A laboratory direct aeration aeration equipment

A laboratory aeration equipment technology, applied in water aeration, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of inapplicability to laboratories, complicated and complex structure, and large floor space. , to achieve the effect of low power consumption, good experimental effect and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

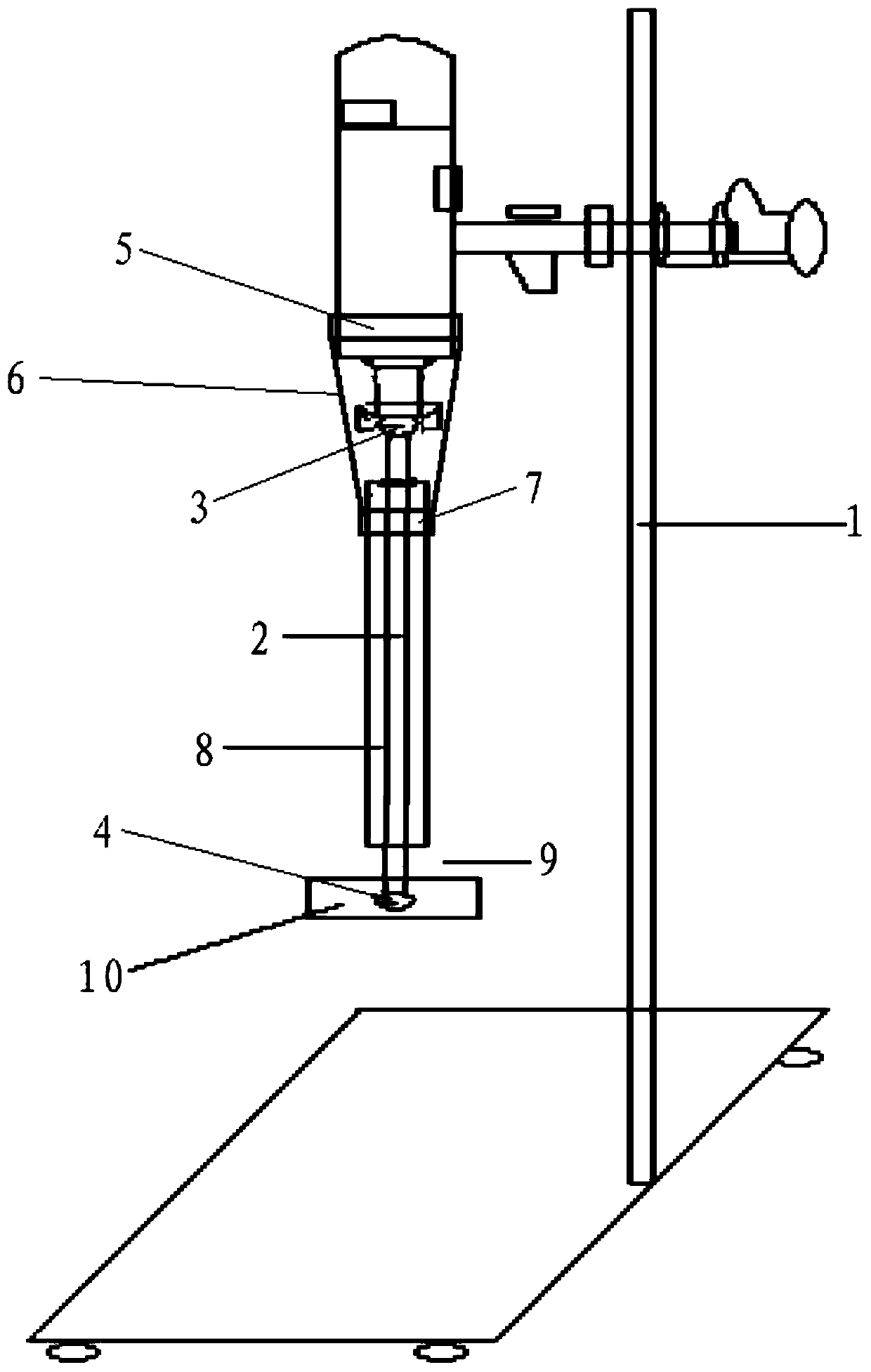

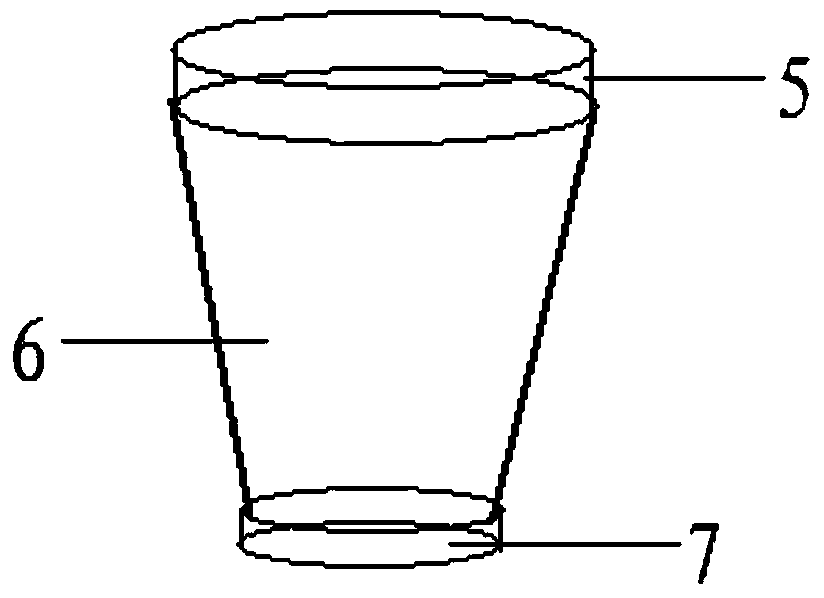

[0012] The main structure of the laboratory direct aeration type aeration equipment involved in this embodiment (such as figure 1 As shown) includes mixer 1, rotating shaft 2, shaft interface 3, closed impeller interface 4, motor card 5, guide vane 6, shaft sleeve tube card 7, shaft sleeve inlet pipe 8, water absorption gap 9 and closed impeller 10, cylinder The upper end and the lower end of the rotating shaft 2 with a threaded structure are respectively a shaft interface 3 and a closed impeller interface 4. The motor shaft of the mixer 1 is connected to the rotating shaft 2 through the shaft interface 3, and the rotating shaft 2 is connected to the closed impeller through the closed impeller interface 4. 10 detachable connection; the outside of the rotating shaft 2 is covered with an inner hollow tubular structure of the sleeve air intake pipe 8 for the suction of air, and the upper end of the shaft sleeve air intake pipe 8 is provided with a shaft sleeve pipe clip 7 and a gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com