Patents

Literature

1152results about How to "Avoid yellowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

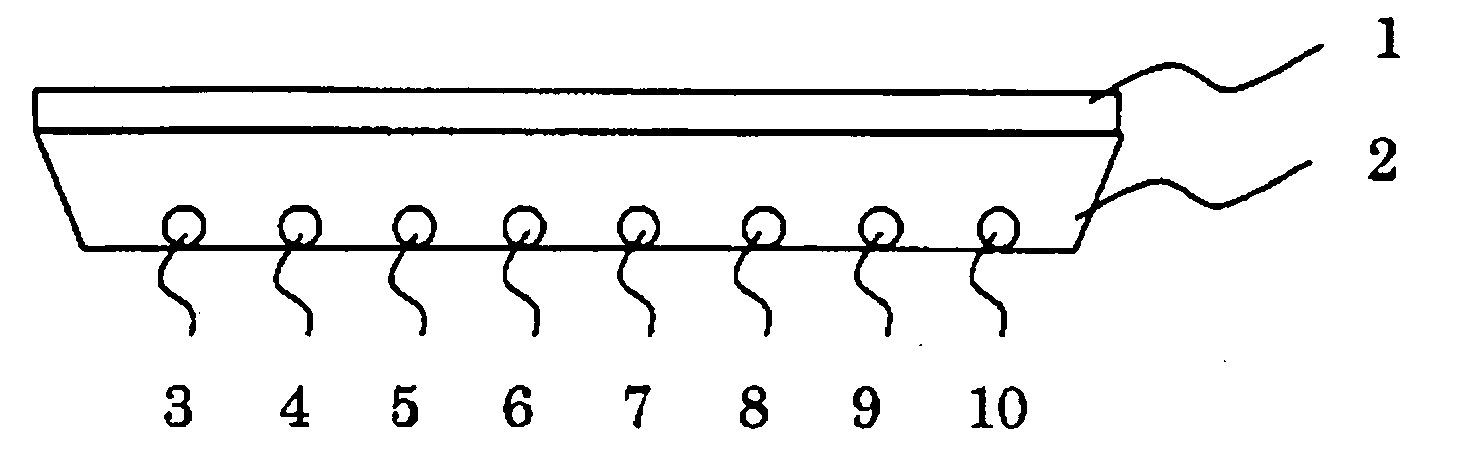

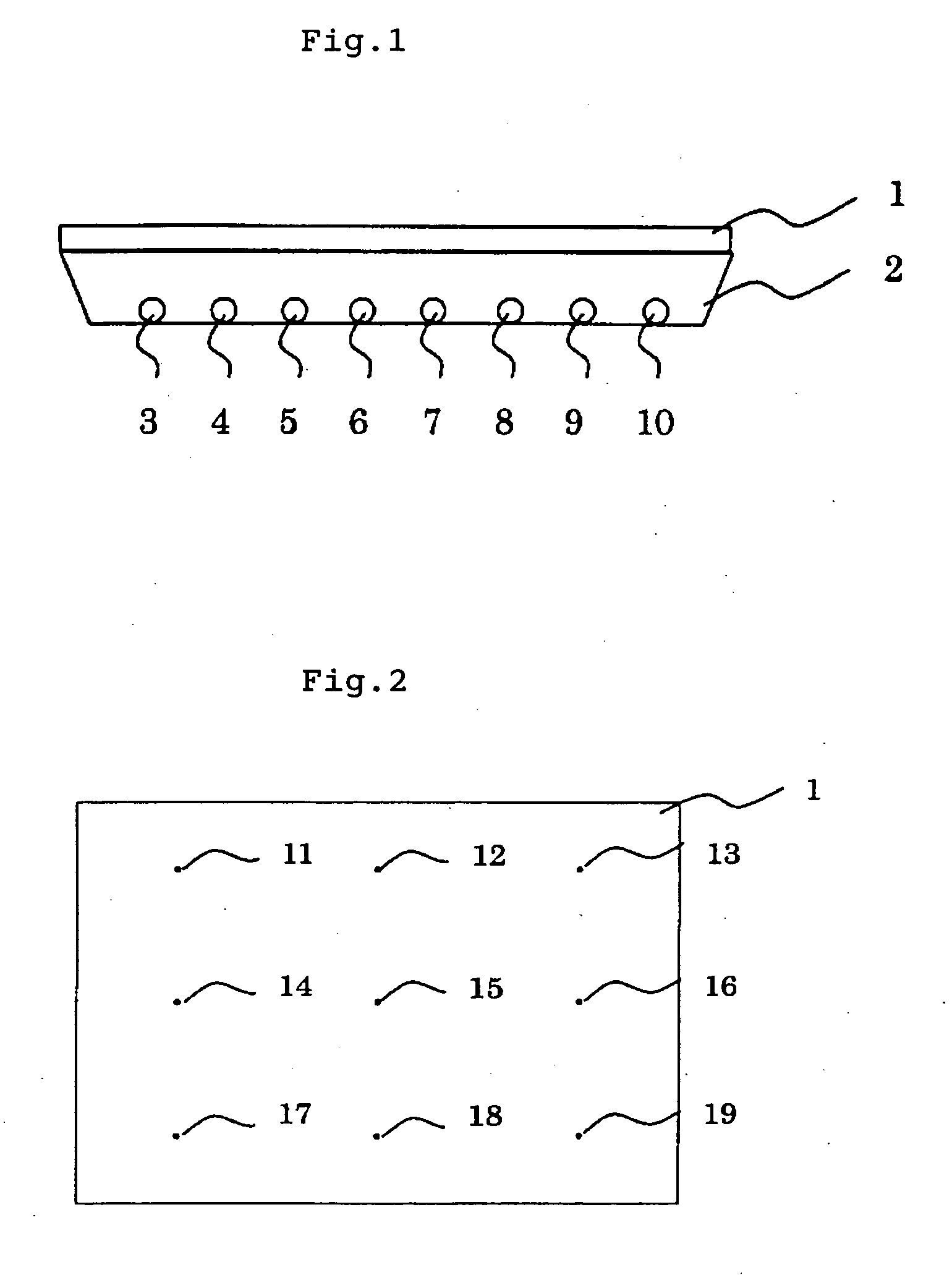

Direct back light type liquid crystal display and light diffuse plate

InactiveUS20060146228A1Good light diffusion effectPrevent discolorationLiquid crystal compositionsMeasurement apparatus componentsWhitening AgentsPhosphate

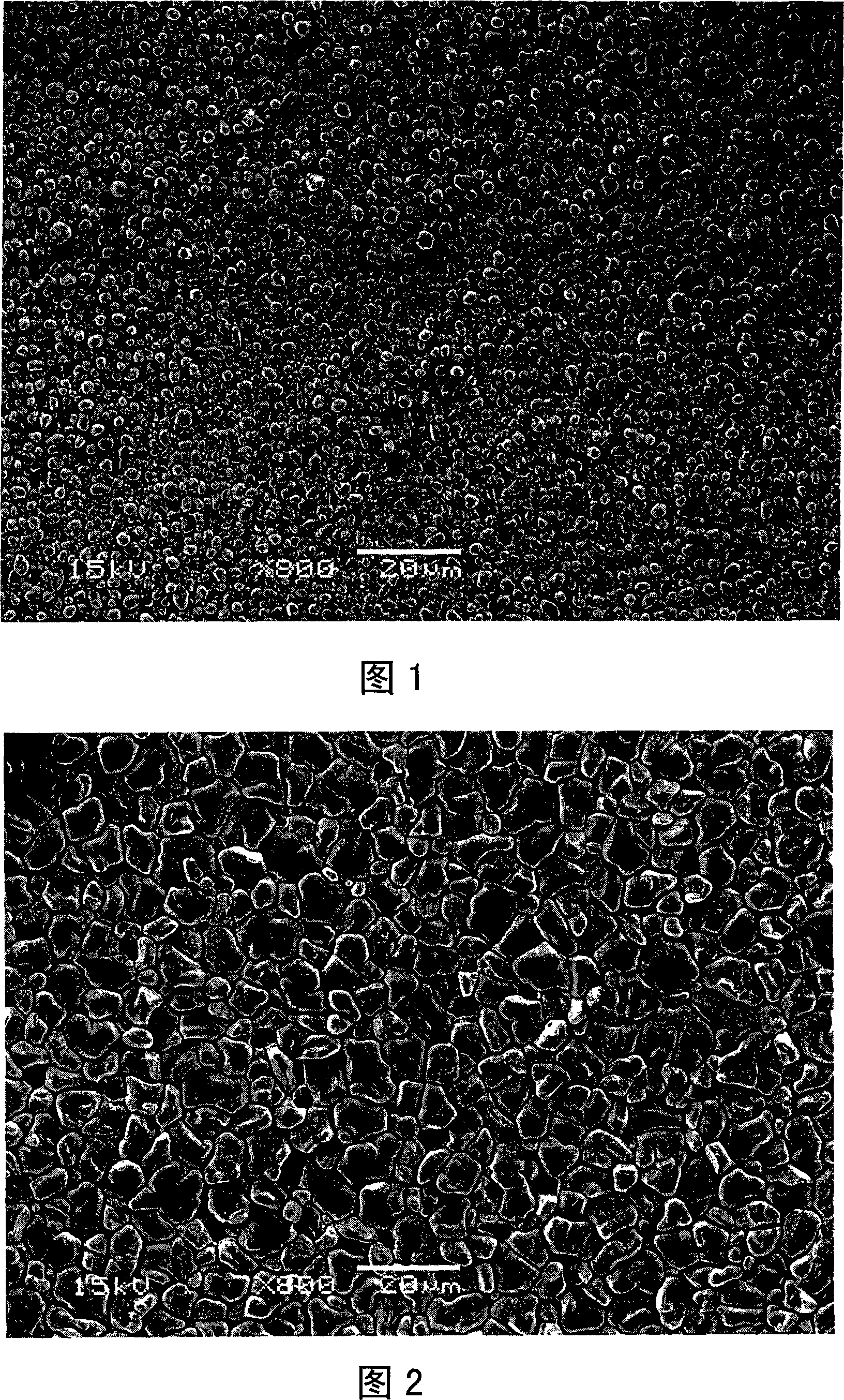

There is provided a direct backlight type liquid crystal display device having high light diffusability, keeping excellent color and having high brightness. The direct backlight type liquid crystal display device is a direct backlight type liquid crystal display device comprising: a backlight source, a light diffusion sheet which may have a protective film on a surface thereof which faces the backlight source or both surfaces thereof as desired, a light ray adjusting film, and a liquid crystal panel, wherein the light diffusion sheet is formed from a composition comprising predetermined amounts of (C) at least one heat stabilizer (component C) selected from the group consisting of a phosphate compound (component C-1), a phosphate compound (component C-2) and a phosphonite compound (component C-3), (D) an ultraviolet absorber (component D) and (E) a fluorescent whitening agent (component E), based on 100 parts by weight of the total of (A) an aromatic polycarbonate resin (component A) and (B) polymeric fine particles (component B) having an average particle diameter of 0.01 to 50 μm.

Owner:TEIJIN KASEK KK

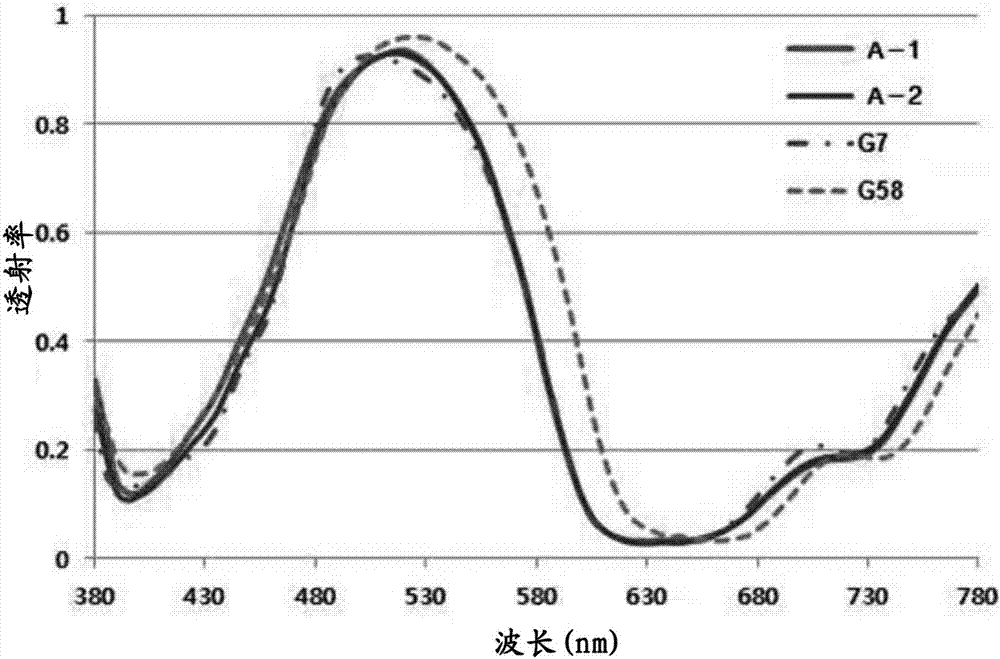

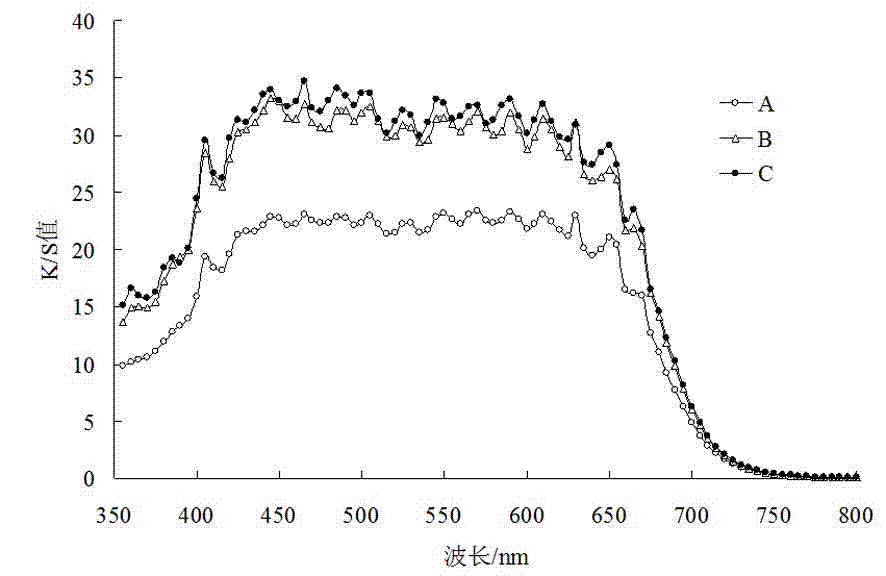

Colored photosensitive resin composition, color filter, method for producing the same, and image display device

ActiveCN106909027AExcellent adhesionPrevent peelingPhotosensitive materials for photomechanical apparatusOptical elementsSolventOrganosilicon

The present invention provides a colored photosensitive resin composition, a color filter, a method for producing the same, and an image display device, the colored photosensitive resin composition comprising: (A) a colorant, (B) an alkali-soluble resin, (C) a photopolymerizable compound, (D) a photopolymerization initiator, (E) one or more compounds selected from the group consisting of a polyfunctional thiol compound and an organosilicon compound, and (F) a solvent. The colorant (A) contains one or more of Pigment Green 59, 62 and 63 selected from C.I. and one or more selected from pigments and dyes.

