Patents

Literature

105 results about "Lauroyl peroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

LAUROYL PEROXIDE is a white solid with a faint soapy odor. Less dense than water and insoluble in water.Hence floats on water.Melting point 49°C. Toxic by ingestion and inhalation.

Macroporous strong alkaline carbon nanotube composite ion exchange resin and preparation method thereof

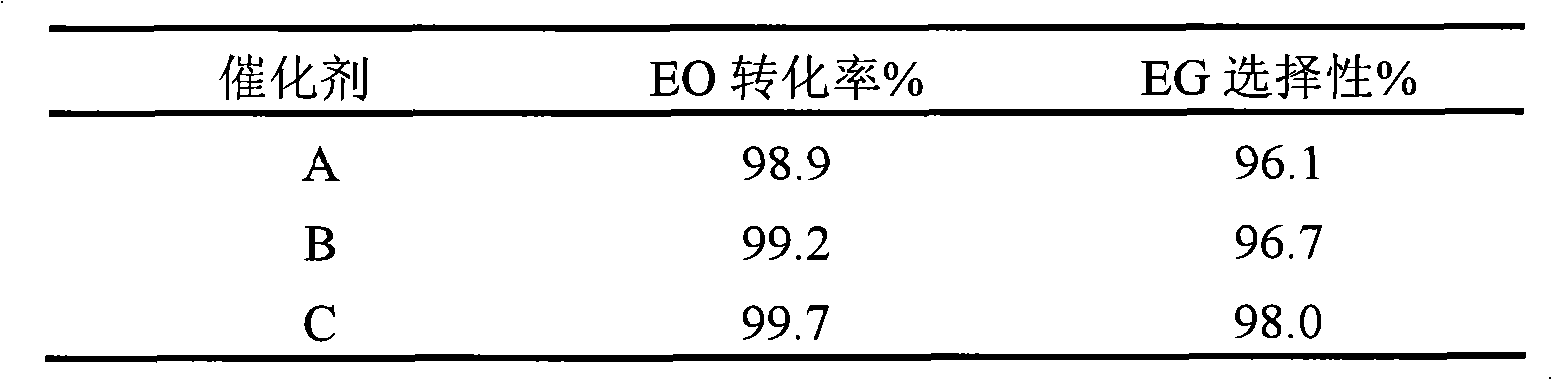

ActiveCN102372812ASolve compound problemsIn situ functionalizationAnion exchangersHydration reactionCarbon nanotube

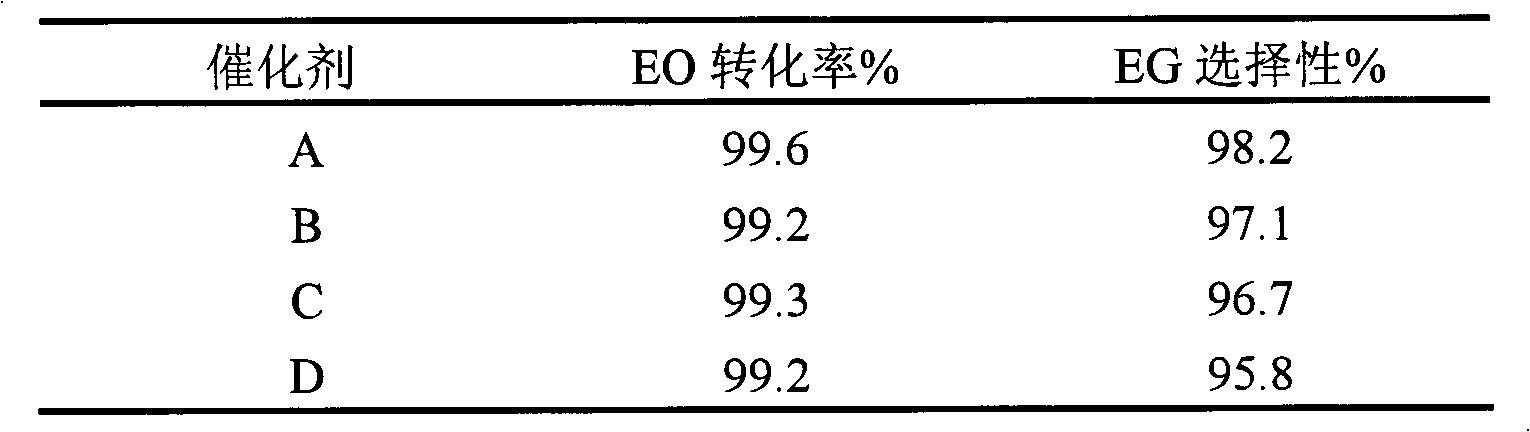

The invention relates to a macroporous strong alkaline carbon nanotube composite ion exchange resin and a preparation method thereof, and aims to solve problems of weak heat resistance and weak swelling resistance of an ion exchange resin in a prior art. The macroporous strong alkaline carbon nanotube composite ion exchange resin comprises the following components: (1) 40-65% of monomer; (2) 3-10% of copolymerization monomer; (3) 0.1-10% of nano material; and (4) 0.1-2% of initiator. The monomer is at least one selected from p-chloromethyl styrene, 4-(3-chloropropyl) styrene, 4-(3-bromopropyl) styrene, 4-(4-chlorobutyl) styrene, 4-(4-brombutyl) styrene, 4-(5-chloroamyl) styrene and 4-(5-bromoamyl) styrene; the copolymerization monomer is at least one selected from EGDMA, dipropenyl benzene, divinyl phenyl methane and divinyl benzene; the nano material is at least one selected from multi-wall carbon nanotube, single arm carbon nanotube and fullerene of C60 or C70; the initiator is at least one selected from benzoyl peroxide, azodiisobutyronitrile, lauroyl peroxide and cumyl hydroperoxide. The invention also provides a preparation method of the macroporous strong alkaline carbon nanotube composite ion exchange resin. The above technical scheme well solves the problems and can be applied to industrial production of ethylene oxide catalytic hydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

