Temperature-sensitive swelling microcapsule anti-gas-channeling agent and anti-gas-channeling cement slurry system

An expansion microcapsule and anti-gas channeling agent technology, applied in the field of cement slurry, can solve the problems of demulsification, insufficient expansion performance, large addition amount, etc., and achieve the effect of making up for volume shrinkage and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of temperature-sensitive expansion microcapsule anti-gas channeling agent (the following materials are all parts by weight), the process is as follows:

[0029] Formula 1: 3 parts of acrylonitrile, 0.4 parts of methyl acrylate, 2 parts of methyl methacrylate, 1 part of initiator lauroyl peroxide, 10 parts of foaming agent isobutane, crosslinking agent 1,4-butanediol Dissolve 0.1 part of dimethacrylate with electromagnetic stirring, transfer to a reaction glass kettle, add 20 parts of dispersant nano-silica, 300 parts of deionized water, stir at 1200r / min for 8-10min, and react in a constant temperature water bath at 62°C under nitrogen protection After 24 hours, cool down, wash and dry.

[0030] Formula 2: 15 parts of foaming agent isobutane, the others are the same as formula 1.

[0031] Formula 3: 20 parts of blowing agent isobutane, the others are the same as formula 1.

[0032] Formula 4: 25 parts of blowing agent isobutane, the others are the same...

Embodiment 2

[0036] Embodiment 2 (the following materials are parts by weight)

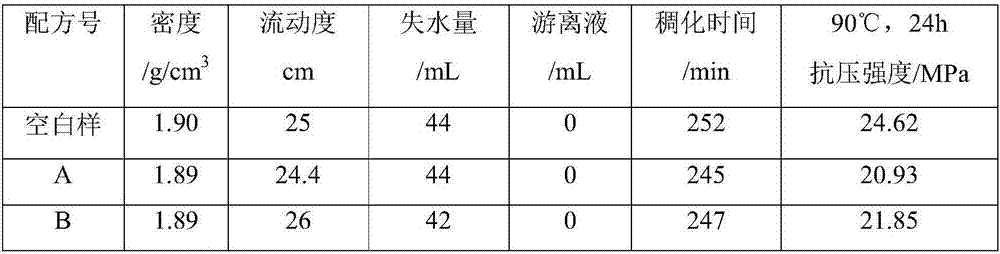

[0037] Blank sample: 100 parts of oil well cement, 2 parts of dispersant, mix and stir evenly to get dry mixed material; Wet mixing material; under the stirring condition of 4000 rpm, add the dry mixing material into the wet mixing material at a uniform speed (15s), then stir at 12000 rpm for 35s and defoam, and then get the cement slurry of the comparison group system.

[0038] A kind of preparation of temperature-sensitive expansion microcapsule anti-gas channeling cement slurry system, the process is as follows:

[0039] Formula A: 100 parts of oil well cement, 0.1 part of expansion microcapsules of anti-air channeling agent, 2 parts of dispersant, mix and stir evenly to obtain a dry blend material; 1.5 parts of fluid loss reducer, 1 part of retarder, 0.2 part of defoamer Dissolve in 44 parts of water and stir evenly to obtain the wet-mixed material; under the stirring condition of 4000 rpm, add the dry-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com