Owner:DONGWOO FINE CHEM CO LTD

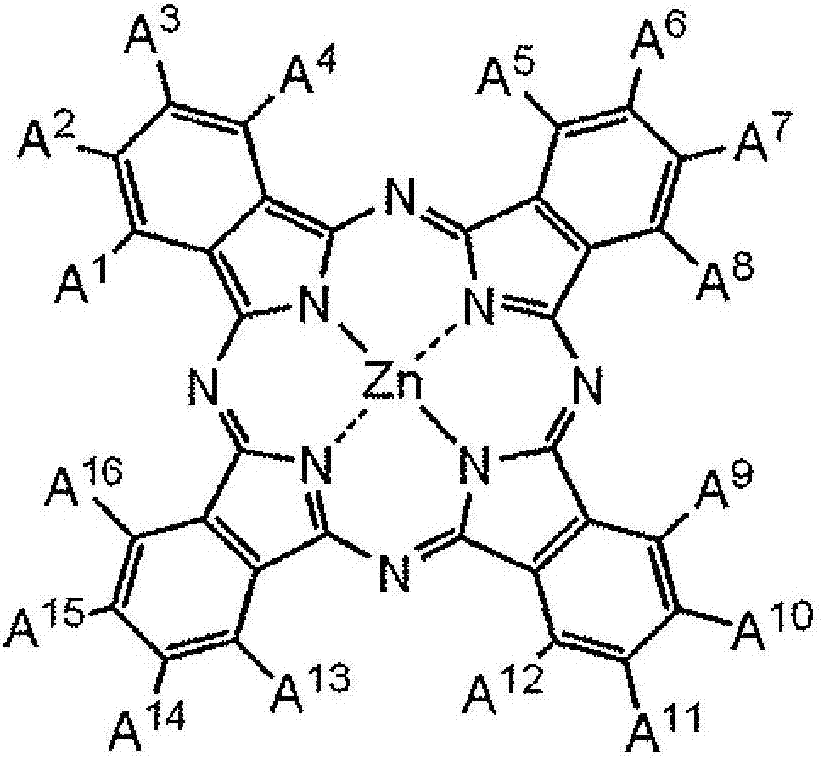

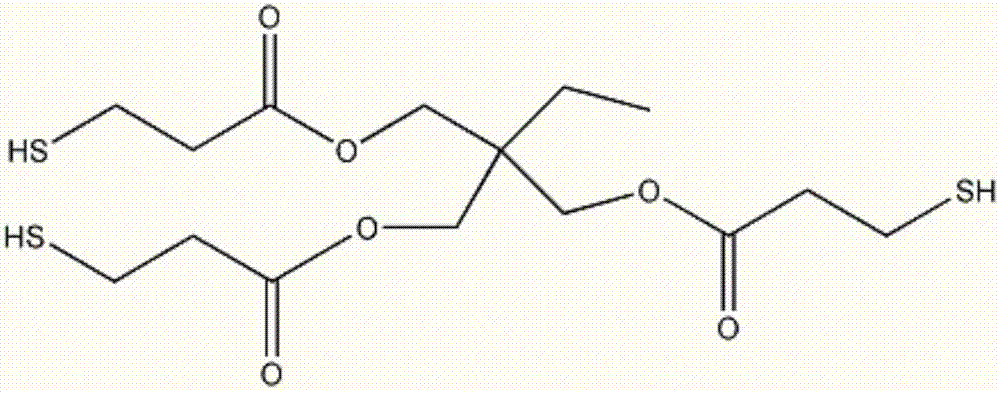

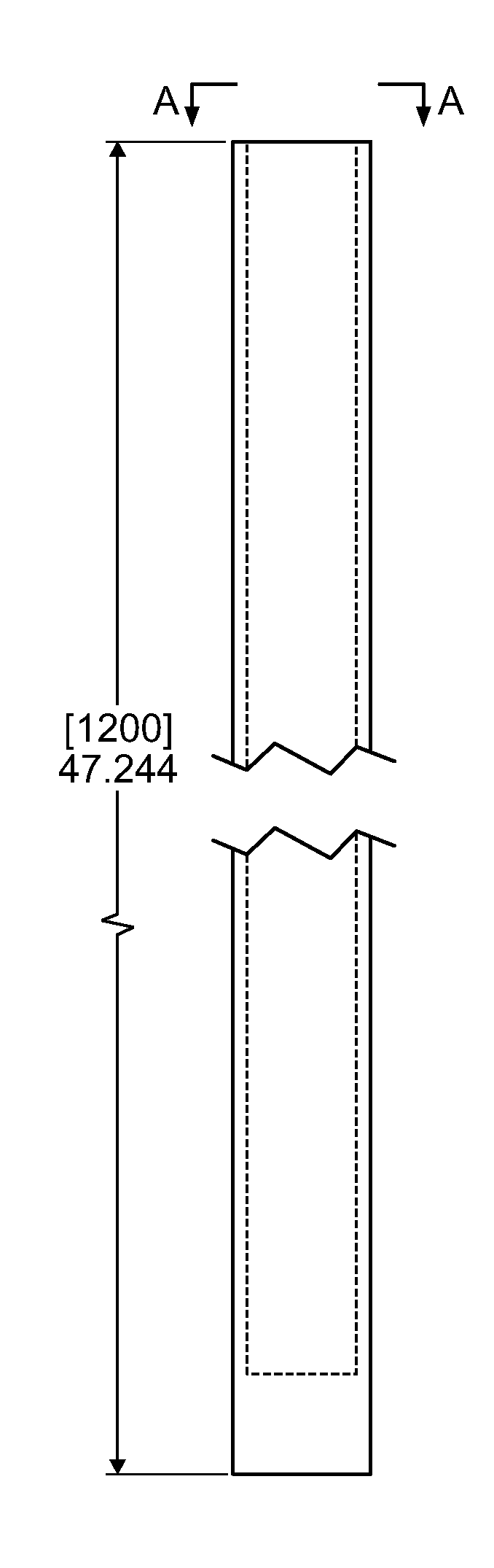

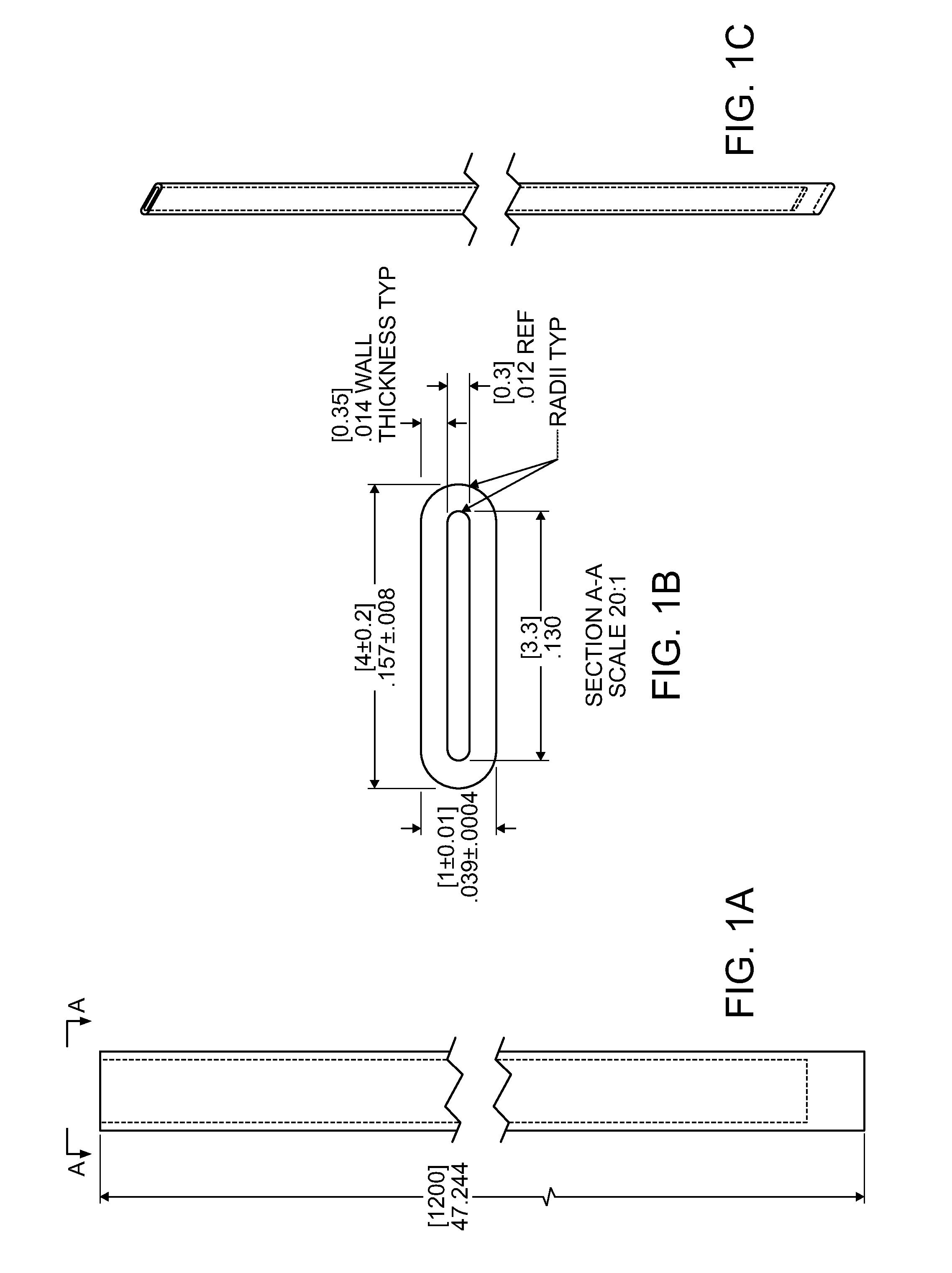

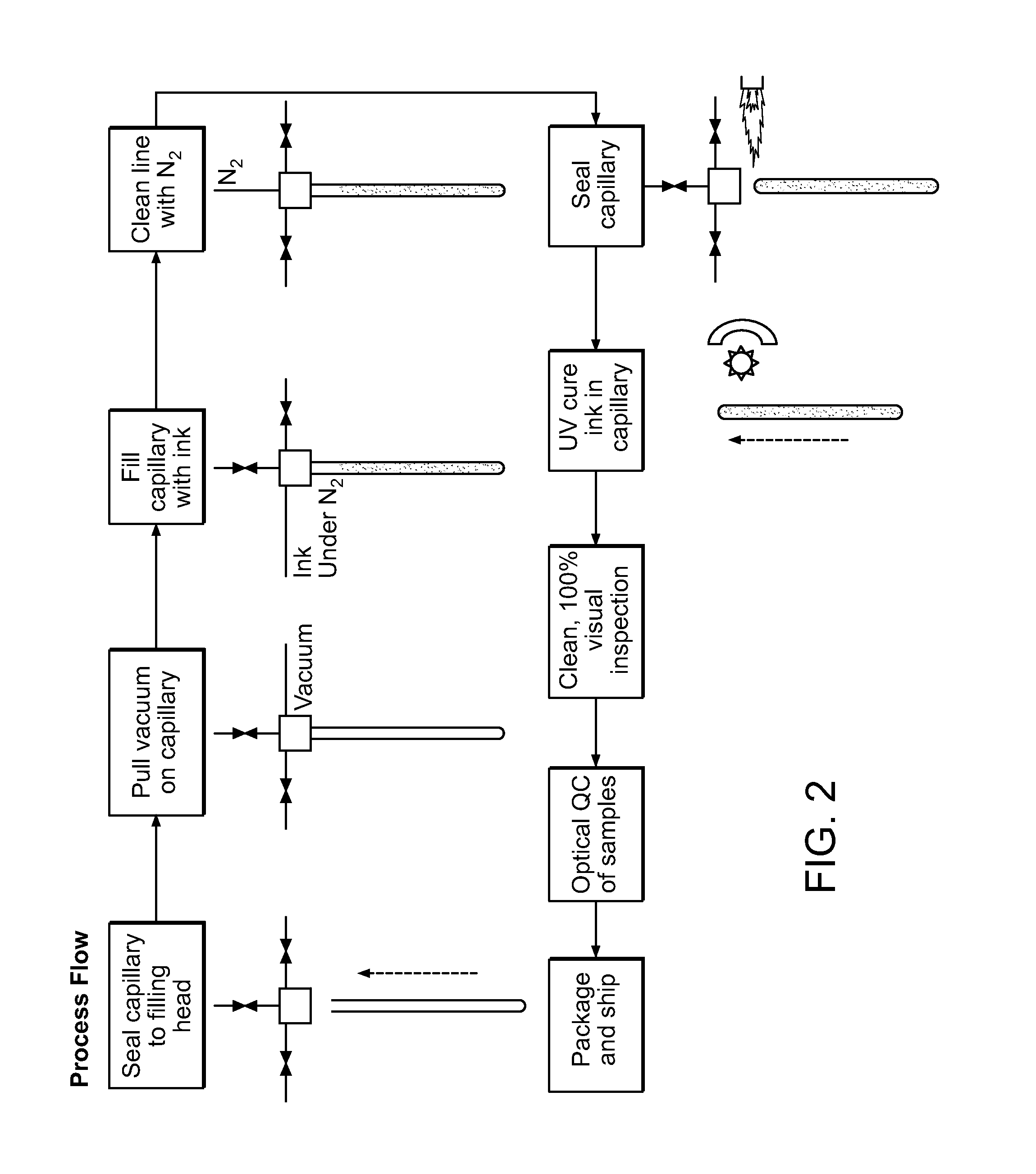

Stress-resistant component for use with quantum dots

ActiveUS20130148376A1Reduced optical performanceAvoid yellowingAircraft componentsLayered productsQuantum dotMaterials science

A glass tube including quantum dots in a polymerized matrix is described. An optical component and other products including such glass tube, a composition including quantum dots, and methods are also disclosed.

Owner:SAMSUNG ELECTRONICS CO LTD

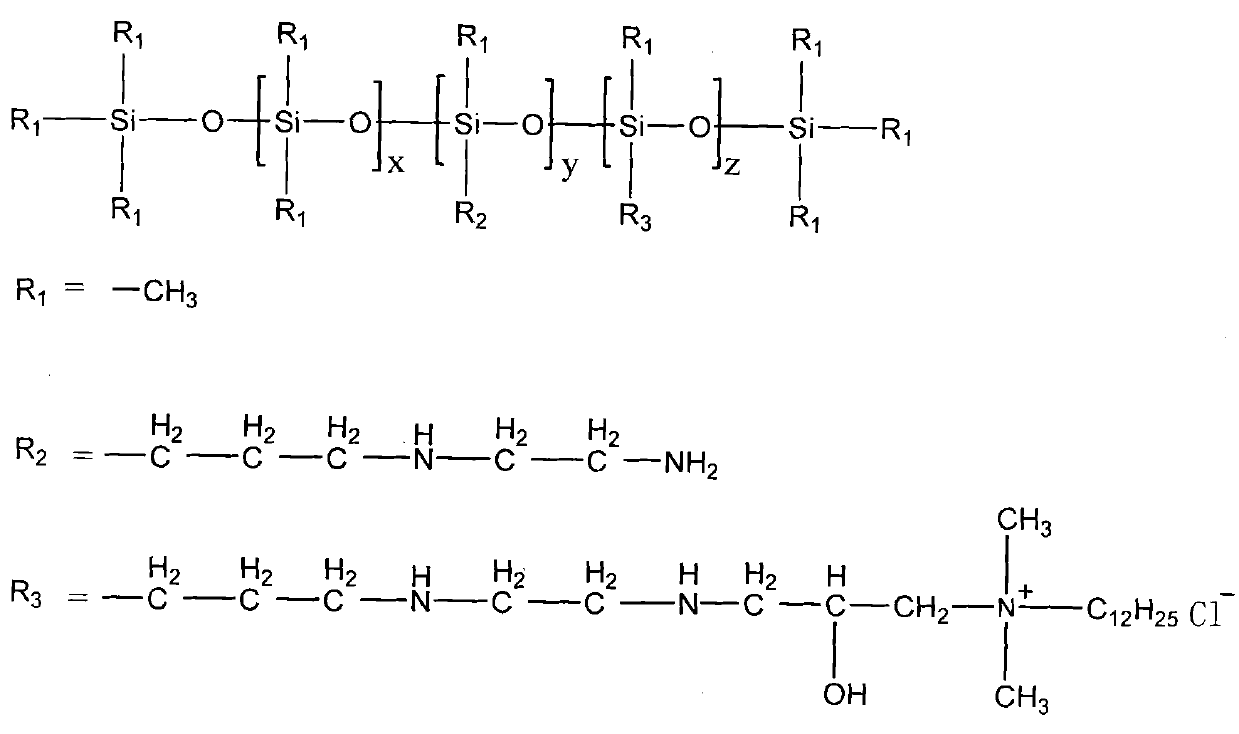

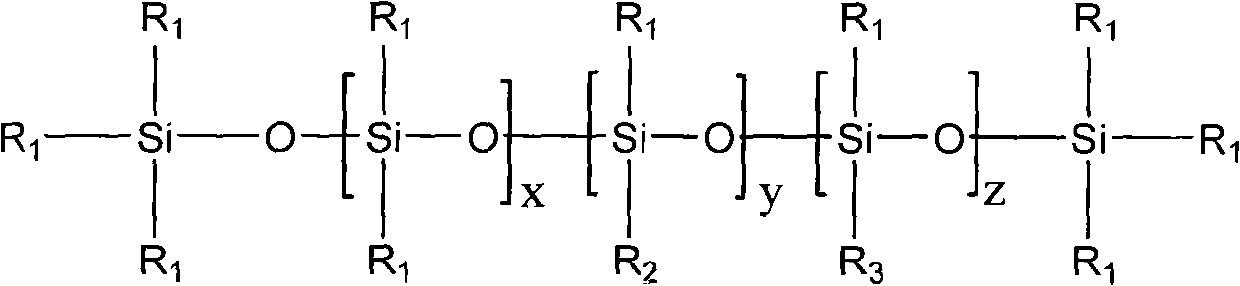

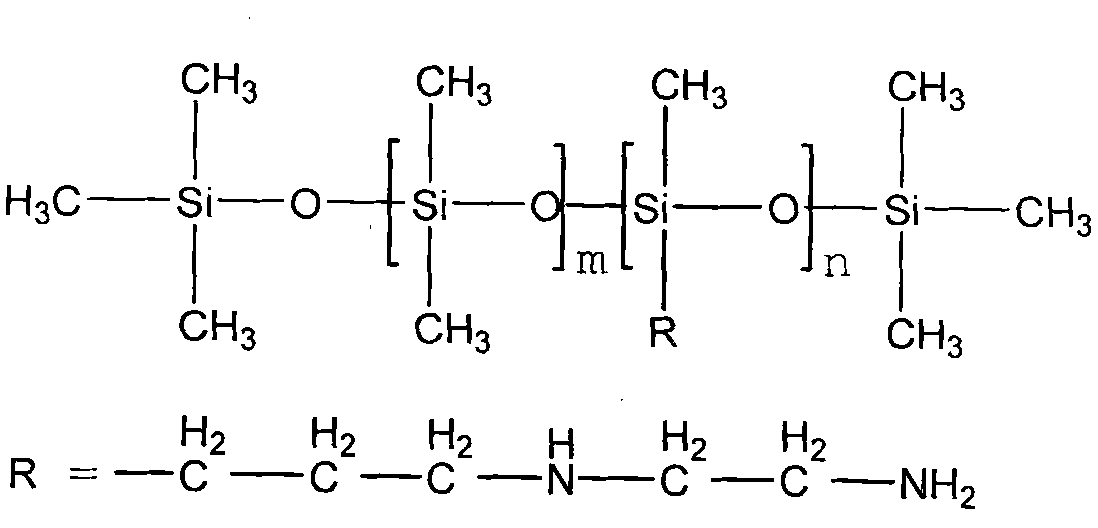

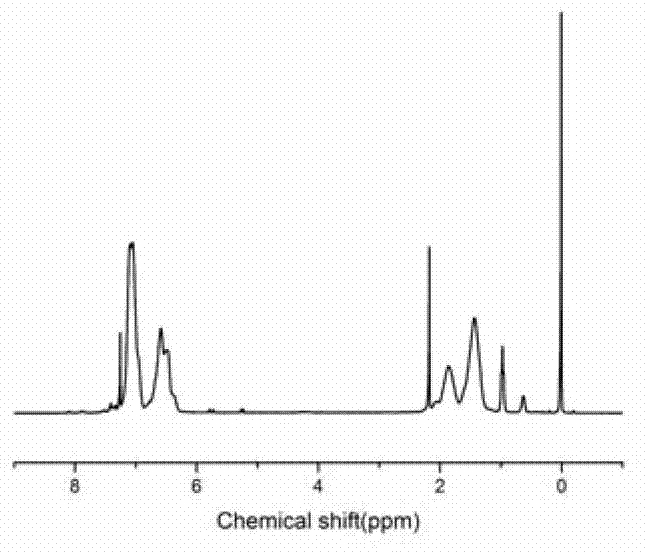

Quaternized modified amino silicone oil softener and preparation and application thereof

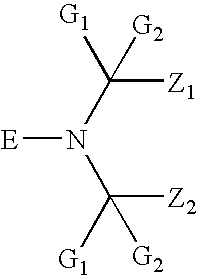

InactiveCN101914206AAvoid yellowingImprove hydrophilicityVegetal fibresTetramethylammonium hydroxideDisiloxane

The invention relates to a quaternized modified amino silicone oil softener and preparation and application thereof. The softener comprises the following general formula in the specification. The preparation comprises the following steps of: (1) adding octamethylcy-clotetrasiloxane into a container, adding a coupling agent N-beta-(aminoethyl)-gamma-aminopropyl methyl dimethoxysilane into the container dropwise, adding a tetramethyl ammonium hydroxide catalyst and subsequently a capping agent hexamethyl disiloxane into the container, and then performing reduced pressure distillation to obtain amino silicon oil; (2) dissolving the amino silicon oil into a solvent, adding the mixture into epichlorohydrin, stirring and heating to react under the protection of nitrogen, and removing the solvent by steaming to obtain an intermediate product; and (3) uniformly mixing N,N-dimethyl-decanamide and the solvent to obtain a mixture, stirring with heating, adding the intermediate product dropwise into the mixture under the protection of nitrogen, performing a thermostatic reaction, and removing the solvent by steaming to obtain the product. The softener of the invention has high hydrophilicity and high stability; fabric processed by the softener has excellent soft handfeel, high hydrophilicity, low yellowing, antibacterial property and the like; and the softener is simple to prepare and is suitable for industrial production.

