitate the desired reaction. Then, the nickel sulfate may be utilized to produce nickel hydroxide.

Owner:CHEVRON TECH VENTURES +1

Method for producing battery grade nickel sulfate and cobalt sulfate by waste nickel cobalt alloy

ActiveCN108622943AMild responseReduce pollutionCobalt sulfatesNickel compounds preparationNew energyEvaporation

The invention discloses a method for producing battery grade nickel sulfate and cobalt sulfate by waste nickel cobalt alloy. The method comprises the following steps of performing pretreatment on nickel cobalt alloy waste materials; then, performing electrochemical dissolution; removing impurities such as iron, chromium and aluminum from the obtained solution step by step by a chemical method andan extraction method; firstly extracting cobalt from the solution subjected to impurity removal; then extracting nickel; thus respectively obtaining extraction liquid containing cobalt and nickel; after the reverse extraction, obtaining nickel sulfate and cobalt sulfate solution; then, respectively performing evaporation, cooling crystallization, and centrifugal dewatering on the solution to obtain a product of the battery grade nickel sulfate and cobalt sulfate. The problems of low nickel and cobalt leaching efficiency, low dissolution speed and the like in the waste nickel and cobalt alloy recovery process by a conventional wet process can be effectively solved; the battery grade nickel sulfate and cobalt sulfate conforming to the product quality standard requirement can be produced, andcan be used as a new energy source battery raw material to be applied to the field of new energy source battery manufacturing. The process is simple; the environment pollution is low; the metal recovery rate is high; good practical values and economic values are realized.

Owner:HOHAI UNIV

Consecutive or simultaneous leaching of nickel and cobalt containing ores

InactiveUS7871584B2Minimize equipment sizeIncrease consumptionCobalt ammonia complexesIron oxides/hydroxidesPregnant leach solutionSulfide

A process for the recovery of nickel and cobalt from nickel and cobalt containing ores, including the steps of first leaching a laterite ore and / or a partially oxidized sulfide ore with an acid solution to produce a pregnant leach solution containing at least dissolved nickel, cobalt and ferric ions, and subsequently leaching a sulfide ore or concentrate with the pregnant leach solution to produce a product liquor. Alternatively, the laterite ore and / or partially oxidized sulfide ore can be leached in a combined leach with the sulfide ore or concentrate. The ferric ion content in the pregnant leach solution or in the combined leach is sufficient to maintain the oxidation and reduction potential in the sulfide leach high enough to assist in leaching nickel from the sulfide ore or concentrate.

