Method and means for using microwave energy to oxidize sulfidic copper ore into a prescribed oxide-sulfate product

a technology of oxide-sulfate and copper ore, which is applied in the field of recovery of base metals, can solve the problems of high-value grinding, unavoidable step, and high cost of copper product production, and achieve the effect of inexpensive recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

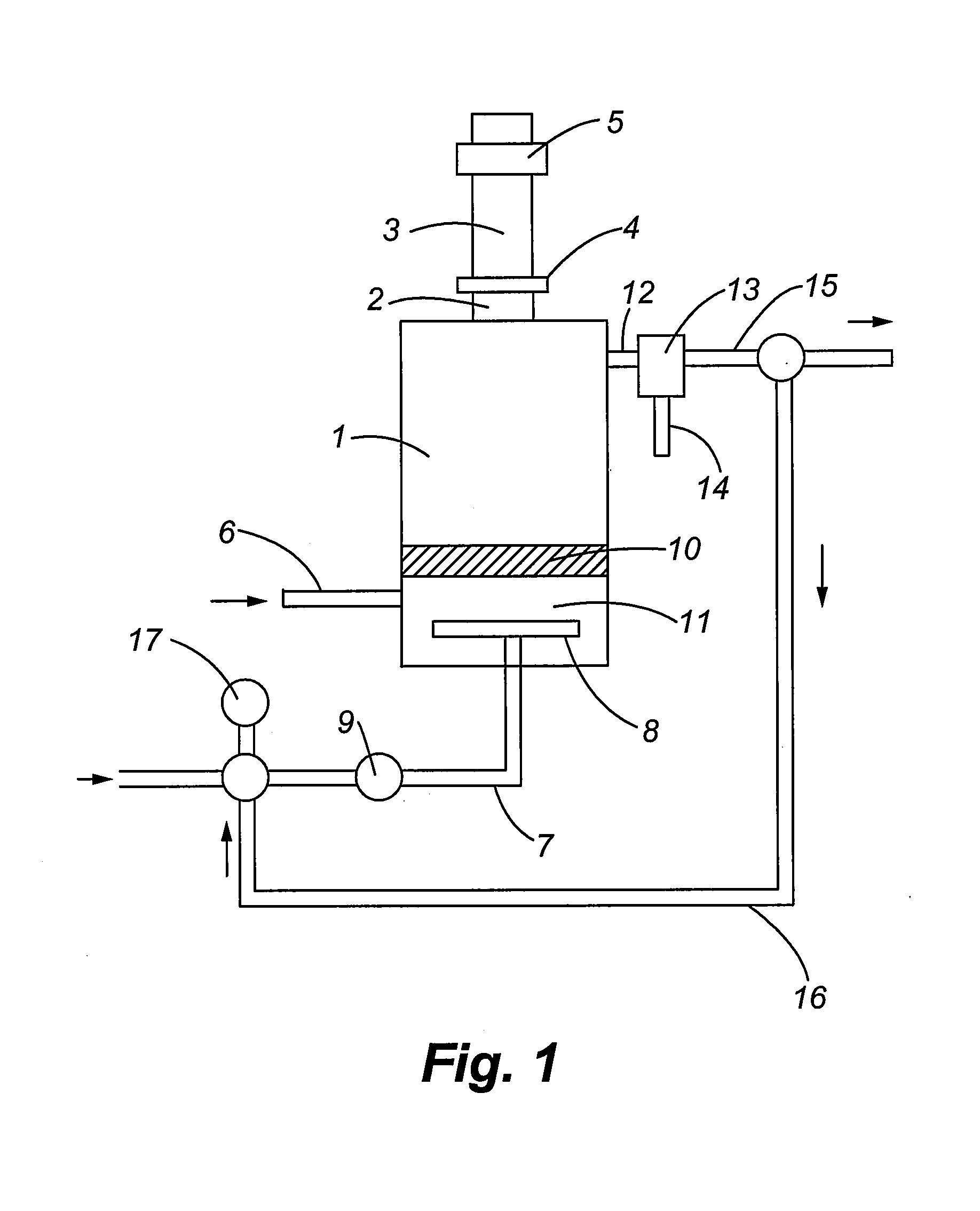

[0036]The present invention discloses a means by which microwave energy is used to initiate and sustain the reactions described in (1) and (2) above. For sulfur concentrations above approximately 7 wt. %, these reactions, once initiated, will continue autogeneously using the heat generation from the burning sulfur; below 7 wt. % concentration, the process requires additional energy, which is herein disclosed as being microwave energy. Because the operation does not rely on the autogenous burning of sulfur as an energy source, the temperature may be controlled by a variety of means preferably to less than about 690° C. and more preferably within the range of about 580° C.-680° C. so as to prevent the formation of insoluble spinel and to control the oxide-sulfate ratio of the calcine product.

[0037]Microwave energy is particularly attractive because it heats selectively certain components of the material more than others. For most sulfidic materials, the gangue is weakly microwave abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com