Owner:DONGHUA UNIV

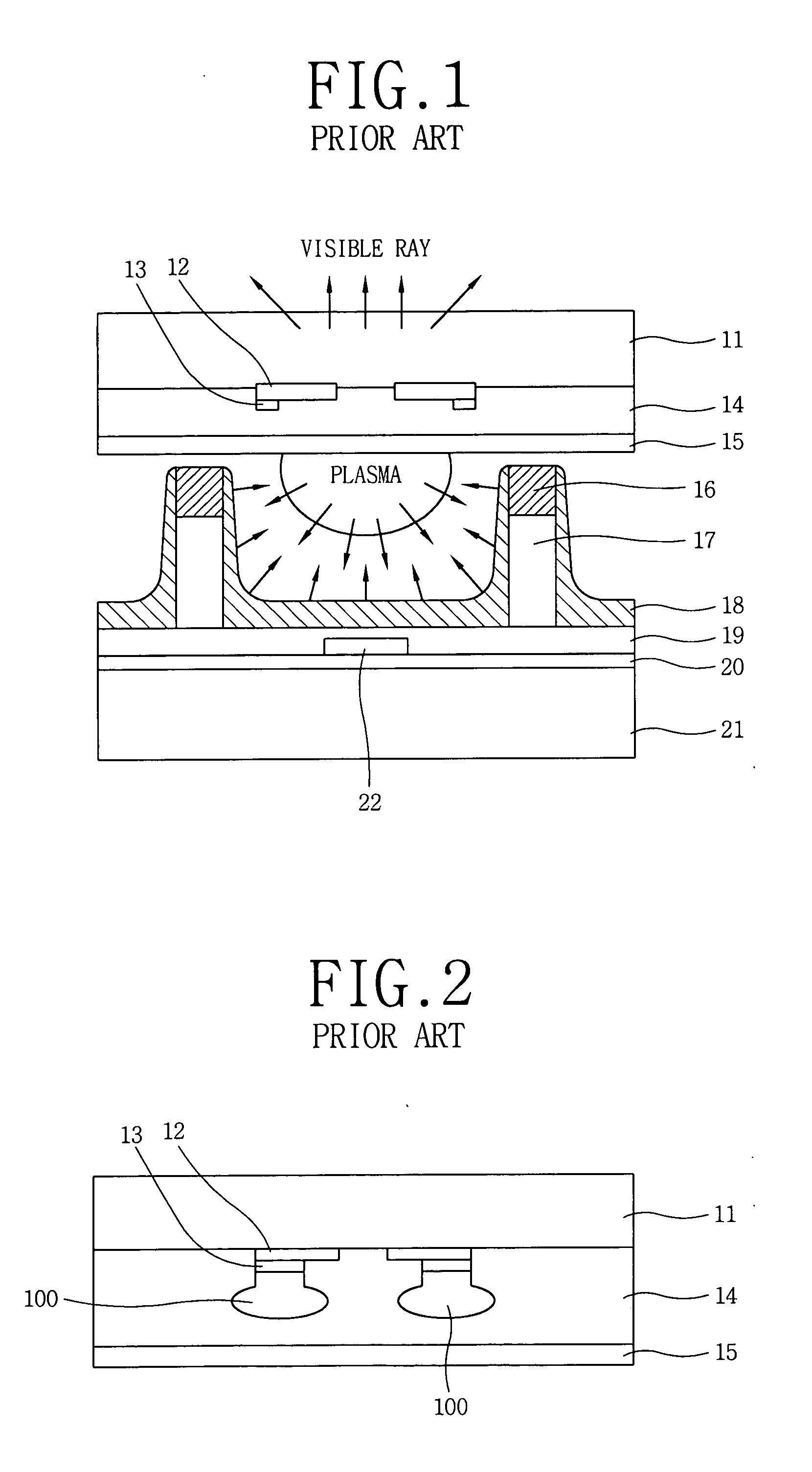

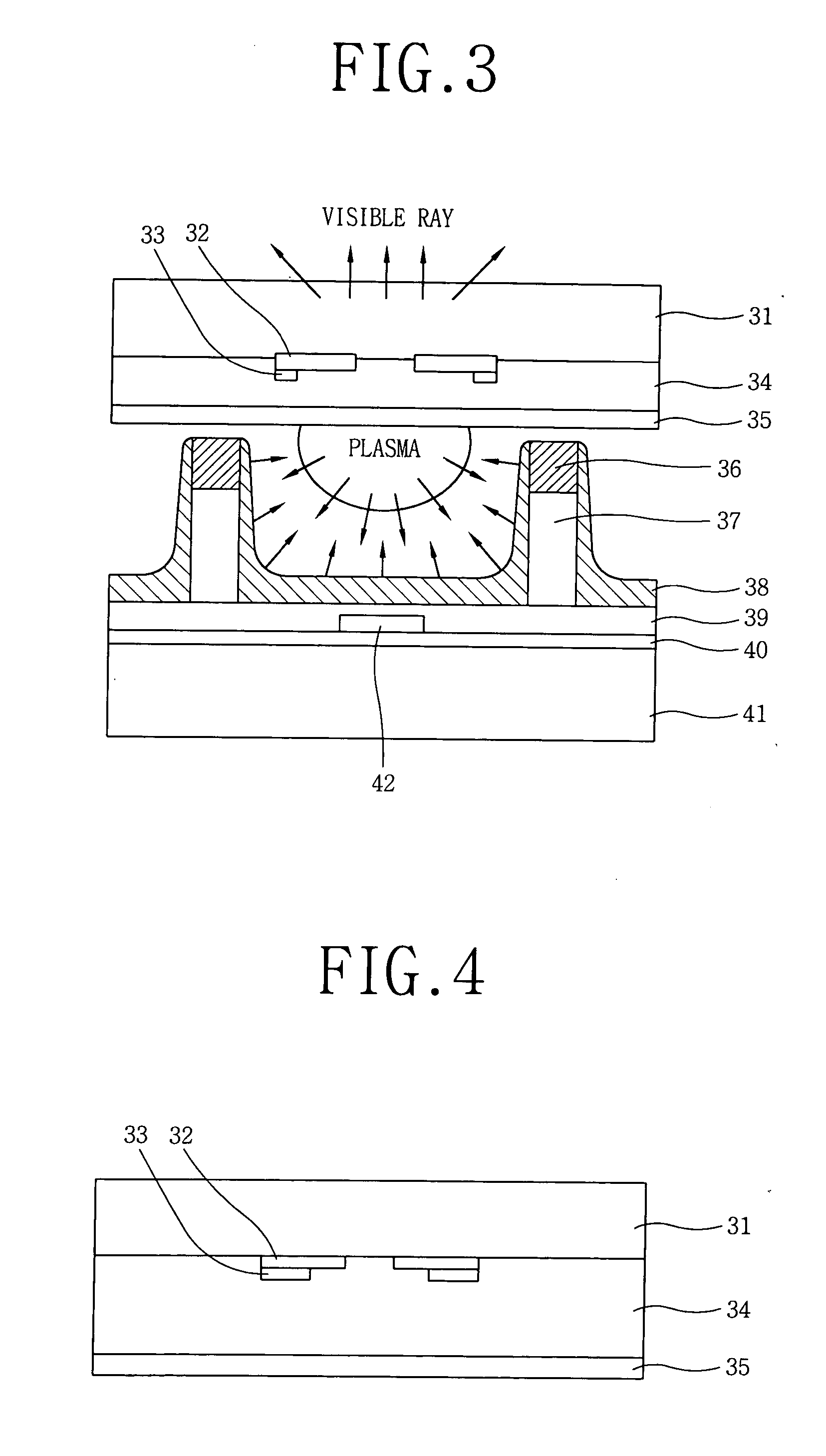

Glass composition for covering electrodes and glass paste containing the same

InactiveUS20060276322A1Improve reliabilityImprove pressure resistanceSustain/scan electrodesGas discharge fillingPolymer chemistryElectrode

Owner:PANASONIC CORP

Compositions and processes for paper production

ActiveUS20070062653A1Increase brightnessIncrease resistanceCellulosic pulp after-treatmentNatural cellulose pulp/paperPapermakingPaper production

Compositions and processes that preserve and enhance the brightness and improve color of pulp or paper when applied during different stages of the papermaking process are identified. The composition and method maintains and / or enhances brightness, prevent yellowing, and enhances the performance of paper products. Used in combination with optical brighteners and / or chelants the described agents produce a synergistic effect not previously identified in the paper process.

