Method for recycling waste positive electrode materials of lithium batteries

A recycling method and cathode material technology, which are used in the wet recycling of lithium valuable metals, nickel, aluminum and cobalt in waste lithium batteries, and can solve problems such as environmental hazards of heavy metals and waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

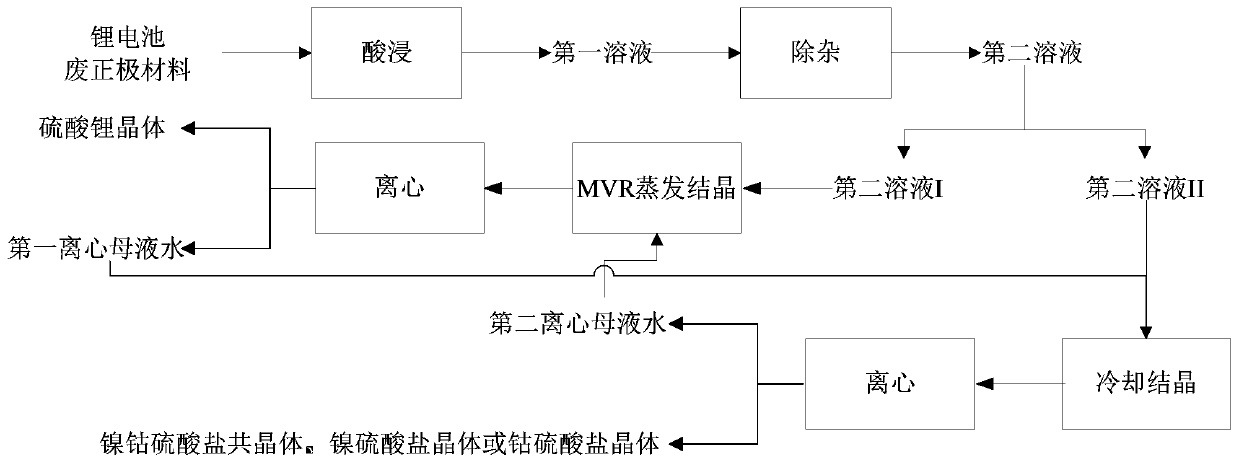

[0025] A kind of recycling method of waste cathode material of lithium battery, such as figure 1 shown, including the following steps:

[0026] 1) Take 3.1 tons of lithium battery cathode materials, including 927kg of nickel, 662kg of cobalt, 156kg of lithium, and 113kg of aluminum, and add them to 25m 3 Beat in soft water, add sulfuric acid and hydrogen peroxide, react for 3 hours and the pH of the solution reaches 2, press filter to get the first solution 21m 3 , in which the total concentration of nickel, cobalt and manganese reaches 76g / l;

[0027] 2) Adjust the pH of the first solution to 4 with nickel carbonate, and obtain the second solution after pressure filtration, wherein the aluminum ion concentration is 7 mg / l;

[0028] 3) the second solution that step 2) obtains is divided into 19m 3 Second solution I and 2m 3 second solution II;

[0029] 4) The second solution I enters the MVR evaporation system, and the evaporation temperature is 70°C. When it is concentra...

Embodiment 2

[0032] A kind of recycling method of waste cathode material of lithium battery, such as figure 1 shown, including the following steps:

[0033] 1) Take a total of 3.3 tons of lithium battery cathode materials, lithium cobalt oxide cathode materials, etc., including 1053kg of nickel, 960kg of cobalt, 191kg of lithium, and 101kg of aluminum, and add them to 23m 3 Make slurry in soft water, add sulfuric acid and hydrogen peroxide, react for 5 hours and the pH of the solution reaches 3, press filter to obtain the first solution 20m 3 , where the total concentration of nickel, cobalt and manganese reaches 96g / l;

[0034] 2) Adjust the pH of the first solution to 6 with nickel carbonate, obtain the second solution after pressure filtration, wherein the aluminum ion concentration is 5 mg / l;

[0035] 3) the second solution that step 2) obtains is divided into 15m 3 Second solution 1 and 5m 3 second solution II;

[0036] 4) The second solution I enters the MVR evaporation system, ...

Embodiment 3

[0039] A kind of recycling method of waste cathode material of lithium battery, such as figure 1 shown, including the following steps:

[0040]1) Take a total of 3.5 tons of lithium cobaltate positive electrode materials and lithium nickelate positive electrode materials, including 1122kg of nickel, 558kg of cobalt, 203kg of lithium, and 81kg of aluminum, and add them to 23m 3 beating in soft water, adding sulfuric acid and hydrogen peroxide, the pH of the solution reached 2.3 after 4 hours of reaction, press filtration to obtain the first solution of 20.5m 3 , wherein the total concentration of nickel, cobalt and manganese reaches 82g / l;

[0041] 2) Adjust the pH of the first solution to 5 with nickel carbonate, obtain the second solution after pressure filtration, wherein the aluminum ion concentration is 7 mg / l;

[0042] 3) the second solution that step 2) obtains is divided into 16.5m 3 Second solution I and 4m 3 second solution II;

[0043] 4) The second solution I e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com