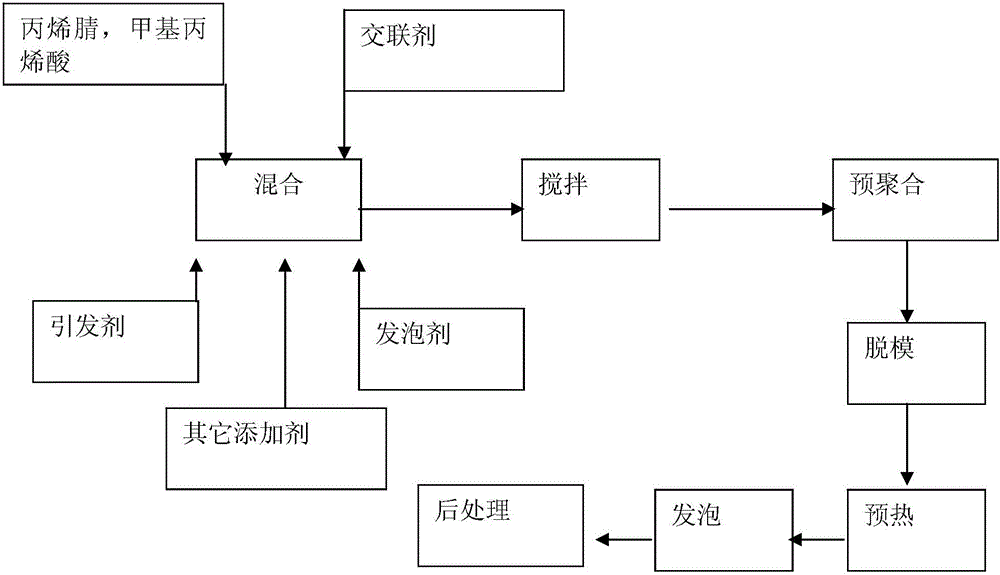

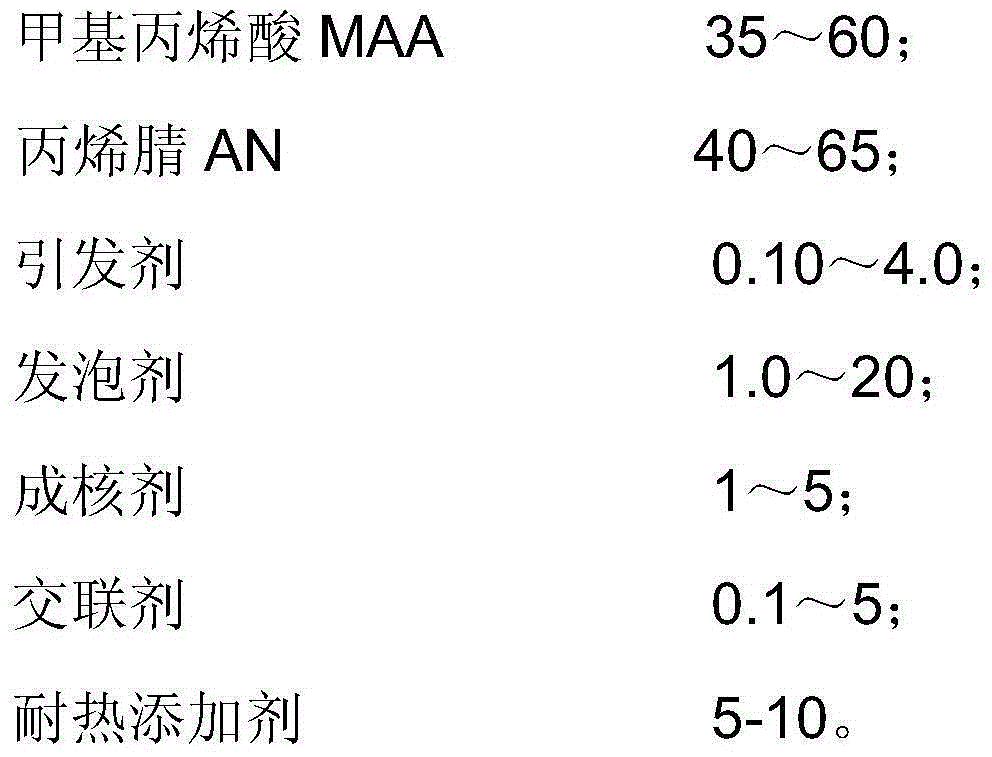

Acrylonitrile-based polymethacrylimide foam and preparation method therefor

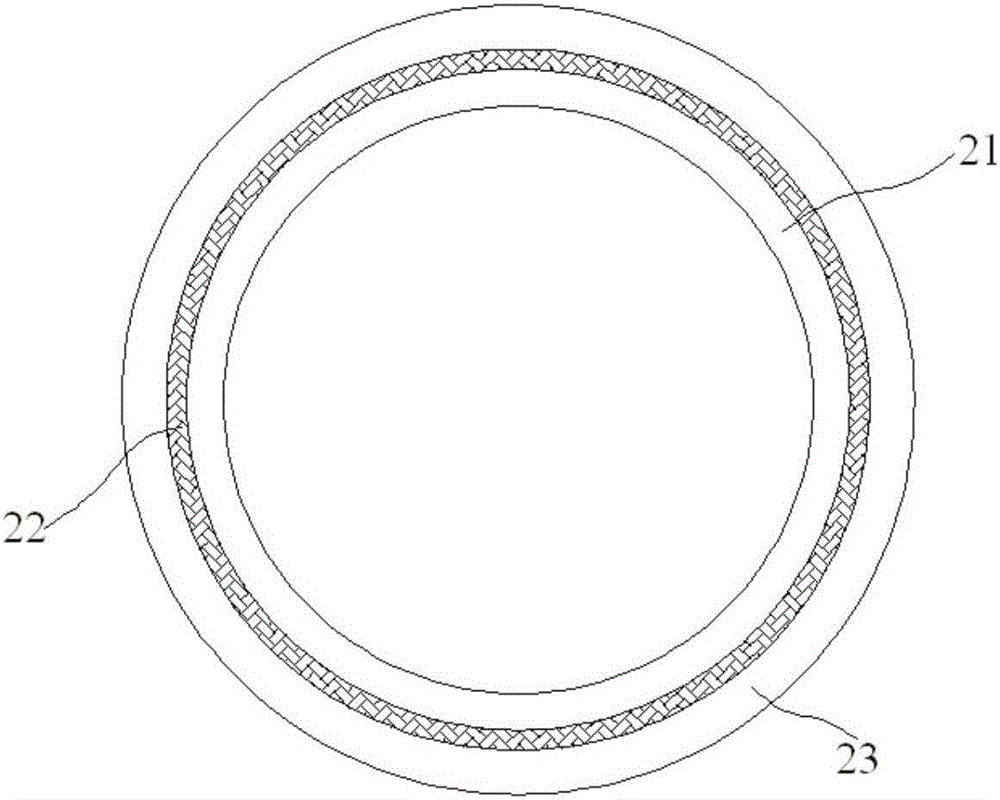

ActiveCN105111354AImprove heat resistanceHigh heat distortion temperatureAcrylonitrileDibenzoyl Peroxide

The invention relates to acrylonitrile-based polymethacrylimide foam which comprises the following components in parts by mass: 35-60 parts of methacrylic acid MAA, 40-65 parts of acrylonitrile AN, 0.10-4.0 parts of an initiator, 1.0-20 parts of a foaming agent, 1-5 parts of a nucleating agent, 0.1-5 parts of a crosslinking agent and 5-10 parts of a heat resisting additive, wherein the initiator is an azo compound or a mixture of the azo compound and a peroxide and the initiator at least comprises three different compounds at the same time; the azo compound is azobisisobutyronitrile AIBN, azobisisoamylonitrile or 2,2'-azobisisoheptonitrile; the peroxide is dibenzoyl peroxide, lauroyl peroxide, tert-butyl peroxyoctoate or tert-butyl peroxybenzoate. The acrylonitrile-based polymethacrylimide foam provided by the invention is good in heat resistance, high in heat deformation temperature which is greater than 220 DEG C and excellent in mechanical property.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Strongly basic carbon nanotube composite resin and its preparation method

The invention relates to strongly basic carbon nanotube composite resin and its preparation method, and mainly aims to solve the problems of poor heat resistance and swelling resistance of ion exchange resin involved in previous technologies. The composite resin of the invention comprises: (1) 75-90% of a monomer; (2) 5-15% of a comonomer; (3) 0.1-5% of a nano-material; (4) 0.1-10% of an initiator. Specifically, the monomer is at least one of p-chloromethyl styrene, 4-(3-chloropropyl) styrene, 4-(3-bromopropyl) styrene, 4-(4-chlorobutyl) styrene, 4-(4-brombutyl) styrene, 4-(5-chloropentyl) styrene or 4-(5-bromopentyl) styrene; the comonomer is at least one of glycol dimethacrylate, 2-propenylbenzene, divinyl phenylmethane, and divinylbenzene;the nano-material is at least one of a multi-walled carbon nanotube, a single-walled carbon nanotube, C60 or C70 etc. fullerene; and the initiator is at least one of benzoyl peroxide, azodiisobutyronitrile, lauroyl peroxide, and cumene hydroperoxide. The composite resin and its preparation method of the invention well solves the above problems, and can be used in the industrial production of oxirane catalytic hydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