Owner:ECOLAB USA INC

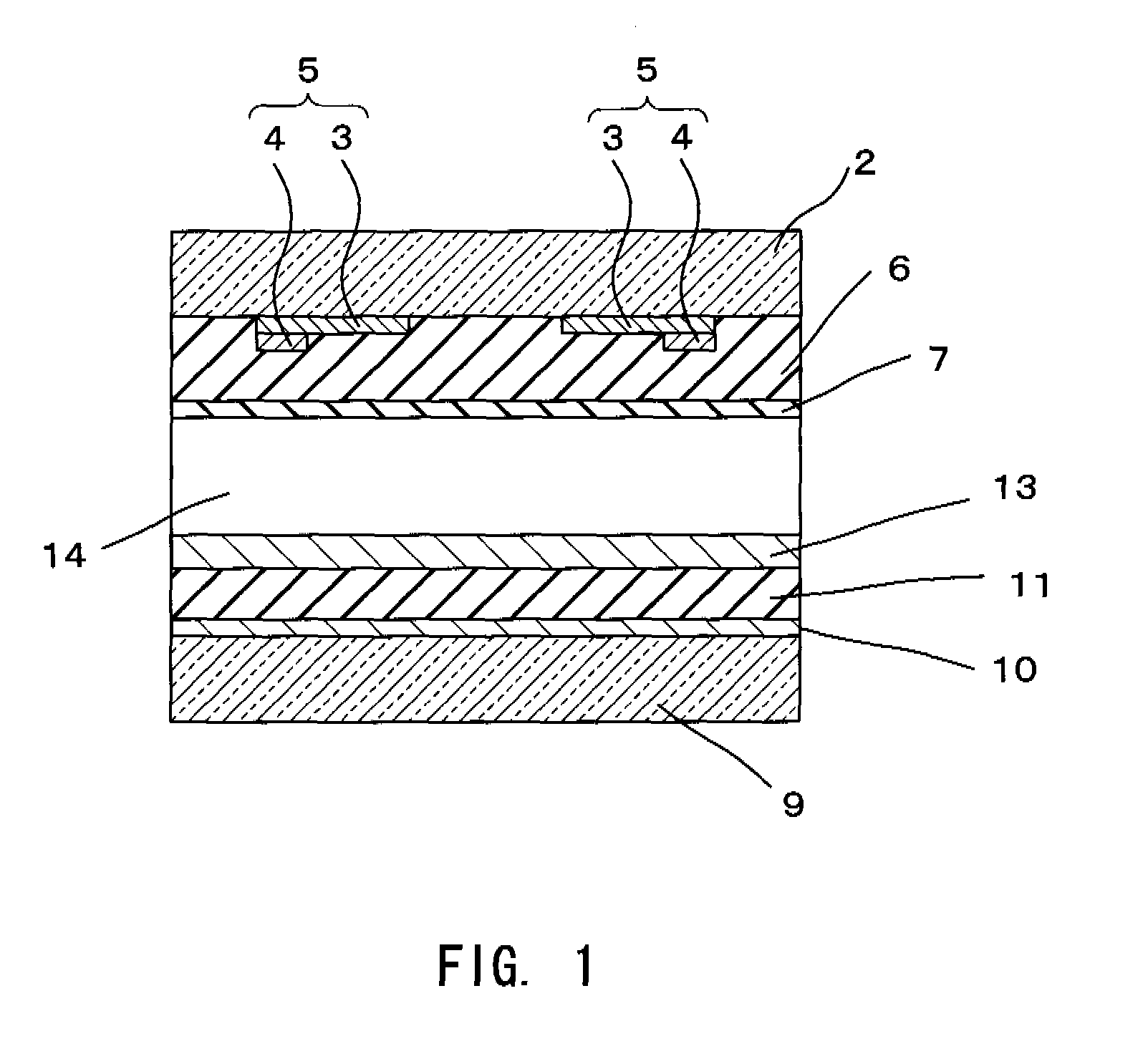

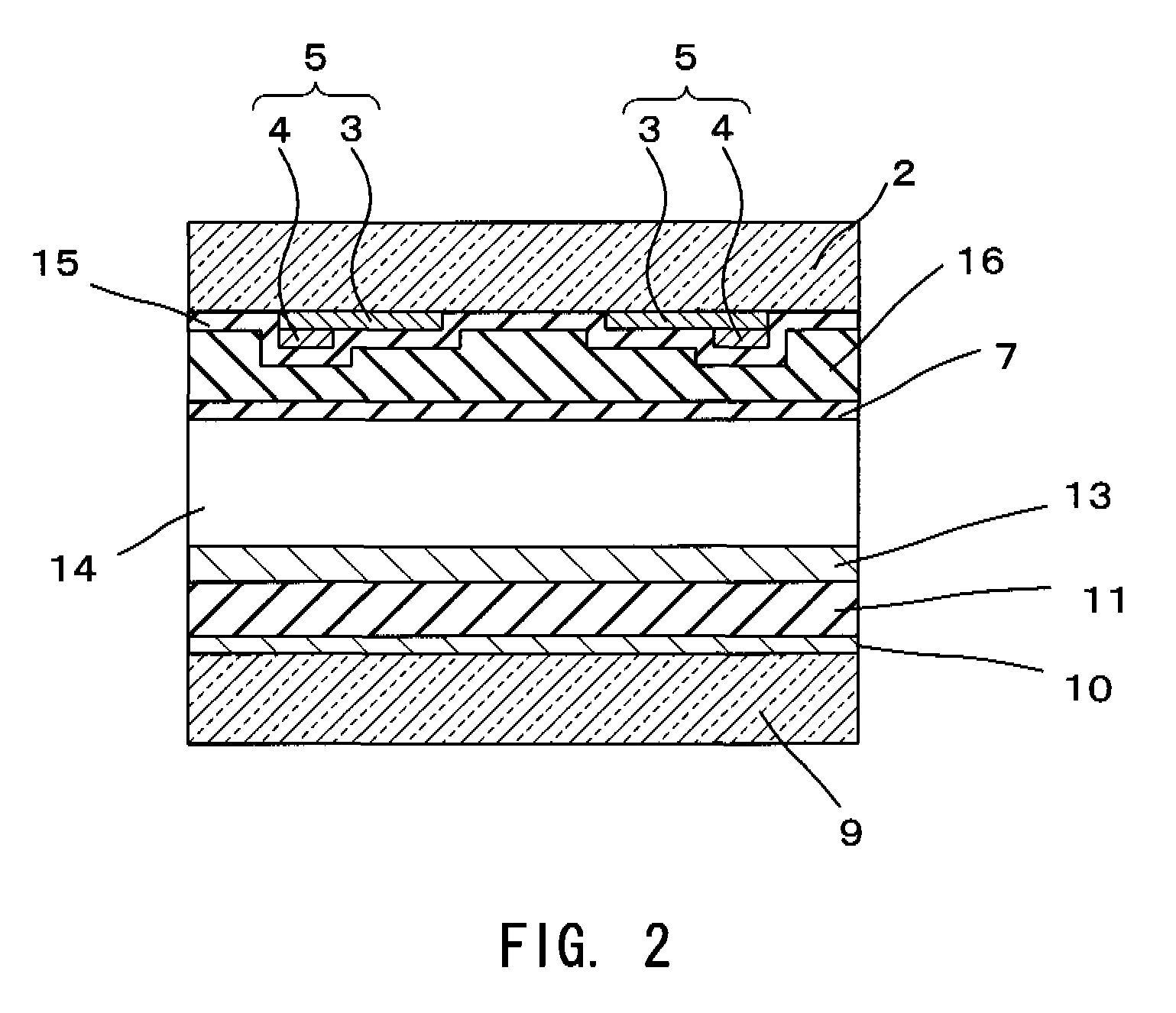

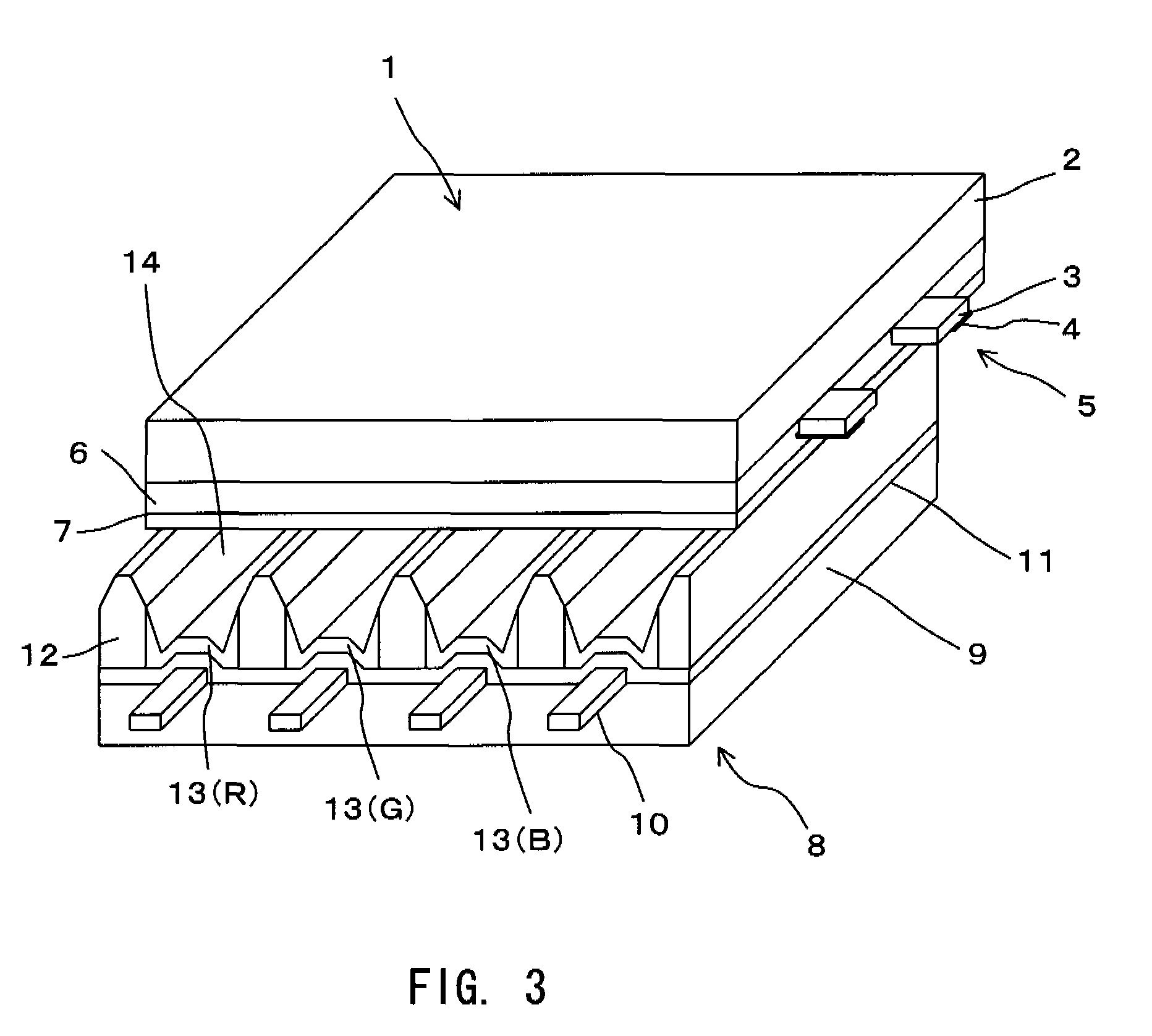

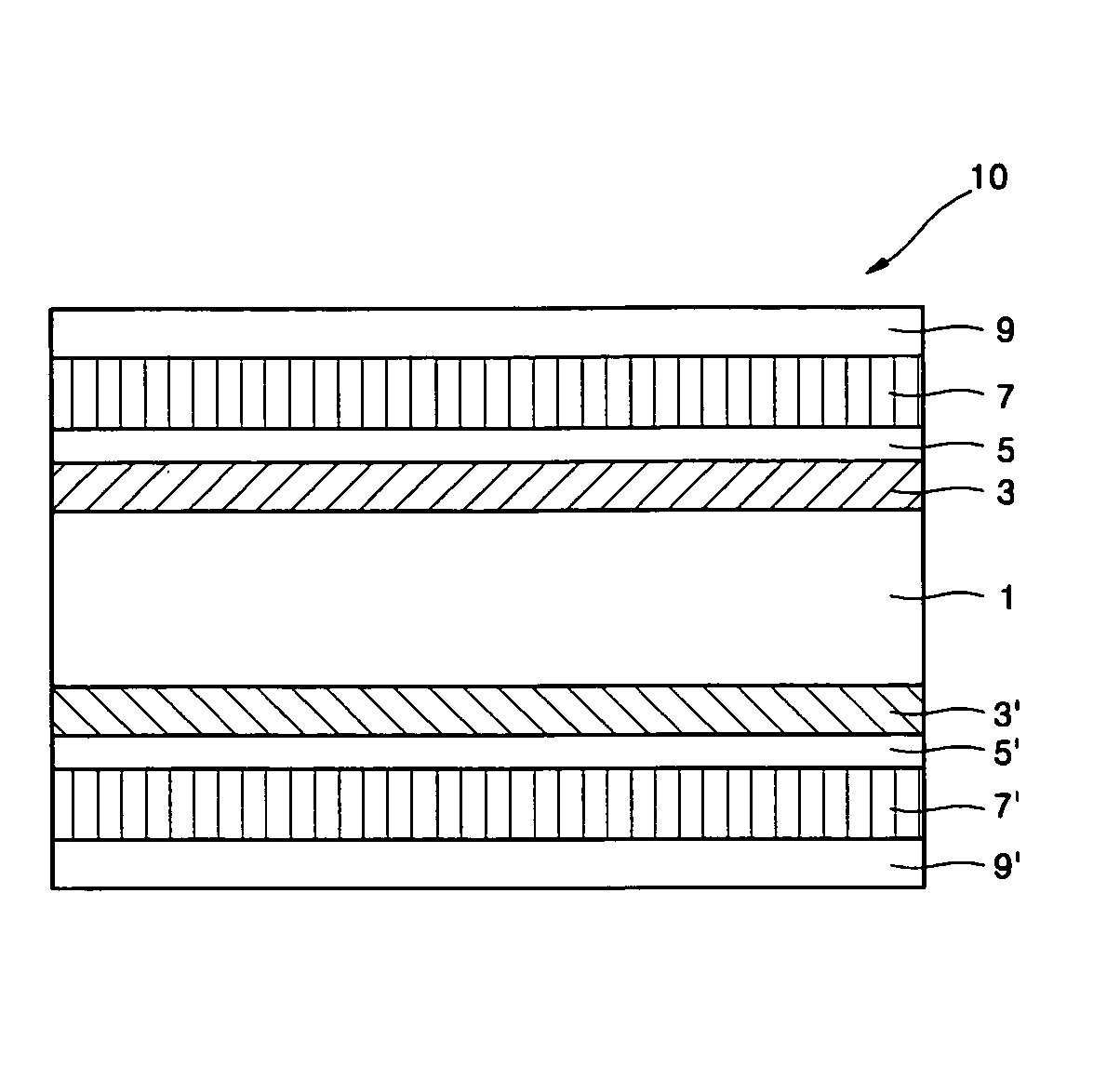

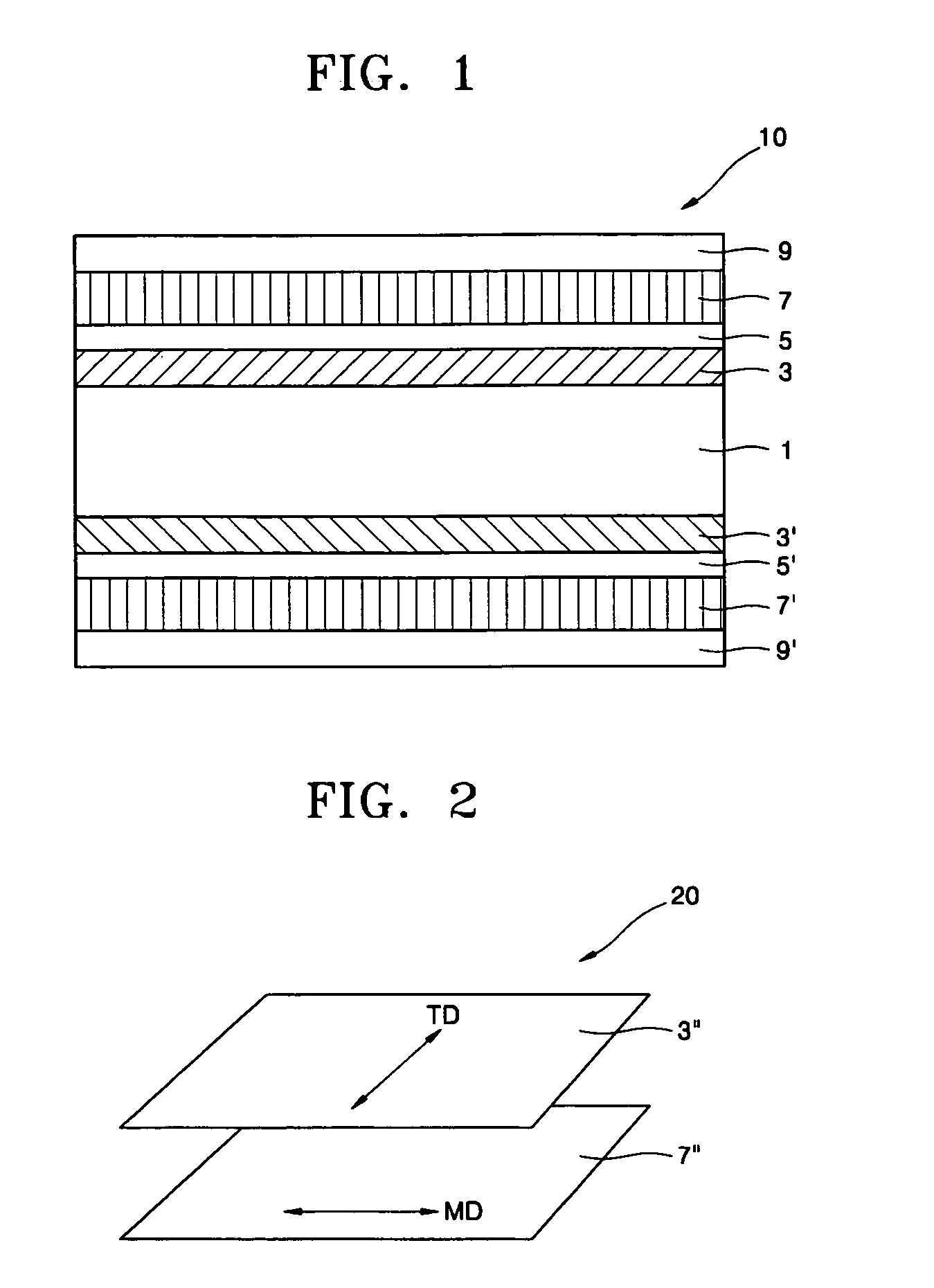

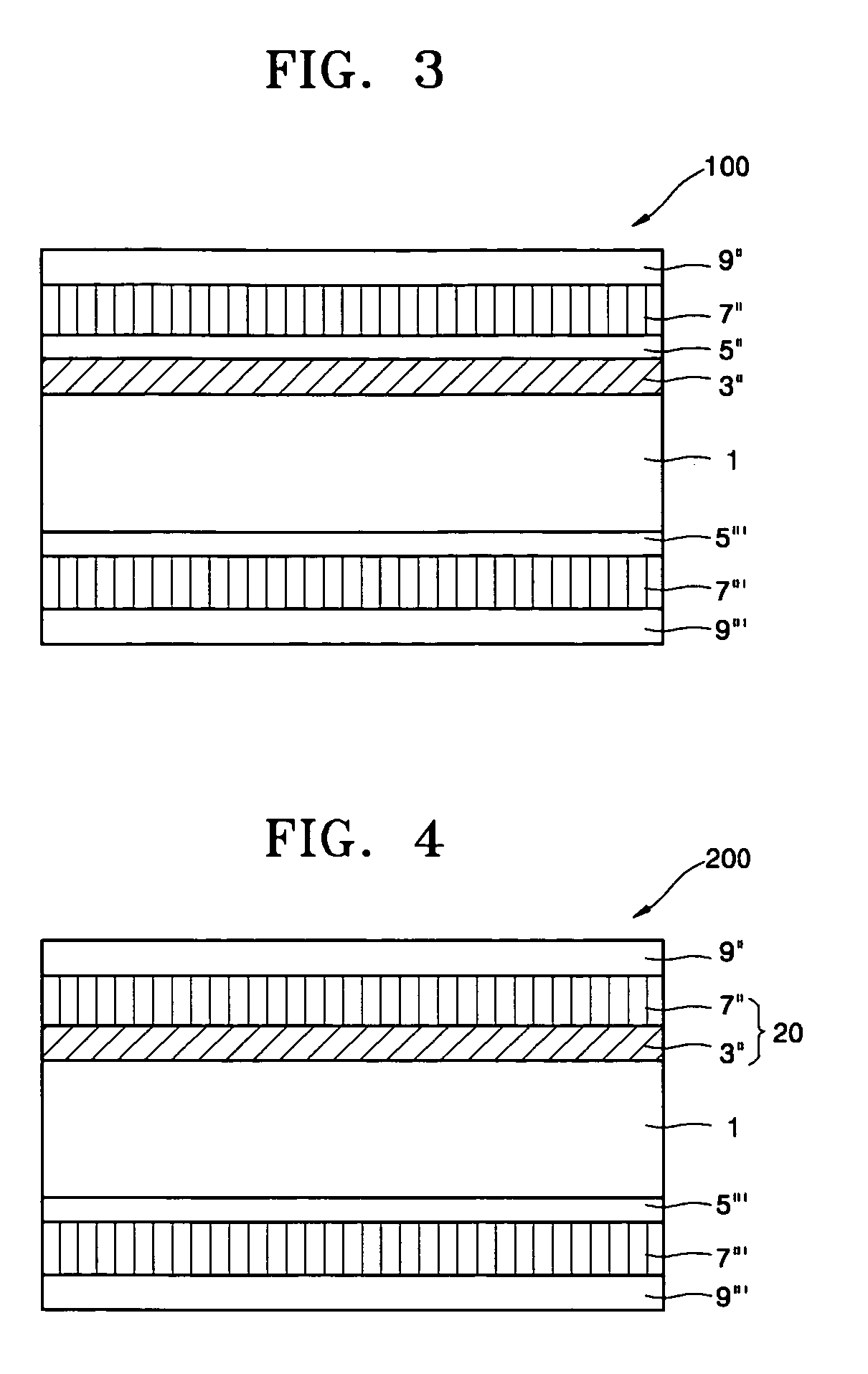

Biaxial-optical polynorbornene-based film and method of manufacturing the same, integrated optical compensation polarizer having the film and method of manufacturing the polarizer, and liquid crystal display panel containing the film and/or polarizer

ActiveUS20060105117A1High light transmittanceUniform in-plane retardation valueLiquid crystal compositionsOptical articlesIn planePolymer dissolution

A method of manufacturing a biaxial-optical polynorbornene-based film is provided, including: preparing a polynorbornene-based polymer containing composition by dissolving a polynorbornene-based polymer in a mixed solvent containing a high-boiling solvent and a low-boiling solvent, with a difference in boiling points of the two solvents of 20° C. or greater and an amount of the high-boiling solvent being 0.1 to 15 wt % based on a weight of the polynorbornene-based polymer; casting and partially drying the composition to obtain a polynorbornene-based film containing 1 to 6 wt % of the mixed solvent based on a total weight of the polynorbornene-based film; and uniaxially stretching the partially dried film in one direction parallel with the surface of the film at a stretching temperature less than or equal to the boiling point of the high-boiling solvent +20° C. and drying the stretched film at a temperature greater than or equal to the boiling point of the high-boiling solvent. According to the method of manufacturing a biaxial polynorbornene-based film, a compensation film which has good light transmittance and a uniform in-plane retardation value and can function as both a negative C-plate and an A-plate can be obtained.

Owner:LG CHEM LTD

Flame-proof reinforced polypropylene material and method for preparing same

The invention discloses a fire-resistance enhancing polypropylene material and a preparing method for the polypropylene material. The material comprises the following components and portions by weight: PP resin 100, halogen-free expanding fire retardant 50-75, enhancing modifier 15-75, and antioxidant 0.2-1.0, wherein, the fire retardant is a self-prepared built halogen-free expanding fire retardant, formed by physically mixing N-P fire retardant and polyorganoxiloxane in 1:0.1-1:0.3 by weight. The invention complexes N-P fire retardant of high fire resistance with a flame-resisting assistant, namely organic silicon, and improves the OI value of material. The product from the material will not frost on surface when storing for a long time, and 5-30% talcum powder or glass fiber can be added, so the invention thoroughly solves the shortcoming of prior product that the surface will frost if storing for a long time and no mineral filler can be added to increase the material strength, truly realizes halogen freedom, environmental friendliness, high strength and usability for a long term. The preparing process of the fire-resistance enhancing polypropylene is simple without adding any complex equipment.