Owner:BHP BILLITON SSM TECH PTY LTD

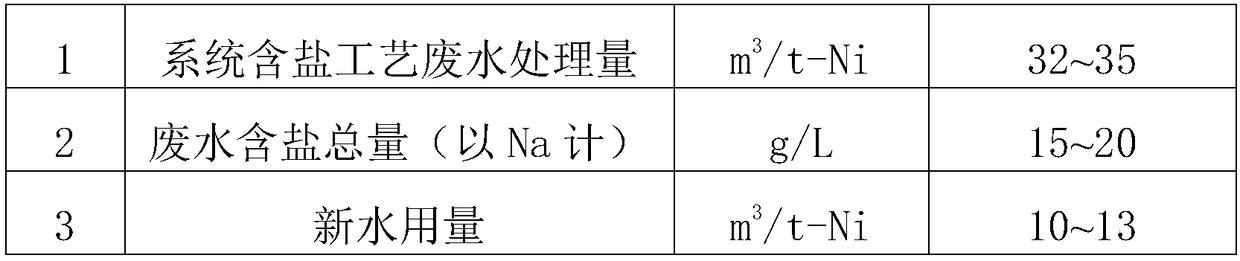

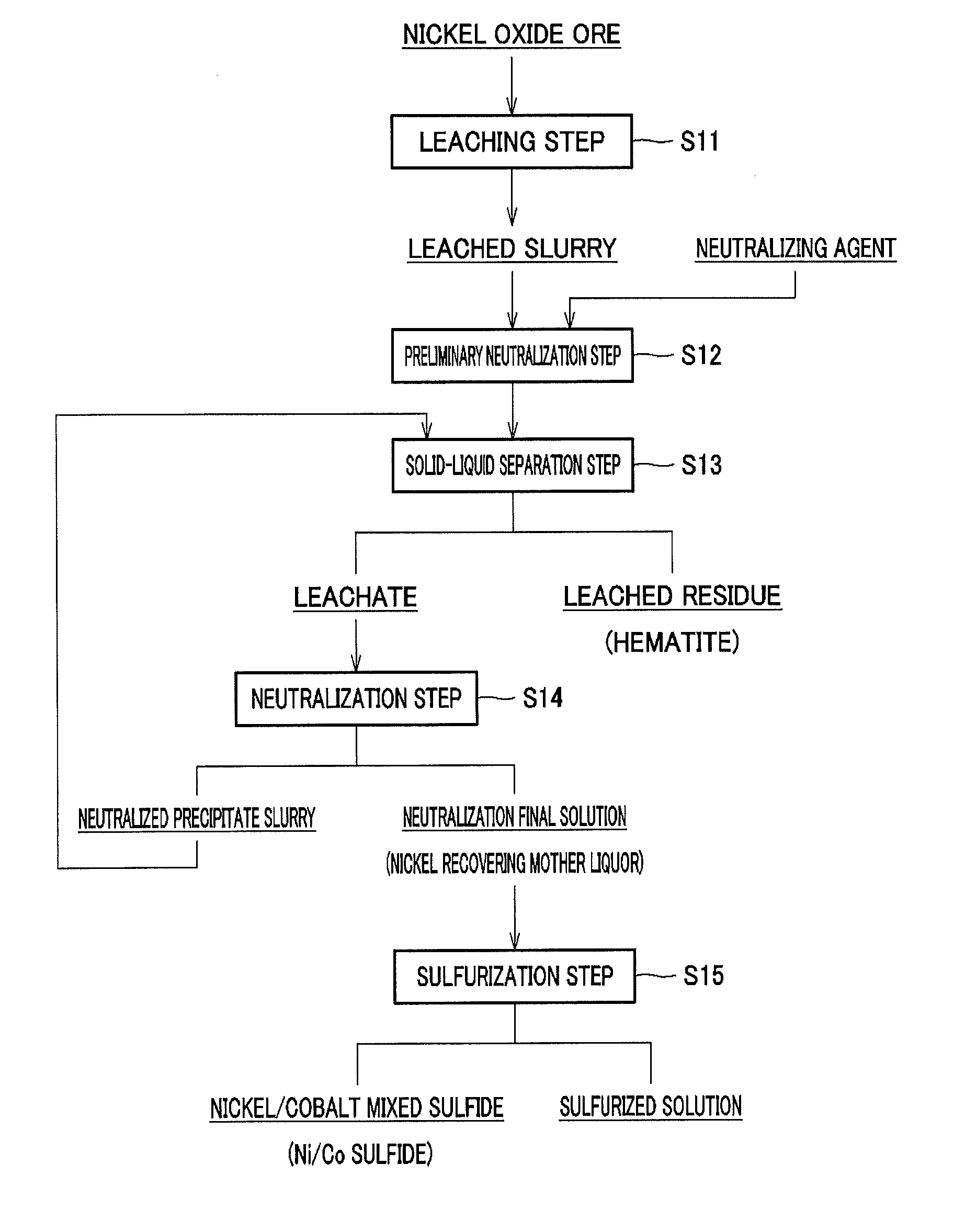

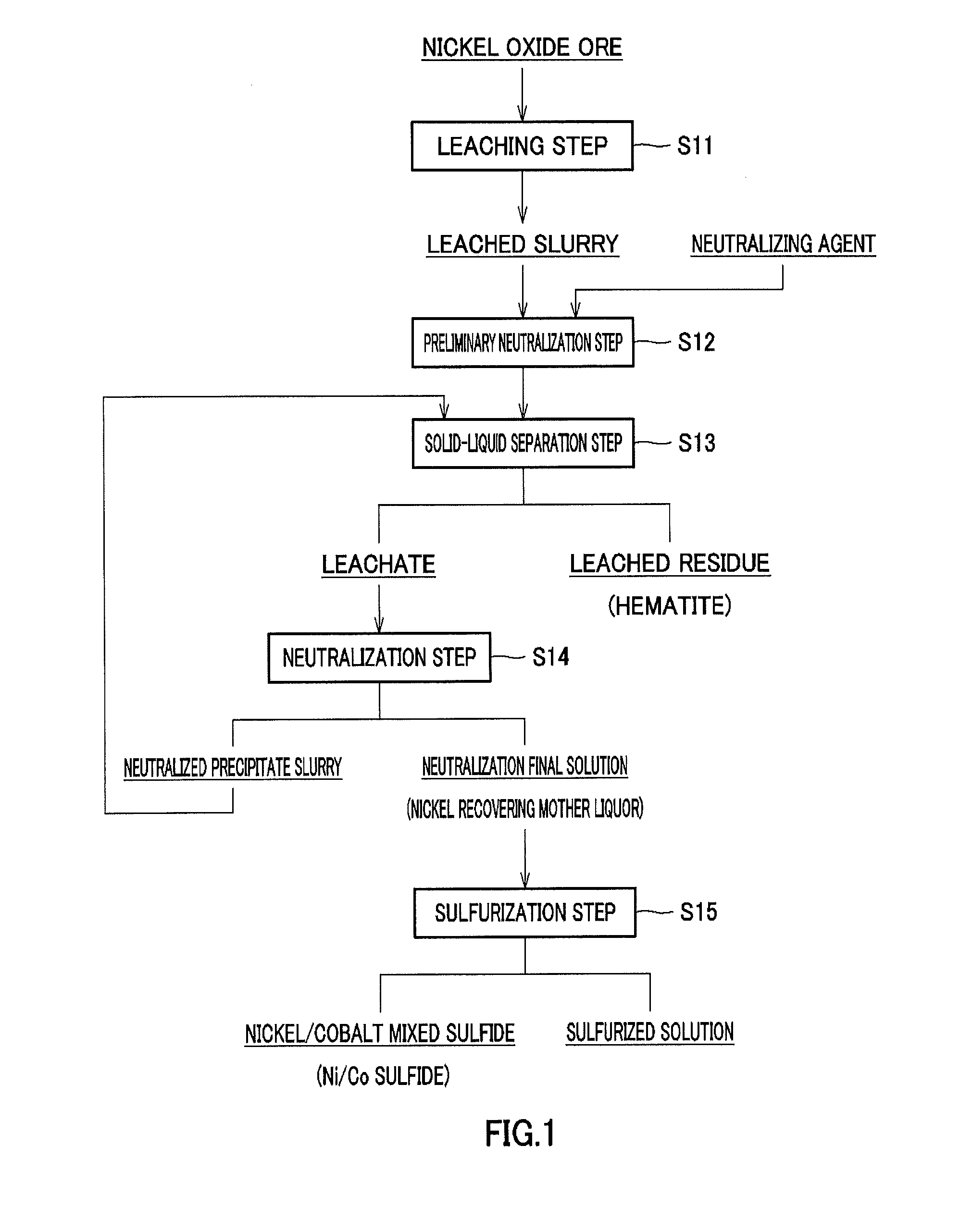

Hematite manufacturing process and hematite manufactured by same

InactiveUS20160137524A1Reduce the presence of impuritiesHigh purityCobalt sulfatesWater contaminantsManganeseSlurry