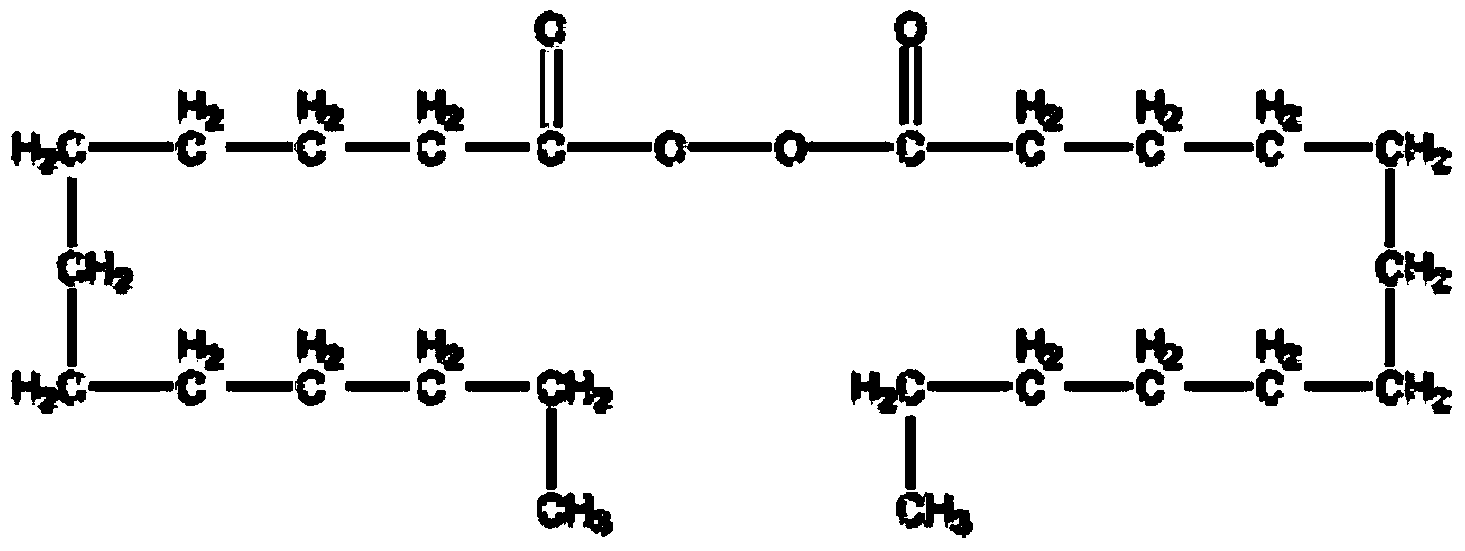

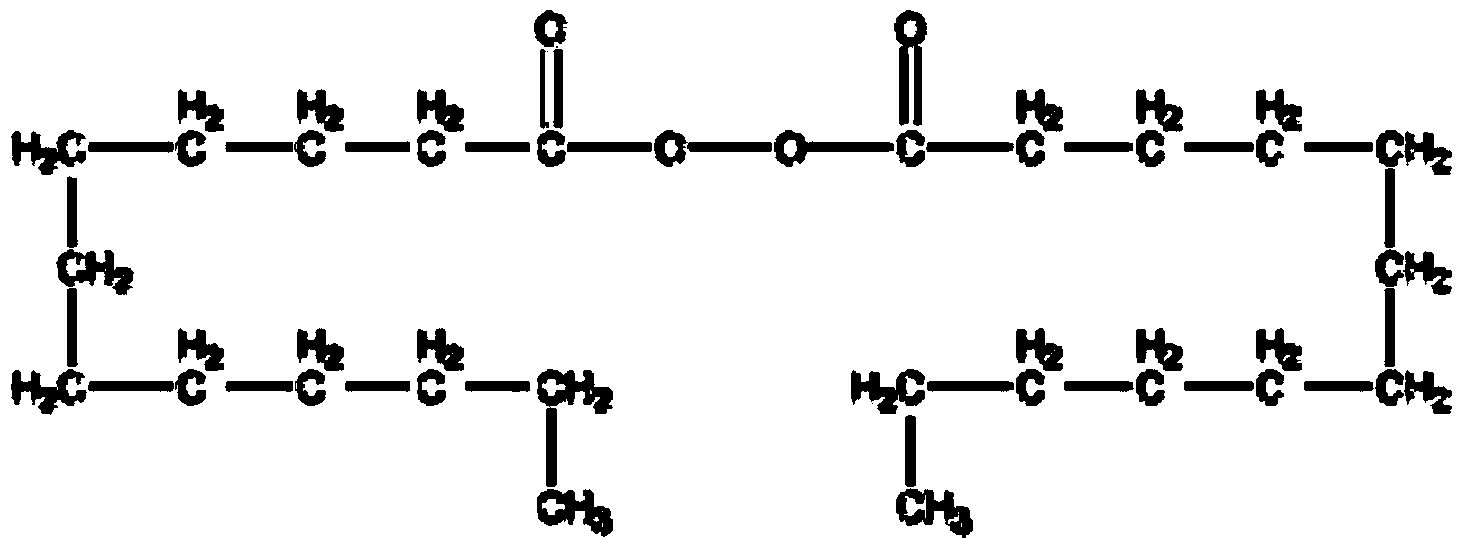

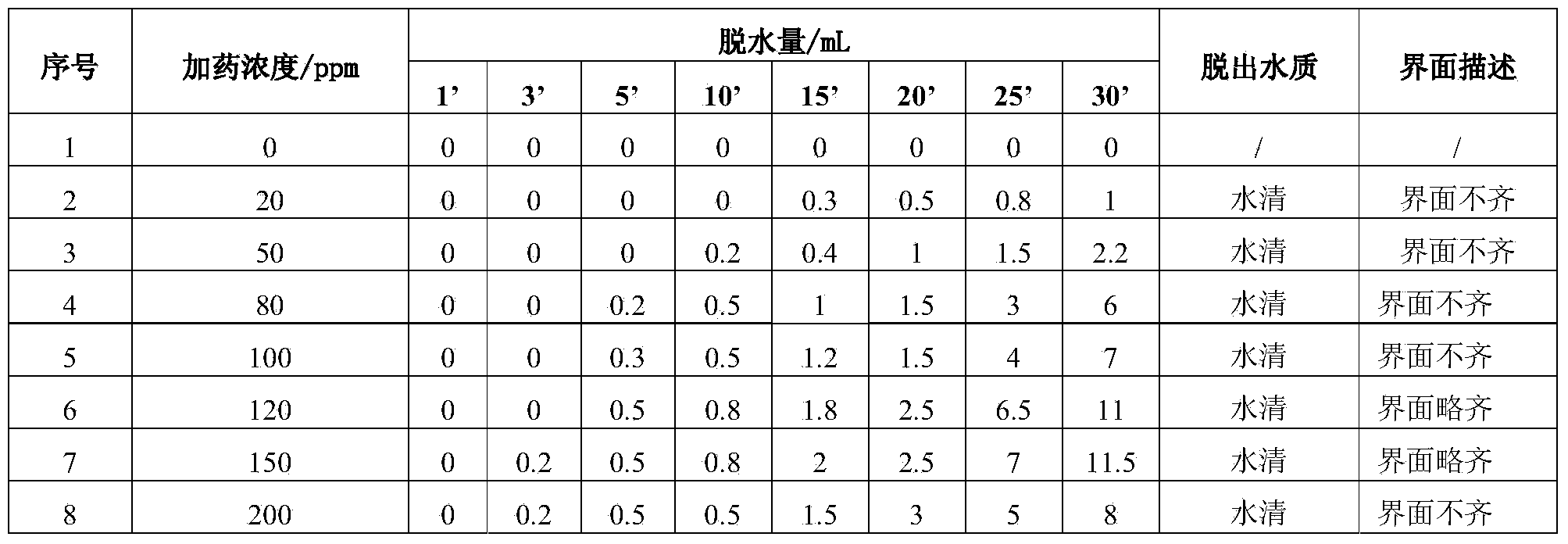

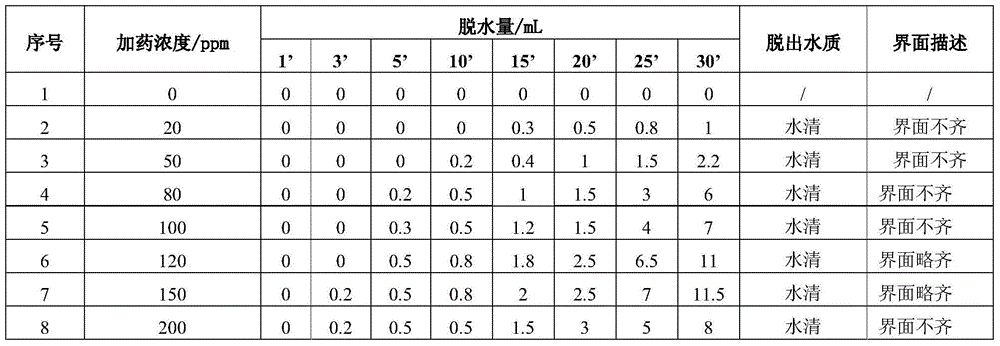

Ageing oil demulsifier and preparation method thereof

ActiveCN103666542AStrong demulsifierImprove dehydration abilityDewatering/demulsification with chemical meansLauroyl peroxideDemulsifier

The invention relates to an ageing oil demulsifier and a preparation method thereof, and belongs to the technical field of petroleum processing. The ageing oil demulsifier comprises mixed acid, a demulsifier monomer and an initiator, wherein the mixed acid consists of acrylic acid and maleic anhydride based on the molar ratio of (1-3): (0.5-1.5); the molar ratio of the mixed acid to the demulsifier monomer, namely, alkyl phenolic resin-polyoxyethylene polyoxypropylene ether, is (0.5-1.7): (0.5-1.5); the initiator, namely, lauroyl peroxide, accounts for 8 to 12% of the mass of the mixed acid. The preparation method comprises the following processes: adding the initiator, namely lauroyl peroxide to mixed acid and demulsifier monomer, namely alkyl phenolic resin-polyoxyethylene polyoxypropylene ether; polymerizing for 1 to 4 hours under a temperature of 70 to 100 DEG C; heating to reach 100 to 150 DEG C; esterifying for 3 to 7 hours to obtain the ageing oil demulsifier. The ageing oil demulsifier has the characteristics of being simple in components, simple in process, convenient, fast and efficient to prepare, low in cost, small in dosage, small in toxic and side effects, wide in application scope, good in demulsifying effect, etc.

Owner:河南鼎源化工科技有限公司

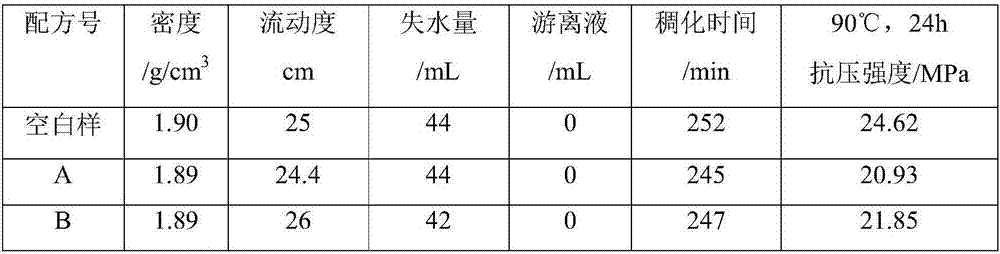

Temperature-sensitive swelling microcapsule anti-gas-channeling agent and anti-gas-channeling cement slurry system

ActiveCN106947447AGas volume controllableStable performance on the groundDrilling compositionMicroballoon preparationCross-linkWater baths

The present invention discloses a temperature-sensitive swelling microcapsule anti-gas-channeling agent and an anti-gas-channeling cement slurry system. The temperature-sensitive expansion microcapsule anti-gas-channeling agent preparation method comprises: adding 3-4 parts of acrylonitrile, 0.4-0.5 part of methyl acrylate and 2-3 parts of methyl methacrylate to a beaker, adding 1-2 parts of lauroyl peroxide as an initiator, 10-30 parts of a low boiling point solvent as a foaming agent, and 0.1-0.2 part of 1, 4-butanediol dimethacrylate as a cross-linking agent, carrying out stirring dissolving, transferring into a glass reaction kettle, adding 20-25 parts of nano-silica as a dispersant and 300-350 parts of deionized water, carrying out a constant temperature water bath reaction for 20-24 h at a temperature of 60-70 DEG C under nitrogen protection, cooling, washing, and drying. The anti-gas-channeling cement slurry system comprises 100 parts of oil well cement, 1.5-2 parts of a fluid loss additive, 2-3 parts of a dispersant, 0.1-1 part of an anti-gas-channeling agent, 0-3 parts of a retarder, 0.2 part of a defoamer, 0-50 parts of a density adjuster, and 44 parts of water. According to the present invention, with the temperature-sensitive expansion microcapsule anti-gas-channeling agent and the anti-gas-channeling cement slurry system, the cement stone volume shrinkage can be effectively made up, the stratum fluid can be sealed, the channeling can be prevented, the occurrence of the annulus pressure phenomenon can be prevented, and the service life of the oil well can be prolonged.

Owner:SOUTHWEST PETROLEUM UNIV

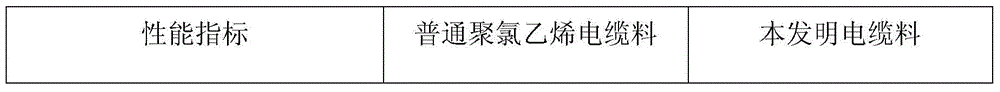

Anti-tear cable material used for high-speed railway motor train unit and preparation method of anti-tear cable material

The invention discloses an anti-tear cable material used for a high-speed railway motor train unit and a preparation method of the anti-tear cable material. The anti-tear cable material used for the high-speed railway motor train unit comprises the following raw materials in parts by weight: 67 to 89 parts of polyurethane rubber, 22 to 36 parts of styrene-butadiene rubber, 15 to 25 parts of thermoplastic polyester elastic bodies, 4 to 8 parts of vinyl silicone oil, 17 to 26 parts of fumed silica, 3 to 6 parts of cadmium carbonate, 2 to 3 parts of lauroyl peroxide, 1.5 to 2.5 parts of triallyl isocyanurate, 1 to 2 parts of ammonium benzoate, 3 to 5 parts of poly-alpha-olefin, 5 to 10 parts of tert-butyl phenolic tackifying resin, 2 to 4 parts of triethylhexanoin, 10 to 15 parts of methylpentachlorostearate, 14 to 18 parts of carbon nano tubes, 10 to 15 parts of a diopside powder, 1 to 2 parts of 4,4'-dithiodimorpholine, 0.5 to 1 part of P-tert-butylphenol, and 20 to 25 parts of a composite flame retardant. The cable material provided by the invention combines the advantages of the raw materials such as the polyurethane rubber, the styrene-butadiene rubber, and the thermoplastic polyester elastic bodies, the tearing strength of a conventional cable material is improved, and the cable material is enabled to have excellent tear resistance, has the effect of bearing relatively great mechanical external force, and has the advantages of excellent chemical stability, heat resistance and age resistance, and long service life.

Owner:ANHUI KANGLIYA CO LTD

Medical anti-microbial dressing and preparation method thereof

InactiveCN105079862AImprove stabilityImprove permeabilityAbsorbent padsBandagesFiltrationWater soluble chitosan

The invention discloses medical anti-microbial dressing and a preparation method thereof. The medical anti-microbial dressing comprises a bacterial cellulose membrane, nano-silver, water soluble chitosan, sodium alginate, polyvinylpyrrolidone and a composite cross-linking agent, wherein the composite cross-linking agent is prepared by compounding lauroyl peroxide, methacrylic acid-2-hydroxyethyl ester and 2-ethyl-4-methylimidazole. The preparation method comprises the steps that the sodium alginate is added into deionized water and is heated and mixed evenly to obtain a mixed liquid I; the polyvinylpyrrolidone is dissolved in ethylene glycol, the nano-silver is added, temperature rise is kept for a certain time, filtration is performed, solid matter is cleaned with deionized water and then is dried and smashed to obtain a material I; the water soluble chitosan and the material I are added into the mixed liquid I to be mixed evenly, the bacterial cellulose membrane is added, the composite cross-linking agent is added after the temperature rise is kept for a certain time, and temperature rise reaction is performed to obtain the anti-microbial dressing. The anti-microbial dressing has good anti-microbial dressing, bleeding-stop and wound surface healing effects and can be better applied to the medical field.