Owner:SHENZHEN KEJU NEW MATERIAL

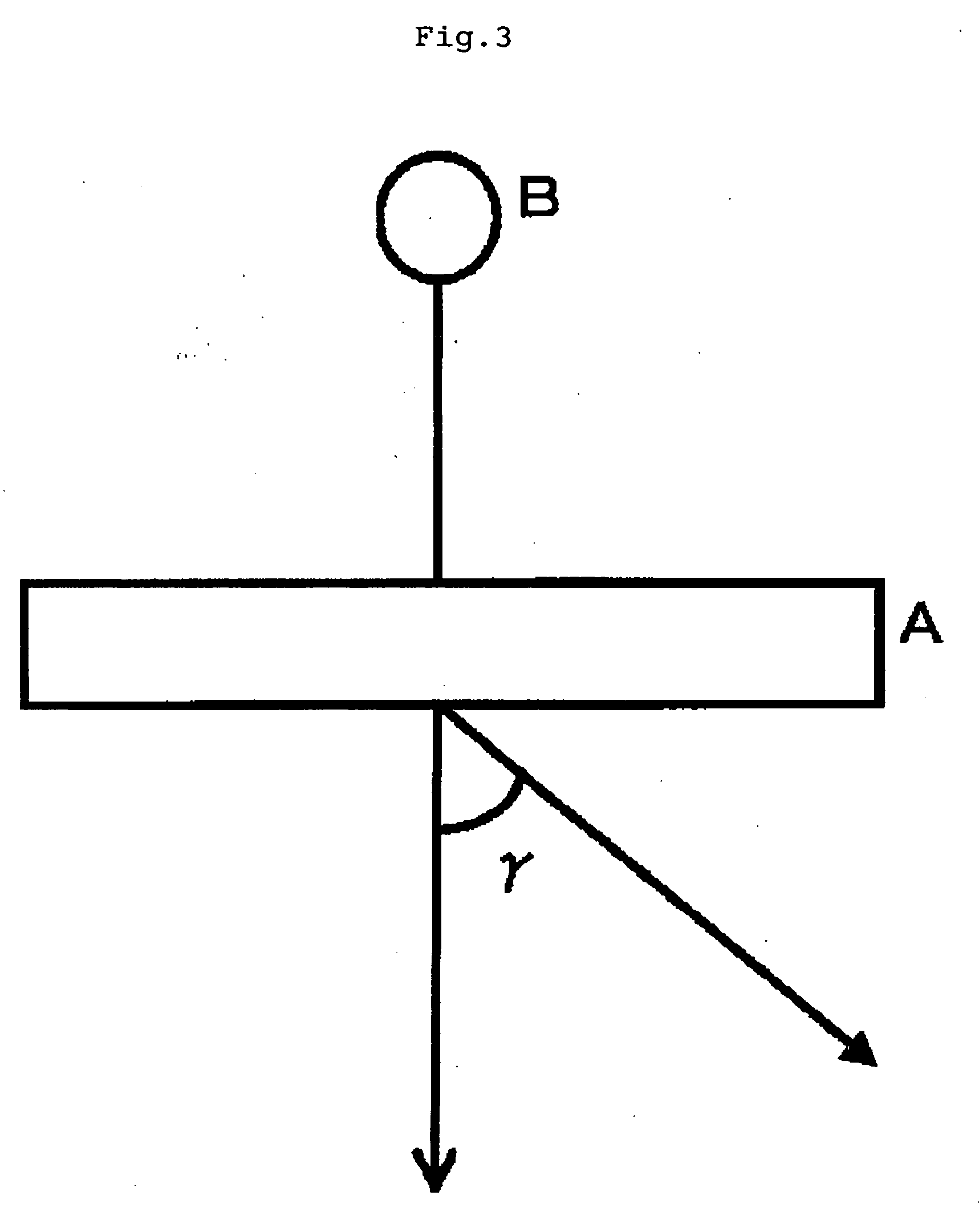

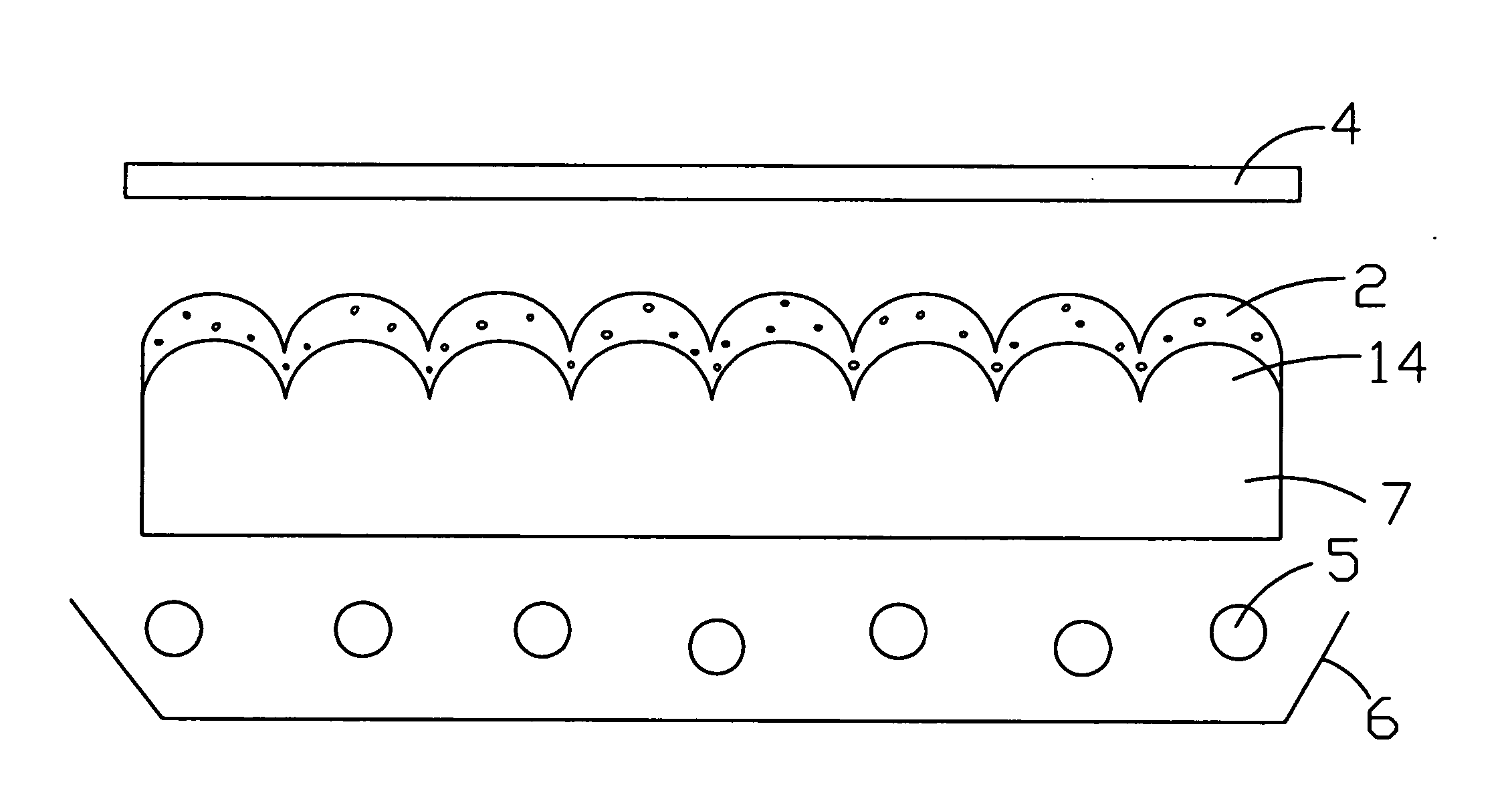

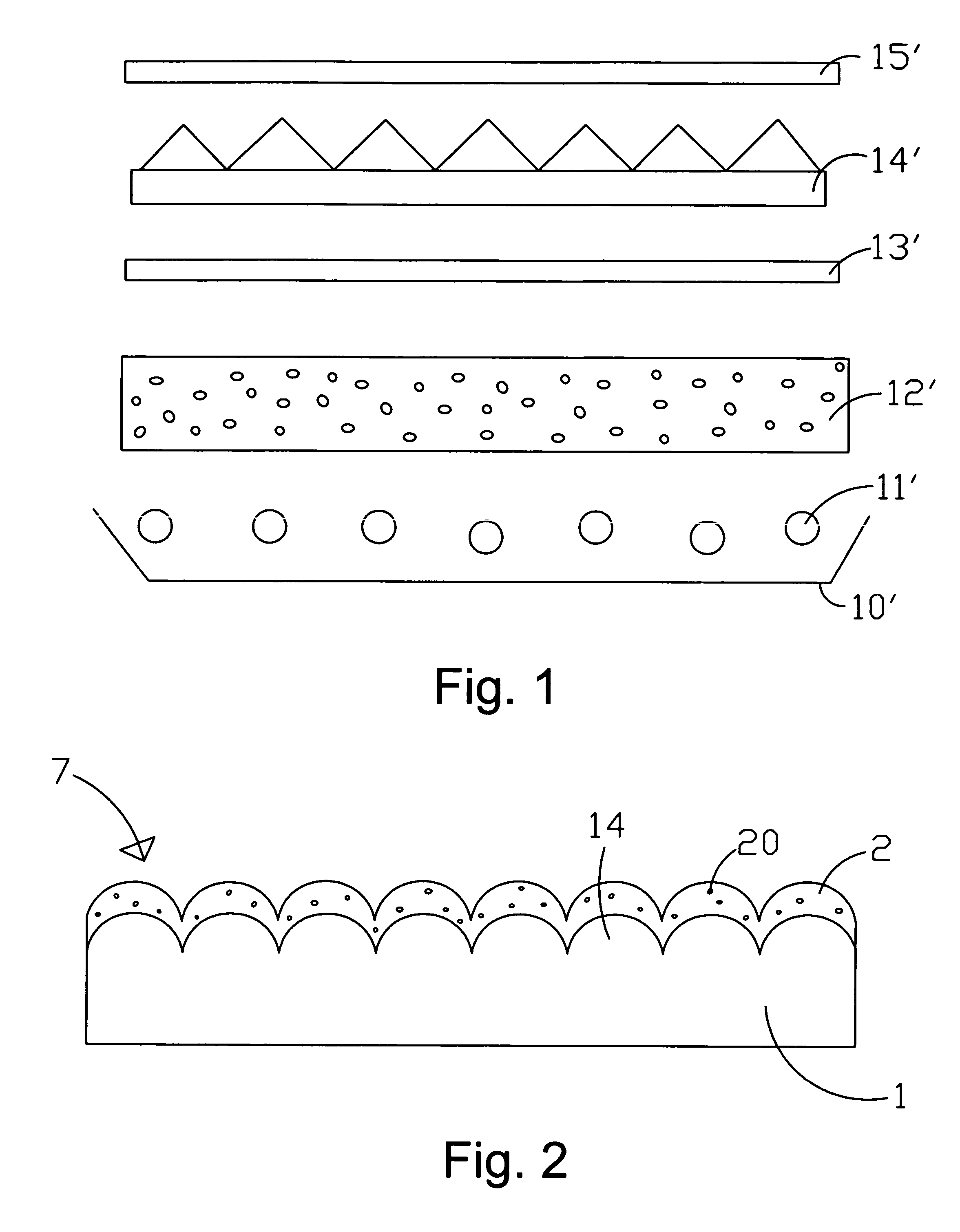

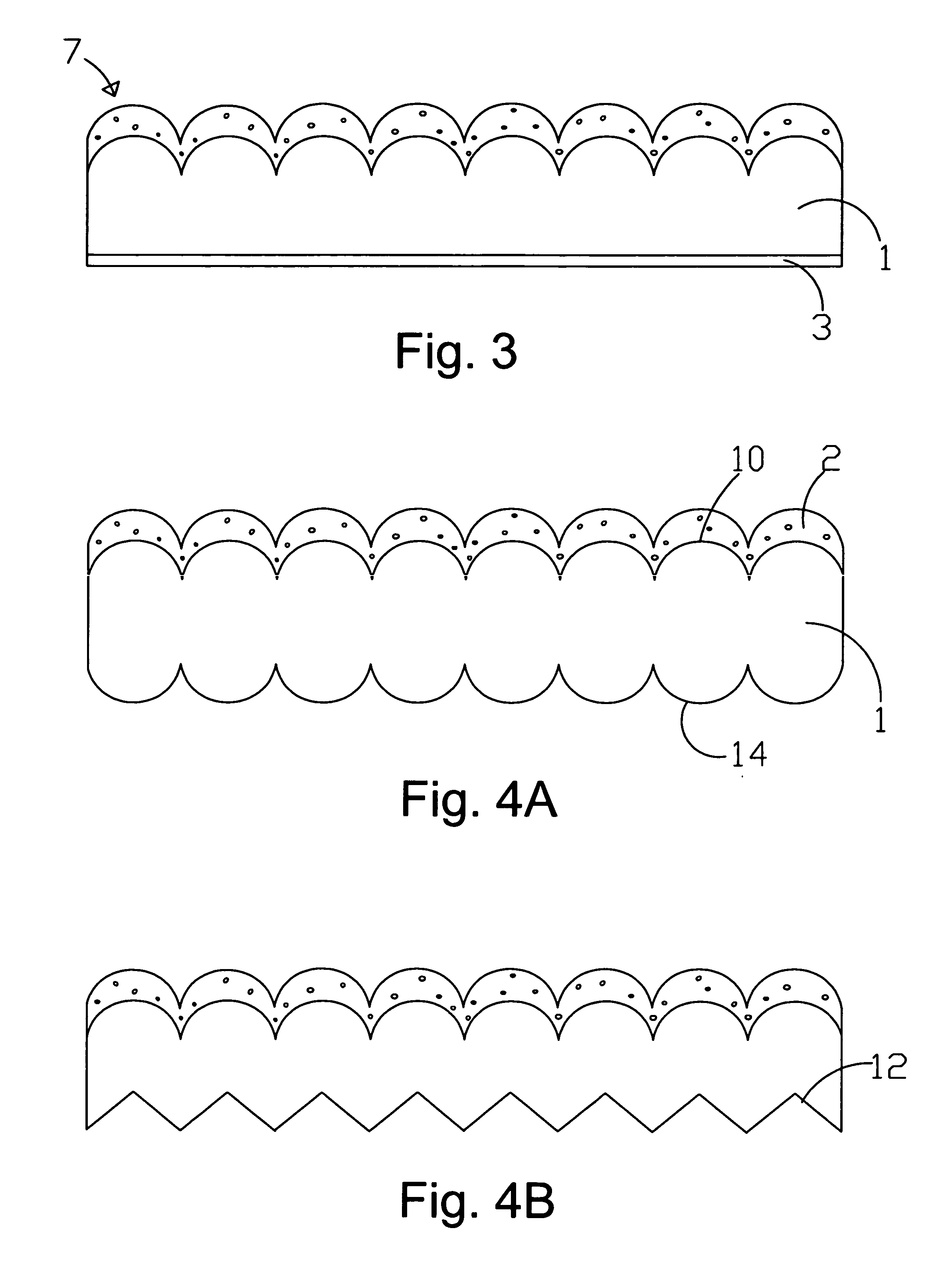

Diffuser plate with higher light diffusion efficiency and brightness

ActiveUS20070159699A1Improve diffusion efficiencyIncrease brightnessPrismsDiffusing elementsDiffusionLenticular lens

A diffuser plate with higher light diffusion efficiency and brightness applied to backlight module of Liquid Crystal Display TV (LCD TV) for providing uniform light is disclosed. An optical lens with a diffusion layer is disposed on one side of the substrate. The diffusion layer is arranged above the optical lens for enhancing diffusion effect. The other side of the diffuser plate can be a plane or having a lens structure. By Lenticular lens, the homogeneity of emitted light is improved so as to reduce the amount of diffusion particles being added into the diffusion plate Therefore, the light transmission is increased and the brightness is enhanced. Meanwhile, ability of shielding lamps is considered and Moiré effect is eliminated. Moreover, the diffusion layer is co-extruded on surface of the Lenticular lens together with the substrate so that the device is easy to be produced.

Owner:ENTIRE TECH CO LTD

Pressure sensitive adhesive composition, product using the same, and display using the product

InactiveUS20090068459A1Excels in adhesivenessExcels in coatabilityLayered productsEster polymer adhesivesPolymer scienceAlkoxy group

Disclosed is a pressure-sensitive adhesive composition which contains an acrylic polymer and a crosslinking agent. The acrylic polymer has a weight-average molecular weight of 40×104 to 160×104 and contains at least an alkoxyalkyl acrylate (Component A) and an acrylic monomer having a crosslinkable functional group (Component B). The monomer components constituting the acrylic polymer contain 45 to 99.5 parts by weight of Component A and 0.5 to 4.5 parts by weight of Component B to 100 parts by weight of total monomer components constituting the acrylic polymer, and the monomer components constituting the acrylic polymer contain substantially no carboxyl-containing monomers. This relates to improvements to provide pressure-sensitive adhesive compositions that show excellent coatability, transparency, adhesion (typically low-temperature adhesion), and resistance to blistering / separation and concurrently have anticorrosive properties.