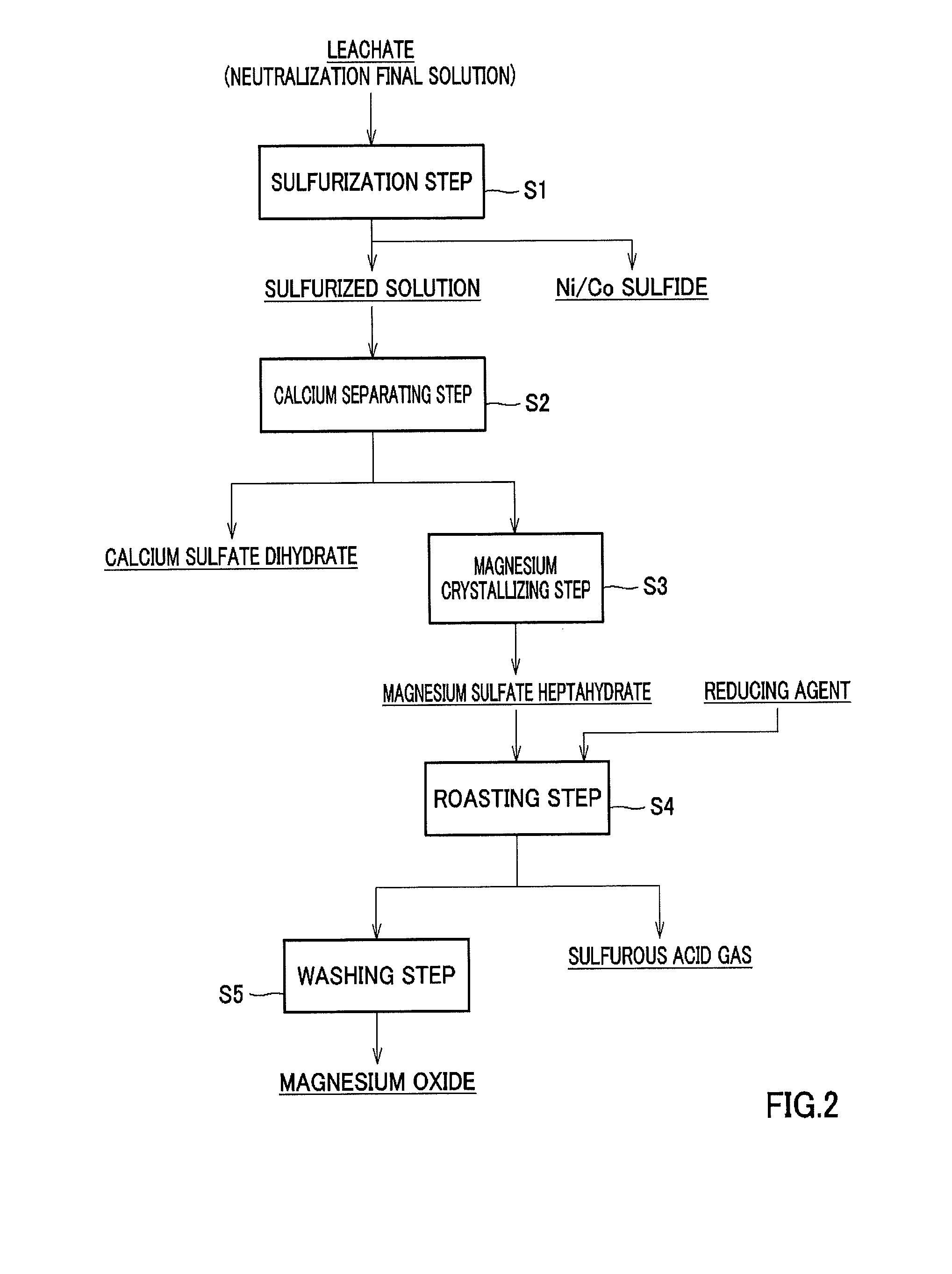

Magnesium oxide produced by a process is used as a neutralizing agent for preliminary neutralization treatment of a leached slurry obtained by leaching a nickel oxide ore at a high temperature and pressure with sulfuric acid added. A neutralizing agent is added to a leachate, obtained by leaching a nickel oxide ore, to separate impurities, and a sulfurizing agent is added to the resulting neutralized solution to obtain nickel and cobalt sulfides, followed by separating the sulfurized solution; discharge waste water, obtained by adding a neutralizing agent to the sulfurized solution to separate aluminum and manganese, is concentrated to precipitate and separate calcium contained in the discharge waste water as calcium sulfate; the resulting solution is concentrated to precipitate magnesium in the solution as magnesium sulfate; the magnesium sulfate is roasted with a reducing agent to obtain magnesium oxide and a sulfurous gas; and the magnesium oxide is washed.

Owner:SUMITOMO METAL MINING CO LTD

Method for extracting cobalt-manganese metal compound from active sludge

InactiveCN101037235AAvoid pollutionHigh recovery rateSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationActivated sludgeFiber

The present invention relates to a method of extracting metallic compound of cobalt and manganese from activated sludge, which belongs to the technique field of environmental protection comprehensive treatment and utilization. In the present invention, the activated sludge is subjected to drying, incinerating, acid-dissolution and relative adsorption, and extraction technology so as to obtain cobaltous sulfate and manganess sulfate. The rate of recovery of cobalt and manganese is more than 90%; the cost is low, the processing cost of metallic cobalt is only 50 thousand yuan per tone; the purity is high, the purity of cobaltous sulfate and manganese sulfate can meet the relative standard. The present invention has obvious economic benefits and social benefits, which can not only solve the sludge pollution caused by chemical fiber industry, but also obtain economic interest during the harnesing of sludge pollution.

Owner:YIZHENG MAORUI CHEM

Recycling method of waste ternary battery material lithium nickel cobalt manganese

PendingCN113415813AReduce consumptionNo pollution in the processCobalt sulfatesWaste accumulators reclaimingManganeseLithium sulfate

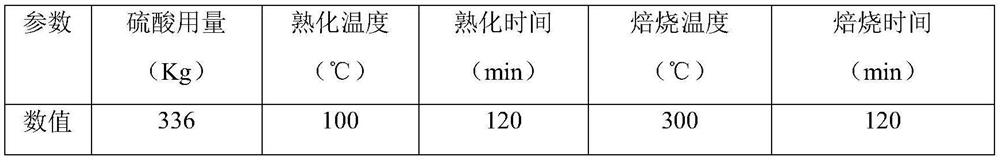

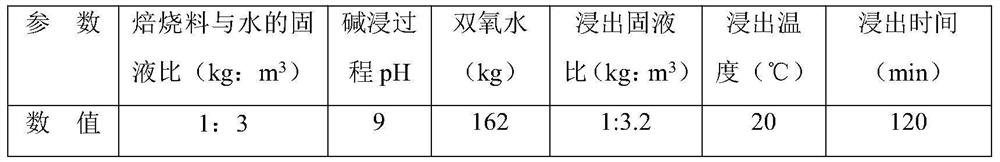

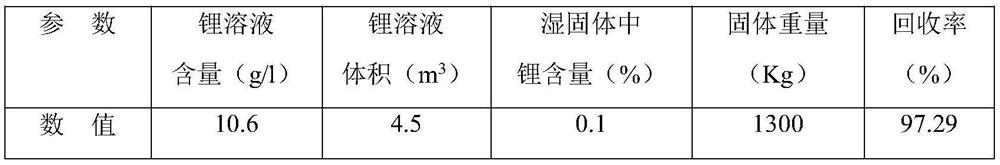

The invention belongs to the technical field of recycling treatment of waste ternary batteries, and particularly relates to a recycling method of a waste ternary battery material lithium nickel cobalt manganese. The technical problem to be solved by the invention is to reduce the consumption of auxiliary materials and improve the metal yield. The method comprises the following steps: a, adding sulfuric acid into the waste ternary battery material, uniformly conducting mixing, and conducting curing and roasting to obtain a roasted material; b, adding water into the roasted material, and carrying out oxidation leaching and solid-liquid separation to obtain solid powder containing nickel, cobalt and manganese and a lithium sulfate solution; c, stirring and mixing the solid powder containing nickel, cobalt and manganese with water, gradually adding an acid d for leaching, conducting heat preservation, and conducting solid-liquid separation to obtain a nickel, cobalt and manganese solution and trivalent solid manganese; and d, sitrring and mixing trivalent solid manganese and water, adding a reducing agent for leaching while an acid is added, and conducting solid-liquid separation to obtain a manganese salt solution. The whole recovery process of the method is low in auxiliary material consumption, high in metal yield and free of environmental pollution.