Owner:JIANGSU LANWAN BIOTECH

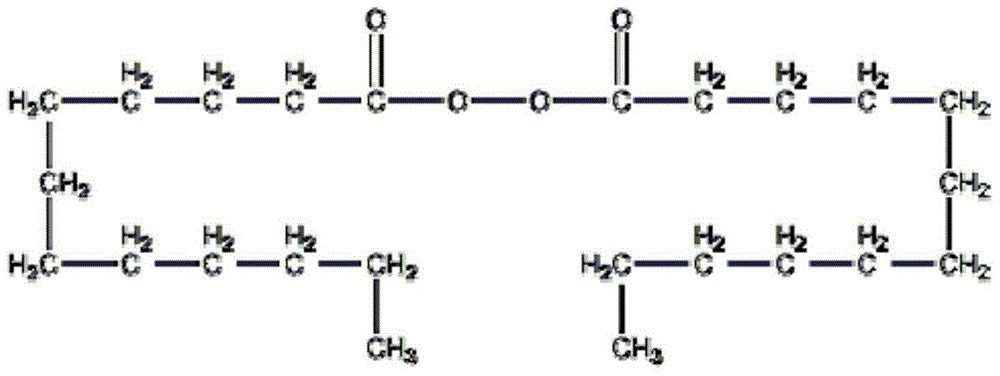

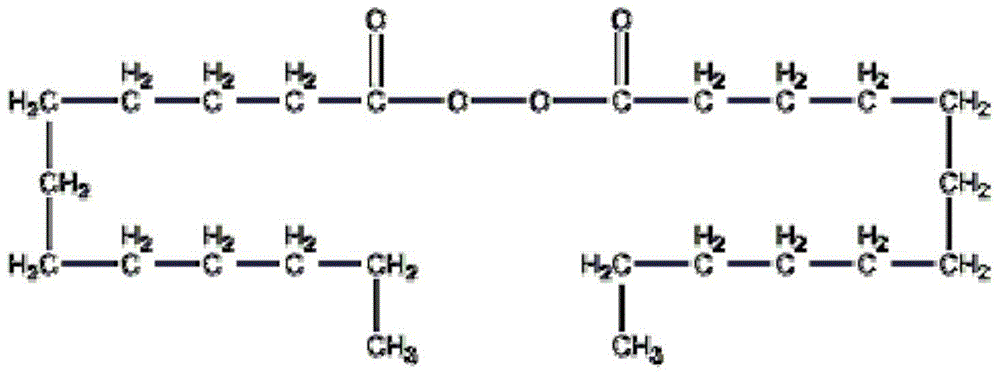

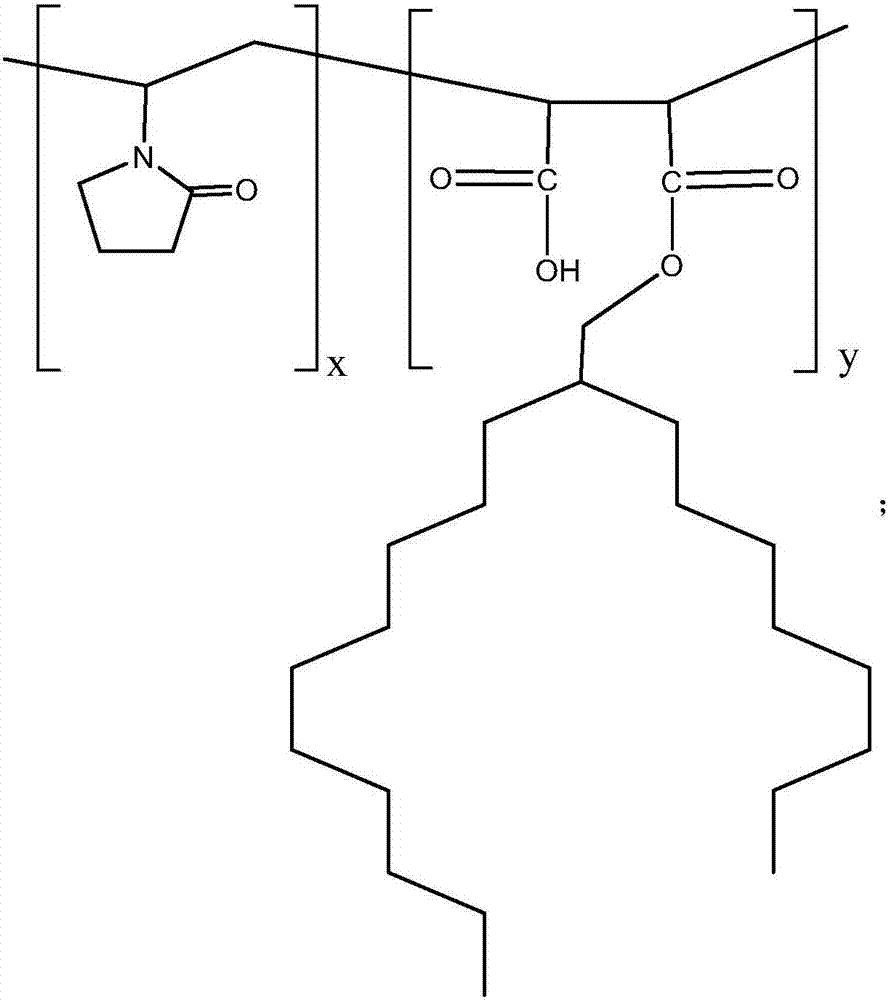

Preparation method and application of amphiphilic polymer

InactiveCN106432607AImprove bioavailabilitySmall toxicityOrganic active ingredientsPharmaceutical non-active ingredientsDodecaneSide effect

The invention relates to a preparation method and application of an amphiphilic polymer. The problems that an insoluble drug is poor in absorption and treatment effect and low in bioavailability and has more adverse effects can be effectively solved. According to the technical scheme, the amphiphilic polymer is formed by connecting a N-vinyl pyrrolidone monomer with maleic acid Guerbet eicosanol monoester, the maleic acid Guerbet eicosanol monoester is generated through esterification of maleic anhydride and 2-octyl-dodecane Guerbet alcohol, a free radical polymerization reaction is conducted in n-heptane by taking lauroyl peroxide as an initiating agent and taking N-vinyl pyrrolidone and the maleic acid Guerbet eicosanol monoester as monomers, and then the amphiphilic polymer is obtained. According to the preparation method and application of the amphiphilic polymer, the insoluble drug is embedded into polymeric micelles by taking the amphiphilic polymer as a carrier material to prepare an insoluble drug-loaded micelle injection, a very good tumor inhibiting effect is achieved, the toxicity is low, the water solubility of the insoluble drug can be enhanced, the bioavailability of the drug can be improved, and the toxic and side effects of the drug can be reduced.

Owner:ZHENGZHOU UNIV

Low-temperature and crack resistant chlorinated polyethylene cable material and preparation method thereof

InactiveCN106589634AImprove low temperature resistanceImprove cold resistancePlastic/resin/waxes insulatorsFiberImidazolidinethione

The invention discloses a low-temperature and crack resistant chlorinated polyethylene cable material and a preparation method thereof. The cable material is prepared from, by weight, 60-80 parts of chlorinated polyethylene, 26-30 parts of low-phenyl silicone rubber, 30-40 parts of a tetrafluoroethene-perfluoromethyl vinyl ether copolymer, 8-12 parts of stearic acid, 7-9 parts of magnesium oxide, 5-8 parts of di-n-hexyl azelate, 25-35 parts of di(butylcarbitol) adipate, 5-7 parts of bis-(gamma-triethoxysilylpropyl)tetrasulfide, 6-8 parts of 2-imidazolidinethione, 1-2 parts of lauroyl peroxide, 6-8 parts of stannous chloride and 25-35 parts of silicon oxynitride. The low-phenyl silicone rubber and the tetrafluoroethene-perfluoromethyl vinyl ether copolymer added in the invention have excellent low-temperature resistance, and can be combined with the chlorinated polyethylene to form one body in order to effectively improve the low-temperature resistance of the chlorinated polyethylene cable material; and the di-n-hexyl azelate and di(butylcarbitol) adipate added in the invention enhance the cold resistance of the material, and can cooperate with the silicon oxynitride and calcium titanate nano-fibers to enhance the crack resistance of the material.

Owner:WENZHOU RENHE CULTURAL ORIGINALITY CO LTD

Anti-bacterial and fungus-resistant cable material applicable to humid environments and preparation method of cable material

The invention discloses an anti-bacterial and fungus-resistant cable material applicable to humid environments. The cable material is characterized by being prepared from raw materials in parts by weight as follows: 13-15 parts of CNTs (carbon nanotubes), 12-14 parts of 1,4-butene diacrylate, 5.5-6.6 parts of magnesium hydroxide, 0.8-1.2 parts of CTAB (cetyl trimethyl ammonium bromide), 0.02-0.03 parts of lauroyl peroxide, 67-70 parts of PVC (polyvinyl chloride), 9.5-12.5 parts of DIBA (diisobutyl adipate), 0.1-0.2 parts of eucalyptus oil, 1-2 parts of ribbed smoked sheets, 4-6 parts of methyl acrylate and 7-9 parts of an aid. Due to addition of the eucalyptus oil, the cable material has natural anti-bacterial and fungus-resistant properties and is safe, effective and environment-friendly; due to addition of polymer masterbatch prepared from the CNTs, the compactness and the flexibility of the cable material are enhanced; due to addition of the aid, the weather resistance of the cable material is enhanced, the processability is good, and the service life is prolonged; the cable material is applicable to outdoor humid environments.

Owner:HEFEI HEAN MACHINERY MFG

Abrasion-resistant and corrosion-resistant organic glass and preparing method thereof

The invention discloses abrasion-resistant and corrosion-resistant organic glass. The abrasion-resistant and corrosion-resistant organic glass comprises, by weight, 70-90 parts of methyl methacrylate, 25-35 parts of perfluorinated phenyl methacrylates, 45-55 parts of isophorone diisocyanate, 60-70 parts of polyethylene glycol, 4-6 parts of pentaerythrite di-acrylic easer, 1-2 parts of Tridecafluoro-1-octanol, 2-4 parts of orgo-montmorillonite, 7-9 parts of fire retardant, 2-4 parts of epoxidized soybean oil, 8-10 parts of rubber particles, 1-2 parts of Si69, 0.5-0.7 part of lauroyl peroxide and 0.2-0.4 part of dibutyltin dilaurate. The invention further discloses a preparing method of the abrasion-resistant and corrosion-resistant organic glass. The abrasion-resistant and corrosion-resistant organic glass is good in abrasion-resistant performance, high in rigidity, good in corrosion-resistant performance, and good in mechanical performance.