Owner:NITTO DENKO CORP

Stabilized electrochromic media

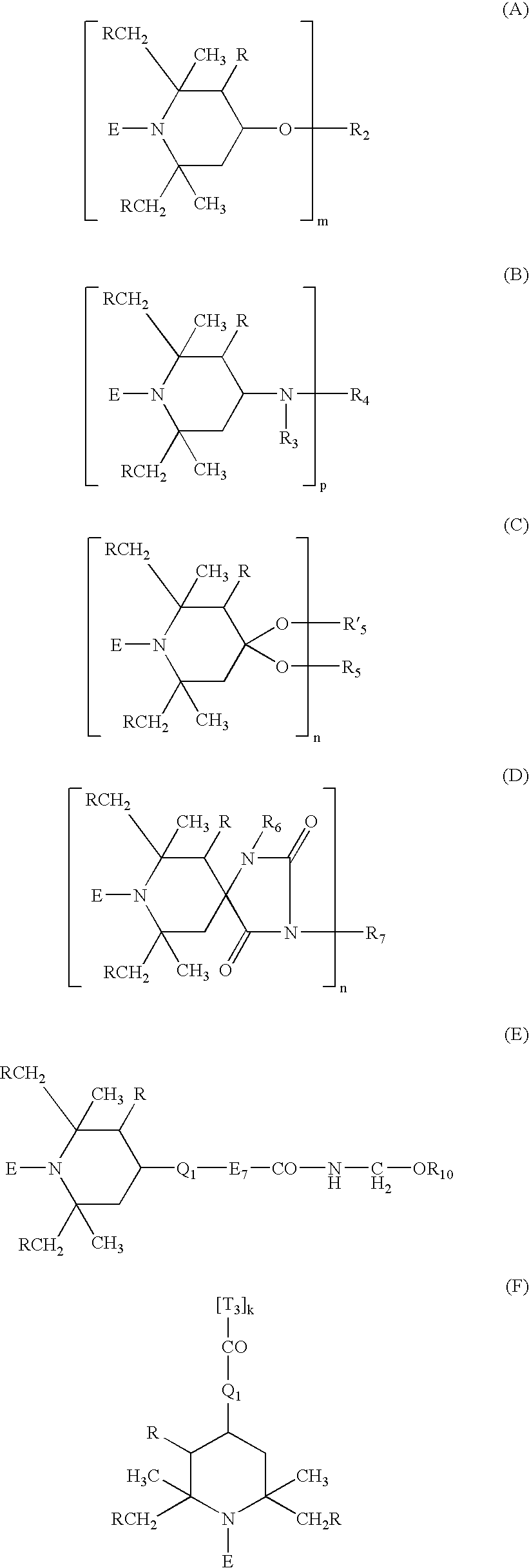

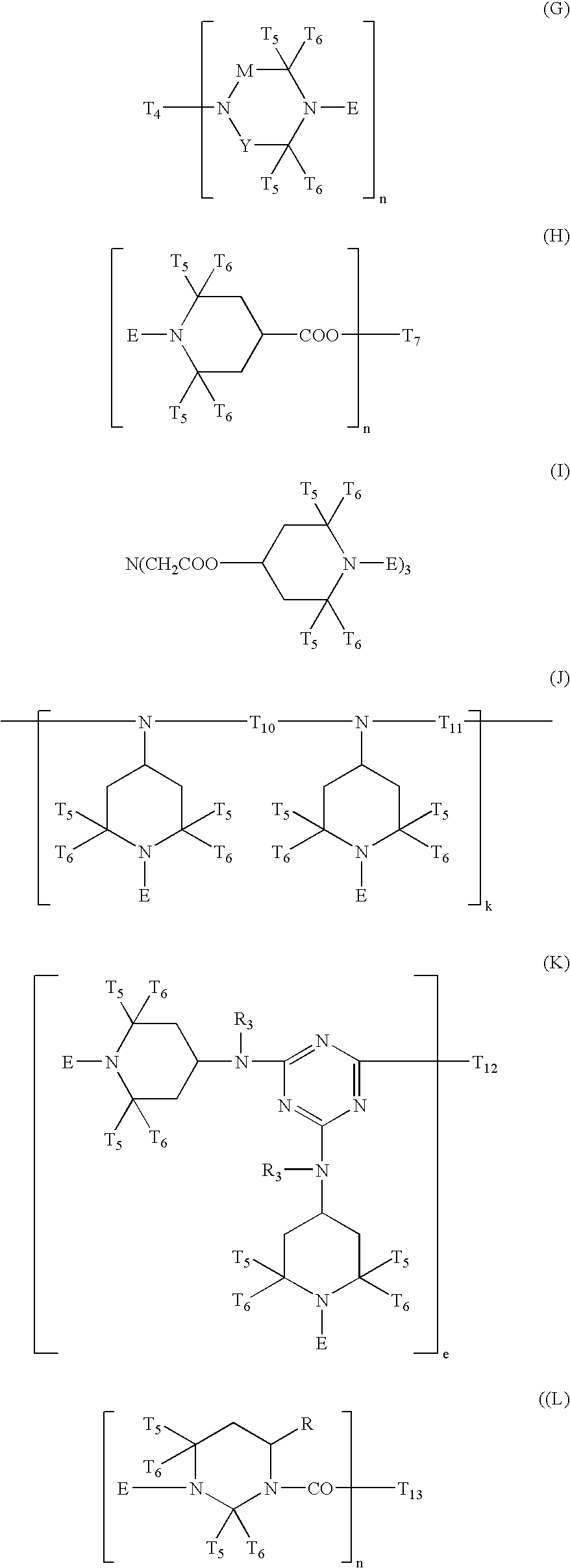

InactiveUS20060007519A1Avoid yellowingExtended service lifeTenebresent compositionsNon-linear opticsHindered amine light stabilizersPhotochemistry

Disclosed are compositions, which are stabilized against degradation and yellowing during exposure to ultraviolet light by the presence of certain hindered amine additives, a method of stabilizing the compositions by the addition of said additives, to the use of such compositions as media in electroactive devices such as electrochromic and electrophoteric devices, and the electroactive devices comprised of these media.

Owner:CIBA SPECIALTY CHEM CORP

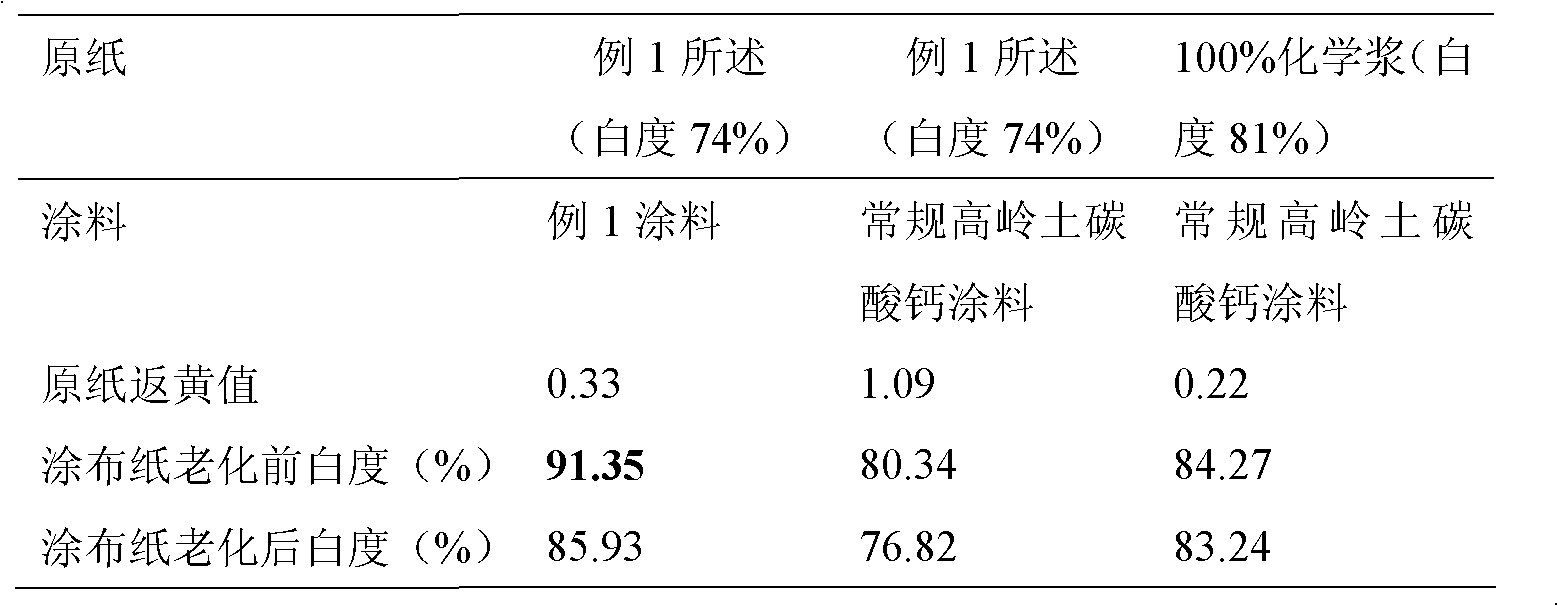

High-whiteness coated paper coated by using raw paper with medium whiteness, coating method and coating

InactiveCN102199897AReduce whitenessFulfil requirementsCoatings with pigmentsReinforcing agents additionCardboardManufacturing technology

The invention relates to high-whiteness coated paper coated by using raw paper with medium whiteness, a coating method and a coating. The coating method is mainly characterized by greatly reducing the whiteness of the raw paper for producing conventional high-grade coated paper such as copper plate paper and coated white cardboards. The coating mode is a common single-side or double-side two-layer (double-coating) or multi-layer coating mode in a papermaking plant. By using the mechanical property of the raw paper, the printing property of coatings and the synergetic whitening effect between the coatings, yellowing of the raw paper is inhibited, and the whiteness of the coated paper is improved to over 86 percent so as to meet the requirements of national standards on the high-grade copper plate paper. The raw paper of the high-grade coated paper can be made by using various kinds of environment-friendly and resource-saving pulp of medium whiteness more widely, and is favorable for promoting the development of the low-carbon manufacturing technology of the pulping papermaking industry. The newly invented coated paper can substitute the traditional high-grade paper such as the copper plate paper, the coated white cardboards and the like in the fields of printing and packing.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for modifying nano calcium carbonate and polyolefin master batch containing nano calcium carbonate

ActiveCN101260249ASolve problems that are prone to reunionImprove temperature resistancePigment treatment with non-polymer organic compoundsAluminatePolyolefin

The invention provides a modification method of nano calcium carbonate and polyolefin master batch containing the nano calcium carbonate. The modification method comprises the following steps: coupling agent (a boric acid ester or an ester aluminate) is added in nano calcium carbonate slurry at 70 DEG C to 90 DEG C, and the pH value of the system is controlled within 8 to 10 so as to carry out the surface treatment of nano calcium carbonate; and then the nano calcium carbonate is collected after surface treatment. The modification method, which selects novel coupling agent and adopts wet-way coating modification, solves the problem that nano calcium carbonate agglomeration is easy to occur in polyolefin product, thereby making full use of the performance of nano calcium carbonate; moreover, the modification method improves the mechanical property of calcium carbonate-filled polyolefin product and the adaptability to the manufacturing temperature of polyolefin so as to avoid the problem of material surface yellowing caused by the addition of nano calcium carbonate at a higher manufacturing temperature.

Owner:SHANXI LANHUA HUAMING NANO MATERIALS

Adhesive composition for optical member, adhesive layer for optical member, adhesive optical member, transparent conductive laminate, touch panel, and image display device

ActiveCN101679819AAvoid yellowingAvoid foamingConductive layers on insulating-supportsNon-macromolecular adhesive additivesMeth-High humidity

Disclosed is an adhesive composition for optical members, which contains a (meth)acrylic polymer containing 0.2-20 parts by weight of a carboxyl group-containing monomer as a monomer unit, namely as acopolymerization component, per 100 parts by weight of an alkyl (meth)acrylate having an alkyl group with 4-14 carbon atoms. The adhesive composition for optical members also contains, as crosslinking agents, 0.02-2 parts by weight of a peroxide and 0.005-5 parts by weight of an epoxy crosslinking agent per 100 parts by weight of the (meth)acrylic polymer. The adhesive composition for optical members can be suppressed in yellowing at high temperatures and in high-temperature high-humidity environments. Consequently, the adhesive composition enables formation of an adhesive layer which is suppressed in foaming, separation and the like at high temperatures and in high-temperature high-humidity environments.

Owner:NITTO DENKO CORP

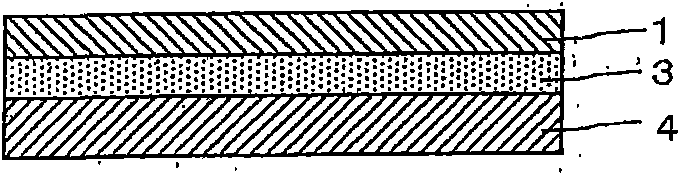

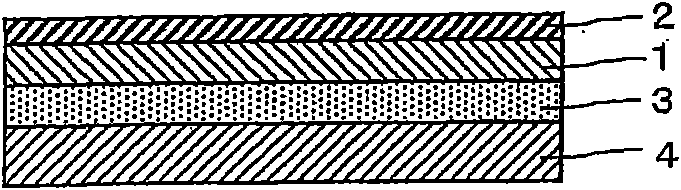

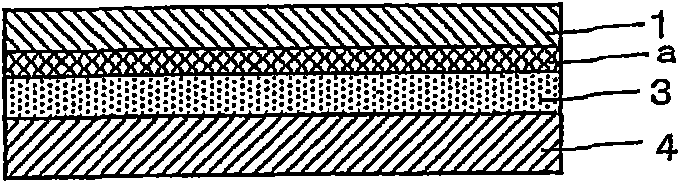

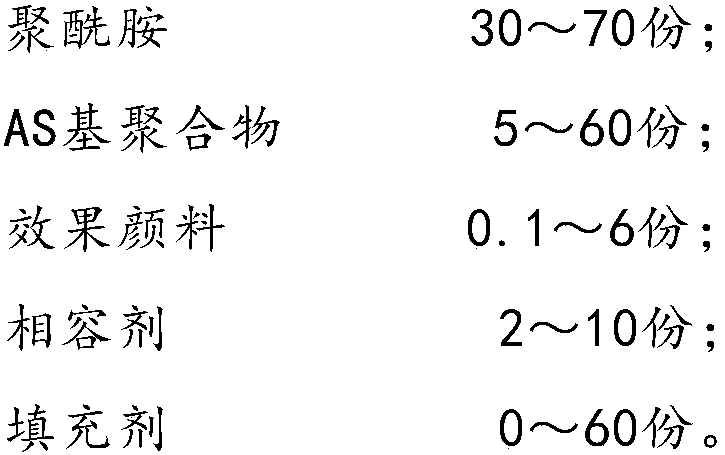

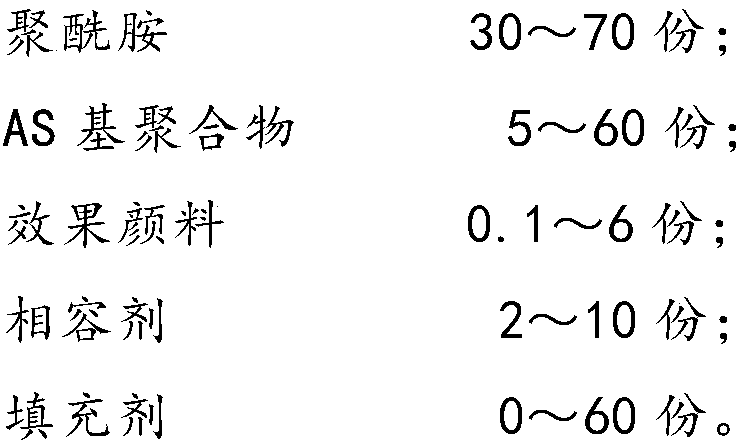

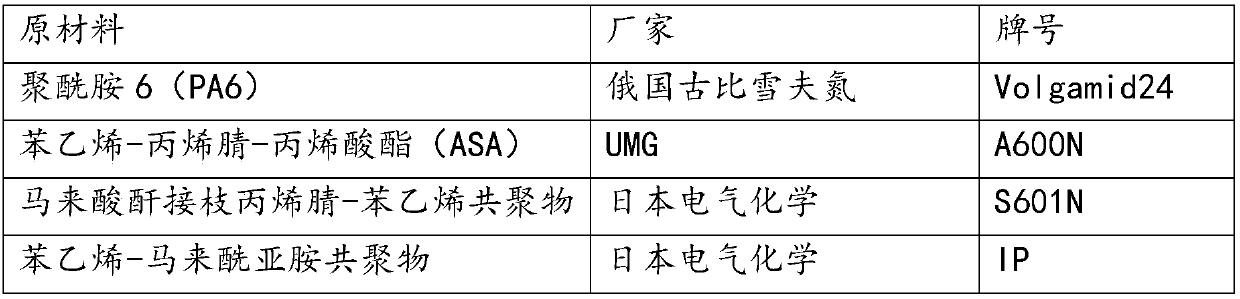

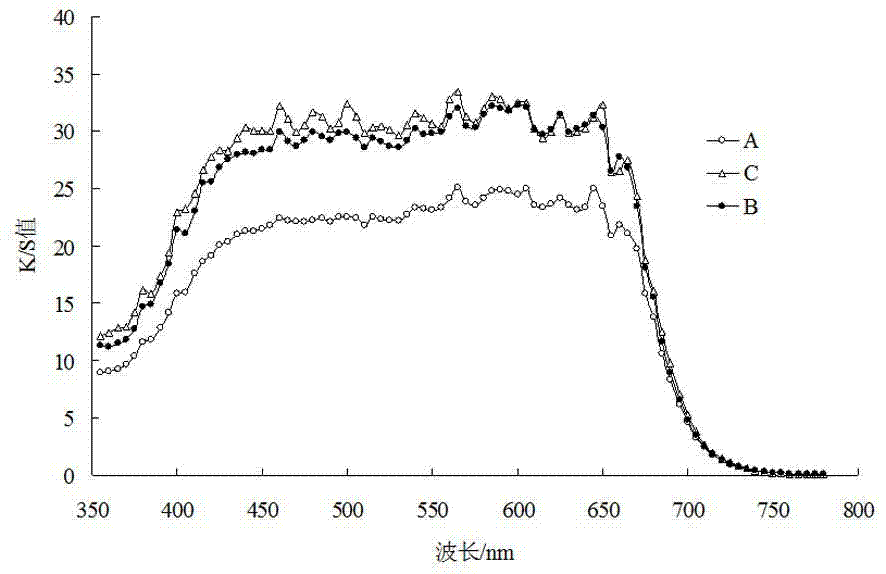

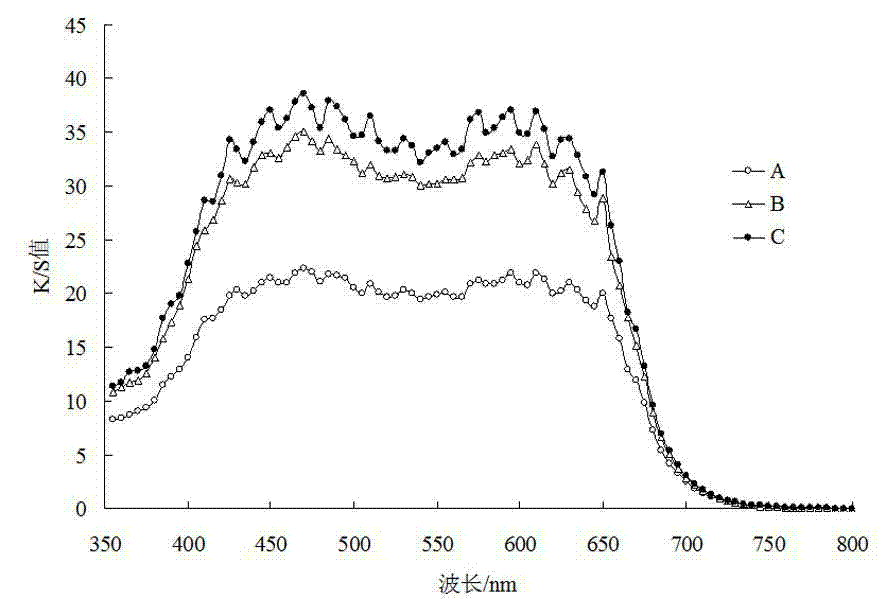

Spraying-free polyamide resin complex and preparation method thereof

The invention discloses a spraying-free polyamide resin complex and a preparation method thereof. The polyamide resin complex is prepared from the following components in parts by weight: 30 to 70 parts of polyamide, 5 to 60 parts of AS-based polymer, 0.1 to 6 parts of effect pigment, 2 to 10 parts of compatilizer and 0 to 60 parts of filler. The spraying-free polyamide resin complex provided by the invention has excellent weather fastness and dimensional stability, especially excellent weather fastness; an American automobile association SAEJ2527 standard test result shows that a change deltaE of a color different value is smaller than 3; the spraying-free polyamide resin complex has yellowing prevention better than a common spraying-free nylon product.