Owner:四川长虹格润环保科技股份有限公司

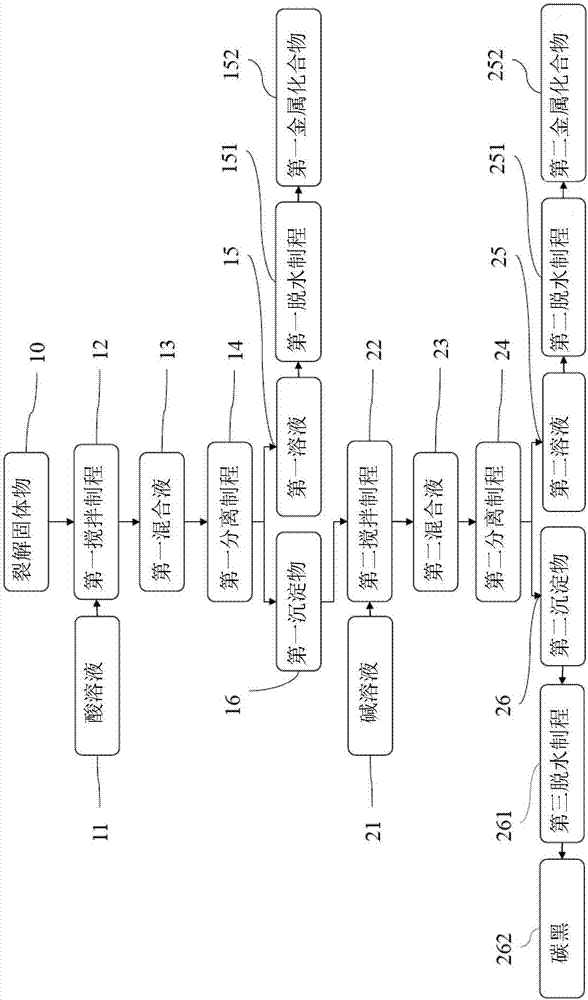

Chemical extraction and recovery method for carbon black after waste rubber decomposition

The invention provides a chemical extraction and recovery method for carbon black after waste rubber decomposition. The chemical extraction and recovery method at least comprises following steps: providing a decomposed solid which is obtained through waste rubber decomposition; providing an acid solution, placing the acid solution and the decomposed solid in a stirring device, carrying out a firststirring process, and generating a first mixed solution; separating the first mixed solution into a first solution and a first precipitate through a first separation process, and obtaining a first metallic compound from the first solution through a first dehydration process; providing an alkaline solution, placing the alkaline solution and the first precipitate in the stirring device, carrying out a second stirring process, and generating a second mixed solution; separating the second mixed solution into a second solution and a second precipitate through a second separation process, and obtaining a second metallic compound from the second solution through a second dehydration process; and obtaining carbon black from the second precipitate through a third dehydration process.