Owner:安徽亚克力实业有限公司

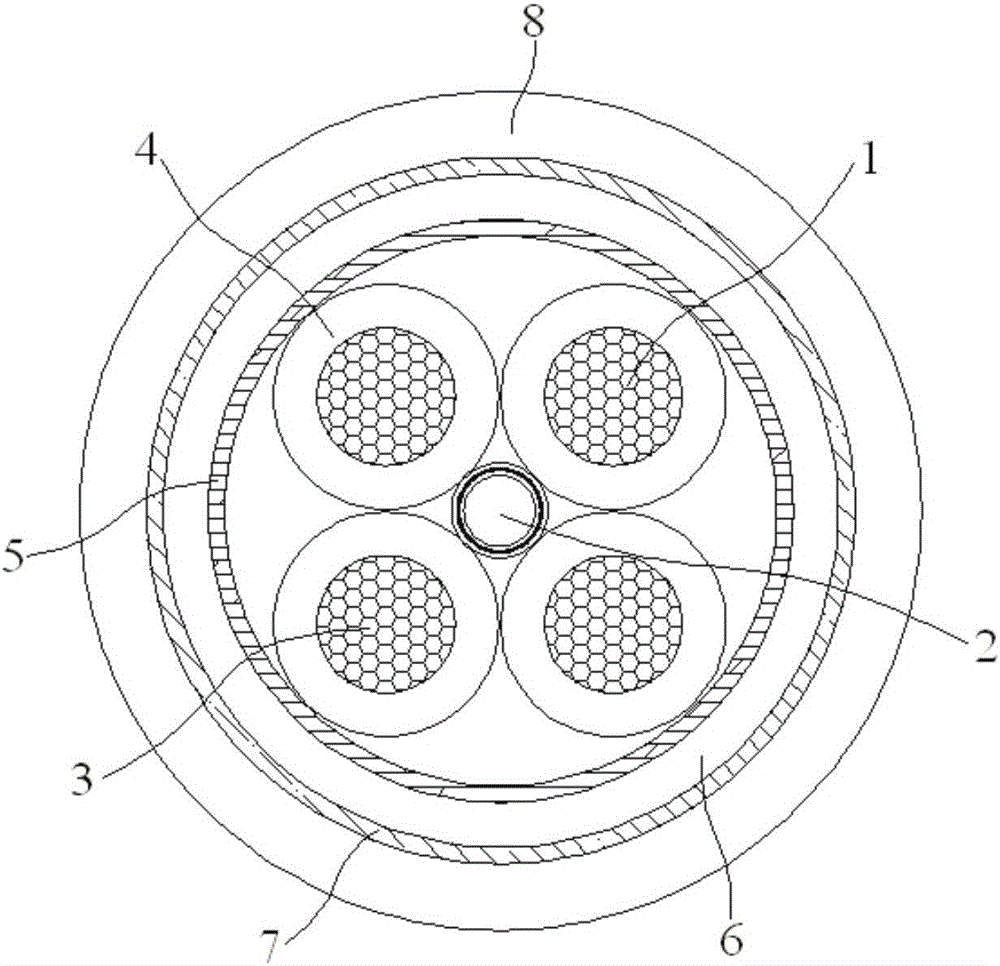

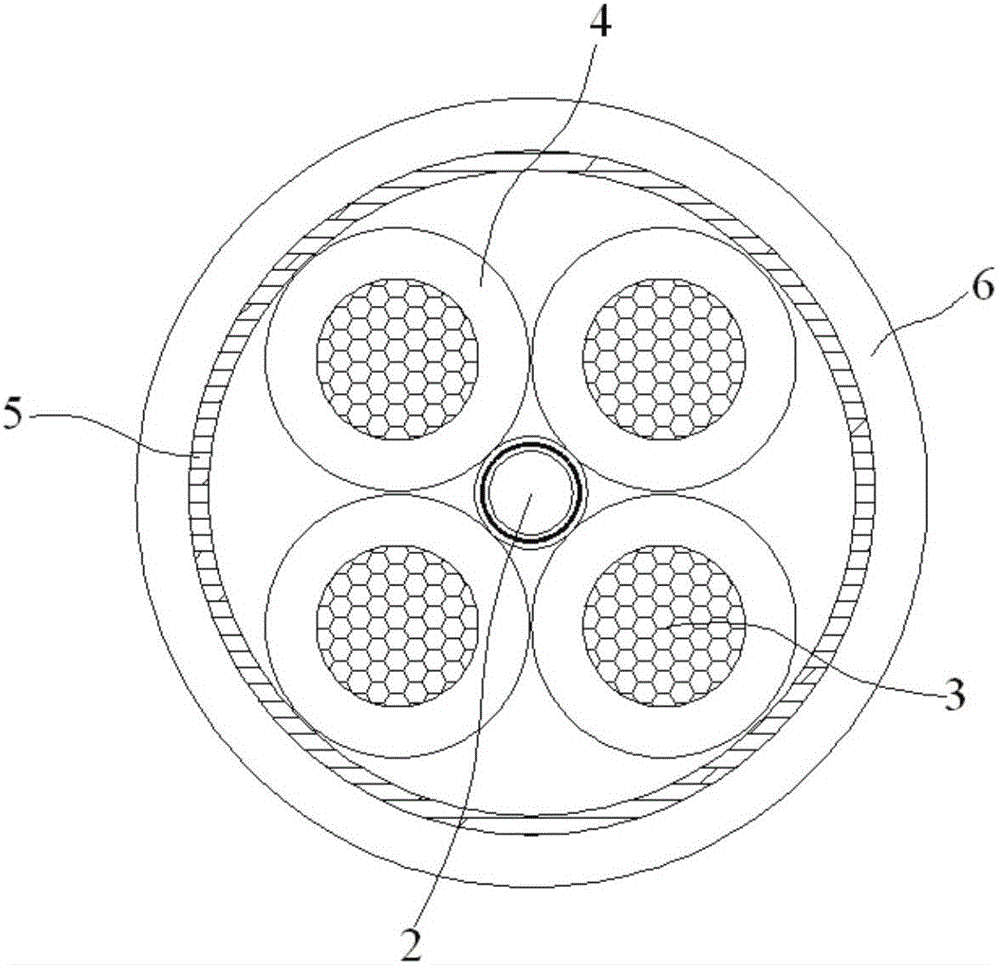

High-tensile-strength power transmission cable

InactiveCN106448871AReduce resistanceIncrease air pressureSynthetic resin layered productsInsulated cablesElectric power transmissionElectrical conductor

The invention discloses a high-tensile-strength power transmission cable comprising four circular conductive units and one hollow micro-tube used for embedding of an optical fiber. Each conductor unit comprises a conductive wire core and an insulating layer which wraps the external surface of the conductive wire core, wherein the conductive wire core and the insulating layer are arranged from inside to outside in turn. The four circular conductive units are arranged along the circumferential direction of the hollow micro-tube. A wrapping tape wraps the external surface of the four circular conductive units. The external surface of the wrapping tape is wrapped by an internal sheath layer. An armored layer wraps the external surface of the internal sheath layer. The external surface of the armored layer is wrapped by an external sheath layer. Maleic anhydride grafted amorphous polyolefin is prepared in a way that amorphous polyolefin, maleic anhydride, lauroyl peroxide and ethylene bisstearamide are put into a double-screw extruder according to the proportion of 100:0.4-3:0.03-1:0.1-0.3 through graft polymerization The situation that common air blowing laying is only suitable for parallel laying can be overcome, air pressure of the air compressor can be increased and finally the bending air blowing laying function can be realized.

Owner:JIANGSU HENGTONG POWER CABLE

A kind of aging oil demulsifier and preparation method thereof

ActiveCN103666542BEffective prolapseImprove dehydration efficiencyDewatering/demulsification with chemical meansDemulsifierLauroyl peroxide

Owner:河南鼎源化工科技有限公司

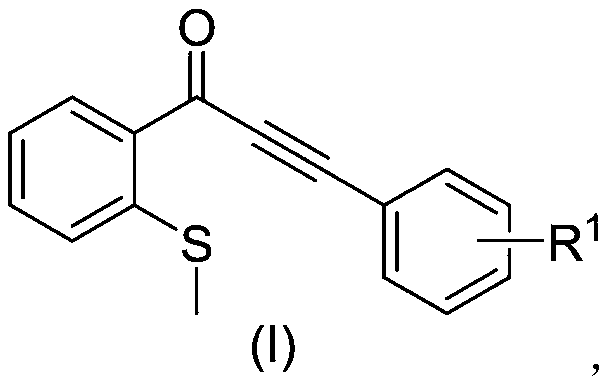

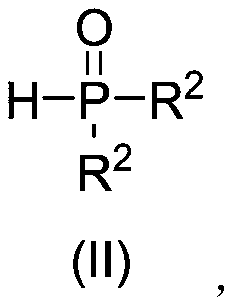

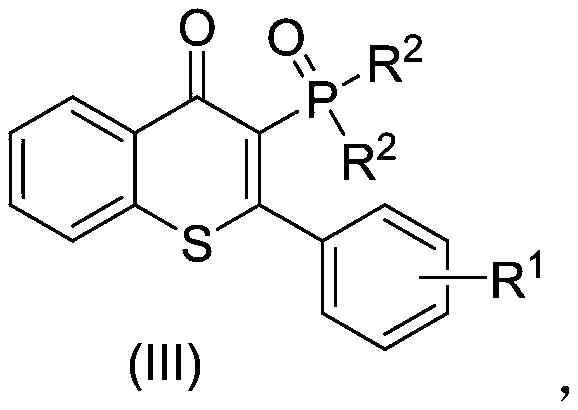

Preparation method of 2-phosphonothioflavone compound

ActiveCN110903319AEfficient constructionPotential application value is goodGroup 5/15 element organic compoundsPhotocatalytic reactionTetrazole

The invention discloses a preparation method of a 2-phosphonothioflavone compound, which is a method for synthesizing the 2-phosphonothioflavone compound by utilizing water phase visible light catalysis. According to the invention, tetrazole m-dibenzonitrile (4-CzIPN) is used as a photosensitizer, lauroyl peroxide is used as an oxidizing agent, 2-methylthiophenyl propynone and diarylphosphine oxide are used as initial raw materials, water is used as a solvent, and under the protection of nitrogen, an illumination reaction is carried out at room temperature for 24 hours to obtain a target product. The invention provides a method for preparing the 2-phosphonothioflavone compound through water-phase photocatalysis of radical series cyclization reaction for the first time. Compared with a traditional method, according to the method, traditional precious metal (such as ruthenium and iridium) organic photosensitizers do not need to be used, the 2-phosphonothioflavone compound is rapidly andefficiently synthesized under the extremely mild and environment-friendly reaction condition, and the method has huge potential application value in the fields of environment-friendly synthetic chemistry, heterocyclic compound construction through photocatalytic reaction and pharmaceutical and chemical engineering.

Owner:XINYANG AGRI & FORESTRY UNIV

Fibrilia-reinforced polypropylene engineering composite as well as preparation method and application of fibrilia-reinforced polypropylene engineering composite

The invention discloses a fibrilia-reinforced polypropylene engineering composite, a preparation method thereof and application of the fibrilia-reinforced polypropylene engineering composite to preparation of automobile parts. The composite is prepared from the following raw materials in percentage by weight: 59-80% of polypropylene, 19-30% of fibrilia, 1-5% of epoxy furan, 1-10% of a toughening agent and 0.1-3% of lauroyl peroxide, wherein both the fibrilia and epoxy furan are from renewable biomasses and meet the requirements of low carbon, environment friendliness and sustainable economic development. According to the fibrilia-reinforced polypropylene engineering composite, epoxy furan can reactively improve the interfacial compatibility of polypropylene and fibrilia under the initiating action of lauroyl peroxide, so that the composite is kept to have excellent mechanical property and processability and can be used for preparing the automobile parts. The preparation method of the composite, disclosed by the invention, can be used for preparing the composite through one-step extrusion and is simple, easy to operate and suitable for industrial production.