Owner:SHANGHAI KINGFA SCI & TECH +2

Deepening agent and preparation method thereof, as well as method for improving color fastness of dyeing textiles

InactiveCN103614910AImprove bindingAvoid yellowingFibre treatmentDyeing processOrganosiliconColour fastness

The invention discloses a deepening agent and a preparation method thereof, as well as a method for improving the color fastness of dyeing textiles. The deepening agent consists of amino organic silicon, ternary copolymerized organosilicon, alkyl ketene, an emulsifier and water. Deepened textiles finished by the deepening agent have good deep color property and high color fastness. In addition, the preparation method of the deepening agent and a finishing processing method of the textiles are low in production cost, simple to operate and applicable in the field of finishing of dyeing textiles.

Owner:ZHEJIANG QUEPING TEXTILE CHEM

Pest-control composite preparation and preparation process thereof

The invention provides a pest-control composite preparation and a preparation process thereof, belongs to the technical field of preparing the crop insecticides, and in particular relates to a pest-control composite preparation formed by compounding a plurality of raw materials and a preparation process thereof. The pest-control composite preparation is characterized in that the raw materials of the preparation include bittern, tobacco juice, a traditional Chinese medicine preparation extract and ferrous sulfate; the tobacco juice is a soup which is obtained by decocting tobacco leaves with water proportionally, filtering and purifying; the traditional Chinese medicine preparation extract is a soup which is obtained by decocting traditional Chinese medicines having insecticidal efficacy with water proportionally, filtering and purifying. The pest-control composite preparation is especially suitable for irrigating vegetables such as Chinese chives and peanut and crops as an auxiliary, and has the positive effects of good pest control effect, no damage on ecological balance and improvement effect on soil properties.

Owner:SHANDONG YULI VEGETABLE

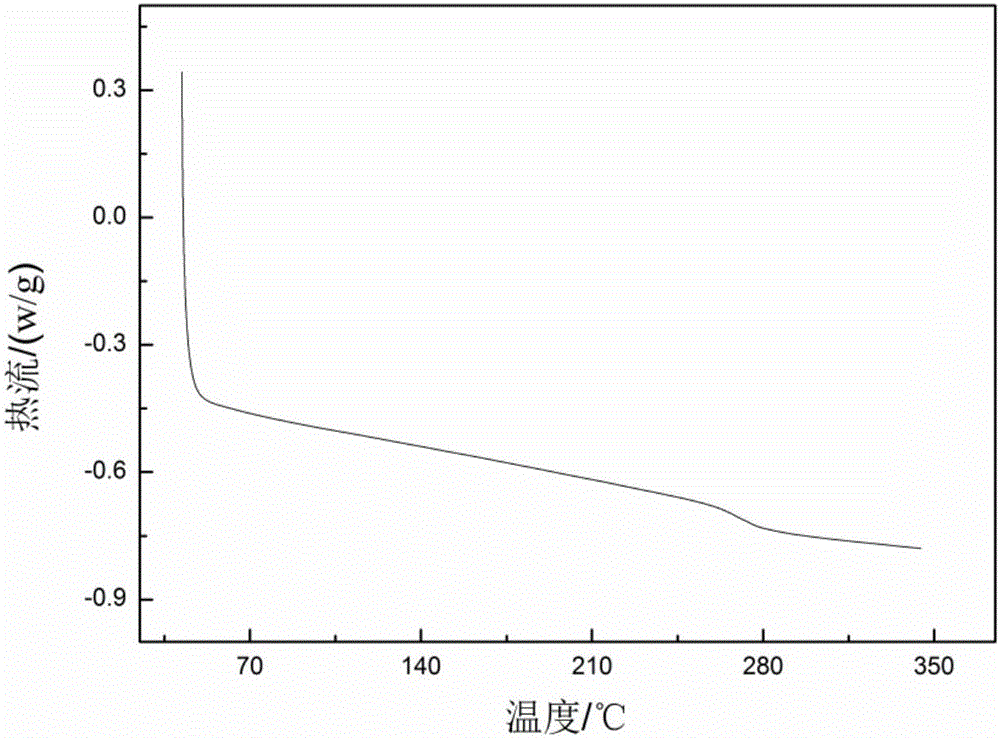

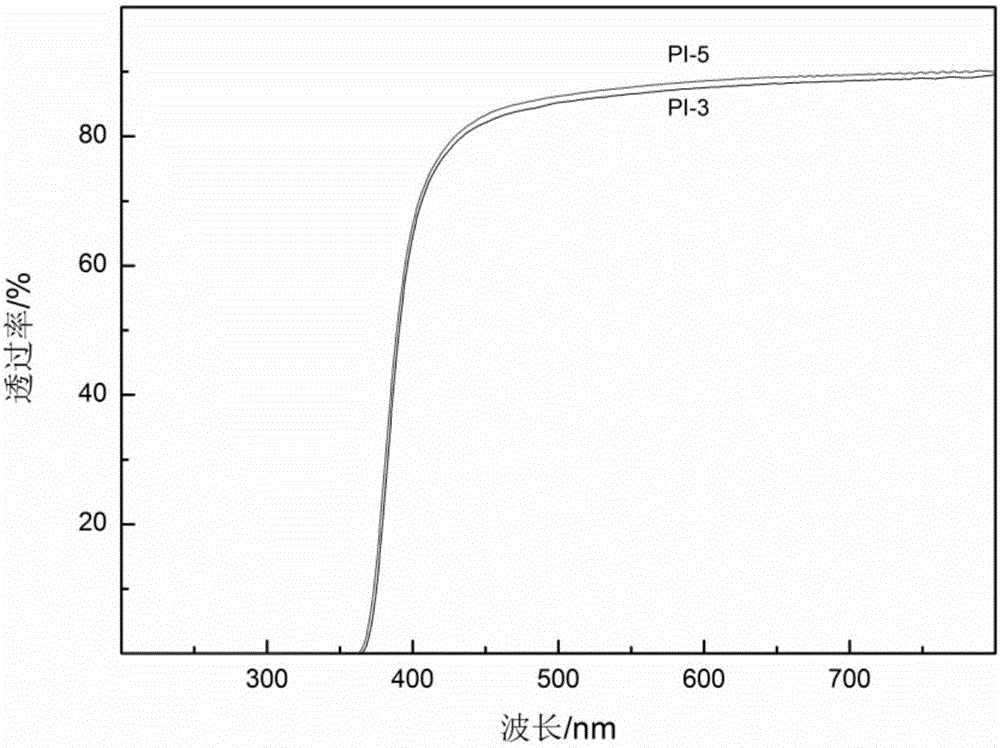

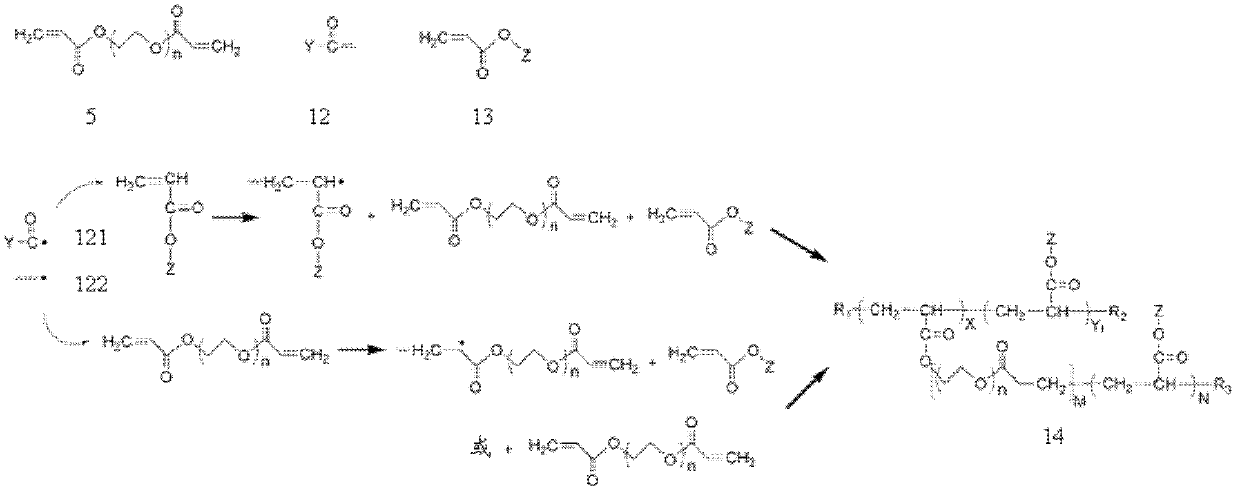

Method for preparing polyimide

The invention discloses a method for preparing polyimide and belongs to the field of polymer materials. The method includes the steps that in a first polar solvent, diamine, dianhydride and an end-capping reagent react to obtain a polyamide acid solution, wherein the end-capping reagent is monoanhydride containing active functional groups which can have radical polymerization; the polyamide acid solution is imidized and extracted to obtain polyimide prepolymer; the polyimide prepolymer is dissolved in a second polar solvent, a radical initiator is added, a mixed glue solution is obtained, the mixed glue solution is solidified, cooled to room temperature and stripped, and membrane-shaped polyimide is obtained. The active groups of the end-capping reagent are cross-linked at low temperature, so a polyimide membrane keeps high transparency, and application range of the polyimide membrane in the field of flexible display materials is widened.

Owner:JIANGHAN UNIVERSITY

Frame sealant composition, liquid crystal pollution prevention method, liquid crystal display panel and display device

InactiveCN102702987AReduce spreadImprove anchoring abilityOther chemical processesLayered productsDisplay deviceEngineering

The invention provides frame sealant composition, a liquid crystal display unit and a liquid crystal pollution prevention method using the frame sealant composition. The frame sealant composition comprises, by weight, 20-30 parts of ultraviolet double-bond polymeric monomer, 15-20 parts of thermally polymerized monomer, 5-20 parts of polymerizable oligomer, 0.1-5 parts of optical initiator, 10-20 parts of thermal curing agent and 0-20 parts of granulated additive. The polymerizable oligomer is polyethyleneglycol diacrylate or derivatives thereof. The polymerizable oligomer reacts with polymer of the ultraviolet double-bond polymeric monomer to generate network high polymer, and accordingly anchorage of the network high polymer on surrounding unreacted thermally polymerized monomers is enhanced effectively, and pollution of liquid crystal by the frame sealant is reduced.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

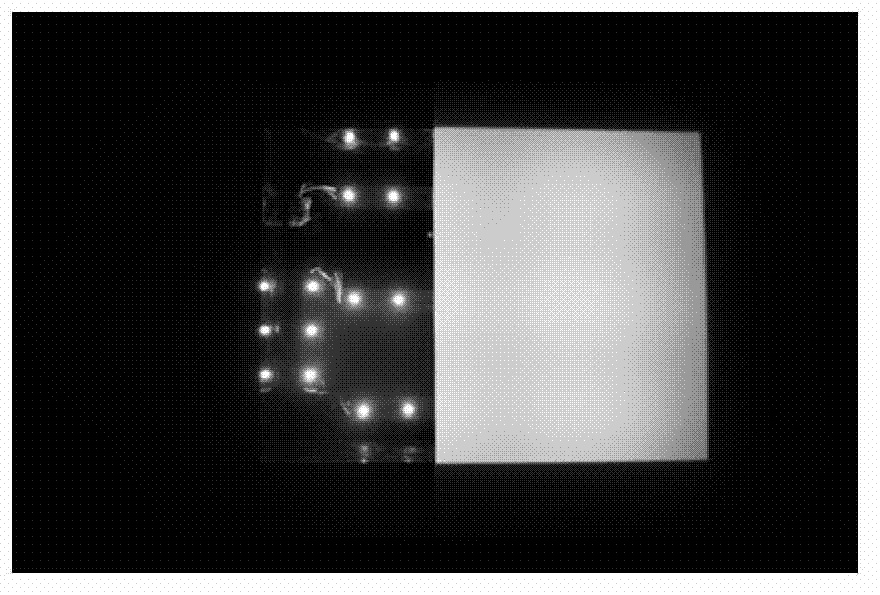

Light diffusing agent, PMMA (polymethyl methacrylate) light diffusing plate and manufacturing method thereof

ActiveCN103193915AImprove performanceImprove mechanical propertiesDiffusing elementsOligomerRefractive index

The invention relates to a light diffusing agent, a PMMA (polymethyl methacrylate) light diffusing plate and a manufacturing method thereof. The light diffusing agent is a random copolymer of styrene (St) and methacryloxypropylisobutyl polyhedral oligomer silsesquioxane (MAiBuPOSS). The PMMA light diffusing plate comprises the following components in percentage by weight: 97.0-99.5% of polymethyl methacrylate and 0.5-3.0% of light diffusing agent. The refractive indexes of the styrene component and the MAiBuPOSS component in the light diffusing agent differ from the refractive index of PMMA; when passing through a material, a light ray is refracted for many times and becomes bright and soft after passing through a substrate. Meanwhile, the MAiBuPOSS component ensures that the dispersibility of PS (Poly Styrene) in PMMA is remarkably improved, excellent light transmission and light scattering are obtained, and the optical efficacy is high. The PMMA light diffusing plate manufactured by the invention can be used for LED (Light Emitting Diode) illumination lamps, such as a plate lamp, an advertising lamp box, a professional film viewer, a down lamp and the like.

Owner:石狮市天生化工有限公司 +1

Lead-free solder alloy

ActiveCN101208174AAvoid yellowingInhibited porosityPrinted circuit assemblingWelding/cutting media/materialsDrop impactImpurity

Disclosed is a lead-free solder alloy exhibiting improved drop impact resistance even after thermal aging while being good in soldering properties, void formation and discoloration. Specifically disclosed is a solder alloy consisting essentially of, in mass %, (1) 0.8-2.0% of Ag, (2) 0.05-0.3% of Cu, (3) one or more elements selected from not less than 0.01% and less than 0.1% of In, 0.01-0.04% of Ni, 0.01-0.05% of Co and 0.01-0.1% of Pt, and if necessary (4) one or more elements selected from Sb, Bi, Fe, Al, Zn and P in an amount of not more than 0.1% in total, and the balance of Sn and unavoidable impurities.

Owner:SENJU METAL IND CO LTD

Method for preparing transparent dealcoholized single-component room temperature vulcanized silicone rubber

ActiveCN102146208AAvoid yellowingSolve the problem of short storage periodNon-macromolecular adhesive additivesOther chemical processesAlkanePolymer science

The invention discloses a method for preparing transparent dealcoholized single-component room temperature vulcanized silicone rubber. The method is characterized by comprising the steps of mixing 80-90% of alpha, omega-dihydroxydimethylpolysiloxane, 1-15% of white carbon black reinforcing filler and 5-10% of alkane mixture plasticizer in a blender in a vacuum state at a room temperature; and then adding 1-5% of siloxane crosslinking agent to be mixed in a vacuum state; adding 0.01-2% of siloxane titanate TiOSi catalyst, 0.01-3% of organic tin catalyst and 0.01-5% of silane coupling agent to be mixed in a vacuum state; and discharging out and packaging. Through the method disclosed by the invention, rubbers can be effectively prevented from yellowing on the basis of keeping the catalytic efficiency, and the problem of short storage life of the rubber can be effectively solved.