Owner:张瑞永

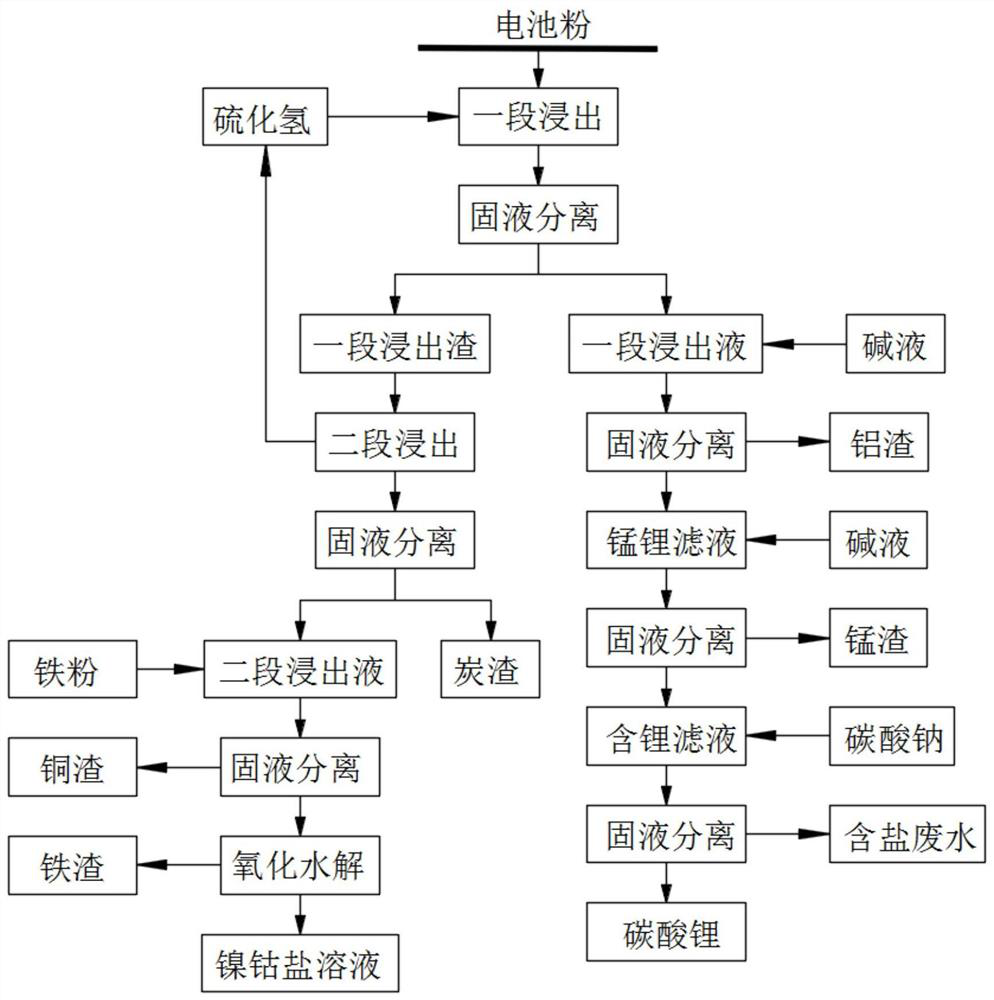

Method for recycling valuable metals in lithium battery through wet process

ActiveCN113802002AEasy to separateWaste accumulators reclaimingProcess efficiency improvementPregnant leach solutionManganese

The invention discloses a method for recycling valuable metals in a lithium battery through a wet process. According to the method, waste lithium battery powder is selectively leached under the condition that hydrogen sulfide gas is pressurized and introduced, so that Mn < 2 + >, Li < + > and Al < 3 + > metal ions enter a first-stage leaching solution, nickel, cobalt, copper and iron exist in first-stage leaching residues in the form of sulfides, only a small amount of sulfuric acid is consumed in the process, then the pH value of the first-stage leaching solution is adjusted to remove aluminum and manganese, in the process, metal separation is extremely thorough, a prepared product is relatively pure, first-stage leaching residues are subjected to negative pressure leaching in acid liquor, the sulfides of nickel, cobalt, iron and copper are dissolved in second-stage leaching solution, generated hydrogen sulfide gas can be recycled and pressurized to the first-stage leaching procedure, in the whole reaction process, only a very small amount of hydrogen sulfide is consumed, and copper and iron are removed by utilizing the properties that copper is easy to replace and iron is easy to hydrolyze, so that a relatively pure nickel-cobalt salt mixed solution is obtained and can be directly used for synthesizing a positive electrode material precursor.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

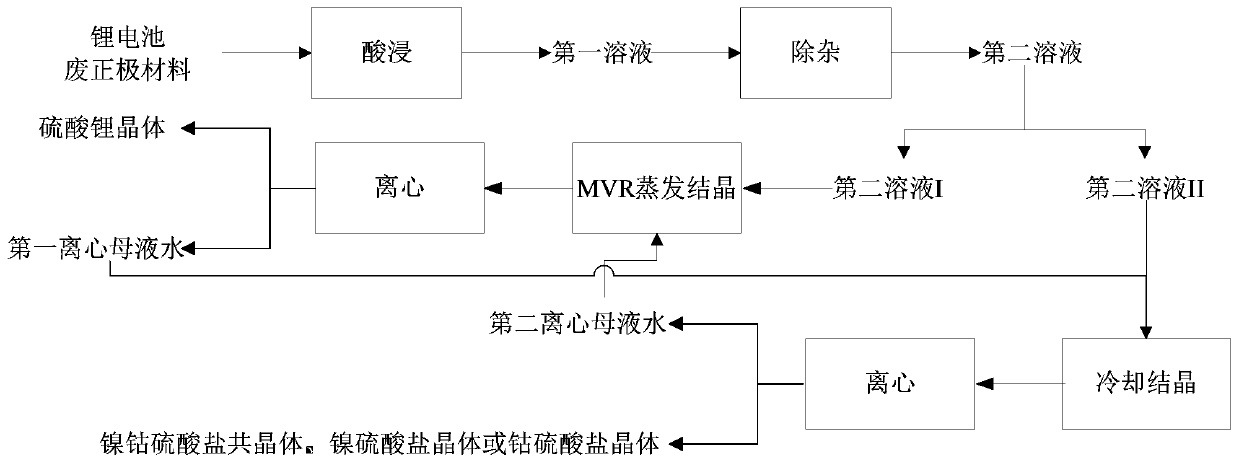

Method for recycling waste positive electrode materials of lithium batteries

InactiveCN109734107AHigh puritySimple recycling methodCobalt sulfatesWaste accumulators reclaimingLithium hydroxideChemistry

The invention provides a method for recycling waste positive electrode materials of lithium batteries. The method includes steps: 1) subjecting the waste positive electrode materials of the lithium batteries to reductive acid leaching in sulfuric acid and hydrogen peroxide, and performing filter pressing to obtain first solution; 2) adjusting a pH value of the first solution, and performing filterpressing to obtain second solution; 3) dividing the second solution into second solution I and second solution II; 4) subjecting the second solution I to MVR evaporative concentration, and centrifuging to obtain lithium sulfate crystal and first centrifugal mother liquor; 5) adding the second solution II into the first centrifugal mother liquor to dilute, cooling, crystallizing and centrifuging to obtain one of nickel-cobalt sulfate eutectic crystal, nickel sulfate crystal and cobalt sulfate crystal and second centrifugal mother liquor. By the method for recycling, the lithium sulfate crystaland one of the nickel-cobalt sulfate eutectic crystal, nickel sulfate crystal and cobalt sulfate crystal are used as a raw material for production of lithium carbonate or lithium hydroxide and a rawmaterial for production of precursors of positive electrode materials respectively.