Owner:ZHEJIANG XINLI NEW MATERIAL CO LTD

Cardanol grafted high-density polyethylene synthesized by reactive extrusion and application thereof in bamboo-plastic composite material

The invention discloses cardanol grafted high-density polyethylene synthesized by reactive extrusion and application thereof in a bamboo-plastic composite material. A method comprises the following steps: a) a step of preparing the cardanol grafted high-density polyethylene, namely a step of dissolving a compound initiator which includes lauroyl peroxide (LPO) and dibenzoyl peroxide (BPO) into cardanol, adding the mixture into high-density polyethylene (HDPE) resin, uniformly stirring and mixing the mixture at a high speed, then performing extrusion by using an extruder, and carrying out watercooling and granulation to obtain the cardanol grafted high-density polyethylene synthesized by reactive extrusion; and b) a step of application of the cardanol grafted high-density polyethylene, namely a step of uniformly stirring and mixing the cardanol grafted high-density polyethylene prepared in the step a) with bamboo powder and plastic at a high speed, and performing extrusion, injection molding or hot press molding to obtain the bamboo-plastic composite material. The cardanol grafted high-density polyethylene prepared by reactive extrusion utilizing the composite initiator has the advantages of stable free radical concentration, low processing temperature, no need of purification of the product and high grafting rate, and can prevent thermal degradation of the bamboo powder when used as a plastic matrix or a coupling agent of the bamboo-plastic composite material.

Owner:QUANGANG PETROCHEM RES INST OF FUJIAN NORMAL UNIV

Infrared curable ink compositions

Infrared curable ink compositions are provided. The ink composition comprises an acrylate and an infrared activated initiator. The infrared activated initiator may be lauroyl peroxide, dicumyl peroxide, pentanedione-peroxide, tert-amyl peroxy-benzoate, 1,1′-azobis-cyclohexane carbonitryle or any combination thereof.

Owner:HEWLETT PACKARD IND PRINTING LTD

Modified polyvinyl chloride cable material with favorable antioxidation and anti-aging effects and preparation method thereof

InactiveCN104761853AImprove antistatic performanceImprove flame retardant performanceInsulatorsCarbon nanotubePolyvinyl chloride

The invention discloses a modified polyvinyl chloride cable material with favorable antioxidation and anti-aging effects. The invention is characterized in that the polyvinyl chloride cable material is prepared from the following raw materials in parts by weight: 13-15 parts of carbon nanotube, 12-14 parts of polyethylacrylate, 1.2-1.3 parts of titanate coupling agent TC-F, 5-7 parts of flame retardant DOPO, 0.03-0.04 part of lauroyl peroxide, 67-70 parts of polyvinyl chloride resin SG, 10-12 parts of light calcium carbonate, 1-1.2 parts of dimethyl fumarate, 8-10 parts of DBP (dibutyl phthalate), 2-3 parts of polyethylene wax, 0.5-0.8 part of bis thiodipropionic acid, 0.8-1.2 parts of 2,6-di-tert-butyl-4-methylphenol, 2-3 parts of monoglyceryl stearate and 7-9 parts of assistant. The formula is special, and the carbon-nanotube-base polymer is added into the cable material to enhance the antistatic property and flame retardancy of the polyvinyl chloride. The 2,6-di-tert-butyl-4-methylphenol and the like are added to obviously enhance the antioxidation and anti-aging effects.

Owner:HEXIAN ELECTRICAL POWER WIRE & CABLE

A kind of preparation method and application of amphiphilic polymer

InactiveCN106432607BImprove bioavailabilitySmall toxicityOrganic active ingredientsPharmaceutical non-active ingredientsPolymer scienceDodecane

The invention relates to a preparation method and application of an amphiphilic polymer. The problems that an insoluble drug is poor in absorption and treatment effect and low in bioavailability and has more adverse effects can be effectively solved. According to the technical scheme, the amphiphilic polymer is formed by connecting a N-vinyl pyrrolidone monomer with maleic acid Guerbet eicosanol monoester, the maleic acid Guerbet eicosanol monoester is generated through esterification of maleic anhydride and 2-octyl-dodecane Guerbet alcohol, a free radical polymerization reaction is conducted in n-heptane by taking lauroyl peroxide as an initiating agent and taking N-vinyl pyrrolidone and the maleic acid Guerbet eicosanol monoester as monomers, and then the amphiphilic polymer is obtained. According to the preparation method and application of the amphiphilic polymer, the insoluble drug is embedded into polymeric micelles by taking the amphiphilic polymer as a carrier material to prepare an insoluble drug-loaded micelle injection, a very good tumor inhibiting effect is achieved, the toxicity is low, the water solubility of the insoluble drug can be enhanced, the bioavailability of the drug can be improved, and the toxic and side effects of the drug can be reduced.

Owner:ZHENGZHOU UNIV

Anti-flaming organic glass and preparation method thereof

InactiveCN106589753AEvenly dispersedIncrease flame retardancy and environmental protectionFiberOXALIC ACID DIHYDRATE

The invention discloses anti-flaming organic glass which comprises the following raw materials in parts by weight: 100-120 parts of methyl methacrylate, 5-10 parts of composite flame retardant, 10-12 parts of oxalic acid acrylate, 1-3 parts of trioctyl acetylcitrate, 13-17 parts of rubber particles, 2-4 parts of carboxymethylcellulose, 2-4 parts of modified carbon fibers and 0.5-1 part of lauroyl peroxide. The preparation process of the composite flame retardant comprises the following steps: uniformly mixing diethyl chlorophosphate with tetrahydrofuran; regulating the temperature; adding triethylamine and uniformly mixing; dropwise adding hydroxyethyl acrylate into the tetrahydrofuran solution and stirring under the heat preservation mode; increasing the temperature to the room temperature; stirring under the heat preservation mode and then purifying, thereby acquiring a material A; mixing the material A with expansible graphite and ammonium polyphosphate, thereby acquiring the composite flame retardant. The invention also discloses a preparation method for the anti-flaming organic glass. The anti-flaming organic glass is high in fire resistance and toughness.

Owner:安徽亚克力实业有限公司

PVC pipe toughened and modified by acrylate and preparing method thereof

The invention discloses a PVC pipe toughened and modified by acrylate. The PVC pipe is characterized by being prepared from, by weight, polyvinyl chloride resin, butyl titanate, hydrochloric acid solution of 8-10%, absolute ethyl alcohol, a coupling agent KH-570, (2- ethylhexyl) acrylate, chloroethylene, methylcellulose, dioctyl sulfo substituted succinate, lauroyl peroxide, polyethylene, calcium stearate, zinc laurate, polyethylene wax, 1,3-dimethyl-6-aminouracil, octadecyl dihydroxy ethyl methyl ammonium bromide, polyethylene glycol and an appropriate amount of deionized water. The prepared PVC pipe has the advantages of being high in strength, tenacity and impact resistance and has high market competitiveness as the product component is low in price.

Owner:ANHUI LANTONG TECH CO LTD

Preparing method for anti-freezing premixed mortar

The invention relates to a preparing method for anti-freezing premixed mortar and belongs to the technical field of building material preparation. The preparing method mainly comprises the steps that octamethylcyclotetrasiloxane, isobutyltriethoxysilane and other substances are subjected to a polymerization reaction, and a vinyl polysiloxane mixture solution is obtained; styrene, absolute ethyl alcohol, acrylic ester and other substances are mixed and heated, and polystyrene acrylate is obtained; then polystyrene acrylate and the vinyl polysiloxane mixture solution are mixed and heated, lauroyl peroxide, copper chloride and other substances are added, and an organic silicon modified styrene-acrylate copolymer is obtained and then mixed with cellulose ether, hollow glass beads and other substances, and mixed paste is obtained; finally, the mixed paste, ceramic fine sand, montmorillonite and other substances are stirred and mixed, and the anti-freezing premixed mortar can be obtained. The anti-freezing premixed mortar prepared with the method is high in anti-freezing performance and strength, wherein the lowest anti-freezing temperature can reach minus 6 DEG C, and the strength can reach 18.9 MPa or above.

Owner:广州市盈坚建材科技发展有限公司

Preparation method of chitosan modified amphiprotic crosslinked starch sludge dehydrating agent

InactiveCN105968371ANo pollution in the processSimple and fast operationSludge treatment by de-watering/drying/thickeningLauroyl peroxideDistillation

The invention discloses a preparation method of a chitosan modified amphiprotic crosslinked starch sludge dehydrating agent and belongs to the technical field of dehydrating agent preparation. The preparation method comprises the following steps of adding methacryloyloxyethyl trimethyl ammonium chloride, hydrochloric acid, ammonium sulfate and azobisisobutryamide chloride into prepared crosslinked starch; performing a stirring reaction to obtain cation crosslinked starch; then preparing amphiprotic crosslinked starch; then adding chitosan, lauroyl peroxide and the azobisisobutryamide chloride into the amphiprotic crosslinked starch; obtaining chitosan modified amphiprotic crosslinked starch after a reaction; carrying out reduced pressure distillation and drying to obtain the chitosan modified amphiprotic crosslinked starch sludge dehydrating agent. Examples prove that according to the preparation method, the problem of resource exhaustion is solved when the cost is reduced; in addition, in the preparation process, the environment is not polluted, the prepared sludge dehydrating agent can self-degrade under the nature conditions, the water content of sludge can be lowered from original 60 percent to below 10 percent after the chitosan modified amphiprotic crosslinked starch sludge dehydrating agent is used, and the dehydrating efficiency is very dramatic.

