Frame sealant composition, liquid crystal pollution prevention method, liquid crystal display panel and display device

A frame sealing glue and composition technology, which is applied in the direction of sealing devices, chemical instruments and methods, non-polymer organic compound adhesives, etc., can solve the problems of ineffective anchoring of thermally polymerized monomers, liquid crystal pollution, etc., and achieve Effects of avoiding yellowing and unevenness, reducing contamination, and enhancing anchoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

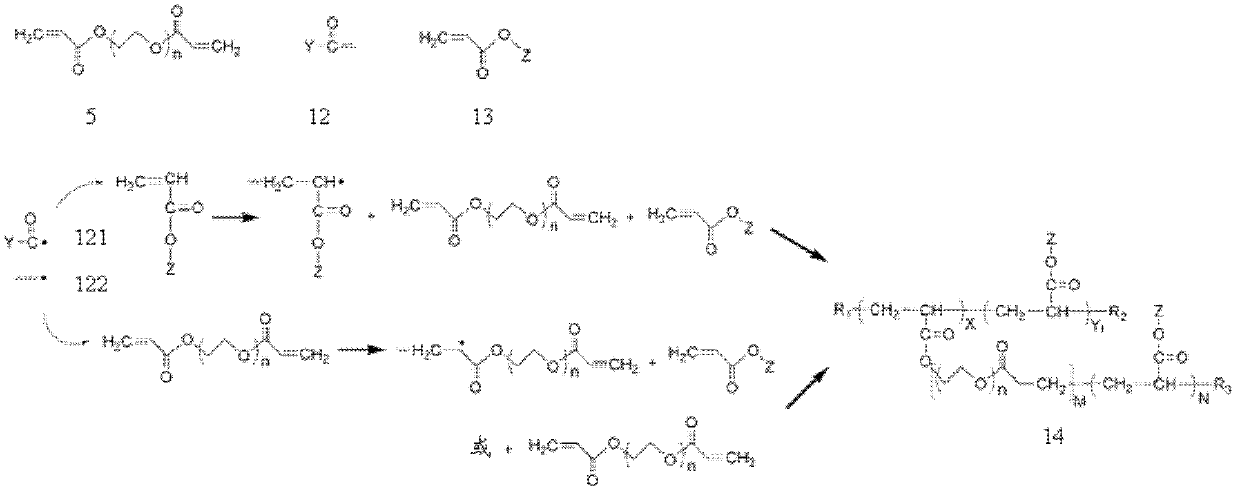

Method used

Image

Examples

Embodiment 1

[0079] Example 1: Frame sealant 1

[0080] a) 20 parts by weight of ultraviolet double bond polymerizable monomer (ethyl acrylate), 15 parts by weight of thermally polymerizable monomer (ethylene glycol diglycidyl ether), 7 parts by weight of polymerizable oligomer (polyethylene Diol diacrylate, containing 2 C-C double bonds, molecular weight 2500), 0.1 parts by weight of photoinitiator (dibenzoyl peroxide) and 10 parts by weight of thermosetting agent (1,8-diamino-3, 6-dioxa-octane) to obtain a homogeneous mixture, and put the above mixture into a defoamer for 1 h in the dark;

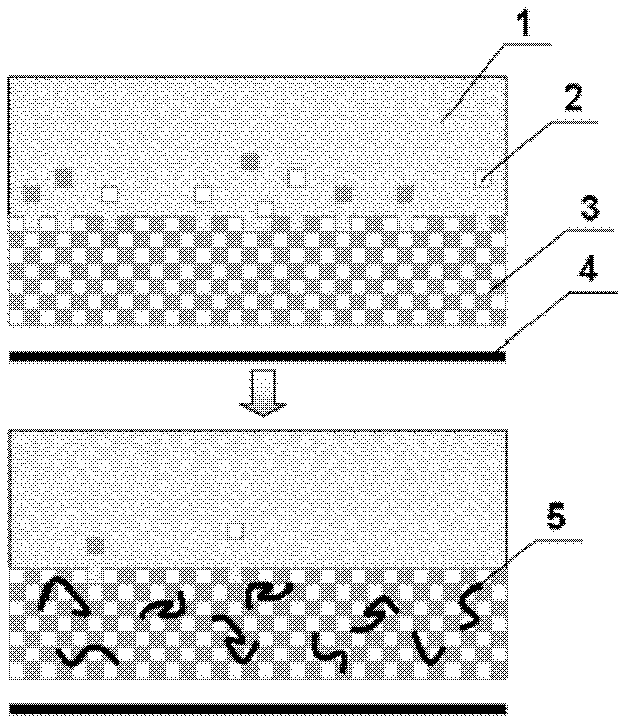

[0081] b) uniformly coating the mixture obtained in step a) on the color filter substrate, and then filling the color filter substrate and the array substrate with liquid crystals and aligning the cells to obtain a liquid crystal display panel;

[0082] c) Use ultraviolet light to irradiate the liquid crystal display panel, wherein the wavelength of ultraviolet light is 350nm, the irradiation time of...

Embodiment 2

[0084] Example 2: Frame sealant 2

[0085] a) 21 parts by weight of ultraviolet double bond polymerizable monomer (methyl acrylate), 16.5 parts by weight of thermally polymerizable monomer (ethylene glycol diglycidyl ether), 5 parts by weight of polymerizable oligomer (polyethylene Diol diacrylate, containing 2 C-C double bonds, molecular weight 3000), 0.5 parts by weight of photoinitiator (lauroyl peroxide), 12 parts by weight of thermosetting agent (1,8-diamino-3,6 - dioxoctane) and 2 parts by weight of the particle additive (silicon dioxide) are mixed to obtain a homogeneous mixture, and the mixture is put into a defoamer for 1.5 hours of light-shielding defoaming treatment;

[0086] b) uniformly coating the mixture obtained in step a) on the color filter substrate, and then filling the color filter substrate and the array substrate with liquid crystals and aligning the cells to obtain a liquid crystal display panel;

[0087] c) Irradiate the liquid crystal display panel w...

Embodiment 3

[0089] Example 3: Frame sealant 3

[0090] a) 23 parts by weight of ultraviolet double bond polymerizable monomer (methyl methacrylate), 15 parts by weight of thermally polymerizable monomer (ethylene glycol diglycidyl ether), 10 parts by weight of polymerizable oligomer ( Polyethylene glycol diacrylate, containing 2 C-C double bonds, molecular weight 2000), 1 weight part of photoinitiator (azobisisobutyronitrile), 13 weight parts of thermosetting agent (1,8-diamino- 3,6-dioxa-octane) and 5 parts by weight of granular additives (silicon dioxide) were mixed to obtain a homogeneous mixture, and the above-mentioned mixture was put into a defoamer for 2 h in the dark;

[0091] b) uniformly coating the mixture obtained in step a) on the array substrate, then filling the color filter substrate and the array substrate with liquid crystals and aligning the cells to obtain a liquid crystal display panel;

[0092]c) Irradiate the liquid crystal display panel with ultraviolet light, whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com