Owner:池州西恩新材料科技有限公司

Resource utilization method of wastewater slag of cobalt and nickel metallurgy

ActiveCN108977652AAchieve recyclingIncrease added valueCobalt sulfatesAlkali orthophosphate fertiliserSlagResource utilization

The invention discloses a resource utilization method of the wastewater slag of cobalt and nickel metallurgy. The method comprises the following steps of levigating a material through ball milling, then sieving, then reducing through high-pressure hydrogen to reduce nickel, cobalt, copper and the like therein into metal elements, wherein calcium, magnesium, manganese and the like are not reduced,then sorting through gravity to separating the metal elements such as nickel, cobalt and copper from other sizing agents to realize the separation of nickel, cobalt, copper and iron from other metals,then adopting magnetic separation to separate nickel, cobalt and iron from copper, smelting copper powder, then electrorefining to obtain cathode copper, then adding nickel, cobalt and iron powder inphosphoric acid to dissolve, adding hydrogen peroxide to obtain an iron phosphate precipitate, wherein nickel and cobalt are not oxidized so that the precipitation of nickel, cobalt and iron is realized, then extracting, performing reverse extraction by stages after extracting nickel and cobalt to realize the separation of nickel and cobalt, and enabling raffinate to be subjected to concentrationand crystallization to obtain an ammonium phosphate compound fertilizer. The method can be used for realizing the separation and recovery of all ingredients, the recovery rate is high, the finally obtained product has high purity, and the added value of the product is high.

Owner:唐山文丰资源综合利用有限公司

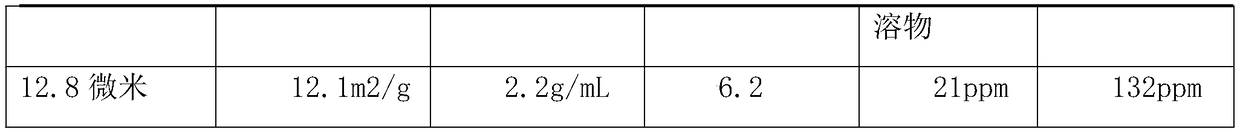

Method for removing fluorine and silicon ions from nickel cobalt manganese sulfate solution

InactiveCN106745343AHigh recovery rateGood effect of removing impuritiesCobalt sulfatesNickel sulfatesIonL&D process

The invention discloses a method for removing fluorine and silicon ions from a nickel cobalt manganese sulfate solution. The method comprises the following process flow: (A) diluting: diluting the nickel cobalt manganese sulfate solution with water; (B) adjusting the pH (Potential of Hydrogen): adjusting the pH of the diluted nickel cobalt manganese sulfate solution to be 4 to 6 with an inorganic acid; (C) extracting: carrying out multi-grade counter-current extraction on the solution with the pH adjusted by the step B by utilizing a mixed extracting agent of P507 and sulfonated kerosene; (D) washing: eluting an extracted organic phase separated in the step C by utilizing pure water; (E) carrying out reverse extraction: carrying out multi-grade counter-current reverse extraction on the washed organic phase with an inorganic acid with the concentration of 2mol / L to 6mol / L; (F) removing oil: standing and layering a reverse extraction water phase obtained by the step E, and removing the oil by utilizing an oil remover to obtain the purified nickel cobalt manganese sulfate solution. The method for removing the fluorine and silicon ions from the nickel cobalt manganese sulfate solution, disclosed by the invention, has the advantages of good impurity removing effect, high recovery rate of valuable metal including nickel, cobalt and manganese, simple process and low production cost, and is suitable for industrialized production.

Owner:GANFENG LITHIUM CO LTD

Method of producing a nickel salt solution

A method for converting nickel into a nickel salt solution. Nickel is dissolved and reacted in an oxygen-enriched acidic solution to produce a nickel salt solution as illustrated in the following chemical equation, wherein X is a conjugate base: Ni+H2X+½O2->NiX+H2O.