Owner:郭舒洋

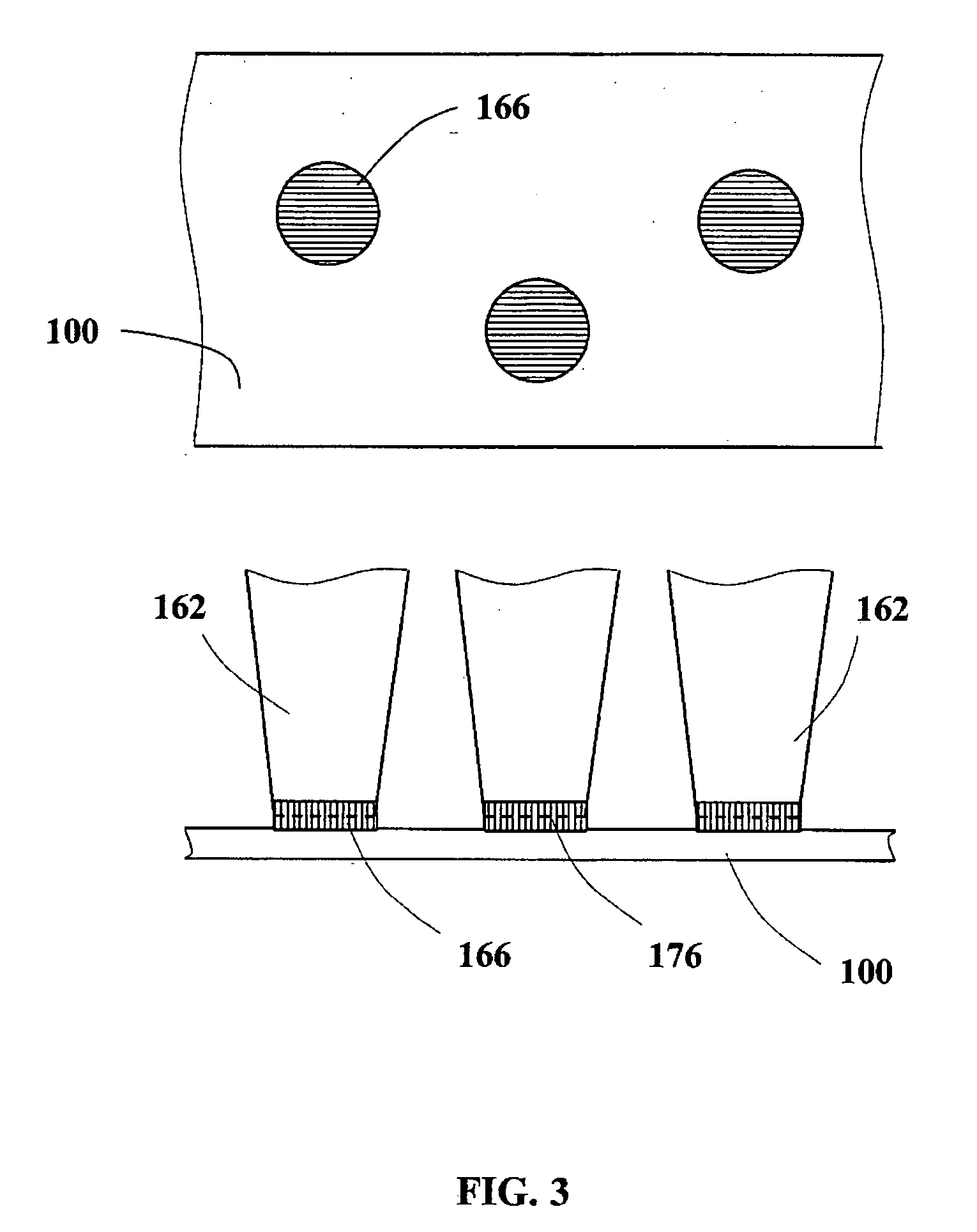

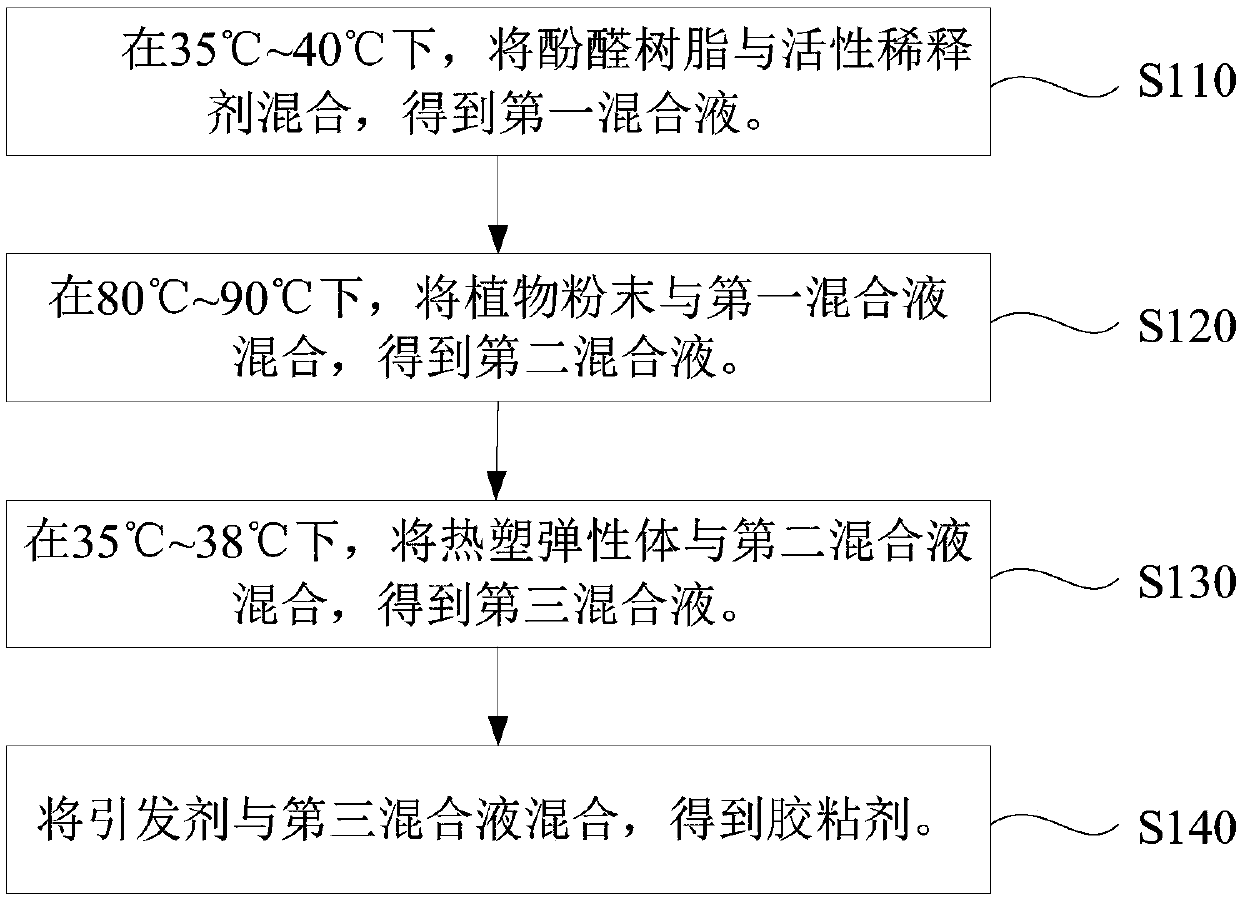

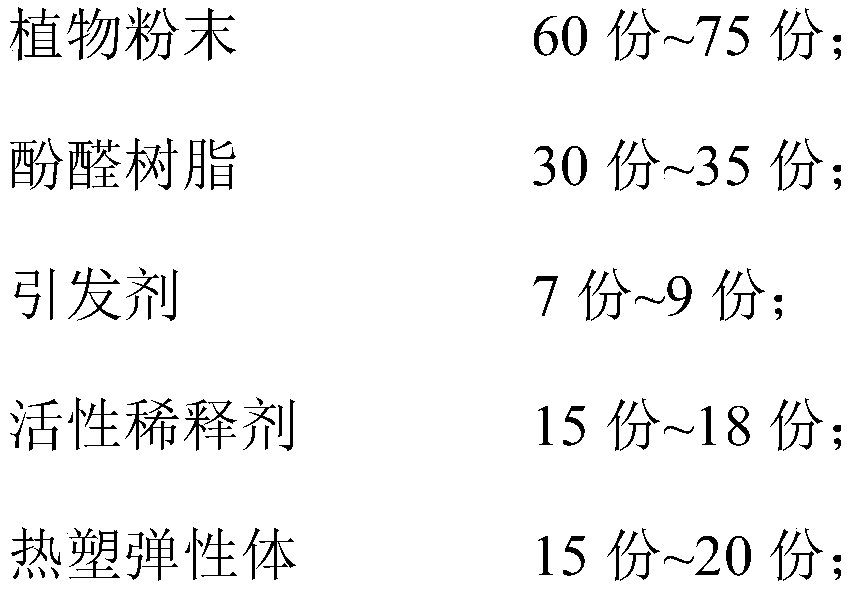

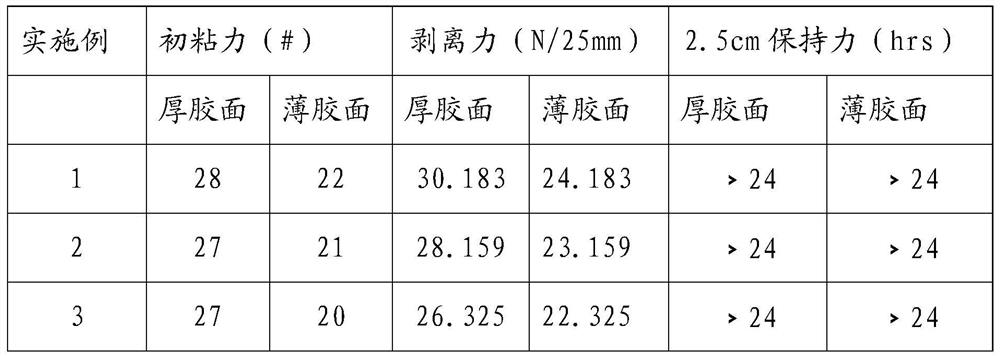

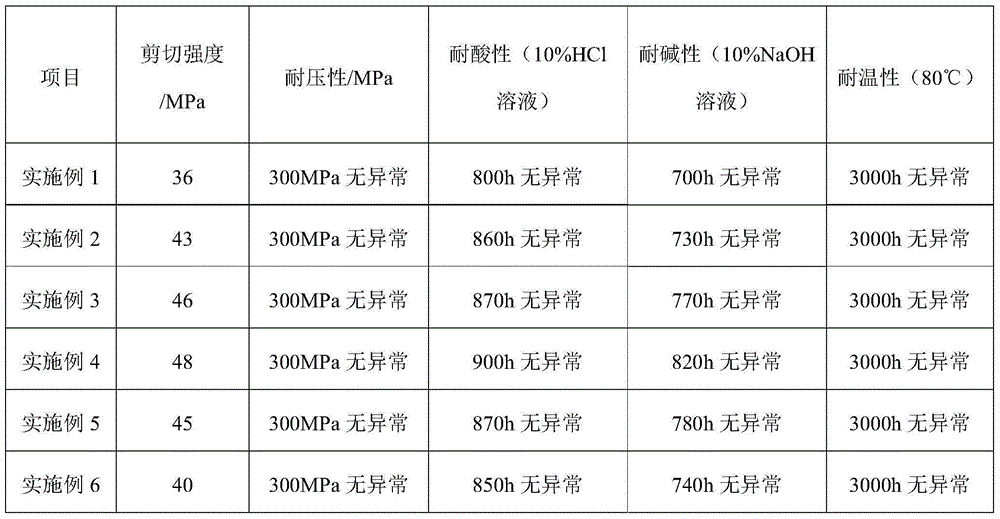

Adhesive, and preparation method and application thereof

InactiveCN110734720AImprove adhesionThe group ratio is reasonableHemicellulose adhesivesNon-macromolecular adhesive additivesElastomerAdhesive cement