Owner:GUANGZHOU GLORYSTAR CHEM +1

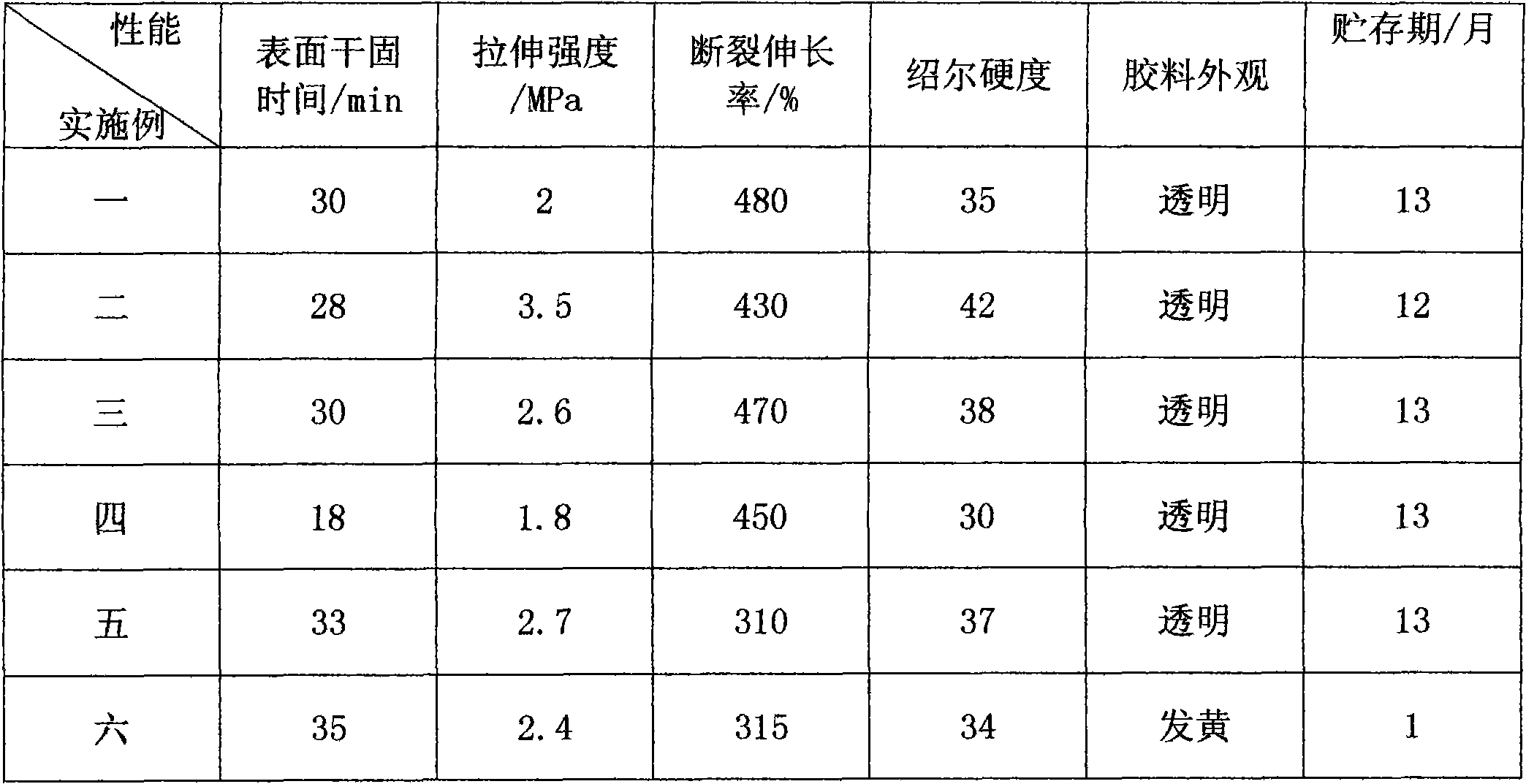

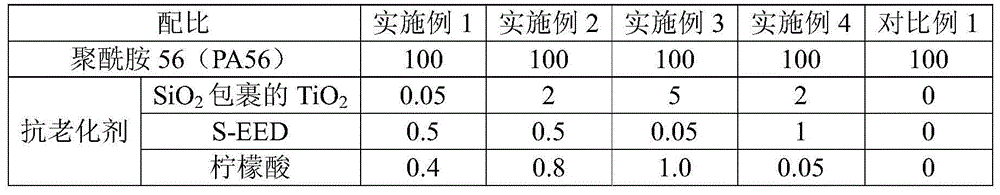

Anti-yellowing polyamide composition and preparation method of anti-yellowing polyamide

The invention provides an anti-yellowing polyamide composition and a preparation method of anti-yellowing polyamide; the yellowing polyamide composition includes polyamide 56 and anti-aging agents, wherein the anti-aging agents include a heat stabilizer, a light stabilizer and an amino functional group end-capping agent. The preparation method of the anti-yellowing polyamide comprises that the components of the anti-yellowing polyamide composition are subjected to melt mixing, and thus the anti-yellowing polyamide is obtained. The anti-yellowing polyamide not only has durable anti-yellowing property, but also has excellent mechanical properties and processability.

Owner:CATHAY R&D CENT CO LTD

Preparation method of aqueous polyester polyol dispersoid

InactiveCN101824208AImproved mechanical performance and durabilityImprove stabilityPolyurea/polyurethane coatingsChemical industryDicarboxylic acid

The invention belongs to the chemical industry field, and relates to a preparation method of high-performance aqueous polyester polyol dispersoid. The preparation method comprises the following steps: firstly enabling dicarboxylic acid with a sulphonate-SO3M group to react with diatomic alcohol to obtain a polyester intermediate, enabling a certain amount of polyester intermediate to react with polybasic carboxylic acid and polyhydric alcohol to synthesize polyester resin with hydroxyl, and then directly adding de-ionized water to disperse so as to obtain the aqueous polyester polyol dispersoid. The aqueous polyester polyol dispersoid prepared by the invention has the characteristics of no organic solvent, high solid content, low viscosity, high storage stability, no need of neutralization by amine neutralizer and simple preparation method, and is mainly used for preparing high-performance coating material. For example, the polyester polyol dispersoid can be used with water-based polyisocyanate curing agent for preparing water-based bi-component polyurethane coating, and can also be used with water-based amine resin curing agent as water-based automobile finish.

Owner:HUNAN UNIV

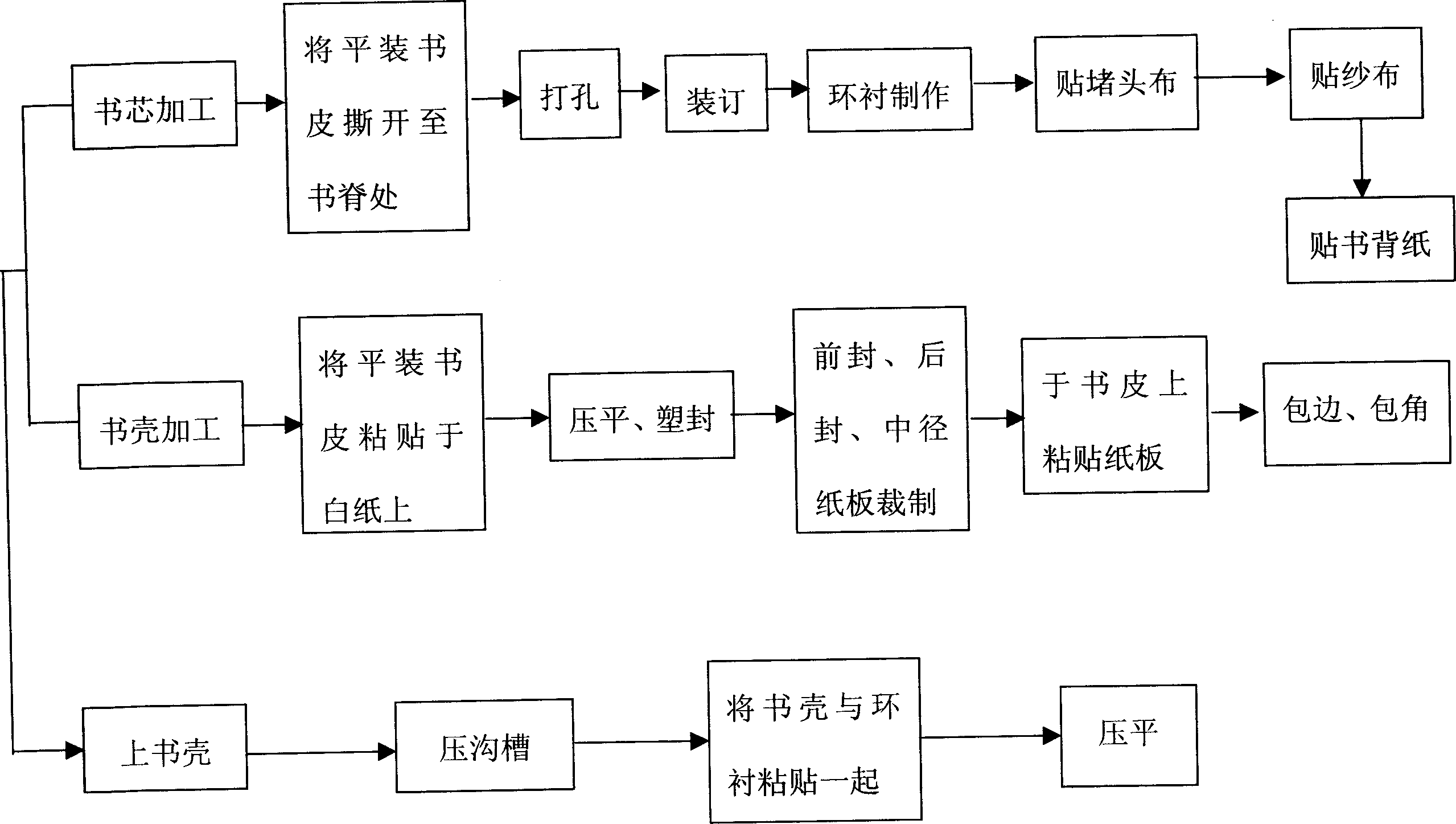

Method for changing paperback to exquisitely binding book

InactiveCN1865018AGood effectMeet quality requirementsBookbinding casesBook rebindingPulp and paper industryPaper sheet

The invention relates to a method for changing the soft-covered book into hard-cover book, which comprises three steps as processing book core, processing book cover, and mounting the book cover. Wherein, first, removing the cover of soft-covered book; then making holes, binding, preparing annular liner, adhering block cloth, adhering gauze, adhering book back paper to complete processing the book core; the second step is that adhering the cover on the white paper, then flattening the coat film, cutting the front and back seal, and the middle paper sheet, then folding edge and packing corner; the third step comprises pressing groove, adhering annular liner and flattening. The inventive method can overcome the defects of present technique, with simple operation and lower cost.

Owner:王超 +1

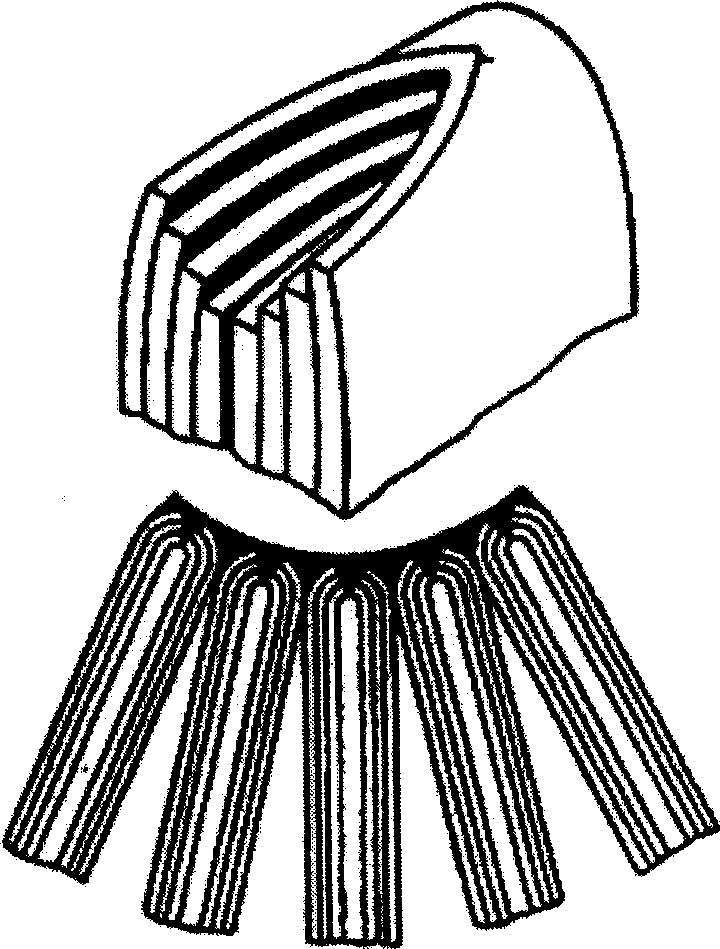

Composition of dielectric for plasma display panel

InactiveUS20050179117A1Preventing colloid generationAvoid yellowingAddress electrodesSustain/scan electrodesDielectricCopper oxide

Owner:LG ELECTRONICS INC

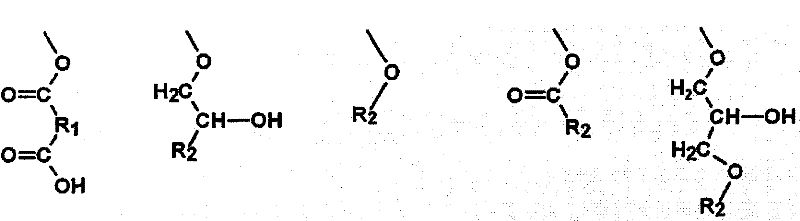

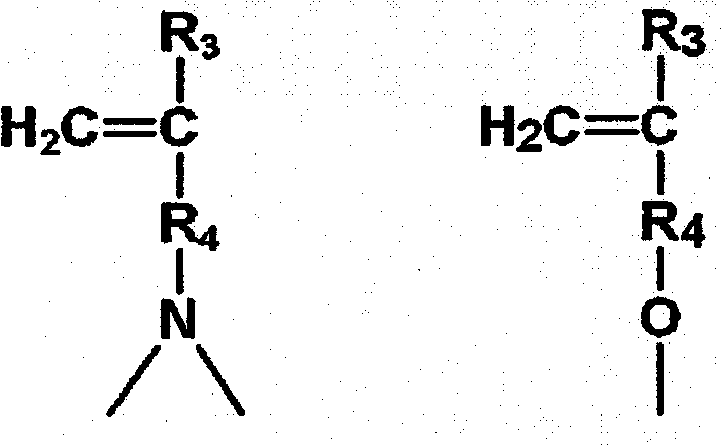

Composition comprising polyoxyalkylene-based polymer composition

InactiveCN102197125AGood dispersionAvoid yellowingOrganic detergent compounding agentsPolymer scienceDouble bond

[Purpose] The purpose of the present invention is to produce a polymer composition with an improved dispersibility for lime soap when used as a detergent and to provide a method for production of the same. [Means of Solution] A laundry detergent or cleaning composition which comprises a polymer composition containing a polymer obtained by polymerizing a polyoxyalkylene-based compound and an unsaturated monomer containing an acid group in the presence of a polymerization initiator, which is characterized by that the polyoxyalkylene-based compound includes 1) a group containing a carbon-carbon double bond, 2) a polyalkylene glycol chain, and 3) one of the groups shown in formulas (1)-(5), and the amount of solvent used at the time of the polymerization is 10 parts or less for 100 parts of the polyoxyalkylene-based compound.

Owner:PROCTER & GAMBLE CO

Single-component silane modified polyether sealant composition and sealant and preparation method thereof

ActiveCN108795360AGood weather resistanceIncreased durabilityNon-macromolecular adhesive additivesPolyether adhesivesSilanesUv absorber

The invention relates to the field of high molecular sealing materials and discloses a single-component silane modified polyether sealant composition and a sealant prepared from the single-component silane modified polyether sealant composition. The single-component silane modified polyether sealant composition disclosed by the invention is prepared from silane modified polyether resin, alkoxy terminated polydimethylsiloxane, a plasticizing agent, reinforcing filler, a water removal agent, a light stabilizing agent, an ultraviolet absorbent, a coupling agent and a catalyst. The sealant disclosed by the invention has the advantages of good smell, good ageing resistance, high recovery rate and the like.

Owner:浙江中天东方氟硅材料股份有限公司

Photodiffusion film and preparation method thereof

The invention relates to a photodiffusion film and a preparation method thereof. The photodiffusion film comprises the following components in percentage by weight: 95.0-99.9% of macromolecular base material and 0.1-5.0% of photo scattering agent. The preparation method comprises the steps of: adopting macromolecular base as a main body, adding the photo scattering agent, and evenly diffusing in a solution to prepare the photodiffusion film. The photodiffusion film can be used for preparing various related products in the optical field, is environment-friendly, high in safety property, and suitable for manufacturing lampshade materials for LEDs (Light-Emitting Diode). The problem that the photo scattering agent is unevenly diffused in the macromolecular base can be solved by adopting a solution process, so that the obtained photodiffusion material has high transmittance and haze, and is superior to samples produced under ordinary technological conditions in term of property. In addition, the film with high haze and high transmittance can be prepared by adopting the solution process, and the problems that the base material such as polycarbonate and the like is degraded and yellowed when the melt blending is used can be solved.

Owner:SHANGHAI UNIV

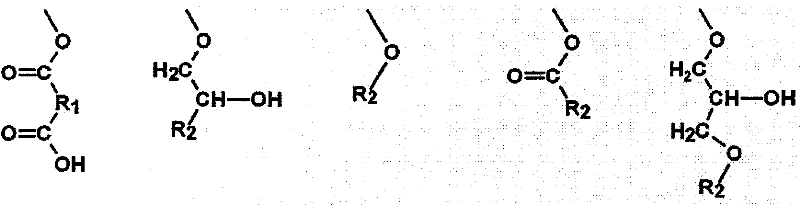

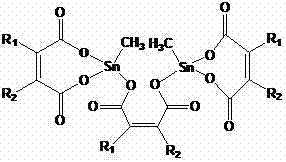

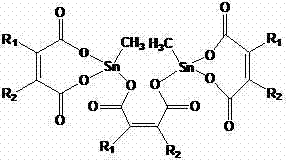

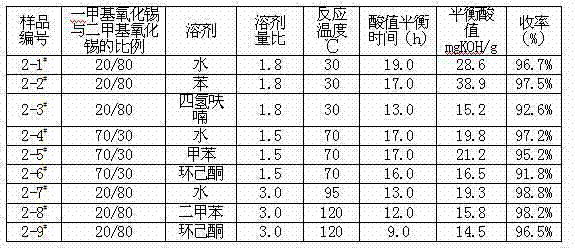

Methyltin maleate and preparation method thereof

The invention discloses methyltin maleate and a preparation method thereof, belonging to the technical field of novel halogen-containing polymer thermal stabilizers. The methyltin maleate comprises mono-methyltin maleate and dimethyltin maleate. In the methyltin maleate and the preparation method thereof, the methyltin maleate is a thermal stabilizer used in processing of a halogen-containing polymer, so that yellowing of the halogen-containing polymer is prevented during molding processing; and moreover, production is easy to control, production cost is low, and an obtained product has good and stable quality.

Owner:衢州建华南杭药业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com