Owner:CHEVRON TEXACO TECH VENTURES

Ammonia storage for on-vehicle engine

Ammonia is used as precursor source of hydrogen fuel in an on-vehicle internal combustion engine. Ammonia is stored as, for example, a ligand in an on-vehicle transition metal composition. Upon demand for hydrogen by the vehicle's engine control system, ammonia is expelled as a gas from some of the composition and the ammonia gas is dissociated into a mixture of hydrogen and nitrogen and delivered as a fuel-containing mixture to the engine. In a preferred embodiment, the hydrogen is used as a supplement to gasoline as a fuel for engine operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for the manufacture of ferric sulfate solution and a water treatment agent using the same

InactiveUS6375919B1Improve solubilitySmall particle sizeCobalt sulfatesWater softeningIron(III) sulfateNuclear chemistry

A method for the manufacture of a ferric sulfate solution is provided, characterized in that, iron ore containing 30% by weight or more FeOOH as a trivalent iron (Fe3+) is calcined at 200-600° C., and then dissolved in sulfuric acid. A water treatment agent consisting of a basic ferric sulfate solution manufactured by the above mentioned manufacturing method is used as a coagulating agent for water treatment.

Owner:TAKI CHEM CO LTD

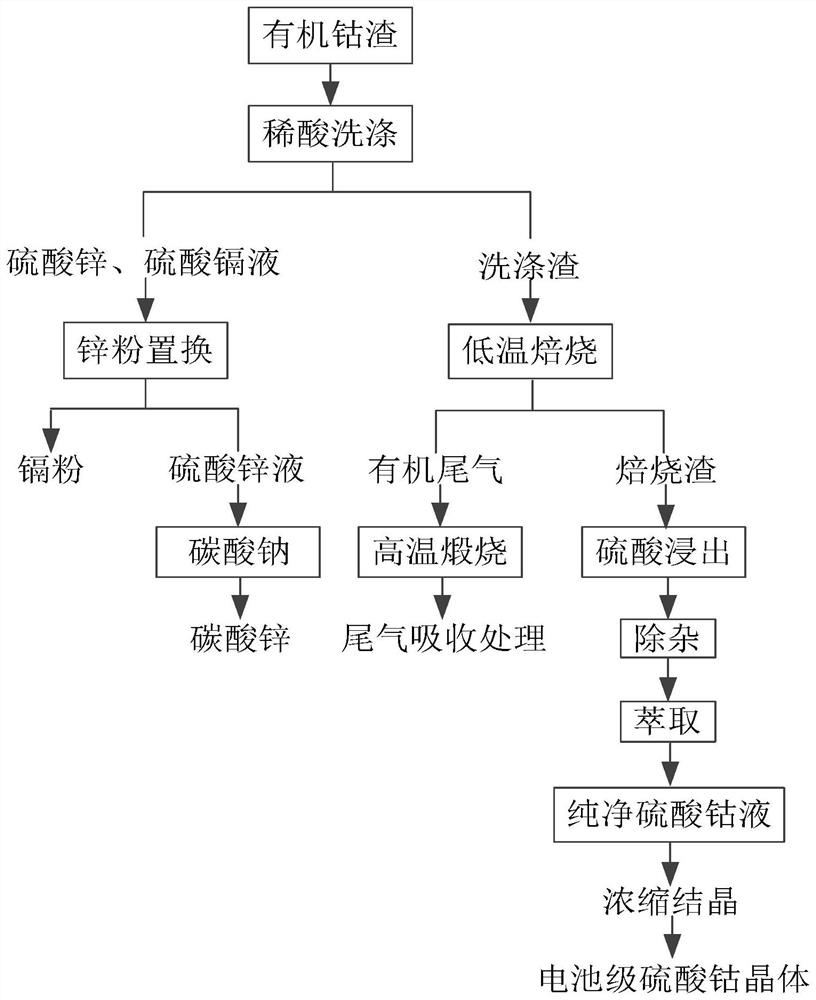

Method for producing cobalt sulfate by utilizing organic cobalt slag of zinc smelting plant

PendingCN112520790ADifficult to handleFully recycleCobalt sulfatesZinc compoundsSulfate zincZinc smelter

The invention discloses a method for producing cobalt sulfate by utilizing organic cobalt slag of a zinc smelting plant, and belongs to the field of non-ferrous metal hydrometallurgy. The method comprises the following steps: firstly, washing organic cobalt slag of a zinc smelting plant with dilute acid, enabling zinc and cadmium in the organic cobalt slag to react with dilute sulfuric acid to generate zinc sulfate and cadmium sulfate, enabling the zinc sulfate and cadmium sulfate to enter a solution, performing filtering, and recycling the solution to obtain cadmium powder and zinc carbonate;carrying out low-temperature roasting on the filter residues, carrying out high-temperature roasting on organic tail gas obtained by low-temperature roasting, carrying out high-temperature decomposition on the organic tail gas, carrying out cyclic absorption tail gas treatment through alkali liquor, carrying out low-temperature roasting to obtain cobalt oxide slag, performing leaching through sulfuric acid to obtain a solution containing cobalt sulfate, carrying out P204 extraction to deeply remove impurities, completely removing the impurities, extracting cobalt by using P507 to obtain a high-purity cobalt sulfate solution, and performing evaporation, concentration and crystallization to obtain a battery-grade cobalt sulfate crystal product. The application of the method develops a new cobalt raw material source for the field of non-ferrous metal hydrometallurgy, and the method has remarkable economic value and social value.

Owner:MEISHAN SHUNYING POWER BATTERY MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com