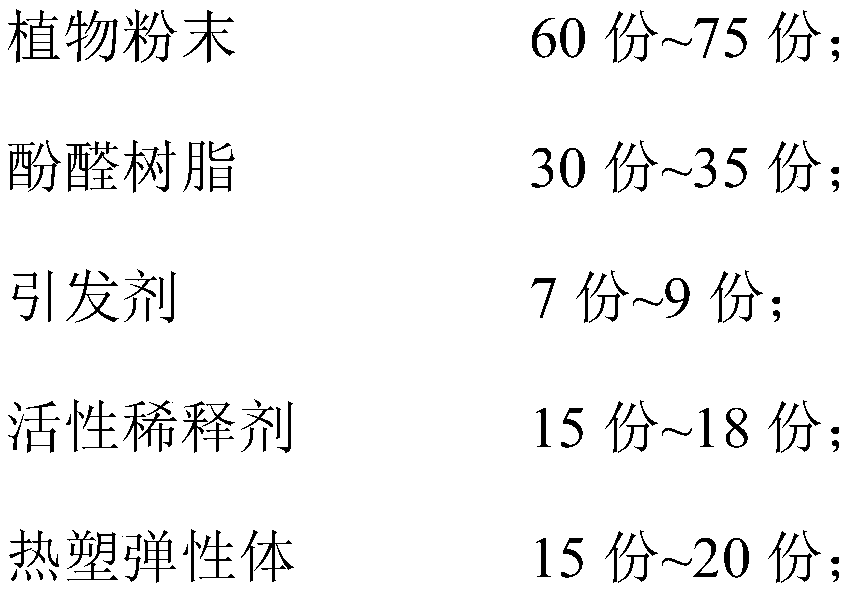

The invention relates to an adhesive, and a preparation method and an application thereof. The adhesive comprises the raw materials for preparing the adhesive in parts by mass: 60 parts-75 parts of plant powder, 30 parts-35 parts of phenolic resin, 7 parts-9 parts of an initiator, 15 parts-18 parts of an active diluent and 15 parts-20 parts of a thermoplastic elastomer, wherein the initiator is selected from at least one of tert-butyl hydroperoxide, lauroyl peroxide and methyl ethyl ketone peroxide, and the reactive diluent is selected from at least one of butyl glycidyl ether, epoxypropane butyl ether and diglycidyl ether. The adhesive has the advantages of being environmentally friendly and good in adhesive property.

Owner:O FILM IMAGE TECH (GUANGZHOU) CO LTD

High-temperature-resistant anti-aging resin anchoring agent

InactiveCN107417170AFixed tightlyImprove high temperature resistanceNatural resinDimethylaniline N-oxide

The invention discloses a high-temperature-resistant anti-aging resin anchoring agent, belonging to the technical field of roadway support materials. According to the invention, montmorillonite is crushed, then impregnated with hydrochloric acid and finally undergoes filtering and separation so as to obtain filter residues; the filter residues are mixed with moss pulp prepared from Polytrichum alpinum for culture, then the cultured filter residues undergo oscillation together with a sodium silicate solution, and the obtained mixture is subjected to filtering and separating so as to obtain a filter cake; the obtained filter cake and hydrochloric acid are subjected to oscillation, dipping and heating reaction, and then filtering and separating are carried out so as to obtain a pre-modified filter cake; the pre-modified filter cake is carbonized and then undergo mixing and grinding together with natural resin so as to obtain a modified self-made high-temperature-resistant anti-aging filling material; the filling material, bisphenol A type unsaturated polyester resin, dimethylaniline and tetrachlorobenzoquinone are uniformly mixed to obtain a component A; lauroyl peroxide, dibenzoyl peroxide and water are uniformly mixed to obtain a component B; and in use, the component A and the component B are mixed so as to obtain the high-temperature-resistant anti-aging resin anchoring agent. The high-temperature-resistant anti-aging resin anchoring agent has excellent ageing resistance, can maintain high compressive strength and anchoring force under a high temperature condition and exerts good supporting effect in a severe underground environment.

Owner:常州瑞坦商贸有限公司

Glass fiber grid adhesive tape and preparation method thereof

InactiveCN111777966AWith wear resistanceWaterproofFilm/foil adhesivesMacromolecular adhesive additivesIsooctyl acrylatePolymer science

The invention relates to the technical field of adhesive tapes, and especially relates to a glass fiber grid adhesive tape and a preparation method thereof. The glass fiber grid adhesive tape comprises a glass fiber grid cloth layer and a glue layer coated on the surface of the glass fiber grid cloth layer, wherein the glue layer is prepared by mixing the following components in parts by weight; 0.5 to 1.0 part of acrylic acid, 0.3 to 0.5 part of hydroxyethyl acrylate, 29 to 32 parts of iso-octyl acrylate, 9 to 11 parts of butyl acrylate, 7 to 10 parts of vinyl acetate, 47 to 53 parts of ethylacetate, 0.2 to 0.3 part of lauroyl peroxide and 7 to 9 parts of ethyl acetate. The glass fiber grid cloth keeps dimensional stability in a very wide temperature range, and can provide longitudinal and transverse stable dimensions without deformation. The adhesive tape has the advantages of high viscosity, high biaxial tensile strength, softness, fitness, wear resistance, water resistance and moisture resistance, and can also be used for firmly adhering rough or irregular surfaces.

Owner:福建友谊胶粘带集团有限公司

Ramming paste adhesive for aluminum electrolytic cells and preparation method thereof

ActiveCN104530989AHigh bonding strengthImprove pressure resistanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEpoxyGlycidyl methacrylate

The invention discloses a ramming paste adhesive for aluminum electrolytic cells and a preparation method thereof. The adhesive comprises the following components in parts by weight: 10-15 parts of brominated epoxy resin, 1-4 parts of antimony trioxide, 1-4 parts of carnauba wax, 2-8 parts of glycidyl methacrylate, 1-5 parts of a coupling agent, 1-3 parts of lauroyl peroxide, 2-6 parts of a stearic acid, 1-4 parts of barium stearate, and 5-10 parts of phenolic polybutadiene. The preparation method comprises the following steps: adding brominated epoxy resin, antimony trioxide, carnauba wax, glycidyl methacrylate, a stearic acid, barium stearate and phenolic polybutadiene into a reaction kettle, heating for reacting under the condition of inert gas protection, adding a coupling agent and lauroyl peroxide, uniformly stirring, heating for reacting under vacuum conditions, and cooling to room temperature, so that the ramming paste adhesive for aluminum electrolytic cells is obtained. The ramming paste adhesive for aluminum electrolytic cells provided by the invention has a good adhesive property, and is high temperature resistant, and acid and alkaline resistant.

Owner:NANTONG RUIDA ELECTRONICS MATERIAL

Wear-resisting and shock-resisting polypropylene material for inner barrel of washing machine and preparation method thereof

The invention discloses a wear-resisting and shock-resisting polypropylene material for an inner barrel of a washing machine and a preparation method thereof. The wear-resisting and shock-resisting polypropylene material is prepared from, by weight, 90-110 parts of polypropylene, 20-30 parts of acrylic acid, 3-5 parts of lauroyl peroxide, 8-10 parts of xylene, 40-50 parts of acetone, 20-25 parts of ethylene-trifluorochlor oethylene copolymer, 5-7 parts of tetra-(2-ethylhexyl)pyromellitate, 7-9 parts of cotton stalk bark fiber, 4-6 parts of aerosol, 5-7 parts of zinc stearate, 2-4 parts of dibasic lead stearate, 6-8 parts of polyethylene wax, 8-10 parts of epoxy linseed oil, 15-20 parts of sub-white corundum fine powder, 10-12 parts of hollow glass bead, 7-9 parts of graphene oxide, and 5-7 parts of nepheline powder, and so on. Through blending and modifying polypropylene resin by ethylene- trifluorochlor oethylene copolymer, the mechanical strength and wear resistance of the composite polypropylene material are improved, and the corrosive resistance and creep resistance are also improved; acrylic acid is grafted with modified polypropylene, so as to improve the compatibility between the mixed filler consisting of sub-white corundum fine powder, graphene oxide and others, and organic resin, promote the wear resistance, shockproof and anti-impact performances of the composite materials.

Owner:杨烨

Insulating paint for computer cables and preparation method thereof

InactiveCN107325697AImprove performanceImprove insulation performanceEpoxy resin coatingsPolyester coatingsAntimony trioxideSodium salt

The invention discloses insulating paint for computer cables. The insulating paint comprises the following materials in parts by weight: 20-40 parts of unsaturated polyester resin, 15-35 parts of organic sodium salt modified water-soluble acrylic emulsion, 13-22 parts of epoxy acrylate, 12-26 parts of ethylene-vinyl acetate, 10-20 parts of methyl phenyl silicone resin, 3-8 parts of mica powder, 5-12 parts of glass fiber, 3-6 parts of lauroyl peroxide, 7-15 parts of bentonite, 4-8 parts of boron compound, 3-5 parts of antimony trioxide, 5-9 parts of polysiloxane, 10-15 parts of linoleic acid, 2-3 parts of wetting dispersant, 1-4 parts of flame retardant, 2-3 parts of defoaming agent, 1-2 parts of curing agent and 2-5 parts of diluent. The insulating paint disclosed by the invention has good insulating property, stable property and good film-forming effect, and a preparation method is simple, is easy to operate and is suitable for industrial production.

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

Exterior wall protecting coating and preparation method thereof

ActiveCN104250502AExtended service lifeGood weather resistanceBituminous coatingsSodium bicarbonateAcrylic resin

The invention provides an exterior wall protecting coating and a preparation method thereof. The exterior wall protecting coating comprises the following components in part by mass: 11.5-24 parts of silicone acrylic resin, 3-6.5 parts of organic silicone oil, 0.5-1.5 parts of protective glue, 1-4 parts of polyoxyethylene stearate, 0.7-1.5 parts of sodium dodecyl benzene sulfonate, 0.2-0.45 part of lauroyl peroxide, 0.08-0.13 part of sodium bicarbonate, 1.5-3.5 parts of low-wax asphalt, 0.1-0.3 part of dodecanol ester, 0.5-1 part of ethyl acetate and 15-29 parts of deionized water. The exterior wall protecting coating provided by the invention has high weather resistance, strong adhesion and high water resistance, is suitable for coating an exterior wall of a building, has an excellent building beautifying effect, and can protect the building from invasion of outside air, ultraviolet light, rainwater and chemical substances so as to prolong the service life of the exterior wall.

Owner:沧州佳迎漆业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com