Automatic edge sealing device for plywood production

An edge banding device and plywood technology, which is applied to other plywood/plywood appliances, conveyor control devices, household components, etc., can solve problems such as waste of space resources, easy deformation of plates, and inability to use all support and guide rollers. The effect of ensuring uniformity and preventing sheet deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

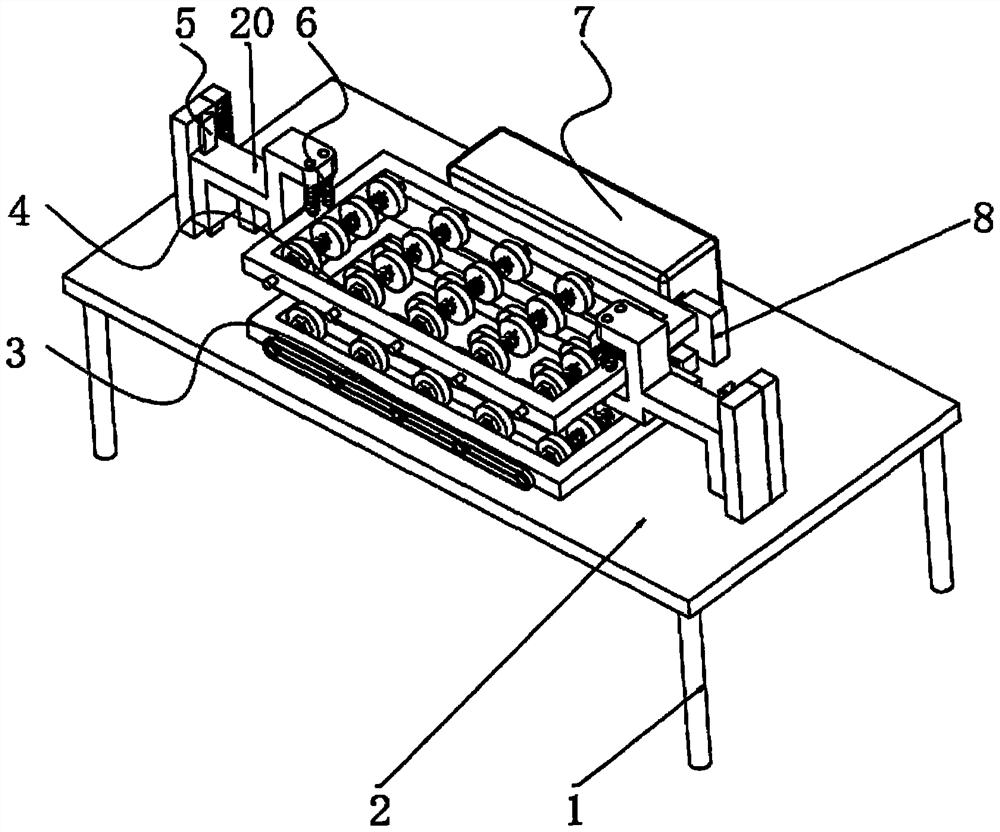

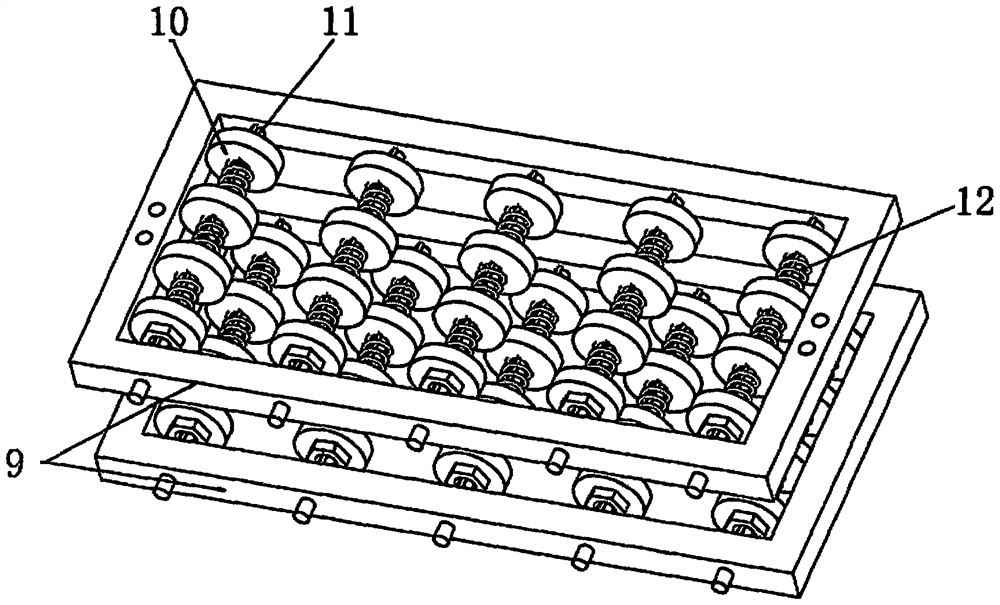

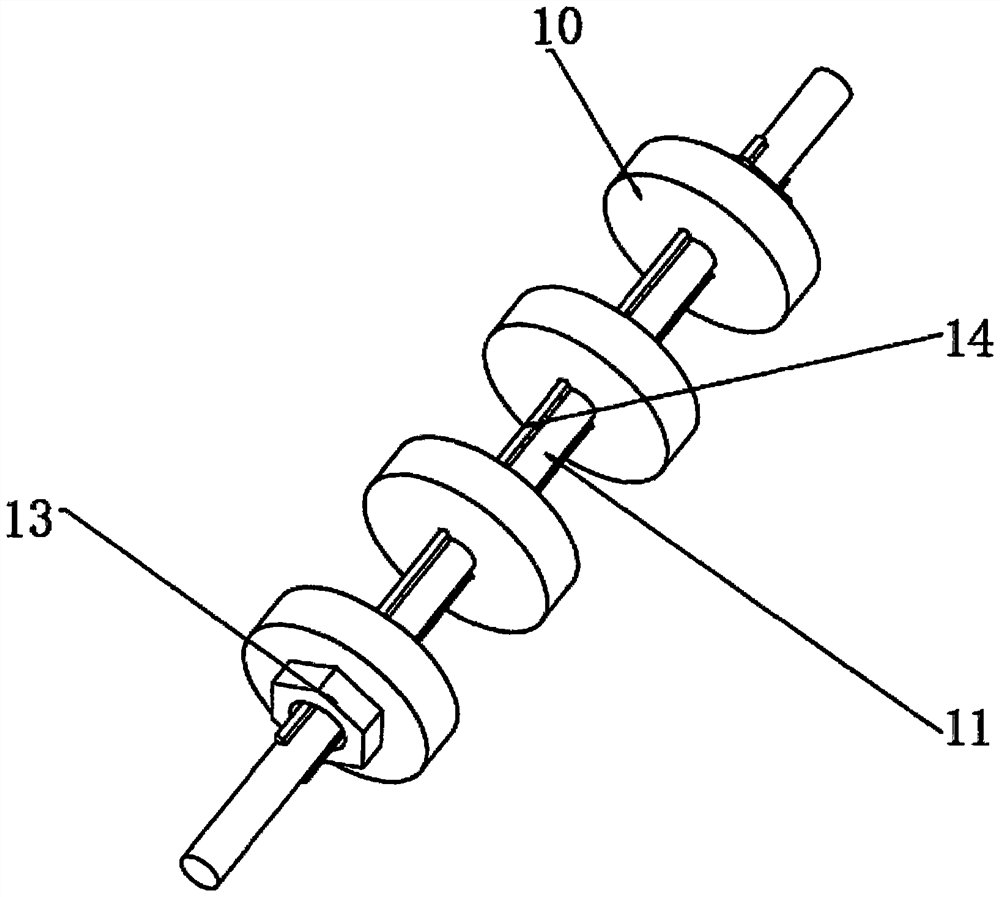

[0037] An automatic edge banding device for plywood production, such as Figure 1-3As shown, it includes a base 2 that is supported and fixed on the ground by legs 1. The top outer wall of the base 2 is provided with an active conveying assembly 3. The outer wall of the base 2 is connected with a bracket 20 through two sets of drive lifting components 5. The bracket 20 is connected by The member 6 is connected with the same group of passive pressing components 4. The active conveying component 3 has the same structure as the passive pressing component 4, and specifically includes a rectangular frame 9 and multiple sets of rollers 10. The inner wall of the rectangular frame 9 is rotatably connected to multiple set transmission shaft 11, the outer wall of the transmission shaft 11 is welded with a transmission protrusion 14, the inner wall of the roller 10 is provided with a groove matching the transmission protrusion 14, and the groove and the transmission protrusion 14 are in c...

Embodiment 2

[0044] An automatic edge banding device for plywood production, such as figure 1 As shown, in order to solve the problem of precise control of position; this embodiment makes the following improvements to the driving lifting assembly 5 in Embodiment 1: the driving lifting assembly 5 includes a rack 23, a gear 24 and a "U" frame 27, the The top outer wall of the base 2 is fixed with a support plate 22 by bolts, and the support plate 22 is slidably connected with the bracket 20 through a linear slide rail 21. On the outer wall of the bracket 20, one side outer wall of the gear 24 meshes with the outer wall of the rack 23, and the other side outer wall of the gear 24 meshes with the "U" frame 27 through the teeth 26 arranged on the side wall of the gear 24, The inner wall of the "U" frame 27 is slidably connected with a guide slide bar two 28, and the guide slide bar two 28 is fixed on the bottom outer wall of the base 2 by bolts, and the bottom outer wall of the base 2 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com